Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

254 results about "Backscattered electron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

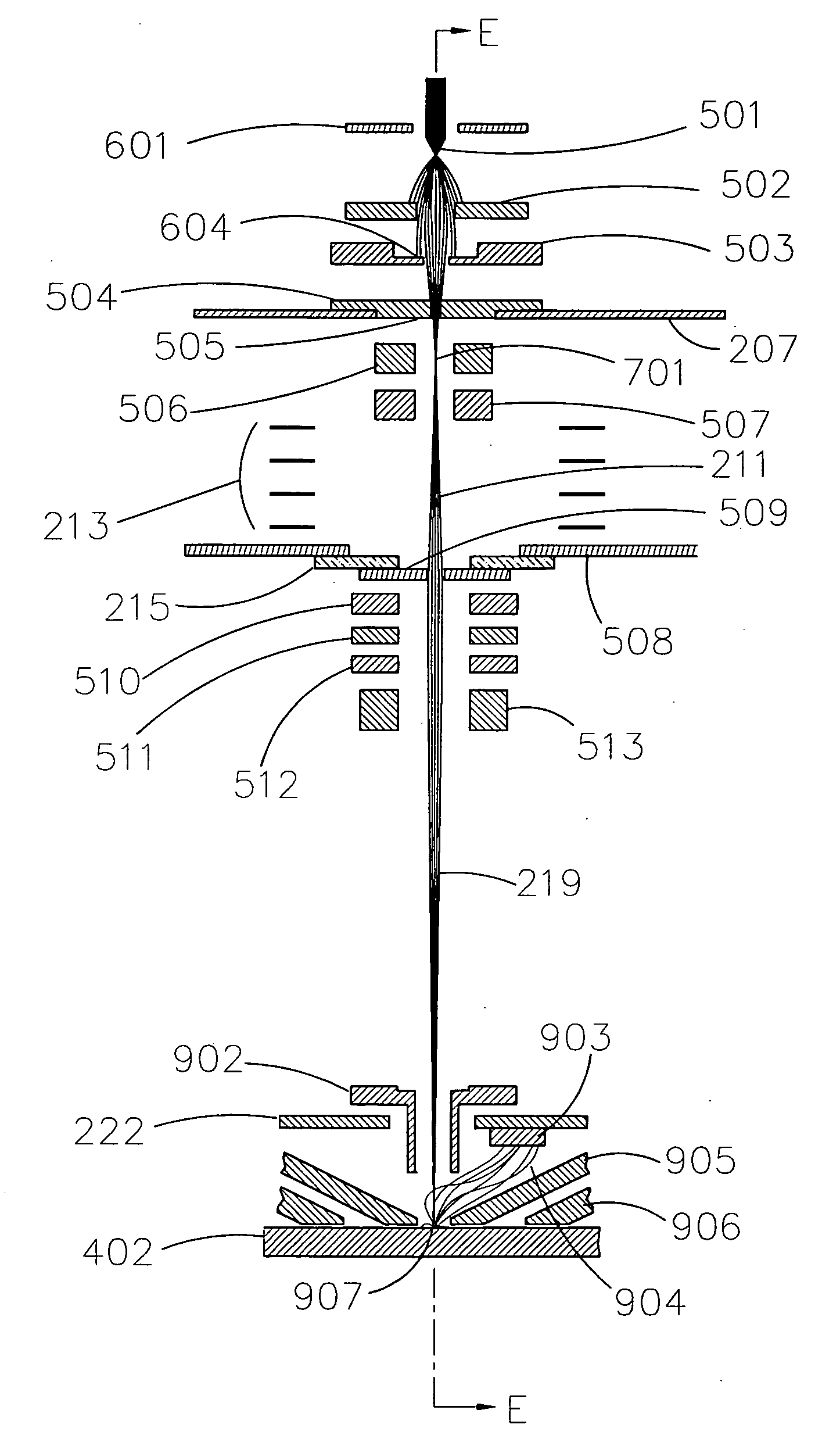

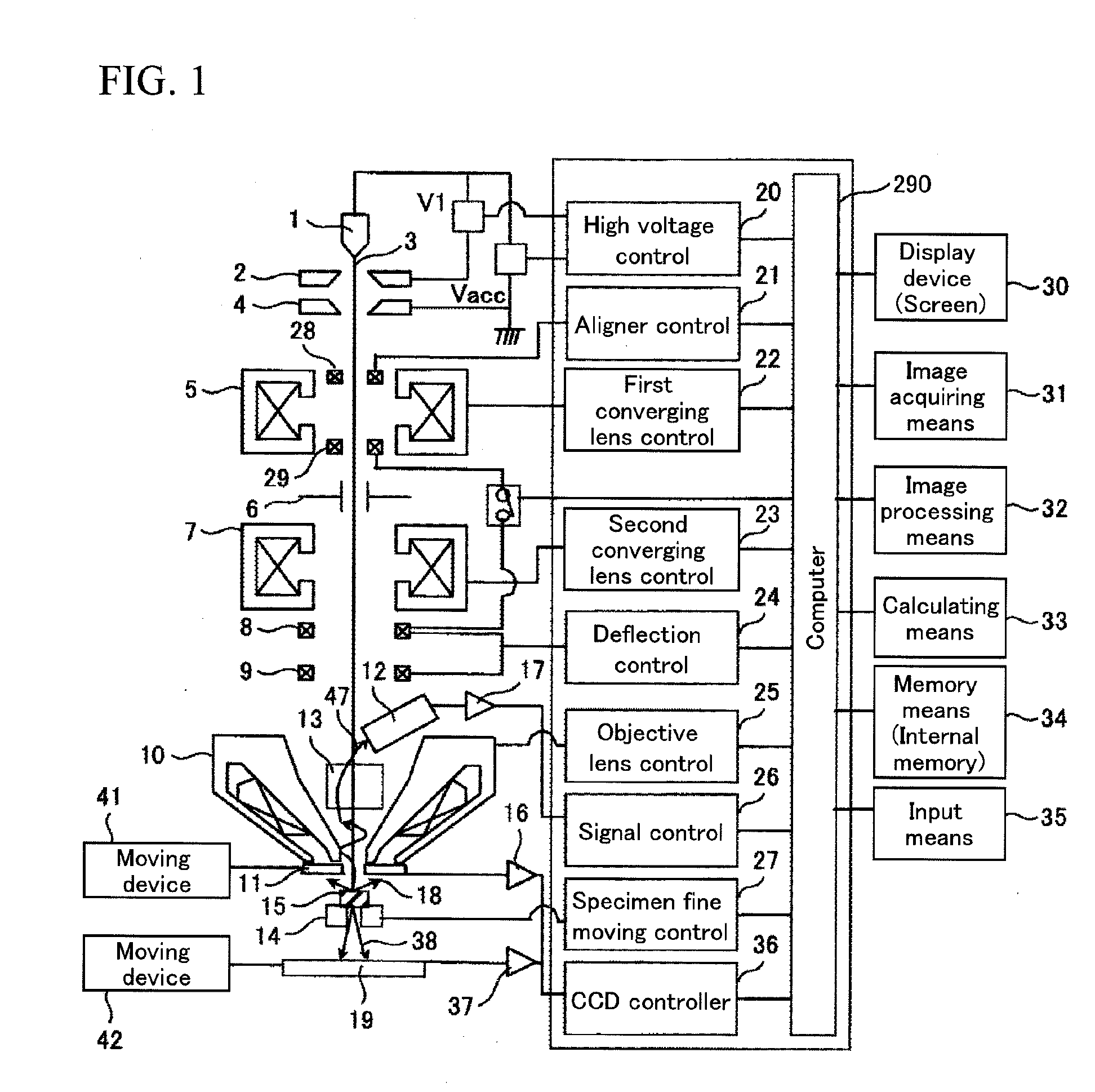

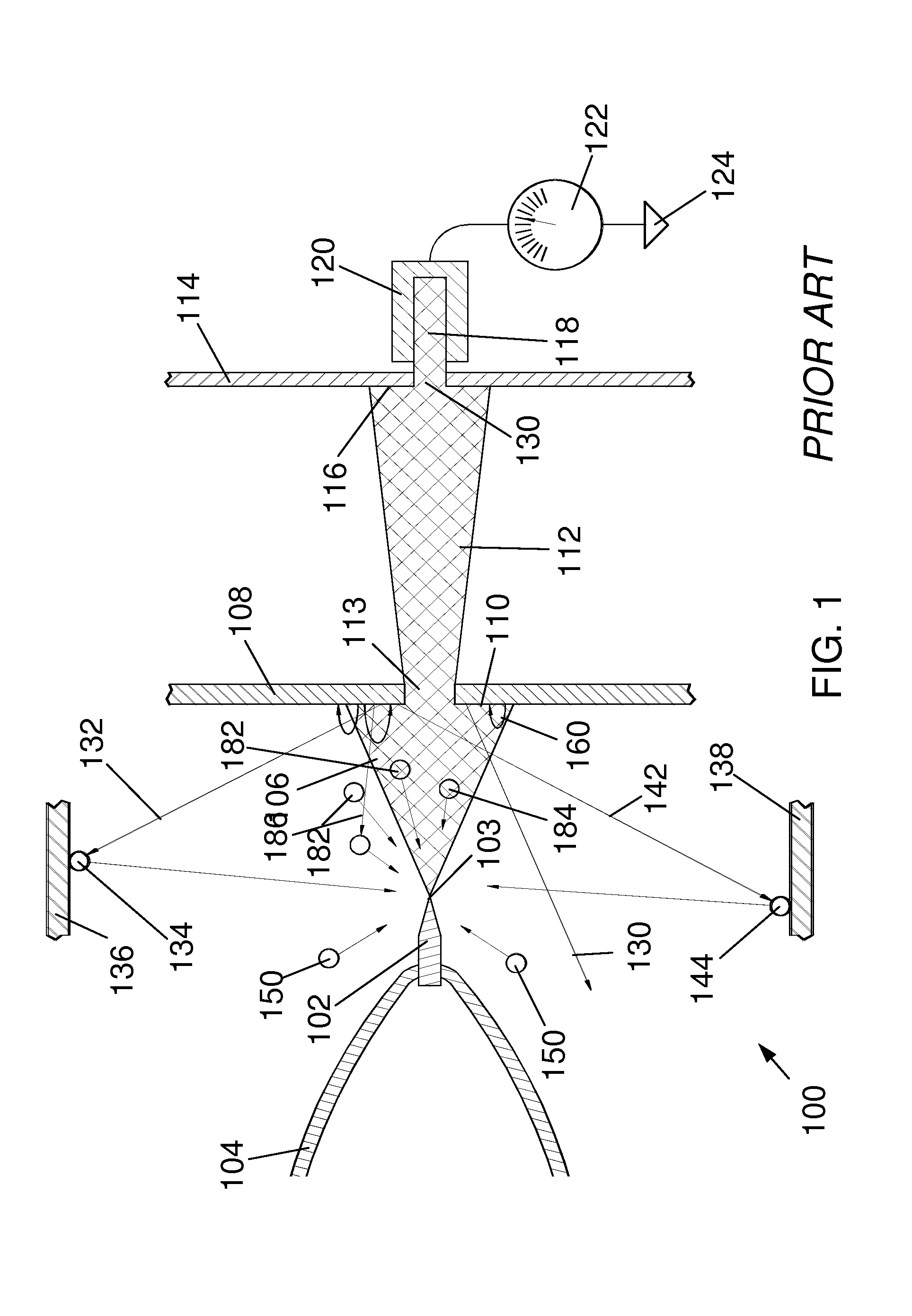

Scanning electron microscope

ActiveUS20060060782A1Improve transport efficiencyImprove efficiencyMaterial analysis using wave/particle radiationElectric discharge tubesAngle of incidenceElectron source

In a scanning electron microscope, an emitted primary electron beam is diverted by an angle of at least about 45 degrees prior to incidence with a specimen. The beam may be bent by a magnetic separator. The separator may also serve to deflect secondary electron and back scattered electrons. As the angle of emissions and reflections from the specimen is close to the angle of incidence, bending the primary electron beam prior to incidence, allows the electron source to be located so as not to obstruct the travel of emissions and reflections to suitable detectors.

Owner:NAT UNIV OF SINGAPORE

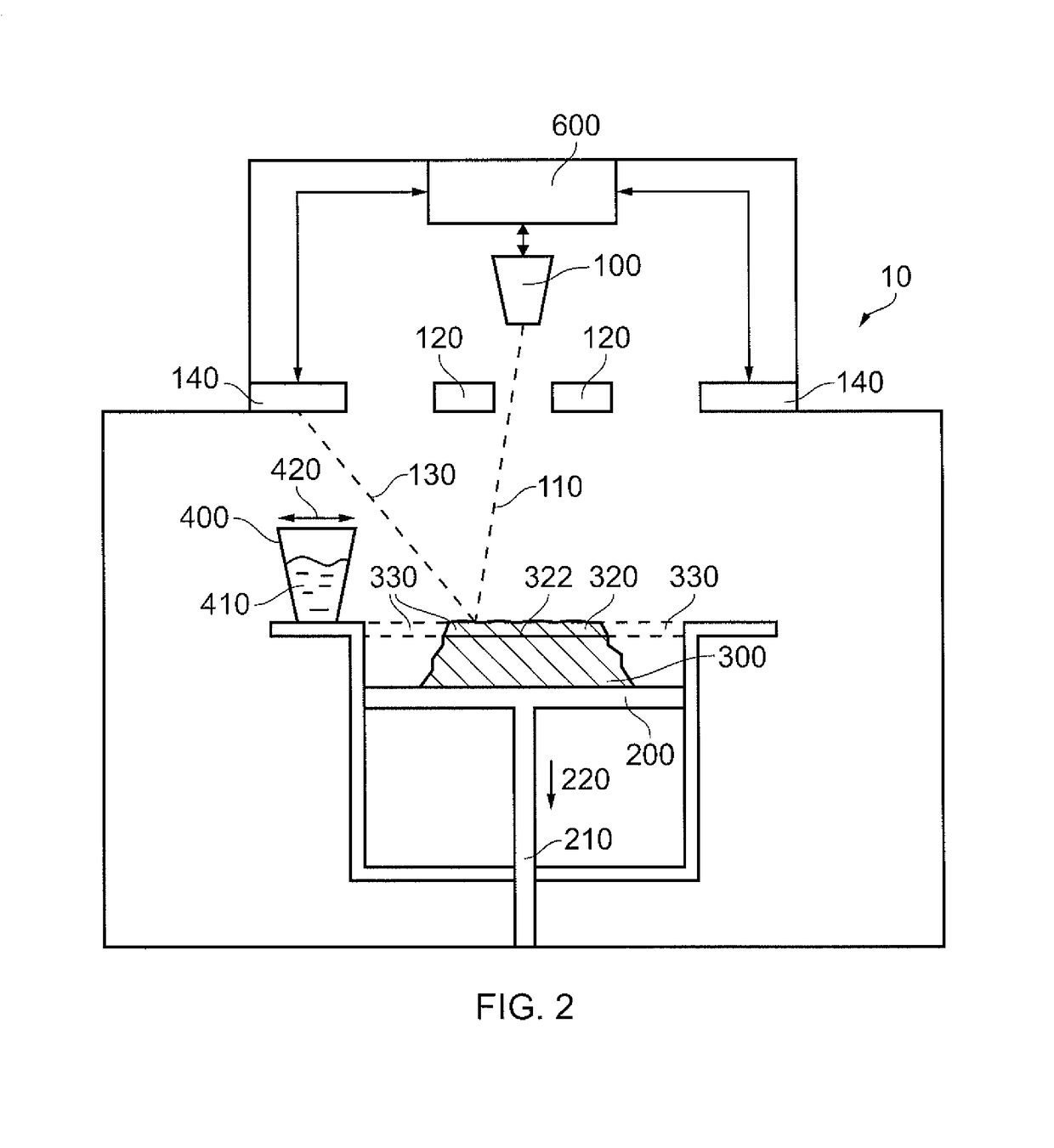

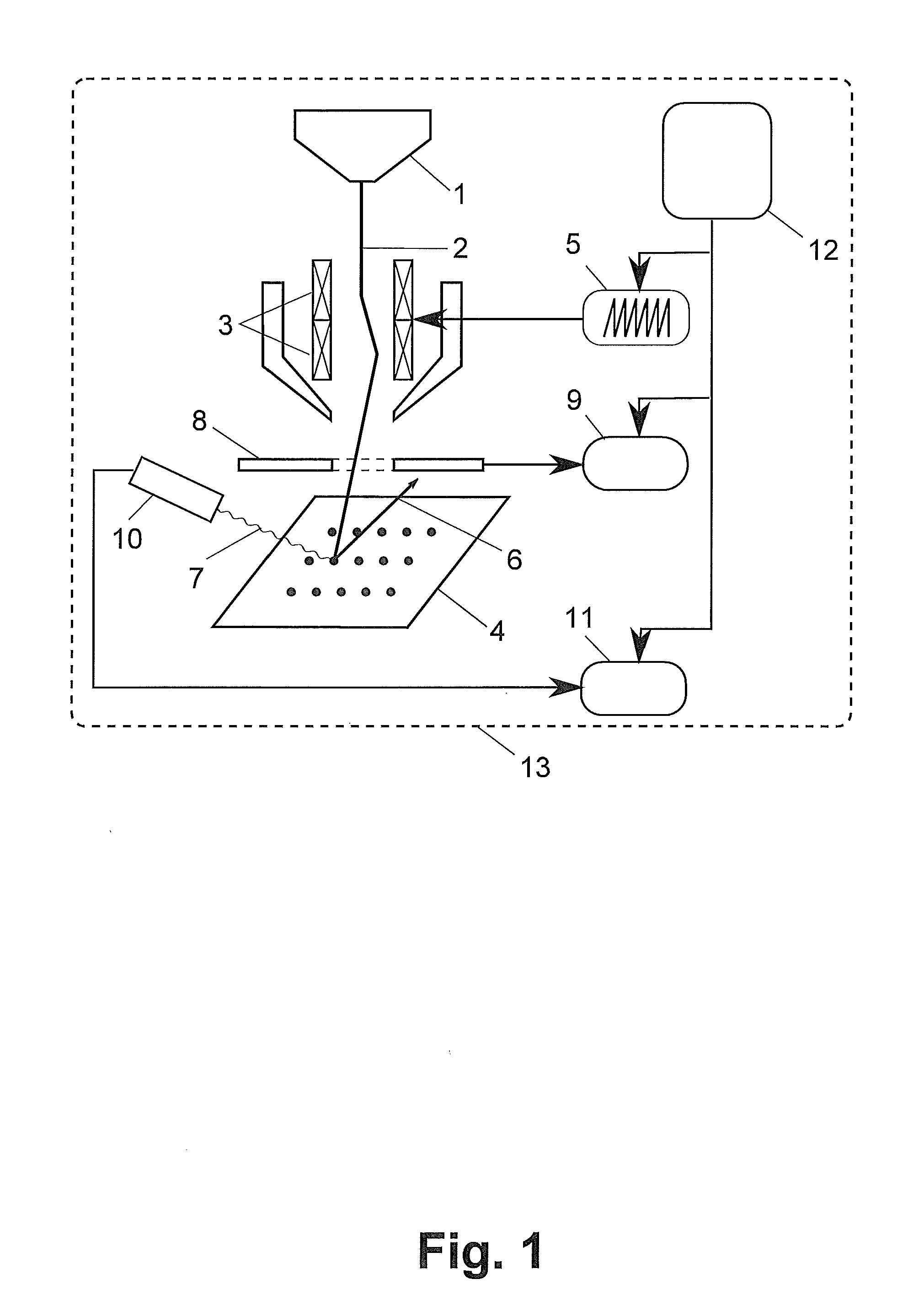

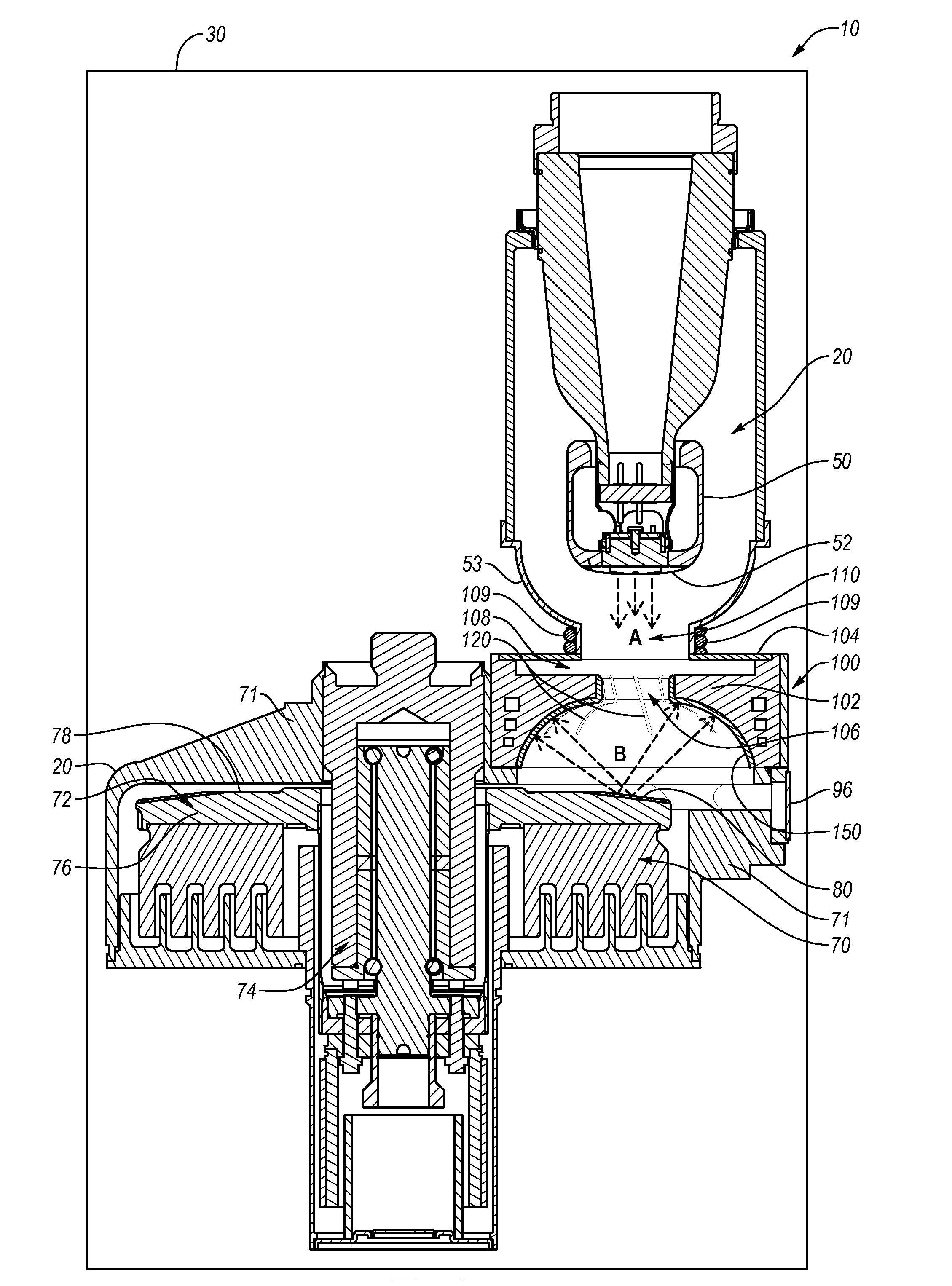

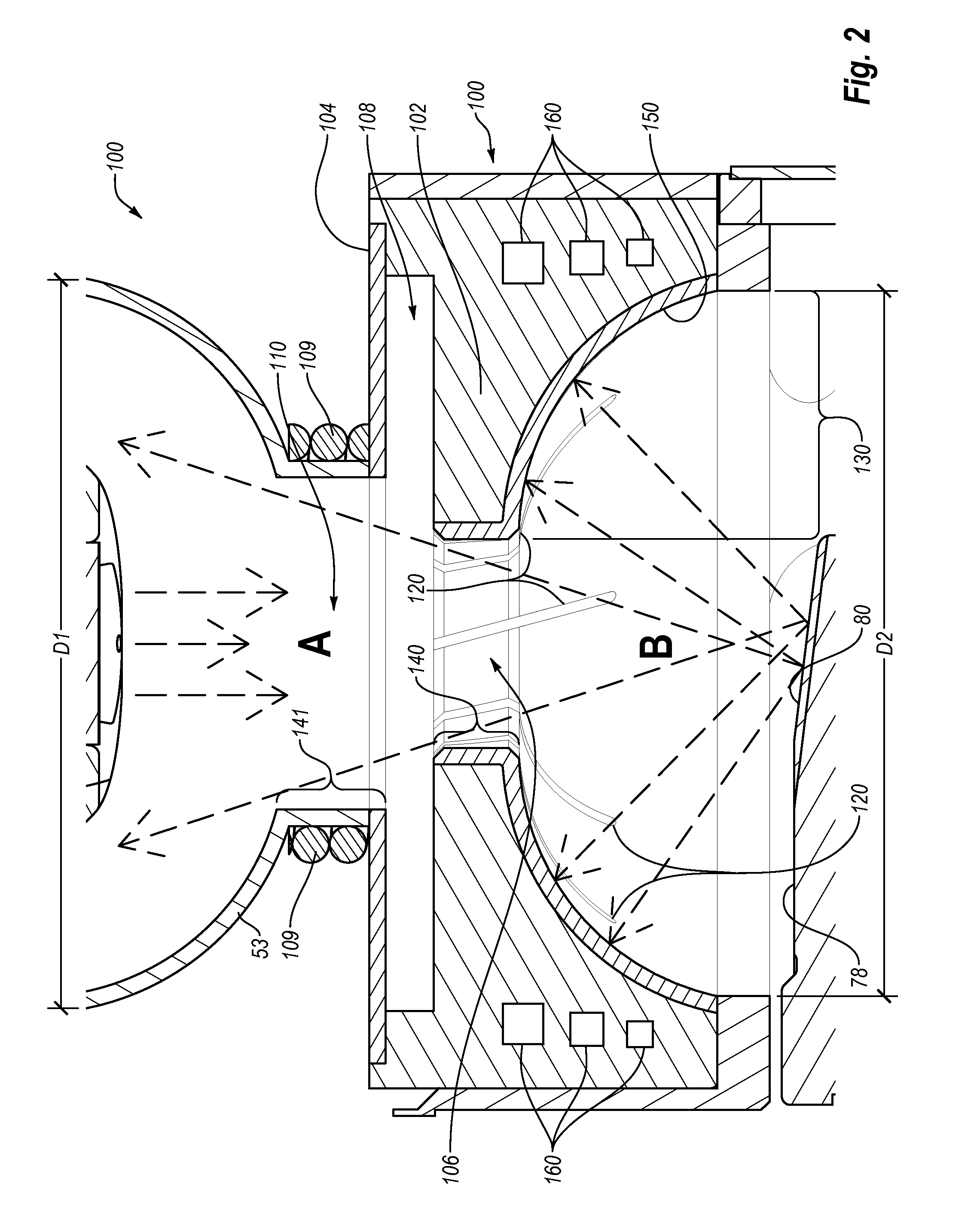

Method of manufacturing a component

ActiveUS10046412B2Few and small defectAdditive manufacturing apparatusMaterial analysis using wave/particle radiationElectronMaterials science

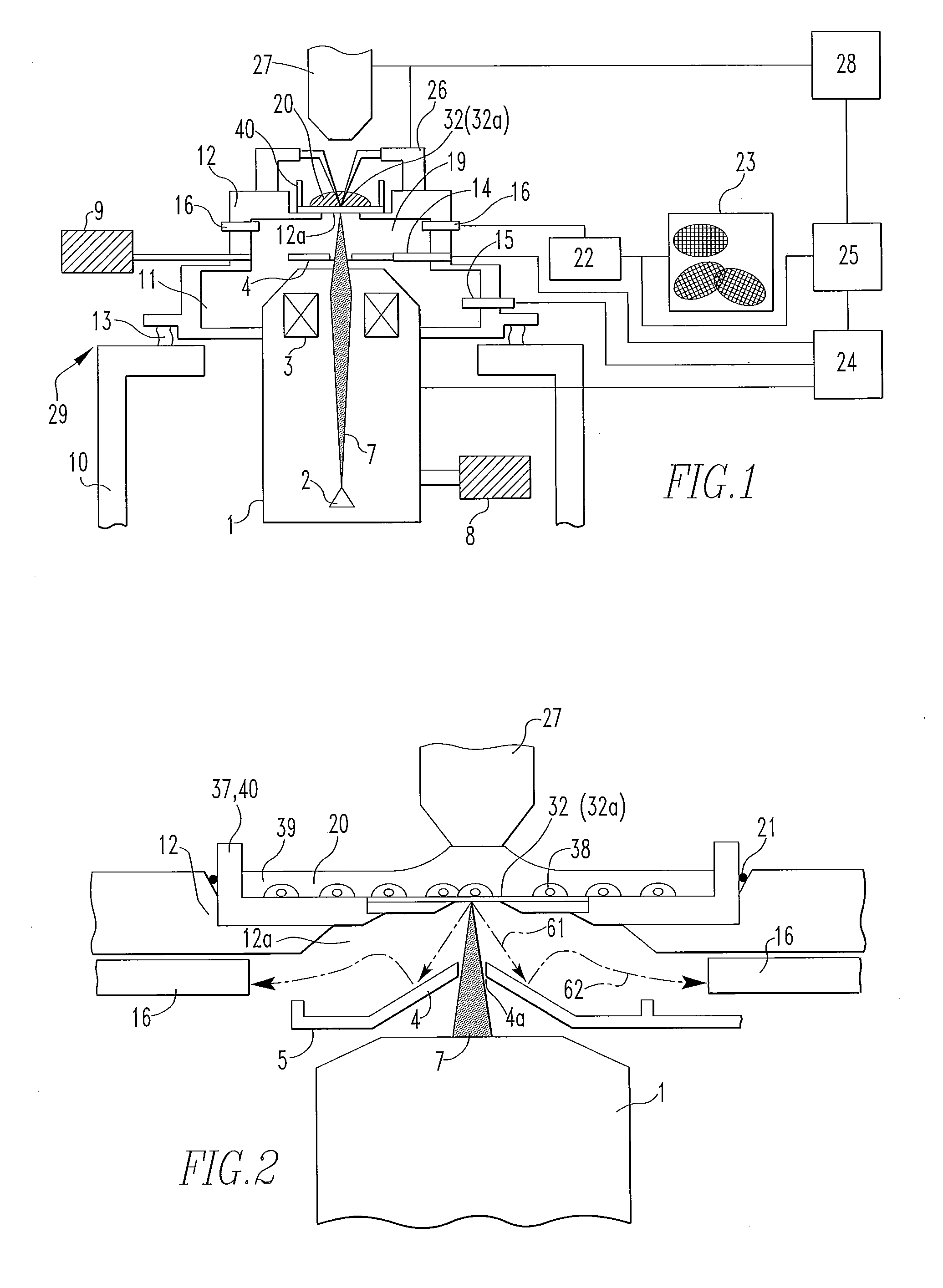

A method of manufacturing a component includes providing a powder layer; scanning the powder layer using an electron beam; detecting back scattered electrons produced by the interaction of the electron beam with the powder layer; identifying, from the detected back scattered electrons, any defects in the powder layer; selectively melting at least a part of the powder layer so as to generate a solid layer; and repeating these steps at least once so as to build up a shape corresponding to the component. The method may also includes steps of making a decision about whether to remove any identified defects in the powder layer, and adjusting one or more parameters of the step of providing a powder and / or adjusting one or more parameters of the selective melting step so as to avoid future recurring defects at that position based on stored data relating to the scanned powder layer.

Owner:ROLLS ROYCE PLC

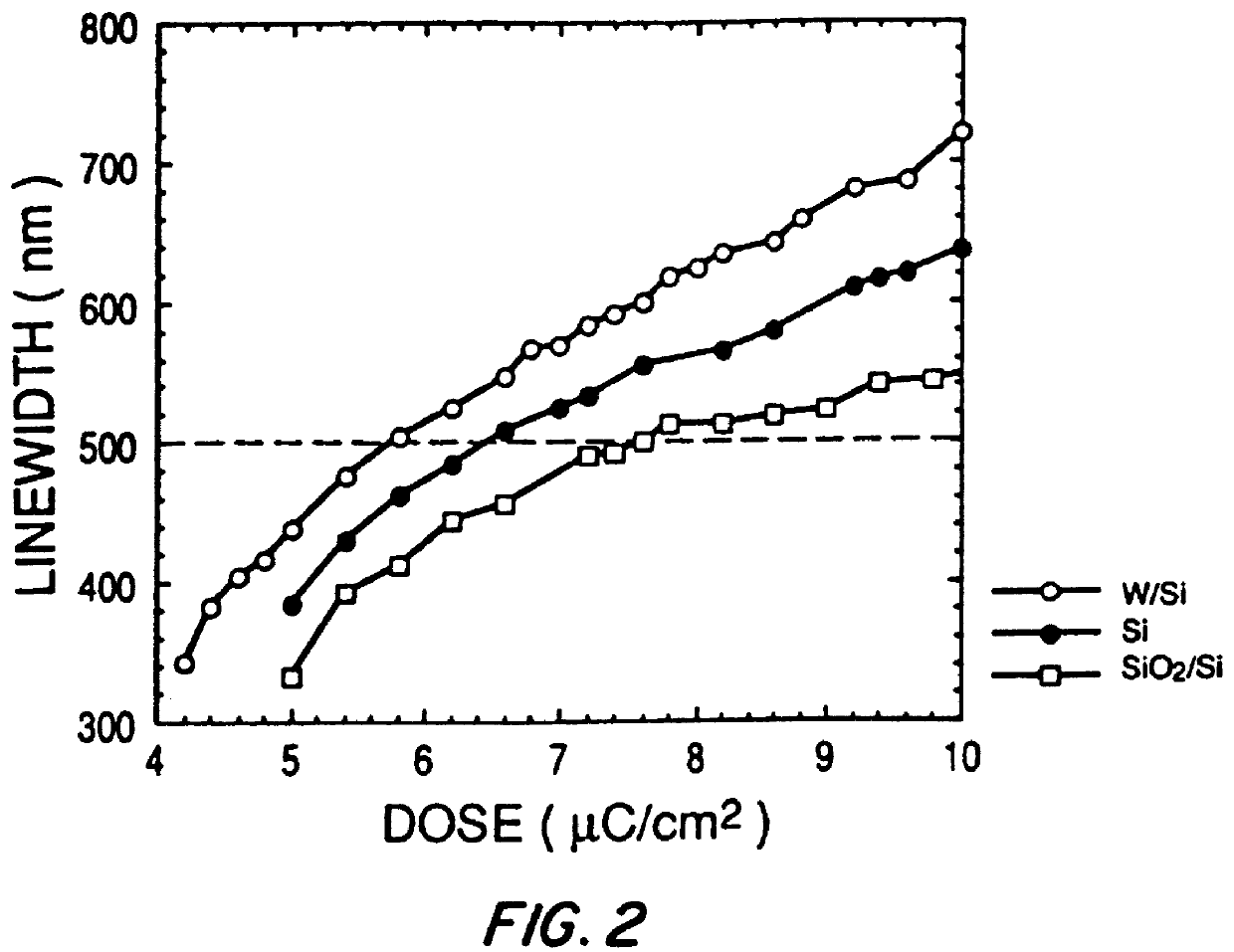

Lithographic mask and method for fabrication thereof

InactiveUS6017658AReduce and eliminate effectReduce and eliminate detrimental effectElectric discharge tubesPhotomechanical exposure apparatusResistImage resolution

Improvement in resolution in terms of minimum feature sizes and proximity effects in an electronic mask is attained by making the mask using a high voltage electron beam which deflects or blocks backscattered electrons. The novel mask structure comprises a transparent support, an absorber layer disposed on said support, a dielectric layer disposed on said absorber layer, and a resist layer disposed on said dielectric layer. It is the dielectric layer which is credited for improving resolution in said mask which can be used a multiple number of times in printing a pattern for various applications, including electronic devices and integrated circuits.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

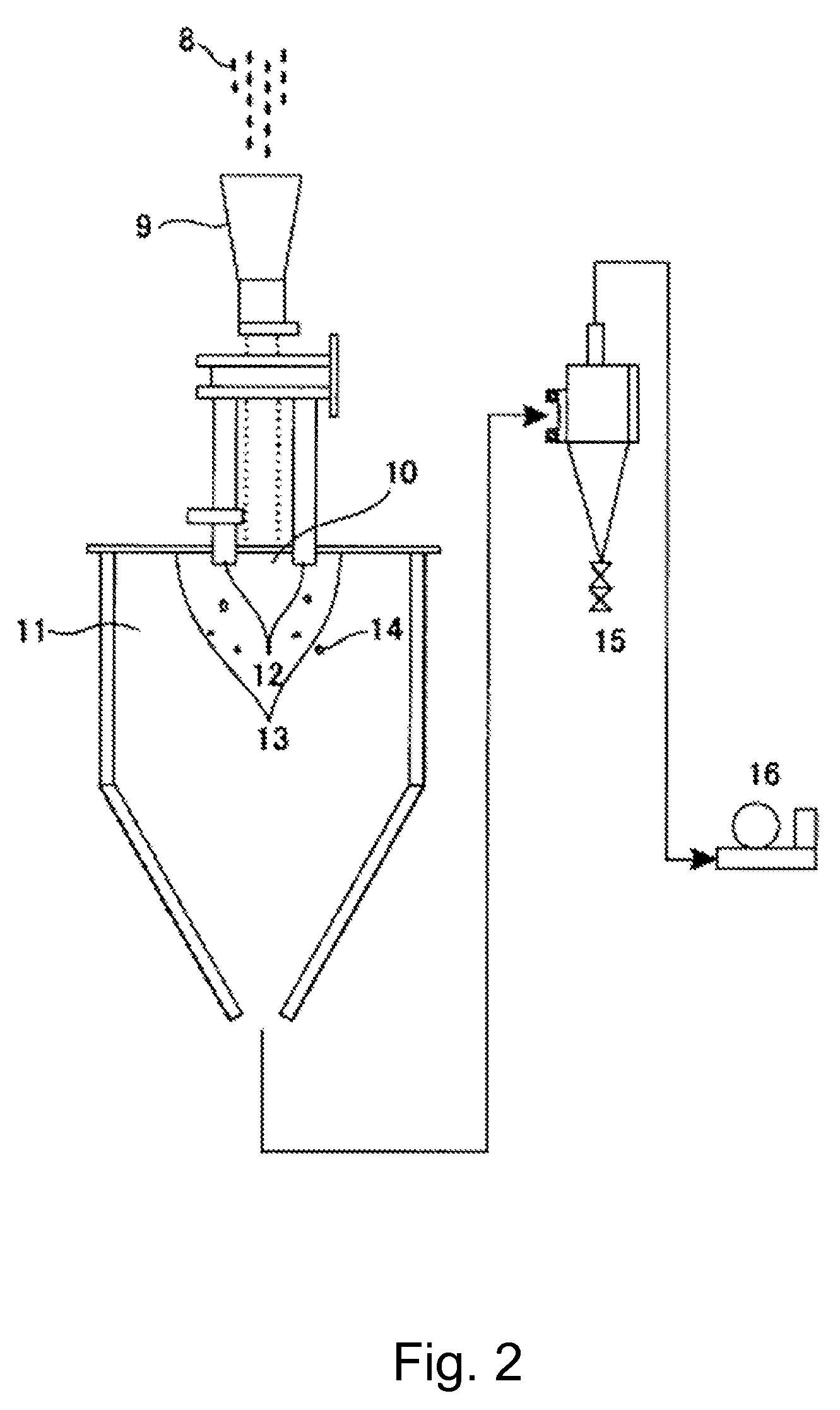

Method of manufacturing a component

ActiveUS20150034606A1Few and small defectAdditive manufacturing apparatusMaterial analysis using wave/particle radiationMechanical propertyElectron

An additive layer manufacture machine generates a first electron beam for scanning a powder layer to be melted in a selective melting process. Backscatter electrons from the interaction between the first electron beam and the powder layer is detected by a backscatter detector. Any defects in the powder layer can then be identified, or inferred, from the detected backscatter electrons. If necessary, any defects can be removed from the powder layer before selective melting. Once the powder layer has been inspected and if necessary improved, selective melting of the layer is performed in order to produce a layer of the component. The process may be repeated to generate a finished component with good mechanical properties.

Owner:ROLLS ROYCE PLC

Method of manufacturing a component

ActiveUS10052712B2Reduce number/percentageLow costAdditive manufacturing apparatusElectric discharge tubesMetal powderElectron

A method of manufacturing and measuring the geometry of at least a part of a component, and a method of manufacturing a component, both include providing a powder layer to a melt region; selectively melting the powder layer using an energy source, the melted powder subsequently solidifying to form a solid layer; scanning the melt region, including the solid layer, using a scanning electron beam; detecting backscattered electrons resulting from the interaction of the scanning electron beam with the melt region; determining the geometry of the solid layer from the detected backscattered electrons; and storing data relating to the determined geometry of the solid layer. The methods may also include adjusting parameters of the steps of providing a powder layer and / or selectively melting the powder layer to avoid future recurring errors, or generating a virtual 3-D model of the manufactured component, using the stored data.

Owner:ROLLS ROYCE PLC

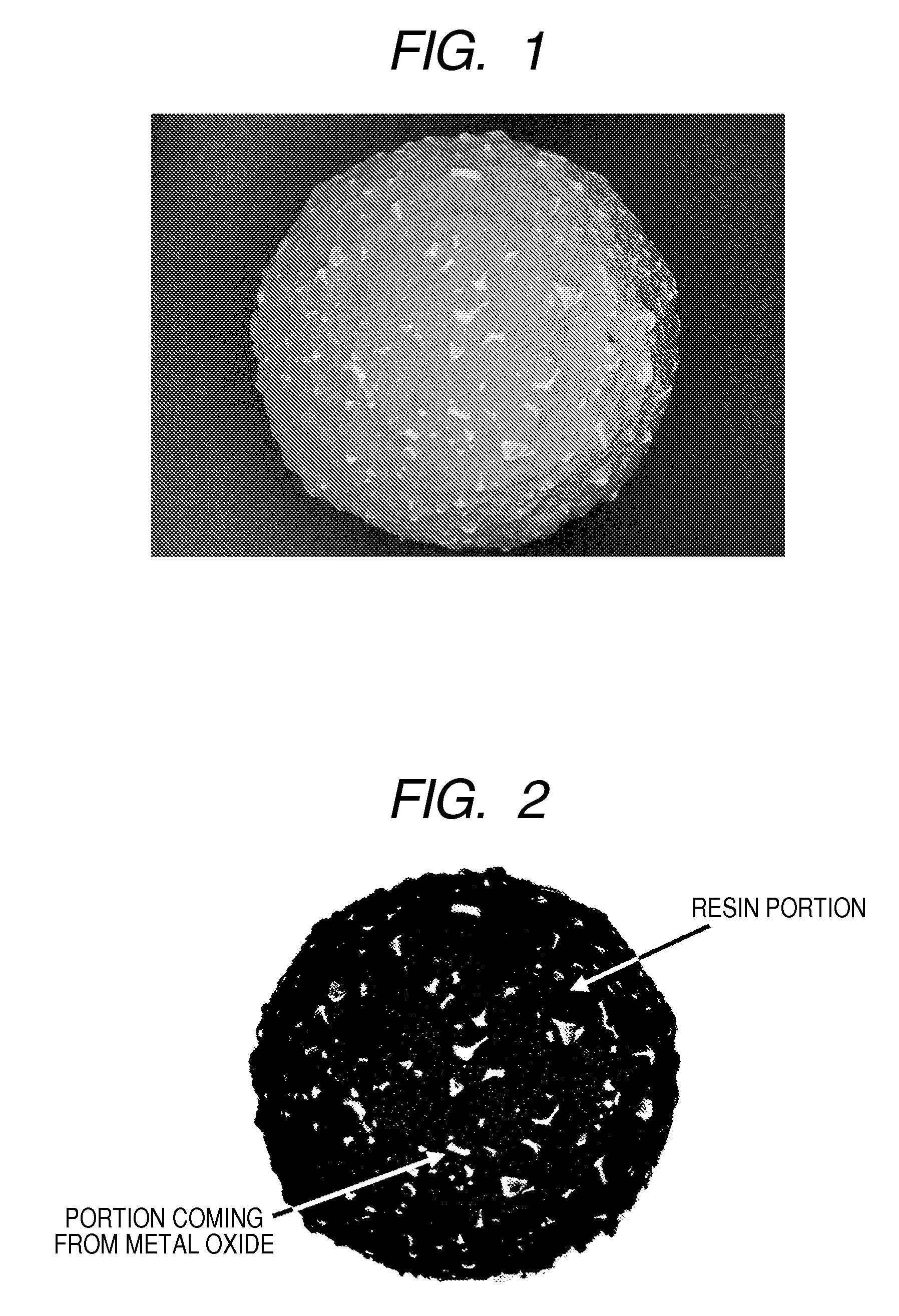

Magnetic carrier and two-component developer

Owner:CANON KK

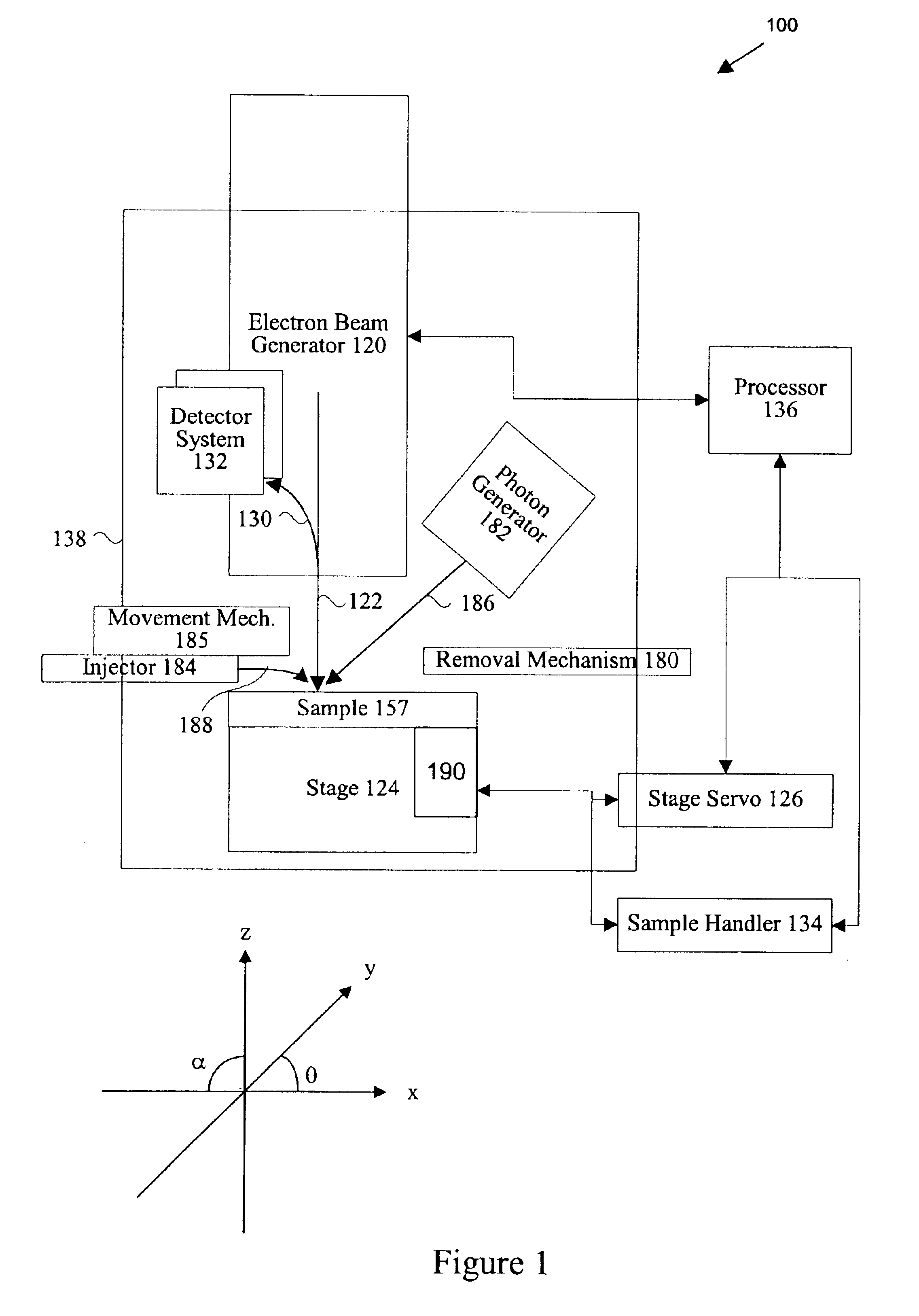

Apparatus and Method for Inspecting Samples

InactiveUS20100243888A1Easy maintenanceLow costElectric discharge tubesGamma-ray/x-ray microscopesLight beamEngineering

An inspection apparatus and method capable of well observing or inspecting a specimen contained in a liquid. The inspection apparatus has a film including first and second surfaces. Furthermore, the apparatus has a vacuum chamber for reducing the pressure in the ambient in contact with the second surface of the film, primary beam irradiation column connected with the vacuum chamber, and a shutter for partially partitioning the space between the film and the primary beam irradiation column within the vacuum chamber. A liquid sample is held on the first surface of the film. The primary beam irradiation column irradiates the sample. Backscattered electrons (a secondary beam) produced from the sample by the primary beam irradiation are directed at the shutter, producing secondary electrons (a tertiary signal).

Owner:JEOL LTD

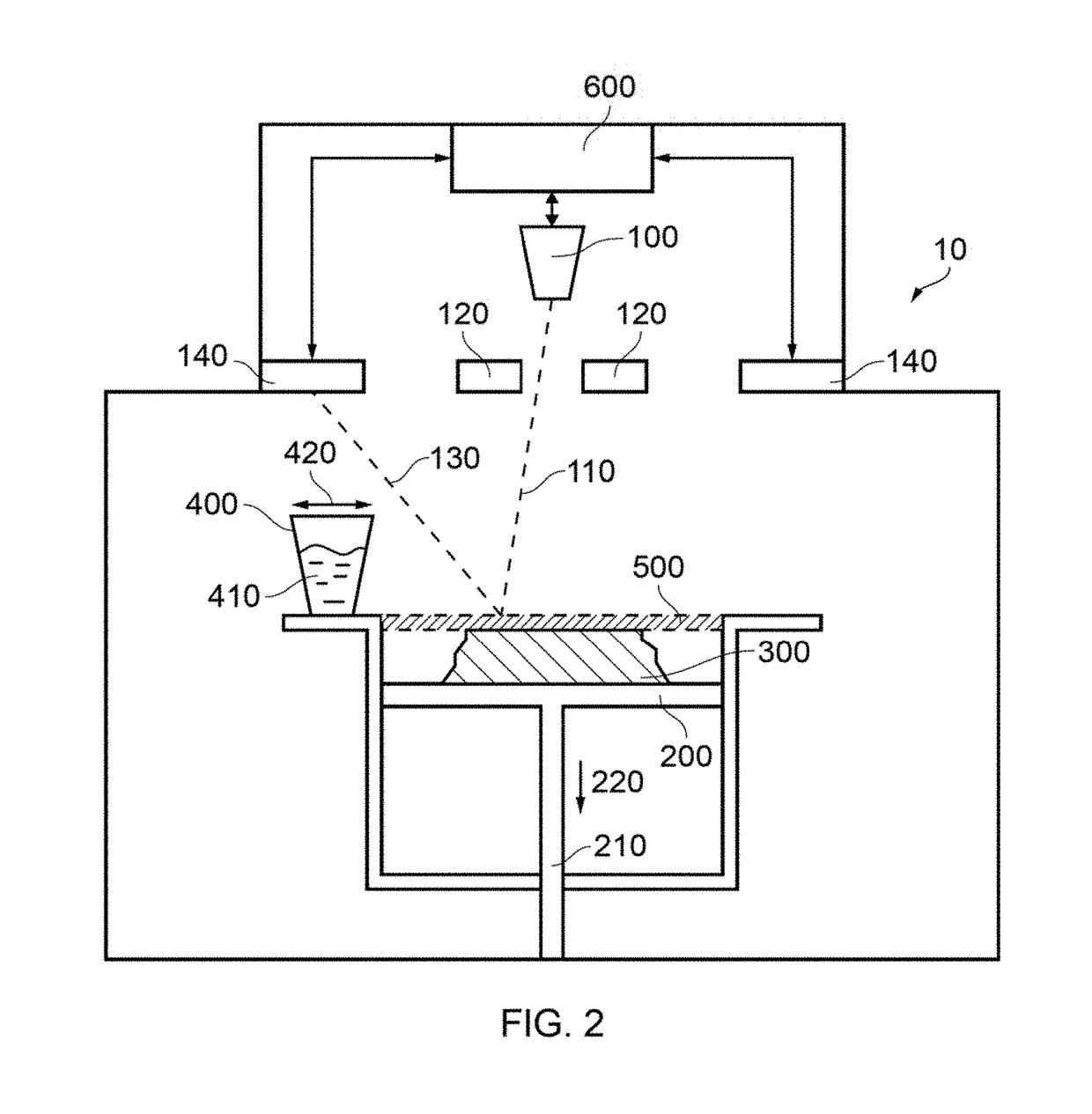

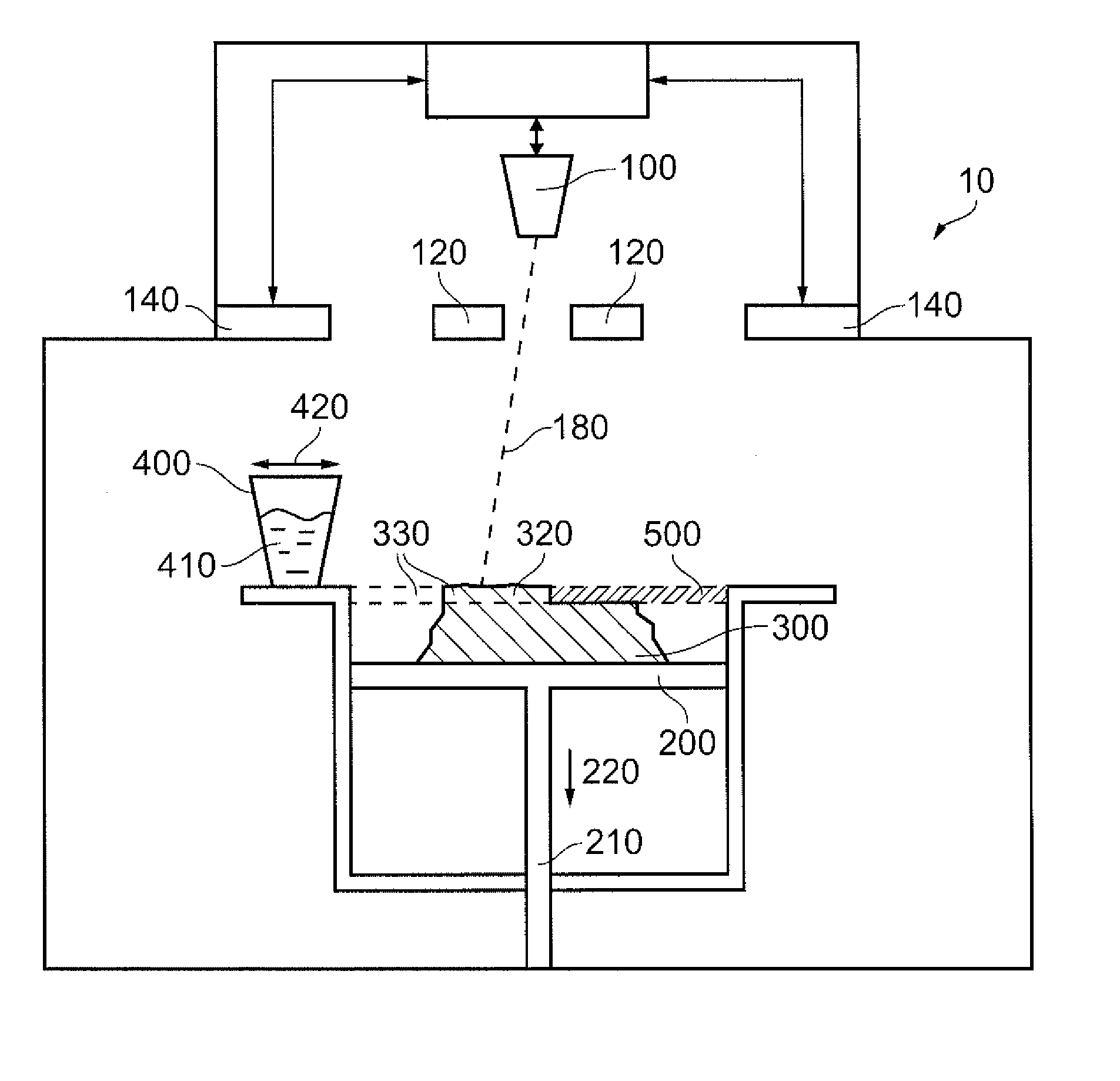

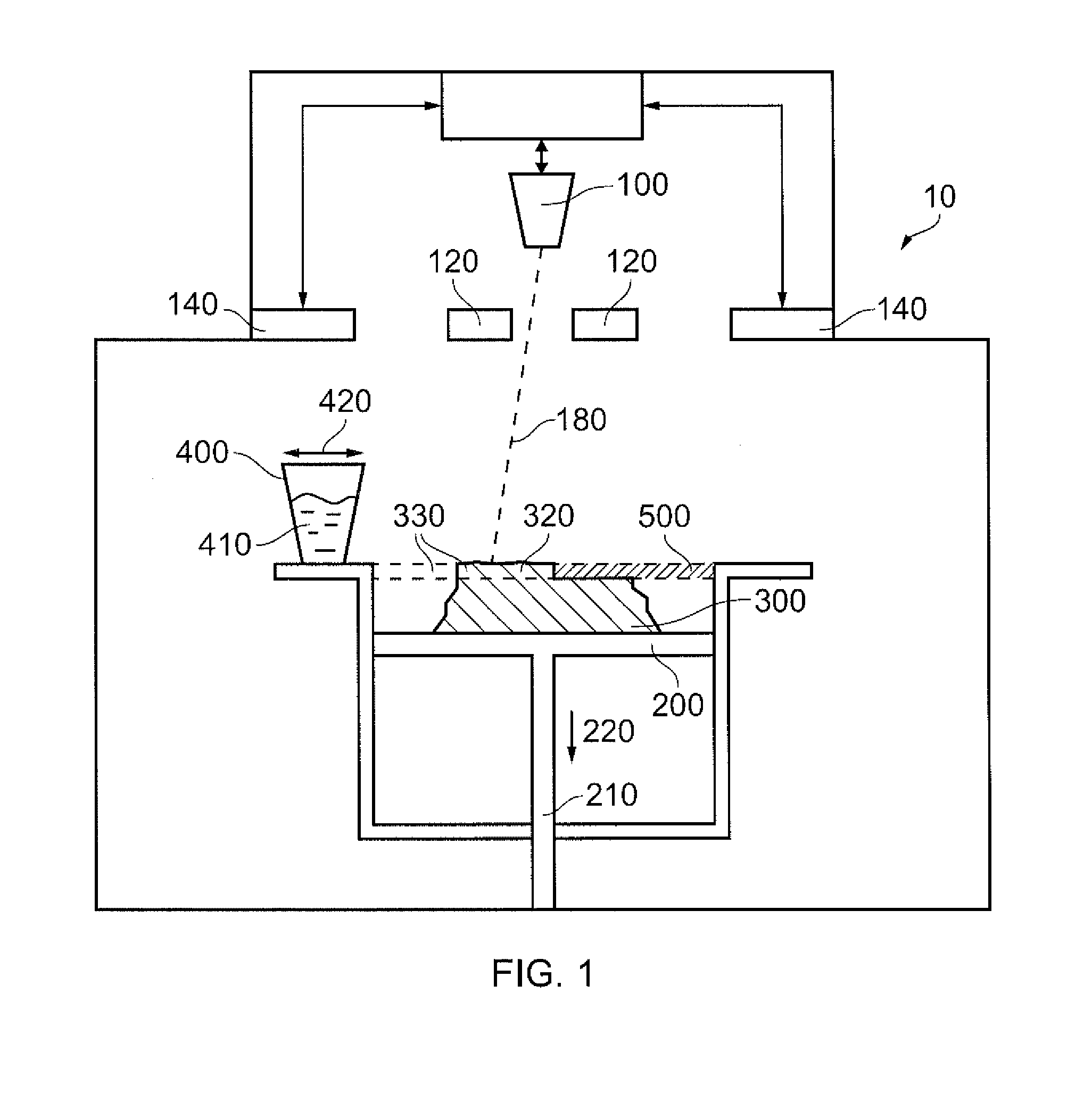

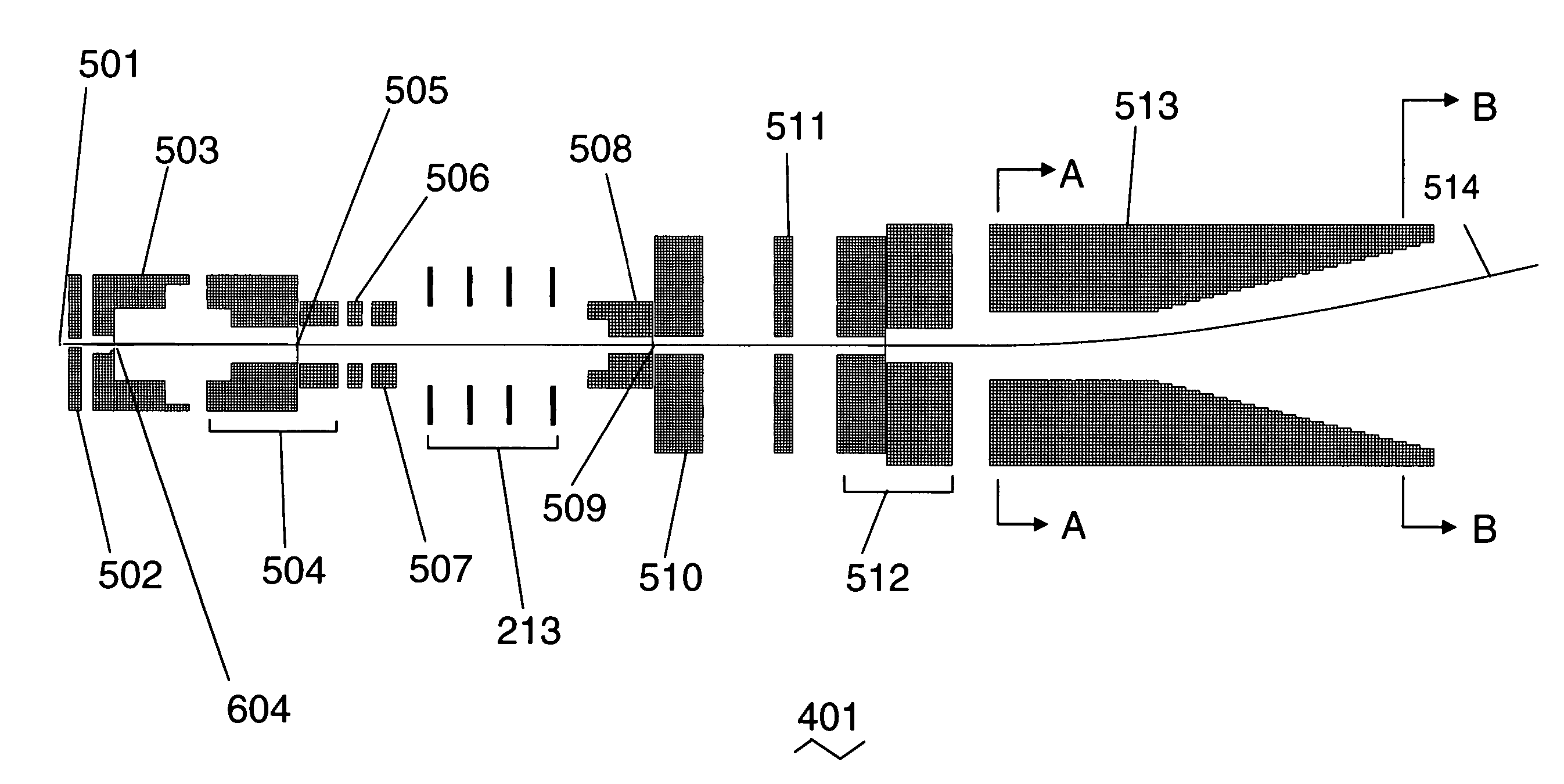

Method of manufacturing a component

ActiveUS20150037601A1Reduce number/percentageLow costAdditive manufacturing apparatusElectric discharge tubesMetal powderMechanical property

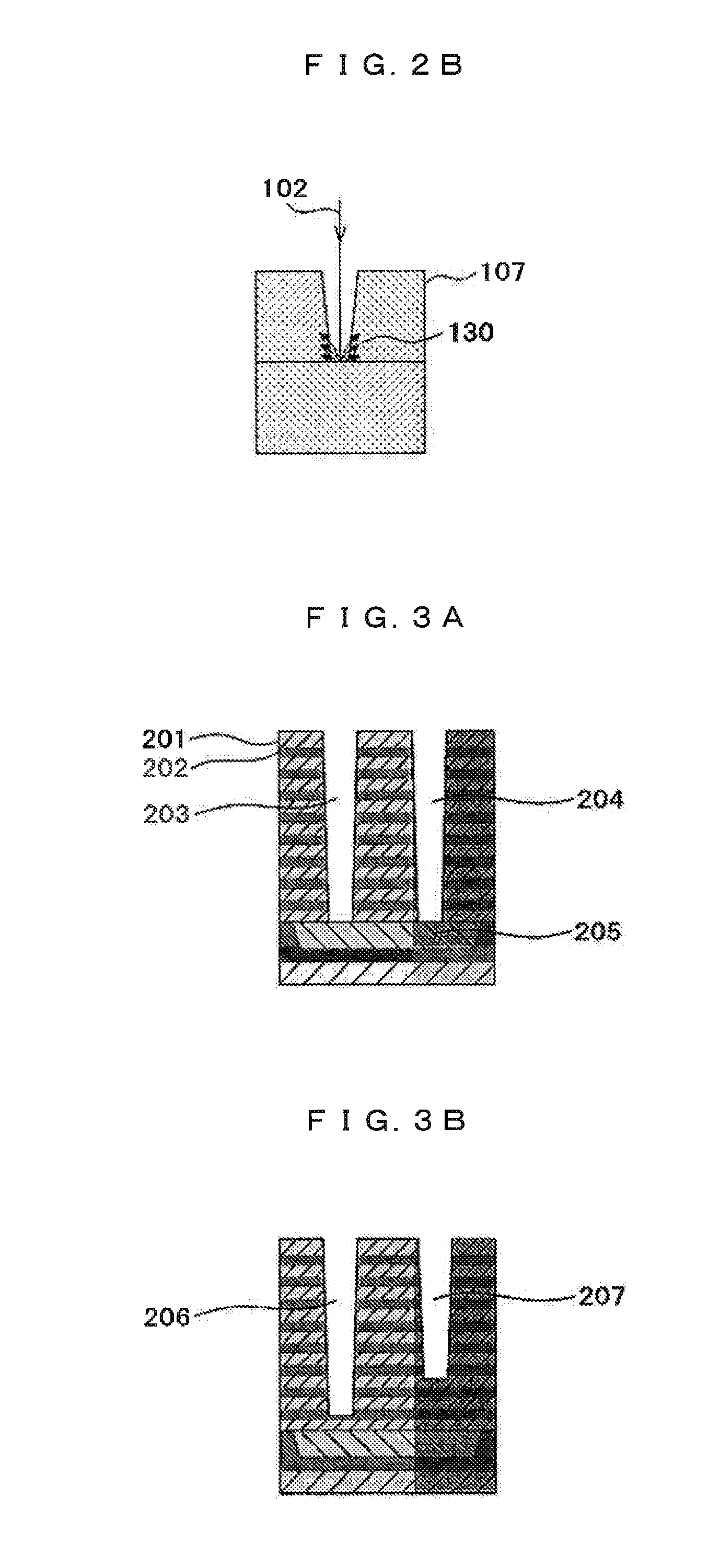

An additive layer manufacture (ALM) machine comprises an energy source (180) for selectively melting a layer of metal powder (500), and an electron beam (110) for determining the shape of the selectively melted solid layer (320) once it has solidified. The shape is determined by detecting backscattered electrons (130) from the interaction between the electron beam (110) and the solid layer (320). If the shape of the solid layer (320) is outside a determined tolerance, it may be corrected before proceeding. The process may be repeated to generate a finished component (300) with good mechanical properties and accurate geometry.

Owner:ROLLS ROYCE PLC

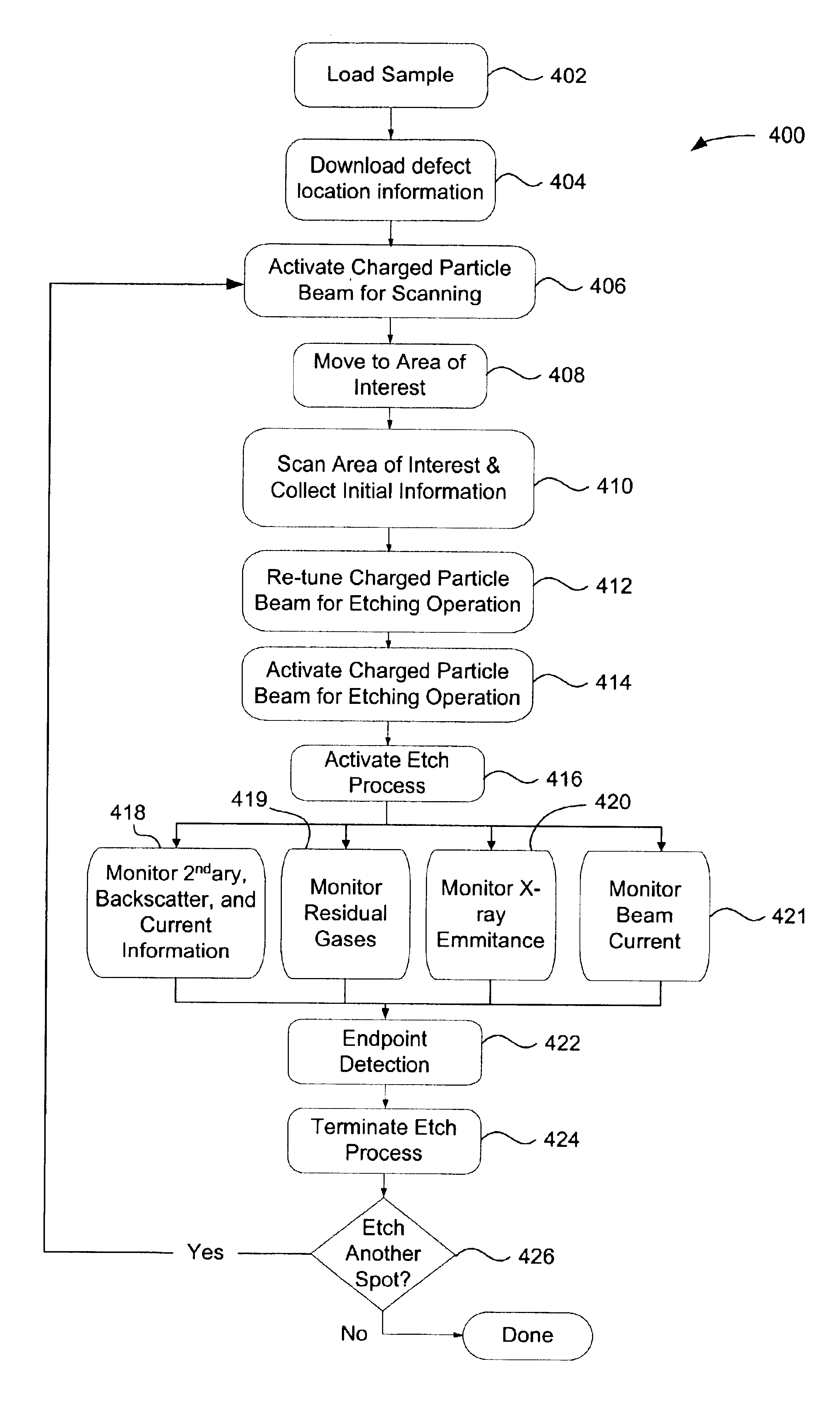

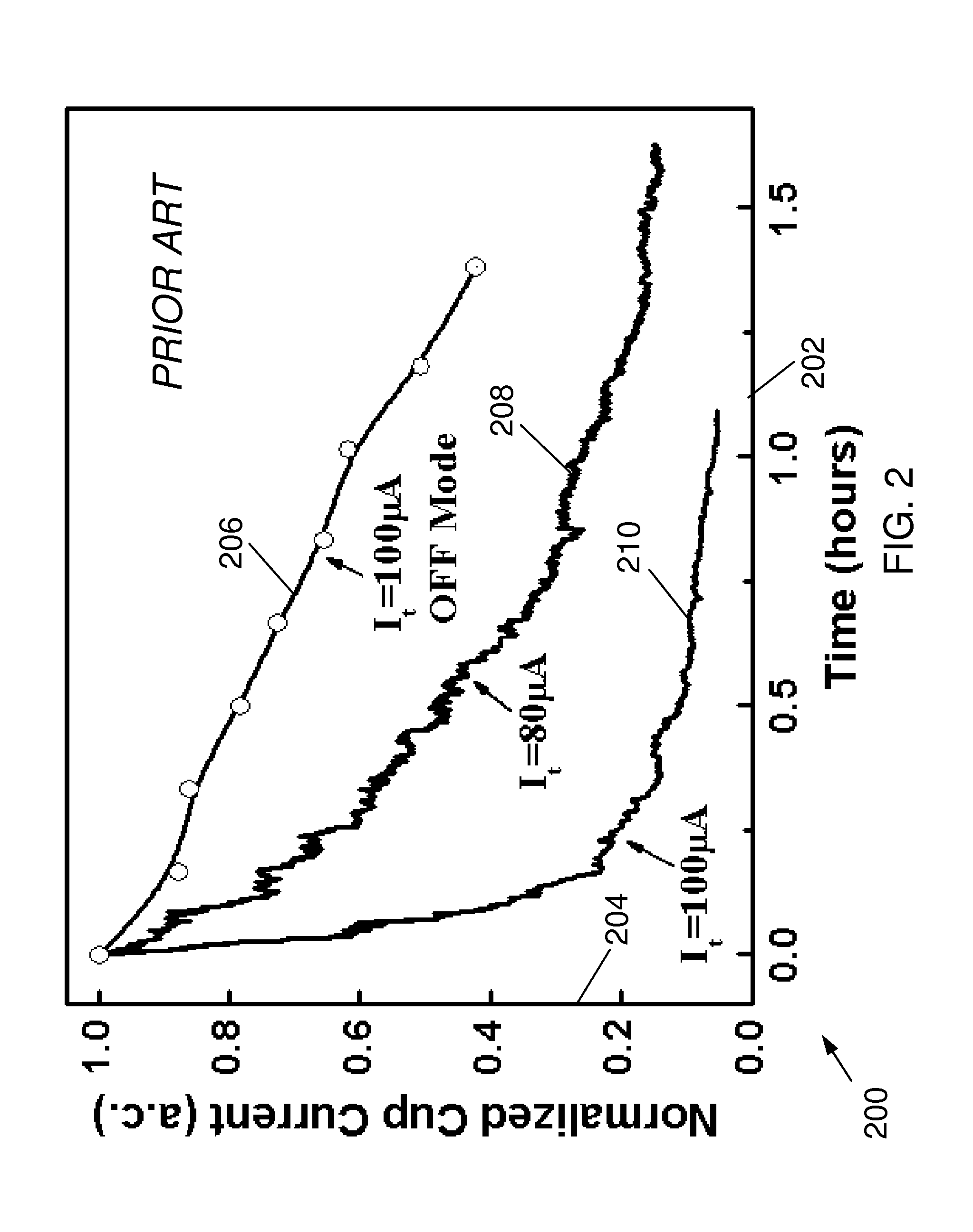

Method and apparatus for endpoint detection in electron beam assisted etching

InactiveUS6843927B2Semiconductor/solid-state device testing/measurementElectric discharge tubesSecondary electronsPhoton beam

Techniques for detecting endpoints during semiconductor dry-etching processes are described. The dry-etching process of the present invention involves using a combination of a reactive material and a charged particle beam, such as an electron beam. In another embodiment, a photon beam is used to facilitate the etching process. The endpoint detection techniques involve monitoring the emission levels of secondary electrons and backscatter electrons together with the current within the sample. Depending upon the weight given to each of these parameters, an endpoint is identified when the values of these parameters change more than a certain percentage, relative to an initial value for these values.

Owner:KLA TENCOR TECH CORP

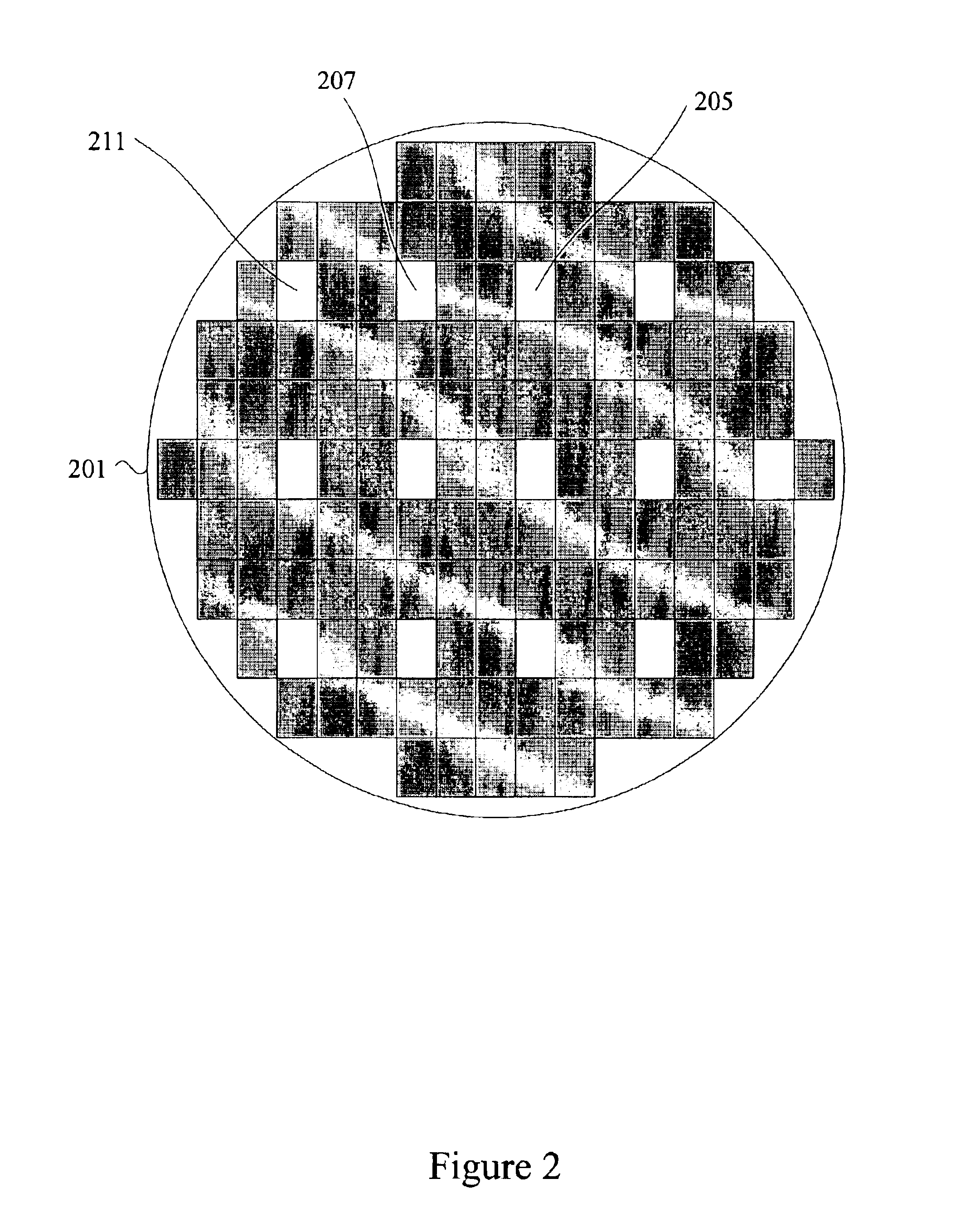

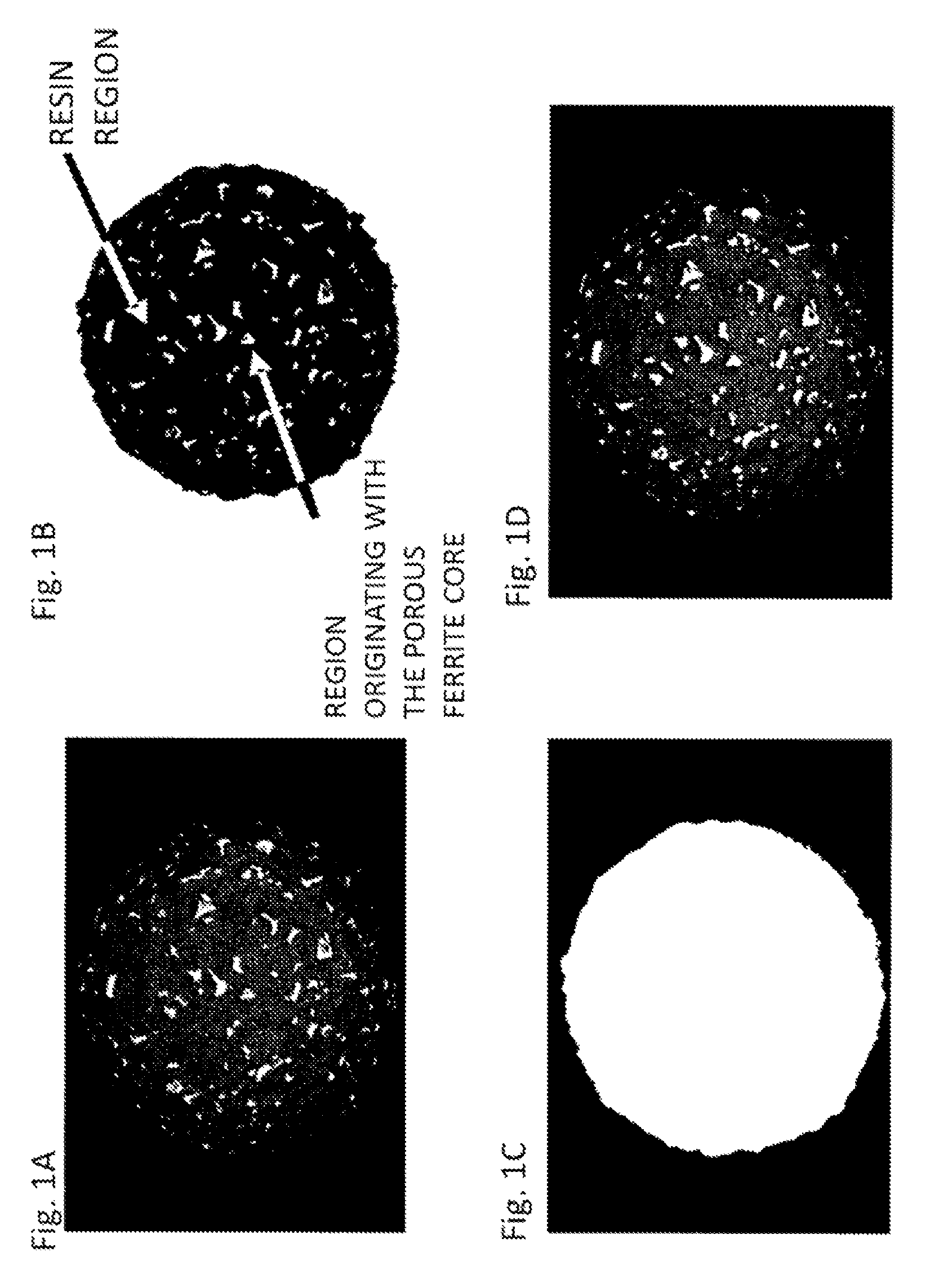

Magnetic carrier and two-component developer

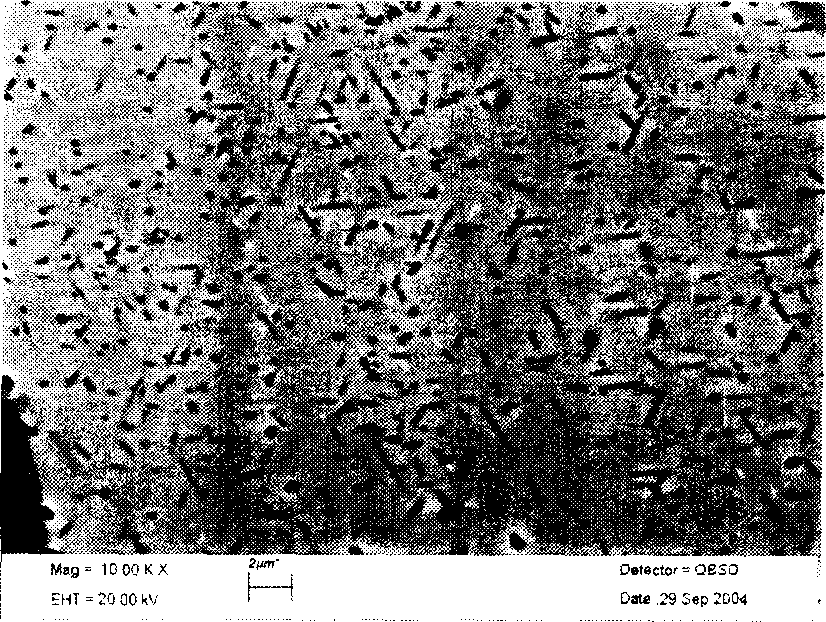

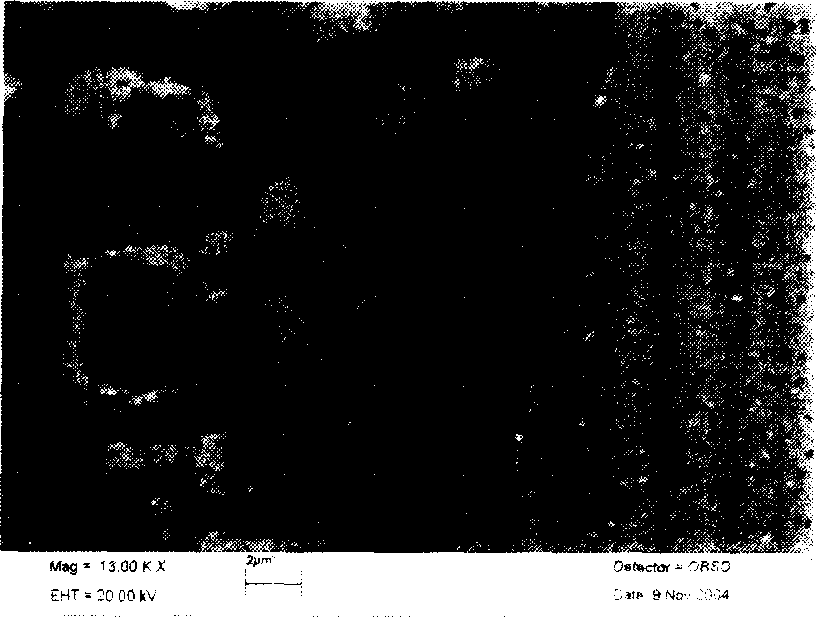

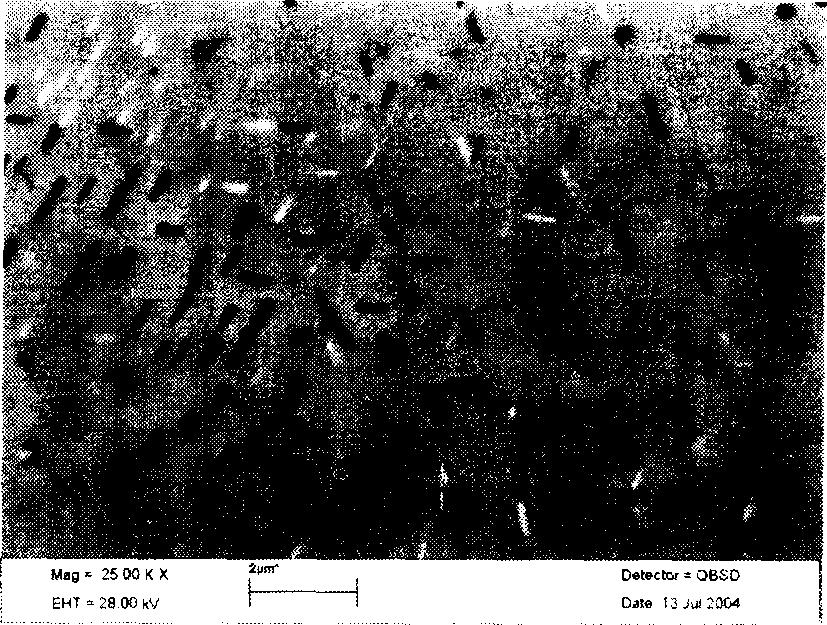

The present invention provides a magnetic carrier that can stably impart charge to a toner on a long term basis and that exhibits an excellent toner separation property and thus exhibits an excellent developing performance. This magnetic carrier is a magnetic carrier in which a vinyl resin coats the surface of a resin-filled core in which a resin is filled in pores of a porous ferrite particle, wherein the resistivity, Mg content, and total content of Sr and Ca oxides of the porous ferrite particle exhibit prescribed values and the magnetic carrier has a total area—in the backscattered electron projection image obtained by observation using a scanning electron microscope at an acceleration voltage of 2.0 kV—for a region originating with the porous ferrite particle of from at least 0.2 area % to not more than 5.0 area % with reference to the projected area of the magnetic carrier.

Owner:CANON KK

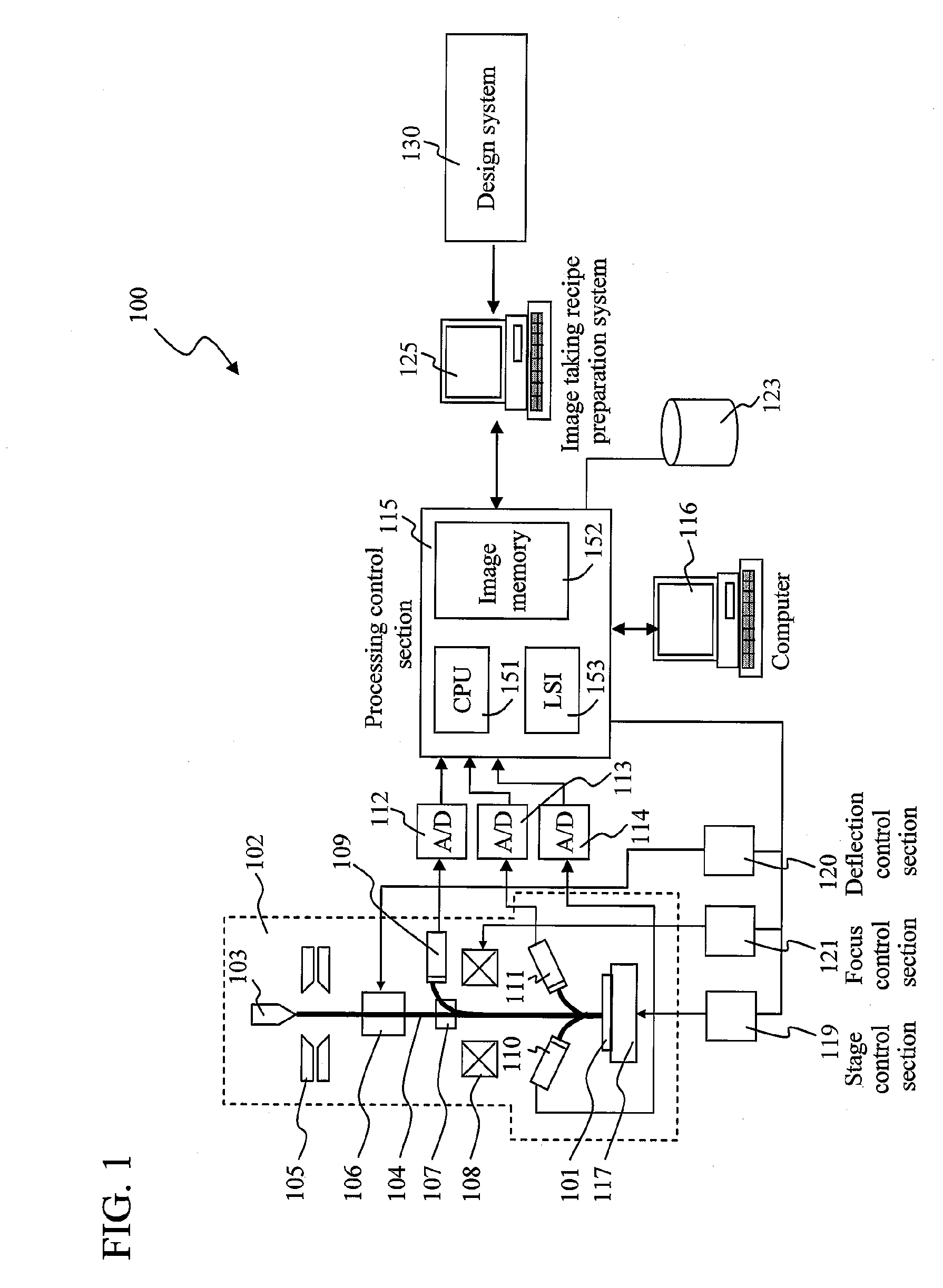

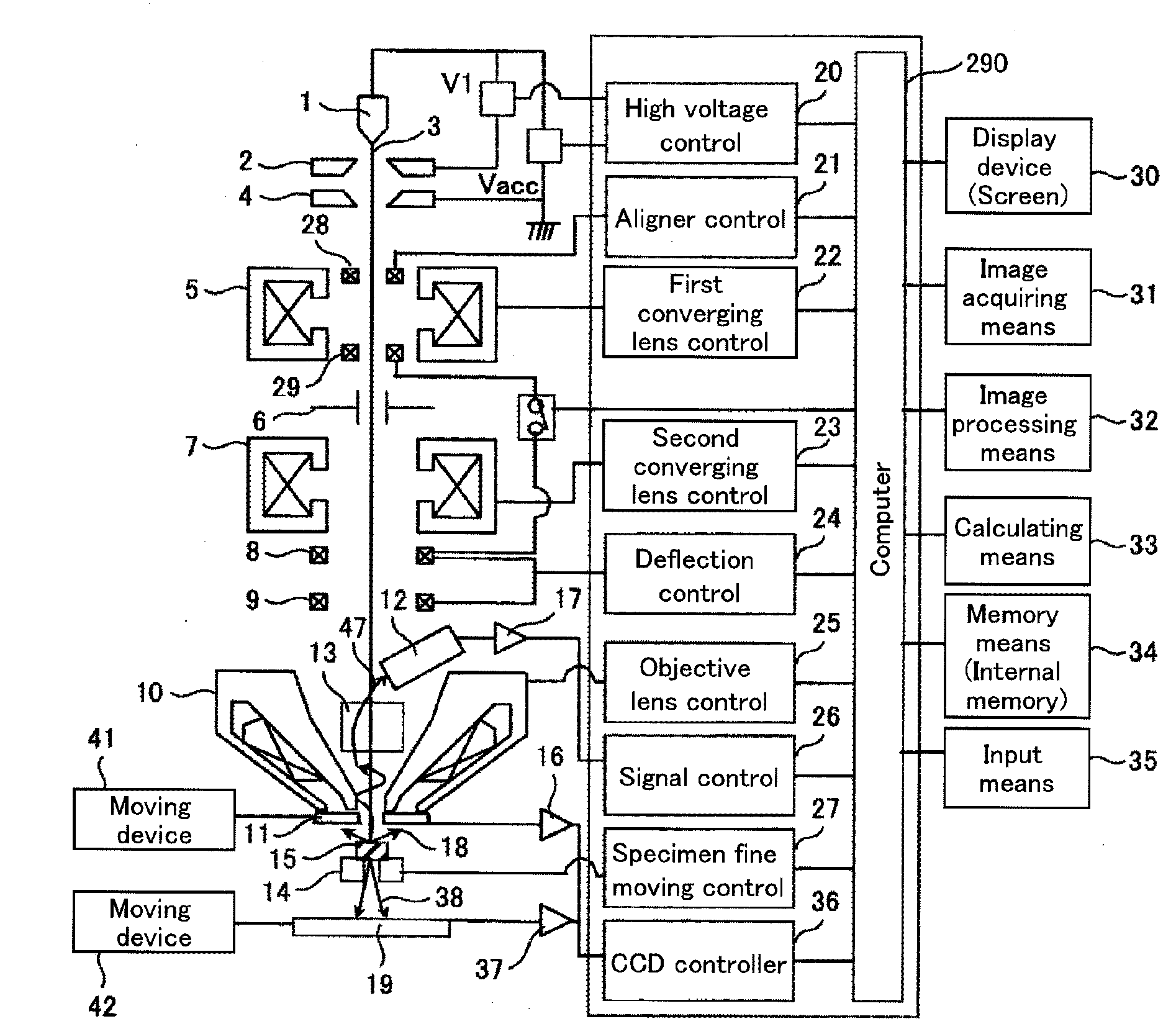

Scanning Electron Microscope System, Pattern Measurement Method Using Same, and Scanning Electron Microscope

ActiveUS20160379798A1High aspect ratioMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementElectron microscopeCalibration curve

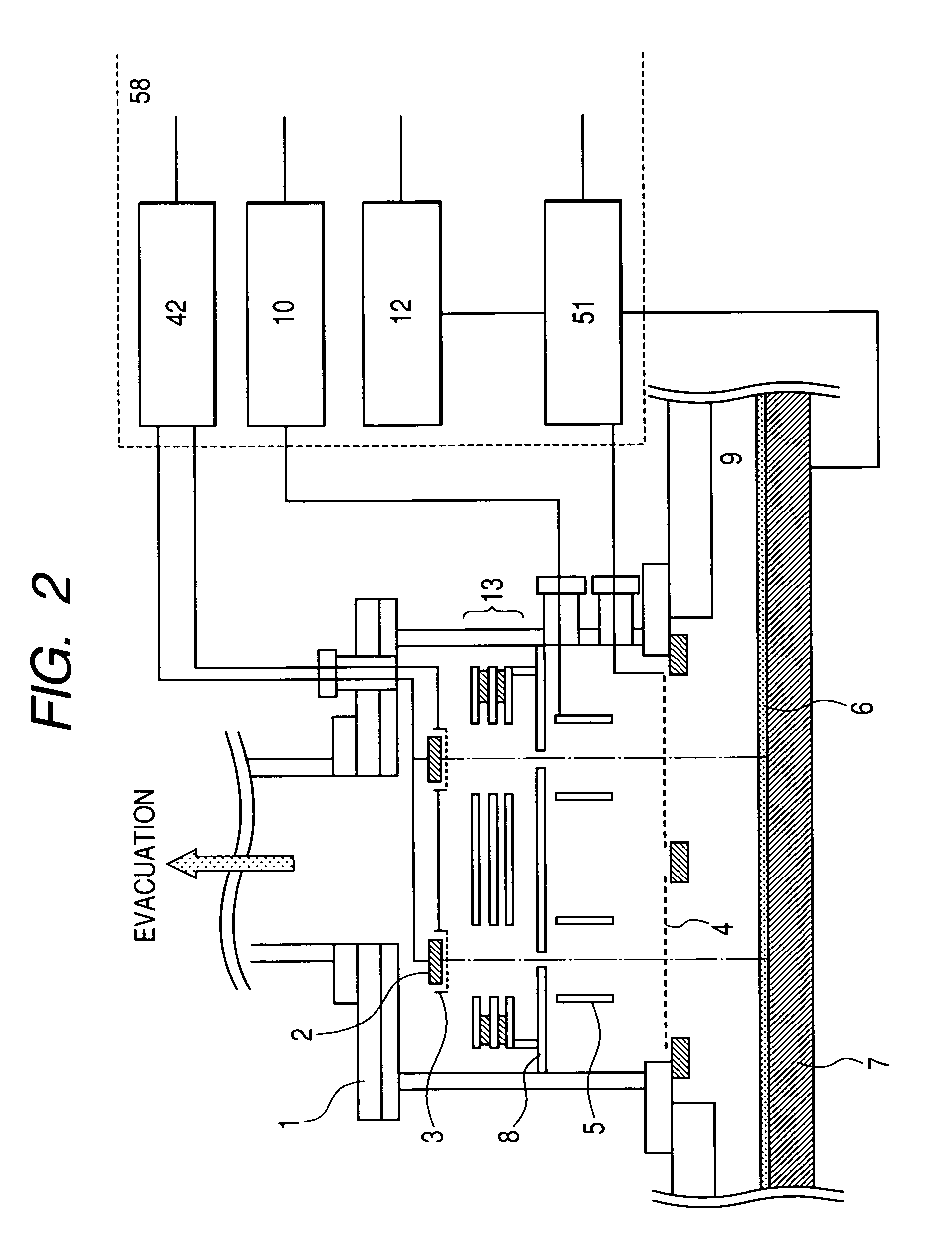

In order to allow detecting backscattered electrons (BSEs) generated from the bottom of a hole for determining whether a hole with a super high aspect ratio is opened or for inspecting and measuring the ratio of the top diameter to the bottom diameter of a hole, which are typified in 3D-NAND processes of opening a hole, a primary electron beam accelerated at a high accelerating voltage is applied to a sample. Backscattered electrons (BSEs) at a low angle (e.g. a zenith angle of five degrees or more) are detected. Thus, the bottom of a hole is observed using “penetrating BSEs” having been emitted from the bottom of the hole and penetrated the side wall. Using the characteristics in which a penetrating distance is relatively prolonged through a deep hole and the amount of penetrating BSEs is decreased to cause a dark image, a calibration curve expressing the relationship between a hole depth and the brightness is given to measure the hole depth.

Owner:HITACHI HIGH-TECH CORP

Charge control apparatus and measurement apparatus equipped with the charge control apparatus

ActiveUS7683319B2Perform charge processingIncrease speedMaterial analysis using wave/particle radiationElectric discharge tubesElectron sourceCarbon nanotube

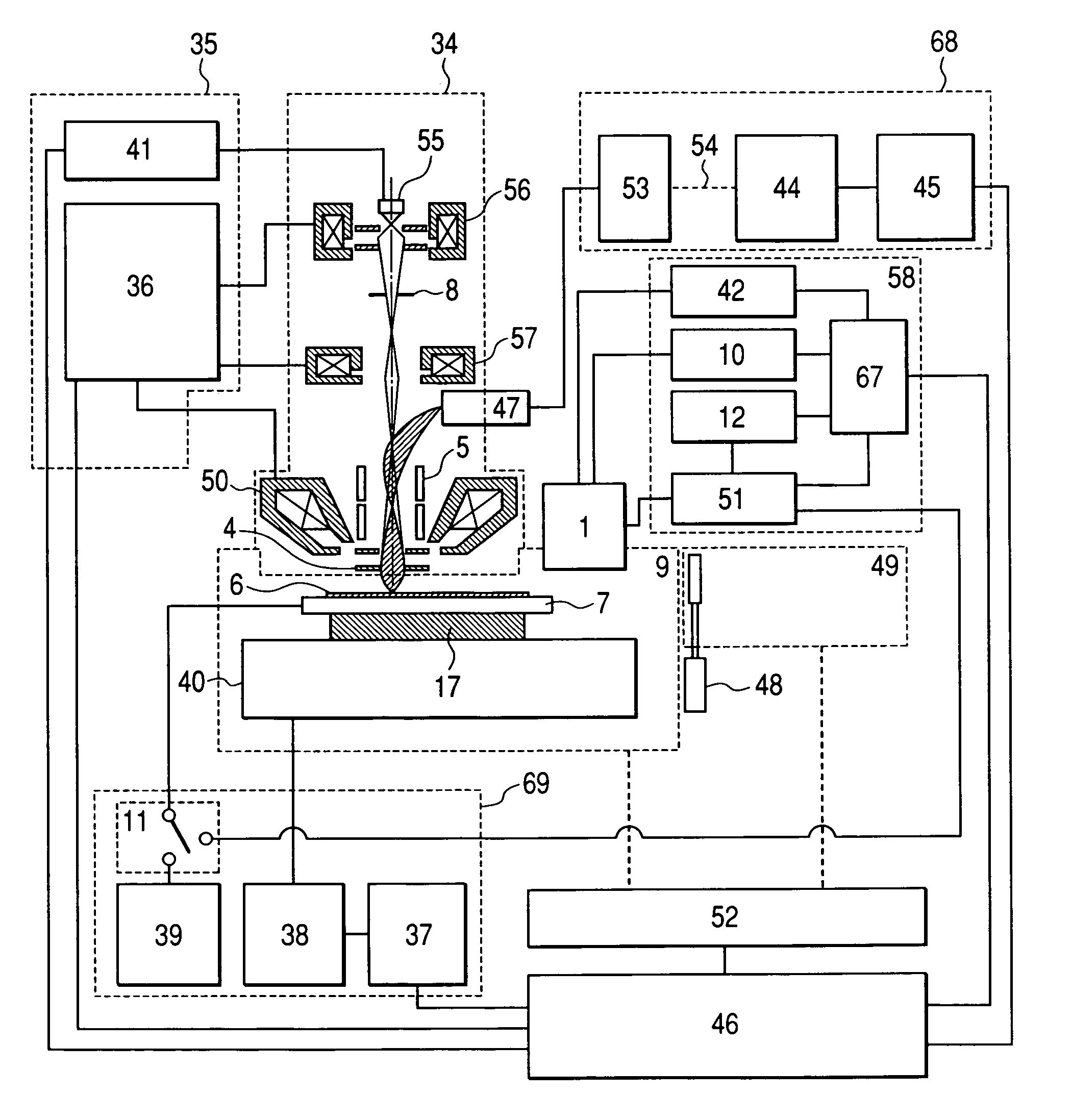

The invention solves charge nonuniformity of a specimen surface resulting from emission variation of a carbon nanotube electron source and individual difference of emission characteristics. During charge control processing, charge of the specimen surface is measured in real time. As means for solving charge nonuniformity resulting from nonuniformity of electron illumination density, electrons illuminating the specimen and the specimen are moved relatively to average electron illumination density. Moreover, an absorption current flowing into the specimen and the numbers of secondary electrons emitted from the specimen and of backscattered electrons are measured as means for monitoring charge of the specimen surface in real time.

Owner:HITACHI HIGH-TECH CORP

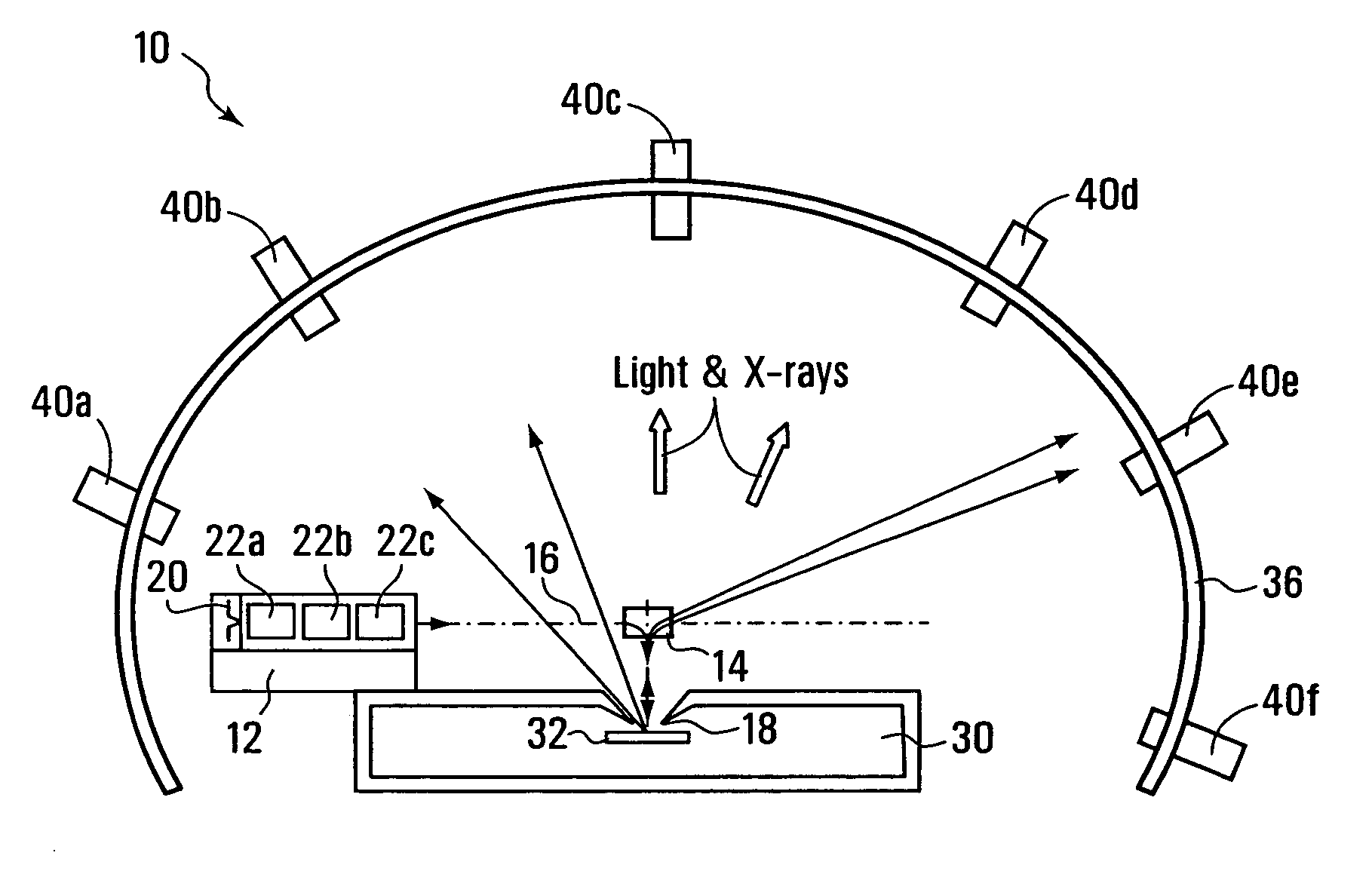

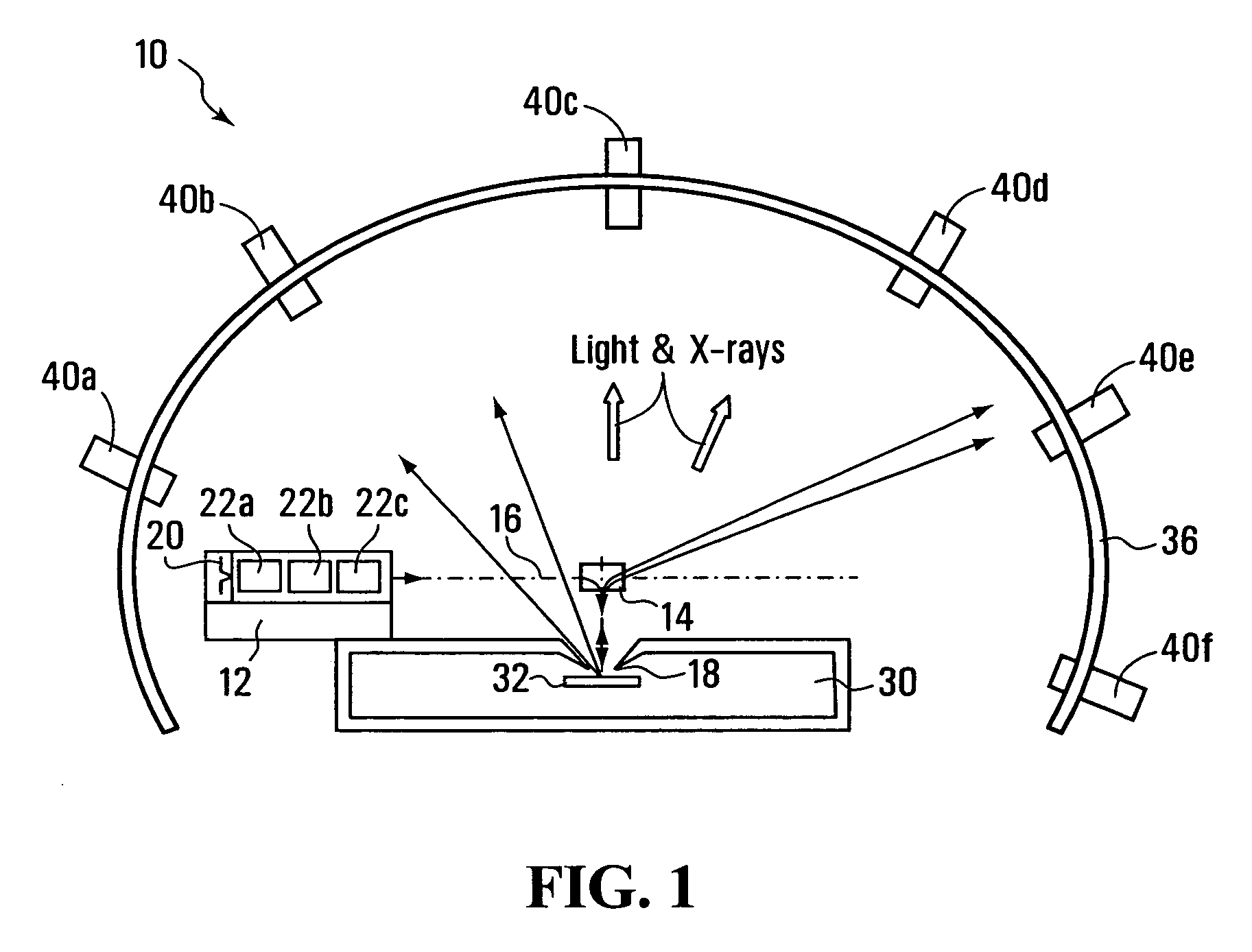

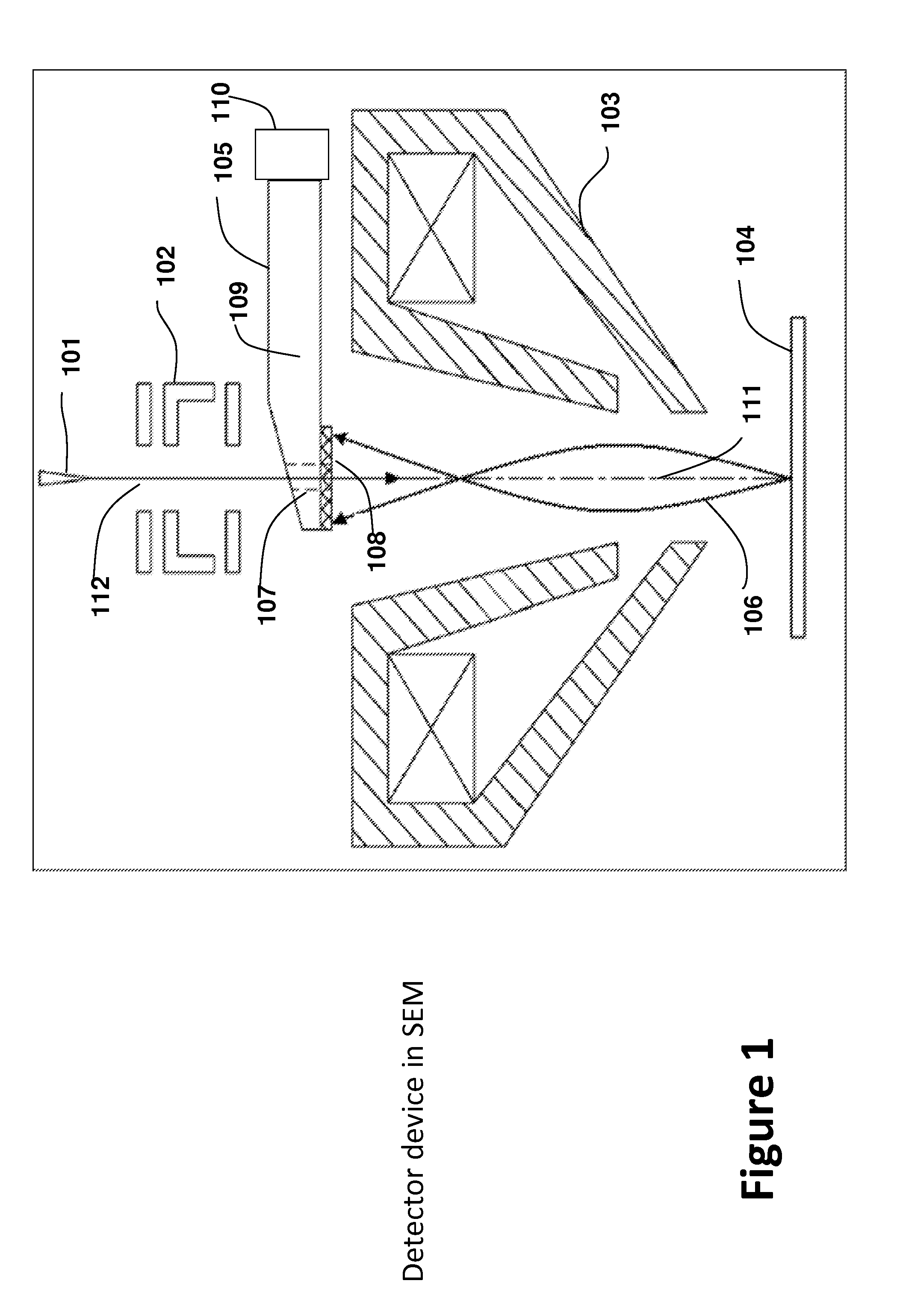

High efficiency secondary and back scattered electron detector

ActiveUS20130234032A1Light collection efficiency is improvedLight collection efficiencyElectric discharge tubesMaterial analysis by optical meansThin metalLight guide

An assembly for a charged particle detection unit is described. The assembly comprises a scintillator disc, a partially coated light guide a thin metal tube for allowing the primary charged particle beam to pass through and a photomultiplier tube (PMT). The shape of scintillator disc and light guide are redesigned to improved the light signal transmission thereafter enhance the light collection efficiency. A light guide with a conicoidal surface over an embedded scintillator improved the light collection efficiency of 34% over a conventional design.

Owner:ASML NETHERLANDS BV

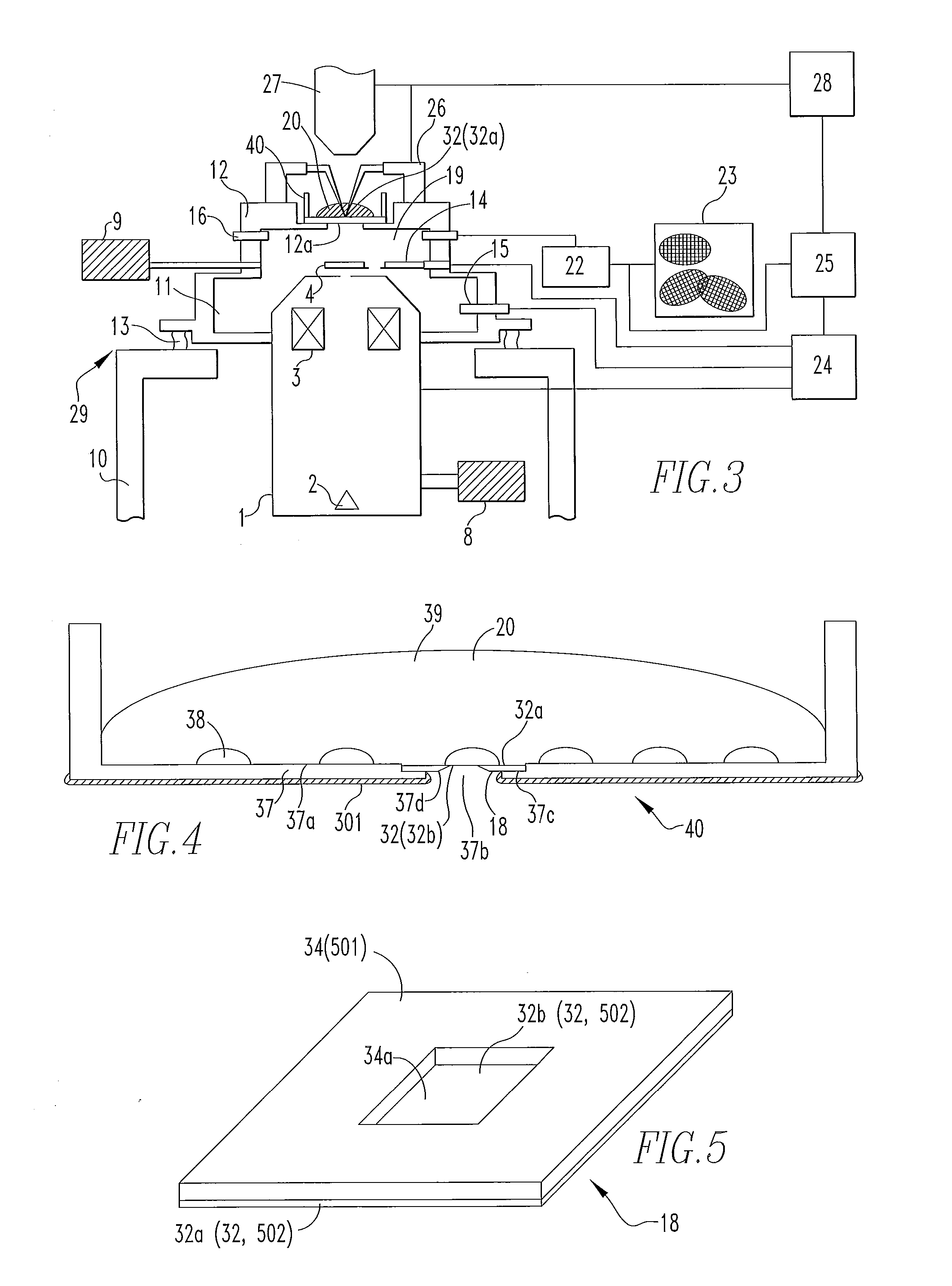

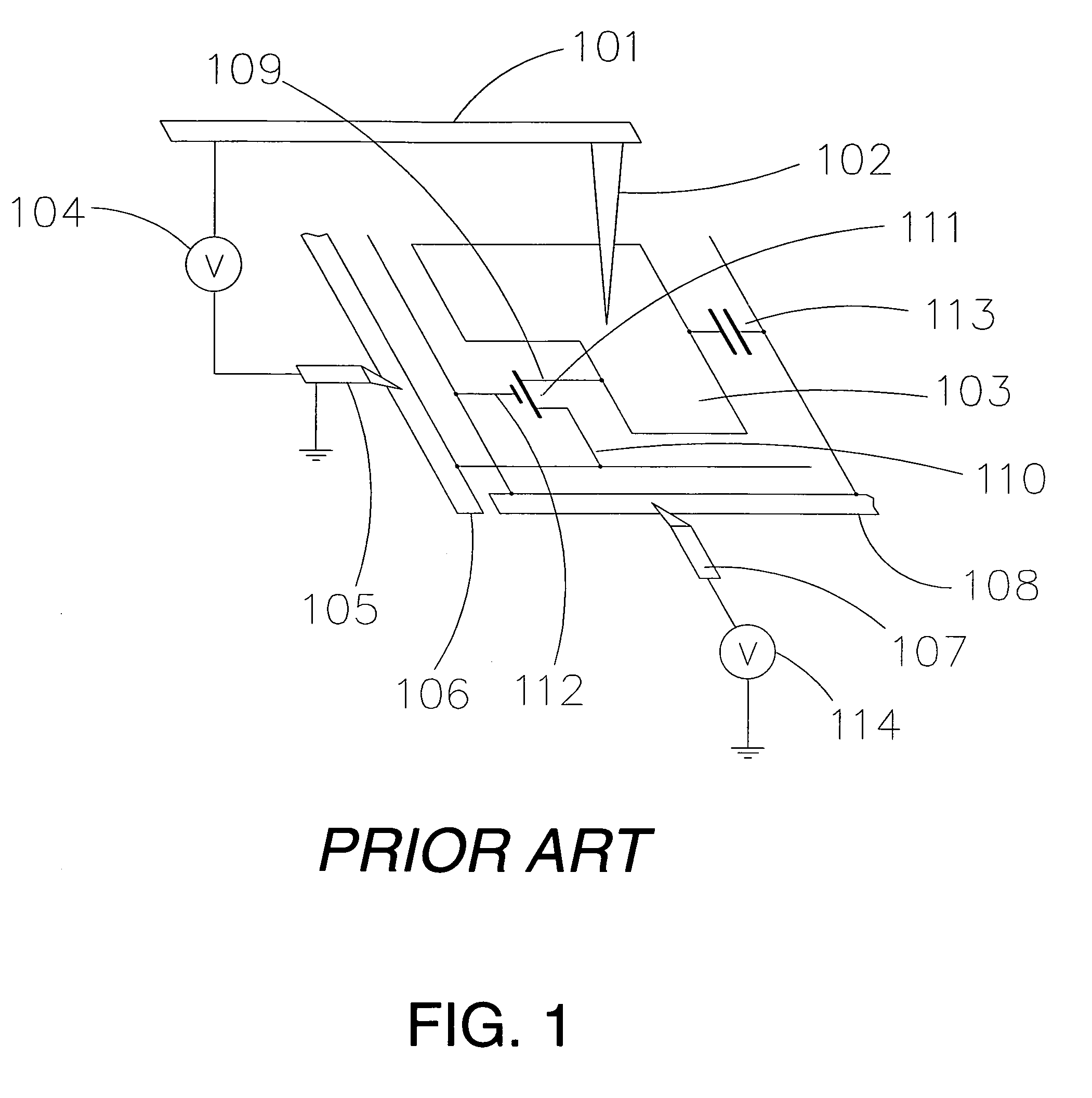

Apparatus and method for inspection and testing of flat panel display substrates

ActiveUS20060145087A1Increase vacuumReduce transmittanceThermometer detailsStability-of-path spectrometersParallel plateDisplay device

A charged particle optical system for testing, imaging or inspecting substrates comprises: a charged particle optical assembly configured to produce a line of charged particle beams equally spaced along a main scan axis, each beam being deflectable through a large angle along the main scan axis; and linear detector optics aligned along the main scan axis. The detector optics includes a linear secondary electron detector, a field free tube, voltage contrast plates and a linear backscattered electron detector. The large beam deflection is achieved using an electrostatic deflector for which the exit aperture is larger than the entrance aperture. One embodiment of the deflector includes: two parallel plates with chamfered inner surfaces disposed perpendicularly to the main scan axis; and a multiplicity of electrodes positioned peripherally in the gap between the plates, the electrodes being configured to maintain a uniform electric field transverse to the main scan axis.

Owner:MULTIBEAM CORP

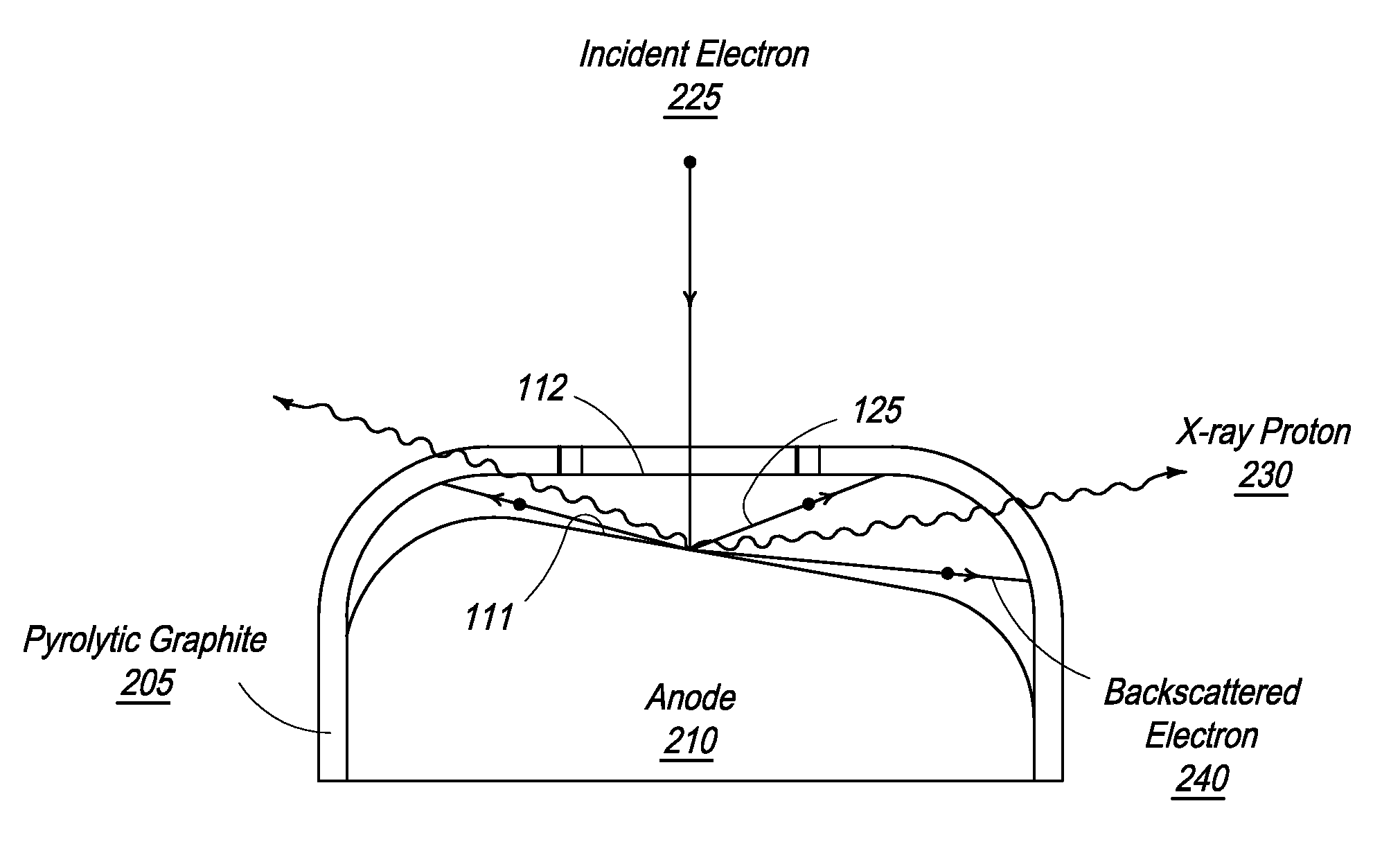

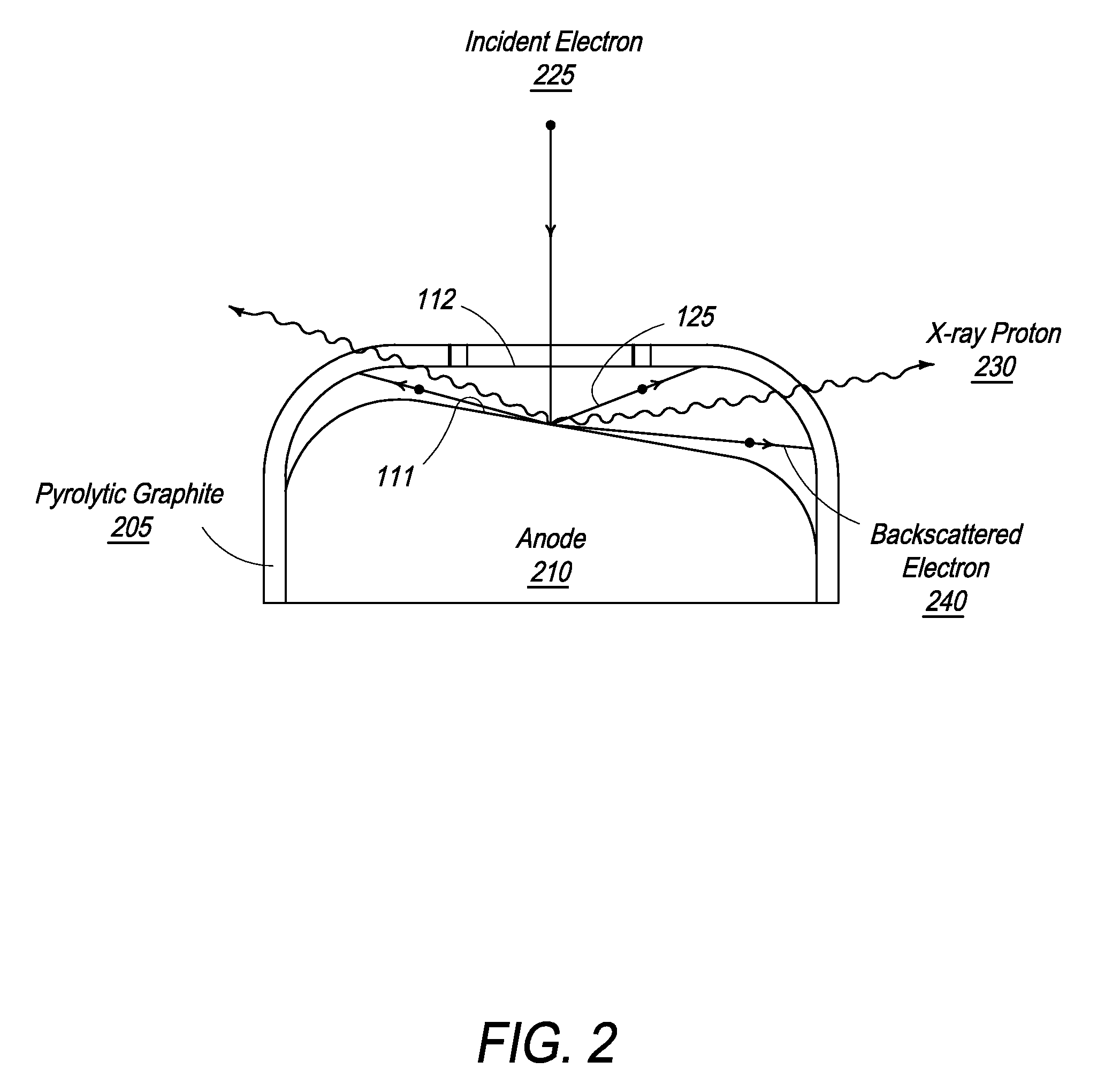

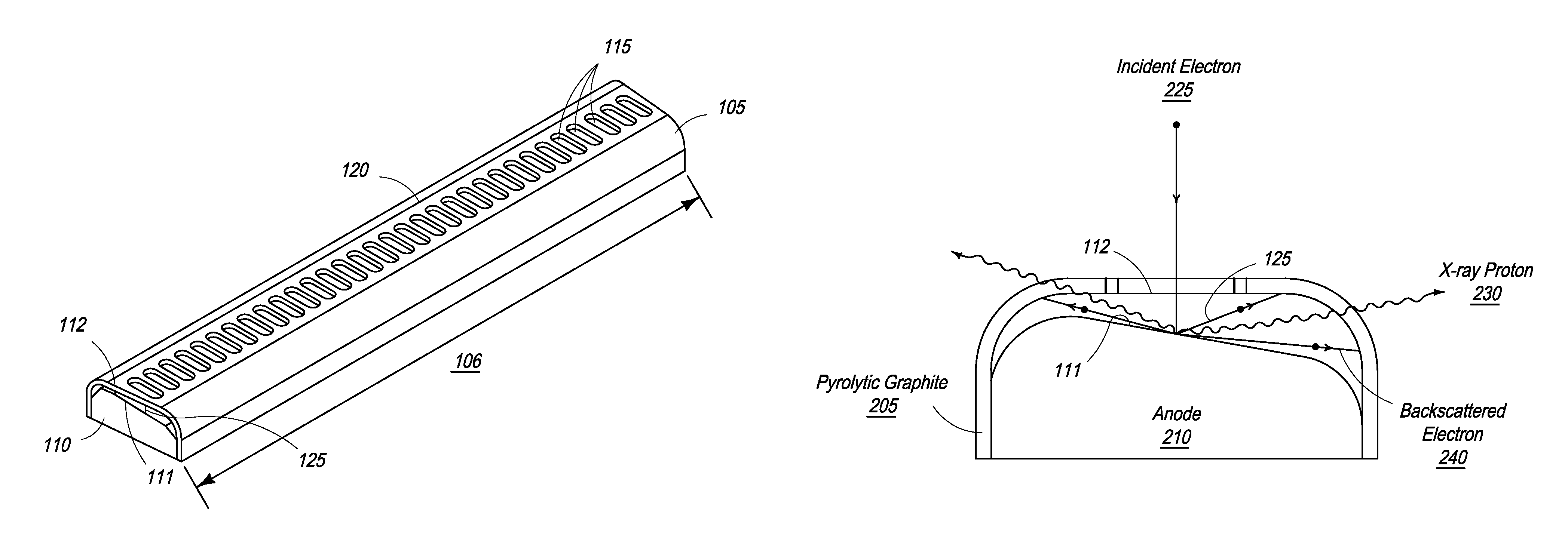

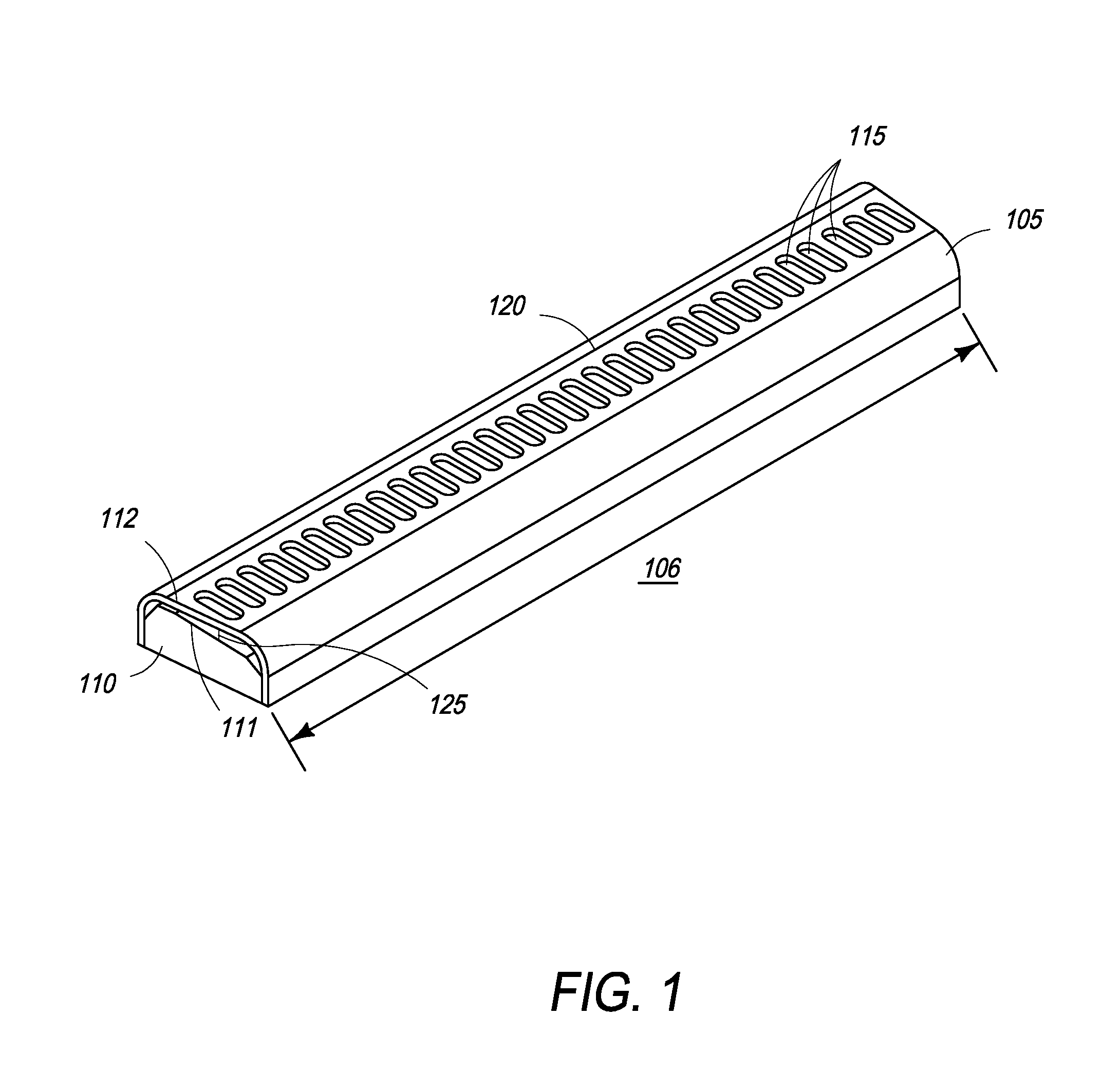

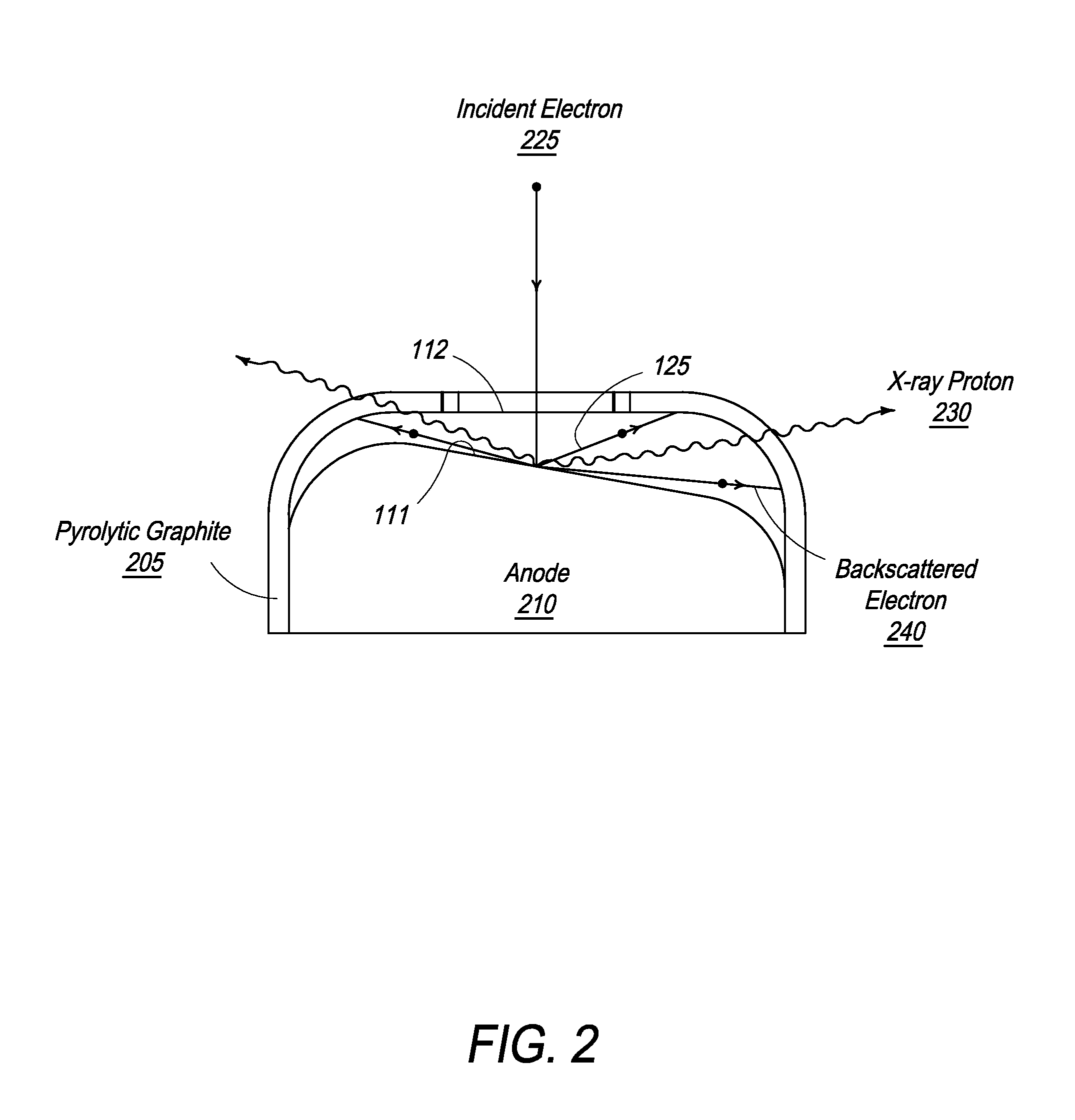

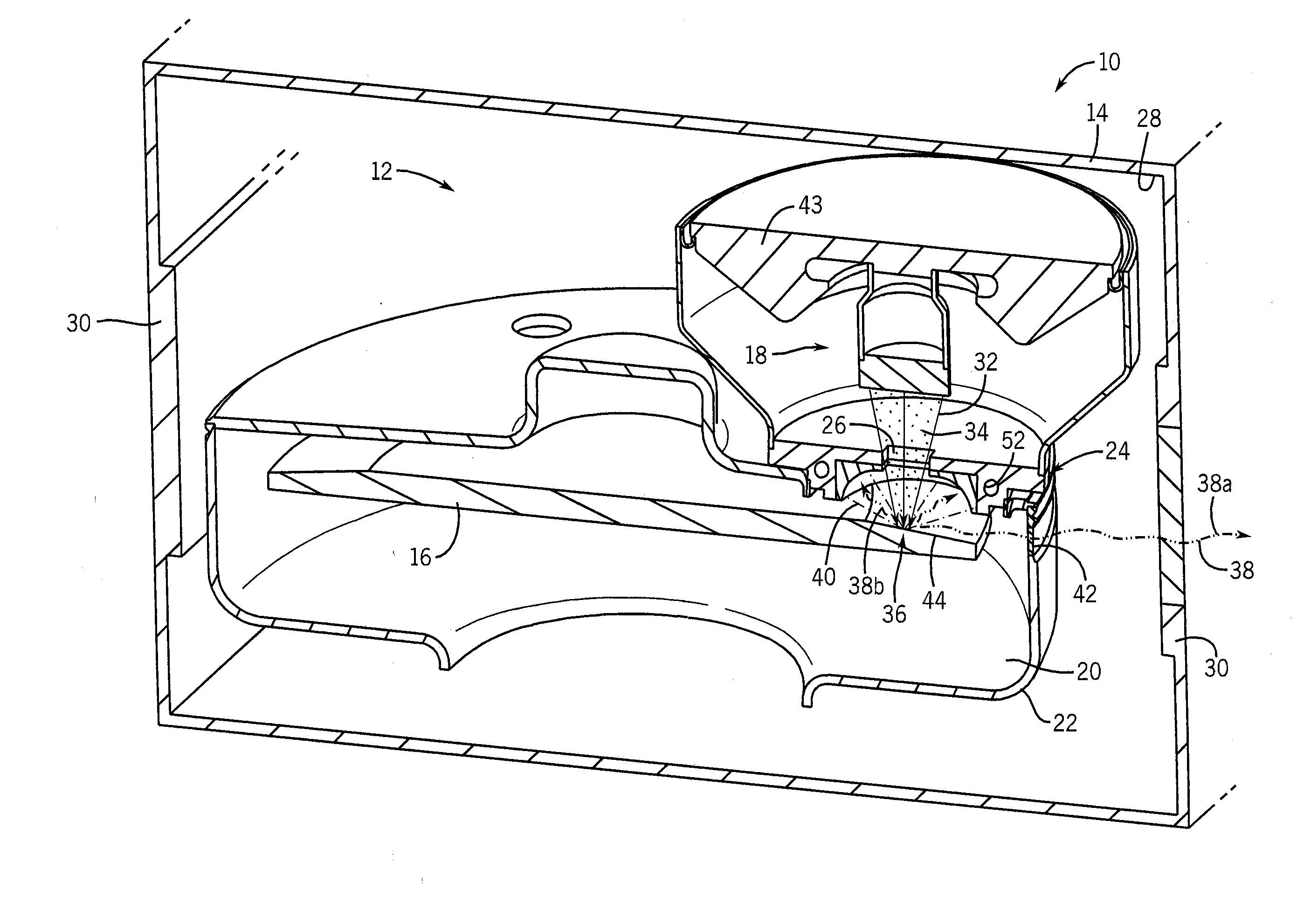

Graphite backscattered electron shield for use in an X-ray tube

The present invention is a shielded anode having an anode with a surface facing an electron beam and a shield configured to encompass the anode surface. The shield has at least one aperture and an internal surface facing the anode surface. The shield internal surface and anode surface are separated by a gap in the range of 1 mm to 10 mm. The shield of the present invention is fabricated from a material, such as graphite, that is substantially transmissive to X-ray photons.

Owner:RAPISCAN SYST INC (US)

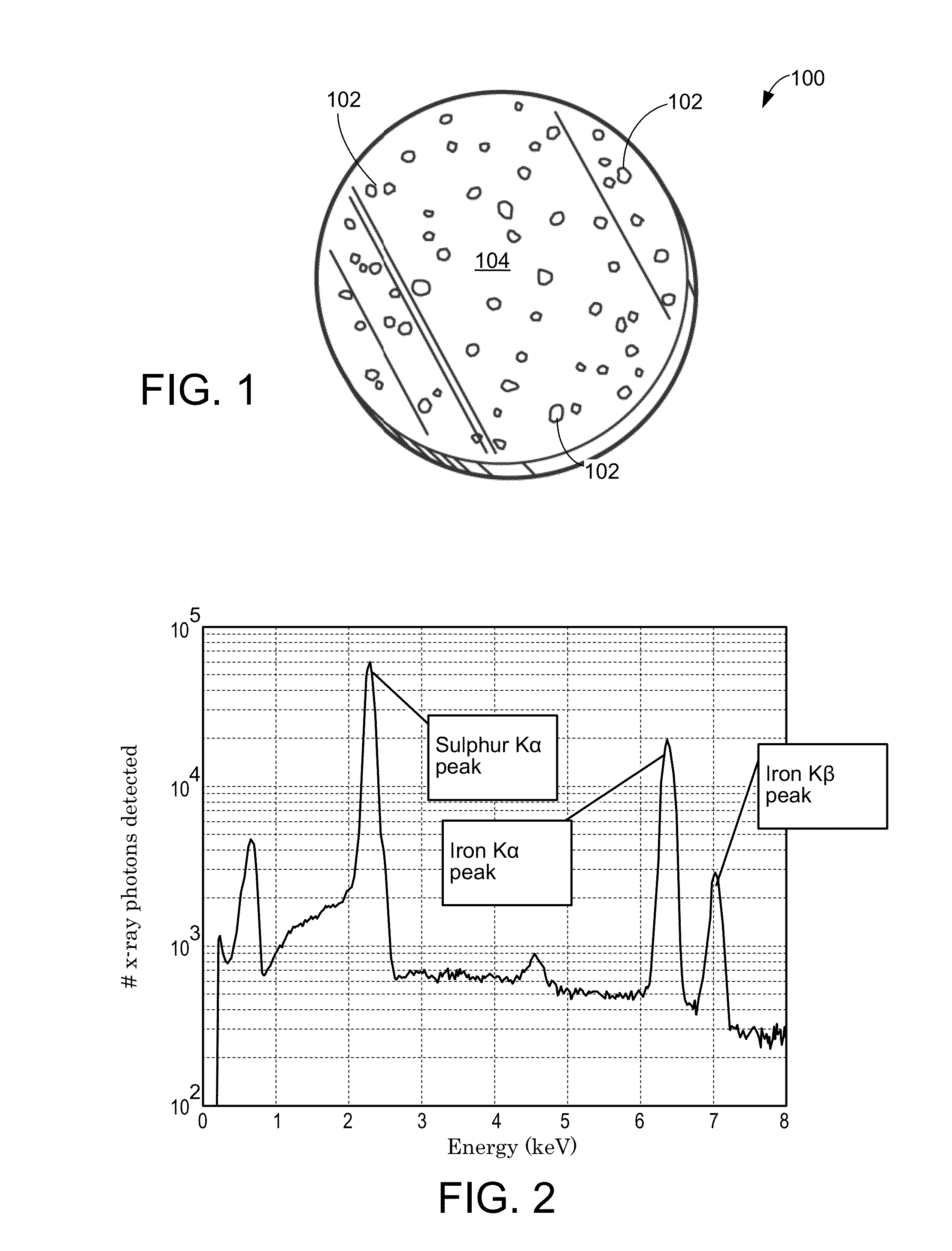

Process for Performing Automated Mineralogy

ActiveUS20140183357A1Easy to useMaterial analysis using wave/particle radiationElectric discharge tubesElectron microscopeAutofocus

A method and system for determining the mineral content of a sample using an electron microscope. The method includes directing an electron beam toward an area of interest of a sample, the area of interest comprising an unknown composition of minerals. The working distance between the backscattered electron detector of the microscope and the area of interest of the sample is determined. Compensation is made for the difference between the working distance and a predetermined working distance in which the predetermined working distance being the working distance that provides desired grayscale values for detected backscattered electrons. One way of compensating for working distance variation is to used an autofocus feature of the microscope to adjust the working distance. Backscattered electrons from the area of interest of the sample are then detected.

Owner:FEI CO

Graphite backscattered electron shield for use in an X-ray tube

ActiveUS8331535B2Non-insulated conductorsMaterial analysis using wave/particle radiationGraphiteX ray photons

Owner:RAPISCAN SYST INC (US)

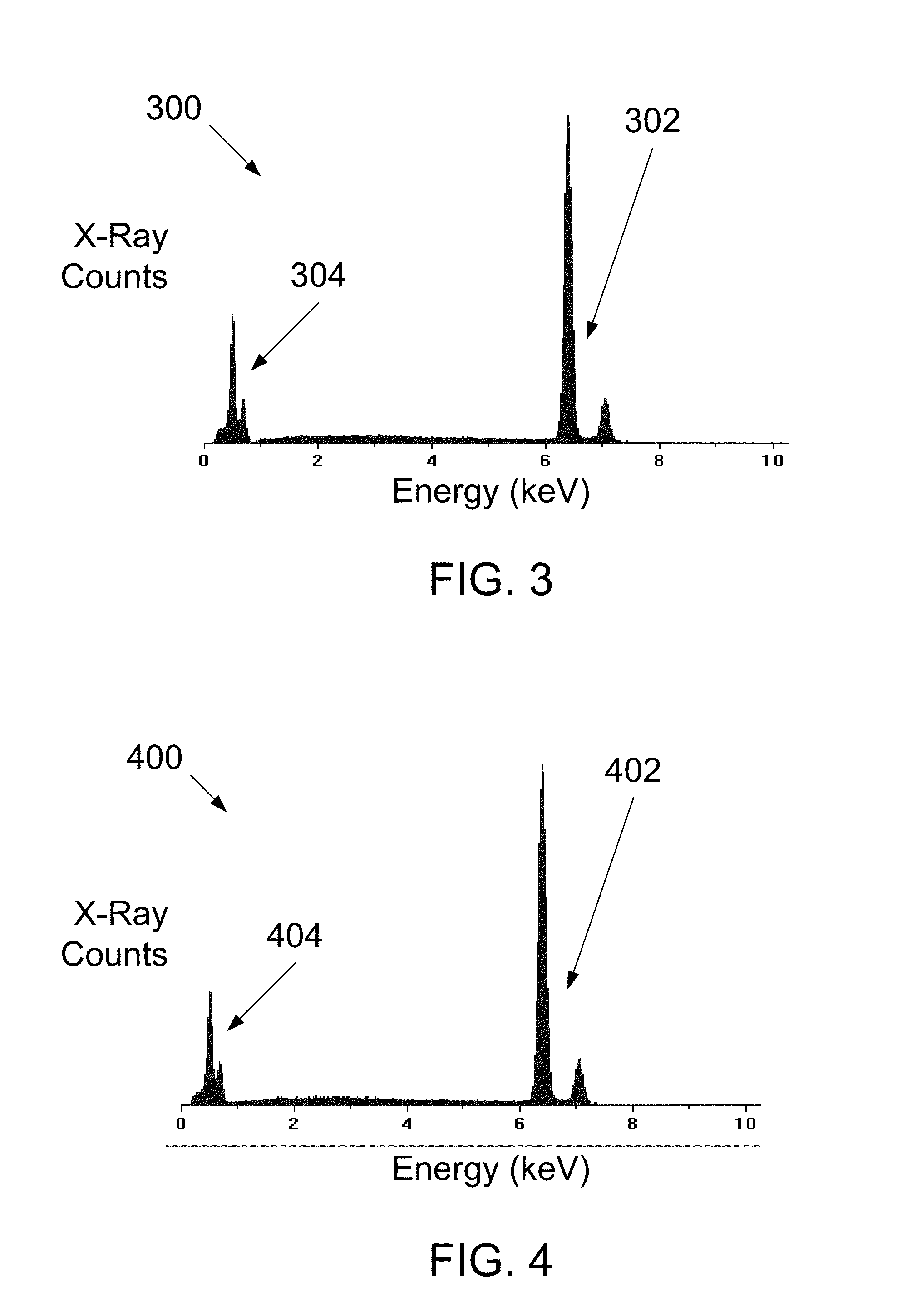

Method and apparatus for material analysis by a focused electron beam using characteristic x-rays and back-scattered electrons

InactiveUS20130054153A1Eliminate disadvantagesElectric discharge tubesSpecial data processing applicationsParticle physicsPeak intensity

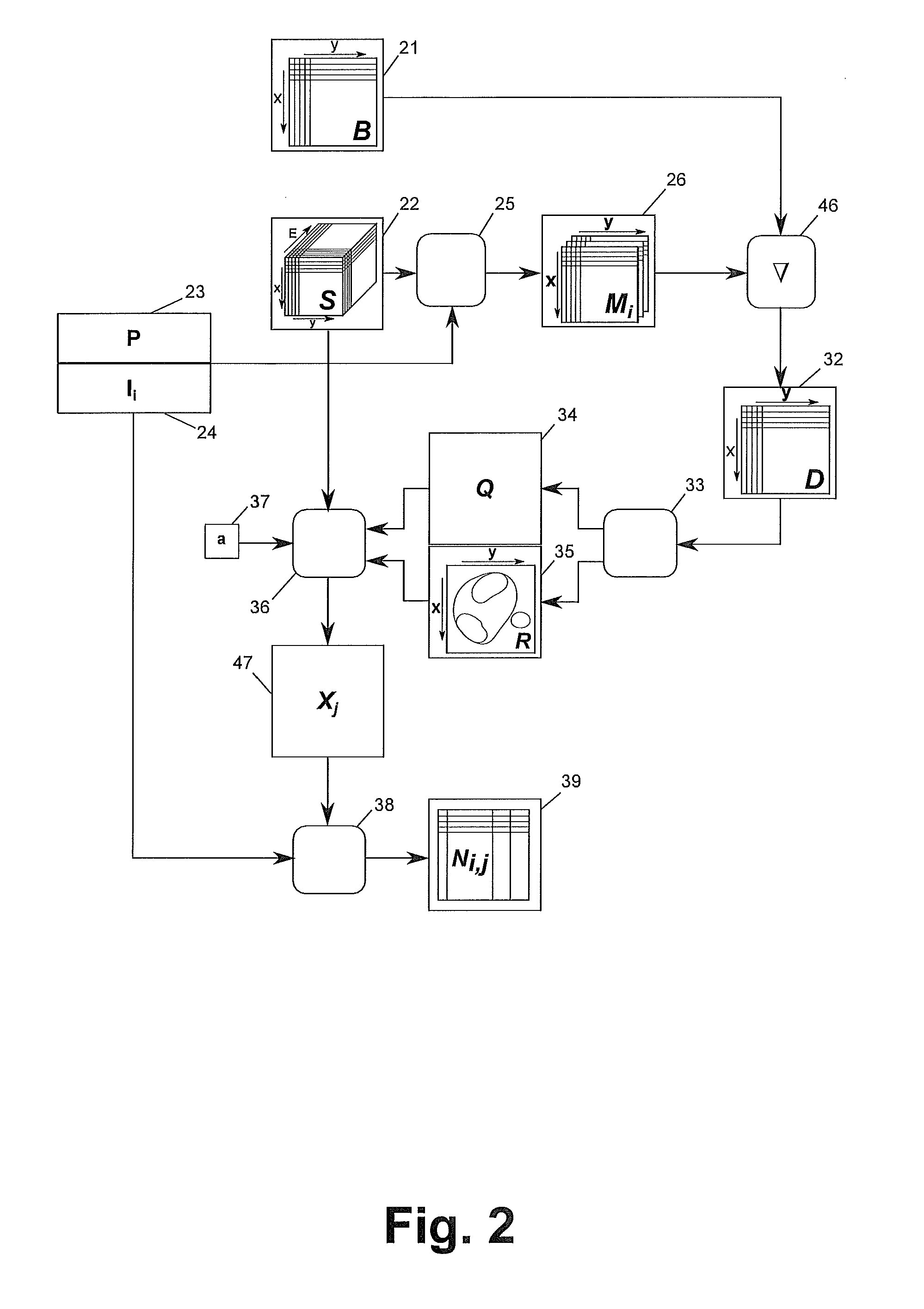

A material analysis method by a focused electron beam and an equipment for performing such an analysis where an electron map B is created describing the intensity of emitted back-scattered electrons at various points on a sample, and a spectral map S is created describing the intensity of emitted X-rays at points on the sample depending on the radiation energy. For selected chemical elements, X-ray maps Mi are created representing the intensity of X-rays characteristic for such elements. The X-ray maps Mi and the electron map B are converted into differential X-ray maps Di, which are subsequently merged into a final differential X-ray map D. The final differential X-ray map D is then used to search particles. Subsequently, a cumulative X-ray spectrum Xj is calculated for each particle and subsequently the classification of particles based on the peak intensities and the intensity of back-scattered electron is performed.

Owner:TESCAN

Method for observing microscopic structure of stainless steel

InactiveCN1916597AAvoid formingAvoid corrosion damageSurface/boundary effectPreparing sample for investigationElectrolysisDistilled water

A method for observing microscopic structure of stainless steel includes using alcohol, perchloric acid and so on to prepare electrolytic polishing liquid; polishing prepared test piece; using electrolytic polisher with 23v-40 voltage and 10-30deg.c electrolytic polishing liquid to carry out electrolytic polishing on test piece then washing test piece; placing electrolytic polished test piece into sample chamber of scan electronic microscope and using back scattering electronic detector to observe microstructure of test piece.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

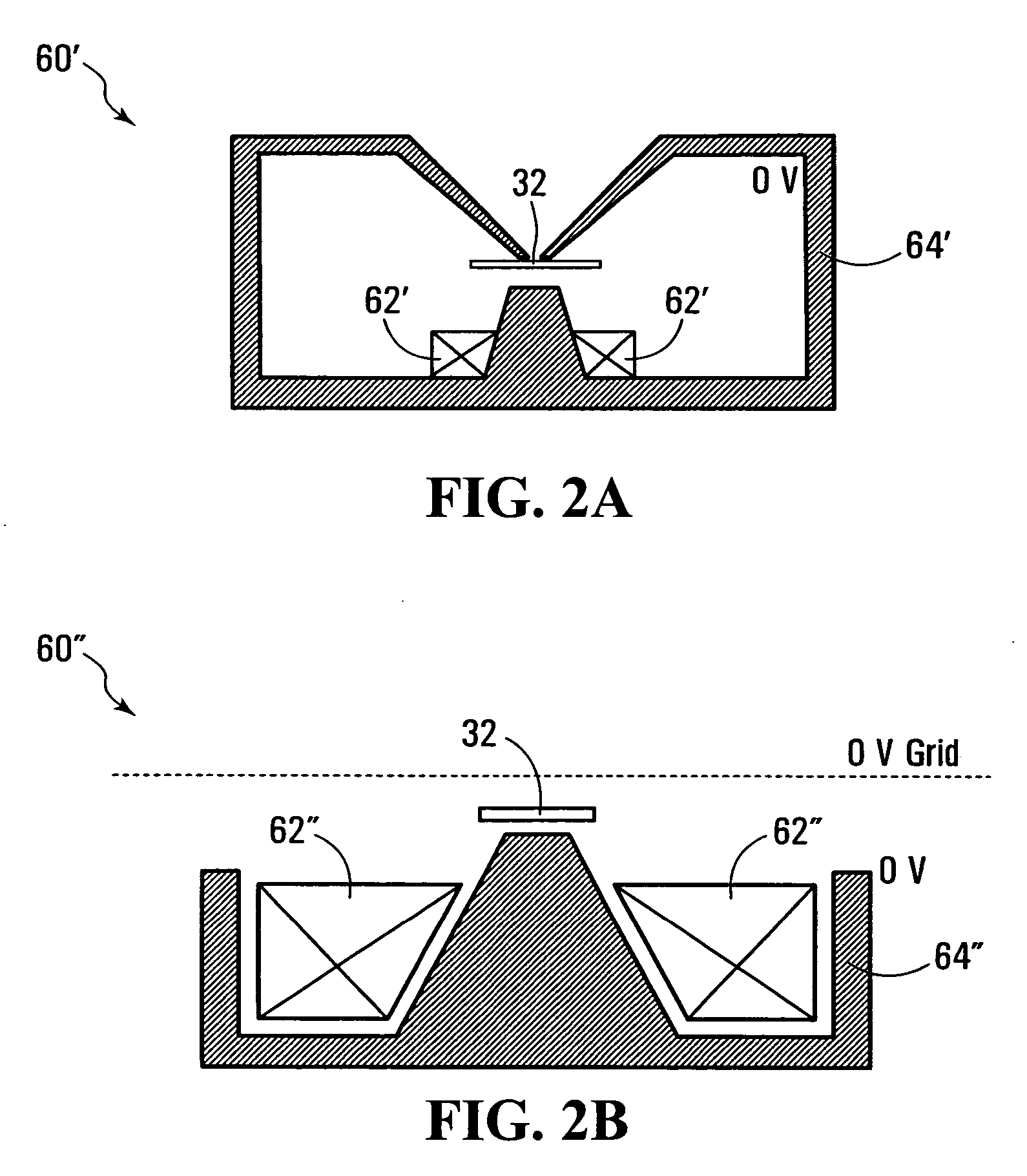

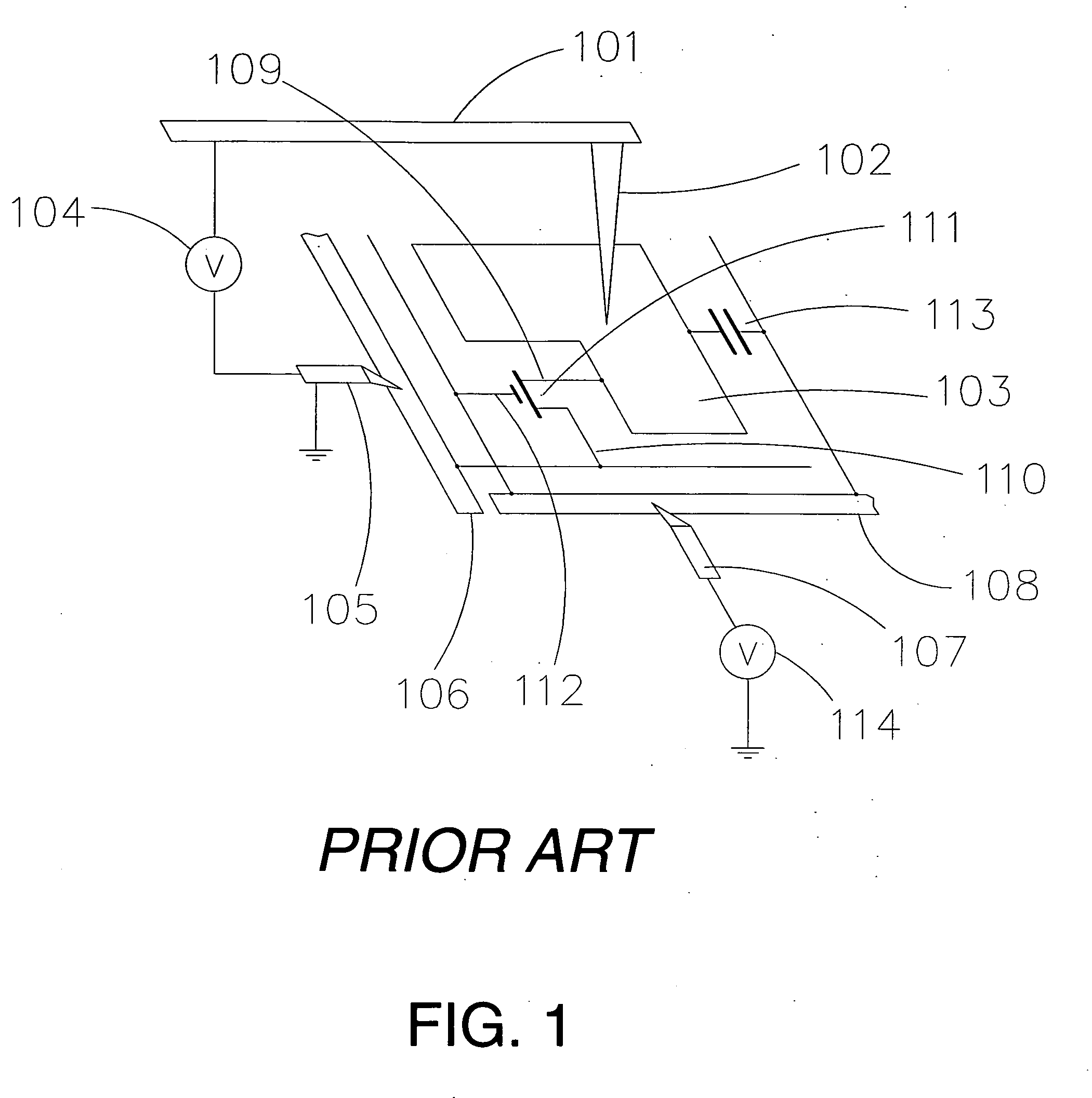

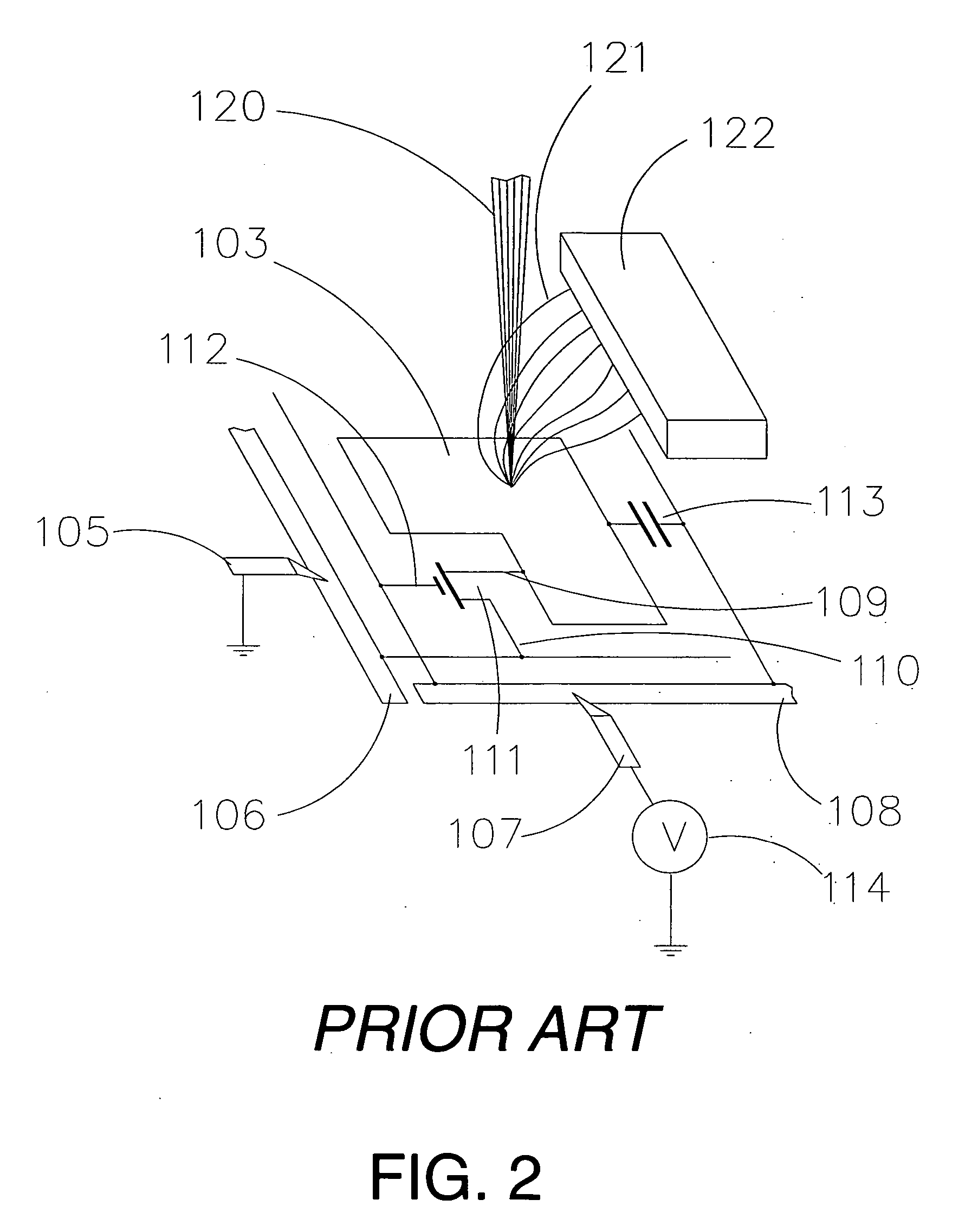

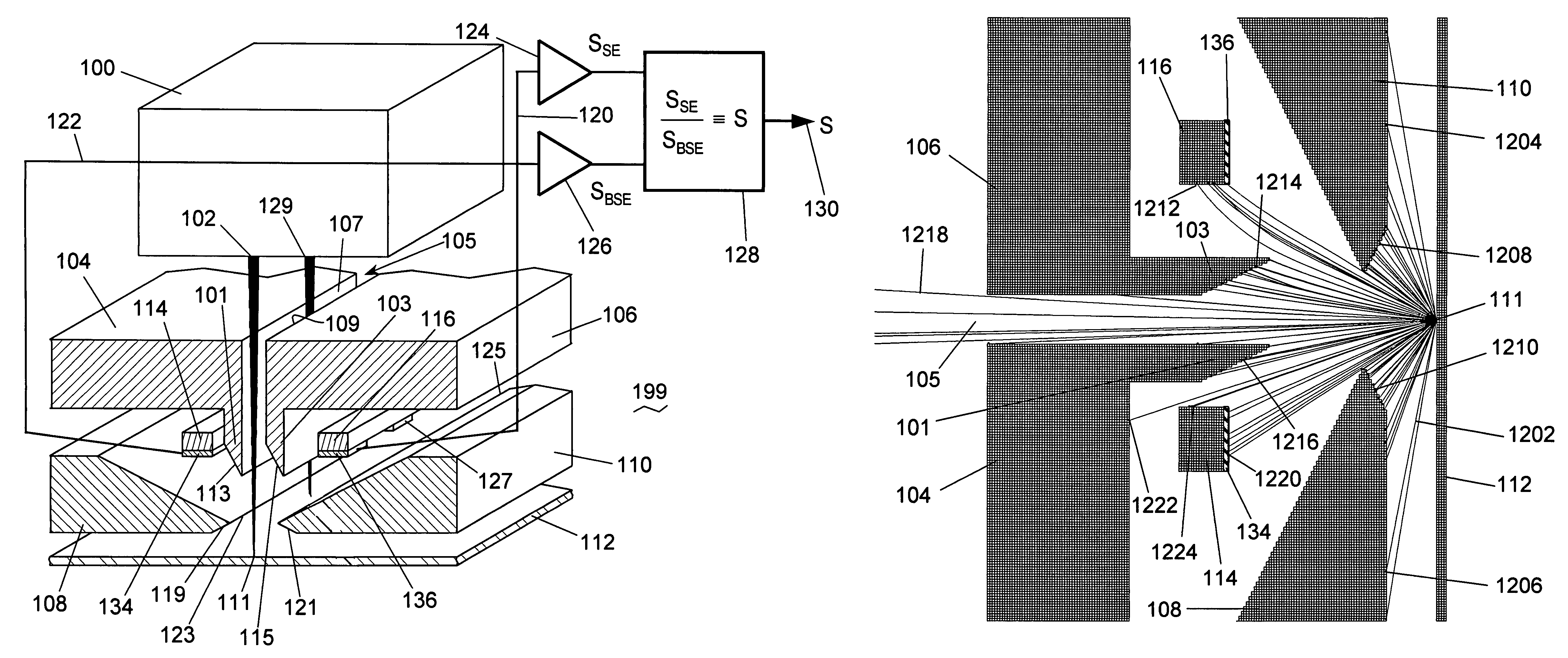

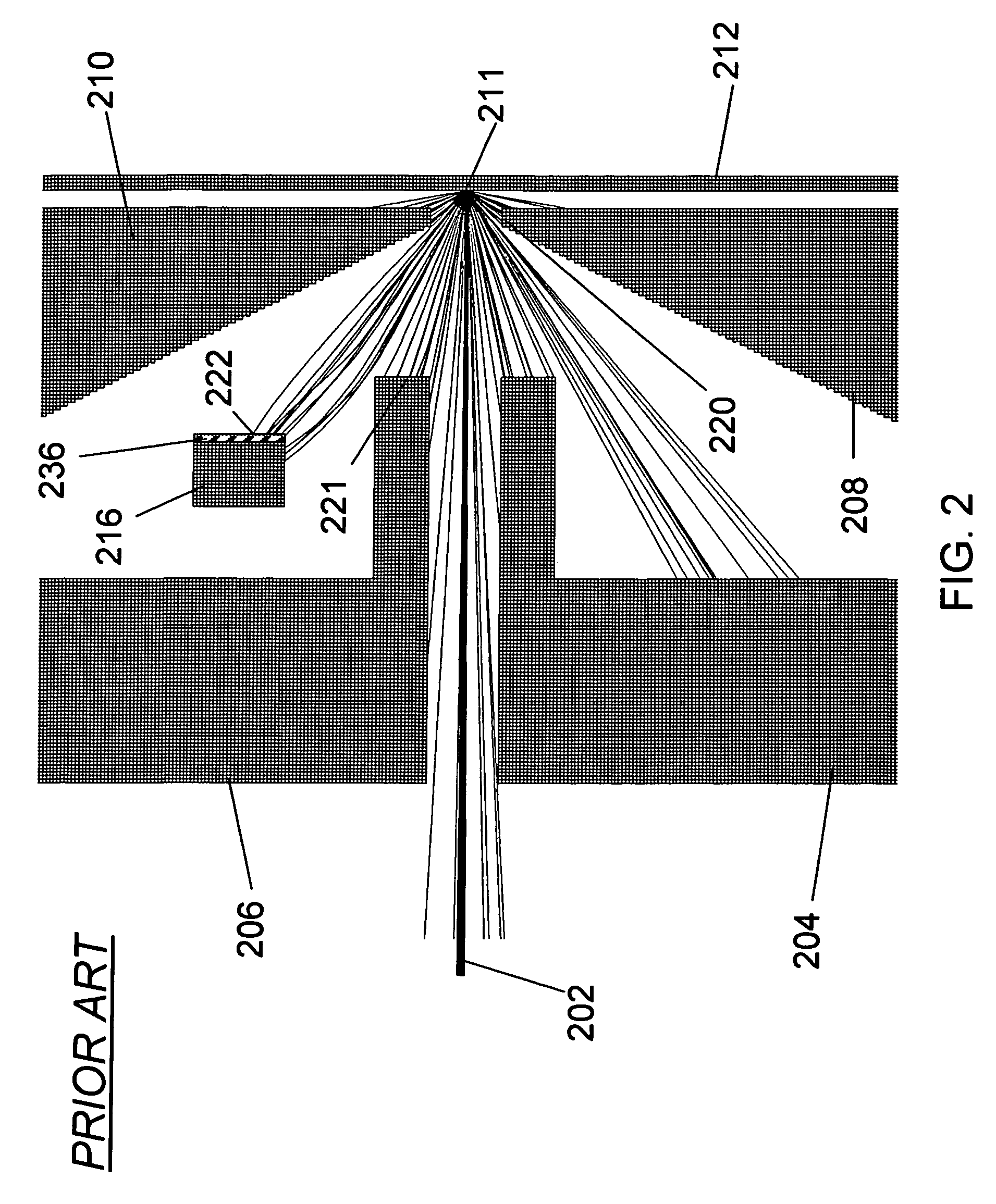

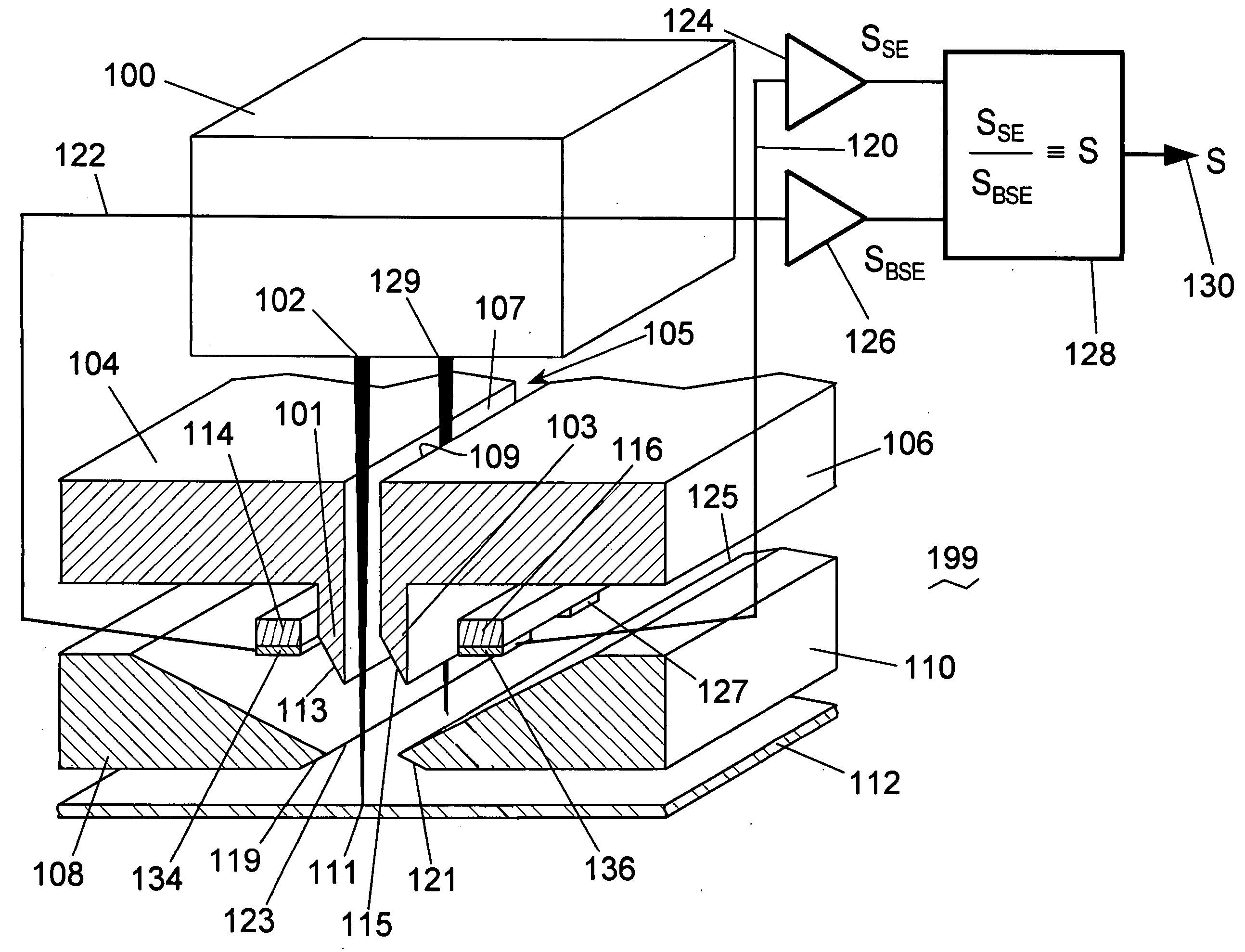

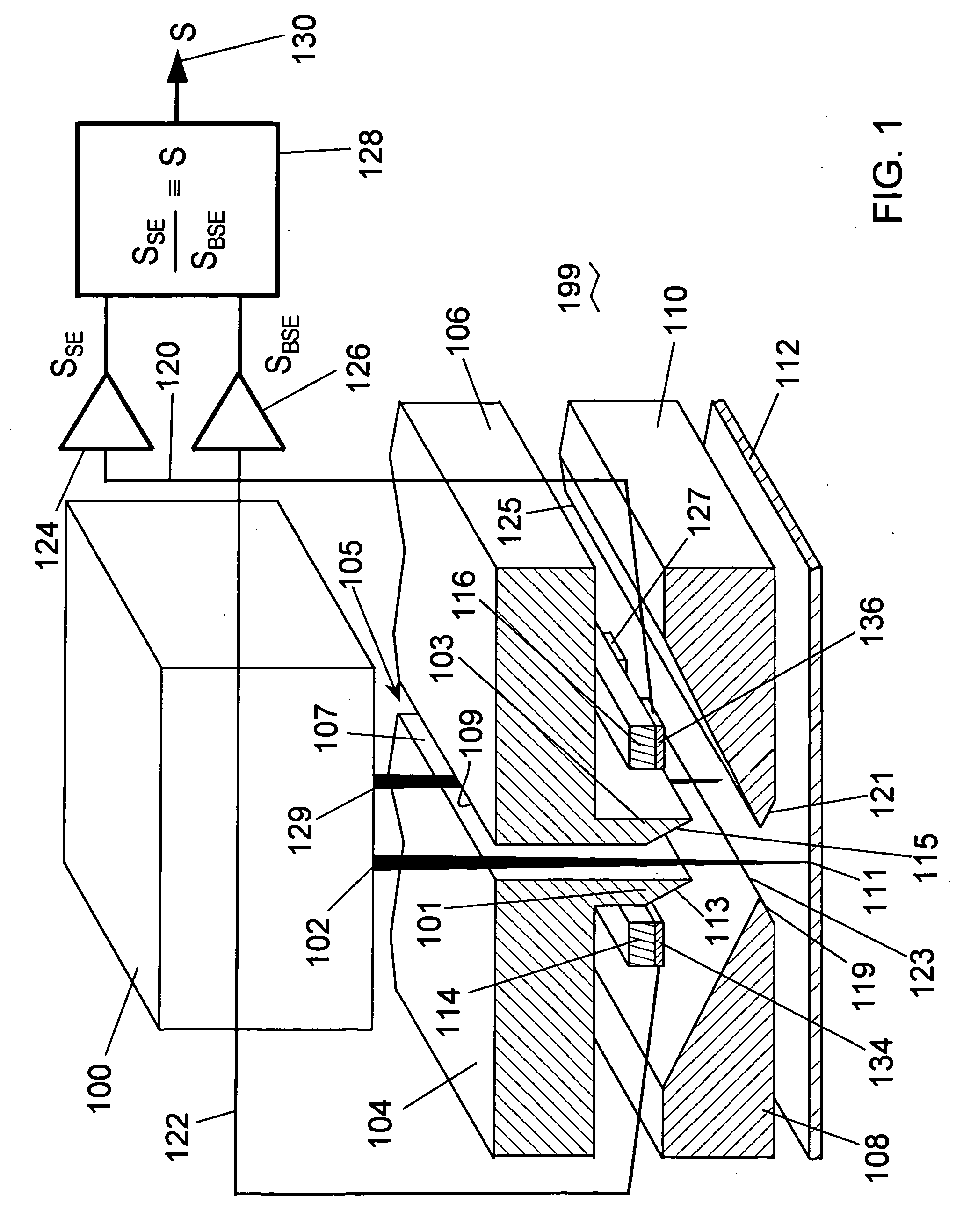

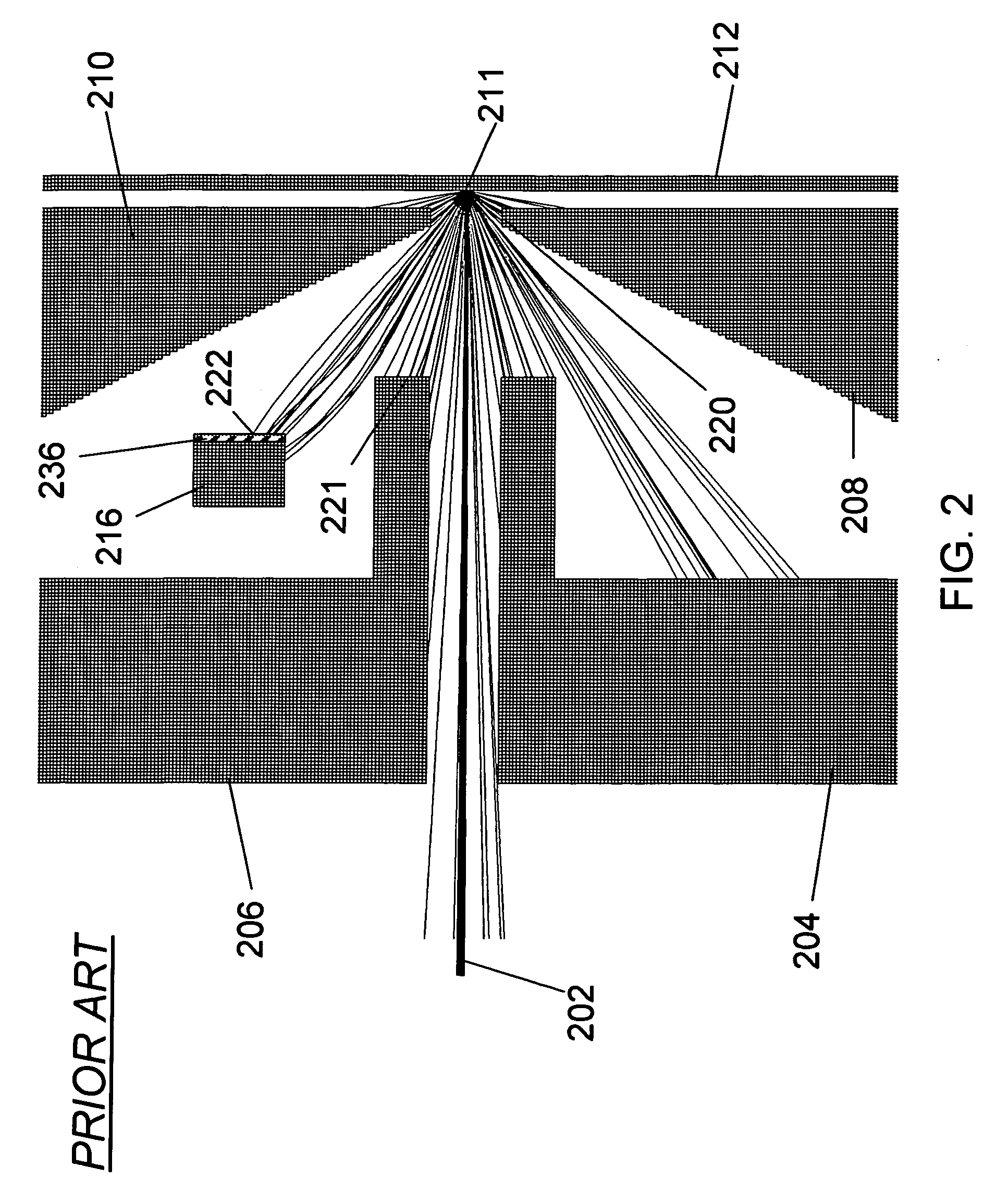

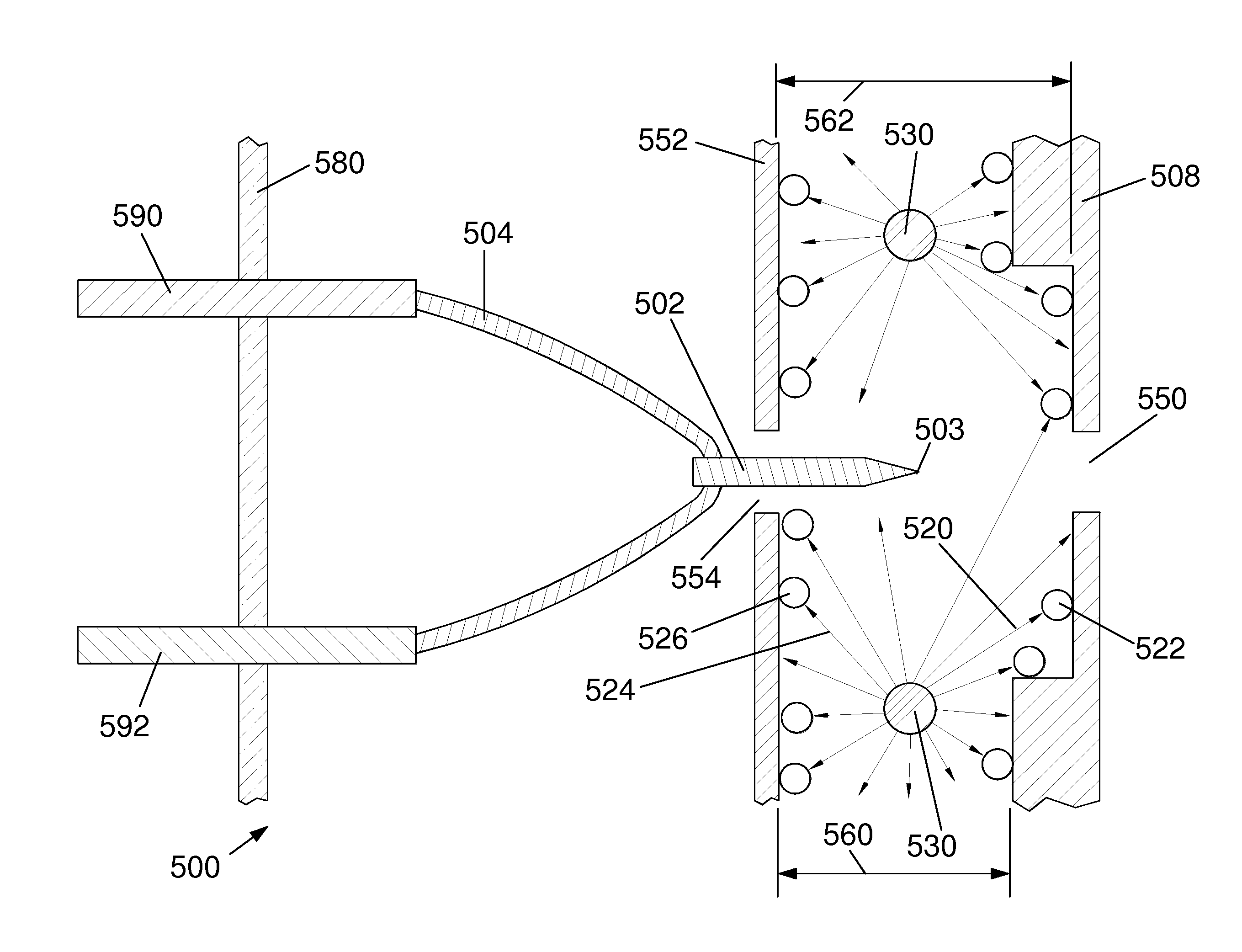

Dual detector optics for simultaneous collection of secondary and backscattered electrons

ActiveUS7227142B2Reduce complexityLow costThermometer detailsMaterial analysis using wave/particle radiationElemental compositionElectron probe microanalysis

A detector optics system for an electron probe system is disclosed. Aspects of the detector optics system include: the ability to simultaneously detect two electron populations, secondary electrons (SEs) and backscattered electrons (BSEs), wherein both populations are emitted from a substrate due to the impact of the electron probe. The design of the detector optics utilizes a field-free tunnel and substrate electric-field control electrodes to enable separation of the SEs and BSEs into two detectors, allowing simultaneous acquisition of topographic and elemental composition data, with minimal impact on the electron probe. The secondary electron signal is a monotonically-varying function of the voltage on the substrate surface. The ratio of the SE signal to the BSE signal gives a testing signal which is independent of the primary beam current and serves as an absolute voltage probe of surface voltages without the need for an external reference voltage.

Owner:MULTIBEAM CORP

Electron absorption apparatus for an x-ray device

A shield assembly for an x-ray device is disclosed herein. The shield assembly includes a radiation shielding layer comprised of a first material; and a thermally conductive layer attached the radiation shielding layer. The thermally conductive layer is comprised of a second material. The shield assembly also includes an electron absorption layer attached to the radiation shielding layer. The electron absorption layer is comprised of a third material. The electron absorption layer is configured to absorb backscattered electrons.

Owner:GENERAL ELECTRIC CO

Pattern Inspection Method and Pattern Inspection System

ActiveUS20090039261A1Combined image becomes shrunkIncrease in semiconductor circuit observation timeMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementPattern recognitionPattern detection

A pattern data examination method and system capable of accurately and speedily examining a circuit pattern without failing to extract pattern contour data are provided. While pattern comparison is ordinarily made by using a secondary electron image, a contour of a pattern element is extracted by using a backscattered electron image said to be suitable for observation and examination of a three dimensional configuration of a pattern element, and pattern inspection is executed by using the extracted contour of the pattern element. More specifically, pattern inspection is executed by comparing a contour of a pattern element with design data such as CAD data to measure a difference between the contour and the data, and by computing, for example, the size of the circuit pattern element from the contour of a pattern. From two or more backscattered electron images formed by detecting backscattered electrons at two or more different spatial positions, pattern contour data contained in the backscattered electron images may be obtained.

Owner:HITACHI HIGH-TECH CORP

Dual detector optics for simultaneous collection of secondary and backscattered electrons

ActiveUS20060054817A1Reduce complexityLow costThermometer detailsMaterial analysis using wave/particle radiationElemental compositionVoltage reference

A detector optics system for an electron probe system is disclosed. Aspects of the detector optics system include: the ability to simultaneously detect two electron populations, secondary electrons (SEs) and backscattered electrons (BSEs), wherein both populations are emitted from a substrate due to the impact of the electron probe. The design of the detector optics utilizes a field-free tunnel and substrate electric-field control electrodes to enable separation of the SEs and BSEs into two detectors, allowing simultaneous acquisition of topographic and elemental composition data, with minimal impact on the electron probe. The secondary electron signal is a monotonically-varying function of the voltage on the substrate surface. The ratio of the SE signal to the BSE signal gives a testing signal which is independent of the primary beam current and serves as an absolute voltage probe of surface voltages without the need for an external reference voltage.

Owner:MULTIBEAM CORP

Electron microscopy

InactiveUS20090242792A1Easy to operateMore accuracyThermometer detailsMaterial analysis using wave/particle radiationBeam scanningElectron microscope

Using, as a detector, a CCD detector having a CCD element to which a scintillator is closely fixed, a backscattered or scanning transmission image is obtained by the following method. The detector is disposed directly under an objective lens to obtain the backscattered electron image. When one point of a specimen is irradiated with an electron beam, backscattered or transmission electrons generated from the specimen collide with the scintillator to form a luminescent pattern. This pattern is detected by the CCD detector, and stored in a memory. This processing is sequentially repeated for each irradiation position to obtain all the patterns in an electron beam scanning range. Arithmetic processing is performed on each pattern to convert it into an image. Usually, image data for one pixel is calculated from one pattern. By sequentially repeating this, a backscattered or transmission electron image in the electronic beam scanning range can be obtained.

Owner:HITACHI HIGH-TECH CORP

Apparatus and method for inspection and testing of flat panel display substrates

ActiveUS7435956B2Increase vacuumReduce transmittanceThermometer detailsMaterial analysis using wave/particle radiationParallel plateDisplay device

Owner:MULTIBEAM CORP

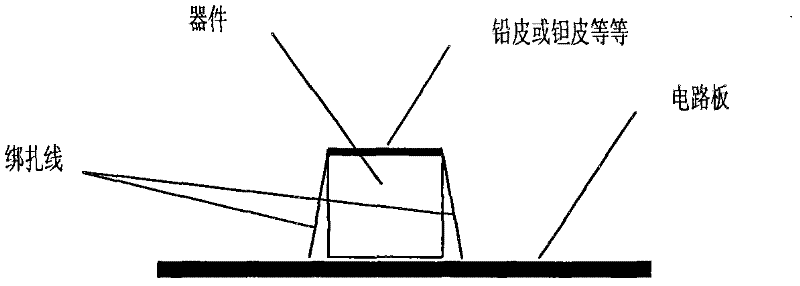

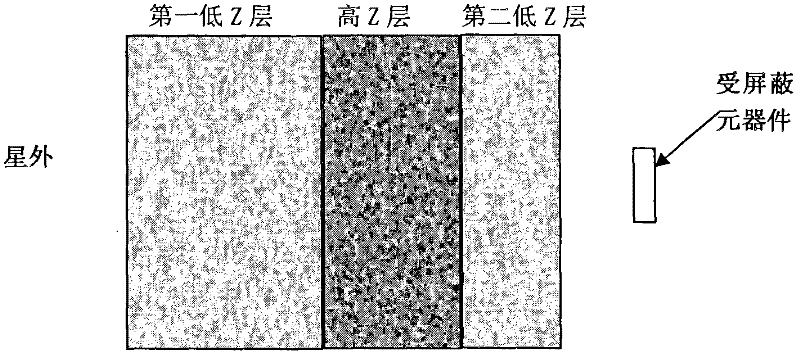

Anti-total-dose shielding device

InactiveCN102490913AImprove total dose resistanceExtend your lifeCosmonautic radiation protectionSoft x rayX-ray

The invention provides an anti-total-dose shielding device, which comprises a first low Z layer, a high Z layer and a second low Z layer, wherein the first low Z layer is used for moderating and shielding primary electrons, the high Z layer is used for scattering electrons and absorbing secondary bremsstrahlung photons, and the second low Z layer is used for absorbing photoelectrons and back scattered electrons generated in high Z materials and restraining secondary photoelectron emission and electron back scattering generated by action of X-rays and materials. The first low Z layer is the outmost layer and close to the space outside a satellite, and the second low Z layer is the innermost layer and close to a component to be shielded. The first low Z layer and the second low Z layer are made of materials formed by elements of atomic numbers smaller than or equal to 30. The thickness of the first low Z layer ranges from 1 to 3mm, and the thickness of the second low Z layer ranges from 0.2 to 0.4mm. The high Z layer is made of materials formed by elements of atomic numbers larger than or equal to 50, and the thickness of the high Z layer ranges from 0.1 to 0.3mm.

Owner:SHANGHAI SATELLITE ENG INST

Stable cold field emission electron source

ActiveUS8736170B1Improved emission stabilityReduce noiseMagnetronsTransit-tube electron/ion gunsConventional transmission electron microscopeDesorption

A cold field emission (CFE) electron source for a focused electron beam system such as a transmission electron microscope (TEM), scanning transmission electron microscope (STEM), or scanning electron microscope (SEM) is disclosed. The source employs an emitter enclosure electrode behind the CFE tip which, in conjunction with the extractor electrode, defines a closed volume that can be thoroughly cleaned by electron impact desorption (EID) and radiative heating from a heated filament located between the emitter enclosure electrode and extractor electrode. The extractor electrode may have a counterbore which restricts backscattered electrons generated at the extractor from reaching portions of the source and gun which have not been cleaned by EID. Pre-cleaning of the emitter enclosure electrode and extractor electrode prior to cold field emission substantially improves both source emission stability and frequency noise characteristics, enabling source operation over time intervals adequate for application to TEMs, STEMs, and SEMs.

Owner:FEI CO

X-ray tube aperture body with shielded vacuum wall

ActiveUS20130195253A1Reduce failure rateExtended service lifeCathode ray concentrating/focusing/directingX-ray tube vessel coolingElectronAtomic physics

X-ray tube aperture body with shielded vacuum wall. In one example embodiment, an aperture body for use in an x-ray tube having an anode and a cathode includes an electron shield and a vacuum wall. The electron shield is configured to intercept backscattered electrons from the anode. The vacuum wall is separated by a gap from the electron shield and is shielded from the backscattered electrons by the electron shield. The aperture body also includes an electron shield aperture defined in the electron shield and a vacuum wall aperture defined in the vacuum wall through which electrons may pass between the cathode and the anode.

Owner:VAREX IMAGING CORP

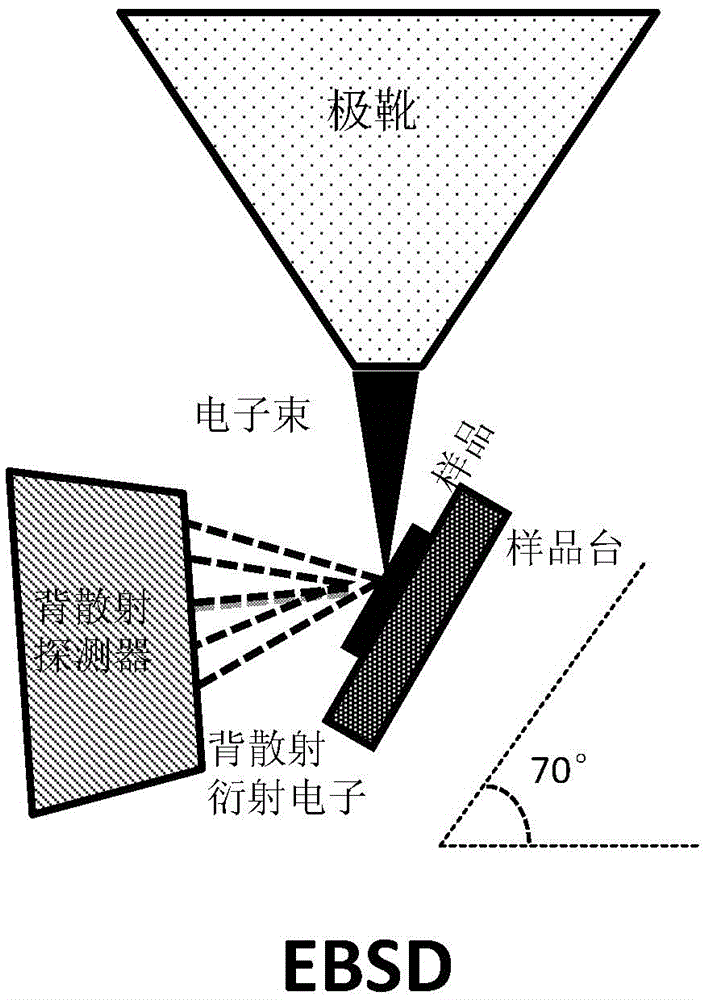

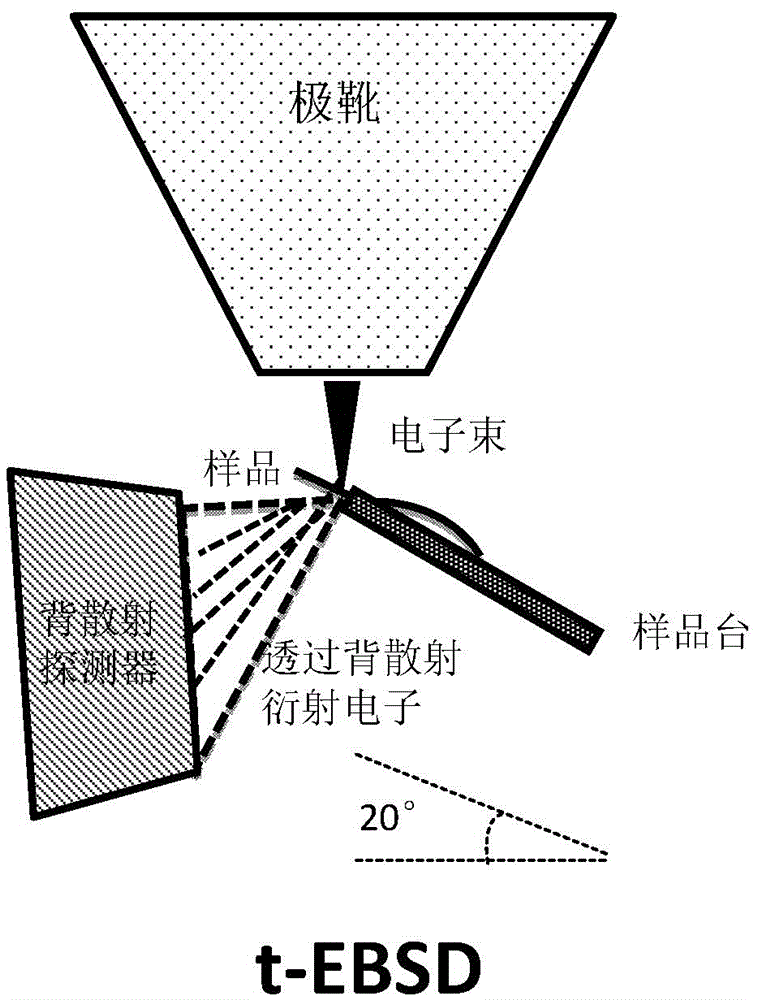

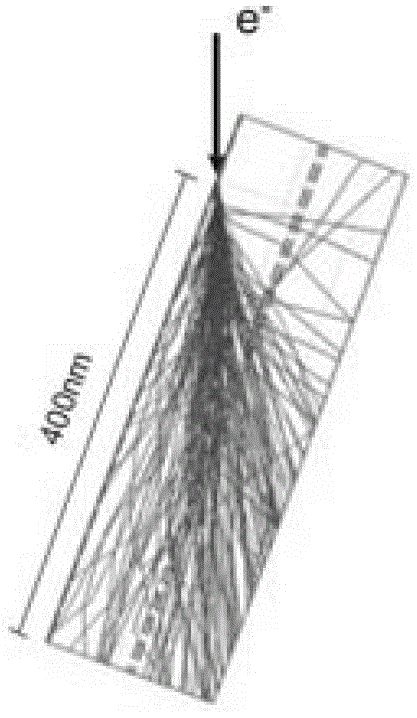

SEM transmission electron Kikuchi diffraction apparatus and analytical method

InactiveCN105651792AImprove spatial resolutionShorten working distanceNanoparticle analysisParticle size analysisCrystal twinningNanoscopic scale

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

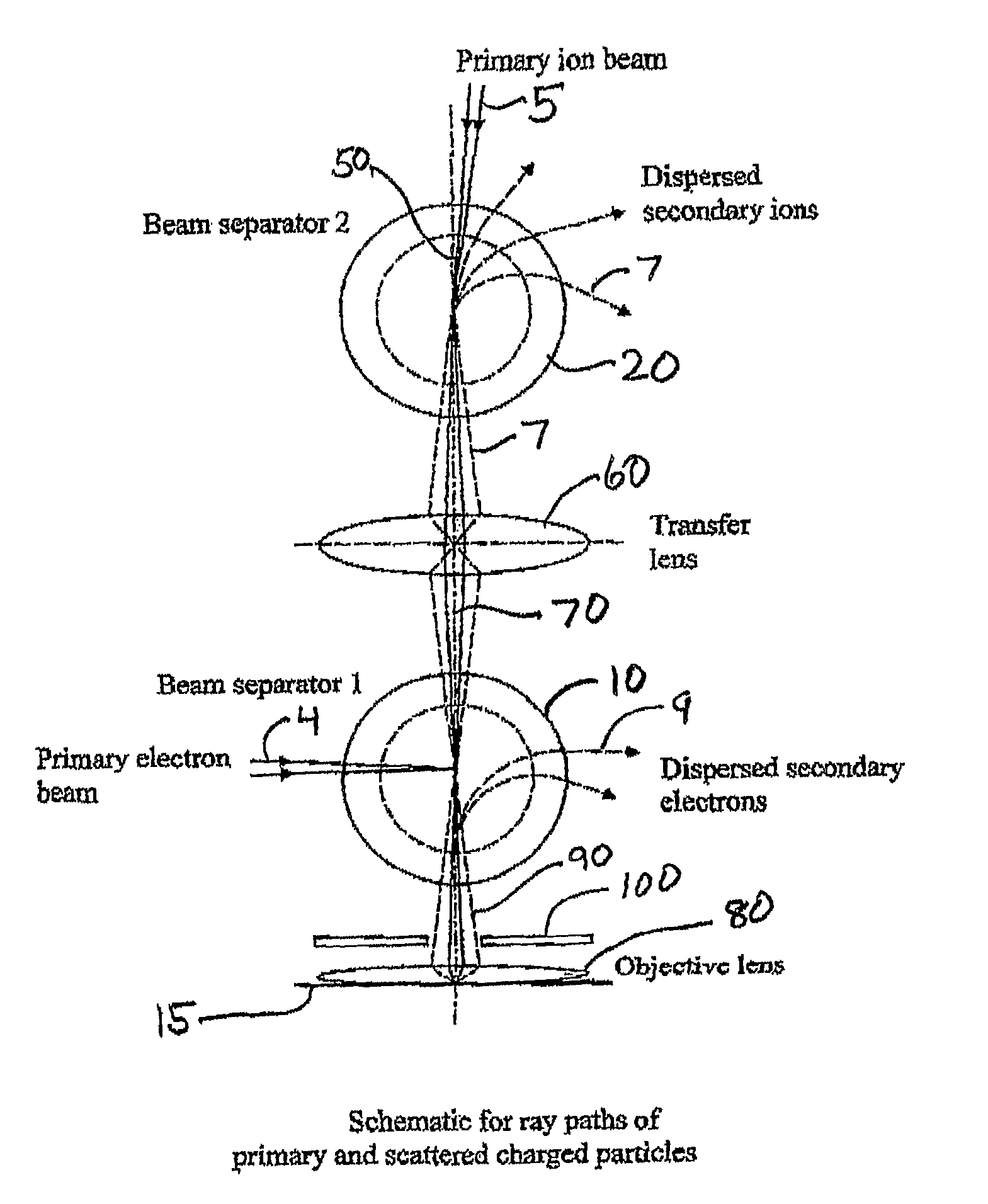

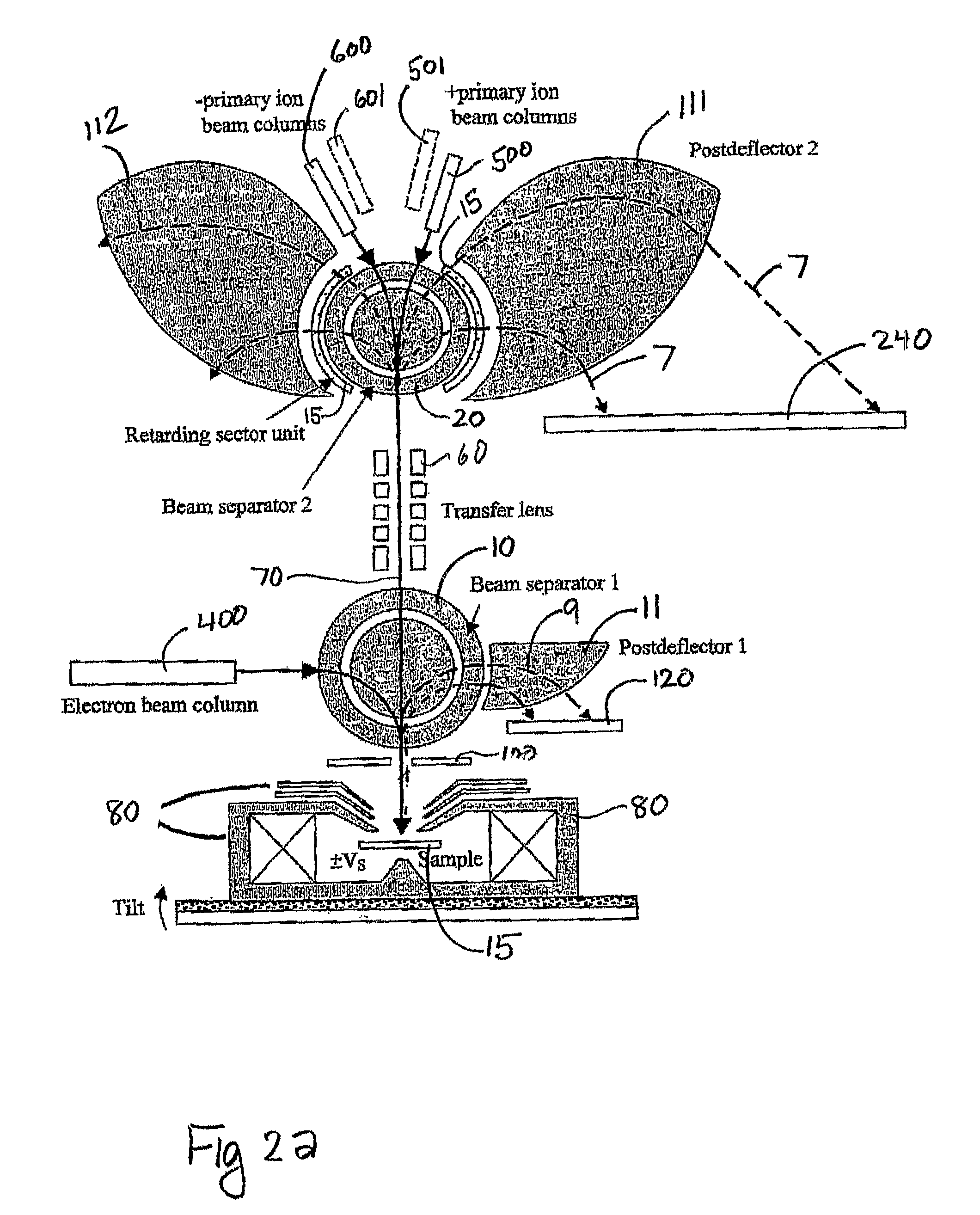

Multi-beam ion/electron spectra-microscope

InactiveUS7947951B2Good dispersionMinimize aberrationMaterial analysis using wave/particle radiationParticle separator tubesSecondary electronsOxygen

Owner:NAT UNIV OF SINGAPORE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com