Steel austenite grain boundary display method and steel austenite grain size evaluation method

A technology of austenite grain boundary and display method is applied in the field of austenite grain size evaluation of steel and austenite grain boundary display field of steel, which can solve the difficulty in showing grain boundaries, affecting the observation and evaluation of grain size, and purchasing difficulties. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

[0051] A method for assessing the austenite grain size of a steel product, comprising:

[0052] S1. Sample processing: Use a sawing machine to cut a test sample with a length, width and height of 20mm*15mm*30mm at the 1 / 4 diameter of a GCr15 round steel with a diameter of 80mm. The critical temperature of the GCr15 round steel is 760°C.

[0053] S2. Sample heat treatment: Heat the sample to be tested to the preset temperature and keep it warm for 30 minutes, then put it into the cooling liquid and cool it to room temperature within 5 seconds.

[0054] S3. Fracture preparation: After the heat treatment is completed, the sample to be tested is cleaned and dried, and then cut with a metallographic cutting machine along the direction perpendicular to the quenching crack generated on the sample to be tested during heat treatment, so that the fracture surface formed by the crack is exposed .

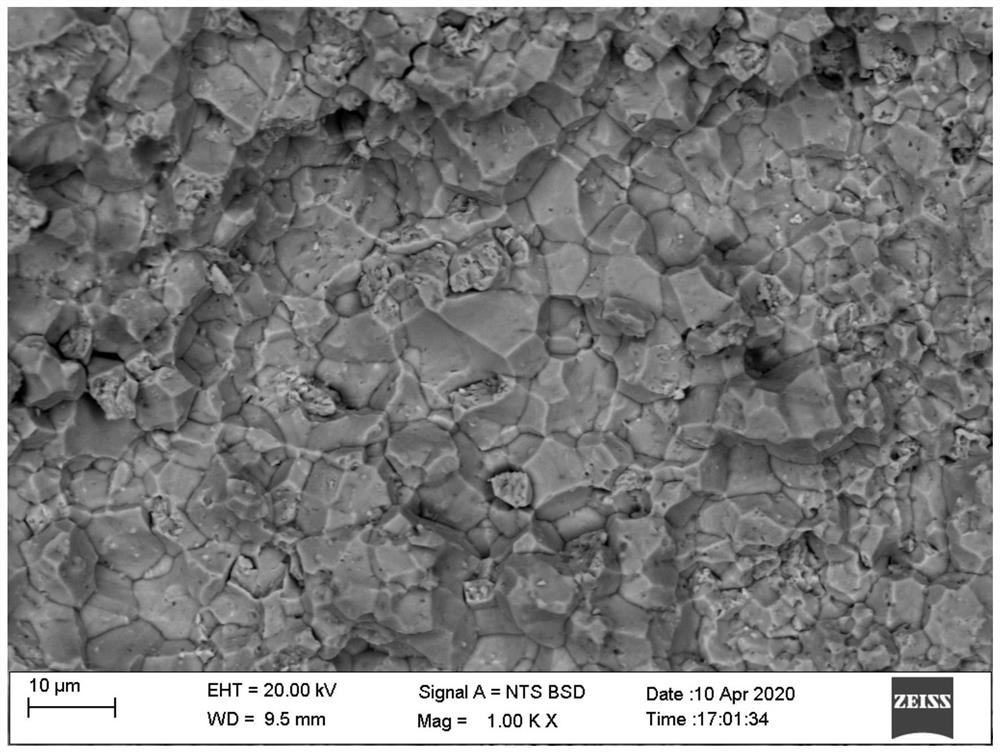

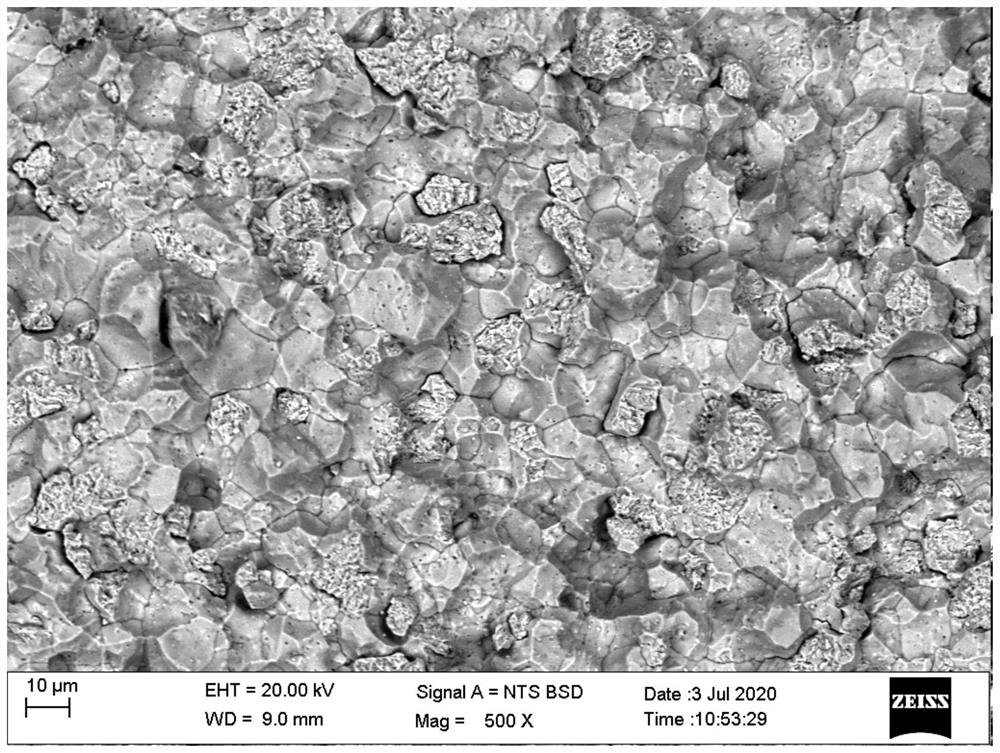

[0055] S4. Fracture observation: Use scanning electron microscope to observe the fracture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com