Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

234results about How to "Improve high temperature cycle performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

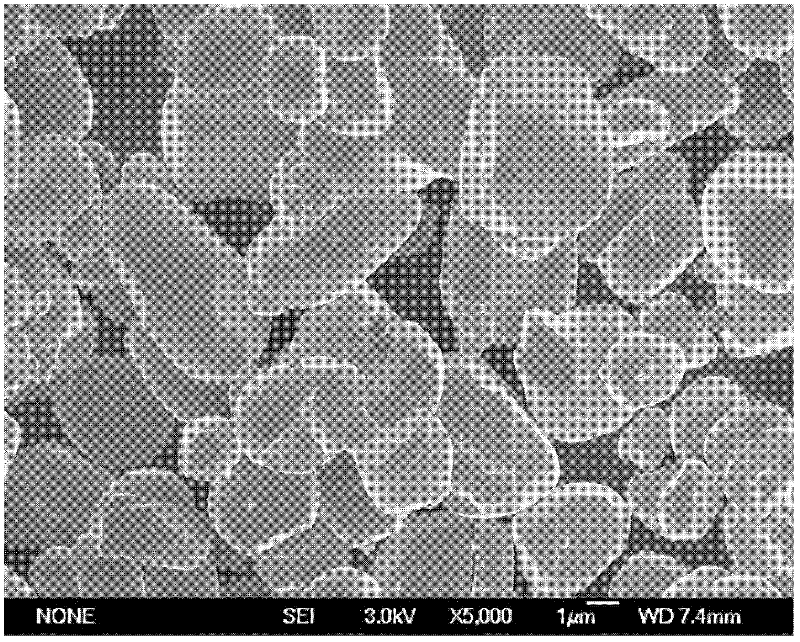

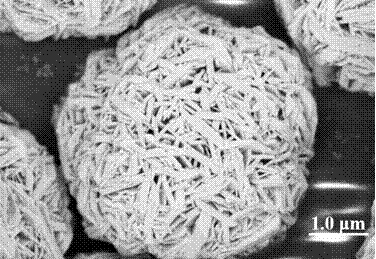

Preparation method of lithium ion battery ternary cathode material

The invention discloses a preparation method of a lithium ion battery ternary cathode material. According to the preparation method, full grinding is performed through a colloid mill to improve the reactivity of a precursor and a lithium salt and the uniformity of a mixed material; and a carbon chain organic additive is added in the process of grinding to improve the viscosity of a sizing material, inhibit raw material segregation in the process of drying, quickly balance the temperature of each part of a system in the process of high-temperature reaction and inhibit agglomeration among particles, so that a uniform-appearance and regular mono-crystal ternary cathode material is obtained. Meanwhile, the ternary cathode material is doped and subjected to surface coating modification, so that the structure of the material is stabilized, the side reaction between the material and electrolyte is inhibited, and the high-temperature cycle performance of the material is improved.

Owner:PULEAD TAIAN TECH IND

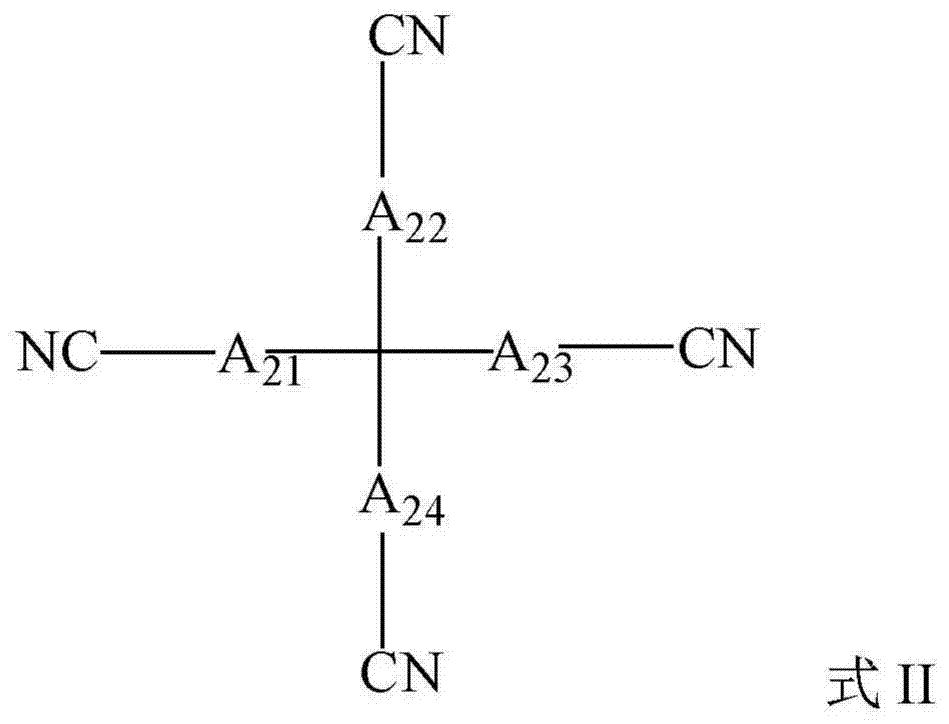

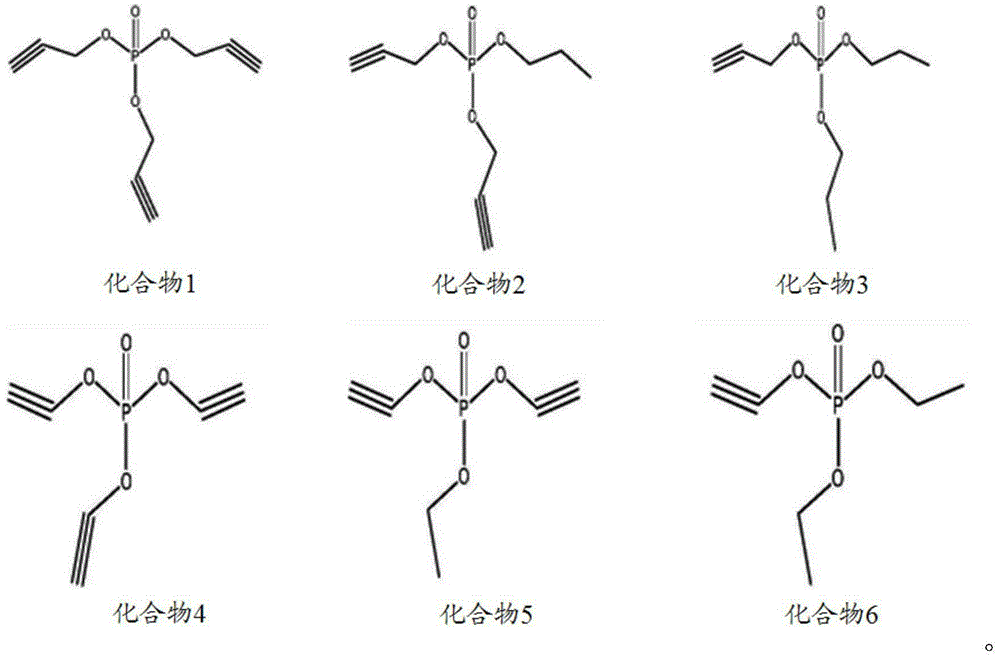

Electrolyte additive and application thereof in lithium ion battery

ActiveCN104766995AImprove cycle lifeImprove featuresLi-accumulatorsOrganic electrolytesHigh temperature storageSulfur

The invention discloses an electrolyte additive and an application thereof in a lithium ion battery. The electrolyte additive comprises a polynitrile-based compound and a compound comprising a sulfur bond and an oxygen bond. When the electrolyte additive is applied to the lithium ion battery, good cycle life, good low-temperature discharging property and good high-temperature storage property of the lithium ion battery under the high voltage still can be maintained.

Owner:CONTEMPORARY AMPEREX TECH CO

Method for preparing positive electrode material of lithium ion accumulator

InactiveCN1595680AReduce manufacturing costImprove securityElectrode manufacturing processesSecondary cellsLithium hydroxideLithium carbonate

The invention relates to a manufacture method for positive material of lithium ion accumulator , whose component concentration is: at least one element between LiNi0.5-xM0.5-XM2xO2 (M=Co,Ti,Al) (0<=X<0.5). The manufacture method includes the following steps: dry or wet mix of sentiment hydroxide or carbonate compounds of at least one element between Ni,Mn,Co,Ti and Al or its oxide and lithium hydroxide or carbonate lithium (dry for the material of wet mixture); accumulate the mixture whose width is 2mm~60mm; make particle under the pressure of 4MPa~40MPa; high temperature solid state reaction happens under the temperature of 700~1050deg.C; shatter it after cooling, the diameter of particle is 0.5~25mu m. The manufacture method can make the density of products reach 2.0g / cm3~2.8g / cm3, increase positive filler level of lithium ion and lithium polymer accumulator and its capacity.

Owner:吴孟涛

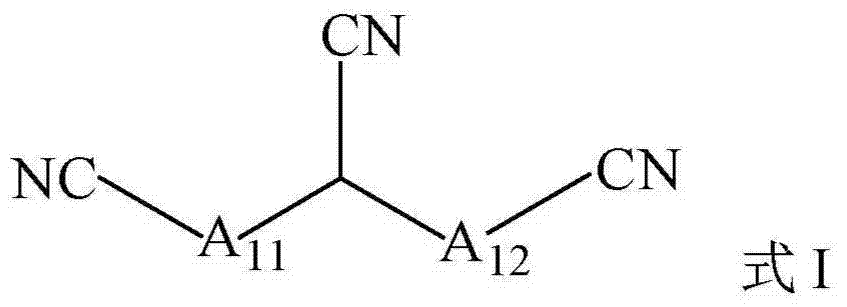

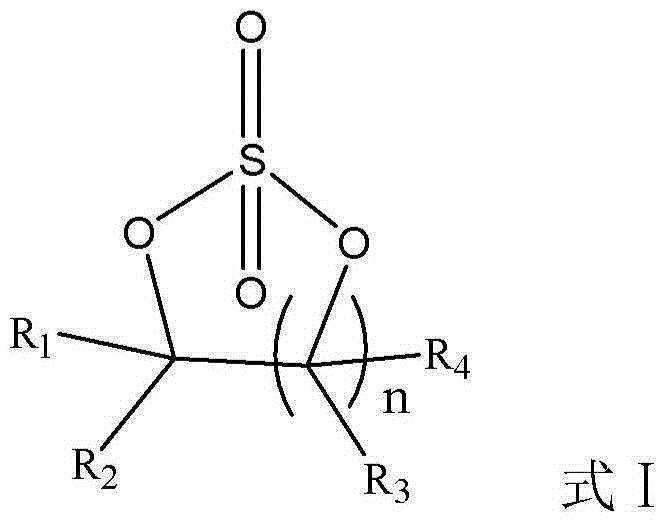

Lithium ion battery electrolyte with high-temperature and low-temperature properties

ActiveCN103000944AImprove wettabilityLower impedanceSecondary cellsElectrolytic agentOrganic solvent

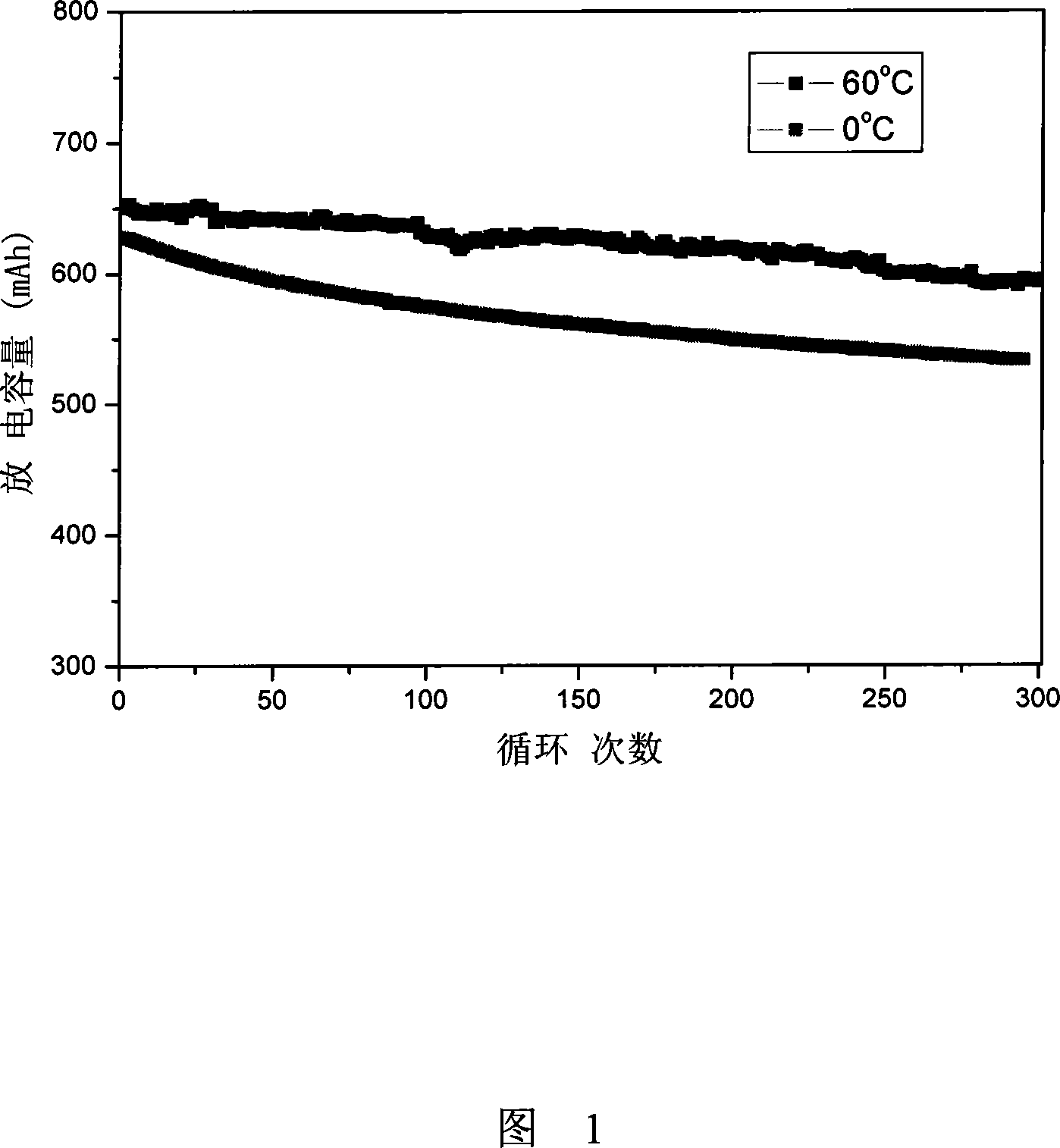

The invention relates to lithium ion battery electrolyte, and mainly relates to lithium ion battery electrolyte with high-temperature and low-temperature properties, which belongs to the field of a lithium ion battery. The lithium ion battery electrolyte with the high-temperature and low-temperature properties comprises organic solvents, lithium salt and additives, wherein the organic solvents comprise linear carbonic ester, cyclic carbonate, linear carboxylic acid ester and cyclic carboxylic acid ester; the additives comprise a high-temperature additive and a multifunctional additive which is expressed by a structural formula 1 and accounts for 0.5%-15% in the total mass of the electrolyte; and according to the structural formula 1 shown in the specification, R1 is one of H, F, CH2=CH and CH3-CH=CH, and R2 is one of H, F, CN and CH2=CH. The electrolyte provided by the invention has a wide working temperature window and a good discharging property, and can not only solve the problem of low discharging efficiency at a low temperature of -40 DEG C, but also meet the requirement on circulation at a high temperature of 60 DEG C.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

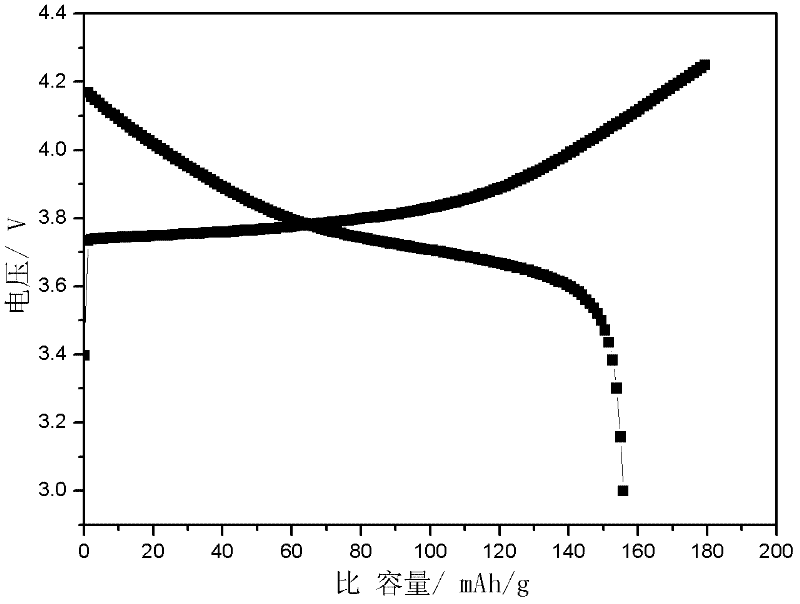

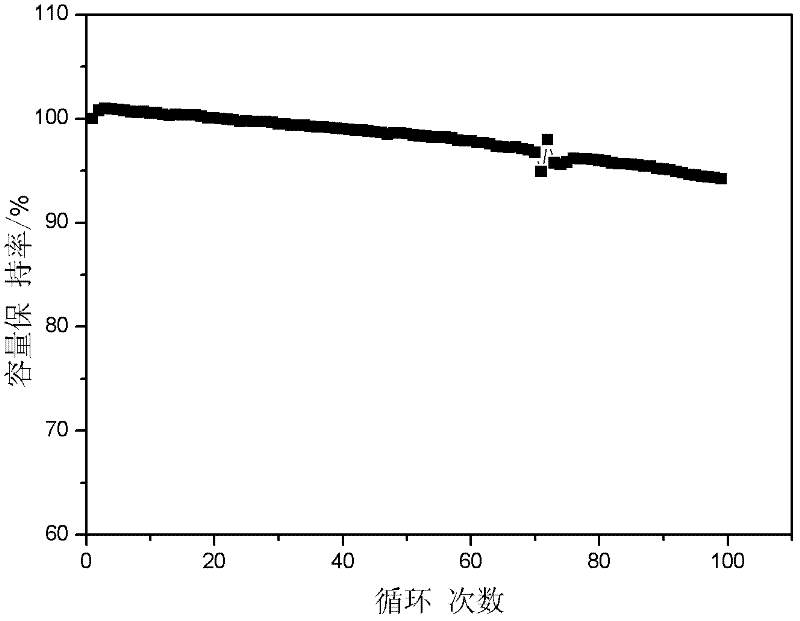

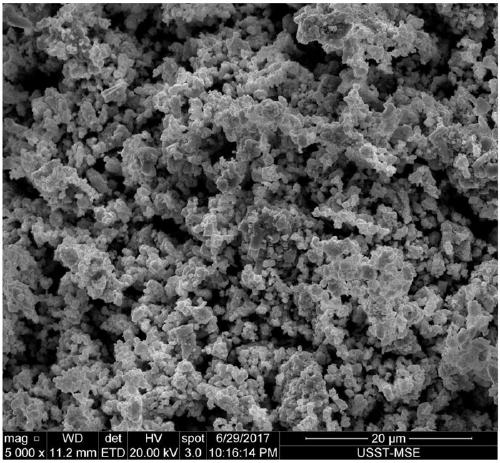

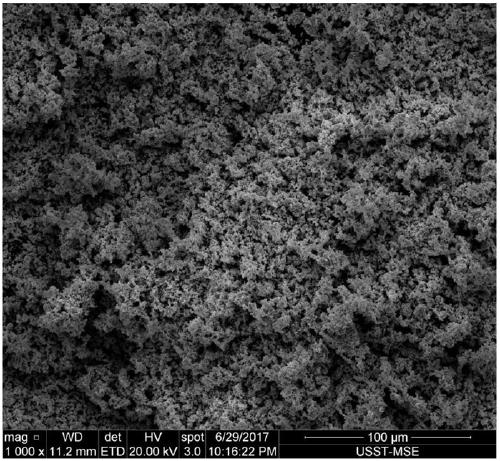

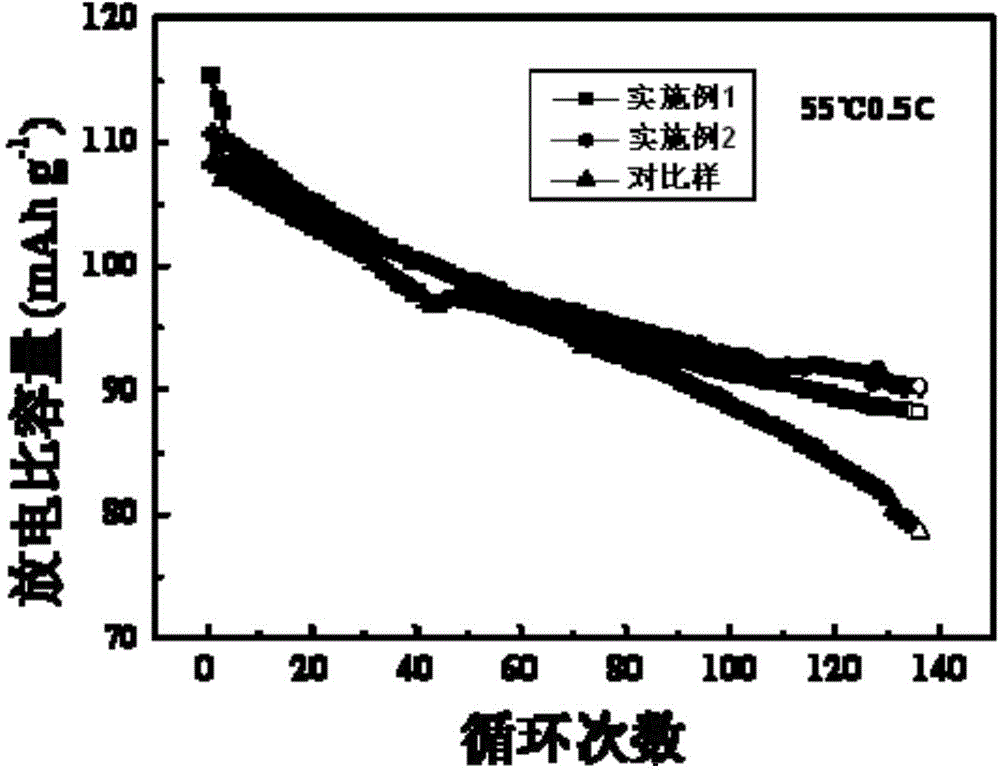

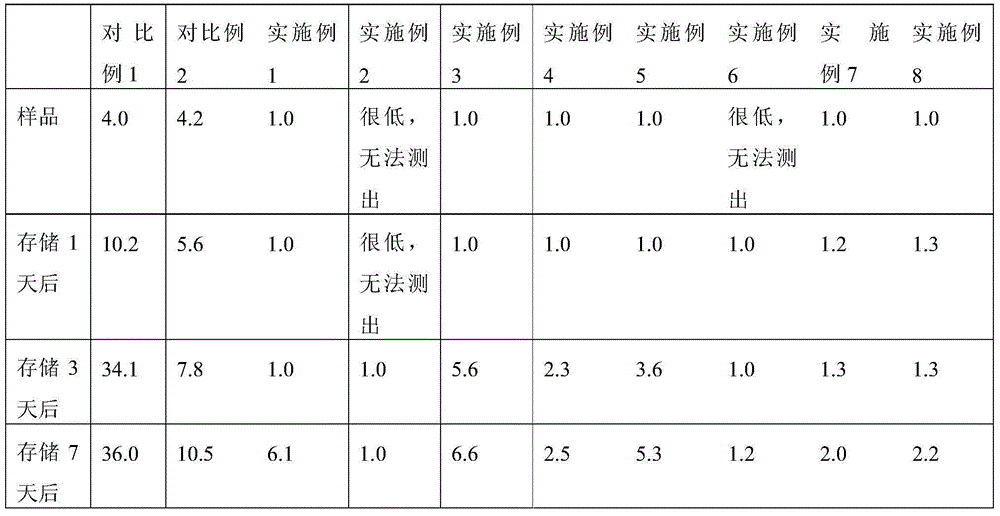

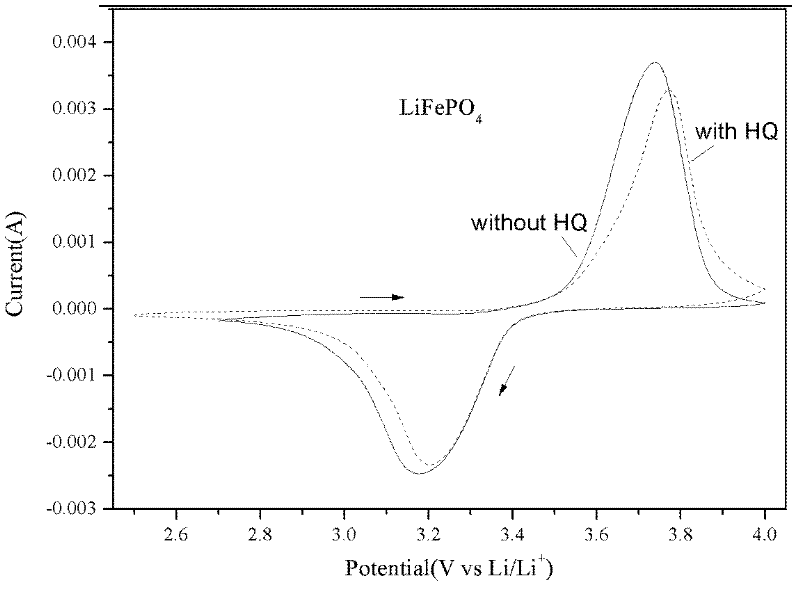

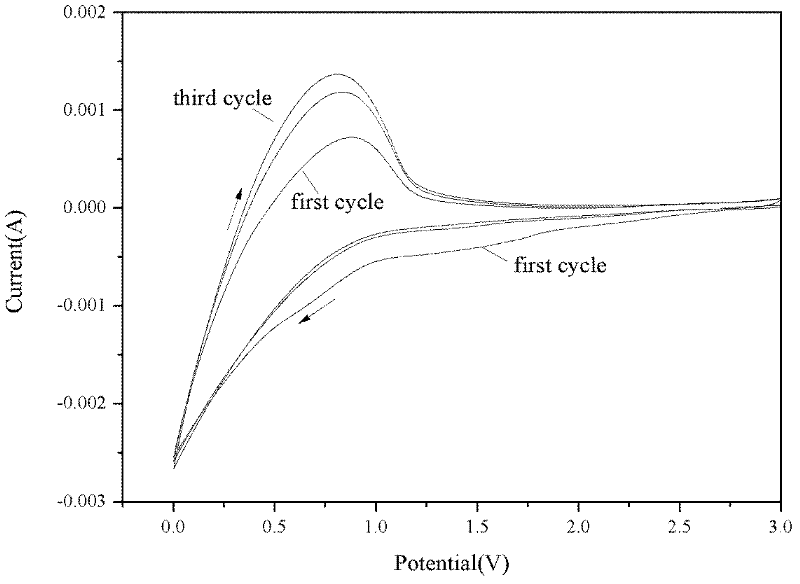

Modification method for improving high-temperature cycle performance and ionic conductance of lithium iron phosphate material

The invention discloses a modification method for improving the high-temperature cycle performance and ionic conductance of a lithium iron phosphate material. The method mainly comprises the following steps of: mixing an organic compound which contains silicon, aluminum and titanium with lithium iron phosphate; performing certain heat treatment; and coating silicon dioxide, aluminum oxide or titanium oxide onto the surface of the lithium iron phosphate material to fulfill the aim of improving the electrochemical performance of the lithium iron phosphate material. The high-temperature cycle performance and the high-magnification charging-discharging current cycle capacity of coating-modified lithium iron phosphate are enhanced, and the impedance of a prepared electrode is remarkably reduced. The lithium iron phosphate material can be applied to more fields. A coating method has the advantages of simple process, low cost, stable and controllable product performance and suitability for industrial production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Preparation method of manganese-based compound positive pole material for secondary lithium ion battery

InactiveCN102820464AIncrease energy densityIncrease capacityCell electrodesChemistryCapacity efficiency

The invention provides a preparation method of a manganese-based compound positive pole material for a secondary lithium ion battery. The general constitution formula of the positive pole material is Li (LixMn2-x-yMy) O4 / Az, wherein x is more than or equal to 0 and less than or equal to 0.5, y is more than or equal to 0 and less than or equal to 2, and z is more than or equal to 0 and less than or equal to 0.5; and M is a doped modified element, and A is an oxide of a coating element or a phthalocyanines large-ring transition metal complex. When the positive pole material is prepared, a lithium source and an M source are added into mixing equipment containing a medium and a dispersing agent to be mixed and dried; then the mixture and a manganese source are added into the mixing equipment containing the medium and the dispersing agent to be mixed and dried; then the new mixture is roasted and then is cooled to a room temperature; and the new mixture and an A source are added into the mixing equipment containing the medium and the dispersing agent to be mixed and dried, are roasted again, are cooled to the room temperature and are mixed and crushed to obtain the manganese-based compound positive pole material. The preparation method disclosed by the invention has the advantages of simple process, low raw material cost and processing cost, simple process route, short period and low energy consumption. The produced manganese-based compound positive pole material has the advantages of high energy density, mass specific capacity, power performance, high-temperature circulating performance and high-temperature storage performance; and the capacity efficiency of the material is high at -40 DEG C.

Owner:济宁市无界科技有限公司

Method for preparing difluorine oxalic acid boracic acid lithium

InactiveCN101139352AImprove solubilityImprove high temperature cycle performanceGroup 3/13 element organic compoundsLithium compoundLithium-ion battery

The present invention discloses a preparation method of the difluoride lithium oxalate borate. The method is characterized in that the compounds containing the fluorin, boron, lithium and oxalate react at a certain temperature and under a certain pressure to produce the crude material of the difluoride lithium oxalate borate; then the organic solvent is used for extracting and purifying; finally, the recrystallization and vacuum drying are done to get the battery-level lithium fluoride oxalate borate. The advantage is that the preparation method of the difluoride lithium oxalate borate can improve the high-temperature and low-temperature performance, the cycle performance, power characteristics and other comprehensive performances of the lithium-ion battery.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

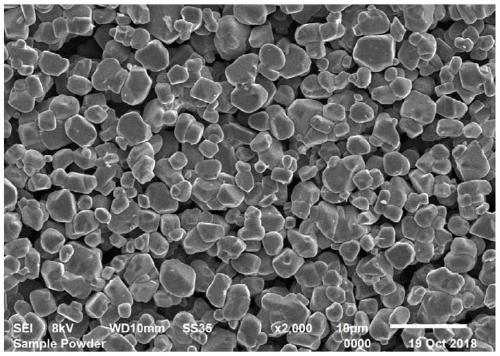

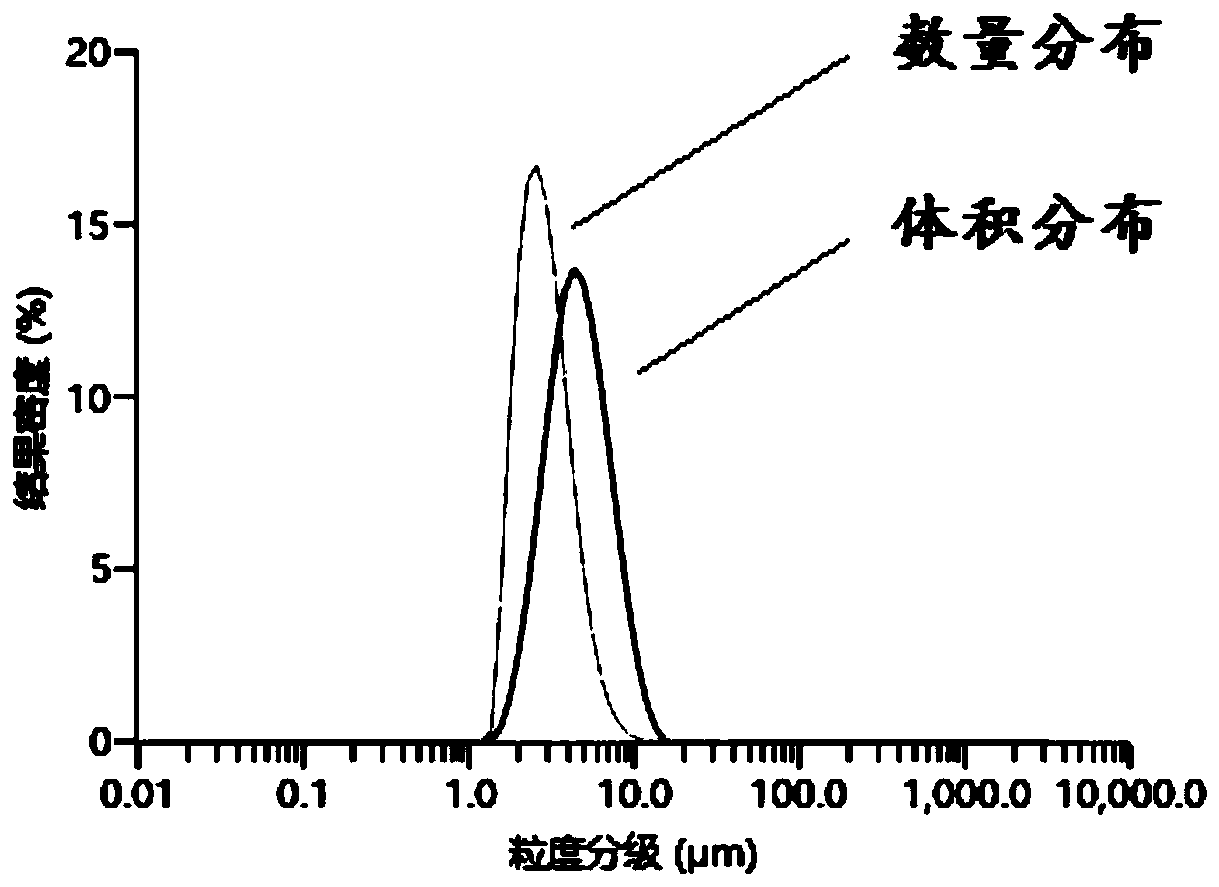

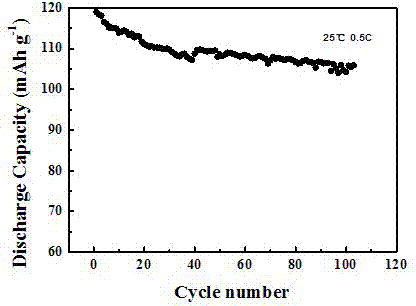

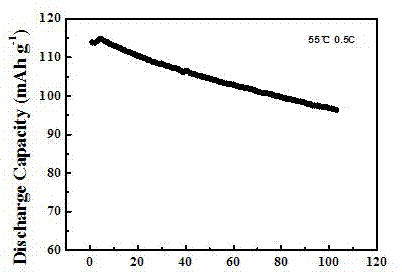

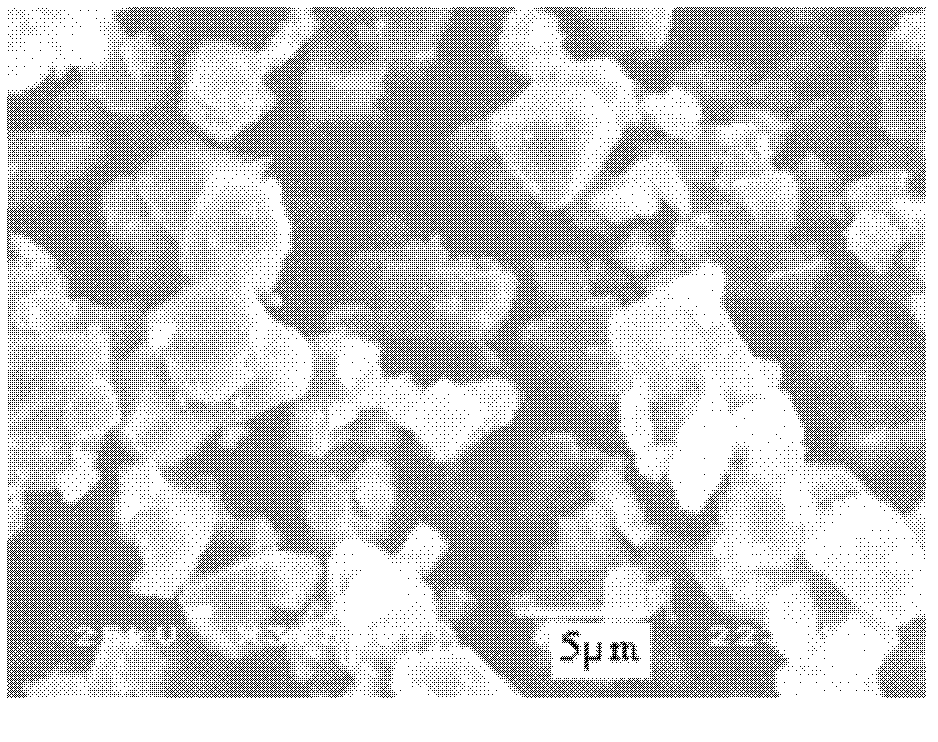

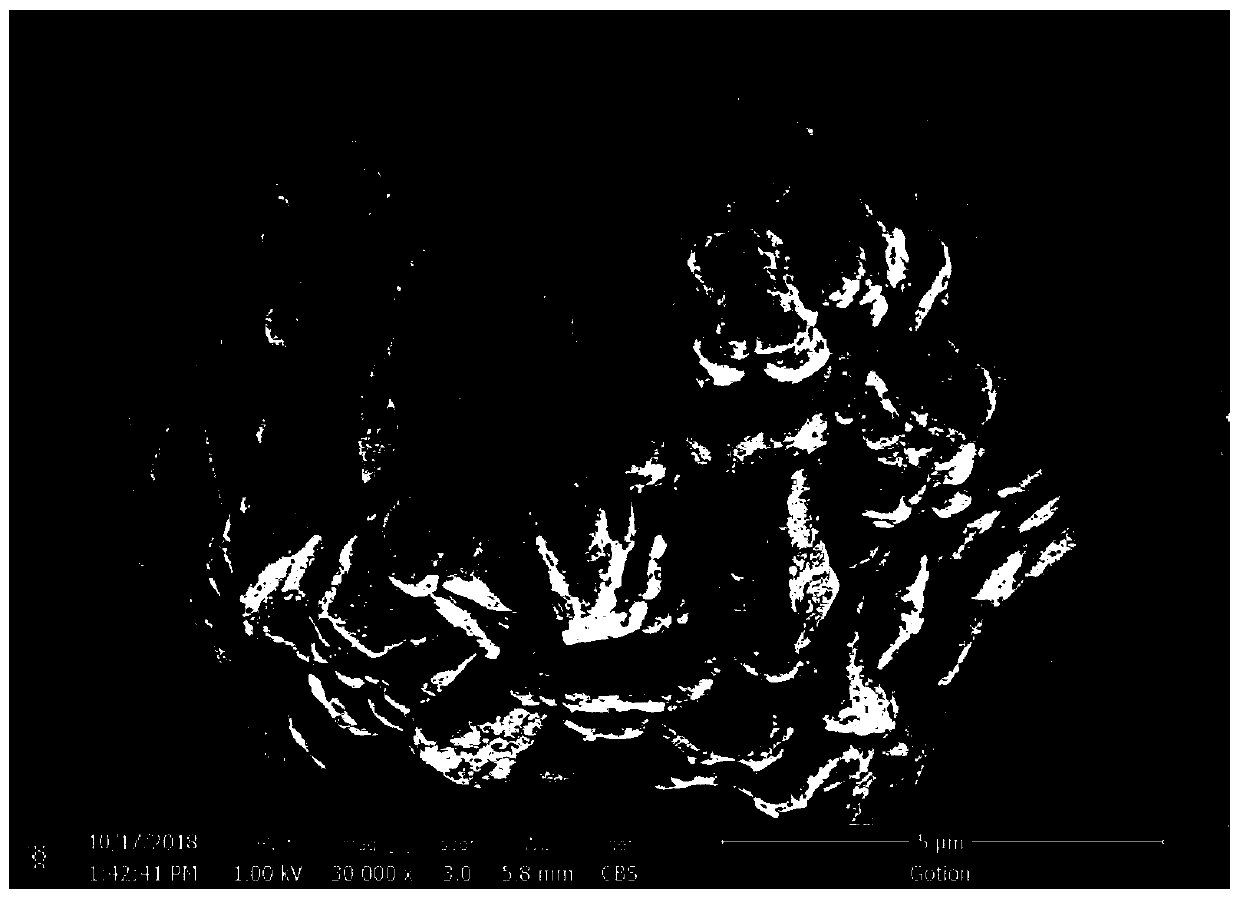

Method for preparing high-nickel long-cycle single-crystal lithium ion battery positive-pole material

InactiveCN110451585AImprove uniformityImprove stabilityCell electrodesSecondary cellsNickel saltLithium hydroxide

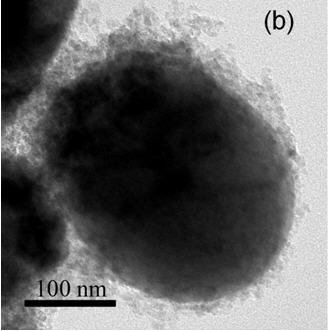

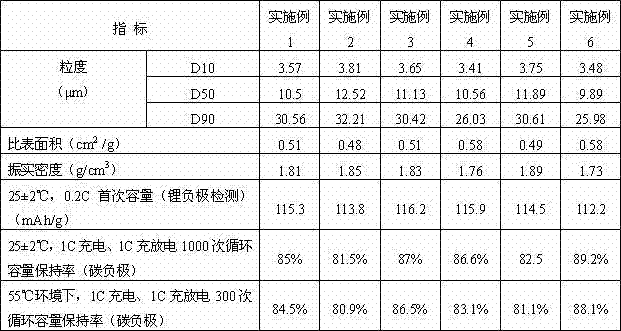

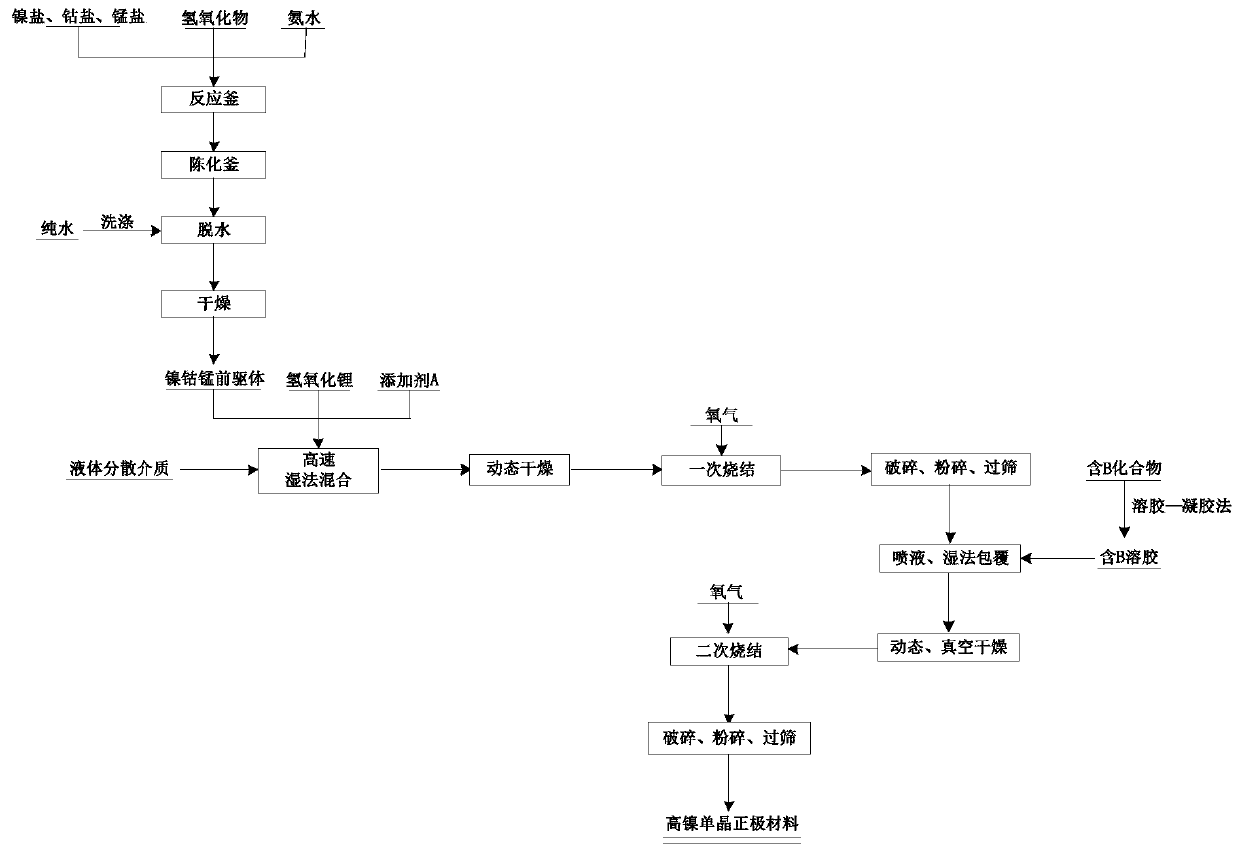

The invention relates to a method for preparing a high-nickel long-cycle single-crystal nickel-cobalt-manganese (NCM) lithium ion battery positive-pole material. The preparation method comprises the following steps: (1) mixing a soluble nickel salt, a cobalt salt, a manganese salt, an alkali metal hydroxide and ammonia water, and enabling the mixture to flow into a reaction kettle for constant-temperature coprecipitation to obtain a high-nickel NCM ternary precursor material; (2) uniformly mixing the high-nickel NCM ternary precursor, lithium hydroxide and an additive A in a wet high-speed mixing mode, carrying out drying, then carrying out primary sintering in an oxygen-enriched atmosphere to obtain a spherical high-nickel NCM ternary positive-pole material; (3) carrying out crushing, smashing and sieving to obtain a high-nickel NCM ternary positive-pole material; and (4) carrying out wet mixing and drying on the high-nickel NCM ternary positive-pole material with a coating agent B, carrying out secondary sintering in an oxygen-enriched atmosphere, and carrying out crushing, smashing and sieving to obtain the high-nickel single-crystal NCM lithium ion battery positive-pole material. The positive-pole material prepared by the method has the advantages of high capacity, good cycle performance, high compaction density and the like.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

Preparation method of electrolyte used for lithium manganate power battery at high temperature

InactiveCN103715458AImprove performanceReduce solubilitySecondary cells servicing/maintenanceElectrolyte accumulators manufacturePower batteryOrganic solvent

The invention provides a preparation method of an electrolyte used for a lithium manganate power battery at a high temperature, and relates to the technical field of lithium manganate power batteries. The components in the formula of the electrolyte comprise a non-aqueous organic solvent, a lithium salt, a high temperature additive, 0.1-5% by mass of a film forming additive, 0.1-10% by mass of a fire retardation additive, 0.1-10% by mass of an overcharge-preventing additive and 0.001-1% by mass of a stabilizer. The preparation method comprises: at a room temperature, weighing a film forming additive, a non-aqueous organic solvent, a high temperature additive, an overcharge-preventing additive, a fire retardation additive, a stabilizer and a lithium salt in a glove box filled with argon, pouring the raw materials into a beaker, placing on a magnetic stirrer, controlling the stirring rate until completely dissolving the lithium salt, and uniformly mixing various solvents so as to obtain the non-aqueous electrolyte, wherein the non-aqueous electrolyte has excellent high temperature cycle performance and excellent safety.

Owner:JIANGXI YOULI NEW MATERIALS

A high-voltage electrolyte for a lithium ion battery and a lithium ion battery using the electrolyte

InactiveCN109244529AImprove low temperature performanceImprove high temperature cycle performanceSecondary cellsHigh temperature storageDecomposition

A high-voltage electrolyte for a lithium ion battery and a lithium ion battery using the electrolyte are disclosed. The high-voltage electrolyte for the lithium ion battery comprises lithium salt, anorganic solvent and an additive. Wherein the organic solvent comprises one or more of a chain carbonate esters, cyclic carbonate esters, carboxylic esters, silicon-substituted organic solvents, wherein the additive comprises a polynitrile compound, and the preparation method of the lithium ion battery comprises injecting the high-voltage electrolyte for the lithium ion battery into a sufficientlydried lithium cobalt oxide / graphite soft-clad battery of 4.45 V, carrying out the steps of shelving at 45 DEG C, high-temperature clamping formation and secondary sealing. The high-voltage electrolytefor lithium ion battery of the present invention can effectively inhibit metal dissolution, reduce decomposition gas production of the electrolyte, protect the positive electrode, improve high-temperature cycling performance and high-temperature storage performance of the battery, reduce the increase of impedance, and improve low-temperature performance of the lithium ion battery.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

Functional additive for lithium ion battery electrolyte, lithium ion battery electrolyte and lithium ion battery

ActiveCN106848404AGood high temperature performanceImprove thermal stabilityFinal product manufactureElectrolyte accumulators manufactureOrganic solventPhosphate

The invention relates to a functional additive for a lithium ion battery electrolyte, the lithium ion battery electrolyte and a lithium ion battery and belongs to the technical field of lithium ion batteries. The functional additive is prepared from the components in parts by weight as follows: 0.5-3 parts of vinylene carbonate, 0.1-2 parts of lithium difluoro(oxalato) borate, 0.1-2 parts of lithium difluoro phosphate, 3-5 parts of fluorobenzene and 0.1-1 part of methylene methanedisulfonate. The electrolyte comprises lithium salt, an organic solvent and the functional additive, wherein the mass percents of the components of the functional additive in the electrolyte are as follows: 0.5%-3% of vinylene carbonate, 0.1%-2% of lithium difluoro(oxalato) borate, 0.1%-2% of lithium difluoro phosphate, 3%-5% of fluorobenzene and 0.1%-1% of methylene methanedisulfonate. The invention further relates to the lithium ion battery using the electrolyte. The high-temperature cycle performance of the lithium ion battery is significantly enhanced.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

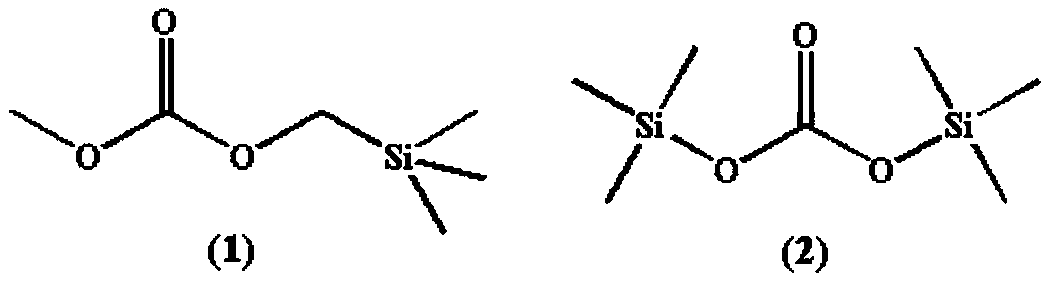

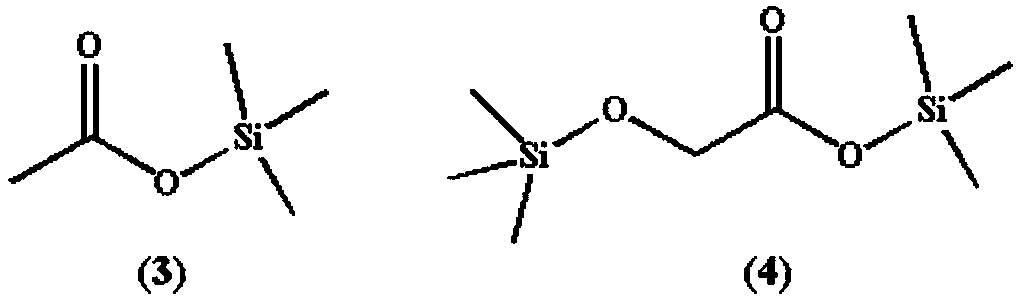

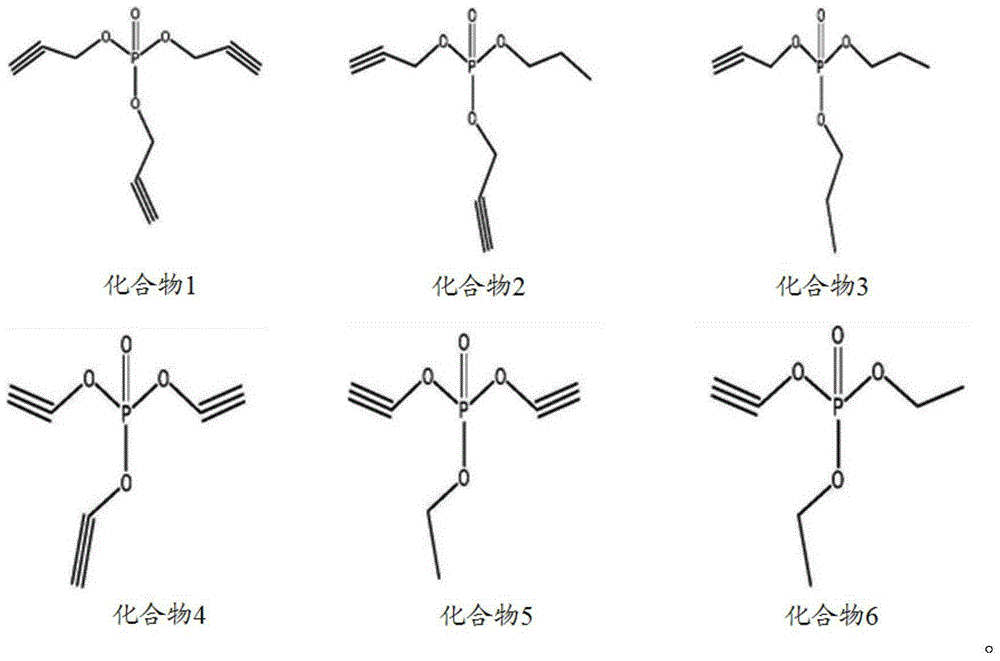

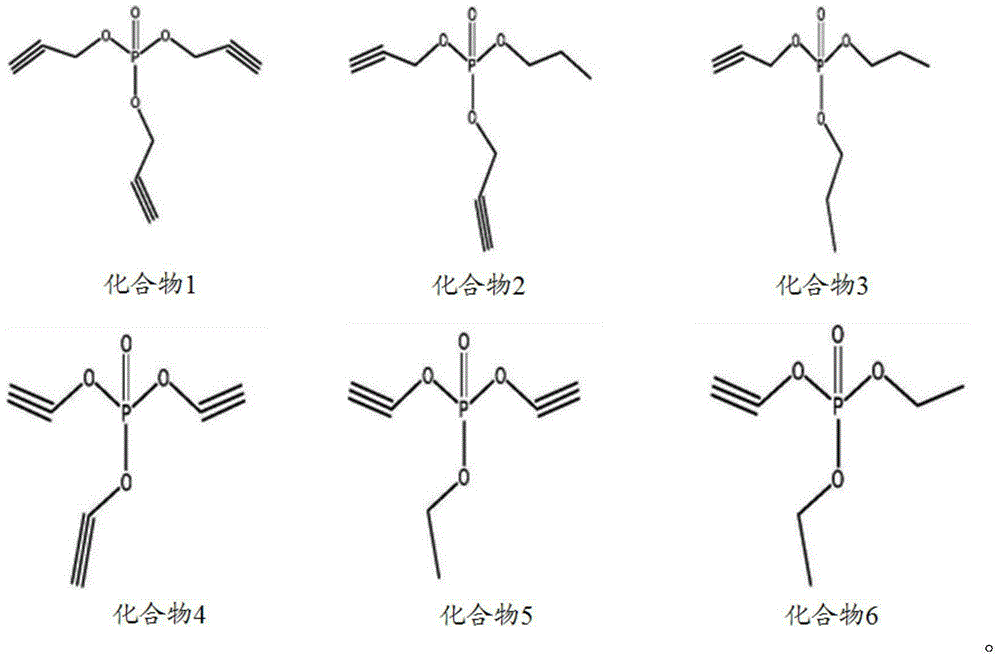

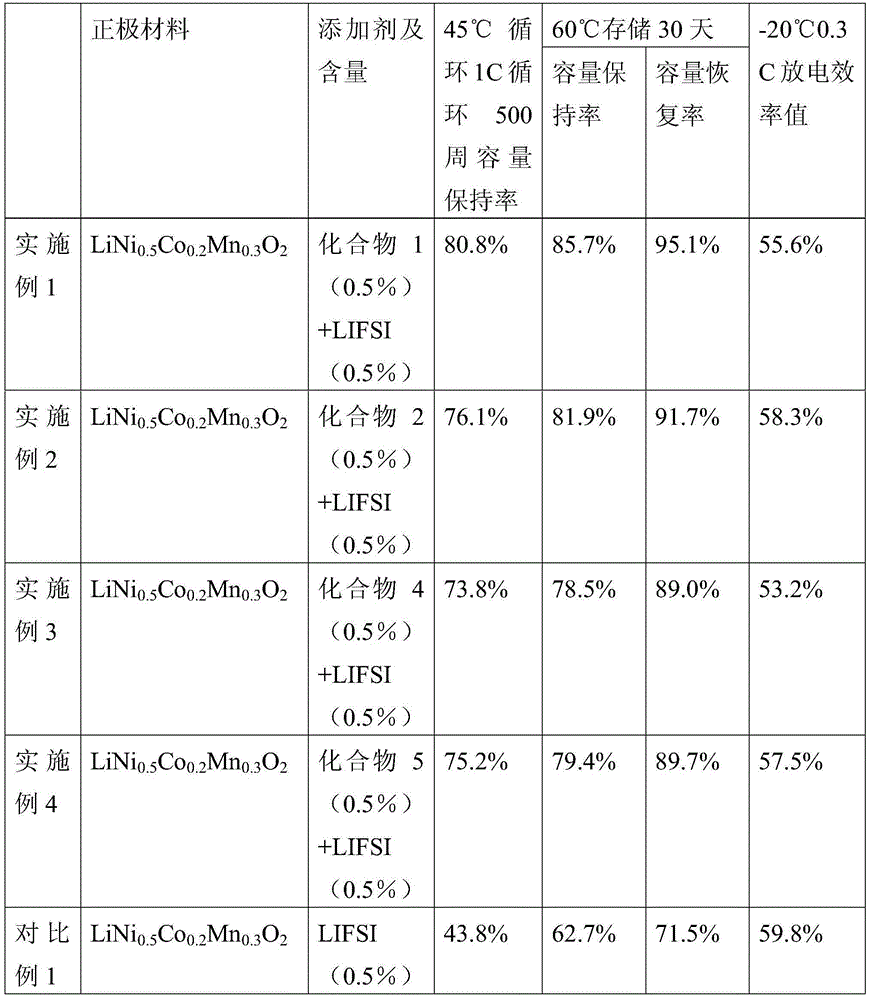

Non-aqueous electrolyte of lithium ion battery and lithium ion battery

InactiveCN105161763AImprove high temperature performanceLower impedanceSecondary cellsPhosphateLithium-ion battery

The invention discloses a non-aqueous electrolyte of a lithium ion battery and the lithium ion battery. The electrolyte comprises a non-aqueous organic solvent, a lithium salt and an additive, wherein the additive comprises substances of (A) and (B): (A) is shown in the description, wherein R1, R2 and R3 are respectively and independently selected from alkyl with carbon atoms of 1to 4, and at least one of the R1, the R2 and the R3 is unsaturated alkyl containing triple bonds; and (B) tris(trimethylsilyl) phosphate. By the non-aqueous electrolyte of the lithium ion battery, disclosed by the invention, the lithium ion battery acquires low impedance, and favorable low-temperature performance and high-temperature performance.

Owner:SHENZHEN CAPCHEM TECH CO LTD

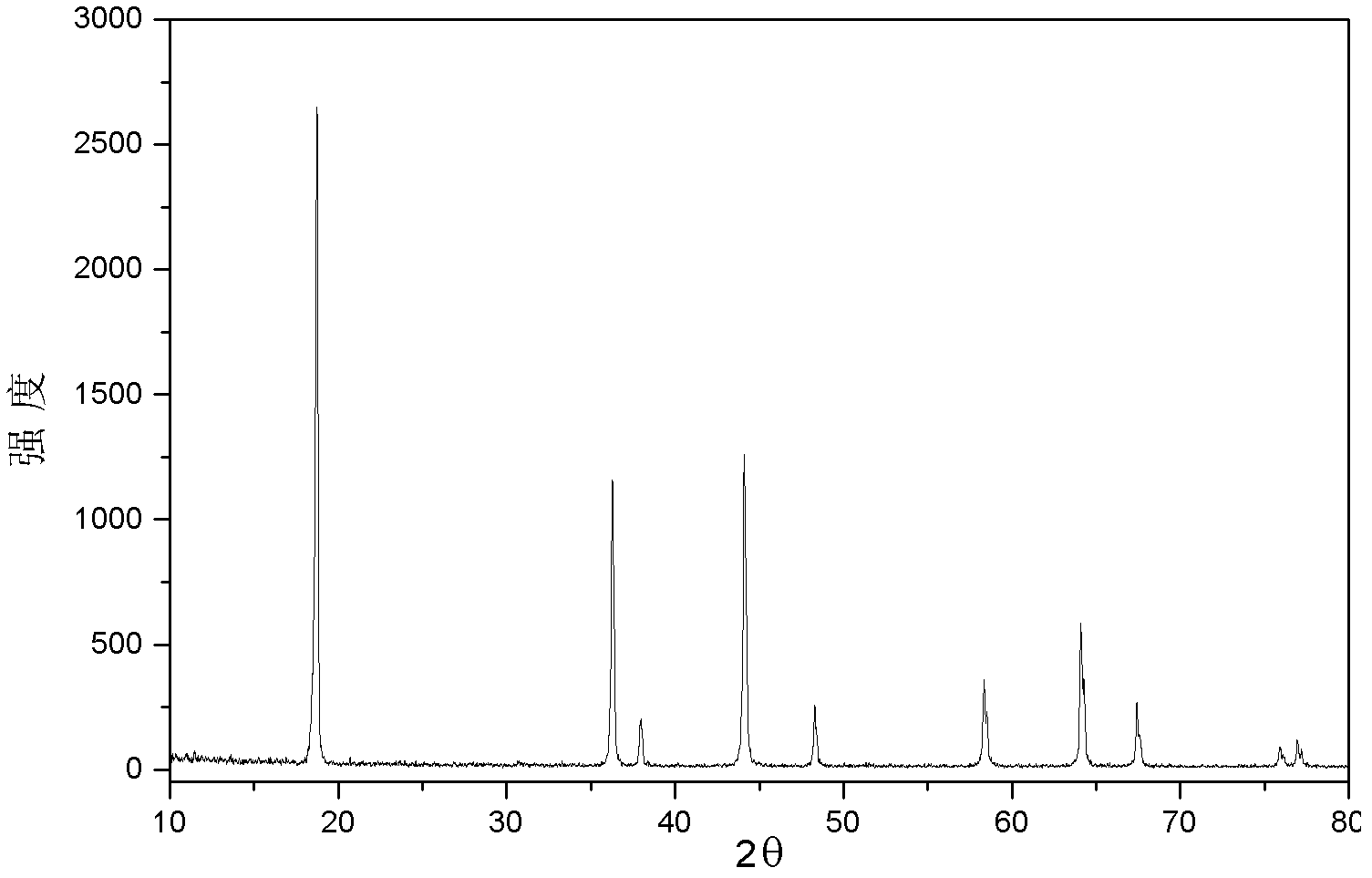

Method for preparing spinel lithium manganate serving as cathode material of lithium ion power battery

InactiveCN102306767AThe crystal structure has good cycle stabilityImprove high temperature cycle performanceCell electrodesSource materialManganate

The invention relates to a method for preparing spinel lithium manganate serving as a cathode material of a lithium ion power battery. The method comprises the following steps of: 1) selecting raw materials, namely mixing manganese oxide, a lithium source material and doped metal element oxide; and 2) uniformly mixing the mixture obtained in the step 1), feeding into a continuous sintering furnace, performing high-temperature gradient sintering (namely sintering at the temperature of between 1,000 and 1,200 DEG C for 3 to 5 hours in the first sintering step, sintering at the temperature of between 800 and 900 DEG C for 4 to 6 hours in the second step and sintering at the temperature of between 500 and 700 DEG C for 5 to 8 hours in the third step), introducing compressed air simultaneously, naturally cooling after the sintering is finished, grinding, performing grading treatment, and thus obtaining the cathode material. The invention has the advantages that: the method has a simple process; the crystallinity and the surface state of lithium manganate are controlled through the high-temperature sintering, so that the dissolving rate of manganese is reduced; and then oxygen defects are controlled or overcome through low-temperature sintering.

Owner:WUHAN UNIV OF TECH

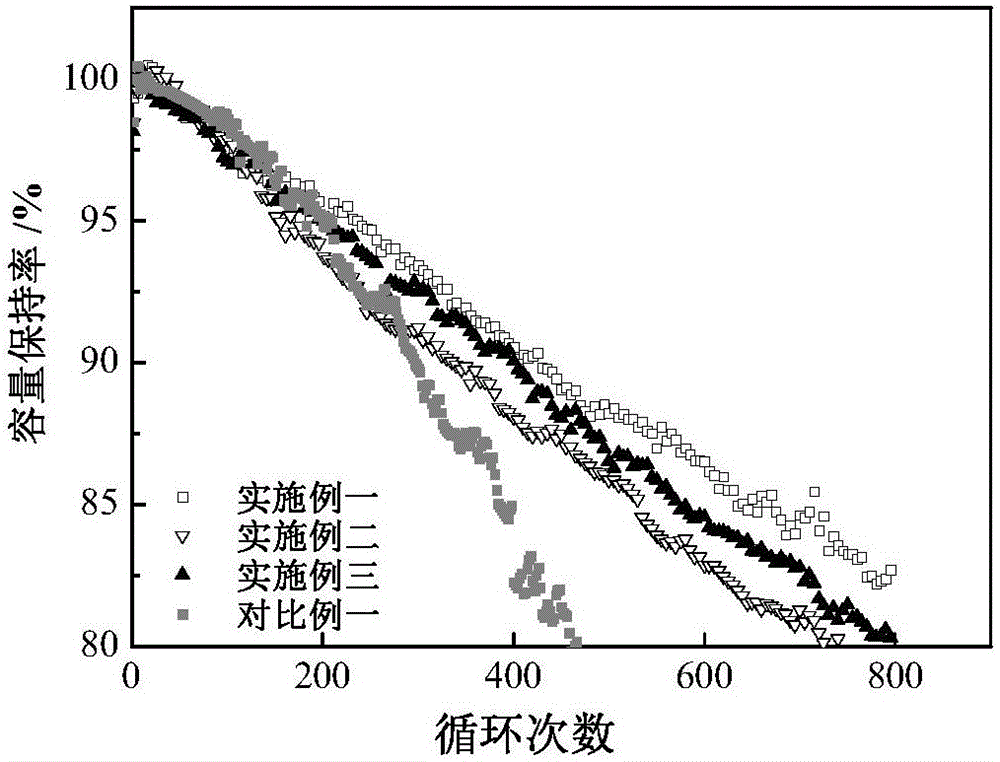

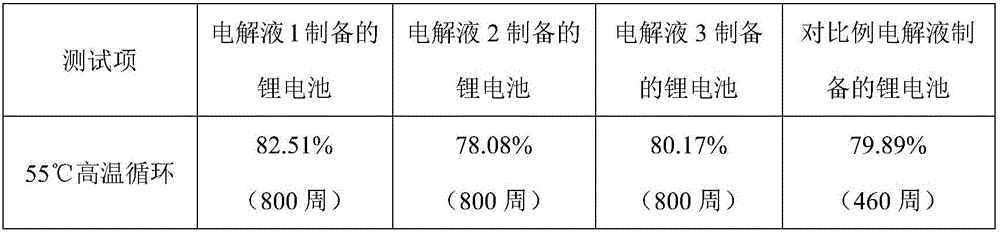

Electrolyte and lithium ion battery comprising the same

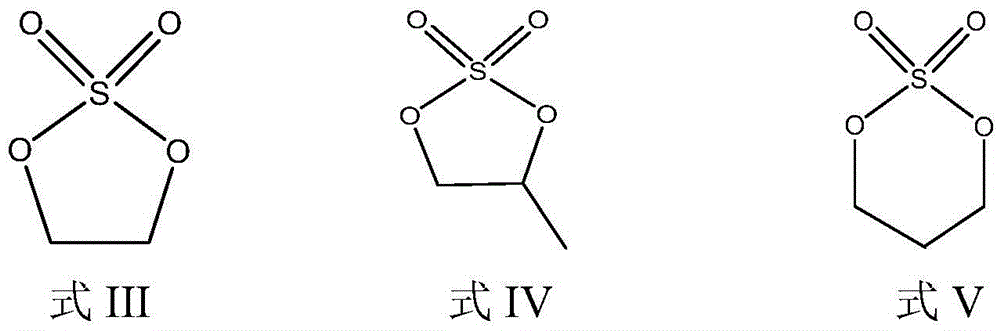

ActiveCN105098242AImprove high temperature cycle performanceImproved magnification performanceFinal product manufactureSecondary cellsOrganic solventSulphate Ion

The application relates to an electrolyte and a lithium ion battery comprising the electrolyte. The electrolyte comprises a lithium salt, an organic solvent and additives. The additives comprise difluoro lithium phosphate and a cyclic sulphate ester compound. The electrolyte provided by the application is applied to the lithium ion battery. Specifically, after the electrolyte is applied to the lithium ion battery whose pole piece has heavy coating weight at the single-sided active substance layer, not only high-temperature cycle performance of the lithium ion battery is improved, but also the rate capability and the low-temperature discharging performance of the lithium ion battery is improved.

Owner:NINGDE AMPEREX TECH

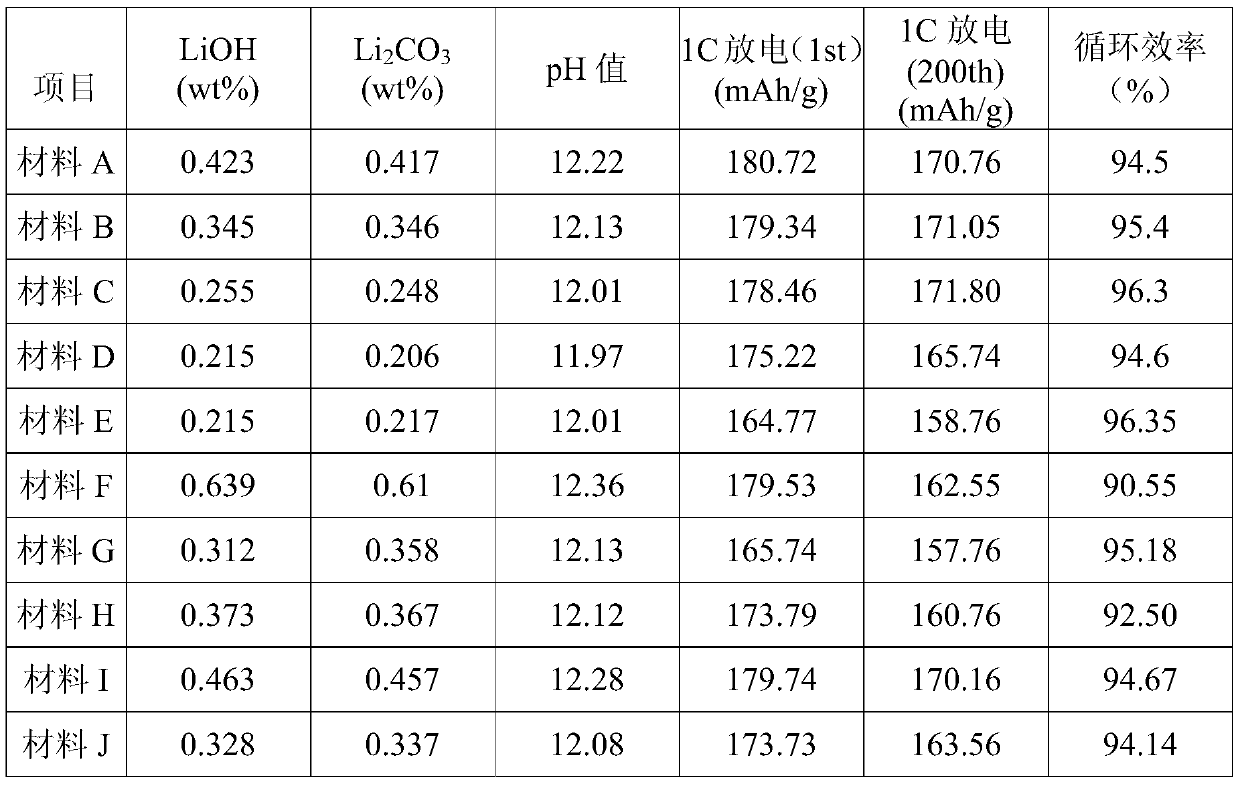

Modified low residual alkali type high nickel ternary cathode material and preparation method and application thereof

InactiveCN109768254AResidual alkalinity and pH decreaseRemoval of residual alkaliCell electrodesSecondary cells servicing/maintenanceSolventIon

The invention provides a modified low residual alkali type high nickel ternary cathode material and a preparation method and application thereof. According to the preparation method, a high nickel ternary cathode material and hydrogen phosphate are dispersed in a solvent uniformly, then an obtained mixed solution is stoved, then a stoved product is sintered, so as to enable residual alkali on thesurface of the high nickel ternary cathode material and hydrogen phosphate to react to generate phosphate. The process shows how the modified low residual alkali type high nickel ternary cathode material is produced. Remarkable reduction of residual alkali and pH of the modified low residual alkali type high nickel ternary cathode material help prevent residual alkali from directly contacting withelectrolyte to produce side effects, and cause high ionic conductivity between reaction interfaces of the modified low residual alkali type high nickel ternary cathode material and the electrolyte, thereby reducing impedance; further, the rate performance of the material is improved remarkably; and high temperature cycle performance of the material is improved remarkably.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

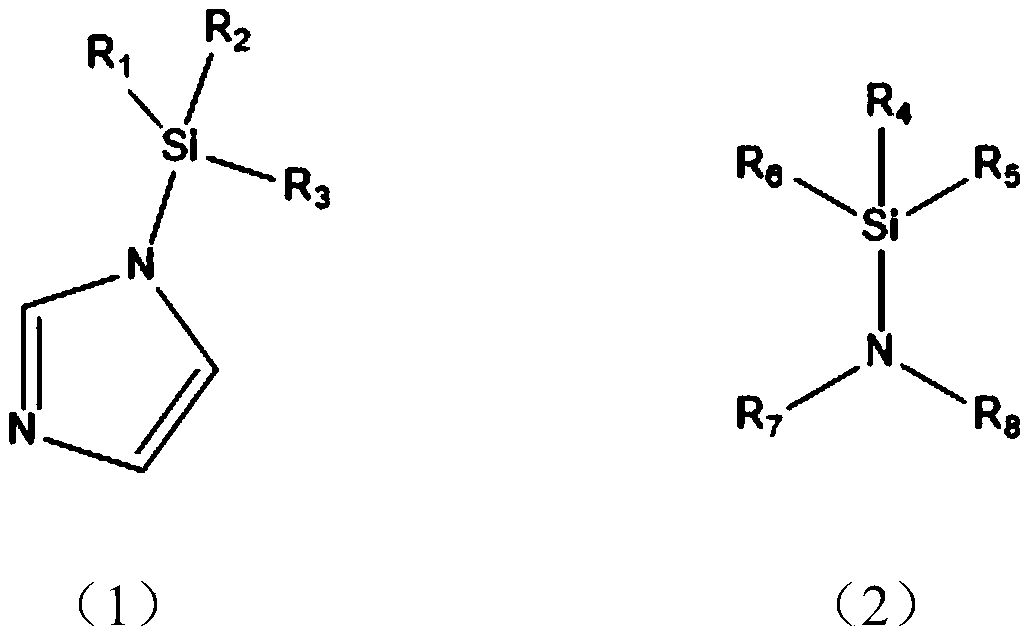

High-temperature high-voltage non-aqueous electrolyte and lithium ion battery containing non-aqueous electrolyte

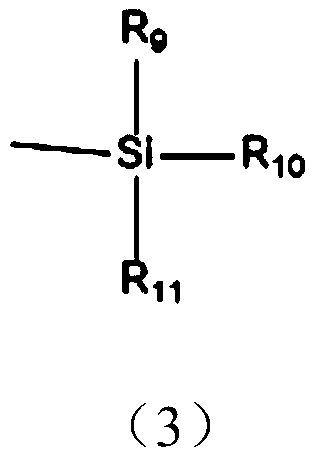

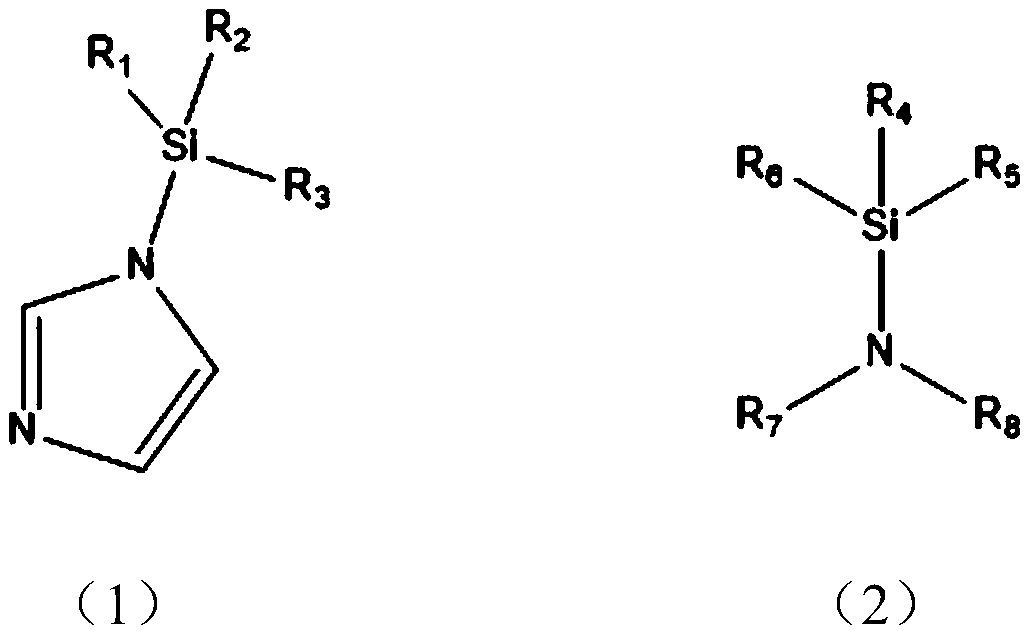

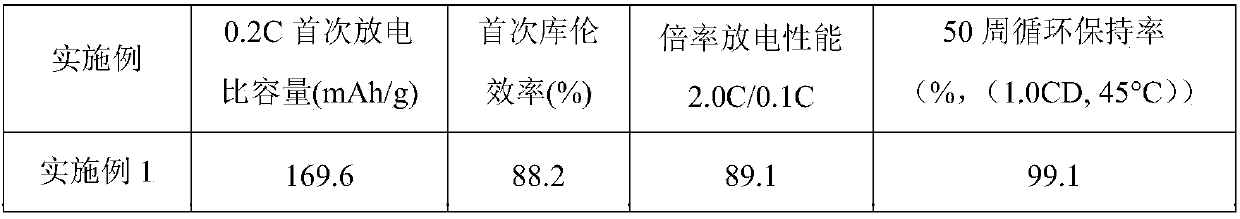

ActiveCN109818064AImprove cycle performanceGood high and low temperature performanceSecondary cellsHigh temperature storageSodium-ion battery

The invention relates to the technical field of lithium ion batteries, in particular to a high-temperature high-voltage non-aqueous electrolyte and a lithium ion battery containing the non-aqueous electrolyte. The high-temperature high-voltage non-aqueous electrolyte comprises a lithium salt, a non-aqueous solvent and an additive, wherein the additive comprises a first borate additive, a second nitrogen-containing lithium salt additive, a third silicon-nitrogen-based additive and a fourth sulfonate and sulfate mixed additive. According to the present invention, after the various additives areproperly proportioned, the advantages of the additives can be provided, the disadvantages of the additives can be mutually inhibited, the high-temperature storage performance of the battery is improved through the synergistic effect of the additives, the high-temperature cycle performance of the battery is improved, and the application prospect is good under the conditions of high temperature andhigh voltage.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

Lithium ion power battery with good safety performances

ActiveCN103746139AImprove cycle lifeImprove securityElectrode carriers/collectorsSecondary cellsElectrolytic agentPower battery

The invention relates to the technical field of lithium ion power batteries, and particularly relates to a lithium ion power battery with good safety performances. The lithium ion power battery includes a positive pole, a diaphragm, a negative pole and an electrolyte, the negative pole comprises a negative pole current collector and a negative pole active material layer, the negative pole active material layer includes a negative pole active material and a conductive material, the negative pole active material is lithium titanate, and the ratio of the negative pole cathode and the positive pole capacity is 0.65-0.68. The lithium ion power battery effectively increases the battery cycle life, the battery safety performances and the battery large-current charge and discharge performances.

Owner:东莞维科电池有限公司

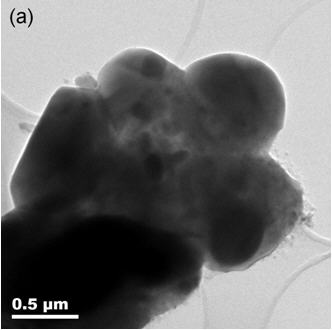

Preparation method of coated ternary nickel-cobalt-manganese lithium oxide positive electrode material

InactiveCN109638232AHigh ion conductivityImprove high temperature cycle performanceCell electrodesSecondary cellsLithium oxideElectrical conductor

The invention discloses a preparation method of a coated ternary nickel-cobalt-manganese lithium oxide positive electrode material. The preparation method comprises the following steps of (1) preparing a ternary nickel-cobalt-manganese lithium precursor; (2) preparing an oxide-coated ternary nickel-cobalt-manganese lithium precursor; and (3) preparing an ion conductor oxide-coated ternary nickel-cobalt-manganese lithium positive electrode material. By the preparation method of the positive electrode material, a lithium ion is easy to de-intercalate from a surface layer of the material, and thehigh-temperature circulation performance of the material is improved; a coating layer does not react with an electrolyte, interface side reaction caused by contact of the main body material and the electrolyte is reduced, and the safety of the material is improved; the processing performance of a pole plate during the uniform coating process is improved, and the high-temperature circulation performance of the material after being assembled into a battery is improved; and the prepared positive electrode material does not need to be subjected to a roasting process for two times, the energy consumption is reduced, and the cost is reduced.

Owner:宁夏汉尧富锂科技有限责任公司

Method for preparing cesium tungstate of tungsten bronze structure

ActiveCN109368702AIncrease compaction densityDistortion activationTungsten compoundsAir atmosphereTungstate

The invention provides a method for preparing cesium tungstate of a tungsten bronze structure. The method comprises the following steps: (1) mixing cesium carbonate and tungsten oxide with deionized water so as to obtain a mixture A, adding a trace amount of sintering aids, and performing normal-temperature wet-method ball milling so as to obtain mixed slurry; (2) taking out the mixed slurry, drying, and carrying out thermal treatment on the dried material in a mixed atmosphere of H2 and N2 at 450-500 DEG C for 2-5 hours; (3) performing secondary sintering on the material obtained in step (2)so as to obtain a blue material, wherein the sintering conditions are that the sintering temperature is 800-1000 DEG C, the temperature keeping time is 1-4 hours, and an air atmosphere is provided; (4) carrying out ball milling and crushing on the blue material obtained in step (3), thereby obtaining blue cesium tungstate powder. By adopting the method, complex preparation processes in the prior art are simplified, the method is environmentally friendly, the cost is low, compared with a conventional solid-phase synthesis method, the method is simple to operate, and a process of one-time atmosphere protection sintering is avoided.

Owner:ANHUI SHENGHONG ELECTRONICS

Electrolyte for improving high temperature performance of lithium manganate power battery and lithium manganate power battery

InactiveCN103985903AImprove high temperature cycle performanceImprove high temperature performanceSecondary cells servicing/maintenanceOrganic electrolytesPower batteryElectrolyte

The invention provides an electrolyte for improving high temperature performance of a lithium manganate power battery and the lithium manganate power battery. The electrolyte comprises the following components: 75wt%-88wt% of non-aqueous organic solvent, 10wt%-17wt% of lithium salt, 0.5wt%-6wt% of film forming additive, 0.5wt%-5wt% of high temperature additive, 0.5wt%-3wt% of surfactant and 0.001wt%-1wt% of stabilizing agent; the electrolyte is capable of inhibiting the capacity reduction of spinel LiMn2O4 under high temperature through control of proportion of non-aqueous organic solvent, application of combination of LiPF6 and novel lithium salt, and addition of the film forming additive, the high temperature additive, the surfactant and the stabilizing agent which have cooperative effect. The high temperature cycle performance of the lithium manganate power battery by using the electrolyte can be obviously increased.

Owner:CENT SOUTH UNIV

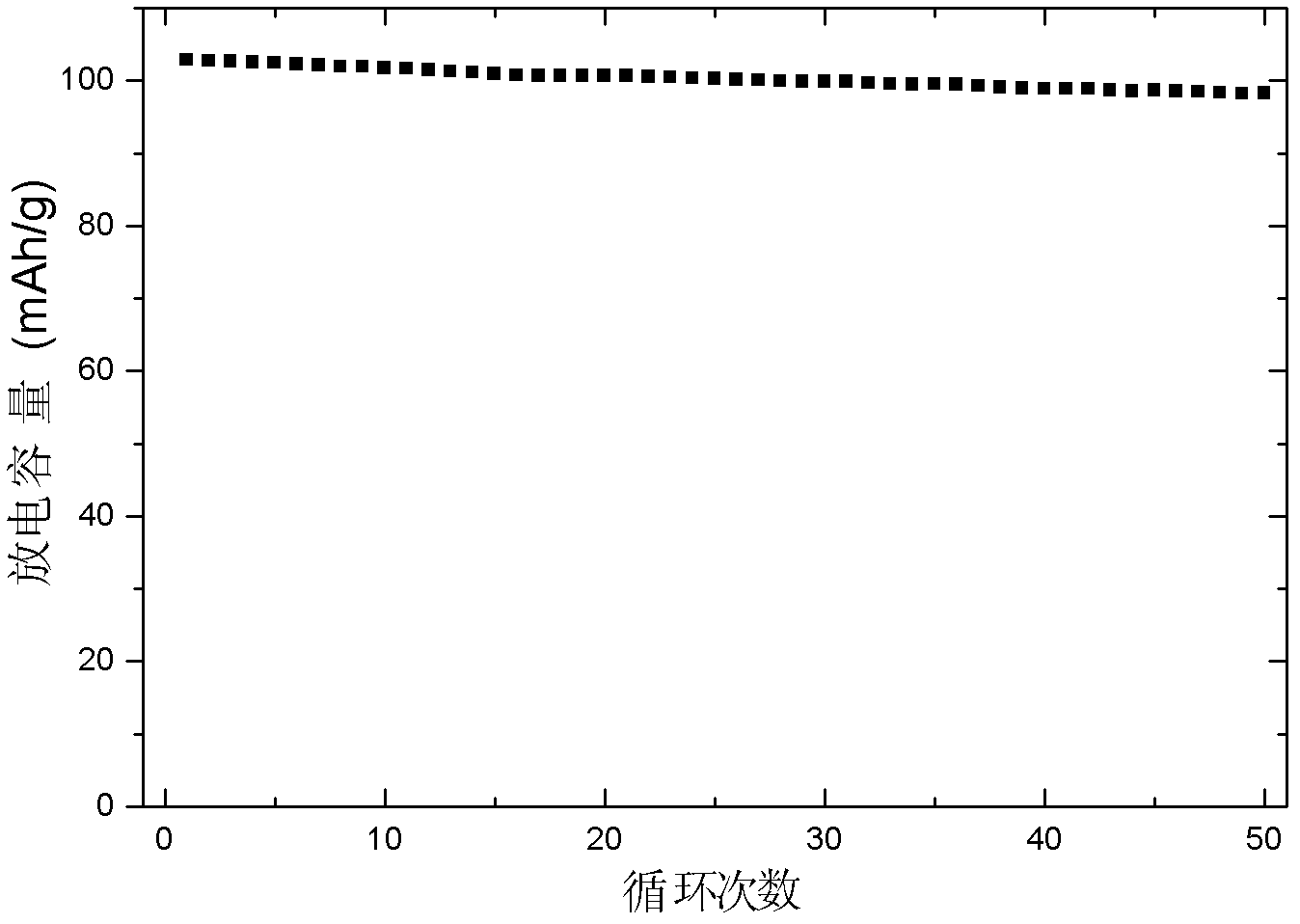

Long-circulation and high-power lithium ion battery positive electrode material and preparation method thereof

ActiveCN112768685ARaise room temperatureImprove high temperature cycle performancePolycrystalline material growthCell electrodesElectrical batteryPhysical chemistry

The invention discloses a long-circulation and high-power lithium ion battery positive electrode material, of which the molecular formula is LiNi<x>Co<y>Mn<1-x-y-z>Z O<2>. The long-circulation and high-power lithium ion battery positive electrode material comprises a single crystal or quasi-single crystal shell layer and a hollow part, wherein the single crystal or quasi-single crystal shell layer is formed by mutual fusion of primary particles, and the volume of the hollow part of secondary particles accounts for 0.8-50% of the volume of the whole secondary particles. The invention further discloses a preparation method, which comprises the following steps of: preparing a hydroxide precursor with crystallinity and morphology difference in the radial direction; and mixing the precursor with a lithium compound, and carrying out two-stage sintering on the mixture to obtain the lithium ion battery positive electrode material, wherein the first sintering is rapid heating, the temperature of the second sintering is higher than that of the first stage, and the second sintering enables the primary particles to be fused and mutually fused to form a single single crystal shell layer. The lithium ion battery positive electrode material disclosed by the invention is good in normal-temperature and high-temperature cycle performance and safety performance, can improve mechanical and electrochemical performance and compaction density, has the characteristics of quick charge, high capacity, high voltage, high cycle and low cost, and can be suitable for high-power motor vehicles.

Owner:HUNAN CHANGYUAN LICO CO LTD +1

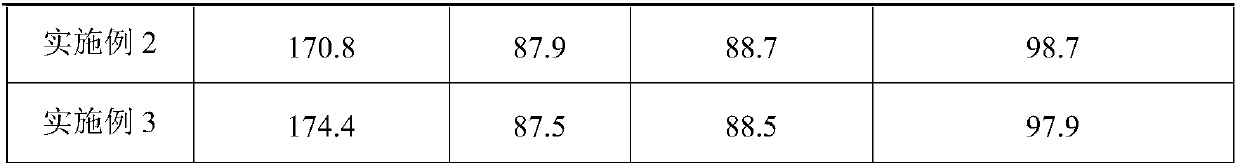

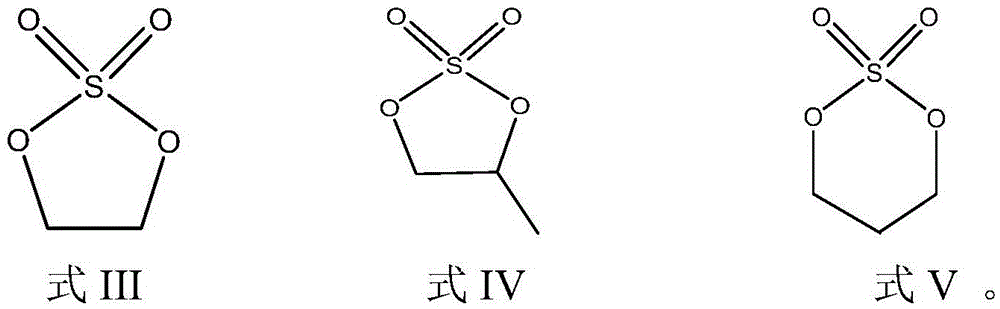

Lithium ion battery non-aqueous electrolyte and lithium ion battery

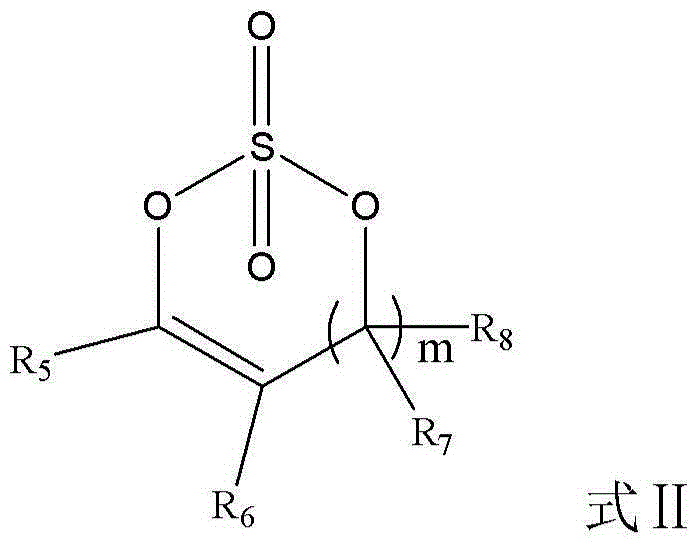

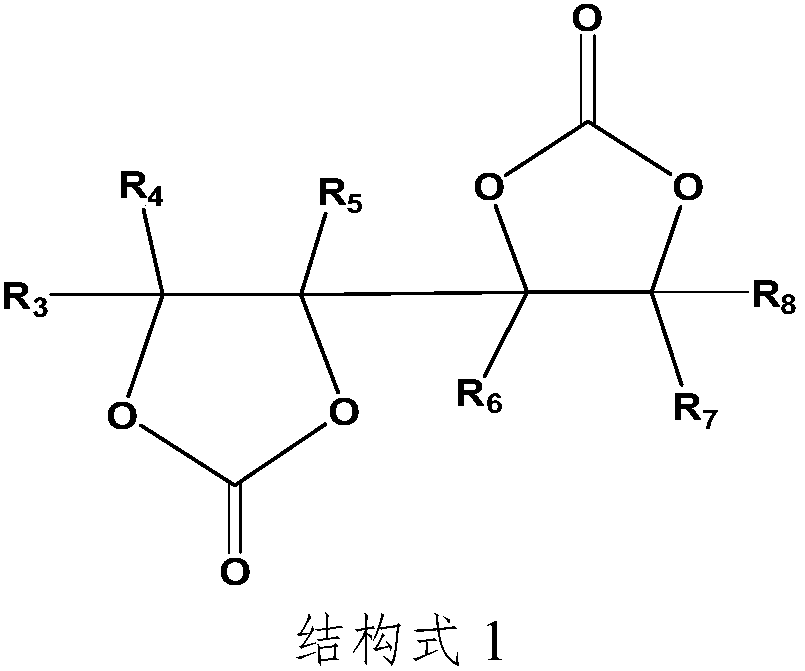

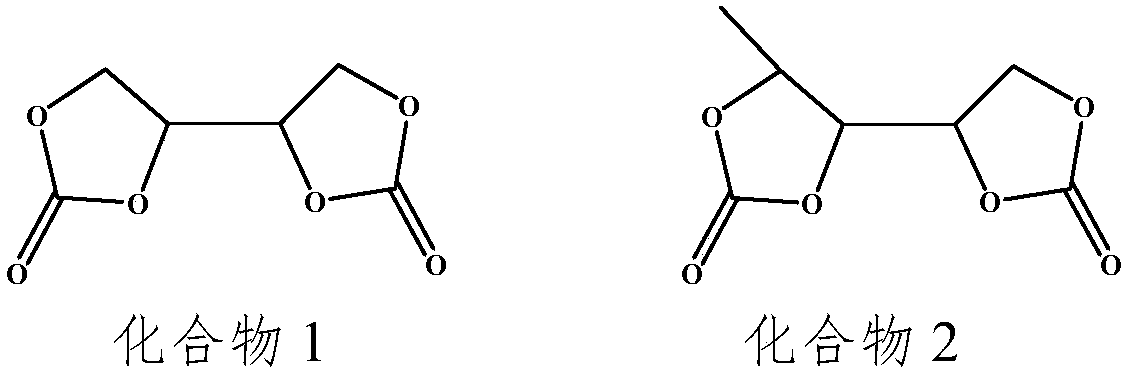

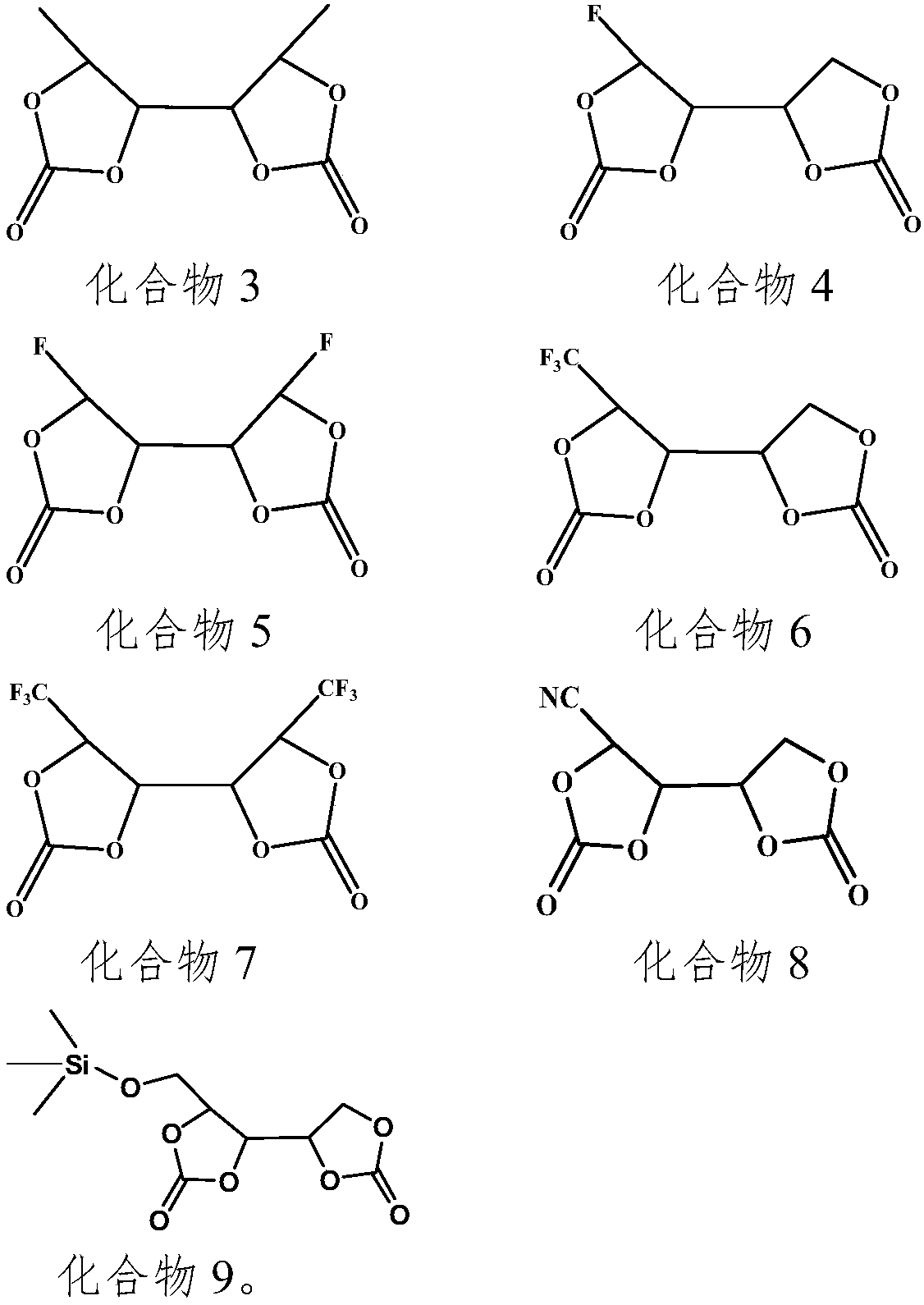

ActiveCN109950621AInhibits high temperature storage inflationImproved high temperature storage capacitySecondary cells servicing/maintenanceOrganic electrolytesHigh temperature storageStructural formula

In order to overcome the problems that a current lithium ion battery is poor in high-temperature storage performance and high-temperature cycle performance, the present invention provides a lithium ion battery non-aqueous electrolyte. The lithium ion battery non-aqueous electrolyte comprises a bicyclic sulfate compound and a compound A shown in a structural formula 1, in the formula 1, R3, R4, R5,R6, R7 and R8 are respectively selected from hydrogen atoms, fluorine atoms or a group containing 1-5 carbon atoms. The present invention further discloses a lithium ion battery comprising the lithium ion battery non-aqueous electrolyte. The lithium ion battery non-aqueous electrolyte facilitates improvement of the high-temperature storage and high-temperature cycle performances.

Owner:SHENZHEN CAPCHEM TECH

Mixed positive material of lithium-ion power battery

InactiveCN103618084AImprove the shortcoming of low compaction densityIncrease compaction densityCell electrodesSecondary cellsPolypyrroleManganese

The invention belongs to the technical field of lithium-ion power batteries, and in particular relates to a mixed positive material of a high-capacity lithium-ion power battery. The mixed positive material comprises lithium iron phosphate A and a lithium nickel cobalt manganese ternary active substance B, wherein the surface of the A is coated with a polypyrrole layer; the median particle size of the A is smaller than or equal to 15 microns; the sizes of single-crystal particles of the B are greater than or equal to 1.0 microns; the surface of the B is coated with a metal fluoride layer. Compared with the prior art, the disadvantage of low compaction density caused by a ternary material is effectively overcome by reasonably optimizing the sizes of the single-crystal particles of the ternary material and the median particle size of the lithium iron phosphate, so that the mixed positive material has high compaction density; the surface of the lithium iron phosphate is coated with the polypyrrole layer and the surface of the ternary material is coated with the metal fluoride layer, so that the safety performance, the rate performance, the high-temperature cycling performance, the low-temperature performance and the safety performance of the lithium-ion power battery with the mixed positive material can be improved.

Owner:刘铁建

High-voltage functional electrolyte and preparation method and application therefor

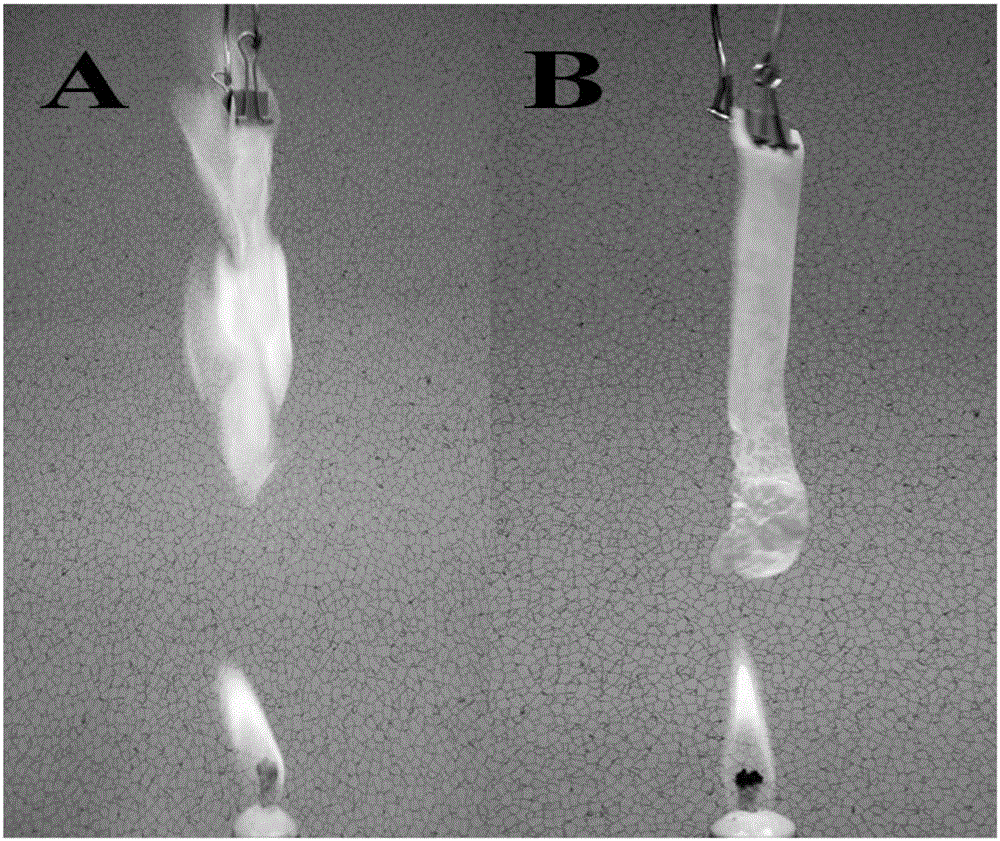

ActiveCN105870501AGood charge and discharge performanceInhibit surface activityFinal product manufactureElectrolyte accumulators manufacturePhosphateRoom temperature

The invention belongs to the technical field of the lithium ion battery, and discloses a high-voltage functional electrolyte and a preparation method and an application therefor. The high-voltage functional electrolyte is prepared by adding a functional additive into the common electrolyte, wherein the functional additive accounts for 0.25-5% of the common electrolyte based on mass percentage; and the structural formula of the functional additive is as shown in the formula (1). The functional additive which is diethyl (thiophene-2-methyl) phosphate can be used as the high-voltage film-forming agent and the flame-retardant additive of the lithium ion electrolyte; the electrolyte containing the functional additive is non-combustible; and the room-temperature and high-temperature cycling performances of the lithium ion battery prepared from the electrolyte are both improved under 3-5.0V, so that the high-voltage functional electrolyte is wide in the application prospect.

Owner:SOUTH CHINA NORMAL UNIVERSITY

High-temperature electrolyte solution of lithium ion battery

InactiveCN106252715AImprove stabilityImprove high temperature cycle performanceSecondary cellsOrganic solventSolvent

The invention discloses a high-temperature electrolyte solution of a lithium ion battery. The high-temperature electrolyte solution comprises an organic solvent, a lithium salt mixture and an additive; the solvent is the hybrid reagent of cyclic carbonate containing volume fraction of 0-40% and chainlike carbonate containing volume fraction of 60-100%, the lithium salt mixture is the mixture of lithium hexafluorophosphate containing lithium molar concentration of 1.0mol / L-1.4mol / L and the novel lithium salt, and the additive is the film-forming additive with mass concentration of 0-3%, or the film-forming additive with mass concentration of 0-3% added with the dehydration acid-removal additive with mass concentration of 0-2.0%. The high-temperature cyclic performance of the lithium ion battery prepared from the high-temperature electrolyte solution provided by the invention is effectively improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Non-aqueous electrolyte and lithium ion battery containing same

ActiveCN105633466AImprove high temperature cycle performanceImprove low temperature discharge performanceSecondary cells servicing/maintenanceOrganic electrolytesOrganic solventSulphate Ion

The invention relates to a non-aqueous electrolyte and a lithium ion battery containing the same. The electrolyte comprises a lithium salt, an organic solvent and additives, wherein the additives comprise cyclic annular sulphate compound and a sodium salt. When the electrolyte provided by the invention is applied to the lithium ion battery, the high-temperature cycling performance of the lithium ion battery is improved; and meanwhile, the rate capability and the low-temperature discharging performance of the lithium ion battery are greatly improved, and lithium separating out in the low-temperature charging process is lowered.

Owner:NINGDE AMPEREX TECH

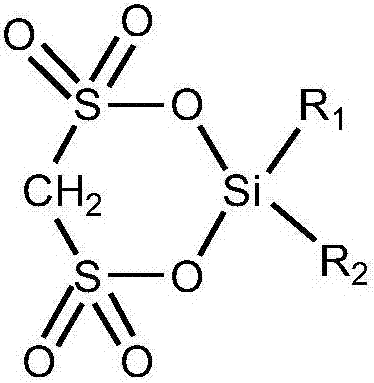

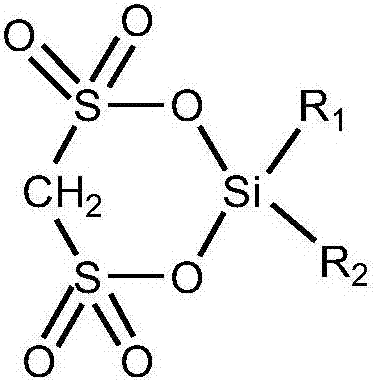

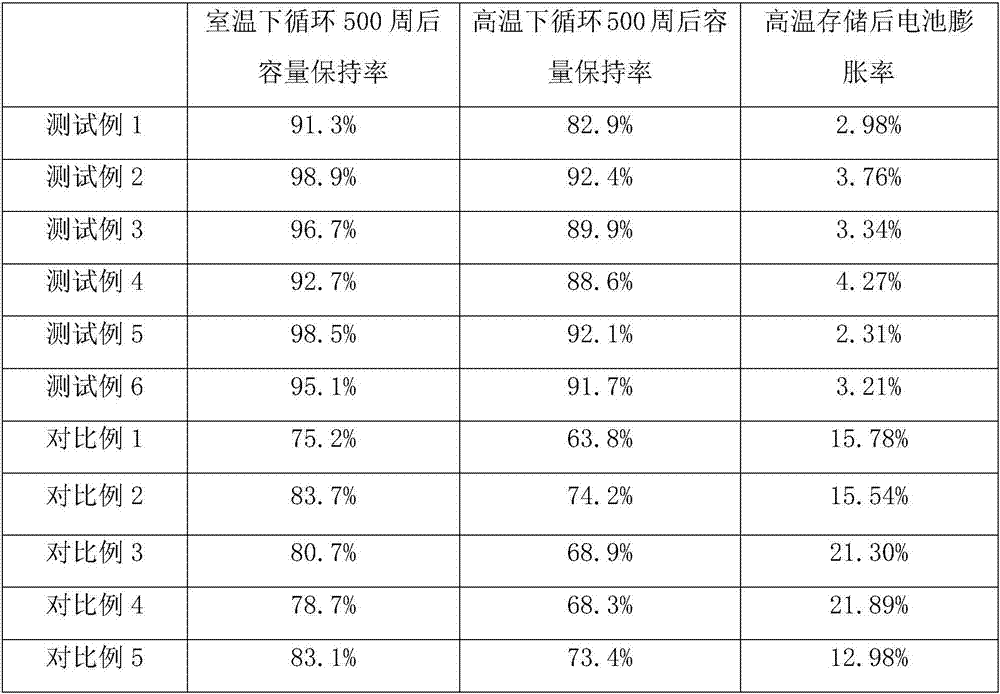

Cyclic silyl disulfonate and preparation method thereof

ActiveCN107573371ARaise room temperatureImprove high temperature cycle performanceSilicon organic compoundsSecondary cellsLithiumSilazane

The invention discloses cyclic silyl disulfonate. The cyclic silyl disulfonate has a structural formula as follows: the formula is shown in the description. A preparation method comprises the following steps: enabling methanedisulphonic acid or methanedisulphonate shown as a general formula (I), a dialkyl silane containing two active functional groups and shown as a general formula (II), dialkyl cyclosiloxane shown as a general formula (III) or dialkyl cyclo-silazane shown as a general formula (IV) to react in a solvent according to a certain ratio; controlling temperature and time of reaction; after finishing the reaction, separating to remove the solvent and a byproduct, so as to obtain the cyclic silyl disulfonate. According to the cyclic silyl disulfonate and the preparation method, the cyclic silyl disulfonate with different substituent groups is innovatively prepared through selecting special raw materials and designing a synthesis technology; room-temperature and high-temperature circulating performance and high-temprature storage performance of a lithium secondary battery can be effectively improved and the thickness swelling of the battery in a high-temprature storage process is reduced; the preparation method of the cyclic silyl disulfonate has simple technological steps and strong enablement; the obtained product has high purity, the chromatographic purity reaches 99percent or more and the product has a wide market prospect.

Owner:CHANGSHU CHANGJI CHEM

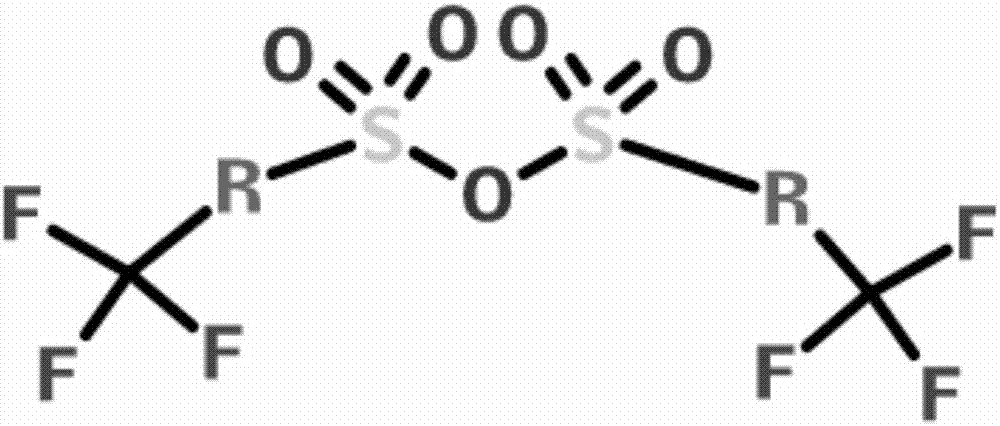

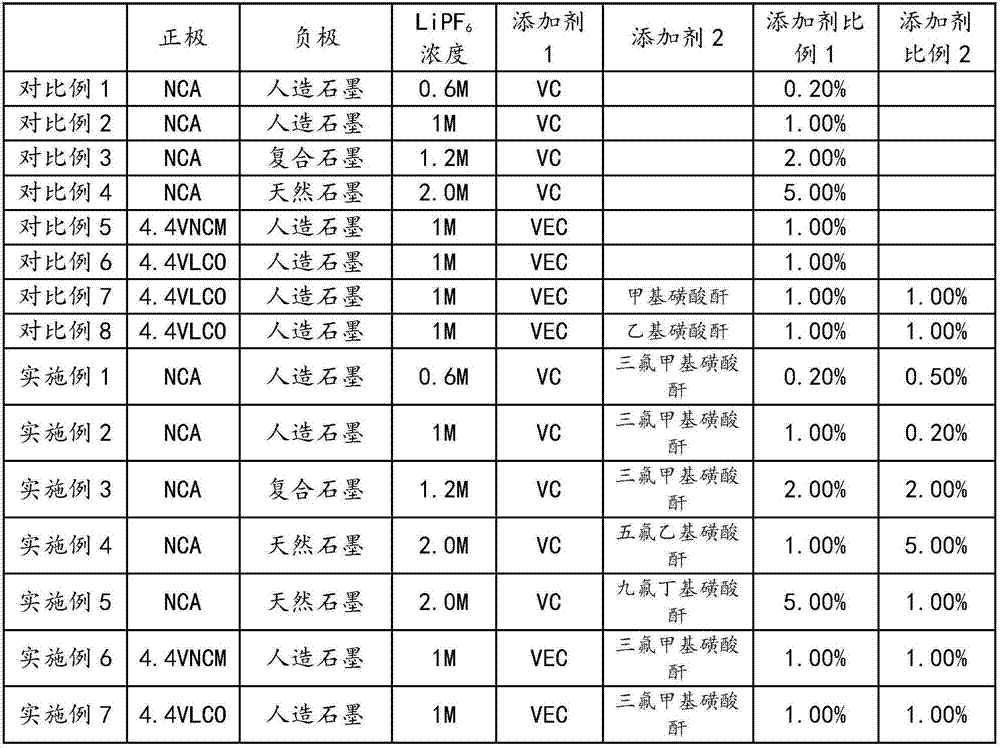

Lithium ion battery, non-aqueous lithium ion battery electrolyte and application of fluoro sulfonic anhydride in preparation of non-aqueous lithium ion battery electrolyte

InactiveCN107146911AImprove ionic conductivityImprove normal temperature cycle performanceSecondary cellsHigh temperature storageOrganic solvent

The invention discloses a lithium ion battery, a non-aqueous lithium ion battery electrolyte and application of fluoro sulfonic anhydride in preparation of the non-aqueous lithium ion battery electrolyte. The lithium ion battery comprises a positive electrode, a negative electrode, a separator and the non-aqueous lithium ion battery electrolyte, wherein the non-aqueous lithium ion battery electrolyte comprises a non-aqueous organic solvent, an electrolyte salt and fluoro sulfonic anhydride, where the fluoro sulfonic anhydride is used as a functional additive, such as trifluoromethyl sulfonic anhydride, pentafluoroethyl sulfonic anhydride and perfluorobutyl sulfonic anhydride. The fluoro sulfonic anhydride is introduced as the functional additive and is applied to the non-aqueous lithium ion battery electrolyte and the battery, a compact and uniform SEI membrane with high lithium ion conductivity can be formed during initial formation of the battery prepared from the non-aqueous lithium ion battery electrolyte, so that the current distribution during charge-discharge period of the battery is uniform, the ion conductivity of lithium ions is improved, and the normal-temperature cycle property, the high-temperature cycle property, the high-temperature storage performance and the low-temperature cycle property of the lithium ion battery are further improved.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

Non-aqueous electrolyte of lithium ion battery and lithium ion battery

InactiveCN105140566AImprove high temperature performanceImprove high temperature cycle performanceSecondary cellsPositive electrodesOrganic solventPhysical chemistry

The invention discloses a non-aqueous electrolyte of a lithium ion battery and the lithium ion battery. The electrolyte comprises a non-aqueous organic solvent, a lithium salt and an additive, wherein the additive comprises a substance containing the following compounds (A) and (B): (A) is shown in the specification, R1, R2 and R3 are respectively and independently selected from alkyl with carbon atom numbers of 1 to 4, at least one of the R1, the R2 and the R3 is unsaturated alkyl containing triple bonds; and (B), imidodisulfuryl fluoride lithium salt. With the adoption of the non-aqueous electrolyte of the lithium ion battery, disclosed by the invention, the lithium ion battery is endowed with low impedance and favorable low-temperature performance and high-temperature performance.

Owner:SHENZHEN CAPCHEM TECH CO LTD

Functional additive applied to non-aqueou electrolyte of lithium ion battery

InactiveCN102340029AImprove cycle performanceImprove high temperature cycle performanceSecondary cellsCarbonate esterPhysical chemistry

The invention discloses a functional additive applied to non-aqueou electrolyte of a lithium ion battery. The use level of the functional additive equivalently accounts for 0.01-5% of the mass of the electrolyte consisting of a carbonate ester solvent and a lithium salt, and preferentially accounts for 0.05-1.5% of the mass of the electrolyte. By applying the additive disclosed by the invention, the high-temperature cycle performance of the lithium ion battery can be effectively improved, meanwhile, the oxidation resistance of the conventional carbonate ester type electrolyte can be increased to 5.0V. The additive disclosed by the invention is low in cost and obvious in effect and has a better application prospect.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com