Method for preparing high-performance cementing material through negative-pressure anaerobic thermal cracking of phosphogypsum

A technology of cementitious materials and phosphogypsum, which is applied in the field of inorganic non-metallic materials, can solve the problems of affecting powder performance, long production cycle, and incomplete removal of impurities, and achieve the goal of reducing impurity content, stable mechanical properties, and good removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

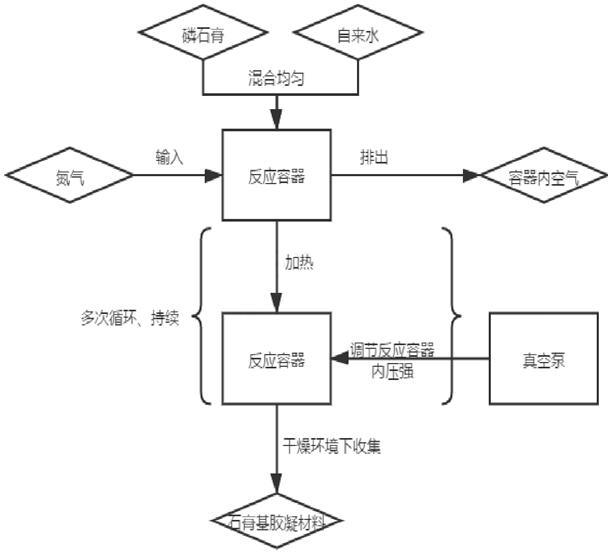

Method used

Image

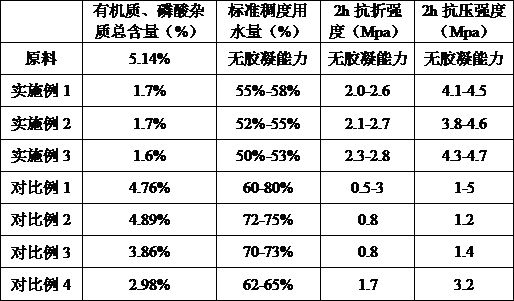

Examples

Embodiment 1

[0022] (1) According to the mass ratio of water and phosphogypsum of 1:1, add water to the phosphogypsum, and fully stir to obtain a slurry;

[0023] (2) placing the slurry in step (1) in a nitrogen environment with a nitrogen content of more than 95%;

[0024] (3) Under the pressure of 0.05MPa, heat the slurry to 55°C; and rotate the reaction vessel at a speed of 40r / min to maintain the temperature of the slurry at 280°C and react for 120min;

[0025] (4) Dry the material in the reaction vessel to make the material humidity less than 5%, and collect to obtain a gypsum-based cementitious material.

Embodiment 2

[0027] (1) According to the mass ratio of water and phosphogypsum of 2:1, add water to the phosphogypsum and fully stir to obtain a slurry;

[0028] (2) placing the slurry in step (1) in a nitrogen environment with a nitrogen content of more than 95%;

[0029] (3) Under the pressure of 0.04MPa, heat the slurry to 60°C; and rotate the reaction vessel at a speed of 30r / min to maintain the temperature of the slurry at 300°C and react for 60 minutes;

[0030] (4) Dry the material in the reaction vessel to make the material humidity less than 5%, and collect to obtain a gypsum-based cementitious material.

Embodiment 3

[0032] (1) According to the mass ratio of water and phosphogypsum of 1:1, add water to the phosphogypsum, and fully stir to obtain a slurry;

[0033] (2) placing the slurry in step (1) in a nitrogen environment with a nitrogen content of more than 95%;

[0034] (3) Under the pressure of 0.06MPa, heat the slurry to 50°C; and rotate the reaction vessel at a speed of 50r / min, so that the temperature of the slurry is maintained at 200°C, and the reaction is performed for 100 minutes;

[0035] (4) Dry the material in the reaction vessel to make the material humidity less than 5%, and collect to obtain a gypsum-based cementitious material.

[0036] The specific implementation method of the present invention has been described in detail above, but the present invention is not limited to the above-mentioned implementation method, and within the scope of knowledge possessed by those of ordinary skill in the art, various changes can also be made without departing from the purpose of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com