Ni-Co-Al-Cr-Fe series single crystal high-entropy high-temperature alloy and preparation method thereof

A high-temperature alloy and high-entropy technology, applied in the field of high-entropy alloys, can solve the problems of less exploration of application potential of high-temperature mechanical properties, failure to meet engineering application requirements, high density and raw material prices, etc., to achieve excellent long-term organizational stability, Excellent room temperature and high temperature strength, and the effect of improving high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

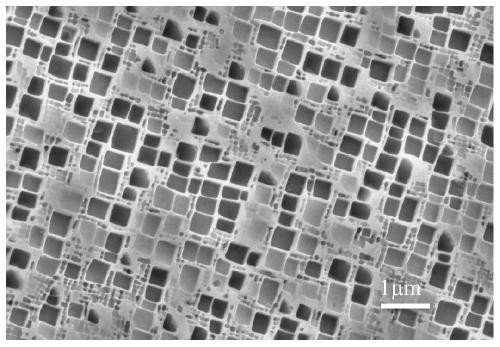

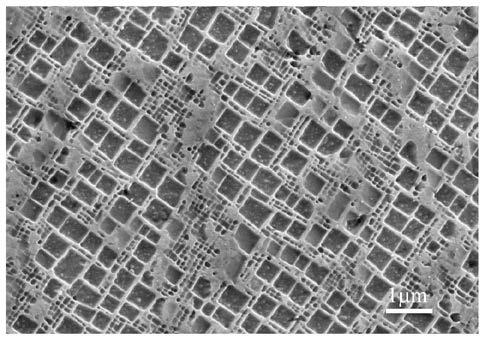

Image

Examples

Embodiment Construction

[0030] In the following, the present invention will be specifically introduced from three aspects of composition design, alloy preparation and structure performance test for some alloys in the examples.

[0031] 1. Alloy design

[0032] Table 1 shows the alloy composition (atomic percentage) of some examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0033] Table 1 is the alloy embodiment composition (at%) of the present invention

[0034]

[0035] 2. Alloy Preparation

[0036] According to the ingredients shown in Alloy 1 in Table 1, weigh Ni, Co, Al, Cr, Fe, Ti, Ta, Mo, W, Re, C, B, Hf, RE raw materials, and weigh them according to weight percentage. put into a melting furnace for smelting, high-temperature refining for 15-30 minutes, and the refining temperature is 1550-1650 ° C, and cast into alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com