Setting phase change energy storage material with high-thermal conductivity and preparation method thereof

A technology of shape-setting phase change and energy storage materials, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problem of limited improvement in thermal conductivity, and achieve improved efficiency, high energy storage utilization, and high thermal conductivity. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

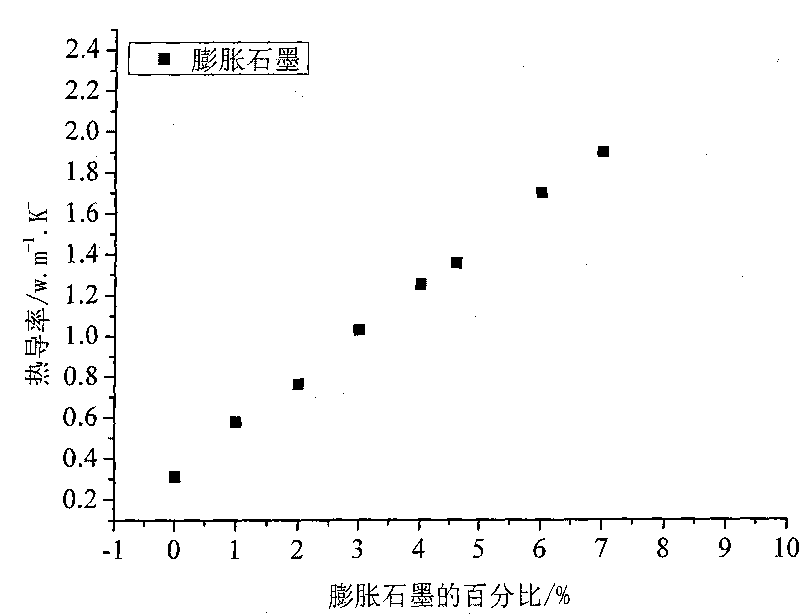

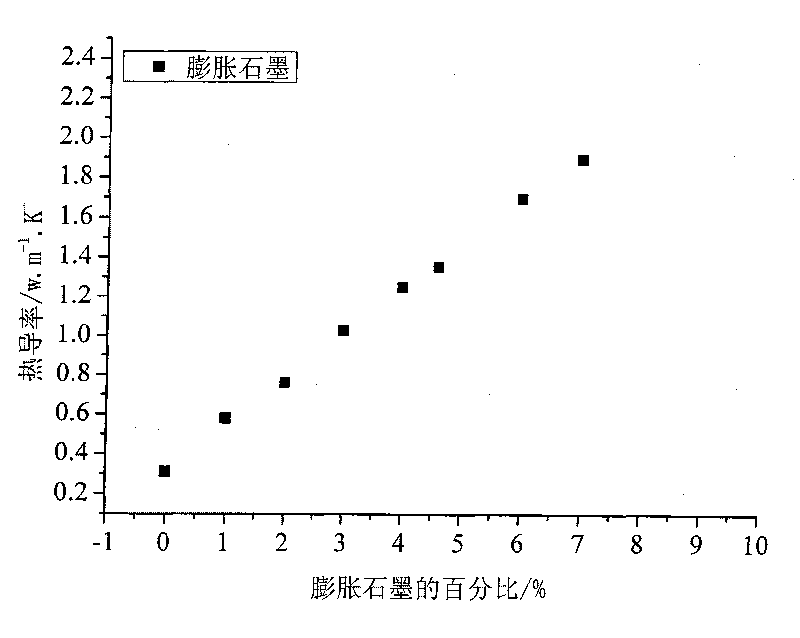

[0024] 3-5g of expandable graphite was dried in a vacuum oven at 65°C for 24 hours, and then heat-treated in a muffle furnace at 800°C for 60s to expand the expandable graphite to obtain fibrous worm-like expanded graphite. Take 316.10g of paraffin substance with a melting point of 44°C and a latent heat of phase transition of 133.1kJ / kg and heat and melt it. When the temperature of the heated liquid wax reaches 170°C, 79.2g Put high-density polyethylene into it (there are two kinds of polyethylene, one is high-density polyethylene, and the other is low-density polyethylene, which is a known technology), and it is melted and stirred in a sealed environment with a vacuum of 0.07mpa until two or completely and uniformly dissolved, the stirring speed is 30r / min, and then 4g of thermal conductivity enhancer expanded graphite is put into it, and stirred evenly in a sealed environment with a vacuum degree of 0.07mpa. The mixture is taken out and put into a hot mold of 90×90×20 mm fo...

Embodiment 2

[0027] 3-5g of expandable graphite was dried in a vacuum oven at 65°C for 24 hours, and then heat-treated in a muffle furnace at 800°C for 60s to expand the expandable graphite to obtain fibrous worm-like expanded graphite. Take 313.6g of paraffin substance with a melting point of 44°C and a latent heat of phase transition of 133.1kJ / kg and heat and melt it. When the temperature of the heated liquid wax reaches 170°C, 78.4g Put high-density polyethylene into it, melt and stir in a sealed environment with a vacuum of 0.07mpa until the two are completely and uniformly dissolved, then put 8g of thermal conductivity enhancer expanded graphite into it, and put it in a sealed environment with a vacuum of 0.07mpa Stir well. The mixture is taken out and put into a hot mold of 90×90×20 mm for compression molding, and then taken out from the mold after natural cooling to obtain the shape-fixed phase change material of the present invention.

[0028] The thermal conductivity of the high...

Embodiment 3

[0030] 3-5g of expandable graphite was dried in a vacuum oven at 65°C for 24 hours, and then heat-treated in a muffle furnace at 800°C for 60s to expand the expandable graphite to obtain fibrous worm-like expanded graphite. Take 310.4g of paraffin substance with a melting point of 44°C and a latent heat of phase transition of 133.1kJ / kg and heat and melt it. When the temperature of the heated liquid wax reaches 170°C, 77.6g Put high-density polyethylene into it, melt and stir in a sealed environment with a vacuum degree of 0.07mpa until the two are completely and uniformly dissolved, and the stirring speed is 30r / min, then put 12g of thermal conductivity enhancer expanded graphite into it, and in a vacuum Stir evenly in a sealed environment with a density of 0.07mpa. The mixture is taken out and put into a hot mold of 90×90×20 mm for compression molding, and then taken out from the mold after natural cooling to obtain the shape-fixed phase change material of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com