Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2823results about "Dry cells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

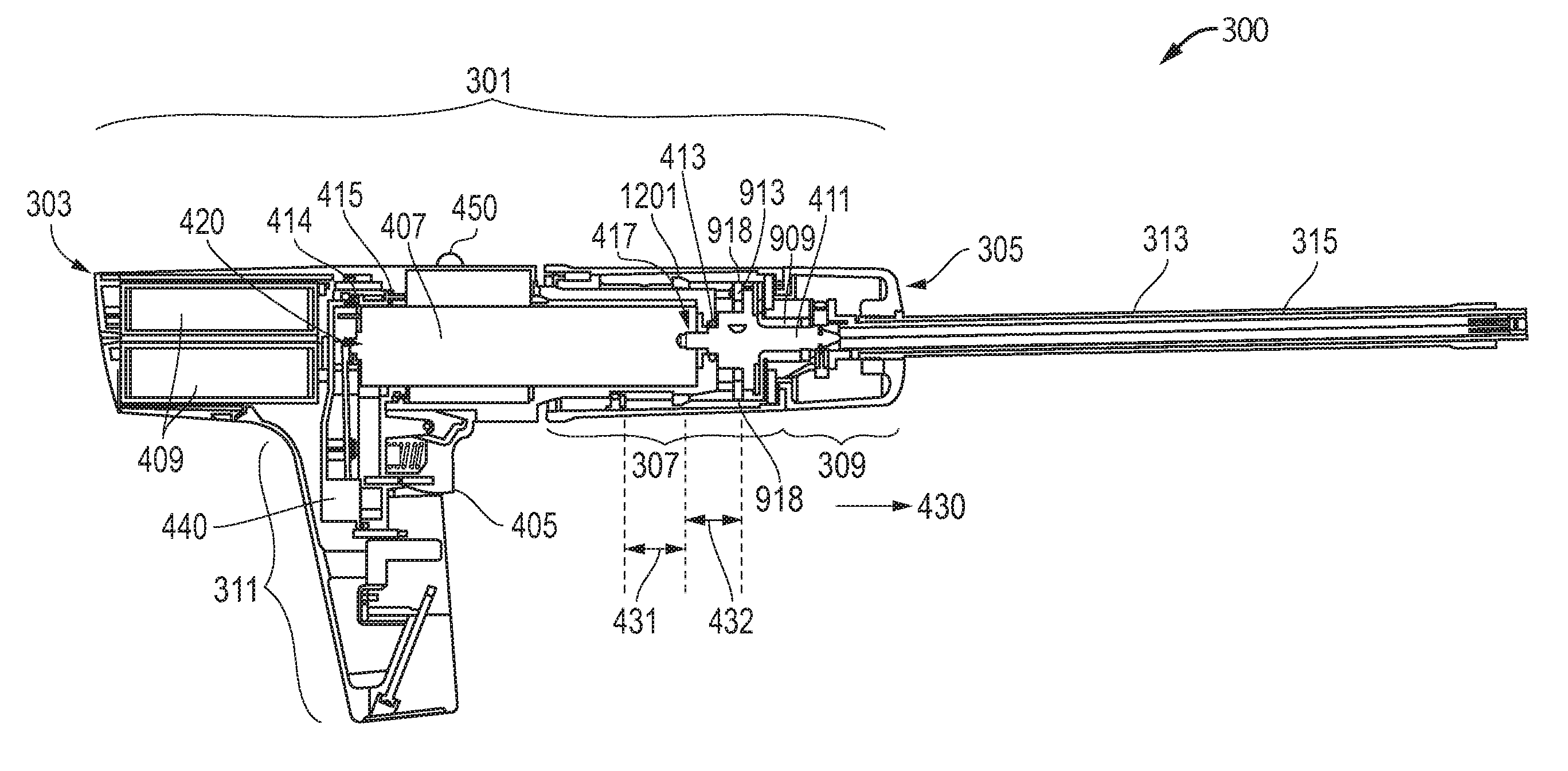

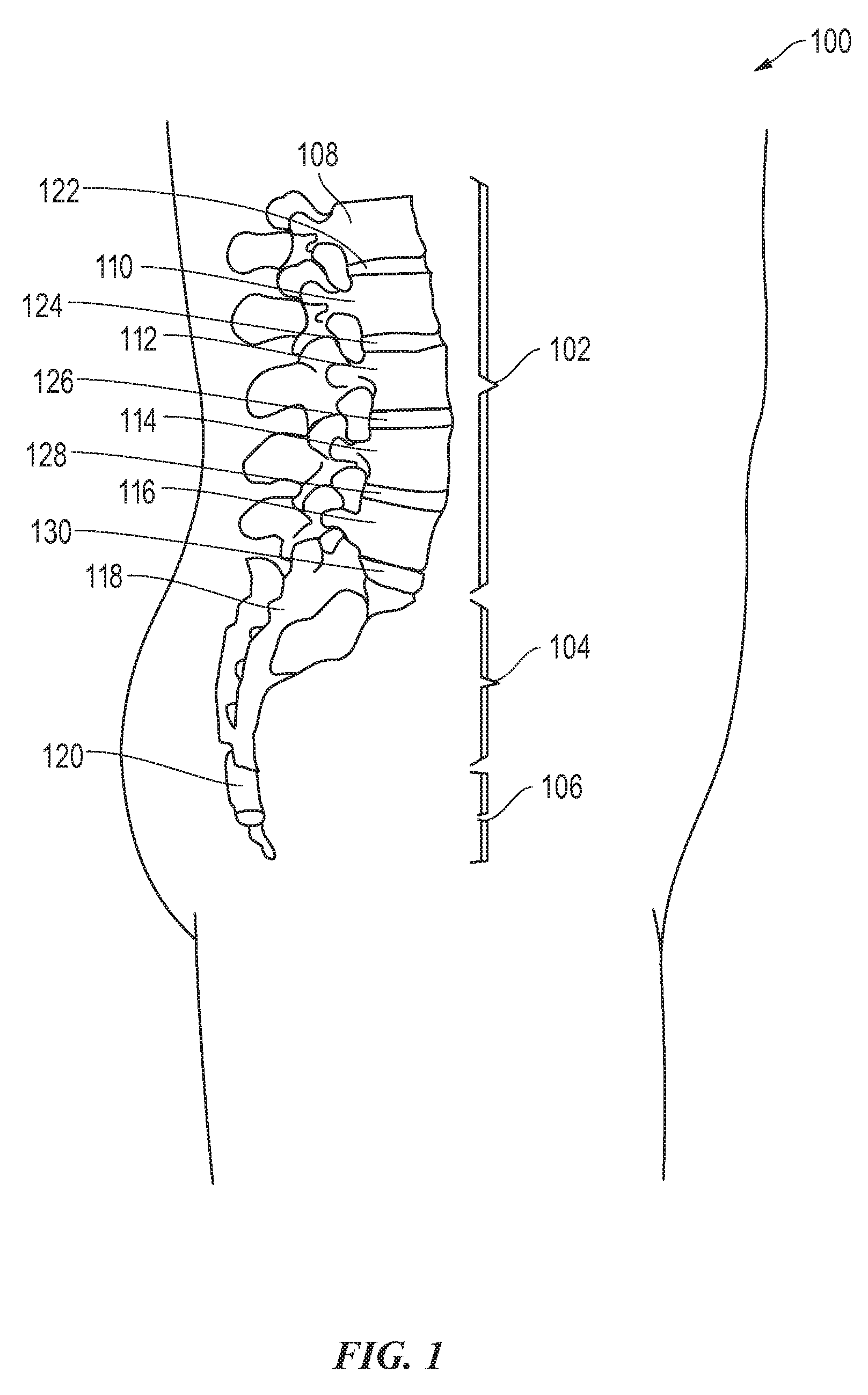

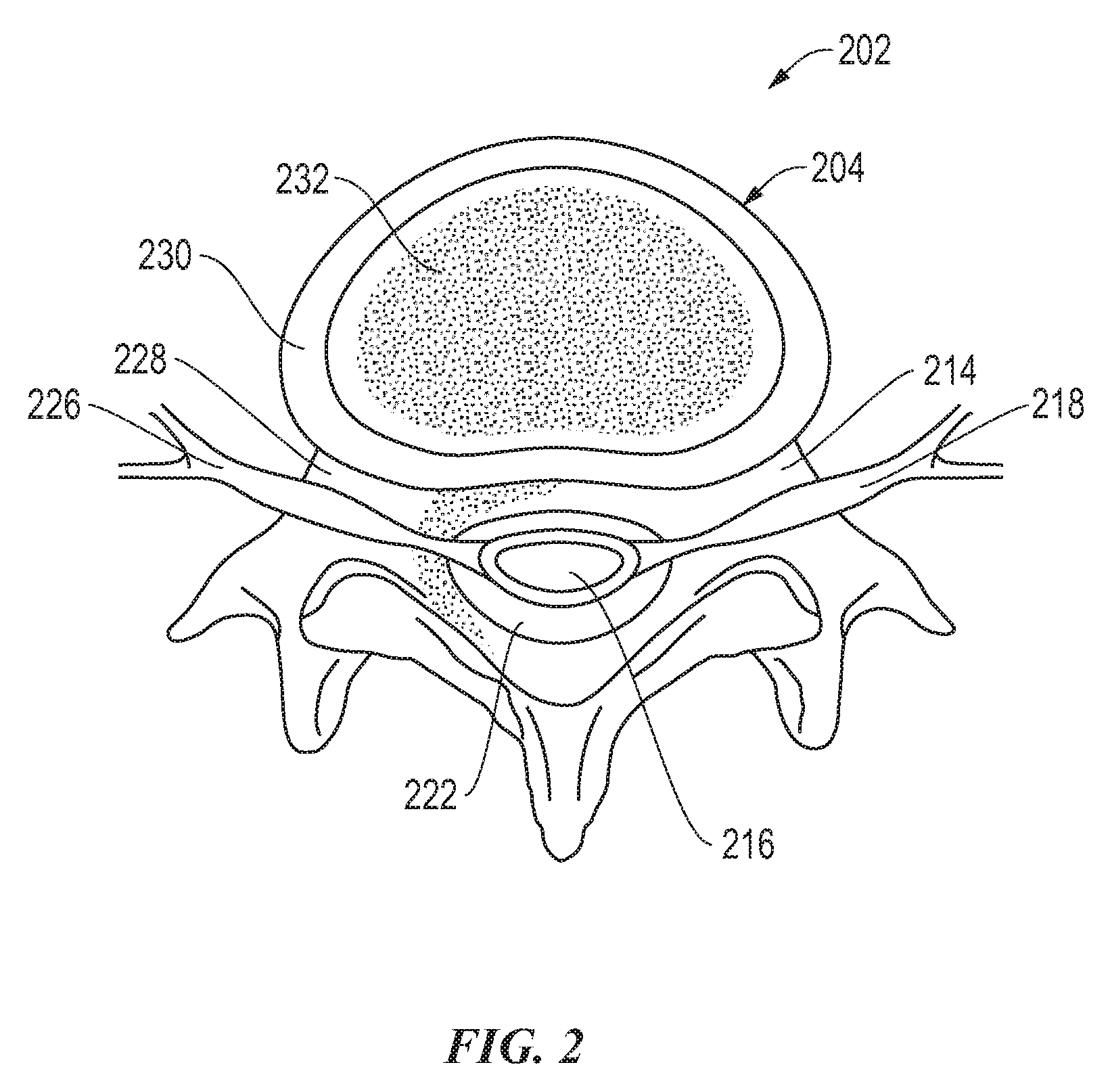

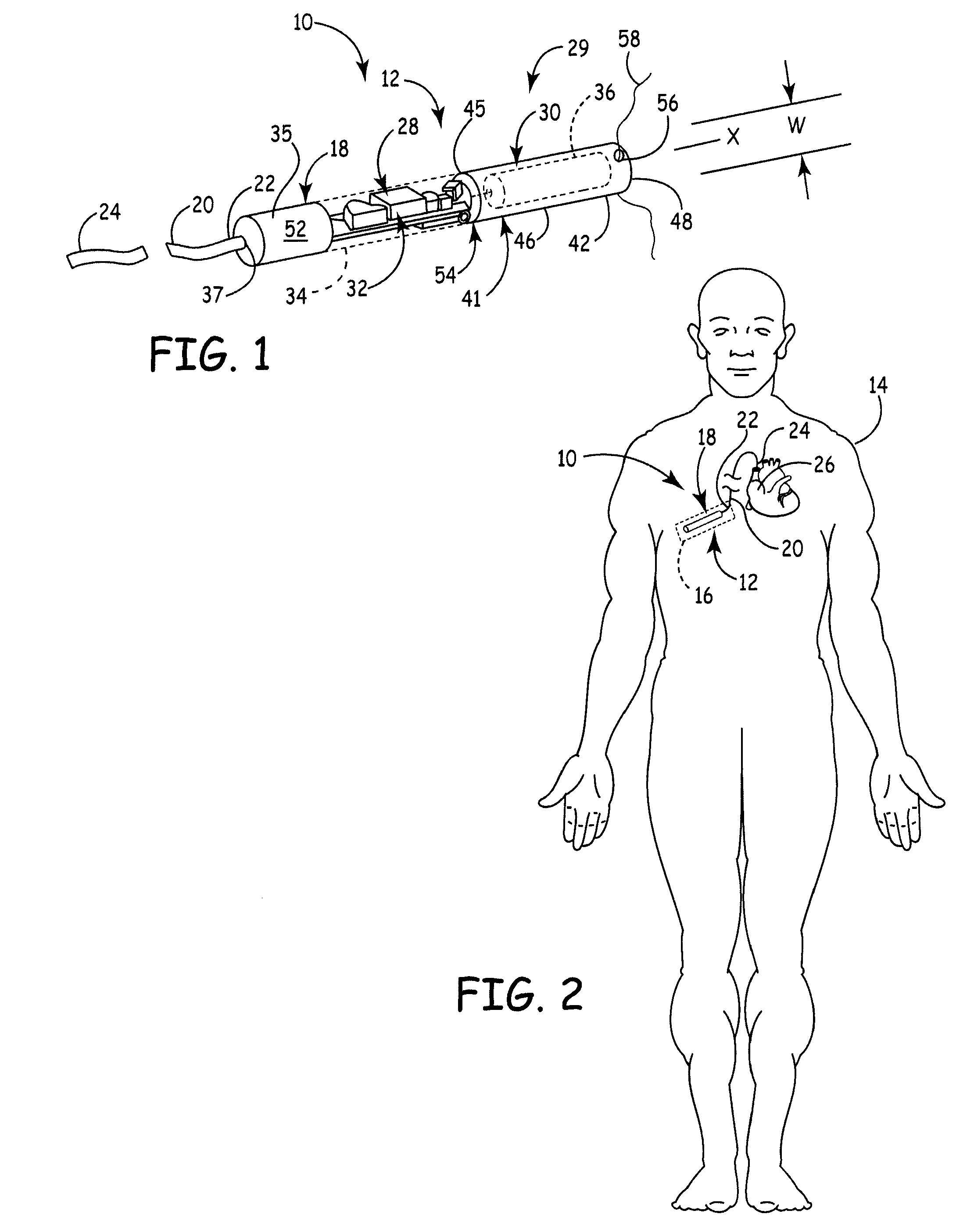

Battery powered surgical tool with guide wire

ActiveUS8974932B2Primary cell to battery groupingInternal osteosythesisElectrical batteryEngineering

A battery pack for a use with a powered surgical tool. The battery pack may include a housing with an outer wall and opposing first and second ends. The housing may include an elongated shape that extends between the first and second ends. A first member may extend across the first end of the housing and include a first aperture, and a second end member may extend across the second end of the housing and may include a second aperture. A passage may extend through the housing with a first end that aligns with the first aperture and a second end that aligns with the second aperture. The housing may be sized for a plurality of storage locations positioned between the first and second members and around the passage, and each of the storage locations may be configured to store a power cell.

Owner:WARSAW ORTHOPEDIC INC

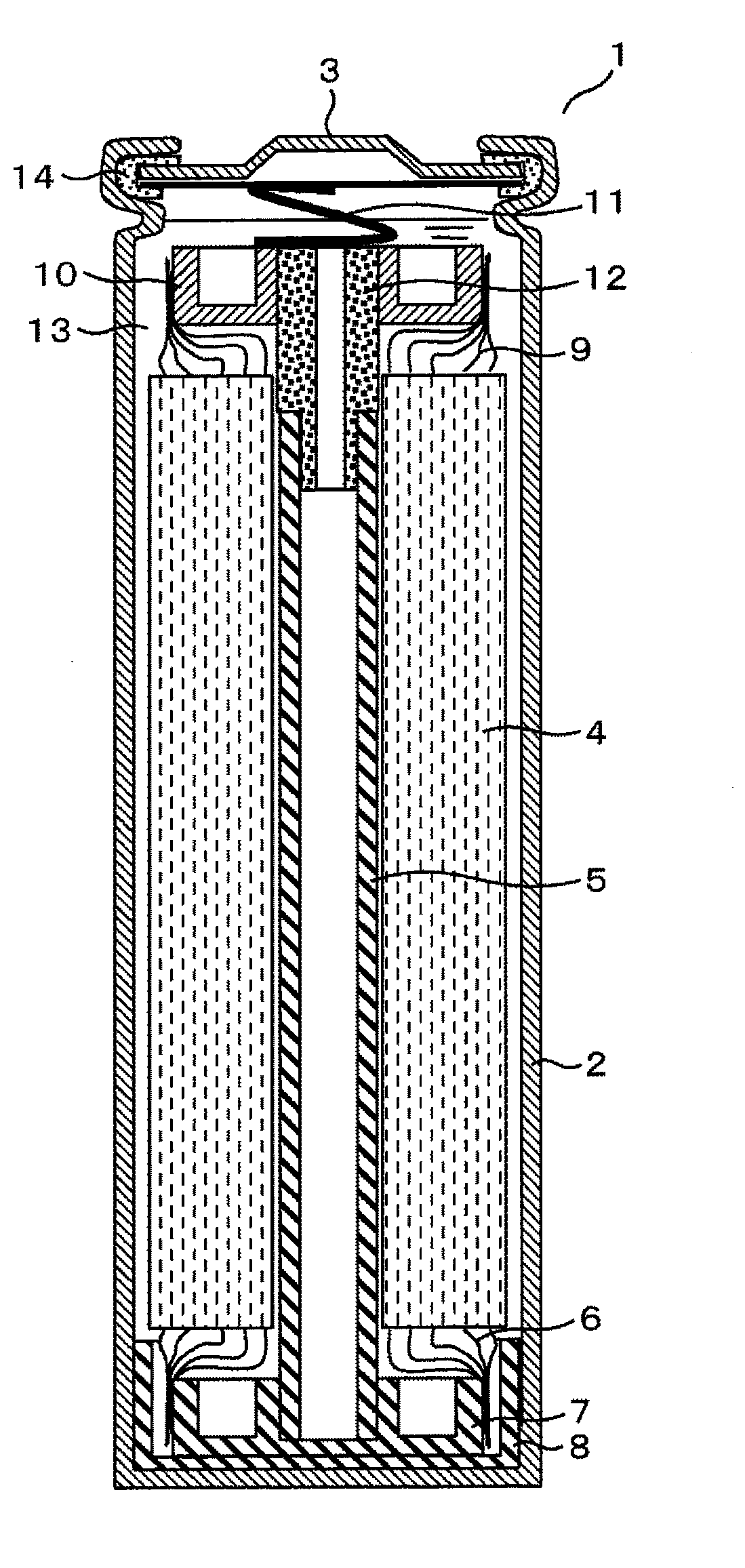

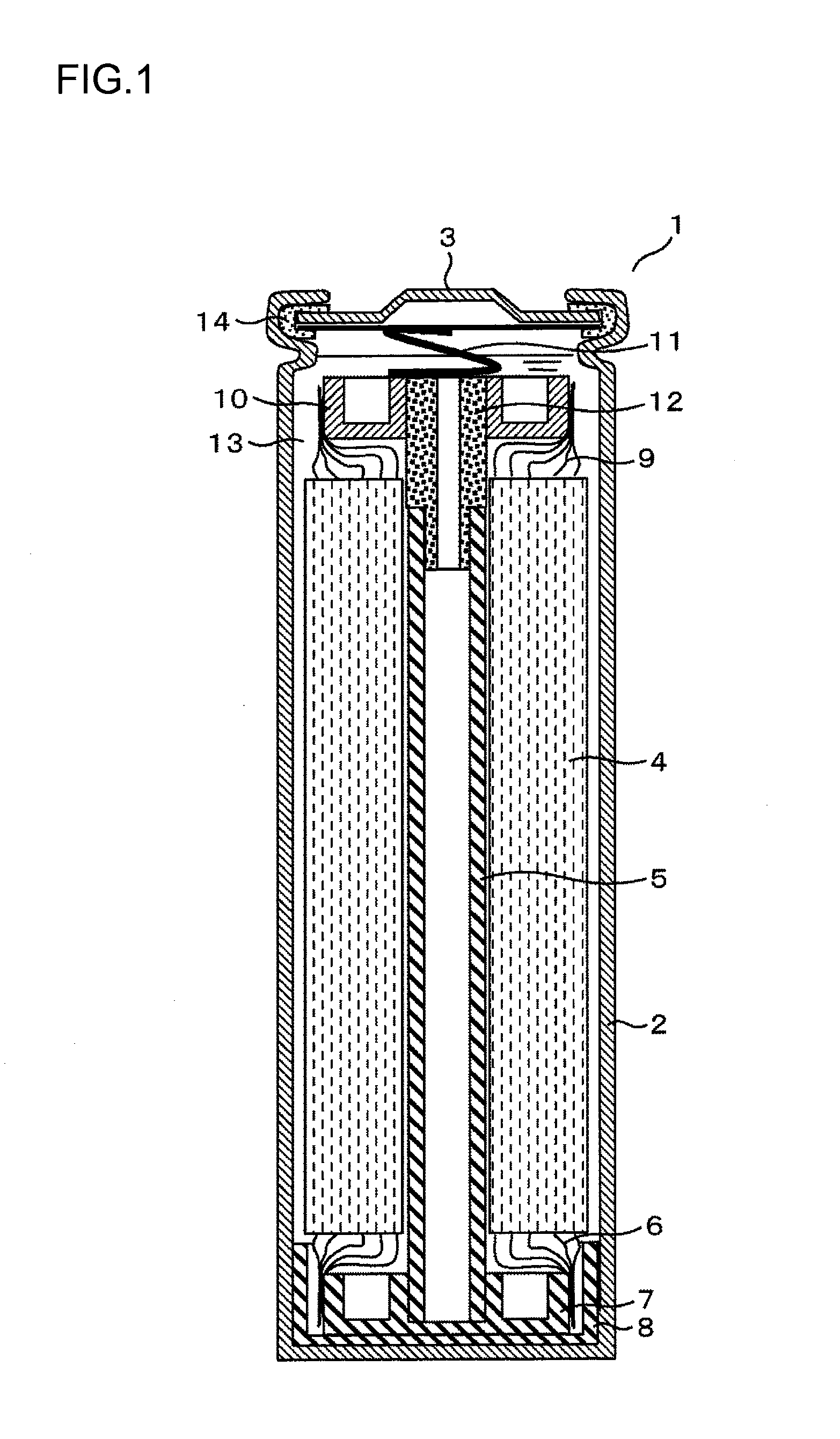

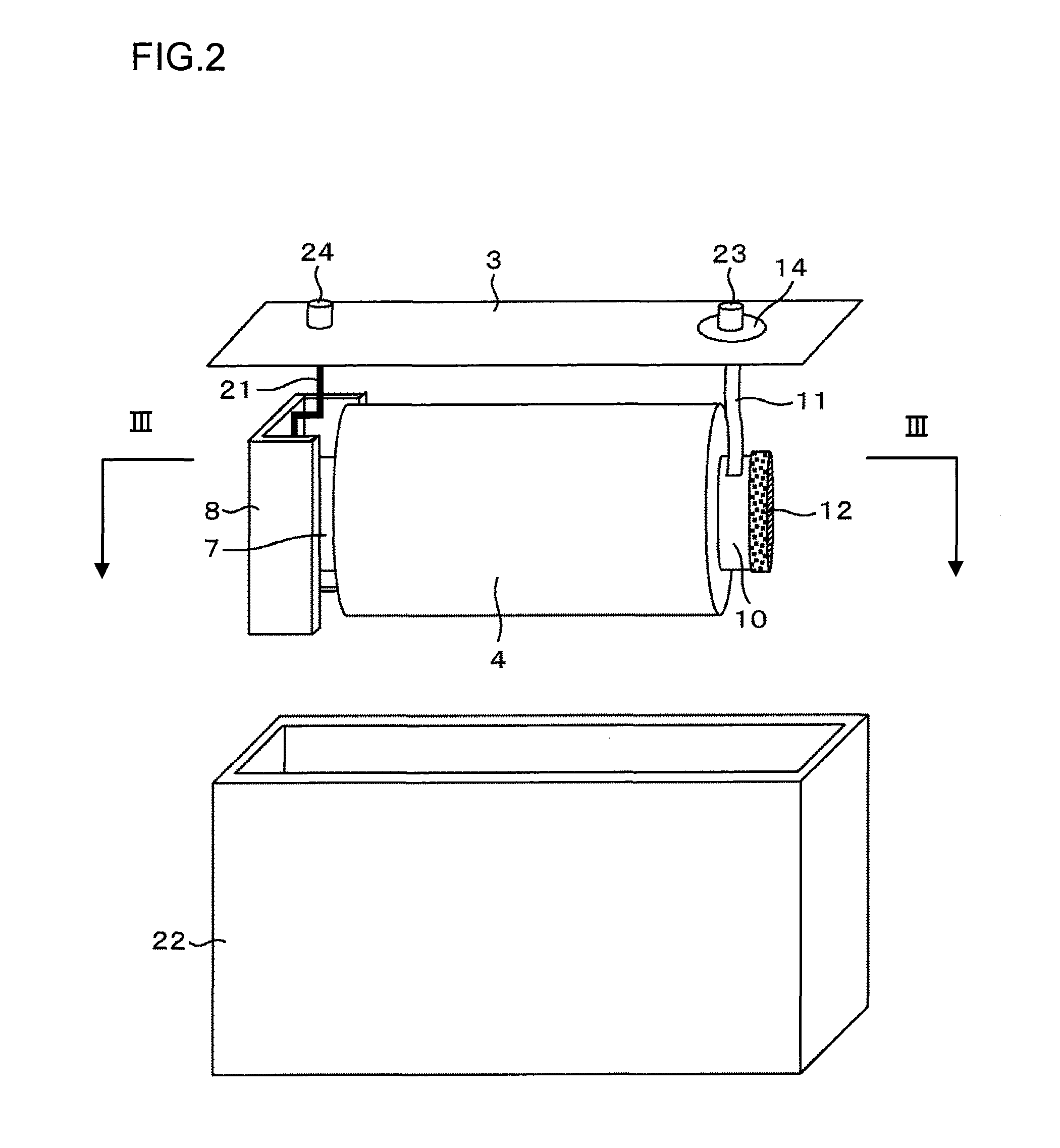

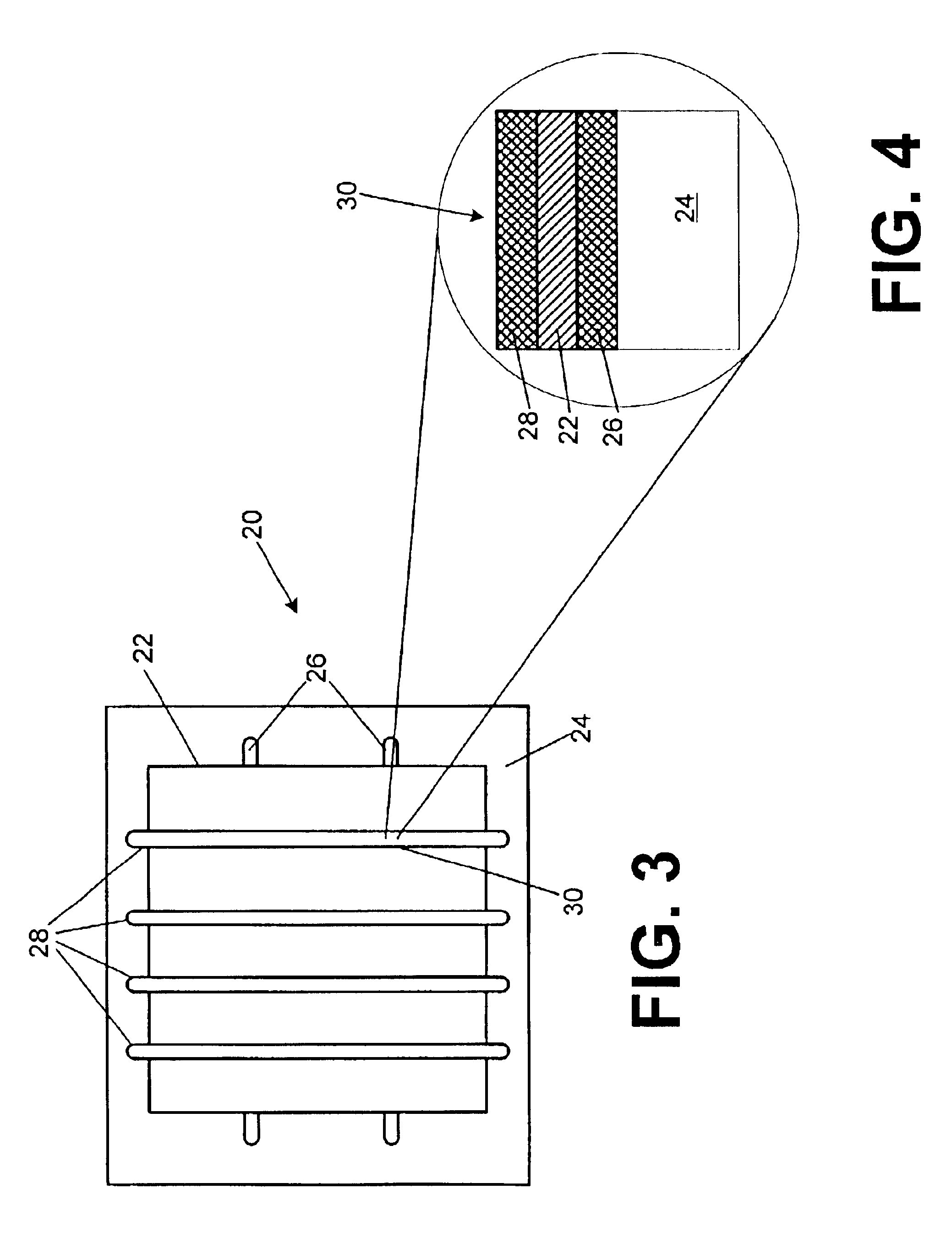

Lithium-Ion Secondary Battery

InactiveUS20110129706A1High levelIncrease battery capacityFinal product manufactureCell temperature controlLithiumEngineering

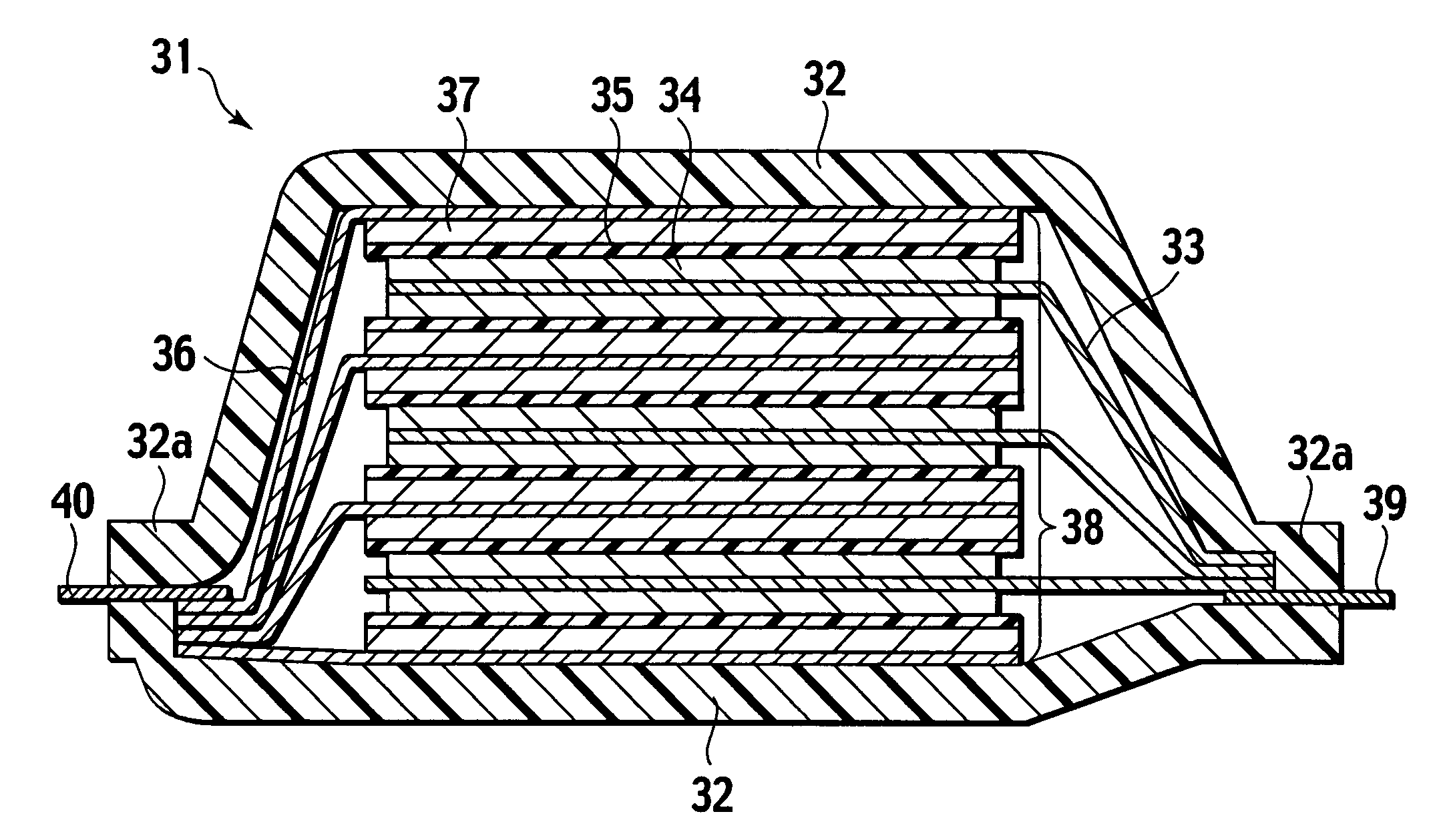

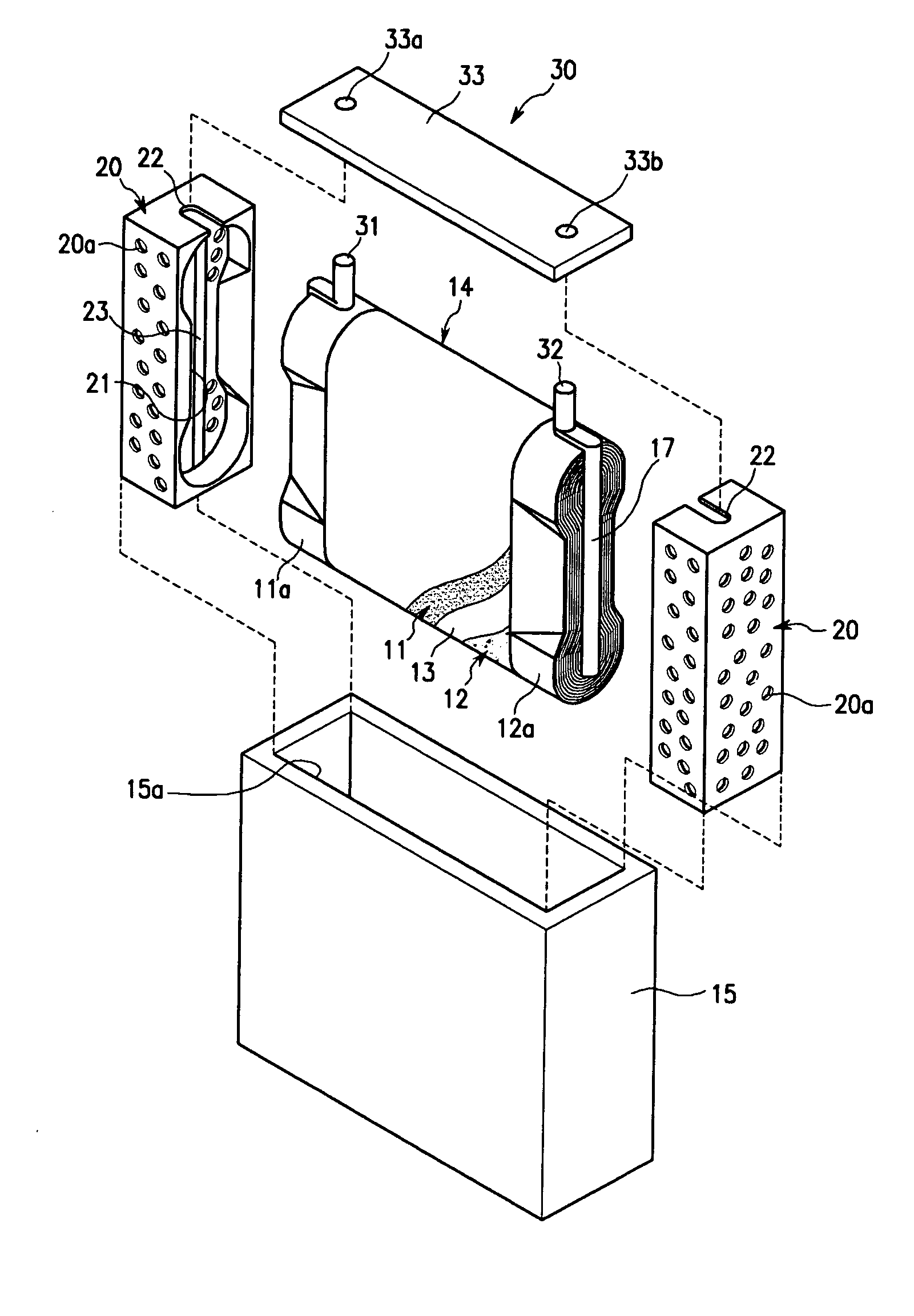

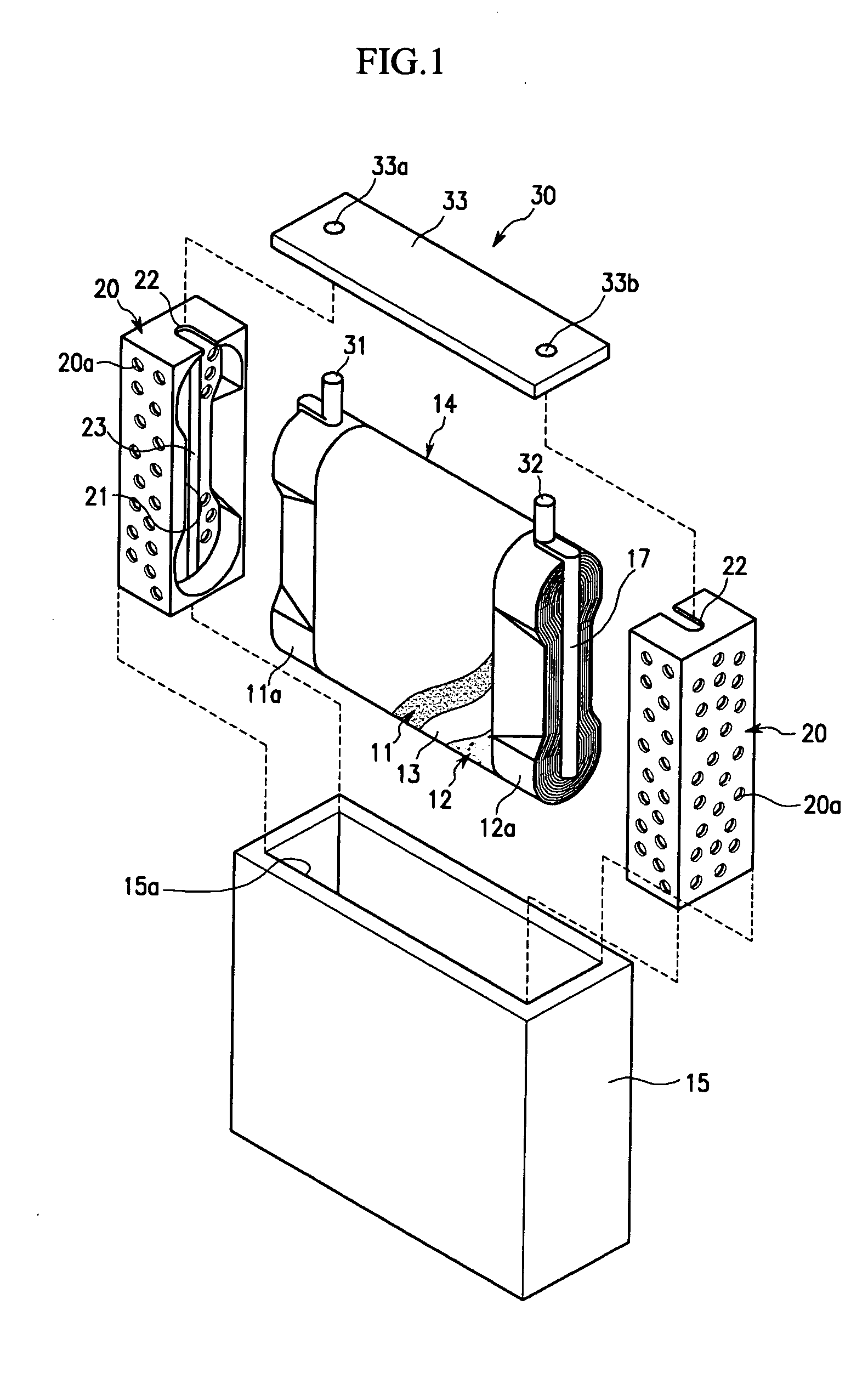

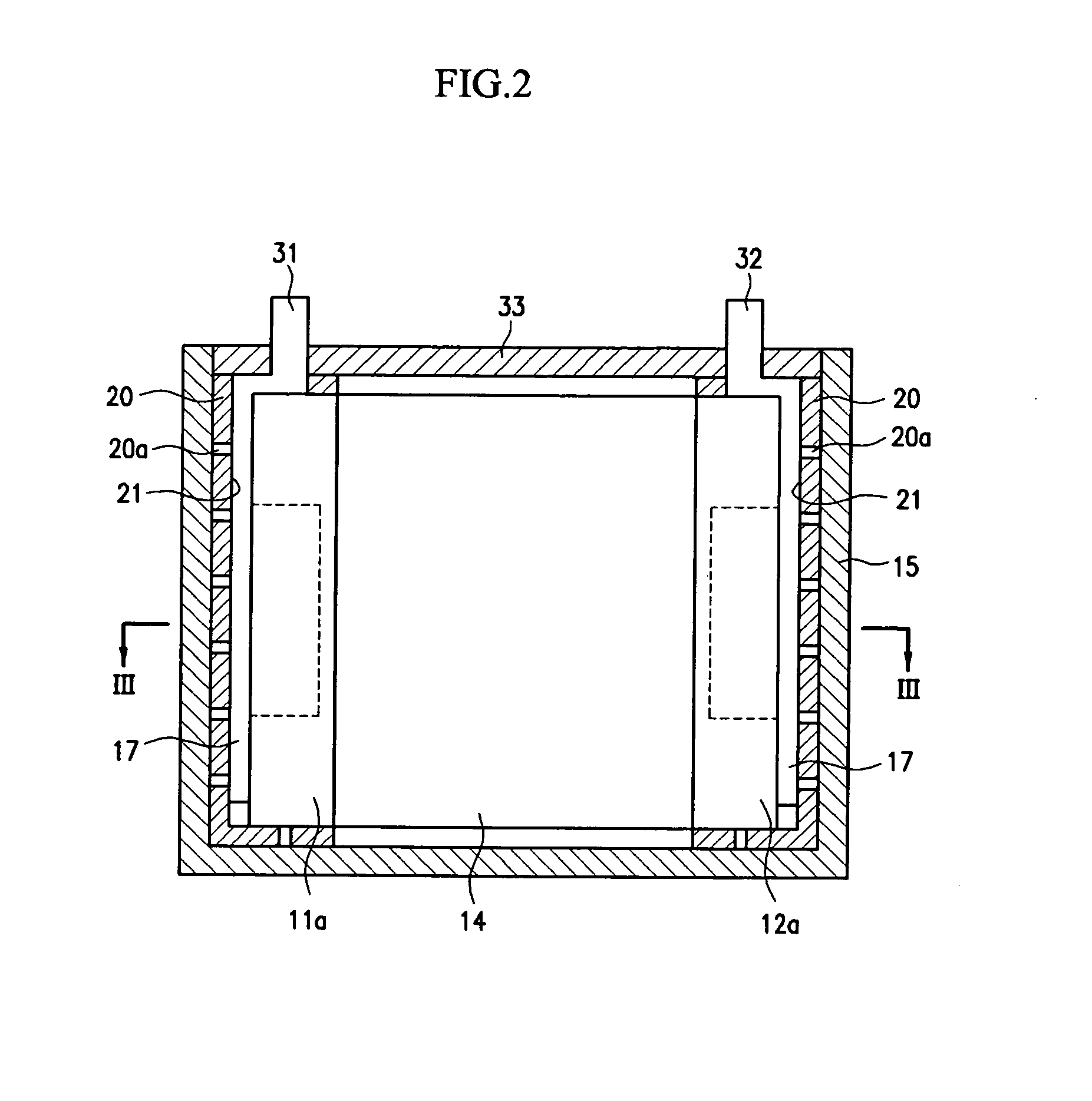

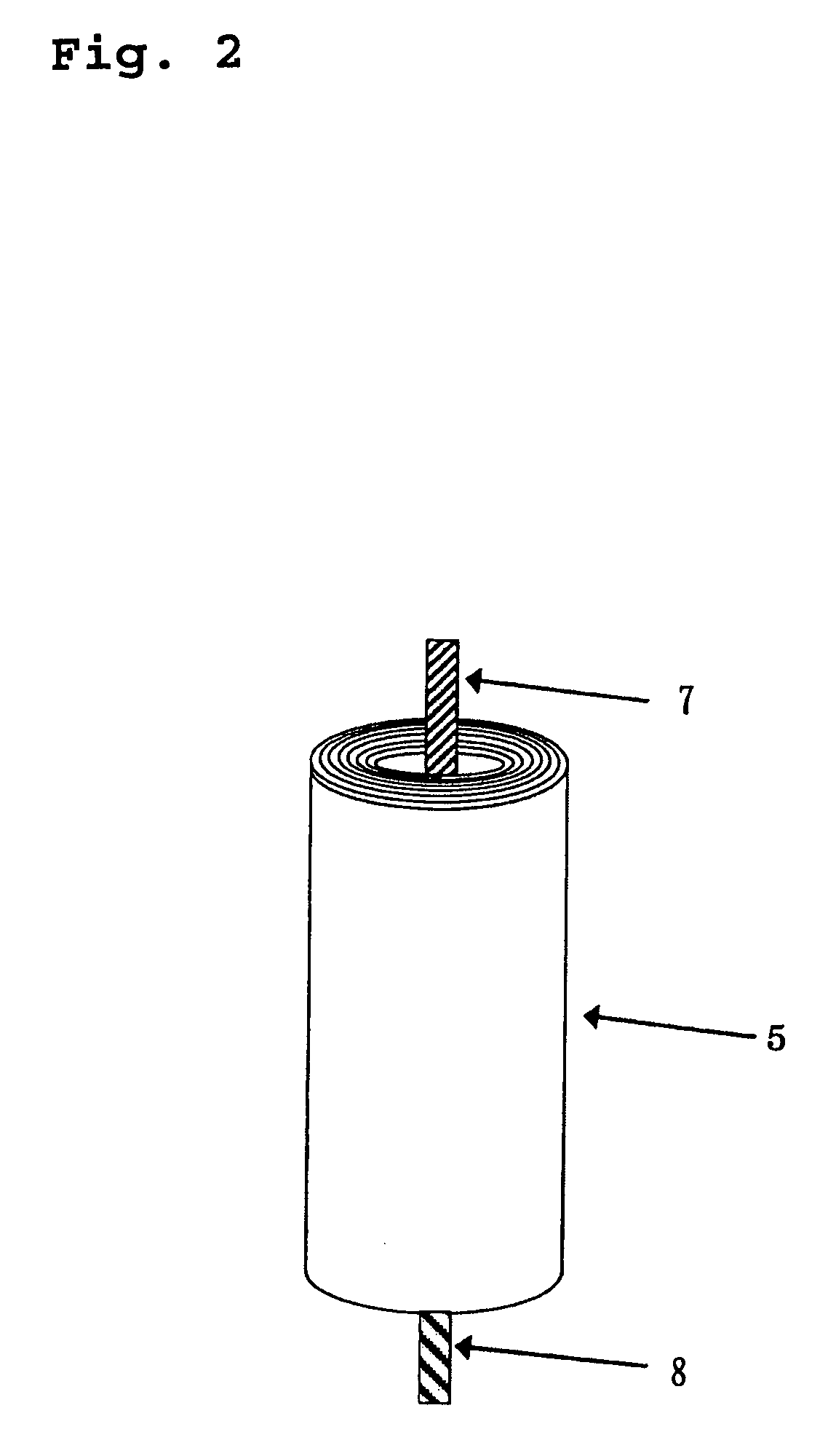

A lithium-ion secondary battery includes: a winding body in a coil formation at a battery container, the winding body wrapping a cathode film in which lithium ions store and from which lithium ions extract and a anode film in which lithium ions store and from which lithium ions extract, and the cathode film and the anode film being electrically separated from each other via a porous separator; and a heat sink disposed inside the battery container, which contacts the battery container and transmits heat inside the winding body to the battery container.

Owner:HITACHI LTD

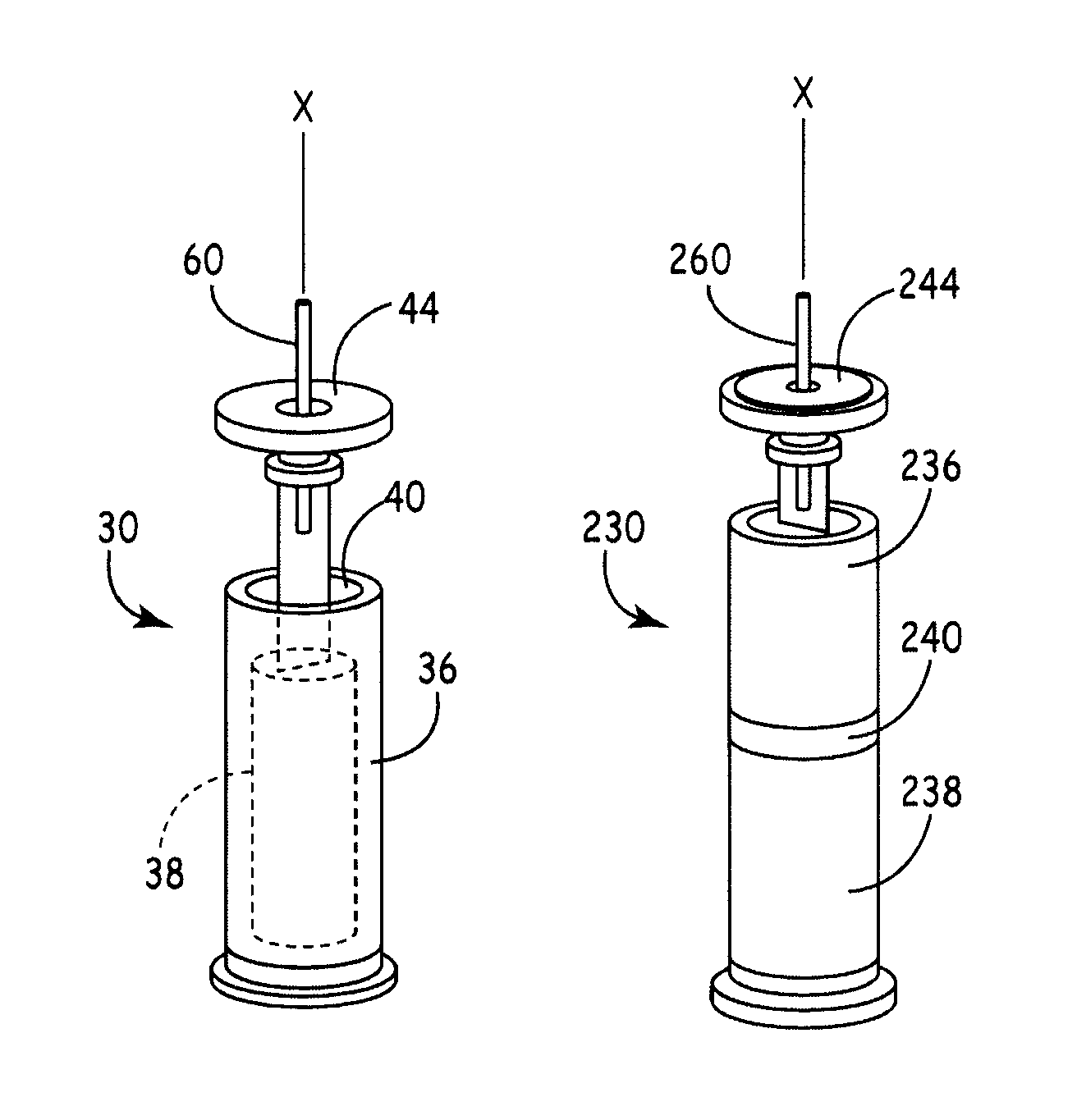

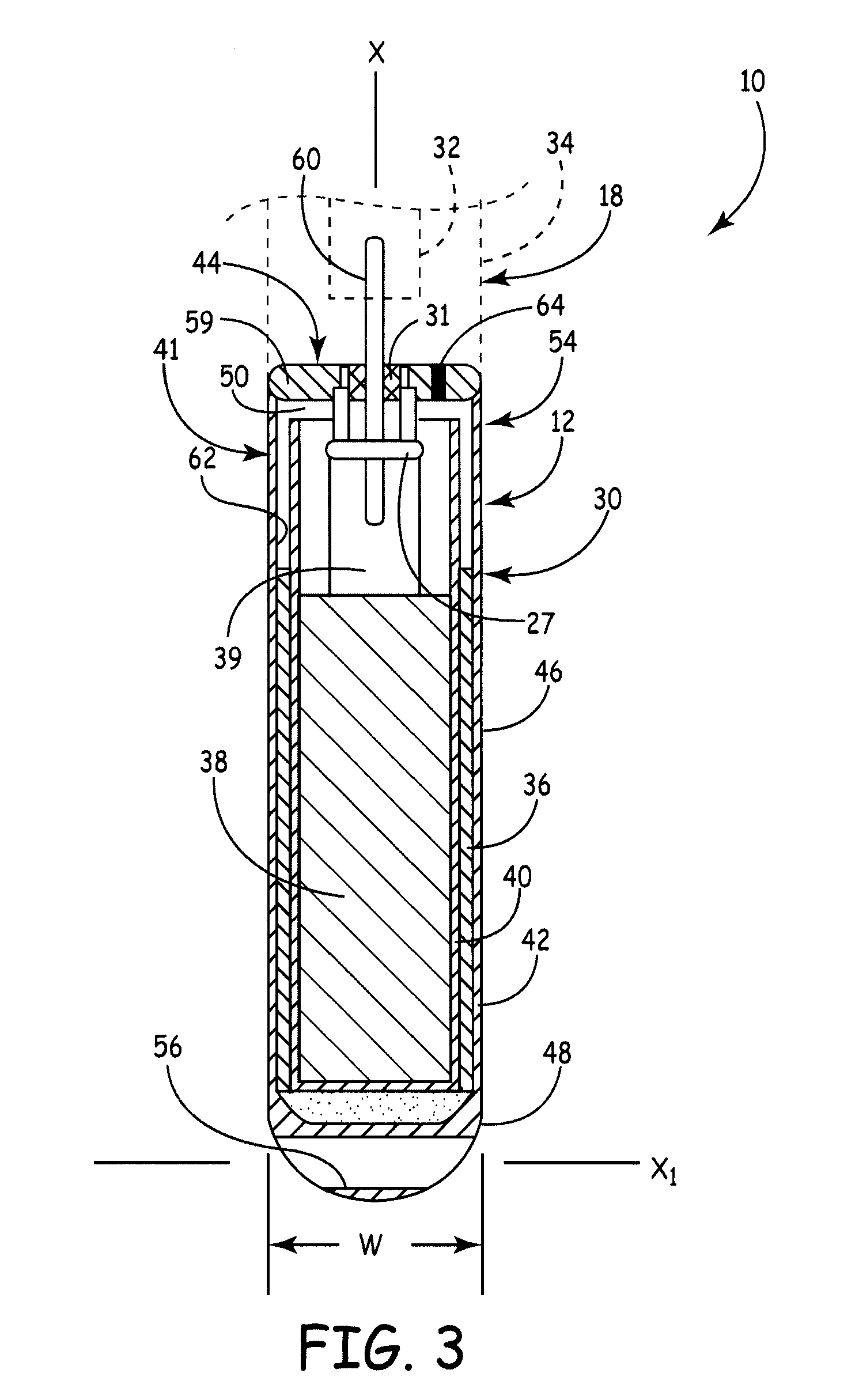

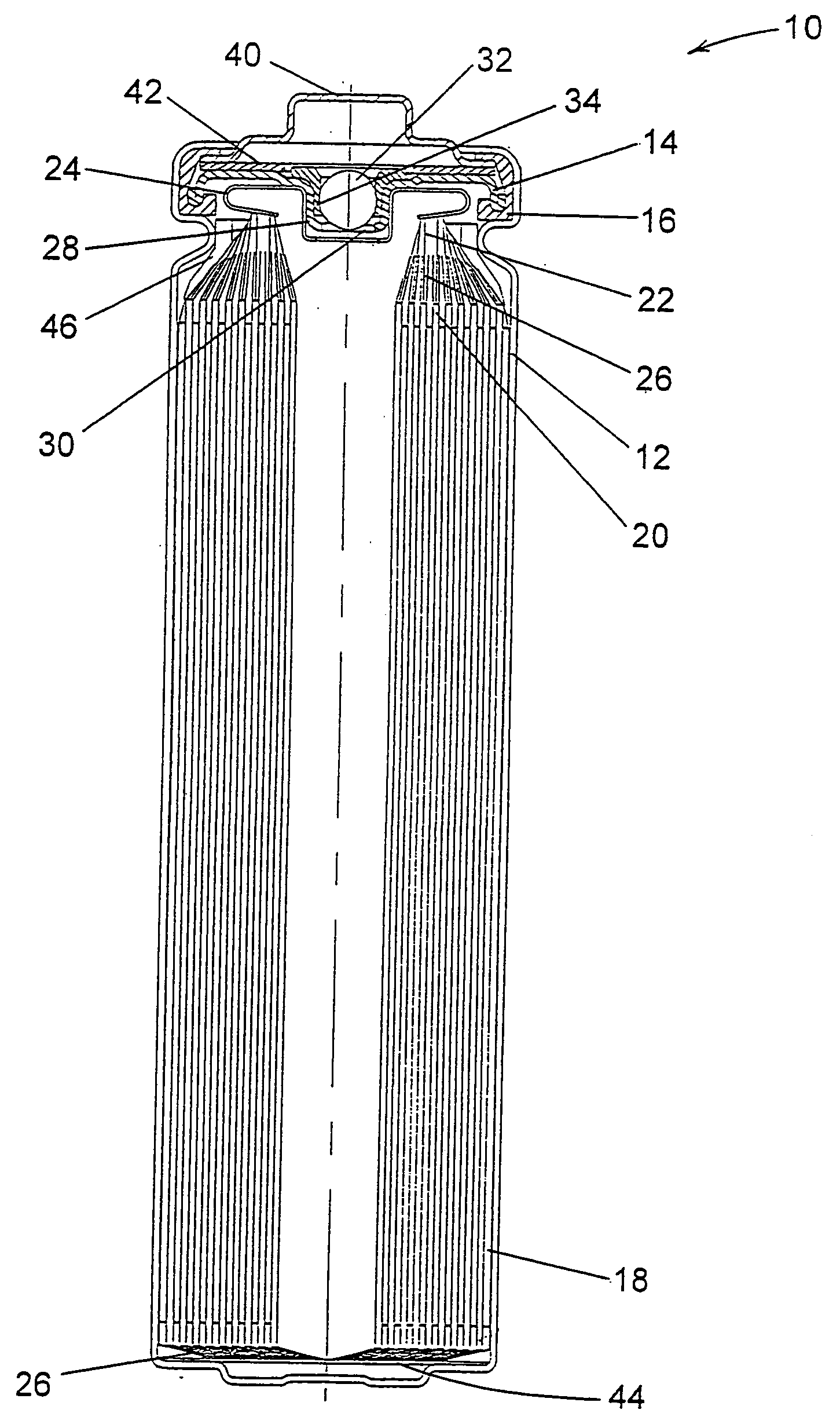

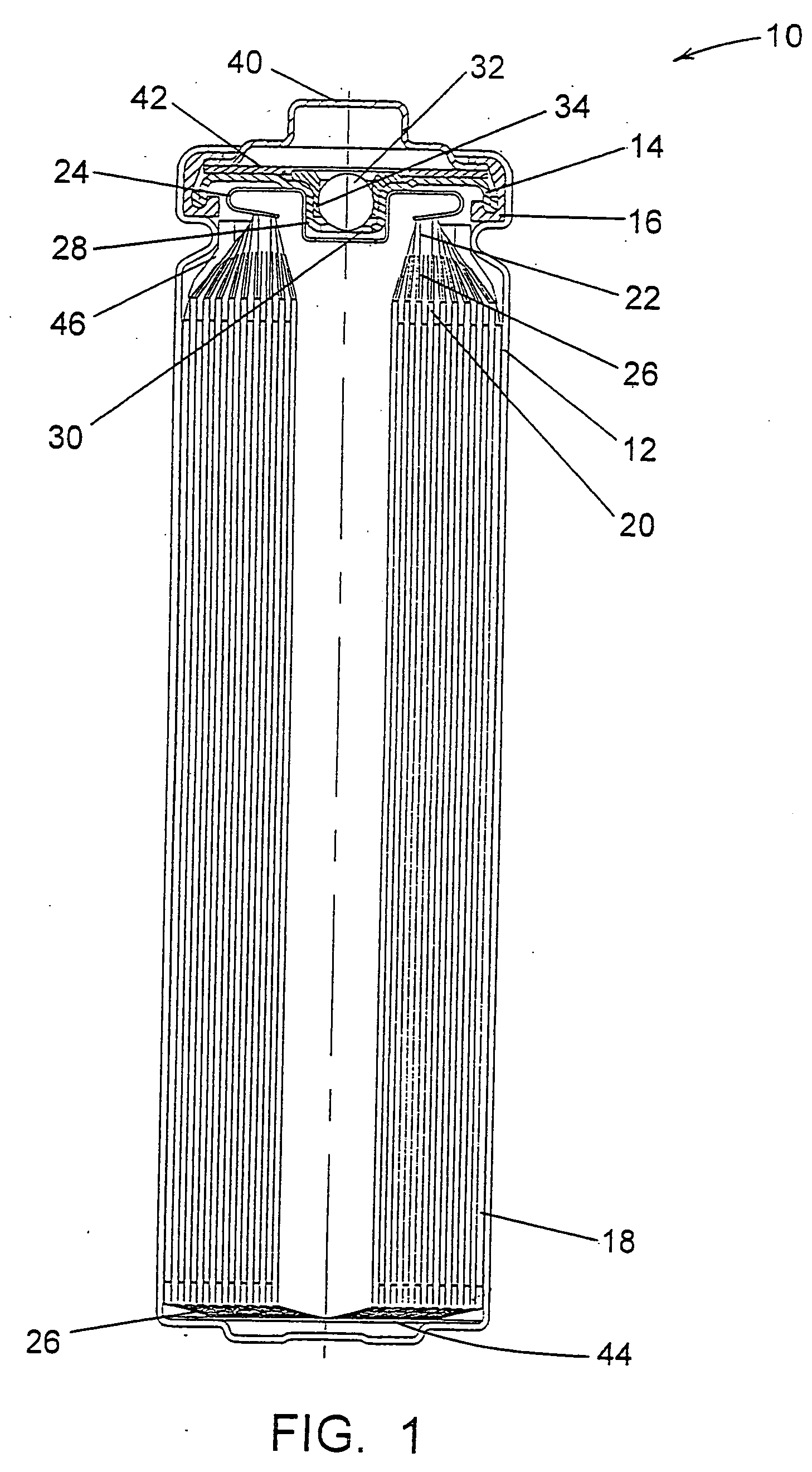

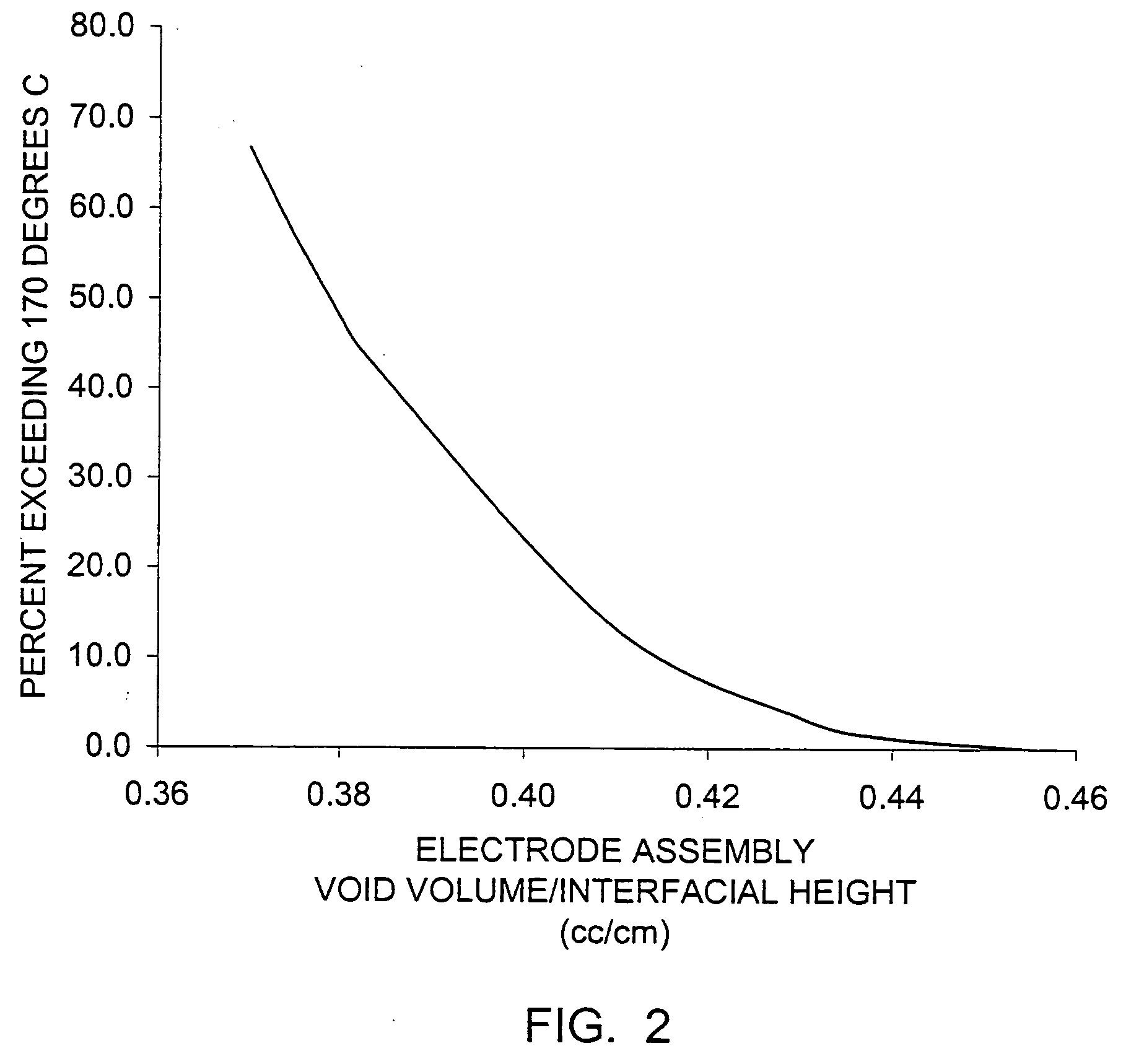

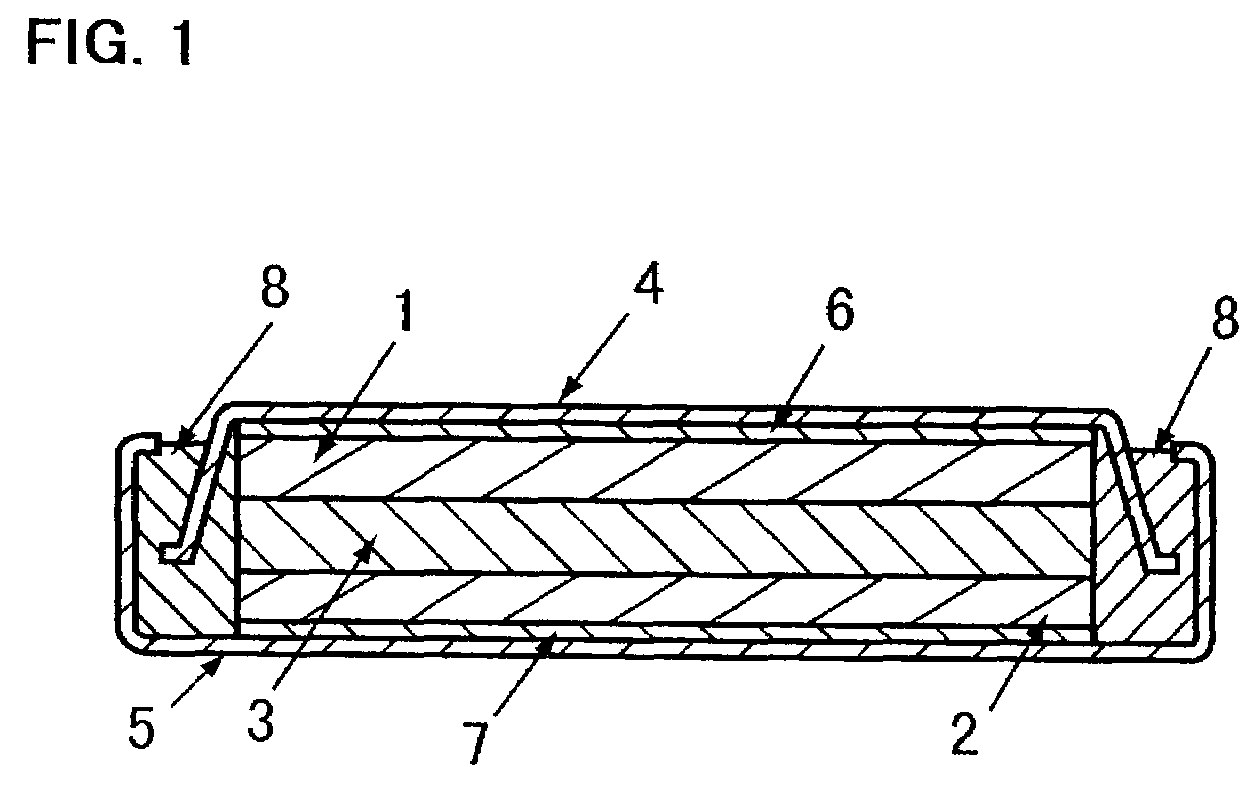

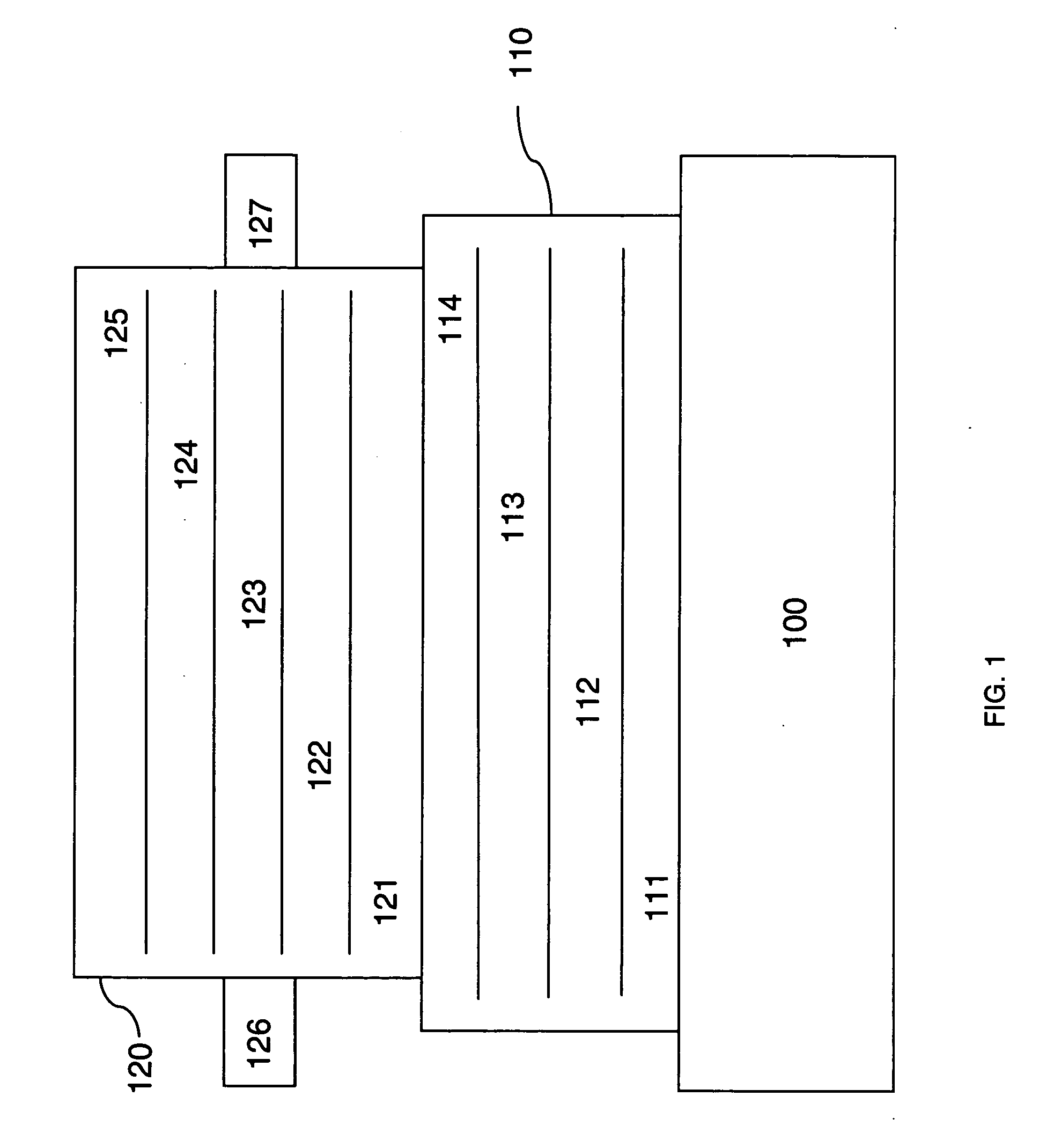

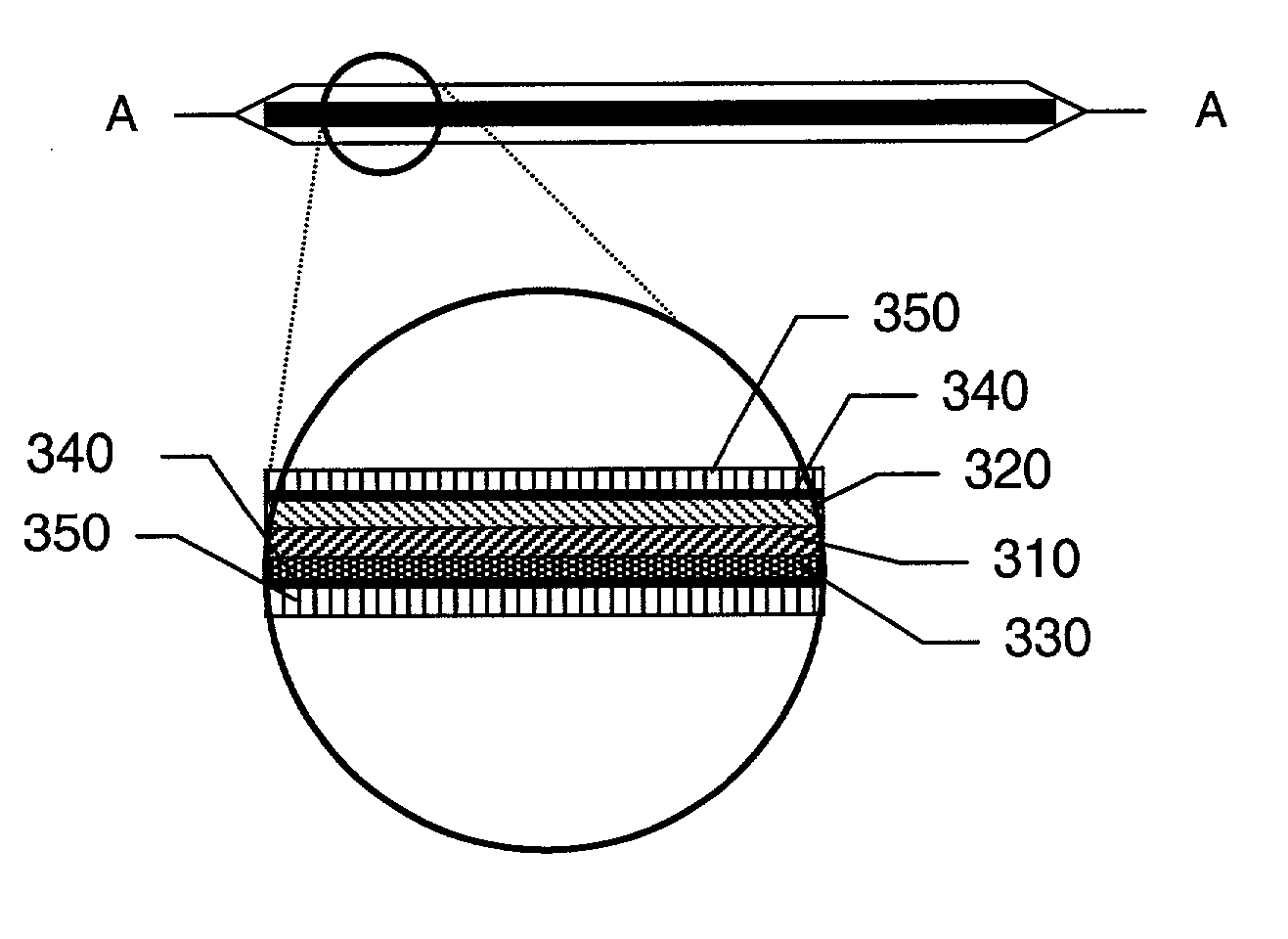

Elongate battery for implantable medical device

A battery assembly for a medical device includes an elongate cathode, an elongate anode, an electrolyte, and an elongate housing assembly encapsulating the cathode, the anode, and the electrolyte. The battery assembly also includes a first electrode that is exposed from and electrically insulated from the housing assembly. One of the anode and the cathode is electrically coupled to the first electrode, and the other of the anode and the cathode is electrically coupled to the housing assembly. One of the cathode and the anode includes a first portion and a second portion disposed in spaced relationship from the first portion. The other of the cathode and the anode is disposed between the first and second portions.

Owner:MEDTRONIC INC

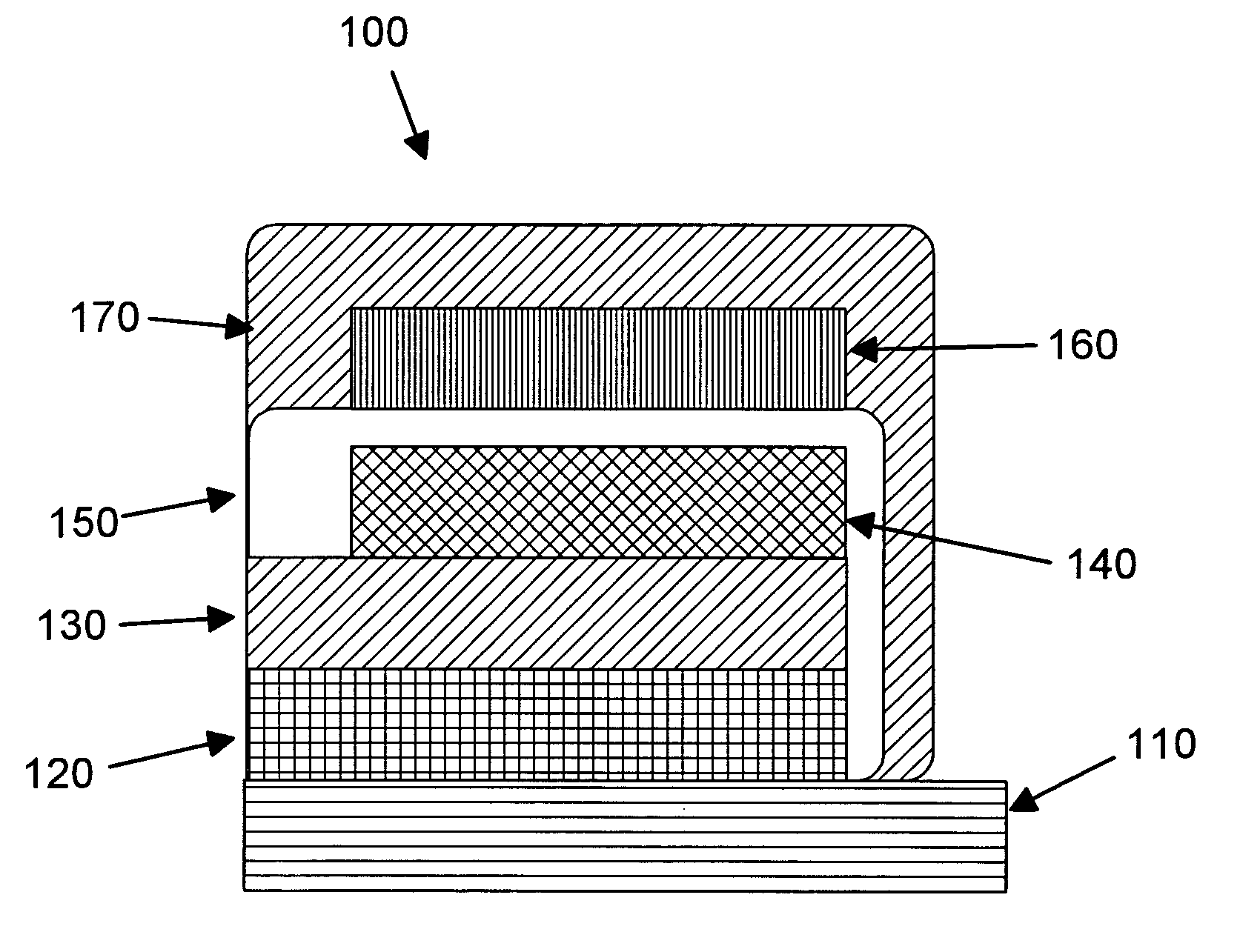

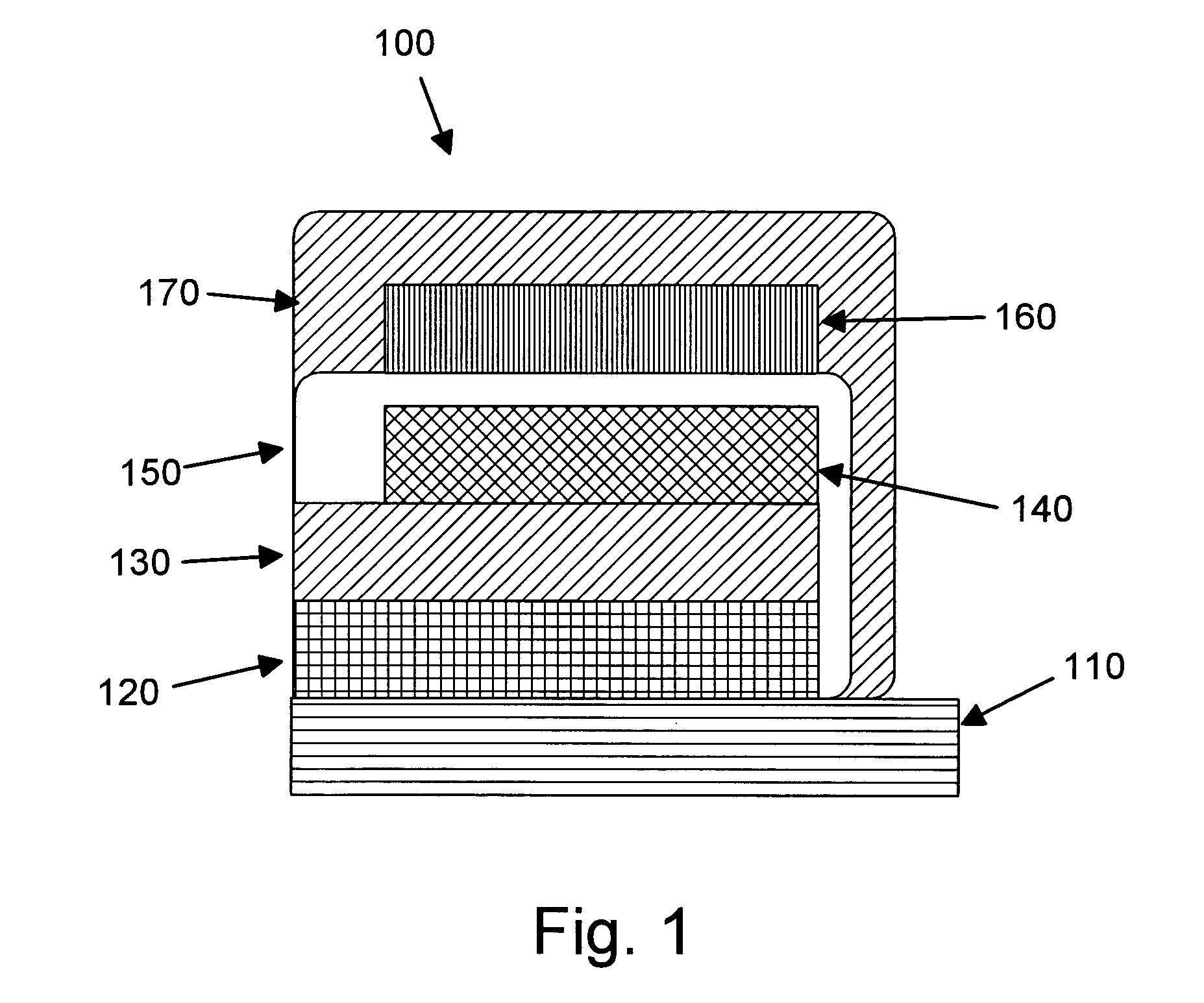

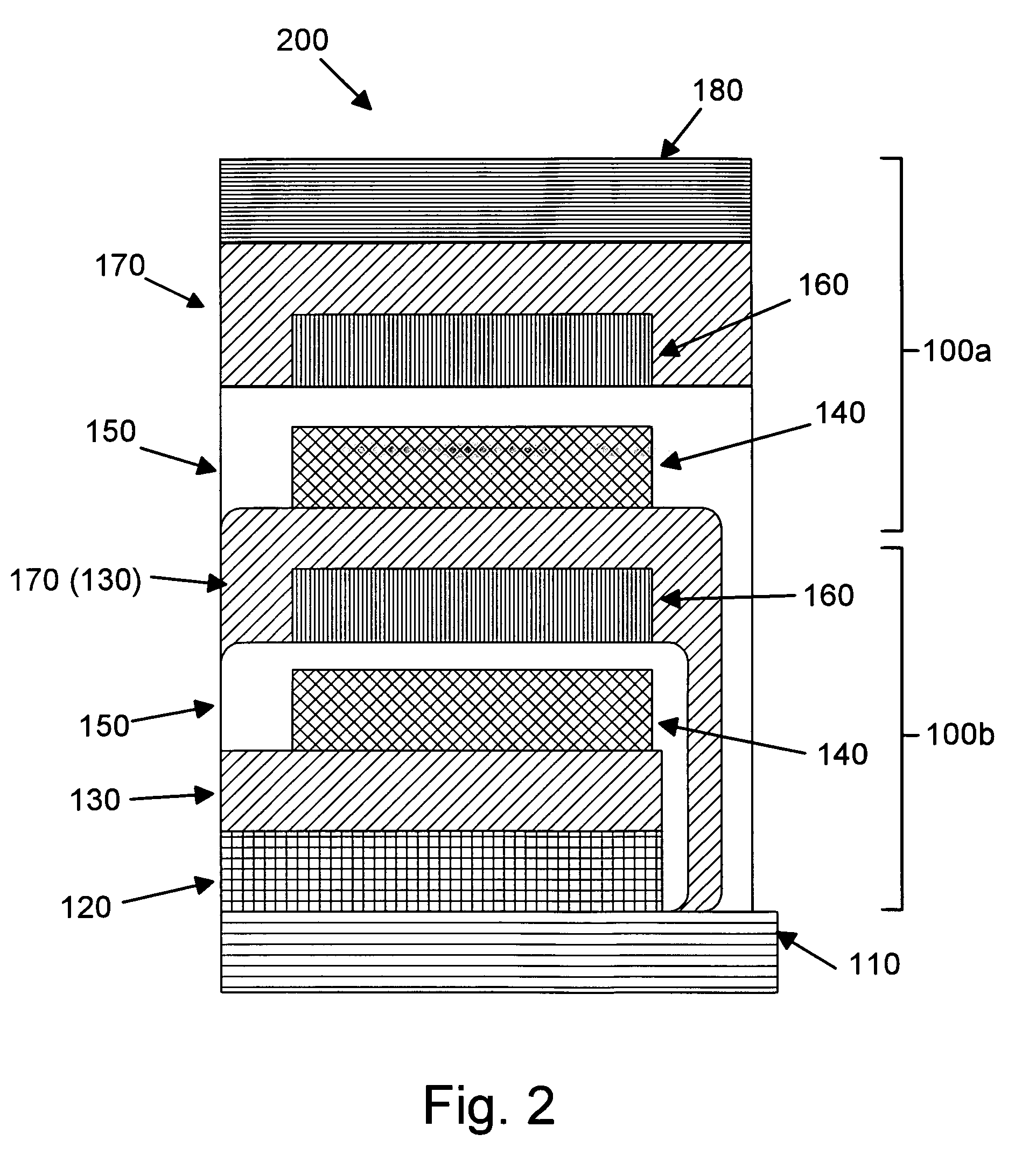

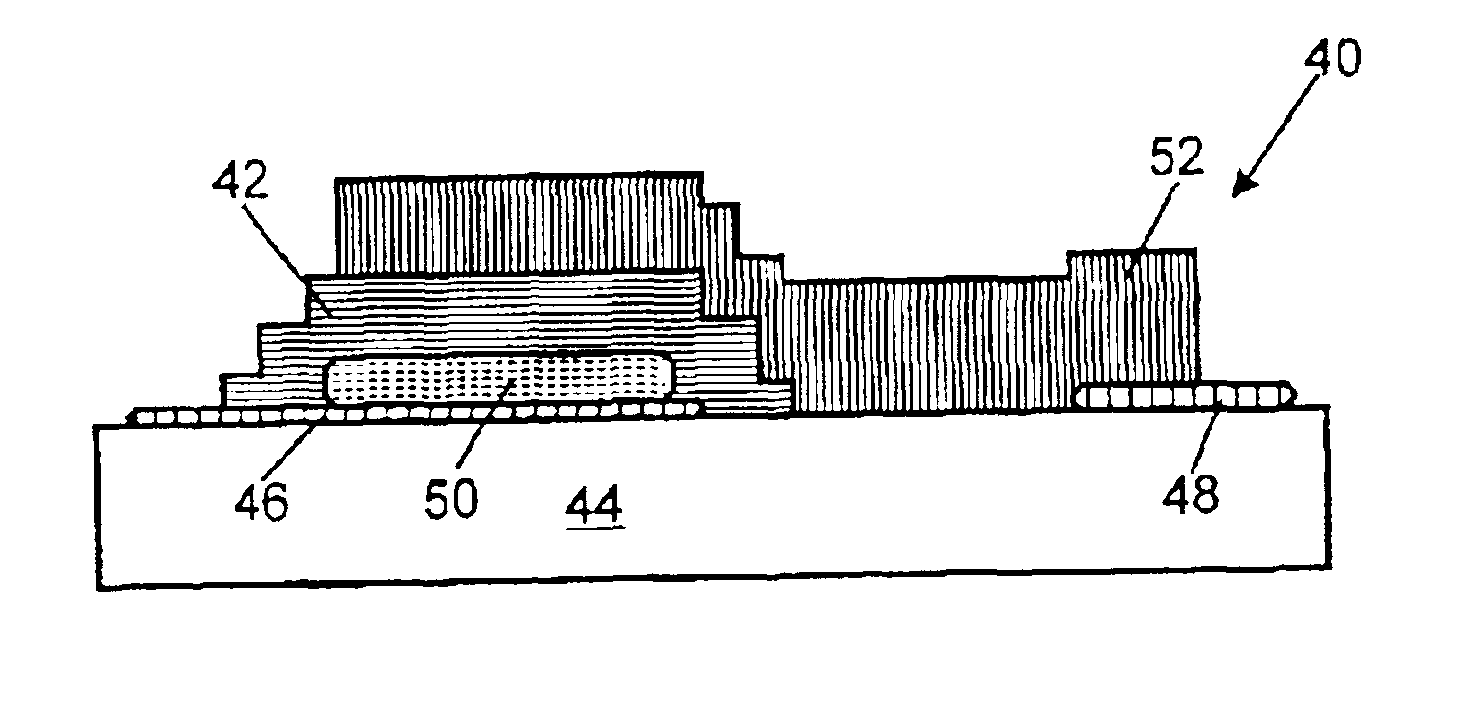

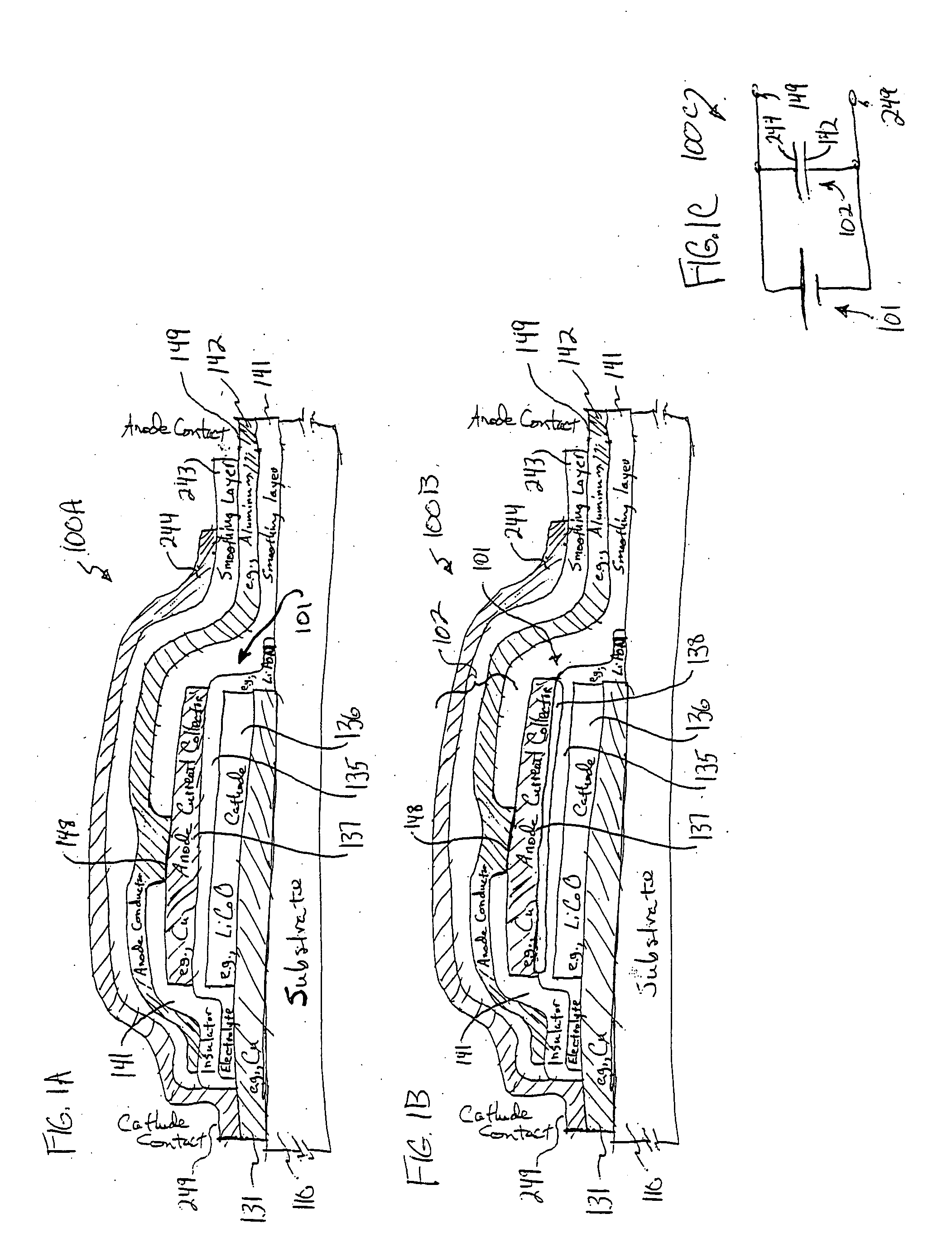

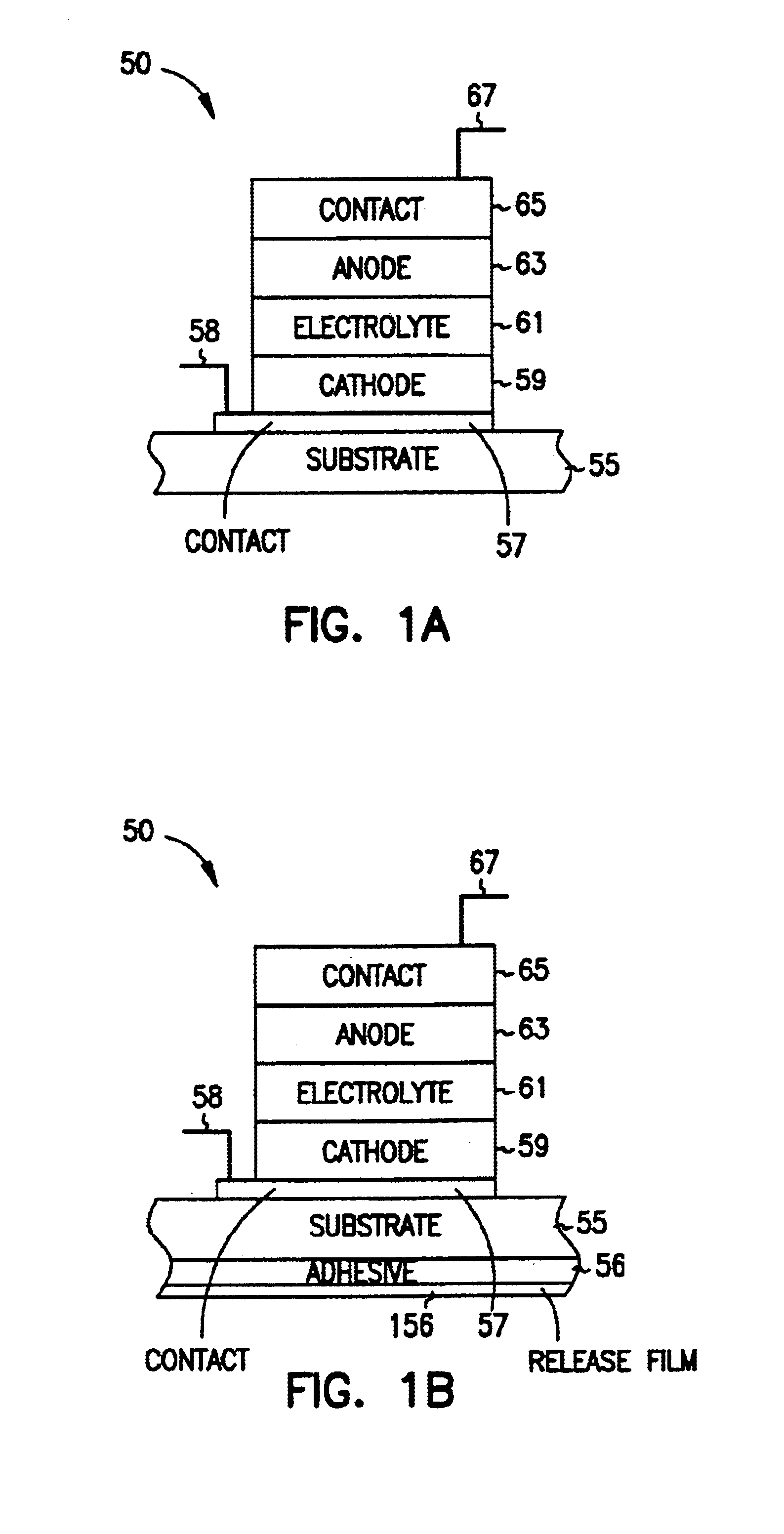

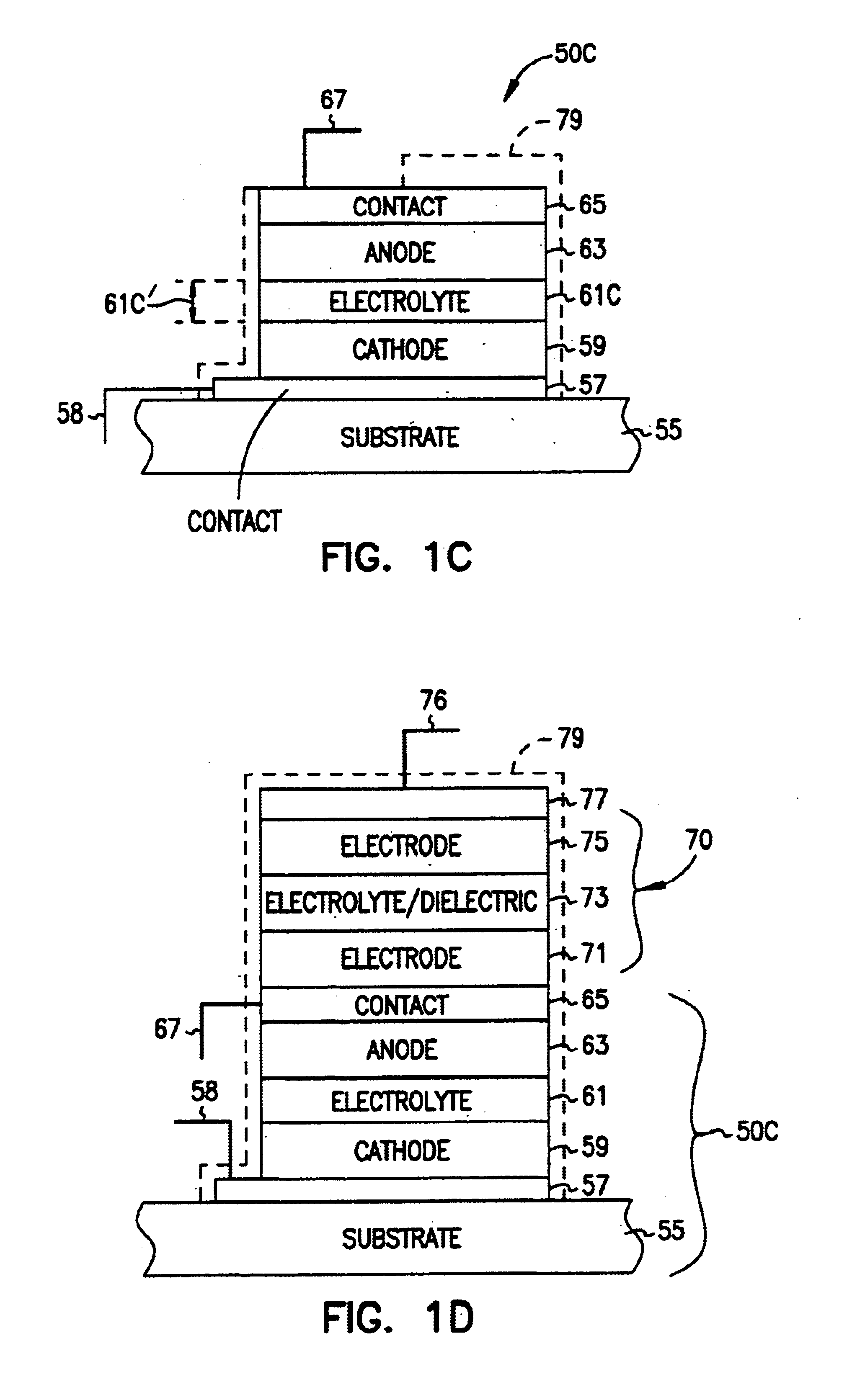

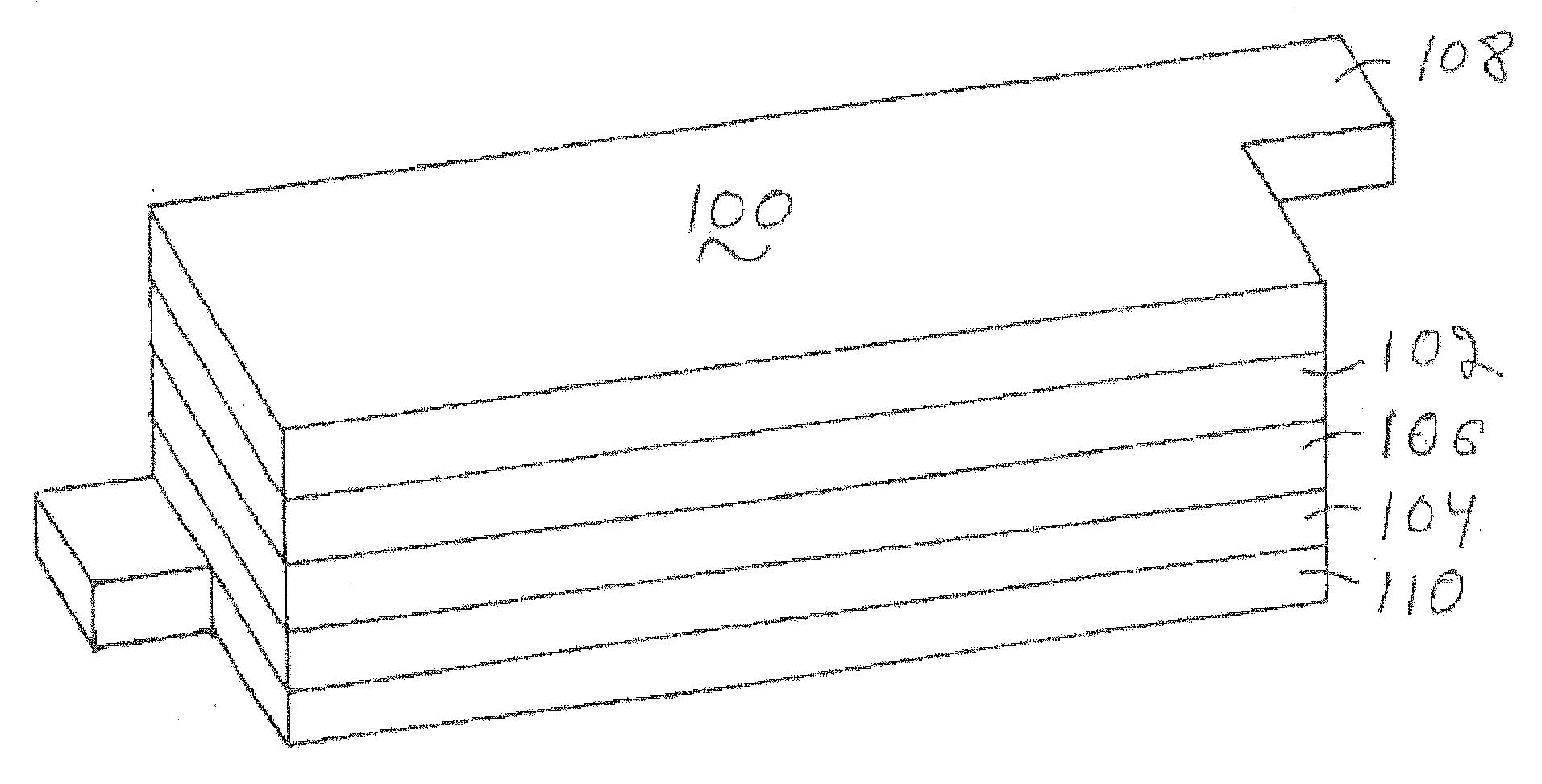

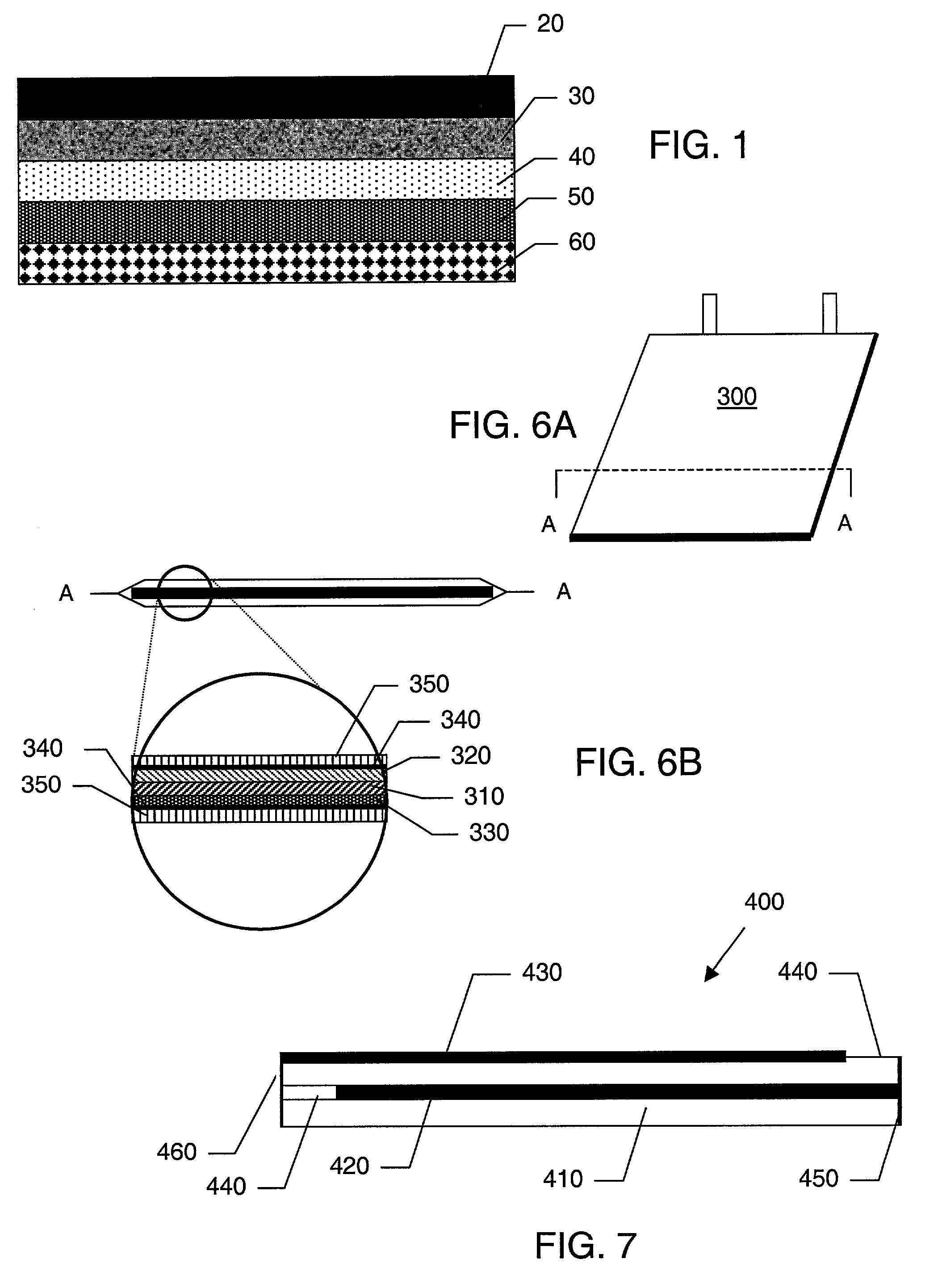

Rechargeable thin film battery and method for making the same

InactiveUS6982132B1Improve lithium ion mobilityHigh voltageElectrode thermal treatmentFinal product manufactureElectrical batteryHigh energy

A rechargeable, stackable, thin film, solid-state lithium electrochemical cell, thin film lithium battery and method for making the same is disclosed. The cell and battery provide for a variety configurations, voltage and current capacities. An innovative low temperature ion beam assisted deposition method for fabricating thin film, solid-state anodes, cathodes and electrolytes is disclosed wherein a source of energetic ions and evaporants combine to form thin film cell components having preferred crystallinity, structure and orientation. The disclosed batteries are particularly useful as power sources for portable electronic devices and electric vehicle applications where high energy density, high reversible charge capacity, high discharge current and long battery lifetimes are required.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

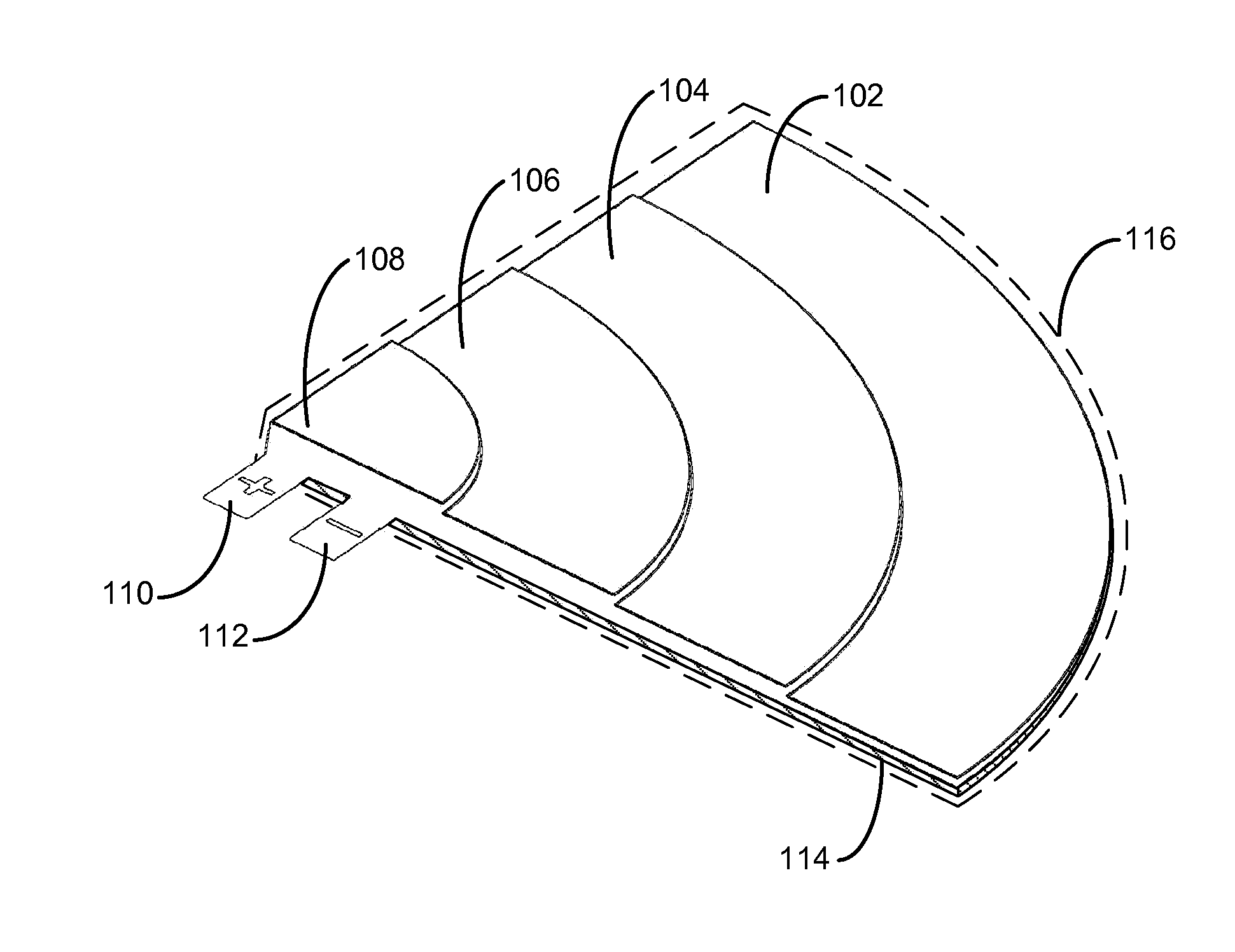

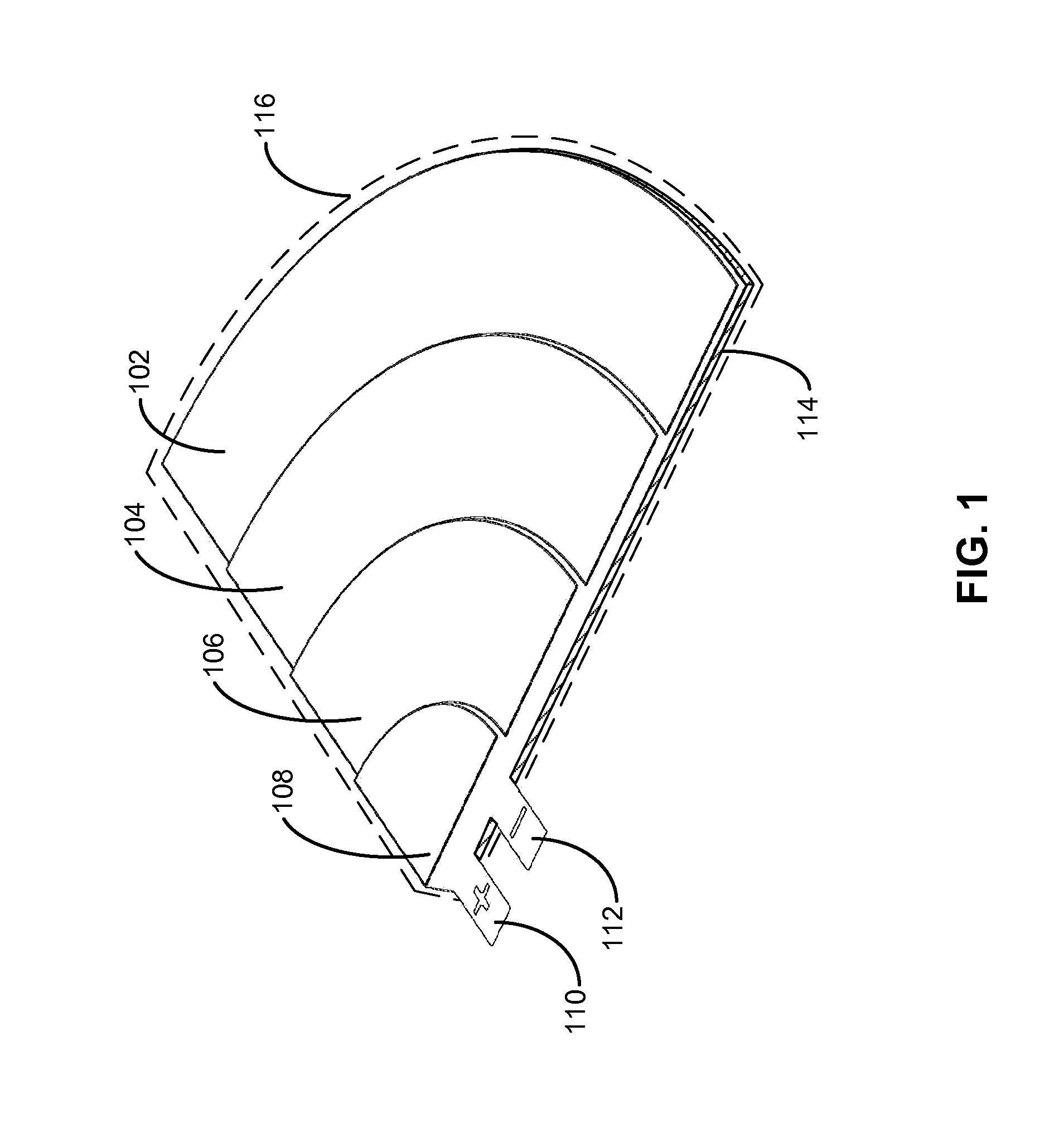

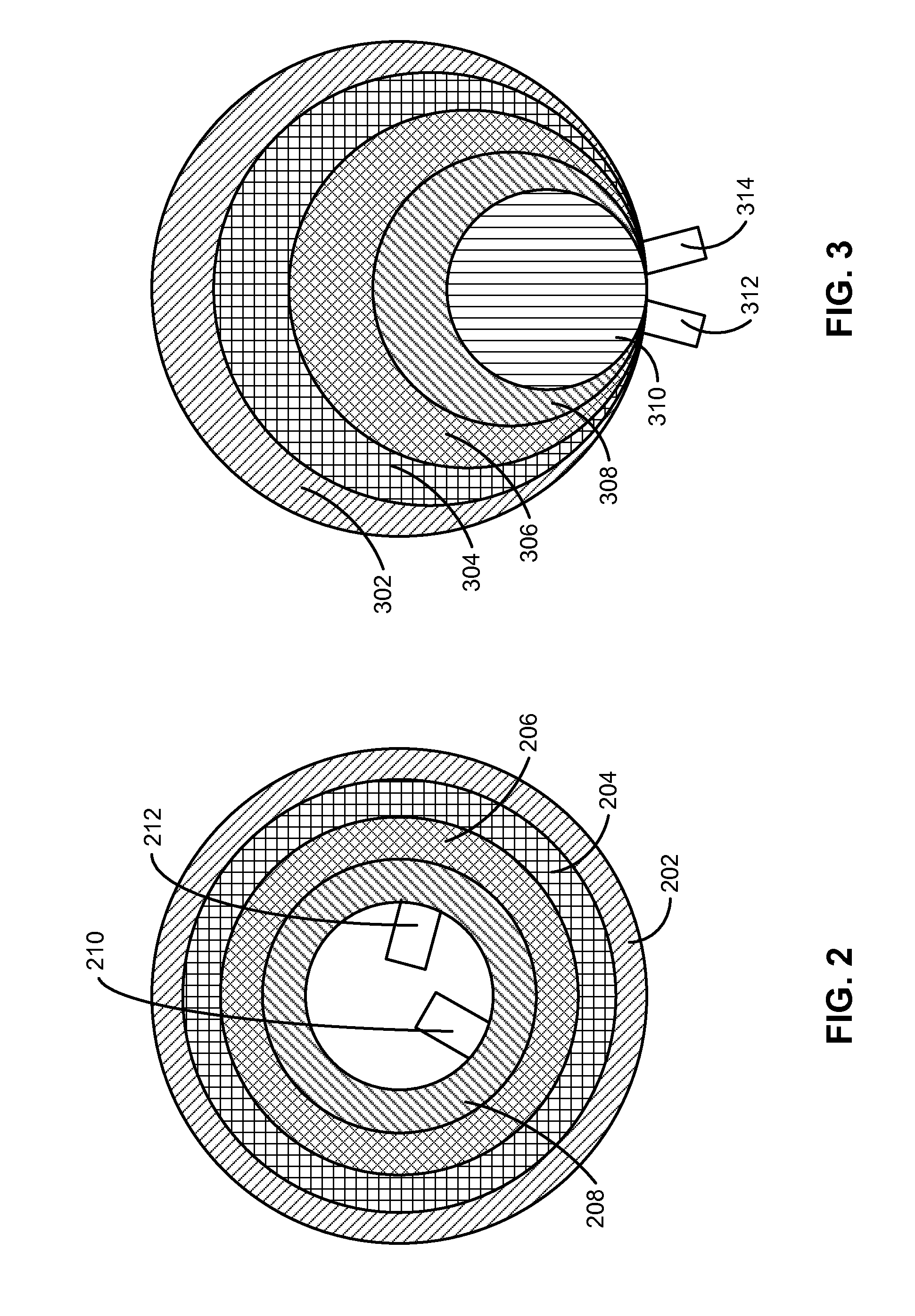

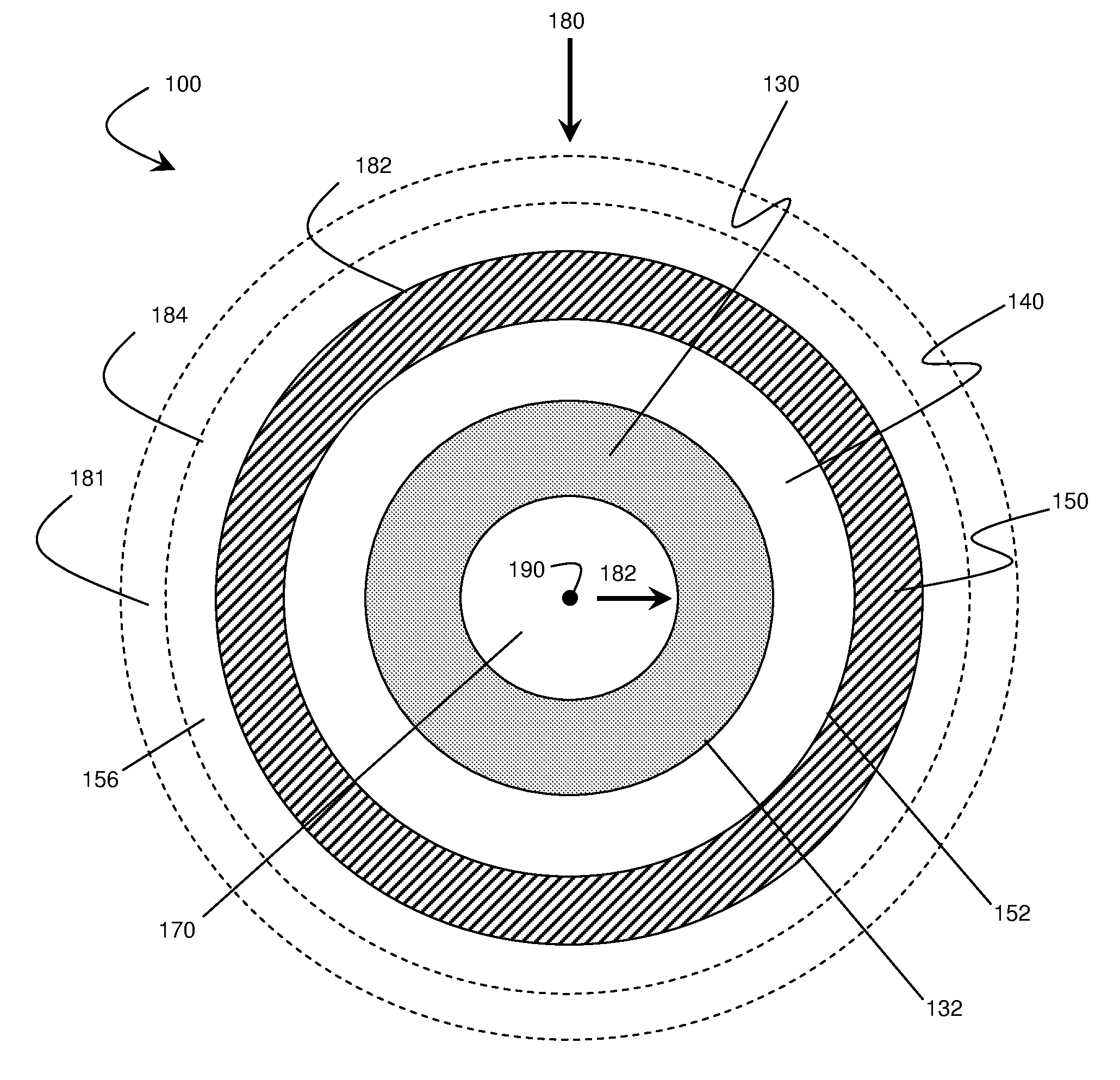

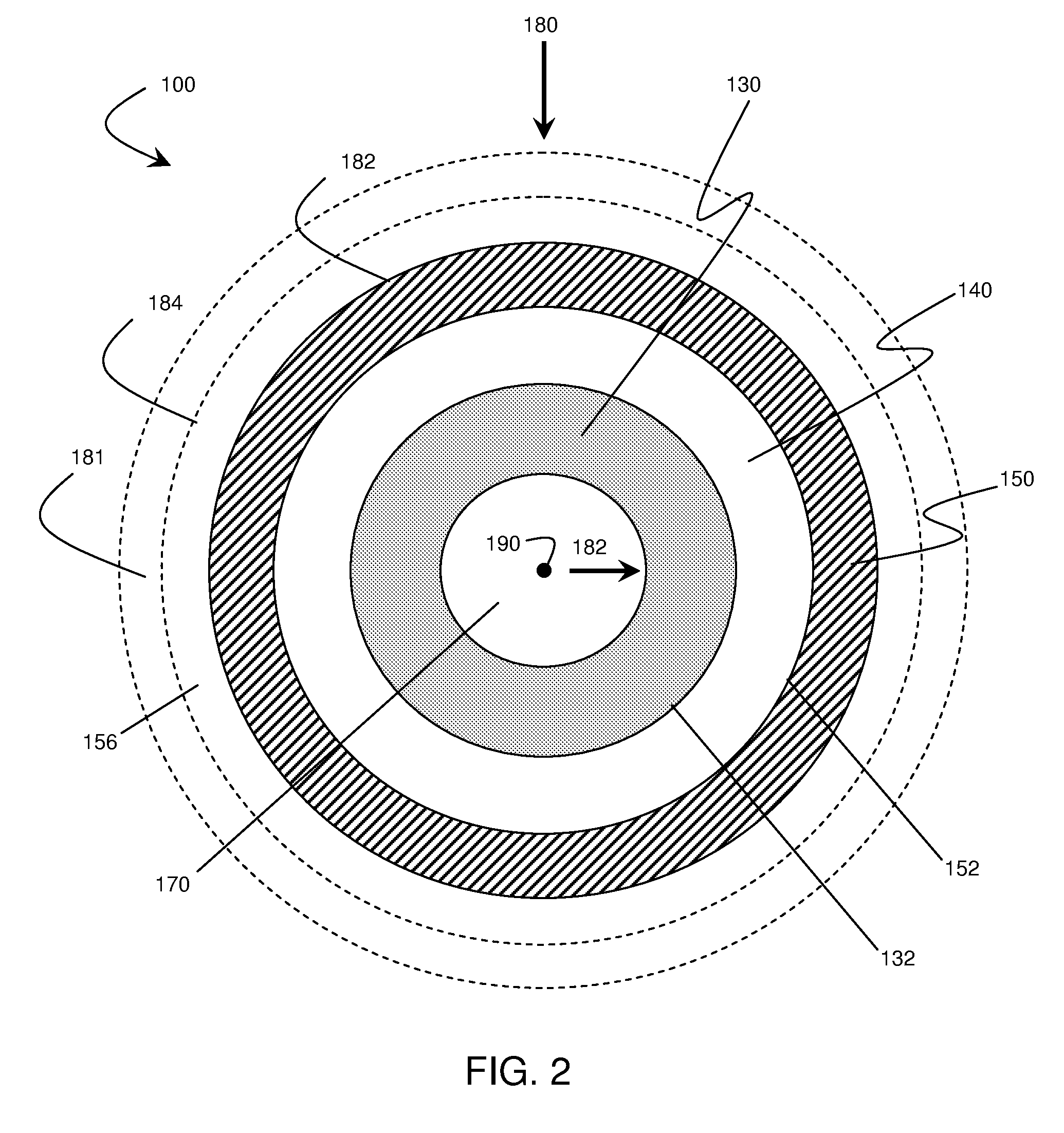

Design and construction of non-rectangular batteries

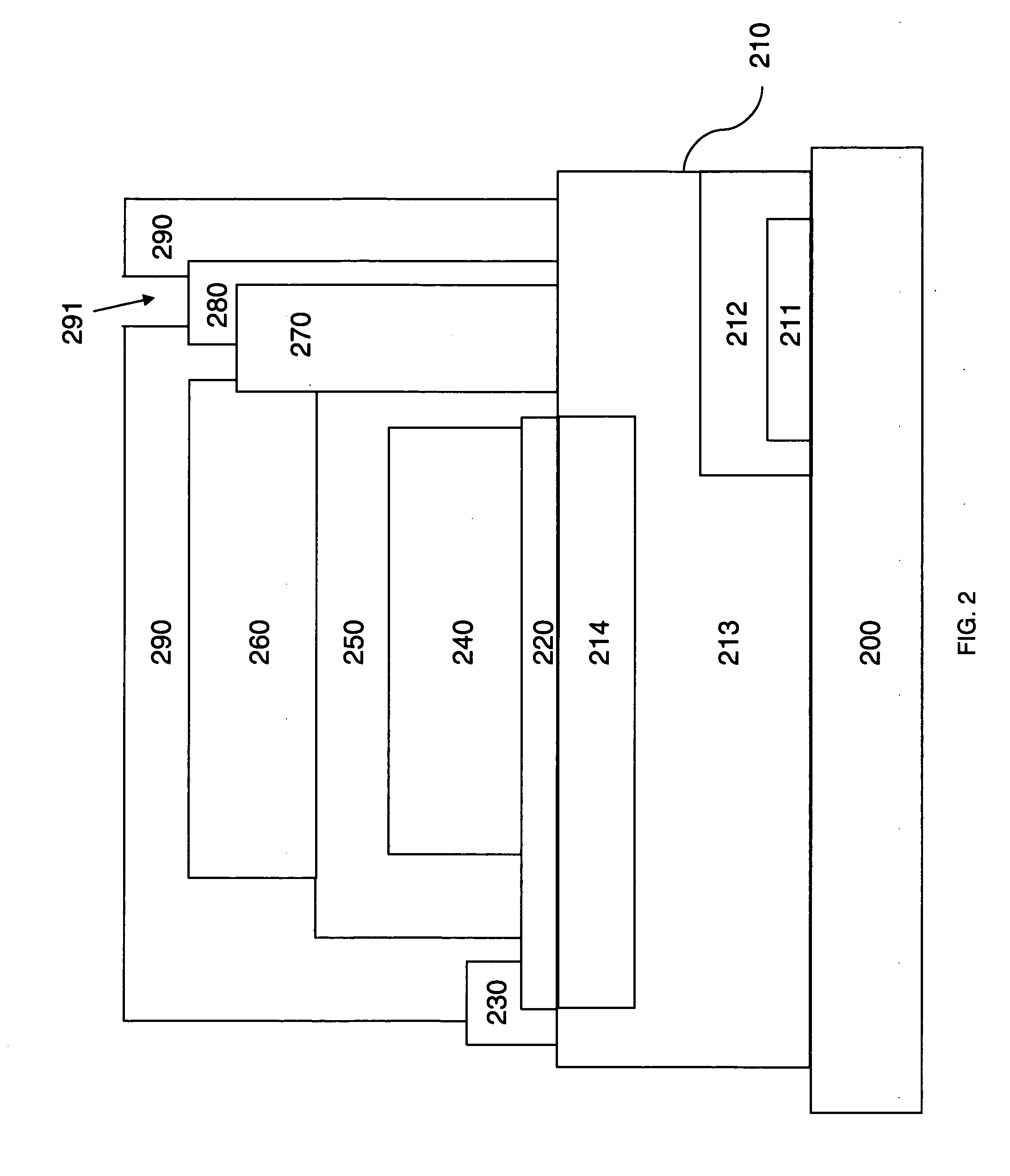

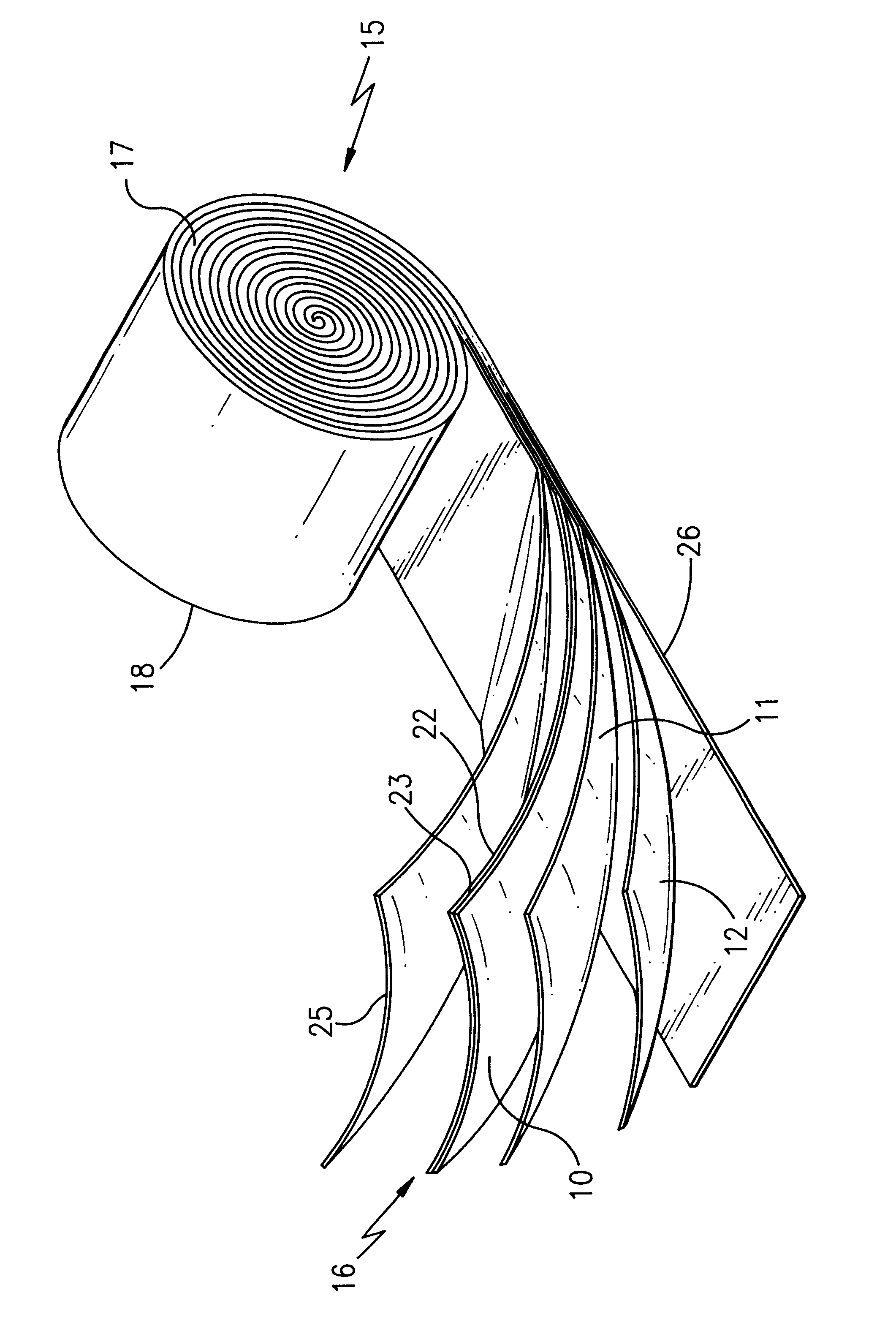

ActiveUS20120015236A1Facilitate efficient use of spaceEasy to carry and useFinal product manufactureSmall-sized cells cases/jacketsEngineeringBattery cell

The disclosed embodiments relate to a battery cell which includes a set of electrode sheets of different dimensions arranged in a stacked configuration to facilitate efficient use of space inside a portable electronic device. For example, the electrode sheets may be arranged in the stacked configuration to accommodate a shape of the portable electronic device. The stacked configuration may be based on a non-rectangular battery design such as a toroidal design, an L-shaped design, a triangular design, a pie-shaped design, a cone-shaped design, and / or a pyramidal design.

Owner:APPLE INC

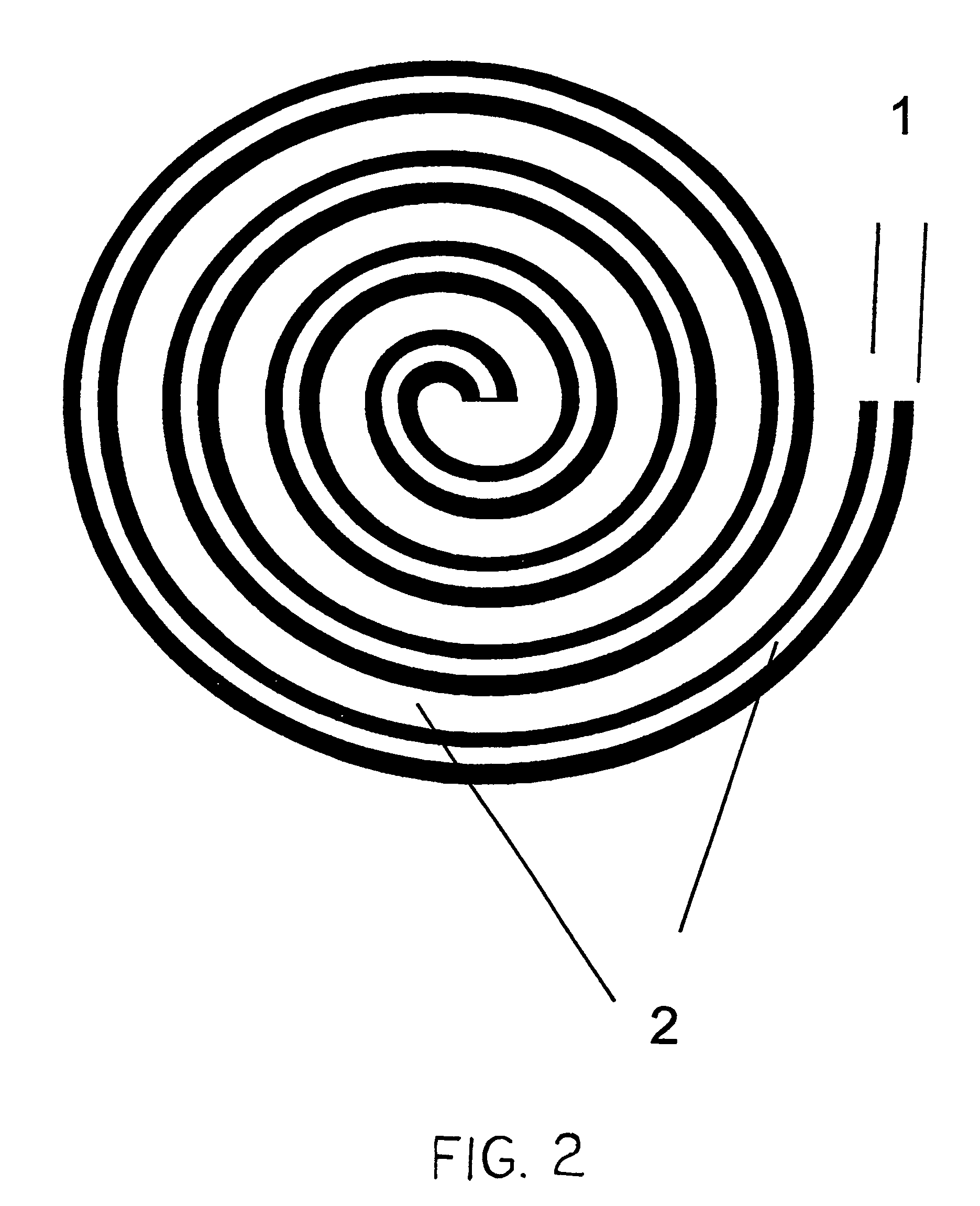

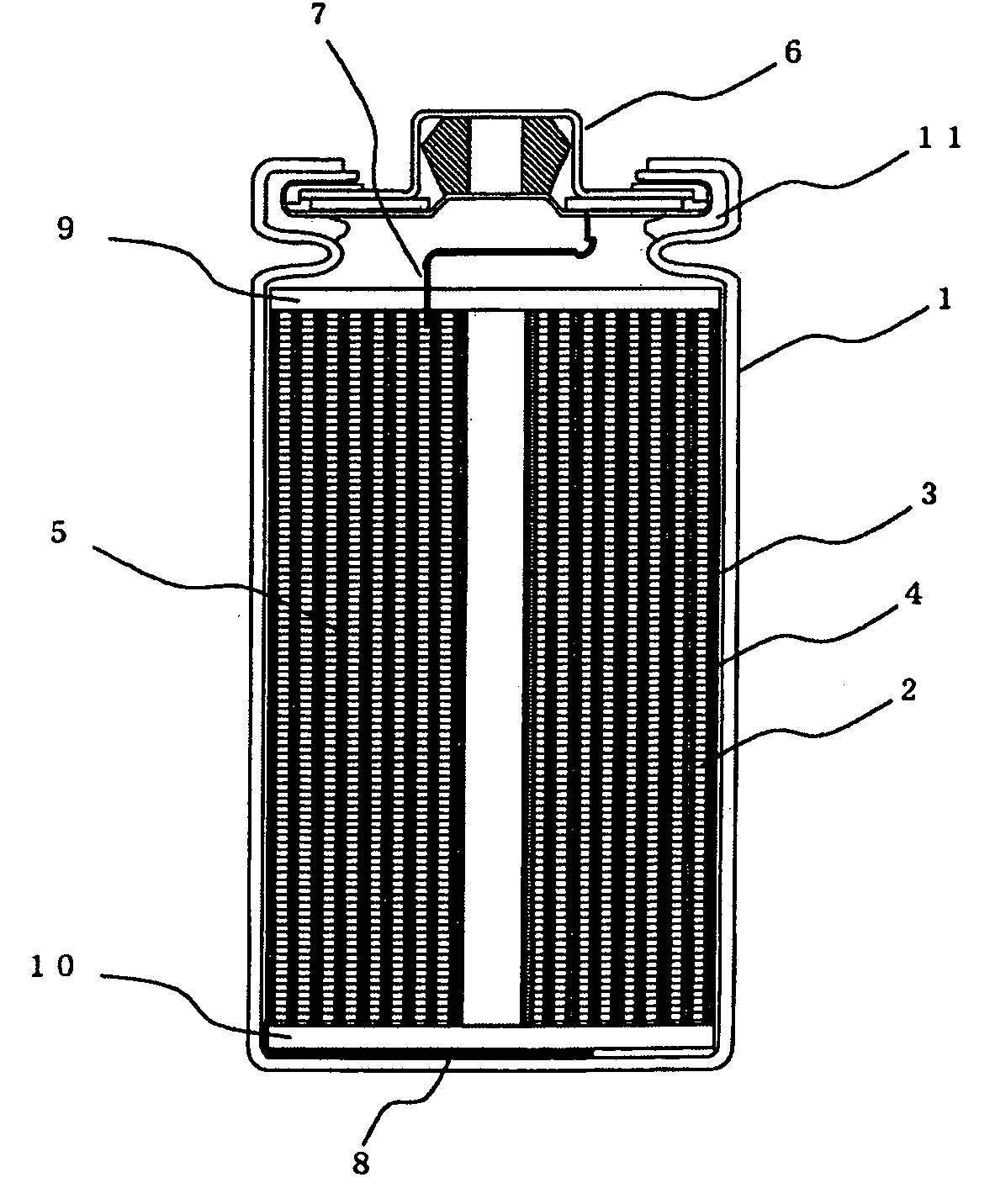

Lithium ion secondary battery

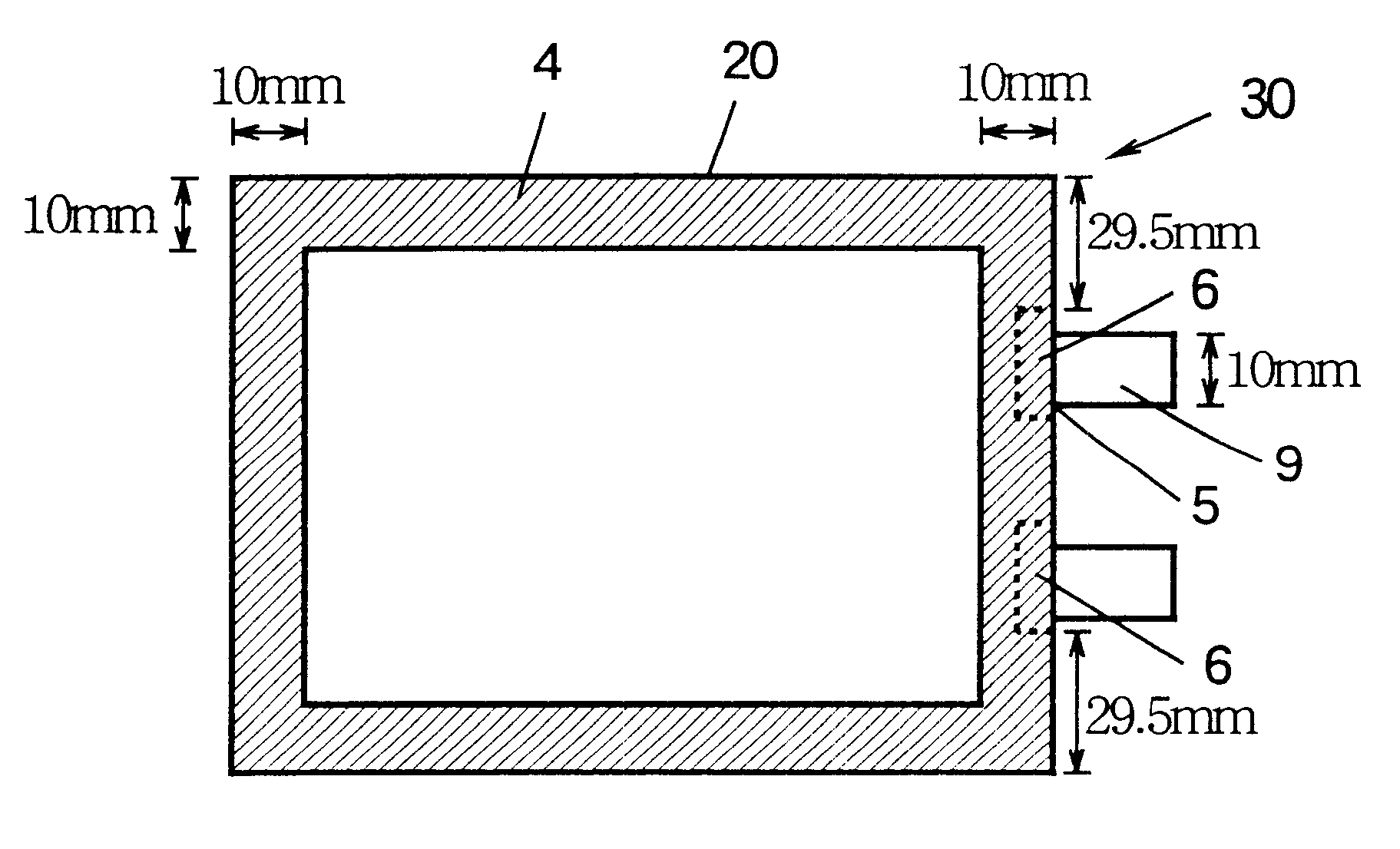

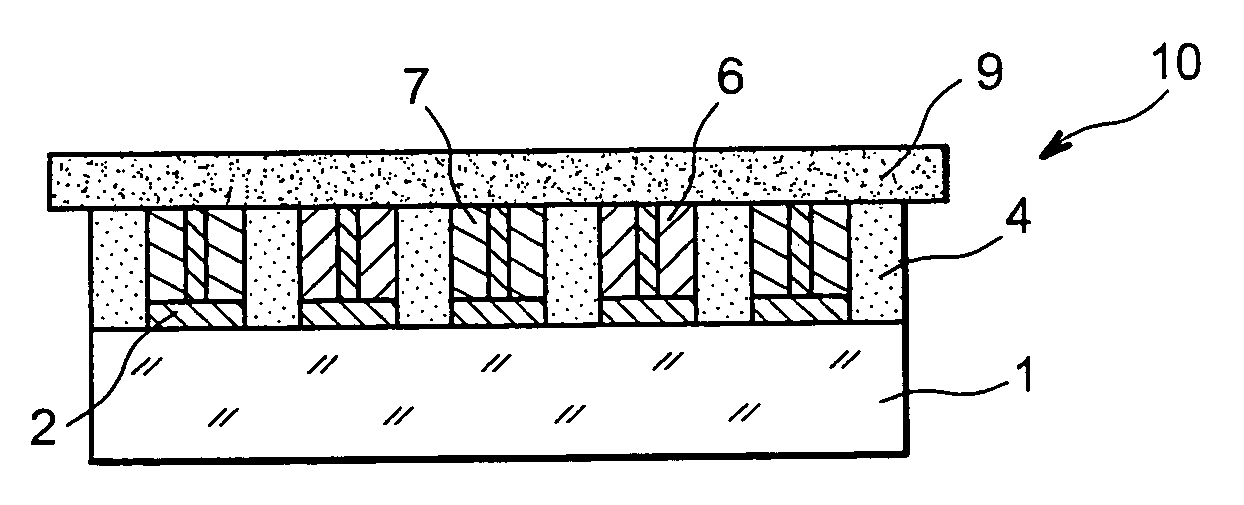

InactiveUS7335448B2Improve securityFinal product manufactureElectrode carriers/collectorsLithiumEngineering

A lithium ion secondary battery includes: (a) a positive electrode plate comprising an active material part and a current collector carrying the active material part, the active material part comprising a positive electrode active material capable of absorbing or desorbing a lithium ion during charge and discharge; (b) a negative electrode plate comprising an active material part and a current collector carrying the active material part, the active material part comprising a negative electrode active material capable of absorbing or desorbing a lithium ion during charge and discharge; (c) a separator interposed between the positive and negative electrode plates; (d) an electrolyte; and (e) a battery case accommodating the positive and negative electrode plates, the separator, and the electrolyte. The positive and negative electrode plates are wound with the separator interposed therebetween, thereby to form an electrode plate assembly. The electrode plate assembly is so configured that each lengthwise edge of the positive electrode current collector is positioned on an outer side of each lengthwise edge of the negative electrode active material part.

Owner:GK BRIDGE 1

Electrode for rechargeable lithium battery and rechargeable lithium battery

InactiveUS7192673B1Improve charge and discharge cycle characteristicsInhibition formationElectrode manufacturing processesSmall-sized cells cases/jacketsAmorphous siliconMaterials science

An electrode for a rechargeable lithium battery which includes a thin film composed of active material that expands and shrinks as it stores and releases lithium, e.g., a microcrystalline or amorphous silicon thin film, deposited on a current collector, characterized in that said current collector exhibits a tensile strength (=tensile strength (N / mm2) per sectional area of the current collector material×thickness (mm) of the current collector) of not less than 3.82 N / mm.

Owner:SANYO ELECTRIC CO LTD

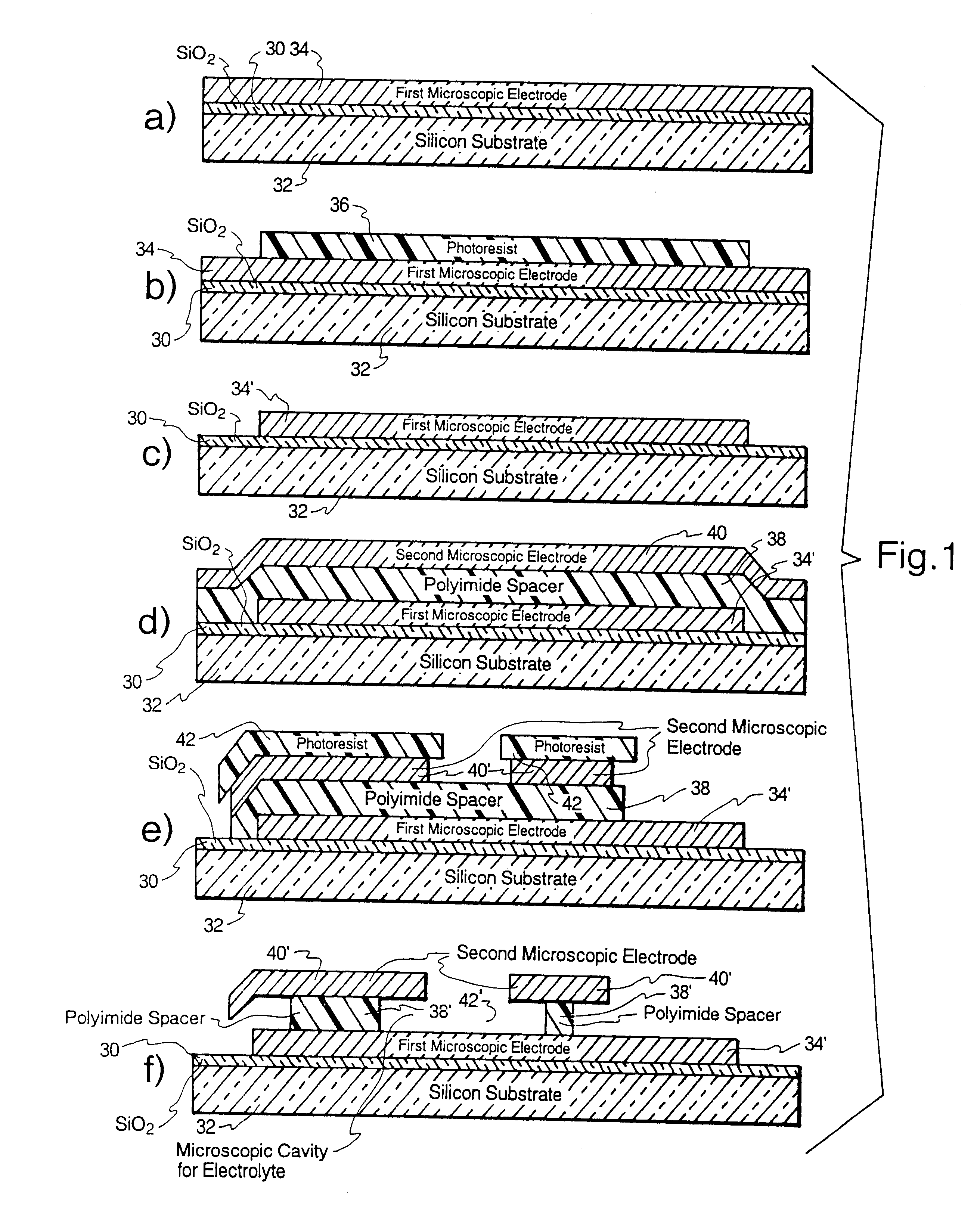

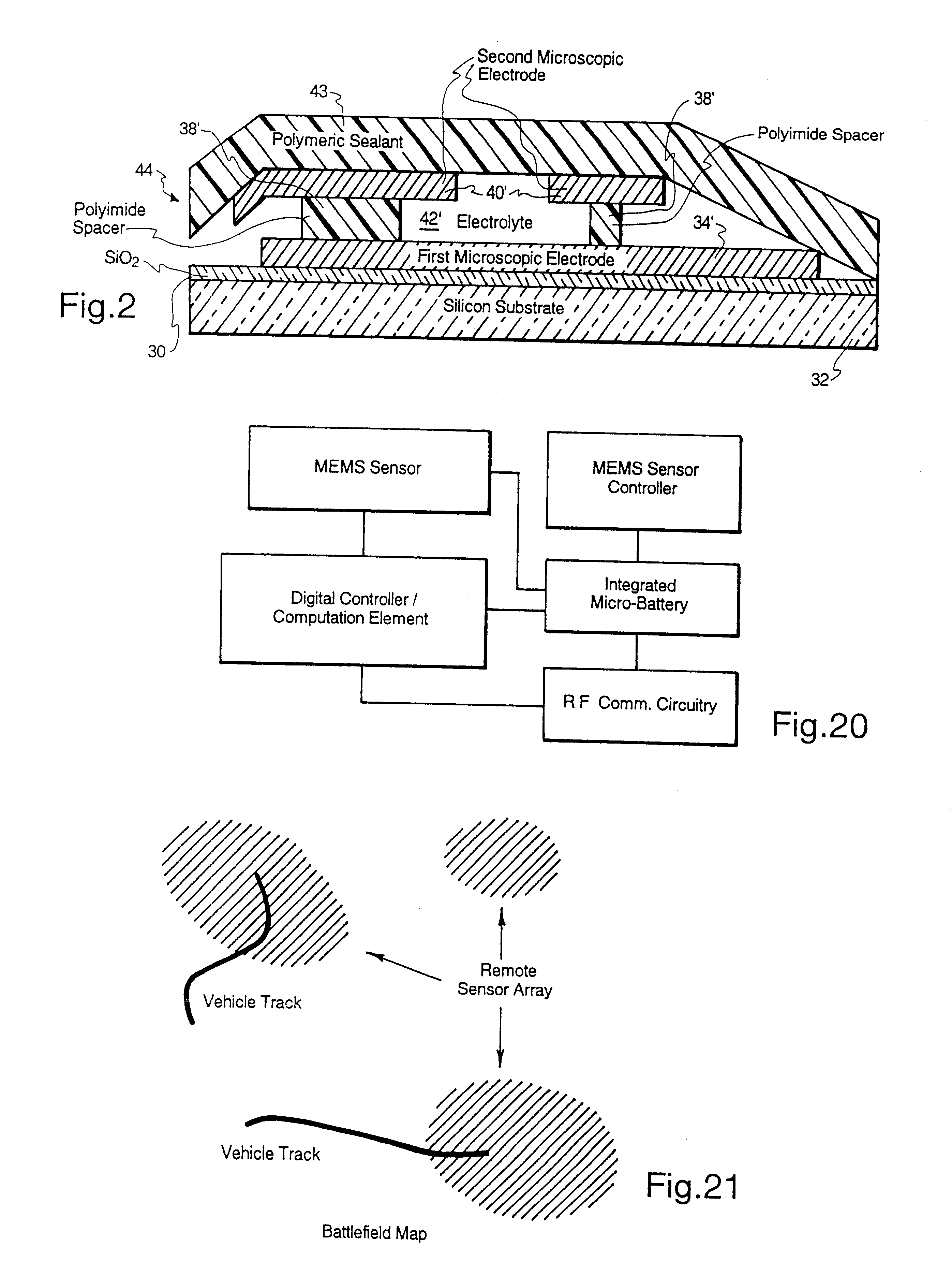

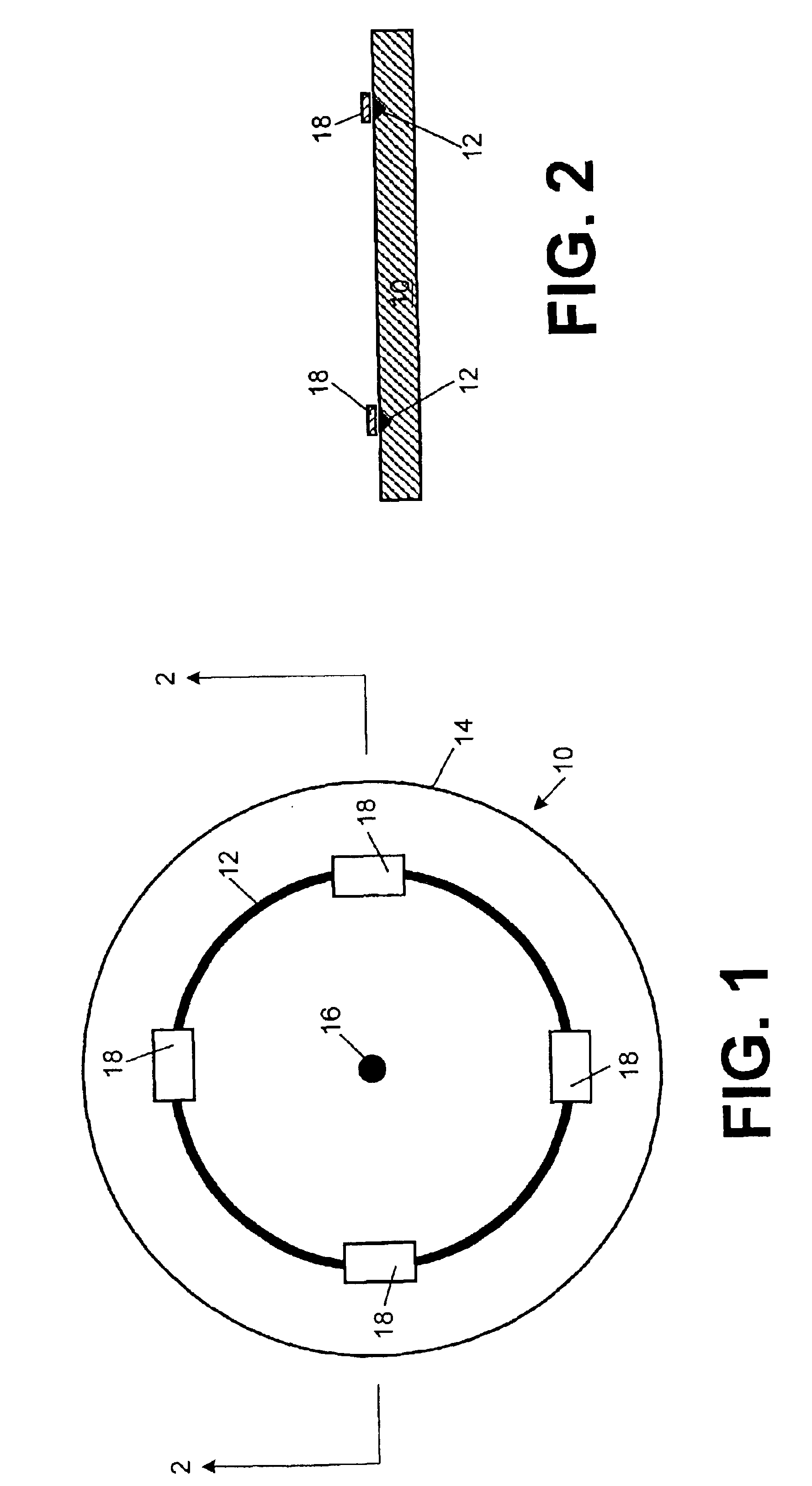

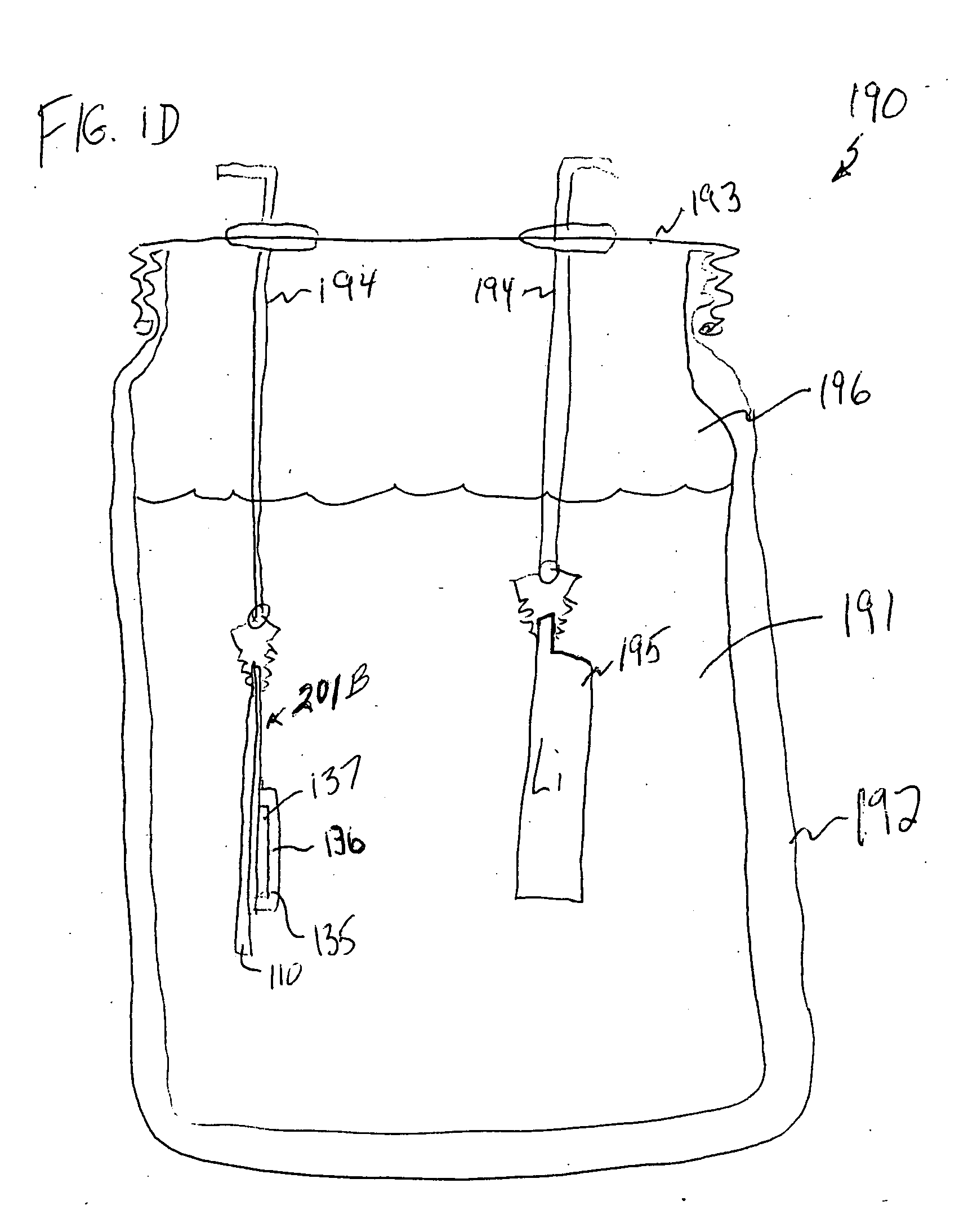

Microscopic batteries for MEMS systems

InactiveUS6610440B1Reduce power lossIncrease powerBatteries circuit arrangementsFinal product manufactureElectricityMicrofabrication

Microscopic batteries, integratable or integrated with microelectromechanical systems or other microscopic circuits, including a MEMS microcircuit, and methods of microfabrication of such microscopic batteries are disclosed, among which comprise closed system microscopic batteries for internal storage of electricity using interval reactants only, which comprise microscopic electrodes, electrolyte and reservoir for the electrolyte.

Owner:BIPOLAR TECH

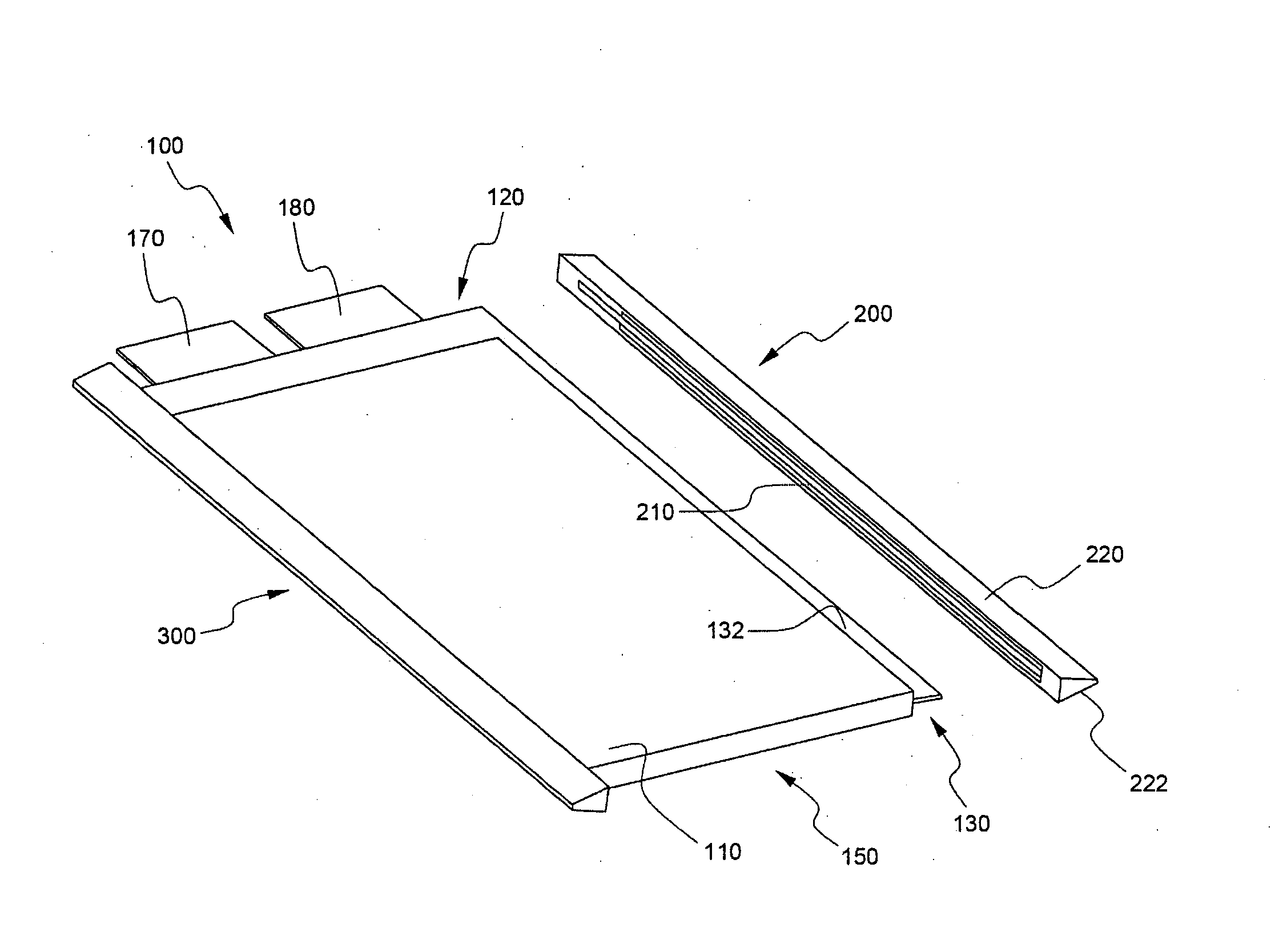

Application of force in electrochemical cells

ActiveUS20100035128A1Improve performancePrimary cell to battery groupingCell seperators/membranes/diaphragms/spacersRough surfaceChemical reaction

The present invention relates to the application of a force to enhance the performance of an electrochemical cell. The force may comprise, in some instances, an anisotropic force with a component normal to an active surface of the anode of the electrochemical cell. In the embodiments described herein, electrochemical cells (e.g., rechargeable batteries) may undergo a charge / discharge cycle involving deposition of metal (e.g., lithium metal) on a surface of the anode upon charging and reaction of the metal on the anode surface, wherein the metal diffuses from the anode surface, upon discharging. The uniformity with which the metal is deposited on the anode may affect cell performance. For example, when lithium metal is redeposited on an anode, it may, in some cases, deposit unevenly forming a rough surface. The roughened surface may increase the amount of lithium metal available for undesired chemical reactions which may result in decreased cycling lifetime and / or poor cell performance. The application of force to the electrochemical cell has been found, in accordance with the invention, to reduce such behavior and to improve the cycling lifetime and / or performance of the cell.

Owner:SION POWER CORP

Thin film battery and electrolyte therefor

A solid amorphous electrolyte composition for a thin-film battery. The electrolyte composition includes a lithium phosphorus oxynitride material containing a sulfide ion dopant wherein the atomic ratio of sulfide ion to phosphorus ion (S / P) in the electrolyte ranges greater than 0 up to about 0.2. The composition is represented by the formula: where 2x+3y+2z=5+w, x ranges from about 3.2 to about 3.8, y ranges from about 0.13 to about 0.46, z ranges from greater than zero up to about 0.2, and w ranges from about 2.9 to about 3.3. Thin-film batteries containing the sulfide doped lithium oxynitride electrolyte are capable of delivering more power and energy than thin-film batteries containing electrolytes without sulfide doping.

Owner:OAK RIDGE MICRO ENERGY

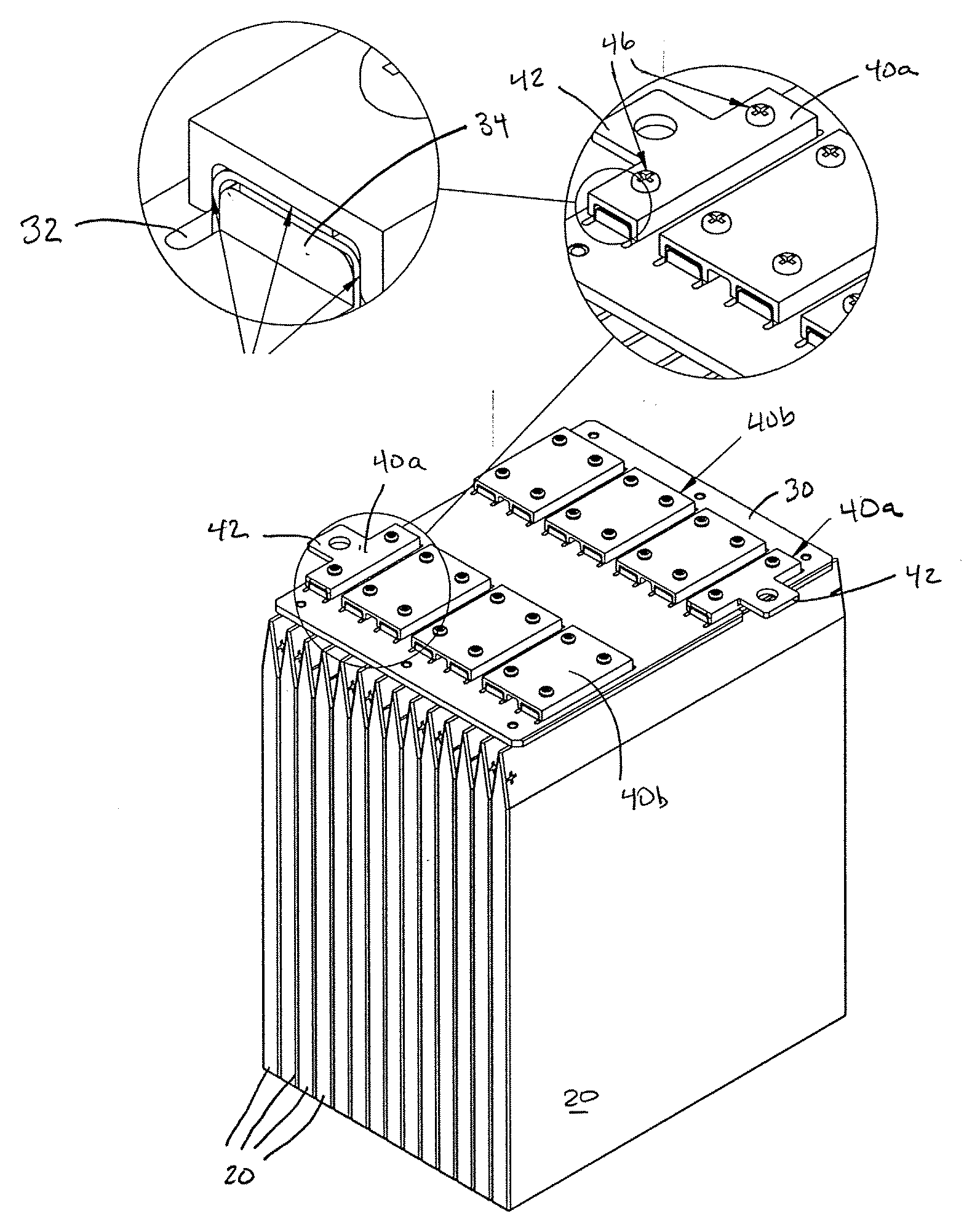

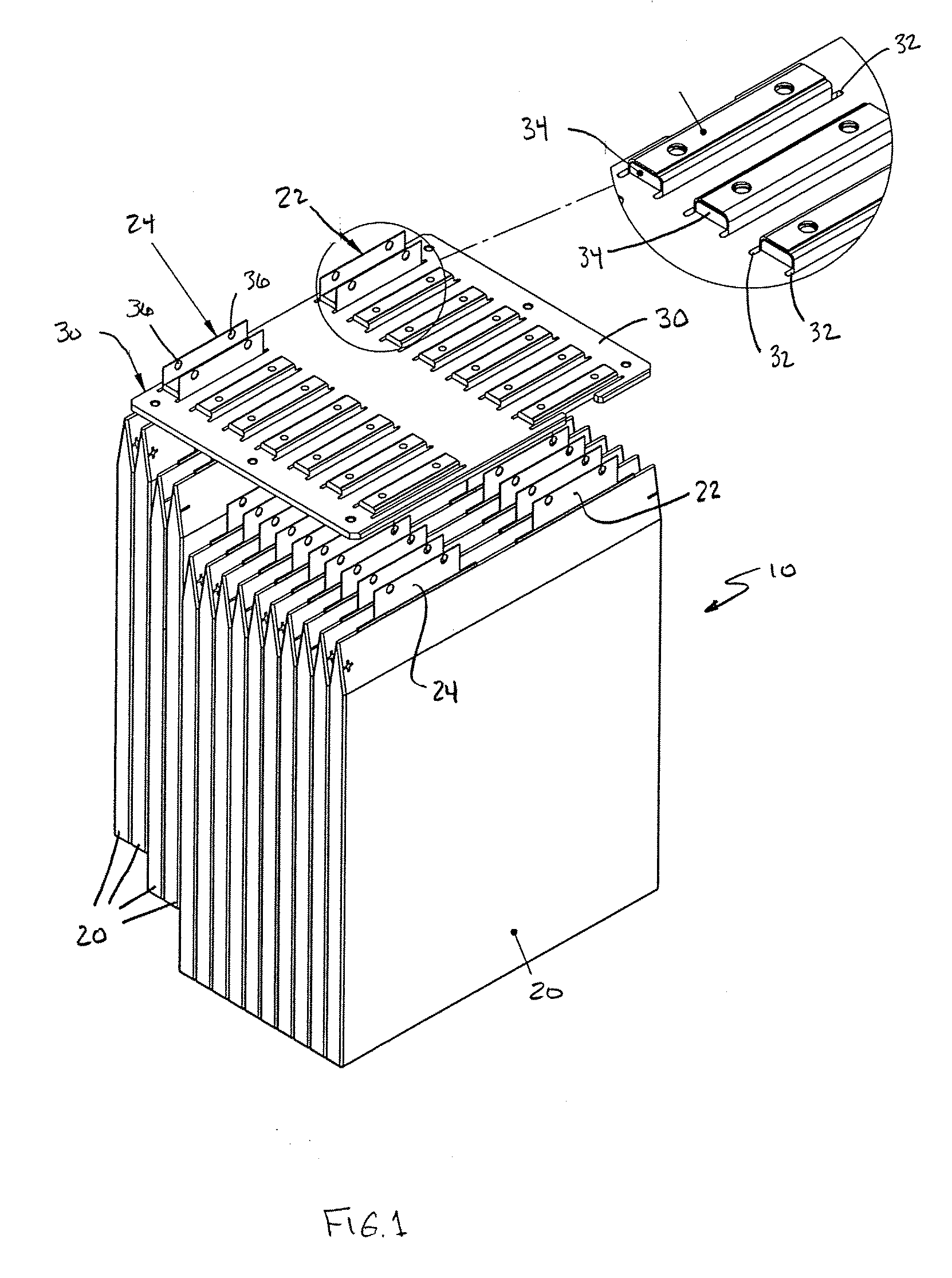

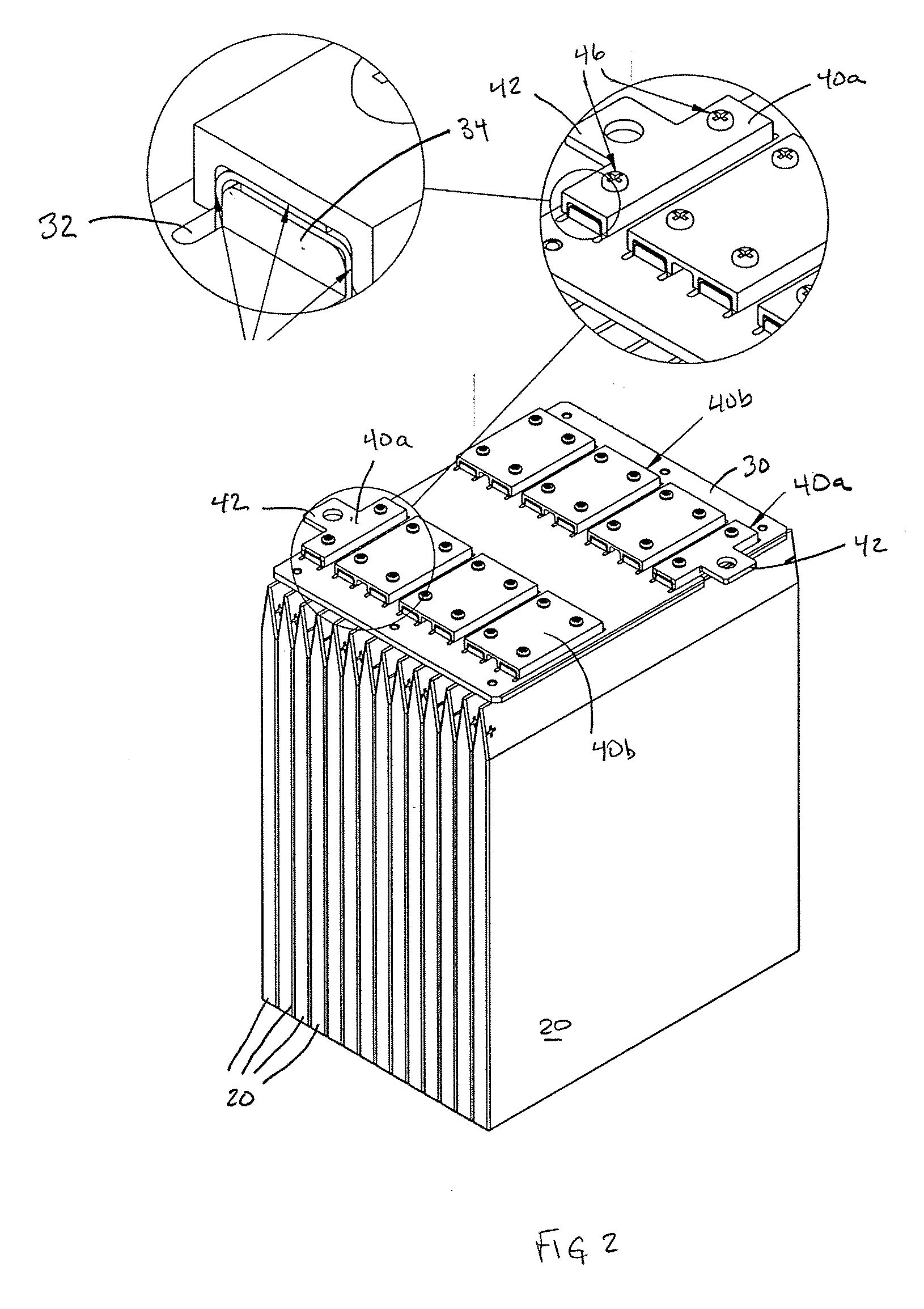

Battery busing scheme

ActiveUS20080124617A1Efficient battery powerIncrease demandSmall-sized cells cases/jacketsPrinted batteriesConductive materialsBattery cell

Owner:SECURAPLANE TECH

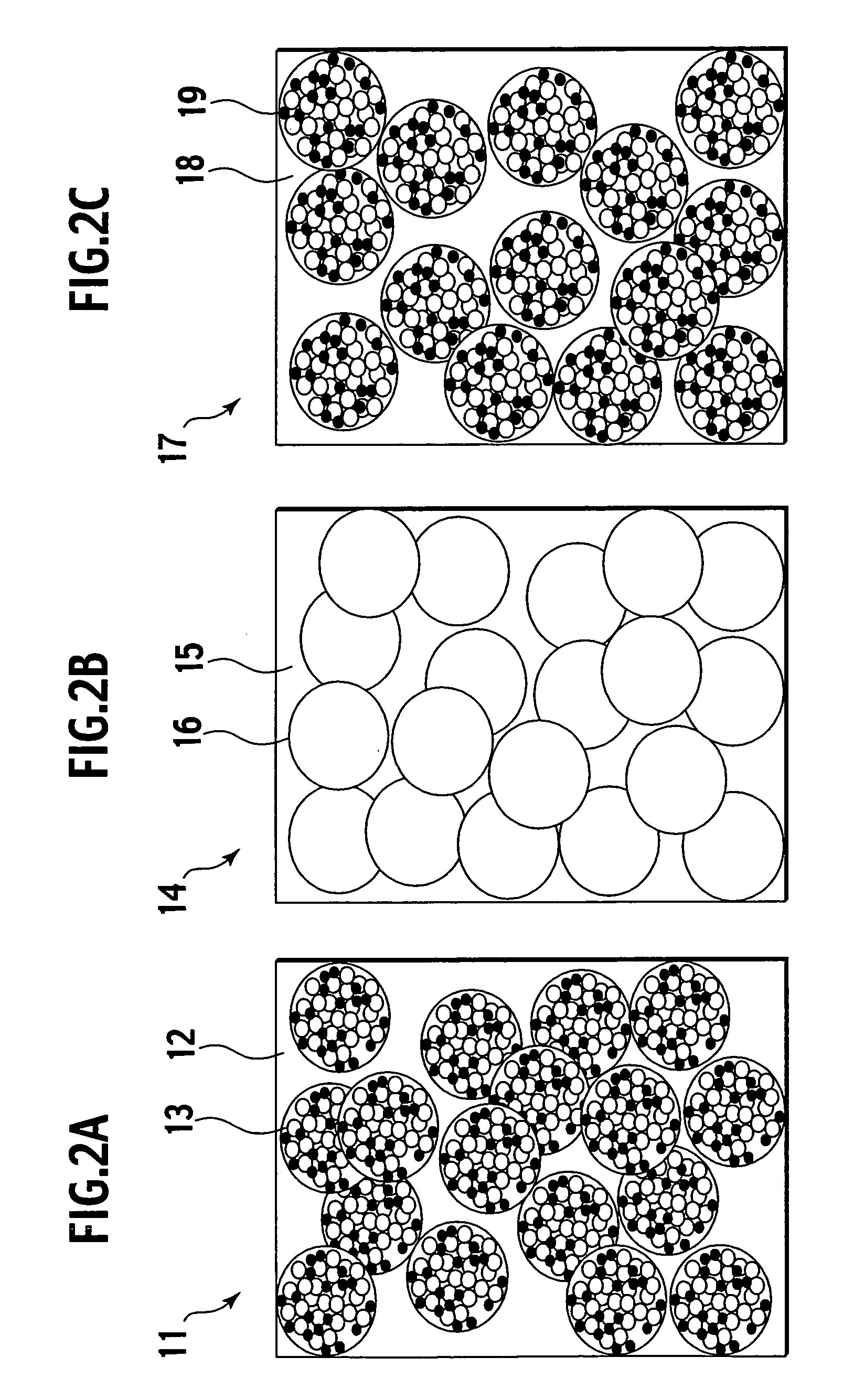

High discharge capacity lithium battery

InactiveUS20050233214A1Improve discharge performanceIncrease energy densityFinal product manufactureOrganic electrolyte cellsHigh rateIron disulfide

A lithium / iron disulfide electrochemical battery cell with a high discharge capacity. The cell has a lithium negative electrode, an iron disulfide positive electrode and a nonaqueous electrolyte. The iron disulfide of the positive electrode has a controlled average particle size range which allows the electrochemical cells to exhibit desired properties in both low and high rate applications. In various embodiments, the iron disulfide particles are wet milled, preferably utilizing a media mill or milled utilizing a non-mechanical mill such as a jet mill, which reduces the iron disulfide particles to a desired average particle size range for incorporation into the positive electrode.

Owner:EVEREADY BATTERY CO INC

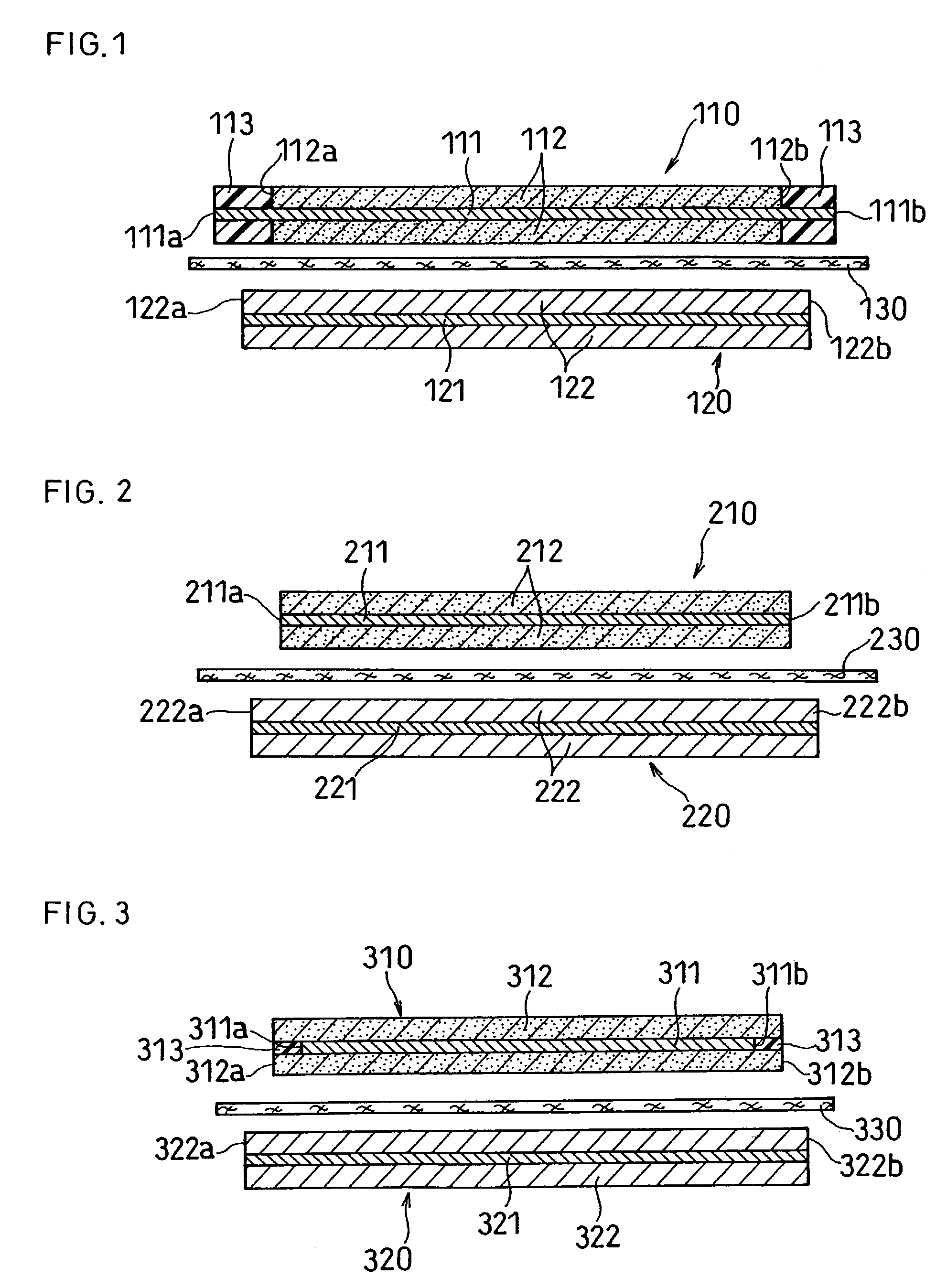

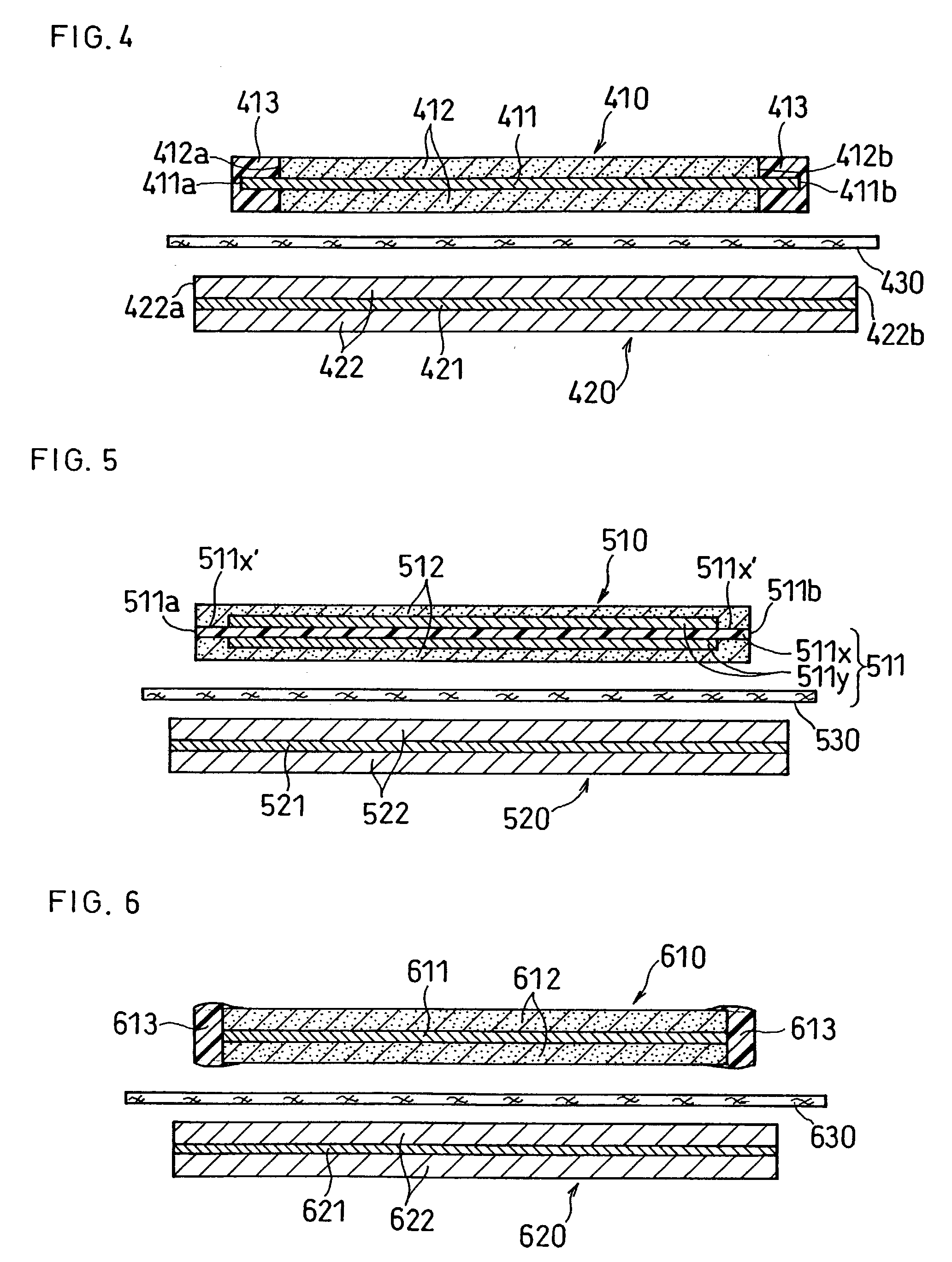

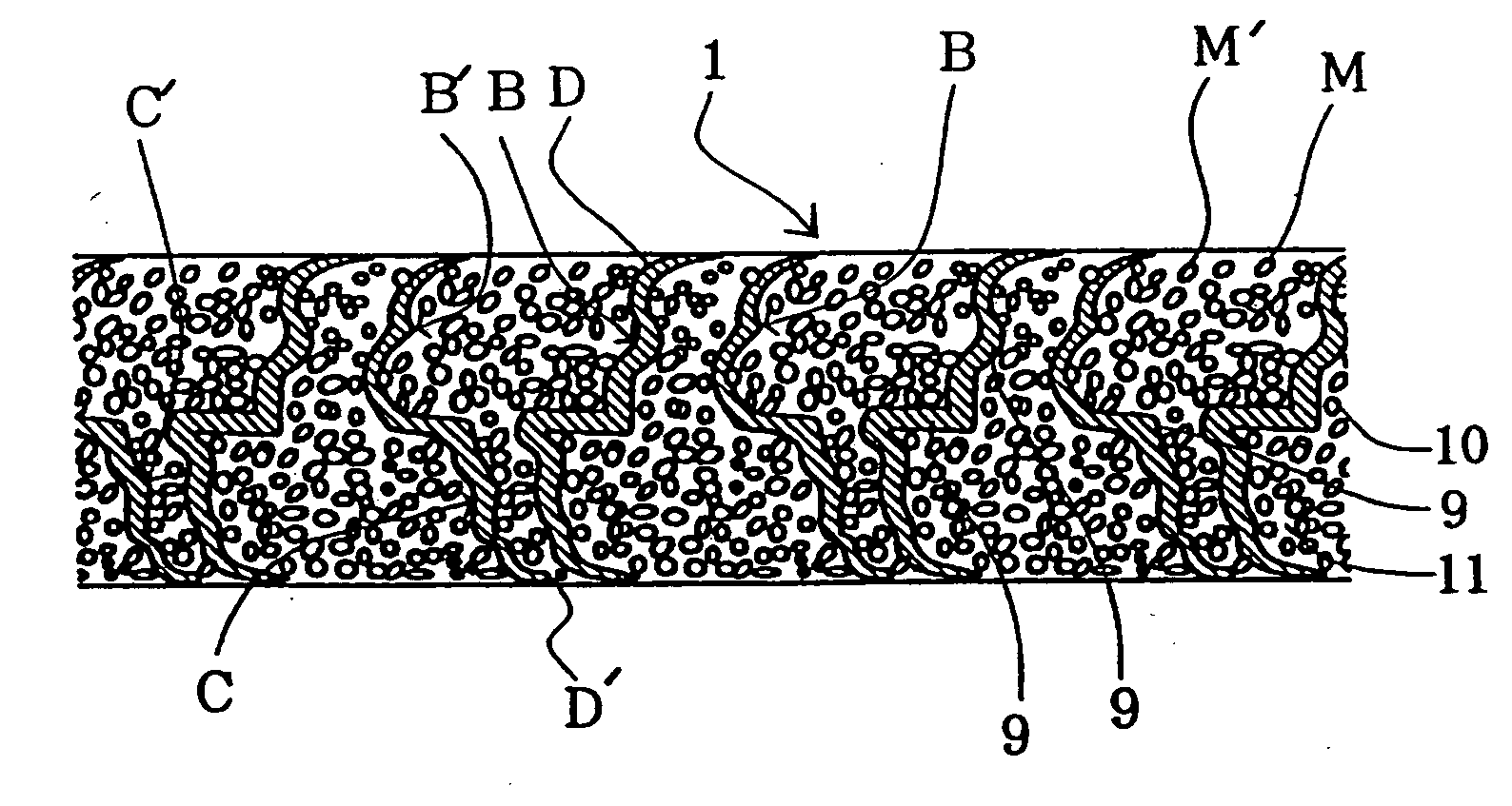

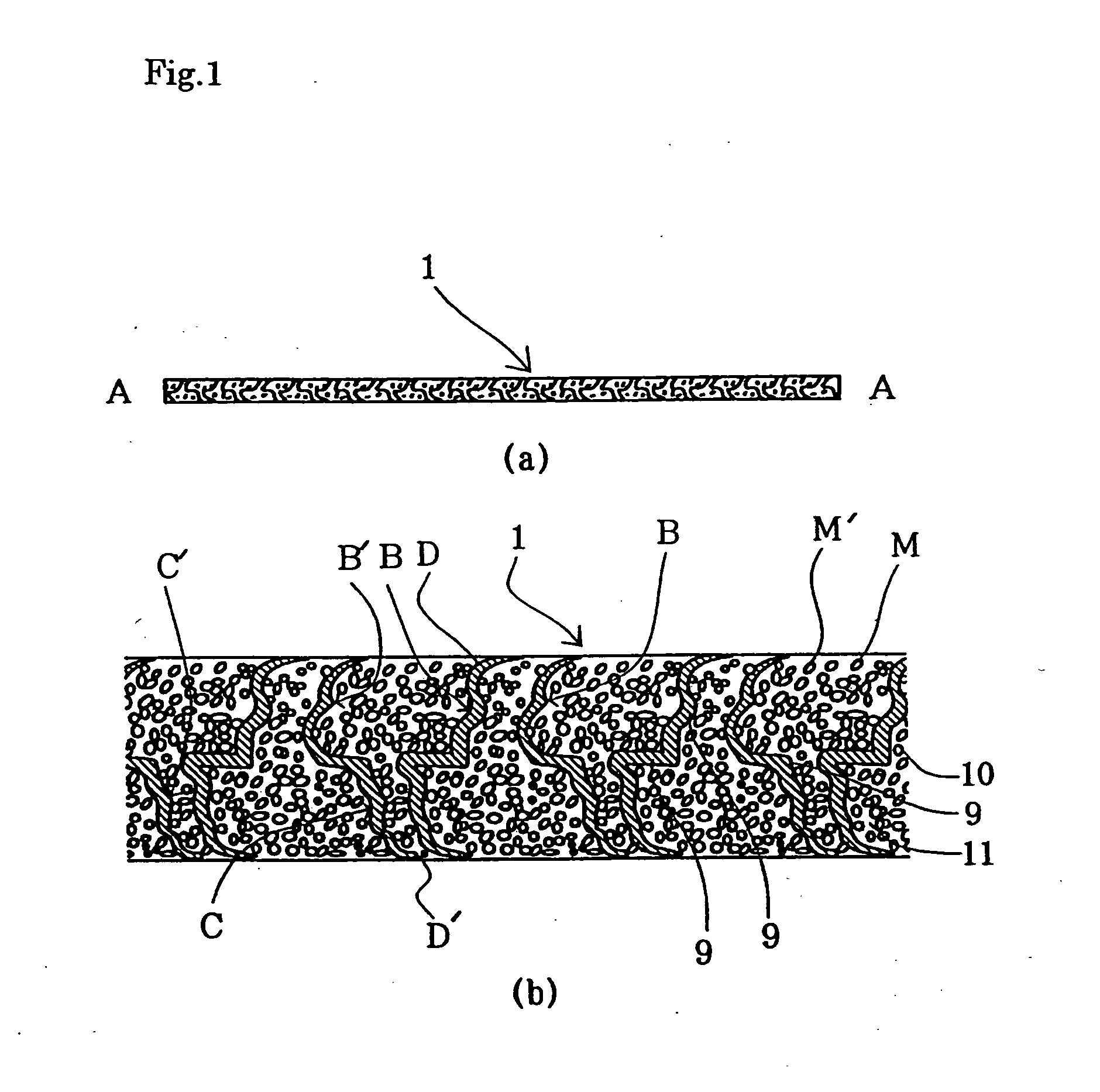

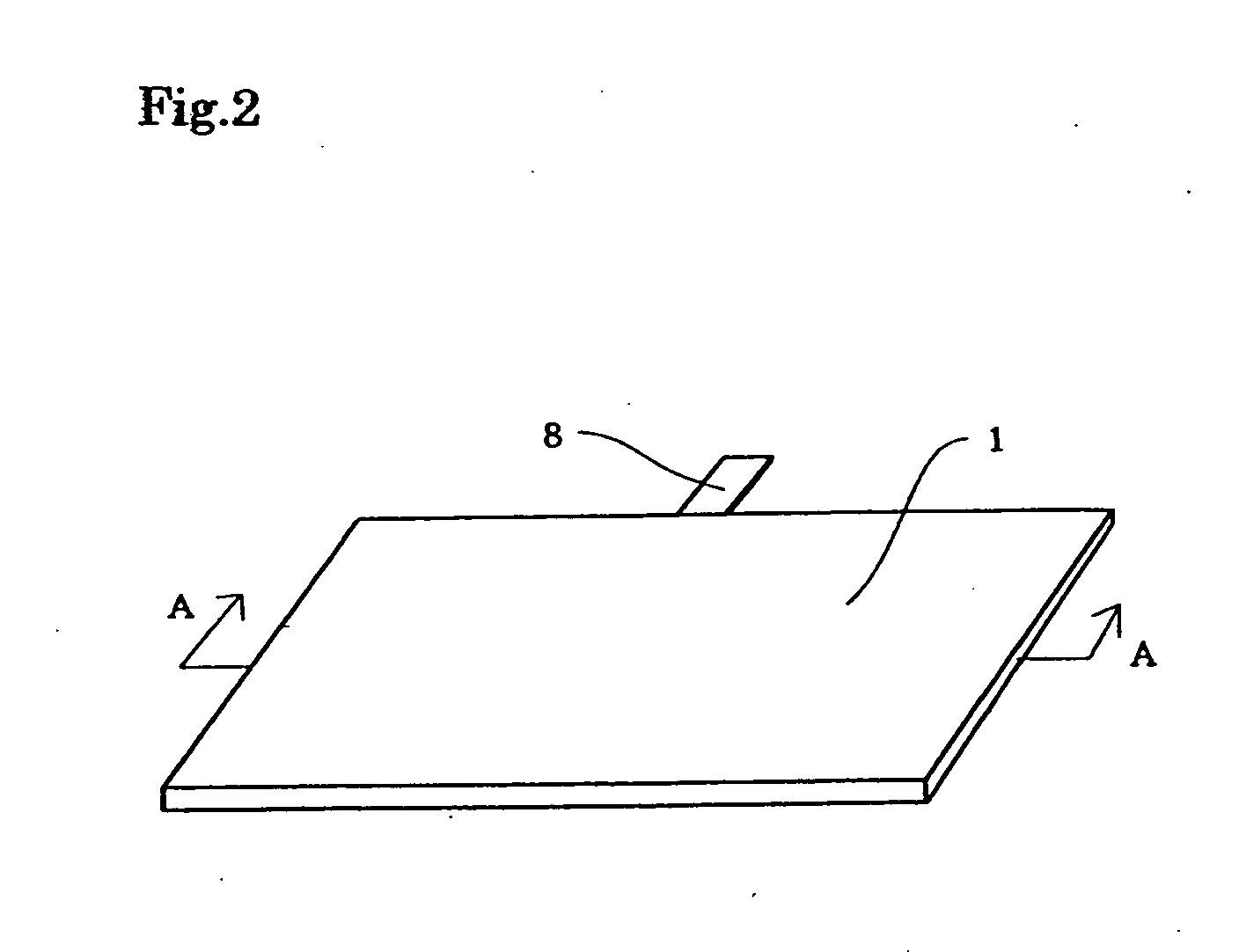

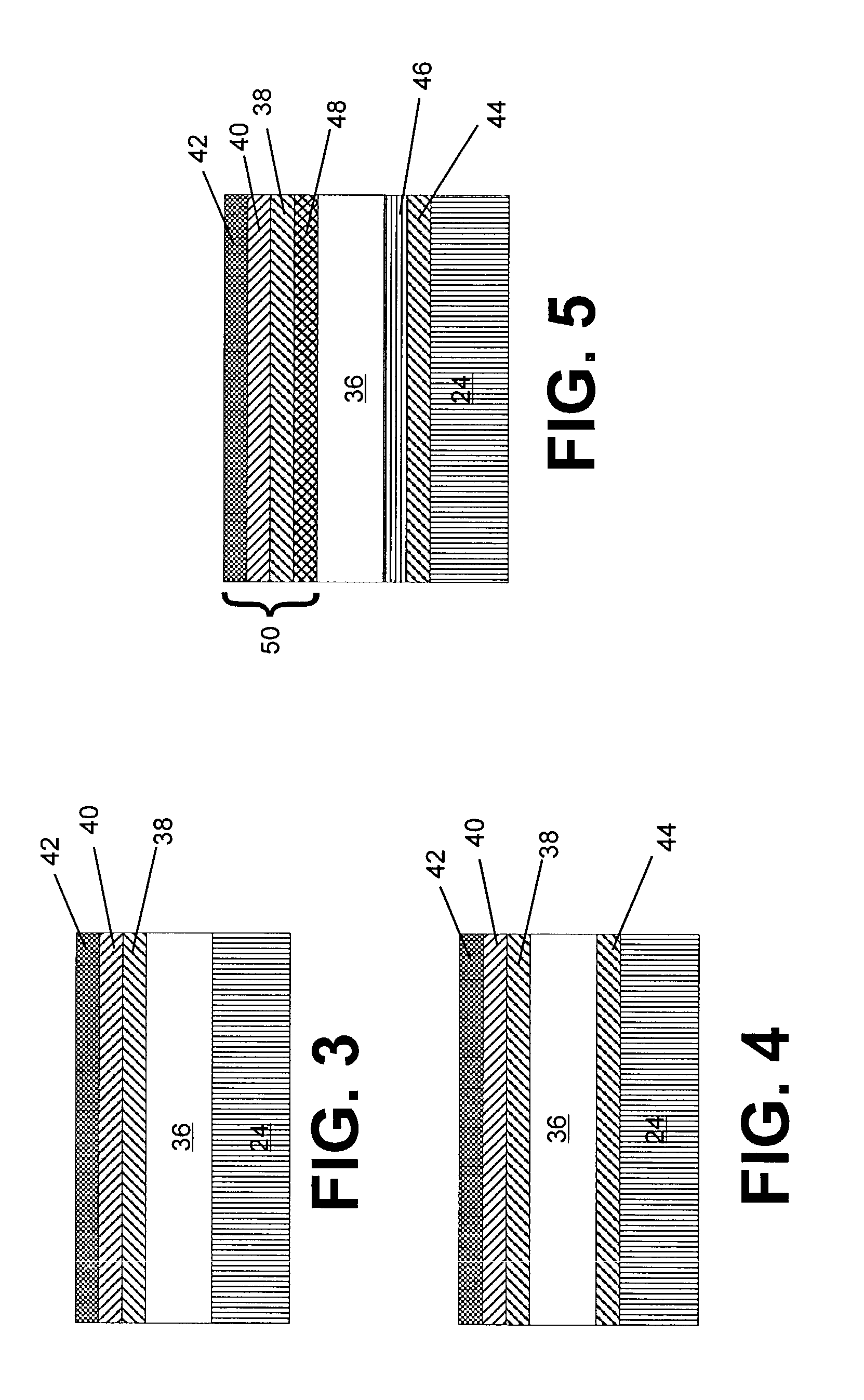

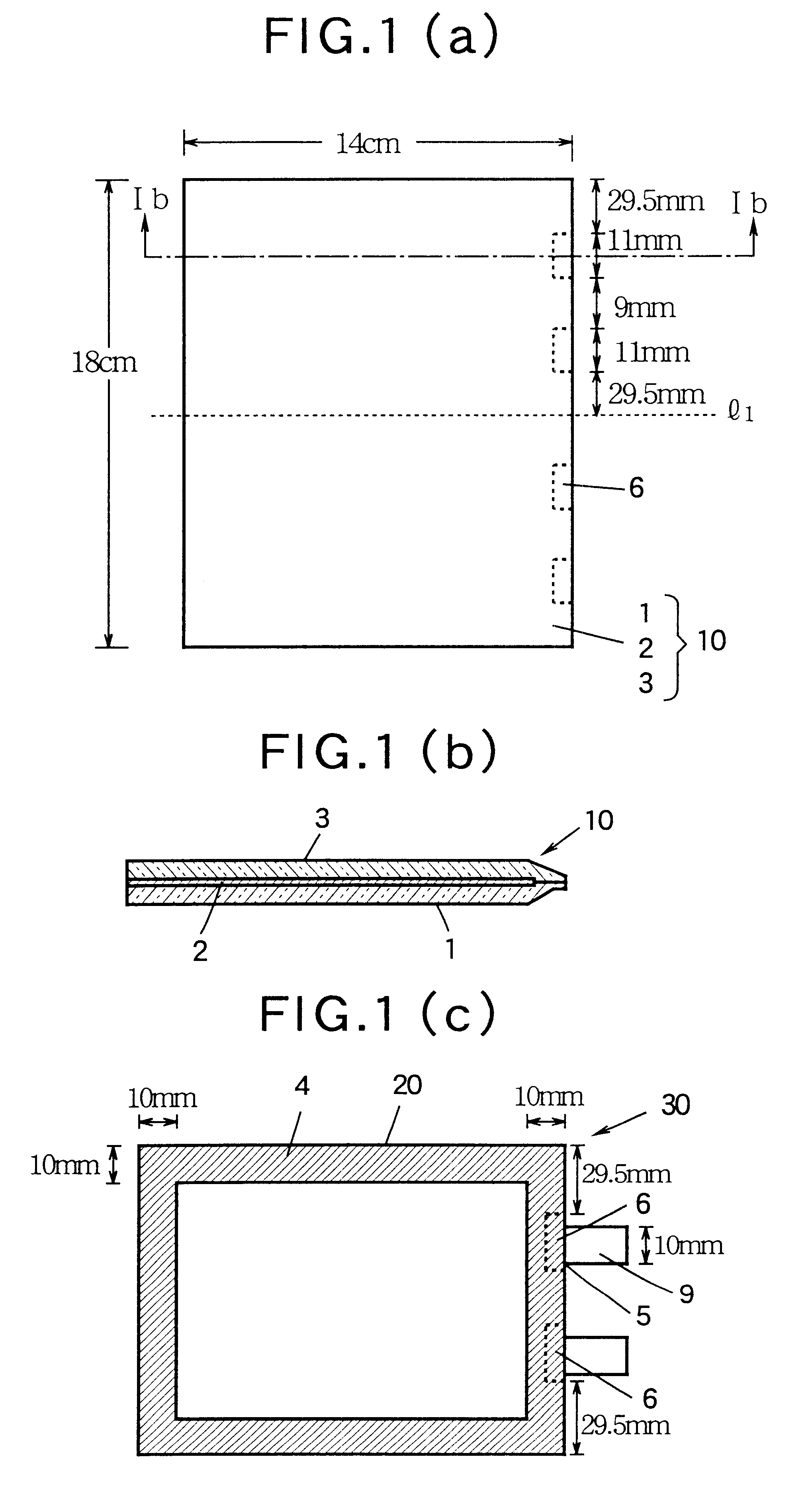

Non-sintered type thin electrode for battery, battery using same and process for same

InactiveUS20050019664A1Prevent peelingPrevent materialElectrode carriers/collectorsActive material electrodesElectrical batteryEngineering

An electrode substrate is formed by mechanically processing a nickel foil so as to be made three dimensional through the creation of concave and convex parts, and then, this substrate is filled with active material or the like so that an electrode is manufactured, wherein the above described concave and convex parts are rolling pressed so as to incline in one direction. Furthermore, an electrode for secondary battery is formed by using the above described method.

Owner:THE UNIV OF QUEENSLAND

Electrode for use in lithium battery and rechargeable lithium battery

InactiveUS7235330B1High charge and discharge capacityImprove featuresElectrode manufacturing processesSmall-sized cells cases/jacketsAmorphous siliconSurface roughness

Owner:SANYO ELECTRIC CO LTD

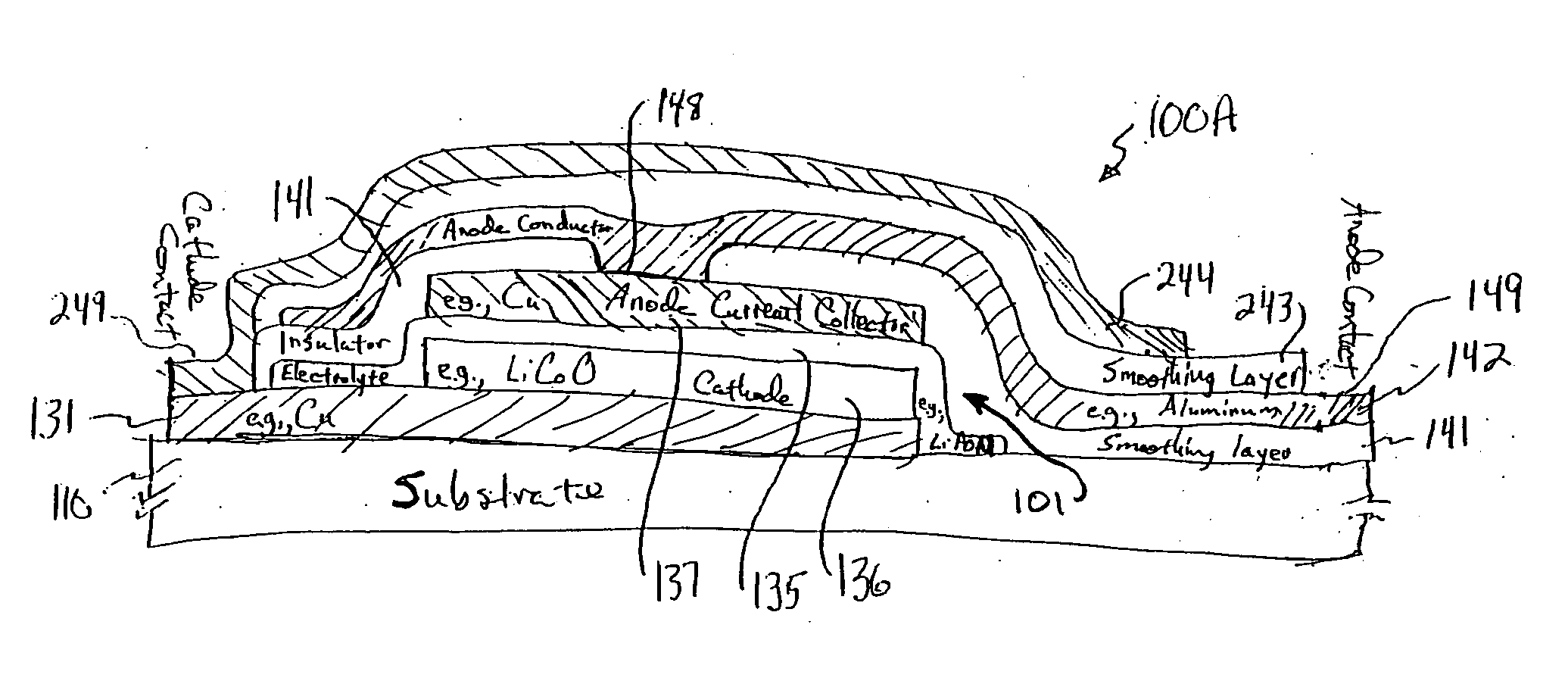

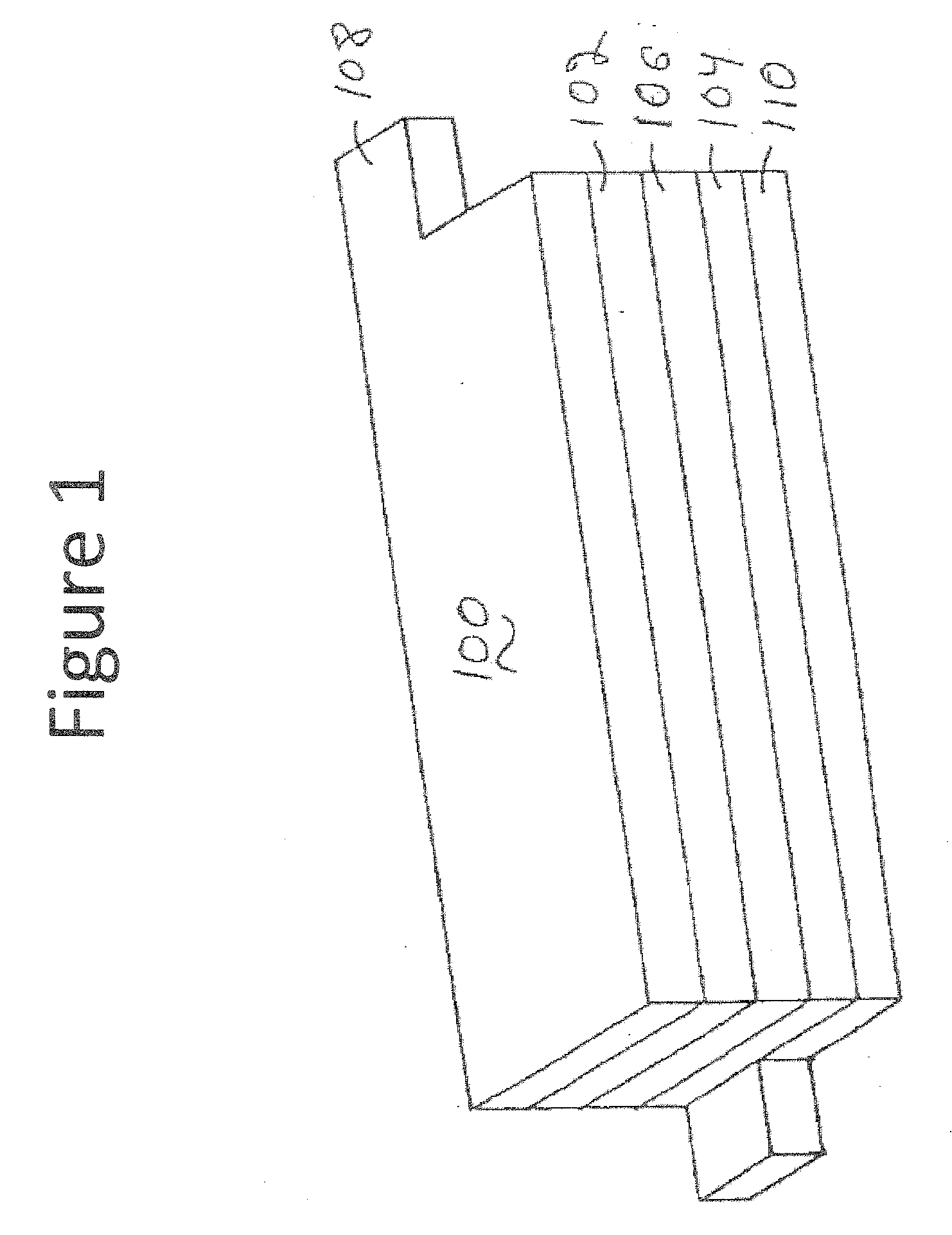

Long life thin film battery and method therefor

InactiveUS6994933B1Extend battery lifeSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsOxygen fluxSurface roughness

A thin film battery including an anode layer, a cathode layer and a solid electrolyte layer. The battery also includes, a planarization layer applied to the thin film battery. The planarization layer has a surface roughness of no more than about 1.0 nanometers root mean square and a flatness no larger than about 0.005 cm / inch. A barrier layer is applied to the planarization layer. The barrier layer is provided by one or more layers of material selected from the group consisting of polymeric materials, metals and ceramic materials. The planarization layer and barrier layer are sufficient to reduce oxygen flux through the barrier layer to the anode layer to no more than about 1.6 μmol / m2-day, and H2O flux through the barrier layer to the anode layer to less than about 3.3 μmol / m2-day thereby improving the life of the thin film battery.

Owner:OAK RIDGE MICRO ENERGY

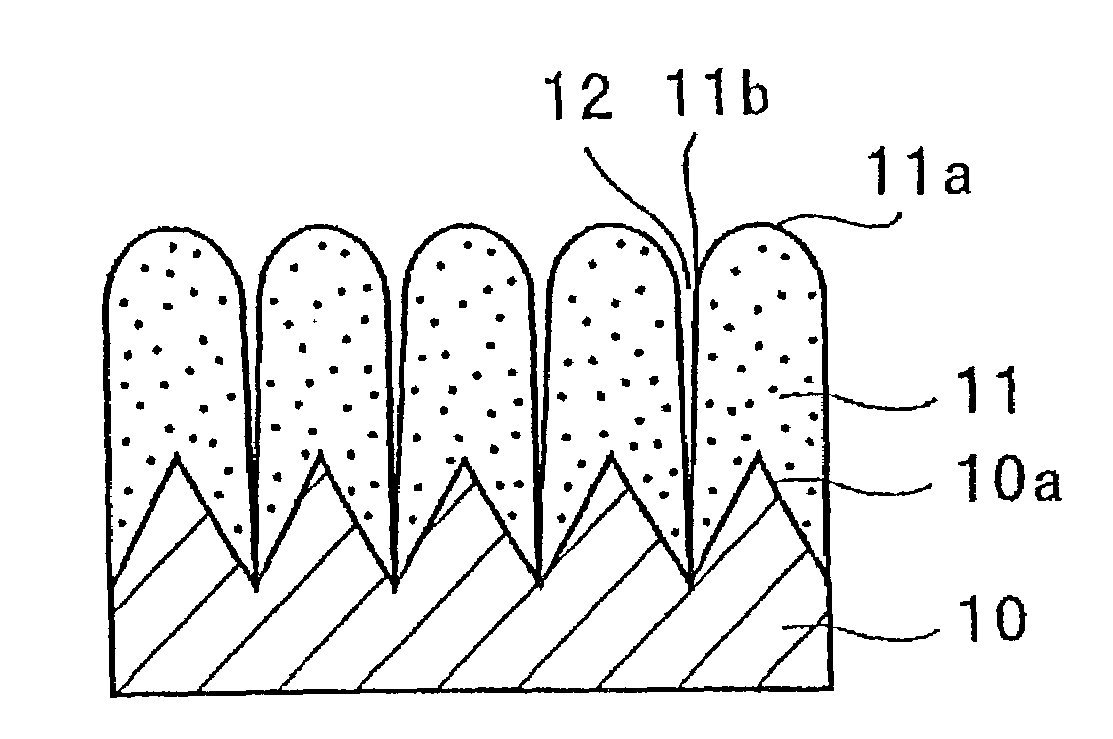

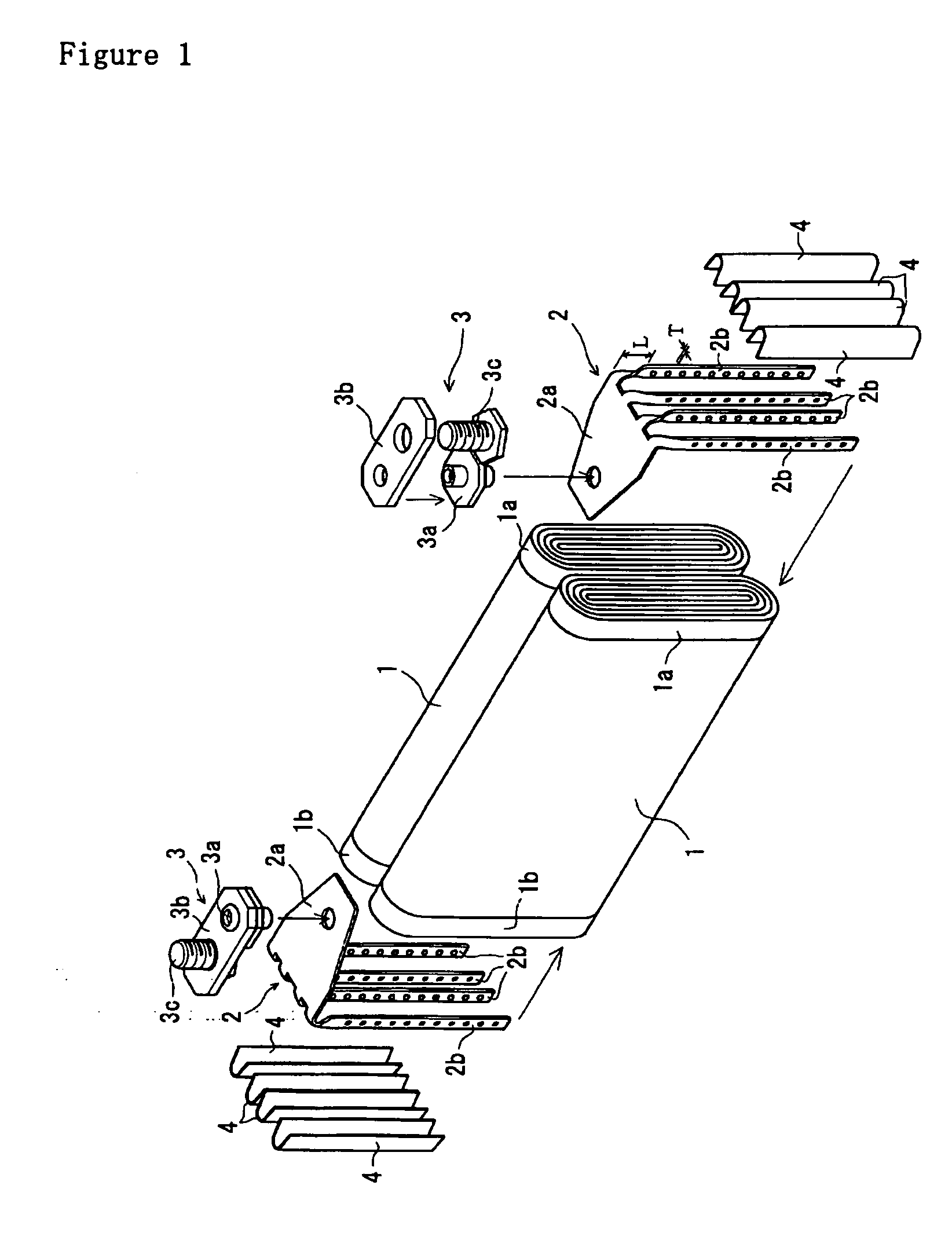

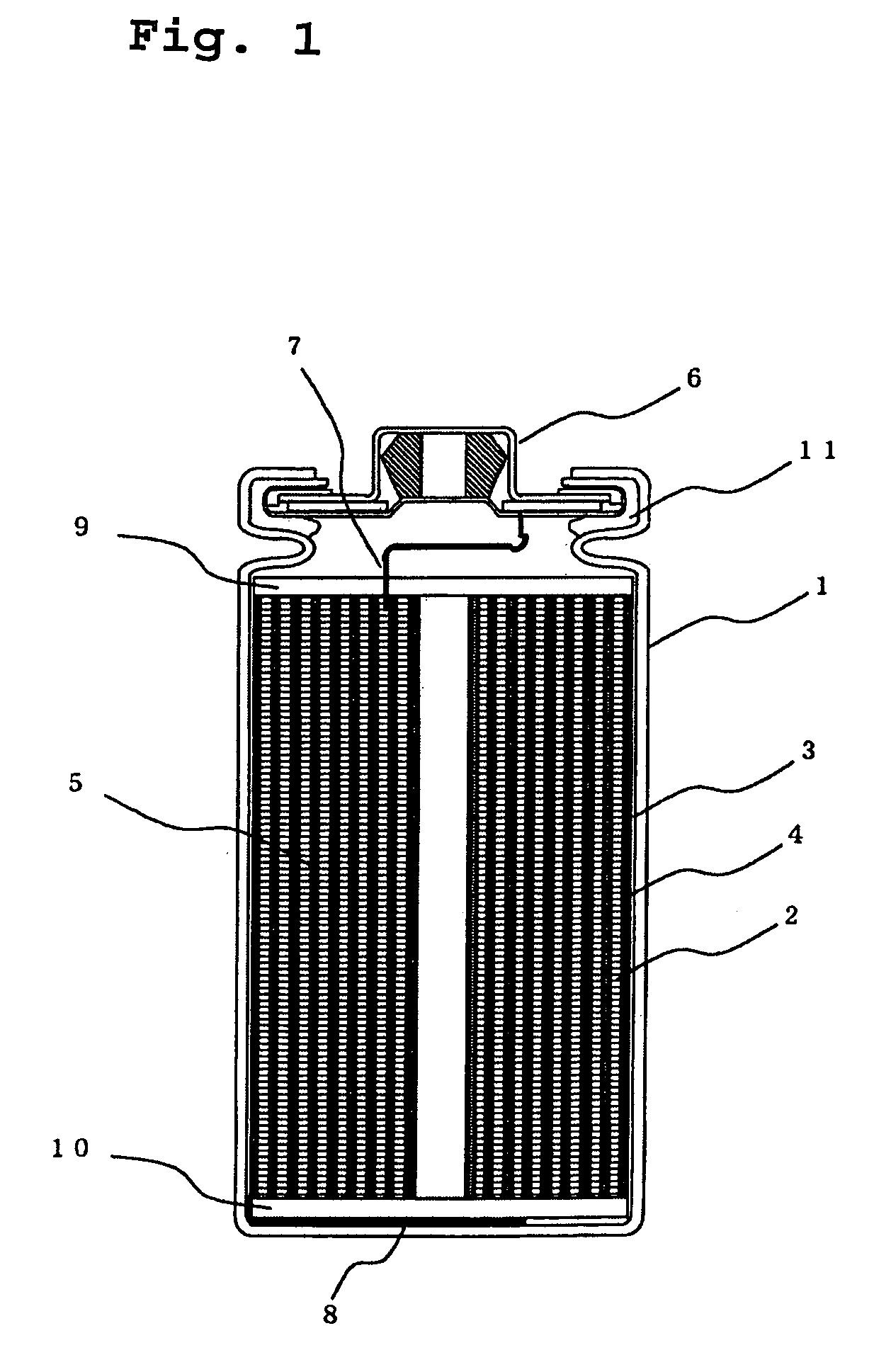

Battery

ActiveUS20060051664A1Simple working processImprove reliabilityFinal product manufactureActive material electrodesMetal foilEngineering

The metal foil of the positive electrode 1a or the negative electrode 1b in the power generating element 1 is connected along the connecting plate portion 2b which is folded, twisted, and provided in a protruding condition from the main portion 2a of the current-collector connector 2; hence the shape of the current-collector connector 2 becomes easy to form, and a battery capable of enhancing current collection efficiency, reliability and workability can be provided.

Owner:GS YUASA INT LTD

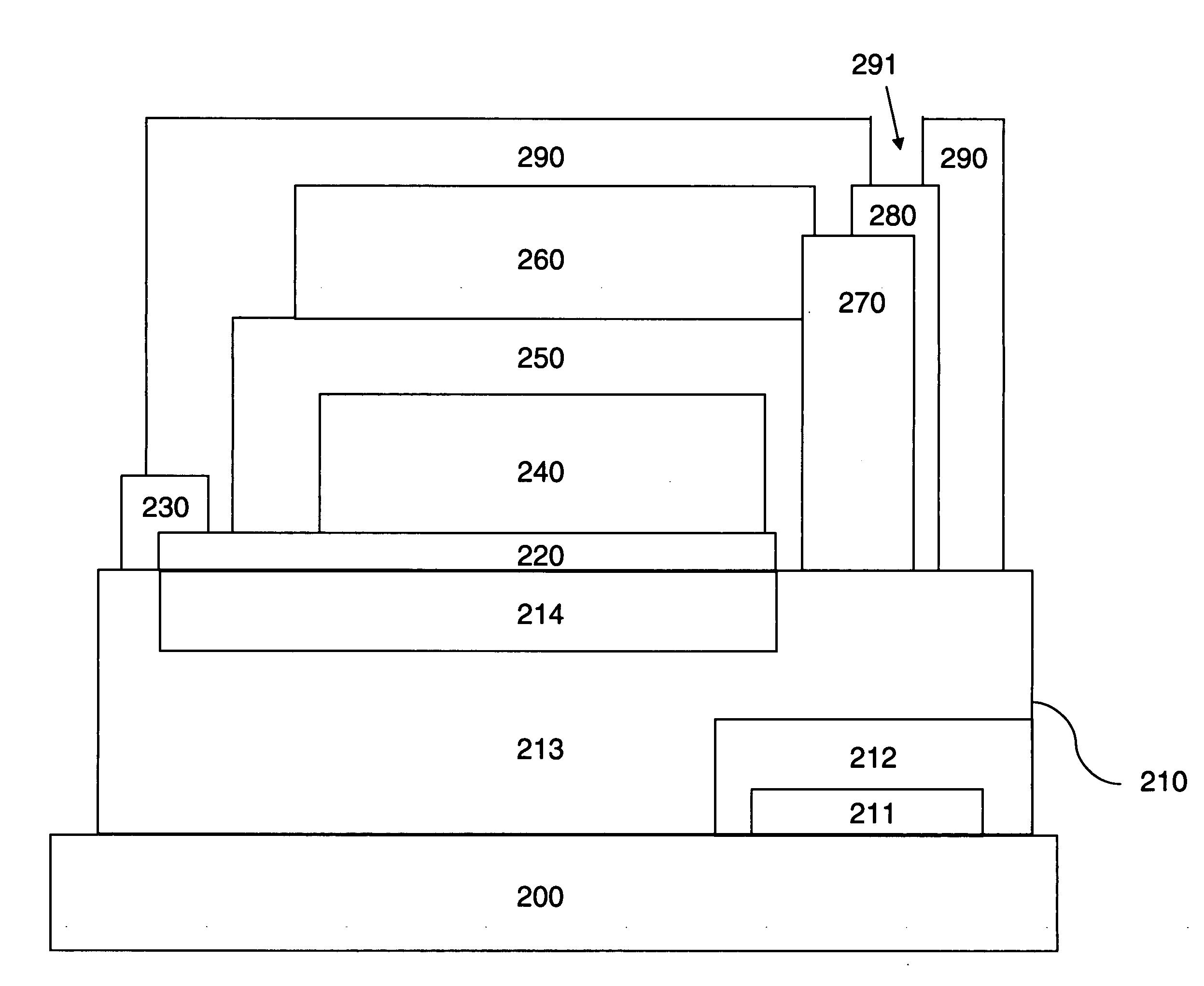

Electrochemical apparatus with barrier layer protected substrate

ActiveUS20060286448A1Inhibited DiffusionEfficient separationFinal product manufactureElectrode carriers/collectorsElectrochemistrySilicon

The present invention relates to apparatus, compositions and methods of fabricating high performance thin-film batteries on metallic substrates, polymeric substrates, or doped or undoped silicon substrates by fabricating an appropriate barrier layer composed, for example, of barrier sublayers between the substrate and the battery part of the present invention thereby separating these two parts chemically during the entire battery fabrication process as well as during any operation and storage of the electrochemical apparatus during its entire lifetime. In a preferred embodiment of the present invention thin-film batteries fabricated onto a thin, flexible stainless steel foil substrate using an appropriate barrier layer that is composed of barrier sublayers have uncompromised electrochemical performance compared to thin-film batteries fabricated onto ceramic substrates when using a 700° C. post-deposition anneal process for a LiCoO2 positive cathode.

Owner:SAPURAST RES

Method of manufacturing solid electrolyte battery

InactiveUS20050132562A1High trafficAvoid excessive power outputNon-aqueous electrolyte accumulatorsFinal product manufacturePolymer electrolytesBattery cell

A method of manufacturing a solid electrolyte battery includes a step of thermally pressing a composite layer including a positive electrode ink layer, an electrolyte ink layer and a negative electrode ink layer that are formed by coating a positive electrode ink, an electrolyte ink and a negative electrode ink. Further, the positive electrode ink, the electrolyte ink and the negative electrode ink contain a polymer electrolyte. By this method, it is possible to improve the flow of ions across respective interlayers of a positive electrode active material layer, a solid electrolyte layer and a negative electrode active material layer.

Owner:NISSAN MOTOR CO LTD

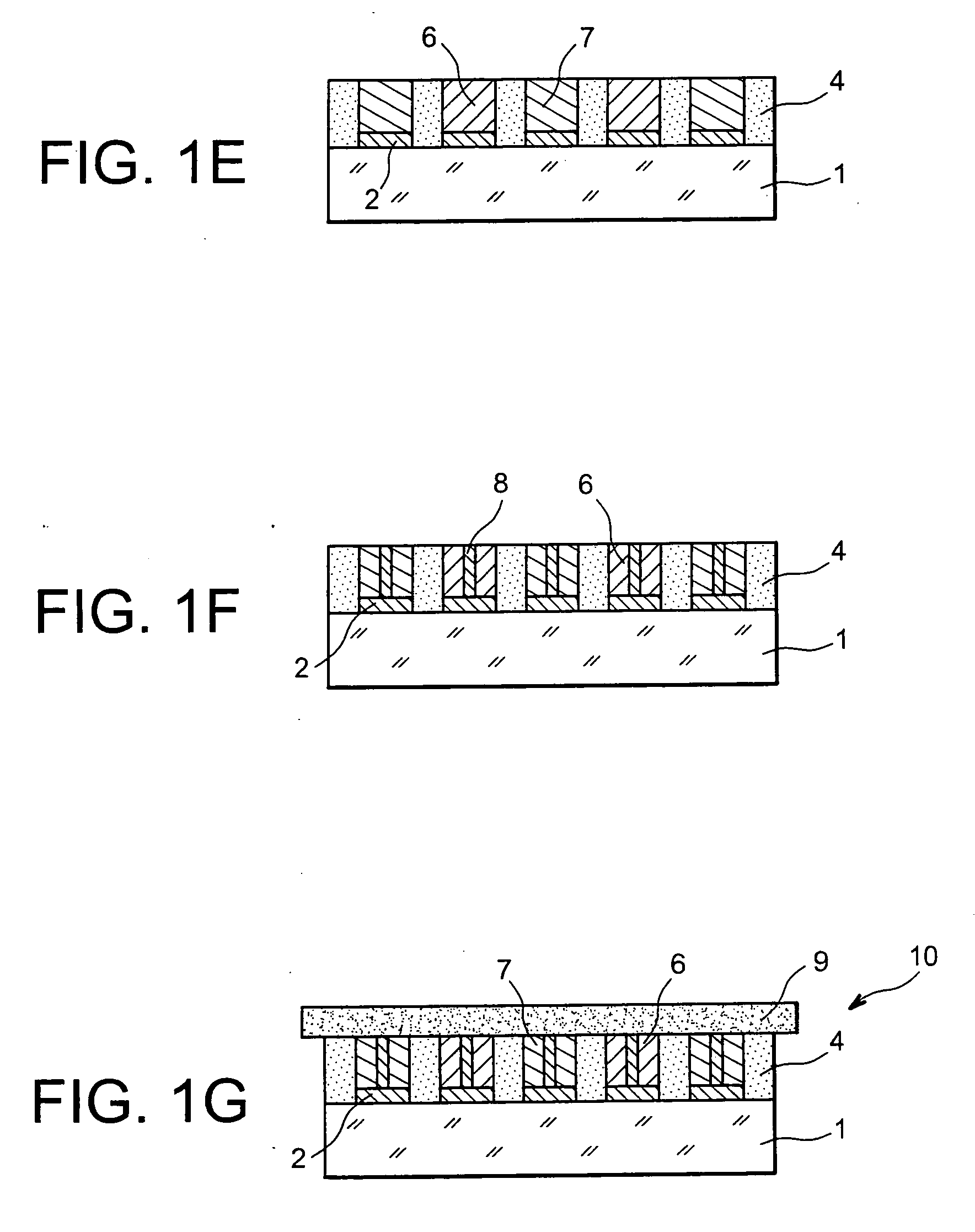

Layered barrier structure having one or more definable layers and method

InactiveUS20050147877A1Reduce transmissionLow rateFuel and primary cellsElectrode manufacturing processesDielectricLithium compound

A system provides an environmental barrier also useful for providing a circuit, for example, one having a thin-film battery such as one that includes lithium or lithium compounds connected to an electronic circuit. An environmental barrier is deposited as alternating layers, at least one of the layers providing a smoothing, planarizing, and / or leveling physical-configuration function, and at least one other layer providing a diffusion-barrier function. The layer providing the physical-configuration function may include a photoresist, a photodefinable, an energy-definable, and / or a maskable layer. The physical-configuration layer may also be a dielectric. A layered structure, including a plurality of pairs of layers, each pair including a physical configuration layer and a barrier layer with low gas-transmission rates, may be used in reducing gas transmission rate to beyond currently detectable levels.

Owner:CYMBET CORP

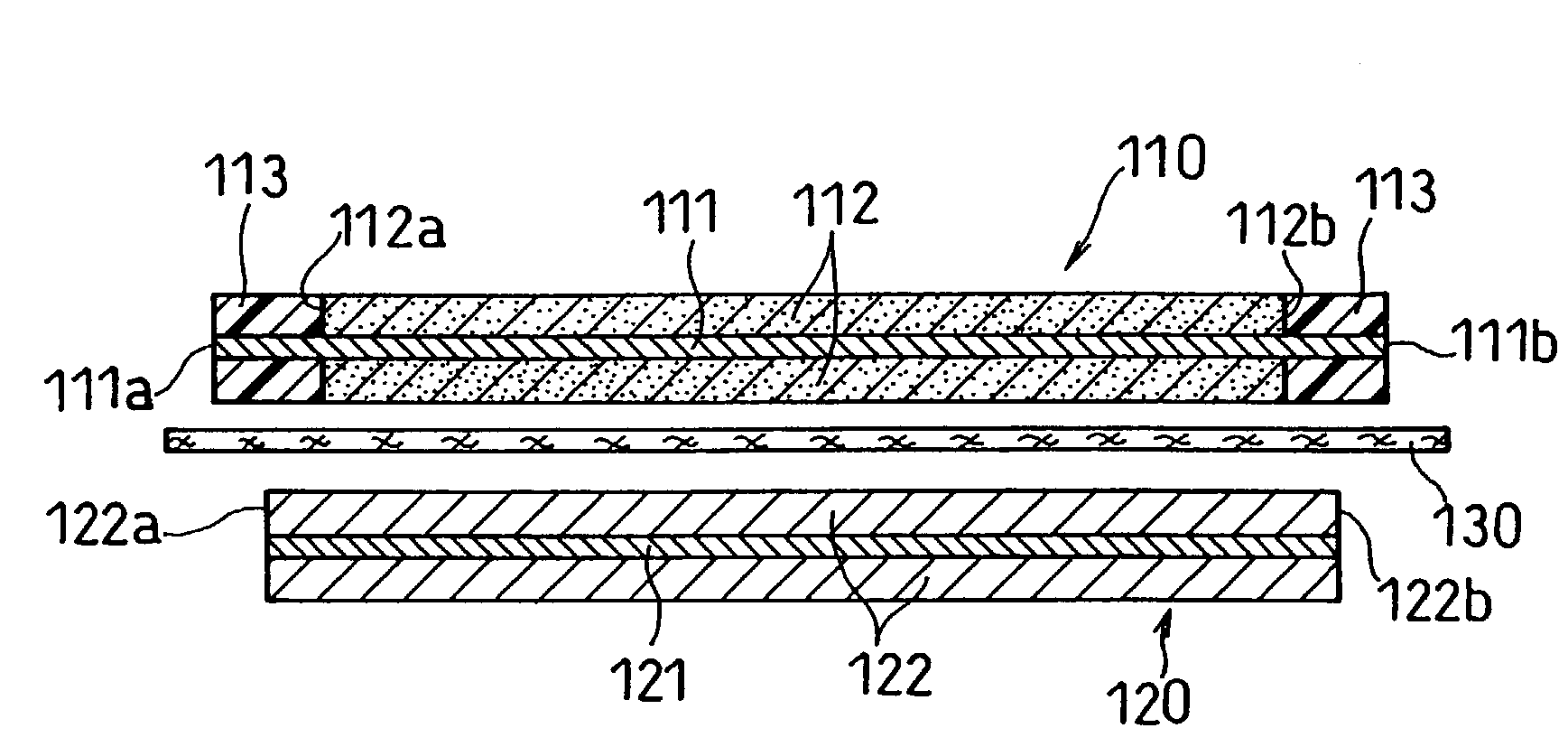

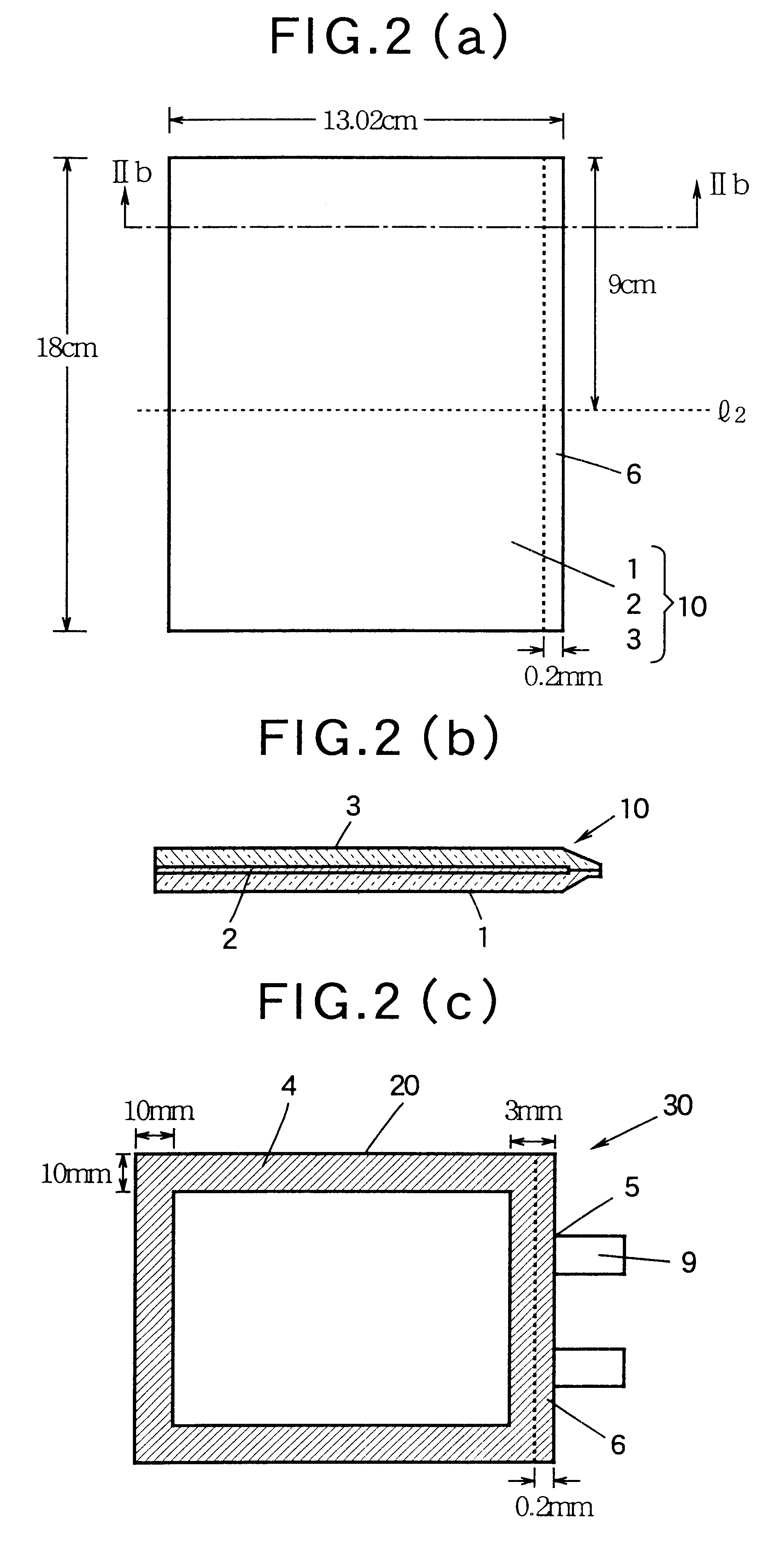

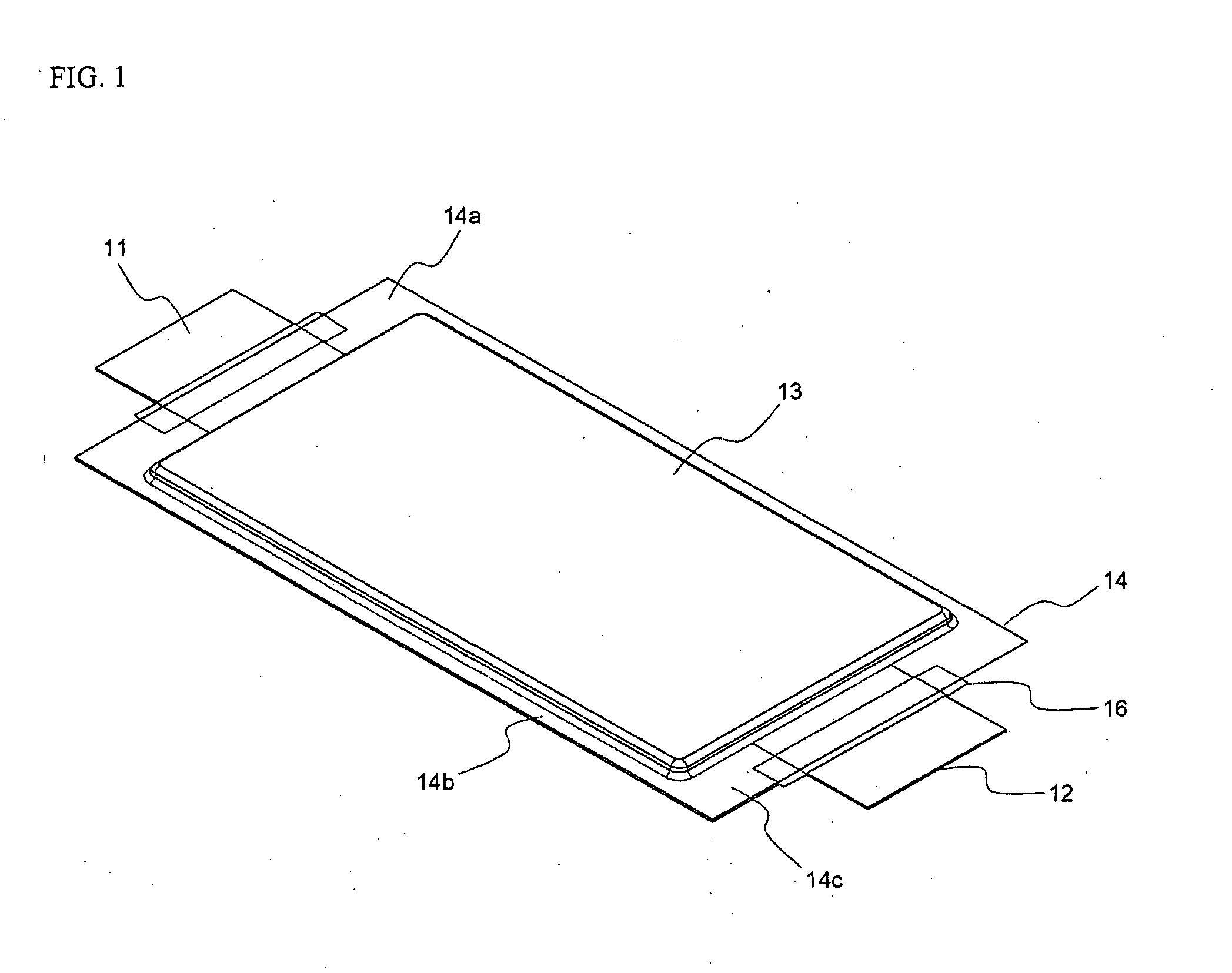

Non-aqueous battery of a thin configuration

InactiveUS6461757B1Small-sized cells cases/jacketsActive material electrodesMetallic foilElectrical battery

A non-aqueous battery is provided in a pouchy casing comprising opposing sheets of at least three-layer laminates, each laminate comprising (1) an inner thermoplastic resin layer, (2) a middle metal foil layer, and (3) an outer electrically insulating material layer, wherein the pouchy casing has an elongated, hermetic adhesion area along a periphery of the pouchy casing, and the middle metal foil layer has a peripheral elongated region in the elongated, hermetic adhesion area of the pouchy casing, and at least a pair of terminals electrically connected to the cathode and anode of the battery extends through and protrudes from the terminal-withdrawal sites in the elongated, hermetic adhesion area toward the outside of the pouchy casing, and the battery has at least one of the following features: (i) the peripheral elongated region of the middle metal foil layer has cut-out portions around the terminal-withdrawal sites and (ii) the surface of the peripheral edge of the pouchy casing is provided with electric insulation at least at portions around the terminal-withdrawal sites.

Owner:ASAHI KASEI ELECTRONICS CO LTD

Secondary battery

ActiveUS20060024578A1Reduced durabilityIncreased durabilityCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesElectrical and Electronics engineeringElectrode

A secondary battery comprising an electrode assembly having a positive electrode plate, a negative electrode plate, and a separator between the positive and negative electrodes is provided. The secondary battery further comprises a case for containing the electrode assembly, and a cap assembly connected to the case. The cap assembly comprises positive and negative terminals electrically connected to the positive electrode plate and the negative electrode plate, respectively. Lead connectors are electrically connected to the positive and negative electrode plates and the positive and negative terminals. A support is connected to each end of the electrode assembly and surrounds the lead connectors. The supports are adapted to fit between the electrode assembly and the case.

Owner:SAMSUNG SDI CO LTD

Solid state activity-activated battery device and method

InactiveUS6906436B2Sufficient energy storageBatteries circuit arrangementsFinal product manufactureEngineeringElectron

A system includes a thin-film battery and an activity-activated switch. The system is placed on a substrate with an adhesive backing. In some embodiments, the substrate is flexible. Also formed on the substrate is an electrical circuit that includes electronics. The activity-activated switch places the thin-film battery in electrical communication with the circuit and electronics. The battery and the circuit are formed on the substrate and may be comprised of one or a plurality of deposited layers.

Owner:CYMBET CORP

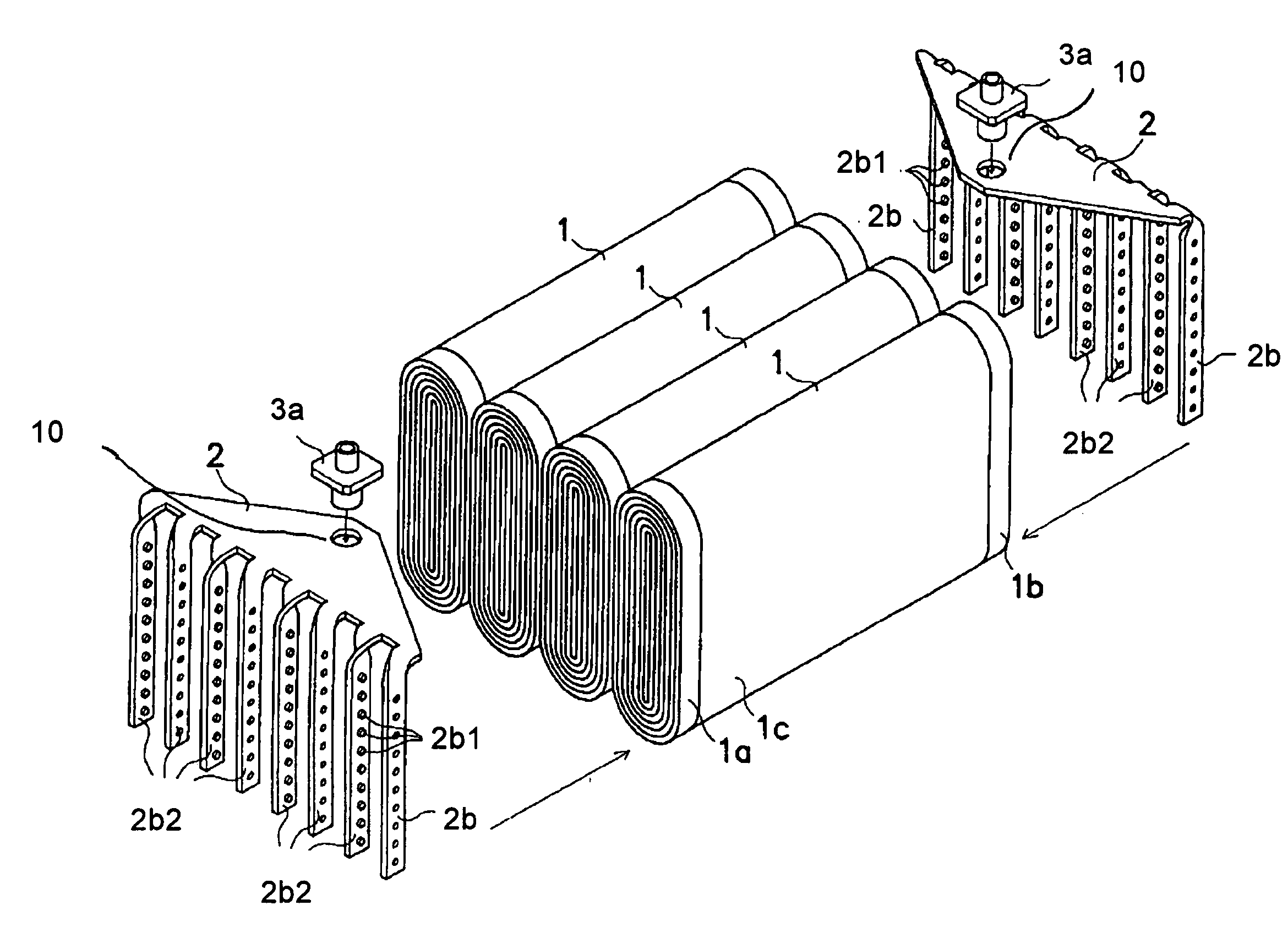

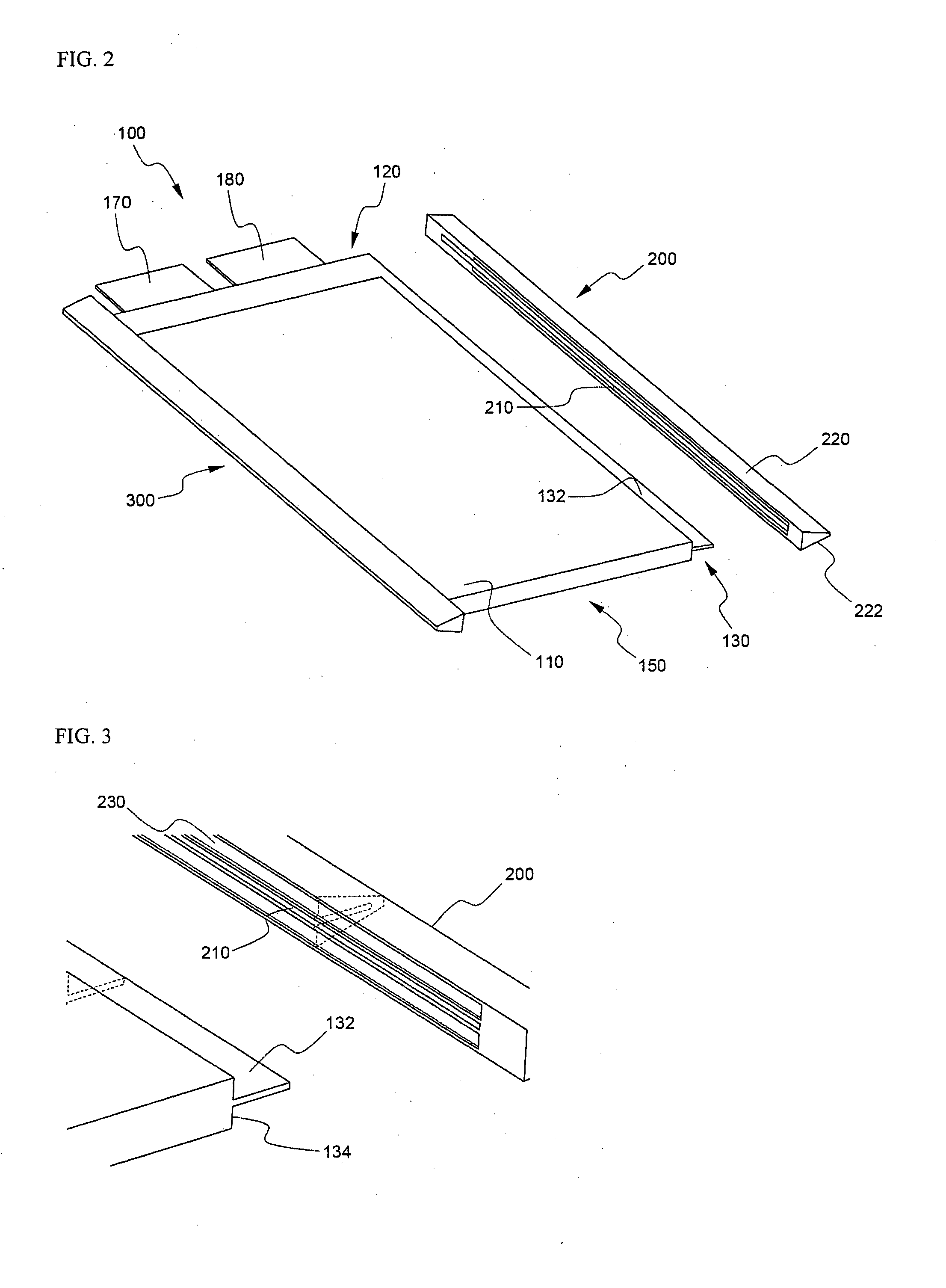

Secondary battery and battery module having the same

ActiveUS20070207377A1Increase productionLarge capacityLarge-sized flat cells/batteriesSmall-sized cells cases/jacketsElectricityElectrical battery

Disclosed herein are a secondary battery, which is formed in the shape of a plate and has an electrode assembly mounted in a battery case made of a laminated sheet including a metal layer and a resin layer, wherein the secondary battery is constructed in a structure in which independent coupling type frame members are mounted to the outside part of a sheathing member serving as the battery case, and a medium- or large-sized battery module including the same as a unit cell. Consequently, the secondary battery has a high mechanical strength and a large sealing force. Furthermore, the electrical connection is accomplished without bending the electrode leads. Also, the battery module, which is constructed with the secondary battery as a unit cell, can be manufactured with a compact structure and a relatively light weight. Furthermore, the assembly process of the battery module is greatly simplified. The structural stability of the battery module according to the present invention is very high, and therefore, the battery module can be preferably used as a power source for electric vehicles, hybrid electric vehicles, electric motor cycles, and electric bicycles.

Owner:LG ENERGY SOLUTION LTD

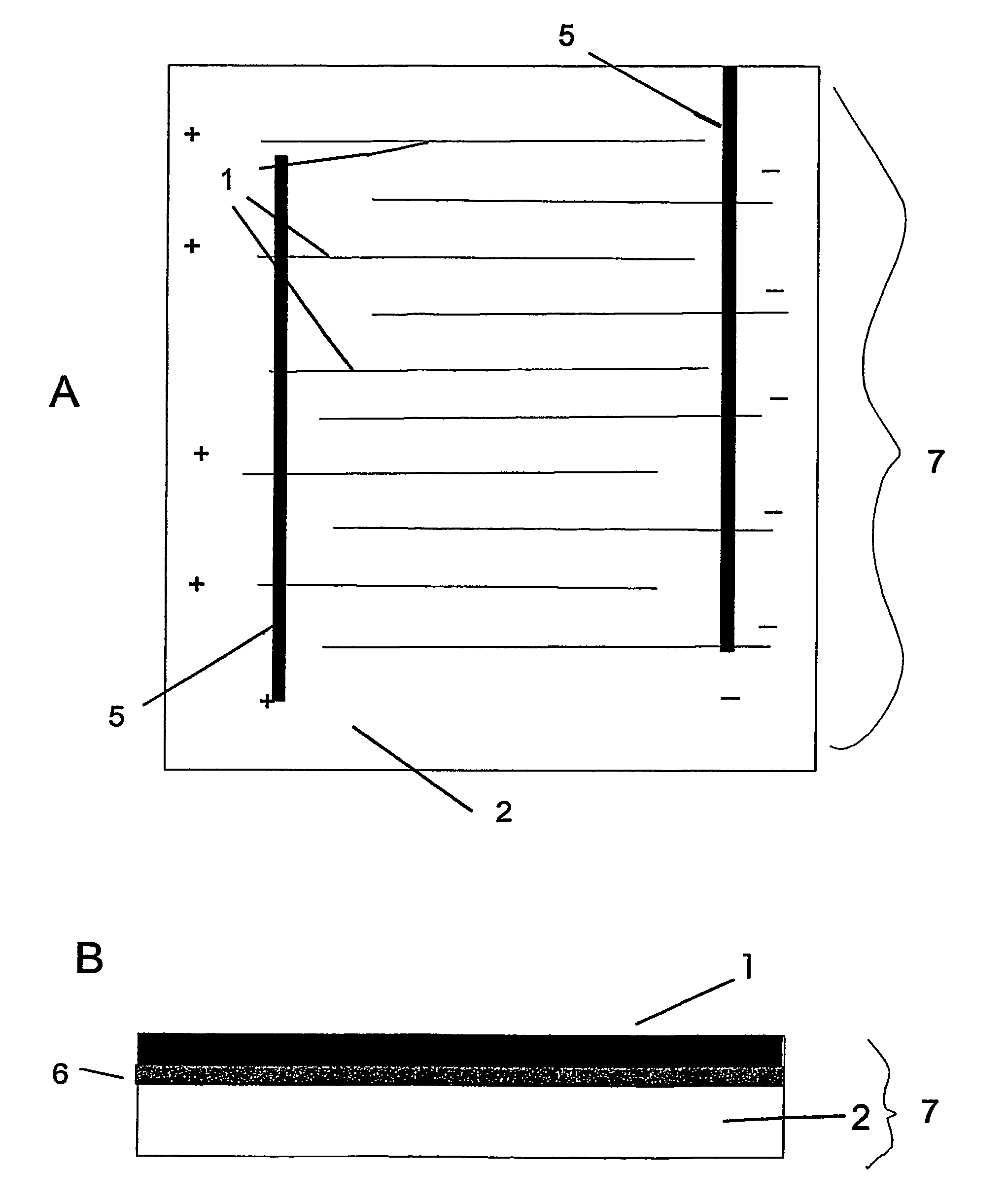

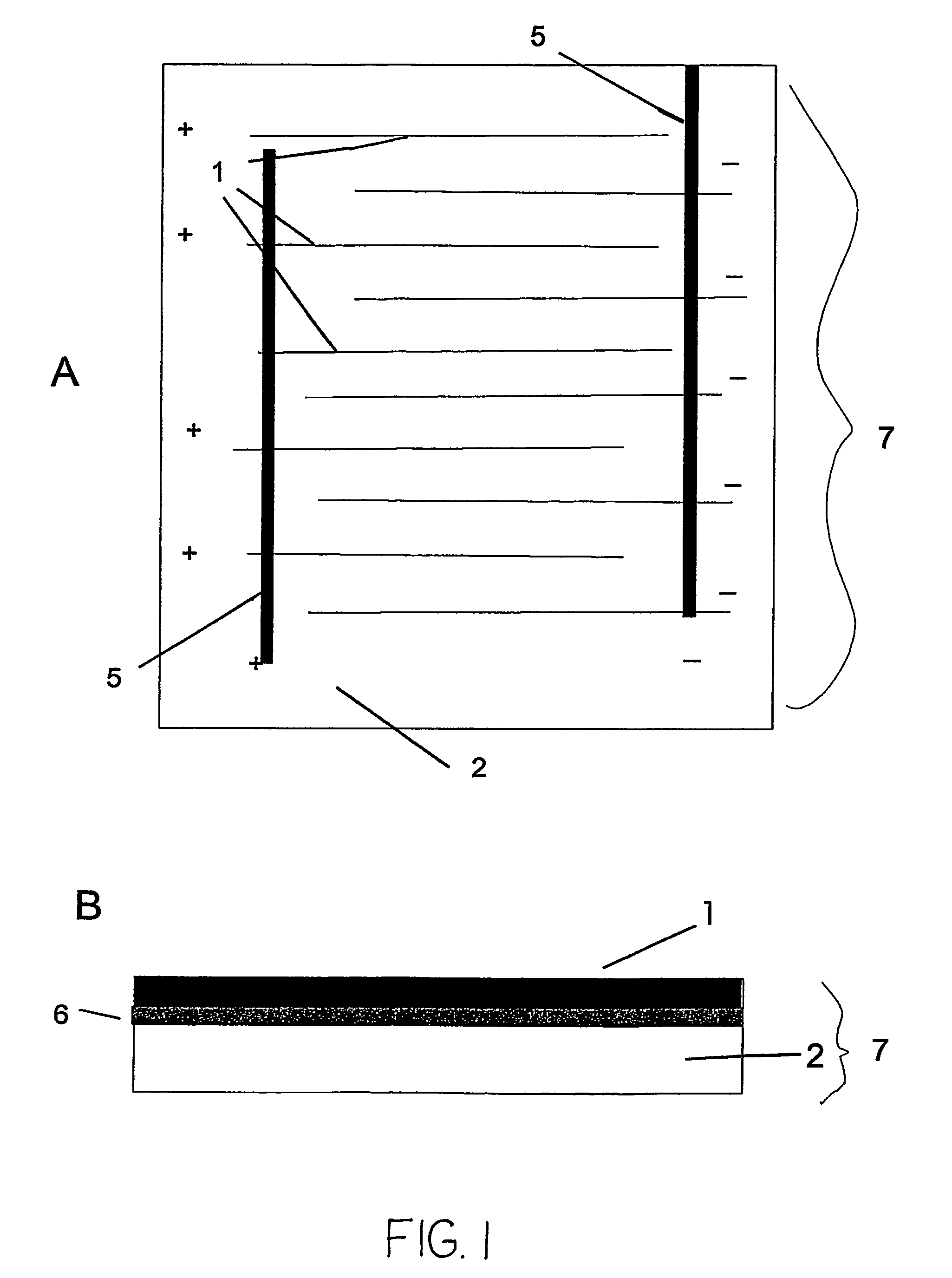

Electrode array for use in electrochemical cells

InactiveUS7368191B2Reduce leakageReduced series resistanceFinal product manufactureFuel cell auxillariesFuel cellsEngineering

The invention features an electrode array (7) in which pairs of electrodes (1) are geometrically arranged so that the broadest faces of the exposed electrodes are not directly opposing to each other. Rather, the broadest facing surfaces of the electrodes in the array are parallel, adjacent, or offset at an angle. The electrode geometry of an electrode array of the invention permits electrodes to be in close proximity, thereby lowering series resistance, while minimizing the possibility for short circuits that can cause electrical leakage. An electrode array of the invention can be used in an electrochemical cell, such as a battery, e.g., a lithium battery, a capacitor, a flow-through capacitor, or a fuel cell.

Owner:BIOSOURCE INC

High Energy Lithium Ion Secondary Batteries

Lithium ion secondary batteries are described that have high total energy, energy density and specific discharge capacity upon cycling at room temperature and at a moderate discharge rate. The improved batteries are based on high loading of positive electrode materials with high energy capacity. This capability is accomplished through the development of positive electrode active materials with very high specific energy capacity that can be loaded at high density into electrodes without sacrificing performance. The high loading of the positive electrode materials in the batteries are facilitated through using a polymer binder that has an average molecular weight higher than 800,000 atomic mass unit.

Owner:IONBLOX INC

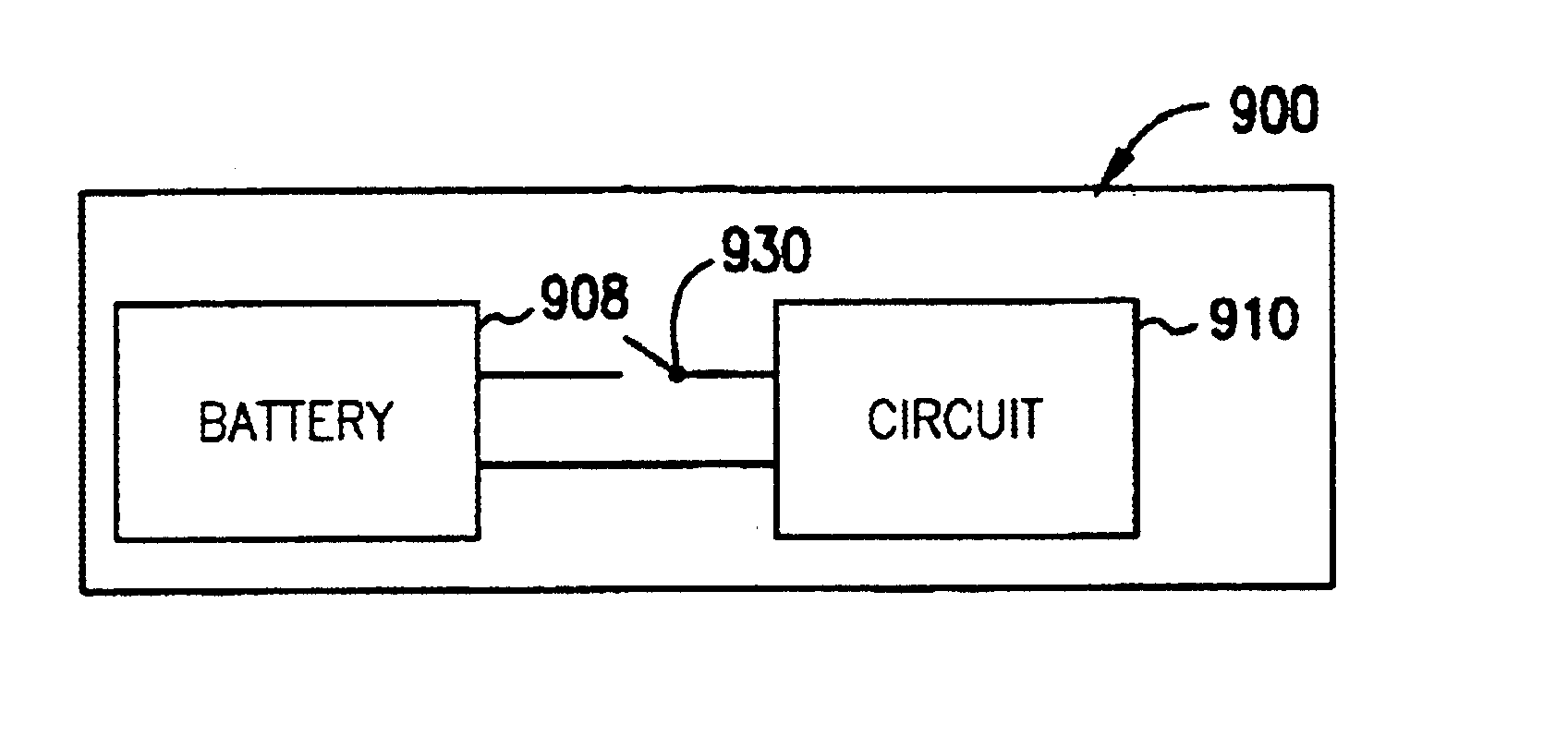

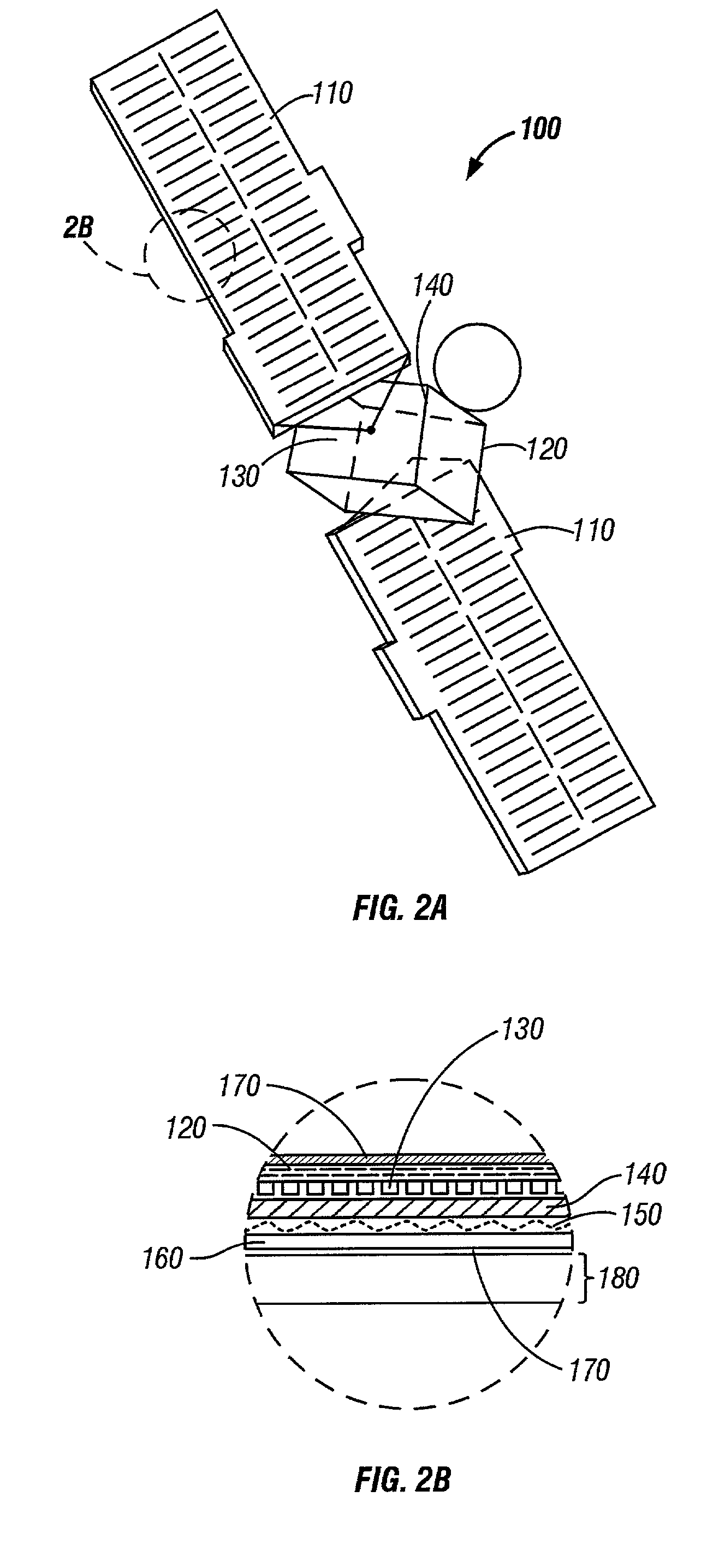

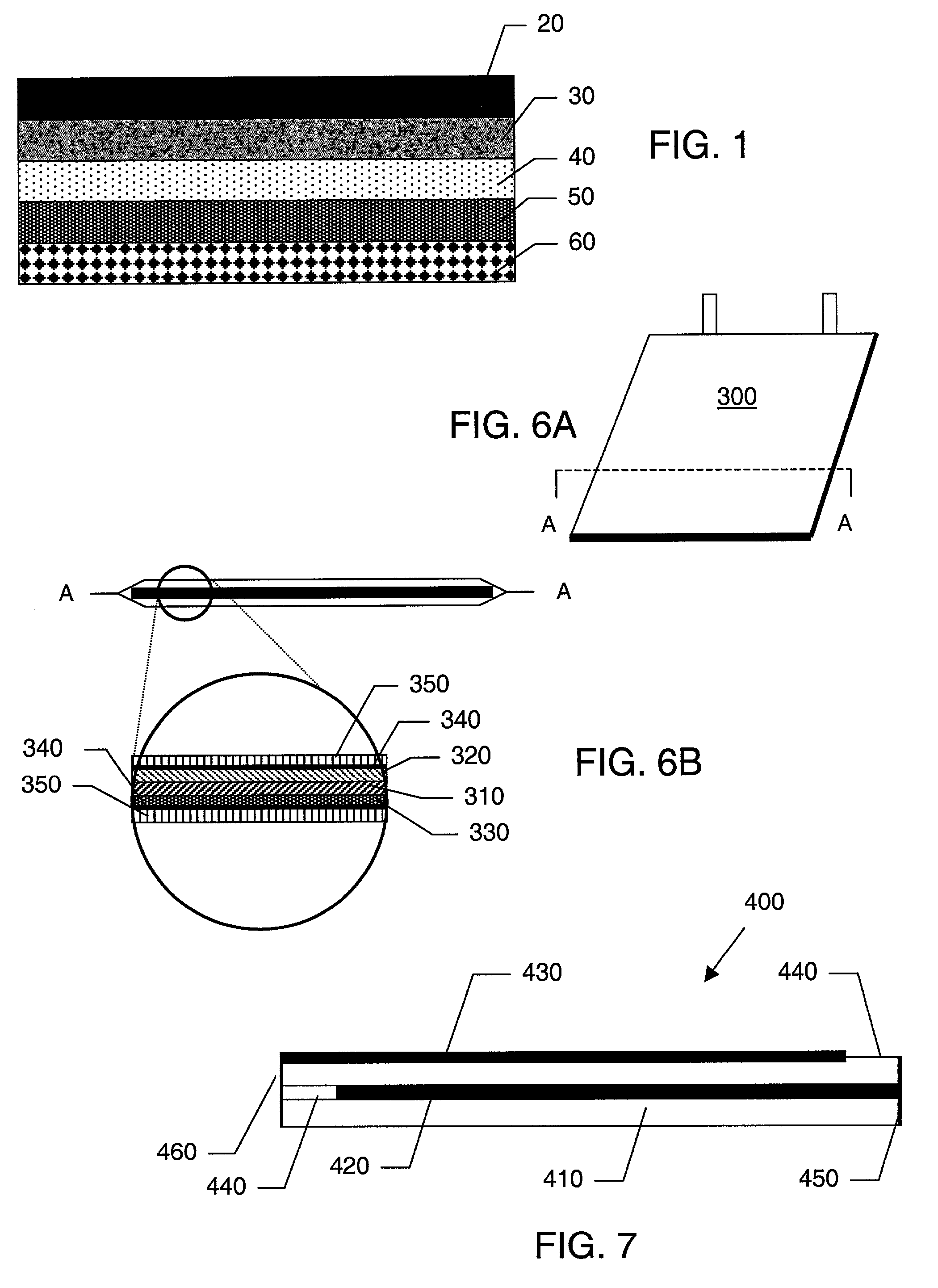

Structurally embedded intelligent power unit

InactiveUS7150938B2Increase capacityImprove power performanceBatteries circuit arrangementsCell temperature controlElectric power systemEngineering

An electrical power system for a spacecraft or other vehicle or structure comprising a structural member containing an integrated solid-state power source is disclosed. The power source includes a solar cell system and an energy storage system that are combined into a single unit or package, and in certain embodiments, are configured into the shape of a flexible aerobot balloon or a rigid nanosat surface panel. The power components of a preferred lightweight power unit, include thinly layered photovoltaic cells, a rechargeable lithium solid polymer electrolyte battery, a capacitor, electronics and thermal management capability.

Owner:LITHIUM POWER TECH

Lithium secondary battery

InactiveUS20090087731A1Improve charge-discharge cycle performanceCell electrodesSecondary cellsSilicon alloyComposite oxide

A lithium secondary battery includes: a positive electrode having a positive electrode active material layer disposed on a positive electrode current collector, the positive electrode active material layer containing a positive electrode binder and a positive electrode active material containing a layered lithium-transition metal composite oxide; a negative electrode having a negative electrode current collector and a negative electrode active material layer disposed on the negative electrode current collector, the negative electrode active material layer containing a negative electrode binder and a negative electrode active material containing particles of silicon and / or a silicon alloy; and a non-aqueous electrolyte. Al2O3 particles are firmly adhered to a surface of the lithium-transition metal composite oxide so that a BET specific surface area of the positive electrode active material after the adherence of the Al2O3 particles is from 1.5 times to 8 times greater than that before the adherence of the Al2O3 particles

Owner:SANYO ELECTRIC CO LTD

Lithium ion polymer electrolytes

InactiveUS6413676B1Prevent kinkingAvoid deformationElectrode manufacturing processesFinal product manufacturePorosityCross-link

A dimensionally stable, highly resilient, hybrid copolymer solid-solution electrolyte-retention film for use in a lithium ion battery in one preferred embodiment has a predominantly amorphous structure and mechanical strength despite contact with liquid solvent electrolyte. The film is a thinned (stretched), cast film of a homogeneous blend of two or more polymers, one of which is selected for its pronounced solvent retention properties. A very high surface area inorganic filler dispersed in the blend during formation thereof serves to increase the porosity of the film and thereby enhance electrolyte retention. The film is soaked in a solution of liquid polymer with liquid organic solvent electrolyte and lithium salt, for absorption thereof. Use of a cross-linked liquid polymer enhances trapping of molecules of the electrolyte into pores of the film. The electrolyte film is sandwiched between flexible active anode and cathode layers to form the lithium ion battery. Novel methods are provided for forming the electrodes, the polymer substrate, and other elements of the battery.

Owner:LITHIUM POWER TECH

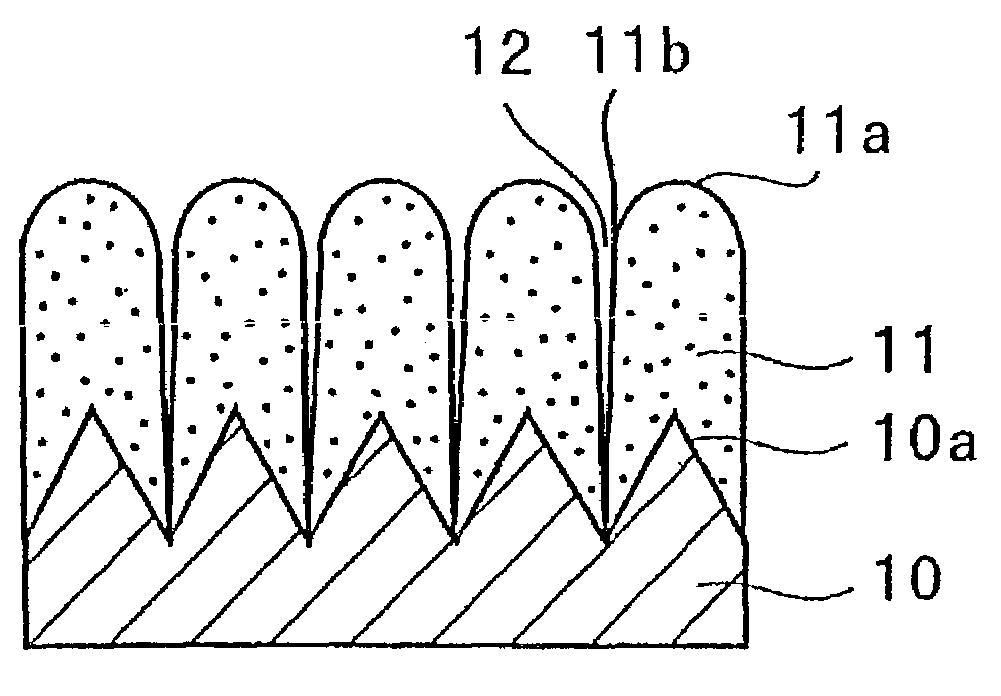

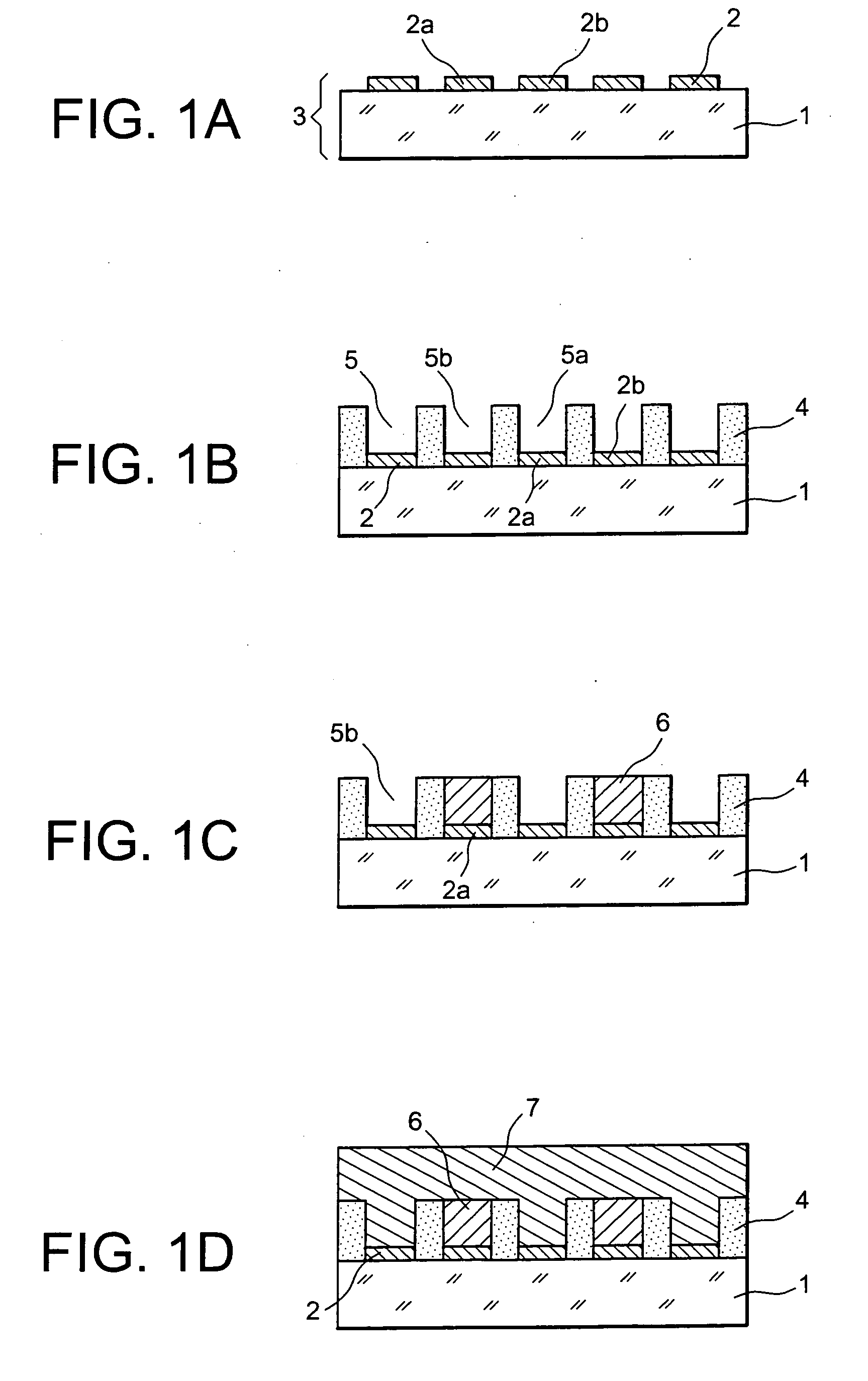

Structured electrolyte for micro-battery

InactiveUS20060154141A1Fine surfaceSolid electrolytesFinal product manufactureOptoelectronicsElectrolyte

In order to increase the capacity of an “all-solid” type micro-battery, the layer of electrolyte is structured: transversing cavities are created in the flat layer, advantageously at the level of patches of collector material, then filled by anode or cathode material.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Structurally embedded intelligent power unit

InactiveUS20030038610A1Batteries circuit arrangementsCell temperature controlElectric power systemEngineering

An electrical power system for a spacecraft or other vehicle or structure comprising a structural member containing an integrated solid-state power source is disclosed. The power source includes a solar cell system and an energy storage system that are combined into a single unit or package, and in certain embodiments, are configured into the shape of a flexible aerobot balloon or a rigid nanosat surface panel. The power components of a preferred lightweight power unit, include thinly layered photovoltaic cells, a rechargeable lithium solid polymer electrolyte battery, a capacitor, electronics and thermal management capability.

Owner:LITHIUM POWER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com