Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Light collection efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

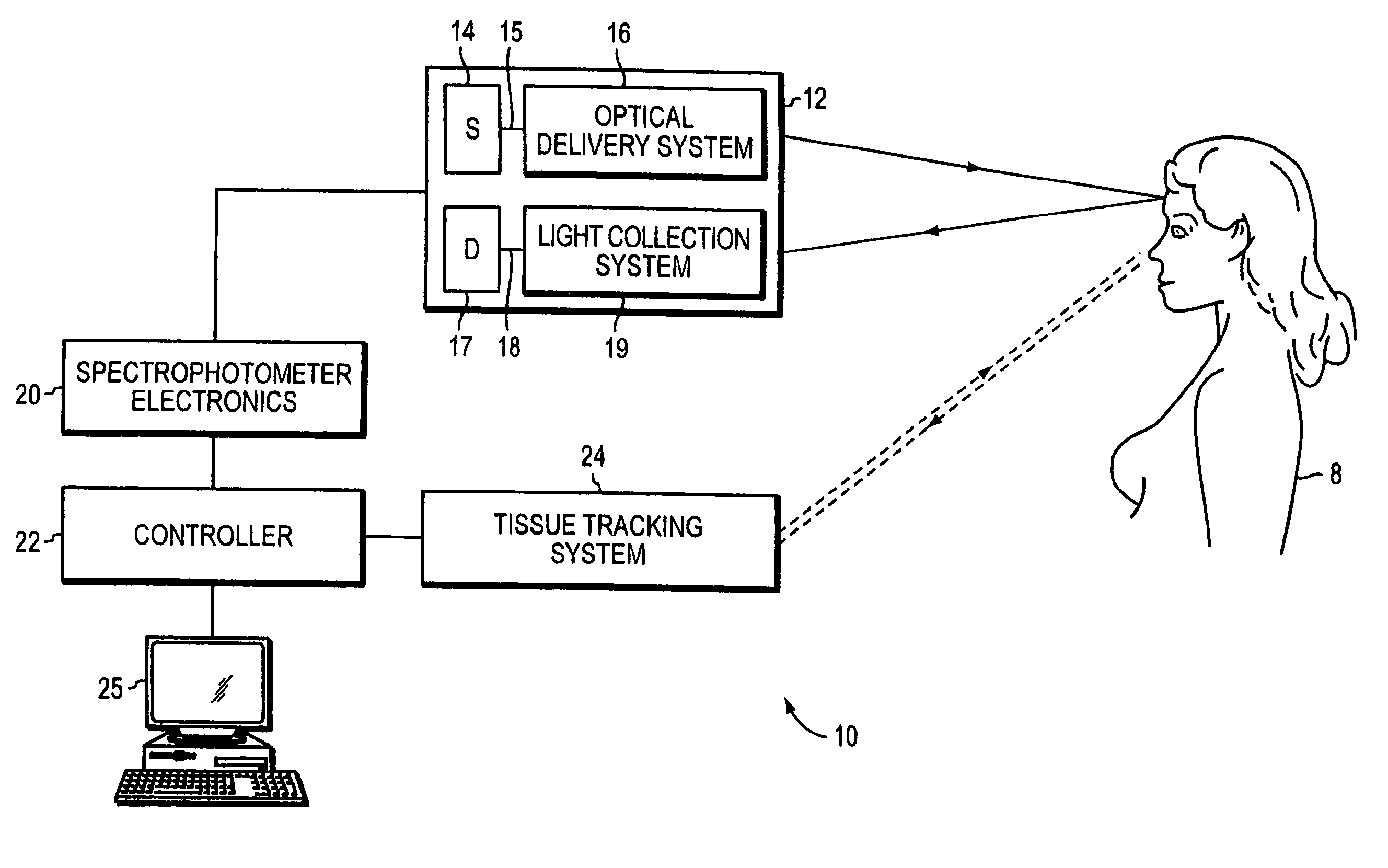

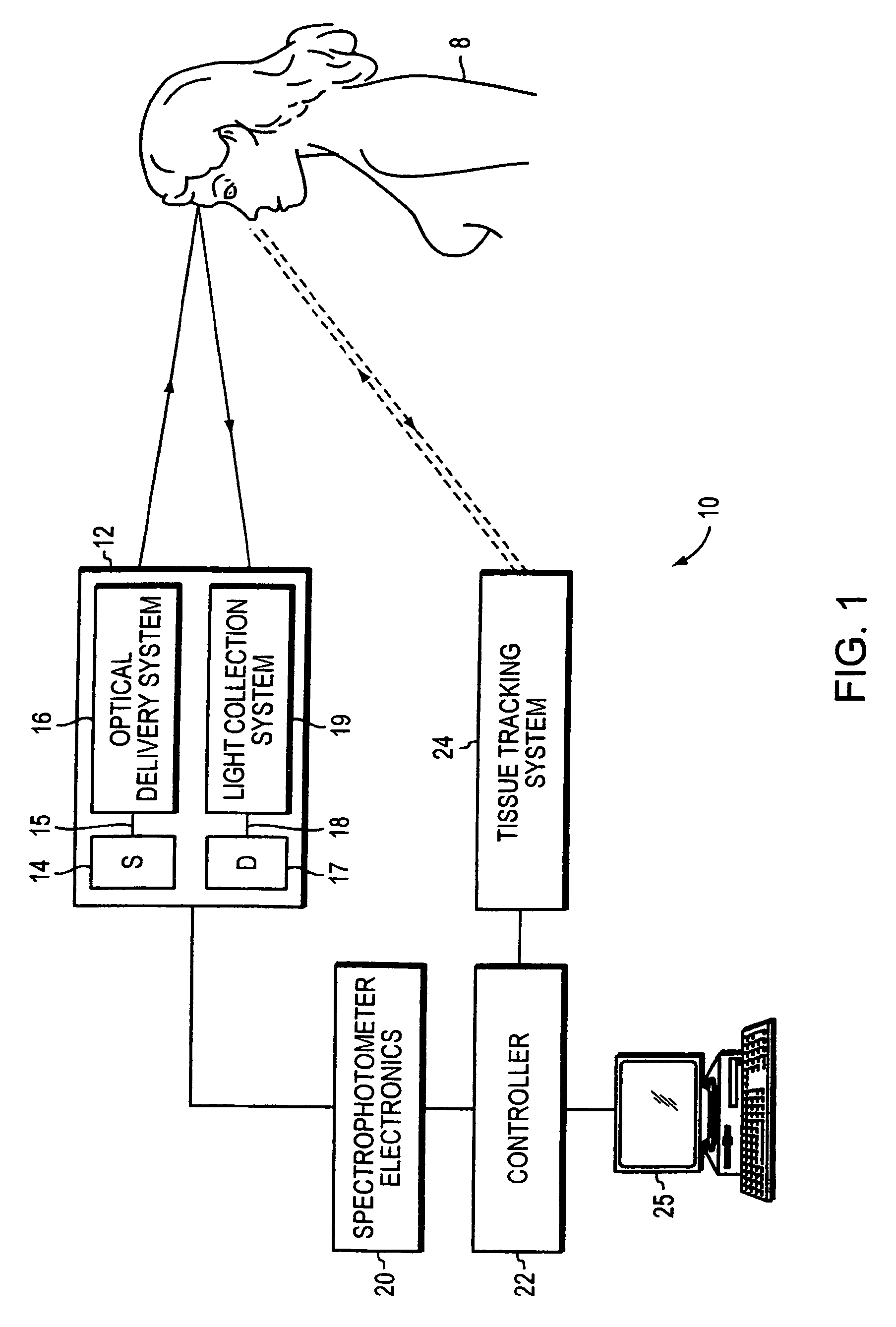

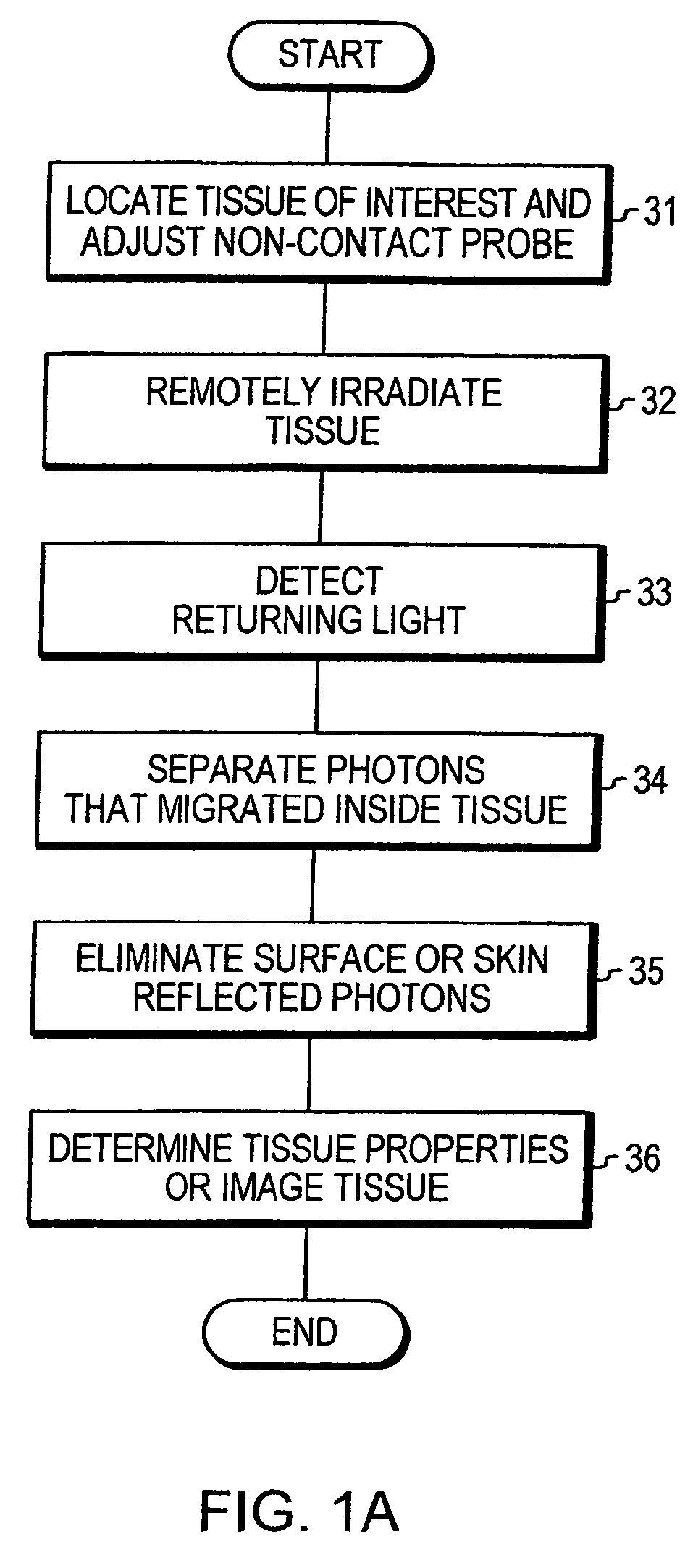

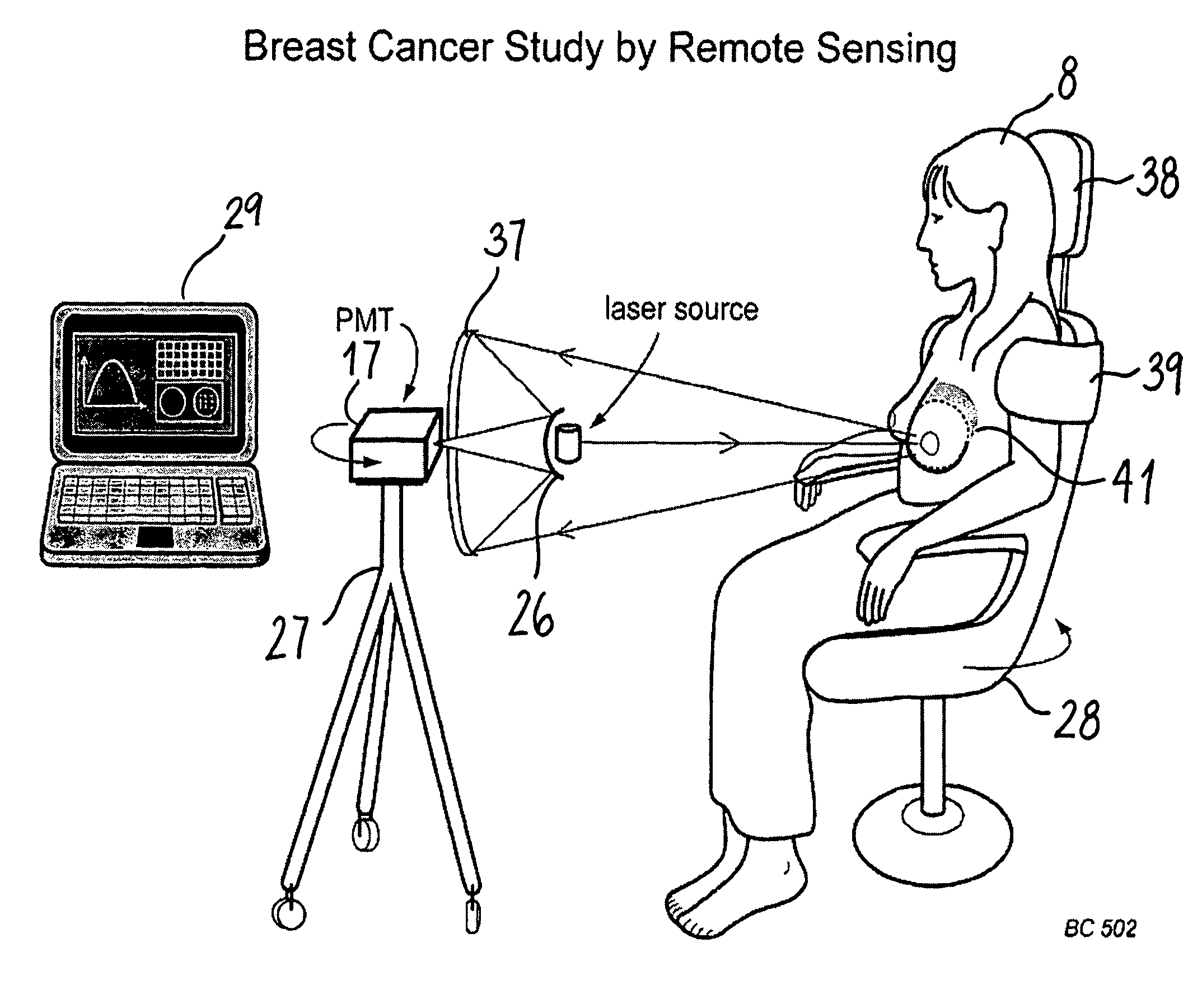

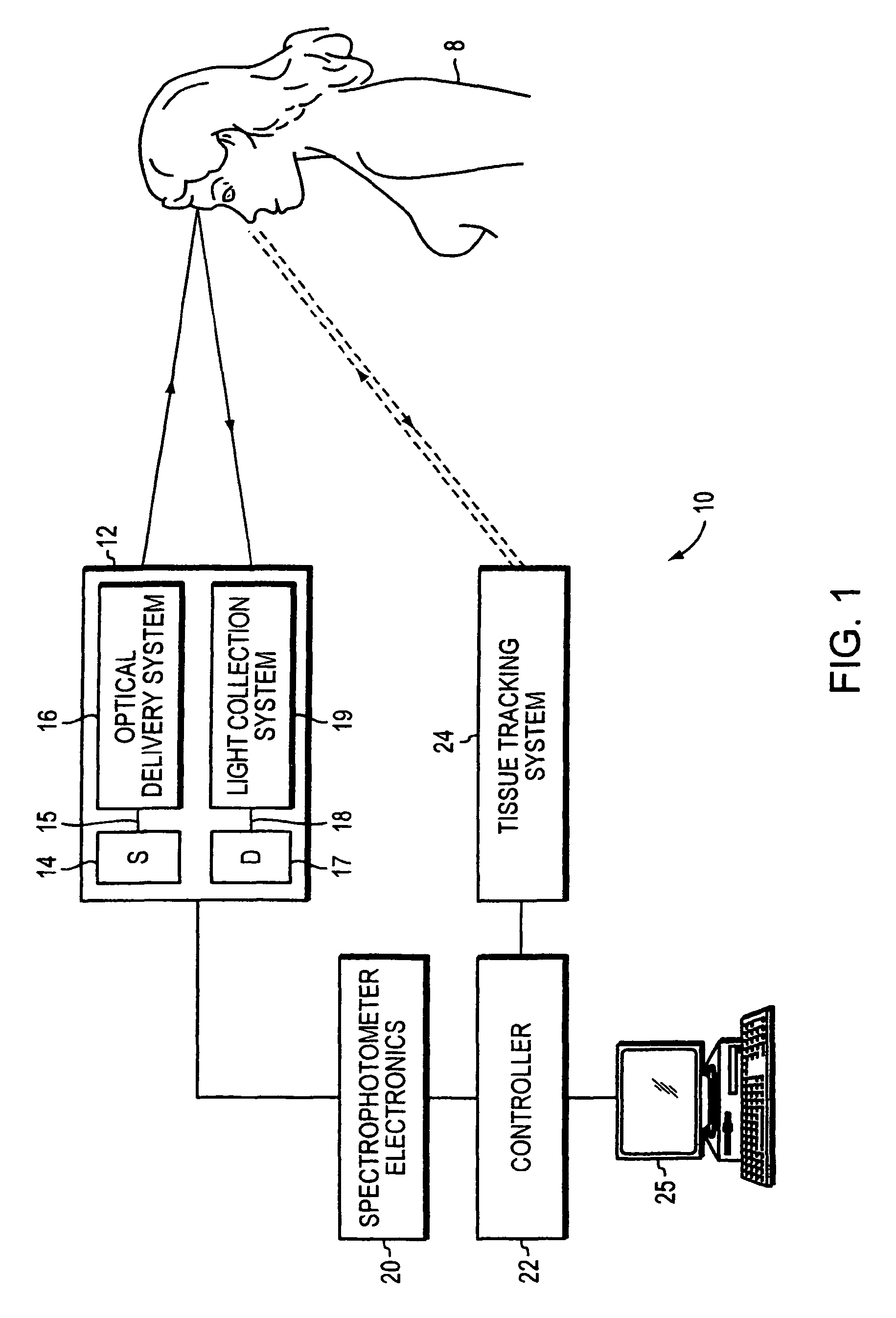

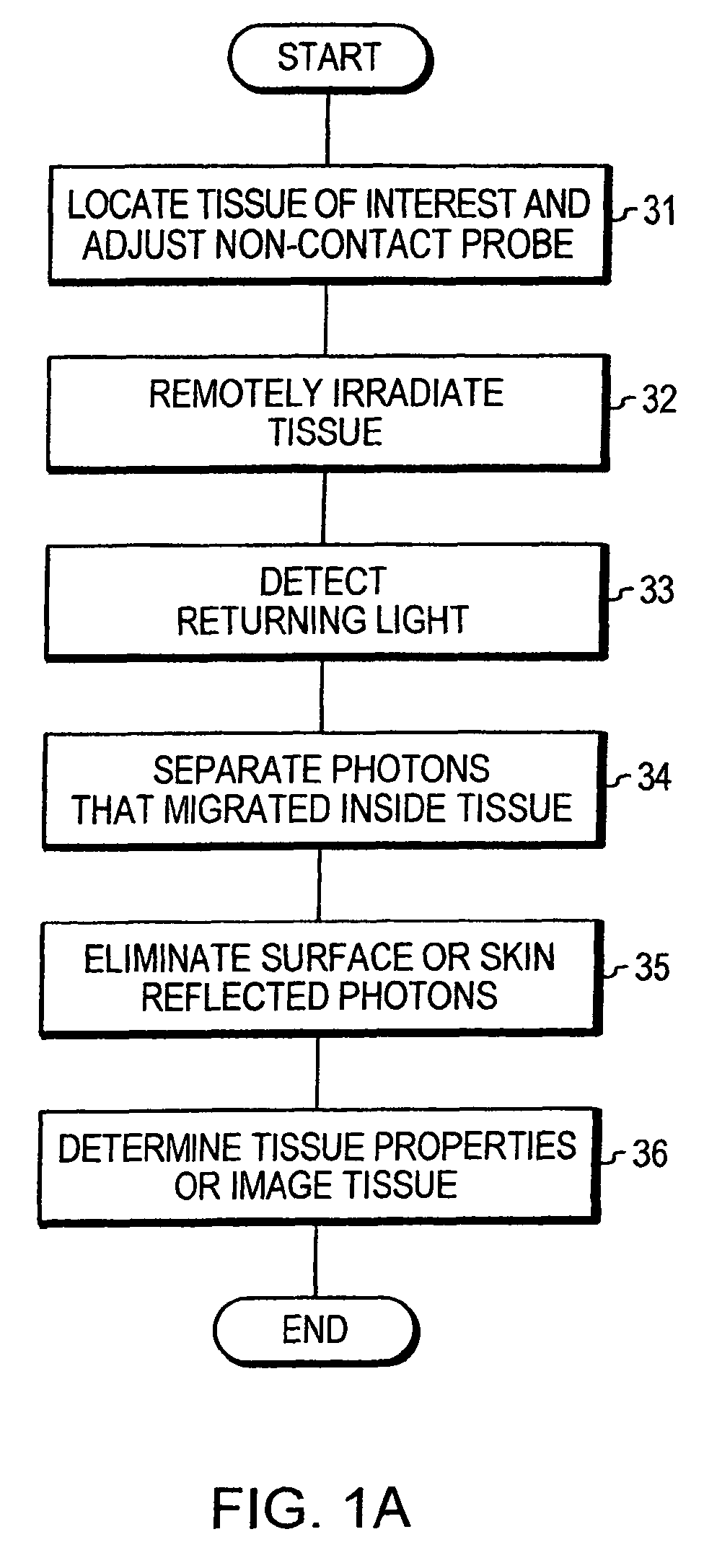

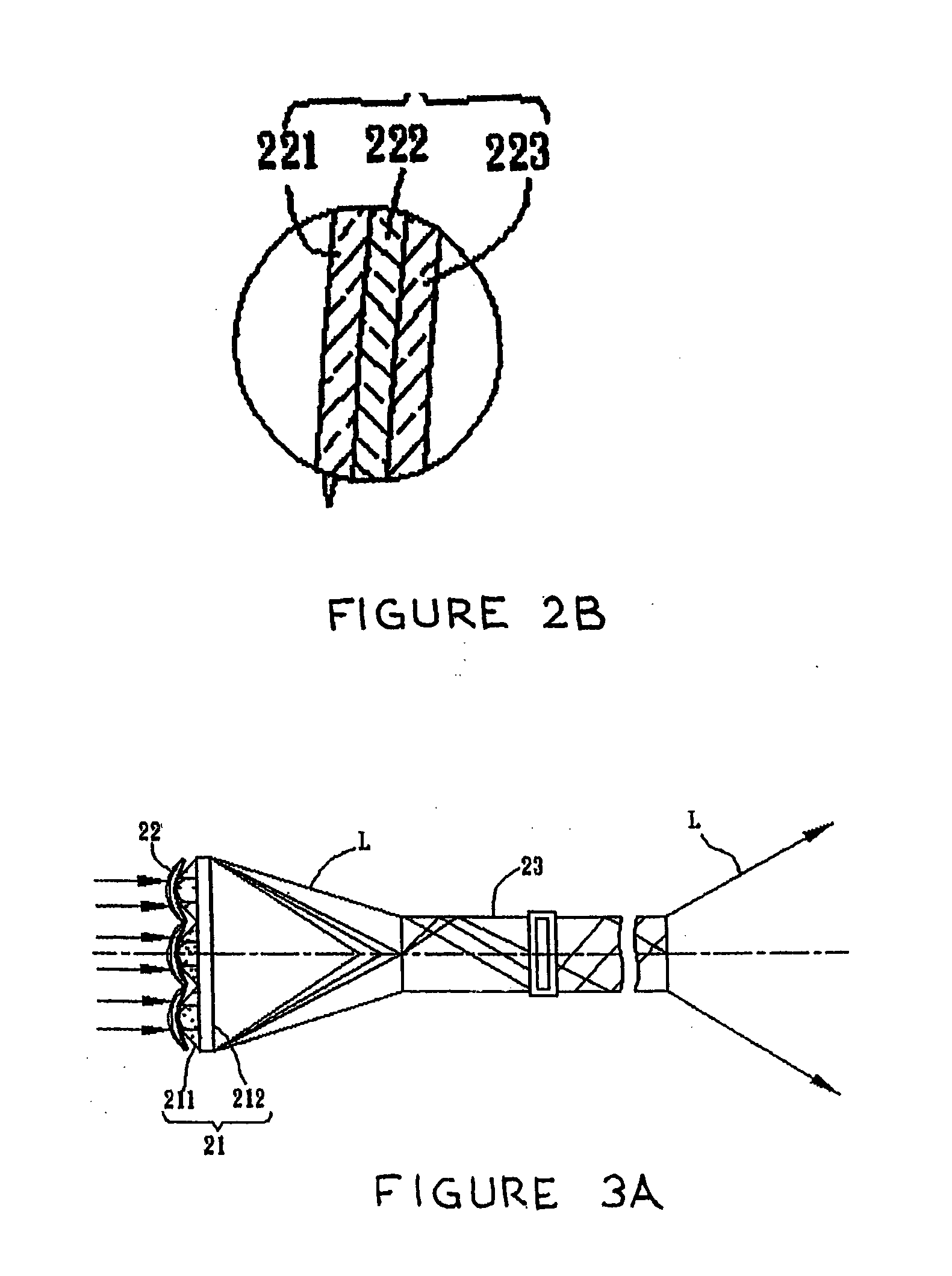

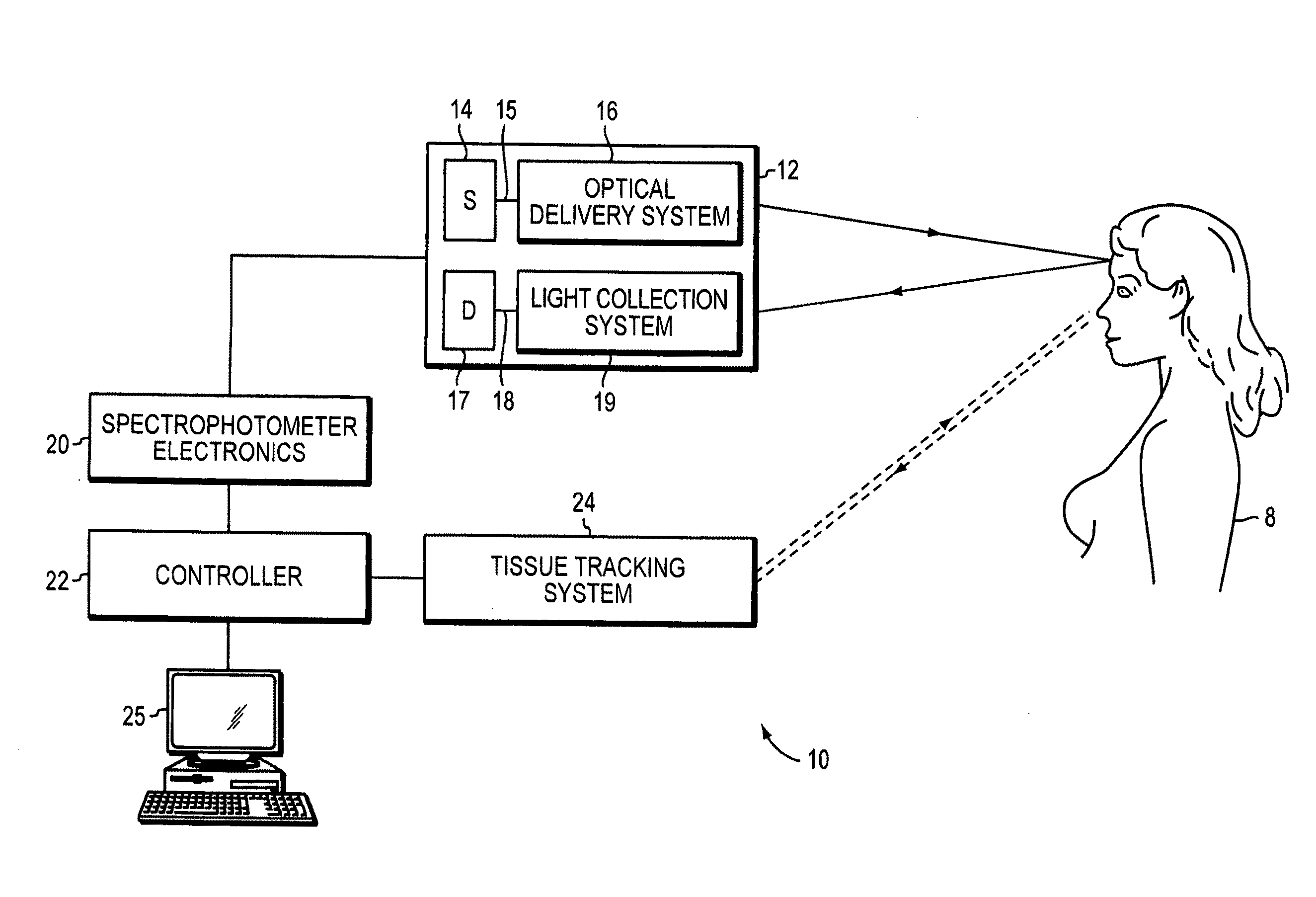

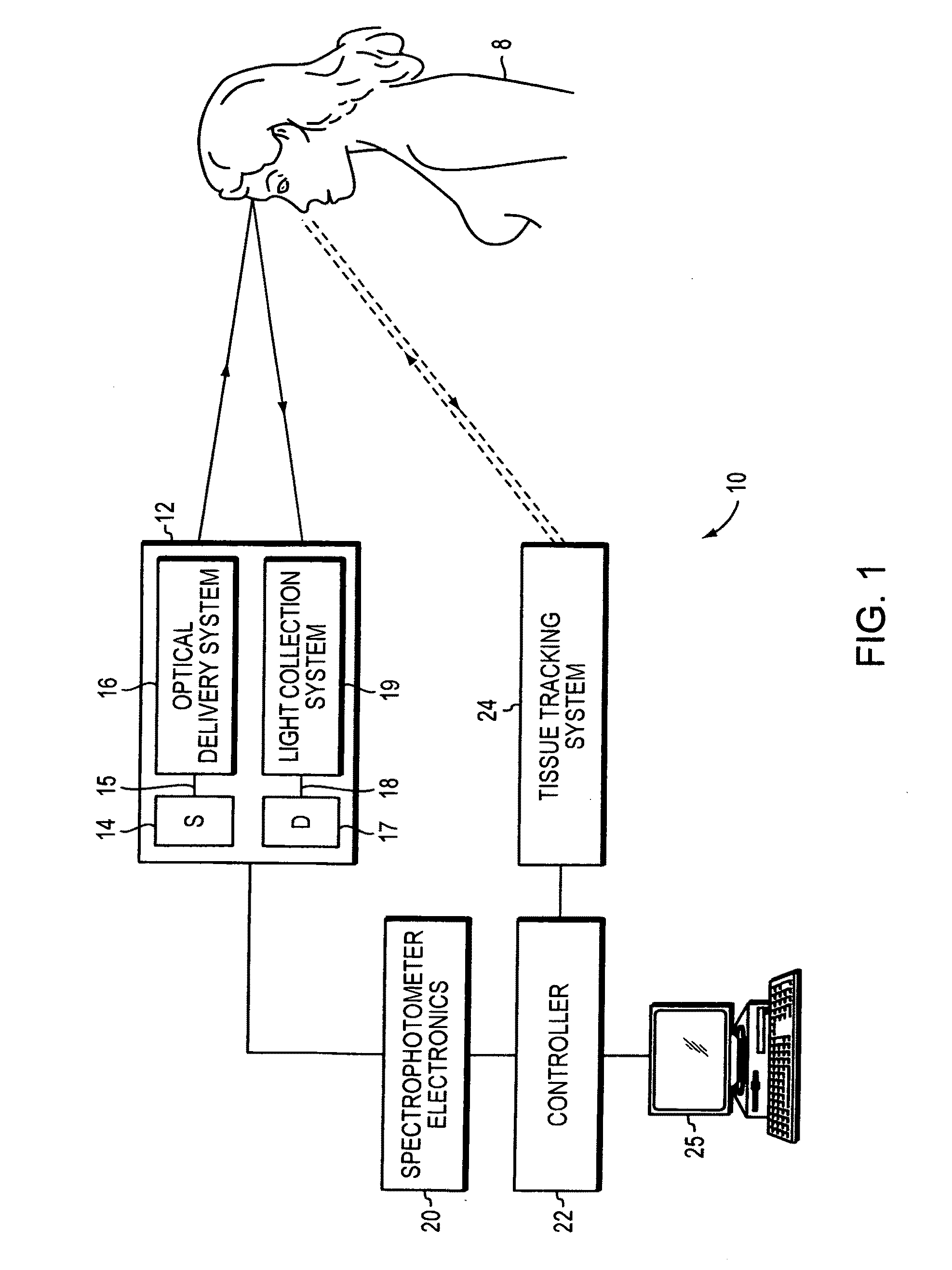

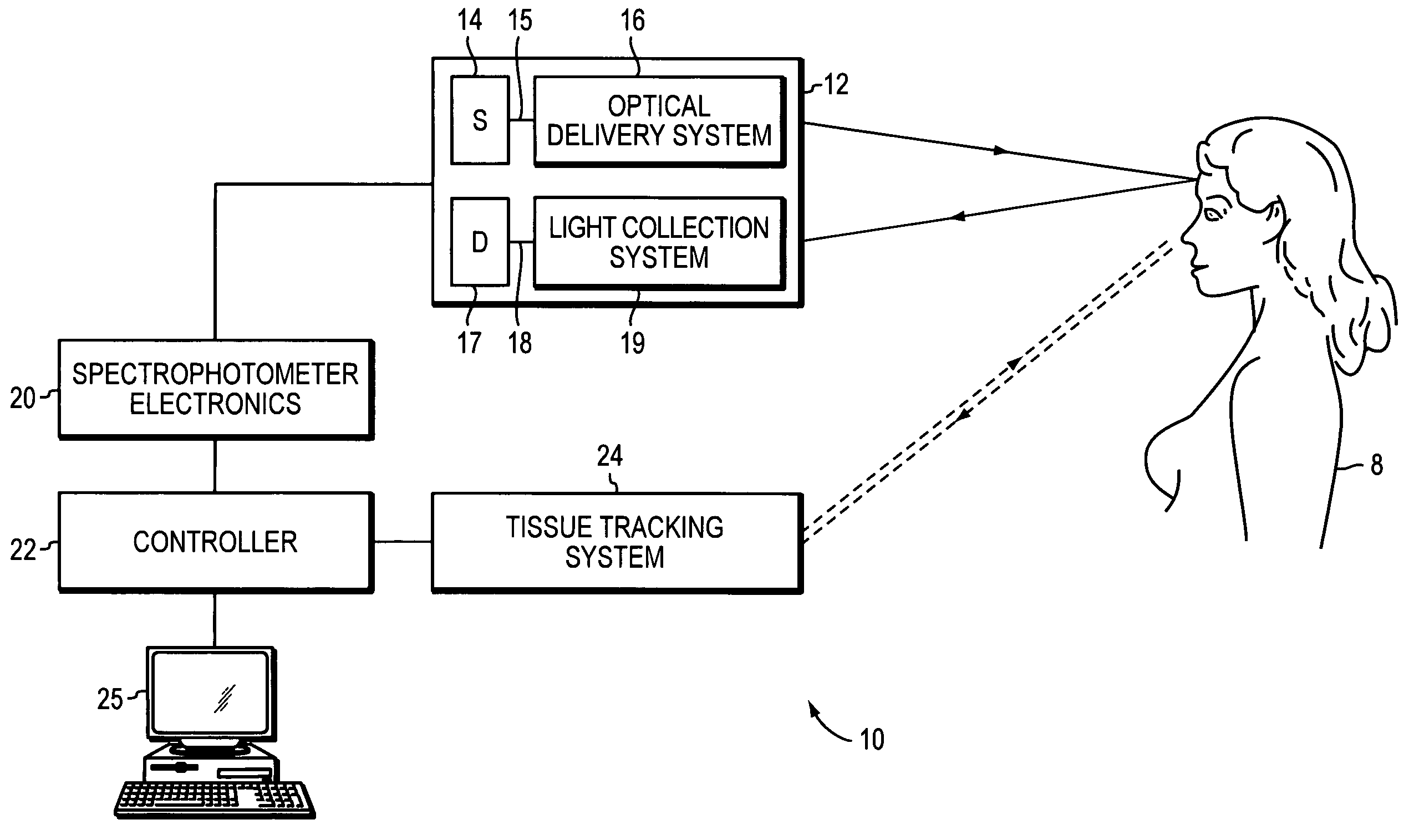

Optical examination of biological tissue using non-contact irradiation and detection

InactiveUS20060058683A1Avoid detectionCancel noiseDiagnostics using lightSensorsLight beamContact position

An optical system for examination of biological tissue includes a light source, a light detector, optics and electronics. The light source generates a light beam, transmitted to the biological tissue, spaced apart from the source. The light detector is located away (i.e., in a non-contact position) from the examined biological tissue and is constructed to detect light that has migrated in the examined tissue. The electronics controls the light source and the light detector, and a system separates the reflected photons (e.g., directly reflected or scattered from the surface or superficial photons) from the photons that have migrated in the examined tissue. The system prevents detection of the “noise” photons by the light detector or, after detection, eliminates the “noise” photons in the detected optical data used for tissue examination.

Owner:NONINVASIVE TECH

Optical examination of biological tissue using non-contact irradiation and detection

InactiveUS7904139B2Avoid detectionCancel noiseDiagnostics using lightSensorsLight beamContact position

An optical system for examination of biological tissue includes a light source, a light detector, optics and electronics. The light source generates a light beam, transmitted to the biological tissue, spaced apart from the source. The light detector is located away (i.e., in a non-contact position) from the examined biological tissue and is constructed to detect light that has migrated in the examined tissue. The electronics controls the light source and the light detector, and a system separates the reflected photons (e.g., directly reflected or scattered from the surface or superficial photons) from the photons that have migrated in the examined tissue. The system prevents detection of the “noise” photons by the light detector or, after detection, eliminates the “noise” photons in the detected optical data used for tissue examination.

Owner:NONINVASIVE TECH

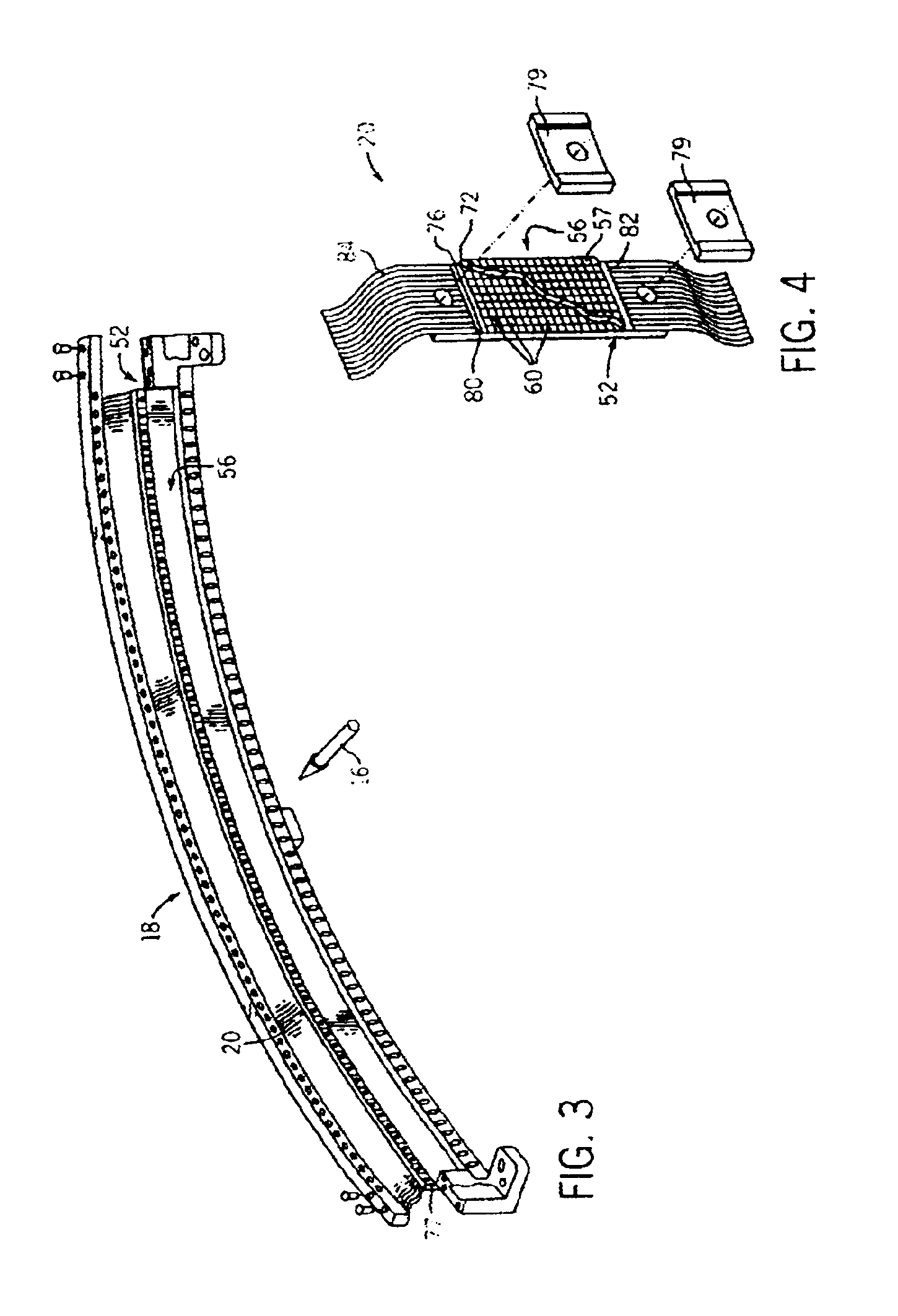

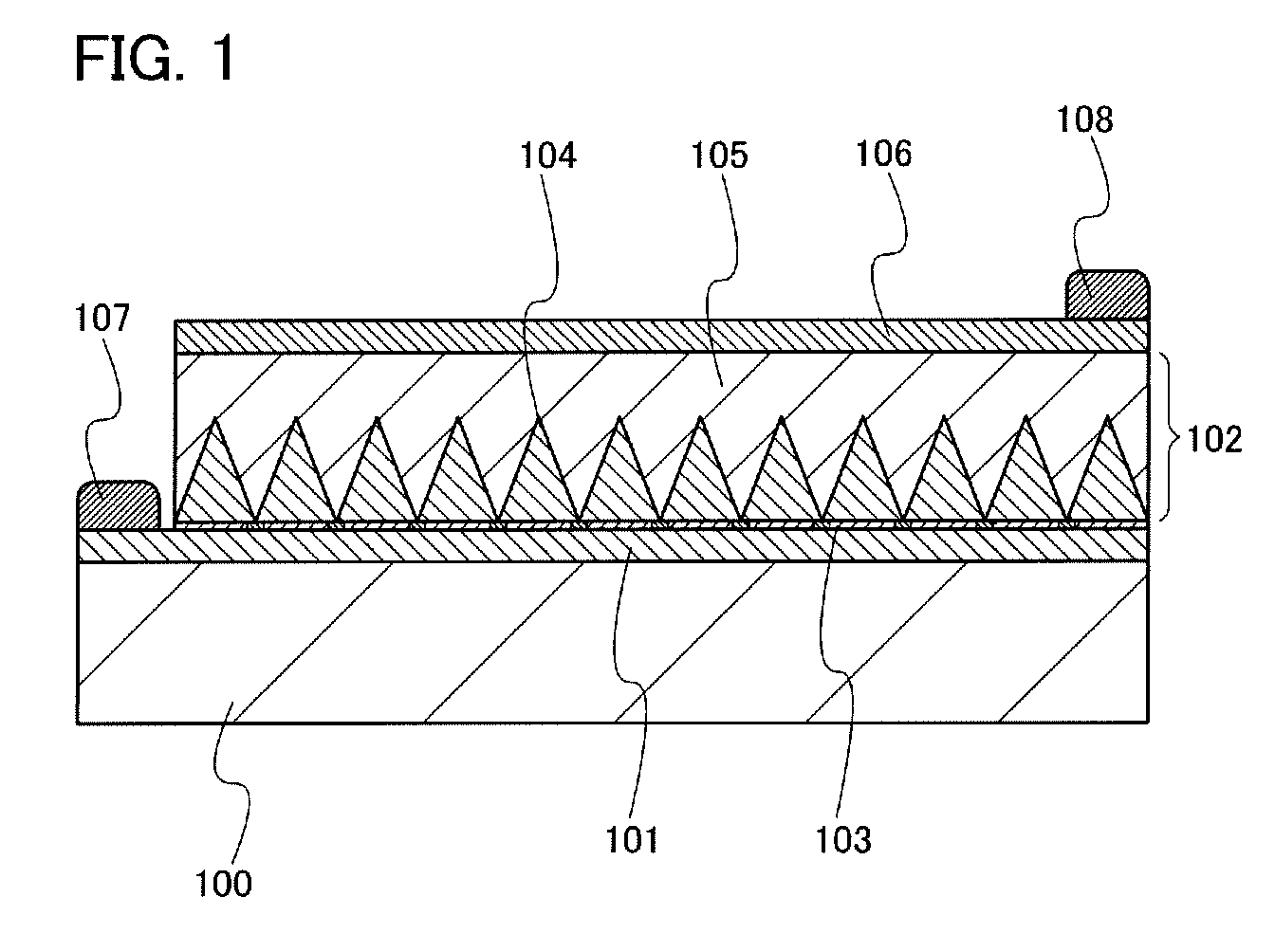

Light collection device

InactiveUS20090032102A1Reduce light reflectionReduce lossesSolar heating energySolar heat devicesFresnel lensOptoelectronics

A light collection device assembled with a light-processing unit comprises a fresnel lens unit, an anti-reflection layer and a light-processing unit. The fresnel lens unit has a light-incident surface and a light-emitting surface. The light-processing unit is positioned with the light-emitting surface for transmitting or converting a light emitted from the fresnel lens unit. The anti-reflection layer is mounted or formed on the light-incident surface of the fresnel lens unit.

Owner:PRODISC TECH INC

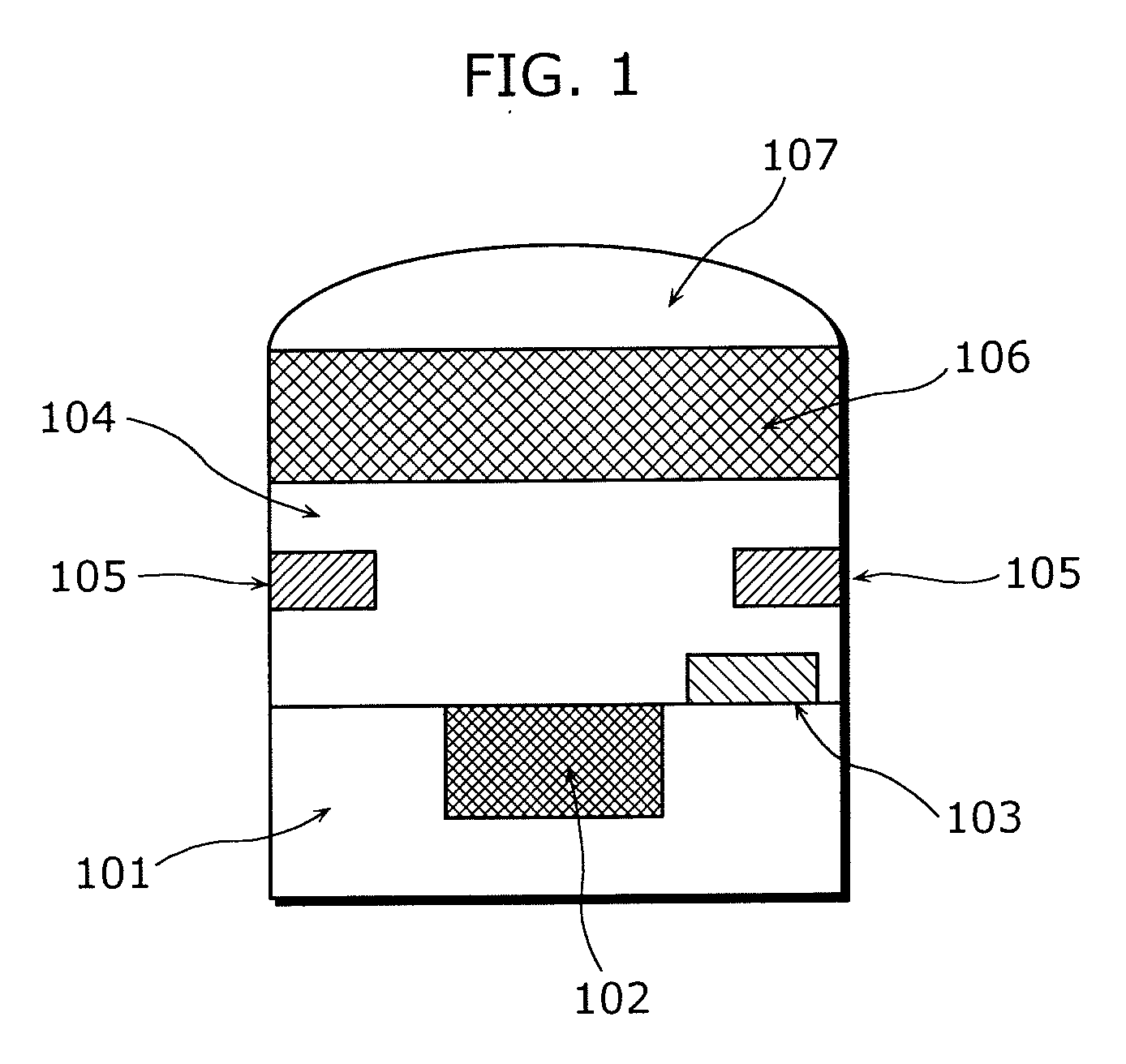

Scintillator array having a reflector with integrated air gaps

InactiveUS6947517B2Light collection efficiency be improveLower cross-talkMaterial analysis using wave/particle radiationRadiation/particle handlingPhysicsRefractive index

The present invention is directed to a scintillator array having an integrated air gap. By integrating an air gap within the reflector, light collection efficiency is improved while simultaneously lowering cross-talk between scintillators. That is, implementing a reflector without chromium oxide (Cr2O3) increases light reflectivity and an air gap lowers cross talk through the reflector. To further improve the reflectivity, the base reflector material may be coated with a low index material and a reflective material such as silver.

Owner:GENERAL ELECTRIC CO

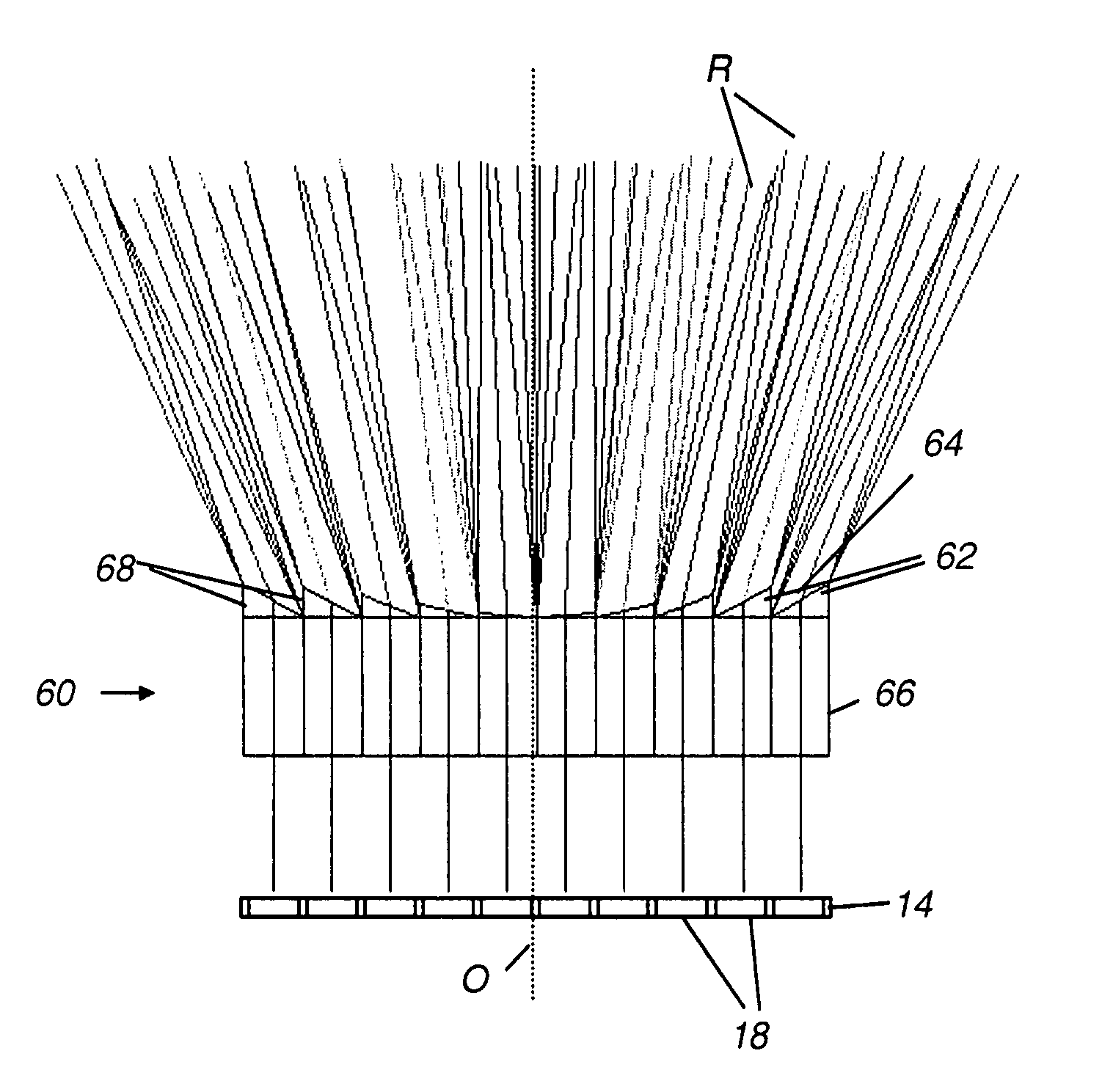

Wide angle camera with prism array

InactiveUS20060215054A1Wide field of viewLight collection efficiency is improvedTelevision system detailsSignal generator with single pick-up deviceOptoelectronicsPrism

An imaging apparatus (40) has an optical sensor (14) with sensing elements (18). Each sensing element (18) has an array of sensing components (28). Each sensing component (28) provides a signal corresponding to a pixel for forming an image as an array of pixels. A lens array (76) has a number of lens elements (66). Each lens element (66) directs light to a corresponding sensing element (18) in the optical sensor (14). A prism array (60) has a number of prism elements (62), each prism element (62) directing incident light from the image field toward a corresponding lens element (66) in the lens array (76).

Owner:EASTMAN KODAK CO

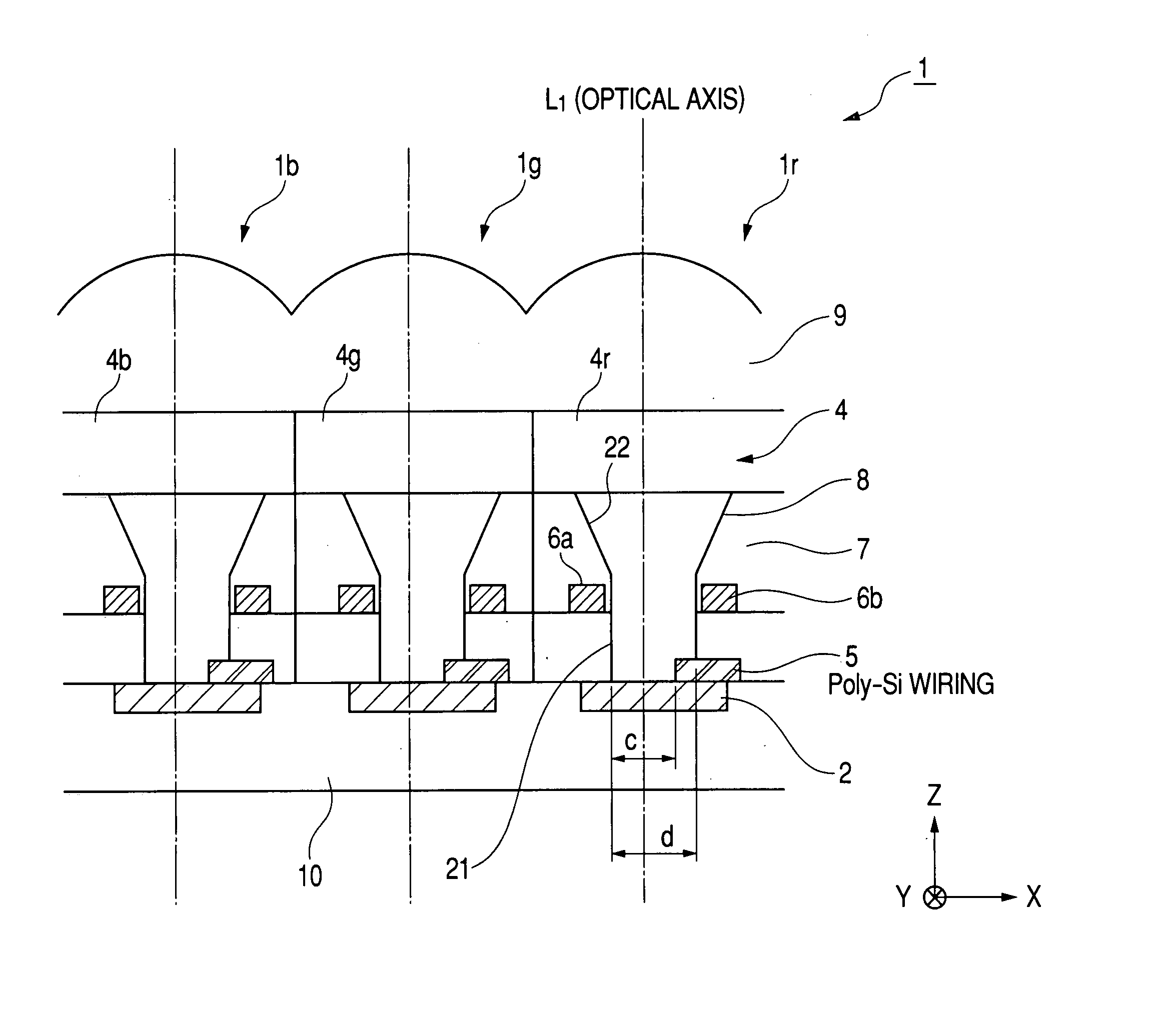

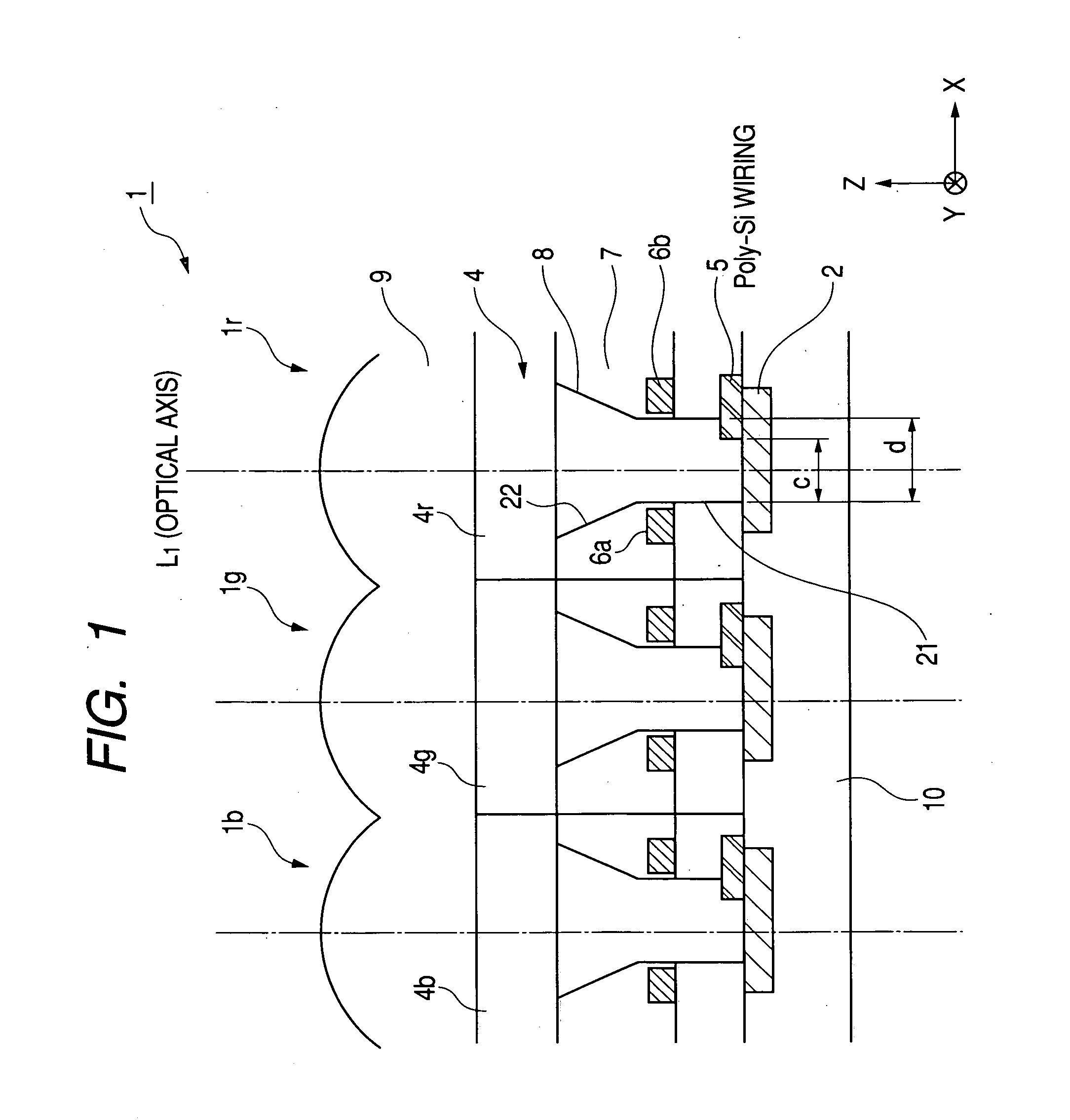

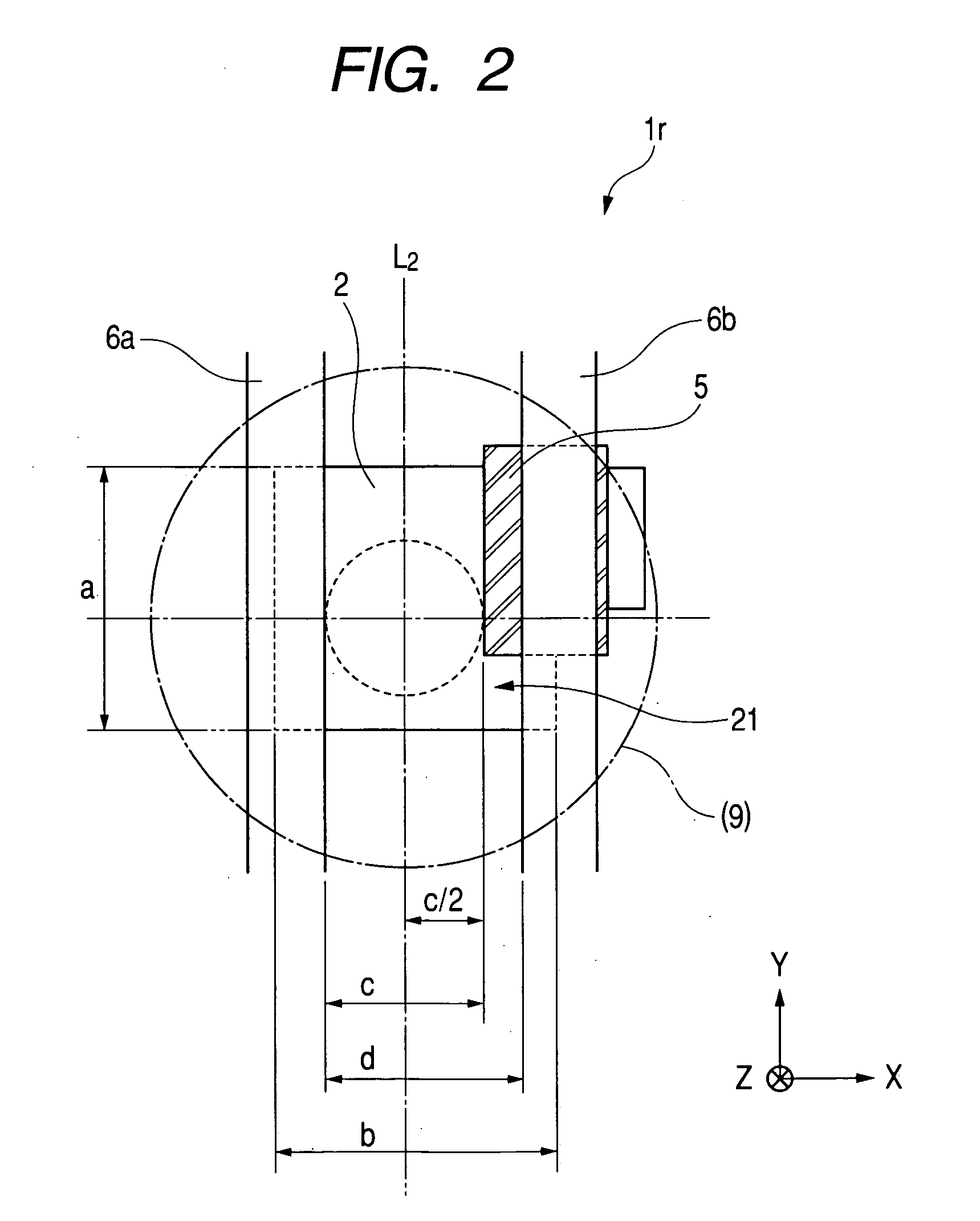

Image pick-up device and image pick-up system using the image pick-up device

InactiveUS20050072906A1High sensitivityLight collection efficiency is improvedTelevision system detailsSolid-state devicesPotential wellEngineering

With an aim of receiving a subject image at good sensitivity by improving the light collection efficiency of incident light, an image pick-up element includes a light-receiving portion, poly-silicon wiring formed on the light-receiving portion, and a potential well structure. The poly-silicon wiring is arranged so as to be overlapped with at least a part of the light-receiving portion, and is electrically connected to the light-receiving portion to perform the control of electric charges generated at the light-receiving portion, the switching of the light-receiving portion, and the like. The potential well structure is formed in at least a part of the area of the light-receiving portion in which the poly-silicon wiring is arranged, and the opened area of the potential well structure is sufficiently secured. The incident light entering the potential well structure is totally reflected by the inner wall of the potential well structure, and reaches the light-receiving portion or the poly-silicon wiring. The incident light reaching the poly-silicon wiring is transmitted through the poly-silicon wiring to be received by the light-receiving portion.

Owner:CANON KK

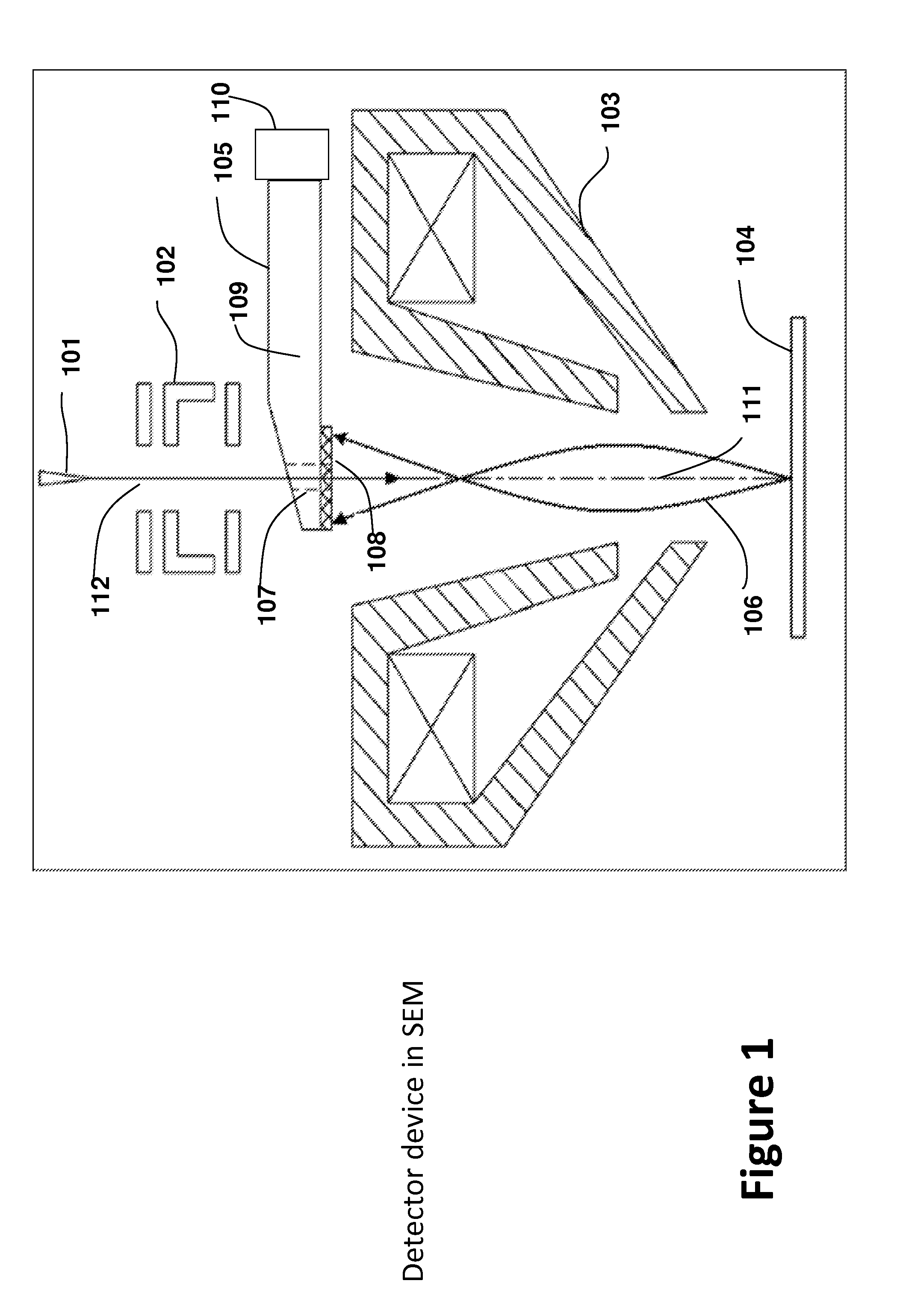

High efficiency secondary and back scattered electron detector

ActiveUS20130234032A1Light collection efficiency is improvedLight collection efficiencyElectric discharge tubesMaterial analysis by optical meansThin metalLight guide

An assembly for a charged particle detection unit is described. The assembly comprises a scintillator disc, a partially coated light guide a thin metal tube for allowing the primary charged particle beam to pass through and a photomultiplier tube (PMT). The shape of scintillator disc and light guide are redesigned to improved the light signal transmission thereafter enhance the light collection efficiency. A light guide with a conicoidal surface over an embedded scintillator improved the light collection efficiency of 34% over a conventional design.

Owner:ASML NETHERLANDS BV

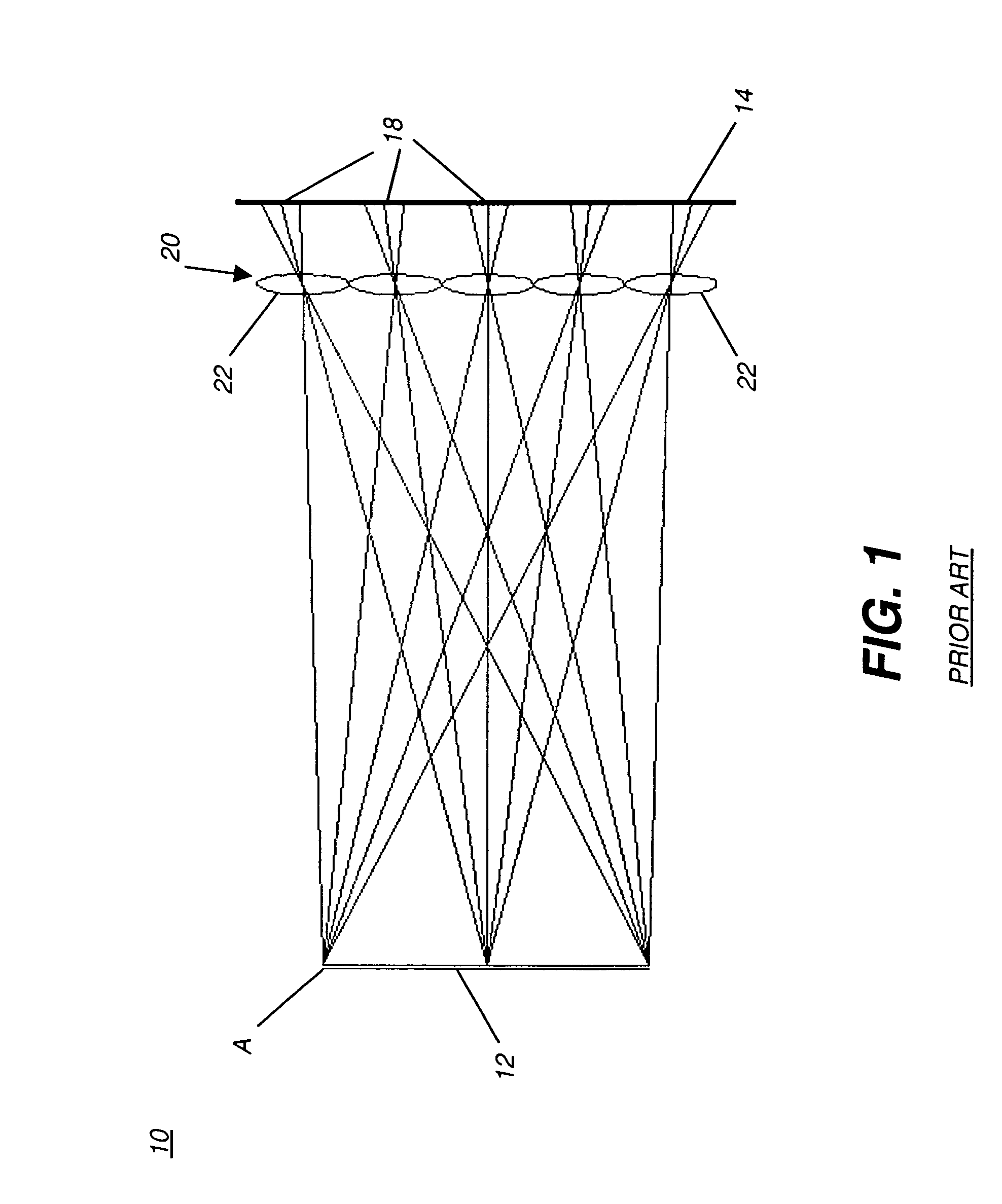

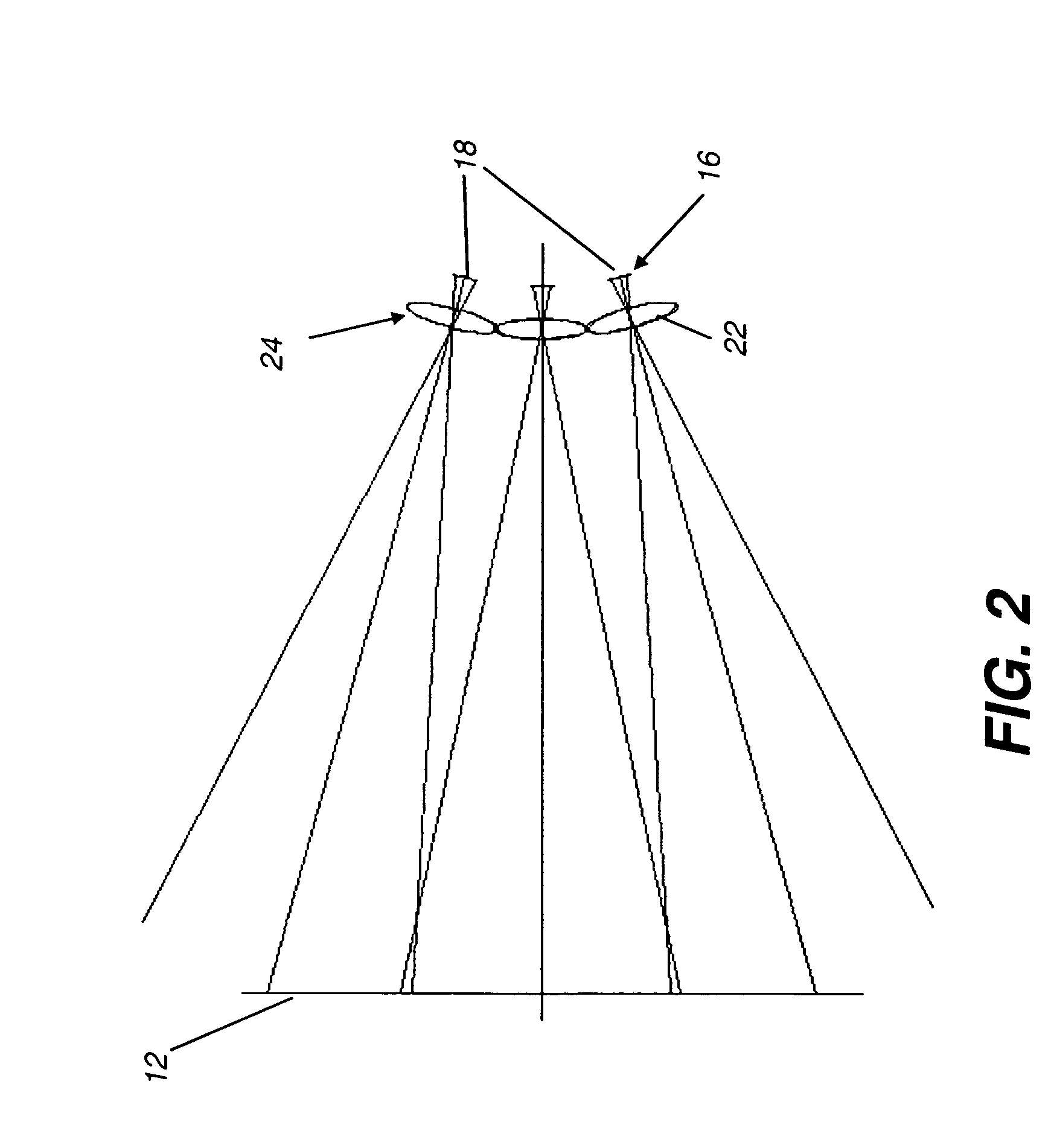

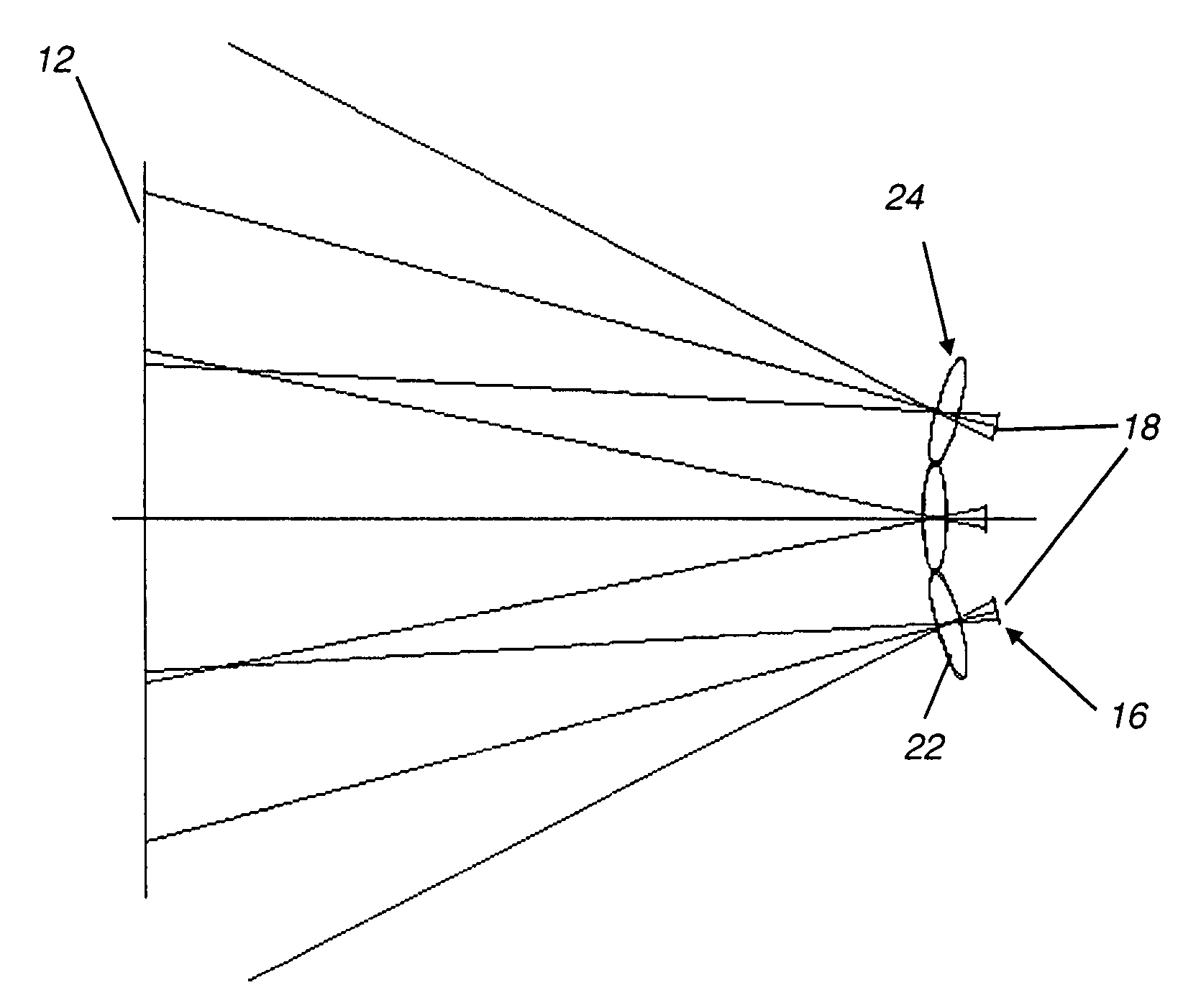

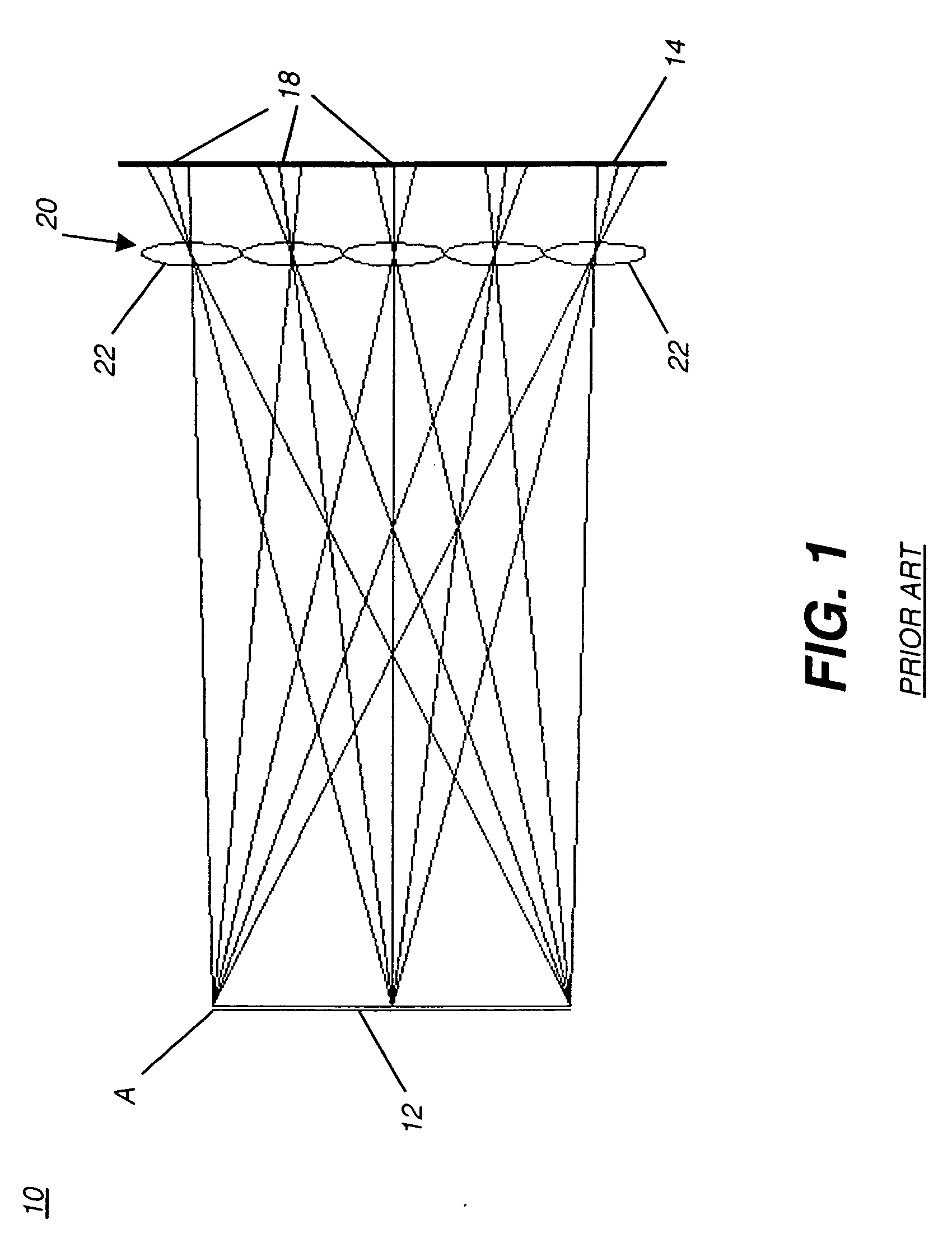

Wide angle lenslet camera

InactiveUS20060044451A1Wide field of viewLight collection efficiency is improvedTelevision system detailsTelevision system scanning detailsSensor arrayImaging equipment

An imaging apparatus (40) has a sensor array (16) comprising a plurality of optical sensors (18) arranged in a convex curvature and a lenslet array (24) with a plurality of lenslets (22) similarly arranged in a convex curvature. At least one lenslet (22) in the lenslet array (24) directs light toward at least one optical sensor (18) in the sensor array (16).

Owner:EASTMAN KODAK CO

Image pick-up device having well structure and image pick-up system using the image pick-up device

InactiveUS7135666B2Light collection efficiency is improvedHigh sensitivityTelevision system detailsSolid-state devicesEngineeringSilicon

Receiving a subject image at good sensitivity by improving the light collection efficiency of incident light, wherein an image pick-up element includes a light-receiving portion, poly-silicon wiring formed on the light-receiving portion, and a well structure. The poly-silicon wiring is arranged so as to be overlapped with at least a part of the light-receiving portion, and is electrically connected to the light-receiving portion to perform the control of electric charges generated at the light-receiving portion, the switching of the light-receiving portion, and the like. The well structure is formed in at least a part of the area of the light-receiving portion in which the poly-silicon wiring is arranged, and the opened area of the well structure is sufficiently secured.

Owner:CANON KK

Photoelectric conversion device and photoelectric conversion device module

InactiveUS20110240086A1Simple structureIncreasing the thicknessElectrolytic capacitorsPV power plantsEngineeringPhotoelectric conversion

The present invention is to provide a photoelectric conversion device including: a first substrate; a collector layer configured to be provided over the first substrate; a second substrate configured to be opposed to a planar surface of the first substrate and be formed of a metal having a concave notch part at one side; and a connection terminal configured to be connected to the collector layer. The connection terminal is disposed opposed to the concave notch part.

Owner:SONY CORP

Solid-state imaging device and manufacturing method thereof

InactiveUS20090250779A1Excellent color separation characteristicHighlight collection efficiencyTelevision system detailsSolid-state devicesPhotoelectric conversionEngineering

A solid-state imaging device in the present invention includes plural photoelectric conversion elements, plural wiring layers, and plural optical waveguide regions each corresponding to and arranged over one of the plural photoelectric conversion elements. A top end of each of the plural optical waveguide regions is higher than a top end of at least one of the plural wiring layers. A bottom end of each of the plural optical waveguide regions is lower than a bottom end of at least one of the plural wiring layers. The plural optical waveguide regions include plural types of optical waveguide regions each having different light absorbing characteristics.

Owner:PANASONIC CORP

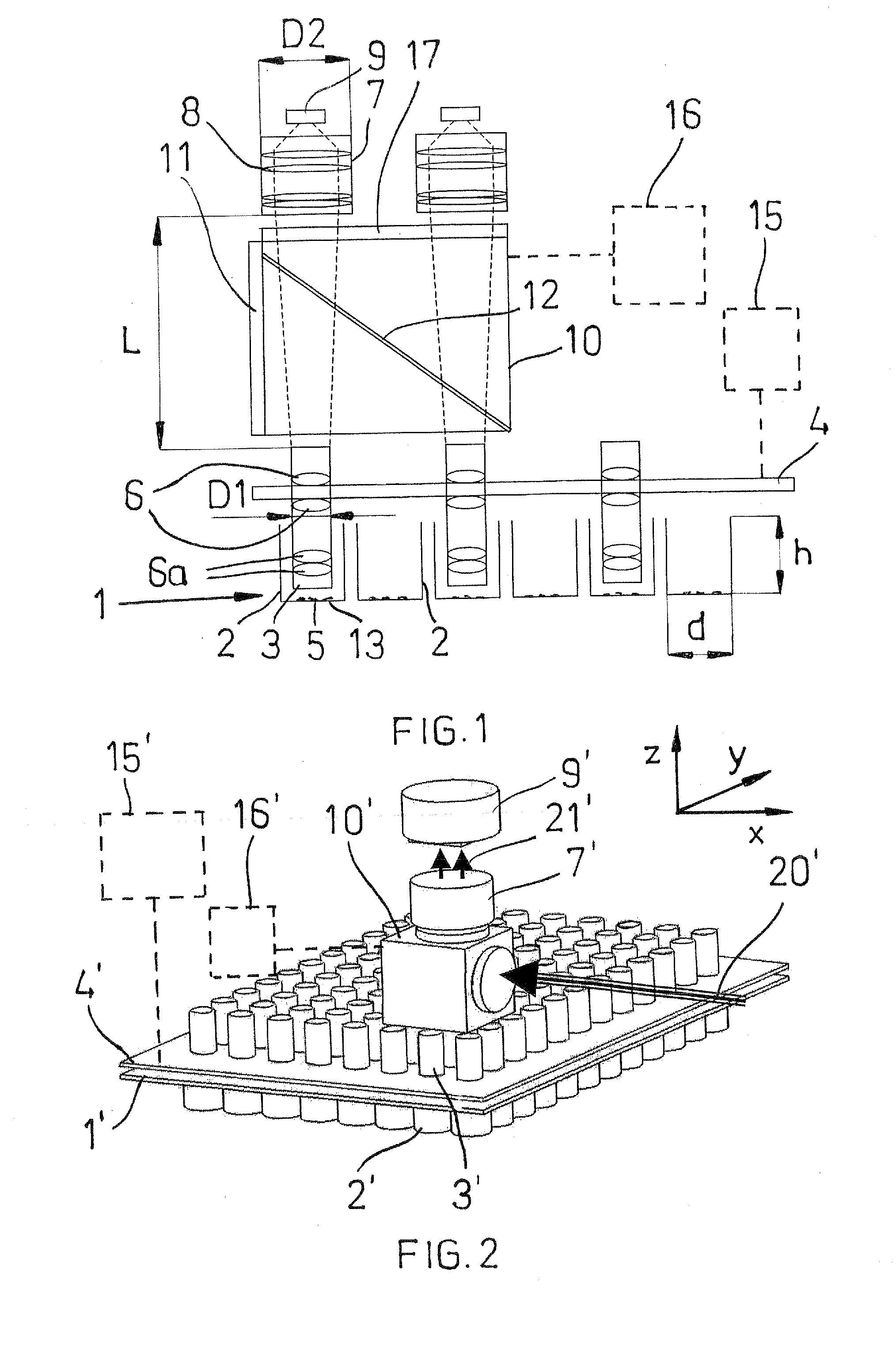

Arrangement in an Imaging System for Microtitre Wells

InactiveUS20080151363A1Easy to installFast imagingColor/spectral properties measurementsMicroscopesRapid imagingImage detection

The disclosure relates to an arrangement in an imaging system for microtitre wells, the arrangement comprising a sample plate having a plurality of wells for samples, and a lens system arranged in connection with the sample plate and comprising an objective and at least one lens group for imaging the rays representing the structure of the samples and passing through the objective to an image detector. In order for the arrangement to enable a rapid imaging of the samples in the wells with a high resolving power, the lens system comprises a plurality of objectives focused to infinity for collecting rays representing the samples, the objectives being at least partly arranged detachably inside wells in the sample plate. The disclosure also relates to a method of imaging samples in microtitre wells.

Owner:WALLAC

Examination of biological tissue using non-contact optical probes

InactiveUS20110172509A1Avoid detectionCancel noiseDiagnostics using lightSensorsLight beamContact position

An optical system for examination of biological tissue includes a light source, a light detector, optics and electronics. The light source generates a light beam to be transmitted to the biological tissue spaced apart from the source. The light detector is located away (i.e., in a non-contact position) from the examined biological tissue and is constructed to detect light that has migrated in the examined biological tissue. The electronics controls the light source and the light detector, and a system separates the reflected photons (e.g., directly reflected or scattered from the surface or superficial photons, i.e., “noise” photons) from the photons that have migrated in the examined biological tissue. This system prevents detection of the “noise” photons by the light detector or, after detection, eliminates the “noise” photons in the detected optical data used for tissue examination.

Owner:CHANCE BRITTON

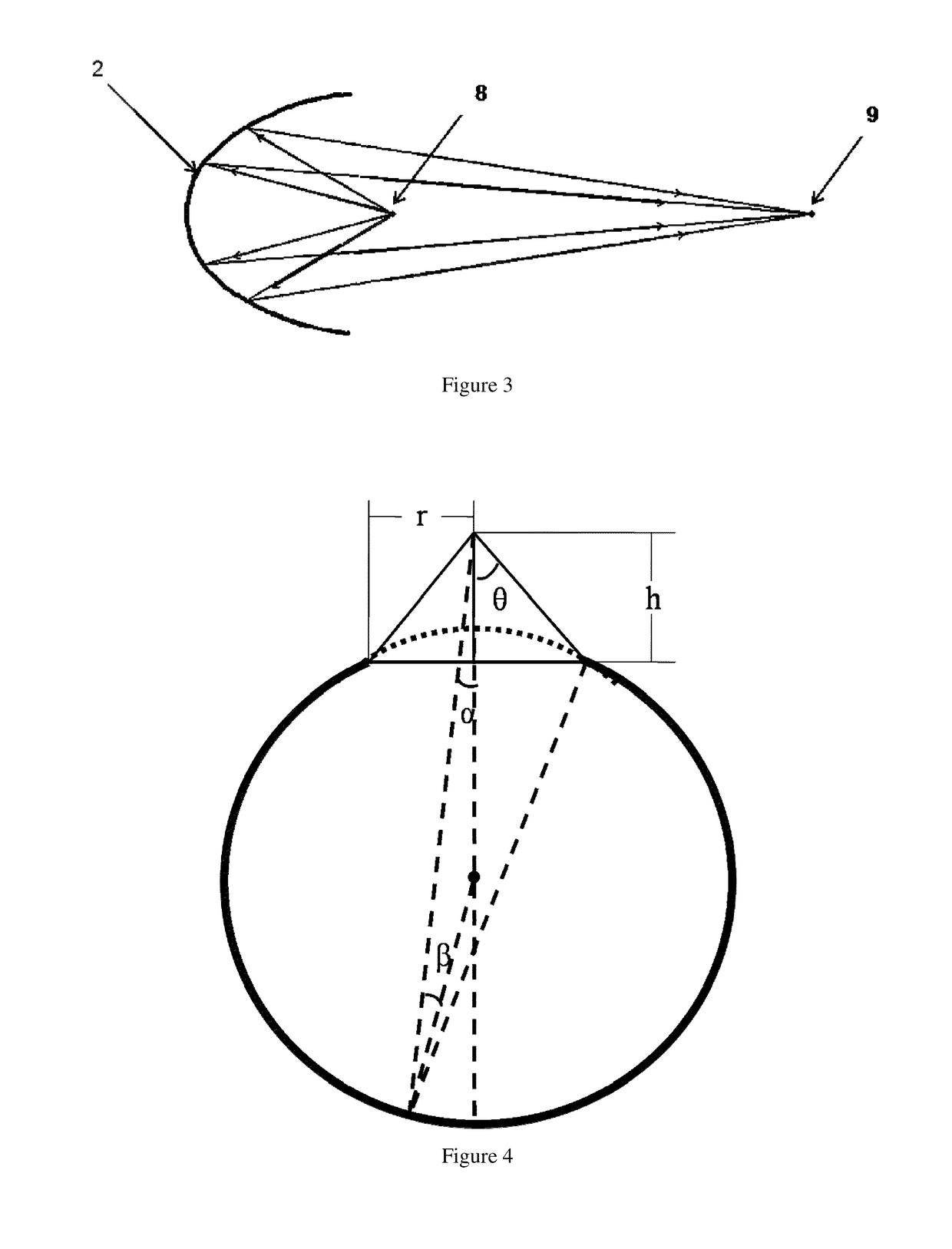

Solar energy systems using external reflectors

ActiveUS8471142B1Light collection efficiency is improvedReduce reflection lossSolar heating energySolar heat devicesOptoelectronicsLight filter

A solar energy concentrating system with high light collection efficiency includes a light concentrating unit, a light homogenizing unit and photovoltaic modules. The light concentrating unit includes a parabolic reflector and an ellipsoidal reflector which are coaxial and confocal. The light homogenizing unit includes an infrared filter and a hollow spherical reflector with a hole in its surface. When the system is under illumination, light is concentrated by the light concentrating unit through the hole in the spherical reflector surface and reflected by the inner surface of the spherical reflector onto the photovoltaic modules. The infrared filter covers the hole in the spherical reflector surface and reduces the heat in the photovoltaic modules under concentrated light. The combination of the parabolic reflector and the ellipsoidal reflector obtain highly concentrated light, and the hollow spherical reflector ensures light uniformity on the photovoltaic modules and light utilization efficiency.

Owner:PU NI TAI YANG NENG HANGZHOU CO

High efficiency secondary and back scattered electron detector

ActiveUS8895935B2Light collection efficiency is improvedLight collection efficiencyElectric discharge tubesMaterial analysis by optical meansThin metalLight guide

An assembly for a charged particle detection unit is described. The assembly comprises a scintillator disc, a partially coated light guide a thin metal tube for allowing the primary charged particle beam to pass through and a photomultiplier tube (PMT). The shape of scintillator disc and light guide are redesigned to improved the light signal transmission thereafter enhance the light collection efficiency. A light guide with a conicoidal surface over an embedded scintillator improved the light collection efficiency of 34% over a conventional design.

Owner:ASML NETHERLANDS BV

Examination of biological tissue using non-contact optical probes

InactiveUS7840257B2Avoid detectionCancel noiseDiagnostics using lightSensorsLight beamContact position

An optical system for examination of biological tissue includes a light source, a light detector, optics and electronics. The light source generates a light beam to be transmitted to the biological tissue spaced apart from the source. The light detector is located away (i.e., in a non-contact position) from the examined biological tissue and is constructed to detect light that has migrated in the examined biological tissue. The electronics controls the light source and the light detector, and a system separates the reflected photons (e.g., directly reflected or scattered from the surface or superficial photons, i.e., “noise” photons) from the photons that have migrated in the examined biological tissue. This system prevents detection of the “noise” photons by the light detector or, after detection, eliminates the “noise” photons in the detected optical data used for tissue examination.

Owner:NONINVASIVE TECH

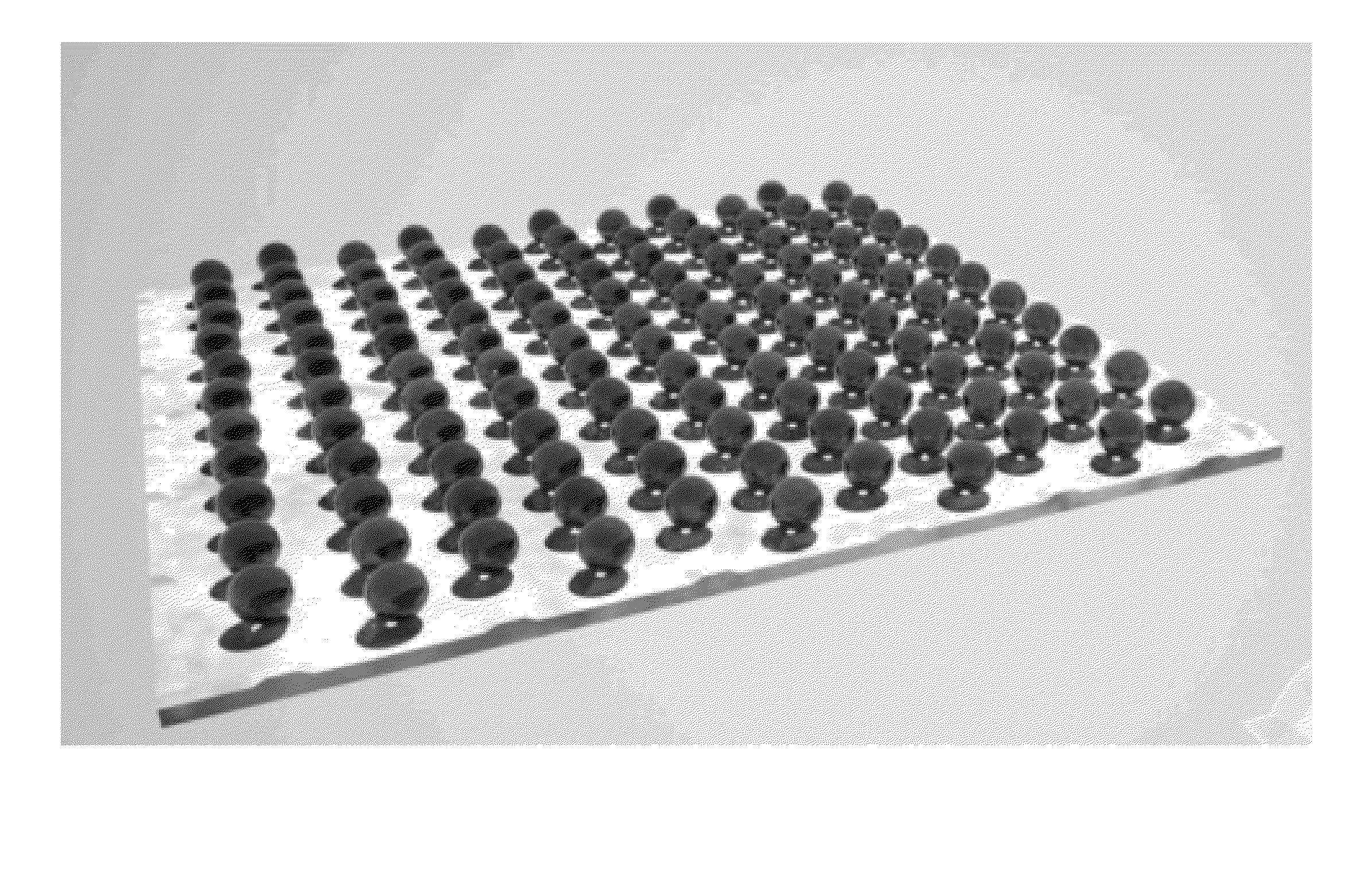

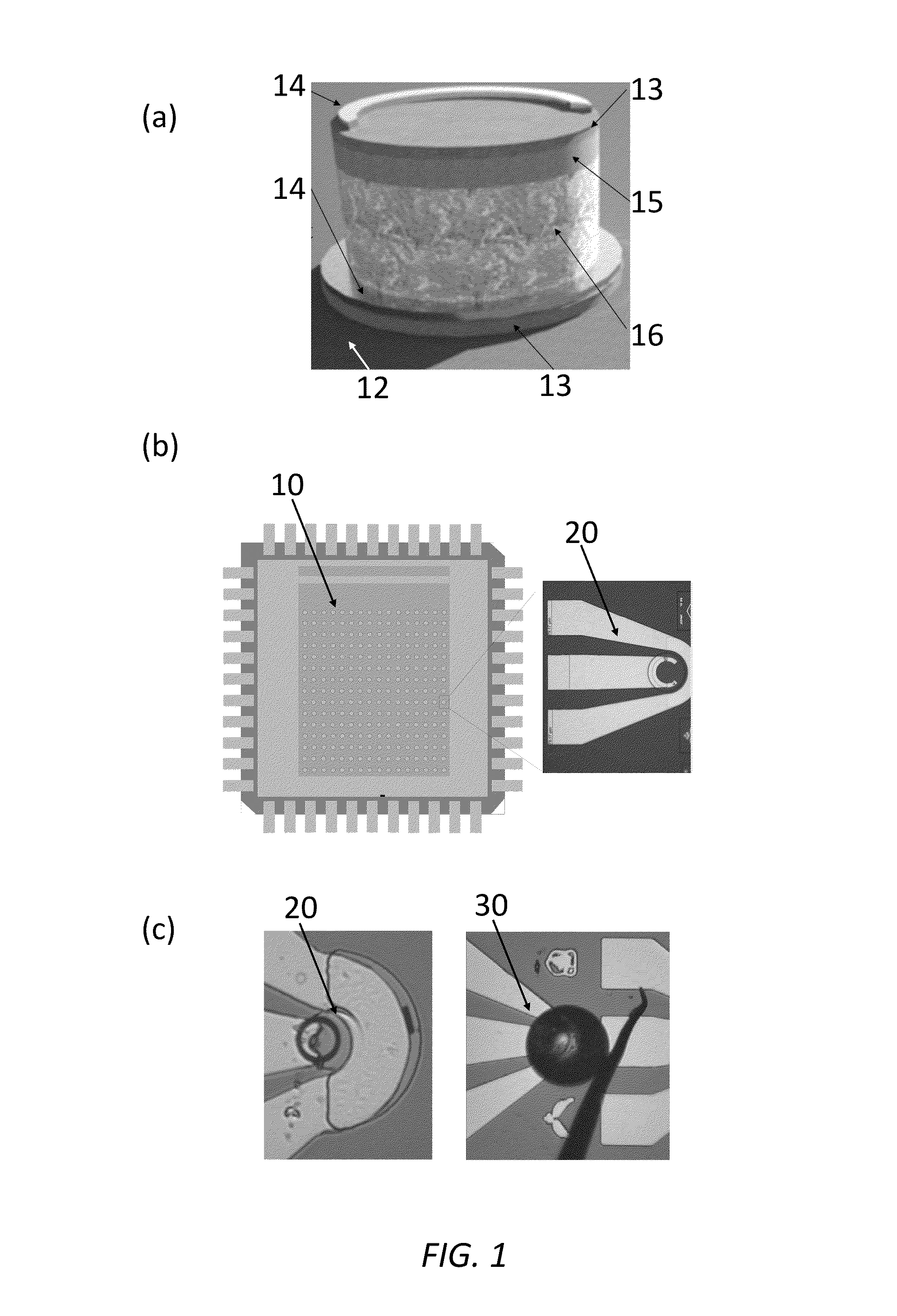

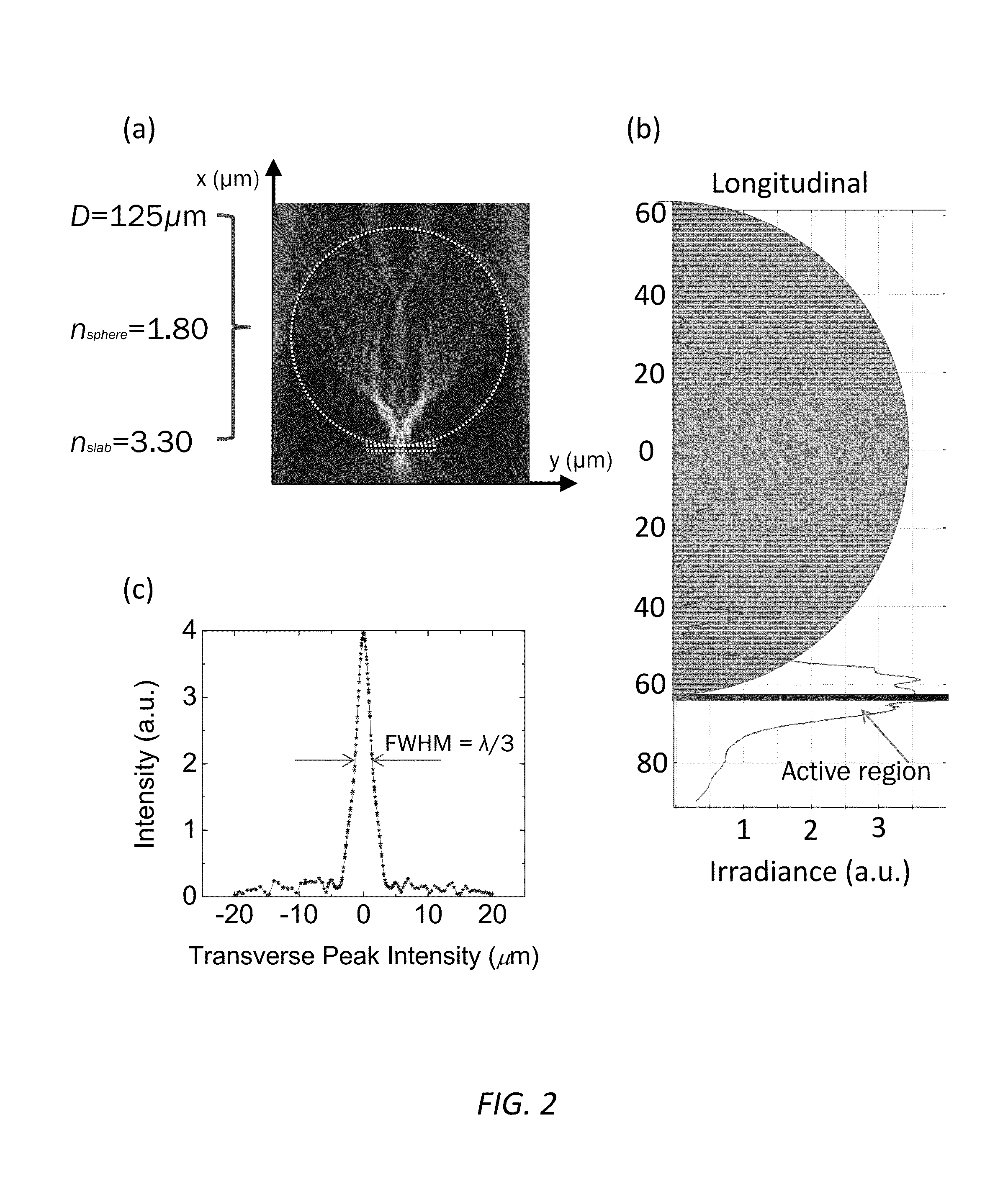

Photodetector focal plane array systems and methods

ActiveUS9362324B1Improve characteristicImprove efficiencySolid-state devicesPretreated surfacesPhotodetectorPhotovoltaic detectors

A photodetector focal plane array system, comprising: a substrate comprising a plurality of photosensitive regions; and a microcomponent disposed adjacent to each of the plurality of photosensitive regions operable for receiving incident radiation and directing a photonic nanojet into the associated photosensitive region. Optionally, each of the microcomponents comprises one of a microsphere and a microcylinder. Each of the microcomponents has a diameter of between between ˜λ and ˜100λ, where λ is the wavelength of the incident radiation. Each of the microcomponents is manufactured from a dielectric or semiconductor material. Each of the microcomponents has an index of refraction of between ˜1.4 and ˜3.5. Optionally, high-index components can be embedded in a lower index material. The microcomponents form an array of microcomponents disposed adjacent to the substrate.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

Colors only process to reduce package yield loss

InactiveUS7183598B2Efficient collectionHigh resolution imageSolid-state devicesSemiconductor/solid-state device manufacturingColor imageReflection loss

Disclosed is an ordered microelectronic fabrication sequence in which color filters are formed by conformal deposition directly onto a photodetector array of a CCD, CID, or CMOS imaging device to create a concave-up pixel surface, and, overlayed with a high transmittance planarizing film of specified index of refraction and physical properties which optimize light collection to the photodiode without additional conventional microlenses. The optically flat top surface serves to encapsulate and protect the imager from chemical and thermal cleaning treatment damage, minimizes topographical underlayer variations which would aberrate or cause reflection losses of images formed on non-planar surfaces, and, obviates residual particle inclusions induced during dicing and packaging. A CCD imager is formed by photolithographically patterning a planar-array of photodiodes on a semiconductor substrate. The photodiode array is provided with metal photoshields, passivated, and, color filters are formed thereon. A transparent encapsulant is deposited to planarize the color filter layer and completes the solid-state color image-forming device without conventional convex microlenses.

Owner:TAIWAN SEMICON MFG CO LTD

Photoelectric conversion device and manufacturing method thereof

InactiveUS20100071767A1Light collection efficiencyImprove conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingElectrical conductorSingle crystal

An object is to increase conversion efficiency of a photoelectric conversion device without increase in the manufacturing steps. The photoelectric conversion device includes a first semiconductor layer formed using a single crystal semiconductor having one conductivity type which is formed over a supporting substrate, a buffer layer including a single crystal region and an amorphous region, a second semiconductor layer which includes a single crystal region and an amorphous region and is provided over the buffer layer, and a third semiconductor layer having a conductivity type opposite to the one conductivity type, which is provided over the second semiconductor layer. A proportion of the single crystal region is higher than that of the amorphous region on the first semiconductor layer side in the second semiconductor layer, and the proportion of the amorphous region is higher than that of the single crystal region on the third semiconductor layer side.

Owner:SEMICON ENERGY LAB CO LTD

Colors only process to reduce package yield loss

InactiveUS20050121737A1Efficient collectionHigh resolution imageSolid-state devicesSemiconductor/solid-state device manufacturingColor imageReflection loss

Disclosed is an ordered microelectronic fabrication sequence in which color filters are formed by conformal deposition directly onto a photodetector array of a CCD, CID, or CMOS imaging device to create a concave-up pixel surface, and, overlayed with a high transmittance planarizing film of specified index of refraction and physical properties which optimize light collection to the photodiode without additional conventional microlenses. The optically flat top surface serves to encapsulate and protect the imager from chemical and thermal cleaning treatment damage, minimizes topographical underlayer variations which would aberrate or cause reflection losses of images formed on non-planar surfaces, and, obviates residual particle inclusions induced during dicing and packaging. A CCD imager is formed by photolithographically patterning a planar-array of photodiodes on a semiconductor substrate. The photodiode array is provided with metal photoshields, passivated, and, color filters are formed thereon. A transparent encapsulant is deposited to planarize the color filter layer and completes the solid-state color image-forming device without conventional convex microlenses.

Owner:TAIWAN SEMICON MFG CO LTD

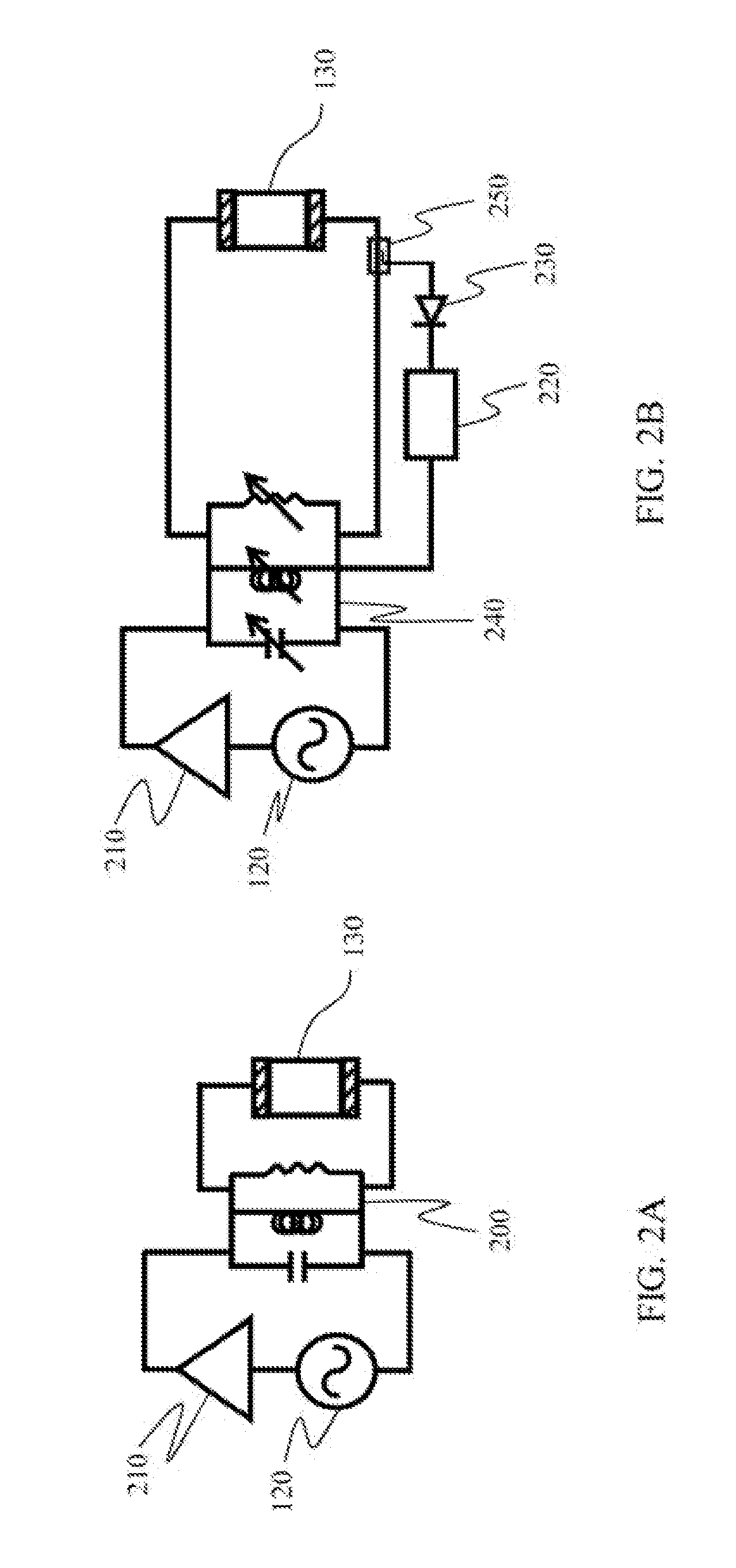

External resonator electrode-less plasma lamp and method of exciting with radio-frequency energy

InactiveUS20120086352A1Increase rangeEffective impedance matchingElectric lighting sourcesGas discharge lamp usageRadio frequency energyElectromagnetic radiation

Described is an electrode-less plasma lamp comprising a gas-fill vessel, a gas-fill contained within the gas-fill vessel, an RF electromagnetic radiation source, an RF electromagnetic resonator, an output probe that couples RF energy from the RF electromagnetic resonator to the gas-fill vessel, an input probe that couples RF energy from the RF electromagnetic radiation source to the resonator, and a grounding strap that holds a metal veneer surrounding the resonator and a portion of the gas-fill vessel at RF ground. Also described are many variations of the electrode-less plasma lamp; non-limiting examples of which include embodiments that employ other probes in a Dielectric Resonant Oscillator to drive the lamp, and many methods of improving light-harvesting, including raising the gas-fill vessel away from the resonator via a coaxial type transmission line, and collecting light with an optical reflector.

Owner:TOPANGA USA

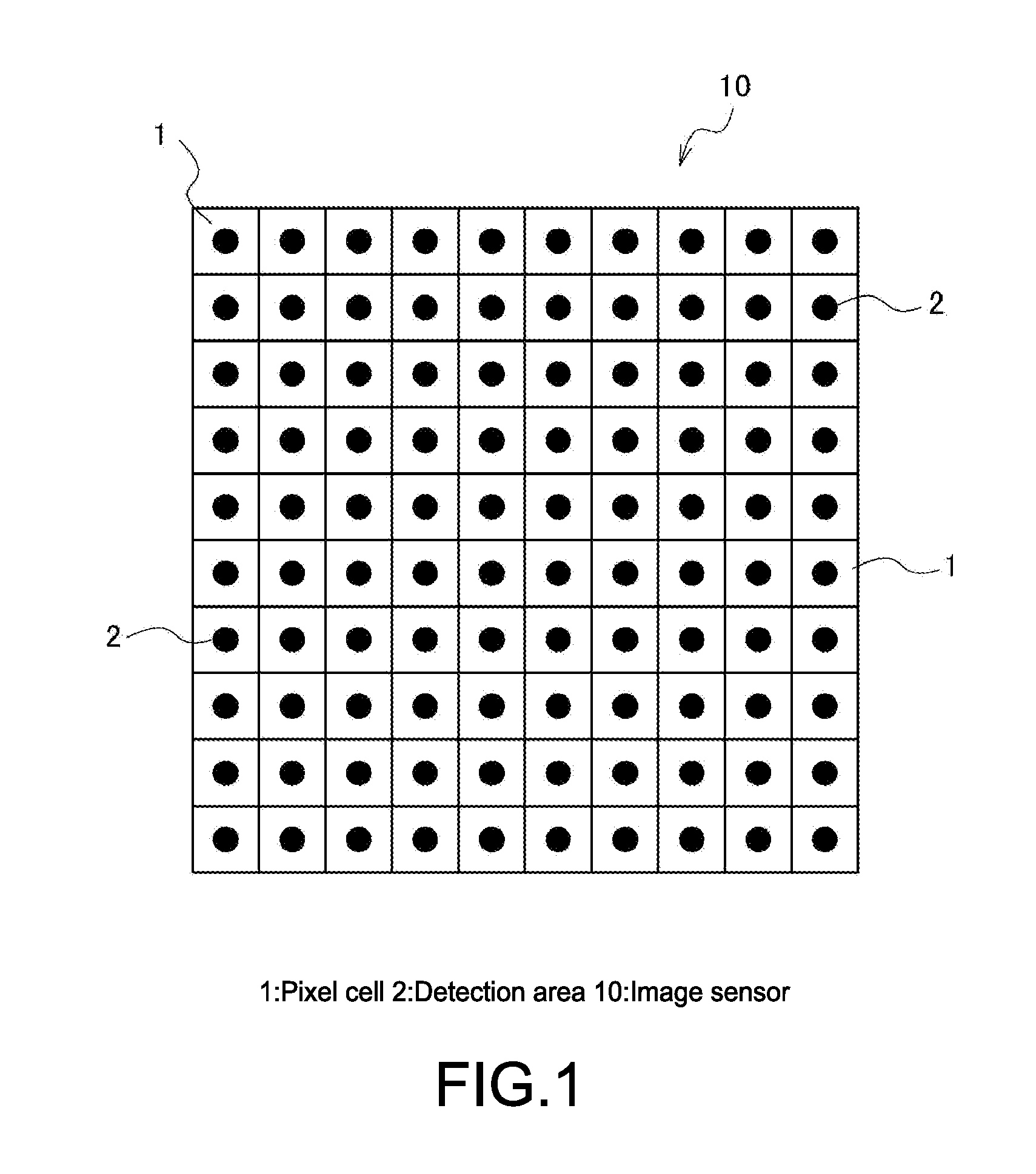

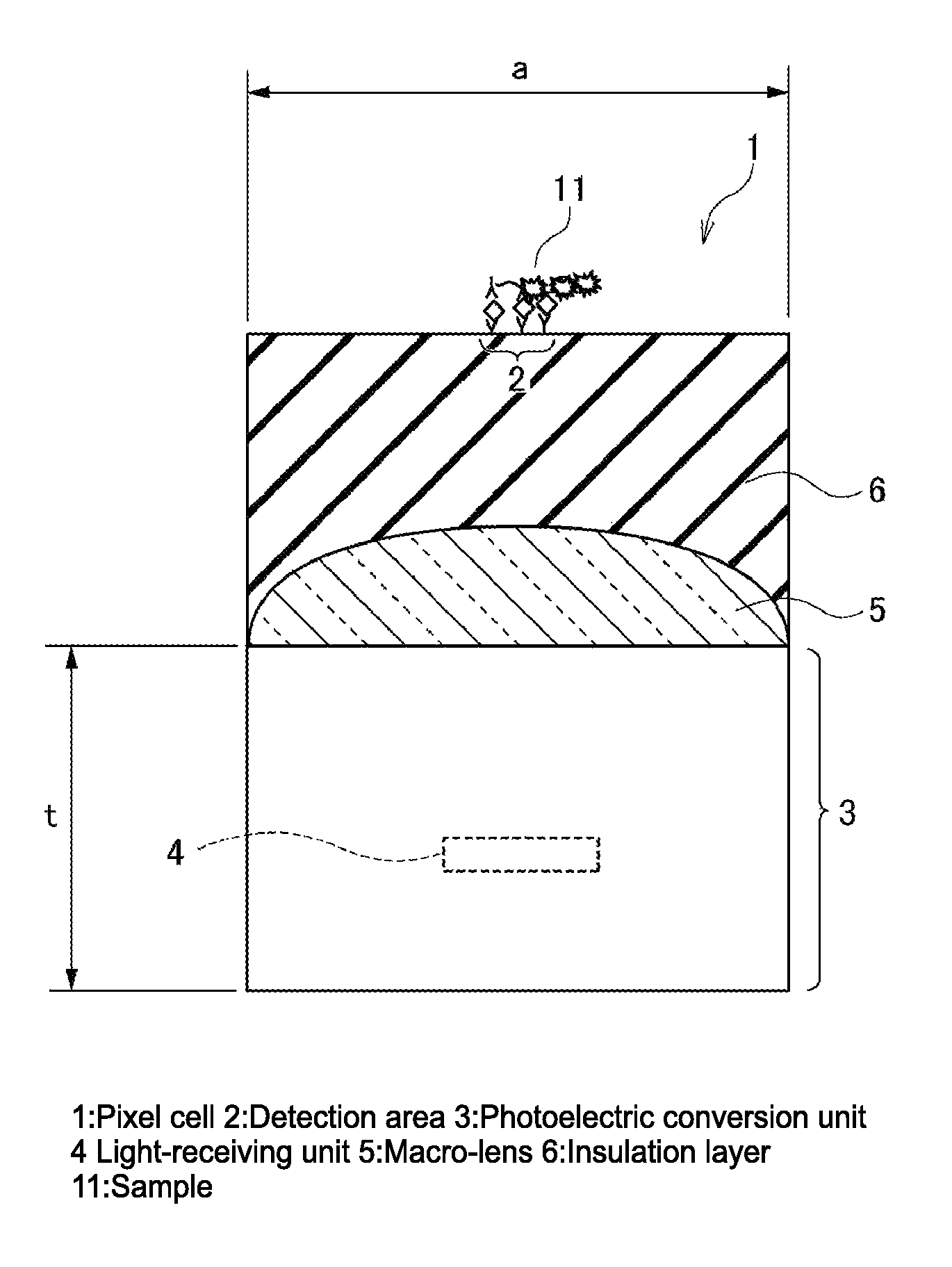

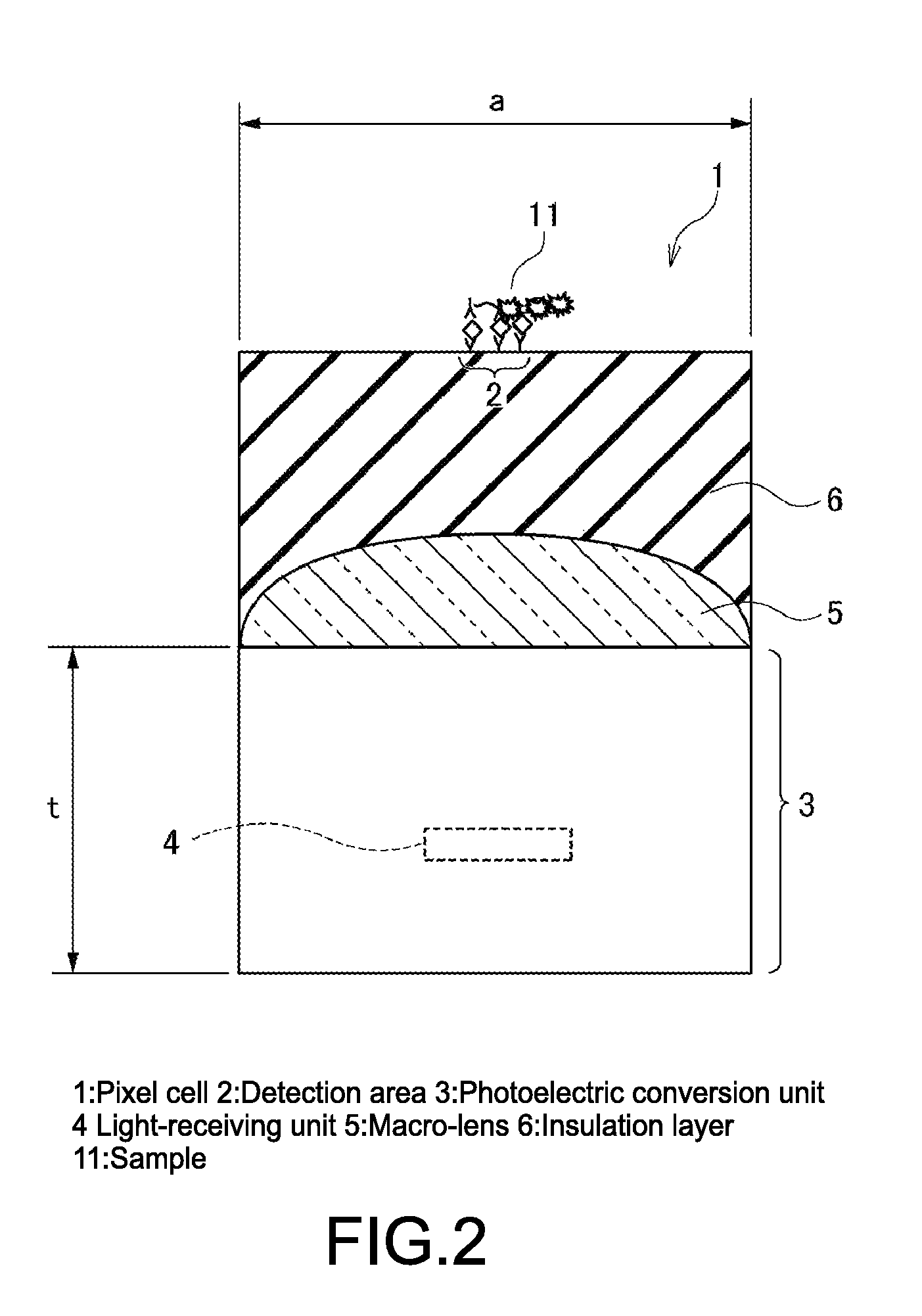

Image sensor, production method therefor, and inspection apparatus

ActiveUS20140118590A1Light collection efficiencyCrosstalk among pixels can be reducedTelevision system detailsTelevision system scanning detailsInsulation layerElectric signal

[Object]To provide an image sensor having high light collection efficiency and less crosstalk among pixels, a production method therefor, and an inspection apparatus.[Solving means]In an image sensor including a light source conversion unit that includes a plurality of light-receiving devices and converts incident light into an electric signal, a plurality of lenses that are provided in an immediately-above area of the light-receiving devices and collect light toward a light-receiving unit of the light-receiving devices positioned right below the lenses, and an insulation layer that is formed of an optically-transparent material and formed above the lenses, detection areas are provided on a surface of the insulation layer while being apart from one another for each of the light-receiving devices, a center of each of the detection areas being positioned on an extended line connecting a center of the light-receiving unit of each of the light-receiving devices and a center of the lens provided right above each of the light-receiving devices. In addition, a sample as a detection target is fixed to at least the detection areas.

Owner:SONY CORP

High efficiency scintillator detector for charged particle detection

ActiveUS8829451B2Improve collection efficiencyLight collection efficiencyElectric discharge tubesMaterial analysis by optical meansLight guidePhotomultiplier

Owner:ASML NETHERLANDS BV

Photodetector focal plane array systems and methods

ActiveUS20160190194A1Improve efficiencyHigh frequency responseSolid-state devicesSemiconductor/solid-state device manufacturingPhotovoltaic detectorsSemiconductor materials

A photodetector focal plane array system, comprising: a substrate comprising a plurality of photosensitive regions; and a microcomponent disposed adjacent to each of the plurality of photosensitive regions operable for receiving incident radiation and directing a photonic nanojet into the associated photosensitive region. Optionally, each of the microcomponents comprises one of a microsphere and a microcylinder. Each of the microcomponents has a diameter of between ˜λ and ˜100λ, where λ is the wavelength of the incident radiation. Each of the microcomponents is manufactured from a dielectric or semiconductor material. Each of the microcomponents has an index of refraction of between ˜1.4 and ˜3.5. Optionally, high-index components can be embedded in a lower index material. The microcomponents form an array of microcomponents disposed adjacent to the substrate.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

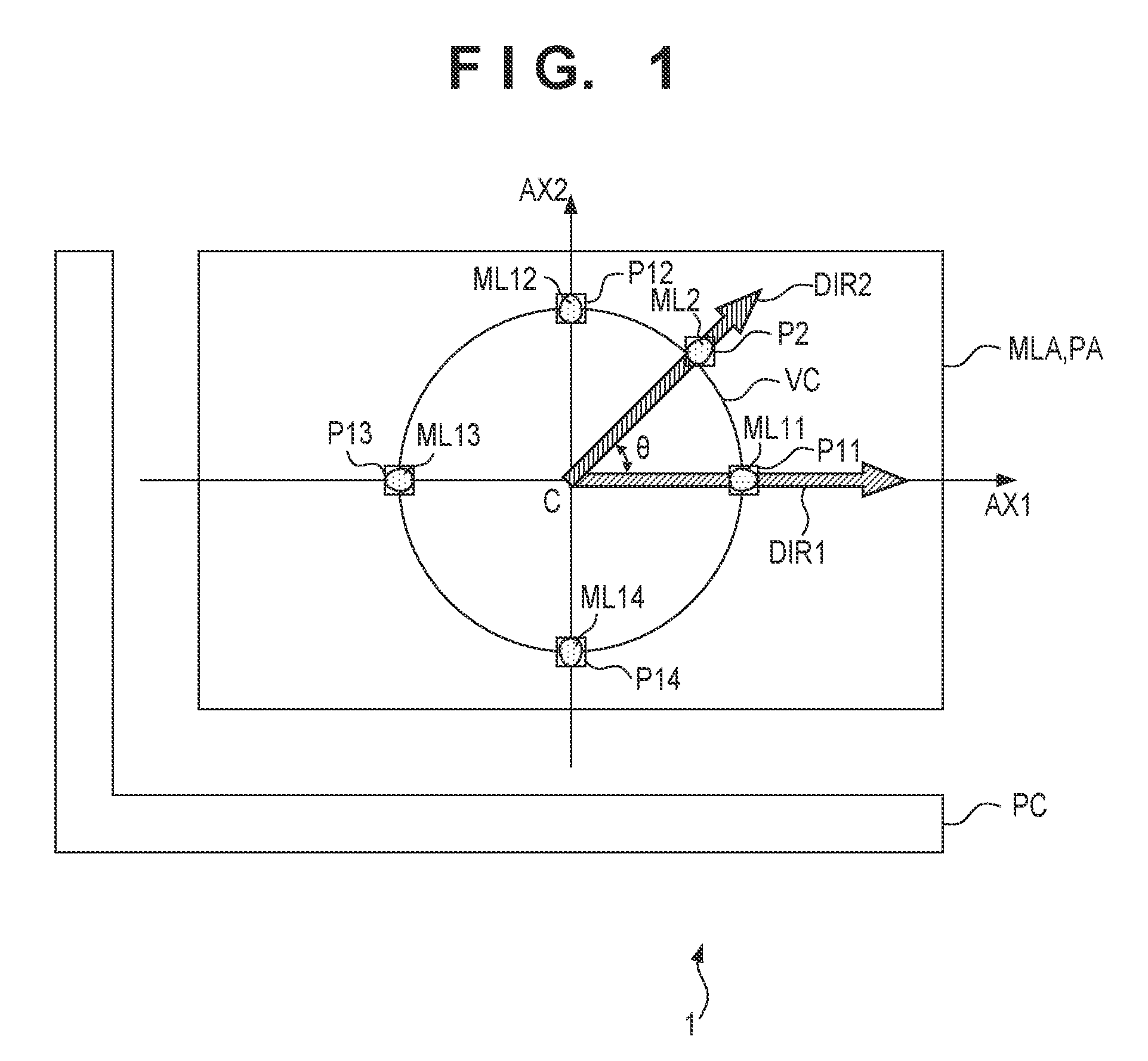

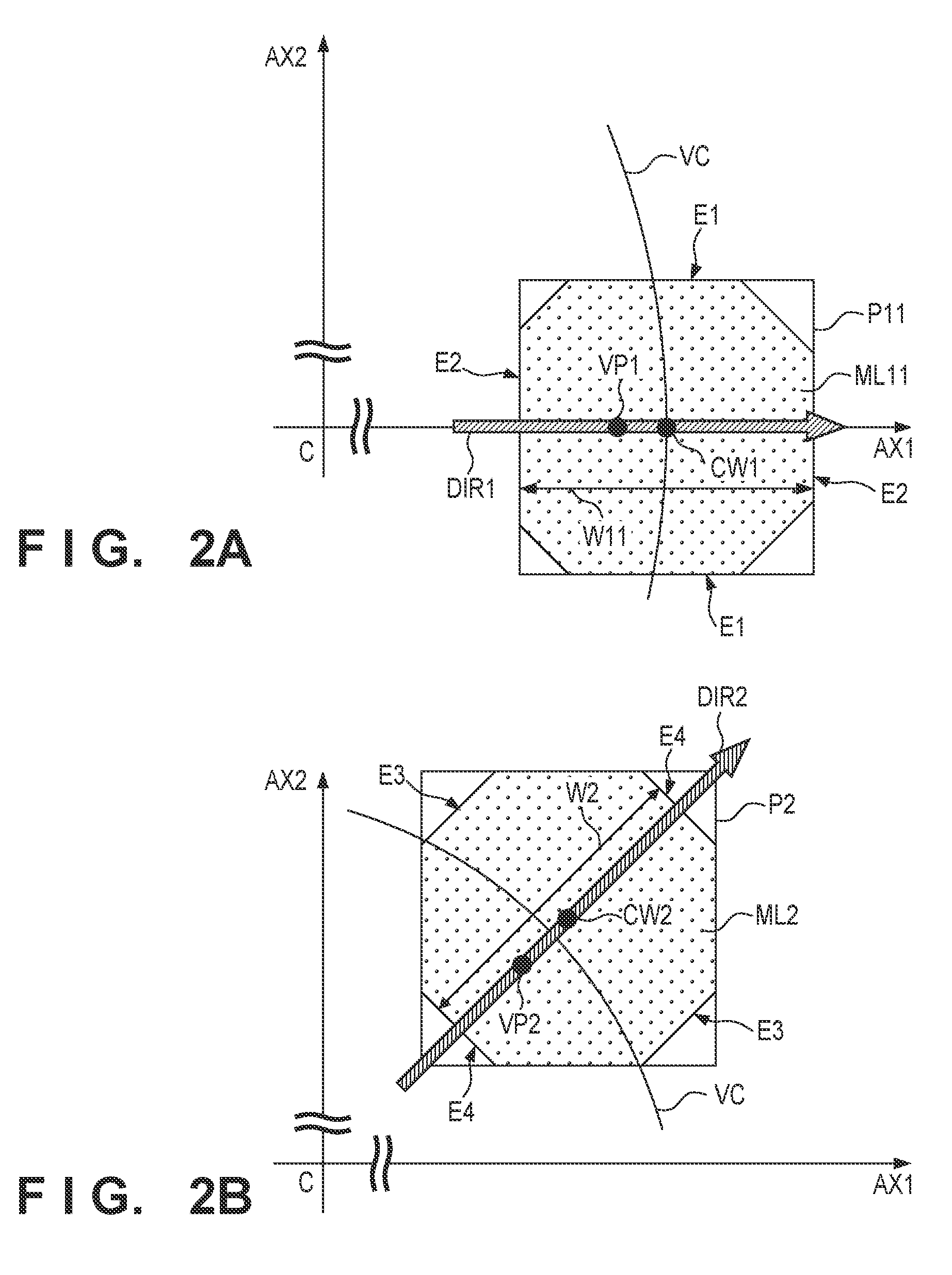

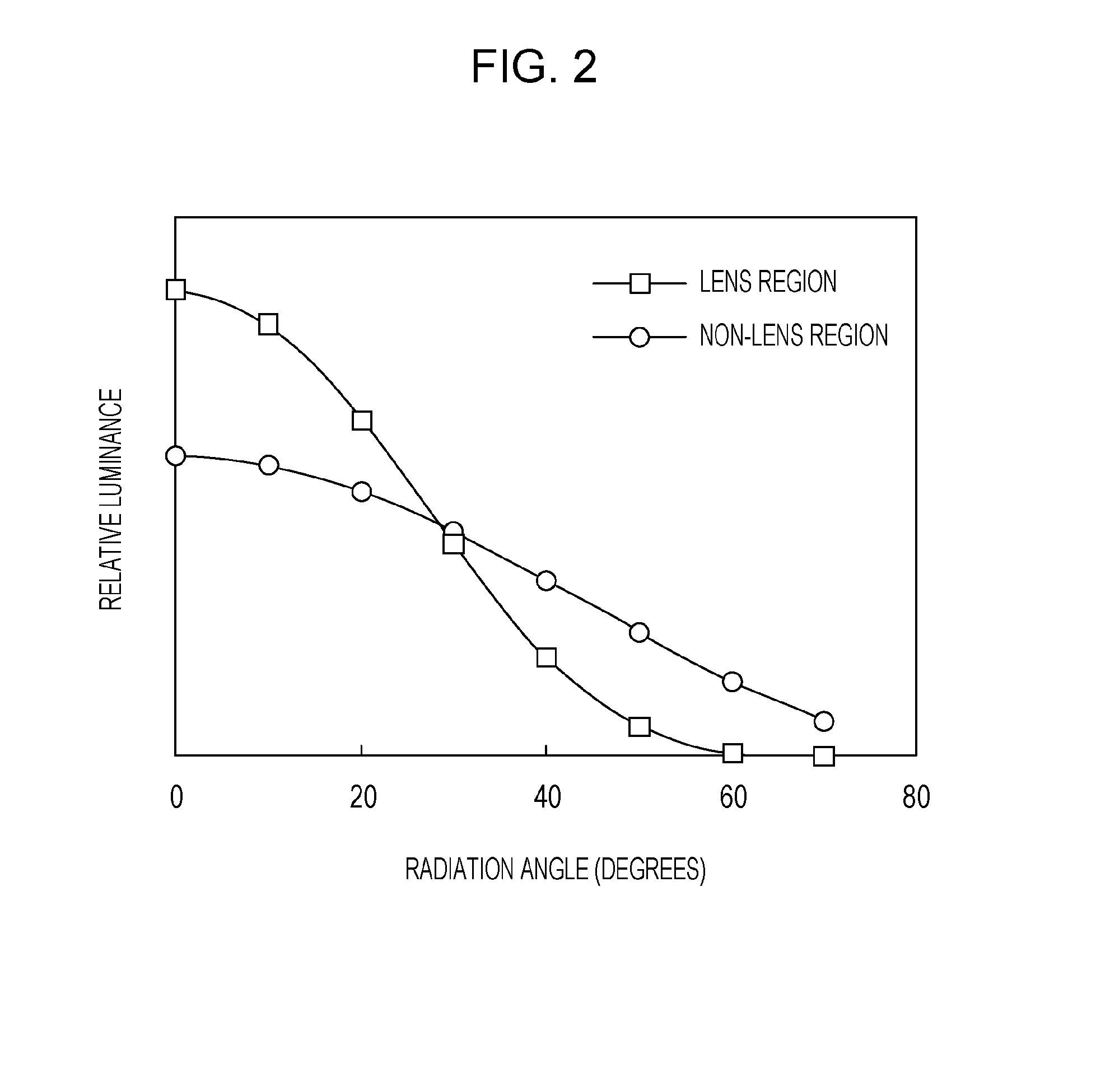

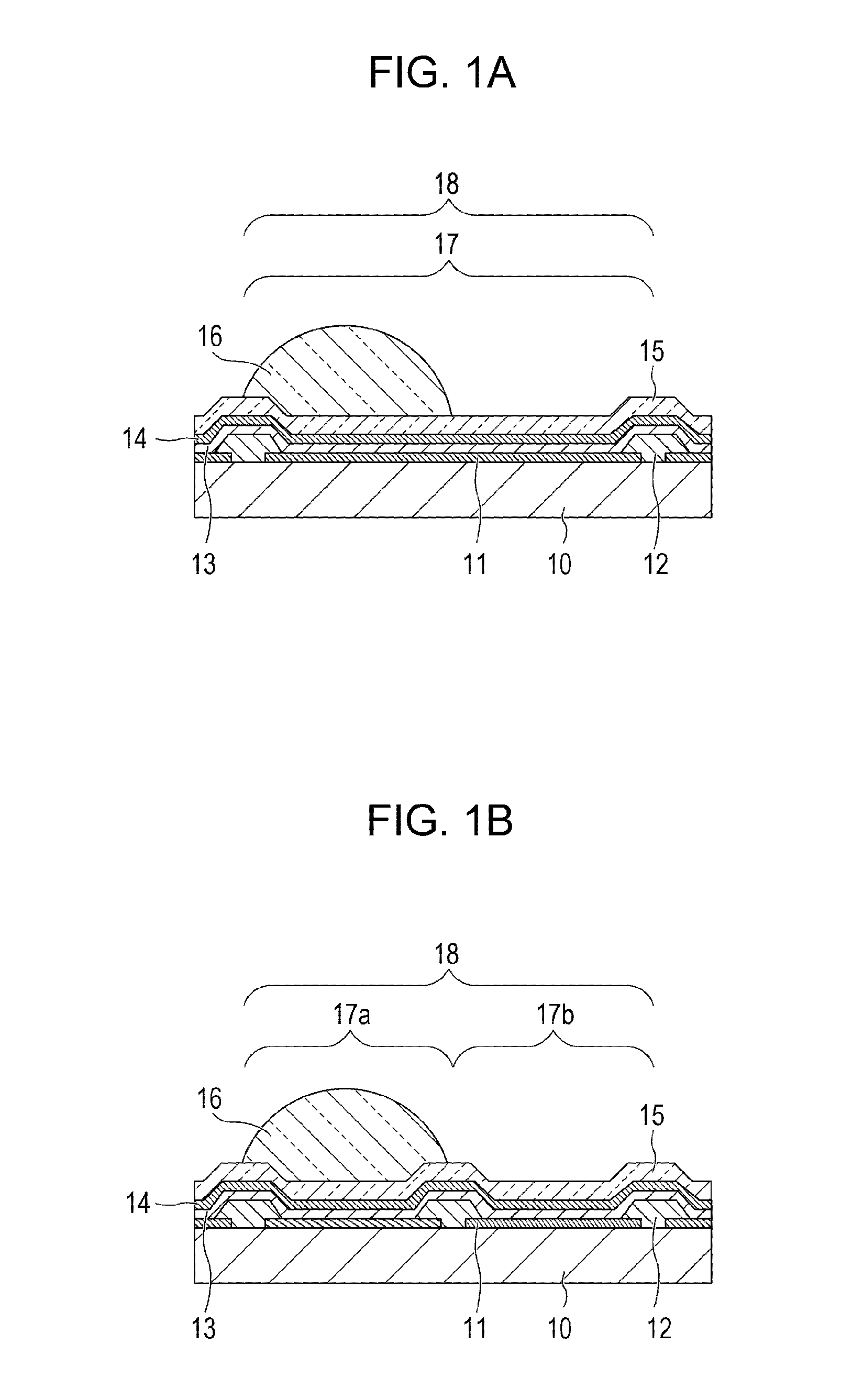

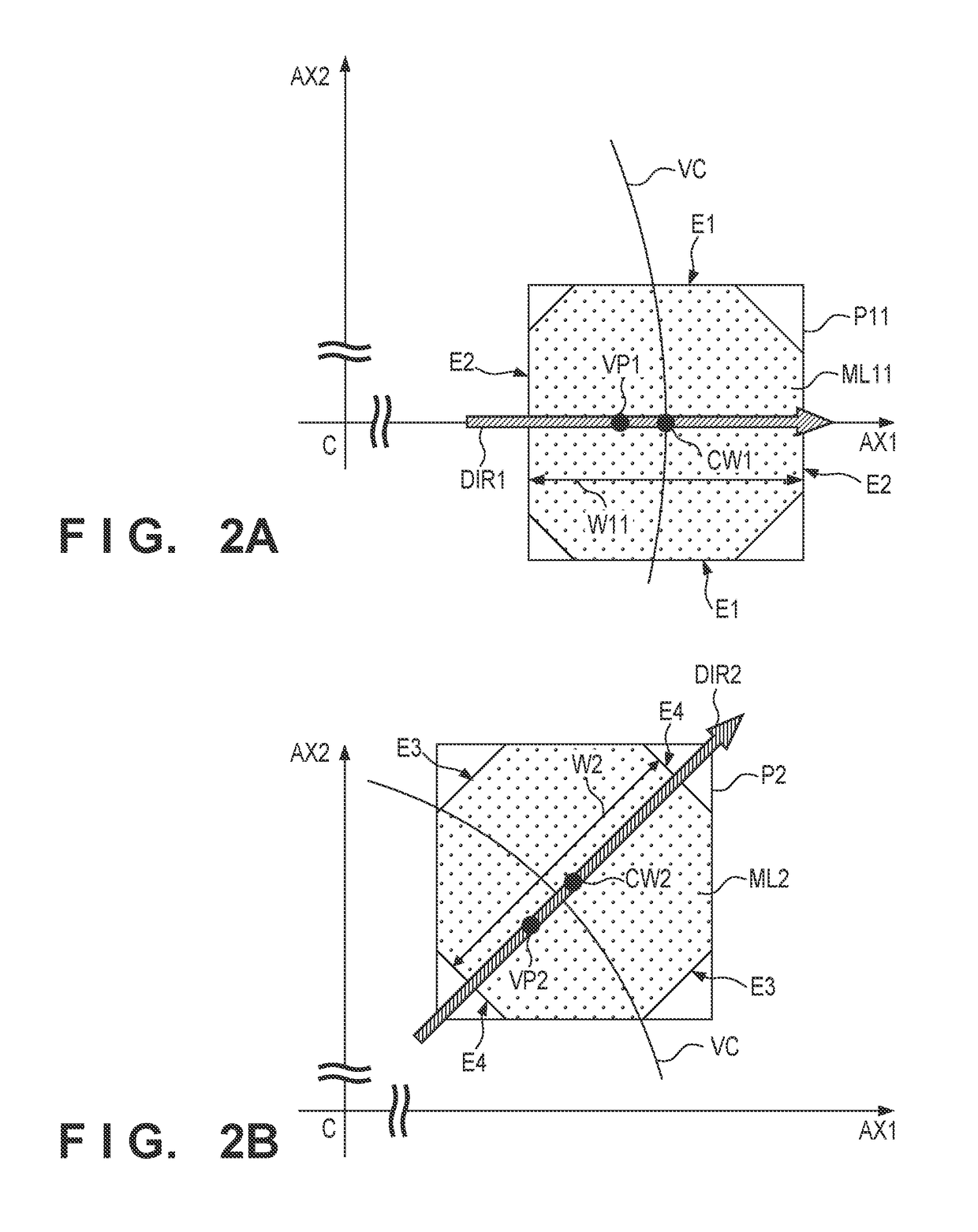

Solid-state image sensor and camera

ActiveUS20160334550A1Light collection efficiency is improvedLight collection efficiencyTelevision system detailsSolid-state devicesMicro lens arrayPhysics

An image sensor includes microlens array having microlenses arranged to constitute rows and columns. When first axis parallel to the rows and passing through array center of the microlens array, and second axis parallel to the columns and passing through the array center are defined, microlens positioned on virtual circle having the array center as center includes first microlens positioned on the first or second axis, and second microlens positioned on neither the first axis nor the second axis. The first and second microlens have non-circular bottom shape, and width of the second microlens in second direction passing through the second microlens and the array center is larger than width of the first microlens in first direction passing through the first microlens and the array center.

Owner:CANON KK

Projector type headlamp of maximized light collecting efficiency

InactiveUS20120182752A1Light collection efficiency is improvedIncrease awarenessNon-electric lightingVehicle headlampsOptical axisOptoelectronics

An improved light collecting efficiency in a projector type automotive headlamp is achieved by including a curved mirror to re-direct light otherwise absorbed by a rear surface of the blocking cut-off shield in “low beam” operating mode of the headlamp. When the shield is moved to a second non-blocking position, a mirror segment conforms to the curved surface of the substantially ellipsoidal reflector to maximize lumen output in “high beam” operating mode of the headlamp. In addition, auxiliary mirror segments may be used to provide a more complete substantially ellipsoidal reflector configuration that maximizes the light collection efficiency. Preferably, the cap holder is purposefully offset in order to position the centerline of the bowed arc of the arc discharge light source in alignment with the optical axis of the optical system in order to maximize light collection efficiency.

Owner:GENERAL ELECTRIC CO

Organic electroluminescence display device

InactiveUS20120038265A1Wide radiation angle characteristicLight utilization efficiency be improveDischarge tube luminescnet screensLamp detailsOrganic electroluminescenceDisplay device

An organic electroluminescence display device includes a plurality of pixels each of which includes at least one organic electroluminescence device and a lens. Each pixel includes a light emitting region provided with a lens and a light emitting region provided with no lens. An area of the light emitting region provided with a lens is smaller than an area of the light emitting region provided without a lens.

Owner:CANON KK

Image sensor, production method therefor, and inspection apparatus

ActiveUS9324751B2Light collection efficiencyCrosstalk among pixels can be reducedTelevision system detailsSolid-state devicesInsulation layerElectric signal

Owner:SONY CORP

Organic electroluminescence display device

InactiveUS20120038266A1Wide radiation angle characteristicLight utilization efficiency can be improvedDischarge tube luminescnet screensLamp detailsDisplay deviceOrganic electroluminescence

An organic electroluminescence display device includes a plurality of pixels and an array of lenses arranged thereupon. Each pixel includes a light emitting region provided with a lens and a light emitting region provided without a lens. The light emitting regions of each pixel includes an organic electroluminescence material. The lenses are arranged in a staggered pattern.

Owner:CANON KK

Solid-state image sensor and camera

ActiveUS10114151B2Light collection efficiencyTelevision system detailsSolid-state devicesMicro lens arrayPhysics

An image sensor includes microlens array having microlenses arranged to constitute rows and columns. When first axis parallel to the rows and passing through array center of the microlens array, and second axis parallel to the columns and passing through the array center are defined, microlens positioned on virtual circle having the array center as center includes first microlens positioned on the first or second axis, and second microlens positioned on neither the first axis nor the second axis. The first and second microlens have non-circular bottom shape, and width of the second microlens in second direction passing through the second microlens and the array center is larger than width of the first microlens in first direction passing through the first microlens and the array center.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com