Preparation method of nitrogen-doped porous-structure carbon material

A technology of porous structure and carbon materials, applied in the preparation/purification of carbon, nanotechnology for materials and surface science, chemical instruments and methods, etc., can solve the problems of limited application and high price, and achieve simple process and large scale Capacitance value, the effect of improving the catalytic activity of oxygen reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of Nitrogen-doped Porous Structure Carbon Materials Using Small Molecule Carbon-Containing Compounds as Raw Materials

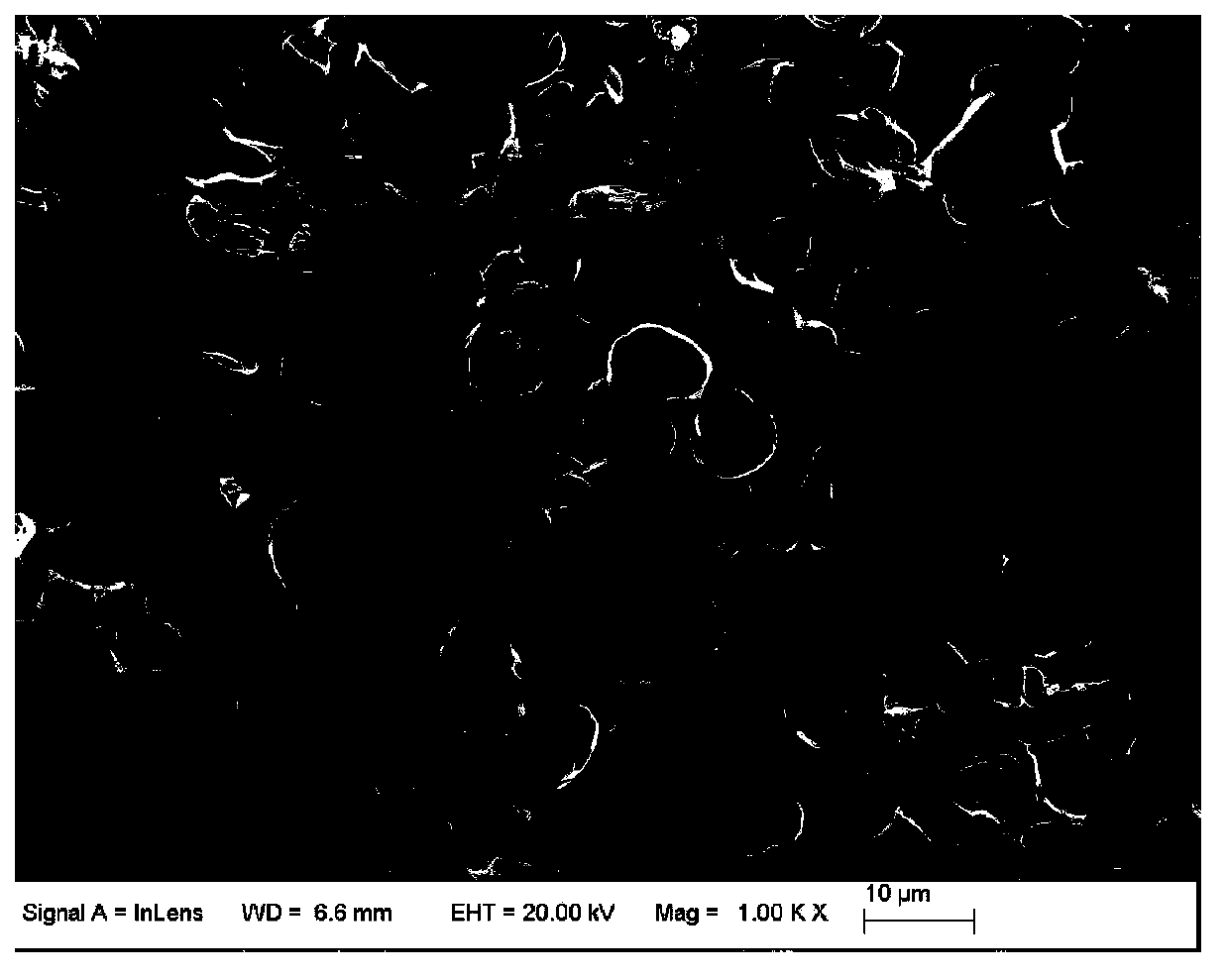

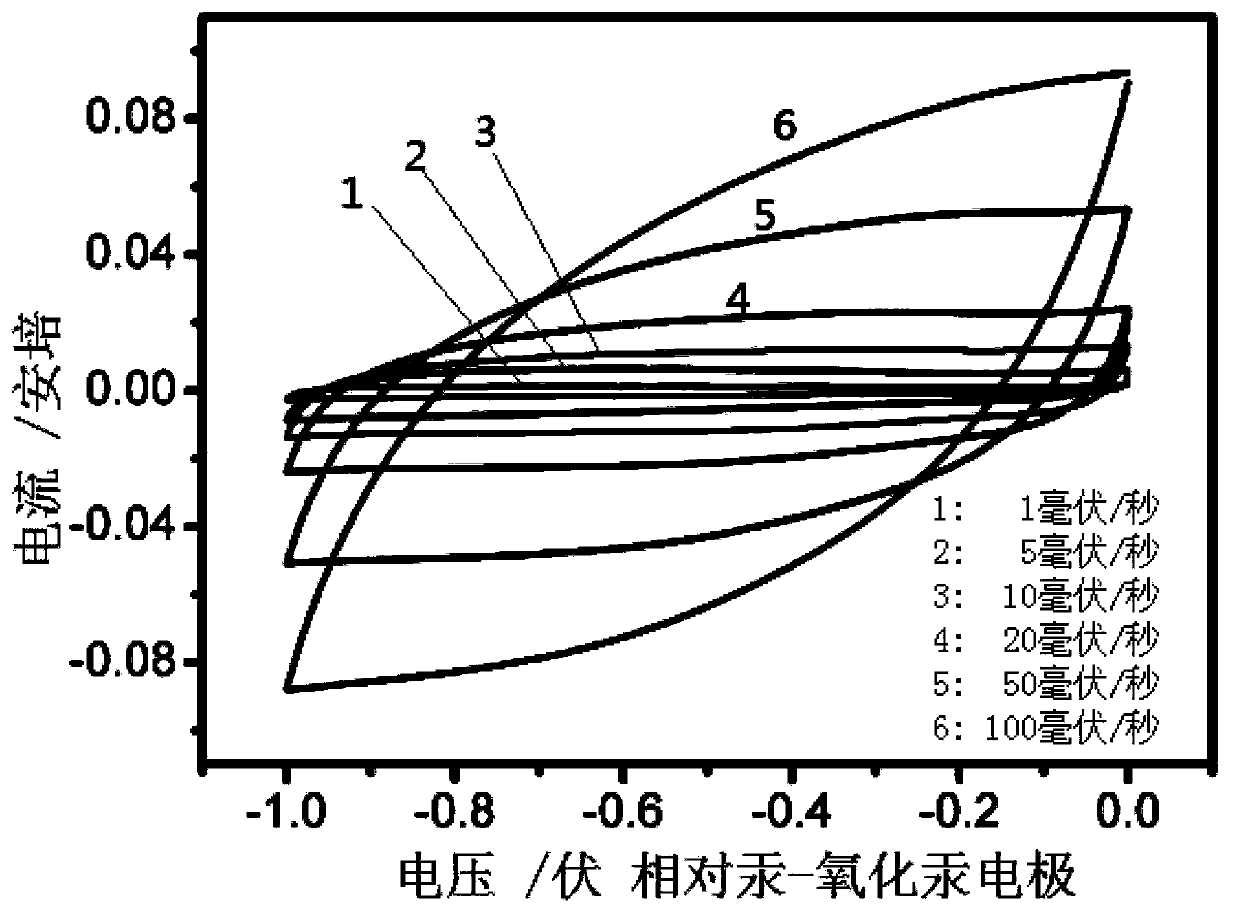

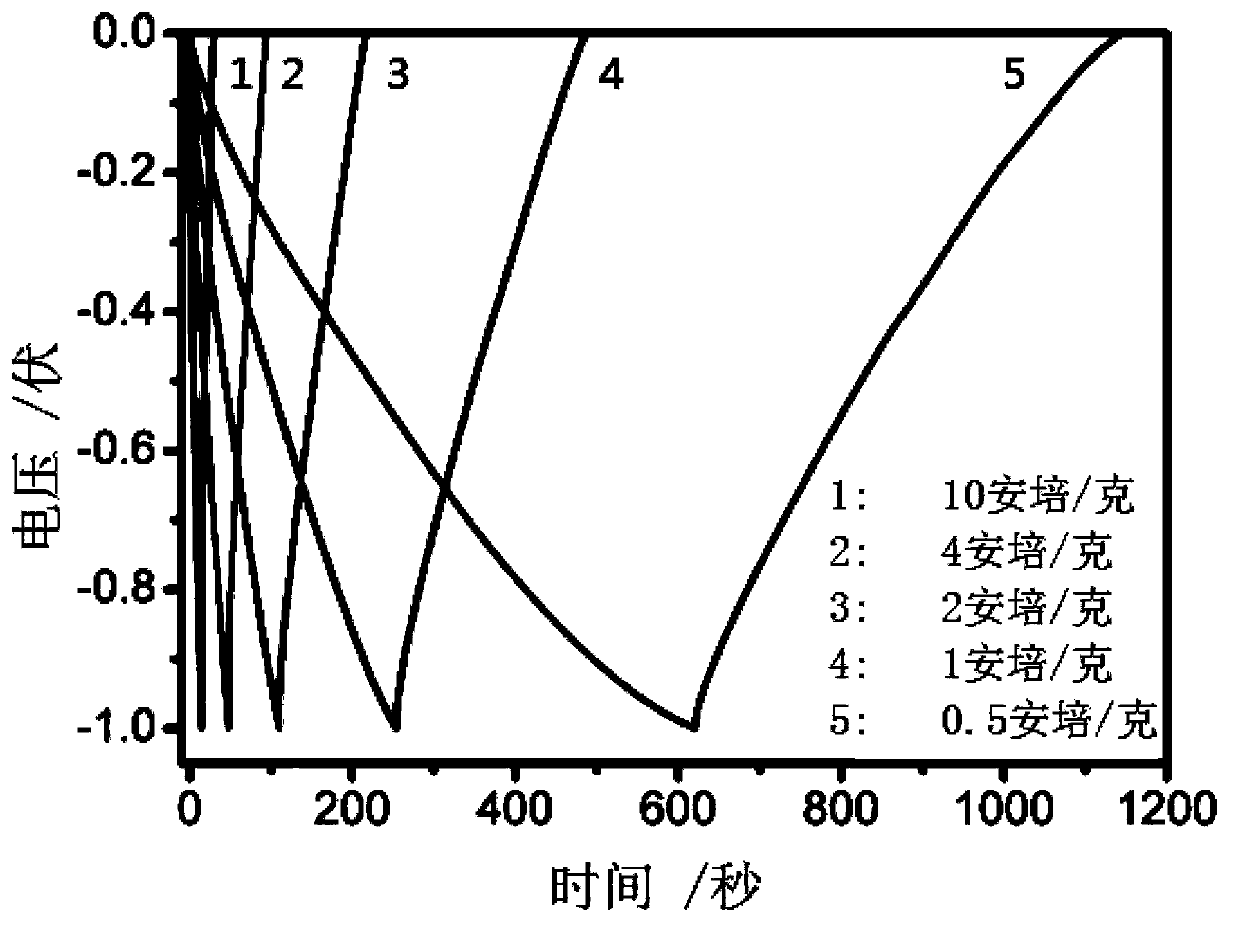

[0031] Take 4 grams of ethylenediaminetetraacetic acid, grind them evenly with 2 grams of potassium hydroxide, transfer them to a heating container, and react at 600°C for 2 hours under the protection of nitrogen. The obtained product is washed three times with deionized water, three times with ethanol, and dried A nitrogen-doped porous carbon material can be obtained. The obtained material has a porous structure, high specific capacitance value and good cycle performance. SEM photo see figure 1 , the capacitive cyclic voltammogram see figure 2 , the capacitance characteristic diagram see image 3 , the capacitance cycle diagram see Figure 4 , X-ray photoelectron spectroscopy see Figure 5 .

[0032] Repeat the above steps, and use 4 grams of ethylenediaminetetraacetic acid instead, 0.5 grams of potassium hydroxide, at a ...

Embodiment 2

[0040] Example 2: Preparation of nitrogen-doped porous structure carbon material from a mixture of small molecule carbon-containing compounds

[0041] Take 2 grams of ethylenediaminetetraacetic acid and 2 grams of dipotassium ethylenediaminetetraacetic acid, grind them evenly with 2 grams of potassium hydroxide, transfer them to a heating container, and react at 600 ° C for 2 hours under the protection of nitrogen, and the obtained product is washed with deionized water Washing three times, washing three times with ethanol, and drying can obtain nitrogen-doped porous structure carbon material. (SEM image see Image 6 )

[0042] Repeat the above operation steps, keep 2 grams of EDTA, 2 grams of potassium hydroxide, add 2 grams of disodium EDTA, and calcining for 1 hour at a temperature of 700 ° C under nitrogen protection to obtain similar products.

[0043] Repeat the above operation steps, keep 2 grams of EDTA, 0.5 grams of potassium hydroxide, add 2 grams of dipotassium ED...

Embodiment 3

[0052] Example 3: Adding organic nitrogen-containing compounds to prepare porous structure carbon materials with high nitrogen content

[0053] Take 4 grams of ethylenediamine tetraacetic acid and 2 grams of potassium hydroxide, grind them evenly with 2 grams of melamine, transfer them to a heating container, and react at 700°C for 2 hours under the protection of nitrogen. The obtained product is washed three times with deionized water and three times with ethanol , drying nitrogen-doped porous carbon material can be obtained (the scanning electron microscope picture is shown in Figure 7 , TEM pictures see Figure 8 )

[0054] Repeat the above operation steps, keep EDTA consumption 4 grams, potassium hydroxide 2 grams, add 16 grams of hexamethylenetetramine, temperature 600 ° C, calcining for 2 hours under nitrogen protection, similar products can be obtained.

[0055] Repeat the above operation steps, keep EDTA consumption 4 grams, potassium hydroxide 2 grams, add urea 2 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com