Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1012 results about "Contact heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contact with heat is the contact of a body part, or whole body, with a heat source. The heat source can be a naked flame, hot gases, steam or any other form of heat with a temperature that can cause burns (1st degree, 2nd degree, or 3rd degree).

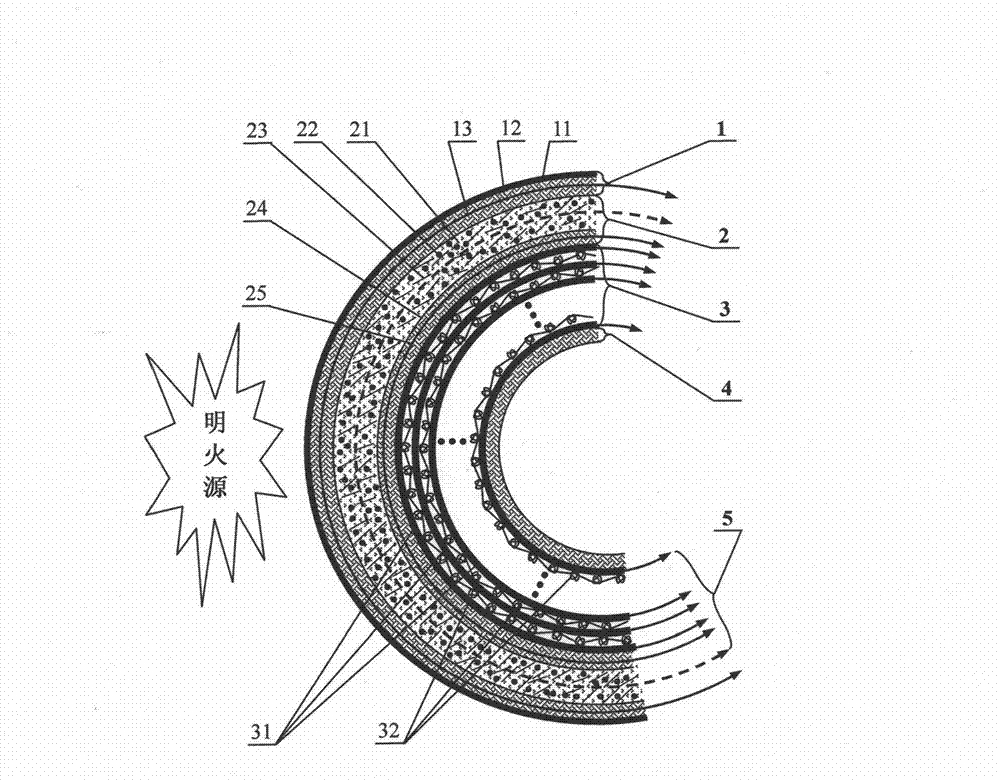

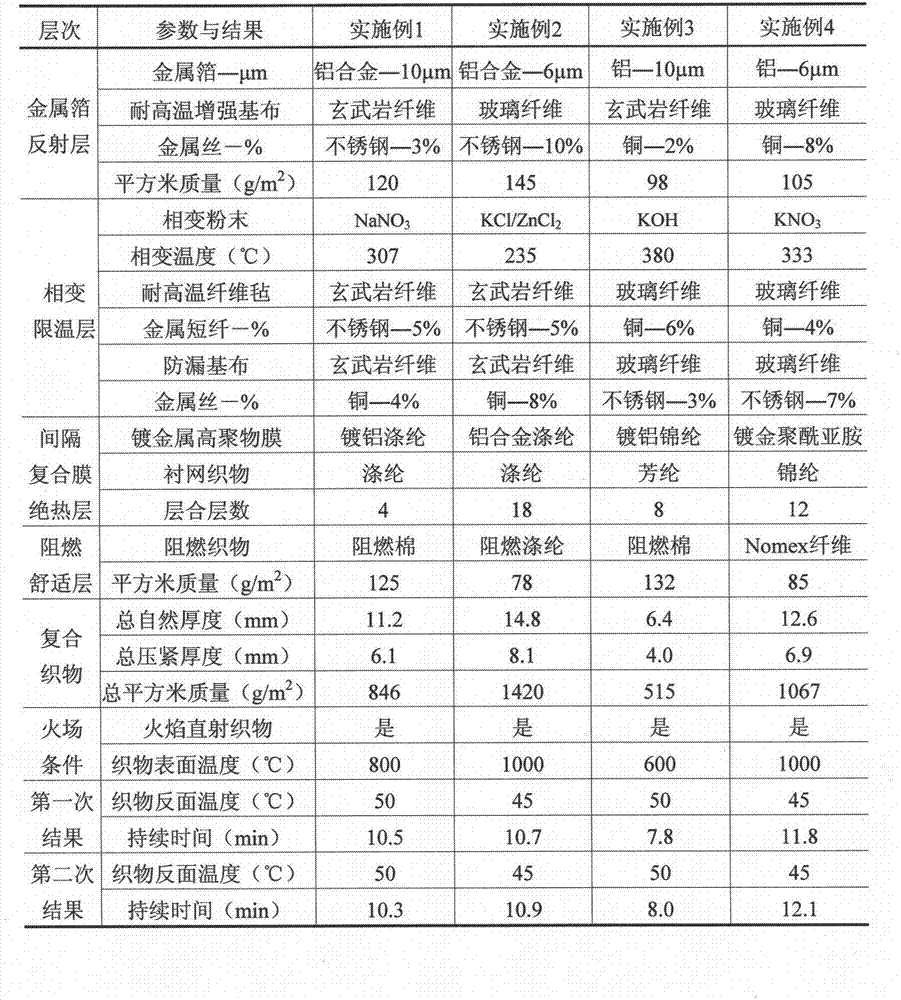

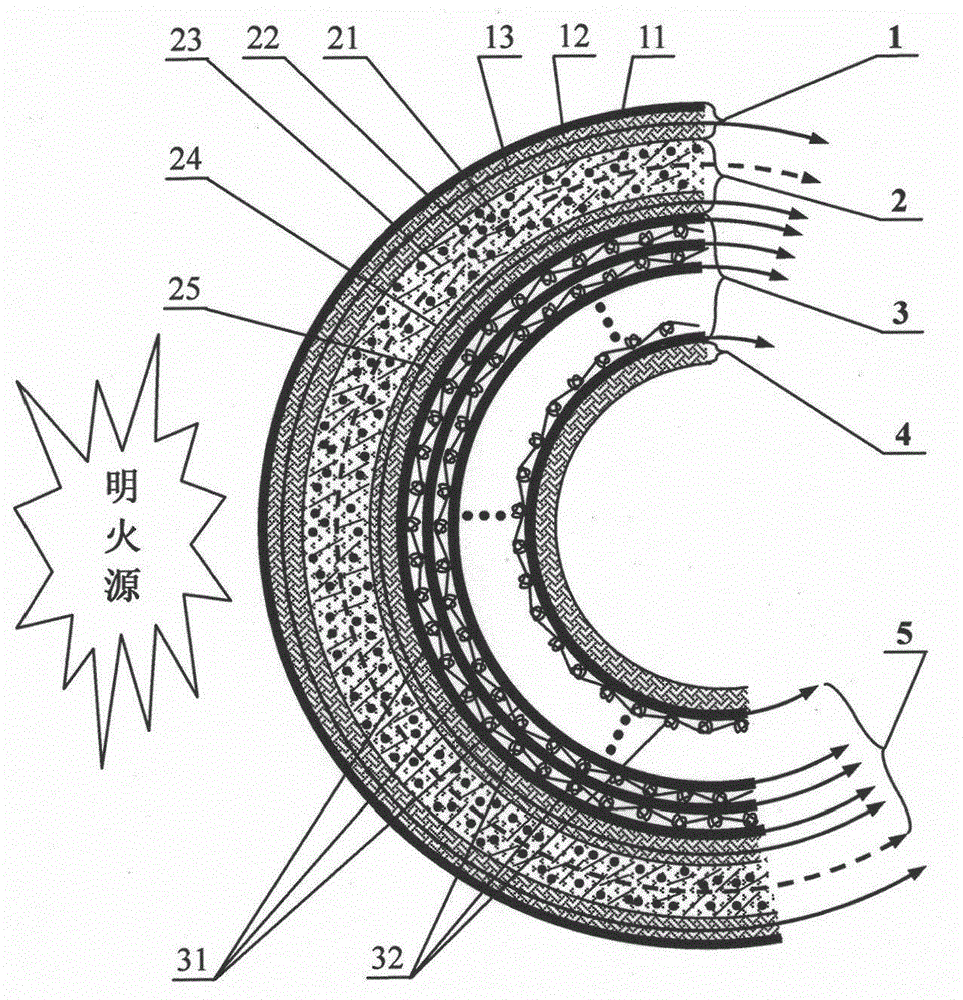

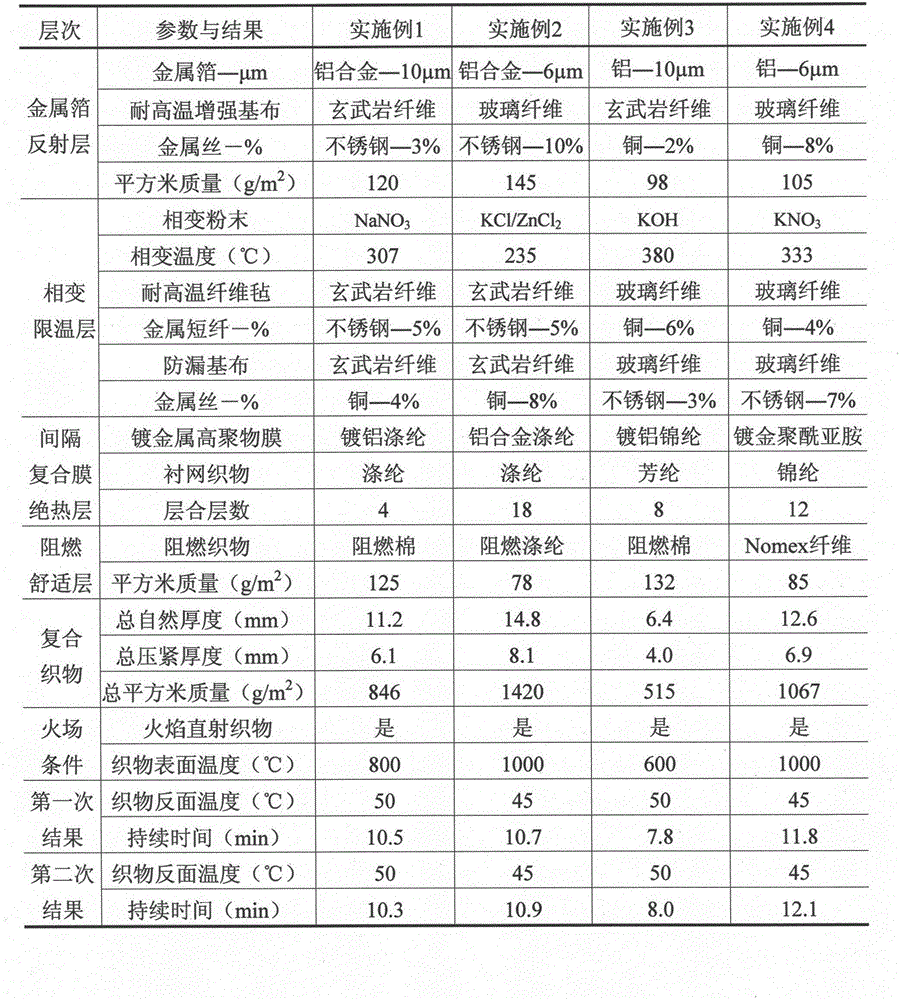

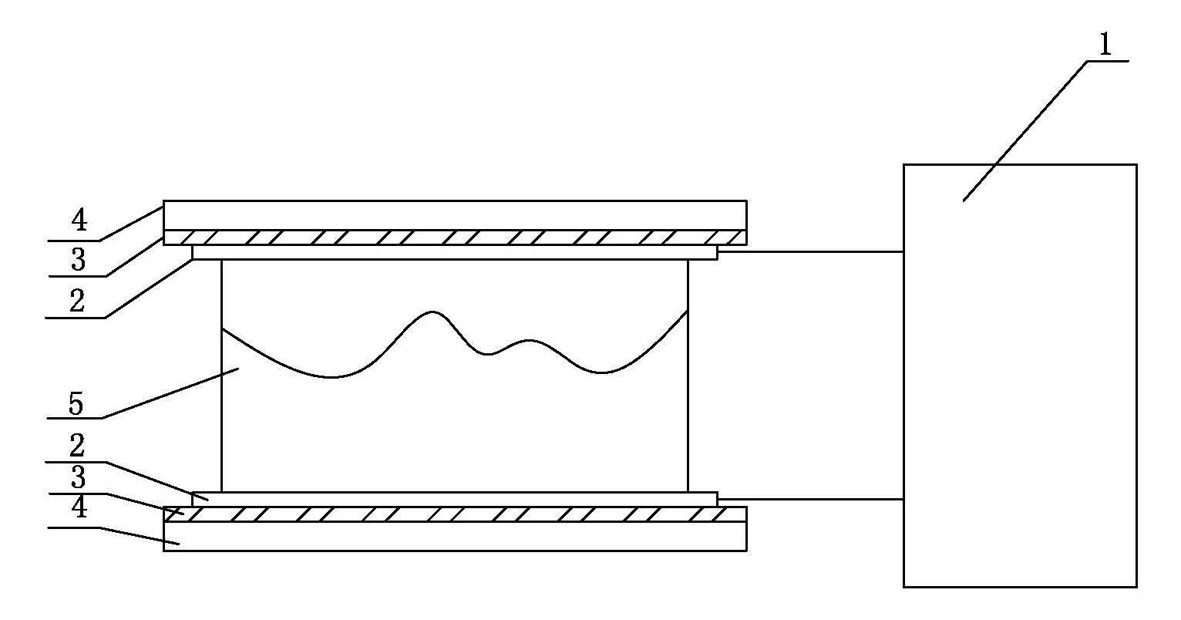

Multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric, preparation method and application

ActiveCN102783741AImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

Fire-proof and heat-insulating composite fabric with multi-stage expansion and heat dissipation, preparation method and application

ActiveCN102783741BImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

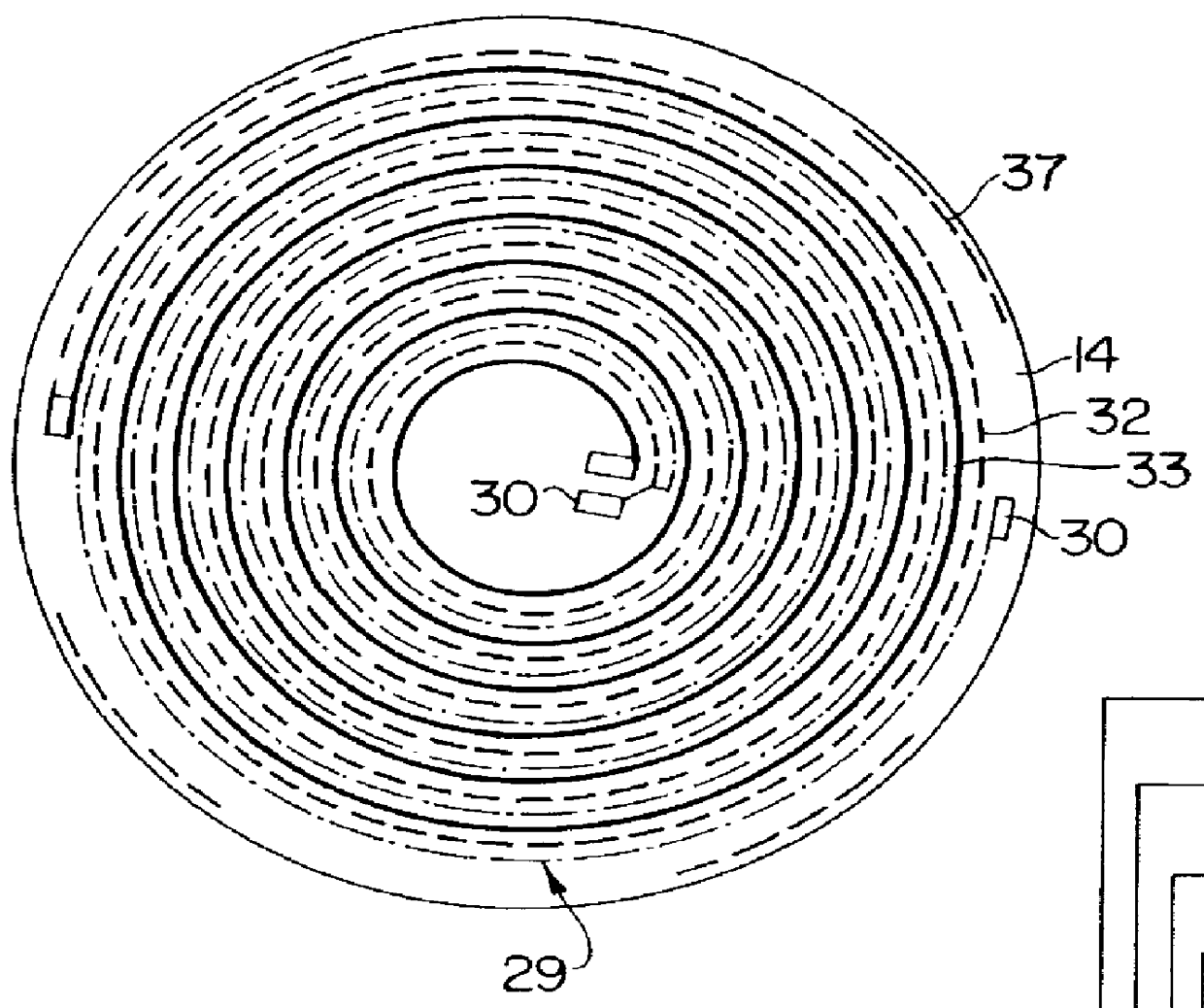

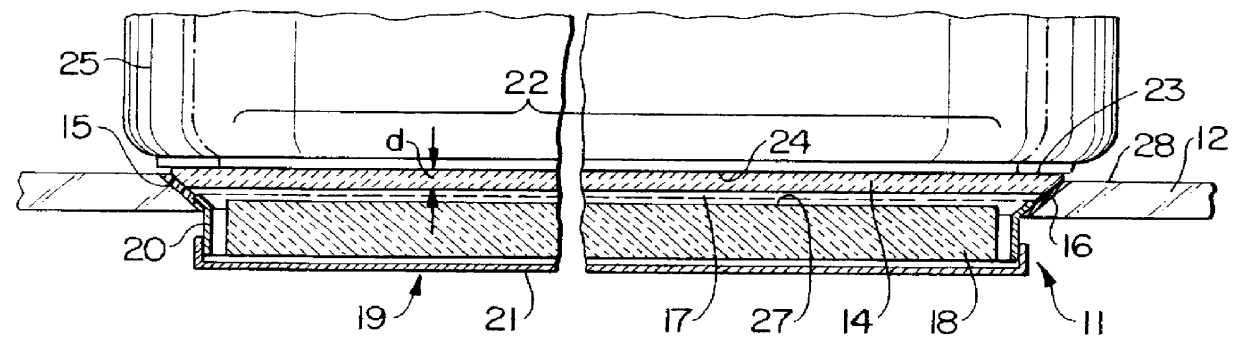

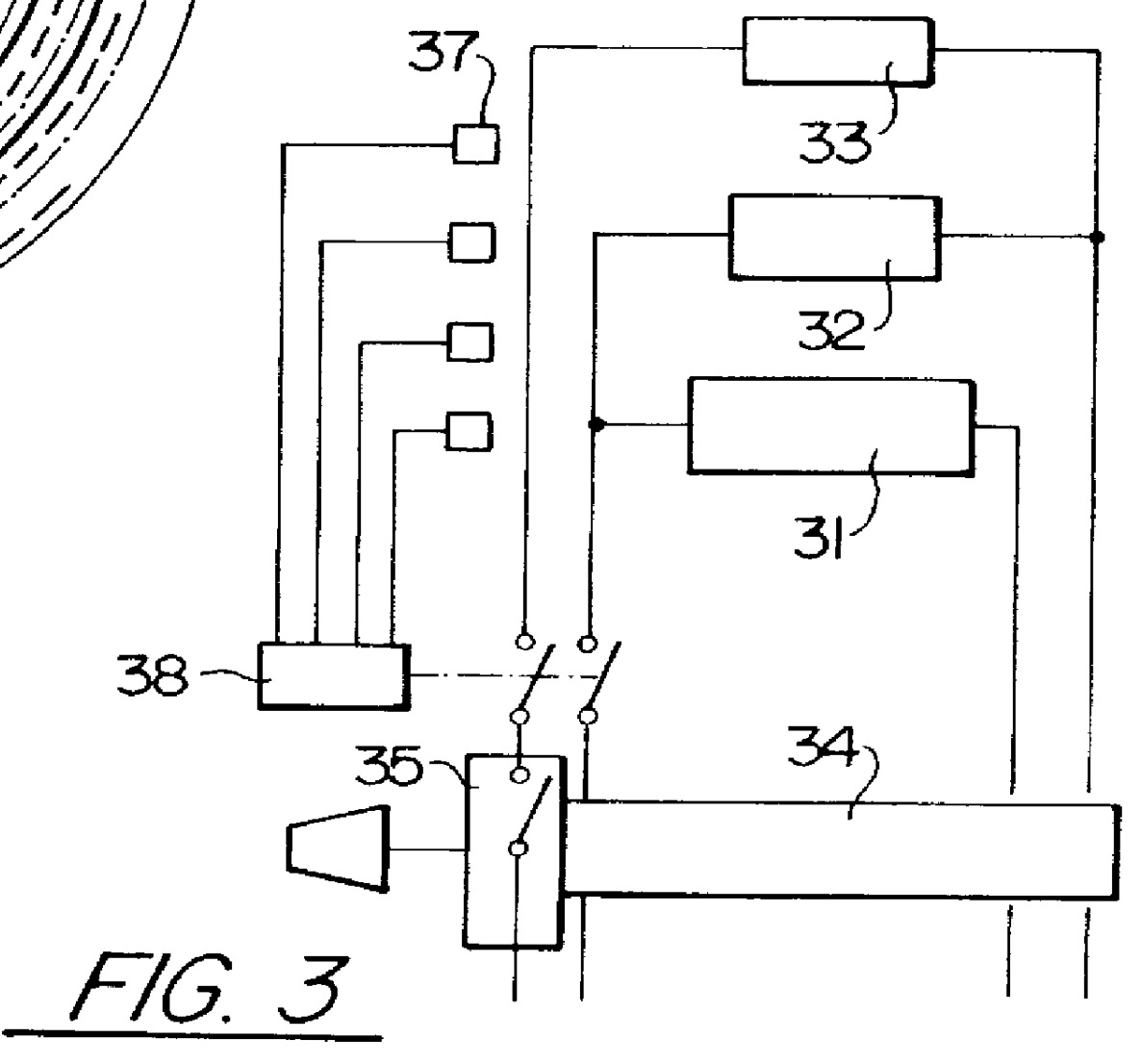

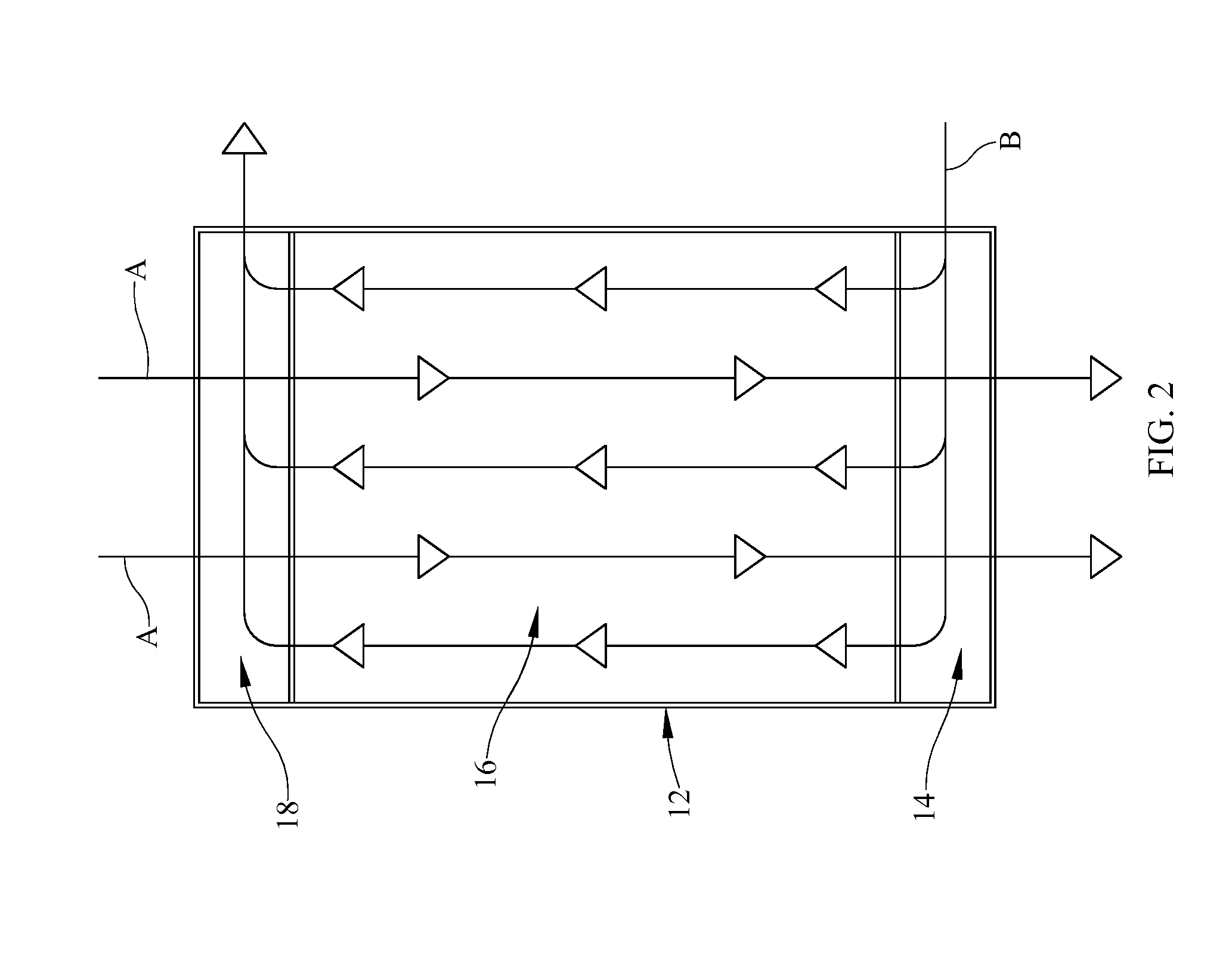

Contact heat-transferring cooking system with an electric hotplate

InactiveUS6150636AImprove heat transfer performanceIncrease temperature differenceCooking-vessel materialsDomestic stoves or rangesCouplingVolumetric Mass Density

A contact heat-transferring electric hotplate (11) is provided, which is made from nonoxidic ceramic, particularly silicon nitride. Its very thin hotplate body (14) in the form of a disk is installed in self-supporting manner in a hob plate, e.g. by bonding, and has an extremely flat surface or which is adapted to the cooking vessel shape, which creates such a small gap with respect to said vessel that a coupling is possible even with higher power densities with only a temperature difference of a few degrees. The heating means (17) is also in contact with or directly connected to the underside of the hotplate body (14).

Owner:E G O ELEKTRO GERAETEBAU GMBH

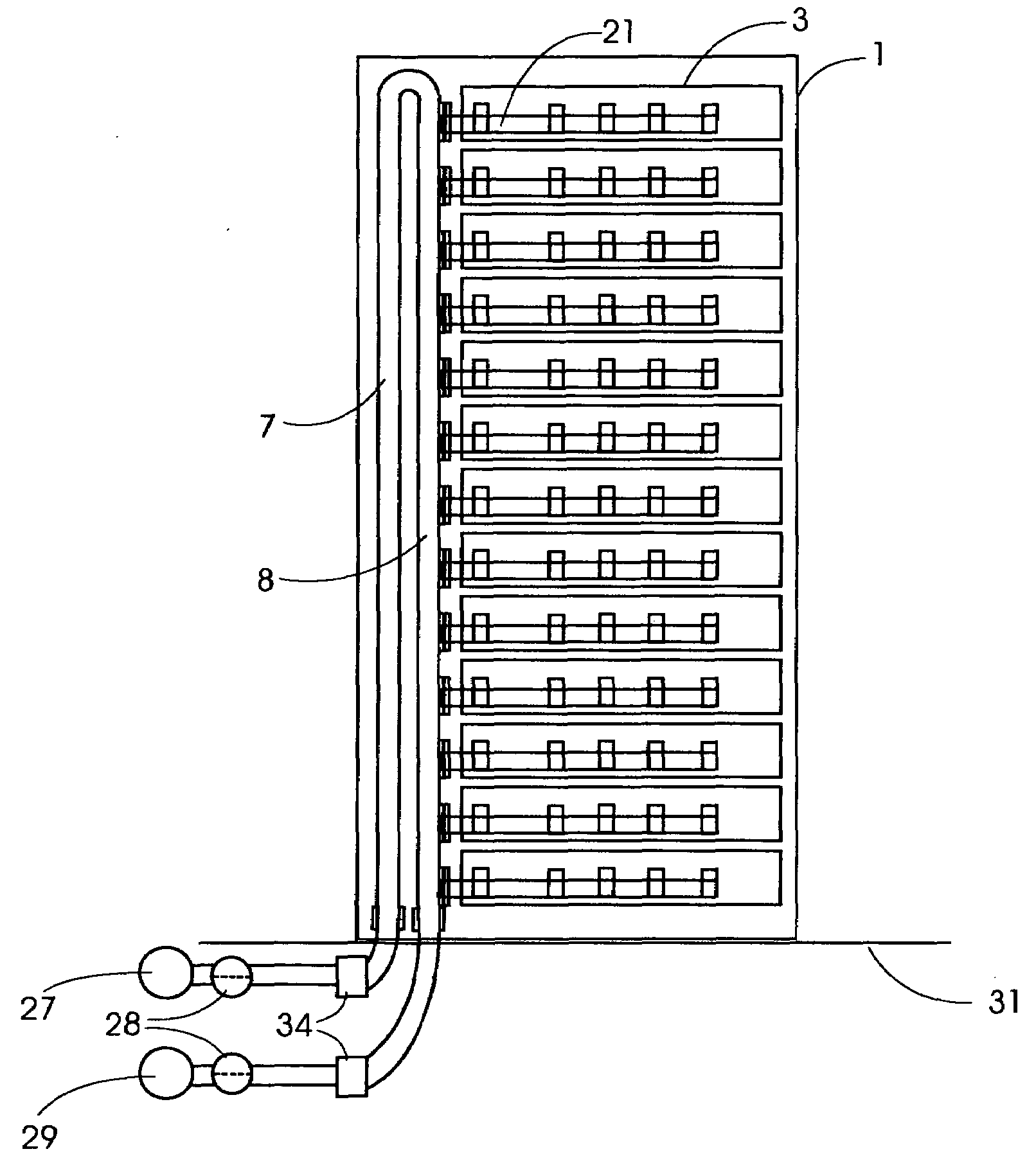

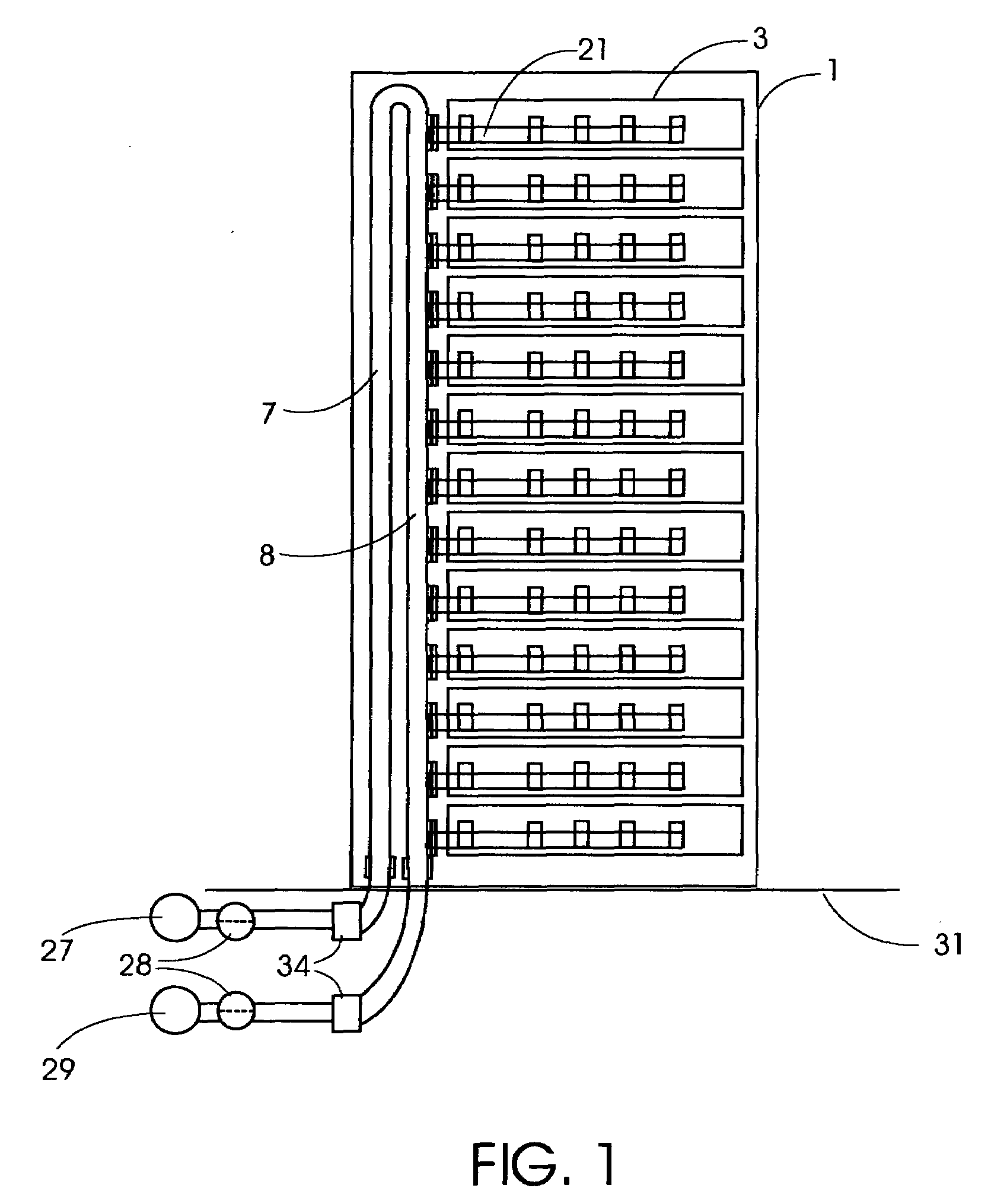

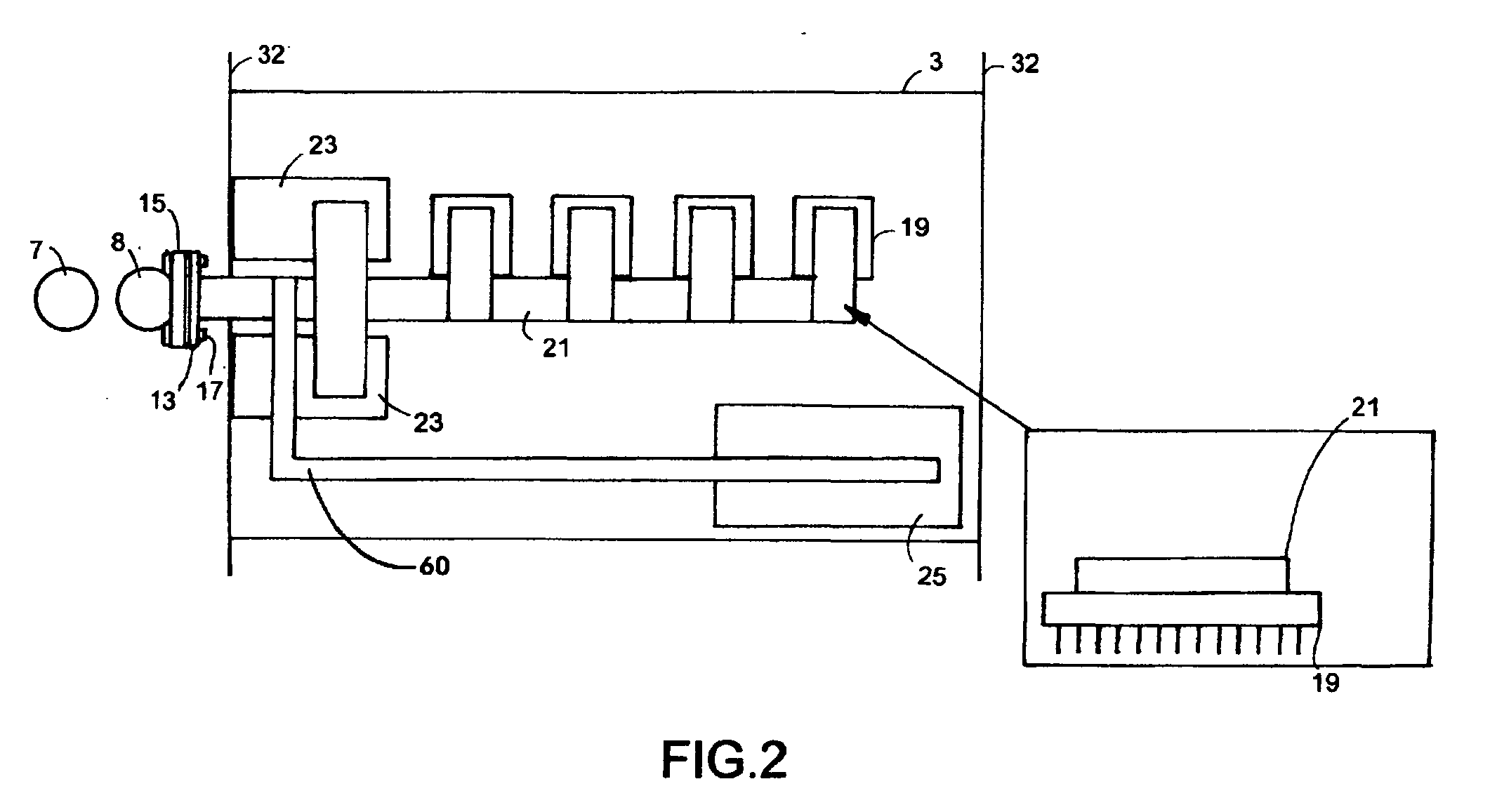

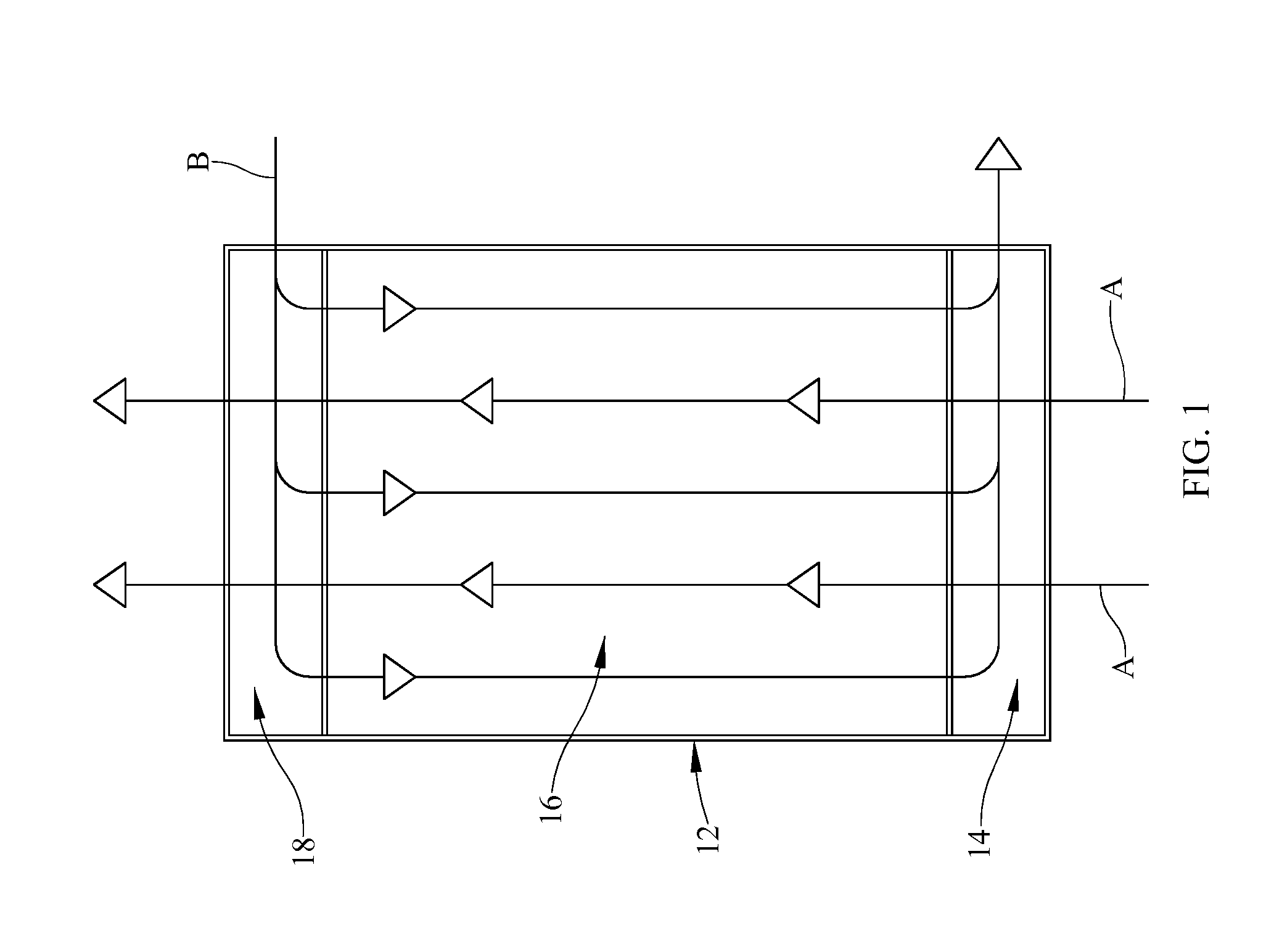

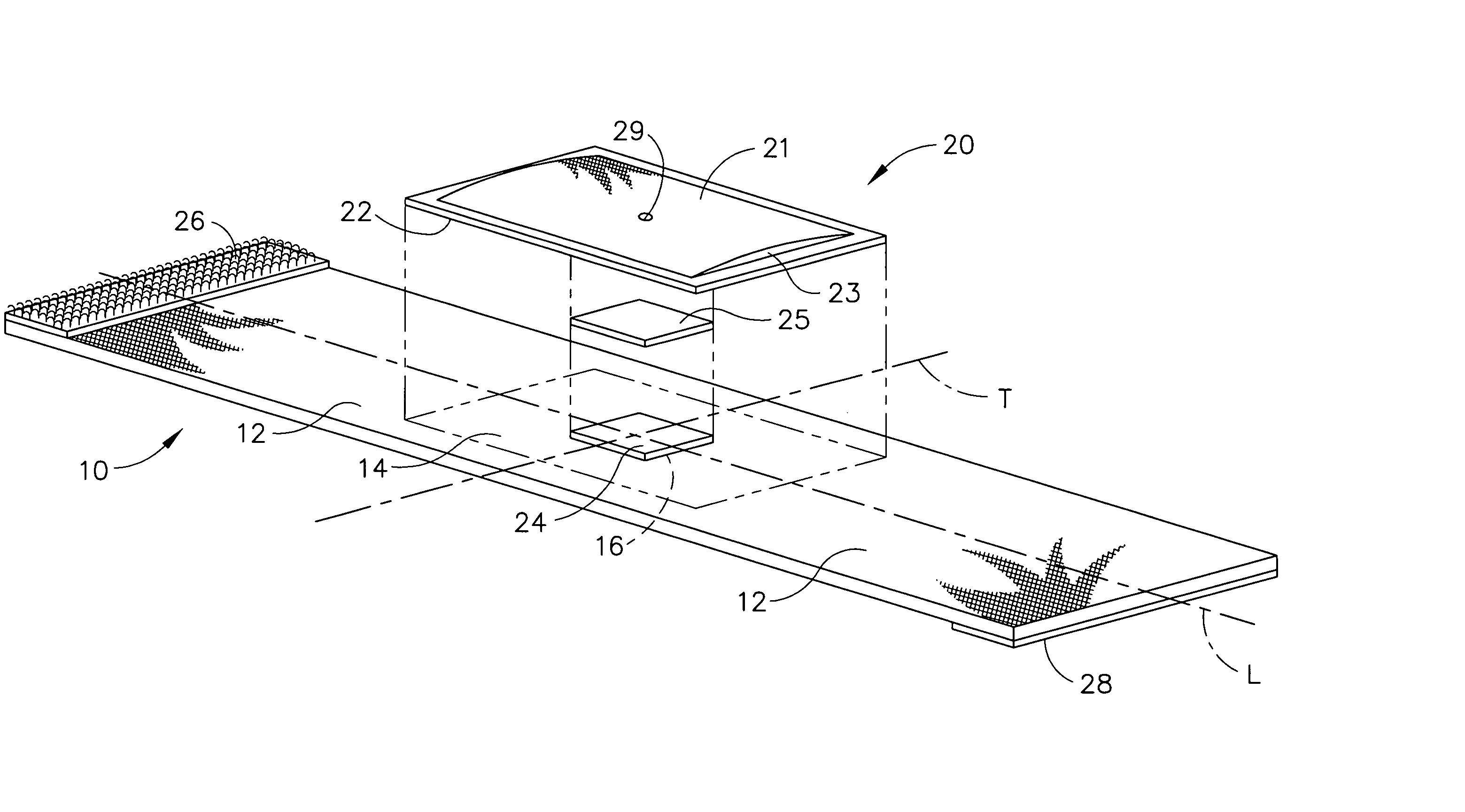

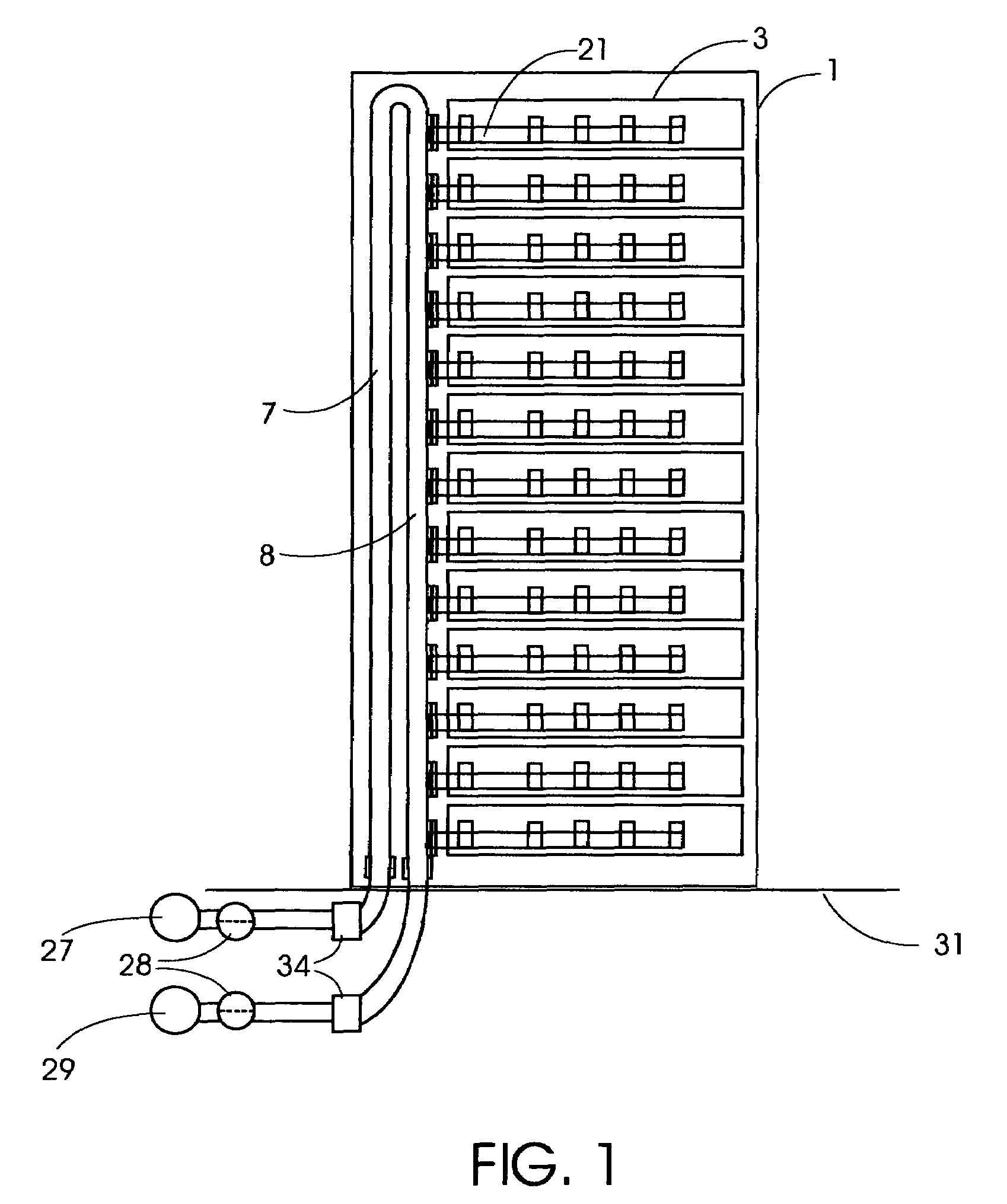

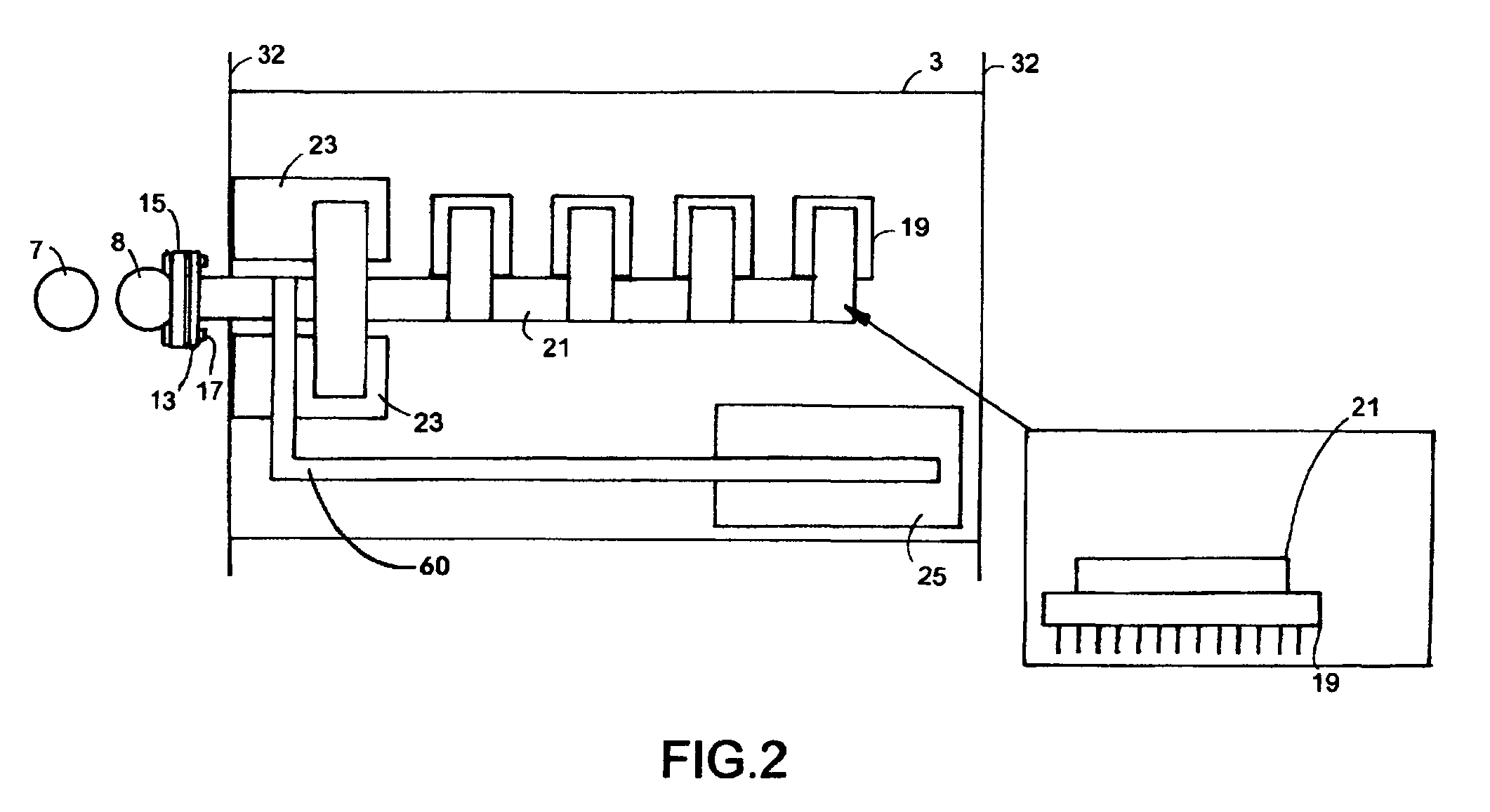

High efficiency heat removal system for rack mounted computer equipment

InactiveUS20090262495A1Minimize energy usageEfficient transportDomestic cooling apparatusDigital data processing detailsHeat conductingEngineering

An efficient method of heat removal from rack mounted computer equipment, network gear and other electronic equipment, consisting of solid heat conducting components in direct contact with the heat generating sources. In particular, this invention is primarily focused on the ability to efficiently and effectively cool computer equipment in standard computer rack cabinets.This invention utilizes a design that retains the general existing form factor of the rack mounted computer equipment, but uses direct contact heat transfer to a metal heat transfer conduit (Copper, Aluminum or other metal or efficient heat conducting material) contained within the computer equipment chassis. Furthermore, it is thermally coupled to an external rack mounted solid-to-fluid heat exchanger as an efficient method of heat transfer and removal. This is much more efficient than air as heat transfer medium which it the common method of heat removal from existing standardized rack mounted computer equipment.This invention covers the design of the heat transfer components within the chassis of rack mounted computer server and the heat transfer system components external to the server within rack enclosure, as well as the external cooling system components necessary to connect to existing fluid based heat transfer and removal systems and processes.

Owner:NEUDORFER JULIUS

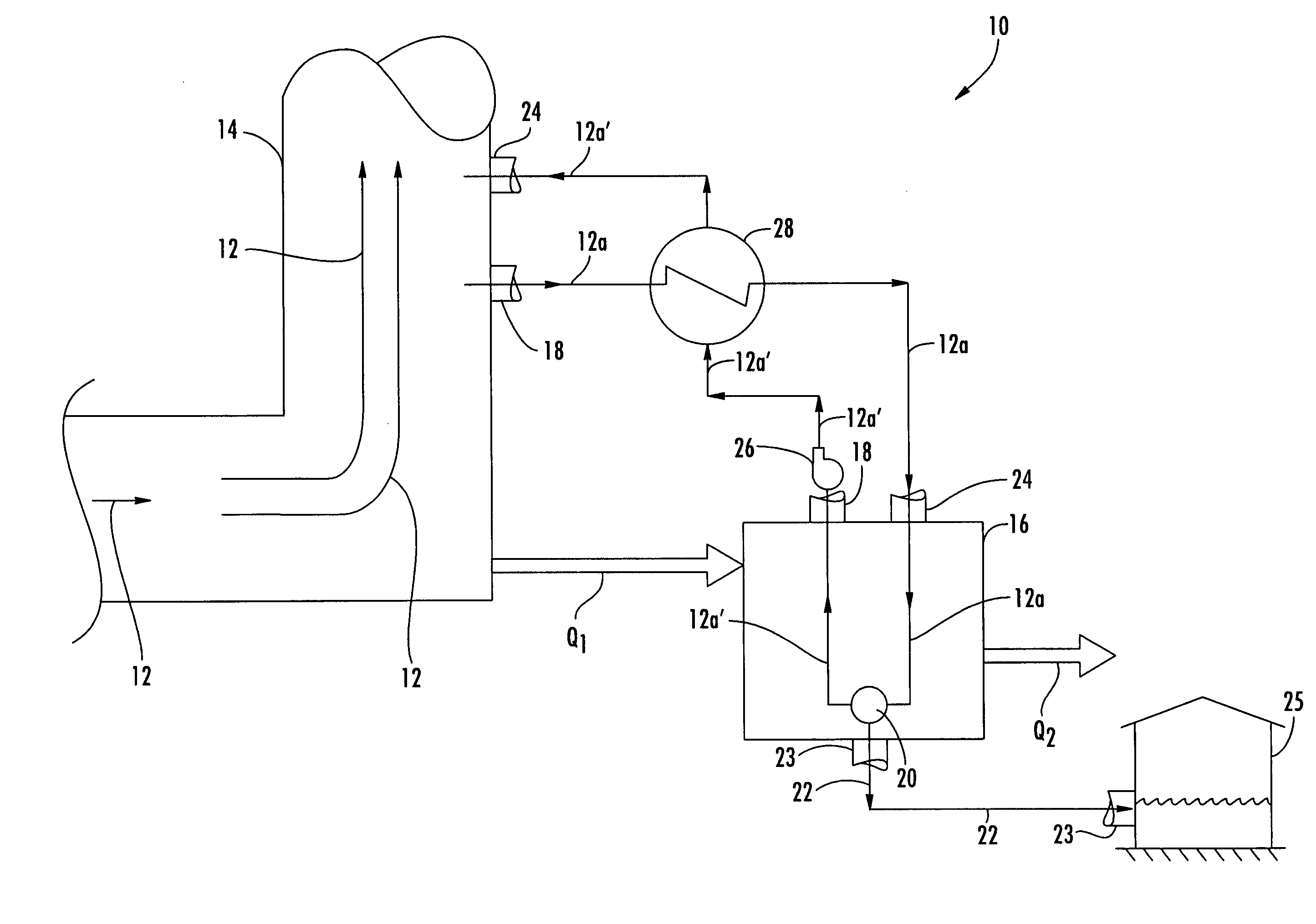

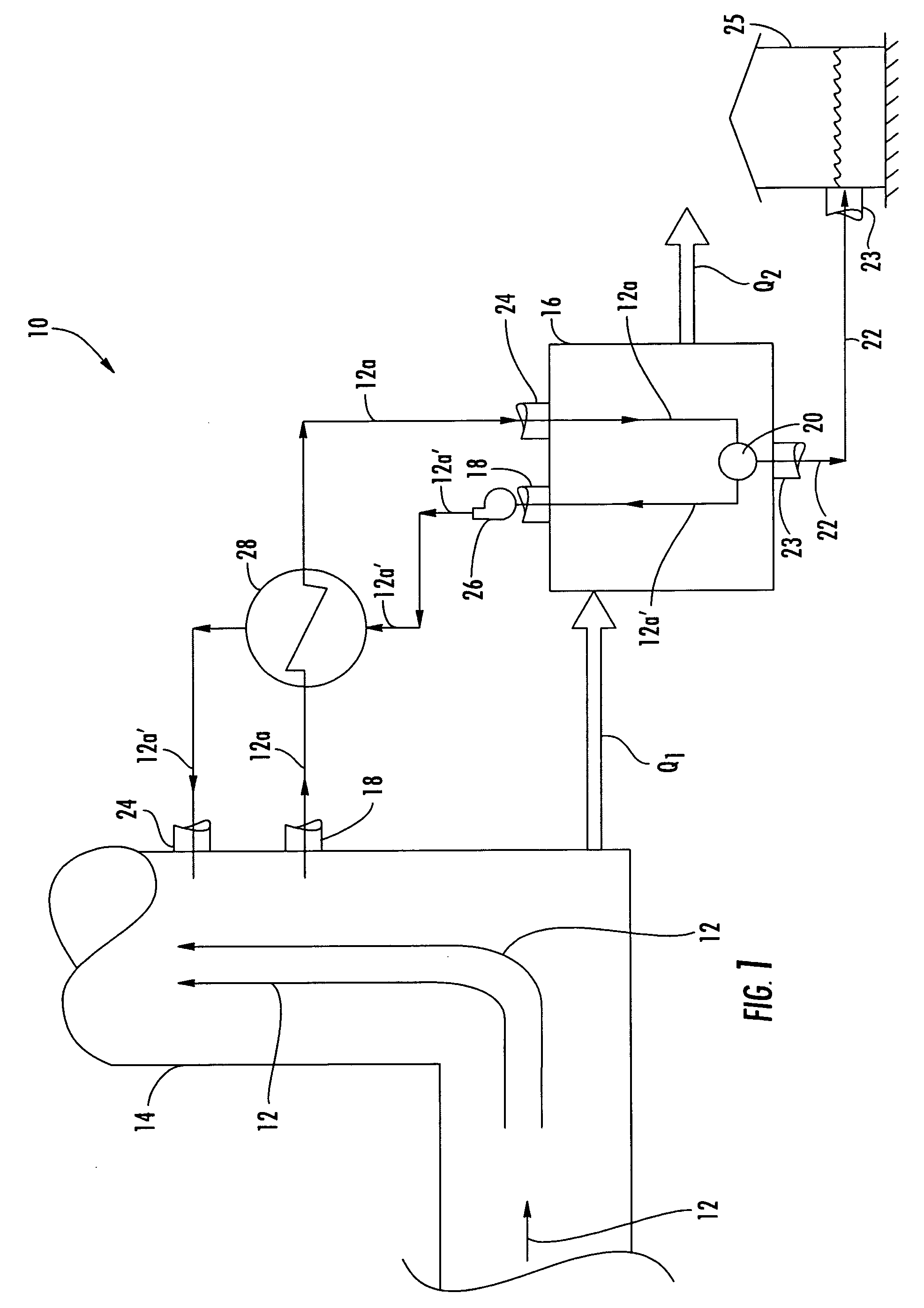

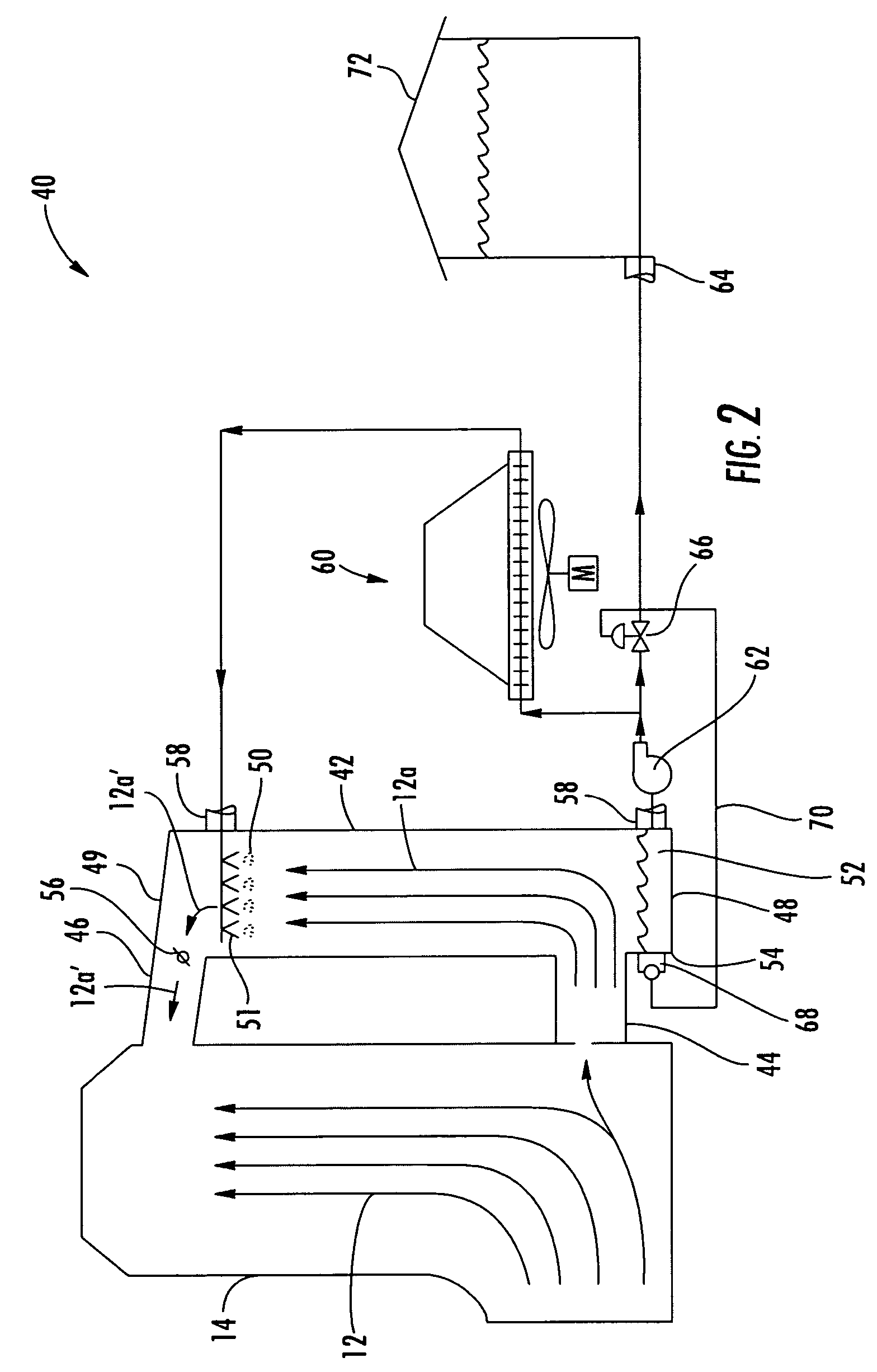

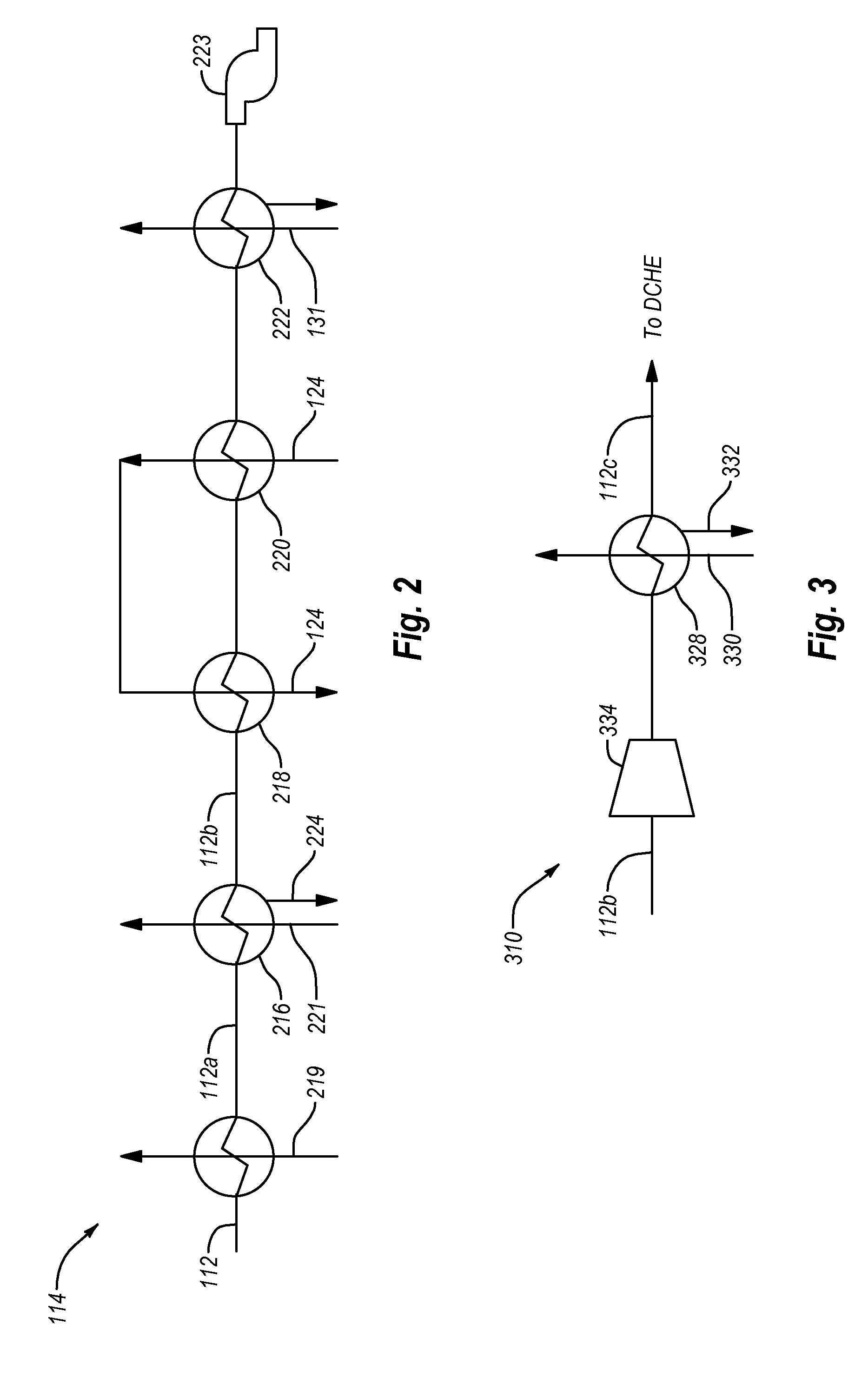

Turbine exhaust water recovery system

ActiveUS7194869B2Reduce the temperaturePromote sportsUsing liquid separation agentGas turbine plantsWater sourceLiquid water

The exhaust gas of a turbine engine can include water vapor. Aspects of the invention relate to various systems for recovering water from the exhaust gas of a gas turbine engine. In one system, a portion of the exhaust gas can be routed to an absorption chiller. In another system, a portion of the exhaust gas can be routed to a direct contact heat exchanger. In a third system, a portion of the exhaust gas can be routed to a fin-fan cooler. In each of these systems, the portion of gas can be cooled below its dew point temperature to release a portion of its humidity as liquid water. Aspects of the invention can be used with the turbine exhaust of simple and combined cycle power plants. A water recovery system according to aspects of the invention can minimize or eliminate a power plant's dependence on local water sources.

Owner:AMEC FOSTER WHEELER IND POWER CO INC

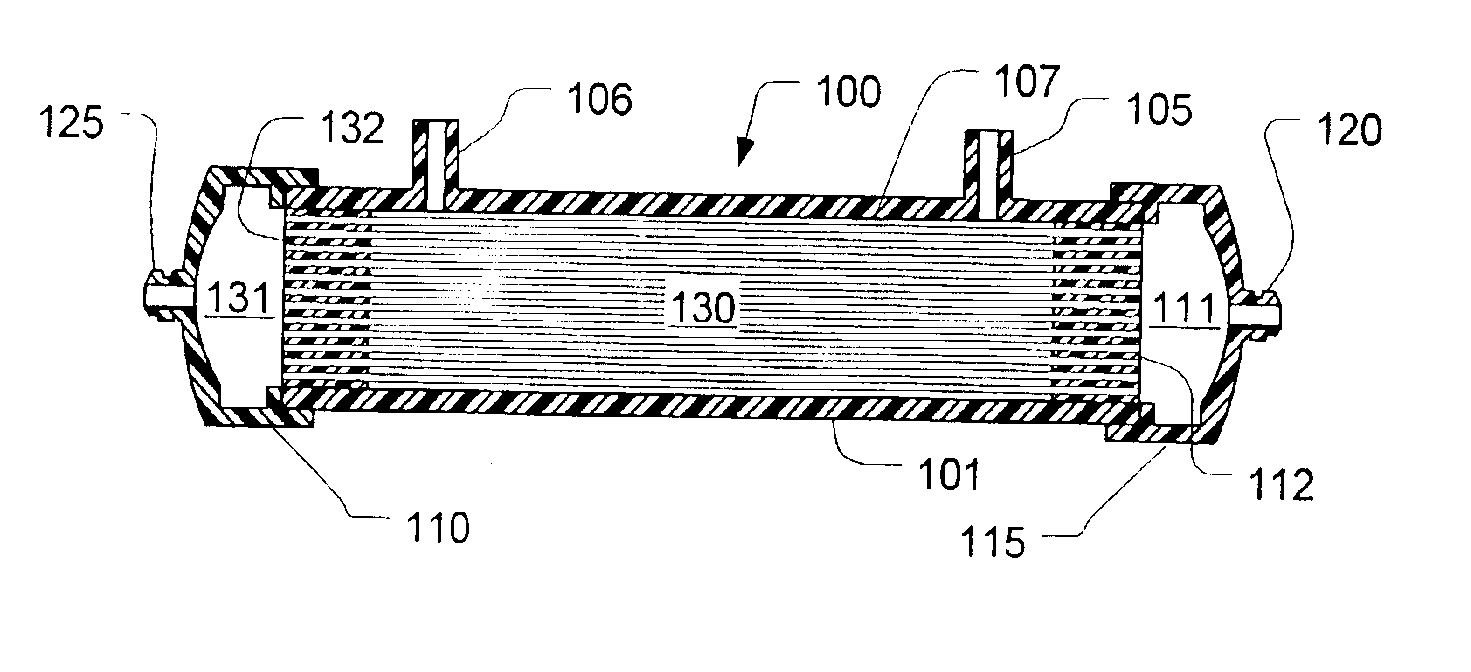

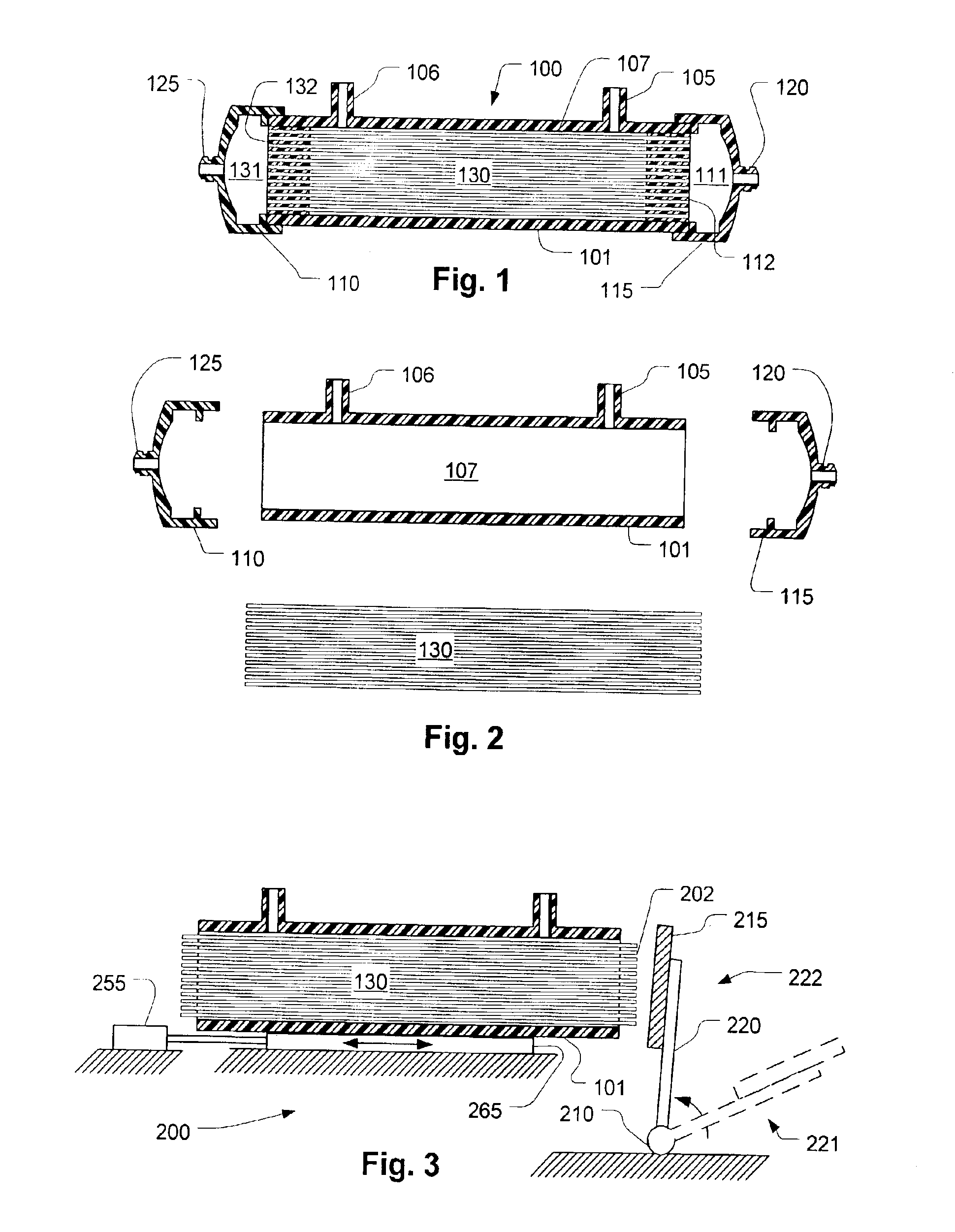

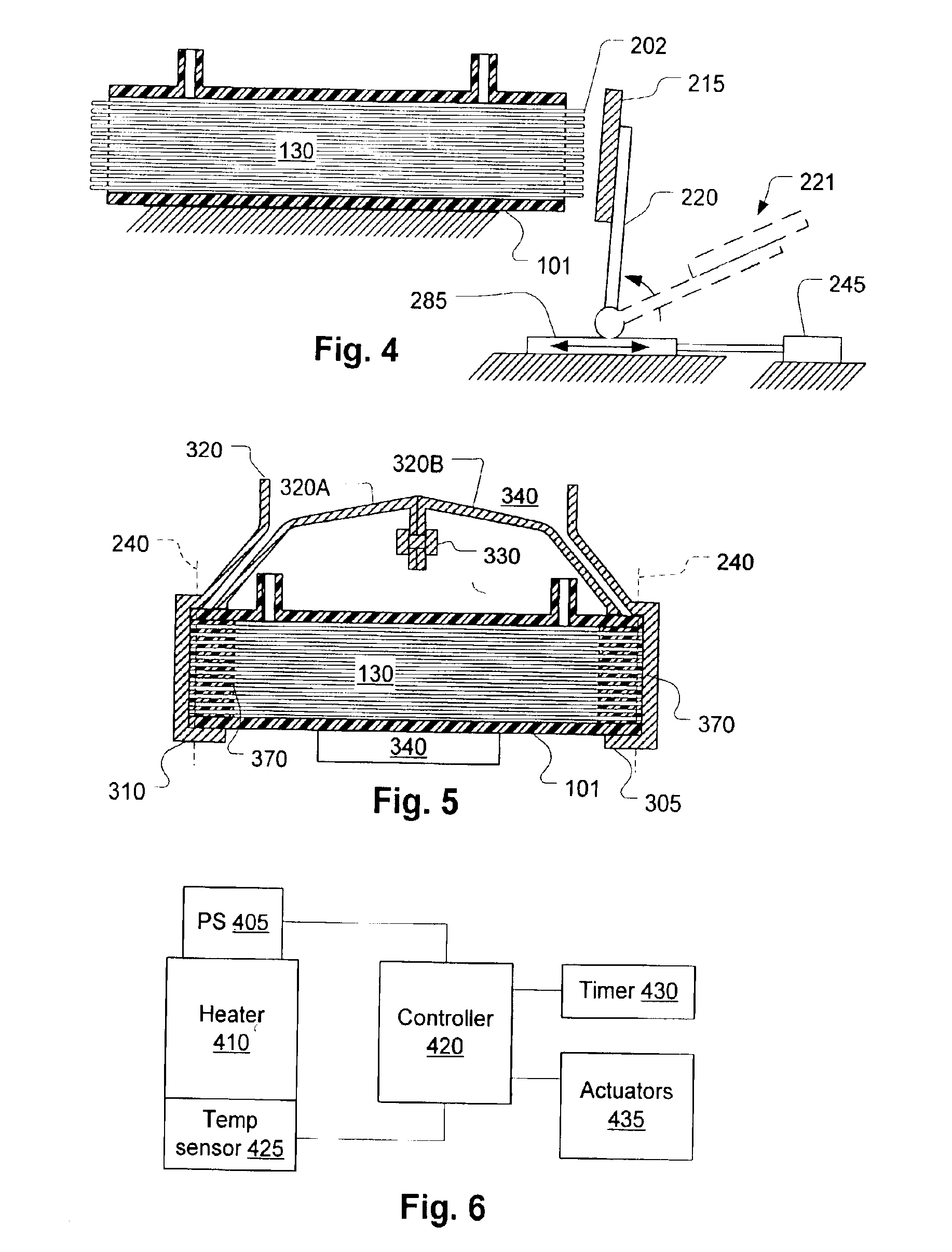

Method and apparatus for manufacturing filters

InactiveUS6872346B2Speed productionShort amount of timeSemi-permeable membranesTailstocks/centresEngineeringMechanical engineering

A problem in the manufacture of filters using tubular membrane bundles is keeping potting material from flowing into the openings at the ends of the tubes. A preferred embodiment of a method for manufacturing a tubular membrane filter employs a non-contact heat source such as radiant heating to melt the tips of the tubular membranes. This prevents the migration of potting material into the tubes when the potting material is flowed into the ends of tube bundles during the manufacturing process for a filter.

Owner:NXSTAGE MEDICAL

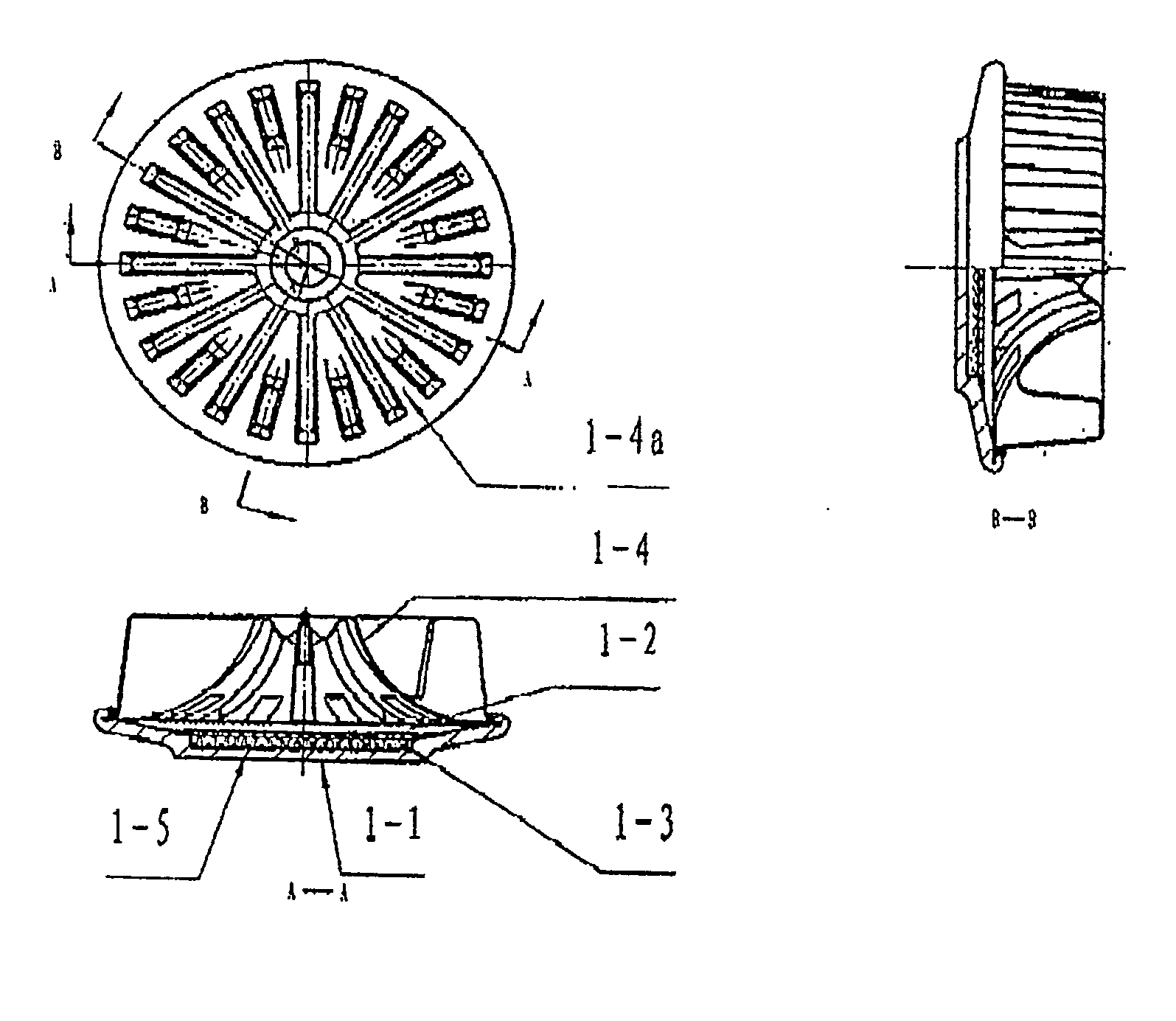

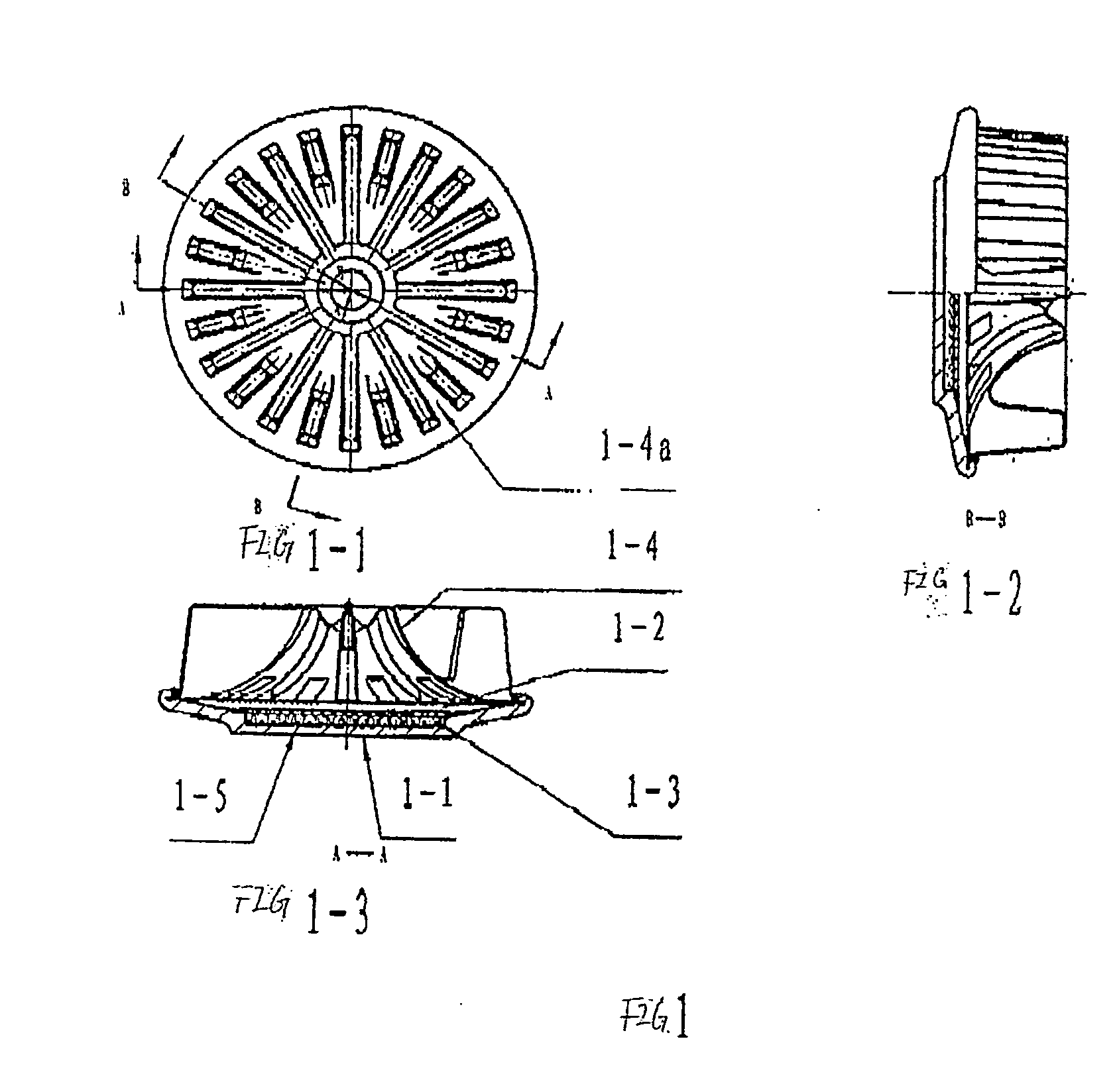

Integrated heat pipe and its method of heat exchange

InactiveUS20050061486A1Improve heat transfer efficiencyRemove heatStationary conduit assembliesHeat carrierEngineering

The present invention relates to a kind of integrated heat pipe and a method of heat exchange. The heat pipe includes a tank (1-2) as a heating potion and a lot of heat carriers (1-4) as a radiating portion. The tank (1-2) and the heat carriers (1-4) have same cavity in which a coolant (1-3) is partially filled. The tank (1-2) is held in close contact with a heat source (such as electronic elements). The heat carriers (1-4) are arranged at an interval so that the radiating channels (1-4a) are formed between them. The coolant (1-3) in the tank (1-2) is heated by the heat sources, vaporized coolant moves to the heat carriers (1-4) and condenses in there. According to the invention, the heat pipe can be increased its radiating surface significantly with the varied arrangement of the heat carriers (1-4).

Owner:YANG HONGWU

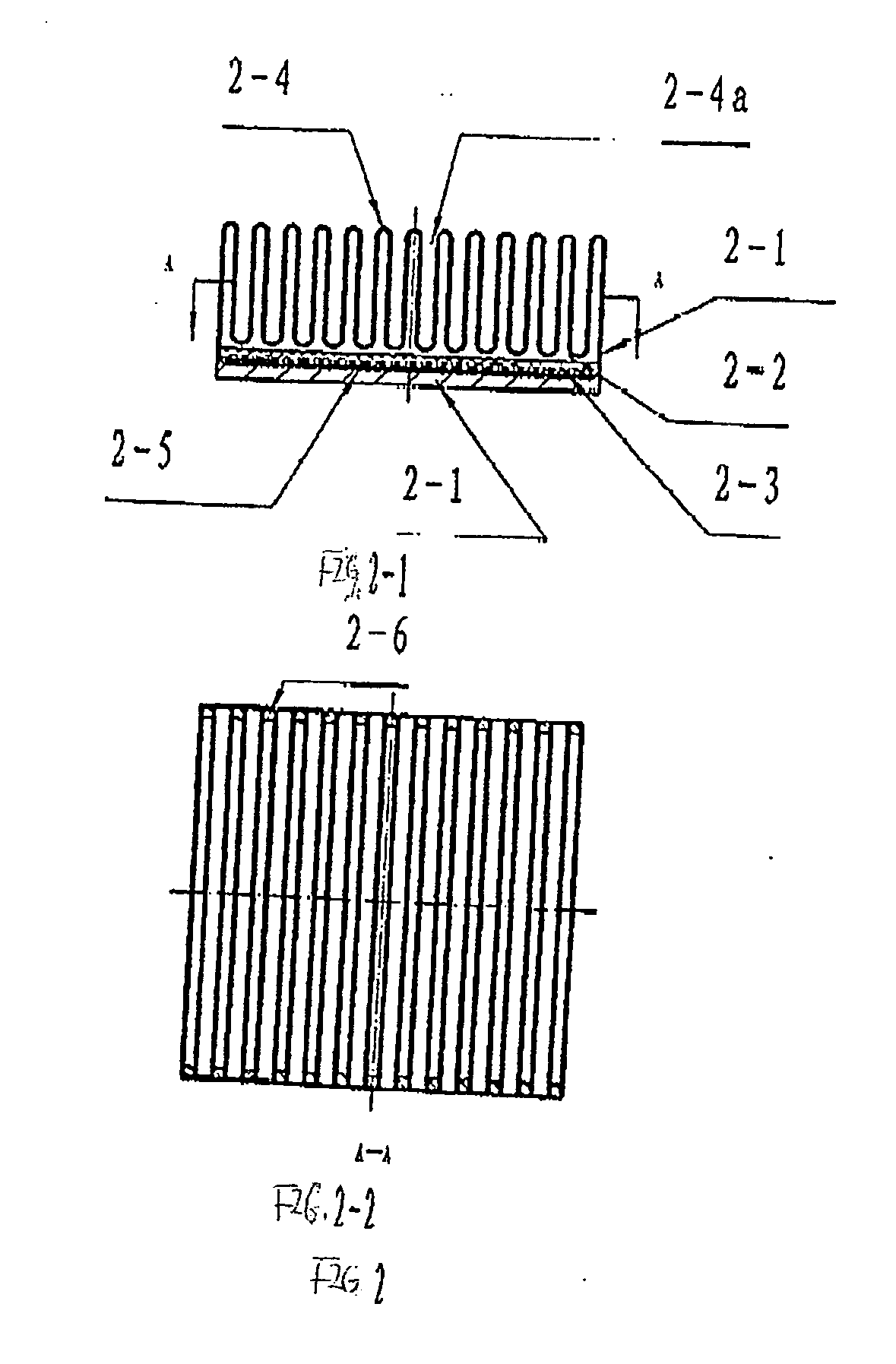

Light-emitting diode lamp

InactiveCN102859256APoint-like light sourceLighting heating/cooling arrangementsLight-emitting diodeHeat spreader

The light-emitting diode lamp comprises: a radiator having a hollow central part and longitudinal radial ribs that form the outer counter of the lamp; and light-emitting diodes mounted on an annular platform at the foot of the radiator so as to be capable of contact heat transfer to the radiator. The ends of the longitudinal radial ribs are connected to the annular platform.

Owner:奥斯曼根纳德维奇库耶夫

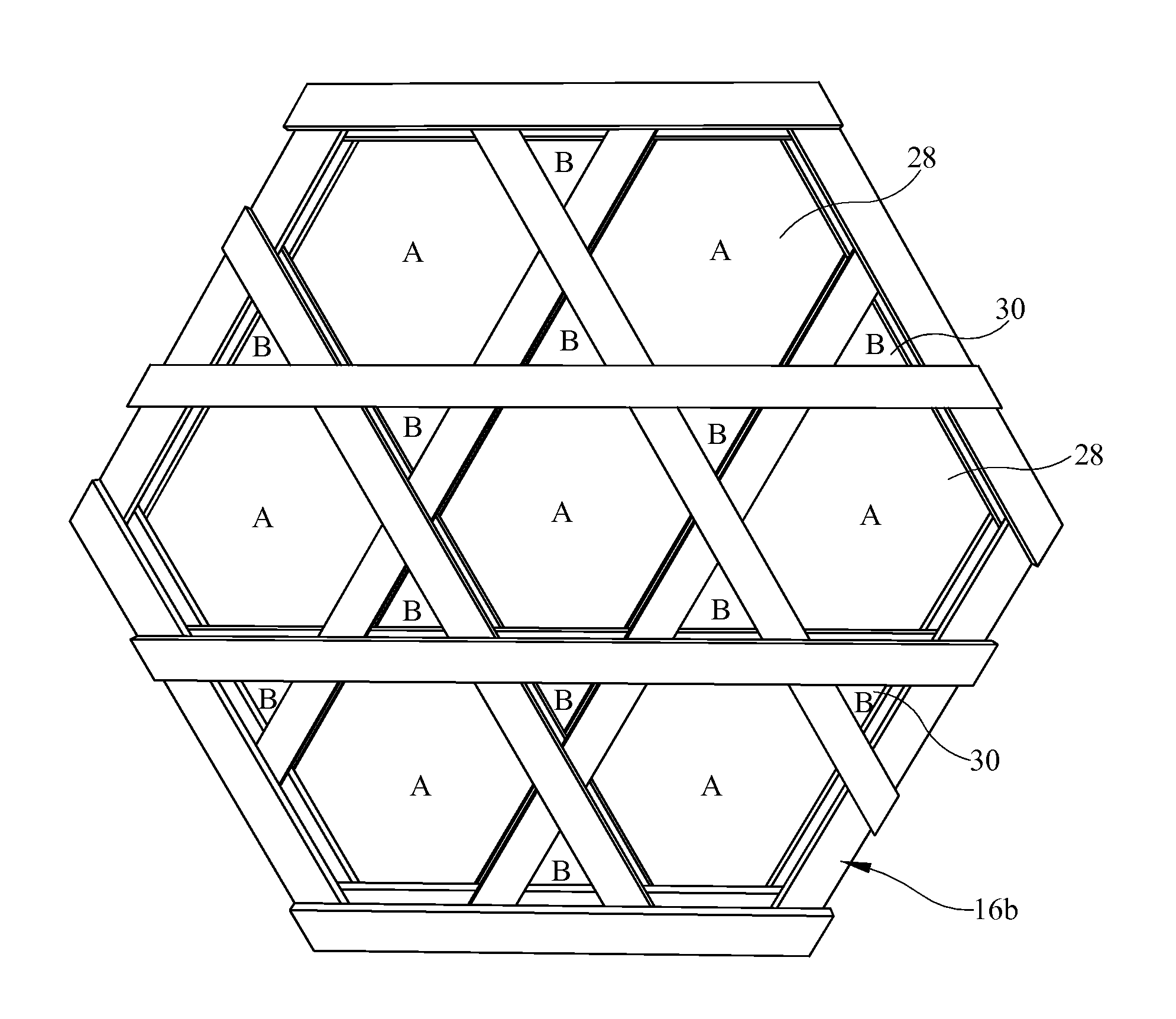

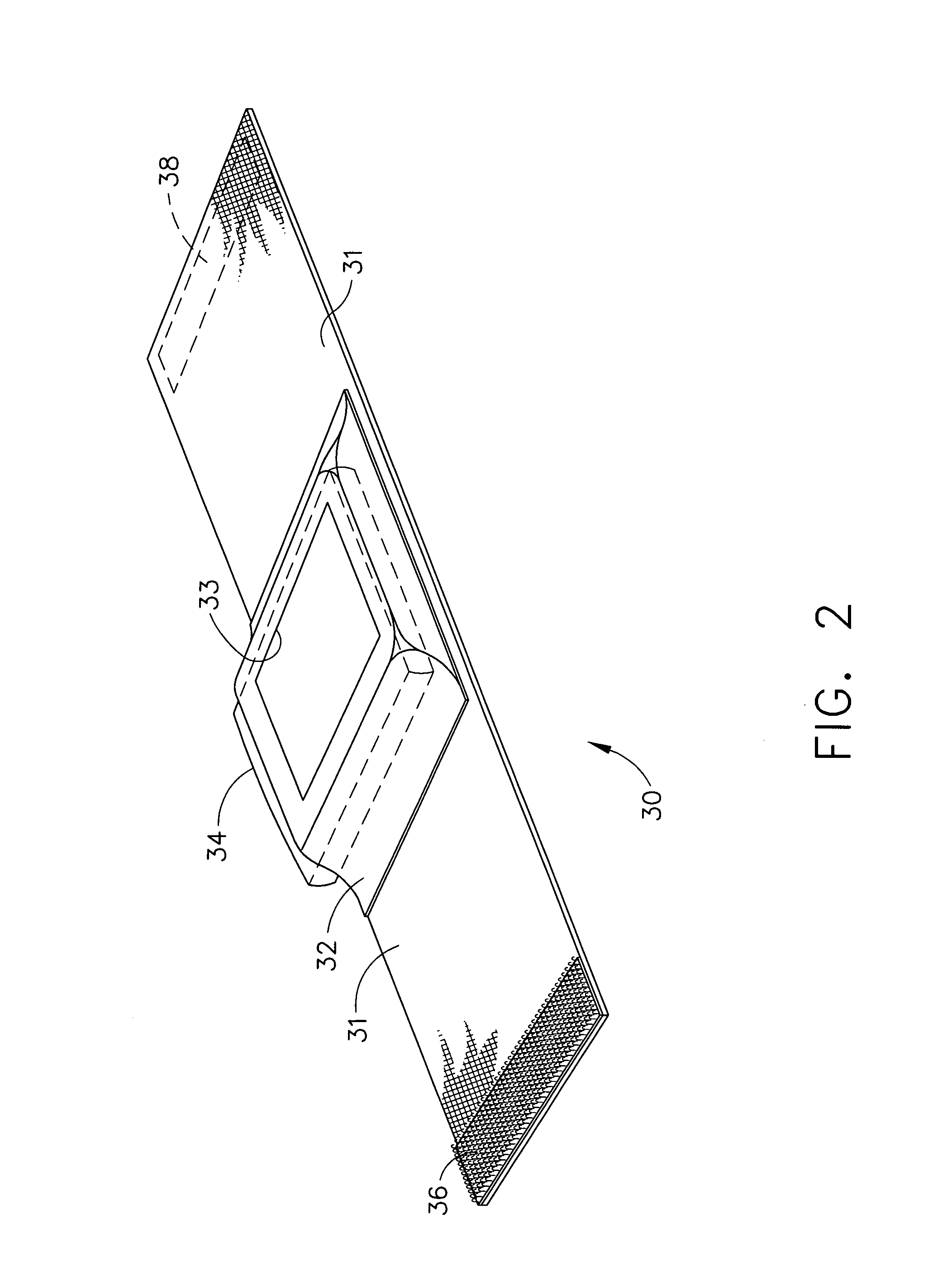

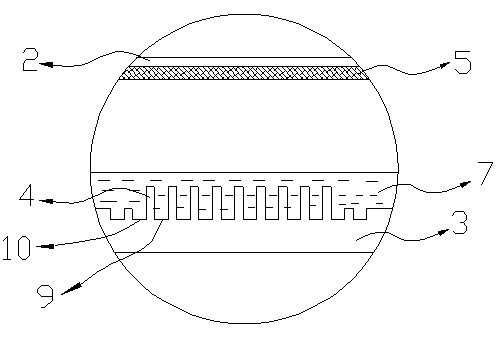

Fill material for direct-contact heat/mass exchangers

InactiveUS20150048528A1Reduced dysfunctionSmall sizeAdditive manufacturing apparatusUsing liquid separation agentFilling materialsLinear element

Fill material for a direct contact heat exchanger wherein the fill material has flow pathways bounded by an array of linear elements, namely a mesh. The invention intentionally uses surface tension and capillary action to anchor the fluid / fluid interface in a desired location. The heat exchanger is wick or collector in direct contact with the fill material (matrix) to extract fluid without formation of large droplets. The mesh is made from a neutrally wetting material.

Owner:BARTON SEAN ANDERSON

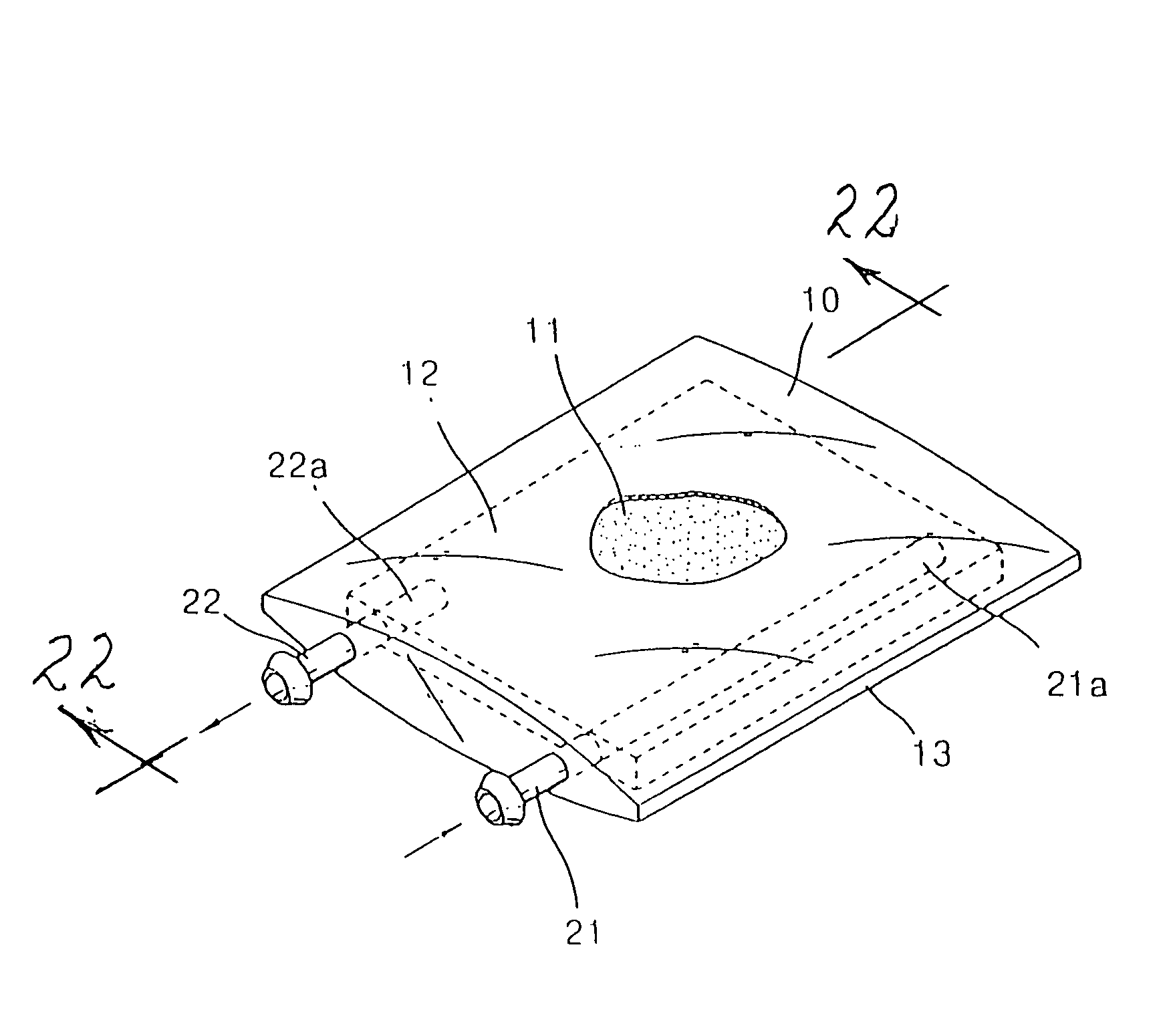

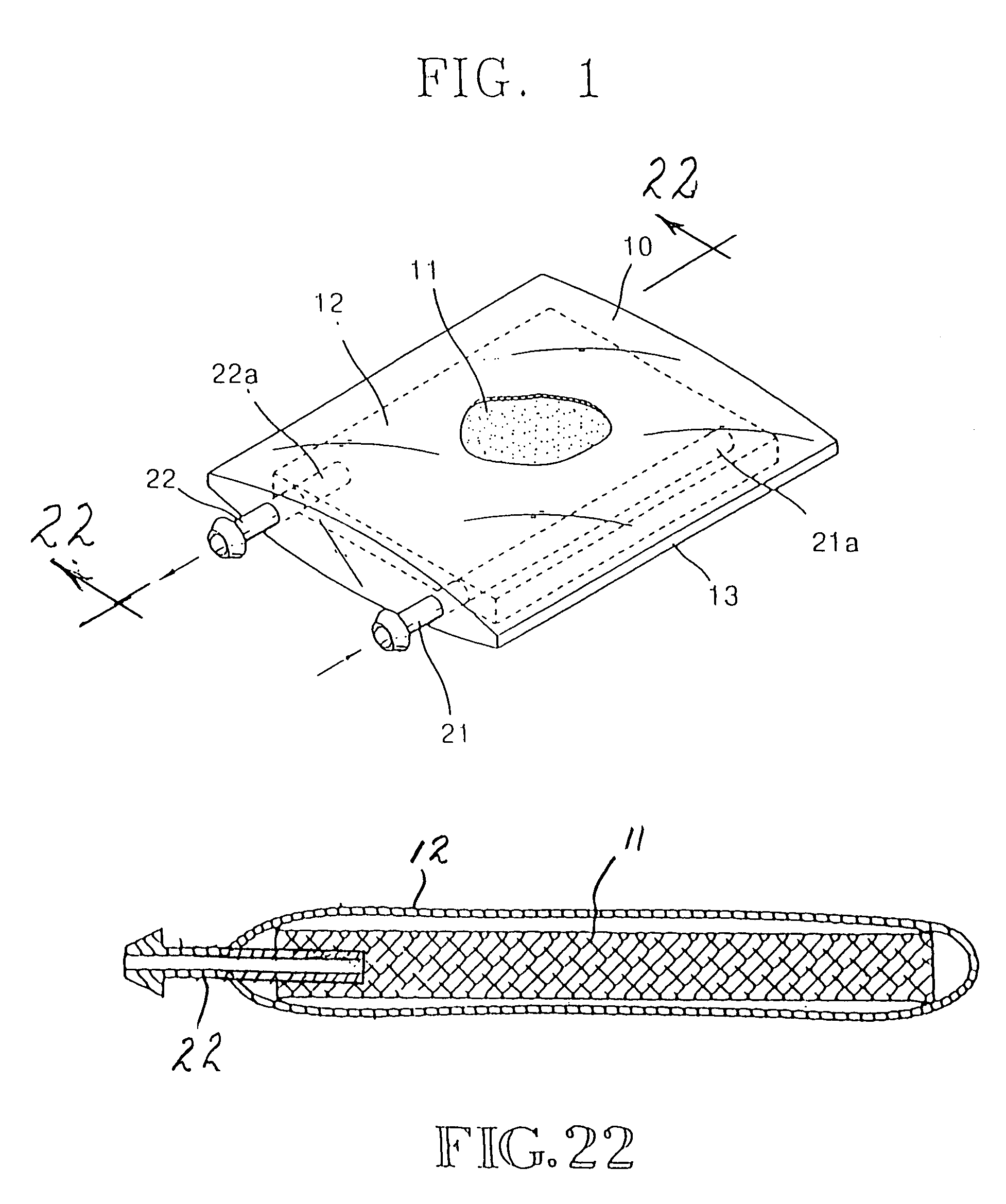

Textile body wrap holder and thermal article

An elastic thermal body wrap system comprising a reusable, washable, textile holder for removably holding at least one thermal pack in close bodily contact. The thermal pack comprises one or more heat cells comprising an exothermic composition. The system comprises a fastening system to hold the holder around a user's body, for example, the back. The invention also relates to a method for holding such a thermal pack in close bodily contact by wearing the holder.

Owner:RUSL

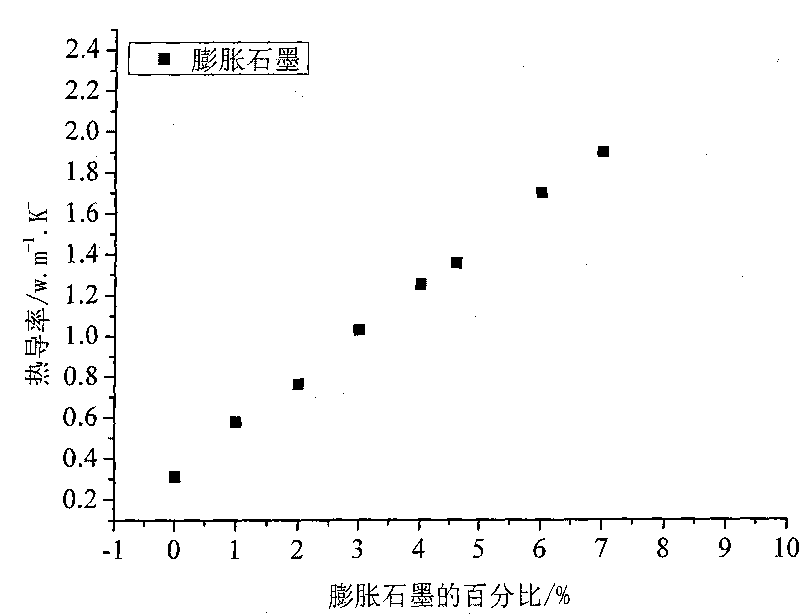

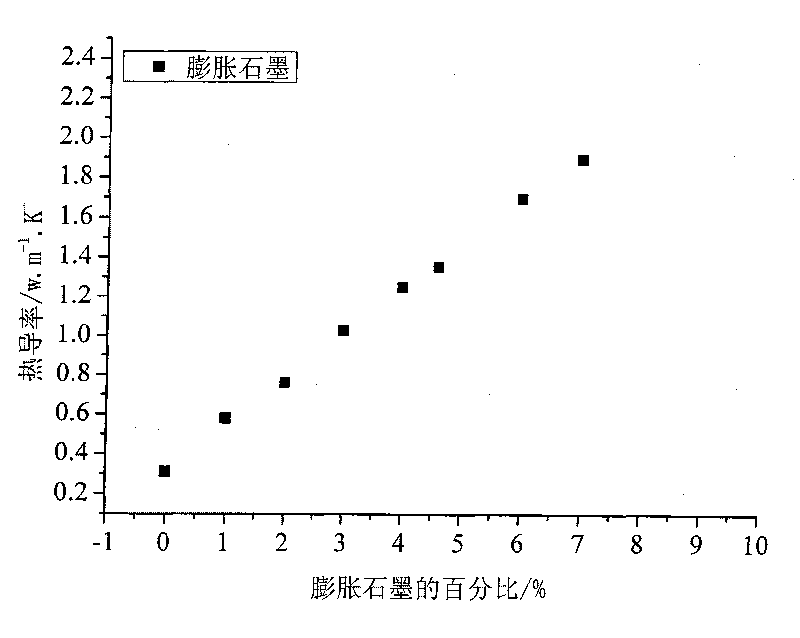

Setting phase change energy storage material with high-thermal conductivity and preparation method thereof

InactiveCN101724381AImprove thermal conductivityImprove heat transfer characteristicsHeat-exchange elementsMolten stateMaterials science

The invention relates to a setting phase change energy storage material with high-thermal conductivity and a preparation method thereof, belonging to the field of phase change heat storage materials. The setting phase change energy storage material with high-thermal conductivity is characterized by containing 65-90 percent by mass of paraffin substances as a phase-change material, 9-34 percent by mass of high-density polyethylene as a support material and 1-7 percent by mass of expanded graphite as a heat conduction intensifier; a method for adding a proper amount of expanded graphite to paraffin / high-density polyethylene in a molten state is adopted to enable the heat conductivity of the setting phase change material to be increased to 1.35W / (m.K) or higher. The method comprises the following steps of: heating to melt the paraffin substances with the mass percent of 65-90 percent, and heating to enable the temperature of the liquid paraffin to reach 120-190 DEG C; adding high-density polyethylene with the mass percent of 9-34 percent and the expanded graphite with the mass percent of 1-7 percent to the liquid paraffin, and then melting and evenly stirring in vacuum; putting the mixture in a hot mould for pressing and molding; taking the mixture from the mould after naturally cooling. The setting phase change material has high thermal conductivity, does not need to be packaged in containers and can directly contact heat-transfer media.

Owner:UNIV OF SCI & TECH OF CHINA

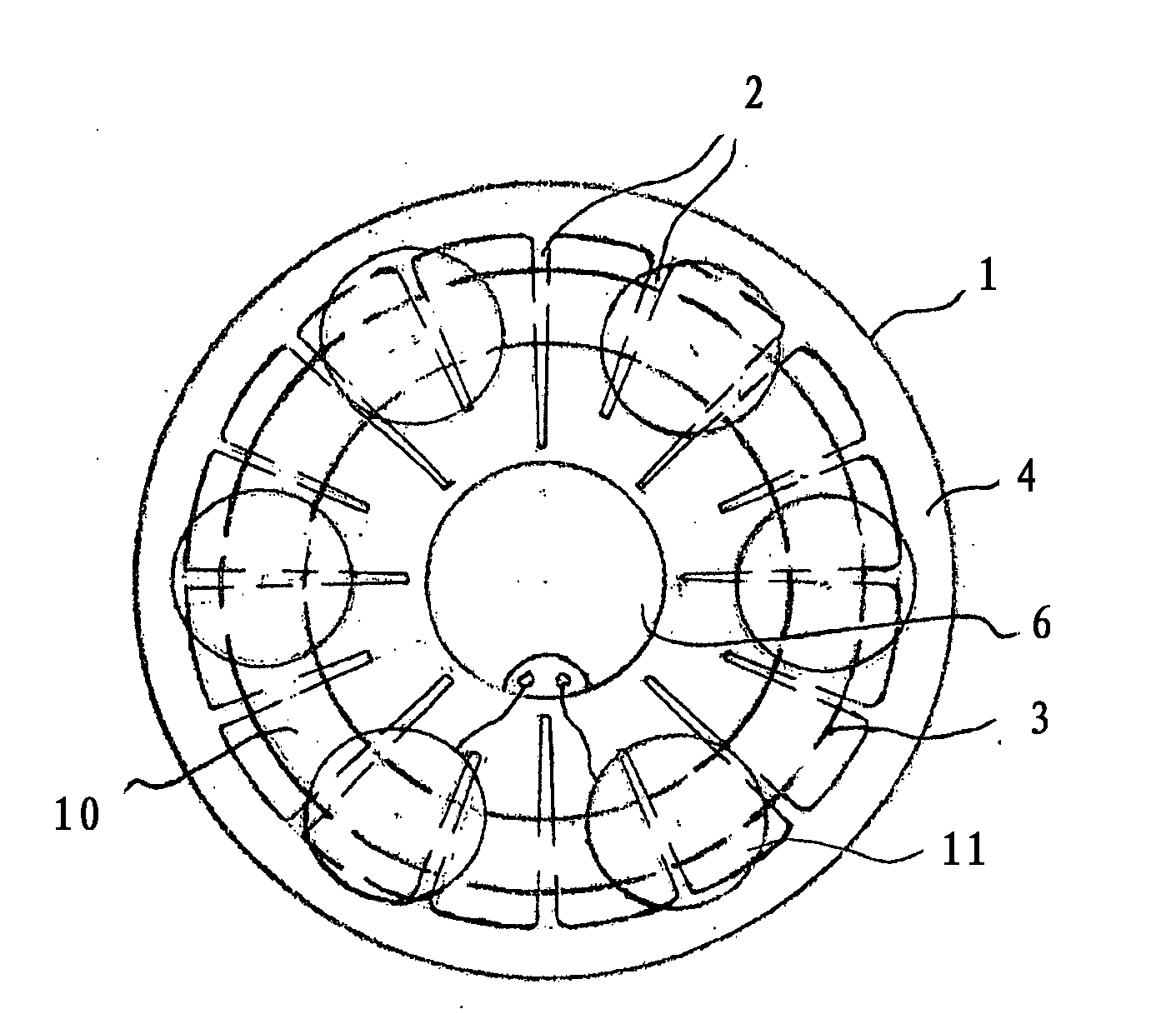

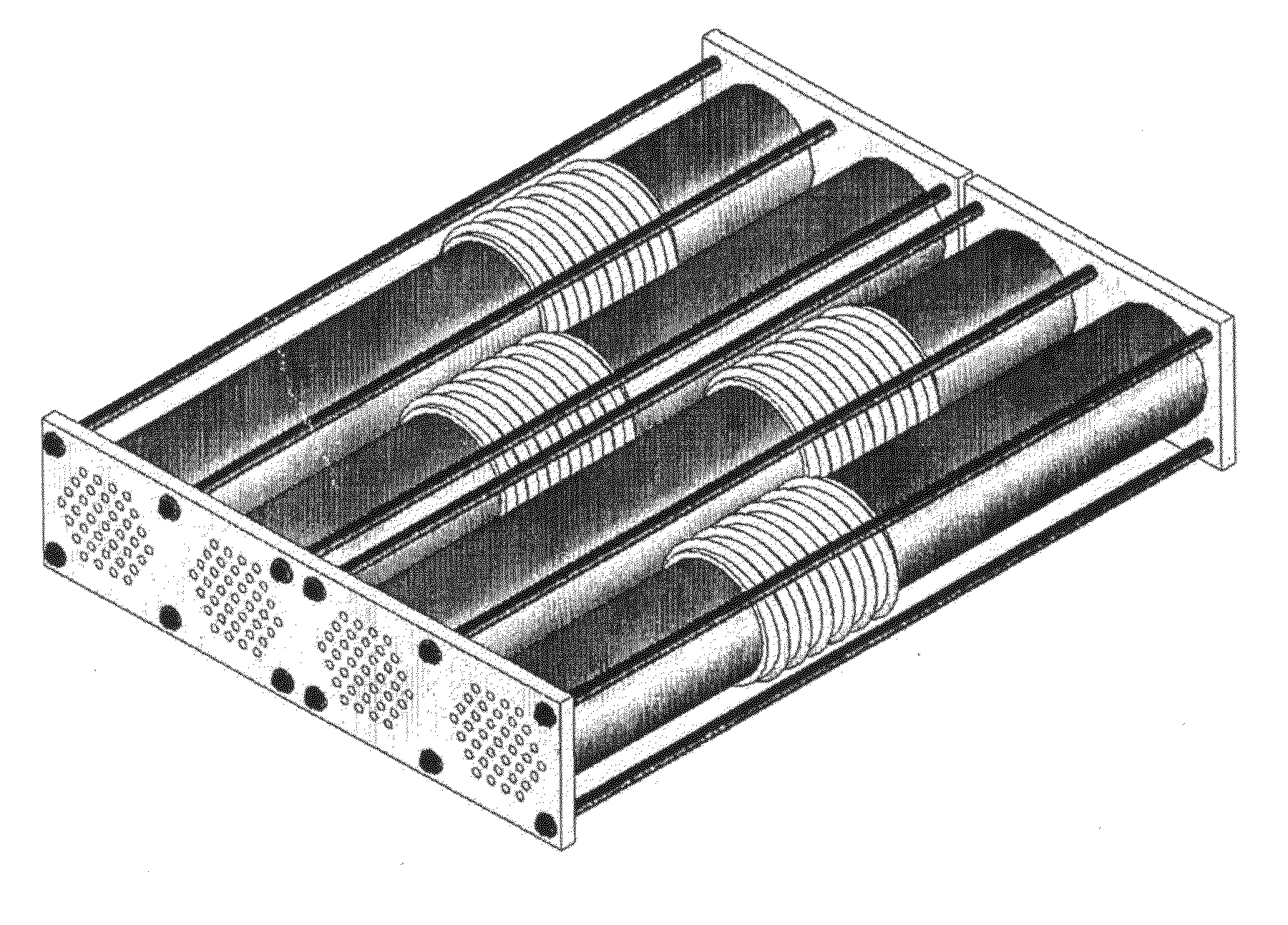

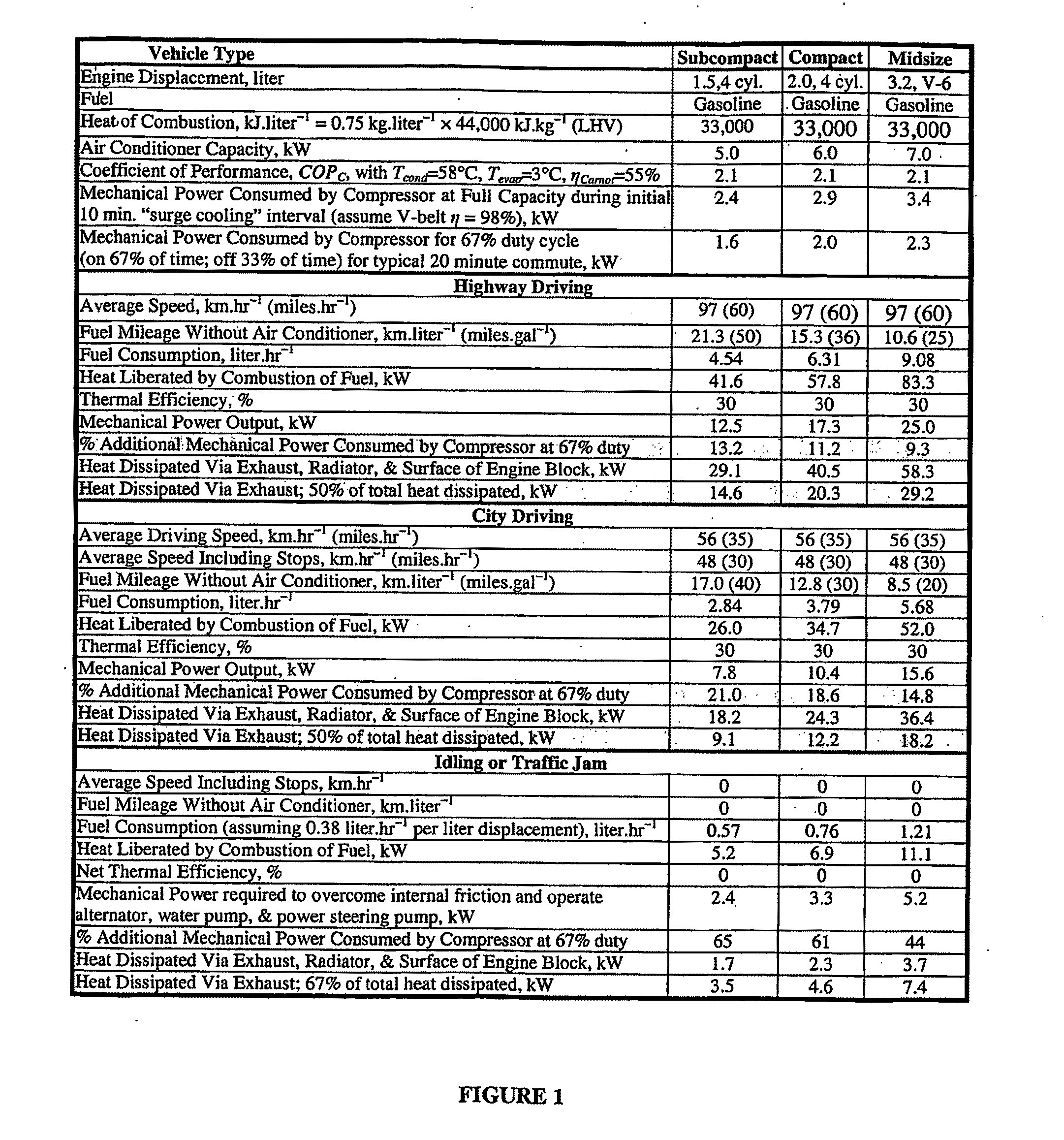

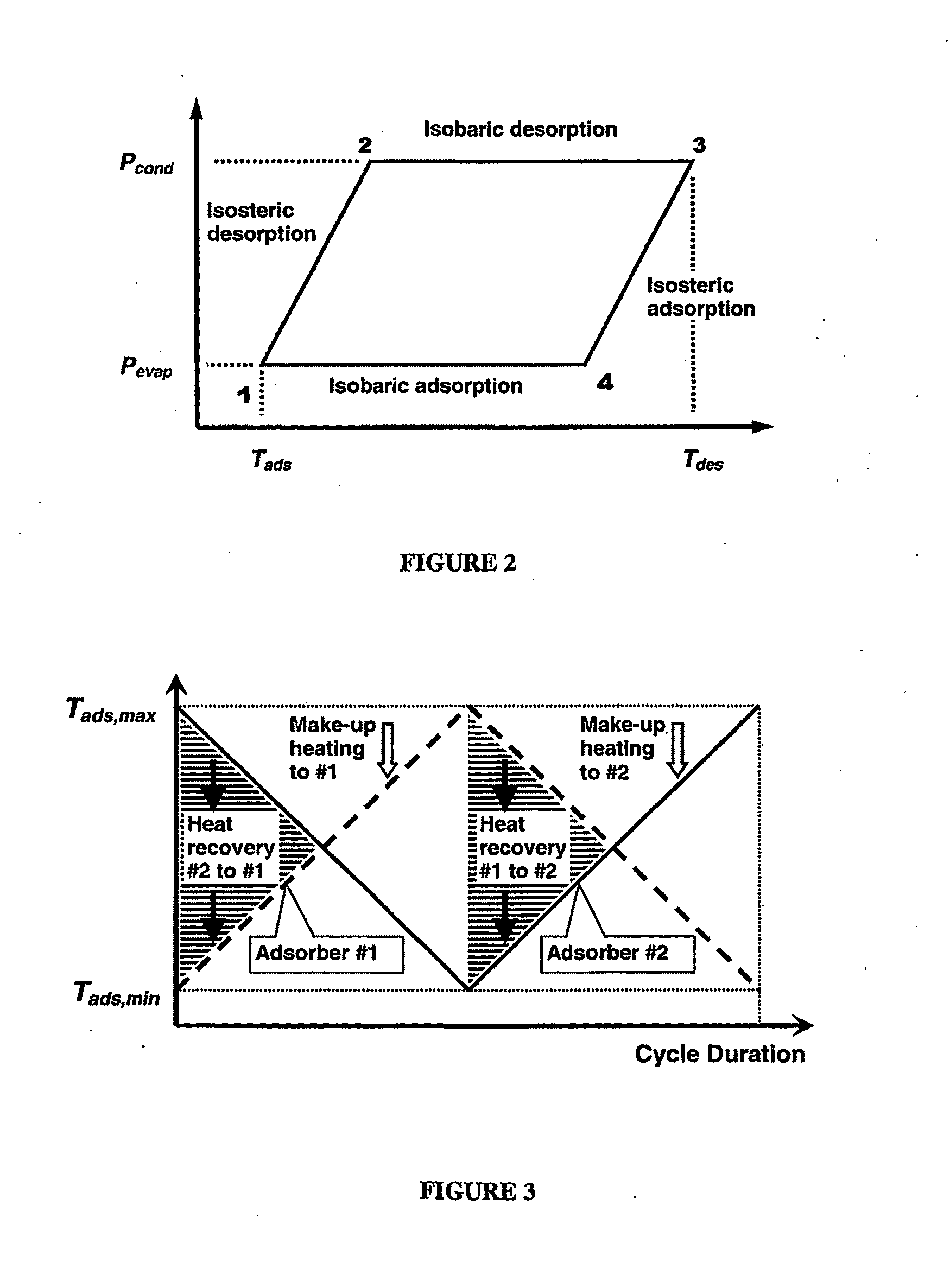

Automotive adsorption heat pump

InactiveUS20110005267A1Efficient and reliableLess expensiveClimate change adaptationVehicle heating/cooling devicesSorbentFresh air

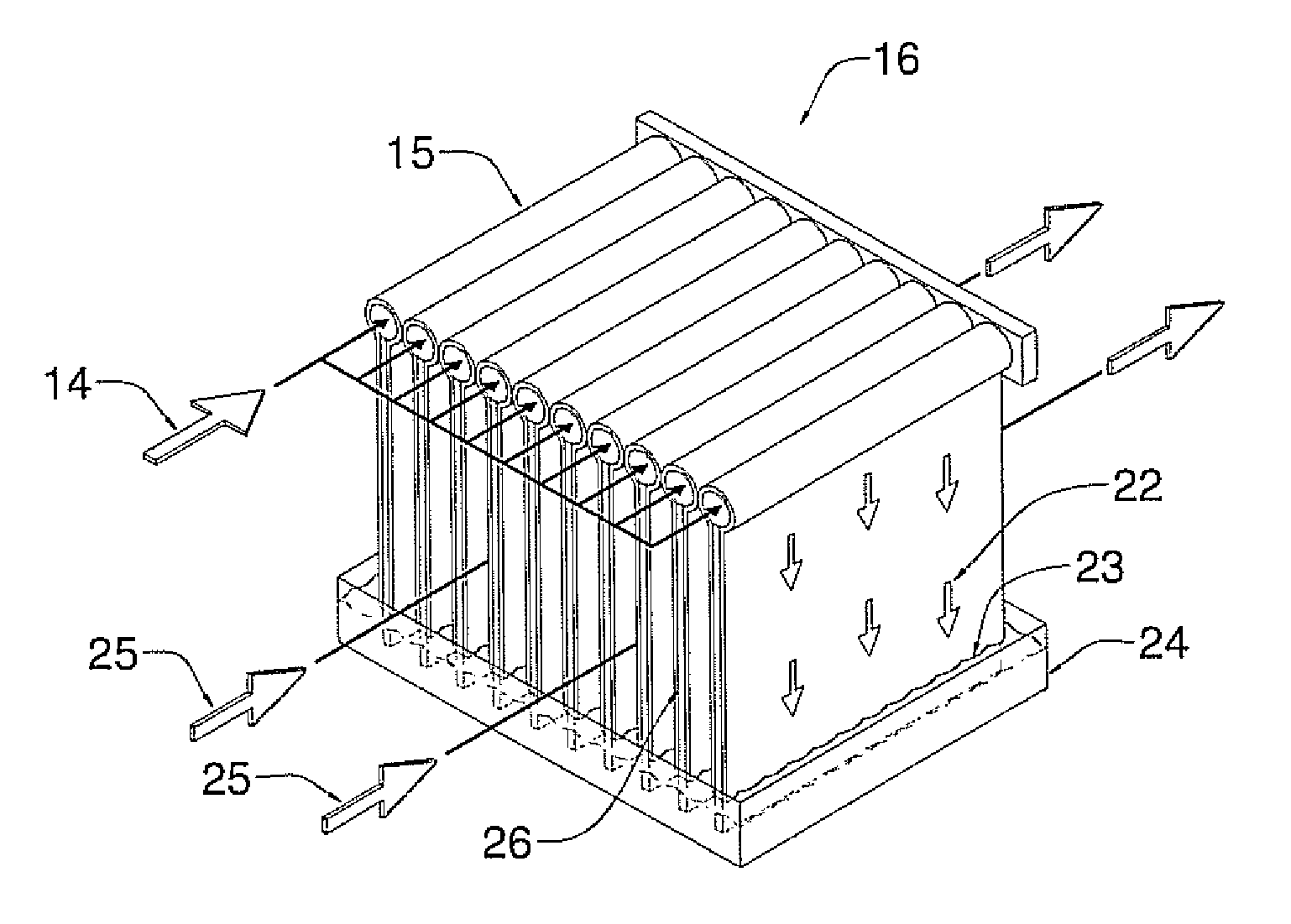

An adsorber unit has an outer shell, a plurality of internal tubes extending through the shell for carrying heat transfer fluid, each tube having outwardly projecting fins along its entire length, and a solid adsorbent material in the shell surrounding the tubes such that the fins project into the adsorbent material, the fins being of a material (e.g., metal) of higher thermal conductivity than the adsorbent material. Metal wool loosely packed inside the tubes, or internal radial fins swaged into the tubes, increase internal surface area thereby enhancing convective heat transfer. Metal wool loosely packed between the external fins, or fine wire metal coils lightly squeezed between the external fins, further increase external surface area of the heat exchanger in contact with the adsorbent thereby enhancing contact heat transfer. Performance is enhanced because the external fins and wool or wire coils transport heat more efficiently to all regions of the adsorbent, and permit less non-adsorbent heat exchanger material (e.g., metal) to be used for a given amount of adsorbent. Two or more such units are used in an adsorption heat pump. This design utilizes existing components (e.g., shell-&-tube heat exchanger, internally and externally finned tubing, and metal wool or wire coils) in a novel manner heretofore untried. In one exemplary embodiment, automobile air conditioning, exhaust heat is used to power such an air conditioner. The significant additional power used by the mechanical compressor of an automobile (12%-17% during commuting for subcompact to midsize cars) can be nearly eliminated by powering the air conditioner with otherwise wasted exhaust heat. The adsorbent is heated and cooled by light oil (called Heat Transfer Fluid, HTF) which in turn is heated and cooled by exhaust and fresh air. Such indirect heating and cooling achieves the required efficiency, and allows using phase change material (e.g., wax) to store and therefore fully utilize exhaust heat. A refrigerant reservoir is included which provides immediate cooling after start-up of a cold engine, while the exhaust system and heat pump are still heating up in order to start pumping refrigerant. Eliminating the mechanical compressor increases fuel mileage by 14-18% for midsize, compact, MS and subcompact cars, or 4.6-6.0% annually, given a four-month cooling season.

Owner:LAMBERT MICHAEL A +1

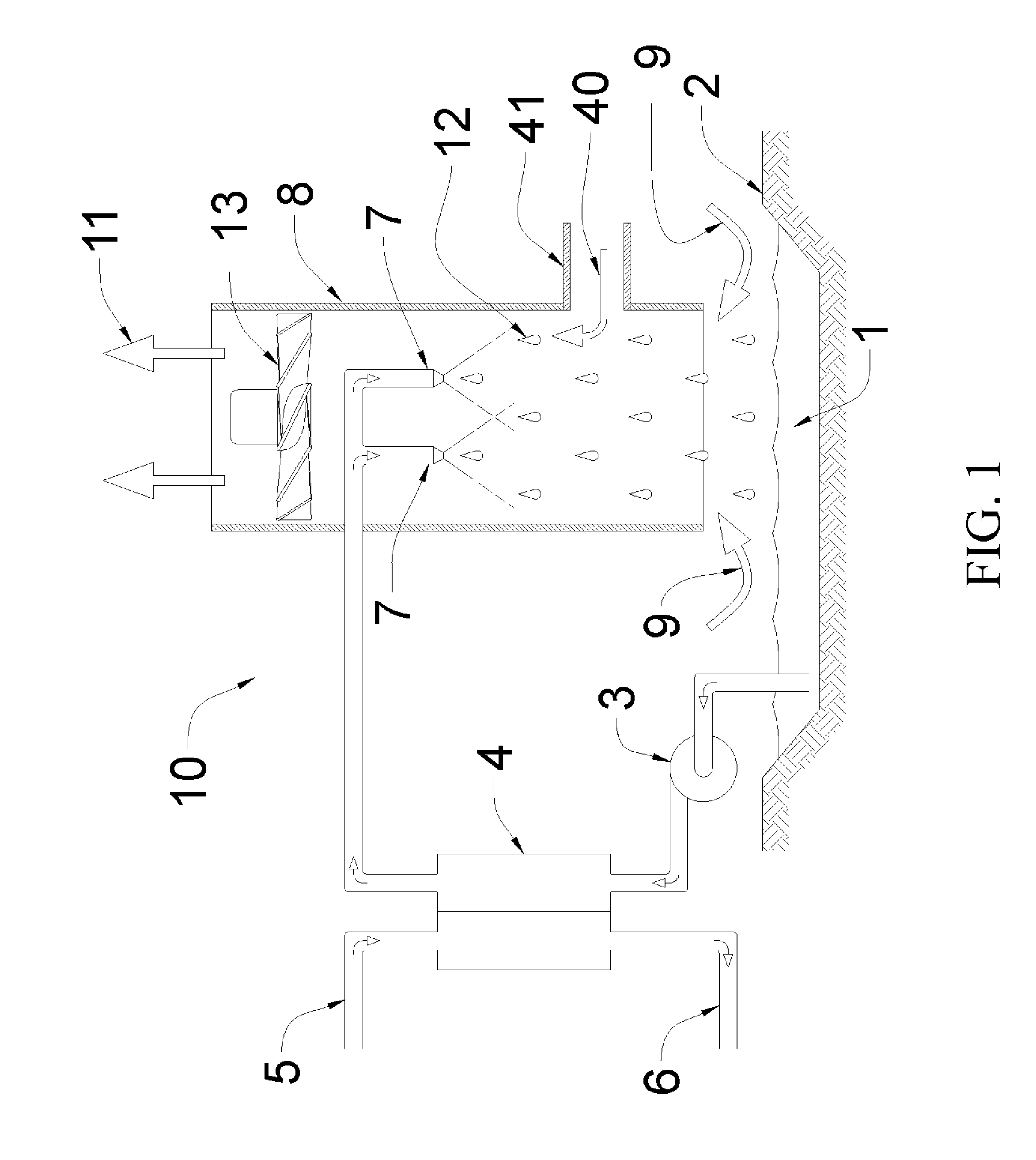

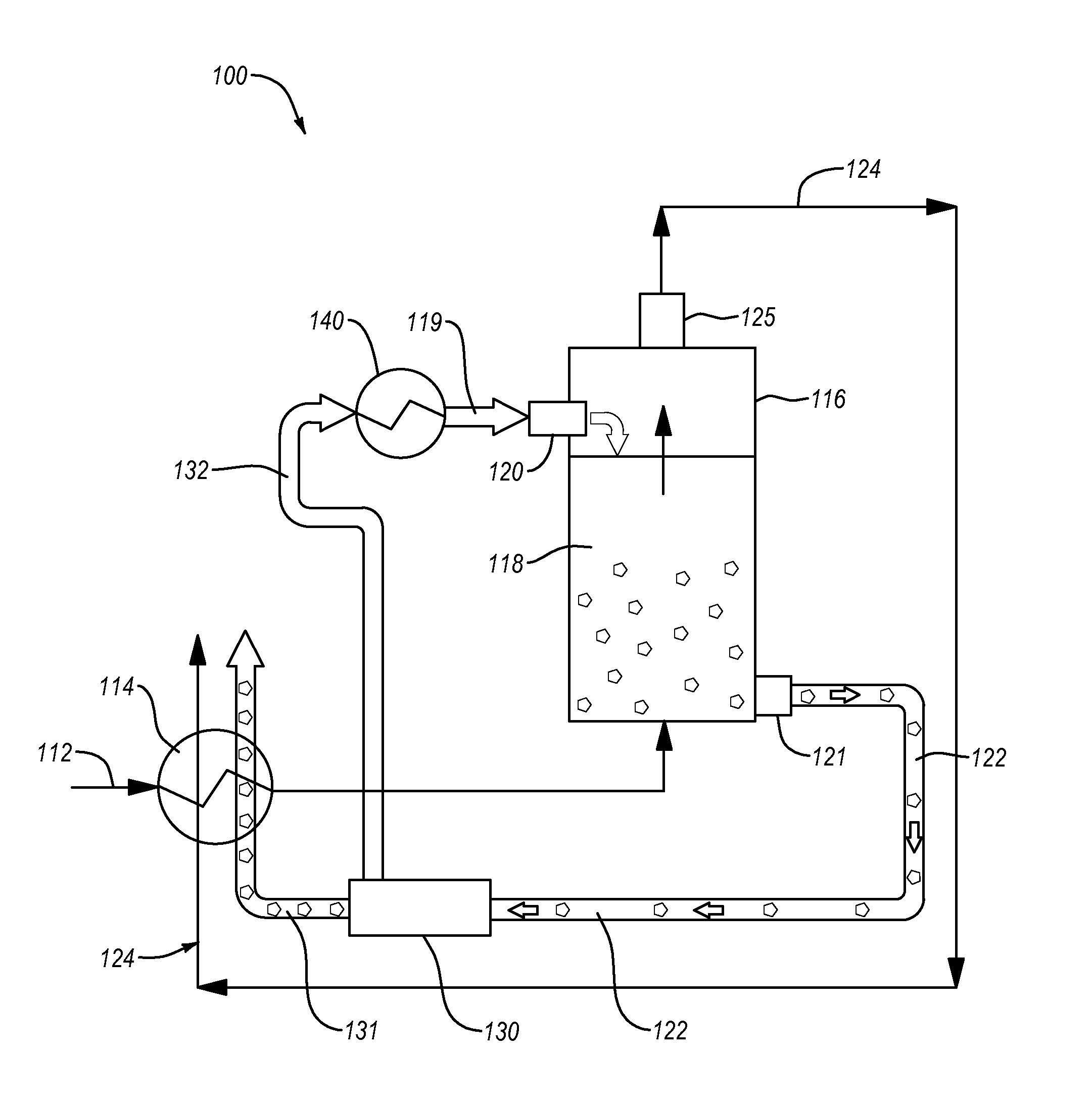

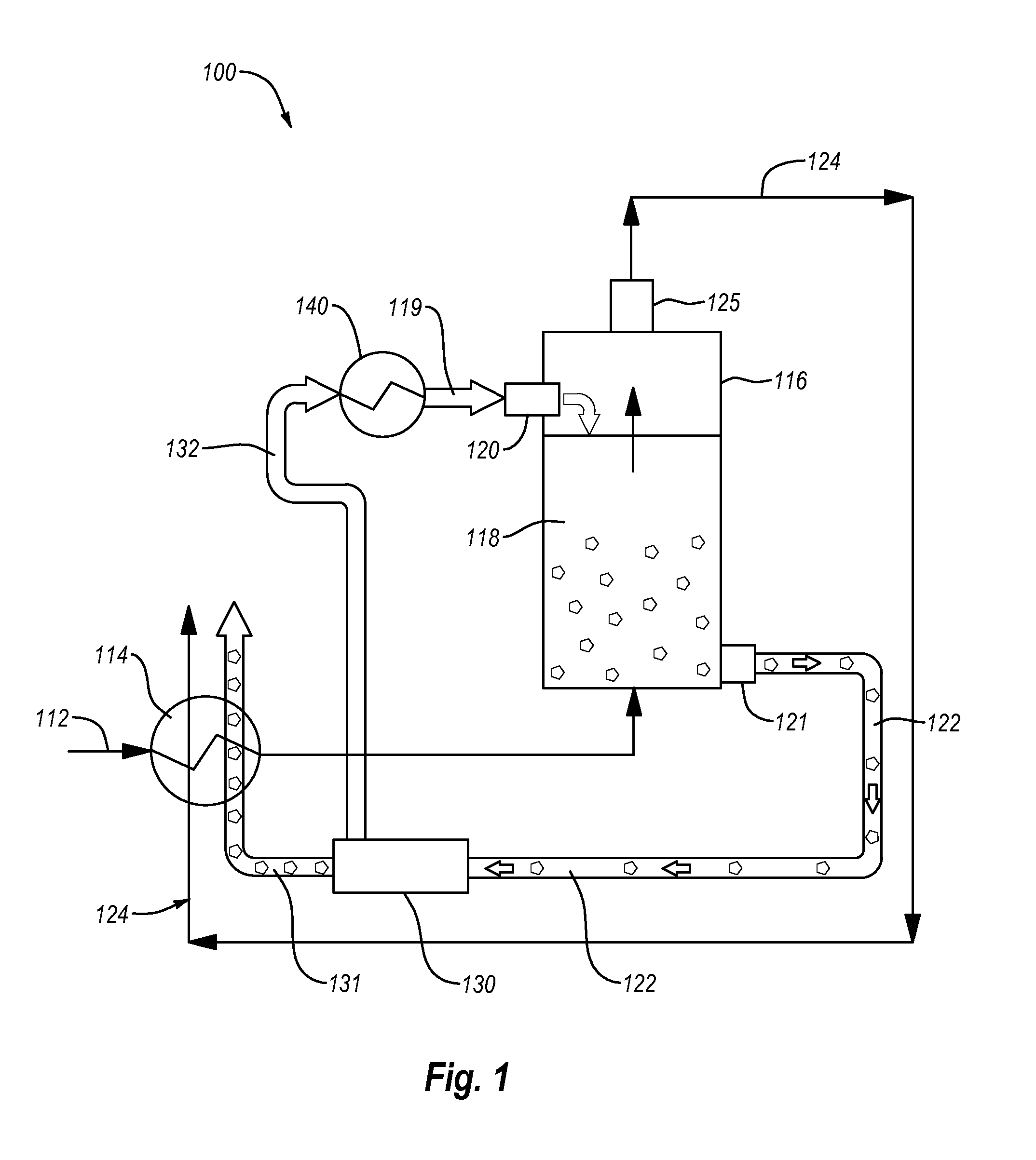

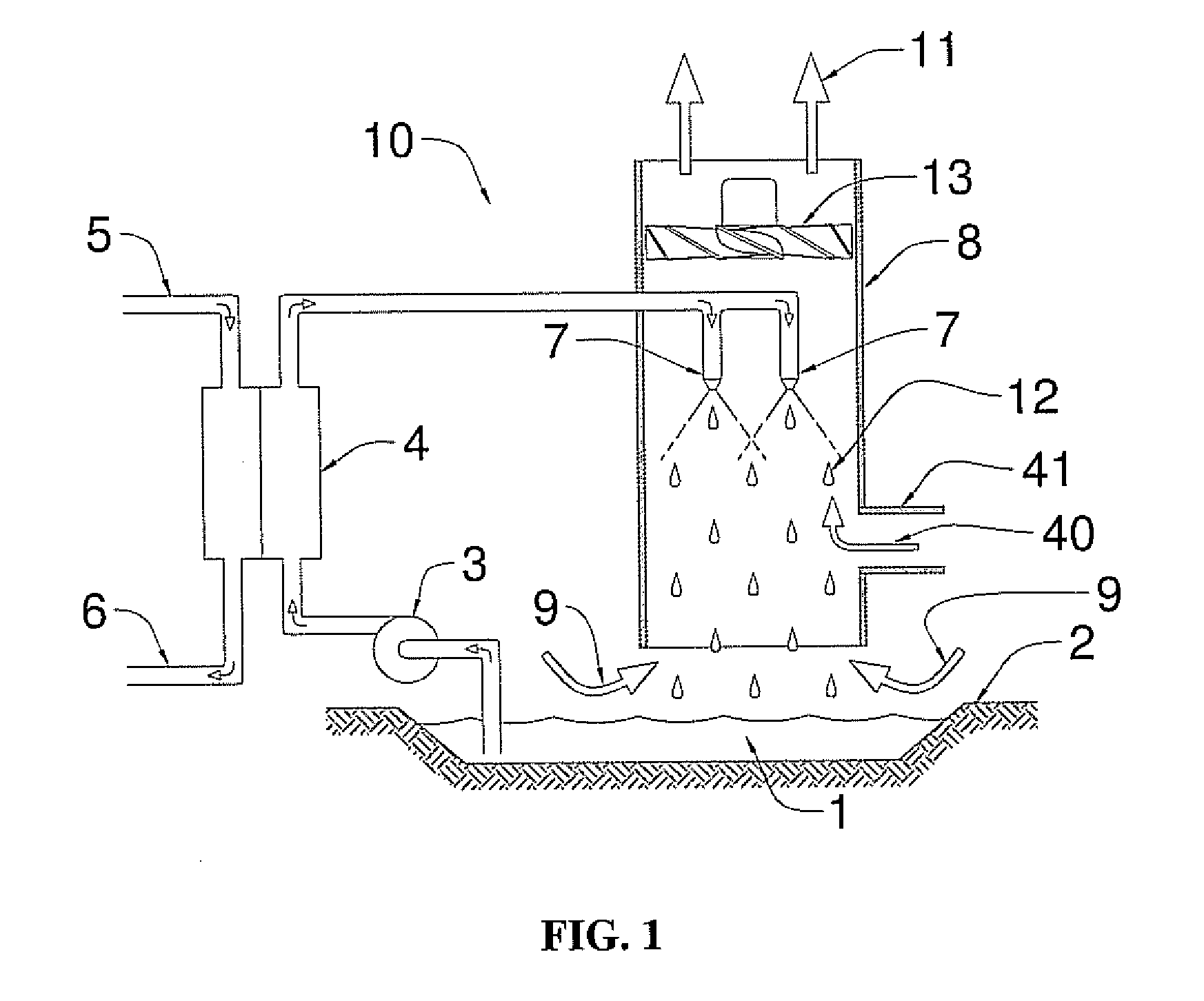

Heat dissipation systems with hygroscopic working fluid

InactiveUS20130305752A1Minimize water consumptionMinimize consumptionSteam/vapor condensersTrickle coolersThermal energyWorking fluid

A heat dissipation system apparatus and method of operation using hygroscopic working fluid for use in a wide variety of environments for absorbed water in the hygroscopic working fluid to be released to minimize water consumption in the heat dissipation system apparatus for effective cooling in environments having little available water for use in cooling systems. The system comprises a low-volatility, hygroscopic working fluid to reject thermal energy directly to ambient air. The low-volatility and hygroscopic nature of the working fluid prevents complete evaporation of the fluid and a net consumption of water for cooling, and direct-contact heat exchange allows for the creation of large interfacial surface areas for effective heat transfer. Specific methods of operation prevent the crystallization of the desiccant from the hygrosopic working fluid under various environmental conditions.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

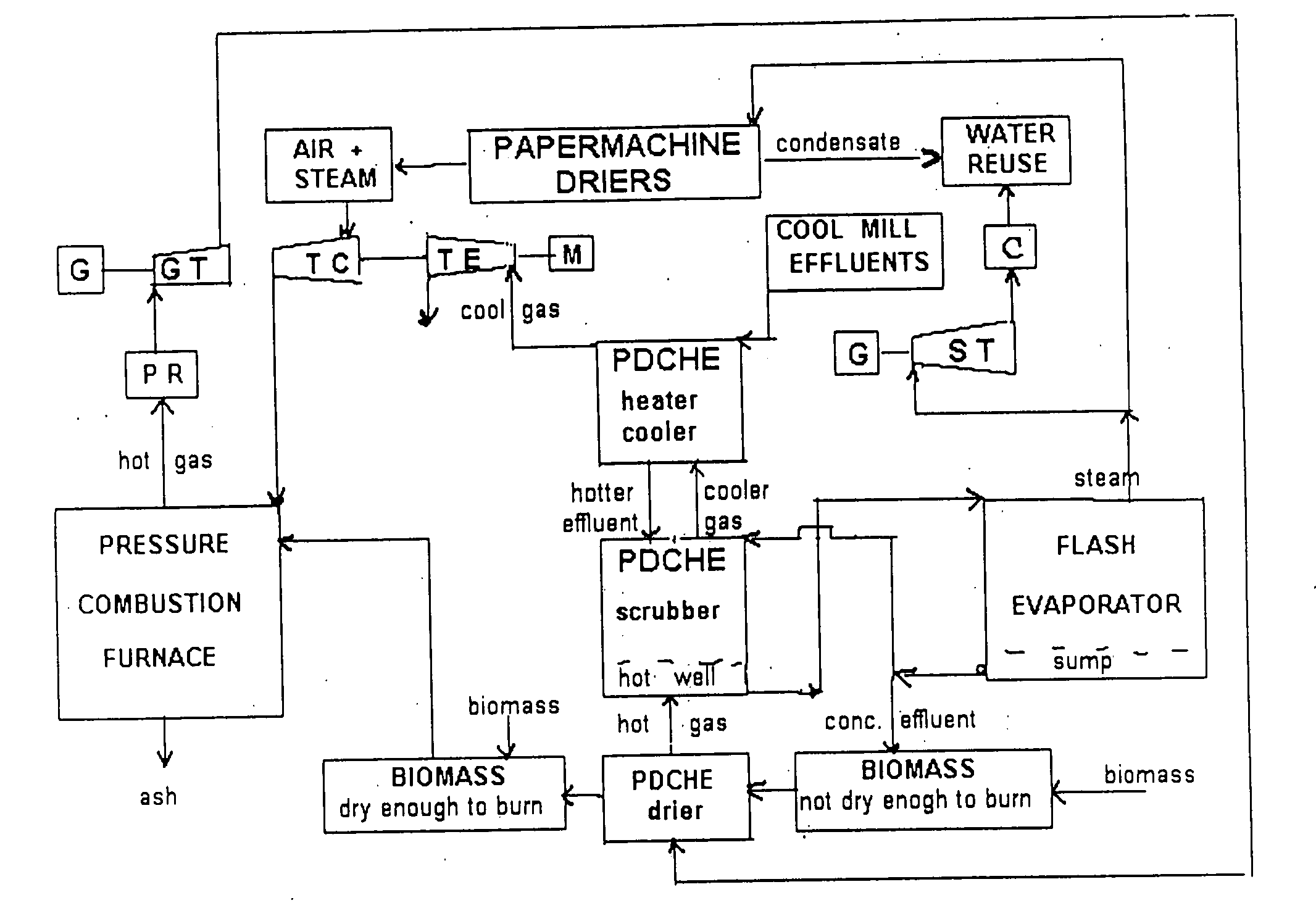

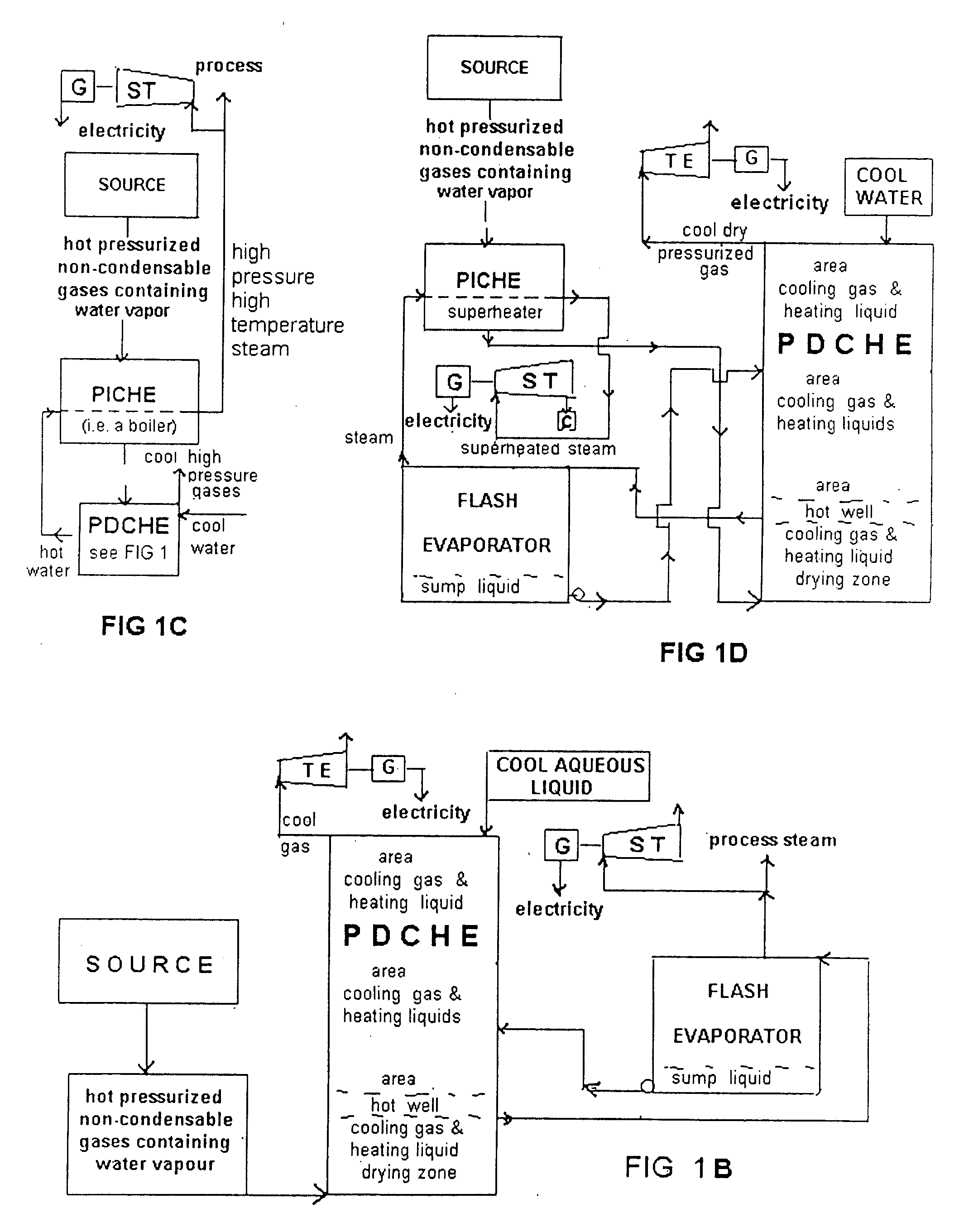

Energy reclaiming process

Owner:HELLEUR DONALD

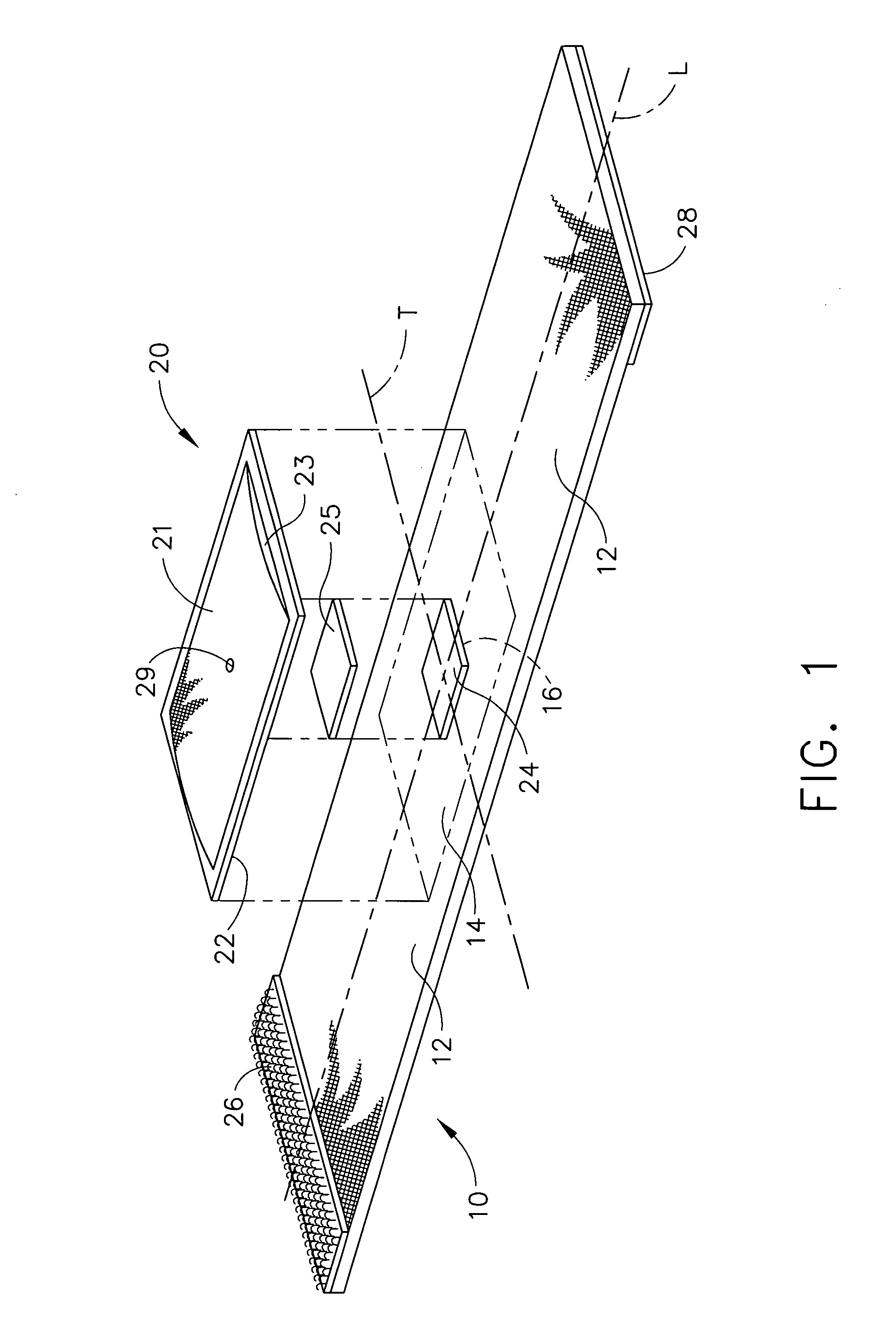

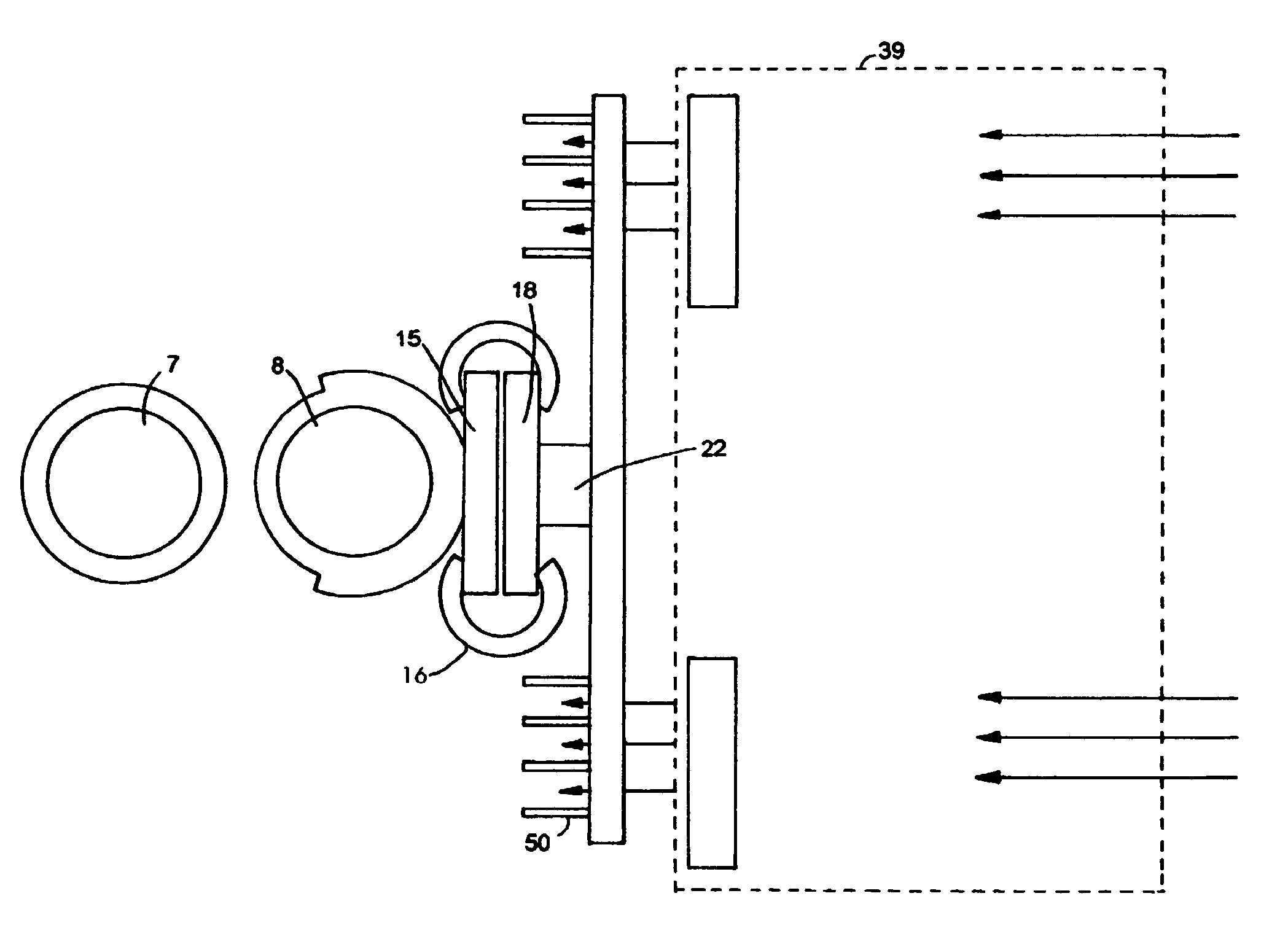

High efficiency heat removal system for rack mounted computer equipment

InactiveUS8164901B2Efficient transportLess air-conditioningDomestic cooling apparatusDigital data processing detailsHeat conductingEngineering

An efficient method of heat removal from rack mounted computer equipment, network gear and other electronic equipment, consisting of solid heat conducting components in direct contact with the heat generating sources. In particular, this invention is primarily focused on the ability to efficiently and effectively cool computer equipment in standard computer rack cabinets.This invention utilizes a design that retains the general existing form factor of the rack mounted computer equipment, but uses direct contact heat transfer to a metal heat transfer conduit (Copper, Aluminum or other metal or efficient heat conducting material) contained within the computer equipment chassis. Furthermore, it is thermally coupled to an external rack mounted solid-to-fluid heat exchanger as an efficient method of heat transfer and removal. This is much more efficient than air as heat transfer medium which it the common method of heat removal from existing standardized rack mounted computer equipment.This invention covers the design of the heat transfer components within the chassis of rack mounted computer server and the heat transfer system components external to the server within rack enclosure, as well as the external cooling system components necessary to connect to existing fluid based heat transfer and removal systems and processes.

Owner:NEUDORFER JULIUS

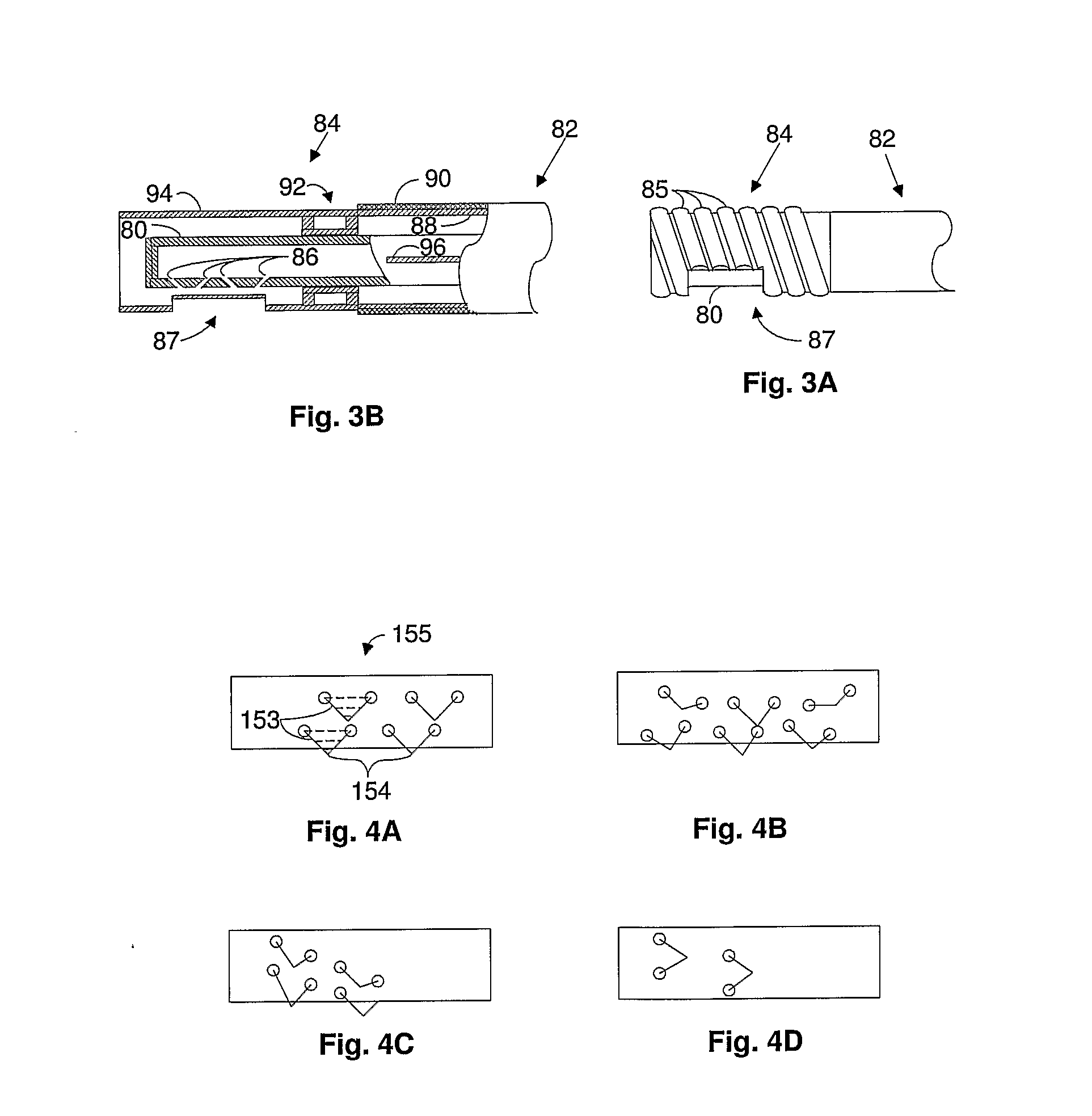

Surgical Instrument

InactiveUS20090254075A1Fluid jet surgical cuttersSurgical instruments for heatingEndoscopic operationsEndoscope

A surgical instrument suitable for endoscopic operations having a gripping handle, tubular body and an operational tip. Jetting outlets laterally disposed at the operational tip provides for jetting pressurized liquid delivered by the tubular body. The jetting outlets are configured as to emit converging jets. Two or more jets converge at a convergence point laterally displaced at a predefined distance from the surface of the operational tip. The operational tip includes a heating member having an active face for contact heating a bleeding tissue. A rotating mechanism provides for independently rotating the jetting outlets and the active surface of the heating member relative to the gripping handle. A method for regulating the operating temperature of the heating member is provided.

Owner:ULTRASURGE TECH

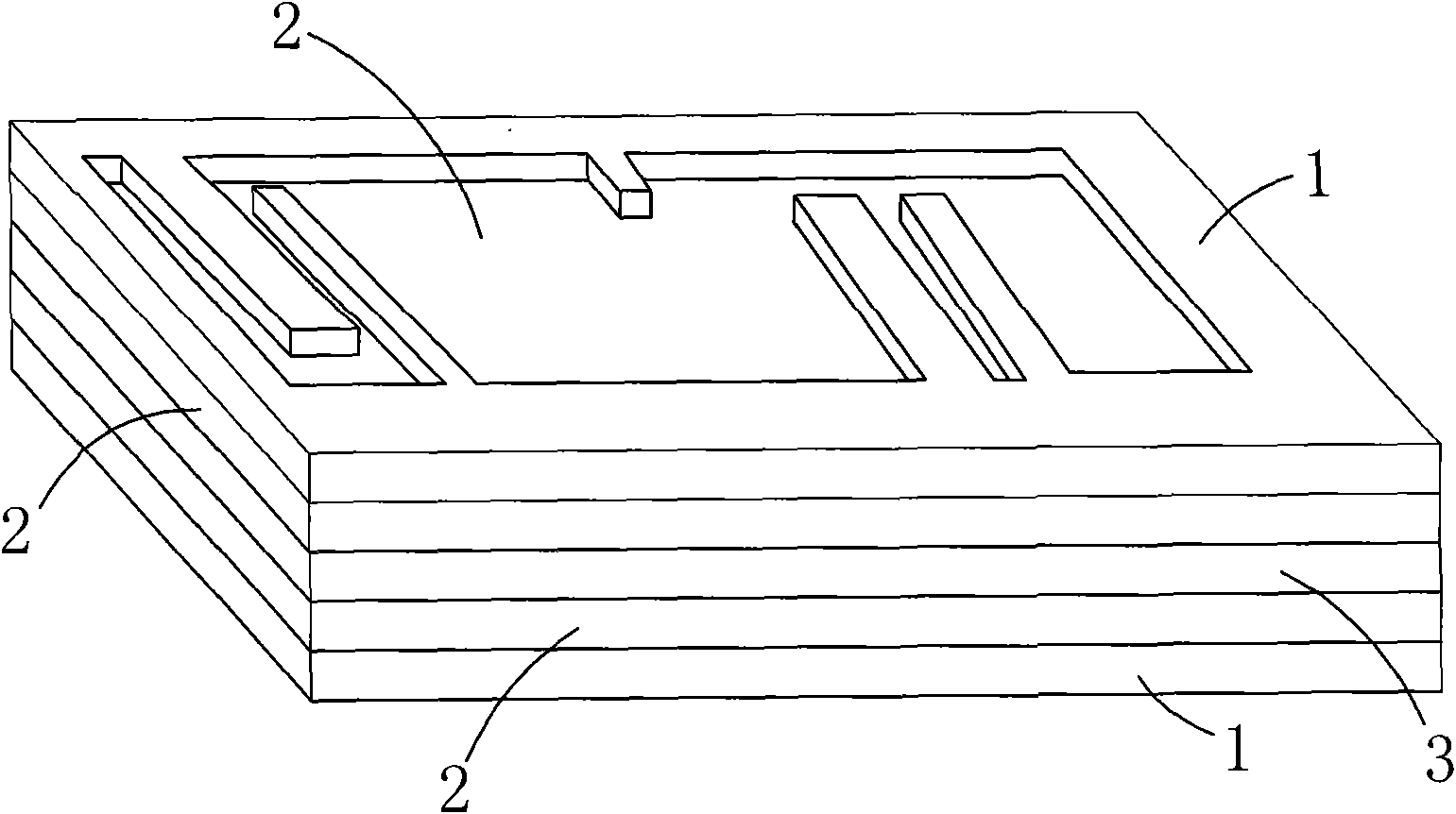

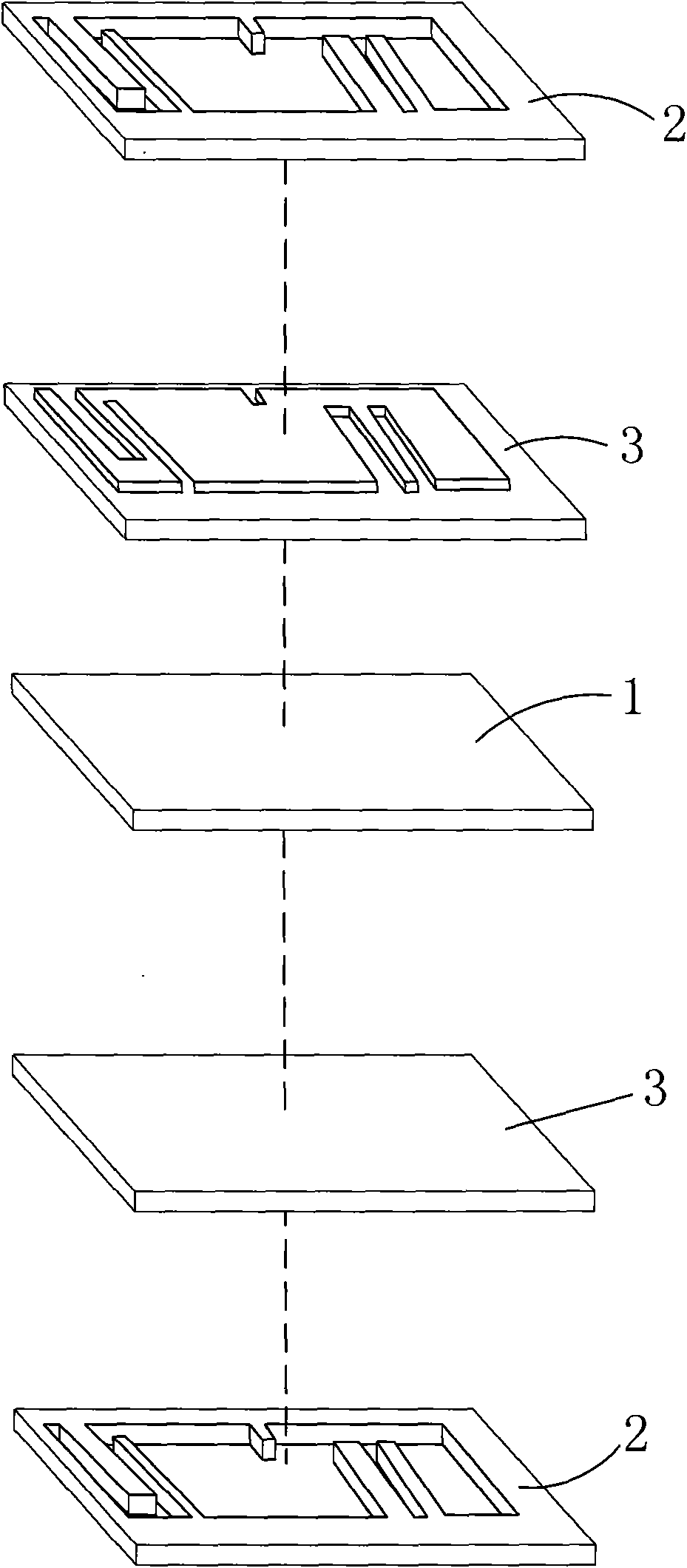

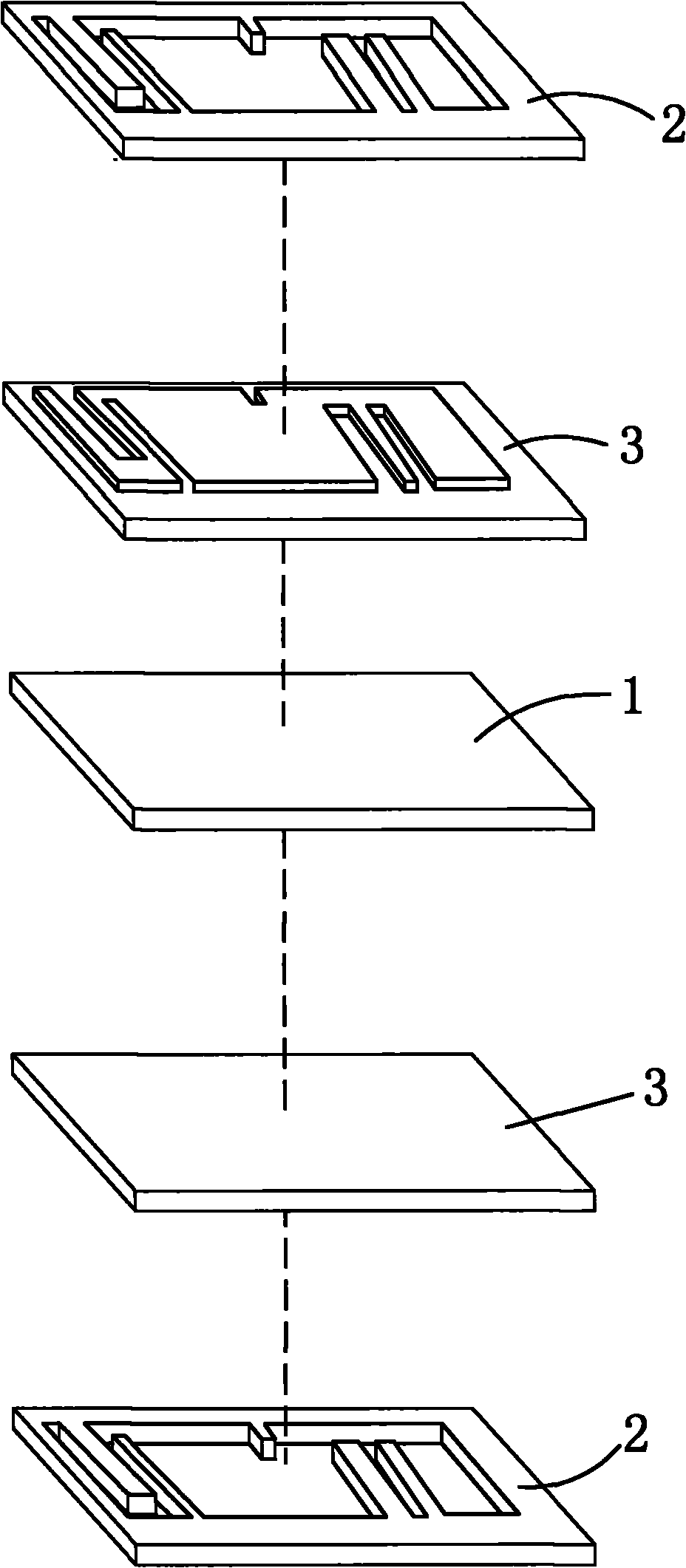

Thick copper circuit board and circuit etching and solder-resisting manufacturing methods thereof

InactiveCN101861049AImprove thermal conductivityGood electrical signal interference shieldingPrinted circuit detailsConductive material chemical/electrolytical removalInsulation layerEtching

The invention discloses a thick copper circuit board and circuit etching and solder-resisting manufacturing methods thereof. Thick copper circuit layers in the circuit board, which contact with heat-conducting insulation layers, are partially embedded into the contacting heat-conducting insulation layers from contact faces. In the manufacture of the structure, the thick copper circuit layers are manufactured by a mode of etching both faces of an ultra-thick copper foil respectively, and the problem of circuit etching of the ultra-thick copper foil is solved; prepregs with high resin content are adopted as the heat-conducting insulation layers, the laminated heat-conducting insulation layers are partially filled into the circuit clearances of the thick copper circuit layers, the height of the thick copper circuit layers arranged at both faces of the circuit board and exposed out of the circuit board is effectively lowered, and the problem of solder resisting of the circuit of the ultra-thick copper foil is solved; the manufacturing process is the prior art and has low cost; and the copper thickness of the circuit layers is greater than 6oz, and the invention has favorable heat conductivity, electric signal interference shielding property and superior supervoltage loading property.

Owner:昆山华升电路板研发基地有限公司

Soft cooling jacket for electronic device

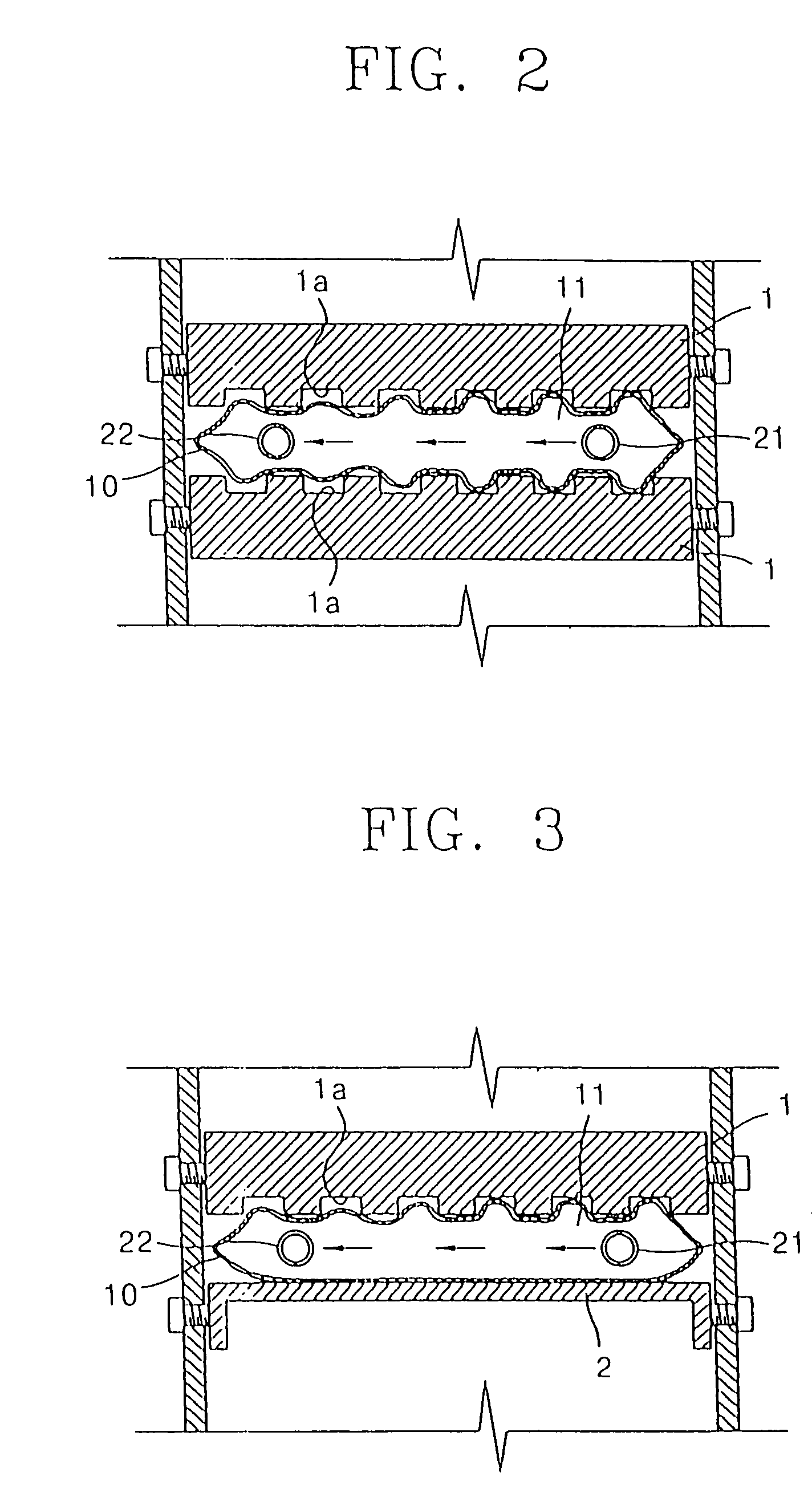

InactiveUS7167366B2Increase heat transfer areaMaximize heat transfer efficiencyDigital data processing detailsHeat exchange apparatusManufacturing cost reductionHard disc drive

Provided is a water cooling type cooling jacket for an electronic device including a pouch body formed of a soft, loose elastic material that is deformable to closely contact heat-generating elements having various shapes due to a contact pressure and accommodating and a coolant, and a coolant inlet tube and a coolant outlet tube formed at one side of the pouch body to allow the coolant to circulate inside the pouch body and connected to coolant circulation lines for circulating the coolant. Therefore, the water cooling type jacket for an electronic device can be adapted to various shapes of heat-generating elements having uneven surfaces and various shapes of installation spaces beyond electrical and mechanical limitation to increase a heat transfer area and maximize a heat transfer efficiency and can be installed at various electronic devices such as hard disk drives, video cards or memory cards and a PCB without spatial limitation. Also, the water cooling type, soft cooling jacket for an electronic device can reduce a fabrication cost by simplifying the structure while maintaining close adhesion and can safely protect various elements by distributing pressure applied to the elements.

Owner:CHEON KIOAN

Method for preparing buffer layer film of cadmium-free copper-indium-gallium-selenium thin-film solar cell

InactiveCN1547262AOvercoming the defect of light absorption dropImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor devicesIndiumSolar battery

The invention refers to a manufacturing method for cadmium-less copper-indium-gallium-selenium film solar battery buffer film. The zinc film is coated on the surface of the copper-indium-gallium-selenium optical absorbing layer, then, the surface of the battery coated with metal zinc film is irradiated by light and heated, the back surface of the substrate is heated with contacting heat source or irradiation mode, the solid selenium source and / or the sulphur source are heated with contacting heat source and irradiation mode, the temperature is controlled at 160-280oC, the light irradiation is used as catalyst to the synthesis reaction between the selenium or the sulphur steam and the zinc film, the temperature in the process of the selendie or sulfide of the zinc film is controlled at 180-420 oC, the time is 2-10 minutes, the zinc film is converted into n-type ZnSe or ZnS semiconductor film material, cadmium-less copper-indium-gallium-selenium film solar battery buffer film can be produced.

Owner:NANKAI UNIV

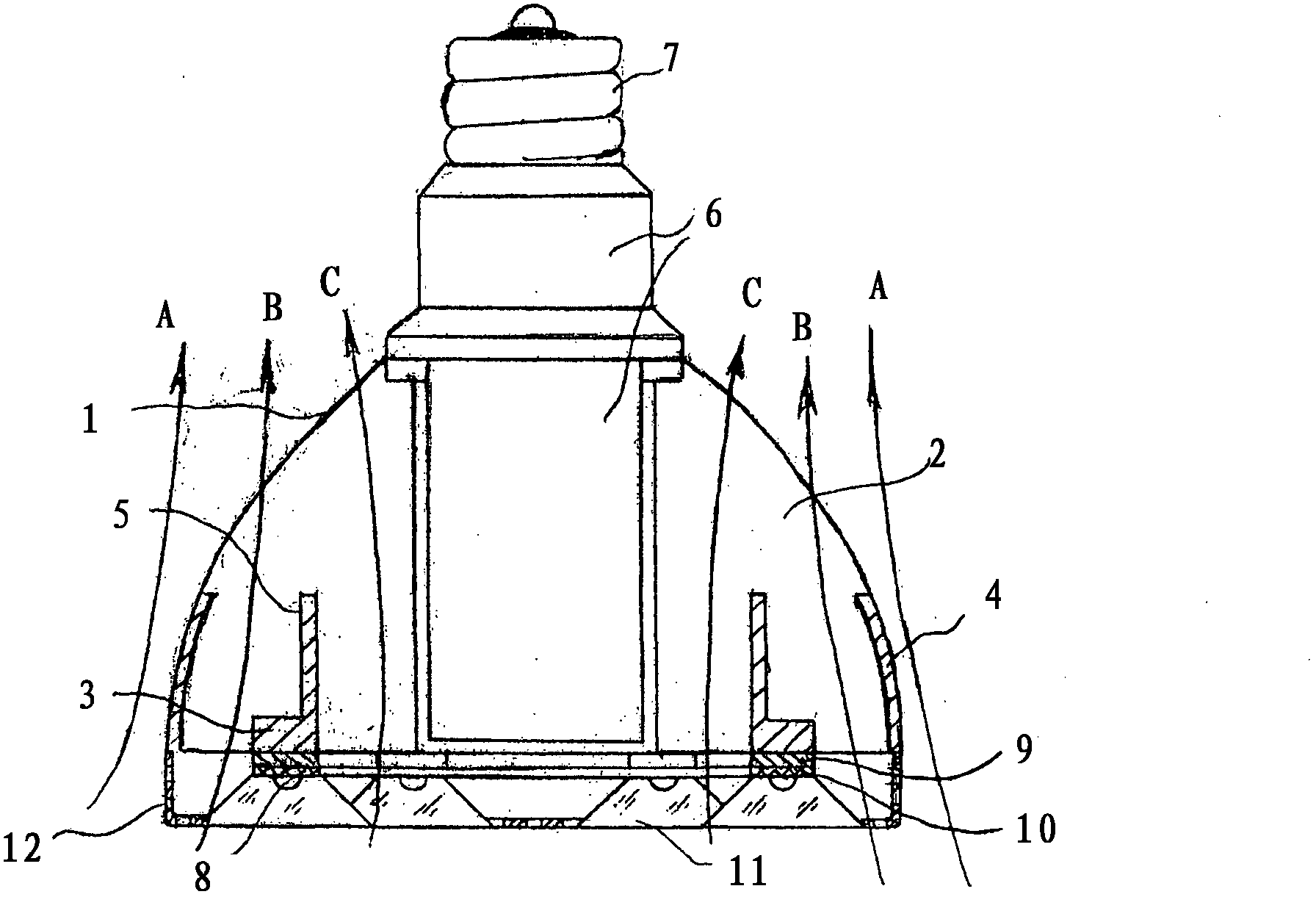

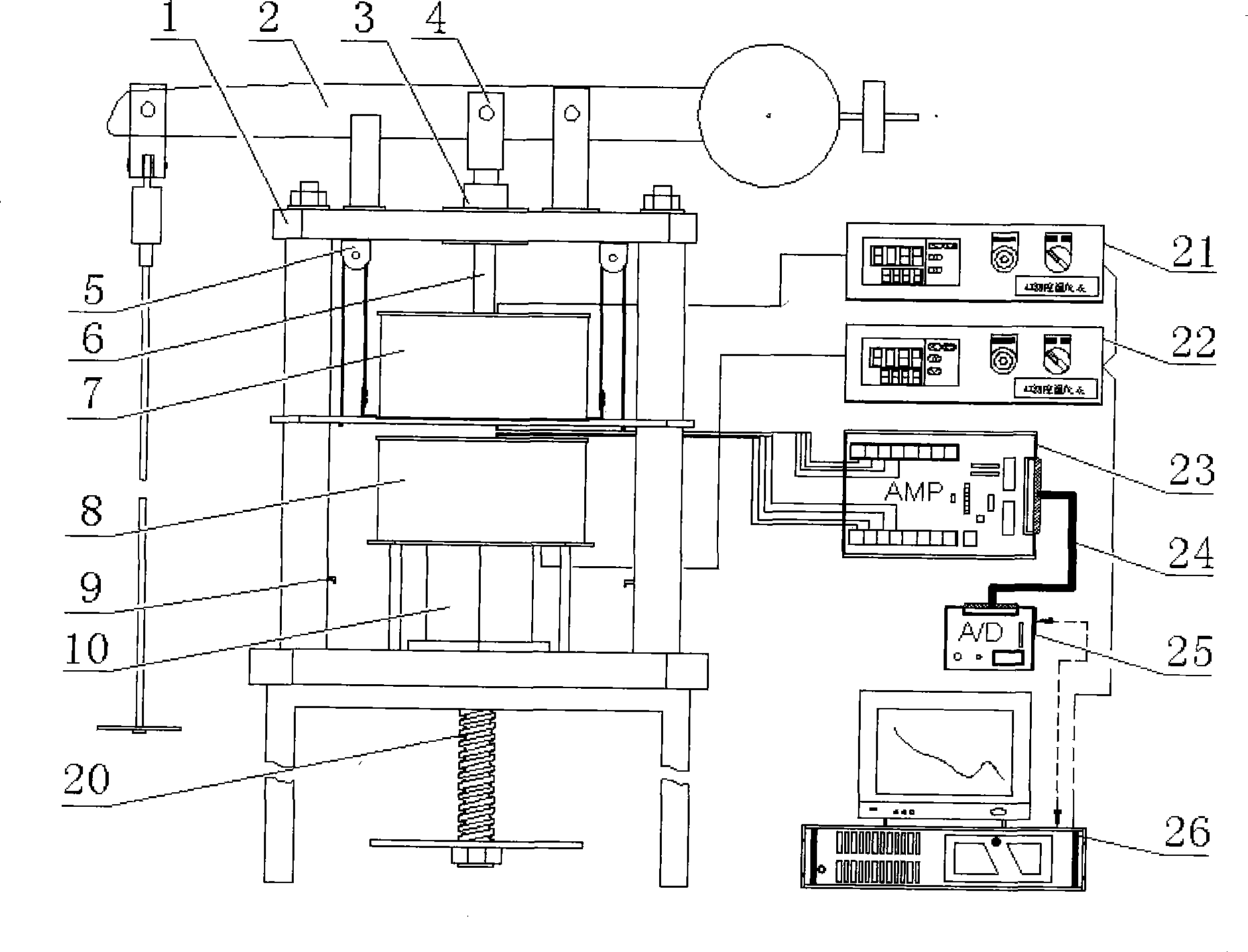

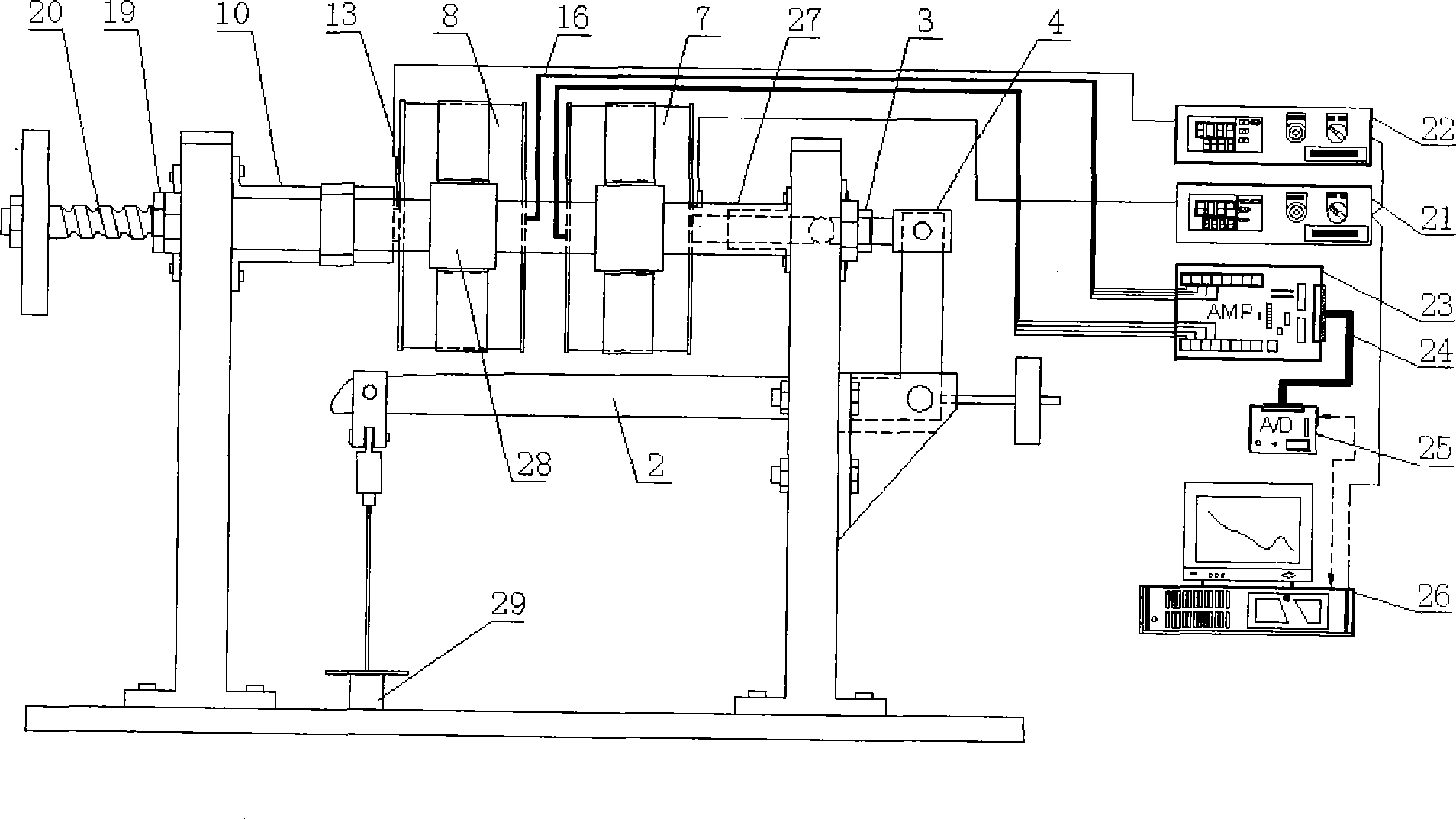

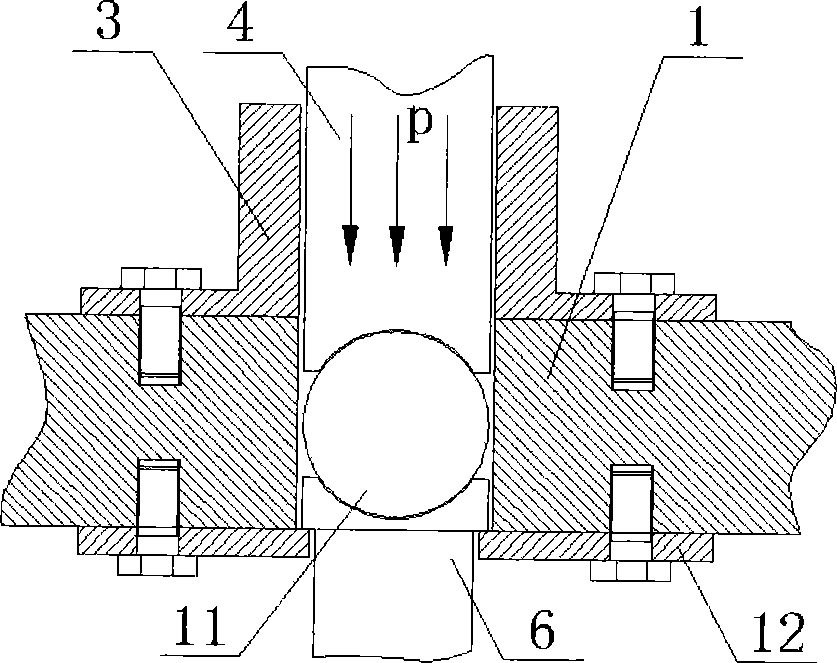

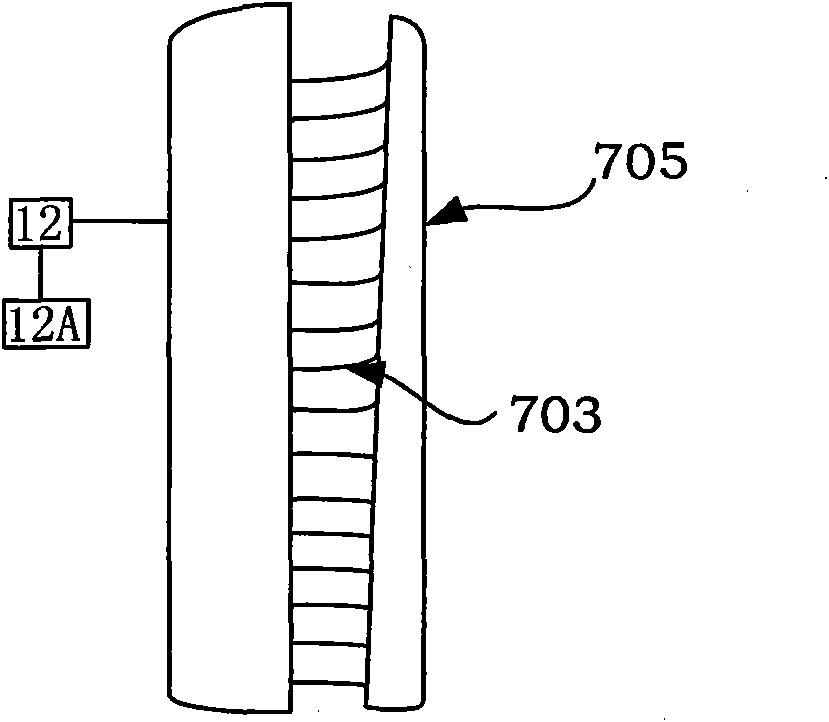

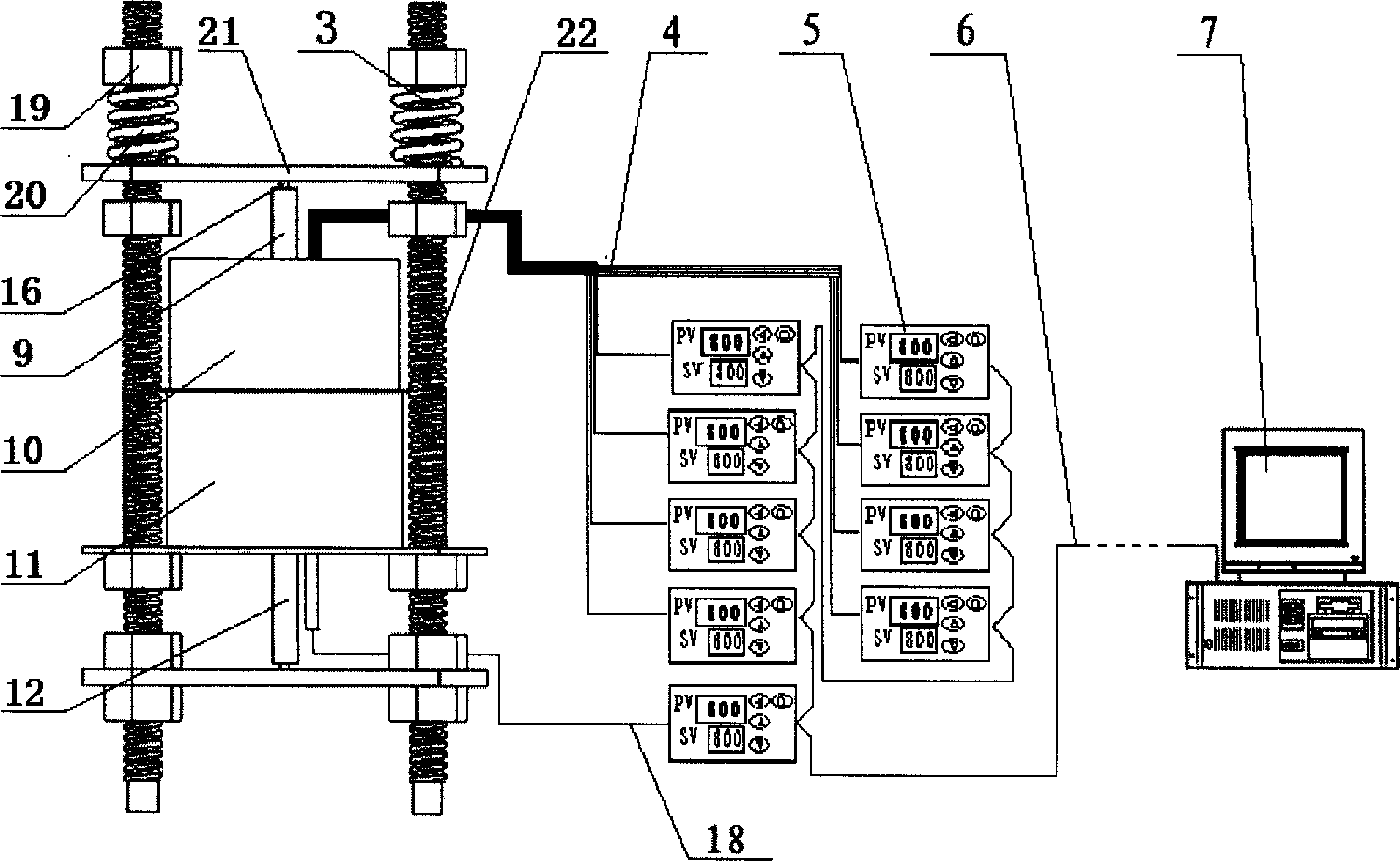

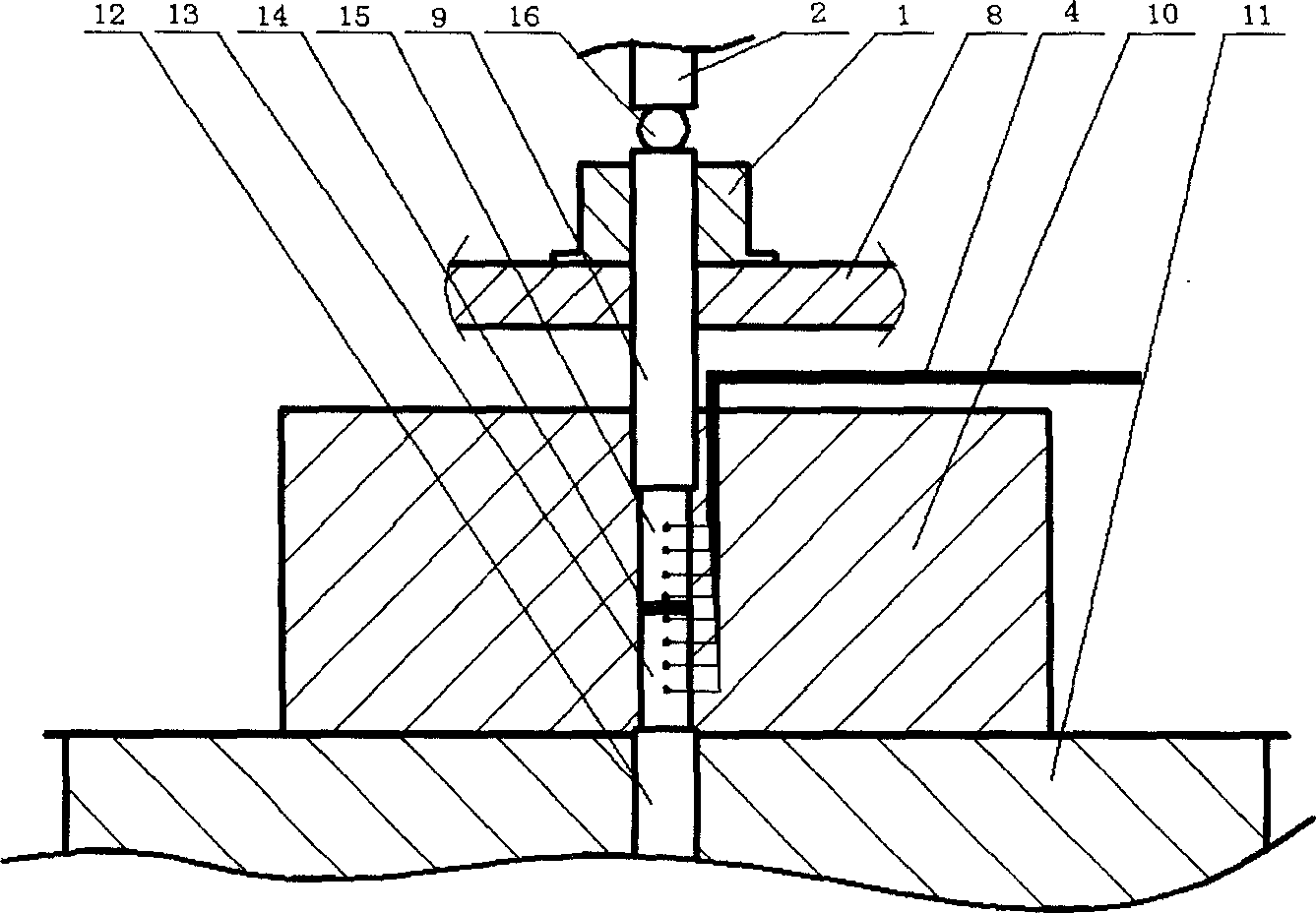

Solid interface contact heat exchange coefficient measurement method and apparatus based on transient method

InactiveCN101393150ARealize dynamic contactHigh heating temperatureMaterial thermal conductivityMaterial heat developmentEngineeringHigh heat

The invention relates to a method and a device for measuring solid interface contacted heat transfer coefficient based on a transient method. The method comprises the following steps: a lever loading device 2 is connected with a pressure turning joint 4, a centering ball 11, a low temperature sample connecting rod 6 and a low temperature sample 14 in turn from the top to the bottom; a positioning block bears pressure in advance; and a thread transmission shaft 20 pushes a high temperature sample 15 out of a heating furnace through a high temperature sample supporting rod 17, contacts and jacks up the low temperature sample 14 to transfer the pressure to the contact surface. A temperature control thermocouple 13 of the heating furnace is connected with a program control meter, the output end of the program control meter is connected in parallel and then is connected with an industrial computer 26 through an RS232 converter, a temperature detecting thermocouple 16 is connected with a preposition multi-path gate amplifier 23 and an A / D converter plate 25 in turn to acquire and process temperature signals of measured points in real time as well as compile a FORTRAN calculation module by applying a counter heat transfer arithmetic. The method has the advantages of high measuring temperature, quick acquisition and practical measuring principle, and is suitable for the research field of solid thermal processing.

Owner:DALIAN UNIV OF TECH

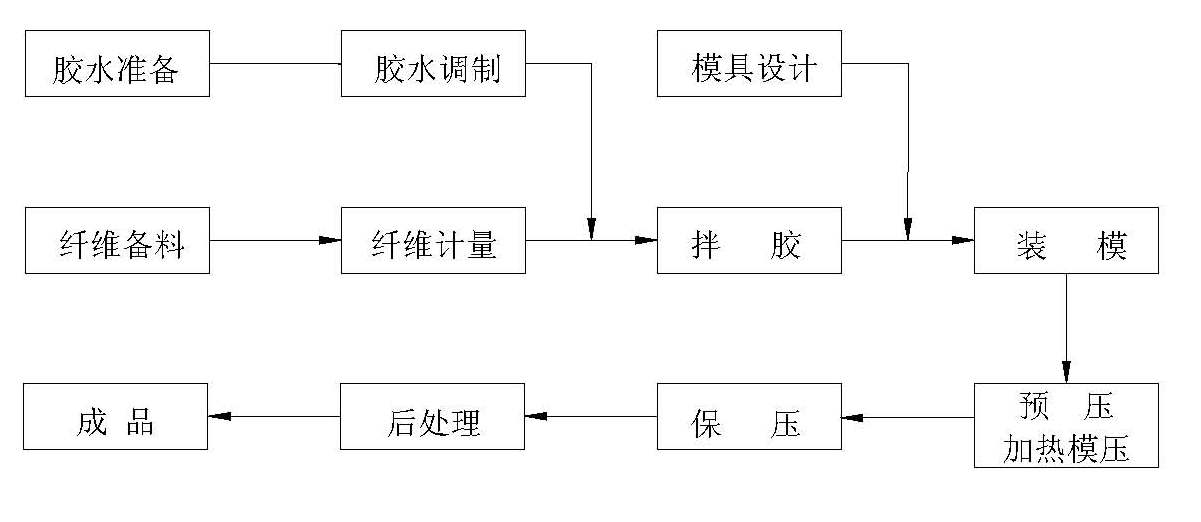

Shaped wooden mould pressing furniture part and manufacturing method thereof

ActiveCN102069523AMitigation resourcesAlleviate the problem of few large-diameter logsWood working apparatusThermal energyAdhesive

The invention belongs to the technical field of wooden furniture and relates to a shaped wooden mould pressing furniture part and a manufacturing method thereof. The part comprises the following materials in parts by weight: 100 parts of wooden material, 8-25 parts of adhesive, 1-3 parts of curing agent and a proper quantity of waterproofing agent. The manufacturing method comprises the following steps of: mixing the materials and then loading into a mould for pressing; heating by adopting a mode of combining contact type heating and high-frequency electric field heating; and shaping, wherein the mixed materials loaded into the mould are subjected to contact heat transfer by a hot press plate while mould pressing and then shaped after heating and curing. In the invention, the surface of the shaped wooden mould pressing furniture part is provided with obviously convex-concave decorative carved patterns, and the patterns have higher simulation degree and can be compared favorably with a carved and shaped furniture part.

Owner:浙江新木材料科技有限公司

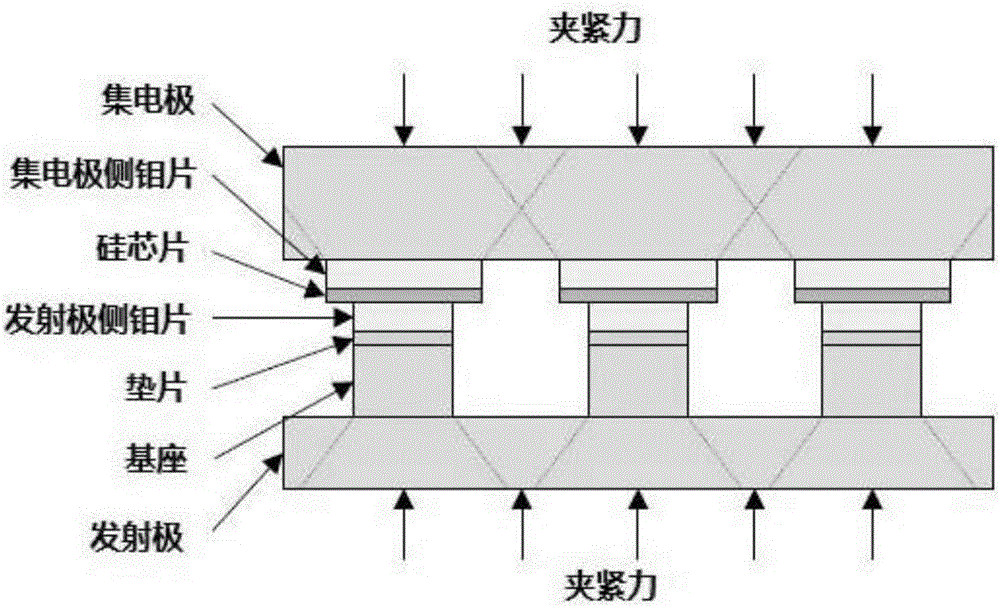

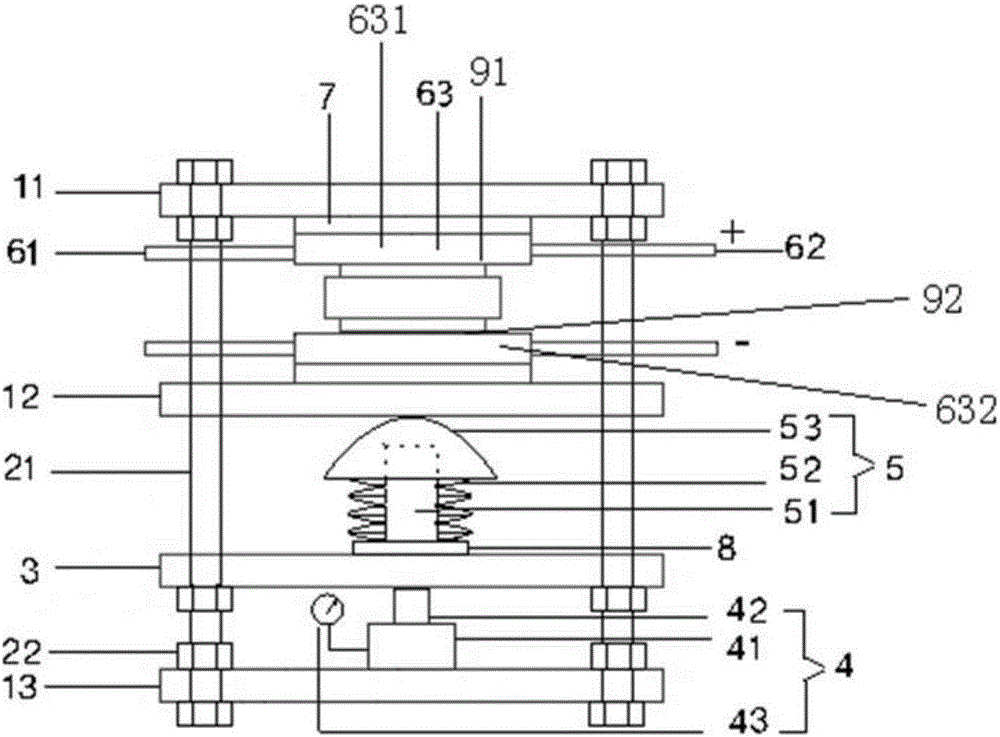

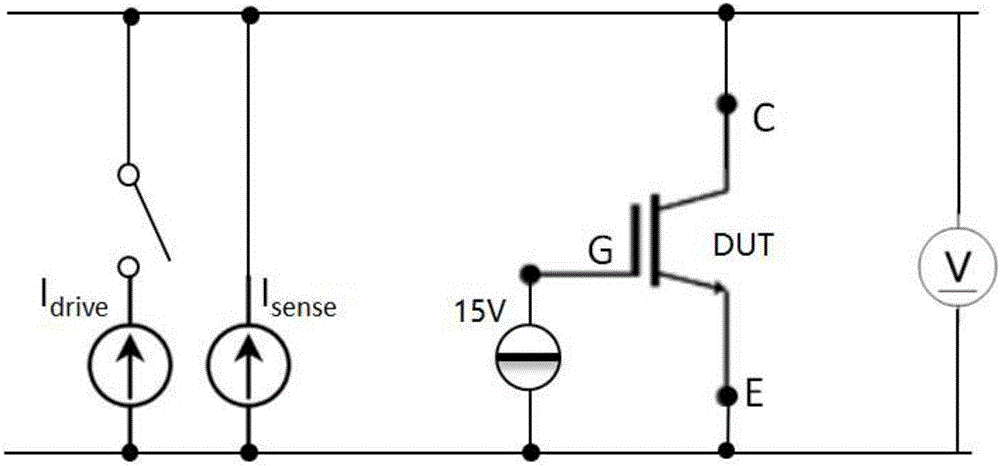

Power semiconductor device internal contact thermal resistance measurement method and measurement clamp

InactiveCN105911447AEasy to measureEasy to drawMeasurement instrument housingIndividual semiconductor device testingPower semiconductor deviceEngineering

The invention provides a power semiconductor device internal contact thermal resistance measurement method and measurement clamp. The measurement method comprises the steps that a relation curve of device electrical parameters and junction temperature is drawn; a transient thermal impedance curve when liquid metal is coated between the surface of a device shell and a heat radiator is drawn; numeric calculation is performed on the transient thermal impedance curve so that the integral structure function and the differential structure function of the device are obtained; and a contact thermal resistance value is solved through reference to the integral structure function and the differential structure function. The measurement clamp is composed of three substrates arranged in a horizontal direction and two columns arranged in a vertical direction. An insulated plate and a heat radiation substrate are longitudinally and symmetrically arranged between the upper substrate and the intermediate substrate. A pressure uniform distribution device, a sensor, a pressure maintaining plate and a pressure applying device are installed between the intermediate substrate and the lower substrate in turn. According to the measurement method, measurement error caused by a thermocouple can be eliminated, the measurement result is real and reliable and the measurement method is simple and efficient.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Thermal contact resistance test equipment

InactiveCN101907590AChange temperatureAvoid lostMaterial heat developmentThermometers using electric/magnetic elementsMonitoring siteTest sample

The invention discloses thermal contact resistance test equipment, which mainly comprises a bracket, a top plate, a bottom plate, a stress loading device, a data acquisition system and a heating device, wherein the heating device, a test sample and the stress loading device are arranged sequentially from the bottom up between the bottom plate and the top plate; the stress loading device is fixed in the centre of the top plate and adjusts four groups of nuts on the top plate; a stress transfer bar of the stress loading device is in contact with the top end of the test sample to load stress to the top end of the test sample; and the bottom plate adjusts a horizontal angle and a vertical height through the four groups of nuts, and is provided with the heating device used for heating the test sample. The equipment provided by the invention can perform thermal contact resistance test experiments under high temperature and high-contact stress, continuously change the temperature (less than or equal to 1,000 DEG C) of a hot end and adjust the loaded stress (less than or equal to 500 MPa), and simultaneously detect, record, analyze and count the temperatures of monitoring points of a plurality of channels so as to avoid errors caused by the loop record of each channel.

Owner:BEIHANG UNIV

Method for preparing selenide or sulfide semiconductor film material of copper-indium-gallium

InactiveCN1547239AEliminate condensationAvoid deformationFinal product manufactureVacuum evaporation coatingWater bathsIndium

The invention refers to a manufacturing method for selenide or sulfide of copper, indium or gallium. In the manufacturing process of copper, indium or gallium selenide and / or sulphur optical absorbing layer film, uses vacuum magnetism control splattering, heating and evaporating method or chemical water bath electrodeposition method to deposit a metal preprocessed layer with chemical formula proportion of Cu, In, Ga on the natrium calcium glass Mo substrate, then carries on optical selenide or / and sulfide reaction in the thermal process vacuum room, the character lies in: the battery base board deposited with the preprocessed layer are heated upon the two surfaces, the back surface of the base board is heated with contacting heat reservoir, the surface coated with metal preprocessed layer is heated with light irradiation, when the temperature rises to the 400-560oC evenly and quickly, carries on the cooperative heating with contacting heat reservoir and light irradiation to the selenium source or the sulphur source, makes the metal preprocessed layer converted into the compound semiconductor photoelectric film material.

Owner:NANKAI UNIV

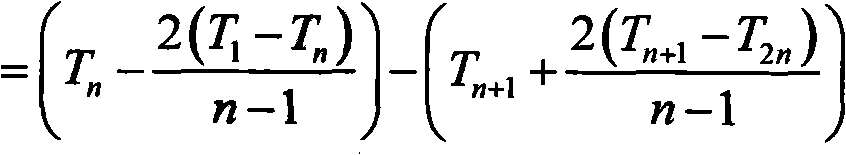

Method and apparatus for measuring solid interface contact heat exchange coefficient

InactiveCN1877313ANo added precision requiredLow costMaterial thermal conductivityMaterial heat developmentTemperature controlTemperature difference

Disclosed are a method and a device for measuring contact heat transfer coefficient on the solid interface. The method comprises connecting heating bar 12, the first sample 13, thin slice 14, the second sample 15, cold-trim bar 9, centring steel ball 16, pressure device 3 in sequence; adding corresponding thin slice 14 between the contacting surface of the two samples; increasing the number of contacting surface and enlarging temperature difference of the contacting surface; connecting the input terminals of thermal couple 4 and temperature control meter 5, and parallel the output terminal of the temperature control meter 5 with the industrial control machine 7 via the RS232 converter; heating the heating bar 12 with the heating stove 11, adding an asbestos heat insulating layer 10 around the sample to insulate heat; the industrial control machine 7 collecting temperature signal via the temperature control meter 5, displaying and analyzing.

Owner:DALIAN UNIV OF TECH

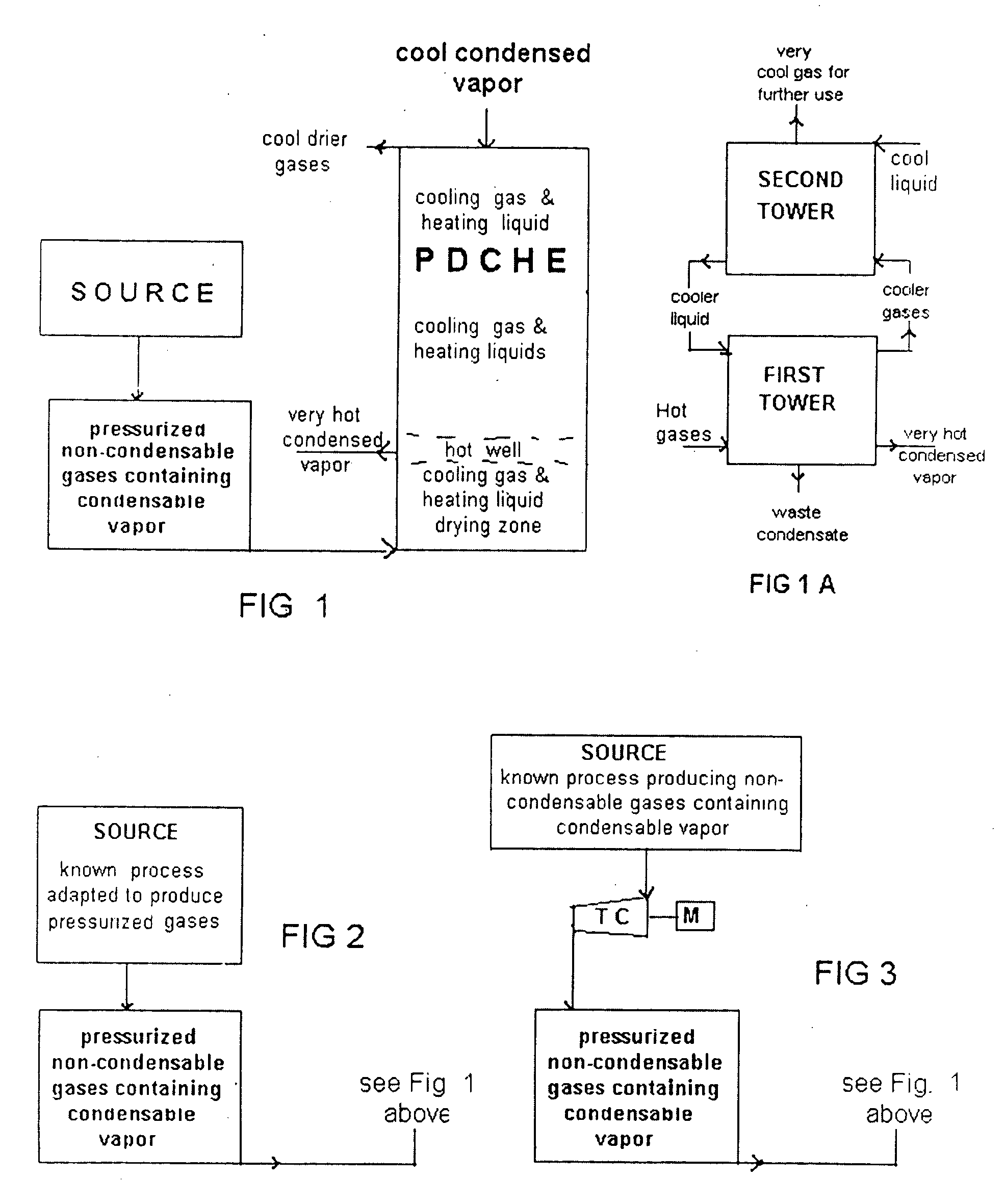

Systems and methods for separating condensable vapors from gases by direct-contact heat exchange

Condensable vapors such as carbon dioxide are separated from light gases in a process stream. The systems and methods employ a direct exchange heat exchanger to desublimate the condensable vapors from the process stream. The condensable vapors are condensed by directly contacting a heat exchange liquid in the direct contact heat exchanger while the uncondensed light gases from the process stream form a separated light-gas stream. The separated light-gas stream can be used in a recuperative heat exchanger to cool the process stream.

Owner:U S BANK TRUST CO NAT ASSOC

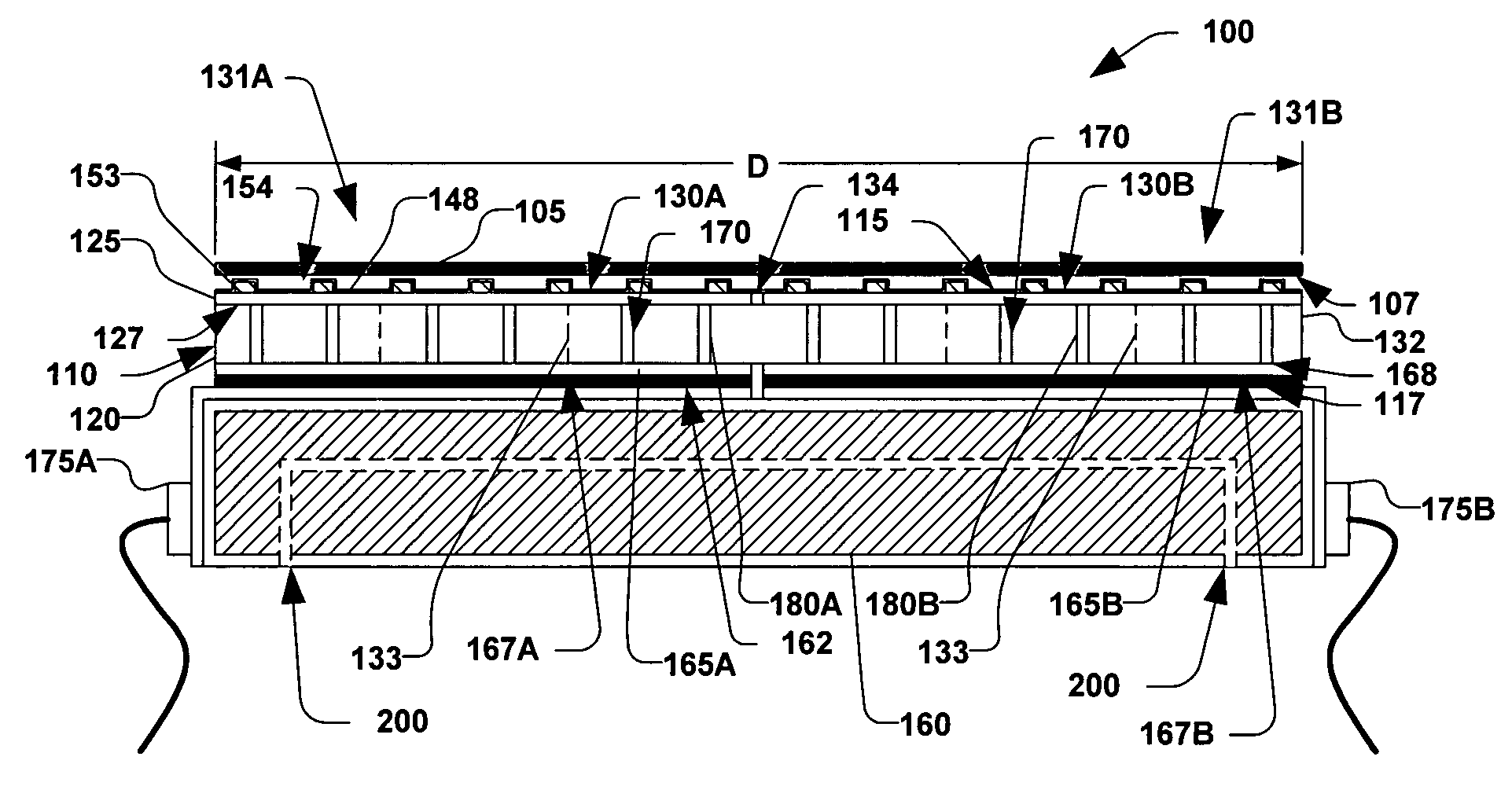

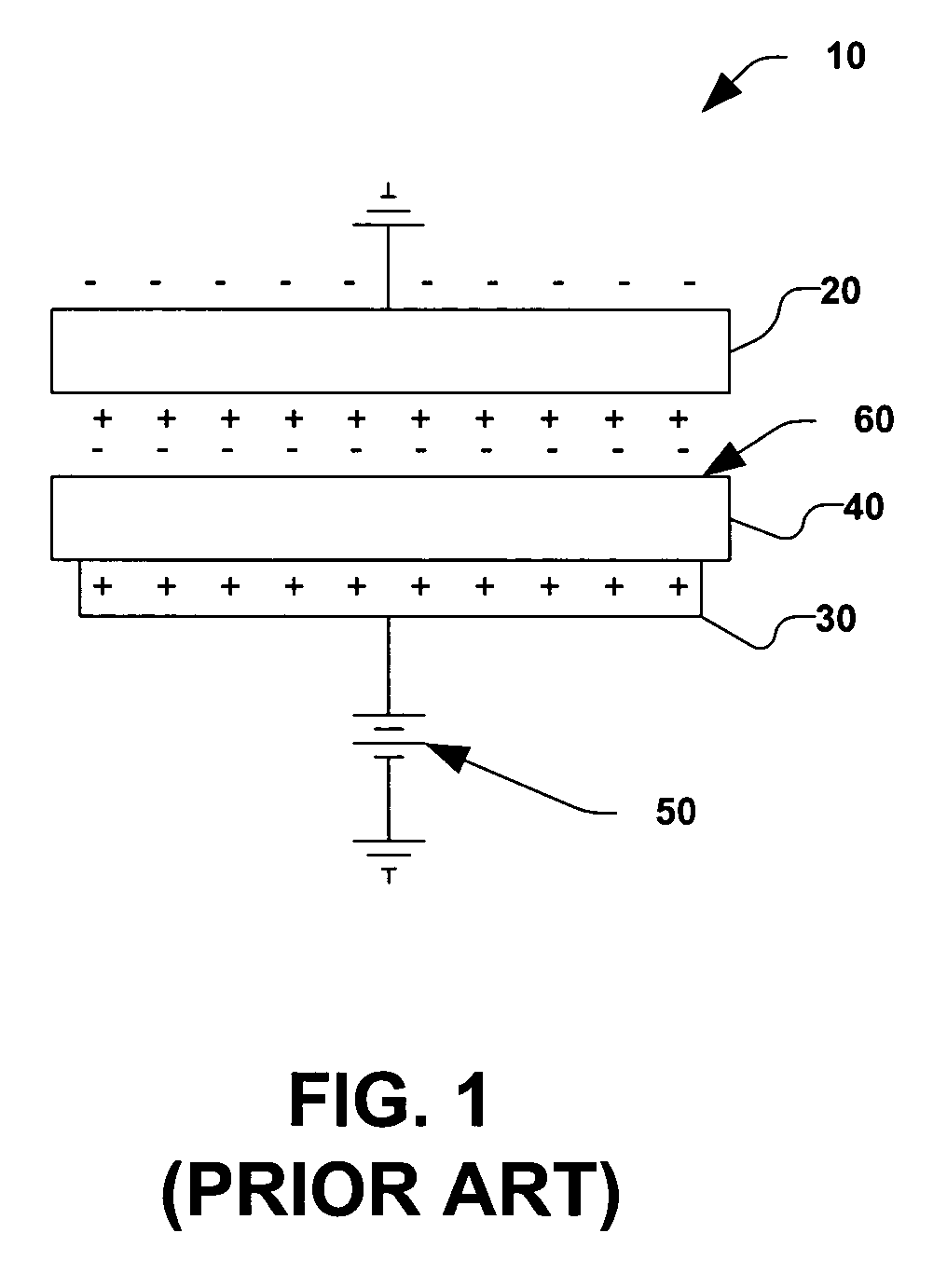

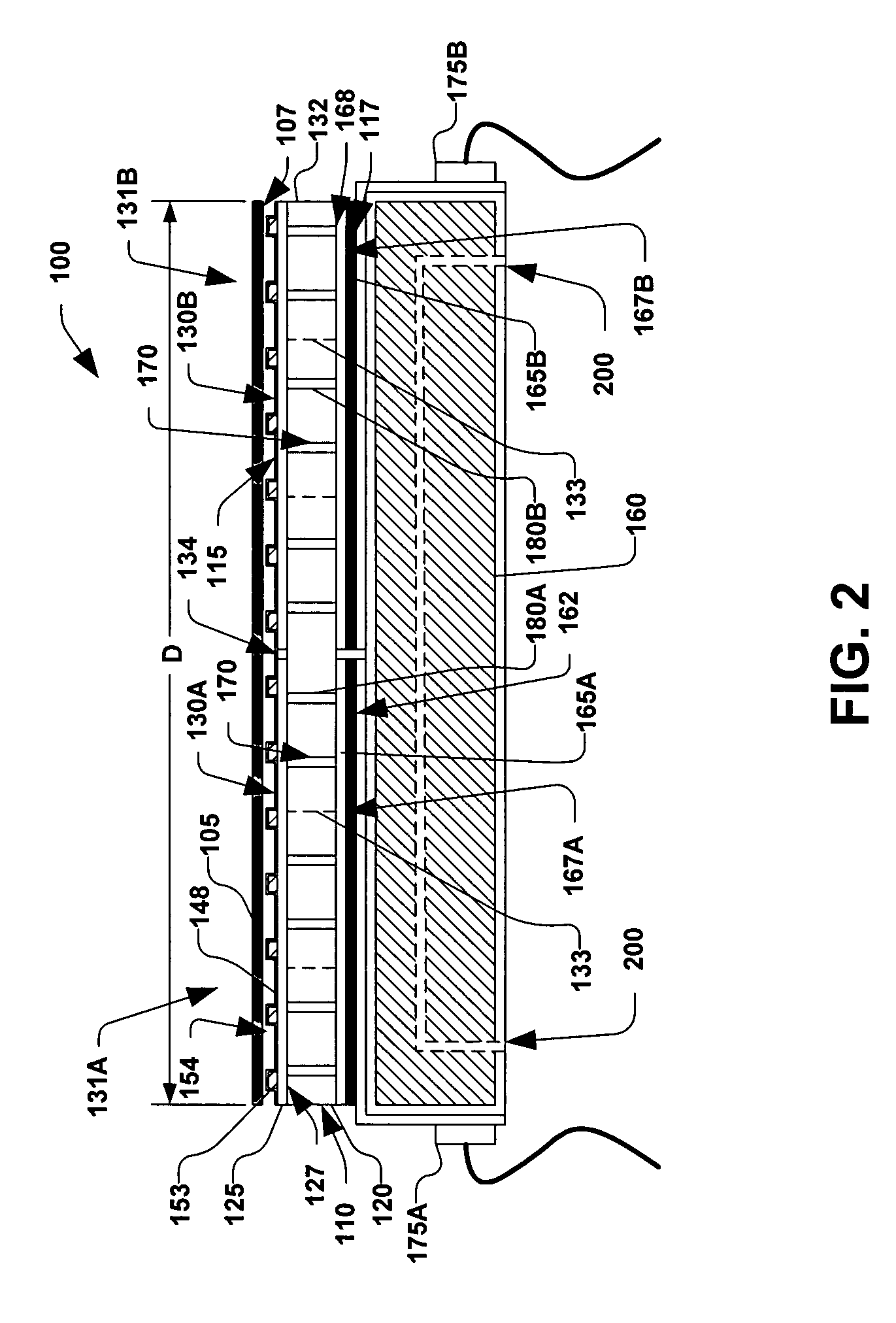

MEMS based contact conductivity electrostatic chuck

InactiveUS20050079737A1Effective clampingEasy to controlSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingContact pressureControl system

The present invention is directed to a method for clamping and processing a semiconductor substrate using a semiconductor processing apparatus. According to one aspect of the present invention, a multi-polar electrostatic chuck and associated method is disclosed which provides heating or cooling of a substrate by thermal contact conduction between the electrostatic chuck and the substrate. The multi-polar electrostatic chuck includes a semiconductor platform having a plurality of protrusions that define gaps therebetween, wherein a surface roughness of the plurality of protrusions is less than 100 Angstroms. The electrostatic chuck further includes a voltage control system operable to control a voltage applied to the electrostatic chuck to thus control a contact heat transfer coefficient of the electrostatic chuck, wherein the heat transfer coefficient of the electrostatic chuck is primarily a function of a contact pressure between the substrate and the plurality of protrusions.

Owner:AXCELIS TECHNOLOGIES

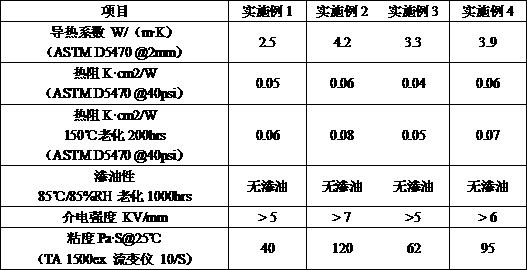

Ultra-low thermal-resistance heat-conducing silicon grease and preparation method thereof

ActiveCN103194067AImprove insulation performanceExcellent dielectric propertiesHeat conductingTemperature resistance

The invention discloses ultra-low thermal-resistance heat-conducing silicon grease. The silicon grease is prepared by the following raw materials according to parts by weight: 100 parts of polydimethylsiloxane, 10-40 parts of polyphenylmethylsiloxane, 1000-2600 parts of aluminum oxide, 20-60 parts of zinc oxide and 1-10 parts of a coupling agent. Furthermore, the invention discloses a preparation method of the ultra-low thermal resistant heat-conducing silicon grease. The heat-conducting silicon grease has the following advantages that the silicon grease has a high heat-conducting coefficient and ultra-low contact thermal resistance, and the contact thermal resistance is lower than 0.06K.cm<2> / W (pressure 40psi); and the silicon grease is stable to store at room temperature, free from oil seepage, good in high-temperature resistance, free from drying after long-time use at high temperature, and excellent in both electric insulating and dielectric performances.

Owner:NICHE TECH KAISER SHANTOU

Heat dissipation system with hygroscopic working fluid

InactiveUS20110283720A1Lighting and heating apparatusCooling fluid circulationThermal energyWorking fluid

A system and method for transferring heat from a process source and dissipating it to the ambient atmosphere. The system uses a low-volatility, hygroscopic working fluid to reject thermal energy directly to ambient air. Direct-contact heat exchange allows for the creation of large interfacial surface areas for effective heat transfer. Heat transfer is further enhanced by water vapor pressure gradients present between the equilibrium moisture content of the working fluid and the ambient air. Cyclic absorption and evaporation of atmospheric moisture dampens variations in cooling capacity because of ambient temperature changes. The low-volatility and hygroscopic nature of the working fluid prevents complete evaporation of the fluid and a net consumption of water.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

Flat-panel vapor chamber

InactiveCN102095323AHigh mechanical strengthReduce the return pathSemiconductor/solid-state device detailsSolid-state devicesComputer moduleElectron

The invention relates to a flat-panel vapor chamber which belongs to a heat radiating device of a micro electronic device and is used for heat diffusion of a power module and solving the surface deformation problem of the traditional flat-panel vapor chamber and a heat source contact surface so as to further reduce the deformation with the contact surface of a heat source part. The flat-panel vapor chamber comprises heat radiating fins and a metal cavity, wherein the metal cavity consists of a box body and a cover plate; the metal cavity is internally pumped with vacuum and filled with liquid working medium; the box body and the heat radiating fins are tightly contacted or connected into a whole; the inner wall surface of the box body is provided with capillary cores, and supporting bodies are arranged between the box body and the cover plate; the central part of the inner wall surface of the cover plate is provided with a boss, and the thickness of the boss is 0.2-2.0mm; the cross section area of the boss is larger than or equal to the contact area of the heat source; and the inner wall surface of the cover plate including the boss is provided with capillary cores. The flat-panel vapor chamber has the advantages of simple structure and convenience for manufacturing and processing, can be used for effectively reducing the surface deformation and the contact heat resistance, and has high working medium refluxing efficiency and higher working efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com