High-temperature high-voltage non-aqueous electrolyte and lithium ion battery containing non-aqueous electrolyte

A non-aqueous electrolyte, high-voltage technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as battery charge-discharge cycle performance degradation, poor battery high-temperature storage performance, and poor electrolyte matching. Achieve the effect of improving high temperature cycle performance, improving high and low temperature performance, improving cycle performance and high temperature storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

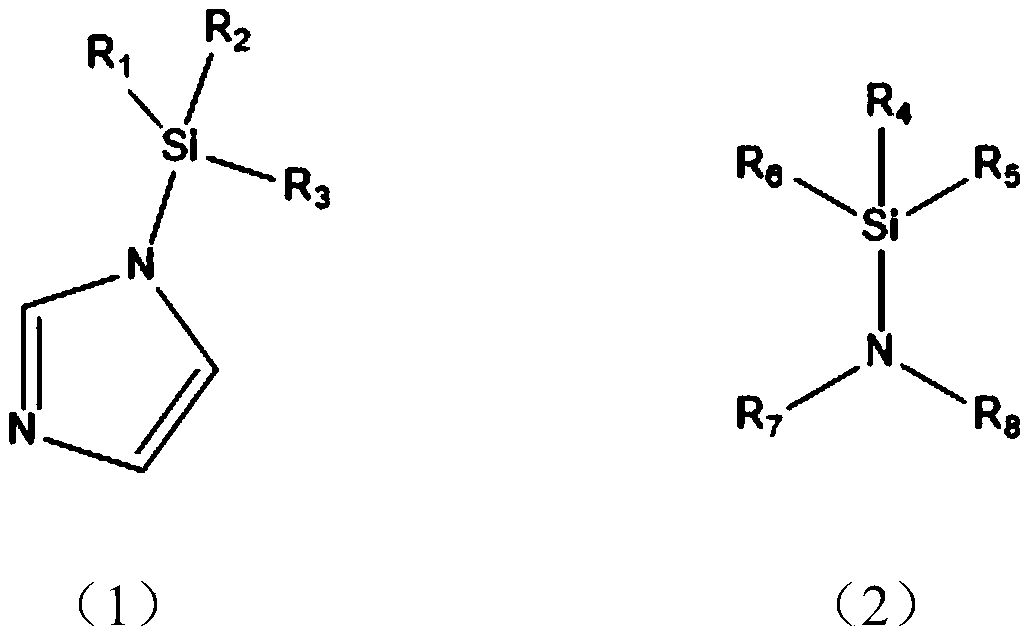

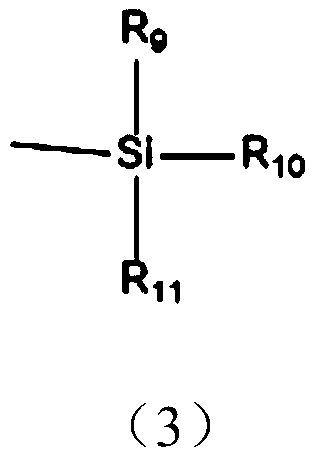

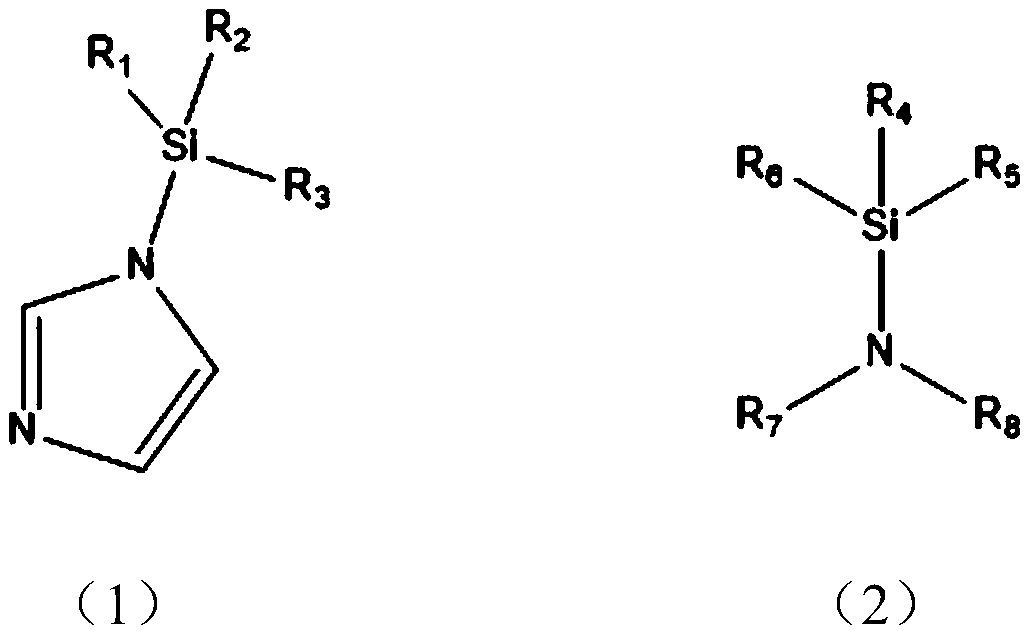

Method used

Image

Examples

Embodiment 1

[0031] In a glove box filled with argon, with an oxygen content of ≤1ppm and a water content of ≤1ppm, uniformly mix ethylene carbonate, ethyl methyl carbonate, and diethyl carbonate at a mass ratio of 1:1:1, and pour into the mixture Add 0.1% of the total mass of the electrolyte 1-(trimethylsilyl) imidazole (TMSI) and 1% of the total mass of the electrolyte vinyl sulfate (DTD), 0.5% of the total mass of the electrolyte 1,3-propenesulfone Acid lactone (PST), and then respectively add lithium hexafluorophosphate (LiPF 6 ) and lithium bisfluorosulfonimide (LiFSI) with 1% of the total mass of the electrolyte, lithium difluorooxalate borate (LiDFOB) with 1% of the total mass of the electrolyte, and stirred to completely dissolve it to obtain the electrolyte of Example 1.

[0032] Inject the prepared electrolyte solution into a soft-packed lithium-ion battery with NCM622 as the positive electrode material and graphite negative electrode as the negative electrode. After the liquid i...

Embodiment 2

[0034] In a glove box filled with argon, with an oxygen content of ≤1ppm and a water content of ≤1ppm, uniformly mix ethylene carbonate, ethyl methyl carbonate, and diethyl carbonate at a mass ratio of 1:1:1, and pour into the mixture Add TMSI with 0.2% total mass of electrolyte, DTD with 1% total mass of electrolyte, PST with 0.5% total mass of electrolyte, and then add LiPF with 12.5% total mass of electrolyte to the mixed solution respectively 6 LiFSI with 1% of the total mass of the electrolyte and LiDFOB with 1% of the total mass of the electrolyte were stirred to dissolve completely, except that, the same operation as in Example 1 was performed to prepare a lithium-ion battery.

Embodiment 3

[0036] In a glove box filled with argon, with an oxygen content of ≤1ppm and a water content of ≤1ppm, uniformly mix ethylene carbonate, ethyl methyl carbonate, and diethyl carbonate at a mass ratio of 1:1:1, and pour into the mixture Add TMSI with 0.5% of the total mass of the electrolyte, DTD with 1% of the total mass of the electrolyte, and PST with 0.5% of the total mass of the electrolyte, and then add LiPF with a total mass of 12.5% of the total electrolyte to the mixed solution 6 LiFSI with 1% of the total mass of the electrolyte and LiDFOB with 1% of the total mass of the electrolyte were stirred to dissolve completely, except that, the same operation as in Example 1 was performed to prepare a lithium-ion battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com