Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14062results about "Urea compound fertilisers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biochar

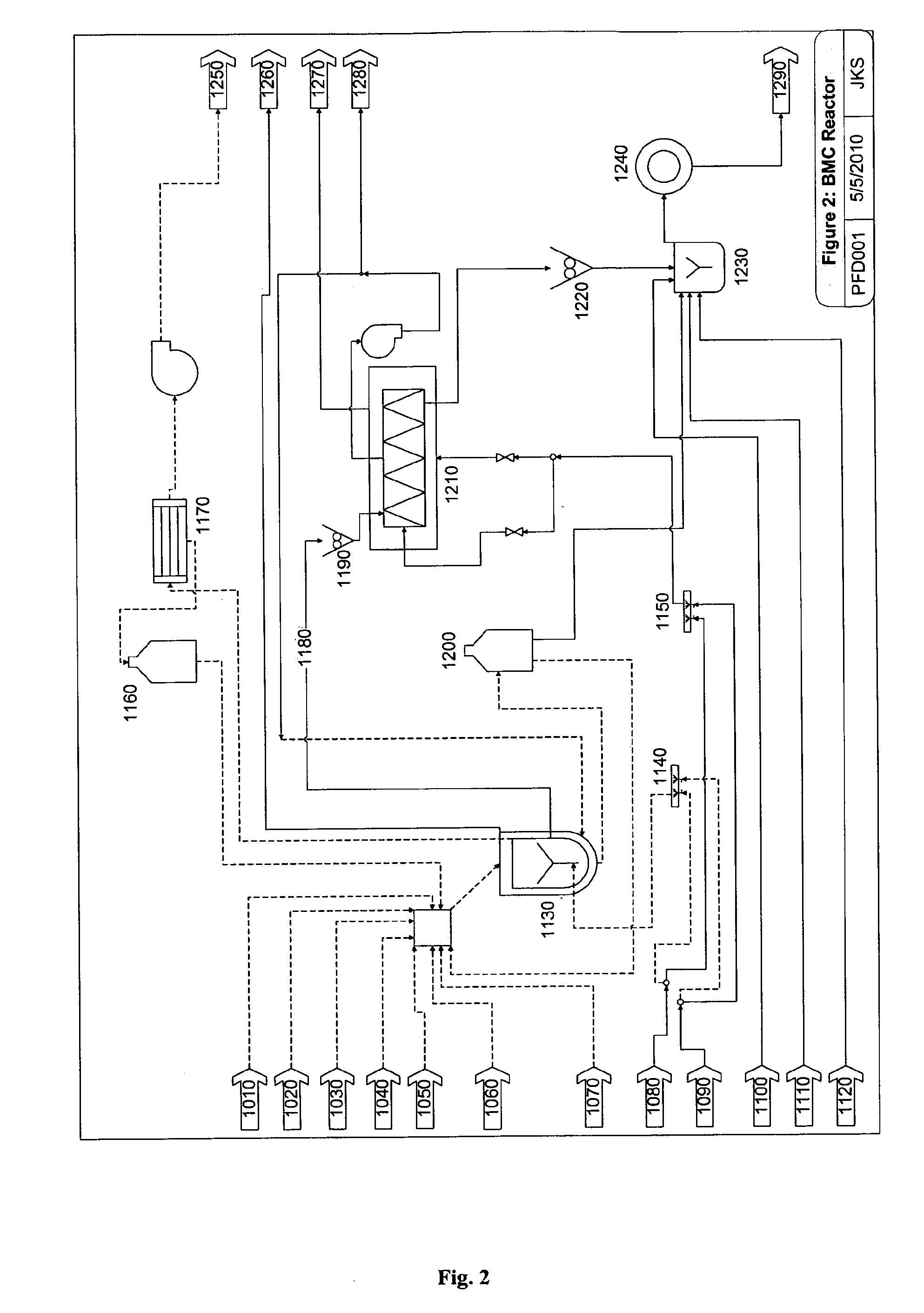

ActiveUS8361186B1Enhanced and functionalizedCalcareous fertilisersMagnesium fertilisersForming gasBiological activation

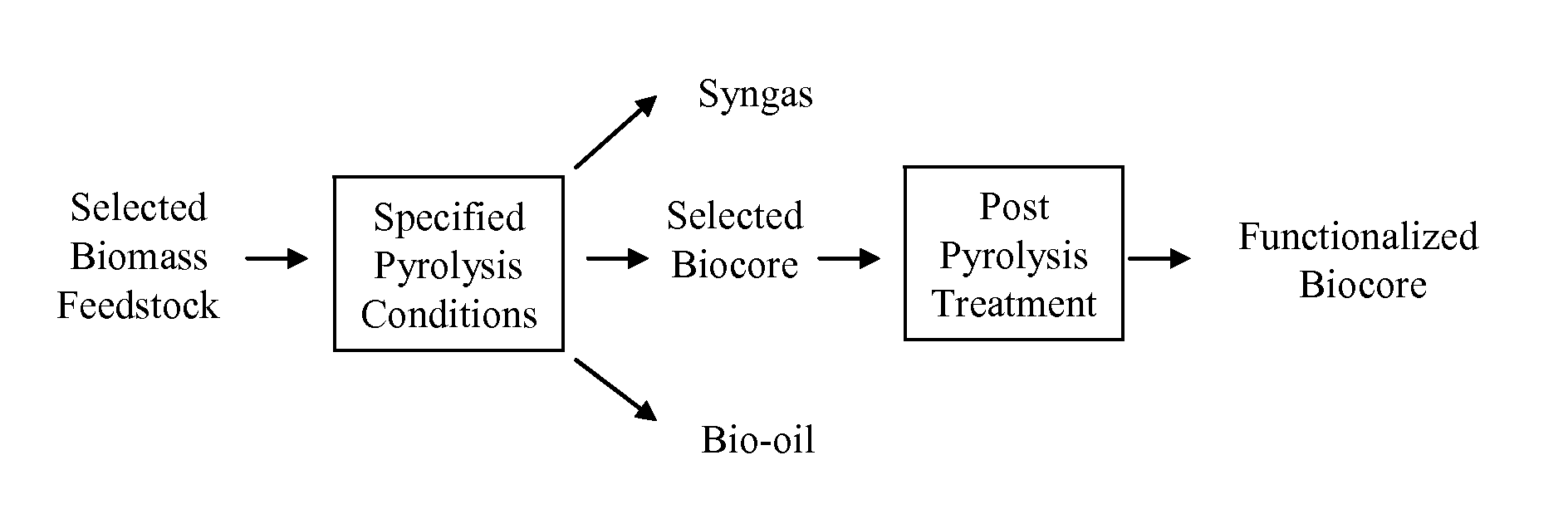

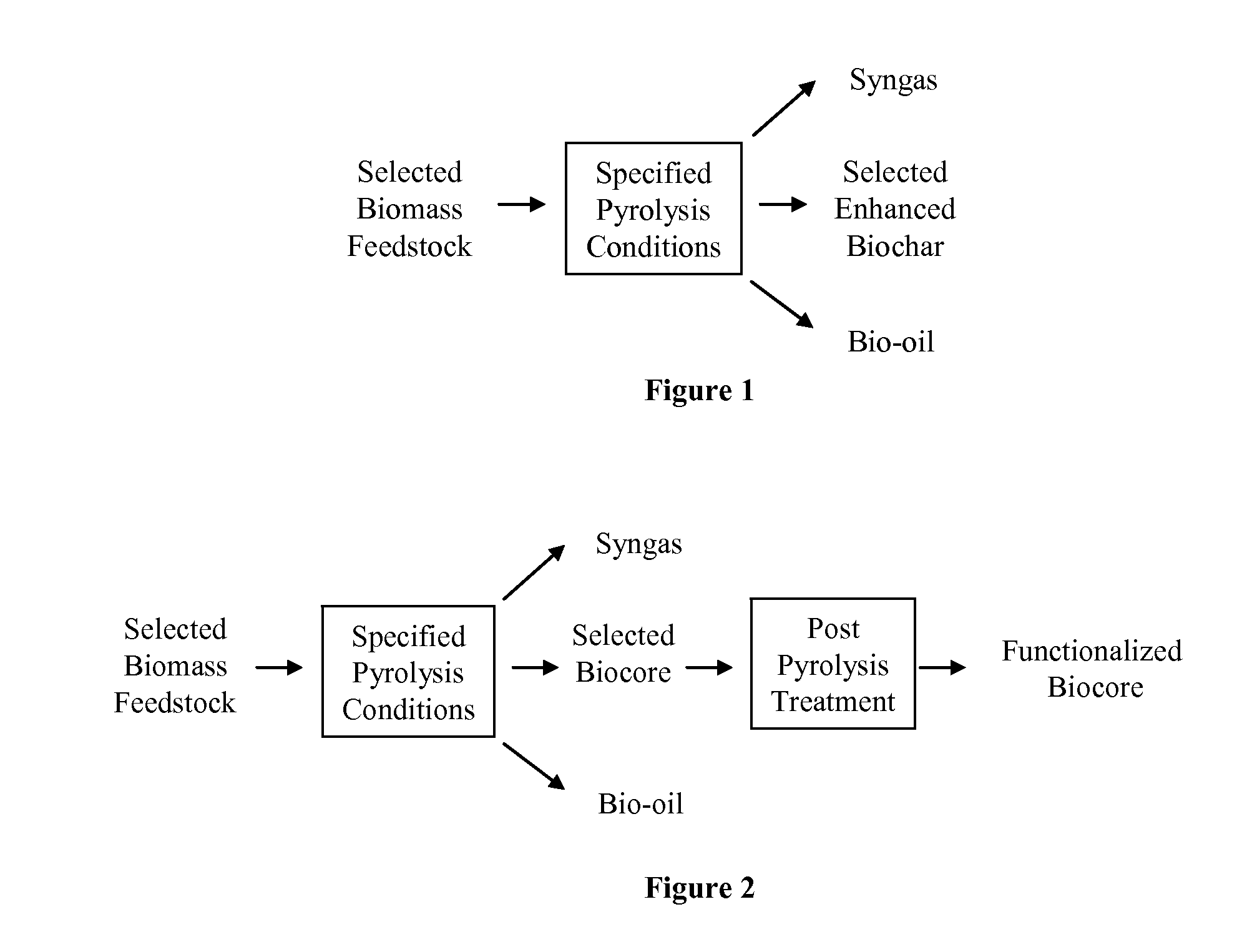

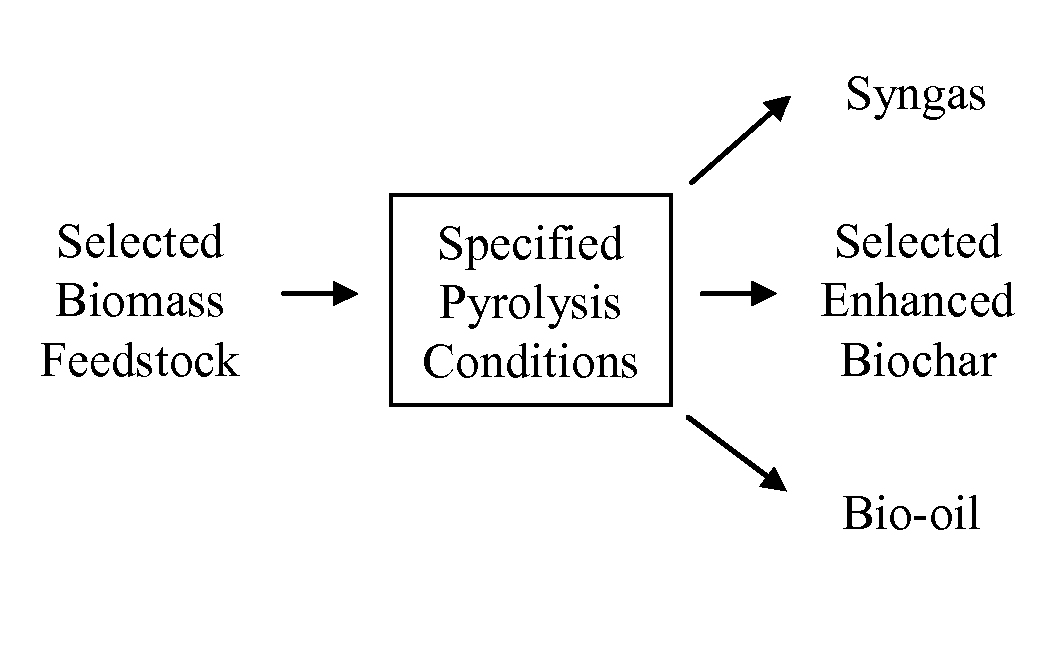

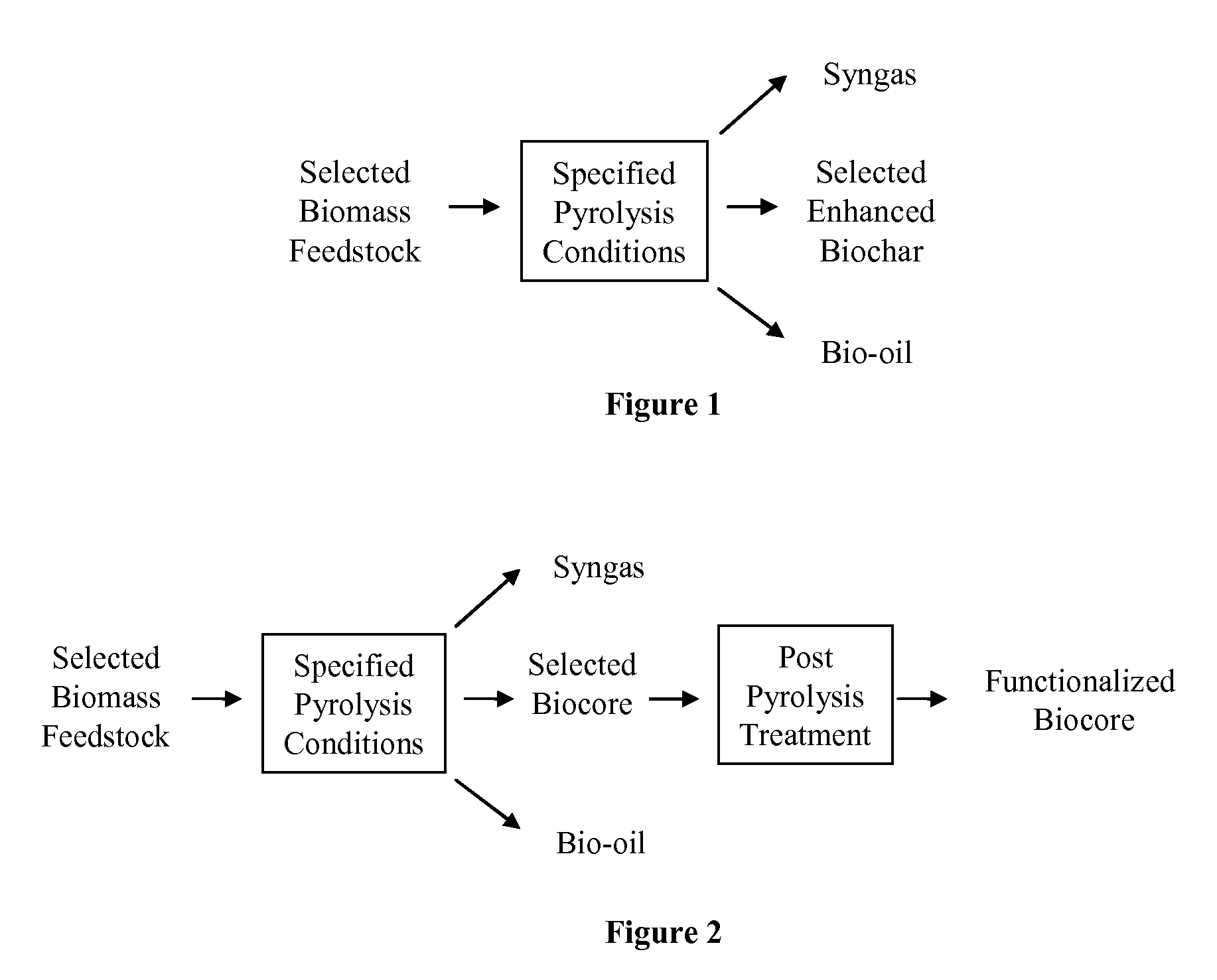

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

Materials and process for enhancing selective separations

Use of a Maillard reaction product as an adjuvant in a variety of applications including solid-liquid separations, corrosion inhibition, emulsification, dust suppression, slow release fertilization, viscosity modification and others and especially as a depressant or collector in separation processes, including the selective separation of solids and / or ionic species from aqueous media, such as in the process of froth flotation.

Owner:GEORGIA PACIFIC CHEM LLC

Humic acid composite material and preparation method thereof

InactiveCN101041600APromote absorptionGood water solubilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorNitrogen

The invention discloses a particle-typed composite fertilizer of humic acid and manufacturing method, which consists of dressing and karyosome, wherein the dressing contains nitrogen, phosphor and potassium. The manufacturing method comprises the following steps: graining humic acid; cladding; graining; solidifying fused fertilizer on the particle of humic acid; making the composite fertilizer dissolved into water without falling; fitting for large scale of agricultural product.

Owner:阴高鹏

Heavy polymer coated slow-release fertilizer with sulfide as bottom coat

InactiveCN1569774AStrong impact resistanceImprove wear resistanceFertiliser formsUrea compound fertilisersControl releaseCoated urea

The invention relates to an enveloped controlled release fertilizer and method for preparation which consists of, preheating the urea particles to a predetermined temperature, spraying the molten liquid state sulfur to the urea particles, forming a layer of smooth and compact sulfur-coated urea, charging hot-curing resin component on the sulfur-coated urea for even distribution onto the urea particle surface and fast formation.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Slow release nitrogen seed coat

Owner:KOCH AGRONOMIC SERVICES LLC

Biochar complex

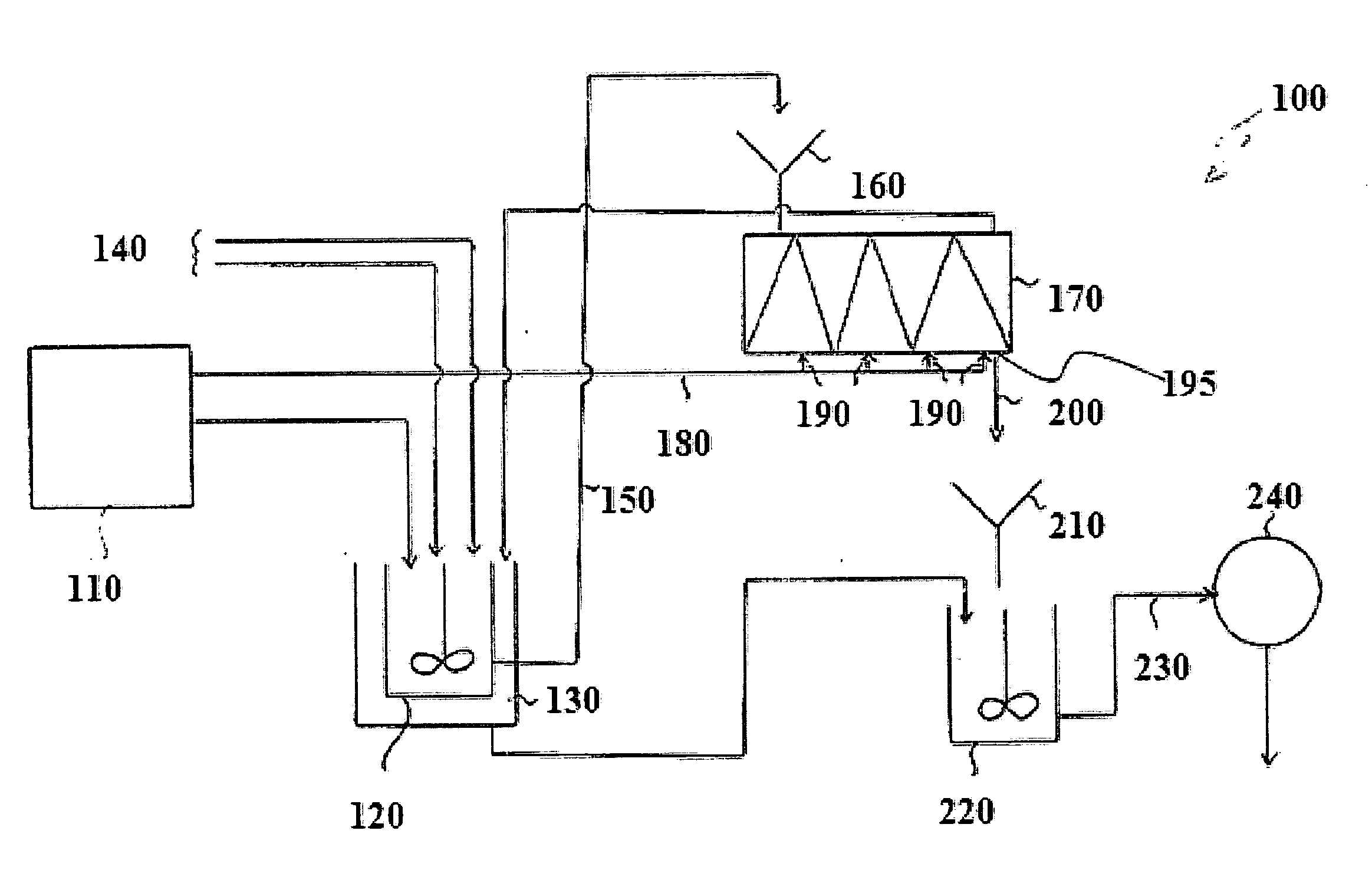

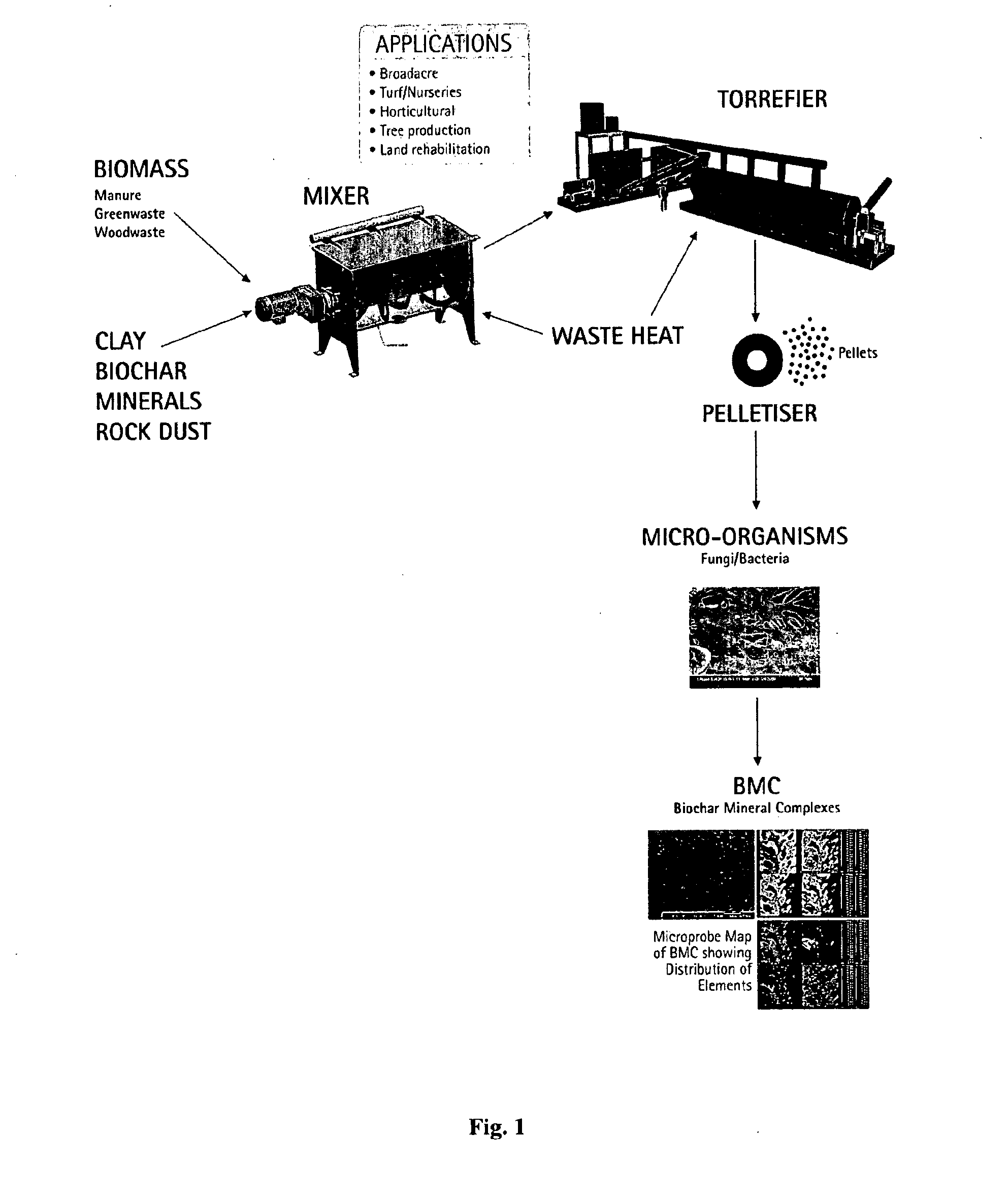

InactiveUS20120125064A1Increase productionLow application rateDirect heating destructive distillationBiofuelsGrowth plantClay minerals

The invention relates to a biochar-containing composition comprising biochar having organic matter therein and / or thereon, clay associated, optionally intercalated, with the organic matter, a non-clay mineral and optionally also a plant growth promoter.

Owner:VENEARTH GRP

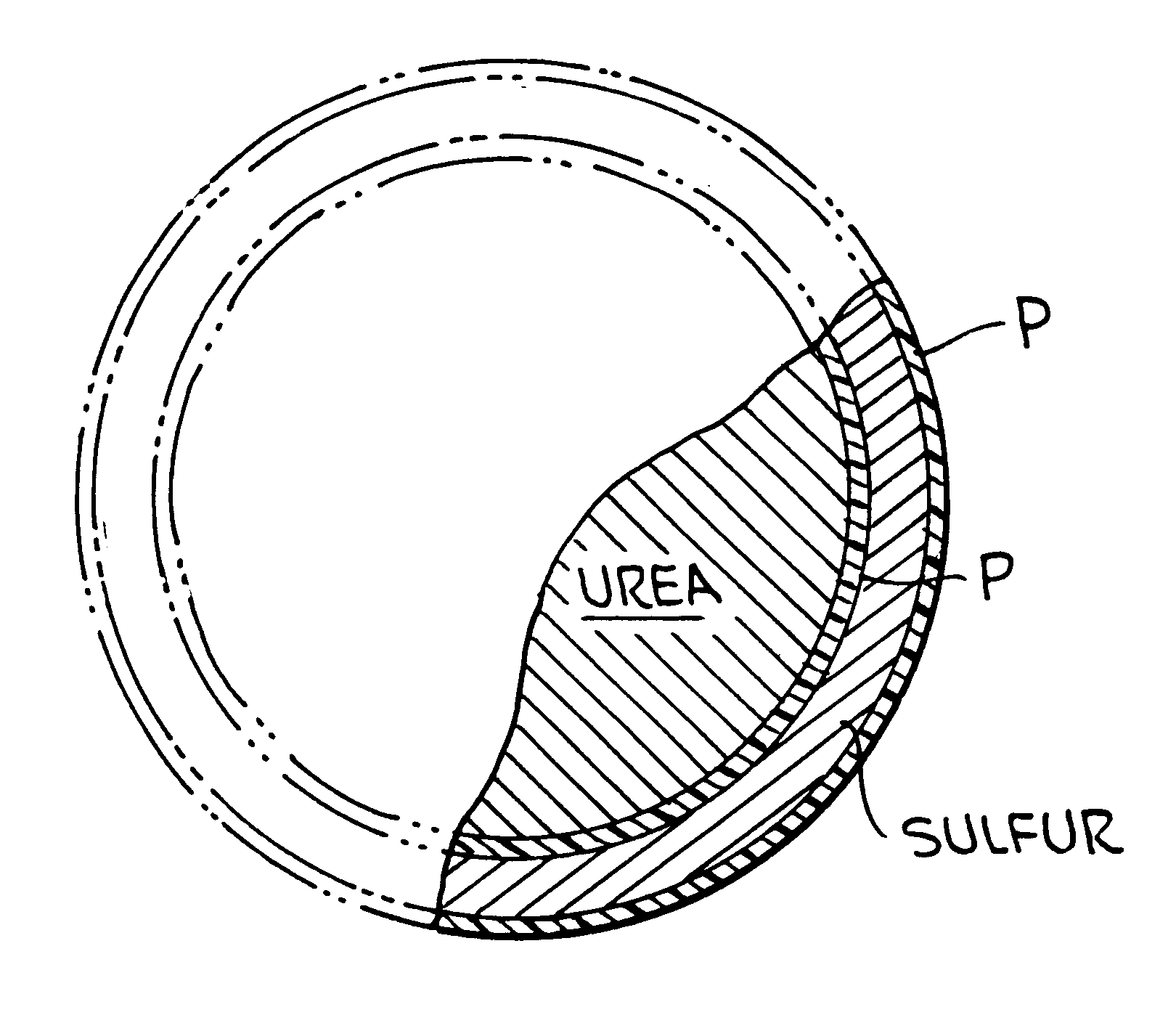

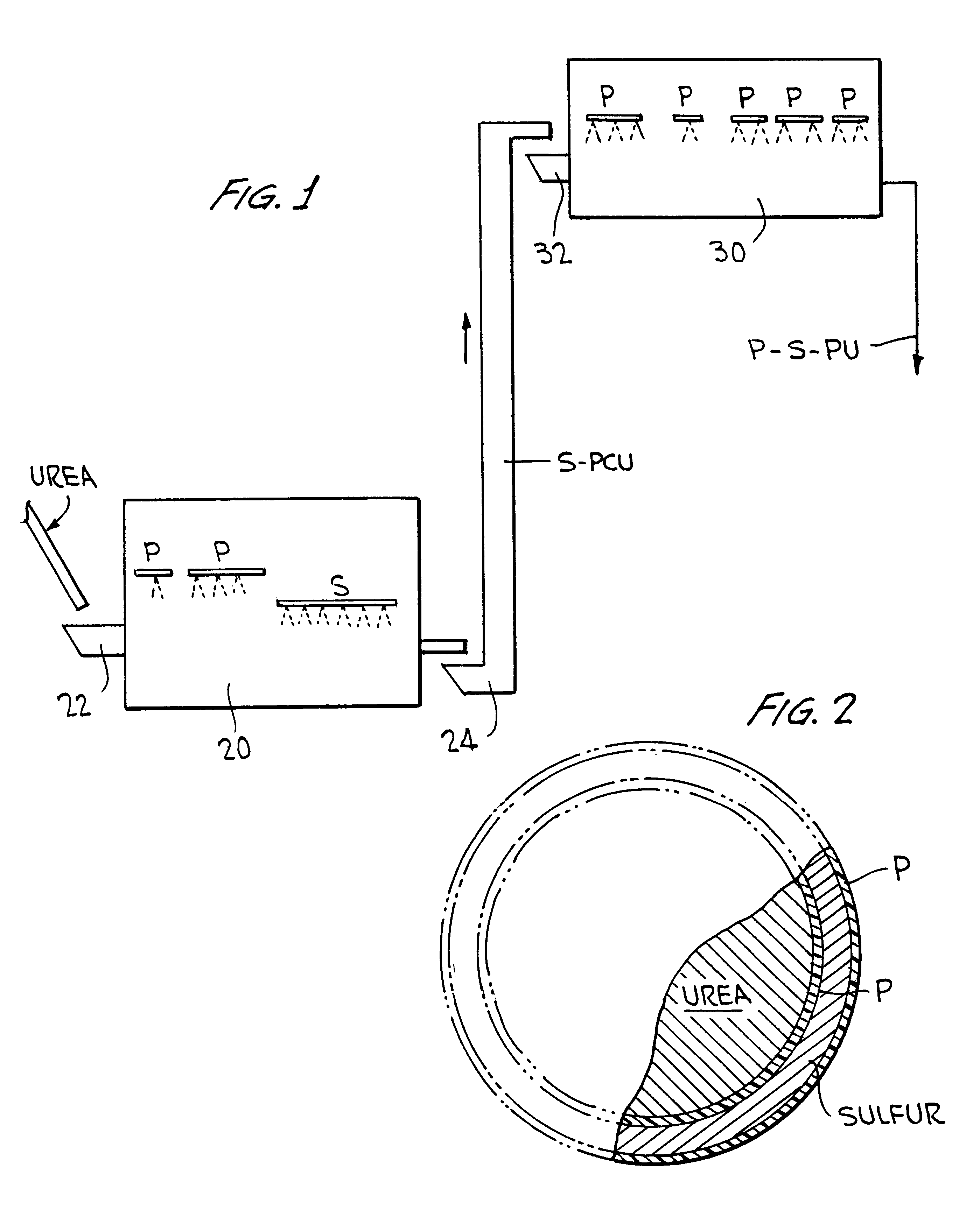

Polymer-sulfur-polymer coated fertilizers

InactiveUS6338746B1Good resistance to abrasionAvoid serious impactBiocideMaterial granulationControlled releasePositive control

The present invention described a polymer coated fertilizer, such as urea, subsequently coated with a layer of sulfur and thereafter a further coating of polymer. Preferably, the polymer coatings are formed by the direct in situ co-polymerization of the components of the polymer on the fertilizer and on the sulfur coating. The compositions provide positive controlled release characteristics, are abrasion and impact resistant and are substantially more economical to produce than polymer coated fertilizers.

Owner:KOCH AGRONOMIC SERVICES LLC

Whole-nutrition biological flushing and spreading fertilizer and preparation method thereof

InactiveCN101037369ASolve the single nutrientSolve solubilityClimate change adaptationAlkali orthophosphate fertiliserMicroorganismNicotiana tabacum

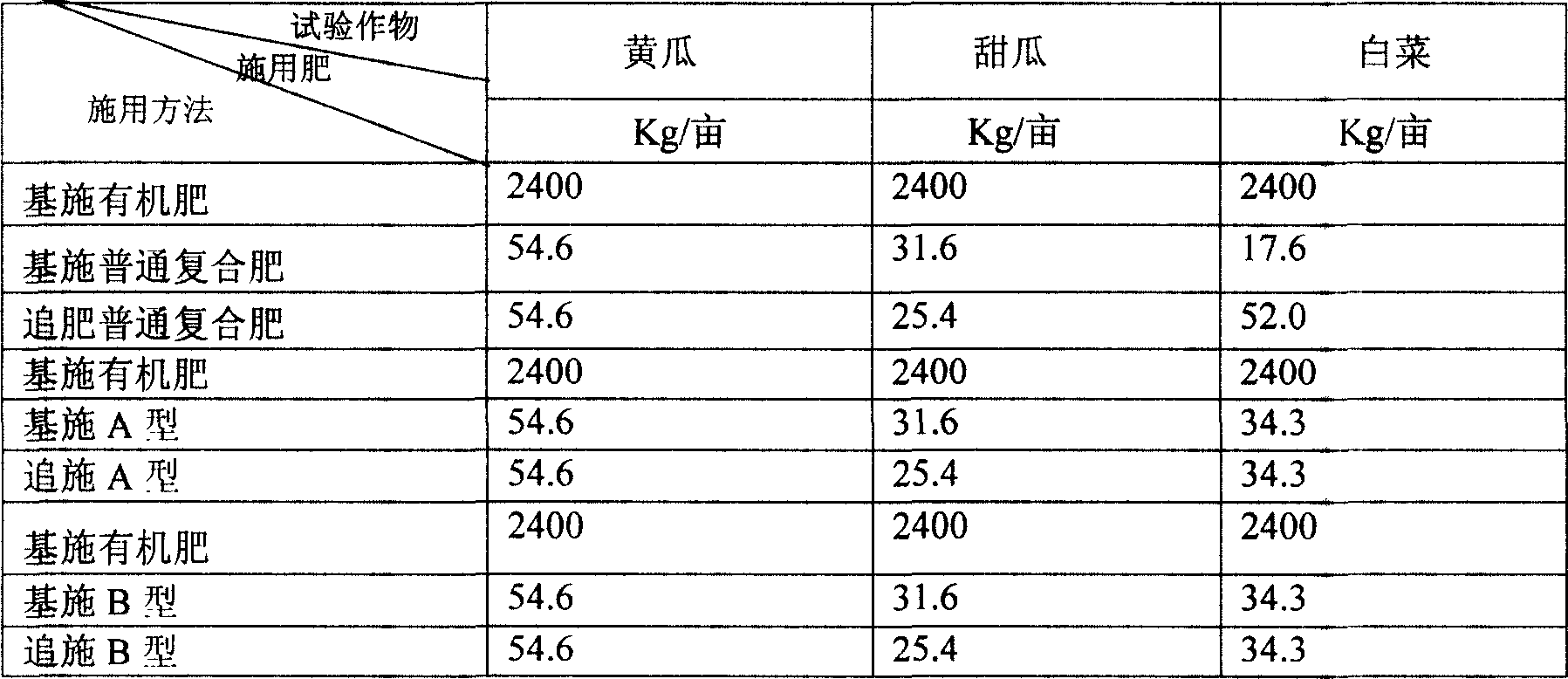

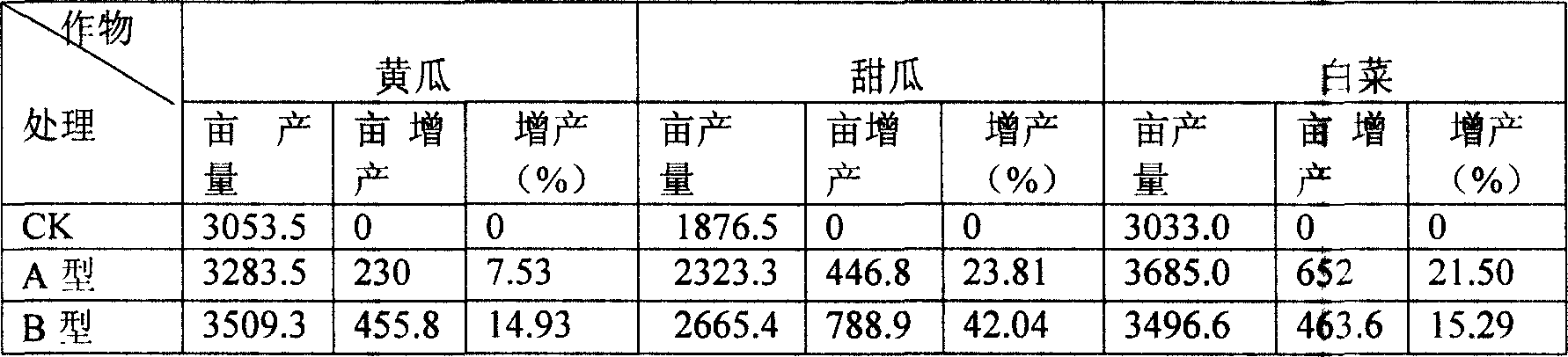

A full nutrition fertilizer of biology type and its producing method belongs to organic complex fertilizer field in biology type. The components of the full nutrition fertilizer is 20-50% of organic waste liquid, 10-30% of urea, 8-15% of diammomium phosphate, 10-25% of potassium sulfate, 5-20% of medium trace element, 1-5% of microbial inoculum, 0-0.2% of root-promoting agent; 0-2% of solutizer, effective viable count content of the microbial inoculum of more than 1010 / g. The fertilizer is produced by adding the urea, diammomium phosphate, potassium sulfate, medium trace element, root-promoting agent, solutizer into organic waste liquid and blending uniformly, then adding microbial inoculum. The invention uses the wastes to produce fertilizer with a low cost a high availability and a good prospect in the fertilizer industry. The fertilizer can be widely applied to the vegetables, melon and fruits, food, tobacco, forests and different commercial crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

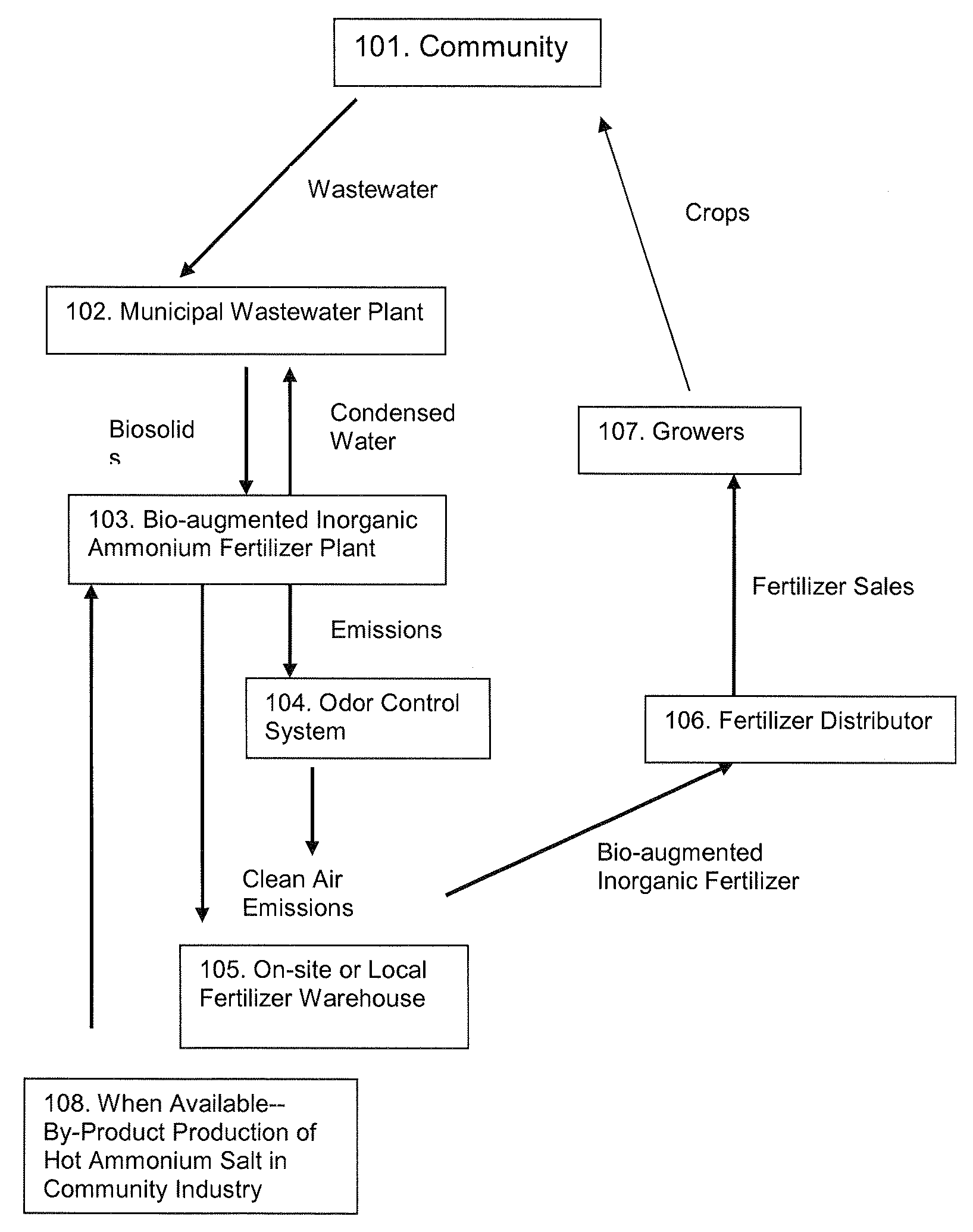

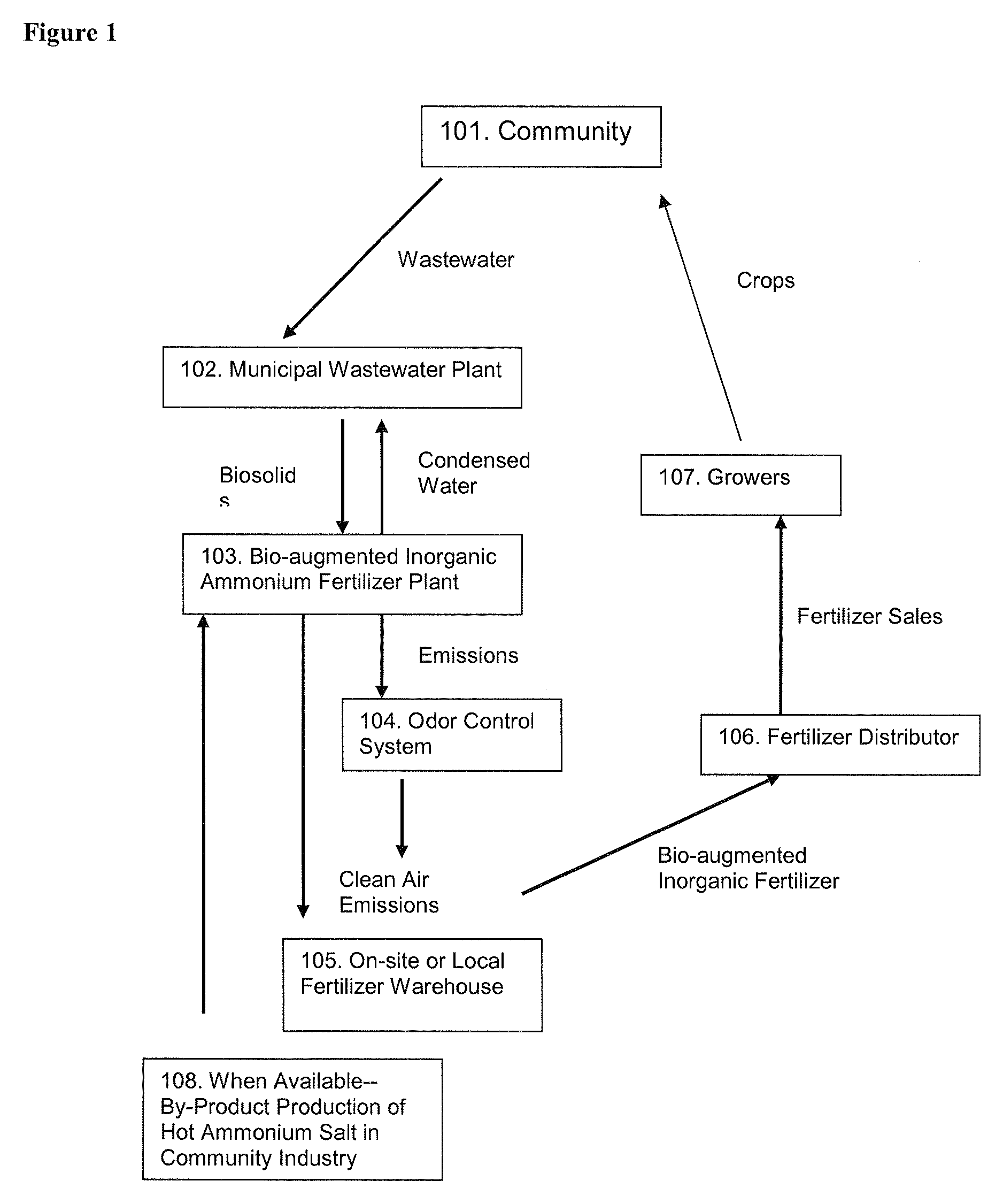

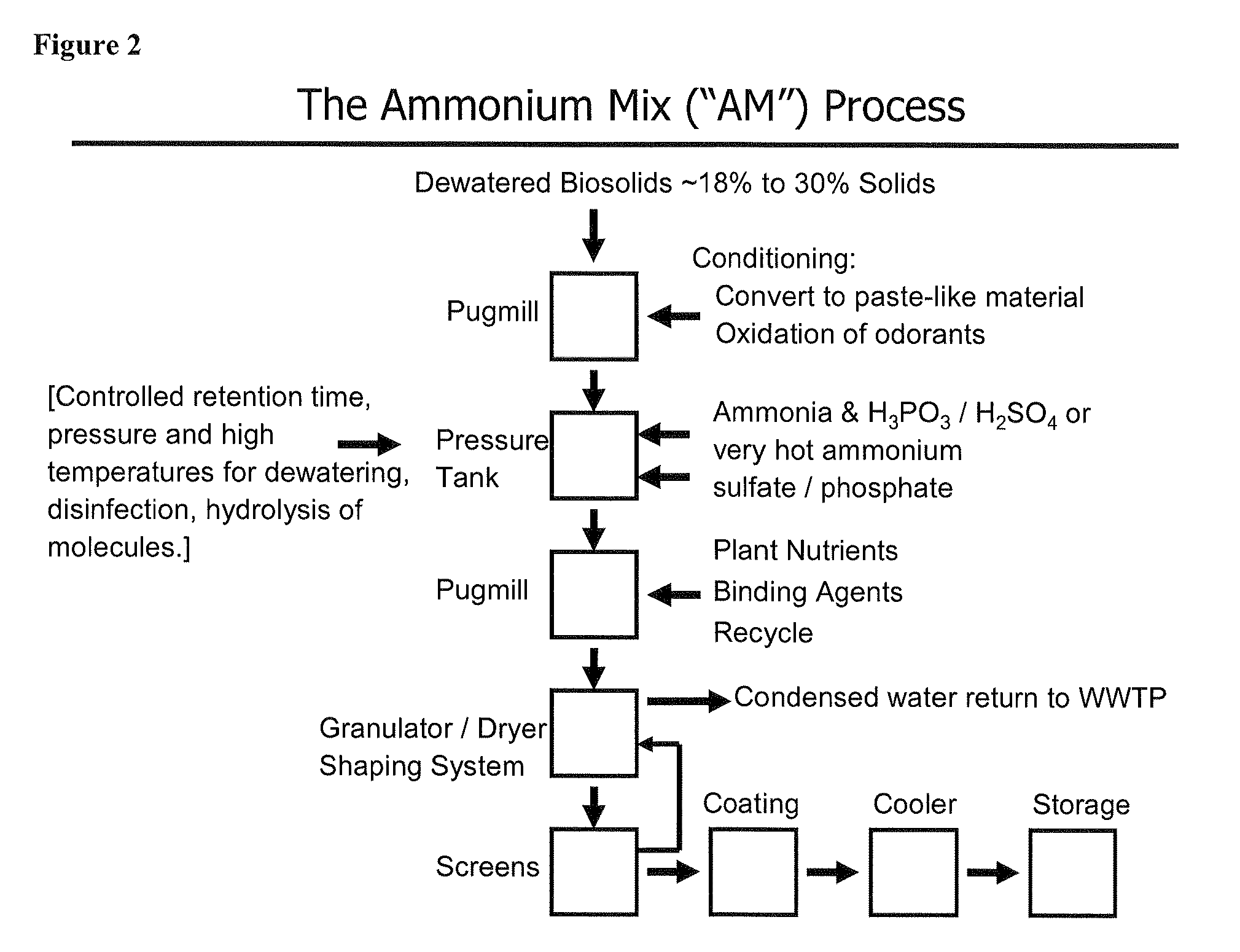

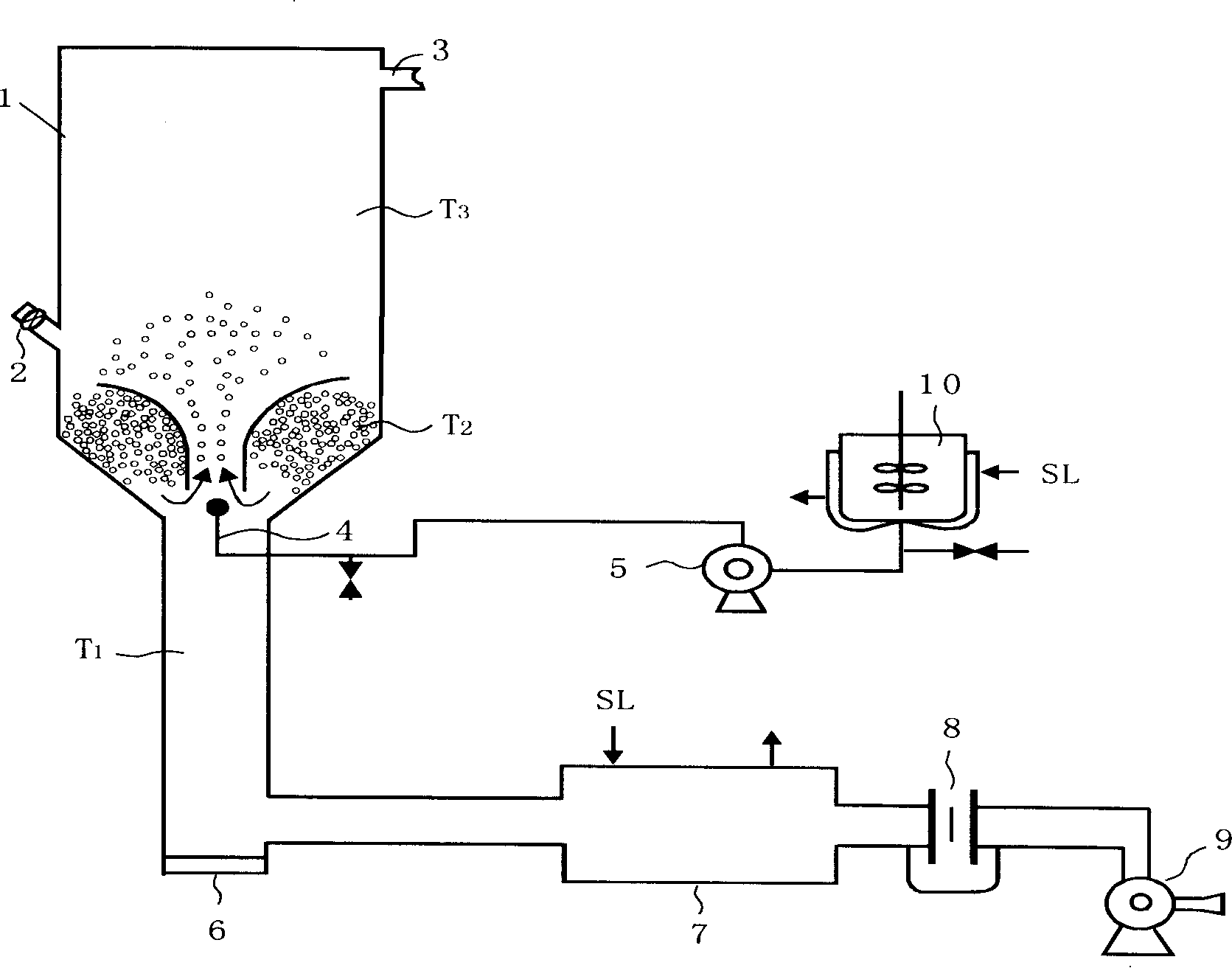

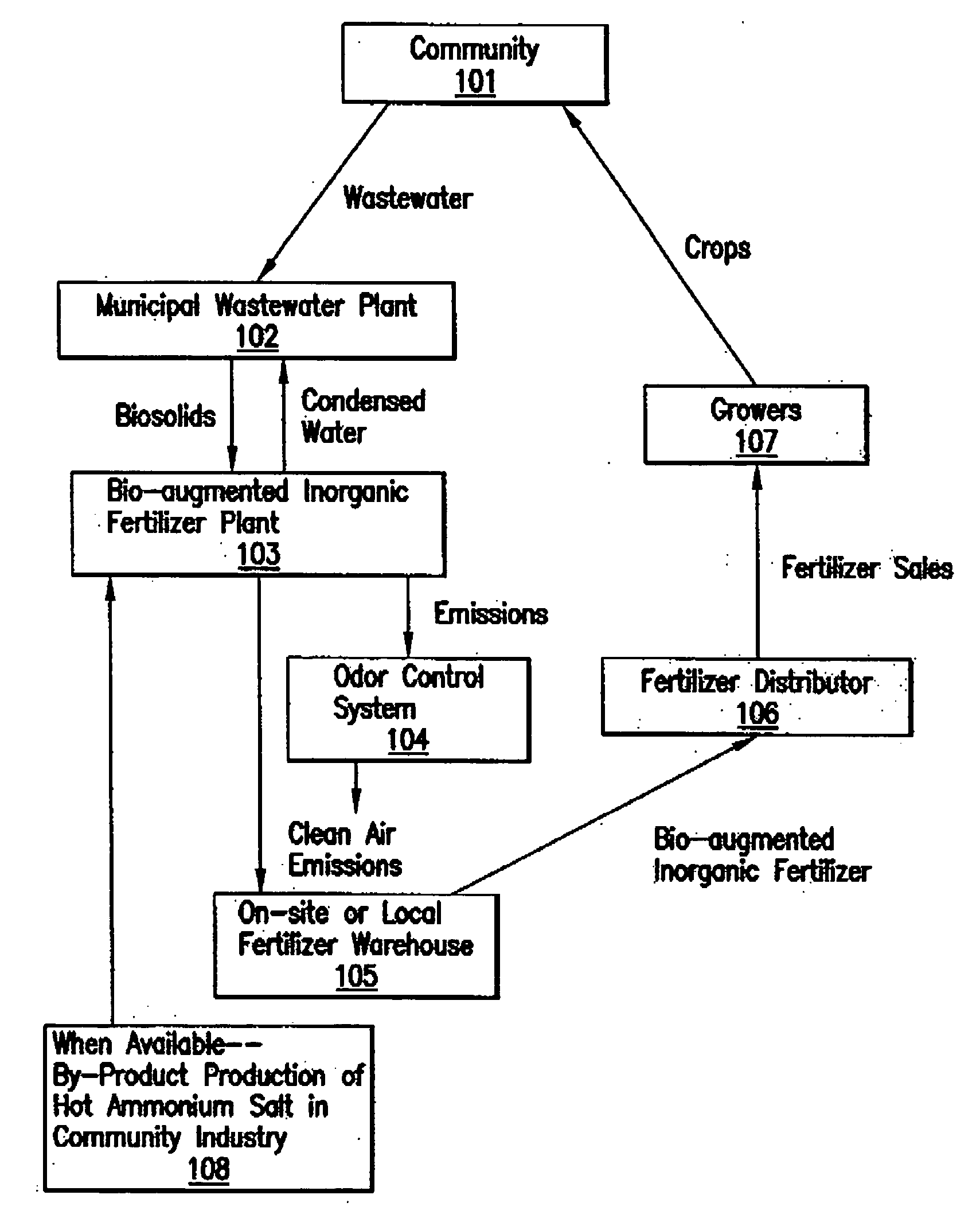

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

ActiveUS20080230484A1Reduce logisticsReduces liabilityByproduct vaporizationExcrement fertilisersPhosphateRetention time

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

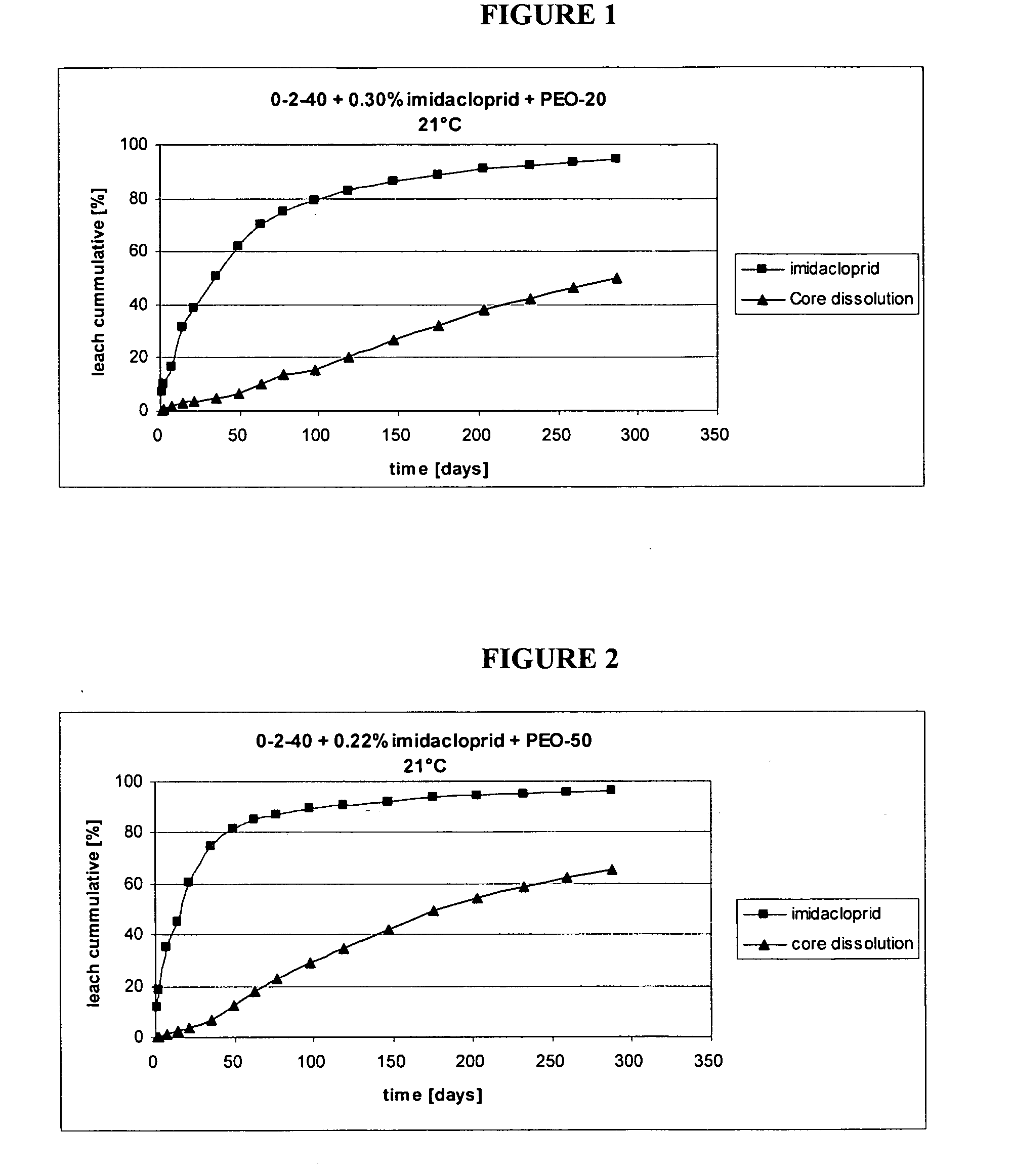

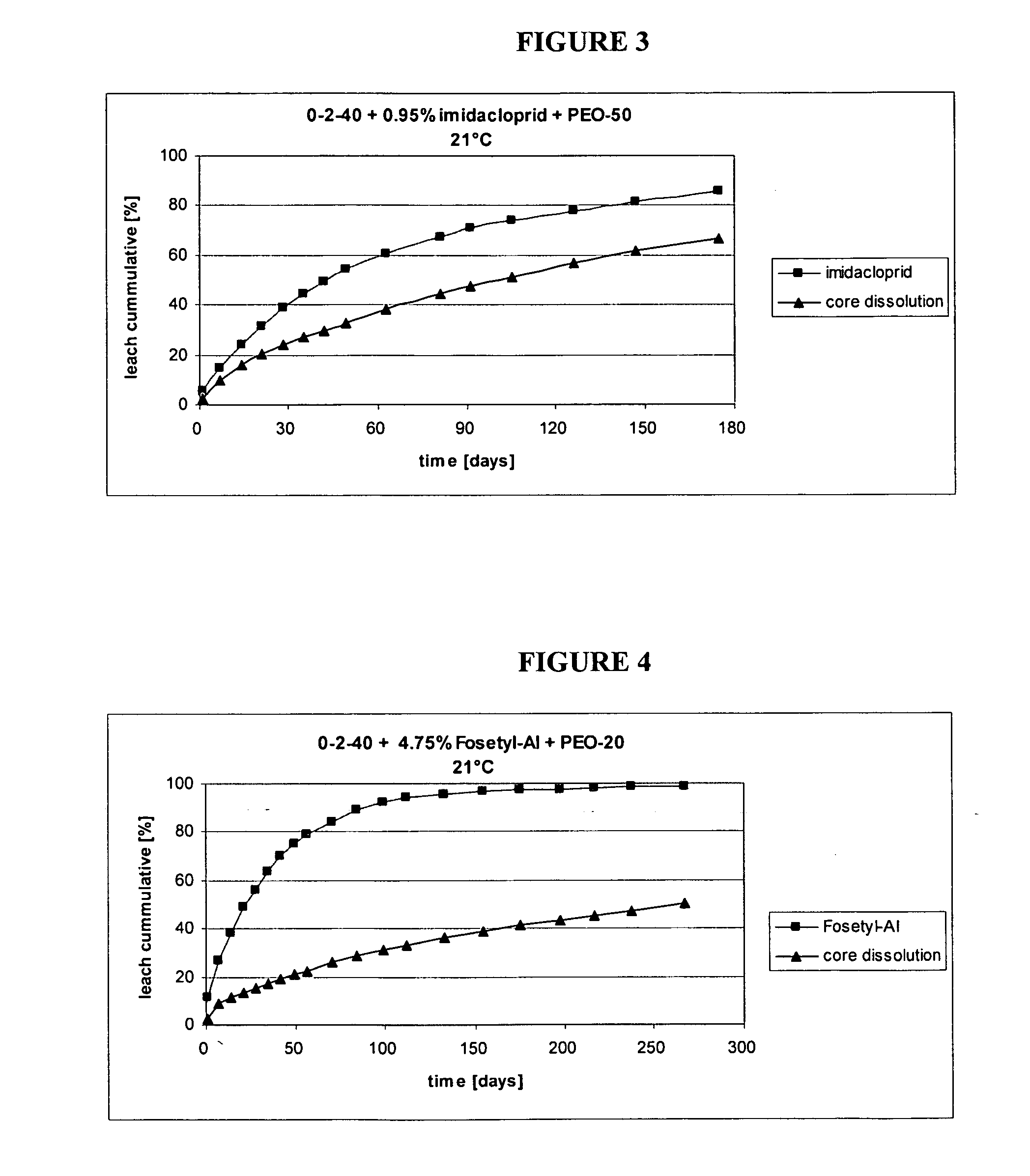

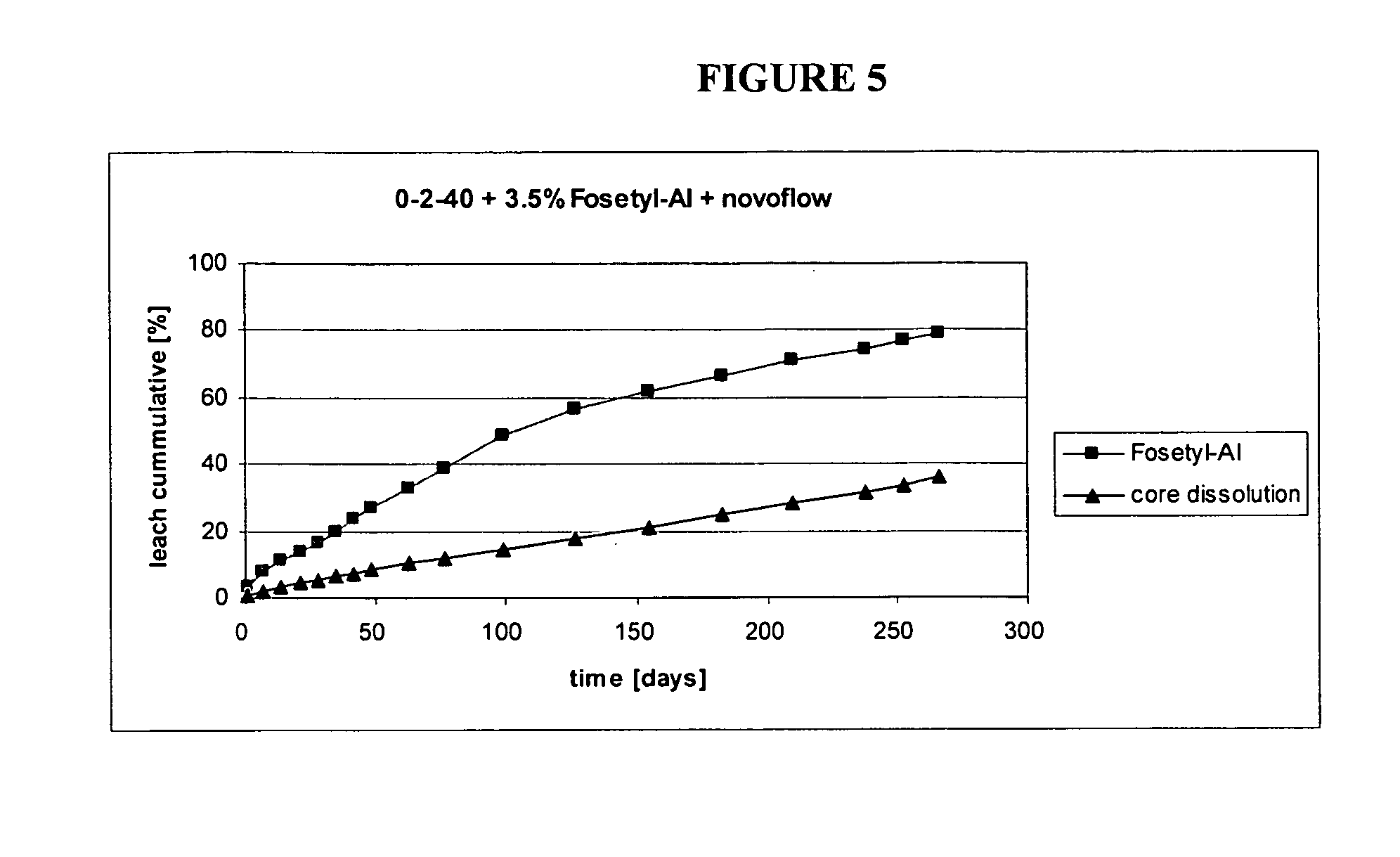

Granular controlled release agrochemical compositions and process for the preparation thereof

A granular agrochemical composition is disclosed including a granular core material having a water soluble portion with a first coating layer applied on the surface of the core material and a second coating layer applied on the surface of the first coating layer. The first coating layer includes a wax composition having a biologically active ingredient incorporated therein and the second coating layer includes a polymeric composition. The granular agrochemical composition exhibits a controlled rate of release of the biologically active ingredient therefrom over a period greater than about 30 days from the date of initial exposure of the granular composition to moisture whereby essentially all of the biologically active ingredient incorporated in the wax material of the first coating layer is released from the granular composition before the water soluble portion of the granular core material is released from the granular composition.

Owner:EVERRIS INT

Heavy polymer coated slow-release fertilizer with sulfide as bottom coat

InactiveCN1246265CStrong impact resistanceImprove wear resistanceFertiliser formsUrea compound fertilisersControl releaseCoated urea

The invention relates to an enveloped controlled release fertilizer and method for preparation which consists of, preheating the urea particles to a predetermined temperature, spraying the molten liquid state sulfur to the urea particles, forming a layer of smooth and compact sulfur-coated urea, charging hot-curing resin component on the sulfur-coated urea for even distribution onto the urea particle surface and fast formation.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Controlled release fertilizer composition

ActiveUS7771505B2Reduce manufacturing costReduce the amount requiredBiocideOrganic phosphatic fertilisersControlled releaseWater insoluble

A controlled release fertilizer composition and methods to produce the controlled release fertilizer composition are described. The controlled release fertilizer composition comprises a water soluble fertilizer core that is coated with a polymeric layer, intermediate layer, and a sulfur layer. If desired, the sulfur layer can be coated with an outer water-insoluble layer.

Owner:KOCH AGRONOMIC SERVICES LLC

Slow release nitrogen root treatment

A method for treating a seedling by dipping the roots of the seedling into a composition containing a slow release, particulate urea-formaldehyde polymer, which is useful as a fertilizer for enhancing the extended delivery of nitrogen needed for plant development and growth and to the composition useful as the root dip, or as a soil drench.

Owner:KOCH AGRONOMIC SERVICES LLC

Water-dispersible pellets

A water-dispersible particle for delivery of nitrogen to a plant is disclosed. The water-dispersible particle also delivers an active ingredient such as a plant hormone to a desirable plant or a pesticide or herbicide to an undesirable organism. Methods for making and using the water-dispersible particle are described.

Owner:THE ANDERSONS

Biochar

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

Liquid fertilizer with pyroligneous liquor and oxalacetic liquor and production thereof

InactiveCN1778773AMagnesium fertilisersFertilisers by pryogenic processesRare-earth elementPlant regulators

A liquid fertilizer containing wood vinegar liquid or oxalic vinegar liquid and its production are disclosed. The liquid fertilizer consists of urea 1í½20.0%, potassium phosphate 1í½20.0%, potassium nitrate 1í½20.0%, lime nitrate 0.1í½10.0%, magnesium sulfate 0.1í½5.0%, ferrous sulfate 0.1í½5.0%, manganous sulfate 0.1í½5.0%, zinc sulfate 0.1í½5.0%, cupric sulfate 0.1í½5.0%, boron sand or boric acid 0.1í½2.0%, sodium molybdate or ammonium molybdate 0.1í½1.0%, plant hormone or plant regulator, rare earth element or humus acid or pesticide auxiliaries etc. The process is carried out by proportioning and mixing. It can improve bacterium inhibiting and plant growth regulating functions.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

Water soluble humic acid multi-element solid fertilizer and production method thereof

InactiveCN101570456ADissolve fastNot easy to agglomerateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSoil scienceWater soluble

The invention discloses a water soluble fertilizer and a production method thereof, in particular to a water soluble humic acid multi-element solid fertilizer and a production method thereof. The water soluble humic acid multi-element solid fertilizer is made by mixing water soluble humic acid, water soluble nitrogenous fertilizer, water soluble phosphorous fertilizer, water soluble potassic fertilizer and water soluble complex trace elements. Compared with the prior art, the water soluble humic acid multi-element solid fertilizer can reduce the transporting and packing cost, can be rapidly dissolved without agglomeration when in use, is applied along with water, and has the advantages of strong points, high nutrient content, complete nutrition, good water-solubility, combination of organic and inorganic matters as well as high effect of fertilizer and utilization rate. The utilization rate of product nitrogen reaches 60%, the utilization rate of phosphorus is 30-35%, and the utilization rate of potassium is 60-70%, so that the fertilizer application utilization rate is increased by more than 10% compared with the conventional fertilizer.

Owner:新疆三赢农业科技发展有限公司

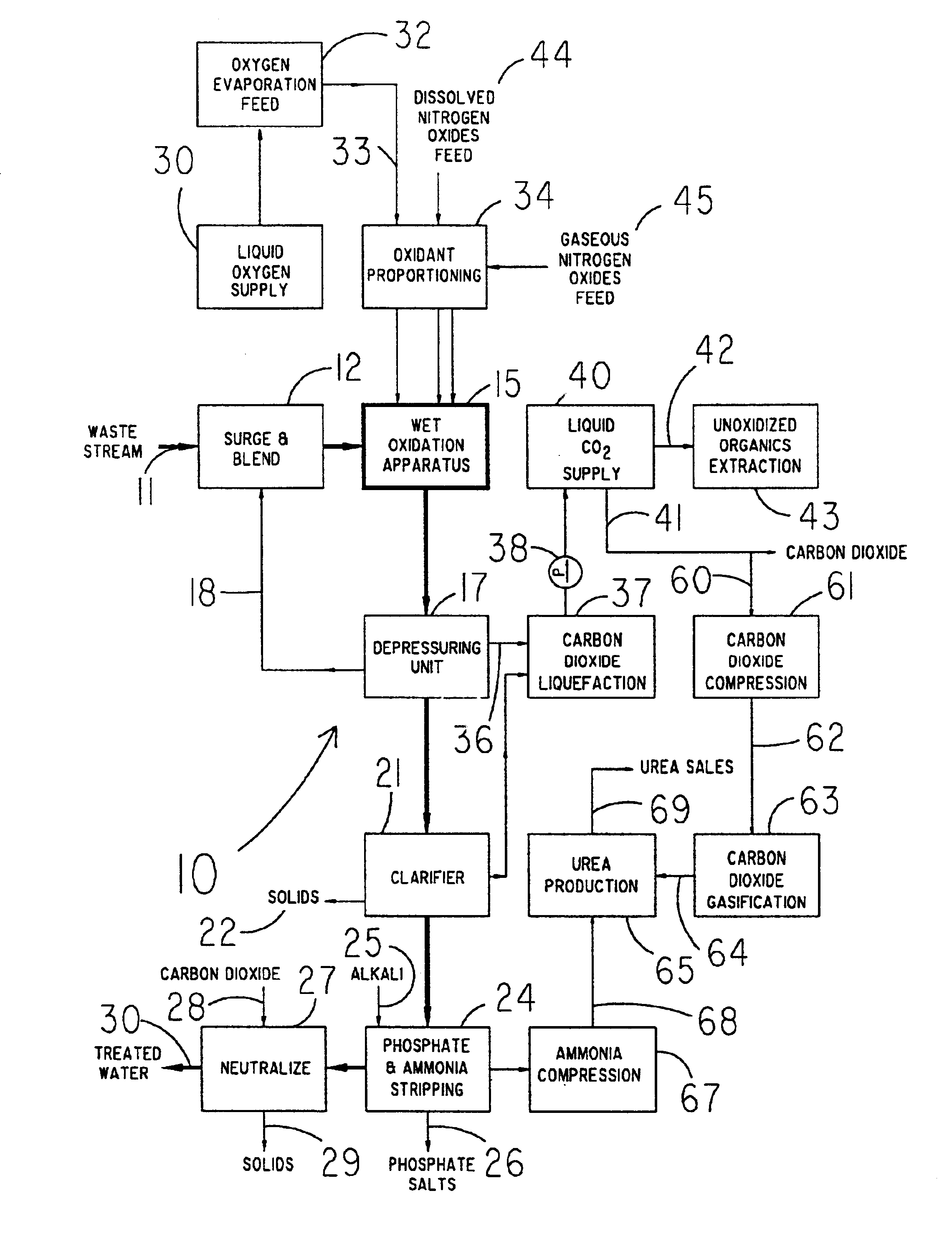

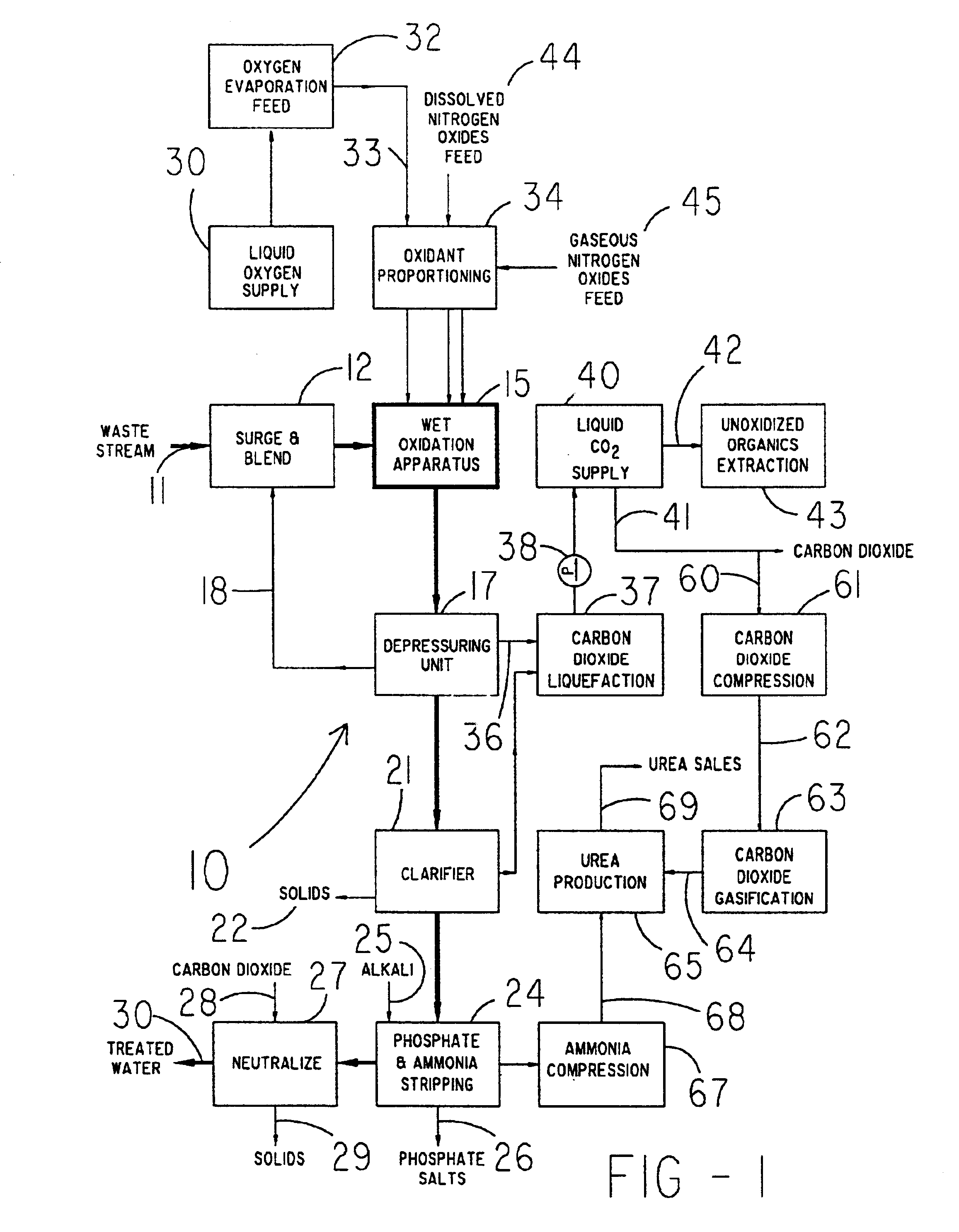

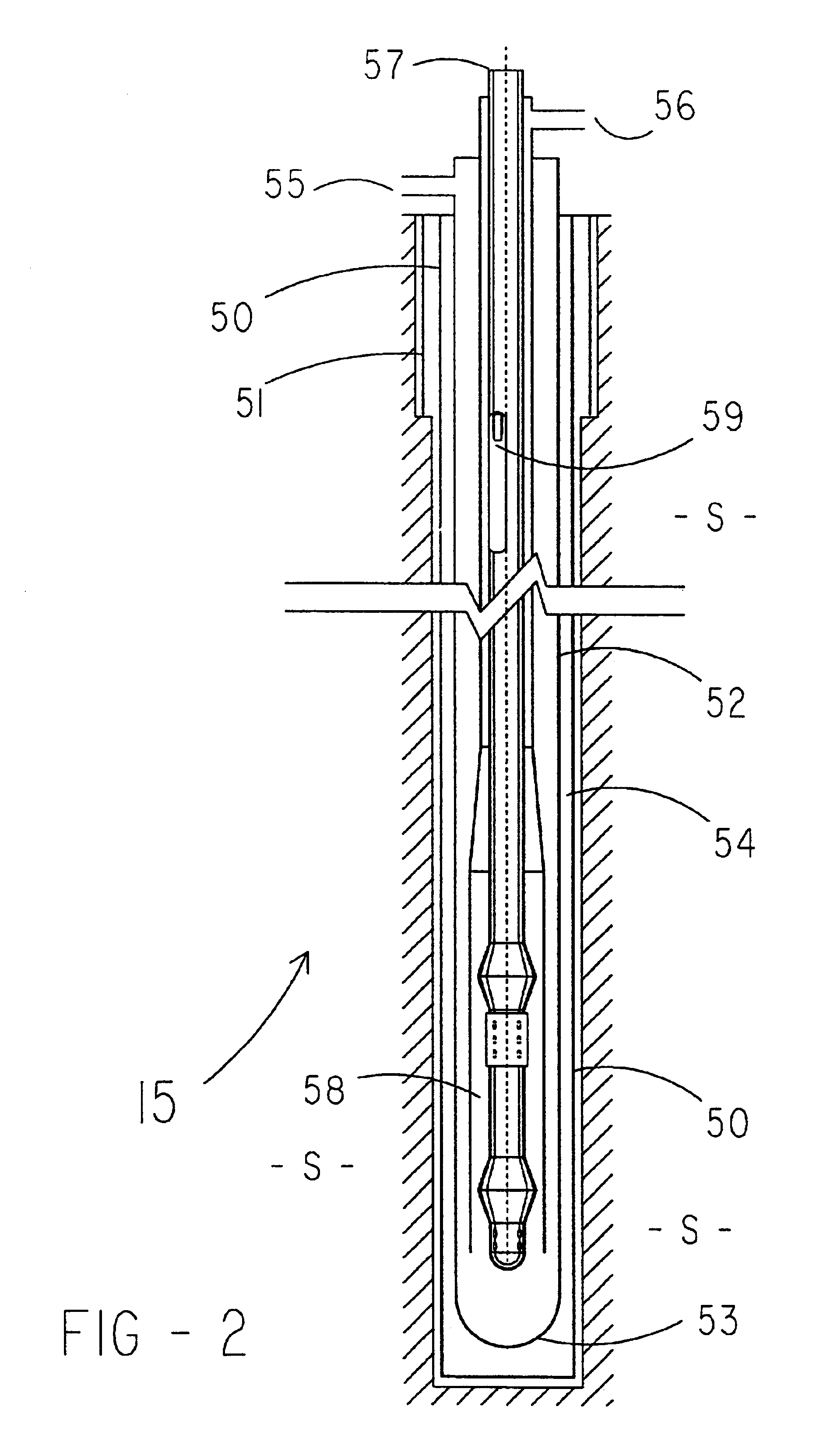

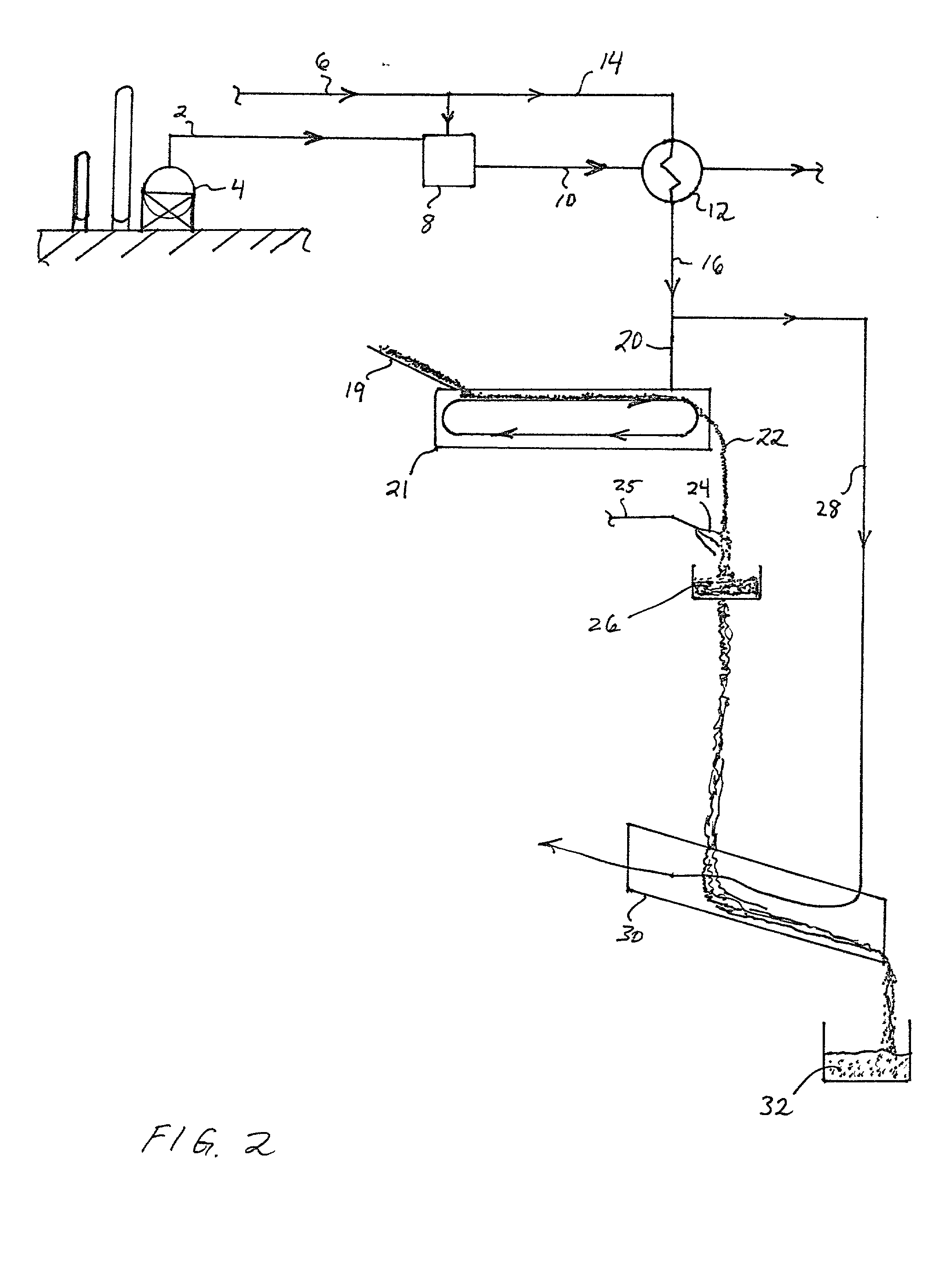

Method and apparatus for treating waste streams

InactiveUS6716360B2Overcome problemsUrea derivatives preparationSludge treatment by oxidationSufficient timeWaste stream

A method for treating a waste stream, the method including the steps of providing a waste stream that includes waste solids suspended in water, feeding the waste stream to the top of a hydraulic downdraft column, conducting the waste stream to the bottom of the hydraulic downdraft column, conducting the waste steam to a first reaction zone, introducing nitrogen-containing oxides into the first reaction zone so that the waste stream is contacted with the nitrogen-containing oxides, conducting the waste stream up a hydraulic updraft column into a second reaction zone, where the second reaction zone is configured to provide sufficient time so that a reaction between the nitrogen-containing oxides and waste solids can take place and substantially consume the nitrogen-containing oxides, introducing oxygen gas into the waste steam after the nitrogen-containing oxides are substantially consumed, thereby providing a second reactant that reacts with waste solids suspended within the stream, conducting the stream to the top of the hydraulic updraft column.

Owner:EAU VIRON

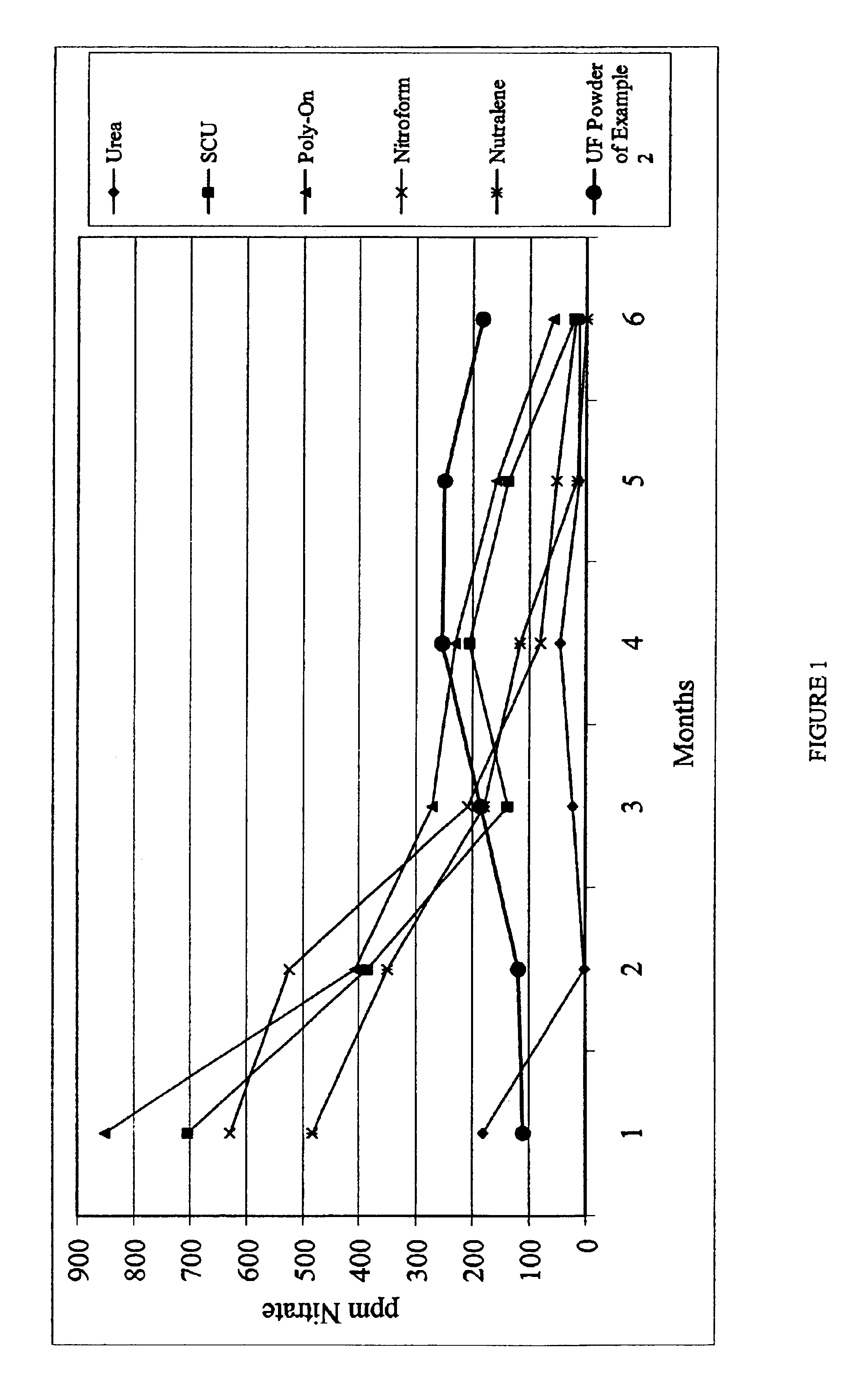

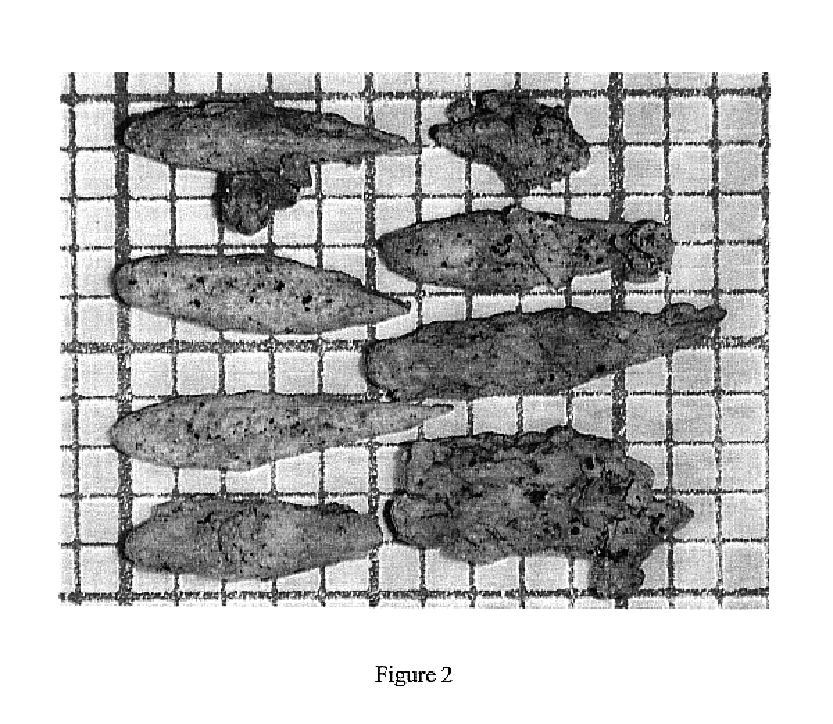

Slow release nitrogen fertilizer

InactiveUS6936681B1Easy to produceGood physical propertiesBiocideAgriculture gas emission reductionParticulatesPolymer

A slow release, particulate urea-formaldehyde polymer useful as a fertilizer for enhancing the extended delivery of nitrogen needed for plant development and growth and a granular fertilizer made with the particulate urea-formaldehyde polymer.

Owner:KOCH AGRONOMIC SERVICES LLC

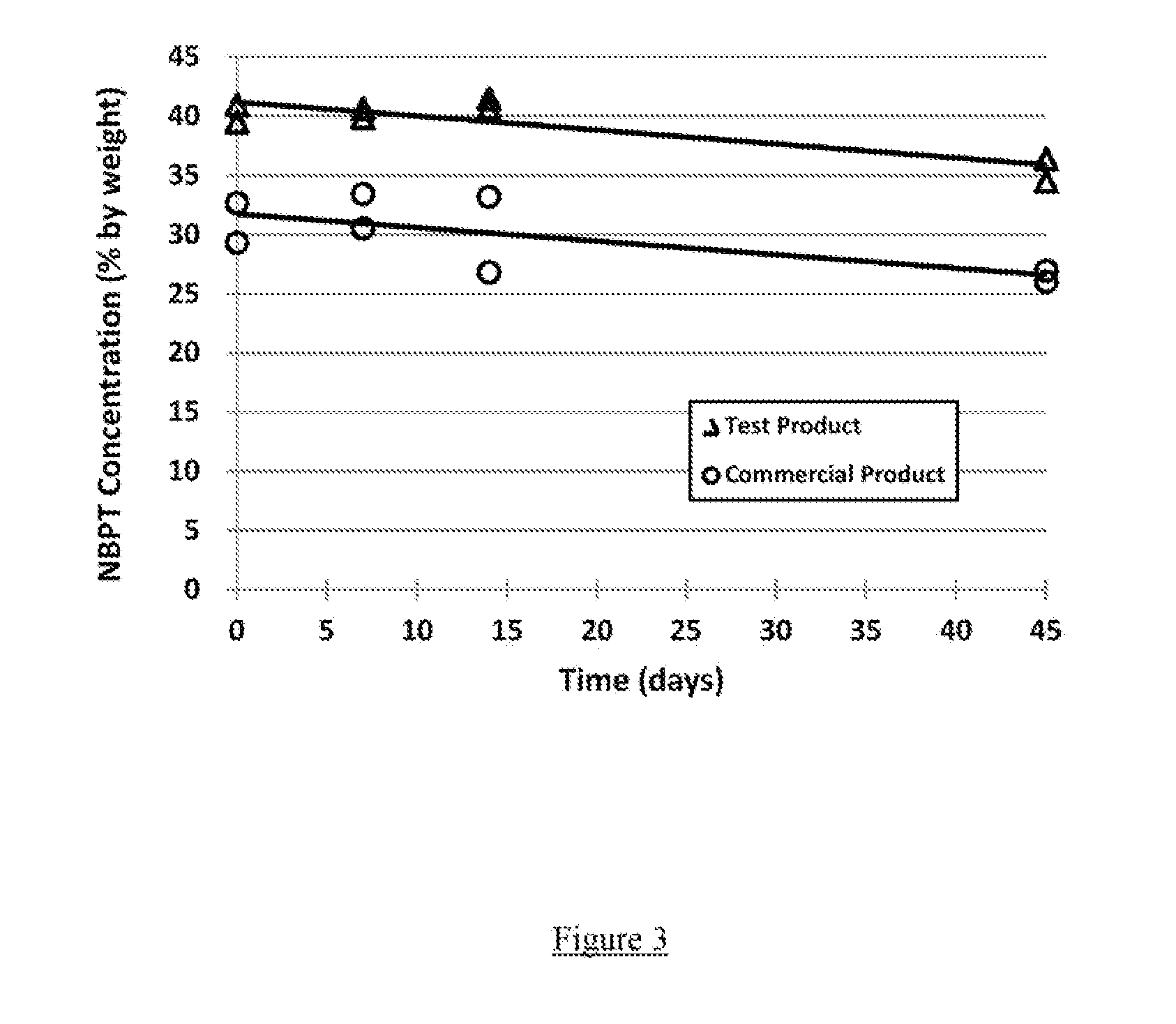

Liquid dicyandiamide and/or alkyl thiophosphoric triamide compositions and their use in agricultural applications

ActiveUS20140174140A1Favorable ecological profileFavorable toxicological profileAgriculture gas emission reductionCyanamide fertilisersOrganic solventAlcohol

An inhibitor composition contains dicyandiamide as a nitrification inhibitor, alkyl thiophosphoric triamide as a urease inhibitor, or a combination thereof, dissolved in a liquid medium comprising an organic solvent selected from, among others, one or more polar aprotic solvents, amine solvents, heterocyclic alcohol solvents, and mixtures thereof, is useful in making fertilizer compositions and in a method of fertilizing target plants.

Owner:RHODIA OPERATIONS SAS

Liquid Formulations of Urease Inhibitors for Fertilizers

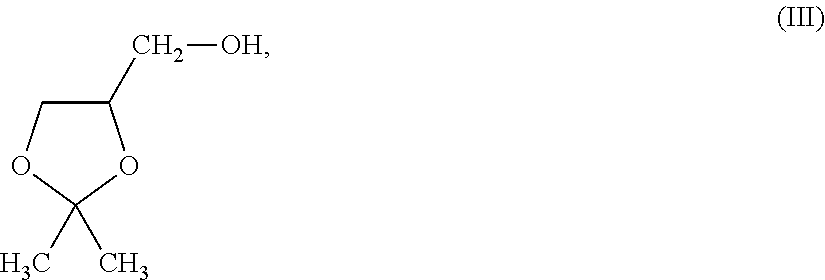

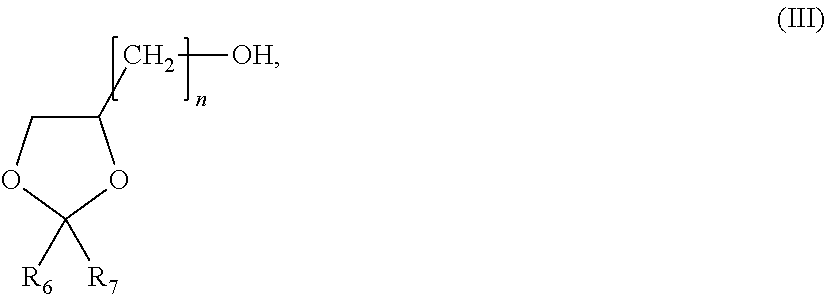

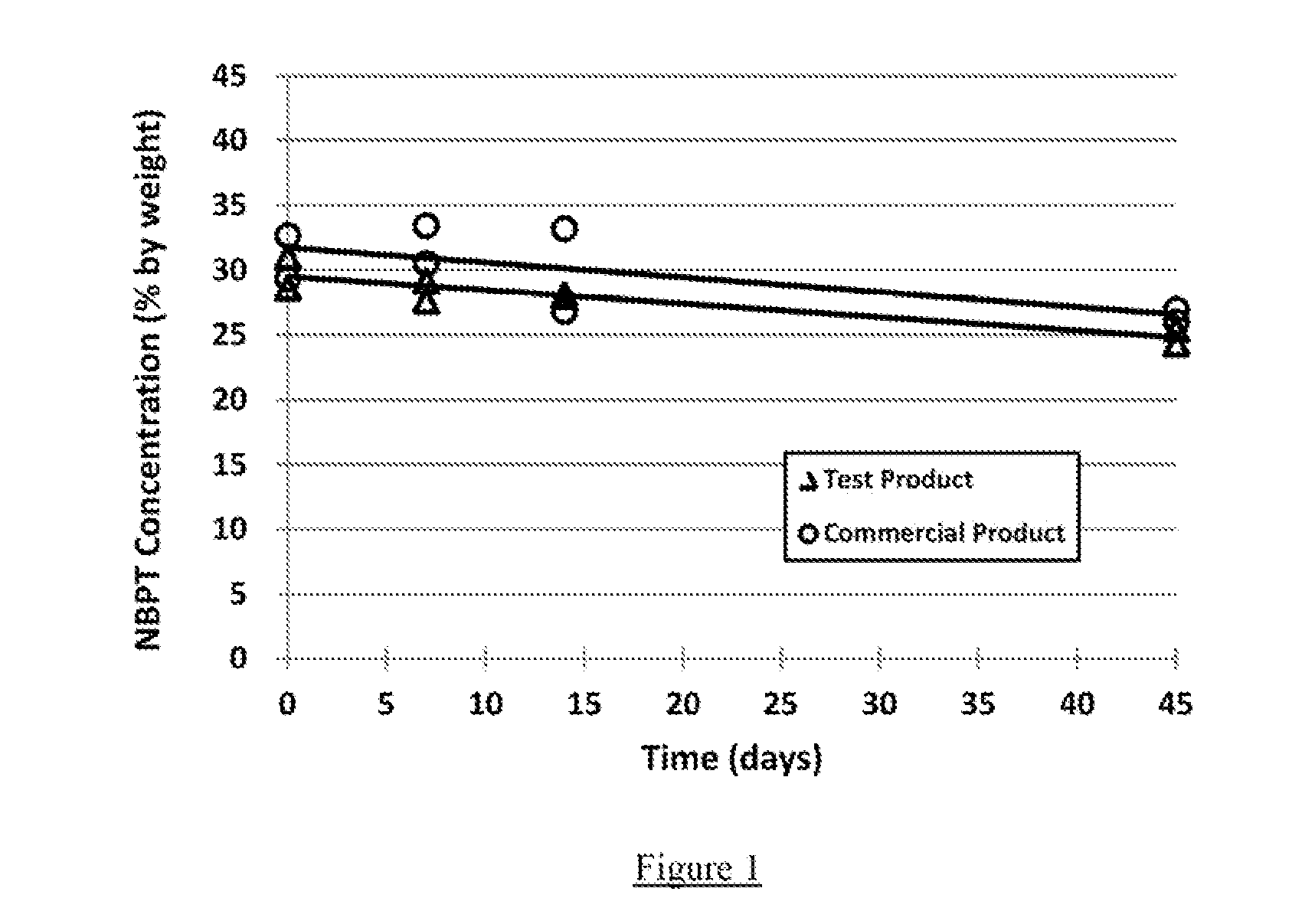

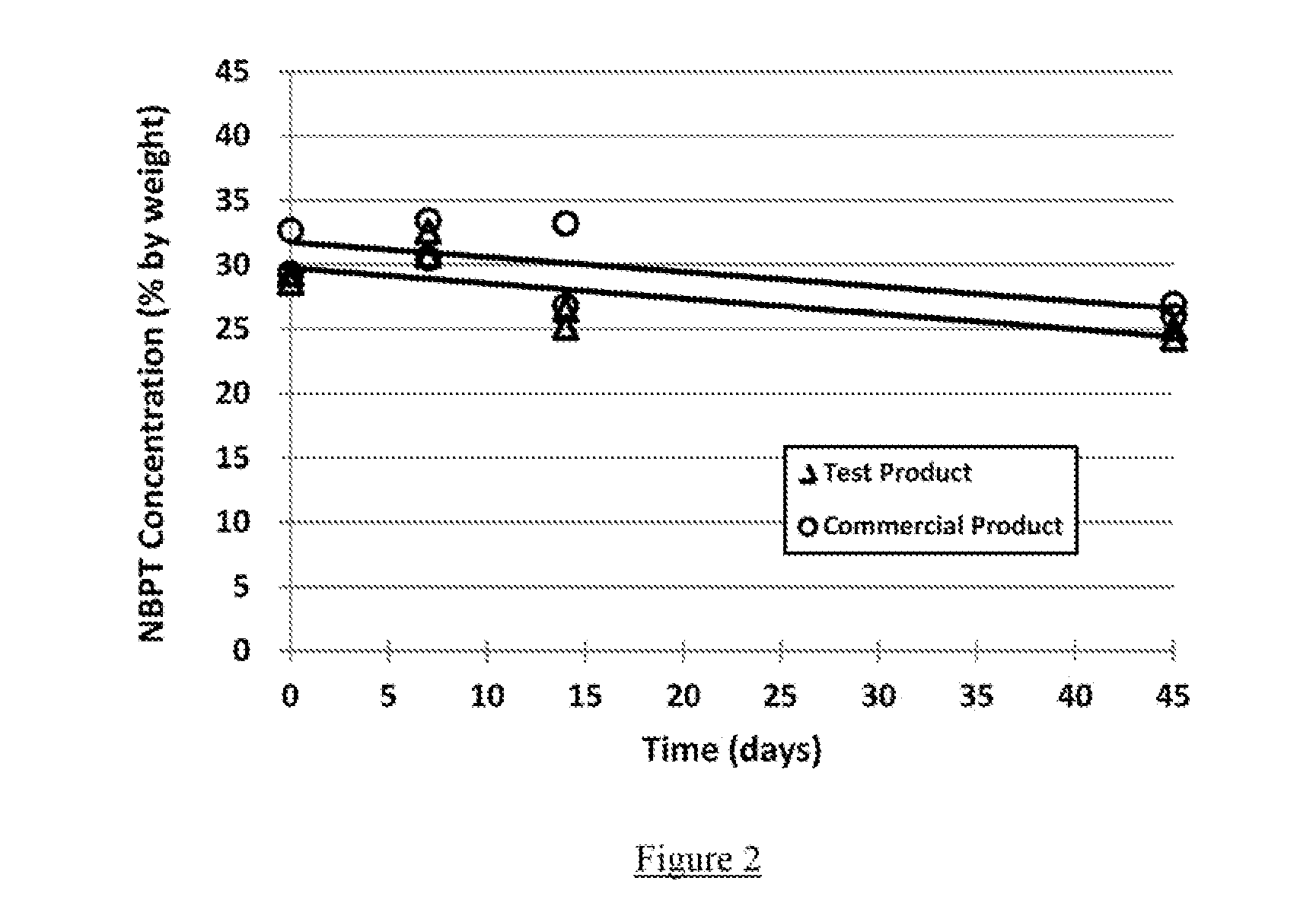

ActiveUS20140090432A1Promote more developedOther chemical processesGroup 5/15 element organic compoundsOrganic baseEnzyme inhibitor

An improved solvent system for the formulation and application of N-alkyl thiophosphoric triamide urease inhibitors. These formulations provide safety and performance benefits relative to existing alternatives and enable storage, transport and subsequent coating or blending with urea based or organic based fertilizers. These formulations are comprised primarily of environmentally friendly aprotic and protic solvents (particularly dimethyl sulfoxide and alcohols / polyols) to stabilize the urease inhibitor.

Owner:SOILGENIC TECH LLC

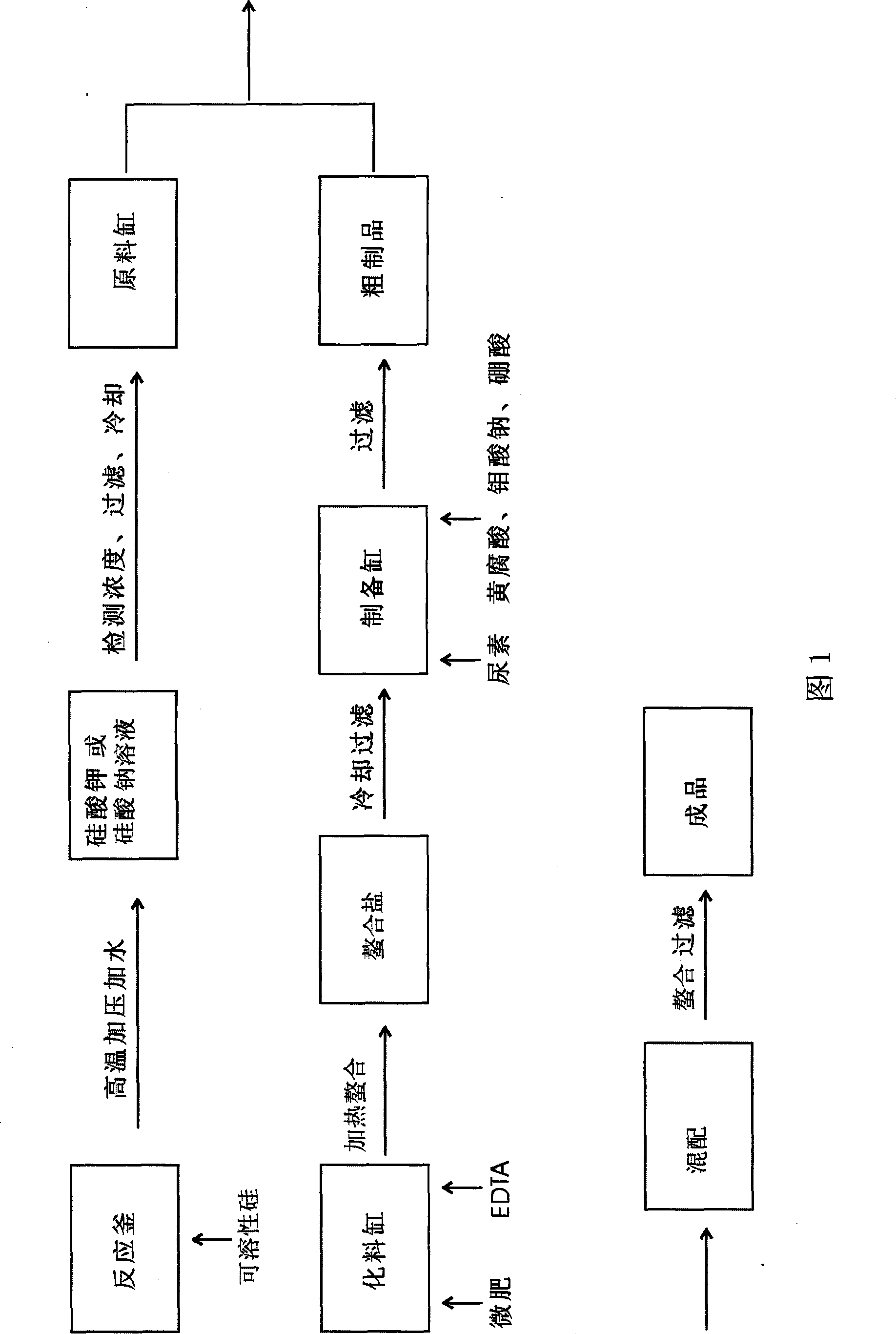

Liquid silicon fertilizer and technique for producing the same

InactiveCN101440001APromote growthIncrease resistanceOrganic fertilisersUrea compound fertilisersMetasilicateSilicic acid

The invention relates to a liquid silicon fertilizer and a production technique thereof, and belongs to the technical field of fertilizer. The liquid silicon fertilizer is characterized in that raw materials comprise soluble silicon, urea, trace elements, chelate and fulvic acid, which are prepared into the balanced compound fertilizer. The production technique comprises the following steps: 1, dissolving solid potassium metasilicate; 2, dissolving sulfate of the trace elements in water, and adding EDTA into the mixture to obtain the chelate of the EDTA trace elements; and adding boric acid, ammonium molybdate, the urea and the fulvic acid into the mixture after cooling and filtration; and 3, blending the chelate into the mixture to obtain the liquid silicon fertilizer. The production technique is characterized in that (1) the production technique uses water glass and the fulvic acid chelate, has better buffer action for alkali, and can effectively improve stability of SiO3; and (2) the trace elements are chelated twice by using the EDTA and the fulvic acid to form chelated metal ions, so as to prevent silicic acid radicals and the metal ions reacting to form silicate difficult to be dissolved in water, and influence utilization rate of silicon element. The production technique uses the liquid potassium metasilicate and large amount of elements, trace elements and organic substances to establish a balanced compound system, and can effectively improve utilization rate of the silicon element and various nutrient elements for the crops.

Owner:于春开

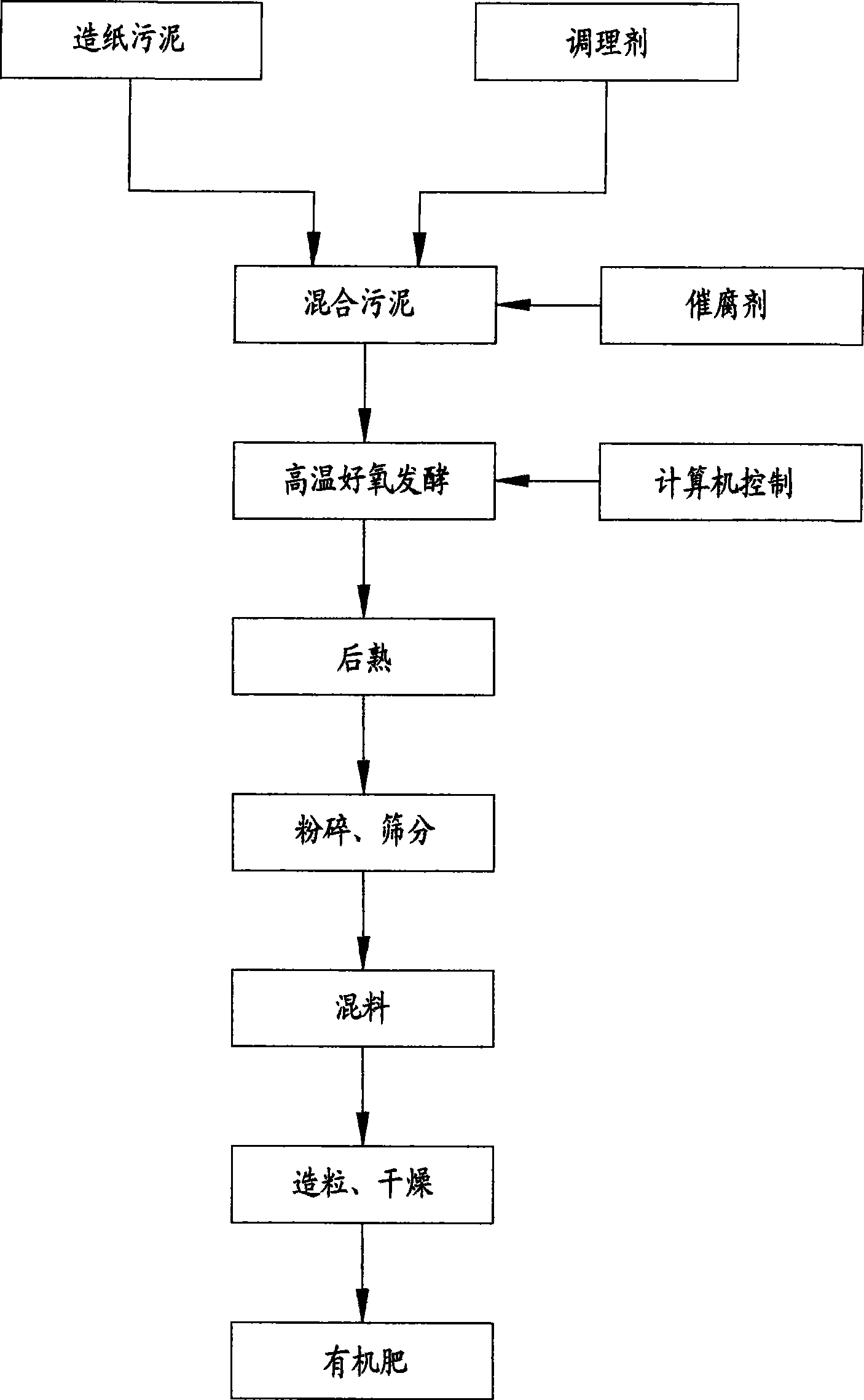

Method for producing fertilizer with papermaking sewage sludge

InactiveCN101429066ARealize comprehensive utilizationSolve processing problemsBio-organic fraction processingOrganic fertiliser preparationSludgePotassium

The invention discloses a method for preparing organic fertilizer from paper-making sludge. The materials such as paper-making sludge, amendment are mixed, subjected to high-temperature aerobic fermentation, post maturation and crushing, screened, and mixed with fertilizer of nitrogen, phosphorus, potassium and the like and medium and micro elements to prepare the organic fertilizer. The method has the advantages of simple process, easy operation, obvious innocuous effect, no environmental pollution and little nutrient loss; and the organic fertilizer prepared by the method is widely applied to industrial crops such as vegetables, fruit trees, Chinese herbal medicines, flowers and field crops such as wheat, corn, paddy rice.

Owner:SHOUGUANG CAILUN ZHONGKE FERTILIZER

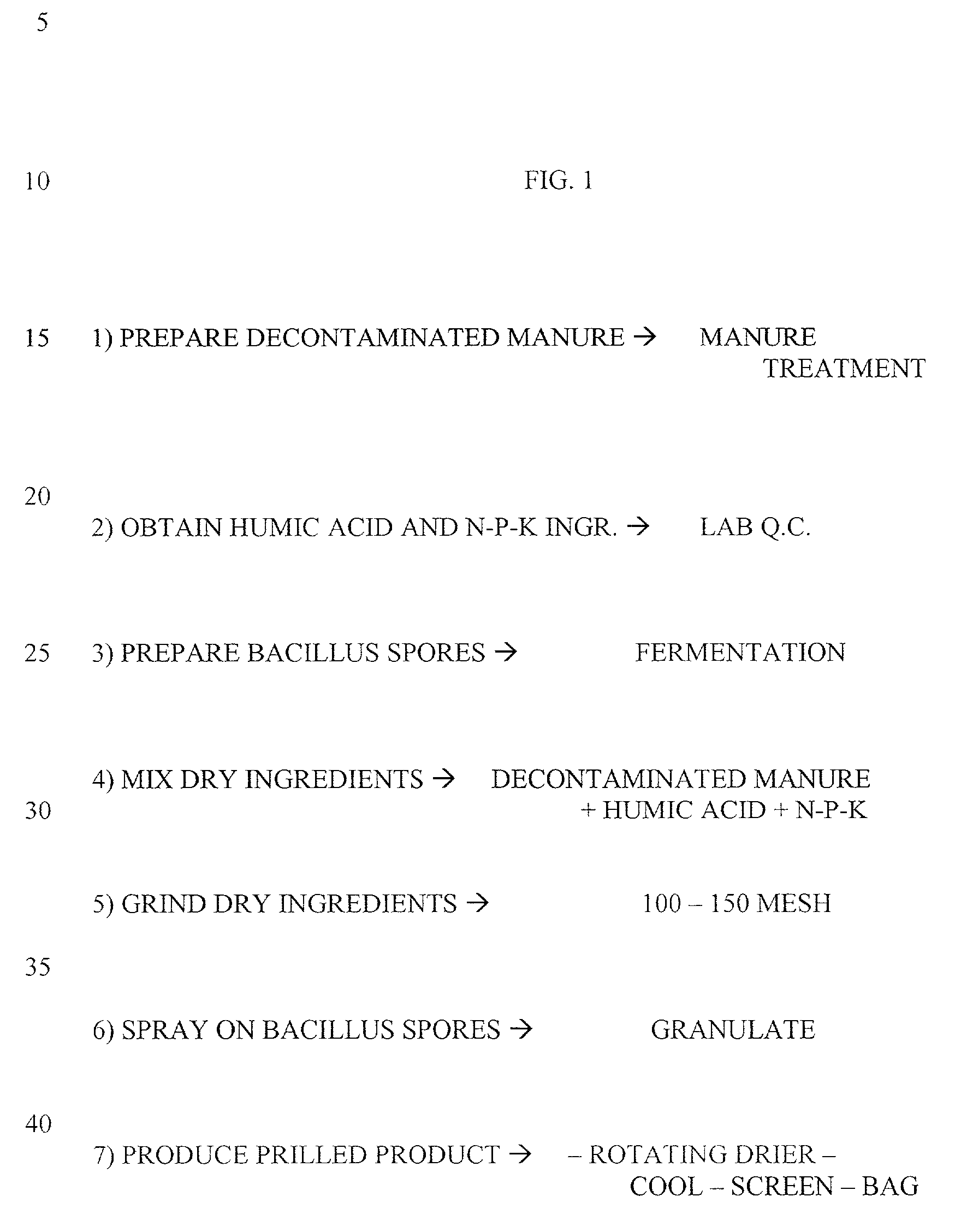

Fertilizer compositions and methods of making and using same

Fertilizer compositions for plant production are described, comprised of decontaminated manure and Bacillus spores, preferably a humic acid derived from lignite and, optionally, one or more of N compounds, P compounds, K compounds, and combinations of two or more of these compounds. Preferred compositions are those wherein the ingredients are blended into an admixture resulting in a granular product. Other preferred compositions are those blended into an admixture resulting in a powdered product. Preferably, the ingredients are formed into hardened prills or pellets. Processes for production and use are also presented.

Owner:MICROBES

Acetic ester coated controlled-release urea fertilizer and preparation technique

InactiveCN101200400ALow priceReduce manufacturing costAgriculture gas emission reductionUrea compound fertilisersGreen environmentControl release

The invention relates to a coated urea fertilizer, substantially an acetate starch-coated controlled-release urea fertilizer which is prepared by utilizing high-substitute degree acetate starch and a preparation process. The urea is implemented on coating by the coating material which is made by utilizing high-substitute degree acetate starch and other ingredients, so that the acetate starch-coated controlled-release urea fertilizer is generated; the coated urea can be ordinary bulky grain urea or the bulky grain urea with biochemical inhibitor on the surface; the biochemical inhibitor is urease inhibitor or / and nitrification inhibitor, thereby the acetate starch-coated controlled-release urea fertilizer is made. The most notable characteristic of the acetate starch-coated controlled-release urea fertilizer is that: the coating is implemented by utilizing the coating material high-substitute degree acetate starch which can be biodegraded fully, the soil environmental will not be polluted after being fertilized on by the coated urea fertilizer, thereby the coated urea fertilizer is a real green environment-friendly coated fertilizer. And the source of coated material is board and is easy to be obtained, and the price is lower, so the production cost of the coated urea fertilizer can be reduced greatly.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Highly available particulate controlled release nitrogen fertilizer

InactiveUS6048378ASpeed up the conversion processImprove efficiencyBiocideGranulation in rotating dishes/pansParticulatesWater insoluble

A method preparing controlled release nitrogen in particulate fertilizers which exhibit single growing season availabilities to plants of about 80 percent or higher. The method utilizes relatively low urea and ammonia to formaldehyde mol ratios of about 1.7 urea to 0.1 ammonia to 1 formaldehyde to assure high conversions to controlled release nitrogen with low free ureas, and carefully controlled elevated temperatures, acid dehydration condensation catalyst concentrations and short dehydration reaction times of about 2-4 minutes to provide effective conversion of hydroxymethyl nitrogen compounds by dehydration condensation reaction to controlled release methylene nitrogen compounds. Quick neutralization of the dehydration catalyst in a turbulent mixing reactor minimizes the formation of undesirable methylene nitrogen polymers which are hot water insoluble and unavailable to plants in a single growing season.

Owner:AGRINUTRIENTS TECH GRP INC

Manufacturing of bioorganic-augmented high nitrogen-containing inorganic fertilizer

The invention describes a new method for the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method creates a thixotropic paste-like material from the biosolids or organic sludge that is blended with hot or molten ammonium salts, especially a mixture of ammonium phosphate and ammonium sulfate. The invention can be an add-on to commercial production of ammonium salts or it can stand alone by manufacturing ammonium salts prior to their introduction to the conditioned biosolids. The invention is oriented to be tailored to production facilities for individual municipal waste treatment plants in order to keep manufacturing plants small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

Compositions of Substantially Spherical Particles and Methods of Making Thereof

InactiveUS20140047884A1Group 5/15 element organic compoundsOrganic phosphatic fertilisersActive agentChemistry

An improved composition comprising substantial spherical UFP particles and an active agent, such as NBPT, and optionally other components is used as an additive for liquid and solid fertilizers, typically containing urea. Methods of making the compositions and their use are also disclosed.

Owner:KOCH AGRONOMIC SERVICES LLC

Microbial organic fertilizer and compound fertilizer, and preparation methods thereof

InactiveCN101602623AImprove the immunityImprove immunityBio-organic fraction processingClimate change adaptationPhosphatePeat

The invention relates to microbial organic fertilizer and compound fertilizer, and preparation methods thereof, belonging to the field of fertilizer production. Firstly, chicken manure, grass peat, brown sugar, carbamide, powdered rock phosphate, rice bran or wheat bran and zymocyte are proportionally mixed and then are fermented, and the microbial organic fertilizer can be prepared by adding functional bacteria to the mixture after the fermentation; and inorganic fertilizer, medium trace elements, humic acid, biologic protein and functional bacteria are proportionally added to the prepared microbial organic fertilizer, the obtained mixture is thoroughly stirred and then is processed by granulation, polishing, drying and screening, thereby obtaining the compound fertilizer. The functional bacteria include photosynthetic bacteria, lactic acid bacteria, microzyme, Gram positive actinomycetes, phosphate-solubilizing bacteria, potassium-solubilizing bacteria and nitrogen-fixing bacteria. The fertilizer prepared by the invention can effectively improve the ecology environment for the growth of crop, increase the quality of the crop, inhibit plant diseases and insect pests and kill pathogenic bacteria, and the medium trace elements contained are of many types, are sufficient in quantities and present high fertilizer efficiency; and during application, the fertilizer just needs to be applied for once, thereby saving labor power and causing no environmental pollution.

Owner:WUHAN CHENGYI BIO PRODS

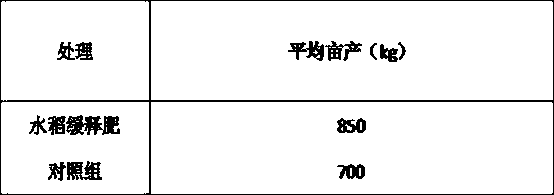

Rice slow-release fertilizer and preparation method thereof

InactiveCN107673927APhysiological characteristics are diverseWidely distributedCalcareous fertilisersMagnesium fertilisersCelluloseTrace element

The invention discloses a rice slow-release fertilizer and a preparation method thereof. The rice slow-release fertilizer comprises the following raw material components by weight: 25-40 parts of compound bacteria, 500-600 parts of an organic material, 800-1200 parts of an inorganic material, 100-150 parts of a fertilizer core, 20-30 parts of trace elements, 120-150 parts of additives, 70-80 partsof cellulose and 2500-3500 parts of a solvent.

Owner:INST OF SOIL FERTILIZER & ENVIRONMENT RESOURCE HEILONGJIANG ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com