Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

282 results about "Radiative heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiant heat is heat which radiates out from an element, warming objects rather than the air. An example of this heat that many people may be familiar with is the heat which comes off an electric element on a stove.

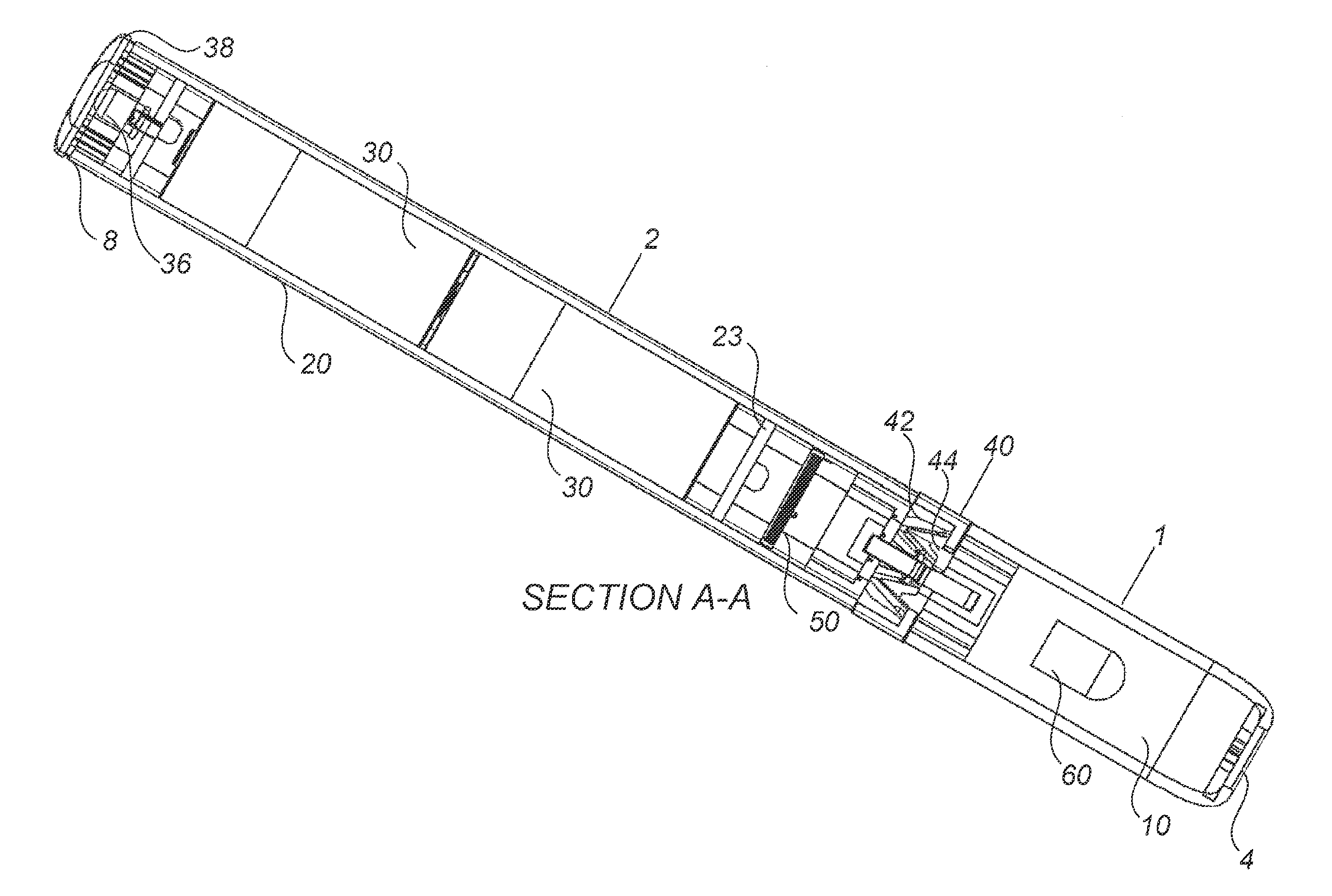

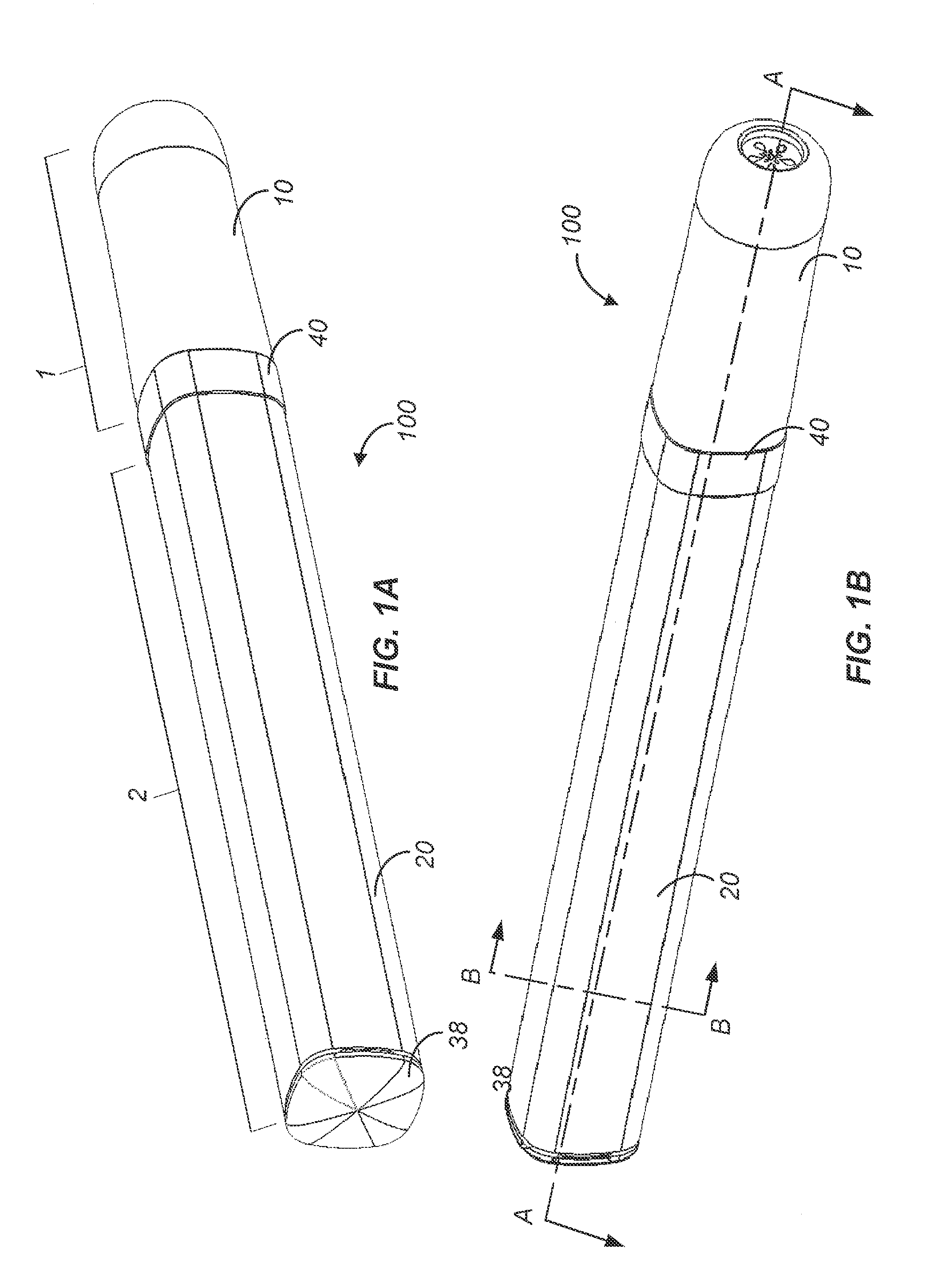

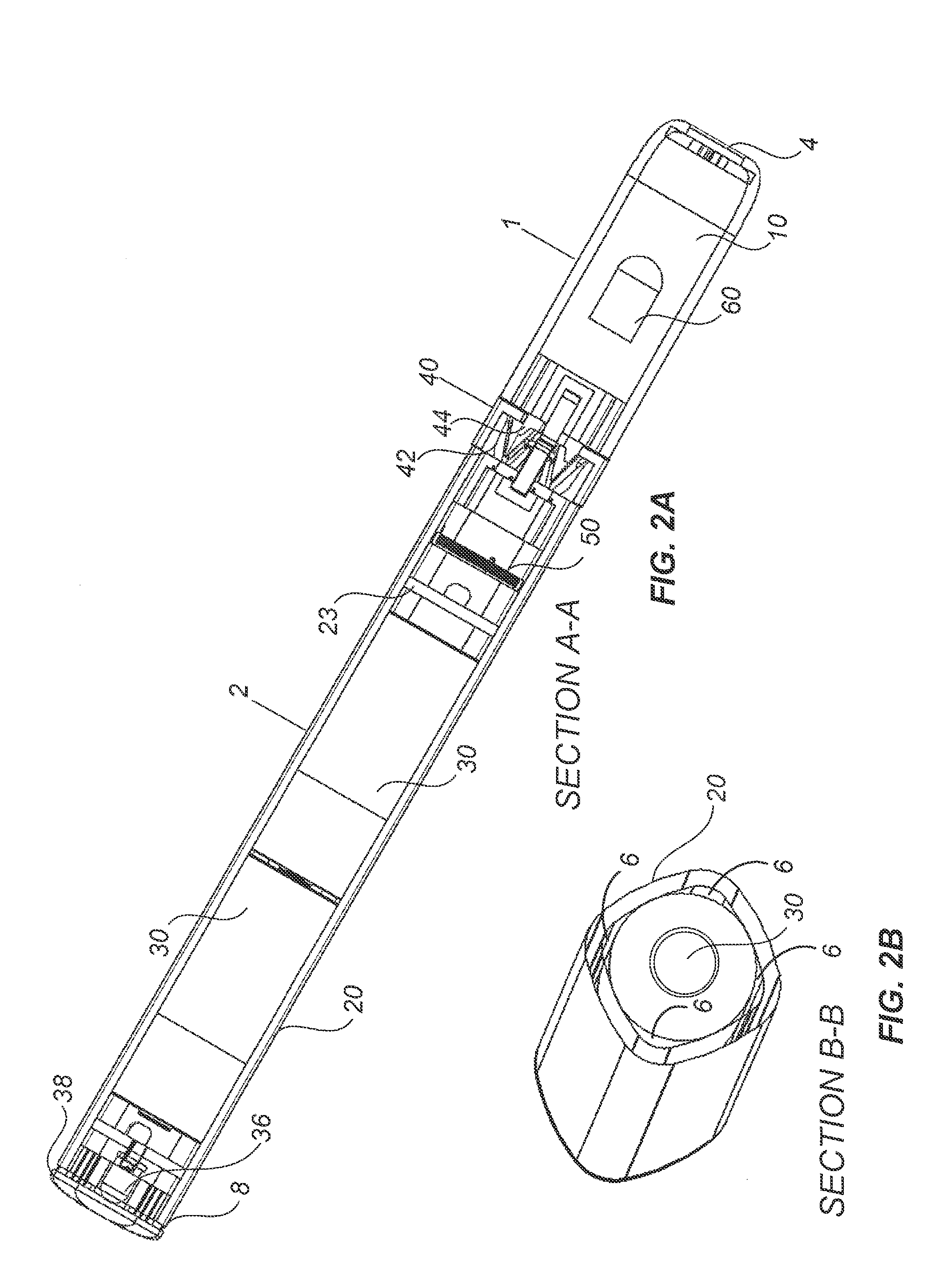

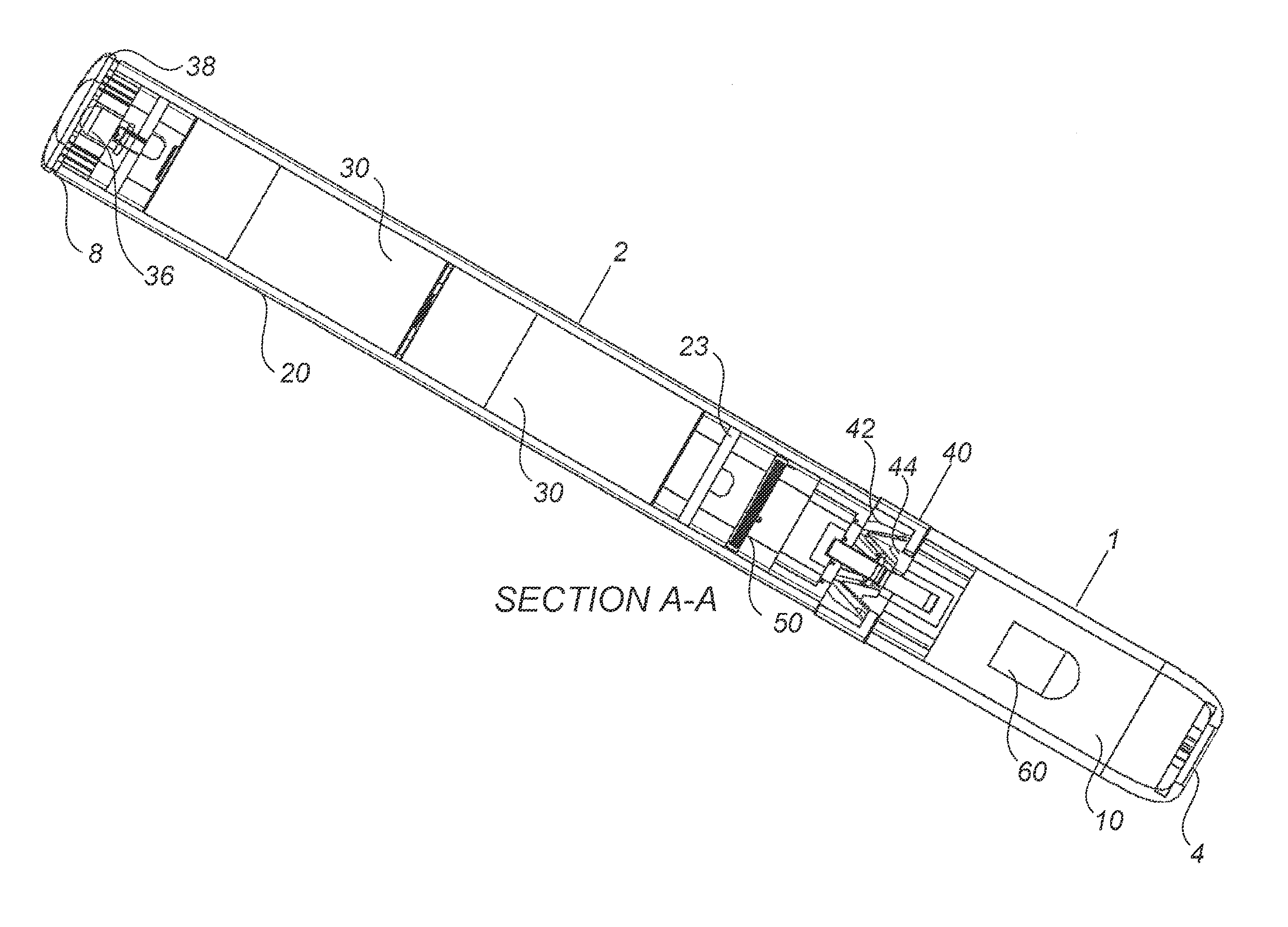

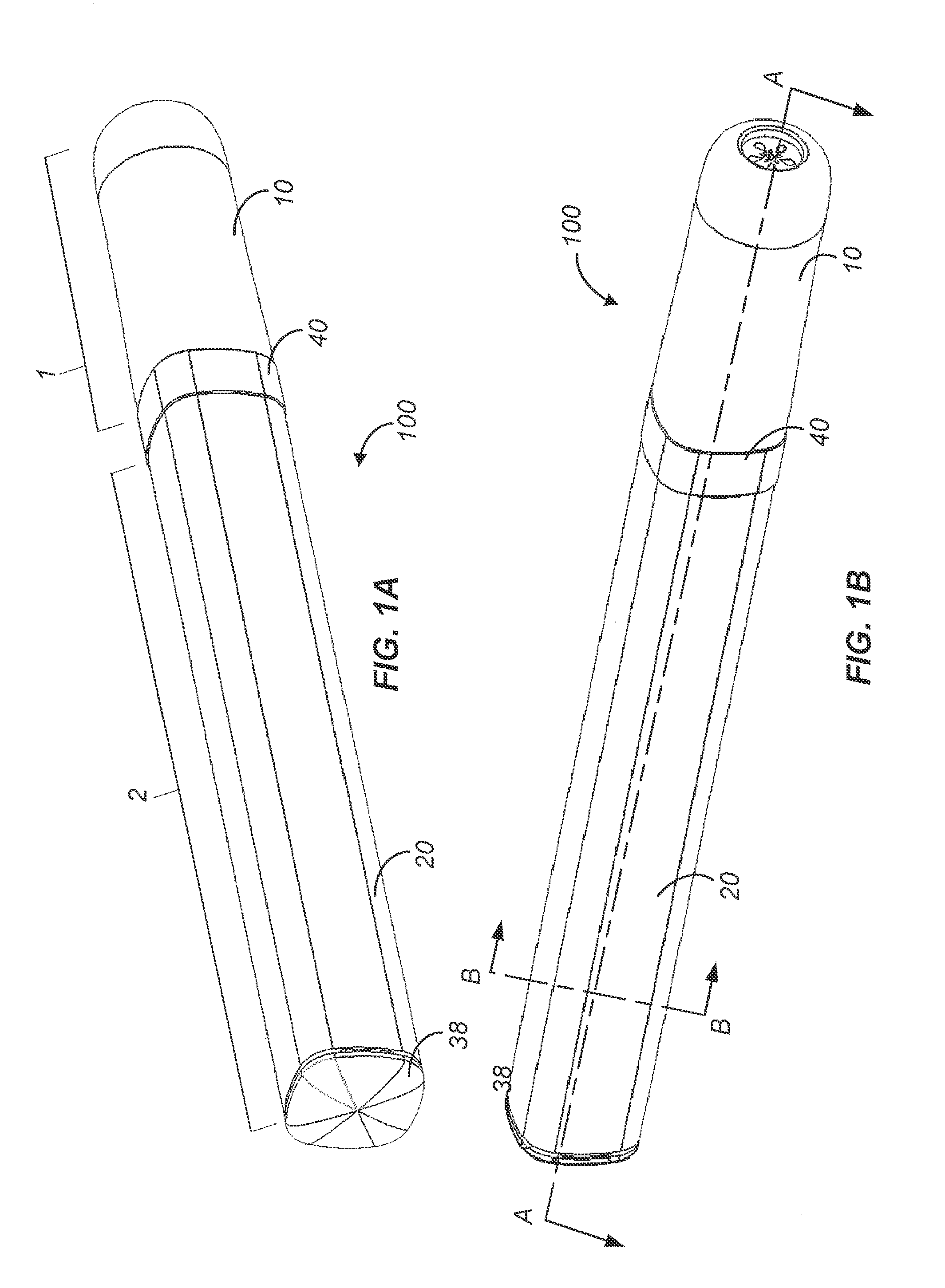

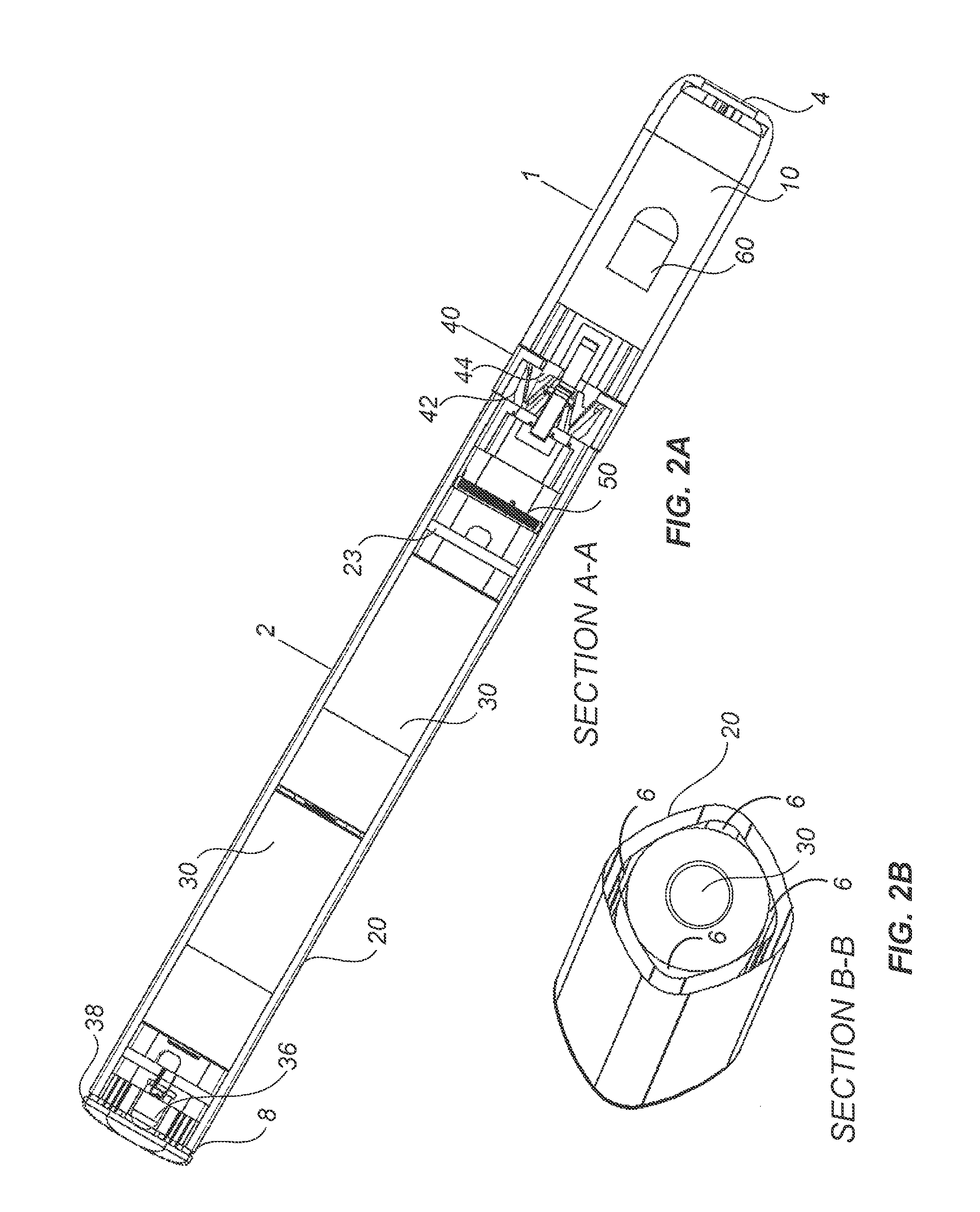

Electronic vaporizing device and methods for use

InactiveUS20130298905A1Increase heatImproved vaporizing capabilityTobacco devicesInhalatorsCelluloseBrick

Devices and methods for vaporizing active ingredients of a selected substance for inhalation using a portable vaporization device are provided herein. In certain aspects, the device includes a portable power source, a heating portion, an inhalation sensor, a temperature sensor, a distal light source, and a grinding portion. In response to an inhalation by a user, the power source energizes a heating element of the heating portion so as to heat air flow to a desired vaporization temperature within a few seconds of detecting inhalation, using convection and radiative heating. The device may include a receptacle for receiving a cartridge containing a pre-prepared substance, such as a liquid, gel, powder, or solid brick, and a grinding portion to allow a user to grind intact portions of cellulose-based material into smaller pieces to facilitate vaporization by manually rotating portions of the device relative to each other.

Owner:UPTOKE

Process chamber for dielectric gapfill

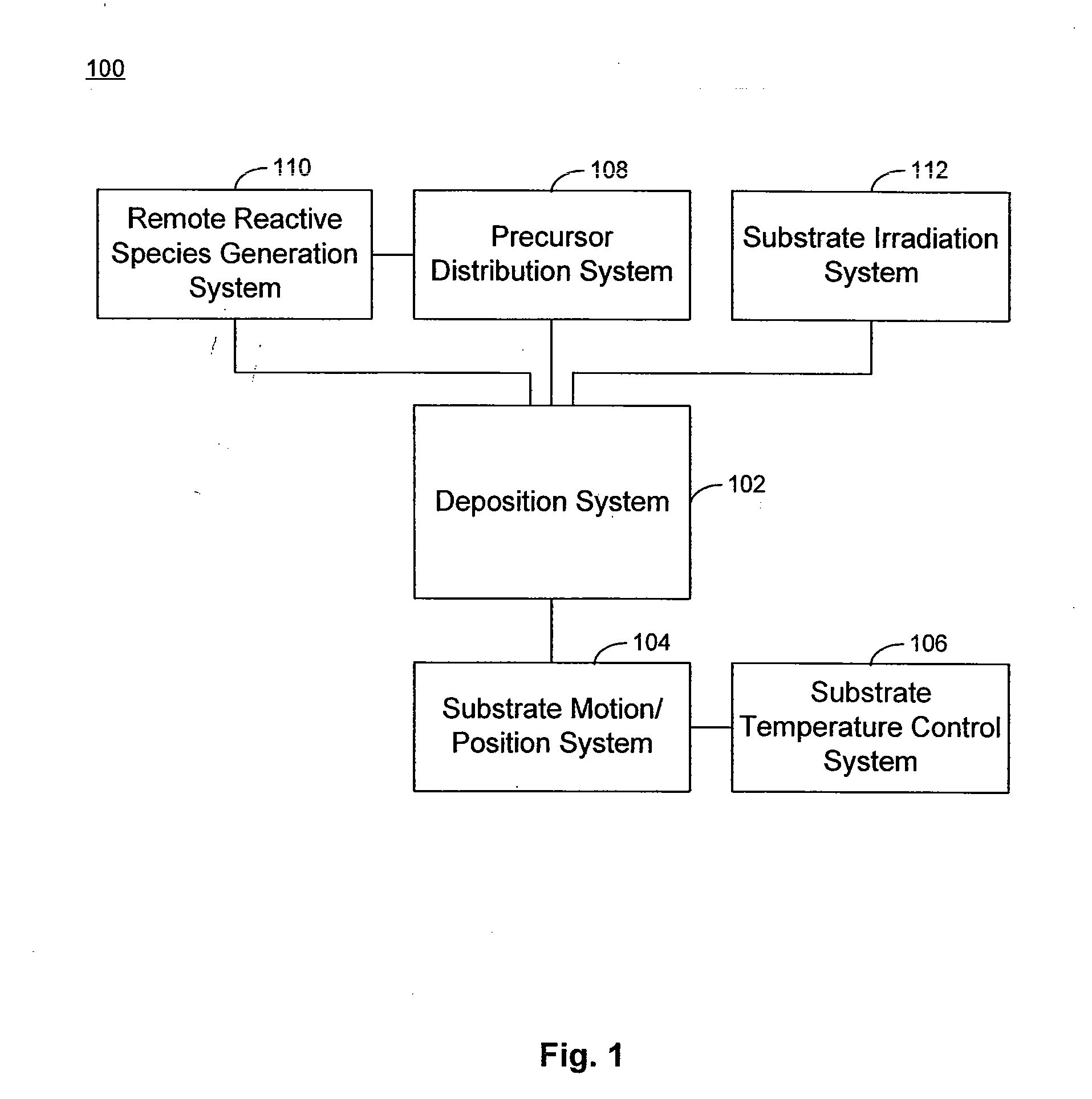

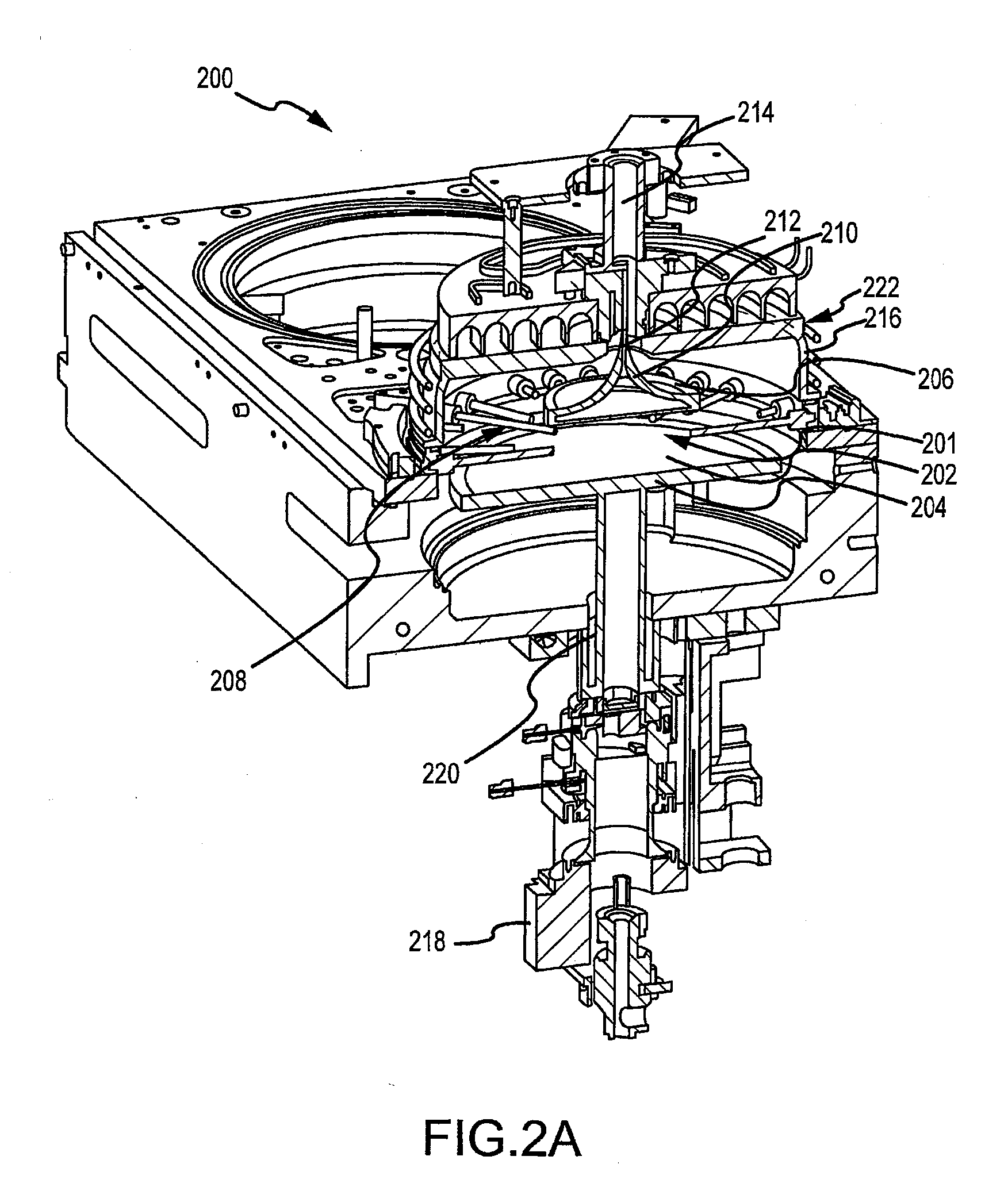

InactiveUS20070289534A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaPhysical chemistry

A system to form a dielectric layer on a substrate from a plasma of dielectric precursors is described. The system may include a deposition chamber, a substrate stage in the deposition chamber to hold the substrate, and a remote plasma generating system coupled to the deposition chamber, where the plasma generating system is used to generate a dielectric precursor having one or more reactive radicals. The system may also include a radiative heating system to heat the substrate that includes at least one light source, where at least some of the light emitted from the light source travels through the top side of the deposition chamber before reaching the substrate. The system may also include a precursor distribution system to introduce the reactive radical precursor and additional dielectric precursors to the deposition chamber. An in-situ plasma generating system may also be included to generate the plasma in the deposition chamber from the dielectric precursors supplied to the deposition chamber.

Owner:APPLIED MATERIALS INC

Electronic vaporizing device and methods for use

Devices and methods for vaporizing active ingredients of a selected substance for inhalation using a portable vaporization device are provided herein. In certain aspects, the device includes a portable power source, a heating portion, an inhalation sensor, a temperature sensor, a distal light source, and a grinding portion. In response to an inhalation by a user, the power source energizes a heating element of the heating portion so as to heat air flow to a desired vaporization temperature within a few seconds of detecting inhalation, using convection and radiative heating. The device may include a receptacle for receiving a cartridge containing a pre-prepared substance, such as a liquid, gel, powder, or solid brick, and a grinding portion to allow a user to grind intact portions of cellulose-based material into smaller pieces to facilitate vaporization by manually rotating portions of the device relative to each other.

Owner:UPTOKE LLC

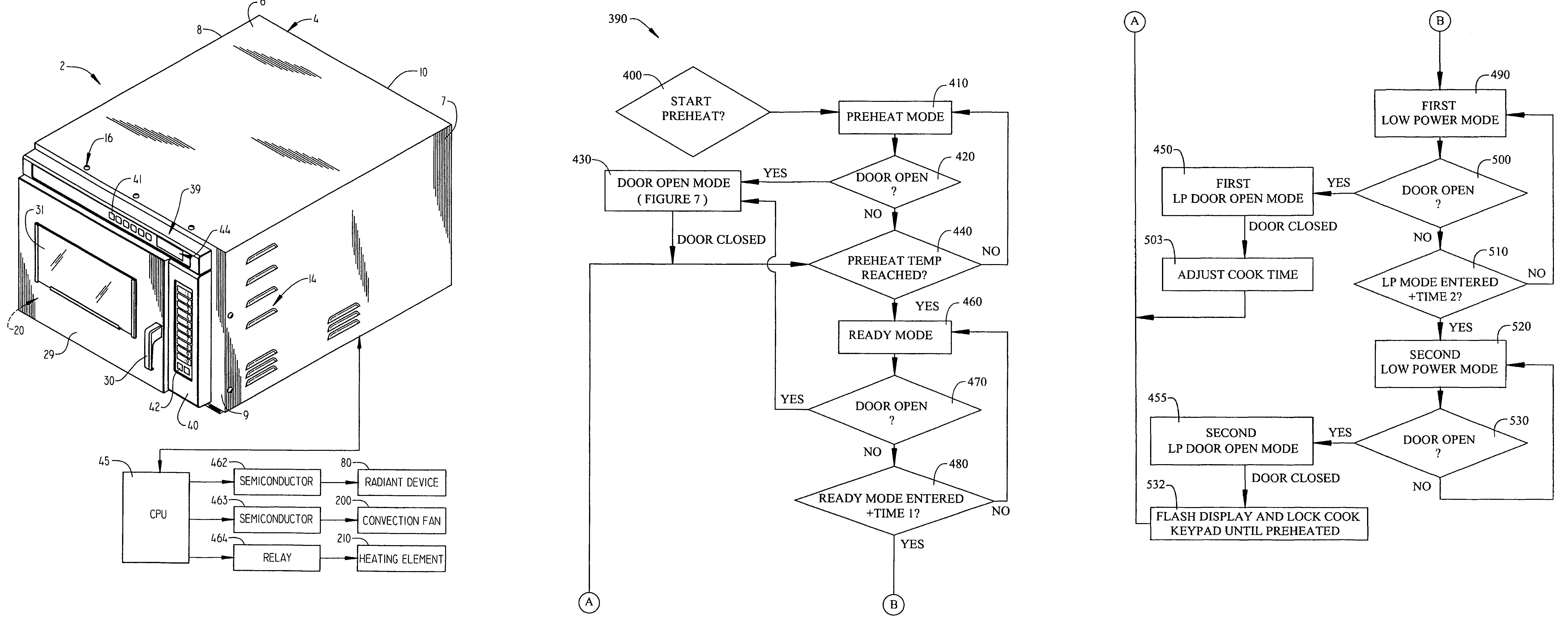

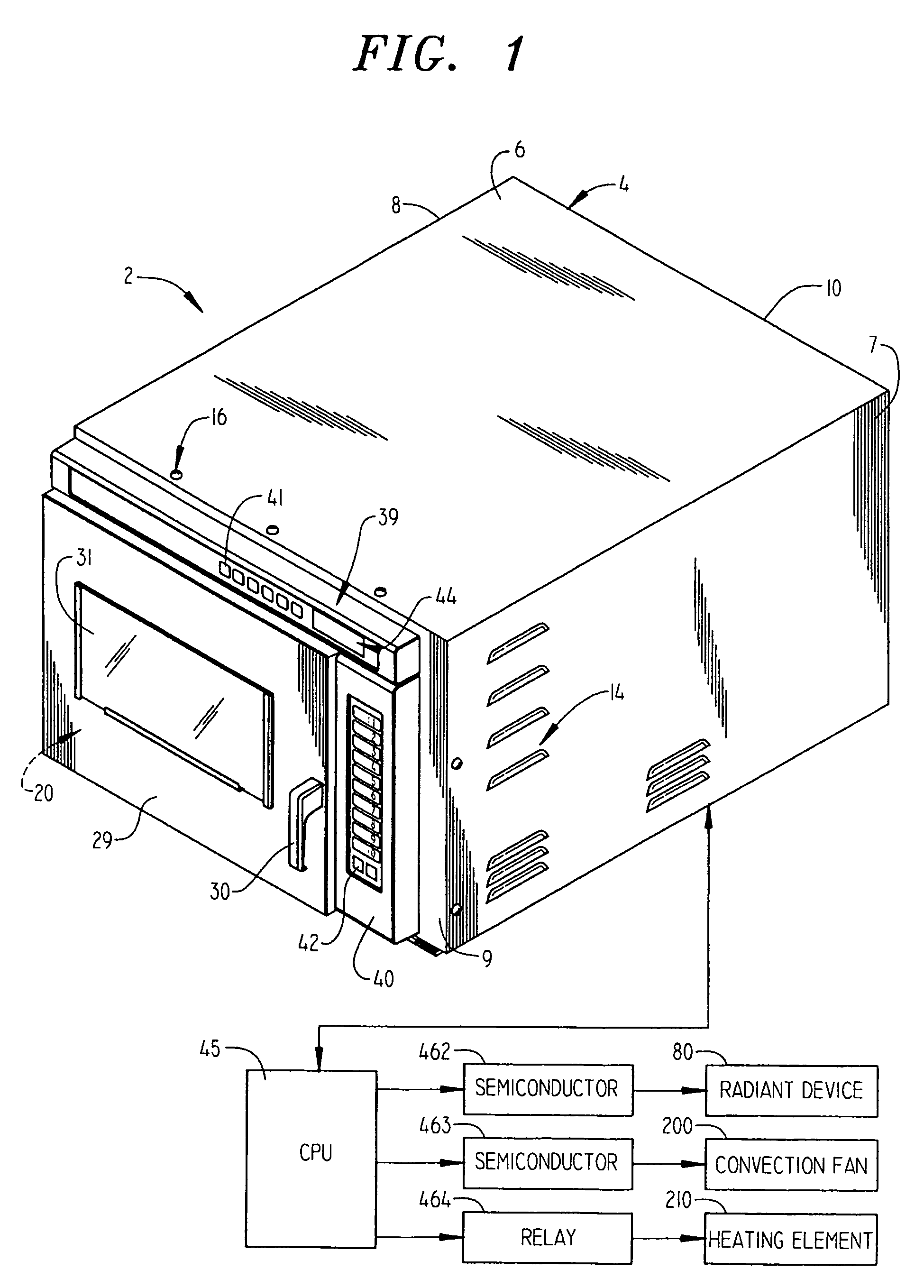

Operational modes for a cooking appliance employing combination cooking technology

A cooking appliance includes a controller for establishing a plurality of operating modes for heating an oven cavity. Specifically, the controller establishes one of a pre-heat mode, a ready mode, a first low power mode and a second low power mode for controlling a temperature of the oven cavity. Upon selecting a temperature for the oven cavity, the controller operates a radiant heating device, a convection fan and a convection heating device at full power to establish the selected temperature. After the selected temperature is achieved, the controller switches to a ready mode and reduces heat output of both the radiant heating device and the convection heating device, while also reducing fan speed. After respective periods of time in which a door of the appliance is not opened, the controller switches to first and second low power modes to conserve energy.

Owner:ACP OF DELAWARE

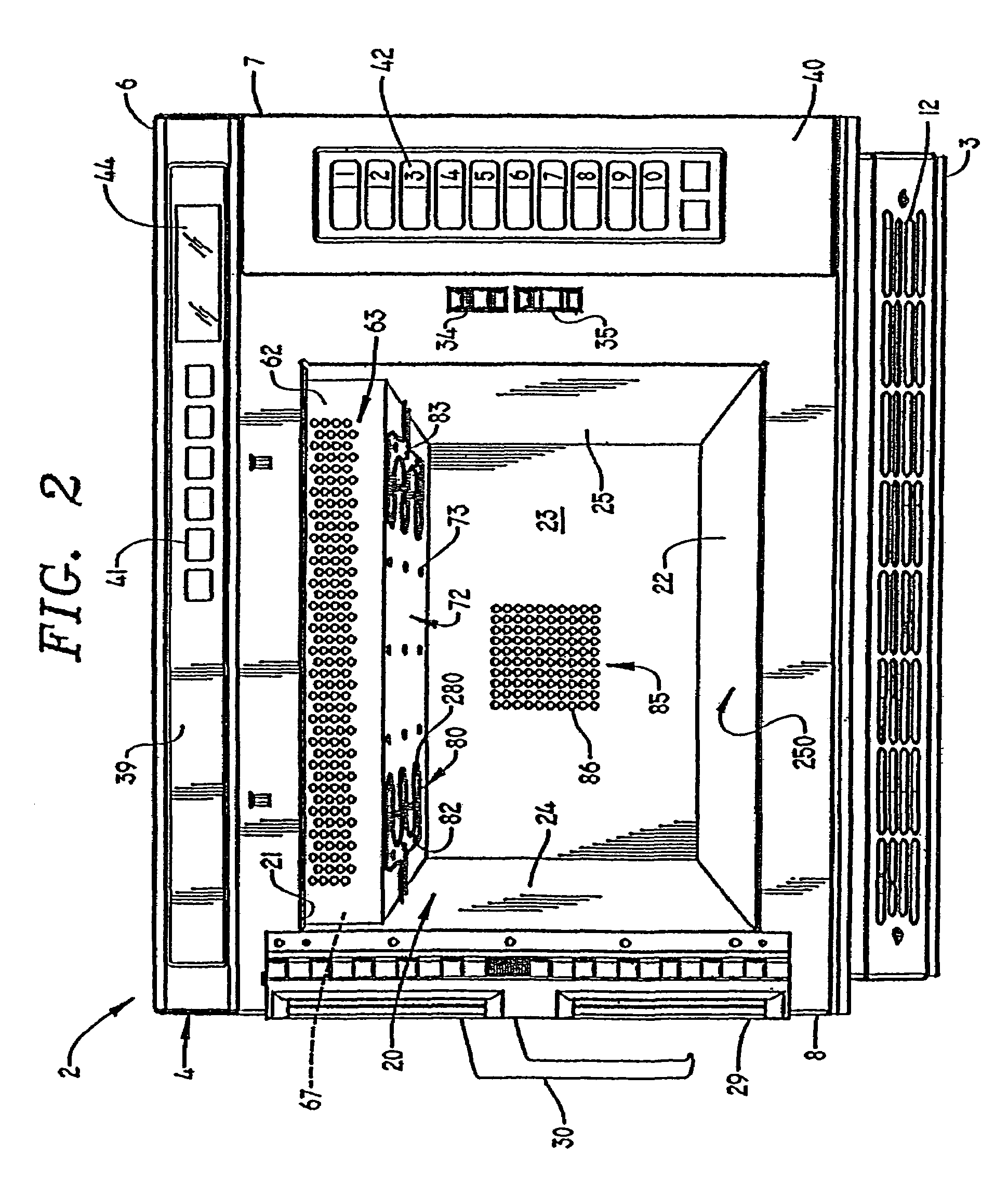

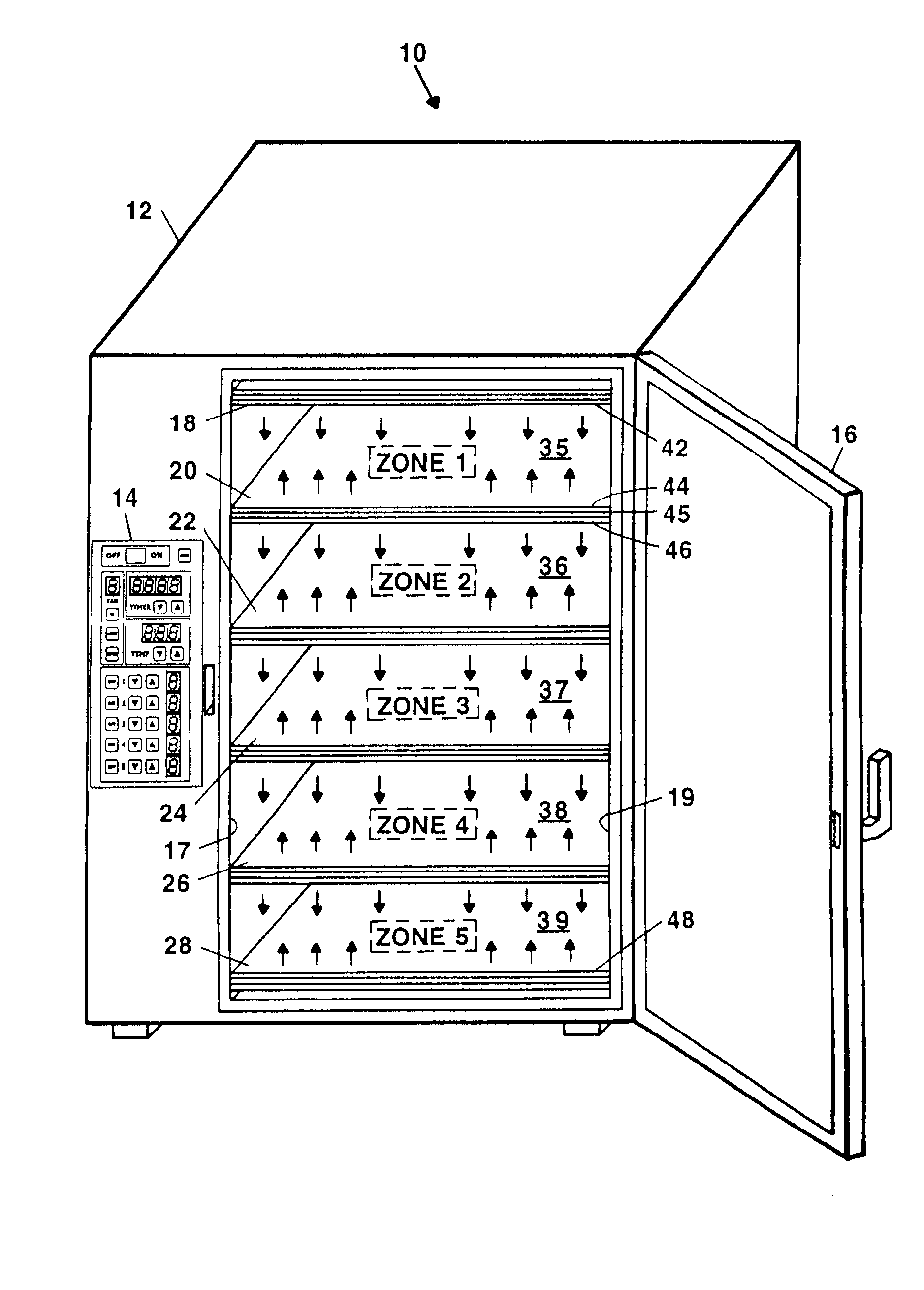

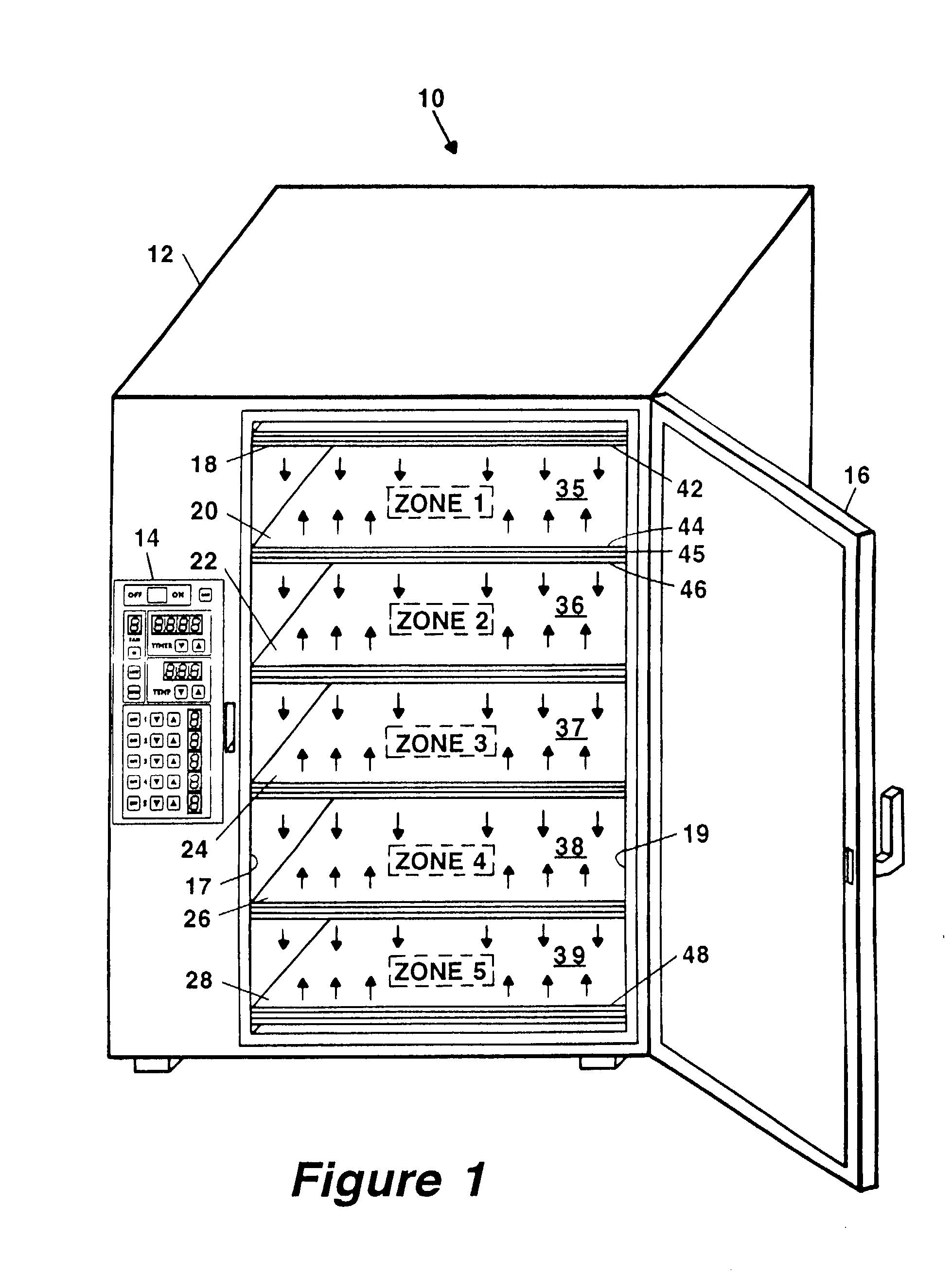

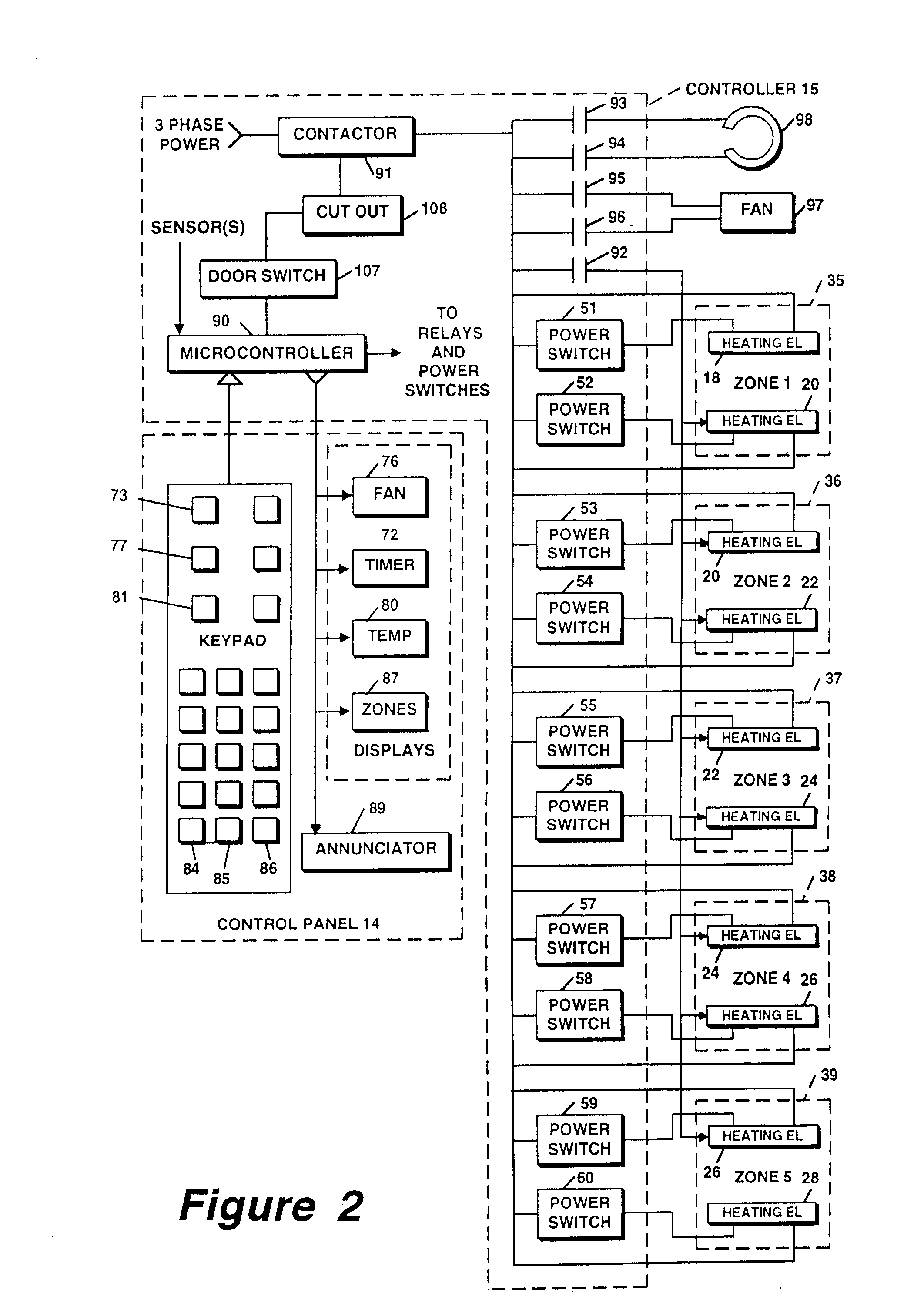

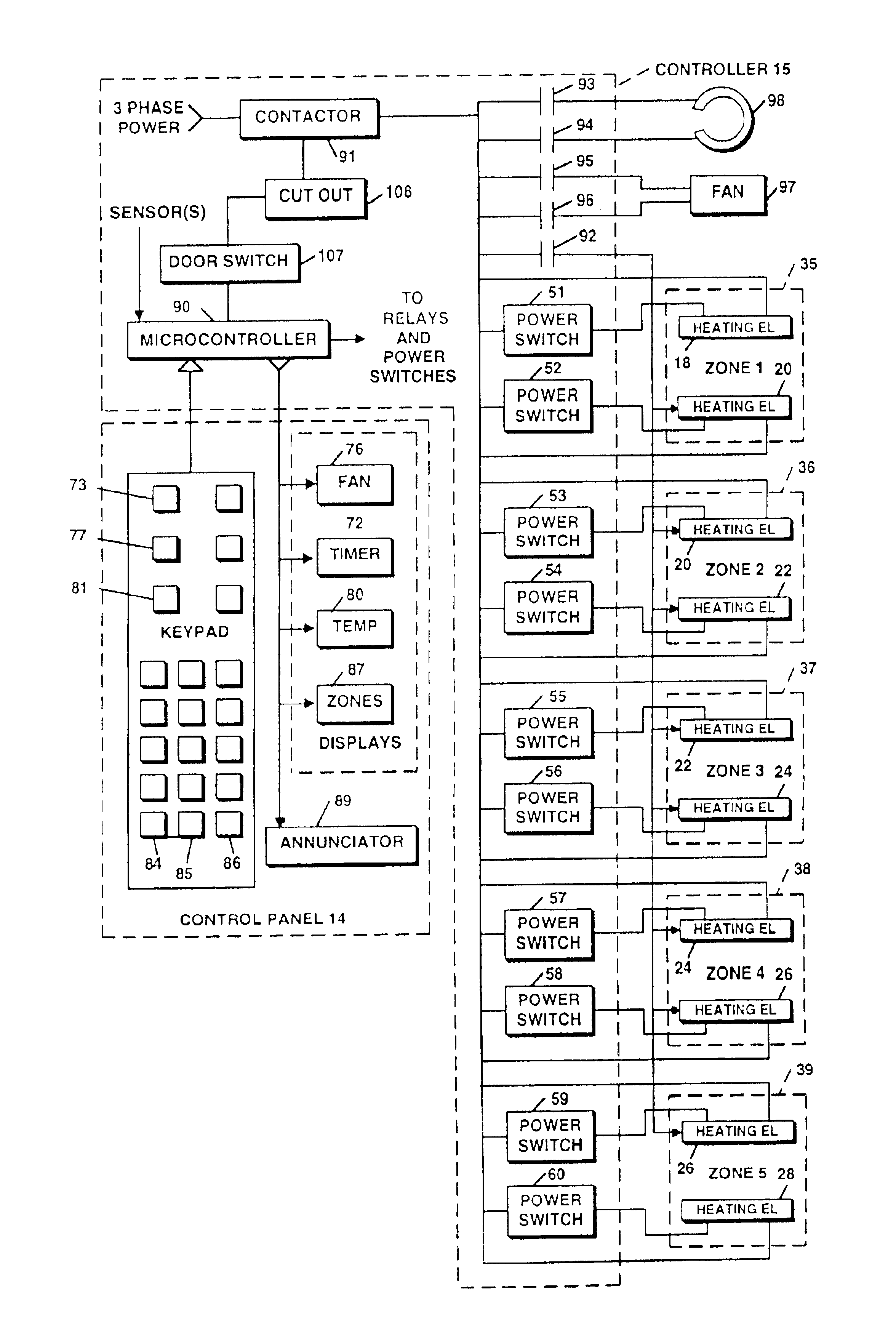

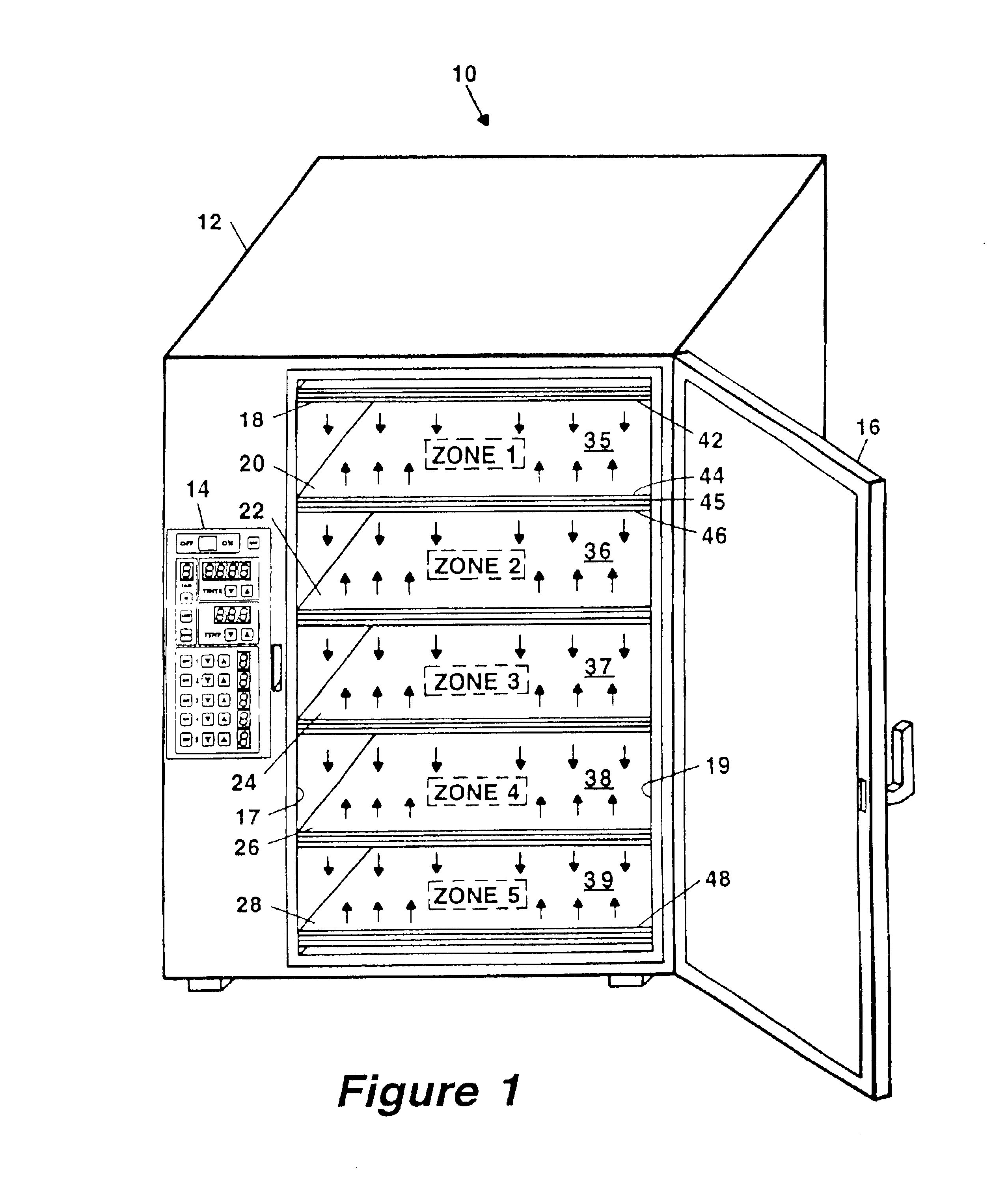

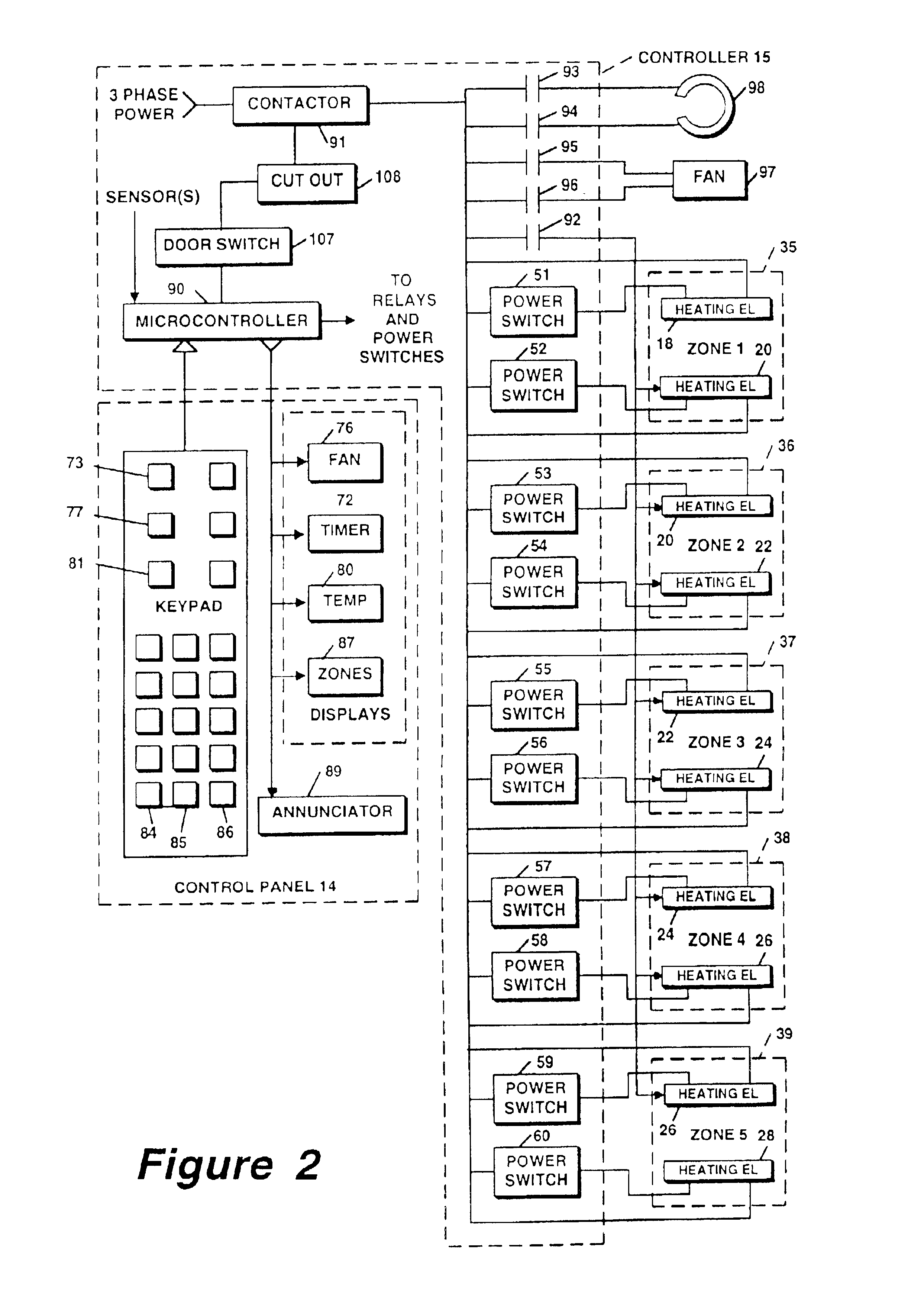

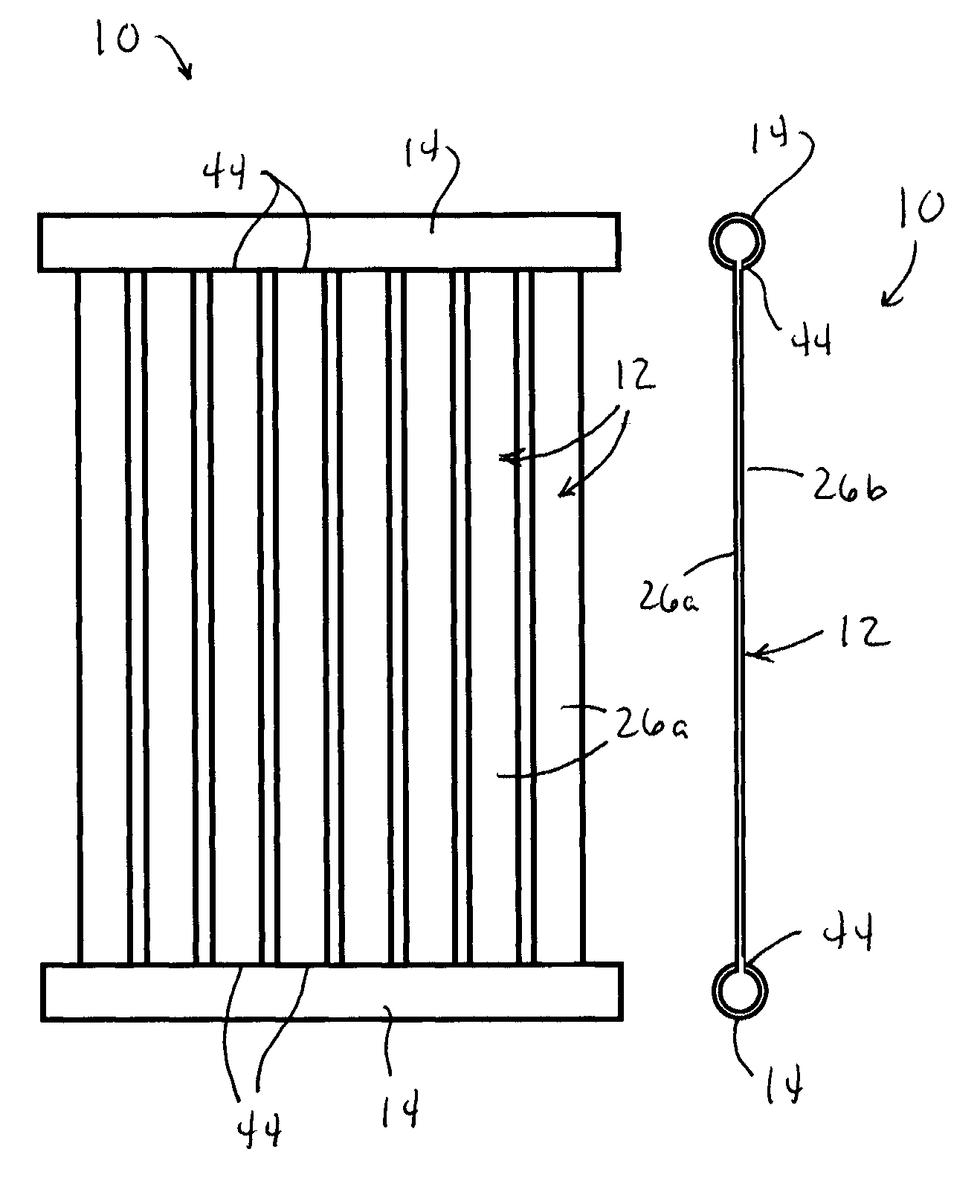

Multiple panel oven having individual controls for combined conductive and radiant heating panels

A multiple panel cooking oven having individual controls for combined conductive and radiant heating. Each panel comprises an upper heating element for conductive heating and a lower heating element for radiant heating to obtain uniform baking within a zone between panels in the oven. A control panel having displays and keypads interfaces with a processor which provides control signals for adjusting the temperature of the heating elements of the panels. Cooking energy efficiency is increased through the use of radiative and conductive heat transfer, to reduce bake times by significantly increasing heat transfer to the food products. Independent cook zones allow preparation of multiple products simultaneously under different cooking conditions. The oven, in one embodiment may include a convection heating mode of operation. In an alternative embodiment no convection mode is provided and the sole source of heat is provided by the conductive / radiant panels.

Owner:TIAX LLC

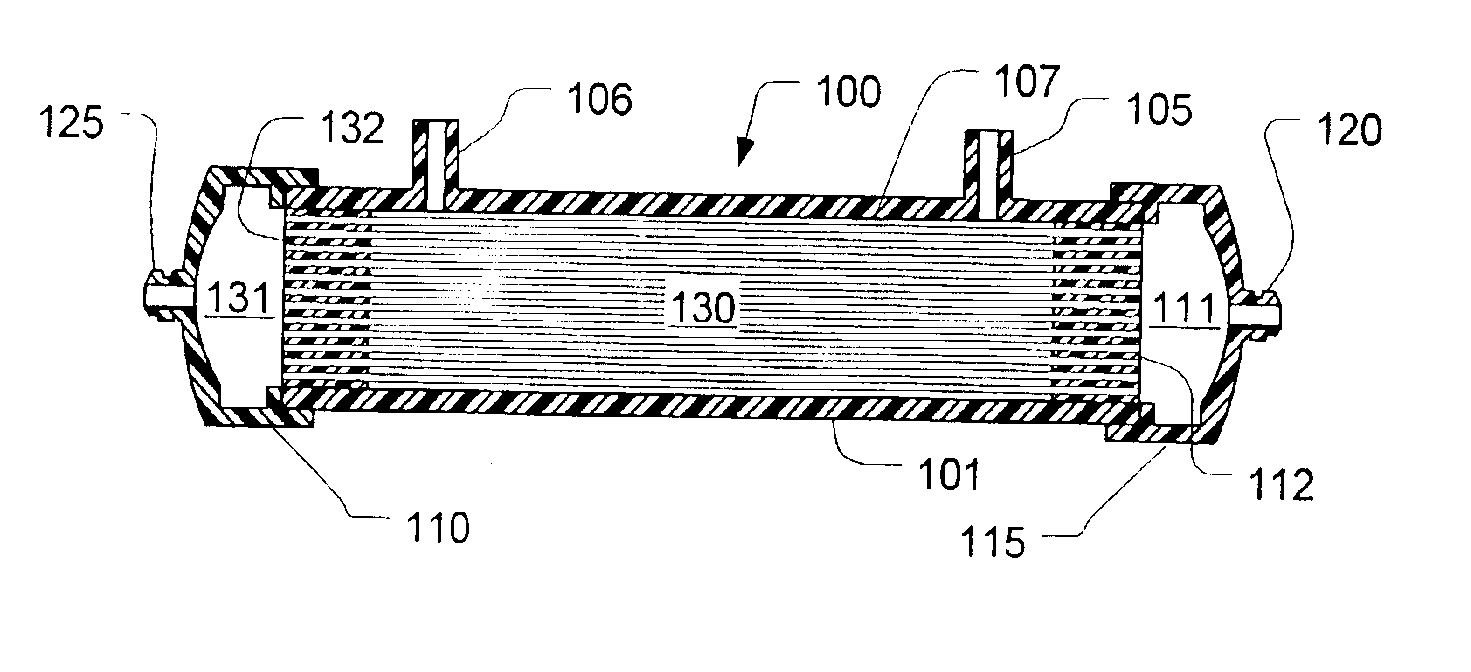

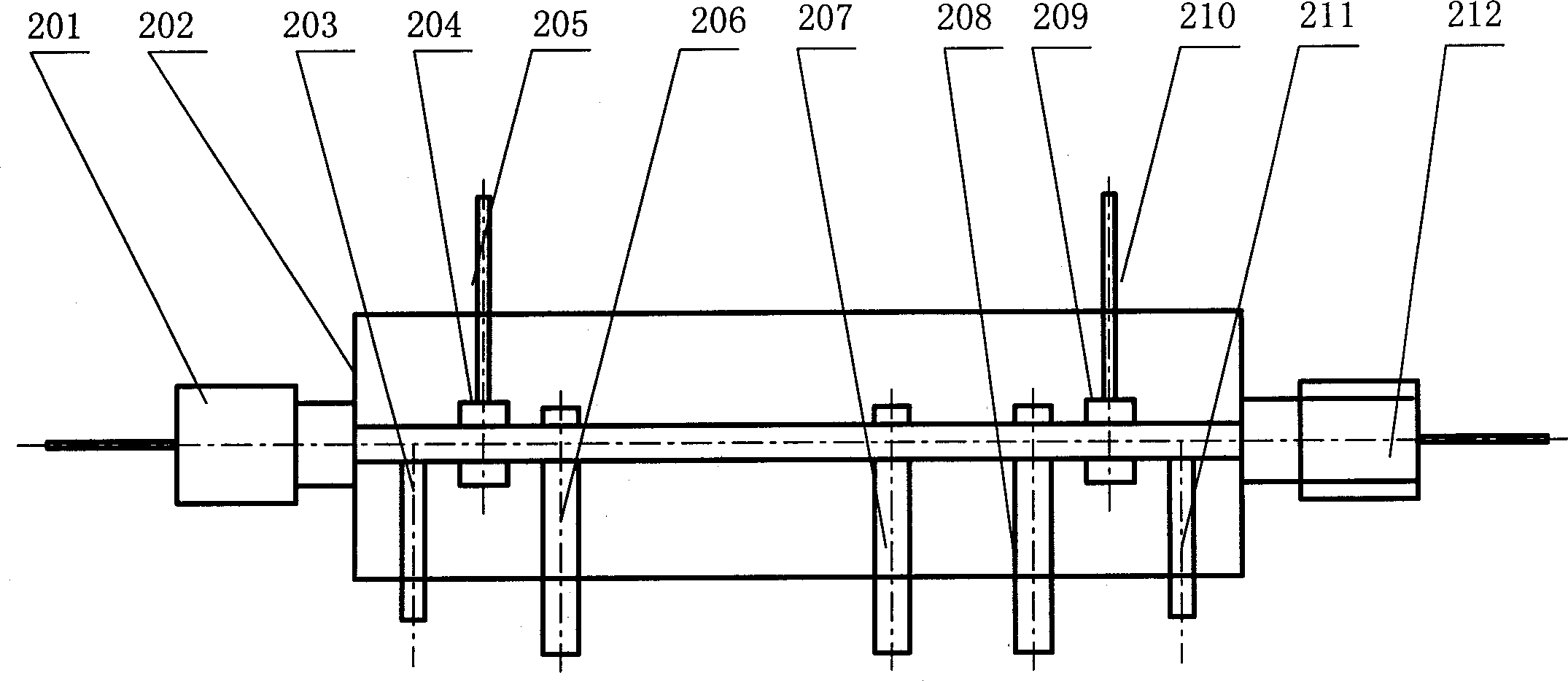

Method and apparatus for manufacturing filters

InactiveUS6872346B2Speed productionShort amount of timeSemi-permeable membranesTailstocks/centresEngineeringMechanical engineering

A problem in the manufacture of filters using tubular membrane bundles is keeping potting material from flowing into the openings at the ends of the tubes. A preferred embodiment of a method for manufacturing a tubular membrane filter employs a non-contact heat source such as radiant heating to melt the tips of the tubular membranes. This prevents the migration of potting material into the tubes when the potting material is flowed into the ends of tube bundles during the manufacturing process for a filter.

Owner:NXSTAGE MEDICAL

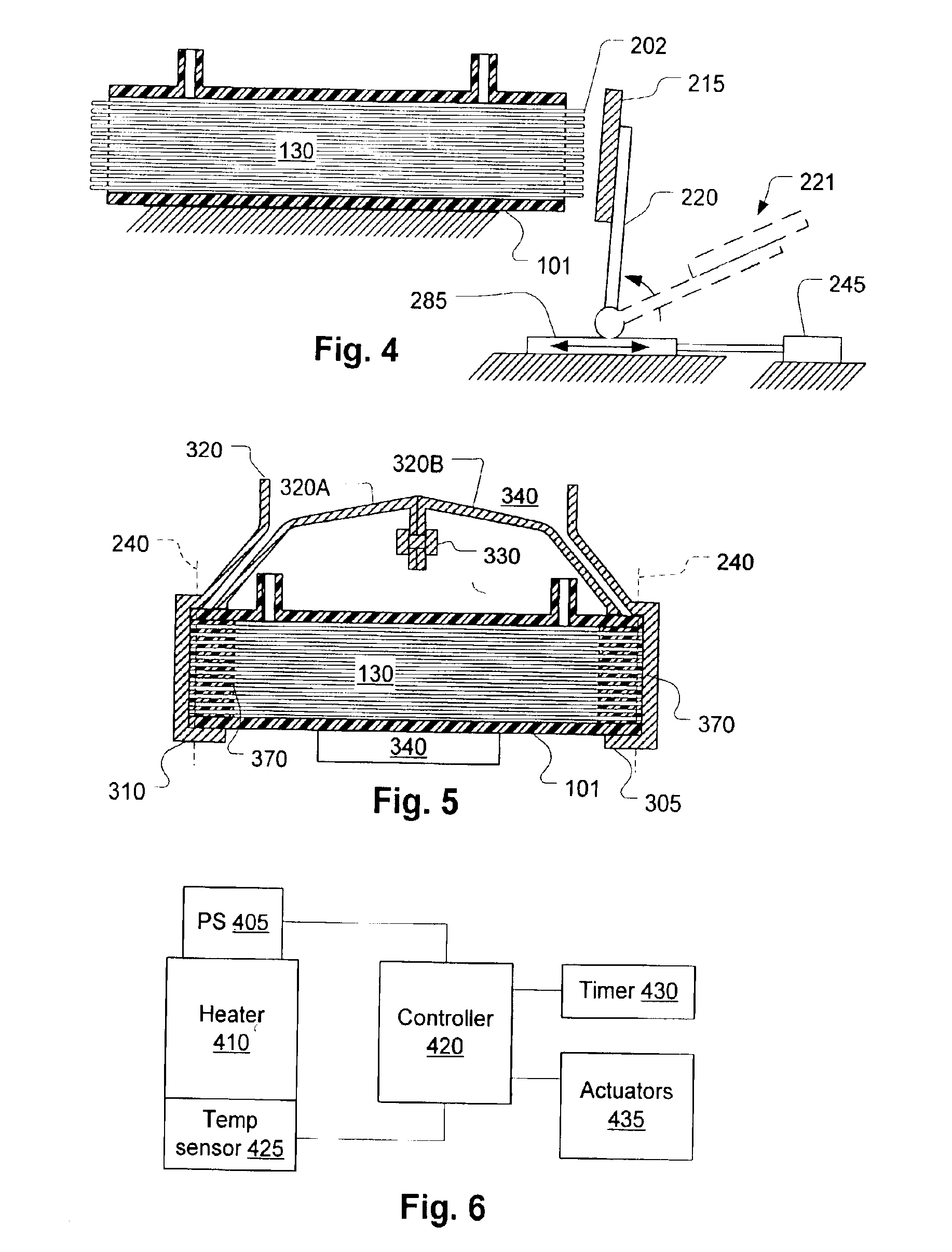

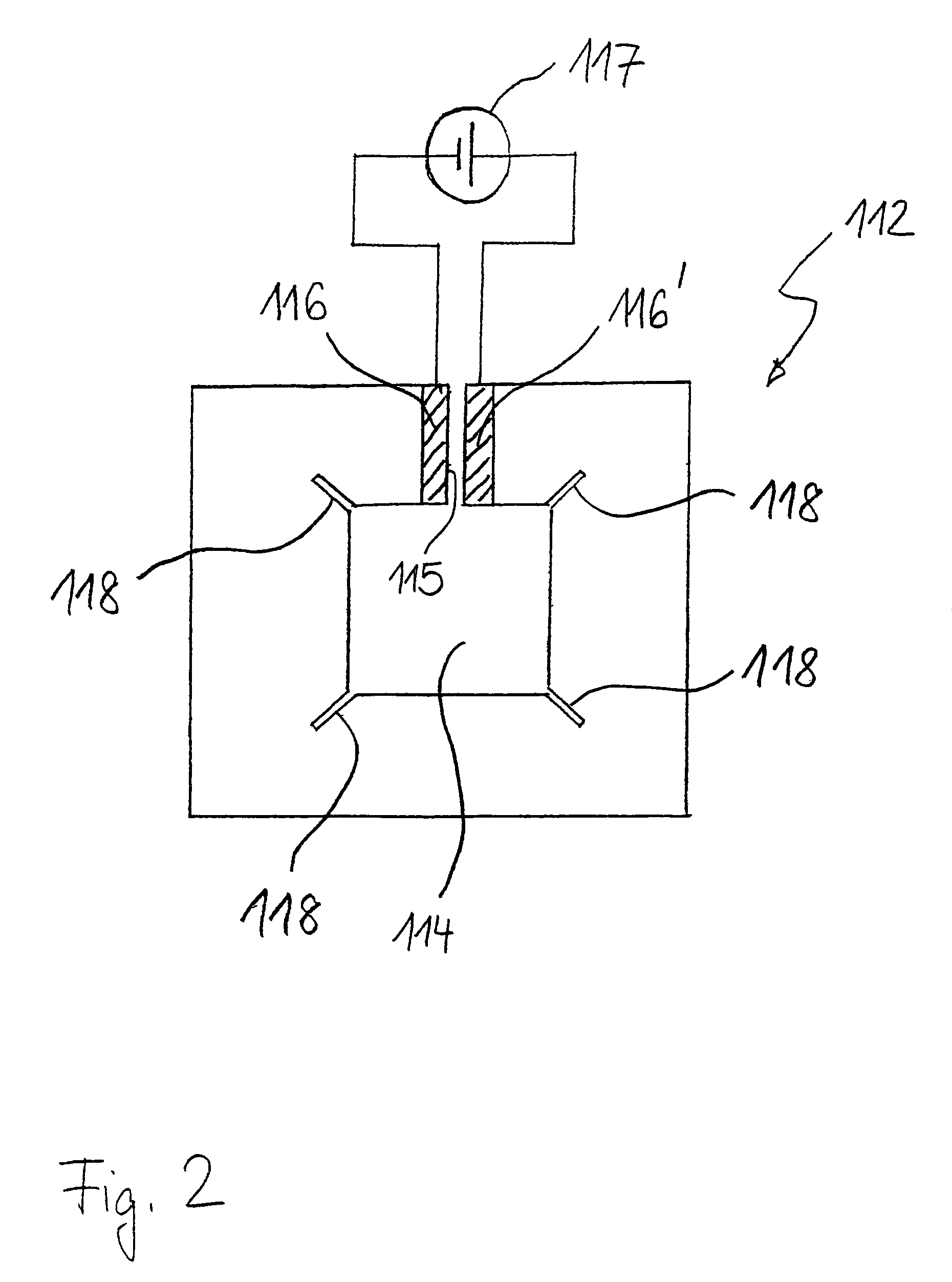

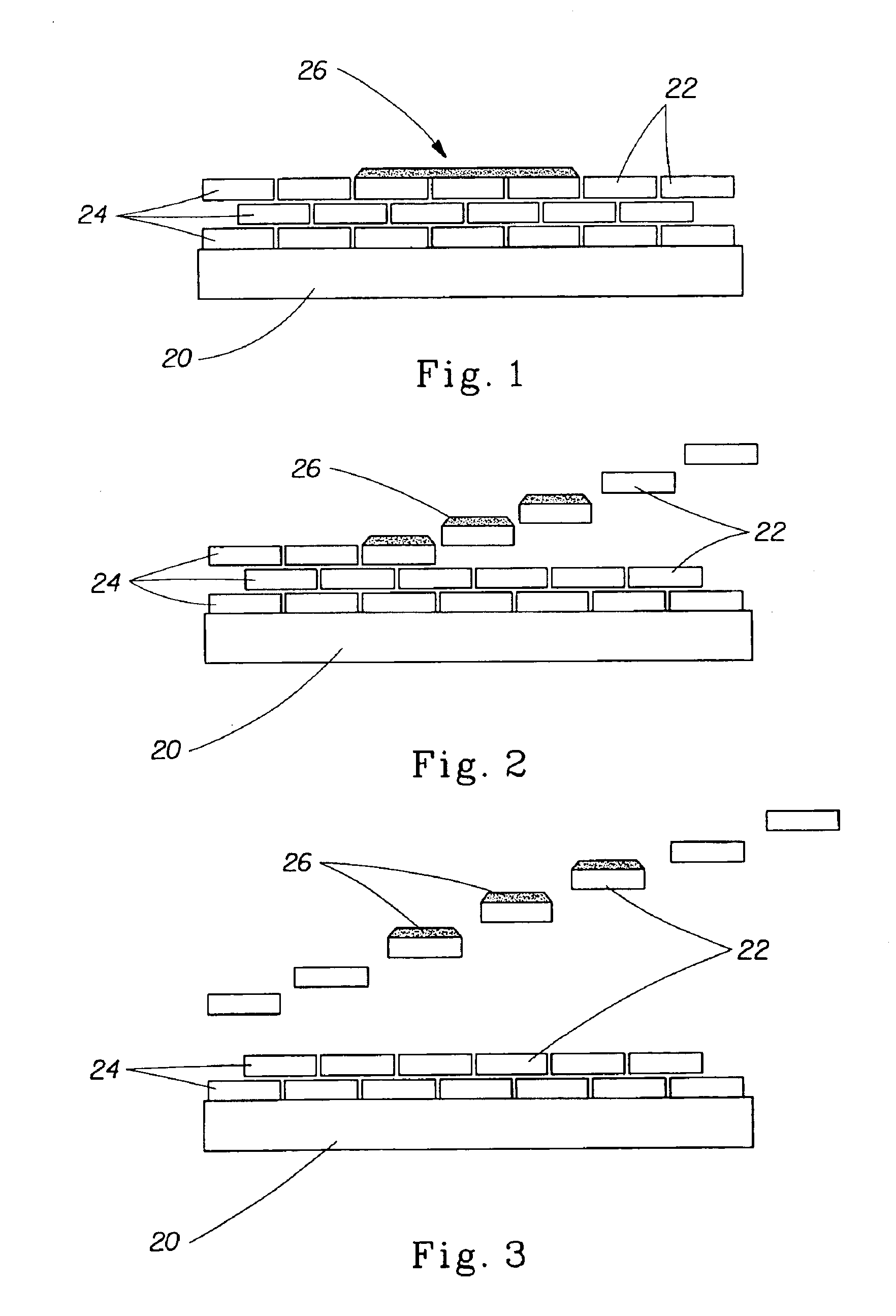

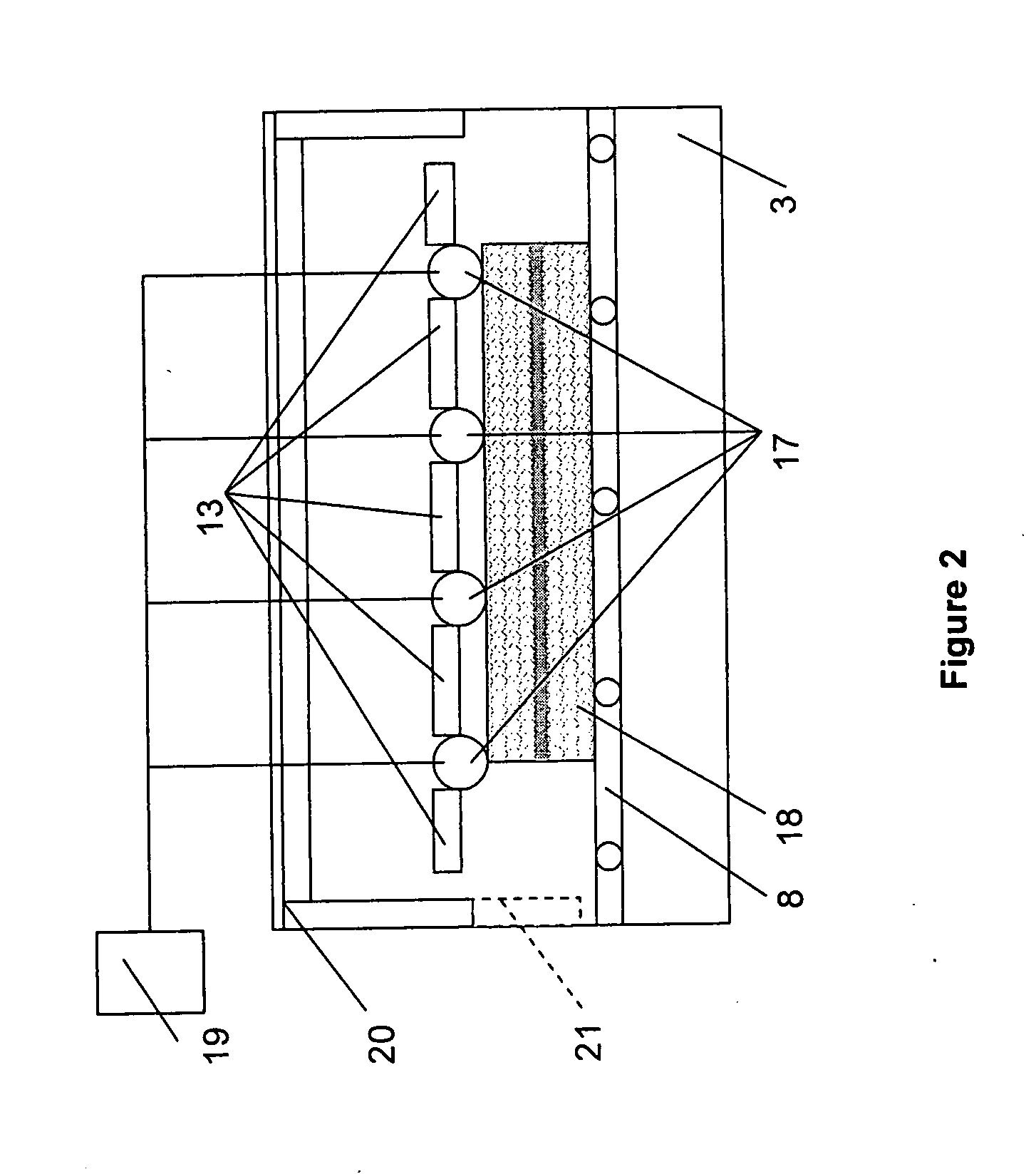

Radiant heater for heating the building material in a laser sintering device

InactiveUS8073315B2Reduce the temperatureThermal inertiaDomestic stoves or rangesDrying solid materials with heatRadiant heaterMetallurgy

A radiant heating for heating the building material in a laser sintering device and a laser sintering device having such a radiant heating are described. The radiant heating has a sheet-like heat radiating element (113, 213, 313), which is characterized in that it is made of a material, that has a low thermal inertia with a thermal diffusivity of preferably more than 1.5·10−4 m2 / s and preferably has a thickness of 2 mm or less.

Owner:EOS ELECTRO OPTICAL SYST

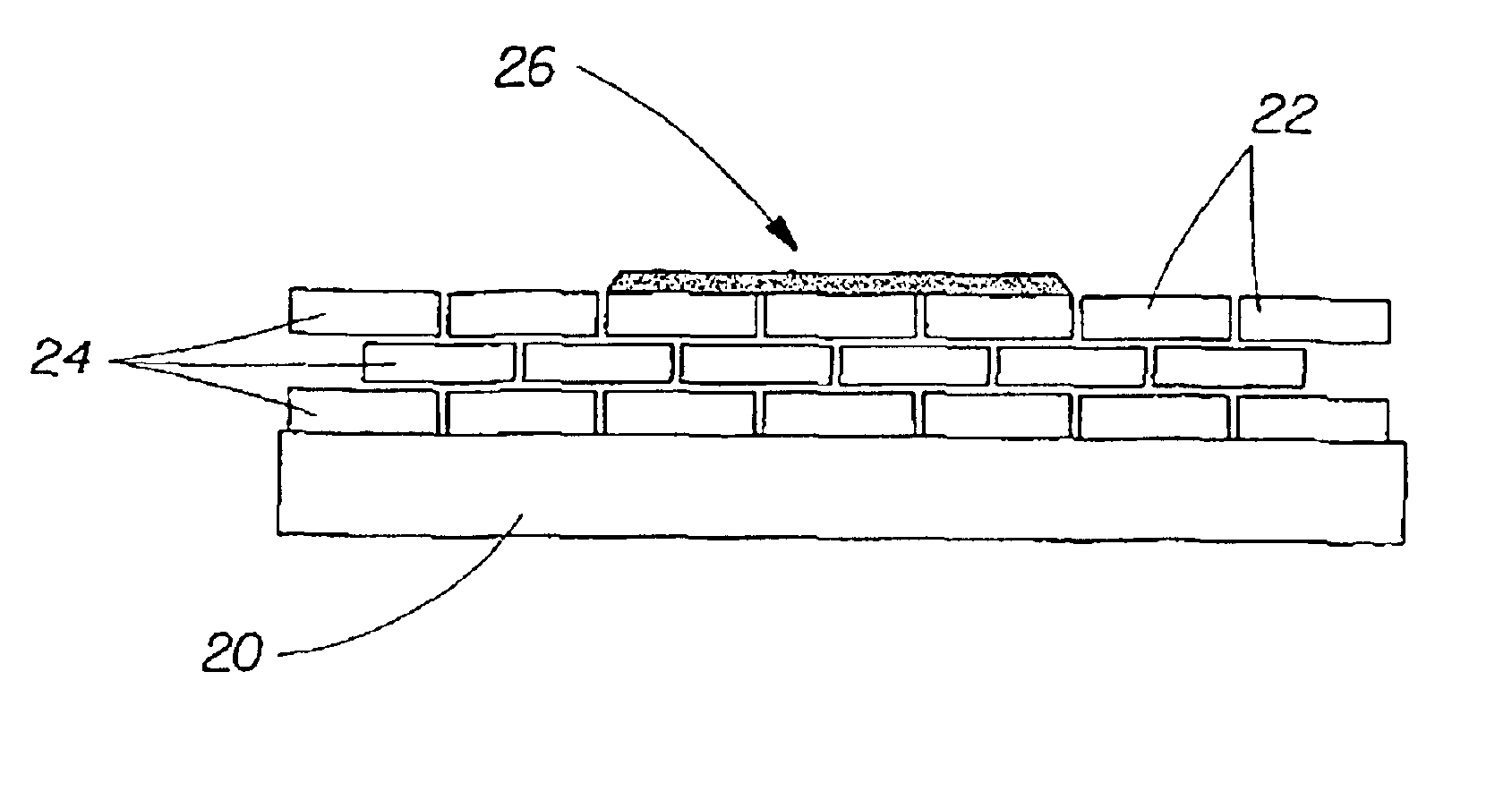

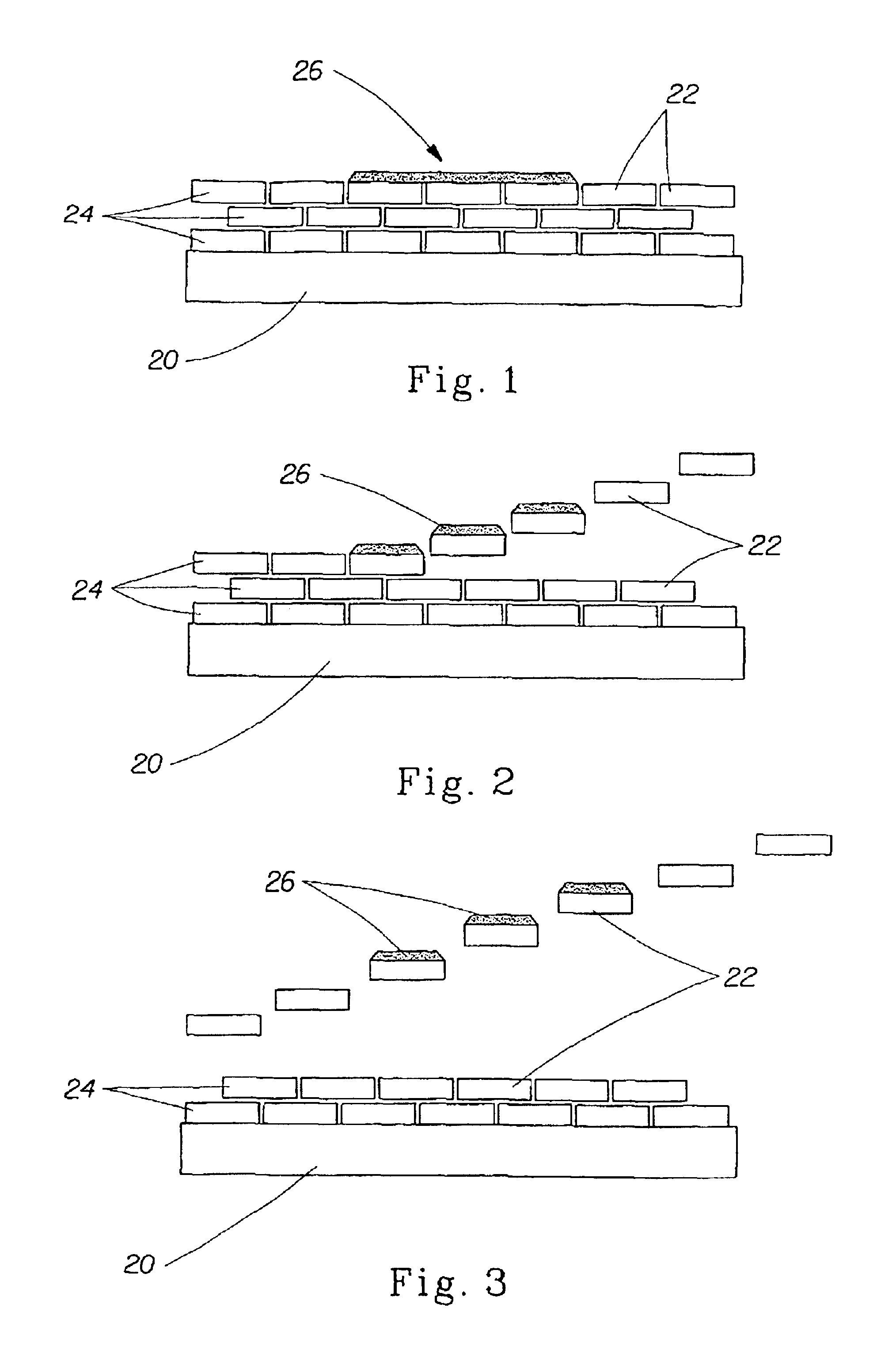

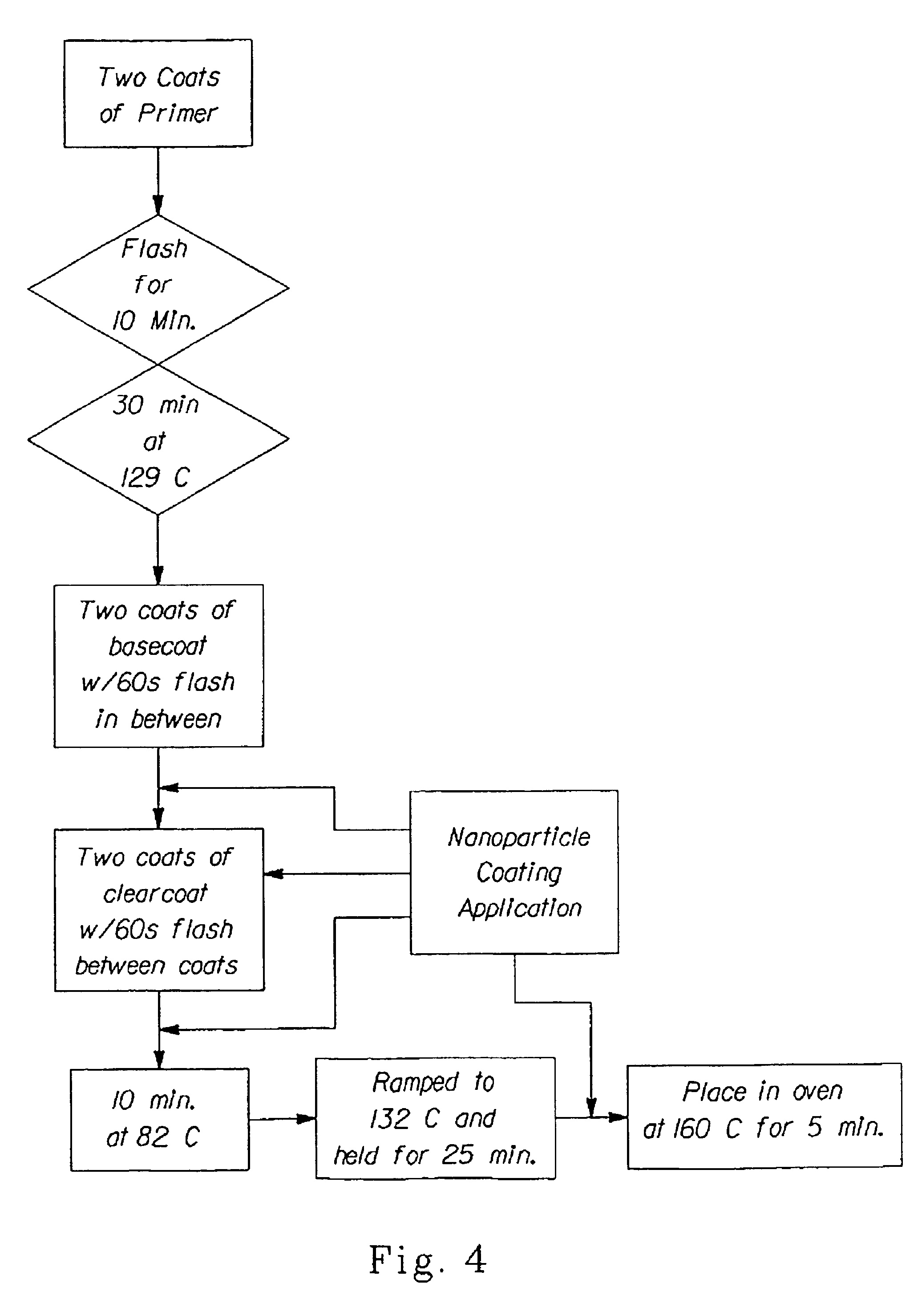

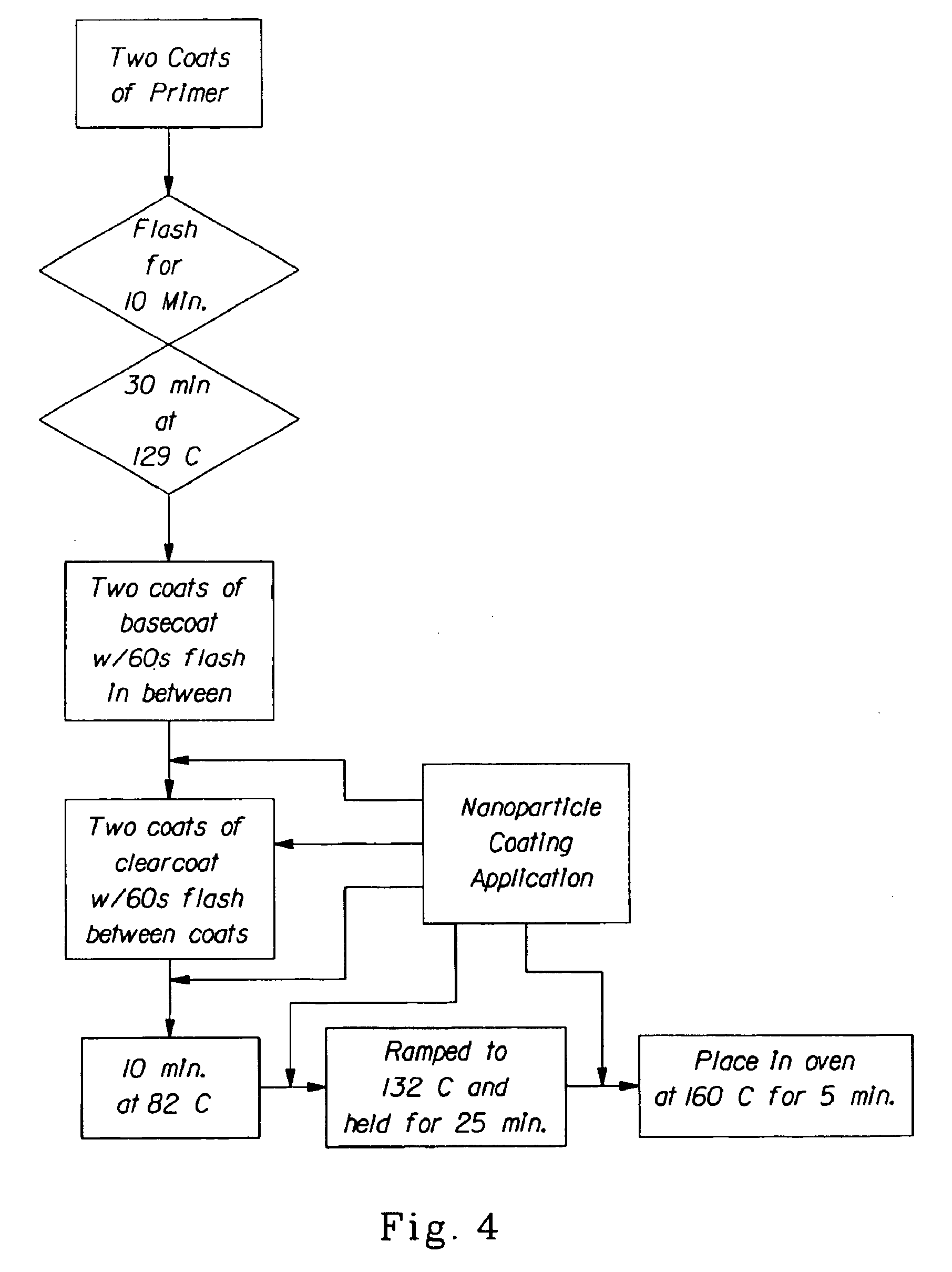

Long lasting coatings for modifying hard surfaces and processes for applying the same

InactiveUS6955834B2Improve smoothnessImprovement in wetting and sheetingInorganic/elemental detergent compounding agentsOrganic anion exchangersMetallurgyDefect repair

Materials for coating, coating compositions, methods and articles of manufacture comprising a nanoparticle system or employing the same to impart surface modifying benefits for all types of inanimate hard surfaces are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to modified hard surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that include at least one of the following improved surface properties: wetting and sheeting, quick drying, uniform drying, soil removal, self-cleaning, anti-spotting, anti-soil deposition, cleaner appearance, enhanced gloss, enhanced color, minor surface defect repair, smoothness, anti-hazing, modification of surface friction, release of actives and transparency, relative to hard surfaces unmodified with such nanoparticle systems. Actively curing the coating composition on the hard surfaces, including, but not limited to by radiative heating the air surrounding the hard surface with the coating thereon can be used to increase the durability of the hard surface coating.

Owner:THE PROCTER & GAMBLE COMPANY

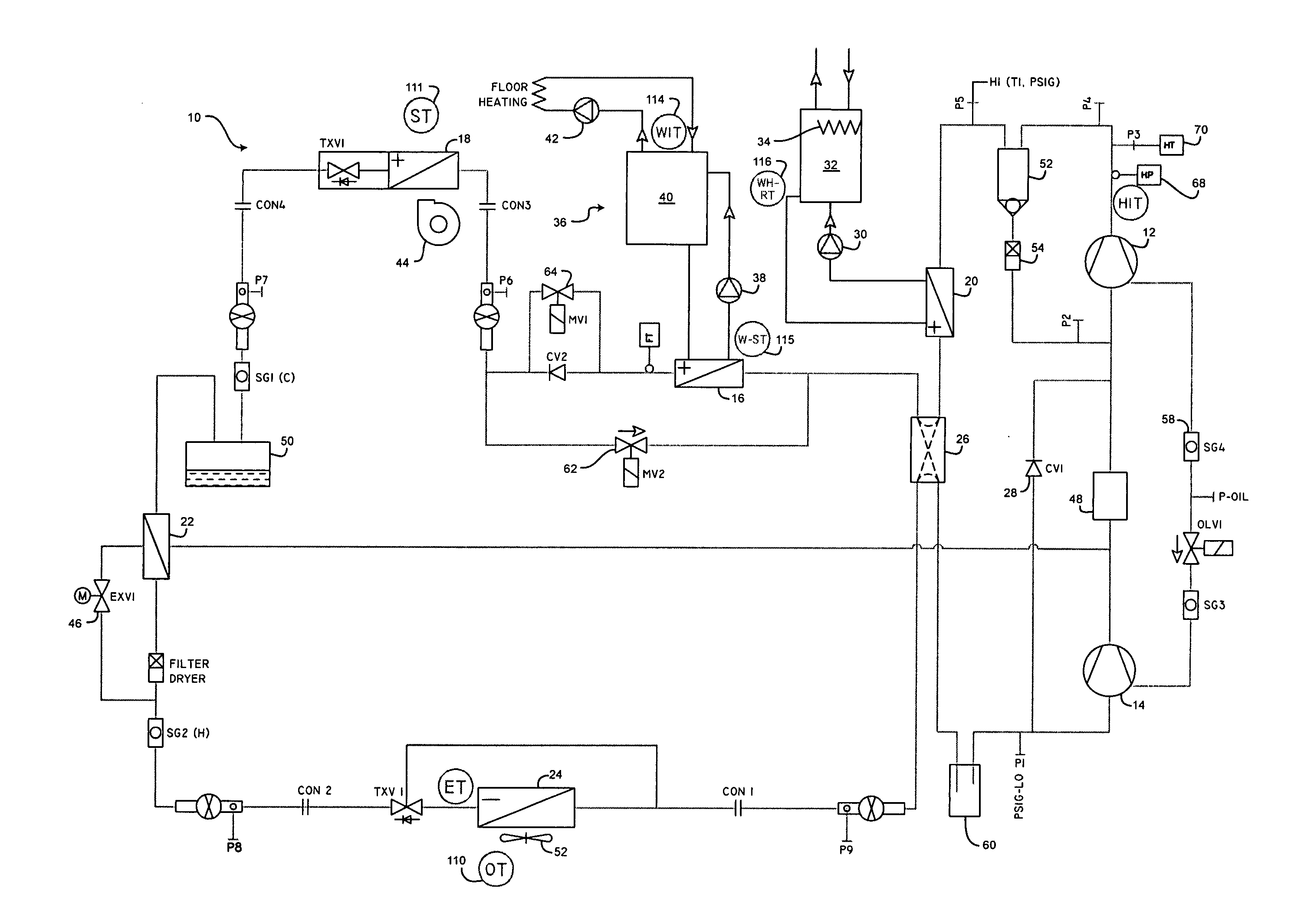

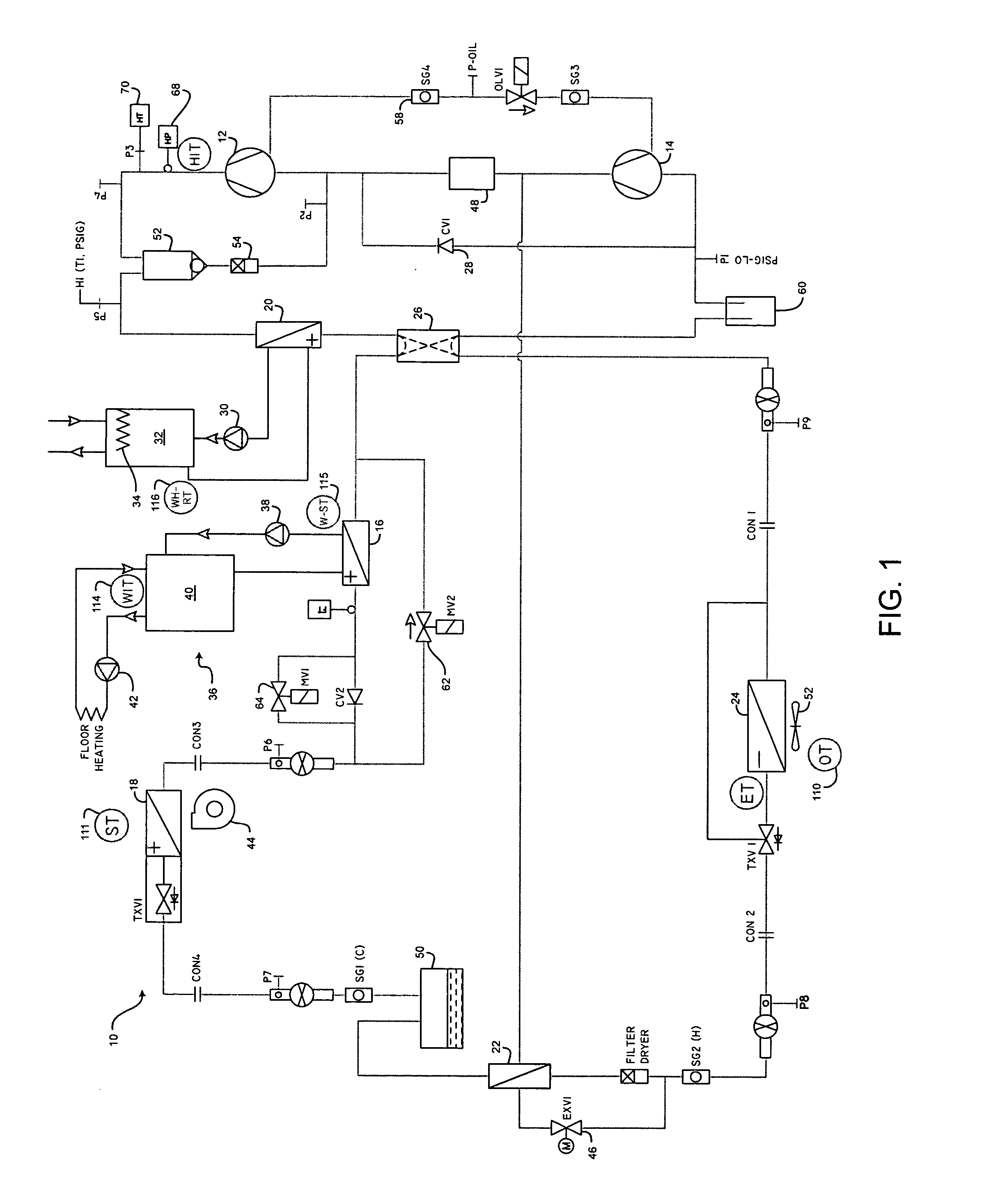

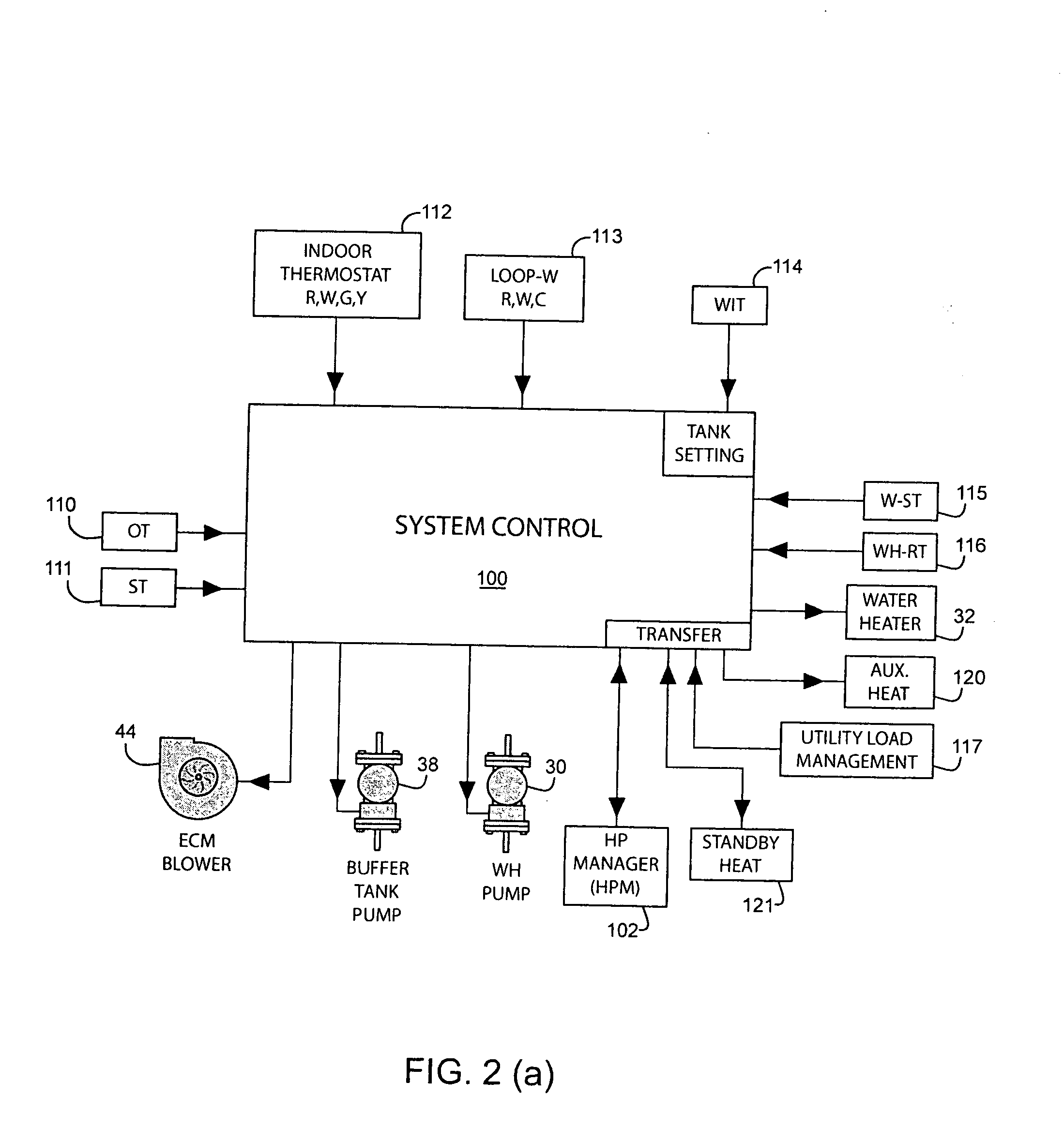

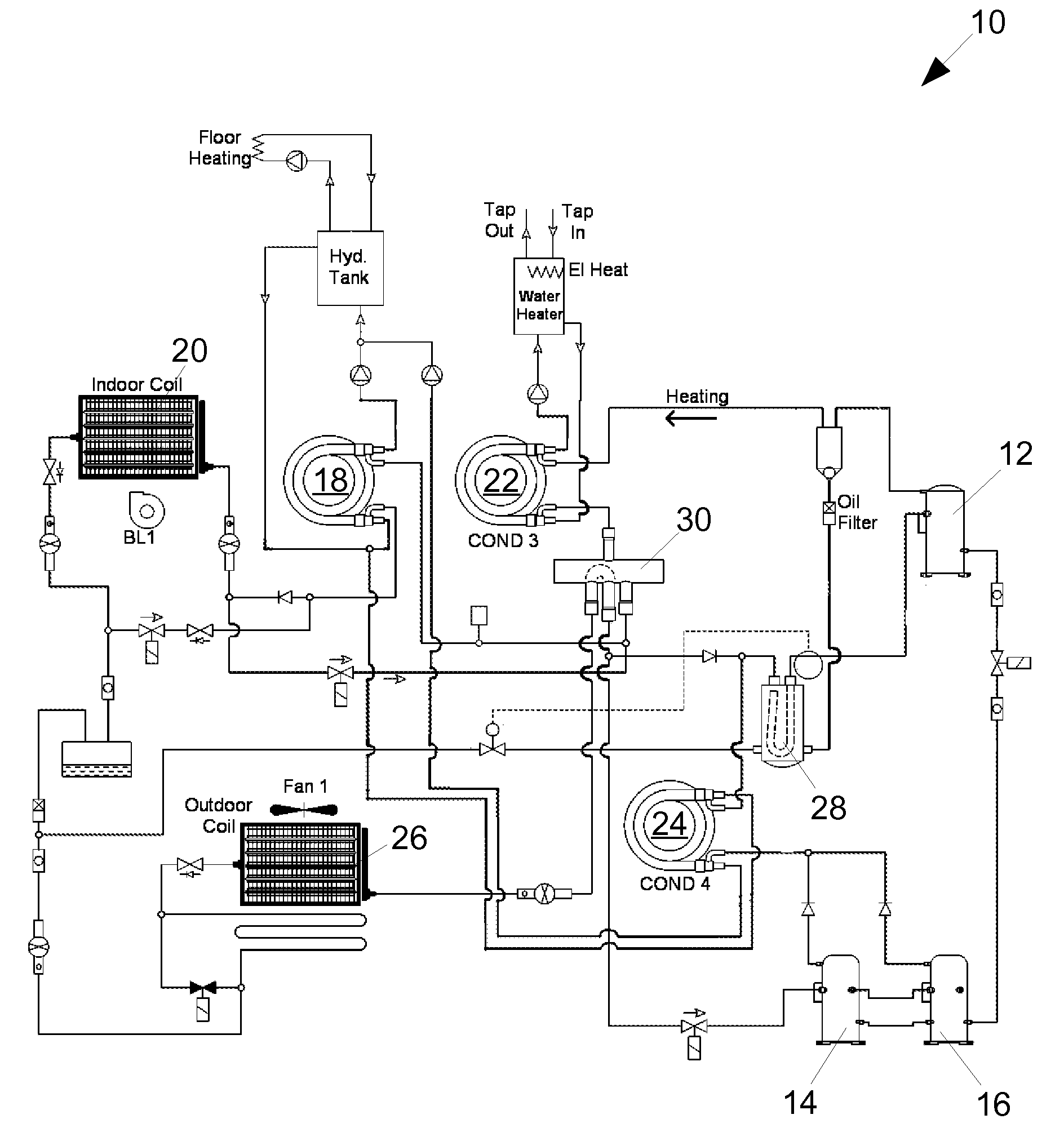

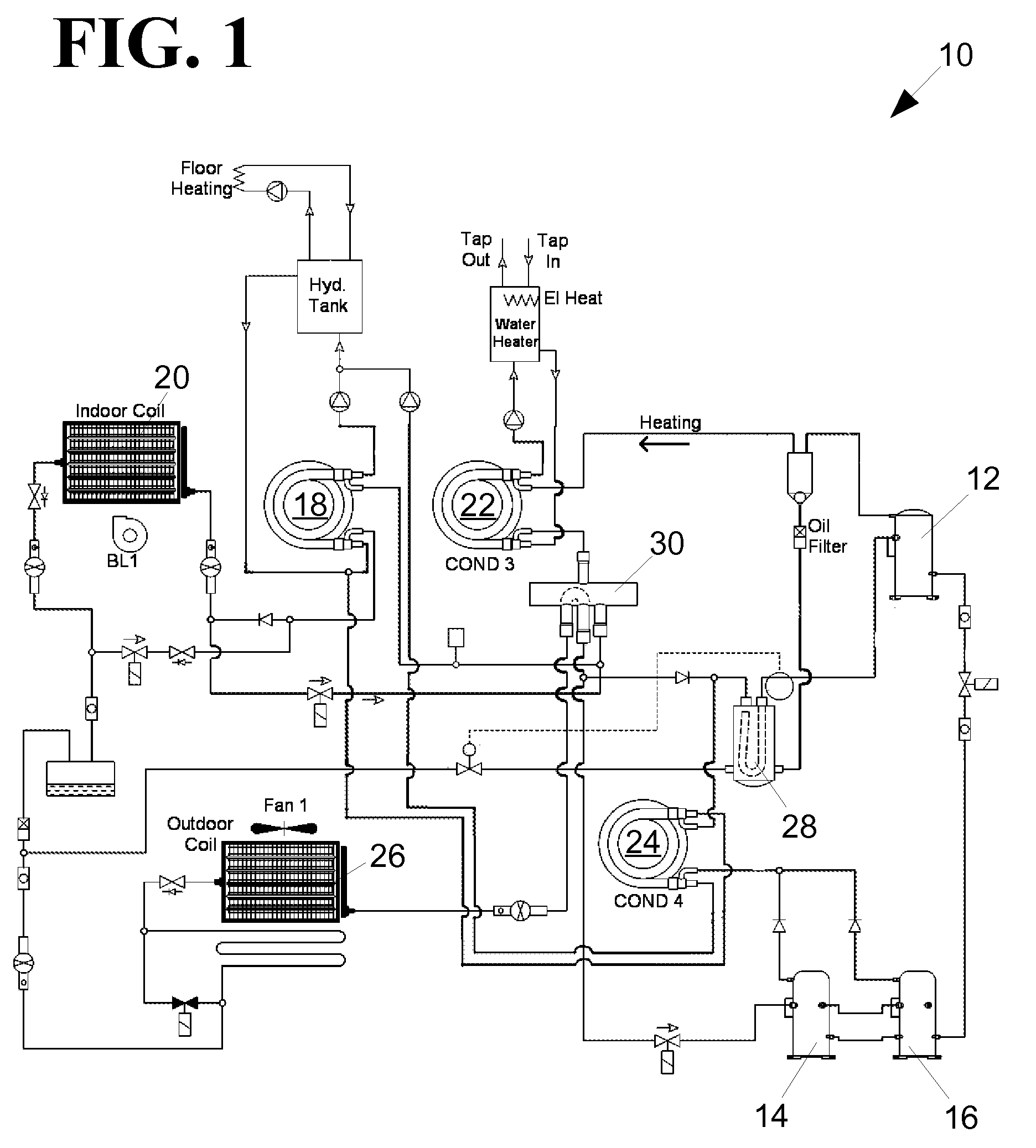

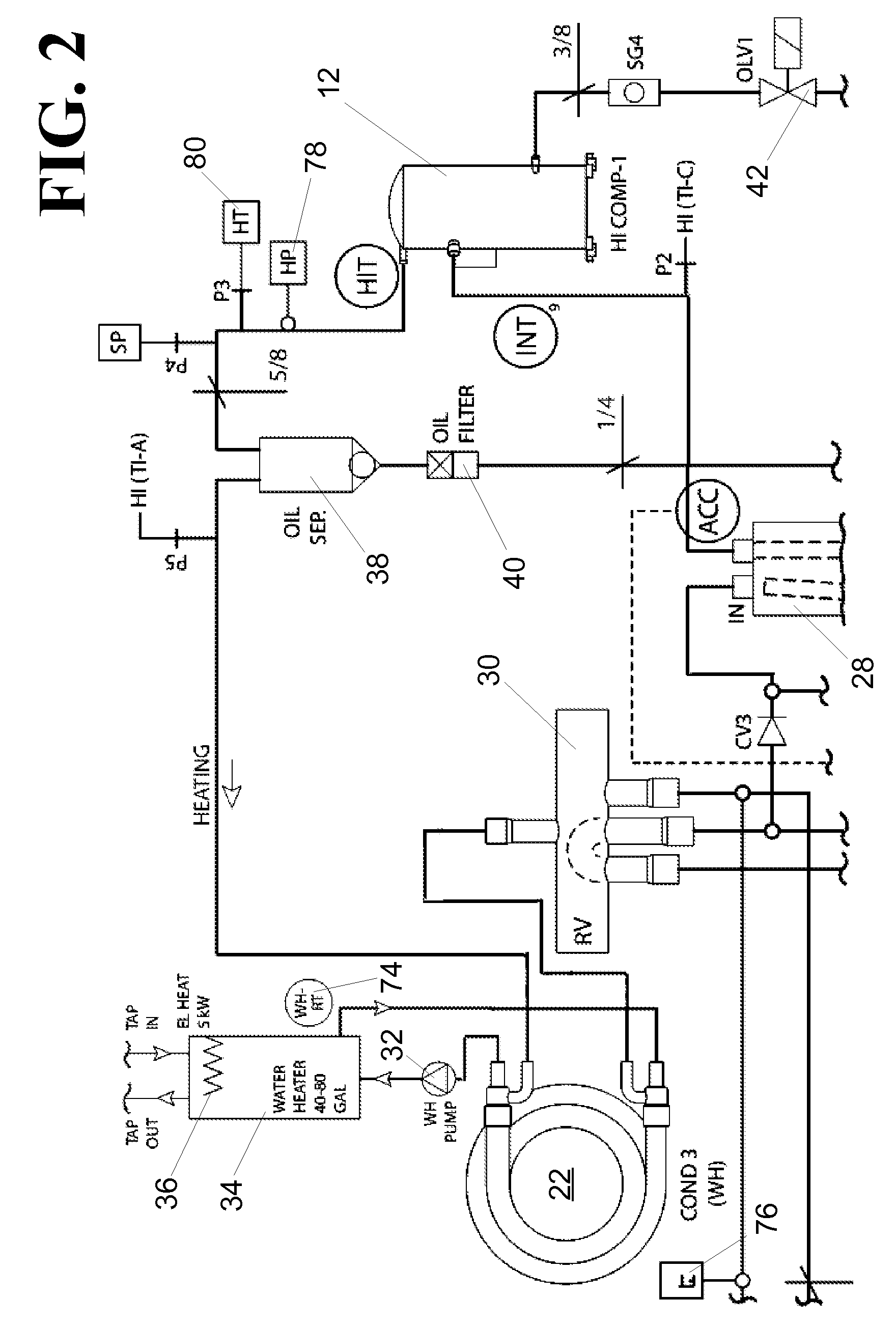

Heat pump system and controls

InactiveUS20080098760A1Improve the heating effectEasy transferCompression machines with non-reversible cycleEvaporators/condensersForced-airEngineering

A heat pump system is disclosed that utilizes one or two compressors and multiple heat exchangers to provide forced air heating, radiant heating and / or water heating for an interior space. A controller directs energy to these multiple system outputs to provide maximum comfort, effectively utilize any excess energy, address fluctuations in energy output, prevent unsafe operating conditions and avoid intermittent compressor operation. The system may provide energy for a water heater in both heating and cooling mode, and control operation of the water heater to utilize system energy whenever possible and avoid use of a conventional water heater heating element. Load Management Control is also provided so that the system may be shut down remotely by a utility company.

Owner:ELECTRO IND

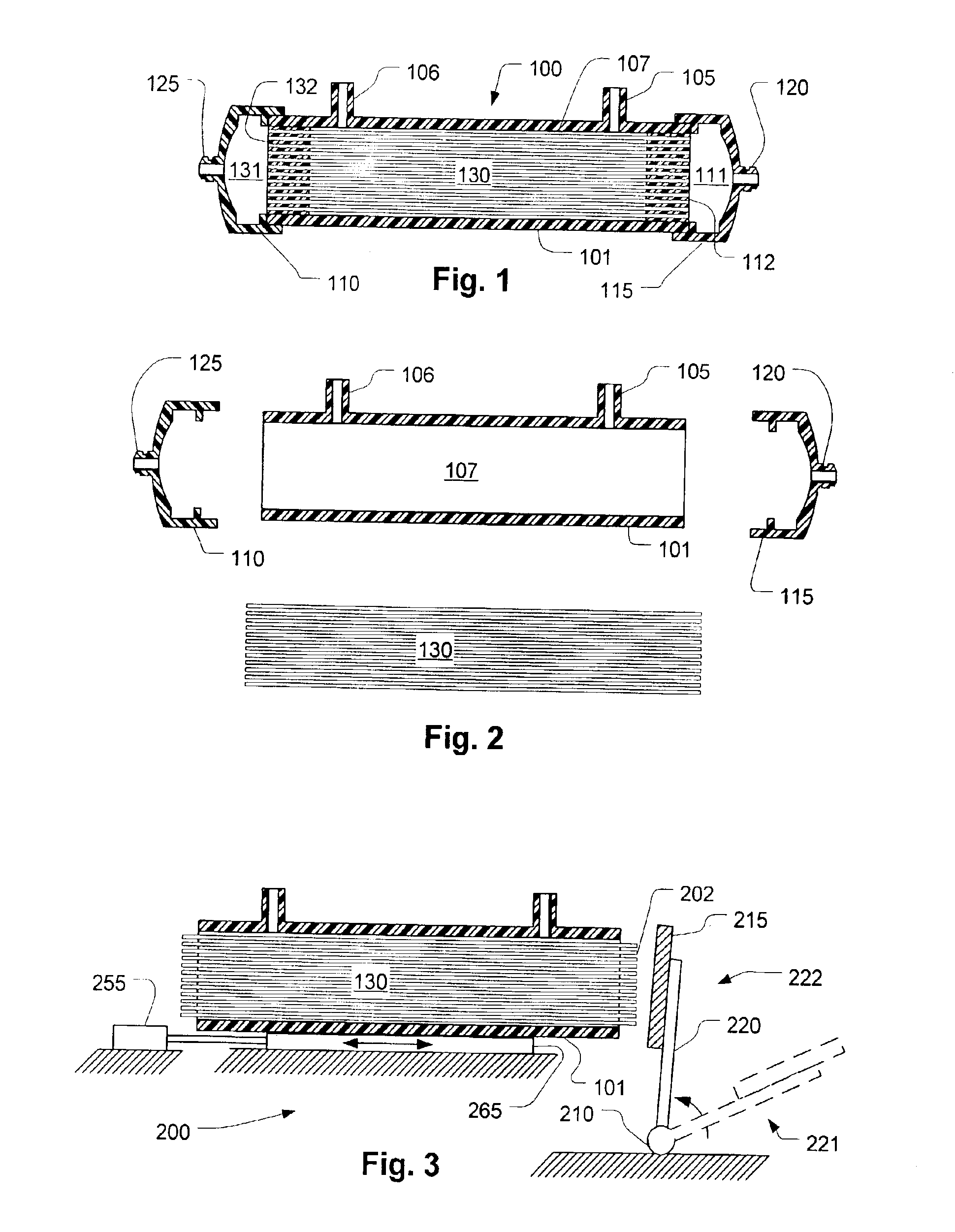

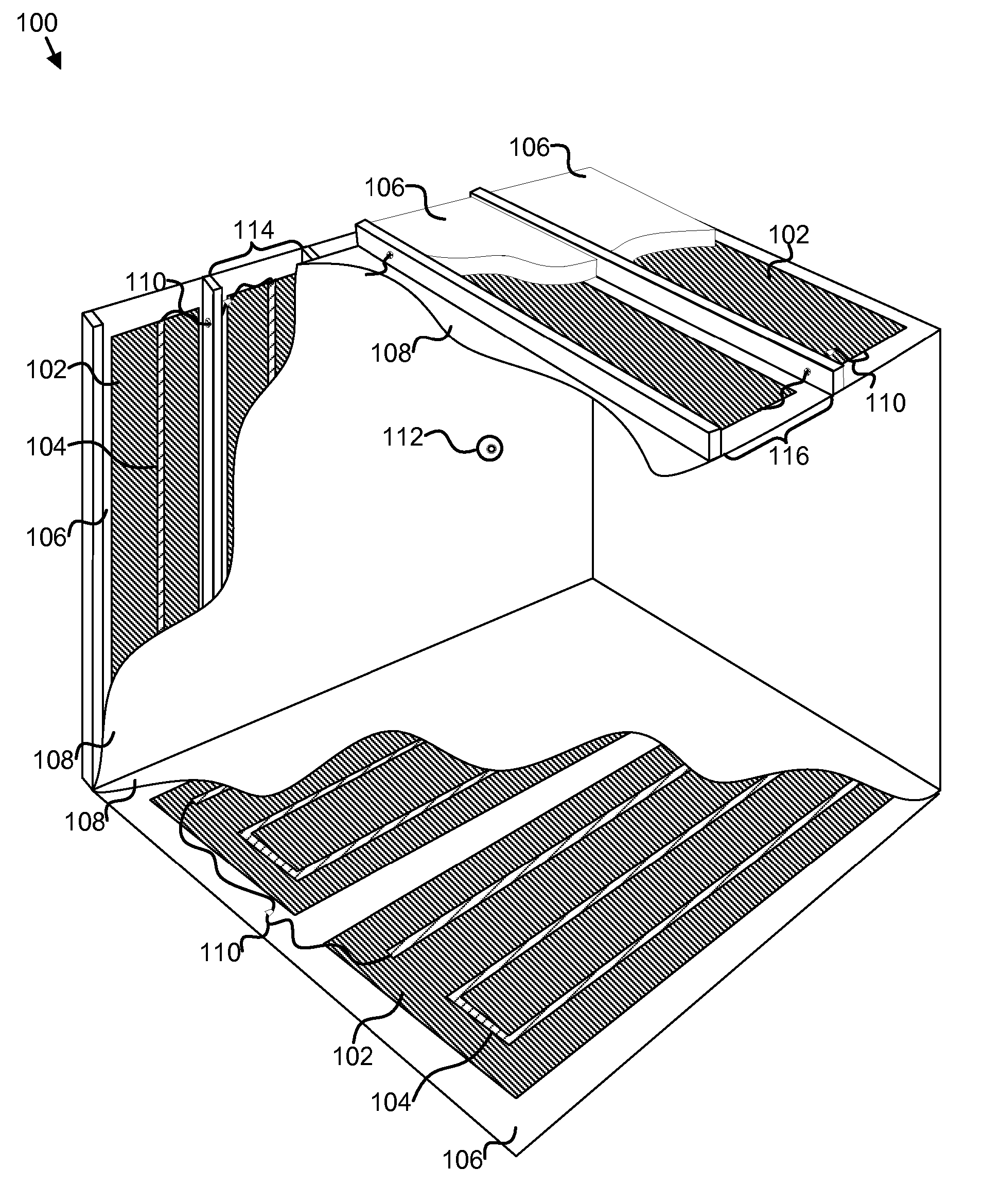

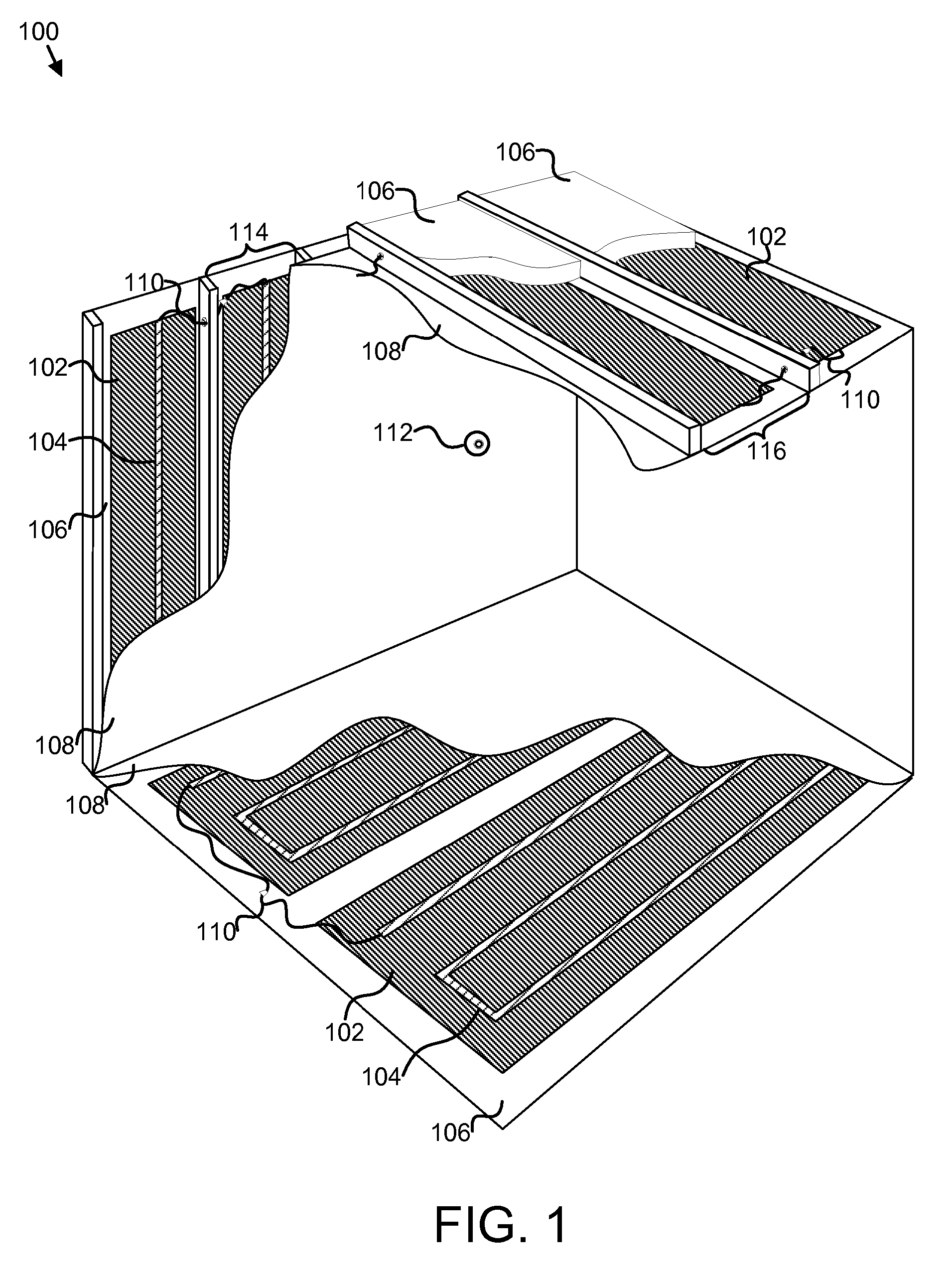

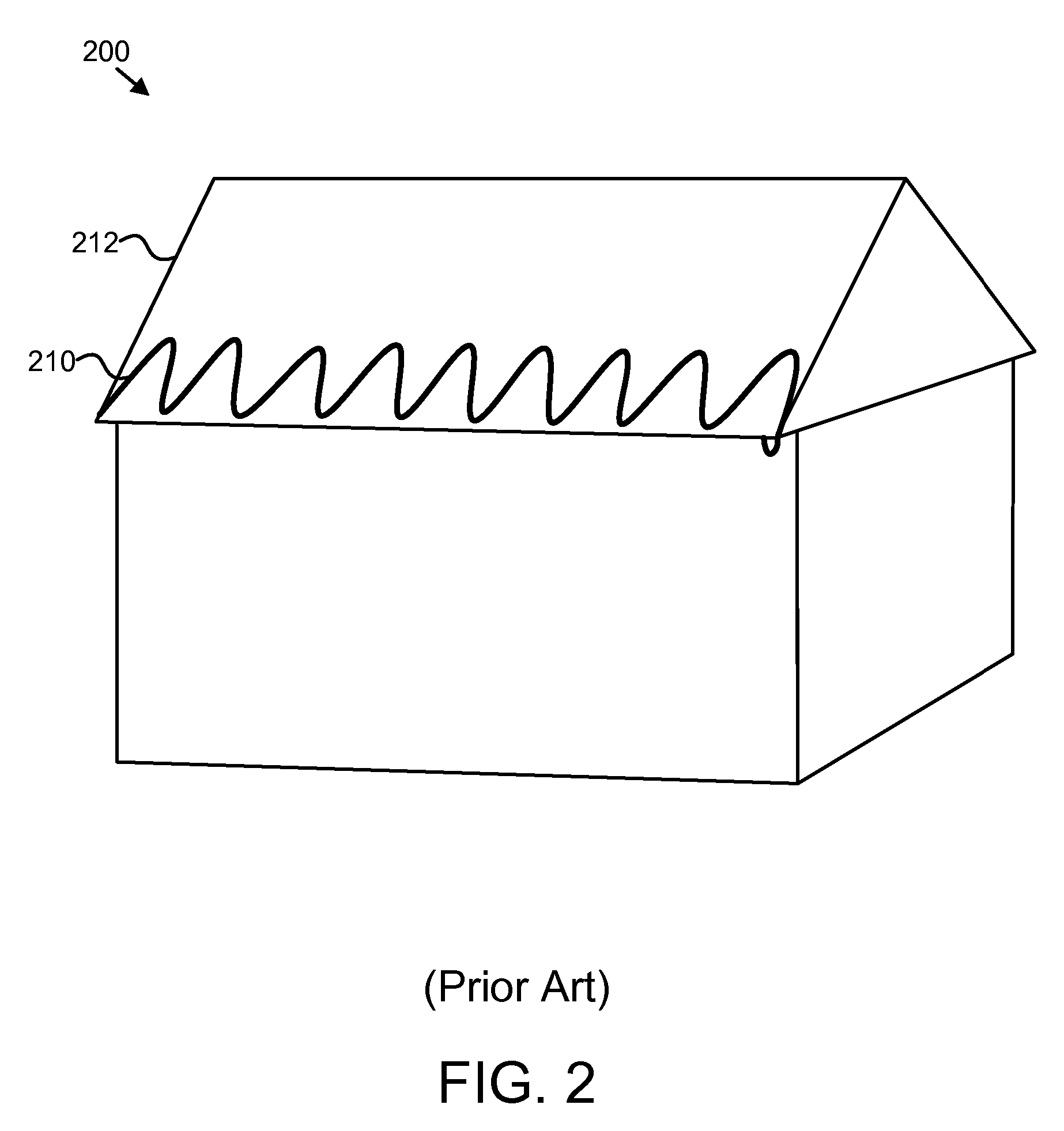

Modular radiant heating apparatus

ActiveUS20060289000A1Improve protectionRoof coveringDomestic stoves or rangesThermal isolationCoupling

The radiant heating apparatus is disclosed, having a planar electrical heating element, a planar heat spreading layer, a finishing layer, a thermal isolation layer, and an electric power coupling. The planar electrical heating element converts electrical energy to heat energy. The planar heat spreading layer is in contact with the planar electrical heating element, and draws the heat energy out of the planar electrical heating element and distributes the heat energy. The finishing layer is disposed to one side of the planar heat spreading layer. The thermal isolation layer is disposed to an opposite side of the planar heat spreading layer as the finishing layer. Heat from the planar heat spreading layer conducts away from the thermal isolation layer and toward the finishing layer. The electric power coupling is connected to the electrical heating element to supply electrical power.

Owner:GREENHEAT IP HLDG LLC

Rinse aid surface coating compositions for modifying dishware surfaces

InactiveUS7087662B2Increased durabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsStainingNanoparticle

Rinse aid materials for coating, coating compositions, methods and articles of manufacture for use in automatic dishwashing appliances comprising a nanoparticle system or employing the same to impart surface modifying benefits for all types of dishware surfaces are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of rinse aid surface coating compositions, methods and articles of manufacture that create multi-use benefits to modified dishware surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that include at least one of the following improved surface properties: wetting and sheeting, uniform drying, anti-spotting, anti-staining, anti-filming, self cleaning, and durability benefits, relative to dishware surfaces unmodified with such nanoparticle systems. In some embodiments, actively curing the rinse aid surface coating composition on the dishware surfaces, including, but not limited to by radiative heating the air surrounding the dishware surface with the coating thereon can be used to increase the durability of the dishware surface coating.

Owner:THE PROCTER & GAMBLE COMPANY

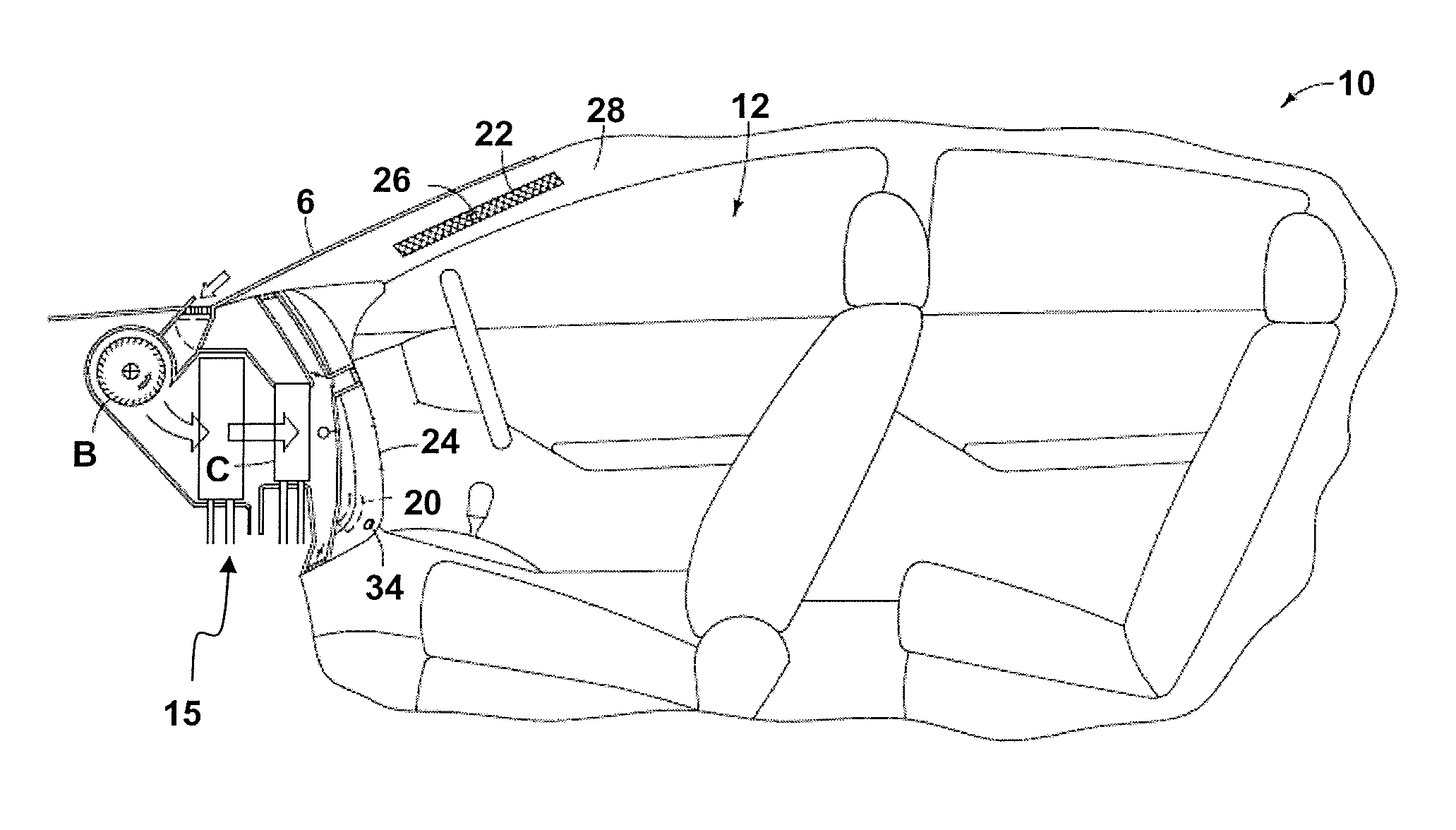

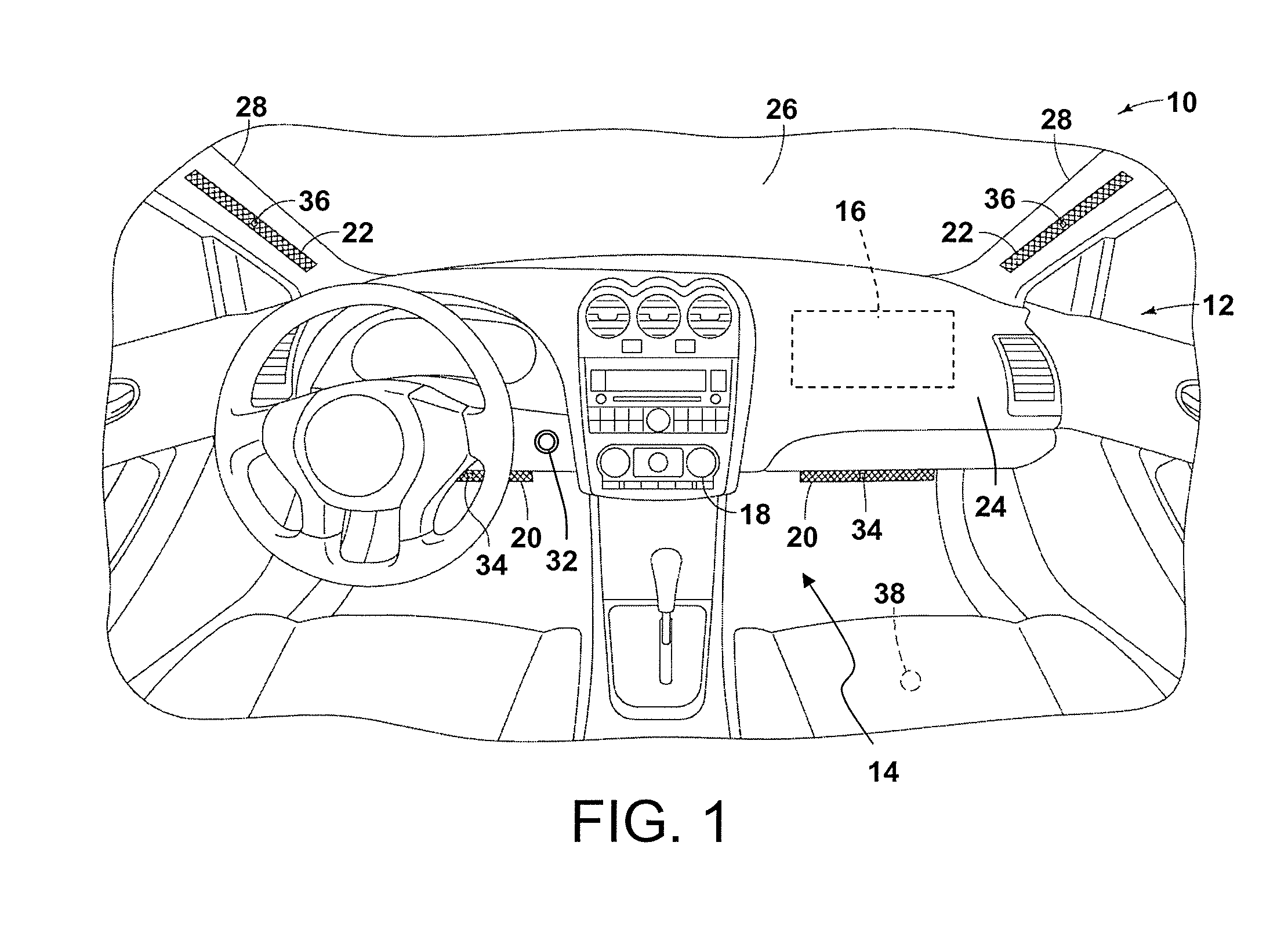

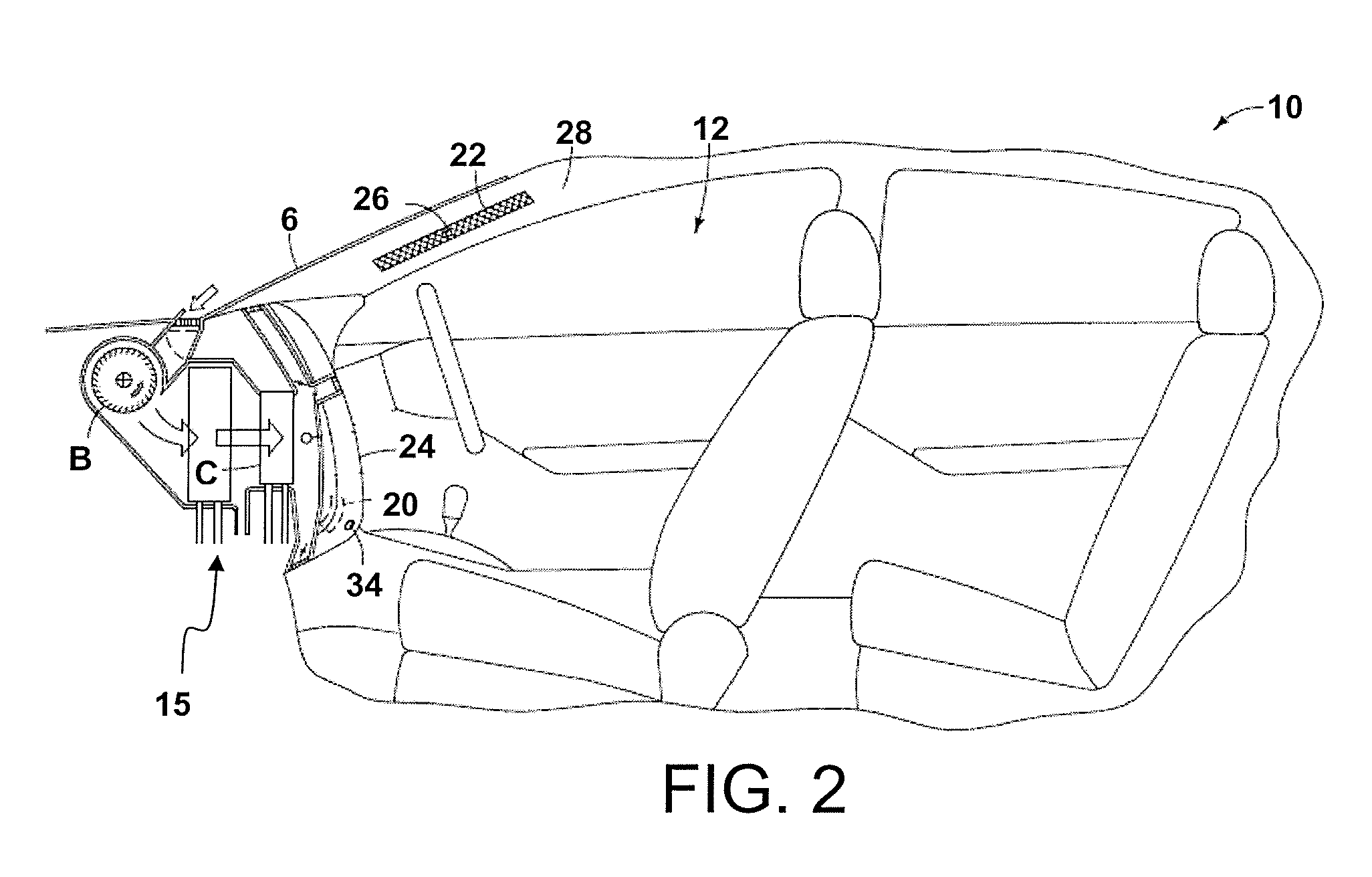

Vehicle radiant heating control system

InactiveUS20110127246A1Good suitVehicle heating/cooling devicesOhmic-resistance heating detailsControl systemRadiative heating

A vehicle radiant heating control system is provided that comprises a radiant heating element, a power source and a controller. The power source is operatively connected to the radiant heating element. The controller operatively controls the radiant heating element and the power source. The controller operates the radiant heating element by intermittently supplying power generated by the power source to the radiant heating element.

Owner:NISSAN MOTOR CO LTD

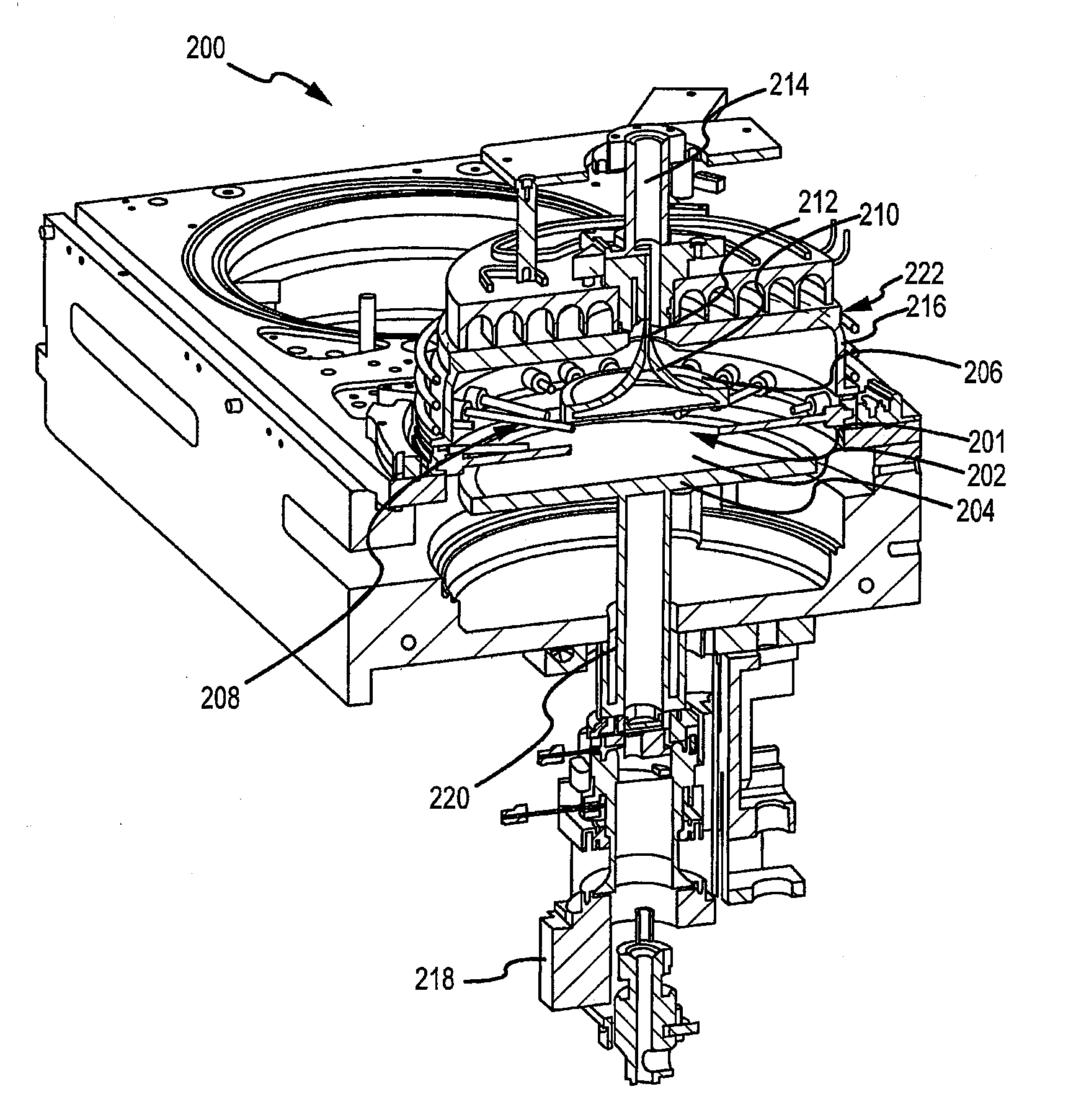

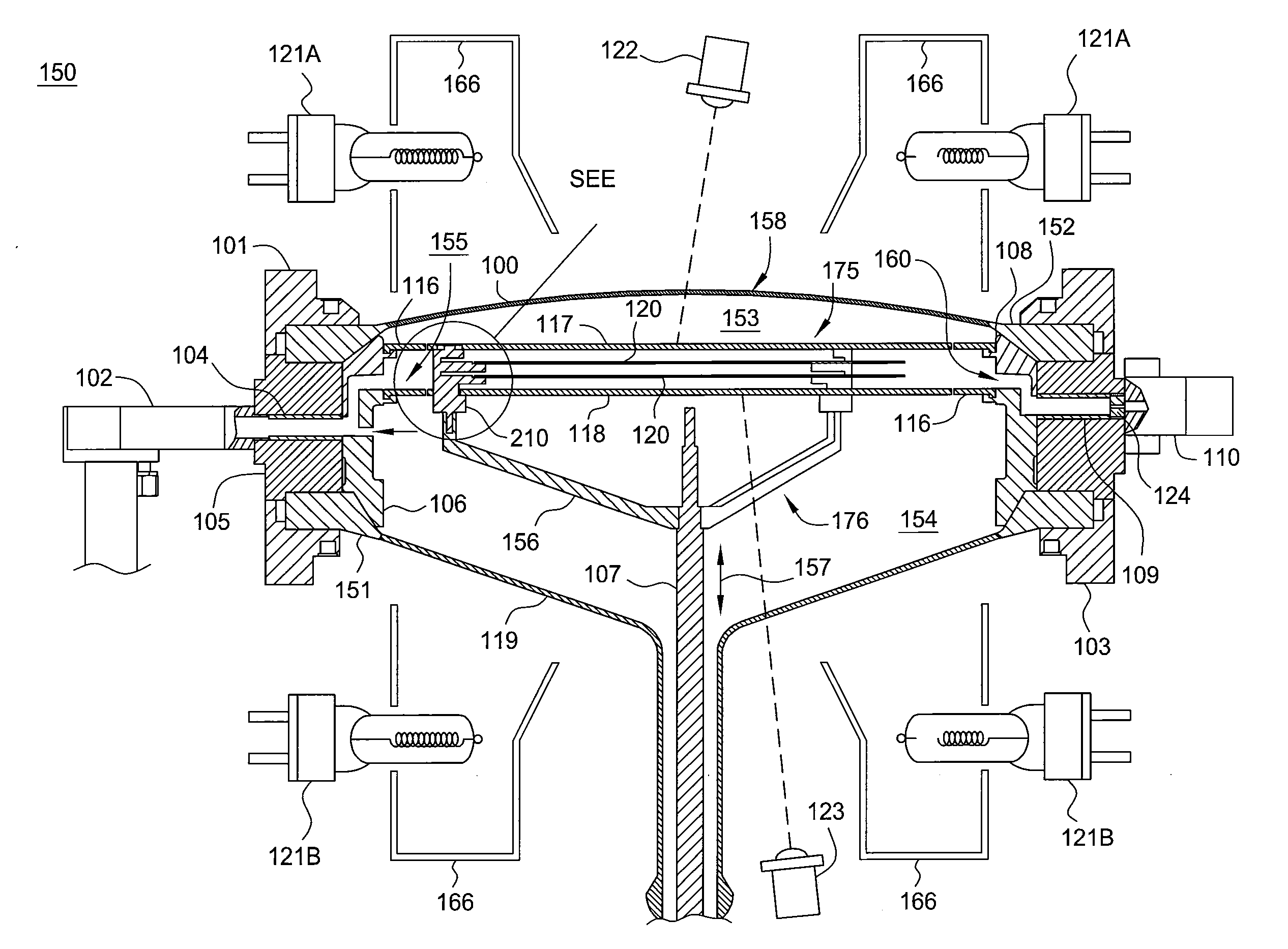

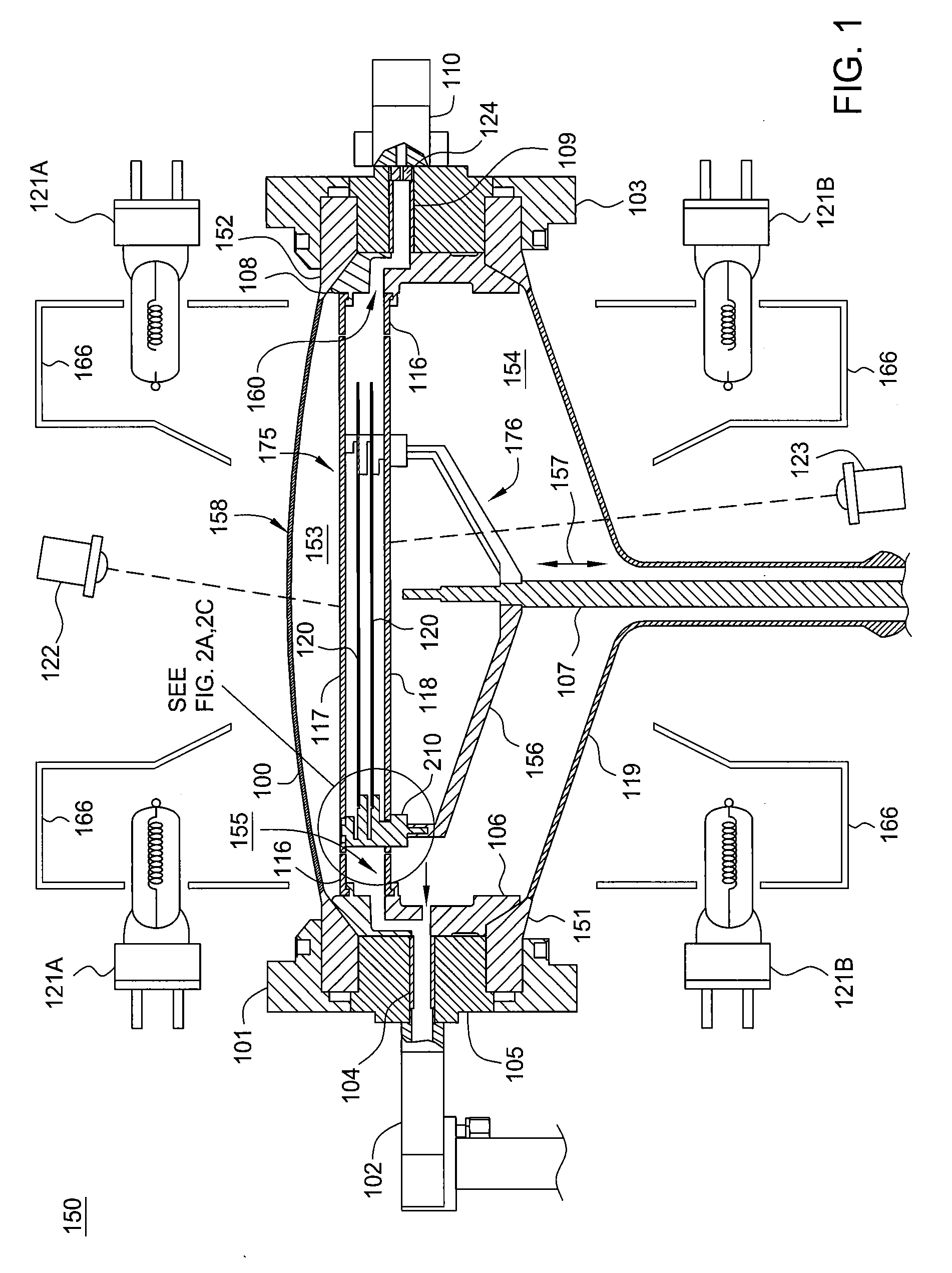

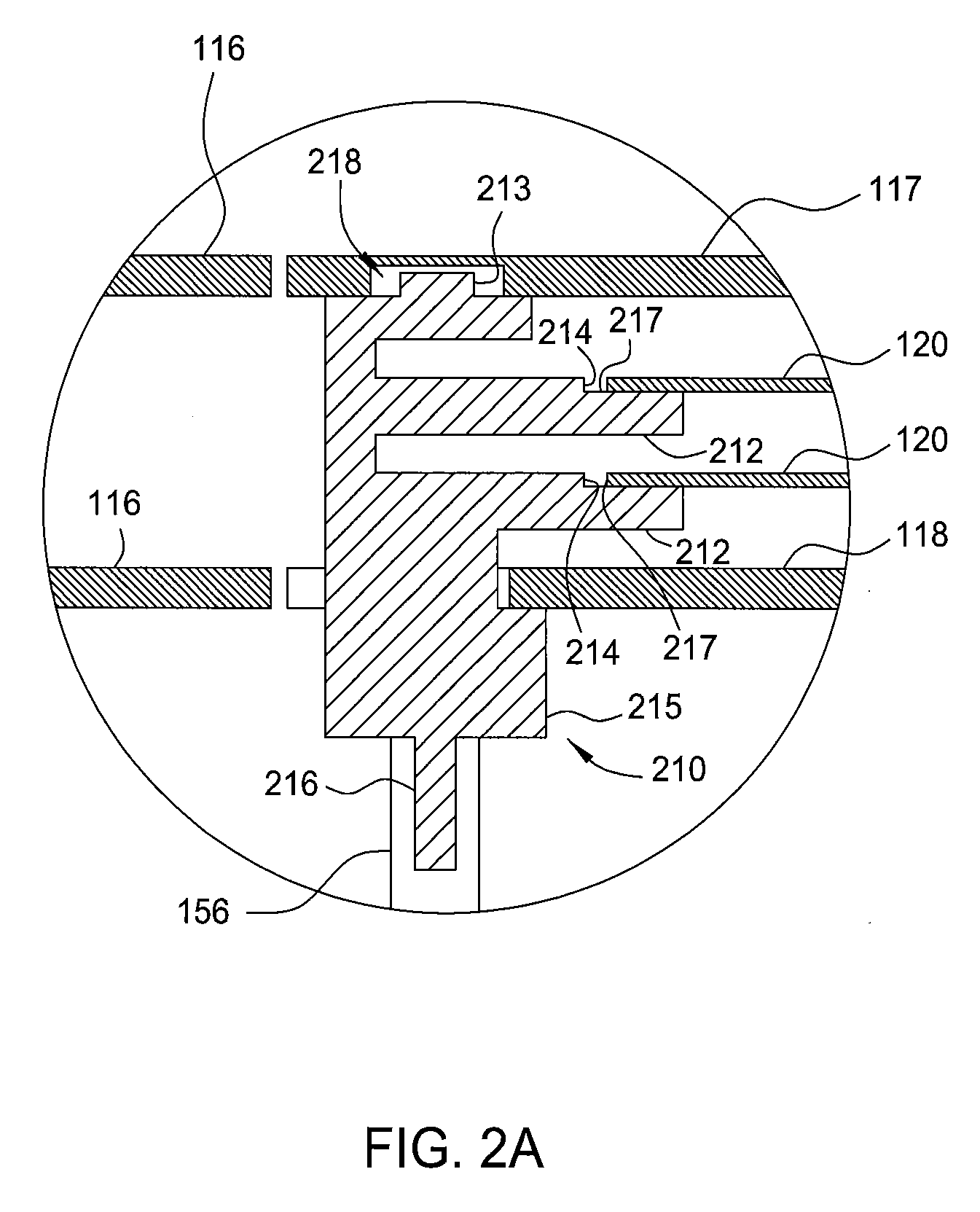

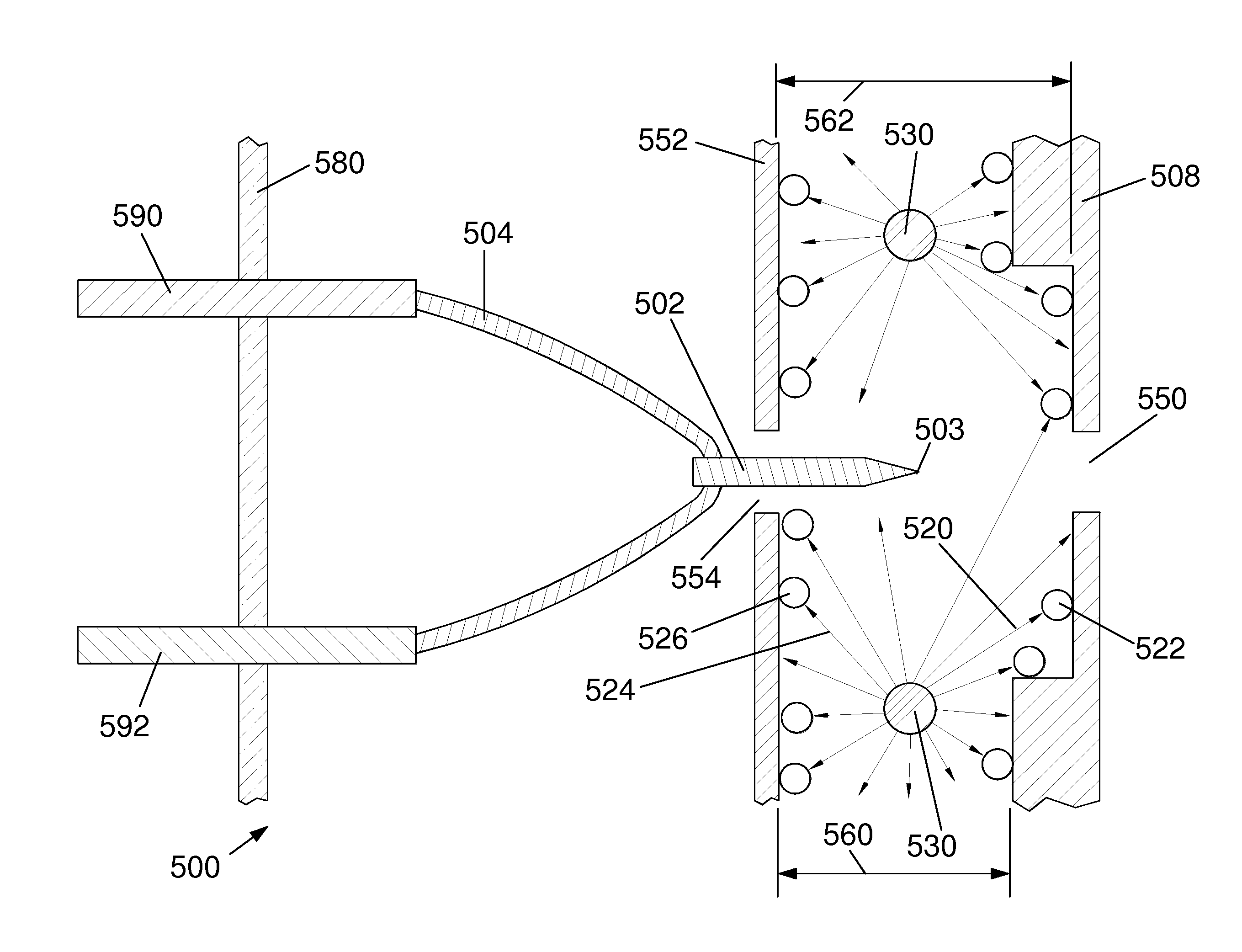

Microbatch deposition chamber with radiant heating

InactiveUS20080220150A1Polycrystalline material growthPretreated surfacesEngineeringRadiative heating

The present invention generally provides an apparatus and method for processing and transferring substrates in an epitaxial deposition chamber. Embodiments of the invention described herein are adapted to maximize chamber throughput and improve film deposition uniformity. In one embodiment, two substrates are processed simultaneously using radiant heating of the substrates in a cold wall, low pressure chemical vapor deposition reactor.

Owner:APPLIED MATERIALS INC

Heat pump with forced air heating regulated by withdrawal of heat to a radiant heating system

InactiveUS20080276638A1Easy transferImprove the heating effectSpace heating and ventilation safety systemsSpace heating and ventilation control systemsThermal energyCirculator pump

A heat pump system is disclosed that utilizes a variable speed hydronics pump to selectively divert heat energy from a forced air heating system to a hydronics radiant heating system. By actively controlling the speed of the withdrawal of heat, the temperature of the forced air output may be maintained while maximizing the amount of heat delivered by the efficient hydronics system. The heat pump system also actively controls the blower of the forced air system. To reduce the frequency of the compressors cycling on and off, a tank may be used to store and dispense heat if the hydronics system is not of sufficient size.

Owner:ELECTRO IND

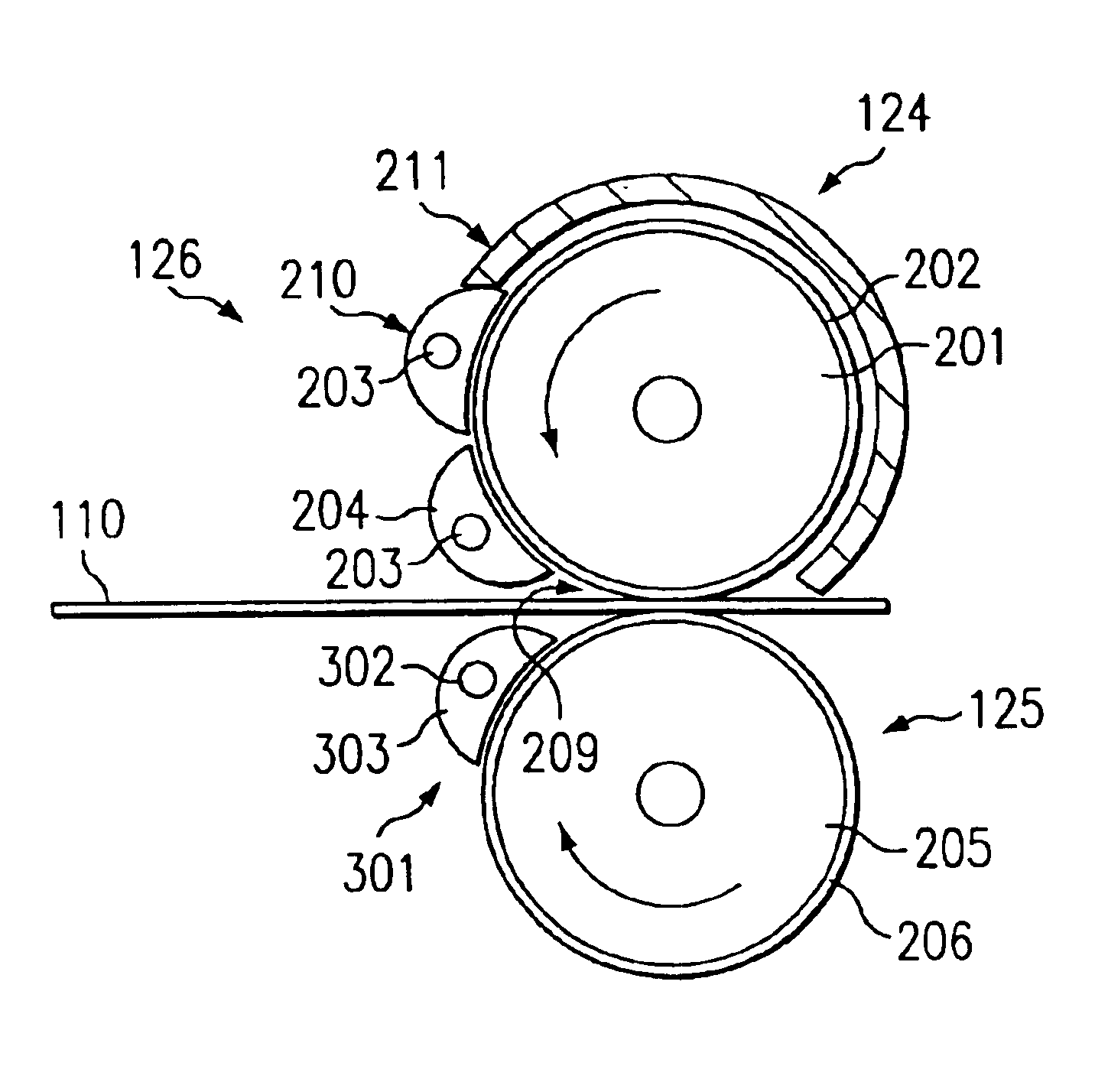

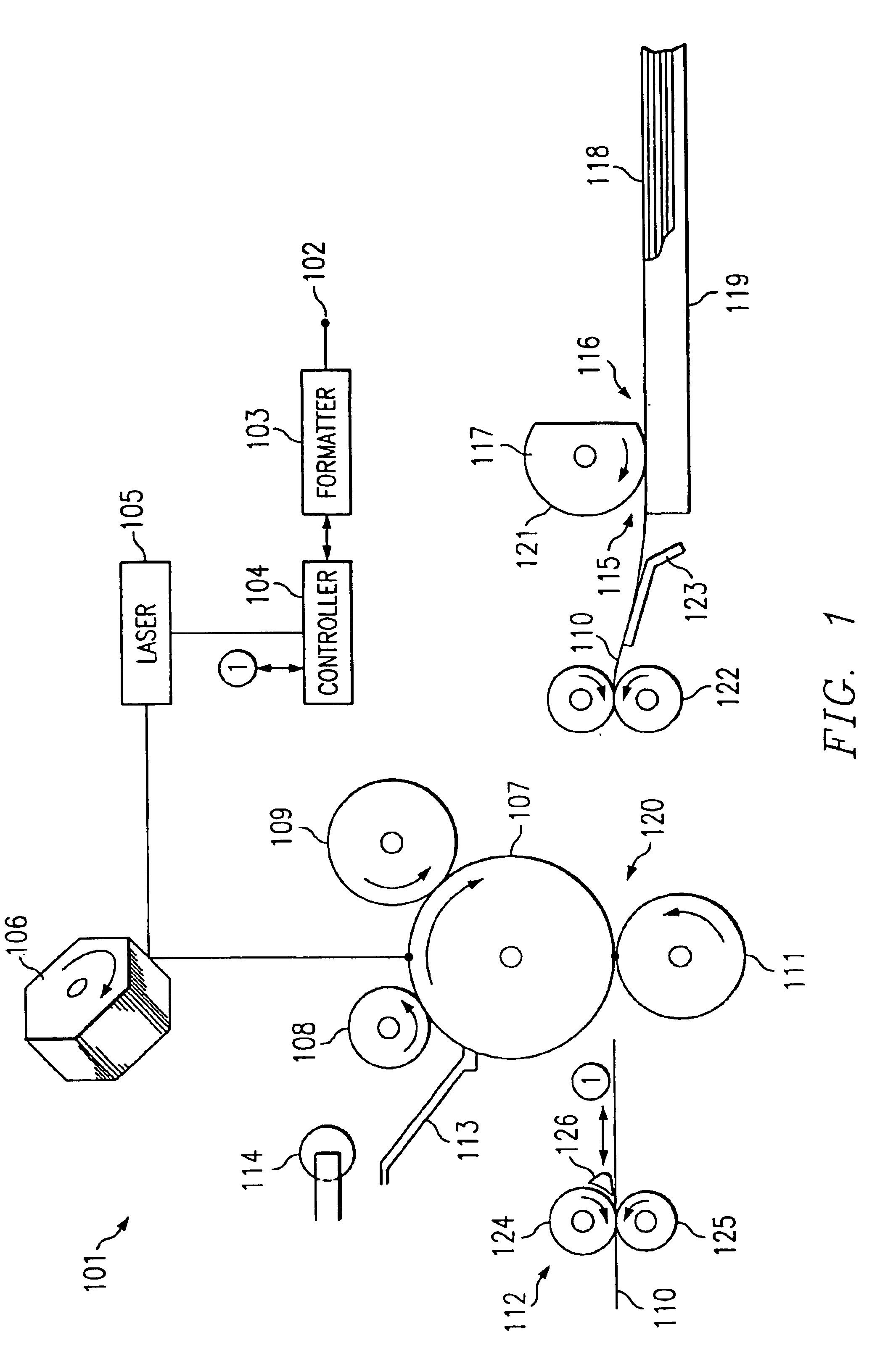

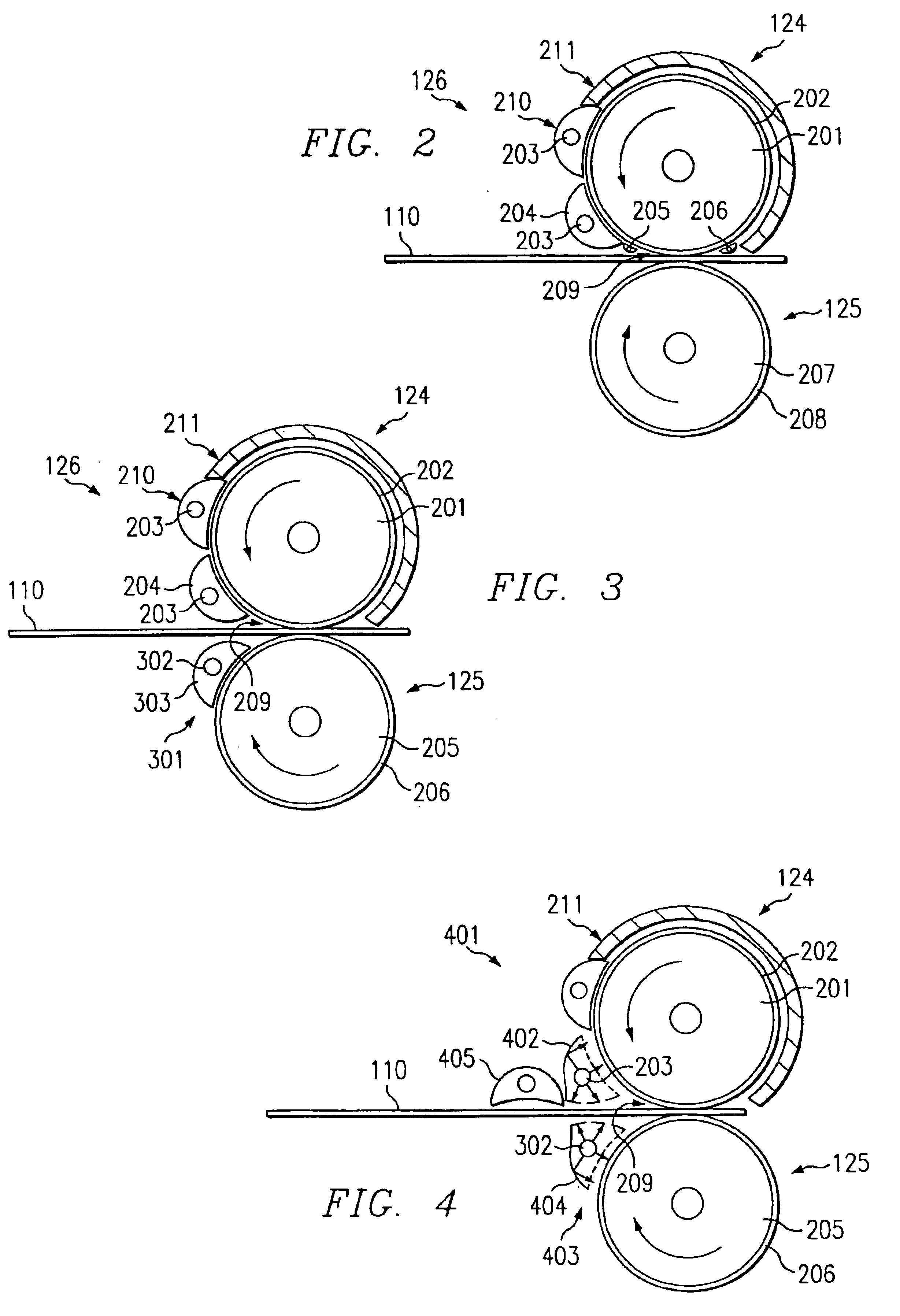

Low thermal mass heated fuser

InactiveUS6898410B2Ohmic-resistance heatingElectrographic process apparatusEngineeringRadiative heating

A fuser assembly with a roller having a heat absorptive outer layer on an inner core of a thermally isolating material and a radiant heating element positioned adjacent and external to the outer layer of a roller.

Owner:HEWLETT PACKARD DEV CO LP

Coatings for modifying hard surfaces and processes for applying the same

InactiveUS7066998B2Fine surfaceClean appearanceInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsMetallurgyNanoparticle

Materials for coating, coating compositions, methods and articles of manufacture comprising a nanoparticle system or employing the same to impart surface modifying benefits for all types of hard surfaces are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to modified hard surfaces. In some embodiments, actively curing the coating composition on the hard surfaces, including, but not limited to by radiative heating the air surrounding the hard surface with the coating thereon can be used to increase the durability of the hard surface coating.

Owner:THE PROCTER & GAMBLE COMPANY

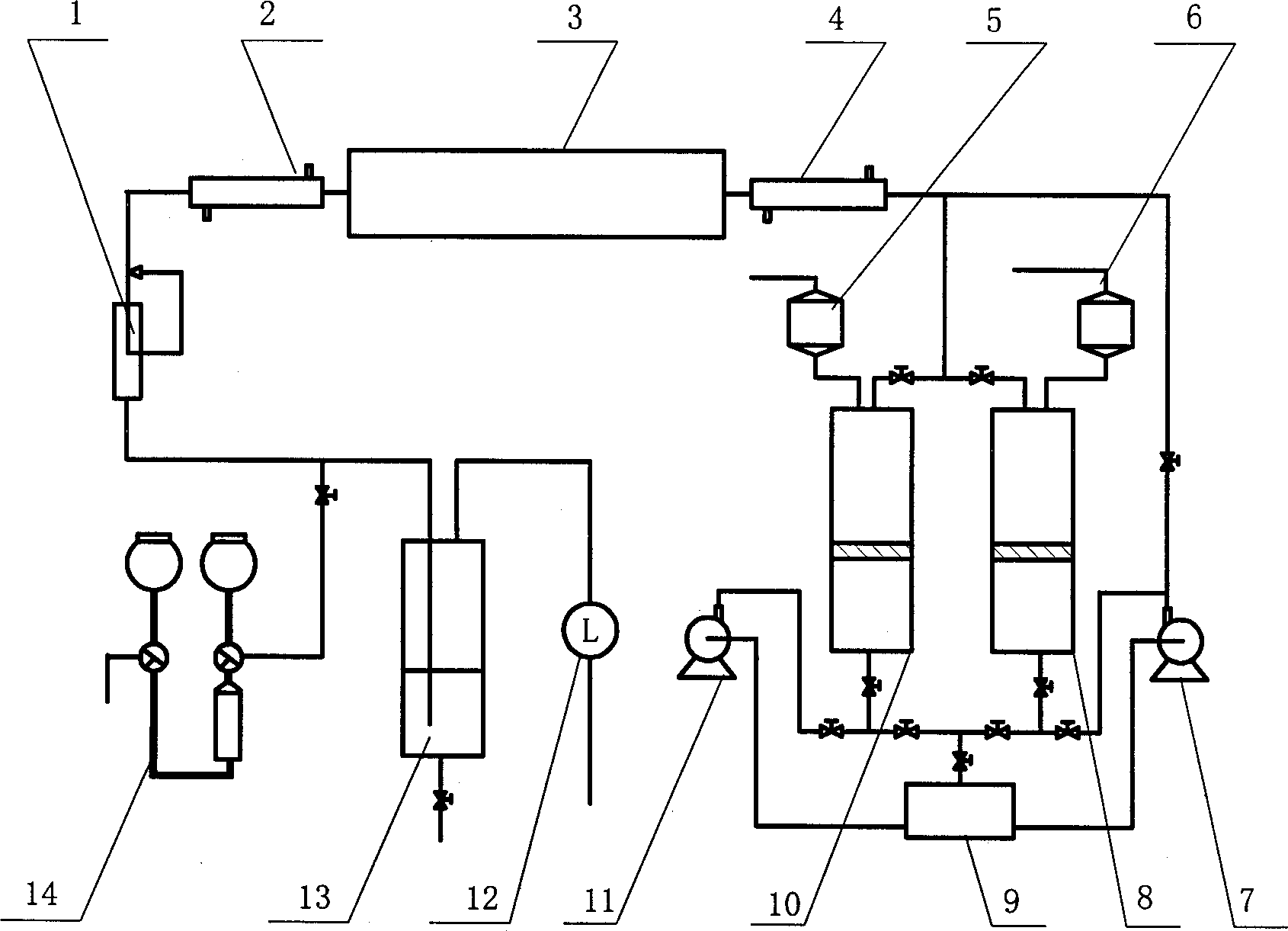

Continuous supercritical water gasifying hydrogen producing method and apparatus with organic solid matter

InactiveCN1375447AHeating up fastFast and efficient gasification reactionPlastic recyclingHydrogen productionHigh pressureSolid matter

The solid raw material has no need of drying treatment, can be pulverized and directly added into reaction system; said invention uses carboxymethyl-cellulose sodium as additive and implement high-pressure multiphase mixed continuous transmission of solid raw material; its reaction equipment is formed from double-pump, double feeding system, reactor, back pressure valve, gas-liquid separator, sampling device and wet gas flowmeter; it adopts the reactor with current heating mode and radiation heating mode, can implement quick heating and high-effective gasification reaction. The hydrogen-making and sampling device provided by said invention can product hydrogen gas and CO2 gas as main product, its CO volume content is less than 1%, and its gasification rate can be up to 100%.

Owner:陕西中核交大超洁能源技术有限公司

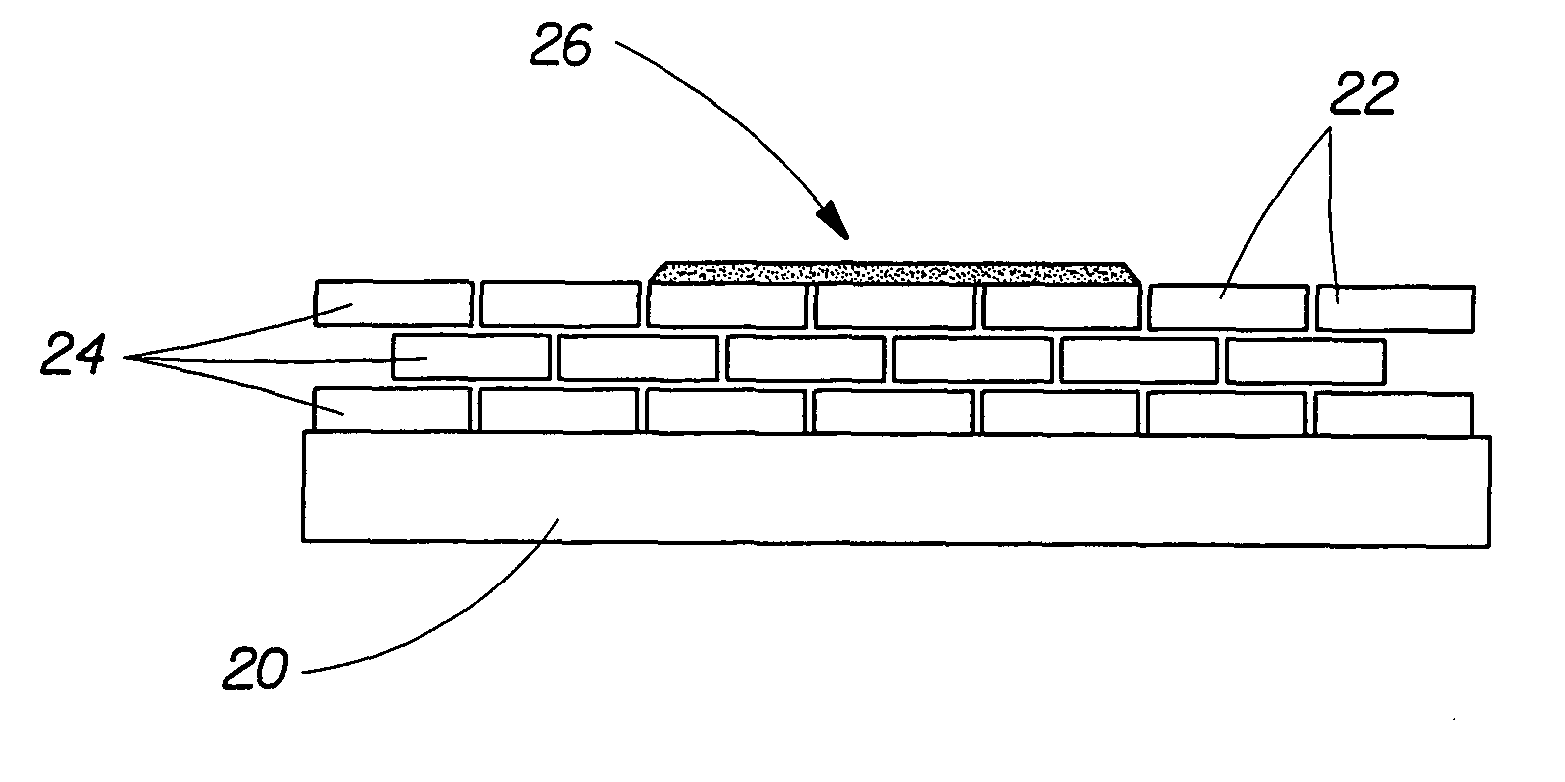

Multiple panel oven having individual controls for combined conductive and radiant heating panels

A multiple panel cooking oven having individual controls for combined conductive and radiant heating. Each panel comprises an upper heating element for conductive heating and a lower heating element for radiant heating to obtain uniform baking within a zone between panels in the oven. A control panel having displays and keypads interfaces with a processor which provides control signals for adjusting the temperature of the heating elements of the panels. Cooking energy efficiency is increased through the use of radiative and conductive heat transfer, to reduce bake times by significantly increasing heat transfer to the food products. Independent cook zones allow preparation of multiple products simultaneously under different cooking conditions. The oven, in one embodiment may include a convection heating mode of operation. In an alternative embodiment no convection mode is provided and the sole source of heat is provided by the conductive / radiant panels.

Owner:TIAX LLC

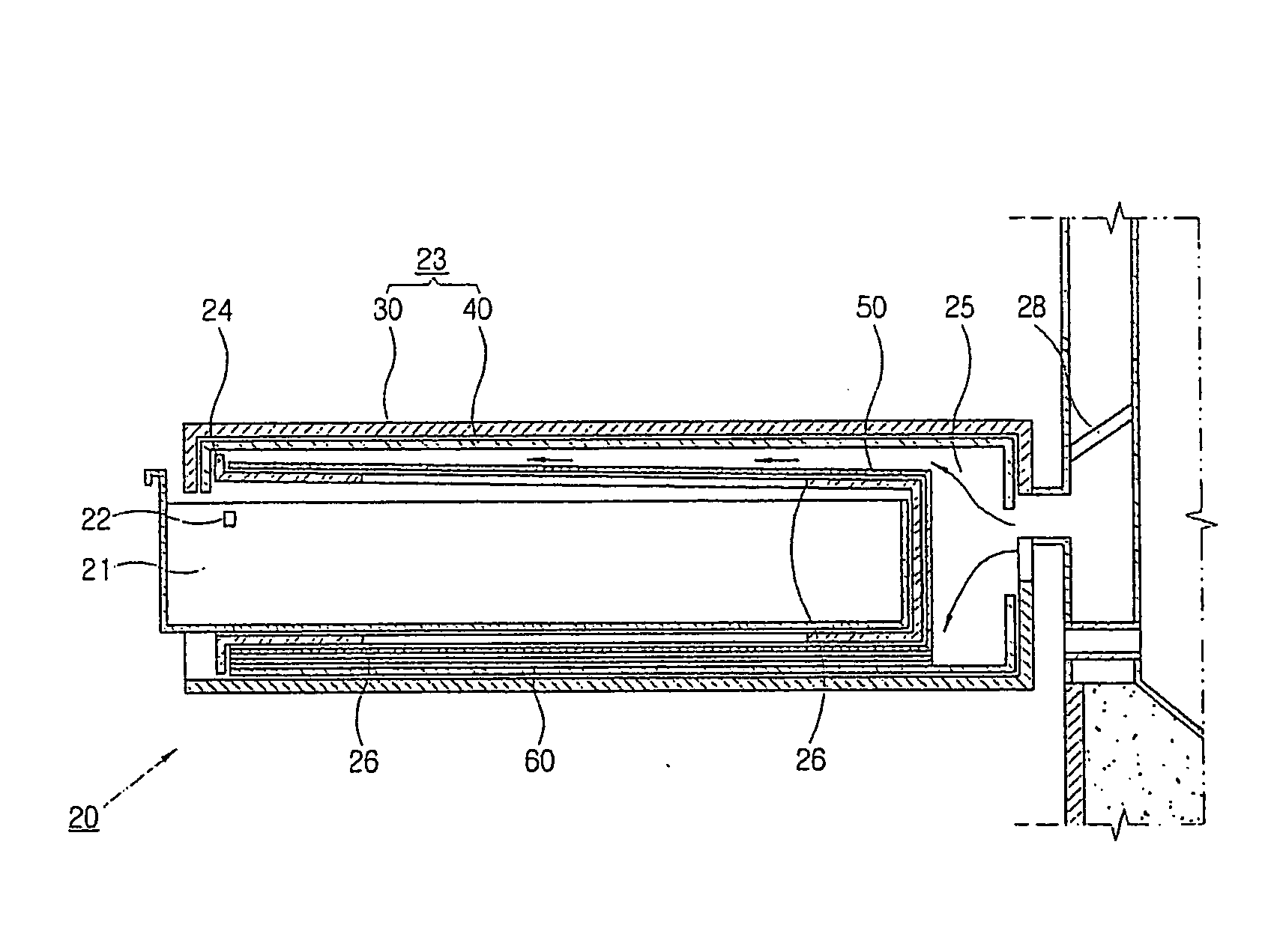

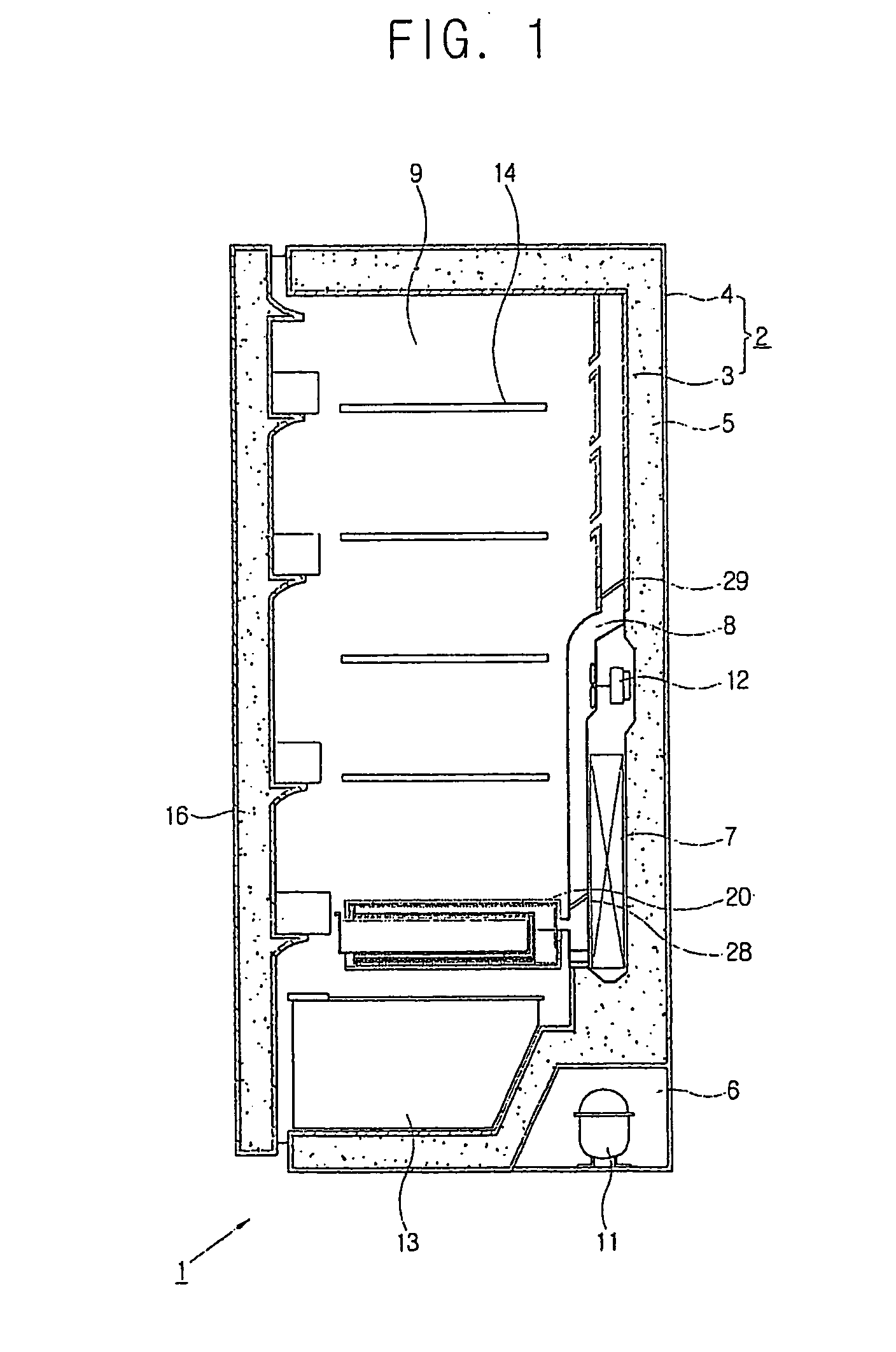

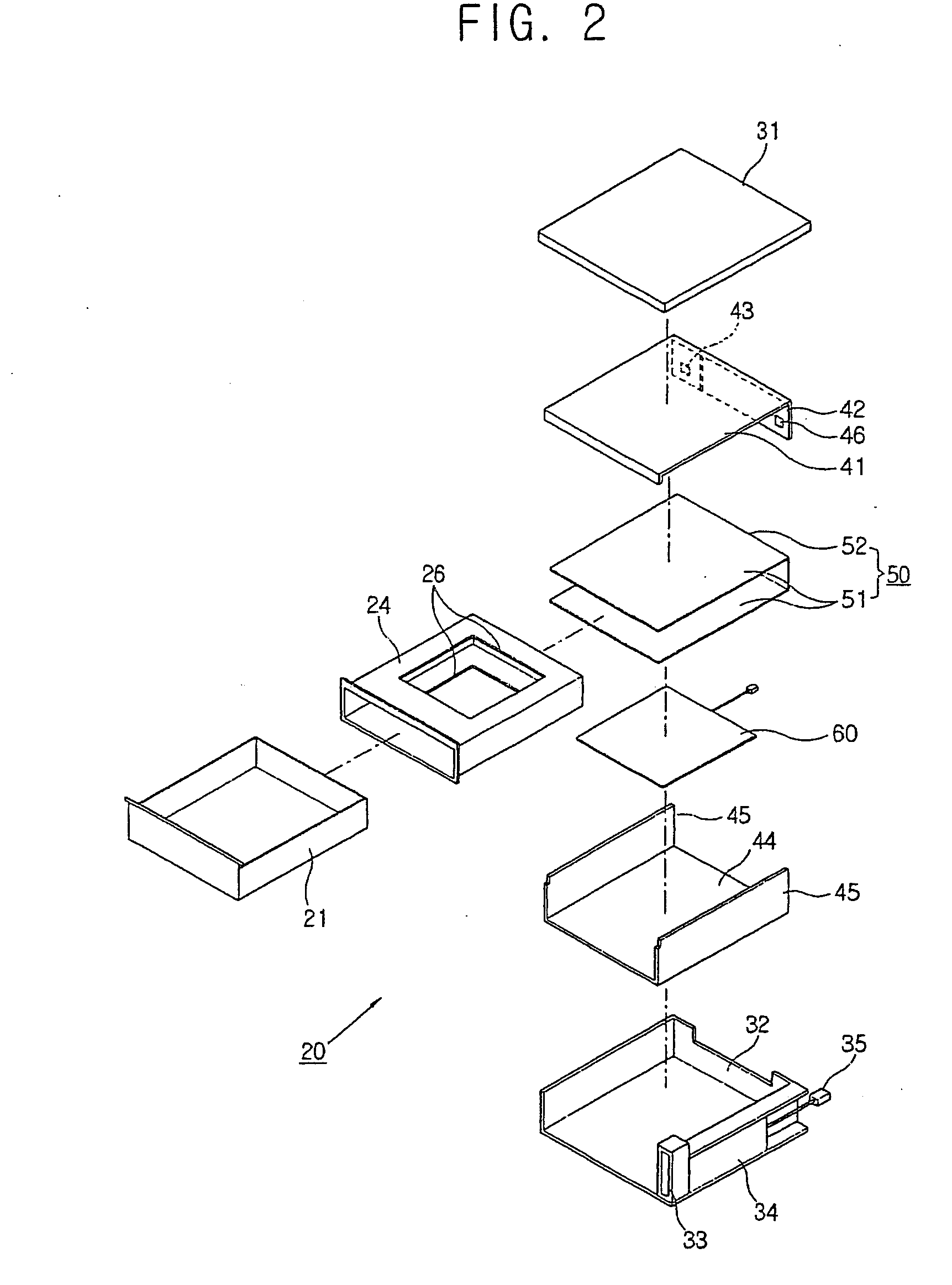

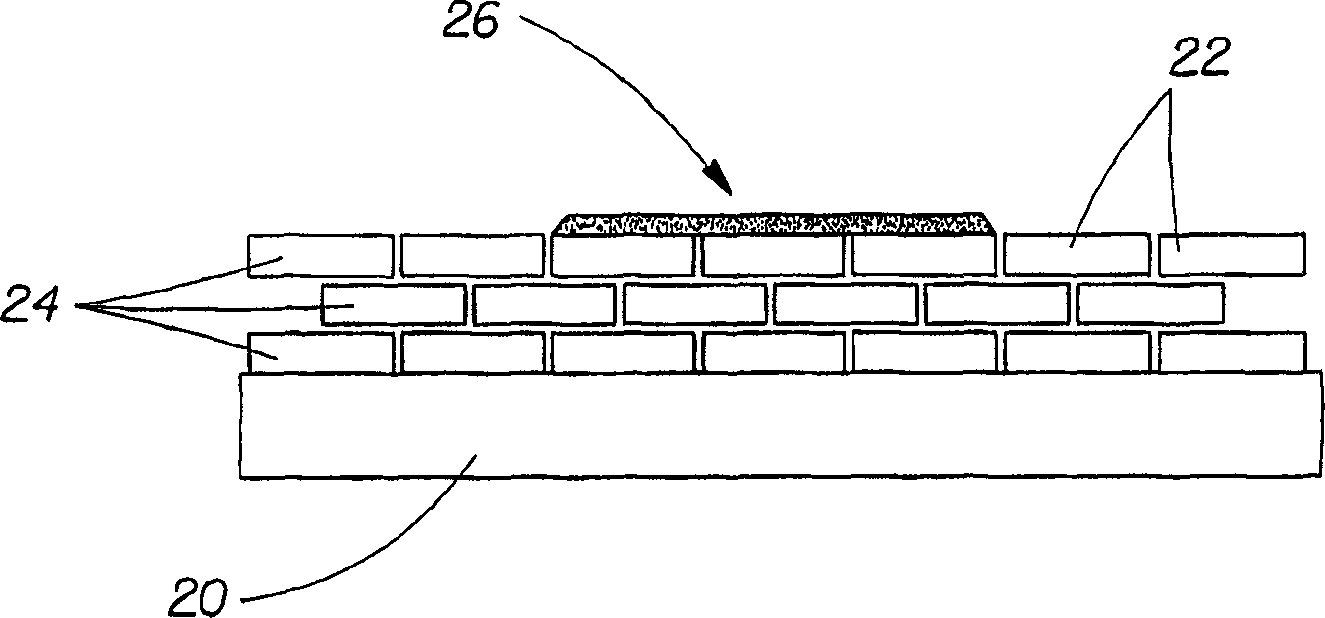

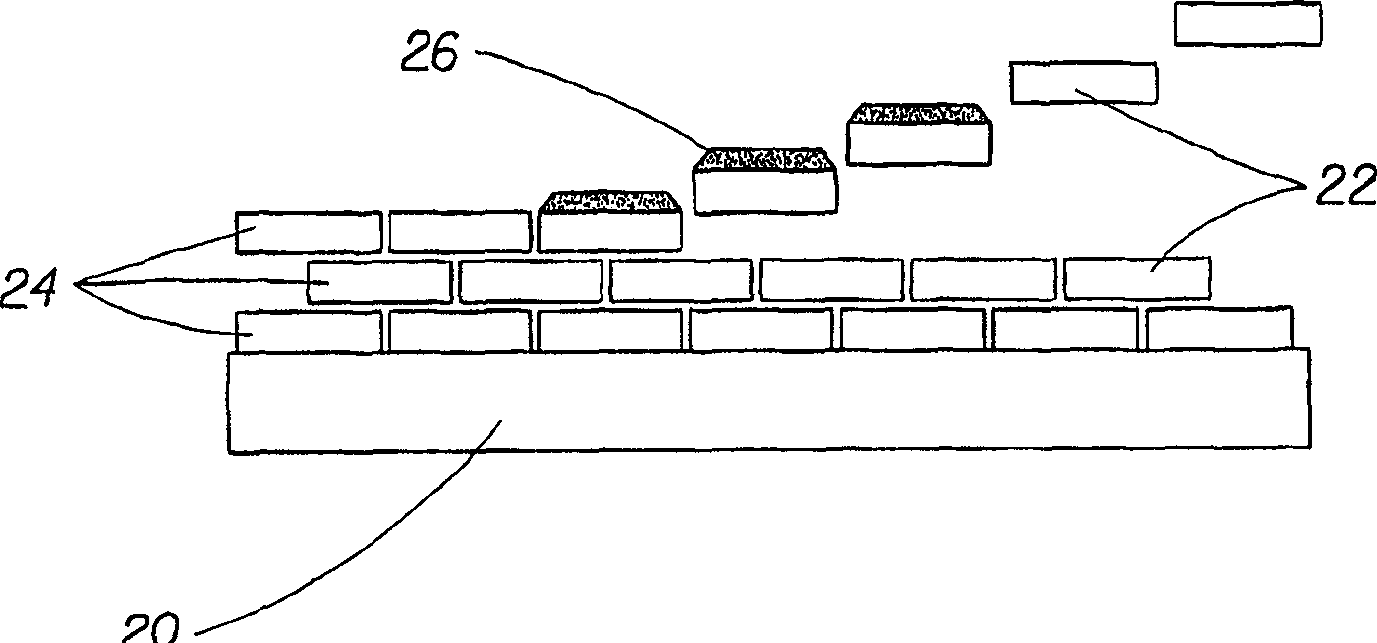

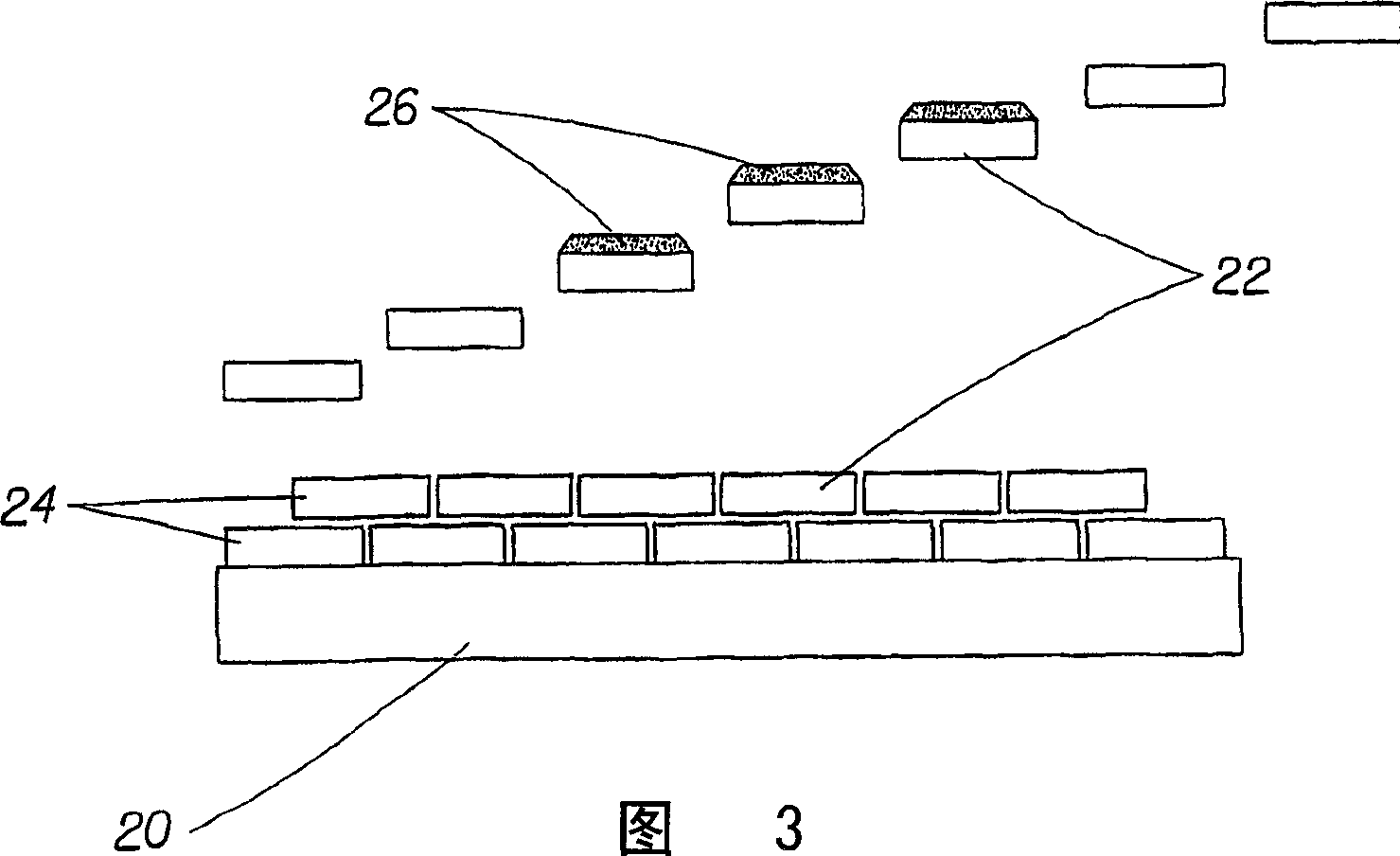

Refrigerator with temperature control and operating method therefor

InactiveUS20070163291A1Unnecessary operationImprove freshnessLighting and heating apparatusDomestic refrigeratorsTemperature controlProcess engineering

A refrigerator having a main body including a refrigerating compartment, a cool air duct supplying cool air to the refrigerating compartment, and a sub storage compartment provided in the main body independently maintaining a temperature thereof with respect to the refrigerating compartment and being indirectly cooled or indirectly heated by radiation.

Owner:SAMSUNG ELECTRONICS CO LTD

Coating compositions for modifying hard surfaces

InactiveCN1439041AInorganic/elemental detergent compounding agentsOrganic anion exchangersStainingNanoparticle

Rinse aid materials for coating, coating compositions, methods and articles of manufacture for use in automatic dishwashing appliances comprising a nanoparticle system or employing the same to impart surface modifying benefits for all types of dishware surfaces are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of rinse aid surface coating compositions, methods and articles of manufacture that create multi-use benefits to modified dishware surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that include at least one of the following improved surface properties: wetting and sheeting, uniform drying, anti-spotting, anti-staining, anti-filming, self cleaning, and durability benefits, relative to dishware surfaces unmodified with such nanoparticle systems. In some embodiments, actively curing the rinse aid surface coating composition on the dishware surfaces, including, but not limited to by radiative heating the air surrounding the dishware surface with the coating thereon can be used to increase the durability of the dishware surface coating.

Owner:THE PROCTER & GAMBLE COMPANY

Variable low intensity infrared heater

ActiveUS20050175944A1Improve liquidityEasy to controlDomestic stoves or rangesPilot flame ignitersRadiant heaterCombustor

A radiant heater including a burner having an inlet for receiving an air and gas mixture and an exhaust for emitting exhaust gases generated by combustion of the air and gas mixture within the burner, an elongated radiant heating tube having an inlet for receiving the exhaust gases emitted by the burner, a gas flow control assembly for controlling the flow of gas to the burner, and a blower for controlling the flow of air to the burner. The blower comprises a two-stage blower including a motor having a low winding corresponding to a low blower speed and a high winding corresponding to a high blower speed. The gas flow control assembly comprises a two-stage regulator or two stage two-stage valve having a low setting for delivering a low gas flow to the burner and a high setting for delivering a high gas flow to the burner.

Owner:SOLARONICS

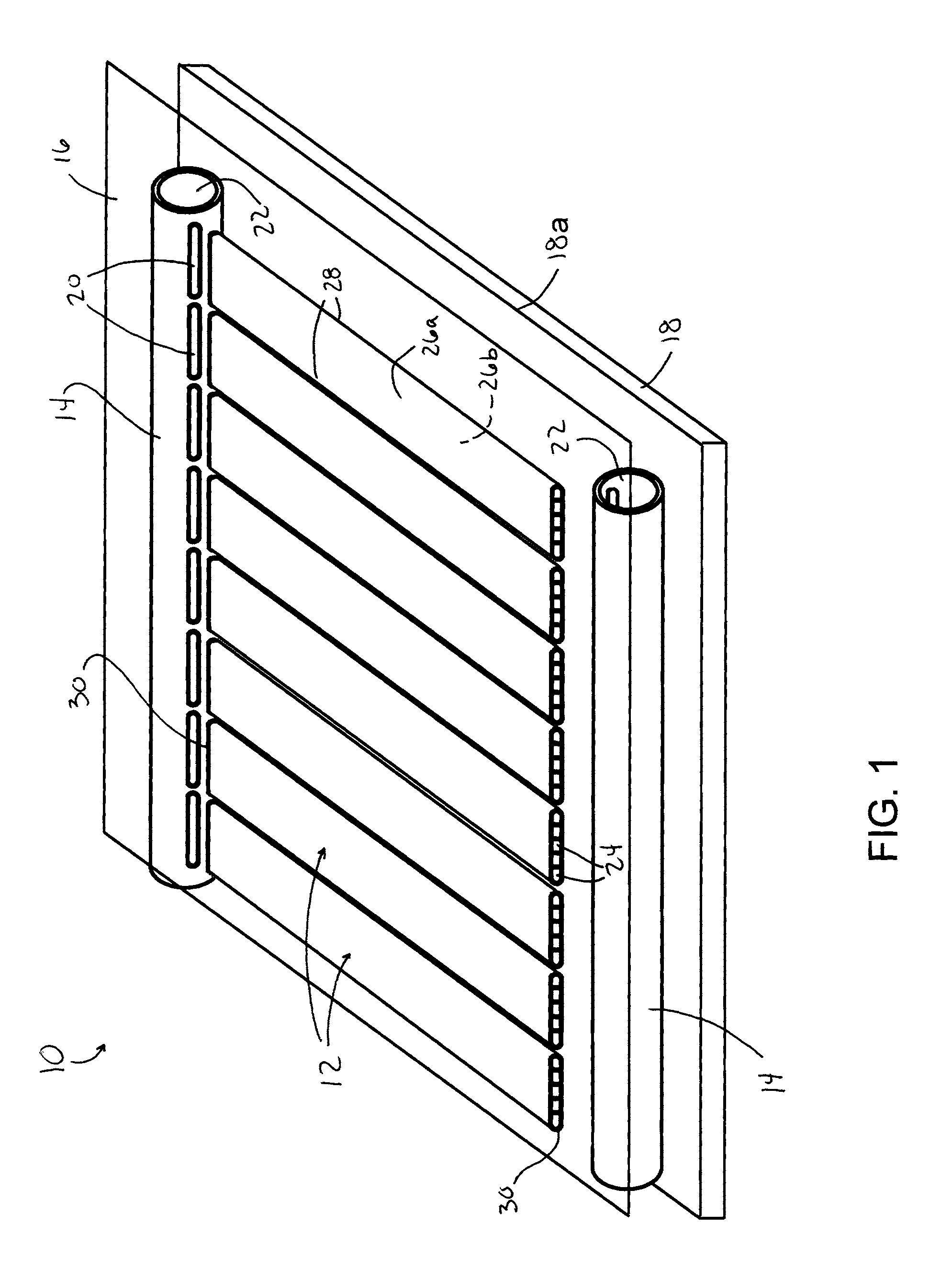

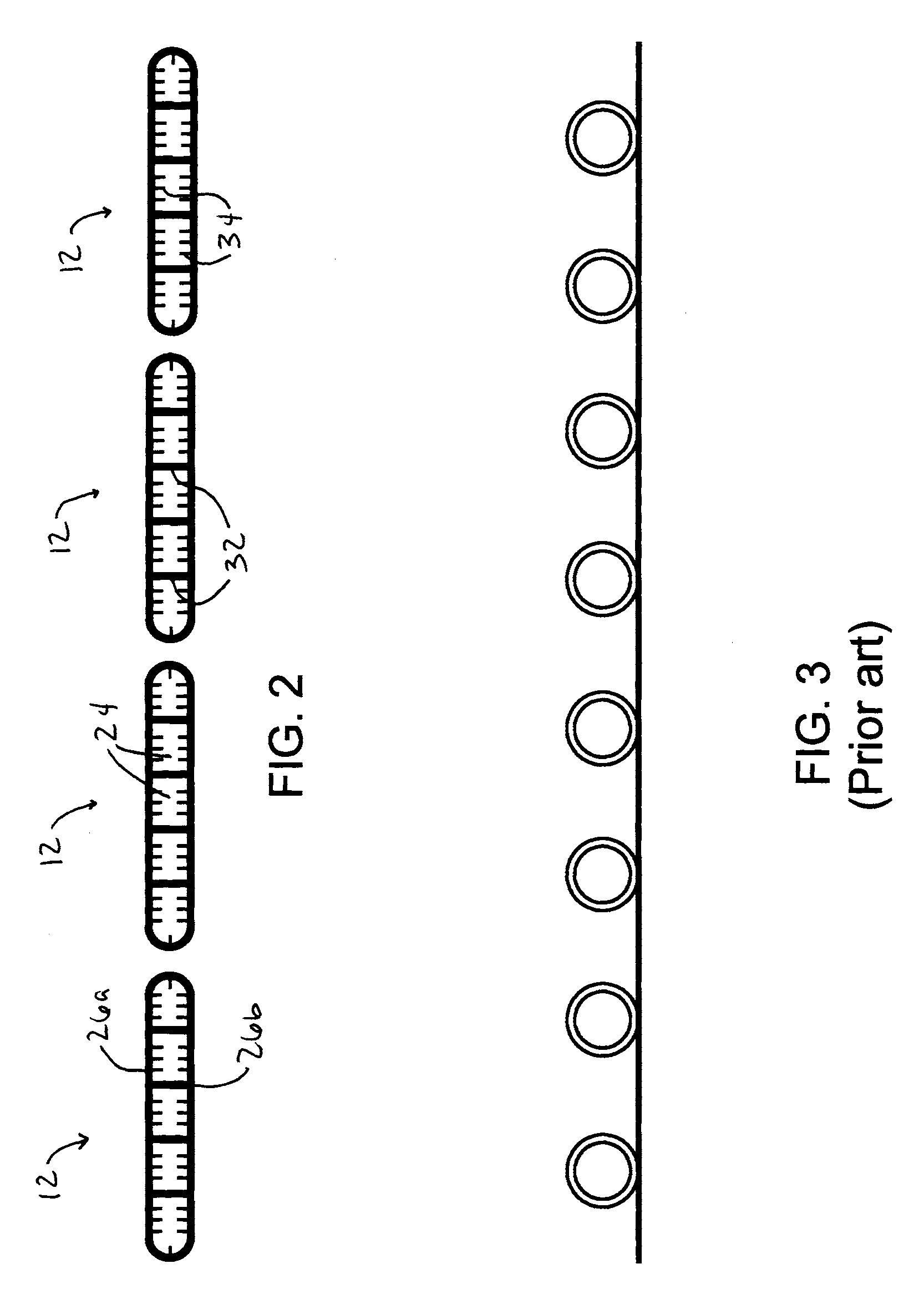

Solar energy collecting system and method

InactiveUS20100206300A1Low costLow transportation costSolar heating energySolar heat collector controllersMetallic materialsEngineering

A solar energy collecting system and method suitable for hot water generation using solar energy. The system includes multiport tubes between inlet and outlet manifolds. The tubes are formed of a metallic material, each tube has oppositely-disposed first and second flat surfaces between lateral edges thereof, longitudinally-opposed first and second ends, and multiple fluid channels between the first and second ends that are in fluidic parallel to each other. The inlet and outlet manifolds are coupled to the first and second ends of the tubes so that chambers within the inlet and outlet manifolds are fluidically connected to the fluid channels of the multiport tubes. During operation of the system, a fluid flowing through the fluid channels of the tubes is heated by direct solar radiation impinging the first flat surfaces of the tubes and optionally by reflected solar radiation impinging the second flat surfaces of the tubes.

Owner:MILL MASTERS

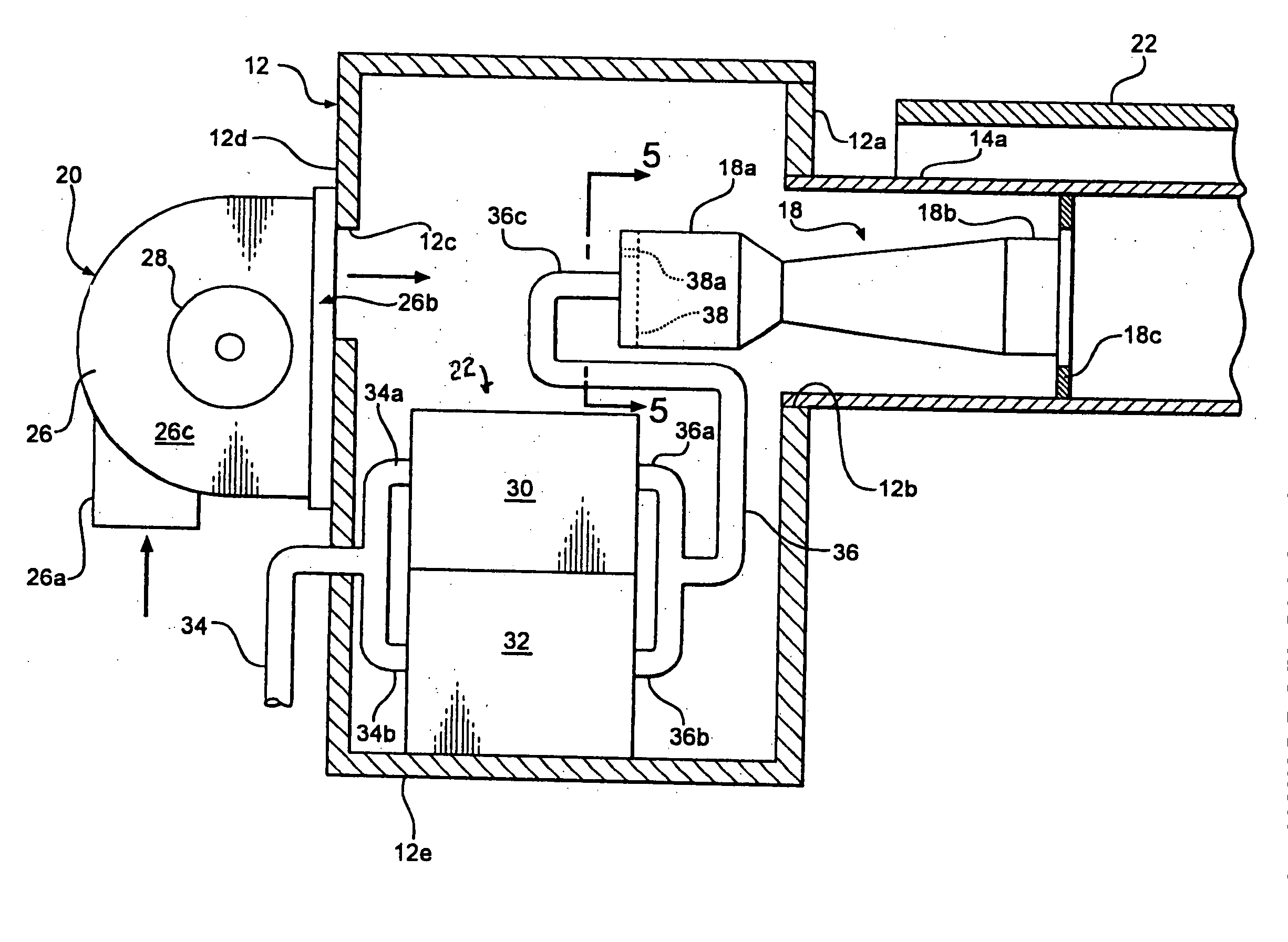

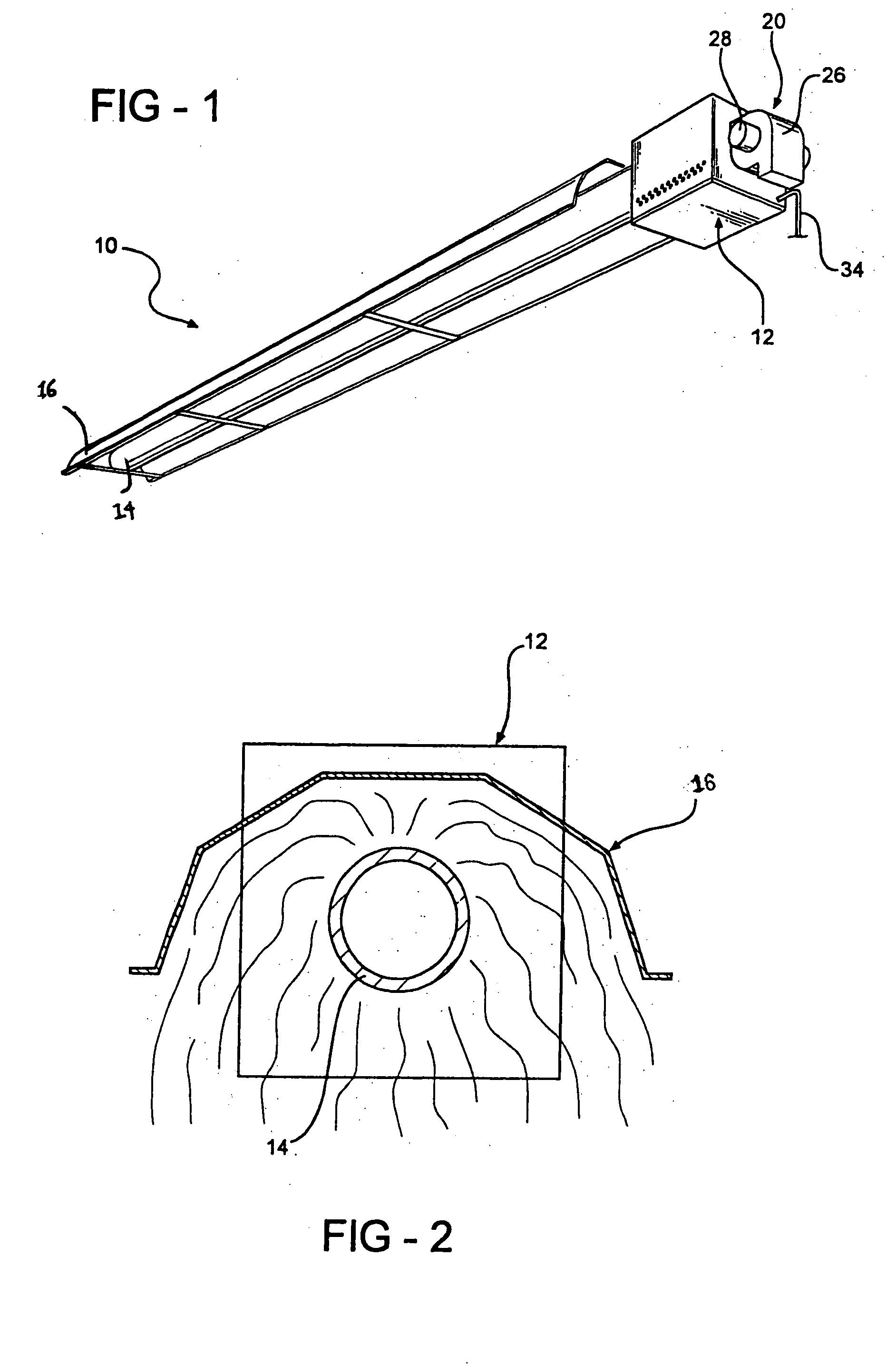

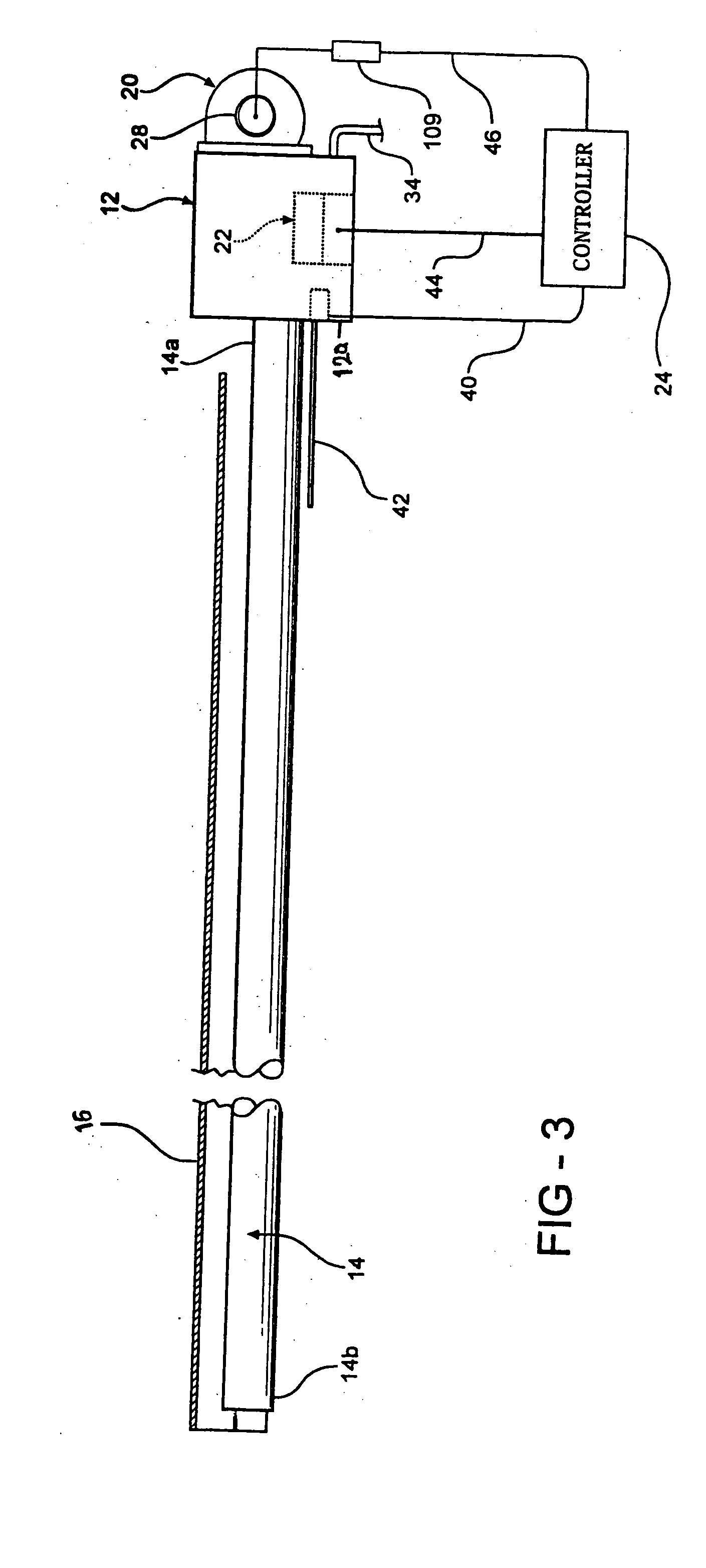

Variable input radiant heater

A variable demand radiant heating system applies variable burner control technology to singular or mulit-burner radiant heating systems. A radiant heater consists of a burner connected to an elongated heat exchanger tube. The combustion air is supplied to the burner via blower or draft inducer. Fuel is supplied to the burner via fuel regulator. Fuel and air are mixed in burner and communicated to the inlet end of the heat exchanger tube. Spent products of combustion are expelled from the heat exchanger at the outlet end. The burner controls continuously vary gas supply pressure (volume), via a modulating gas regulator, and combustion air pressure (volume), via a variable speed blower, communicated to the burner mixing chamber, which in turn, varies the burner input on a continuous curve (not stepped or staged) within a pre-determined input range as heat demand varies.

Owner:ROBERTS GORDON INC

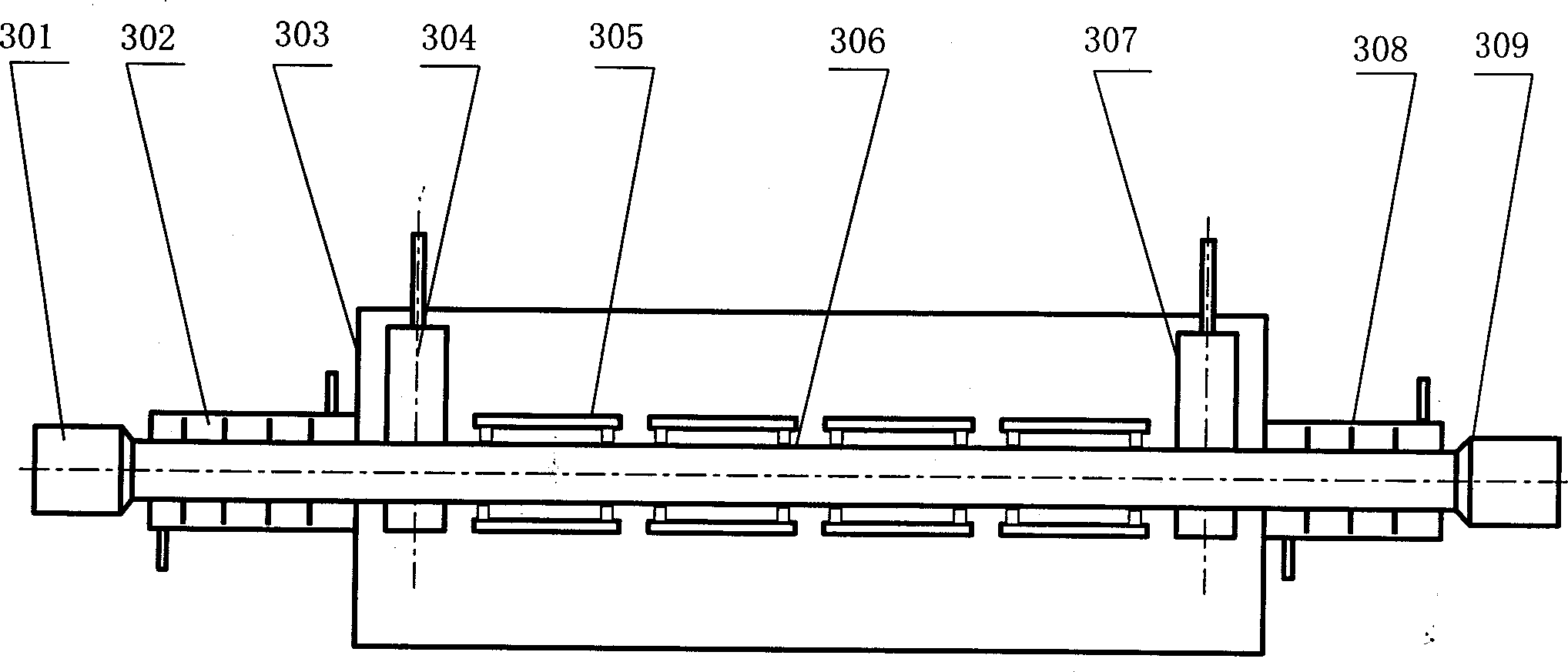

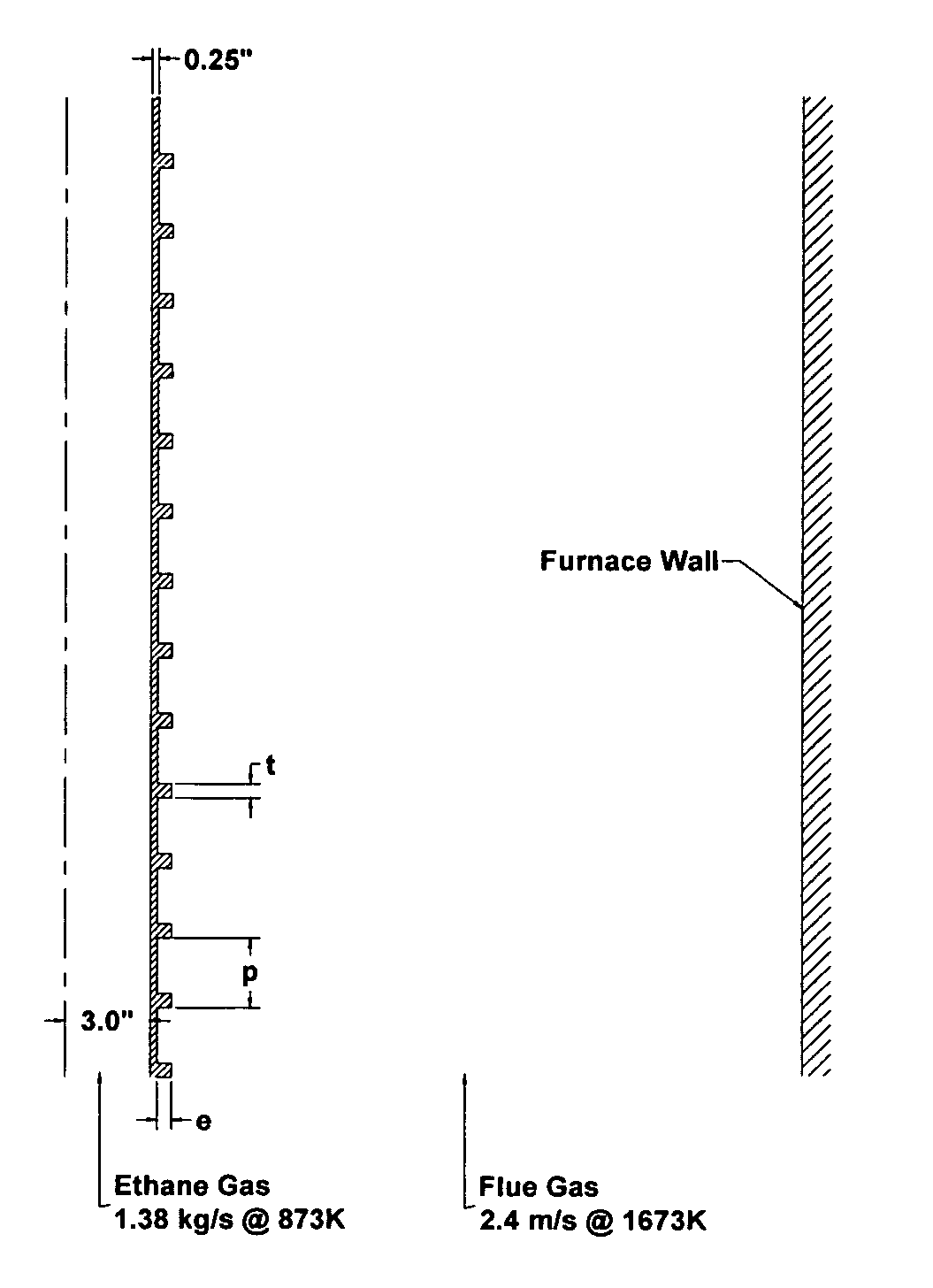

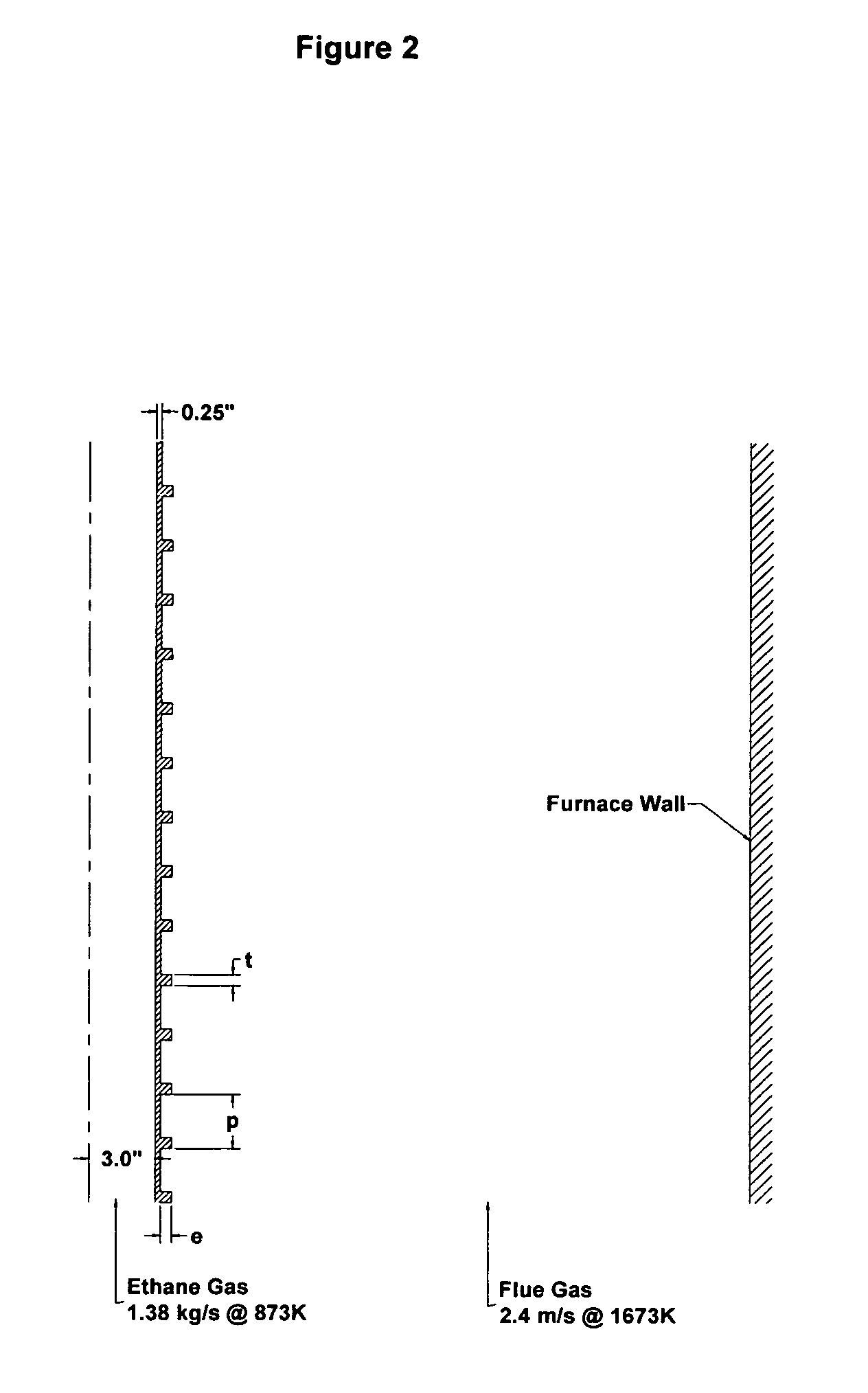

External ribbed furnace tubes

ActiveUS7128139B2Thermal non-catalytic crackingMetal-working apparatusVertical tubeRadiative heating

In a radiant heating box there is a convection current which flows over the surface of tubes in the box. Adding ribs to the external surface of vertical tubes provides an enhancement to the heat transfer by convection and increases the heat transfer to the tubes.

Owner:NOVA CHEM (INT) SA

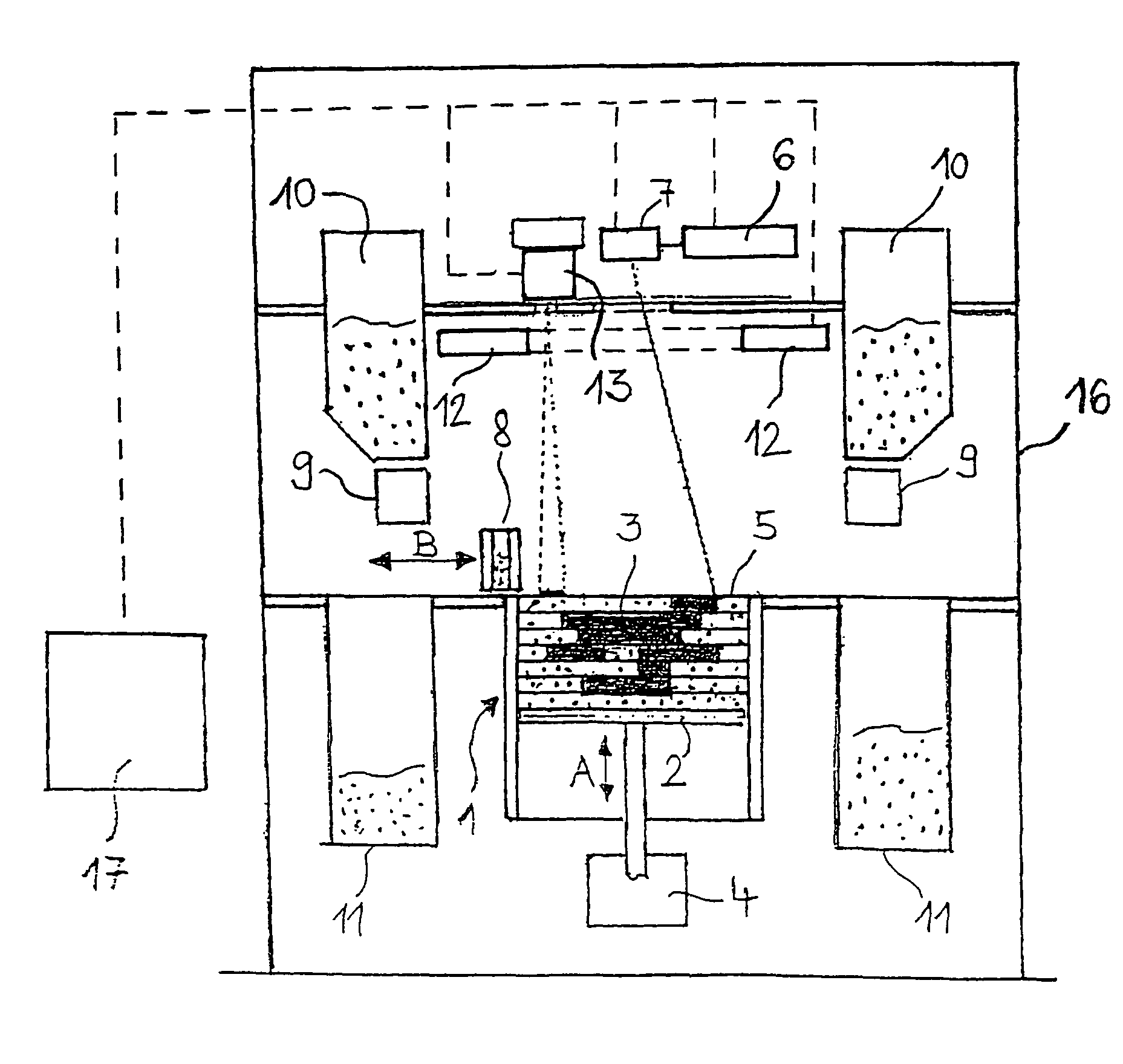

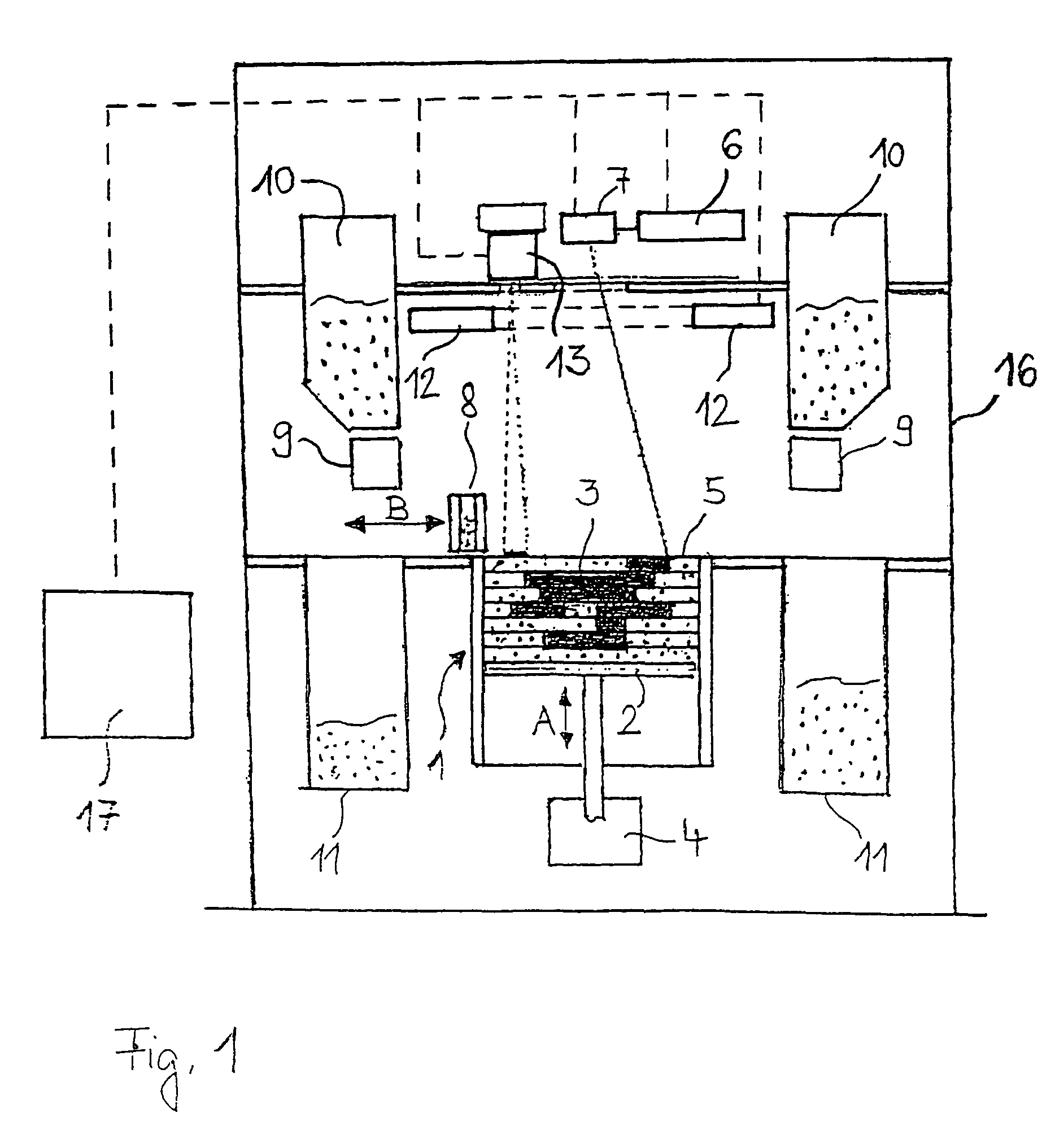

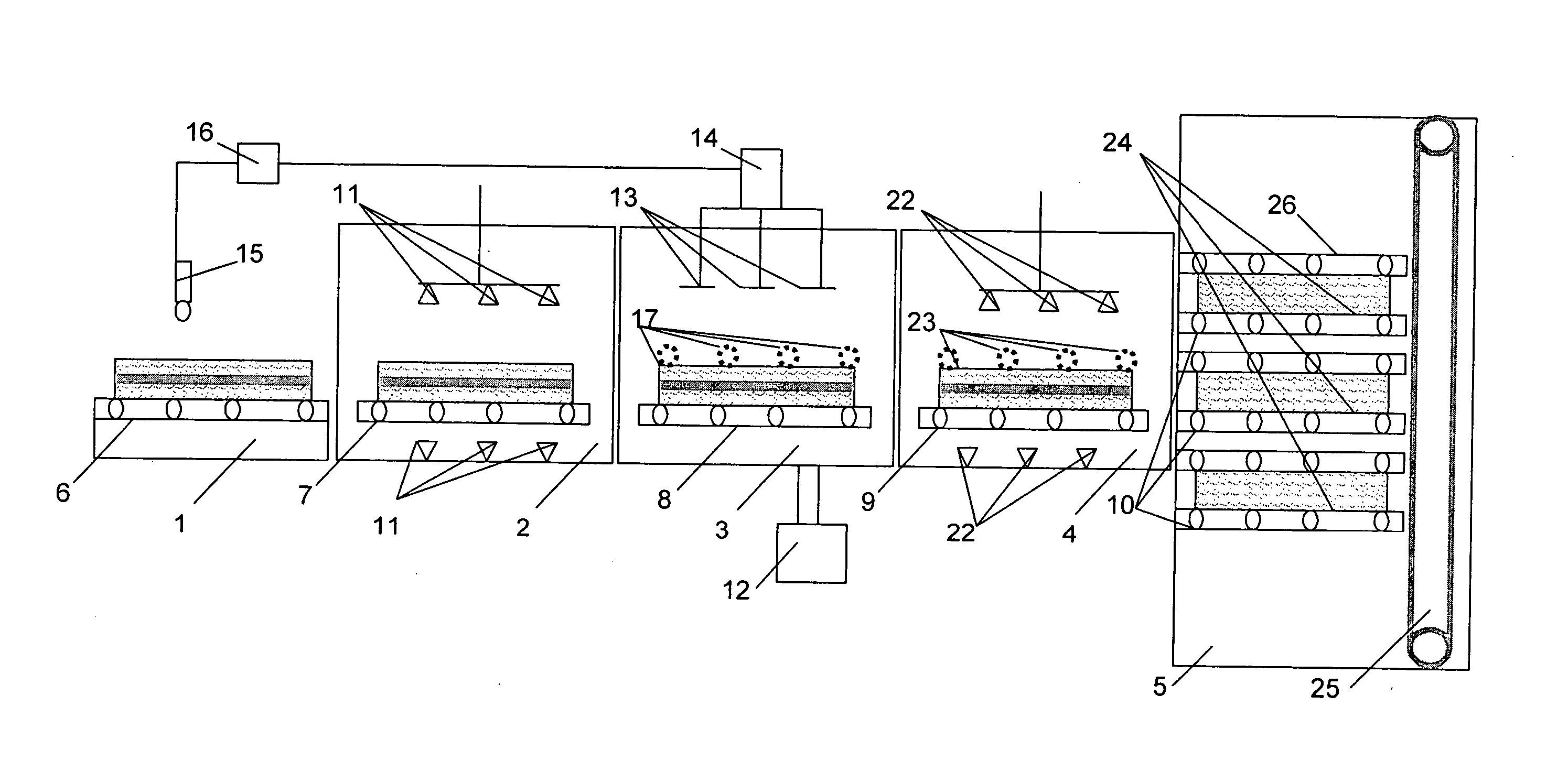

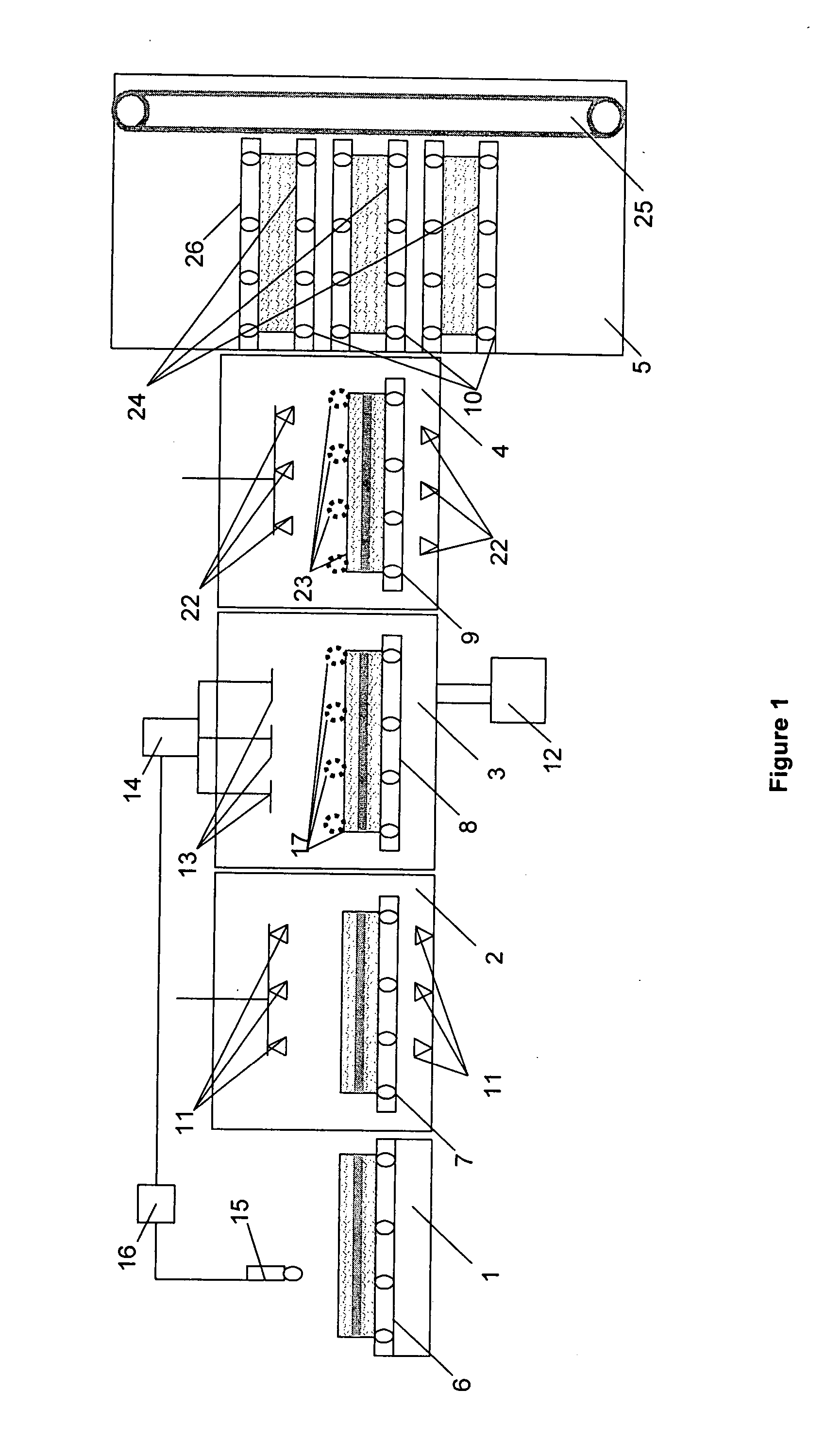

Method and apparatus for laminating glass sheets

ActiveUS20080060744A1Reduce manufacturing costImprove productivityMechanical working/deformationLamination ancillary operationsProduction rateCooling chamber

The invention relates to a method and apparatus for laminating glass articles without using an autoclave. The sandwich structure to be laminated is preheated than is placed in a controllable vacuum and subjected to electromagnetic radiation with specified frequencies and power. The final heating is provided by convectional heat source. Pressure that is applied continuously during the radiating, heating and cooling steps is also specified for achieving an appropriate bond. An apparatus appropriate for realizing the invented process is also provided. The apparatus includes a loading table, three furnaces, and a cooling chamber which are adjusted to and adjoined to each to other. These parts provide the necessary conditions for high-quality laminating simple and multi-sandwich structures with high production rate and efficiency. The apparatus is inexpensive and fits into the space of two glass article lengths.

Owner:GYROTRON TECH

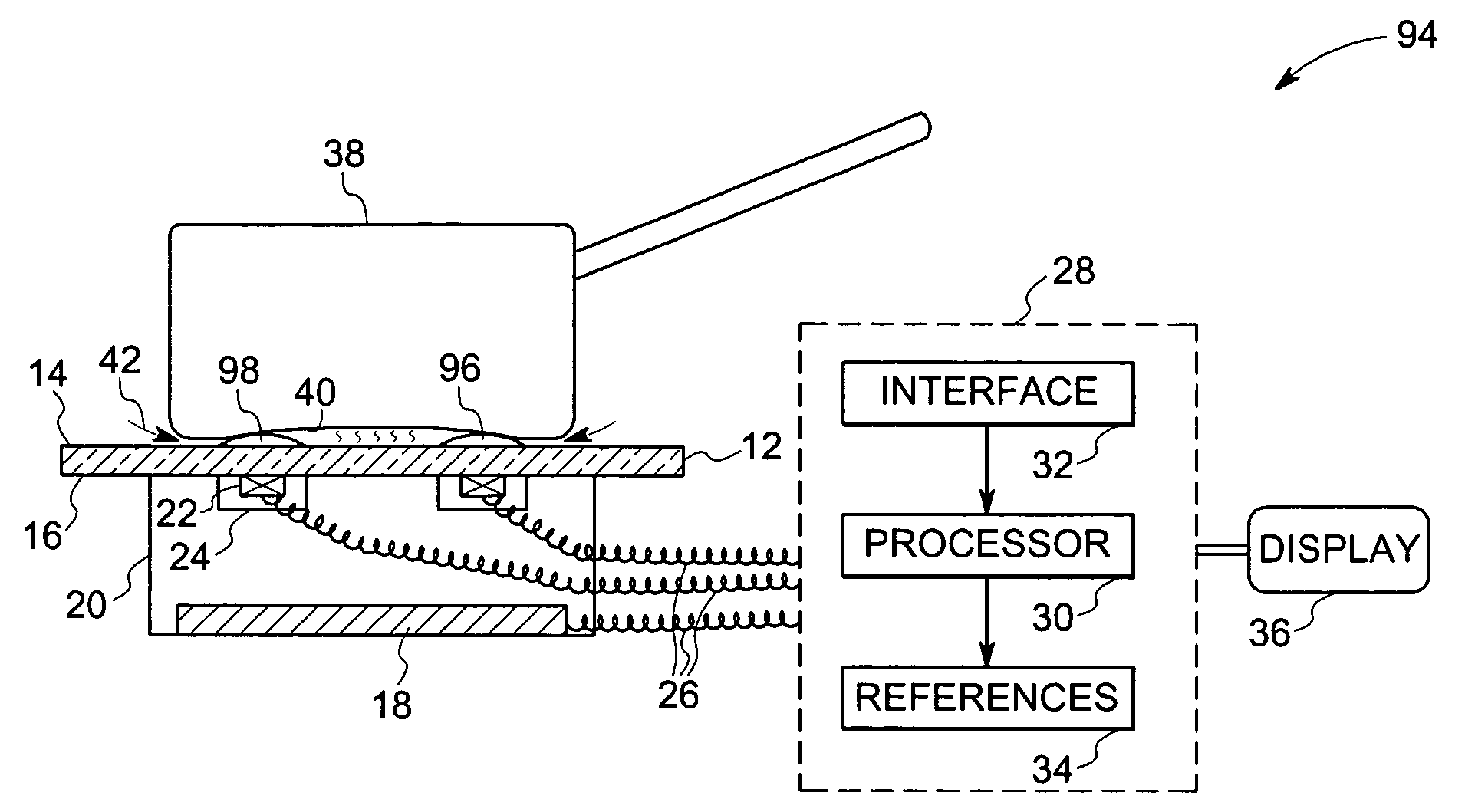

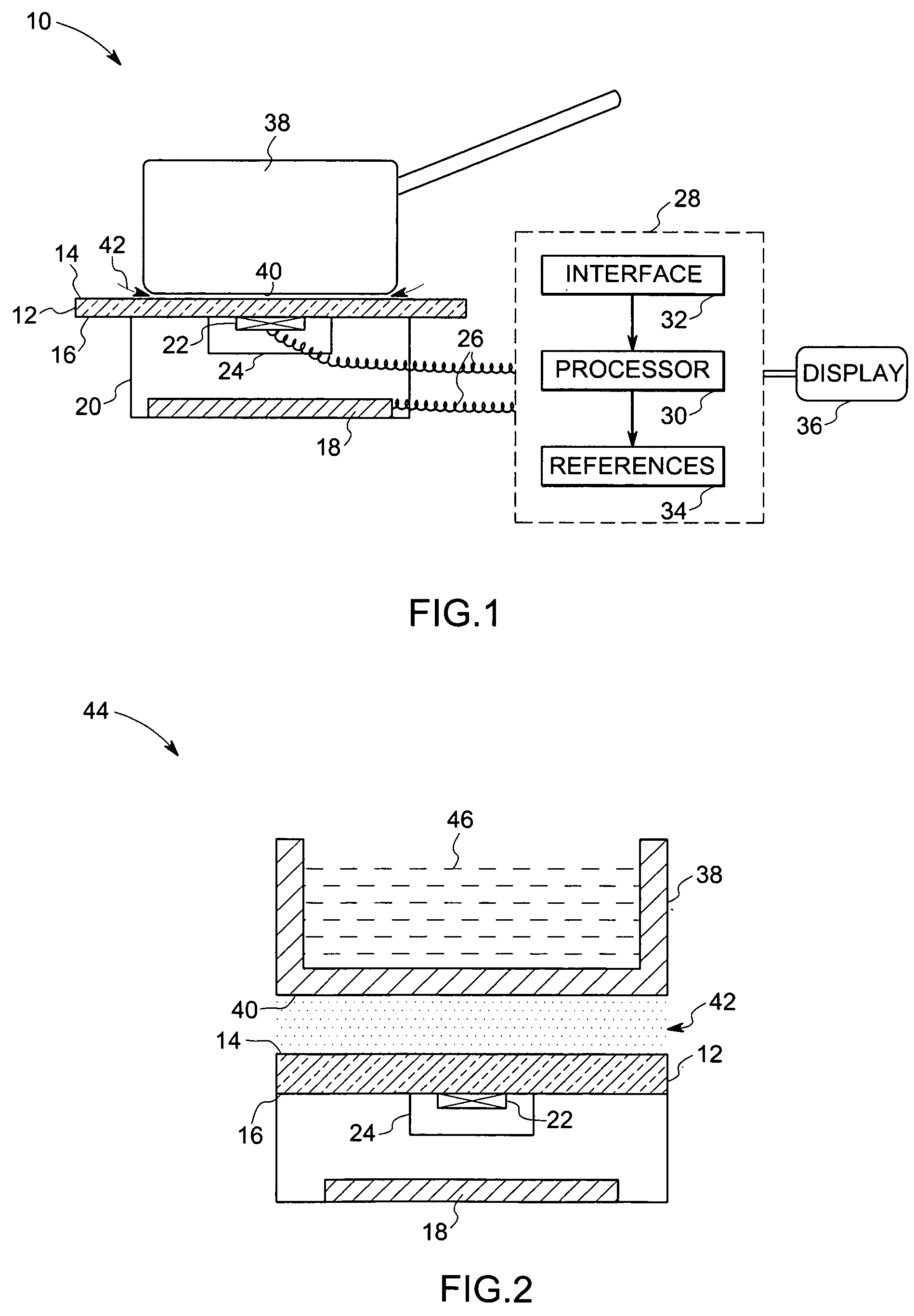

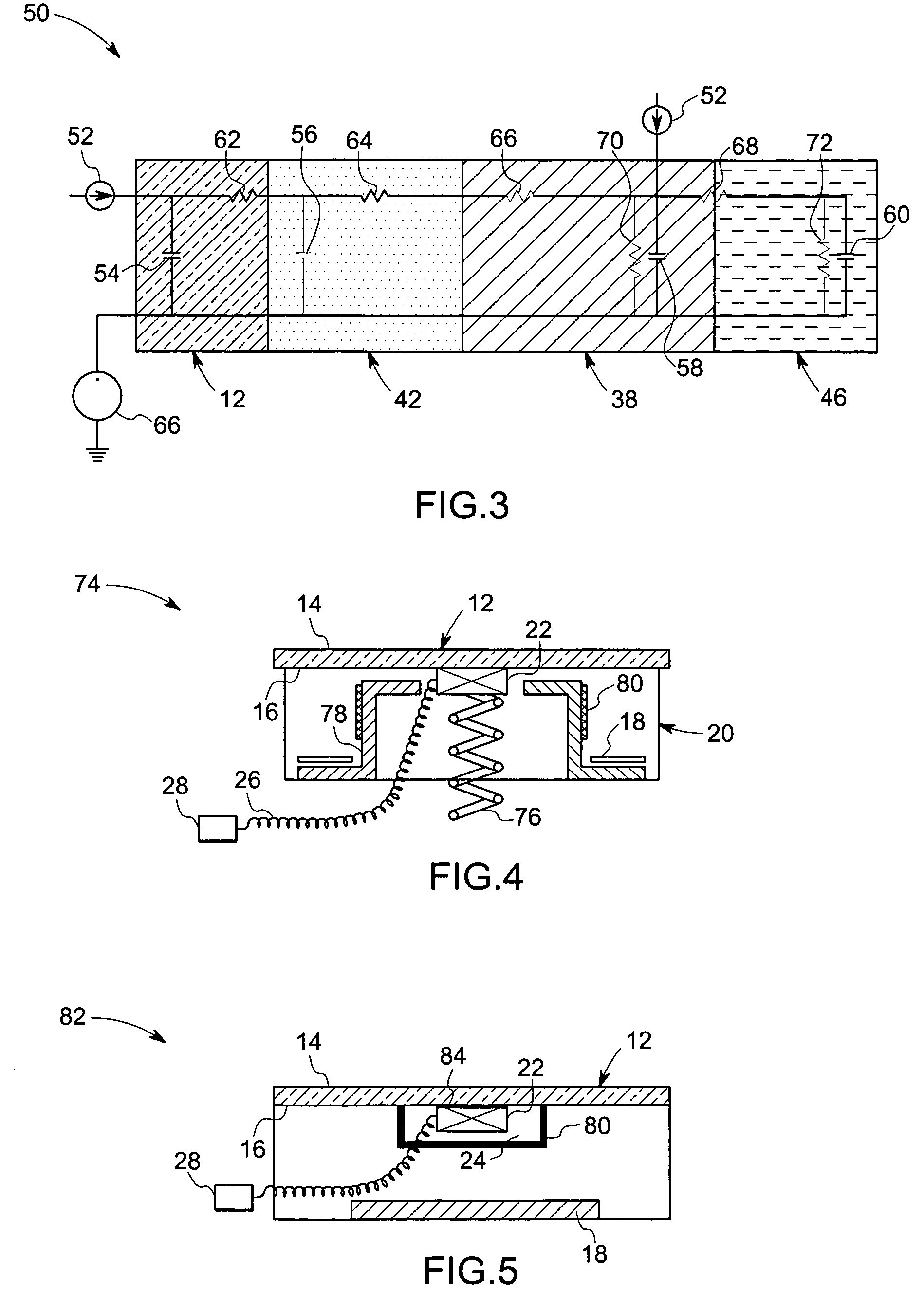

System and method of detecting temperature of a cooking utensil over a radiant cooktop

ActiveUS7307246B2Thermometer detailsTemperature measurement in household appliancesThermal insulationRadiative heating

A system for detecting temperature of a cooking utensil over a radiant cooktop includes a cooktop having an upper surface and a lower surface and a radiant heating element adapted to heat the cooktop. A temperature detector is disposed adjacent the lower surface of the cooktop and is adapted to detect temperature of the lower surface of the cooktop. The system also includes a thermal insulation barrier disposed intermediate the temperature detector and the radiant heating element.

Owner:HAIER US APPLIANCE SOLUTIONS INC

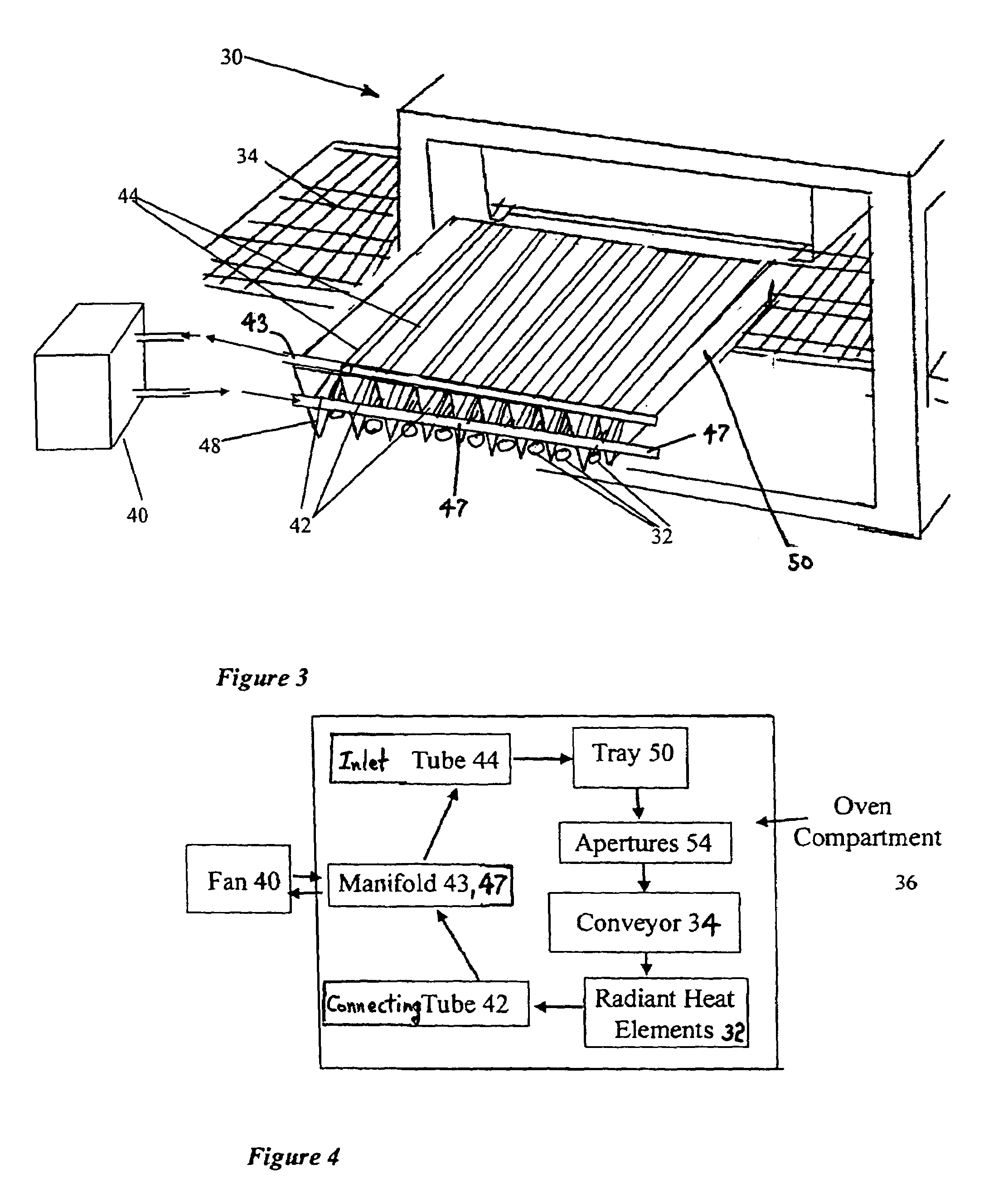

Impingement oven with radiant heating

An oven for providing radiant and impingement heat to a food item. The oven includes a fan mechanism for drawing air around the radiant heat elements of the oven. The air is then delivered to an impingement tray located adjacent the food item. The air is forced through a series of apertures and onto the food item. At the same time the oven is also being heated by the radiant heat elements. This allows greater heat to be applied to specific locations on the food item. An external heat source is not required to heat the air as the air is heated by the existing radiant heat elements.

Owner:QUIZ FRANCHISOR LLC +1

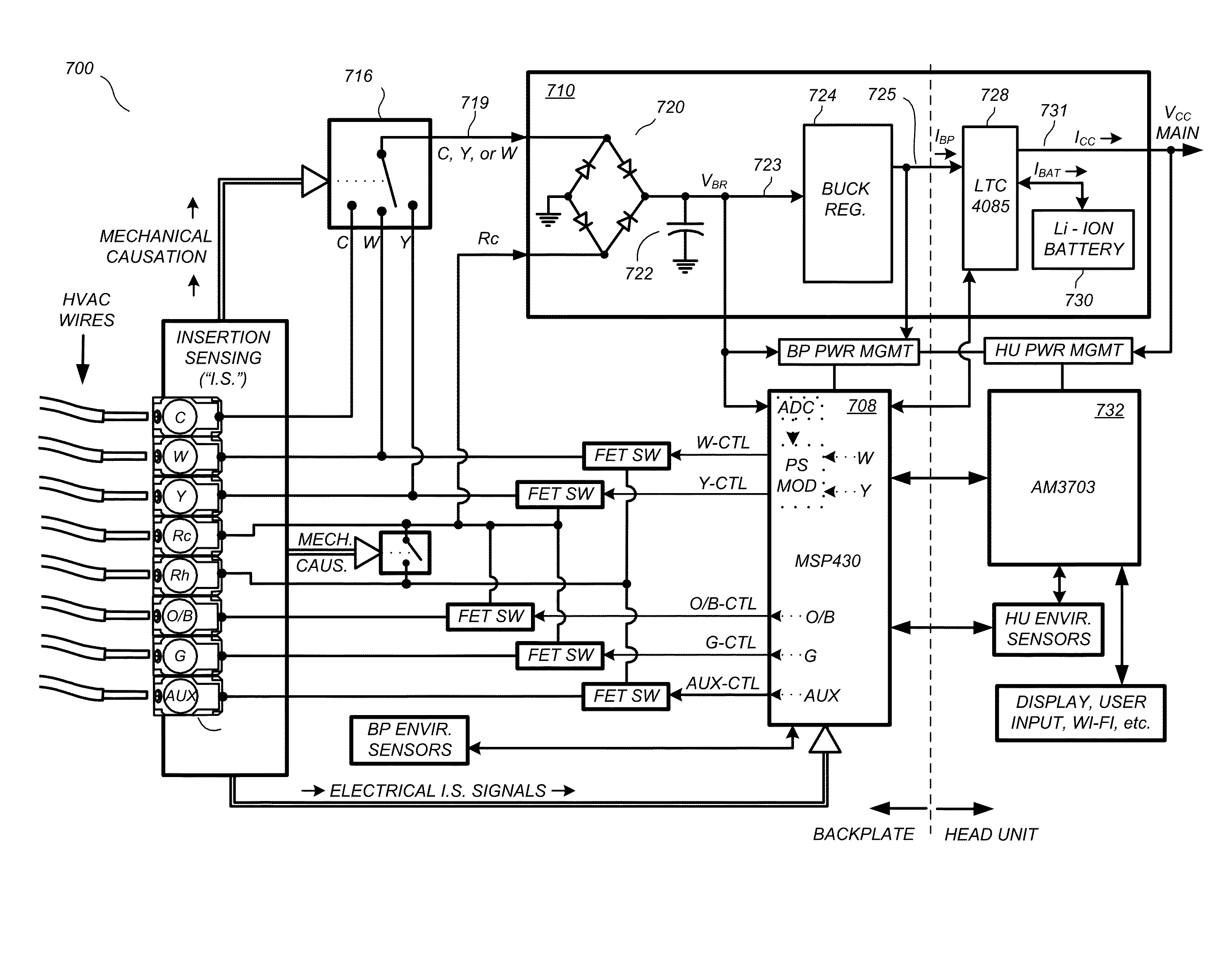

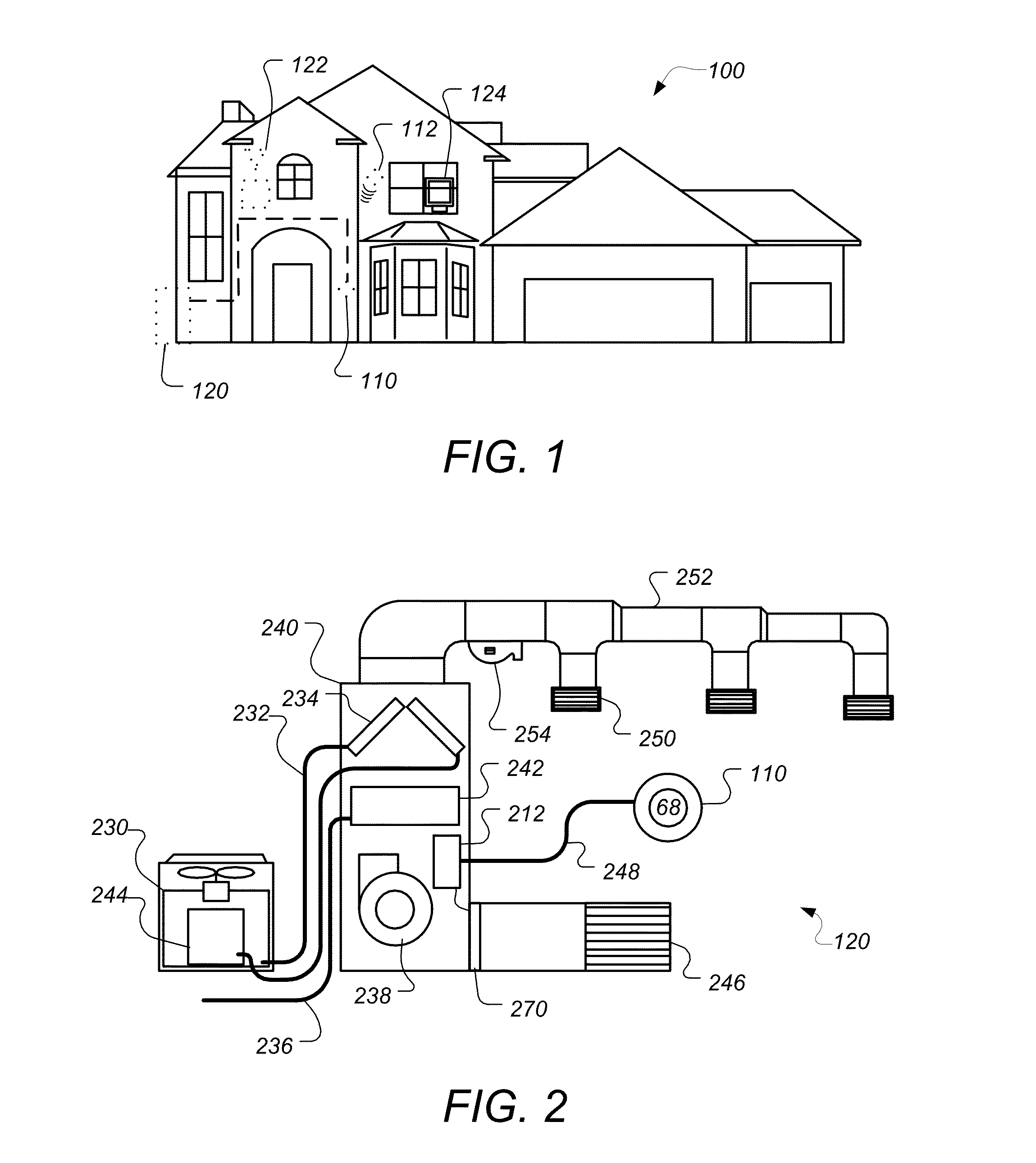

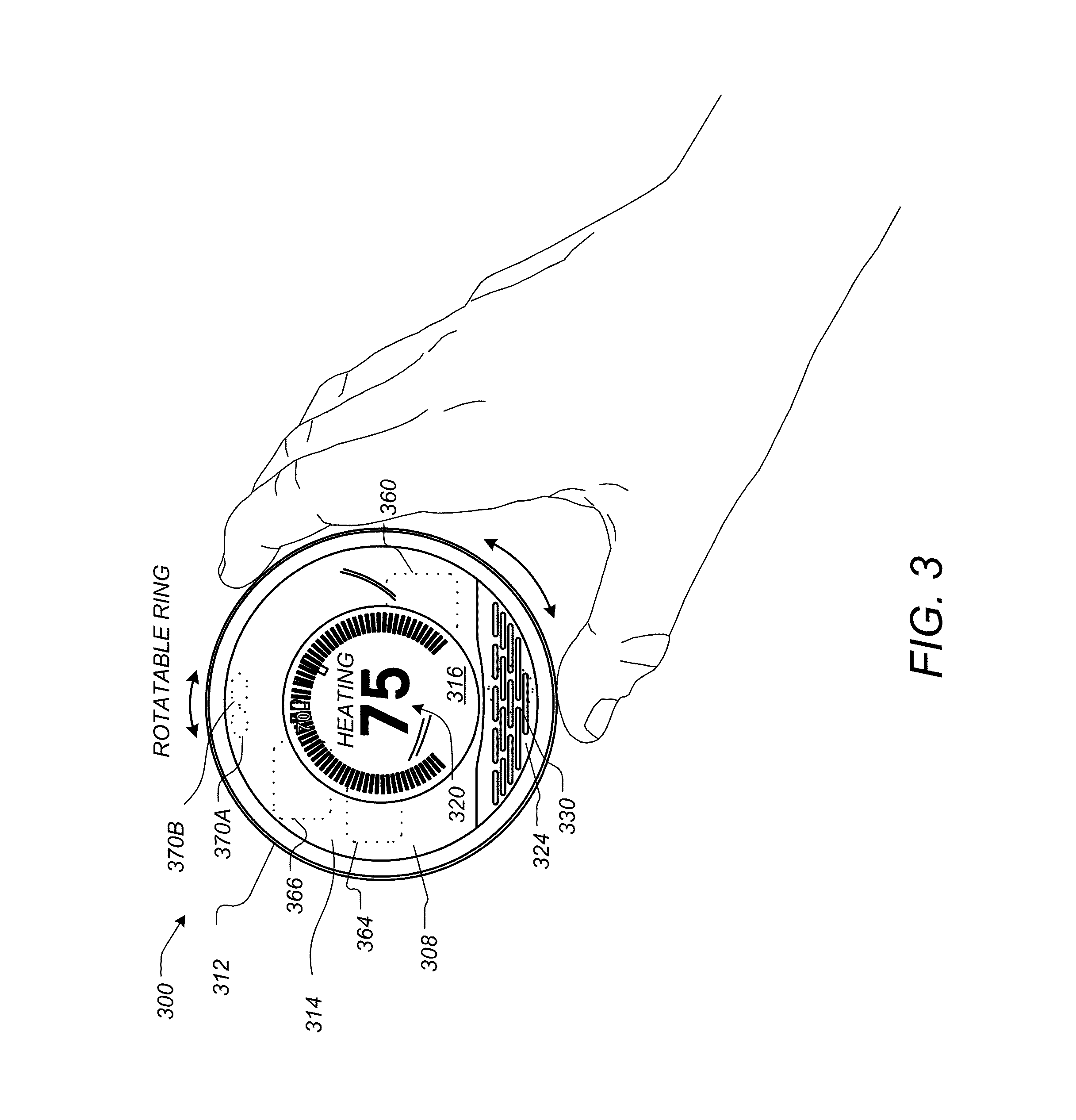

Radiant heating controls and methods for an environmental control system

InactiveUS20140156085A1Function increaseIncrease valueSampled-variable control systemsMechanical apparatusControl systemOptimal control

Embodiments of the invention describe thermostats that use model predictive controls and related methods. A method of controlling a thermostat using a model predictive control may involve determining a parameterized model. The parameterized model may be used to predicted ambient temperature values for an enclosure. A set of radiant heating system control strategies may be selected for evaluation to determine an optimal control strategy from the set of control strategies. To determine the optimal control strategy, a predictive algorithm may be executed, in which each control strategy is applied to the parameterized model to predict an ambient temperature trajectory and each ambient temperature trajectory is processed in view of a predetermined assessment function. Processing the ambient temperature trajectory in this manner may involve minimizing a cost value associated with the ambient temperature trajectory. The radiant heating system may subsequently be controlled according to the selected optimal control strategy.

Owner:GOOGLE LLC

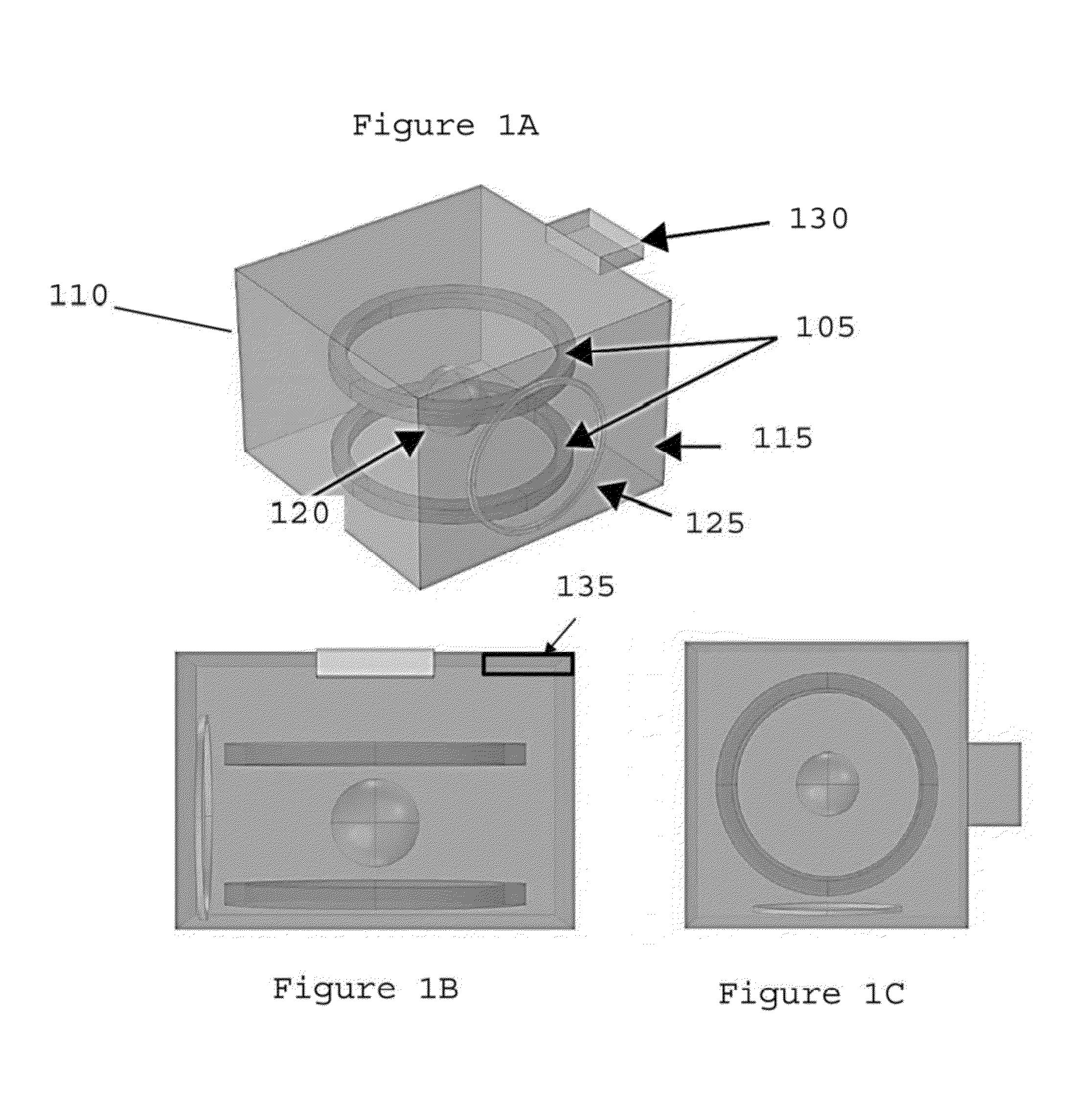

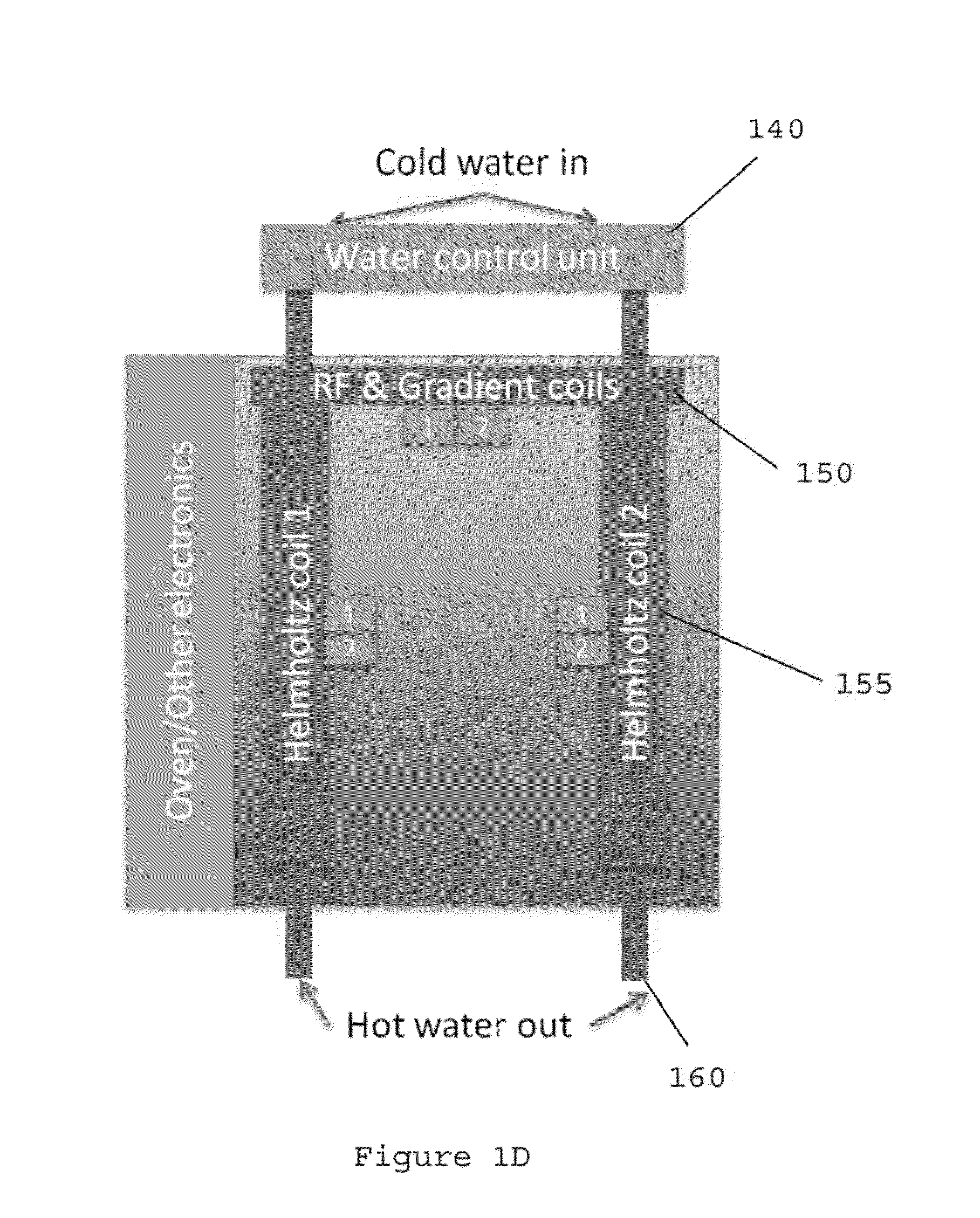

System and method for providing magnetic resonance temperature measurement for radiative heating applications

ActiveUS20160273970A1Broaden applicationFacilitate depositionMagnetic measurementsThermometers using value differencesResonanceRadiative heating

Exemplary embodiments of an apparatus according to the present disclosure comprise a radiative heating system with a radiation source configured to generate radiation for absorption by an object. A magnetic resonance system is provided with one or more coils configured to transmit and receive radio frequency energy to and from the object. A processor is configured to determine at least one of a temperature of the object and a change in the temperature of the object, based on the radio frequency energy received. A magnetic field source can be configured to generate a magnetic field within the object, and the radio frequency of the energy can be selected for magnetic resonance interactions in the object, based on a strength of the magnetic field.

Owner:NEW YORK UNIV

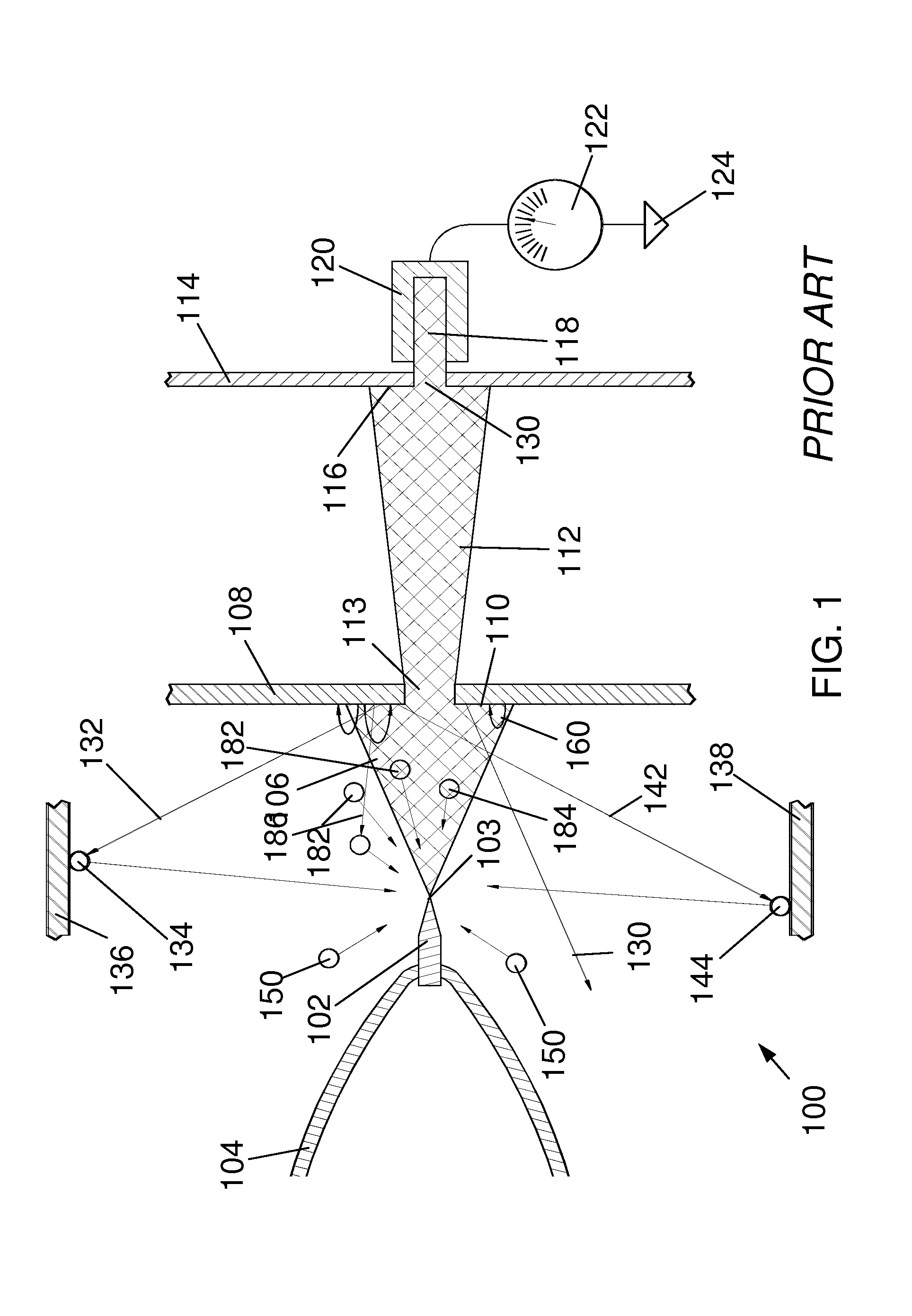

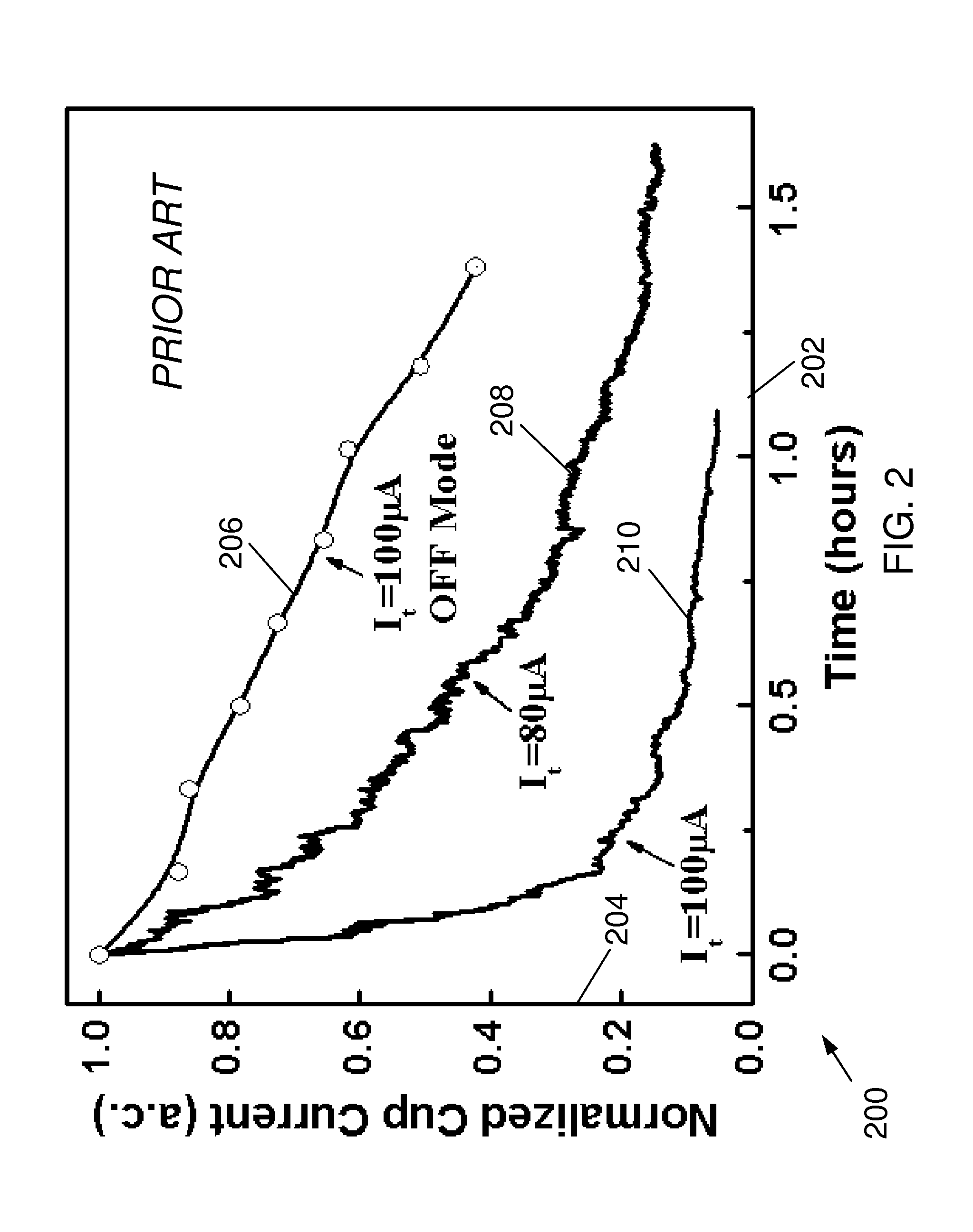

Stable cold field emission electron source

ActiveUS8736170B1Improved emission stabilityReduce noiseMagnetronsTransit-tube electron/ion gunsConventional transmission electron microscopeDesorption

A cold field emission (CFE) electron source for a focused electron beam system such as a transmission electron microscope (TEM), scanning transmission electron microscope (STEM), or scanning electron microscope (SEM) is disclosed. The source employs an emitter enclosure electrode behind the CFE tip which, in conjunction with the extractor electrode, defines a closed volume that can be thoroughly cleaned by electron impact desorption (EID) and radiative heating from a heated filament located between the emitter enclosure electrode and extractor electrode. The extractor electrode may have a counterbore which restricts backscattered electrons generated at the extractor from reaching portions of the source and gun which have not been cleaned by EID. Pre-cleaning of the emitter enclosure electrode and extractor electrode prior to cold field emission substantially improves both source emission stability and frequency noise characteristics, enabling source operation over time intervals adequate for application to TEMs, STEMs, and SEMs.

Owner:FEI CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com