Diffusion welding method for tungsten-titanium alloy target and copper alloy back plate

A tungsten-titanium alloy and diffusion welding technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of poor welding effect between tungsten-titanium alloy target and copper alloy back plate, harsh process conditions, etc., and achieve The effect of reducing the difference in local welding effects, low temperature requirements, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

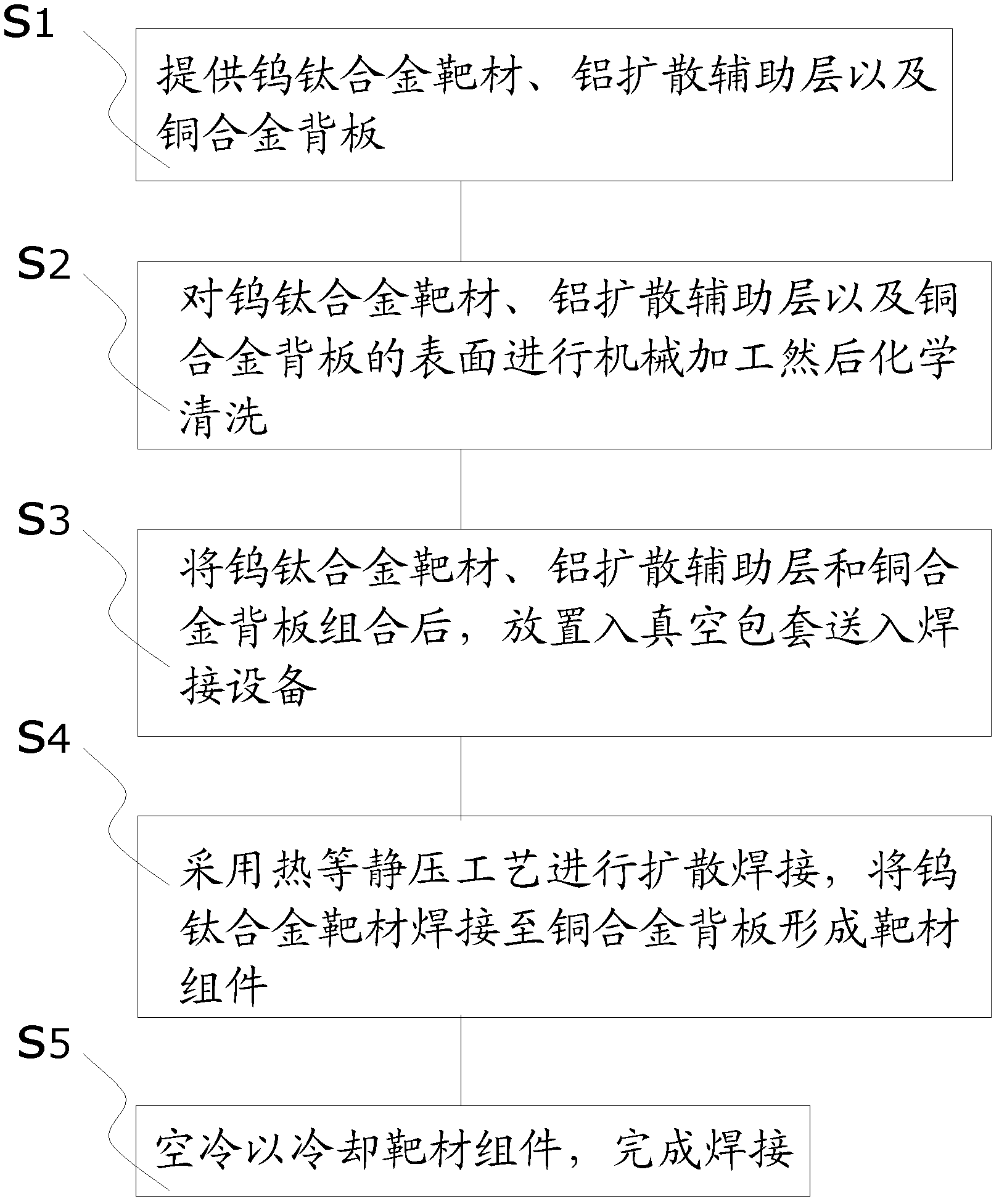

Method used

Image

Examples

Embodiment 1

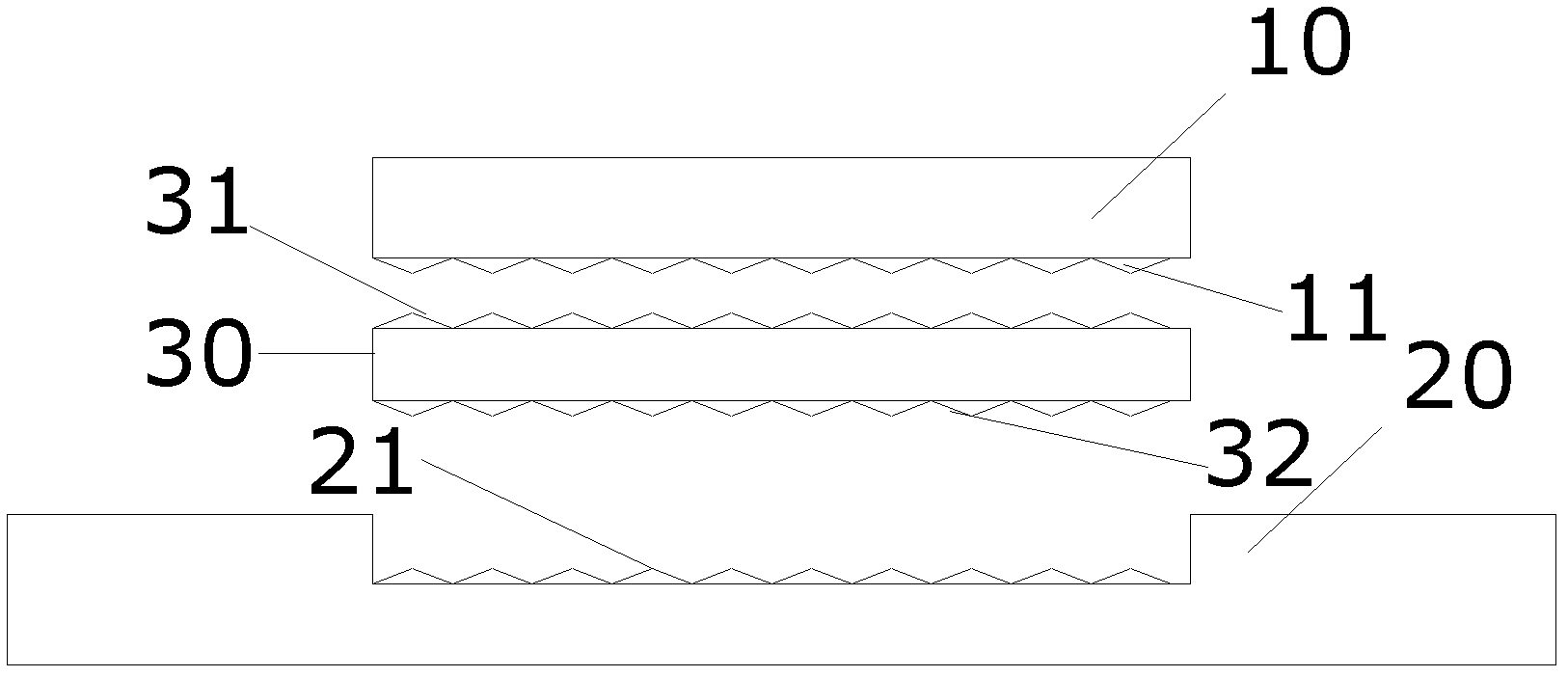

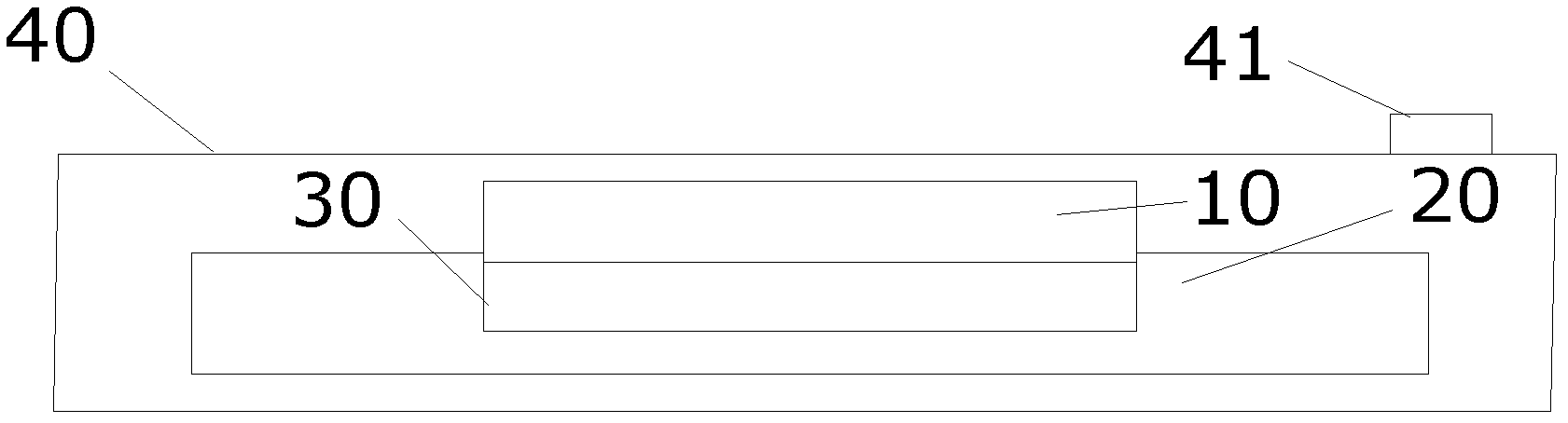

[0053] The following are the process steps and welding results of diffusion welding of 99.995% high-purity tungsten-titanium alloy target material (the purity ratio of tungsten to titanium is 9:1) and copper alloy back plate. Wherein, the tungsten-titanium alloy target is rectangular, and the area of its pre-bonded surface (that is, the welding surface with the copper alloy back plate) is 0.15m 2 .

[0054] (1) Surface processing of tungsten-titanium alloy target, aluminum diffusion auxiliary layer and copper alloy back plate: pre-bonding surface of tungsten-titanium alloy target, copper alloy back plate pre-bonding surface, and upper and lower aluminum diffusion auxiliary layer The end surface is machined to make it bright, and the smoothness of the contact surface of the three reaches 0.25μm.

[0055] (2) Chemical cleaning of tungsten-titanium alloy target, aluminum diffusion auxiliary layer and copper alloy back plate: the surface of tungsten-titanium alloy target, alumi...

Embodiment 2

[0065] The following are the process steps and welding results of diffusion welding of 99.99% high-purity tungsten-titanium alloy target (the purity ratio of tungsten to titanium is 9:1) and copper alloy backplane: wherein, the tungsten-titanium alloy target is circular , the diameter of its pre-combined surface is 400mm.

[0066] (1) Surface processing of tungsten-titanium alloy target, aluminum diffusion auxiliary layer and copper alloy back plate: pre-bonding surface of tungsten-titanium alloy target, copper alloy back plate pre-bonding surface, and upper and lower aluminum diffusion auxiliary layer The end surface is machined to make it bright, and the smoothness of the contact surface of the three reaches 0.30μm.

[0067] (2) Chemical cleaning of tungsten-titanium alloy target, aluminum diffusion auxiliary layer and copper alloy backplane: the surface of tungsten-titanium alloy target, aluminum diffusion auxiliary layer and copper alloy backplane is cleaned with hydrochlo...

Embodiment 3

[0077] The following are the process steps and welding results of diffusion welding of 99.99% high-purity tungsten-titanium alloy target (the purity ratio of tungsten to titanium is 9:1) and copper alloy backplane: wherein, the tungsten-titanium alloy target is circular , the diameter of its pre-combined surface is 450mm.

[0078] (1) Surface processing of tungsten-titanium alloy target, aluminum diffusion auxiliary layer and copper alloy back plate: pre-bonding surface of tungsten-titanium alloy target, copper alloy back plate pre-bonding surface, and upper and lower aluminum diffusion auxiliary layer The end surface is machined to make it bright, and the smoothness of the contact surface of the three reaches 0.32μm.

[0079] (2) Chemical cleaning of tungsten-titanium alloy target, aluminum diffusion auxiliary layer and copper alloy back plate: the surface of tungsten-titanium alloy target, aluminum diffusion auxiliary layer and copper alloy back plate is cleaned with hydroch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com