Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

349results about How to "Improve high temperature mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

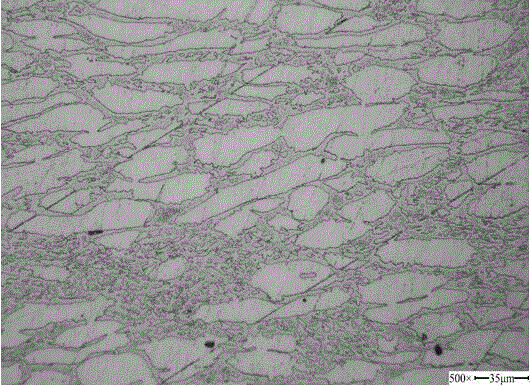

Secondary cooling method for reducing transverse cracks of corners of microalloy sheet billet

The invention relates to a secondary cooling method for reducing transverse cracks of corners of a microalloy sheet billet, which is characterized in that the cooling temperature of a casting blank is facilitated to reach a temperature for starting the transformation from gamma to alpha by controlling the secondary cooling speed at an earlier stage when the casting blank passes through a vertical section after being delivered out of a crystallizer; at the later stage, the cooling water quantity of the casting blank is reduced, potential heat produced by the solidification of the casting piece is used for reheating the casting piece, and the reheating temperature is controlled to make the casting blank reach more than an austenite phase changing temperature when the casting piece is delivered out of the vertical section; the entire process is under the transformation of gamma to alpha to gamma, so that crystal grains of a final transformation product are smaller; and after the casting blank leaves the vertical section, the casting blank enters the subsequent secondary cooling area in a slowly cooling mode. By optimizing the continuous-casting billet cooling mode, the crystal grains are refined, and second-phase particles in the steel are controlled, so that the high-temperature mechanical property of the casting blank can be improved, simpleness in operation is realized, and the transverse cranks on the surface of the casting blank can be effectively reduced.

Owner:WISDRI ENG & RES INC LTD

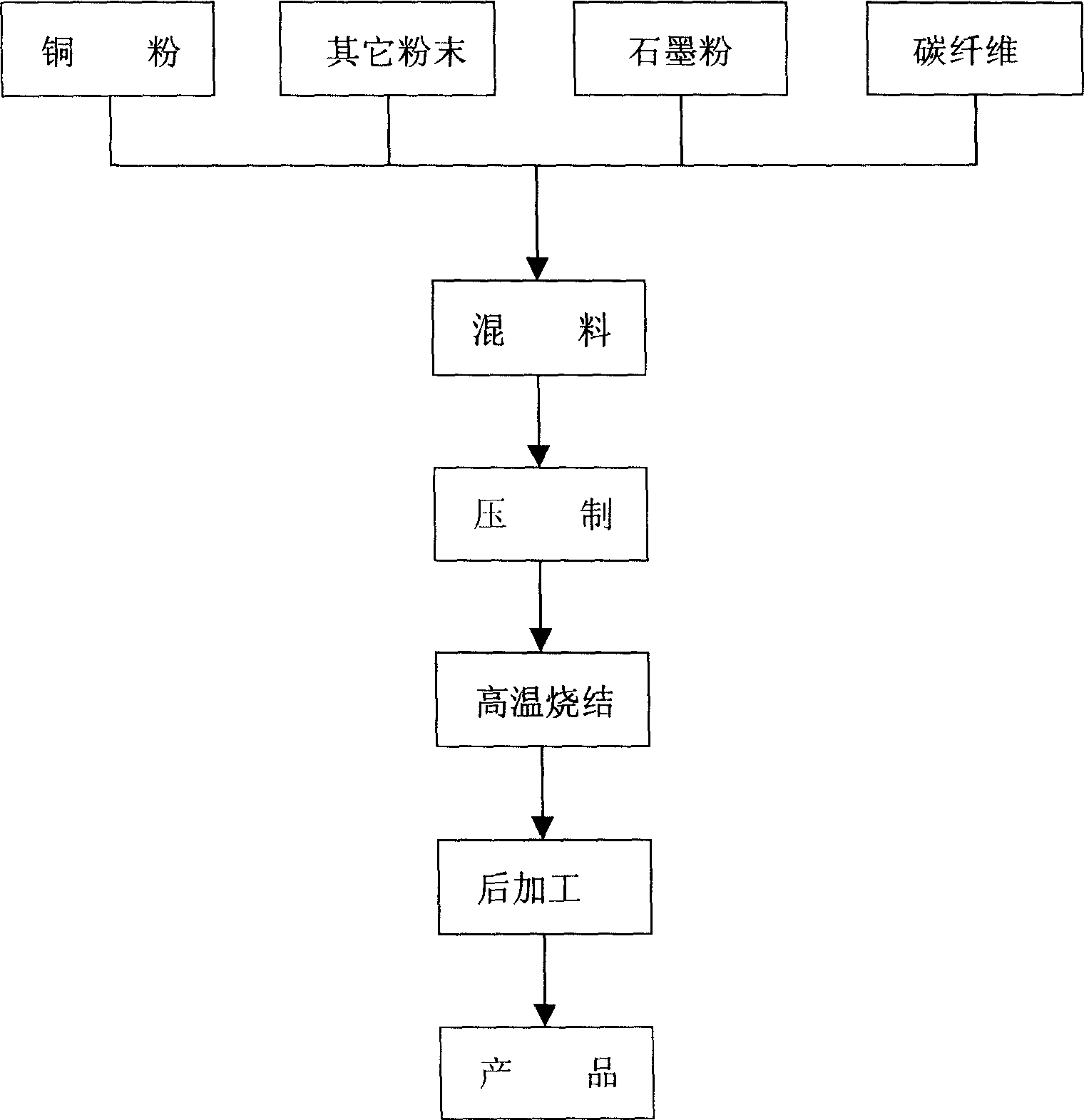

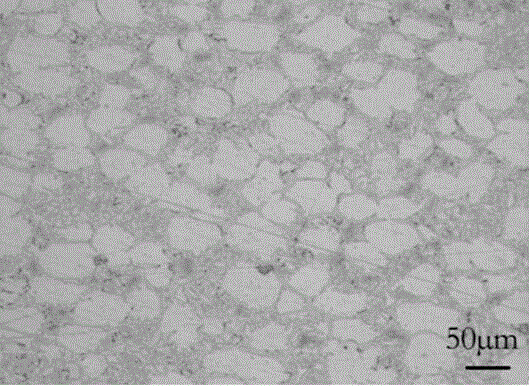

Leadless copper base high temperature self lubricating composite material

InactiveCN1718795AImprove toughnessImprove heat resistanceChemical vapor deposition coatingChemical compositionGraphite

A high-temp self-lubricating non-Pb Cu-base composition has a chemical formula: Ni+C+Sn+Zn+MX+Fe+Cu, where MX is chosen from BN, Si3N4, SiC, Al2O3, TiN, TiC and Cr3 C2 and C is graphite and carbon fibres. It has anti-oxidizing, anti-corrosion and high-temp anti-wear characteristics.

Owner:合肥波林新材料股份有限公司

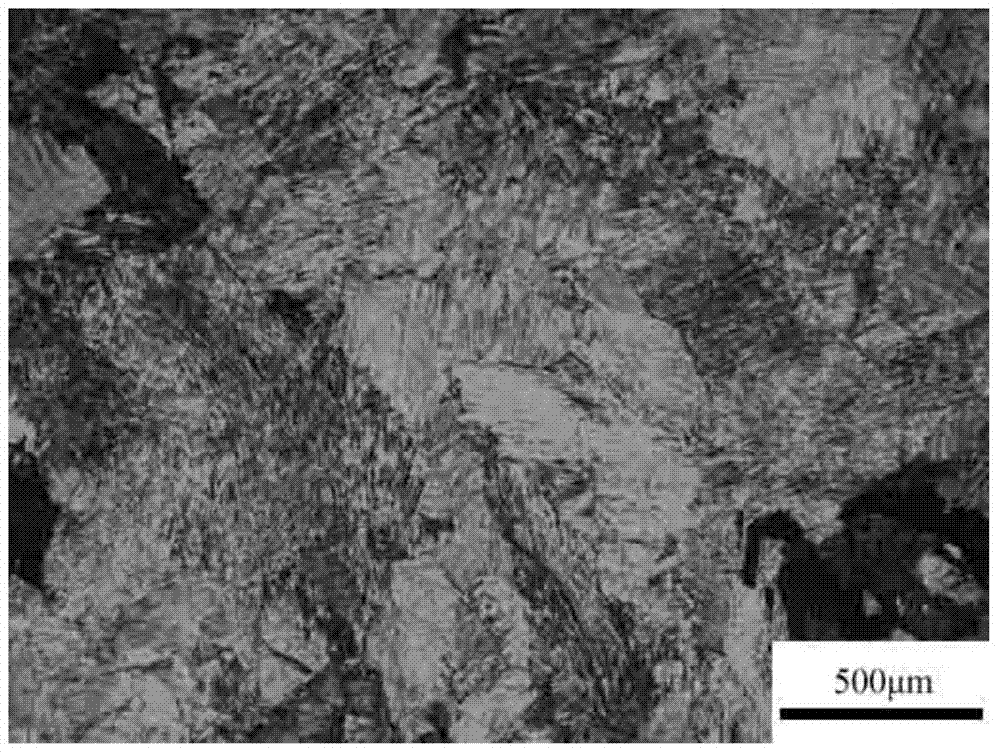

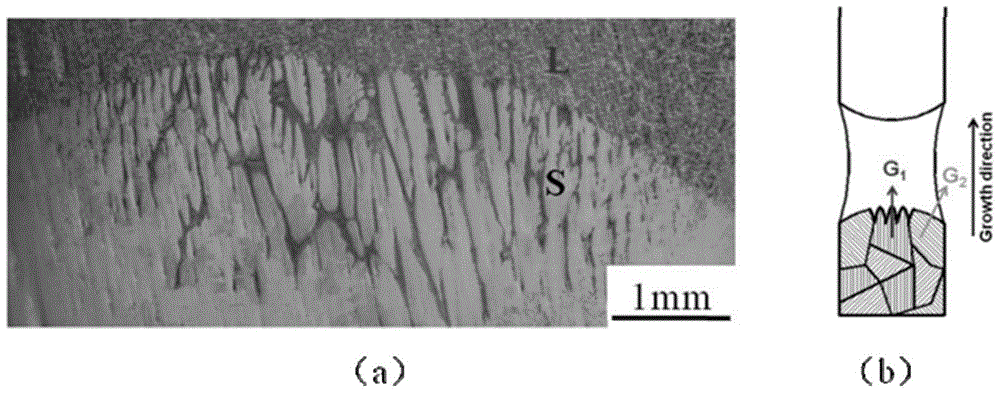

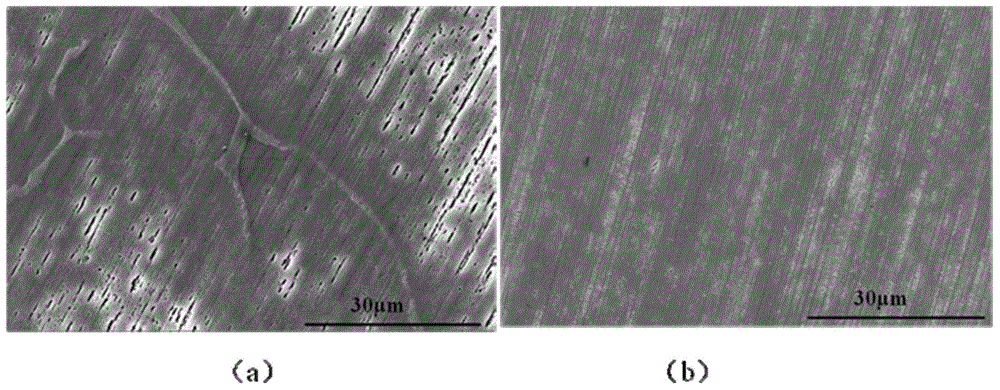

Directional TiAl-based alloy and preparation method thereof

ActiveCN103789598AImprove high temperature mechanical propertiesKeep low densityDirectional solidificationMaterials science

The invention discloses directional TiAl-based alloy and a preparation method thereof. According to the atomic percentage, TiAl alloy components are expressed as Ti-(40-50)Al-aNb-bCr-cMo-dV-eMn, wherein in the formula, a, b, c, d, e are atomic percentages, a+b+c+d+e is less than or equal to 10, and the balance is Ti. The method for preparing the columnar crystal TiAl-based alloy includes the following steps that mother alloy is smelted through vacuum induction suspension, and a mother alloy cast rod is prepared through vacuum suction casting; an optical floating zone crystal growth system is adopted, argon is used as protection gas, the flow speed is 3-3.6L / min, the width of a regional heating zone is 6-6.7mm, heat treatment is performed on the TiAl-based alloy cast rod, the heating temperature is controlled to be 1250-1350 DEG C, the drawing speed is in the range of 3-13 micrometers per second, and the columnar crystal TiAl-based alloy is prepared. Compared with a directional solidification technology, in the preparation method, peritectic reaction is omitted, and therefore peritectic segregation is avoided; the problem that refractory metal and alloy, such as tungsten and molybdenum, with direction tissue cannot be prepared through the direction solidification technology can also be solved.

Owner:NANJING UNIV OF SCI & TECH

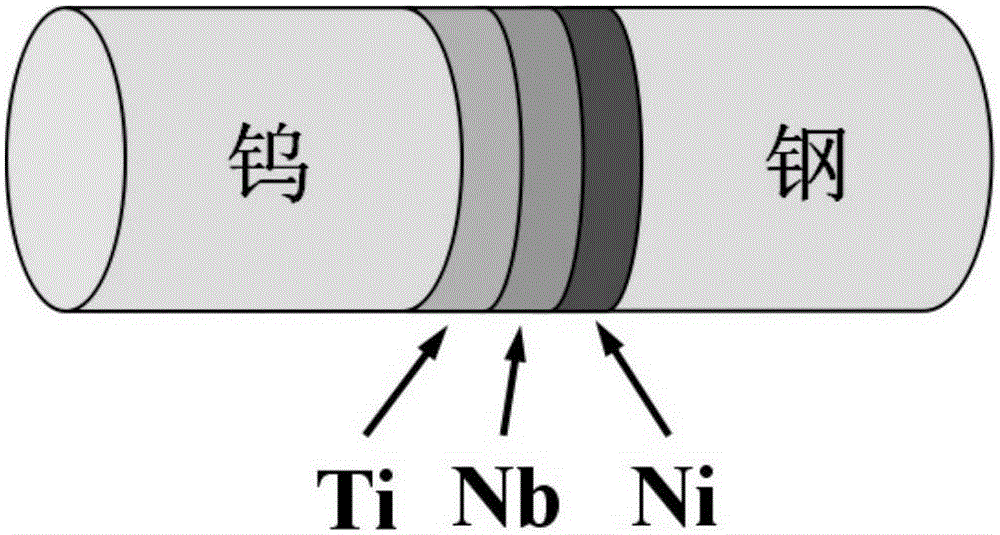

High-performance tungsten/steel composite material based on high-temperature application and preparation method thereof

ActiveCN105216394AHigh tensile strength at room temperatureImprove high temperature mechanical propertiesLaminationLamination apparatusNiobiumJoint stress

The invention relates to a high-performance tungsten / steel composite material based on high-temperature application and a preparation method thereof and belongs to the technical field of preparation of composite materials. By adoption of the high-performance tungsten / steel composite material, the problems of large residual joint stress, low strength, poor heat resistance and high connection temperature in an existing tungsten / steel connector are solved. The high-performance tungsten / steel composite material is prepared from a tungsten-based layer, a titanium layer, a niobium layer, a nickle layer and a steel-based layer which are arranged in sequence and prepared by adopting a welding method. The high-performance tungsten / steel composite material is obtained by superposing the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer in sequence according to the superposition mode of the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer and carrying out vacuum diffusion bonding. The high-performance tungsten / steel composite material has the advantages that the room-temperature tensile strength is larger than or equal to 352MPa, and the tensile strength at the temperature of 650DEG C is larger than or equal to 338MPa; the structure design is reasonable, the process is simple, the large-scale application is convenient, and simultaneously, the high-performance tungsten / steel composite material can be widely applied in diffusion bonding of refractory metal and other dissimilar metal materials.

Owner:CENT SOUTH UNIV

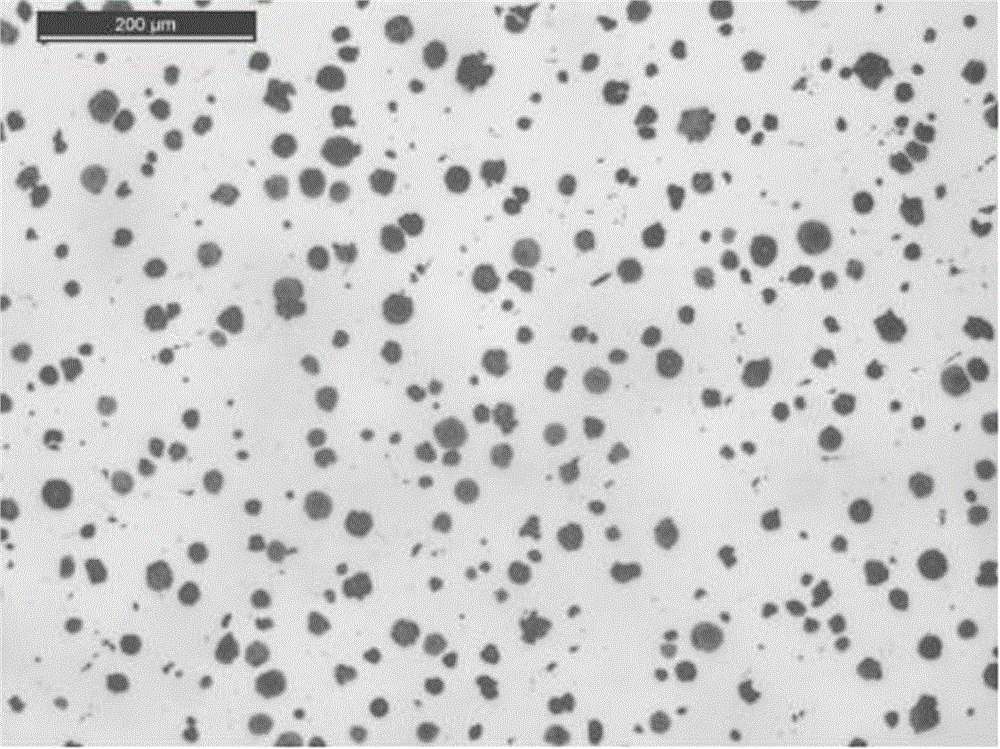

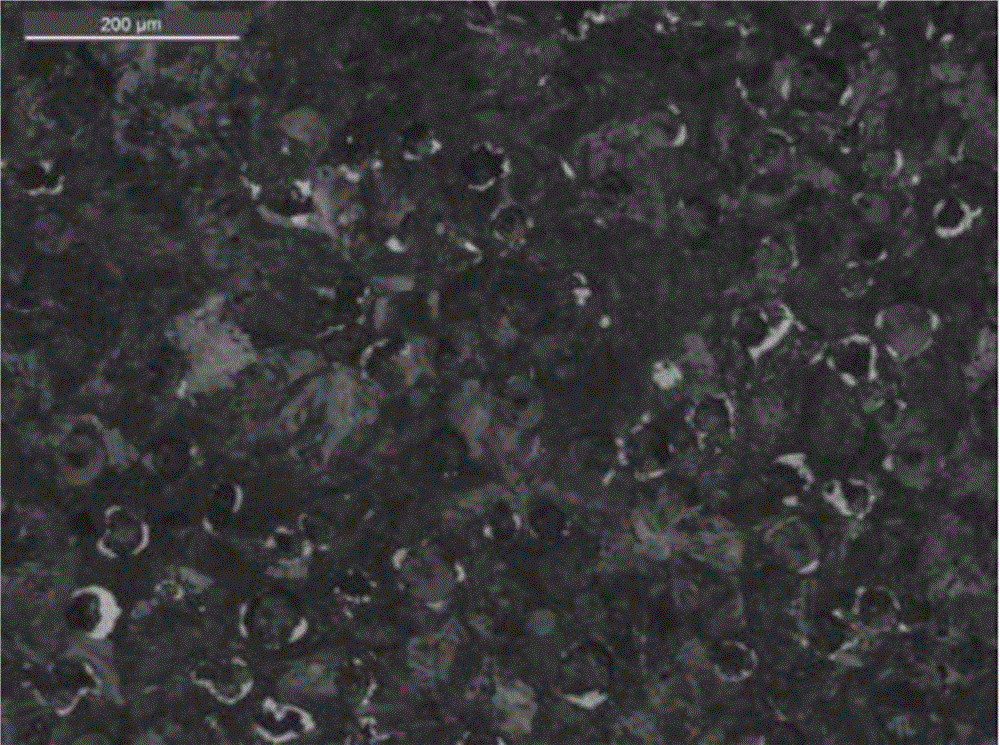

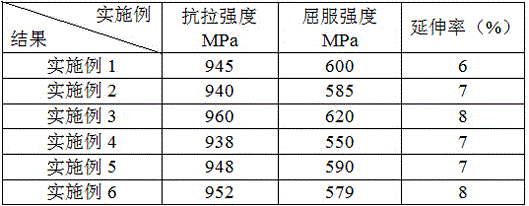

High-strength nodular cast iron QT900-6 and preparation method thereof

ActiveCN106011610AExcellent performanceImprove high temperature mechanical propertiesTrace elementMechanical property

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

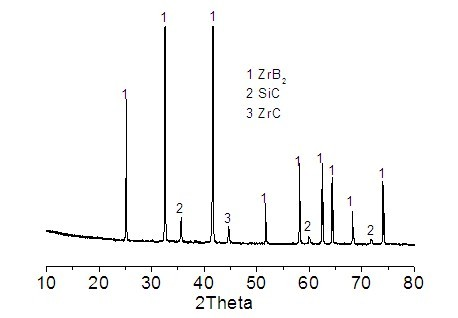

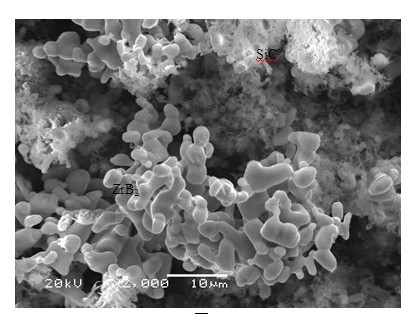

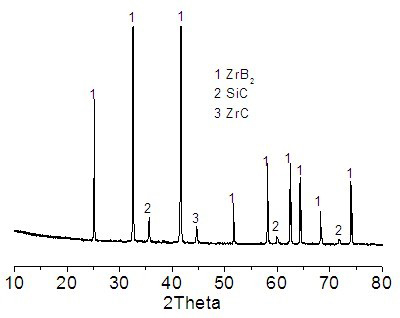

ZrB2-SiC composite powder and preparation method thereof

InactiveCN102320850AFix issues with restricted usageSynthesis temperature is lowUltra-high-temperature ceramicsRefractory

The invention discloses ZrB2-SiC composite powder and a preparation method thereof. According to the invention, zircon sand, a boron raw material and a carbon raw material are adopted as main materials. The main materials are mixed, grinded, and are heated under a temperature of 1350 to 1480 DEG C, such that the powder is obtained. The powder comprises components of, by weight: 37 to 63% of ZrSiO4, 16 to 32% of B2O3, and 20 to 28% of C, wherein the boron raw material is calculated according to the amount of B2O3, and the carbon raw material is calculated according to the amount of C element. According to the invention, natural zircon sand with a relatively low price is used as a raw material for producing high-grade ZrB2-SiC. The advantages of ZrB2 and SiC are combined. Mutual complement of advantages can be realized when ZrB2 and SiC are used in the field of high-temperature materials. ZrB2-SiC provides relatively high thermal conductivity, excellent thermal shock resistance and corrosion resistance. When ZrB2-SiC is introduced into the composite powder, high-temperature mechanical properties, oxidative stabilities and corrosion resistances of ultra-high temperature ceramics and refractory materials can be improved.

Owner:ZHENGZHOU UNIV

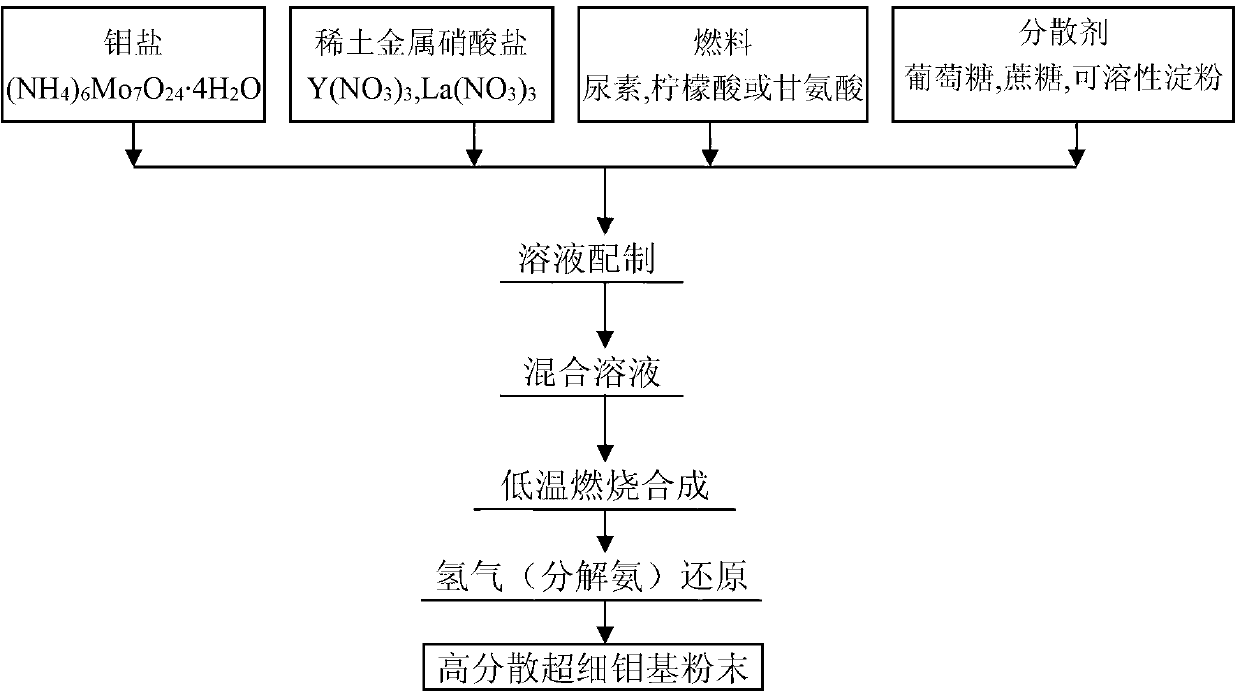

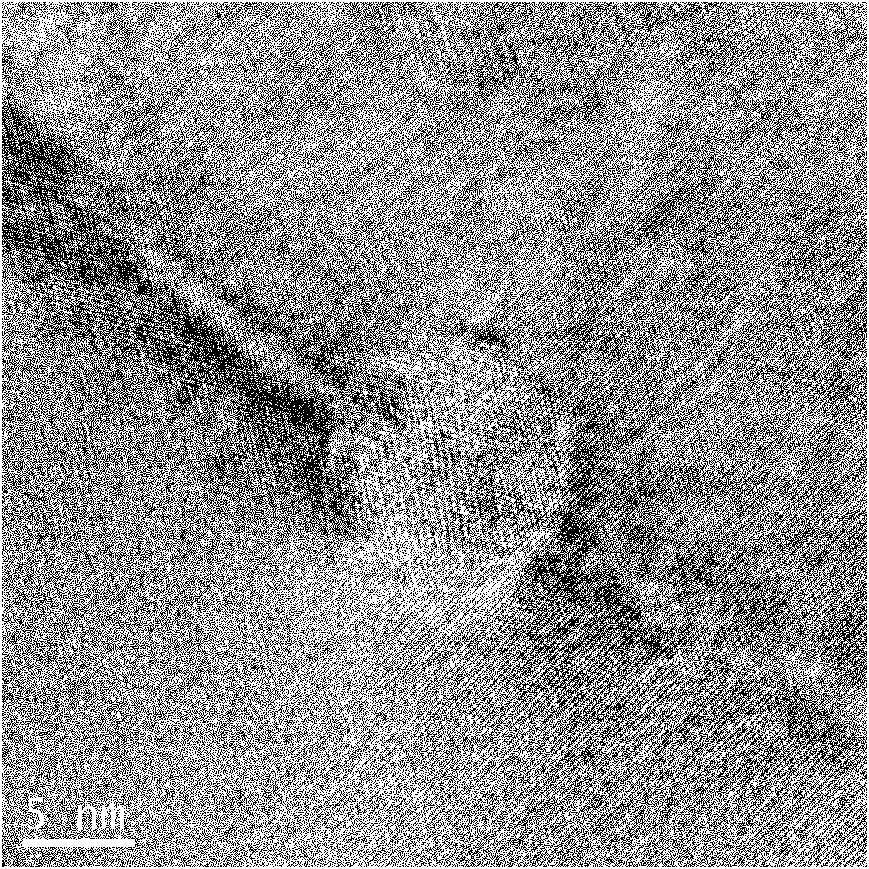

Method for manufacturing high-dispersion ultrafine molybdenum-based powder

The invention discloses a method for manufacturing high-dispersion ultrafine molybdenum-based powder, and belongs to the technical field of rare-earth refractory metal materials. A technological process includes acquiring precursor powder comprising molybdenum oxide, rare-earth oxide (one or two of Y<2>O<3> and La<2>O<3>) or copper oxide which are mixed uniformly by low-temperature combustion synthesis; and reducing the precursor powder in flowing hydrogen atmosphere. The molybdenum oxide and the copper oxide which are easy to reduce are reduced into metal molybdenum and copper, rare-earth oxide particles which cannot be reduced remain, and accordingly high-dispersion ultrafine Mo and rare-earth oxide powder or high-dispersion ultrafine Mo-Cu composite powder is obtained. The weight percent of the rare-earth oxide in the Mo and rare-earth oxide powder ranges from 0.5% to 30%, and the weight percent of the Cu in the Mo-Cu composite powder ranges from 5% to 40%. The method has the advantages that the powder particles are small in diameter and high in surface activity, a dispersion path in a sintering procedure is shortened, and the method is beneficial to acquiring high-density ultrafine-grain / nano-grain molybdenum-based alloy with uniform tissue distribution.

Owner:UNIV OF SCI & TECH BEIJING

Austenite stainless steel and a manufacturing technology thereof

ActiveCN104032233AGood dimensional stabilityImprove mechanical propertiesNuclear reactorManufacturing technology

The invention discloses austenite stainless steel comprising, by weight: C <=0.08%, Si 0.20%-0.70%, Mn 0.50%-1.50%, Ni 19.00%-22.00%, Cr 23.00%-25.00%, Mo 2.65%-2.88%, P <0.005%, S <0.005% and Co < 0.01%. The rest is Fe and impurities. The invention also discloses a manufacturing technology of the above-mentioned austenite stainless steel. The stainless steel of this invention has good creeping performance, oxidation performance, corrosion performance and so on. The stainless steel has good neutron economic performance and cost economic performance. The stainless steel has good anti-neutron void swelling performance, can meet the application needs of SCWR fuel canning or reactor internals, and can provide candidate materials for SCWR. In addition, the stainless steel can also meet the needs of constantly enhanced nuclear reactor temperature, safety and economy.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Light-weight corundum-magnesia alumina spinel refractory material and a preparation method of same

The invention relates to a light-weight corundum-magnesia alumina spinel refractory material and a preparation method of same, wherein porous corundum-magnesia alumina spinel ceramic material granules are used as an aggregate, wherein ceramic material being 3-5 mm in granular size accounts for 10-18 wt%, ceramic material being 1-2.8 mm in granular size accounts for 25-30 wt%, and ceramic material being 0.1-0.8 mm in granular size accounts for 15-20 wt%; a substrate includes 12-18 wt% of porous corundum-magnesia alumina spinel ceramic material fine powder with nano-scale pore diameter, 12-20 wt% of corundum fine powder, 2-5 wt% of magnesite fine powder and 3-8 wt% of alpha-Al2O3 micropowder. The preparation method includes the steps of: 1) placing the aggregate in a vacuum stirrer, vacuumizing the stirrer, and adding a magnesium chloride solution which accounts for 3-8 wt% of the total weight of the aggregate and the substrate, stirring the mixture, and turning off the vacuumizing system; 2) adding the substrate, stirring the materials, shaping and drying the materials, and performing temperature maintenance at 1450-1650 DEG C, cooling the material to produce the refractory material. In the refractory material, diameters of pores are nano-scale, so that the refractory material is low in heat conductivity and high in strength, has high anti-medium erosion performance and excellent thermal shock resistance.

Owner:WUHAN UNIV OF SCI & TECH

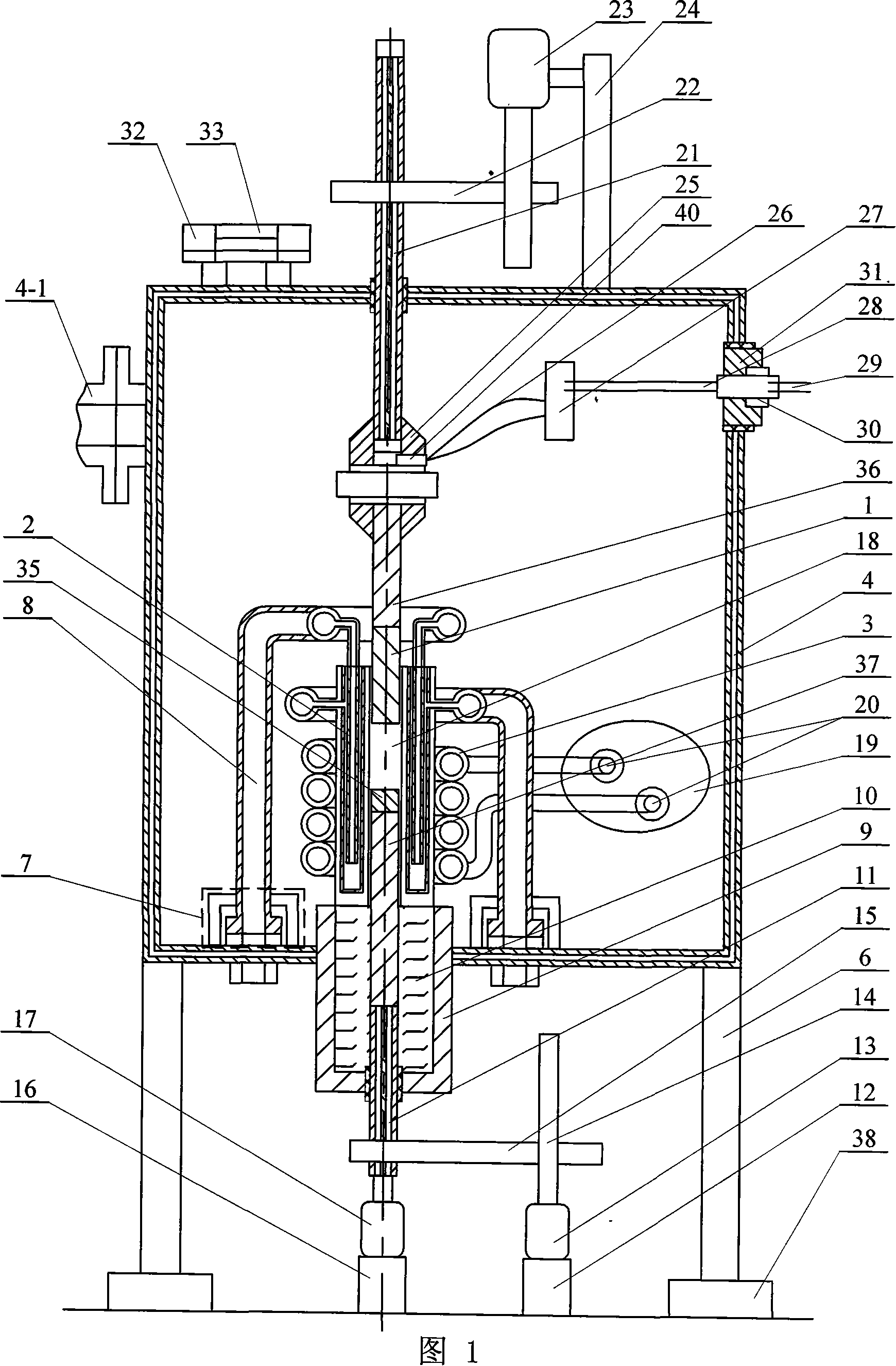

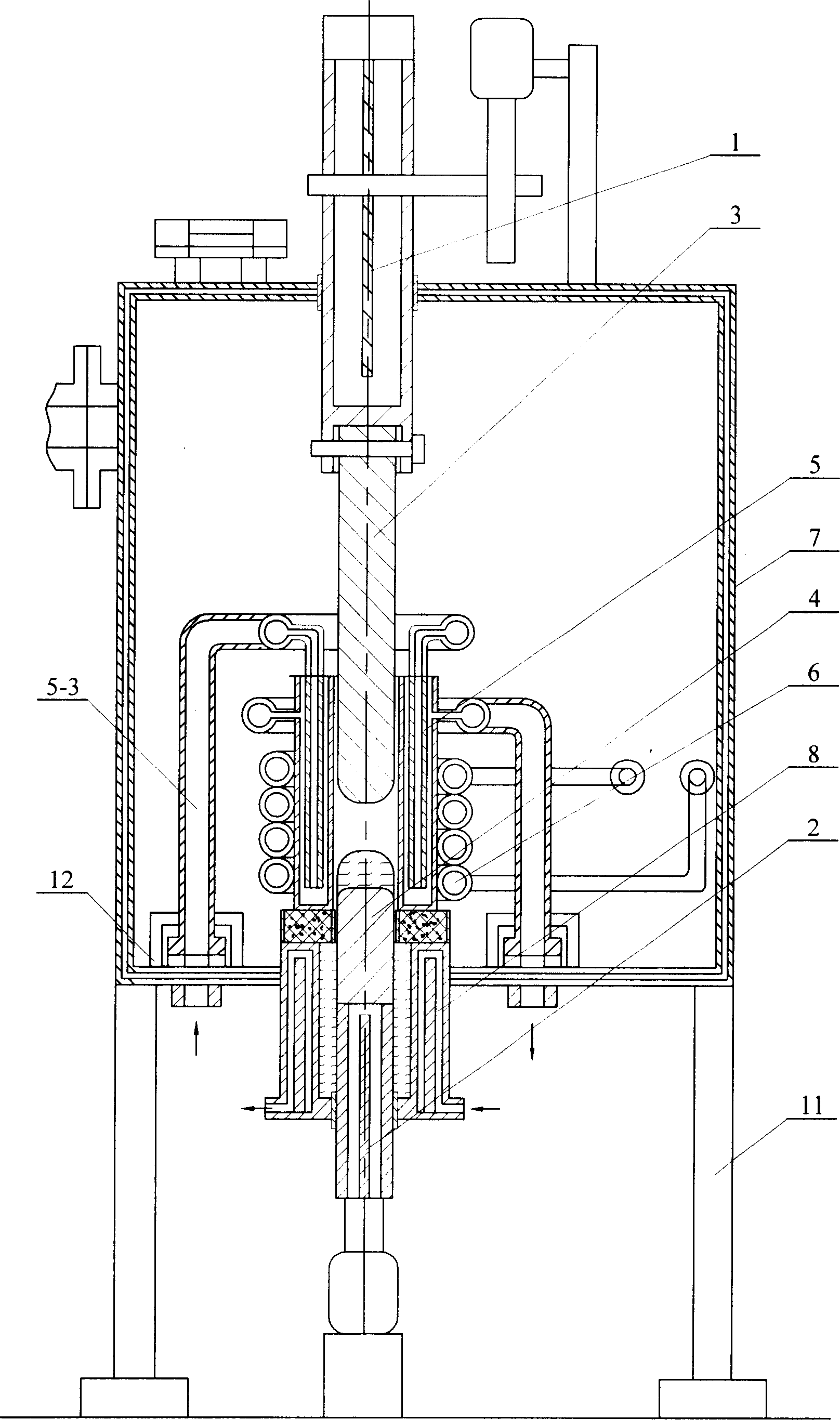

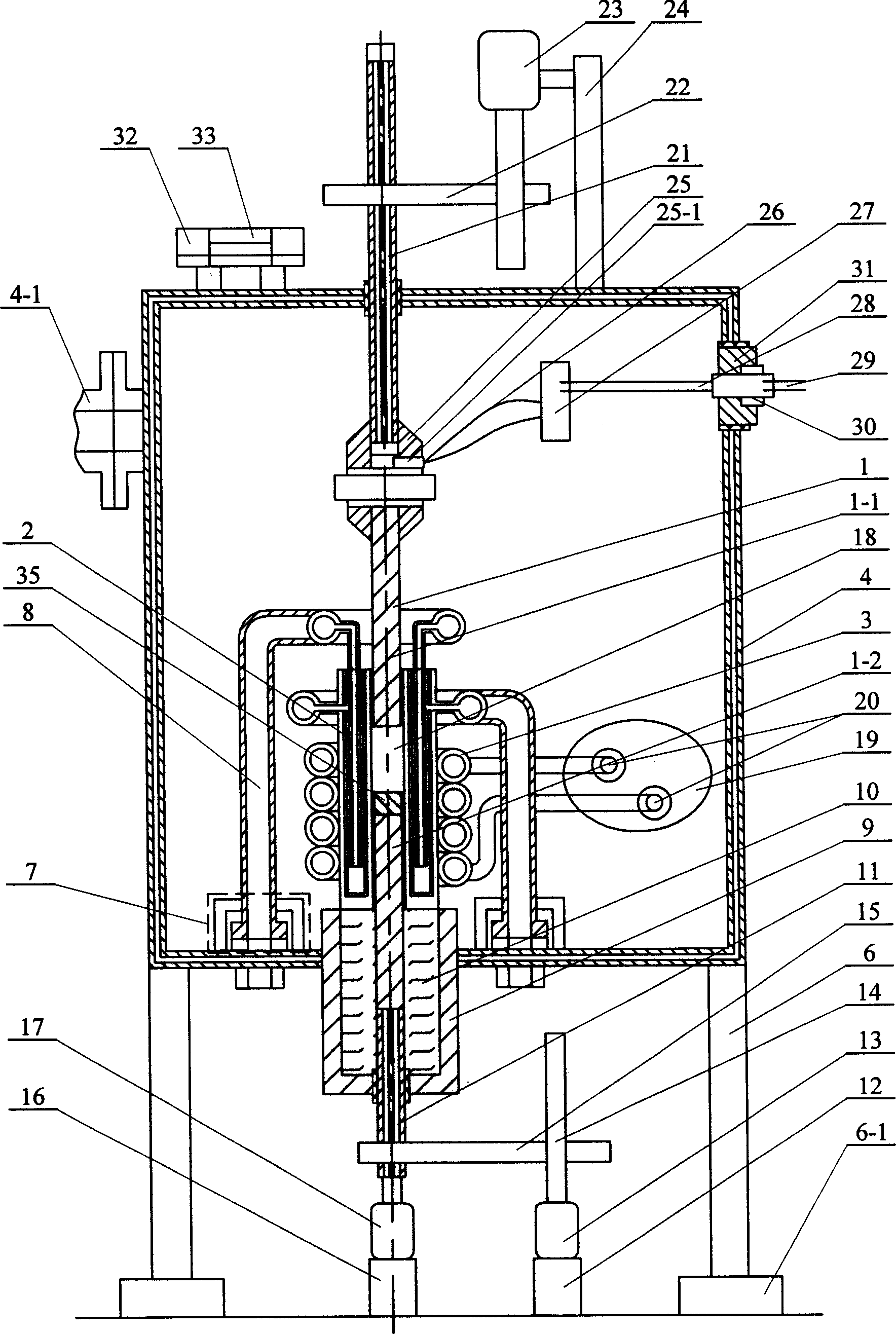

Method for continuously casting titanium alloy near single-crystal ingot by using electromagnetic cold crucible

InactiveCN101121999AImprove comprehensive mechanical propertiesImprove mechanical propertiesPulling actionDirectional solidification

A method of continuously founding the titanium alloy to be close to an single crystal ingot with a magnetic field belongs to a method of making the titanium alloy to be close to the single crystal ingot. The method solves the problem that the container material is easy to pollute the alloy and thus affect the physical and mechanical performances of the single crystal alloy during preparation of single crystal in the current directional solidification methods. The procedures of the invention are as follows: 1. vacuum pumping is conducted in a furnace (4), and then argon is re-charged. 2. induction coils (3) are arranged out of a water-cooled copper crucible (2), and spread on the outer surface of the water-cooled copper crucible (2). 3. a material rod (3) enters into the induction coils (3), the titanium alloy charge enters into the cavity of the water-cooled copper crucible (2), and the diameter of the upper part of the charge is small. 4. After heating, pulling is conducted, the feeding speed must strictly match with the pulling action; a rod enters into a crystallizer (9); the material rod forms close single crystal after pulling, and obtains the single crystal ingot after processing the outer layer. The invention realizes high-grade, high-efficiency, safety, special and low-cost single crystal preparation method for the titanium alloy material.

Owner:HARBIN INST OF TECH

Molten salt corrosion resistant nickel-based superalloy with excellent performance

ActiveCN103966476AImproved resistance to molten salt corrosionImprove durabilityNuclear reactorMetallic materials

Belonging to the technical field of metal materials, the invention discloses a molten salt corrosion resistant nickel-based superalloy with excellent performance. In terms of weight percentage, the alloy comprises: less than or equal to 0.08% of C (preferably in the range of 0.03-0.06%), 0.5-5% of Fe, 6.0-8.0% of Cr, 12-18% of Mo, less than or equal to 2% of Ta, less than or equal to 2% of Ti, less than or equal to 2% of Nb, and the balance Ni, wherein the sum of Ti, Nb and Ta is greater than or equal to 1% and less than or equal to 2%. In addition to excellent room temperature plasticity, high temperature structure stability and high mechanical properties under high temperature, the alloy also has good resistance to molten salt corrosion, and can meet the use demands of molten salts and irradiation environments with high use temperature and performance requirements. Thus, the molten salt corrosion resistant nickel-based superalloy is suitable for high-temperature structural materials of molten salt nuclear reactors.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

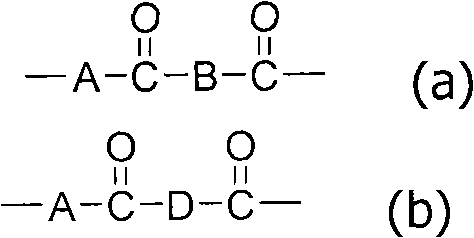

Method for preparing high glass-transition temperature crystal type polyethylene-ketone-ketone resin material

The invention belongs to a new high performance and high polymer material synthesis field, in particular to a method for preparing a novel high glass-transition temperature crystal type polyethylene-ketone-ketone resin material in a such way that a monomer solutions of diphenyl ether and aromatic acyl chloride are dropwise added in a system, and a Friedel-Crafts low temperature solution electrophilic substitution polymerization is carried out. The viscosity of the resin materials synthesized by the method can be precisely controlled within 0.50-1.10+ / -0.10 dL / g, the glass-transition temperature can be controlled between 168 DEG C and 175 DEG C, and the melting temperature can be controlled between 310 DEG C and 360 DEG C. Compared with the FC of the same kind of already commercialized products, under the condition that the materials maintain excellent melting processing performance, the polymer has the glass-transition temperature 15 DEG C higher than that of the products, so that the invention has excellent heatproof performance.

Owner:昆山普利米斯聚合材料有限公司

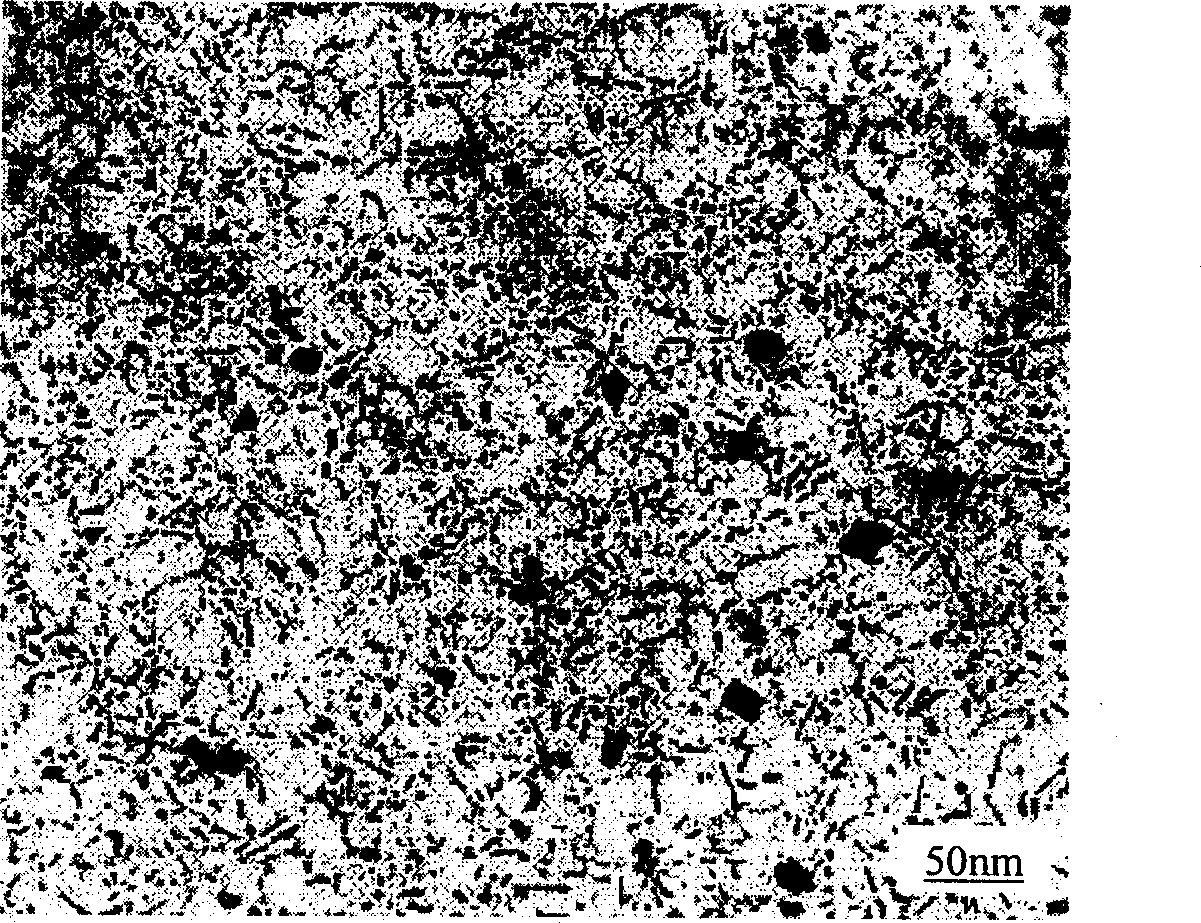

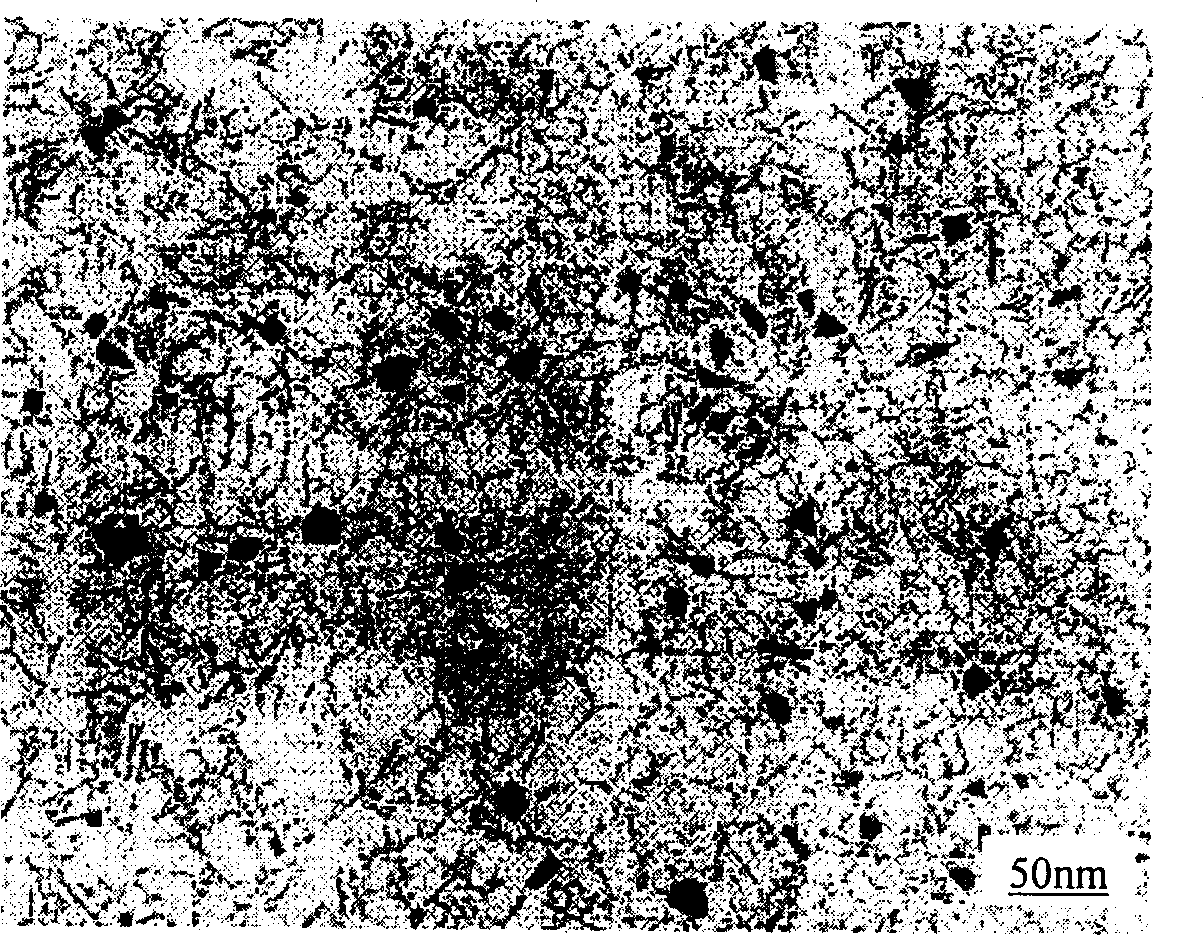

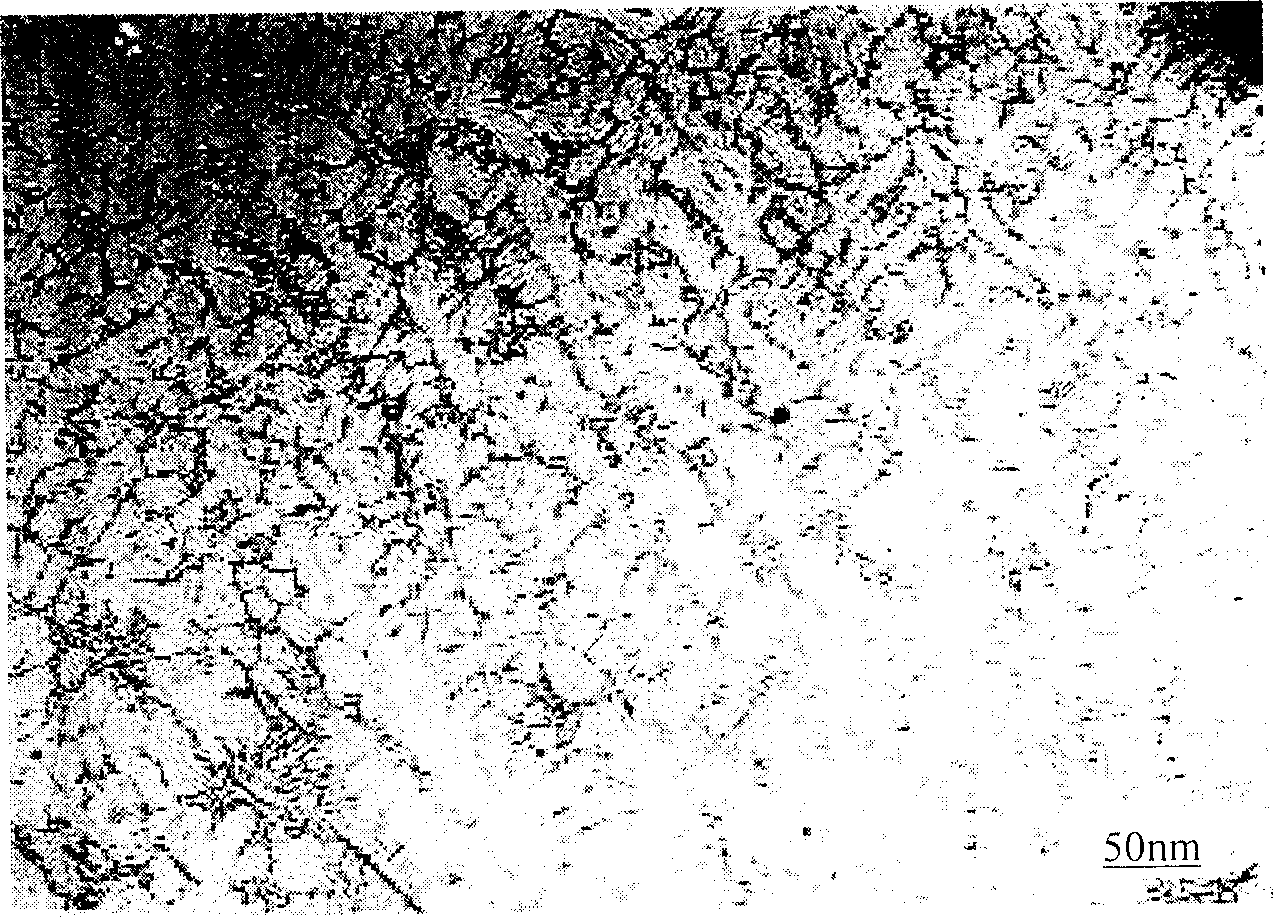

Micro alloyed oxide dispersion-strengthening ferrite steel and preparation method

The invention relates to a micro alloyed oxide dispersion-strengthening ferrite steel, wherein the chemical formula of the steel is Fe-(14-16)Cr-(1-3)W-(0.3-1.0)Ti-(0.3-0.6)Y2O3-(0.5-3)Cu. The preparation method of the steel comprises the following steps of: thermosetting and moulding after mixing and ball milling Fe-Cr-W, Ti, Y2O3 and Cu in proportion, or thermosetting and moulding after mixing ball milling powder and Fe-Cr-W alloy powder in the ratio of 1: (2-4), and then carrying out solution treatment or solution and ageing treatment, thus micro Cu alloyed oxide dispersion-strengthening ferrite steel is obtained. In the invention, Cu is introduced into a matrix lattice by mechanical alloying; nano-scale copper-rich second phase is precipitated from a matrix in the thermosetting, moulding and heat treatment process; and the strength and high-temperature creep resistance of alloy are greatly improved. The invention has the advantages of simple preparation process, short preparation period, low preparation cost and low impurity content, and is easy to operate. The prepared alloy has good room-temperature and high-temperature mechanical properties and is applicable to industrial production.

Owner:CENT SOUTH UNIV

Spinel casting sand and preparation method thereof

InactiveCN104557062AMeet the requirements of refractorinessImprove high temperature mechanical propertiesSodium BentoniteThermal expansion

The invention discloses magnesium-aluminum spinel casting sand prepared by sintering bauxite raw material and industrial magnesium oxide and a preparation process of the magnesium-aluminum spinel casting sand. The magnesium-aluminum spinel casting sand comprises the following main raw materials: 72.9% of bauxite raw material, 98% of magnesium oxide and the like. The preparation process comprises the following steps: weighing bauxite and industrial magnesium oxide powder according to a stoichiometric ratio, adding an appropriate amount of binders, mixing the materials, performing wet grinding, drying, pelletizing in a pelletizing machine, finally putting into a silicon molybdenum rod box type furnace for sintering and performing heat preservation at 1,550 DEG C for 5 h, cooling with the furnace, and then screening to obtain the magnesium-aluminum spinel casting sand. The novel spherical sand prepared by the preparation process disclosed by the invention has the characteristics of high temperature resistance, high strength, low thermal expansion rate, good anti-sticking sand performance, good recycling performance, low production cost and environmental friendliness; in the application aspect, the magnesium-aluminum spinel casting sand is suitable for molding methods of water glass, resin, bentonite and the like, and is suitable for precision casting, expendable pattern casting, V process casting and polishing treatment of nonferrous metals.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +2

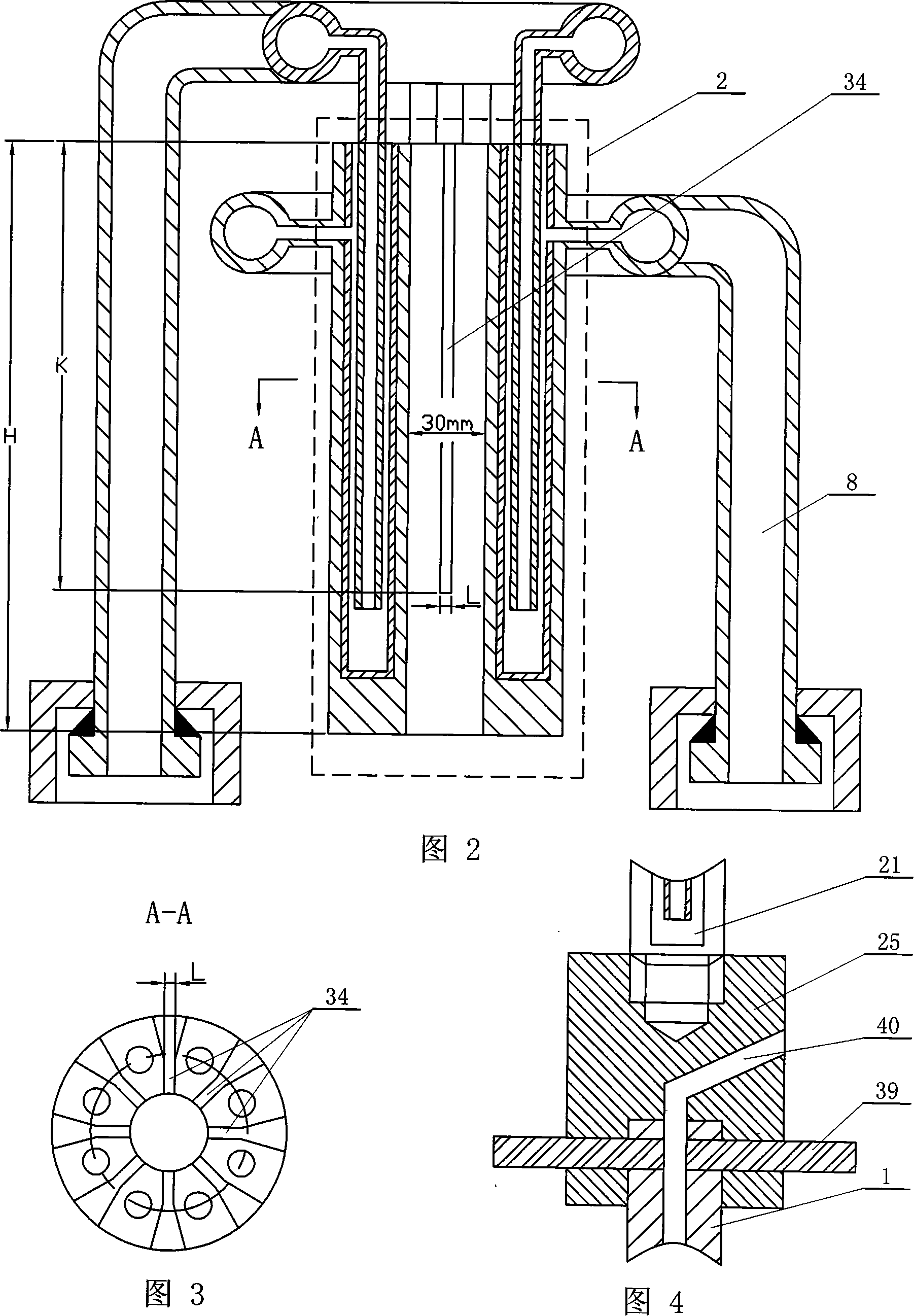

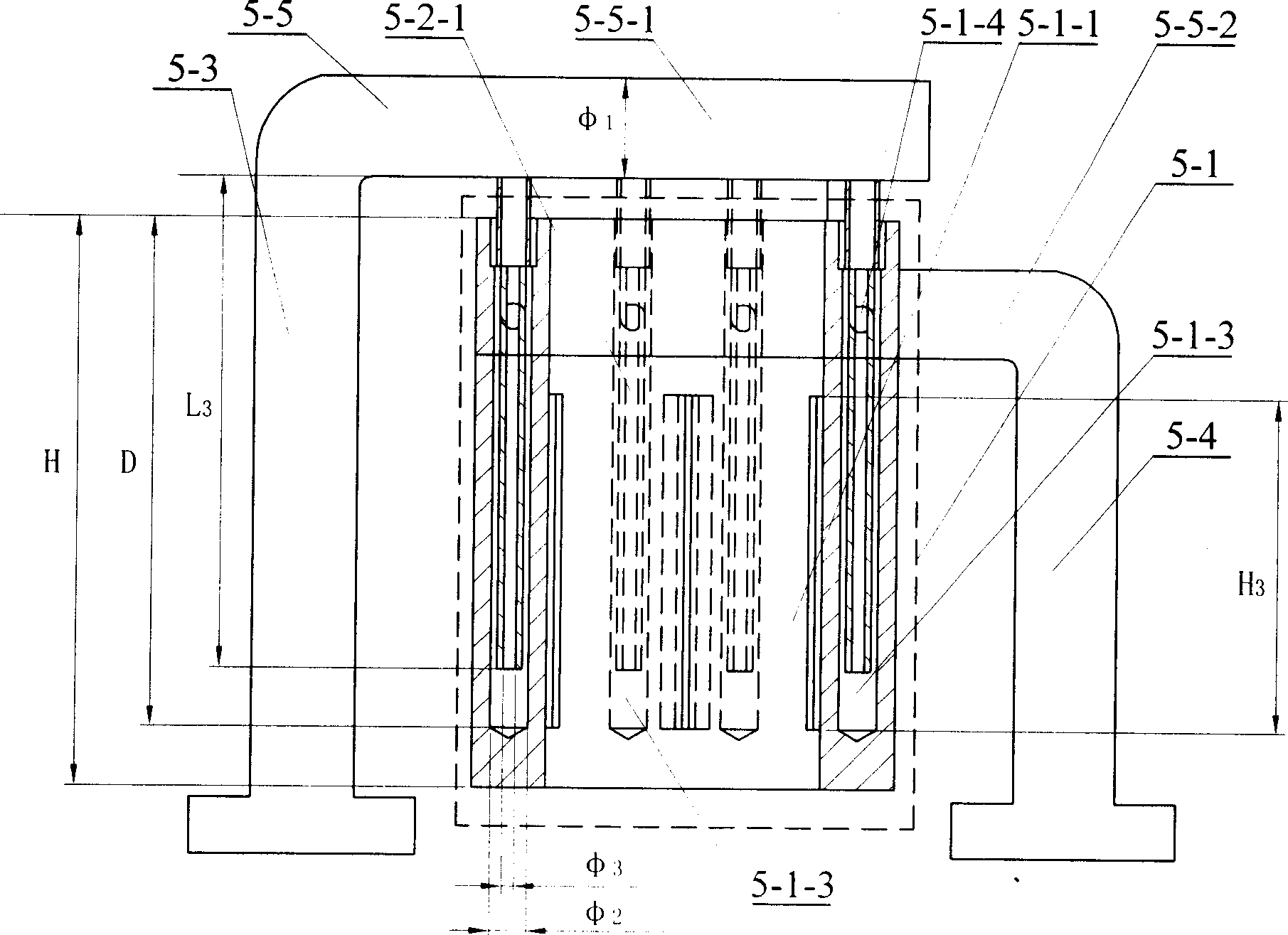

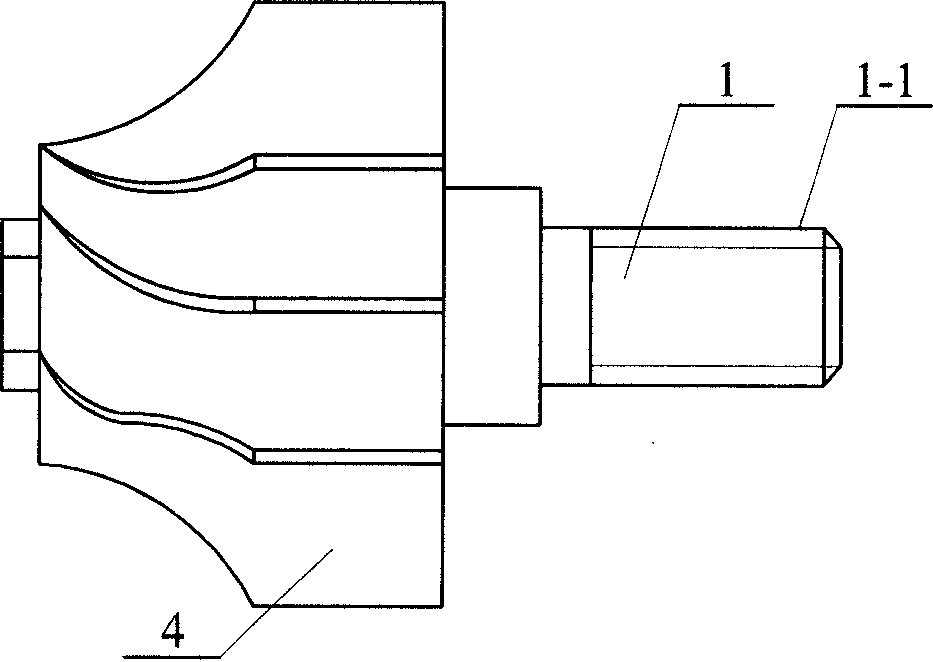

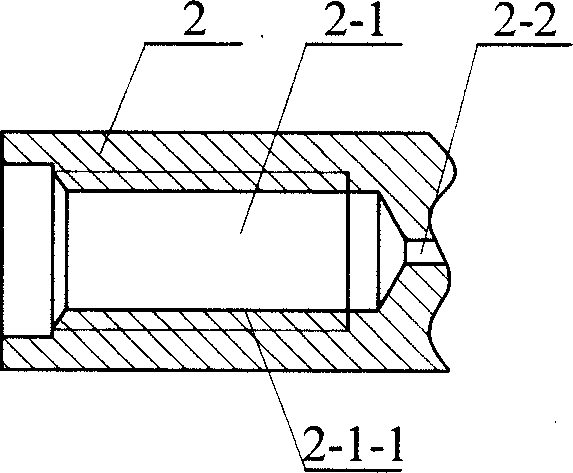

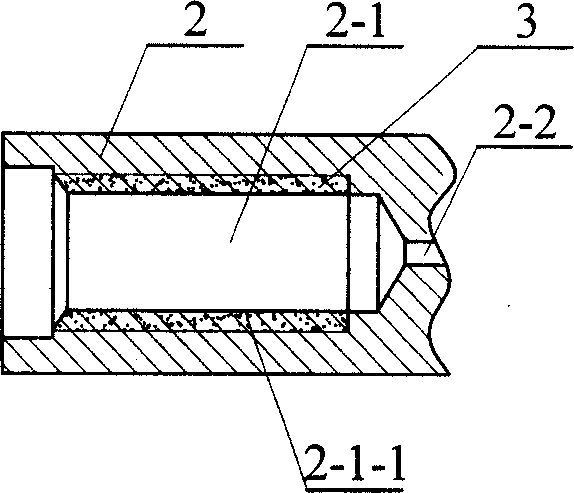

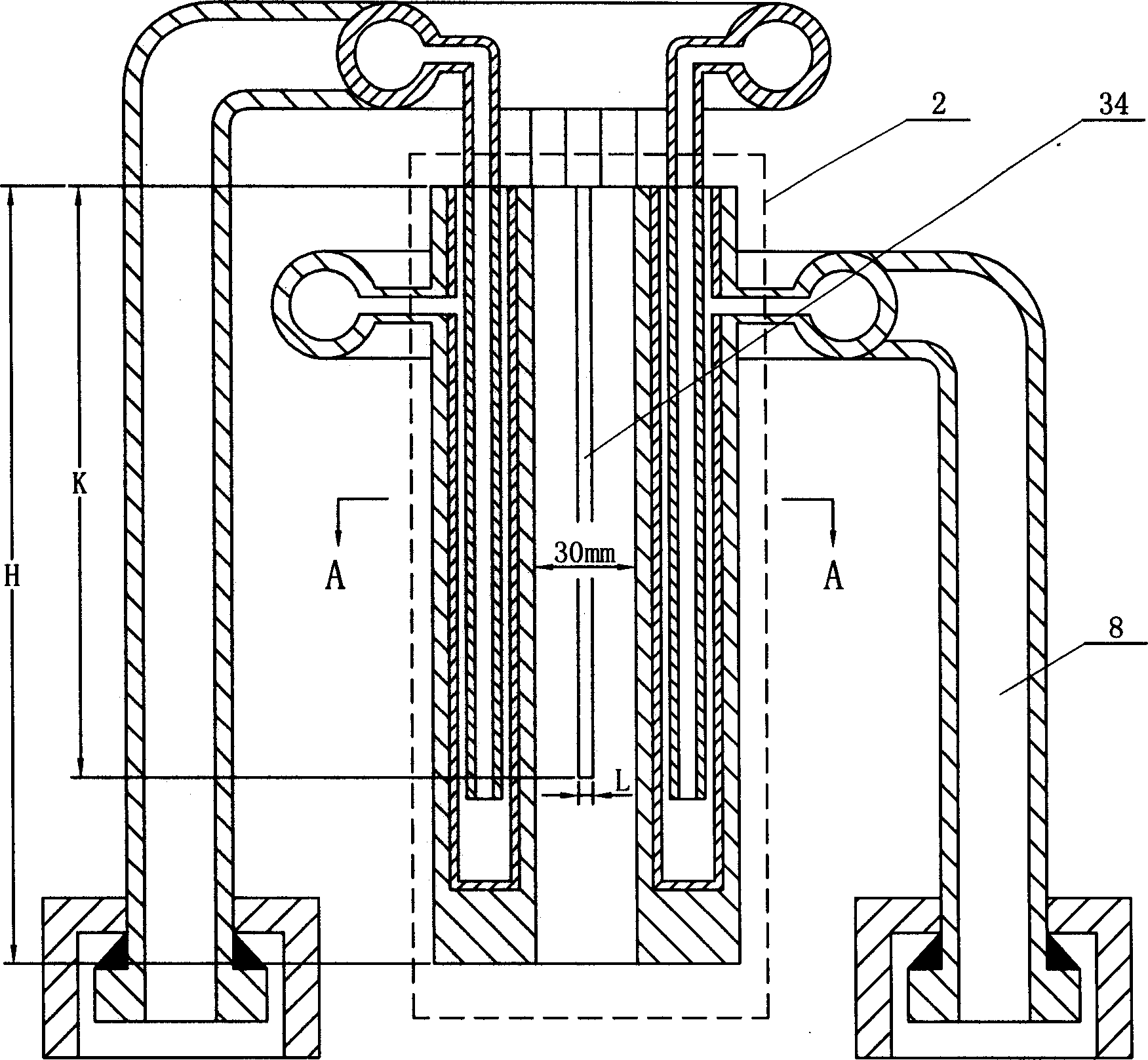

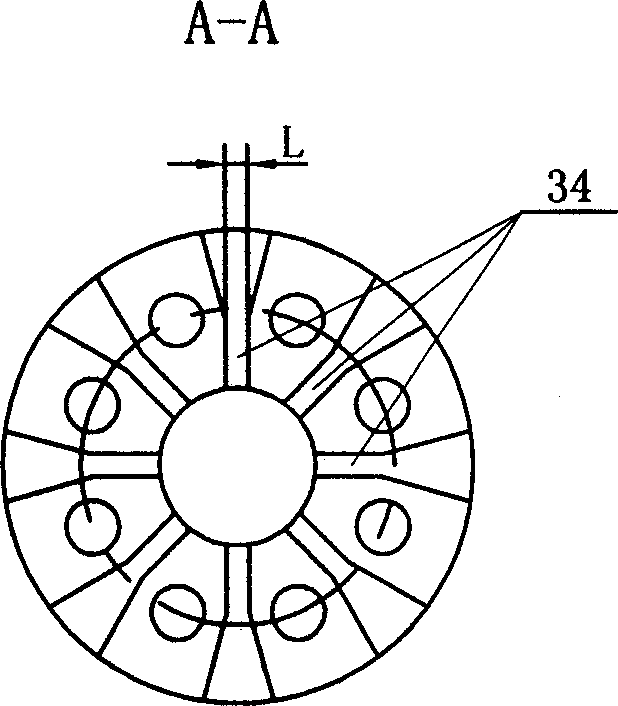

Directional freeze method for TiAl-based alloy plate

The continual casting directional solidification method for TiAl-base alloy plate comprises, putting TiAl alloy material bar 3 and dummy ingot 4 with rectangular intersection into the electromagnetic induction range of coil 6, galvanizing to coil 6 with single-phase alternating current with power of 75~100kW from electrical power for 20~25min; the alloy bar 3 and ingot 4 move downward with velocity of 0.01-0.05mm / min and get into the bottom crystallizer 8. This invention overcomes the limit to rectangular intersection blank and fits to press for high performance material in economy, science and national defense industry.

Owner:HARBIN INST OF TECH

Mineral high-strength wear-resistant material and preparation method thereof

The invention discloses a mineral high-strength wear-resistant material which is prepared from the following raw materials in percentage by weight: 0.30-0.50% of C, 0.10-0.65% of Si, less than or equal to 1.0% of Mn, 1.0-4.5% of Cr, 0.05-3% of Ni, 0.15-1.5% of Mo, 0.05-0.5% of V, 0.010-0.5% of Nb, 0.01-0.5% of Al, less than or equal to 0.025% of P, less than or equal to 0.015% of S and the balanceof Fe. A chain wheel manufactured from the mineral high-strength wear-resistant material is excellent in alloy element proportion, is pure in steel, is uniform in structure, has excellent comprehensive performance, is high in chain gear hardness, is uniform in hardness and is good in wear resistance; and meanwhile, a base body part has good impact toughness and strength. The defects that a commonChinese chain wheel is poor in comprehensive performance and is low in coal passing amount are solved. The mineral high-strength wear-resistant material greatly improves the coal passing amount of the chain wheel, reduces chain wheel use cost, and improves economic benefits.

Owner:YINGKOU SPECIAL STEEL FORGING

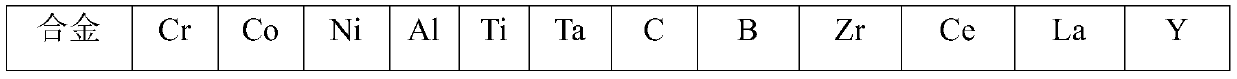

Ni-Co-Al-Cr-Fe series single crystal high-entropy high-temperature alloy and preparation method thereof

ActiveCN110317990AHigh temperature strengthImprove high temperature mechanical propertiesPolycrystalline material growthAfter-treatment detailsRare-earth elementHigh entropy alloys

The invention discloses a high-entropy high-temperature alloy and a preparation method thereof, and belongs to the field of high-entropy alloys. The alloy comprises the following chemical components of, in percentage by atom, 35%-40% of Ni, 30%-35% of Co, 10%-13% of Al, 5%-10% of Cr, 5%-8.5% of Fe, 1%-2.5% of Ti, 1%-3% of Ta, 0.01%-1% of Mo, 0.01%-1% of W, 0-1% of Re, 0.02%-0.12 % of C, 0.002%-0.015% of B, 0.005%-0.12% of Hf, and 0.05%-0.15% of RE, wherein Al+Ti+Ta is greater than or equal to 14% and less than or equal to 16%, and RE is any one rare earth element of Ce, La and Y. The preparation process of the alloy comprises the following steps of weighing and matching alloy elements according to the molar ratio, putting the alloy elements into a smelting furnace for smelting, carrying out high-temperature refining and casting to obtain an alloy ingot, preparing a (001) oriented single crystal high-entropy high-temperature alloy bar by adopting a high-speed solidification Bridgeman method, and then performing solution treatment and secondary aging treatment on the alloy bar. The prepared alloy bar has good high-temperature strength and thermal corrosion resistance, and is a candidate material of a hot-end part of an aero-engine and an industrial gas turbine.

Owner:UNIV OF SCI & TECH BEIJING

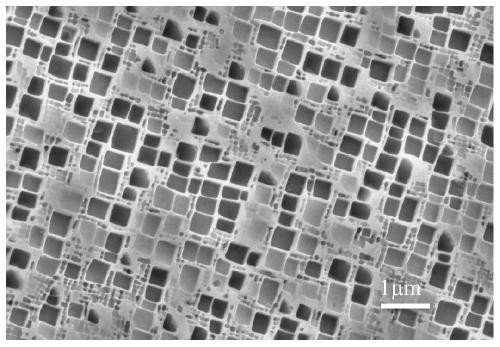

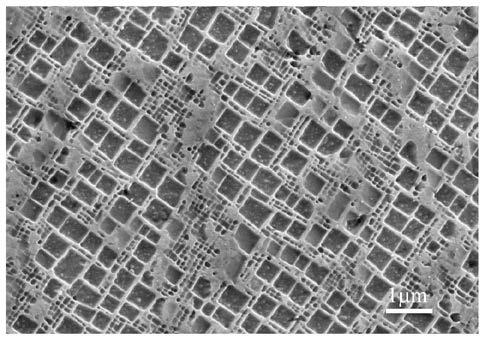

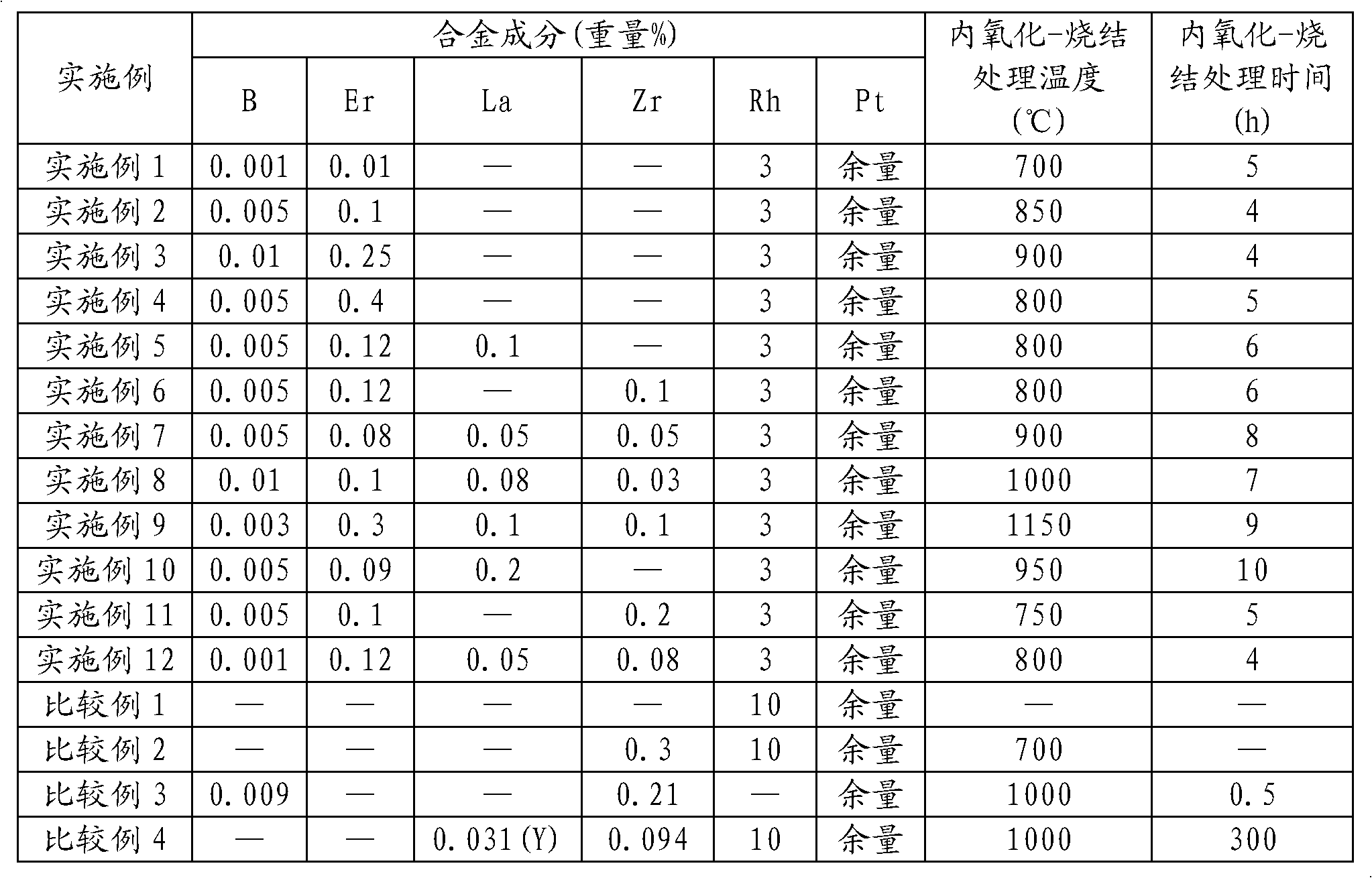

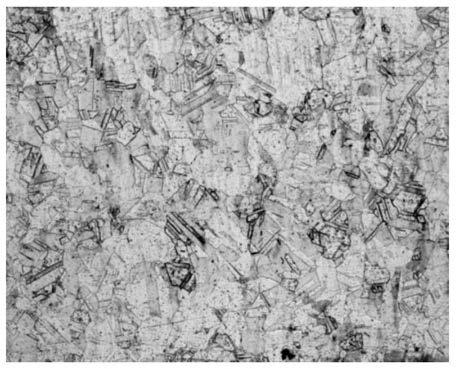

Oxide dispersion reinforced platinum-based alloy and preparation method thereof

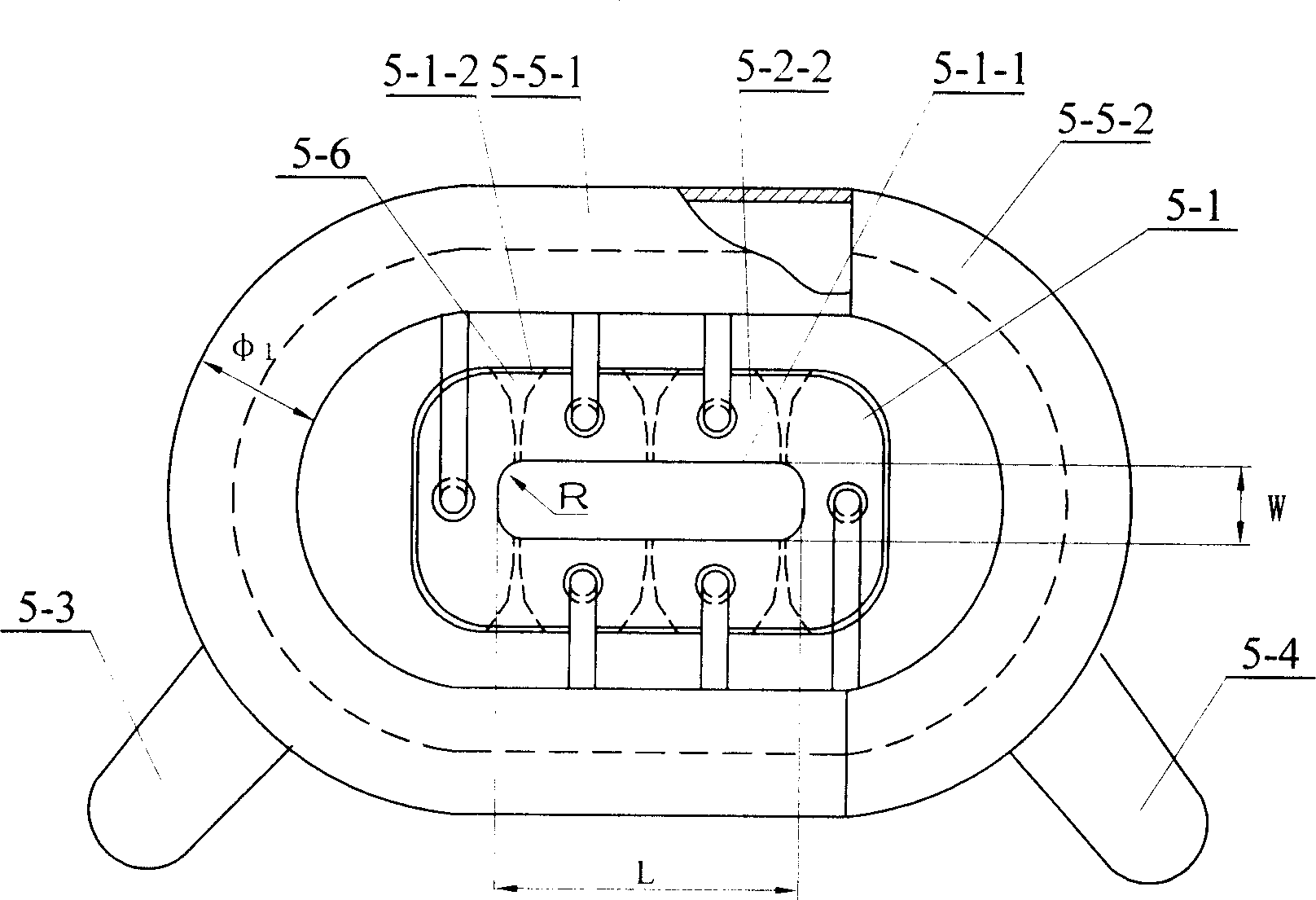

The invention discloses an oxide dispersion reinforced platinum-based alloy, which comprises a platinum alloy base material and a dispersion reinforcing phase dispersed in the platinum alloy base material, wherein the dispersion reinforcing phase consists of an oxide of boron, an oxide of erbium and an oxide of at least one of lanthanum and zirconium; and elements except oxygen in the dispersion reinforcing phase accounts for 0.015 to 0.8 percent of the total weight of the oxide dispersion reinforced platinum-based alloy, wherein at least 85 weight percent of dispersion reinforcing phase is dispersed in the platinum alloy matrix in a nano granule state. The invention also discloses a preparation method for the platinum alloy material. The platinum alloy material has the characteristics of excellent high-temperature mechanical property, short production period and the like, and is particularly suitable for manufacturing a porous dense large-sized glass fiber leakage plate (3,200 to 8,000 holes) and other required platinum-based high-temperature alloy structural materials.

Owner:CHONGQING POLYCOMP INT

High-toughness medium entropy high temperature alloy and preparing method thereof

ActiveCN111500917AHigh strengthImprove high temperature mechanical propertiesIndustrial gasManufactured material

The invention discloses a high-toughness medium entropy high temperature alloy and a preparing method thereof. The alloy comprises chemical components including, by weight percent, 28.5 to 32.5% of Cr, 31.5 to 33.4% of Co, 32 to 35% of Ni, 0.5 to 6% of Al, 0 to 6% of Ti, 0 to 3% of Ta, 0.02 to 0.12% of C, 0.002 to 0.015% of B, 0.005 to 0.12% of Zr, 0.005 to 0.15% of RE, and larger than or equal to2% and smaller than or equal to 6% of Al+Ti+Ta, wherein Re is one of Ce, La and Y. The preparing method of the alloy comprises the steps that the raw materials are burdened and smelted according to the proportion, an electrode bar is forged and subjected to remelting, forging is carried out, an alloy bar is prepared, and the alloy bar is subjected to solid solution and aging heat treatment. The alloy is provided with a reasonable component ratio, a wide heat machining window and a heat processing system, the prepared alloy bar has the higher temperature strength, good heat machining and oxidation resistance properties, and the alloy is a candidate material of aero-engine and industrial gas turbine heat end parts.

Owner:UNIV OF SCI & TECH BEIJING +1

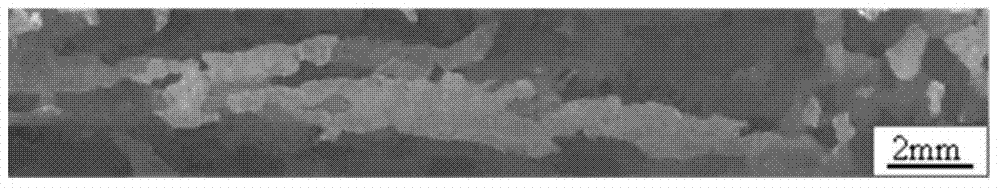

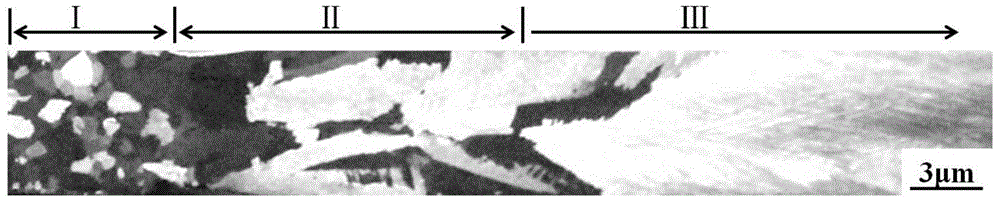

High-temperature high-strength TiAl-Nb monocrystal and preparation method thereof

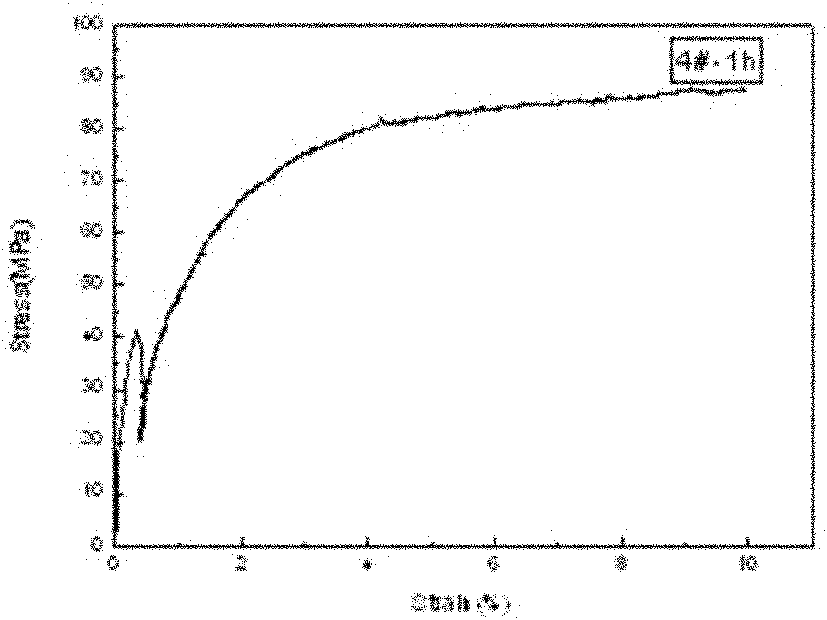

InactiveCN104878452AImprove high temperature mechanical propertiesSolve pollutionPolycrystalline material growthBy zone-melting liquidsDifferential pressureSingle crystal

The invention discloses a high-temperature high-strength TiAl-Nb monocrystal and a preparation method thereof. Based on the atomic percent, the high-temperature high-strength TiAl-Nb monocrystal comprises the alloy components: Ti-(43-47) Al-(6-10)Nb-(0.1-1)(C, Si), and the balance of Ti. The preparation method comprises the following steps: smelting TiAl-Nb button-shaped master alloy ingot casting by using an electro-magnetic induction suspension method; preparing a cylindrical rod-shaped sample by means of differential pressure suction casting or gravity casting; directionally condensing the cylindrical bar by using an optical float-zone crystal growth system to guarantee that the heating power is between 65% and 70%, the growth velocity is 5-30mm / h, the relative rotation speed is 20-40r / min and the argon flow protection is carried out for 3-5L / min; finally obtaining a TiAl-Nb monocrystal test bar; and performing desegregation heat treatment on the TiAl-Nb monocrystal bar to finally obtain the monocrystal test sample. By adopting the TiAl-Nb monocrystal alloy material prepared by using preparation method disclosed by the invention, the alloy pollution caused by a traditional Bridgman directional condensation method can be effectively avoided, a solid-liquid interface shape during condensation is controlled by regulating the heating power so as to quickly obtain the TiAl-Nb monocrystal, and after the desegregation of the TiAl-Nb monocrystal, the high-strength TiAl-Nb monocrystal alloy of which the yield strength is 637MPa at a temperature of 900 DEG C, the elongation percentage is 8.1% and the ductile-brittle transition temperature is not lower than 900 DEG C can be obtained.

Owner:NANJING UNIV OF SCI & TECH

Non-sintering sialon bonded corundum-spinel castable and method for preparing RH (Ruhstahl Hausen) insert tube prefabricated member inner core with same

ActiveCN103880442AImproved thermal shock stabilityImprove high temperature mechanical propertiesMetal powderUltimate tensile strength

The invention discloses a non-sintering sialon bonded corundum-spinel castable and a method for preparing an RH (Ruhstahl Hausen) insert tube prefabricated member inner core with the same. The castable comprises the following raw materials: 50-72% of fused white corundum, 8-21% of spinel, 2-9% of silicon metal powder, 3-11% of 200-mesh fused white corundum, 2-6% of alpha-alumina and 3-7% of rho-alumina; besides, an additive FS60 with weight accounting for 0.04-0.13% of total weight of various raw materials is added. The castable and the method have the beneficial effects that as the castable adopts sialon bonding, impacts of existence of CaO in existing traditional castable cement on the high temperature property and corrosion resistance of the prefabricated member are overcome, thus greatly improving the high temperature strength and thermal shock resistance of the castable; in combination with the 1700 DEG C service conditions of the product, generation of sialon in the service process is achieved, the production cost is effectively reduced, and the service life of the product is prolonged by 30-50%.

Owner:郑州市裕丰耐火材料有限公司

High strength heat resistant alloy

A high-strength refractory Al alloy with high strength, size stability and resistance to high temp (350-400 deg.C) and wearing contains proportionally Si, Cu, Ni, Mn, Mg, Ti, B, Zr, Cd, P and Al. It features that it contains the uniformly distributed Al3X particles with LI2 crystal structure and TiB2 particles with hcc crystal structure.

Owner:XIAN POLYTECHNIC COLLEGE

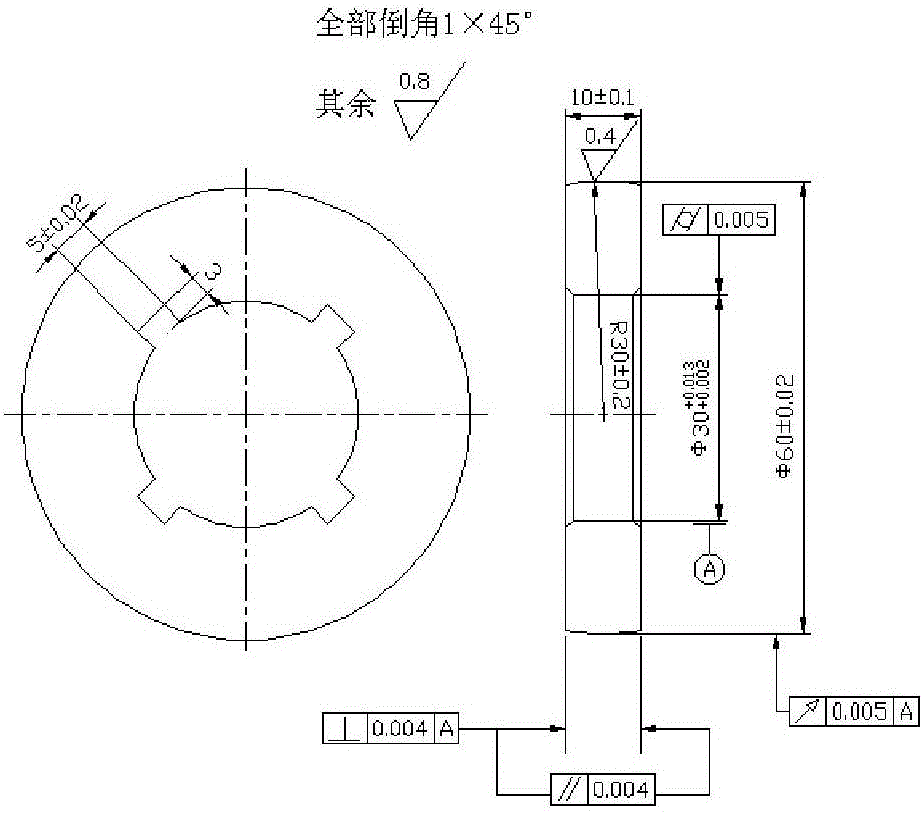

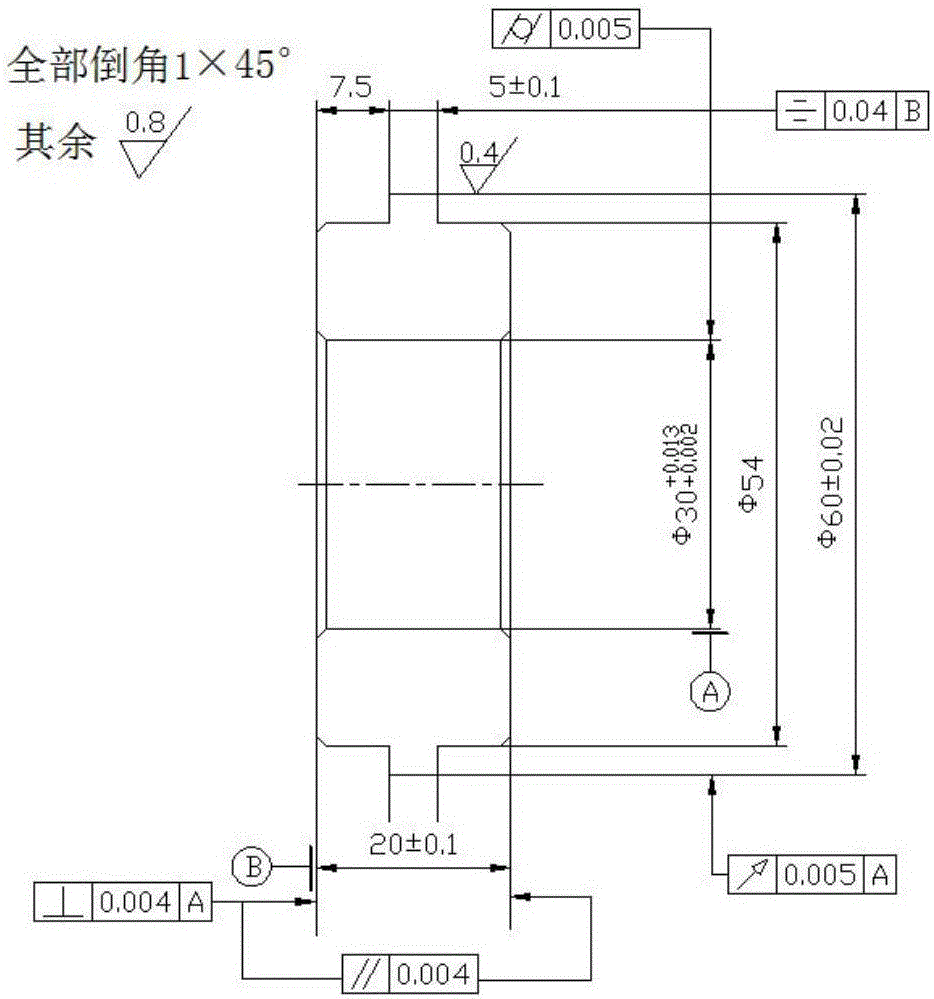

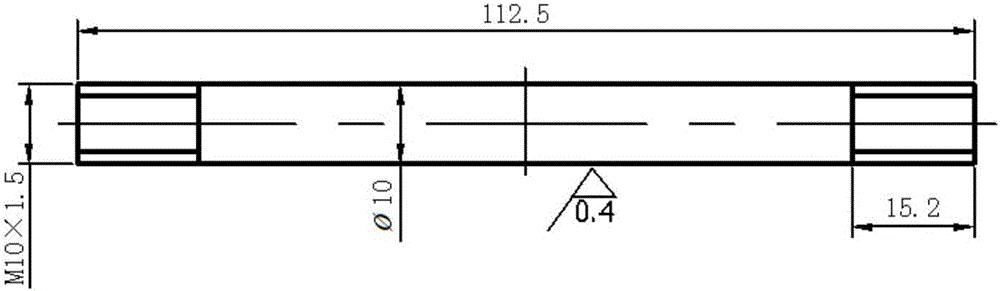

High strength connecting method for TiAl base alloy charging turbine and steel shaft

InactiveCN1748931AImprove high temperature mechanical propertiesIncrease temperatureWelding/cutting media/materialsMetal working apparatusFriction weldingHigh intensity

The high strength connecting process for TiAl base alloy charging turbine and steel shaft includes the following steps: A. machining outer thread in the TiAl base alloy charging turbine and machining inner thread sleeve in the steel shaft and axial technological through hole; B. painting AgCuNiLi brazing paste to the inner wall of the inner thread sleeve; C. assembling the TiAl base alloy charging turbine and the steel shaft together; and D. brazing the assembled TiAl base alloy charging turbine and steel shaft. The present invention has high connection strength.

Owner:HARBIN INST OF TECH

Aluminum-zirconium-phosphorus master alloy and preparation method thereof

The invention belongs to the field of metal materials, relating to an aluminum-zirconium-phosphorus master alloy used for refining eutectic and primary silicon in hypereutectic Al-siliceous ferroalloy and a preparation method thereof. In a master alloy system, P exists in a mode of a ZrP compound which contains the following components by weight percent 78.0 percent to 94.0 percent of aluminum, 3.0 percent to 20.0 percent of zirconium and 1.0 percent to 6.0 percent of phosphorus. The preparation method comprises the following steps: preparing industrial pure aluminum, aluminum-phosphorus master alloy, sponge zirconium or potassium fluorozirconate according to the ratio; melting the industrial pure aluminum to 900 DEG C to 1300 DEG C in a melting furnace; firstly adding the aluminum-phosphorus master alloy to mix for 10 to 20 min; and then adding the sponge zirconium or the potassium fluorozirconate to fully react and uniformly mix, and directly casting the mixture to form a ingot or prepare a wire. The aluminum-zirconium-phosphorus master alloy has favorable refining effect, and can remarkably improve the high temperature mechanical properties of the alloy.

Owner:SHANDONG UNIV

High-gamma'-content nickel-based high-temperature alloy powder for additive manufacturing, using method therefore and nickel-based high-temperature alloy component

ActiveCN112921206AGood printabilityImprove high temperature mechanical propertiesAdditive manufacturing apparatusSelective laser meltingChemical composition

The invention provides high-gamma'-content nickel-based high-temperature alloy powder for additive manufacturing, a using method therefore and a nickel-based high-temperature alloy component, and relates to the technical field of powder-based additive manufacturing. The high-gamma'-content nickel-based high-temperature alloy powder for additive manufacturing comprises the following chemical components in percentage by weight: 12-14% of Cr, 8-9% of Co, 3.8-4.2% of Al, 3.8-4.2% of Ti, 2.4-2.8% of W, 1.9-2.1% of Ta, 1.6-2.0% of Mo, 1.0-1.2% of Nb, 0.1-5% of Fe, 0.1-2.0% of Hf, 0.12% or less of C, 0.1% or less of Si, 0.02% or less of n, less than 0.03% of Zr, 0.01% or less of B, and the balance Ni and impurity elements. By using the high-temperature alloy powder, compact and crack-free complex parts meeting the strength requirement in the ultrahigh-temperature environment can be printed through the selective laser melting technology.

Owner:常州钢研极光增材制造有限公司 +1

High-strength high-corrosion-resistance double-phase heat resistant steel

The invention belongs to the field of heat resistant stainless steel and relates to high-strength high-corrosion-resistance double-phase heat resistant steel. The high-strength high-corrosion-resistance double-phase heat resistant steel comprises 0-0.1% of C, 0.1-1.0% of Si, 0-0.5% of Mn, 12-25% of Cr, 15-22% of Ni, 0-4.0% of Mo, 1.0-6.0% of Al, 0.1-1.0% of Nb, 0-0.05% of B, not larger than 0.03% of P, not larger than 0.02% of S and the balance Fe. A preparation method is characterized in that the vacuum degree is strictly controlled to be smaller than or equal to 5 Pa in the smelting process, so that adverse influences of N and Al chemical compounds are avoided; a hammer forging manner is adopted, and the strain rate is controlled to be not smaller than 1s-1in the hot rolling process; and the reduction in a single pass is not smaller than 35%, and the second-phase size is controlled through rapid cooling. The high-strength high-corrosion-resistance double-phase heat resistant steel enables high-temperature corrosion resistance and high strength to be matched, and the comprehensive performance of the high-strength high-corrosion-resistance double-phase heat resistant steel is obviously higher than that of existing double-phase heat resistant steel when the high-strength high-corrosion-resistance double-phase heat resistant steel is used in a high-temperature corrosive environment.

Owner:ANYANG INST OF TECH

High-hardness wear-resistant wheel steel and wheel preparation method

InactiveCN106435365AImprove the hardnessExcellent overall performanceFurnace typesHeat treatment furnacesWear resistantChemical composition

The invention relates to wheel steel for a wheel and a preparation method therefor. The wheel steel comprises the chemical components in percentages by weight: 0.70-0.80% of C, 0.70-1.80% of Si, 0.40-1.00% of Mn, 0.15-0.30% of Cr, 0.05-0.13% of V, less than or equal to 0.012% of P, less than or equal to 0.012% of S and the balance of Fe and inevitable impurity elements. A C-Cr-V high-hardness wear-resistant wheel is prepared through the steps of electric furnace smelting continuous casting, ingot-slicing rolling, thermal treatment and the like. Compared with an AAR-C wheel steel, the prepared wheel can obviously improve the strength and hardness of the wheel, and a good comprehensive performance is obtained. Meanwhile, the high-temperature mechanical property and the friction-resistant and abrasion-resistant properties of the wheel are improved. At the same time, the wheel prepared from the wheel steel provided by the invention can maintain the texture of the original wheel, and the difficulty of preparing the wheel is not increased.

Owner:MAANSHAN IRON & STEEL CO LTD

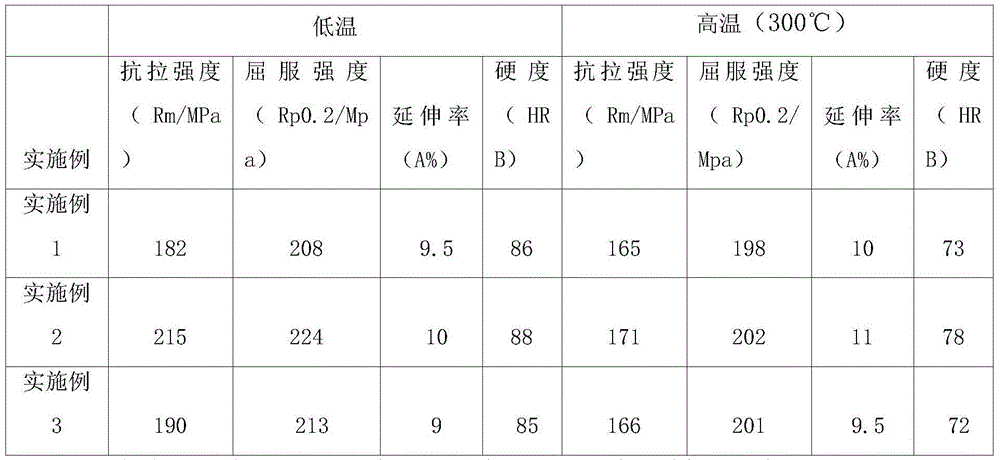

Swash plate of automobile air-condition compressor and production method of swash plate

ActiveCN104831133AImprove cutting performanceLow costPositive displacement pump componentsPositive-displacement liquid enginesPre treatment5005 aluminium alloy

The invention discloses a swash plate of an automobile air-condition compressor. The swash plate is prepared from an aluminium alloy comprising the following components in percentage by weight: 13-15% of Si, 4-5% of Cu, 0.2-0.3% of Mg, 0.8-1.5% of Ni, 0-0.1% of Mn, 0-0.5% of Fe, 0-0.1% of Zn, 0-0.2% of Ti, 0.1-0.3% of C, 0.1-0.3% of RE and the balance of Al. The invention further provides a production method of the swash plate of the automobile air-condition compressor. According to the production method provided by the invention, the high-temperature strength and the high-temperature hardness of the swash plate are improved, the cutting properties and the plasticity are improved, and low-cost production is realized by choosing and controlling elements in the aluminium alloy for the swash plate, and then replacing casting by forging, optimizing the pre-treatment and the post-treatment of the forging, and optimizing process parameters during the various treatment processes.

Owner:SHANDONG HUICHUAN AUTO PARTS

Water cooling electromagnetic copper type directional solidification method of titanium base alloy

A water cooled electromagnetic directional solidifying method for Ti-based alloy features that the furnace containing crucible is vacuumized, and after the single-phase AC is applied to the coil for 4-16 min, the upper material rod and bottom material are moved downward to make the bottom material come in crystallier, resulting in uniform cooling speed and high mechanical performance of product.

Owner:HARBIN INST OF TECH

HIC-resistant heat resistant steel in iron element system and preparation process thereof

The invention relates to hydrogen induced cracking (HIC)-resistant heat resistant steel in an iron element system and a preparation process thereof. The steel comprises the following components in percentage by weight: 0.1 to 0.15 percent of C, 0.2 to 0.5 percent of Si, 0.3 to 0.6 percent of Mn, 2.0 to 2.5 percent of Cr, 0.9 to 1.1 percent of Mo, less than or equal to 0.003 percent of S, less than or equal to 0.010 percent of P and the balance of iron and impurities. The preparation process comprises a heating process, a hot rolling process and a heat treatment process sequentially, wherein the heat treatment process comprises a normalizing process and a tempering process. The steel has a high comprehensive mechanical property, a high low-temperature impact property, high HIC resistance and relatively low tempering tendering sensitivity; and the preparation process is simple, easy to operate, low in cost, high in yield and wide in thickness specification ranges, and a small number of alloys with a few varieties are added.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com