Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reliable cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Battery

InactiveUS20030143460A1Avoid crackingReliable crackingFinal product manufactureSmall-sized cells cases/jacketsMetalCopper alloy

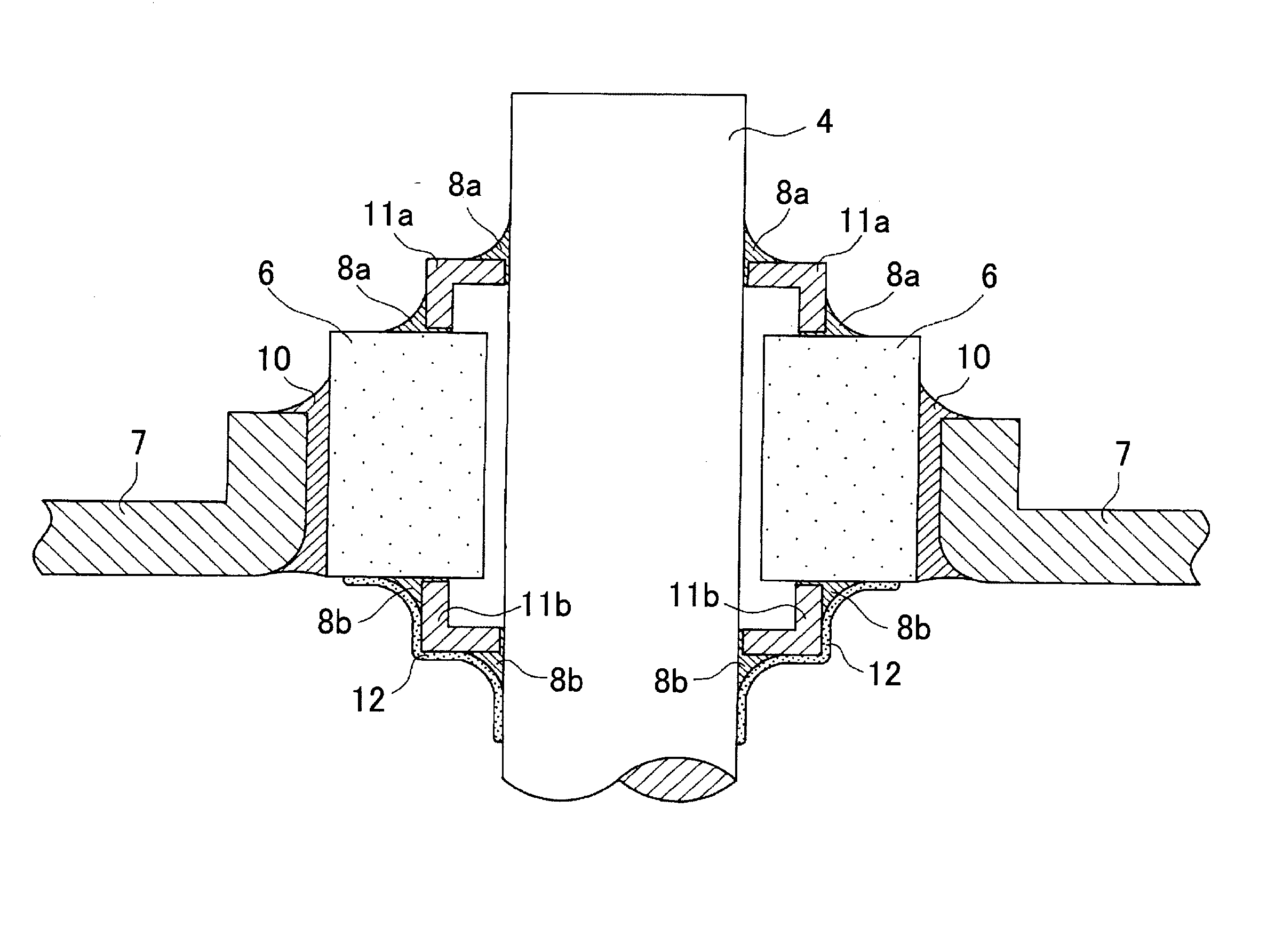

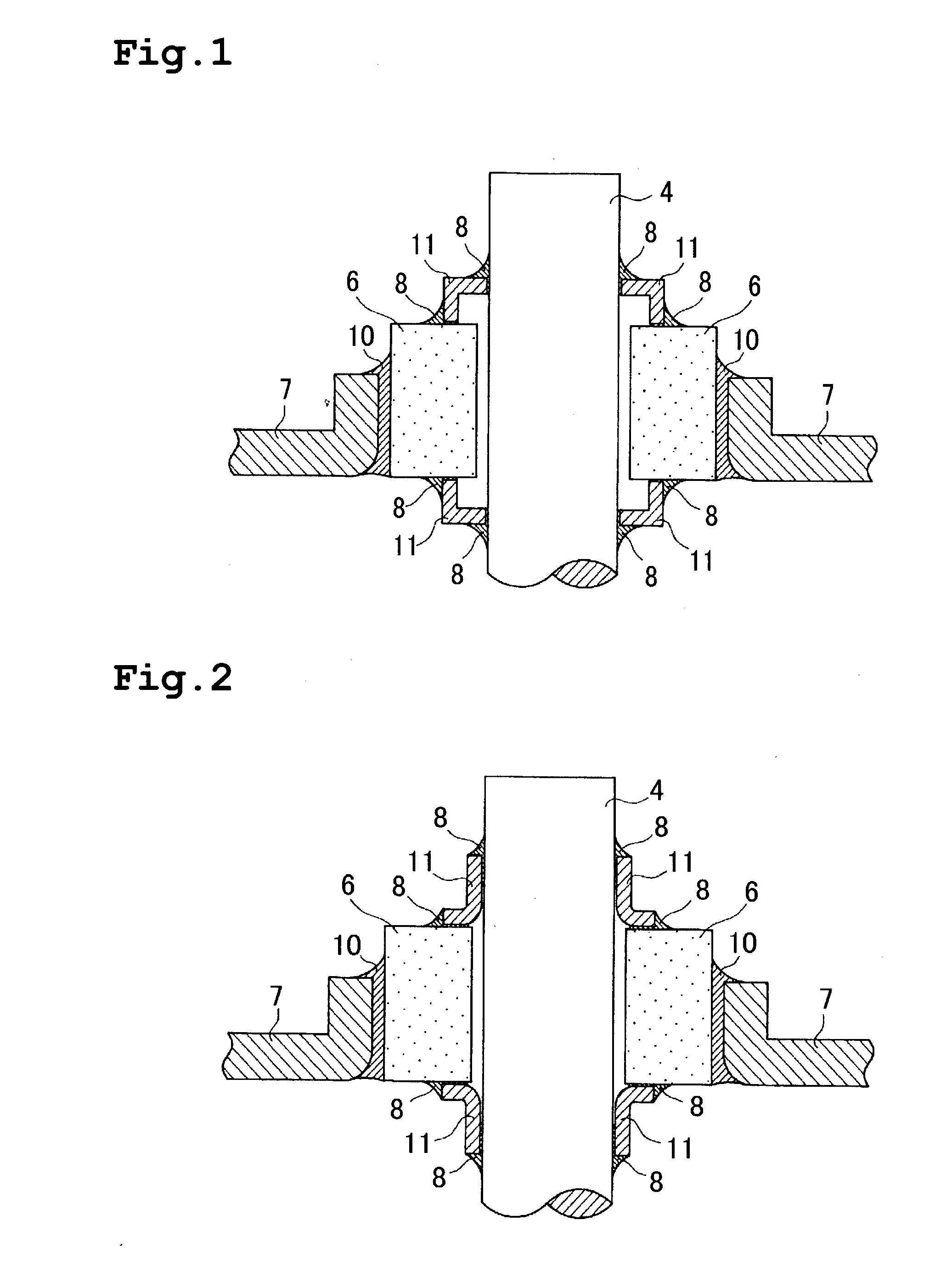

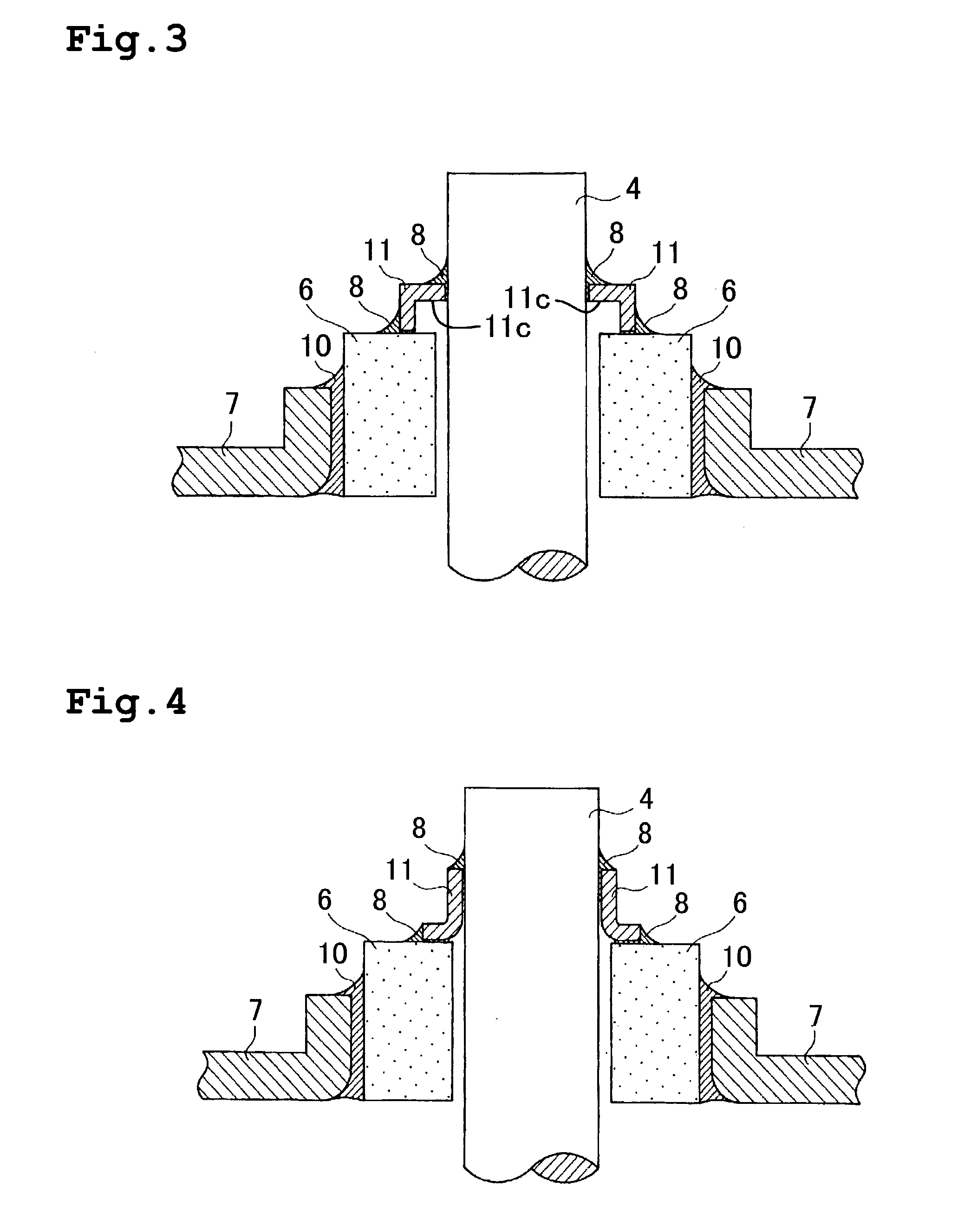

An insulating sleeve 6 made of ceramic hermetically fixed into an opening in a terminal supporting plate 7 in a battery sheath made of metal, a positive terminal 4 made of an aluminum alloy or negative terminal 5 made of a copper alloy is inserted in the insulating sleeve, and a metallic ring is fitted over the positive terminal 4 or negative terminal 5. The inner edge of the metallic ring 11 and the positive terminal 4 or negative terminal 5 are hermetically fixed to each other by an aluminum-based brazing metal 8 or copper-based brazing metal 9, and the outer edge of the metallic ring 11 and the insulating sleeve 6 are hermetically fixed to each other by an aluminum-based brazing metal 8 or copper-based brazing metal 9.

Owner:GS YUASA INT LTD

Metal substrate with insulation layer and manufacturing method thereof, semiconductor device and manufacturing method thereof, solar cell and manufacturing method thereof, electronic circuit and manufacturing method thereof, and light-emitting element and manufacturing method thereof

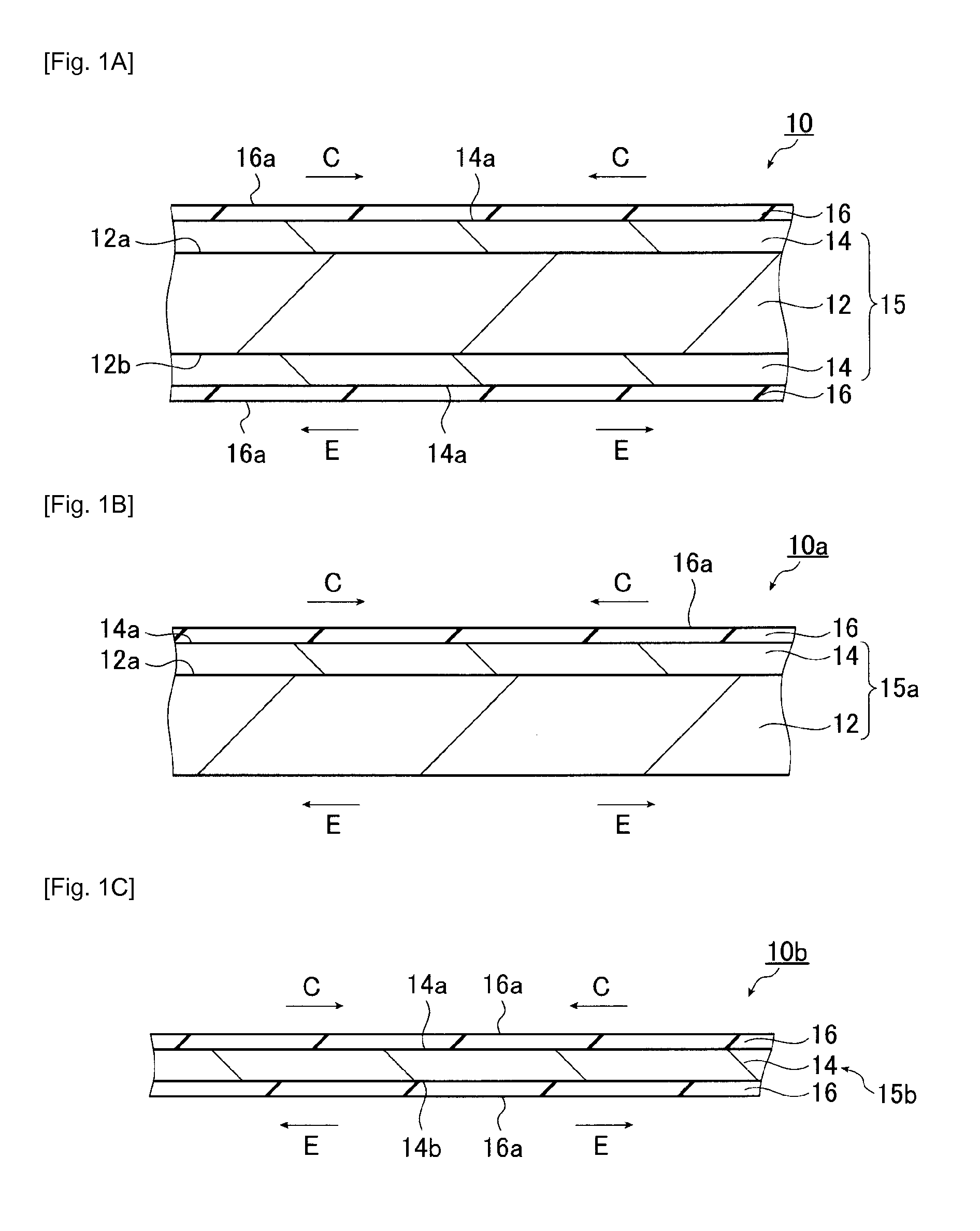

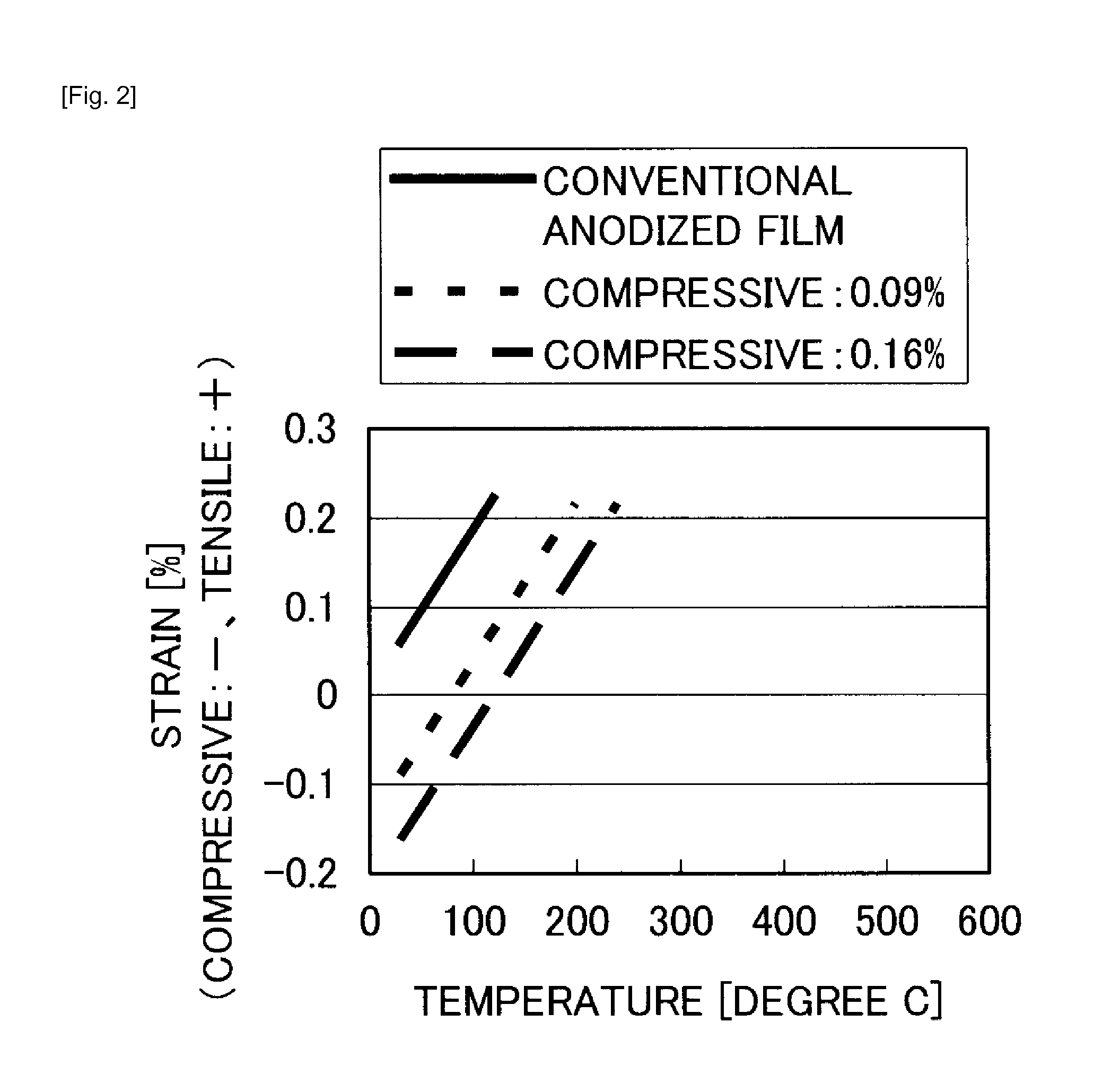

InactiveUS20120273034A1Improve crack resistanceImprove insulation performancePorous dielectricsAnodisationInsulation layerMicrometer

A metal substrate with an insulation layer includes a metal substrate having at least an aluminum base and an insulation layer formed on said aluminum base of said metal substrate. The insulation layer is a porous type anodized film of aluminum. The anodized film includes a barrier layer portion and a porous layer portion, and at least the porous layer portion has compressive strain at room temperature. a magnitude of the strain ranges from 0.005% to 0.25%. The anodized film has a thickness of 3 micrometers to 20 micrometers.

Owner:FUJIFILM CORP

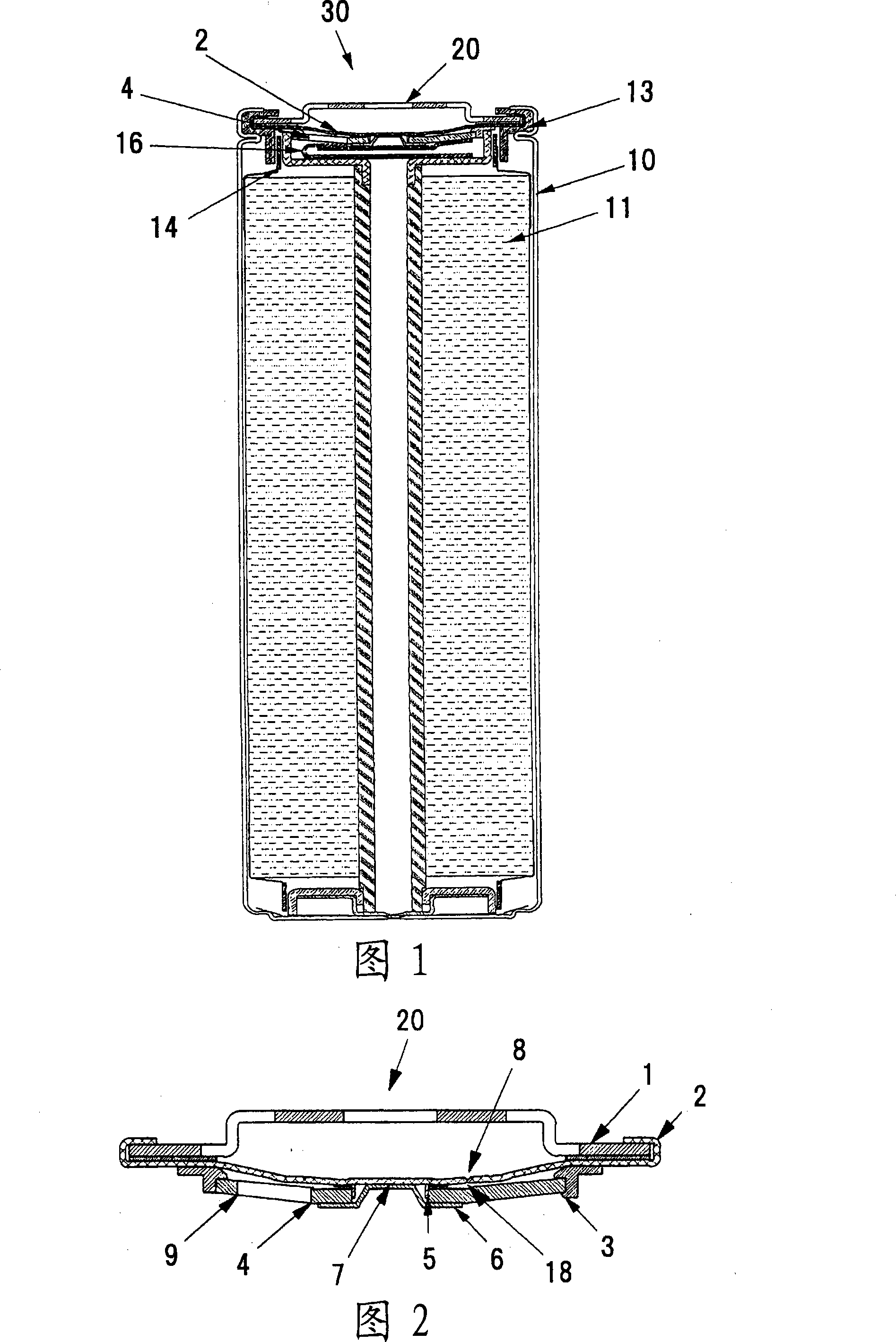

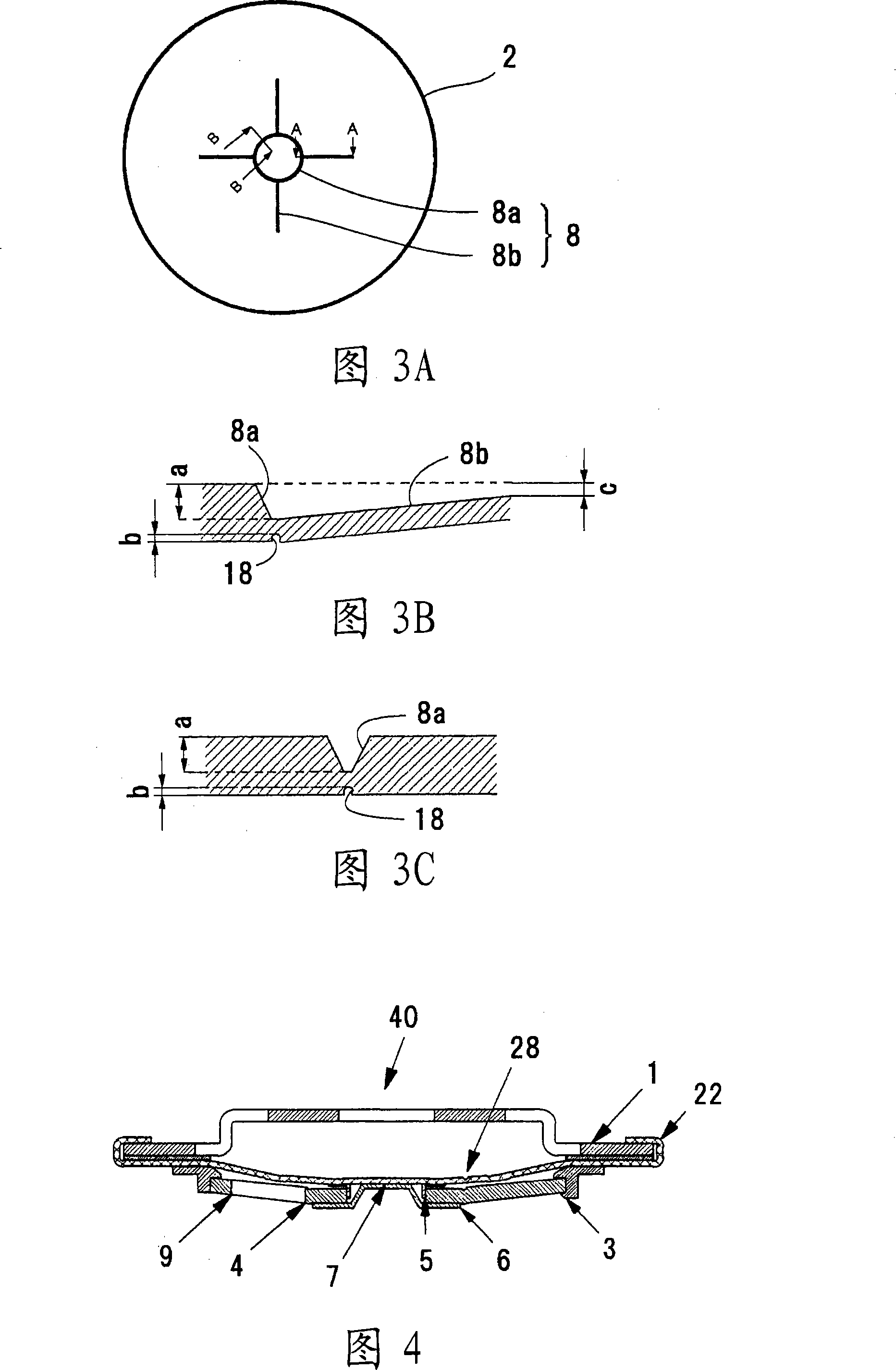

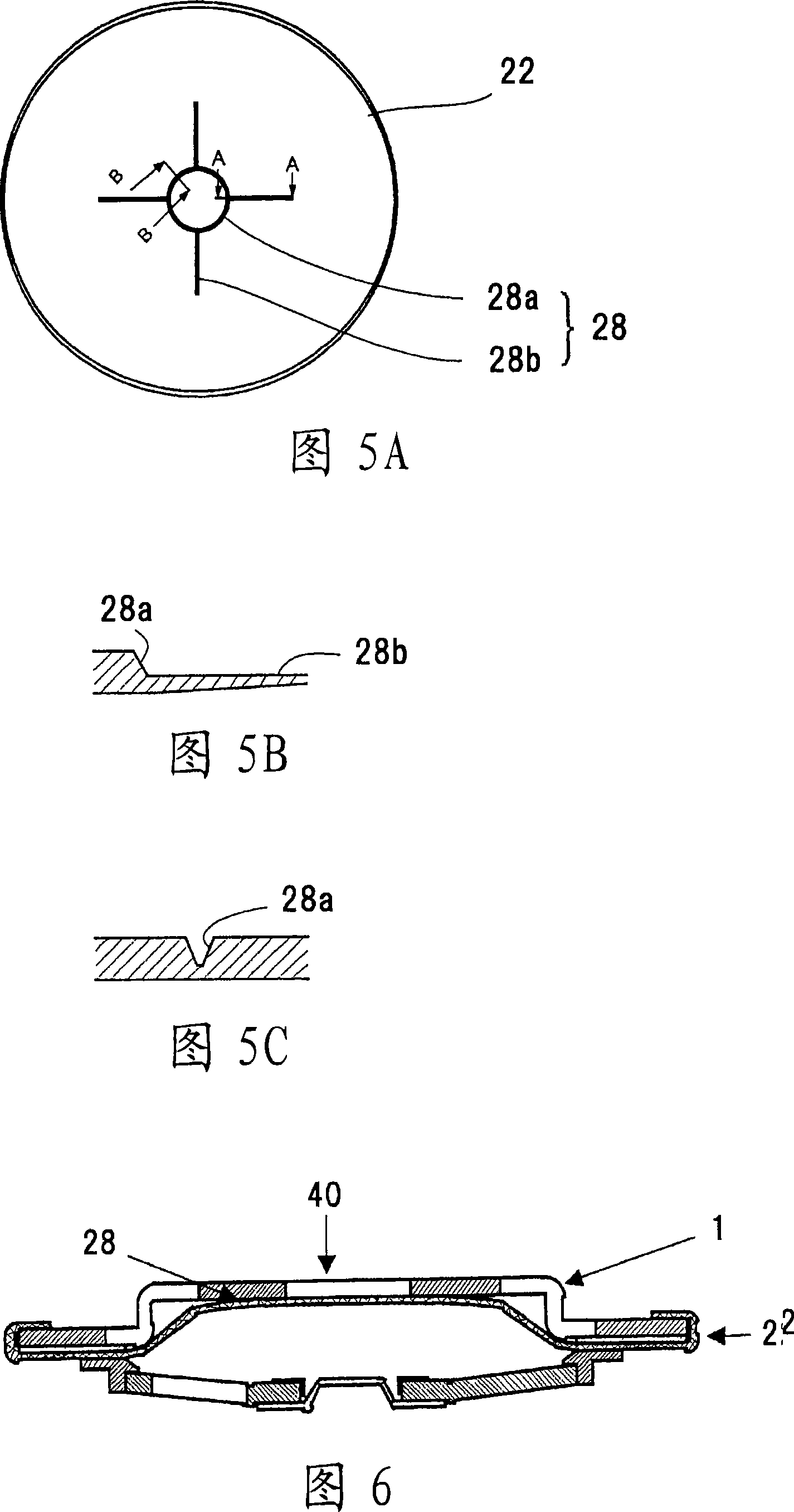

Cylindrical secondary battery

InactiveCN101188280AGuaranteed thicknessReliable crackingFinal product manufactureSmall-sized cells cases/jacketsInternal pressureLithium

A cylindrical secondary battery where safety can be secured even when an external pressure accompanying rapid deformation of the battery acts on the battery is provided in a battery having a large capacity. A lithium ion secondary battery has a capacity of 14Ah, where an upper lid is fixed to a battery can which receives an electrode winding group therein. The upper lid includes a diaphragm (2) formed with a rupturing valve and an upper lid cap whose peripheral edge portion is fixed to a peripheral edge portion of the diaphragm (2). The rupturing valve includes a rupturing groove (8) with a V-shaped section formed on a surface of the diaphragm (2) positioned on the side of the upper lid cap and a rupturing groove (18) with a U-shaped section formed on a surface of the diaphragm (2) positioned on the side of the electrode winding group so as to correspond to the position of the rupturing groove (8). The diaphragm (2) is inverted due to internal pressure rising in the battery so that a current is cut off. When an external force accompanying rapid deformation of the battery acts on the battery, force acting on the diaphragm (2) tends to concentrate on the rupturing groove (18).

Owner:HITACHI AUTOMOTIVE SYST LTD

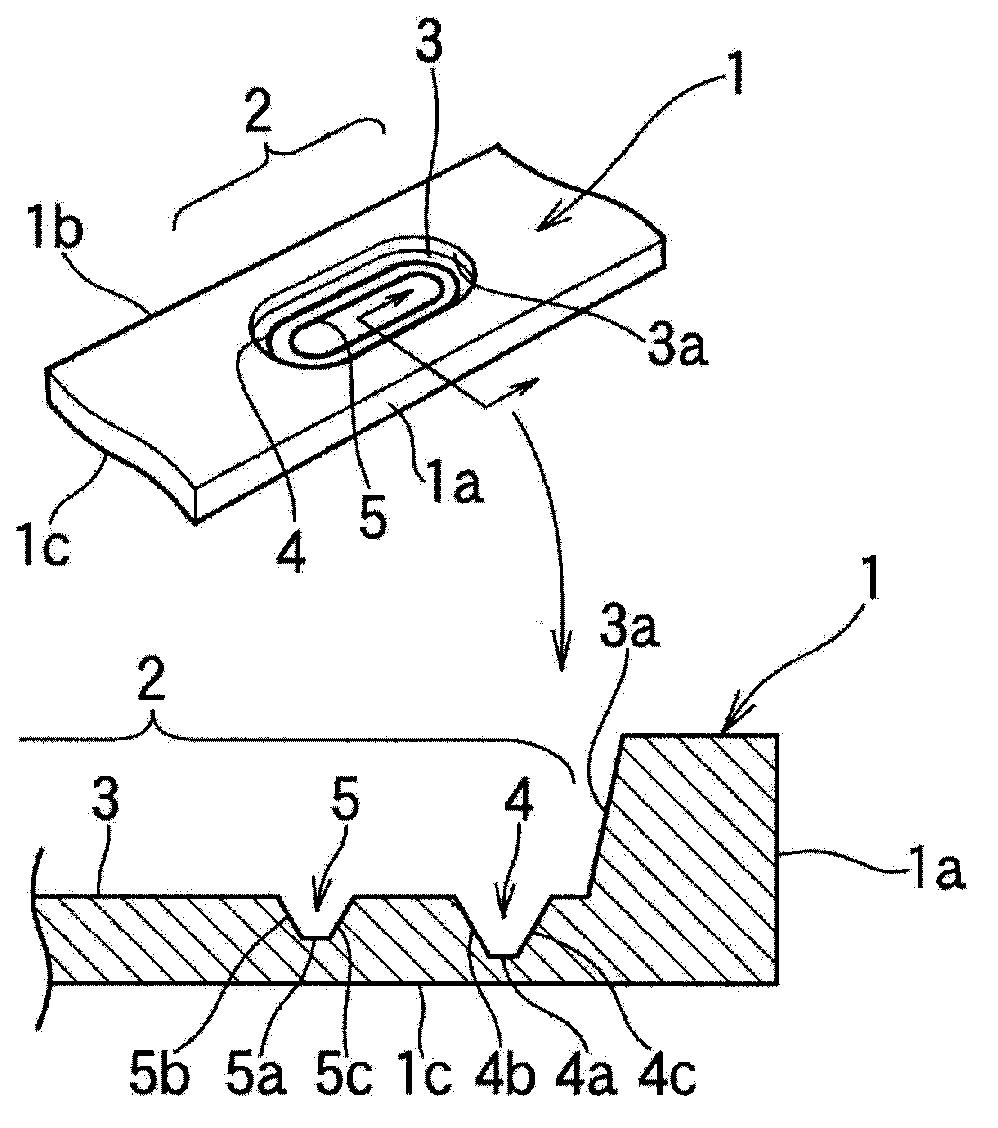

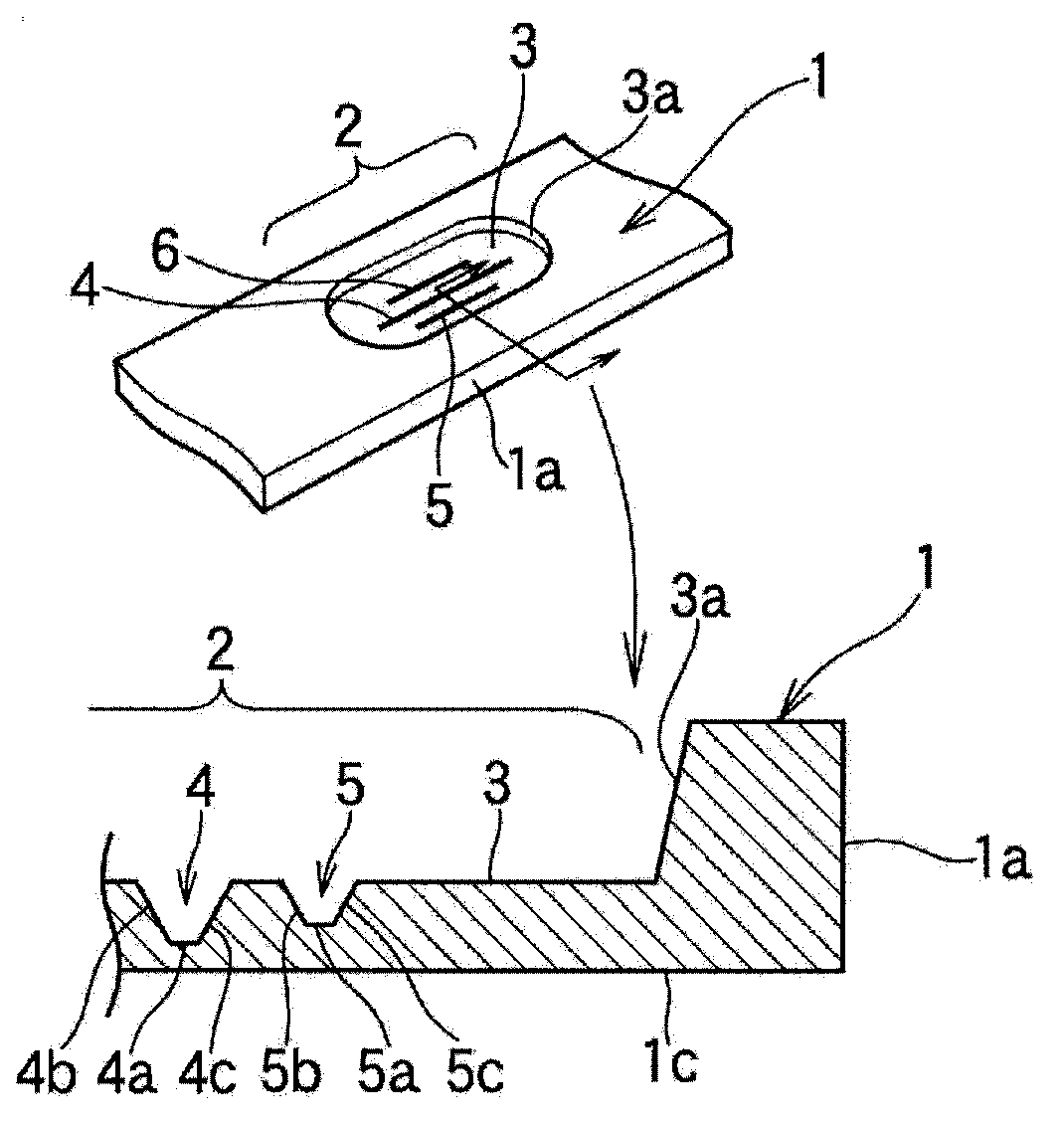

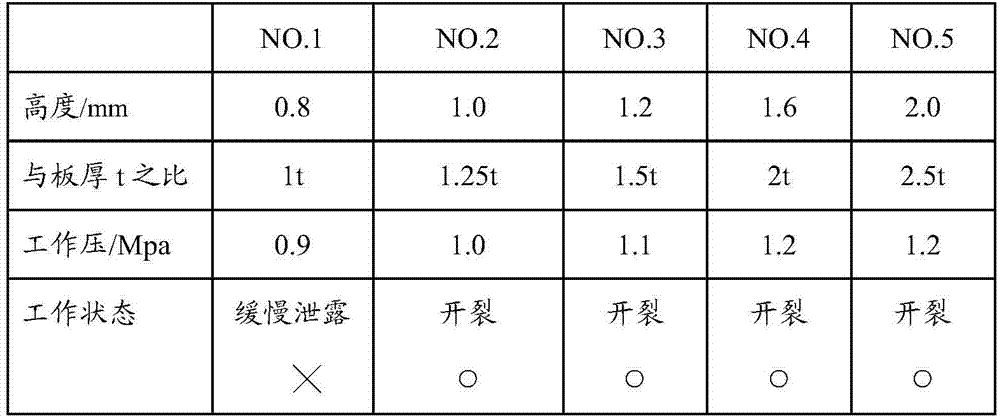

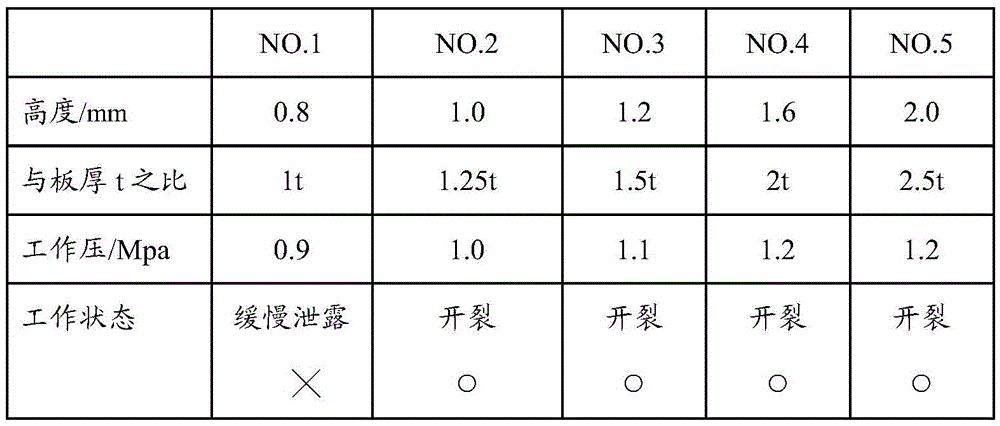

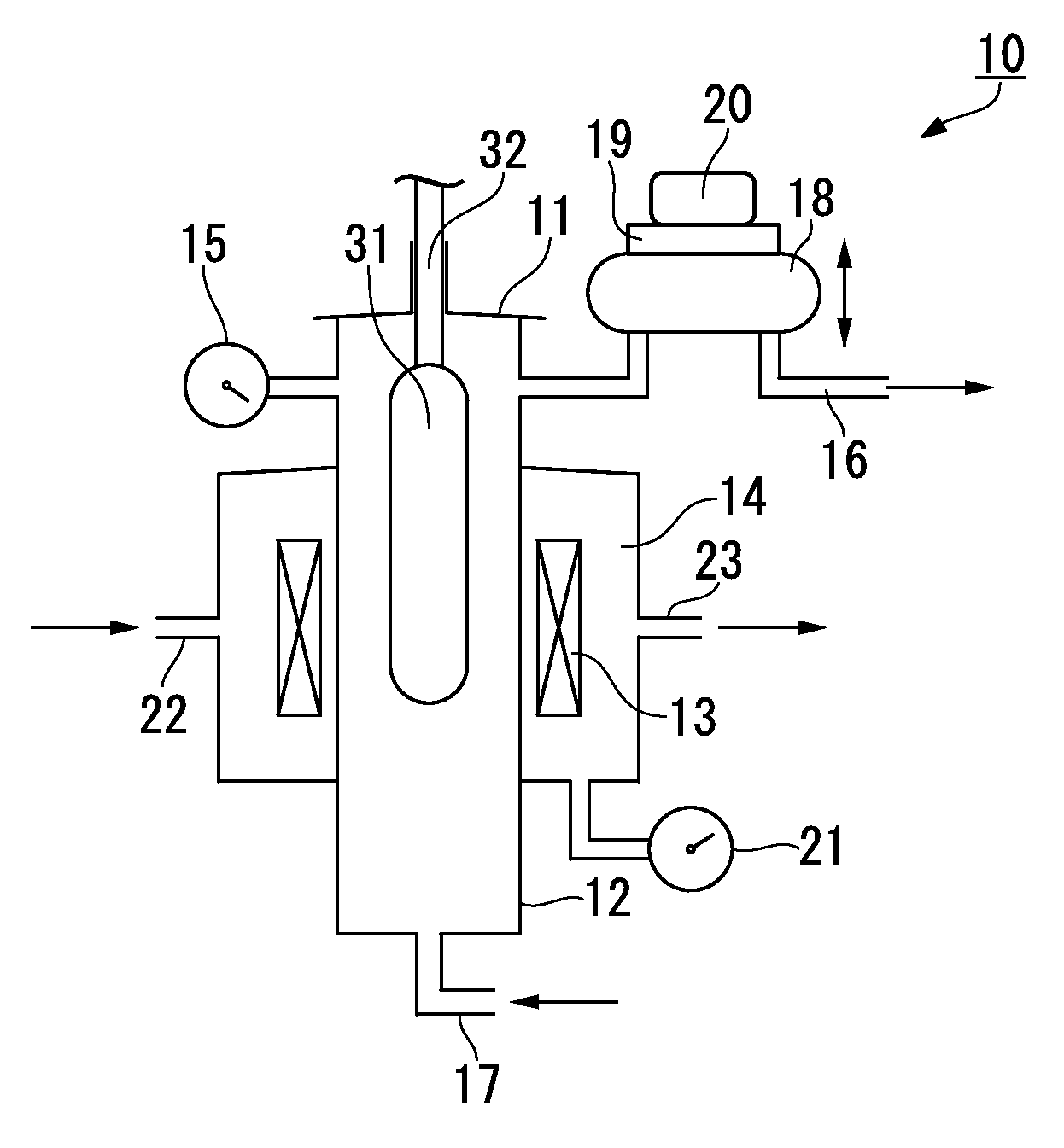

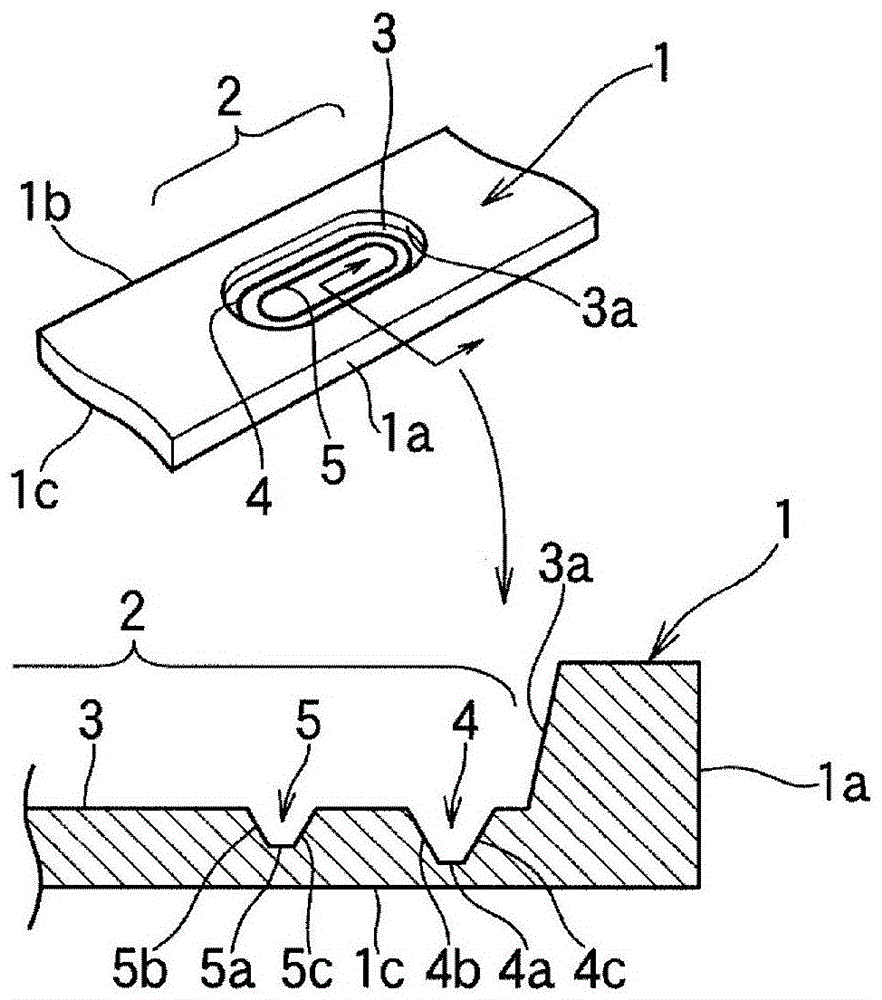

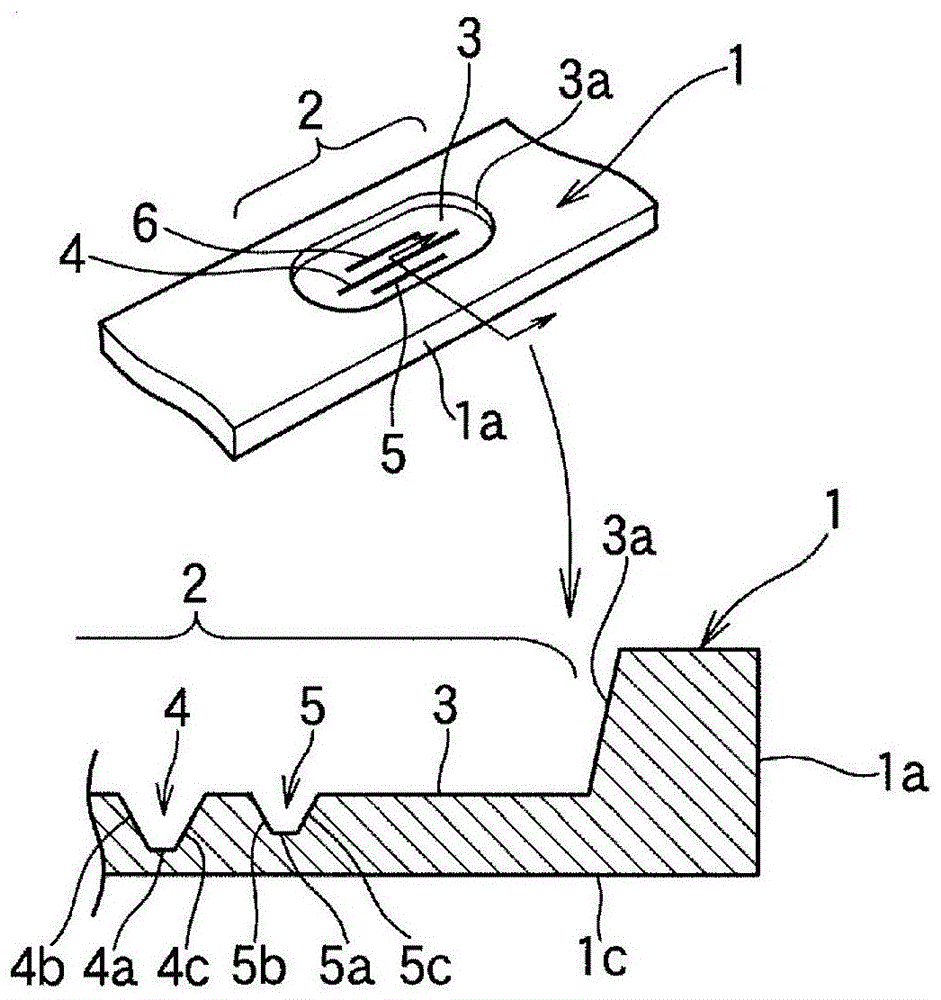

Method for forming the battery case cover and battery explosion valve housing cap

The present invention provides high precision machining of thin-walled aluminum alloy cover breaking with groove, with cracks forming method can reliably explosion mechanism battery case cover and the cover of the battery case explosion valve. The battery case made of aluminum alloy as the explosion-proof valve cover (2), embossing processing using more thin-walled breaking disposed recesses (4) shaped in a thin flat recess (3) while using the coining provided further than breaking recess (4) for assisting a thin thickness but breaking recess (4) forming a groove (5) than the flat-shaped recess (3).

Owner:KOBE STEEL LTD

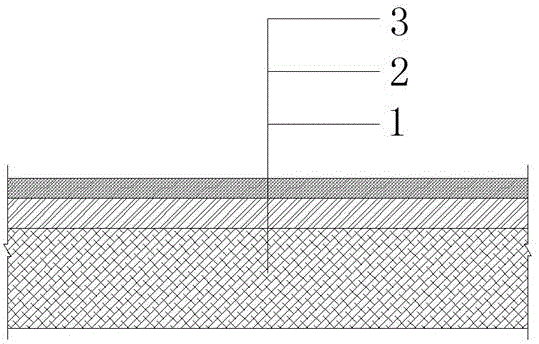

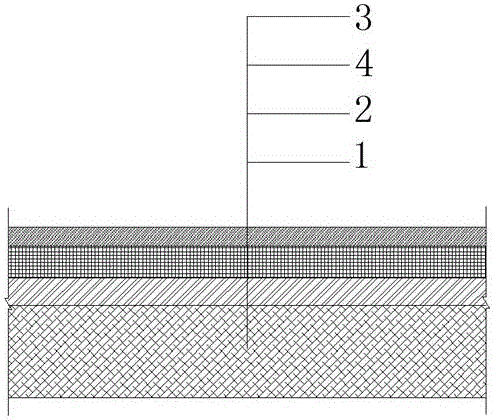

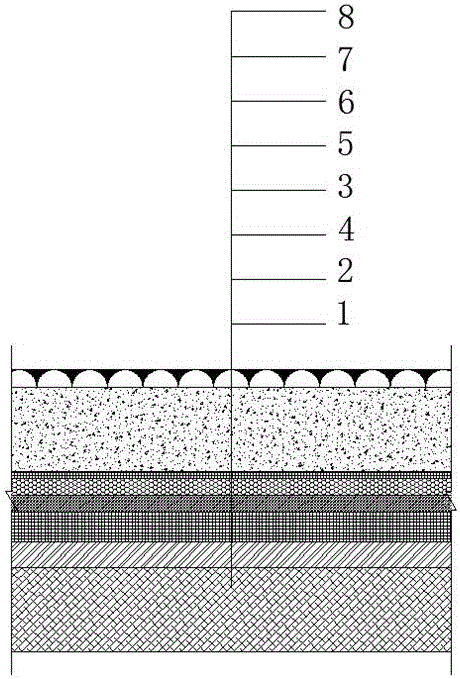

Permanent waterproof layer of building roof

InactiveCN106245864AOvercome the disadvantage of easy crackingOvercome the shortcoming of short waterproof lifeRoof covering insulationsInsulation layerWorking life

The invention relates to a permanent waterproof layer of a building roof. The invention adopts ultra-high-performance concrete, and the integral roof waterproof layer is laid in one or more pouring constructions. The obtained waterproof layer body and seams have reliable functions of anti-crack, anti-seepage, waterproof and thermal insulation layer protection, and can simultaneously improve the strength and rigidity of the roof structure. The waterproof layer is durable and long-lasting, and the working life is the same as that of the building. The construction joint bonding joint and strengthening method of the invention can ensure the crack resistance, seepage resistance and waterproof performance of the joint interface. The permanent waterproof layer of the present invention has relatively simple laying and construction, and is suitable for waterproofing and maintenance of new building roofs and old building roofs of different structures, especially for flat roofs with relatively high loads such as planting, water storage, and parking. The waterproof layer of the cement-based composite material with both toughness and rigidity has no aging problem, and the waterproof and seepage-proof reliability of construction joints is high, which can permanently solve the problem of easy leakage of building roofs.

Owner:JIANGXI BEIRONG CIRCULAR MATERIALS CO LTD

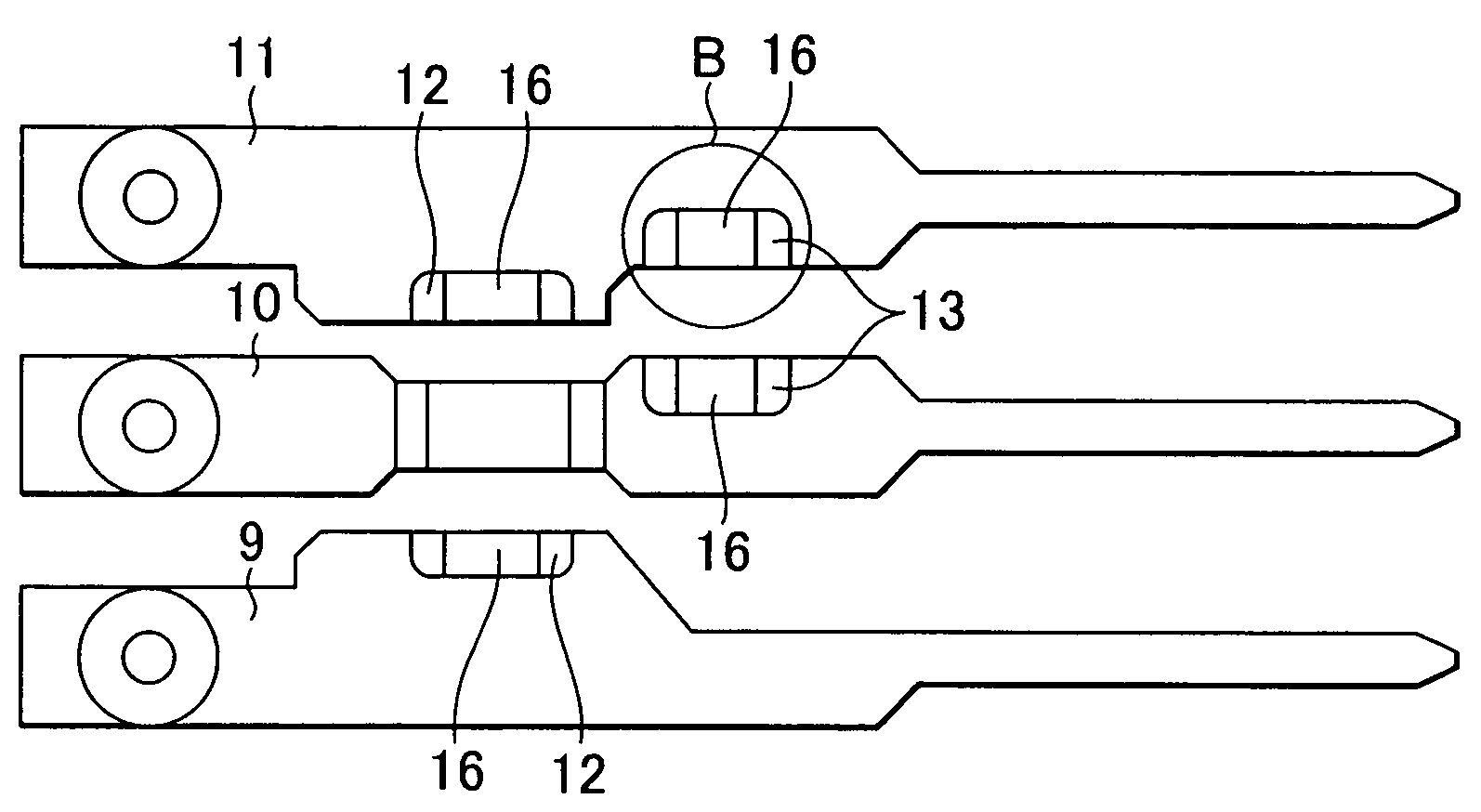

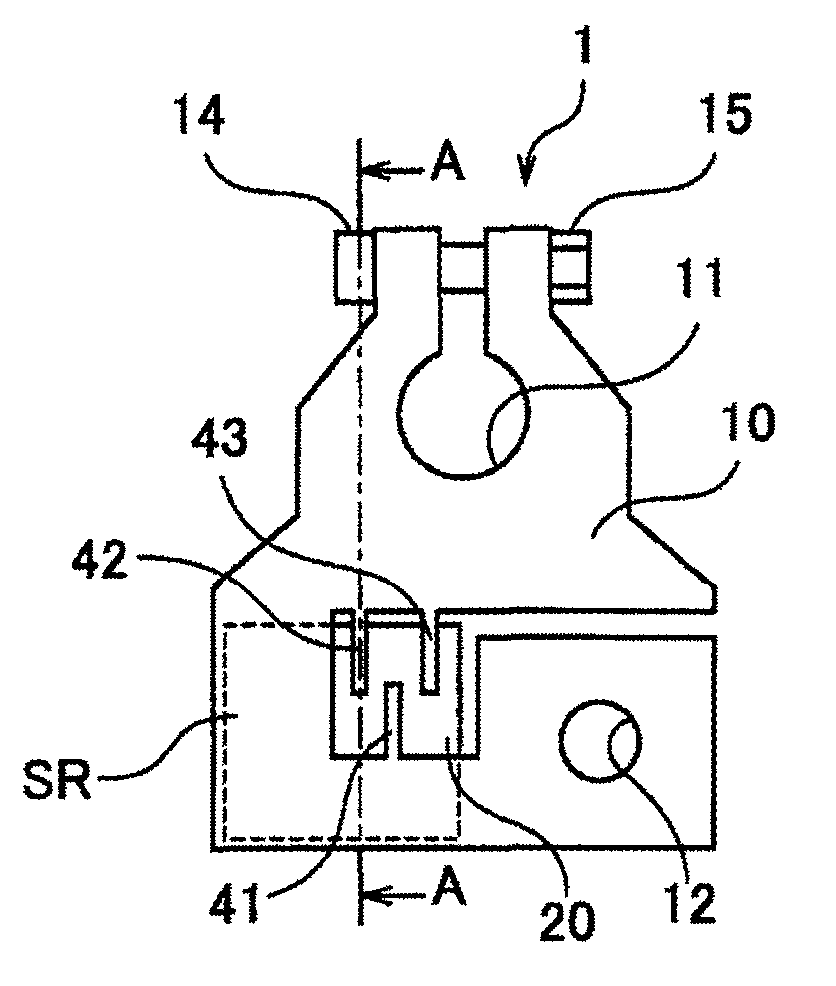

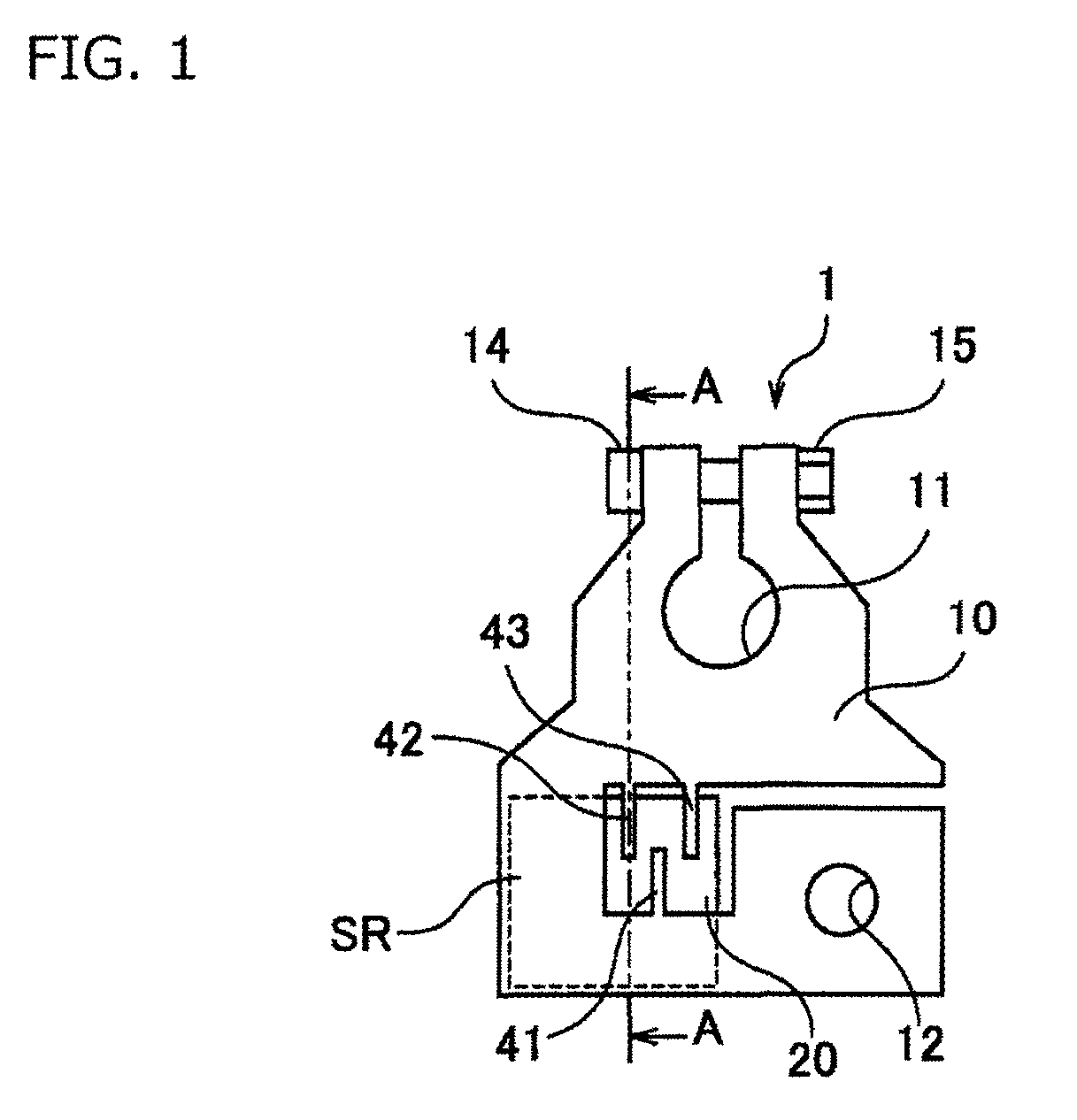

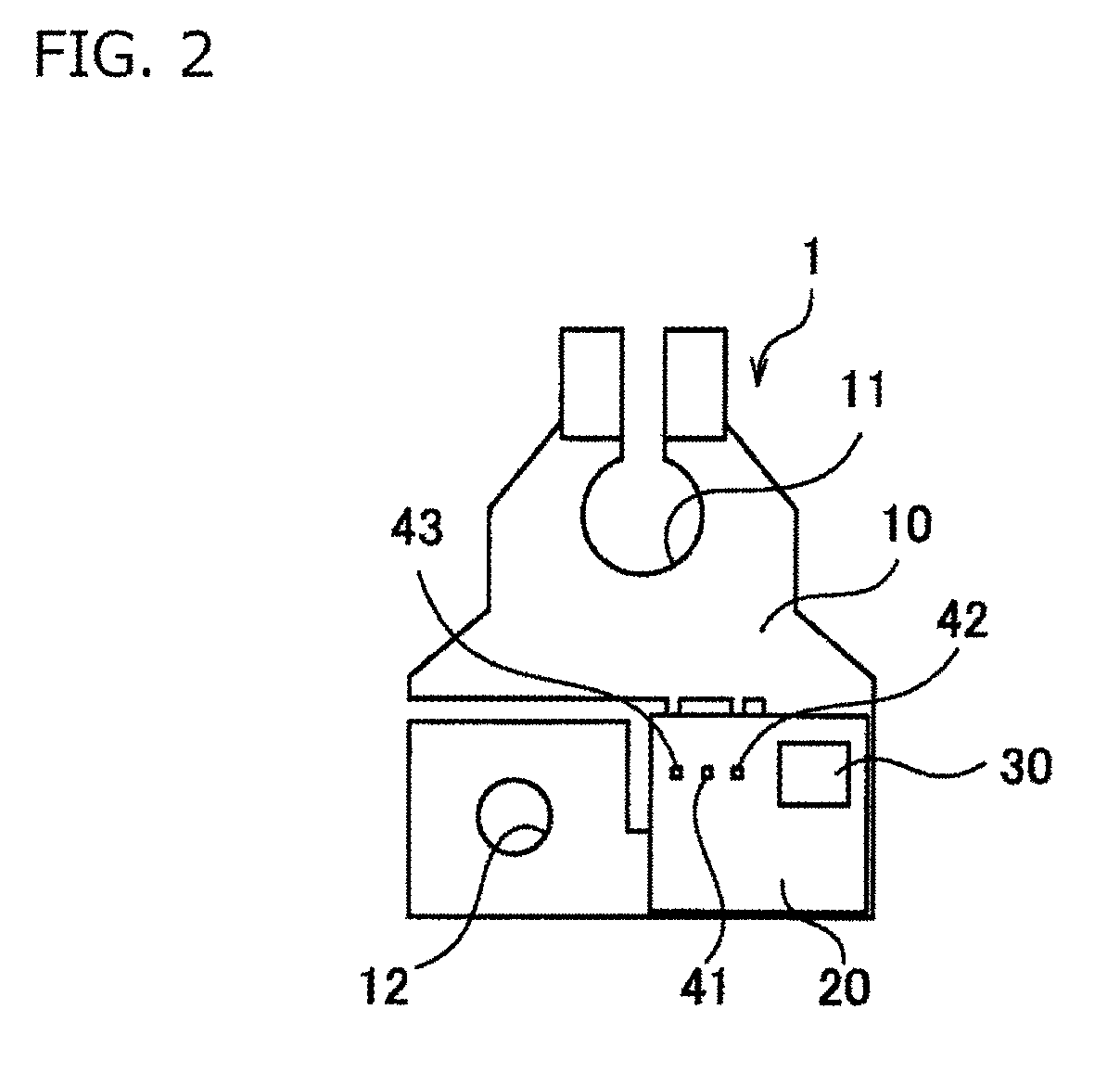

Shunt resistance type current sensor

InactiveUS20160109484A1Easy to transformSolve the large heat dissipationBase element modificationsElectrical testingCurrent sensorEngineering

A shunt resistance type current sensor includes a bus bar, a circuit board disposed to oppose the bus bar, a shunt resistance part in the bus bar, connection terminals which electrically connect the bus bar and the circuit board, and a voltage detector which is mounted on the circuit board and detects a voltage applied to the bus bar to detect a magnitude of current to be measured flowing through the bus bar. The connection terminal is formed integrally with the bus bar as an extending piece extended from an edge part of the bus bar, an area of the connection terminal reduced in its plate thickness than that of the bus bar is set in a range from a tip side thereof, and the tip side of the connection terminal penetrates the circuit board and connects with the circuit board.

Owner:YAZAKI CORP

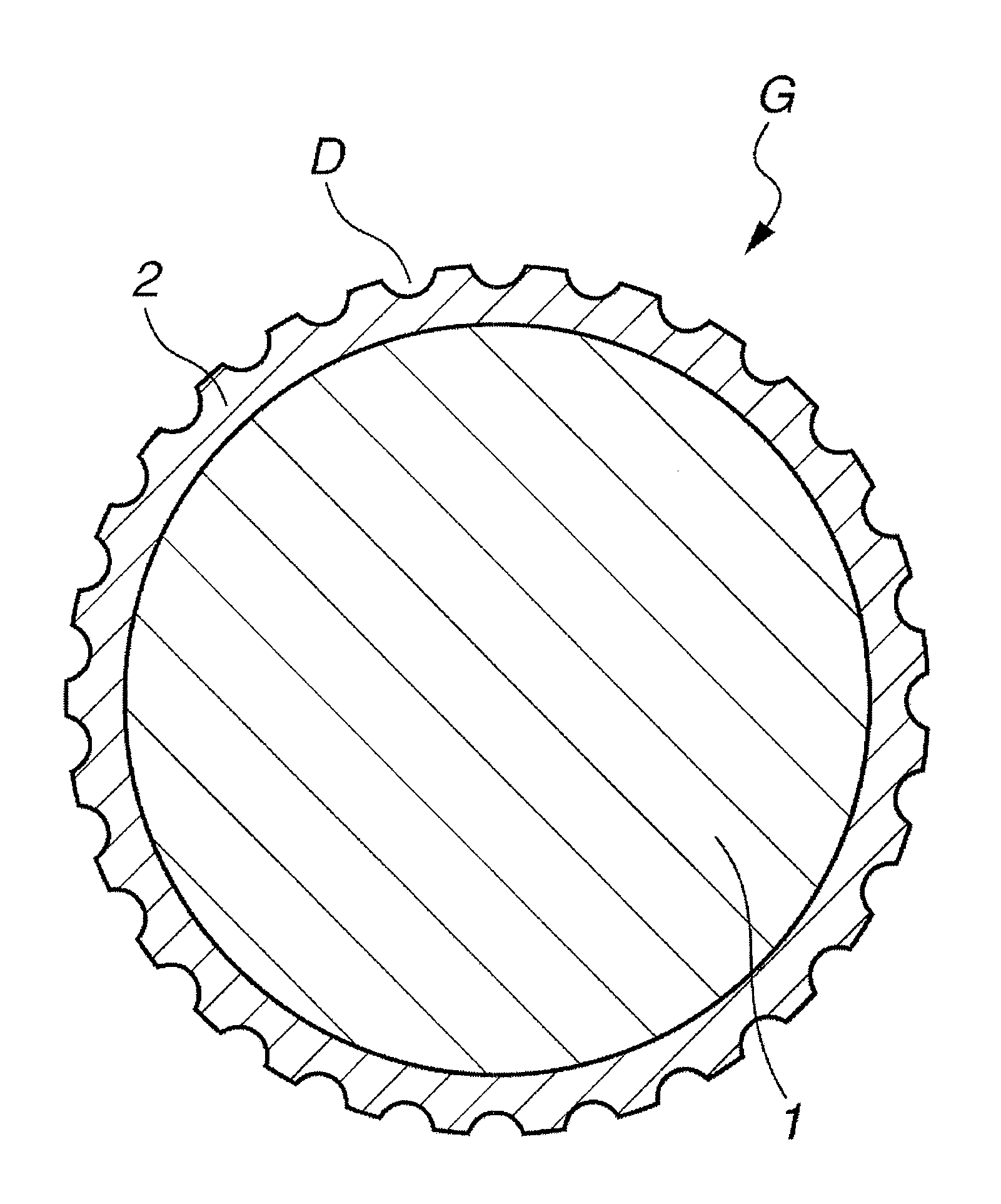

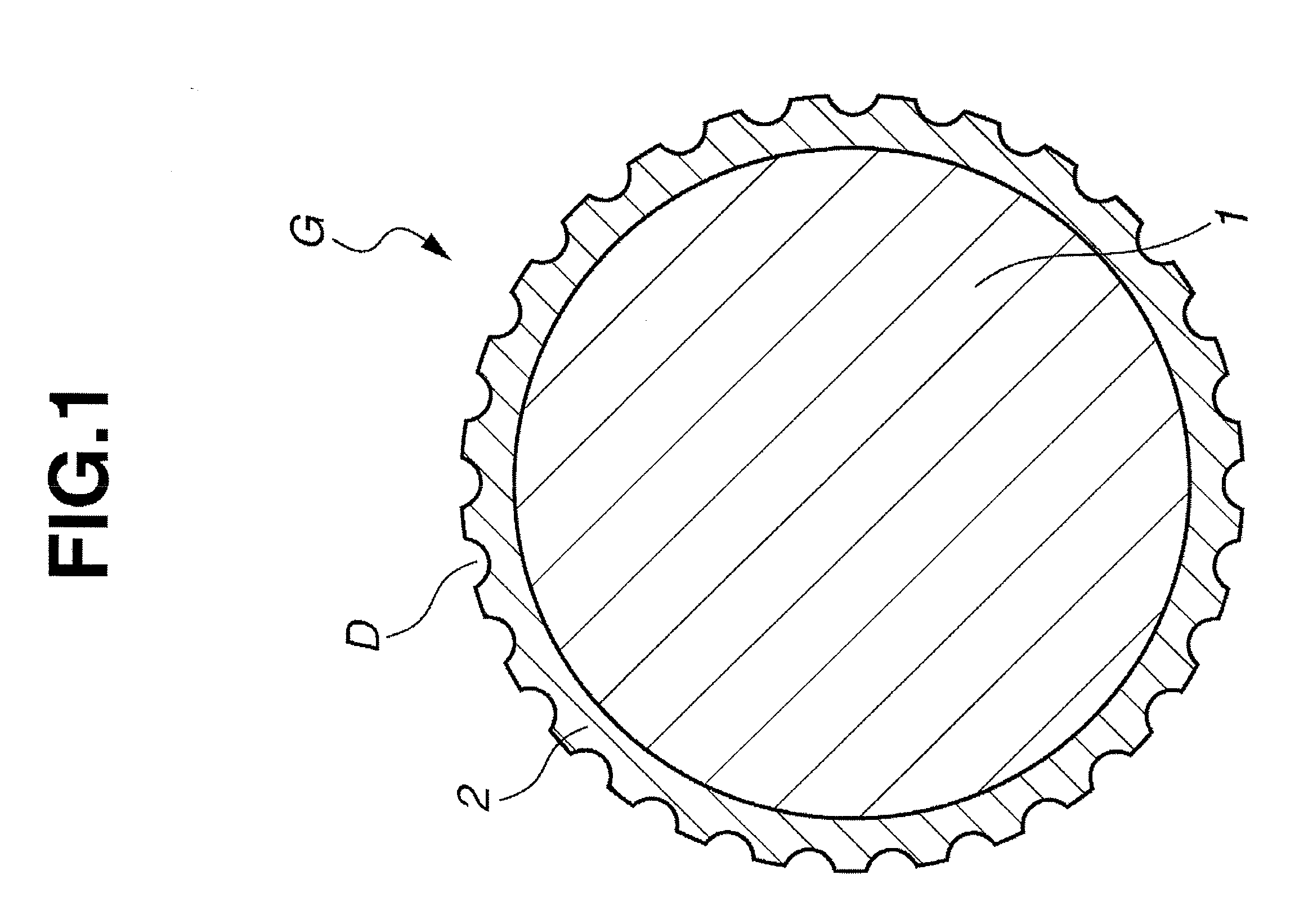

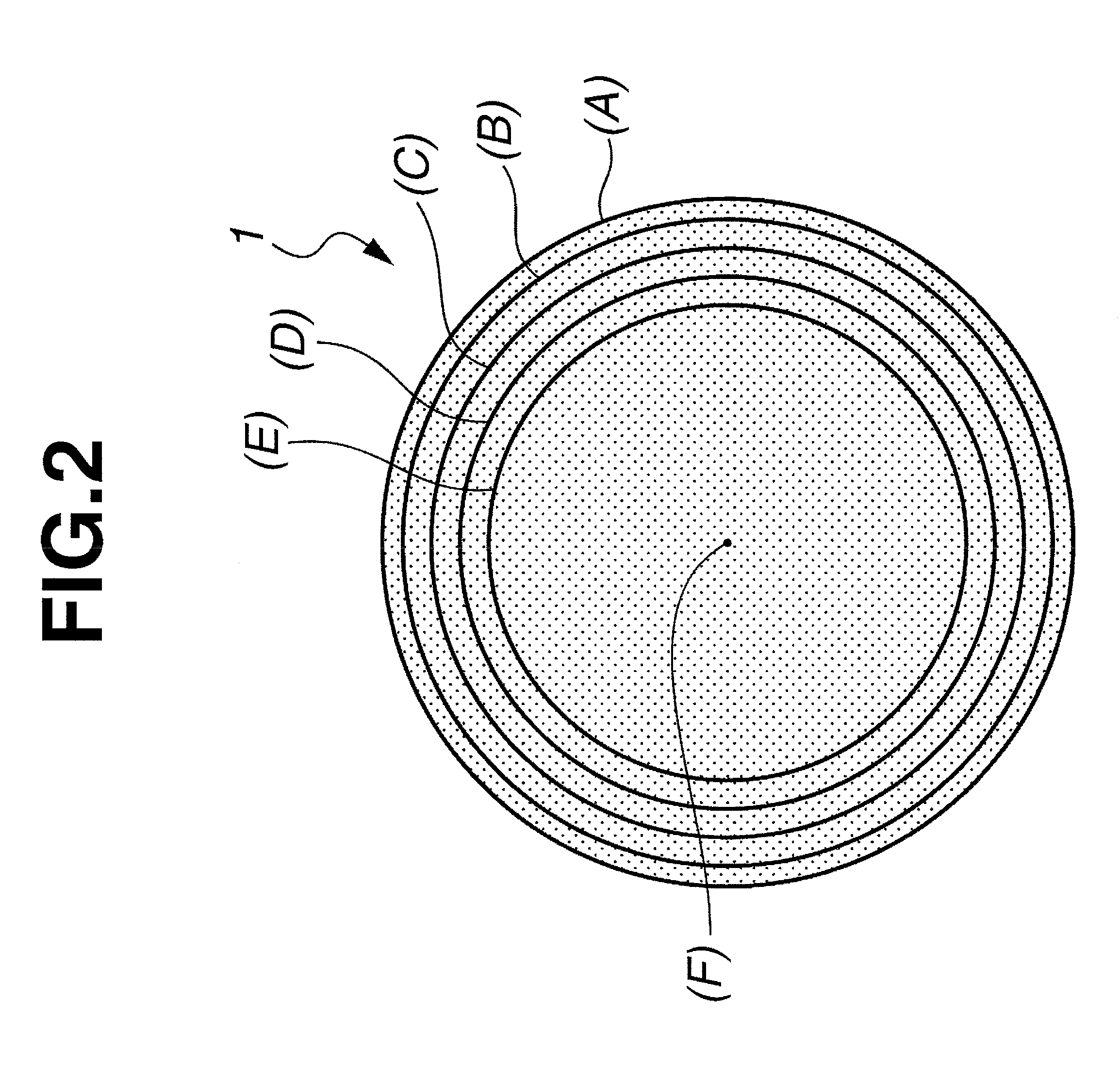

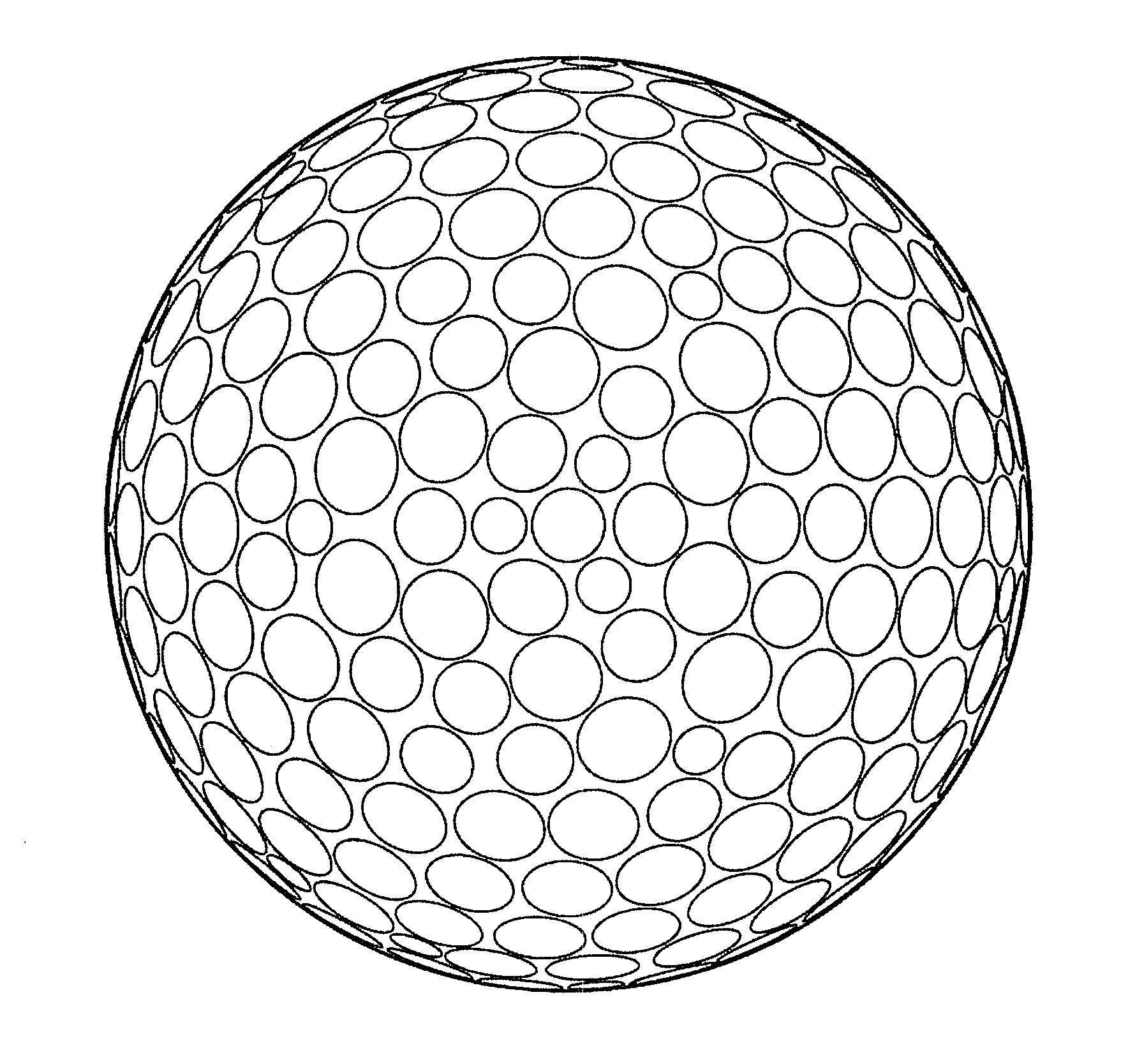

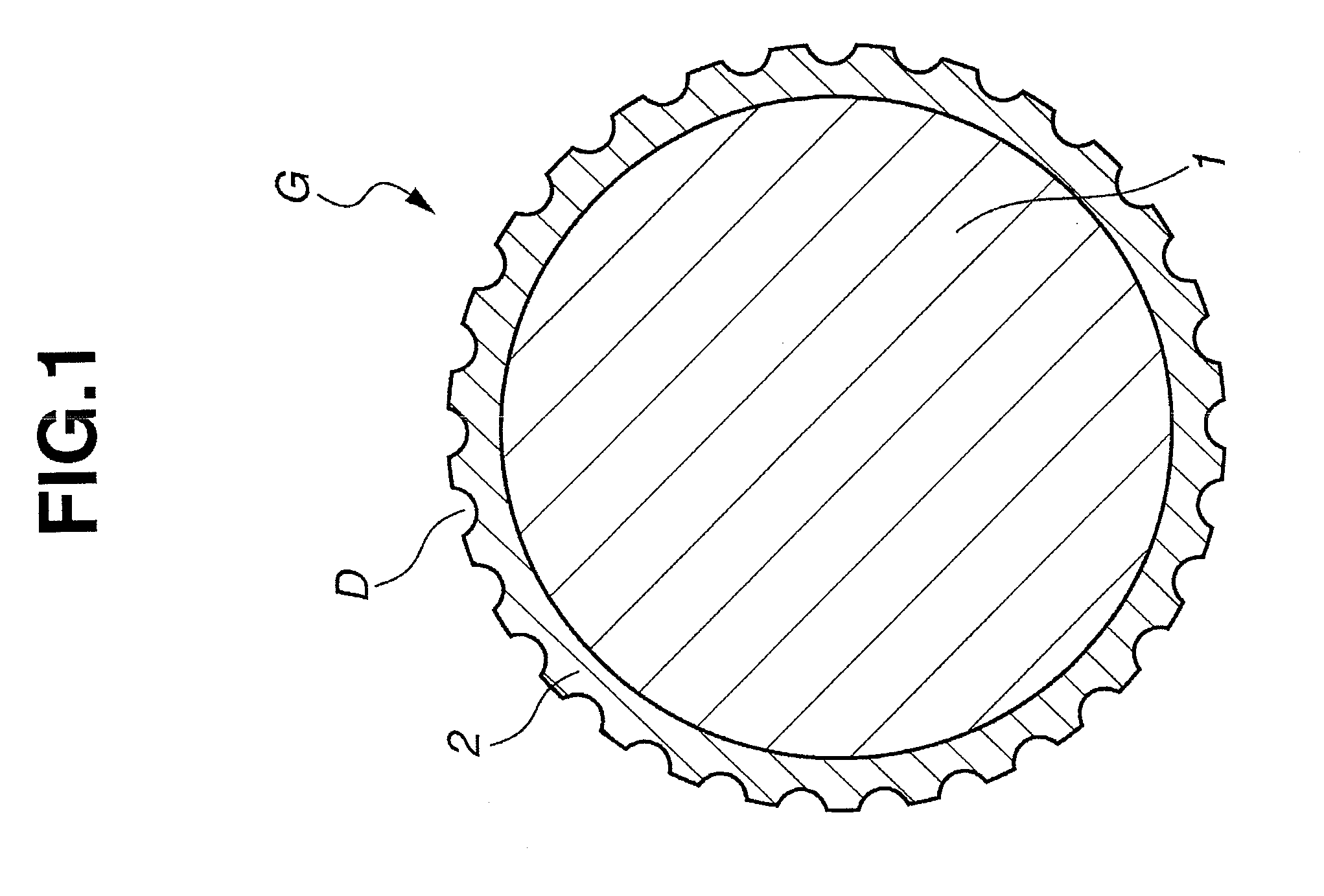

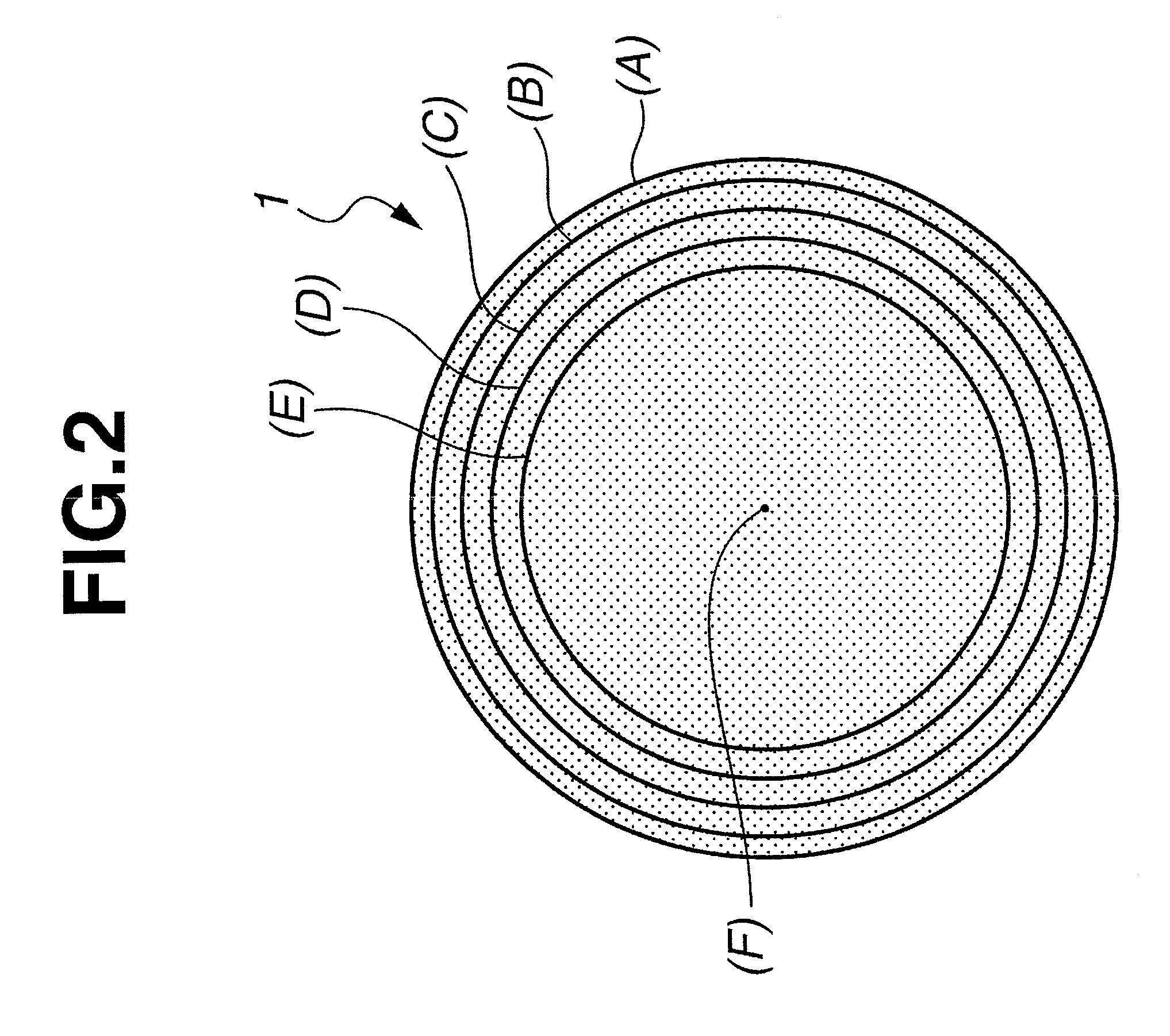

Practice golf ball

A practice golf ball has a core and a cover. The core is made of a rubber composition which includes a base rubber, a co-crosslinking agent, a crosslinking initiator and a metal oxide. The base rubber is a mixture of polybutadiene with styrene-butadiene rubber and / or isoprene rubber, and the co-crosslinking agent is methacrylic acid. The core has a specific deflection under a specific load, and the ball has a specific initial velocity. The dimples on the surface of the ball have a volume ratio VR of from 0.95 to 1.7.

Owner:BRIDGESTONE SPORTS

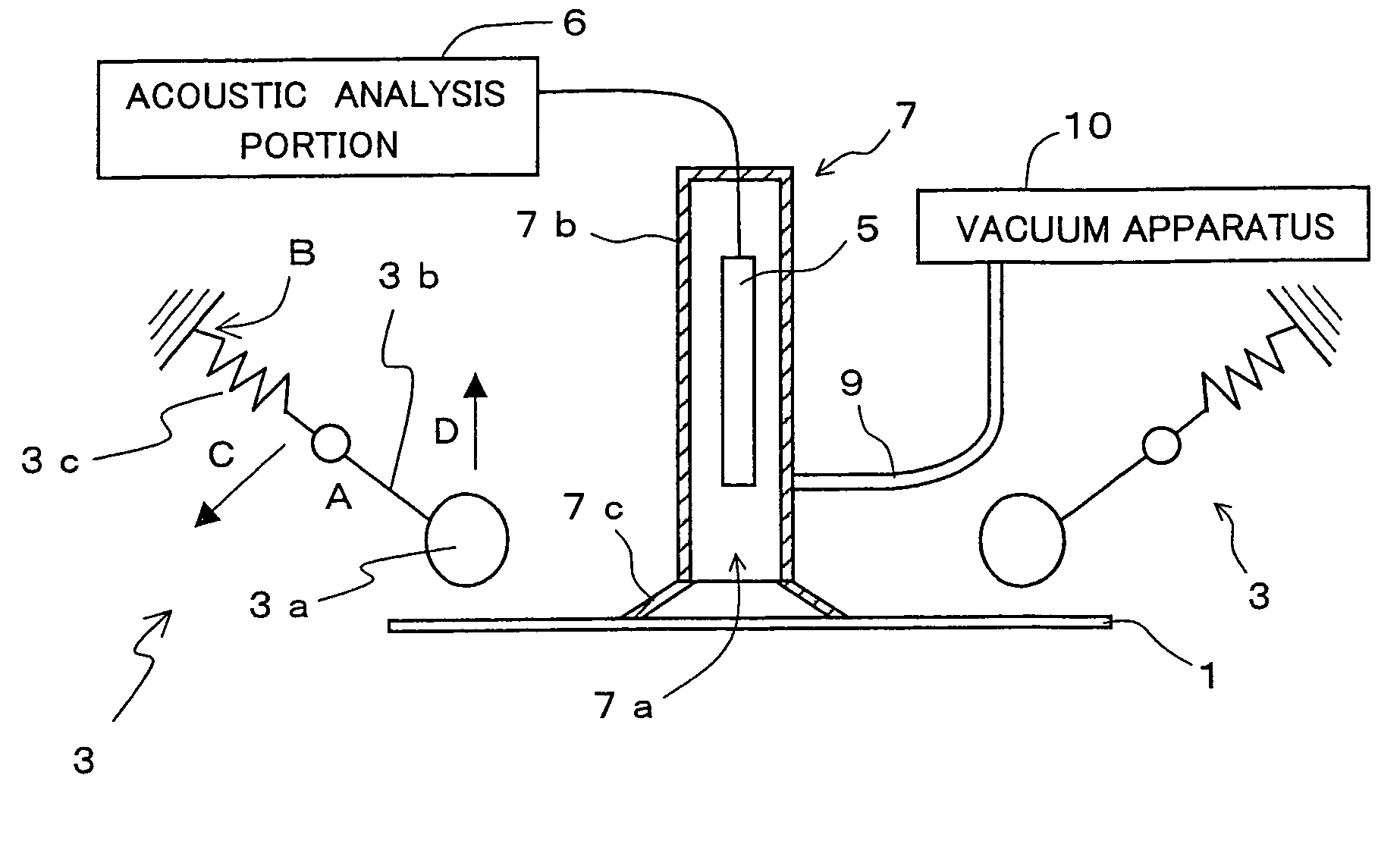

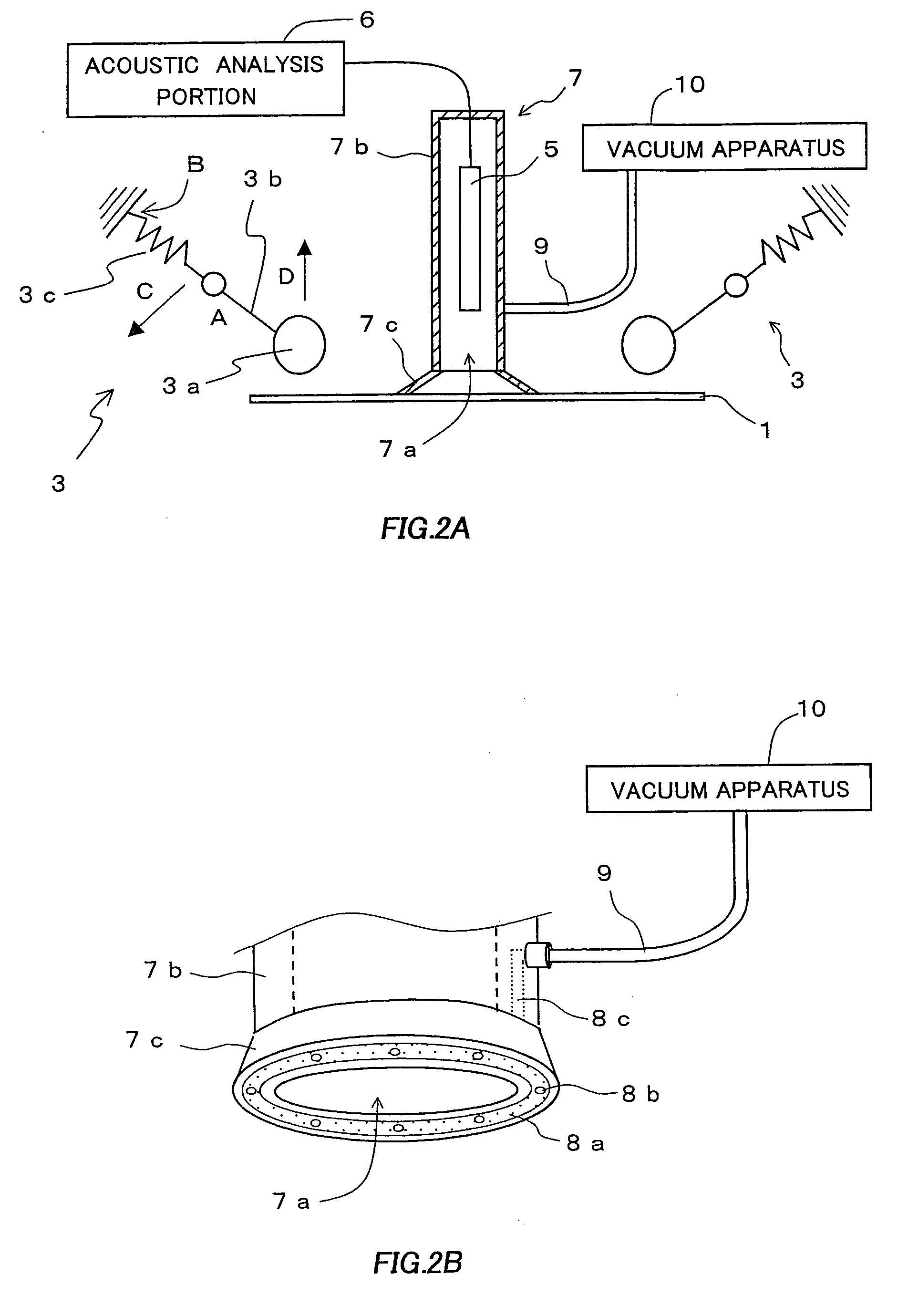

Substrate crack inspection apparatus and substrate crack inspecting method

InactiveUS20060062403A1Highly reliable substrate crack inspectionReliable crackingMaterial analysis using sonic/ultrasonic/infrasonic wavesTransducer casings/cabinets/supportsLight spectrumExternal noise

The present invention aims to provide a substrate crack inspection apparatus comprising: a striking portion for producing a sound by providing a vibration to a substrate; a first microphone for capturing the sound produced by the striking portion; an acoustic analysis portion for carrying out an acoustic analysis of the sound captured by the first microphone to determine a first power spectrum and judging whether or not a substrate crack exists based on a spectral intensity of a predetermined frequency region; and eliminating means for an eliminating the effect of external noise on the produced sound.

Owner:SHARP KK

Pneumatic tire

InactiveUS20110277897A1Avoid crackingControl deformationTyre tread bands/patternsNon-skid devicesMechanical engineeringTread

An object of the present invention is to provide a pneumatic tire capable of, while restricting deformation of groove portions to prevent groove cracks, preventing chipping-off or break-off of protruding portions formed on wall surfaces of the groove as well as preventing irregular wear of the tire. In order to achieve the object, a pneumatic tire comprises a tread surface formed with a plurality of groove portions thereon, wherein at least one of the wall surfaces of the groove portion includes protruding portions and cut-off portions opened to the groove wall surface, and the protruding portions and the cut-off portions are formed alternately on the groove wall surface in an extending direction thereof.

Owner:TOYO TIRE & RUBBER CO LTD

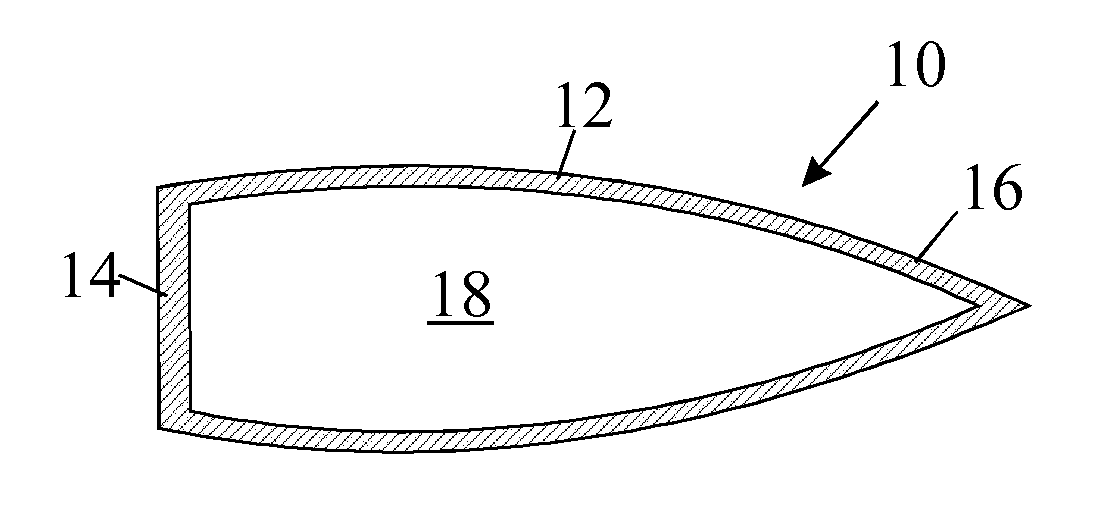

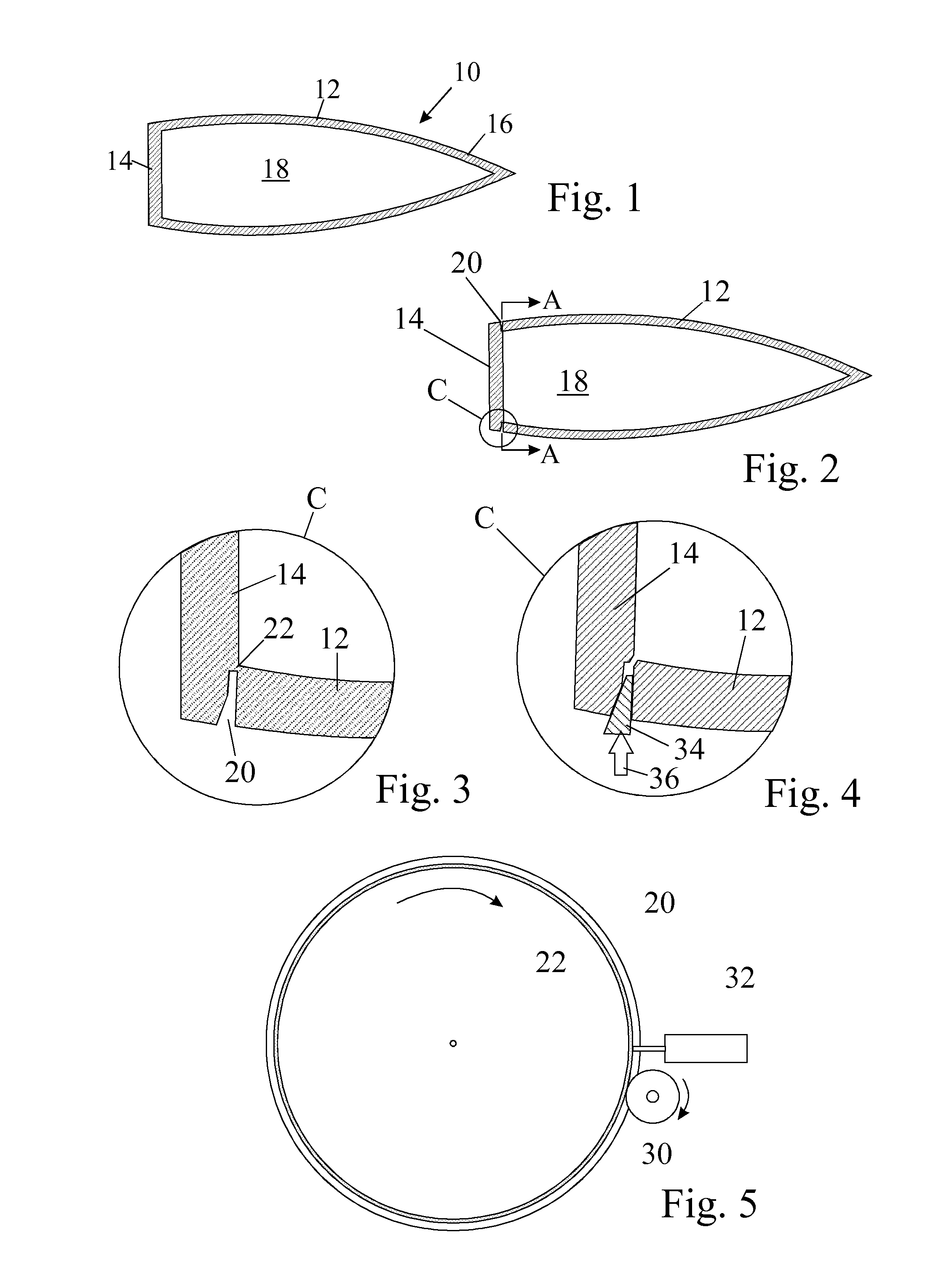

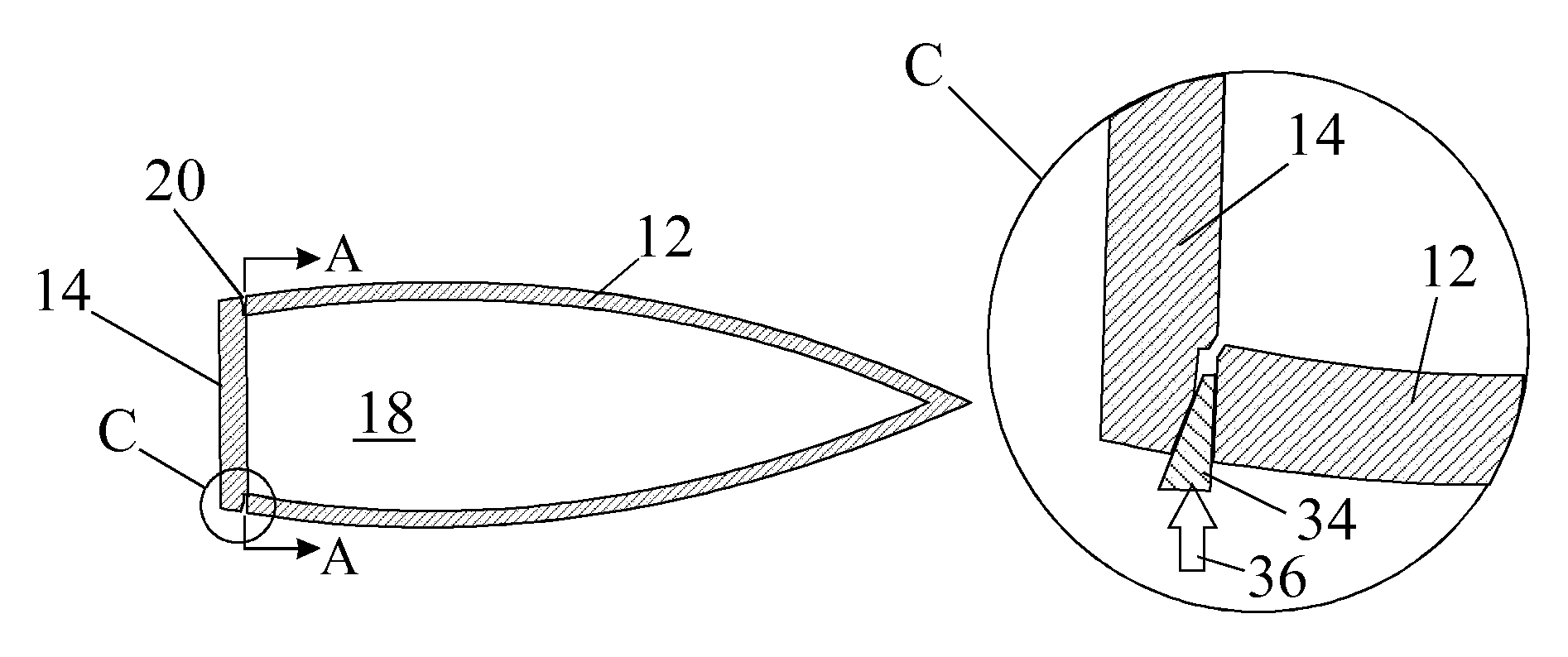

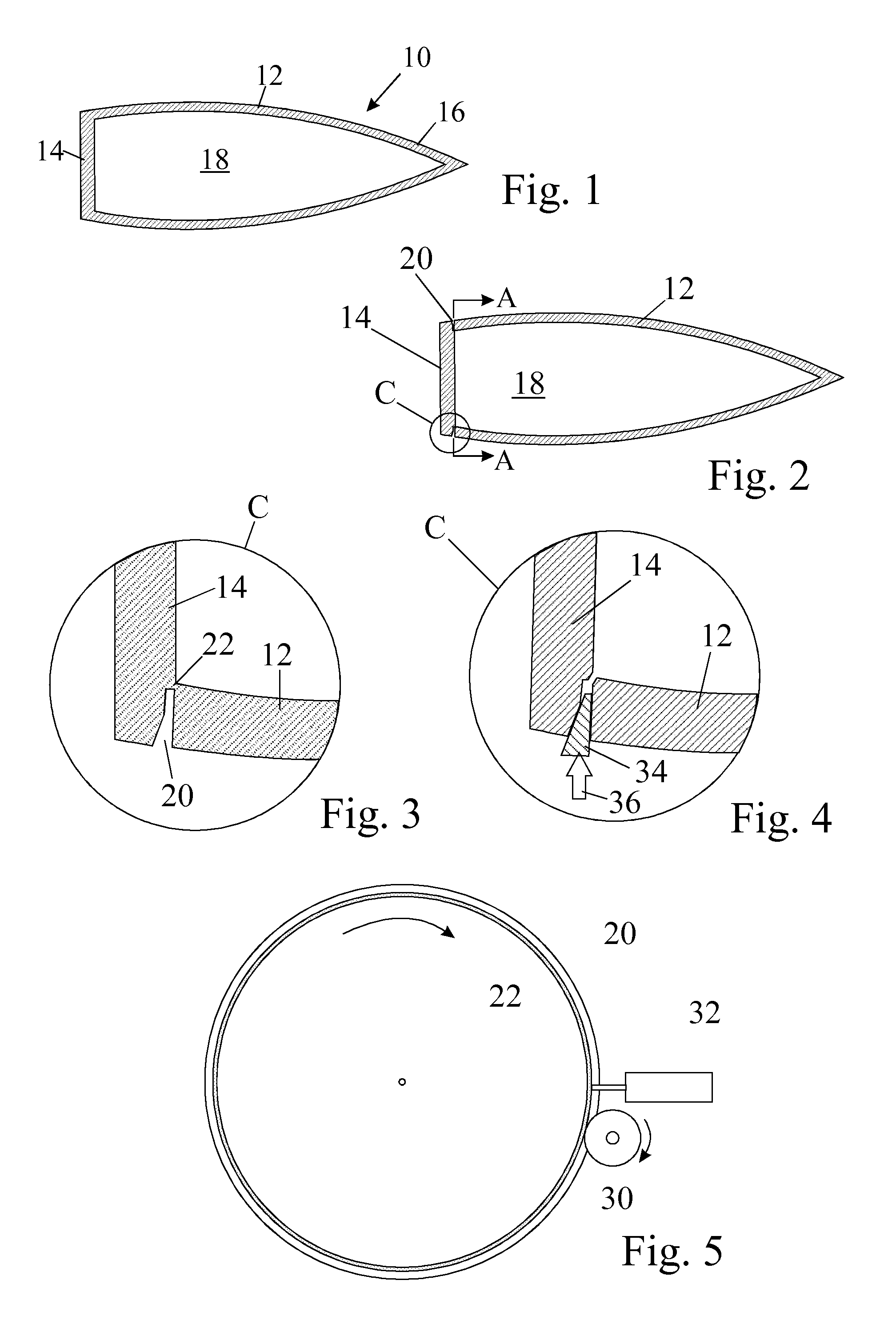

Disposal of Munitions

A method is described for safely opening the shell of a munition (10) having an inner chamber containing an explosive material. The method comprises the steps of machining a groove (20) into the shell along a parting line that encircles the outer surface of the munition and divides the shell into two parts. The groove (20) is of sufficient depth to weaken the shell but not to penetrate into the inner chamber of the munition. After machining the groove (20), the shell is cracked open by prising the two parts of the shell apart by inserting a suitable implement into the groove.

Owner:DISARMCO

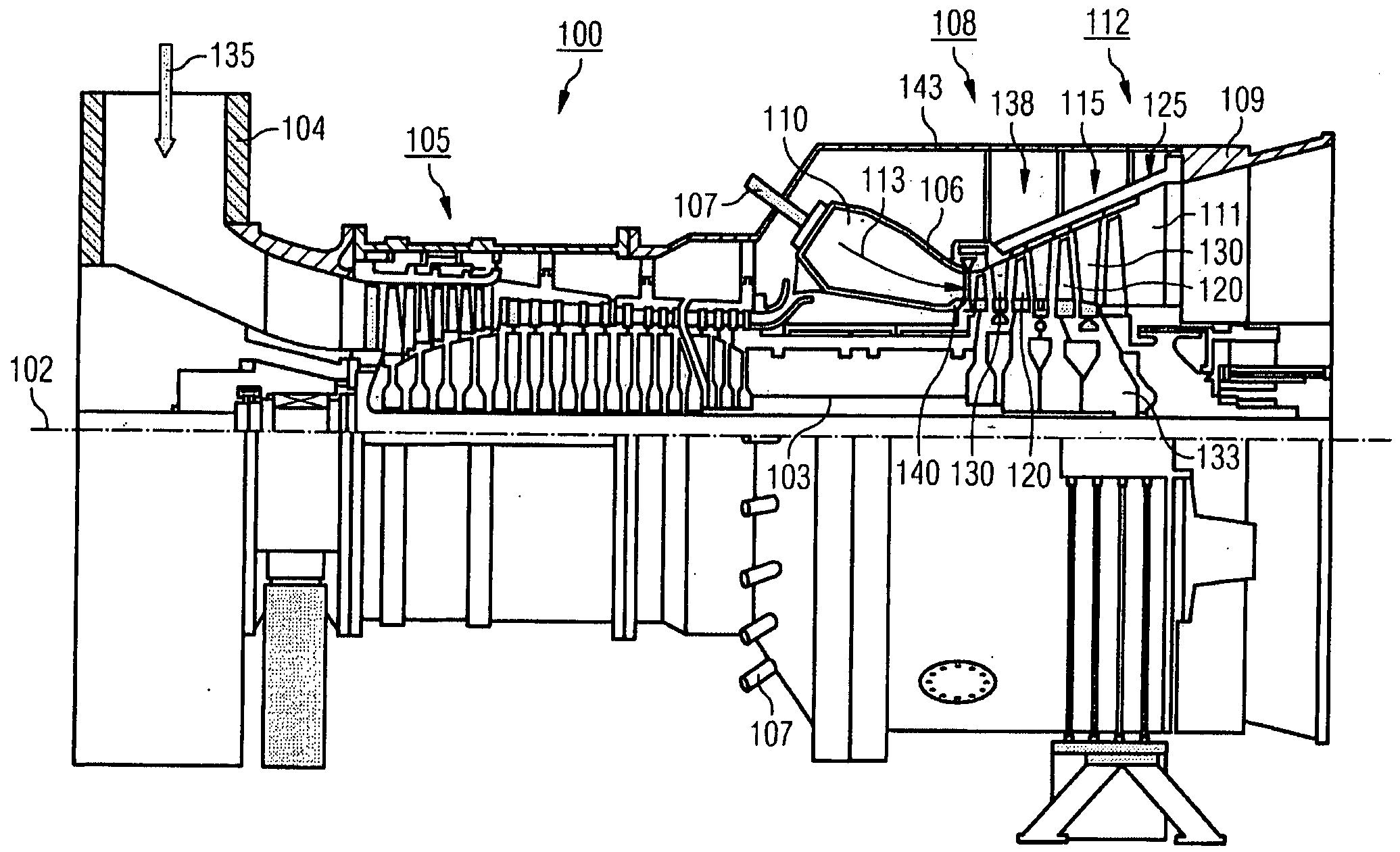

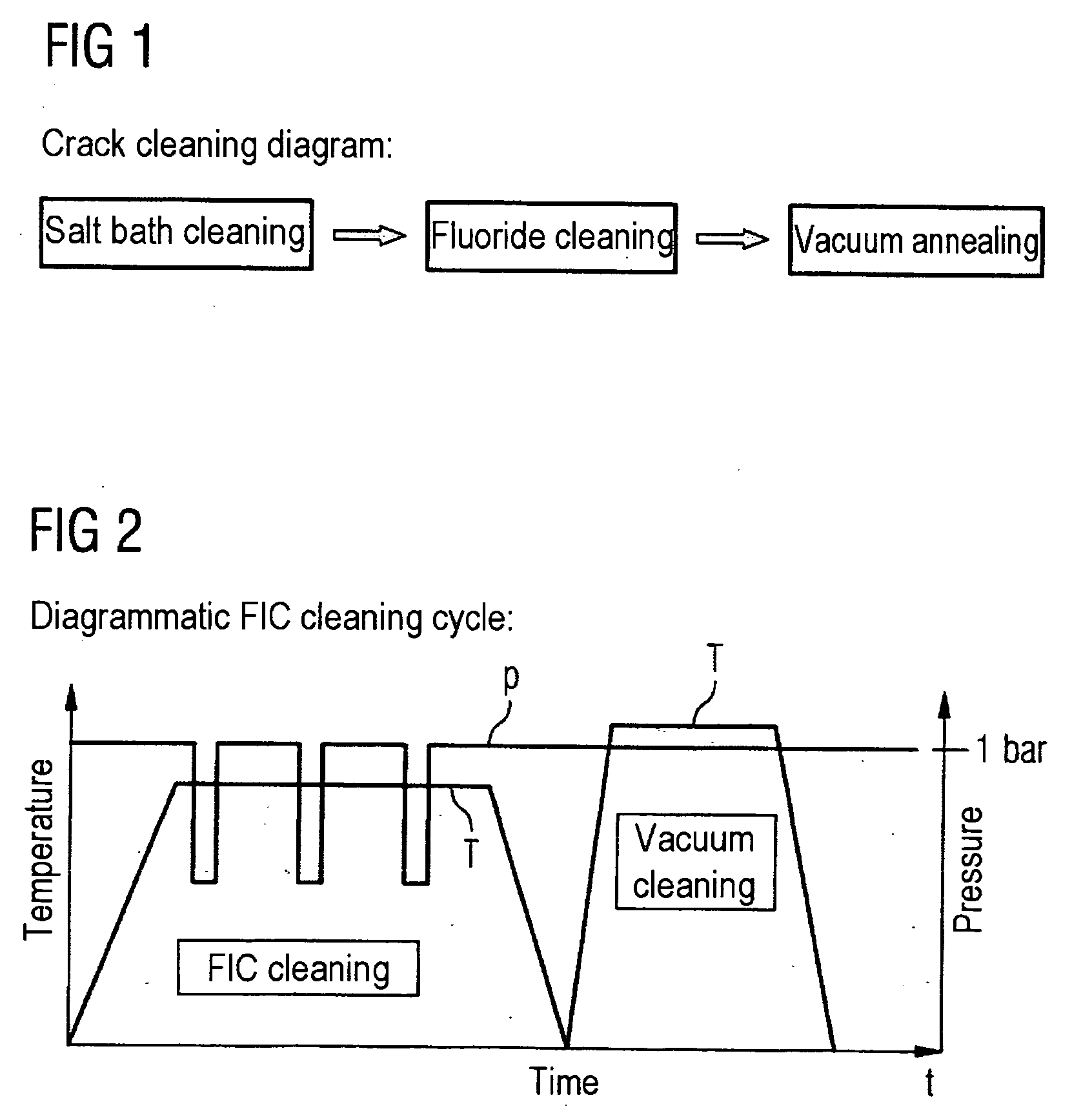

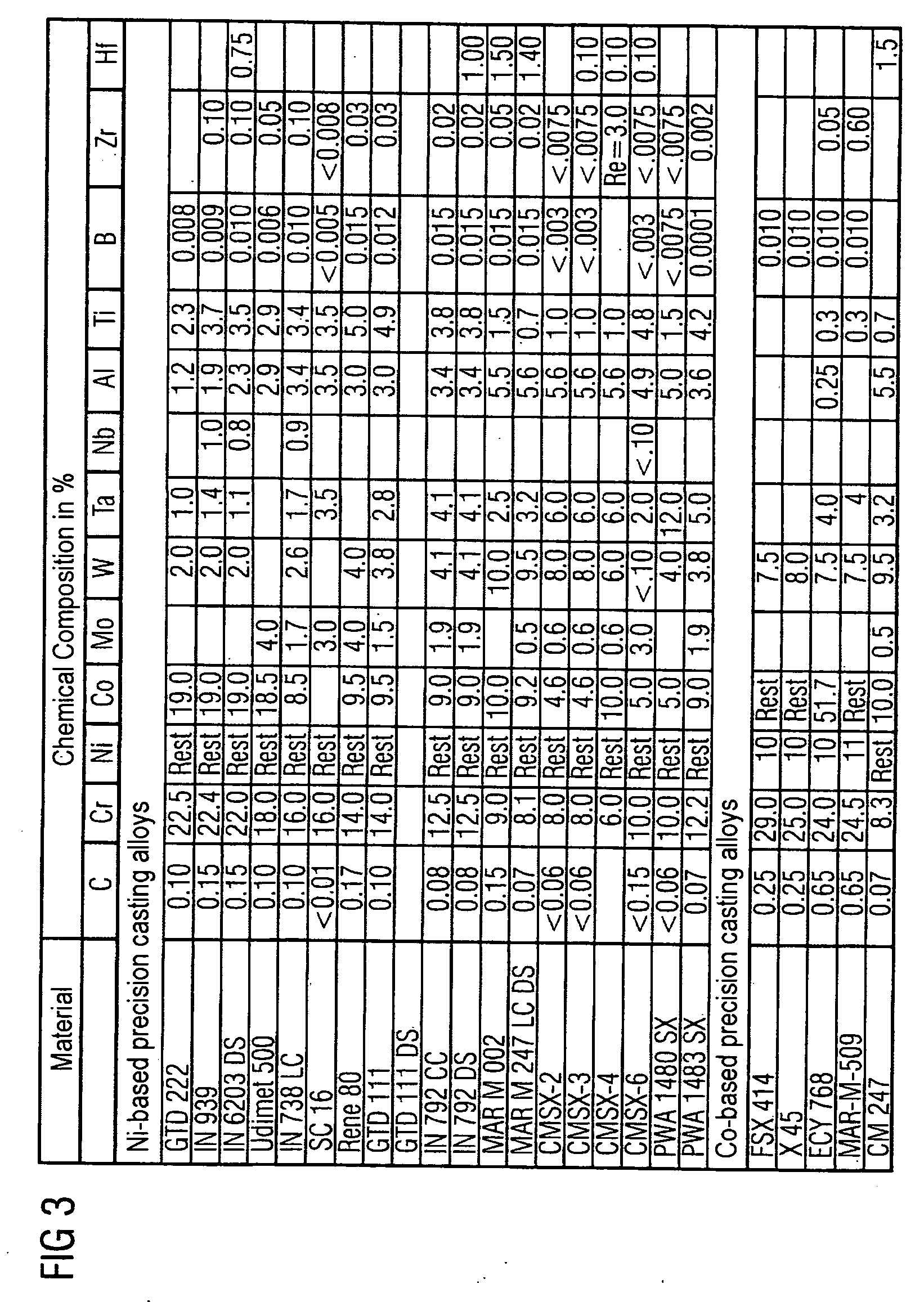

Technology for Cleaning Thermal Fatigue Cracks in Nickel-Based Superalloys With a High Chromium Content

InactiveUS20090107003A1Reliable cleaningReliable crackingDrying solid materials with heatBlade accessoriesIonChemistry

There is described a method for cleaning components that comprise cracks that are polluted with oxides, in particular gas turbine part. In said method, the components to be cleaned are exposed in a cleaning chamber at high temperature to a cleaning gas containing gaseous halogen compounds, which ionize to form halide ions. A cleaning gas is used containing 18 to 30% by volume hydrogen halide.

Owner:SIEMENS AG

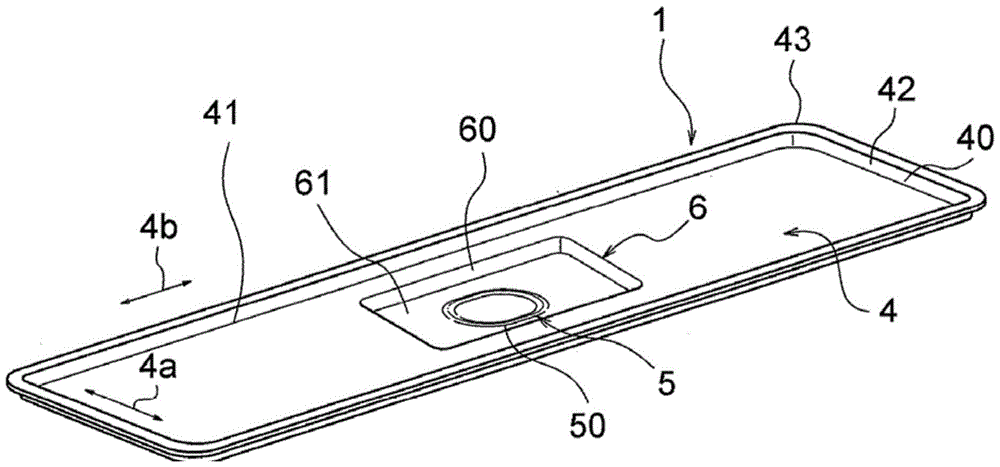

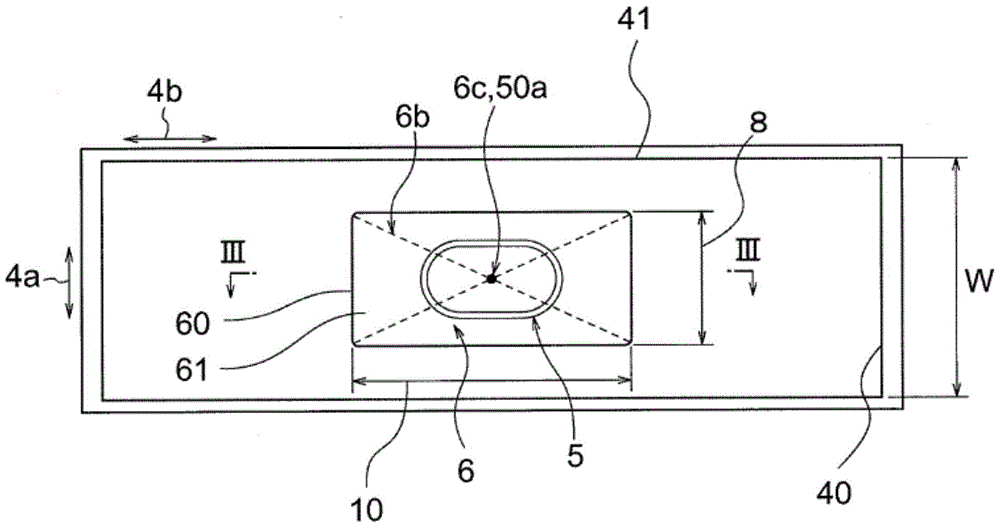

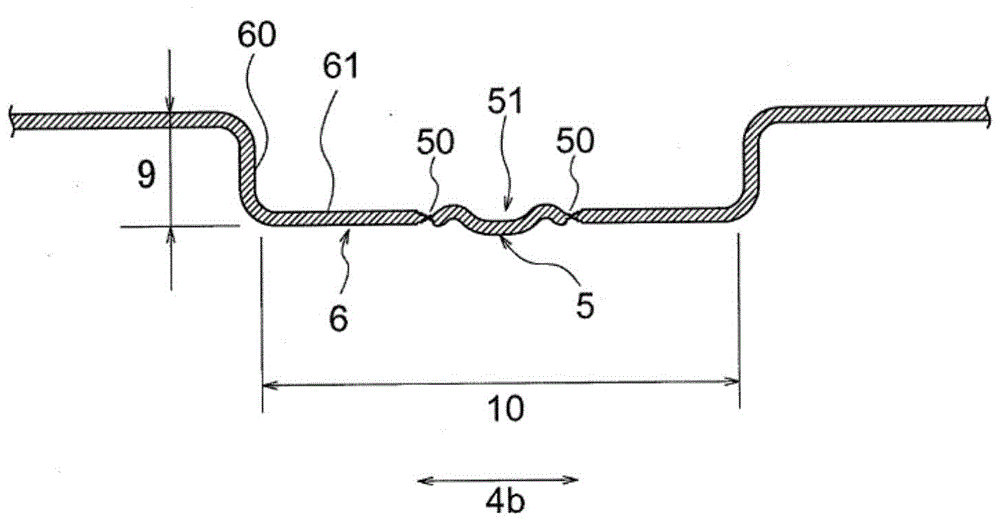

Cover body for battery case

ActiveCN103718332AReliable crackingVent arrangementsSecondary cells manufactureEngineeringMechanical engineering

Owner:NISSHIN STEEL CO LTD

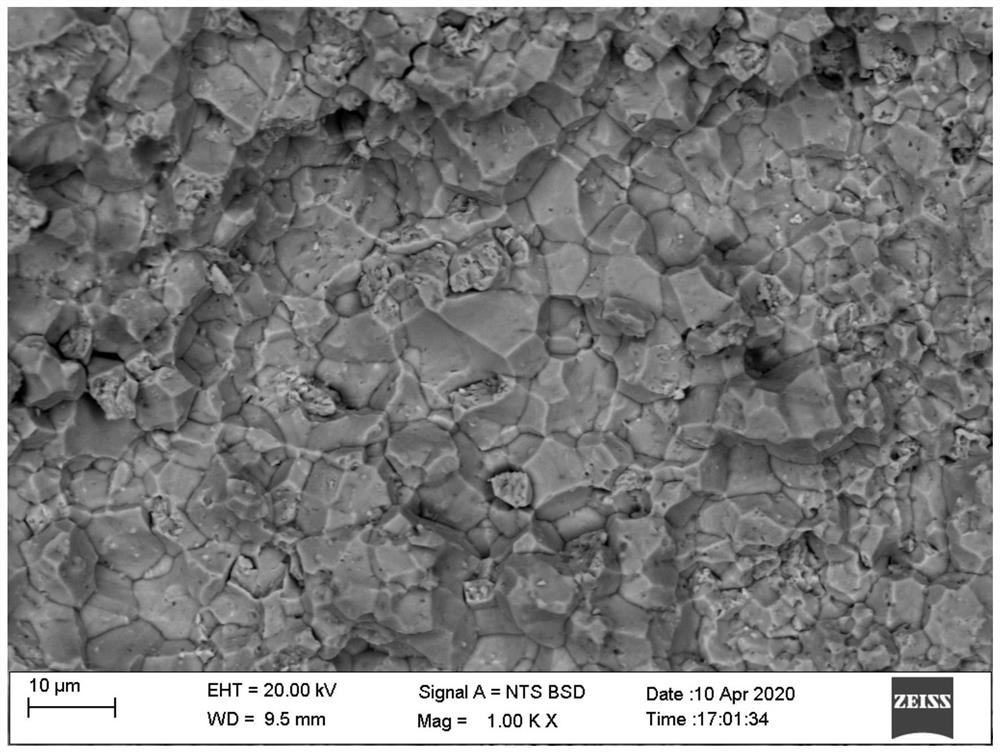

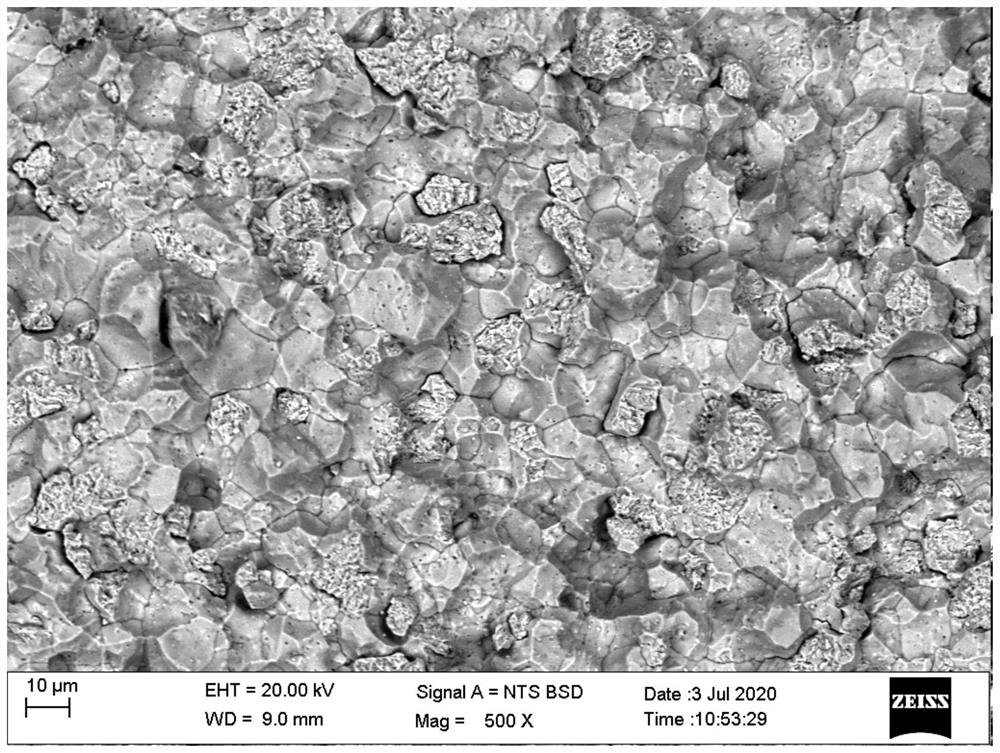

Steel austenite grain boundary display method and steel austenite grain size evaluation method

PendingCN111766257AReliable crackingMaterial analysis using wave/particle radiationAustenite grainTest sample

The invention provides a steel austenite grain boundary display method and a steel austenite grain size evaluation method, and belongs to the technical field of steel structure analysis. The steel austenite grain boundary display method comprises the steps of heating a to-be-tested sample with a carbon content of 0.95-1.10wt% to a temperature higher than a preset critical temperature, carrying outheat preservation to completely austenitize the to-be-tested sample, putting the to-be-tested sample into a cooling liquid within 5s, and cooling at a speed of not less than 150 DEG C / s to obtain theto-be-tested sample with a cracked surface; and cutting the to-be-tested sample with the cracked surface to expose a fracture surface formed by cracking, and shooting a backscattered electron image of the fracture surface by using a backscattered electron probe. The steel austenite grain size evaluation method comprises the step of obtaining a back scattering electron image by adopting the display method; and evaluating the austenite grain size of the backscattered electron image by using an area method or an intercept point method. Metallographic sample preparation and corrosion treatment are not needed, and an austenite grain boundary line can be clearly displayed.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

Practice golf ball

InactiveUS20120277021A1Good lookingImprove flight performanceGolf ballsSolid ballsBreaking strengthSurface loss

A practice golf ball has a core made of a rubber composition which includes a base rubber, a co-crosslinking agent, a crosslinking initiator and a metal oxide, and has a cover which encases the core and is made of a resin material. The co-crosslinking agent is methacrylic acid. The resin material has a breaking strength of 20 to 80 MPa and an elongation of 150 to 600%. The ball is endowed with the properties required of practice balls intended for long-term use, including better durability to cracking and durability of appearance than ordinary game balls, and also better durability to ball surface loss than the one-piece golf balls which are commonly used as practice balls.

Owner:BRIDGESTONE SPORTS

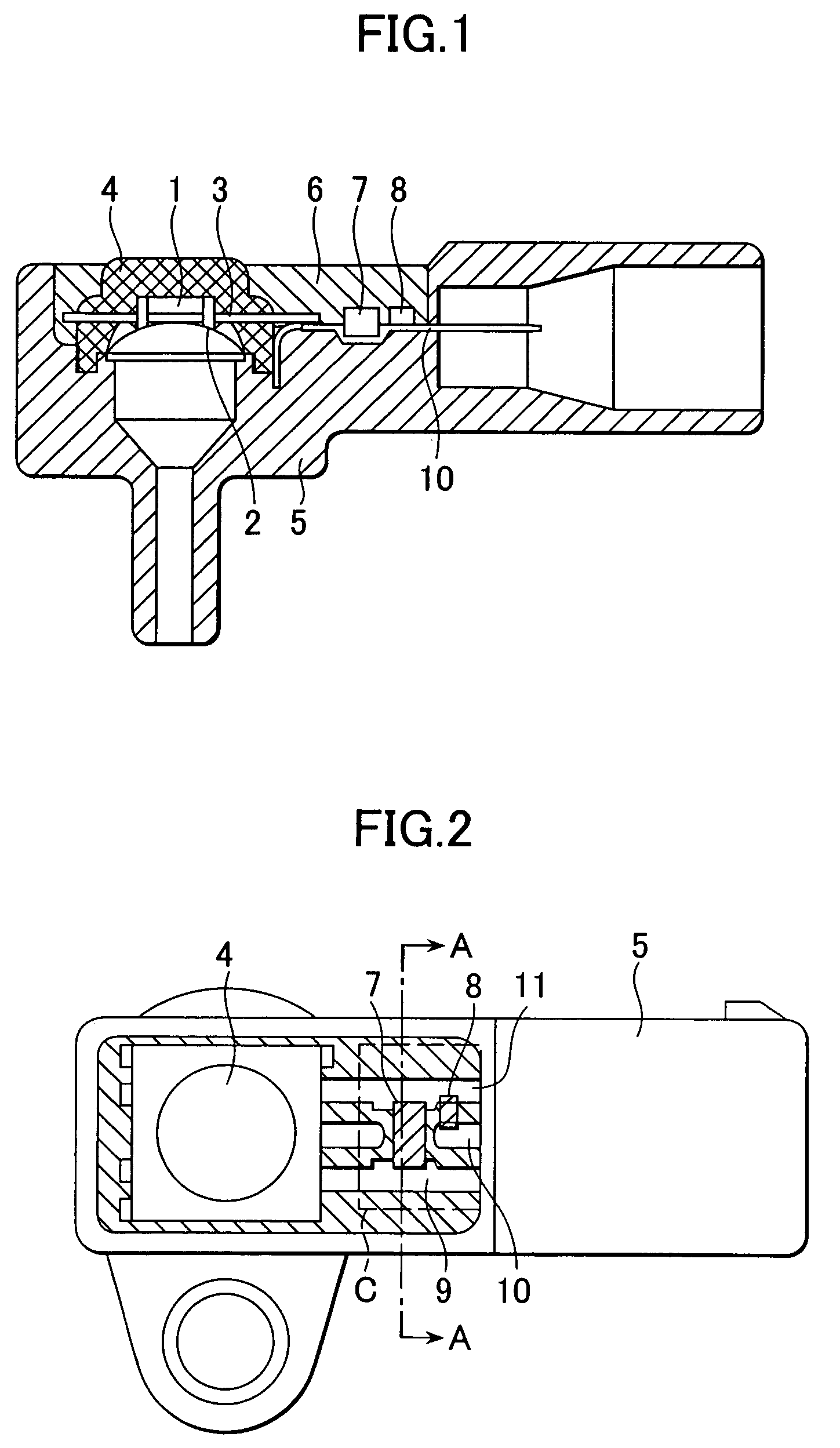

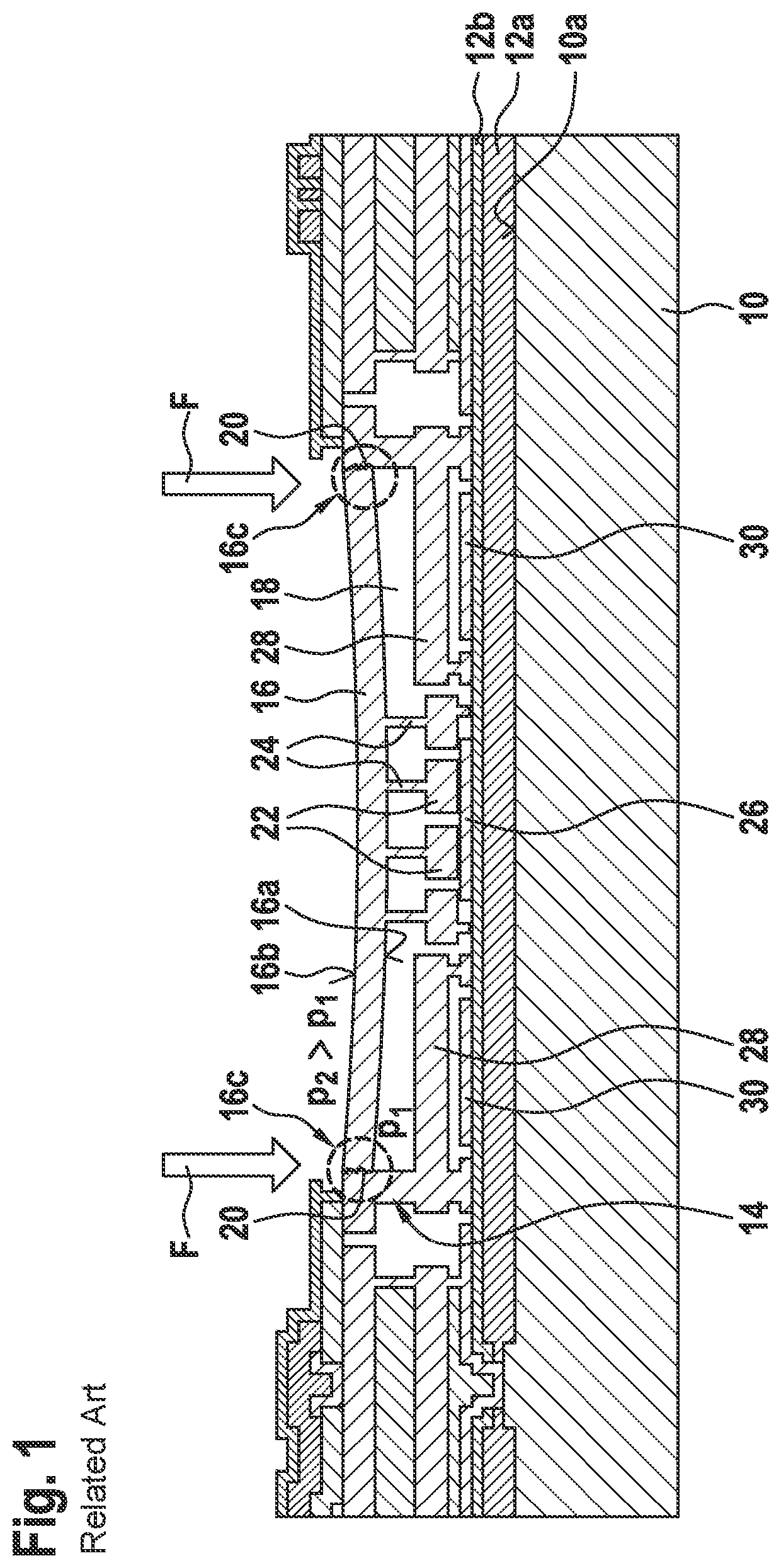

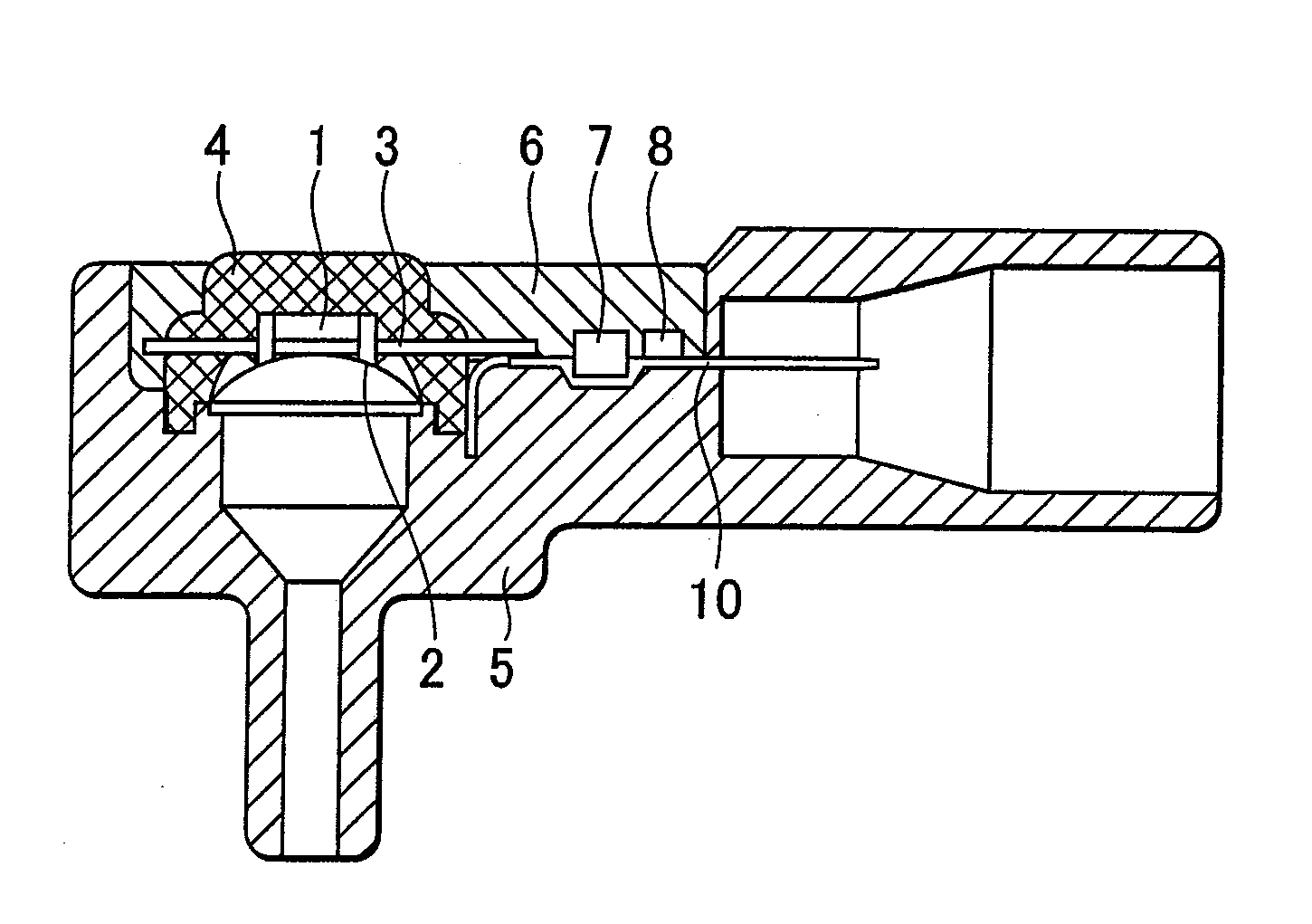

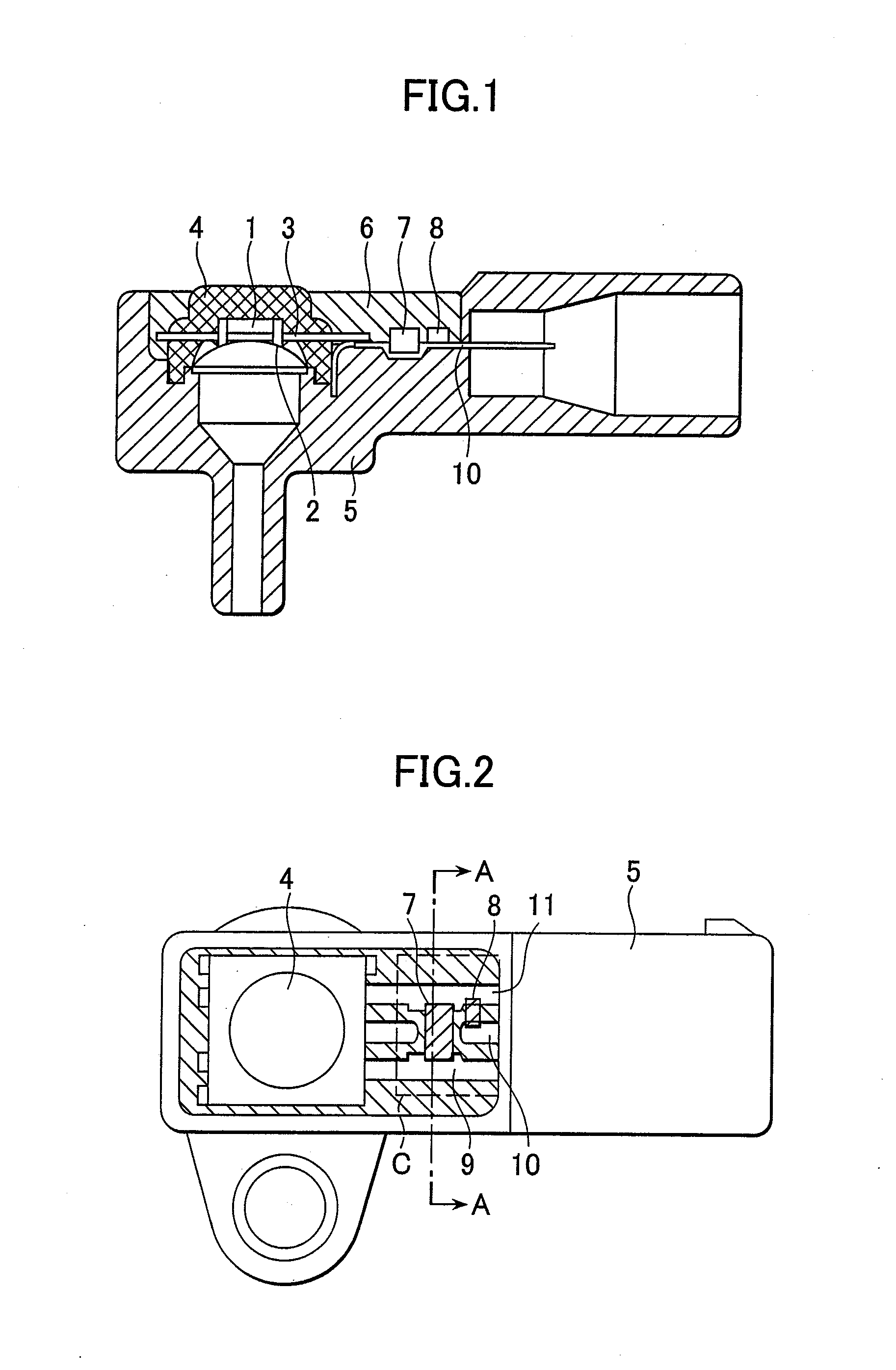

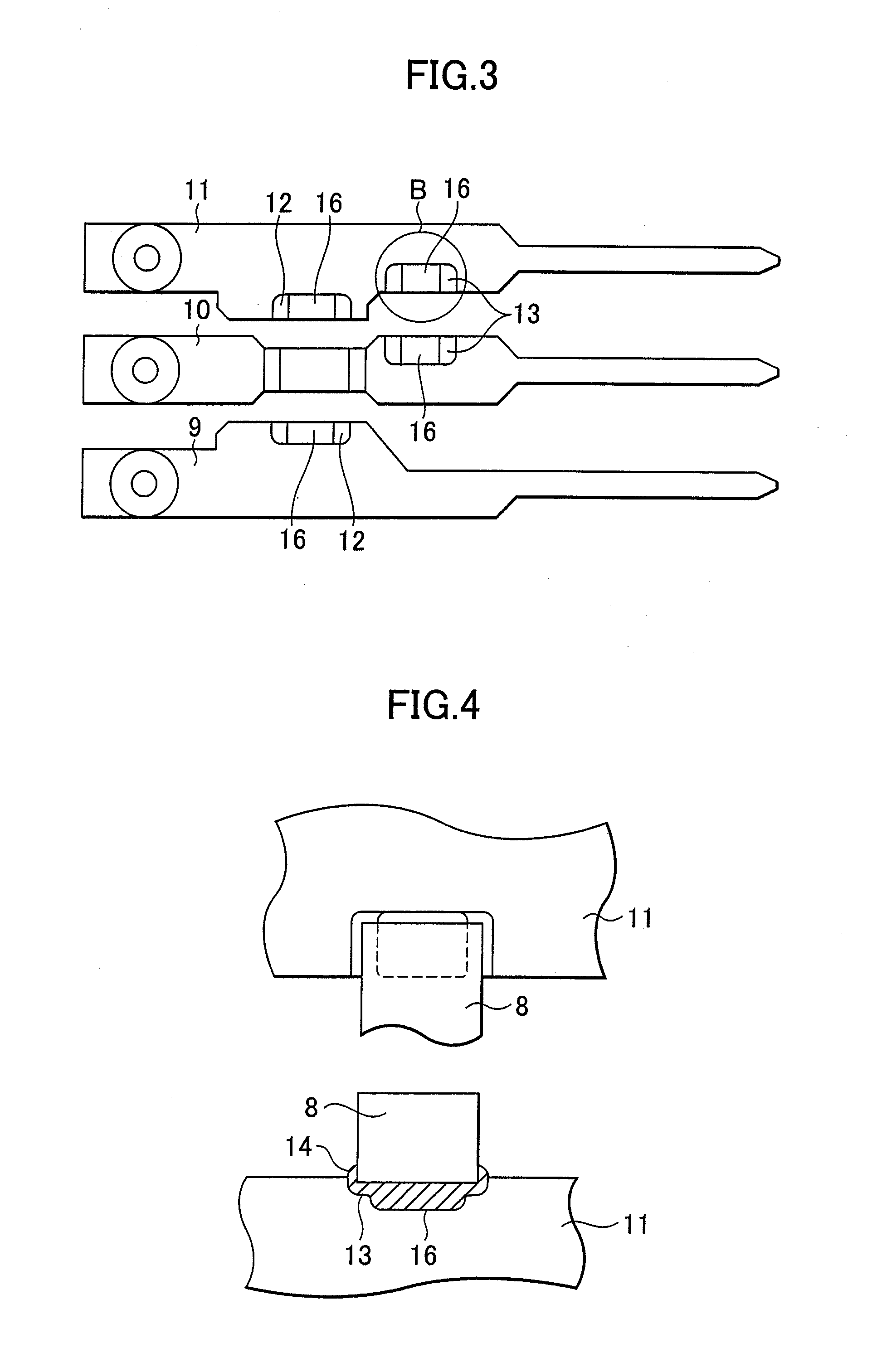

Electronic device and pressure sensor

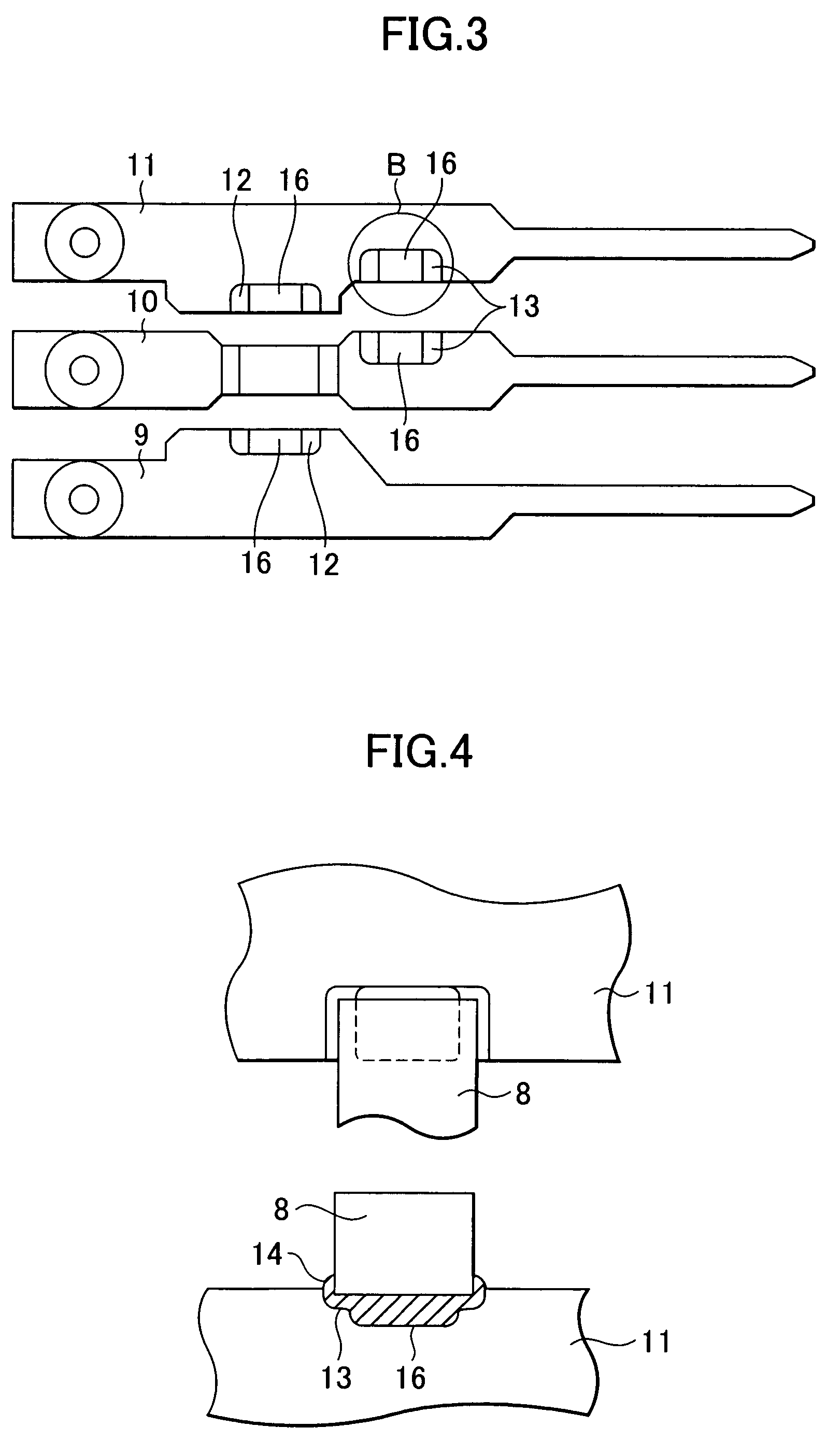

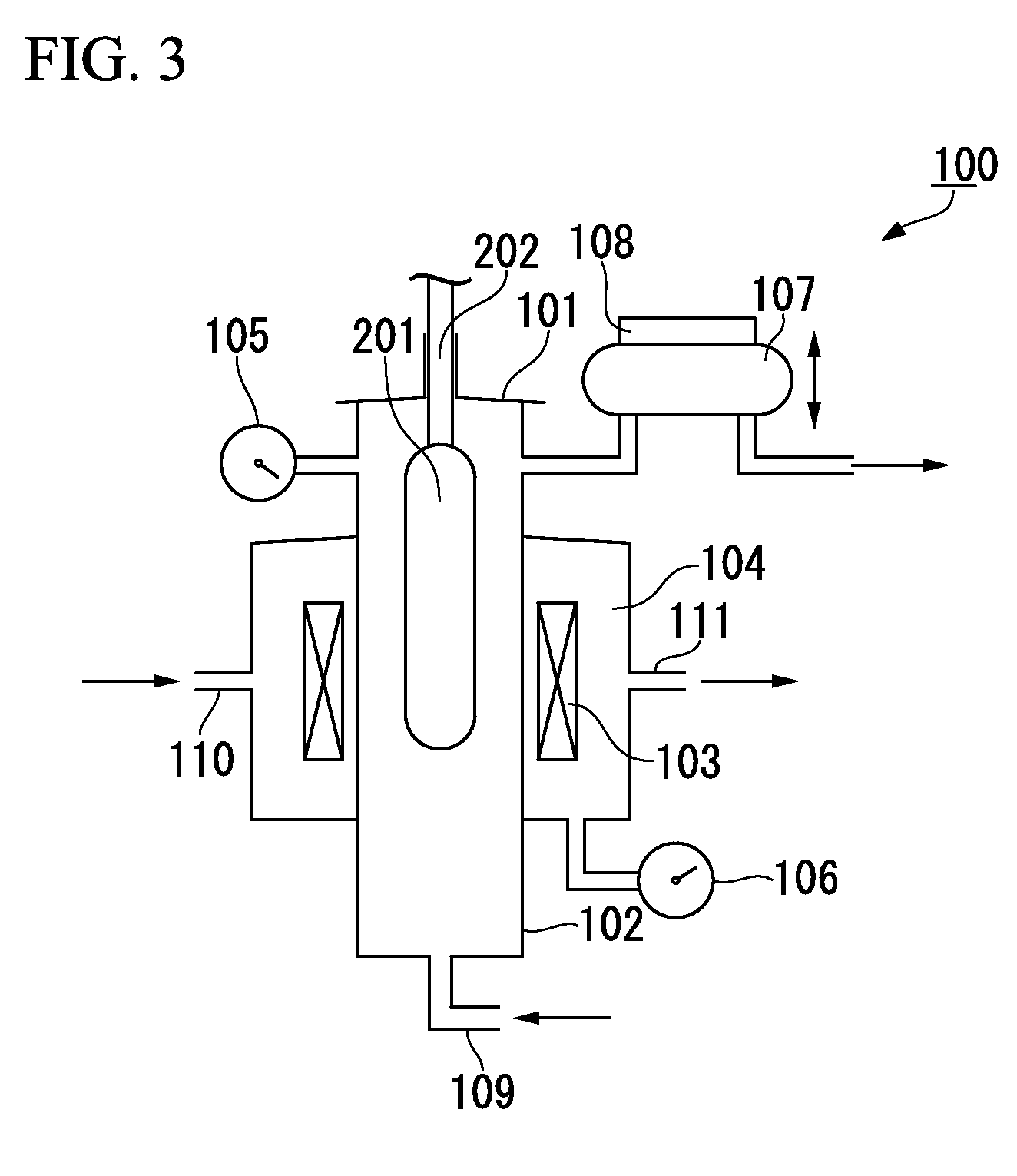

ActiveUS7414307B2Improve reliabilityAvoid position shiftPrinted circuit assemblingFinal product manufactureElectronic componentElectron

An electronic device requires an electronic component to be mounted for the purpose of static shielding. The mounting of such an electronic component raises a problem of avoiding thermal stresses and cracks generated due to the difference between the coefficients of linear expansion of component materials. A positioning recess, a joining-substance thickness ensuring recess, a joining-substance thickness ensuring projection, etc. are formed in a combined manner in an electronic component mount portion of each of leads, whereby spreading of cracks generated in the joining substance can be suppressed and reliability can be improved. Filling a sealing material so as to seal and restrain the electronic component mounted in the electronic component mount portion without leaving voids contributes to further suppressing spreading of cracks generated in the joining substance and ensuring more improved reliability of the joining substance.

Owner:HITACHI ASTEMO LTD

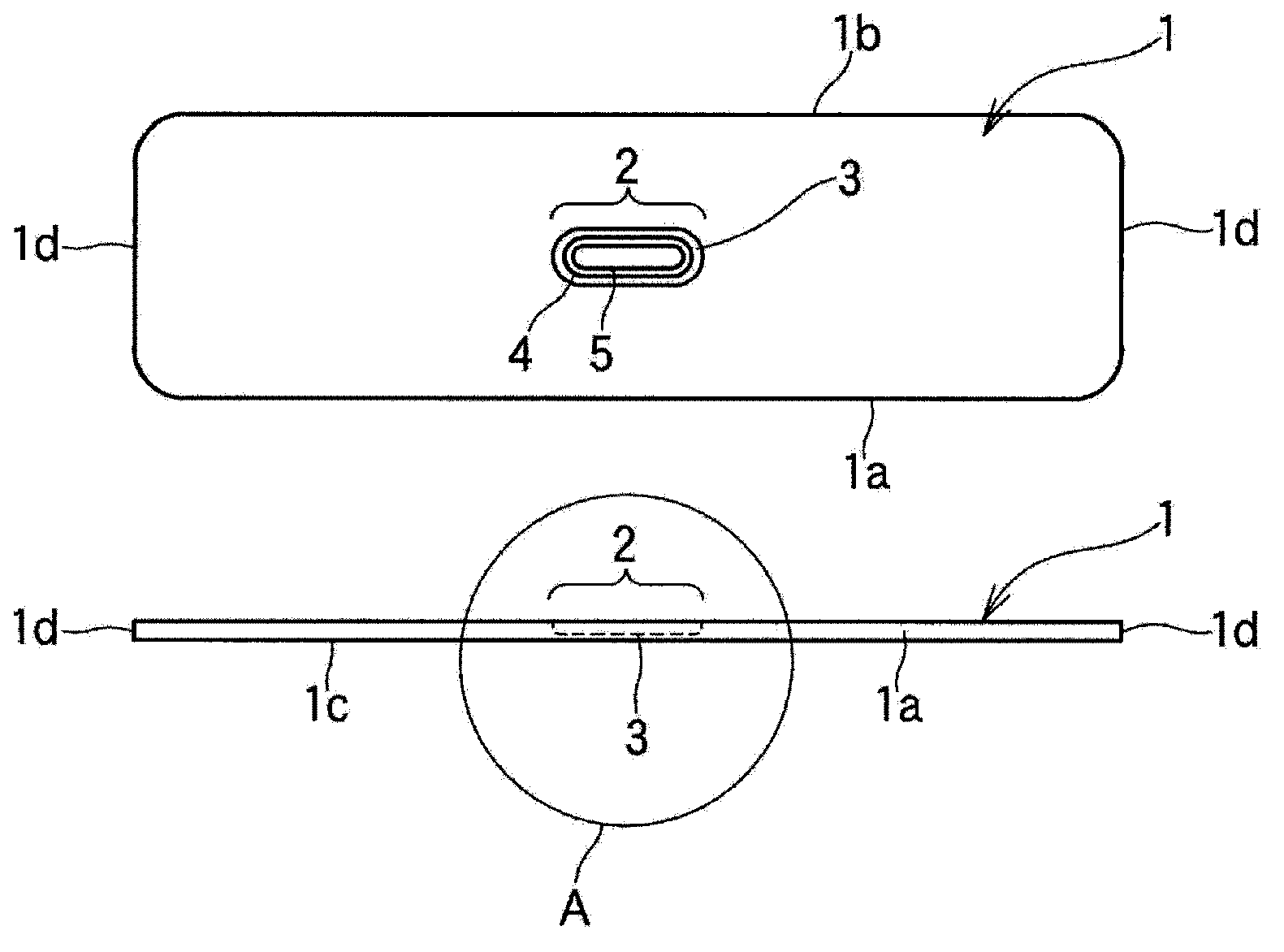

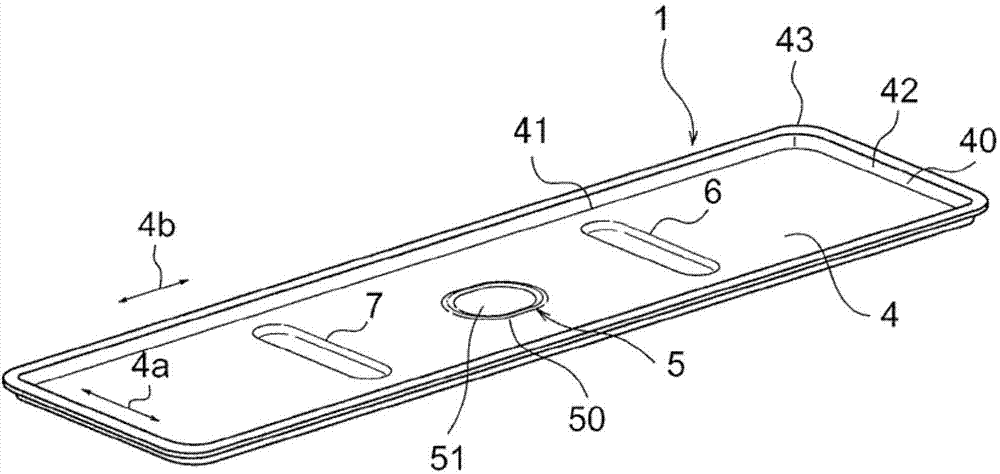

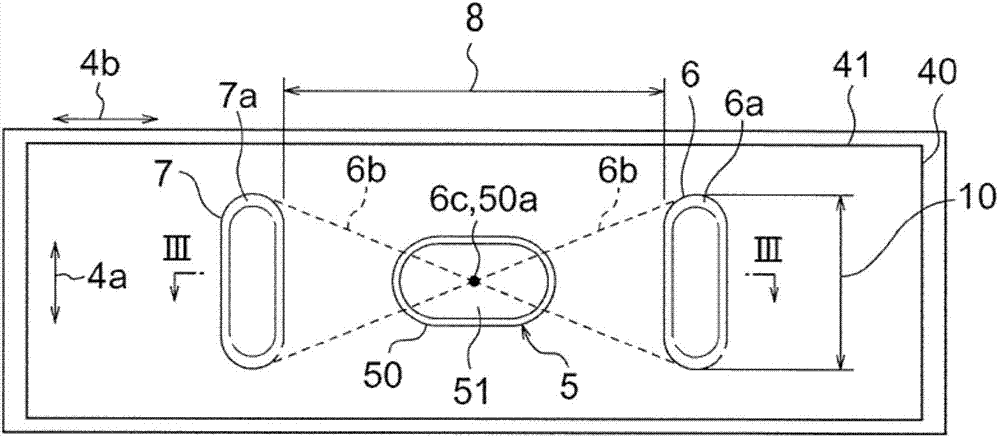

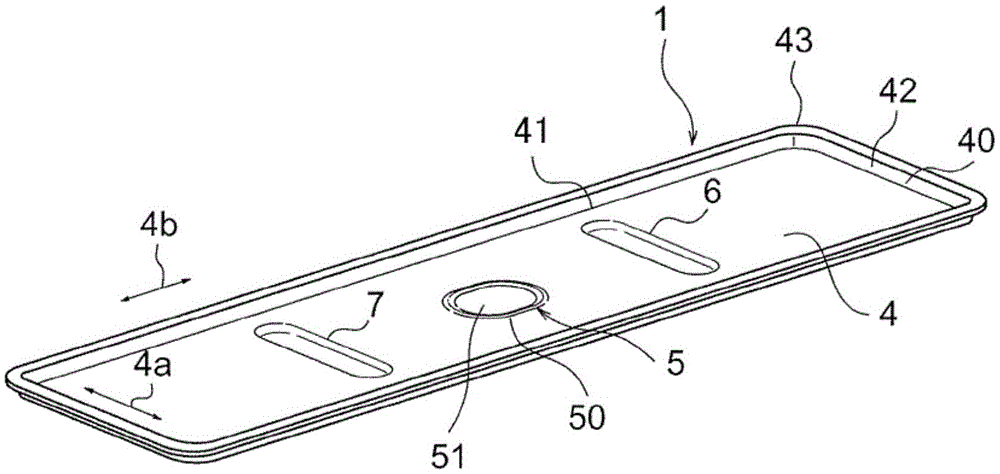

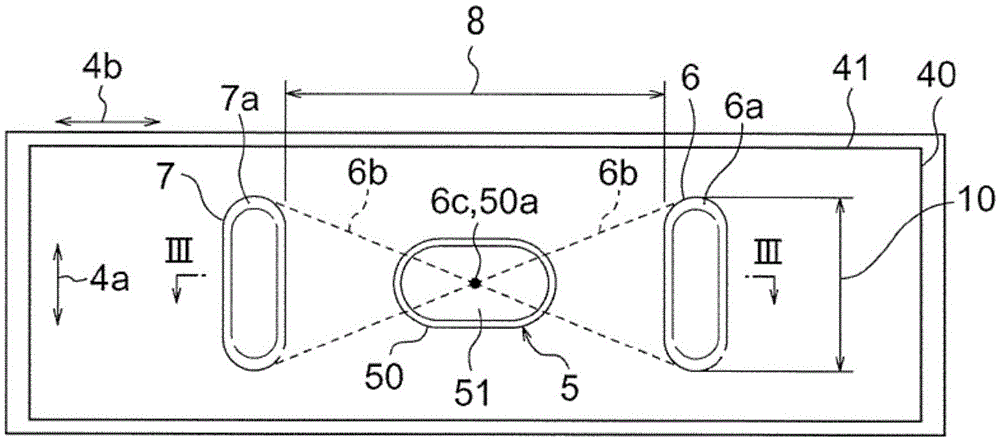

Cover for battery box

ActiveCN103718332BReliable crackingVent arrangementsSecondary cells manufactureEngineeringMechanical engineering

In the present invention, in the structure in which the ring-shaped thin-walled part (50) is integrally formed with the cover main body (4) by embossing, it is formed with the cover main body (4) so as to protrude from the cover main body (4). A pair of integral ribs (6, 7) extend along the short dimension direction (4a) of the cover main body (4), and the pair of ribs (6, 7) are arranged along the cover main body (4 ) on both sides of the annular thin-walled portion (50) in the longitudinal direction (4b).

Owner:NISSHIN STEEL CO LTD

Muffle tube inspection method and manufacturing method of silica glass-based optical fiber preform

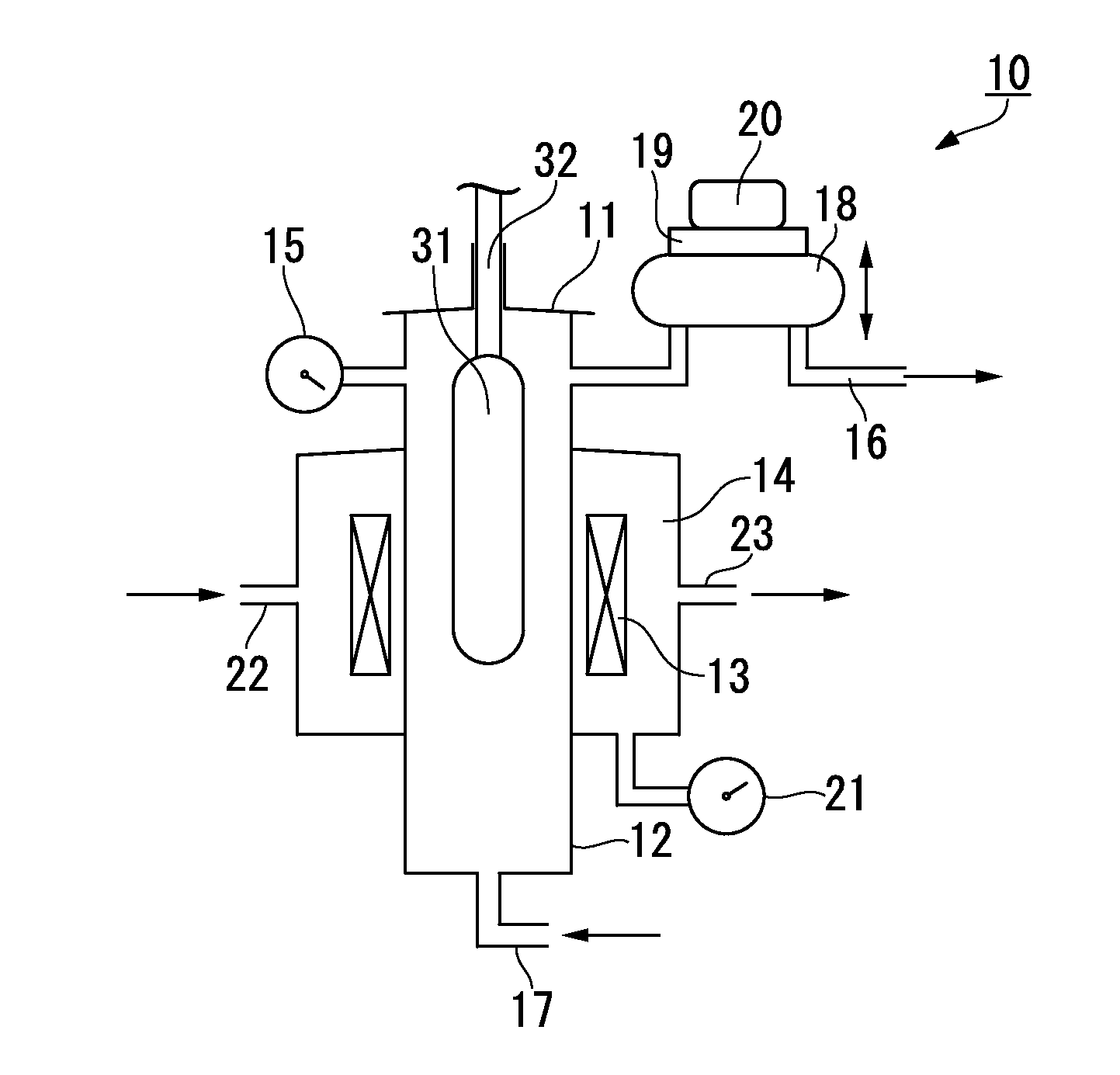

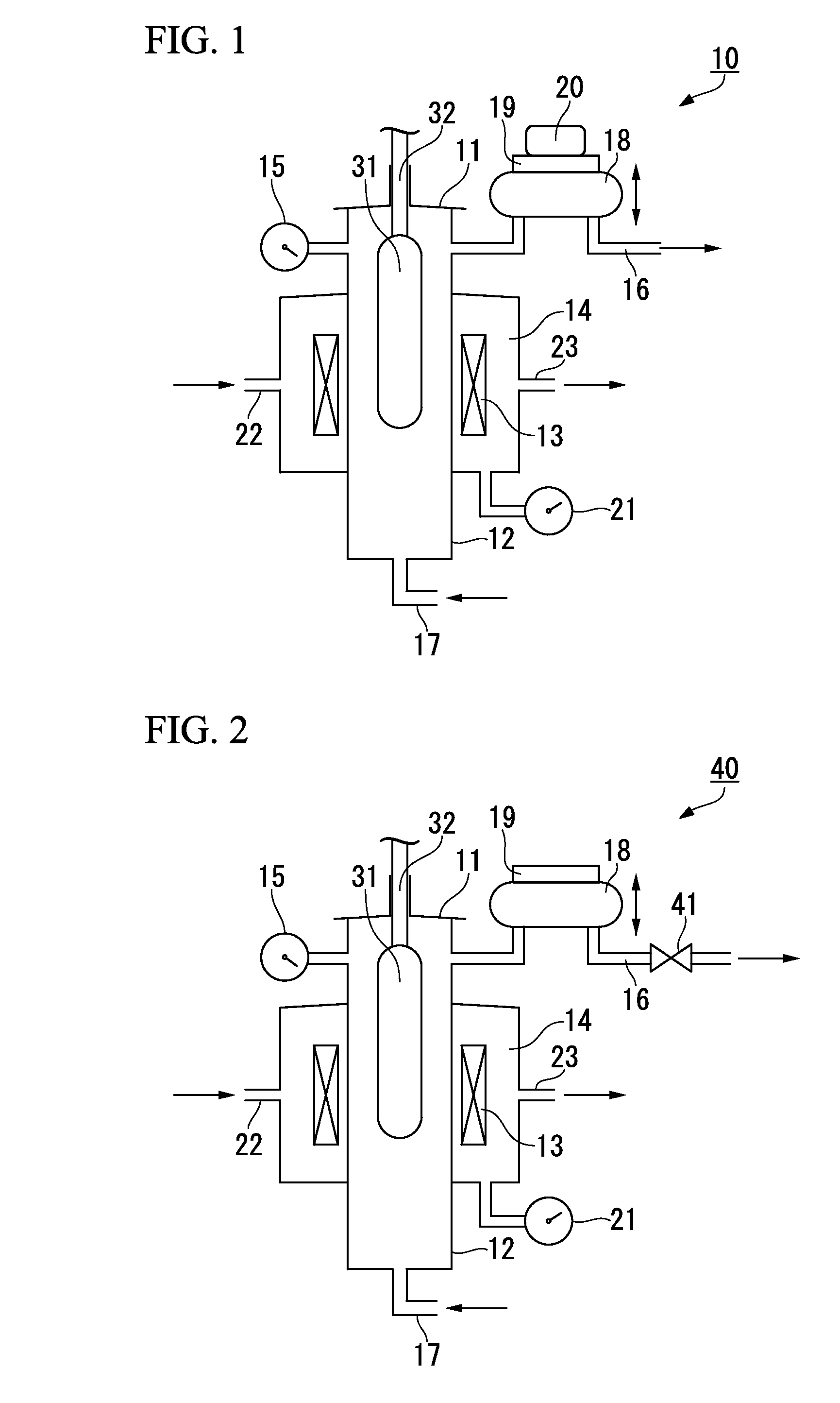

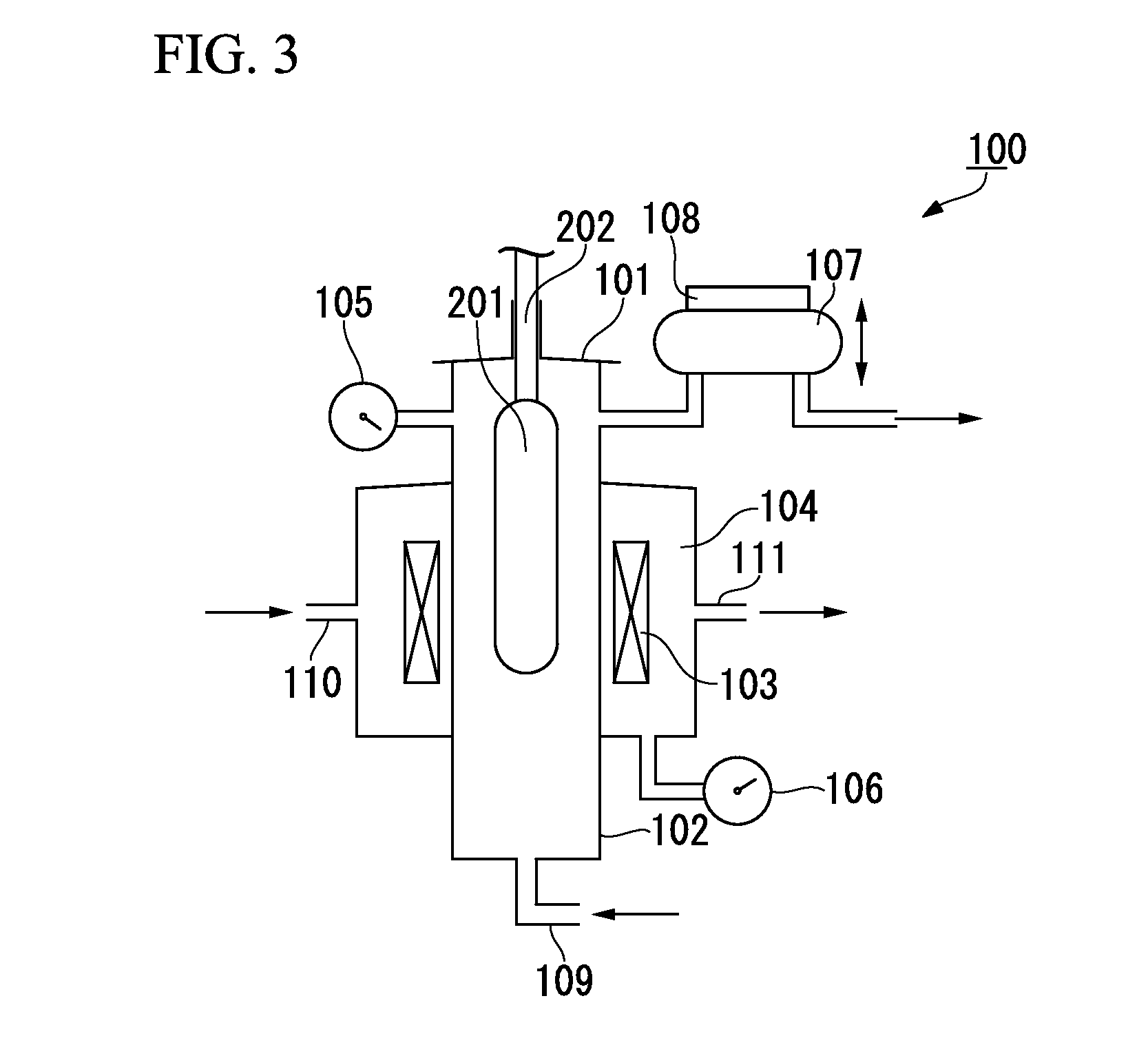

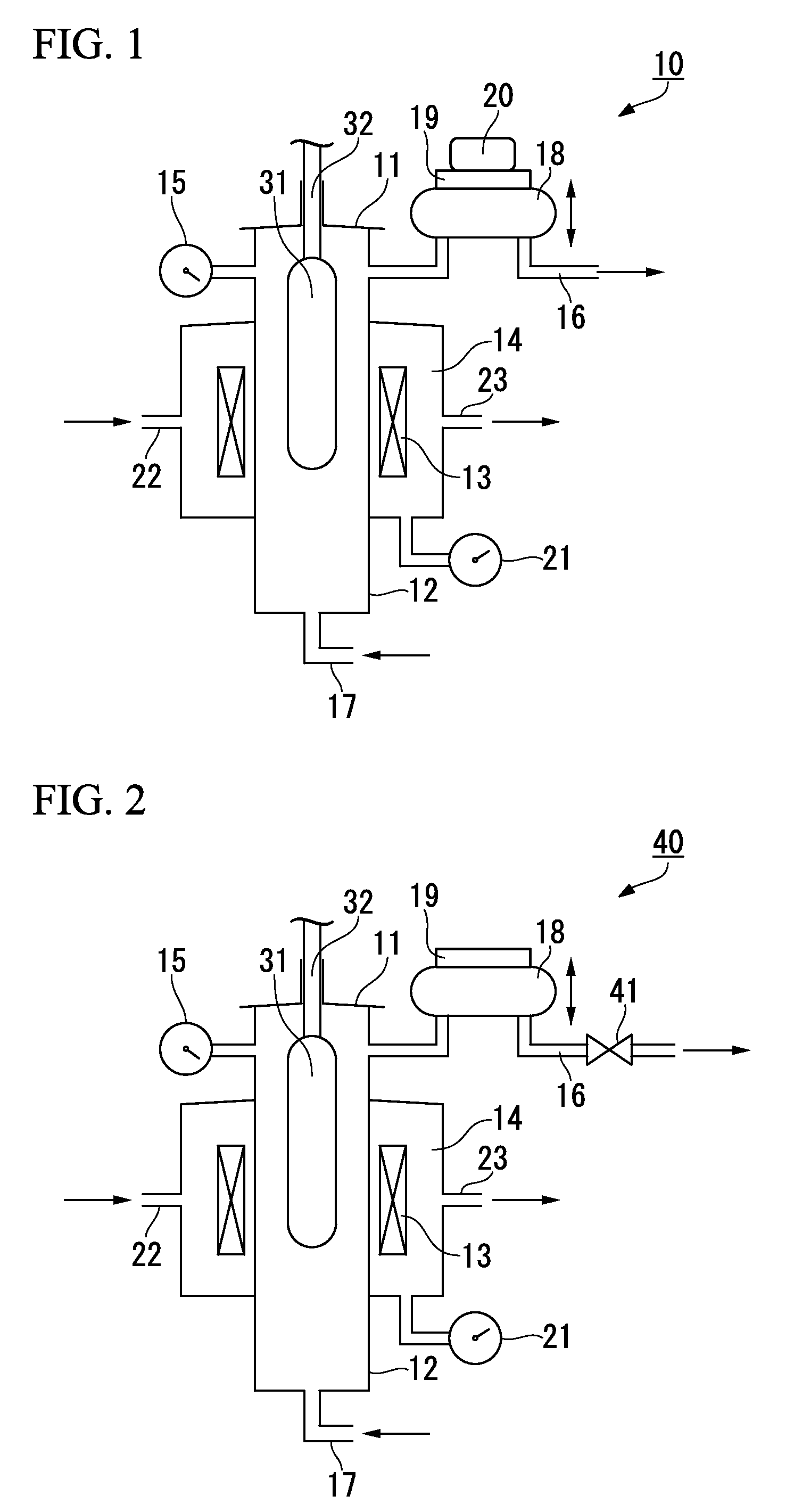

ActiveUS20130098116A1Reliably crack generatedImprove processing yieldGlass making apparatusMeasurement of fluid loss/gain rateQuartzMaterials science

A muffle tube inspection method inspects a muffle tube used for dehydrating and sintering a silica glass-based optical fiber preform, the muffle tube includes a sintering furnace provided with a furnace body covering a heater disposed around a periphery of the muffle tube. The method detects a crack generated at the muffle tube by measuring a pressure inside the furnace body while varying a pressure inside the muffle tube.

Owner:THE FUJIKURA CABLE WORKS LTD

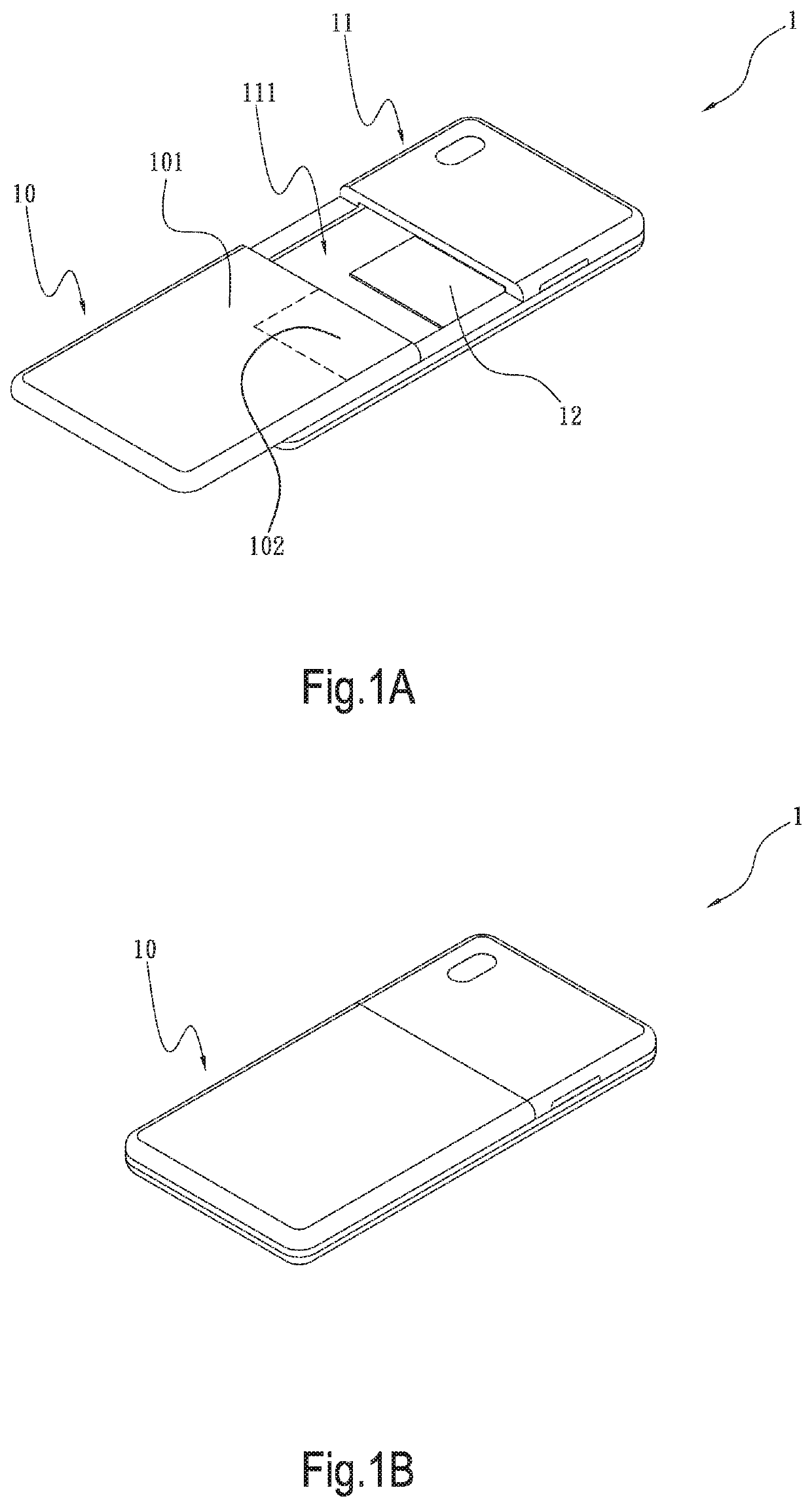

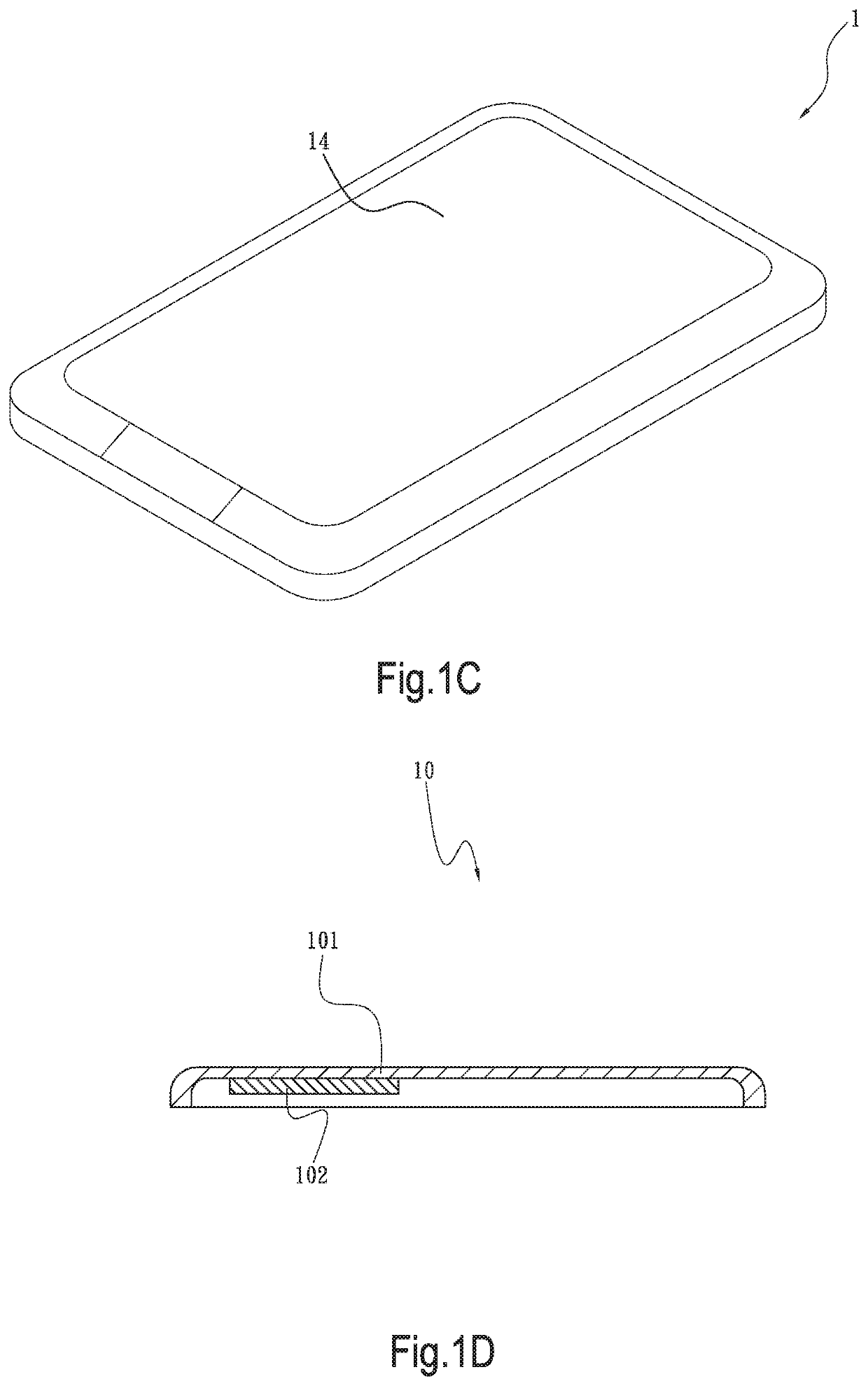

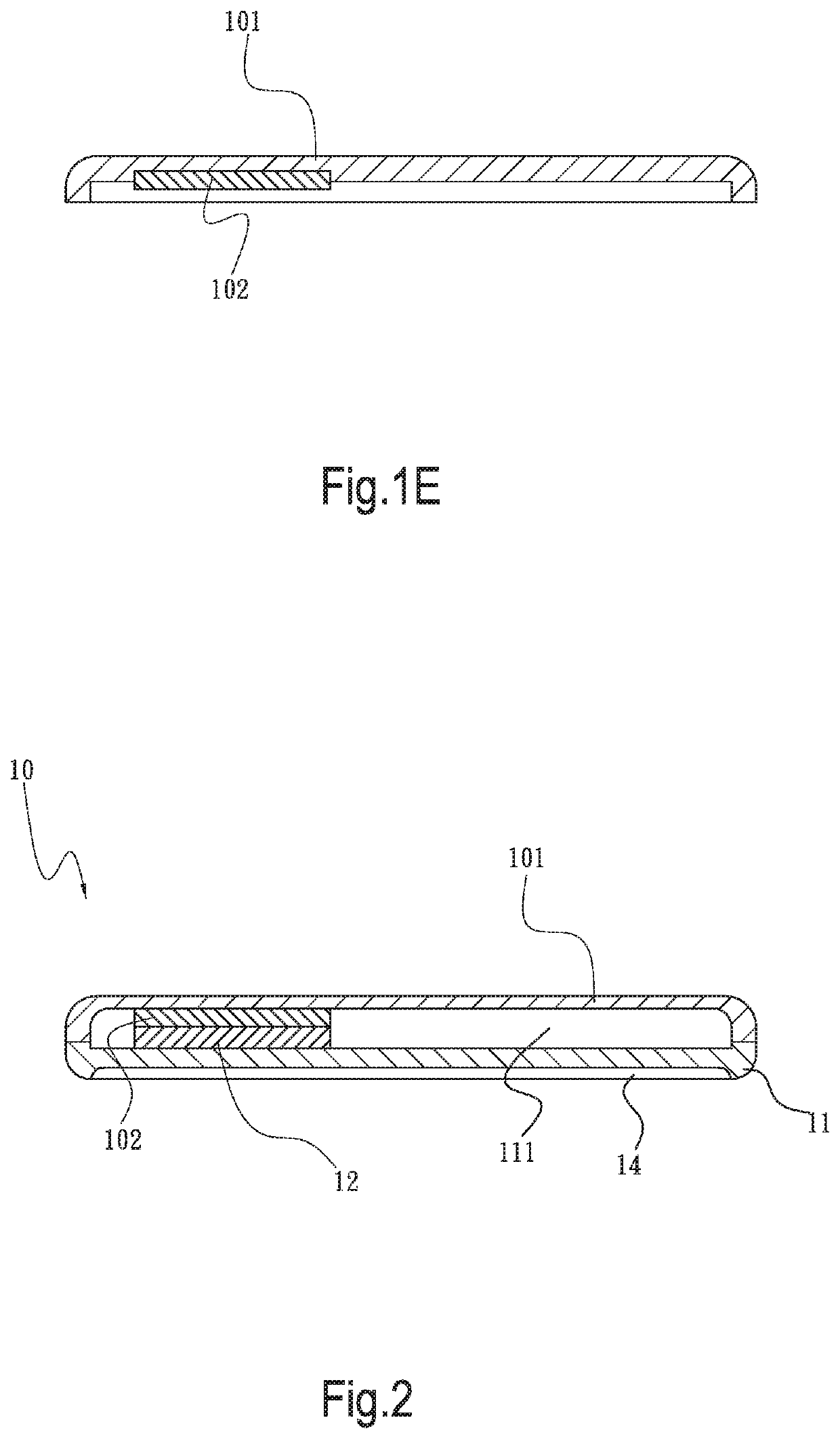

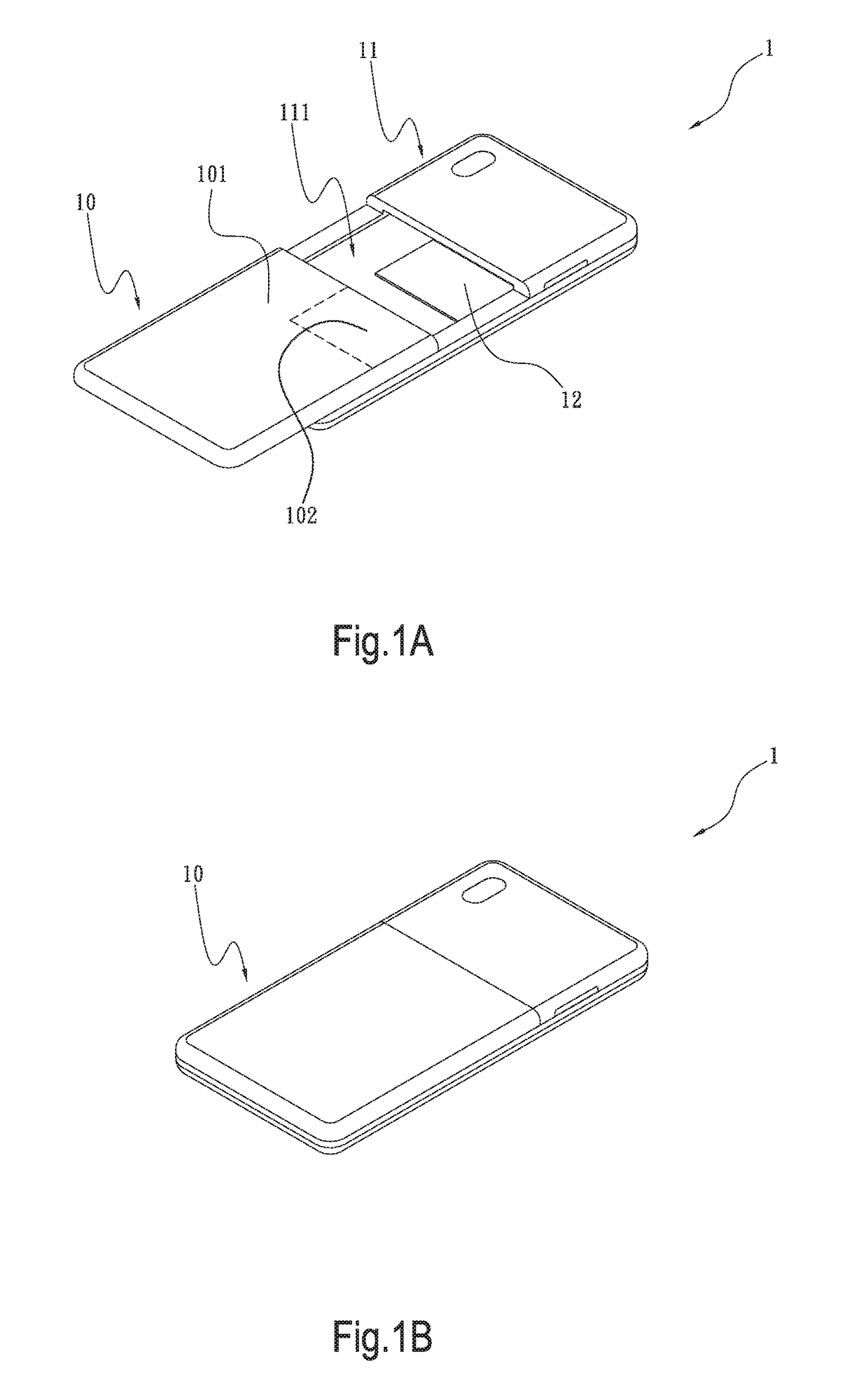

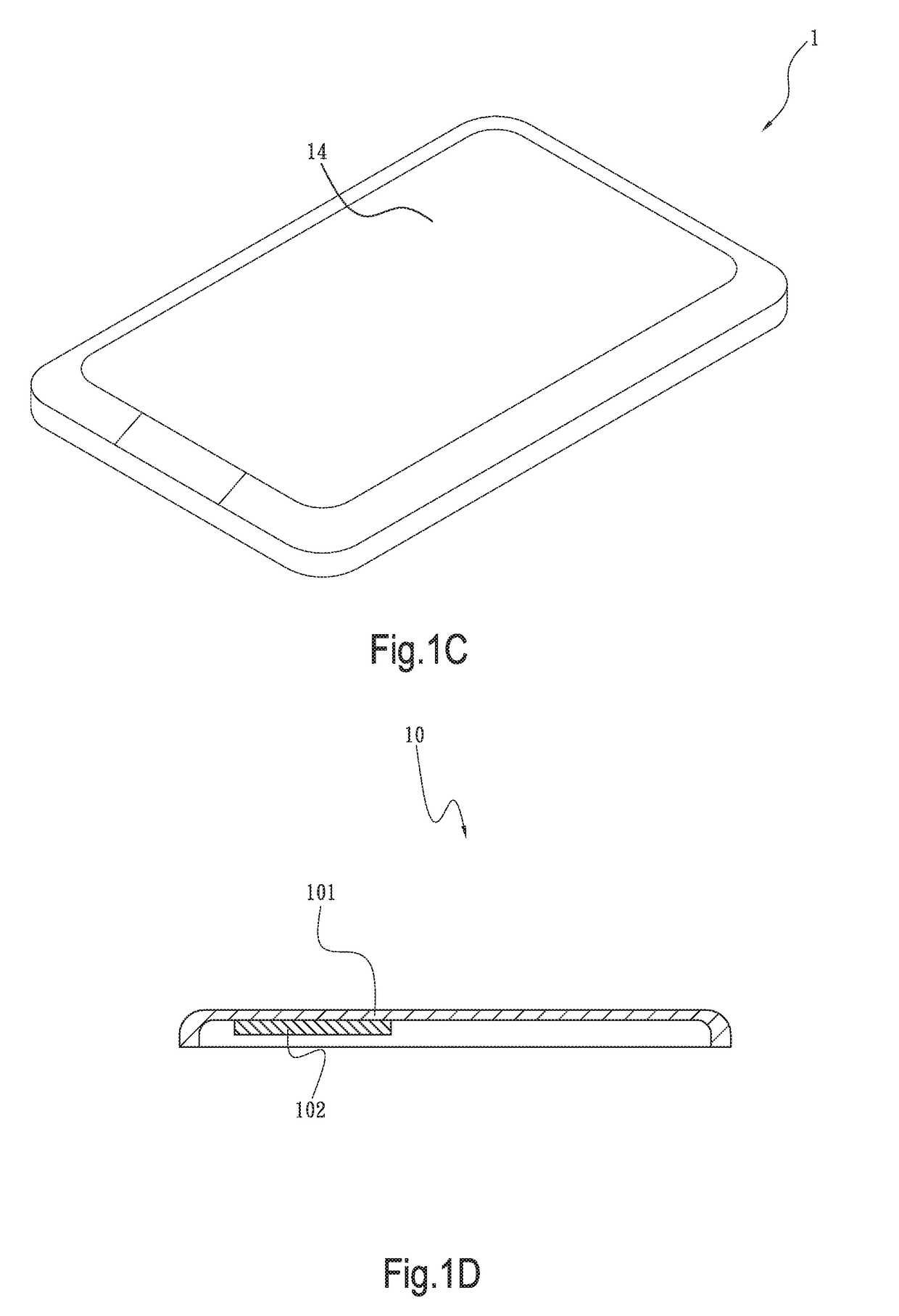

Case heat dissipation unit of handheld electronic device

ActiveUS10785894B2Effective heat conductionHeat dissipationDigital data processing detailsIndirect heat exchangersTitanium metalMaterials science

A case heat dissipation unit of handheld electronic device includes a back cover including a ceramic layer. A titanium metal layer or a stainless steel metal layer is disposed on the ceramic layer in a position corresponding to at least one heat source. The ceramic layer is an outer surface of the handheld electronic device and exposed to an external environment. The titanium metal layer or the stainless steel metal layer faces a receiving space of the handheld electronic device in contact with the heat source in the receiving space. The titanium metal layer or the stainless steel metal layer serves to absorb the heat generated by the heat source and transfer the heat to the ceramic layer for dissipating the heat.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Case heat dissipation unit of handheld electronic device

ActiveUS20180376619A1Effective heat conductionHeat dissipationDigital data processing detailsIndirect heat exchangersTitanium metalTitanium

A case heat dissipation unit of handheld electronic device includes a back cover including a ceramic layer. A titanium metal layer or a stainless steel metal layer is disposed on the ceramic layer in a position corresponding to at least one heat source. The ceramic layer is an outer surface of the handheld electronic device and exposed to an external environment. The titanium metal layer or the stainless steel metal layer faces a receiving space of the handheld electronic device in contact with the heat source in the receiving space. The titanium metal layer or the stainless steel metal layer serves to absorb the heat generated by the heat source and transfer the heat to the ceramic layer for dissipating the heat.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

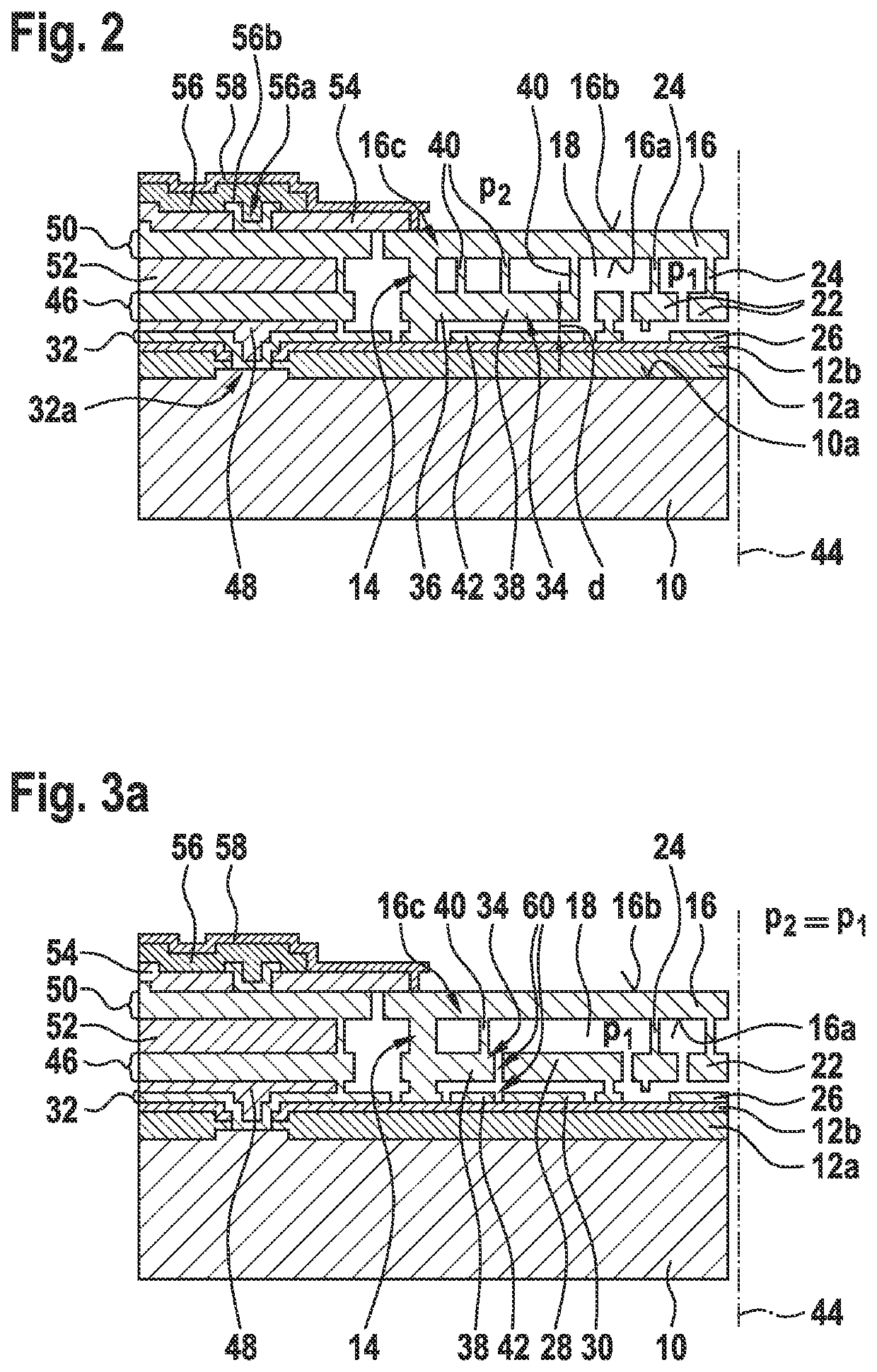

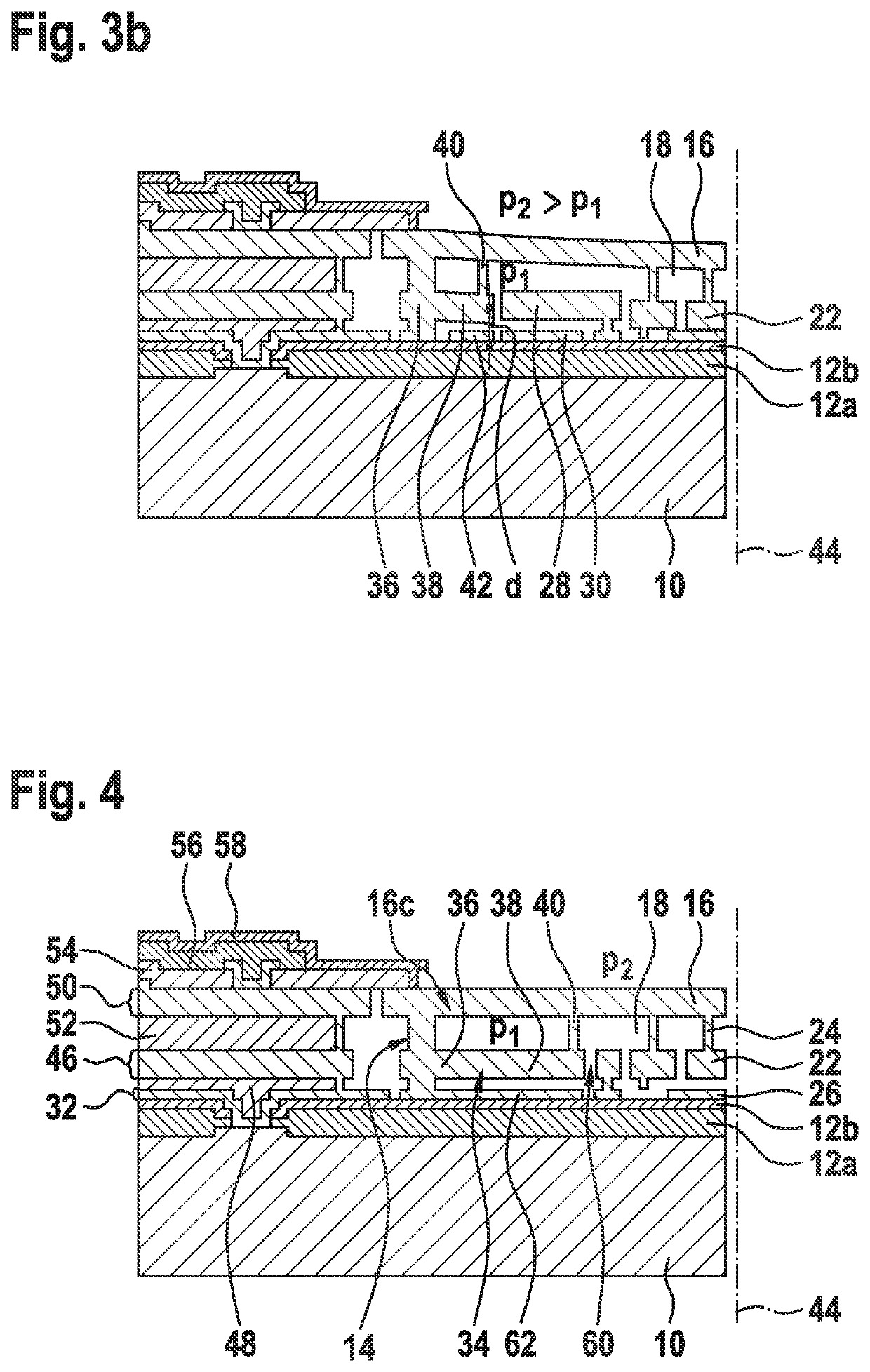

Micromechanical component for a sensor or microphone device

PendingUS20210354978A1Easy and cost-effective to manufactureAvoid crackingPiezoelectric/electrostrictive devicesFlexible microstructural devicesEngineeringMechanical engineering

A micromechanical component for a sensor or microphone device, including a substrate, a frame structure, which is situated on the substrate surface and / or at least one intermediate layer, and a diaphragm, which spans an inner volume, which is at least partially framed by the frame structure. The micromechanical component includes a bending beam structure, which is situated in the inner volume and includes at least one anchoring area, which is attached to the frame structure, to the substrate surface and / or to the at least one intermediate layer, and at least one self-supporting area, which is connected via at least one coupling structure to the diaphragm inner side of the diaphragm in such a way that the at least one self-supporting area is bendable by way of a warping of the diaphragm.

Owner:ROBERT BOSCH GMBH

Cover for battery case

ActiveCN104871340BReliable crackingSmall deformation inhibitionSecondary cellsCell component detailsEngineeringMechanical engineering

In the structure in which the ring-shaped thin-walled portion (50) is integrally formed with the cover main body (4) by embossing, it is formed so as to protrude from the cover main body (4). An integral protruding part (6), and an annular thin-walled part (50) is provided on a flat part (61) of the protruding part (6).

Owner:NISSHIN STEEL CO LTD

Muffle tube inspection method and manufacturing method of silica glass-based optical fiber preform

ActiveUS8978421B2Reliable crackingGlass making apparatusMeasurement of fluid loss/gain rateSilica gelQuartz

A muffle tube inspection method inspects a muffle tube used for dehydrating and sintering a silica glass-based optical fiber preform, the muffle tube includes a sintering furnace provided with a furnace body covering a heater disposed around a periphery of the muffle tube. The method detects a crack generated at the muffle tube by measuring a pressure inside the furnace body while varying a pressure inside the muffle tube.

Owner:FUJIKURA LTD

Method for forming battery case cover and explosion-proof valve of battery case cover

Owner:KOBE STEEL LTD

Disposal of munitions

A method is described for safely opening the shell of a munition (10) having an inner chamber containing an explosive material. The method comprises the steps of machining a groove (20) into the shell along a parting line that encircles the outer surface of the munition and divides the shell into two parts. The groove (20) is of sufficient depth to weaken the shell but not to penetrate into the inner chamber of the munition. After machining the groove (20), the shell is cracked open by prising the two parts of the shell apart by inserting a suitable implement into the groove.

Owner:DISARMCO

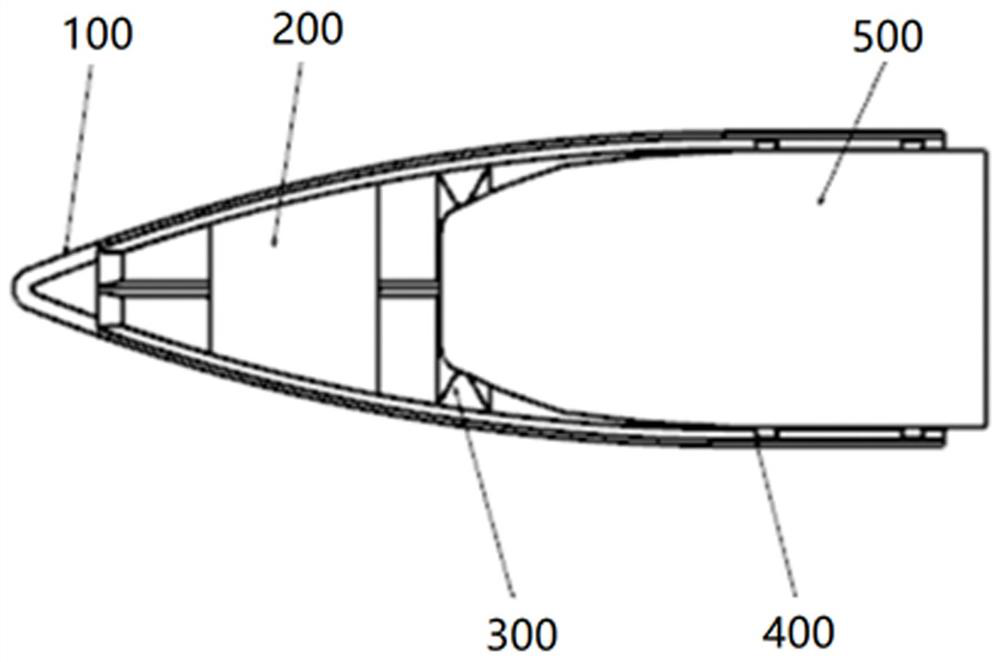

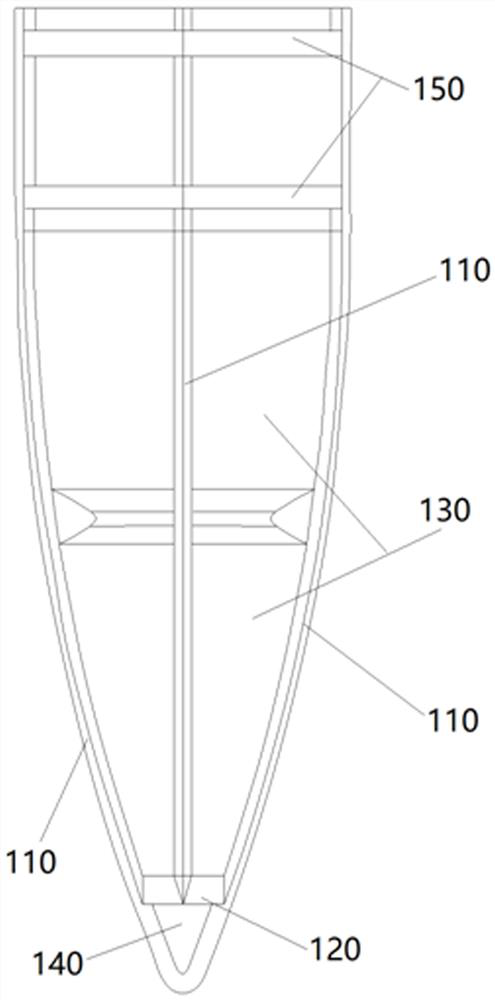

Carbon fiber composite buffering and load-reducing hood and preparation method thereof

PendingCN113932661AReliable crackingGuaranteed coaxialityLamination ancillary operationsMarine torpedoesFibrous compositesMechanical engineering

The invention relates to the technical field of torpedo water entry buffer load reduction design, in particular to a carbon fiber composite buffering and load-reducing hood and a preparation method thereof. The carbon fiber composite buffering and load-reducing hood comprises a carbon fiber composite cover, a buffering and load-reducing assembly, a positioning ring and fixing assemblies. A buffering assembly is located at the position close to the end part of the carbon fiber composite cover and arranged in the carbon fiber composite cover; a positioning ring mounting groove is formed in the carbon fiber composite cover; the positioning ring is fixedly mounted in the positioning ring mounting groove; the tail end of the carbon fiber composite cover is cylindrical; a plurality of fixing assembly mounting grooves are formed in the cylindrical section part of the tail end of the carbon fiber composite cover; the fixing assemblies are fixedly arranged in the fixing assembly mounting grooves respectively; and the carbon fiber composite cover is prepared by performing high-temperature vacuum curing on a carbon fiber paving layer. By using the carbon fiber composite buffering and load-reducing hood and the preparation method disclosed by the invention, the technical problem how to reduce potential damage, caused by a water surface impact load, to internal components when a torpedo enters water is solved.

Owner:北京玻钢院复合材料有限公司

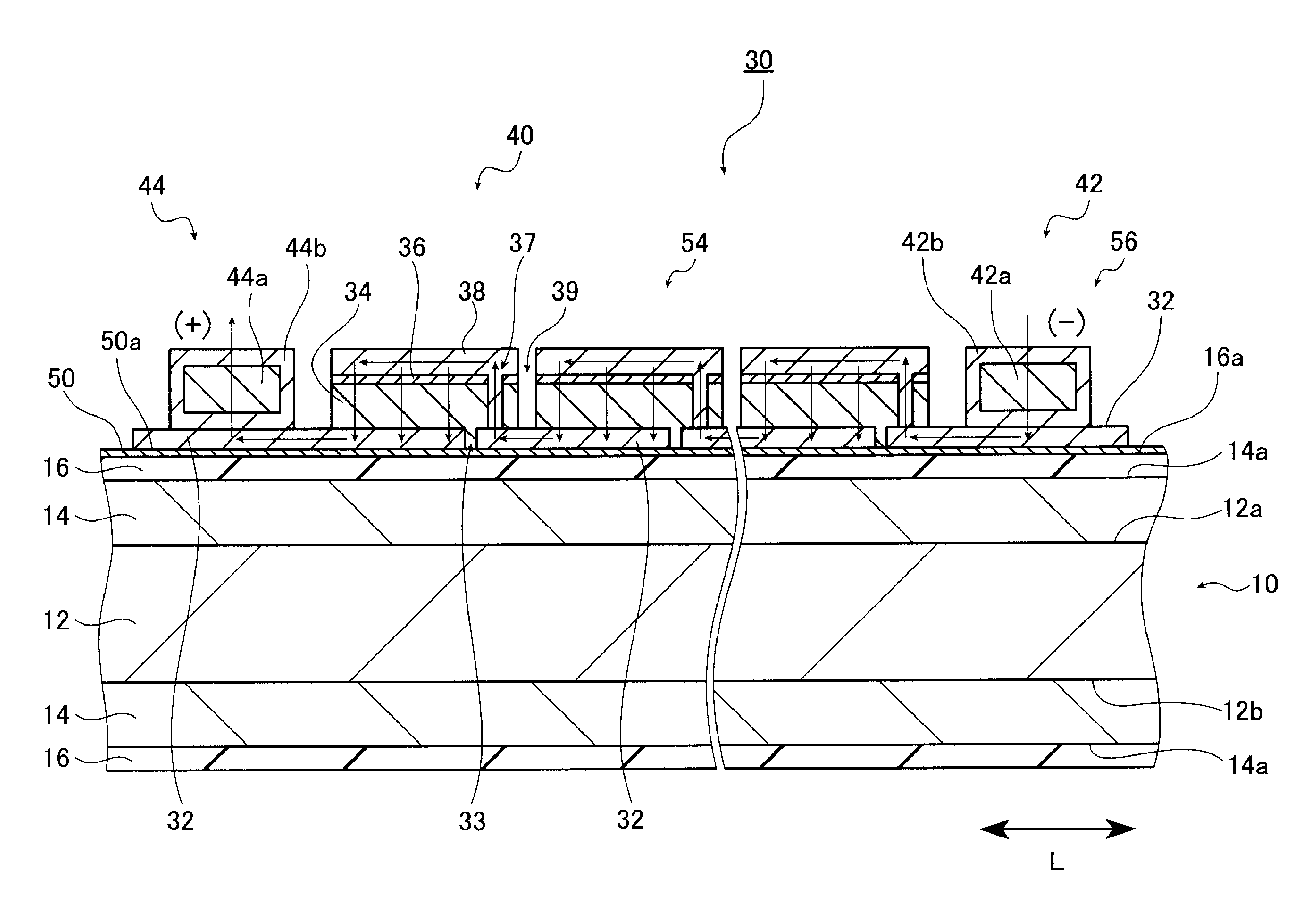

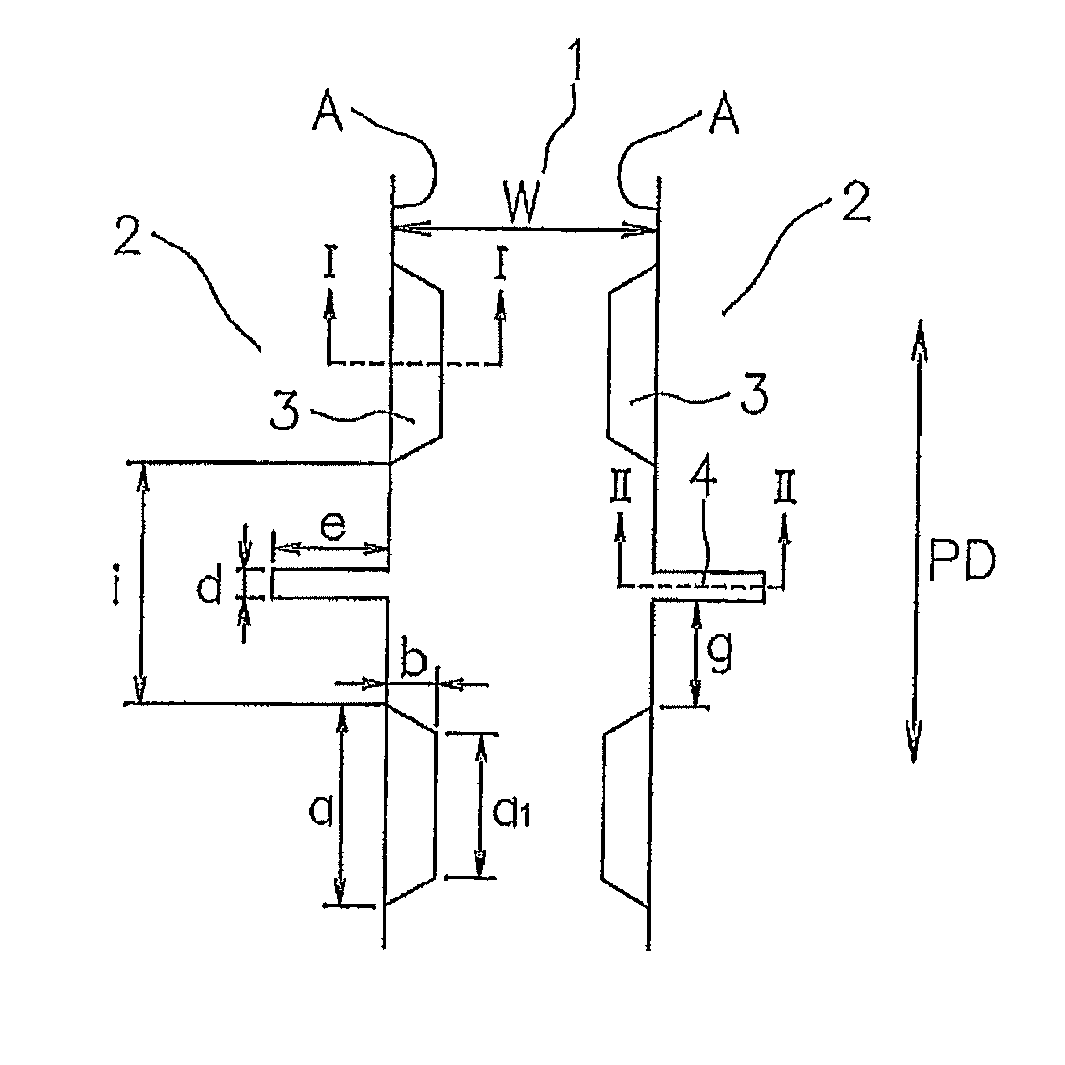

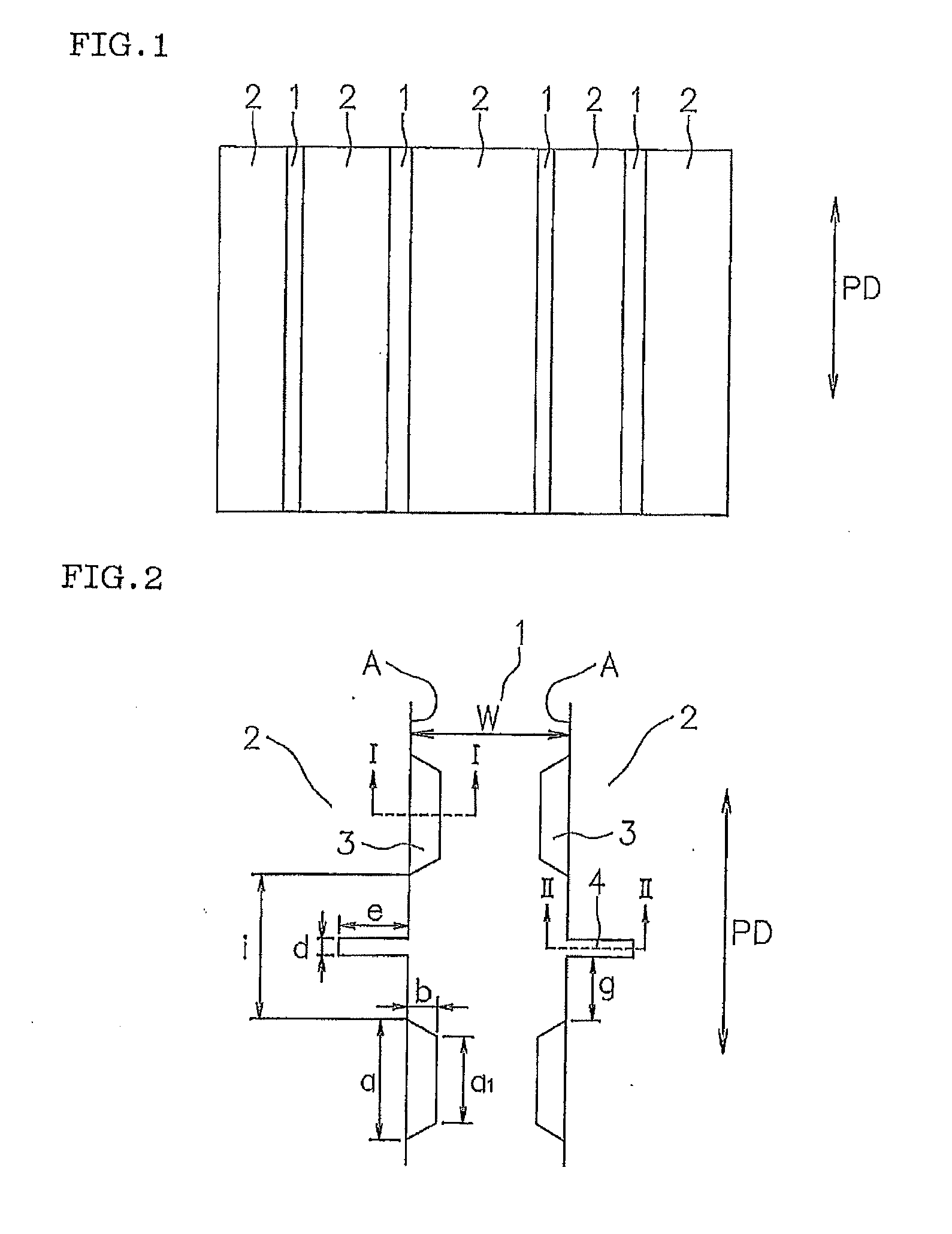

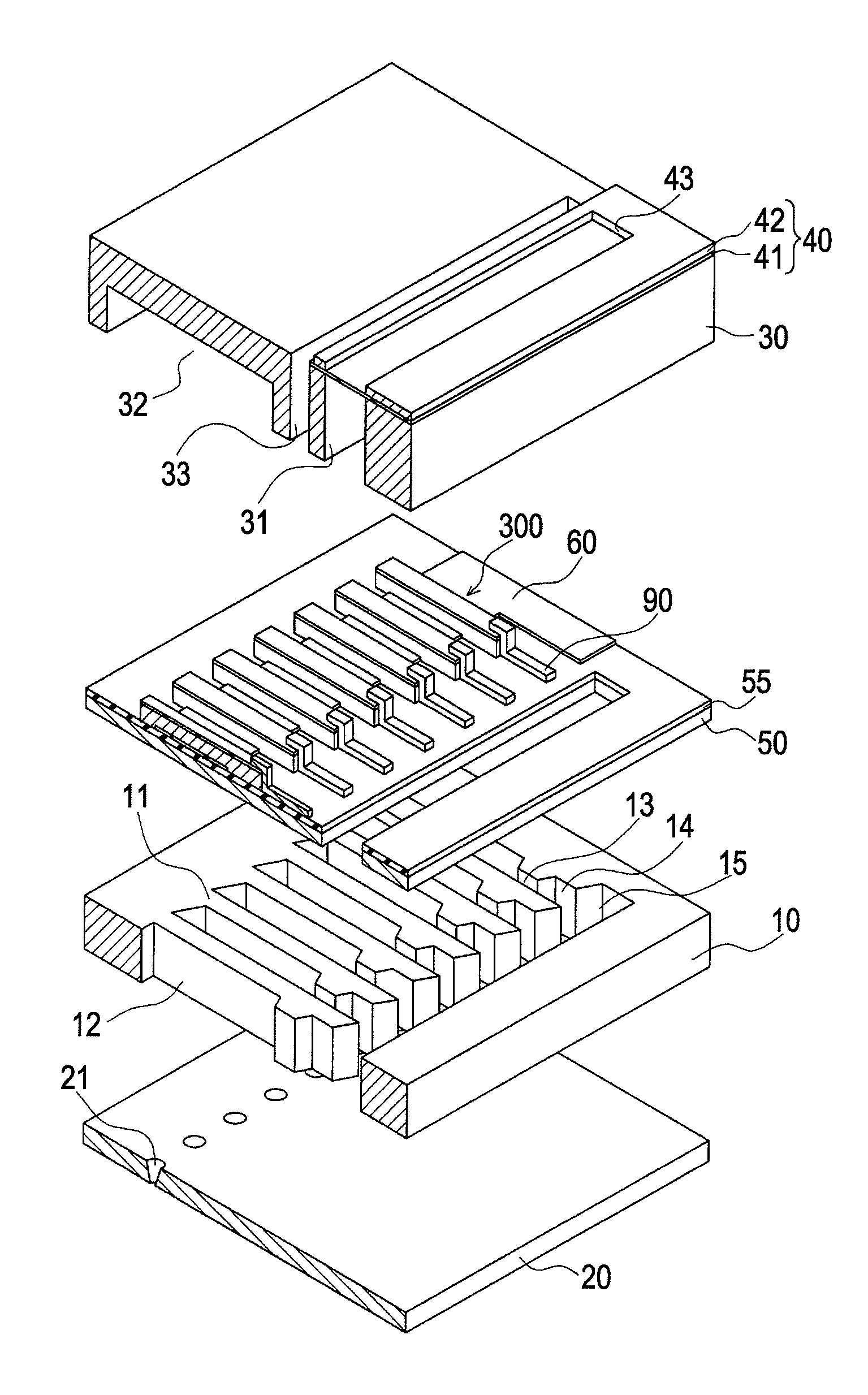

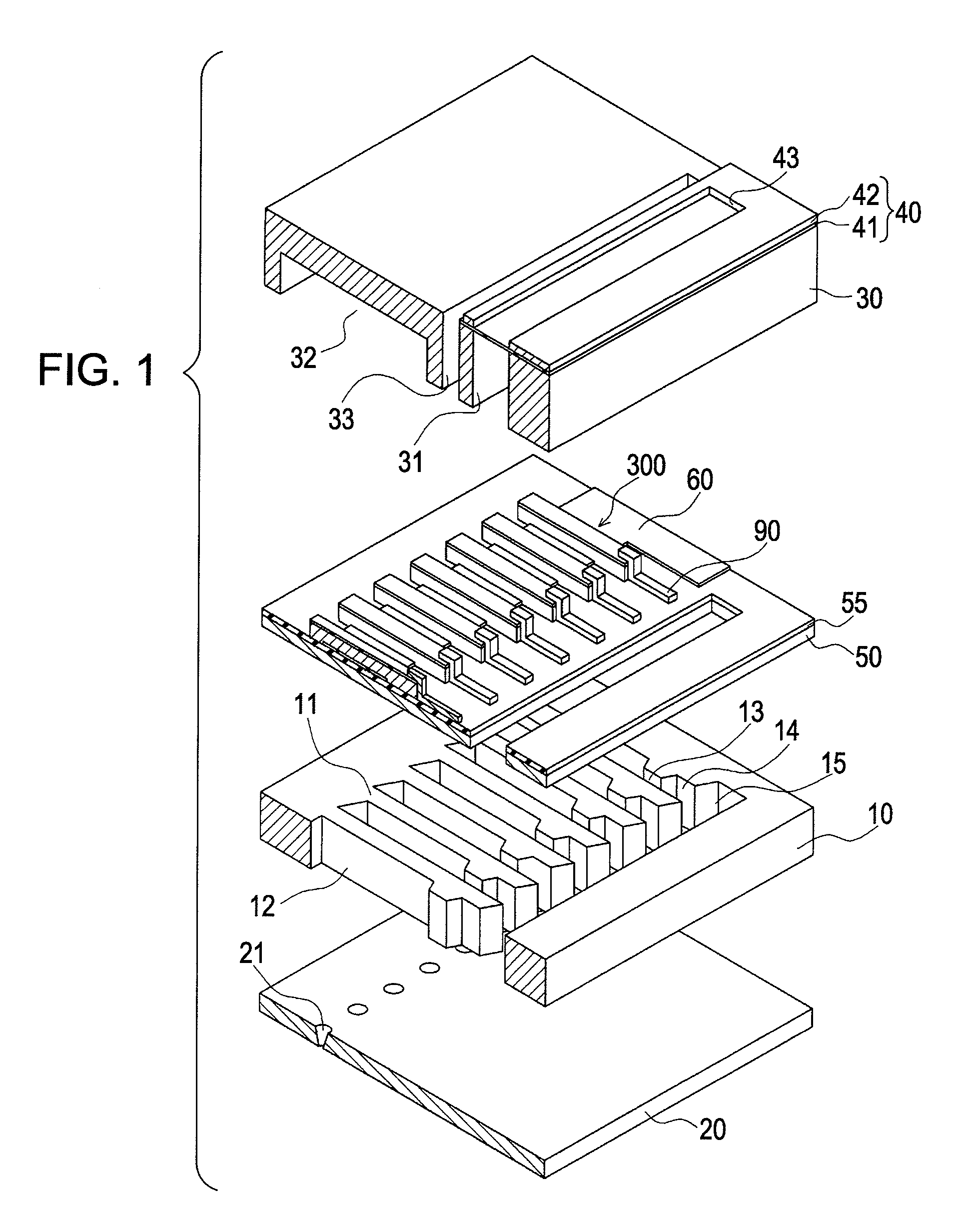

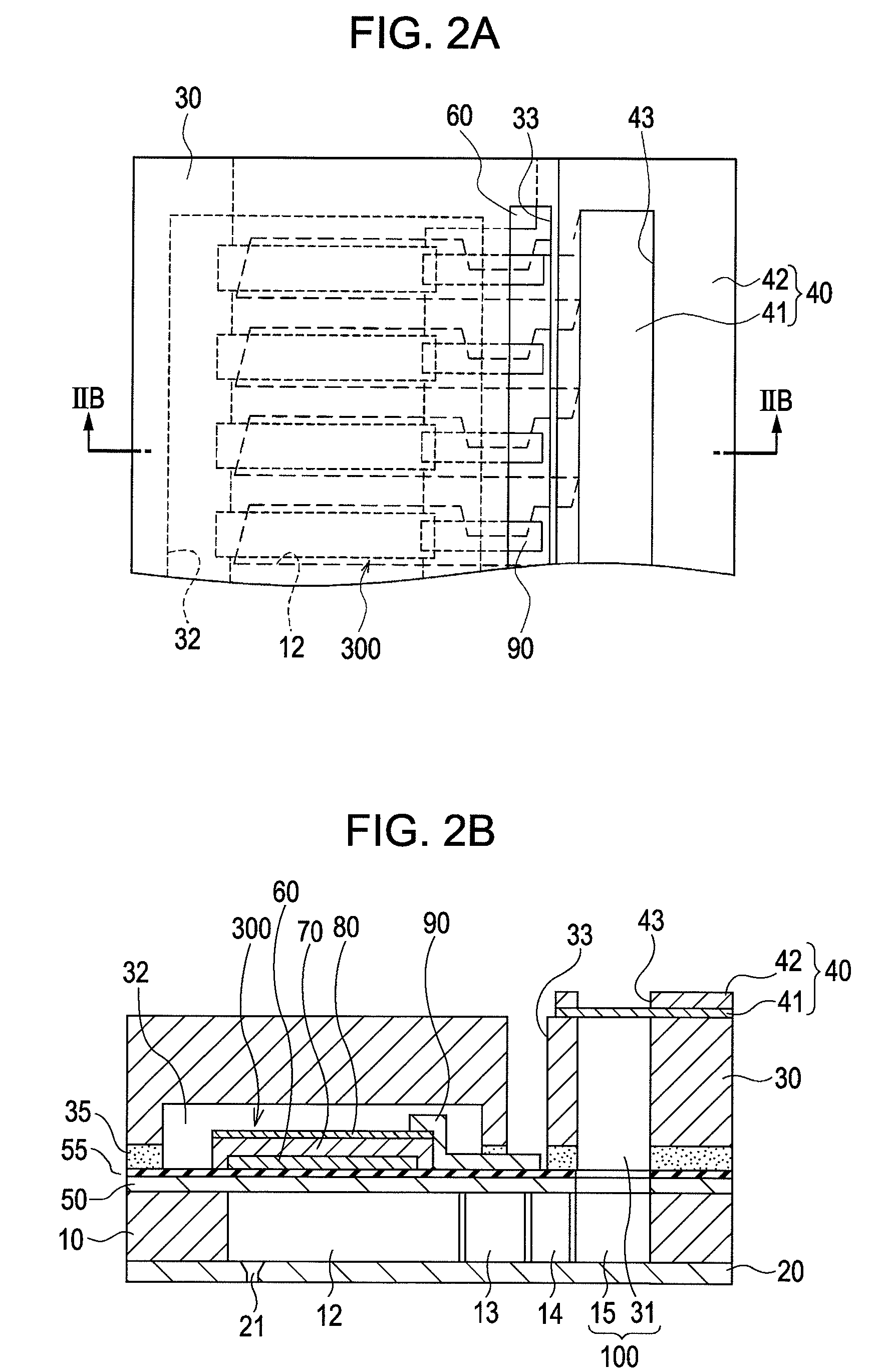

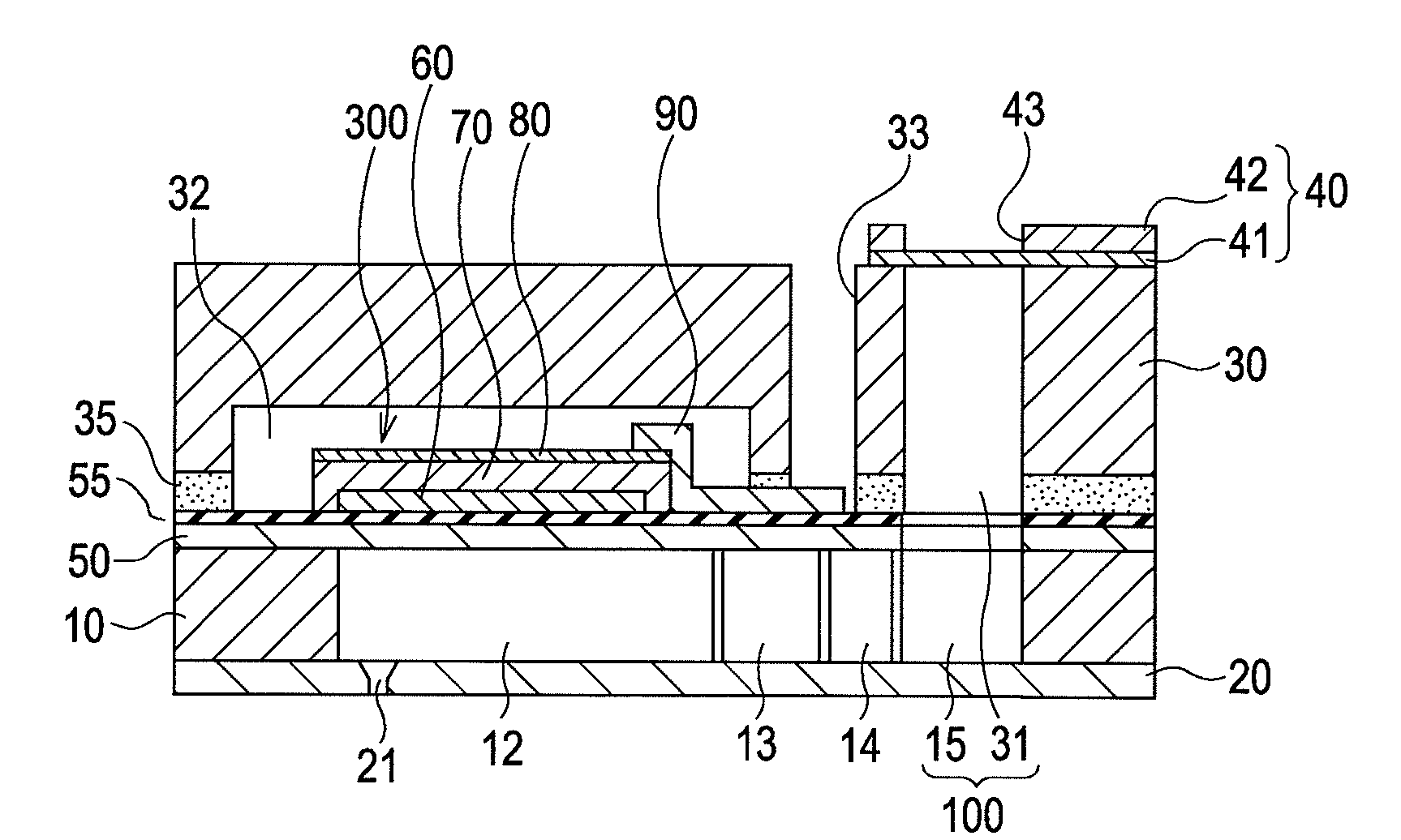

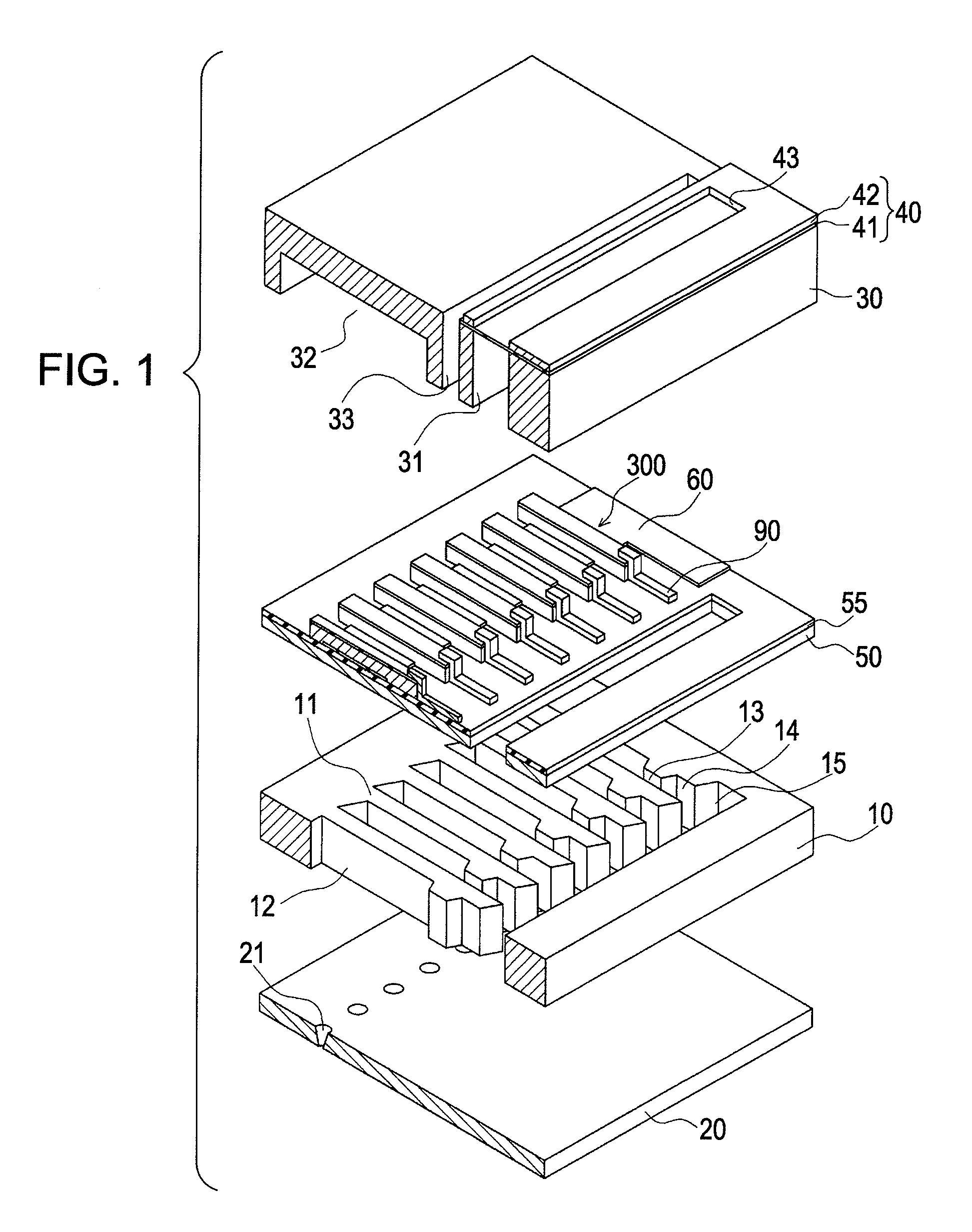

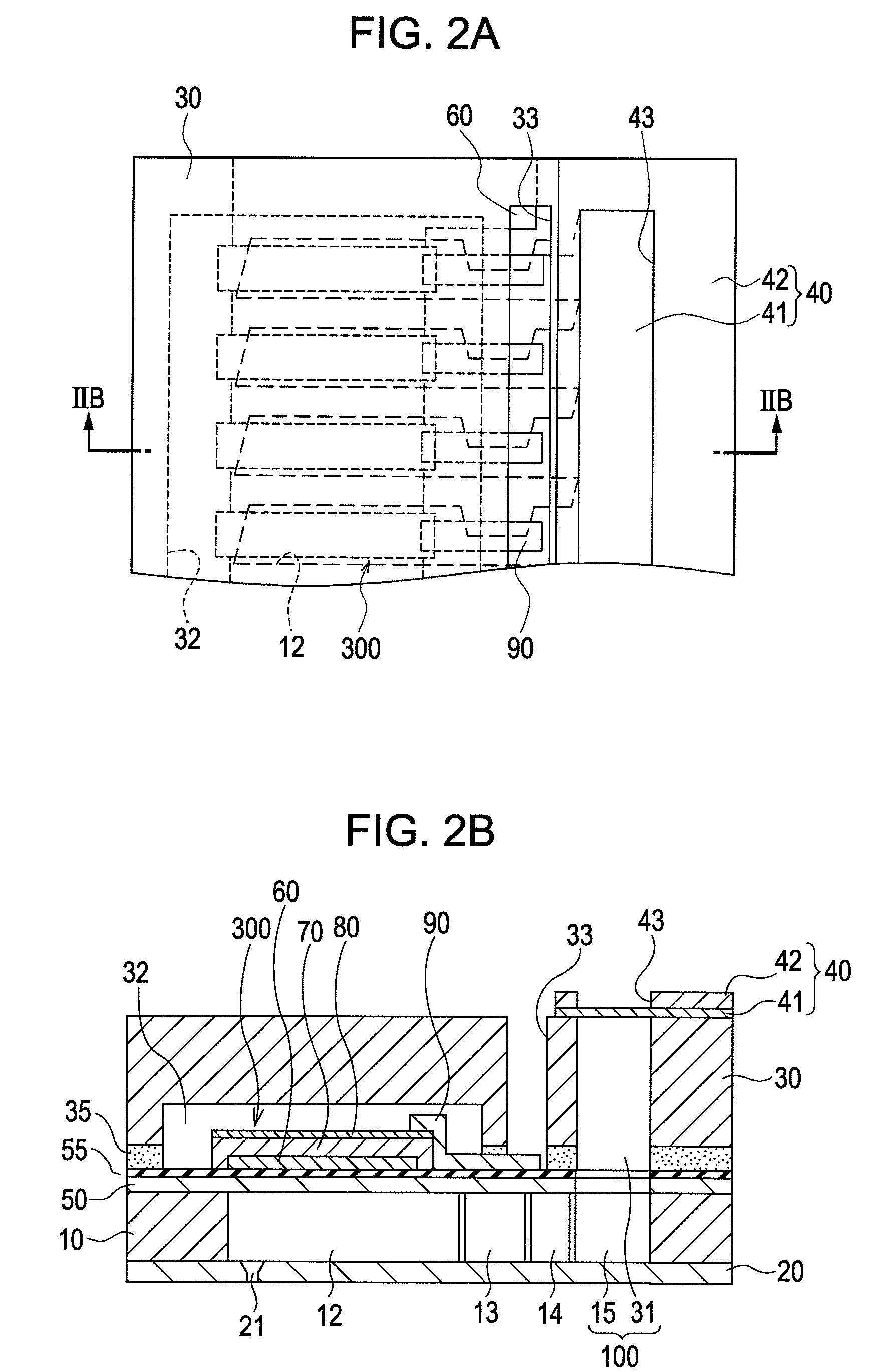

Liquid ejection head and manufacturing method thereof

A liquid ejection head includes a flow channel-forming substrate having a plurality of pressure-generating chambers communicated with nozzles for ejecting droplets, the pressure-generating chambers being arranged in parallel with each other; a plurality of pressure-applying units for applying pressure to interiors of the pressure-generating chambers; and a joining substrate joined onto one surface of the flow channel-forming substrate. The flow channel-forming substrate includes a silicon single crystal substrate having a (110) plane orientation and has a side surface extending in a longitudinal direction of the pressure-generating chambers, the side surface being composed of a first (111) plane perpendicular to a (110) plane. The joining substrate includes a silicon single crystal substrate having a (110) plane orientation and is joined onto the flow channel-forming substrate so that a first (111) plane of the joining substrate perpendicular to the (110) plane intersects the first (111) plane of the flow channel-forming substrate.

Owner:SEIKO EPSON CORP

Liquid ejection head and manufacturing method thereof

A liquid ejection head includes a flow channel-forming substrate having a plurality of pressure-generating chambers communicated with nozzles configured to eject droplets, the plurality of pressure-generating chambers being arranged in parallel with each other; a plurality of pressure-applying units configured to apply pressure to interiors of the pressure-generating chambers; and a joining substrate joined onto one surface of the flow channel-forming substrate. The flow channel-forming substrate includes a silicon single crystal substrate having a (110) plane orientation and has a side surface extending in a longitudinal direction of the pressure-generating chambers, the side surface being composed of a first (111) plane perpendicular to a (110) plane. The joining substrate includes a silicon single crystal substrate having a (110) plane orientation and is joined onto the flow channel-forming substrate so that a first (111) plane of the joining substrate perpendicular to the (110) plane intersects the first (111) plane of the flow channel-forming substrate.

Owner:SEIKO EPSON CORP

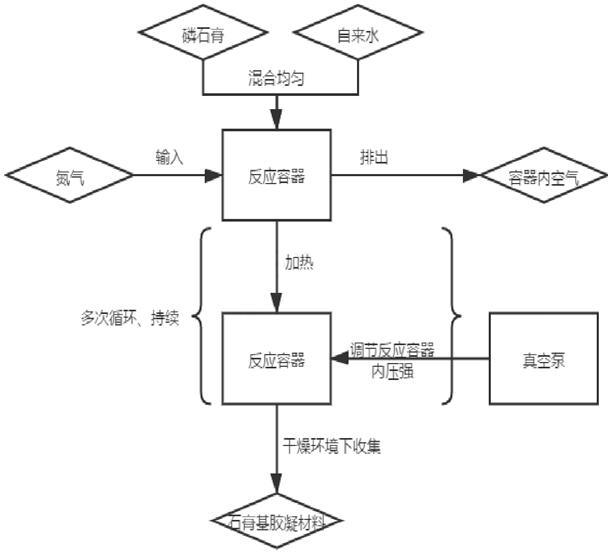

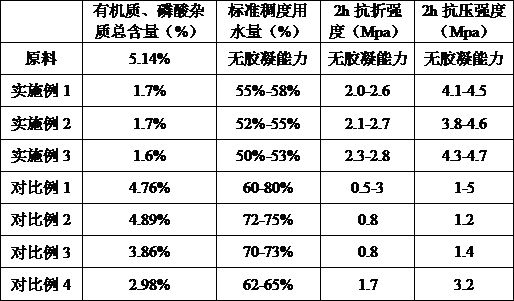

Method for preparing high-performance cementing material through negative-pressure anaerobic thermal cracking of phosphogypsum

ActiveCN114656179ACracking evenly heatedGood removal effectCement productionO-Phosphoric AcidPhysical chemistry

The invention discloses a method for preparing a high-performance cementing material by negative-pressure anaerobic thermal cracking of ardealite, which comprises the following steps: adding water into ardealite, fully stirring to obtain slurry, placing the slurry in a nitrogen environment, and heating the slurry to 50-60 DEG C under the pressure of 0.04-0.06 MPa; the reaction container is rotated at the speed of 30-50 r / min, the temperature of the slurry is maintained at 200-300 DEG C, and the reaction is performed for 60-120 min; and drying and collecting the materials in the reaction container to obtain the gypsum-based cementing material. The material cracking and heating are uniform, the gypsum phase composition is simple, the removal effect on impurities in phosphogypsum is stable, free phosphoric acid and other impurities which have great influence on the performance are removed through over-cracking, and repeated tests prove that the prepared gypsum cementing material is simple in gypsum phase, good in removal effect on organic matter, free phosphoric acid and the like in the material and good in comprehensive performance. The mechanical property is stable.

Owner:云南凝创环保科技有限公司

Electronic Device and Pressure Sensor

ActiveUS20080283997A1Reliable crackingAvoid position shiftPrinted circuit assemblingFinal product manufactureEngineeringElectronic component

An electronic device requires an electronic component to be mounted for the purpose of static shielding. The mounting of such an electronic component raises a problem of avoiding thermal stresses and cracks generated due to the difference between the coefficients of linear expansion of component materials. A positioning recess, a joining-substance thickness ensuring recess, a joining-substance thickness ensuring projection, etc. are formed in a combined manner in an electronic component mount portion of each of leads, whereby spreading of cracks generated in the joining substance can be suppressed and reliability can be improved. Filling a sealing material so as to seal and restrain the electronic component mounted in the electronic component mount portion without leaving voids contributes to further suppressing spreading of cracks generated in the joining substance and ensuring more improved reliability of the joining substance.

Owner:HITACHI ASTEMO LTD

Shunt resistance type current sensor

InactiveUS9618537B2Easy to transformLittle heat dissipationBase element modificationsElectrical testingElectricityCurrent sensor

Owner:YAZAKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com