Continuous supercritical water gasifying hydrogen producing method and apparatus with organic solid matter

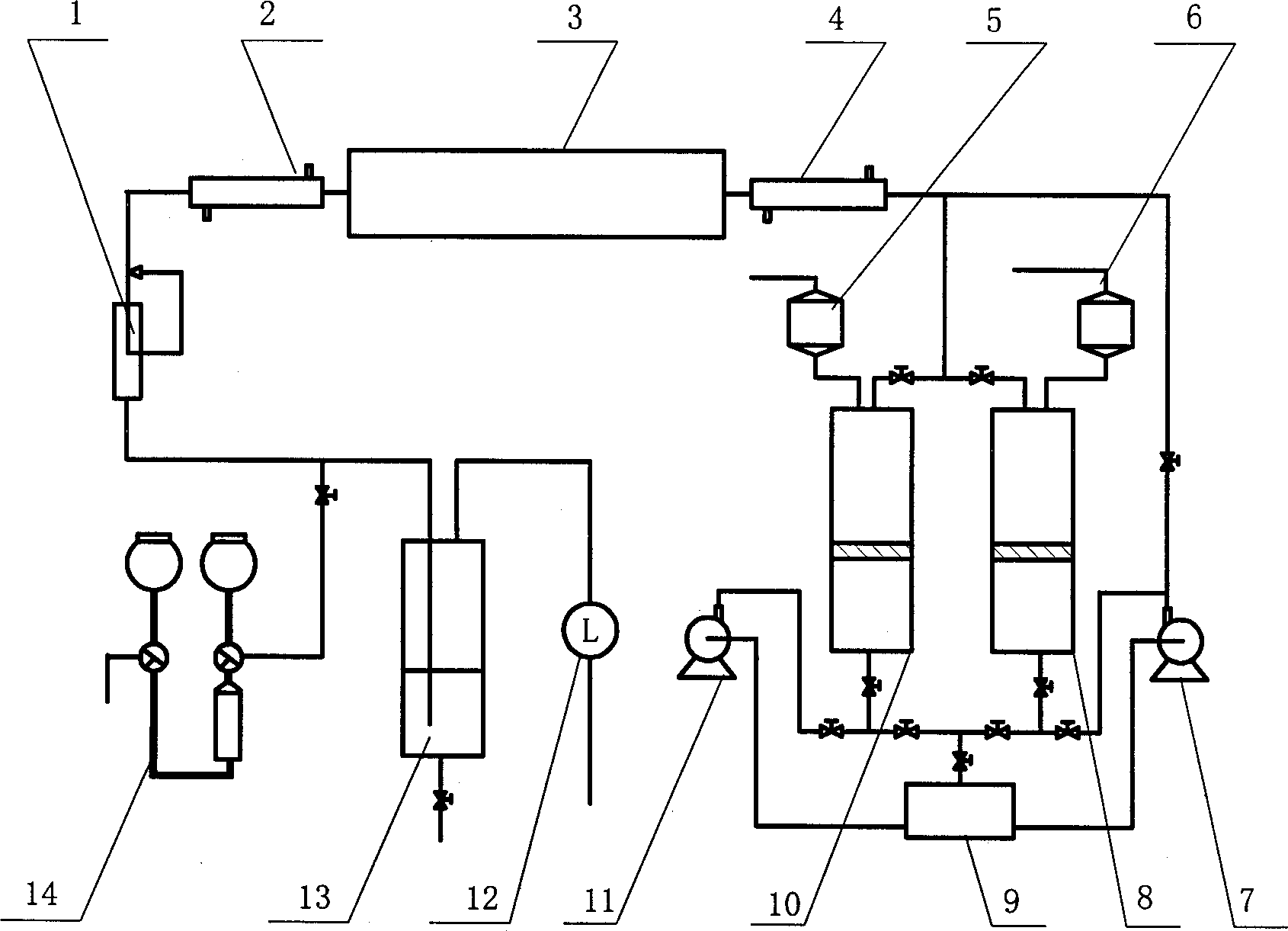

A supercritical water gasification and solid-state technology, applied in chemical instruments and methods, inorganic chemistry, hydrogen, etc., can solve problems such as energy waste, achieve fast and efficient gasification reactions, and achieve the effects of measurement and quantitative analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

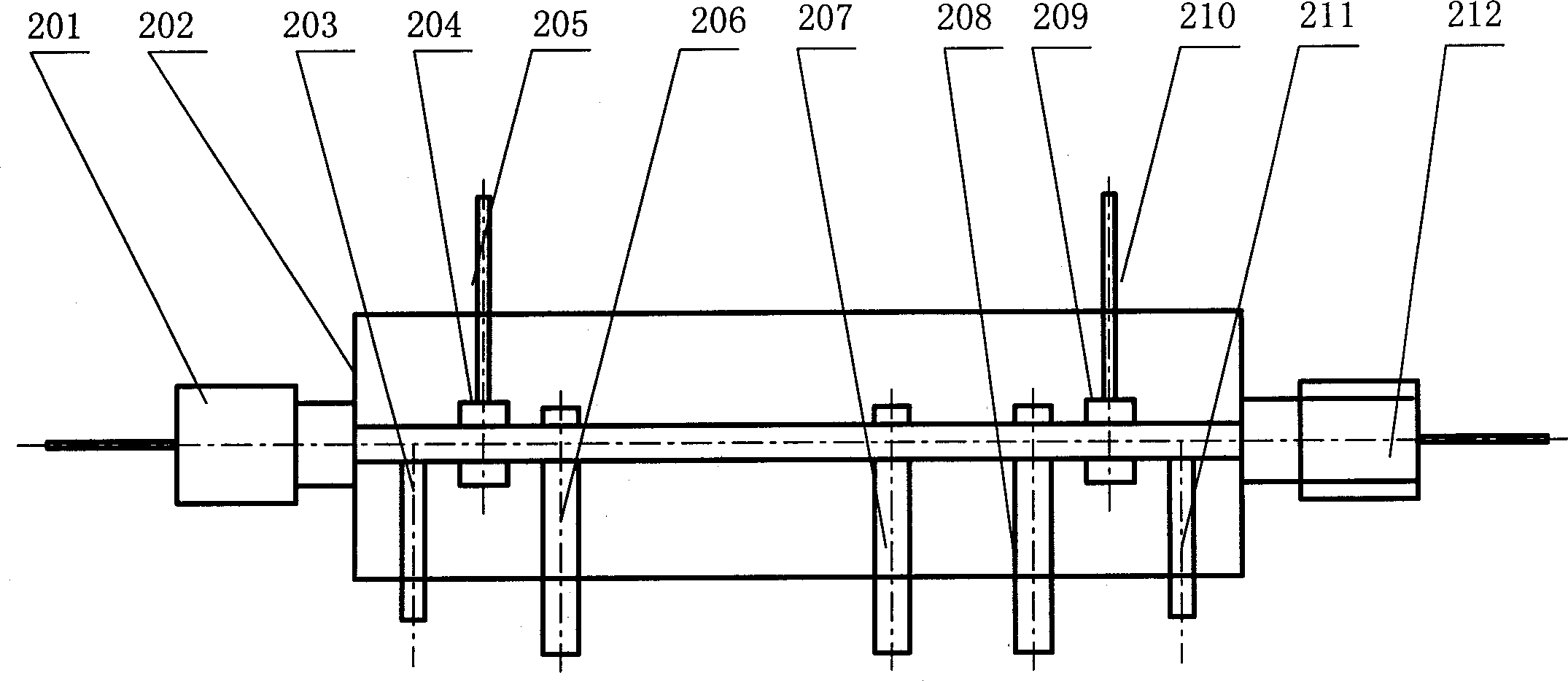

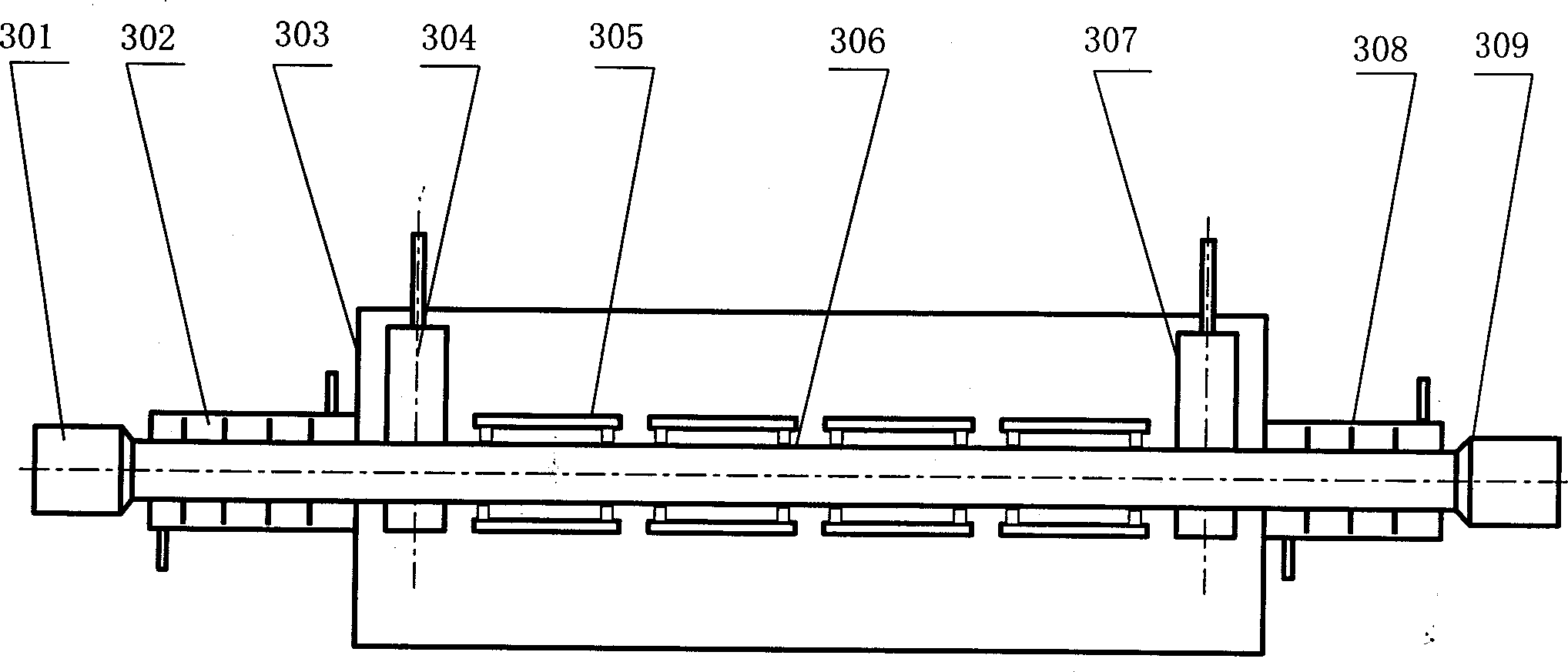

Method used

Image

Examples

Embodiment

[0063] Table 1 shows some experimental results of the hydrogen production reaction of glucose liquid supercritical water gasification carried out in the reaction device system of the present invention. Firstly, experiments and tests were carried out on glucose in a large experimental range. The results showed that 923K, 25MPa, 0.4mol / l glucose, the gasification rate can exceed 100%, and the liquid product is colorless, transparent and recyclable.

[0064] Table 2 shows the gasification experimental results of the CMC aqueous solution, and the CMC aqueous solution is easy to gasify. Better gasification results can be obtained at a higher concentration (8wt%), and the carbon gasification rate can reach more than 90%, which can be used as an additive for biomass gasification.

[0065] Table 3 shows the gasification results of glucose / alkaline additives and sawdust / CMC aqueous solution. Add KOH and Na to the raw material 2 CO 3 Studies have shown that K + 、Na + , the addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com