Method for producing fertilizer with papermaking sewage sludge

A papermaking sludge and organic fertilizer technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts, can solve the problems that affect the rapid reproduction of composting microorganisms, slow humification speed, and low processing efficiency, and achieve Harmless, less nutrient loss, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

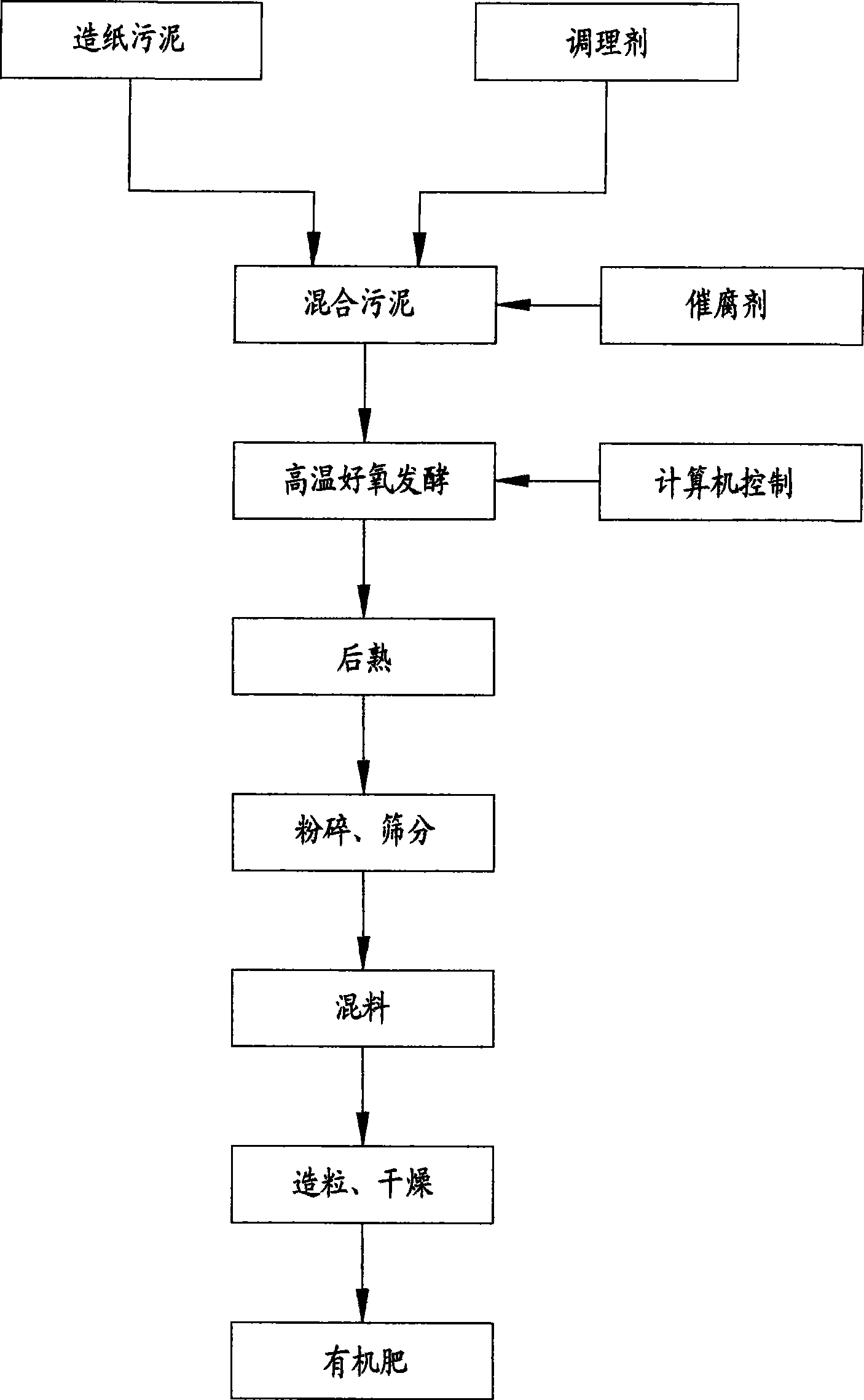

[0027] As shown in the accompanying drawing, the method for utilizing papermaking sludge to prepare organic fertilizer comprises the following steps and process conditions:

[0028] a) Fermentation Mix papermaking sludge with a moisture content of 80% and papermaking dedusting at a volume ratio of 2:1 to prepare a mixed sludge with a moisture content of 60%, a carbon-to-nitrogen mass ratio of 35:1, and an organic matter content of 60%. , according to the proportion of 1% relative to the mixed sludge mass, spray the spoilage yeast waste liquid and put it into the fermentation tank for fermentation. And maintain the temperature for 6 days, start to cool down, and the temperature will drop to 40 ℃ after 2 days;

[0029] b) Post-ripening Put the above-mentioned materials into post-ripening ponds, pile them up to a height of 1.2m for post-ripening, and turn over the stack once a day from the next day to make the stack ferment thoroughly and further reduce the water content. After 5...

Embodiment 2

[0033] As shown in the accompanying drawing, the method for utilizing papermaking sludge to prepare organic fertilizer comprises the following steps and process conditions:

[0034] a) Fermentation Mix papermaking sludge with bark and crop straw mixture (bark and crop straw are mixed in a mass ratio of 1:1) in a volume ratio of 2.5:1 to prepare a moisture content of 55% and a carbon-to-nitrogen mass ratio of 25: 1. For the mixed sludge with 50% organic matter mass content, spray the putrefaction agent wood vinegar in the proportion of 0.8% relative to the mixed sludge mass, and put it into the fermentation tank for fermentation. The height of the fermentation tank is 2m, and the ventilation volume and ventilation are controlled by the computer control system Frequency, reach 60°C within 2 days, and maintain this temperature for 7 days, start to cool down, and the temperature will drop to 35°C after 2 days;

[0035] b) Post-ripening Put the above-mentioned materials into post-r...

Embodiment 3

[0039] As shown in the accompanying drawing, the method for utilizing papermaking sludge to prepare organic fertilizer comprises the following steps and process conditions:

[0040] a) Fermentation Mix papermaking sludge with papermaking dust removal and bark mixture (papermaking dust removal and bark are mixed in a mass ratio of 0.5:1) in a volume ratio of 1.5:1 to prepare a moisture content of 50-55%, carbon and nitrogen mass The mixed sludge with a ratio of 30:1 and an organic matter content of 55% is sprayed with putrefactive yeast waste liquid at a ratio of 1.2% of the mixed sludge mass, and then put into a fermentation tank for fermentation. The fermentation tank is 2m high and controlled by a computer control system. Ventilation volume and ventilation frequency, reach 65°C within 1.5 days, and maintain this temperature for 5 days, then start to cool down, and the temperature will drop to 45°C after 2.5 days;

[0041] b) Post-ripening Put the above-mentioned materials in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com