Granular controlled release agrochemical compositions and process for the preparation thereof

a technology of agrochemical compositions and controlled release, applied in the field of granular agrochemical compositions, can solve the problems of increased risk of leaching to ground water or surface water, inefficiency and unwoundness, and inability to meet the needs of agricultural production, and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

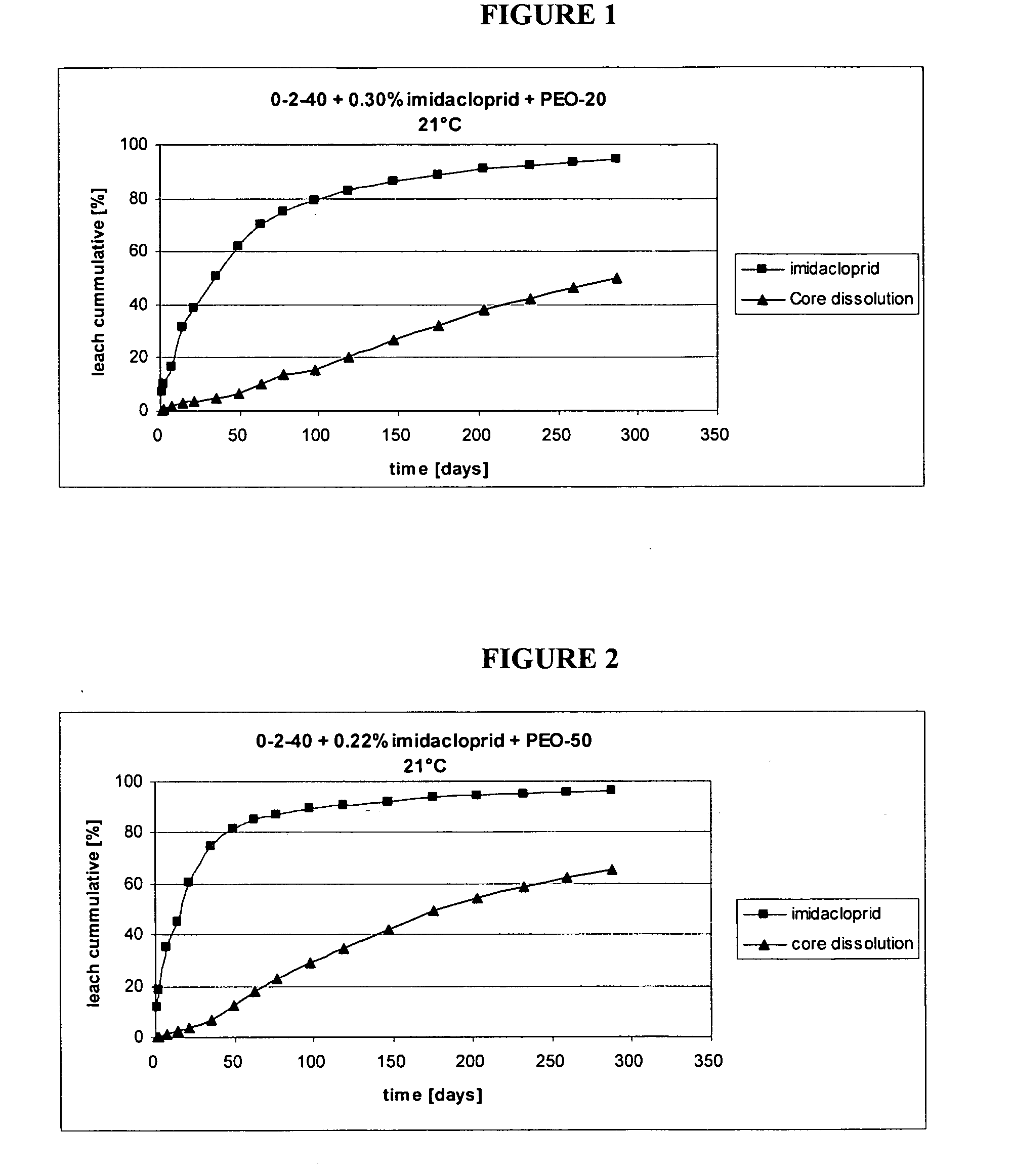

example 1

[0064] A sample of the granular agrochemical compositions of the present invention was prepared employing an 0-2-40 fertilizer granule obtained from The Scotts Company (Howden, UK) as the granular core material. This granular core was predominantly composed of potassium sulfate. The sample composition was prepared by initially heating 50 g of the 0-2-40 fertilizer granules (1.7-2.0 mm) in a rotating drum to 110° C. Then, 0.75 g of a non-ionic surfactant wax (a polyethyleneglycol-block-polyethylene, cas nr.: [251553-55-6], hydroxyl number 52.00 mg KOH / g, containing 20% (by weight) polyethylene glycol, obtained from Sigma-Aldrich), was melted and 0.25 g of a biologically active ingredient (imidacloprid, obtained from Sigma-Aldrich) was mixed into in the molten wax.

[0065] Then, the resulting mixture of imidacloprid and wax was added to the warm fertilizer (potassium sulfate) granules to form a coating layer on the granular core. The granules with the imidacloprid and wax coating there...

example 2

[0069] The composition produced in accordance with this Example 2 is distinguishable from the compositions produced in accordance with Example 1 in regard to the wax material employed in forming the first coating layer of test sample of the granular agrochemical composition of the present invention. The procedure used to produce the test sample of this Example 2 was in accordance with the process of Example 1.

[0070] Specifically, an 0-2-40 fertilizer granule obtained from The Scotts Company which was predominantly composed of potassium sulfate was employed as the granular core material for the sample composition which was prepared by initially heating 50 g of the 0-2-40 fertilizer granules (1.7-2.0 mm) in a rotating drum to 110° C. Then, 0.75 g of a polyethyleneglycol-block-polyethylene, cas nr.: [97953-22-5], hydroxyl number 55.00 mg KOH / g, containing 50% (by weight) polyethylene glycol, obtained from Sigma-Aldrich) was melted and 0.25 g of a biologically active ingredient (imidac...

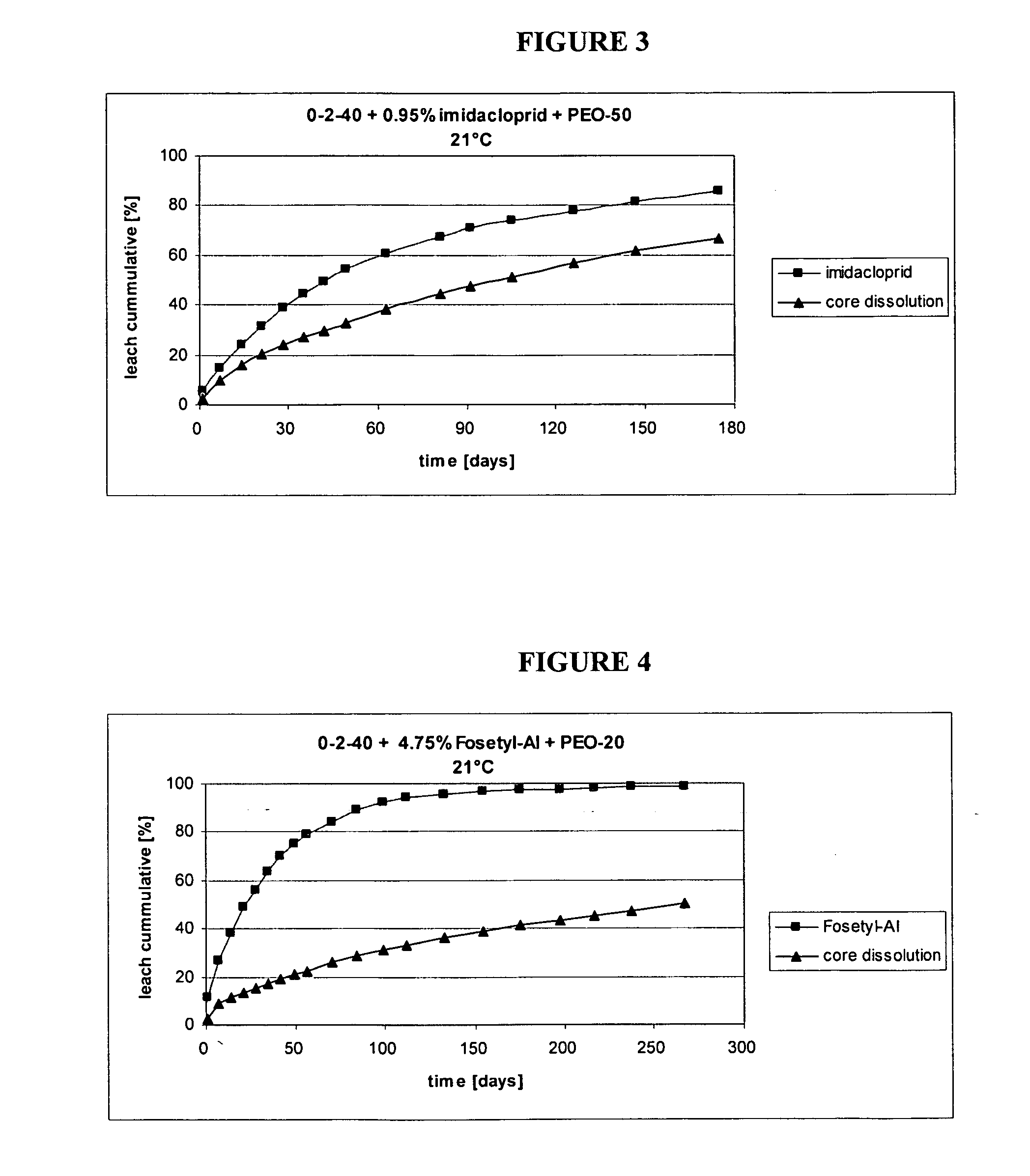

example 3

[0073] The composition produced in accordance with this Example 3 is distinguishable from the compositions produced in accordance with Example 2 in regard to the amount of the active ingredient which was incorporated into the wax material in forming the first coating layer of test sample of the granular agrochemical composition of the present invention.

[0074] The procedure used to produce the test sample of this Example 3 was in accordance with the process of Example 1. Specifically, an 0-2-40 fertilizer granule obtained from The Scotts Company which was predominantly composed of potassium sulfate was employed as the granular core material for the sample composition which was prepared by initially heating 50 g of the 0-2-40 fertilizer granules (1.7-2.0 mm) in a rotating drum to 110° C. Then, 0.75 g of a polyethyleneglycol-block-polyethylene, cas nr.: [97953-22-5], hydroxyl number 55.00 mg KOH / g, containing 50% polyethyleneglycol, obtained from Sigma-Aldrich) was melted and 0.75 g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com