Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5173results about "Secondary cells manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

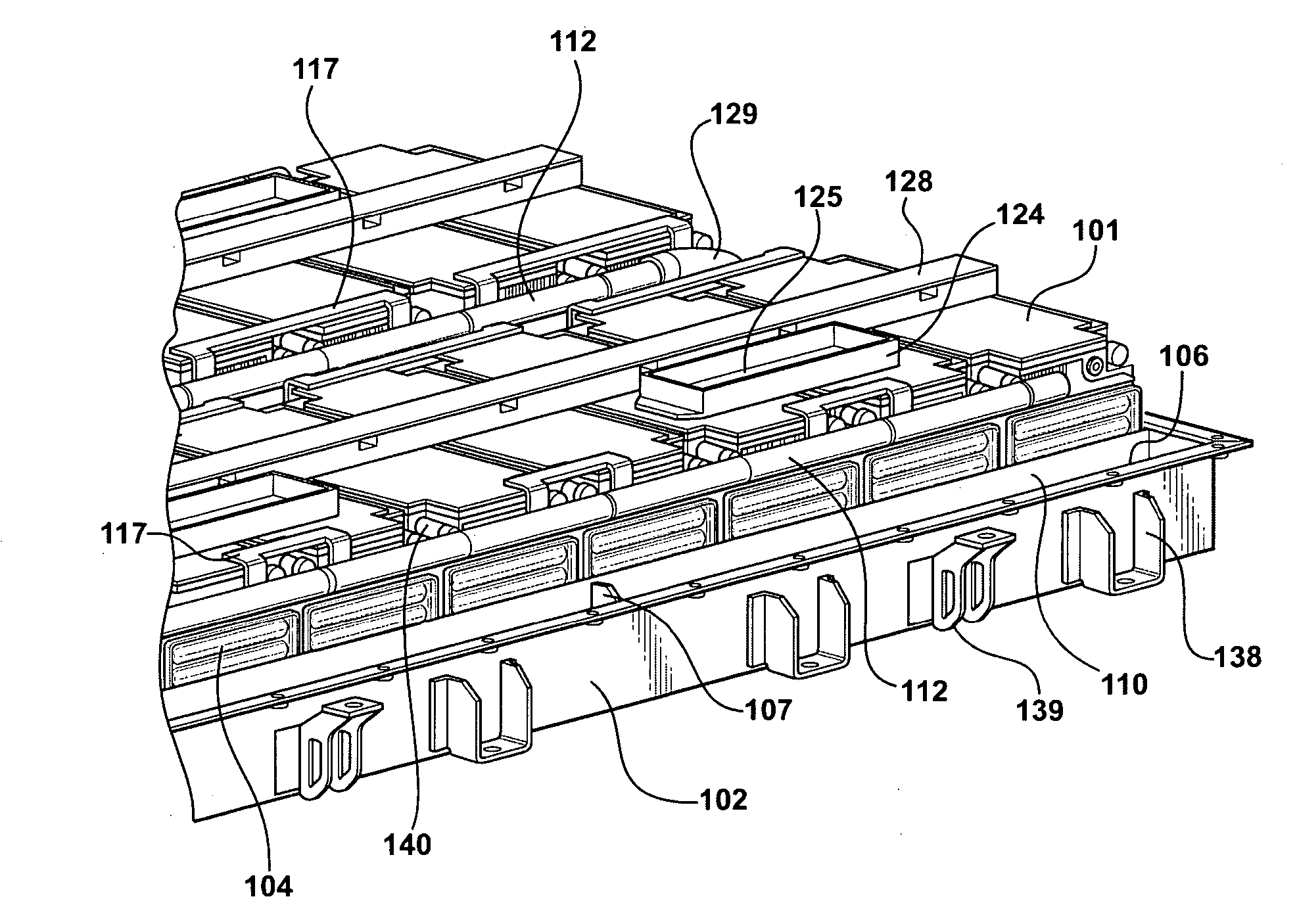

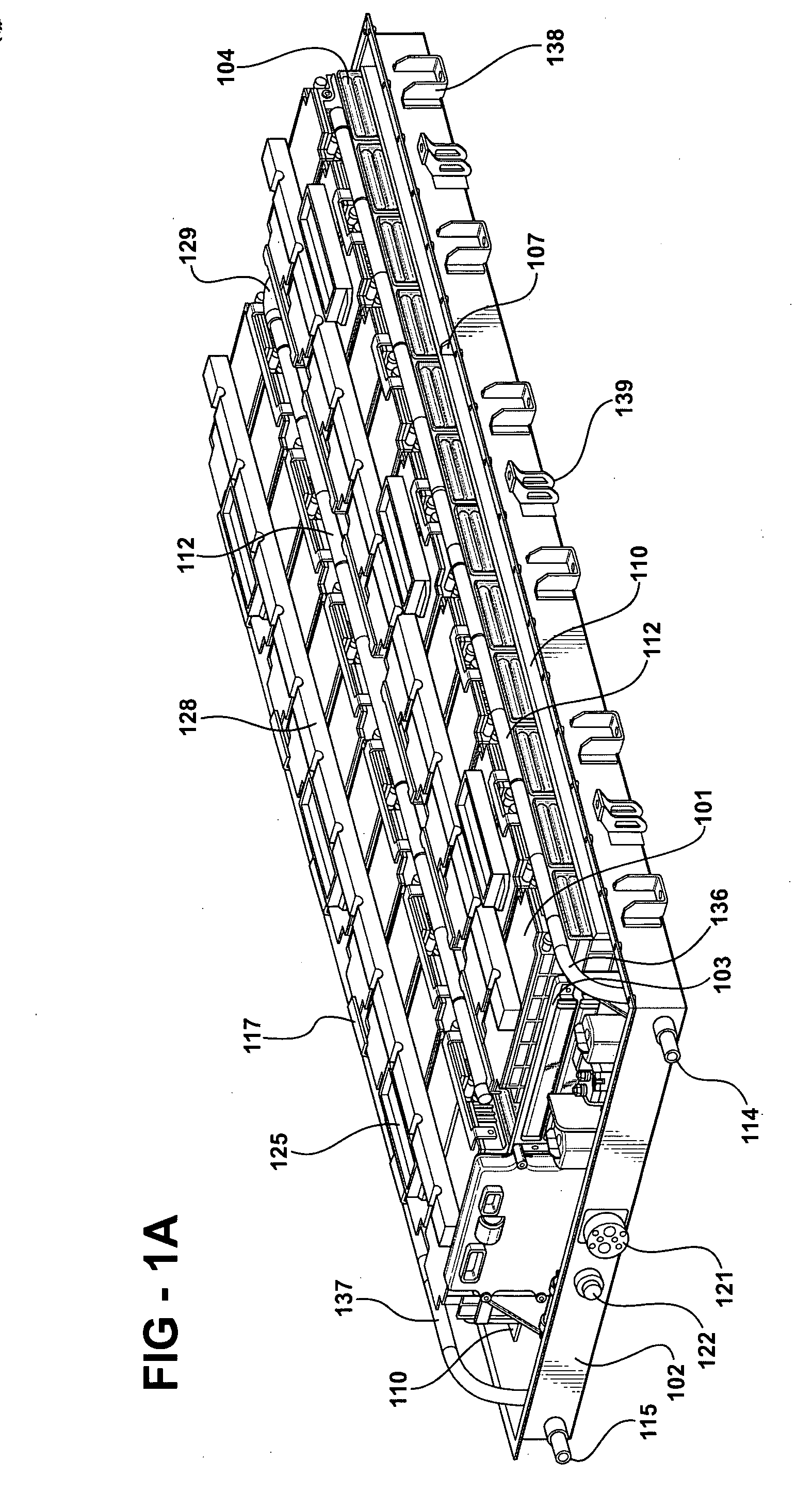

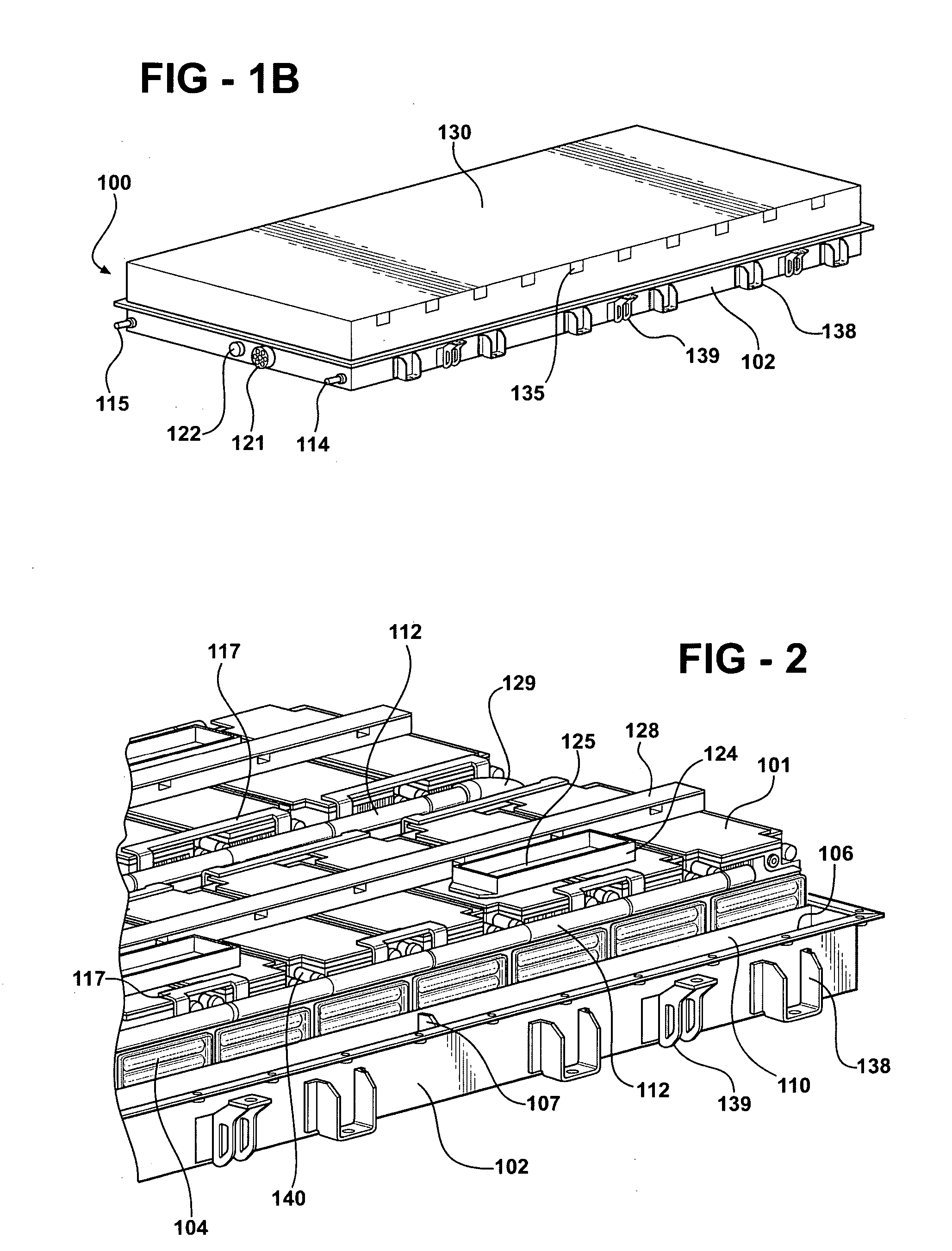

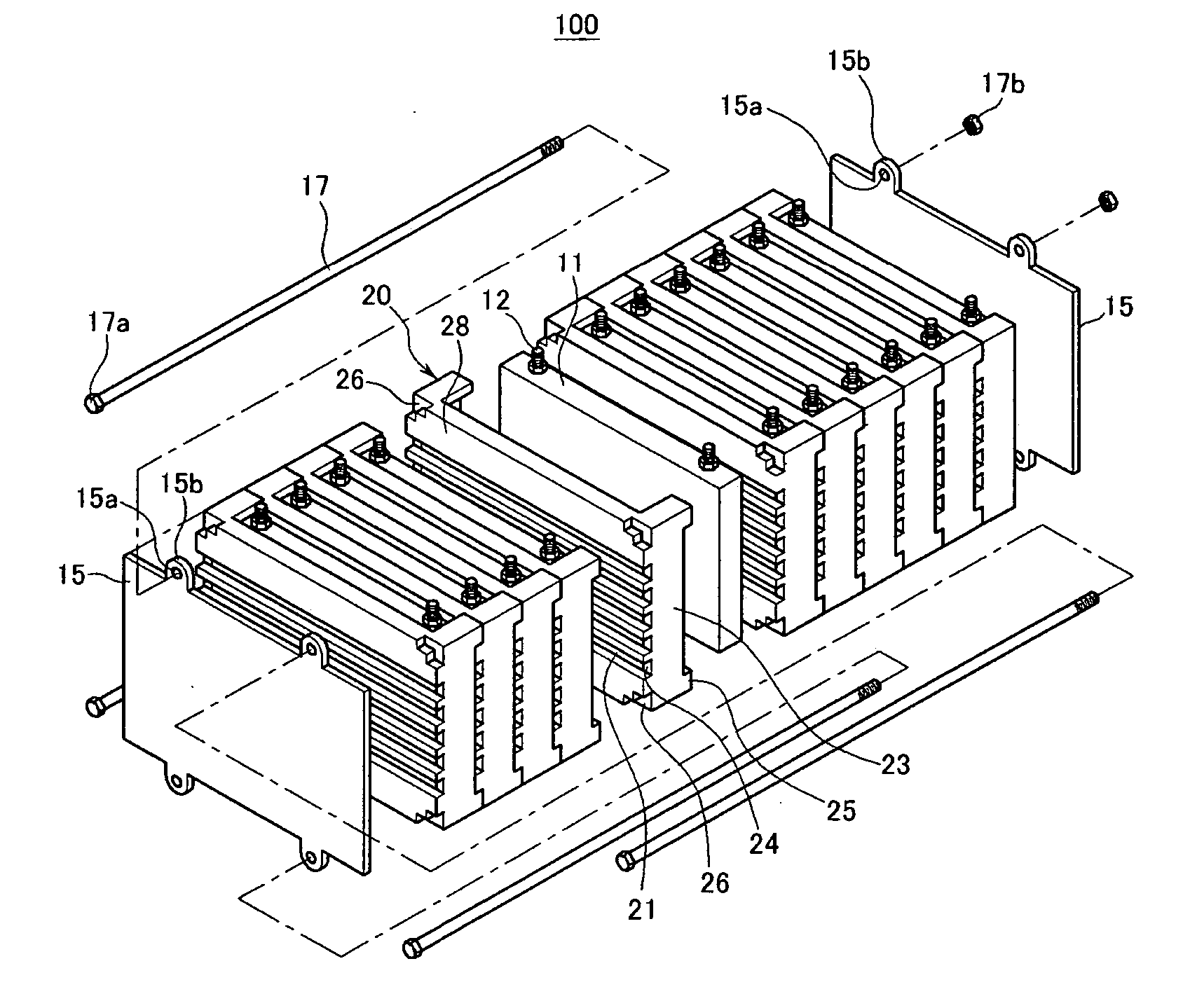

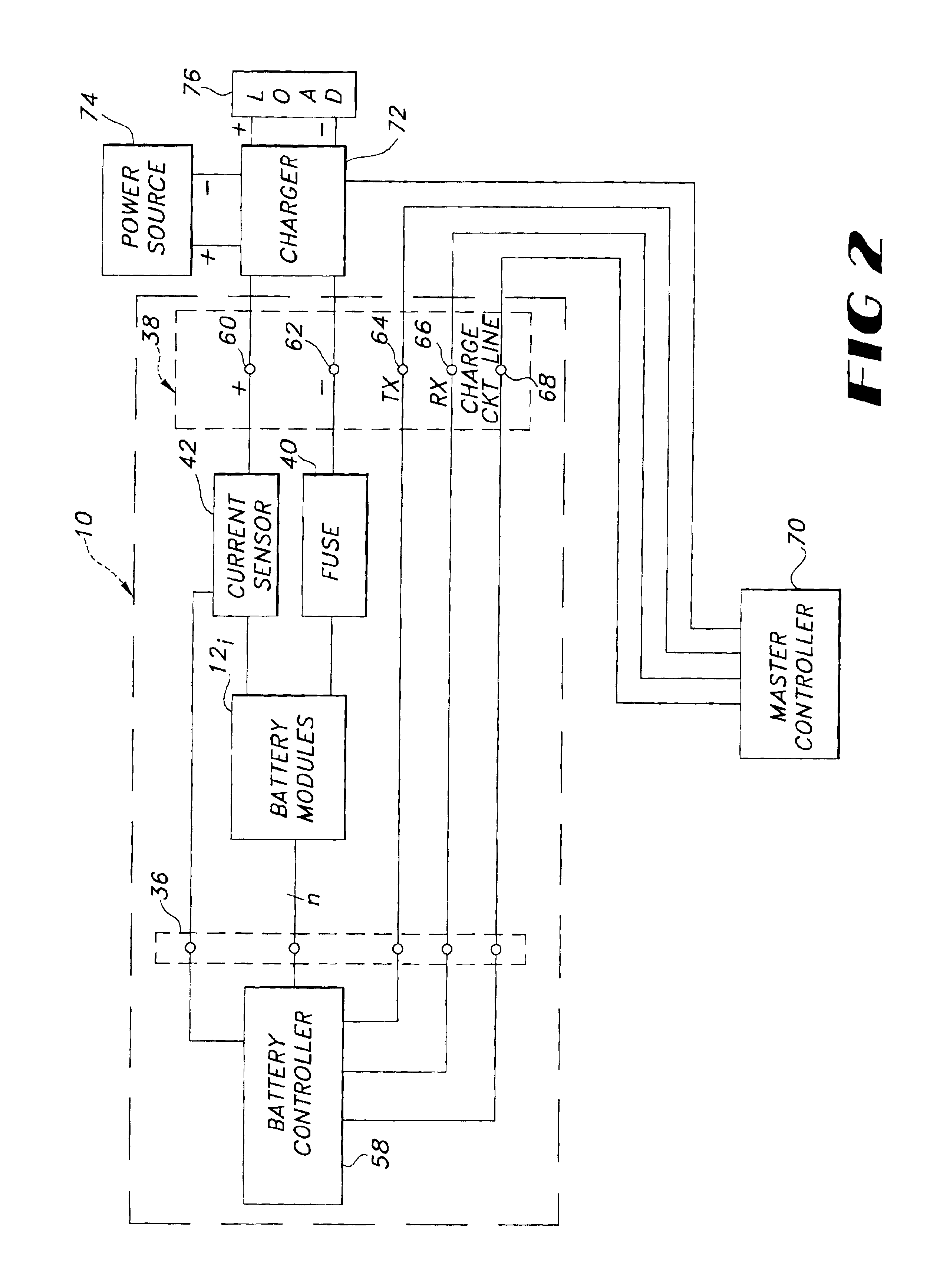

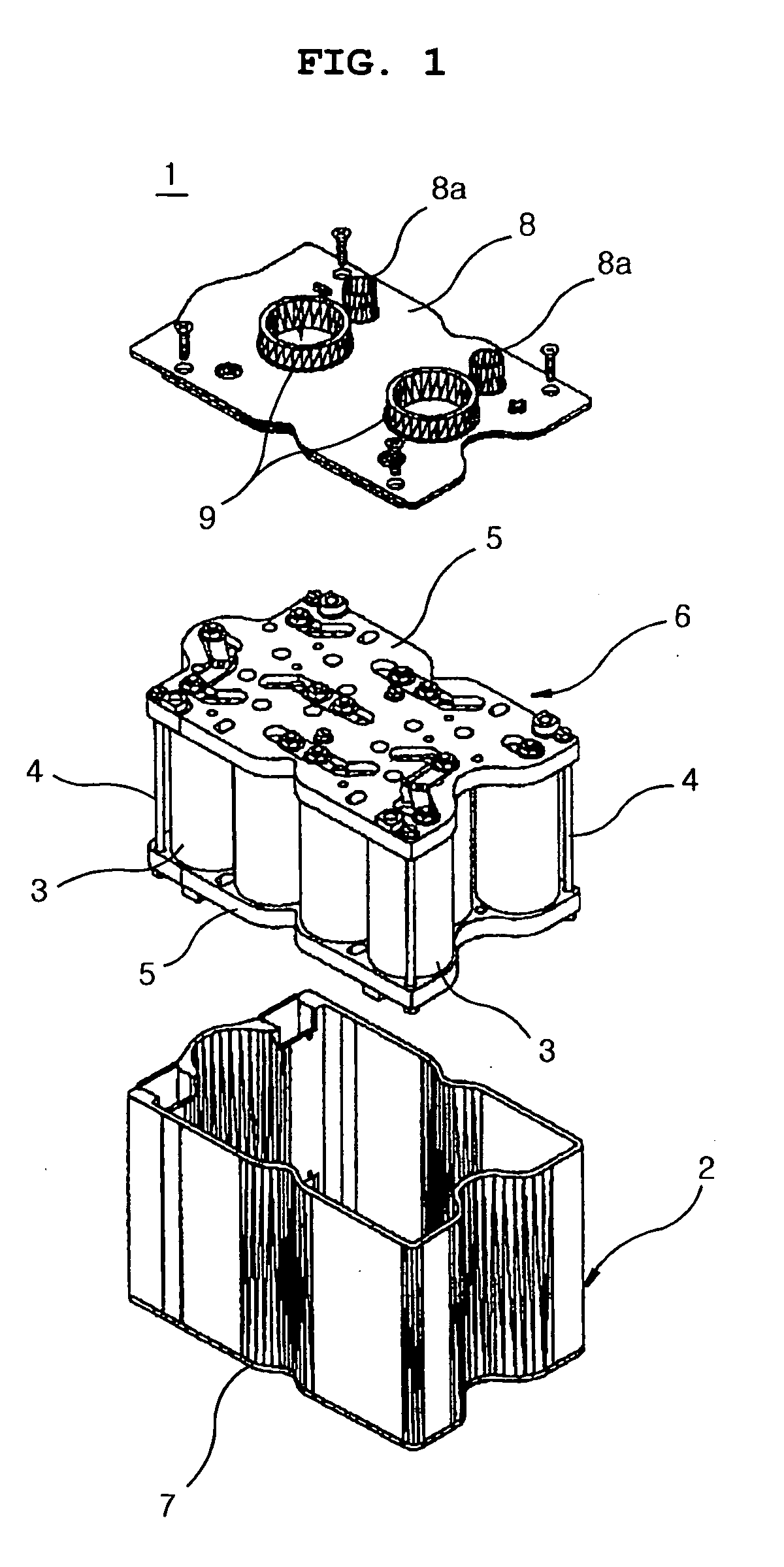

Modular battery system

InactiveUS20070087266A1Primary cell to battery groupingFinal product manufactureCoolant flowMonitoring system

Disclosed herein is a modular battery system having at least one set of battery modules, preferably monoblock modules connected in series. Each of the battery modules may be designed with a first endplate and a second endplate, wherein each battery module is set between the first and second endplates and at least one band member couples the endplates to each other, binding the battery module between the endplates. The endplates are secured between a pair of rails and the system is disposed in a system housing. A cooling manifold provides a system wherein coolant flows into and out of each battery module. The system housing preferably has a coolant inlet and a coolant outlet. The cooling manifold is in flow communication with the coolant inlet and the coolant outlet. A battery monitoring system, which may include a battery control module and at least one remote sensing module, preferably monitors and collects performance and status information, such as voltage and temperature, of the battery modules. An integrated control unit (ICU) may be disposed in the system housing. The ICU supports electronics, some of which are used to collect electrical energy produced by the battery modules and / or monitor the system.

Owner:BATTERY PATENT TRUST

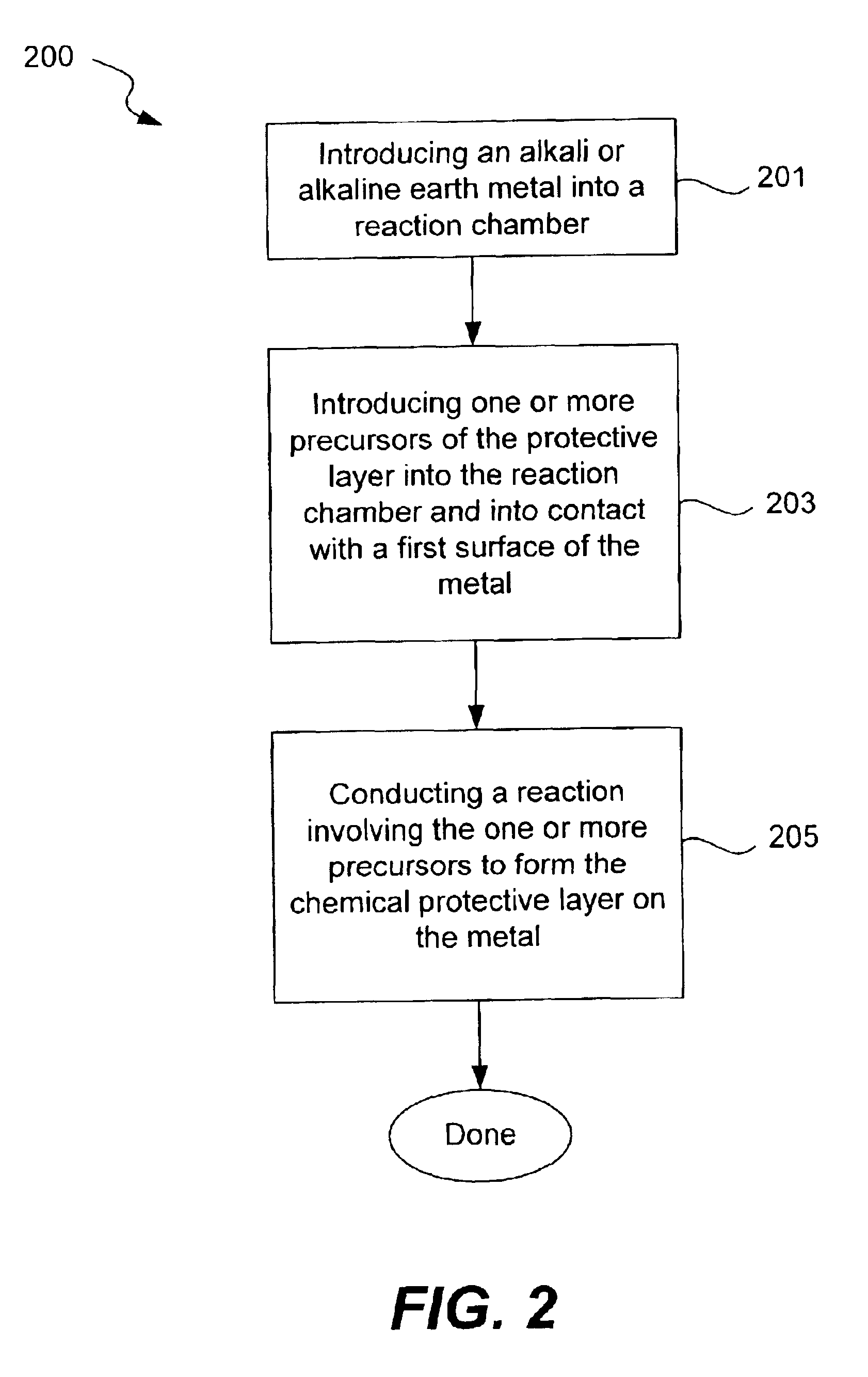

Chemical protection of a lithium surface

InactiveUS6911280B1Easy to produceSimple processElectrochemical processing of electrodesFinal product manufactureAlkaline earth metalLithium metal

Disclosed are compositions and methods for alleviating the problem of reaction of lithium or other alkali or alkaline earth metals with incompatible processing and operating environments by creating a ionically conductive chemical protective layer on the lithium or other reactive metal surface. Such a chemically produced surface layer can protect lithium metal from reacting with oxygen, nitrogen or moisture in ambient atmosphere thereby allowing the lithium material to be handled outside of a controlled atmosphere, such as a dry room. Production processes involving lithium are thereby very considerably simplified. One example of such a process in the processing of lithium to form negative electrodes for lithium metal batteries.

Owner:POLYPLUS BATTERY CO INC

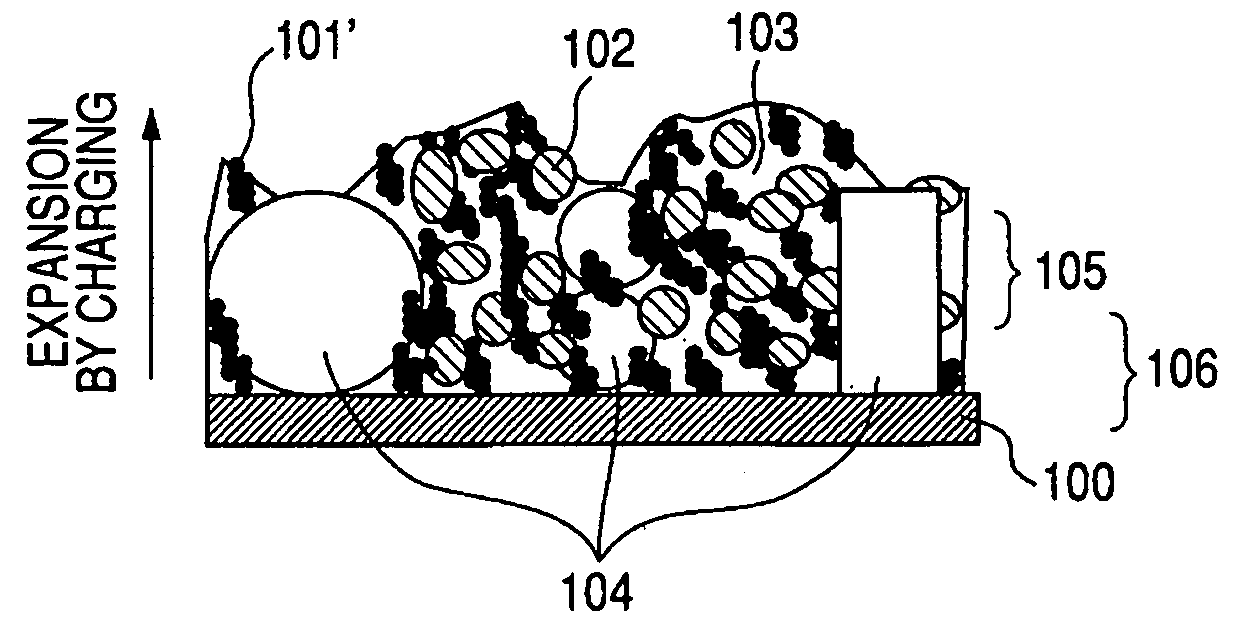

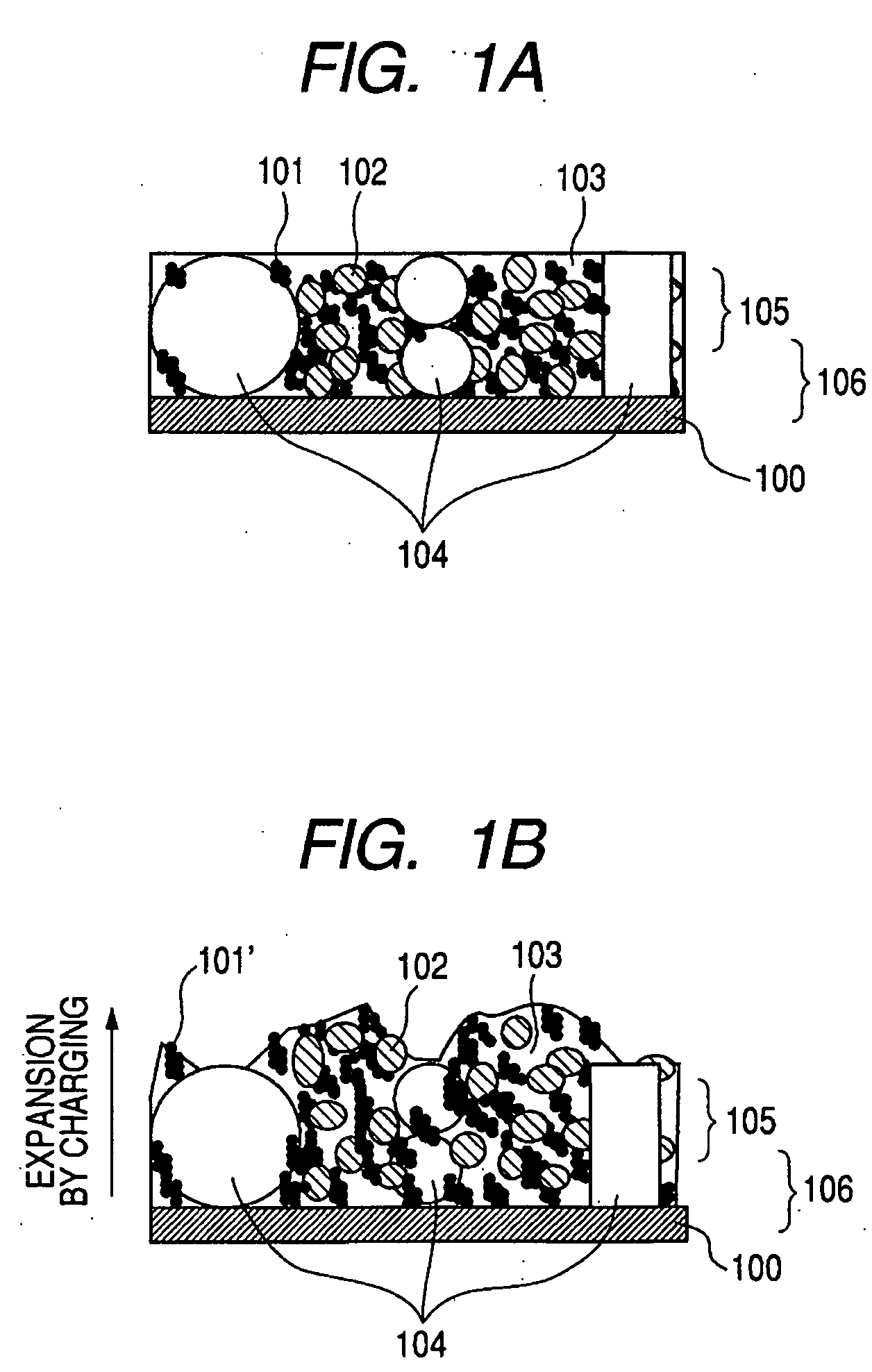

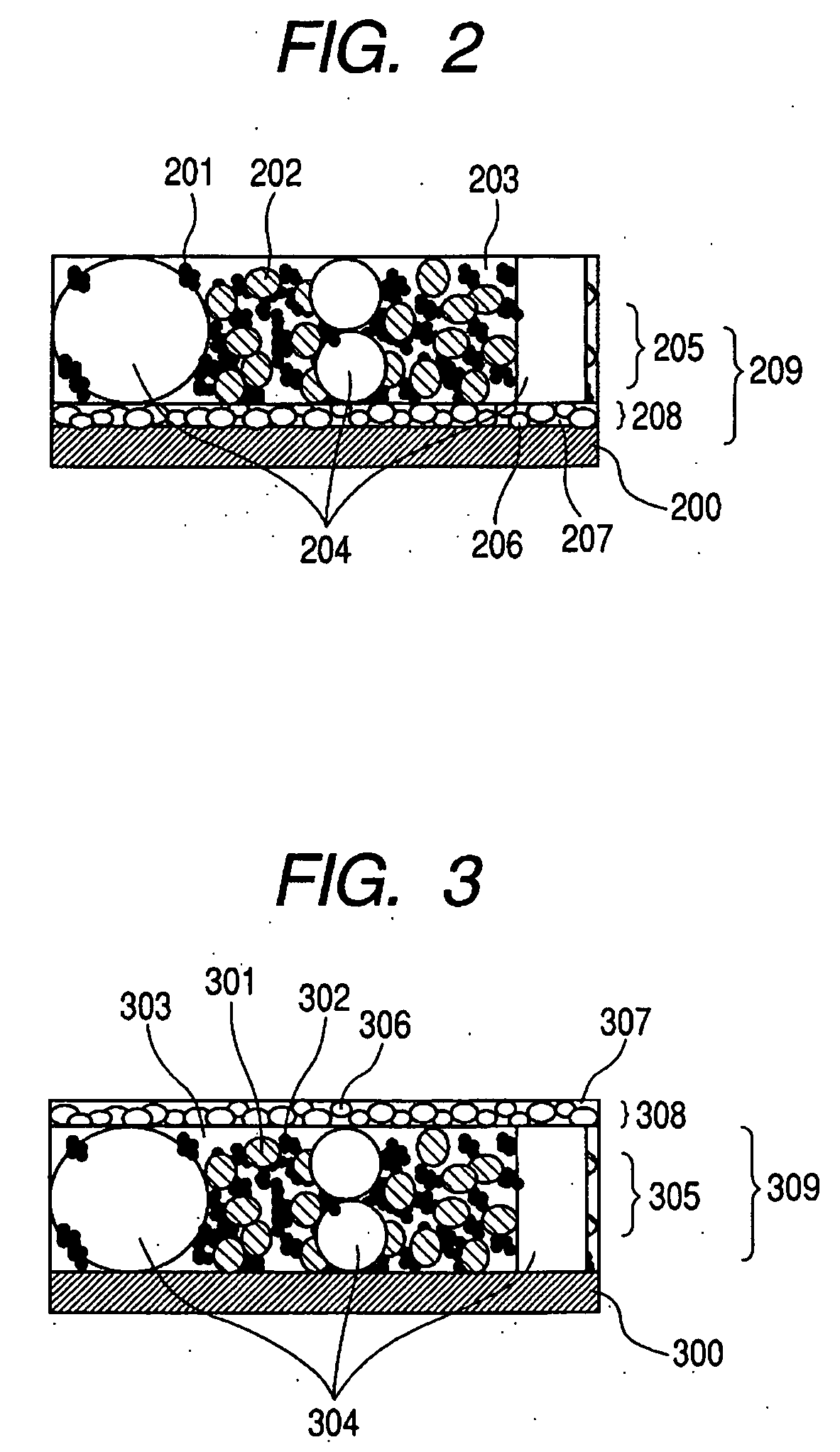

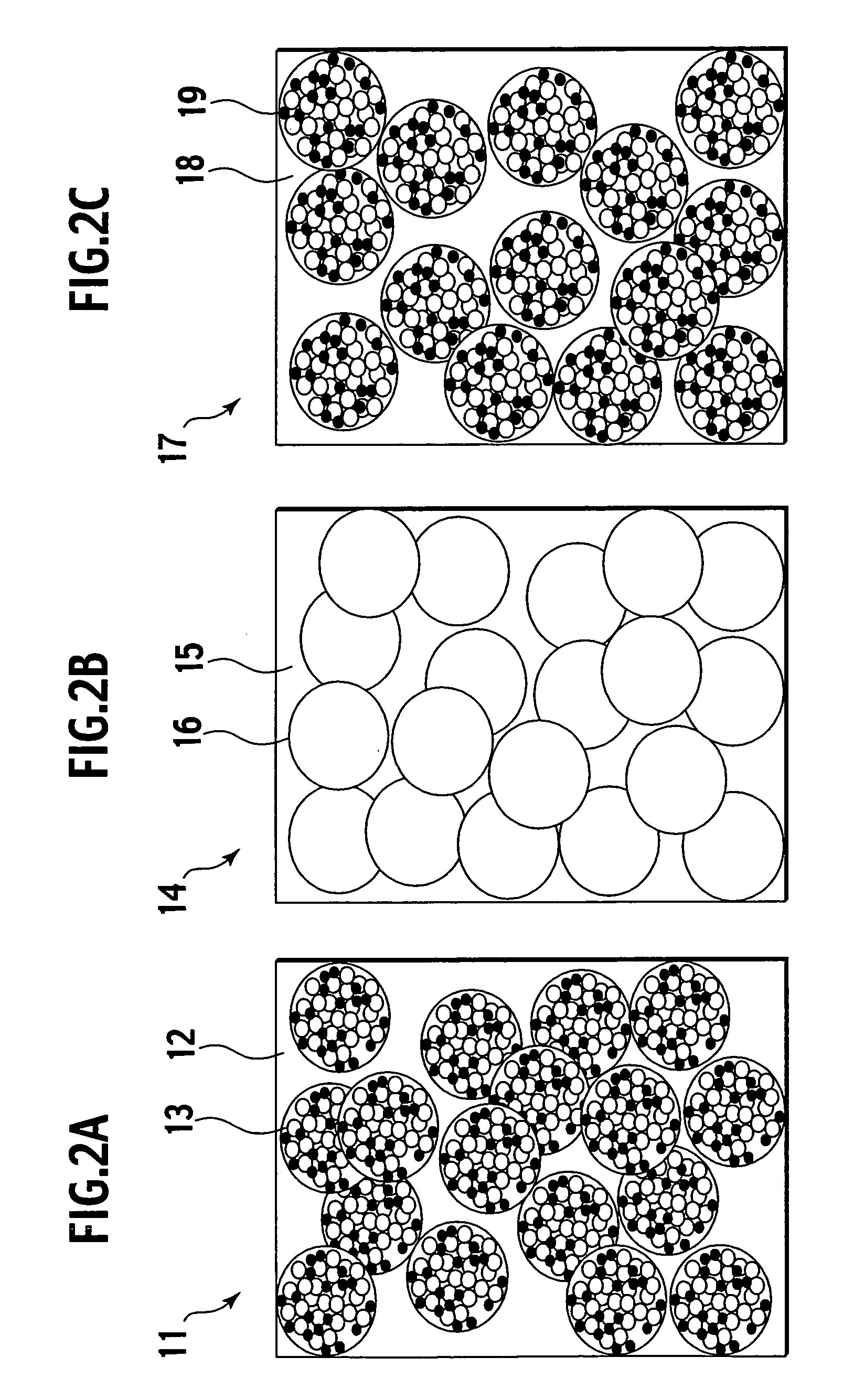

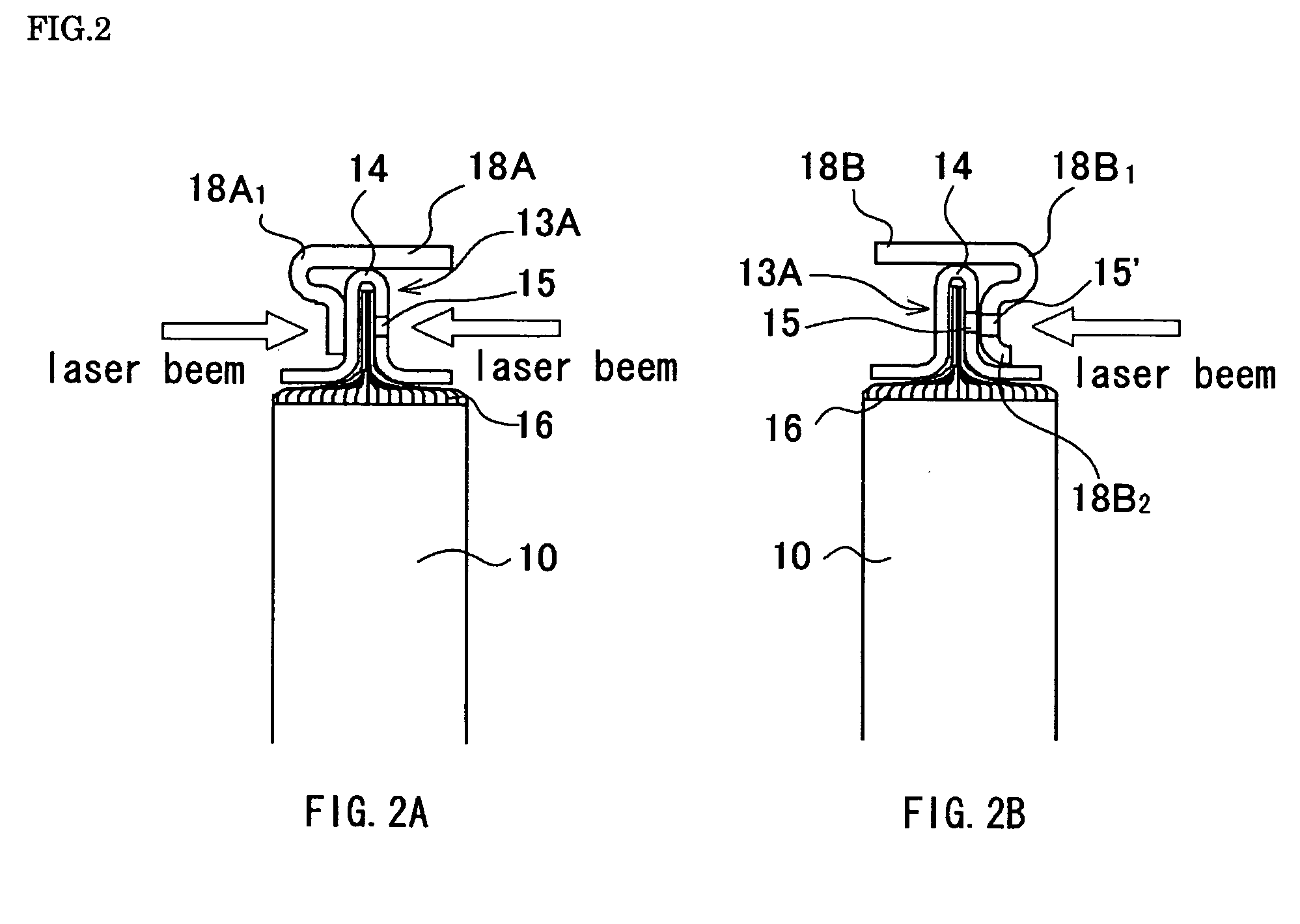

Electrode structure for lithium secondary battery and secondary battery having such electrode structure

InactiveUS20060127773A1Small capacity reductionLarge capacityElectrode manufacturing processesFinal product manufactureElectrochemical responseConductive polymer

In an electrode structure for a lithium secondary battery including: a main active material layer formed from a metal powder selected from silicon, tin and an alloy thereof that can store and discharge and capable of lithium by electrochemical reaction, and a binder of an organic polymer; and a current collector, wherein the main active material layer is formed at least by a powder of a support material for supporting the electron conduction of the main active material layer in addition to the metal powder and the powder of the support material are particles having a spherical, pseudo-spherical or pillar shape with an average particle size of 0.3 to 1.35 times the thickness of the main active material layer. The support material is one or more materials selected from a group consisting of graphite, oxides of transition metals and metals that do not electrochemically form alloy with lithium. Organic polymer compounded with a conductive polymer is used for the binder. There are provided an electrode structure for a lithium secondary battery having a high capacity and a long lifetime, and a lithium secondary battery using the electrode structure and having a high capacity, a high energy density and a long lifetime.

Owner:CANON KK

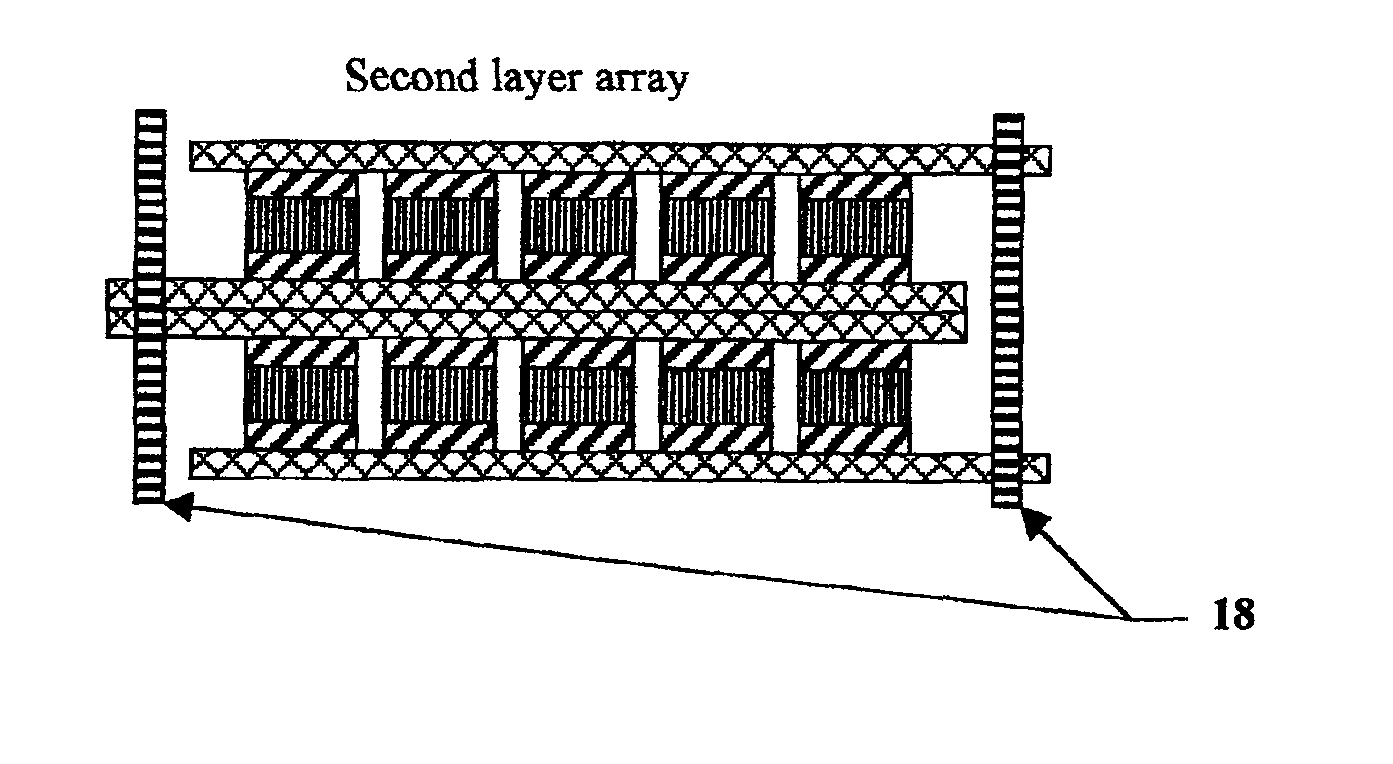

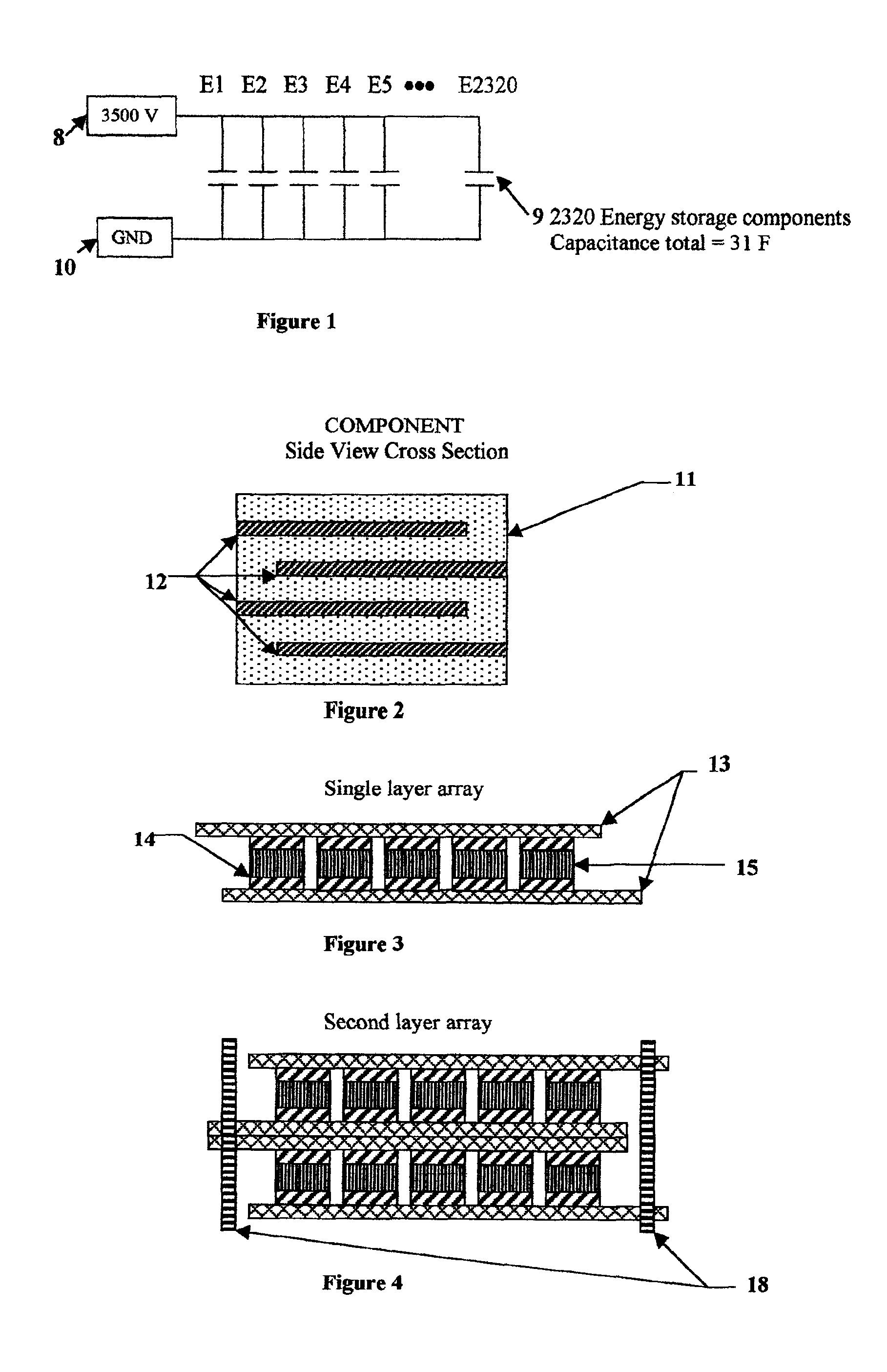

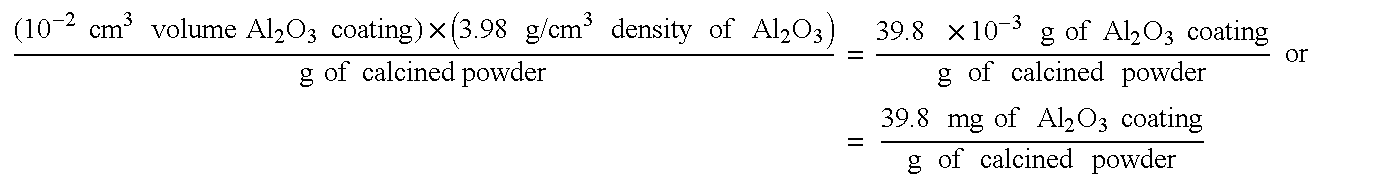

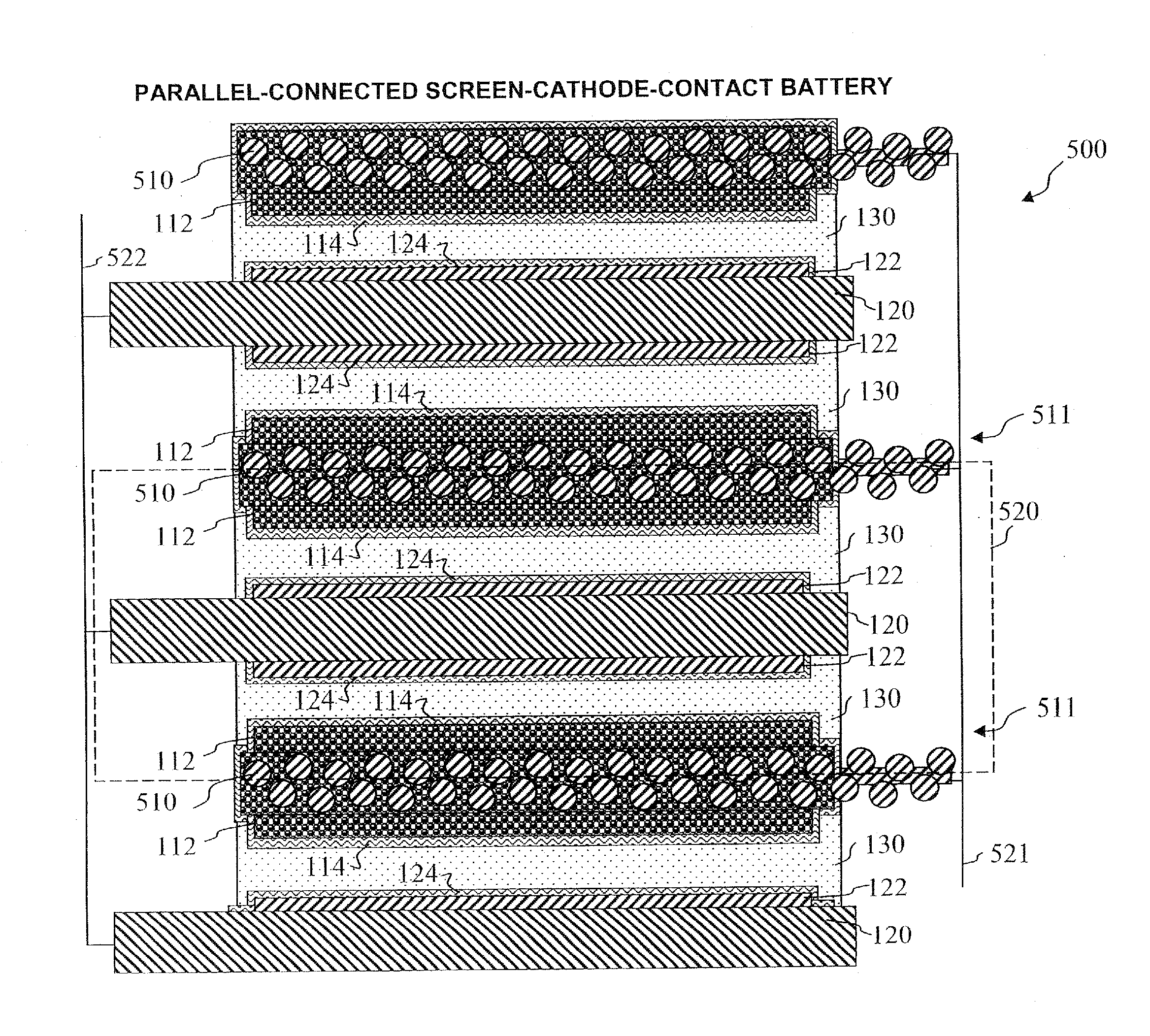

Electrical-energy-storage unit (EESU) utilizing ceramic and integrated-circuit technologies for replacement of electrochemical batteries

InactiveUS7033406B2Reduce sinteringLowering hot-isostatic-pressing temperatureElectrical storage systemFixed capacitor electrodesBarium titanatePermittivity

An electrical-energy-storage unit (EESU) has as a basis material a high-permittivity composition-modified barium titanate ceramic powder. This powder is double coated with the first coating being aluminum oxide and the second coating calcium magnesium aluminosilicate glass. The components of the EESU are manufactured with the use of classical ceramic fabrication techniques which include screen printing alternating multilayers of nickel electrodes and high-permittivitiy composition-modified barium titanate powder, sintering to a closed-pore porous body, followed by hot-isostatic pressing to a void-free body. The components are configured into a multilayer array with the use of a solder-bump technique as the enabling technology so as to provide a parallel configuration of components that has the capability to store electrical energy in the range of 52 kW·h. The total weight of an EESU with this range of electrical energy storage is about 336 pounds.

Owner:EESTOR

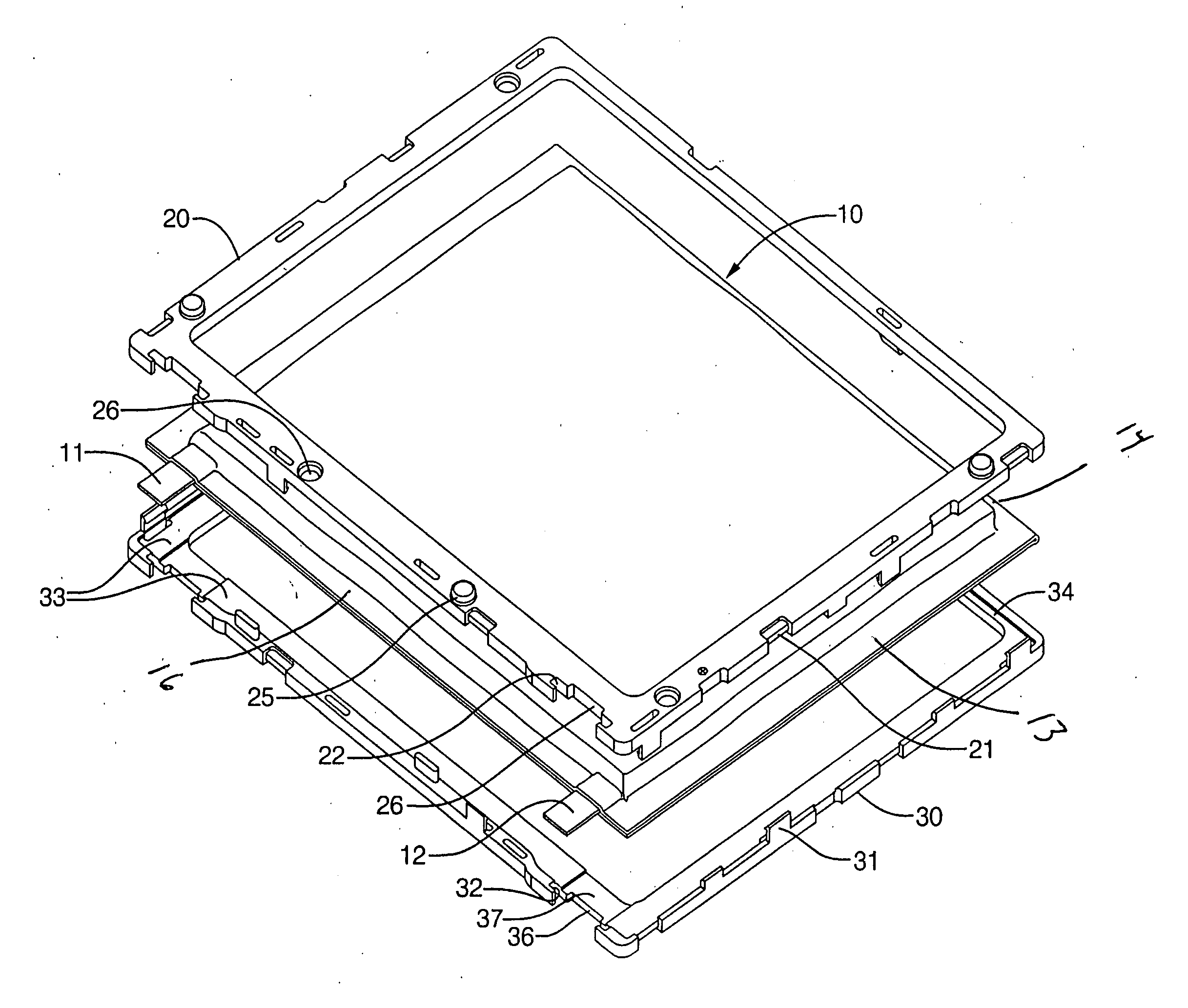

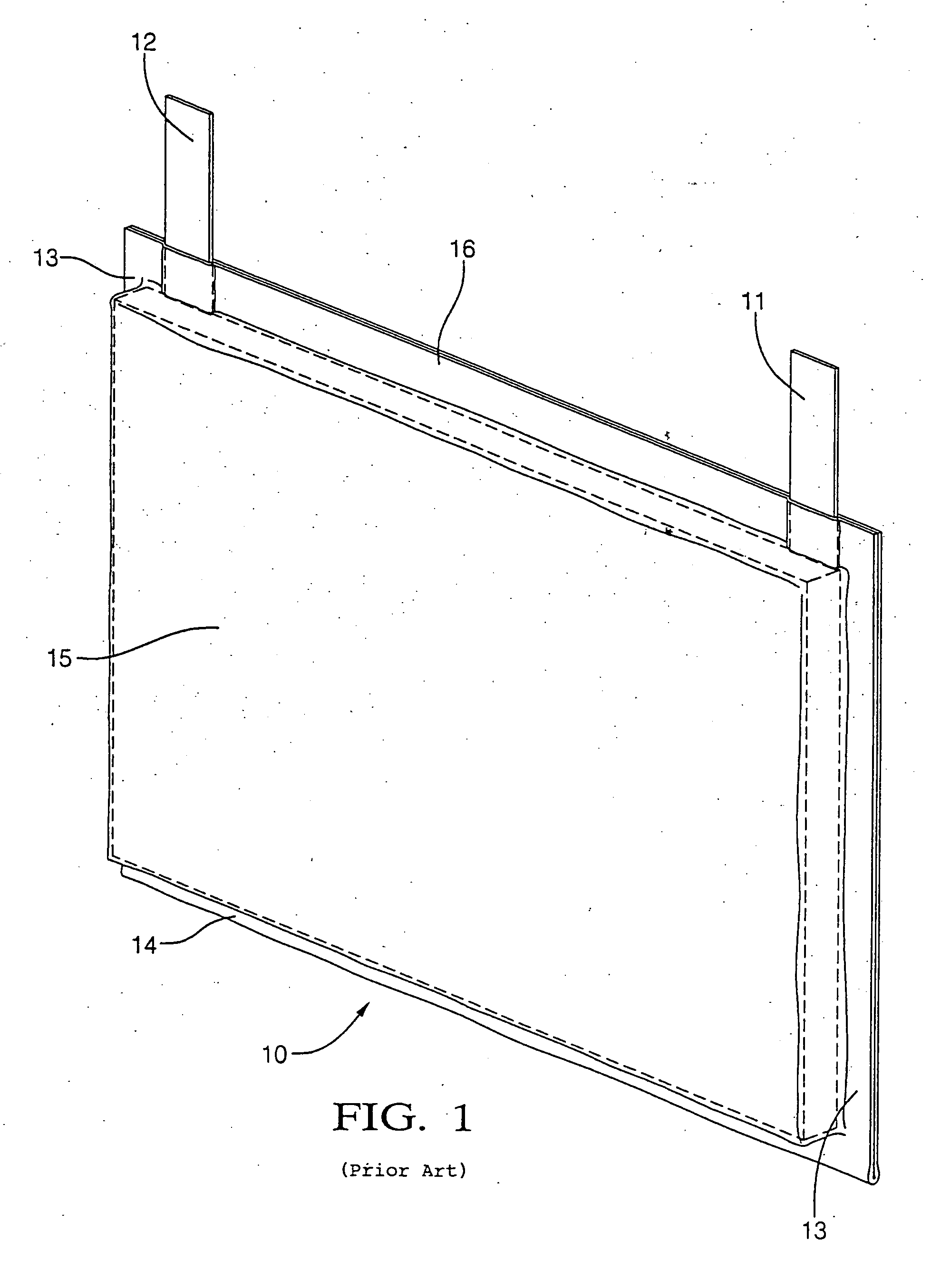

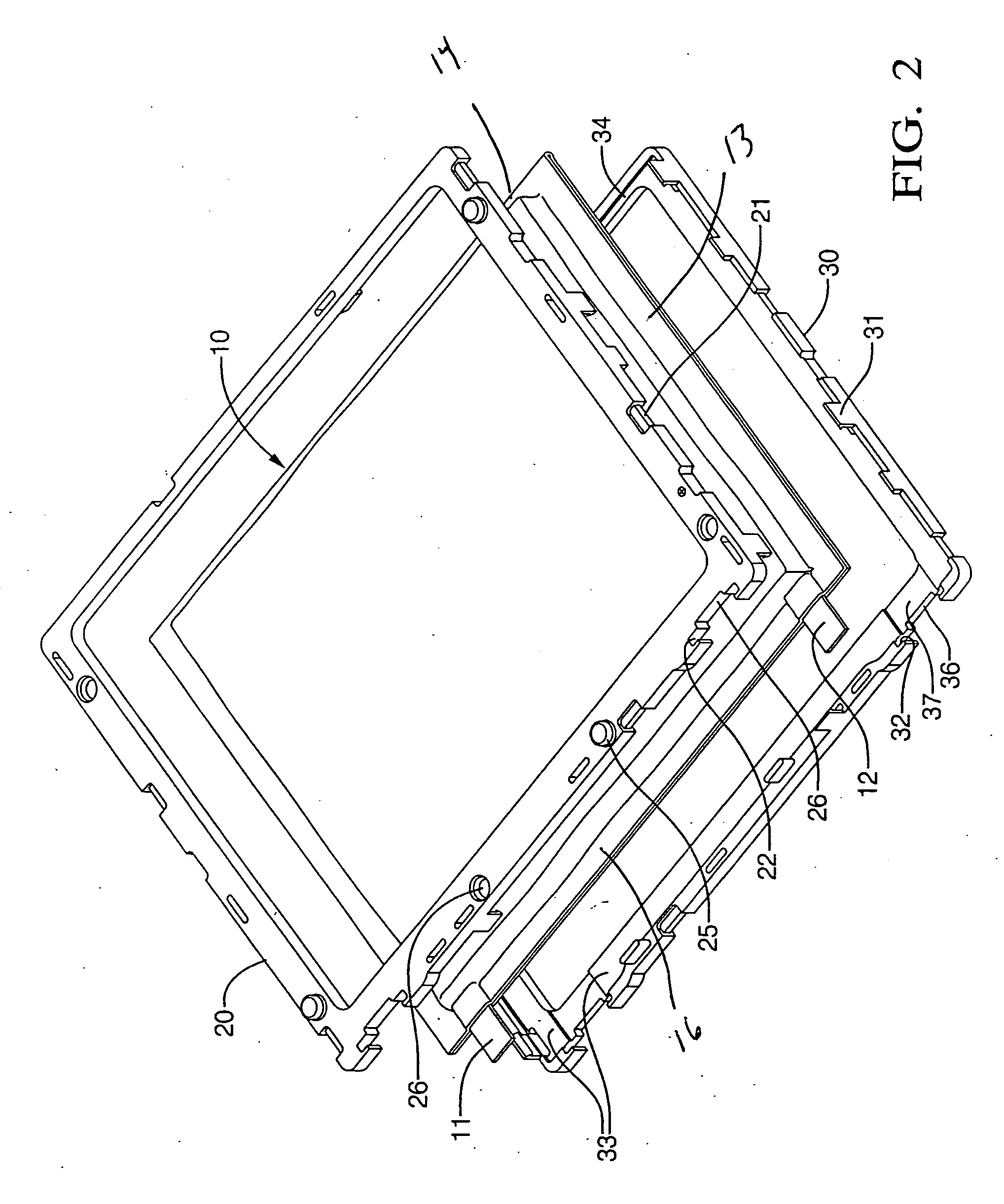

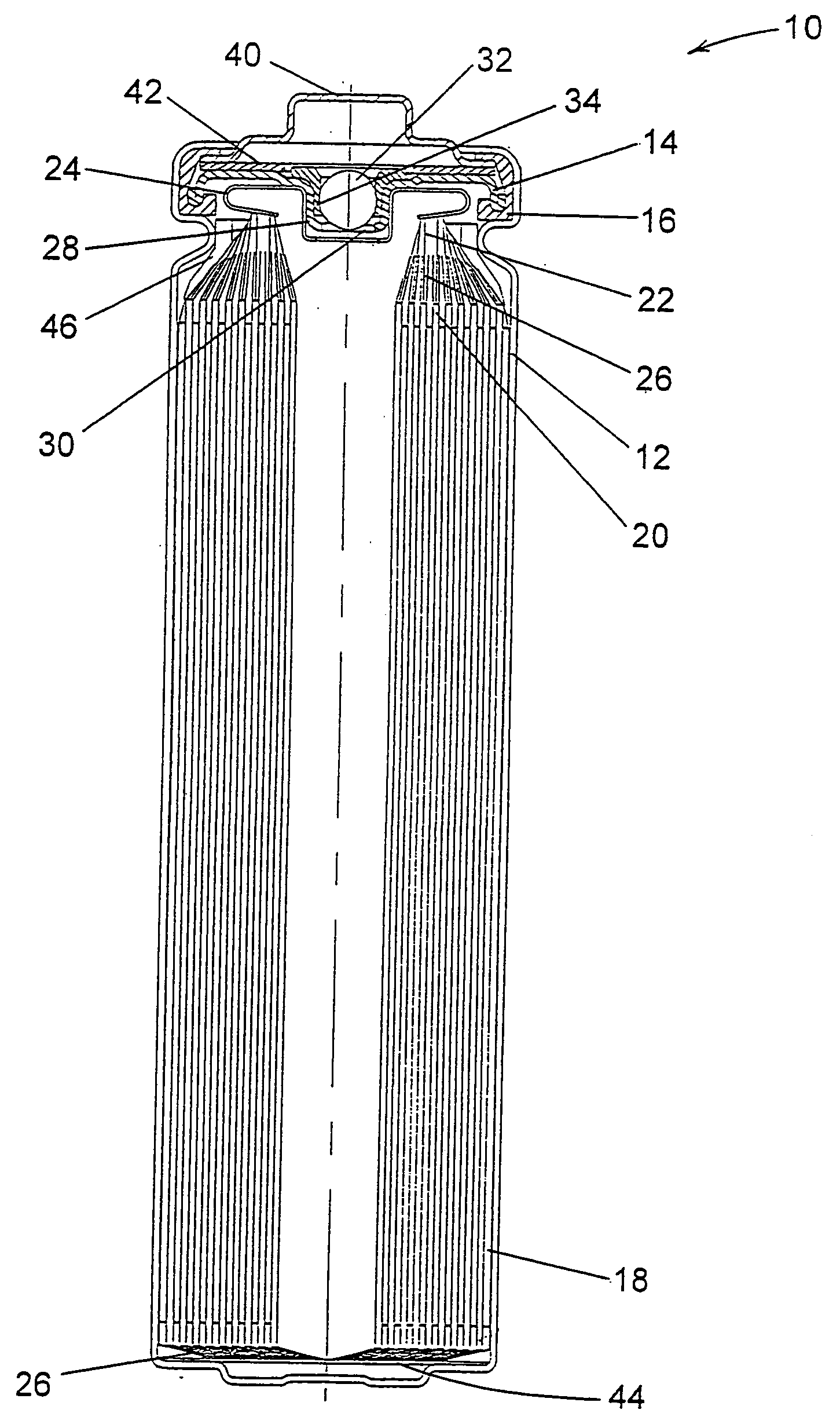

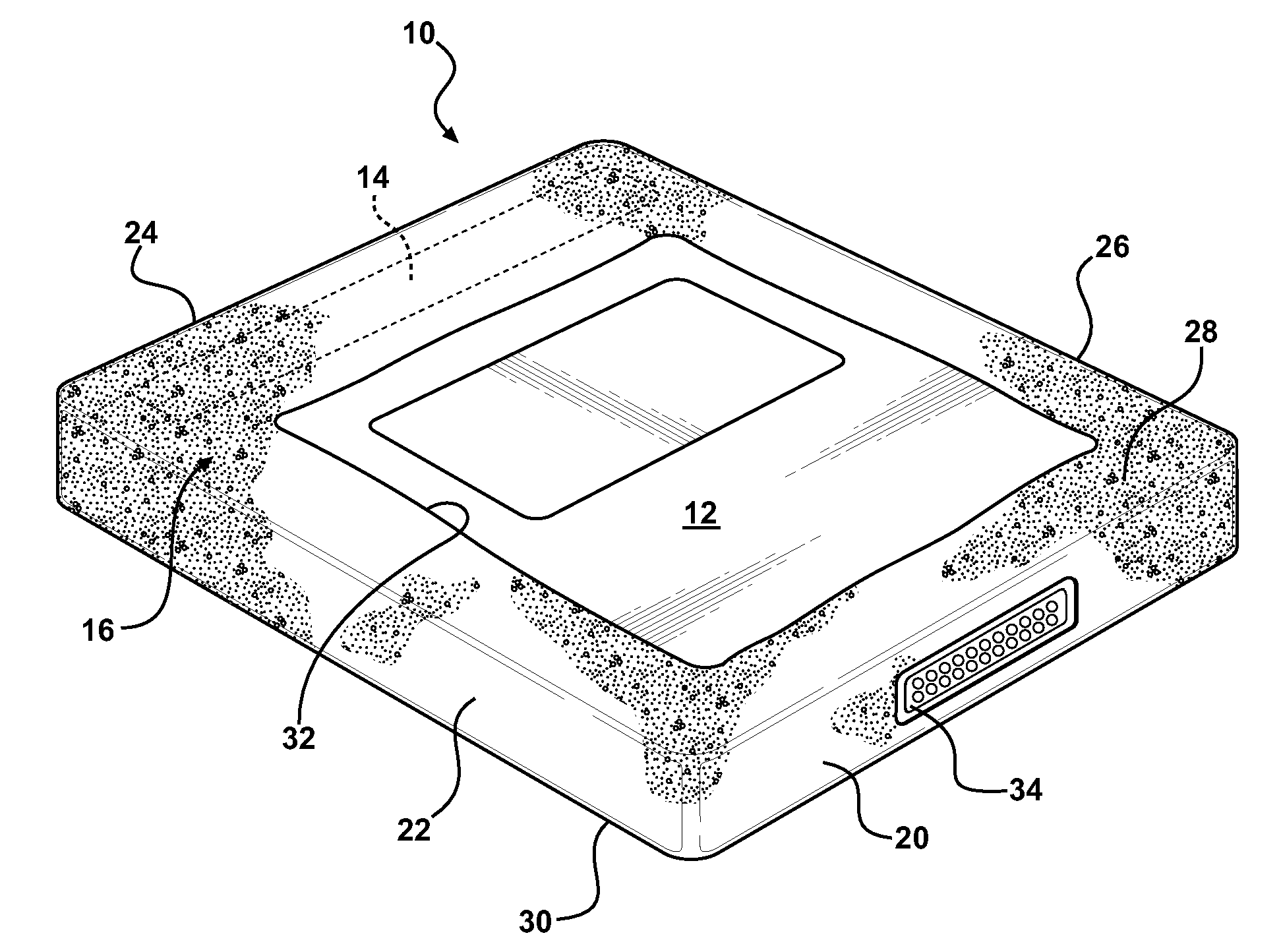

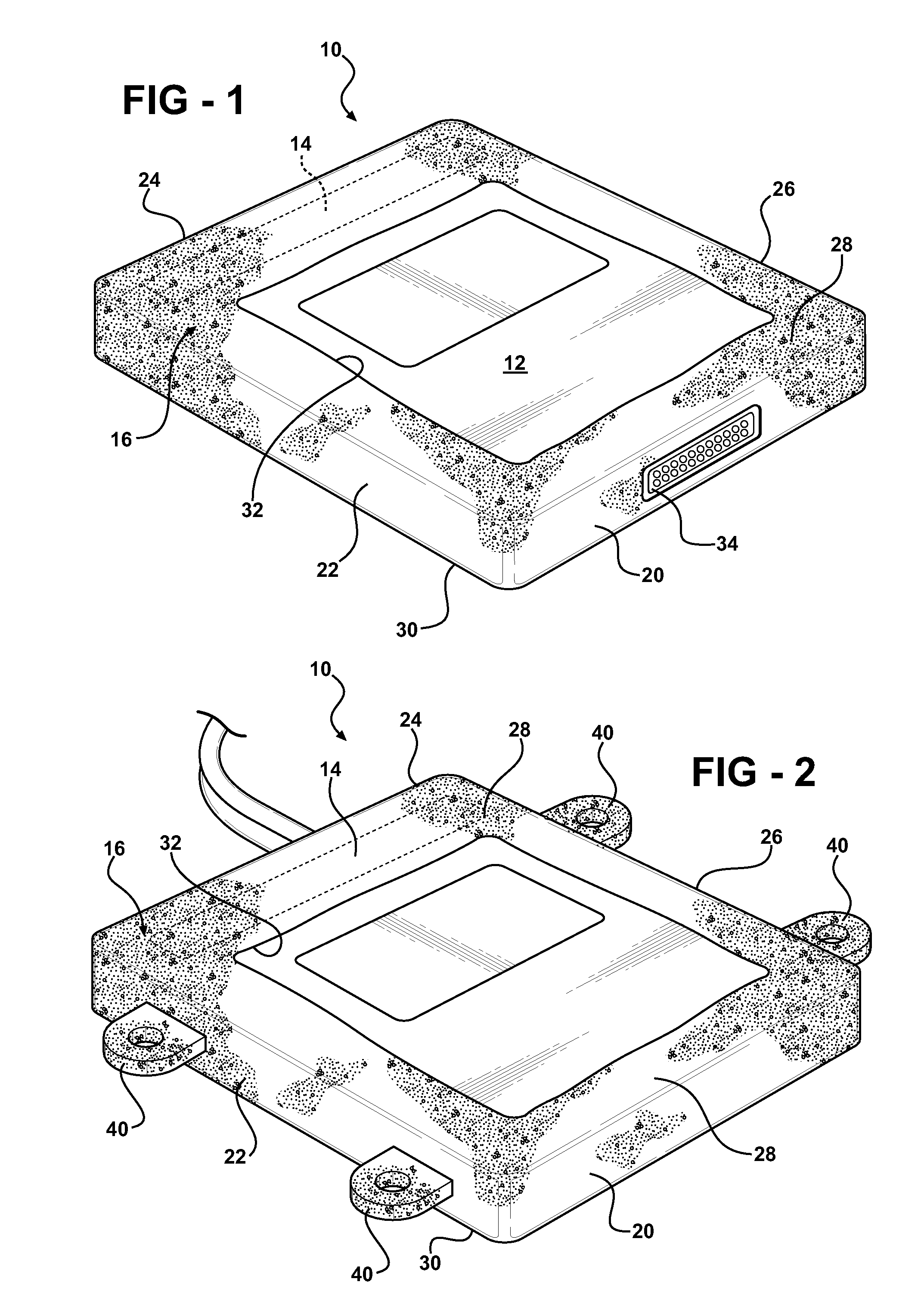

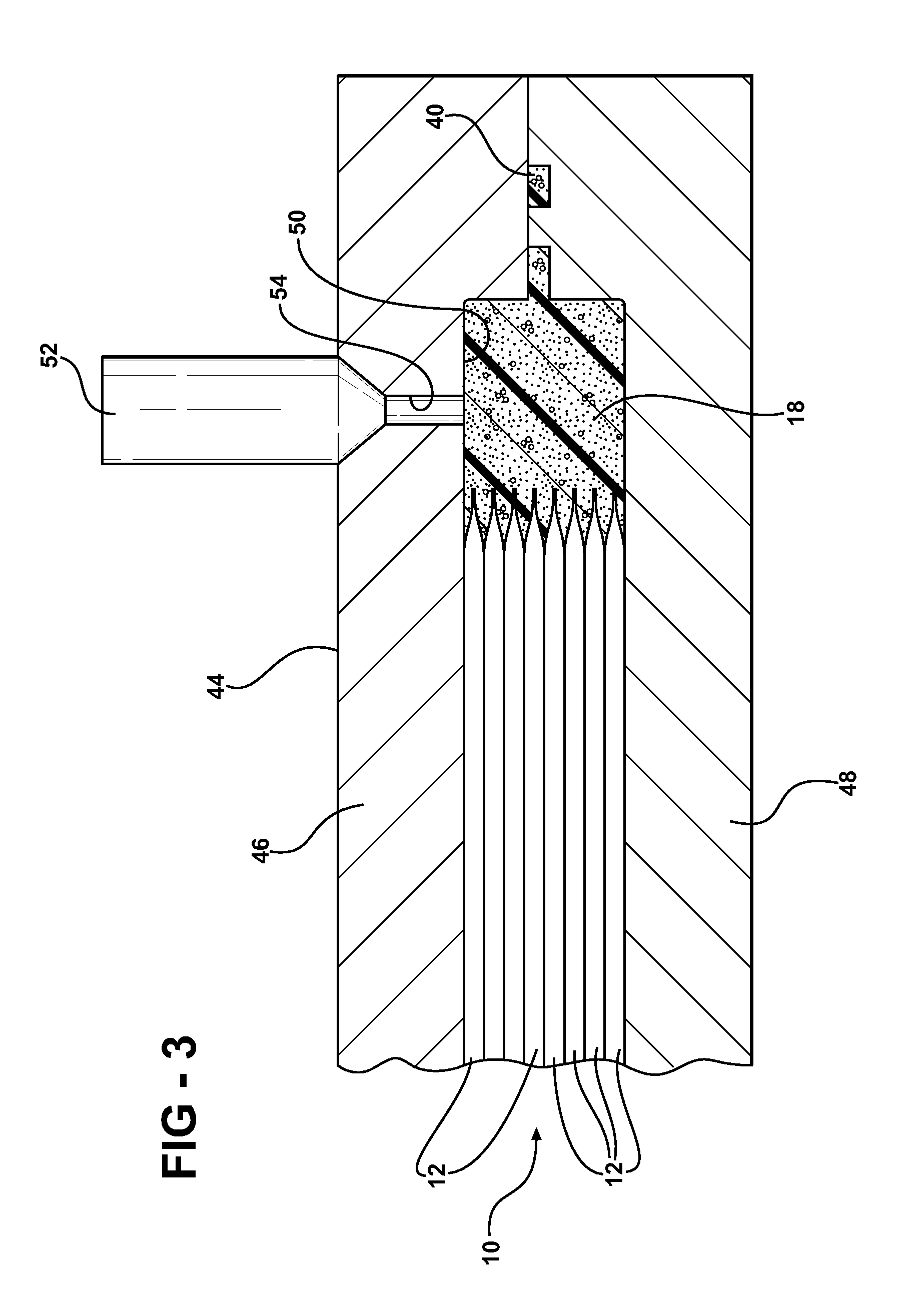

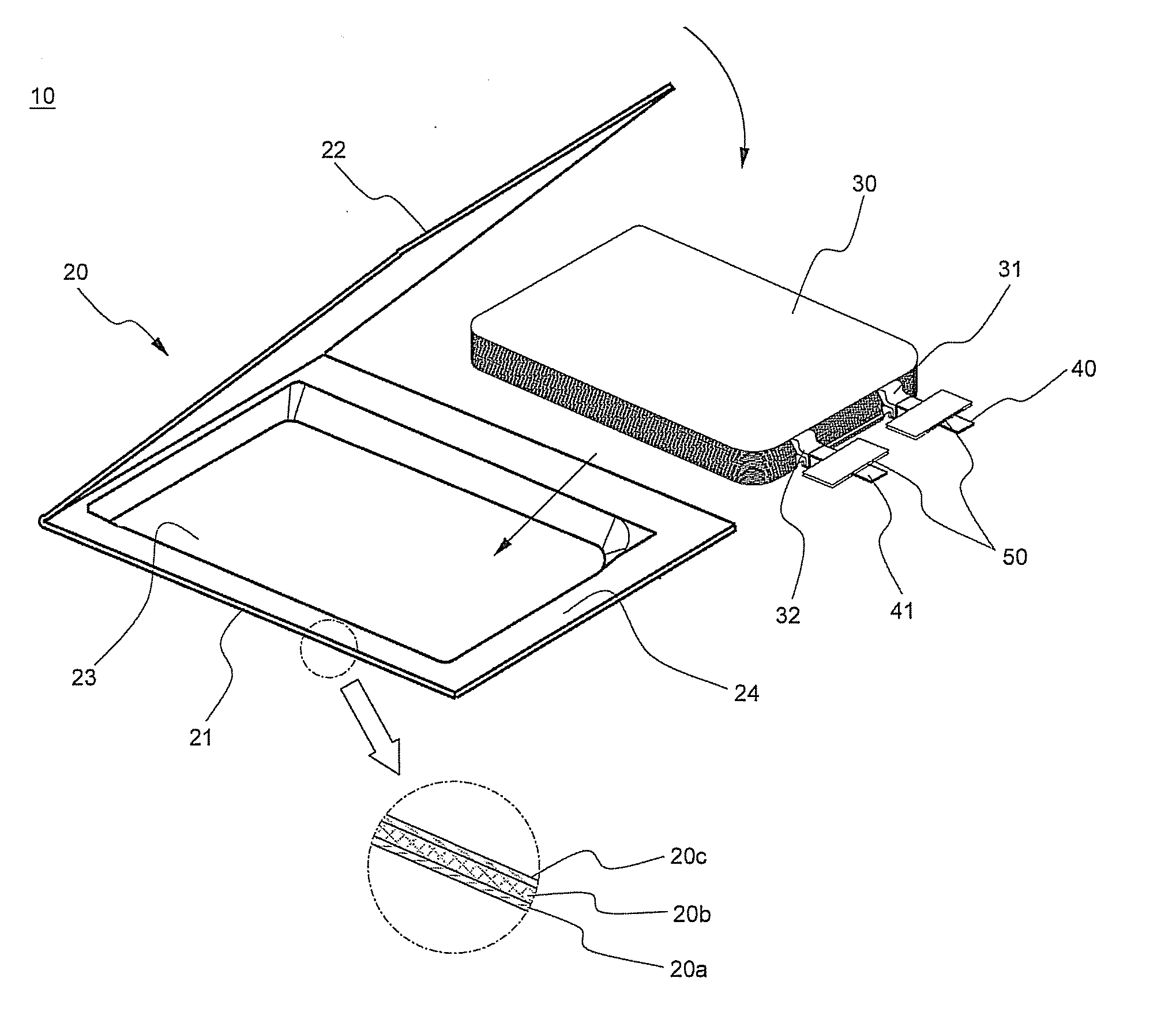

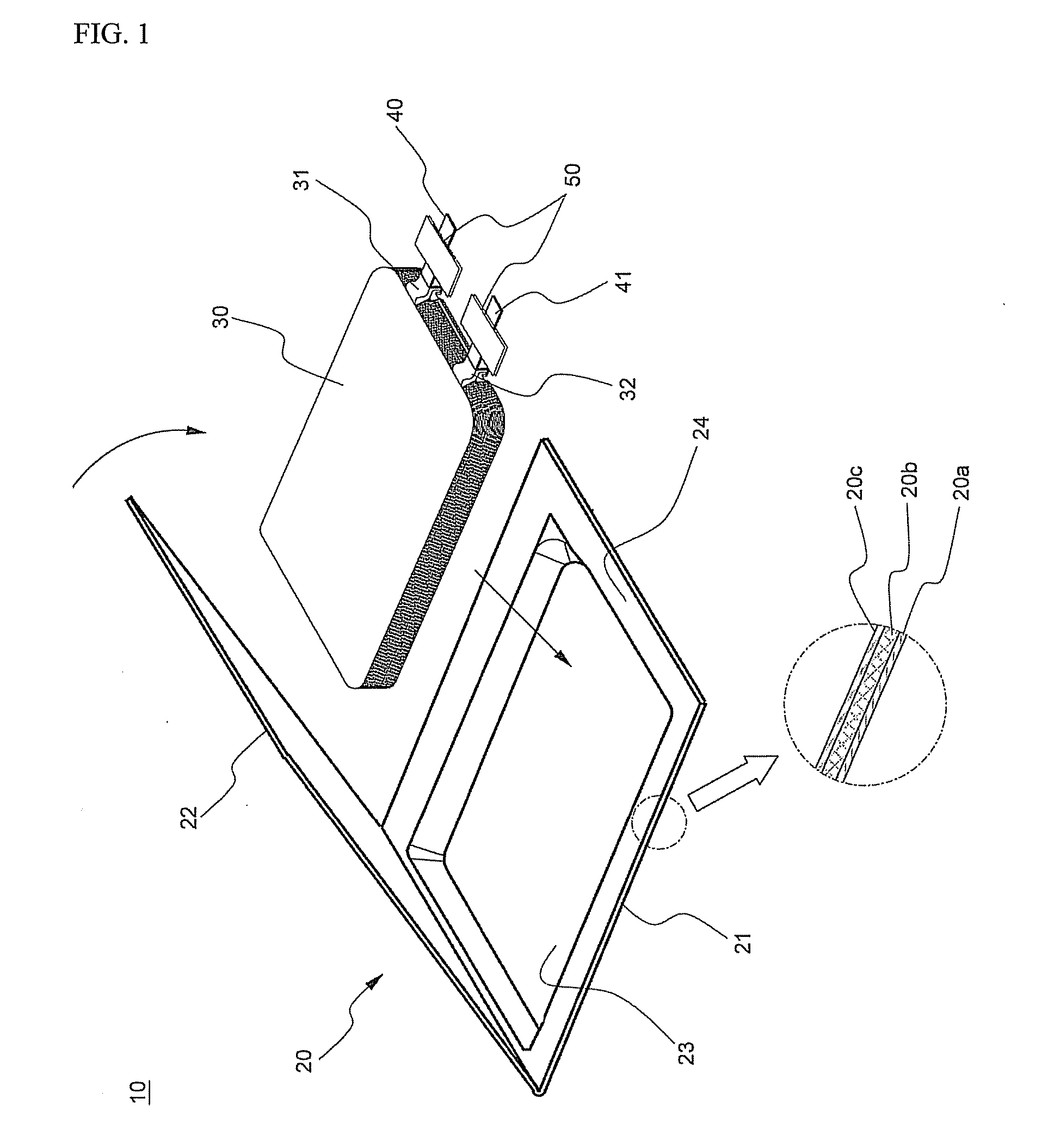

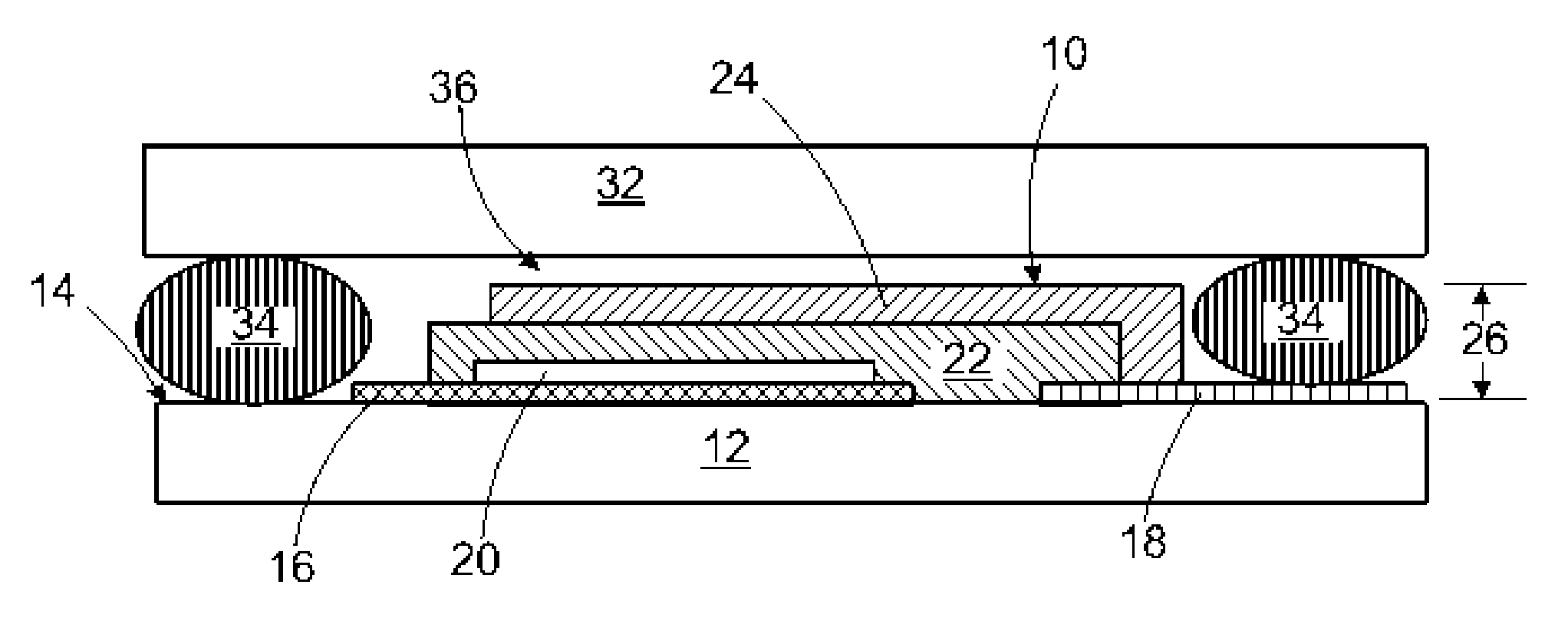

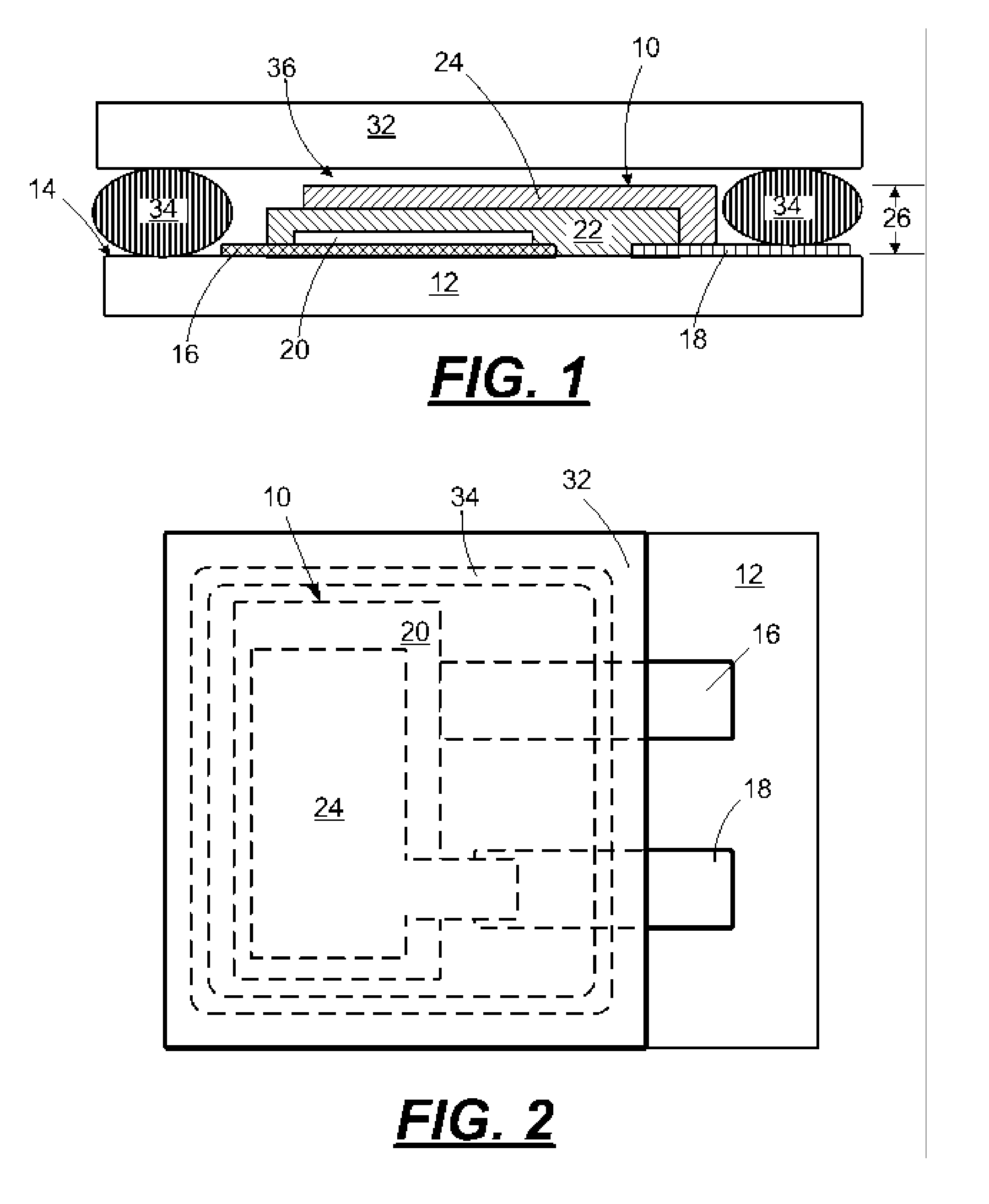

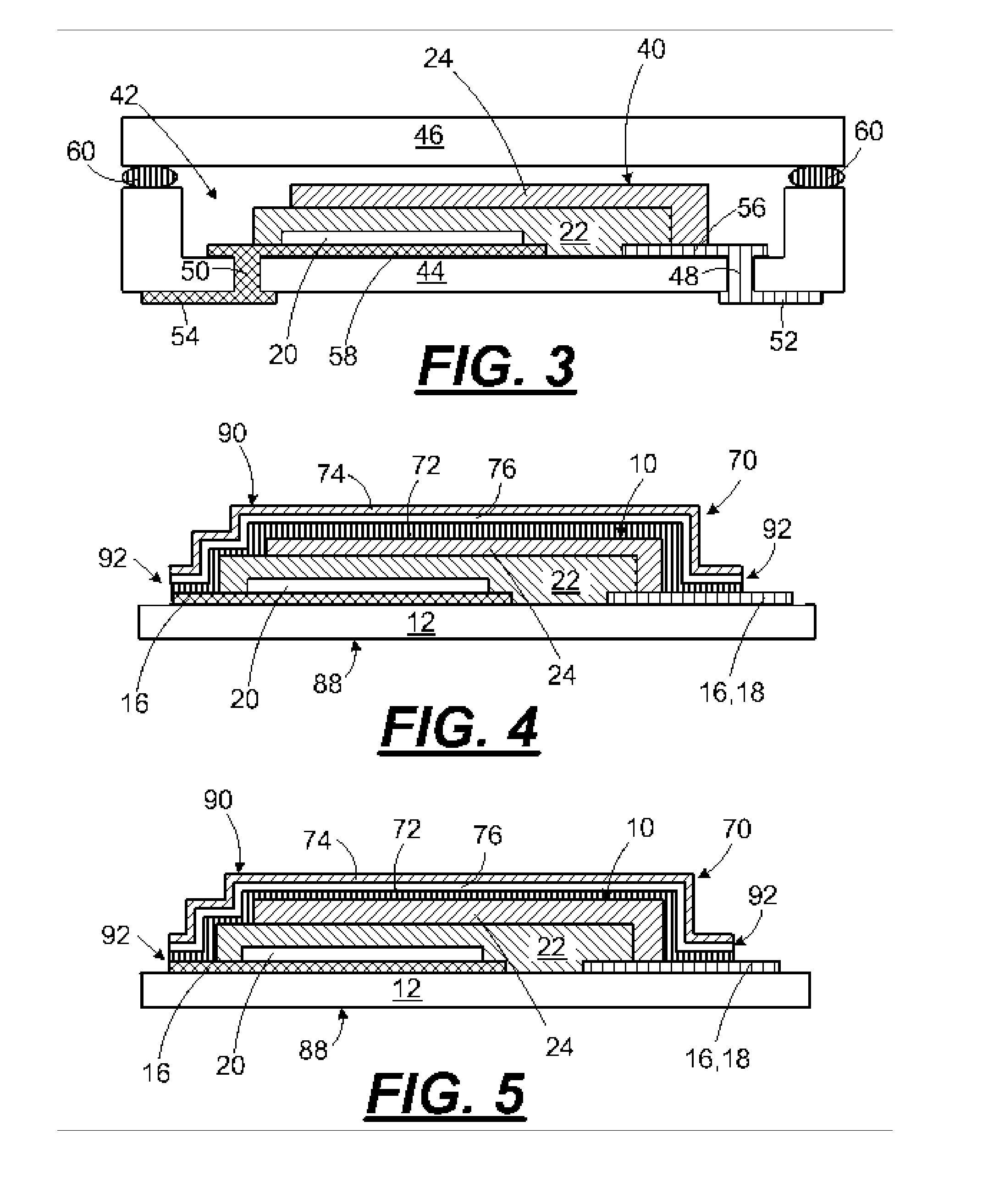

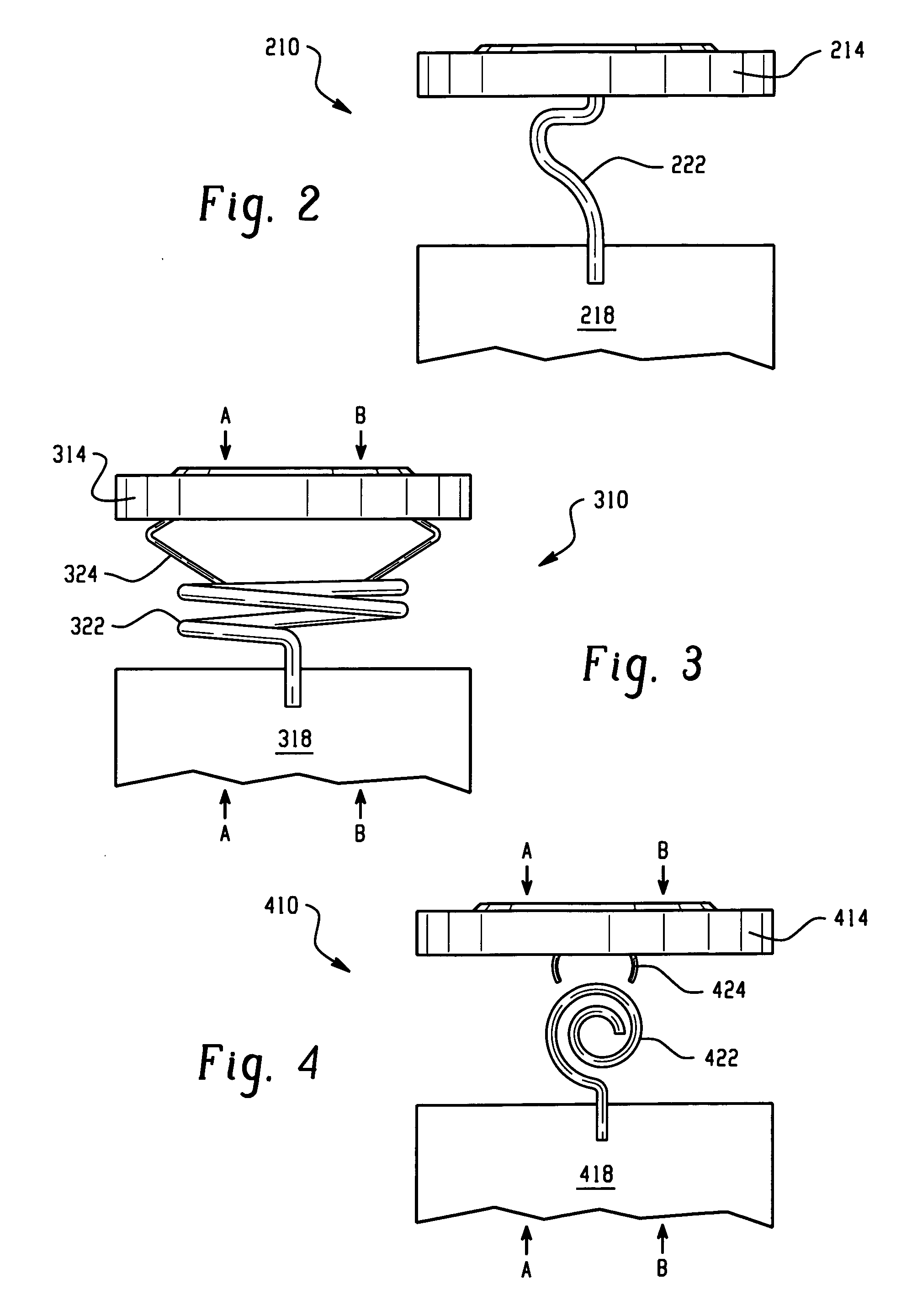

Apparatus and method for securing battery cell packs

ActiveUS20060234119A1Facilitate electrically connectingFacilitate mechanically connectingFinal product manufactureSmall-sized cells cases/jacketsEdge surfaceBattery cell

A framed lithium battery cell group includes a first frame member (20) and a second frame member (30). The frame members are locked together, clamping the lithium battery cell pack (10) on the seal edge surfaces (13, 16), thereby providing structural rigidity and protection from damage due to handling and vibration. Each of the frame members (20, 30) has multiple pins (25) and sockets (26) on the side opposite the clamping surface (33) to facilitate aligning and stacking multiple lithium battery cell pack and frame assemblies to form a lithium battery cell group (50). Each of the frame members (20, 30) include a buss bar capture feature (22, 32) having a bus bar (40) inserted therein for electrically connecting all of the terminals for a given lithium battery pack group to the buss bar (40).

Owner:ENERDEL

High discharge capacity lithium battery

InactiveUS20050233214A1Improve discharge performanceIncrease energy densityFinal product manufactureOrganic electrolyte cellsHigh rateIron disulfide

A lithium / iron disulfide electrochemical battery cell with a high discharge capacity. The cell has a lithium negative electrode, an iron disulfide positive electrode and a nonaqueous electrolyte. The iron disulfide of the positive electrode has a controlled average particle size range which allows the electrochemical cells to exhibit desired properties in both low and high rate applications. In various embodiments, the iron disulfide particles are wet milled, preferably utilizing a media mill or milled utilizing a non-mechanical mill such as a jet mill, which reduces the iron disulfide particles to a desired average particle size range for incorporation into the positive electrode.

Owner:EVEREADY BATTERY CO INC

Method of manufacturing solid electrolyte battery

InactiveUS20050132562A1High trafficAvoid excessive power outputNon-aqueous electrolyte accumulatorsFinal product manufacturePolymer electrolytesBattery cell

A method of manufacturing a solid electrolyte battery includes a step of thermally pressing a composite layer including a positive electrode ink layer, an electrolyte ink layer and a negative electrode ink layer that are formed by coating a positive electrode ink, an electrolyte ink and a negative electrode ink. Further, the positive electrode ink, the electrolyte ink and the negative electrode ink contain a polymer electrolyte. By this method, it is possible to improve the flow of ions across respective interlayers of a positive electrode active material layer, a solid electrolyte layer and a negative electrode active material layer.

Owner:NISSAN MOTOR CO LTD

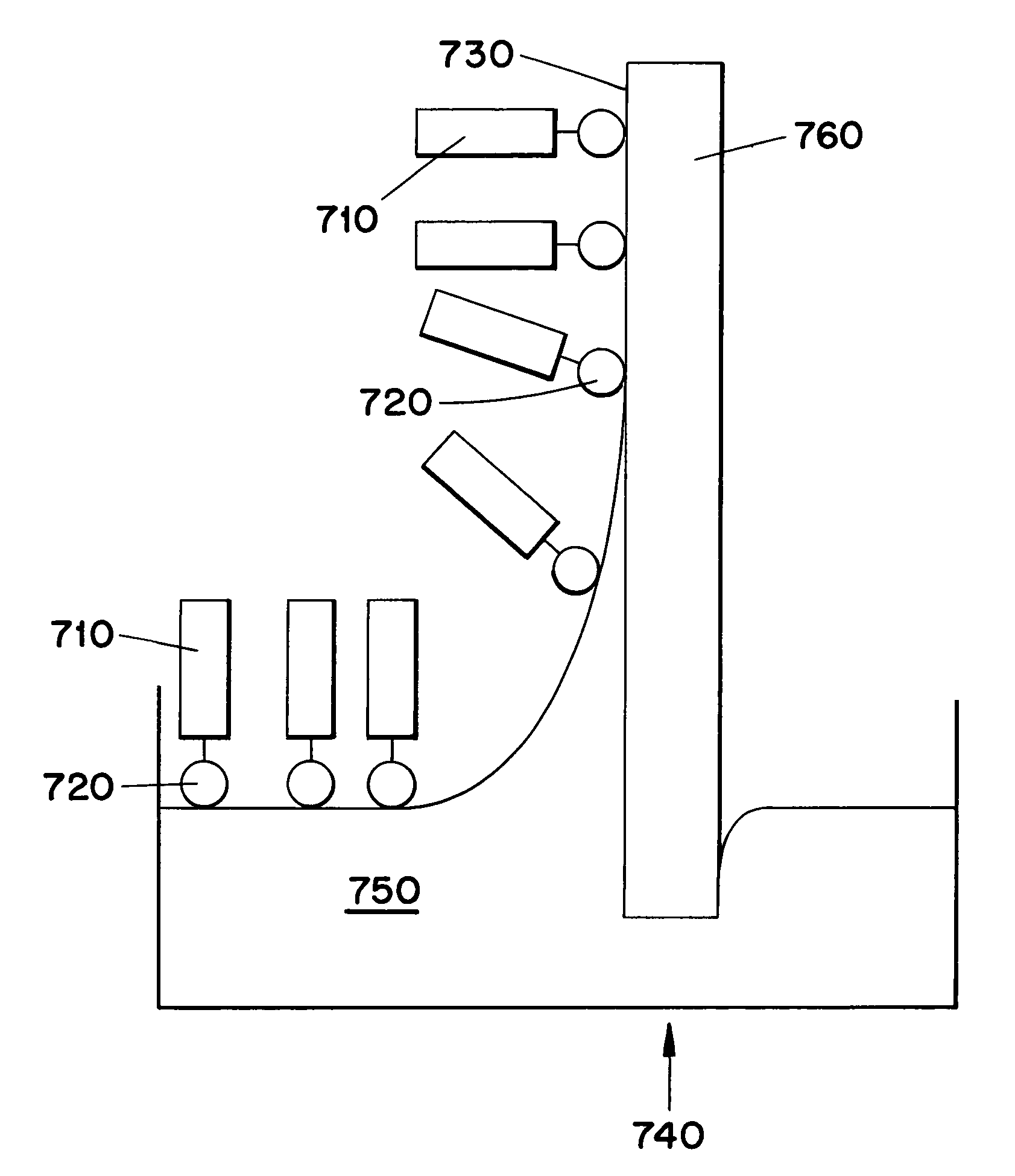

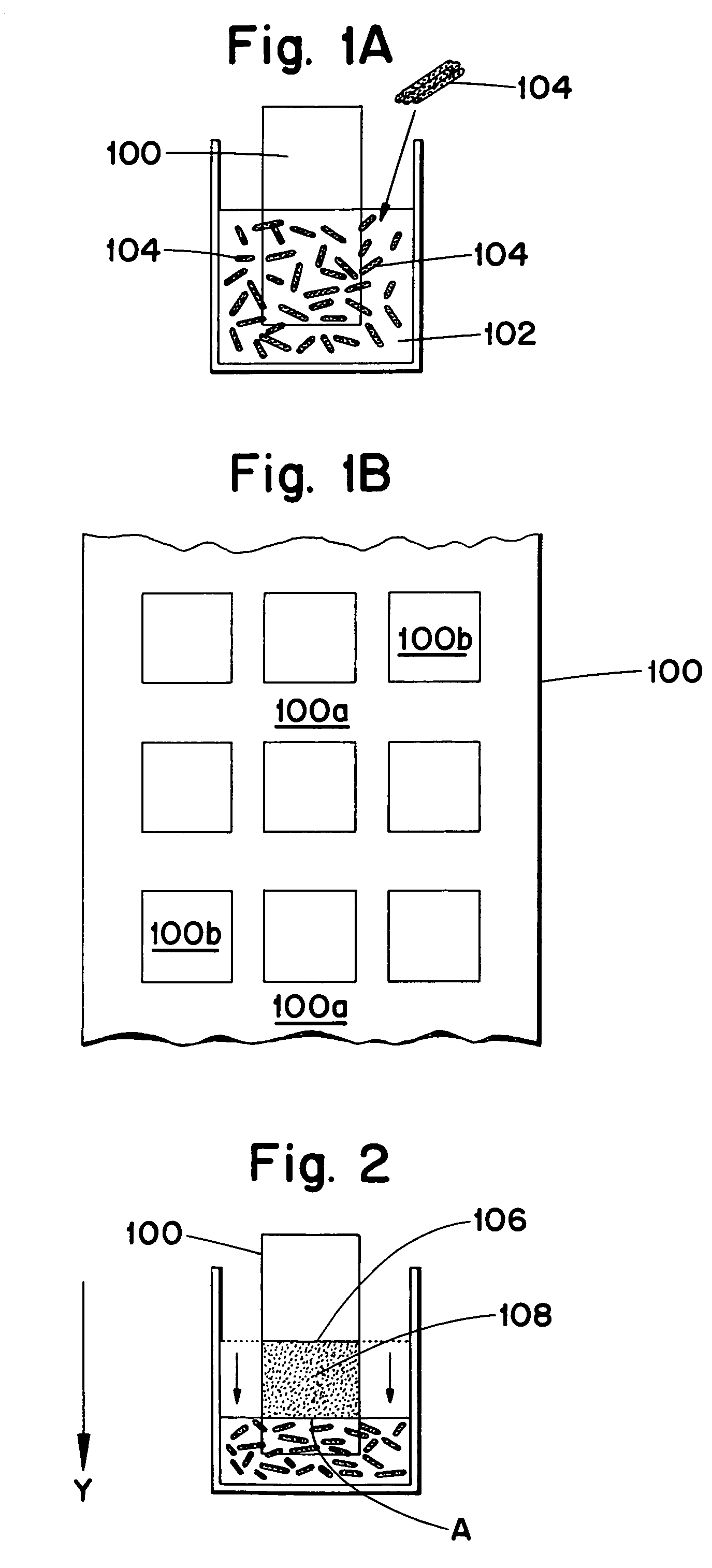

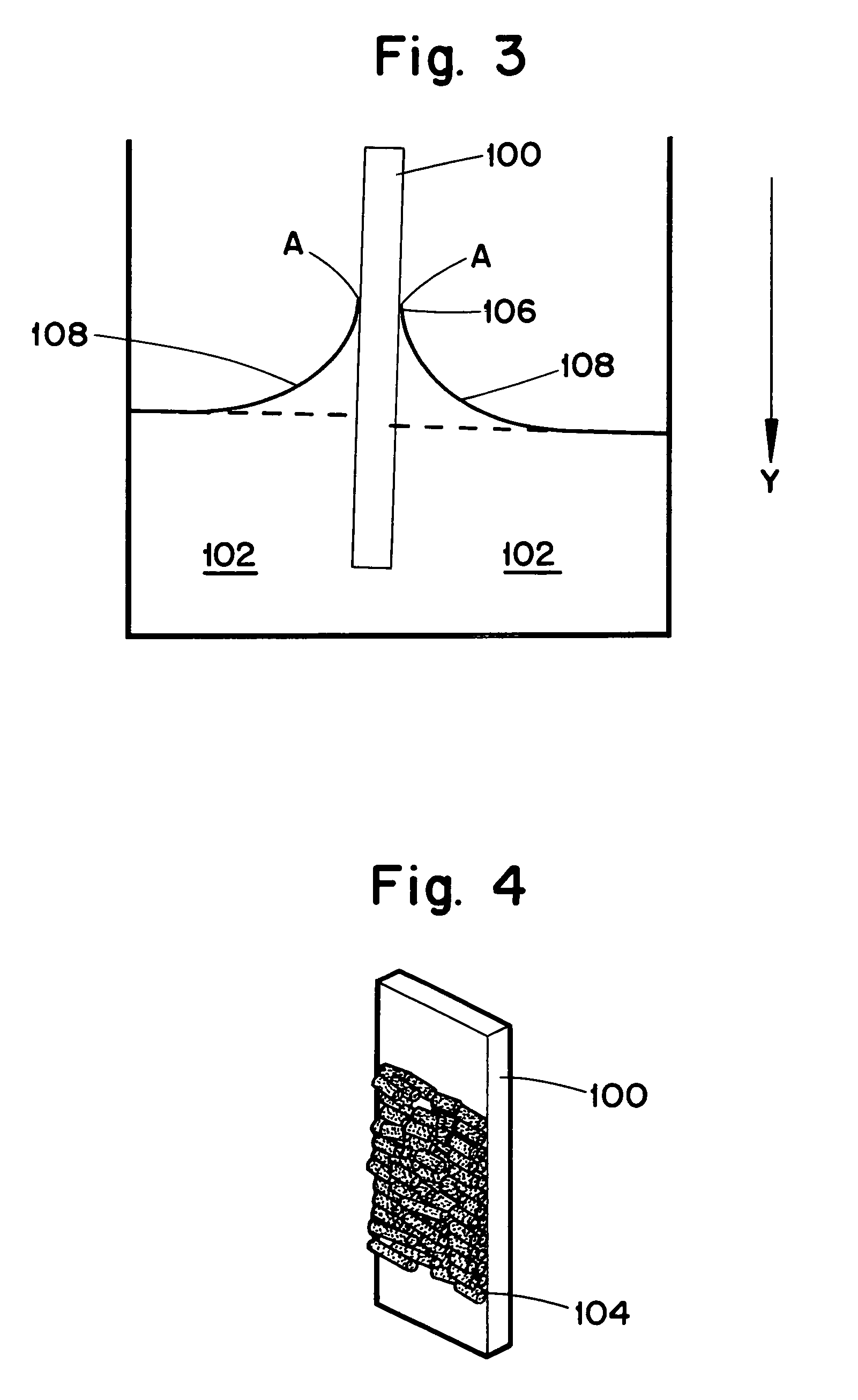

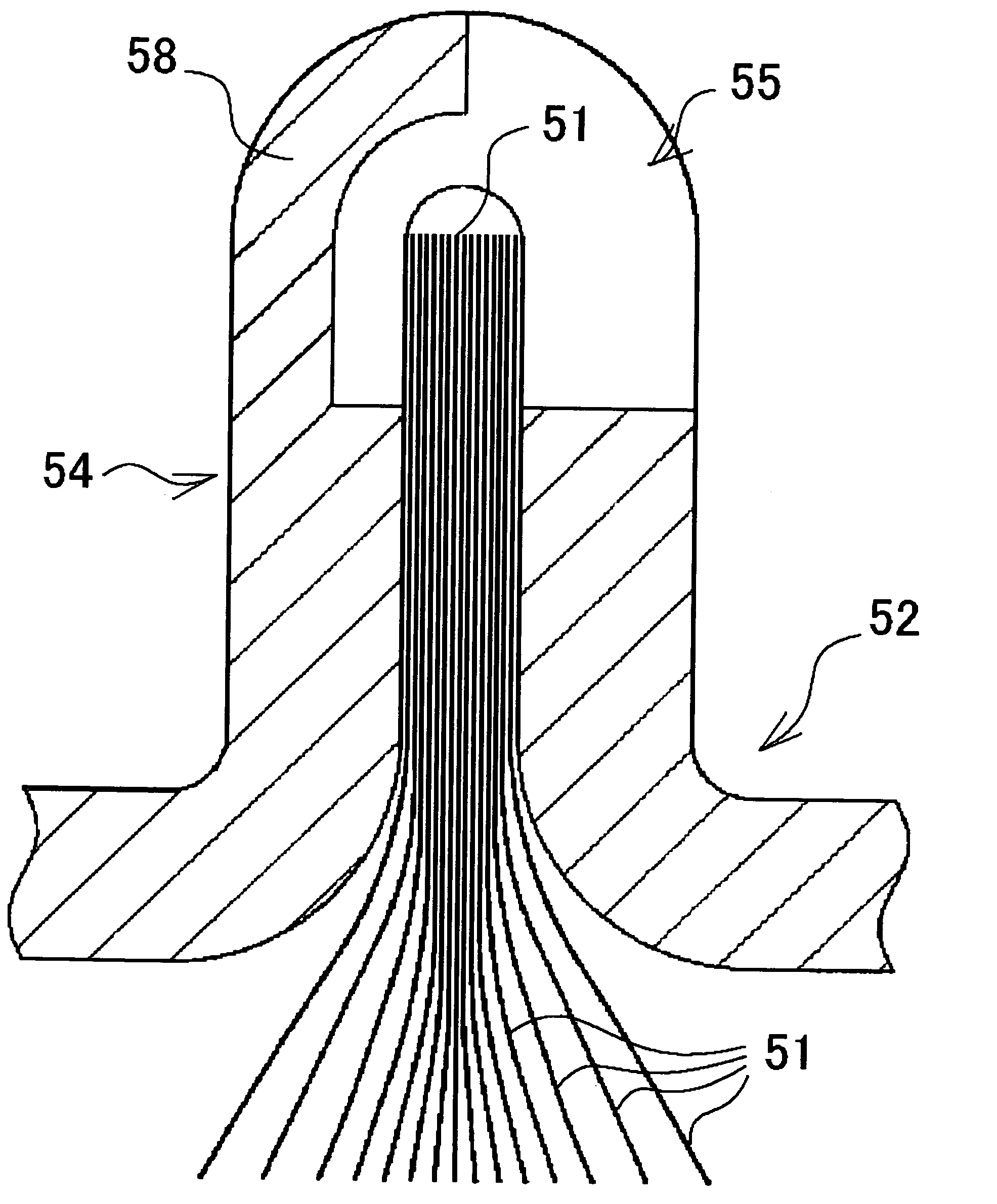

Method for assembling nano objects

InactiveUS7147894B2Orientation can be controlledEfficient assemblyMaterial nanotechnologyNanostructure manufactureEvaporationSolvent

A method for the self assembly of a macroscopic structure with a pre-formed nano object is provided. The method includes processing a nano object to a desired aspect ratio and chemical functionality and mixing the processed nano object with a solvent to form a suspension. Upon formation of the suspension, a substrate is inserted into the suspension. By either evaporation of the solvent, changing the pH value of the suspension, or changing the temperature of the suspension, the nano objects within the suspension deposit onto the substrate in an orientational order. In addition, a seed crystal may be used in place of the substrate thereby forming single-crystals and free-standing membranes of the nano-objects.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

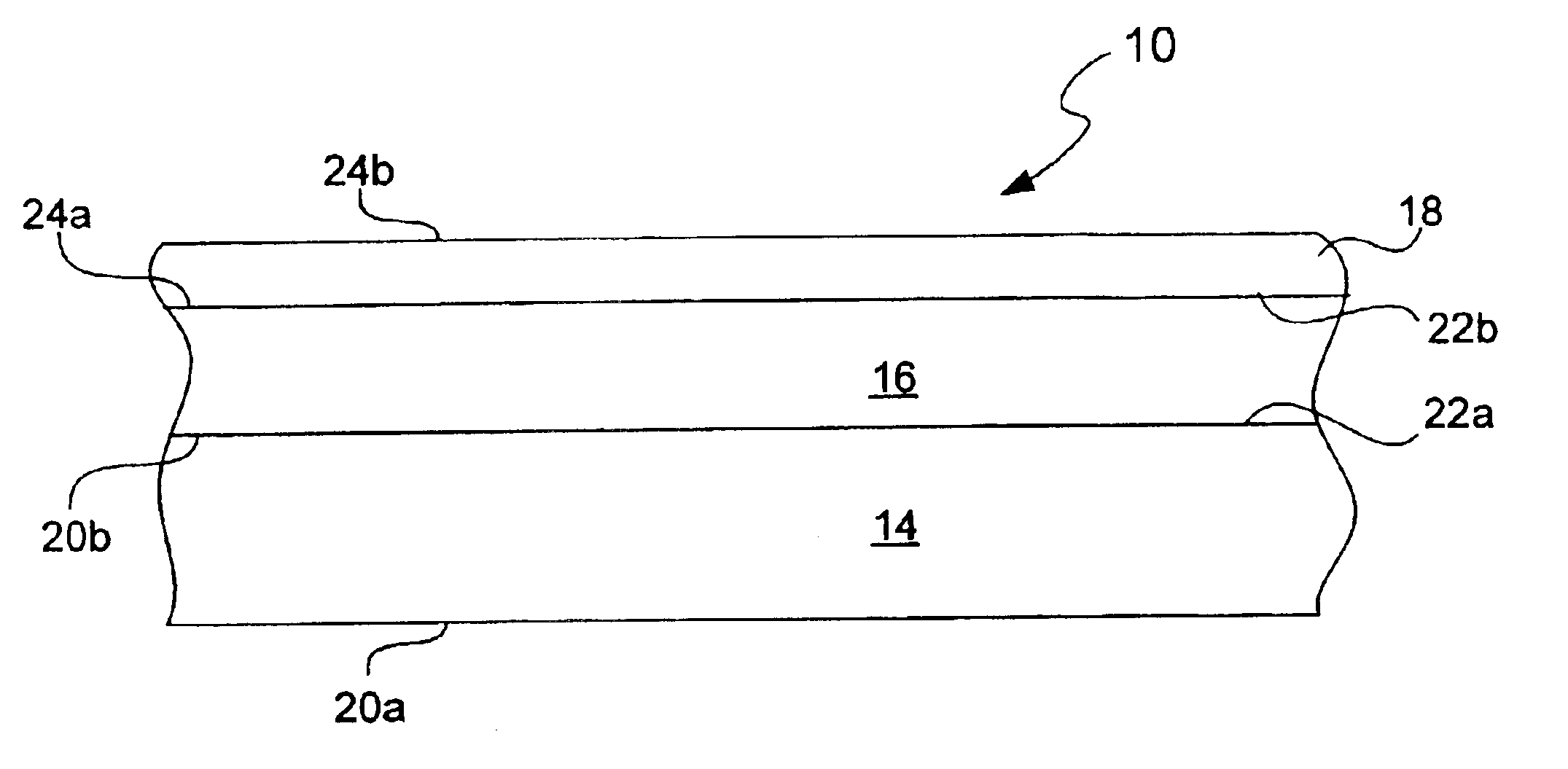

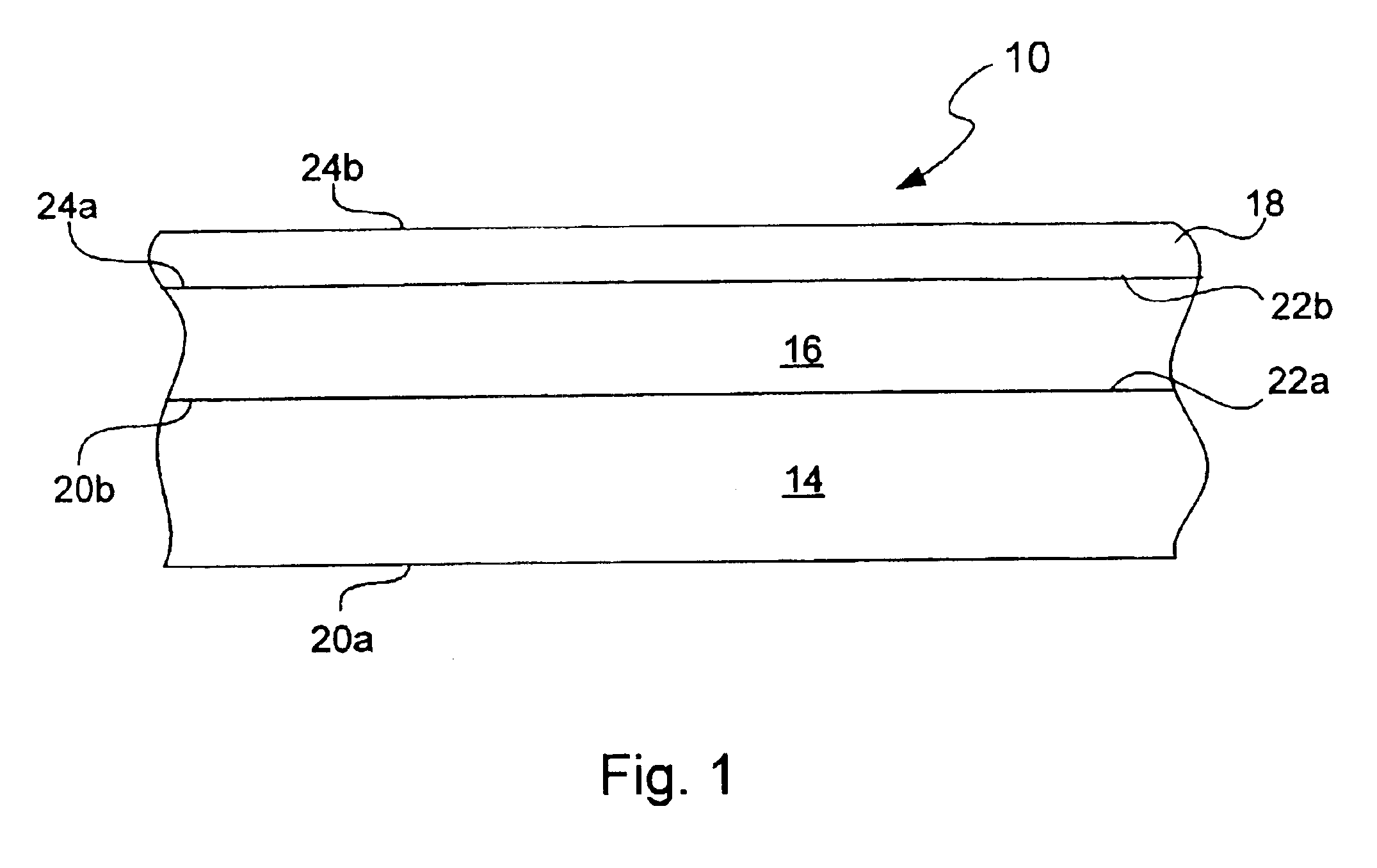

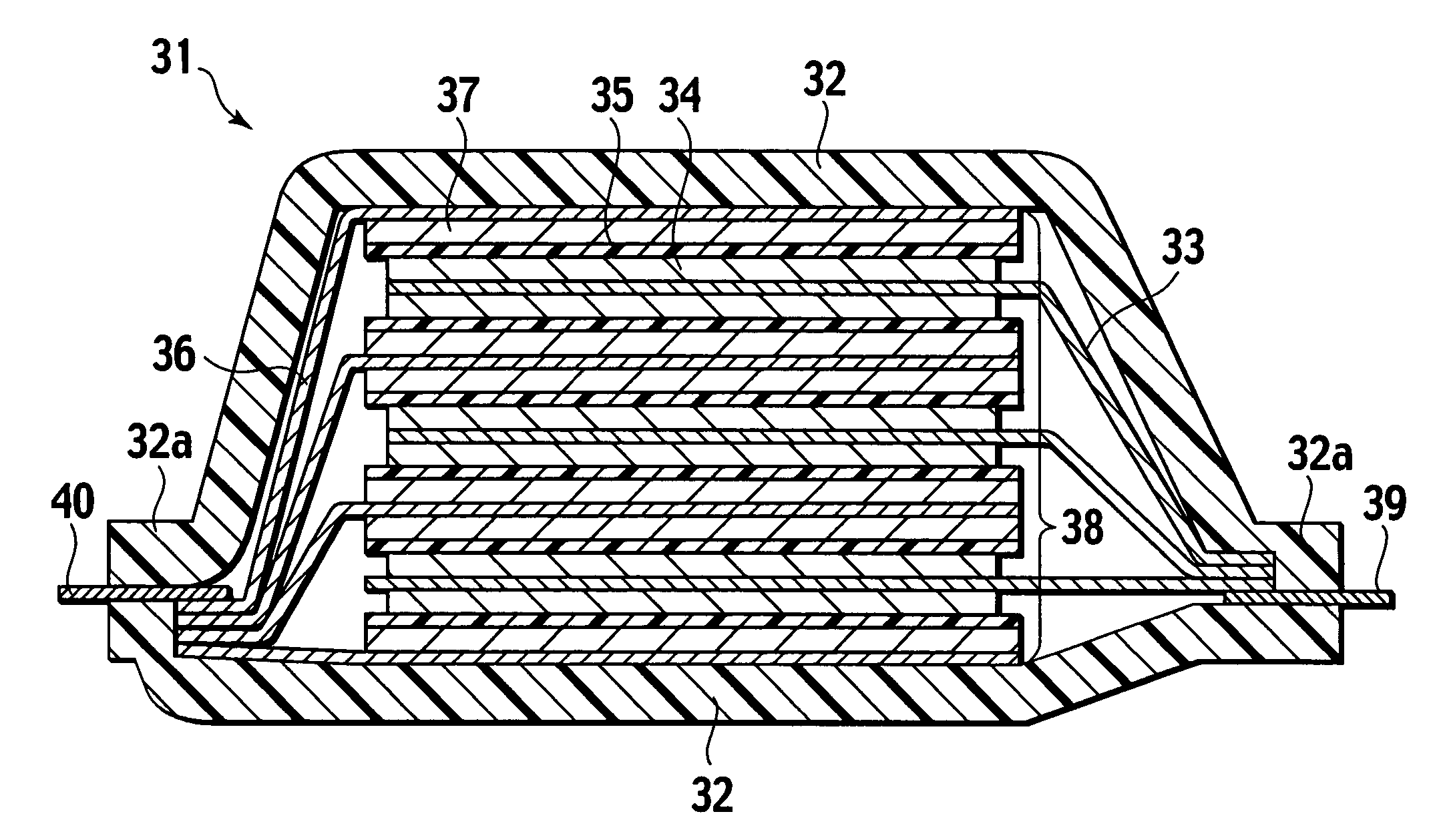

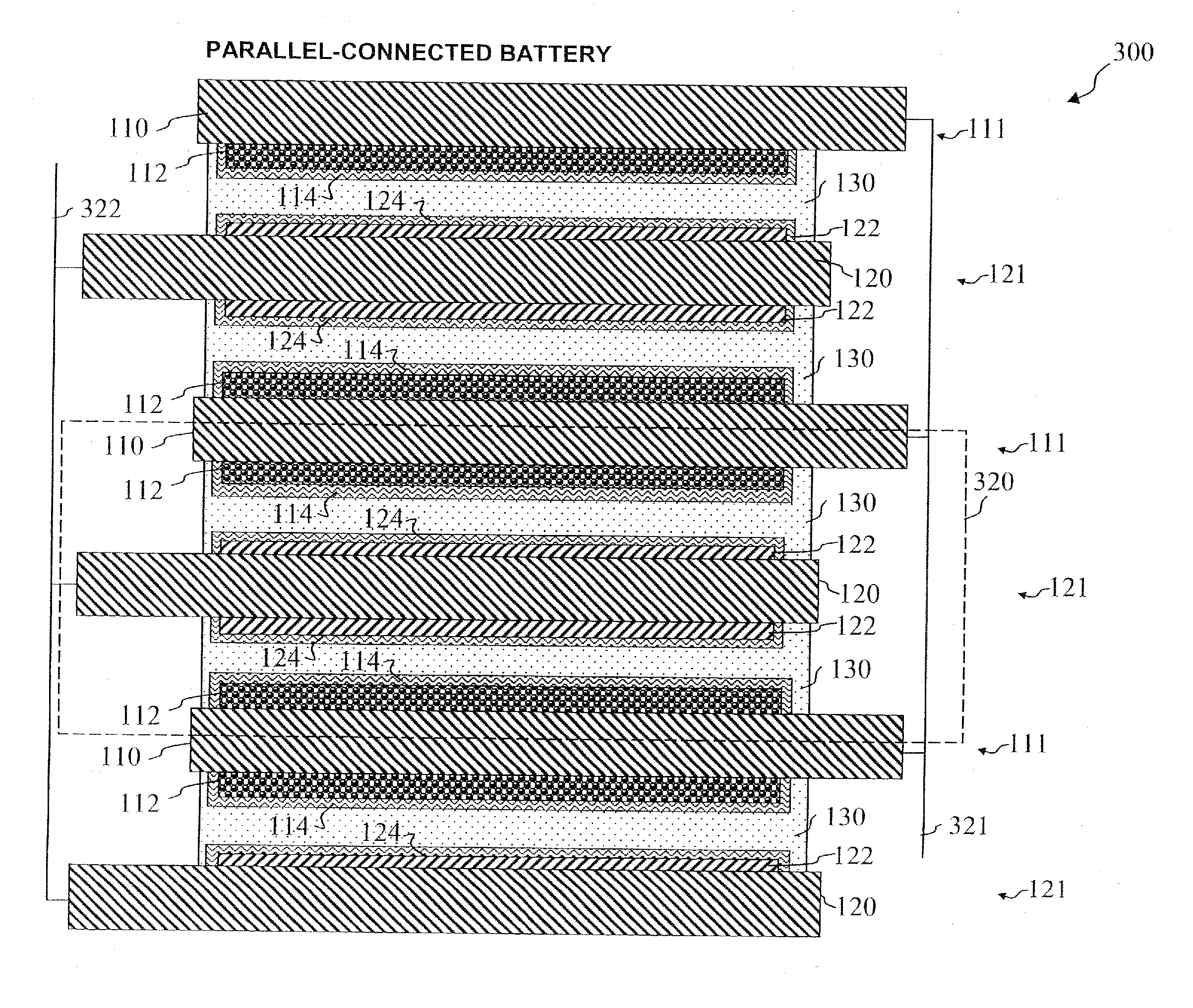

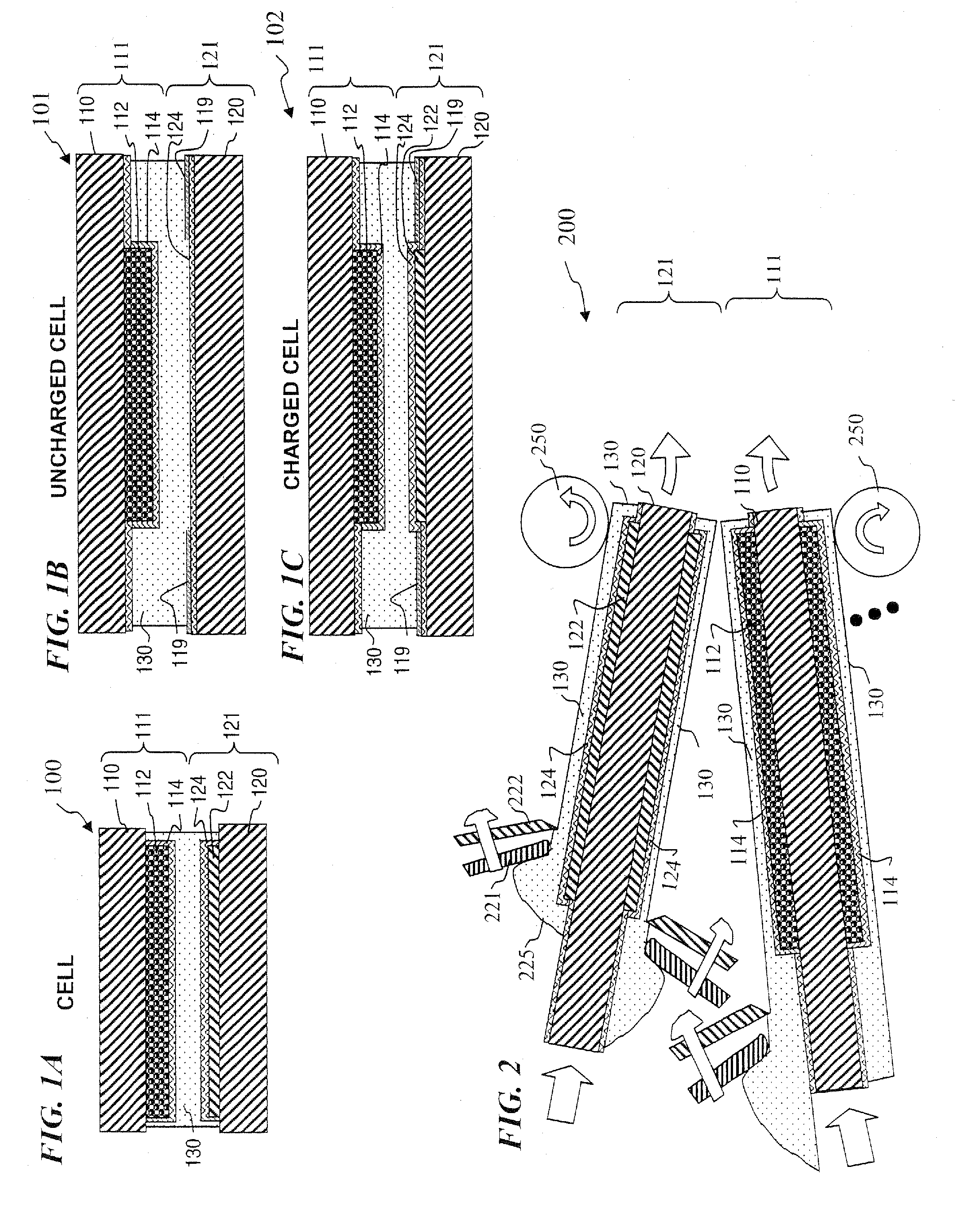

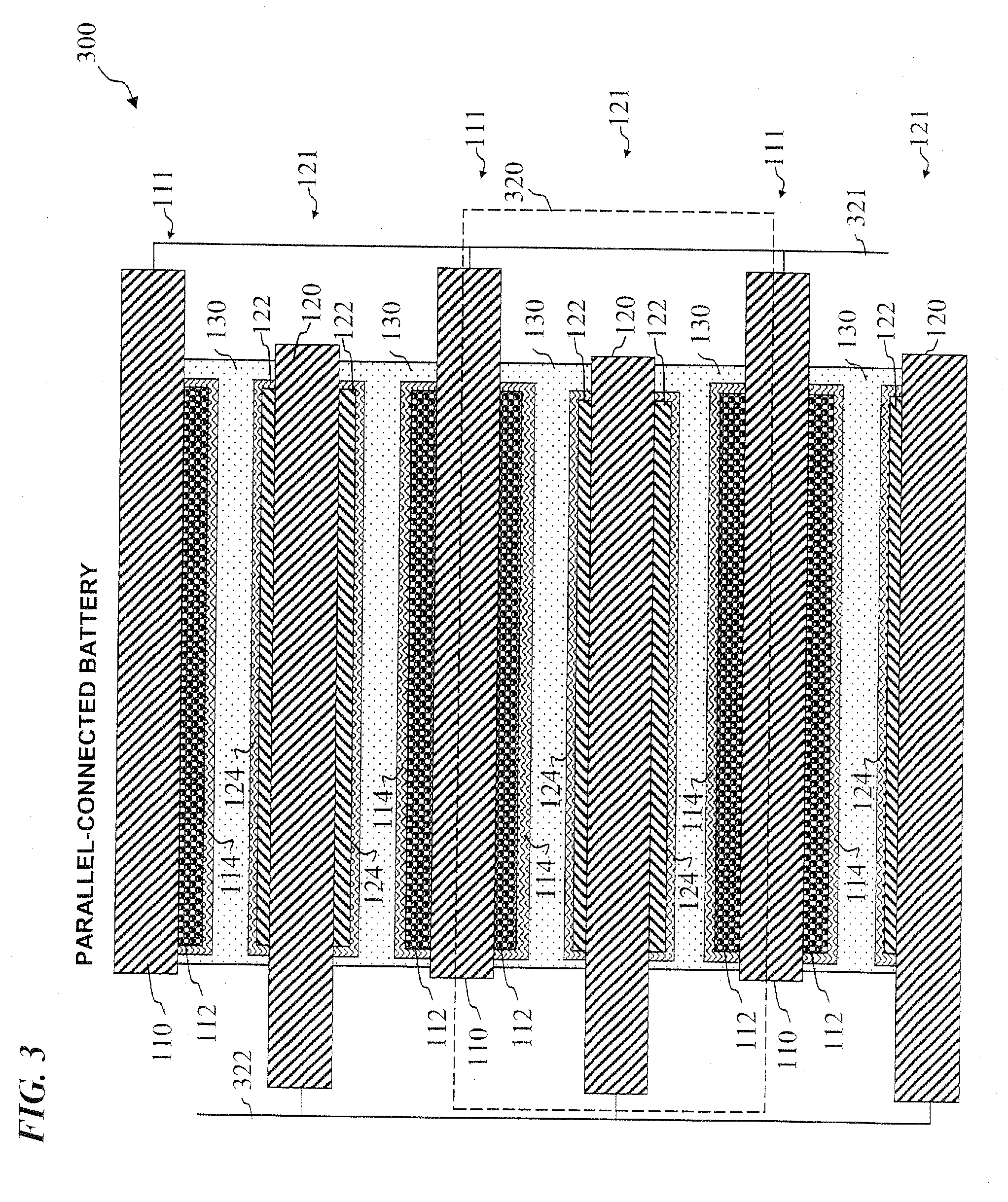

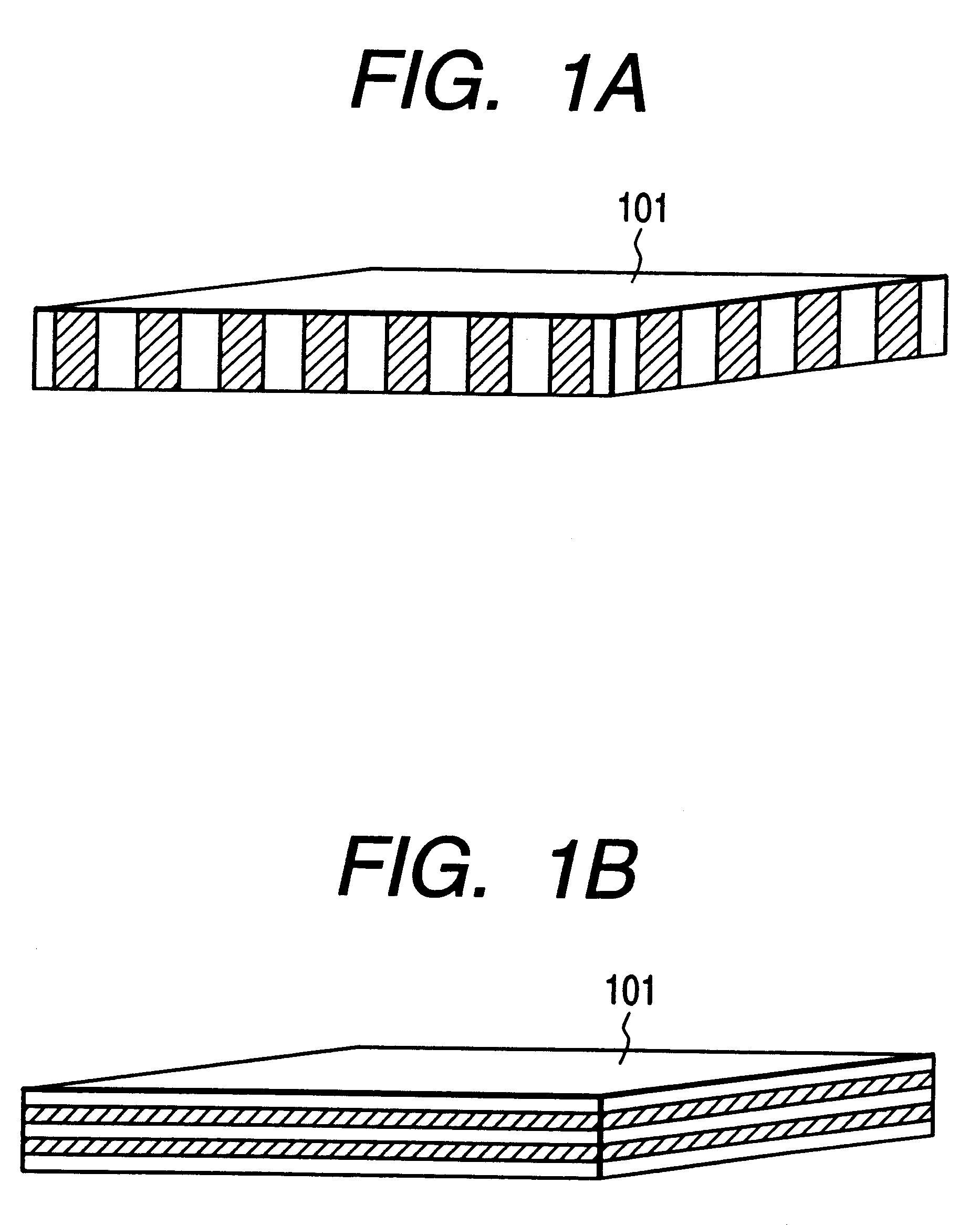

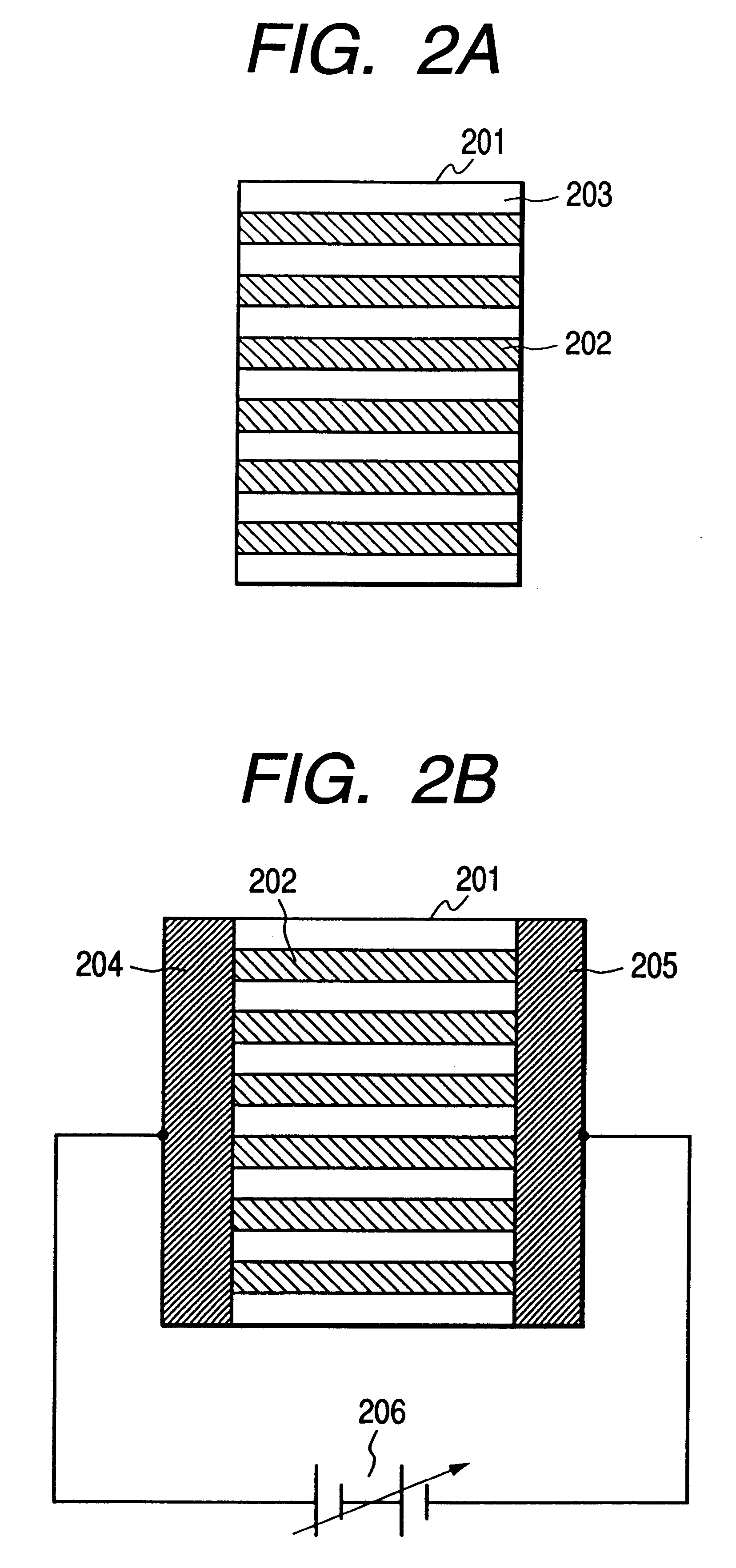

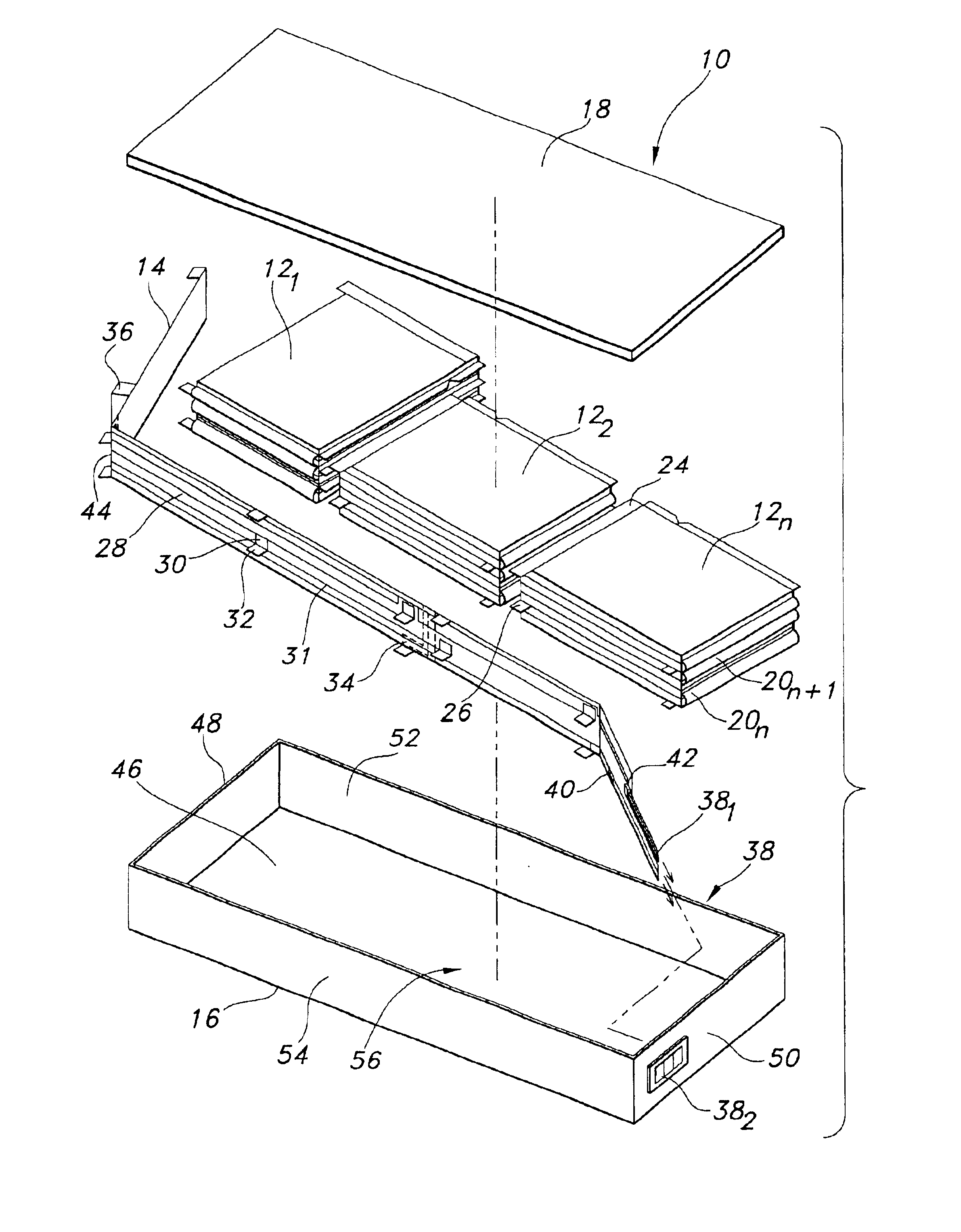

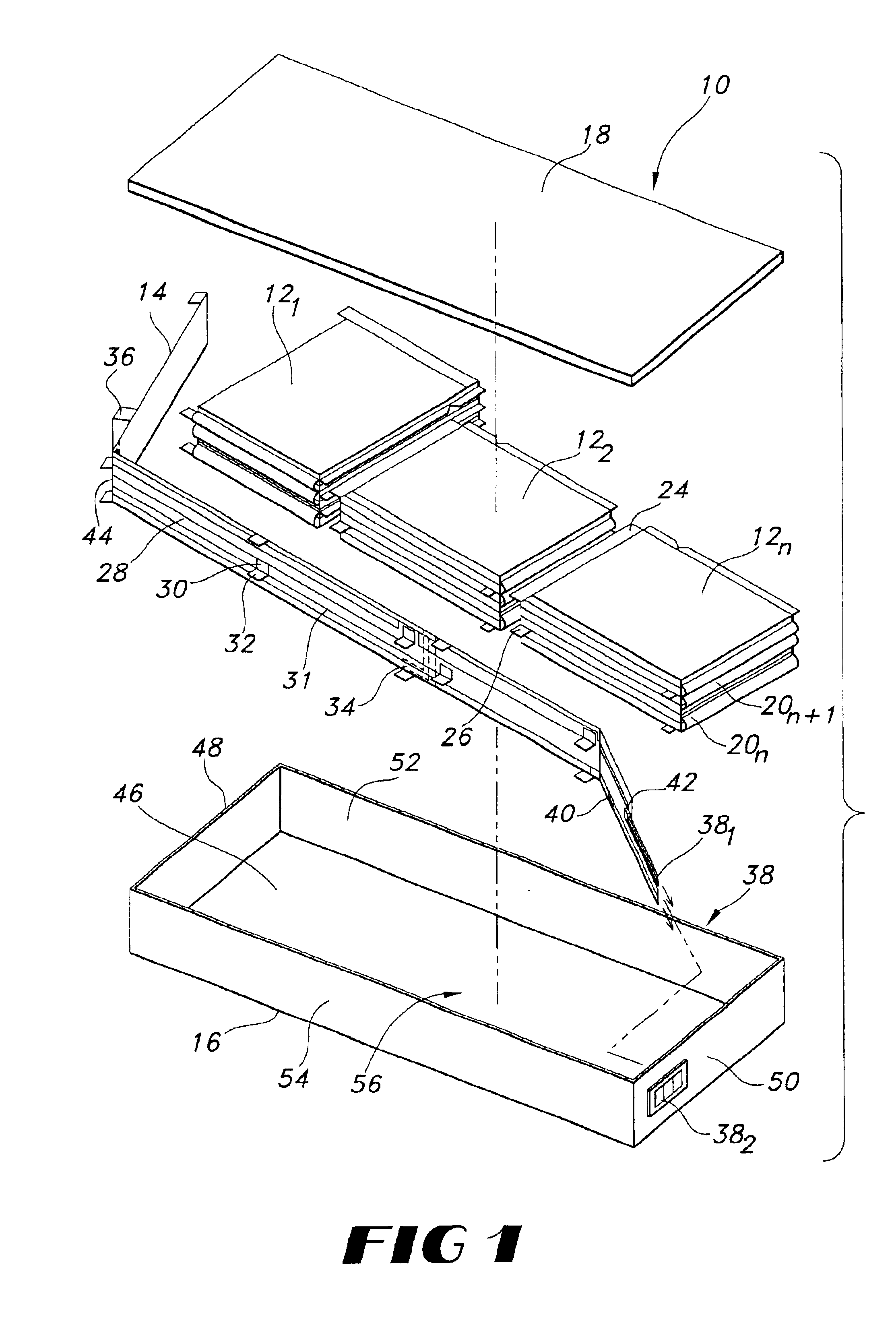

THIN-FILM BATTERIES WITH POLYMER AND LiPON ELECTROLYTE LAYERS AND METHOD

InactiveUS20070015061A1Improve environmental resistanceInhibition formationFinal product manufactureElectrode carriers/collectorsLithium metalPolymer gel

A method and apparatus for making thin-film batteries having composite multi-layered electrolytes with soft electrolyte between hard electrolyte covering the negative and / or positive electrode, and the resulting batteries. In some embodiments, foil-core cathode sheets each having a cathode material (e.g., LiCoO2) covered by a hard electrolyte on both sides, and foil-core anode sheets having an anode material (e.g., lithium metal) covered by a hard electrolyte on both sides, are laminated using a soft (e.g., polymer gel) electrolyte sandwiched between alternating cathode and anode sheets. A hard glass-like electrolyte layer obtains a smooth hard positive-electrode lithium-metal layer upon charging, but when very thin, have randomly spaced pinholes / defects. When the hard layers are formed on both the positive and negative electrodes, one electrode's dendrite-short-causing defects on are not aligned with the other electrode's defects. The soft electrolyte layer both conducts ions across the gap between hard electrolyte layers and fills pinholes.

Owner:CYMBET CORP

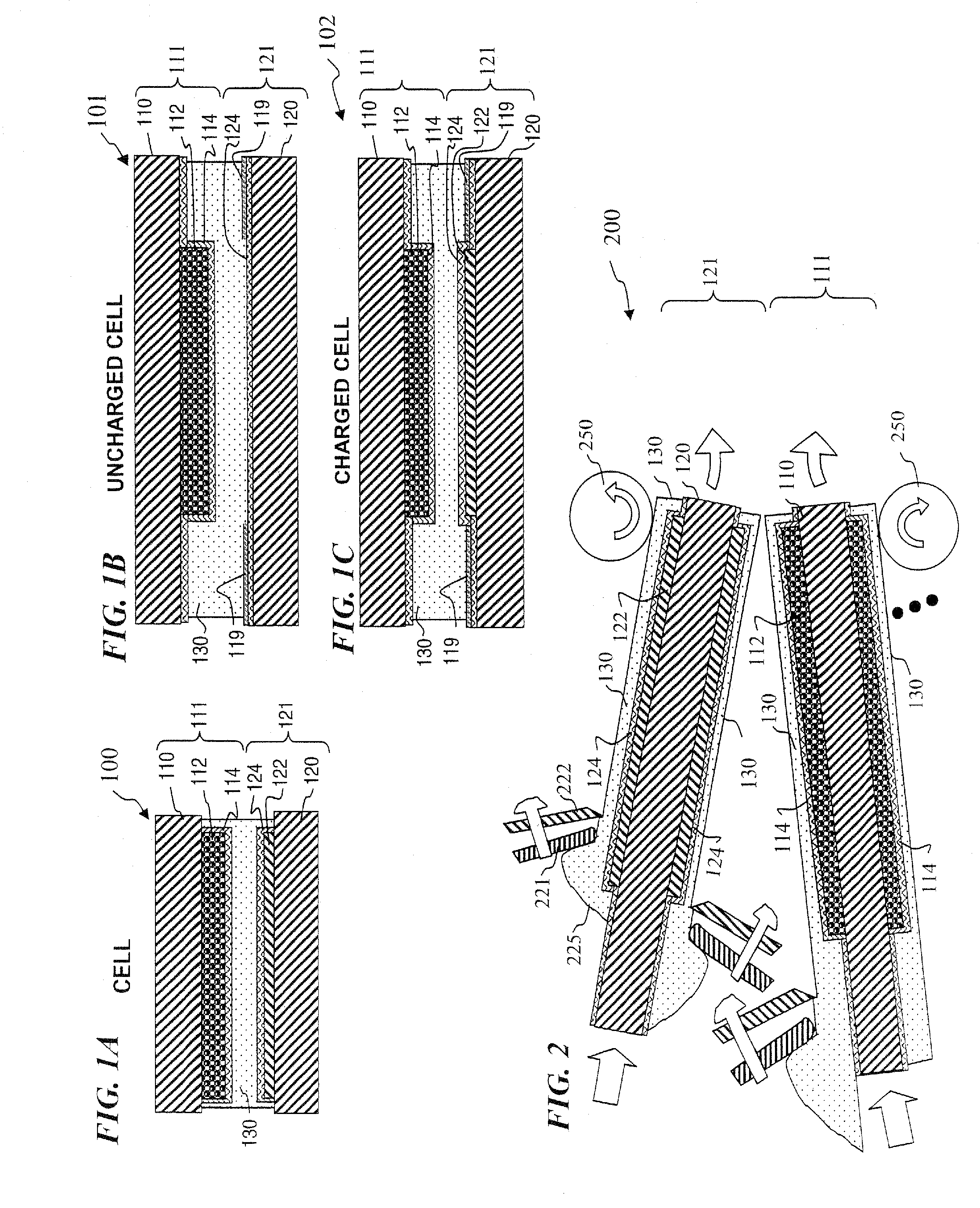

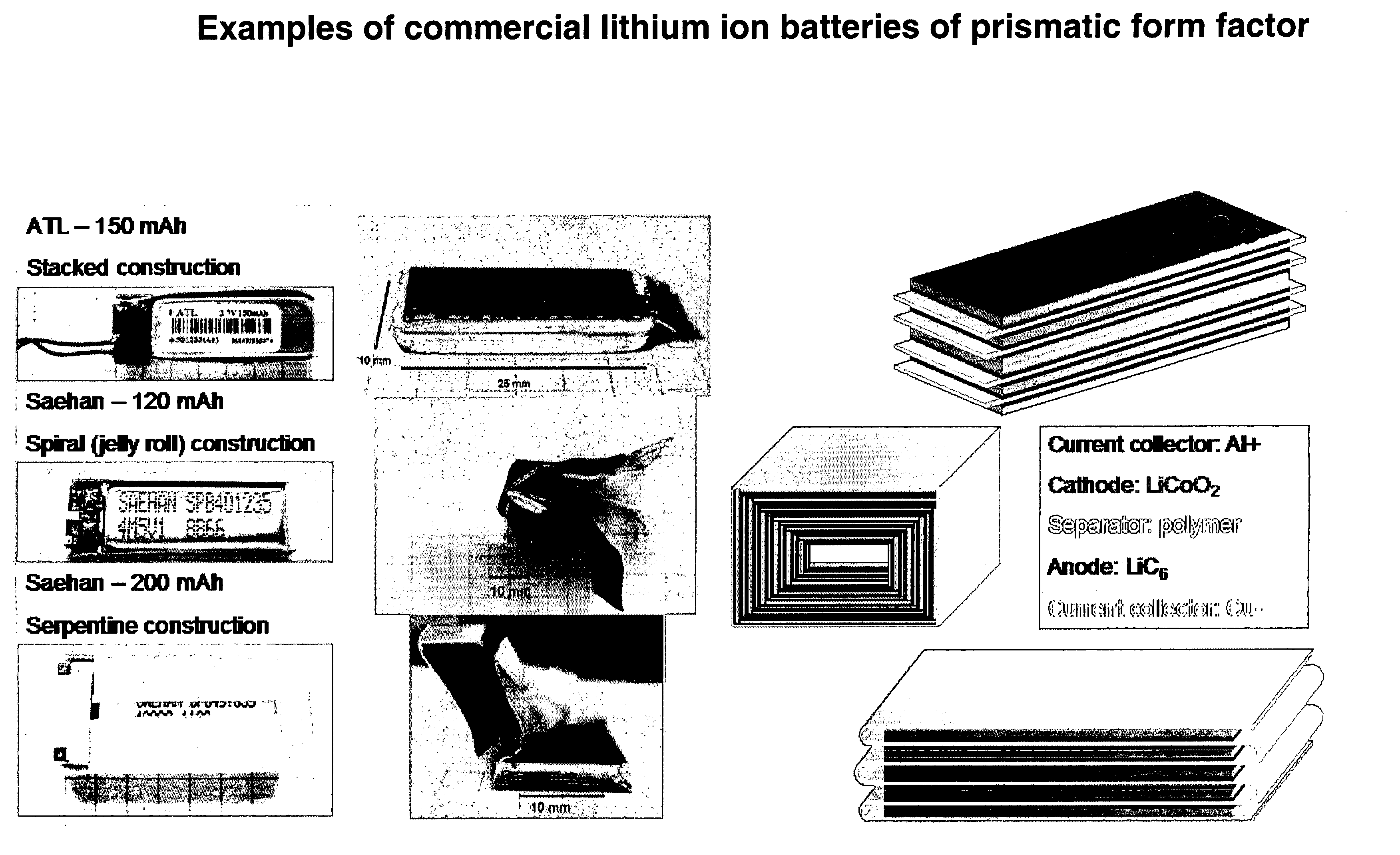

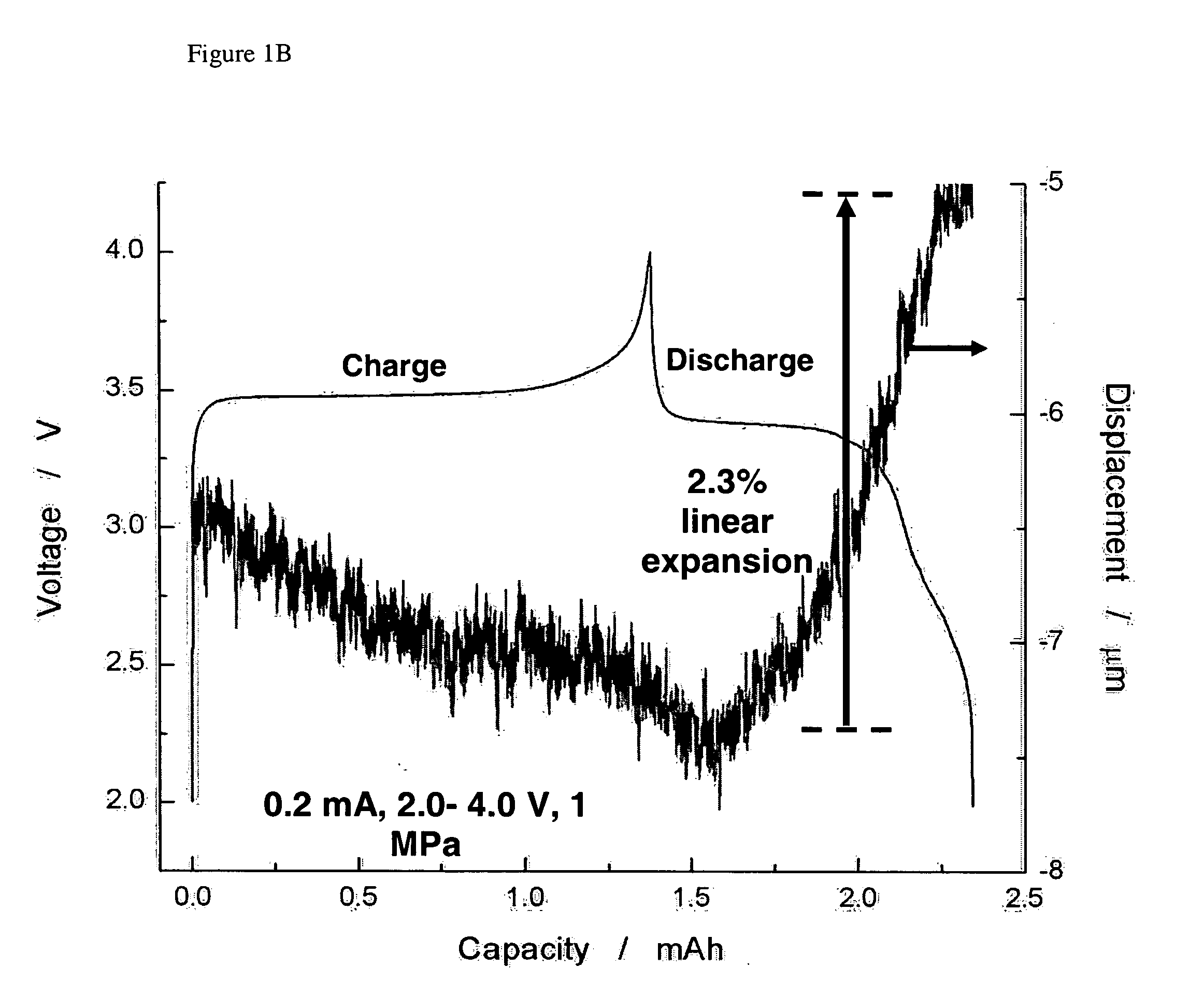

Electrochemical methods, devices, and structures

ActiveUS20060102455A1Increase strainDeferred-action cellsCell seperators/membranes/diaphragms/spacersInorganic compoundElectrochemistry

The present invention provides devices and structures and methods of use thereof in electrochemical actuation. This invention provides electrochemical actuators, which are based, inter-alia, on an electric field-driven intercalation or alloying of high-modulus inorganic compounds, which can produce large and reversible volume changes, providing high actuation energy density, high actuation authority and large free strain.

Owner:MASSACHUSETTS INST OF TECH

Battery assembly with temperature control device

InactiveUS20070259258A1Efficient packaging characteristicEasy to keepPrimary cell to battery groupingFinal product manufactureTemperature controlOperation mode

A battery assembly has a plurality of battery packs each presenting a housing and multiple cells adjacent one and the other and disposed in the housing. A foam solution is injected into the case of each battery pack. The foam extends around each cell and the case to encapsulate each cell thereby eliminating air gaps between the cells and the case and receiving heat generating by the cells in operational mode of the battery pack.

Owner:ENERDEL

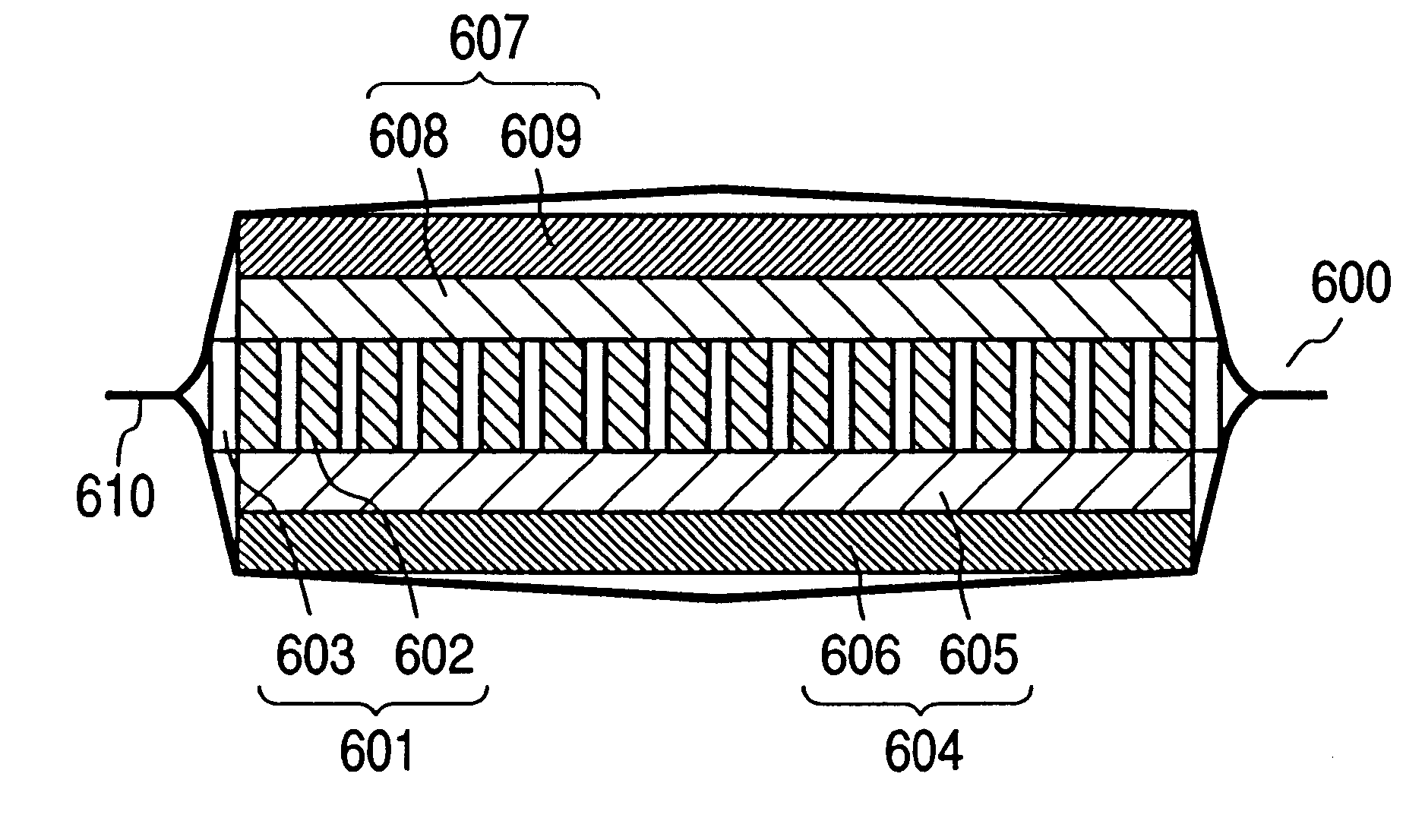

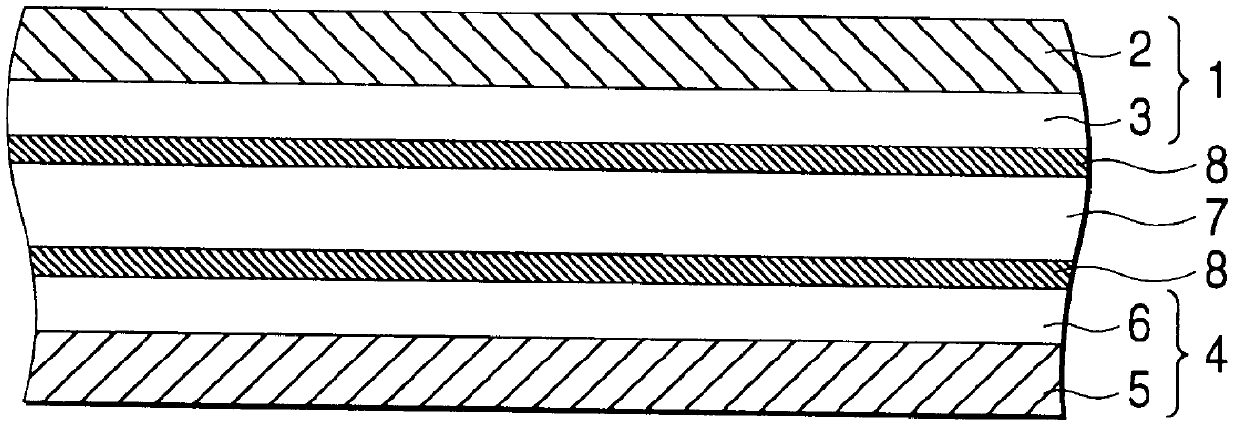

Thin-film batteries with soft and hard electrolyte layers and method

InactiveUS20070015060A1Improve environmental resistanceInhibition formationFinal product manufactureConductive materialLithium metalPolymer gel

A method and apparatus for making thin-film batteries having composite multi-layered electrolytes with soft electrolyte between hard electrolyte covering the negative and / or positive electrode, and the resulting batteries. In some embodiments, foil-core cathode sheets each having a cathode material (e.g., LiCoO2) covered by a hard electrolyte on both sides, and foil-core anode sheets having an anode material (e.g., lithium metal) covered by a hard electrolyte on both sides, are laminated using a soft (e.g., polymer gel) electrolyte sandwiched between alternating cathode and anode sheets. A hard glass-like electrolyte layer obtains a smooth hard positive-electrode lithium-metal layer upon charging, but when very thin, have randomly spaced pinholes / defects. When the hard layers are formed on both the positive and negative electrodes, one electrode's dendrite-short-causing defects on are not aligned with the other electrode's defects. The soft electrolyte layer both conducts ions across the gap between hard electrolyte layers and fills pinholes.

Owner:CYMBET CORP

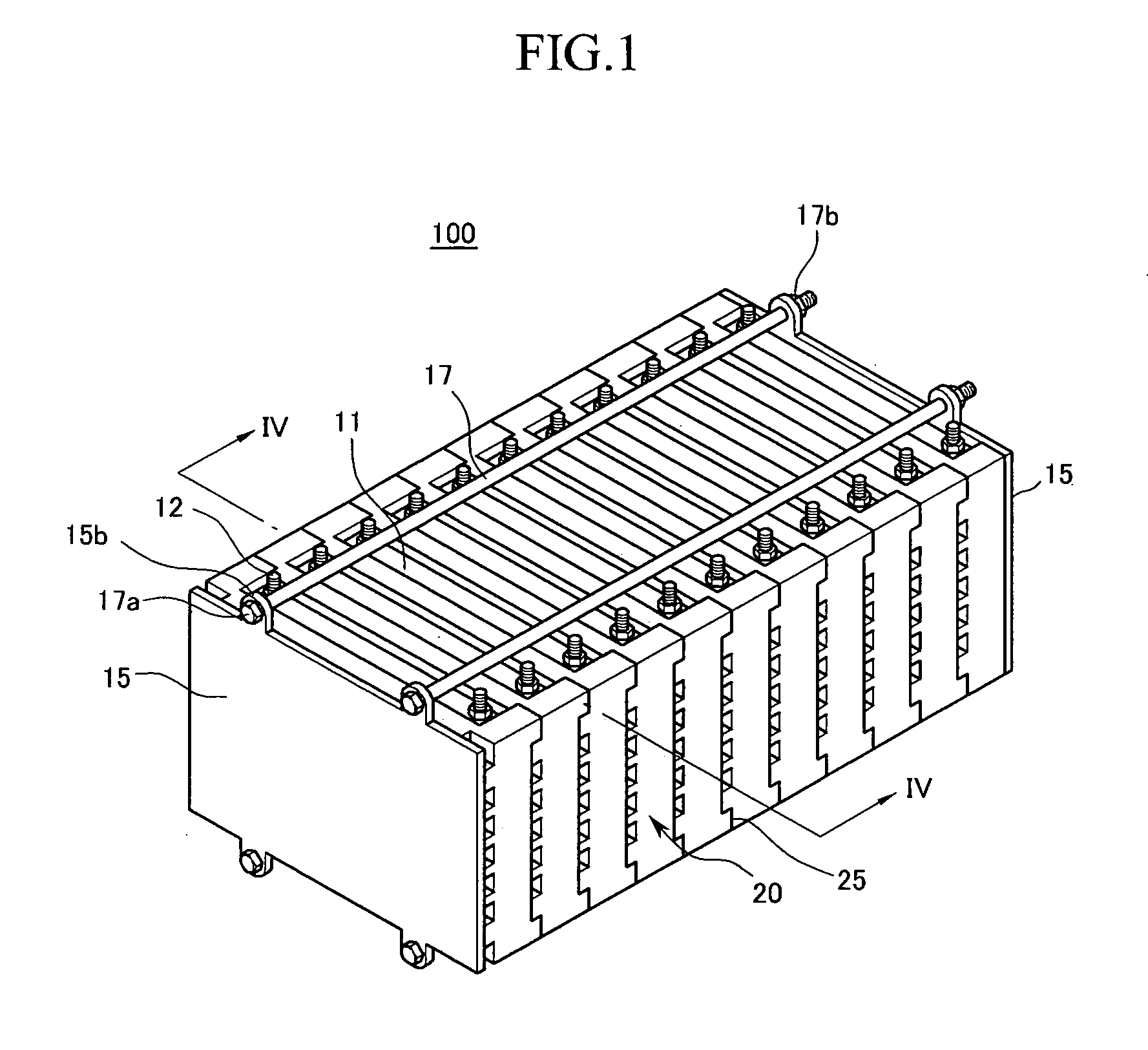

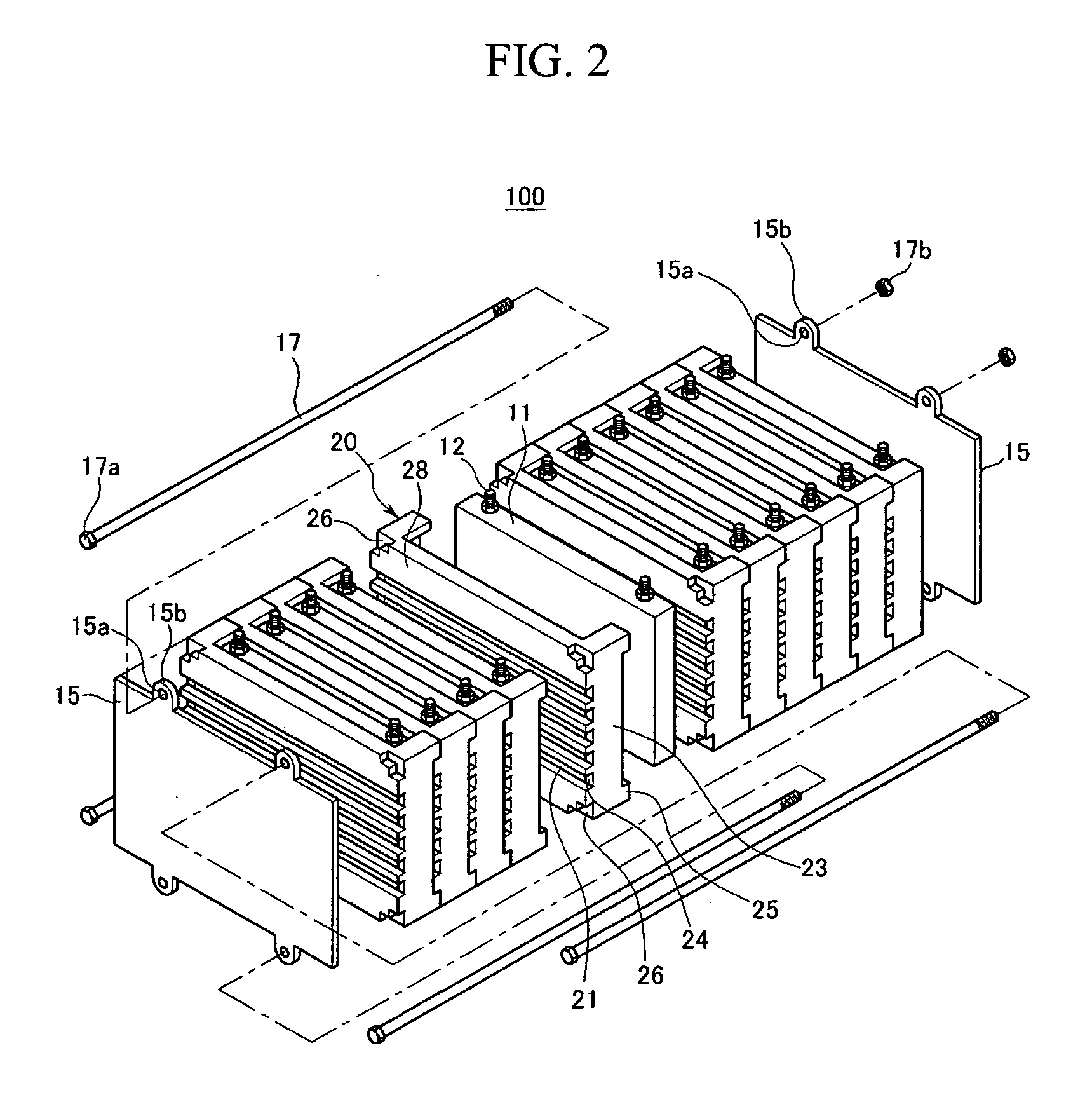

Battery module with improved cell barrier between unit cells

ActiveUS20070037051A1Improved unit cell cooling performanceEasy to makePrimary cell to battery groupingFinal product manufactureBiomedical engineering

Owner:SAMSUNG SDI CO LTD

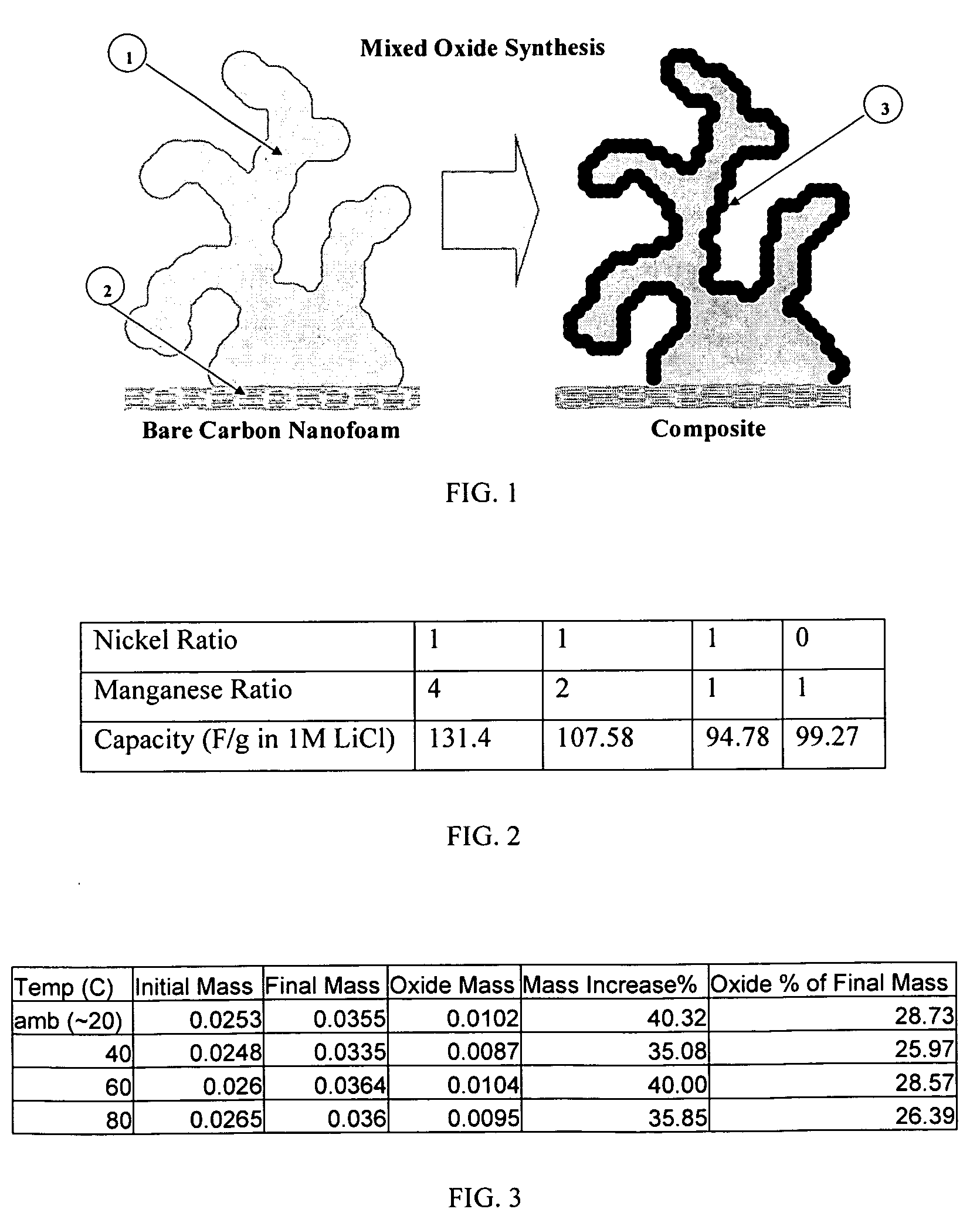

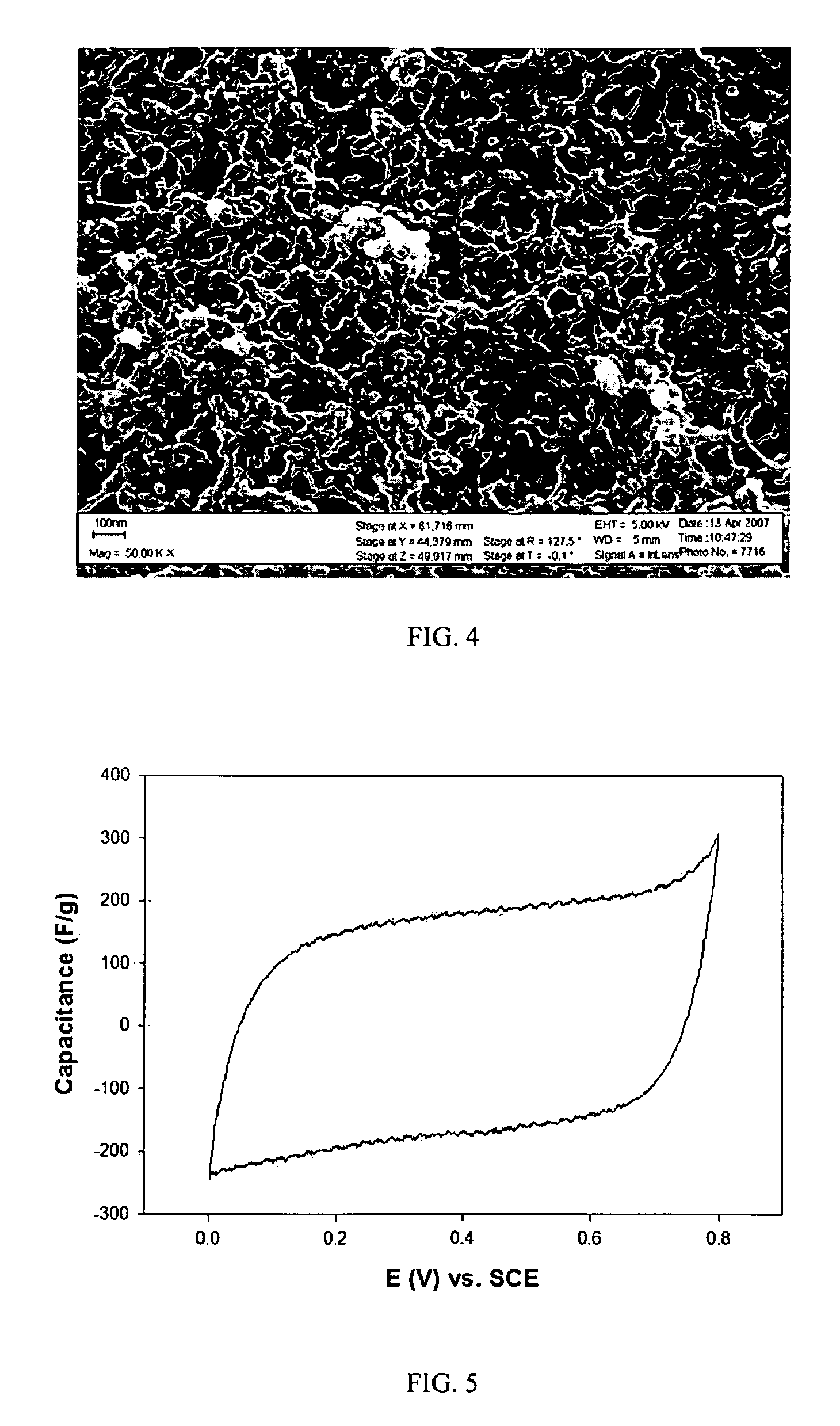

Composite electrode comprising a carbon structure coated with a thin film of mixed metal oxides for electrochemical energy storage

InactiveUS20090185327A1Increase capacityProlong lifeLiquid electrolytic capacitorsFinal product manufactureComposite electrodeMixed oxide

A composite electrode is created by forming a thin conformal coating of mixed metal oxides on a highly porous carbon structure. The highly porous carbon structure performs a role in the synthesis of the mixed oxide coating and in providing a three-dimensional, electronically conductive substrate supporting the thin coating of mixed metal oxides. The metal oxide mixture shall include two or more metal oxides. The composite electrode, a process for producing said composite electrode, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said composite electrode are disclosed.

Owner:SEYMOUR FRASER WADE

Secondary battery having an ion conductive member and manufacturing process thereof

InactiveUS6372387B1Cell seperators/membranes/diaphragms/spacersOrganic electrolyte cellsEngineeringIon channel

Owner:CANON KK

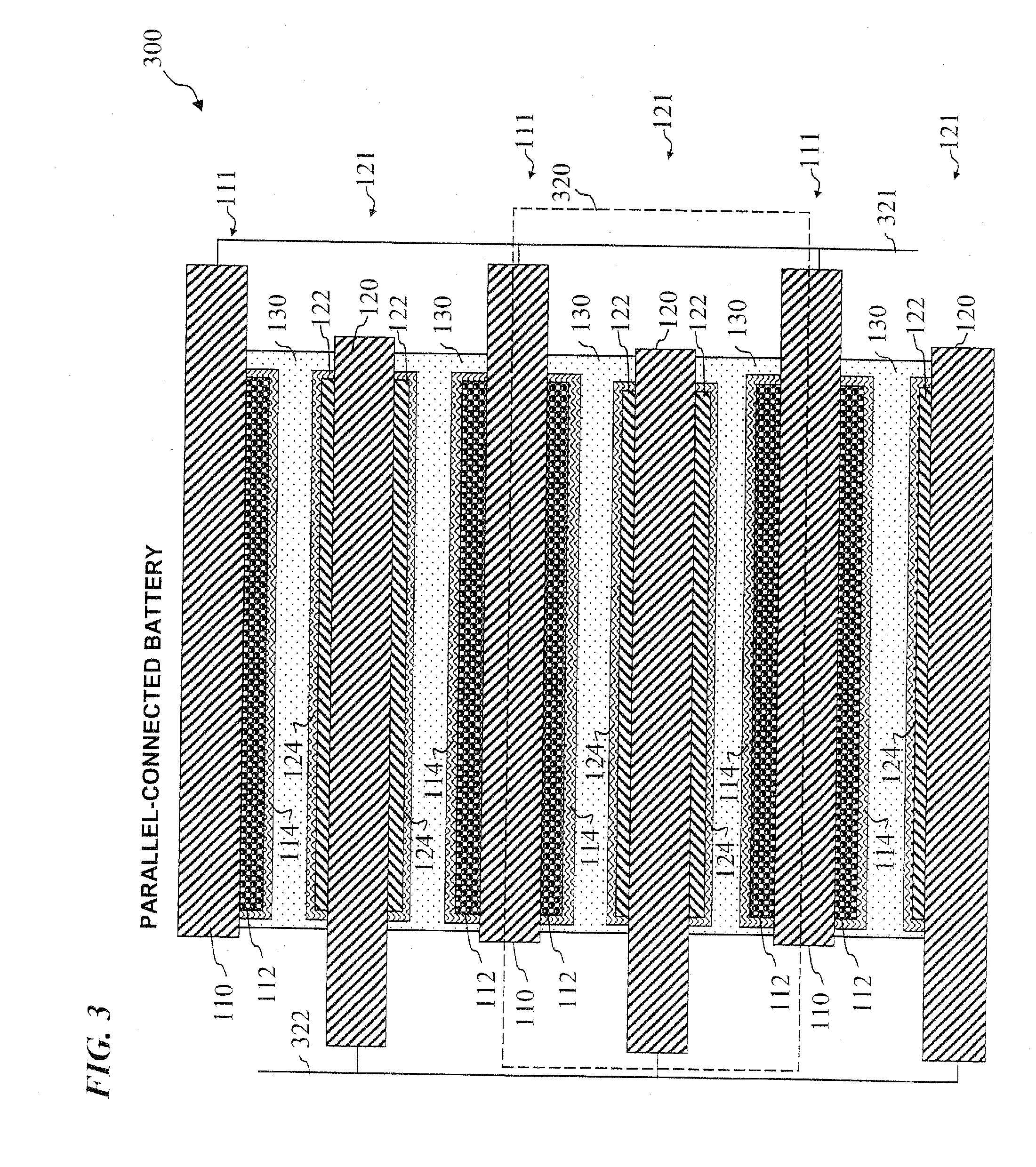

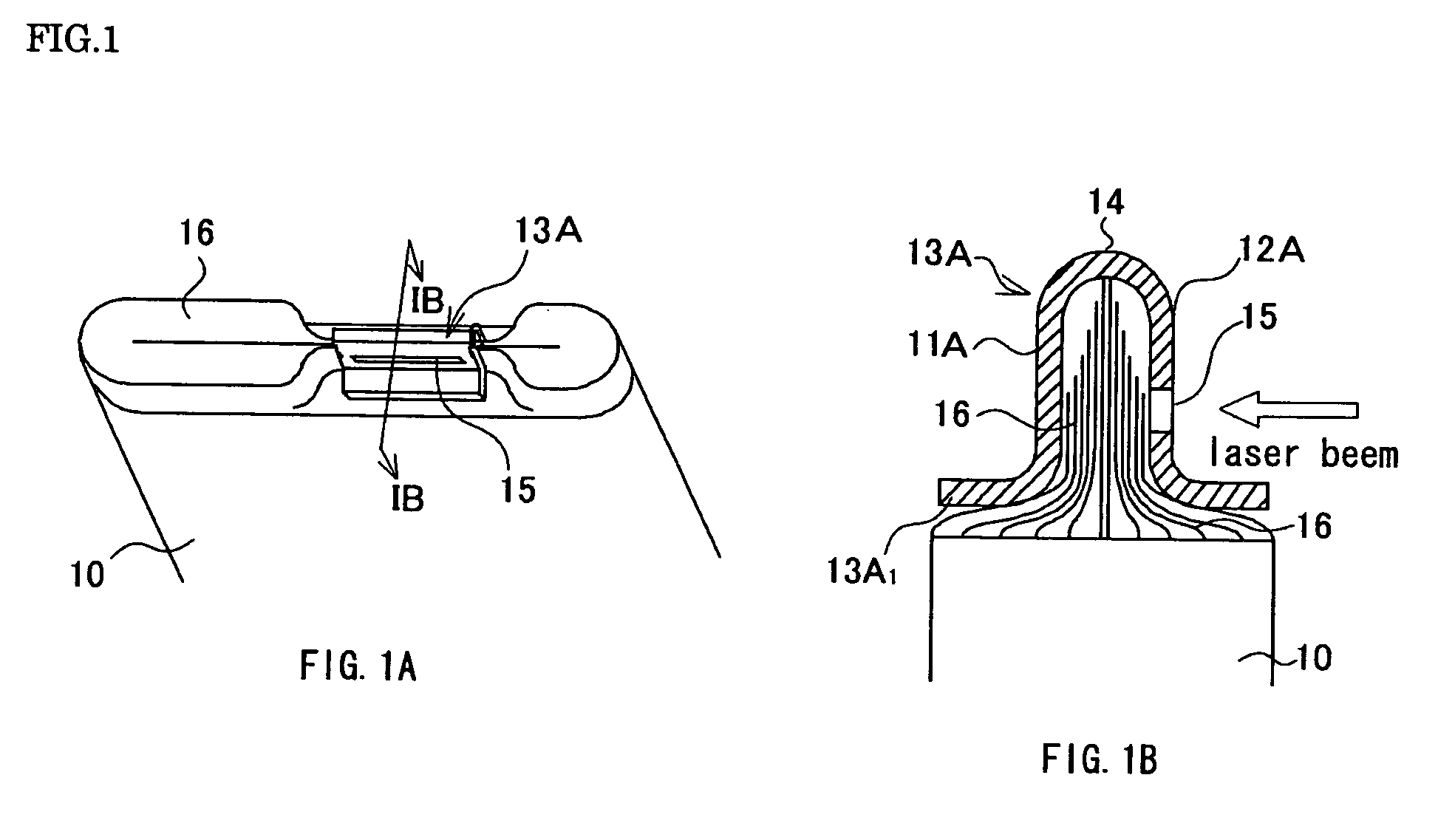

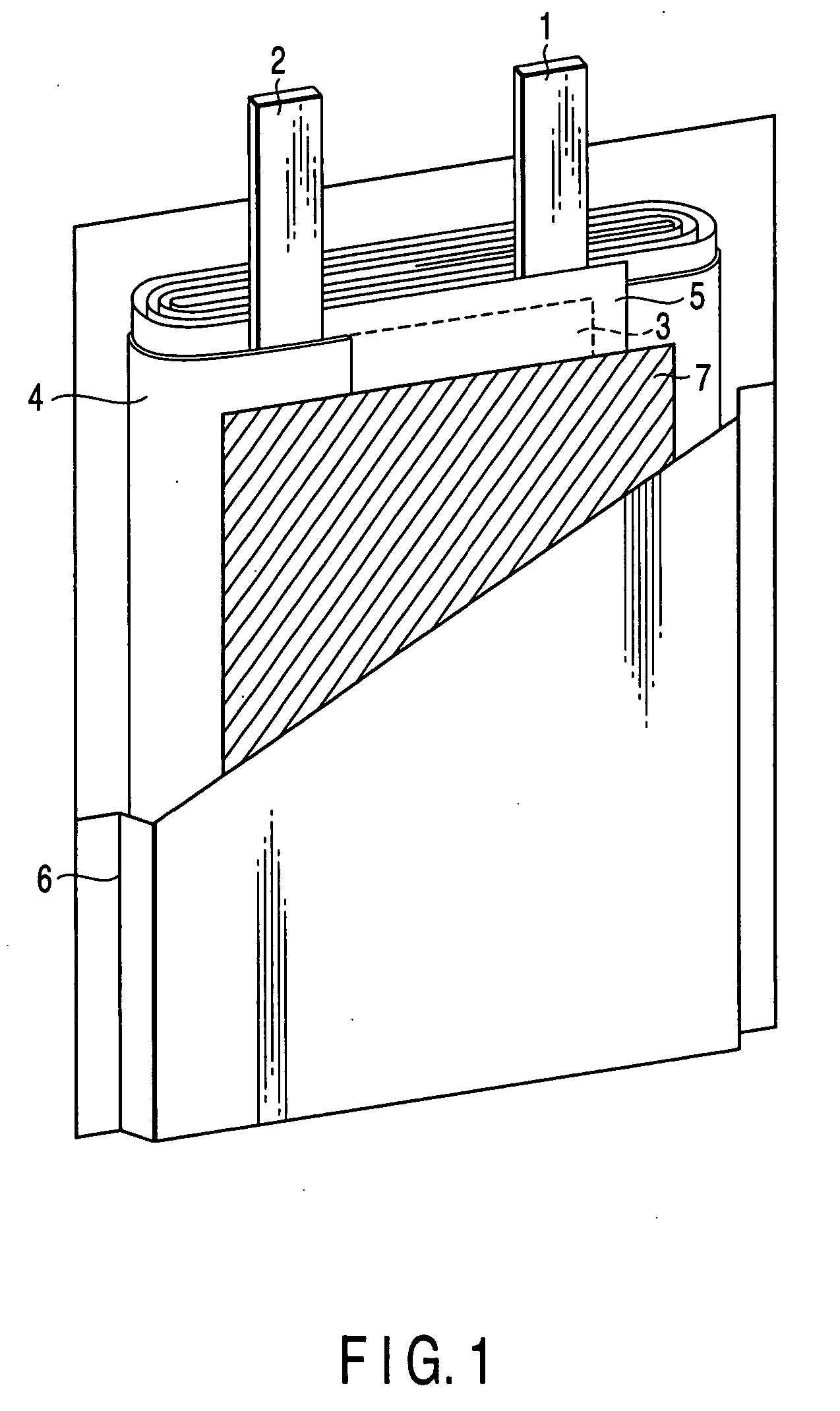

Prismatic battery

ActiveUS20070117009A1Reduce the possibilityNon-aqueous electrolyte accumulatorsCell electrodesElectric vehicleHigh energy beam

A prismatic battery according to one embodiment of the present invention includes a flat electrode group 10 stacked or rolled by mutually positive and negative electrodes with a separator therebetween, a pressing plate 13A, a current collecting body 18A or 18B and a plurality of exposed sections 16, at least one end of the positive and negative electrodes substrates in a width direction being uncoated with a positive or negative electrode mixture. The pressing plate 13A is welded to the exposed sections 16. The pressing plate 13A includes opposing surfaces with a space therebetween provided by folding back a metal plate, and includes a slit 15 along a folded back section at least to one of the opposing surface's side. The exposed sections 16 are inserted into a gap of the pressing plate 13A, and the exposed sections 16 and the pressing plate 13A are welded by a high energy beam from a transverse direction through the slit 15. This provides a prismatic battery for large current application in electric vehicles and hybrid electric vehicles.

Owner:SANYO ELECTRIC CO LTD

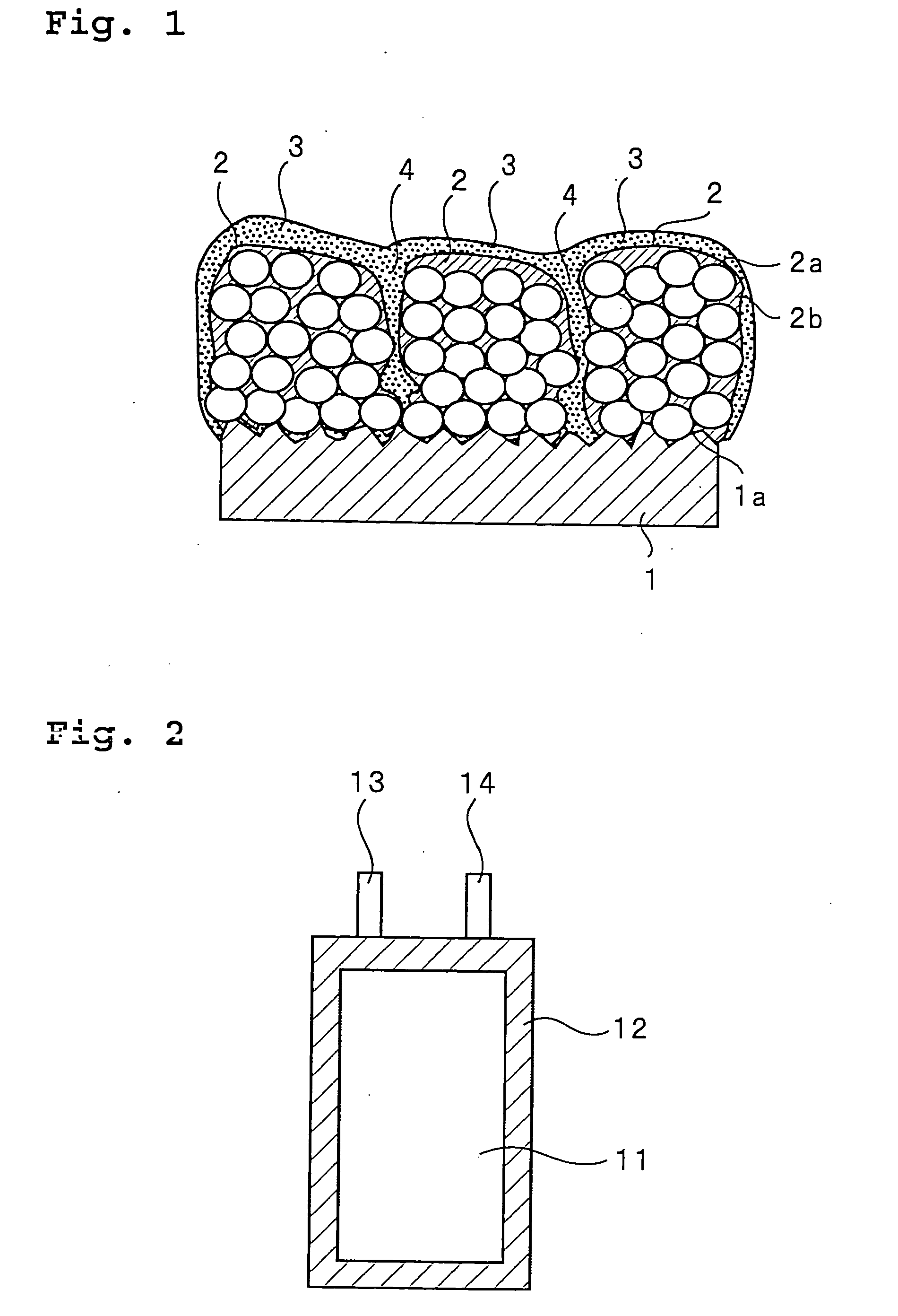

Lithium secondary battery and method for manufacturing thereof

InactiveUS20040072067A1Increase currentExtended discharge cycleFinal product manufactureElectrode carriers/collectorsLithiumElectrochemistry

A lithium secondary battery comprising an electrode in which an active material layer which includes an active material that electrochemically occludes and releases lithium is formed on a current collector, wherein cracks are formed in the active material layer by occlusion and release of lithium ions and thereafter a solid electrolyte is formed in the cracks in the active material layer.

Owner:SANYO ELECTRIC CO LTD

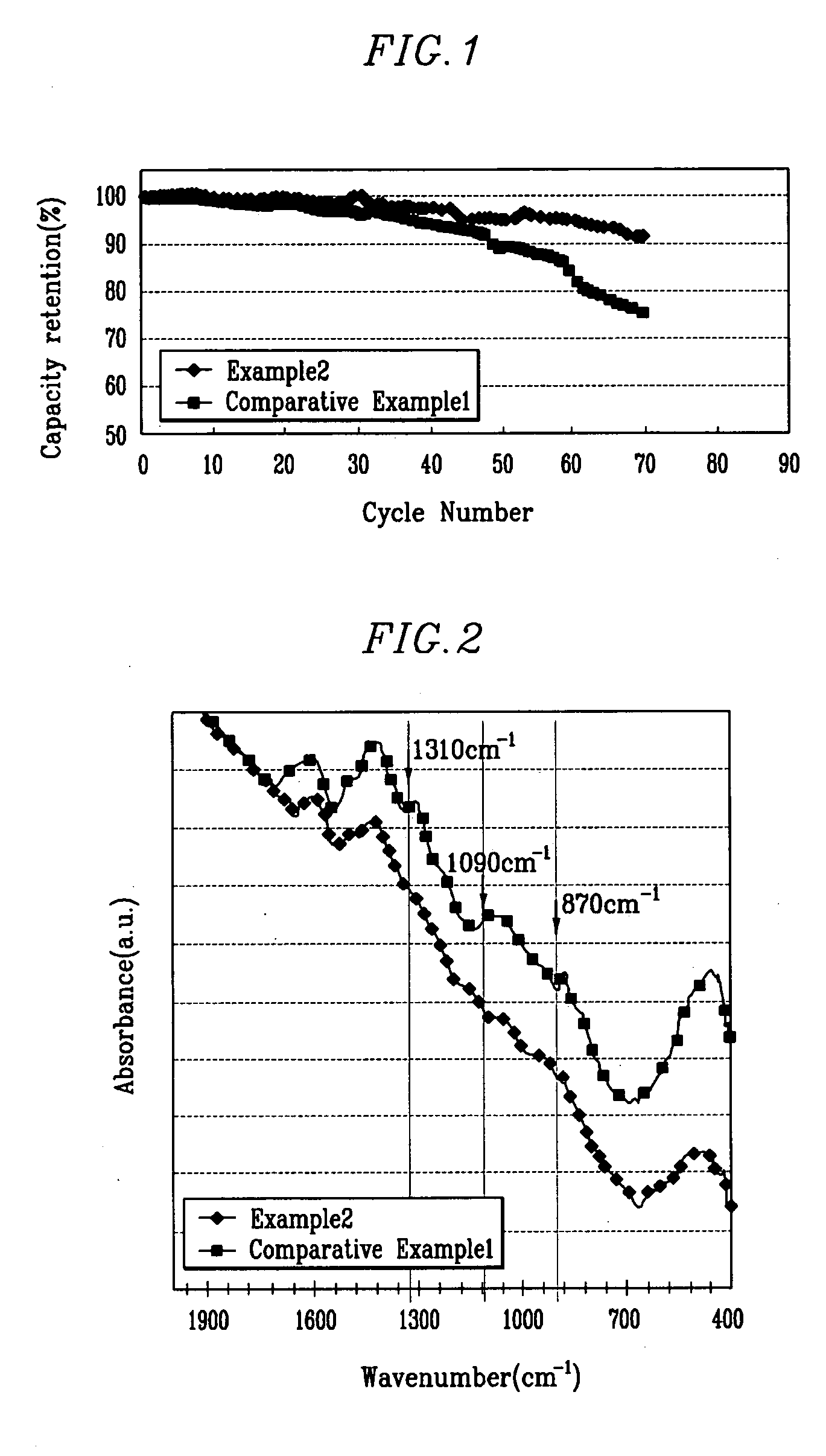

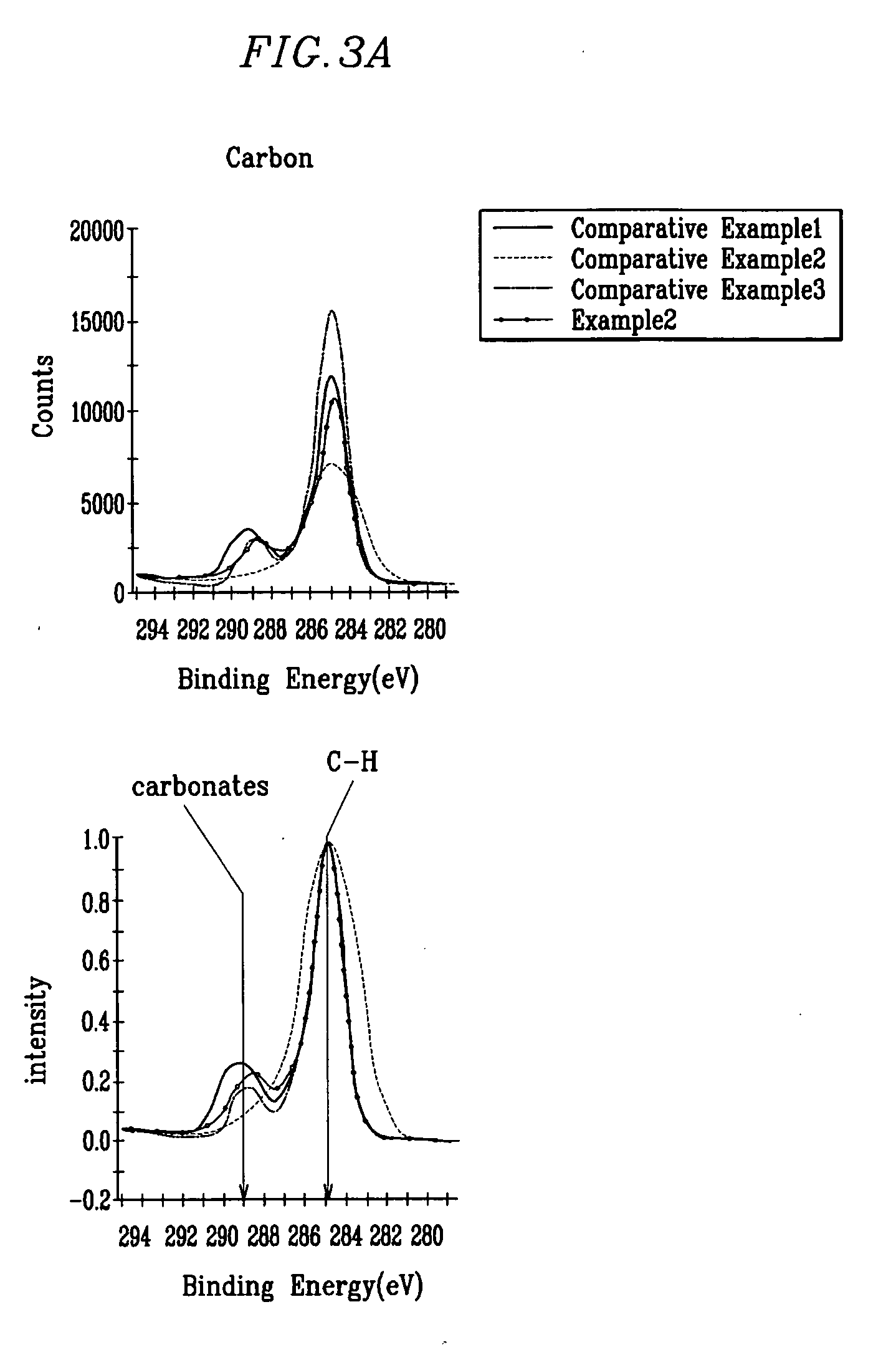

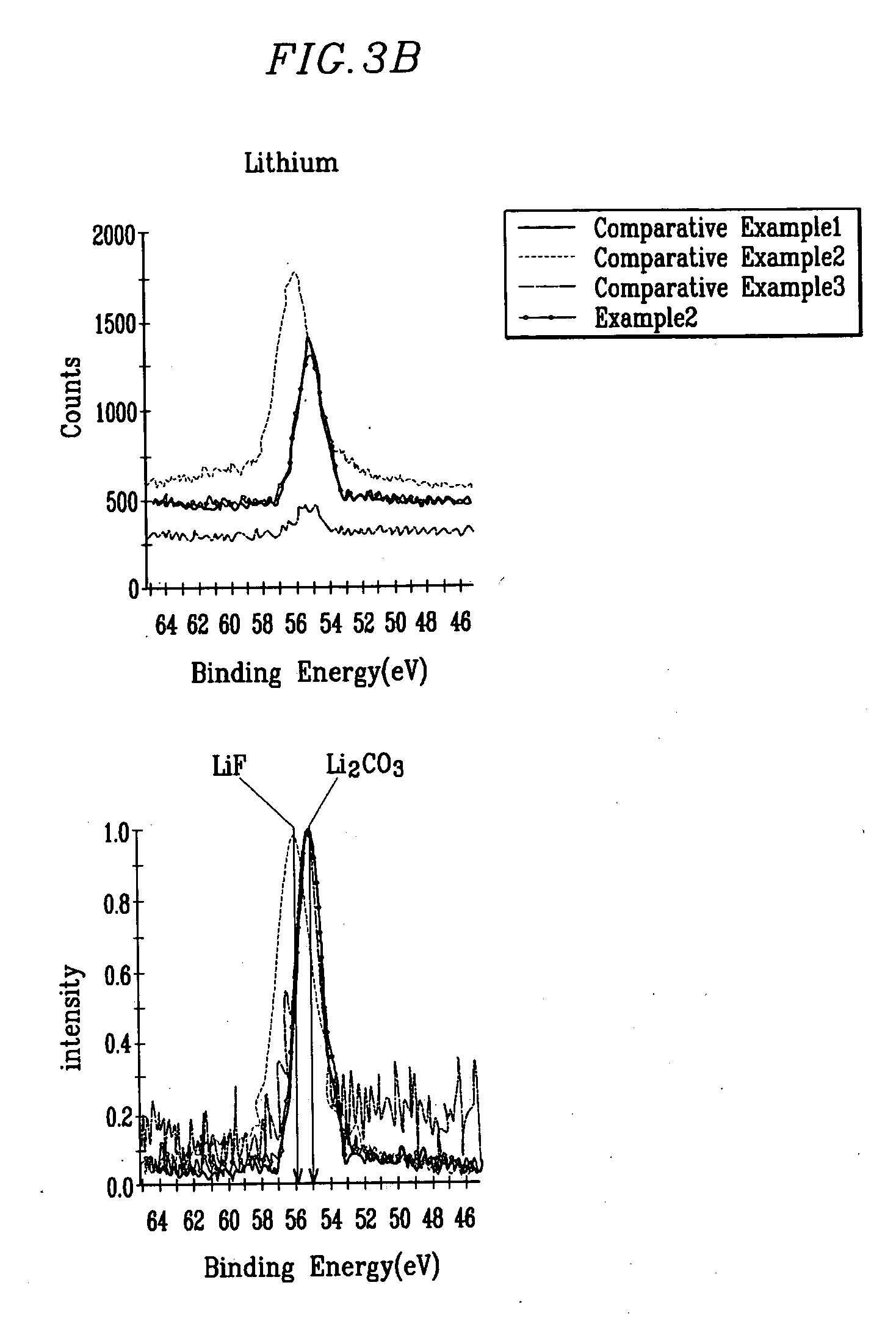

Lithium secondary battery

InactiveUS20070037063A1Large capacityImproved cycle life characteristicsFinal product manufactureOrganic electrolyte cellsOrganic solventHydrogen

Disclosed is a rechargeable lithium battery including an electrolyte comprising an ethylene carbonate compound represented by Formula 1, a non-aqueous organic solvent, and a lithium salt; a negative electrode including a negative active material including a silicon-included alloy and being capable of reversibly forming a compound by reacting with lithium; and a positive electrode including a positive active material comprising a compound being capable of reversibly intercalating and deintercalating lithium ions or a material capable of forming a compound containing lithium by reversibly reacting with lithium. (wherein X and Y are each independently selected from the group consisting of a hydrogen, a halogen, and a fluorinated alkyl having C1 to C5; at least one of X and Y is selected from the group consisting of a halogen, and a fluorinated alkyl having C1 to C5; and M is at least one selected from the group consisting of Al, Sn, Ag, Fe, Bi, Mg, Zn, In, Ge, Pb, and Ti.)

Owner:SAMSUNG SDI CO LTD

Battery pack having flexible circuit connector

InactiveUS6746797B2Reducing and eliminating occurrenceImprove sealingPrimary cell to battery groupingFinal product manufactureAdhesiveFlexible circuits

A battery pack containing a plurality of battery modules, these modules comprising a plurality of individual battery units, these battery units comprising a plurality of bicells with opposing terminals. The battery modules are connected in series by use of a flexible circuit and by opposing positive and negative terminals of each battery unit. The terminals of each battery unit contain a region of apertures which allow the adhesive of the packaging material to seal more effectively, thereby eliminating or reducing the amount of leakage from an individual battery unit.

Owner:ENERDEL

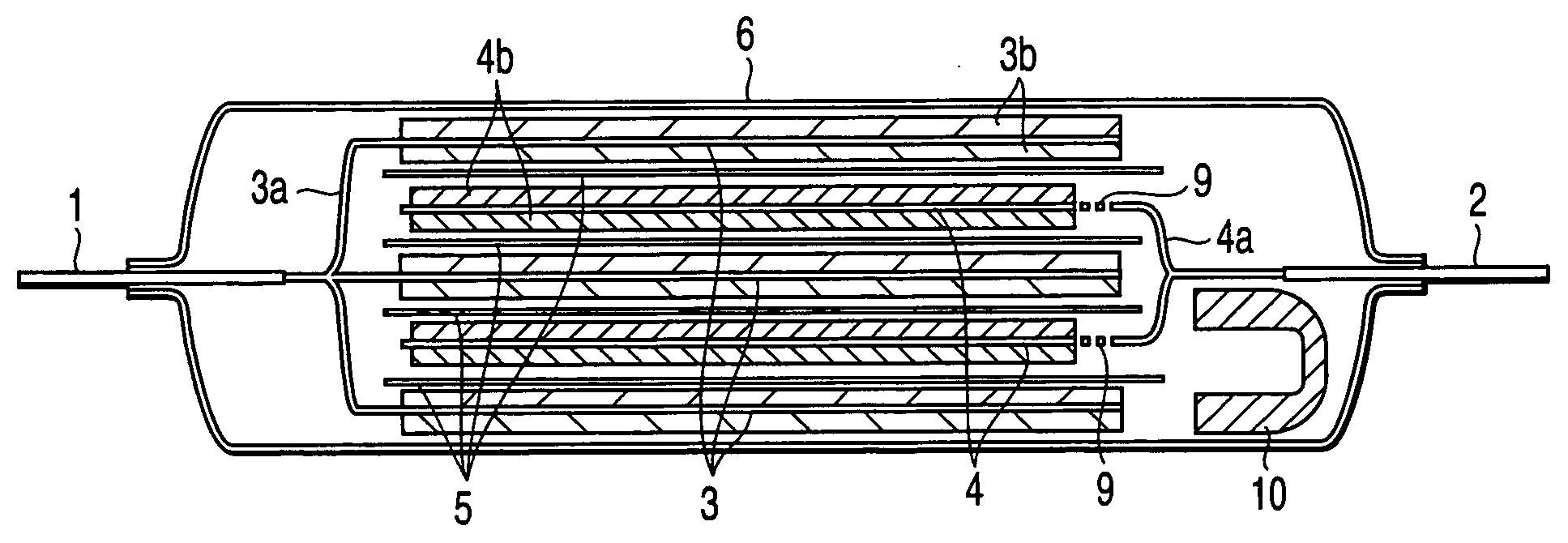

Method of fabricating a lithium ion secondary battery

To provide a process for producing a lithium ion secondary battery which can have any arbitrary shape, such as thin shape, and yet exhibits high performance. In a method of fabricating a battery comprising a positive electrode 1, a negative electrode 4, and a separator 7, a binder resin solution mainly comprising polyvinylidene fluoride is applied to the separator 7, and the positive electrode 1 and the negative electrode 4 are laid thereon, followed by drying to form a battery laminate, which is then impregnated with an electrolytic solution.

Owner:MITSUBISHI ELECTRIC CORP

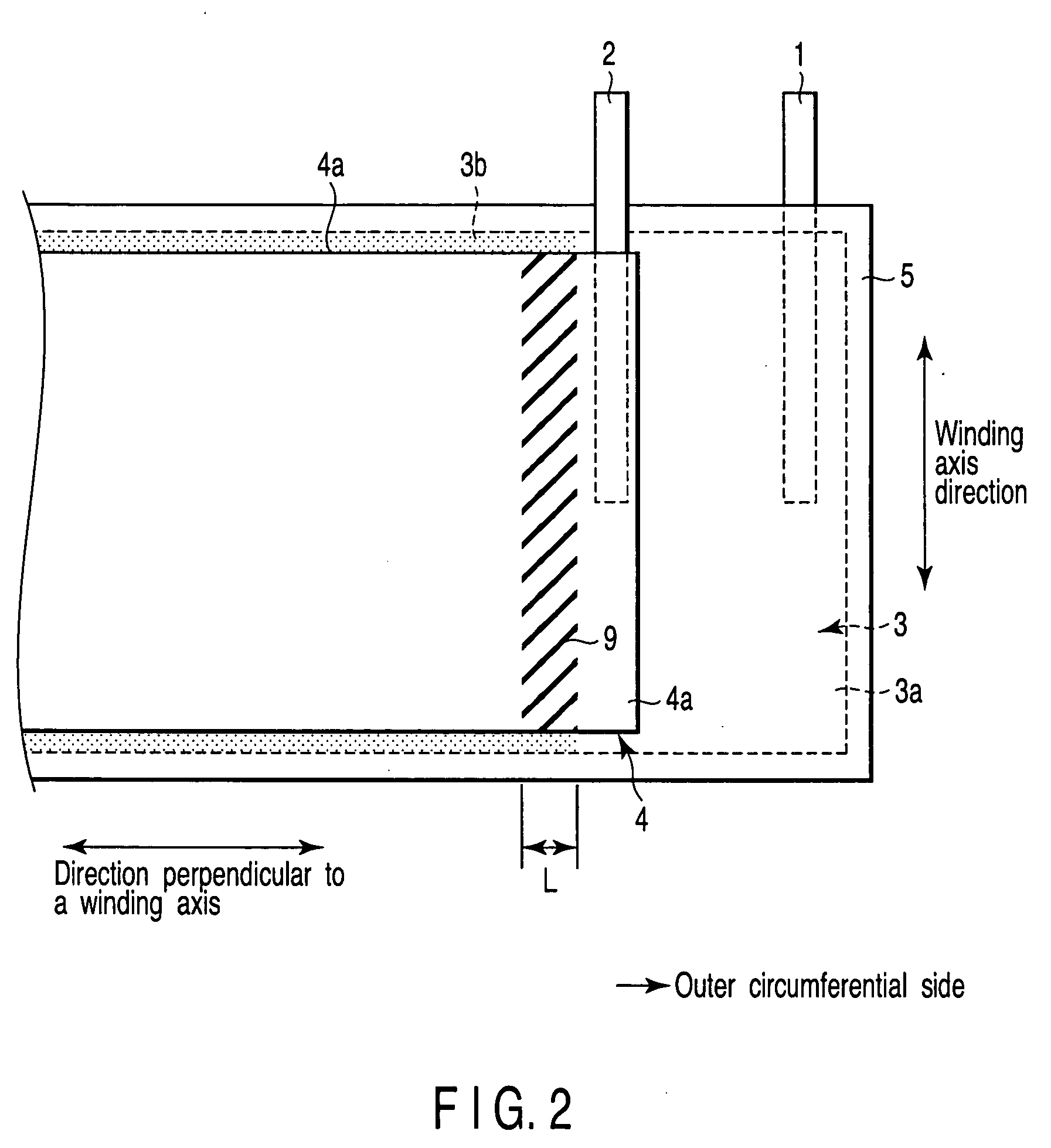

Nonaqueous electrolyte secondary battery

InactiveUS20050221173A1Improve securityFinal product manufactureCell temperature controlShear stressEngineering

A nonaqueous electrolyte secondary battery includes a negative electrode including a negative electrode current collector and a negative electrode active material layer that is formed on a first region of the negative electrode current collector, a negative electrode terminal connected to an edge section of a second region of the negative electrode current collector, a positive electrode including a positive electrode active material layer positioned to face the negative electrode active material layer and the second region, and a stress imparting member which imparts a tensile stress or a shearing stress to the second region.

Owner:KK TOSHIBA

Small battery pack employing PCM on side sealing part

InactiveUS20070264535A1Enhanced couplingAvoid introducingSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringHigh intensity

Disclosed herein is a battery pack constructed such that a battery case, in which an electrode assembly is mounted, is made of a laminate sheet having high strength, side sealing parts of the battery case are formed in a specific shape, and a protection circuit module (PCM) is located in the inner space of at least one of the side sealing parts. The side sealing parts in themselves are used as a structure to decide the external shape of the battery pack, and, at the same time, are used as spaces for mounting the PCM therein. Consequently, it is possible to construct the battery pack without using additional pack sheathing members, to simplify the assembly process of the battery pack, and to manufacture the battery pack in a thinner and more compact structure with the reduced manufacturing costs. Furthermore, the PCM is located at either side of the battery cell while the PCM is spaced apart from electrode terminals. Consequently, the battery pack exhibits high safety against external impacts, such as dropping of the battery pack.

Owner:LG CHEM LTD

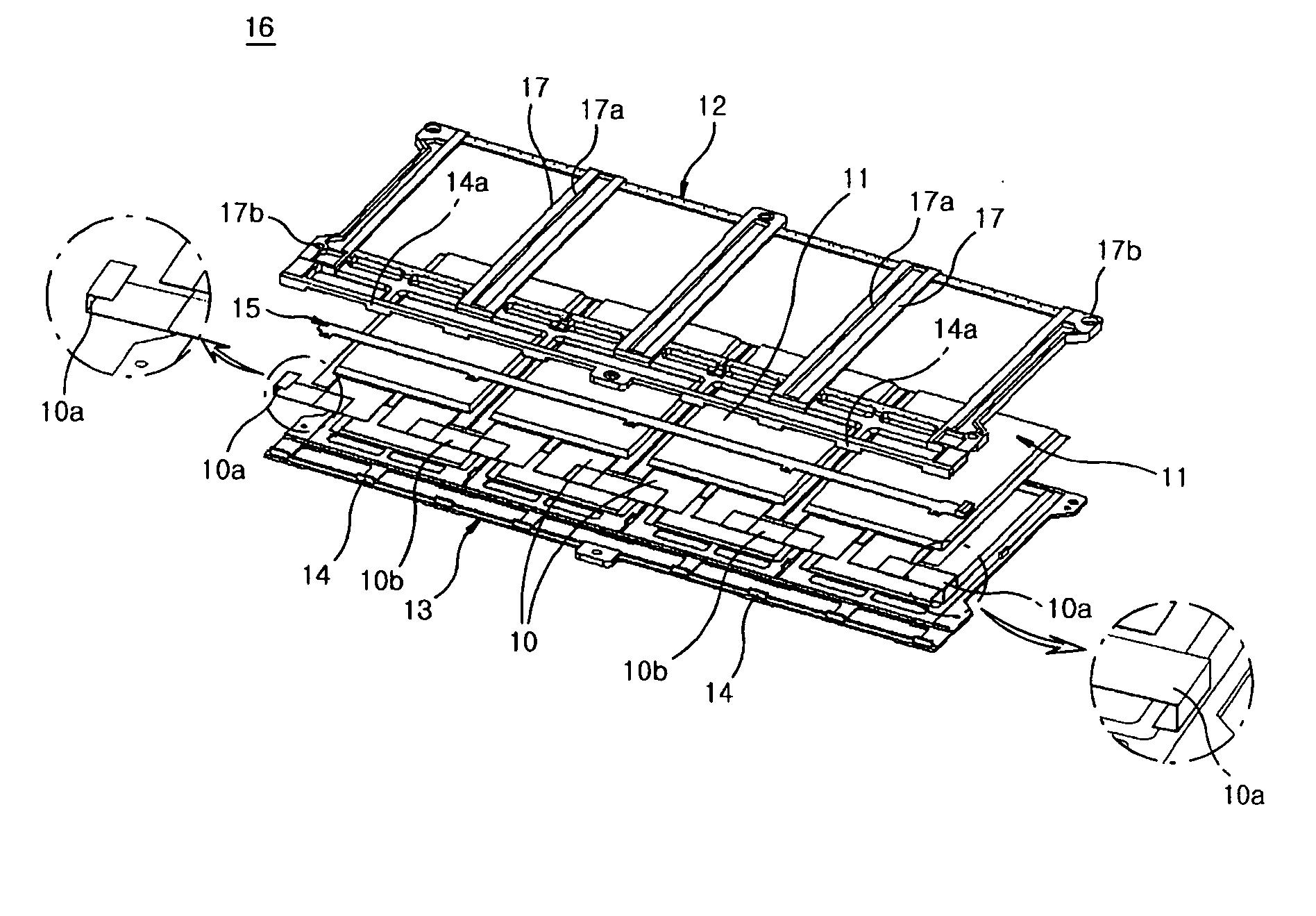

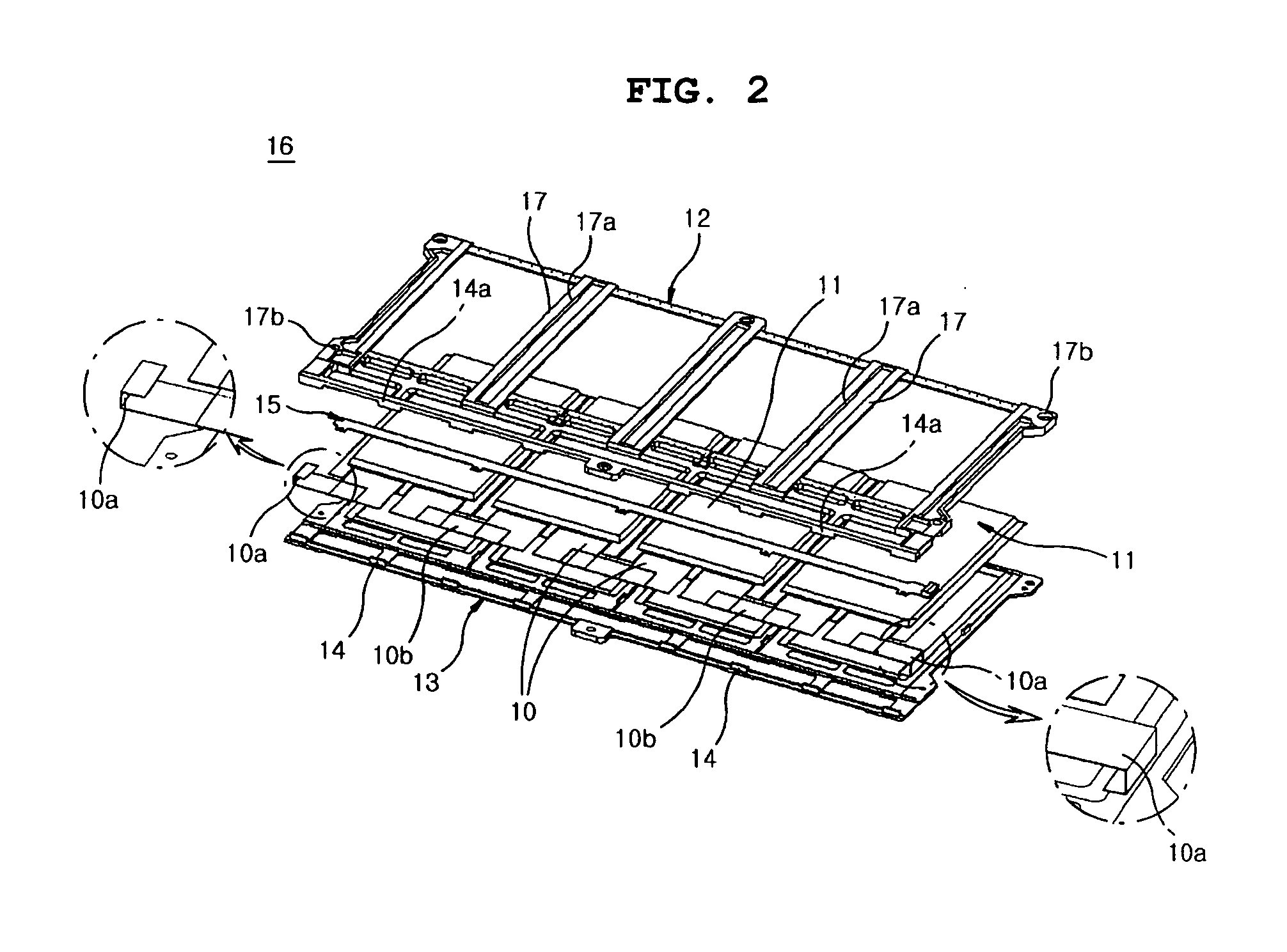

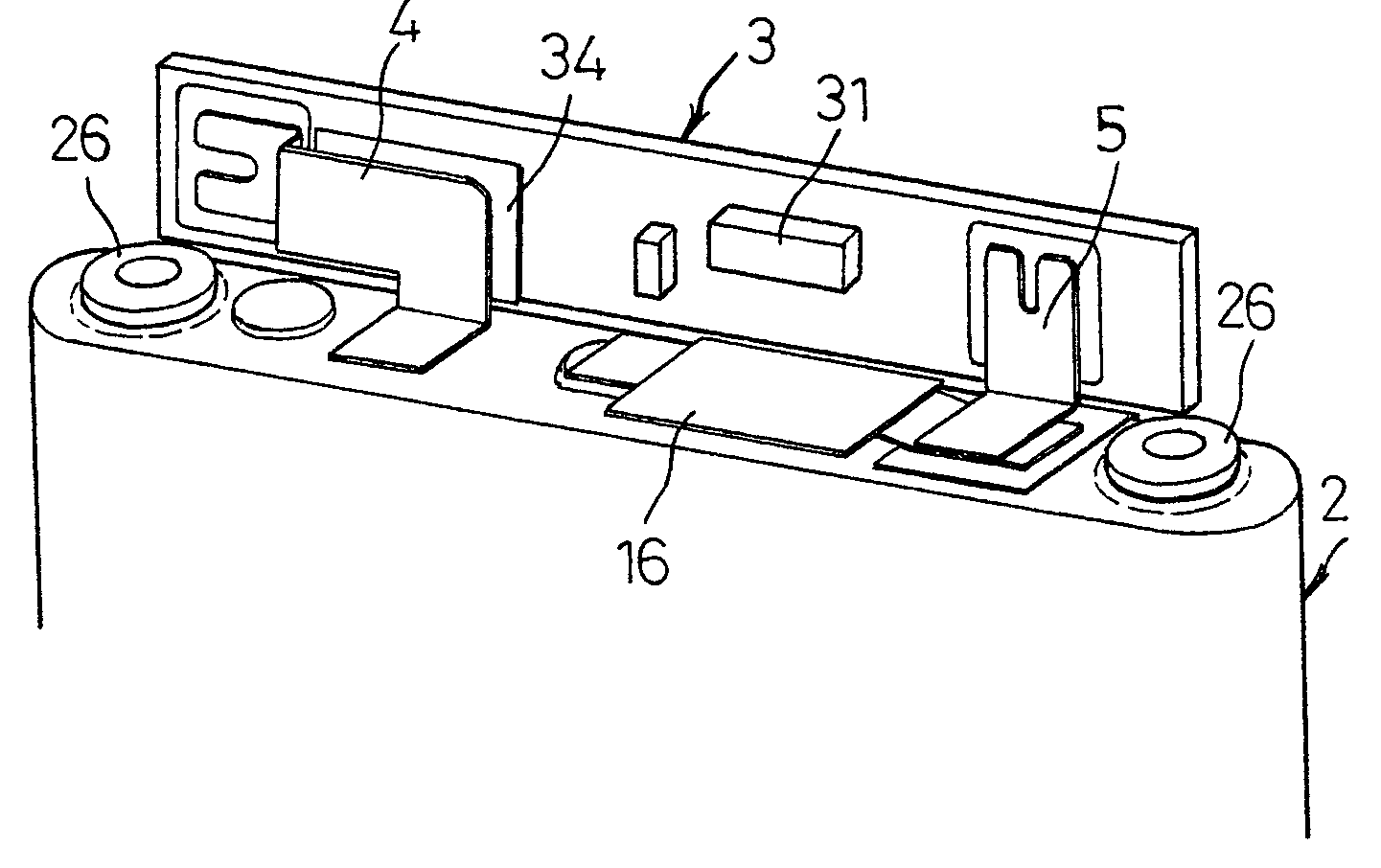

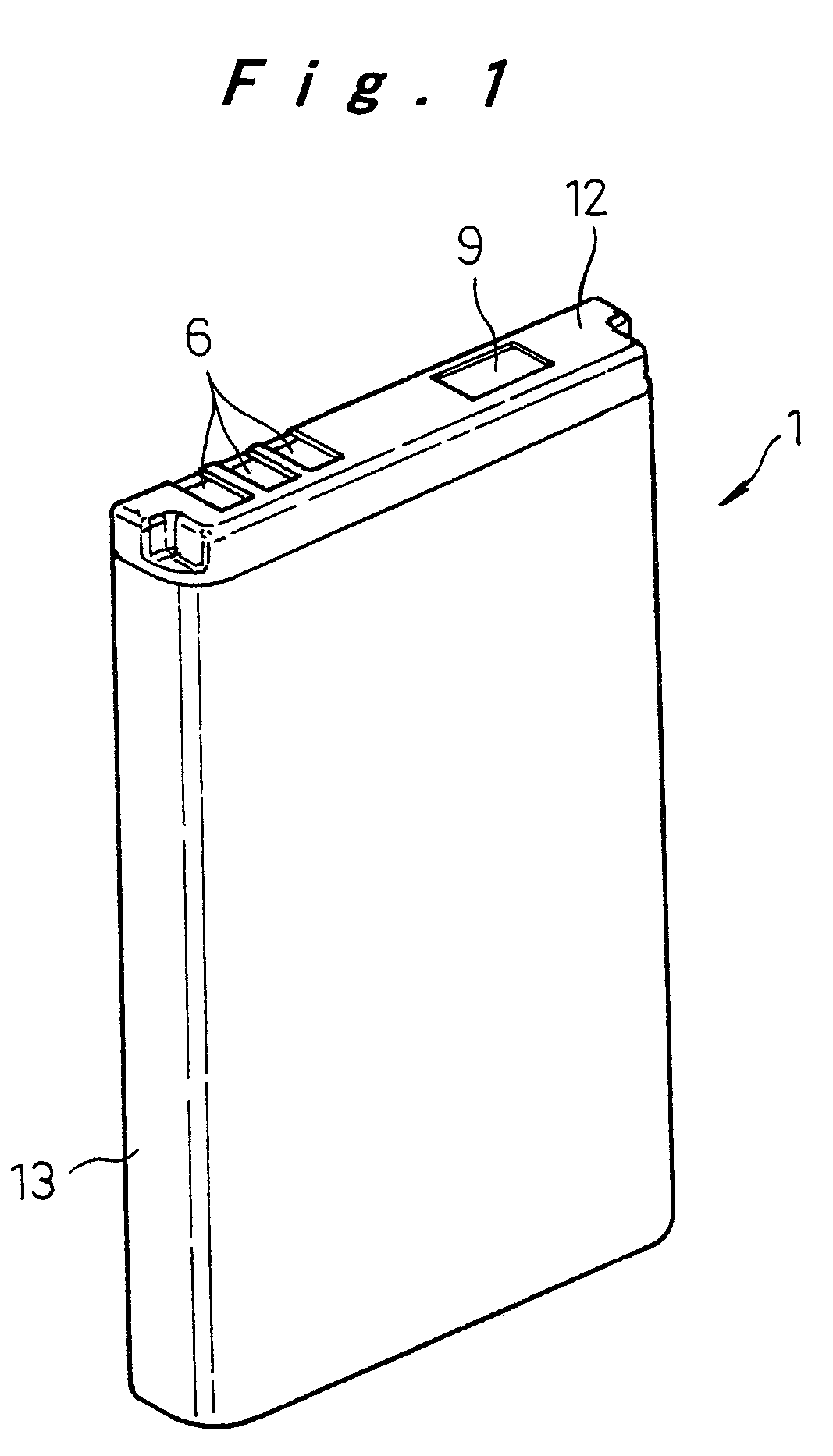

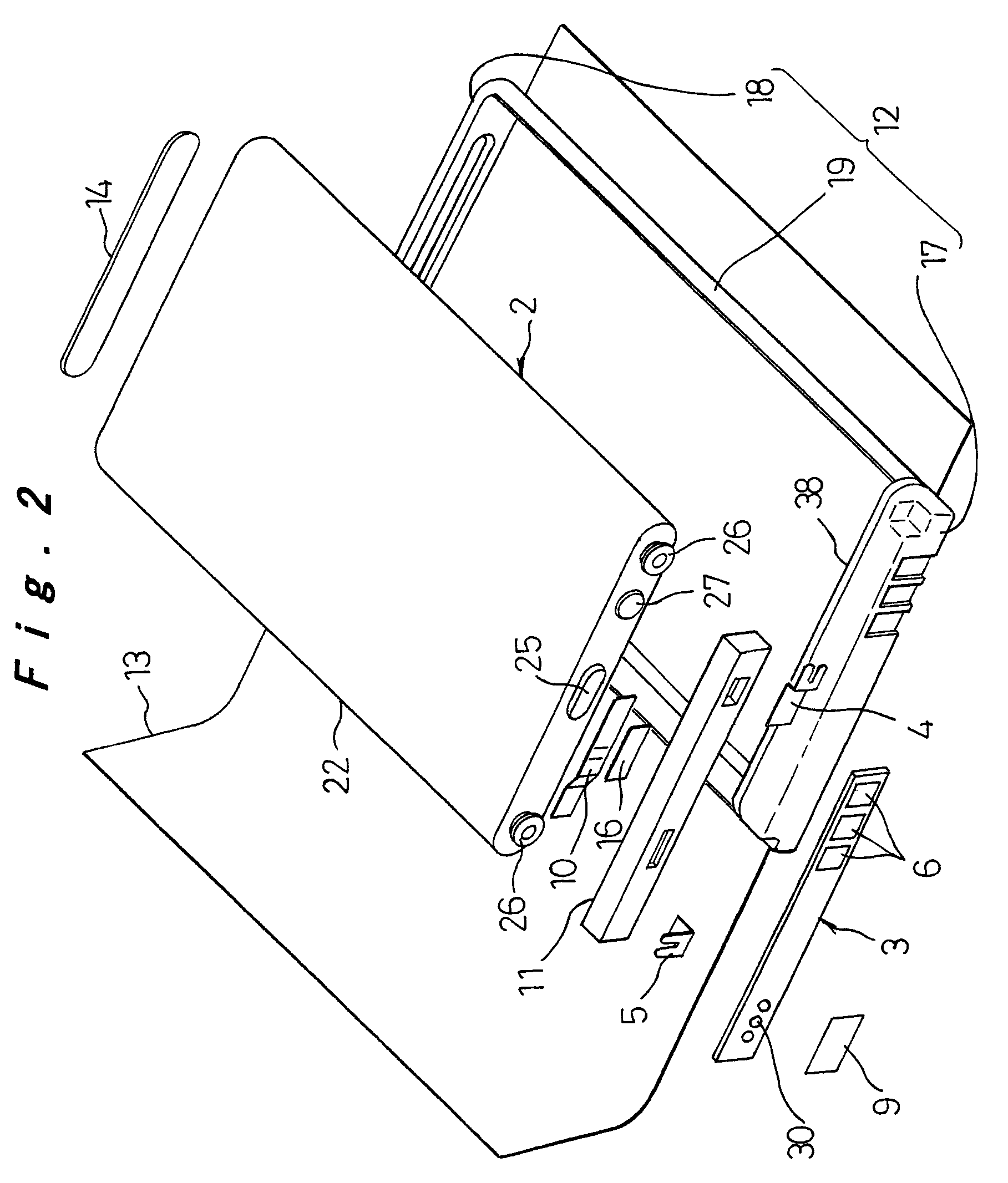

Cartridge-type lithium ion polymer battery pack

ActiveUS20050100783A1Efficient dischargeFinal product manufactureCell temperature controlEngineeringElectric power

Disclosed is a cartridge-type lithium ion polymer battery pack including: at least two lithium ion polymer batteries in which adjacent electrode tabs are connected to each other so as to form a predetermined series circuit with a desired instrument; and an upper plate and a lower plate disposed at the top and the bottom of the whole lithium ion polymer batteries, respectively, and coupled to each other so that each lithium ion polymer battery is partially covered with them. Multiple layers of the battery packs are laminated and fixed with ease so as to conform to the electric power requirement for a desired instrument.

Owner:LG ENERGY SOLUTION LTD

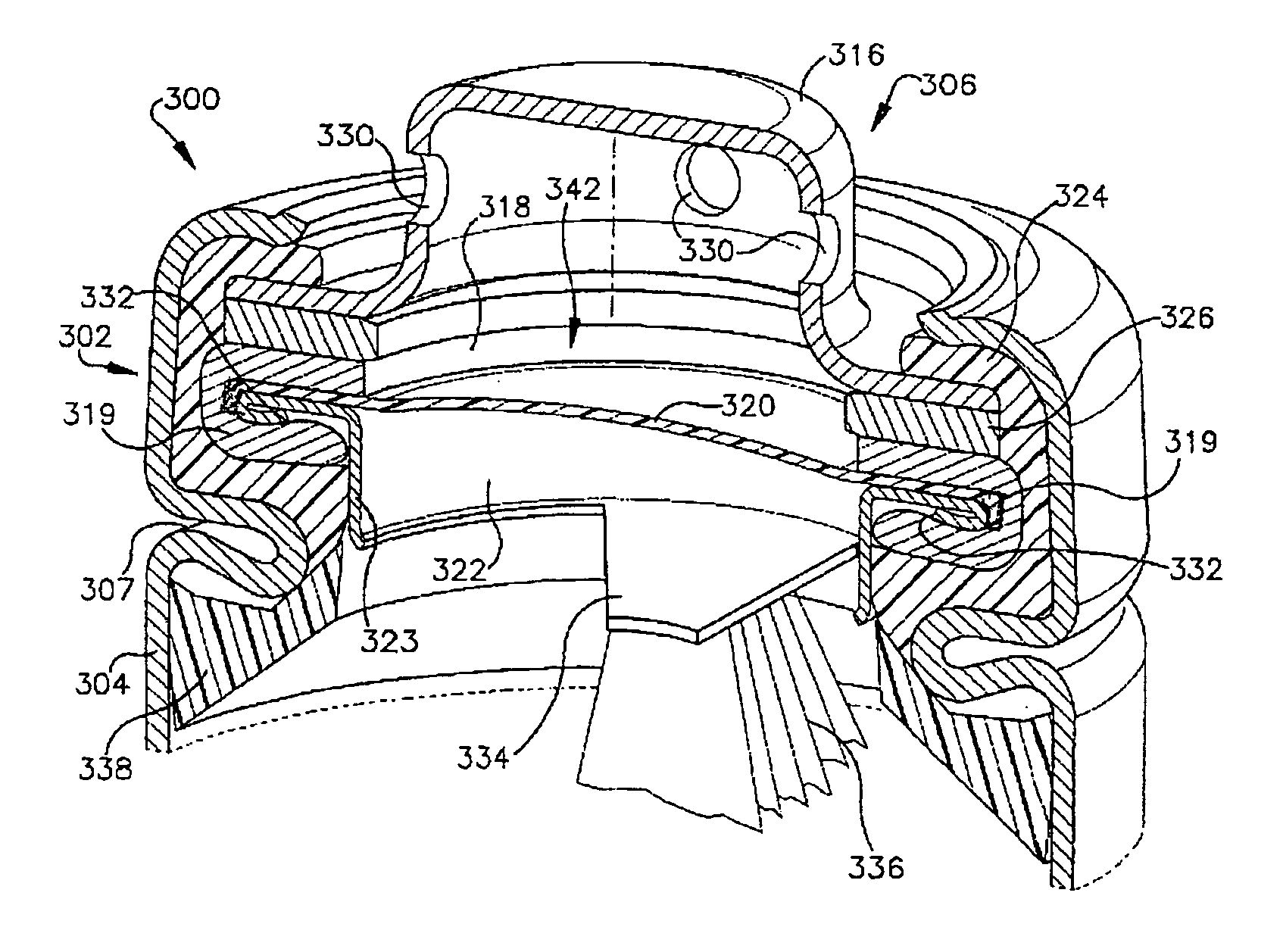

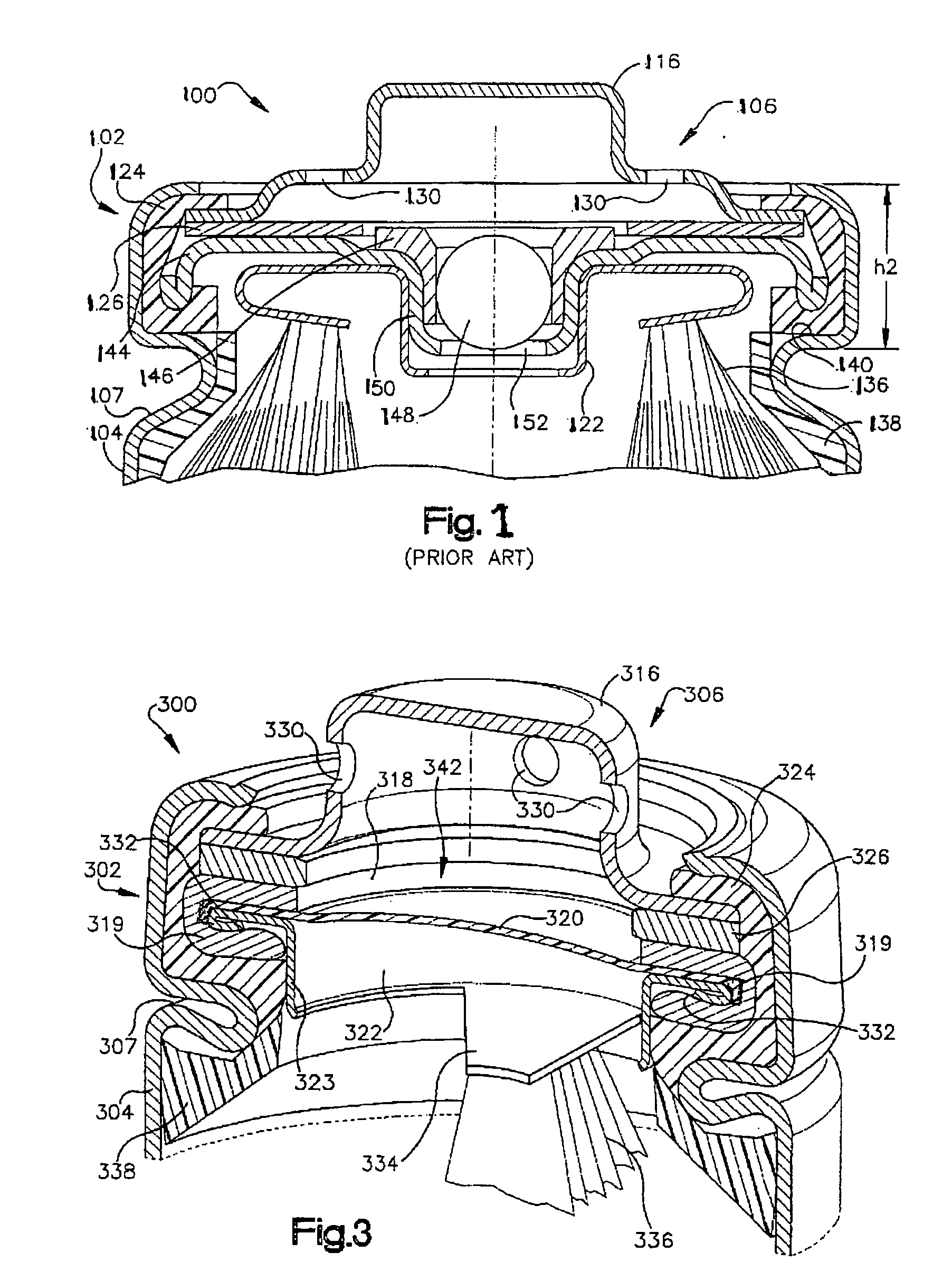

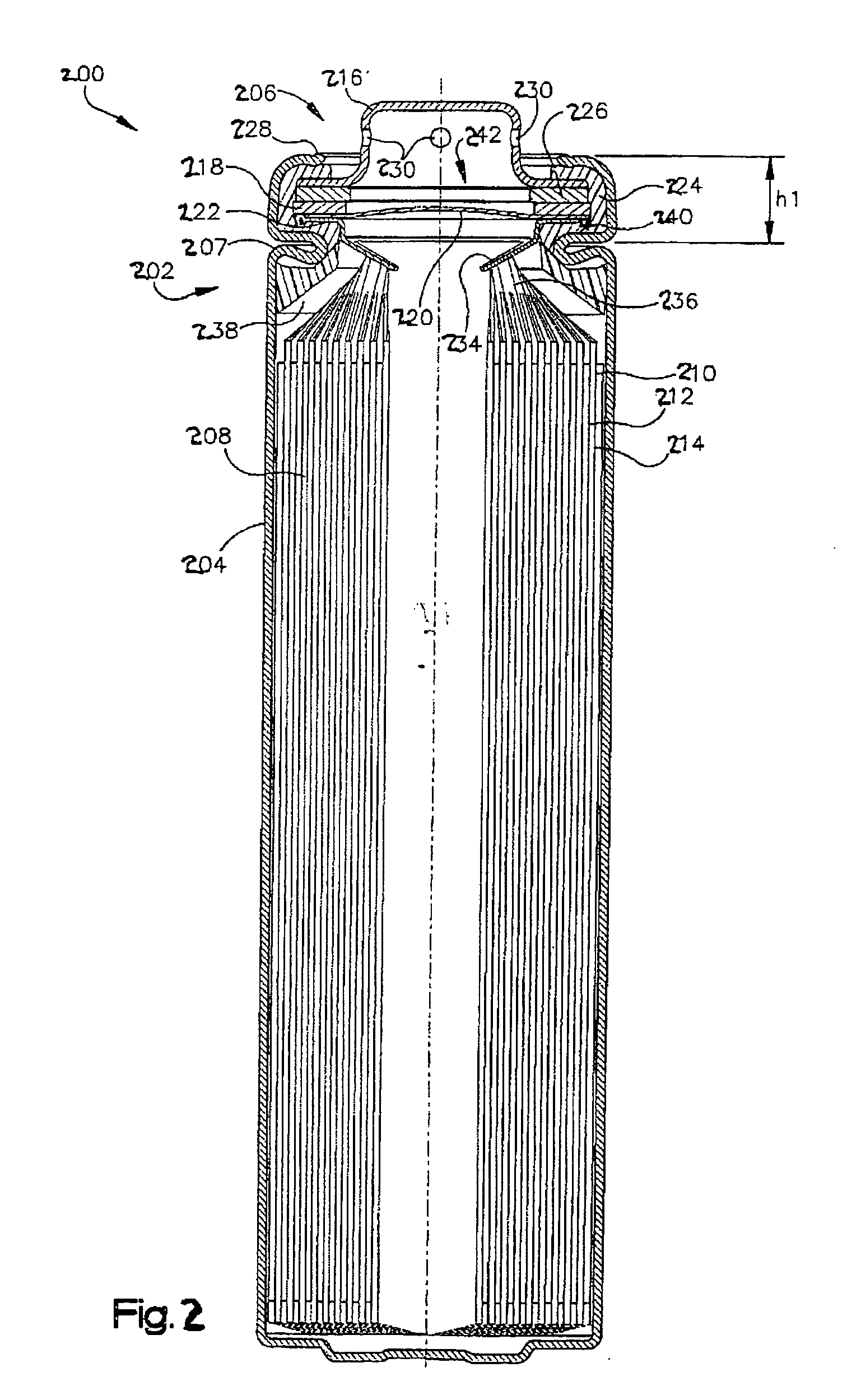

Closure vent seal and assembly

InactiveUS20060228620A1Increase battery capacityThe production process is simpleClosuresFinal product manufactureEngineeringMechanical engineering

A closure assembly and rupturable vent seal adapted for use in an electrochemical battery cell is disclosed. The vent seal includes a series of peripheral projections that can be folded to insure proper sealing of the vent without wrinkles or overlapping folded portions. Methods of accomplishing the invention are also contemplated.

Owner:EVEREADY BATTERY CO INC

Long life thin film battery and method therefor

InactiveUS20080003492A1Improve air tightnessIncrease costSolid electrolytesFinal product manufactureEngineeringThin film rechargeable lithium battery

A method for improving the useful life of a thin film lithium-ion battery containing a solid electrolyte and an anode that expands on charging and long life batteries made by the method. The method includes providing a hermetic barrier package for the thin film battery that includes an anode expansion absorbing structure.

Owner:OAK RIDGE MICRO ENERGY

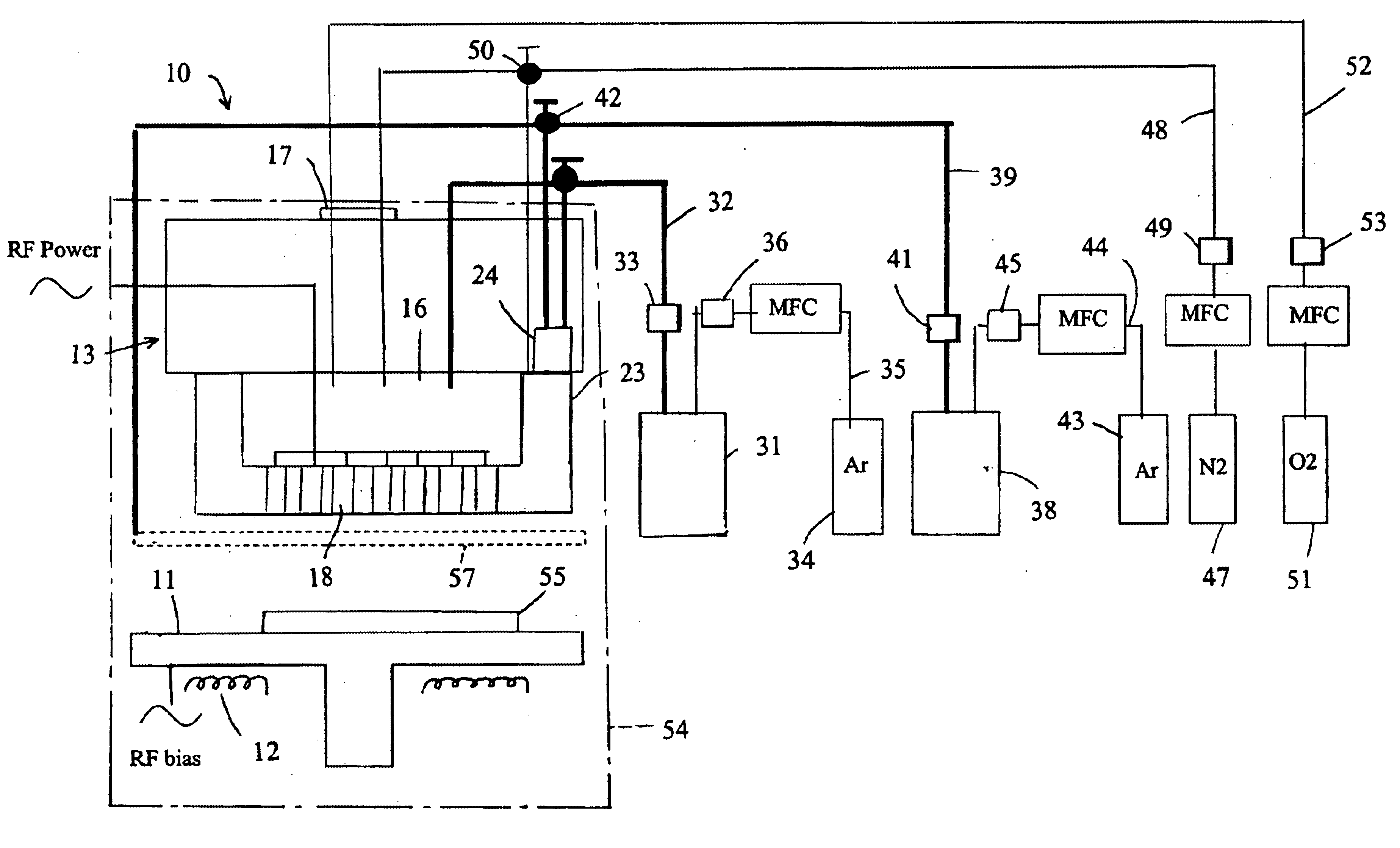

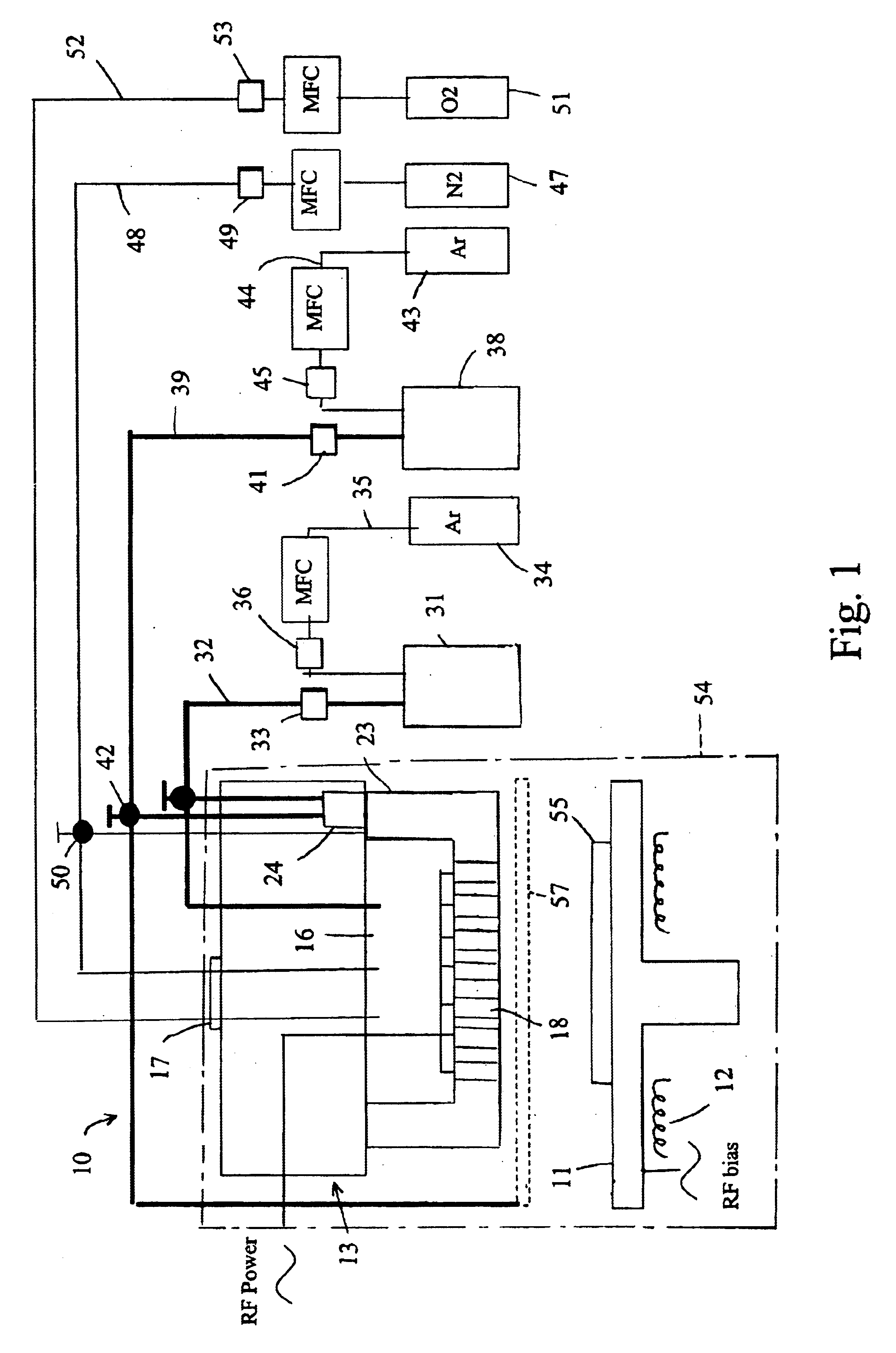

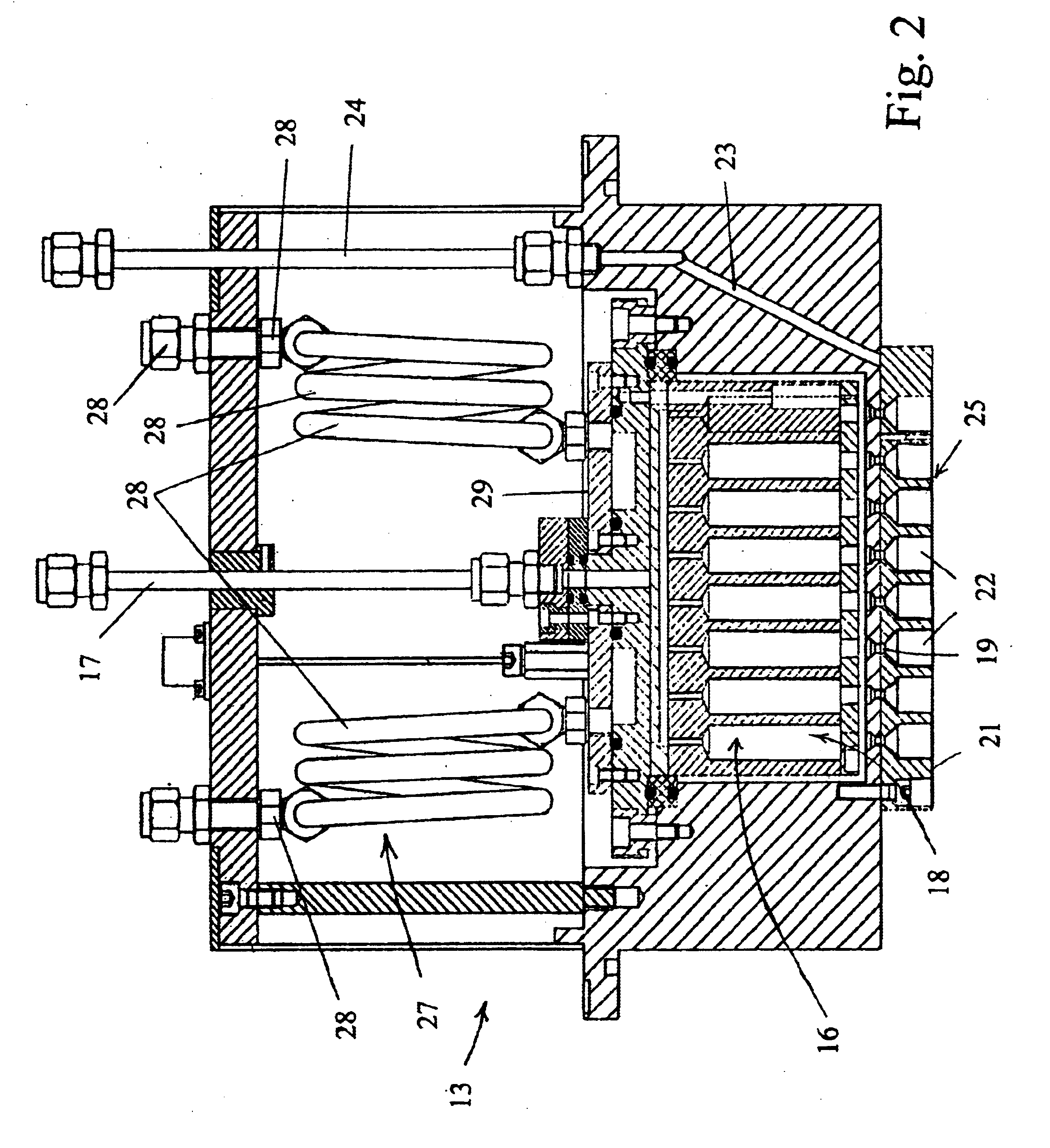

Apparatus for producing thin-film electrolyte

InactiveUS6886240B2Avoid decompositionFinal product manufactureElectrode carriers/collectorsLithiumHydrogen

An apparatus for producing a thin film electrolyte is provided wherein a volatile lithium-containing precursor and a volatile phosphate-containing precursor are mixed into a plasma generated from a plasma source. The mixture is then deposited upon a substrate. The apparatus has a plasma source (13) having a primary plenum (16) and a secondary plenum (23). The primary plenum is in fluid communication with a source of nitrogen gas (47) and a source of hydrogen gas (51). The secondary plenum is in fluid communication with a first bubbler (31) and a second bubbler (38).

Owner:JOHNSON IP HLDG LLC

Method for manufacturing battery pack

InactiveUS20050112456A1Improve thermal conductivityReduce heat transferBatteries circuit arrangementsPrimary cell maintainance/servicingRechargeable cellEngineering

Owner:PANASONIC CORP

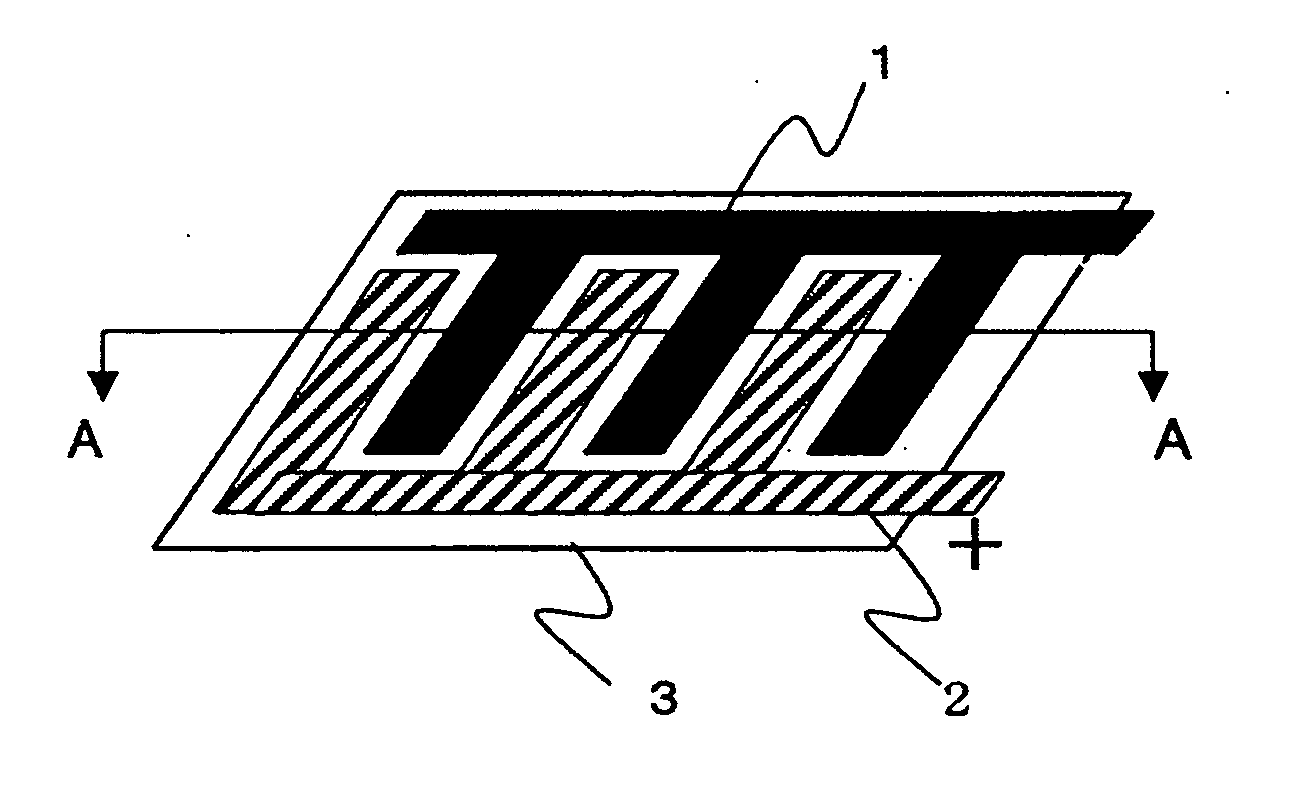

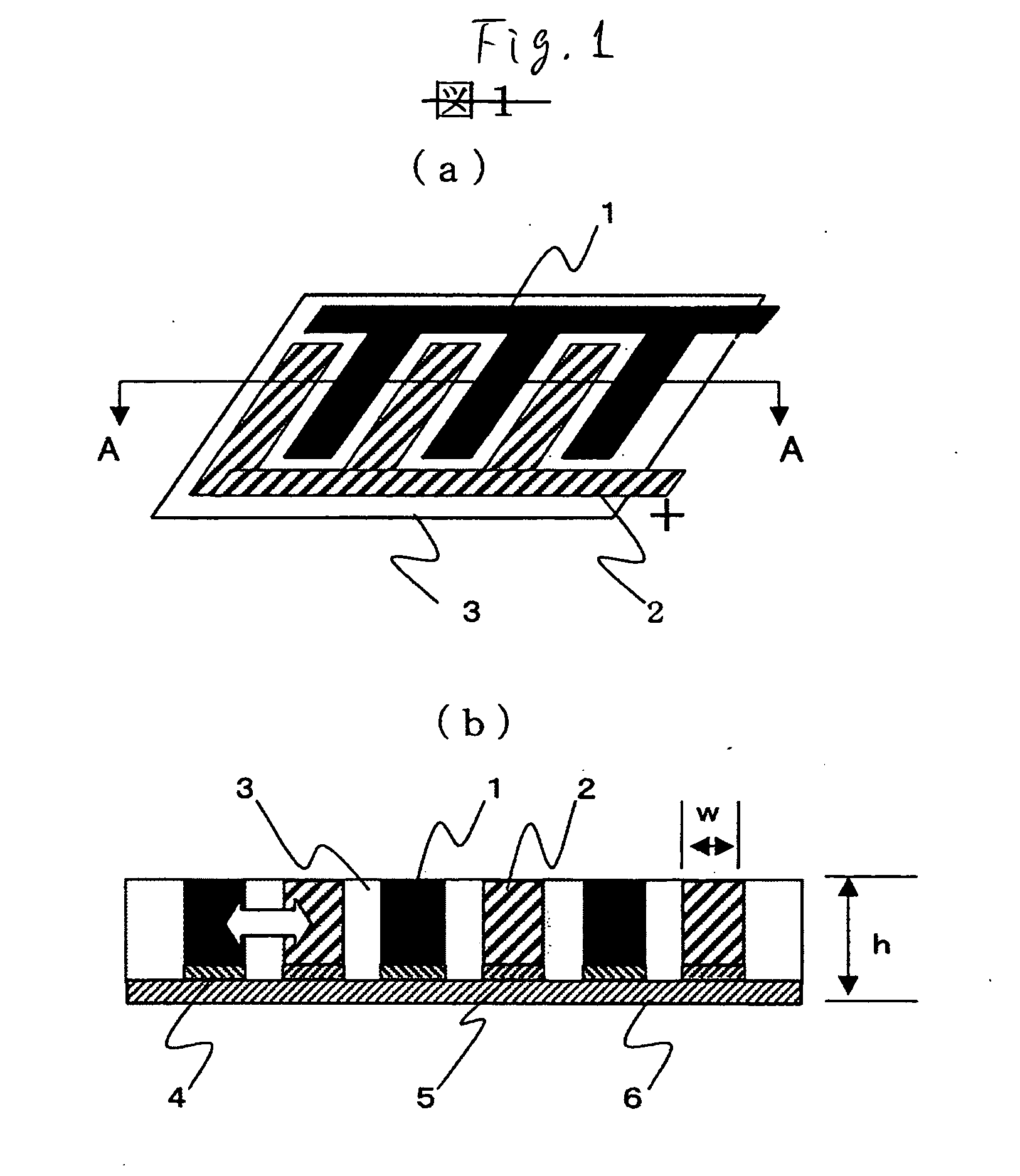

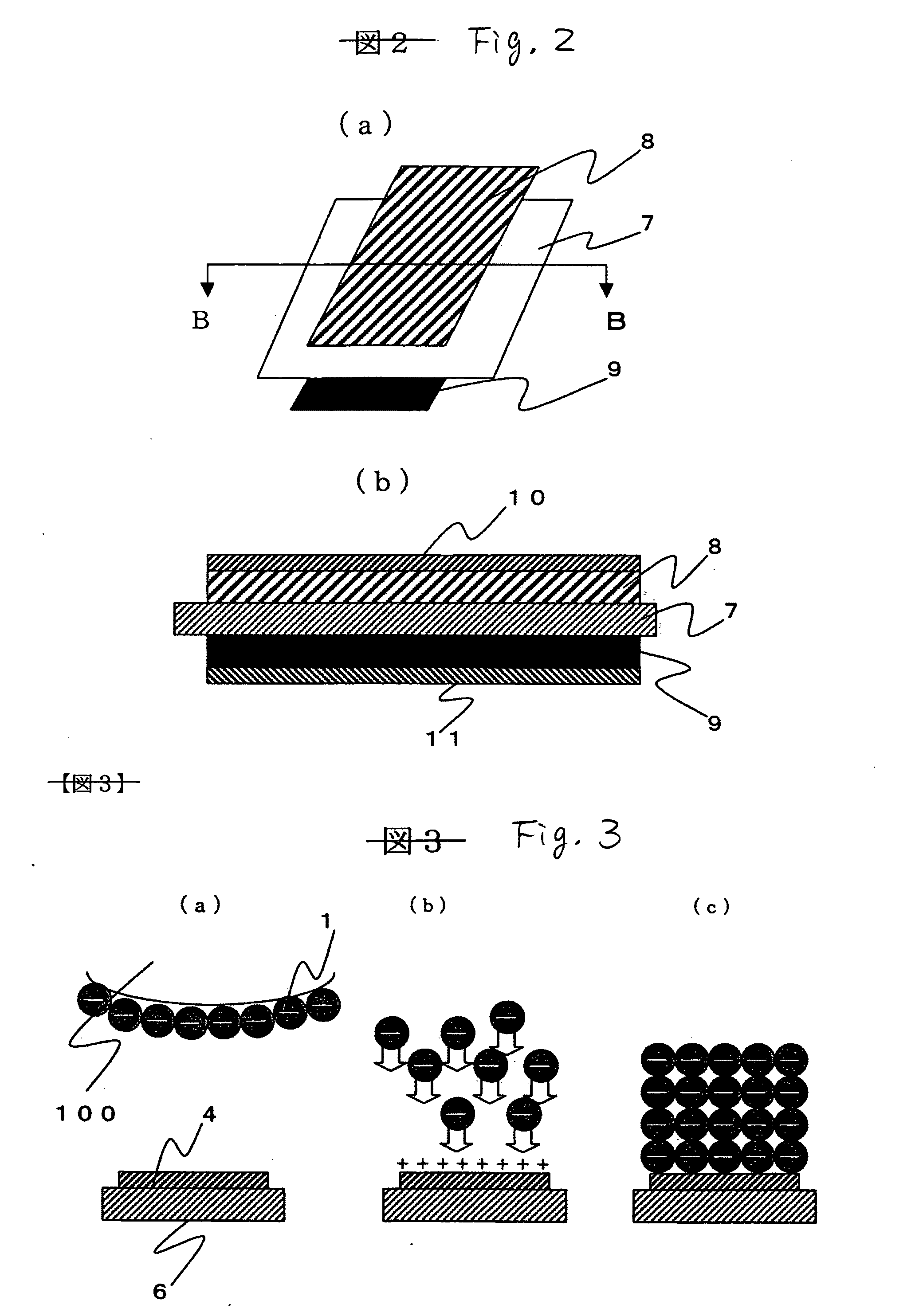

Secondary battery and production method thereof

InactiveUS20060121342A1Increase energy densityLow costSolid electrolytesFinal product manufactureHigh energyReduced size

The present invention proposes a secondary battery structure with a solid electrolyte, which can secure high reliability at a low cost and realize high energy density and high output, and also proposes a method for producing the secondary battery structure simply at a low cost while realizing reduced size and weight. The present invention provides a secondary battery structure of planar, inter digital shape as the one with a solid electrolyte, capable of realizing reduced cost, high safety, high energy density and high output, wherein anode and cathode collectors of pectinate shape are provided to face each other on a flat substrate by patterning, anode and cathode material particles are patterned on the respective anode and cathode collectors by electrophotography in the vertical direction to the collector surface to form the vertical electrodes, and the gap between the adjacent anode and cathode is filled with the solid electrolyte.

Owner:HITACHI LTD

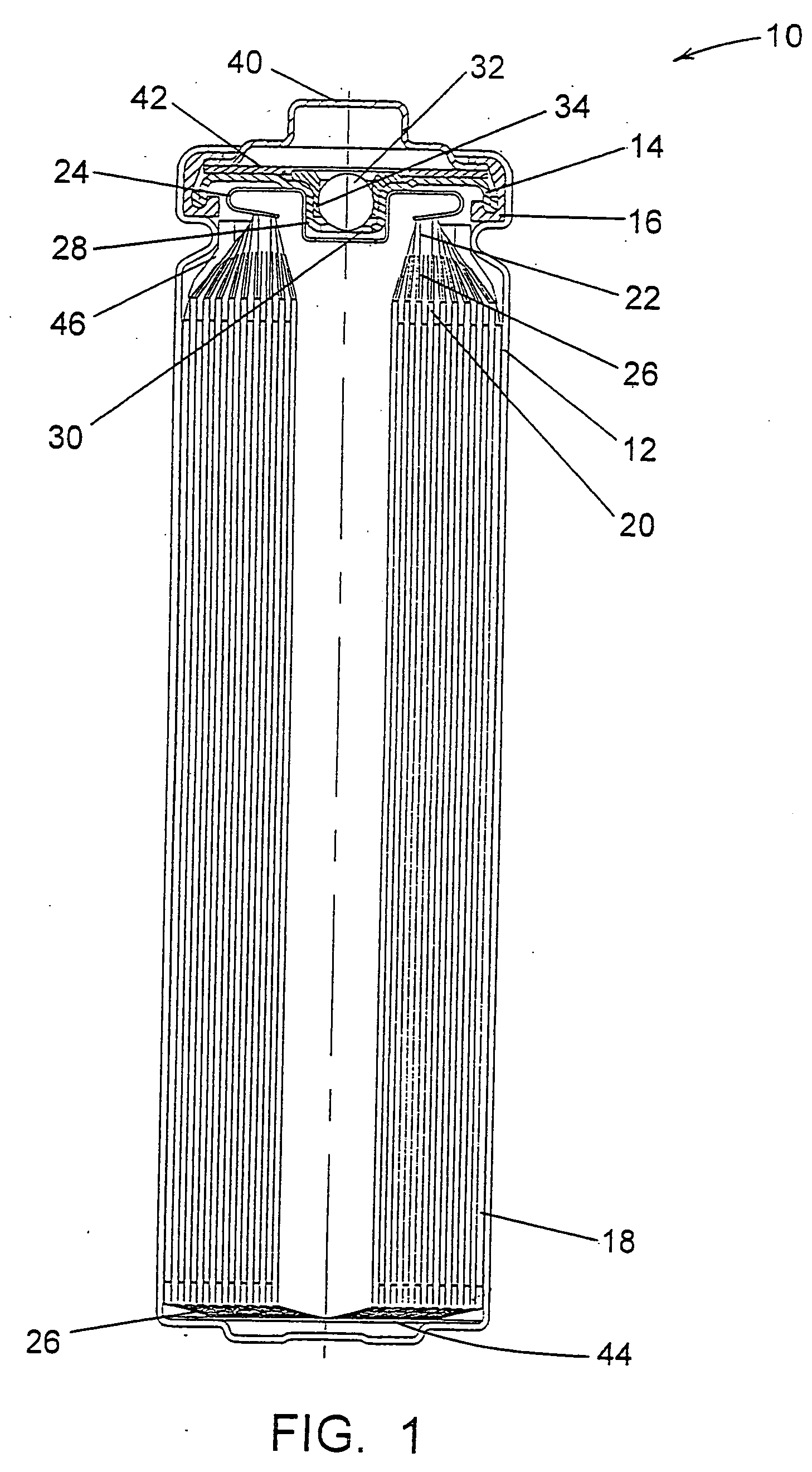

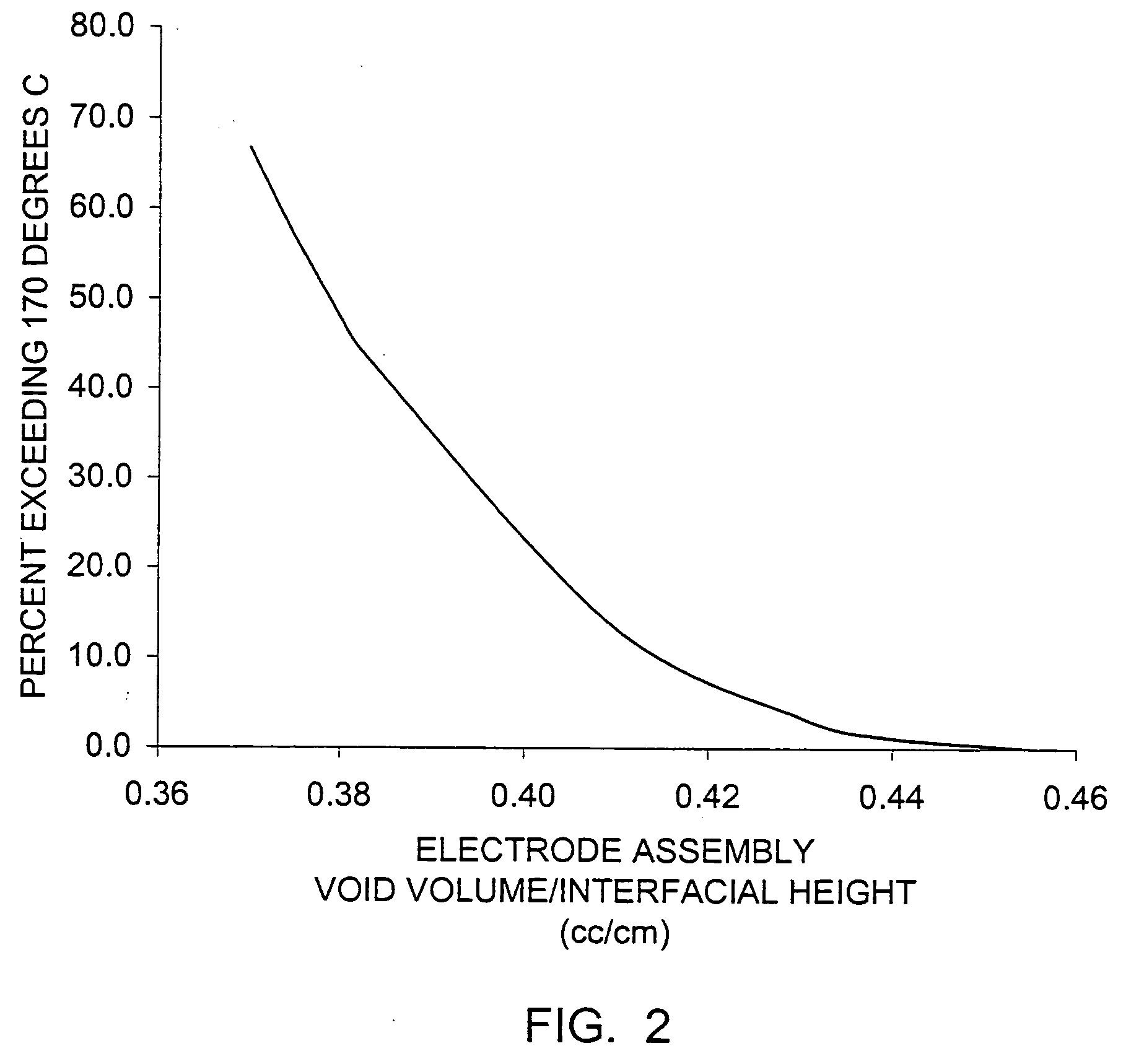

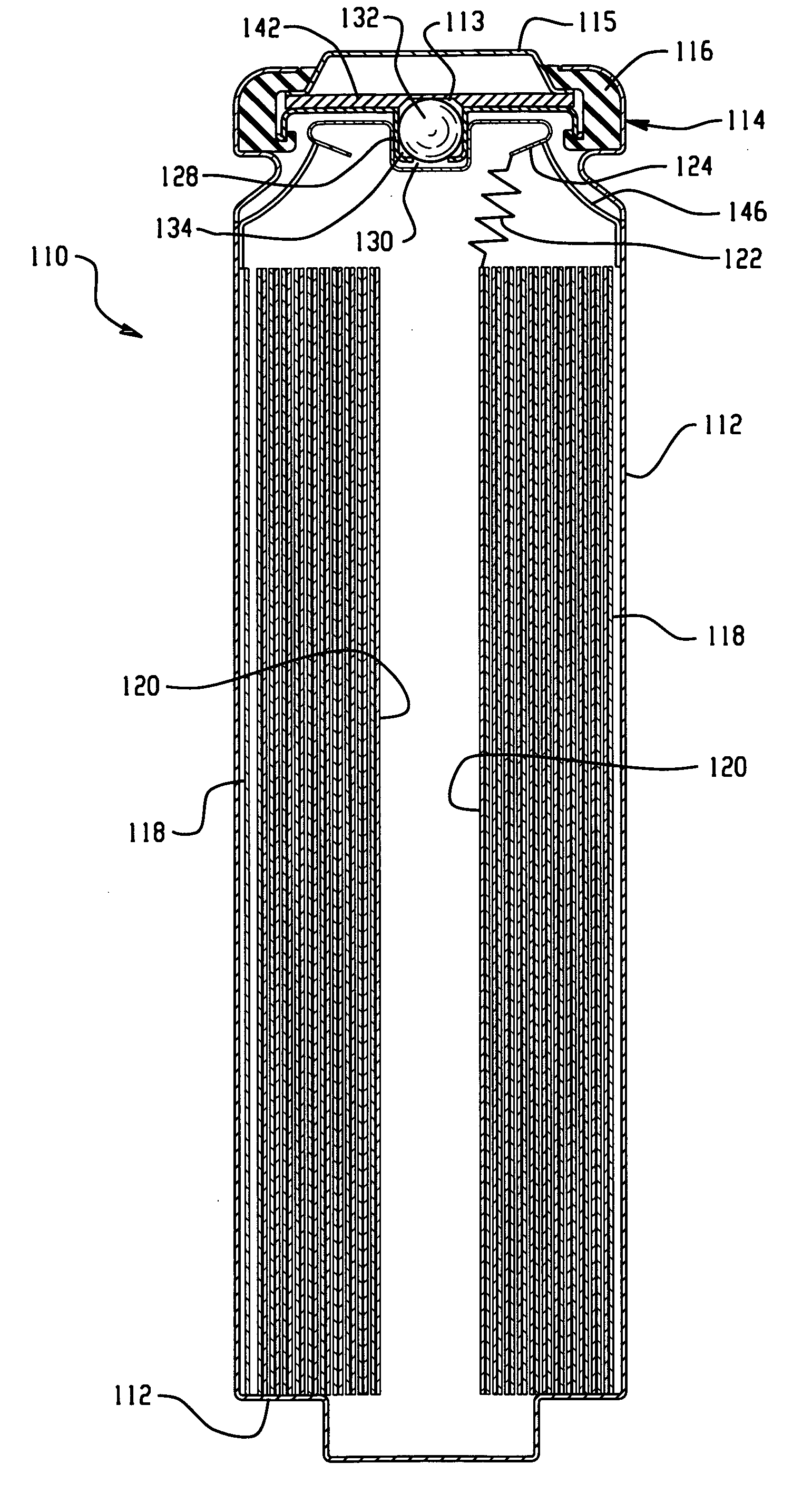

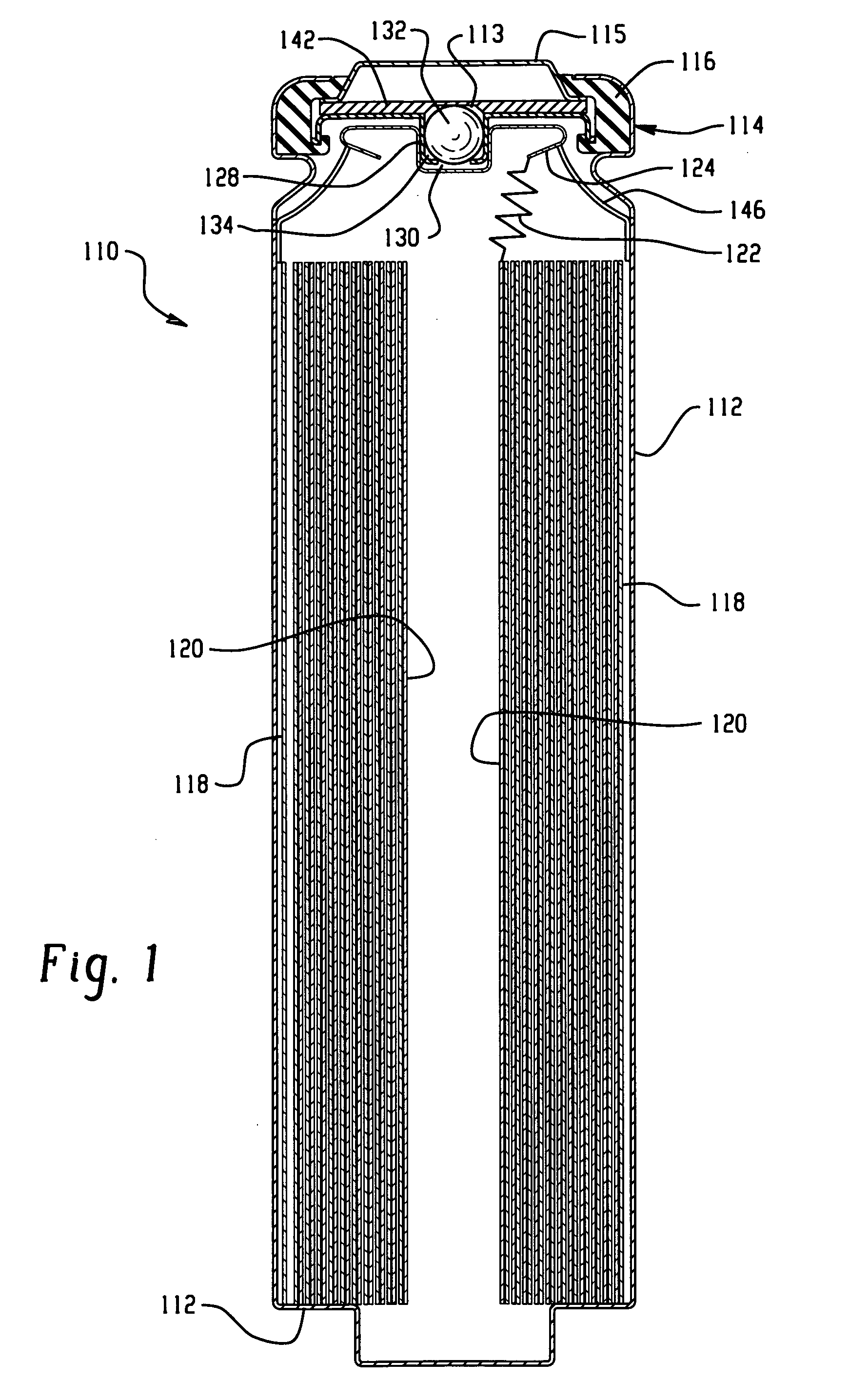

Electrochemical cell with positive container

InactiveUS20080026288A1Improve utilization efficiencyIncrease battery capacityFinal product manufactureElectrode carriers/collectorsSpiral woundEngineering

An electrochemical cell, particularly an electrochemical cell having a container with a positive polarity. In one embodiment, the cell is a primary cell that includes an electrode assembly having a lithium negative electrode and a positive electrode, preferably comprising iron disulfide. The cell is provided with a spiral wound electrode assembly with a portion of the positive electrode contacting the container. The positive electrode current collector contacts the container in one embodiment. The negative electrode includes an electrically conductive member that electrically contacts a cover of the cell and provides the cover with a negative polarity. In a preferred embodiment, the electrically conductive member makes pressure contact with a portion of the cell cover. A method of manufacturing such a cell is also provided.

Owner:EVEREADY BATTERY CO INC

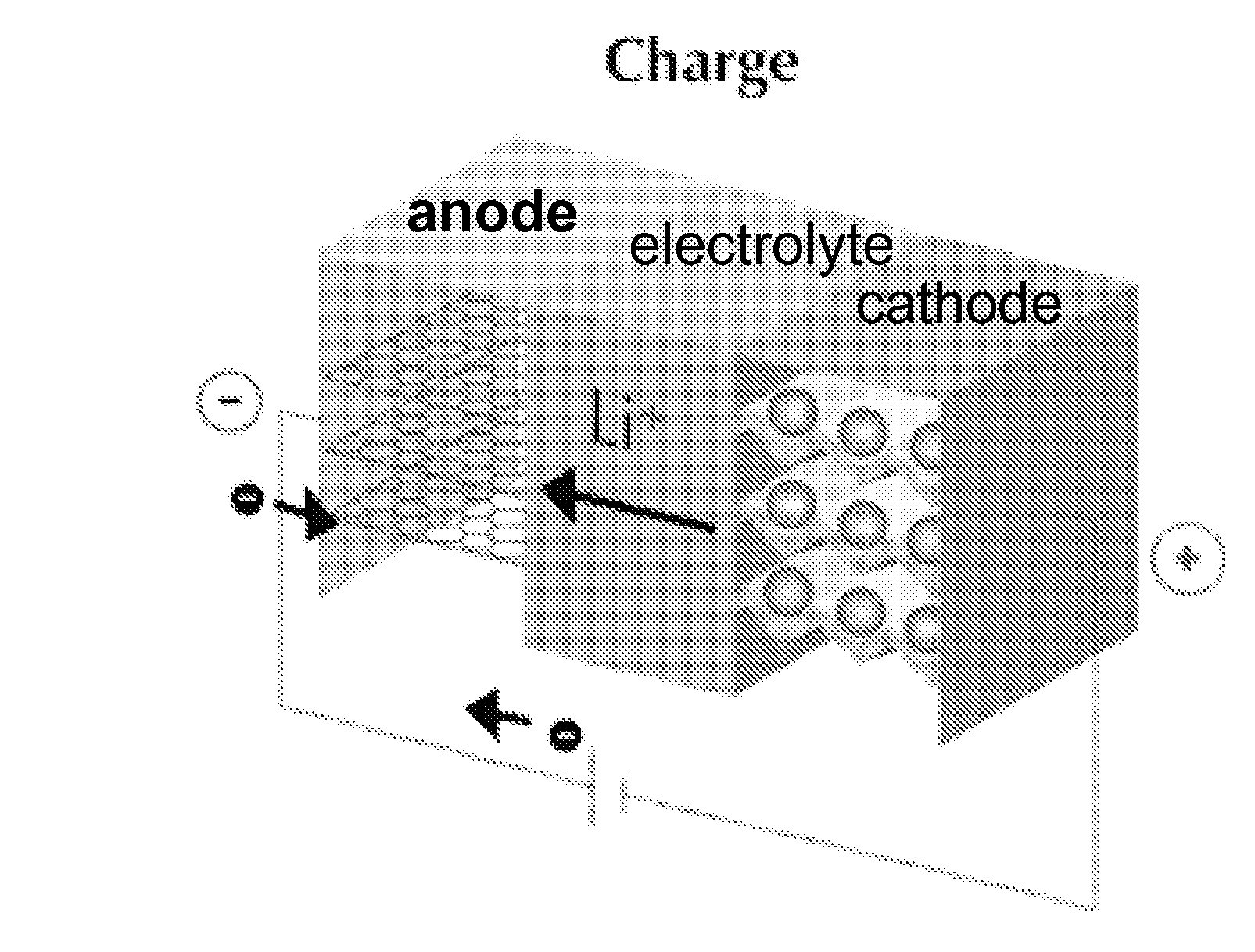

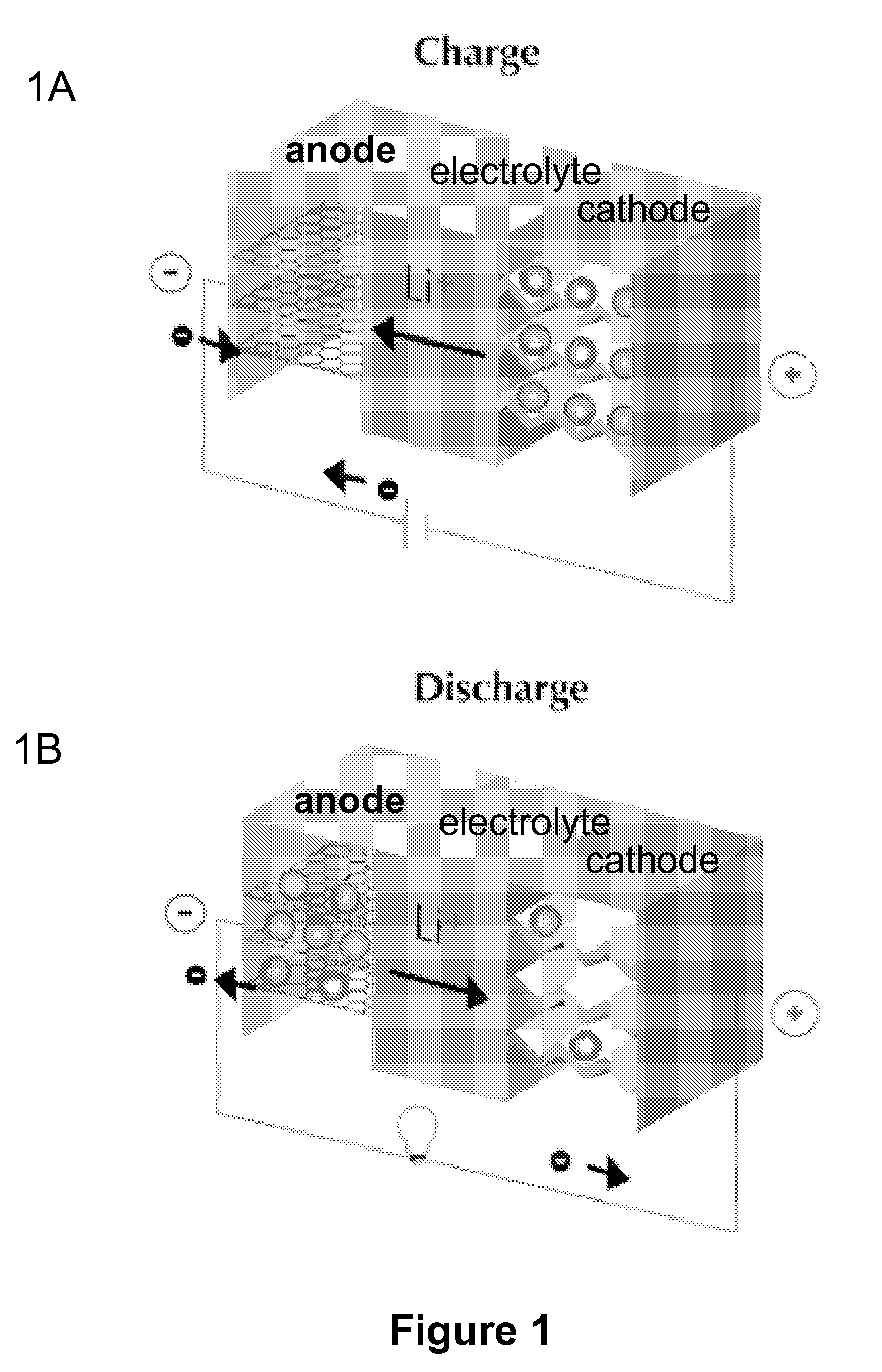

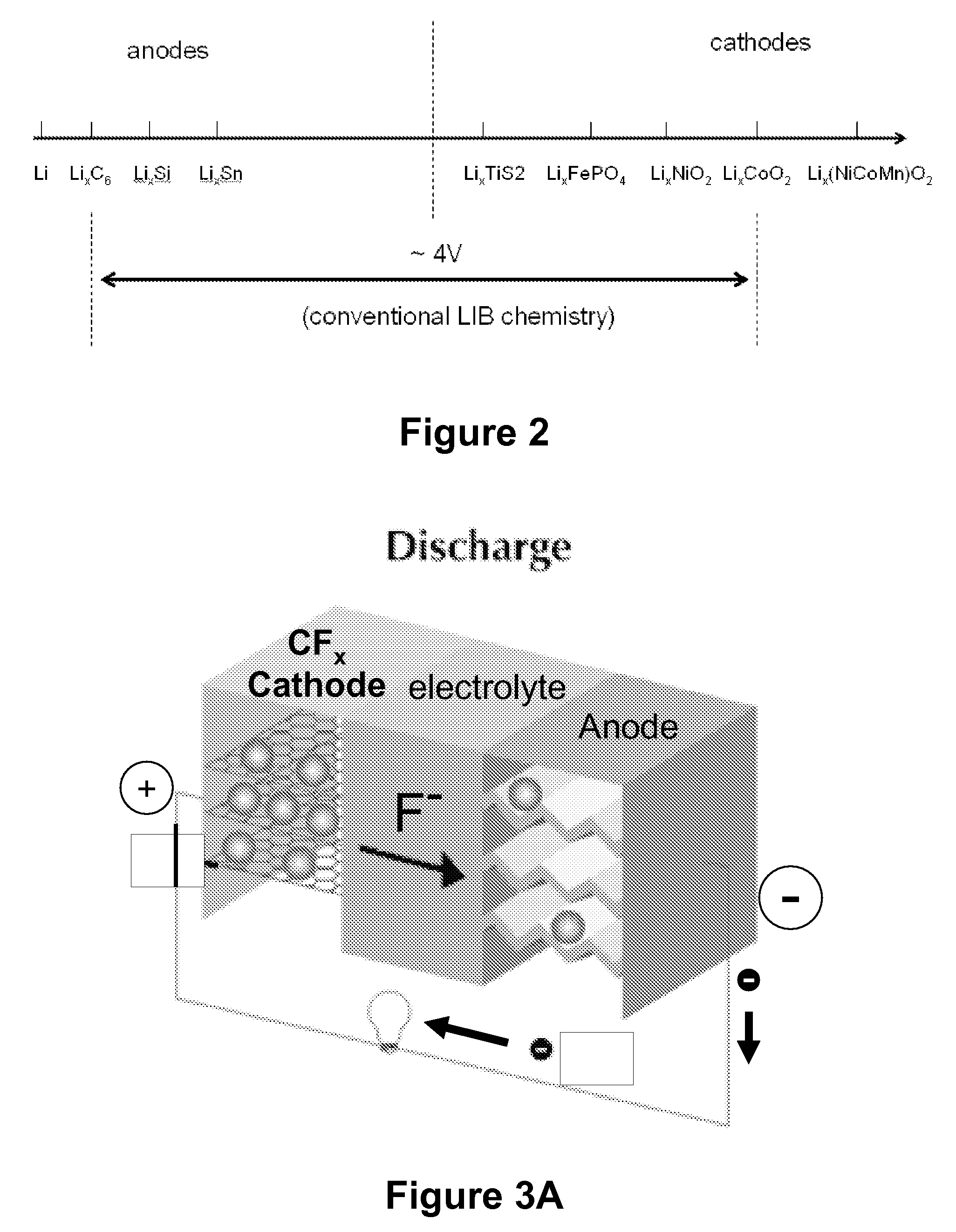

Fluoride ion electrochemical cell

ActiveUS20090029237A1Improve performanceHigh energyAlkaline accumulatorsLead-acid accumulatorsMetallic lithiumState of art

The present invention provides electrochemical cells capable of good electronic performance, particularly high specific energies, useful discharge rate capabilities and good cycle life. Electrochemical cells of the present invention are versatile and include primary and secondary cells useful for a range of important applications including use in portable electronic devices. Electrochemical cells of the present invention also exhibit enhanced safety and stability relative to conventional state of the art primary lithium batteries and lithium ion secondary batteries. For example, electrochemical cells of the present invention include secondary electrochemical cells using anion charge carriers capable of accommodation by positive and negative electrodes comprising anion host materials, which entirely eliminate the need for metallic lithium or dissolved lithium ion in these systems.

Owner:CALIFORNIA INST OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com