Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2458results about How to "Improve welding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low alloy high-strength steel plate capable of being welded in large energy input and method of producing the same

ActiveCN101153370AImprove toughnessSimple designRoll mill control devicesHeat treatment process controlHeat-affected zoneSheet steel

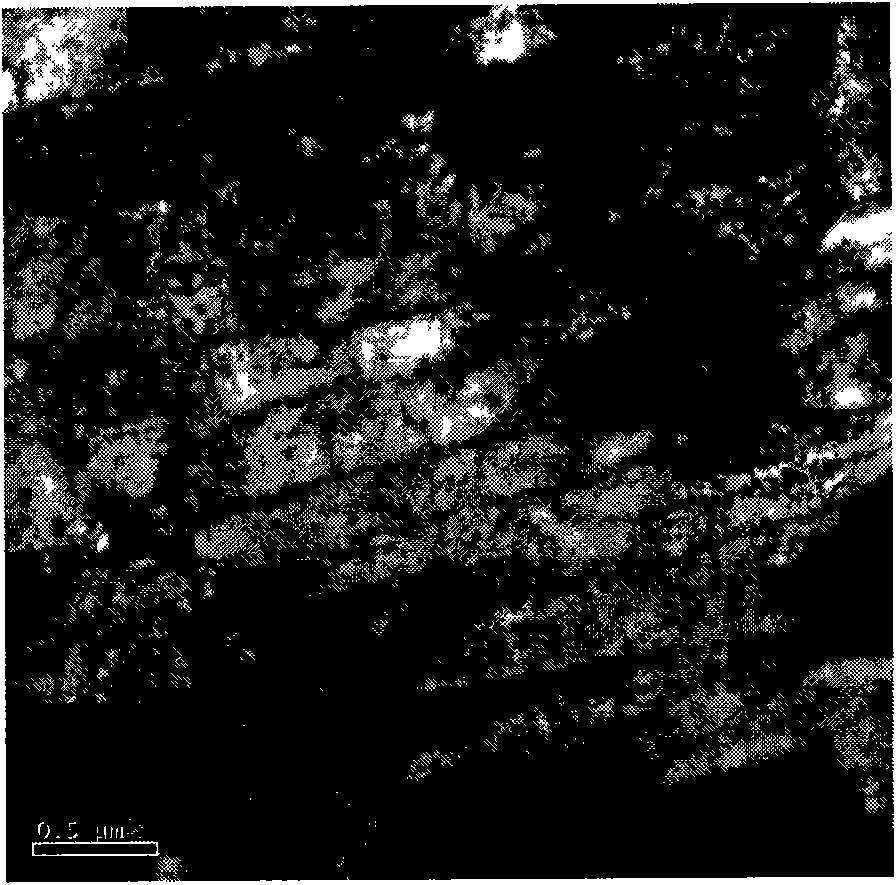

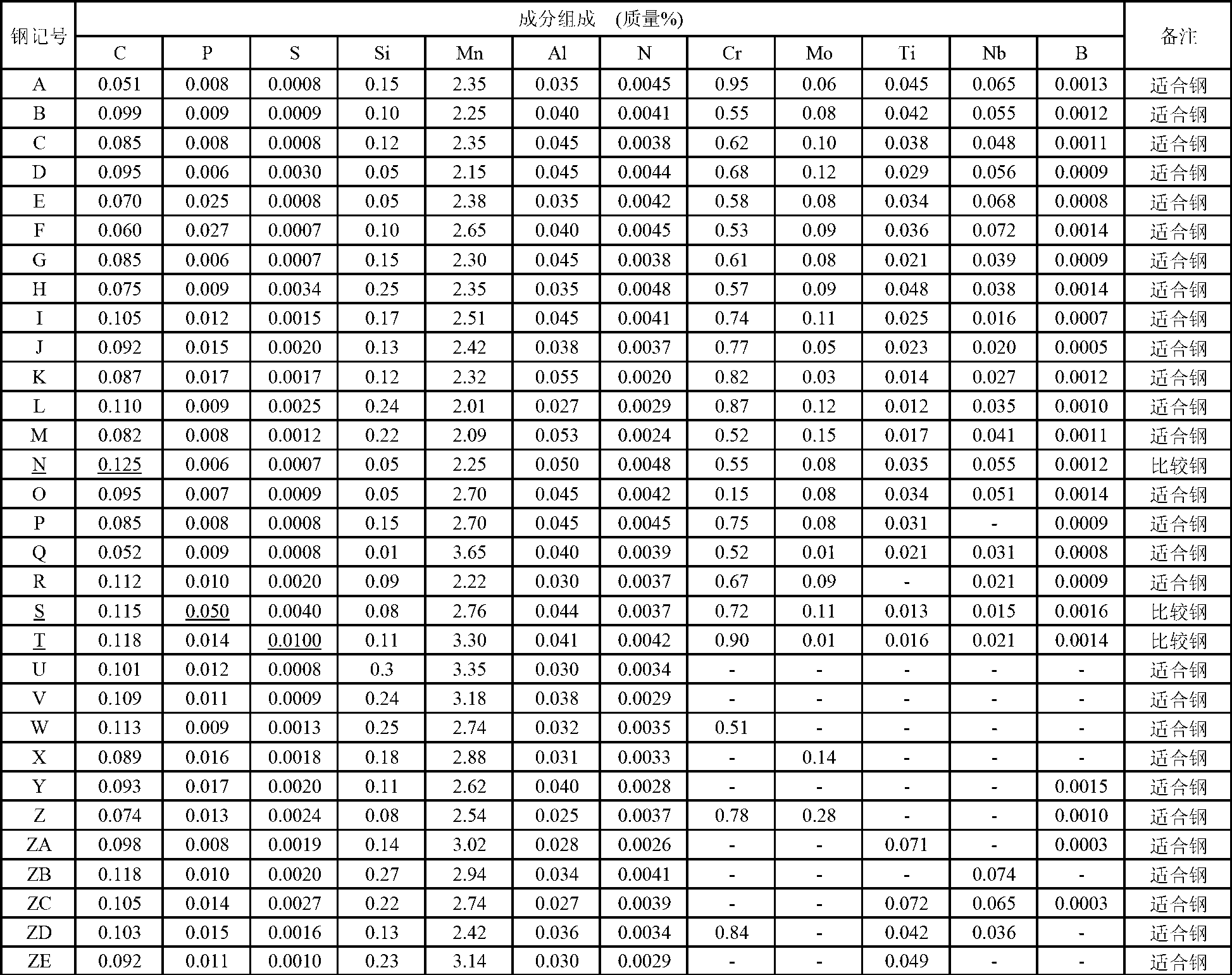

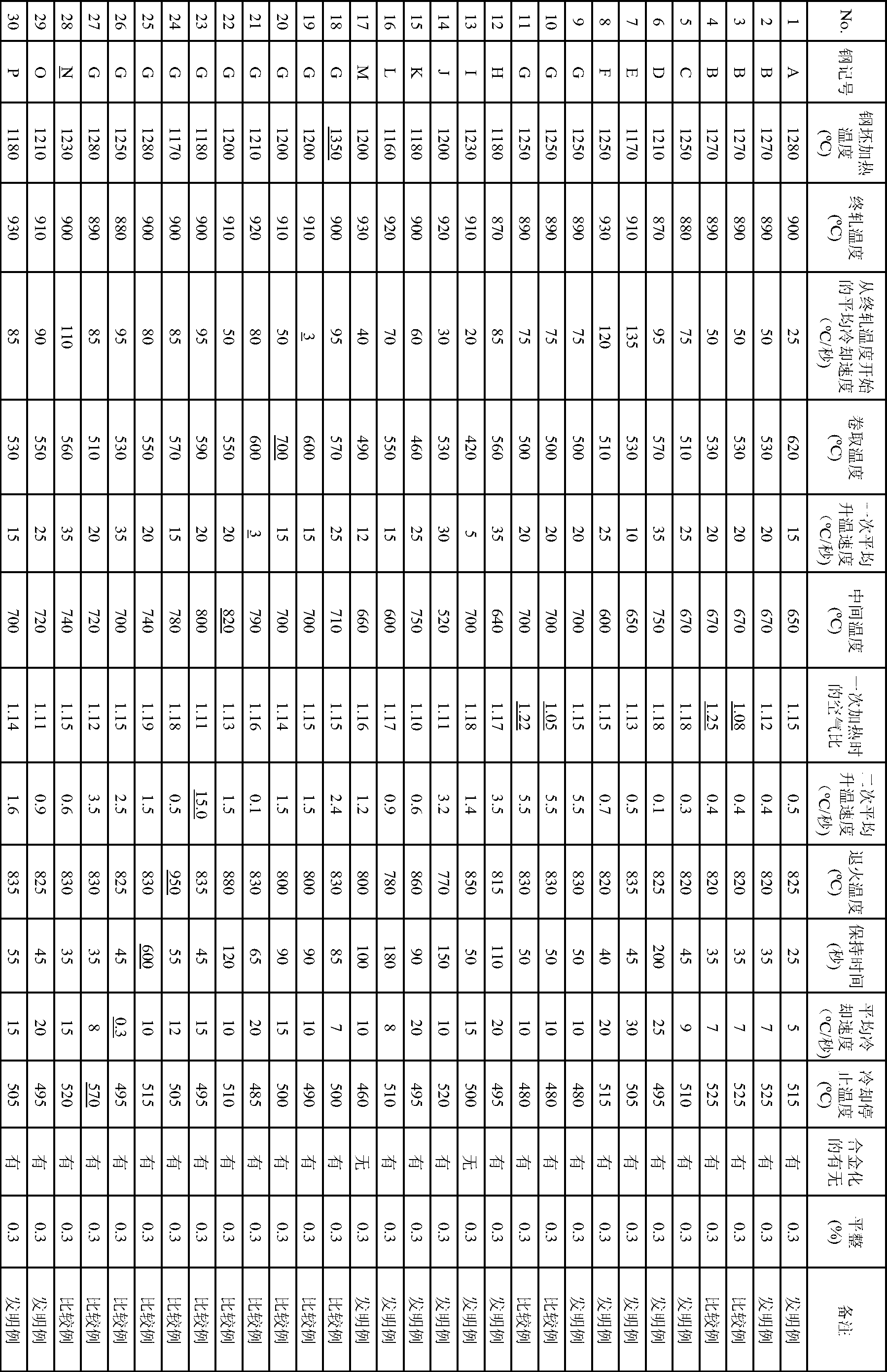

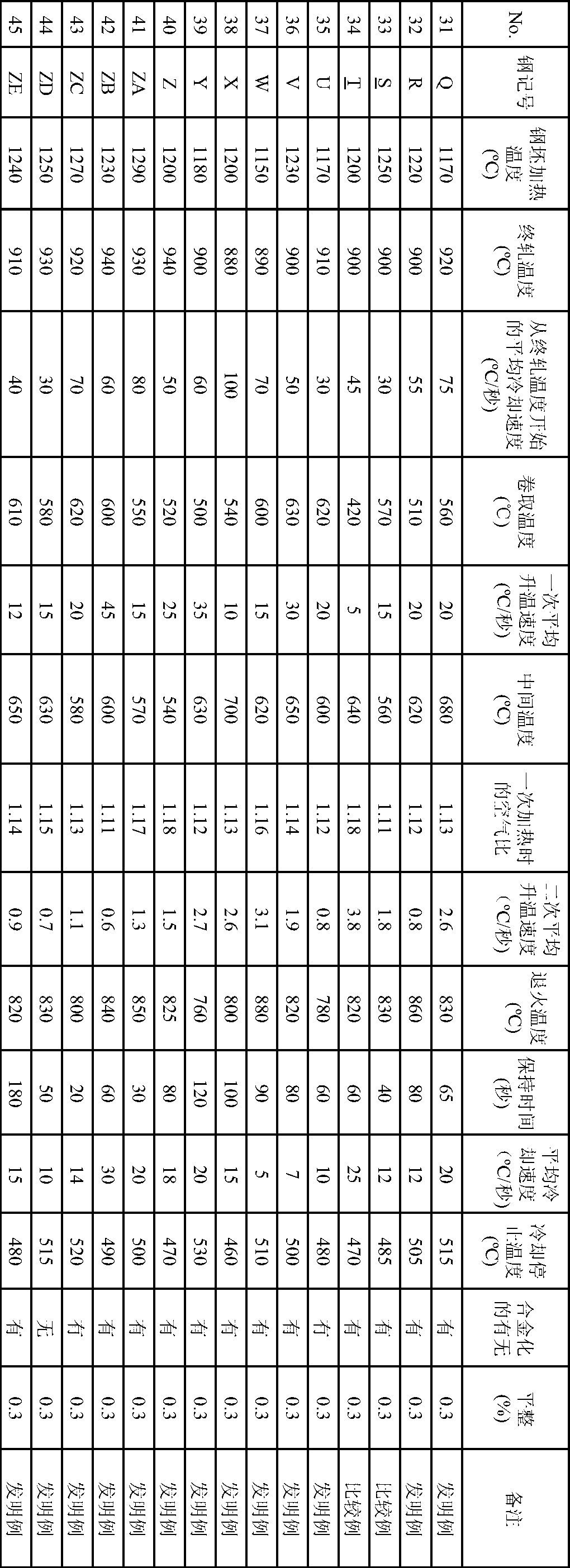

The invention provides a high strength low alloy steel plate suitable for high heat input welding and is characterized in that the chemical composition (wt percent) of steel comprises 0.04 percent to 0.16 percent of C, 0.10 percent to 0.50 percent of Si, 0.40 percent to 1.8 percent of Mn, 0.020 percent to 0.050 percent of Nb, 0.006 percent to 0.030 percent of Ti, 0.0030 percent to 0.010 percent of N, 0.015 percent to 0.060 percent of Al and the rest, Fe and other inevitable impurities; meanwhile, C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4+V / 14 is less than or equal to 0.45 percent and the total amount of Ti and the total amount of N are that [Ti percent]T is more than or equal to 2.667[N percent]T-0.004667 percent; moreover, Ti microalloying is adopted to ensure that the Ti / N ratio in the second sort of particle generated ranges between 2.4 and 3.2. The manufacture method of the steel plate adopts austenite recrystallization zone and austenite non-recrystallization zone rolling and forced water cooling after rolling; moreover, when the steel plate is under 50 KJ / cm to 150 KJ / cm high heat input welding, the welding heat affected zone has excellent toughness. The invention has the advantages of simple production process, low cost and wide applicability.

Owner:ANGANG STEEL CO LTD

Austenitic stainless steel

ActiveCN101194037APrevent peelingIncreased durabilityHeat exchange apparatusRare-earth elementSS - Stainless steel

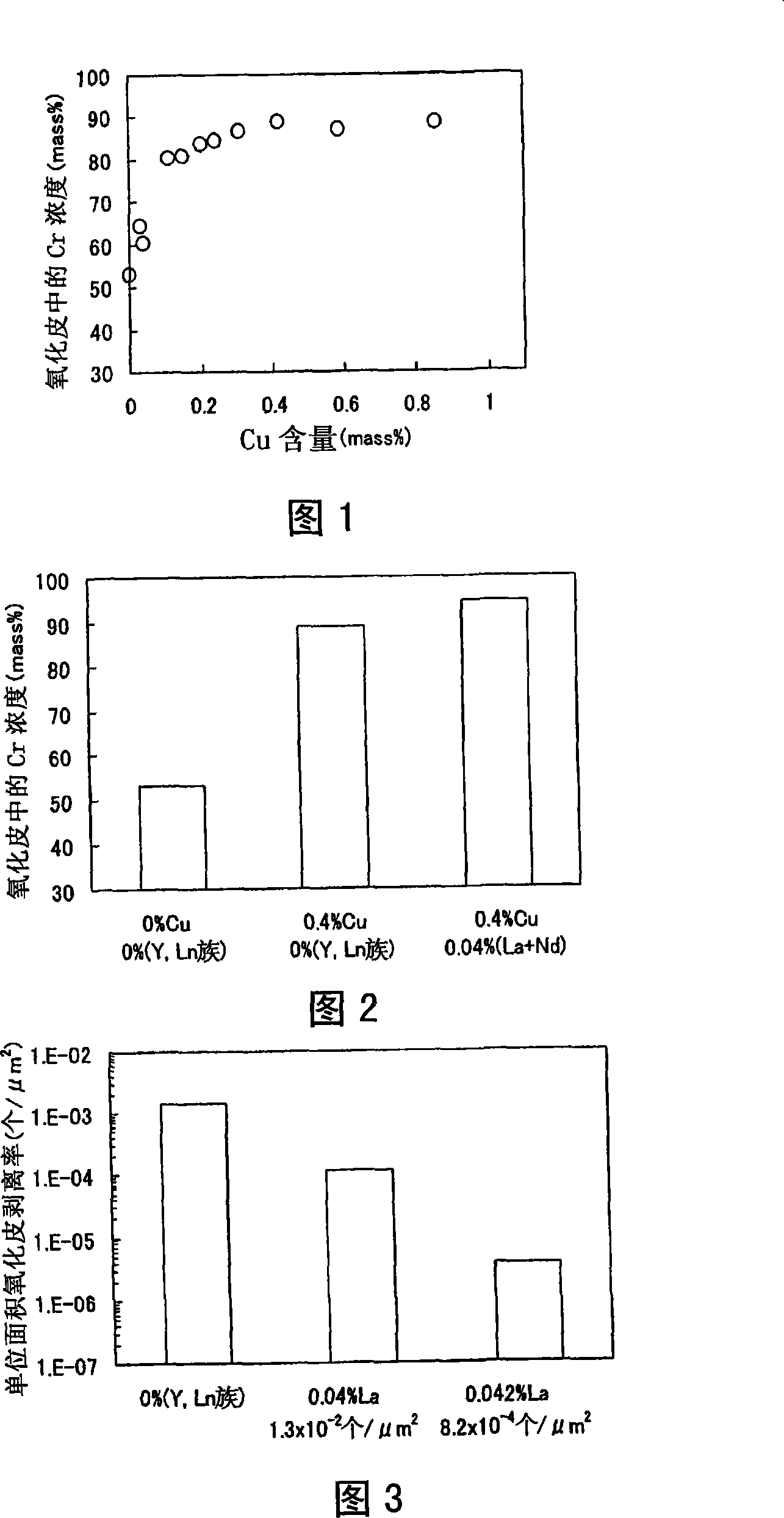

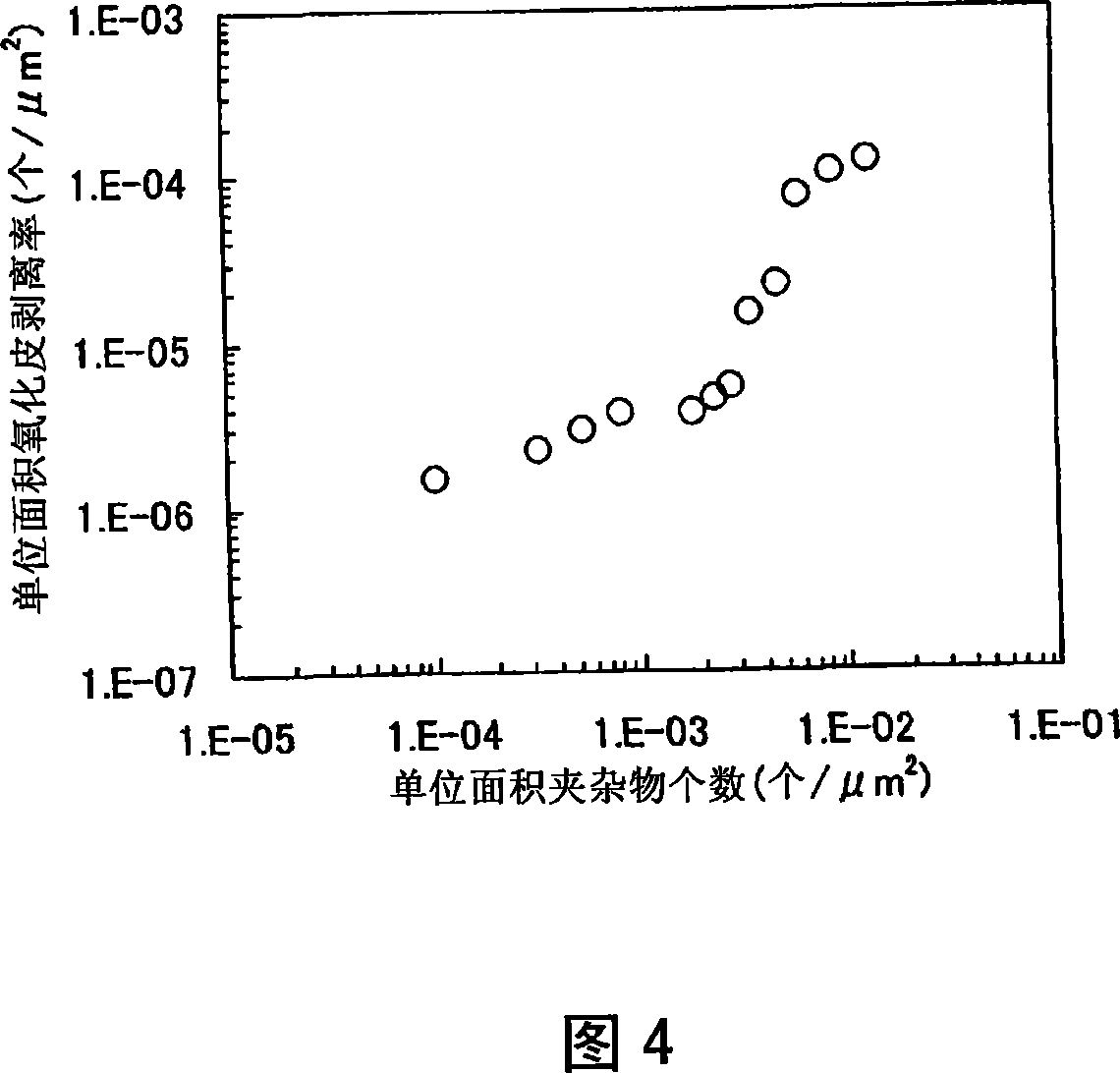

Even after repeated high-temperature heating-cooling cycles, it still has excellent scale peeling resistance that can inhibit the peeling of protective oxide scales formed on the steel surface, and can be used in high temperature, especially high temperature humidified gas environments above 1023K. System stainless steel with the following steel composition: C: 0.01-0.15%, Si: 0.01-3%, Mn: 0.01-2%, Cu: 0.1-2.5%, Cr: 23-30%, Ni: 16-25% , Al: 0.005 to 0.20%, N: 0.001 to 0.40%, P: 0.04% or less, S: 0.01% or less, and one or more rare earth elements selected from the Y and Ln groups: total 0.005 to 0.1%, the balance is substantially composed of Fe and unavoidable impurities, and the inclusions containing Y and Ln group elements on the steel surface are 5×10-3 / μm2 or less.

Owner:NIPPON STEEL CORP

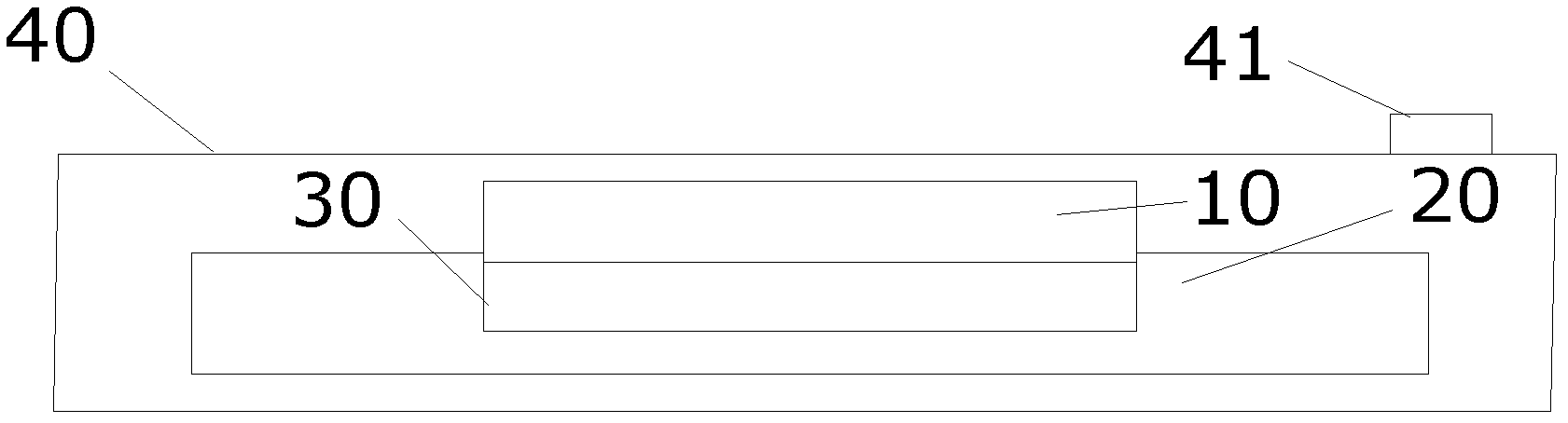

Lithium-ion battery with high rate discharge performance

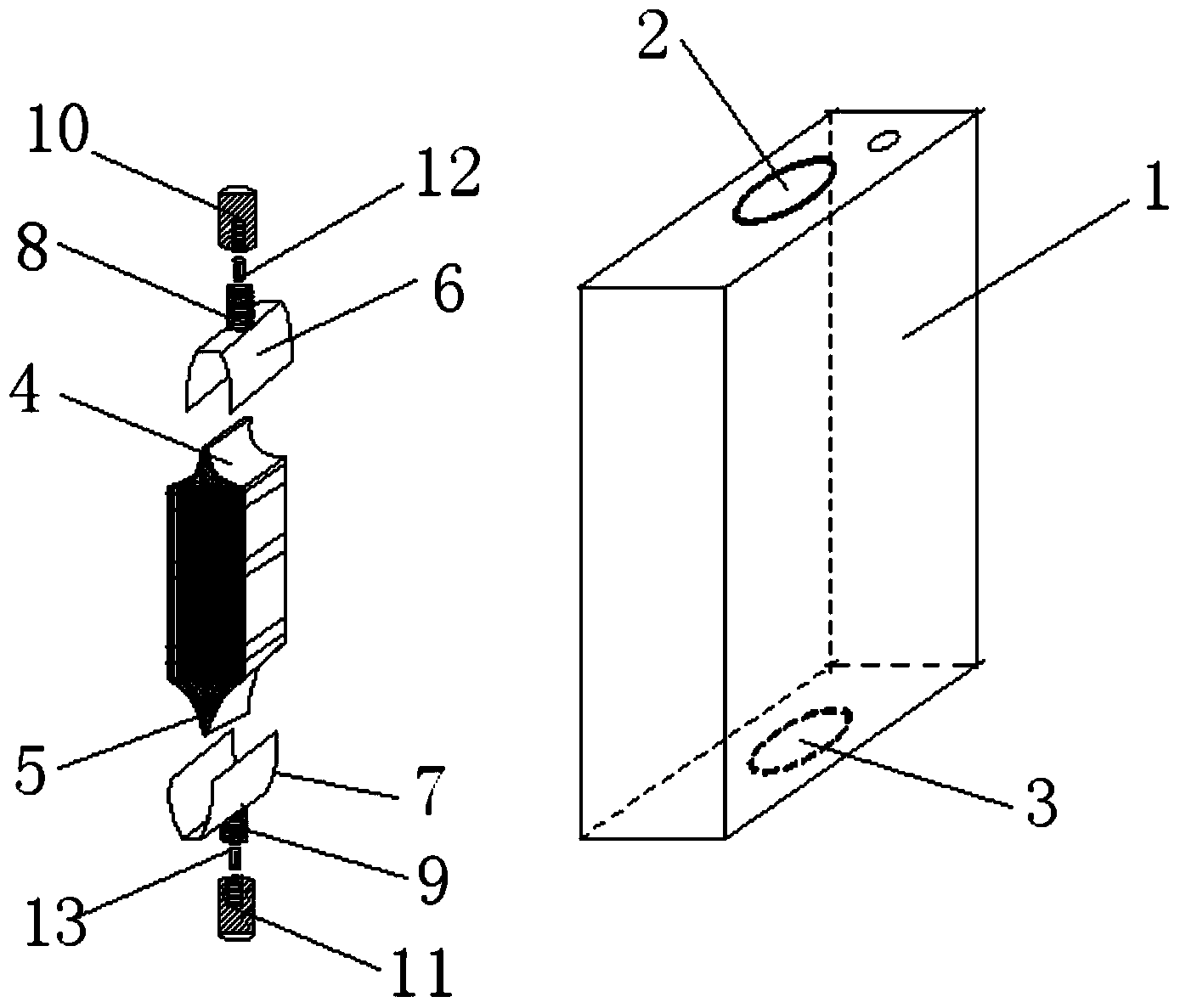

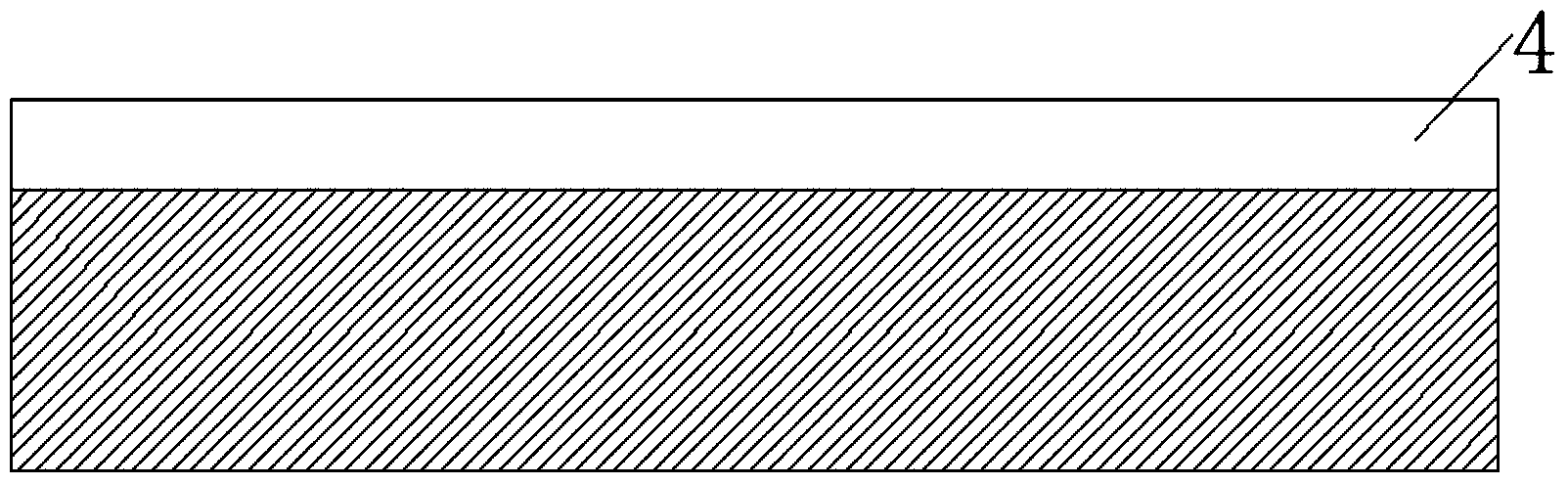

ActiveCN103730625AImprove rate discharge performanceImprove securitySecondary cellsCell component detailsHigh rateEngineering

The invention discloses a lithium-ion battery with high rate discharge performance. The lithium-ion battery comprises a cover, a battery core in the cover, an upper cover plate, and a lower cover plate, wherein the battery core is prepared either by winding or laminating a positive pole piece with a positive pole ear, a negative pole piece with a negative pole ear and a diaphragm. The lithium-ion battery is characterized in that a positive pole piece clamping mechanism and a negative pole piece clamping mechanism are also arranged; the positive pole ear is packed and fixed inside of the positive pole piece clamping mechanism and a positive pole stud is arranged on the outside of the positive pole piece clamping mechanism and is in detachable connection with the upper cover plate; the negative pole ear is packed and fixed inside of the negative pole piece clamping mechanism and a negative pole stud is arranged on the outside of the negative pole piece clamping mechanism and is in detachable connection with the lower cover plate. The lithium-ion battery is particularly applicable to the fields of electrical motorcycles, electrical taxies and electrical buses, and the like, and can meet the requirements for high rate discharge performance of batteries when the vehicles are in the bad circumstances such as climbing, instantaneous starting and instantaneous accelerating.

Owner:安徽金鑫宏运新能源科技有限公司

Aluminum alloy and aluminum alloy extruded profile machining method

The invention discloses aluminum alloy and an aluminum alloy extruded profile machining method. The aluminum alloy comprises, by weight, 0.6-1.4% of Si, 0.7-1.3% of Mg, 0.1-1% of Cu, 0.1-1% of Mn, 0.01-0.15% of Ti, 0-0.2% of Zr, 0-0.5% of Cr, 0-0.4% of Fe, 0-0.25% of Zn and the balance Al. The aluminum alloy also meets the requirements that the weight percentage range of Mg+Si+Cu is 1.4-3.7%, themole ratio of Mg to Si is 0.7-1.5, and the weight percentage range of Mn+Cr+Zr is 0.1-1.5%. The machining method comprises the steps that (1) a cast ingot of the alloy is subjected to homogenization treatment; (2) the cast ingot is extruded into aluminum profile; (3) extrusion production is conducted; (4) on-line quenching is conducted; (5) tension leveling is conducted; and (6) artificial aging is adopted. According to the aluminum alloy and the aluminum alloy extruded profile machining method, the technology is simple, and the production cost is low.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

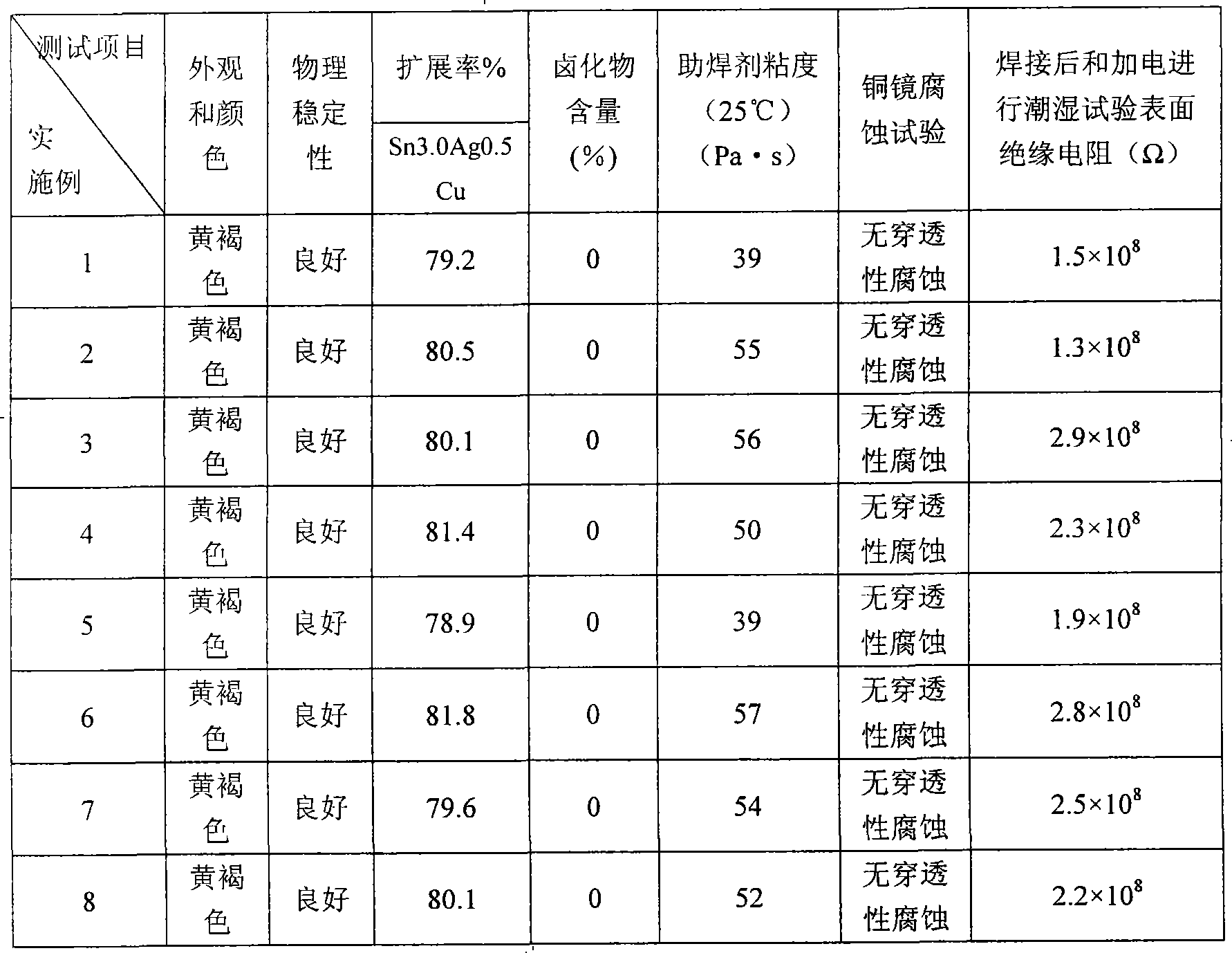

Lead-free solder thread-use colophony type non-halide cleaning-free scaling powder

InactiveCN101157168ANo penetrationSpread evenlyWelding/cutting media/materialsSoldering mediaInsulation resistanceActive agent

The invention relates to a halogen-free non-cleaning soldering flux for a lead-free solder wire, and belongs to the soldering flux field. According to the weight ratio, the invention comprises the following elements that: 4 to 18 wt percent of organic acid active agent, 10 to 30 wt percent of organic solvent, 1 to 6 wt percent of pasting agent, 0.2 to 3wt percent of stabilizer, 0.5 to 5wt percent of thixotropic agent, 0.5 to 4wt percent of surface active agent, 0.5 to 5wt percent of rust inhibition, and the rest comprises colophony. The invention includes no halogen, the speculummetal has no breakthrough after being welded, the insulation resistance is high, and the soldering performance is good, the problem of the potential solder joint short circuit caused by the soldering flux of the prior welding wire that the colophony content is too high, the smoke is large and the derelict is easy to be flaked away is solved, the invention is smooth and has no absorption of moisture under normal temperature, no cleaning is required after being welded, and the welding requirement of normal product can be met.

Owner:BEIJING UNIV OF TECH

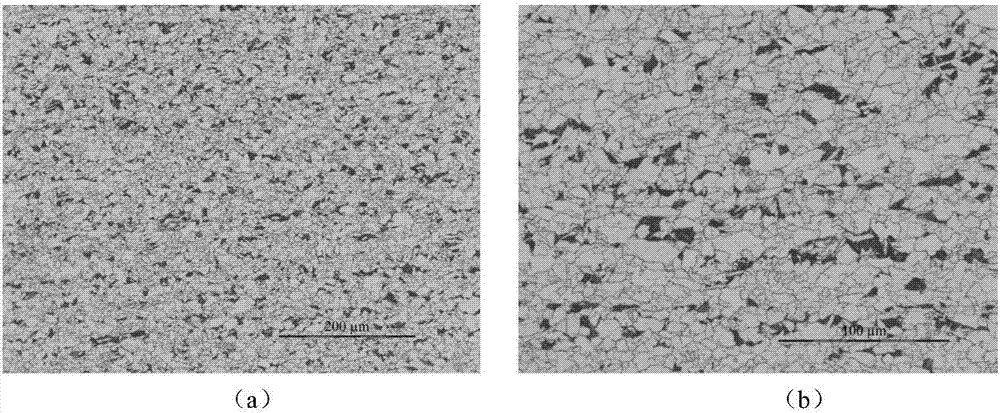

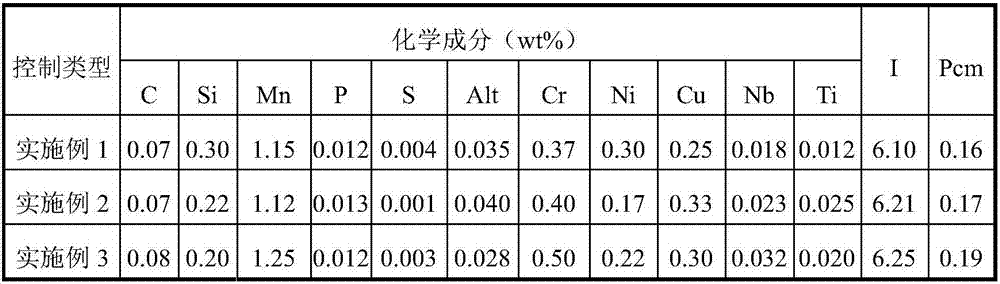

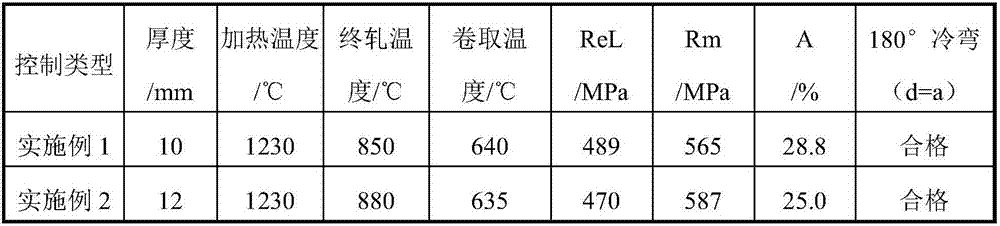

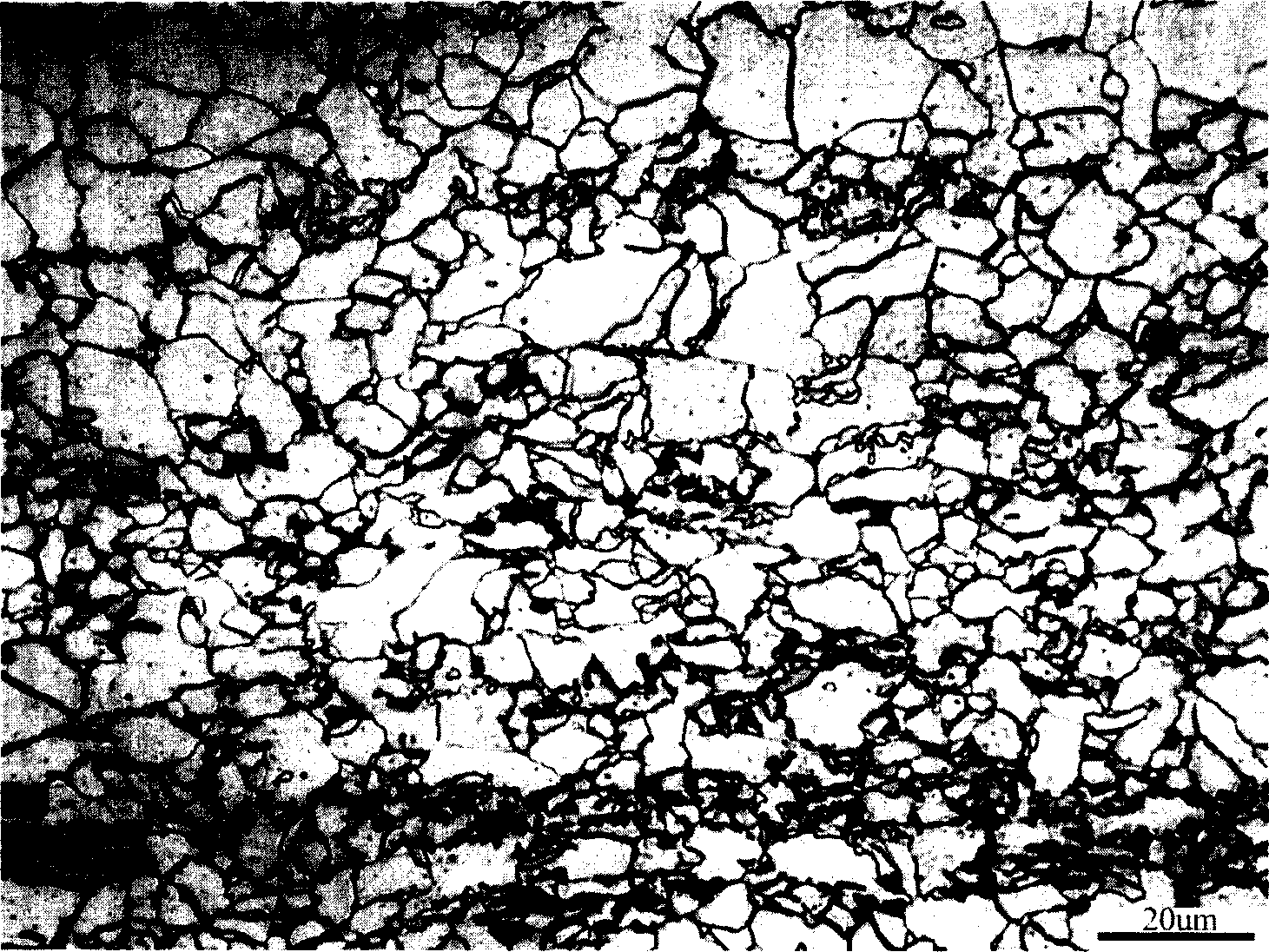

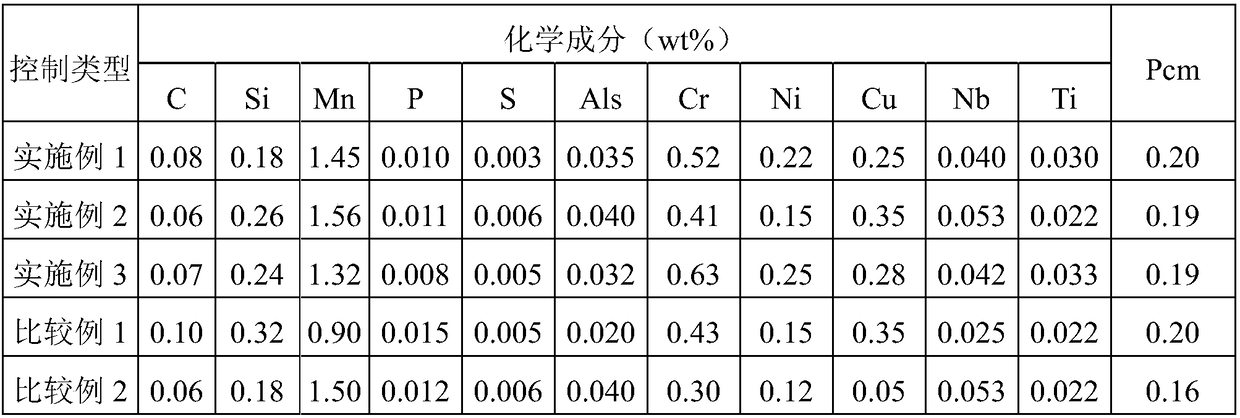

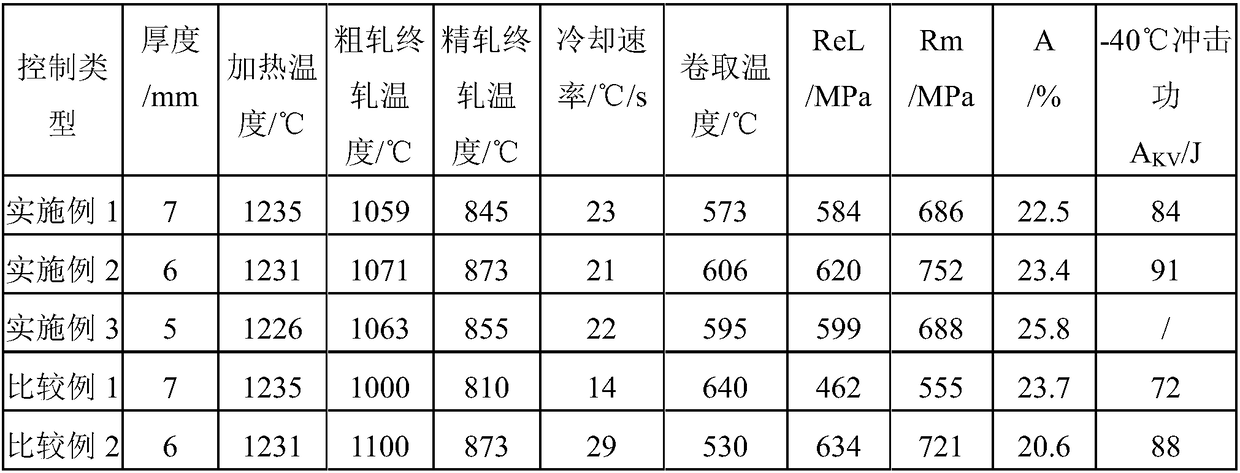

High-strength and high-toughness weather-proof hot-rolled steel plate and preparation method thereof

The invention relates to a high-strength and high-toughness weather-proof hot-rolled steel plate comprising the chemical components in percentage by weight: (wt,%): 0.05%-0.10% of C, 0.10%-0.50% of Si, 1.00%-1.30% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-0.70% of Cr, 0.10%-0.40% of Ni, 0.25%-0.50% of Cu, 0.020%-0.050% of Al, 0.010%-0.040% of Nb, 0.010%-0.030% of Ti and the balance Fe and unavoidable impurity elements. Meanwhile, the traditional hot strip rolling process is adopted, and a preparation method specifically comprises the steps: deep desulphurization of molten iron until S is less than or equal to 0.0050%, converter top and bottom combined blowing, alloy fine adjustment, LF secondary refining, slab continuous casting, heating, two-rack rough rolling and seven-rack finish rolling, laminar cooling and reeling. The steel plate disclosed by the invention has the mechanical properties that ReL is 450-500MPa, the Rm is greater than or equal to 550MPa, A is 25.0%-30.0%, the -60 DEG C longitudinal Charpy V-shaped gap impact power is greater than 300J, the high-strength and high-toughness weather-proof hot-rolled steel plate has good matching of strength and toughness, good cold bending forming and welding properties and favorable atmosphere corrosion resistance, and the corrosion resistance of the high-strength and high-toughness weather-proof hot-rolled steel plate is twice as high as that of Q345B steel.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

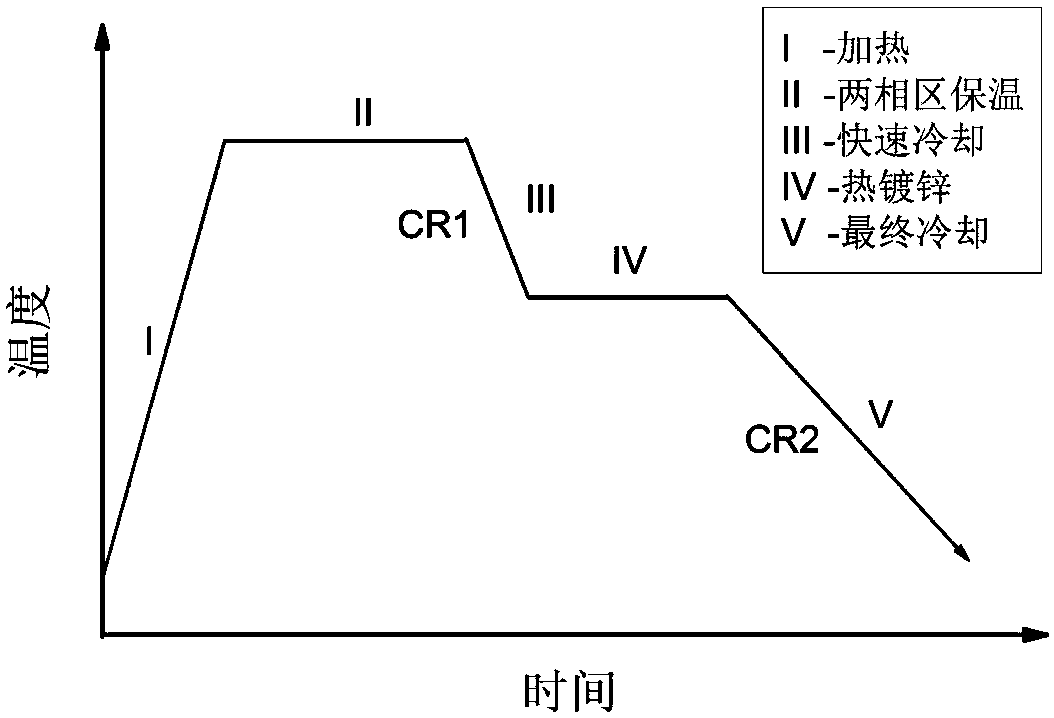

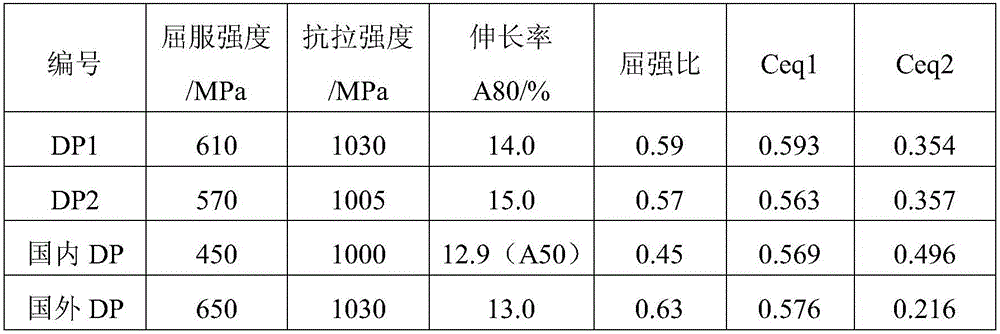

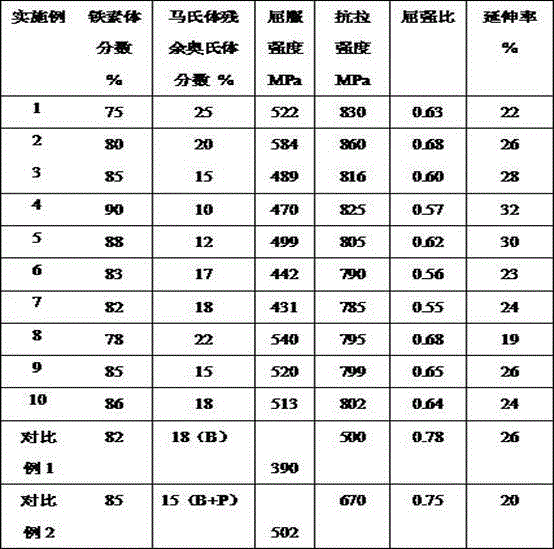

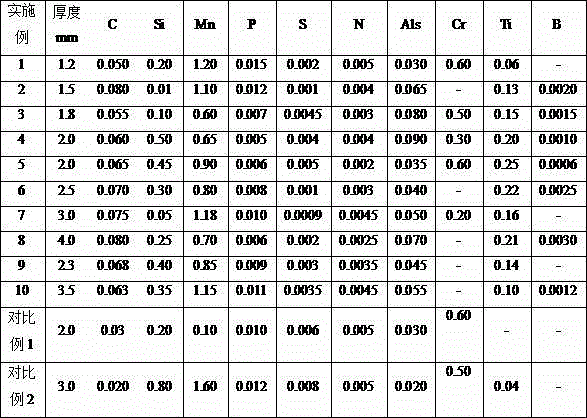

1000 MPa low-carbon hot-galvanized dual-phase steel and preparation method thereof

ActiveCN105950998AGood mechanical propertiesGood formabilityHot-dipping/immersion processesMechanical propertyImpurity

The invention belongs to the technical field of steel for high-strength automobiles and particularly relates to 1000 MPa low-carbon hot-galvanized dual-phase steel and a preparation method thereof. The 1000 MPa low-carbon hot-galvanized dual-phase steel comprises, by weight, 0.05-0.10% of C, 0.20-0.60% of Si, 1.40-1.90% of Mn, 0.20-0.70% of Cr, 0.20-0.50% of Mo, 0.02-0.06% of Al, 0.020-0.050% of Ti, 0.010-0.040% of Nb, 0.0010-0.0030% of B, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.006% of N, and the balance Fe and inevitable impurities. The 1000 MPa low-carbon hot-galvanized dual-phase steel has the high forming property and high welding property and the excellent galvanizing property and mechanical property. The 1000 MPa low-carbon hot-galvanized dual-phase steel is 630-700 MPa in yield strength, 1010-1050 MPa in tensile strength and 11-14% in elongation.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

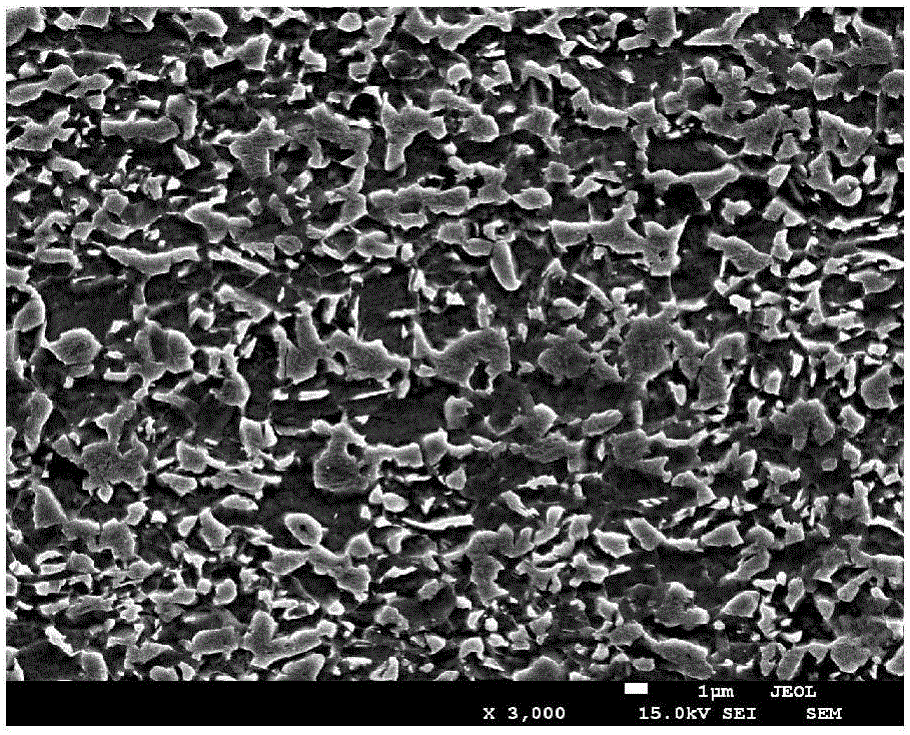

980 MPa-level vanadium-contained ultrafine grain cold rolled dual-phase steel and preparing method thereof

The invention provides 980 MPa-level vanadium-contained ultrafine grain cold rolled dual-phase steel and a preparing method, and belongs to the technical field of cold rolling ultrahigh strength steel for an automobile. The 980 MPa-level vanadium-contained ultrafine grain cold rolled dual-phase steel is composed of, by weight percent, 0.10% to 0.20% of C, 0.30% to 1.00% of Si, 1.50% to 2.50% of Mn, 0.20% to 0.80% of Cr, 0.01% to 0.06% of Al, 0.05% to 0.15% of V, not larger than 0.020% of P, not larger than 0.015% of S, not larger than 0.006% of N and the balance Fe and inevitable impurities. Ferrite and martensite grains are refined through the micro amount of V; and meanwhile, VC dispersed precipitation plays a role in strengthening sedimentation, and the production cost is obviously reduced. The prepared cold rolled dual-phase steel is excellent in mechanical property, forming property and welding property, the cost advantages are obvious, and the obvious economic benefits and social benefits are achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

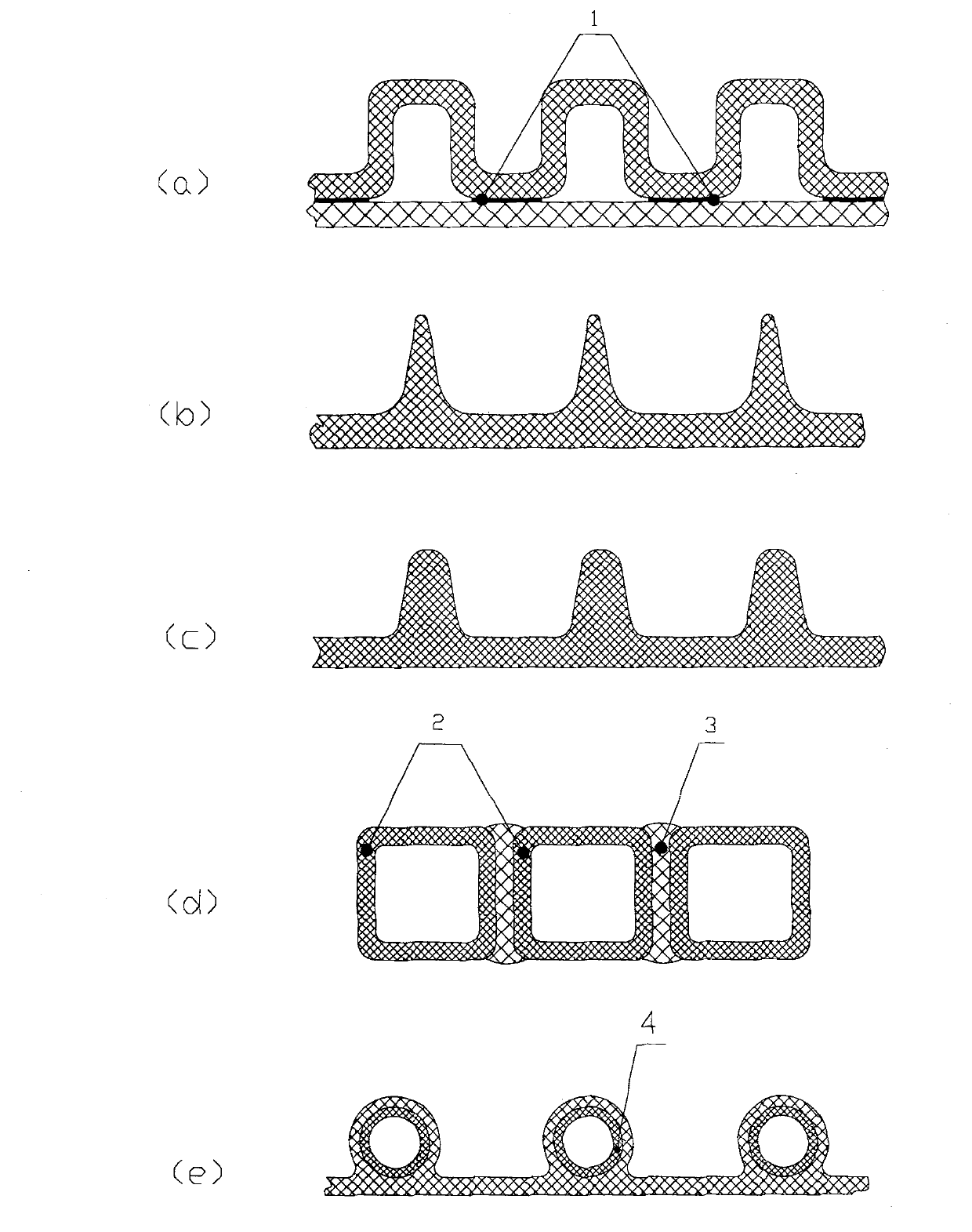

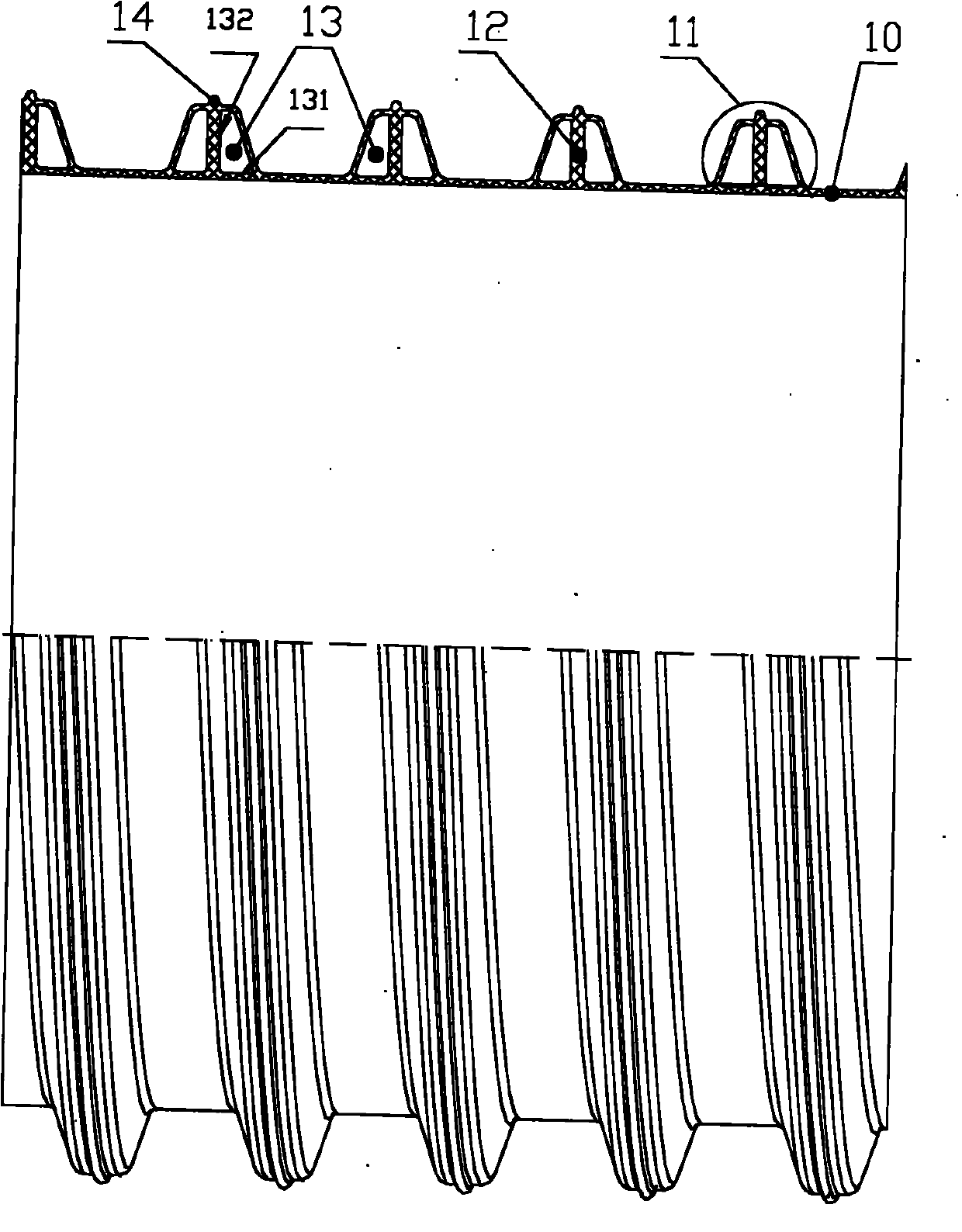

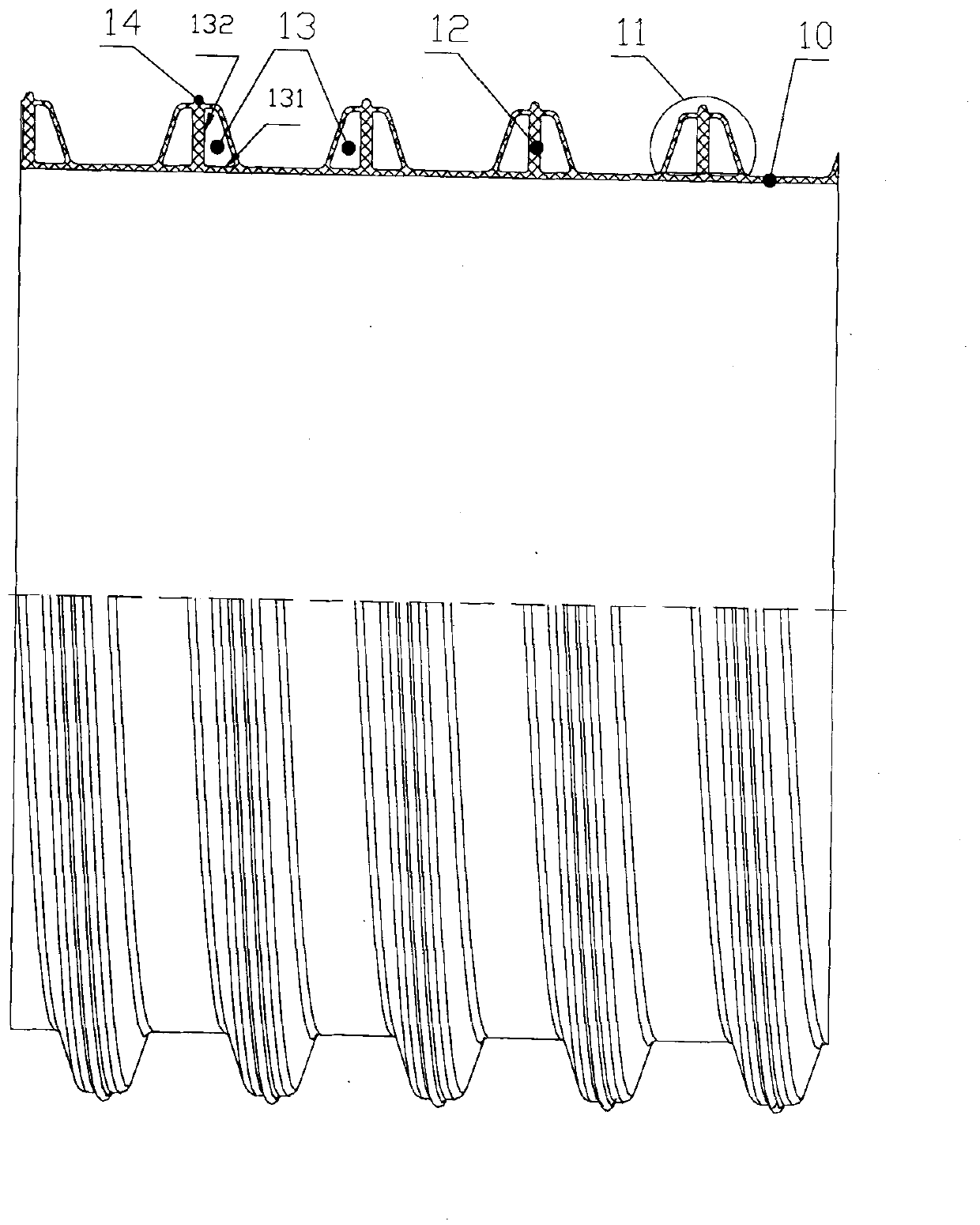

Internal rib reinforcing outer ripple type plastic twining structured wall pipe and manufacturing method thereof

InactiveCN101907207AIncrease the outer surface areaGood synergyRigid pipesTubular articlesMechanical engineeringHot-melt adhesive

The invention relates to an internal rib reinforcing outer ripple type plastic spirally twining structured wall pipe, which comprises a cylindrical surfaced pipe main body and a reinforcing rib wound outside of the pipe main body. The reinforcing rib contains an inner reinforcing rib vertical to the pipe wall, wherein the inner rib divides the reinforcing rib into two parallel hollow cavities. The upper part of the reinforcing rib and the top of the inner rib are both provided with a solid bulge. A method for manufacturing the plastic reinforcing pipe of the invention comprises the steps of: continuously extruding a plastic abnormal strip with two tubular bulges and containing a hollow cavity inside through a first plastic extruder, continuously, regularly, spirally twining the plastic abnormal strip on a formed roller in parallel, at the same time, extruding fused plastic gel in a clearance between adjacent side walls of the spirally wound plastic abnormal strip through a second plastic extruder, rolling two projected tubular cavities corresponding to two sides of the clearances connected by fusing the adjacent plastic abnormal pipe through a rolling wheel which is arranged at the corresponding part on the periphery of the formed roller with a slot structure, forming an outer projected reinforcing rib of the pipe outer wall by fusing the two tubular bulges, and extruding the residual fused gel in the clearance by the rolling wheel so as to form the solid bulge.

Owner:戴爱清

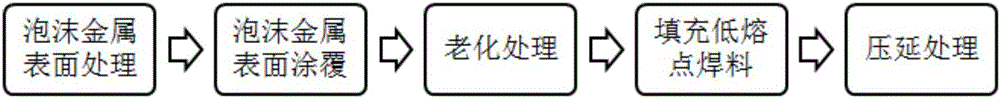

Preparation method of foam metal composite solder piece

ActiveCN106825999AOvercoming the lack of low strengthHigh strengthHot-dipping/immersion processesWelding/cutting media/materialsPorosityChemical plating

The invention discloses a preparation method of a foam metal composite solder piece. According to the method, firstly, the surface of foam metal is treated, the surface of a foam metal matrix is coated with one or more layers of active metal with an electroplating or chemical plating process, annealing treatment is performed, the foam metal with an active metal plating layer is infiltrated into molten solder and taken out after filling is performed, foam metal enhanced low-melting-point composite solder is obtained, finally, calendaring machining is performed, metal solder foil with certain thickness is obtained, and the purposes of improving the strength and the welding performance of foam metal composite solder are achieved. The foam metal is used for enhancing Sn-based or Zn-based solder, and the applied active metal plating layer can improve the strength of the foam metal matrix to a certain extent and make up the influence of foam metal porosity on the strength of the foam metal. Besides, the active metal plating layer is also beneficial to filling of low-melting-point solder to the foam metal and relieves the unfavorable situation that tin and matrix metal are difficult to infiltrate and interface bonding is not firm.

Owner:无锡继平新材料科技有限公司

Ultra-high-strength 9Ni steel for cryogenic environment and preparation process thereof

ActiveCN101864537AReduce usageHigh strengthTemperature control deviceChemical compositionUltimate tensile strength

The invention relates to ultra-high-strength 9Ni steel for cryogenic environment and a preparation process thereof. The 9Ni steel comprises the following chemical components in percentage by weight: 0.01 to 0.2 percent of C, 0.05 to 0.35 percent of Si, 0.1 to 1.0 percent of Mn, less than or equal to 0.0070 of P, less than or equal to 0.0040 percent of S, 8.5 to 10.0 percent of Ni, 0.02 to 0.05 percent of Al, 0.0 to 2.0 percent of Cu and the balance of Fe and impurity elements. A cast blank with the same components as those of the 9Ni steel is subjected to heating, heat preservation, controlled rolling, controlled cooling and thermal processing to prepare the finished sheet material. The 9Ni steel has yield strength of over 710MPa, tensile strength of over 780MPa and impact power at the temperature of 196 DEG C below zero of over 120J, has a microstructure of martensite, ferrite and retained austenite and can effectively improve the comprehensive performance of LNG ships or LNG pipes.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

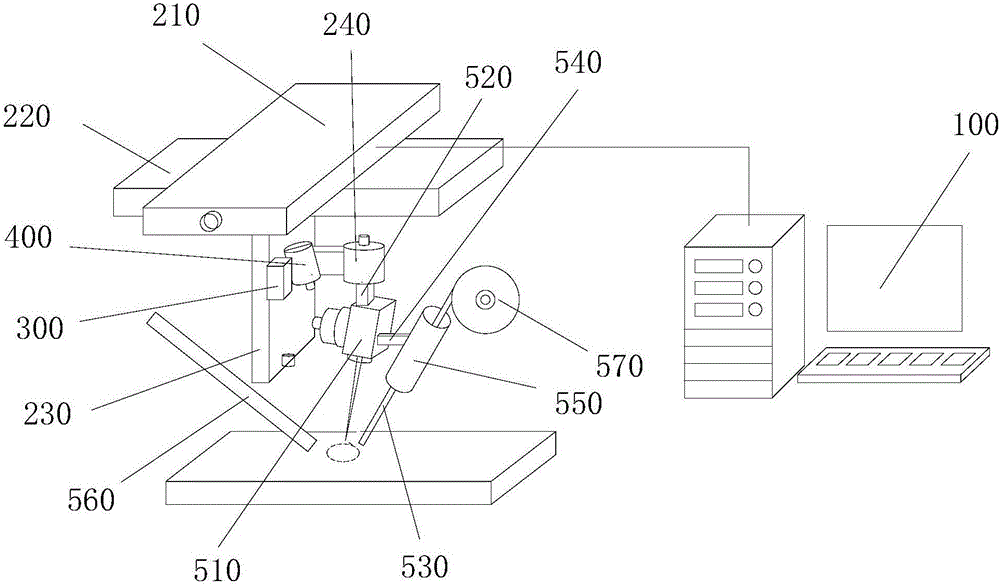

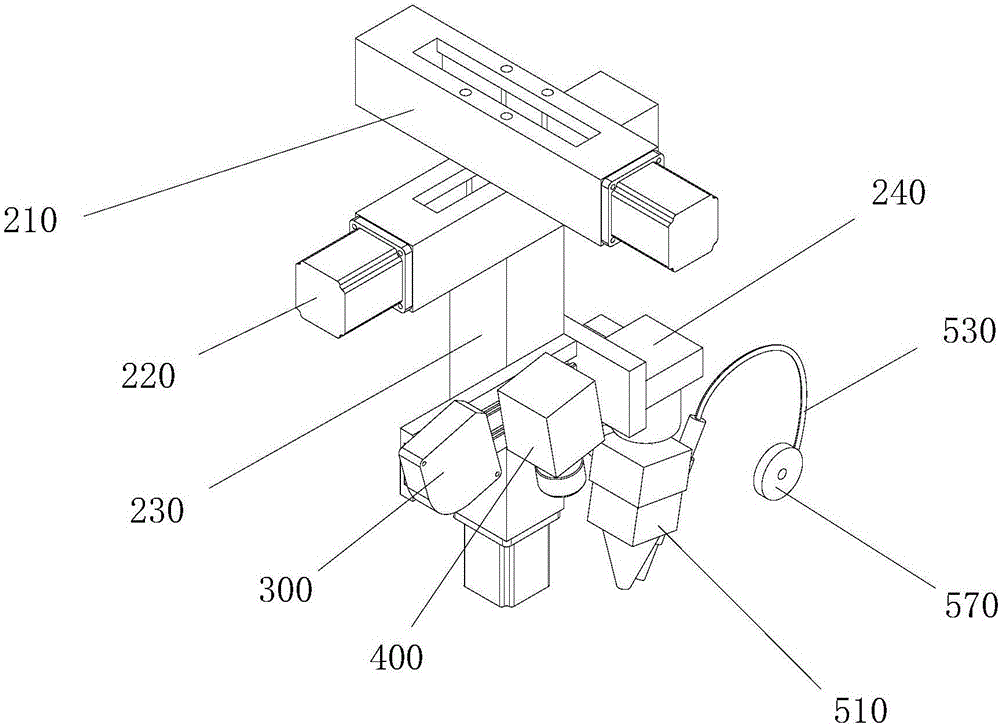

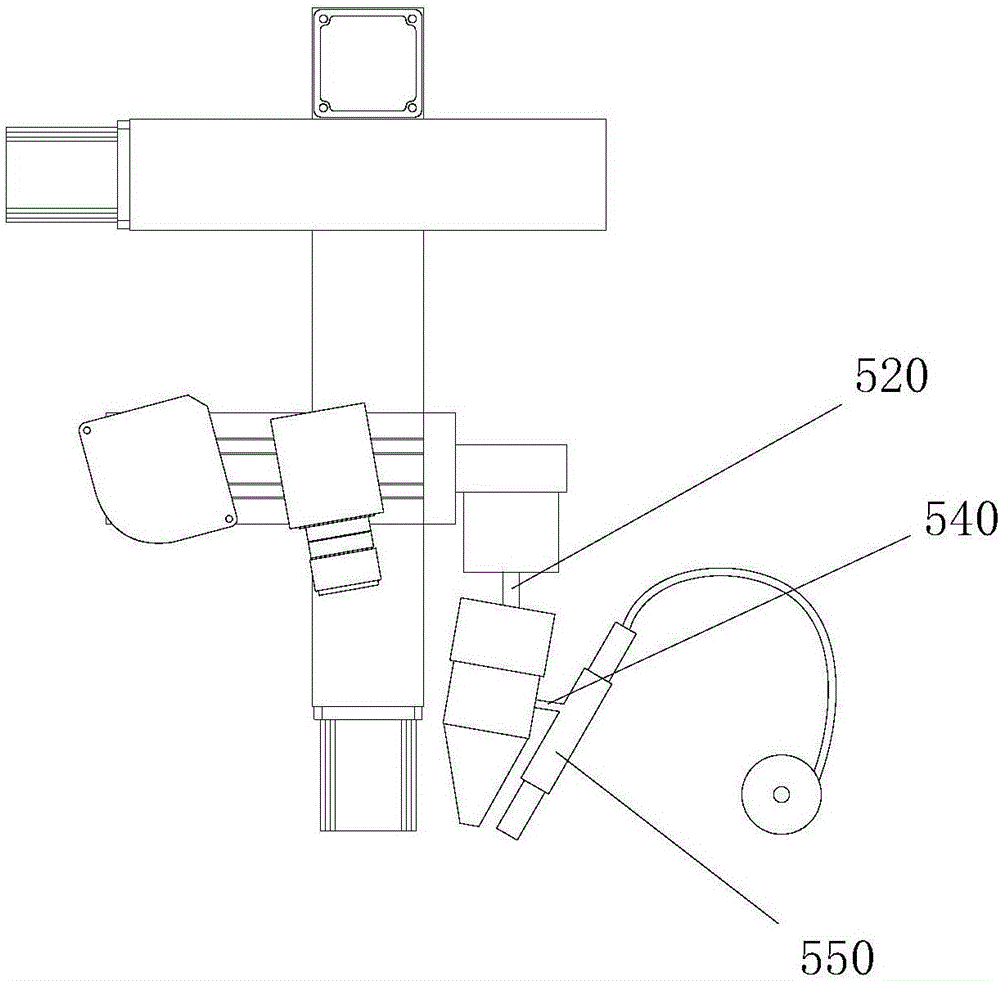

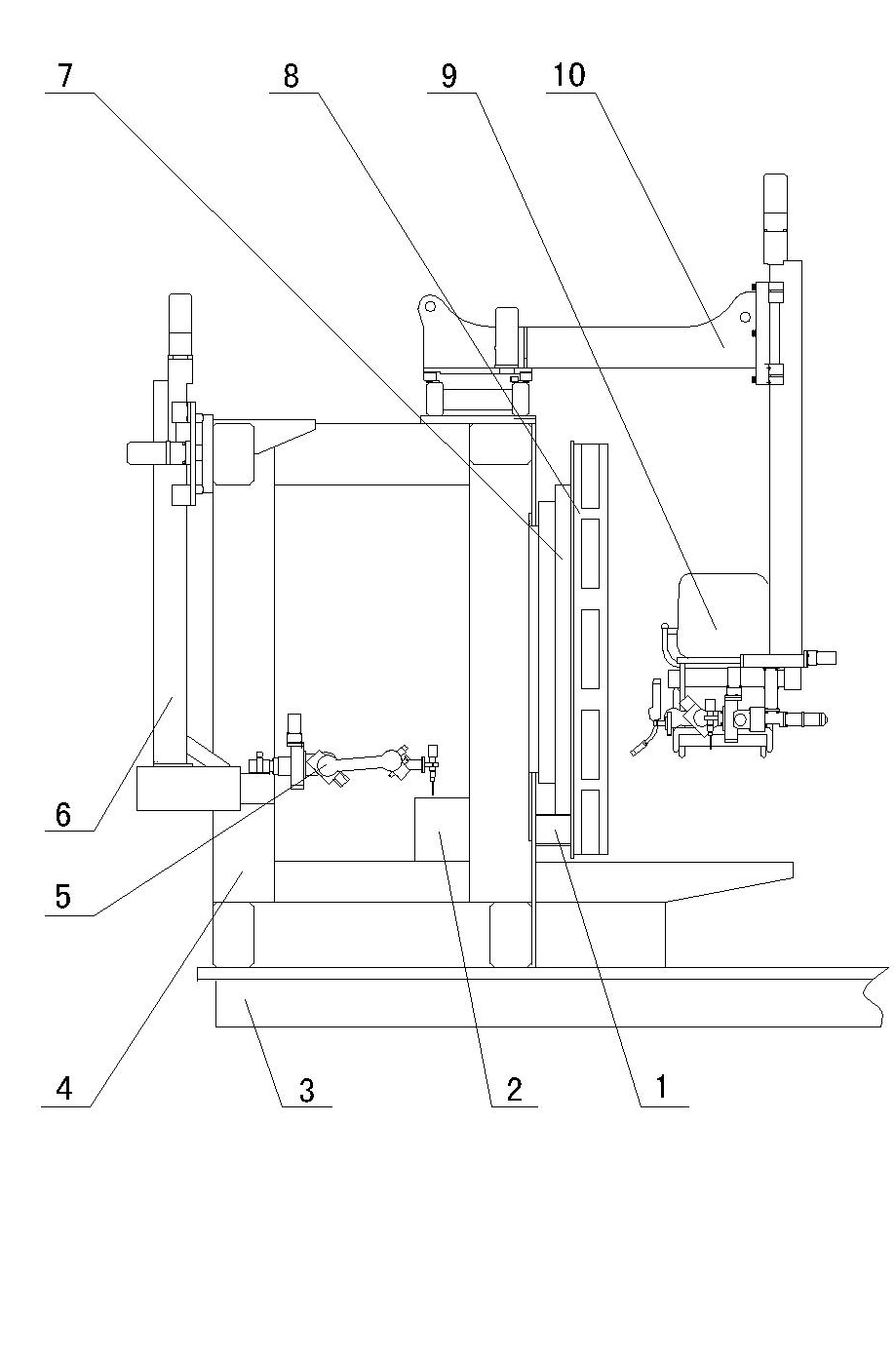

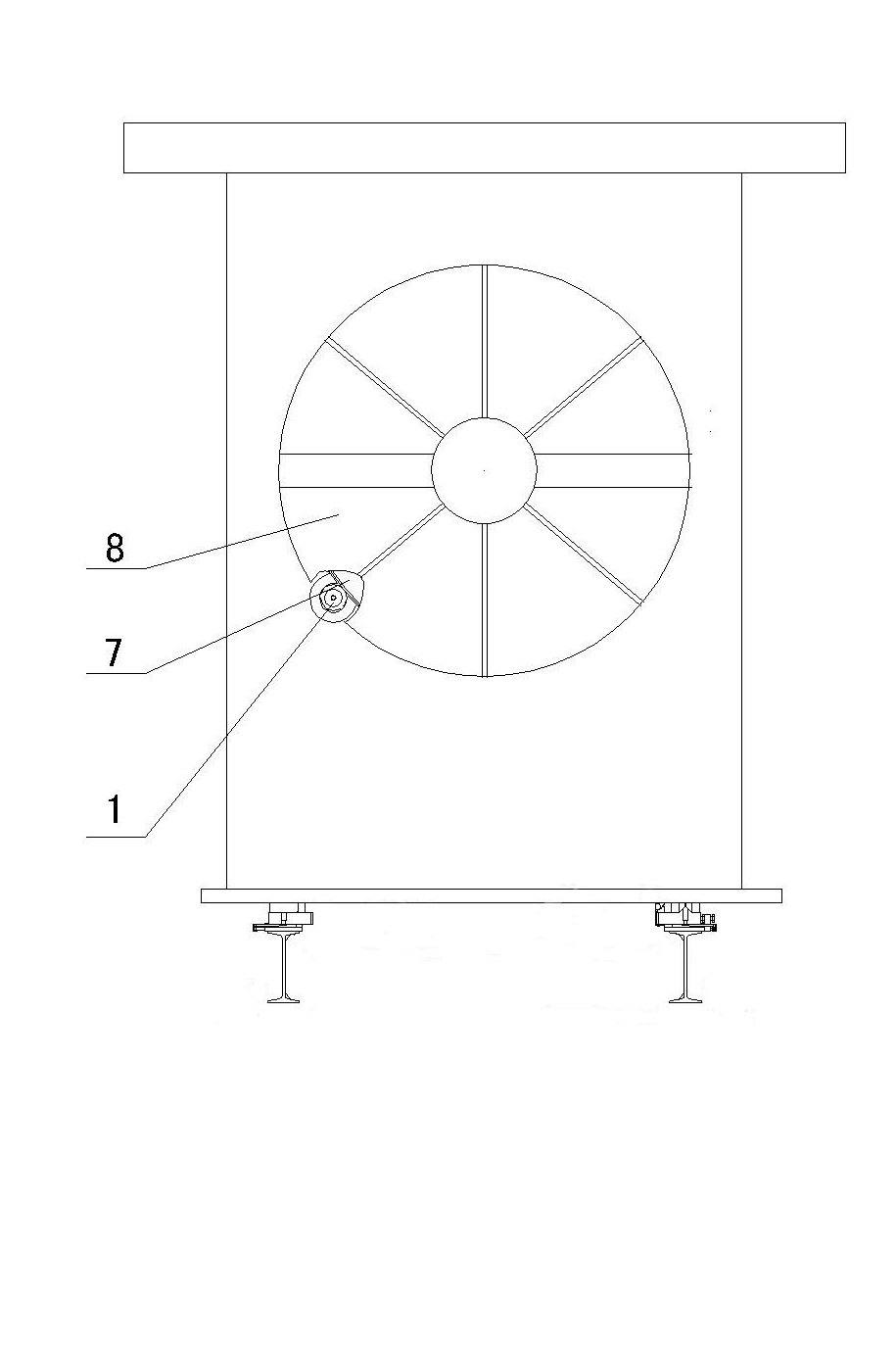

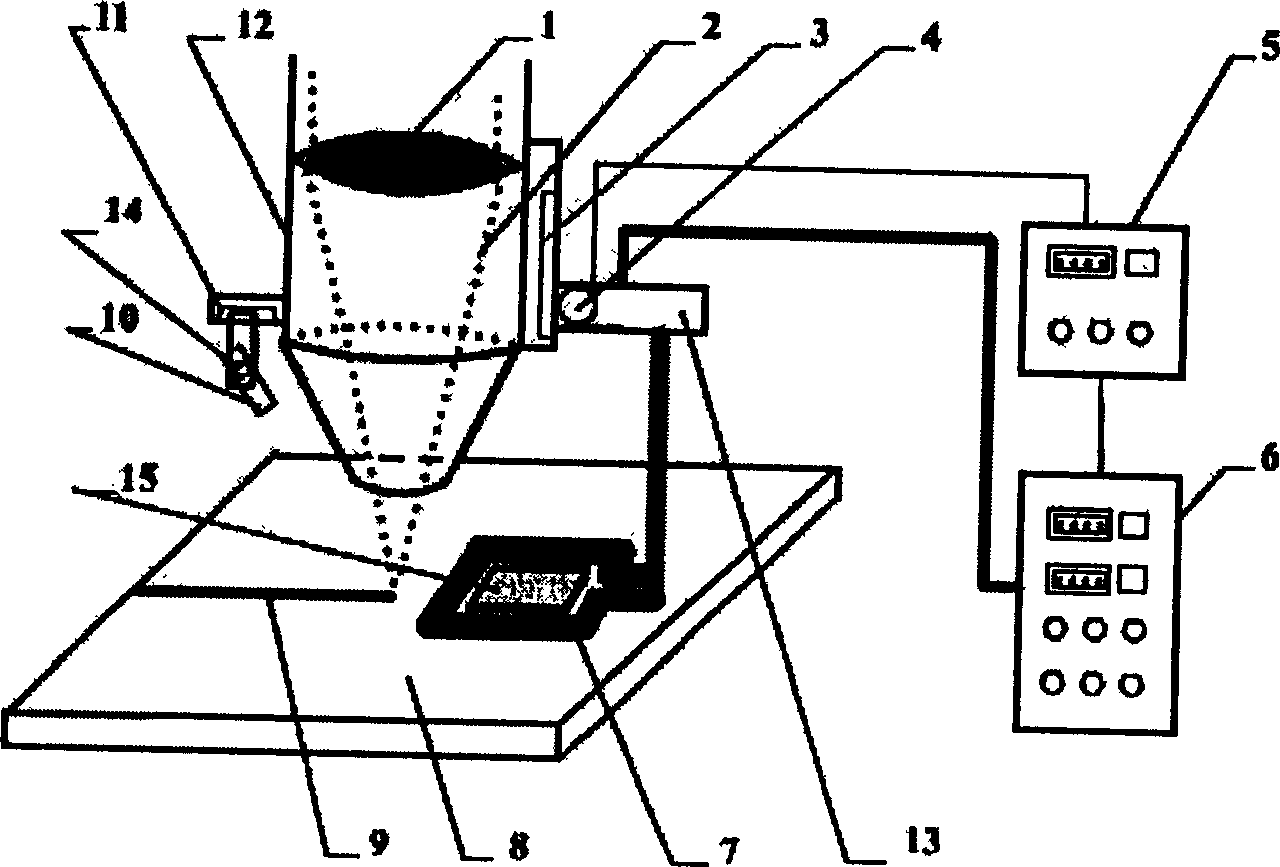

3D additive repair device for laser-arc hybrid welding and repair method

ActiveCN106141435AImprove welding efficiencyImprove welding effectLaser beam welding apparatusEngineeringInfrared vision

The invention discloses a 3D additive repair device for laser-arc hybrid welding and a repair method. The 3D additive repair device comprises a controller, a four-axis linkage platform, a laser vision sensor, an infrared vision sensor, a fixture, a laser welding torch, an arc welding torch, a filling welding wire, a wire reel and a gas guide pipe. The method includes the steps that a defective workpiece is mounted on a repair workbench; the laser vision sensor is driven to scan the three-dimensional profile of a defect; the three-dimensional profile of the defect is rebuilt through the controller; welding parameters are confirmed; the controller drives the near-infrared vision sensor to scan a molten pool, the time-frequency parameter of an image of the molten pool is obtained, a compensation control code is generated according to the time-frequency parameter of the image of the molten pool, and the set welding parameters are corrected in real time; and after repair is completed, the laser vision sensor is driven again to scan the three-dimensional profile of the defect, whether the repaired workpiece meets the standard or not is confirmed, and if not, the defect is repaired again till the repaired defect meets the standard. The 3D additive repair device for laser-arc hybrid welding and the repair method have the beneficial effects that the structure is simple, operation is convenient, and reliability and adaptability are high.

Owner:GUANGDONG UNIV OF TECH

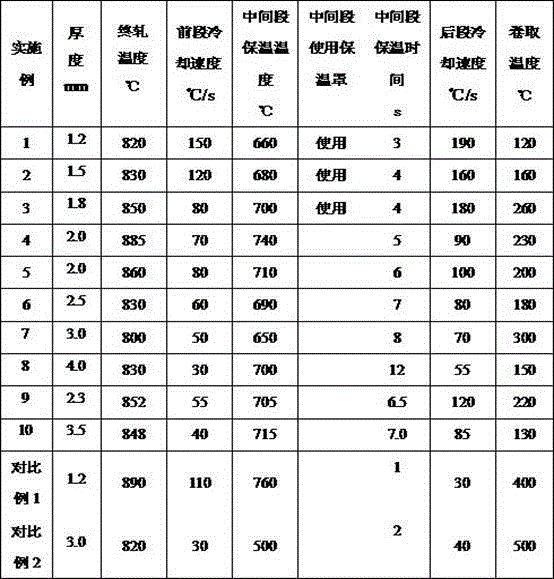

Tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel and production method thereof

The invention provides tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel. The dual-phase steel comprises the following components in percentage by weight: 0.05-0.08 percent of C, not more than 0.5 percent of S, 0.6-1.2 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.006 percent of N, 0.01-0.1 percent of Als, 0.05-0.25 percent of Ti, less than or equal to 0.6 percent of Cr or less than or equal to 0.003 percent of B or mixture of Cr and B. The production method by using CSP comprises the following steps: melting and continuously casting to form a slab; heating the continuous cast slab; rolling; carrying out laminar cooling; reeling; and naturally cooling to room temperature. The hot-rolled dual phase steel has the tensile strength of more than or equal to 780MPa, elongation of more than or equal to 15 percent and yield ratio of less than or equal to 0.70. An insulation cover additionally covers the intermediate insulation section, and the band steel cooling speed is reduced, so that generation of pearlite phase change can be effectively prevented. Production of hot-rolled dual phase steel with thickness of 1.2-4.0mm can be realized, the product has the advantages of uniform structure, small molding resilience and no cracking, existing equipment is utilized without adopting ultra fast cooling and other equipment, the production efficiency is high, and the investment is small.

Owner:武汉钢铁有限公司

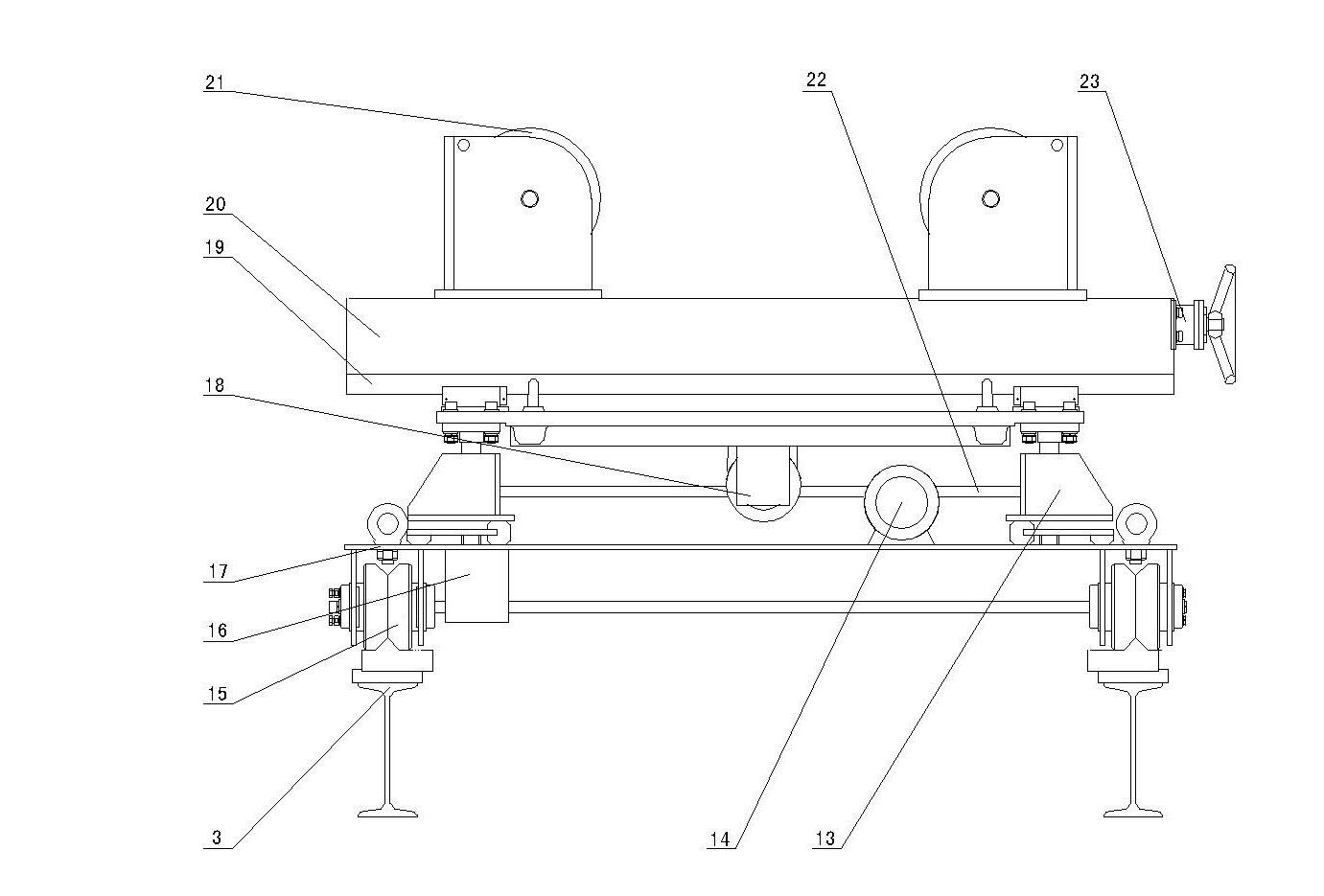

Flange welding method and welding device

ActiveCN102000921AAvoid deformationNot easy to shakeWelding/cutting auxillary devicesAuxillary welding devicesConical tubeEngineering

The invention discloses a flange welding method. The method comprises the following steps of: arranging chunk seats at the two ends of rails; arranging flanges on the chunk seats; placing steel tubes on automatic adjusting brackets; adjusting the positions of the steel tubes so as to butt the steel tubes with the flanges; after finishing butting, performing spot-welding on the flanges; removing the automatic adjusting brackets; driving the chunk seats to rotate by using driving devices; and simultaneously driving the flanges to rotate and welding by using welding equipment. A flange welding device comprises two rails; automatic adjusting brackets are arranged on the rails; a fixed chunk seat and a moveable chunk seat are respectively arranged at the two ends of the rails; and rotary supports, the driving devices and flexible welding equipment are arranged on the two chunk seats. The method and the device have the advantages that: the flanges can be prevented from being deforming when welding so as to ensure welding quality; and the steel tubes cannot jitter when welding seam circular tubes, polygonal tubes and conical tubes with the flanges. The horizontal movement of the steel tubes can be realized by using the automatic adjusting brackets so as to realize the accurate butt of the steel tubes and the flanges.

Owner:辽宁锦兴电力金具科技股份有限公司

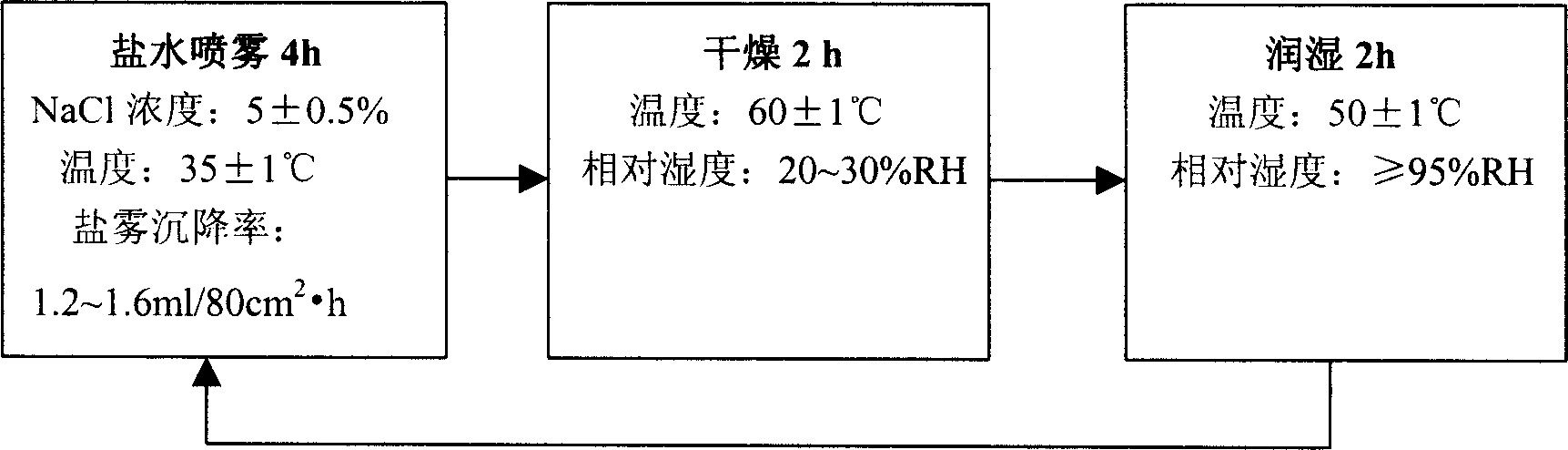

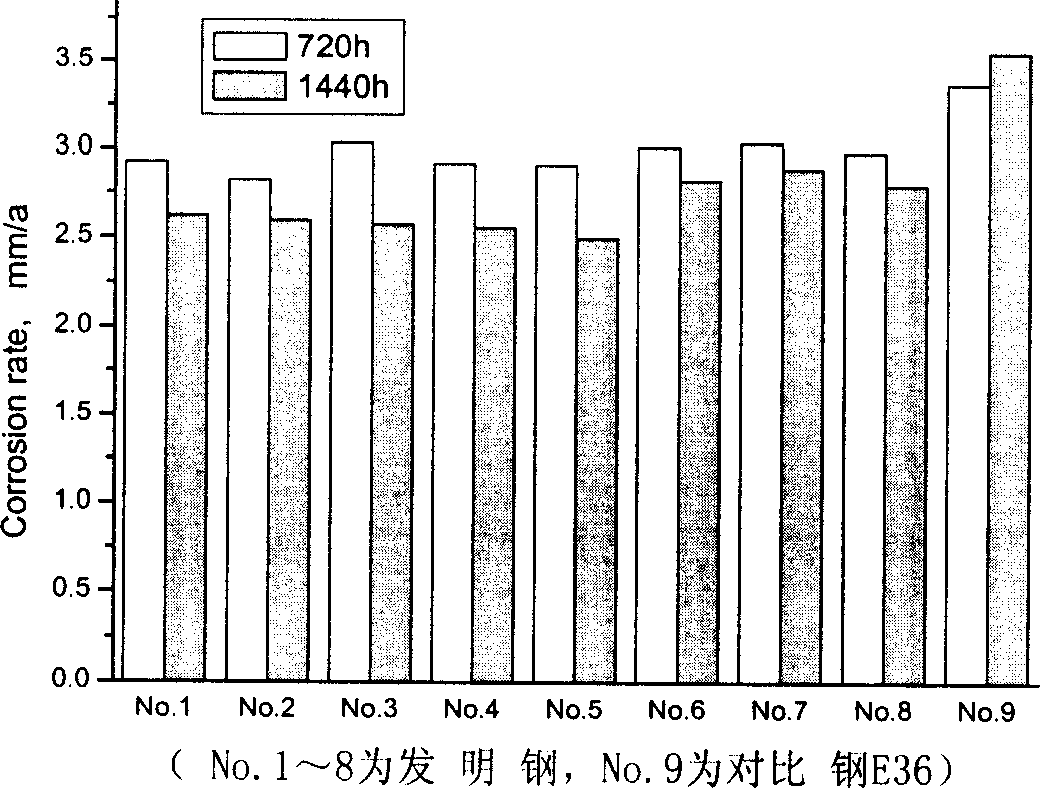

Sea water corrosion resistant steel for ocean drilling/production platform and preparation method thereof

InactiveCN1908217AReduce unevennessAvoid corrosionRoll mill control devicesWelding/cutting media/materialsChemical compositionImpurity

the invention discloses a marine exploiting platform steel of erosion property of sea water resistance, which comprises the following parts: 0.03-0.09% C, 0.90-1.60% Mn, 0.10-0.50% Si, 0.006-0.020% P, 0.004-0.100% Cr, 0.02-0.40% Cu, 0.010-0.060% Als, 0.005-0.060% Nb, 0.005-0.030% Ti, Fe and impurity. the manufacturing method comprises the following steps: desulfurizing; blowing; disposing through vacuum; casting continually; rolling.

Owner:武钢集团有限公司

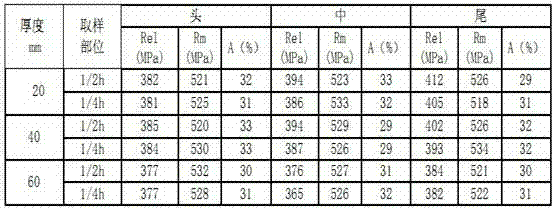

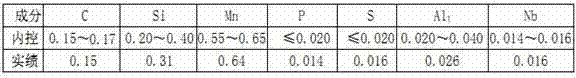

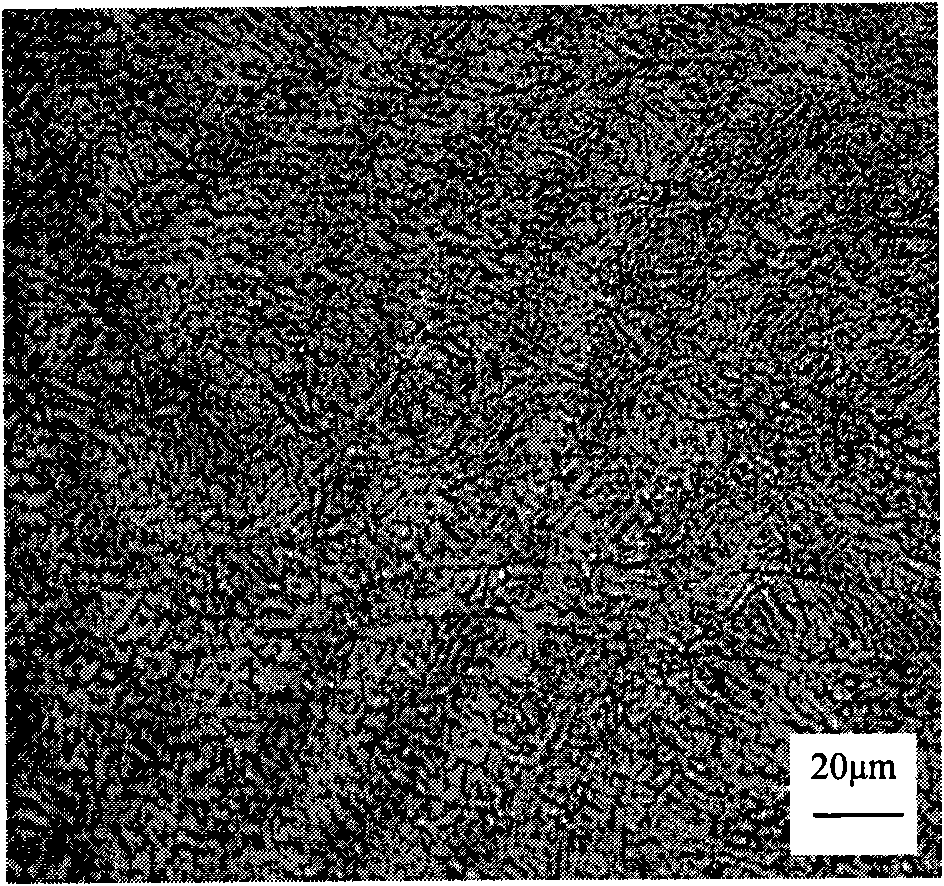

Production method for low-alloy medium-thick steel plate

The invention discloses a production method for a low-alloy medium-thick steel plate. The process route comprises the following stages in turn: converter steelmaking, external refining, continuous casting, heating, rolling, and accelerated cooling. Steel comprises the following components by weight percent: 0.15-0.17% of C, 0.20-0.40% of Si, 0.55-0.65% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.020-0.040% of Al, 0.014-0.016% of Nb, and less than or equal to 0.30% of CEV. The (P+F) micro-structural feature of the traditional Q345D steel plate is maintained by the steel plate; according to the design of the components of the steel plate, the Mn is reduced by 0.9%, no Ni is added and 0.015% of Nb is increased, so that the cost per ton of steel alloy is reduced; the Nb micro-alloying treatment is supplemented with TMCP (Thermo Mechanical Control Process) technology, so that the demand on the performance of the steel plate is met, the percentage elongation is increased by 2%-3% and the impact toughness is increased by about 90J; the CEV of the steel plate is reduced to below 0.30% and the welding property of the steel plate is greatly improved; and the measures, such as, the great reduction of the alloy, the eliminating of ladle furnace process route, the Direct Hot Charging Rolling (DHCR) of hot casting blank, and the like, are taken, so that the production cost of the steel plate is greatly lowered.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

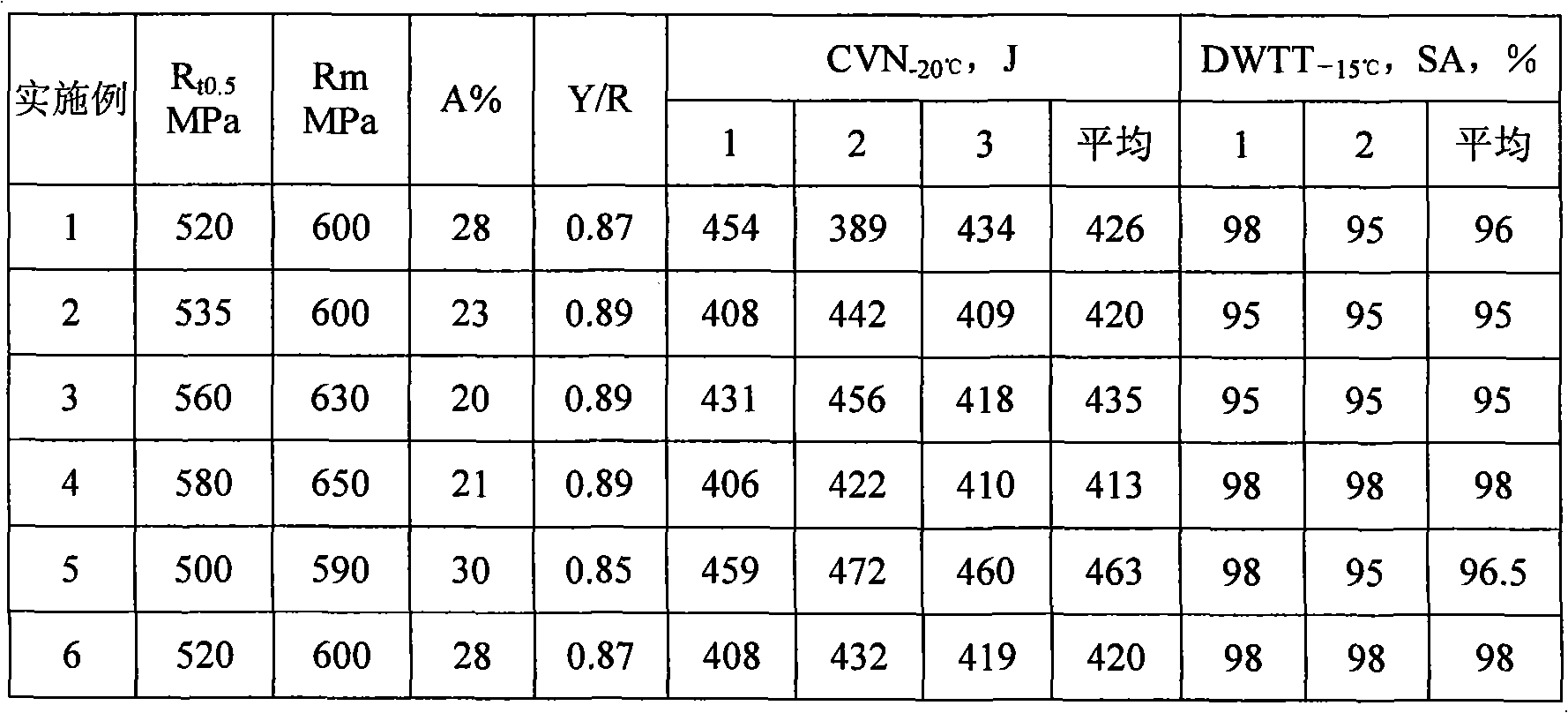

High-strength X100 pipe line steel hot rolling flat plate and method for manufacturing same

InactiveCN101619416AReduce alloy costLow carbon equivalentTemperature control deviceCooling temperatureHigh intensity

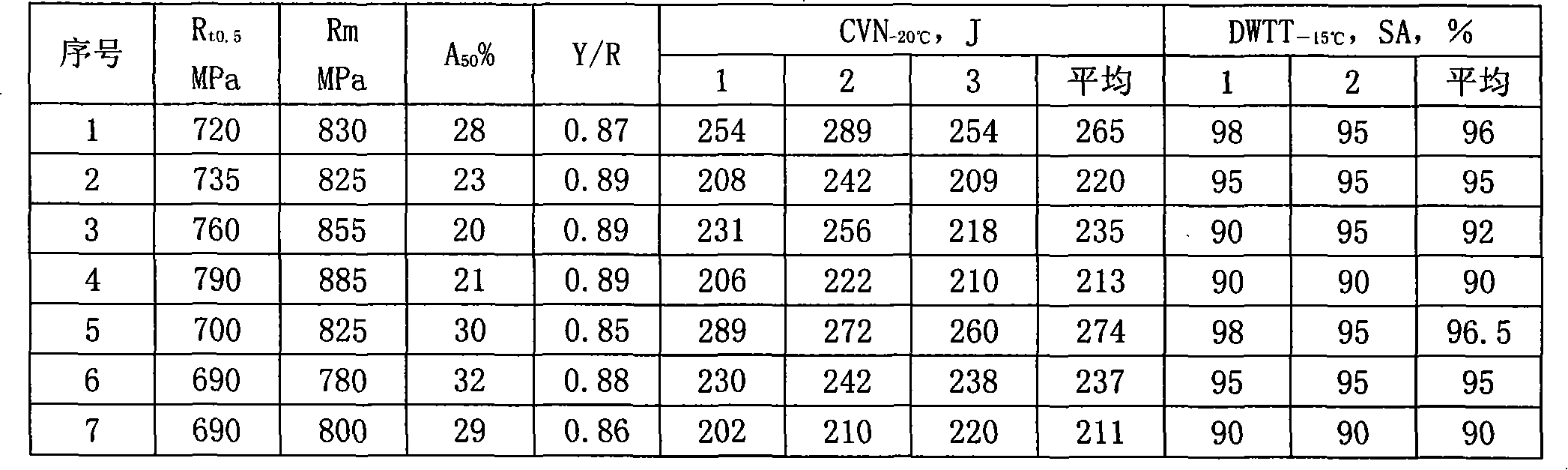

The invention discloses a high-strength X100 pipe line steel hot rolling flat plate and a method for manufacturing the same. The steel comprises the following chemical components in percentage by weight: 0.02 to 0.08 percent of C, 0.10 to 0.35 percent of Si, 1.65 to 2.20 percent of Mn, 0.005 to 0.020 percent of P, less than or equal to 0.003 percent of S, 0.04 to 0.11 percent of Nb, 0.008 to 0.030 percent of Ti, 0.02 to 0.045 percent of Als, one or more of less than or equal to 0.60 percent of Ni, less than or equal to 0.30 percent of Mo and less than or equal to 0.30 percent of Cu, and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps that: the heating temperature of a plate blank is between 1,160 and 1,280 DEG C, the rough rolling temperature is between 1,070 and 1,150 DEG C, the finish rolling temperature is between 830 and 950 DEG C, the finish cooling temperature is between 300 and 550 DEG C, and the controlled cooling speed is between 15 and 30 DEG C / S. By using the method, a complex phase structure mainly comprising the following bainites can be obtained. By adopting the complex phase structure, the yield strength of the pipe line steel hot rolling flat plate reaches 690 to 825MPa, the tensile strength reaches over 780MPa, the impact energy at a temperature of 20 DEG C below zero is more than or equal to 200J, and the shearing area of DWTT at a temperature of 15 DEG C below zero is more than or equal to 90 percent; and the rolling resistance and the straightening resistance are reduced, and the operating rates of the rolling machine and the straightening machine are improved.

Owner:ANGANG STEEL CO LTD

Diffusion welding method for tungsten-titanium alloy target and copper alloy back plate

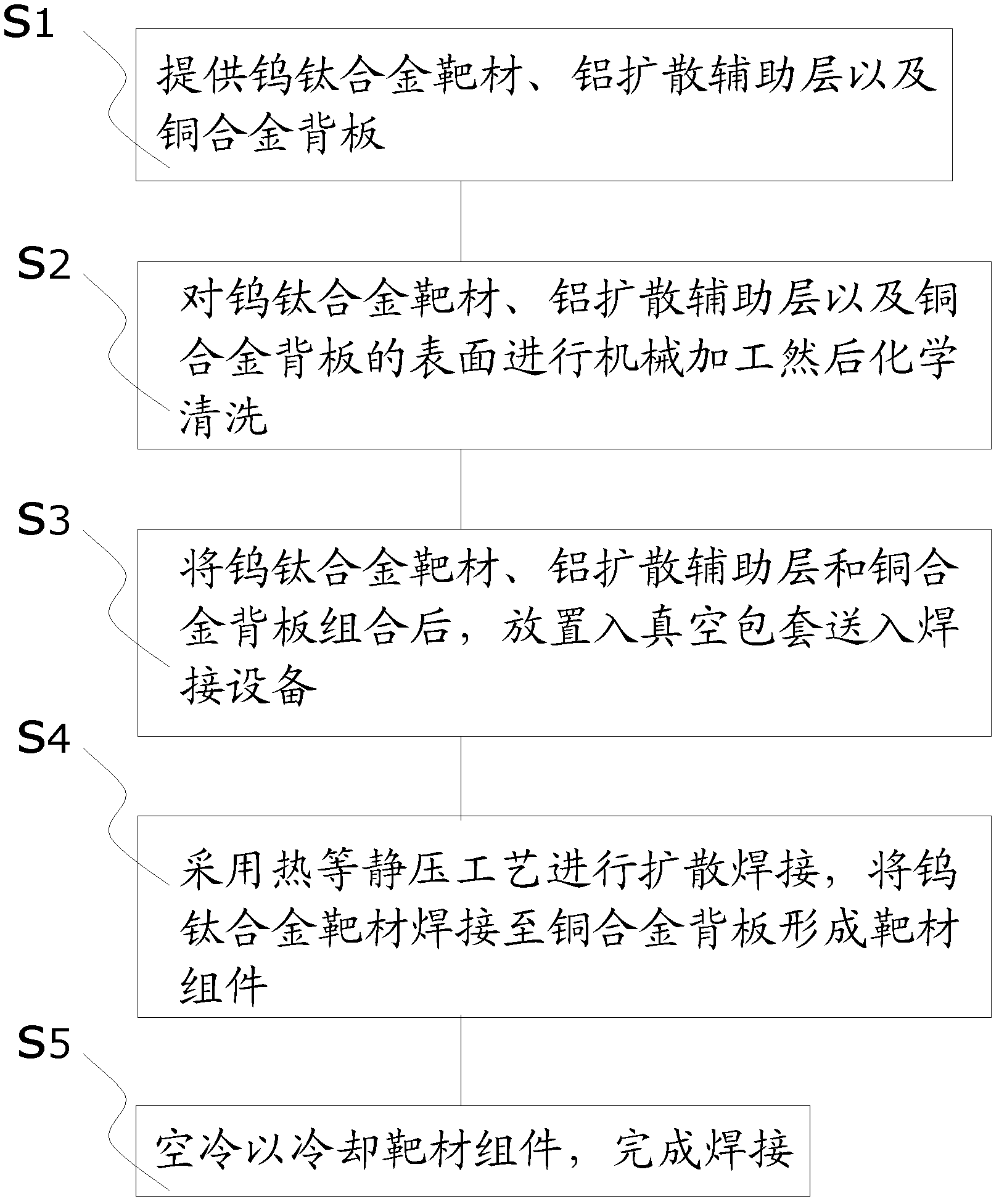

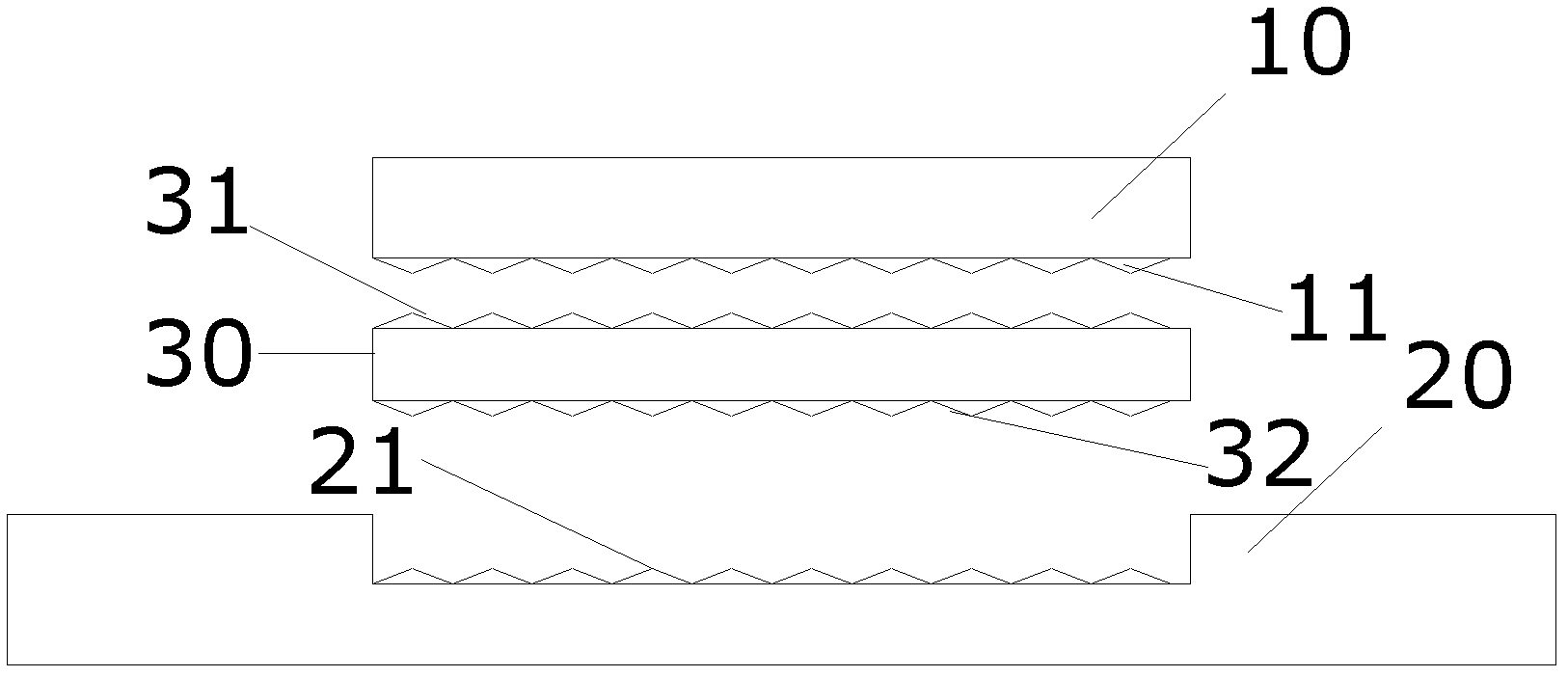

ActiveCN102554455APrevent oxidationLow costNon-electric welding apparatusThermal deformationTitanium alloy

Disclosed is a diffusion welding method for a tungsten-titanium alloy target and a copper alloy back plate. An aluminum diffusion auxiliary layer is arranged between the tungsten-titanium alloy target and the copper alloy back plate, diffusion welding of the tungsten-titanium alloy target, the aluminum diffusion auxiliary layer and the copper alloy back plate is realized by the aid of high-strength atomic diffusivity between the tungsten-titanium alloy target and the aluminum diffusion auxiliary layer and between the aluminum diffusion auxiliary layer and the copper alloy back plate, and finally, welding quality of the tungsten-titanium alloy target and the copper alloy back plate is improved. Diffusion welding of the tungsten-titanium alloy target and the copper alloy back plate is implemented by a hot isostatic pressing process. As diffusion welding is performed in a vacuum sheath and air is isolated, the contact surface of welded metal can be effectively prevented from being oxidized, the bonding strength of the tungsten-titanium alloy target, the aluminum diffusion auxiliary layer and the copper alloy back plate is enhanced, the target is prevented from being separated from the back plate during sputtering, and sputtering coating is normally performed. A target assembly formed by the diffusion welding method has the advantages of high bonding compactness, high thermal deformation resistance and the like.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

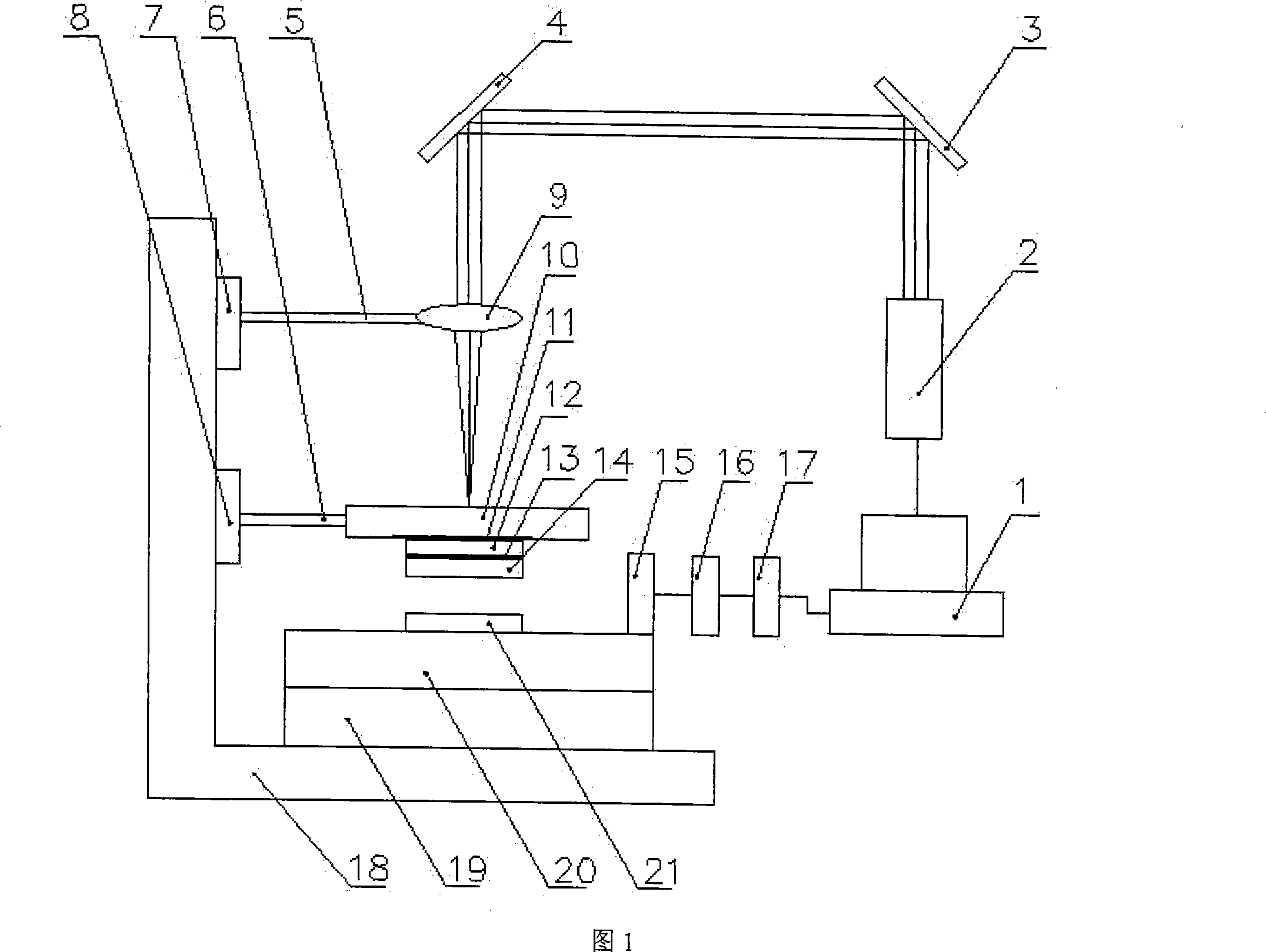

Flying plate driving type laser micro-welding method and device

InactiveCN101239418AImprove flexibilityConvenient distanceLaser beam welding apparatusNon-electric welding apparatusMetallic materialsCam

The invention relates to welding field, especially relates to a flying slice driving laser microwelding method and device, adapted to quick welding between homogeneous or heterogeneous metallic materials. The invented device is composed of a laser, a reflection mirror, a focusing lens, a focusing lens supporting frame, a focusing lens moving platform, a confinement layer, a confinement layer supporting frame, a confinement layer moving platform, a worktable, a three-dimensional moving platform, a L-shaped base, a CCD cam, a D / A converter, an image gathering card, and a computer. The single pulse laser controlled by the computer accurately acts on the front surface of the flying slice to generate explosion plasma which drives the workpiece adhering tightly to the back of the flying slice to moving with a high speed while driving the flying slice moving with a high speed, the flying slice collides with the base after flying for a distance, and high temperature and high pressure are generated on the colliding boundary to implement welding between the workpiece and the base. The invented method and device realize low cost and high efficiency of microwelding, are provided with simple technique and good compatibility, and are suitable for automated production.

Owner:JIANGSU UNIV

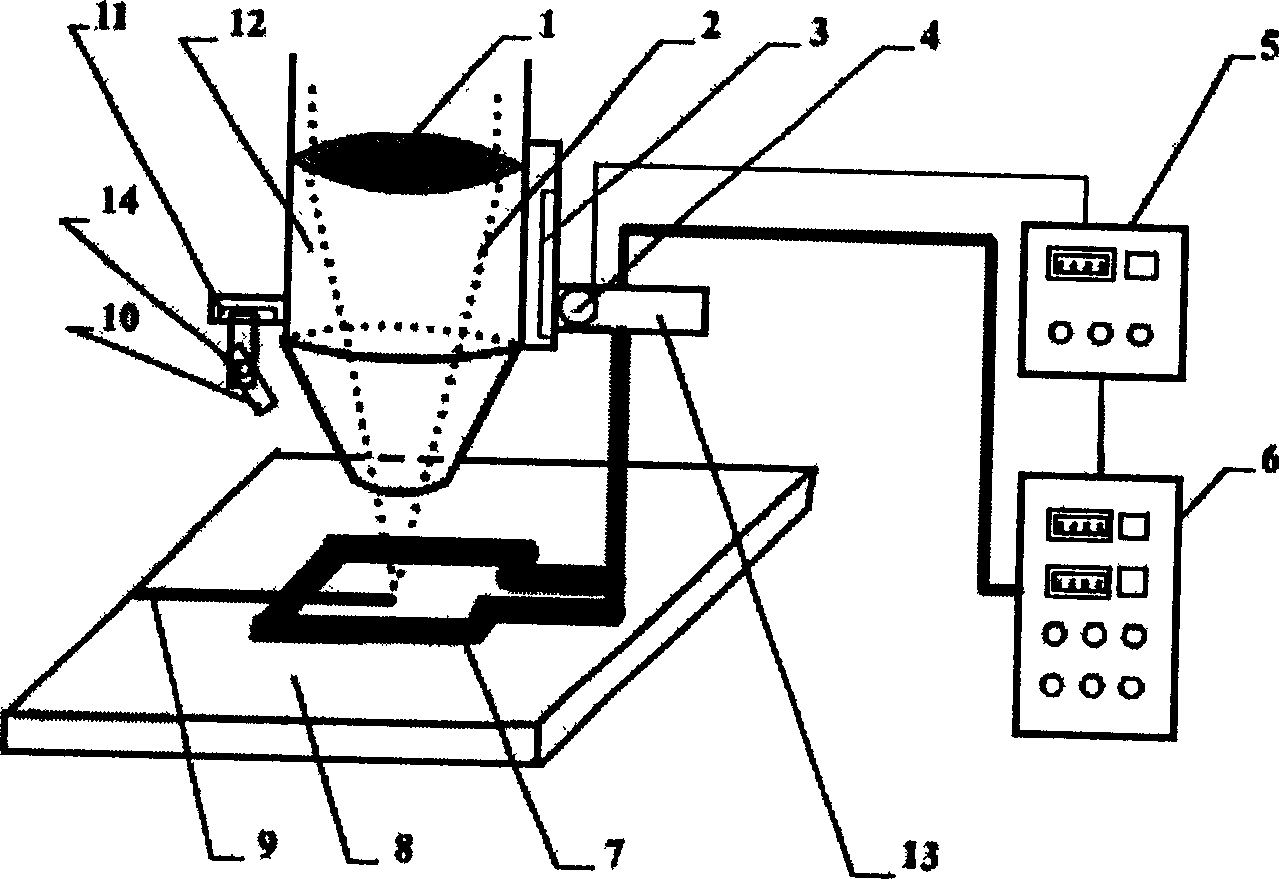

Laser-high frequency induction composite welder and its method

InactiveCN1554510ARealize simultaneous mobile heatingImprove absorption rateHigh frequency current welding apparatusLaser beam welding apparatusMetallic materialsInductor

The present invention provides welder and welding method combining two different kinds of heat source, laser and HF inductor, and adopts real-time temperature monitor and control to overcome the demerits of common laser welding of metal material, which has low energy utilization and is likely to produce air hole. During welding, two kinds of heat source are used to heat the welded part and near part simultaneously. The welder of the present invention has laser welding head as the main body comprising integrated induction heating winding and infrared sensor. Compared with common laser welding, the present invention has greatly raised production efficiency and welding quality and can realize 2D and 3D welding.

Owner:HUAZHONG UNIV OF SCI & TECH

High-strength molten-zinc-plated steel sheet having excellent bendability and weldability, and process for production thereof

ActiveCN102918174AImprove bending performanceImprove welding effectHot-dipping/immersion processesFurnace typesSurface layerHigh intensity

A steel sheet is coated with a molten zinc plating layer, wherein the steel sheet comprises, in mass%, not less than 0.05% and less than 0.12% of C, 0.001 to 0.040% of P and 0.0050% or less of S, has a steel sheet surface layer part (which is a part lying between each of surfaces of the steel sheet and a depth of 10 [mu]m of the steel sheet) and a steel sheet inner layer part (which is a inside part from the depth of 10 [mu]m from each of the surfaces of the steel sheet), and has a tensile strength of 980 MPa or more, wherein the steel sheet surface layer part has a structure that contains a ferrite phase at a volume fraction of more than 70% and the steel sheet inner layer part has a structure that contains a ferrite phase having an average crystal particle diameter of 5 [mu]m or less at a volume fraction of at least 20 to 70%. In this manner, it is possible to produce a high-strength molten-zinc-plated steel sheet having a tensile strength (TS) as high as 980 MPa or more and also having excellent bendability and weldability.

Owner:JFE STEEL CORP

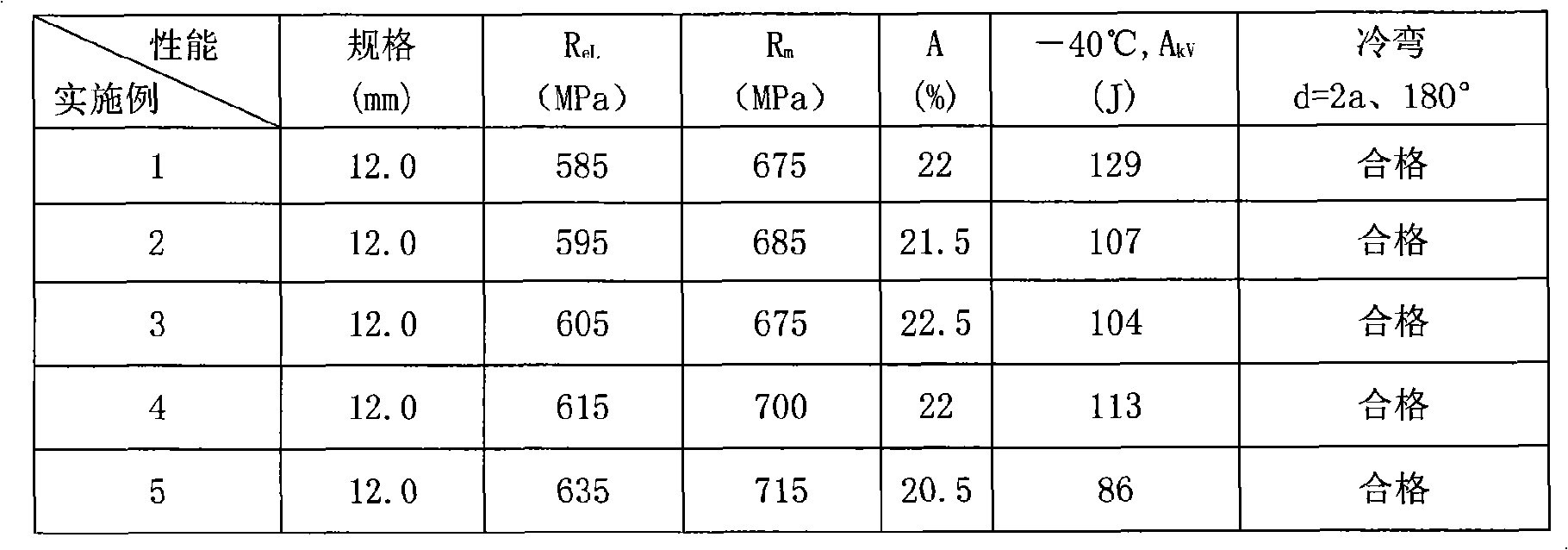

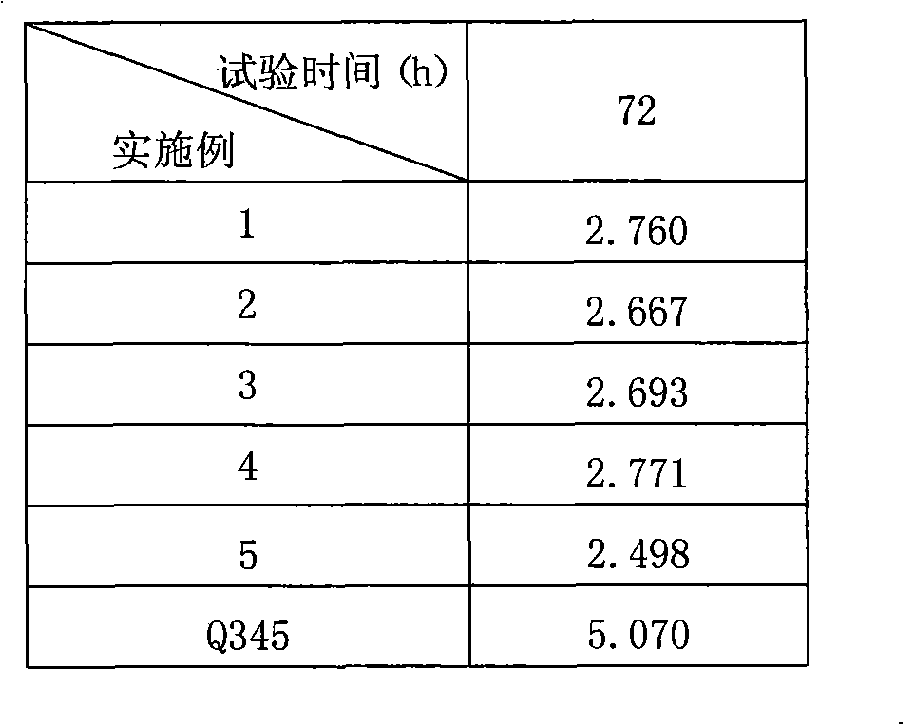

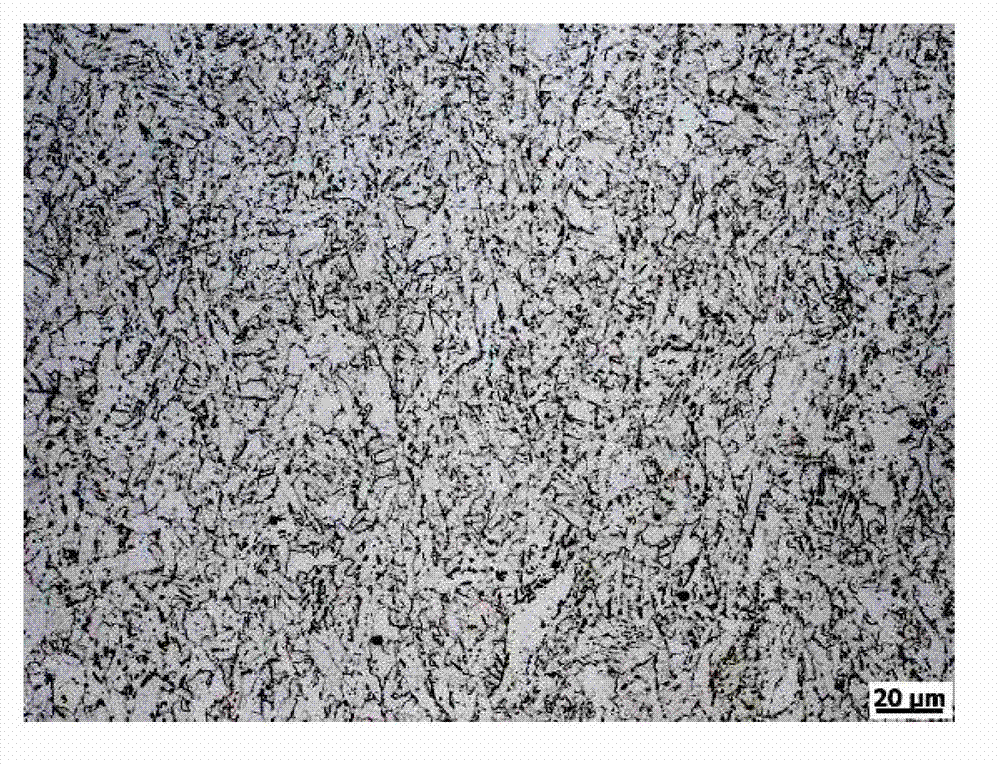

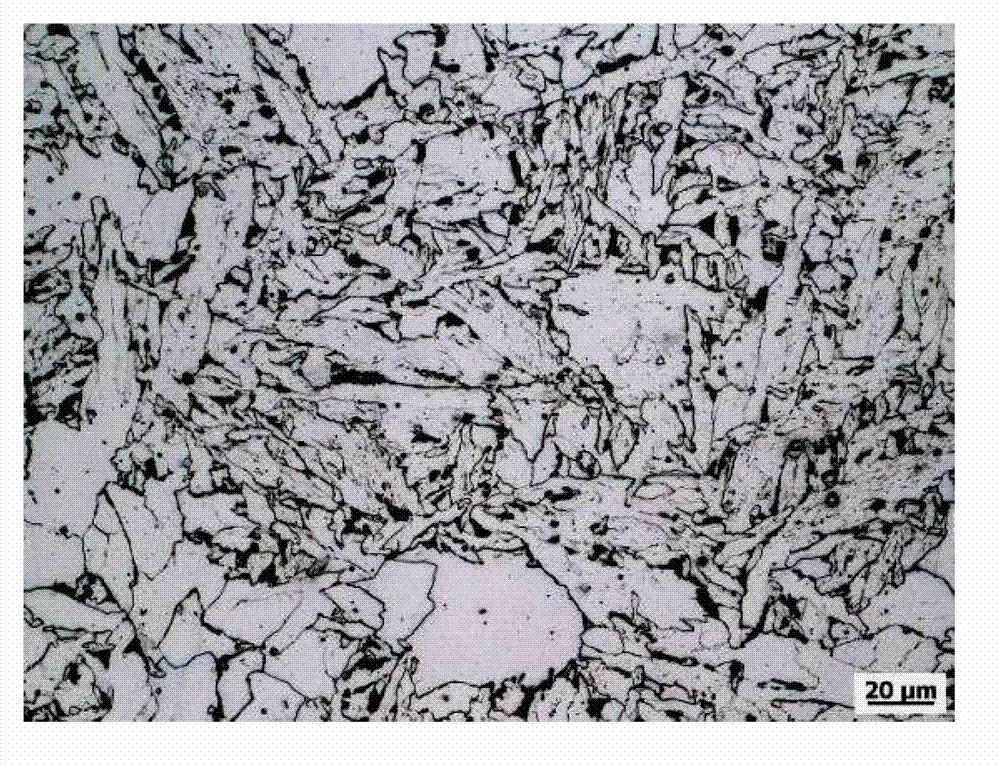

High-toughness weather-resistant steel plate with yield strength of 550MPa and preparation method of high-toughness weather-resistant steel plate

ActiveCN108486466AGood welding performanceExcellent cold forming performanceToughnessAtmospheric corrosion

The invention discloses a high-toughness weather-resistant steel plate with the yield strength of 550MPa and a preparation method of the high-toughness weather-resistant steel plate. The high-toughness weather-resistant steel plate is prepared from the following chemical components by weight percent: 0.05 to 0.10 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.008 percent of S, 0.40 to 0.80 percent of Cr, 0.15 to 0.40 percent of Ni, 0.25 to 0.40 percent of Cu, 0.015 to 0.040 percent of Als, 0.030 to 0.070 percent of Nb, and 0.010 to 0.040 percent of Ti, and the balance of Fe and unavoidable impurities, wherein Pcm is equal to C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B and less than or equal to 0.20 percent. The microscopic tissue of the weather-resistant steel plate obtained according to the method disclosed in the invention is composite-phase tissue of ferrite, granular bainite and little pearlite,the ReL is 560 to 650MPa, Rm is 680 to 780MPa, A is 22.0 to 26.0 percent, and the longitudinal Charpy V-type impact power KV2 is greater than 70J at the temperature of -40 DEG C, and the high-toughness weather-resistant steel plate has excellent welding performance, cold bending forming performance and atmospheric corrosion resistance.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

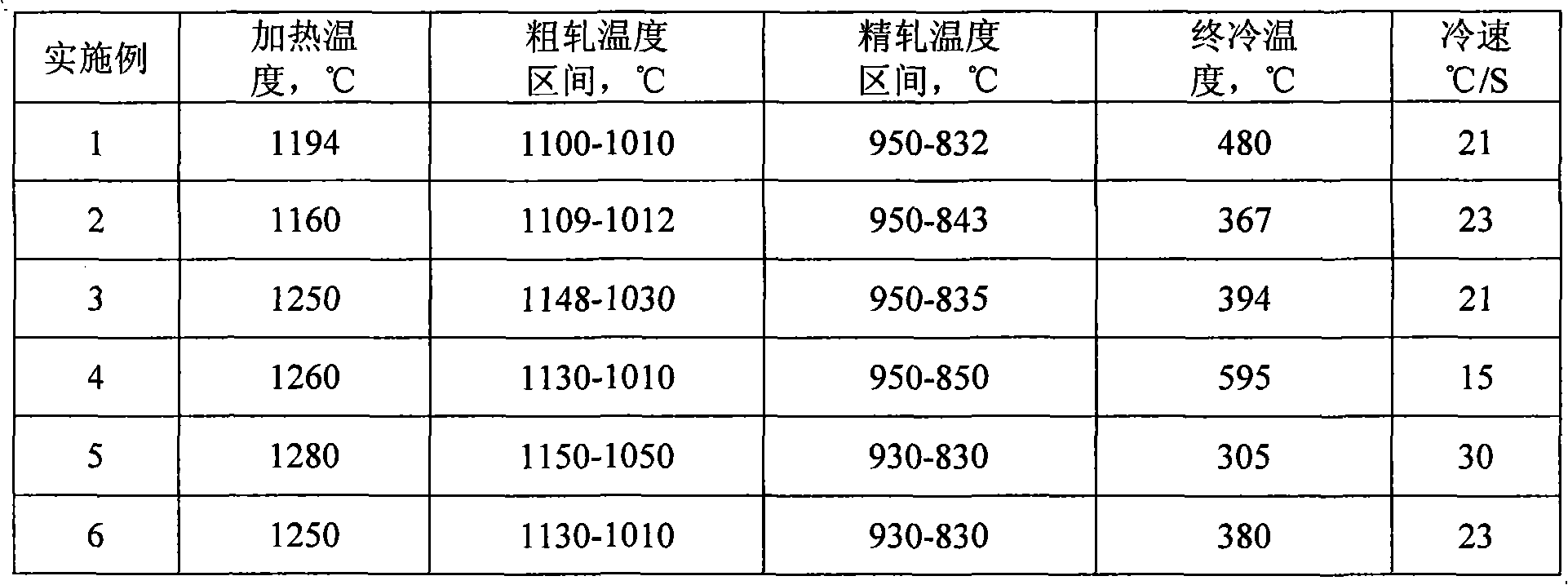

High-strength economical X70 pipeline steel hot-rolling flat plate and production method thereof

ActiveCN101906575ALow costImprove welding effectTemperature control deviceCooling temperatureSteel tube

The invention provides a high-strength economical X70 pipeline steel hot-rolling flat plate and a production method thereof. The high-strength economical X70 pipeline steel hot-rolling flat plate comprises the following chemical components: 0.02-0.08 percent of C, 0.10-0.35 percent of Si, 1.40-1.70 percent of Mn, not more than 0.020 percent of P, not more than 0.005 percent of S, 0.04-0.07 percent of Nb, 0.008-0.030 percent of Ti, 0.02-0.045 percent of Als and the balance of Fe and unavoidable impurities. The production method comprises the steps of smelting, continuous casting and hot rolling and is characterized in that the heating temperature of a hot-rolling plate blank is 1,160-1,280 DEG C; the rough rolling temperature is 1,010-1,150 DEG C, and the finish rolling temperature is 830-950 DEG C; after the plate blank is rolled, the plate blank is subjected to control cooling; the final cooling temperature is 300-600 DEG C, the cooling speed is controlled to be 15-30 DEG C / S, and then the plate is air-cooled to room temperature. The invention has low steel alloy content, no Mo and V, low production cost and high mechanical performance, mouldability and welding performance and is suitable for manufacturing a large-diameter X70 pipeline steel pipe.

Owner:ANGANG STEEL CO LTD

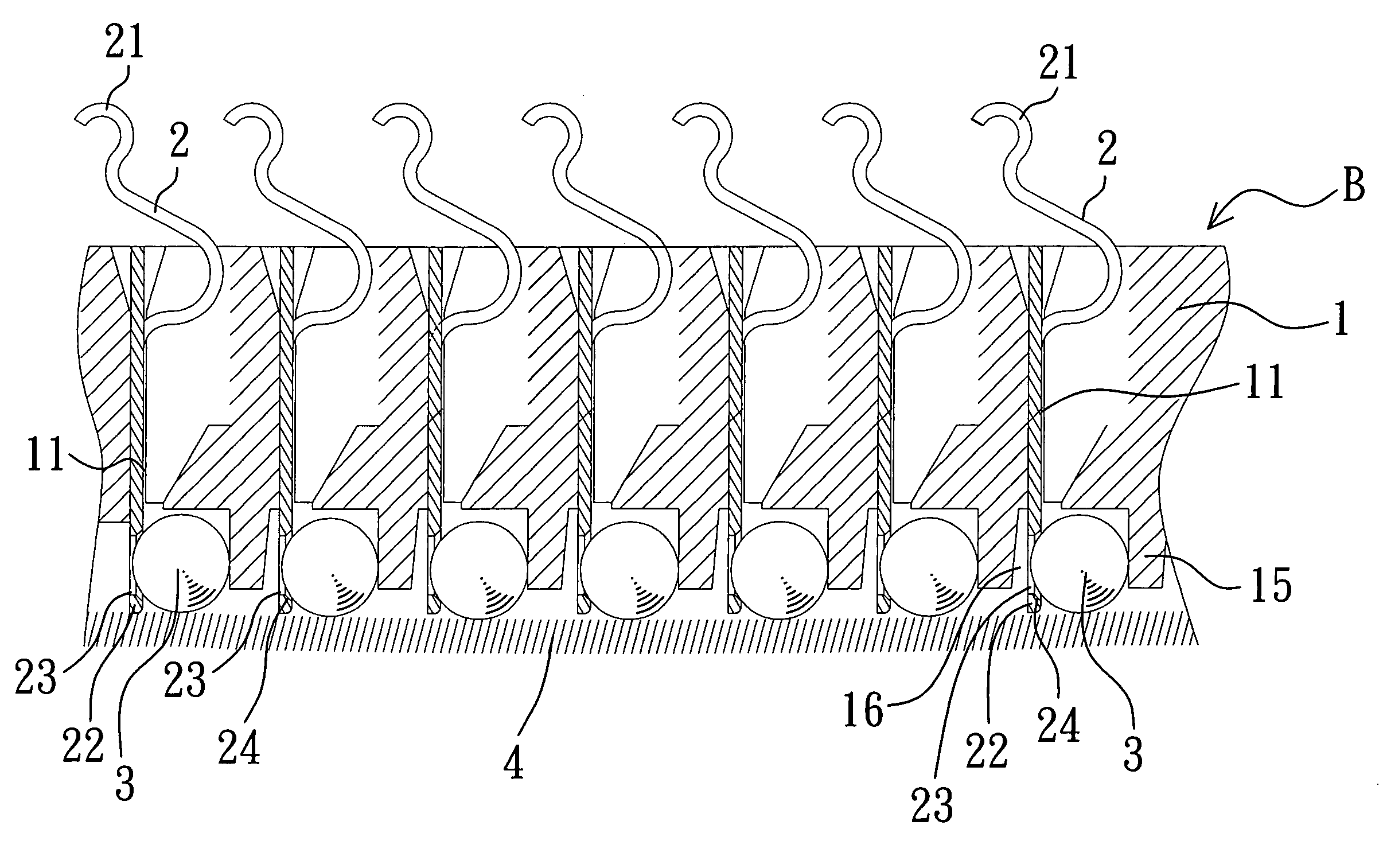

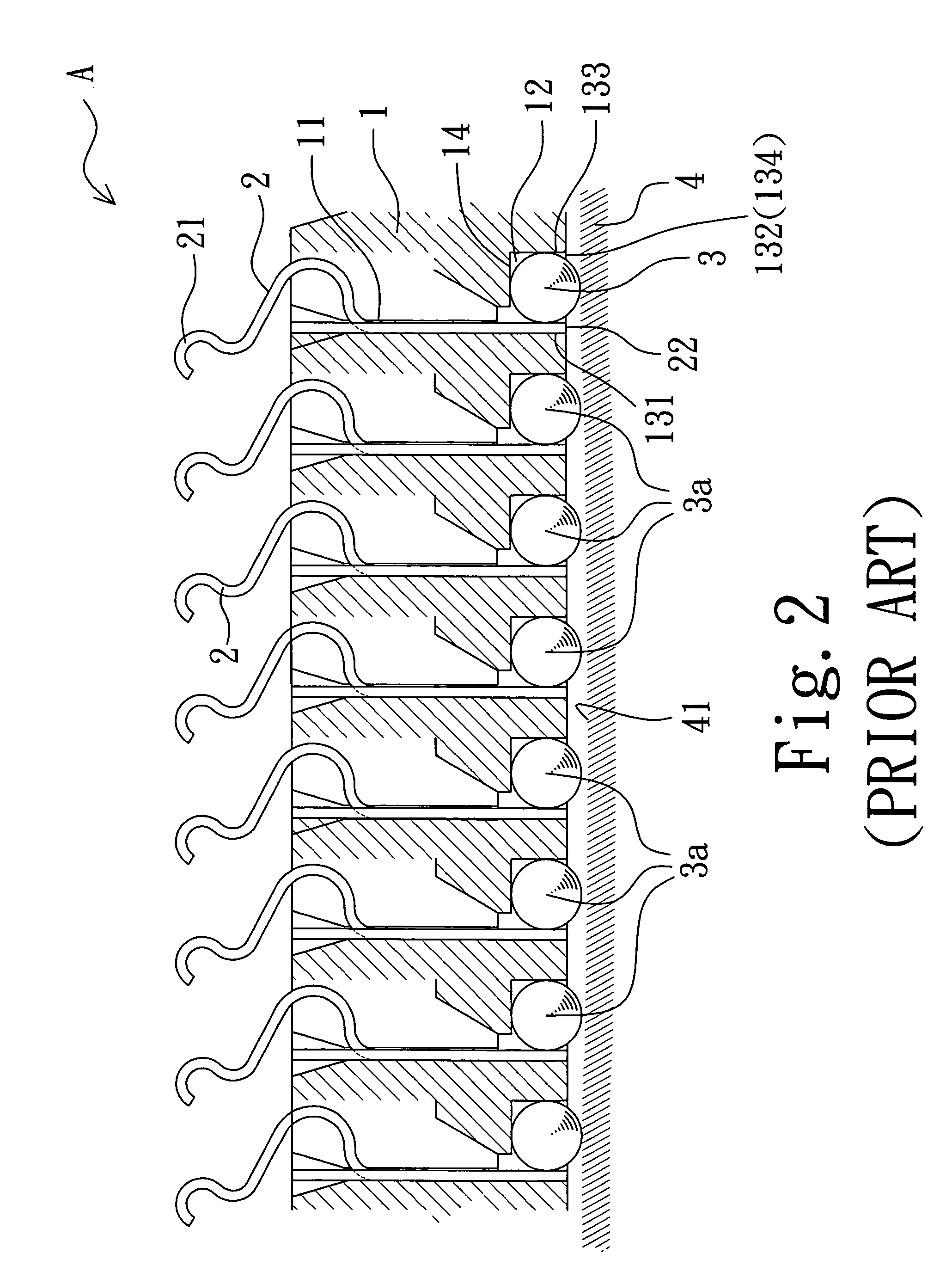

Socket having a structure for grasping solder balls

InactiveUS7147489B1Add depthUp and downLine/current collector detailsFinal product manufactureDielectricSolder ball

A socket having a structure for grasping solder balls is disclosed. A grasping hole is laterally defined in the solder joint of each terminal of the socket, and a stop wall is formed at the dielectric housing spaced from the grasping hole at a proper distance. The solder ball is secured between the stop wall and the solder joint with a portion of the solder ball being received in the grasping hole. The dimension of the grasping hole is slightly larger than that of a side surface of the solder ball received in the grasping hole, whereby the solder ball is freely movable up and down in the grasping hole of the solder joint. Therefore, when the socket is soldered to the circuit board, the solder balls can automatically fully contact the surface of the circuit board.

Owner:TAI TWUN ENTERPRISE CO LTD

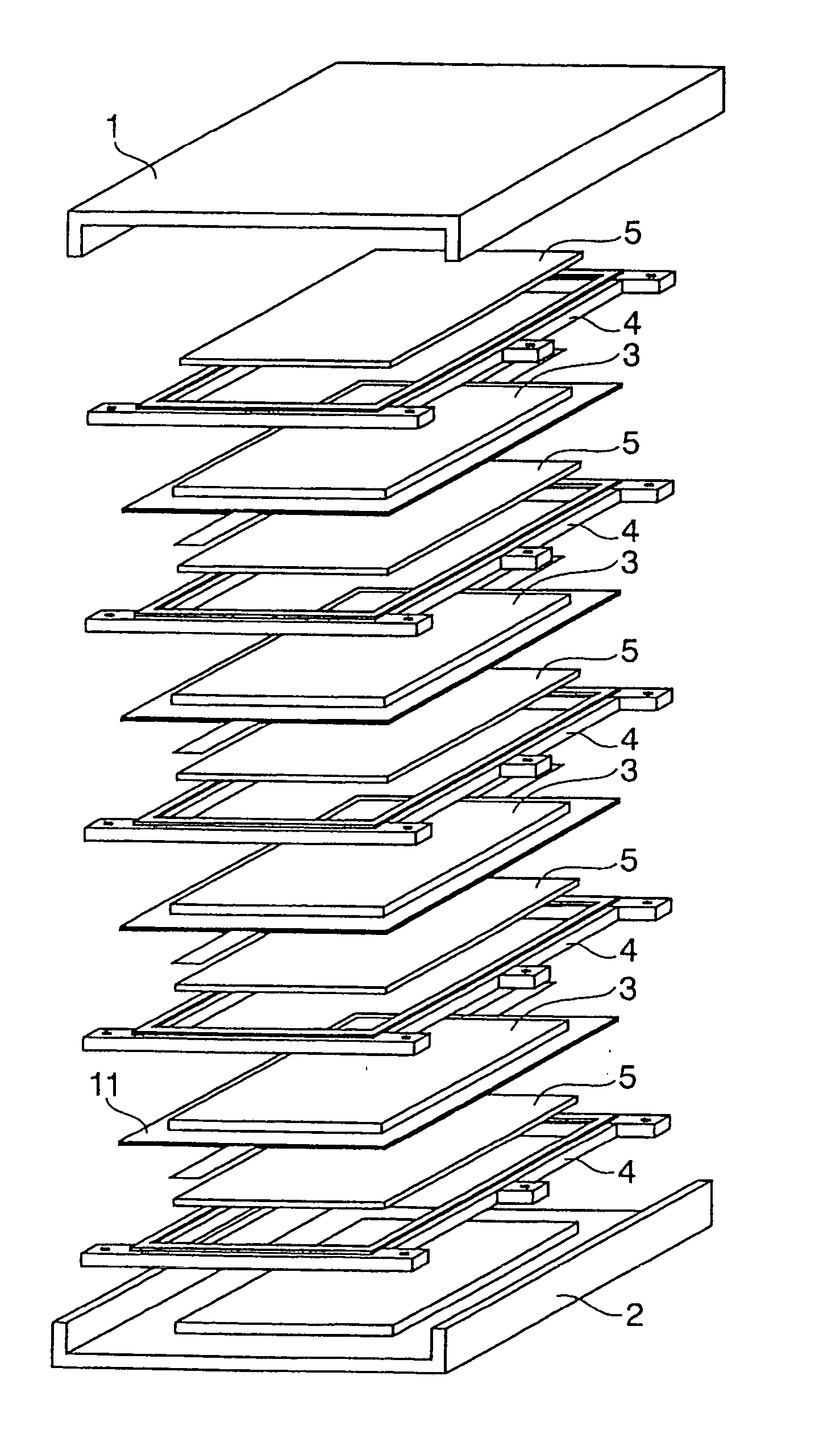

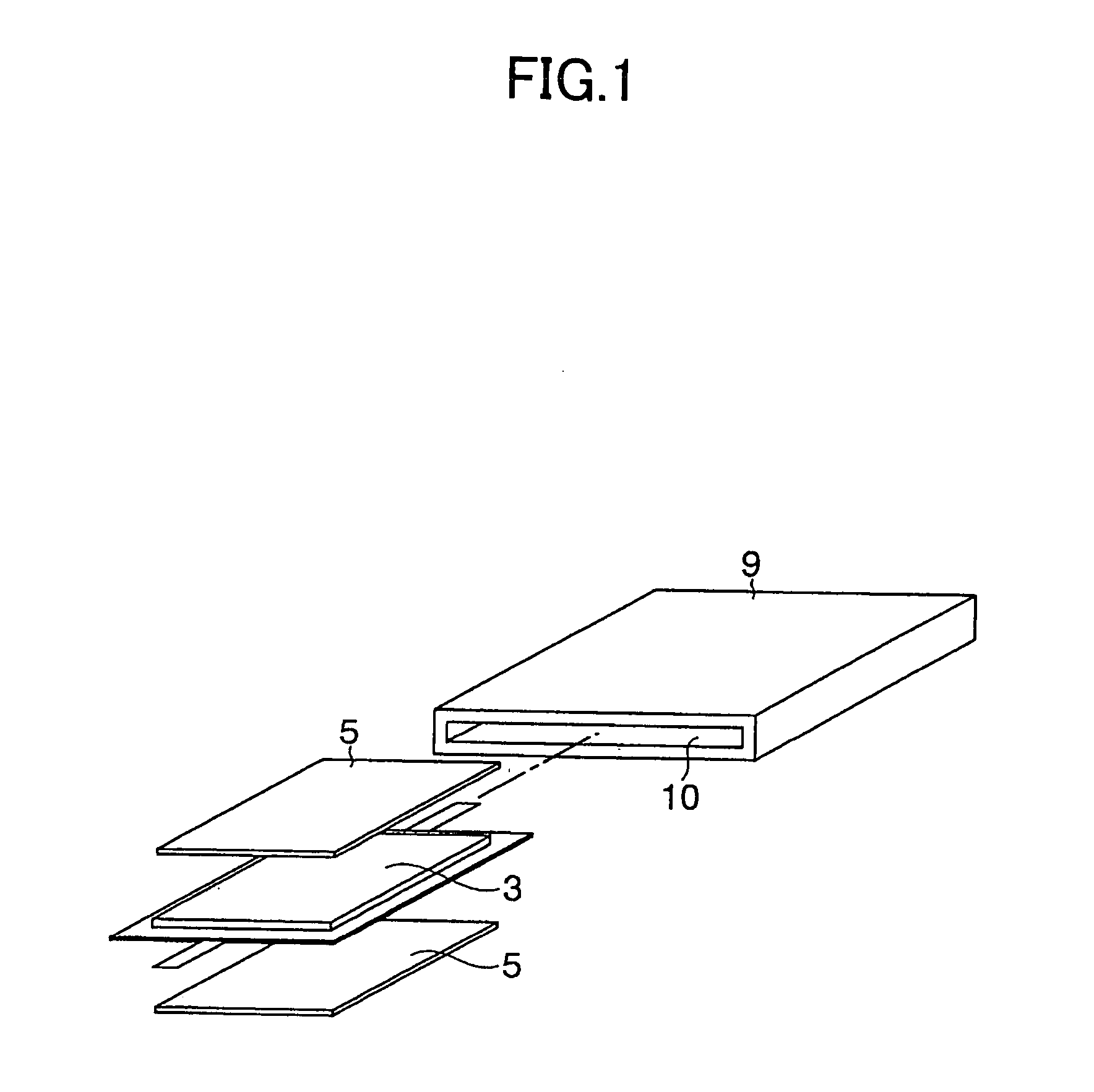

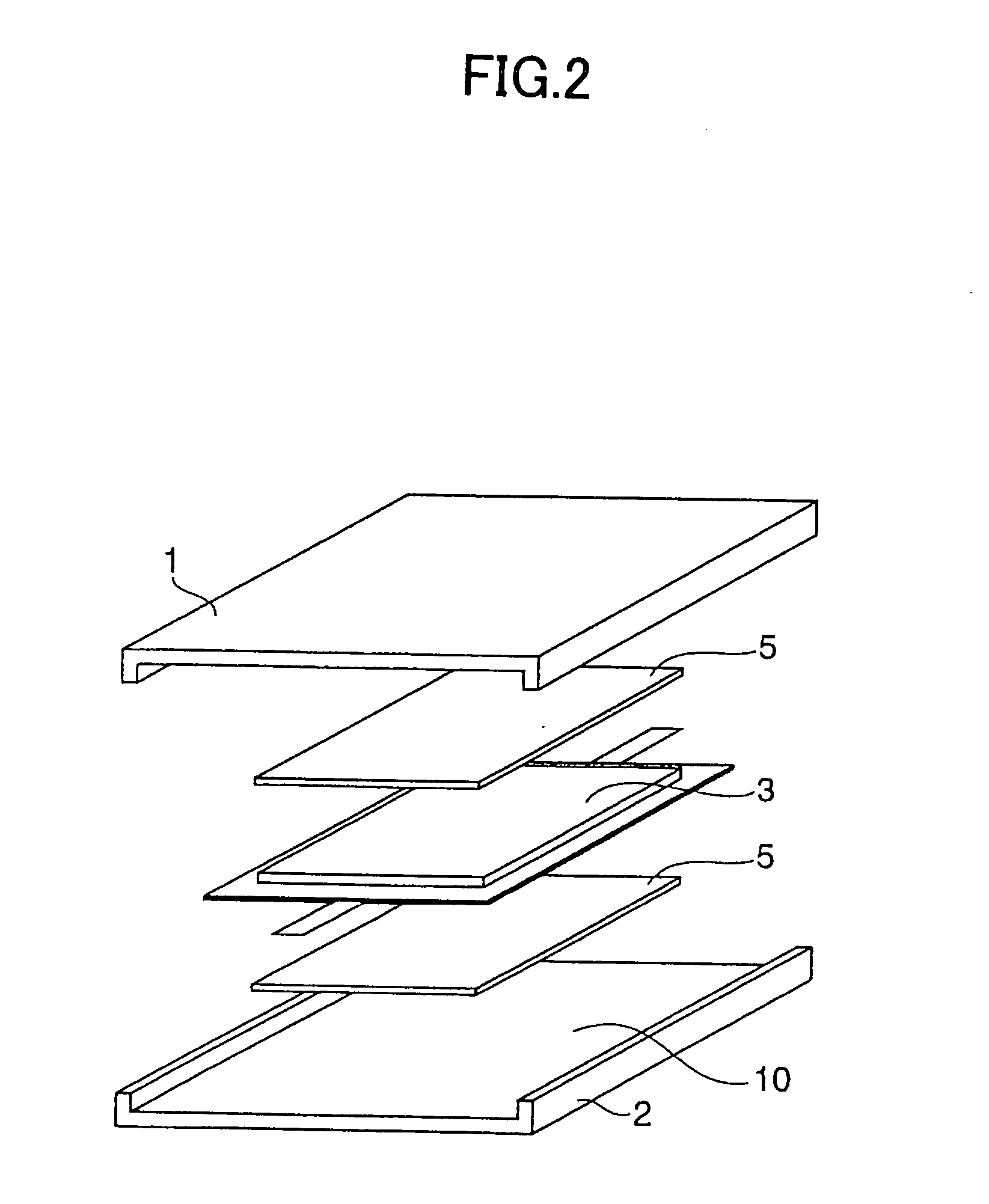

Module

InactiveUS20050042511A1Improve sealing propertyImprove welding effectFinal product manufactureWound/folded electrode electrodesEngineeringElectrical and Electronics engineering

Owner:NEC CORP

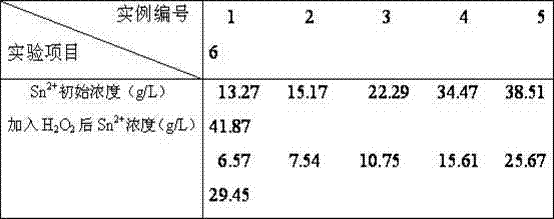

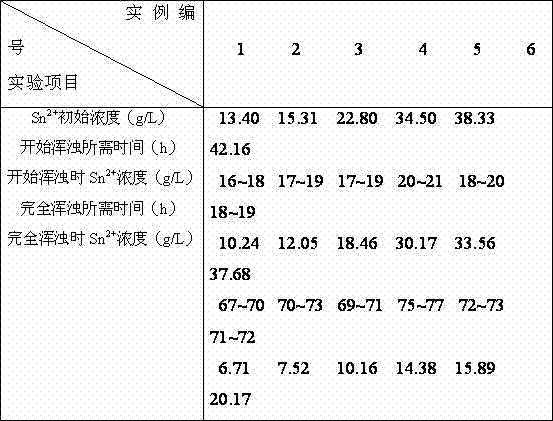

Methyl sulfonate tinning electrolyte and tinning method of steel strip or steel plate

The invention discloses methyl sulfonate tinning electrolyte using cerium salt as an additive. The electrolyte comprises the following components: 30 to 120 g / L of stannous methyl sulfonate, 60 to 180 g / L of methylsulfonic acid, 1 to 10 g / L of cerium sulfate, 0.1 to 2 g / L of antioxidant, 5 to 10 g / L of brightening agent and 5 to 10 g / L of surfactant. The invention also discloses a method for tinning a steel strip or a steel plate by adopting the electrolyte. During plating, the cerium salt in the electrolyte lightens the harm degree of 'hydrogen brittleness', and plays roles of the antioxidant and the brightening agent. On the basis of adaptability to the environment, the electrolyte meets the requirements that the process is simple, the solution is stable, the maintenance is easy and the quality of a coating is high.

Owner:张家港市凤凰科技开发有限公司

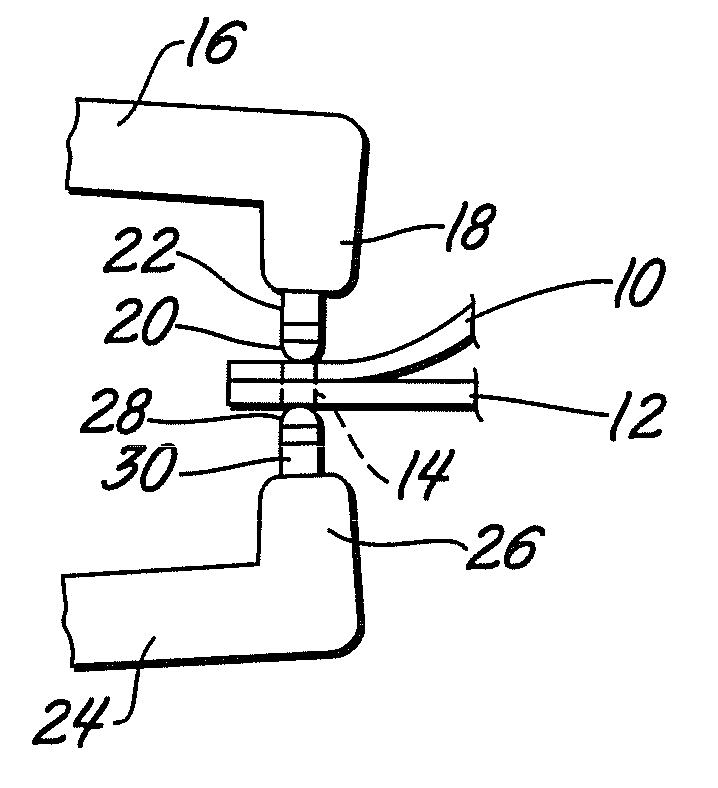

Forming and re-forming welding electrodes with contoured faces

ActiveUS20100258536A1Easily fowled on new electrodesEasy alignmentTurning machine accessoriesPressure electrodesSurface geometryMechanical engineering

A method is disclosed for using welding electrodes with a spherically-domed welding face having concentric contoured features formed into the face for better contact with workpiece surfaces. The concentric contoured features may be initially formed by rotating a cutting tool with a contoured cutting edge, the cutting edge being in engagement with the electrode face. A similar practice may be followed to re-create the weld face surface geometry if it becomes eroded or malformed during welding use. A suitable tool may have a blade-like geometry, with a mounting portion for supporting and positioning the tool in a rotating holder and a cutting edge. The cutting edge may have a contour complementary to that of the weld face and extend at least from the center of the weld face to at least the radial extent of the concentric contoured features.

Owner:GM GLOBAL TECH OPERATIONS LLC

In situ self-spread welding repair method of aluminum mother plate

InactiveCN101474719AQuick Weld RepairUnique process methodAlumino-thermic welding apparatusFusible plugGraphite

The invention relates to a welding repairing method for aluminum parent metal, in particular to an in-situ self-propagting welding repairing method for aluminum parent metal. The method is characterized in that: self-propagting medical preparation is firstly prepared, and cleaning, oil removal, oxide film removal are carried out on parts to be welded of aluminum parent metal, then welding fluid is coated on a groove face; according to the shape and size of the groove, a mould with lower holes is made by graphite and is fixed on the upper part of the groove, and a graphite plate is clamped at the two sides of the groove by a clamping device and forms a melting chamber together with the mould, an automatic fusible plug is laid at the bottom part of the mould, then the self-propagting medical preparation is poured into the mould, pyrophoric powder is coated above the self-propagting medical preparation, after the parent metal is preheated to a certain temperature, the pyrophoric powders is lighted, thus realizing in-situ self-propagting welding repairing of the aluminum parent metal. By the method provided by the invention, intense magnetic field interference can be avoided, welding quality can be improved, labor intensity can be relieved, and the operation is easy and rapid.

Owner:QINGTONGXIA ALUMINUM IND GROUP +1

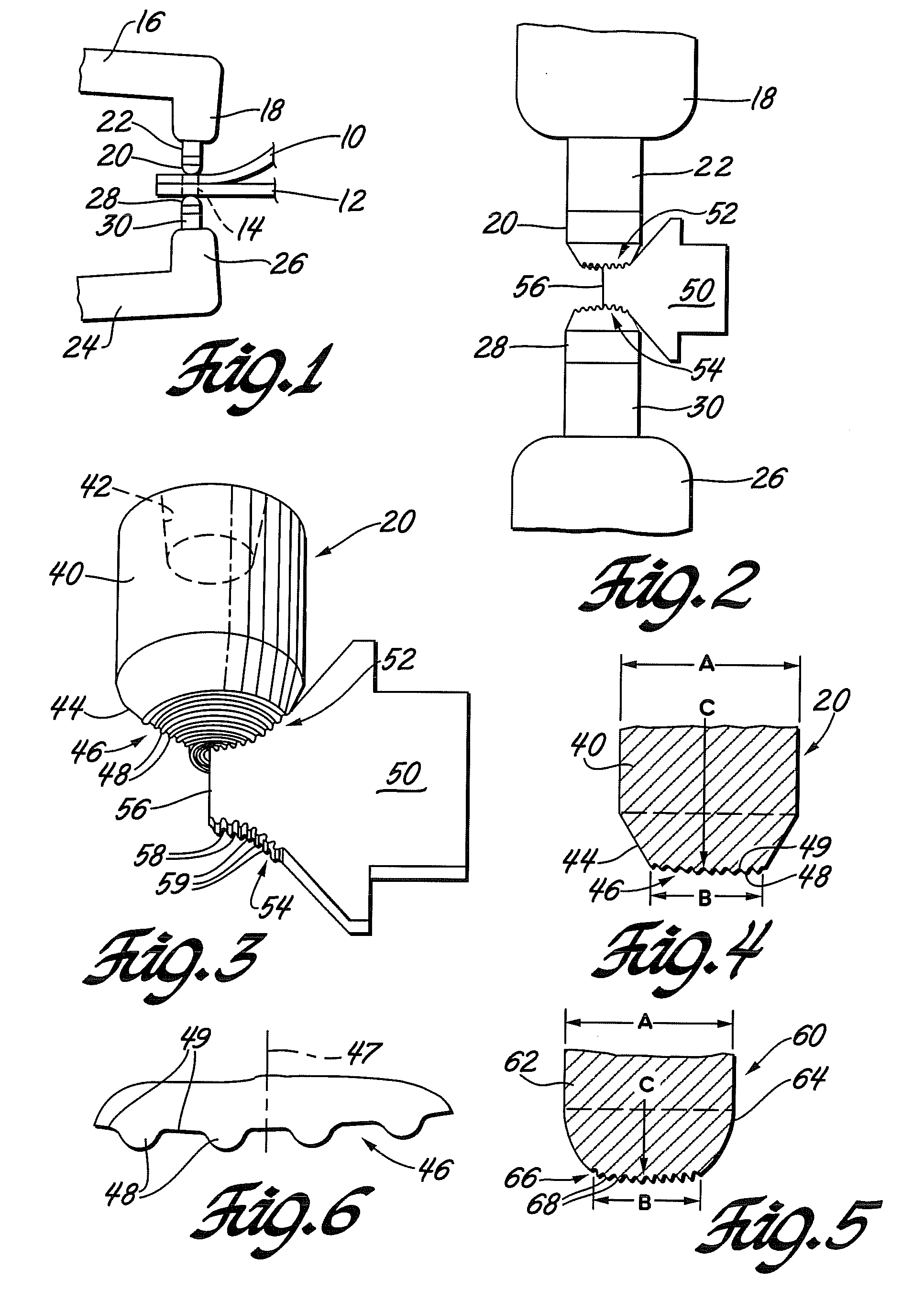

Ultra-low carbon hot rolling weathering steel with yield strength larger than 550MPa

InactiveCN101407892AGood mechanical propertiesSimple chemical compositionMechanical propertyWeathering steel

The invention discloses an ultra low carbon hot rolling weathering steel with the yield strength of more than the grade of 550MPa and belongs to the manufacturing field of low alloy steel. The steel consists of the compositions with the following weight percentages: 0.01 to 0.05 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, equal to or less than 0.02 percent of P, equal to or less than 0.010 percent of S, 0.15 to 0.80 percent of Cu, 0.40 to 1.25 percent of Cr, 0.10 to 0.50 percent of Ni, equal to or less than 0.40 percent of Mo, 0.03 to 0.06 percent of Nb, equal to or less than 0.050 percent of Ti, 0.0010 to 0.0020 percent of Ca and the residual quantity of Fe and unavoidable impurities. The steel has good mechanical properties, the yield strength of equal to or more than 550MPa and the tensile strength of equal to or more than 650MPa which are both higher than that of traditional weathering steel. Besides, Ti is included in the compositions of the steel.

Owner:武钢集团有限公司

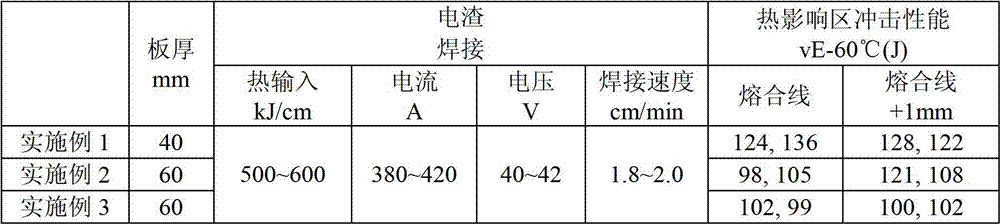

Production method of low-temperature steel plate capable of being welded by high heat input

ActiveCN102766748AImprove welding performanceImprove welding effectProcess efficiency improvementImpact energyFerrotitanium

The invention relates to a production method of a low-temperature steel plate capable of being welded by high heat input. The production method includes the steps of hot metal pretreatment, combined blown converter smelting, ladle furnace (LF) refining, RH refining, wire feeding and continuous casting, white slags are produced by LF refining, ferrotitanium is added at an RH station, vacuum breaking is performed when the temperature of molten steel reaches 1570-1600 DEG C and the content of dissolved oxygen in the molten steel reaches 20-80ppm, magnesium alloy or calcium alloy cored wires which are 200-400 meters long are fed into the molten steel at the speed of 4-6m per second and subjected to continuous casting to obtain continuous casting billets, and the continuous casting billets aresubjected to reheating and heat preservation, controlled rolling and controlled cooling to obtain the low-temperature steel plate capable of being welded by the high heat input. The steel plate is good in low-temperature toughness, Charpy impact energy of the steel plate at the temperature of -80 DEG C is larger than 47J, after the steel plate is welded by the heat input of 500-600 kJ / cm, Charpy impact energy of heat affect zones at the temperature of -60 DEG C is larger than 47J, and the steel plate can be widely applied to energy construction engineering fields of ships, low-temperature pressure containers, ocean platforms and the like.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com