Internal rib reinforcing outer ripple type plastic twining structured wall pipe and manufacturing method thereof

A structural wall pipe, corrugated technology, applied in the direction of pipes, rigid pipes, tubular objects, etc., can solve the problems of reducing the bending strength of pipes, less melted glue, and small welding surface, saving materials, improving stability, The effect of a large moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

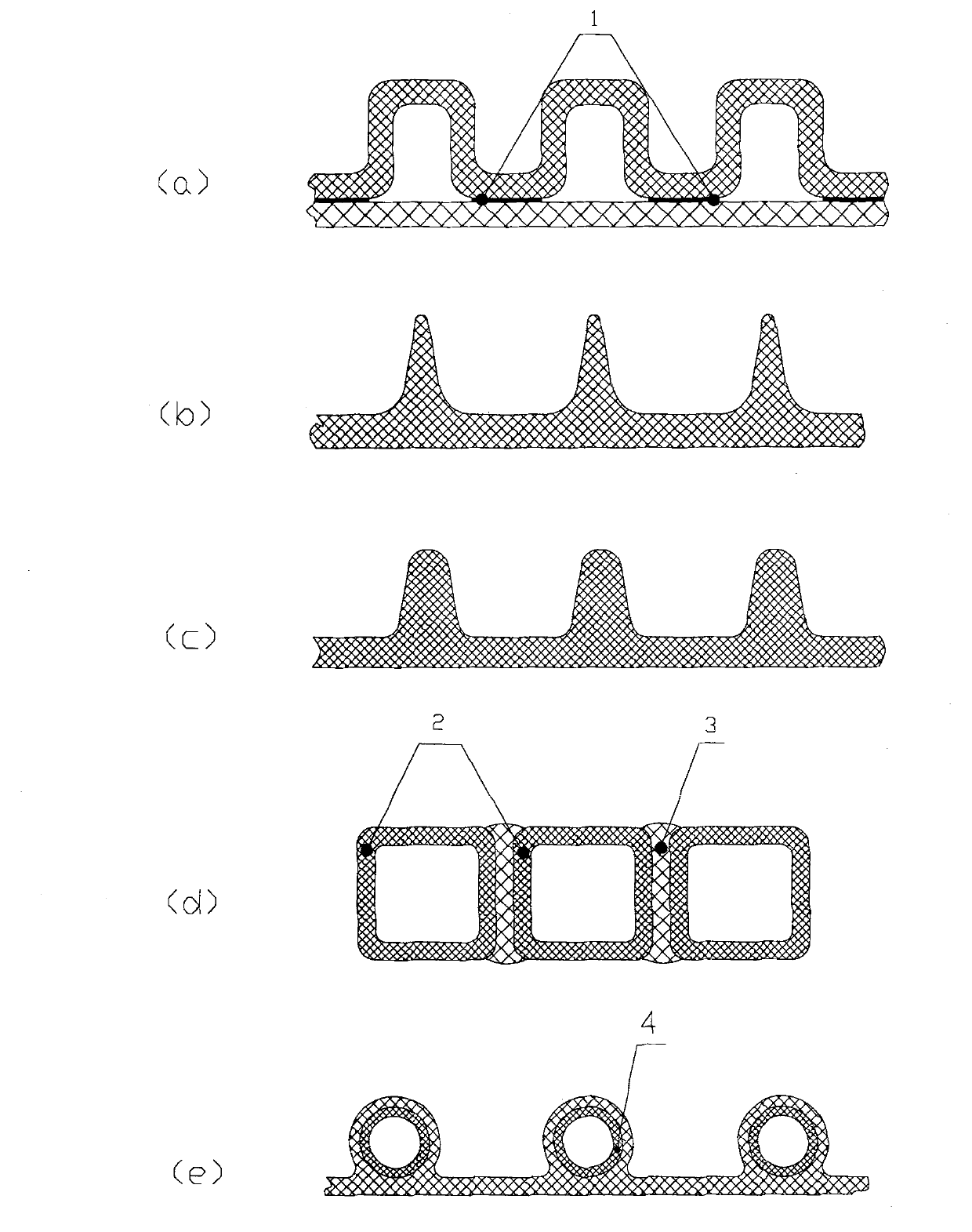

Method used

Image

Examples

Embodiment Construction

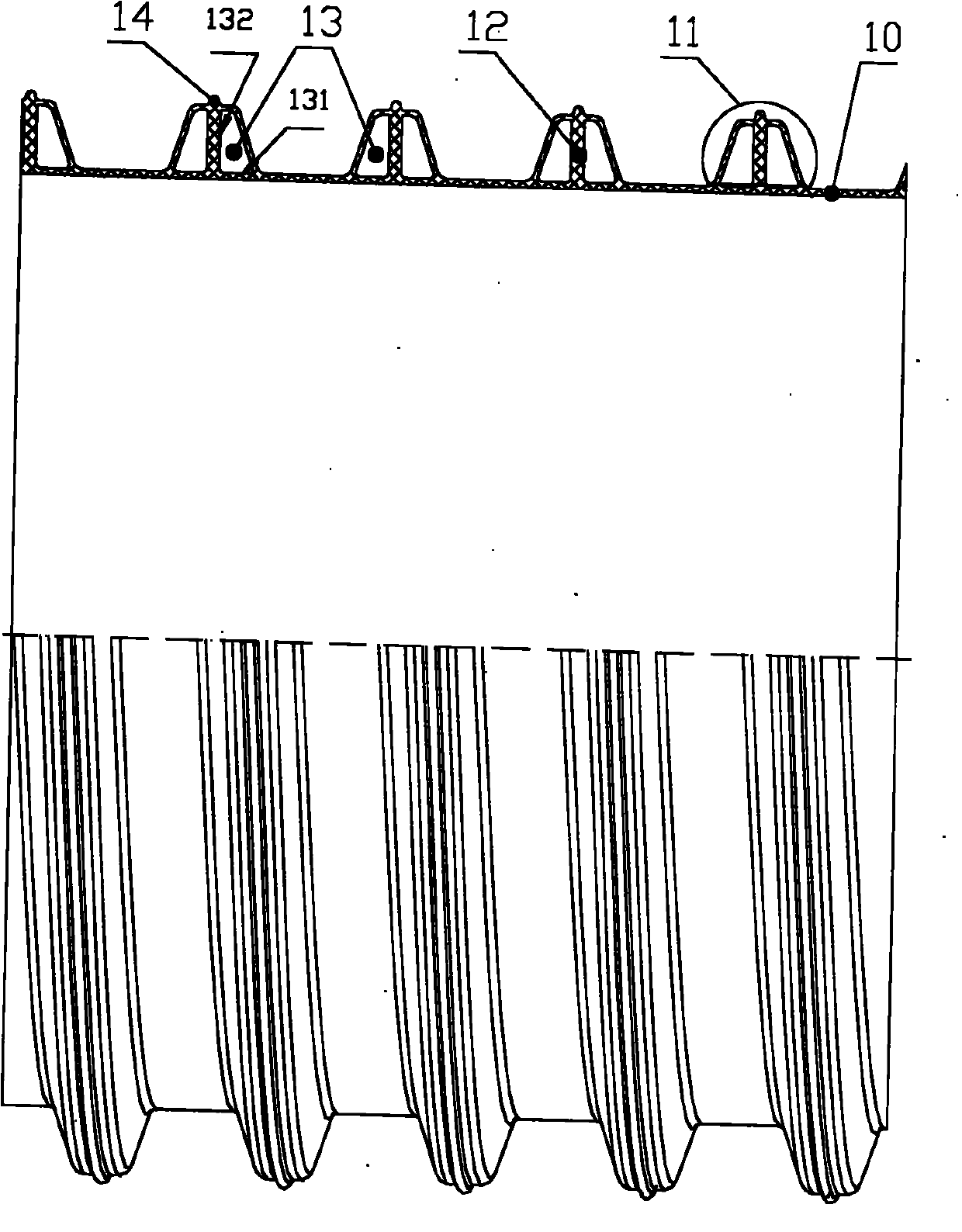

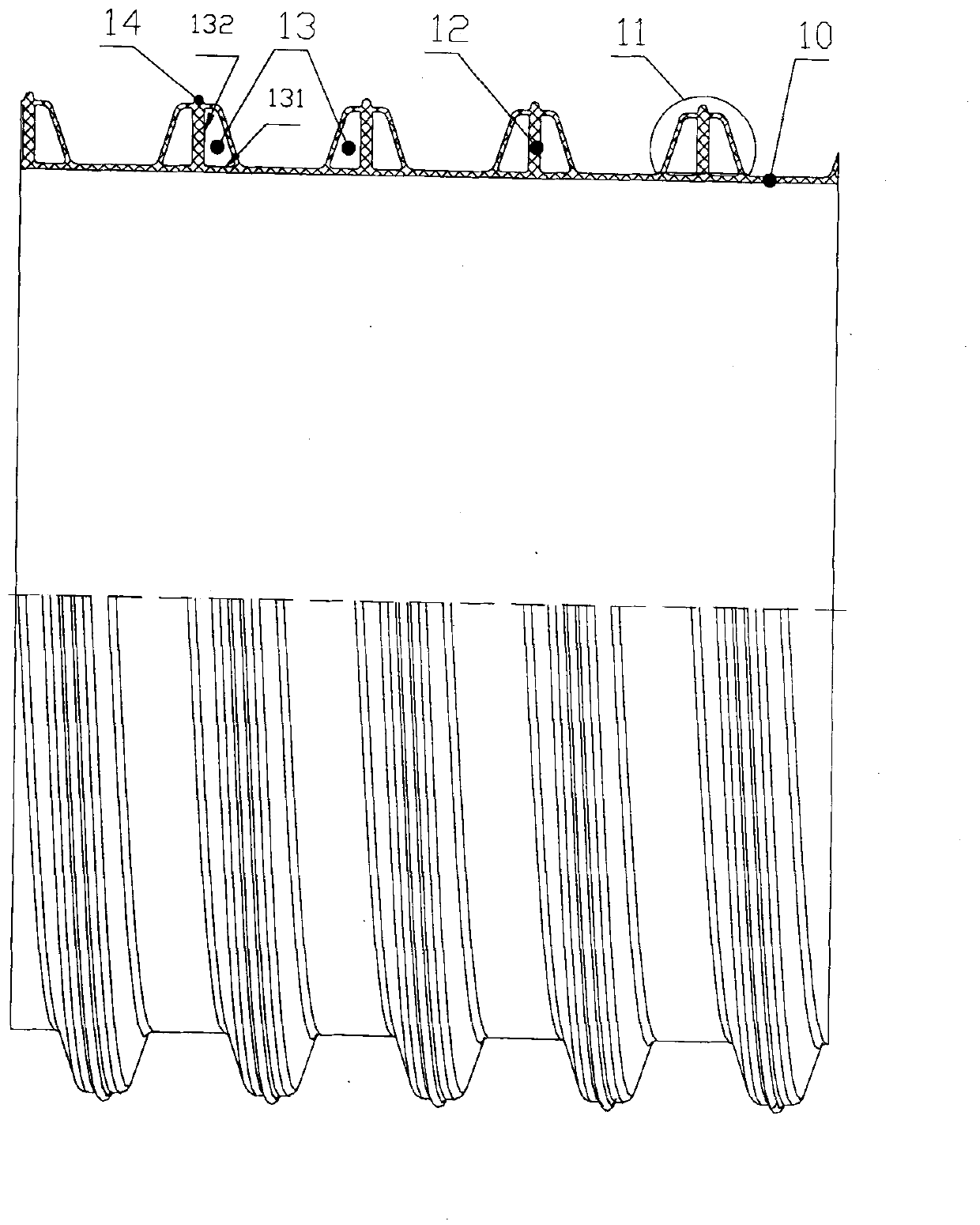

[0044] The mode of implementing the present invention can be combined as Figure 6 For further description, at first the first extruder 18 passes through its supporting profile mold 19, and the blank 20 of extruding the molten plastic special-shaped strip is drawn by the tractor 21, and passes through the vacuum shaping die 23 in the cooling water tank 22, and is cooled and shaped as There are two tubular projections on both sides and a plastic profiled strip 15 containing a hollow cavity. Then under the guidance of a plurality of small rollers 241 driven by the sprocket rotation on the tractor 21 and the forming drum 24, the plastic special-shaped strips 15 are spirally wound side by side on the small rollers 241 on the forming drum 24 continuously and regularly. , the diameter of the forming drum 24 corresponds to the diameter of the forming pipe. At the same time, the second extruder 25 continuously extrudes the melted plastic melt into the gap between the adjacent sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com