Modular battery system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

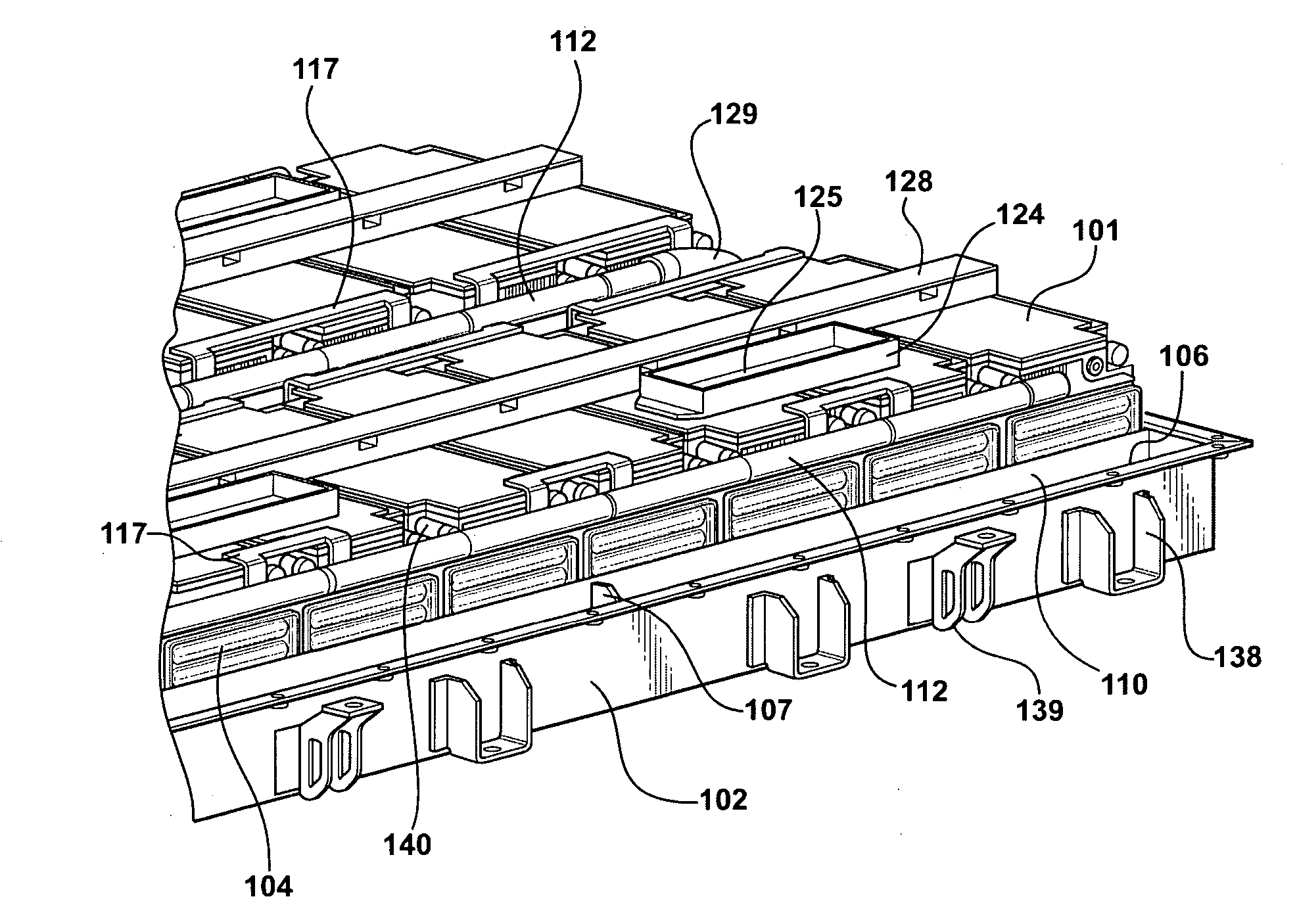

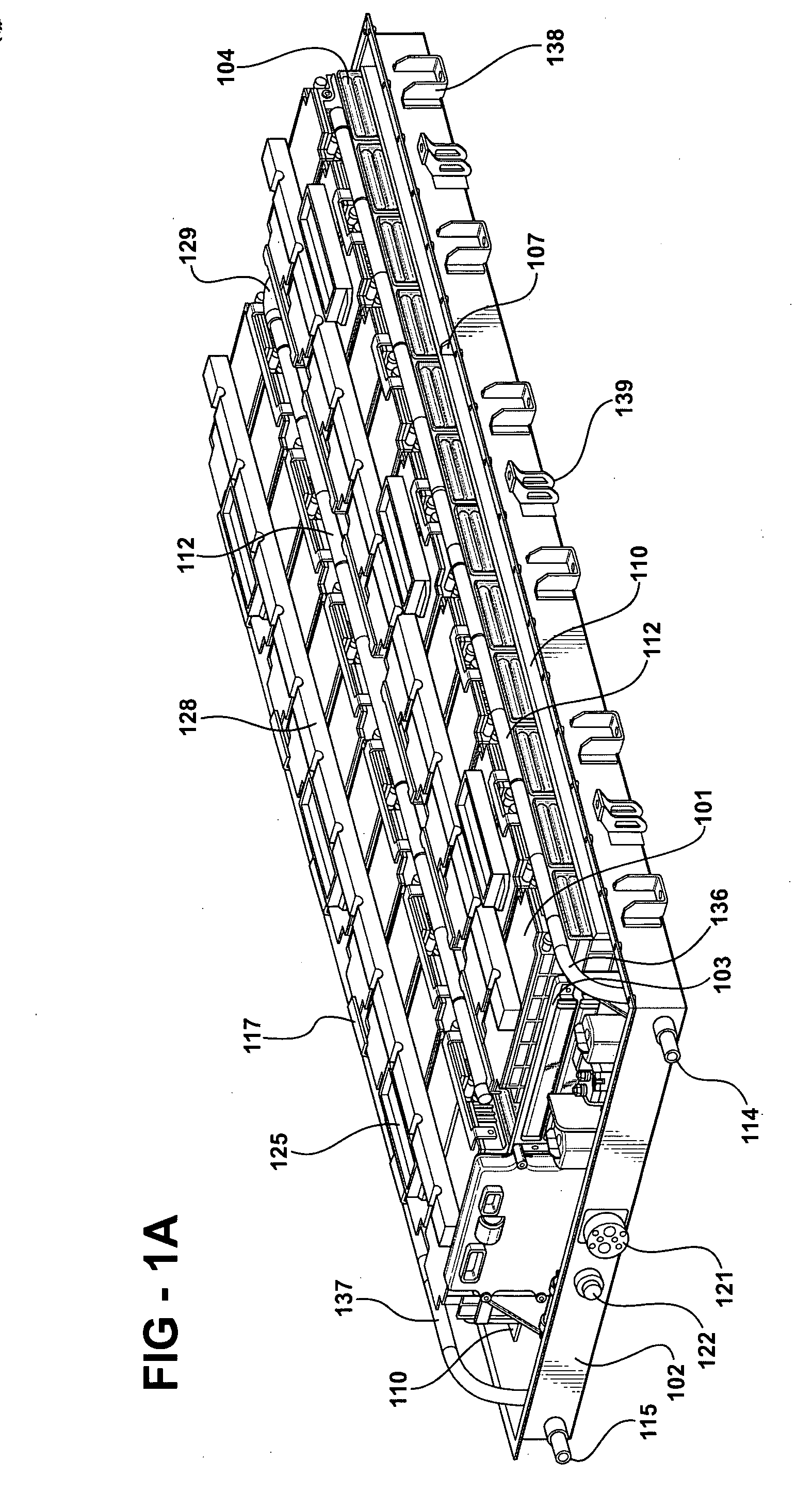

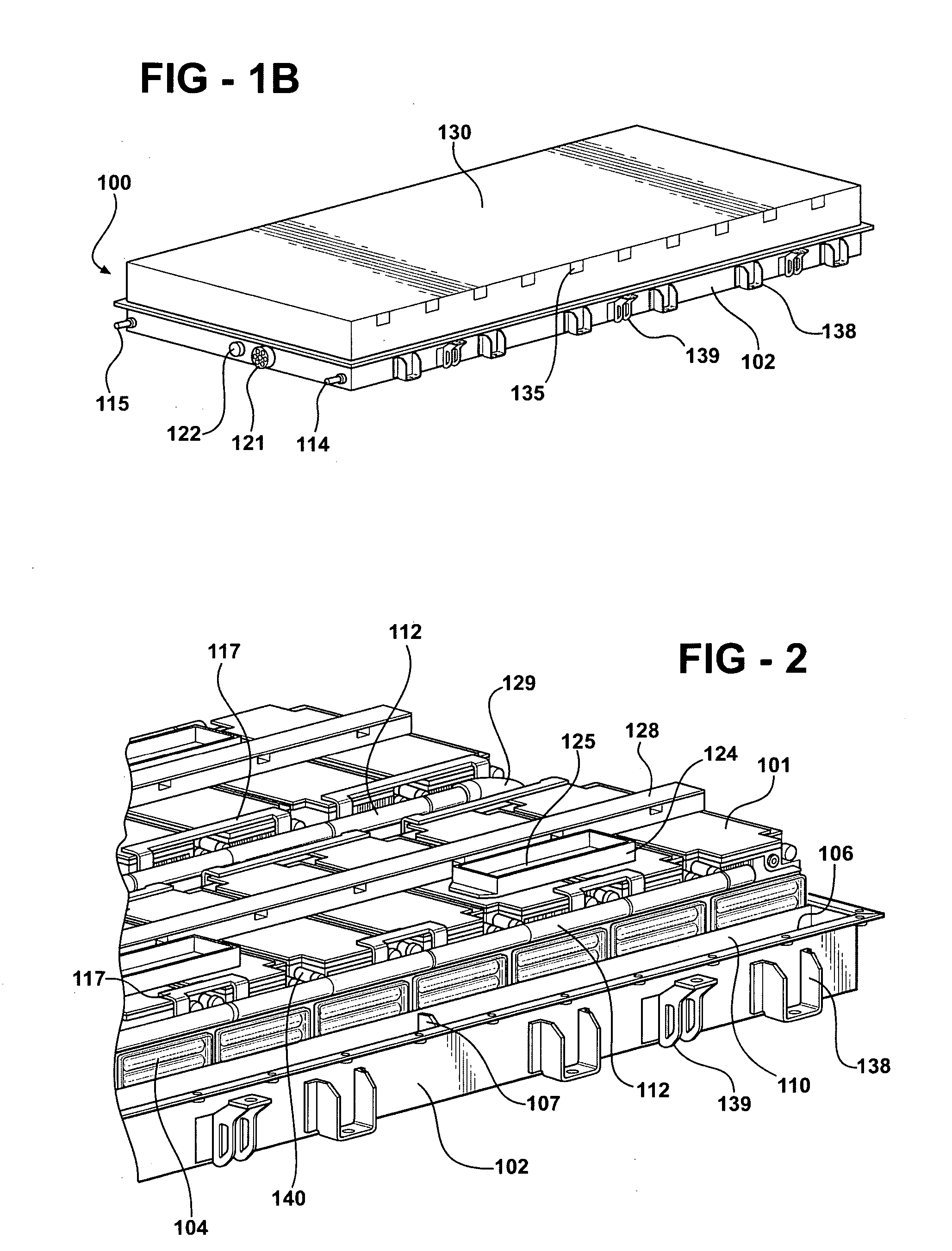

[0043] Disclosed herein is a modular battery system having a plurality of batteries, preferably monoblock batteries, interconnected electrically by bus bars and mechanically by rails and a cooling manifold. Referring to FIG. 1A, illustrated is an embodiment of a modular battery system, generally referred to as 100, wherein monoblock modules 101 are connected in series with bus bars 117. FIG. 1A illustrates a modular battery system comprised of twenty-four battery modules 101 electrically wired in series. The twenty-four battery modules 101 are arranged in a 12×2 array. The modular battery system may be set and secured in a system housing 102 with an integrated control unit (ICU) 103. The ICU 103 secures various components that may be utilized with a preferred embodiment of the system, as discussed below. Each module 101 is preferably secured between a pair of parallel rails. In this illustration, only the outside rail 110 is shown, however; for a view of both rails, refer to FIG. 5B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com