Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

850 results about "Controlled atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

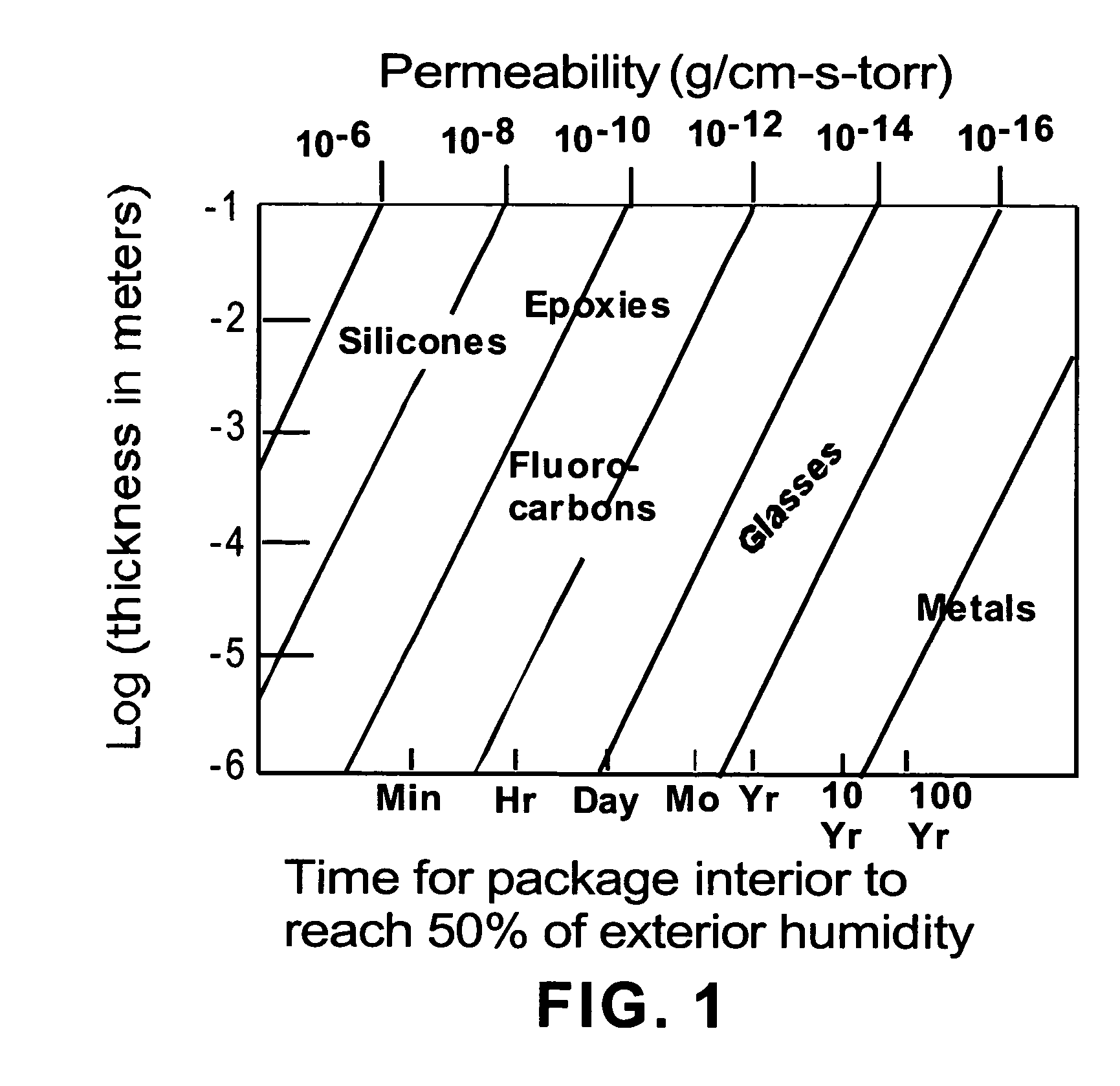

A controlled atmosphere is an agricultural storage method in which the concentrations of oxygen, carbon dioxide and nitrogen, as well as the temperature and humidity of a storage room are regulated. Both dry commodities and fresh fruit and vegetables can be stored in controlled atmospheres.

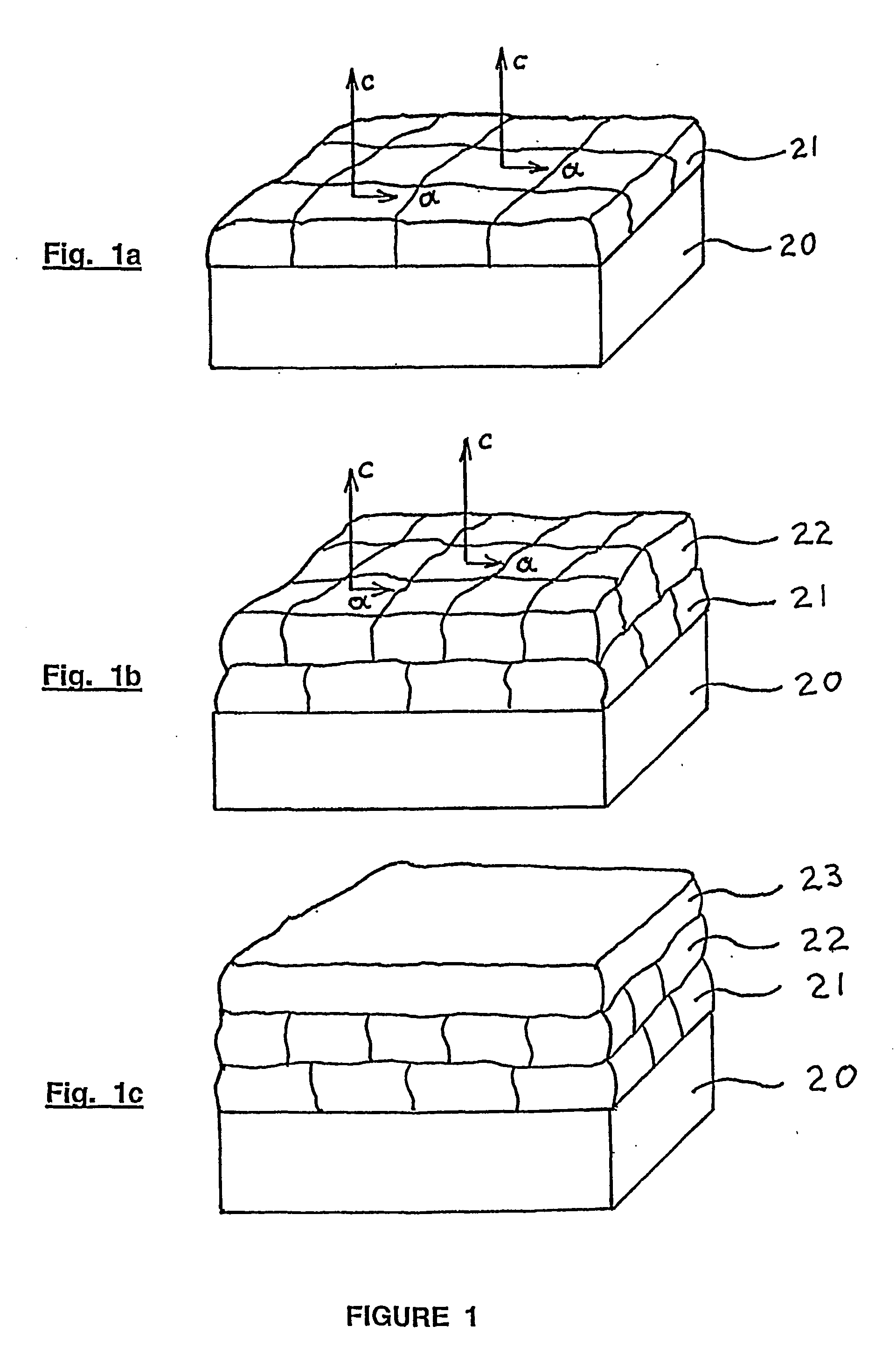

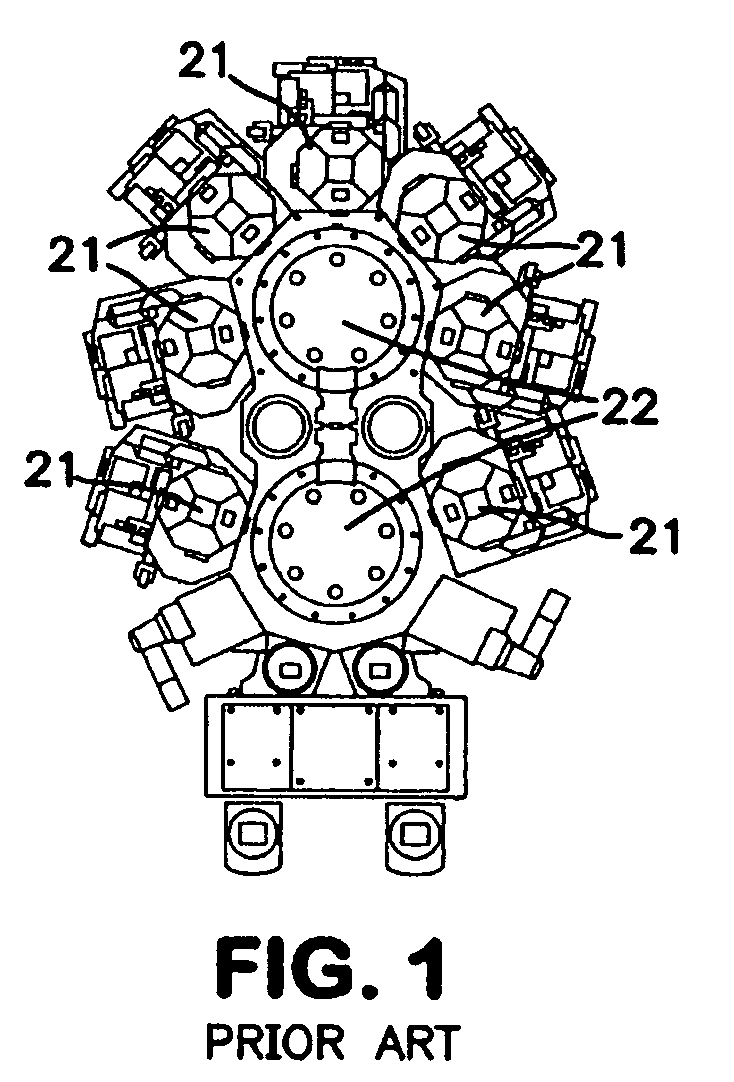

Fabrication of low defectivity electrochromic devices

ActiveUS20100243427A1High level of defectivityVacuum evaporation coatingSputtering coatingArchitectural glassGas phase

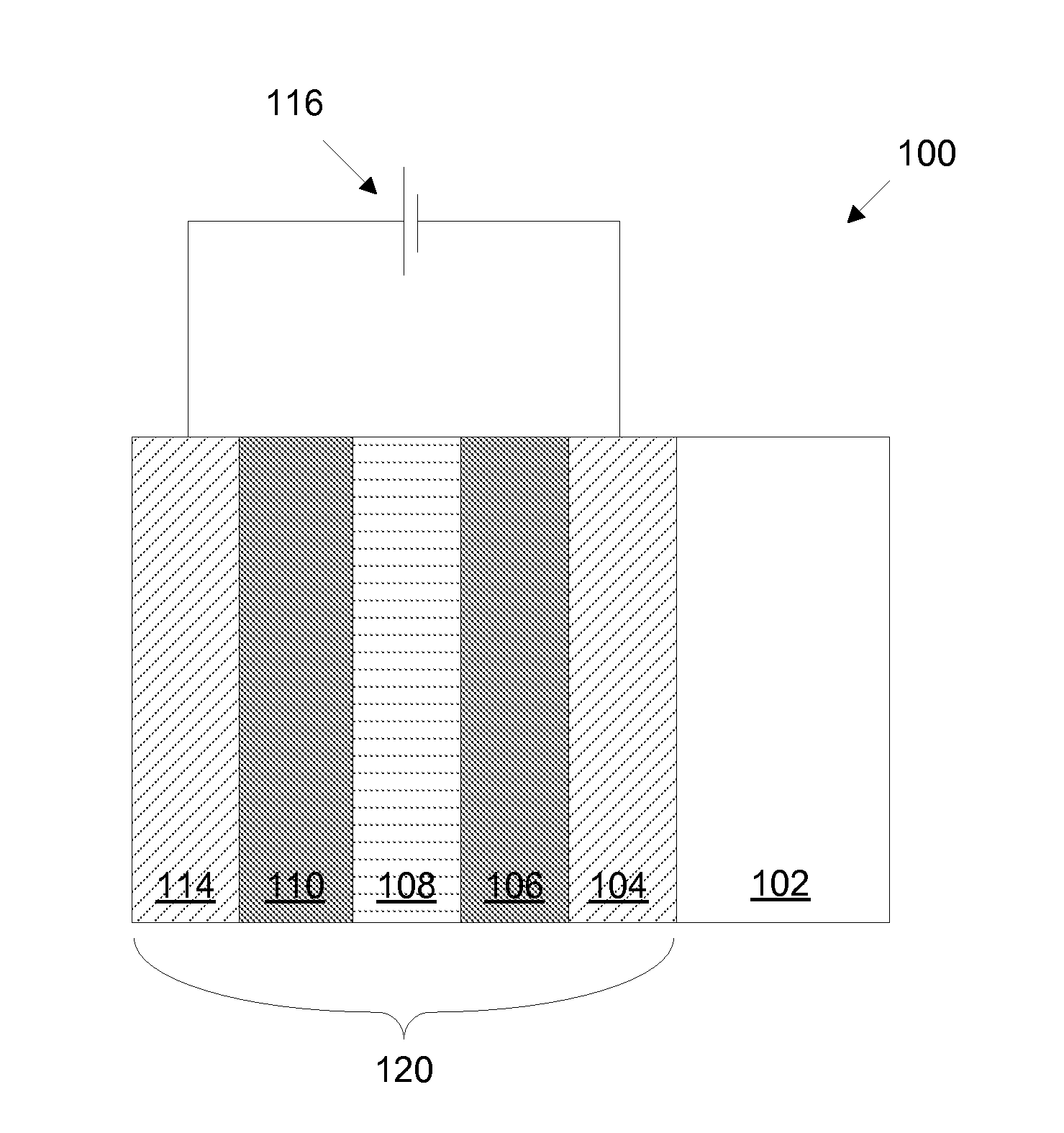

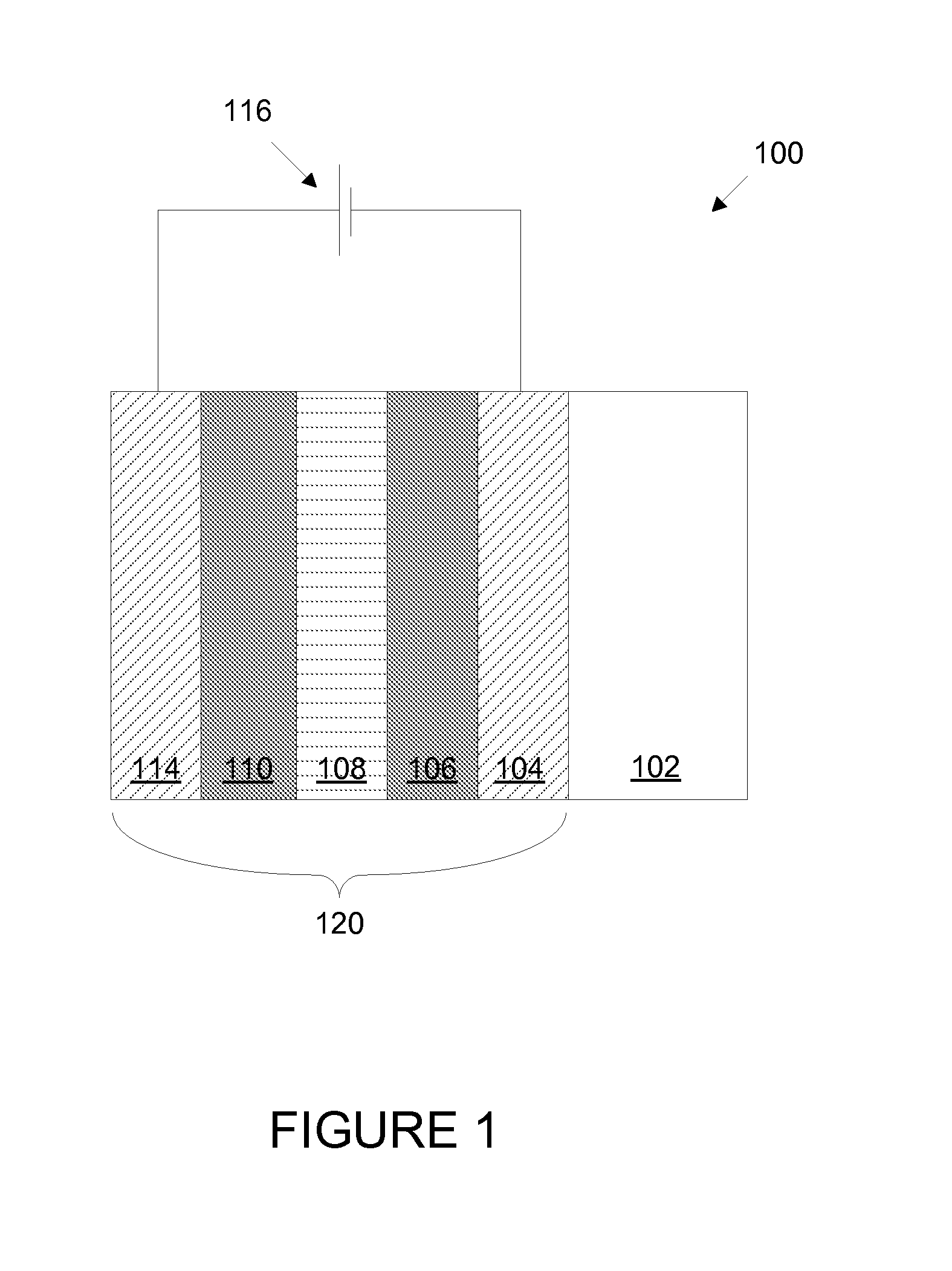

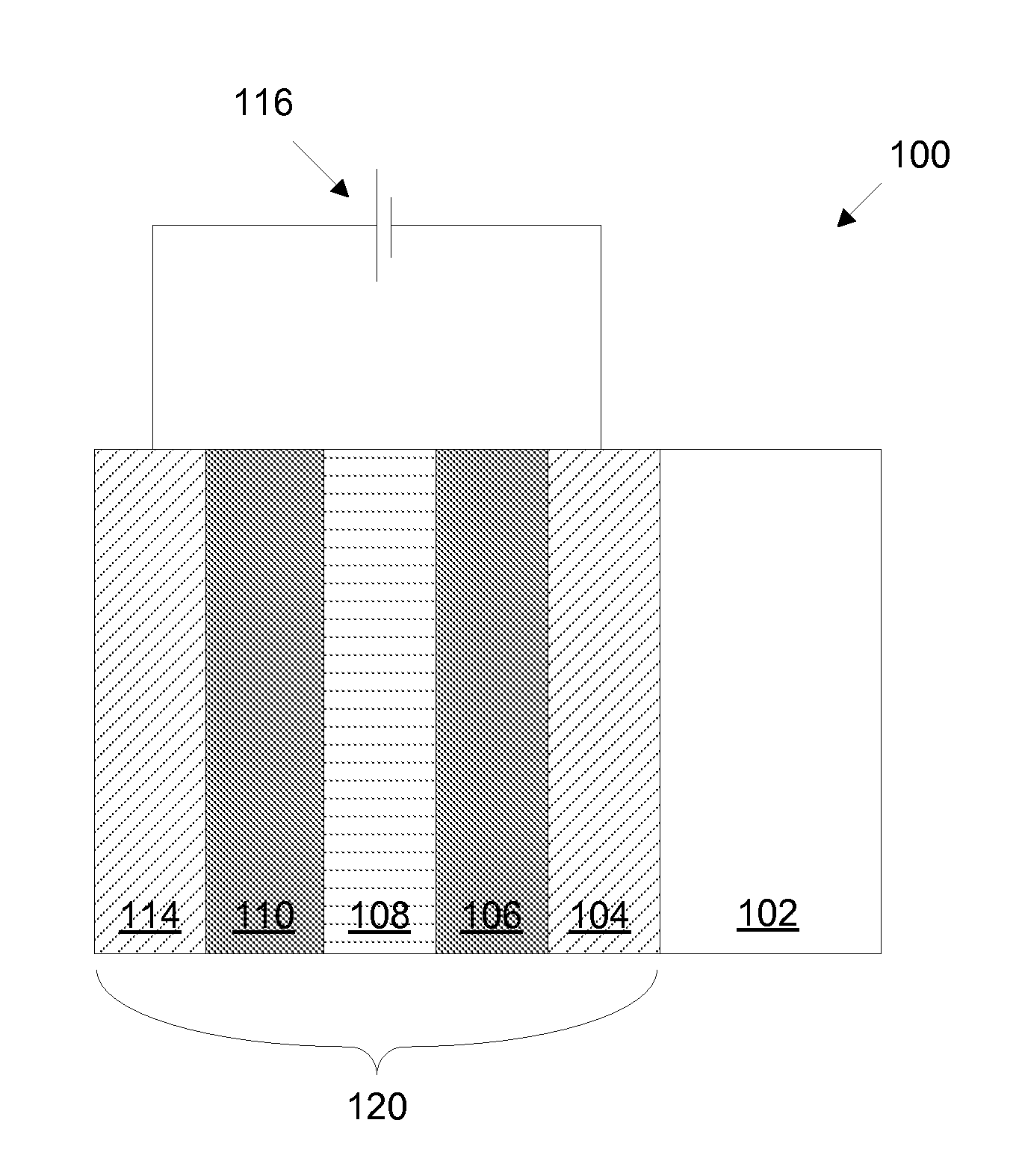

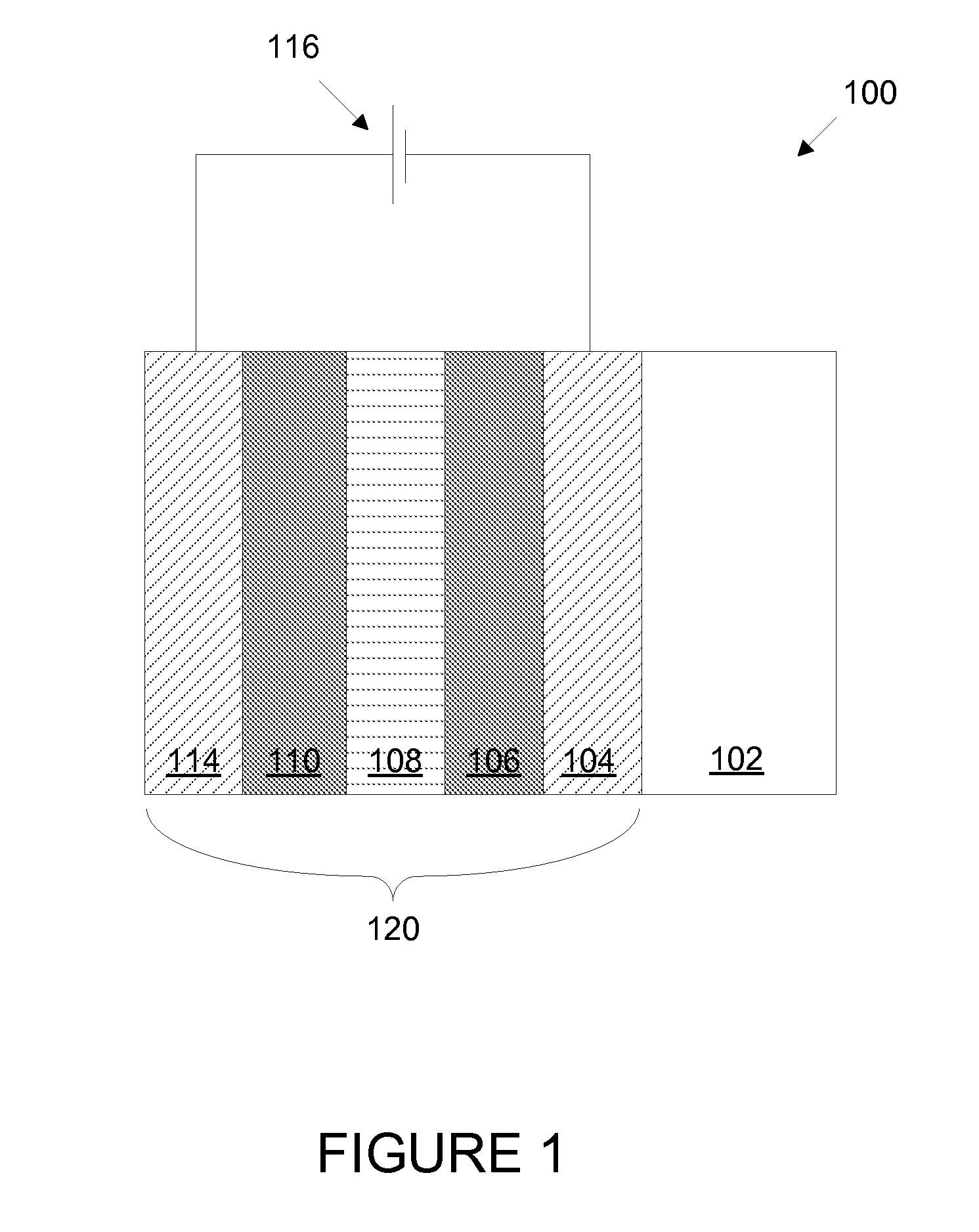

Prior electrochromic devices frequently suffer from high levels of defectivity. The defects may be manifest as pin holes or spots where the electrochromic transition is impaired. This is unacceptable for many applications such as electrochromic architectural glass. Improved electrochromic devices with low defectivity can be fabricated by depositing certain layered components of the electrochromic device in a single integrated deposition system. While these layers are being deposited and / or treated on a substrate, for example a glass window, the substrate never leaves a controlled ambient environment, for example a low pressure controlled atmosphere having very low levels of particles. These layers may be deposited using physical vapor deposition.

Owner:VIEW INC

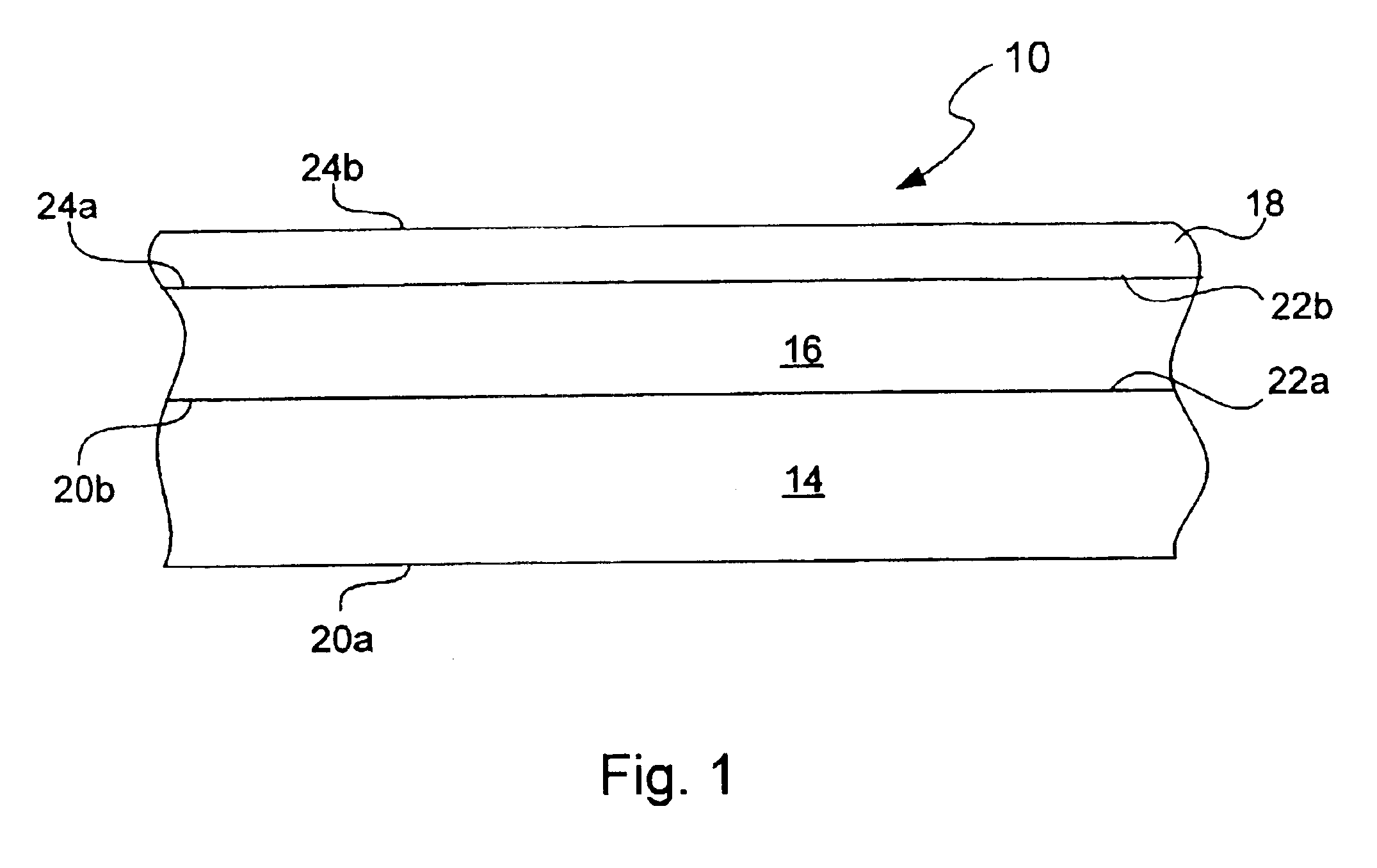

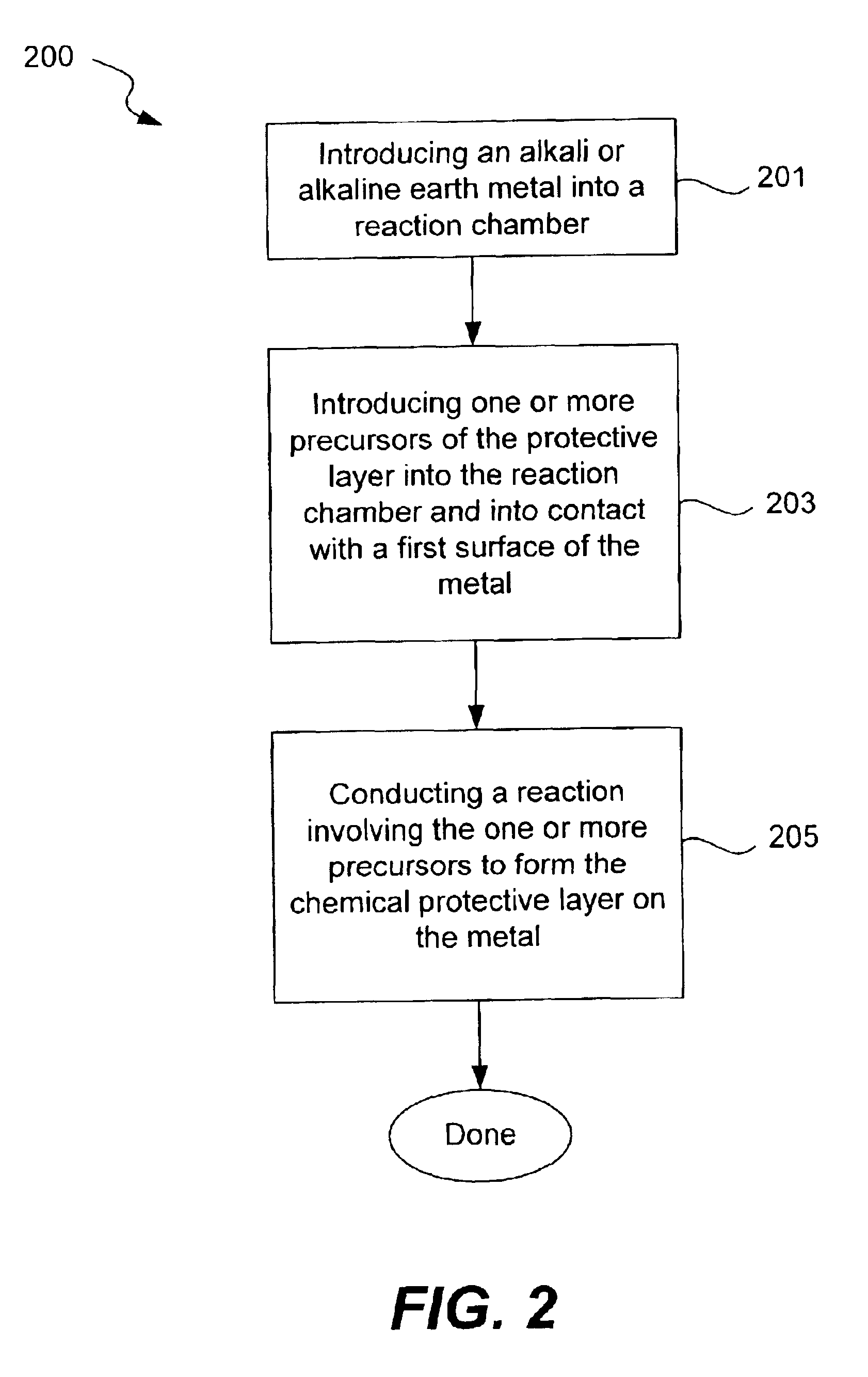

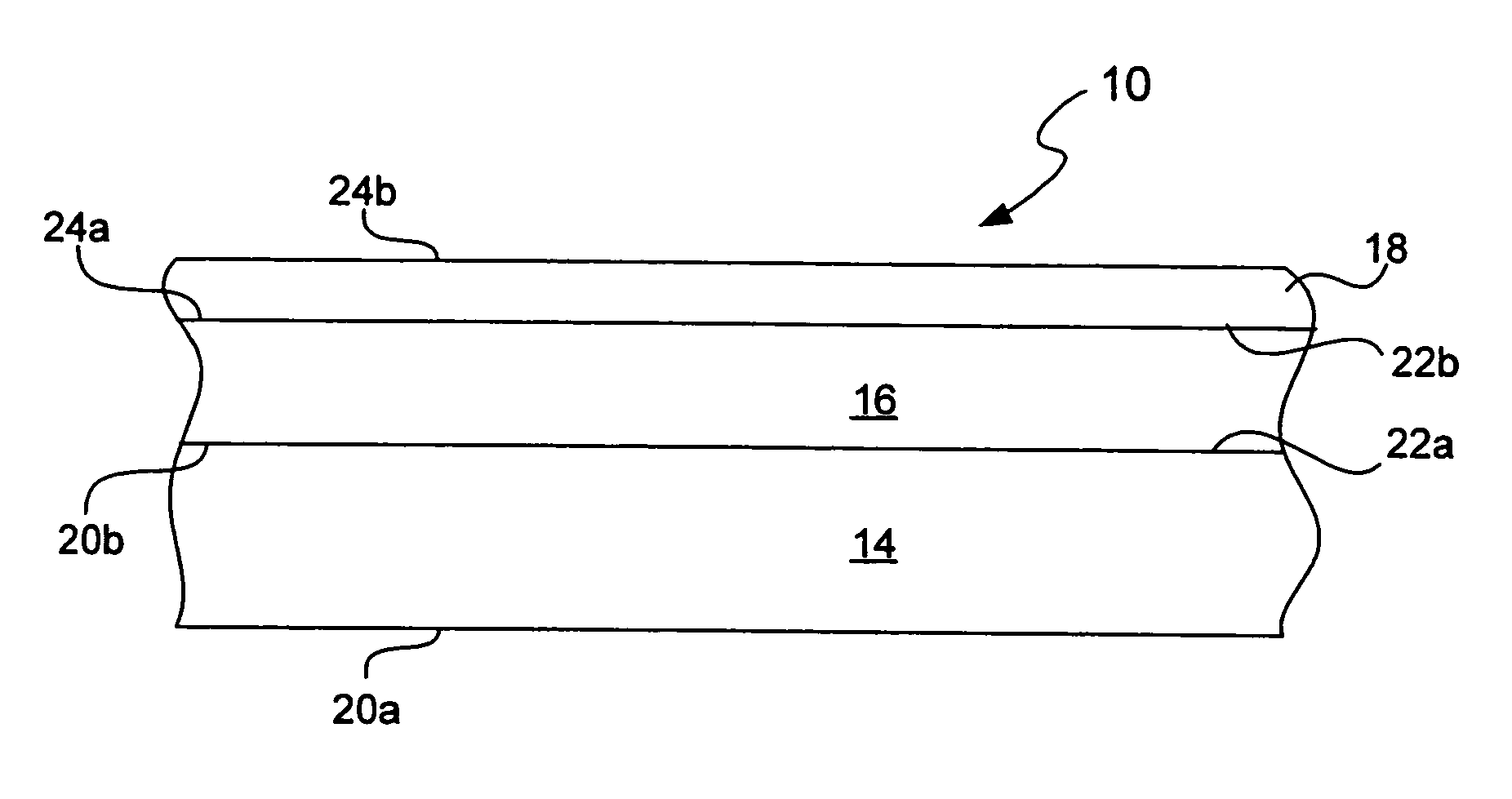

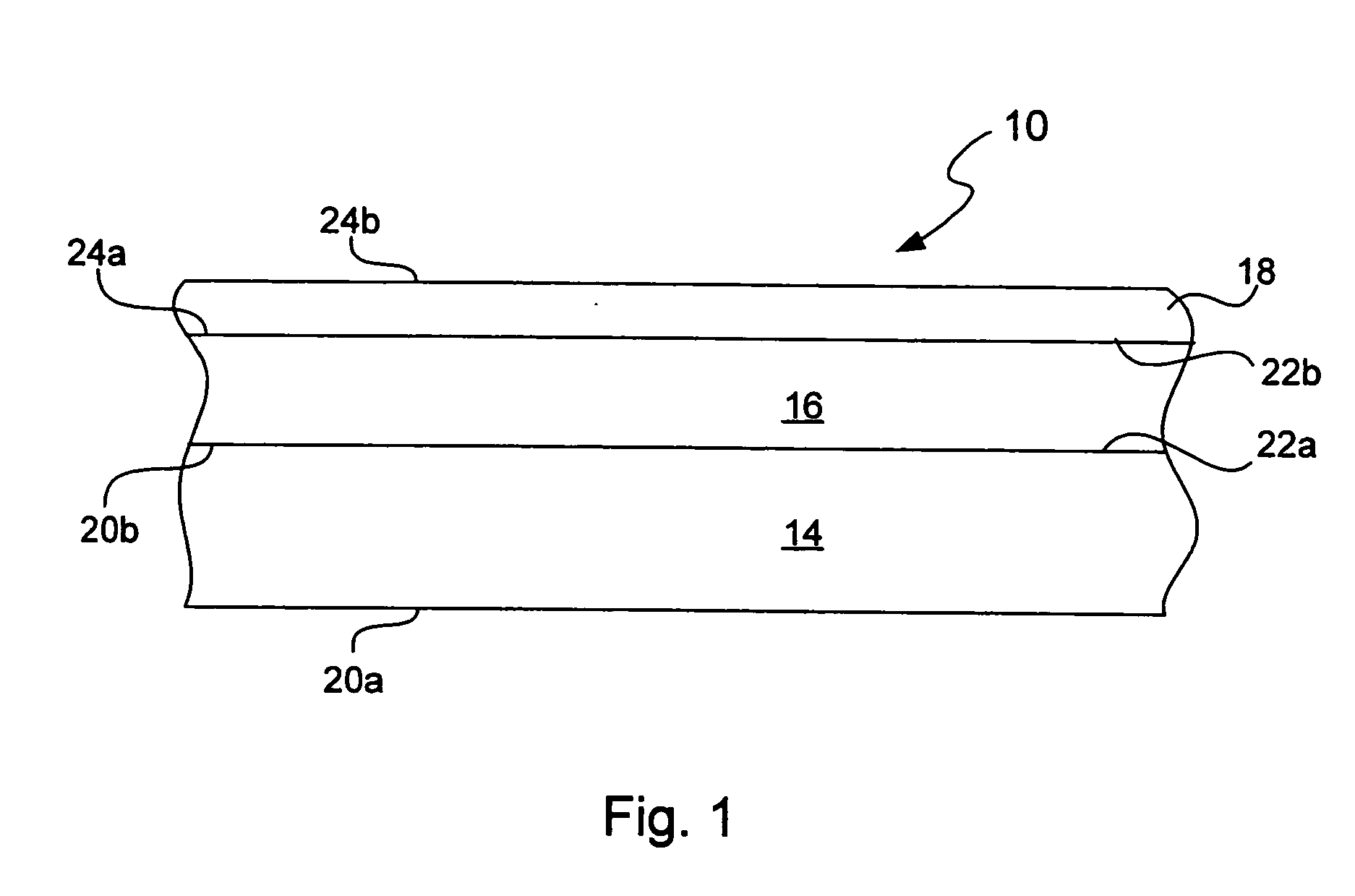

Chemical protection of a lithium surface

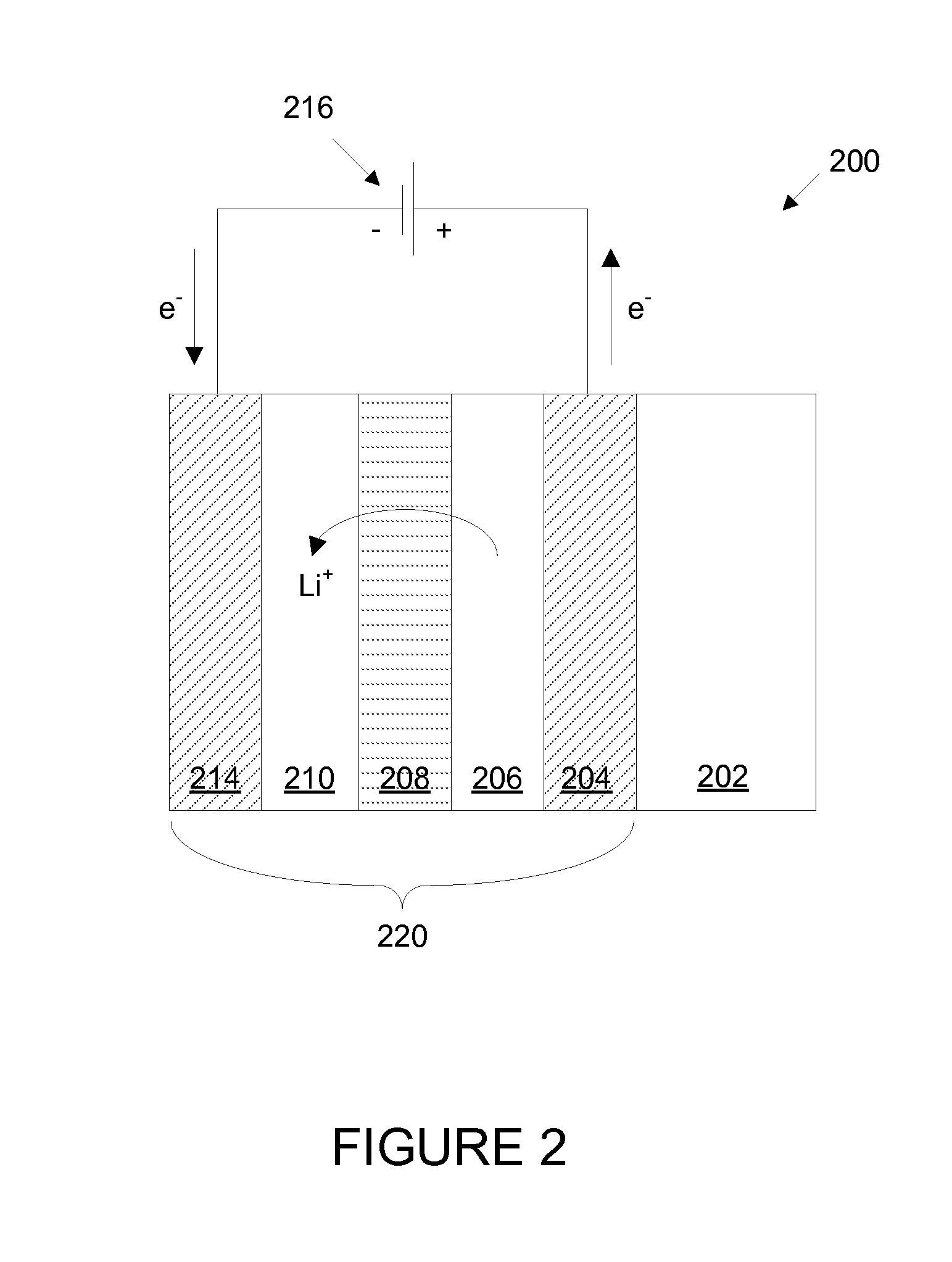

InactiveUS6911280B1Easy to produceSimple processElectrochemical processing of electrodesFinal product manufactureAlkaline earth metalLithium metal

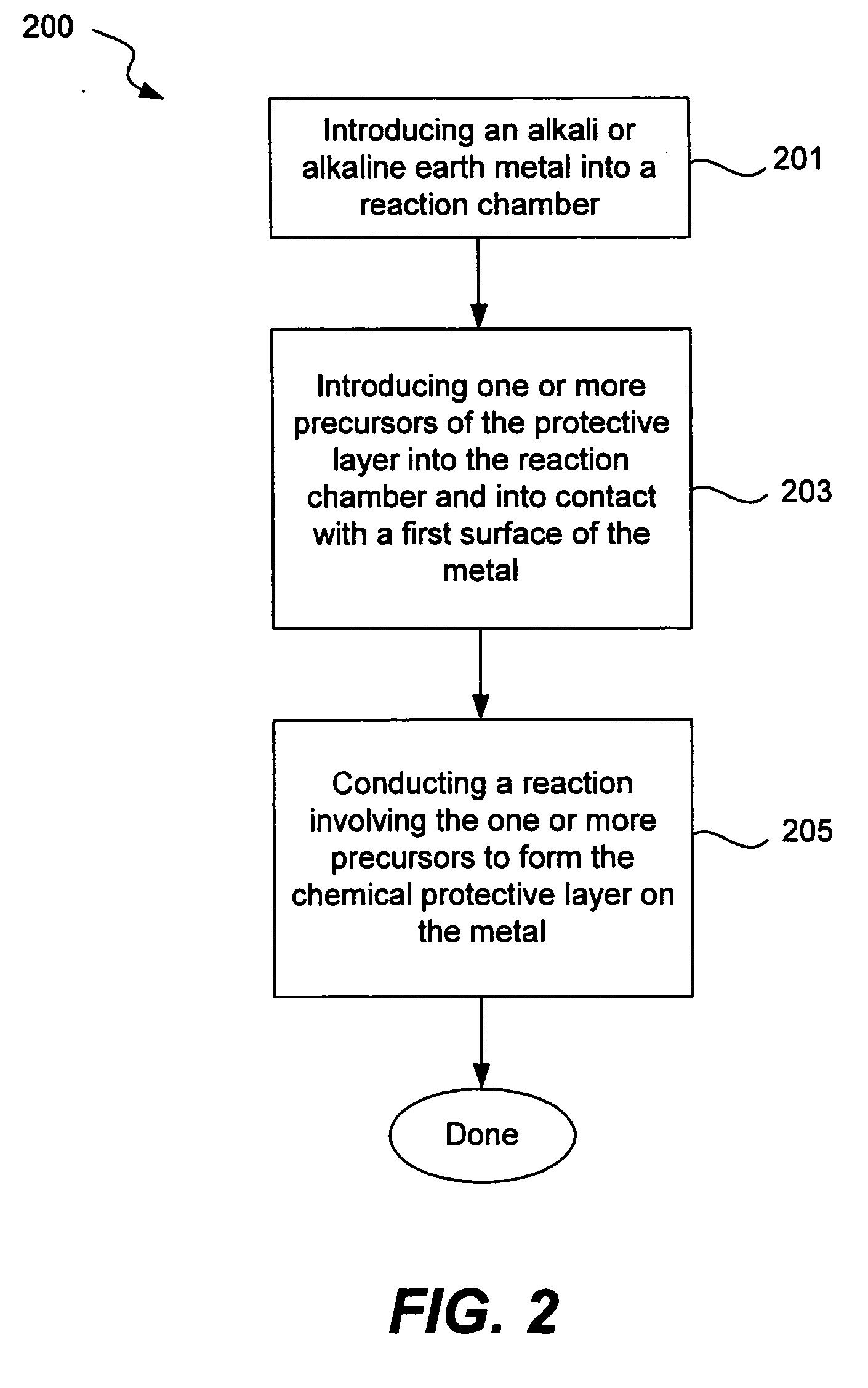

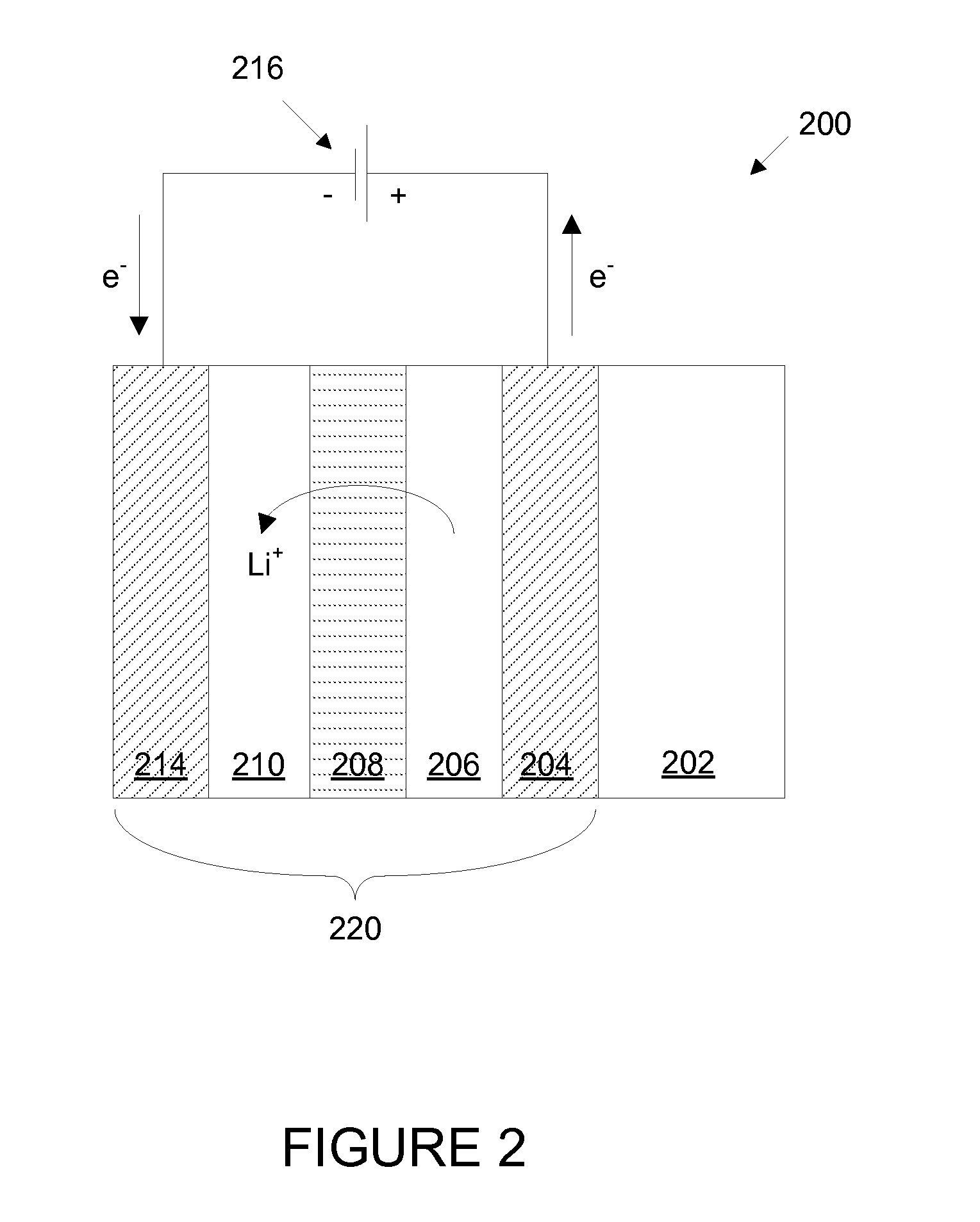

Disclosed are compositions and methods for alleviating the problem of reaction of lithium or other alkali or alkaline earth metals with incompatible processing and operating environments by creating a ionically conductive chemical protective layer on the lithium or other reactive metal surface. Such a chemically produced surface layer can protect lithium metal from reacting with oxygen, nitrogen or moisture in ambient atmosphere thereby allowing the lithium material to be handled outside of a controlled atmosphere, such as a dry room. Production processes involving lithium are thereby very considerably simplified. One example of such a process in the processing of lithium to form negative electrodes for lithium metal batteries.

Owner:POLYPLUS BATTERY CO INC

Chemical protection of a lithium surface

InactiveUS20050186469A1Easy to produceEasy to processElectrochemical processing of electrodesFinal product manufactureAlkaline earth metalLithium metal

Disclosed are compositions and methods for alleviating the problem of reaction of lithium or other alkali or alkaline earth metals with incompatible processing and operating environments by creating a ionically conductive chemical protective layer on the lithium or other reactive metal surface. Such a chemically produced surface layer can protect lithium metal from reacting with oxygen, nitrogen or moisture in ambient atmosphere thereby allowing the lithium material to be handled outside of a controlled atmosphere, such as a dry room. Production processes involving lithium are thereby very considerably simplified. One example of such a process is the processing of lithium to form negative electrodes for lithium metal batteries.

Owner:POLYPLUS BATTERY CO INC

Fabrication of low defectivity electrochromic devices

Prior electrochromic devices frequently suffer from high levels of defectivity. The defects may be manifest as pin holes or spots where the electrochromic transition is impaired. This is unacceptable for many applications such as electrochromic architectural glass. Improved electrochromic devices with low defectivity can be fabricated by depositing certain layered components of the electrochromic device in a single integrated deposition system. While these layers are being deposited and / or treated on a substrate, for example a glass window, the substrate never leaves a controlled ambient environment, for example a low pressure controlled atmosphere having very low levels of particles. These layers may be deposited using physical vapor deposition.

Owner:VIEW INC

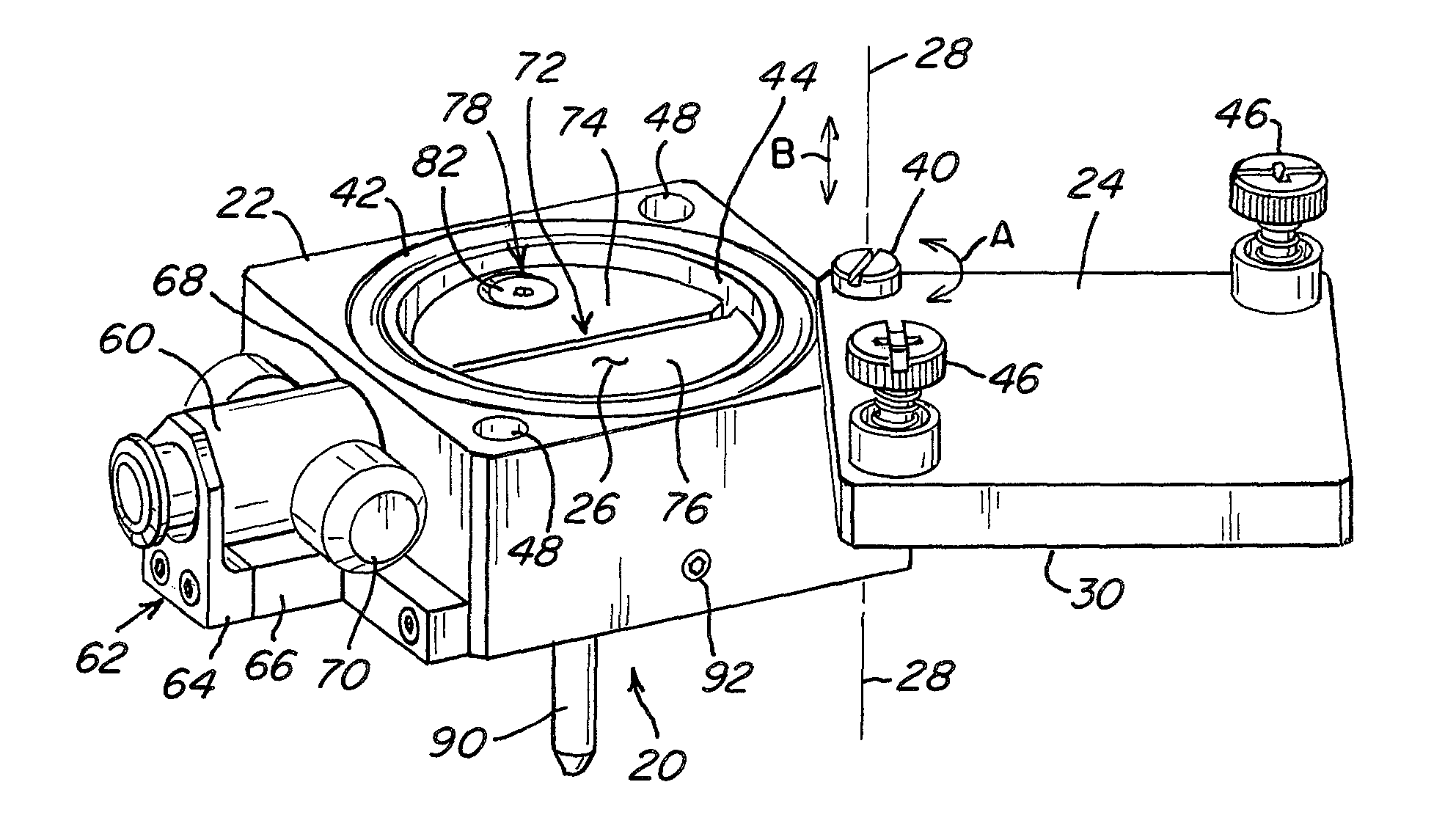

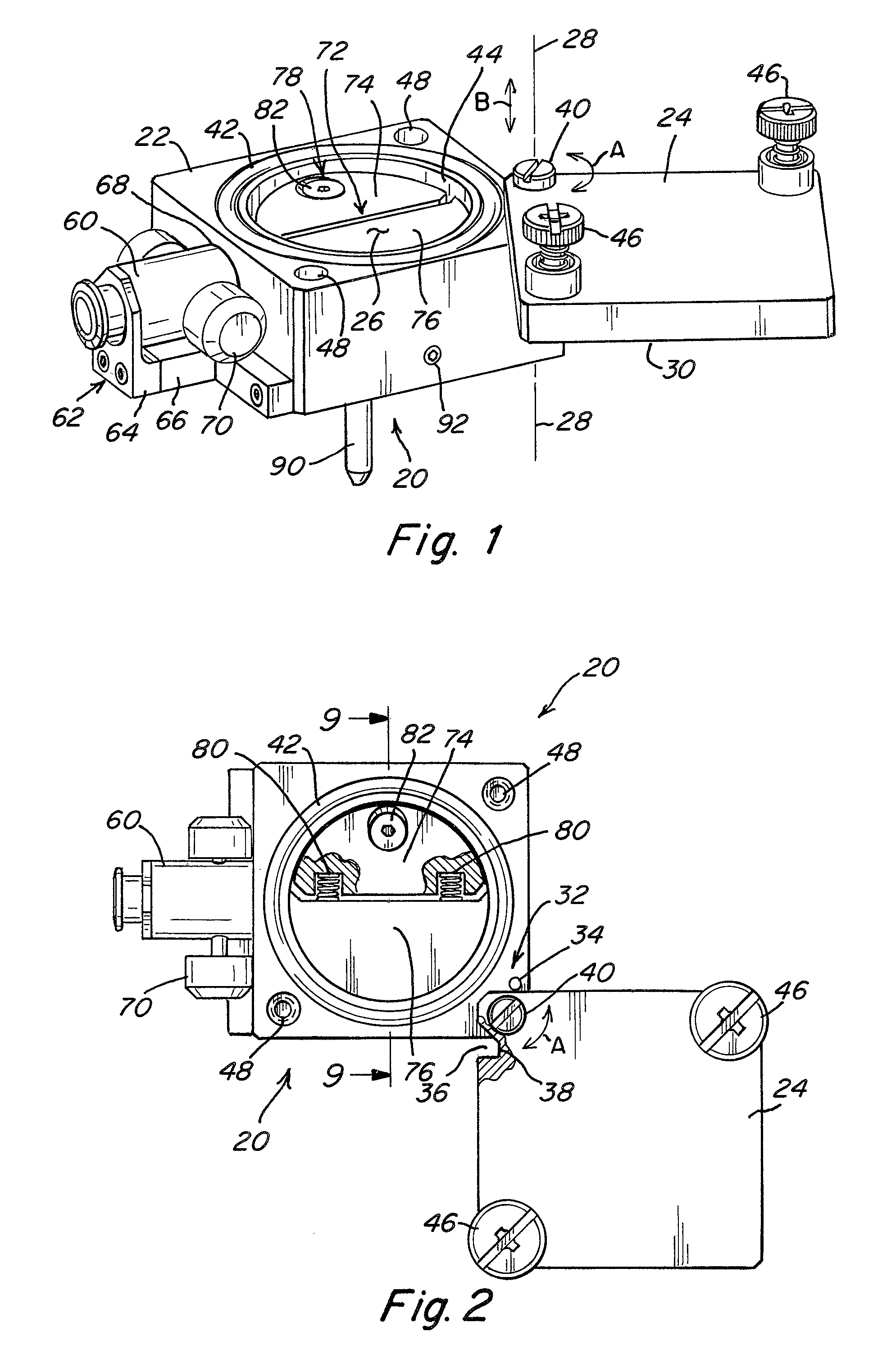

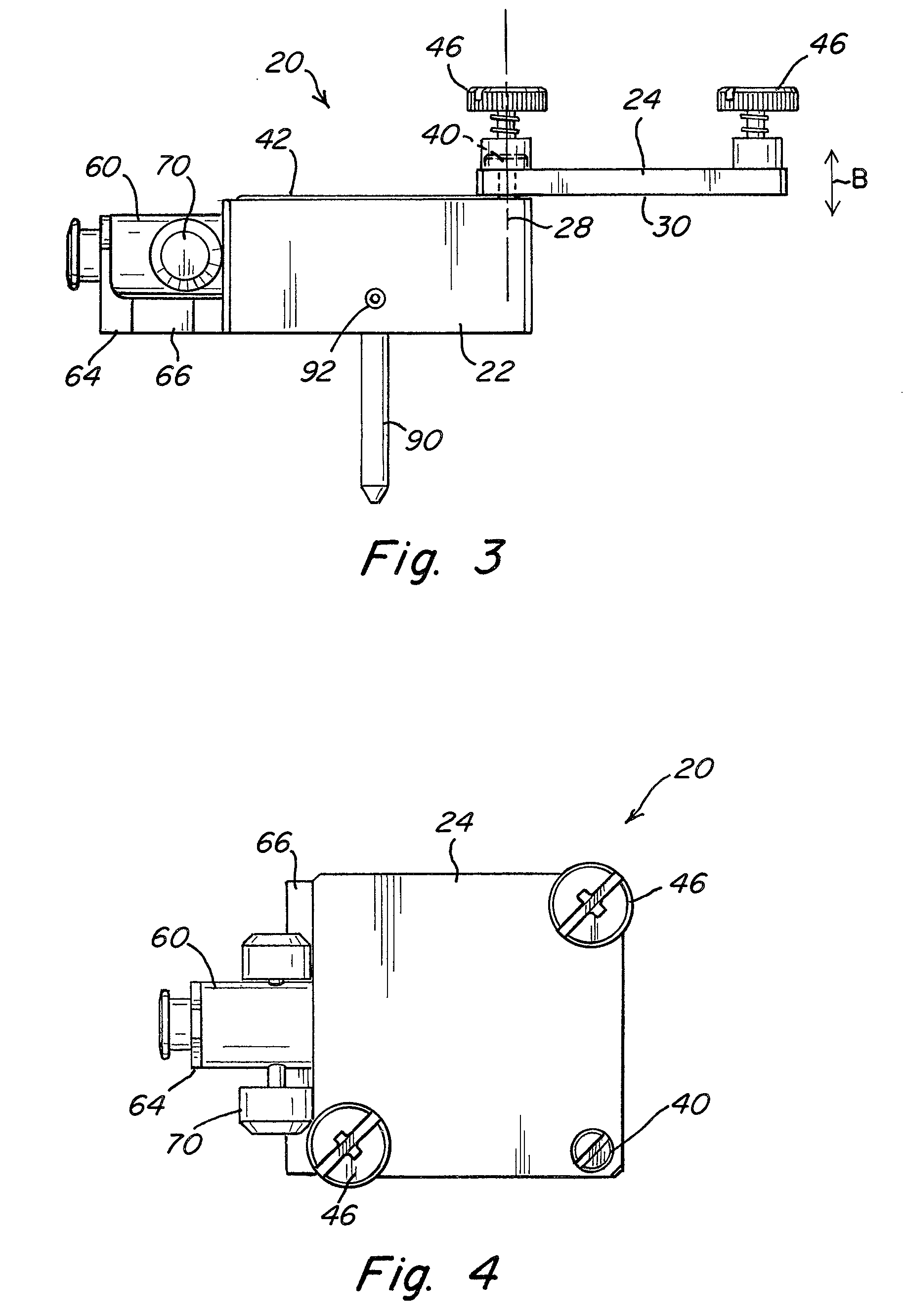

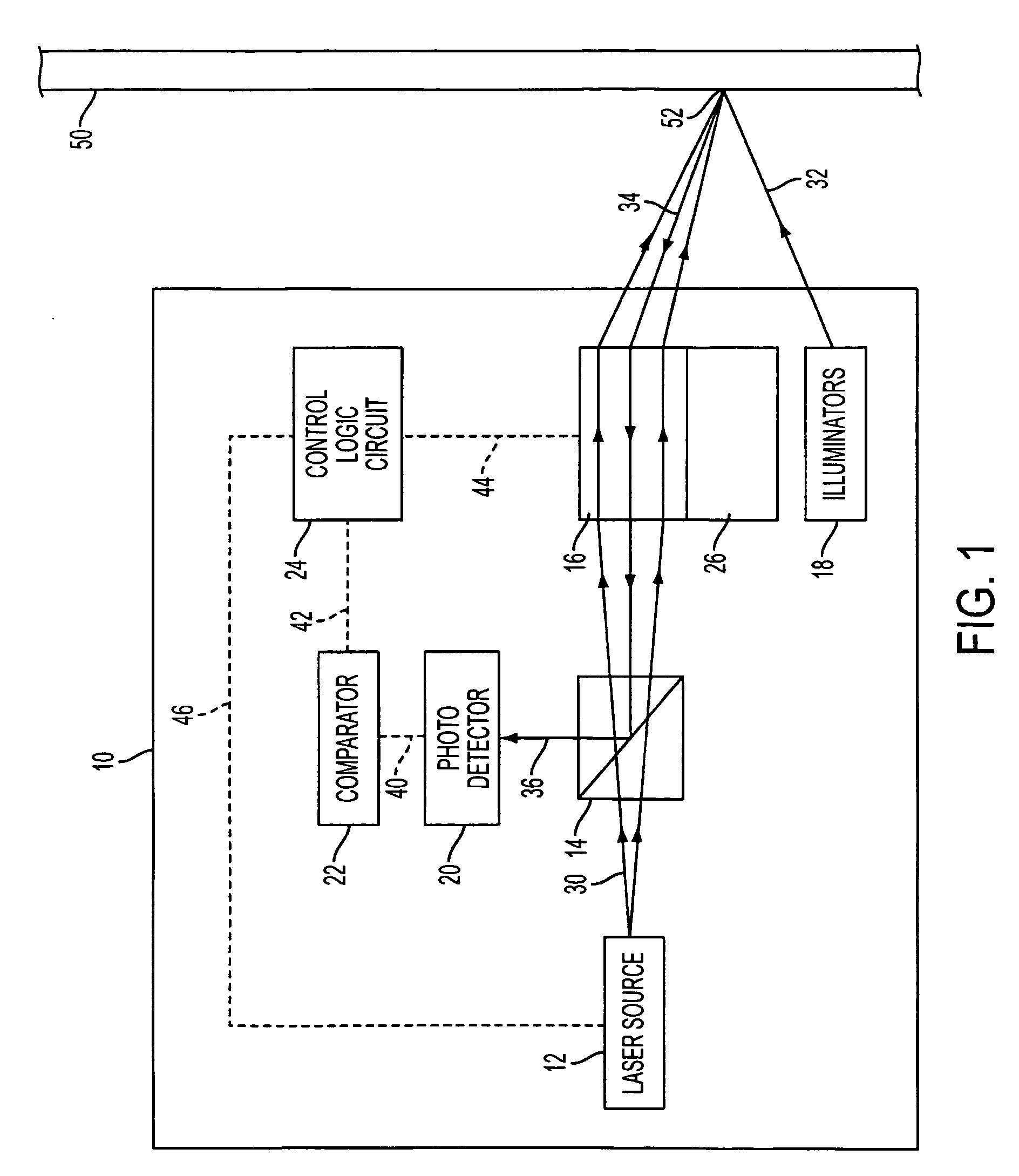

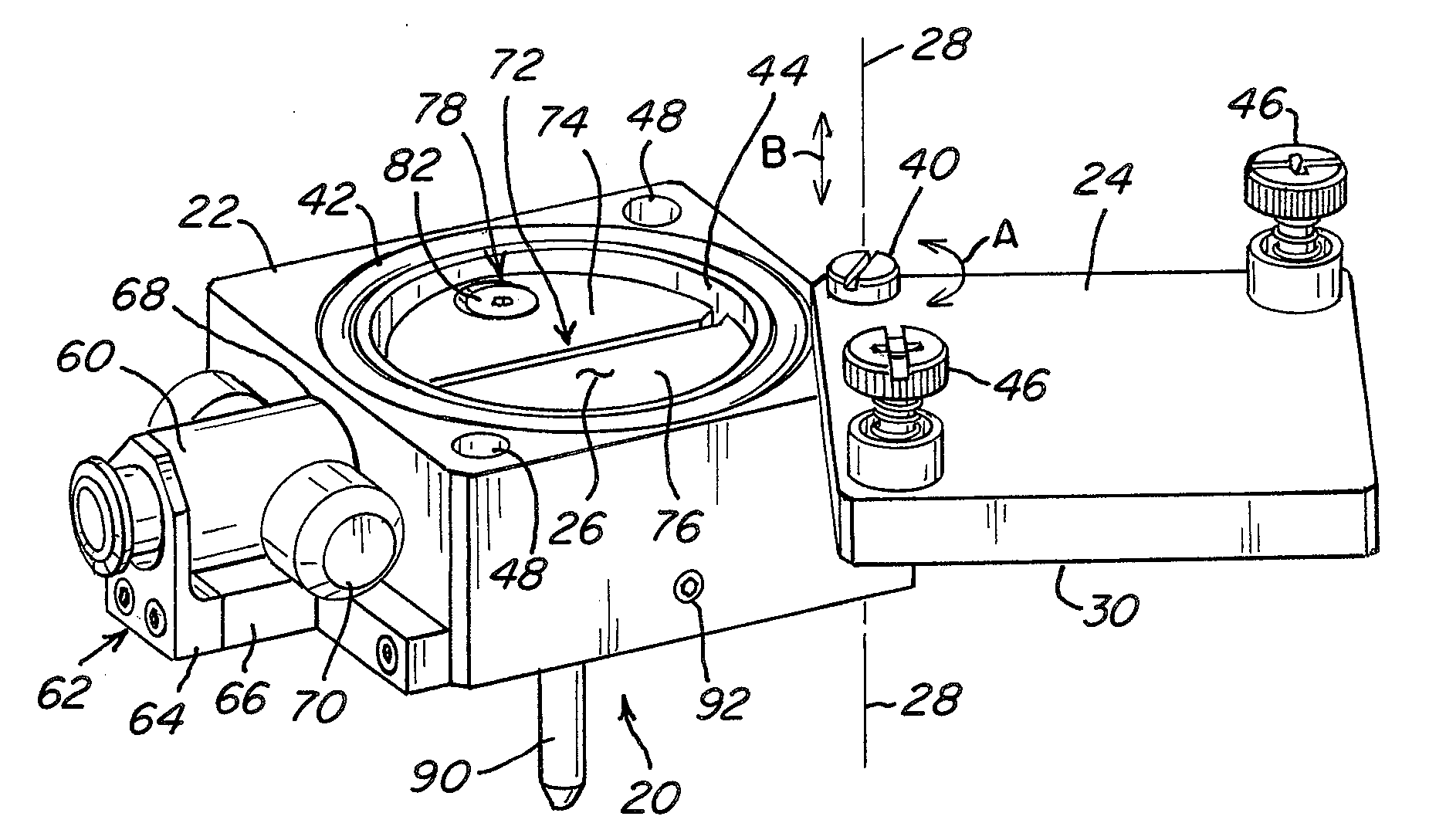

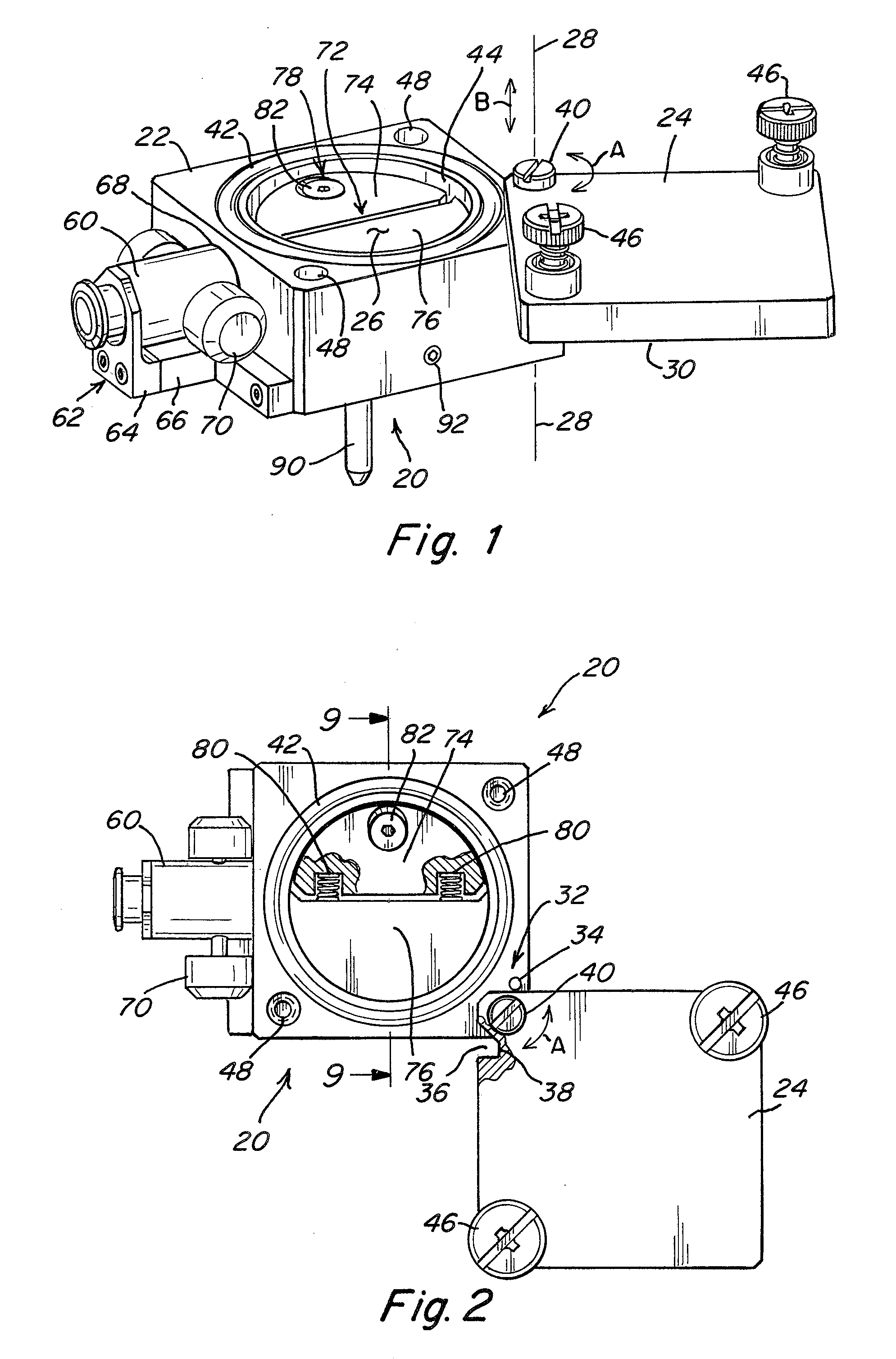

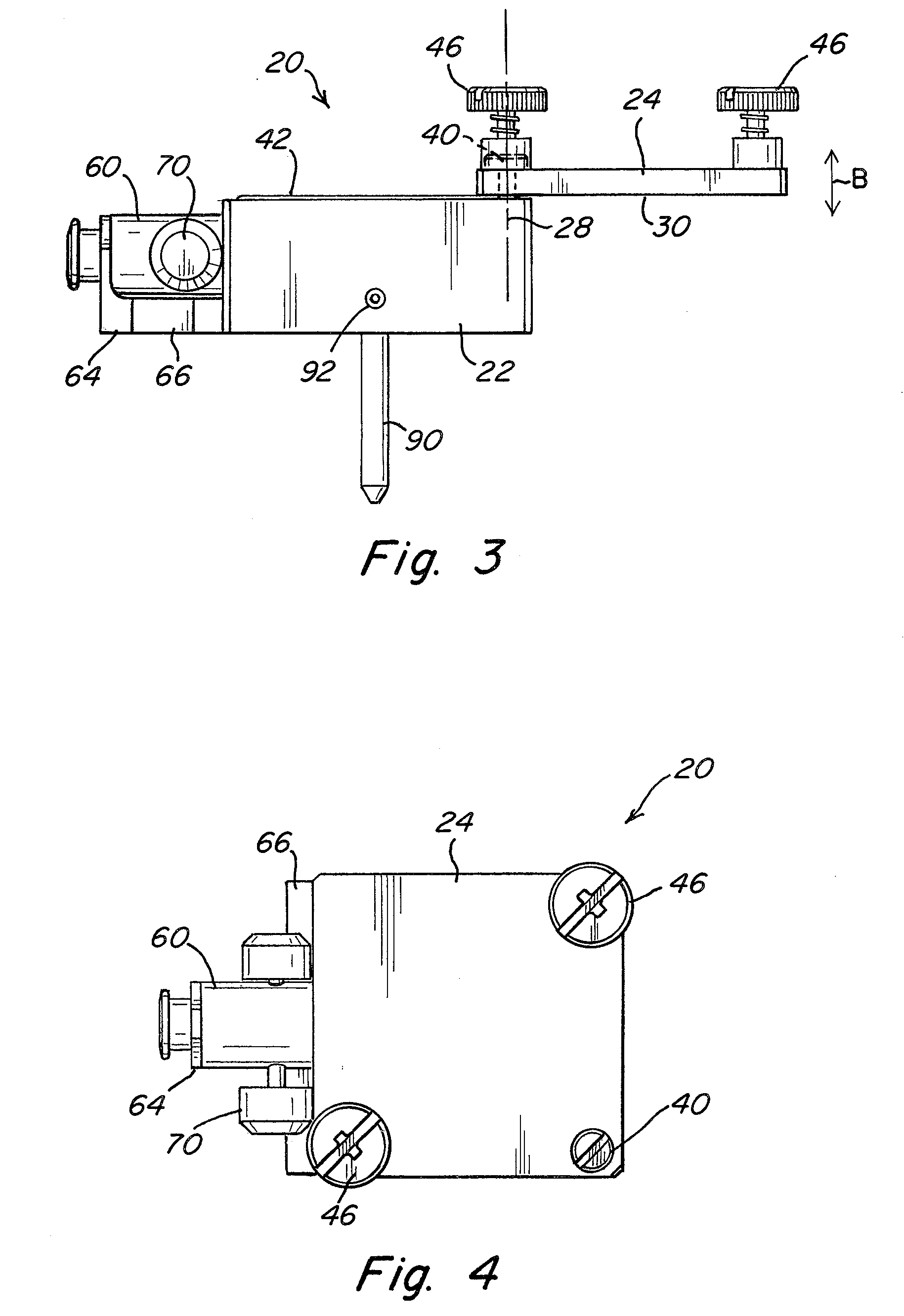

Hermetic sample holder and method for performing microanalysis under controlled atmosphere environment

ActiveUS8087309B2Reduce pressureParticle separator tubesPreparing sample for investigationEngineeringPressure difference

A hermetic sample holder for use in performing microanalysis of a sample under a controlled atmosphere environment. The sample holder comprises a sample holder body with a sample cavity to receive the sample and a cover movably mounted to the holder body between an open position to allow access to the cavity and a closed position to seal the cavity. The cover is secured in and released from the closed position at least in part by a pressure differential between the cavity and the ambient atmosphere. The cover may be biased toward the open position. The cover may be pivotally mounted about an axis that is perpendicular to a sealing surface of the cover and / or movable in a direction along the pivot axis. A valve may be provided to allow direct evacuation of the cavity to create a pressure differential. An adjustable clamp may be located in the cavity to secure the sample.

Owner:SION POWER CORP

Methods for stripping and modifying surfaces with laser-induced ablation

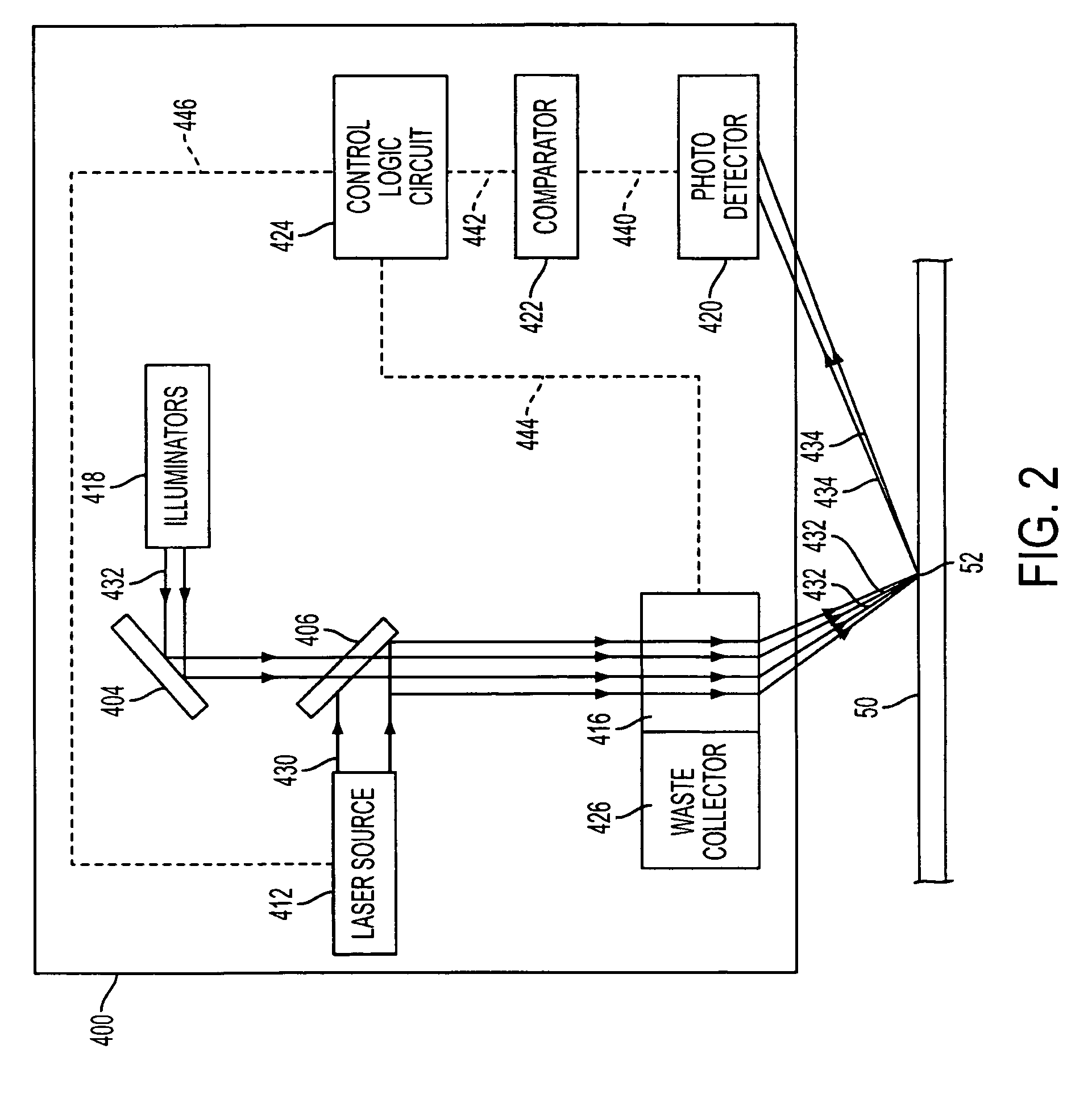

A coating removal apparatus removes a coating from a surface. The apparatus has a movable scanning head and scanning optics. The scanning head is movable in one dimension, and the scanning optics adjust in two dimensions to compensate for movement of the scanning head to implement long range scanning with a uniform scanning pattern. Further, a surface roughness is determined by measuring specular and scattered reflections at various angles. For composite surfaces, the apparatus utilizes UV laser radiation and a controlled atmosphere to remove coating and alter the chemical characteristics at the surface.

Owner:GEN LASERTRONICS

Linear vacuum robot with Z motion and articulated arm

ActiveUS8419341B2Great riskSimplify roboticsMechanical apparatusSemiconductor/solid-state device manufacturingEngineeringThroughput

Owner:BOOKS AUTOMATION US LLC

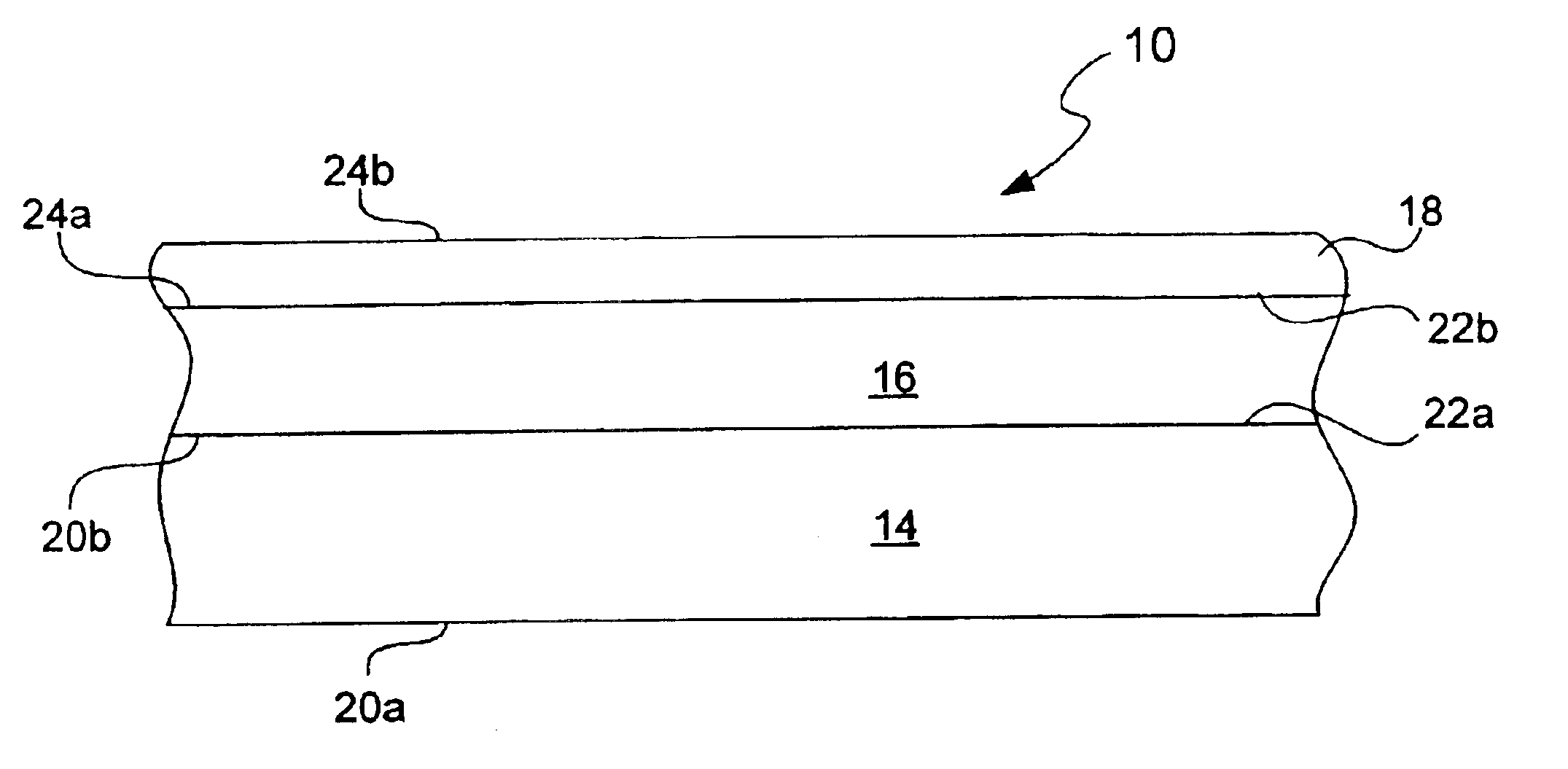

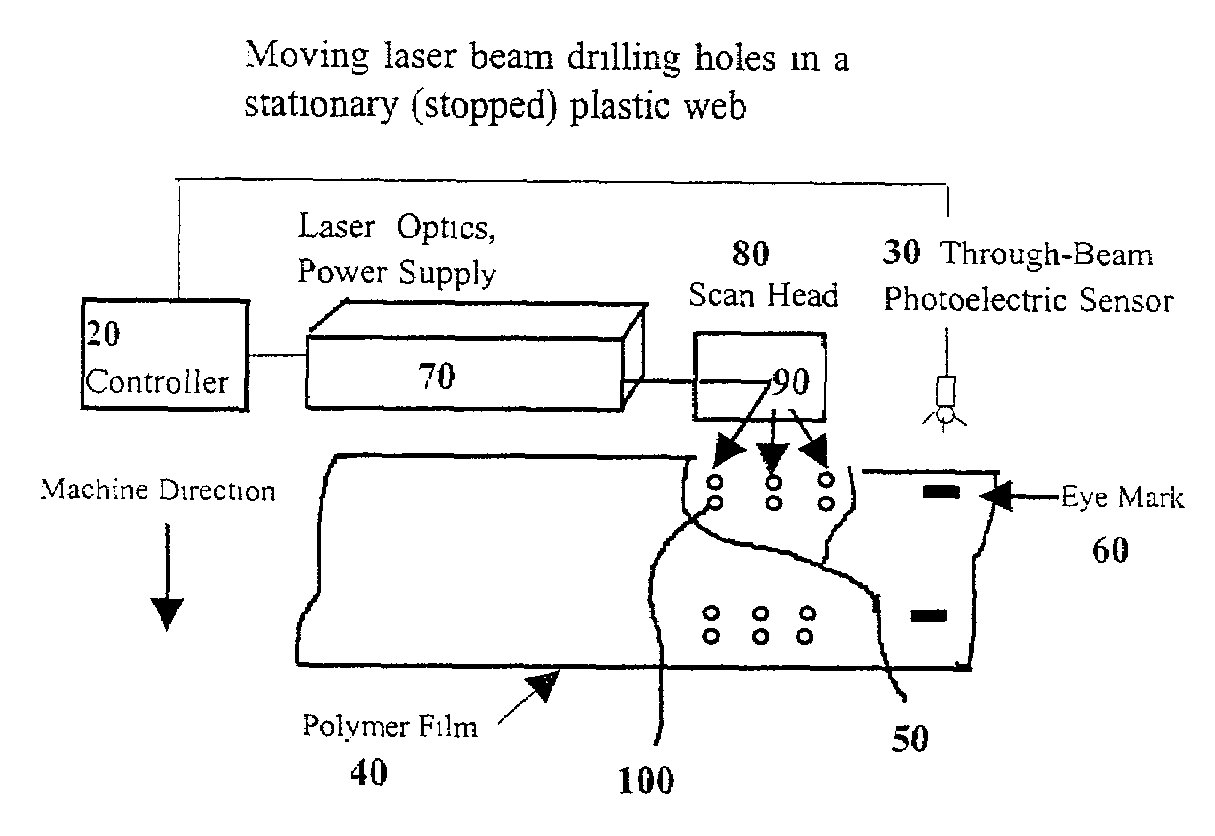

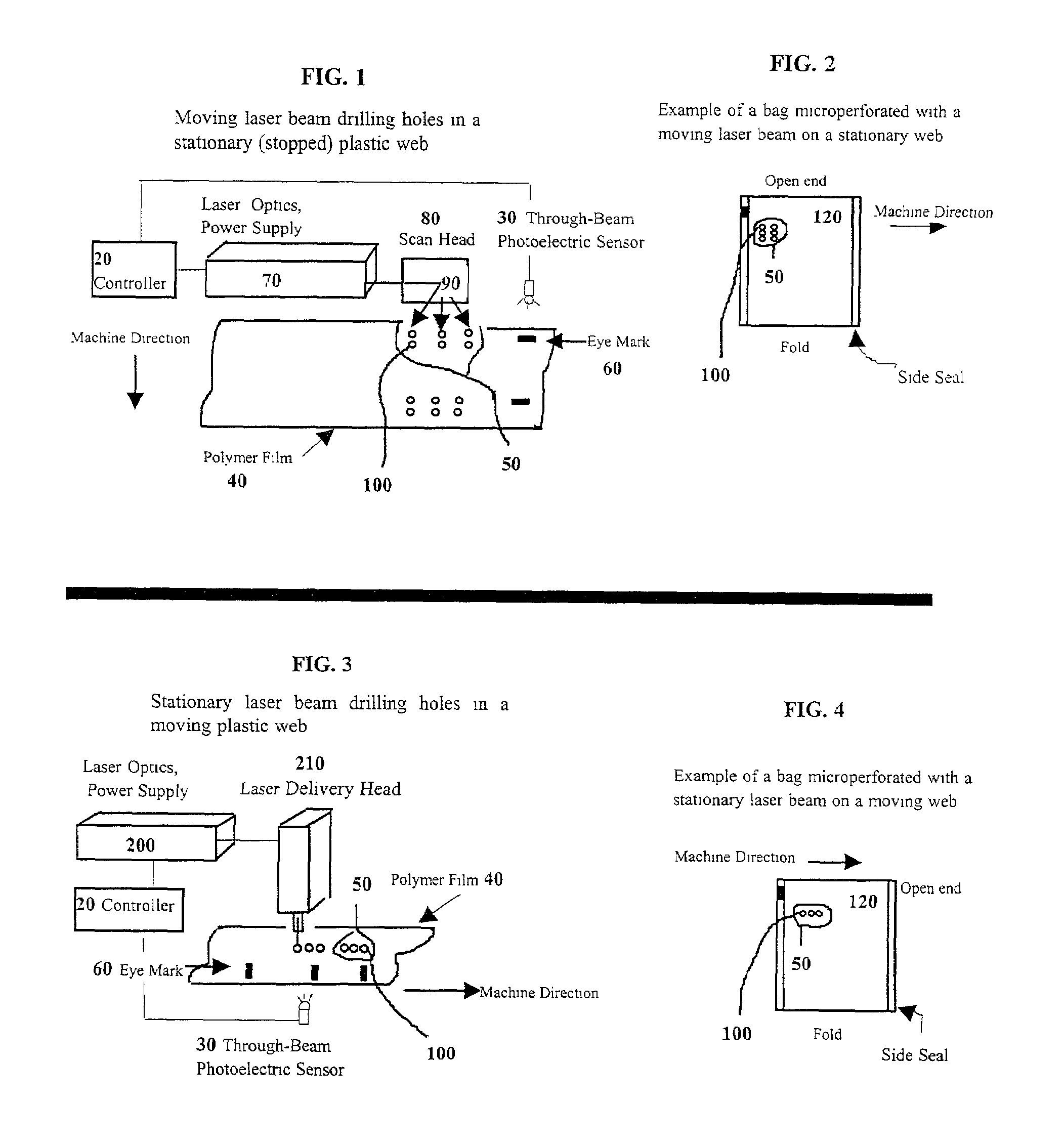

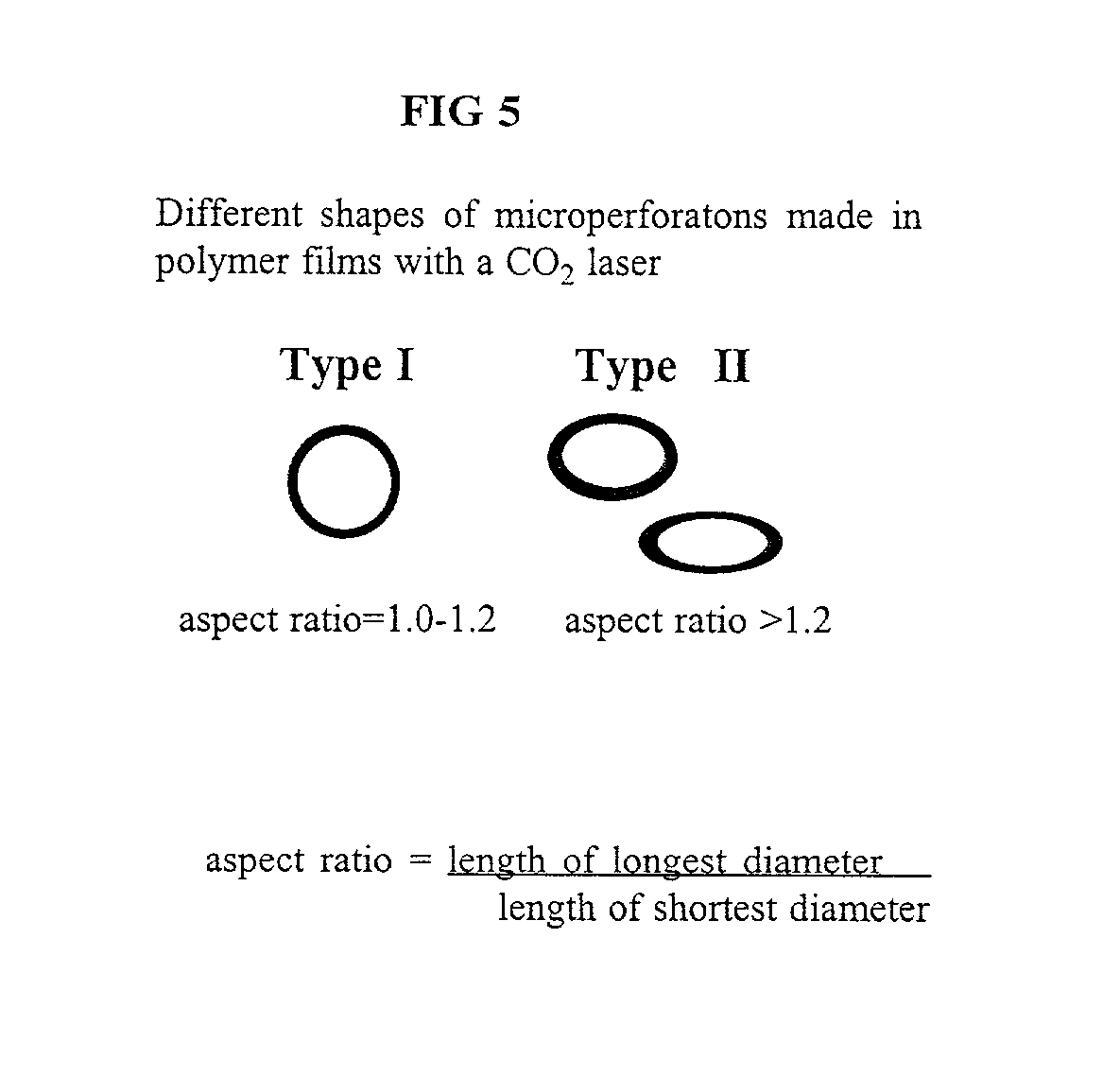

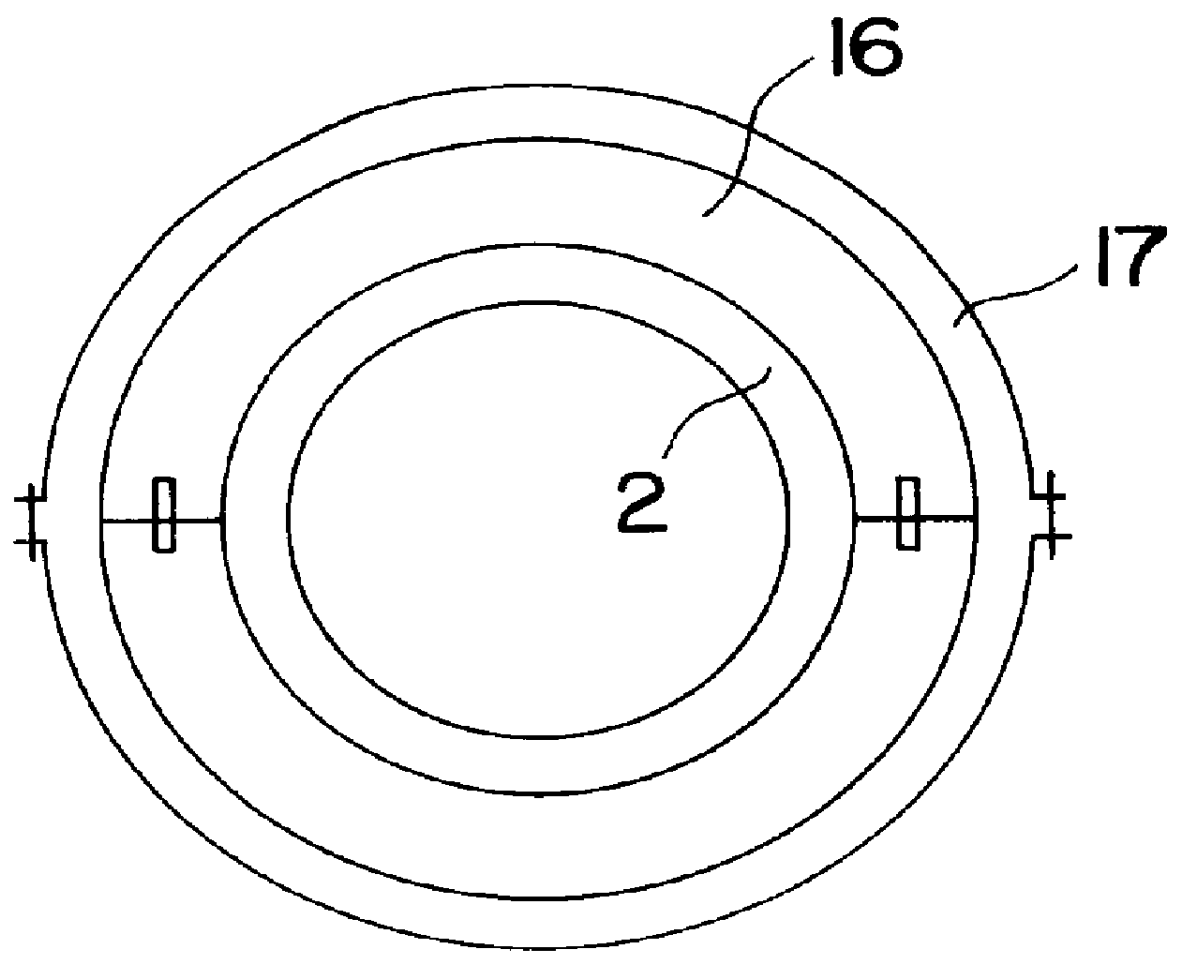

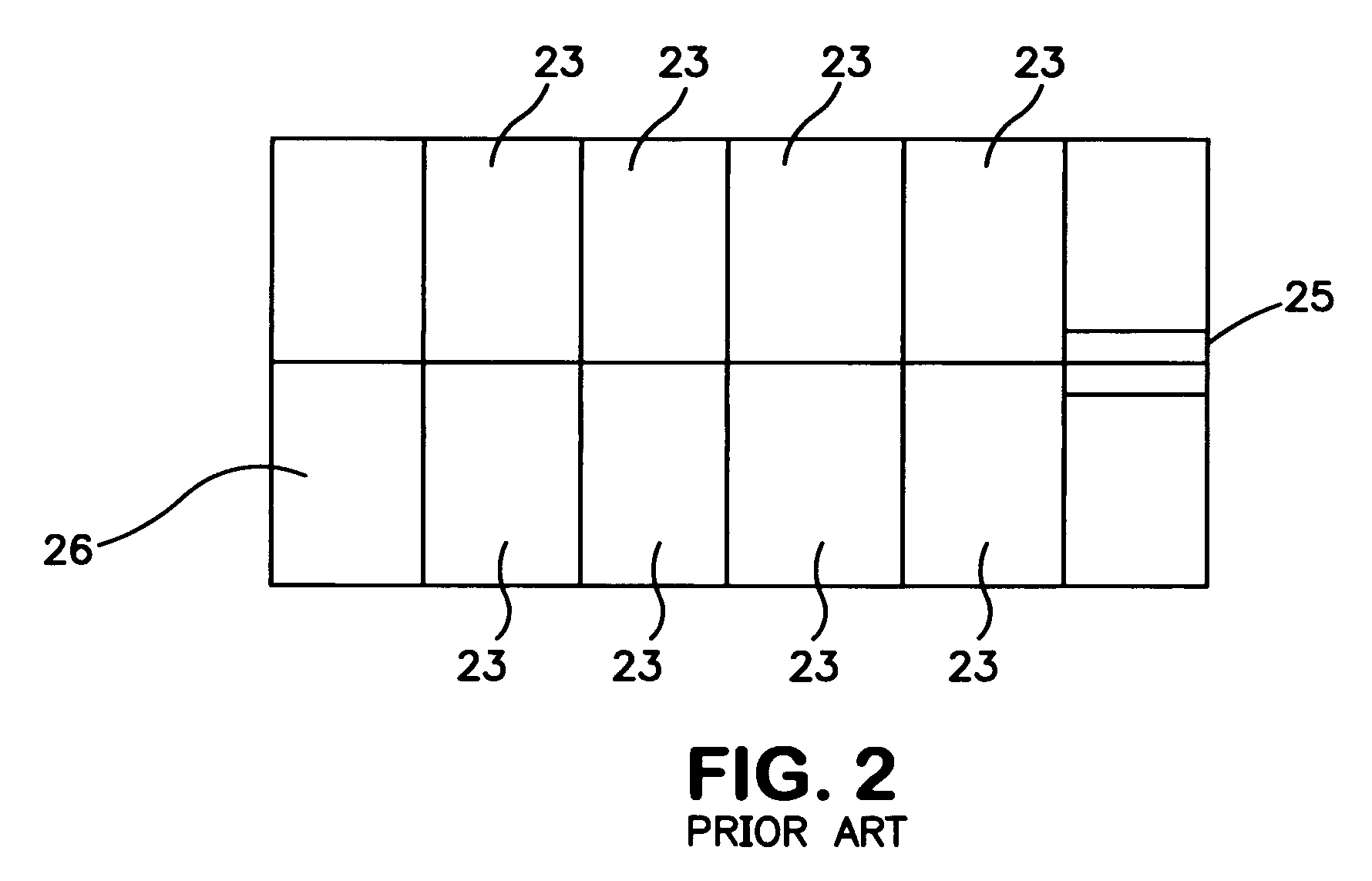

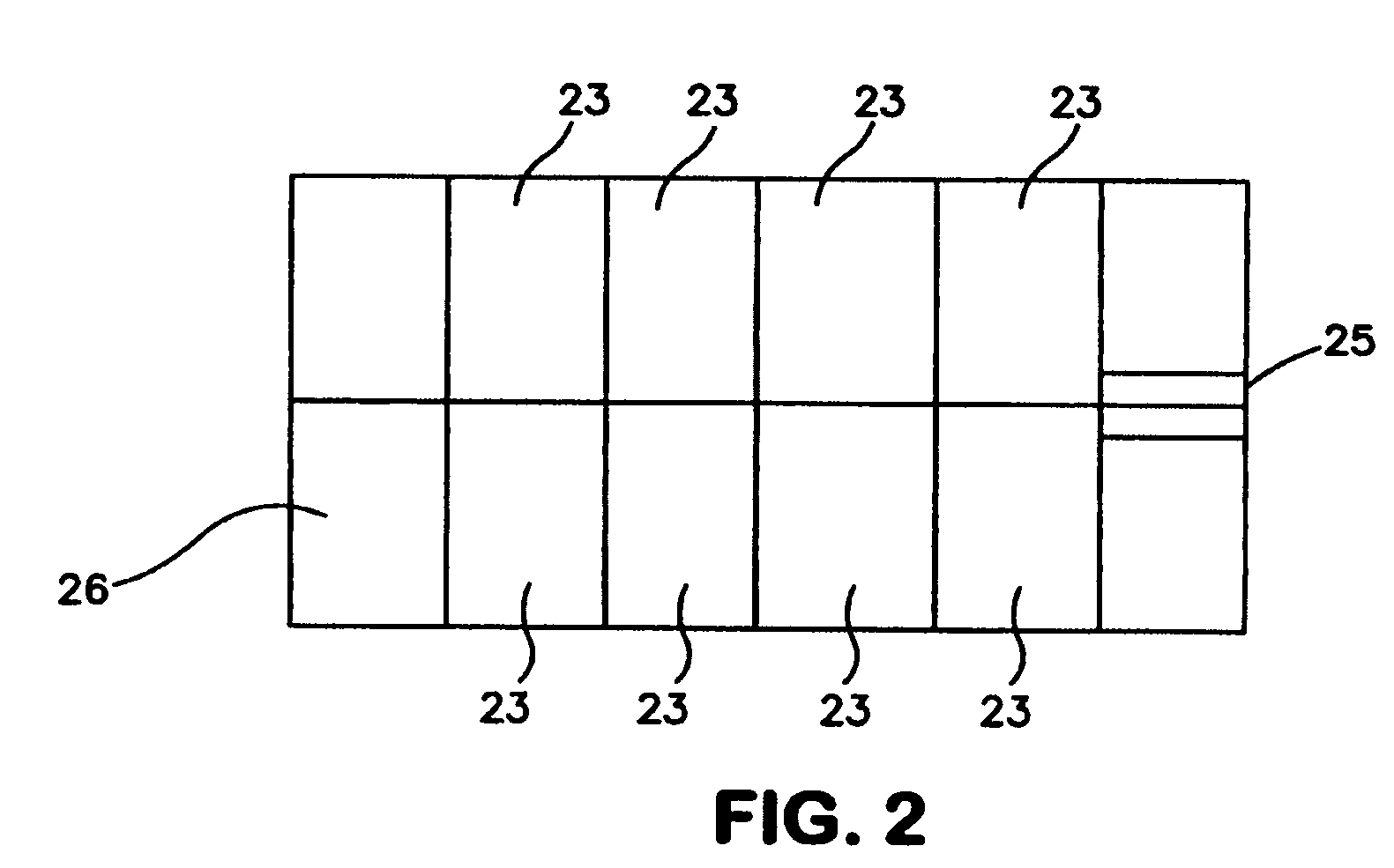

Registered microperforated films for modified/controlled atmosphere packaging

InactiveUS7083837B1Quality improvementOptimize shelf lifeEnvelopes/bags making machinerySynthetic resin layered productsEngineeringOxygen

A microperforated packaging material for use in modifying or controlling the flow of oxygen and carbon dioxide into and / out of a fresh produce container, where the microperforations are specifically tailored in size, location and number for the specific produce. The packaging system specifically tailors microperforated containers and packaging for particular produce to optimally preserve the produce, using a method of making registered microperforations on the packaging material using a CO2 laser and a sensor mechanism.

Owner:MODIFIED ATMOSPHERE ENTERPRISES LLC

Metal seal packaging for organic light emitting diode device

InactiveUS7202602B2Suppress permeation of moistureImprove life performanceDischarge tube luminescnet screensElectroluminescent light sourcesDesiccantLight-emitting diode

A metal sealed organic light emitting diode device comprising a lid, containing a recessed portion to accommodate large quantity of getter / dessicant, a band of metal stack at the perimeter over which is laid a band of low temperature melting solder alloy, pre-tinned subsequently, and a substrate. The substrate containing organic light emitting diode at the central area with a band of metal stack at the perimeter. The lid and the substrate are placed together in substantial alignment such that the pre-tinned low melting solder band of the lid contacts the metal stack of the substrate and thermally sealed in a controlled atmosphere. Multiples of substrates are sealed with a single lid containing multiplicity of recessed portions with multi-segmented metal stack and pre-tinned solder band to derive a large area device.

Owner:ORGANIC LIGHTING TECH

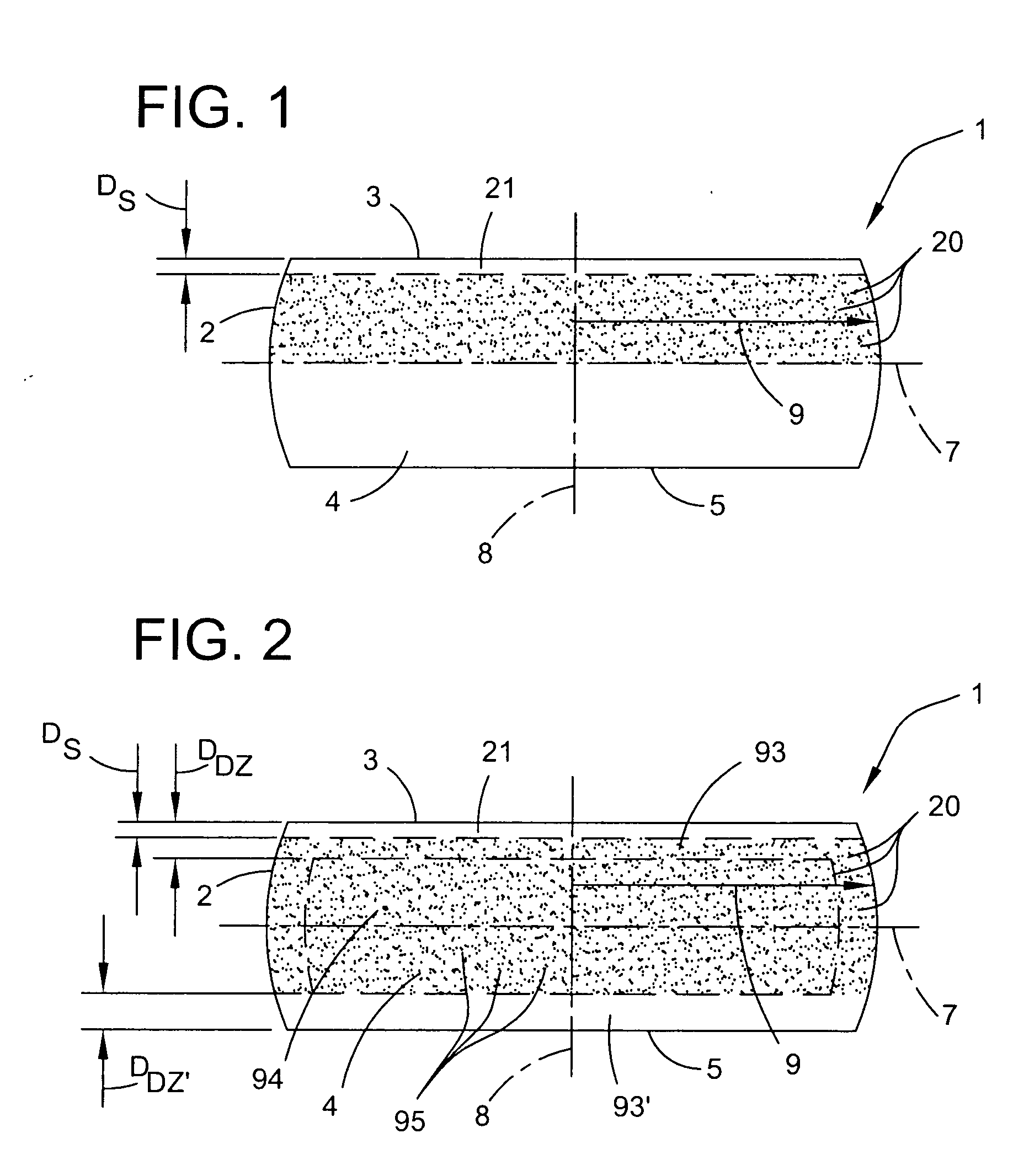

Packaging of respiring biological materials

ActiveUS7601374B2Storage and/or ripeningReady-for-oven doughsFruit and vegetables preservationBiological materialsBiomedical engineering

Packaging of respiring biological materials, particularly bananas and other fruits, in sealed containers. The containers preferably include a gas-permeable membrane comprising (1) a microporous film, and (2) a polymeric coating on the microporous film. Using appropriate containers and appropriate controlled atmospheres around the container, the respiring materials can be stored and / or ripened under controlled conditions. Bananas can be ripened while they are being transported, or in conventional ripening rooms without opening the containers in which they have been transported. The ripe bananas are less dehydrated and remain in a satisfactory ripened state for longer periods of time.

Owner:HAZEL TECH INC

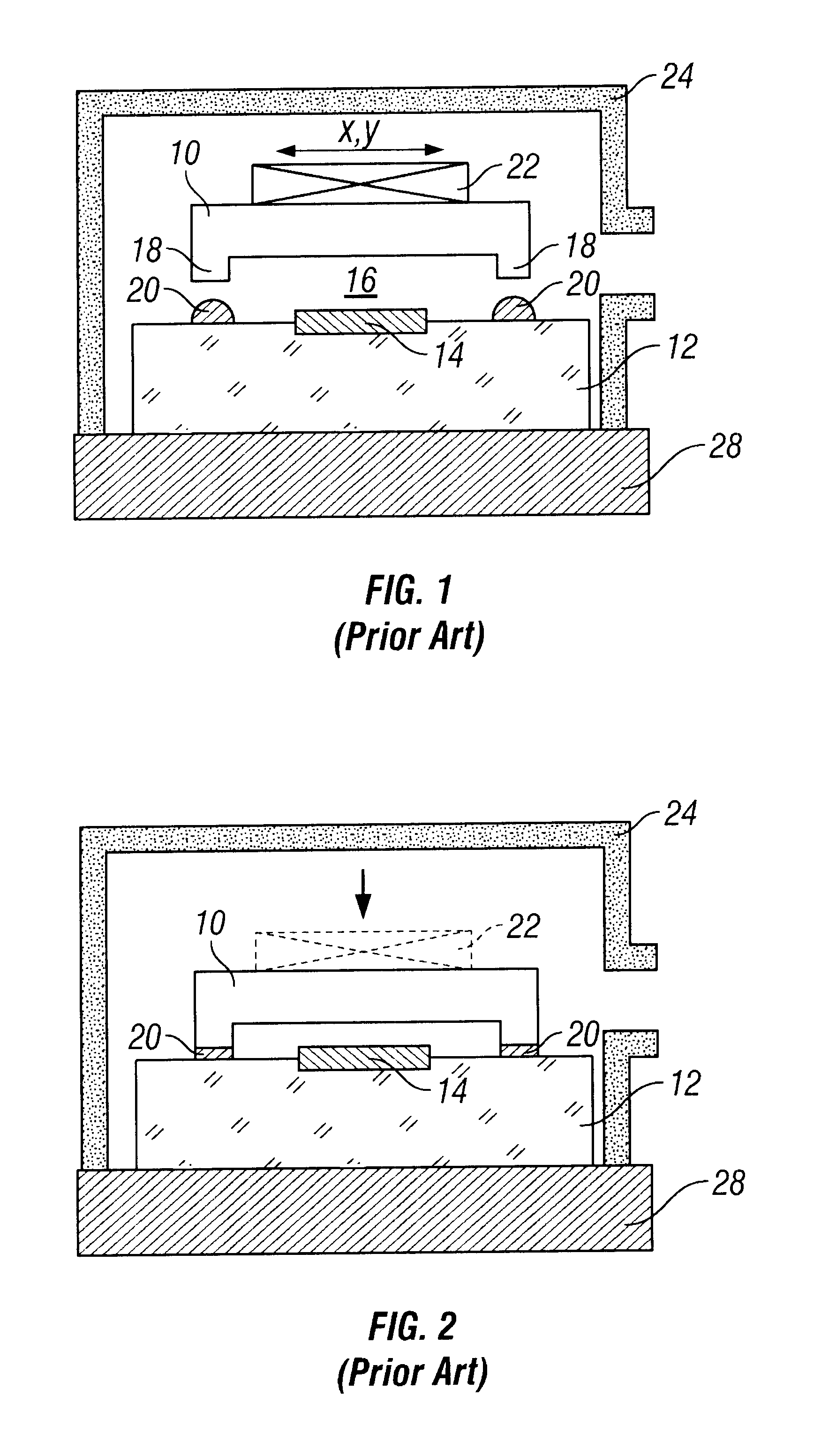

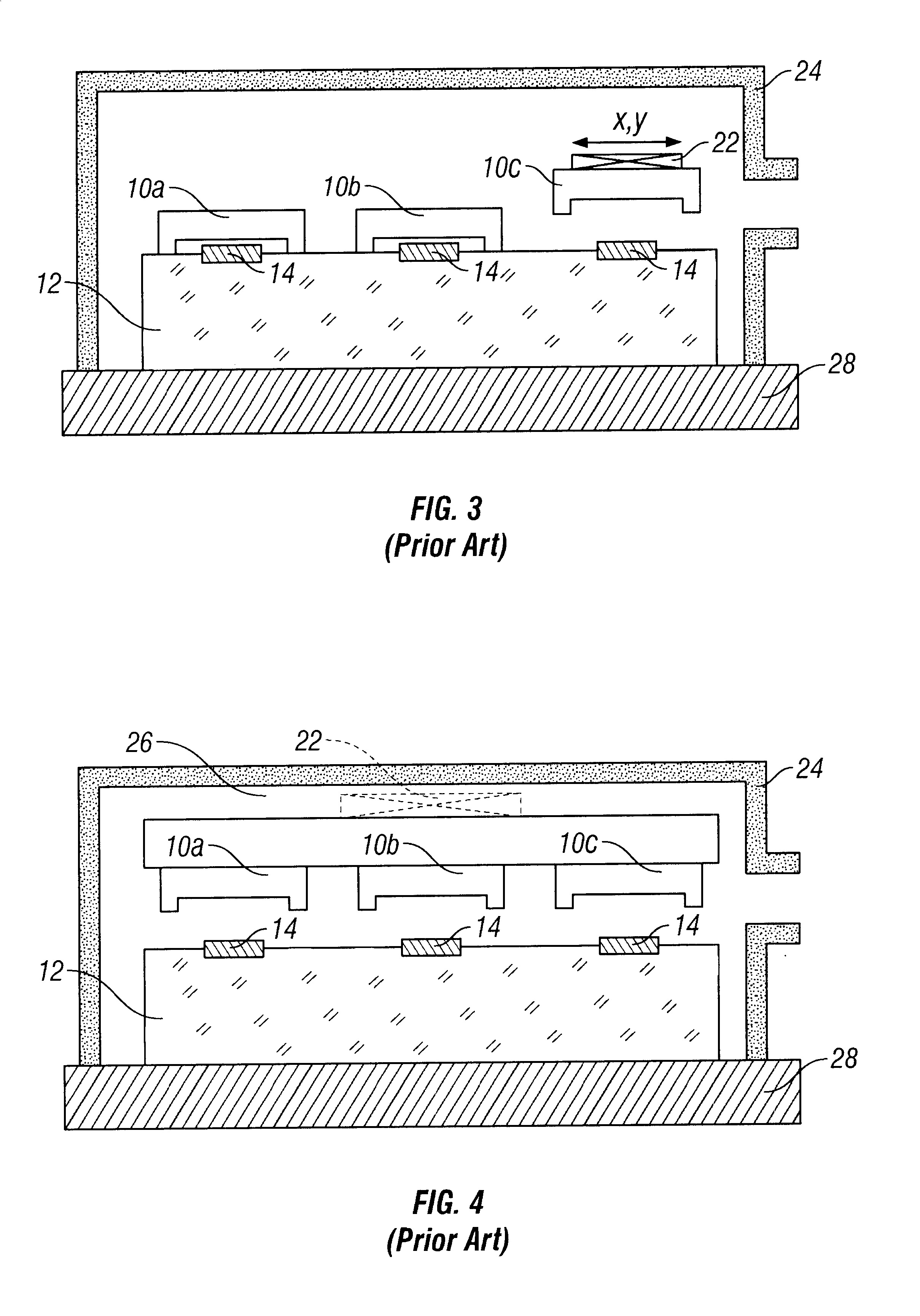

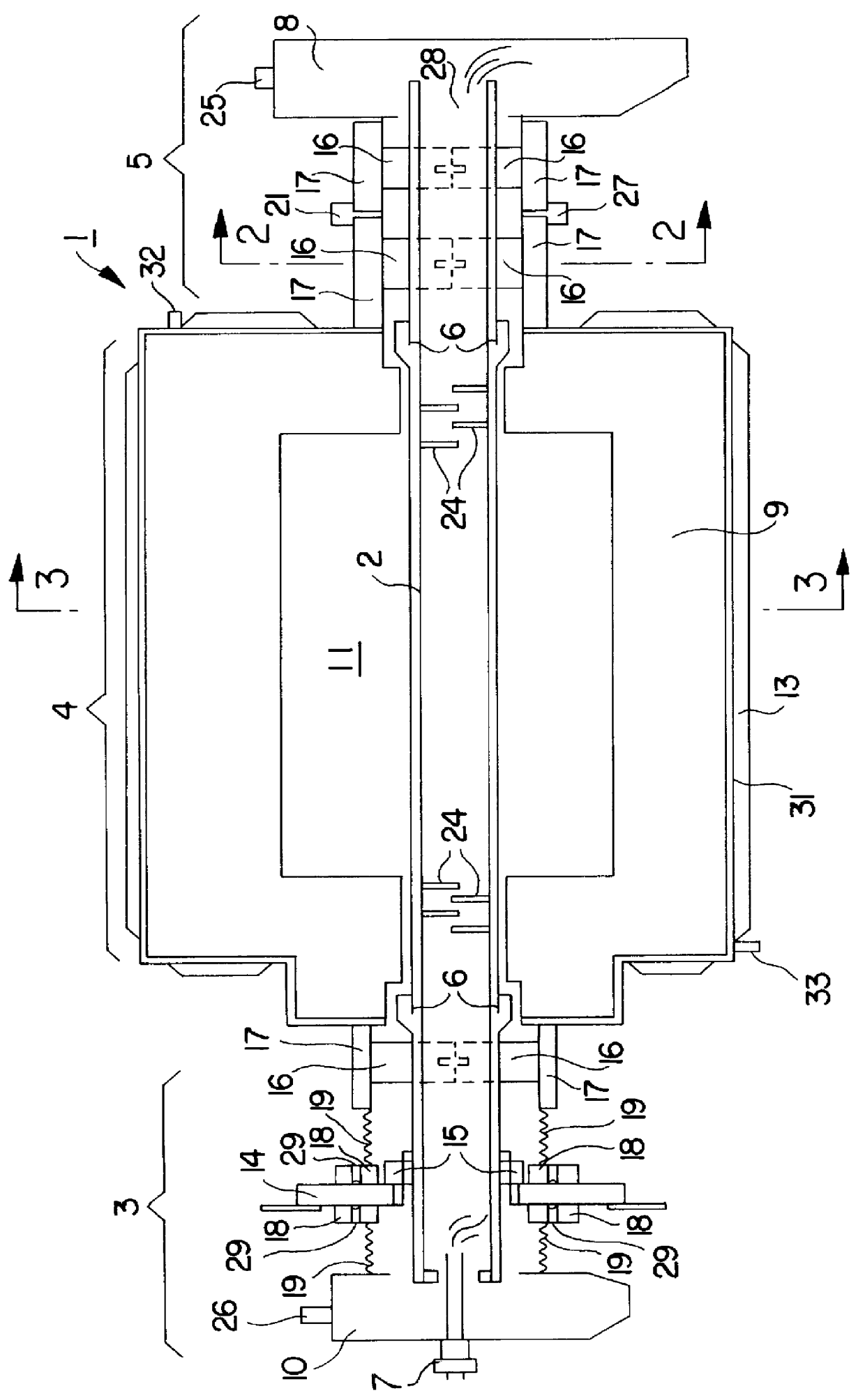

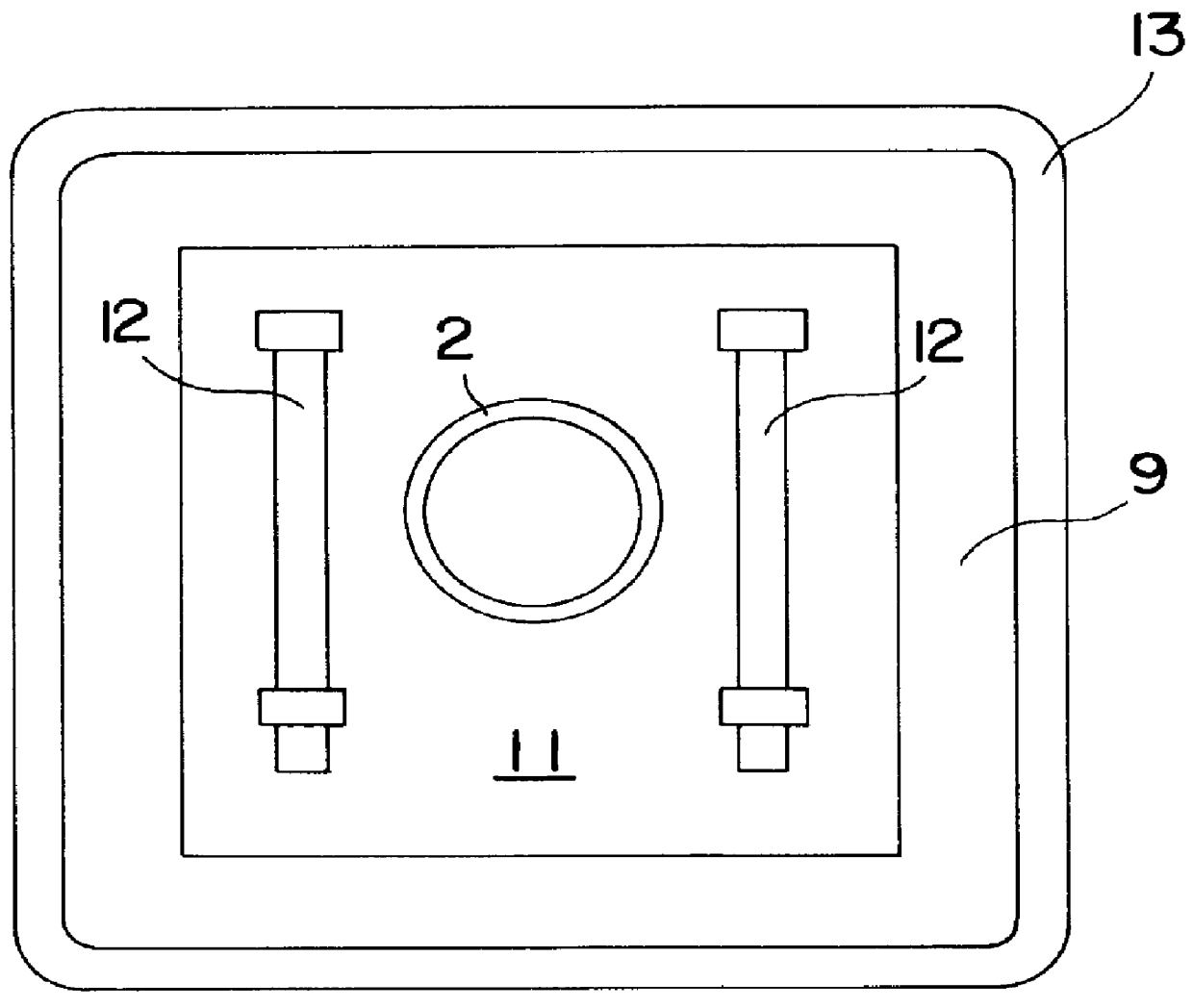

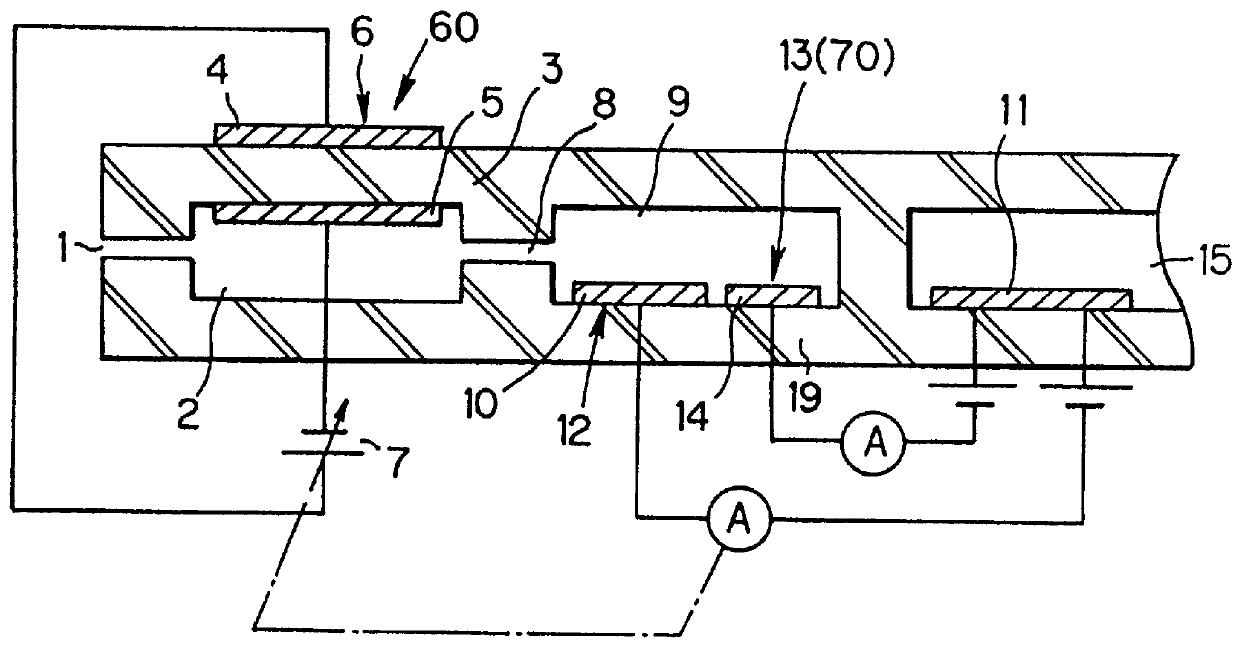

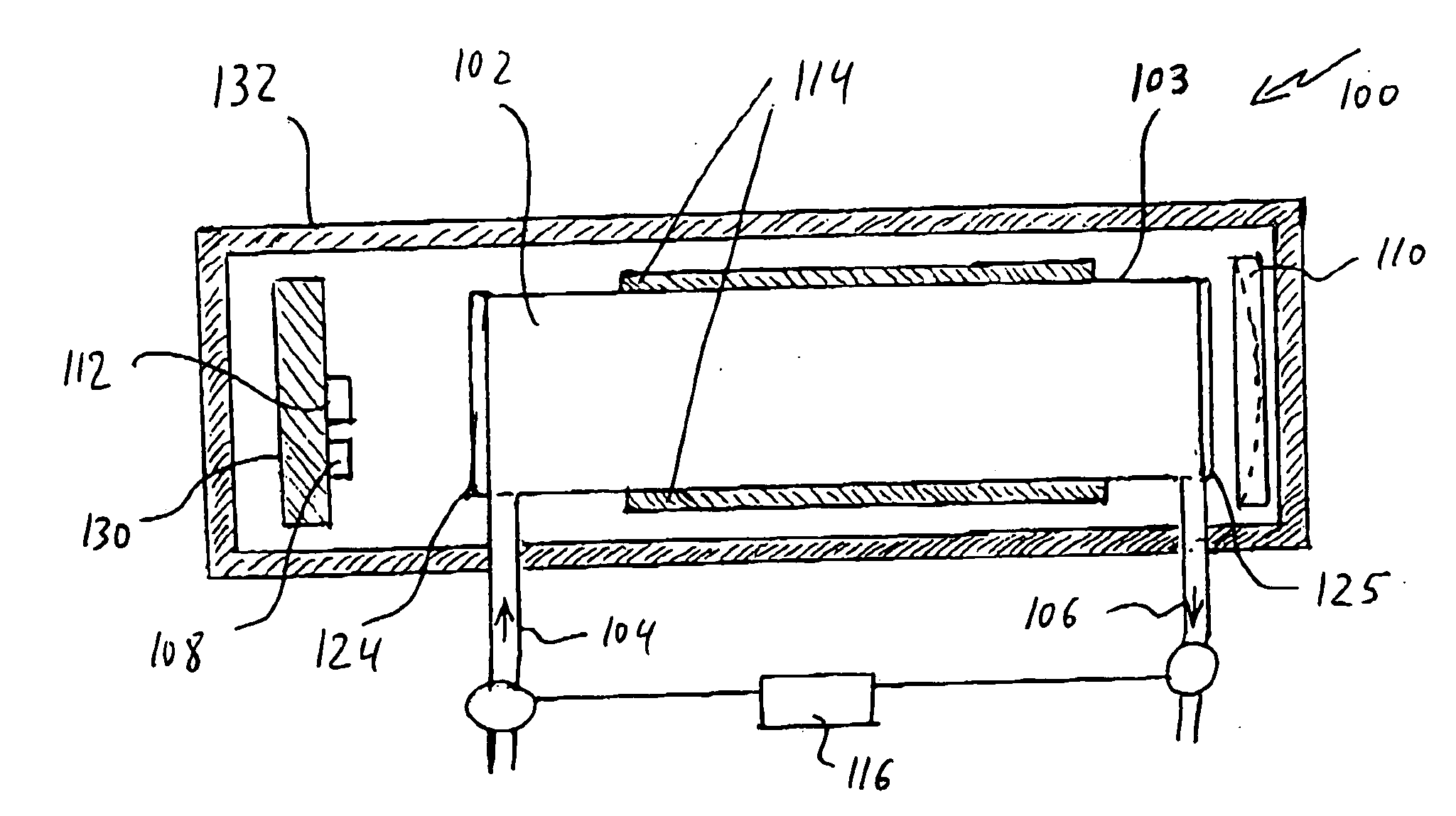

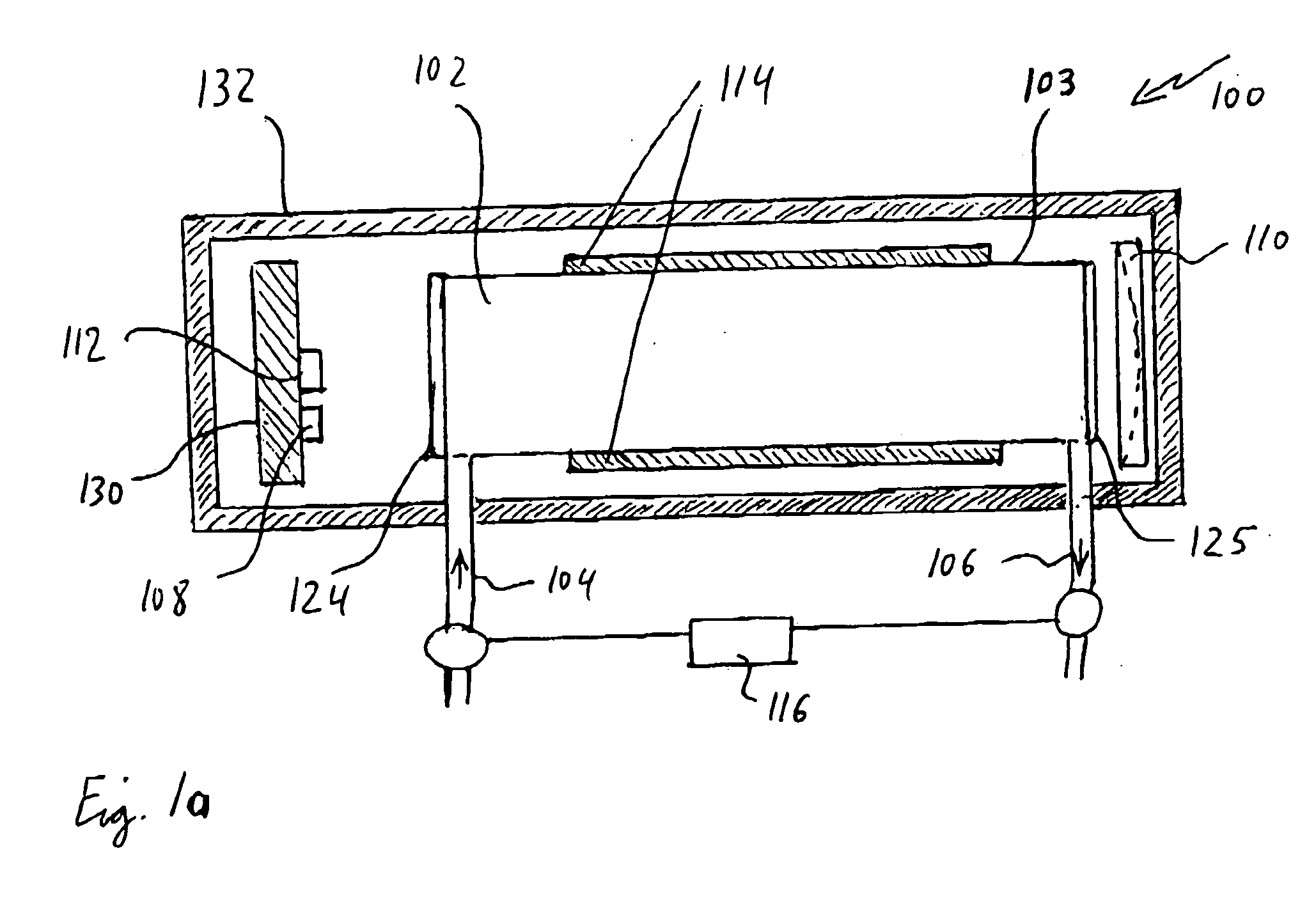

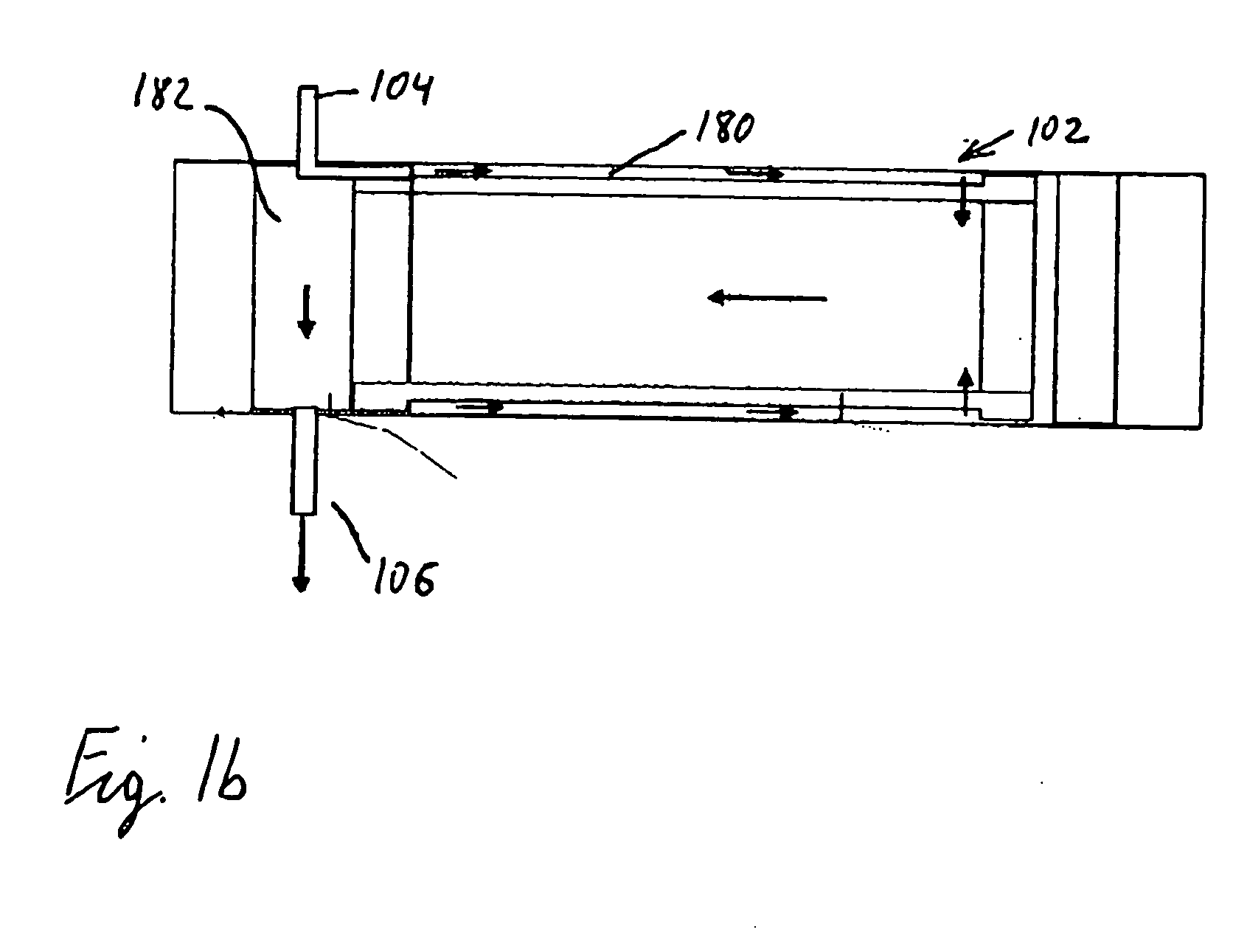

Method for forming a device having a cavity with controlled atmosphere

InactiveUS6566170B1Precision positioning equipmentSemiconductor/solid-state device detailsEngineeringMechanical engineering

Device comprising a carrier (100) and at least one cover (104) able to be bonded to the carrier to form with the carrier at least one cavity (114) having a controlled atmosphere around at least one component (102). In accordance with the invention, at least one of either the cover or the carrier is provided with at least one wedge (110) in fusible material and a strip of insulation (112) formed around said component, and before bonding, the wedge of fusible material is of sufficient thickness to prevent the strip of insulation (112) from coming into contact both with the cover and with the carrier when they are assembled together.Particular application to the encapsulation of electronic, mechanical or electromagnetic components.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Hermetic sample holder and method for performing microanalysis under controlled atmosphere environment

ActiveUS20100294049A1Reduce pressureParticle separator tubesPreparing sample for investigationDifferential pressureEngineering

A hermetic sample holder for use in performing microanalysis of a sample under a controlled atmosphere environment. The sample holder comprises a sample holder body with a sample cavity to receive the sample and a cover movably mounted to the holder body between an open position to allow access to the cavity and a closed position to seal the cavity. The cover is secured in and released from the closed position at least in part by a pressure differential between the cavity and the ambient atmosphere. The cover may be biased toward the open position. The cover may be pivotally mounted about an axis that is perpendicular to a sealing surface of the cover and / or movable in a direction along the pivot axis. A valve may be provided to allow direct evacuation of the cavity to create a pressure differential. An adjustable clamp may be located in the cavity to secure the sample.

Owner:SION POWER CORP

Plasma enhanced materials deposition system

InactiveUS20110318503A1Increase costIncrease system complexityLiquid surface applicatorsMolten spray coatingAtmospheric airProcess region

A system and method for combined material deposition and plasma and / or controlled atmosphere treatment processing of substrates. In one variation, plasma and / or controlled atmosphere treatment and deposition are performed using a single processing system with multiple processing areas. In another variation, plasma and / or controlled atmosphere treatment and deposition are performed using a single processing system with a single processing area. Variations of deposition include printing or direct-write techniques. Processing areas may be atmospherically controlled or selectively sealable.

Owner:LOCKHEED MARTIN CORP

Graphite rotary tube furnace

InactiveUS6042370AMinimizing radiation heat lossStable temperatureRotary drum furnacesCharge supportsRadiative heat lossRadiant heat

A rotary tube furnace suitable for operation in controlled atmospheres at temperatures in the range of 1500 DEG to 2800 DEG comprises a generally horizontal rotatable graphite tube slidably supported on water-cooled split ring graphite bearings. The graphite tube is rotated by means of a stainless steel drive plate and is contained within a flexible atmospheric sealing assembly and enclosure for the containment of a selected atmosphere around and within the tube and allows for the co-current or counter-current flow of gas during operation. Radiation baffles in the interior of the graphite tube inhibit radiant heat loss at the ends of the tube. The graphite tube may be constructed in two or more sections having threaded ends for ease of installation as well as removal or replacement for maintenance purposes. A heating section of the tube is heated by a plurality of graphite electrical heating elements contained within an insulated heating chamber.

Owner:HARPER INT CORP

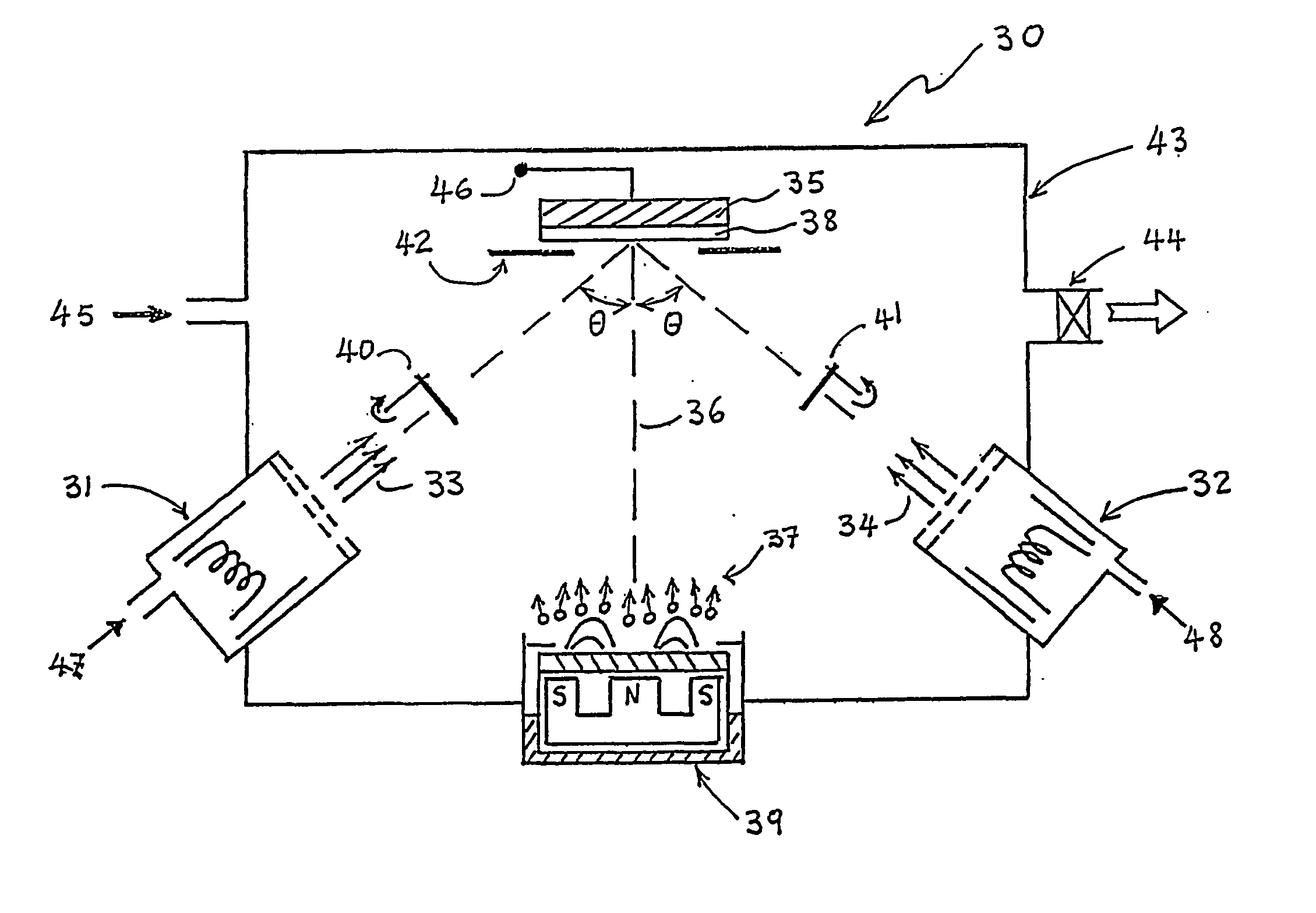

Process and apparatus for producing cystalline thin film buffer layers and structures having biaxial texture

InactiveUS20040168636A1Increase deposition rateEasy alignmentPolycrystalline material growthElectric discharge heatingIon beamOptoelectronics

The invention provides a method of depositing a buffer layer or film onto a surface of a substrate. The method includes providing the substrate in a controlled atmosphere and exposing the substrate to a vapour comprising a film forming species. While the substrate is exposed to the vapour, two or more ion beams are provided incident upon the surface of the substrate to assist formation of the film. The respective axes of incidence of the two or more ion beams are distinct and are selected and controlled in order to maintain the arrival rate ratio, maximise the deposition rate, and maximise the biaxial alignment of the layer so formed.

Owner:COMMONWEALTH SCI & IND RES ORG

Method for measuring nitrogen oxide

InactiveUS6036841AWeather/light/corrosion resistanceVolume/mass flow measurementAtmospheric airDecomposition

A method for measuring nitrogen oxide (NOx) in a gas by decomposing NOx in the gas and measuring an amount of oxygen generated by the decomposition includes: introducing the gas to a first inner space under a first diffusion resistance and connected with an external space, controlling an oxygen partial pressure in an atmosphere in the first inner space to be a predetermined low value at which NO is not decomposed substantially by a main pump means, introducing a controlled atmosphere of the first inner space into a second inner space which is connected with the first inner space and which is under a second diffusion resistance, and converting the atmosphere into an electric signal corresponding to the quantity of oxygen generated by decomposition or reduction of NOx contained in the atmosphere by an electric signal conversion means. A first oxygen concentration detecting means is disposed for detecting an oxygen partial pressure in the second inner space, and a control voltage to be applied to the main pump means is adjusted on the basis of an output of the first oxygen concentration detecting means.

Owner:NGK INSULATORS LTD

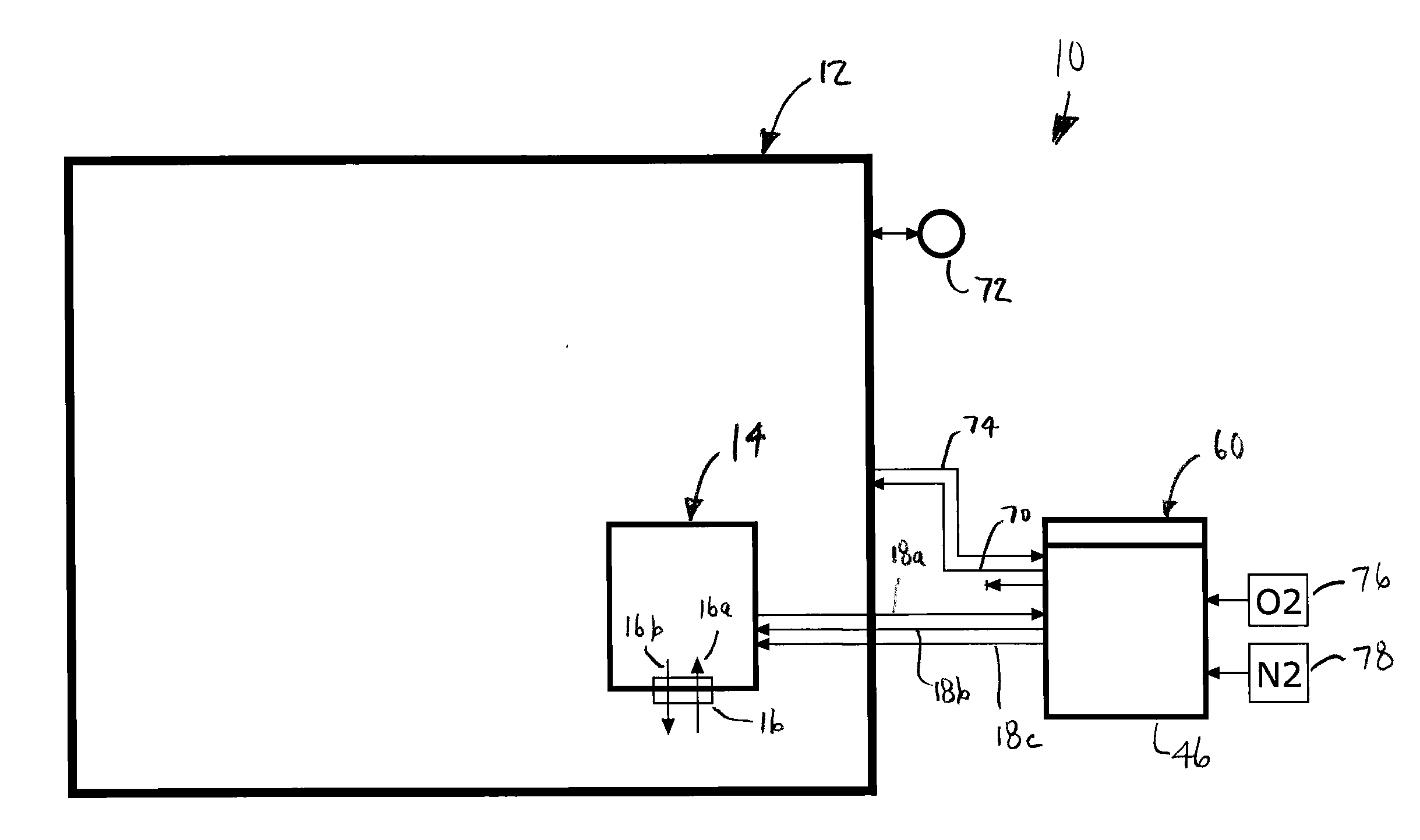

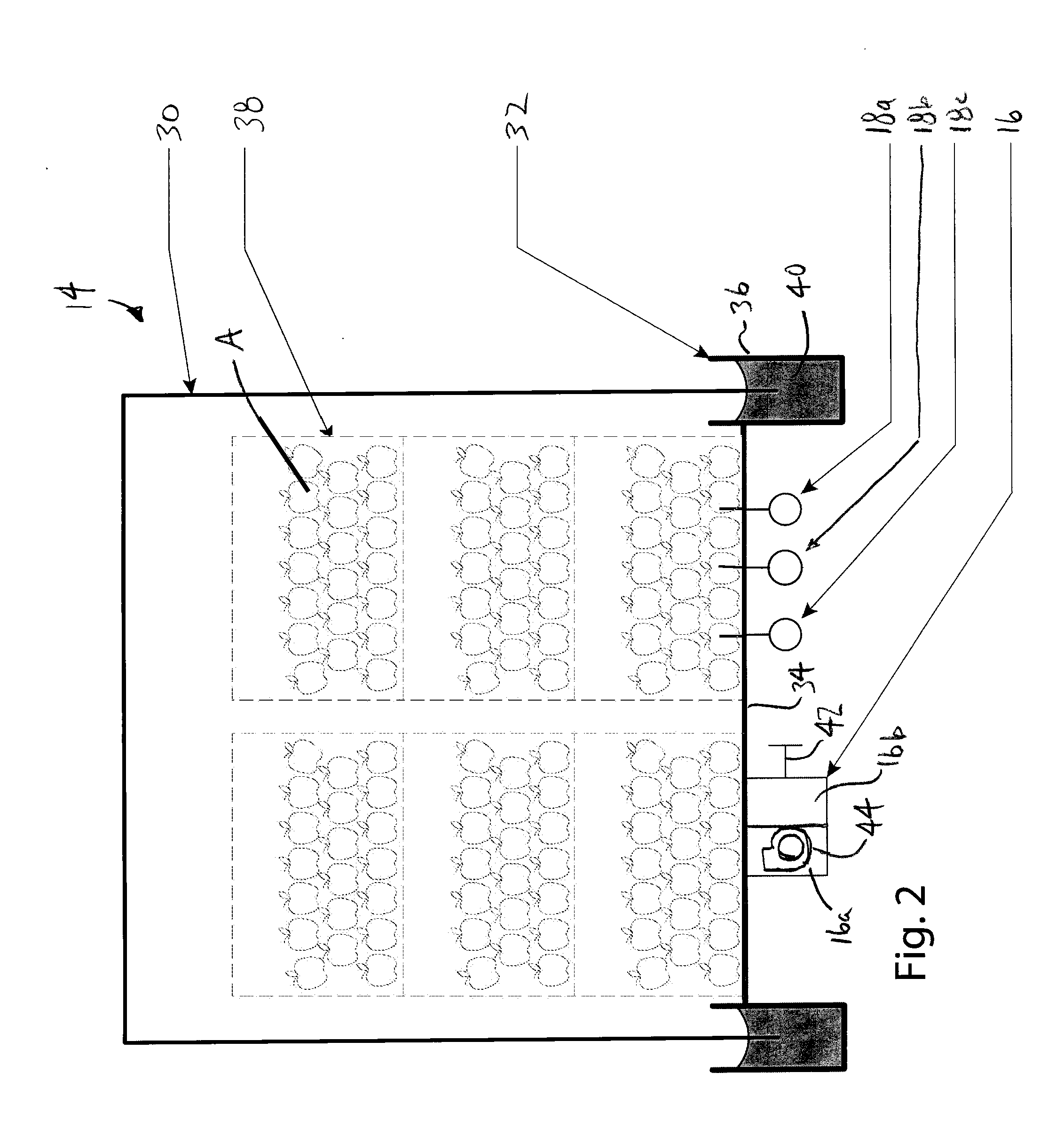

Dynamic control system and method for controlled atmosphere room

ActiveUS20120097050A1Good correlationLarge capacityFruit and vegetables preservationMilk treatmentControl systemRespiratory quotient

A control system for a controlled atmosphere room (“CA room”) for storing perishable commodities, such as fruits and vegetables. The control system includes an enclosure that can be placed within the CA room to store a representative sample of the commodities in the CA room. The control system includes an atmosphere valve selectively operable to provide atmospheric communication between the enclosure and the CA room or to isolate the enclosure from the CA room. The control system includes a sampling control system for determining a dynamic control value based on the isolated representative sample. The dynamic control value may be determined by monitoring the respiratory quotient in the enclosure while it is isolated. Once determined, the control system can use the dynamic control value to adjust the atmosphere of the CA room, thereby using tests on a representative sample to control the atmosphere for the full volume of commodities in the CA room. When not testing, the enclosure generally remains in atmospheric communication with the CA room, which improves the correlation of the representative sample with the commodities in the CA room.

Owner:SCHAEFER JAMES C

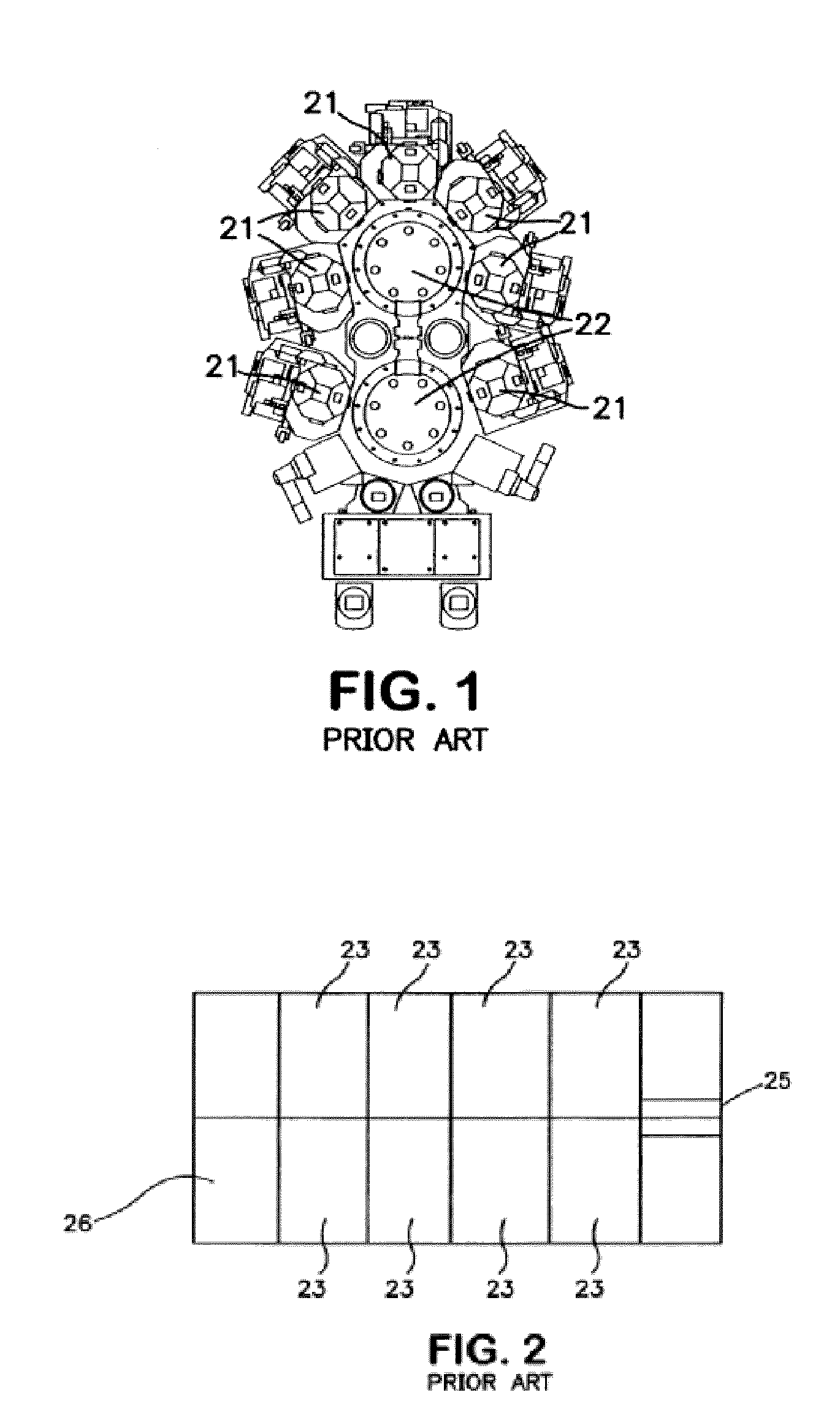

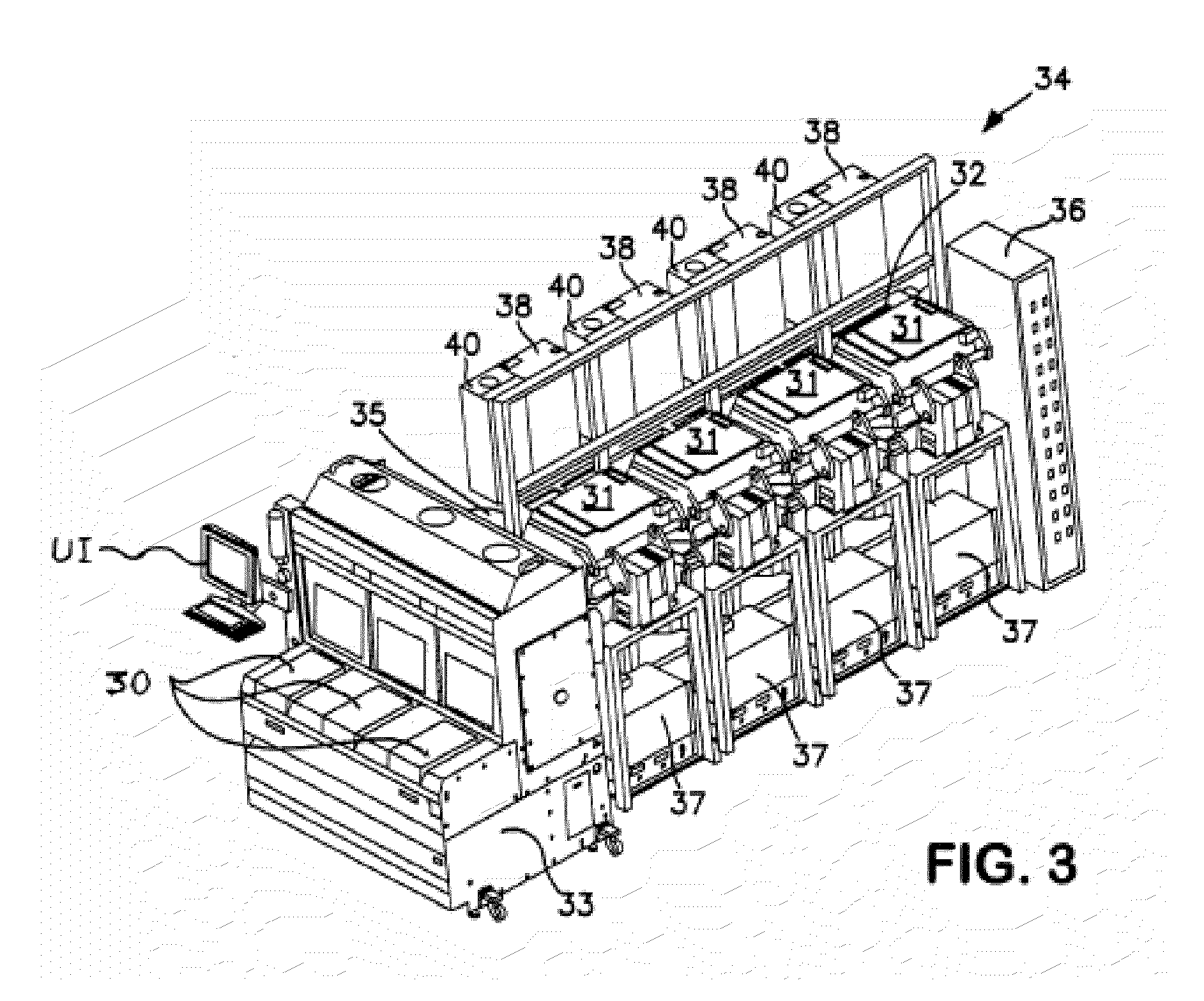

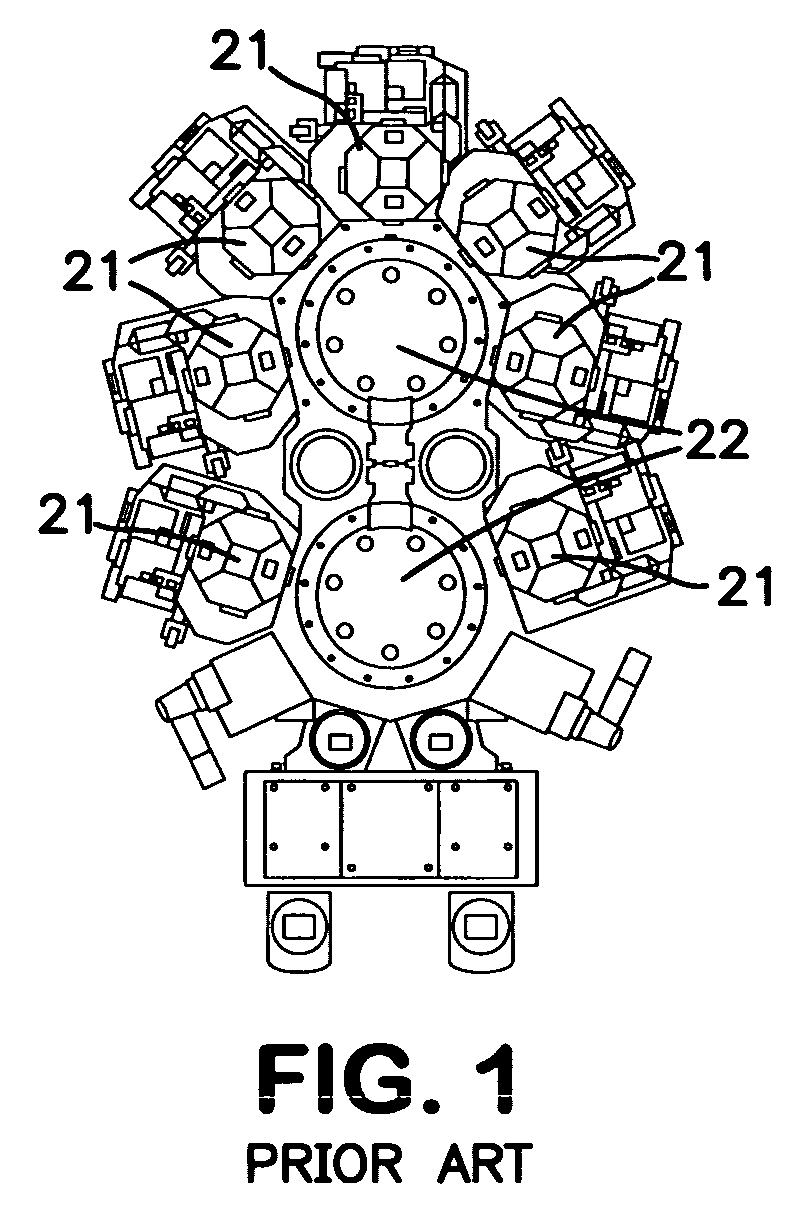

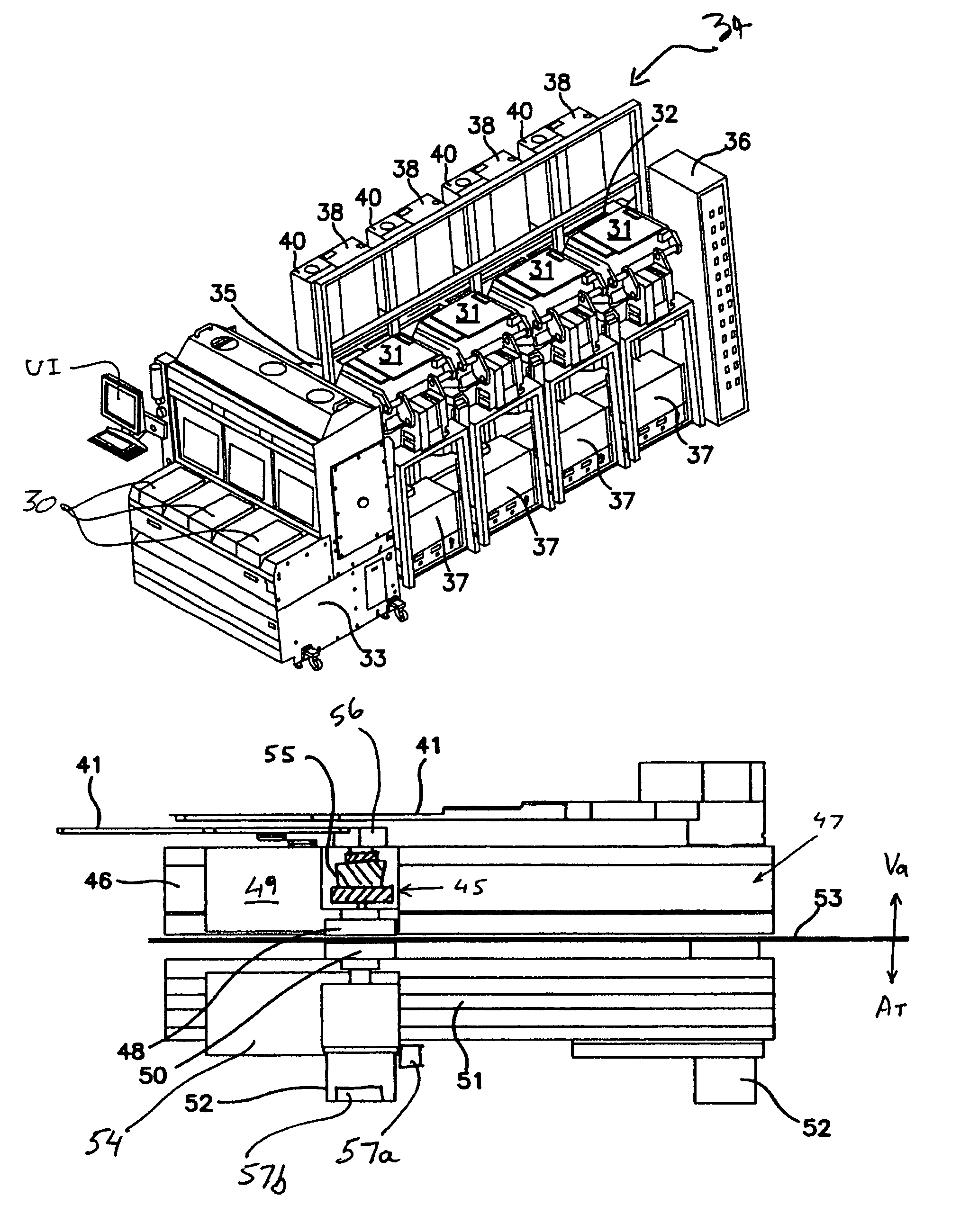

Apparatus and methods for transporting and processing substrates

ActiveUS7901539B2Simplify roboticsSmall footprintCellsVacuum evaporation coatingEngineeringThroughput

There is described apparatus and methods for transporting and processing substrates including wafers as to efficiently produce at reasonable costs improved throughput as compared to systems in use today. A key element is the use of a transport chamber along the sides of processing chambers for feeding substrates into a controlled atmosphere through a load lock and then along a transport chamber as a way of reaching processing chambers and then out of the controlled atmosphere following processing in the processing chambers.

Owner:BOOKS AUTOMATION US LLC

Method for producing carbon molecular sieve membranes in controlled atmospheres

The invention concerns carbon molecular sieve membranes (“CMS membranes”), and more particularly the use of such membranes in gas separation. In particular, the present disclosure concerns an advantageous method for producing CMS membranes with desired selectivity and permeability properties. By controlling and selecting the oxygen concentration in the pyrolysis atmosphere used to produce CMS membranes, membrane selectivity and permeability can be adjusted. Additionally, oxygen concentration can be used in conjunction with pyrolysis temperature to further produce tuned or optimized CMS membranes.

Owner:AIR LIQUIDE ADVANCED TECH U S +1

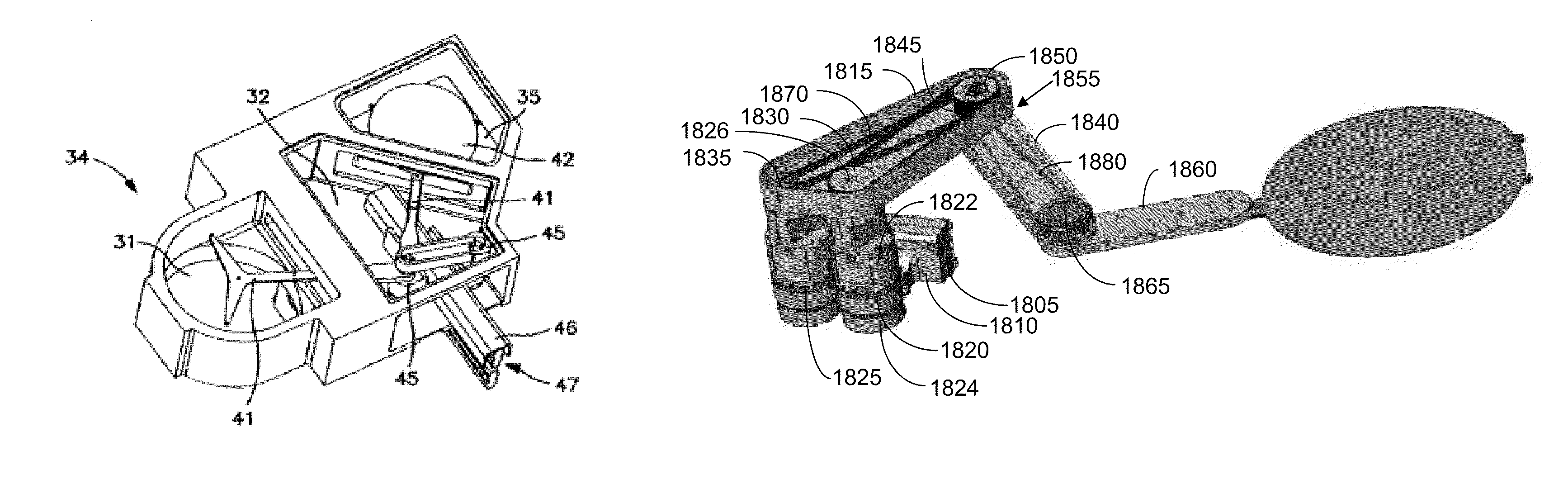

Linear vacuum robot with z motion and articulated arm

There is described apparatus and methods for transporting and processing substrates including wafers as to efficiently produce at reasonable costs improved throughput as compared to systems in use today. A linear transport chamber includes linear tracks and robot arms riding on the linear tracks to linearly transfer substrates along the sides of processing chambers for feeding substrates into a controlled atmosphere through a load lock and then along a transport chamber as a way of reaching processing chambers. A four-axis robot arm is disclosed, capable of linear translation, rotation and articulation, and z-motion.

Owner:BOOKS AUTOMATION US LLC

Apparatus and method for controlling atmospheres in heat treating of metals

InactiveUS20060263256A1High precisionReduce manufacturing costMaterial analysis by electric/magnetic meansMaterial analysis by optical meansAbsorption cellElectromagnetic radiation

The present invention relates to an absorption gas analyzer for measuring a concentration of at least a component gas in a sample gas. The absorption gas analyzer comprises a main absorption cell for containing the sample gas for measurement therein. At least a narrow band emitter emits electromagnetic radiation in at least a predetermined narrow wavelength band which is transmitted through the main absorption cell. A reflecting device is disposed for reflecting the electromagnetic radiation after transmission through the main absorption cell such that the electromagnetic radiation is transmitted again therethrough. At least a detector detect the electromagnetic radiation and provide at least an intensity signal in dependence upon the concentration of the at least a component gas. The absorption gas analyzer enables simultaneous determination of concentration of a plurality of individual component gases with a high level of accuracy.

Owner:NITREX METAL

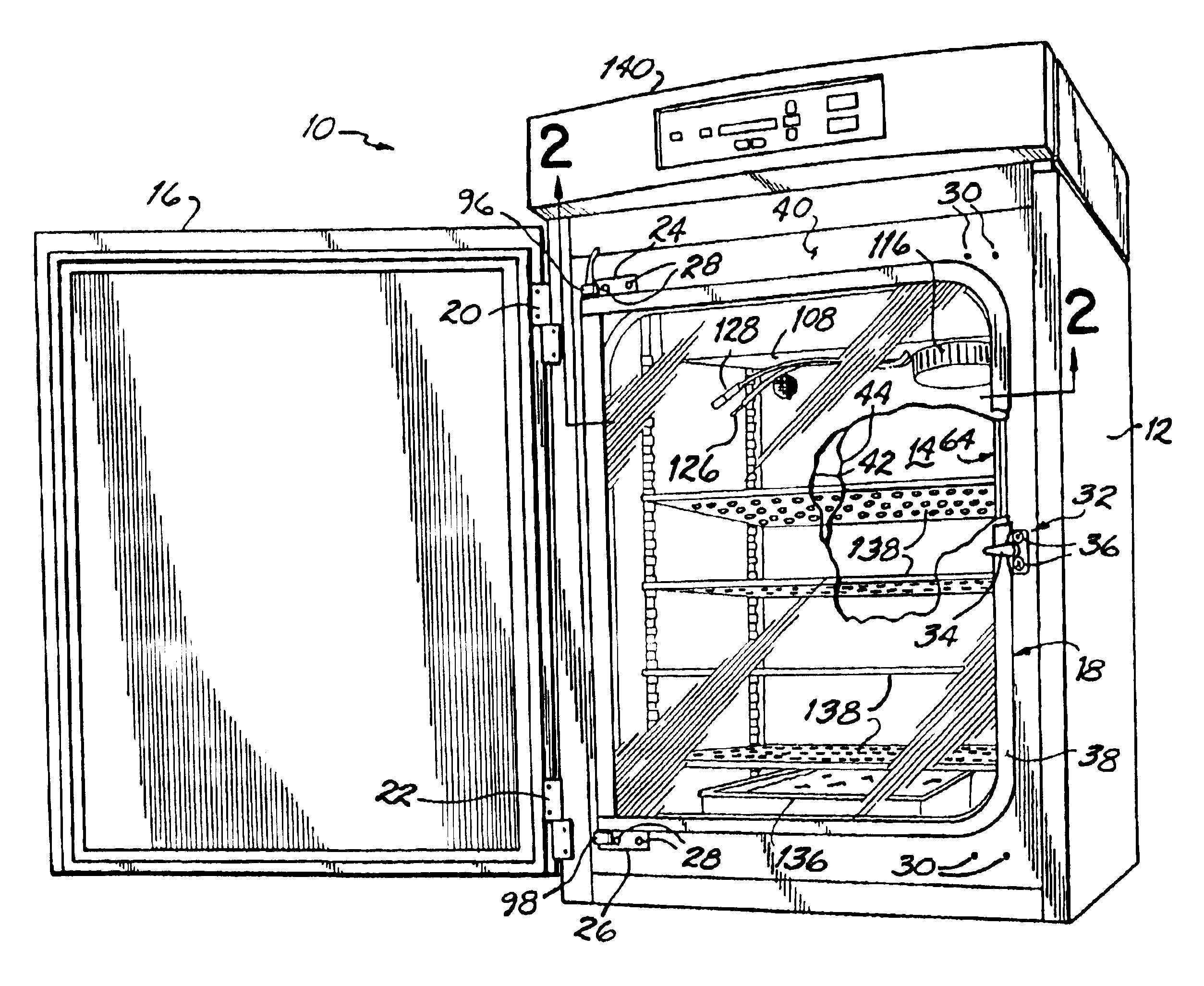

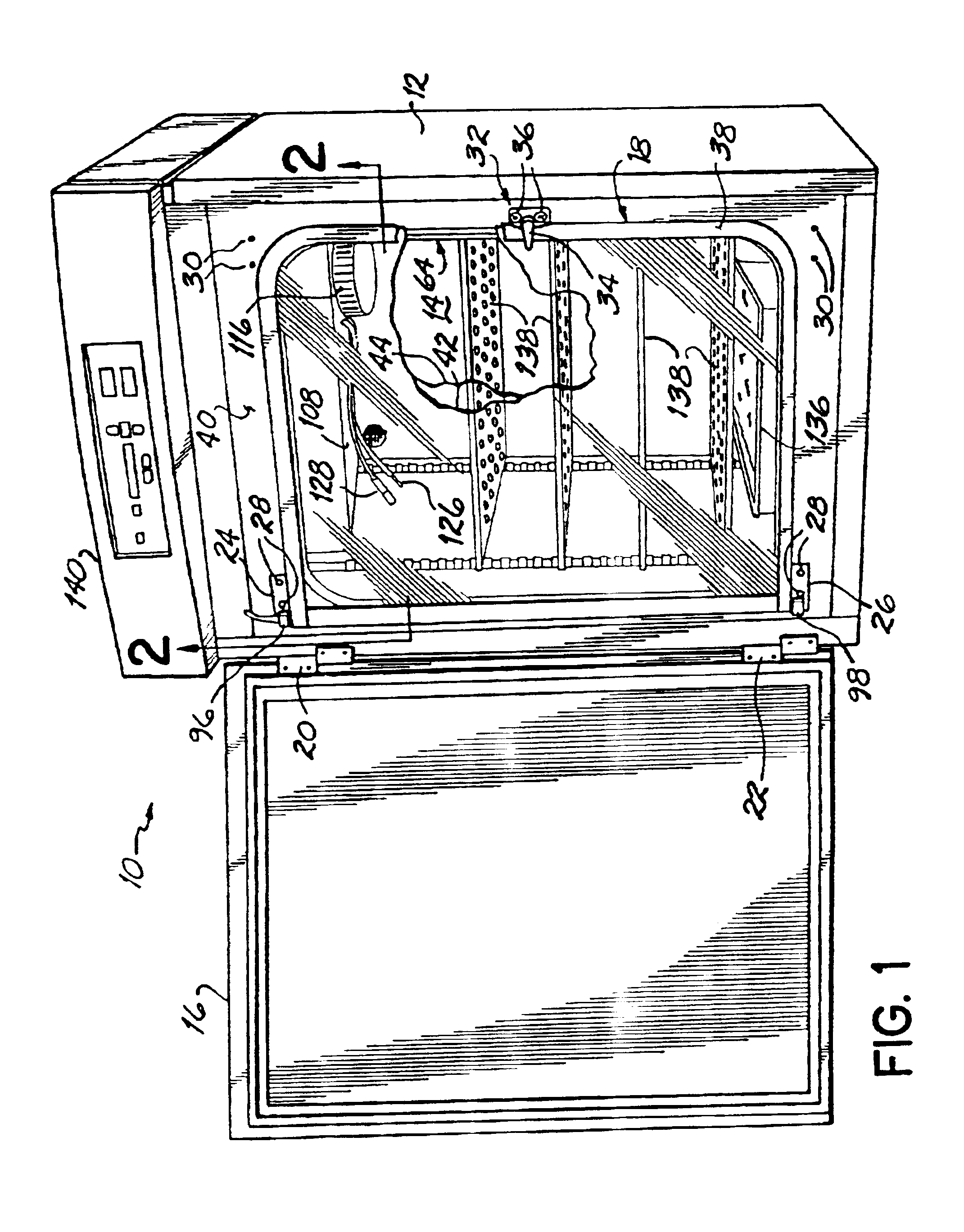

Incubator having combined HEPA and VOC filter

InactiveUS6878177B2Quickly and completely circulatedHigh gas purityCombination devicesBioreactor/fermenter combinationsHEPAControlled atmosphere

A controlled atmosphere incubator having an interior chamber adapted to be heated and humidified. An easily accessed blower is located within the gaseous environment of the incubator chamber and includes a HEPA filter and VOC filter readily replaceable by the user from within the chamber.

Owner:THERMO FISHER SCI ASHEVILLE

Method for producing carbon molecular sieve membranes in controlled atmospheres

The invention concerns carbon molecular sieve membranes (“CMS membranes”), and more particularly the use of such membranes in gas separation. In particular, the present disclosure concerns an advantageous method for producing CMS membranes with desired selectivity and permeability properties. By controlling and selecting the oxygen concentration in the pyrolysis atmosphere used to produce CMS membranes, membrane selectivity and permeability can be adjusted. Additionally, oxygen concentration can be used in conjunction with pyrolysis temperature to further produce tuned or optimized CMS membranes.

Owner:AIR LIQUIDE ADVANCED TECH U S +1

Load lock fast pump vent

ActiveUS8272825B2Semiconductor/solid-state device manufacturingCharge manipulationEngineeringControlled atmosphere

A substrate processing tool including a frame forming at least one isolatable chamber configured to hold a controlled atmosphere, at least two substrate supports located within each of the at least one isolatable chamber, each of the at least two substrate supports being stacked one above the other and configured to hold a respective substrate and a cooling unit communicably coupled to the at least two substrate supports such that the at least two substrate supports and cooling unit effect simultaneous conductive cooling of each of the respective substrates located on the at least two substrate supports.

Owner:BOOKS AUTOMATION US LLC

Apparatus and methods for transporting and processing substrates

ActiveUS8293066B2Simplify roboticsSmall footprintLiquid surface applicatorsVacuum evaporation coatingEngineeringThroughput

There is described apparatus and methods for transporting and processing substrates including wafers as to efficiently produce at reasonable costs improved throughput as compared to systems in use today. A key element is the use of a transport chamber along the sides of processing chambers for feeding substrates into a controlled atmosphere through a load lock and then along a transport chamber as a way of reaching processing chambers and then out of the controlled atmosphere following processing in the processing chambers.

Owner:BOOKS AUTOMATION US LLC

Process for fluxless brazing of aluminium and brazing filler alloy for use therein

InactiveUS20110204124A1Stationary conduit assembliesWelding/cutting media/materialsControlled atmosphereAluminium alloy

This relates to a process for controlled atmosphere brazing including, brazing an aluminium alloy without flux in a controlled atmosphere, while using brazing sheet including an aluminium alloy core upon which on at least one side a layer of filler alloy is clad, the filler clad layer having an inner-surface and an outer-surface, the inner-surface is facing the core, and wherein the filler alloy has a composition which is Na-free, Li-free, K-free, and Ca-free, and including, in wt. %: Si 3% to 15%, Cu 0.3% to 5%, Mg 0.05% to 1%, one or more elements selected from the group of: Bi, Pb, and Sb, and the sum of these elements being 0.35% or less, Fe 0 to 0.6%, Mn 0 to 1.5%, the balance aluminium.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

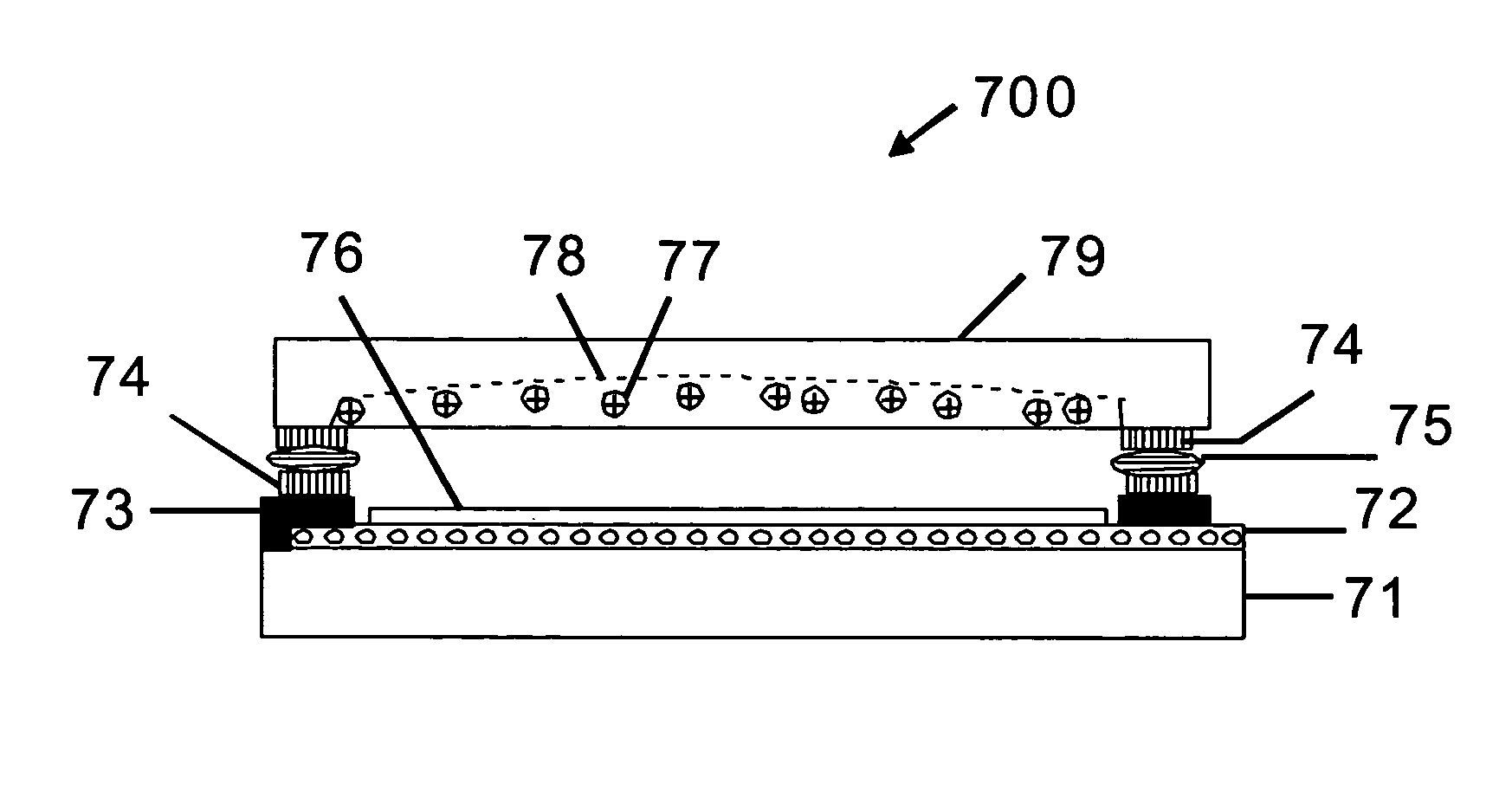

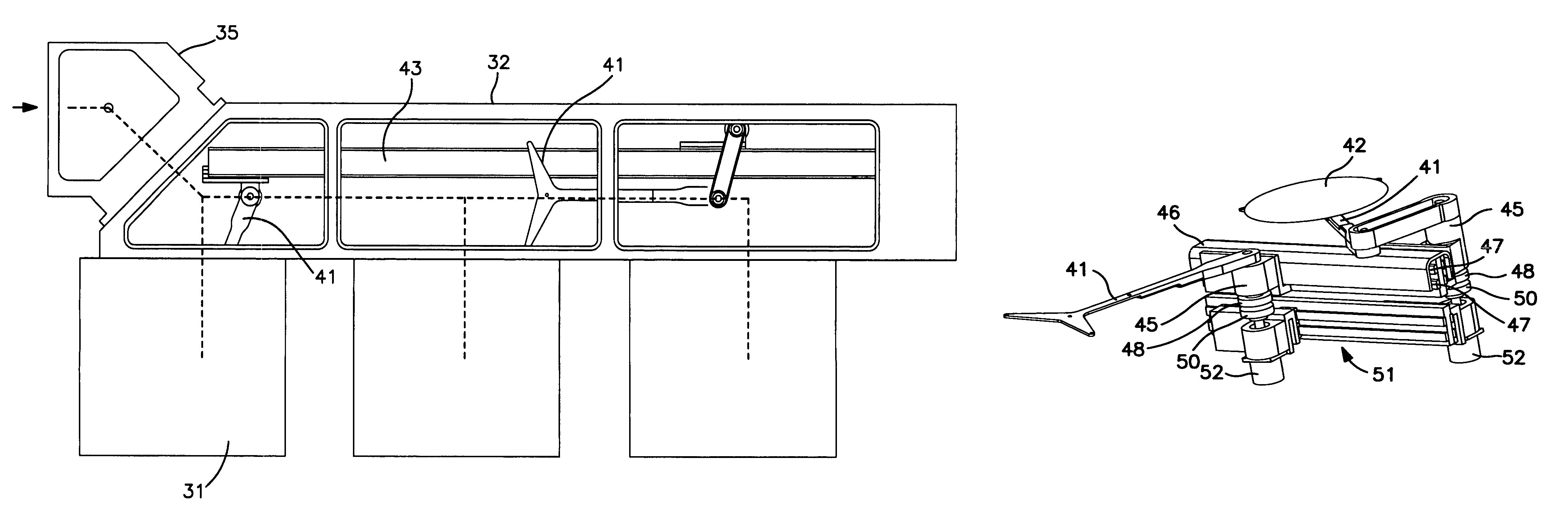

Laser Microperforated Fresh Produce Trays for Modified/Controlled Atmosphere Packaging

A system for laser microperforated fresh produce trays for use in modifying or controlling the flow of oxygen and carbon dioxide into and / out of a fresh produce container, where the microperforations are specifically tailored such as by size, location and number for the specific produce. The packaging system tailors microperforated trays for particular produce to optimally preserve the produce, using a method of making registered microperforations on the trays using at least some of the following: a conveyor, a thickness measuring devise, a sensor mechanism, and a laser system including optics.

Owner:TAYLOR FRESH FOODS INC

Process for metallic contamination reduction in silicon wafers

ActiveUS20050250297A1Promote migrationSmall sizeSemiconductor/solid-state device manufacturingCopperOxygen

A process for removing a contaminant selected from among copper, nickel, and a combination thereof from a silicon wafer having a surface and an interior. The process comprises cooling the silicon wafer in a controlled atmosphere from a temperature at or above an oxidation initiation temperature and initiating a flow of an oxygen-containing atmosphere at said oxidation initiation temperature to create an oxidizing ambient around the silicon wafer surface to form an oxide layer on the silicon wafer surface and a strain layer at an interface between the oxide layer and the silicon wafer interior. The cooling of the wafer is also controlled to permit diffusion of atoms of the contaminant from the silicon wafer interior to the strain layer. Then the silicon wafer is then cleaned to remove the oxide layer and the strain layer, thereby removing said contaminant having diffused to the strain layer.

Owner:GLOBALWAFERS CO LTD

Multilayer aluminium brazing sheet for fluxfree brazing in controlled atmosphere

InactiveUS20150165564A1Improve visual appearanceIncrease costCooking-vessel materialsWelding/cutting media/materialsBraze alloyMelting temperature

An aluminium brazing sheet comprising an aluminium alloy core material covered by an interlayer and an Al—Si braze alloy is disclosed. The interlayer consists of an aluminium alloy comprising ≦1.0% Si and 0.1-2.5% Mg. The Al—Si braze alloy comprises 5-14% Si and 0.01-1.0% Bi. The core material and the interlayer has a higher melting temperature than the braze alloy.

Owner:GRAENGES SWEDEN AB

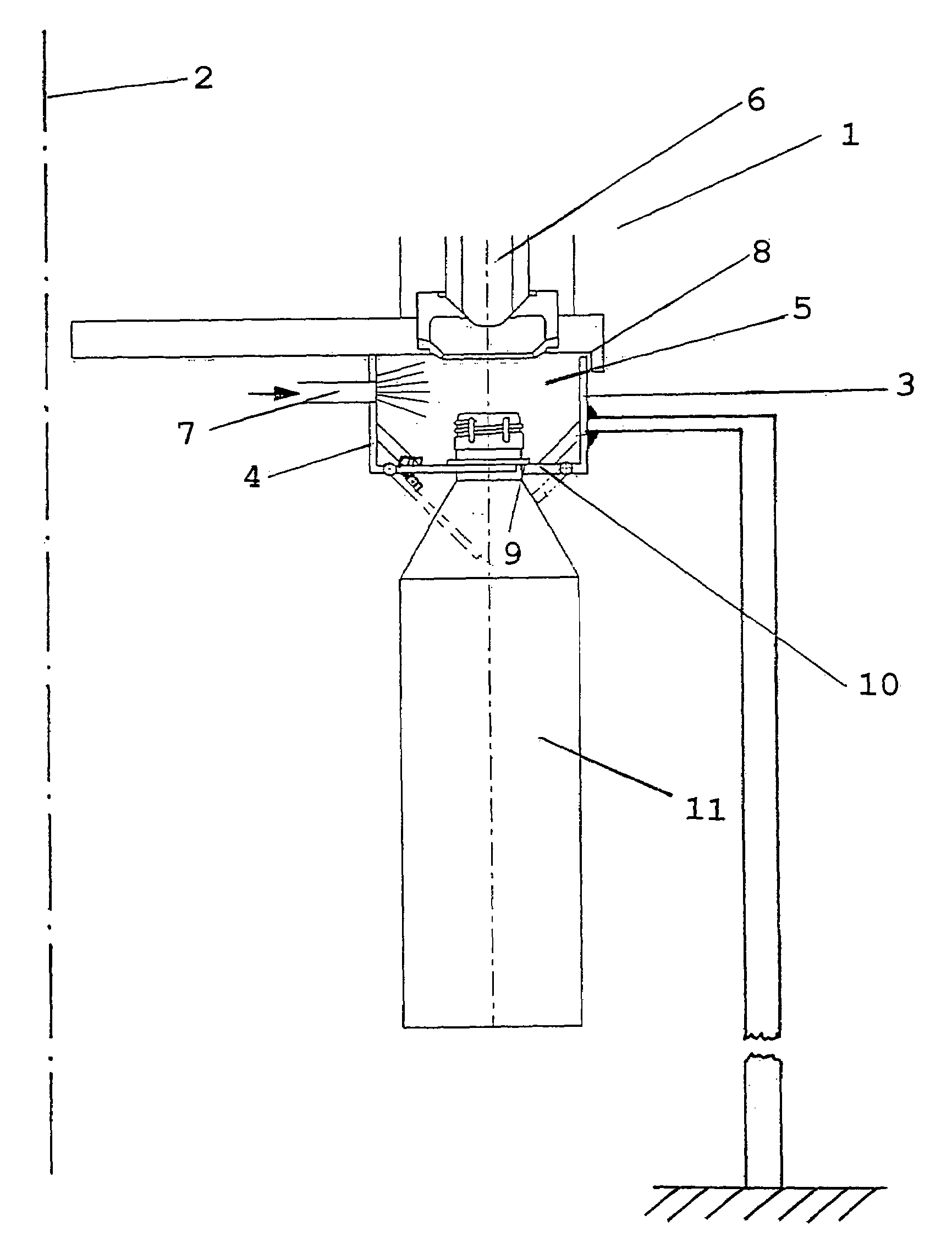

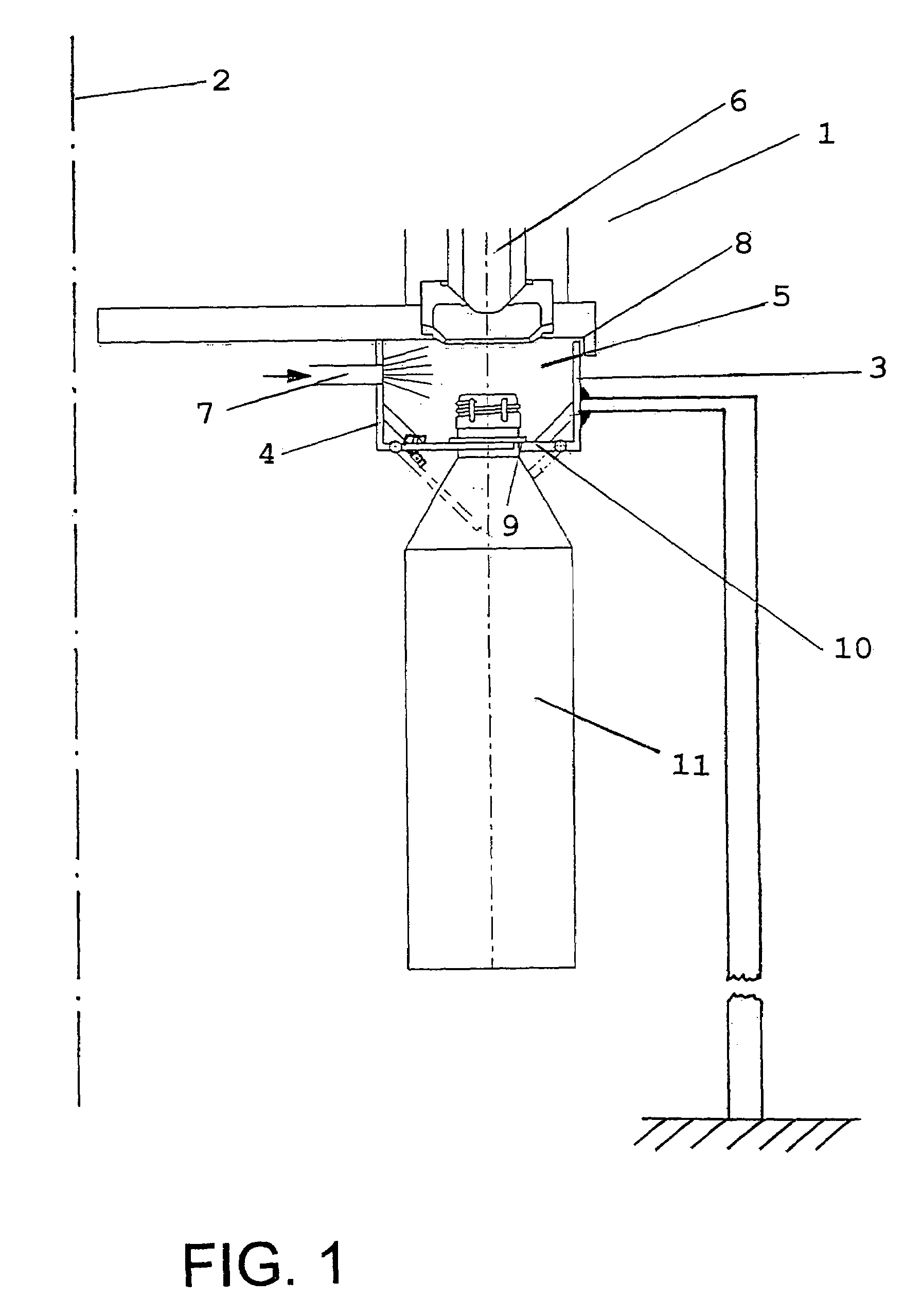

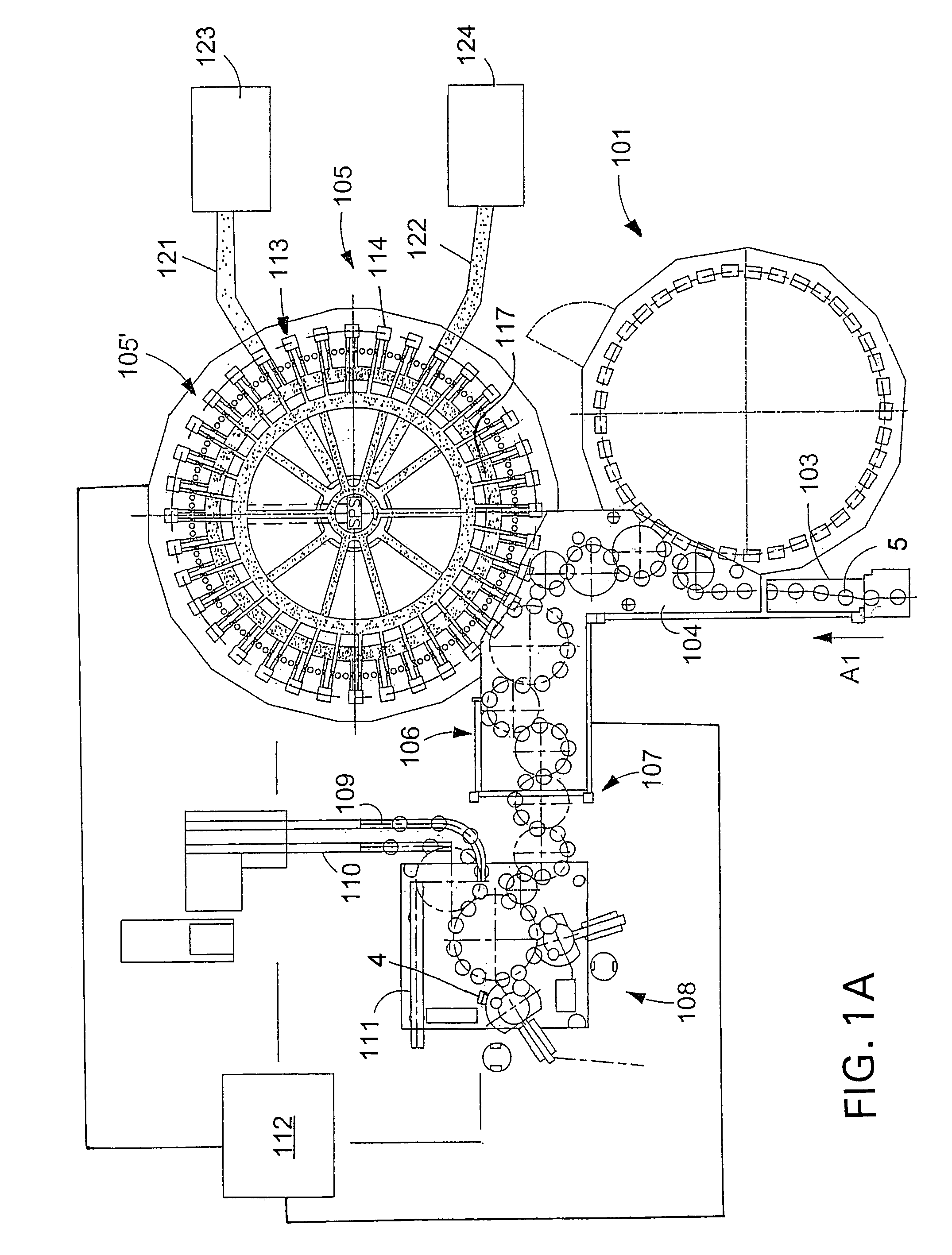

Beverage bottling plant for filling bottles with a liquid beverage filling material, having a container handling machine with interchangeable receptacles for the container mouth

ActiveUS7121062B2Reduce equipment costsFlexible article cleaningPackaging under vacuum/special atmosphereFilling materialsEngineering

A container handling machine for containers, such as bottles, with a carousel that rotates around a vertical axis, with handling stations located at appropriate intervals for the handling of the containers, whereby the handling stations are located in a space that is essentially enclosed and is pressurized with a controlled atmosphere and having rotating portions of the space and non-rotating portions that are stationary with respect to the rotating portions, with receptacles (12) for holding the containers corresponding to each handling station, whereby these receptacles (12) are interchangeable.

Owner:KHS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com