Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3071results about "Wound/folded electrode electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

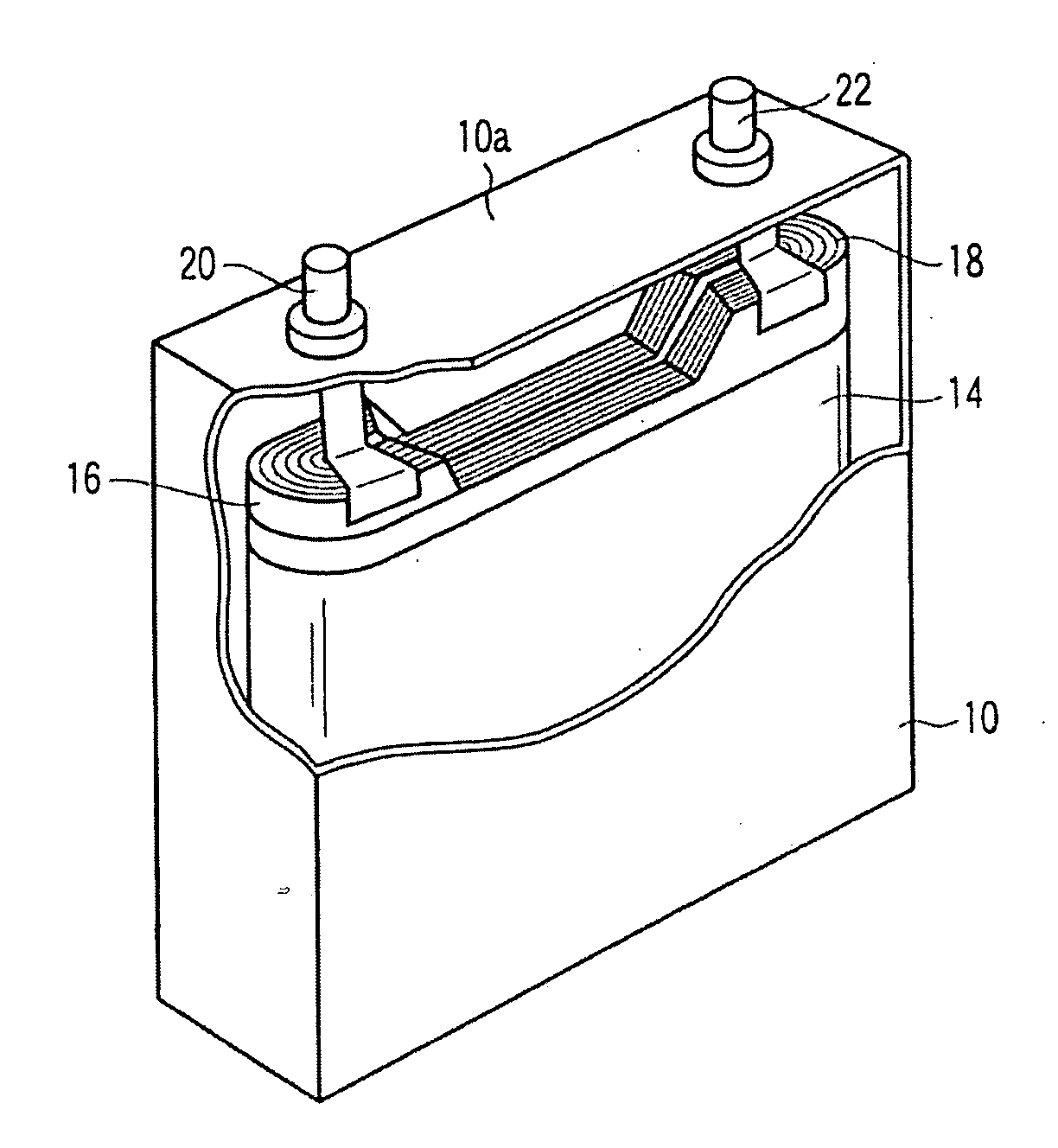

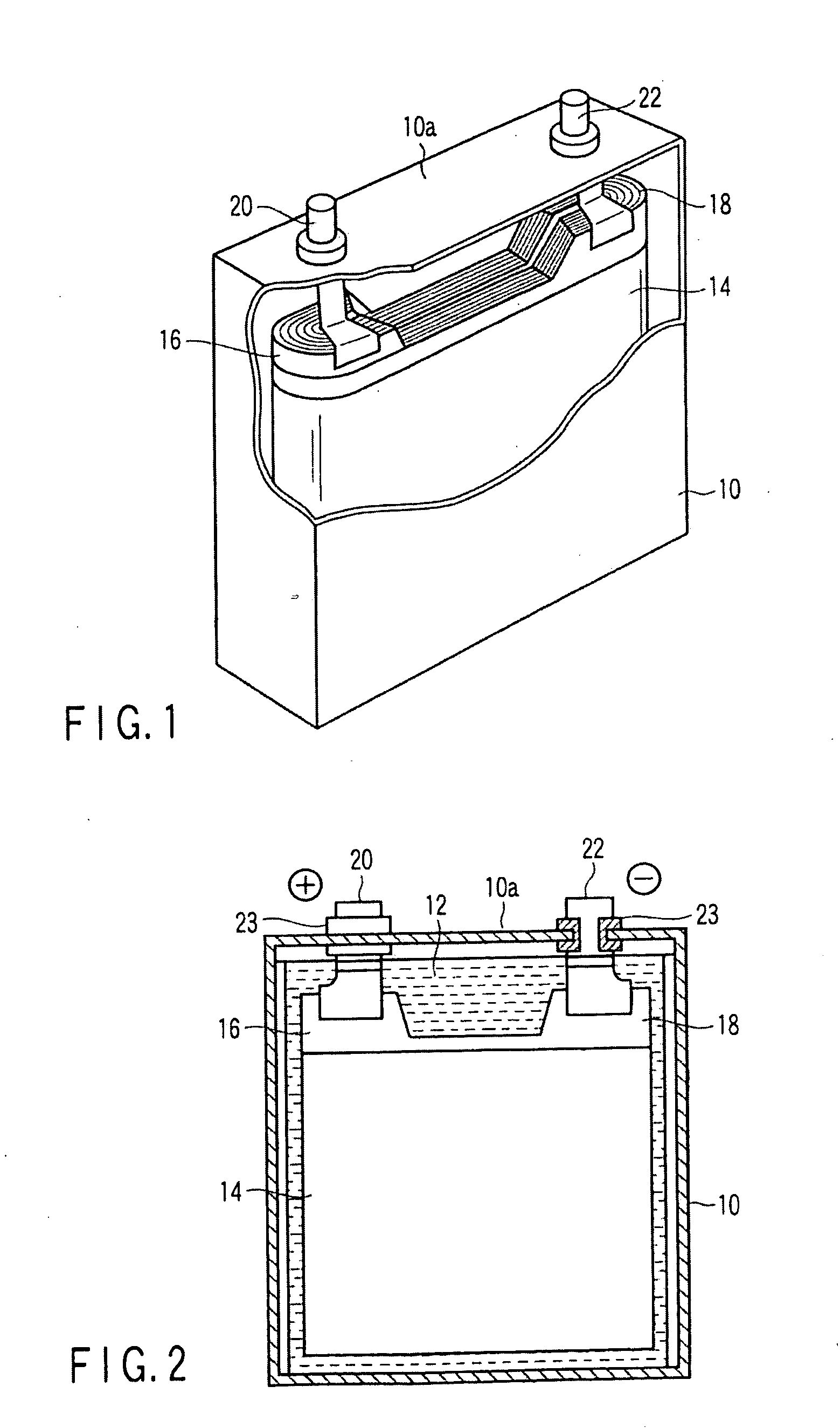

Secondary battery

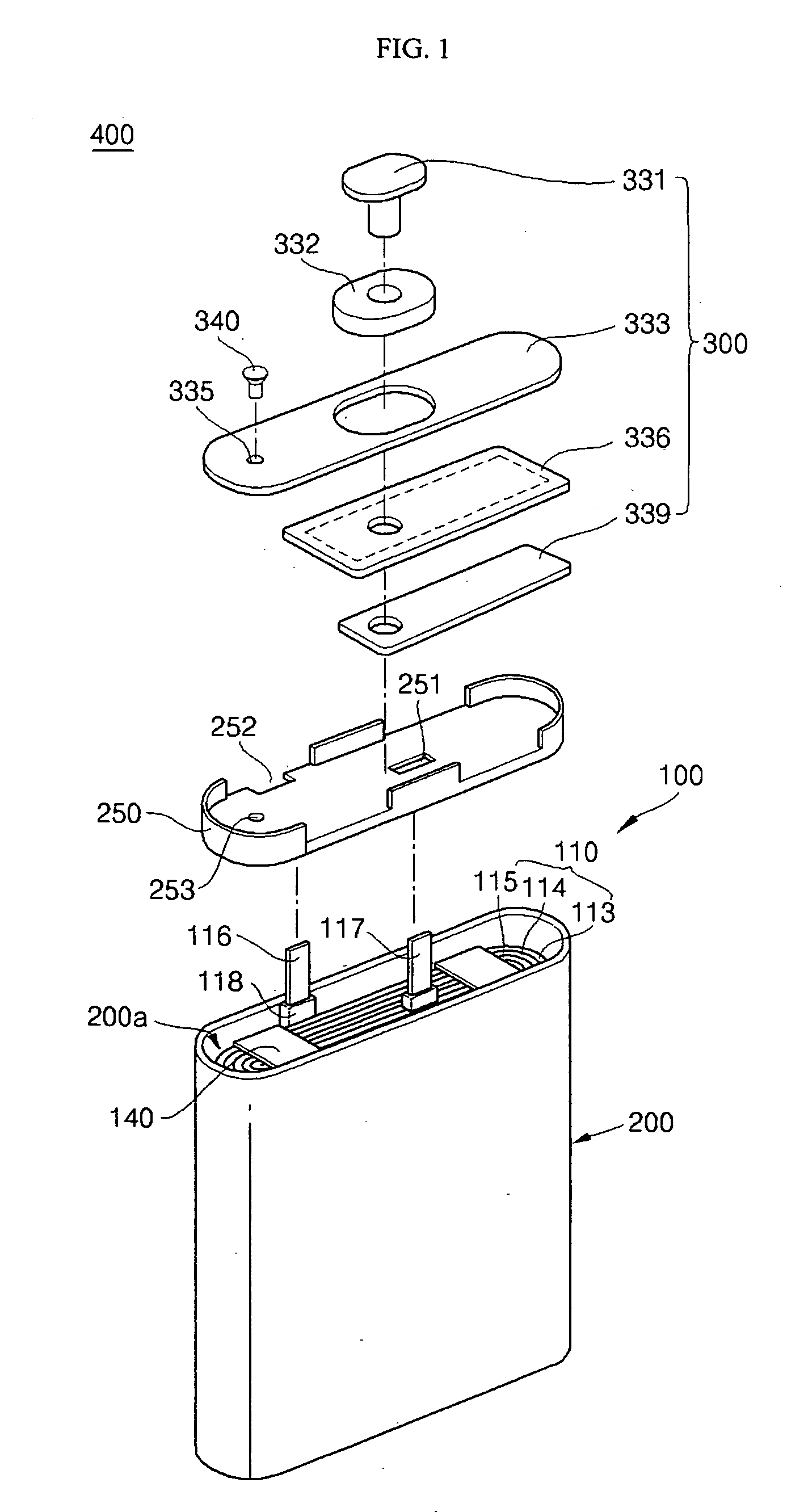

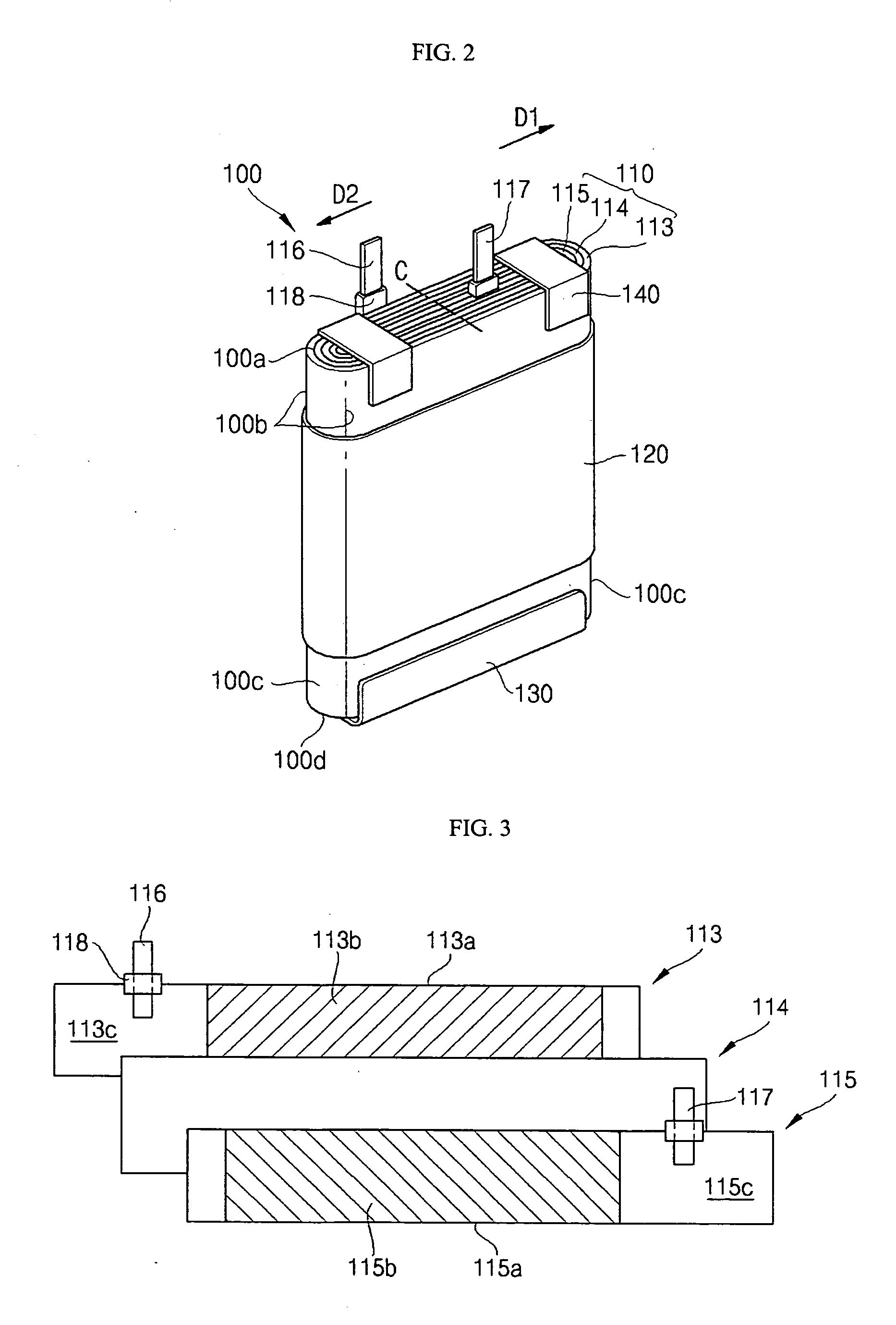

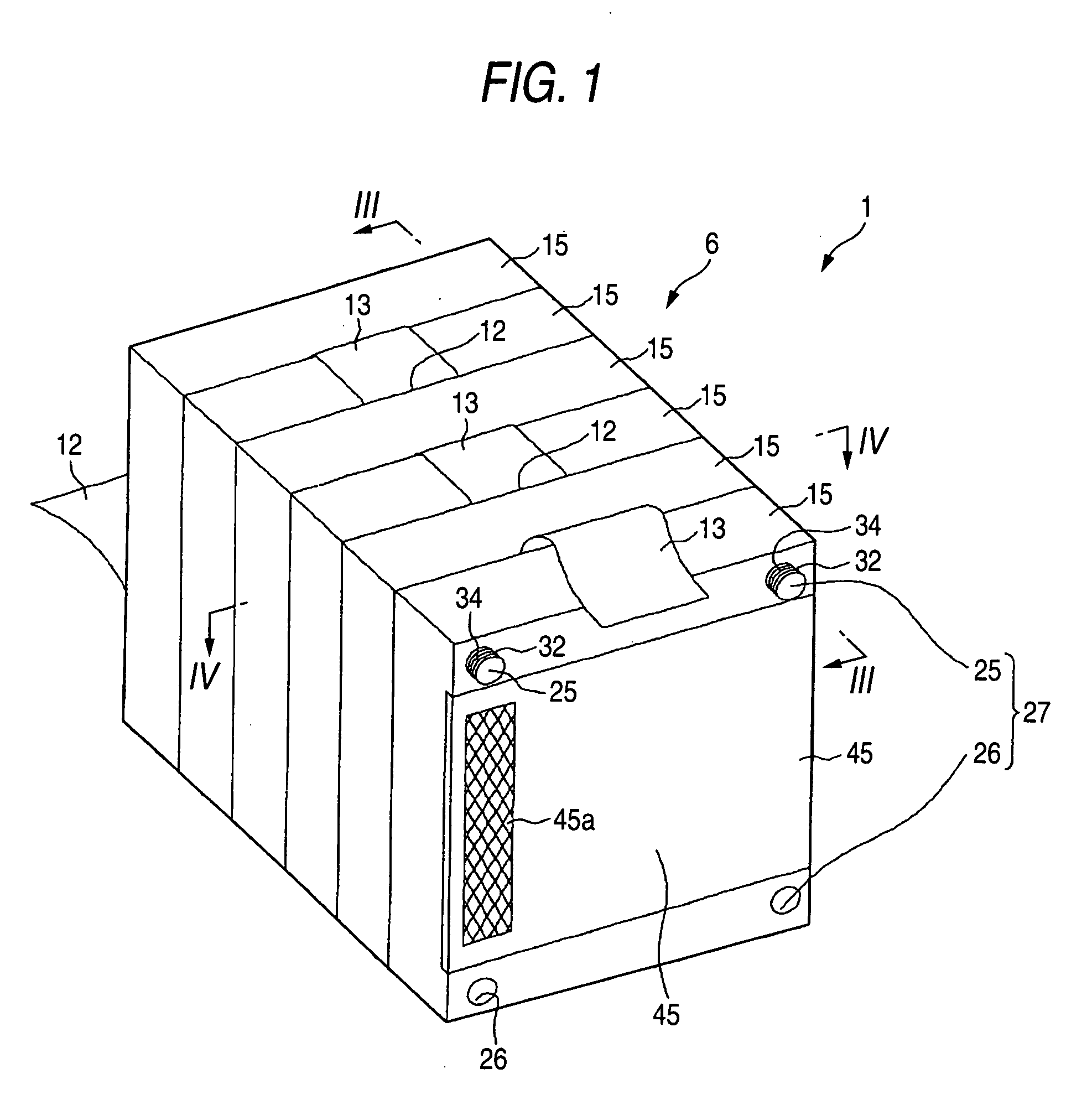

ActiveUS20060024578A1Reduced durabilityIncreased durabilityCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesElectrical and Electronics engineeringElectrode

A secondary battery comprising an electrode assembly having a positive electrode plate, a negative electrode plate, and a separator between the positive and negative electrodes is provided. The secondary battery further comprises a case for containing the electrode assembly, and a cap assembly connected to the case. The cap assembly comprises positive and negative terminals electrically connected to the positive electrode plate and the negative electrode plate, respectively. Lead connectors are electrically connected to the positive and negative electrode plates and the positive and negative terminals. A support is connected to each end of the electrode assembly and surrounds the lead connectors. The supports are adapted to fit between the electrode assembly and the case.

Owner:SAMSUNG SDI CO LTD

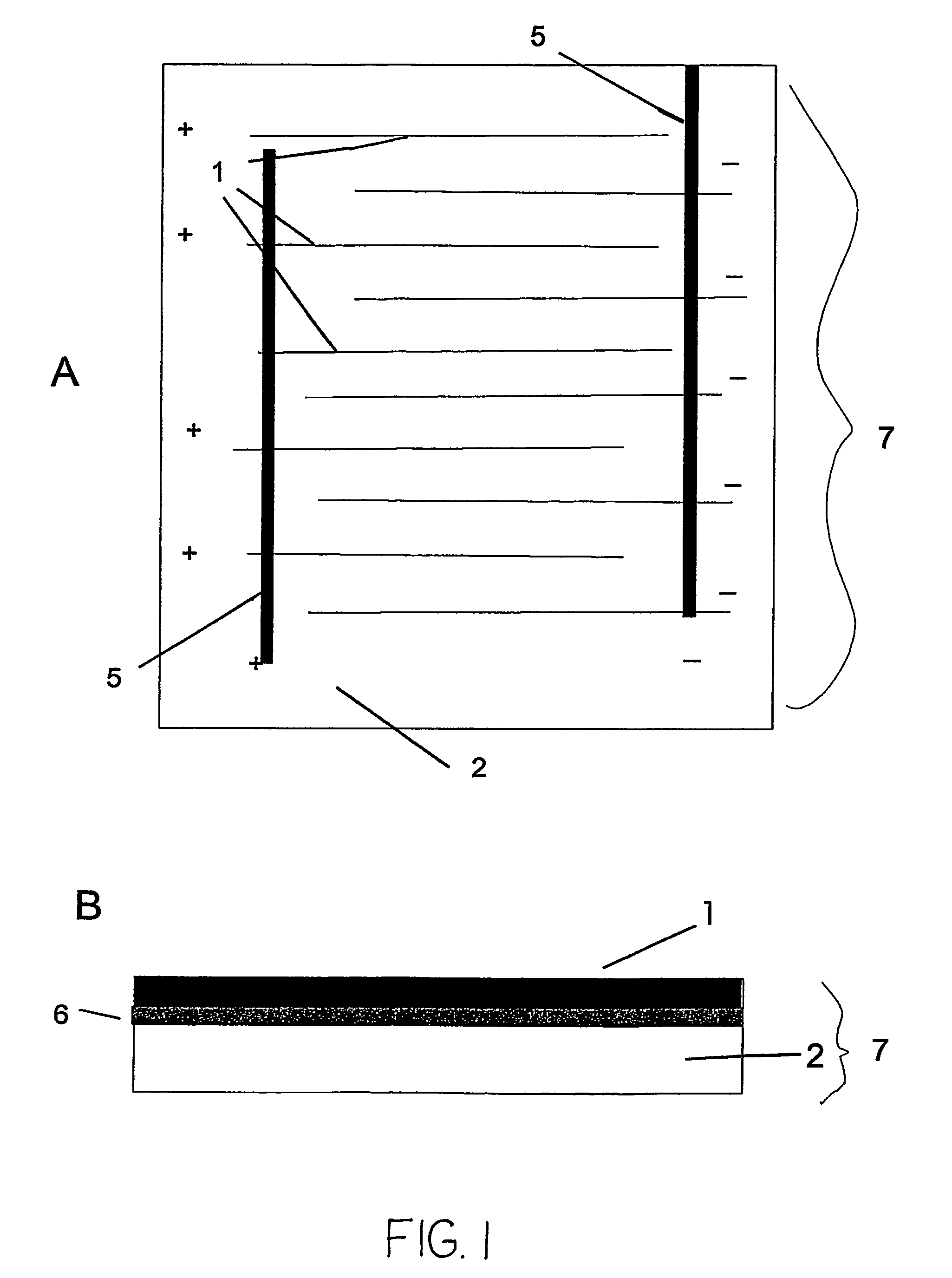

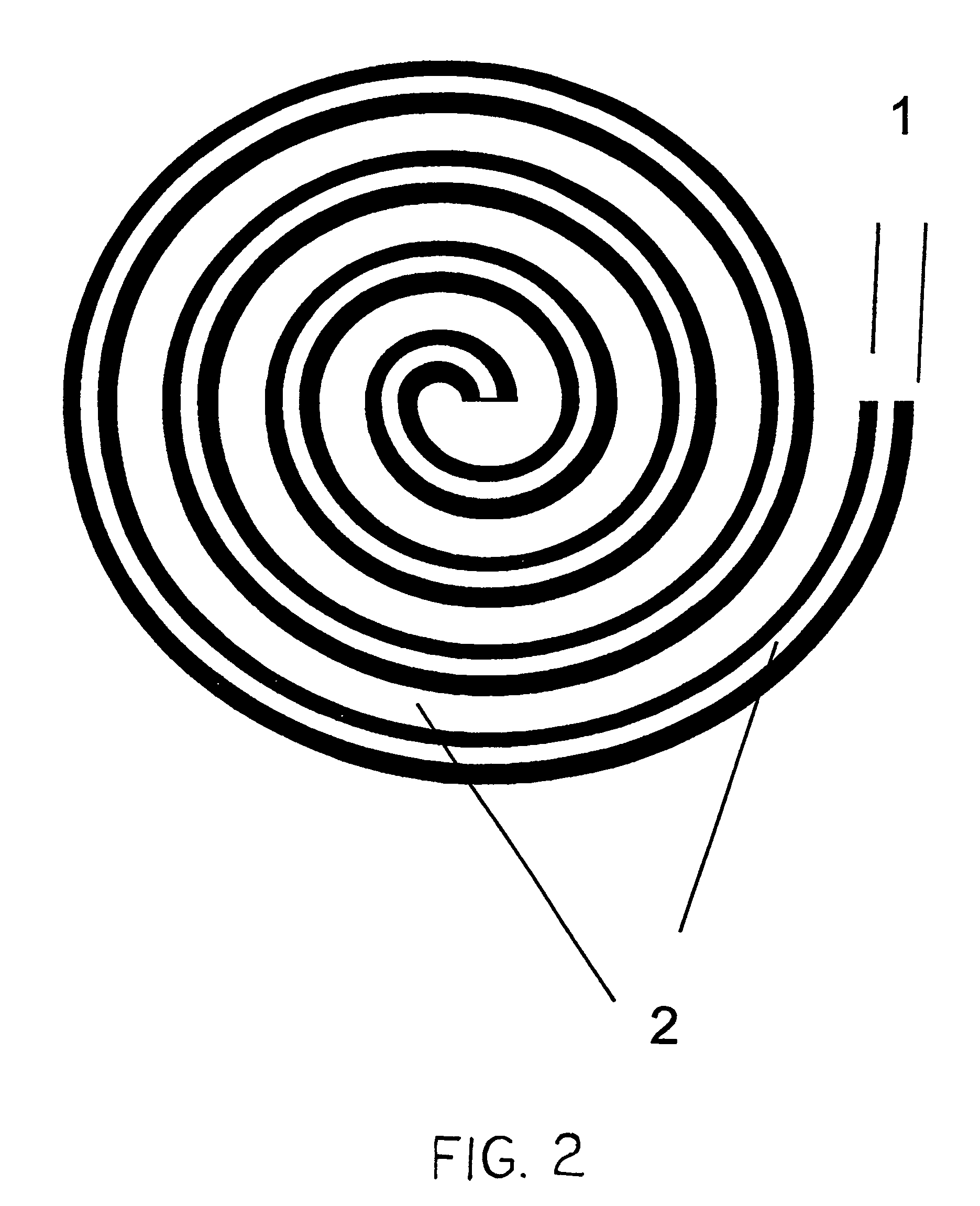

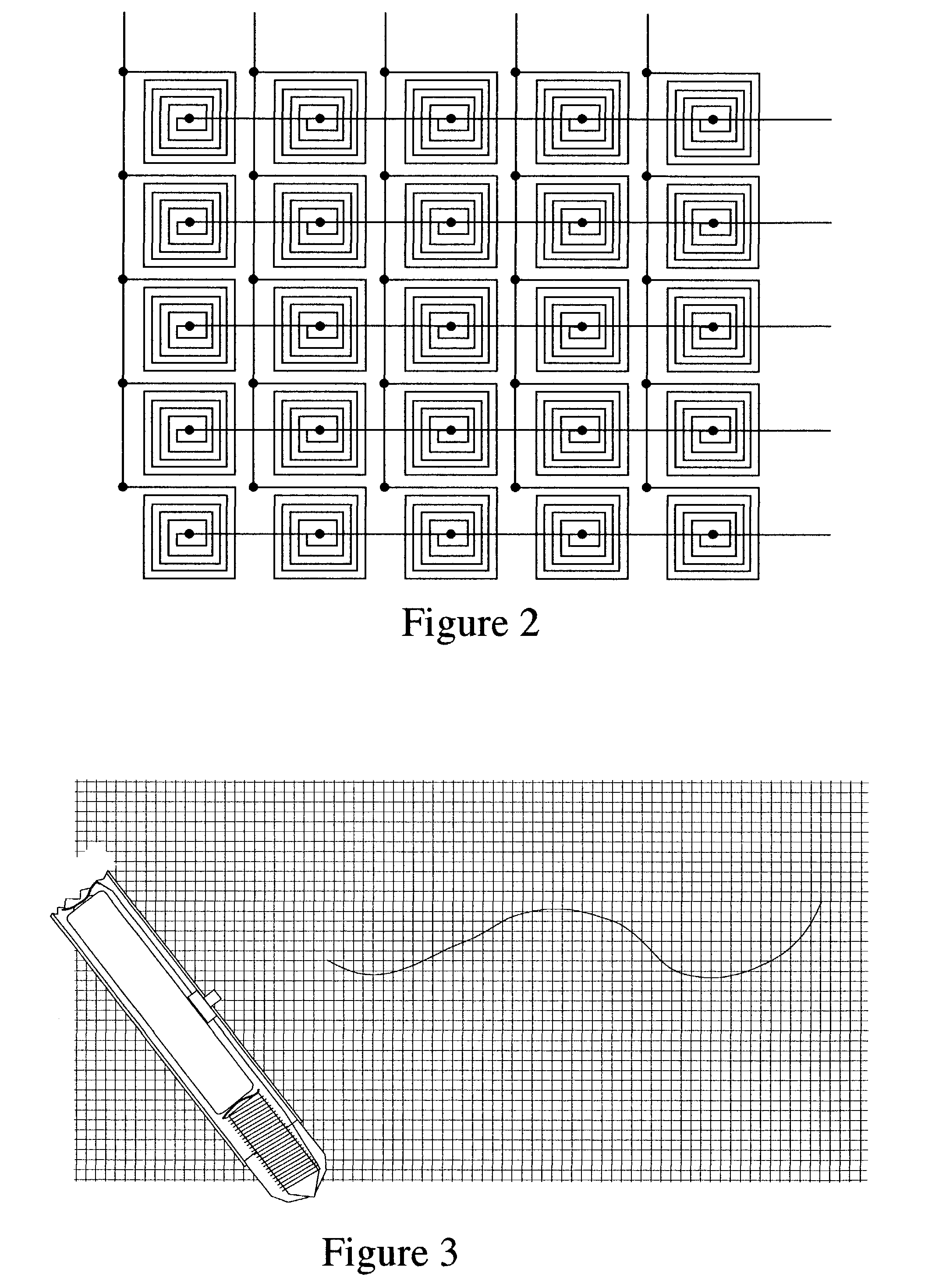

Electrode array for use in electrochemical cells

InactiveUS7368191B2Reduce leakageReduced series resistanceFinal product manufactureFuel cell auxillariesFuel cellsEngineering

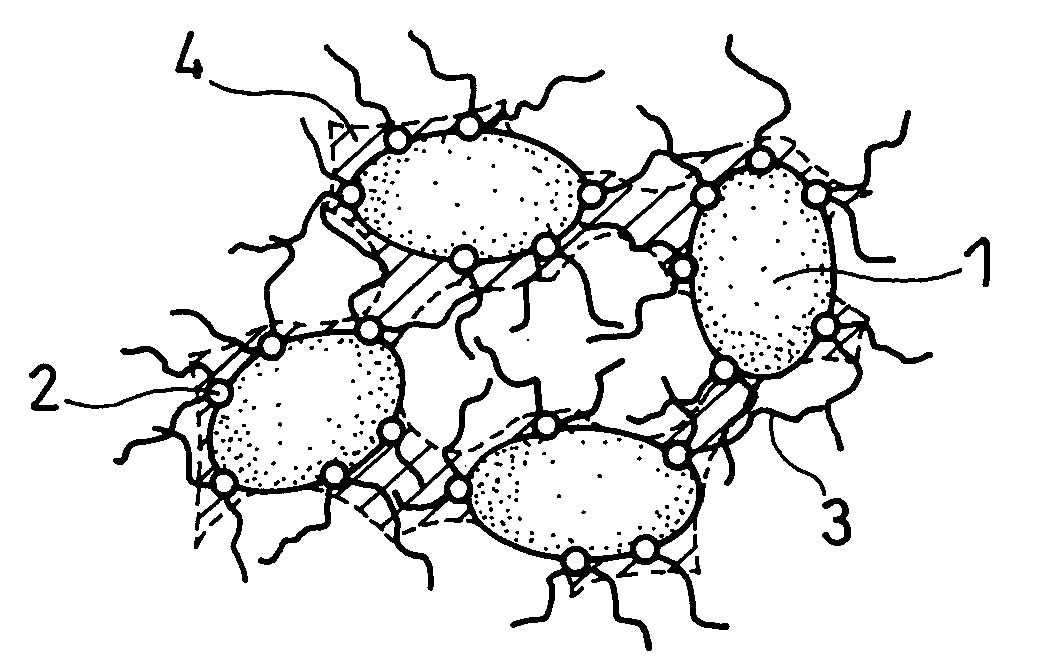

The invention features an electrode array (7) in which pairs of electrodes (1) are geometrically arranged so that the broadest faces of the exposed electrodes are not directly opposing to each other. Rather, the broadest facing surfaces of the electrodes in the array are parallel, adjacent, or offset at an angle. The electrode geometry of an electrode array of the invention permits electrodes to be in close proximity, thereby lowering series resistance, while minimizing the possibility for short circuits that can cause electrical leakage. An electrode array of the invention can be used in an electrochemical cell, such as a battery, e.g., a lithium battery, a capacitor, a flow-through capacitor, or a fuel cell.

Owner:BIOSOURCE INC

Electrical storage device and manufacturing electrical storage device

InactiveUS20060057433A1Improve breakdown voltageIncrease energy densityFinal product manufactureElectrolyte/reactants regenerationElectrode potentialShape change

An electrical storage device of the present invention is characterized in that a positive electrode, a negative electrode, a lithium electrode, and an electrolyte capable of transferring lithium ion is included, the lithium electrode is arranged to be out of direct contact with the negative electrode, and lithium ion can be supplied to the negative electrode by flowing a current between the lithium electrode and the negative electrode through an external circuit. With the above characteristic, problems such as non-uniform carrying of lithium ion to the negative electrode, shape-change of a cell, and temperature increase of an electrolytic solution under incomplete sealing of a cell and the like can be easily solved. A using method of the electrical storage device is characterized in that, by using the lithium electrode as a reference electrode, the positive electrode potential and negative electrode potential can be measured, and the potential of the positive or negative electrode can be controlled when the electrical storage device is charged or discharged. Therefore, the potentials of the positive electrode and negative electrode can be monitored, thereby it can be easily determined whether deterioration of the electrical storage device is caused by the positive electrode or the negative electrode. Also, it is possible to control the device with the potential difference between the negative electrode and reference electrode, that is, the negative potential. In addition, when characteristics deteriorate such as the internal resistance increase, an appropriate amount of lithium ion can be supplied to the negative electrode and / or positive electrode by the lithium electrode.

Owner:FUJI JUKOGYO KK

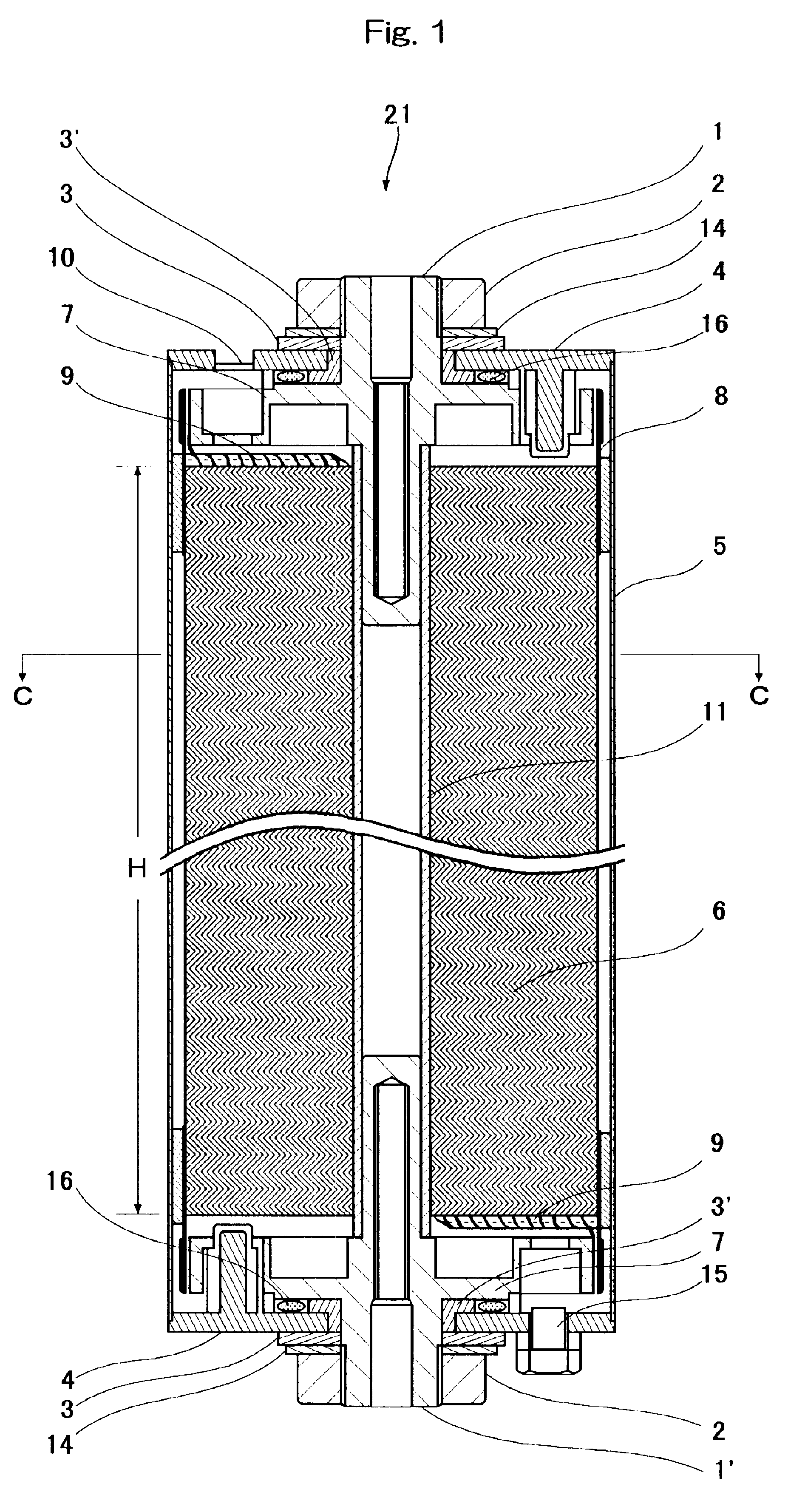

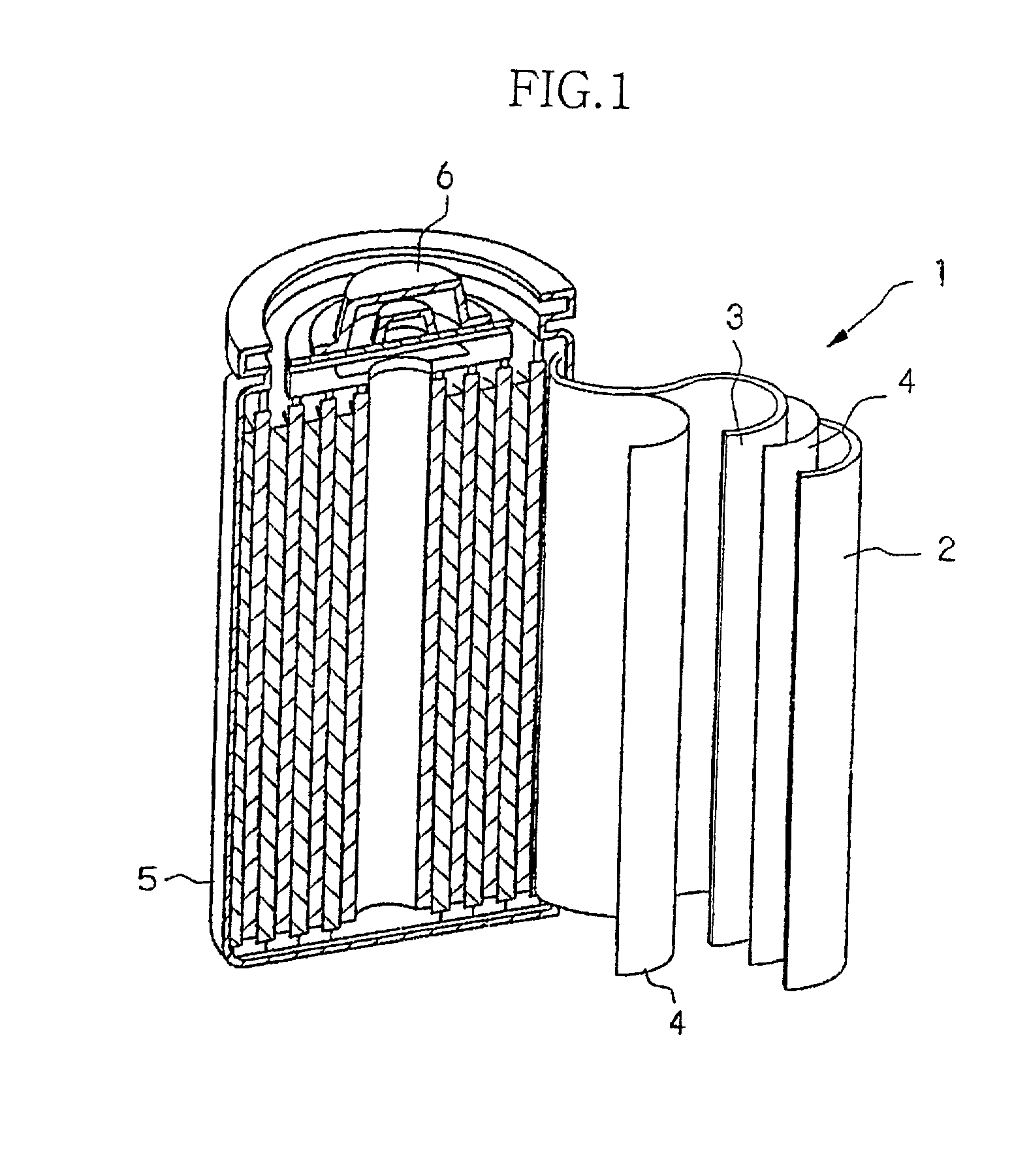

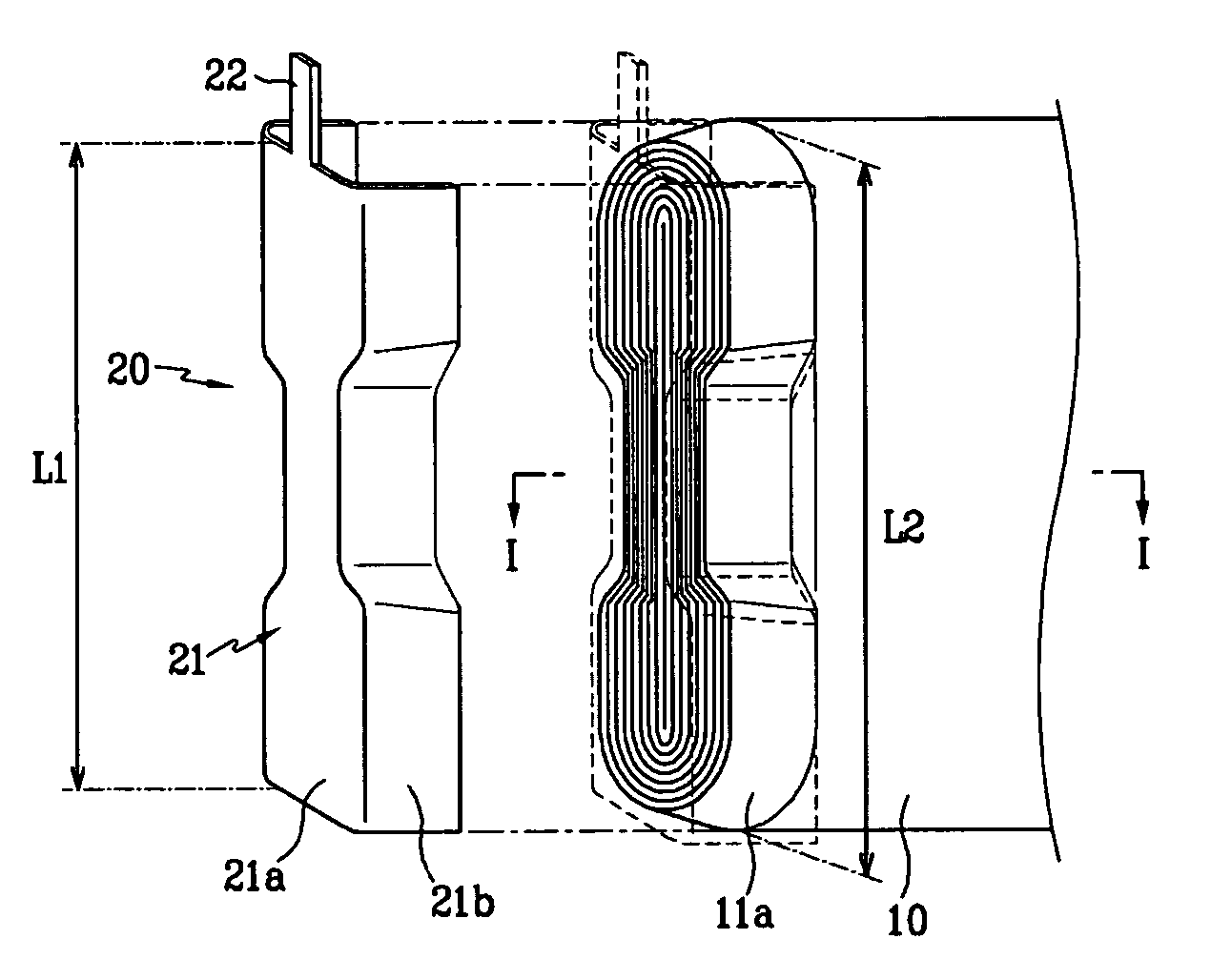

Lithium secondary cell and assembly thereof

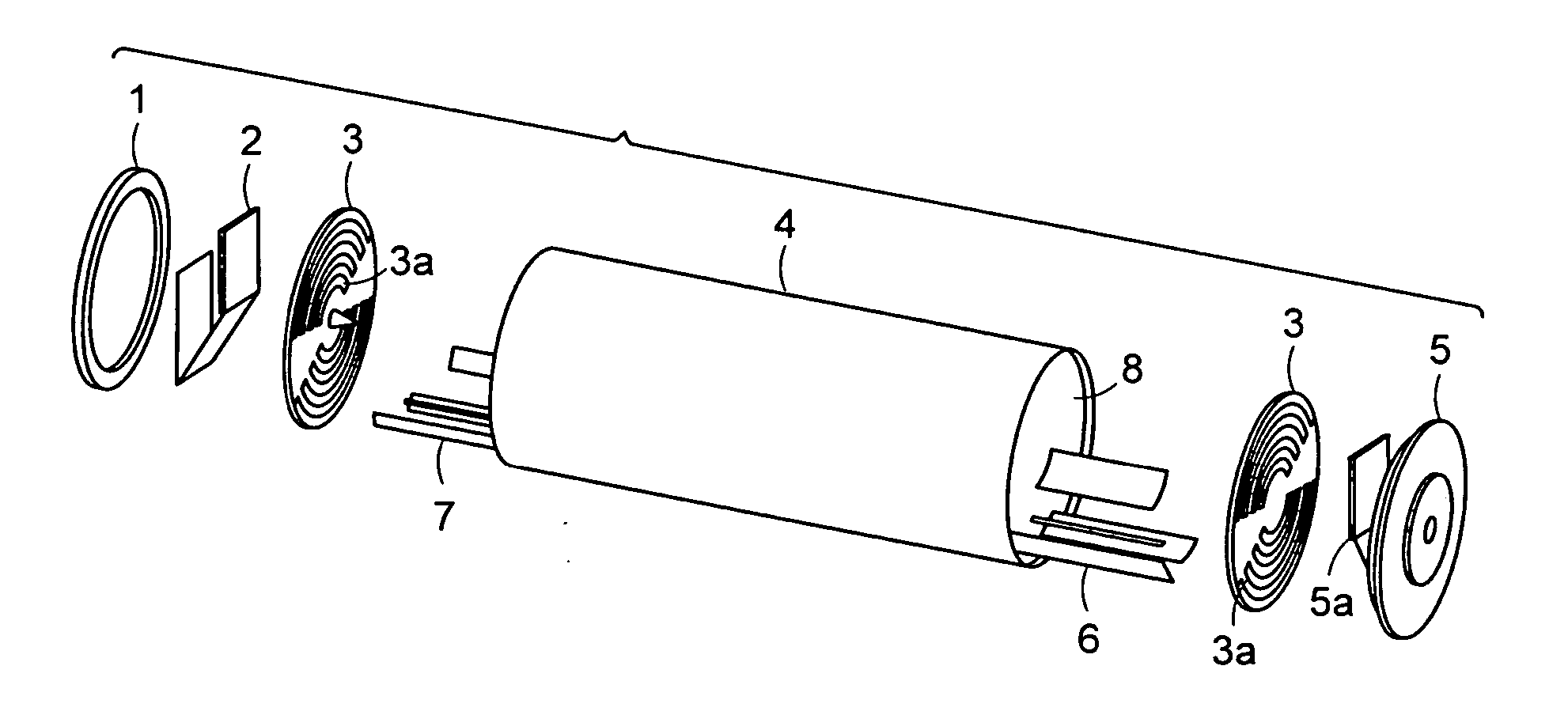

InactiveUS20010049054A1Primary cell to battery groupingNon-aqueous electrolyte accumulatorsElastomerLithium

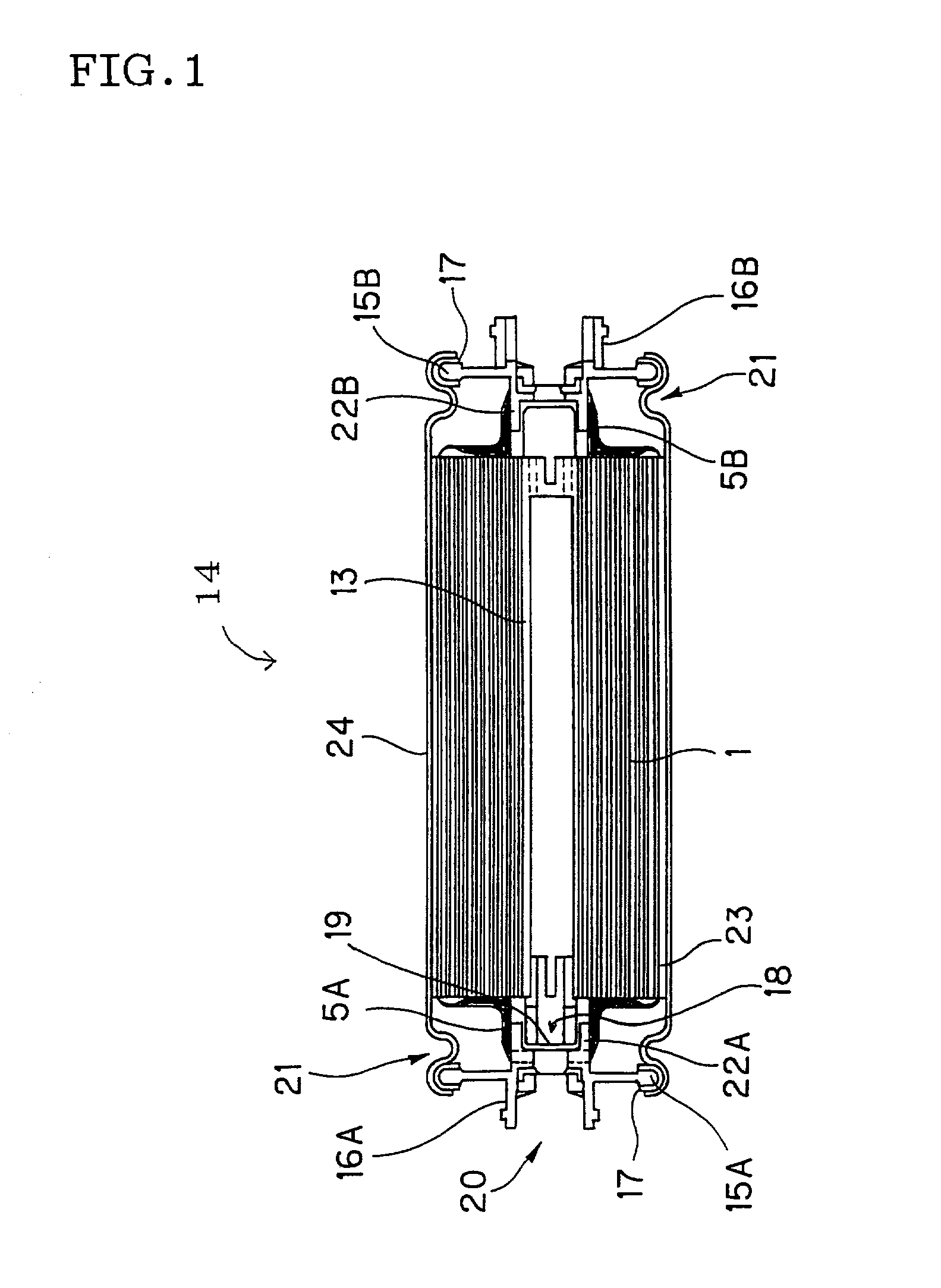

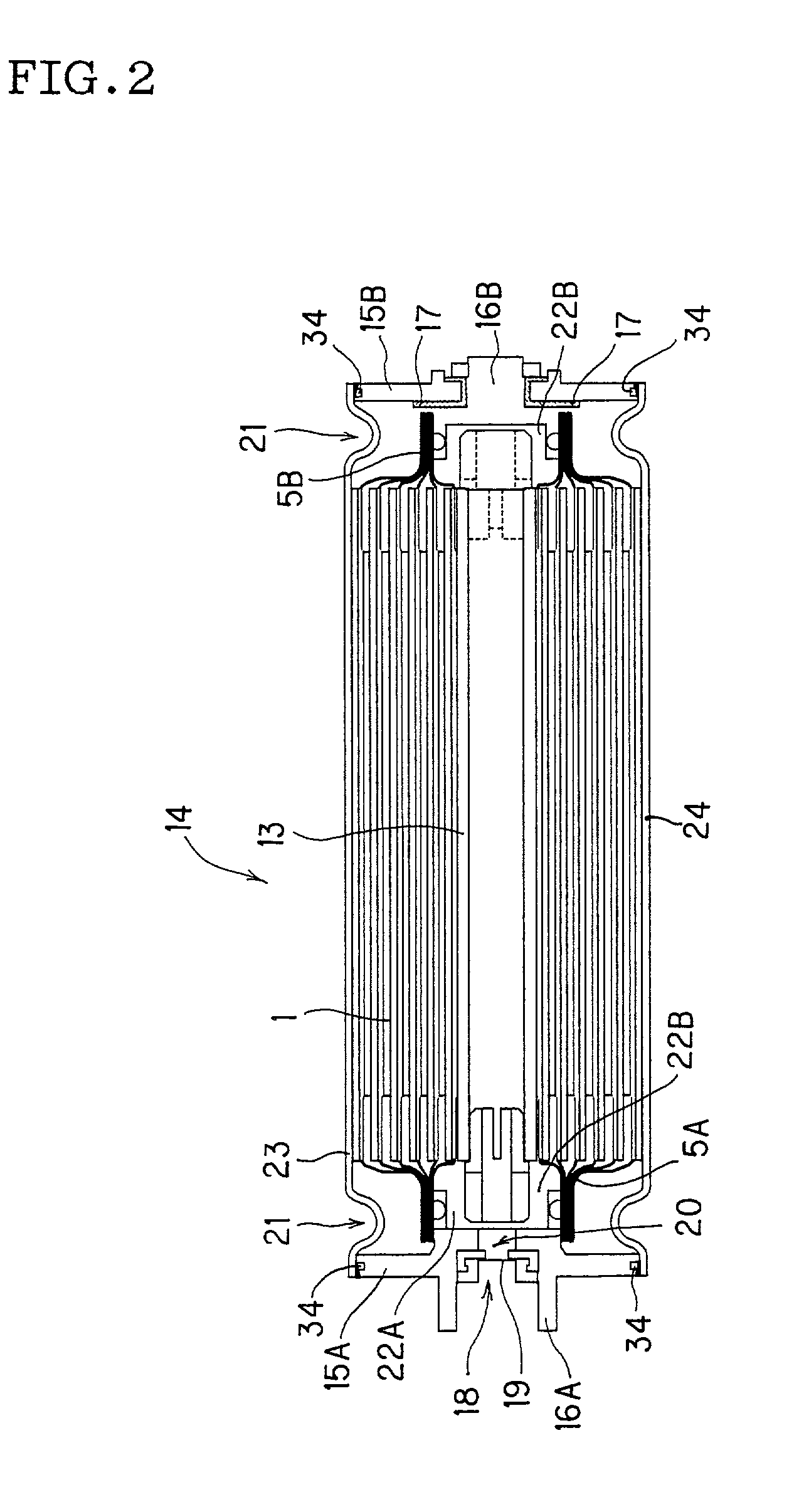

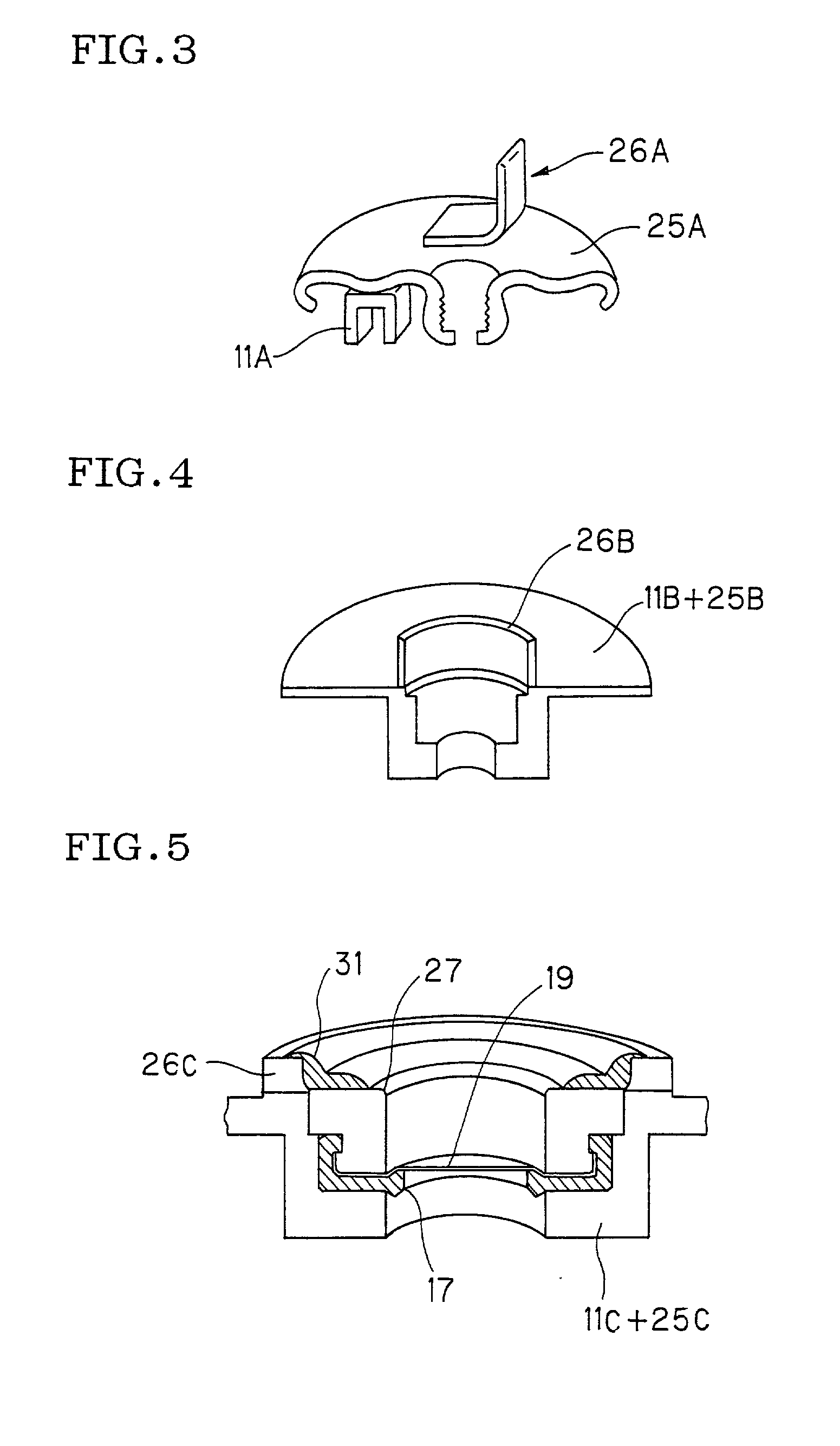

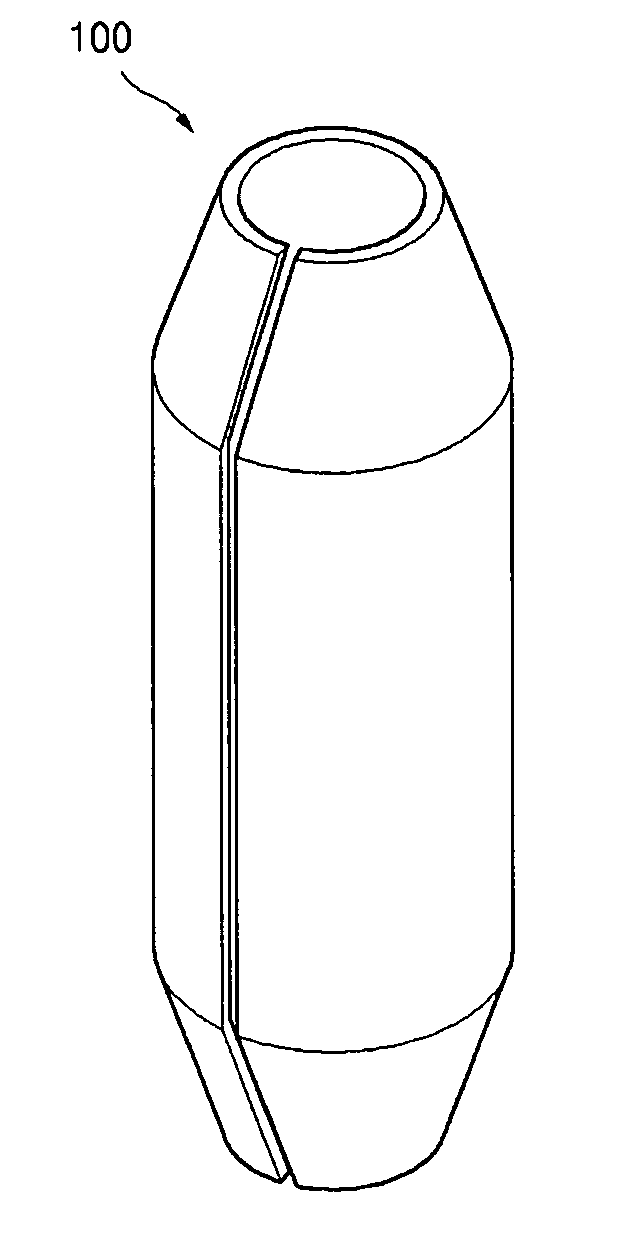

To provide a lithium secondary cell, which is excellent in productivity since a cell structure is simple and easy for assembly. Provided is a lithium secondary cell having: an internal electrode body including a positive electrode plate, a negative electrode plate, the positive electrode plate and the negative electrode plate being wound and laminated around an external periphery wall of a hollow cylindrical winding core, and inside the internal electrode body a nonaqueous electrolyte solution being impregnated, a cylindrical cell case contained in this internal electrode body 1 with both ends being opened, and two electrode caps sealing the above described internal electrode body 1 at both the open ends of this cell case. The electrode cap has a plate member sealing the internal electrode body and disposed so as to seal both the open ends of the above described cell case, an external terminal member protruding onto the surface of the electrode caps to lead out currents to outside, and an internal terminal member brought into connection with the internal electrode body and taking out currents from the internal electrode body, and an elastic body and at least two of the above described plate member, the external terminal member and the internal terminal member are joined together for construction. Furthermore, there is also provided an assembly of lithium secondary cells.

Owner:NGK INSULATORS LTD

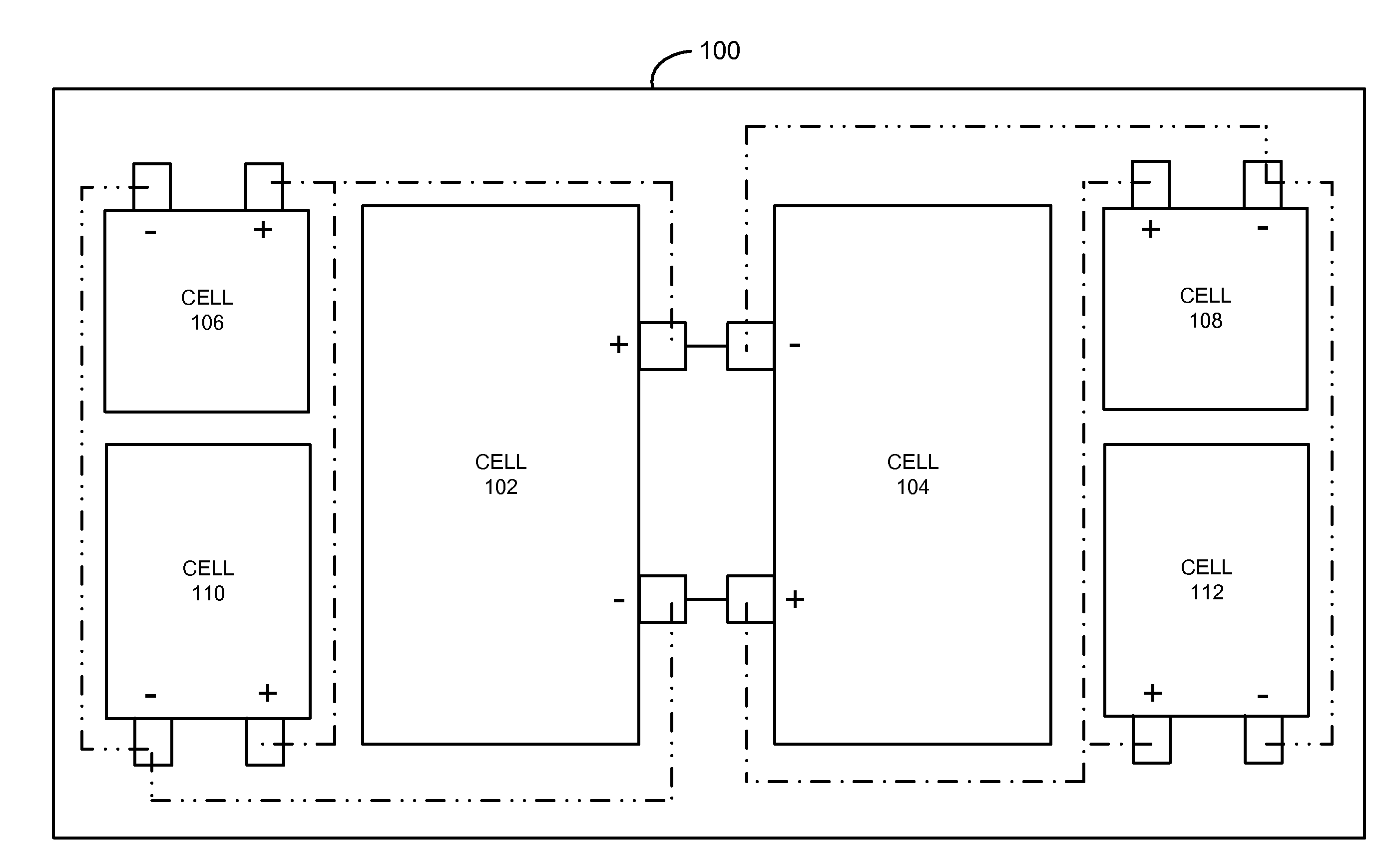

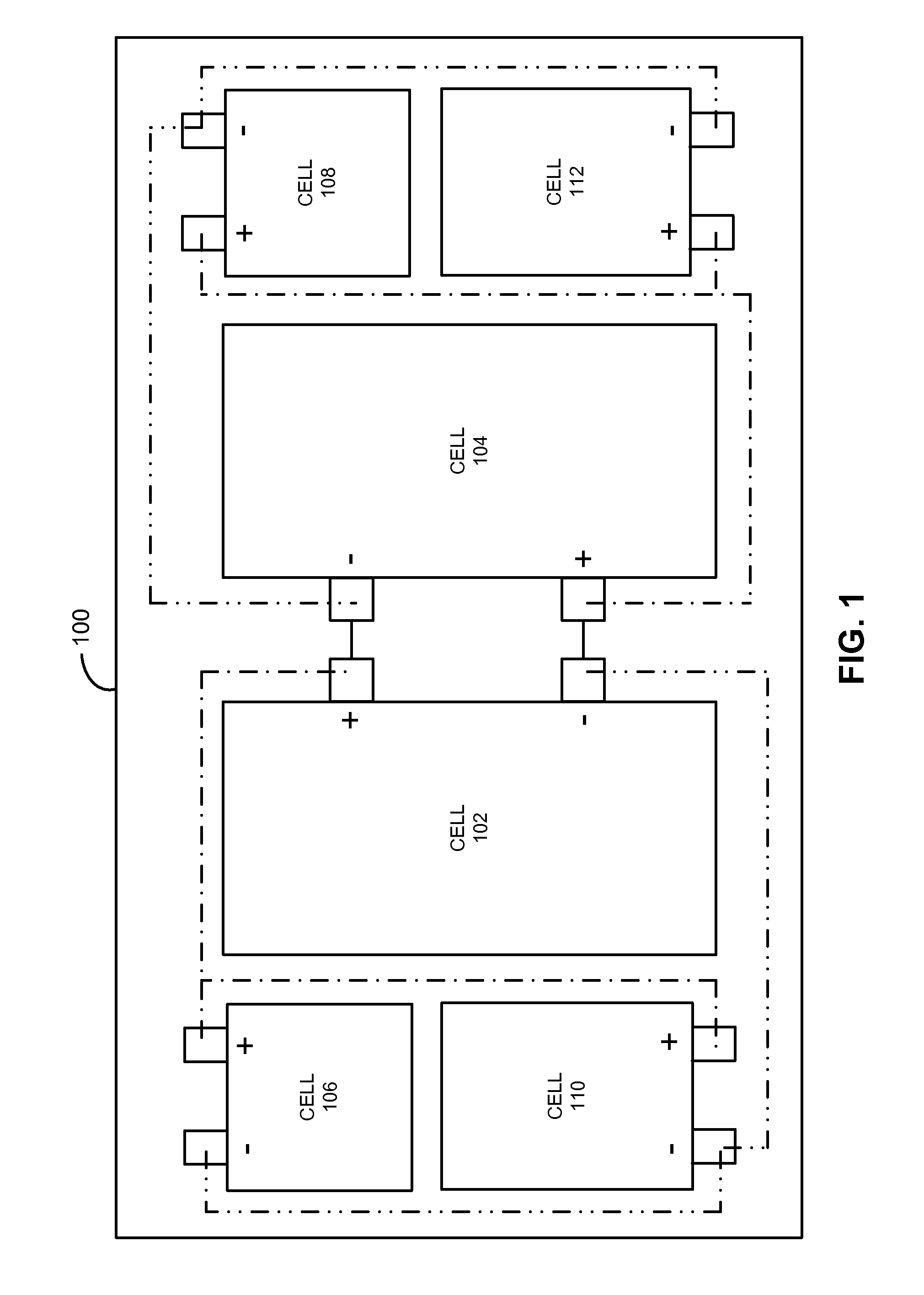

Battery pack with cells of different capacities

ActiveUS20120015223A1Facilitate efficient use of spacePrimary cell to battery groupingSolid electrolytesElectrical batteryEngineering

The disclosed embodiments provide a battery pack for use with a portable electronic device. The battery pack includes a first set of cells with different capacities electrically coupled in a parallel configuration. Cells within the first set of cells may also have different thicknesses and / or dimensions. The first set of cells is arranged within the battery pack to facilitate efficient use of space within a portable electronic device. For example, the first set of cells may be arranged to accommodate components in the portable electronic device.

Owner:APPLE INC

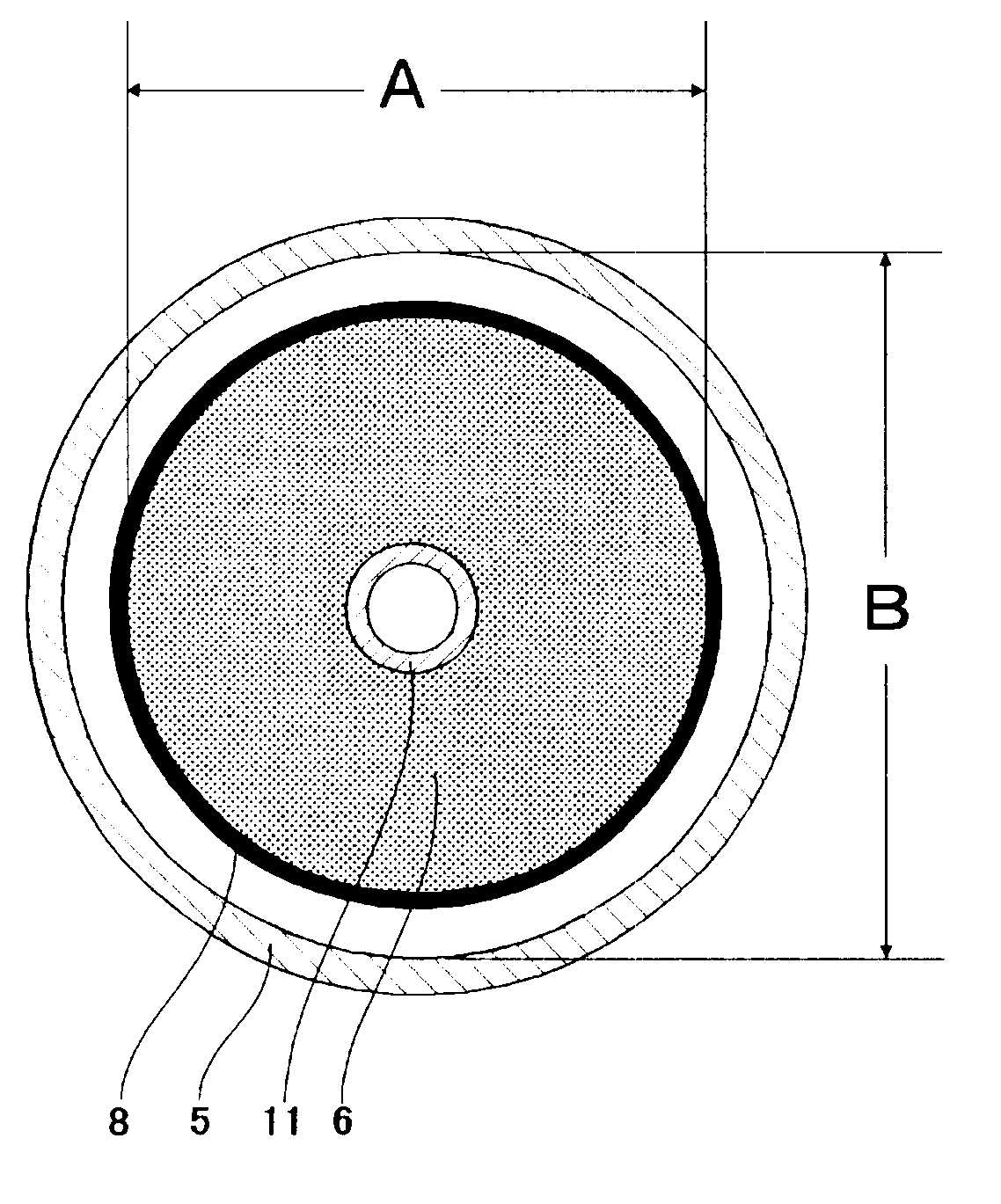

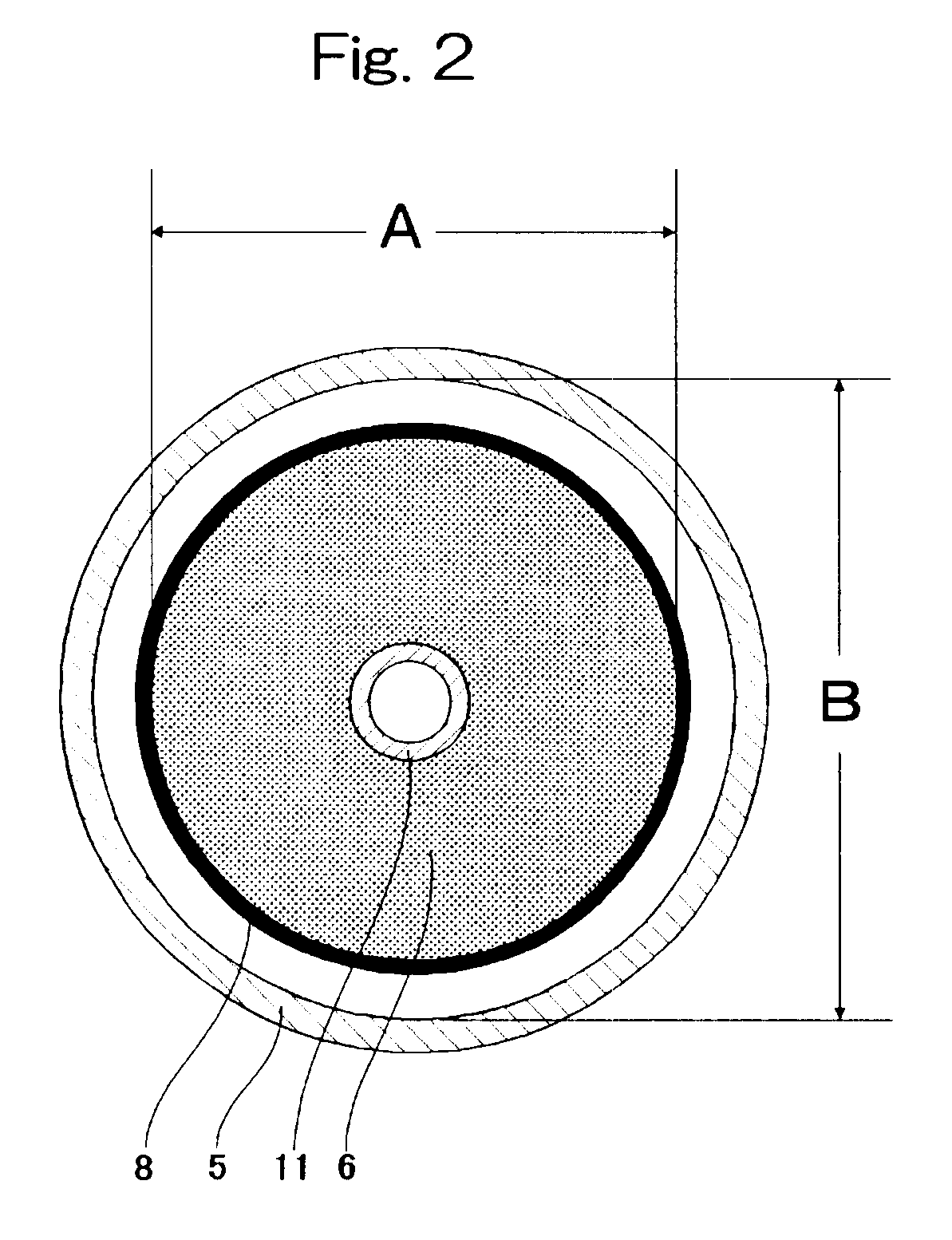

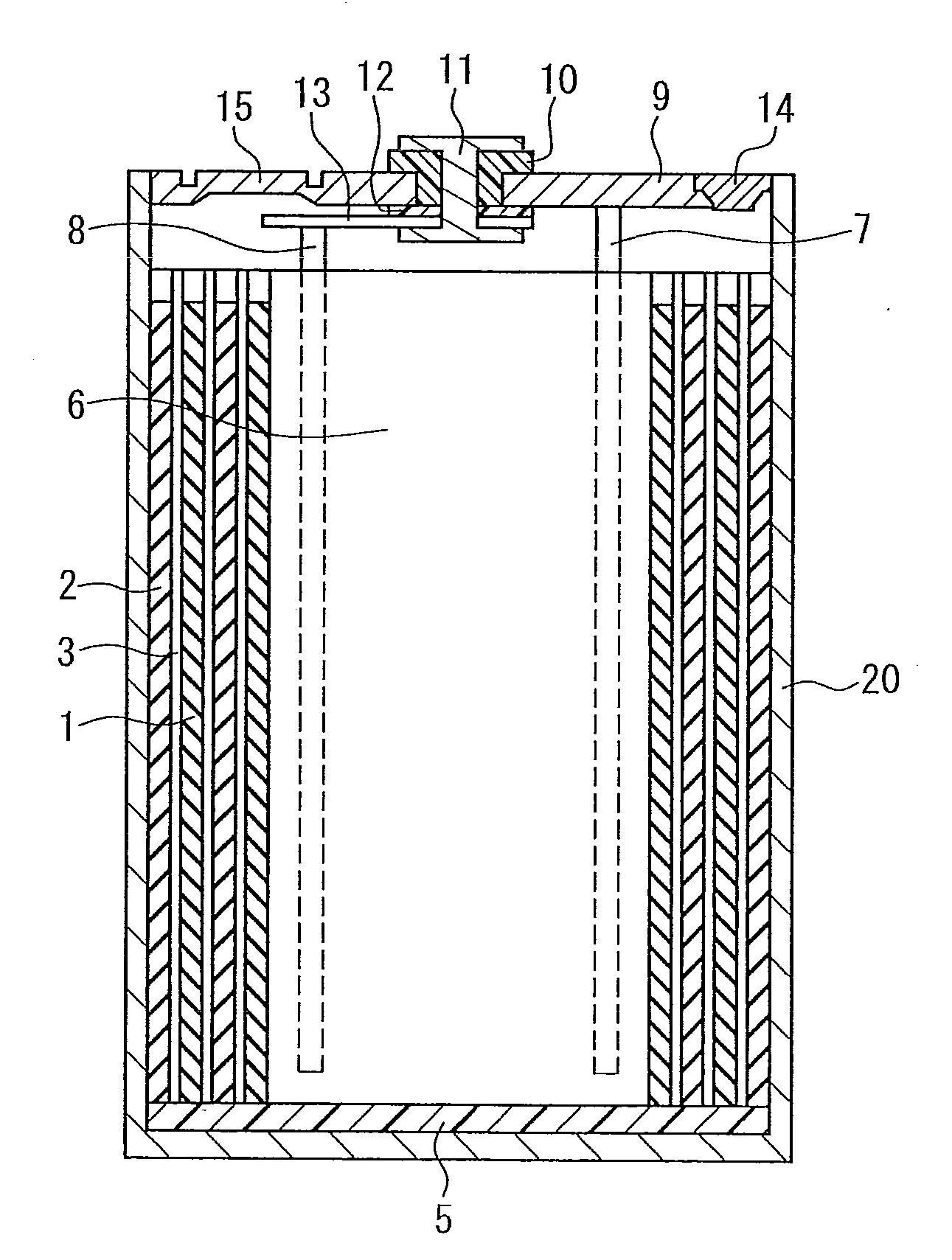

Cylindrical lithium-ion battery

InactiveUS6509114B1Non-aqueous electrolyte accumulatorsFinal product manufactureEngineeringLithium-ion battery

A cylindrical lithium-ion battery with excellent safety where abnormal heat generation and remarkable deformation of a battery container do not occur even at an abnormal time is provided. When an average diameter of a winding group 6 is A mm, an inner diameter of the battery container 5 is B mm, a longitudinal length of the winding group 6 except for lead pieces extending from the winding group 6 is H mm, and the number of windings where a layer of one unit comprising a negative electrode member / separator / negative electrode member / separator is wound around a shaft core 11 is W, a calculation value K obtained by a formula; K=(B-A)x(10000 / (WxH) is set to 0.89 or more. When the calculation value K is 0.89 or more, a gap (B-A) between an outer periphery of the winding group 6 and an inner periphery of the battery container 5 that enables the winding group 6 to expand in its diameter direction at an abnormal time is properly secured.

Owner:HITACHI VEHICLE ENERGY

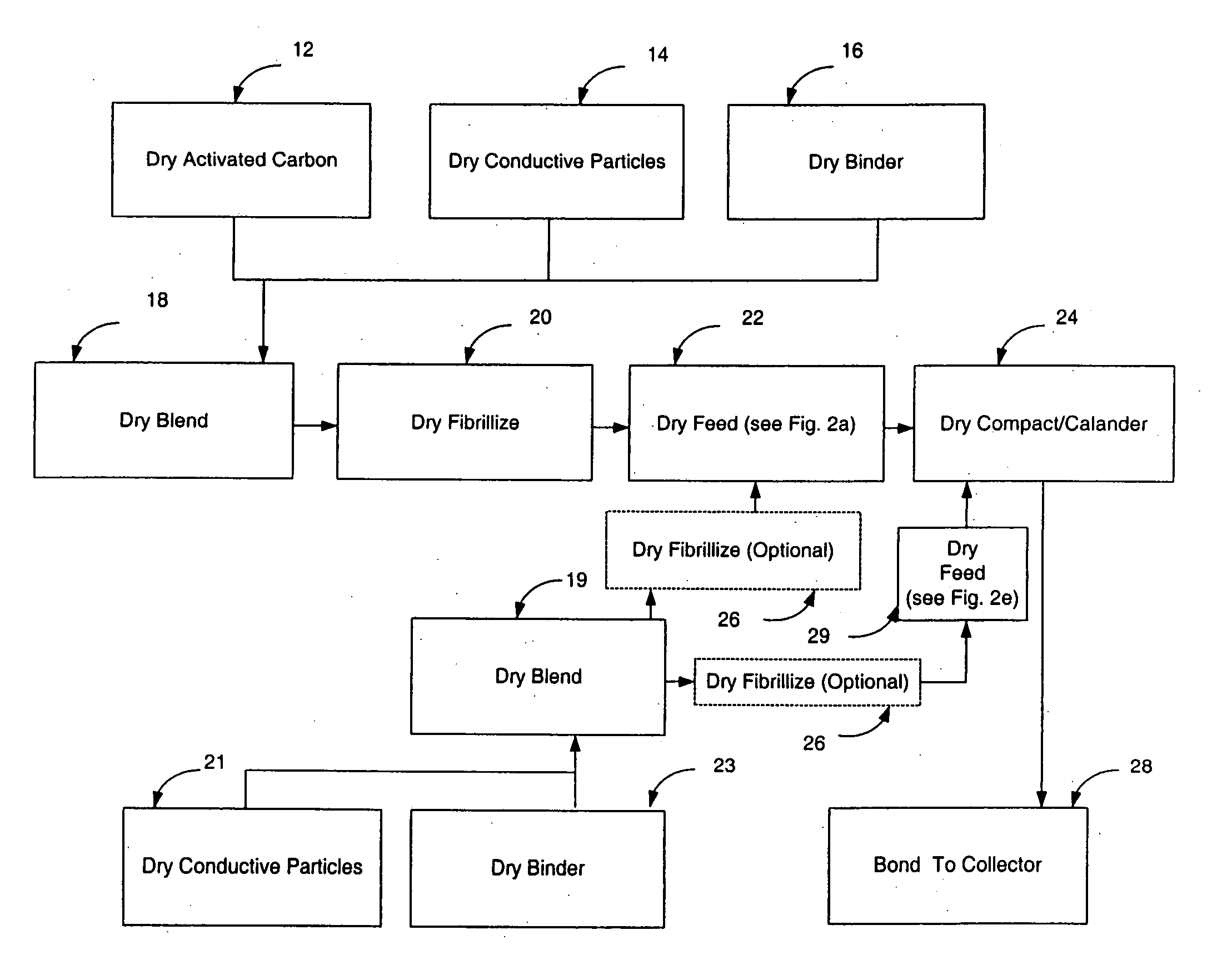

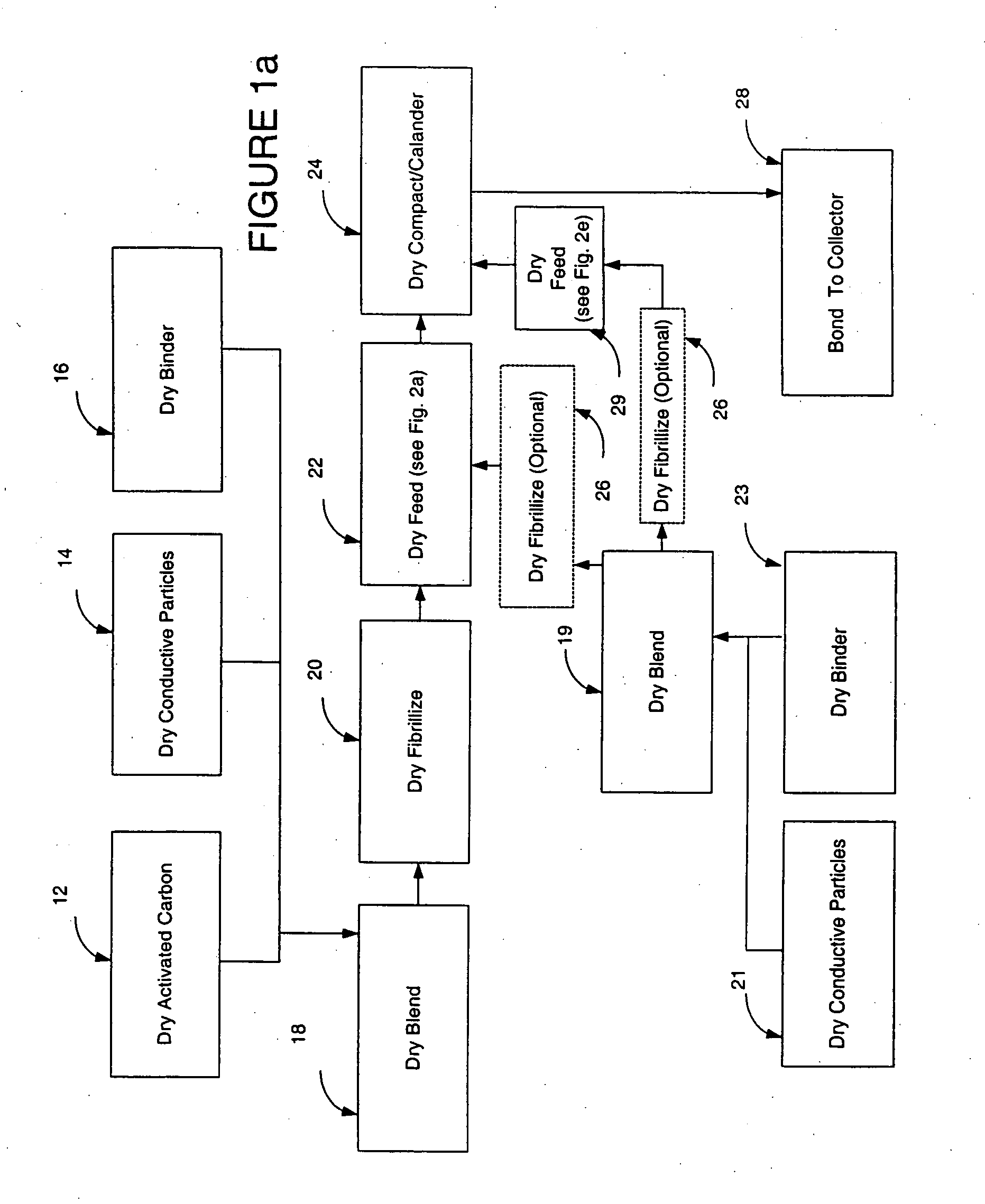

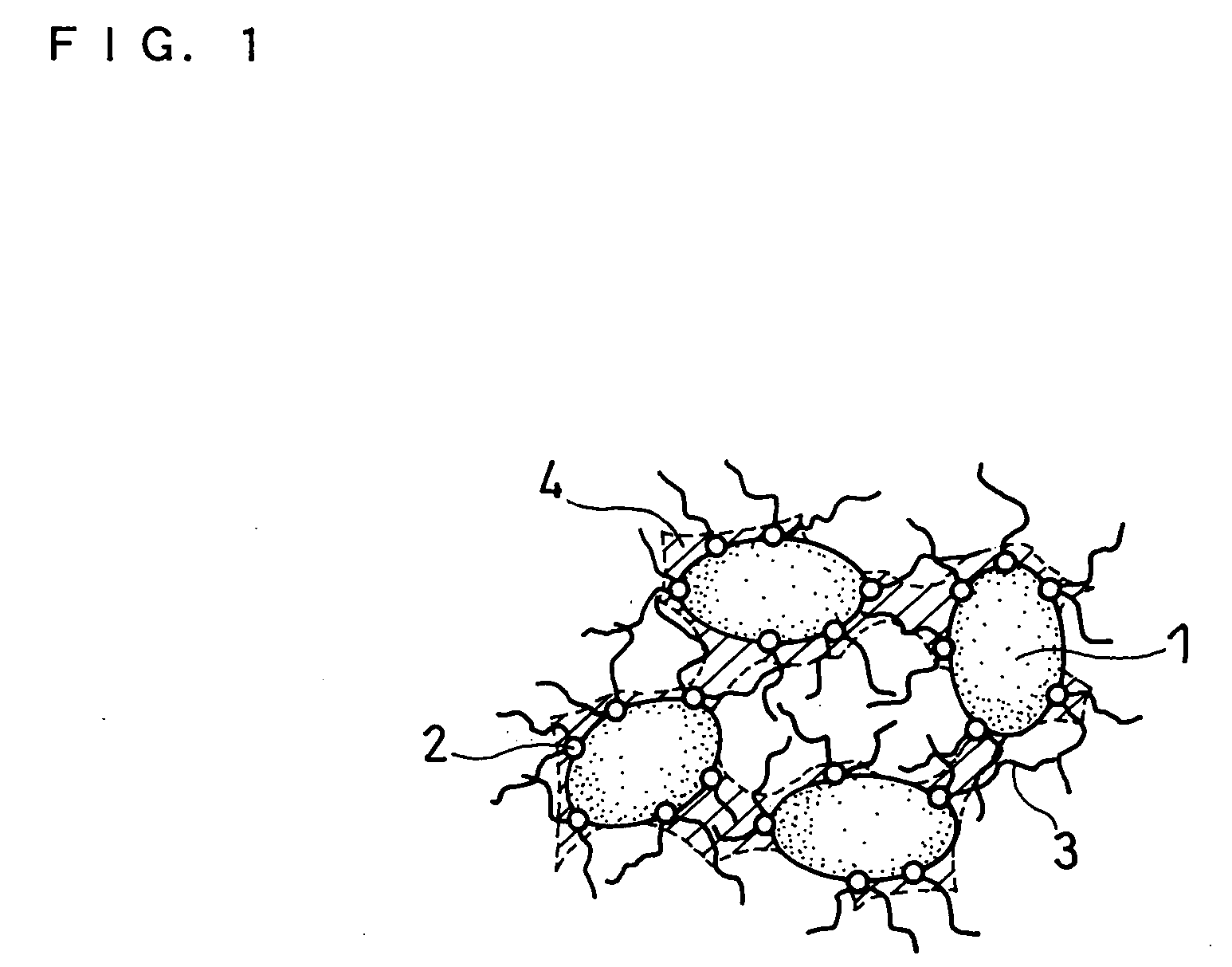

Dry particle based electro-chemical device and methods of making same

InactiveUS20050266298A1Reduce usageHigh yieldElectrode rolling/calenderingFinal product manufactureFuel cellsBiochemical engineering

A dry process-based electro-chemical device and method for making a self-supporting dry electrode film for use therein is disclosed. Cost effective manufacture of electrochemical devices such as batteries, capacitors, and fuel cells is enabled.

Owner:TESLA INC

Negative active material for rechargeable lithium battery and method of preparing same

InactiveUS20020009646A1Increase energy densityImprove cycle lifeElectrode manufacturing processesNon-aqueous electrolyte accumulatorsCarbon filmGraphite particle

Owner:SAMSUNG SDI CO LTD

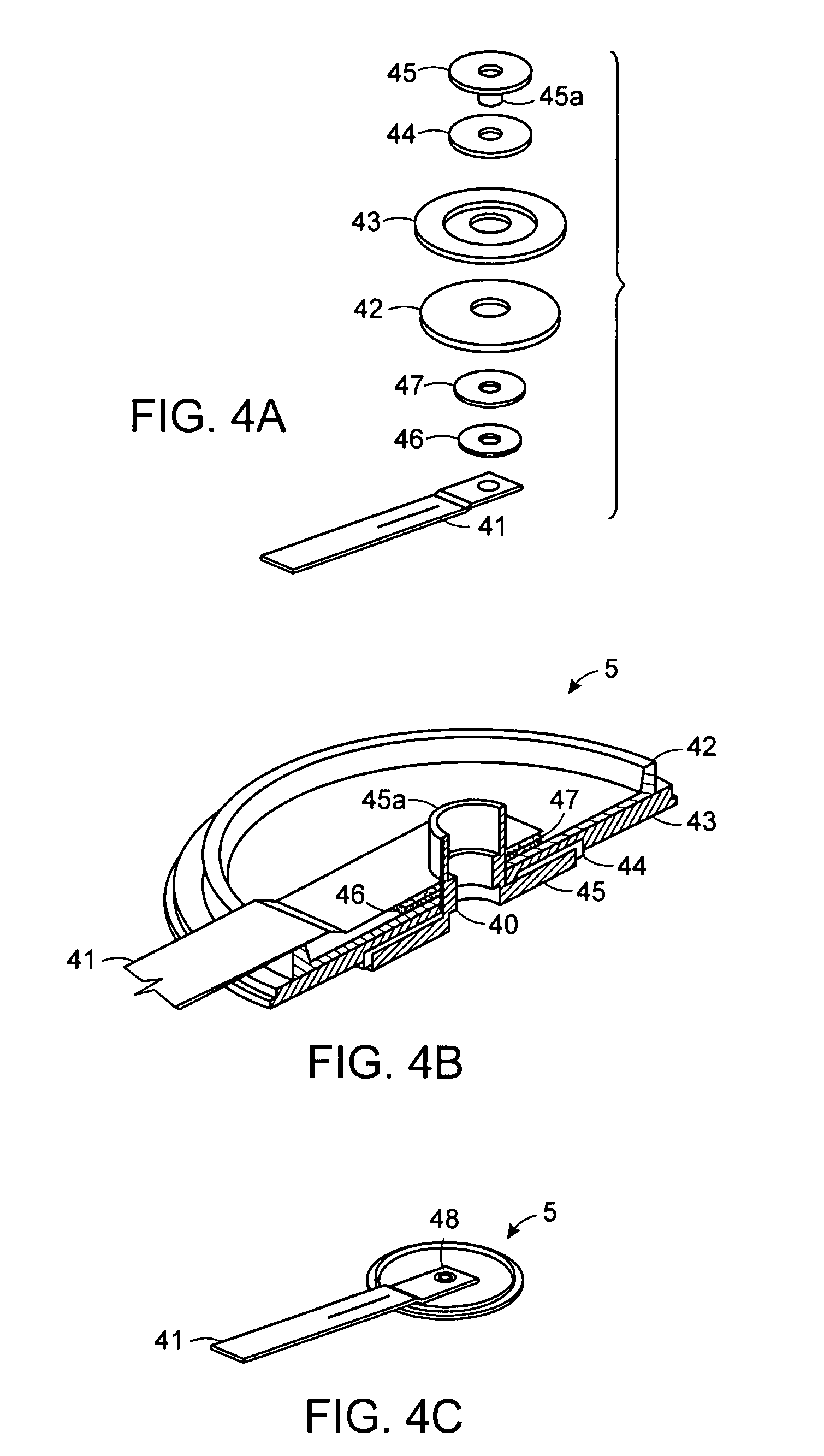

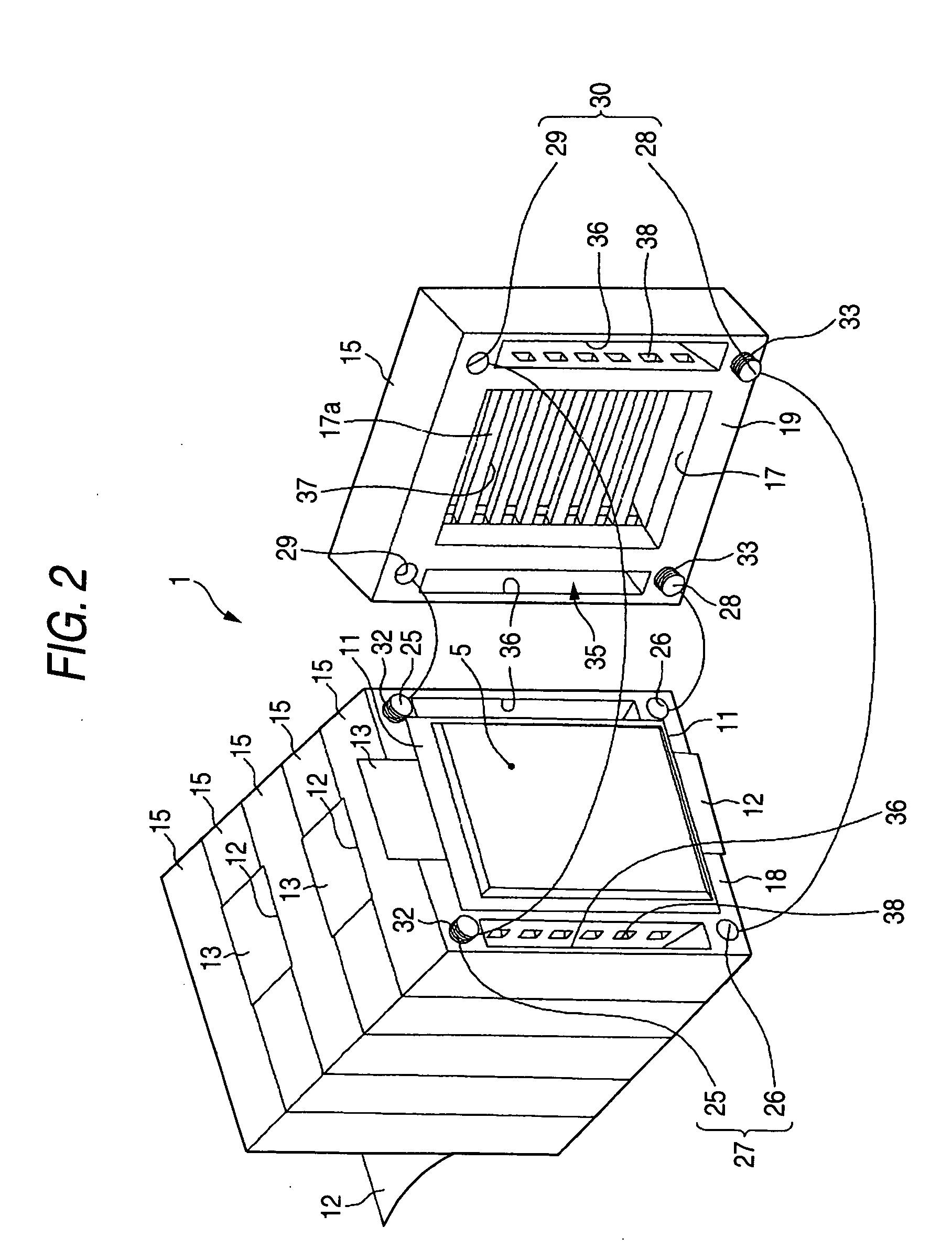

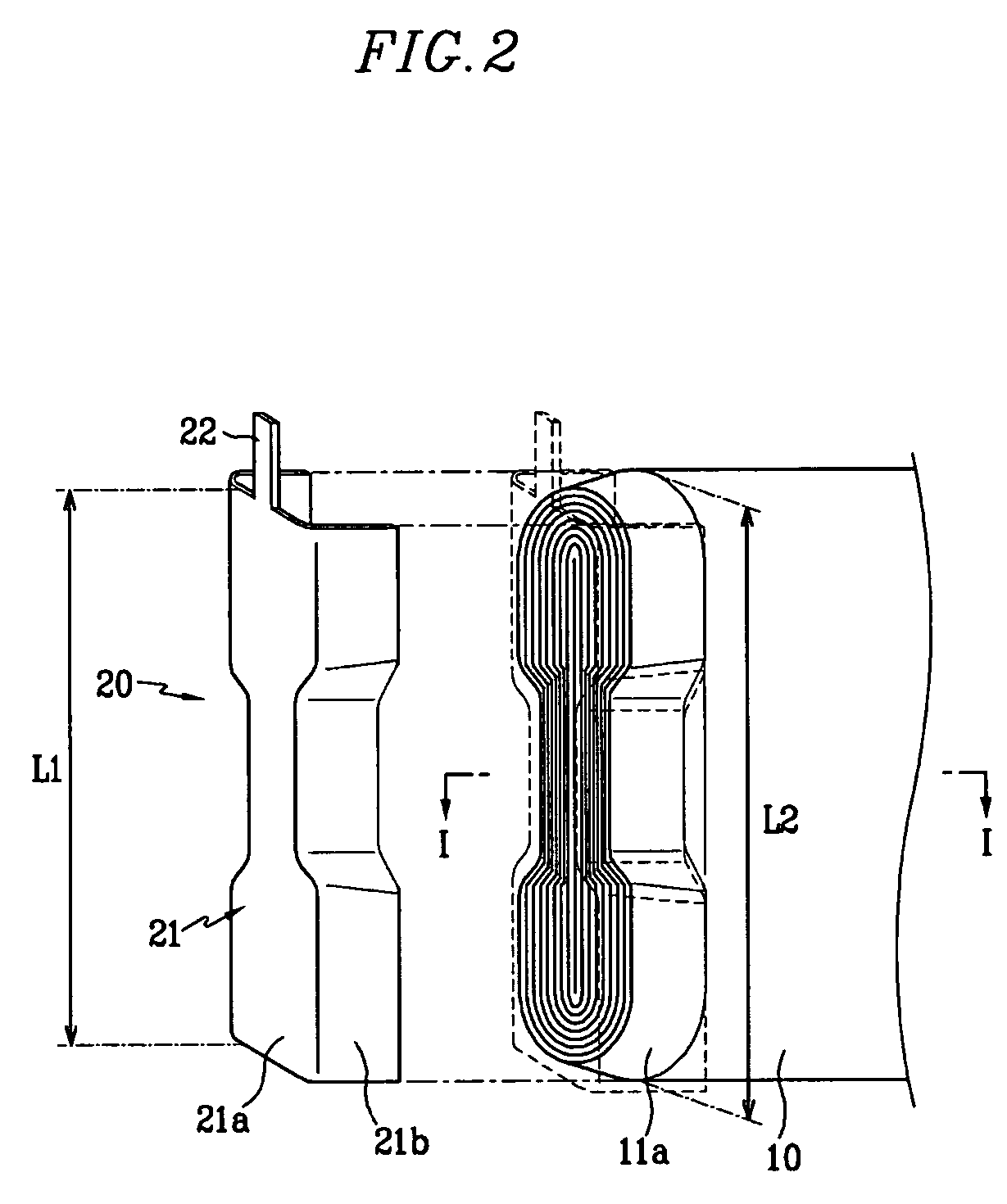

Battery assembly manufacturing method

InactiveUS20100190049A1Efficient preparationPrimary cell to battery groupingAssembling battery machinesElectrical and Electronics engineering

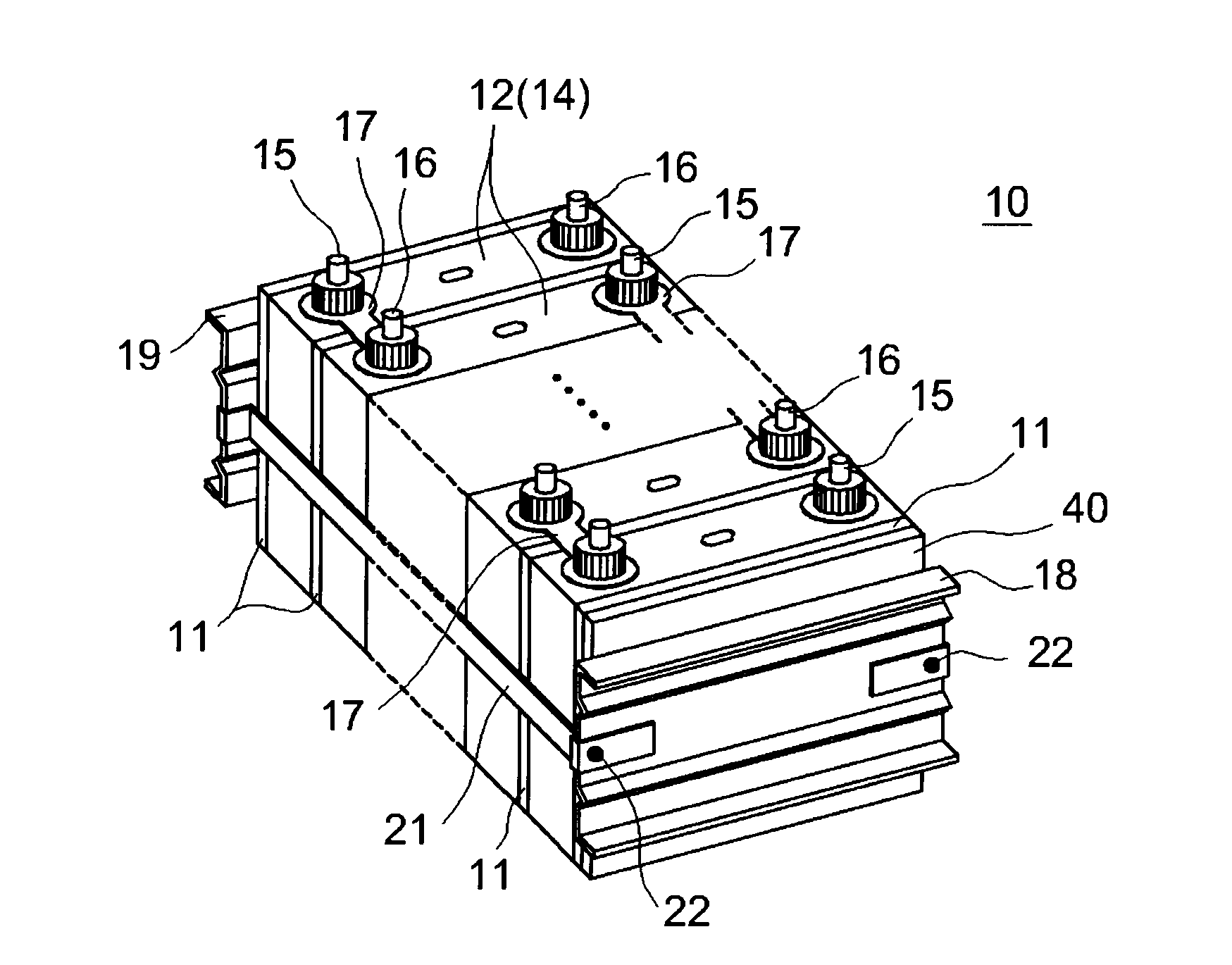

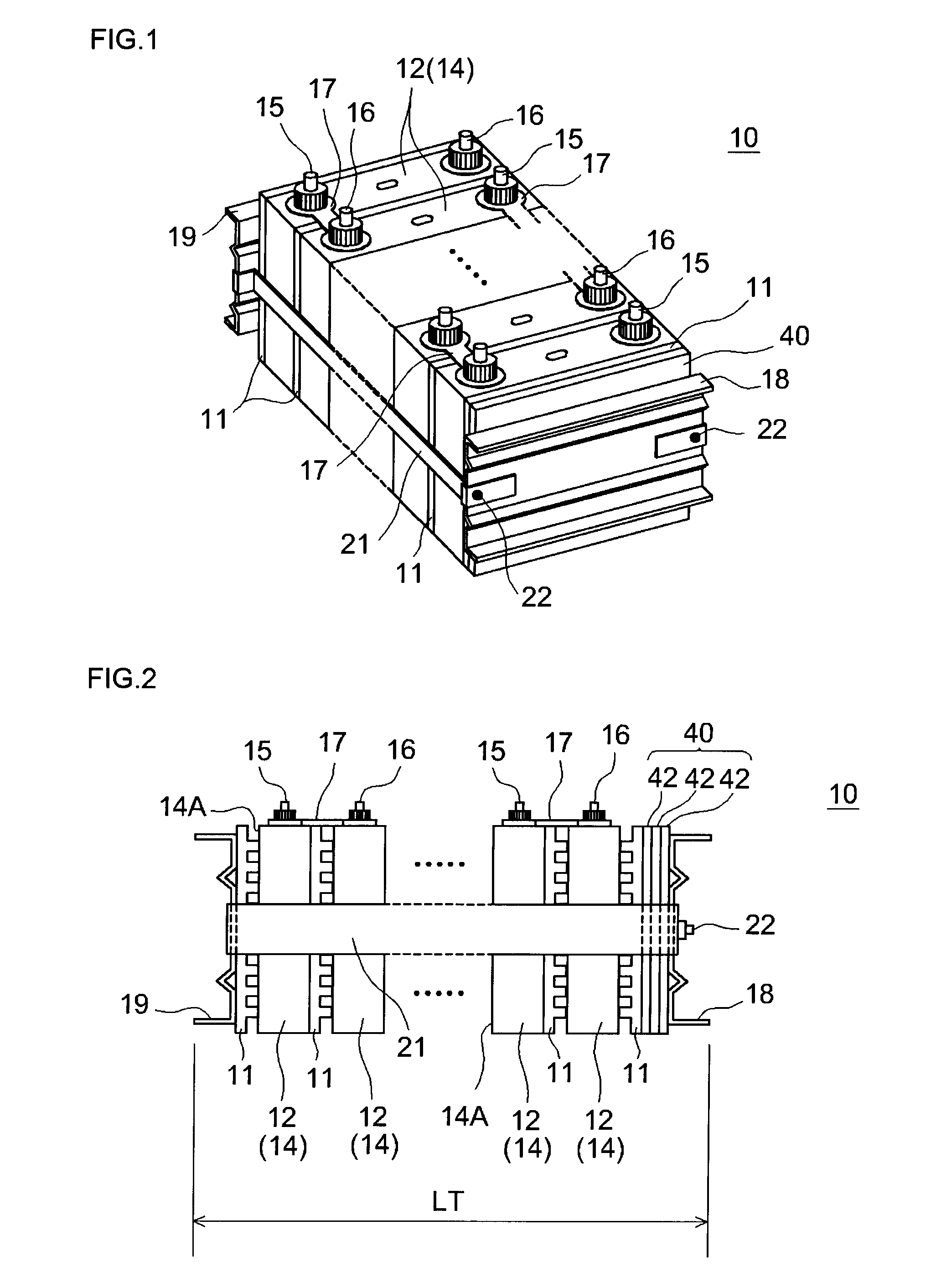

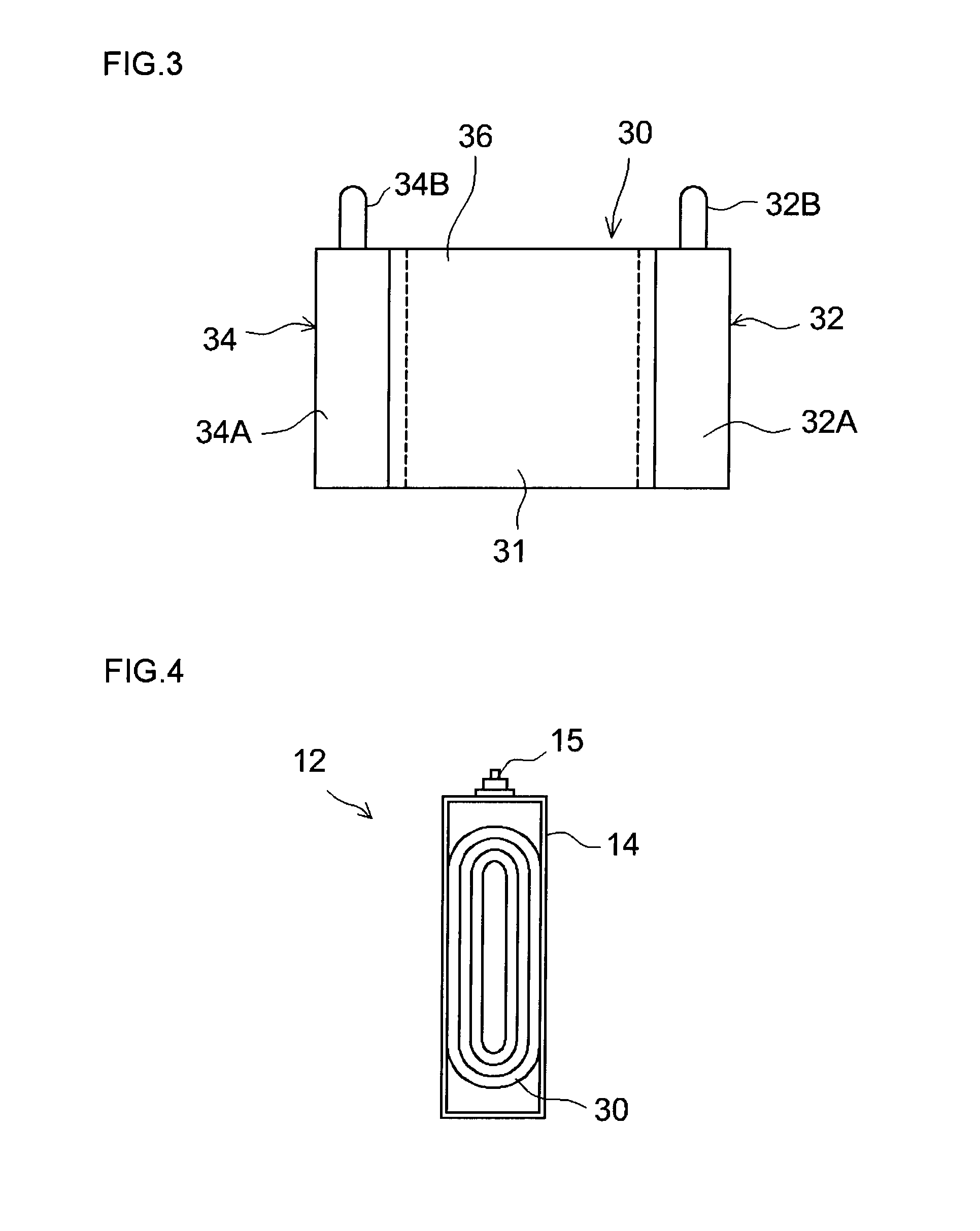

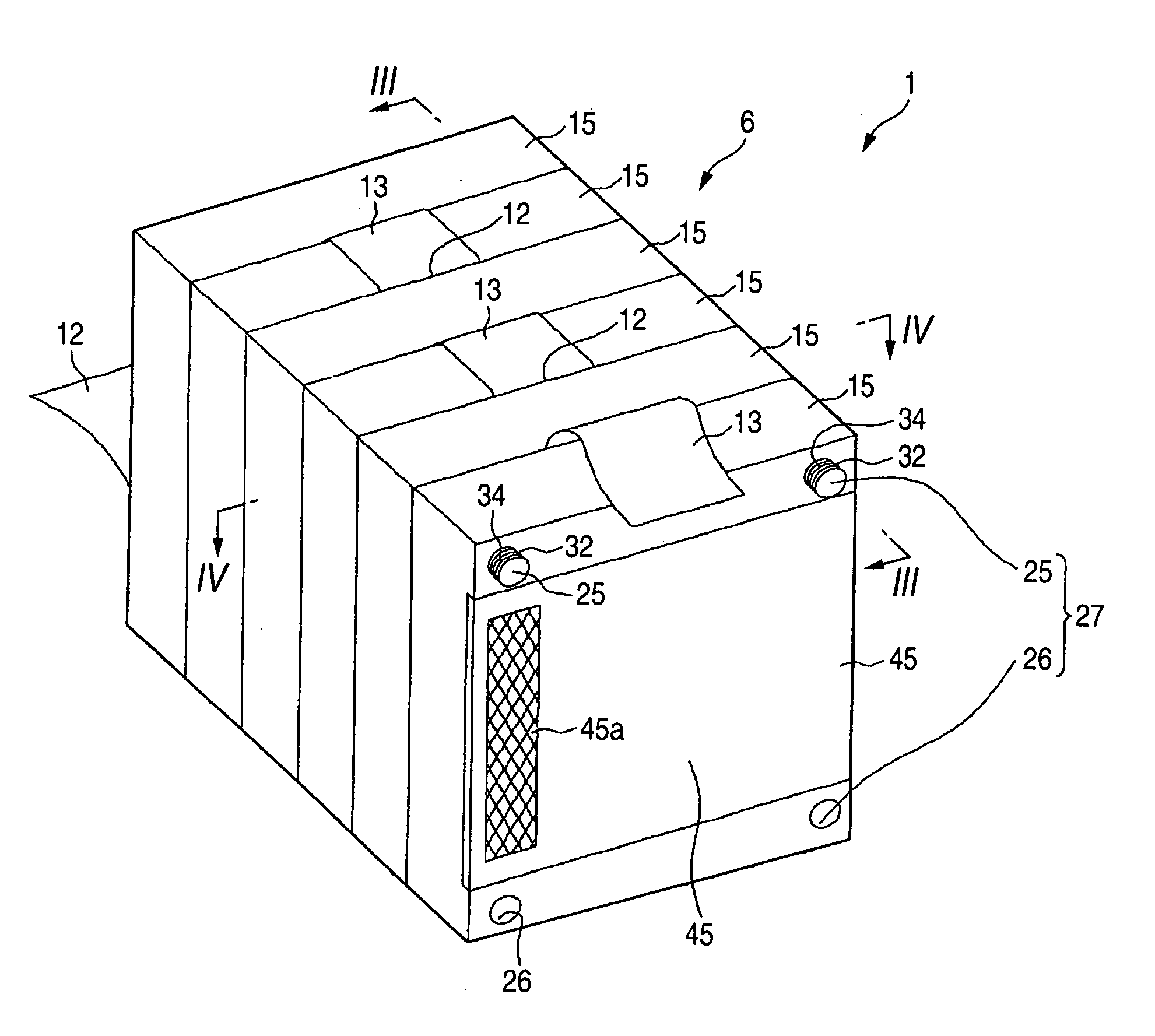

A method for manufacturing a battery assembly provided by the present invention includes a step of measuring a stacking direction length of a stacked body including a predetermined number of unit cells (12) constituting a battery assembly (10) and arranged in the stacking direction; and a step of bundling a body (20) to be bundled that includes the stacked body. Here, the body to be bundled is provided with length adjusting means (40) for converging a spread in stacking direction length. The bundling step is implemented by setting the length adjusting means according to the stacking direction length of the stacked body, so that a length of the battery assembly in the stacking direction is a stipulated length (LT) and a bundling pressure of the body to be bundled is a stipulated pressure.

Owner:TOYOTA JIDOSHA KK

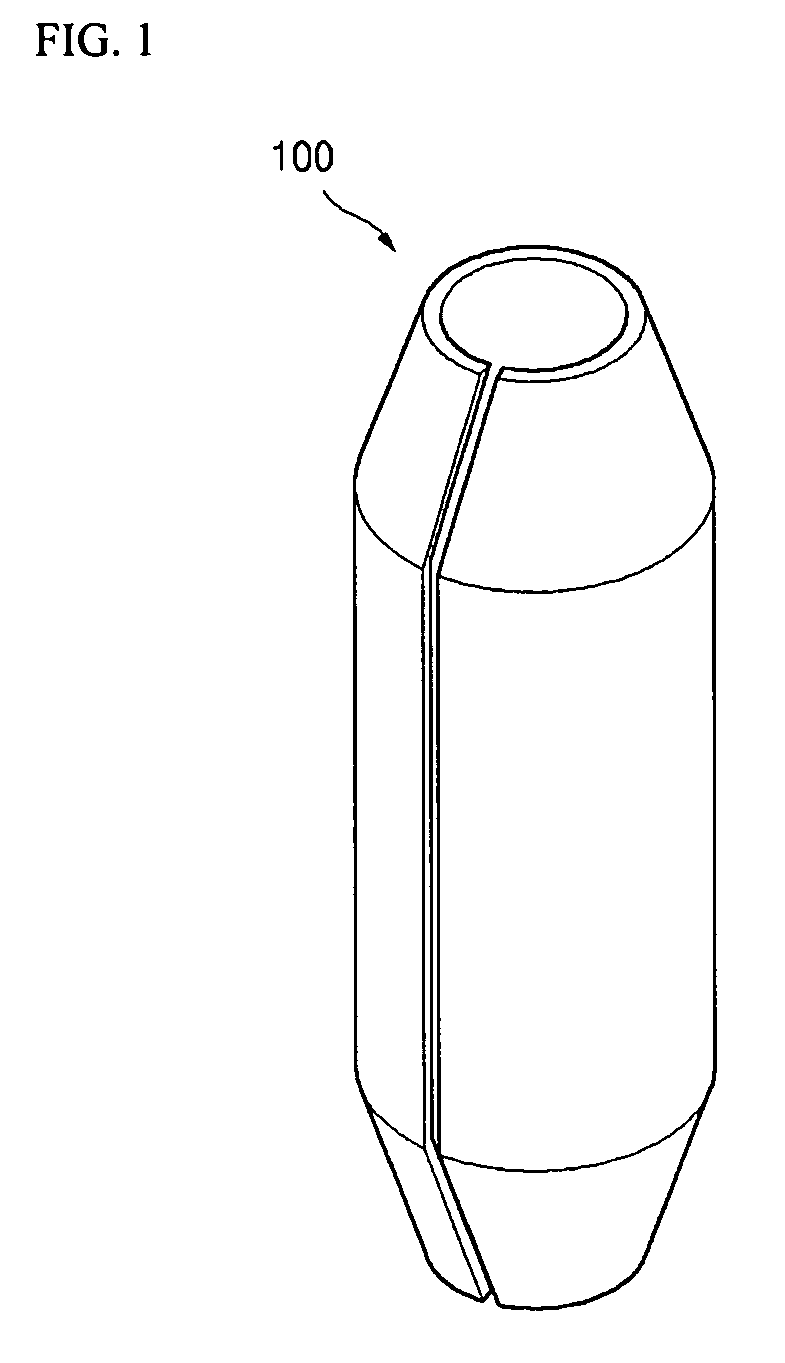

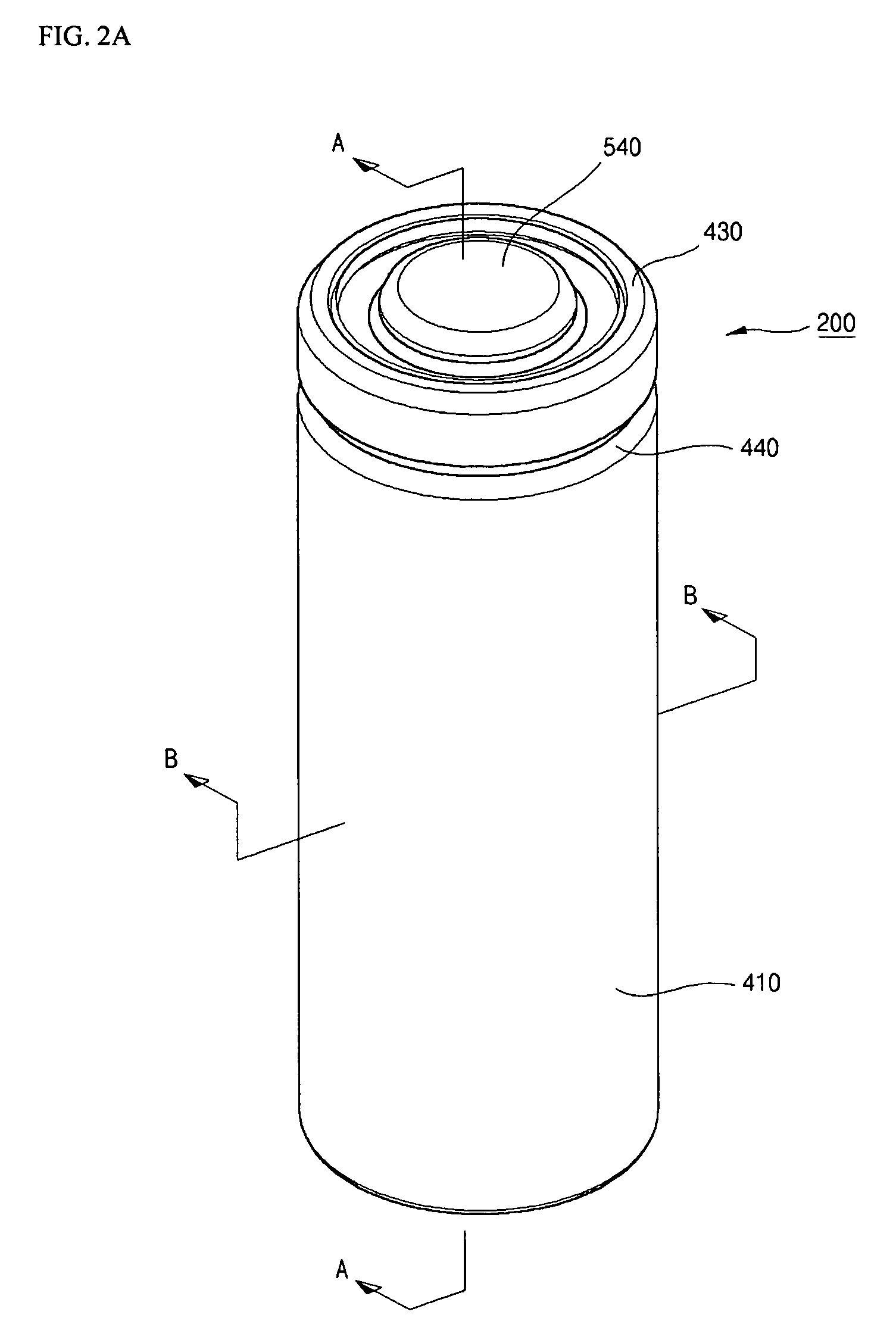

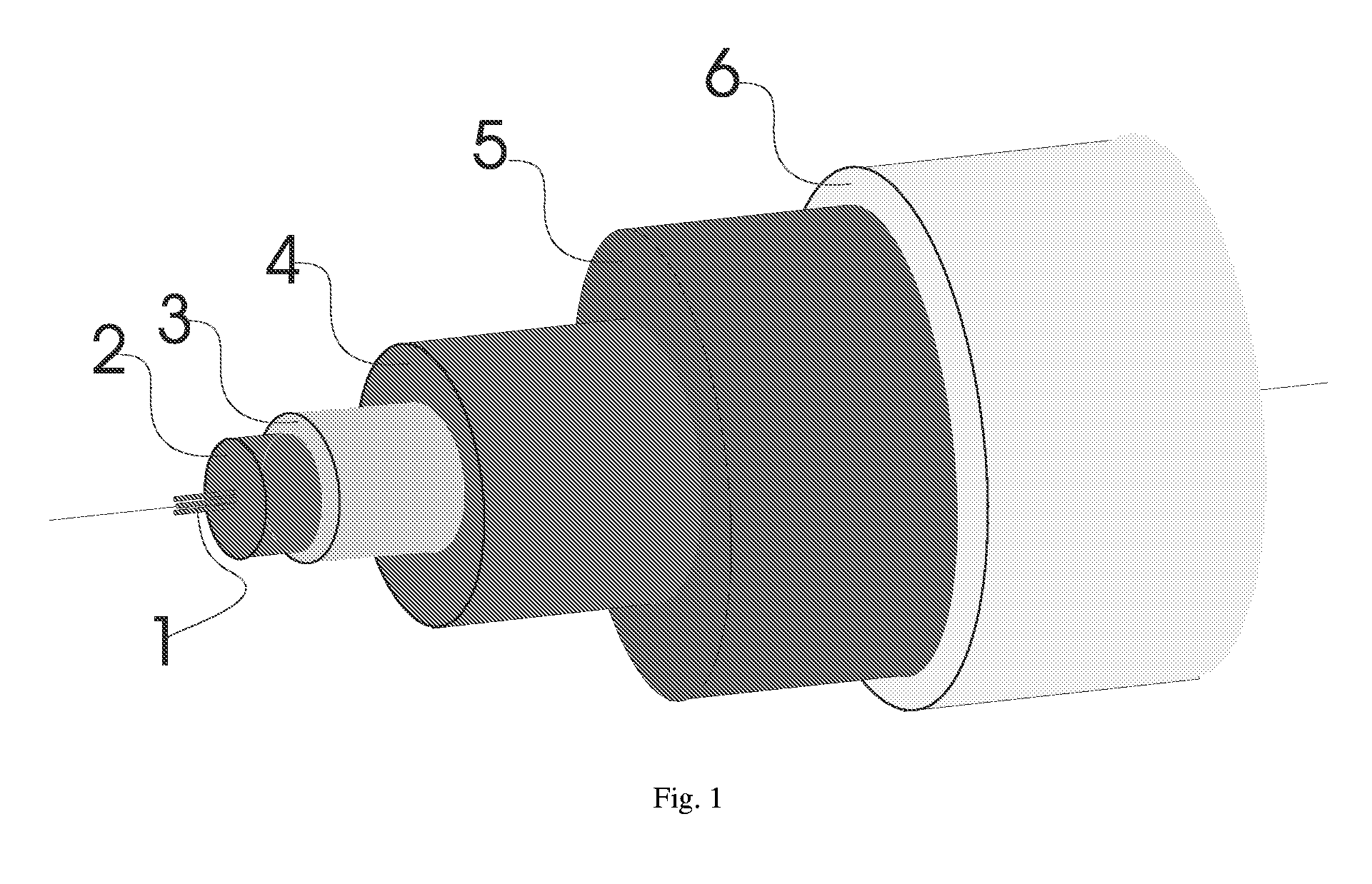

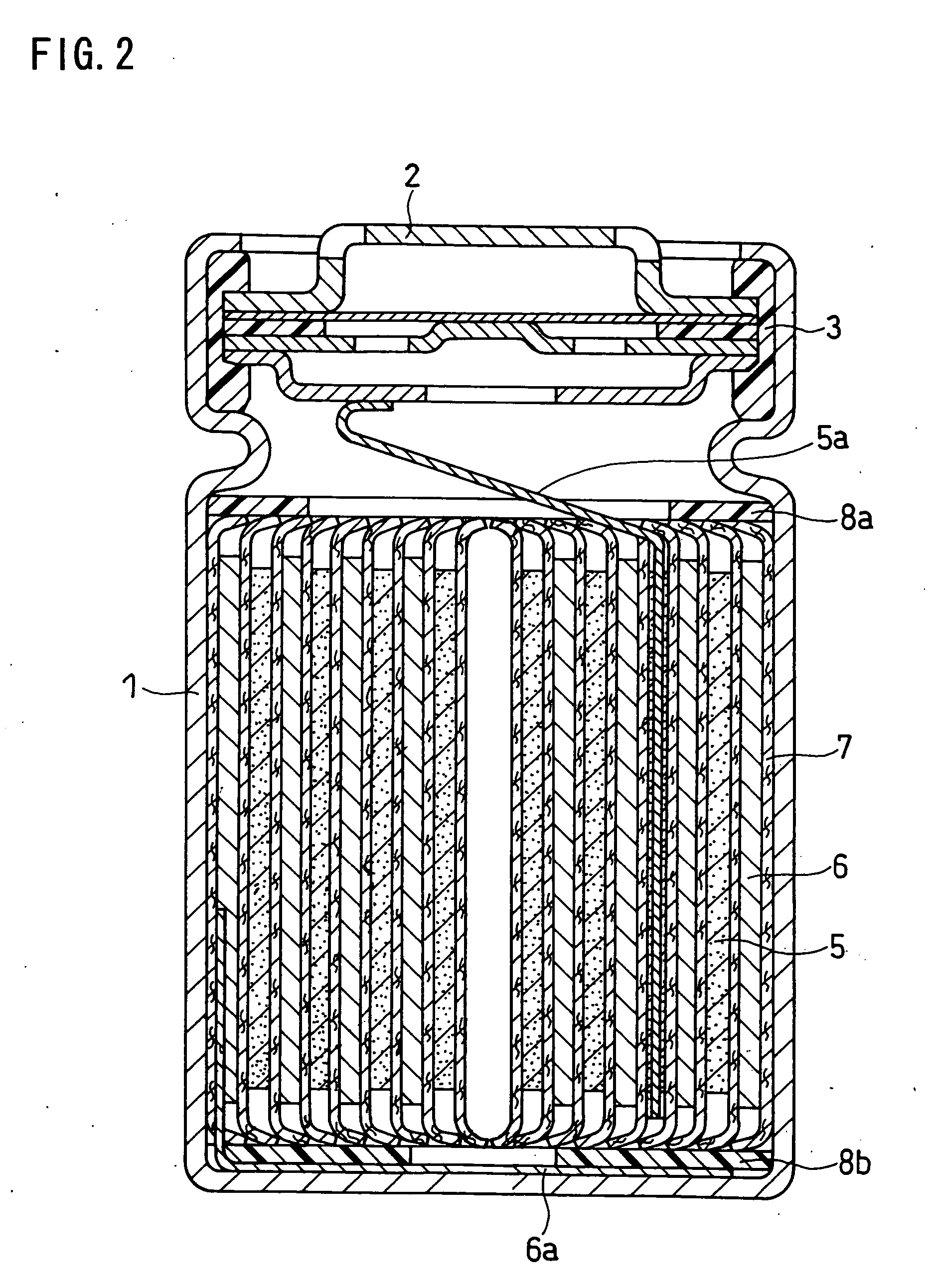

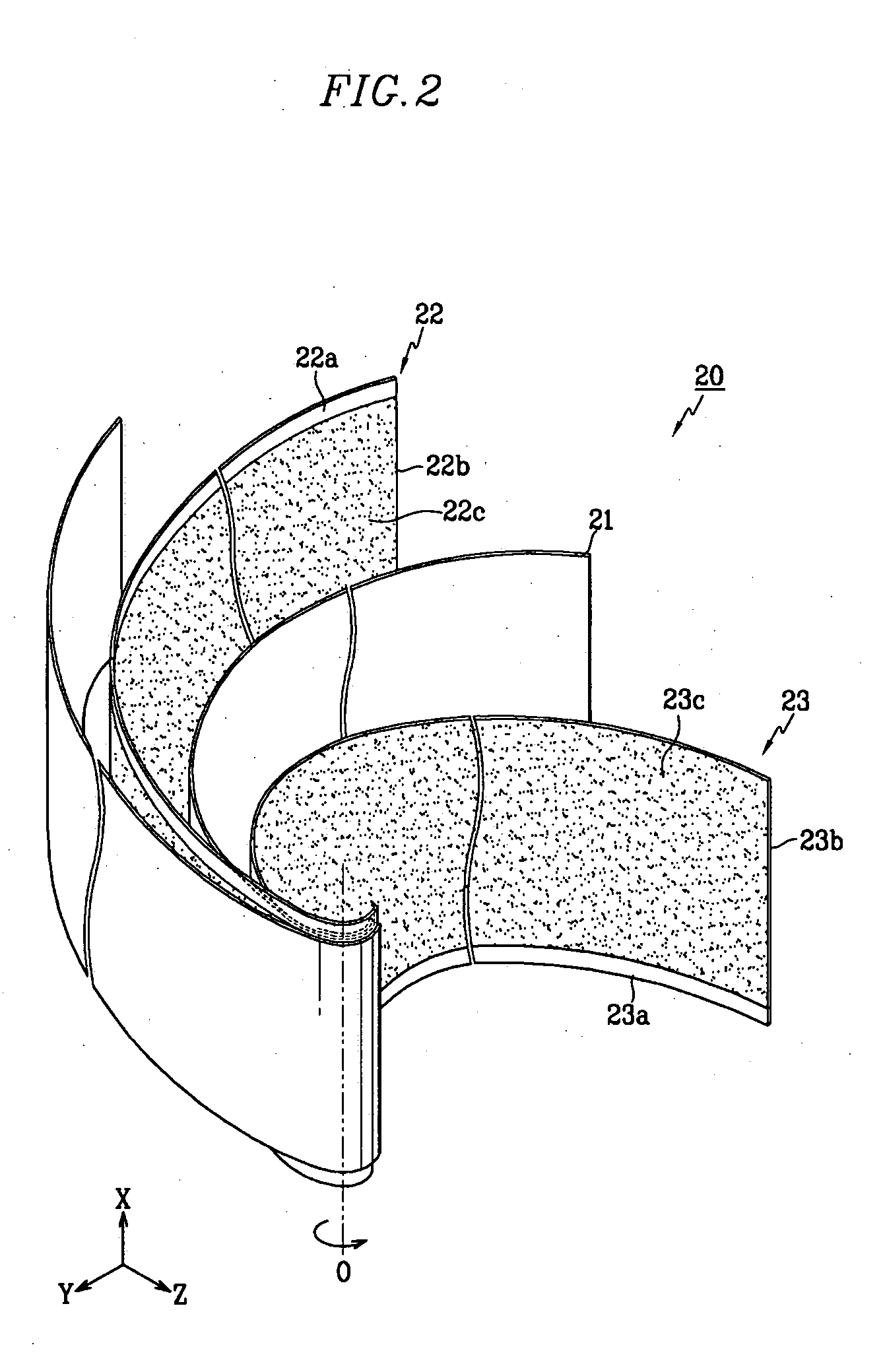

Cylindrical lithium secondary battery

ActiveUS20060263673A1Improve securityFinal product manufactureCell electrodesLithiumBiomedical engineering

A cylindrical lithium secondary battery includes an electrode assembly which has a first electrode plate, a second electrode plate, and a separator provided between the first electrode plate and the second electrode plate, is wound in a spiral shape, and has a central space at the center of winding; a core member which is inserted into the central space of the electrode assembly; a case having a space for containing the electrode assembly; and a cap assembly which is connected to an upper portion of the case so as to seal the case. The core member is formed in a tube shape having a gap along a longitudinal direction, which divides the core member into a body portion and left and right lateral end portions, wherein an imaginary arc line extending from an outer circumferential surface of the body portion of the core member defines an imaginary circumference, and wherein the left and right lateral end portions are located inside the imaginary circumference and comprise a pair of first bending portions, inwardly bending and symmetrically disposed with respect to the gap, and a pair of second bending portions bending in a rotation direction that is opposite to the inwardly bending rotational directions of the first bending portions.

Owner:SAMSUNG SDI CO LTD

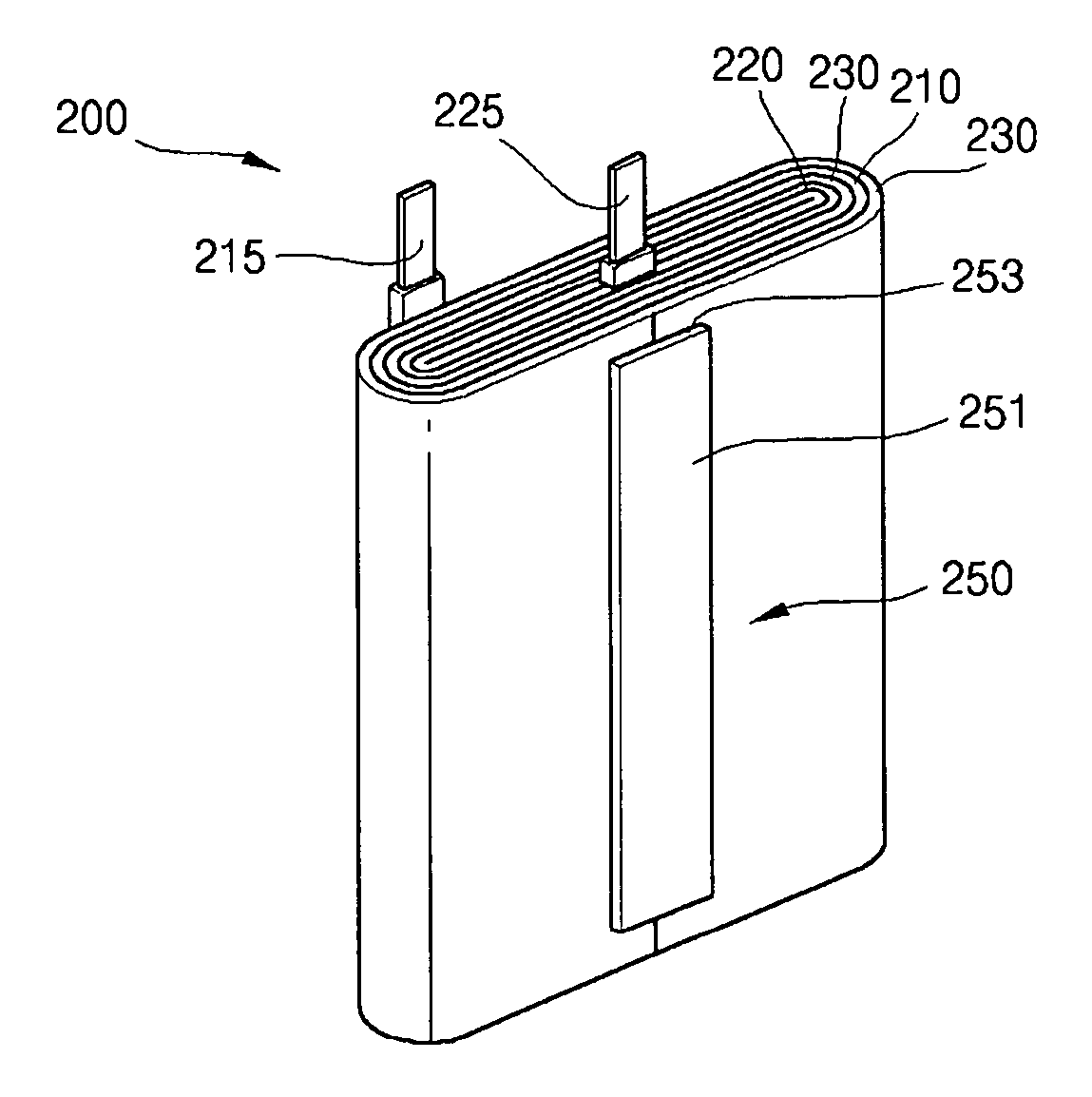

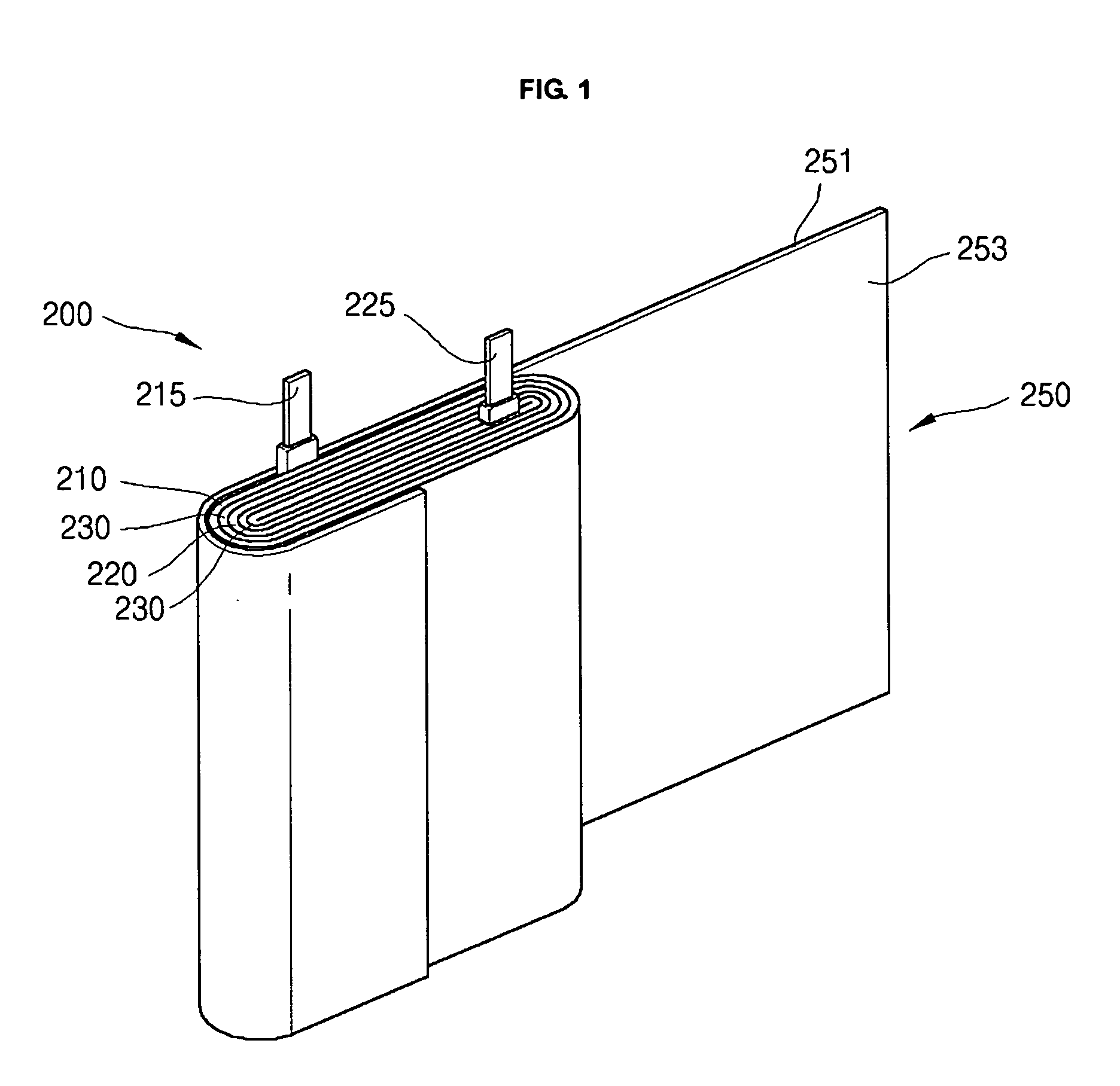

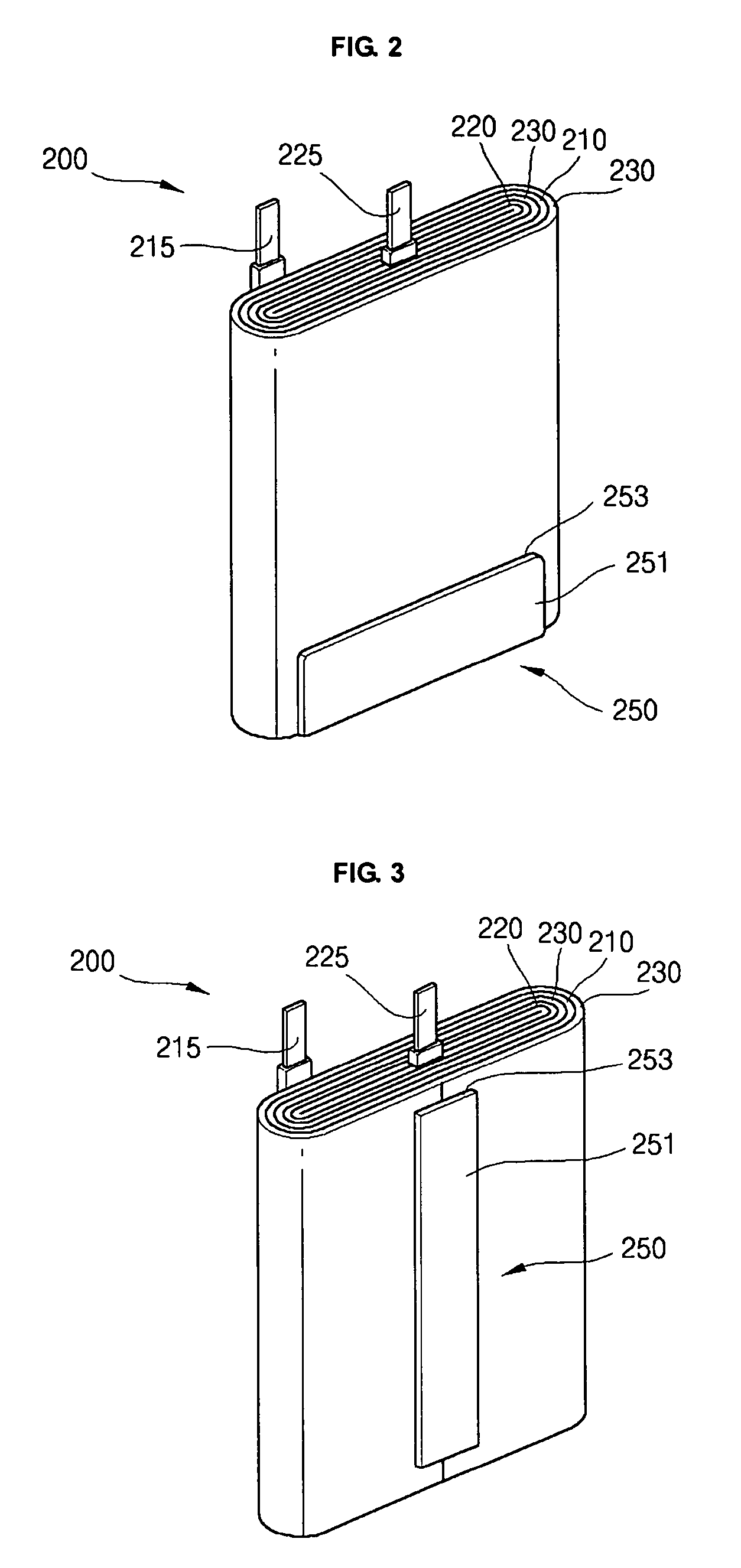

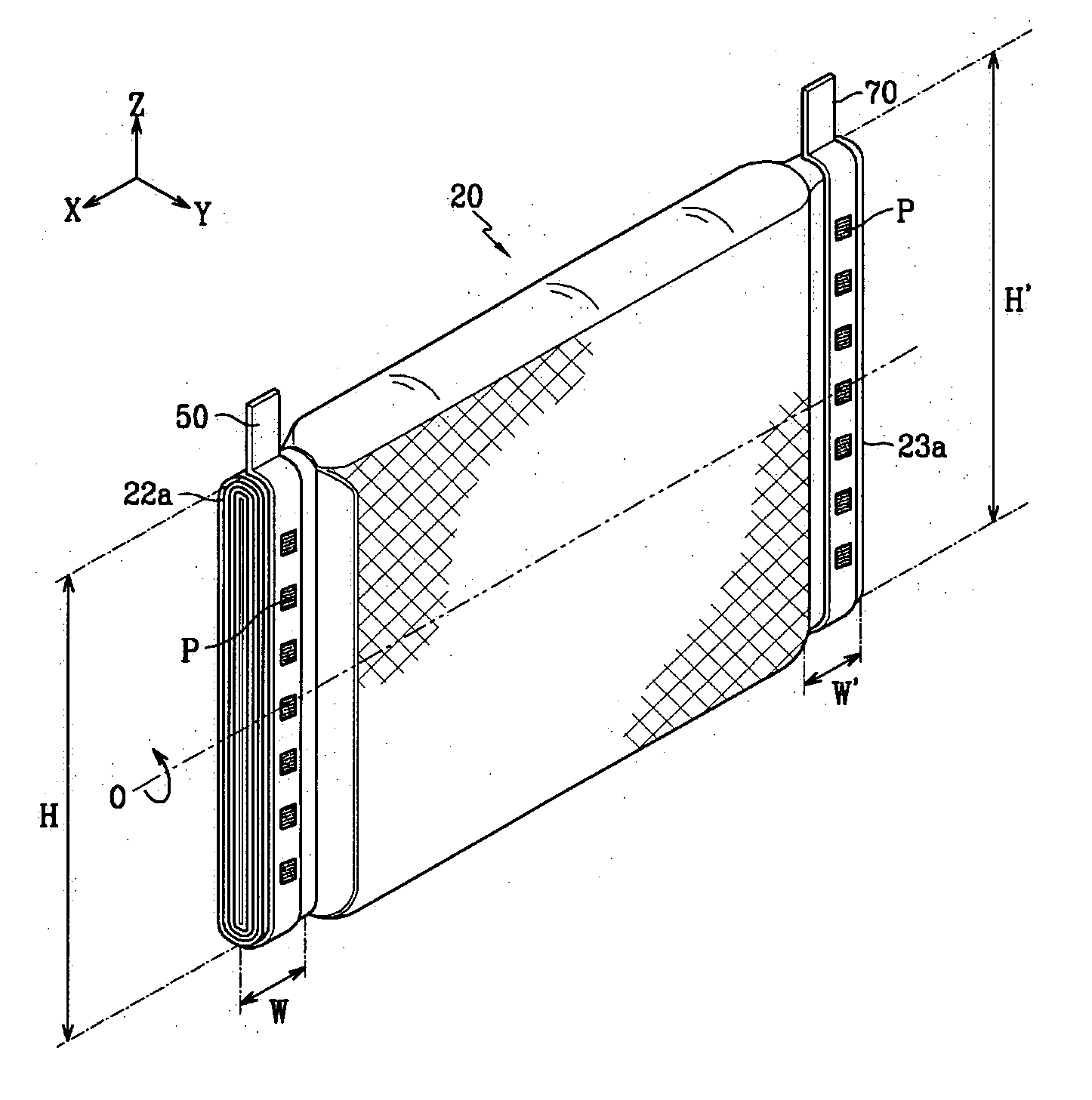

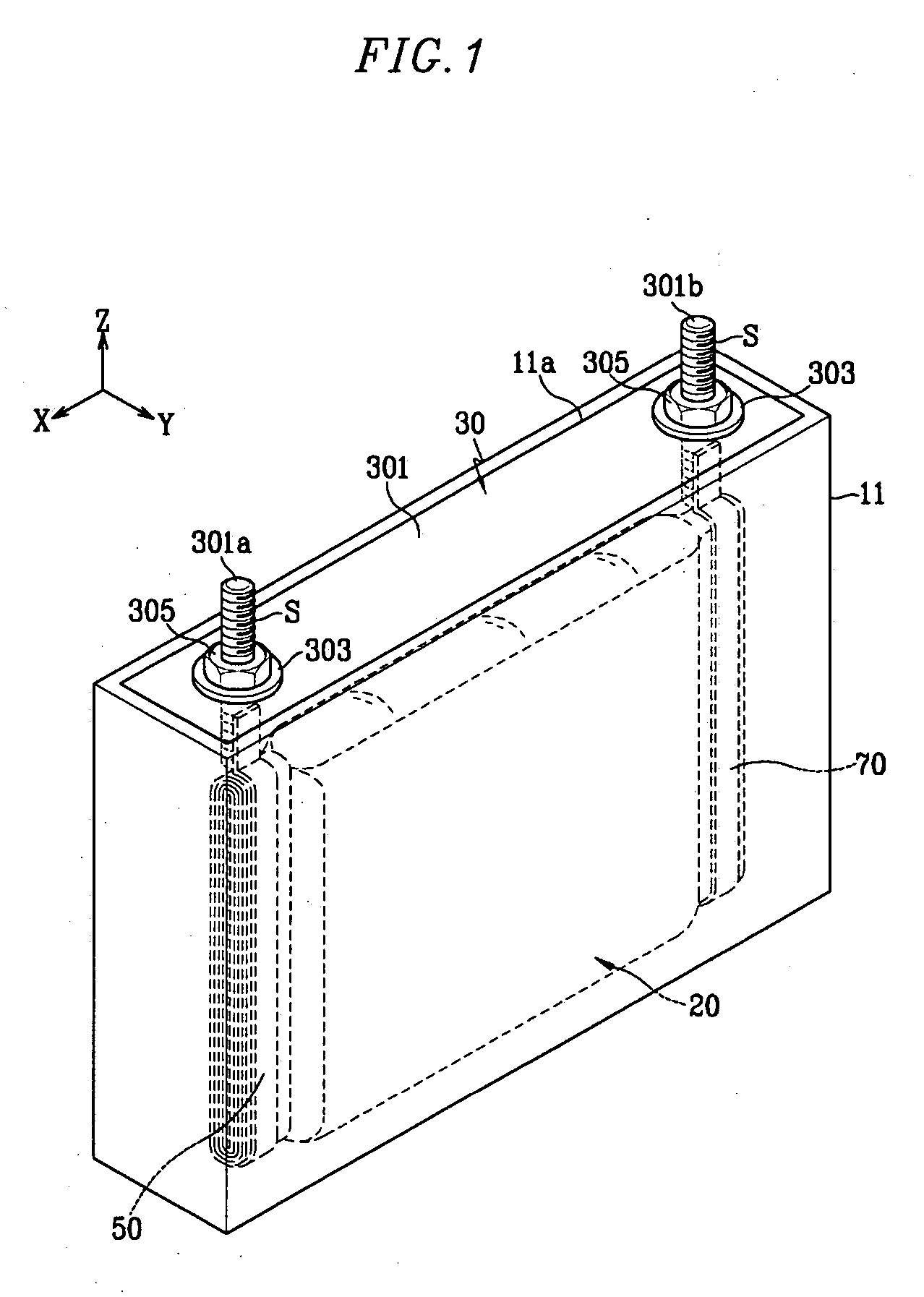

Secondary battery of novel structure and battery pack having the same

ActiveUS20060286450A1Increase productionLarge capacityLarge-sized flat cells/batteriesSmall-sized cells cases/jacketsShell moldingElectric vehicle

Disclosed herein are a secondary battery including an electrode assembly for charging and discharging mounted in a sheathing member including a metal layer and a resin layer, wherein the secondary battery further includes a secondary battery having a molding part of a predetermined thickness at least partially formed at the outside of a sheathing member, preferably, at a sealing region of the sheathing member, and a medium- or large-sized battery pack including the same. The molding part is formed at the outside of the sheathing member of the secondary battery. Consequently, the secondary battery according to the present invention has high mechanical strength, and therefore, it is possible to construct a battery pack without using addition members, such as cartridges. When the molding part is formed at the sealing region, which is weak, the molding part increases the mechanical strength and the sealing force of the secondary battery. Consequently, a battery pack including the secondary batteries as unit cells can be manufactured generally in a compact structure and with relatively small weight, and the assembly process of the battery pack is greatly simplified. The battery pack according to the present invention has high structural stability. Consequently, the battery pack can be preferably used as a power source for electric vehicles, hybrid electric vehicles, electric motorcycles, and electric bicycles.

Owner:LG ENERGY SOLUTION LTD

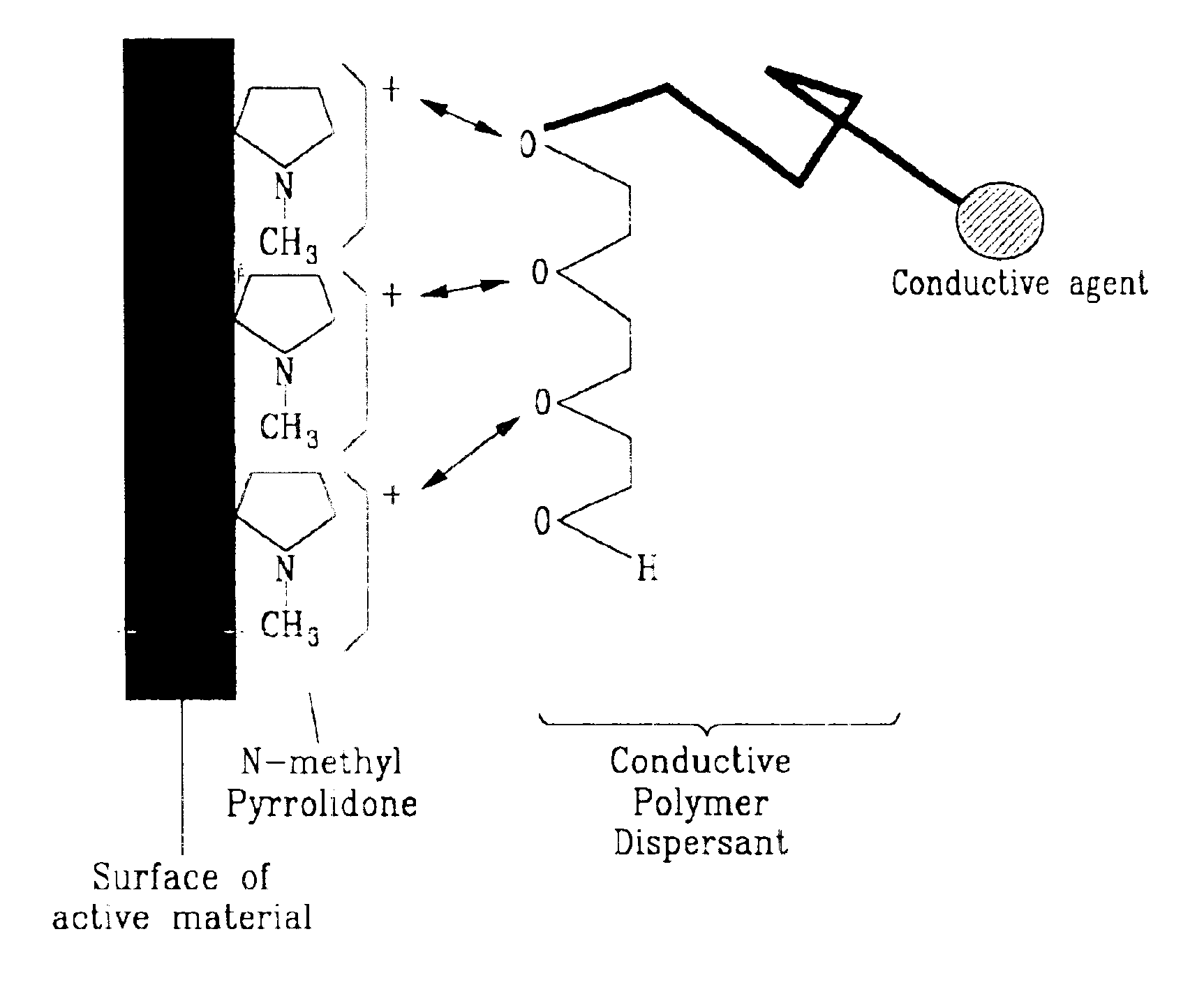

Active material for battery and method of preparing same

InactiveUS6878487B2Excellent electrochemical characteristicImprove thermal stabilityElectrode manufacturing processesFinal product manufactureConductive polymerPolymer chemistry

Owner:SAMSUNG SDI CO LTD

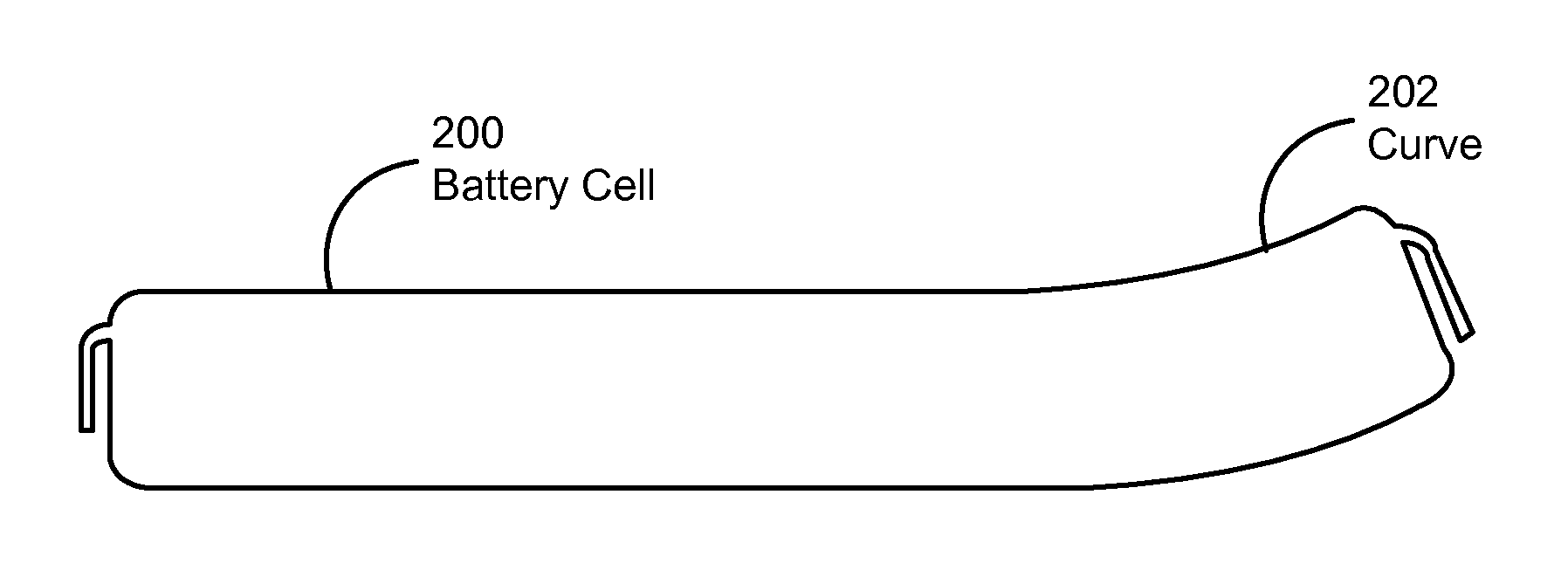

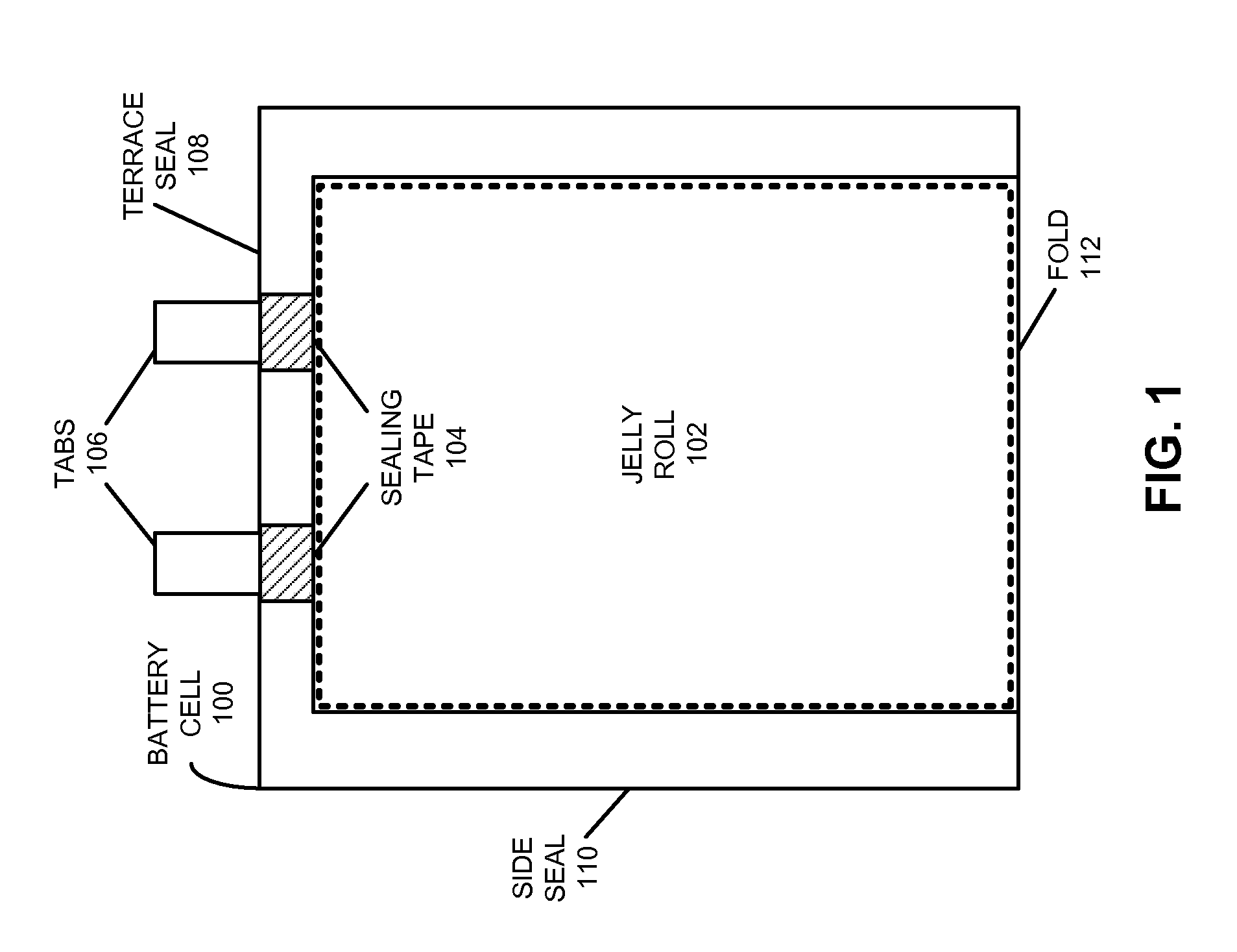

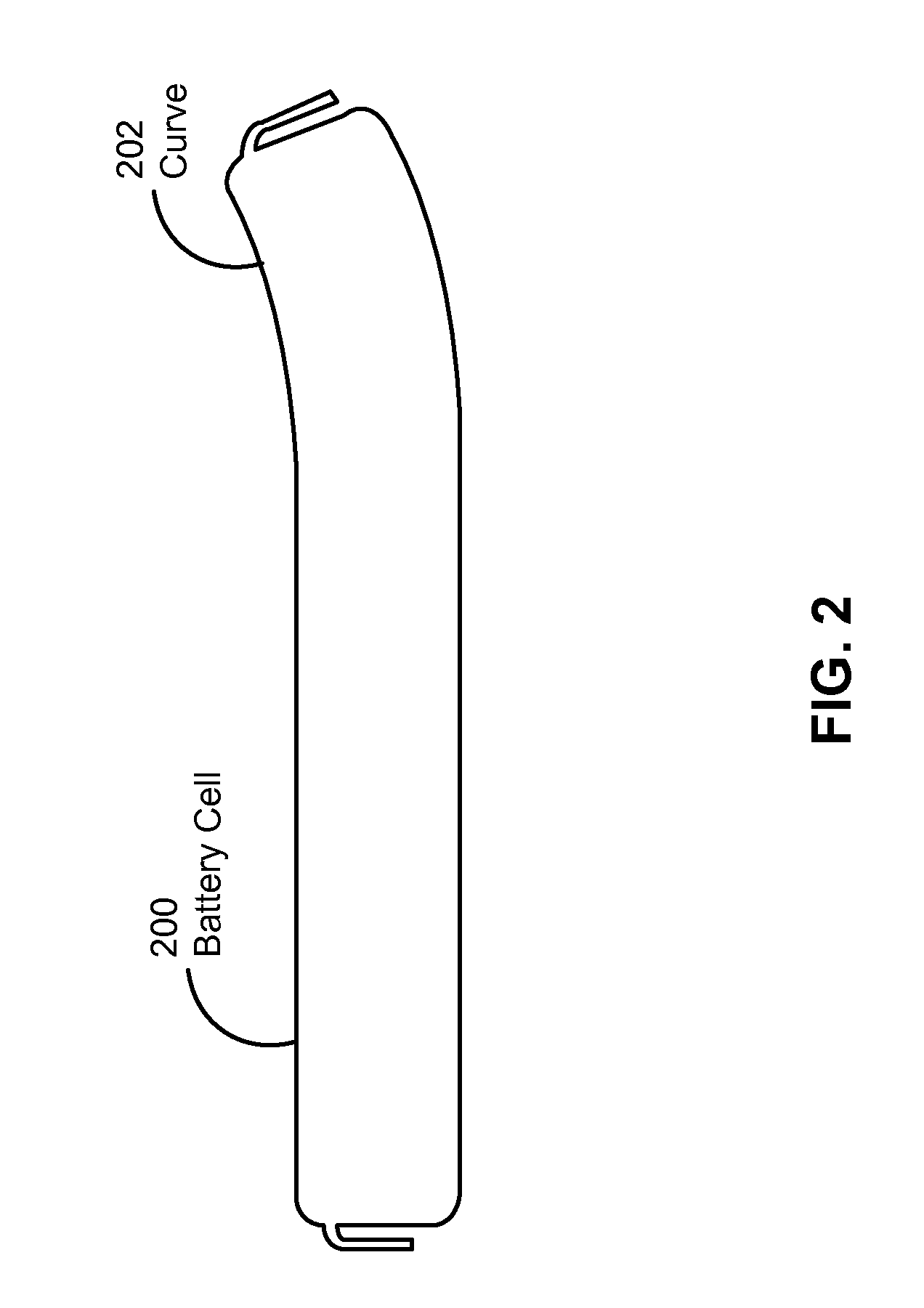

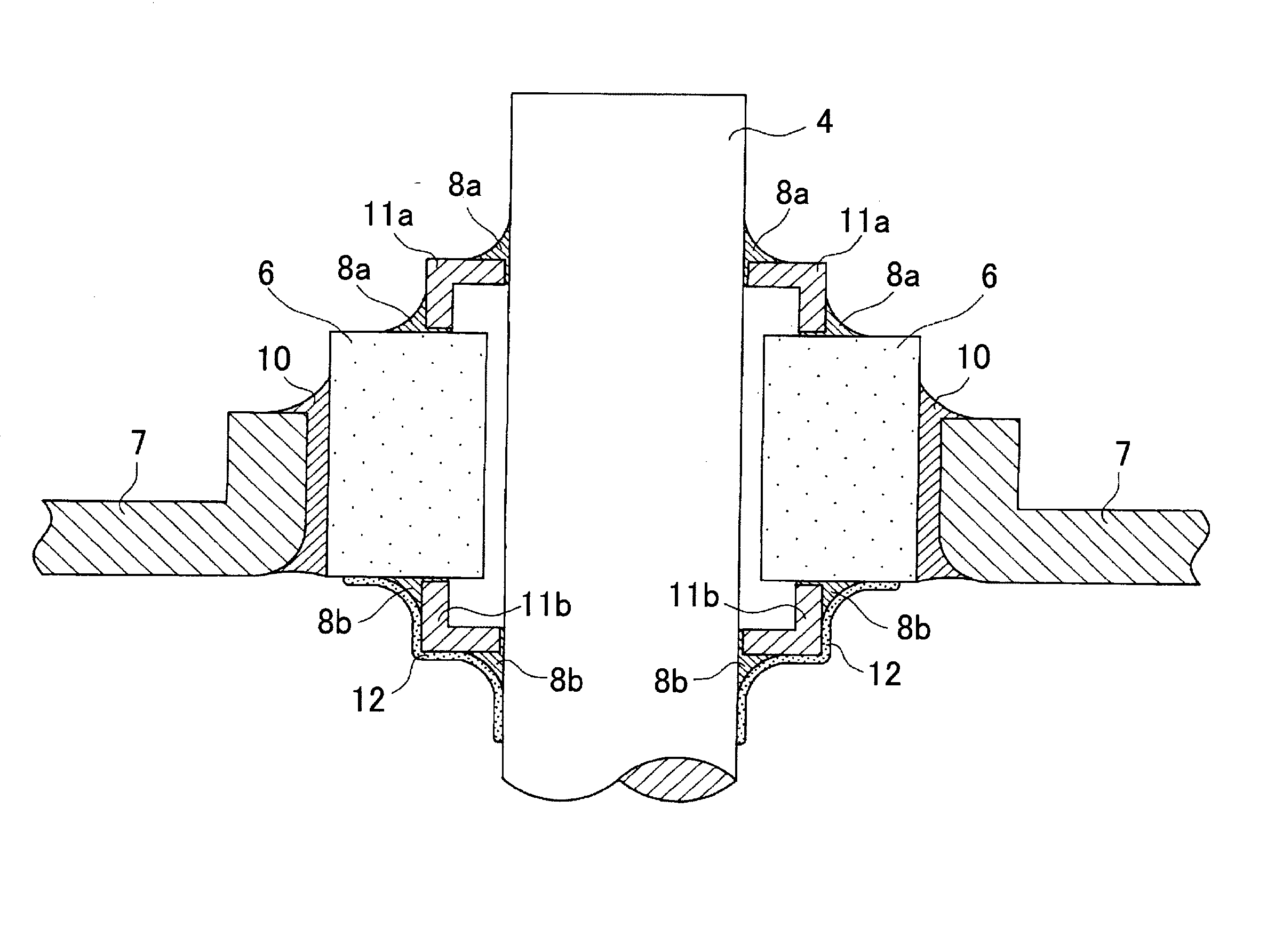

Curved battery cells for portable electronic devices

InactiveUS20130108907A1Facilitate efficient use of spaceBatteries circuit arrangementsFinal product manufactureKilogram-forceSquare Millimeter

The disclosed embodiments relate to the manufacture of a battery cell. The battery cell includes a set of layers including a cathode with an active coating, a separator, and an anode with an active coating. The battery cell also includes a pouch enclosing the layers, wherein the pouch is flexible. The layers may be wound to create a jelly roll prior to sealing the layers in the flexible pouch. A curve may also be formed in the battery cell by applying a pressure of at least 0.13 kilogram-force (kgf) per square millimeter to the layers using a set of curved plates applying a temperature of about 85° C. to the layers.

Owner:APPLE INC

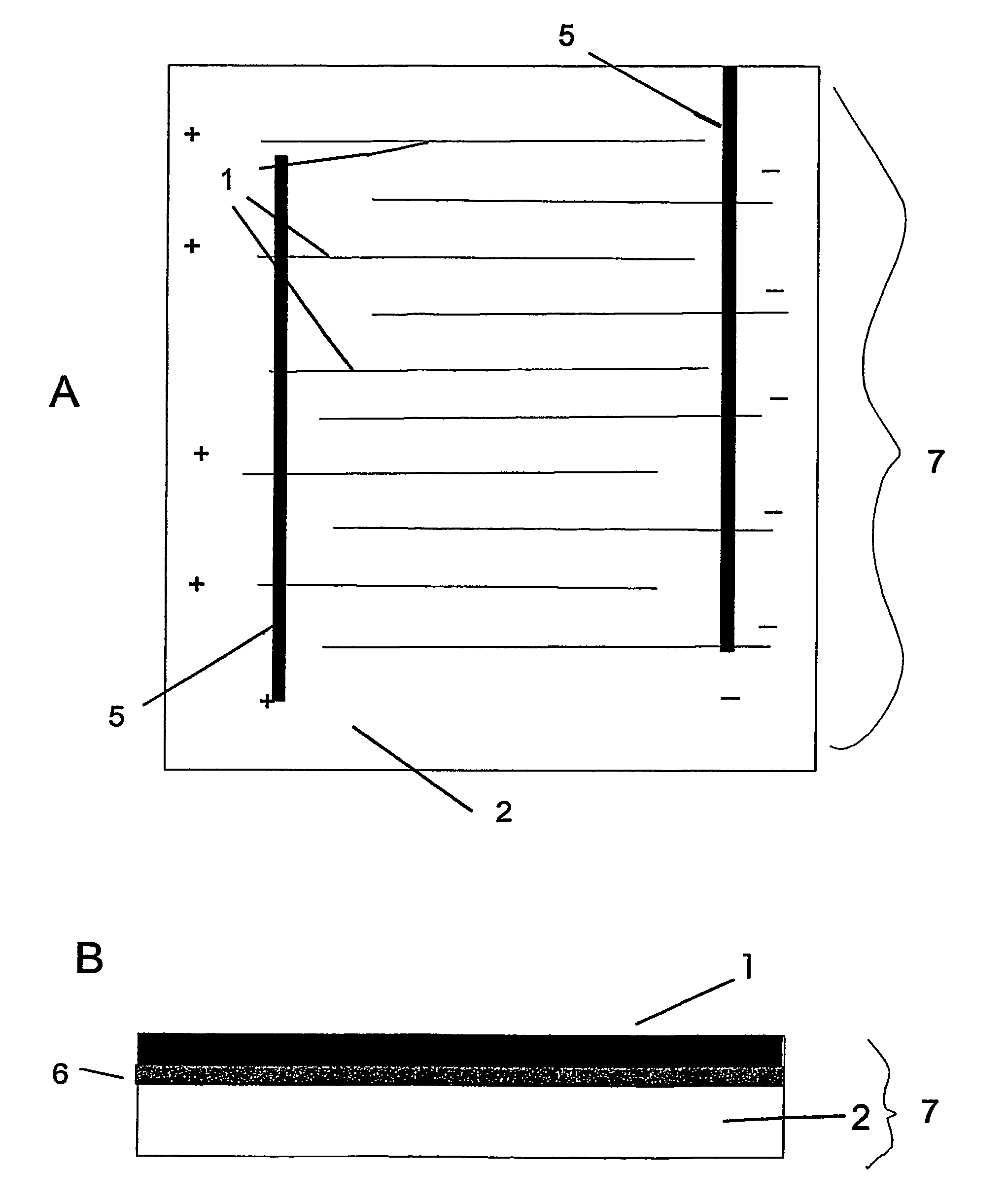

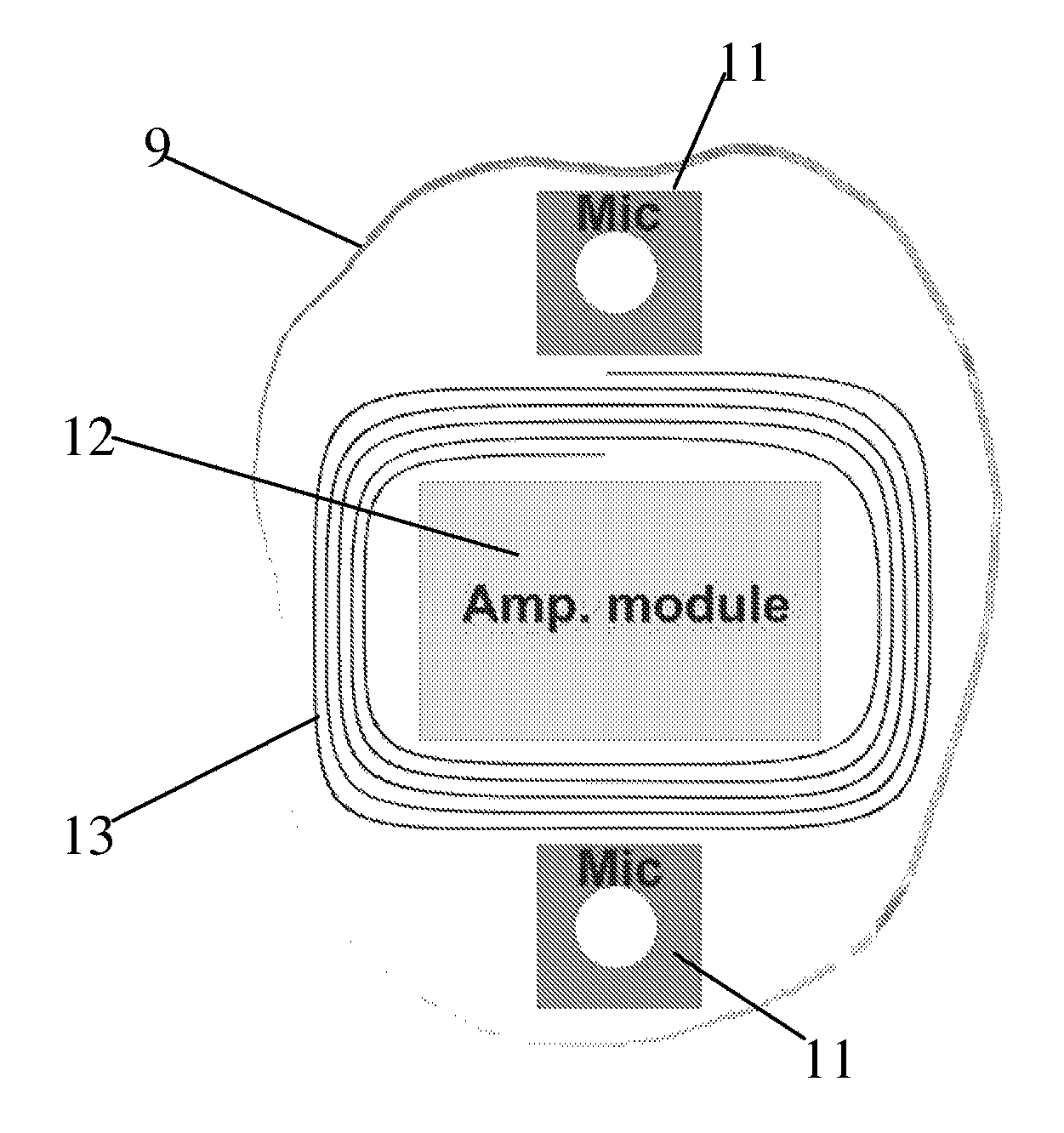

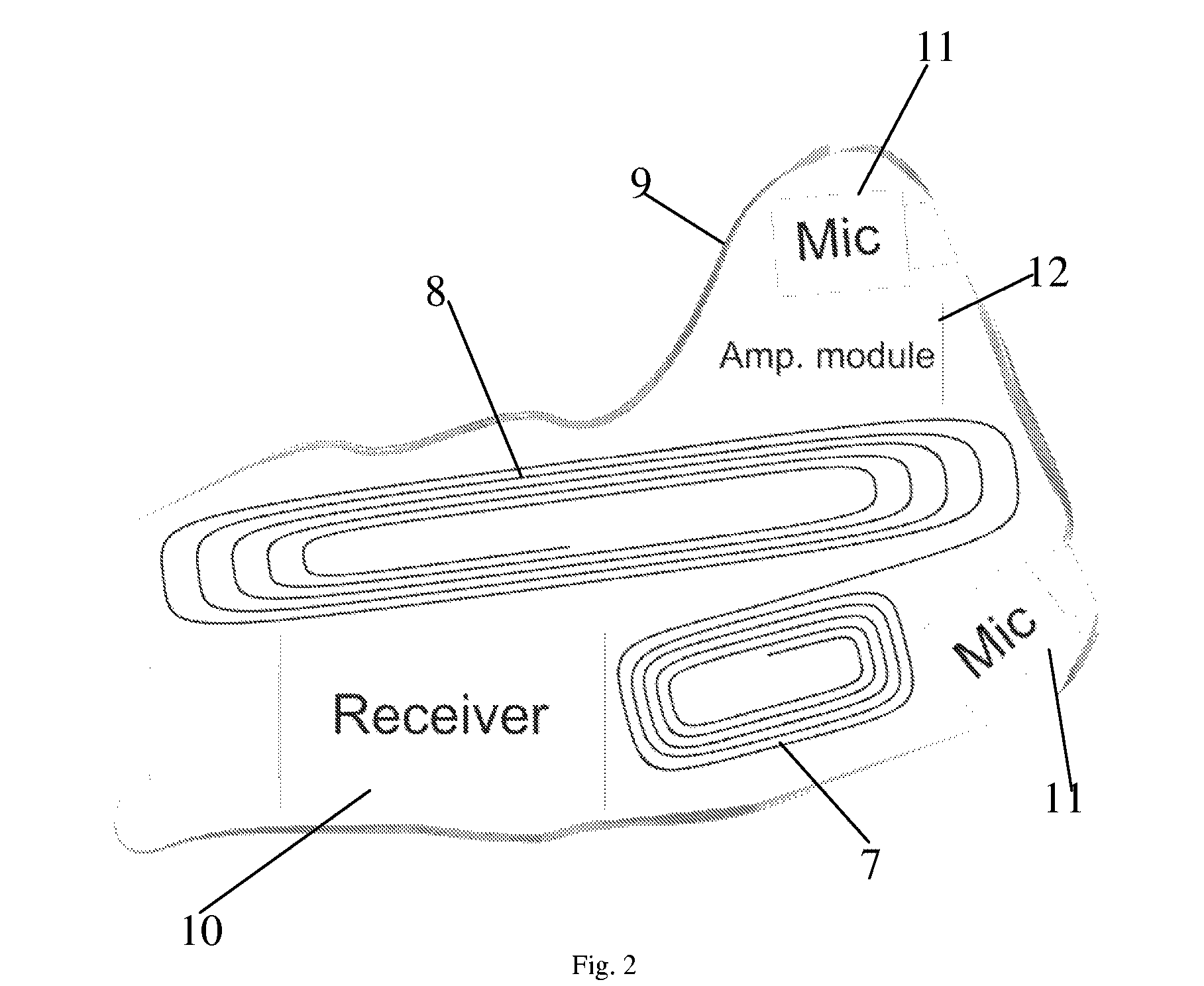

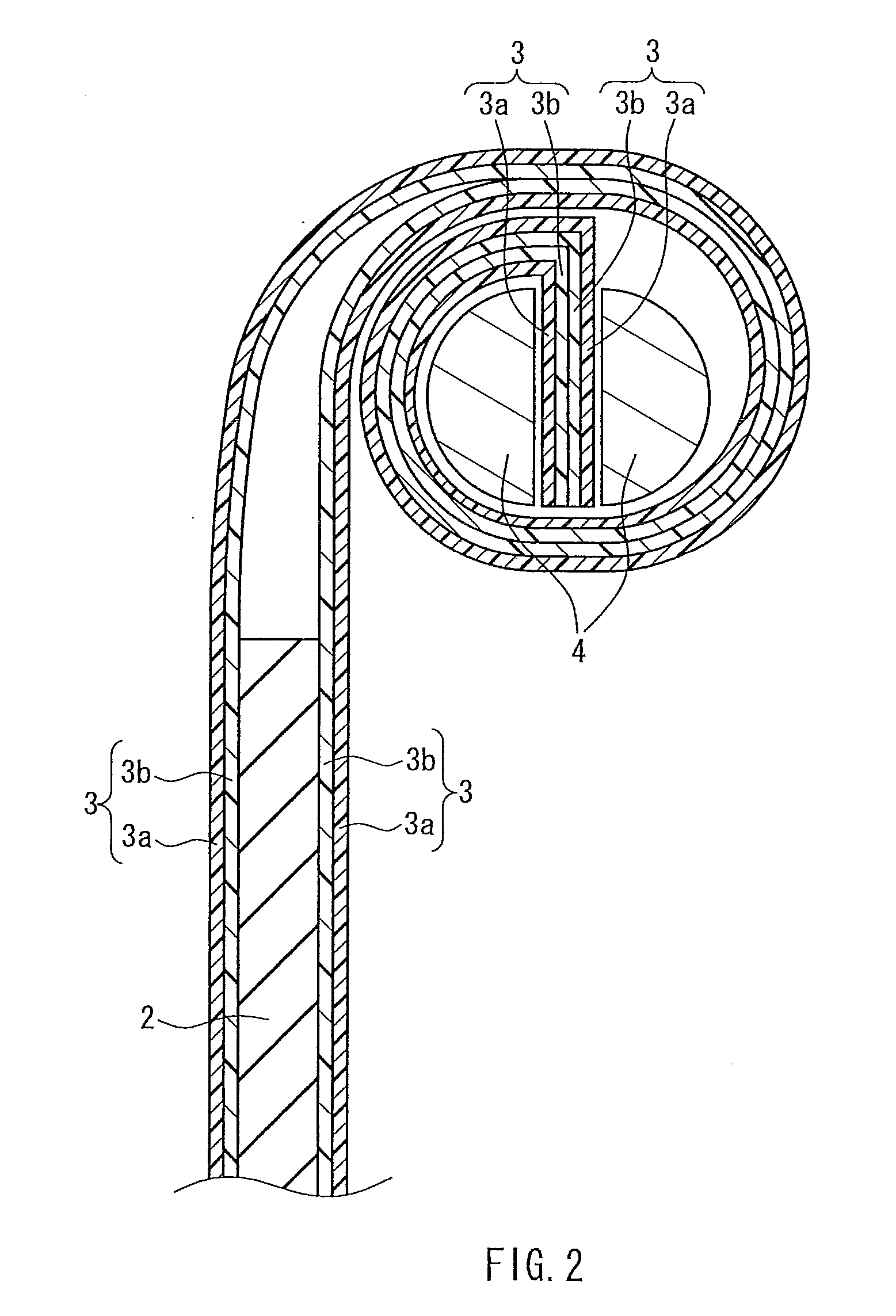

Hearing Aid with Rechargeable Battery and Rechargeable Battery

ActiveUS20080137890A1Incredible flexibilityEasy to storeBatteries circuit arrangementsFinal product manufactureRechargeable cellHearing aid

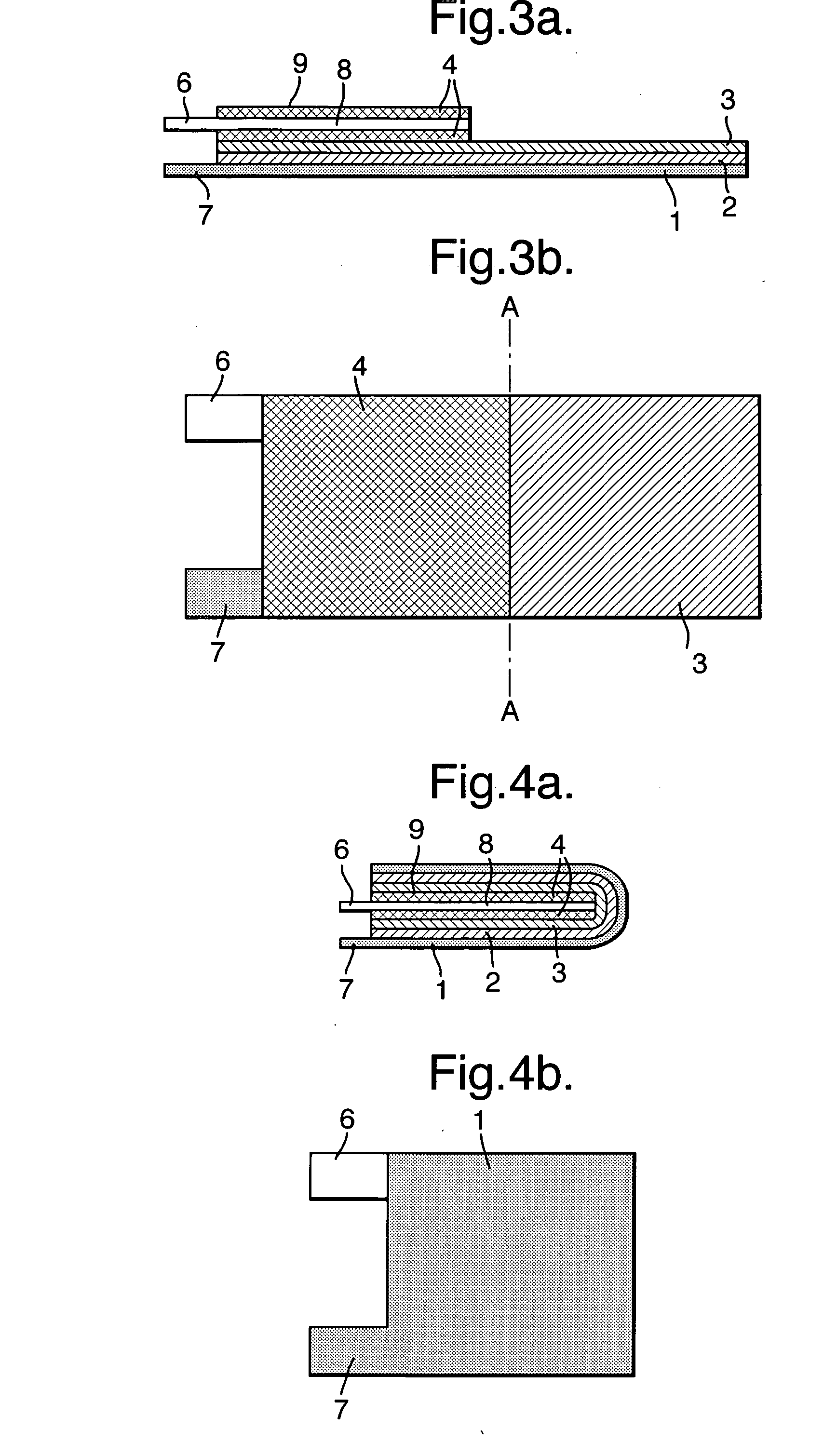

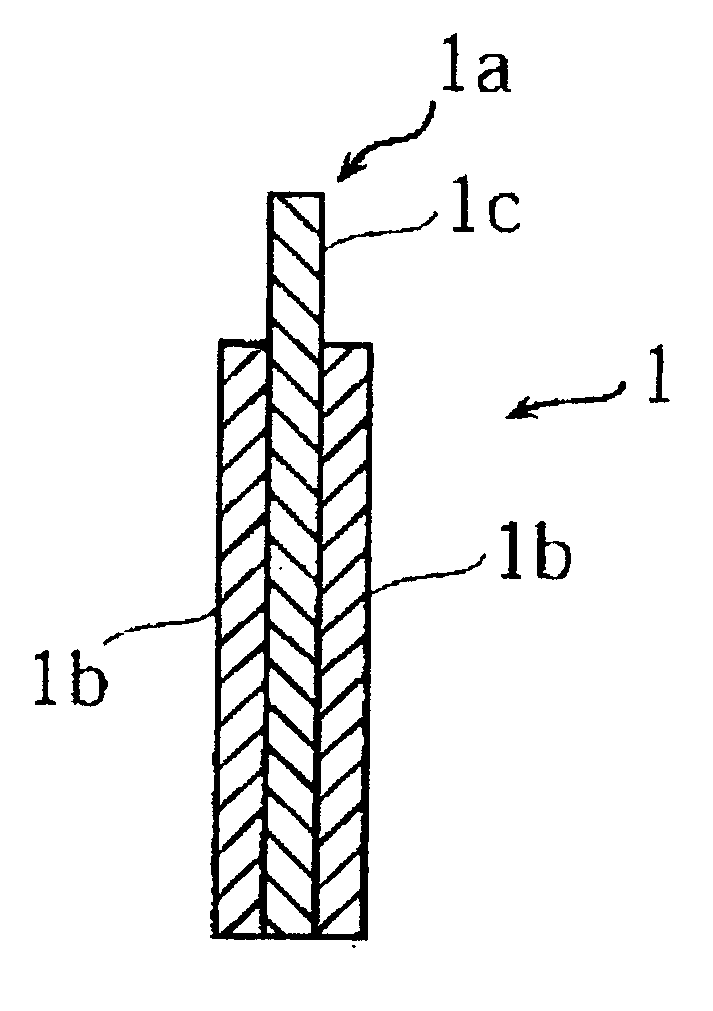

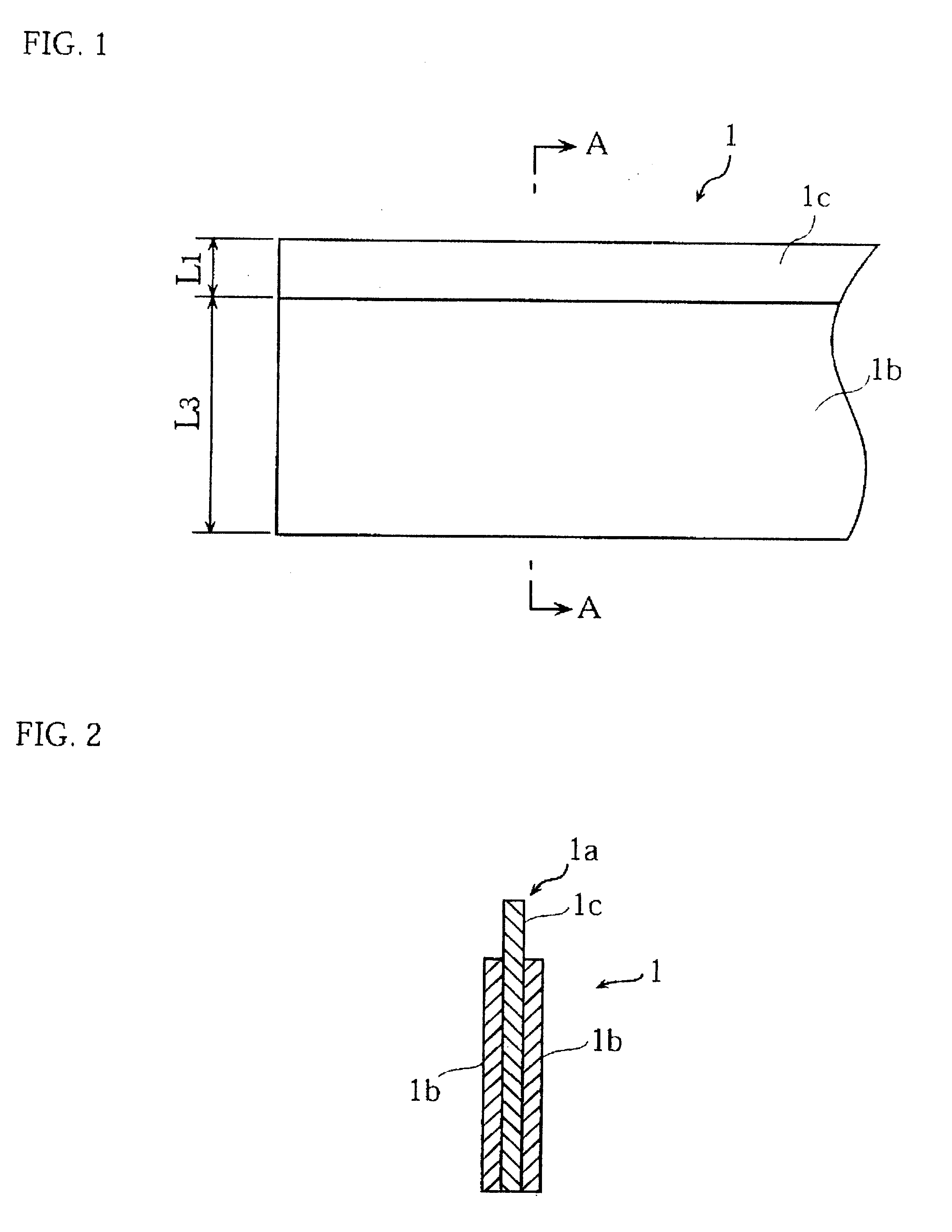

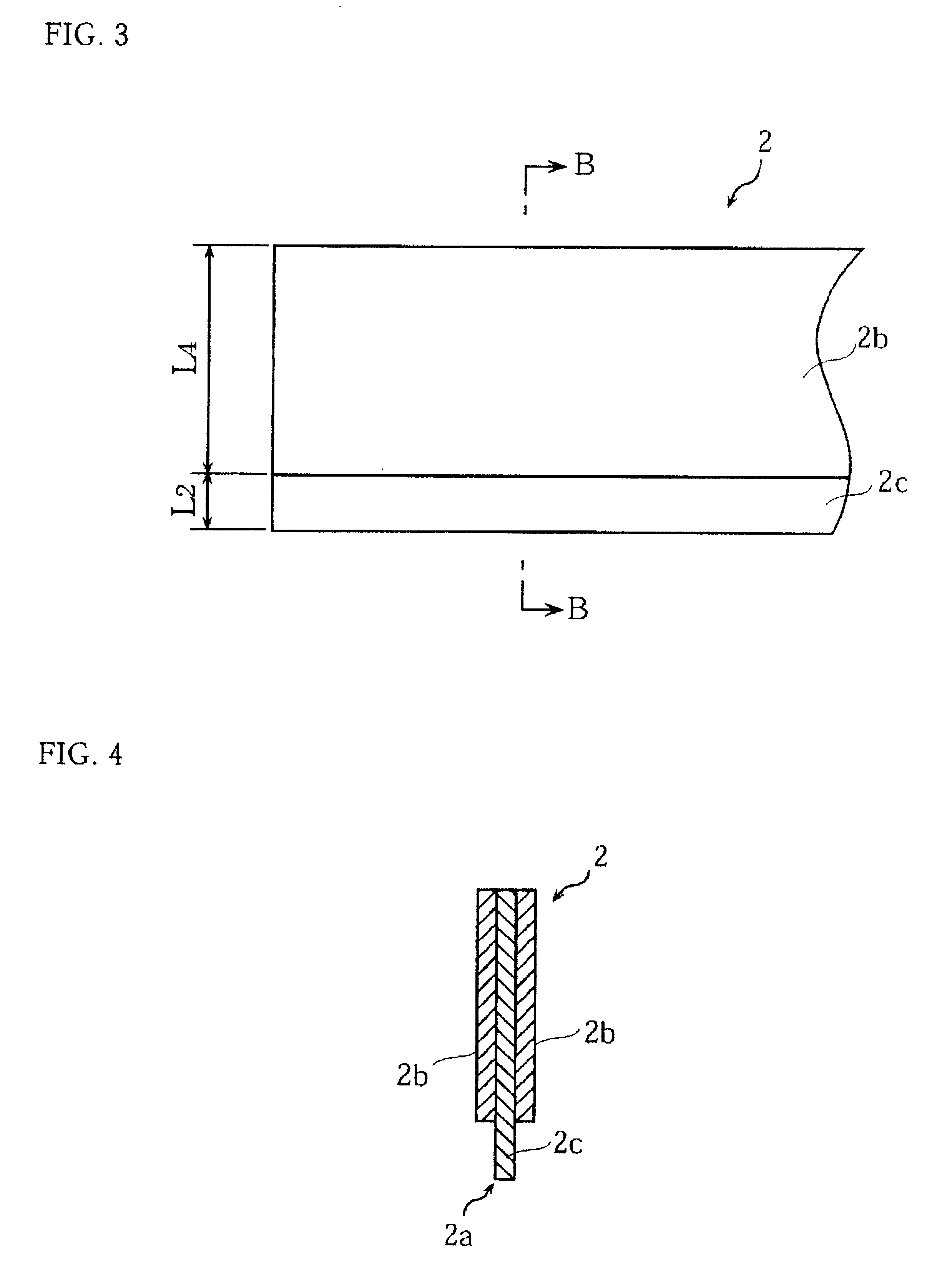

A rechargeable battery is provided comprising a flexible elongate electron conductive core (1) surrounded by a first electrochemically active layer (2), and a second electrochemically active layer (4), separated by a separation layer (3) and where an electron conducting element (5) contacts the outer surface of the second electrochemically active layer, whereby at least one of the two electrochemically active layers (2, 4) and the separation layer (3) are comprised of thin-film layers. Further a hearing aid is provided wherein a battery comprising thin film layers is provided. Such a battery may be curled or wound to accommodate an irregular space inside the hearing aid.

Owner:OTICON

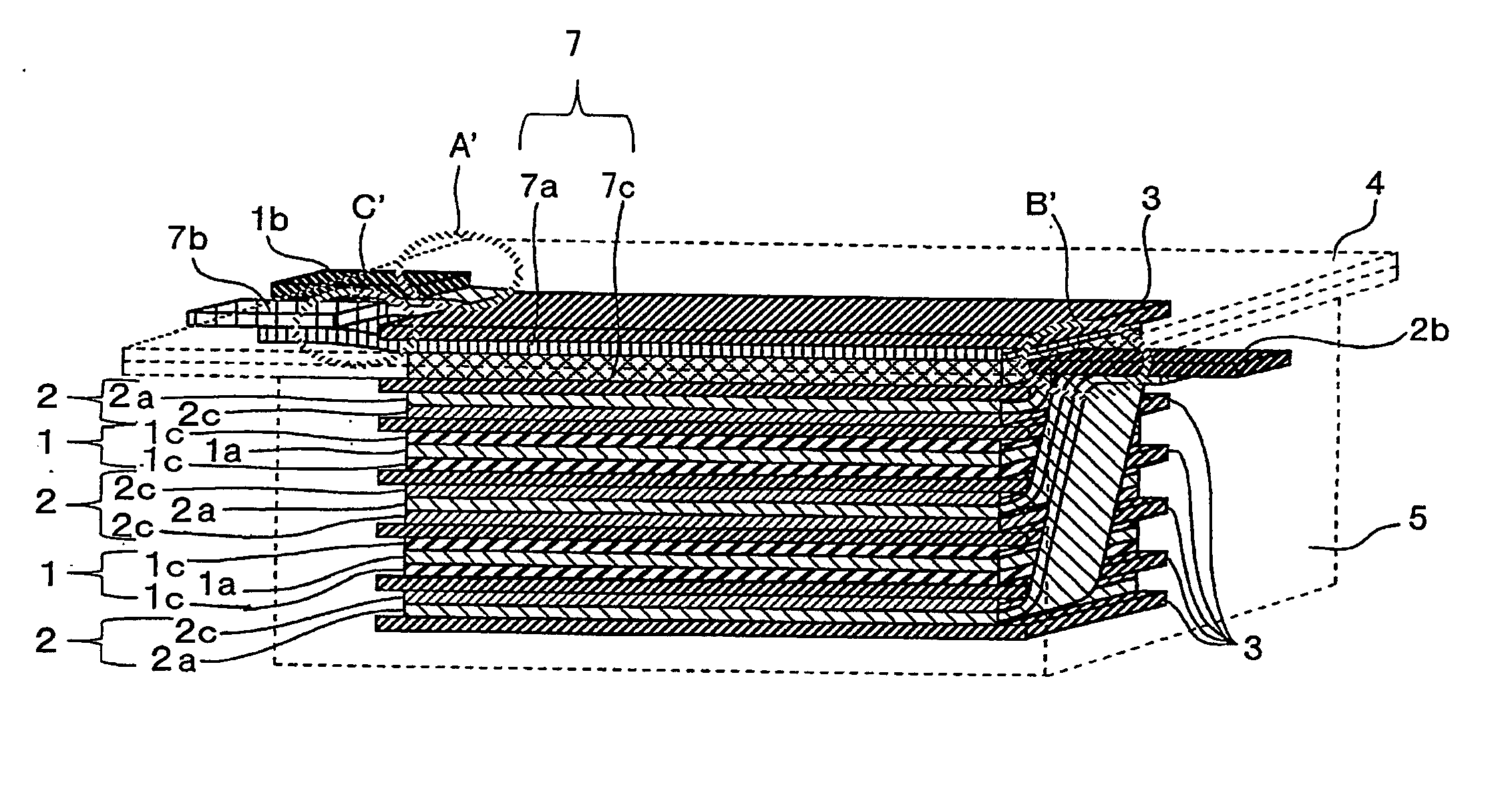

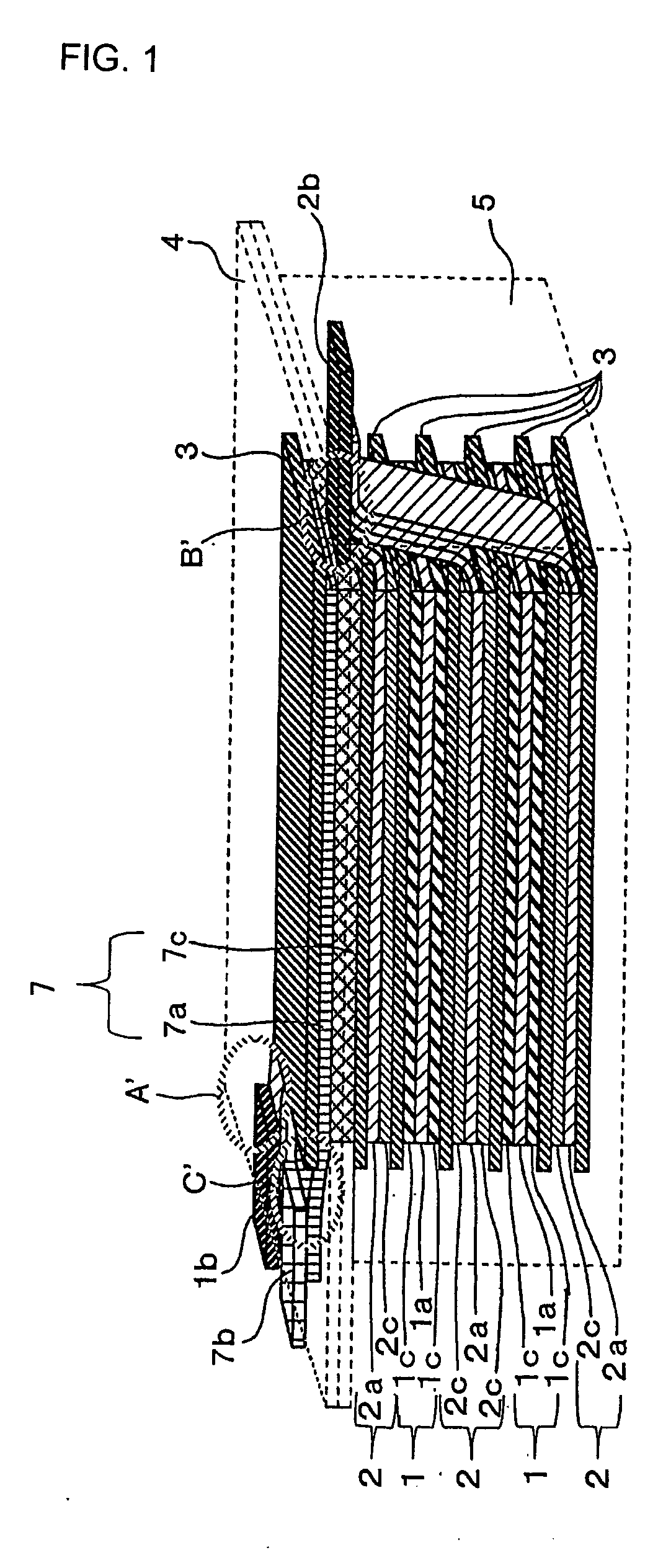

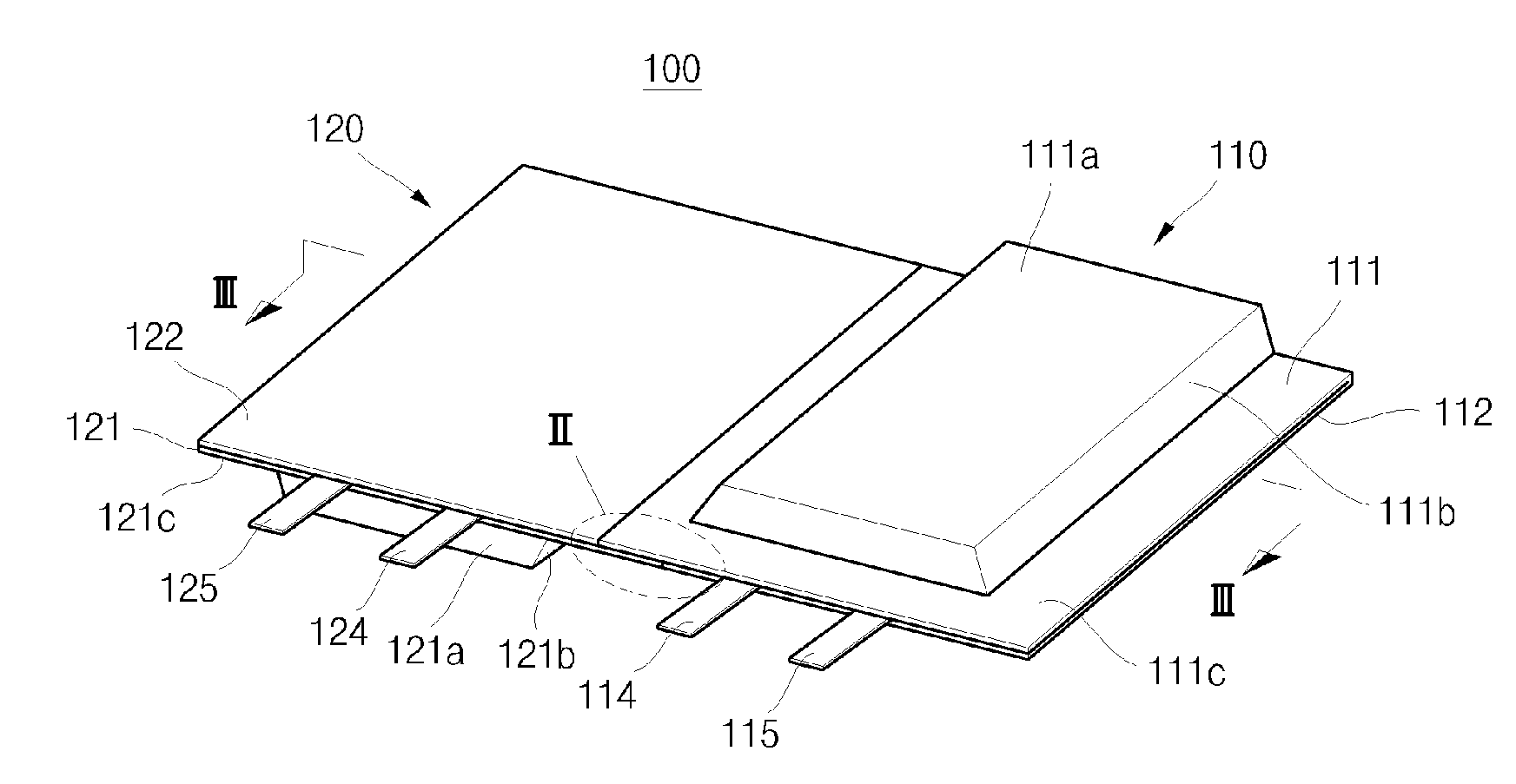

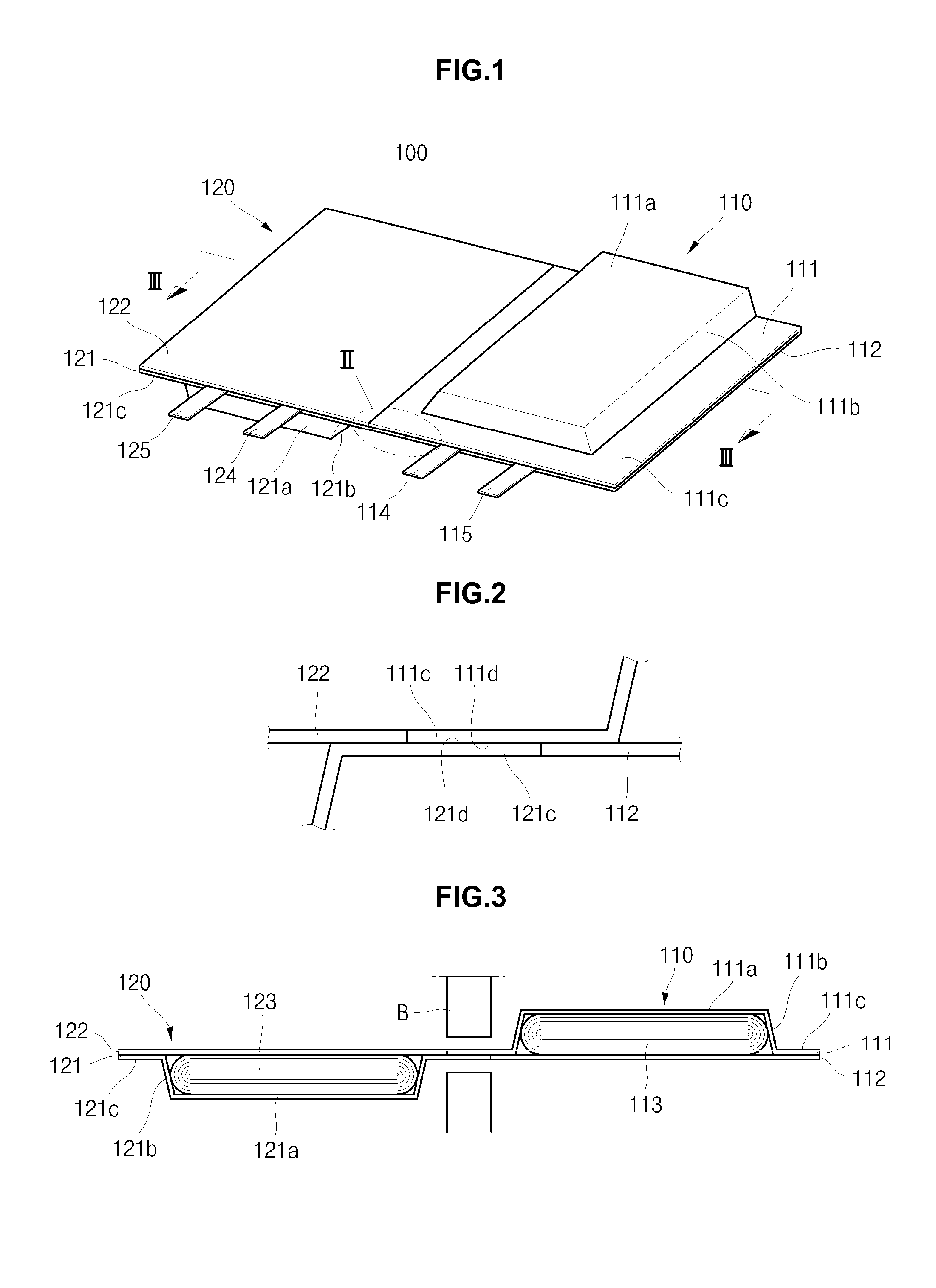

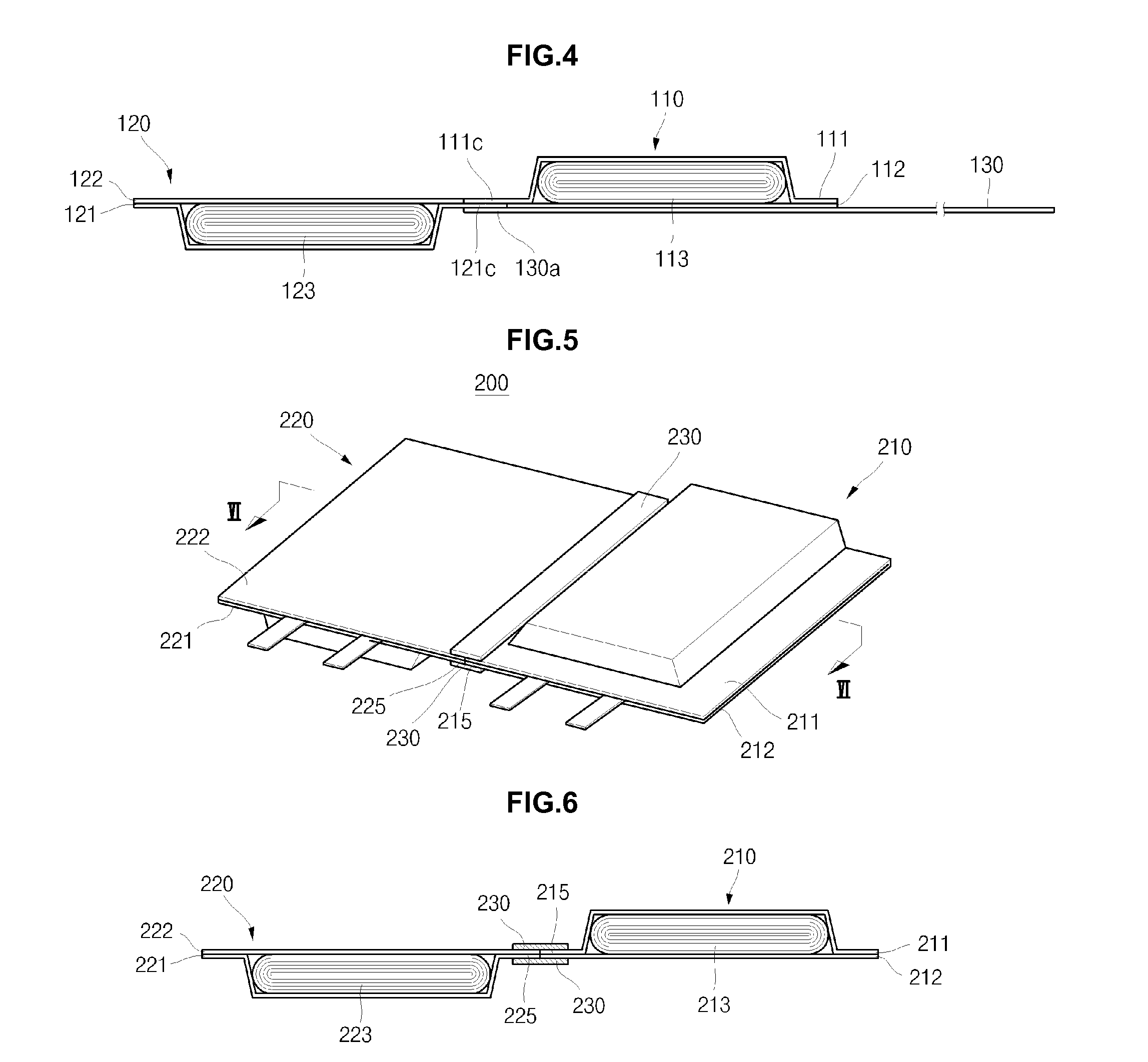

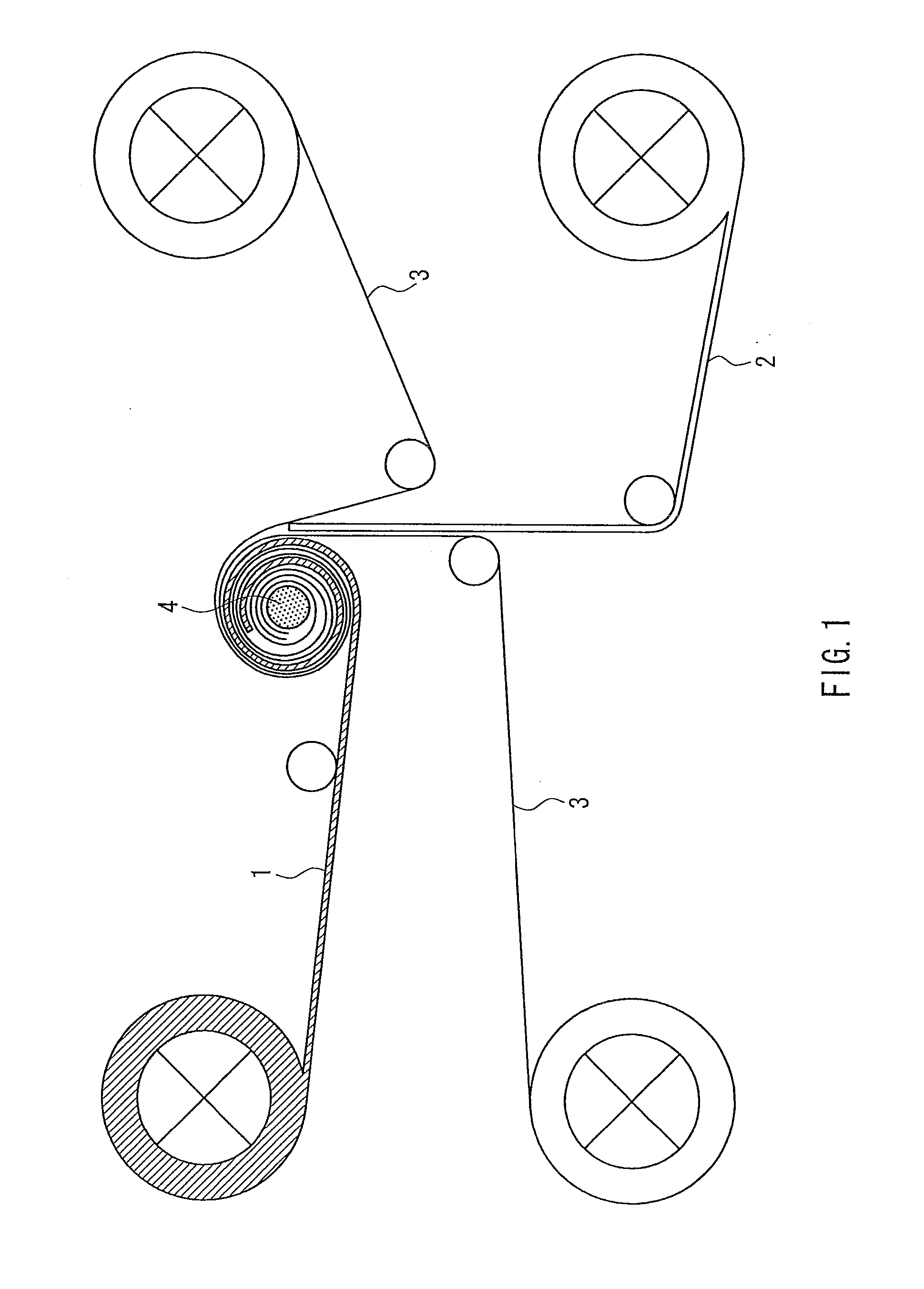

Rolled electrode battery and manufacturing method therefor

InactiveUS20090239133A1Small sizeHigh currentFinal product manufactureElectrode carriers/collectorsBand shapeEngineering

A rolled electrode battery includes a rolled electrode body including band-shaped positive and negative electrode plates formed individually with electrode active material layers, which are rolled with a band-shaped separator interposed between them and formed into a flat shape. Each of the electrode plates includes a band-shaped electrode portion formed with the electrode active material layer and contacting the separator and a side edge portion projecting from the separator and not formed with an electrode active material layer. The side edge portion forms lugs arranged at intervals along the lengths of the electrode plates. The positive and negative electrode plates are rolled in layers so that the lugs of the positive electrode plate are laminated to one another to form a positive electrode tab and that the lugs of the negative electrode plate are laminated to one another to form a negative electrode tab.

Owner:KK TOSHIBA

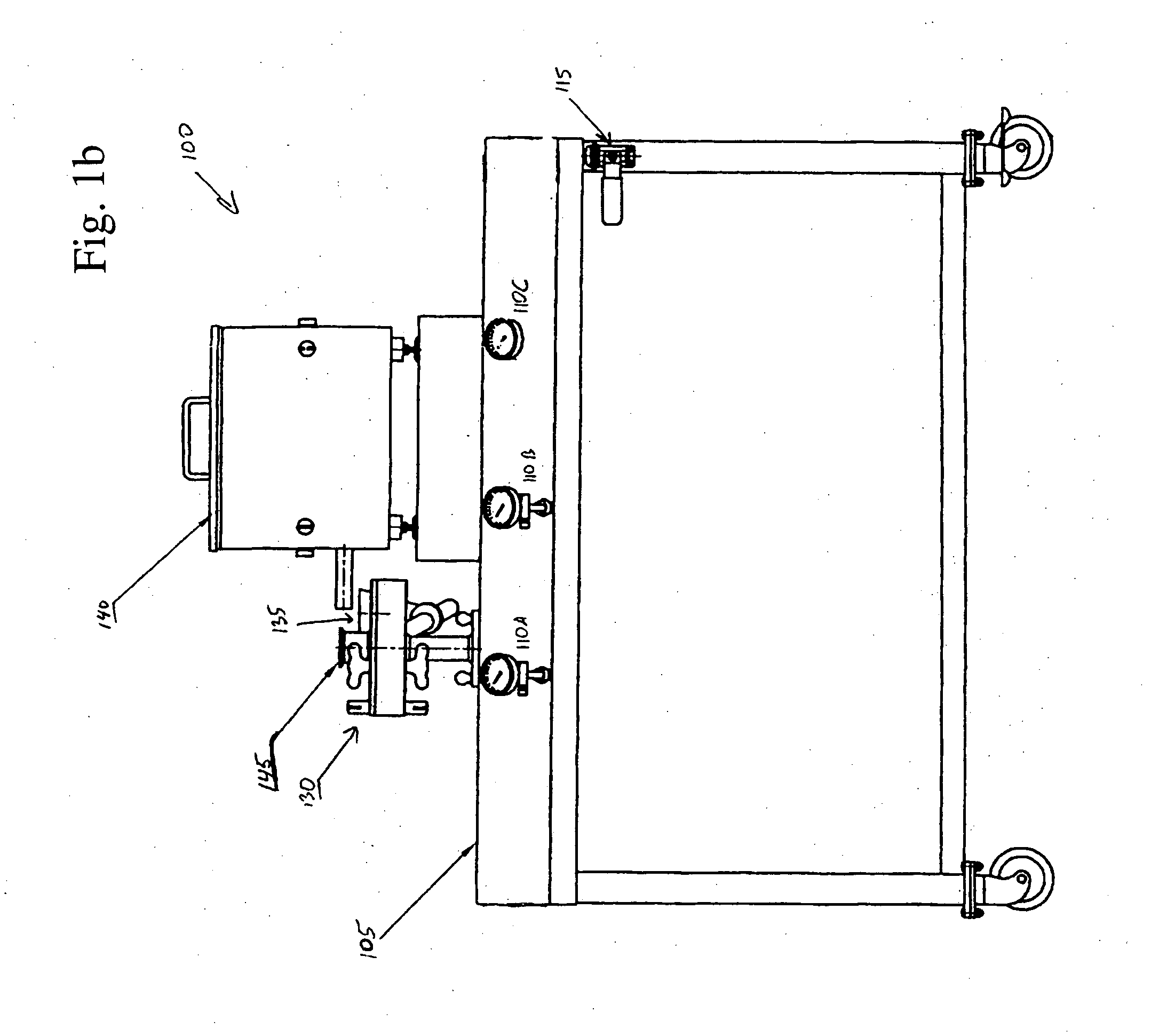

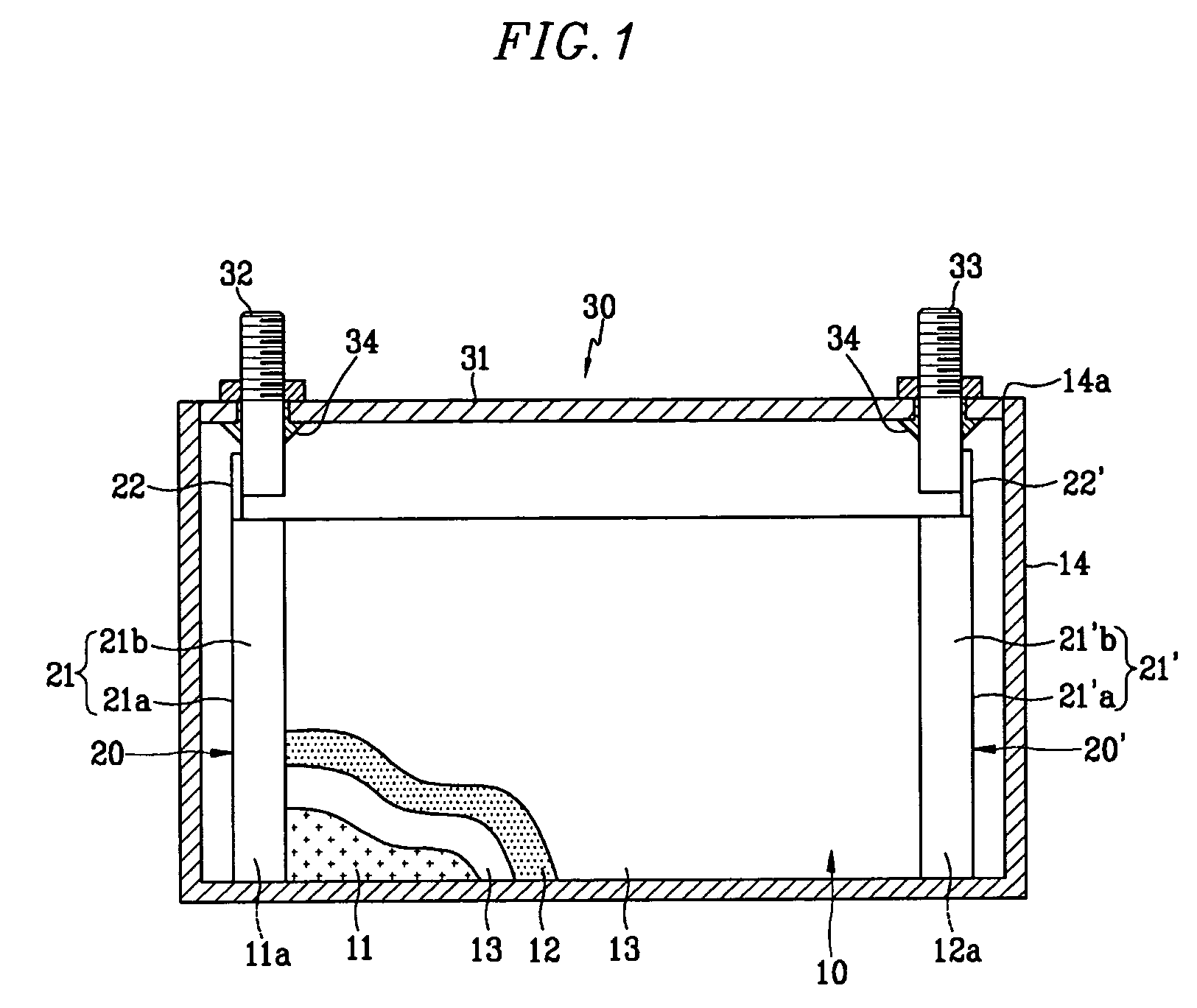

Electrical battery assembly and method of manufacture

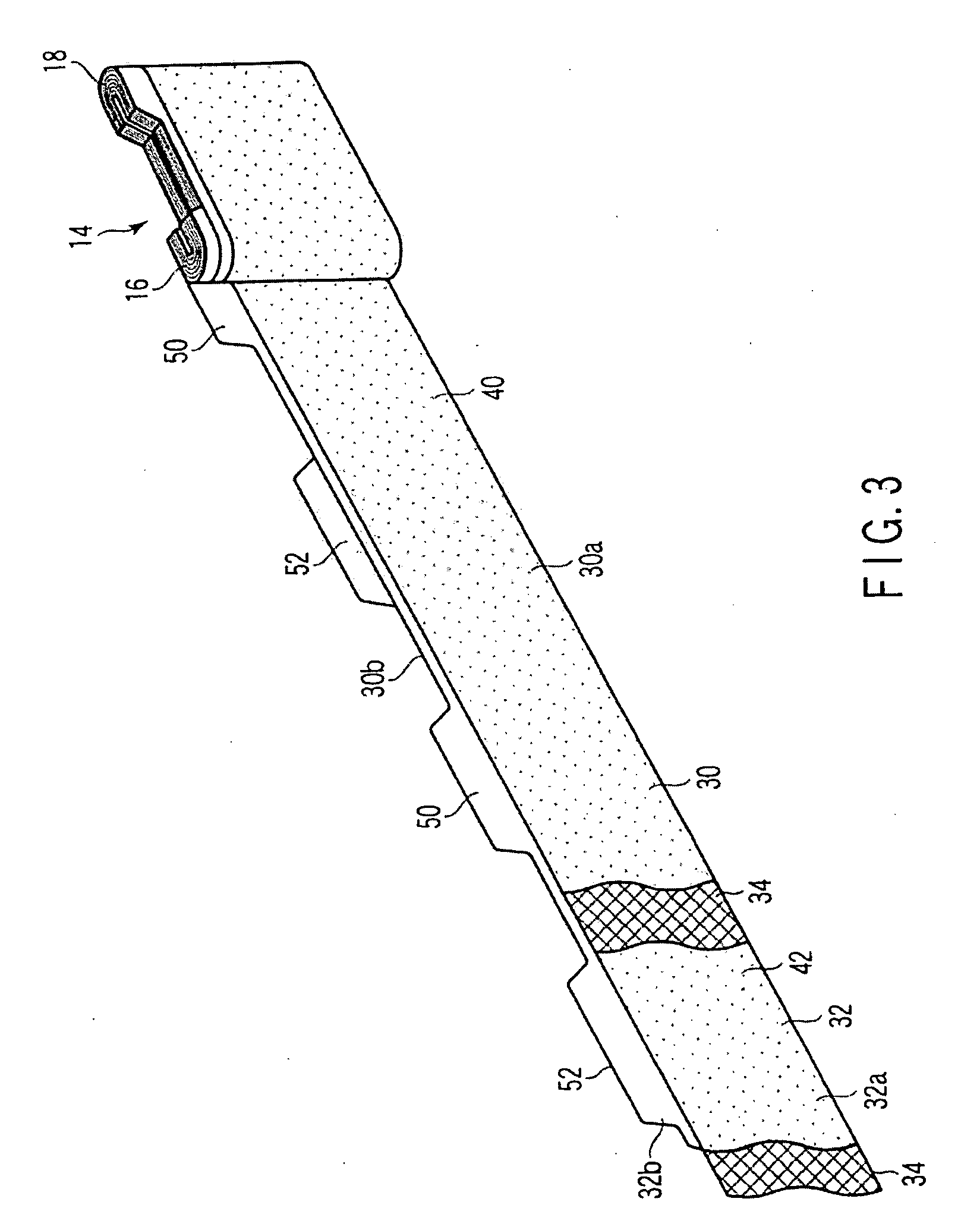

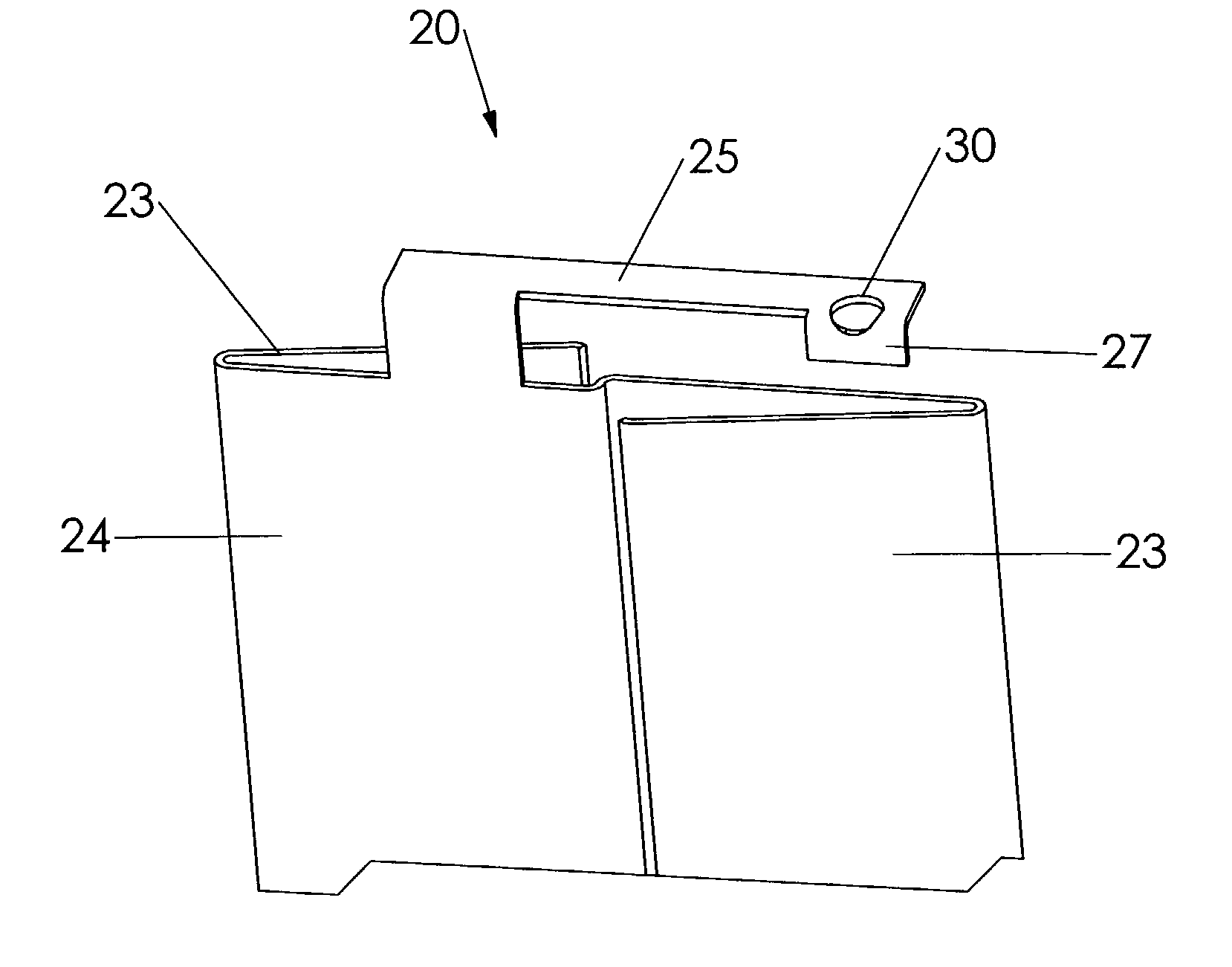

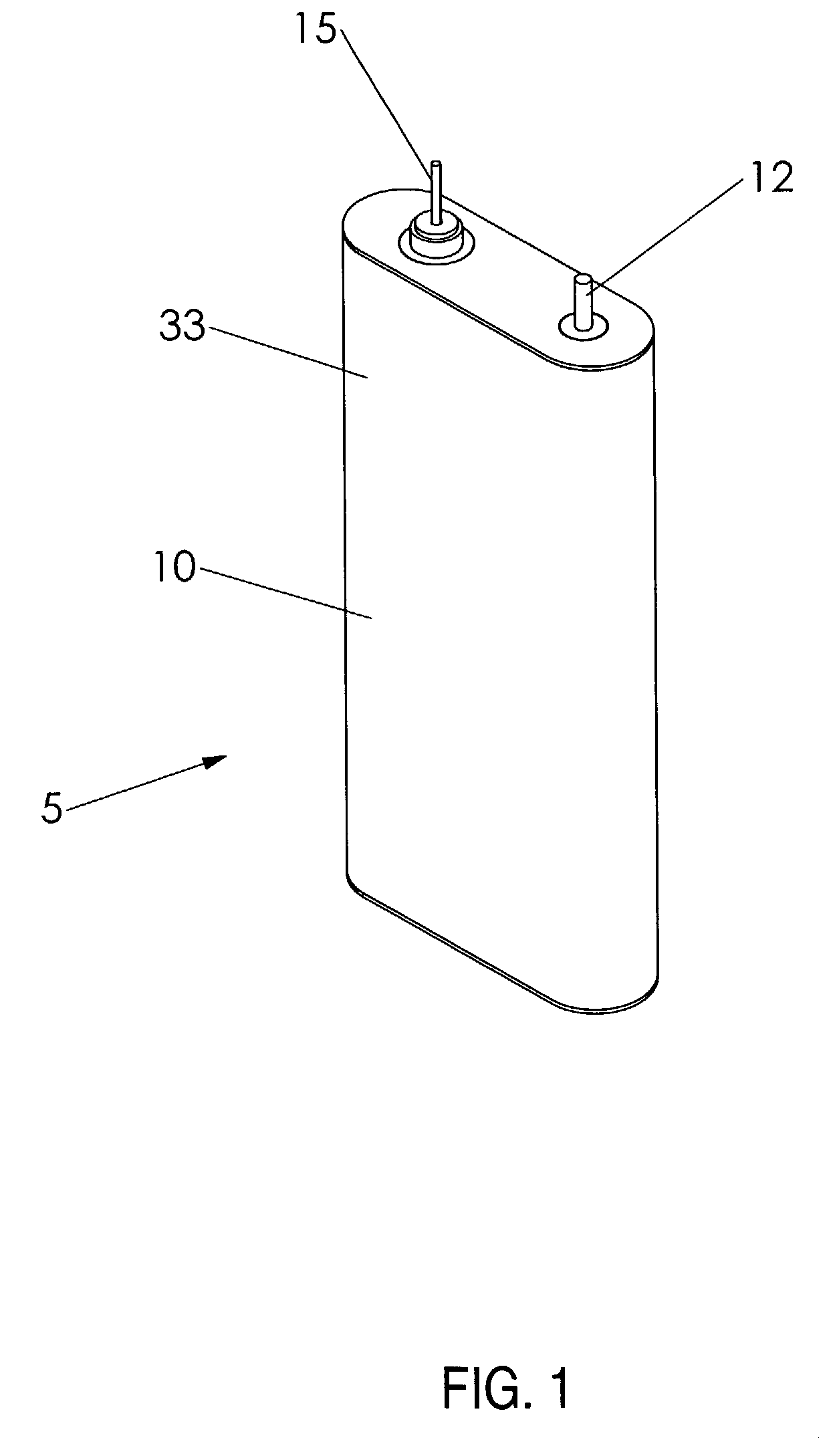

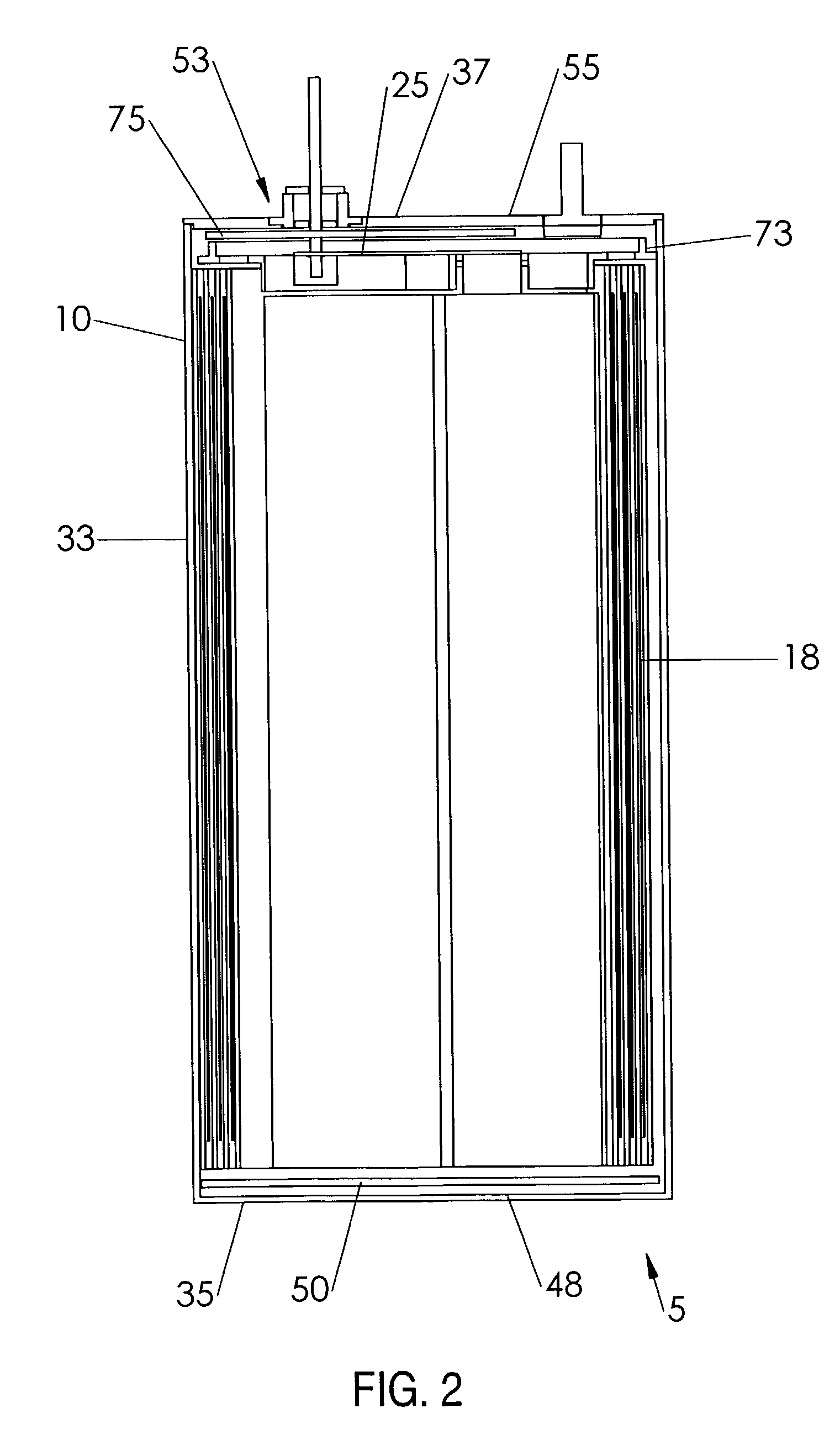

InactiveUS7070881B2Reliable functionEnsure uniformityElectrotherapyCell seperators/membranes/diaphragms/spacersElectricityElectrical battery

The invention provides electrical storage battery assemblies and related methods for assembling such batteries. A battery assembly includes positive and negative electrode sheets and separator sheets sandwiched together and wrapped around a central mandrel to provide a spiral sandwich electrode assembly. The electrode assembly is housed inside a case that includes a case housing open at two ends and covers closing the two openings. The central mandrel of the electrode assembly is in electrical contact with one of the electrode sheets and a first battery terminal that passes through the case. A projecting member on the central mandrel provides the electrical connection between the electrode and the first battery terminal. The other electrode is in electrical contact with the case. A first insulator lies between the electrode assembly and the projecting member. A second insulator is positioned between the projecting member and the case.

Owner:QUALLION

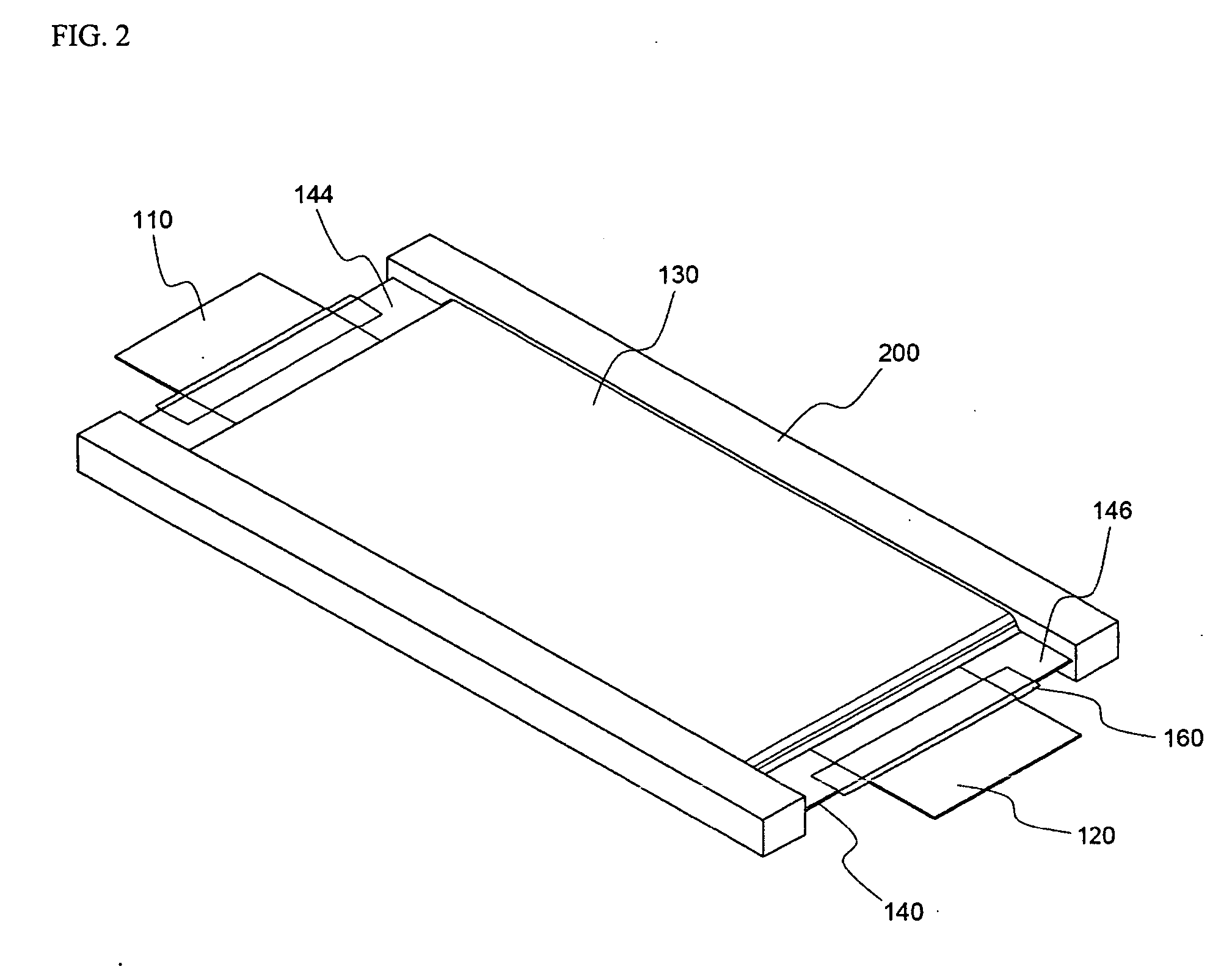

Pouch type battery pack

InactiveUS20090023057A1Avoid damageImprove cooling effectLarge-sized flat cells/batteriesFinal product manufactureEngineeringThermal radiation

A pouch type battery pack, including: a first pouch battery and a second pouch battery adjacent to the first pouch battery, wherein the first and second pouch batteries are combined by bonding an edge of the first pouch battery and an edge of the second pouch battery to each other. Accordingly, the bare cell can be separated without being damaged when the pouch battery is separated from the battery pack. Furthermore, the heat radiation performance is improved by including a heat radiation member between the two pouch batteries when the pouch batteries are stacked.

Owner:SAMSUNG SDI CO LTD

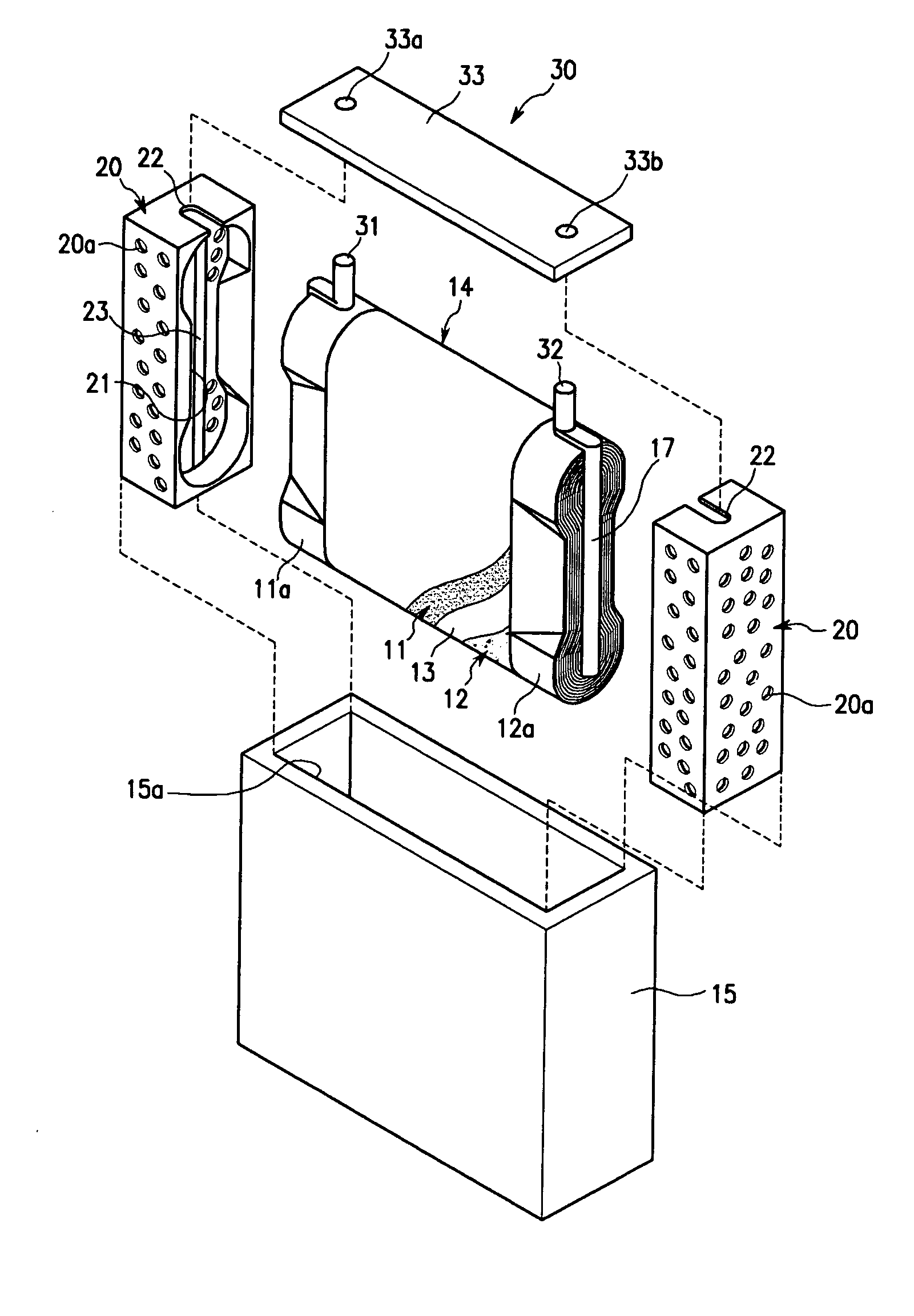

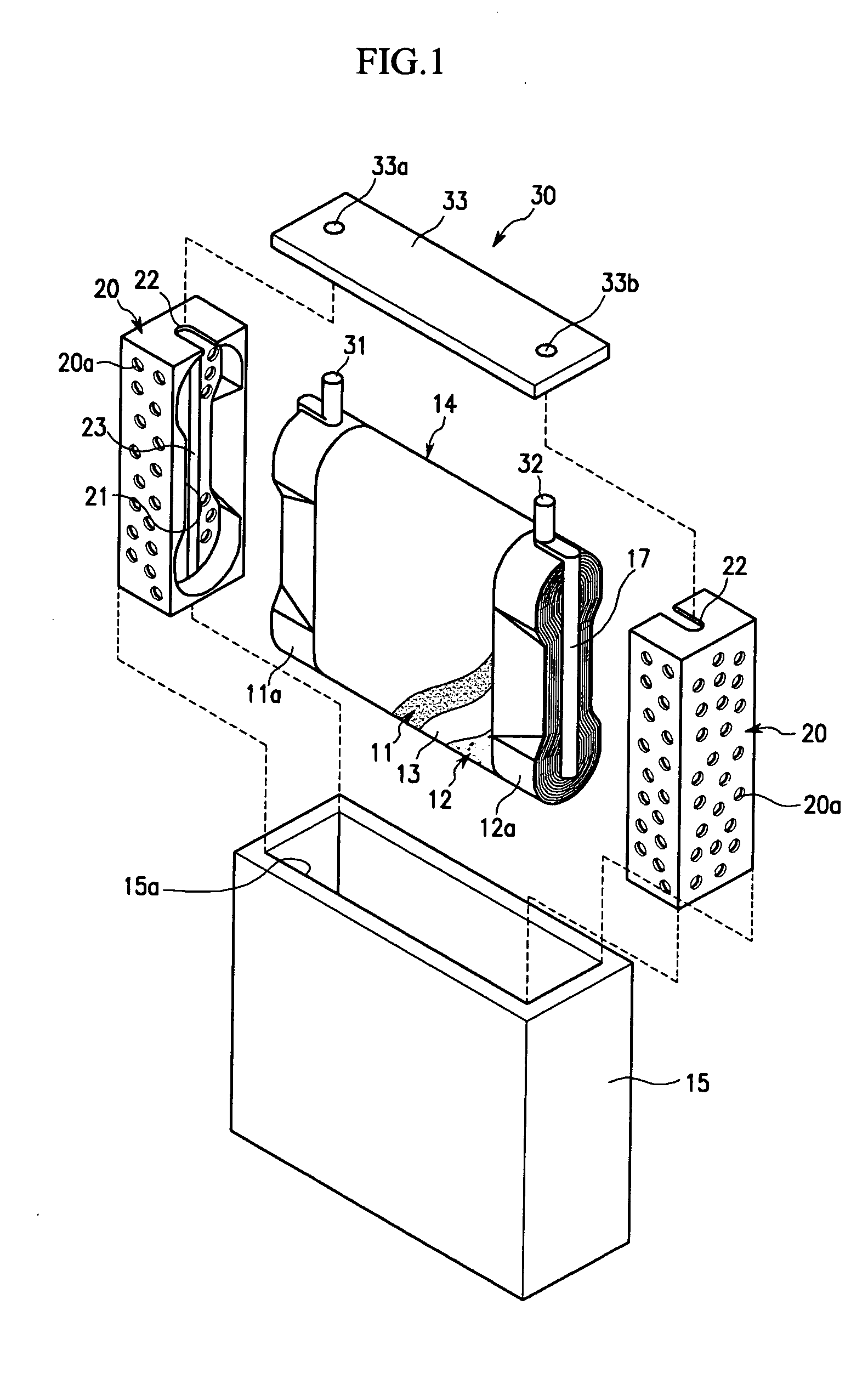

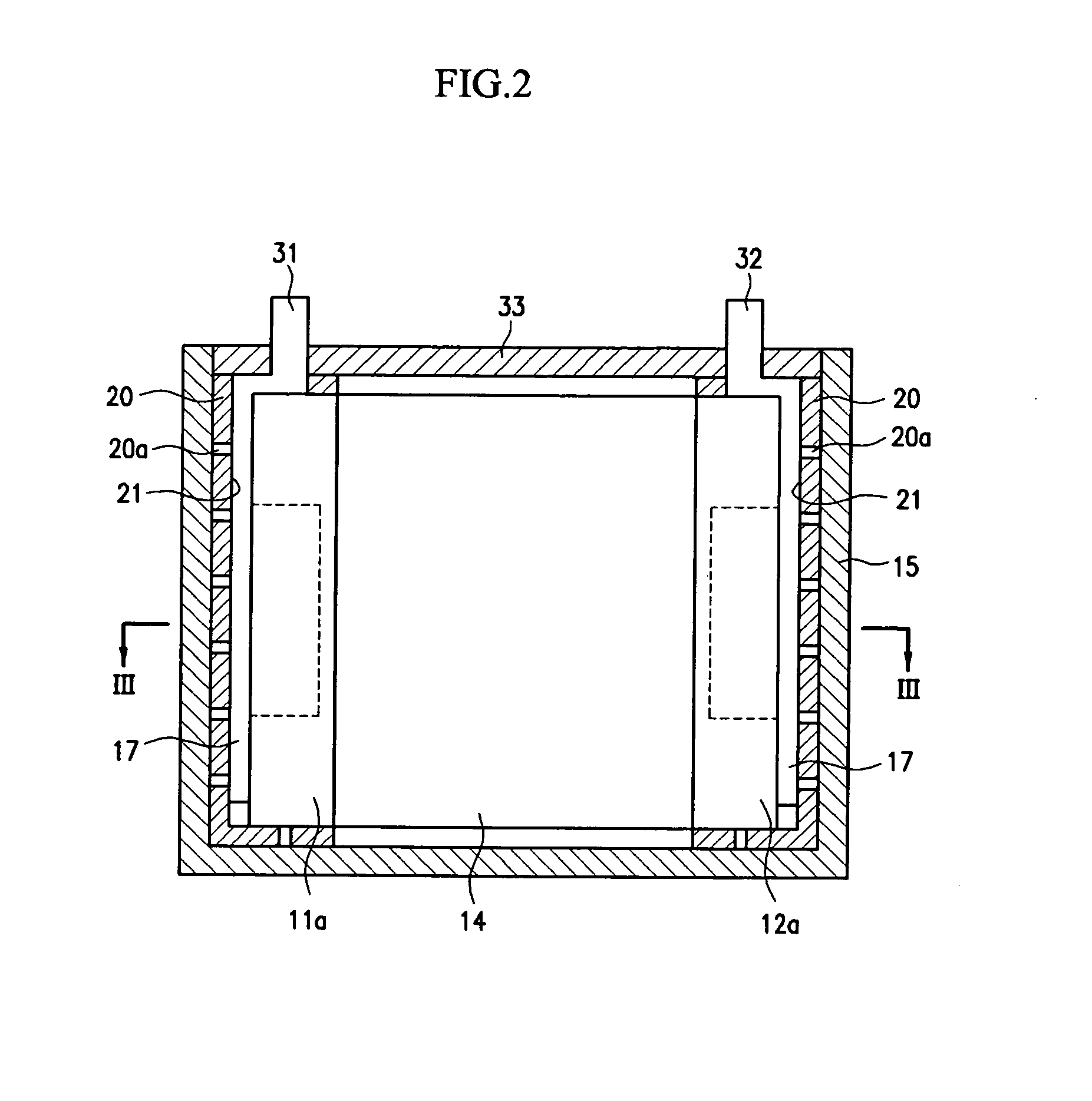

Rechargeable battery and its fabrication method

ActiveUS20080233474A1Preventing electrical shortReduce Shrinkage ProblemsCell seperators/membranes/diaphragms/spacersFinal product manufactureRechargeable cellEngineering

A rechargeable battery and its fabrication method prevents electrical shorts between the electrode plates by decreasing shrinkage of the separator, the battery includes: an electrode assembly including: a wound electrode jelly roll having a first electrode plate with a first electrode tab attached thereto, a second electrode plate with a second electrode tab attached thereto and a separator interposed between the first electrode plate and the second electrode plate, and an upper tape arranged to surround an upper end of the electrode jelly roll where the first electrode tab and second electrode tab extend outward therefrom; a case having an upper end opening arranged to receive the electrode assembly and an electrolyte; and a cap assembly arranged to seal the upper end opening of the case after the electrode assembly has been received in the case; the upper tape 1I is attached to the upper end of the electrode jelly roll and surrounds the separator adjacent to an end of an innermost electrode plate of the first and second electrode plates.

Owner:SAMSUNG SDI CO LTD

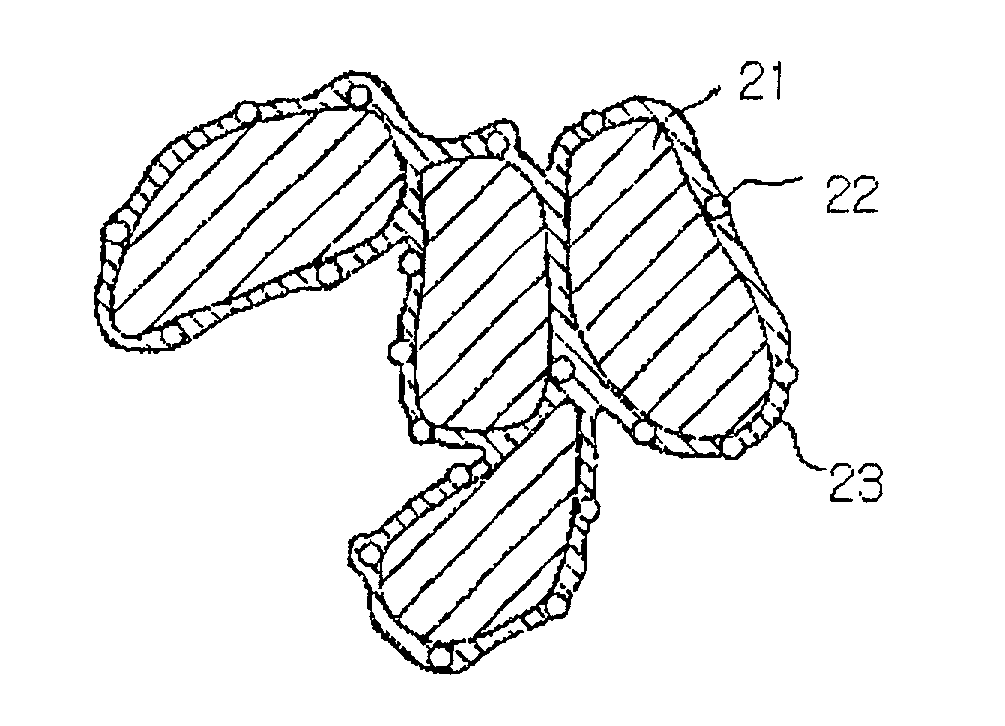

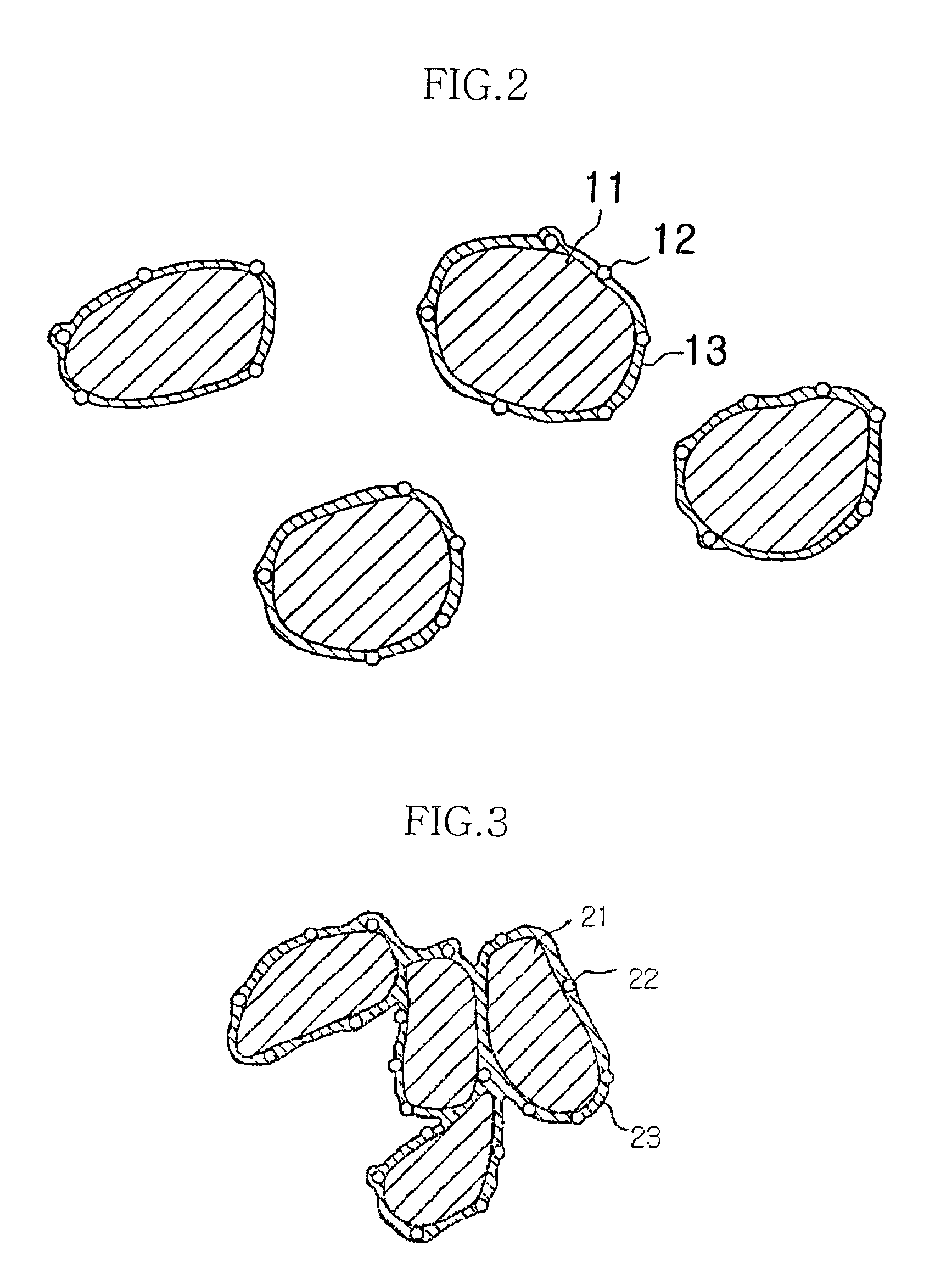

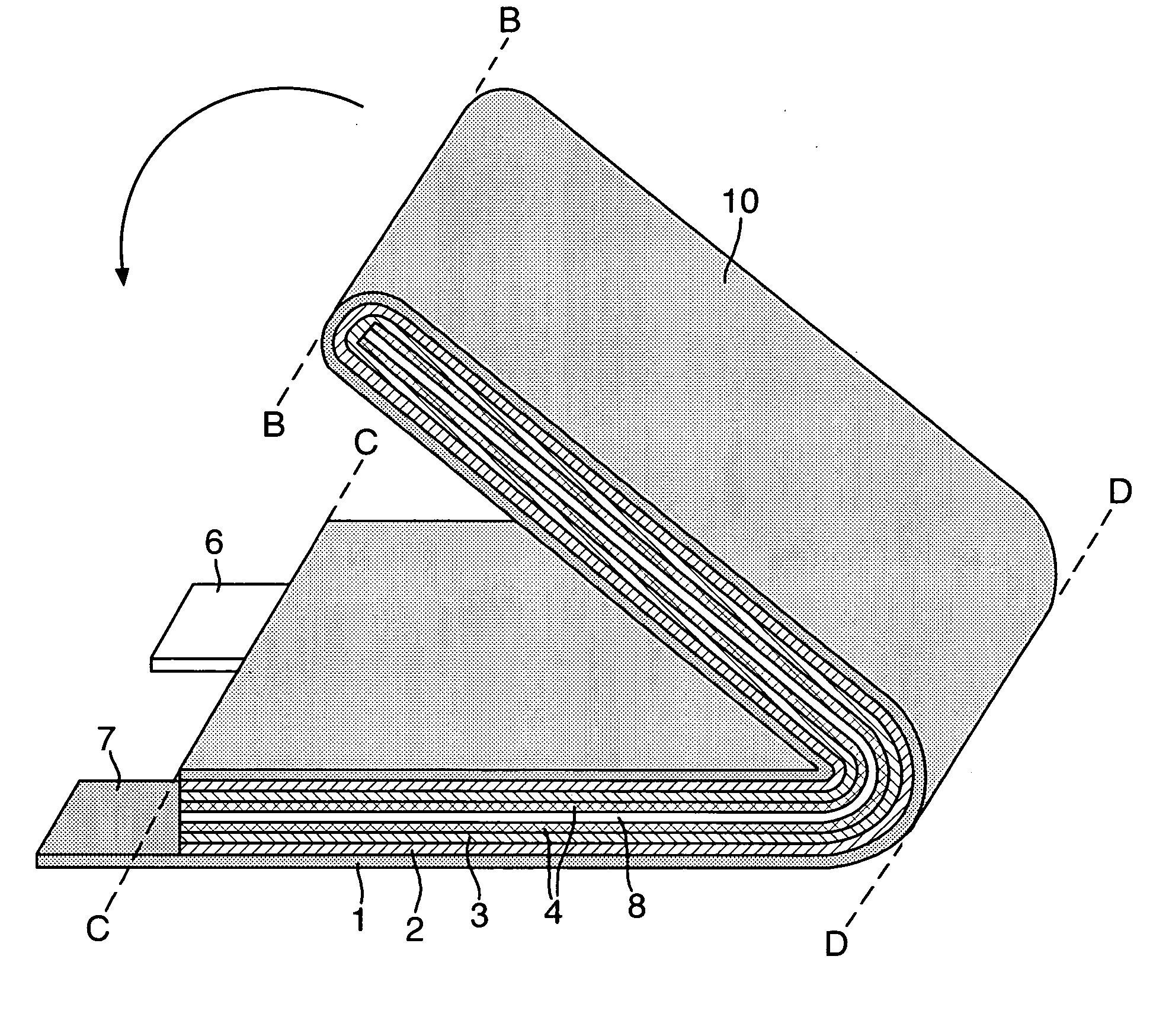

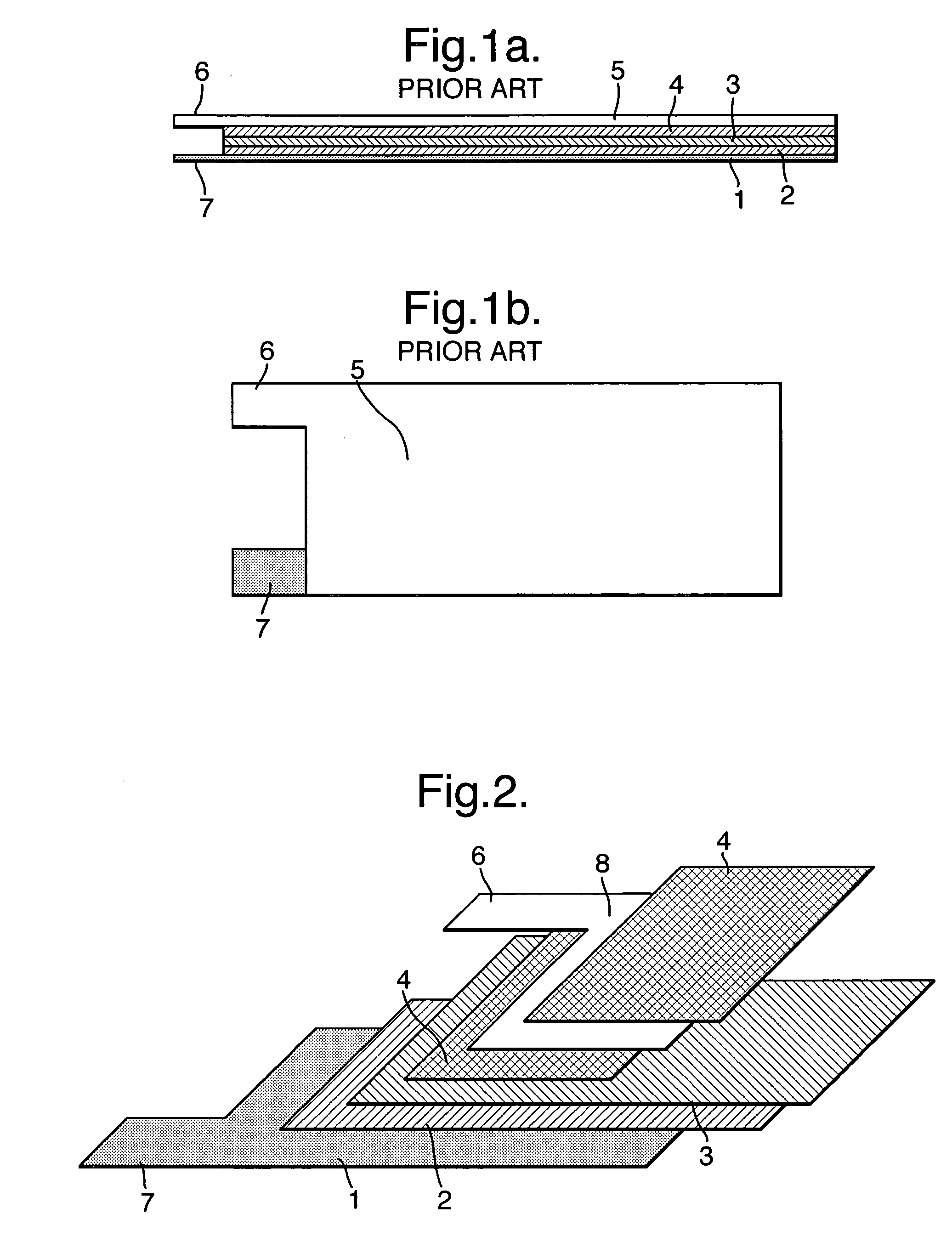

Electrode assembly

ActiveUS20050191545A1Increase energy densityReduce resistancePrimary cell maintainance/servicingFinal product manufactureEngineeringPrimary battery

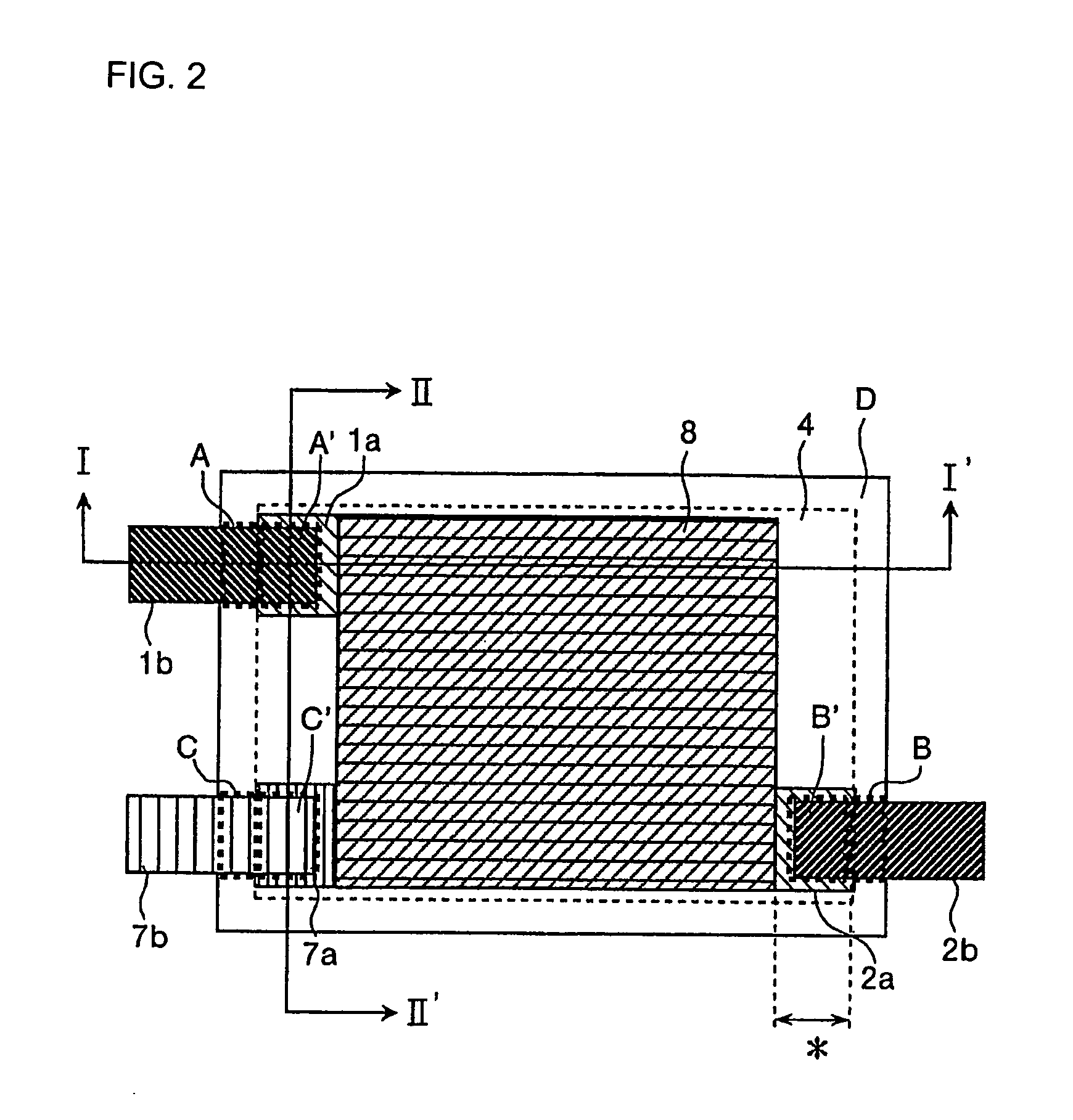

An electrode assembly is formed by respectively overlaying a sheet cathode 1, a sheet separator 3 and a double-sided sheet anode 8 to form a stacked structure 10, and subjecting the stacked structure to multiple folds, wherein the initial fold comprises folding the cathode in half around the double-sided anode so as to surround the respective upper and lower active anode surfaces thereof. The multiple folds may comprise one or more subsequent parallel folds made with the fold line D-D extending perpendicular to the original length of the stacked structure such that its overall length is halved at each fold. A pouch battery comprising said electrode assembly has improved safety and performance characteristics. The pouch battery construction has especial application to lithium primary batteries.

Owner:QINETIQ LTD

Battery cell design and method of its construction

ActiveUS20070269685A1Reduce inductanceEasy to manufactureElectrode manufacturing processesElectrode carriers/collectorsElectrochemical cellBiomedical engineering

A compact, robust, multifunctional and highly manufacturable rechargeable cylindrical electrochemical cell is provided. In some embodiments, a cell can include a spirally wound assembly having an anode sheet and a cathode sheet separated by separator membranes, each sheet having a electroactive layer on a current collector. At least one of the current collectors can be in electrical communication with conducting tabs that extend from at least one of the anode sheet and the cathode sheet, the conducting tabs extends from an end face of the spirally wound assembly. The centers of the plurality of conducting tabs can be located within a 90 degree quadrant of an end face of the spirally wound assembly.

Owner:RIL USA INC +1

Non-aqueous electrolyte secondary battery

InactiveUS20070092796A1High charge and discharge capacityImprove featuresMaterial nanotechnologyFinal product manufactureMethacrylateCarbon nanofiber

Owner:PANASONIC CORP

Secondary battery

InactiveUS20060251962A1Cell seperators/membranes/diaphragms/spacersFinal product manufactureElectrical polarityEngineering

A secondary battery, including a jelly-roll shaped electrode assembly in which first and second electrode plates coated with active material layers having different polarities are wound together with a separator interposed therebetween, a fixing tape disposed around the jelly-roll shaped electrode assembly having a predetermined elasticity so as to maintain a winding state of the jelly-roll shaped electrode assembly, a case to receive the jelly-roll shaped electrode assembly, and a cap assembly to seal the case.

Owner:SAMSUNG SDI CO LTD

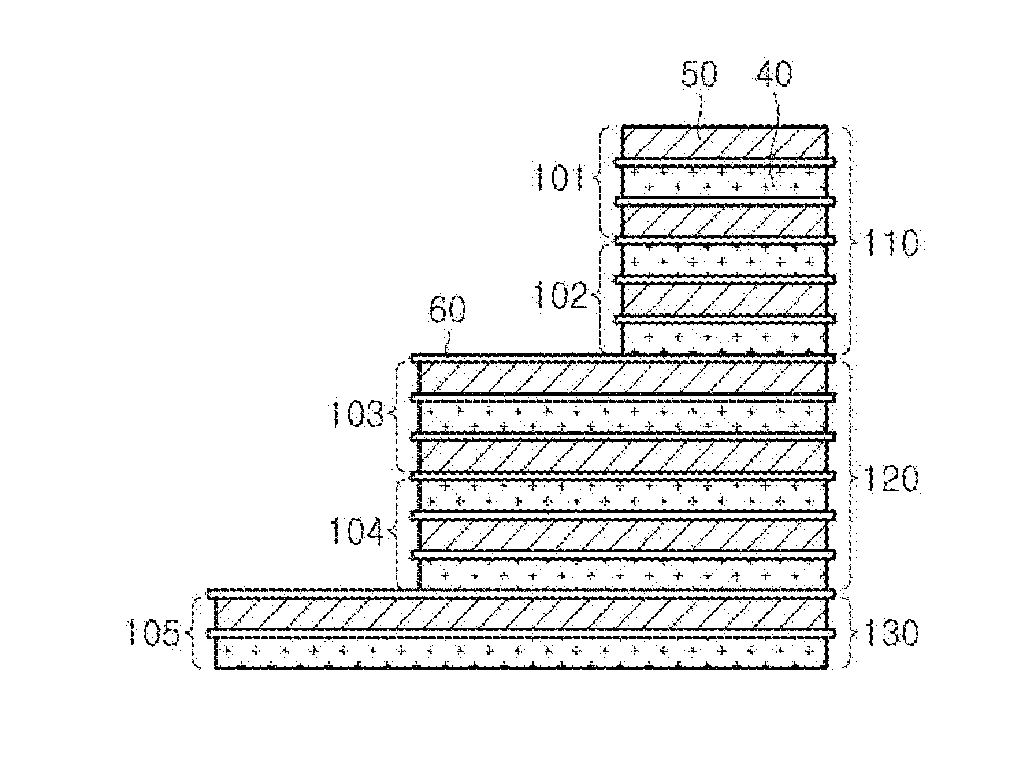

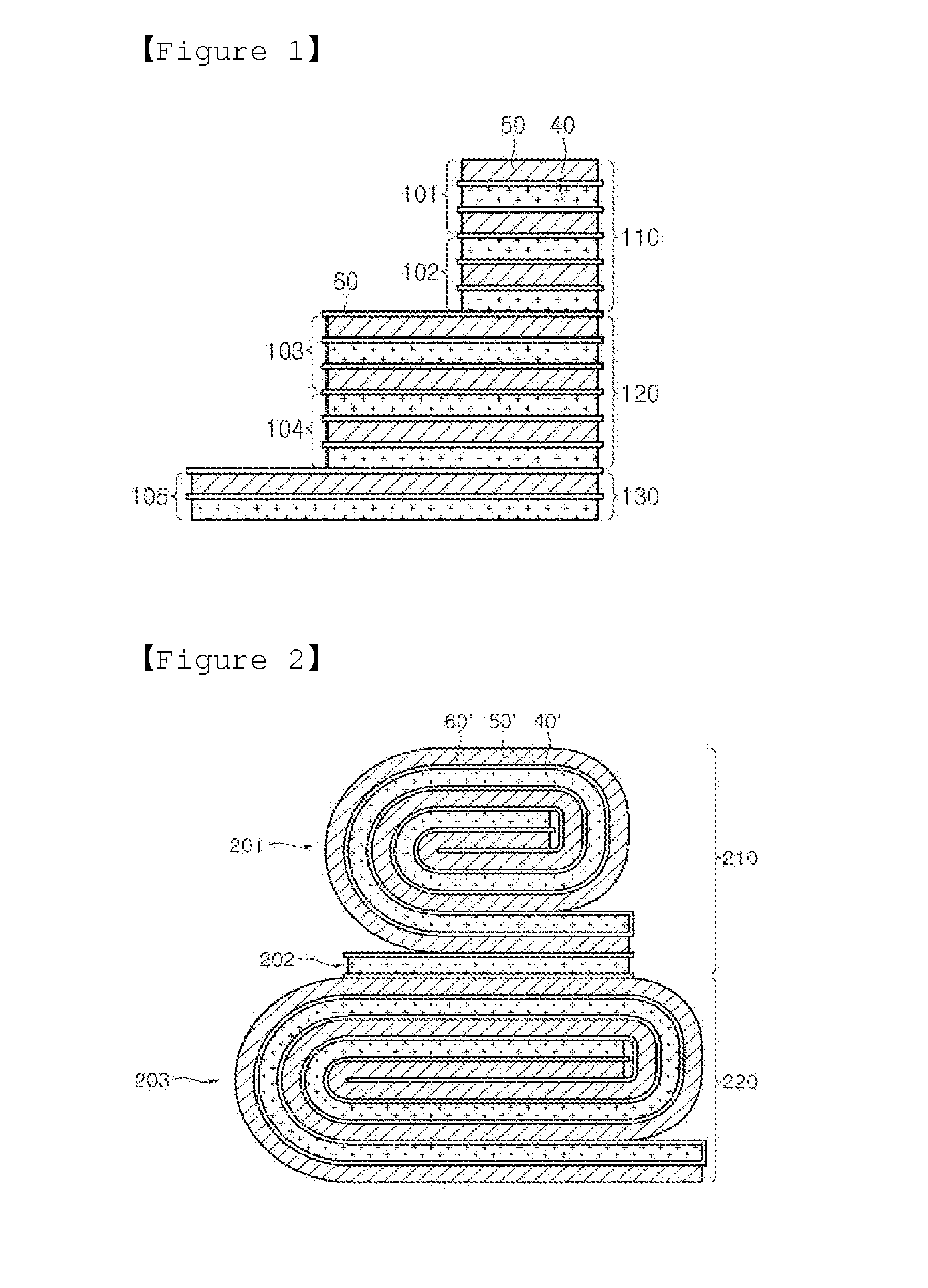

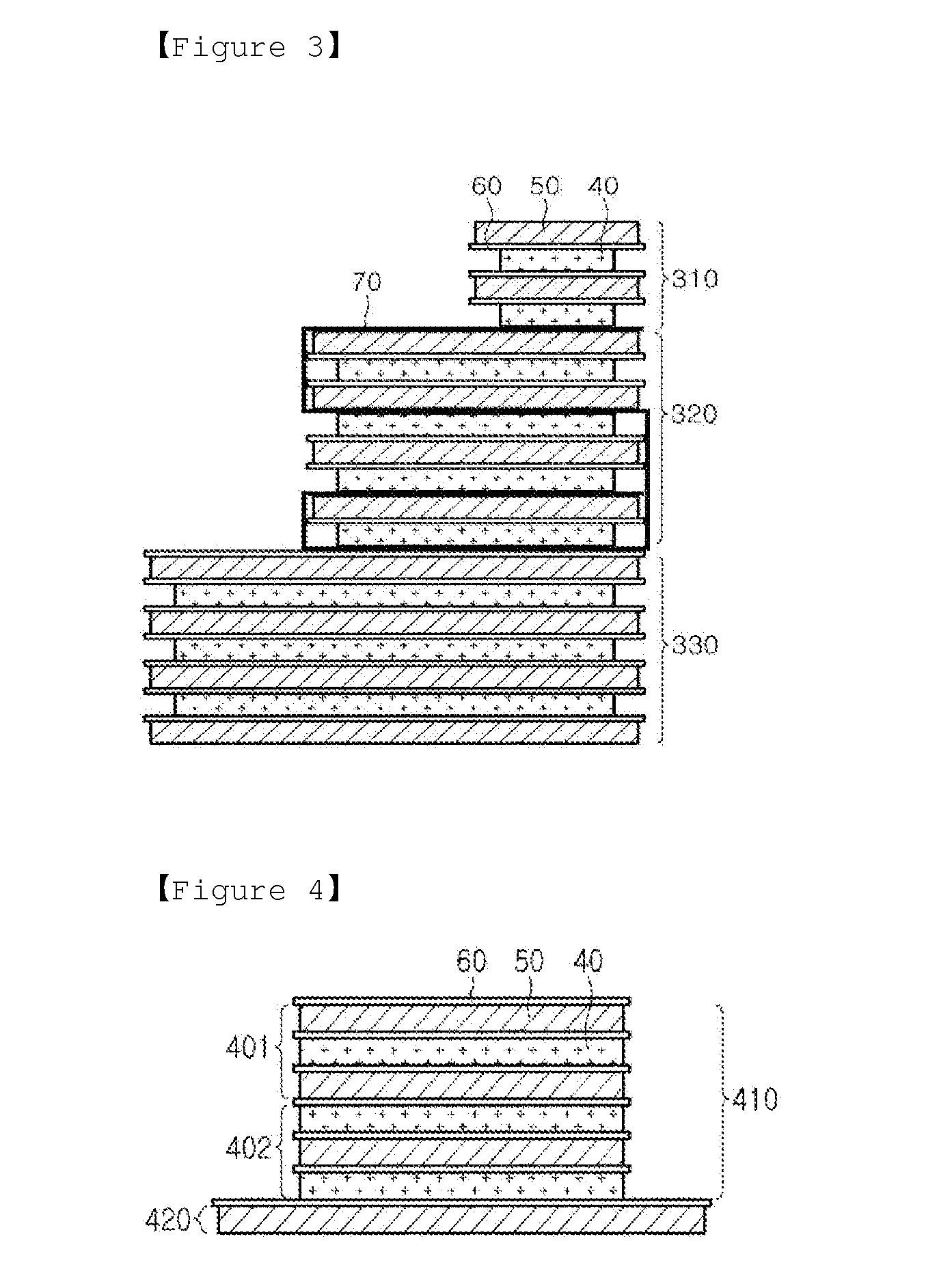

Stepped electrode assembly having predetermined a thickness ratio in the interface between electrode units, battery cell and device comprising the same

ActiveUS20140072850A1Maintaining capacitance characteristicMaintaining characteristic durabilityFinal product manufactureVehicular energy storageBattery cellBiomedical engineering

There are provided an electrode assembly, and a battery cell, a battery pack, and a device. The electrode assembly includes a combination of two or more types of electrode units having different areas, wherein the electrode units are stacked such that steps are formed, and electrode units are formed such that a positive electrode and a negative electrode face one another at an interface between the electrode units.

Owner:LG ENERGY SOLUTION LTD

Method of manufacturing cylindrical non-aqueous electrolyte secondary cell

InactiveUS6193765B1Improve power densityReduce resistanceFinal product manufactureElectrode carriers/collectorsEngineeringLaser beams

Owner:SANYO ELECTRIC CO LTD

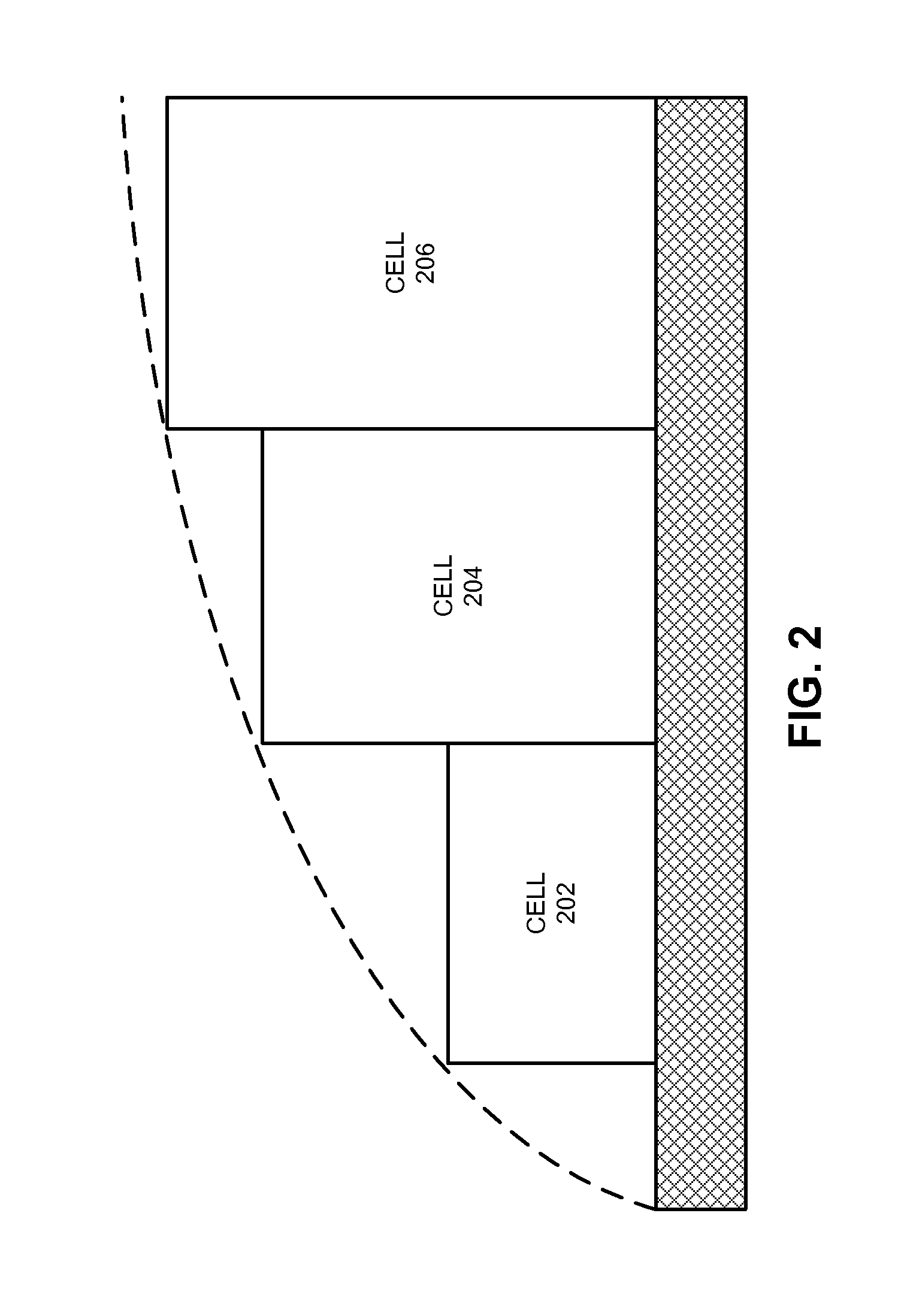

Accumulator device

InactiveUS20050208375A1Highly versatile and simple structureProtection from external shocksProtecting/adjusting hybrid/EDL capacitorElectrolytic capacitorsEngineeringEnergy requirement

A package case is structured by a plurality of substantially identical and flat frames stacked on one another. Flat laminate cells (accumulator cells) are individually accommodated in the frames and stacked on one another, so that the number of flat laminate cells (accumulator cells) can readily be changed simply by increasing / decreasing the number of frames to be stacked to meet energy needs and the like. The accumulator device is segmented using the plurality of flat frames, so that externally applied impacts can readily be dispersed and the impact transmitted to the flat laminate cells (accumulator cells) can be reduced without reinforcing the accumulator device 1 with more than necessary strength.

Owner:SUBARU CORP

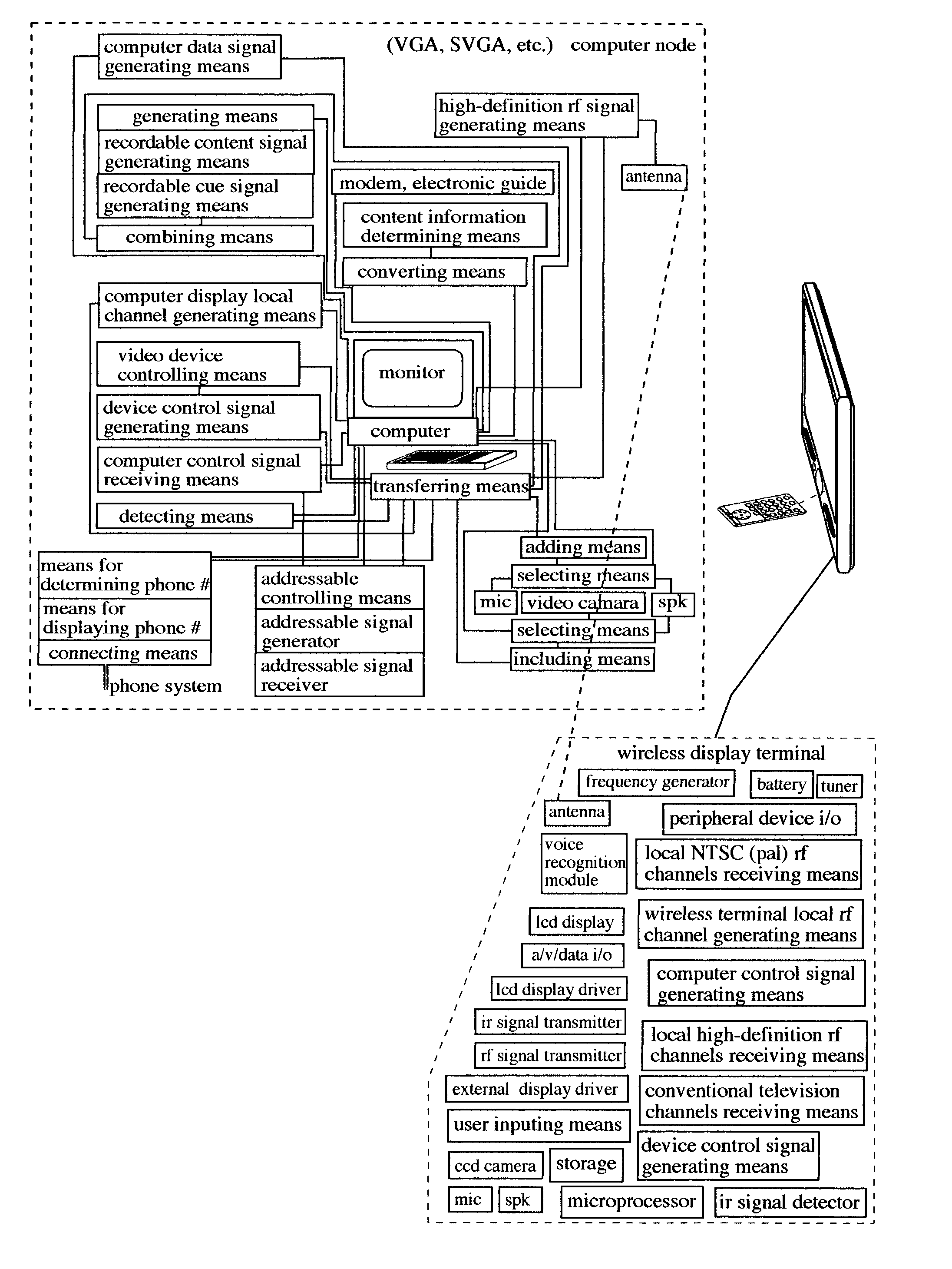

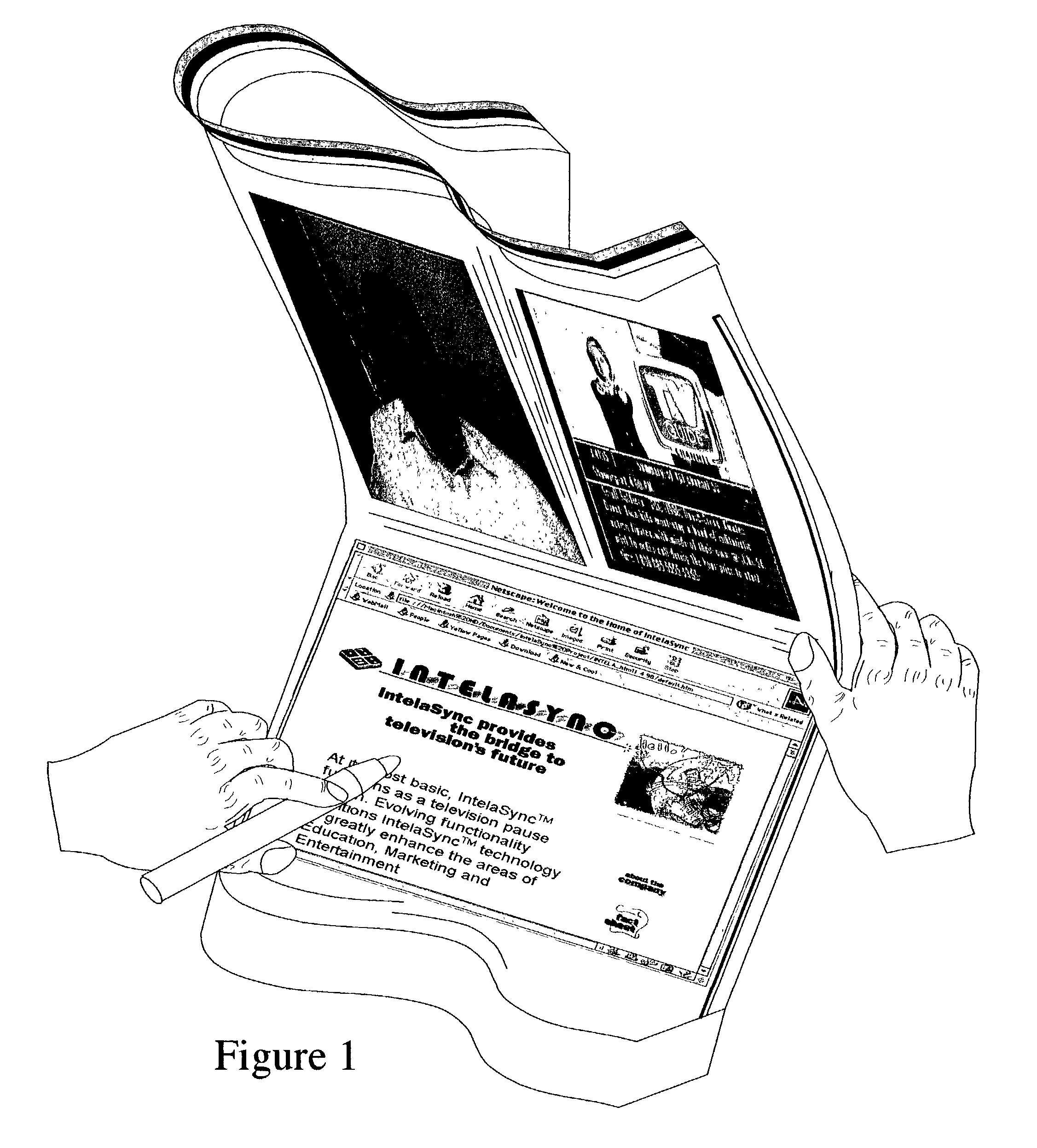

Thin, lightweight, flexible, bright, wireless display

InactiveUS7161590B2Sufficient on-board storageEfficient accessFinal product manufacturePrinted batteriesElectrical conductorConductive polymer

A multilayered thin, lightweight, flexible, bright, wireless display having components capable of being manufactured by a printing method. A flexible substrate provides a support structure upon which components can be manufactured by a printing method. A display stratum includes light emitting pixels for displaying information. The light emitting pixels are formed by printing a pixel layer of light-emitting conductive polymer. An electronic circuit stratum includes signal transmitting components for transmitting user input signals to a display signal generating device for controlling display information transmitted from the display signal generating device. Signal receiving components receive the display information transmitted from the display signal generating device. Display driving components drive the display layer according to the received display information. A user input stratum receives user input and generates the user input signals. A battery stratum provides electrical energy to the electronic circuit stratum, the user input stratum and display stratum components. The signal receiving components may include first radio frequency receiving components for receiving a first display signal having first display information carried on a first radio frequency and second radio frequency receiving components for receiving a second display signal having second display information carried on a second radio frequency. The display driving components may include signal processor components for receiving the first display signal and the second display signal and generating a display driving signal for simultaneously displaying the first display information at a first location on the display stratum and the second display information at a second location on the display stratum. At least some of the components in the battery, display, user input and electronic circuit stratums are formed by printing electrically active material to form circuit elements including resistors, capacitors, inductors, antennas, conductors and semiconductor devices.

Owner:DANIELS JOHN JAMES

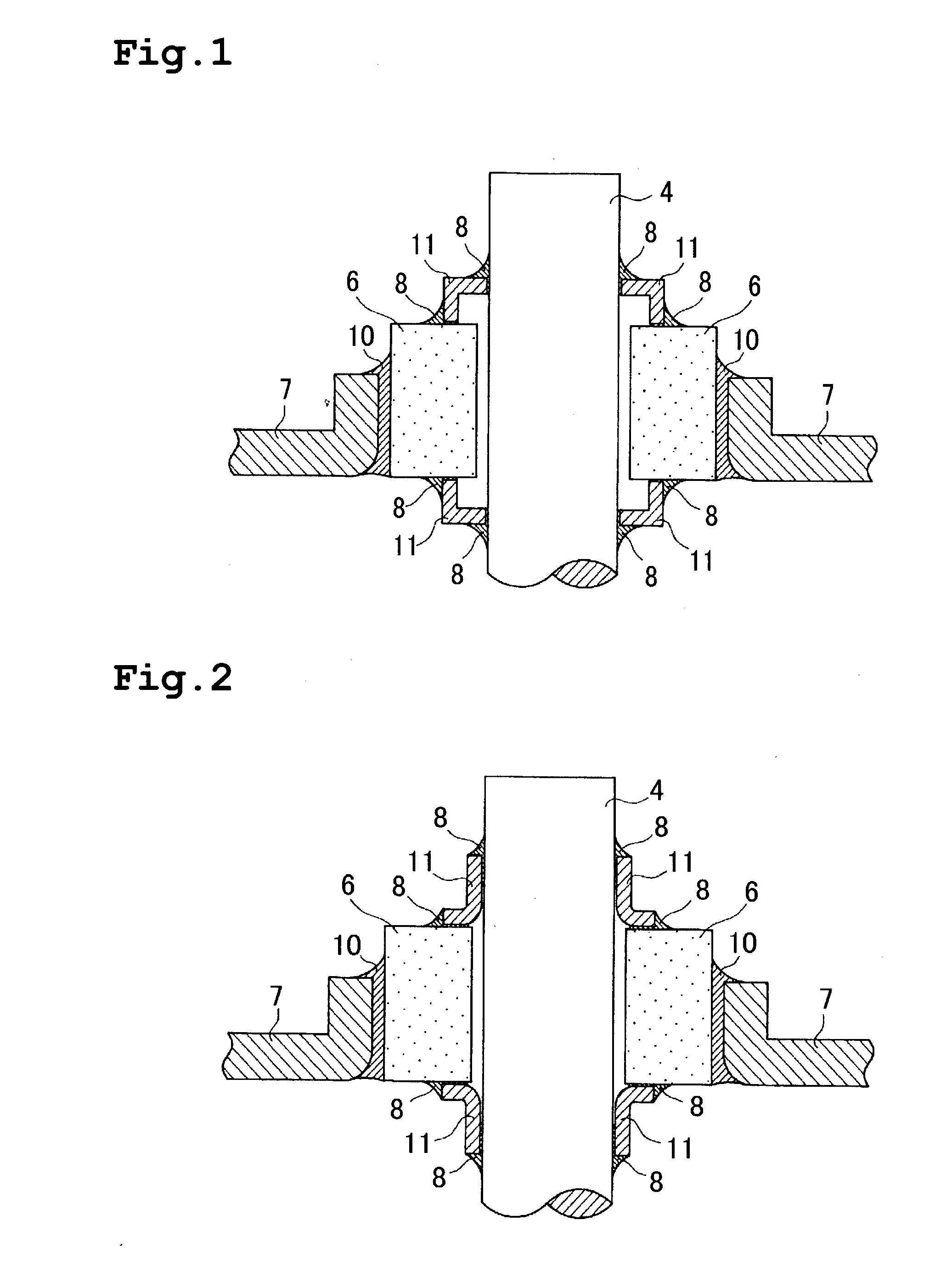

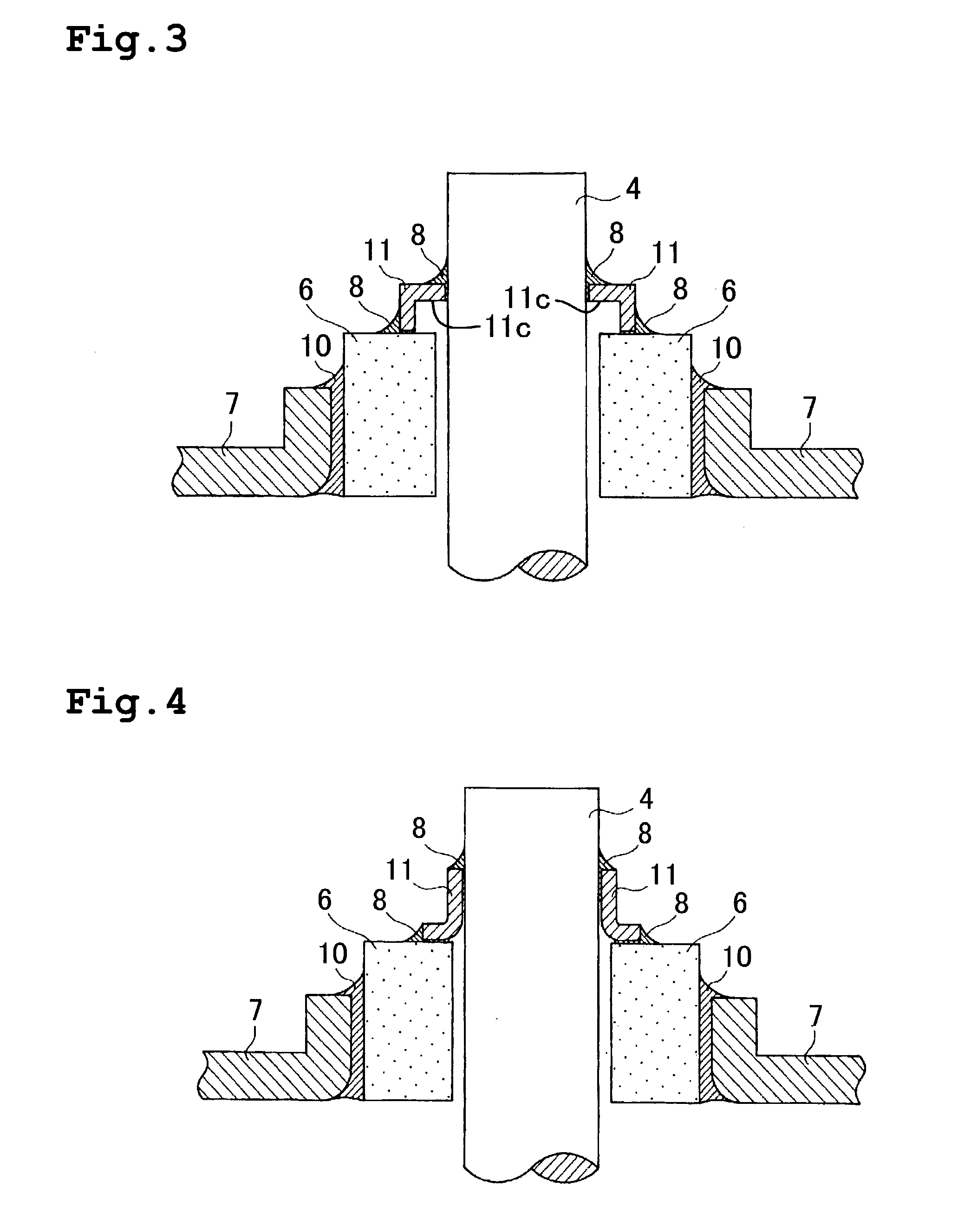

Battery

InactiveUS20030143460A1Avoid crackingReliable crackingFinal product manufactureSmall-sized cells cases/jacketsMetalCopper alloy

An insulating sleeve 6 made of ceramic hermetically fixed into an opening in a terminal supporting plate 7 in a battery sheath made of metal, a positive terminal 4 made of an aluminum alloy or negative terminal 5 made of a copper alloy is inserted in the insulating sleeve, and a metallic ring is fitted over the positive terminal 4 or negative terminal 5. The inner edge of the metallic ring 11 and the positive terminal 4 or negative terminal 5 are hermetically fixed to each other by an aluminum-based brazing metal 8 or copper-based brazing metal 9, and the outer edge of the metallic ring 11 and the insulating sleeve 6 are hermetically fixed to each other by an aluminum-based brazing metal 8 or copper-based brazing metal 9.

Owner:GS YUASA INT LTD

Rechargeable battery

ActiveUS20050287431A1Current collection efficiency can be enhancedIncrease currentFinal product manufactureSmall-sized cells cases/jacketsRechargeable cellEngineering

A rechargeable battery comprises an electrode assembly including a positive electrode, a negative electrode, and a separator that is interposed between the positive electrode and negative electrode. The battery further comprises a case for housing the electrode assembly, a cap assembly for sealing the case, a positive terminal and a negative terminal placed in the cap assembly and coupled with the electrode assembly, and lead elements that are coupled with the electrode assembly and the positive terminal and negative terminal. The positive and negative electrodes include uncoated regions that are not coated with positive active materials or negative active materials, respectively, and the lead elements are placed along the periphery of the uncoated regions to be coupled with at least half of the uncoated regions.

Owner:SAMSUNG SDI CO LTD

Electrochemical device and method for production thereof

ActiveUS20090325058A1Improve securityImprove productivityHybrid capacitor separatorsElectrolytic capacitorsPorous layerMaterials science

An electrochemical device of the present invention includes a positive electrode, a negative electrode, a non-aqueous electrolyte, and a separator. The separator includes a first porous layer composed mainly of a thermoplastic resin and a second porous layer composed mainly of insulating particles with a heat-resistant temperature of 150° C. or higher. The first porous layer is disposed to face the negative electrode.

Owner:MAXELL HLDG LTD

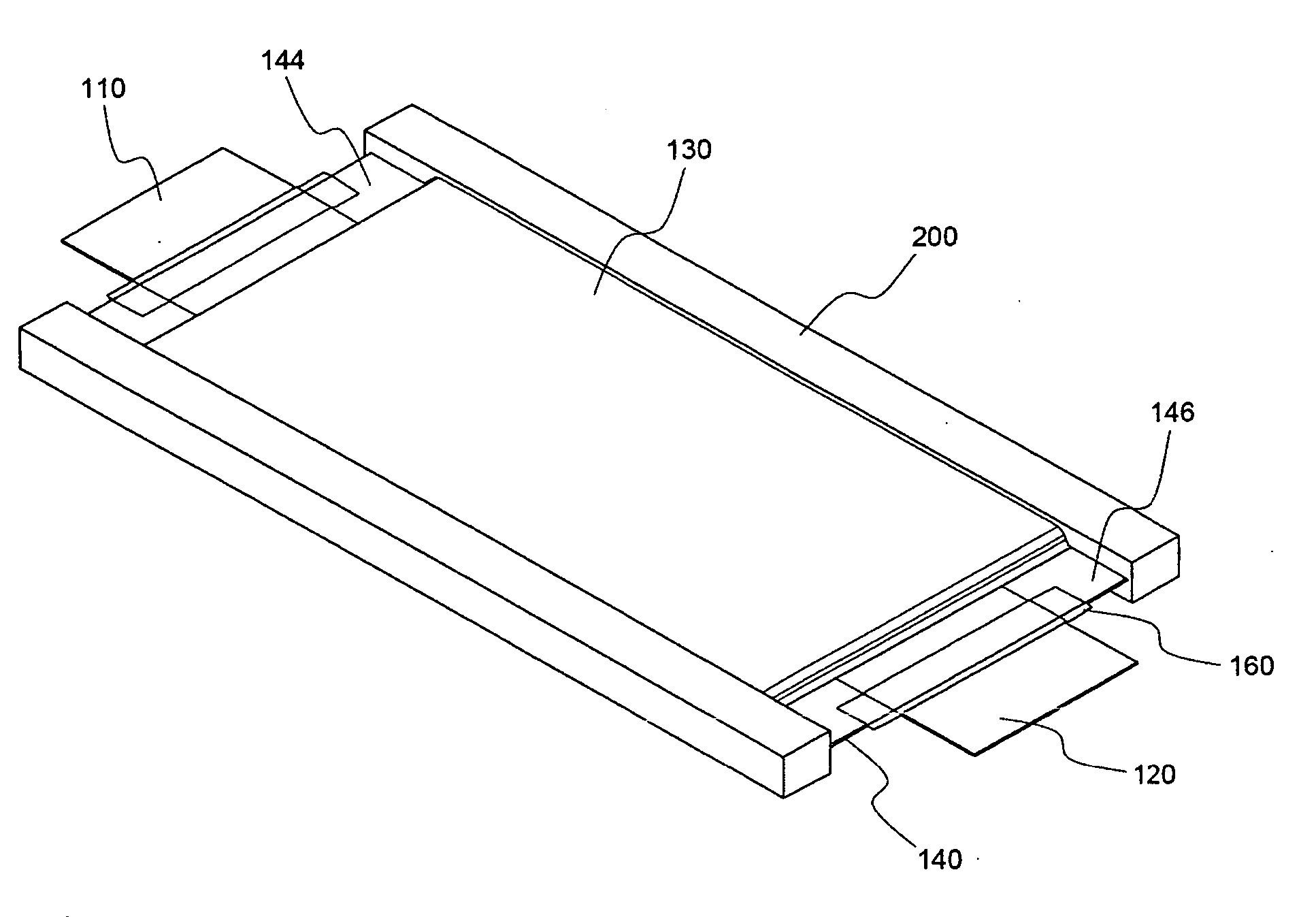

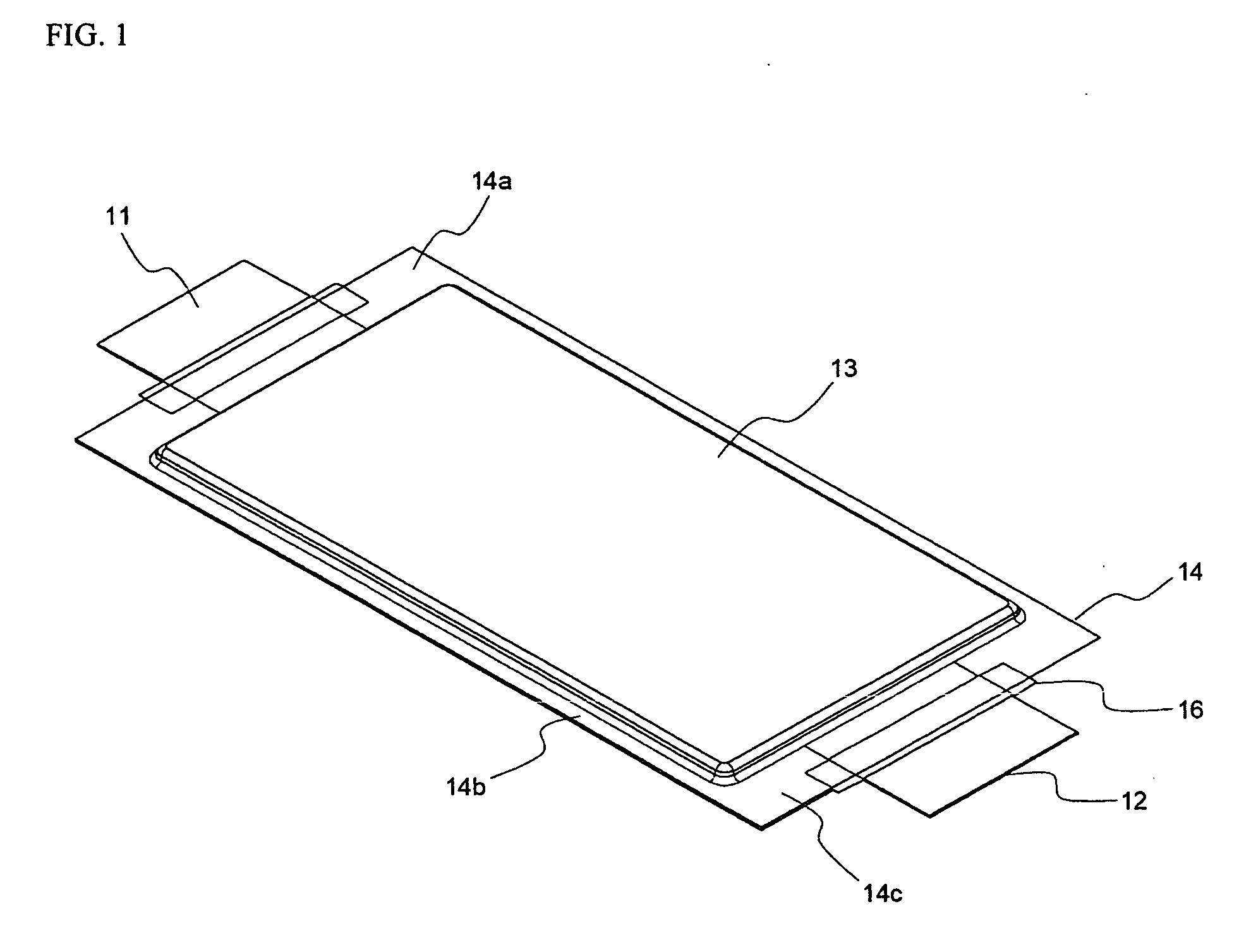

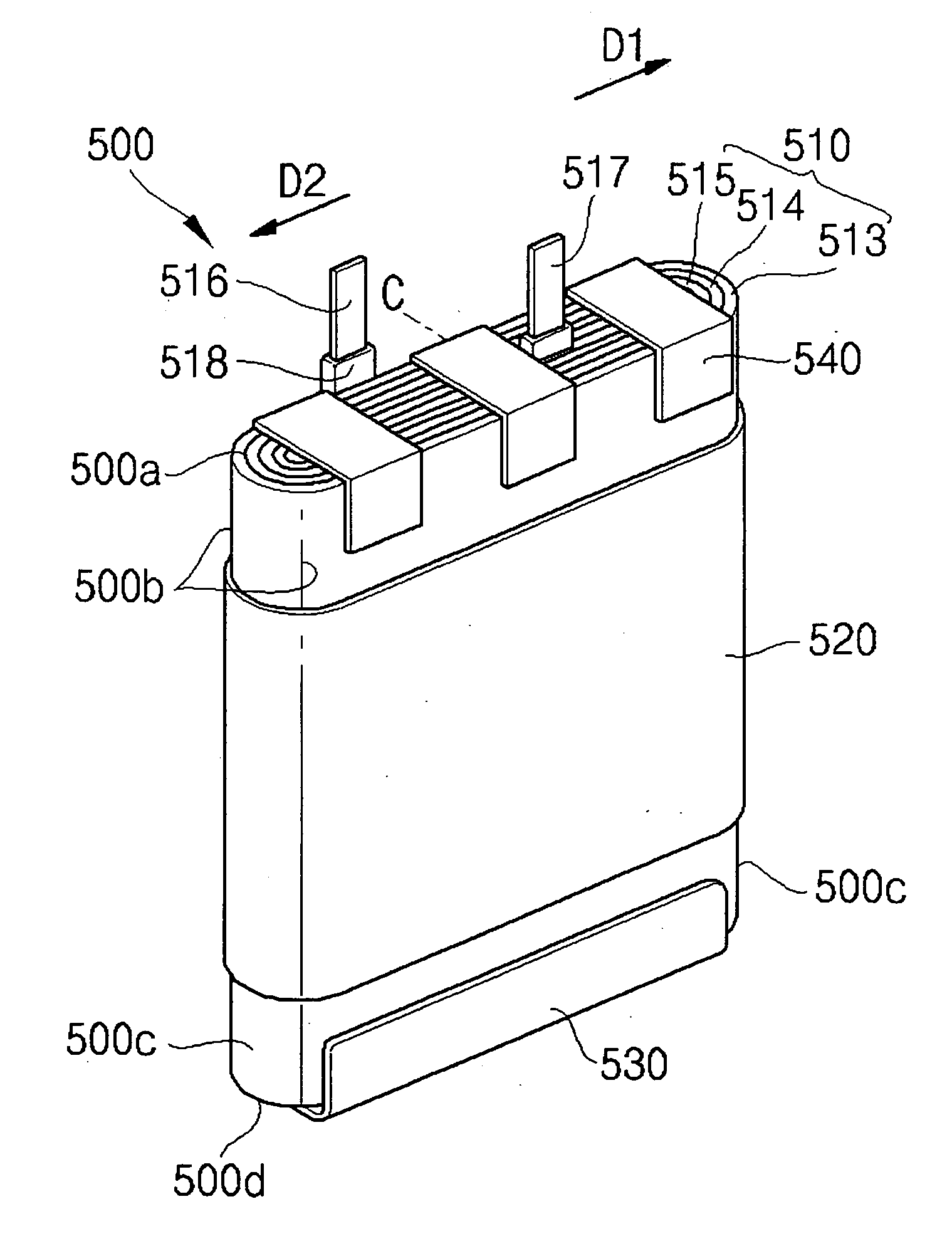

Rechargeable battery

InactiveUS20050287429A1Current collection efficiency can be enhancedStable outputFinal product manufactureSmall-sized cells cases/jacketsRechargeable cellEngineering

A rechargeable battery includes an electrode assembly comprising a positive electrode that has an uncoated region that is not coated with an active material along an edge, a negative electrode that has an uncoated region that is not coated with an active material along an edge, and a separator that is placed between the positive electrode and the negative electrode. The battery further comprises current collecting plates that are joined with the uncoated regions of the positive electrode and negative electrode while covering the uncoated regions, a case for housing the electrode assembly and the current collecting plates, and a cap assembly that is coupled with the case to seal it and includes terminals that are coupled with the current collecting plates.

Owner:SAMSUNG SDI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com