Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1190results about "Non-aqueous electrolyte cells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

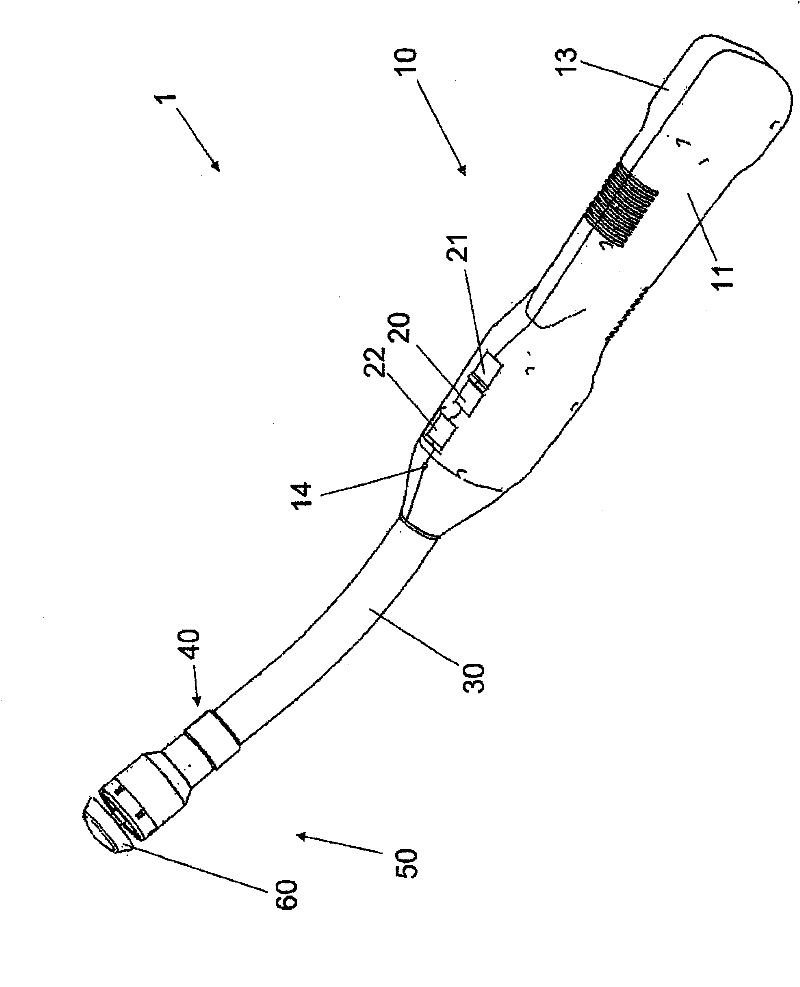

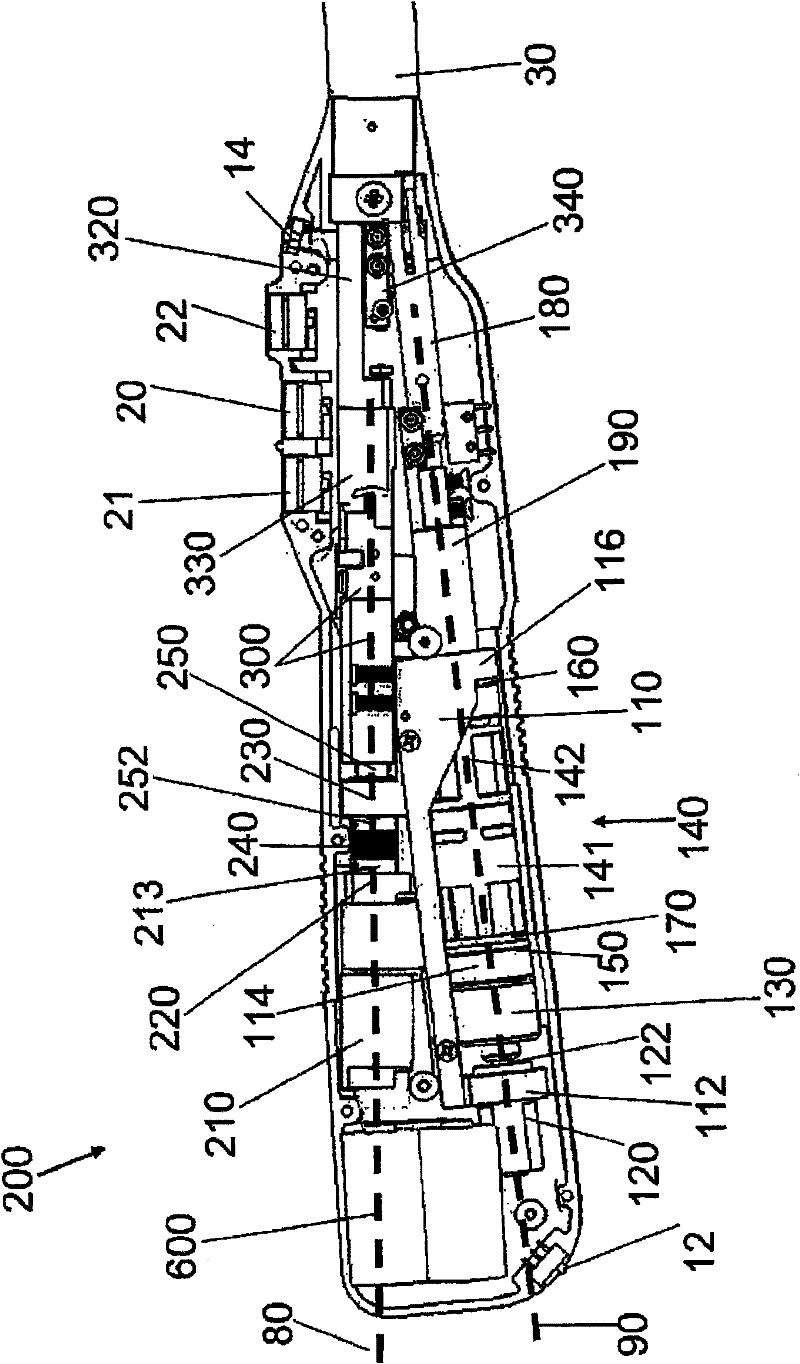

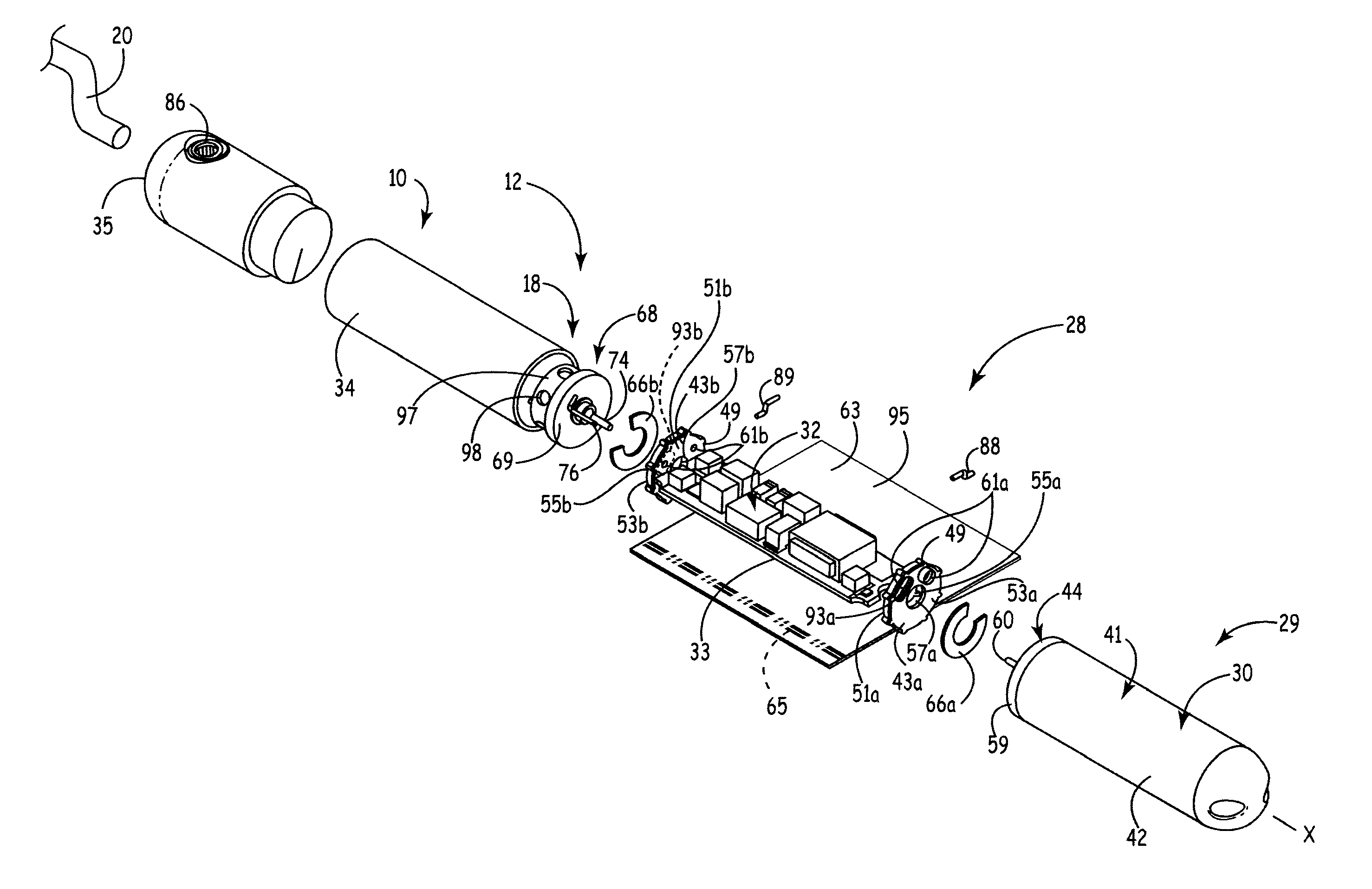

Electrical Surgical Instrument

A method for operating a surgical instrument includes mechanically coupling a manual release to a transmission of a surgical instrument having a self-contained power supply disposed entirely within a handle thereof. The transmission translates movement of an electrically powered motor inside the handle to movement of a part of a surgical end effector connected to the handle. The part is operable to move anywhere between a start position and a fully actuated position. The method further includes selectively interrupting the transmission with the manual release to move the part towards the start position independent of motor operation.

Owner:ETHICON ENDO SURGERY INC

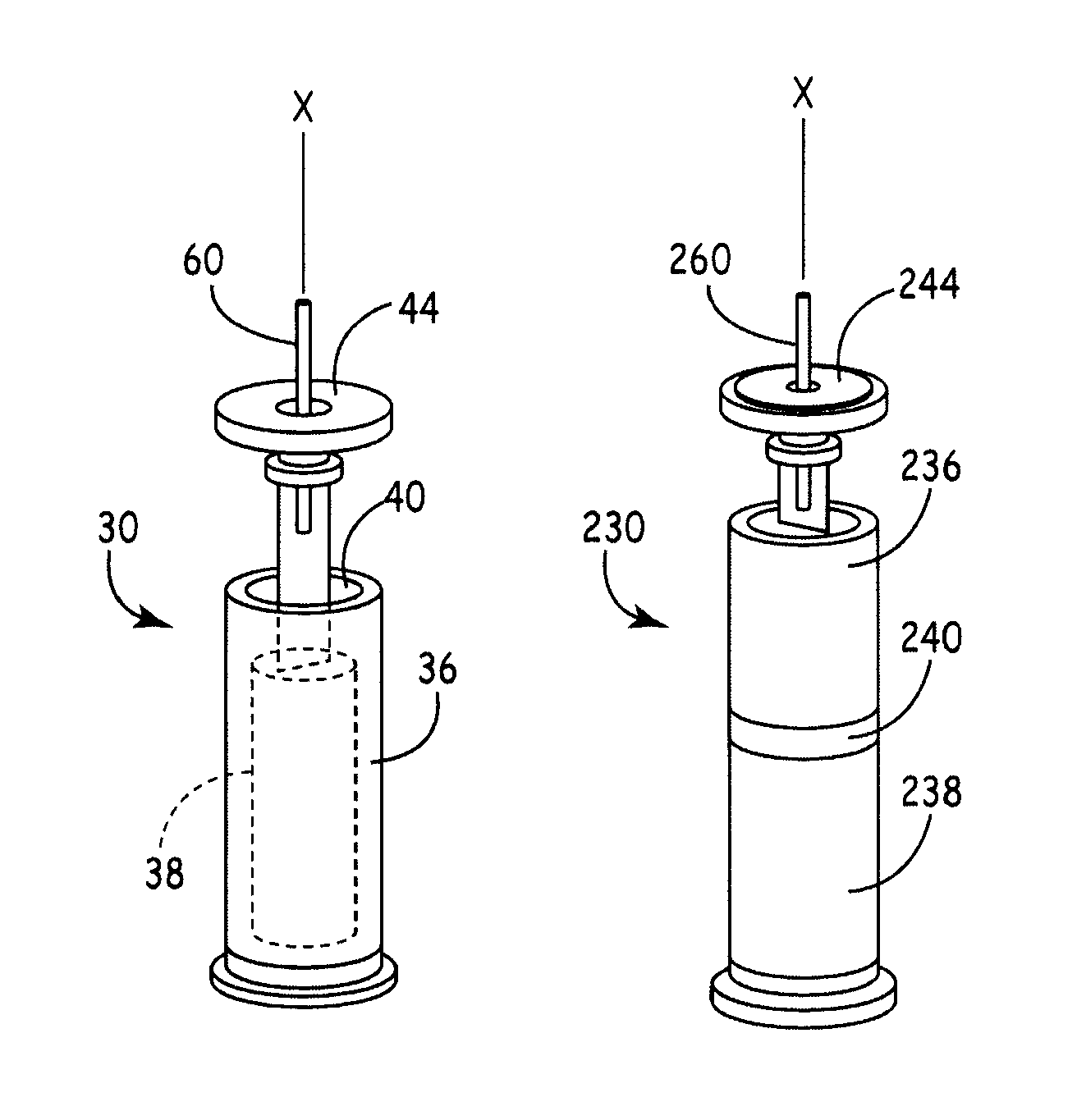

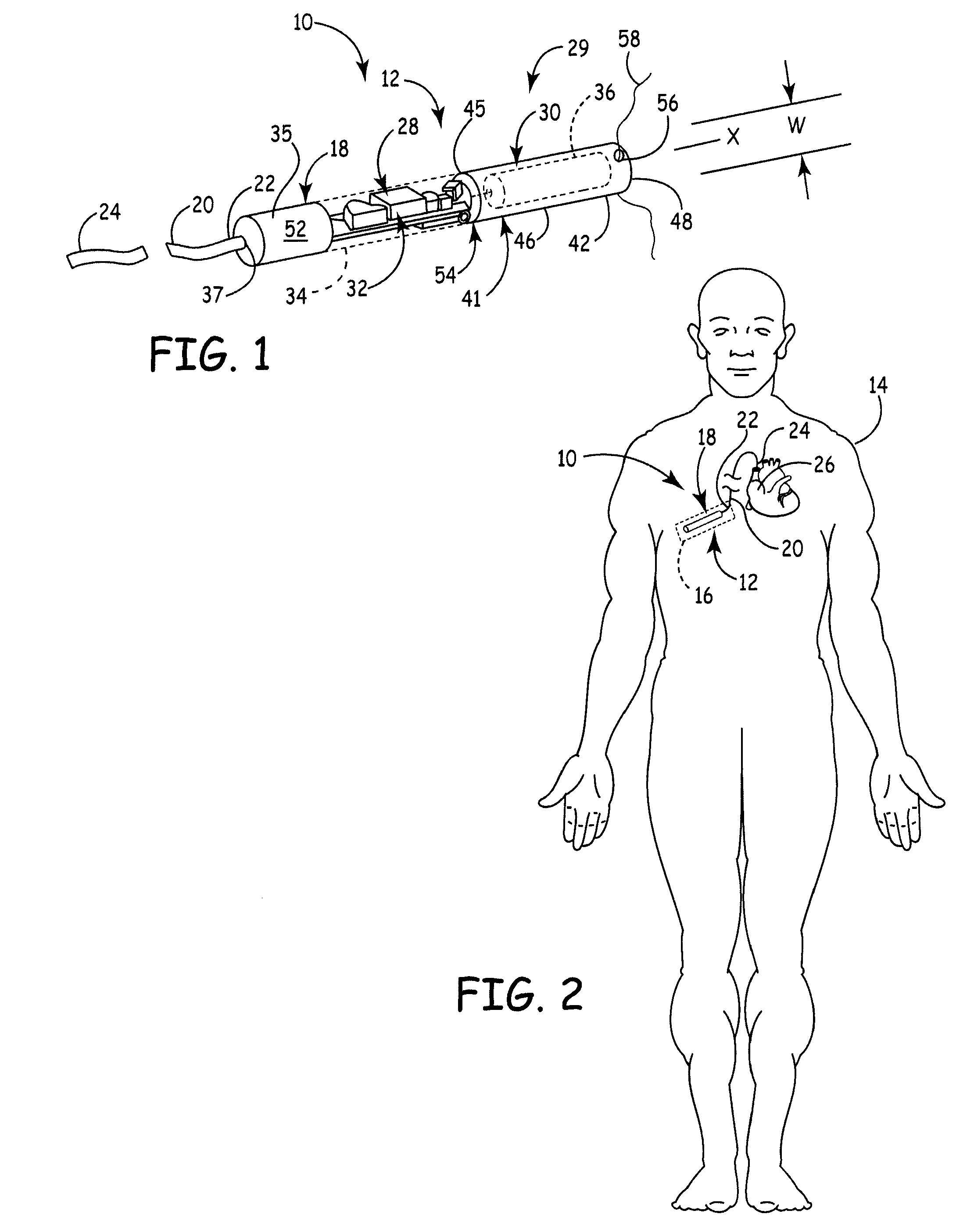

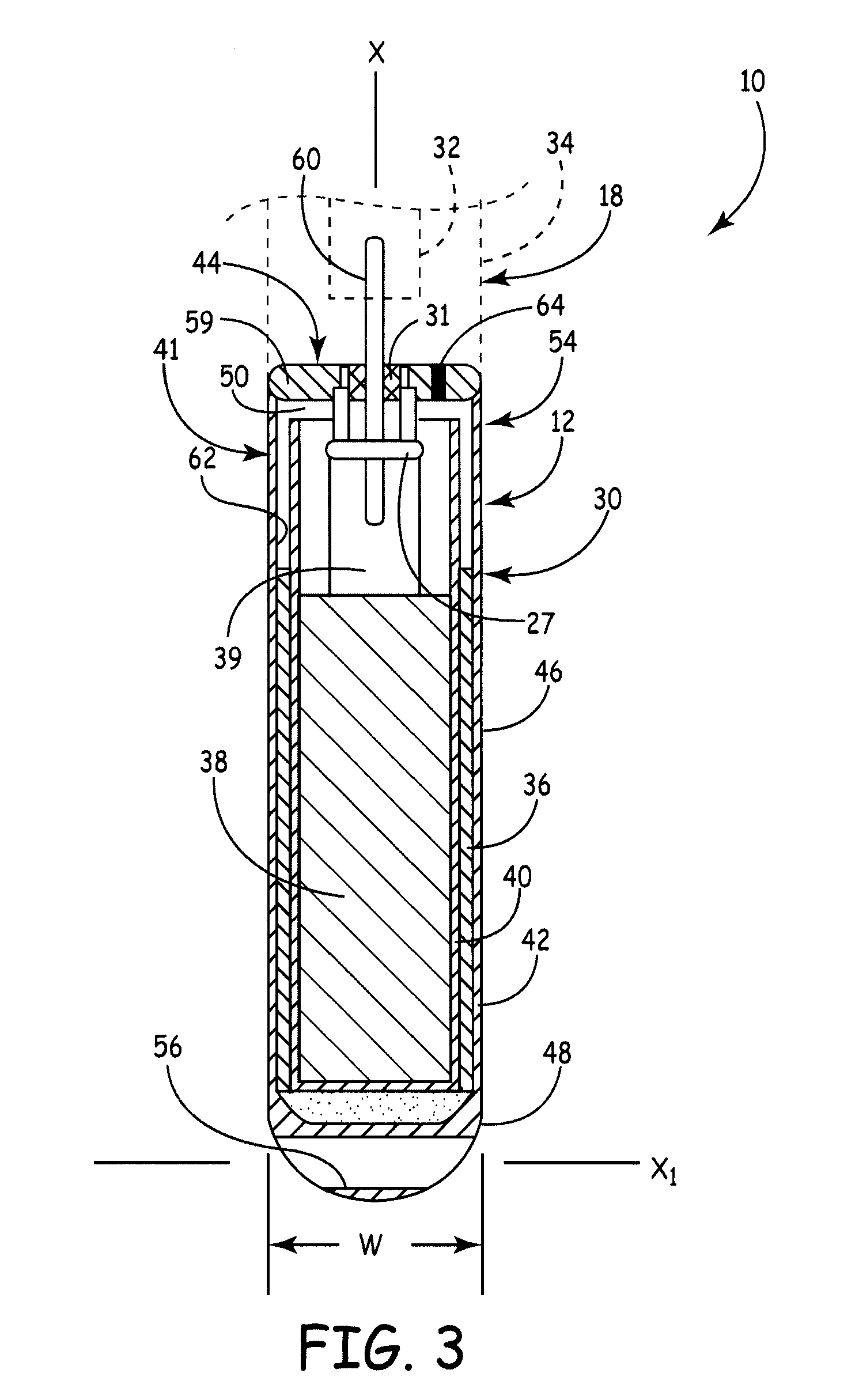

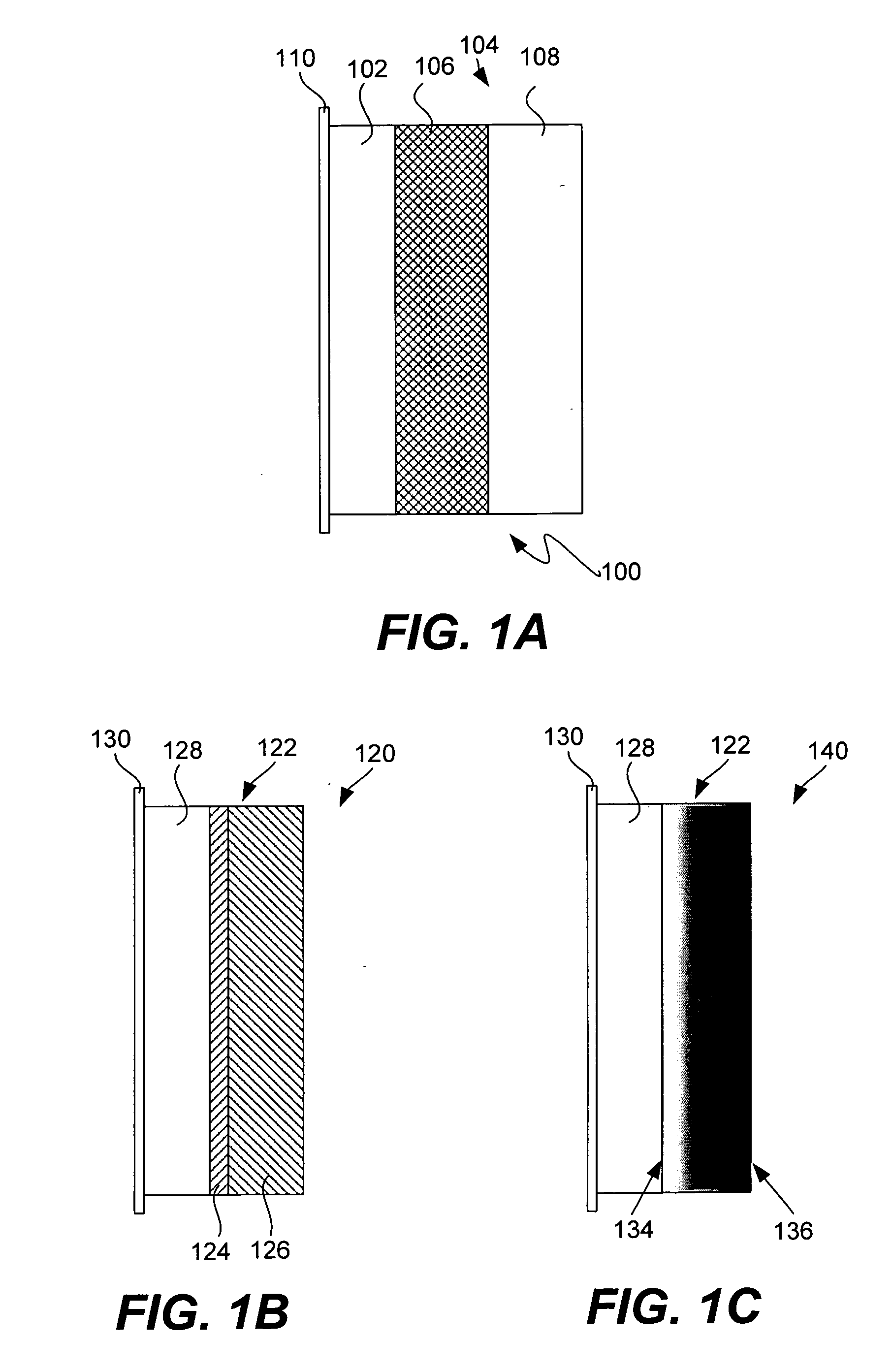

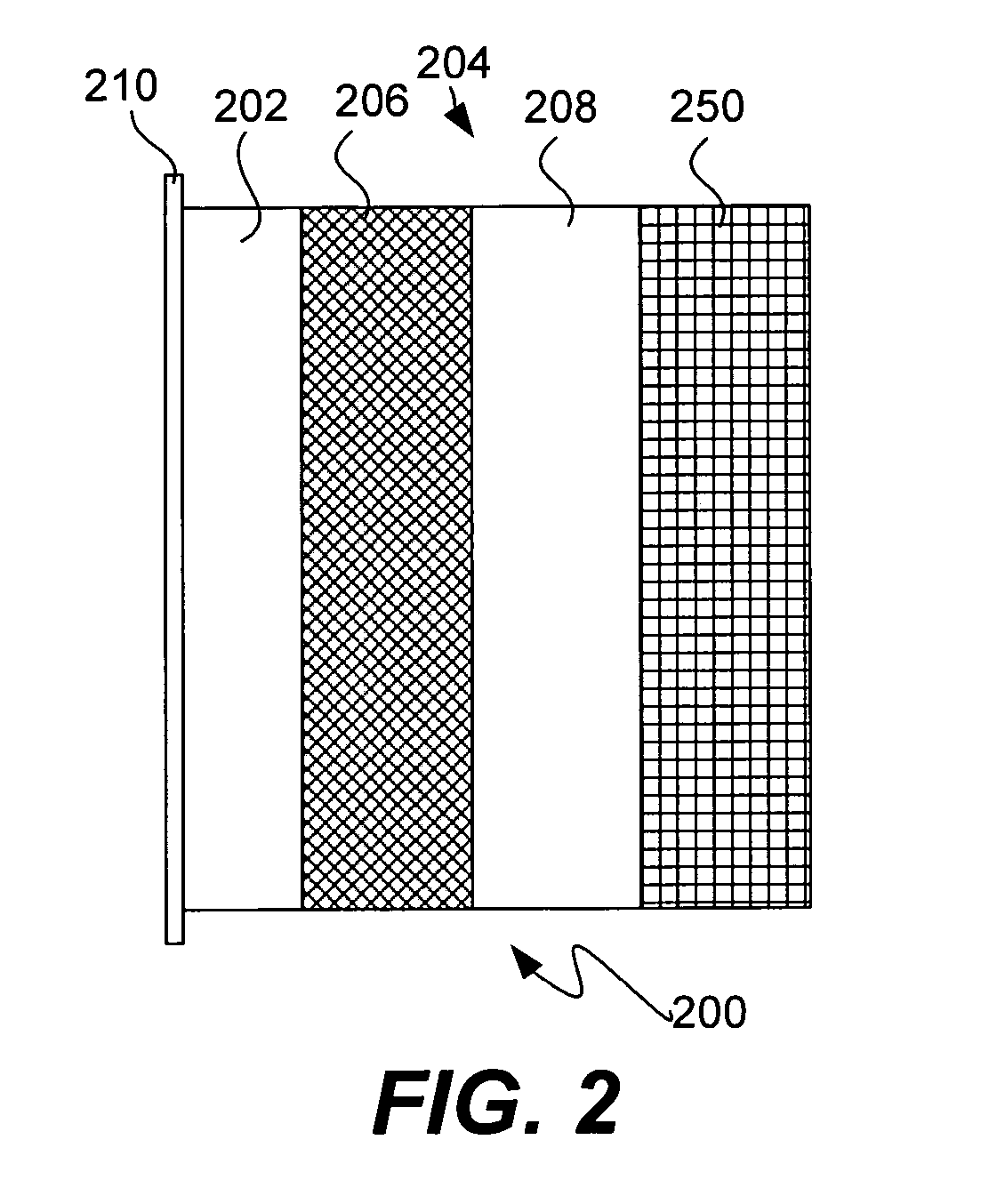

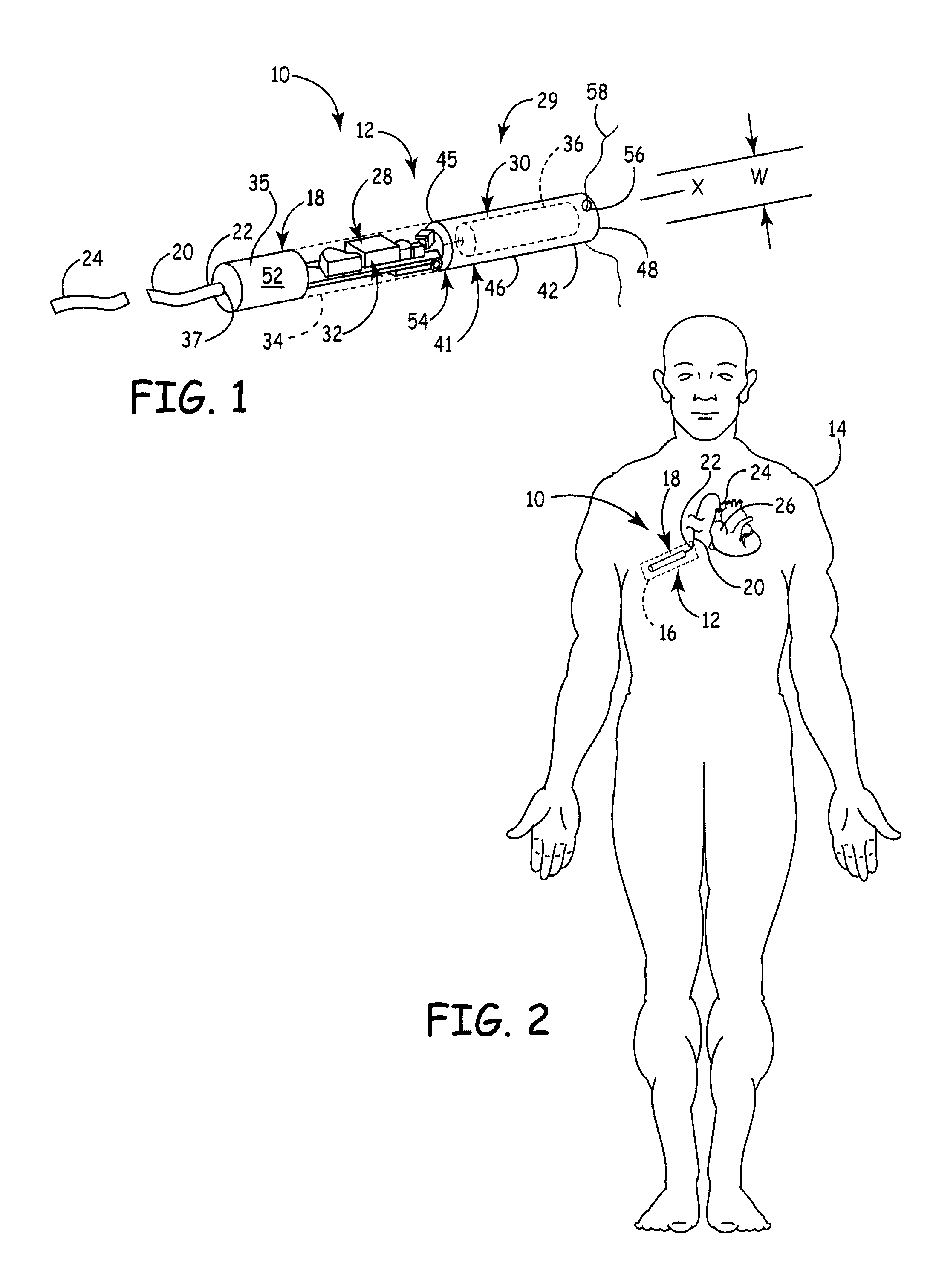

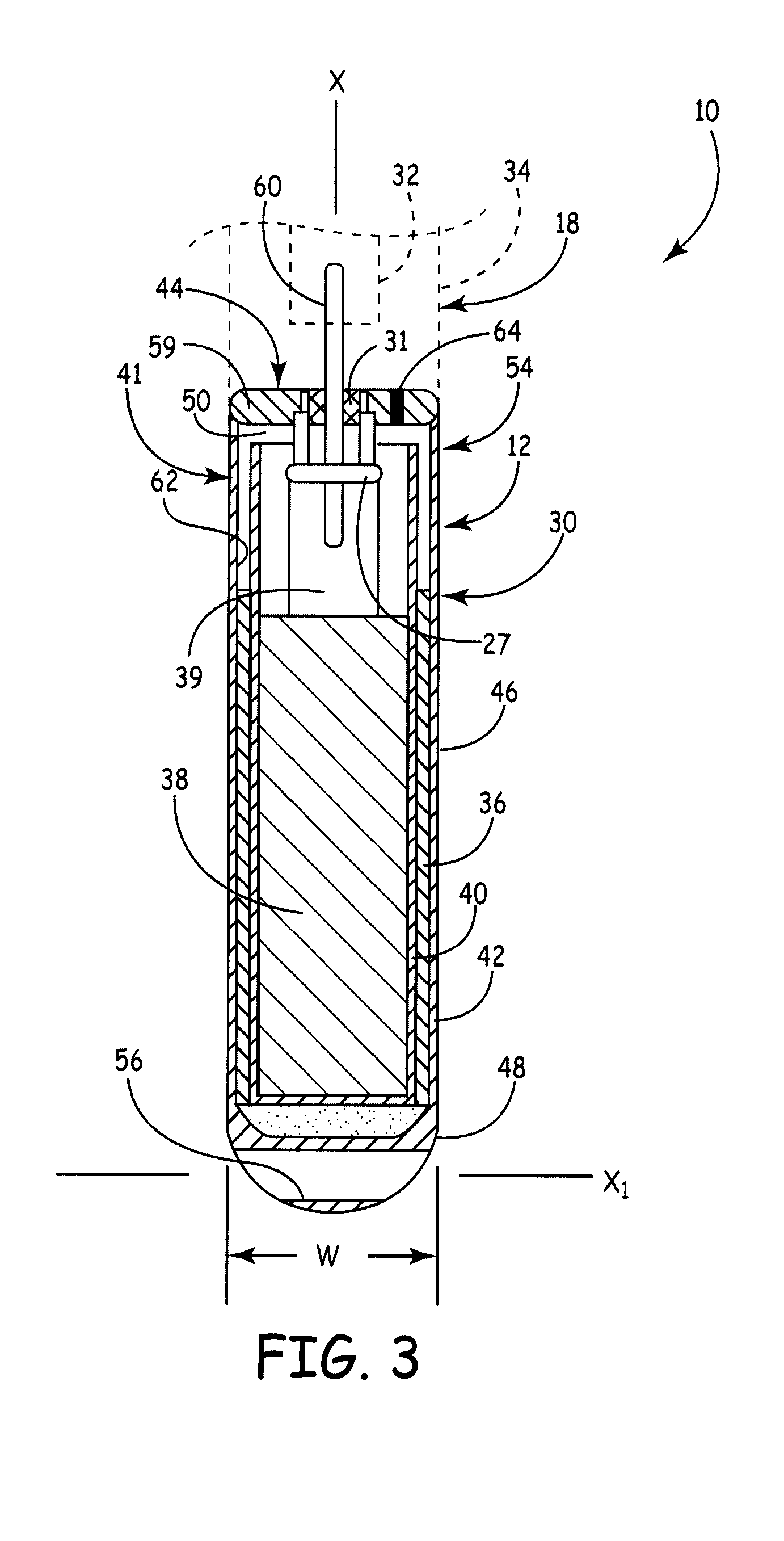

Elongate battery for implantable medical device

A battery assembly for a medical device includes an elongate cathode, an elongate anode, an electrolyte, and an elongate housing assembly encapsulating the cathode, the anode, and the electrolyte. The battery assembly also includes a first electrode that is exposed from and electrically insulated from the housing assembly. One of the anode and the cathode is electrically coupled to the first electrode, and the other of the anode and the cathode is electrically coupled to the housing assembly. One of the cathode and the anode includes a first portion and a second portion disposed in spaced relationship from the first portion. The other of the cathode and the anode is disposed between the first and second portions.

Owner:MEDTRONIC INC

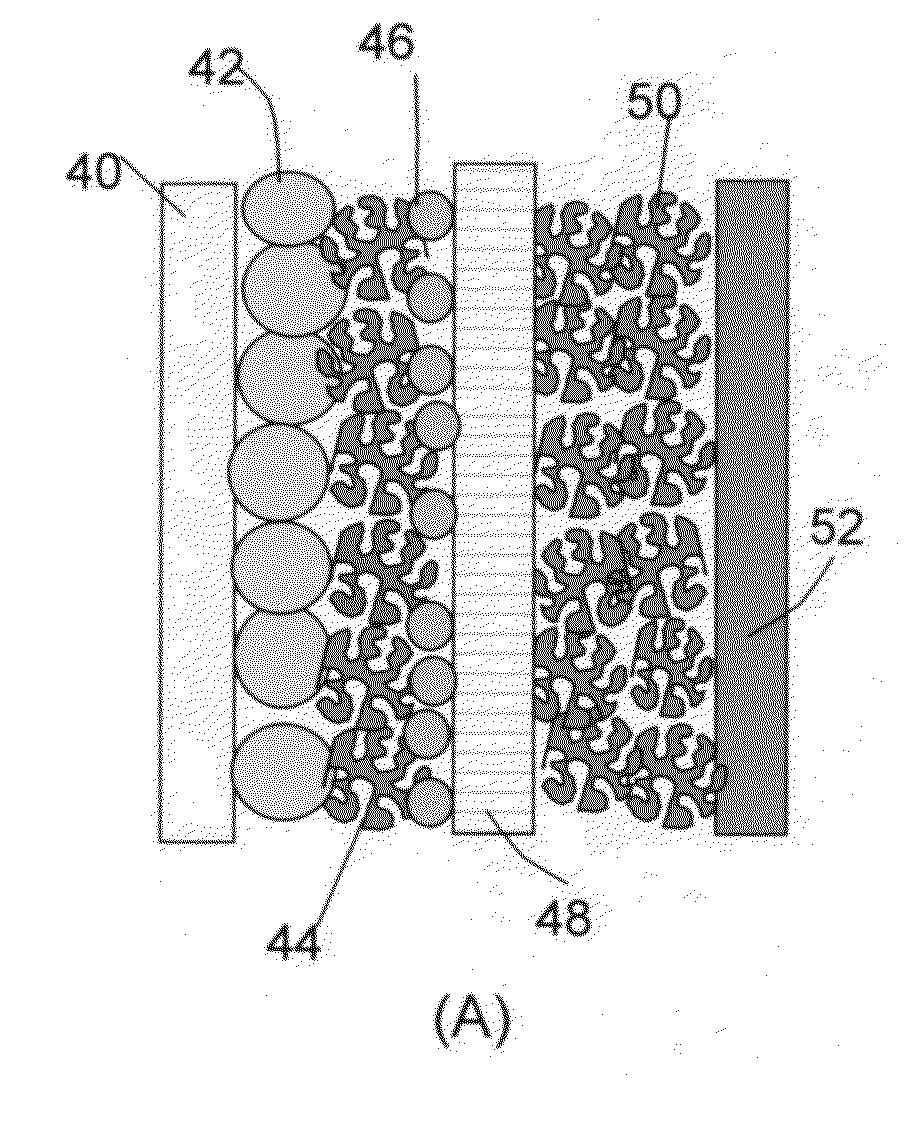

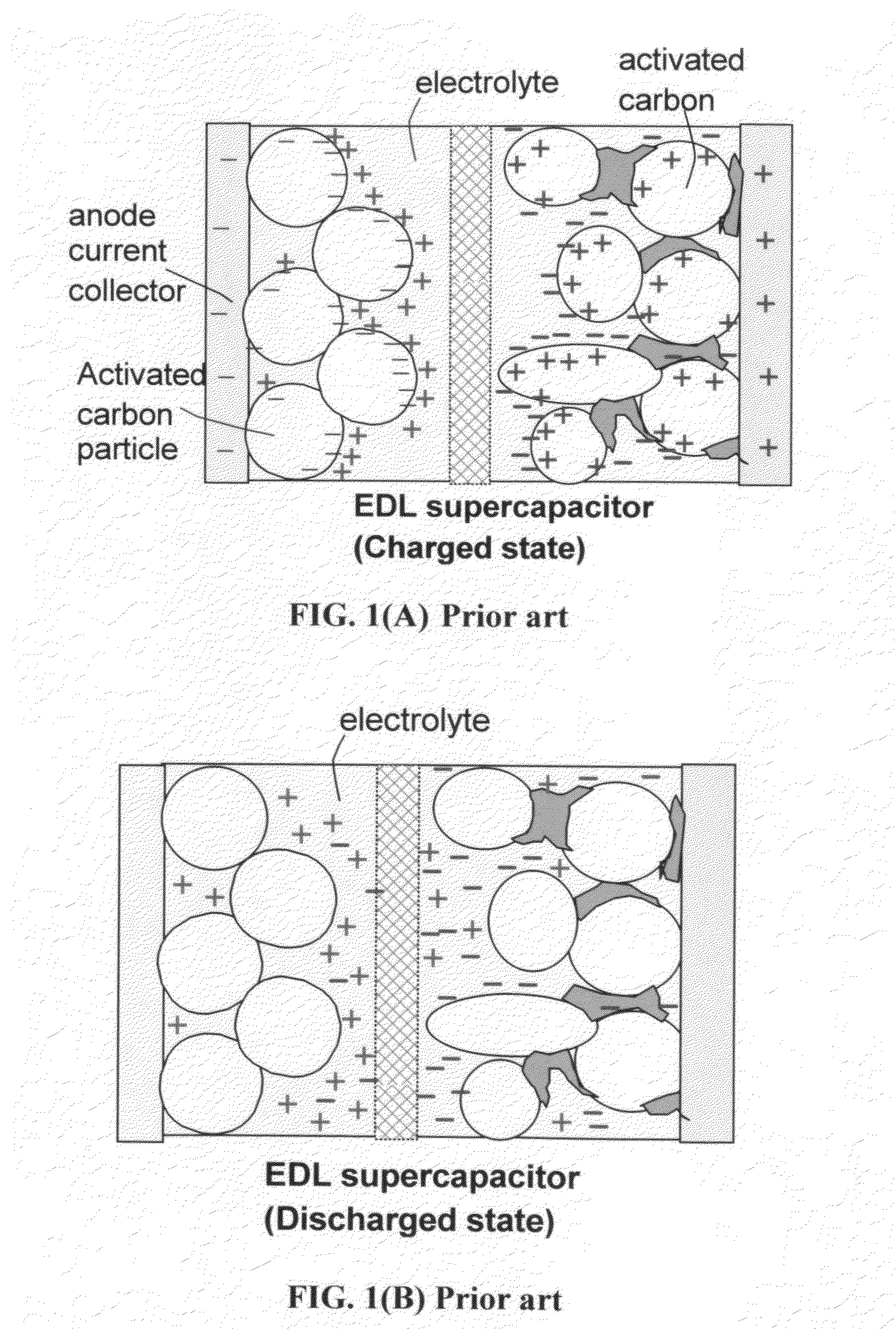

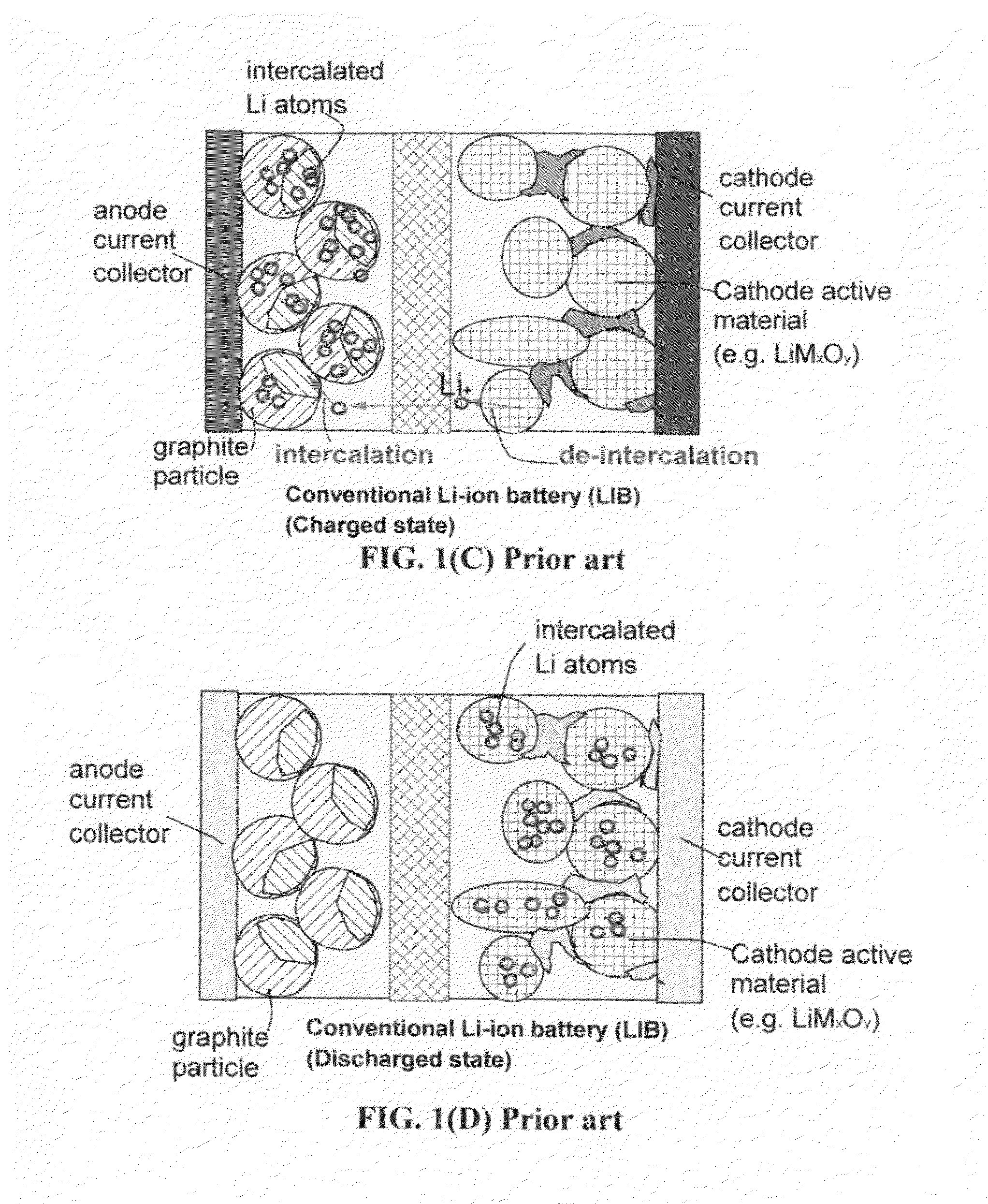

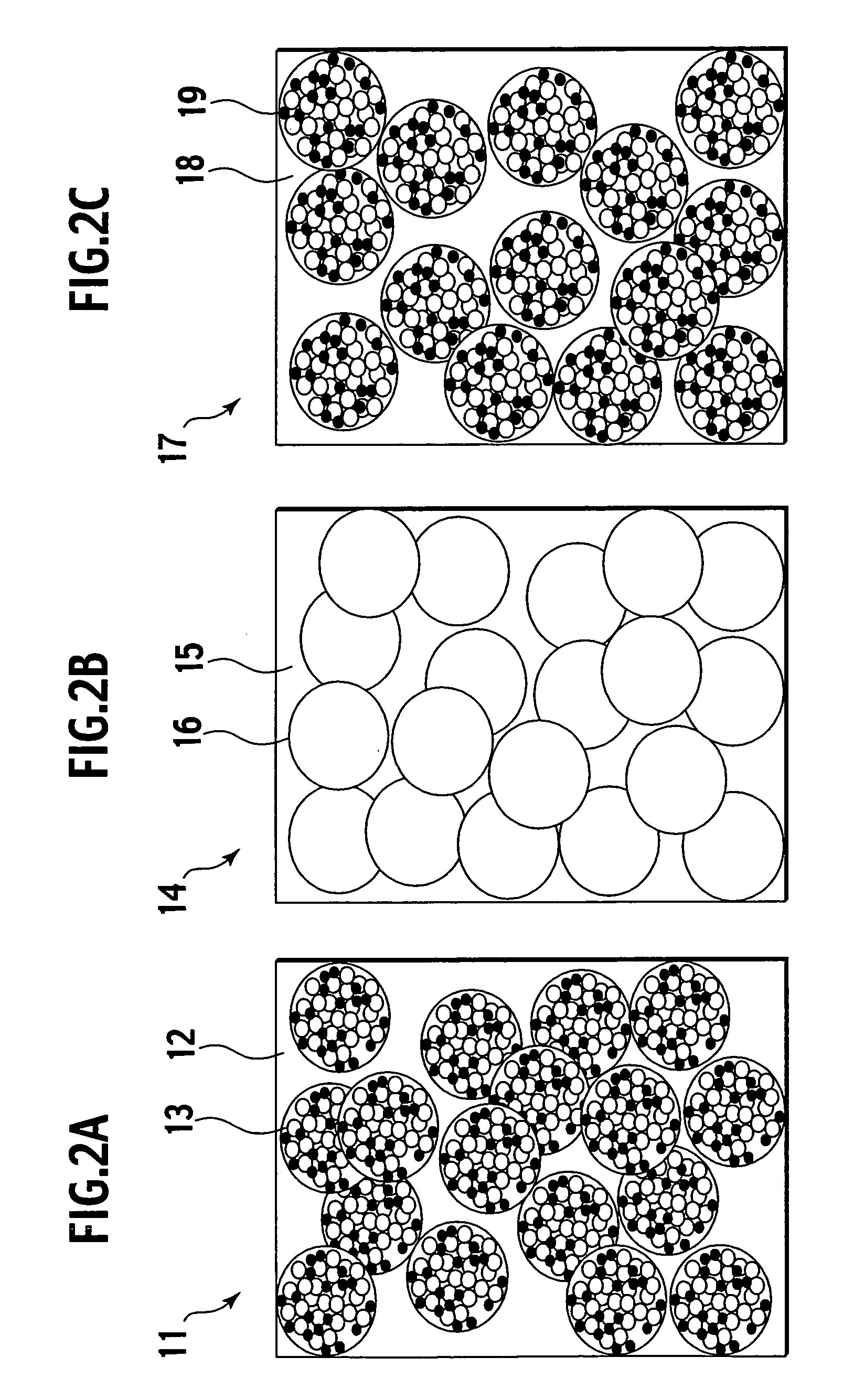

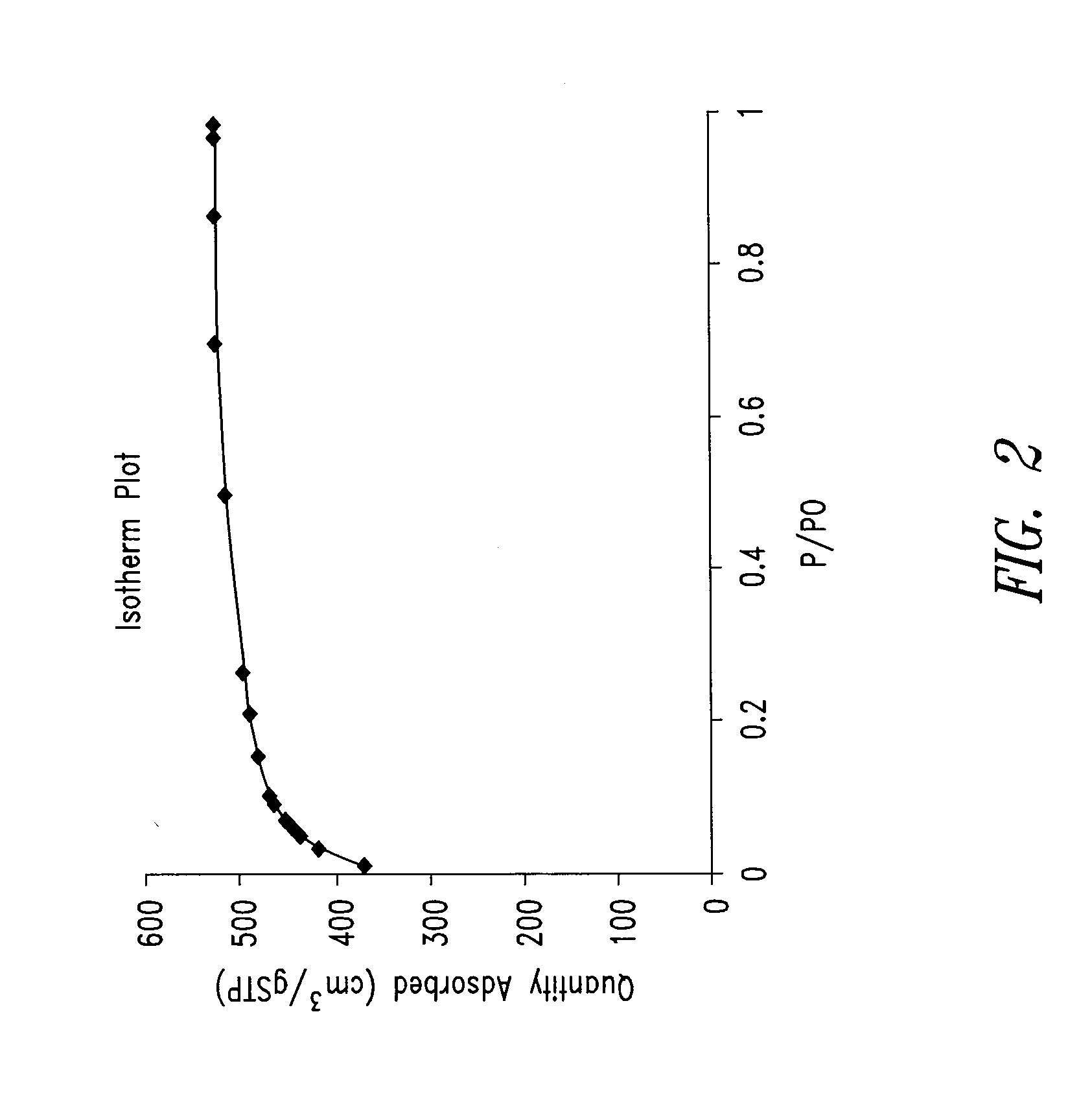

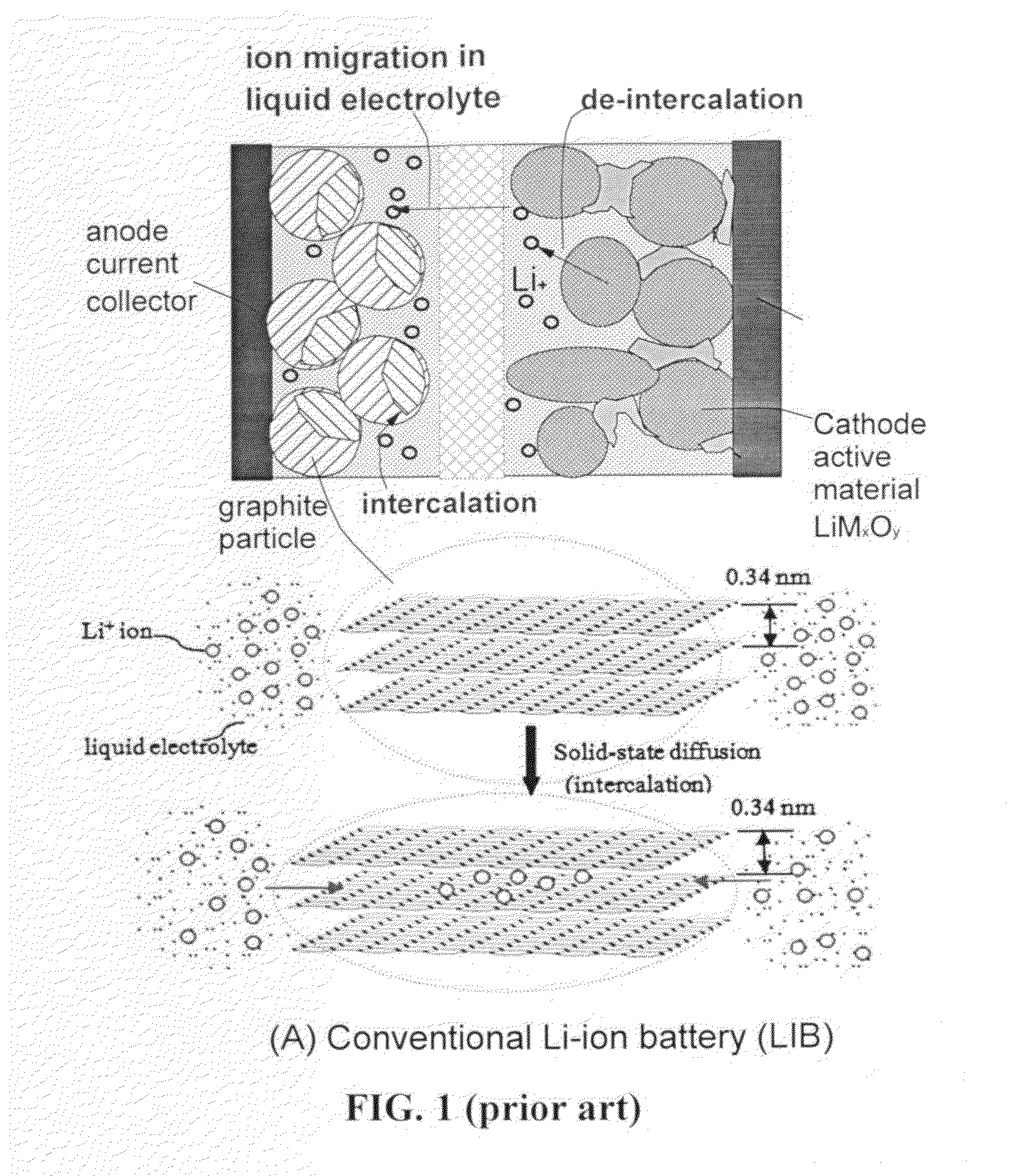

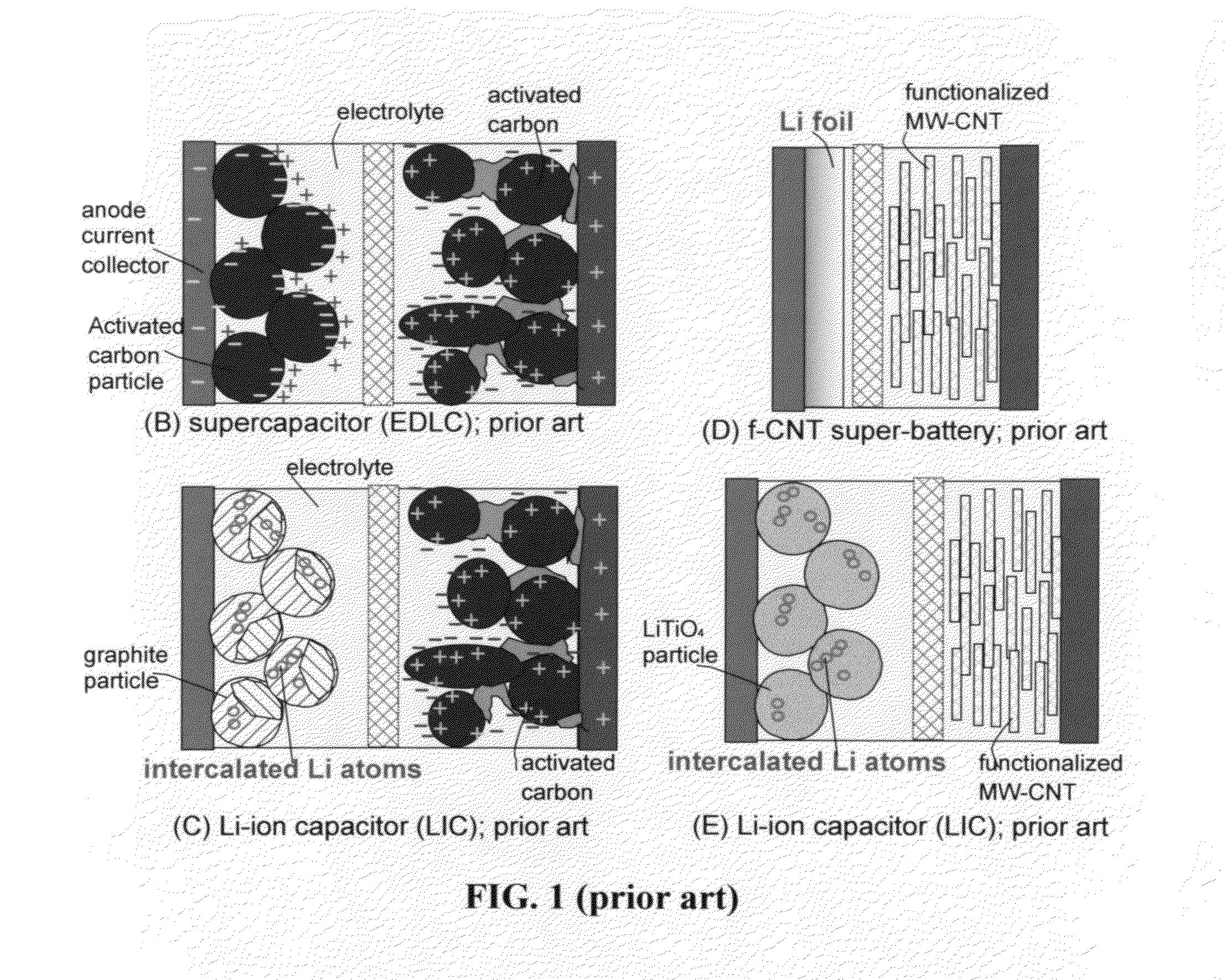

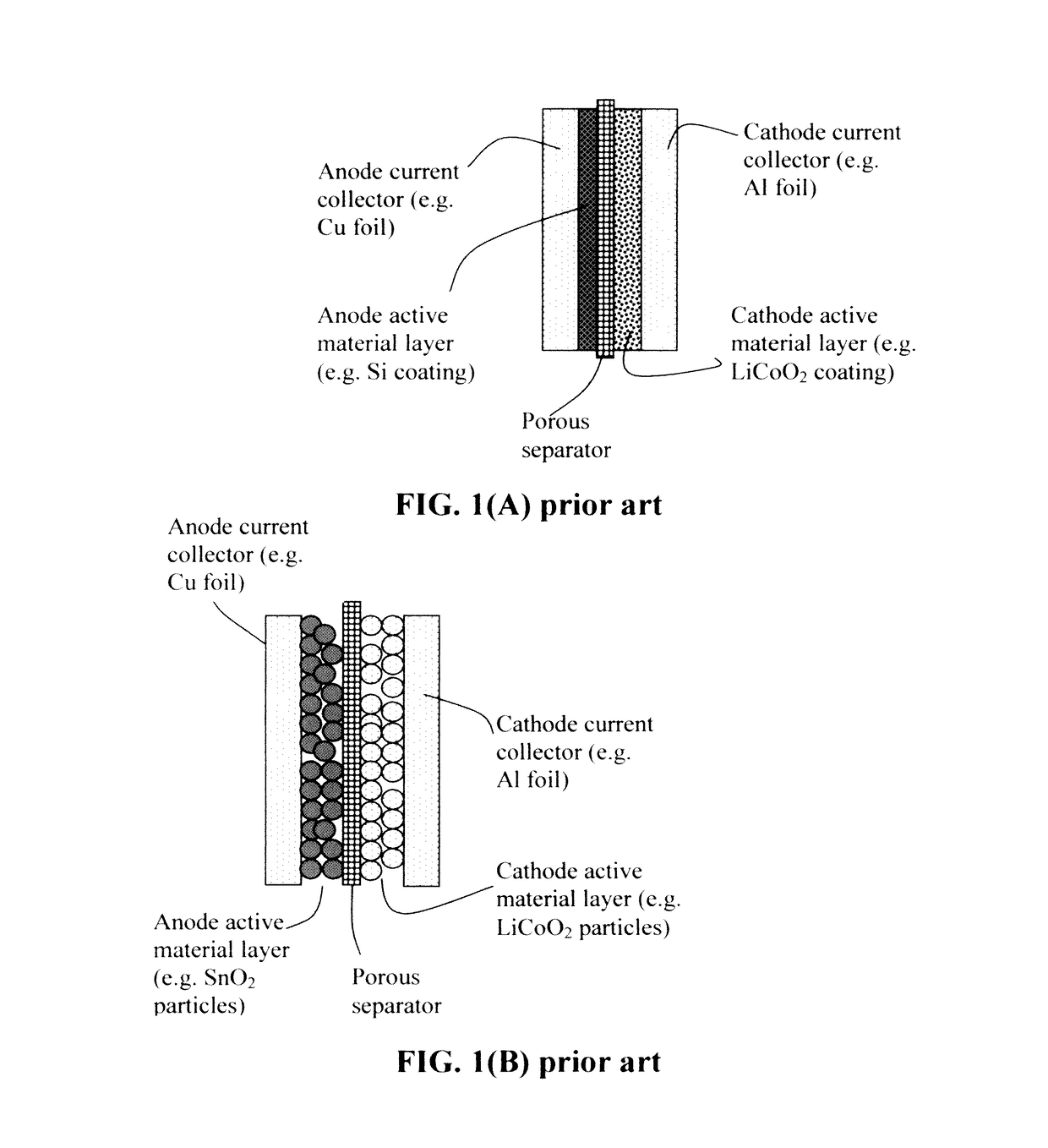

Hybrid electrode and surface-mediated cell-based super-hybrid energy storage device containing same

PendingUS20130171502A1Primary cell to battery groupingMaterial nanotechnologyHigh energyLithium metal

The present invention provides a multi-component hybrid electrode for use in an electrochemical super-hybrid energy storage device. The hybrid electrode contains at least a current collector, at least an intercalation electrode active material storing lithium inside interior or bulk thereof, and at least an intercalation-free electrode active material having a specific surface area no less than 100 m2 / g and storing lithium on a surface thereof, wherein the intercalation electrode active material and the intercalation-free electrode active material are in electronic contact with the current collector. The resulting super-hybrid cell exhibits exceptional high power and high energy density, and long-term cycling stability that cannot be achieved with conventional supercapacitors, lithium-ion capacitors, lithium-ion batteries, and lithium metal secondary batteries.

Owner:GLOBAL GRAPHENE GRP INC +1

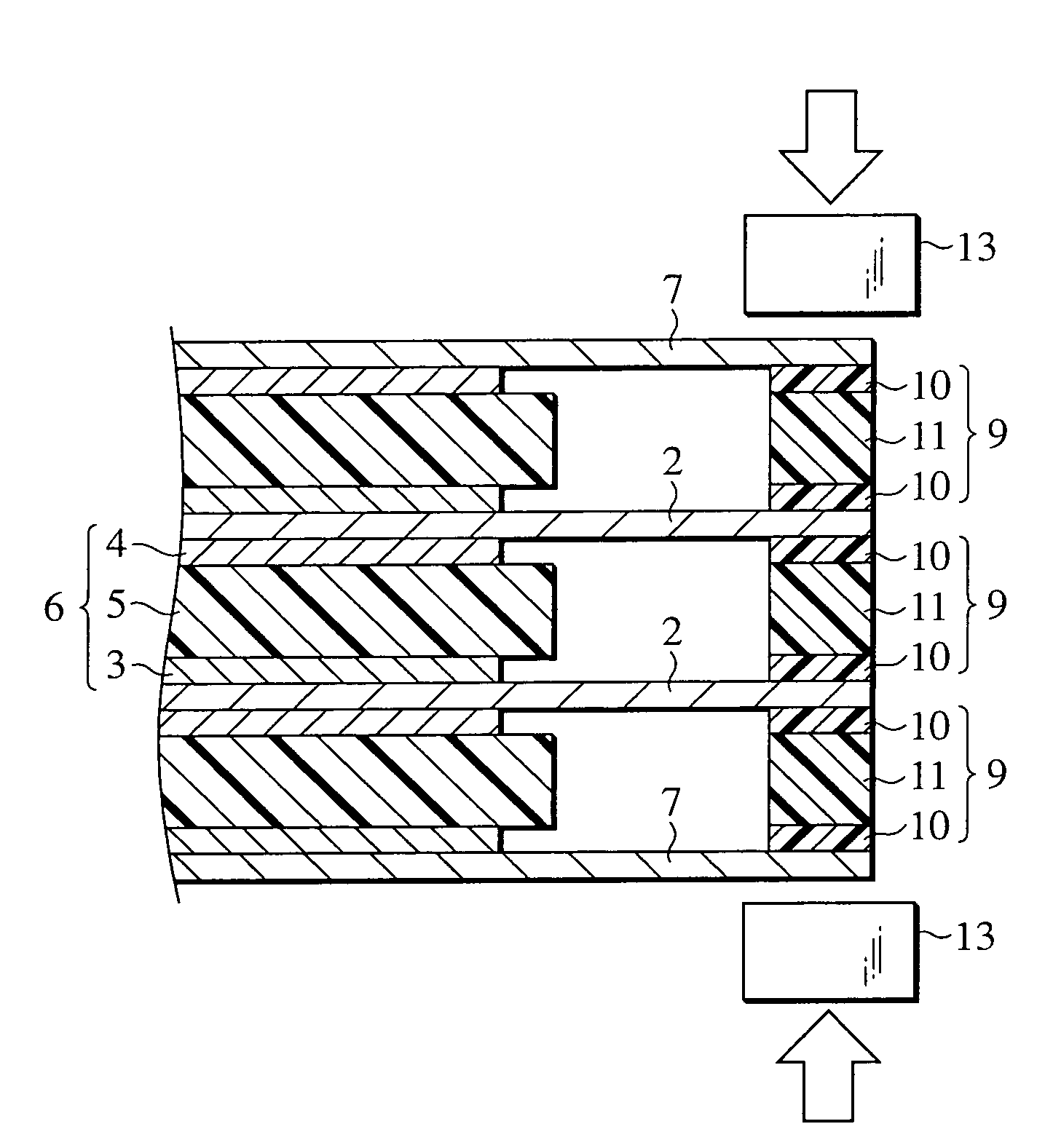

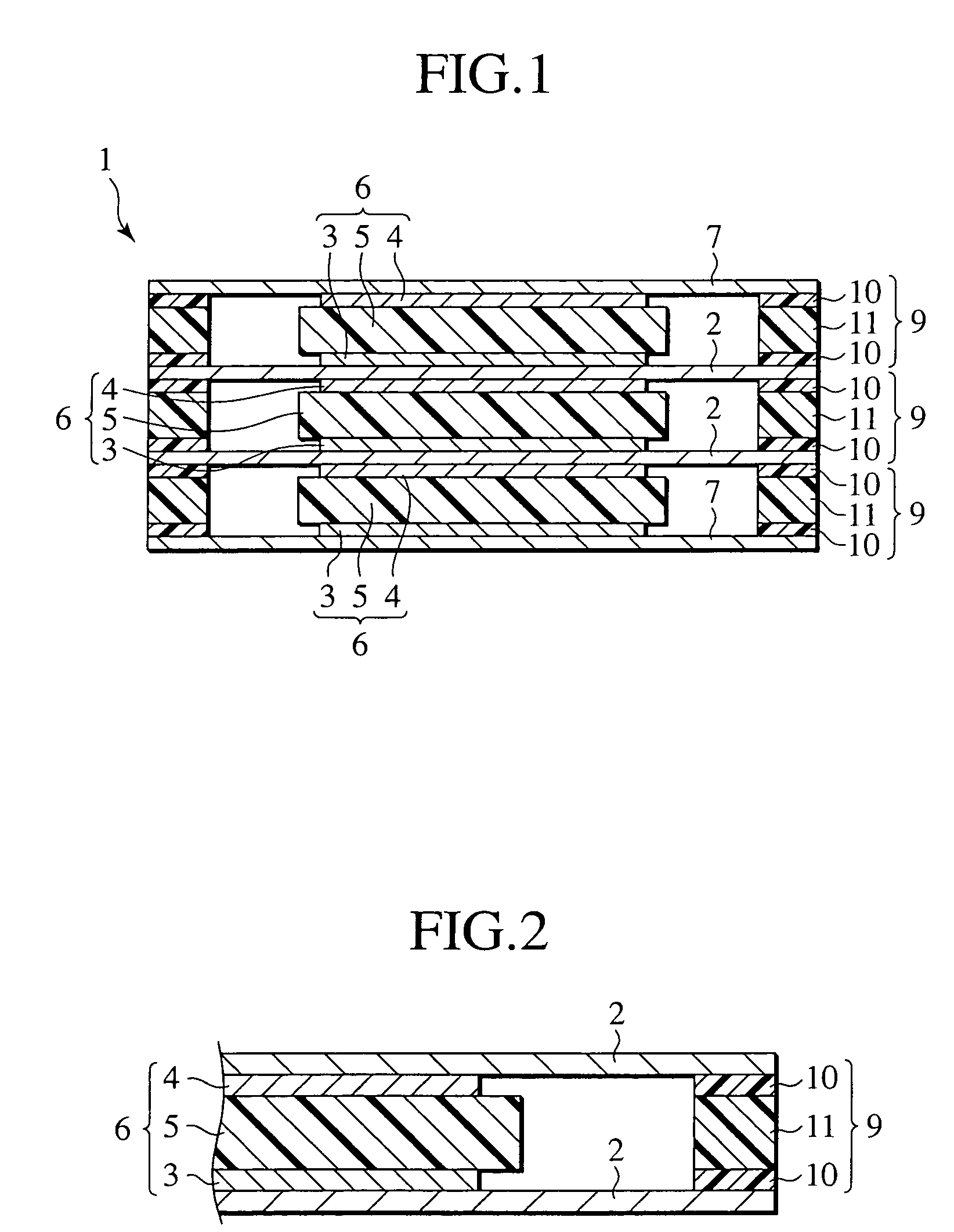

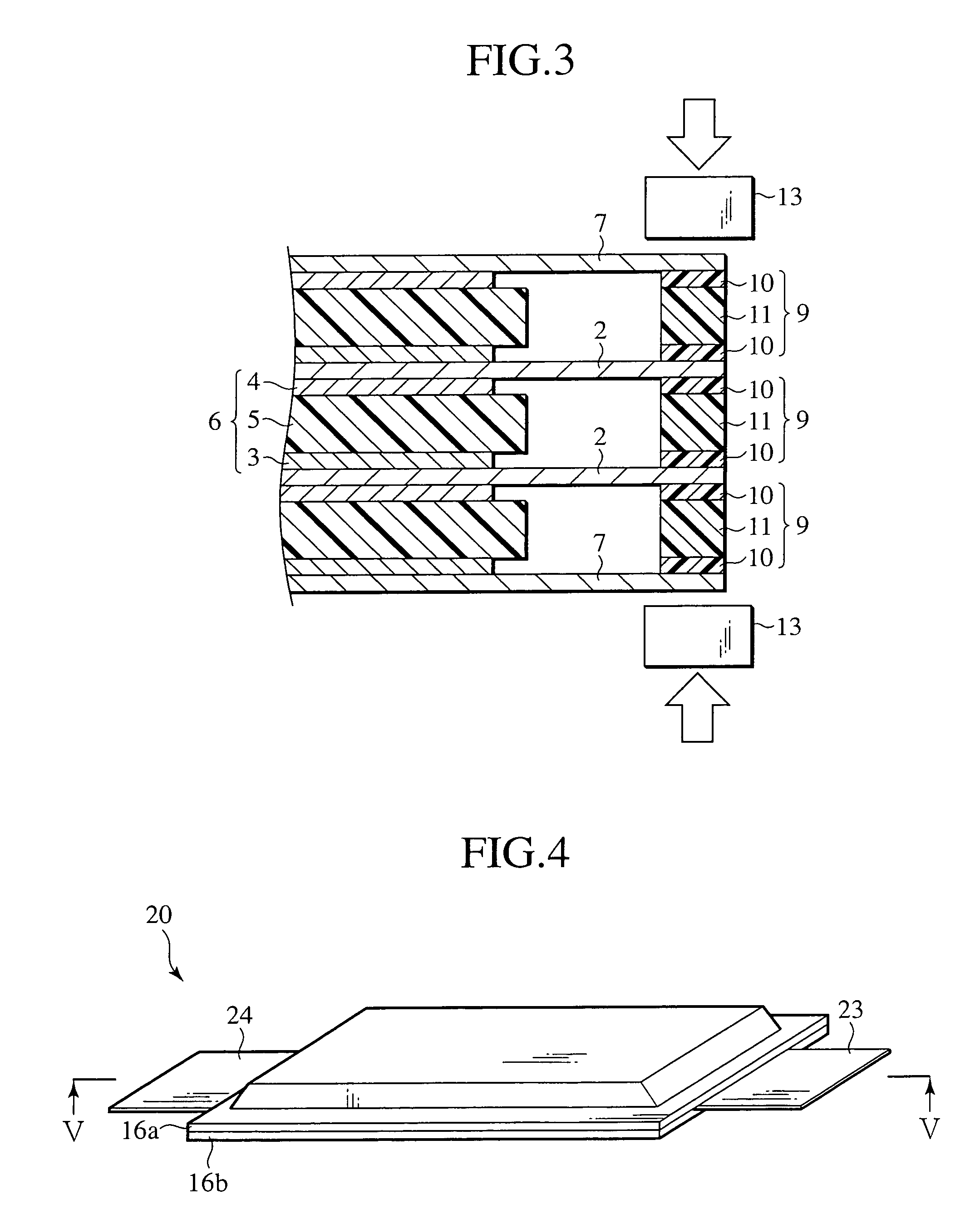

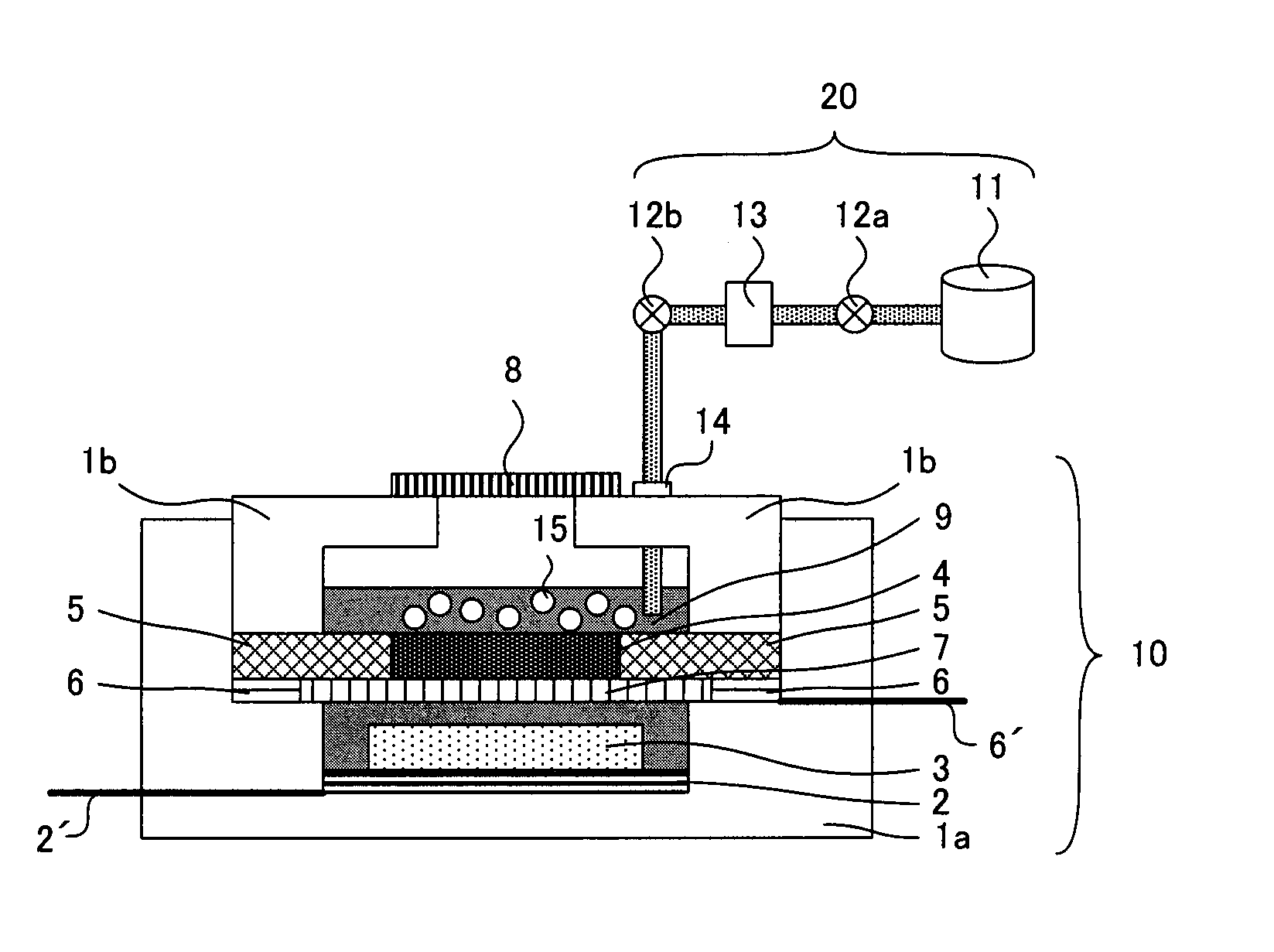

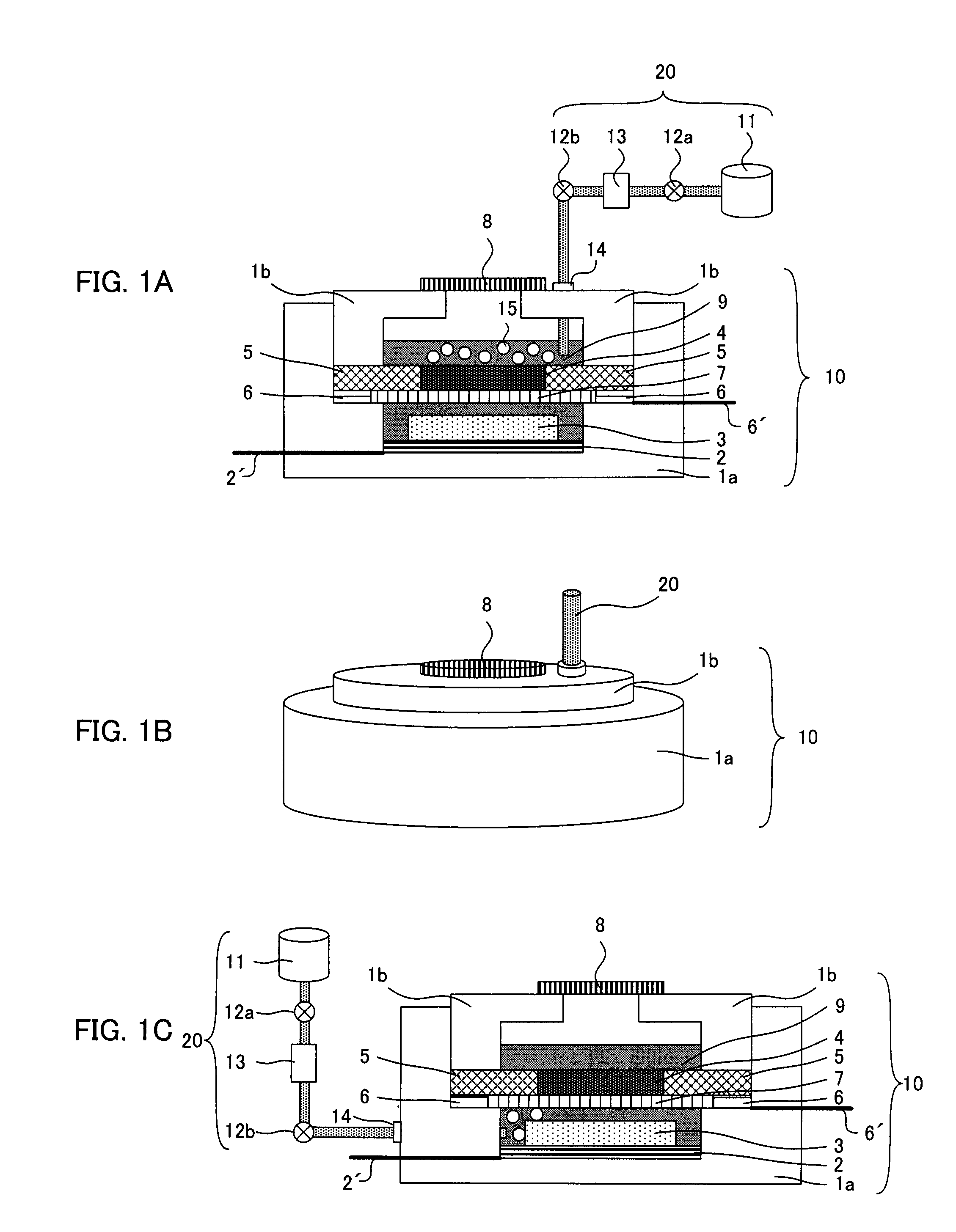

Method of manufacturing solid electrolyte battery

InactiveUS20050132562A1High trafficAvoid excessive power outputNon-aqueous electrolyte accumulatorsFinal product manufacturePolymer electrolytesBattery cell

A method of manufacturing a solid electrolyte battery includes a step of thermally pressing a composite layer including a positive electrode ink layer, an electrolyte ink layer and a negative electrode ink layer that are formed by coating a positive electrode ink, an electrolyte ink and a negative electrode ink. Further, the positive electrode ink, the electrolyte ink and the negative electrode ink contain a polymer electrolyte. By this method, it is possible to improve the flow of ions across respective interlayers of a positive electrode active material layer, a solid electrolyte layer and a negative electrode active material layer.

Owner:NISSAN MOTOR CO LTD

Solid electrolytes based on lithium hafnium phosphate for active metal anode protection

InactiveUS20060078790A1Avoid harmful reactionsCell electrodesNon-aqueous electrolyte cellsPhosphateOrganic liquids

Active metal electrochemical structure, in particular an active metal negative electrode (anode) protected with an ionically conductive protective architecture incorporating a glassy, ceramic or glass-ceramic solid electrolyte material based on lithium hafnium phosphate, and associated electrochemical devices and methods, provides advantages over conventional structures. The protective architecture prevents the active metal from deleterious reaction with the environment on the other (cathode) side of the architecture, which may include aqueous, air or organic liquid electrolytes and / or electrochemically active materials.

Owner:POLYPLUS BATTERY CO INC

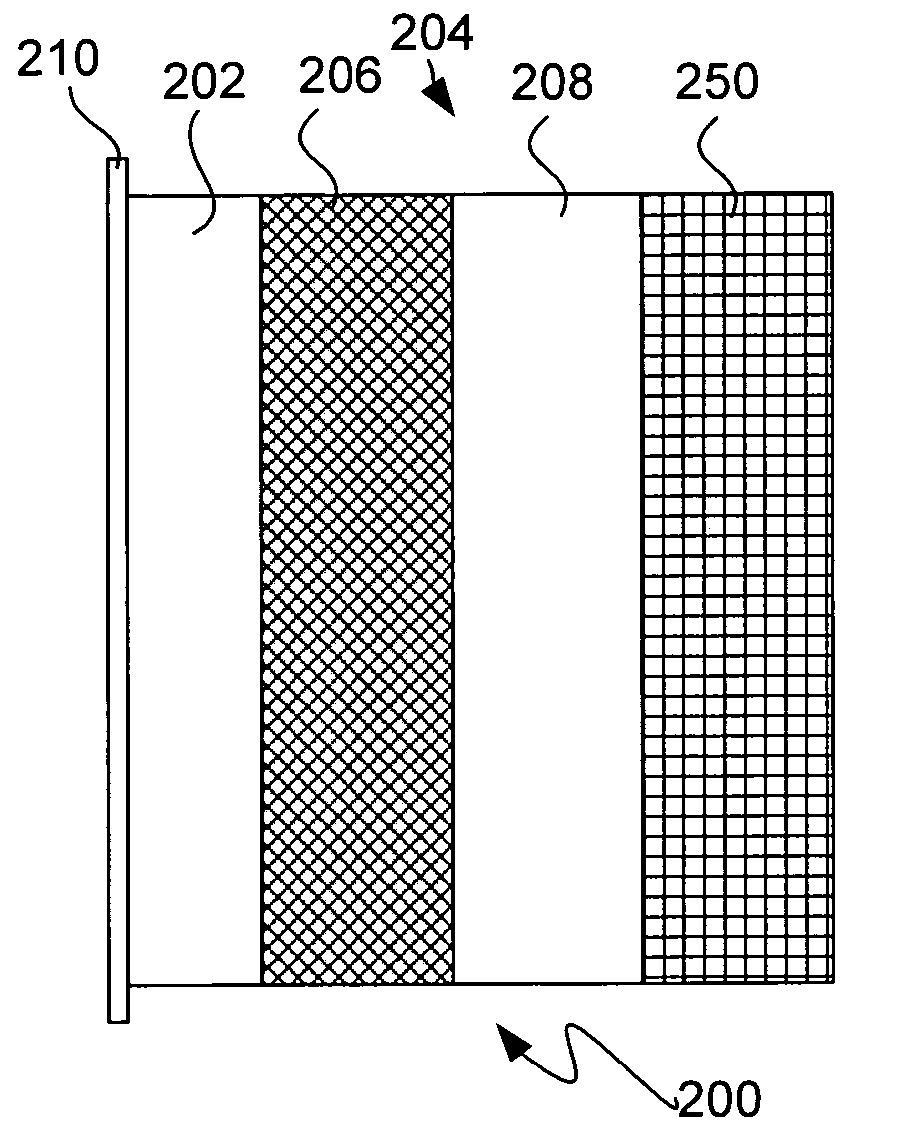

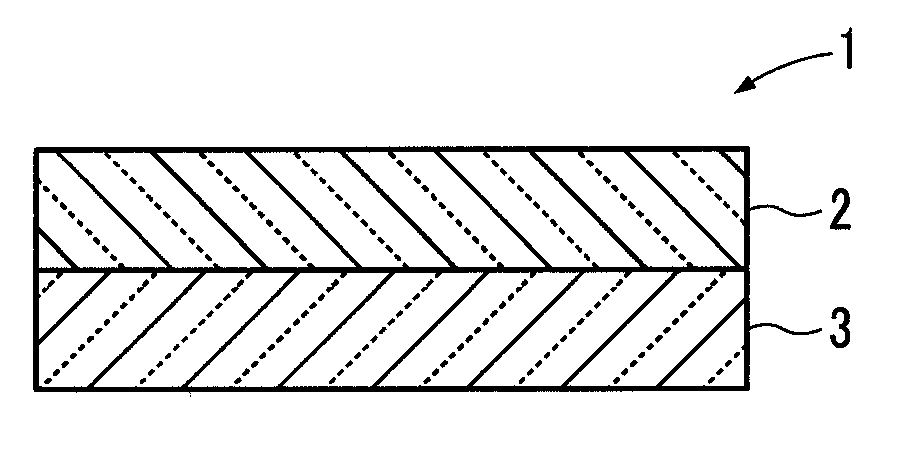

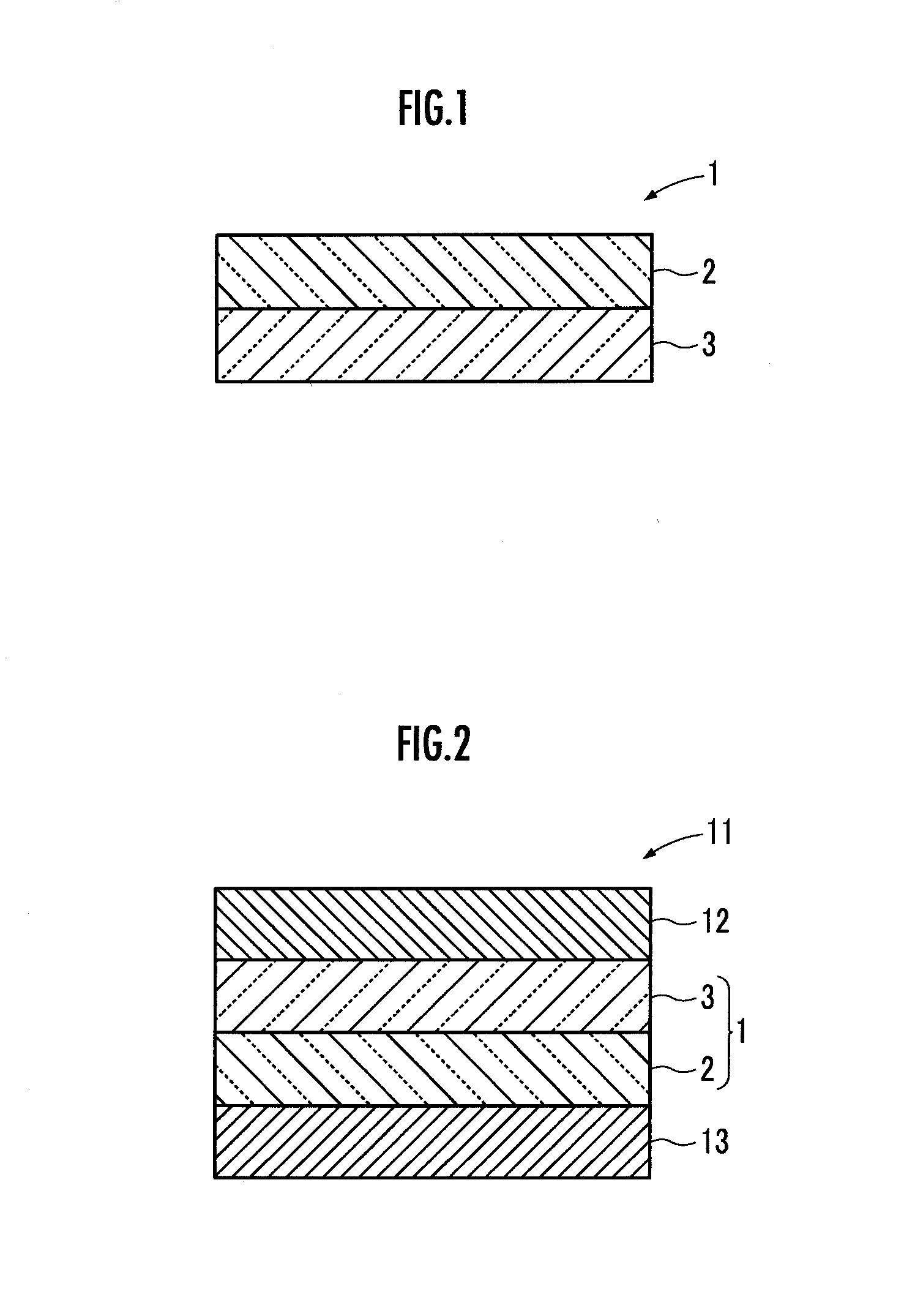

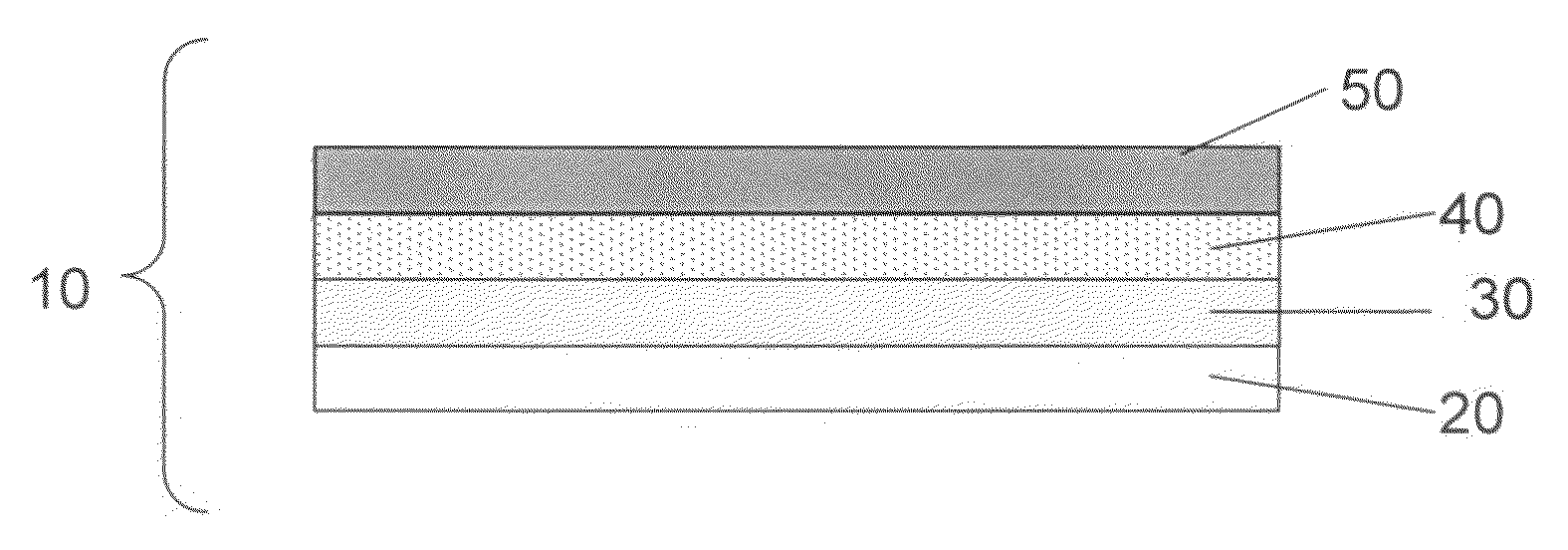

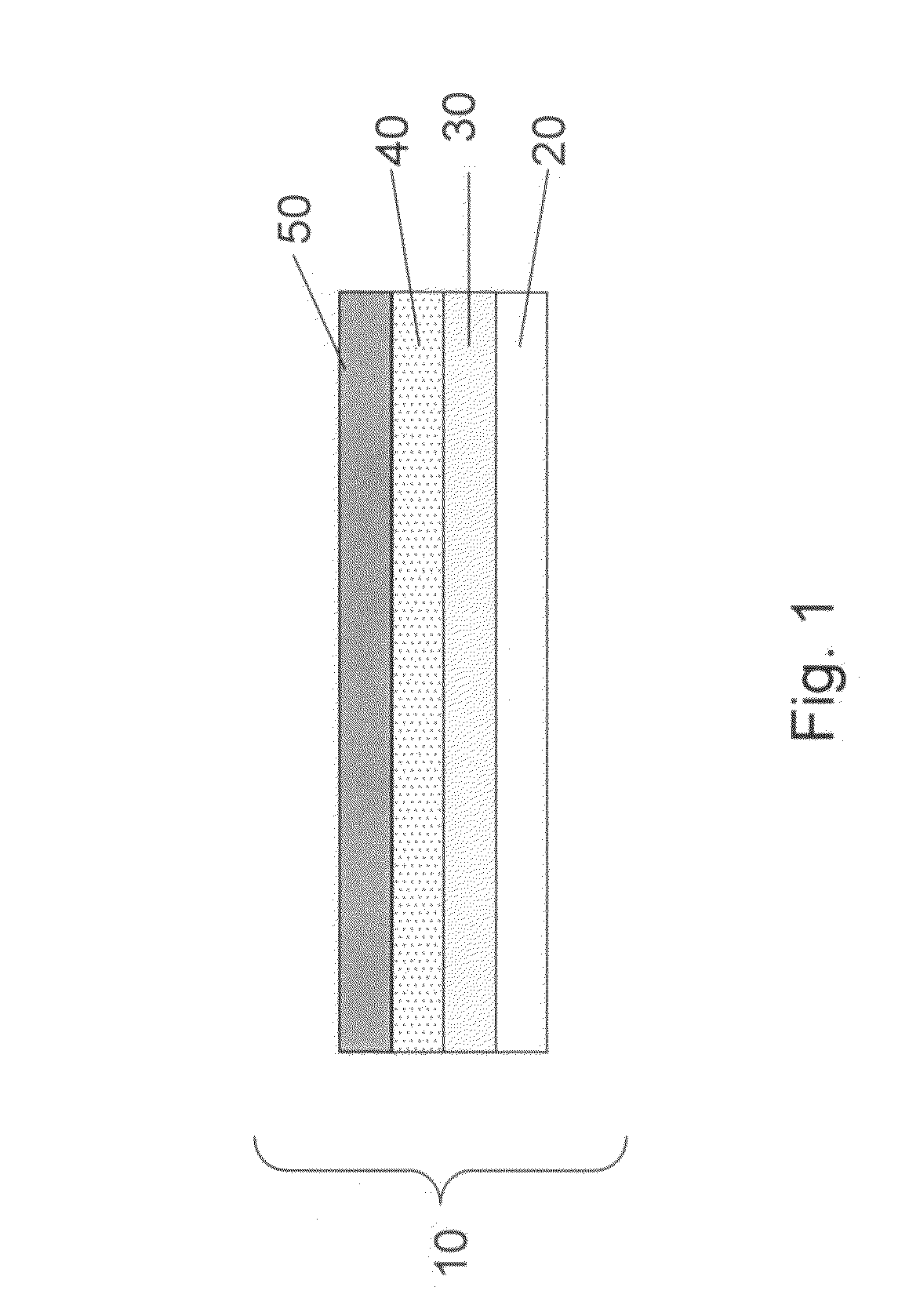

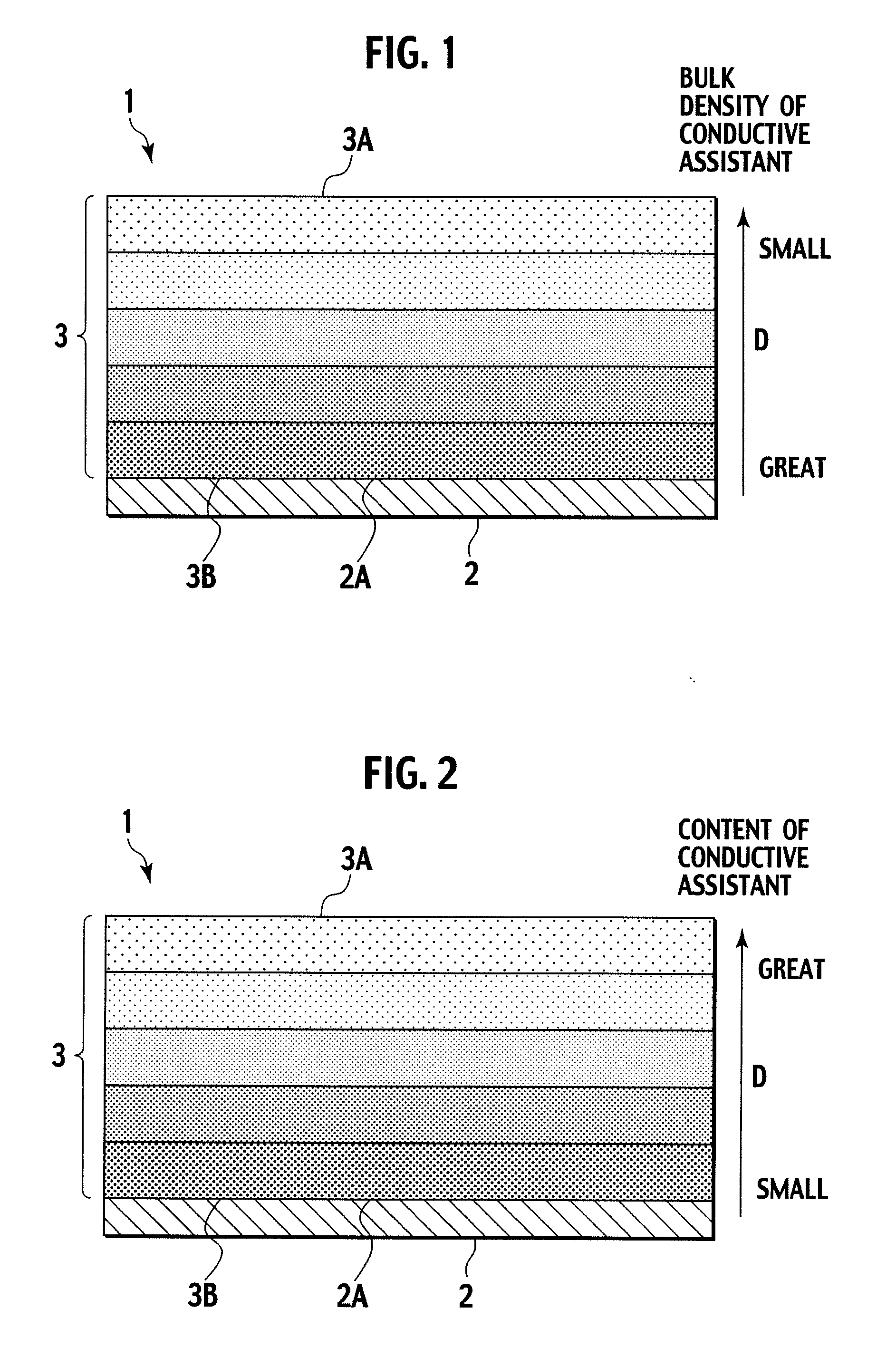

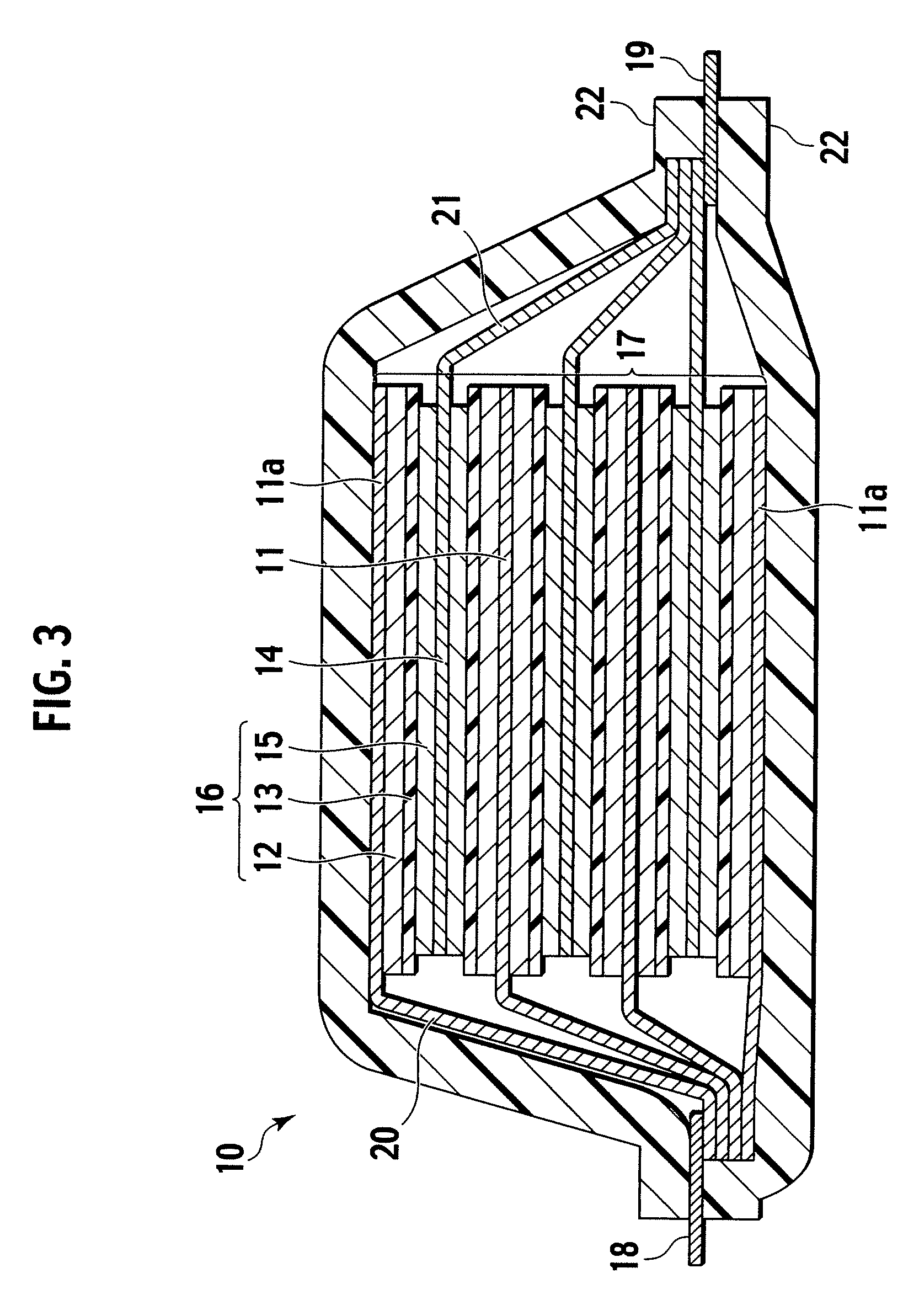

Lithium ion conductive composite electrolyte and lithium ion secondary battery using same

ActiveUS20130230778A1Improve cycle performancePrevent electrolyte leakageNon-aqueous electrolyte cellsSecondary cellsComposite electrolyteConductive polymer

Provided is a lithium ion conductive composite electrolyte that can prevent leakage of electrolyte solution, and that have excellent cycle performance and lithium ion conductivity, and a lithium ion secondary battery. A lithium ion conductive composite electrolyte 1 is formed so that a lithium ion conductive polymer gel electrolyte is held in a porous body 2 formed from lithium ion conductive inorganic solid electrolyte particles and an organic polymer. The lithium ion conductive inorganic solid electrolyte particles are formed from a composite metal oxide that has a garnet structure, and is represented by the chemical formula Li7−yLa3−xAxZr2−yMyO12 (wherein 0≦x 3, 0≦y≦2, A is one of Y, Nd, Sm, and Gd, and M is Nb or Ta). A lithium ion secondary battery 11 includes the lithium ion conductive composite electrolyte 1 between a positive electrode 12 and a negative electrode 13.

Owner:HONDA MOTOR CO LTD

Carbon materials comprising an electrochemical modifier

InactiveUS20110159375A1Prolong lifeImprove stabilitySilver accumulatorsConductive materialElectrical devicesMaterials science

The present application is directed to carbon materials comprising an electrochemical modifier. The carbon materials find utility in any number of electrical devices, for example, in lead acid batteries. Methods for making the disclosed carbon materials are also disclosed.

Owner:BASF AG

Non-aqueous liquid electrolyte and non-aqueous liquid electrolyte secondary battery

InactiveUS20090325065A1Improve charging capacityMaintain good propertiesAlkaline accumulatorsElectrode manufacturing processesLithiumCarbonate

A non-aqueous liquid electrolyte secondary battery using negative-electrode active material having Si, Sn and / or Pb, with high charge-capacity, superior characteristics including discharge-capacity retention rate over long is provided. Its non-aqueous liquid electrolyte contains carbonate having unsaturated bond and / or halogen and compounds like LiPF6 and / or LiBF4 (first lithium salt) and lithium salt different from said first one, represented by formula below (second lithium salt).Lil(αmXan)

Owner:MITSUBISHI CHEM CORP

Lithium-Selenium secondary batteries having non-flammable electrolyte

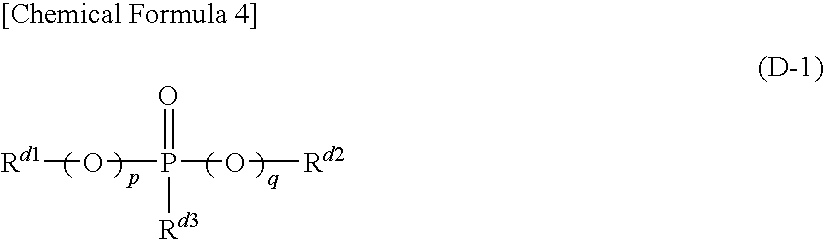

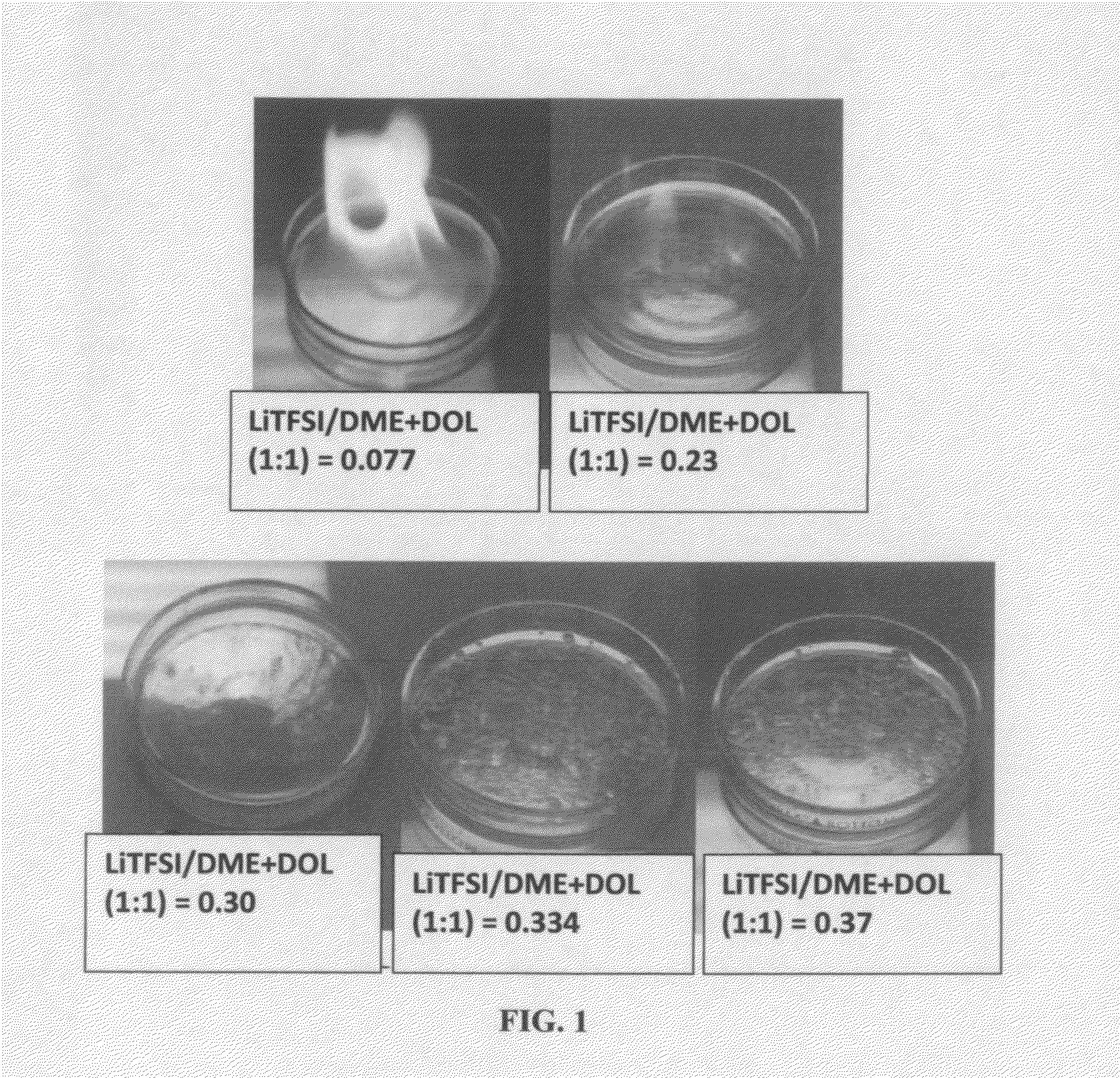

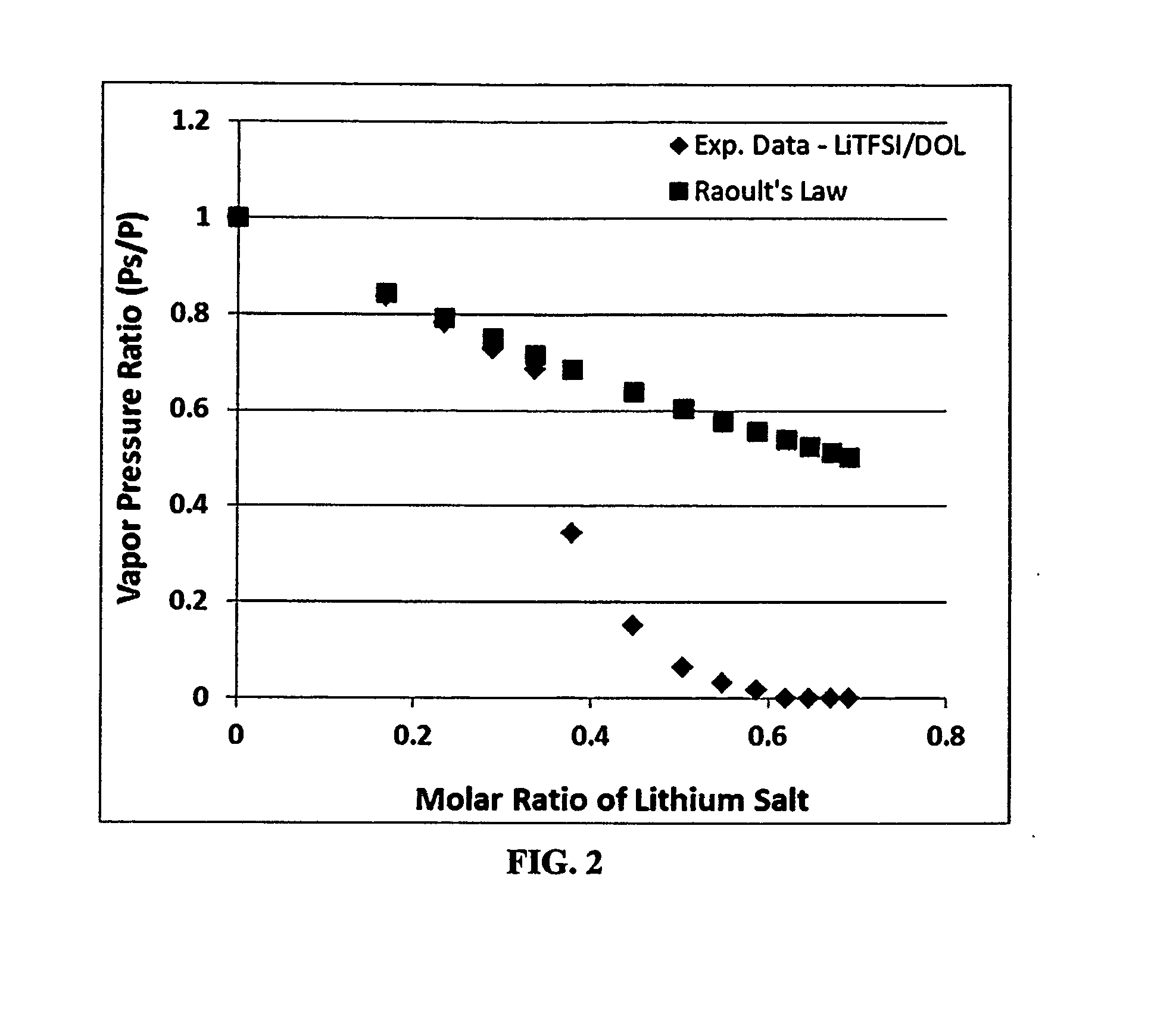

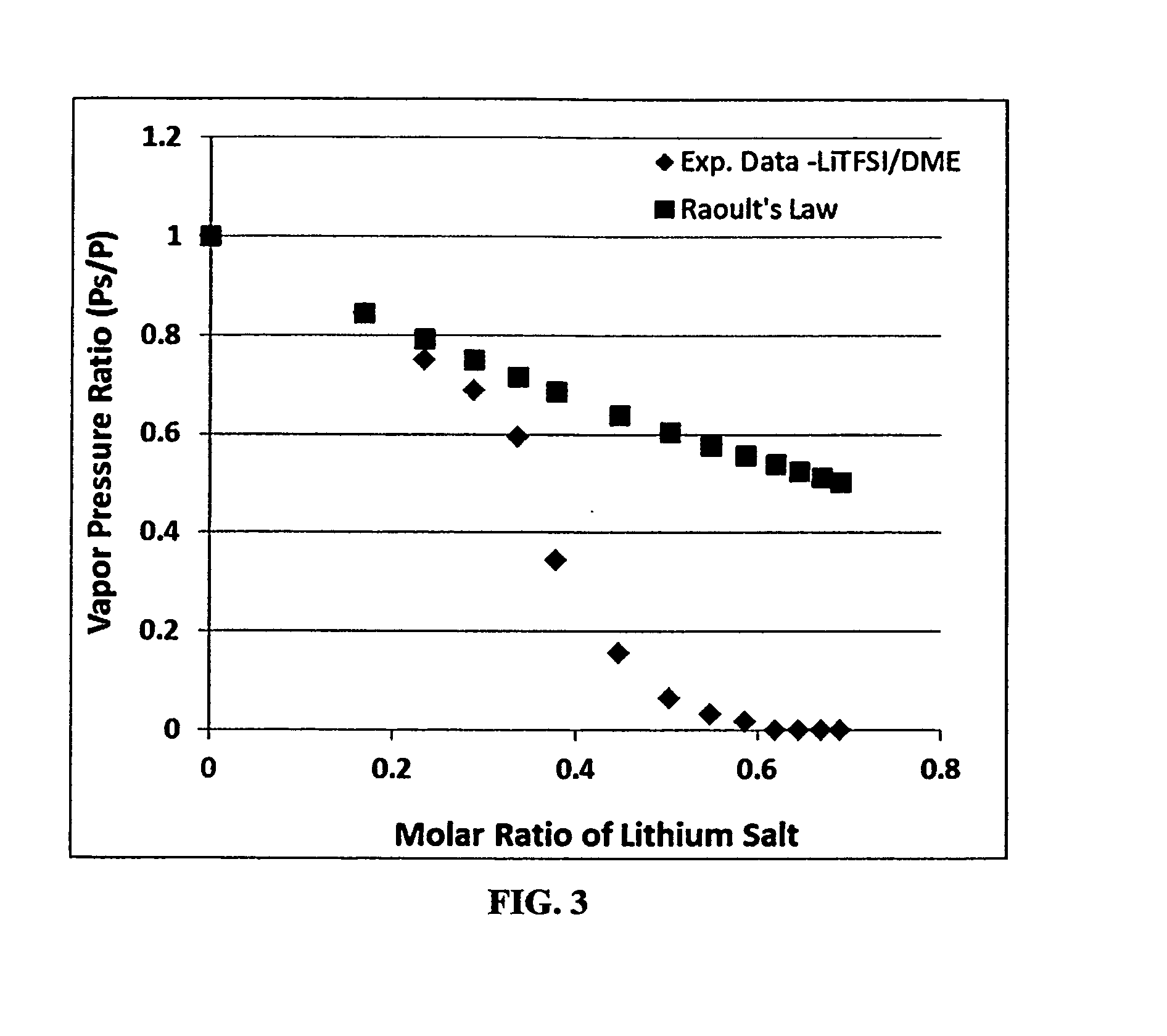

ActiveUS20150064575A1Improve solubilityFlammability of any organic solvent can be effectively suppressedNon-aqueous electrolyte cellsCell electrodesCelsius DegreeHigh energy

A rechargeable lithium-selenium cell comprising a cathode having a cathode active material selected from Se or SexSy (x / y ratio=0.01 to 100), an anode having an anode active material, a porous separator electronically separating the anode and the cathode, a non-flammable quasi-solid electrolyte in contact with the cathode and the anode, wherein the electrolyte contains a lithium salt dissolved in a first organic liquid solvent with a lithium salt concentration sufficiently high (at least 2.0 M, more preferably >3.0 M) so that the electrolyte exhibits a vapor pressure less than 0.01 kPa when measured at 20° C., a flash point at least 20 degrees Celsius higher than the flash point of the first organic liquid solvent alone, a flash point higher than 150° C., or no flash point. This battery cell is non-flammable and safe, has a long cycle life, high capacity, and high energy density.

Owner:GLOBAL GRAPHENE GRP INC

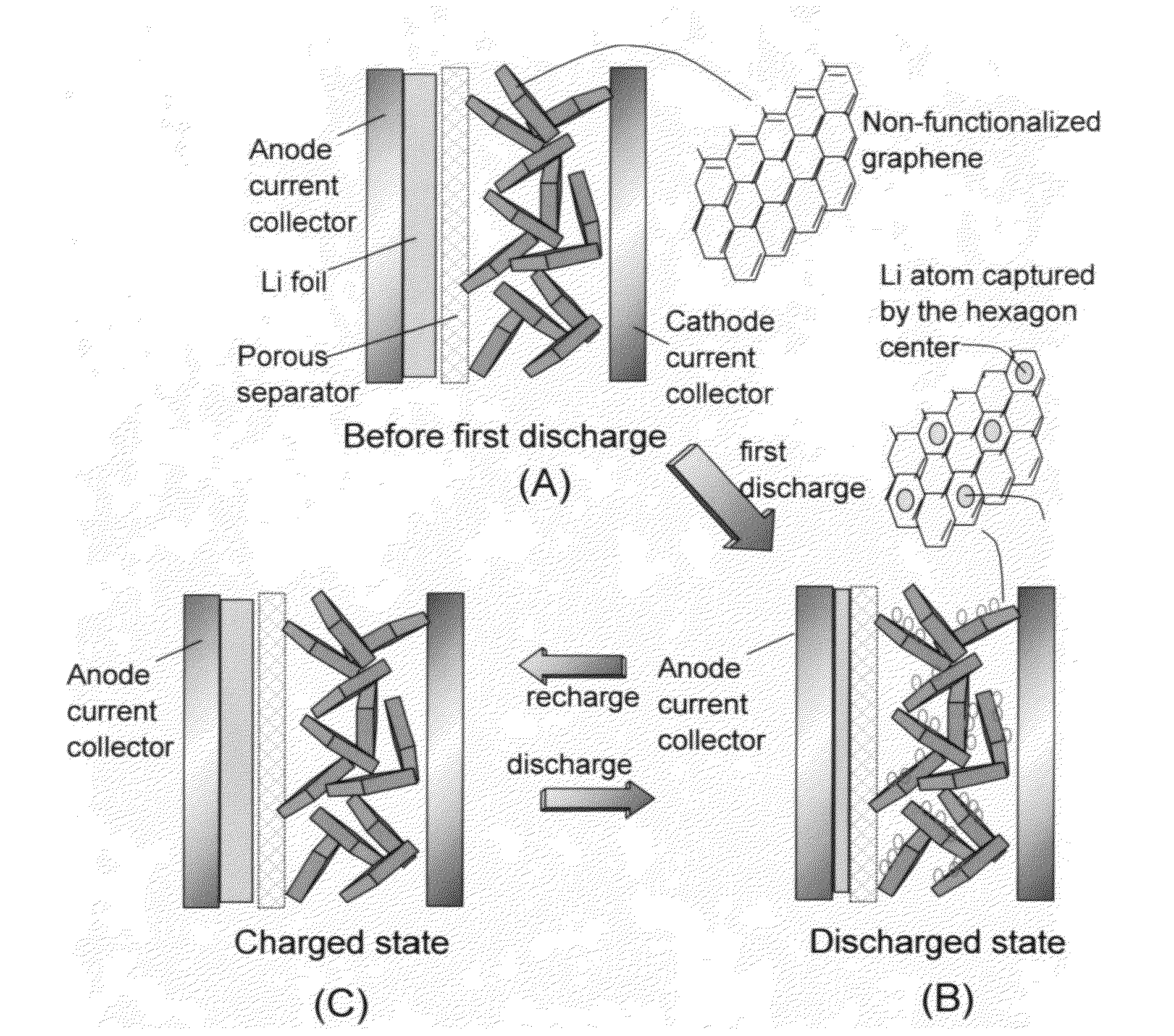

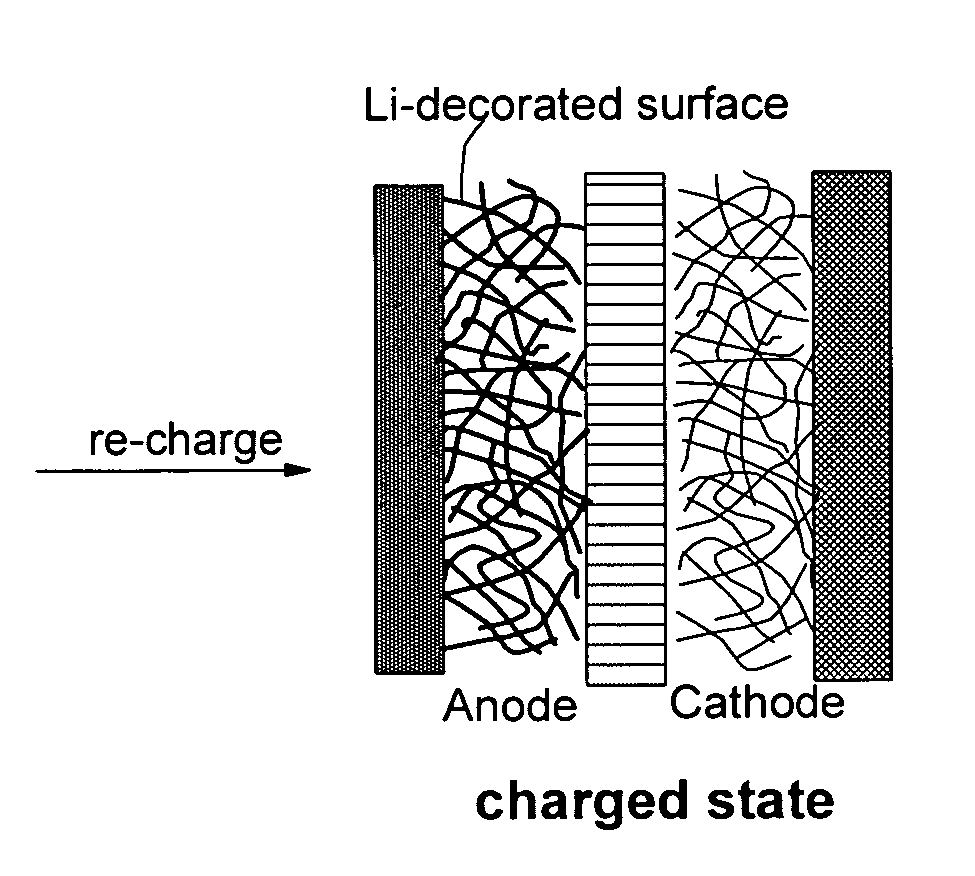

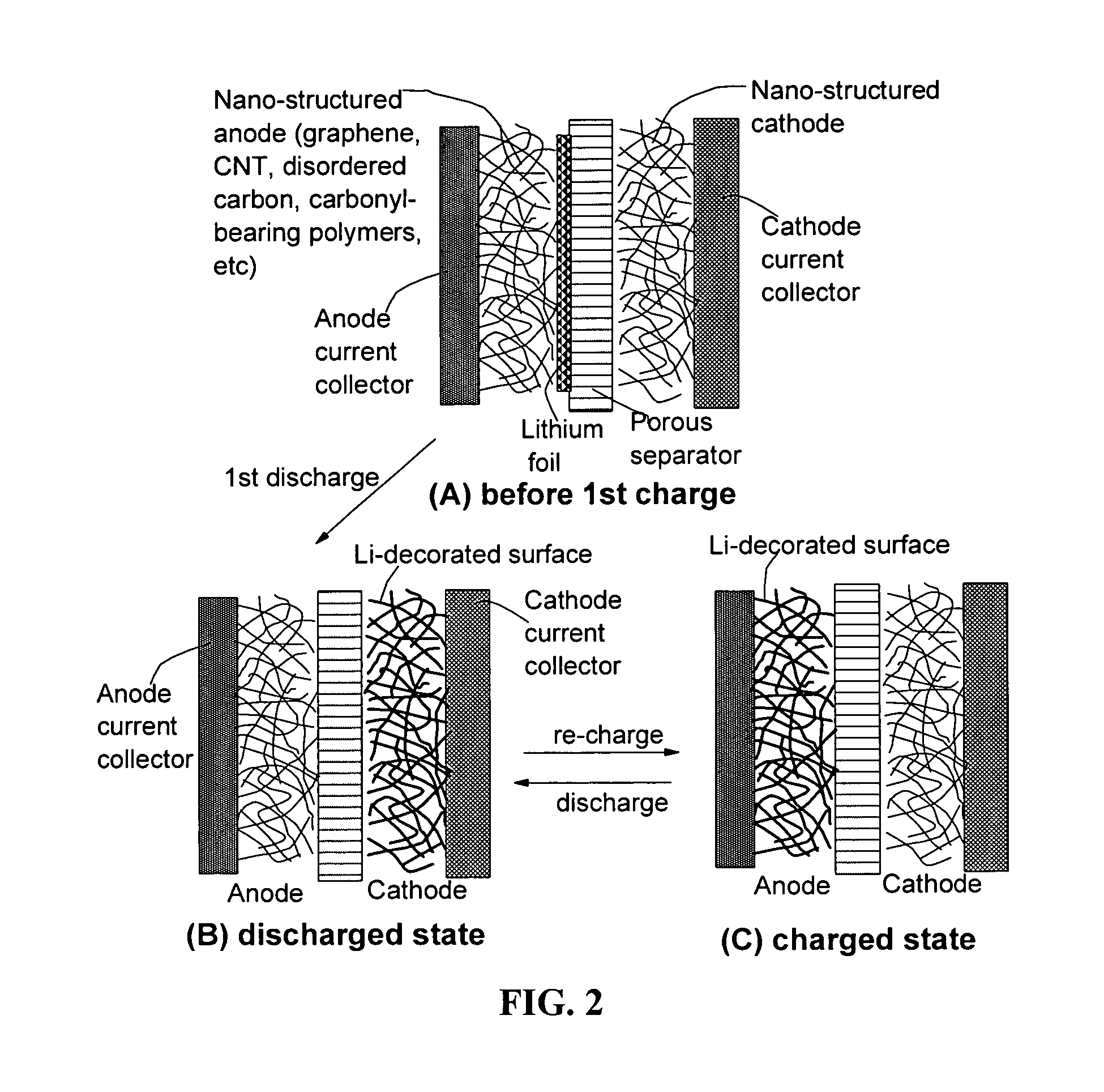

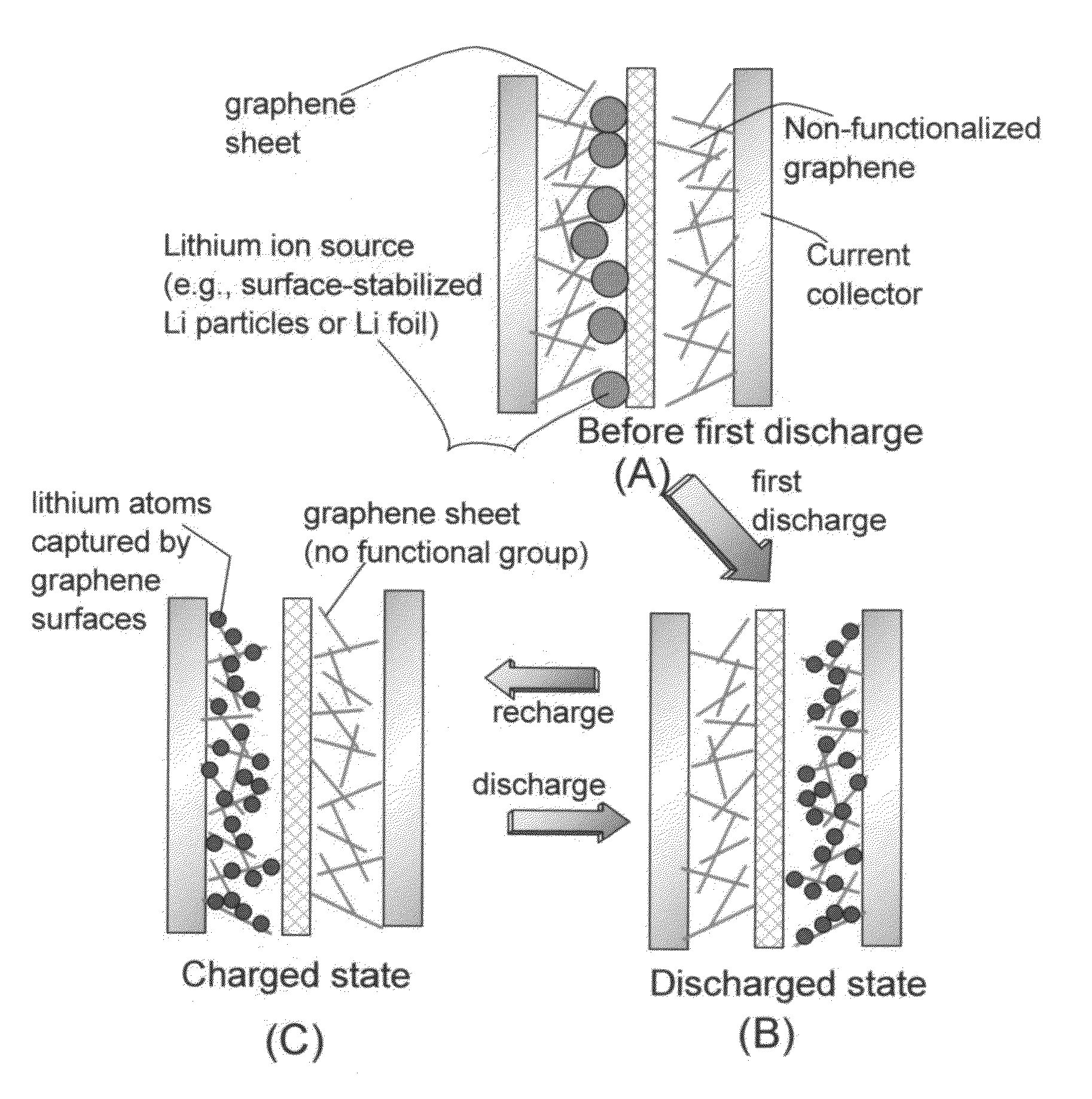

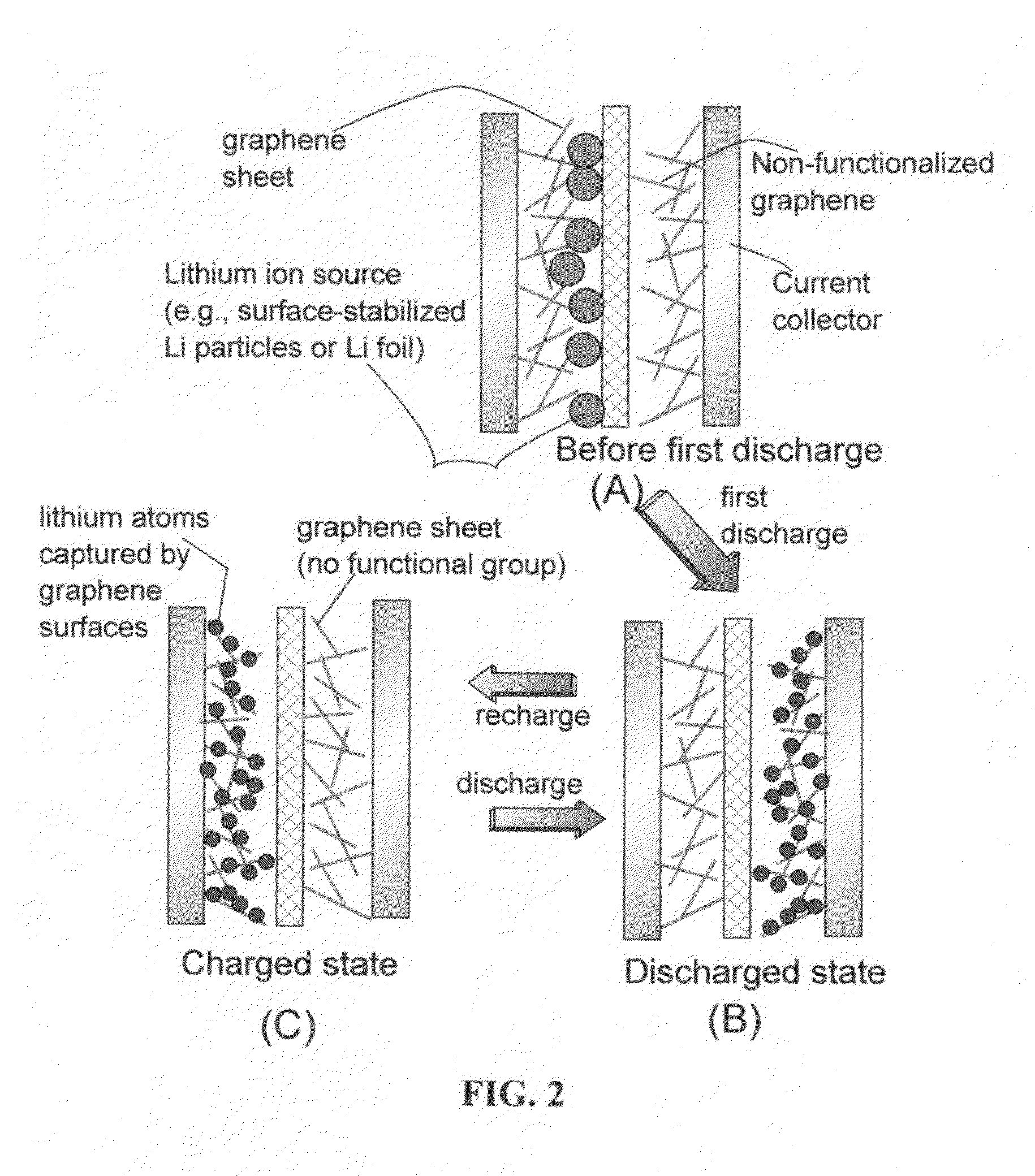

Partially surface-mediated lithium ion-exchanging cells and method for operating same

ActiveUS20130059174A1Short charging timeEasy to handleHybrid capacitor electrolytesAlkaline accumulatorsIon exchangeSupercapacitor

A lithium super-battery cell comprising: (a) A cathode comprising a cathode active material having a surface area to capture or store lithium thereon, wherein the cathode active material is not a functionalized material and does not bear a functional group; (b) An anode comprising an anode current collector; (c) A porous separator disposed between the two electrodes; (d) A lithium-containing electrolyte in physical contact with the two electrodes, wherein the cathode active material has a specific surface area of no less than 100 m2 / g being in direct physical contact with the electrolyte to receive lithium ions therefrom or to provide lithium ions thereto; and (e) A lithium source implemented at one or both of the two electrodes prior to a first charge or a first discharge cycle of the cell. This new generation of energy storage device exhibits the best properties of both the lithium ion battery and the supercapacitor.

Owner:GLOBAL GRAPHENE GRP INC +1

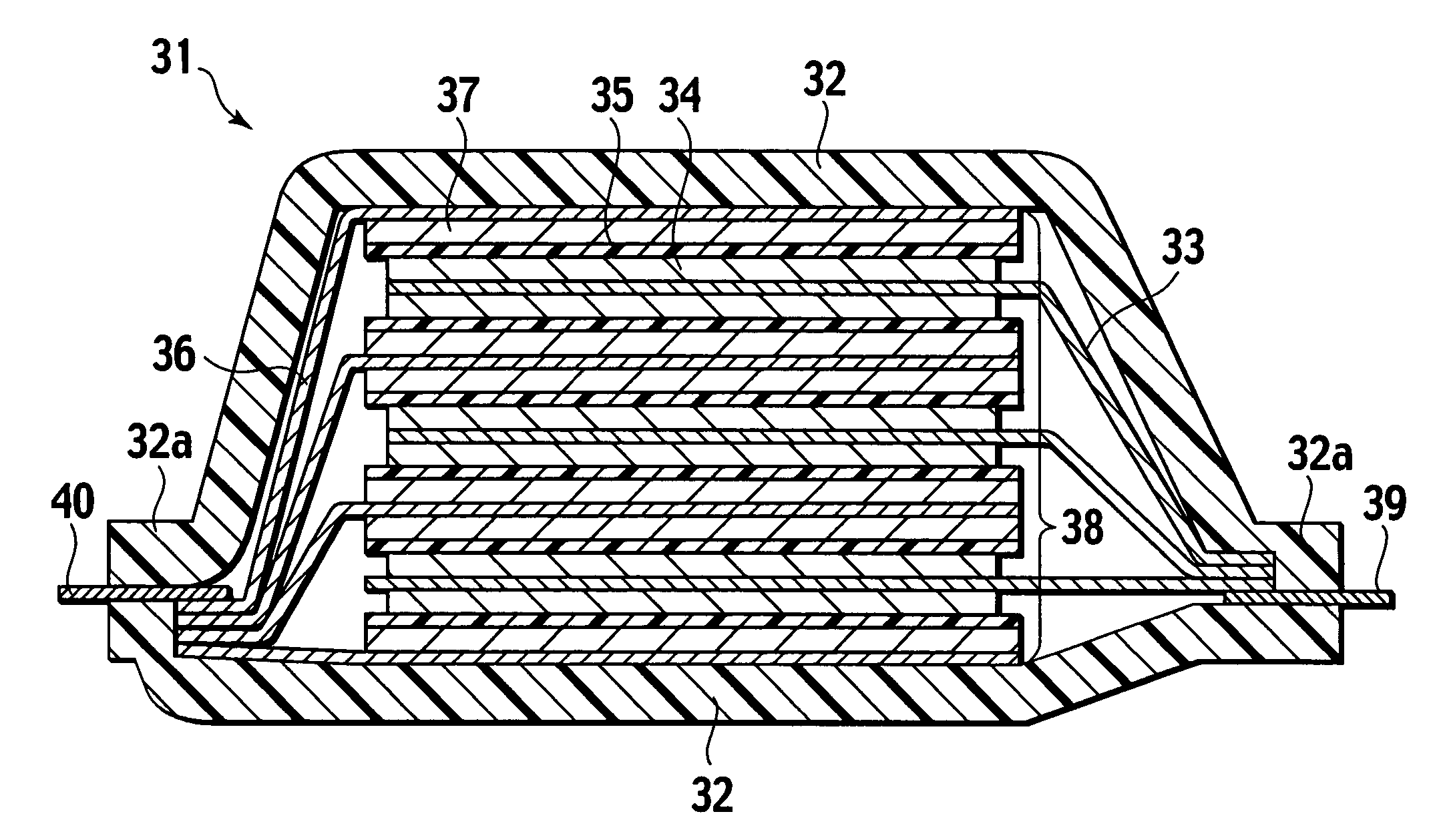

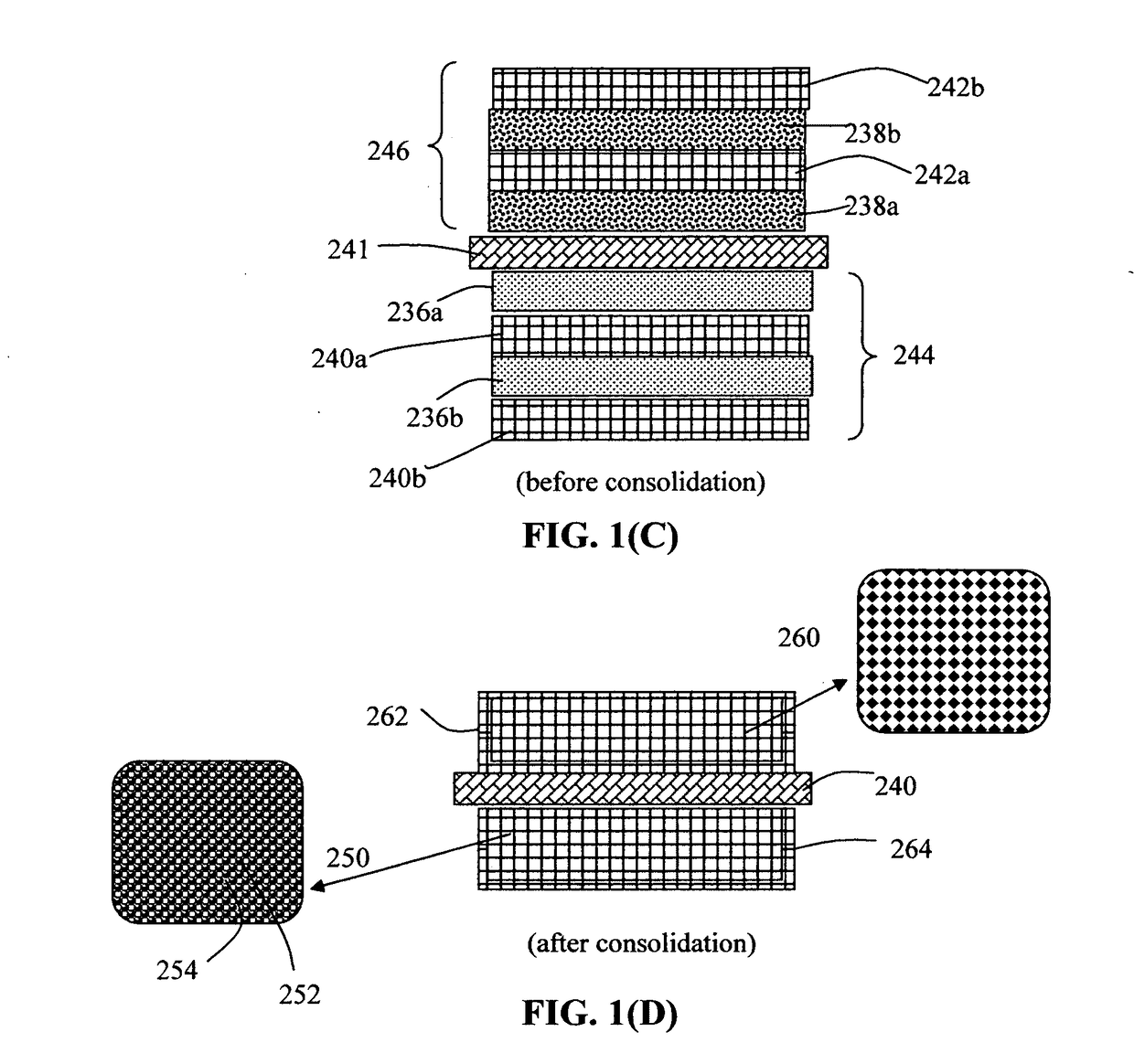

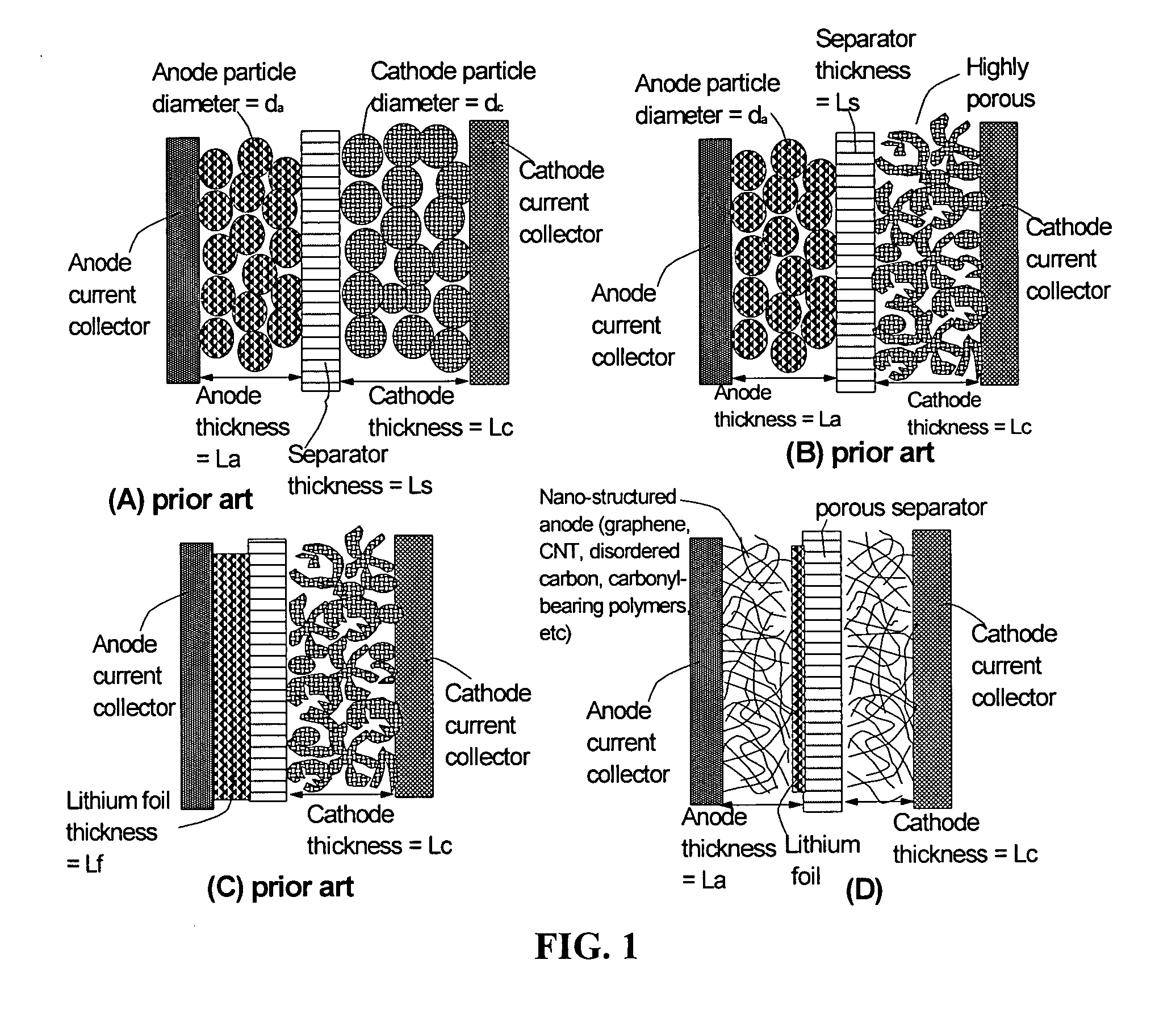

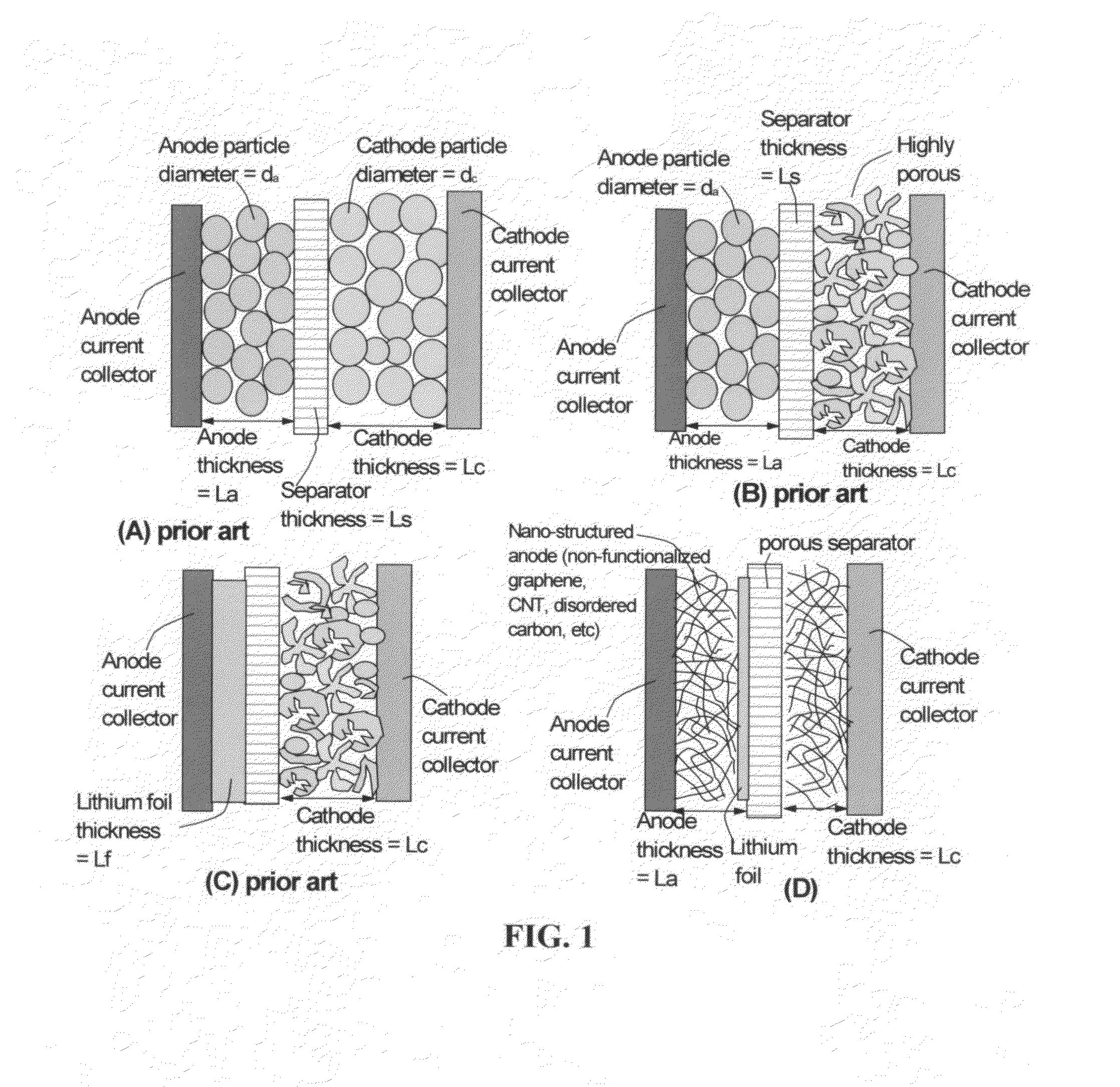

Process for producing lithium batteries having an ultra-high energy density

ActiveUS20170098856A1Increase energy densityImprove power densityFinal product manufactureNon-aqueous electrolyte cellsPorous layerHigh energy

A process for producing a lithium battery, comprising: (A) Preparing a plurality of conductive porous layers, wet anode layers, and wet cathode layers; (B) Stacking a desired number of porous layers and wet anode layers in an alternating manner to form an anode electrode having a thickness no less than 100 μm; (C) Placing a porous separator layer in contact with the anode electrode; (D) Stacking a desired number of porous layers wet cathode layers in an alternating manner to form a cathode electrode in contact with the porous separator, wherein the cathode electrode has a thickness no less than 100 μm; and (F) Assembling and sealing the anode electrode, separator, and cathode electrode in a housing to produce the lithium battery. The consolidated anode or cathode layer is preferably thicker than 300 more preferably thicker than 400 μm, and further more preferably greater than 500 μm.

Owner:GLOBAL GRAPHENE GRP INC

Swelling inhibition in batteries

InactiveUS20090035646A1Increase in sizeNon-aqueous electrolyte cellsSecondary cells charging/dischargingBiologyElectrochemical cell

The present invention relates generally to electrochemical cells, and more specifically, to additives for electrochemical cells which may enhance the performance of the cell. In some cases, the additive may advantageously interact with at least one component or species of the cell to increase the efficiency and / or lifetime of the cell. The incorporation of certain additives within the electrolyte of the cell may improve the cycling lifetime and / or performance of the cell.

Owner:SION POWER CORP

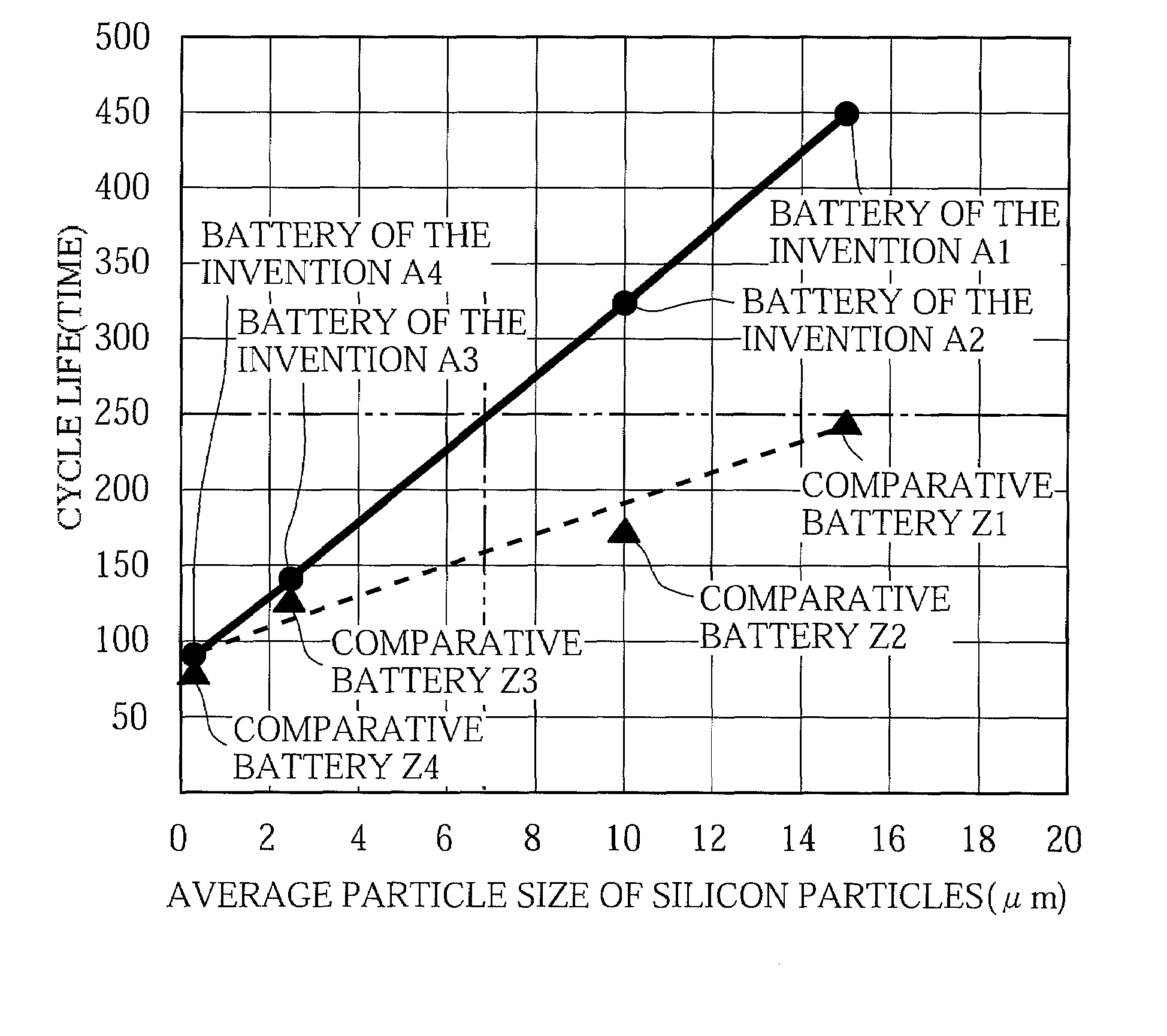

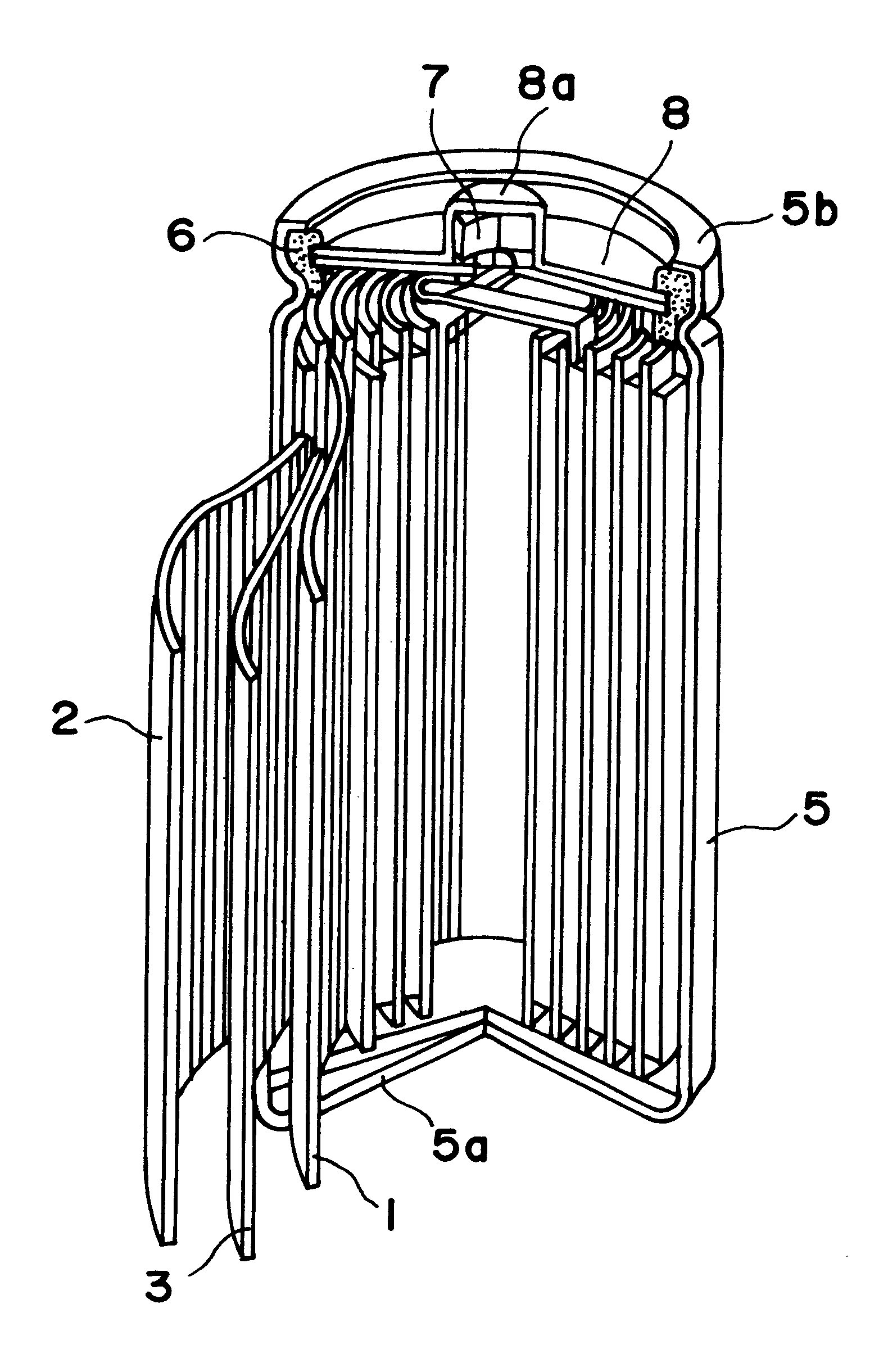

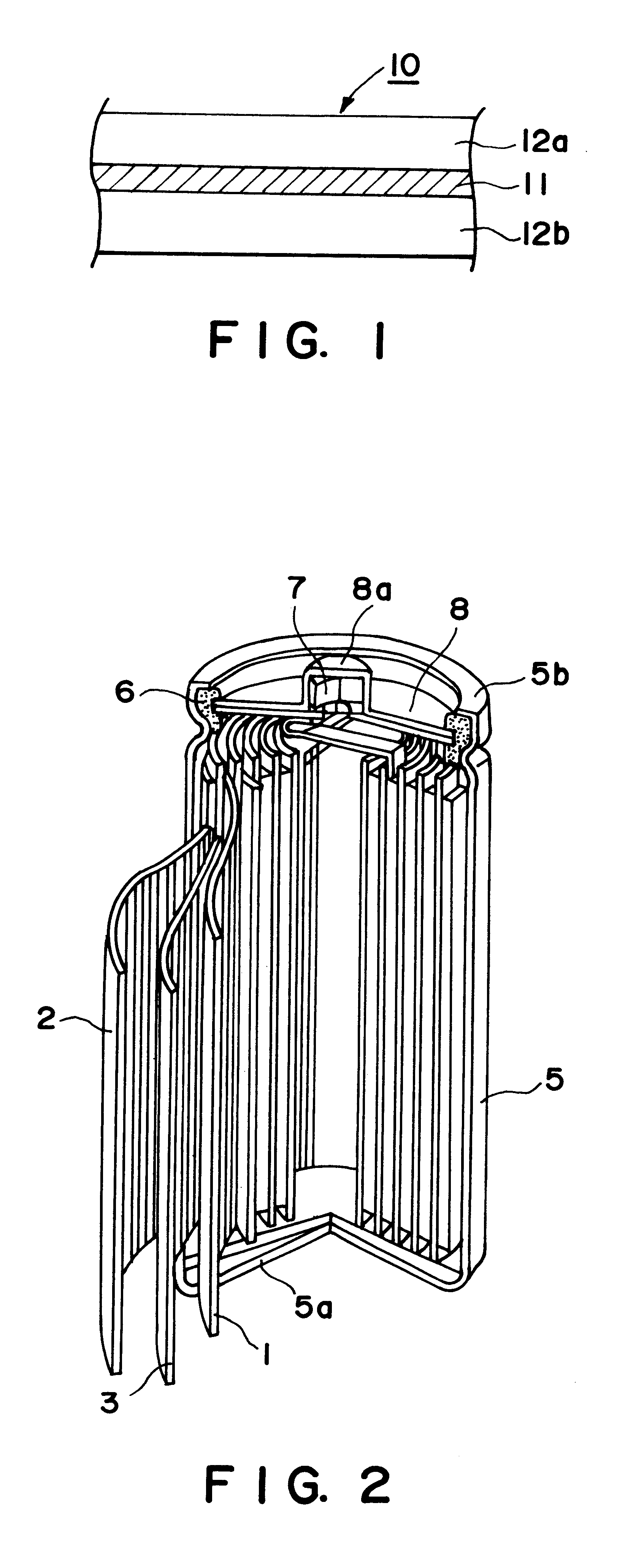

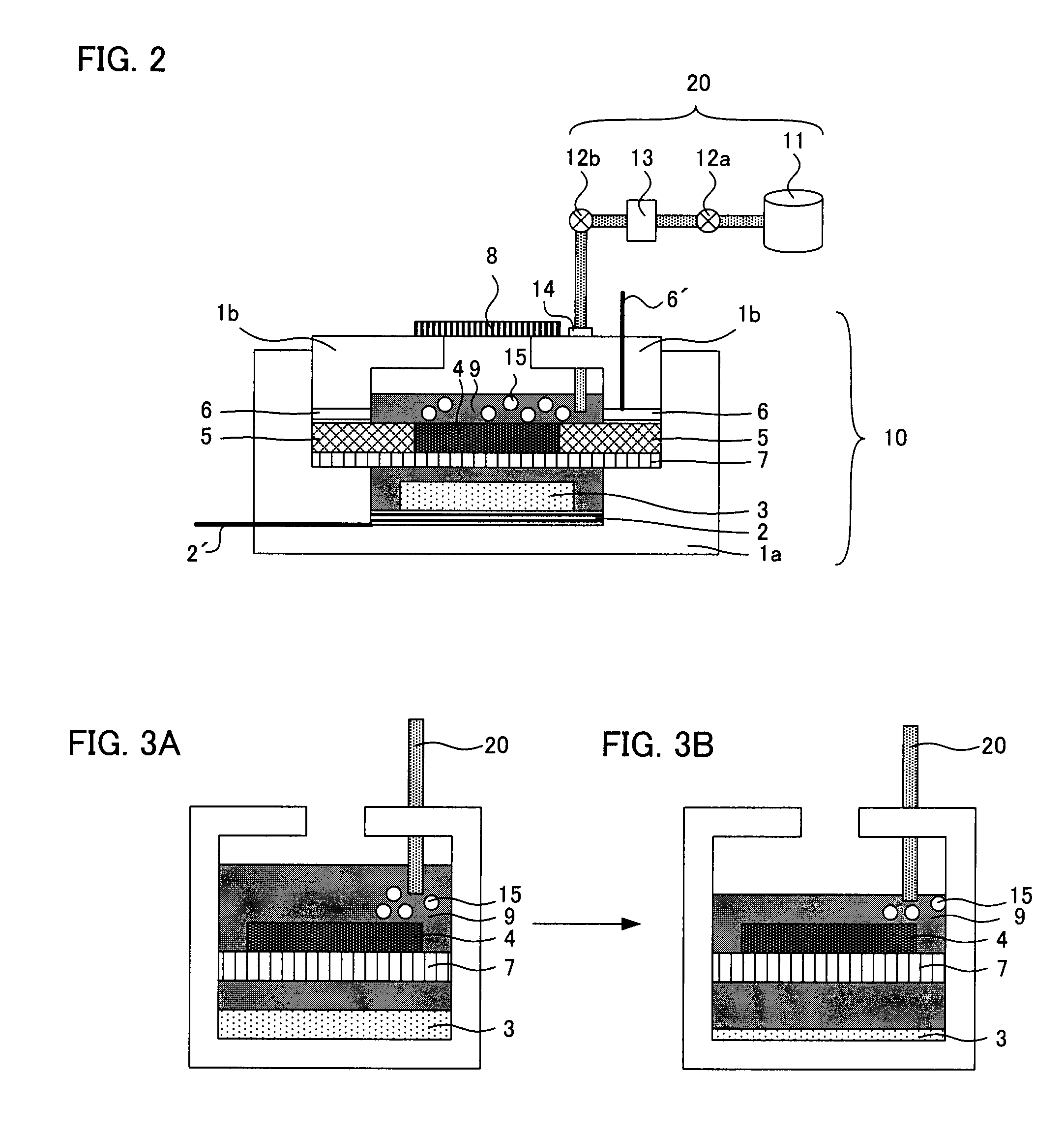

Lithium secondary battery and method of manufacturing the same

ActiveUS20090305129A1Excellent charge and discharge characteristicsImprove responseElectrode manufacturing processesFinal product manufactureSilicon alloyEngineering

[Problem] An object of the invention is to provide a lithium secondary battery that shows good cycle performance and at the same time prevents a battery thickness increase due to charge-discharge cycles, and a method of manufacturing such a battery.[Means for Solving the Problem] A lithium secondary battery includes a negative electrode (2) having a negative electrode current collector (11) and a negative electrode active material layer (12) disposed on the negative electrode current collector (11), a positive electrode (1) having a positive electrode active material, a separator (3), and a non-aqueous electrolyte. The negative electrode active material layer includes negative electrode active material particles and a negative electrode binder, and the negative electrode active material particles include silicon particles and / or silicon alloy particles. The silicon particles and the silicon alloy particles have a crystallite size of 100 nm or less.

Owner:PANASONIC ENERGY CO LTD

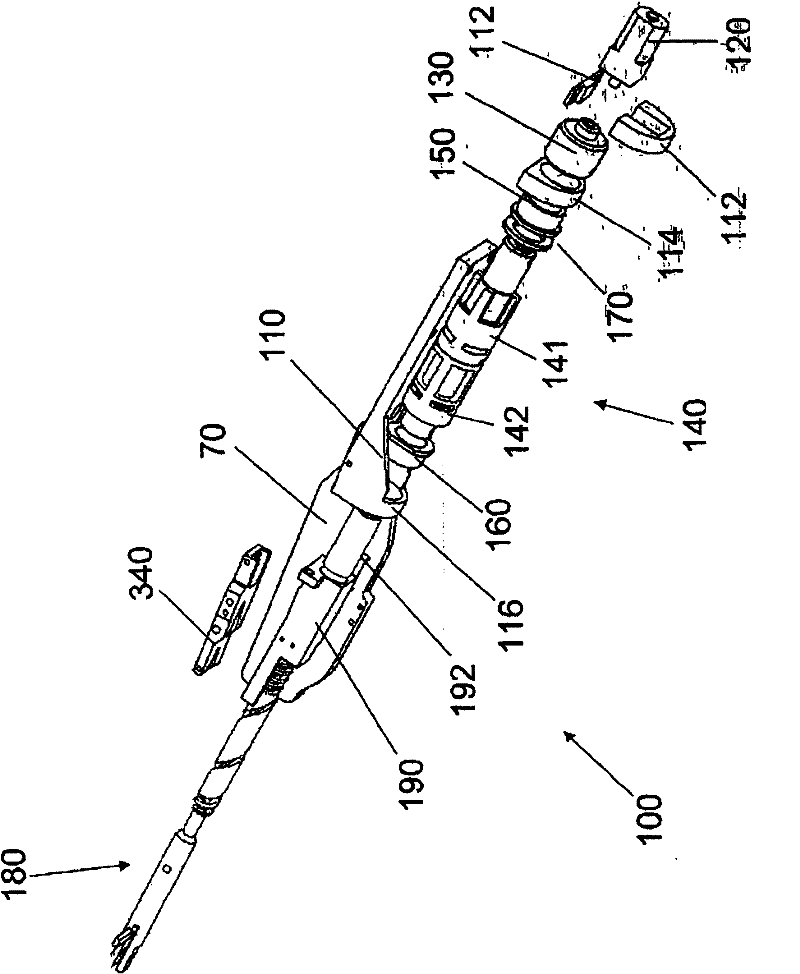

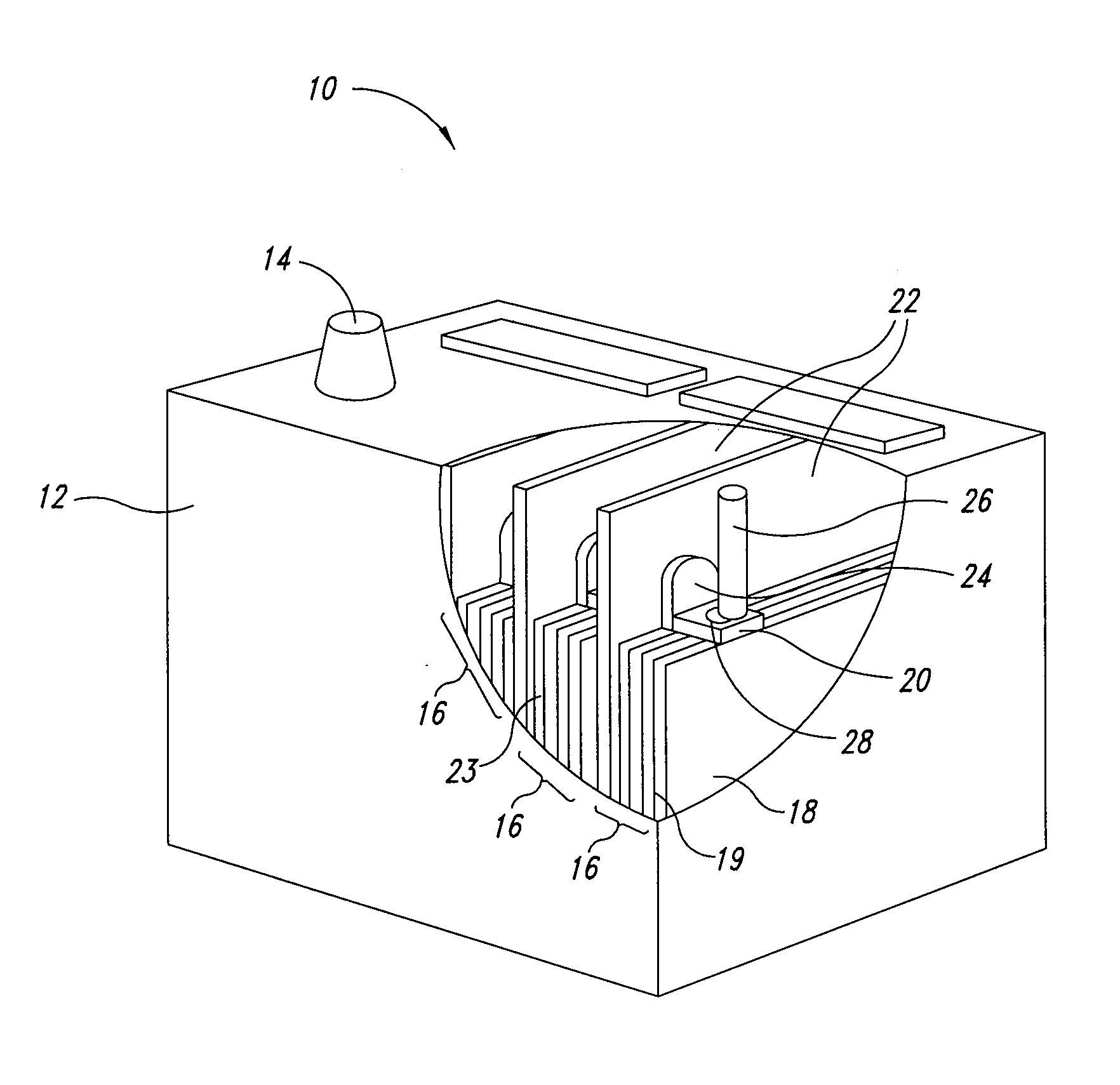

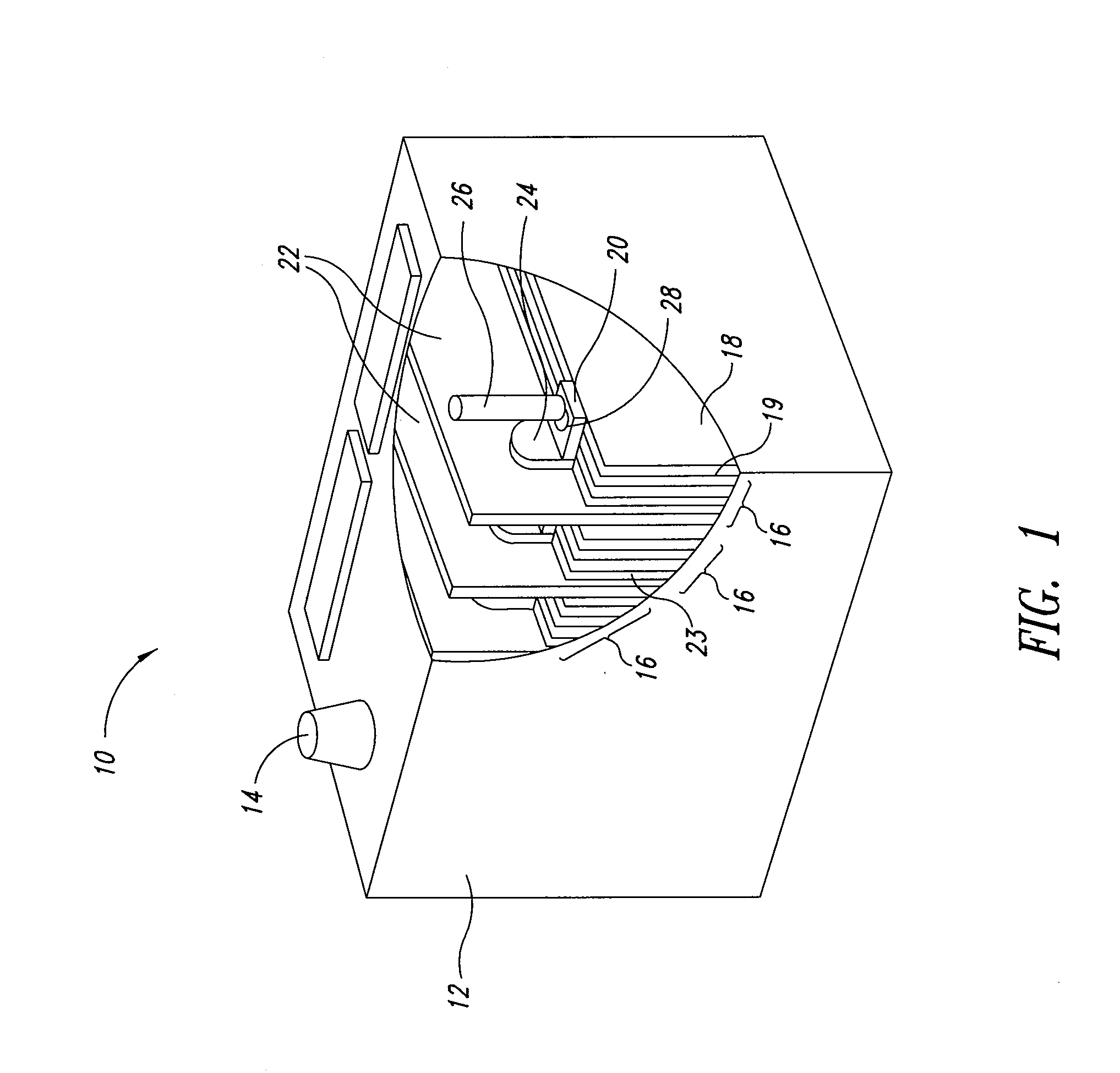

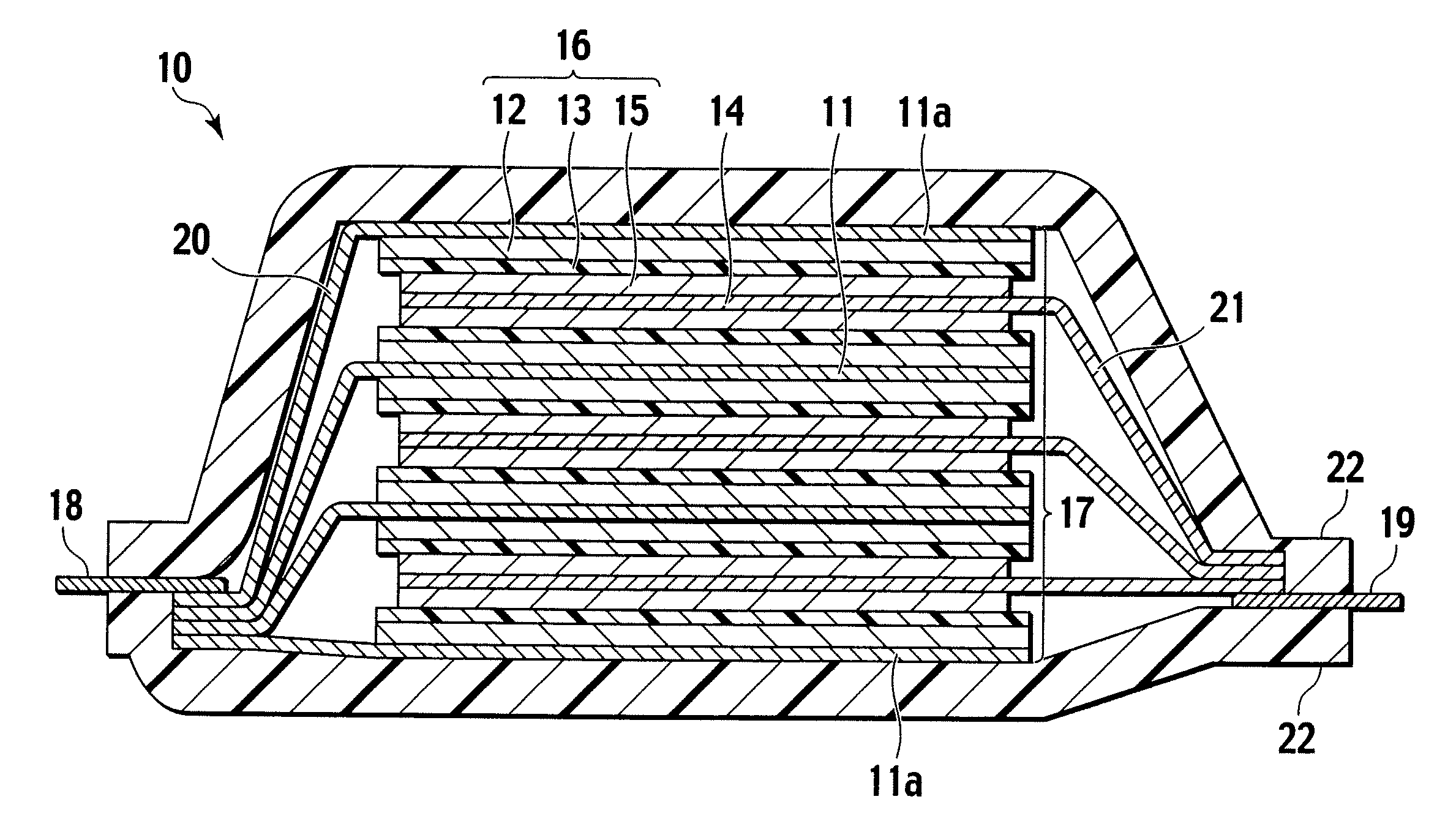

Elongate battery for implantable medical device

ActiveUS20100305629A1Robust controlSufficient operating lifeElectrode carriers/collectorsPrimary cell electrodesElectrical batteryEngineering

A battery assembly for a medical device includes an elongate cathode, an elongate anode, an electrolyte, and an elongate housing assembly encapsulating the cathode, the anode, and the electrolyte. The battery assembly also includes a first electrode exposed from and electrically insulated from the housing assembly. One of the anode and the cathode is electrically coupled to the first electrode, and the other of the anode and the cathode is electrically coupled to the housing assembly. Respective axes of the cathode and the anode are substantially parallel to an axis of the housing assembly, and the cathode and anode each include a flat portion that face each other.

Owner:MEDTRONIC INC

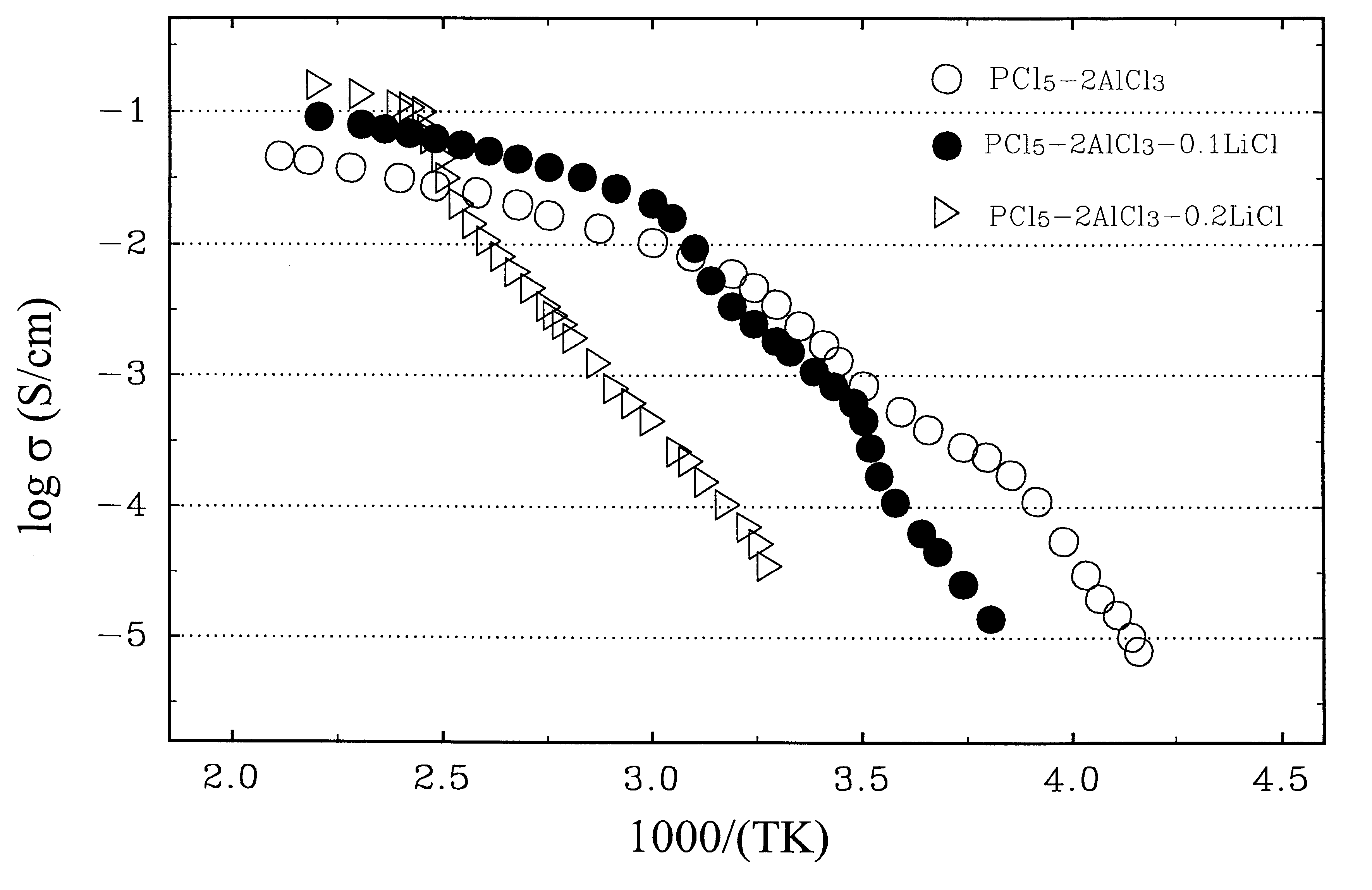

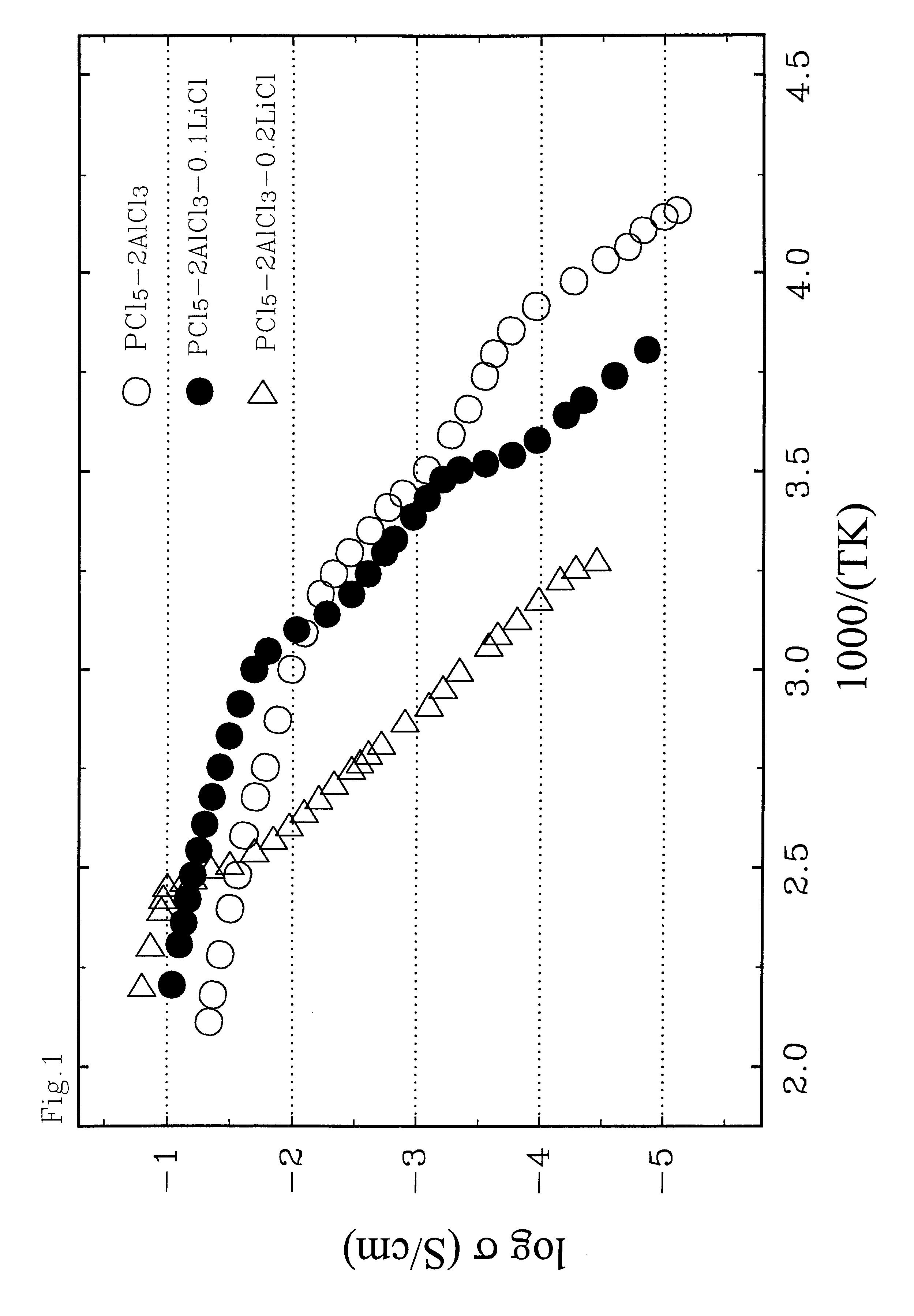

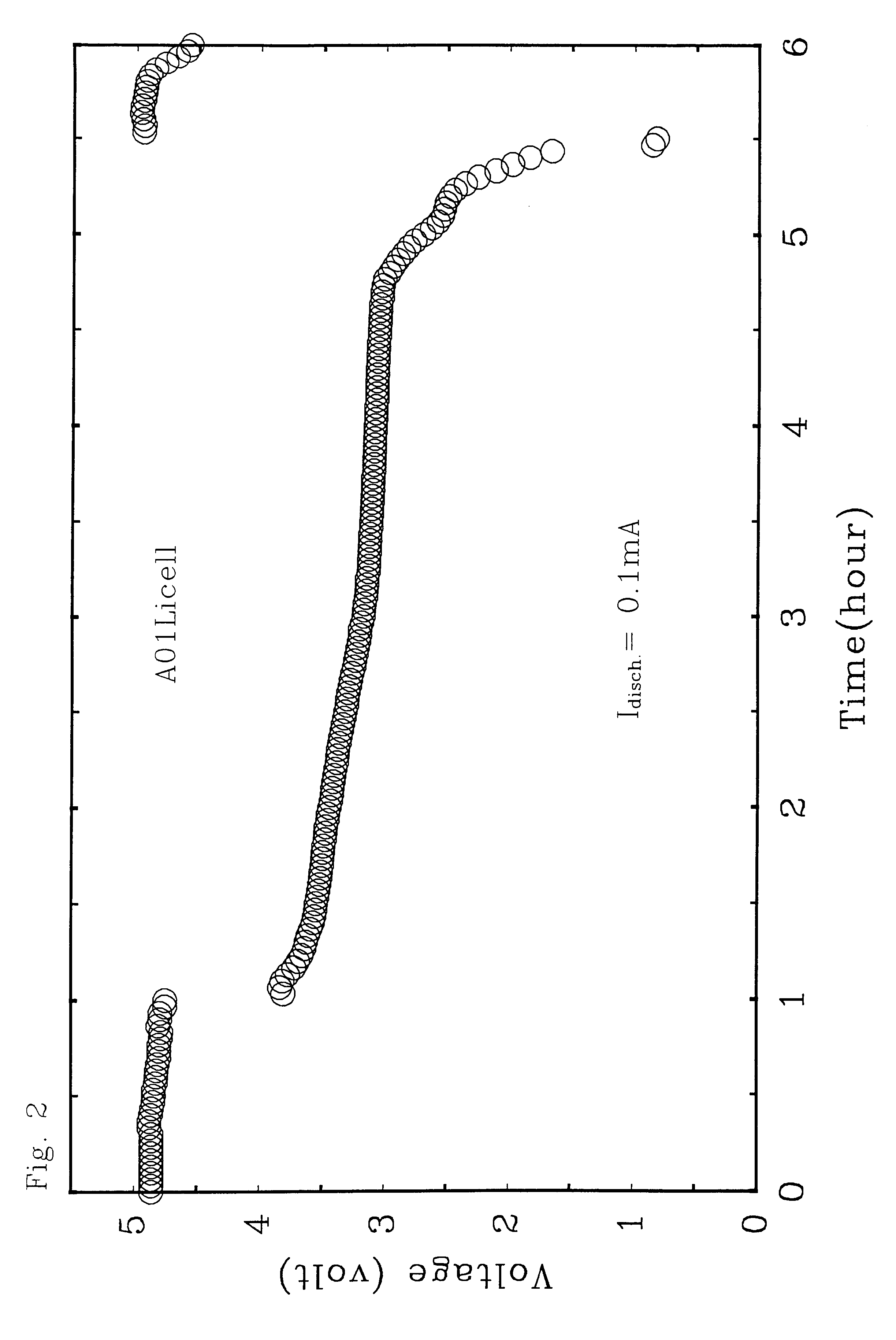

Ambient temperature, rechargeable cells with metal salt-based electrodes and a system of cell component materials for use therein

InactiveUS6187479B1Improve battery performanceImprove performanceLead-acid accumulatorsNon-aqueous electrolyte cellsHalogenRechargeable cell

A rechargeable battery or cell is disclosed in which the electrode active material consists of at least one nonmetallic compound or salt of the electropositive species on which the cell is based, and the electrolyte or electrolyte solvent consists predominantly of a halogen-bearing or chalcogen-bearing covalent compound such as SOCl2 or SO2Cl2. Also disclosed are cell component materials which include electrodes that consist primarily of salts of the cell electropositive species and chemically compatible electrolytes. These latter electrolytes include several newly discovered ambient temperature molten salt systems based on the AlCl3-PCl5 binary and the AlCl3-PCl5-PCl3 ternaries.

Owner:LIU CHANGLE

Electrolyte for lithium ion secondary battery and lithium ion secondary battery comprising the same

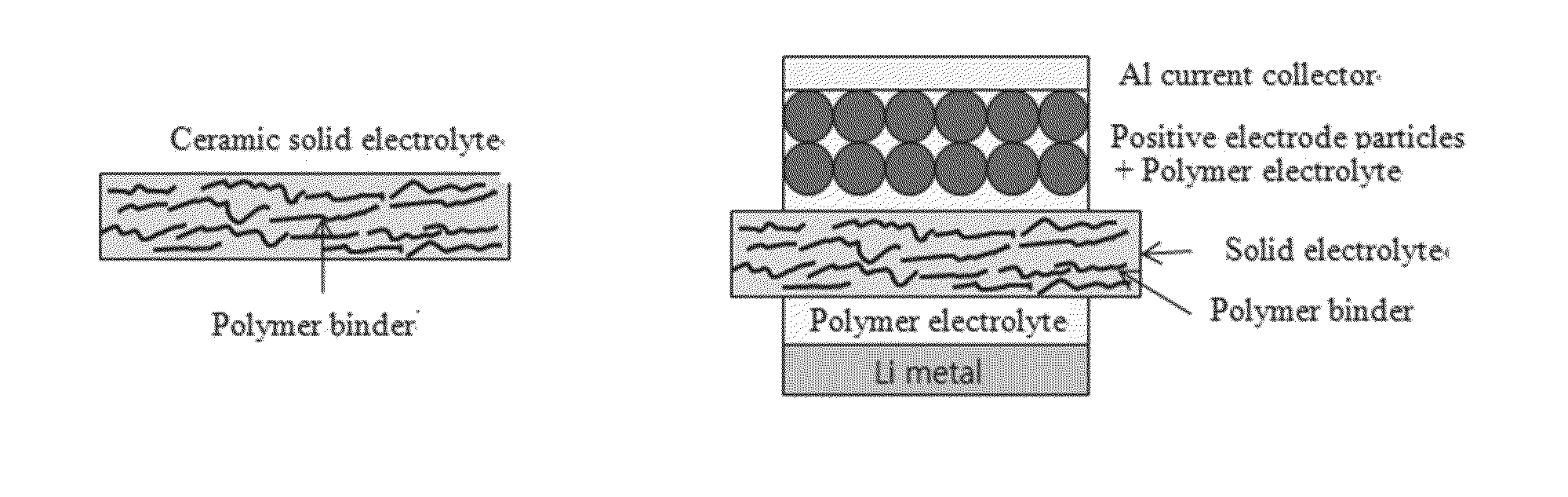

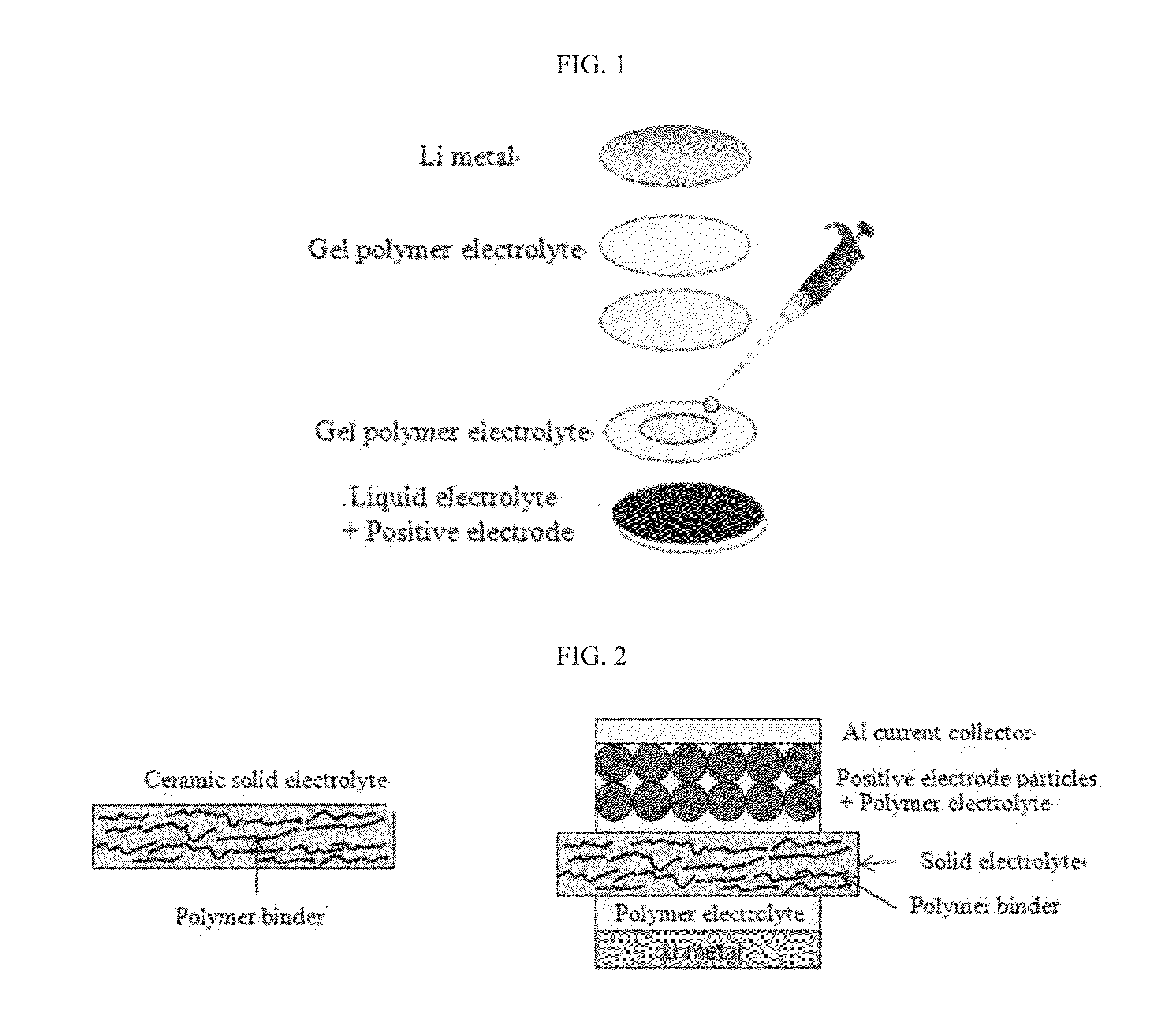

ActiveUS20130260257A1Improve ionic conductivityIncrease flexibilitySolid electrolytesNon-aqueous electrolyte cellsIonLayered structure

Provided are a multi-layered structure electrolyte including a gel polymer electrolyte on opposite surfaces of a ceramic solid electrolyte, for a lithium ion secondary battery including positive and negative electrodes capable of intercalating / deintercalating lithium ions, and a lithium ion secondary battery including the electrode. The electrolyte includes a gel polymer electrolyte on opposite surfaces of a ceramic solid electrolyte.

Owner:SAMSUNG SDI CO LTD

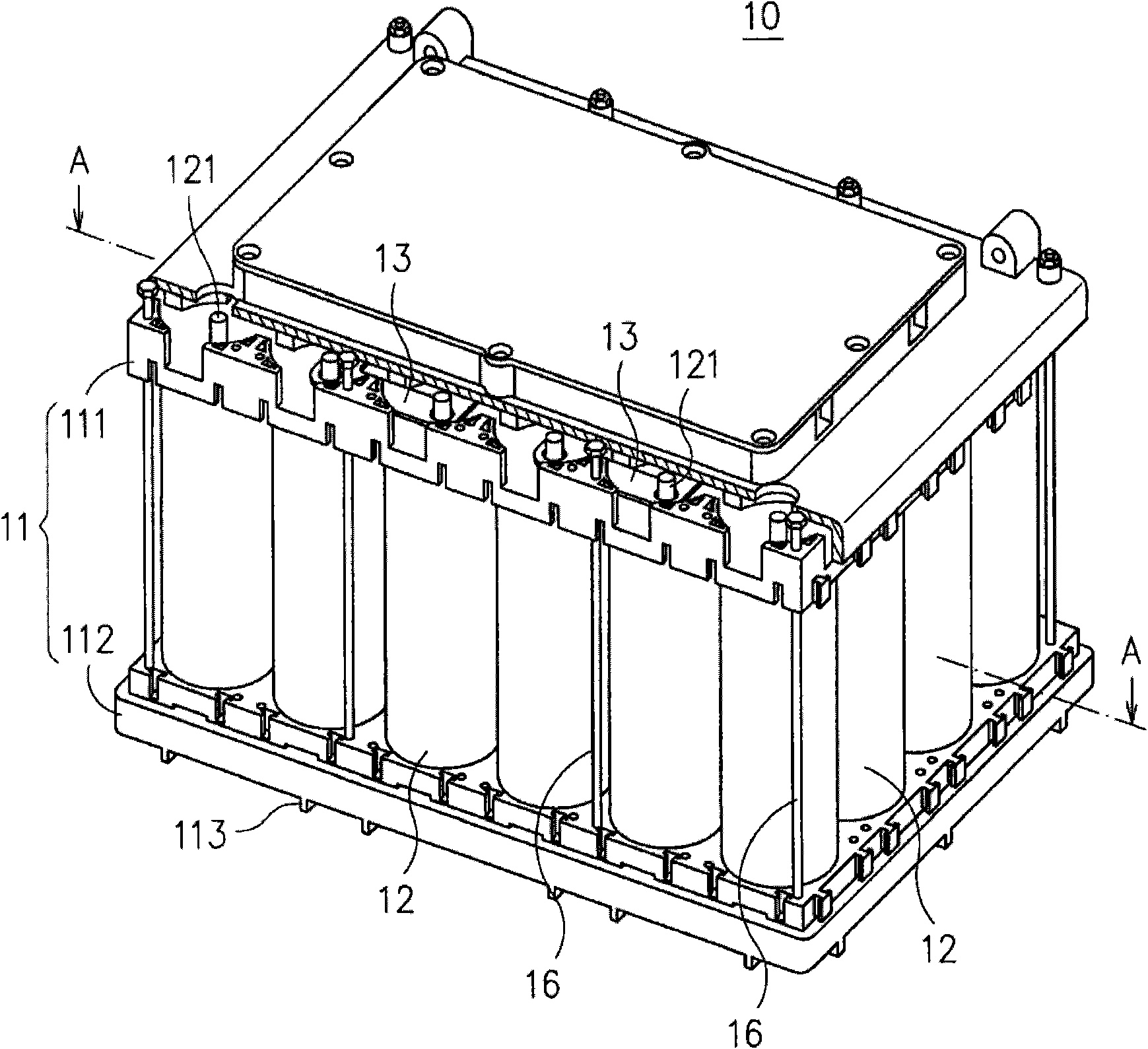

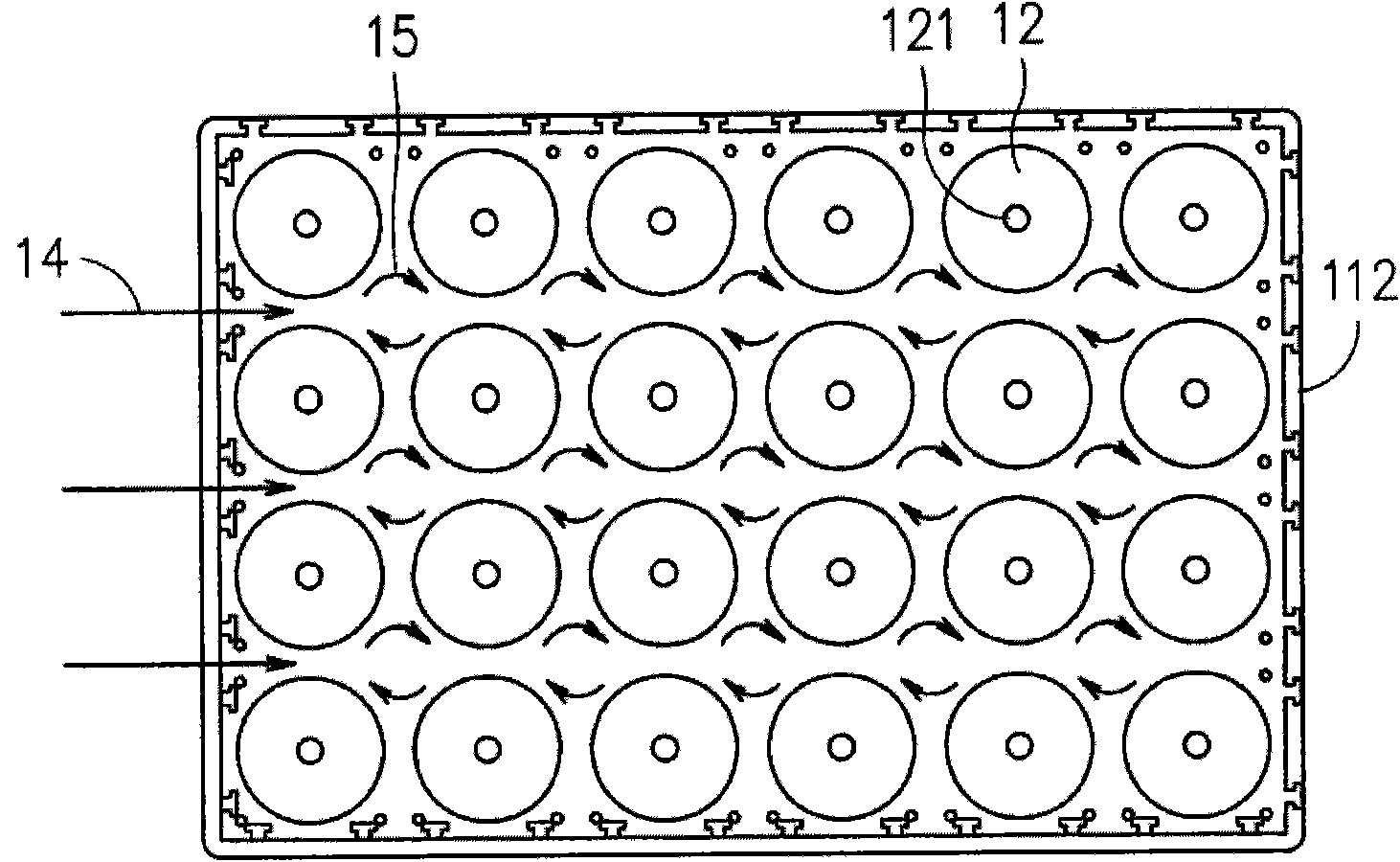

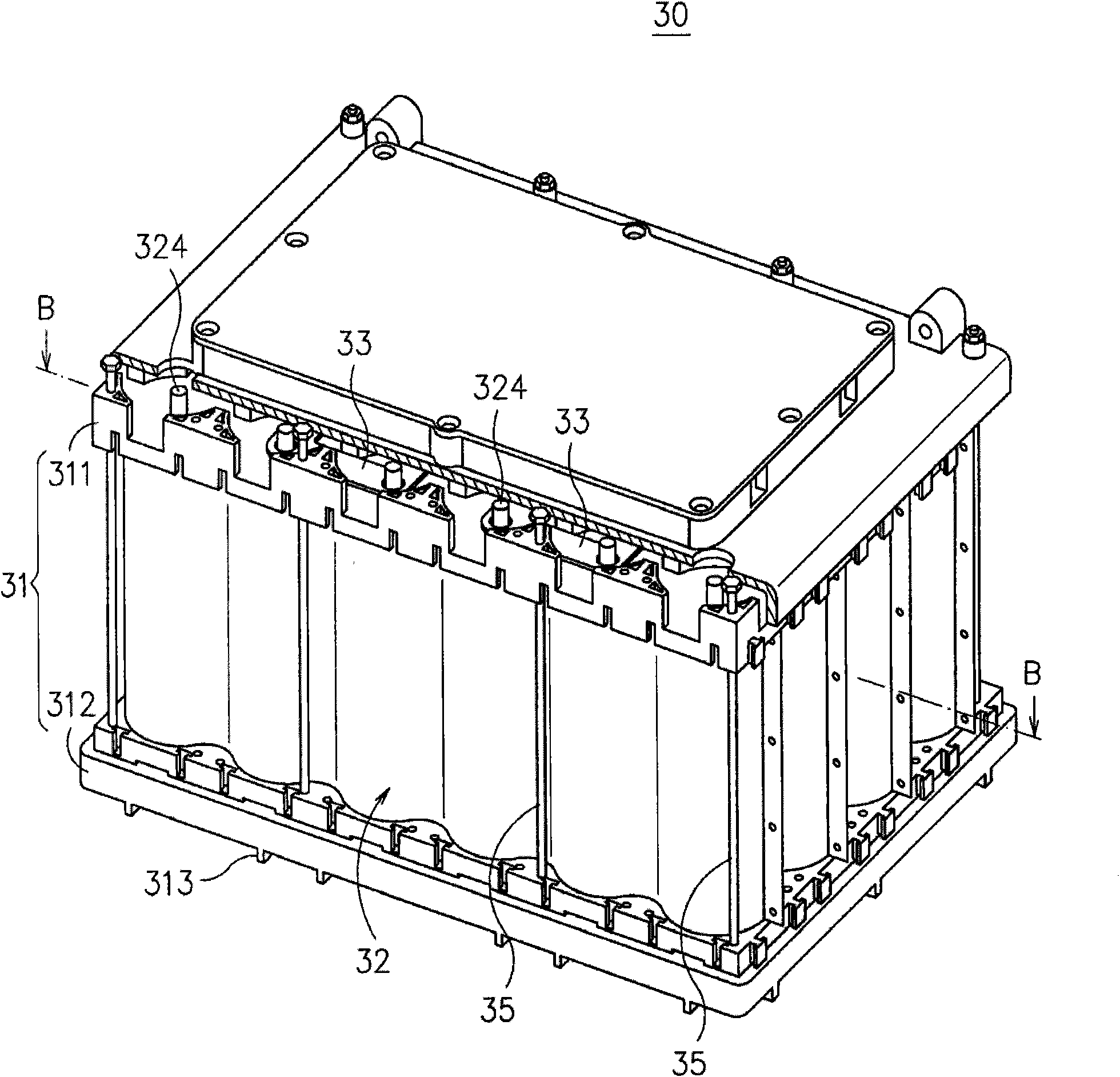

Battery pack with thermal conducting adhesives

InactiveCN102055003ALower working temperatureAverage temperature differencePrimary cell maintainance/servicingNon-aqueous electrolyte cellsElectricityAdhesive

The invention discloses a battery pack with thermal conducting adhesives. The battery pack comprises a shell and a plurality of battery units, wherein the shell is provided with a cooling device, the battery units are arranged in the shell, the thermal conducting adhesives with an electric insulation characteristic and a thermal conducting characteristic are arranged outside the battery units and are in contact with the outer surfaces of the battery units.

Owner:IND TECH RES INST

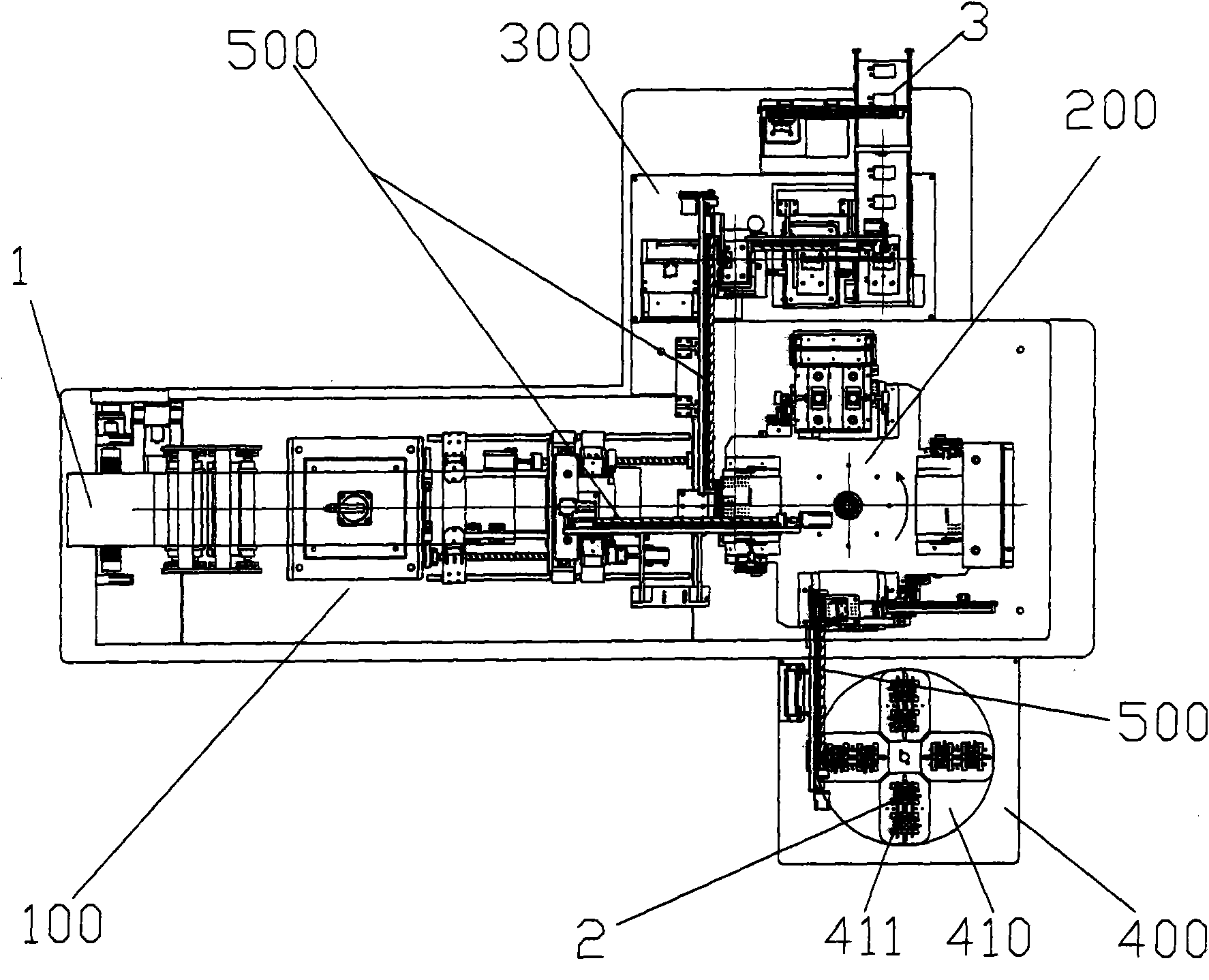

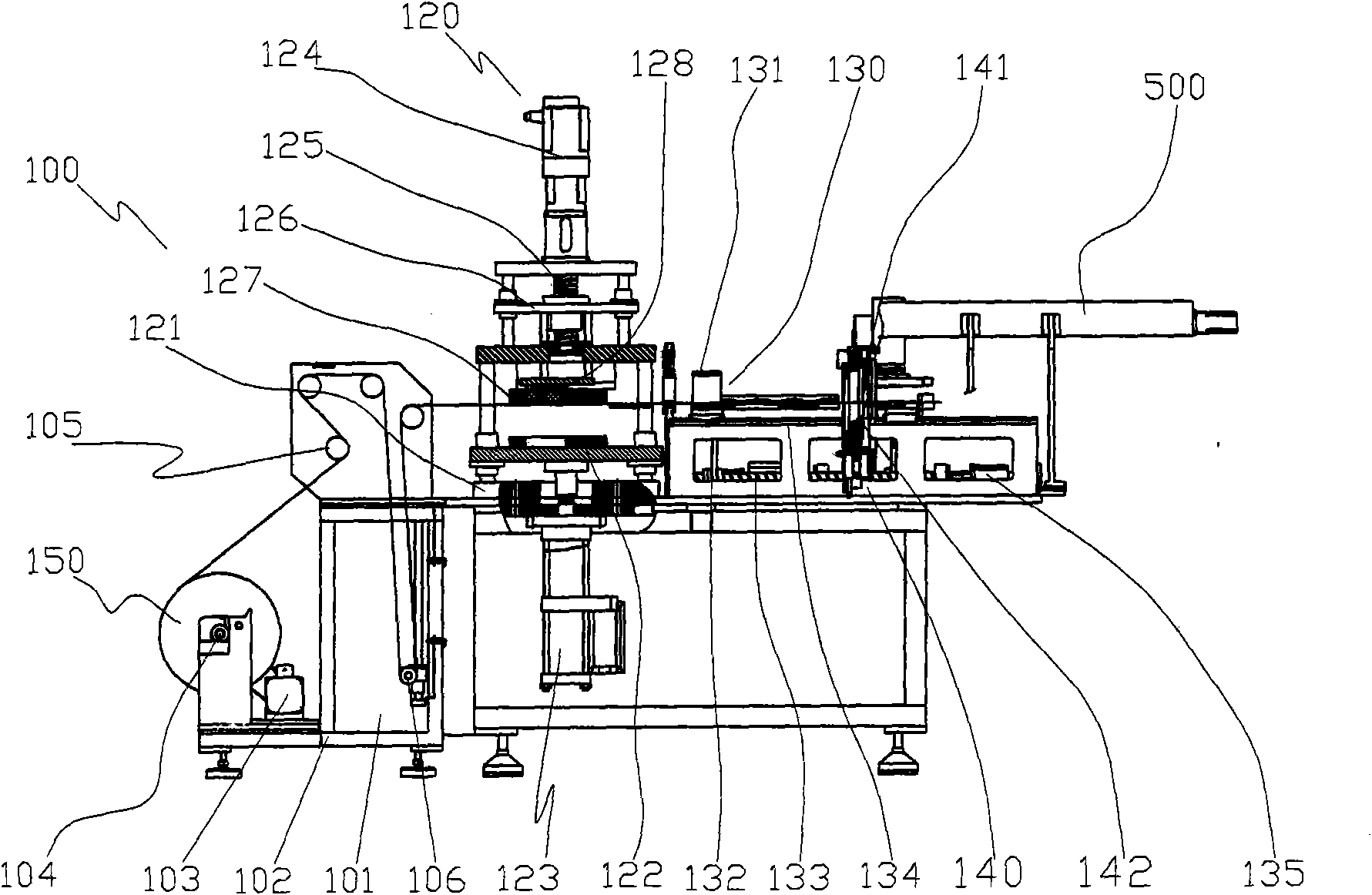

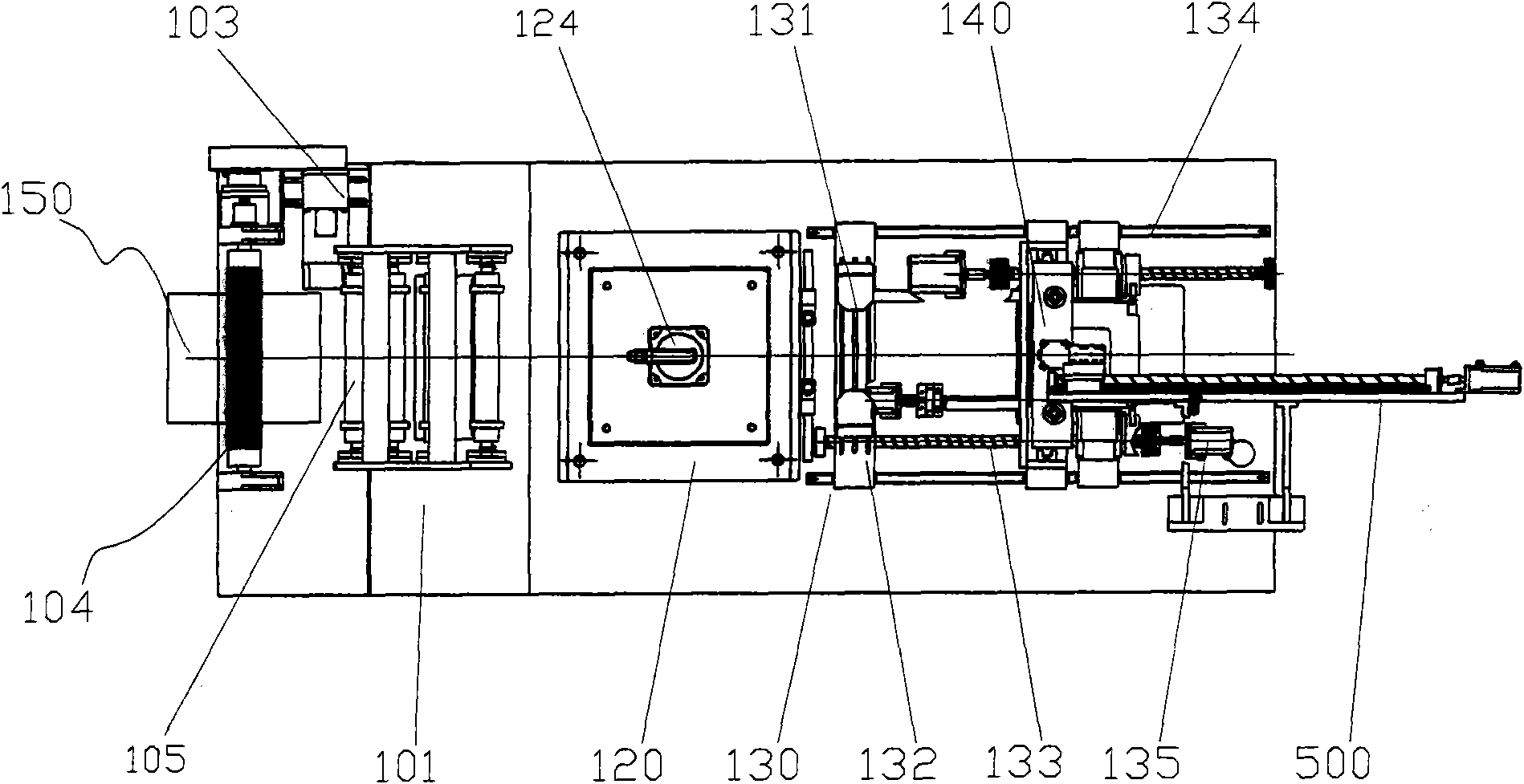

Battery assembling and packaging device

ActiveCN101789525AIncrease the level of automationImprove performanceFinal product manufactureNon-aqueous electrolyte cellsProduction linePunching

The invention relates to a battery assembling and packaging device, comprising an aluminium plastic film forming flaking unit, an assembling and packaging unit, an electrode group charging unit and an auxiliary unit. Aluminium plastic film punching and forming, electrode group feeding and automatic assembly of the two are sequentially realized, then top edge and side edge of packaging bag are sealed and adhered, and test classification is carried out on packaging product, thus automation of batter production line can be effectively improved. The invention has the advantages of convenient operation, high production efficiency, reliable product performance, low production cost and less waste.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

Gel electrolytes for dye sensitized solar cells

Replacing liquid electrolytes with solid or quasi-solid electrolytes facilitates the production of photovoltaic cells using continuous manufacturing processes, such as roll-to-roll or web processes, thus creating inexpensive, lightweight photovoltaic cells using flexible plastic substrates.

Owner:MERCK PATENT GMBH

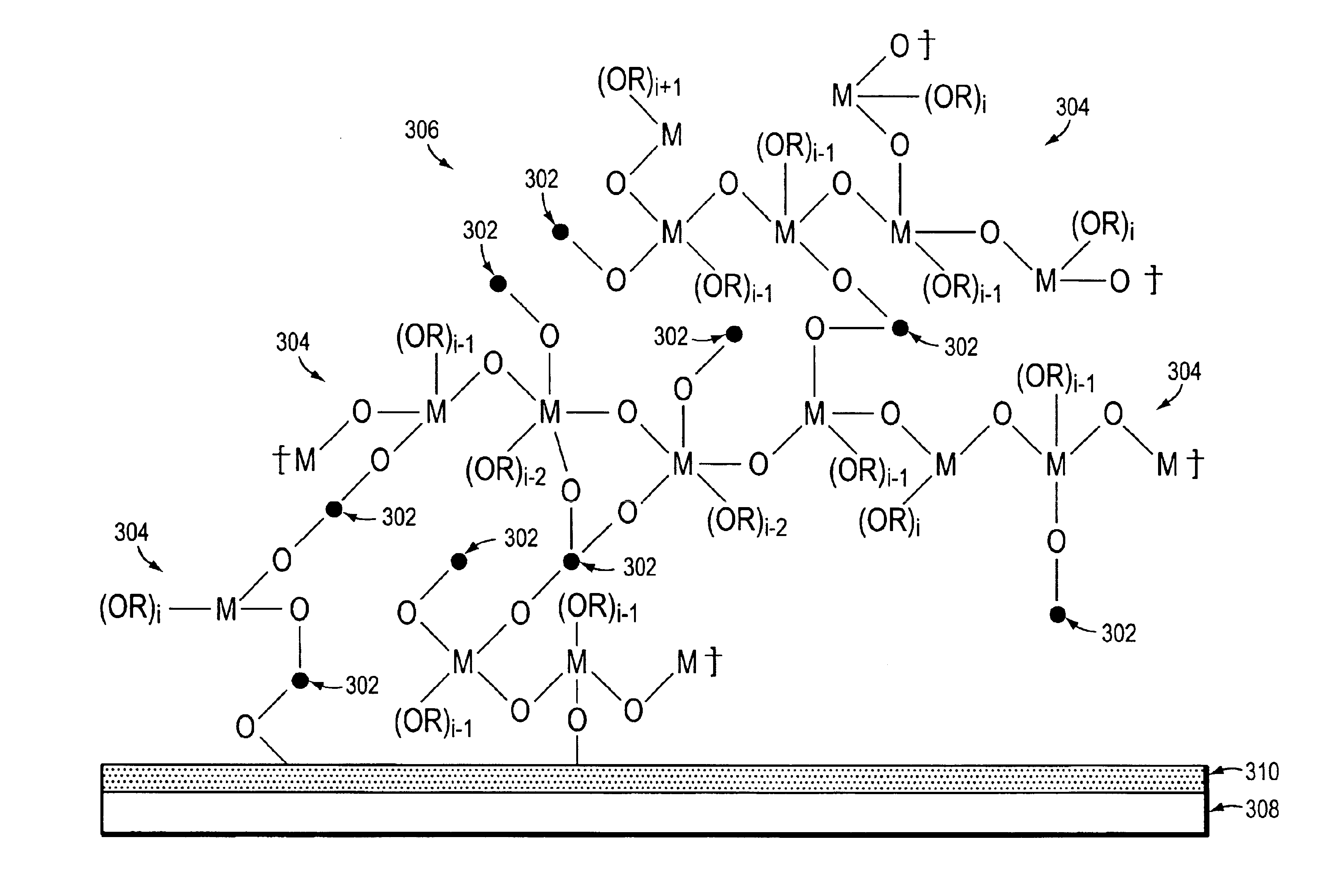

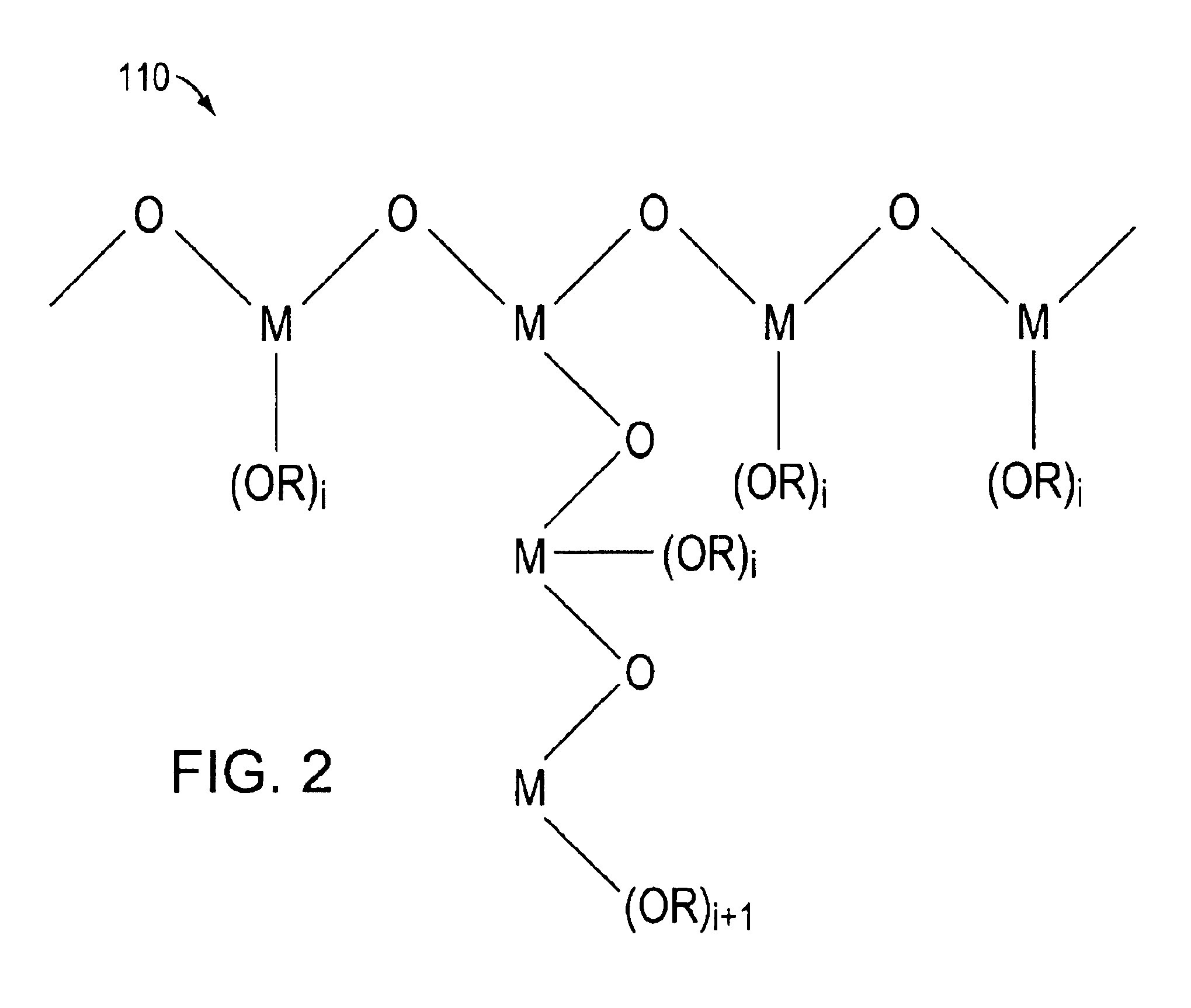

Surface -controlled lithium ion-exchanging energy storage device

ActiveUS20120164539A1Easy to handleShort charging timeAlkaline accumulatorsHybrid capacitor electrolytesElectrical batterySupercapacitor

A surface-controlled, lithium ion-exchanging battery device comprising: (a) A positive electrode (cathode) comprising a first functional material having a first lithium-capturing or lithium-storing surface; (b) A negative electrode (anode) comprising a second functional material having a second lithium-capturing or lithium-storing surface; (c) A porous separator disposed between the two electrodes, and (d) A lithium-containing electrolyte (preferably liquid or gel electrolyte) in physical contact with the two electrodes; wherein at least one of the two electrodes contains therein a lithium source (e.g., lithium foil, lithium powder, stabilized lithium particles, etc) prior to the first charge or the first discharge cycle of the battery device. This new generation of energy storage device exhibits the best properties of both the lithium ion battery and the supercapacitor.

Owner:GLOBAL GRAPHENE GRP INC +1

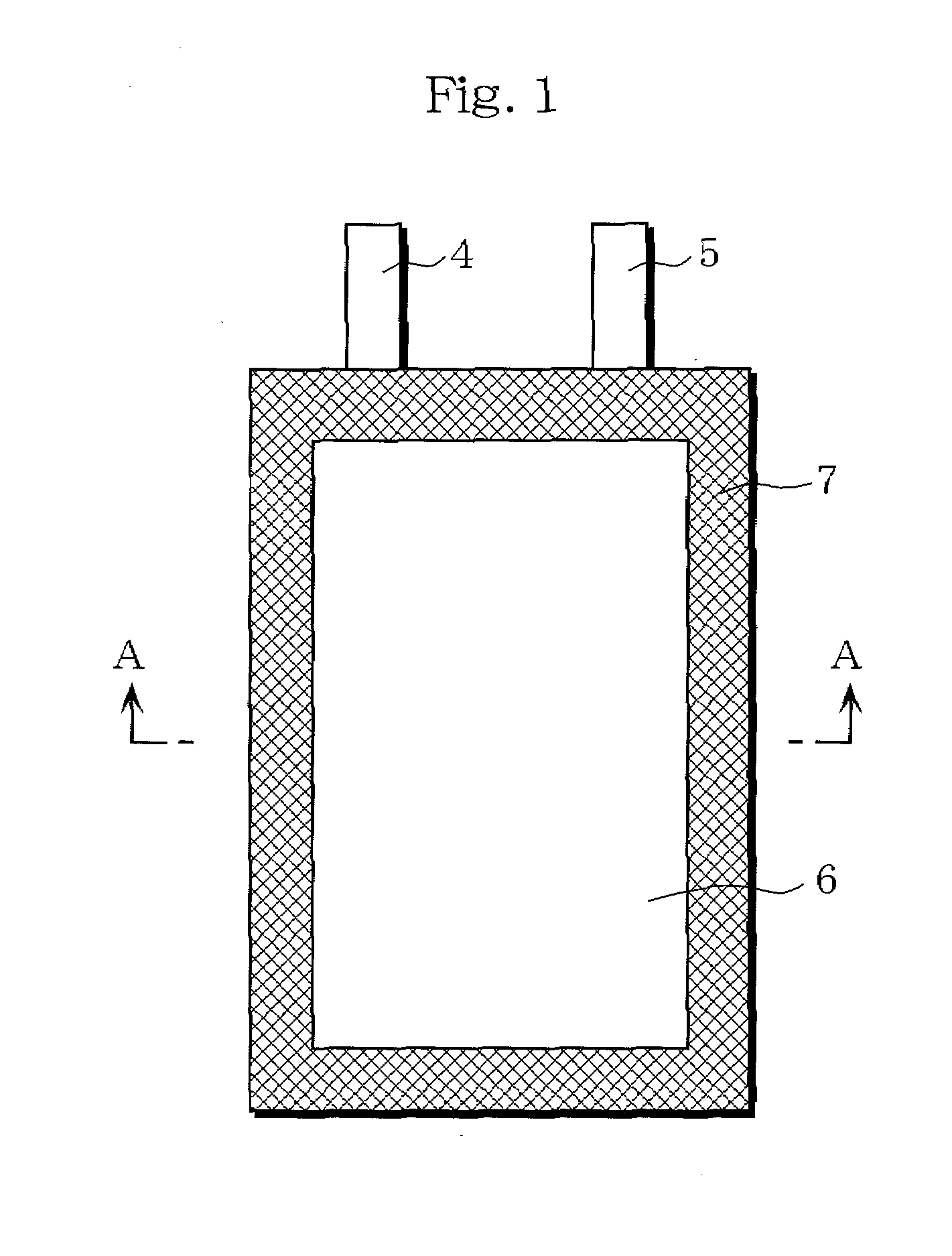

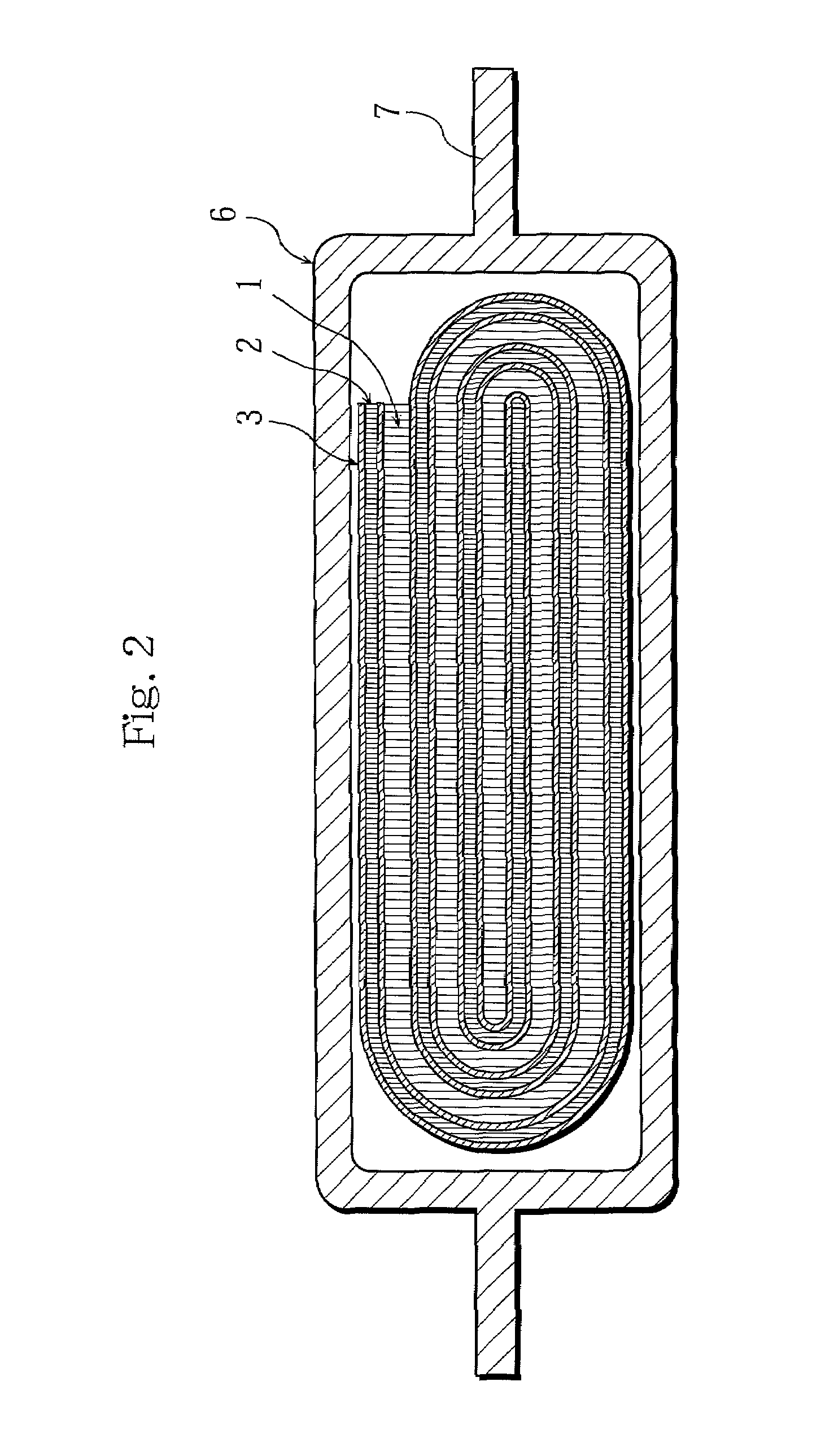

Bipolar battery

ActiveUS7163765B2Liquid junctionFinal product manufactureElectrode carriers/collectorsEngineeringCurrent collector

A bipolar battery comprises a bipolar electrode in which a positive electrode is provided on one surface of a collector and a negative electrode is provided on the other surface of the collector, a gel electrolyte sandwiched between the positive electrode and the negative electrode, and a sealing layer which is provided between the collectors and surrounds a periphery of a single cell including the positive electrode, the negative electrode, and the gel electrolyte.

Owner:NISSAN MOTOR CO LTD

Non-aqueous electrolyte secondary cell

InactiveUS20080038628A1Easily volatilizedWell formedNon-aqueous electrolyte cellsFinal product manufactureWorking pressureEngineering

A non-aqueous electrolyte secondary battery has a pressure-sensitive elastic element reliably operating at a desired operating pressure. The battery includes an outer can having an opening; an electrode assembly which is housed in the outer can and comprises a positive electrode having a positive electrode current collector and a negative electrode having a negative electrode current collector; a sealing plate sealing the opening; an external electrode terminal whose one end is engaged with the throughhole of the sealing plate and whose other end projects outside the sealing plate; and a pressure-sensitive elastic element which is disposed inside the sealing plate in the battery and deforms in accordance with an increase in the gas pressure in the battery, the external electrode terminal. The external electrode terminal includes therein a hole connecting the outside of the battery and the space in contact with the outer side of pressure-sensitive elastic element.

Owner:SANYO ELECTRIC CO LTD

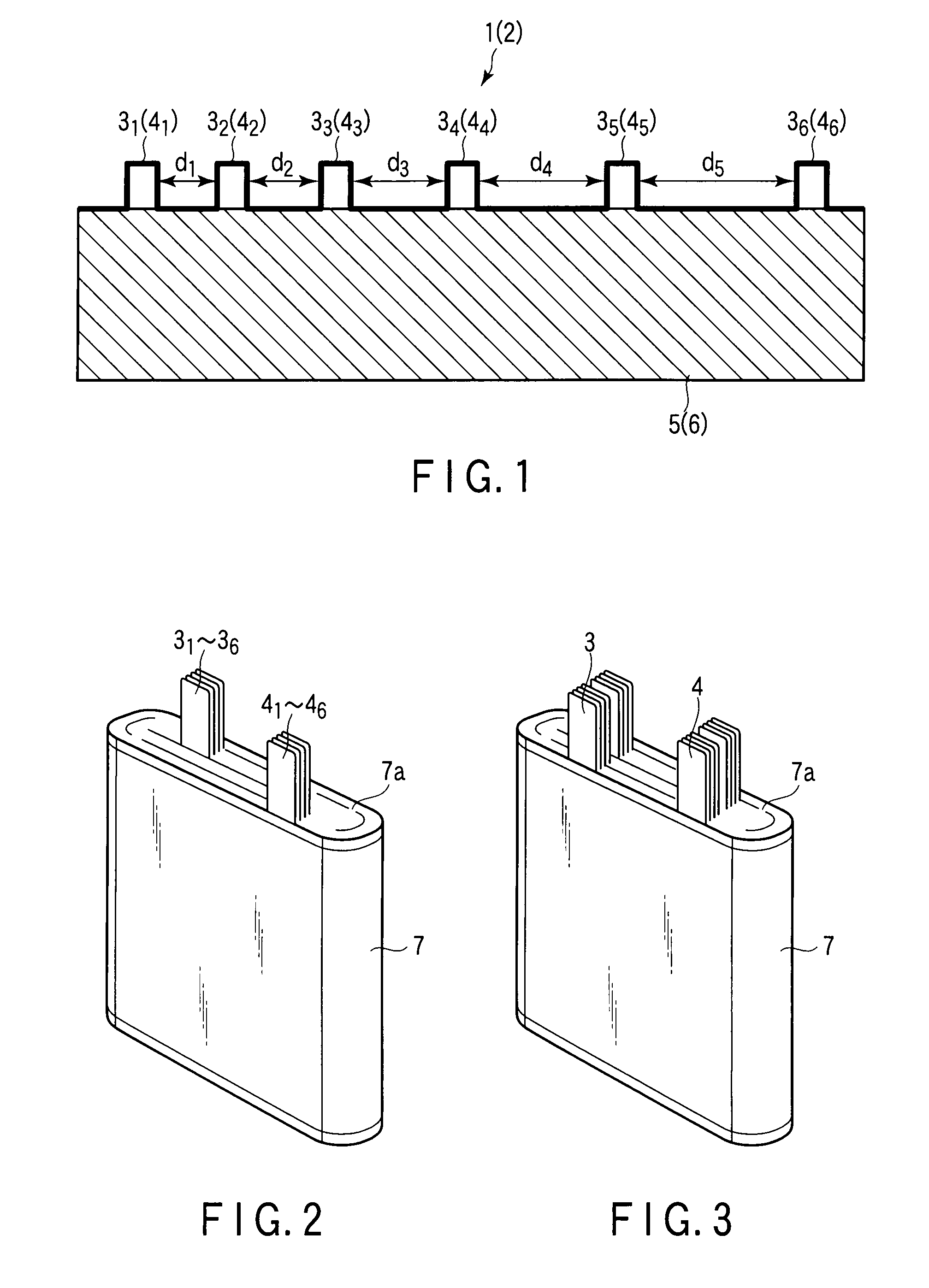

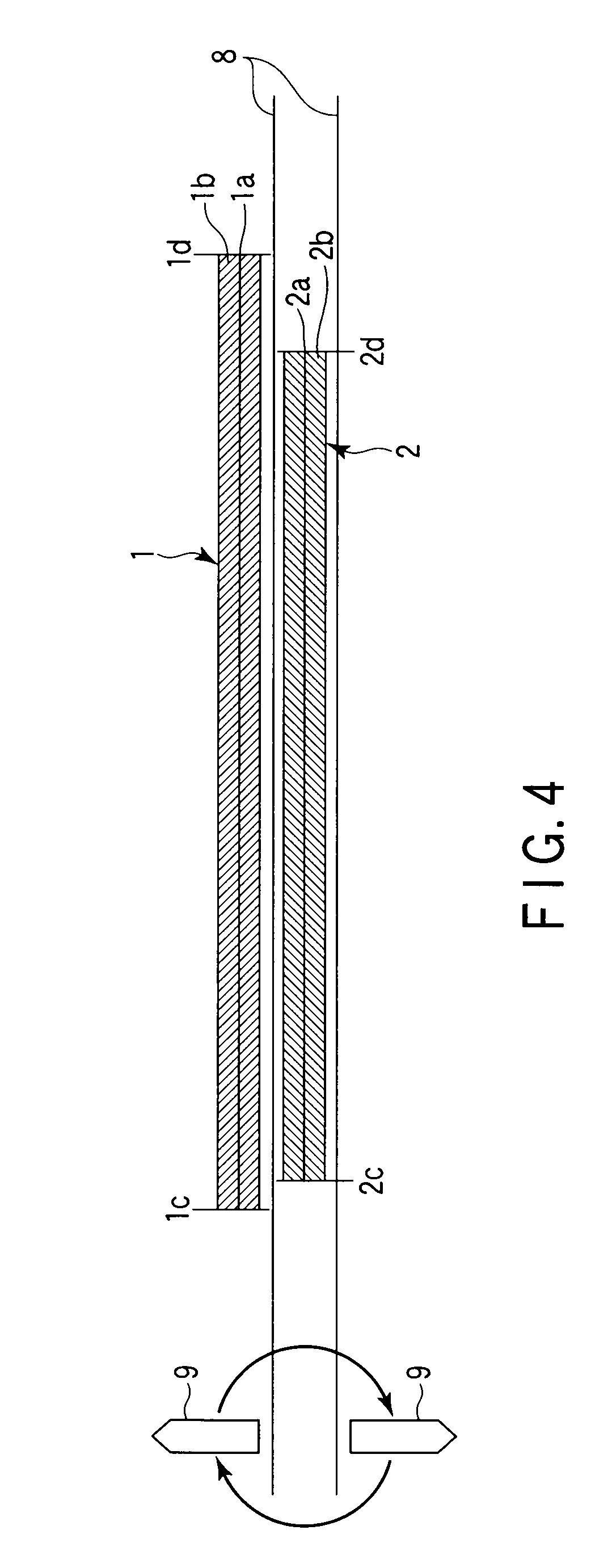

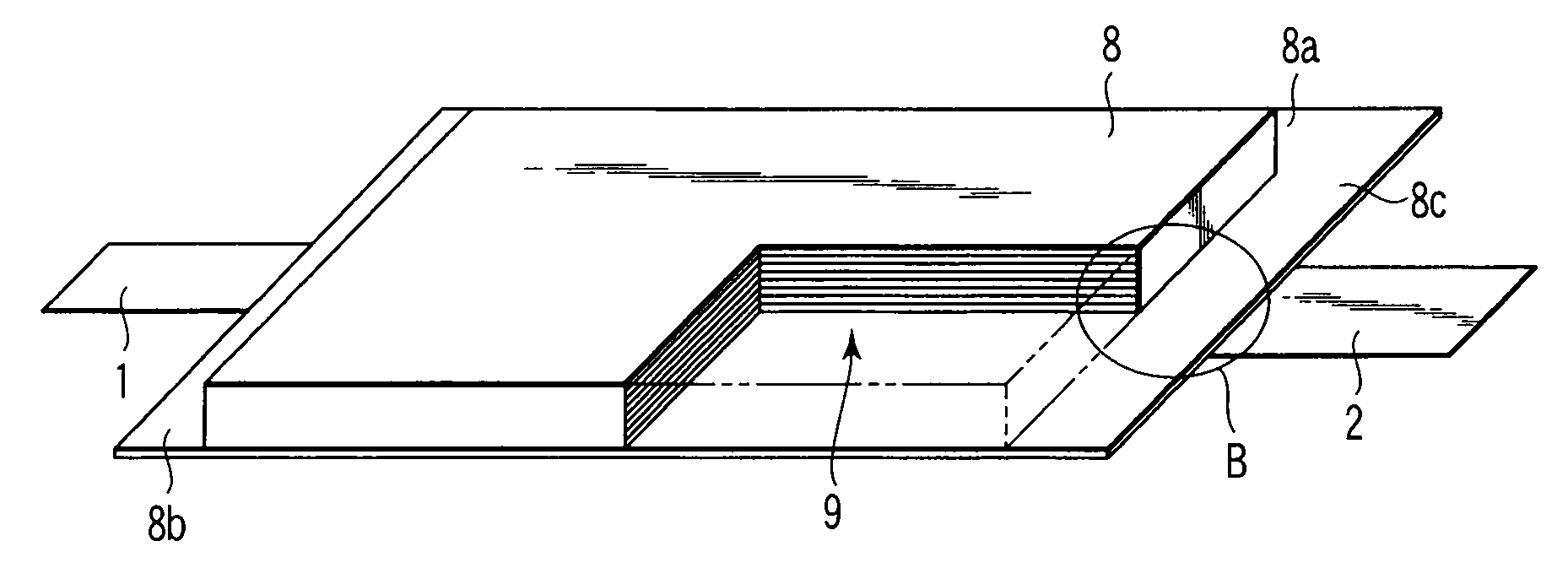

Nonaqueous electrolyte battery, cutter and method of manufacturing electrode

A nonaqueous electrolyte battery includes a case, an electrode group, positive electrode tabs and negative electrode tabs. The electrode group comprises a positive electrode, a negative electrode and a separator. The positive electrode, the negative electrode and the separator are spirally coiled in a flat form. The positive electrode tabs are electrically connected to at least two positions among tab positions Pn of the positive electrode and projected from one end surface of the electrode group. The negative electrode tabs are electrically connected to at least two positions among tab positions Nn of the negative electrode and projected from the one end surface.

Owner:KK TOSHIBA

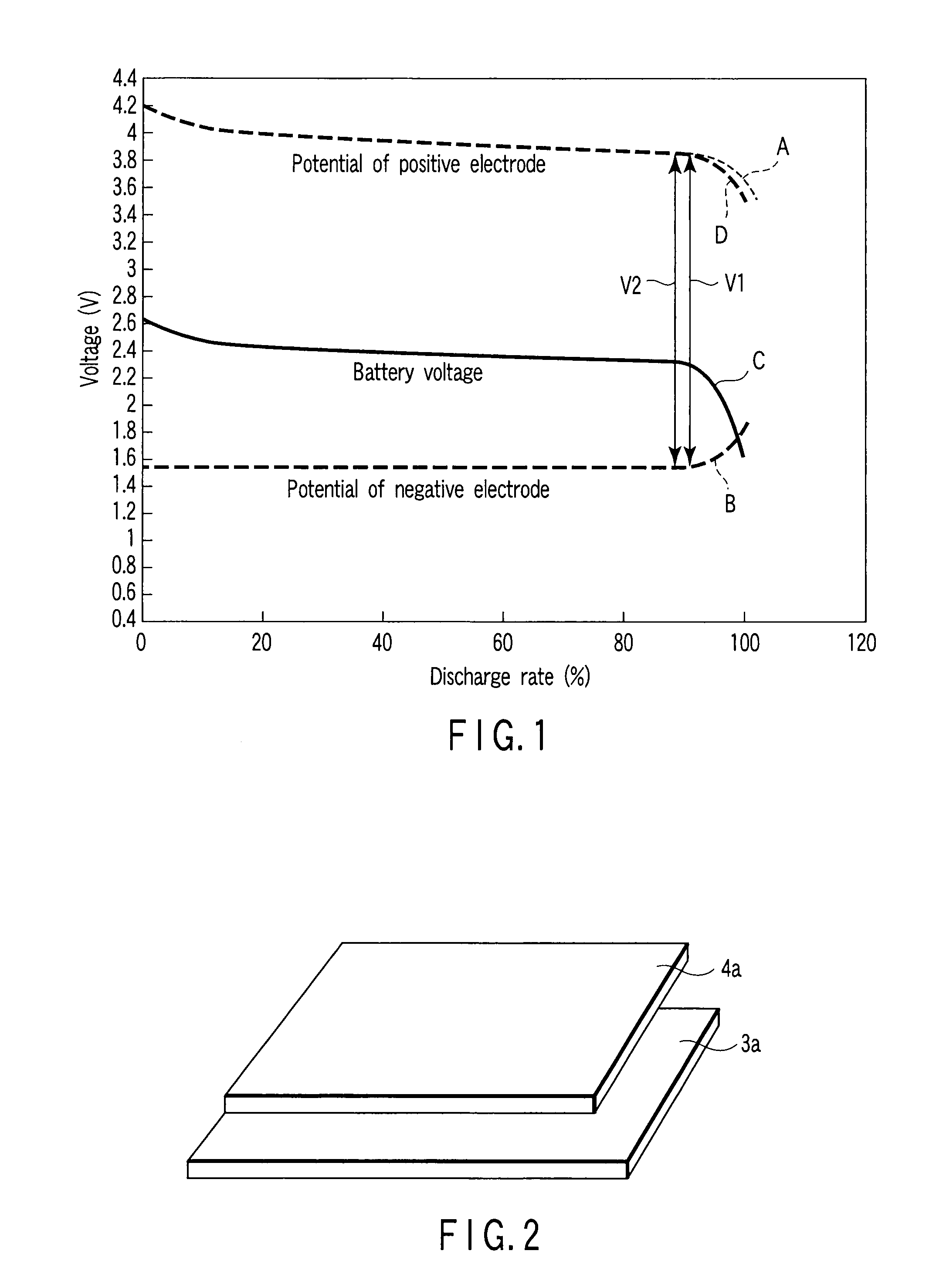

Nonaqueous electrolyte battery, battery pack and vehicle

ActiveUS20080241689A1Improve corrosion resistanceHigh strengthFinal product manufactureElectrode carriers/collectorsCapacitanceLithium

A nonaqueous electrolyte battery includes a negative electrode and a positive electrode. The negative electrode includes a negative electrode current collector and a negative electrode active material having a lithium ion absorption potential of 0.4 V (vs. Li / Li+) or more. The negative electrode current collector is made of aluminum or an aluminum alloy. The positive electrode includes a positive electrode current collector and a positive electrode active material. The positive electrode current collector has a total area and specific capacitance larger than those of the negative electrode current collector, and is made of aluminum or an aluminum alloy.

Owner:KK TOSHIBA

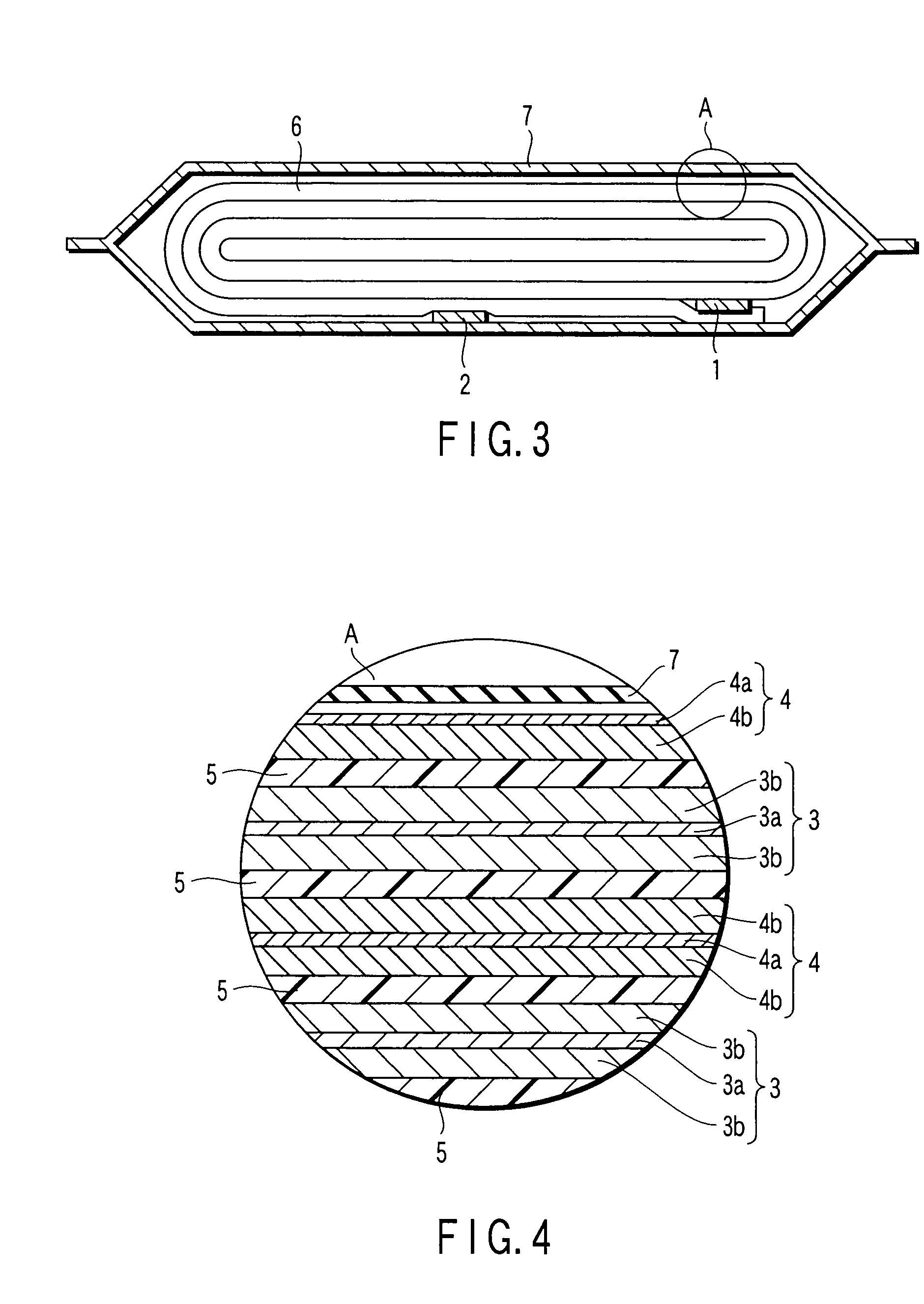

Battery electrode

InactiveUS20080318133A1Increase productionEnergy densityElectrode manufacturing processesNon-aqueous electrolyte accumulatorsEngineeringBattery cell

A battery electrode, includes: a collector; and an active material layer formed on a surface of the collector and including: an active material, and a conductive additive having a bulk density which is gradually decreased in a direction from a collector side of the active material layer to a surface side of the active material layer.

Owner:NISSAN MOTOR CO LTD

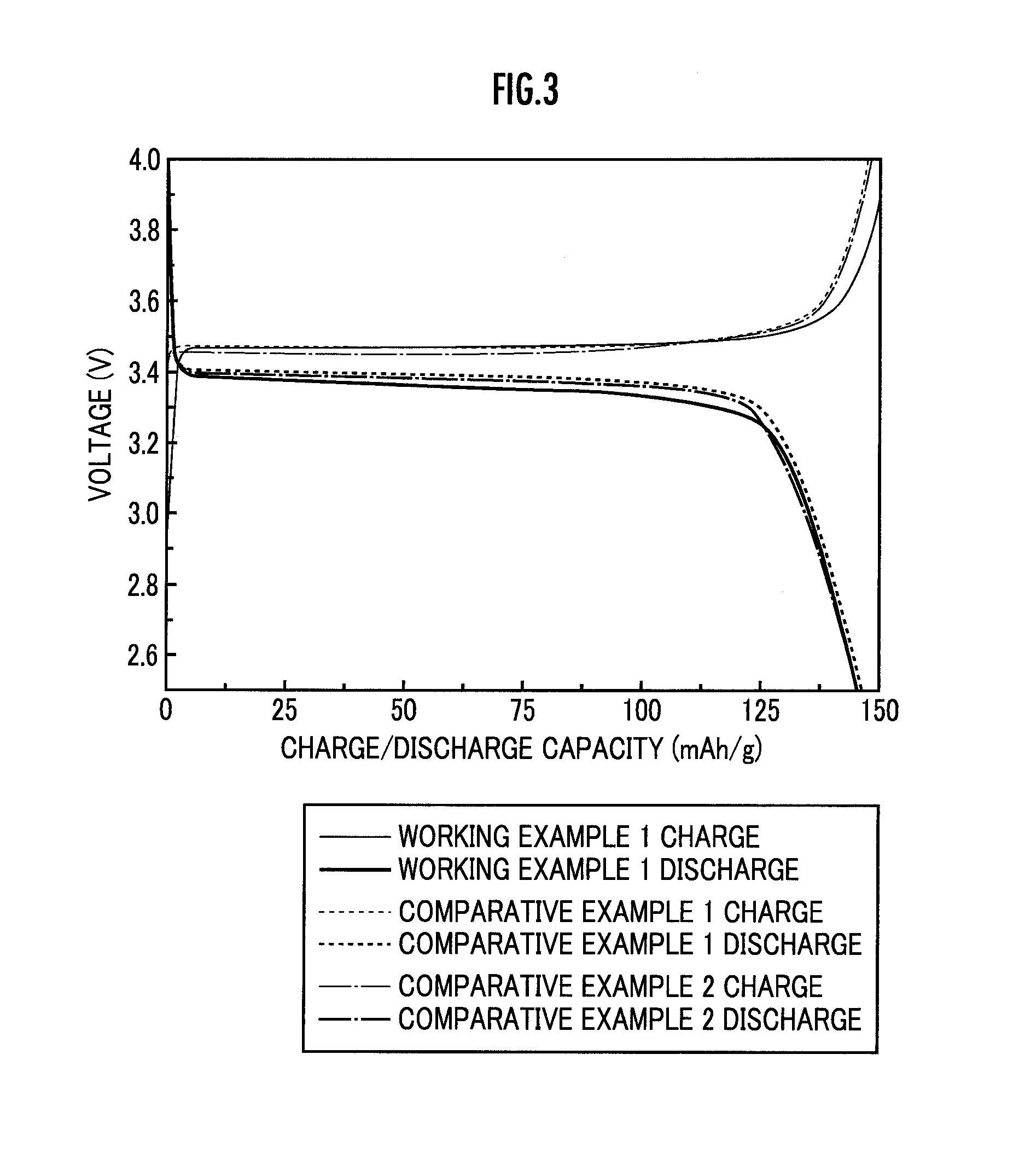

Surface-mediated cells with high power density and high energy density

ActiveUS20130202945A1Improvement factorImprove diffusivityPrimary cell to battery groupingMaterial nanotechnologyElectrical batteryHigh energy

A surface-mediated cell (SMC) comprising: (a) a cathode comprising a carbon-based cathode active material having a surface area to capture or store lithium thereon; (b) an anode comprising an anode current collector alone, or combined anode current collector and anode active material; (c) a porous separator disposed between the anode and the cathode; (d) a lithium-containing electrolyte, wherein the anode and / or cathode active material has a specific surface area no less than 100 m2 / g in direct physical contact with the electrolyte to receive lithium ions therefrom or to provide lithium ions thereto; and (e) a lithium source disposed in at least one of the two electrodes when the cell is made, and the cell has an open-circuit voltage (OCV) of at least 0.8 volts; wherein the cell operates between a lower voltage limit lower than the OCV and an upper limit of between 3.8 and 4.5 volts.

Owner:GLOBAL GRAPHENE GRP INC +1

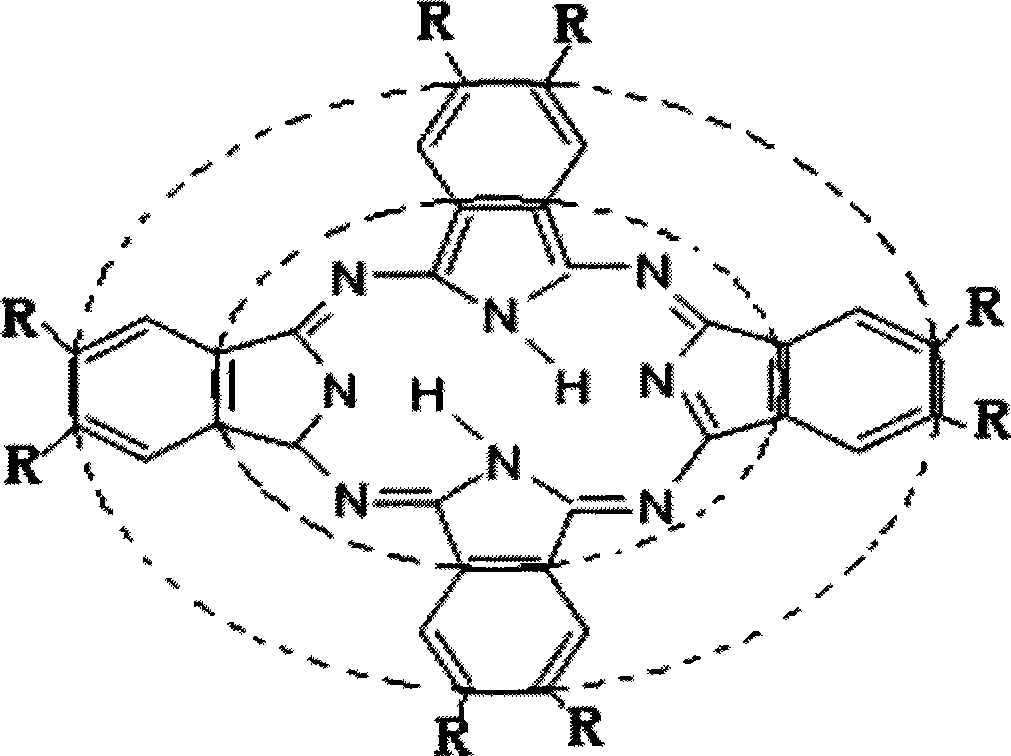

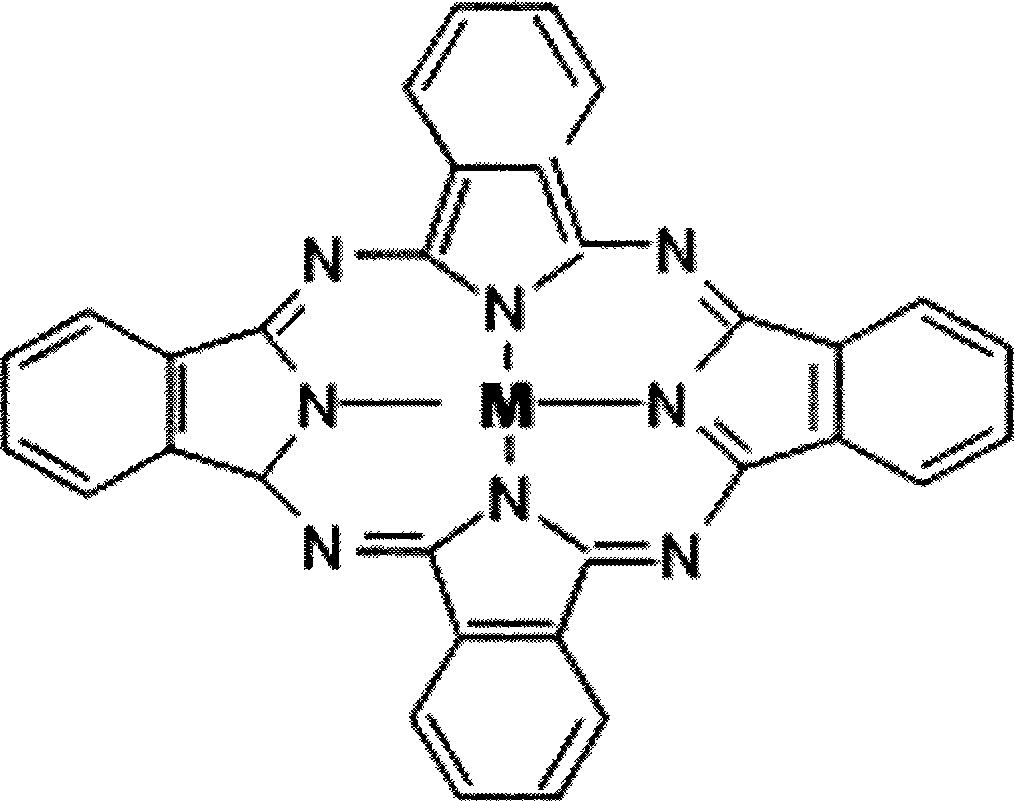

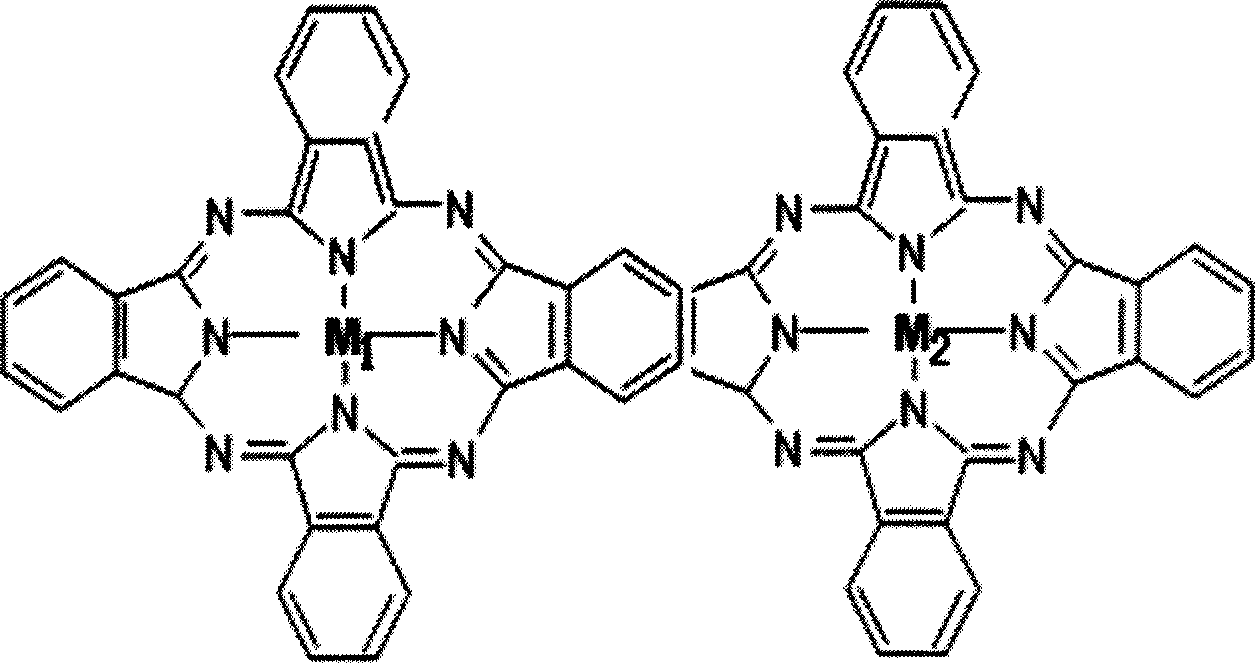

Metal phthalocyanine/carbon nano tube composite catalyst and its preparation method and lithium/thinly chloride battery using the catalyst

InactiveCN101507930ALarge specific surface areaLarge migration spaceCell electrodesOrganic-compounds/hydrides/coordination-complexes catalystsCarbon nanotubePhthalocyanine

The invention discloses a metal phthalocyanine / carbon nanometer pipe compound catalyst, a method for preparing the same and a lithium / thionyl chloride battery using the same, wherein the metal phthalocyanine / carbon nanometer pipe compound catalyst is prepared by evenly and closely loading metal phthalocyanine compounds on a carbon nanometer pipe; and the metal phthalocyanine / carbon nanometer pipe compound catalyst is mixed with carbon black and a binding agent, and the mixture subjected to forming and drying to prepare an anode carbon plate of the lithium / thionyl chloride battery using the catalyst. The metal phthalocyanine compounds are evenly and closely loaded on the carbon nanometer pipe. On one hand, the electrically discharged product of a LiCl film can be loosened by the catalysis of the metal phthalocyanine compounds; on the other hand, a network structure is built up in the carbon anode of the carbon nanometer pipe, which facilitates the electric communication of electrolytes and the improvement of electric conductivity of the electrodes. Due to the synergetic effect of the metal phthalocyanine compounds and the carbon nanometer pipe, the operating voltage of the lithium / thionyl chloride battery is improved. The method has advantages of simple process, simple operation, the suitability for industrialized production and obvious practical values and economic benefits.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

Binder solution and electrode-forming composition for non-aqueous-type battery

InactiveUS6200703B1Good gelHigh affinityNon-aqueous electrolyte cellsNon-aqueous electrolyte accumulator electrodesOrganic acidOrganic solvent

A vinylidene fluoride polymer binder solution for forming an electrode for a non-aqueous-type battery is formed by adding an acid, preferably an organic acid, as a stabilizer to a solution of a vinylidene fluoride polymer in an organic solvent. The acid is preferably added in an amount sufficient to ensure a pH of at most 9 when measured with respect to a 10-times dilution of the binder solution with deionized water. The acid addition is effective for preventing a problematic viscosity increase in the binder solution and also gelling of an electrode-forming composition formed by adding a powdery electrode material in the binder solution.

Owner:KUREHA KAGAKU KOGYO KK

Air battery system

InactiveUS20100151336A1Avoid internal resistanceFuel and primary cellsFuel and secondary cellsHigh rateInternal resistance

A main object of the present invention is to provide an air battery system which can restrain the internal resistance caused by the shortage of liquid electrolyte from increasing and which can carry out a high-rate discharge. The present invention resolves the above-mentioned object by providing an air battery system comprising: an air battery cell which contains an air cathode, an anode, and a separator; and an oxygen gas supply means for supplying an oxygen gas by bubbling to a liquid electrolyte, characterized in that the air cathode further contains an air cathode layer containing a conductive material, and an air cathode current collector for collecting current of the air cathode layer; the anode further contains an anode layer containing an anode active material which stores and releases a metal ion, and an anode current collector for collecting current of the anode layer; and the separator is provided between the air cathode layer and the anode layer, and characterized in that the air cathode layer and the anode layer are constantly filled with the liquid electrolyte at a time of a change in a volume of the electrode caused by a discharge or a discharge and charge.

Owner:TOYOTA JIDOSHA KK

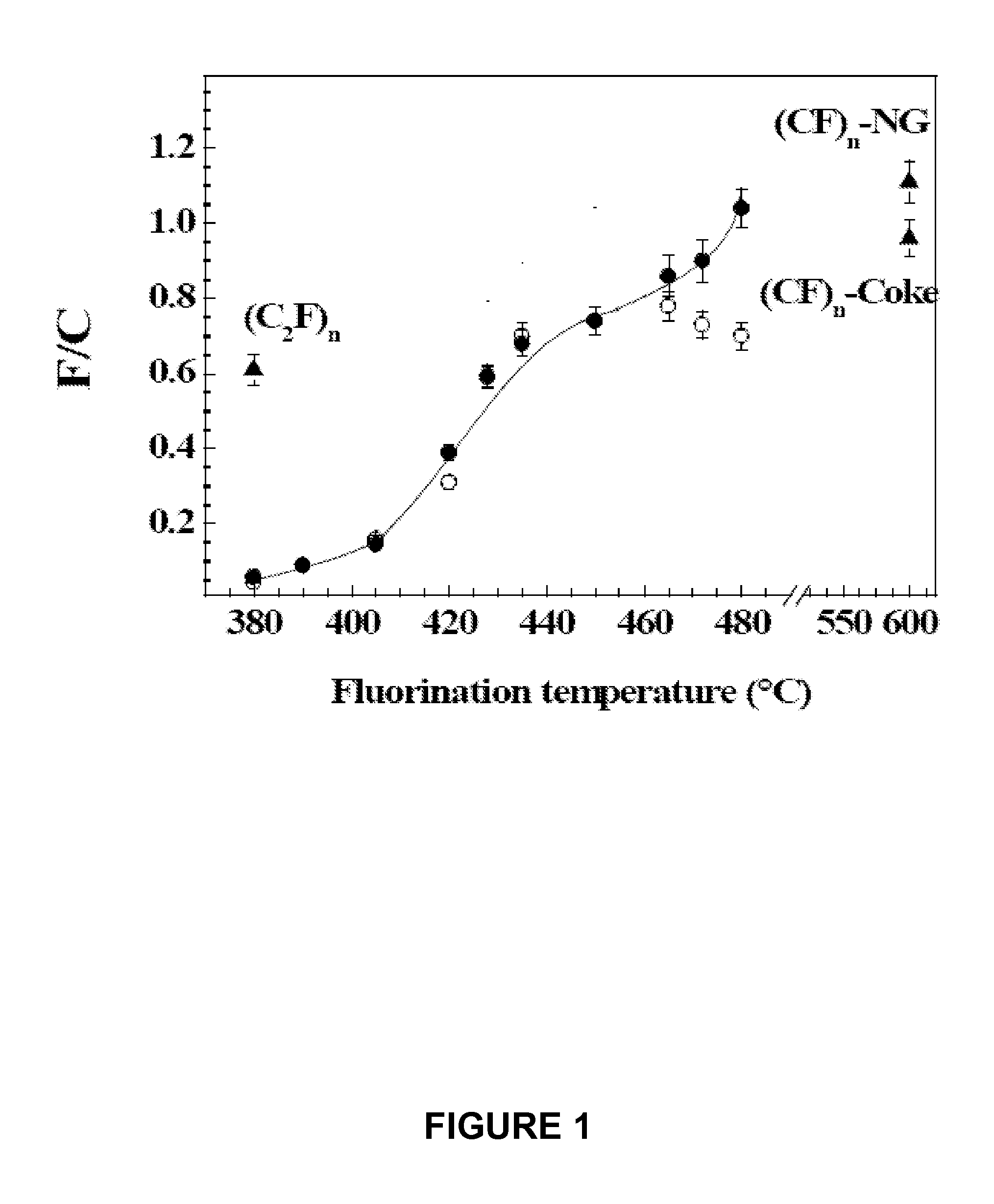

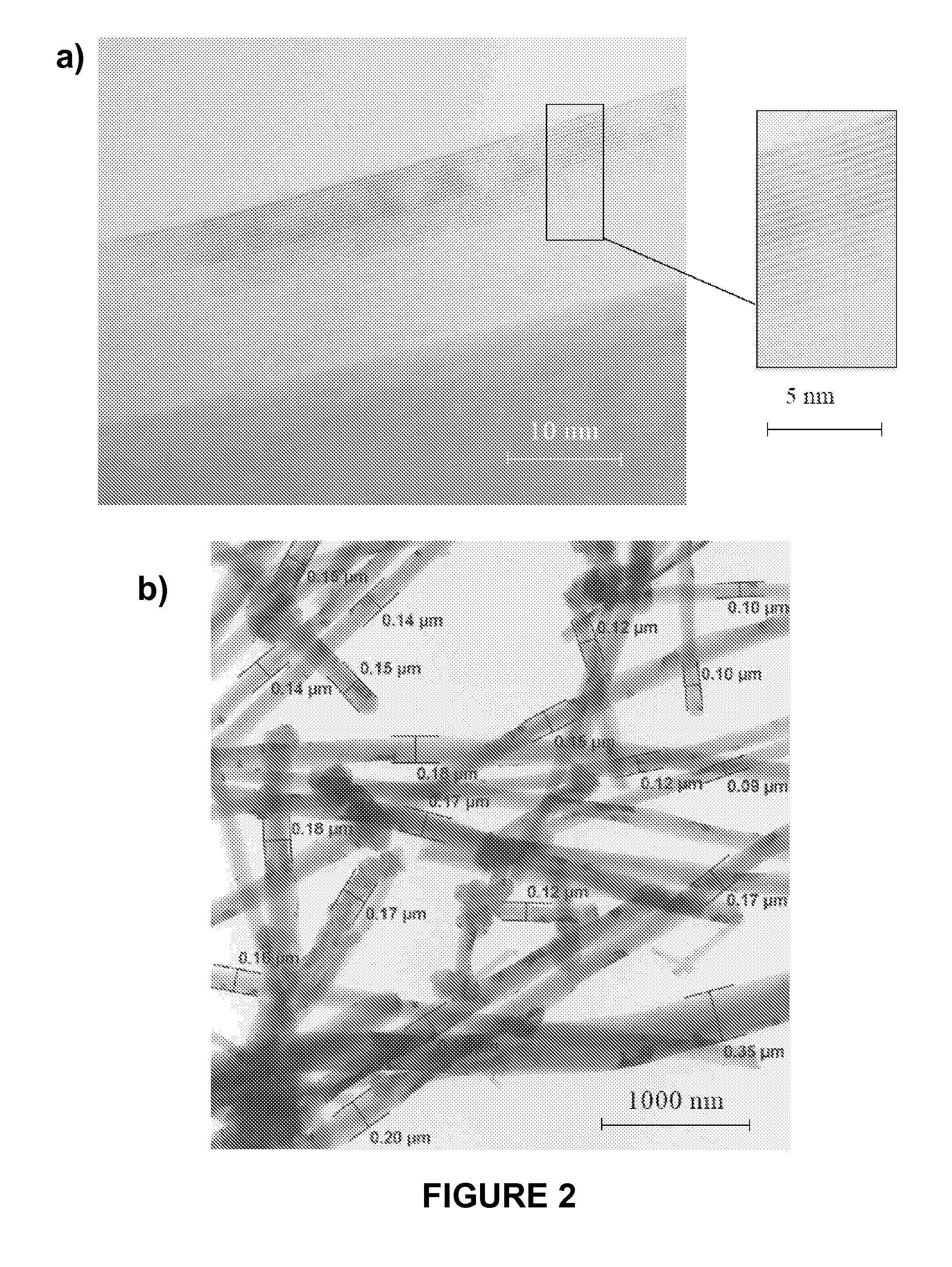

Fluorination of multi-layered carbon nanomaterials

ActiveUS20070231696A1Improve battery performanceHigh discharge rateMaterial nanotechnologyPigmenting treatmentLithiumElectrochemistry

The invention provides fluorinated multi-layered carbon nanomaterials and methods for their production. In one aspect of the invention, the carbon nanomaterials are partially fluorinated and retain some unreacted carbon. The invention also provides electrodes and electrochemical devices incorporating the fluorinated carbon nanomaterials of the invention. In one aspect of the invention, the electrochemical has a first electrode including the at least partially fluorinated carbon materials of the invention and a second electrode including a source of lithium ions

Owner:CENT NAT DE LA RECHERCHE SCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com