Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64 results about "Radiative heat loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiant heat loss occurs as a result of highly energized molecules transmitting heat by way of waves or particles. For significant heat loss to occur from radiation, the hotter surface must be well above ambient temperature — much higher than what is observed in typical heat trace applications.

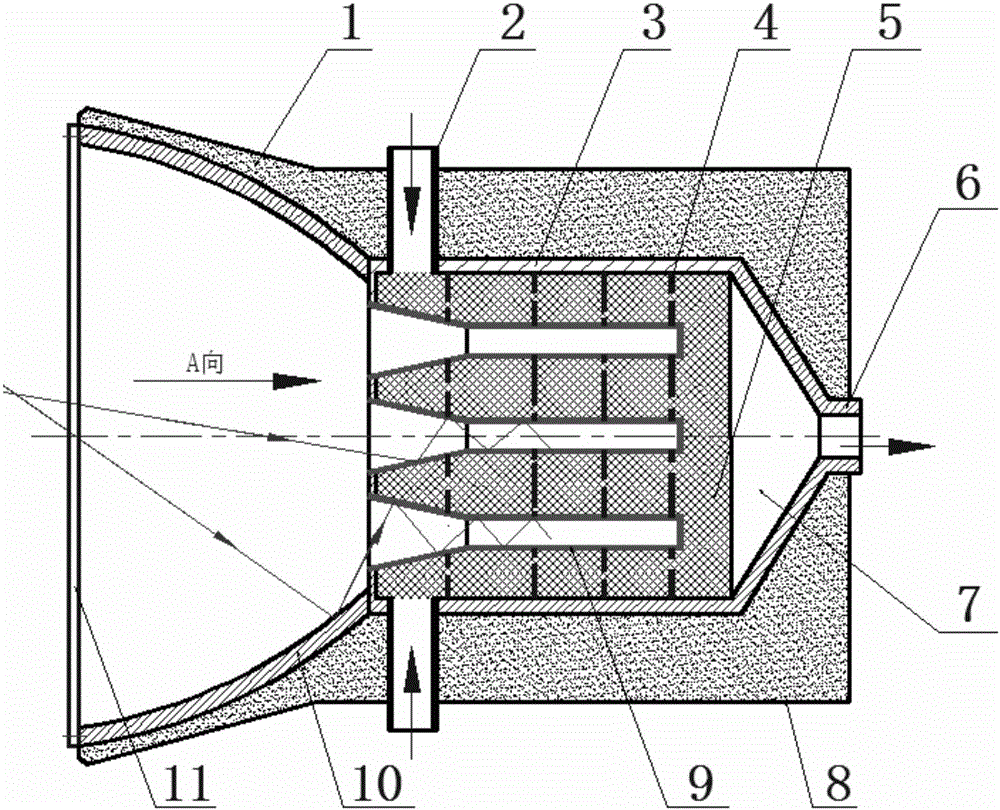

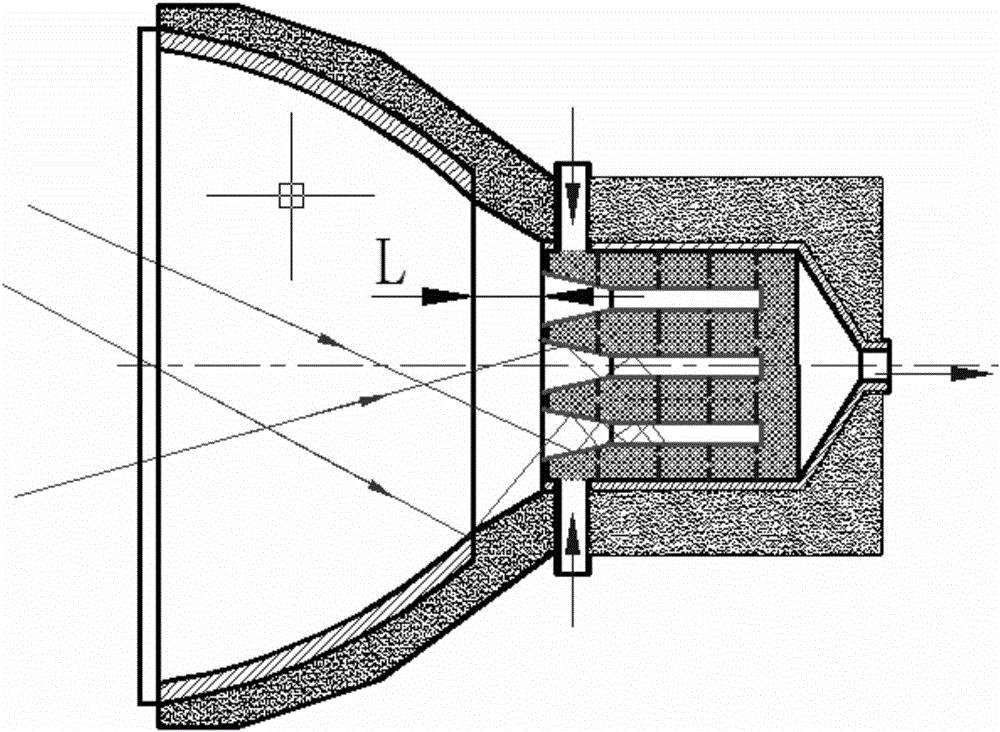

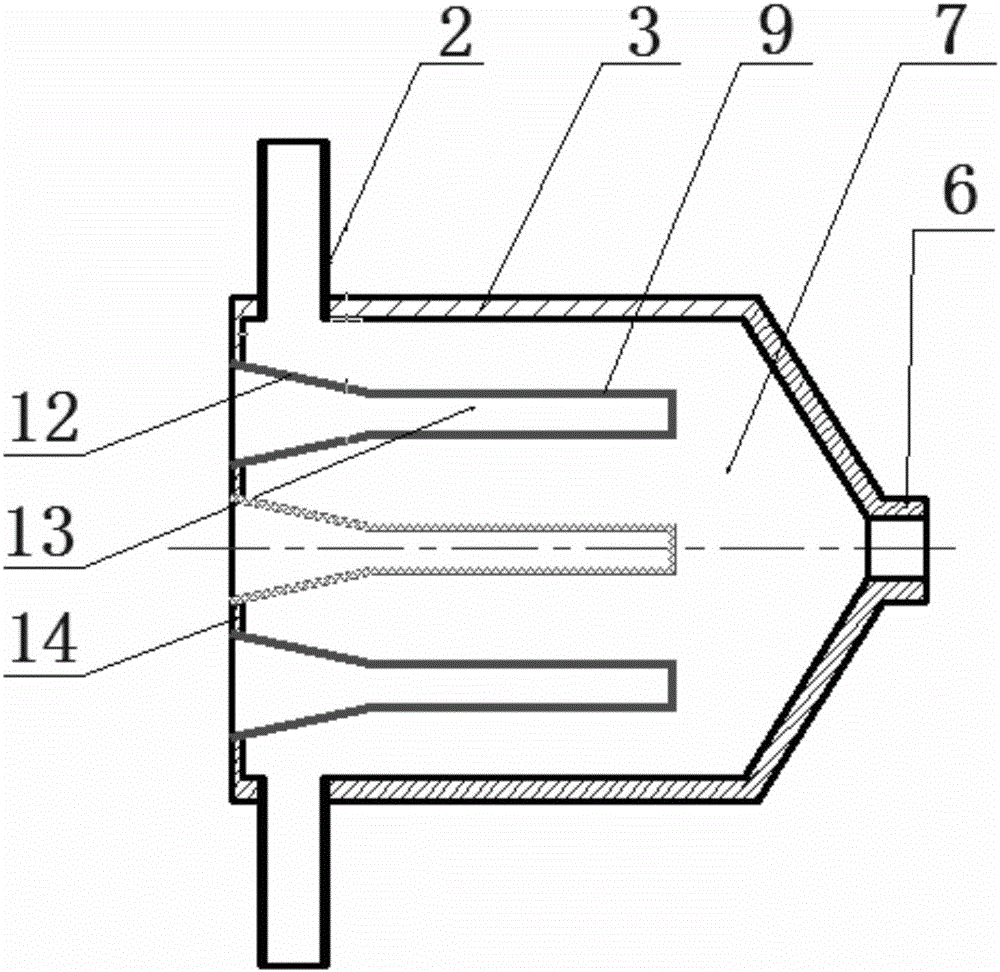

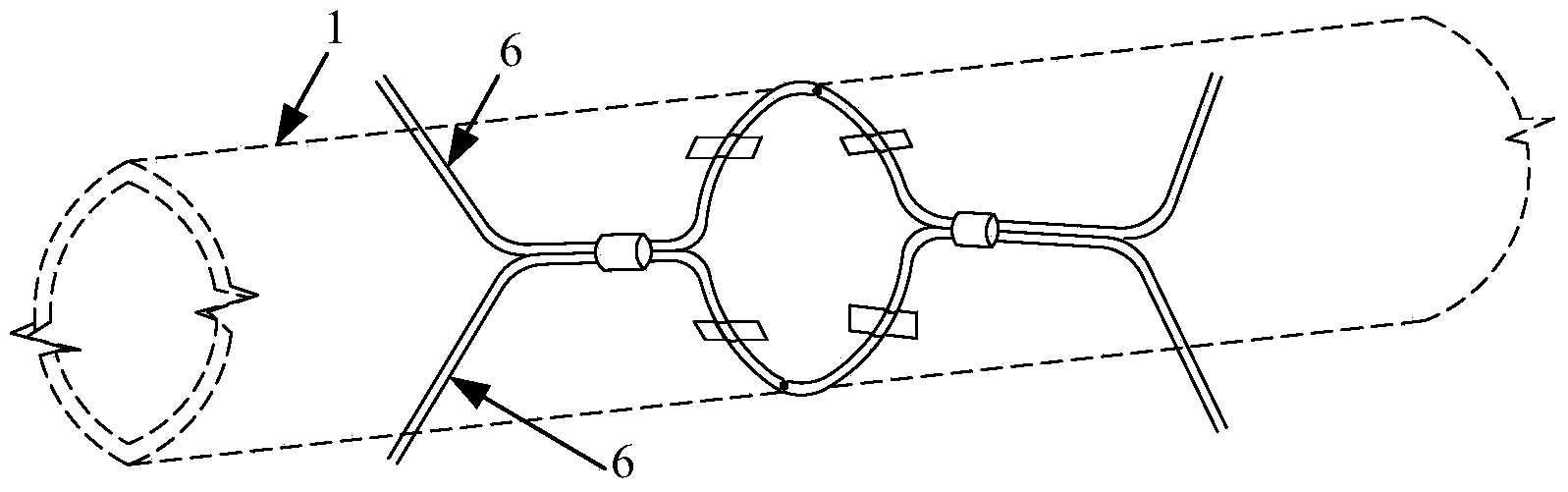

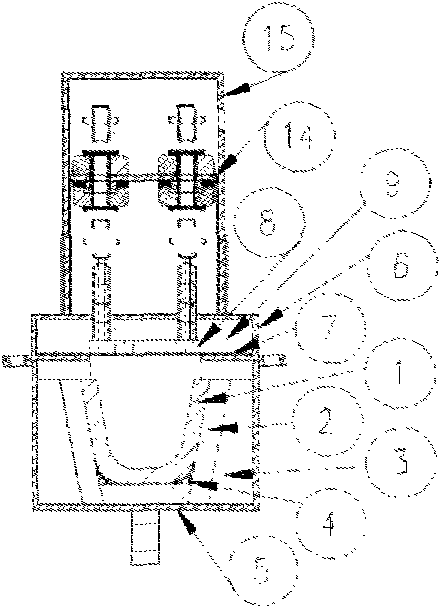

Graphite rotary tube furnace

InactiveUS6042370AMinimizing radiation heat lossStable temperatureRotary drum furnacesCharge supportsRadiative heat lossRadiant heat

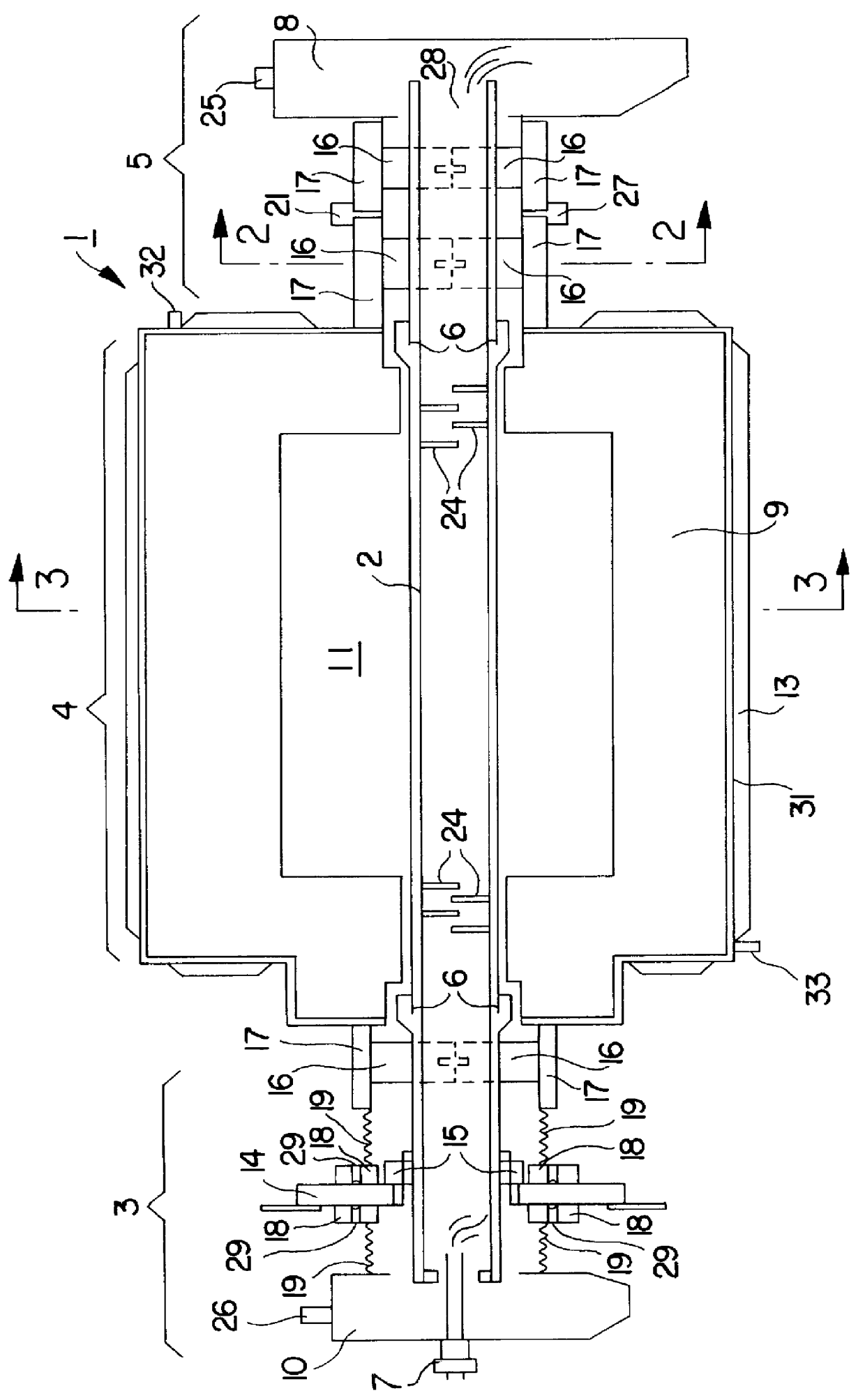

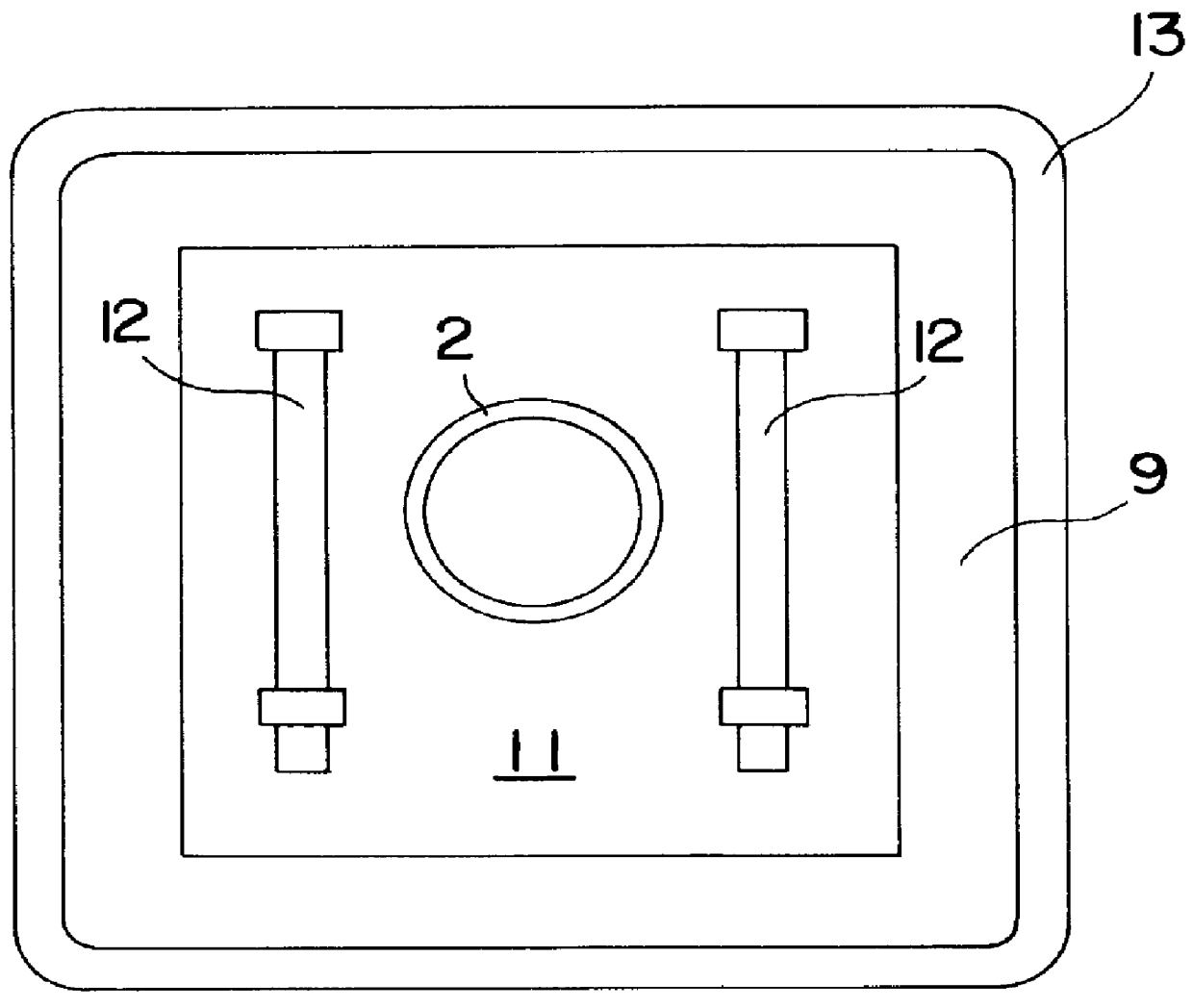

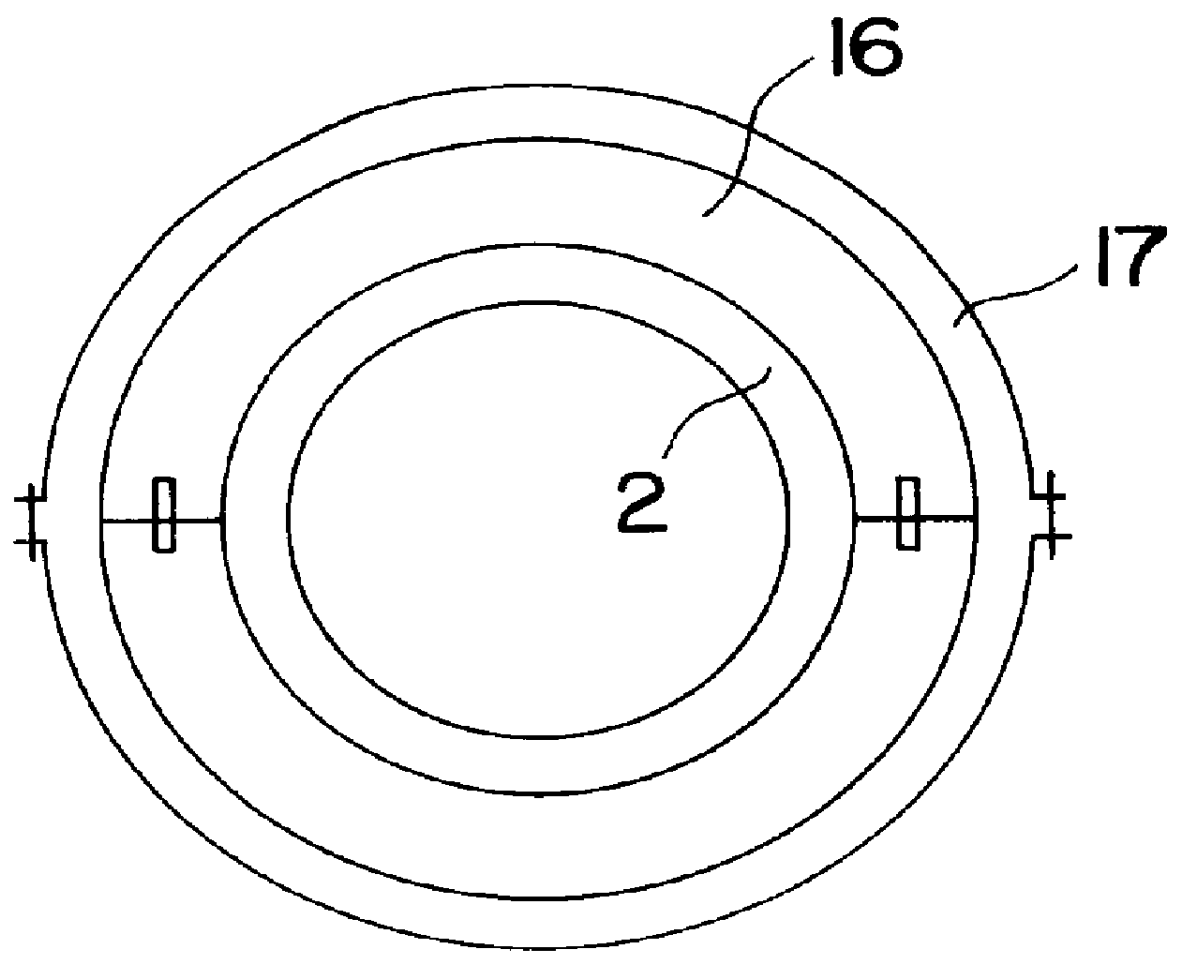

A rotary tube furnace suitable for operation in controlled atmospheres at temperatures in the range of 1500 DEG to 2800 DEG comprises a generally horizontal rotatable graphite tube slidably supported on water-cooled split ring graphite bearings. The graphite tube is rotated by means of a stainless steel drive plate and is contained within a flexible atmospheric sealing assembly and enclosure for the containment of a selected atmosphere around and within the tube and allows for the co-current or counter-current flow of gas during operation. Radiation baffles in the interior of the graphite tube inhibit radiant heat loss at the ends of the tube. The graphite tube may be constructed in two or more sections having threaded ends for ease of installation as well as removal or replacement for maintenance purposes. A heating section of the tube is heated by a plurality of graphite electrical heating elements contained within an insulated heating chamber.

Owner:HARPER INT CORP

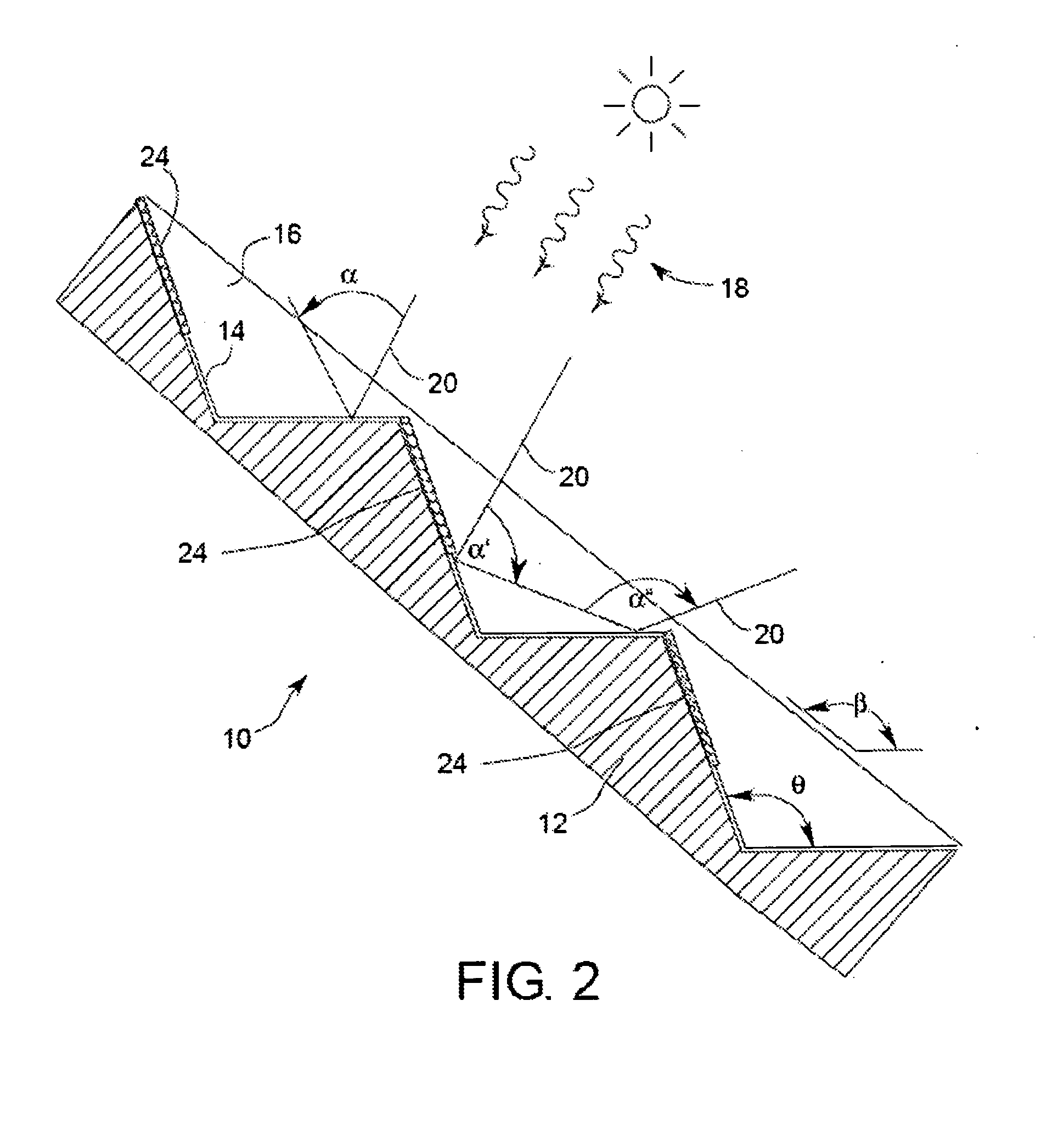

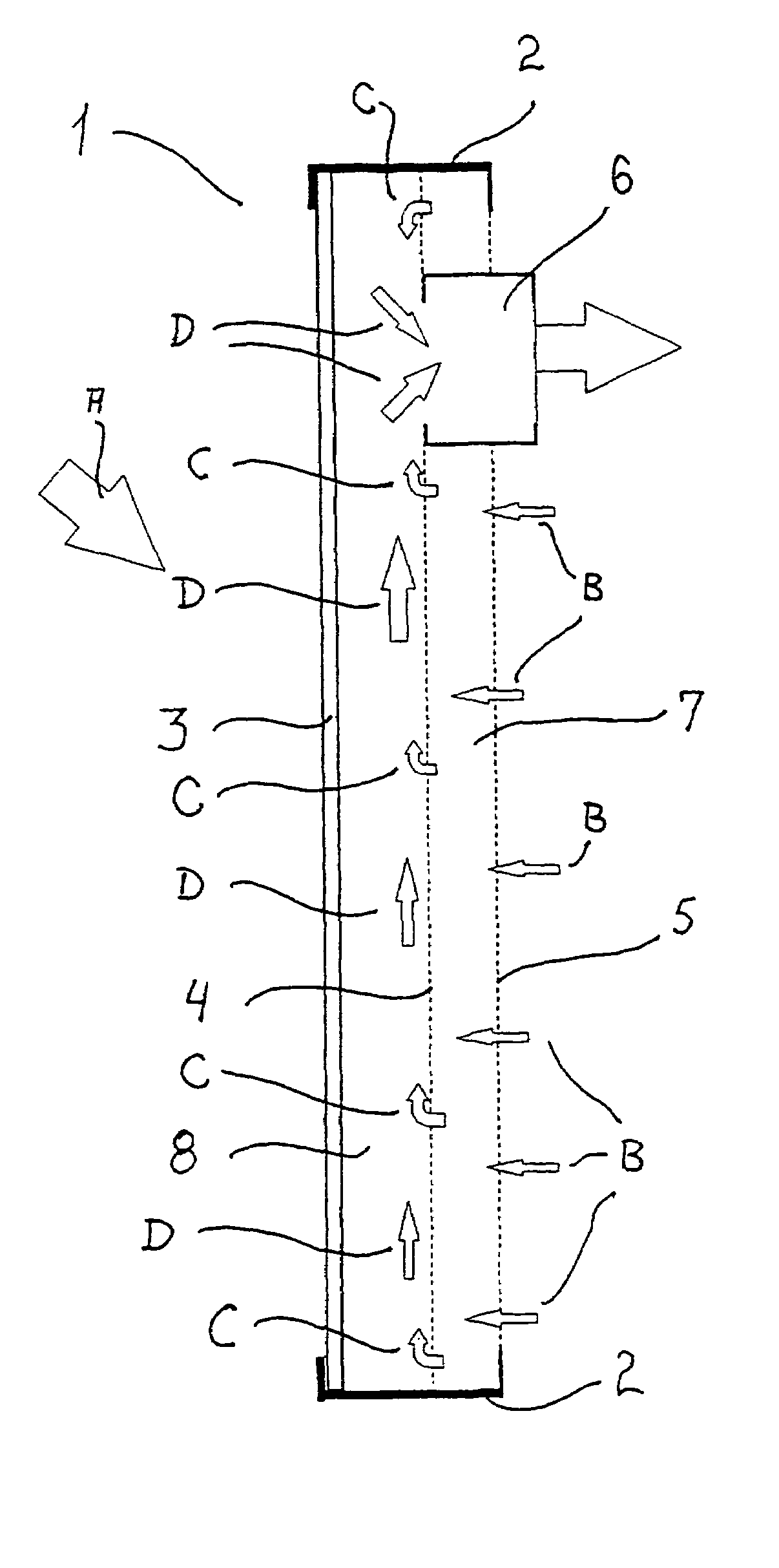

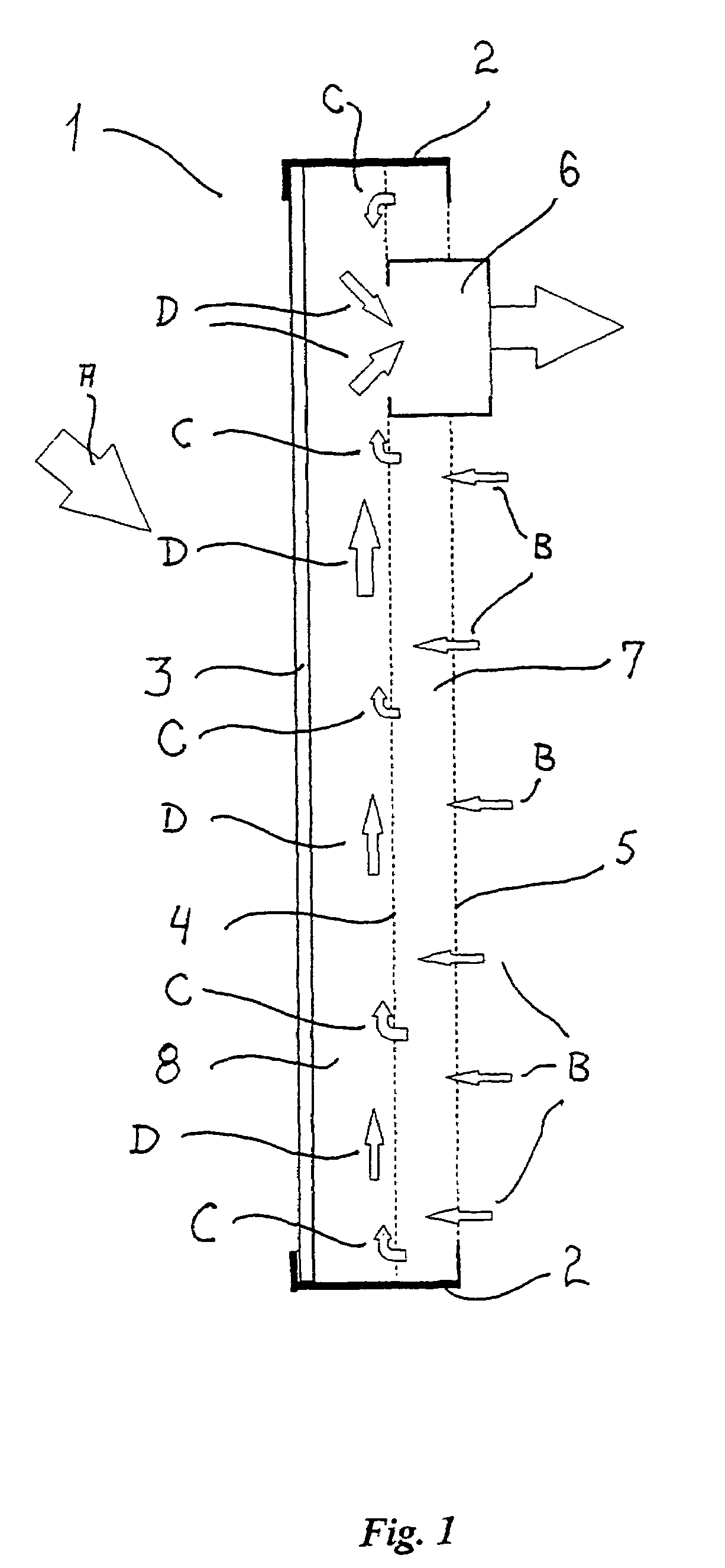

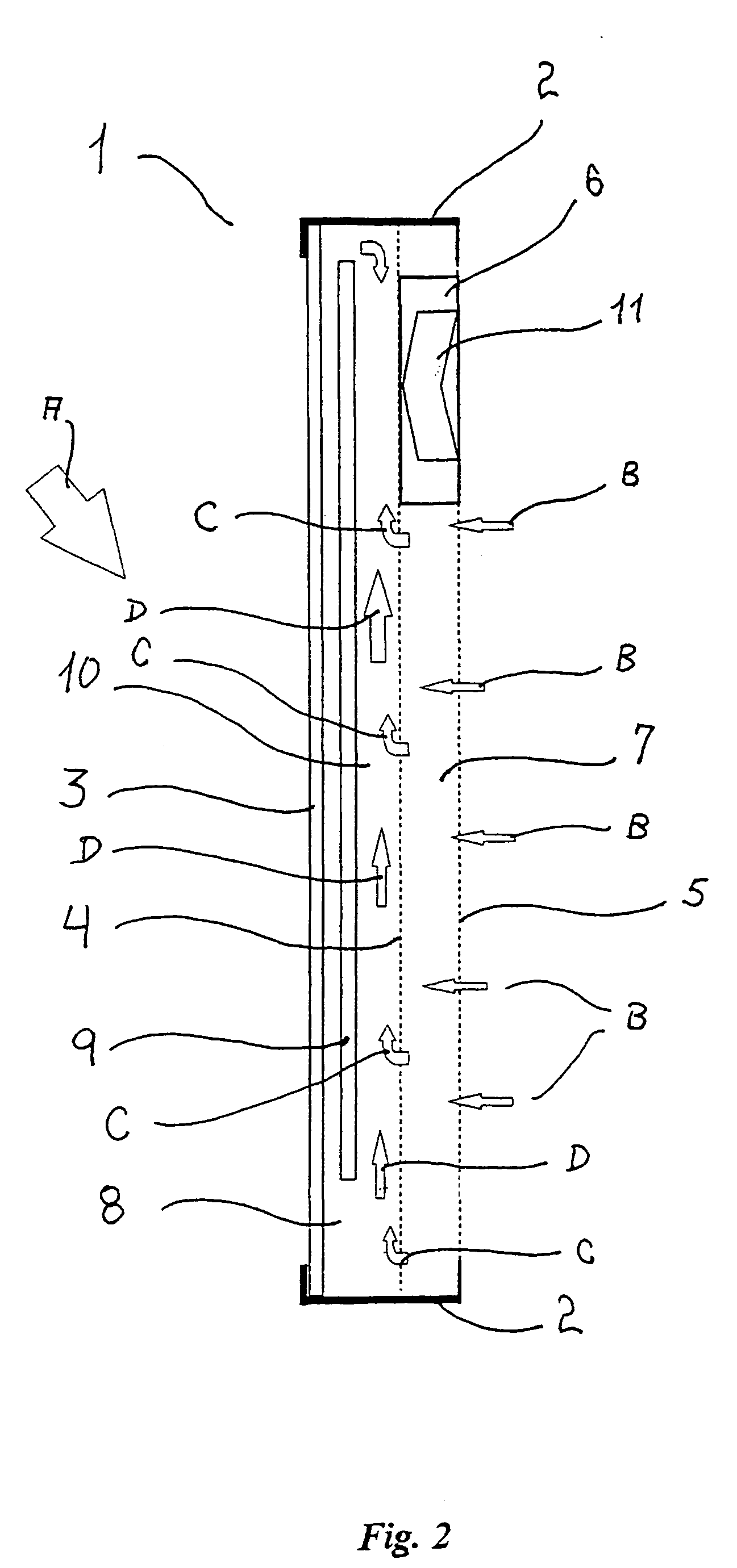

Solar collector panel for heating ventilation air

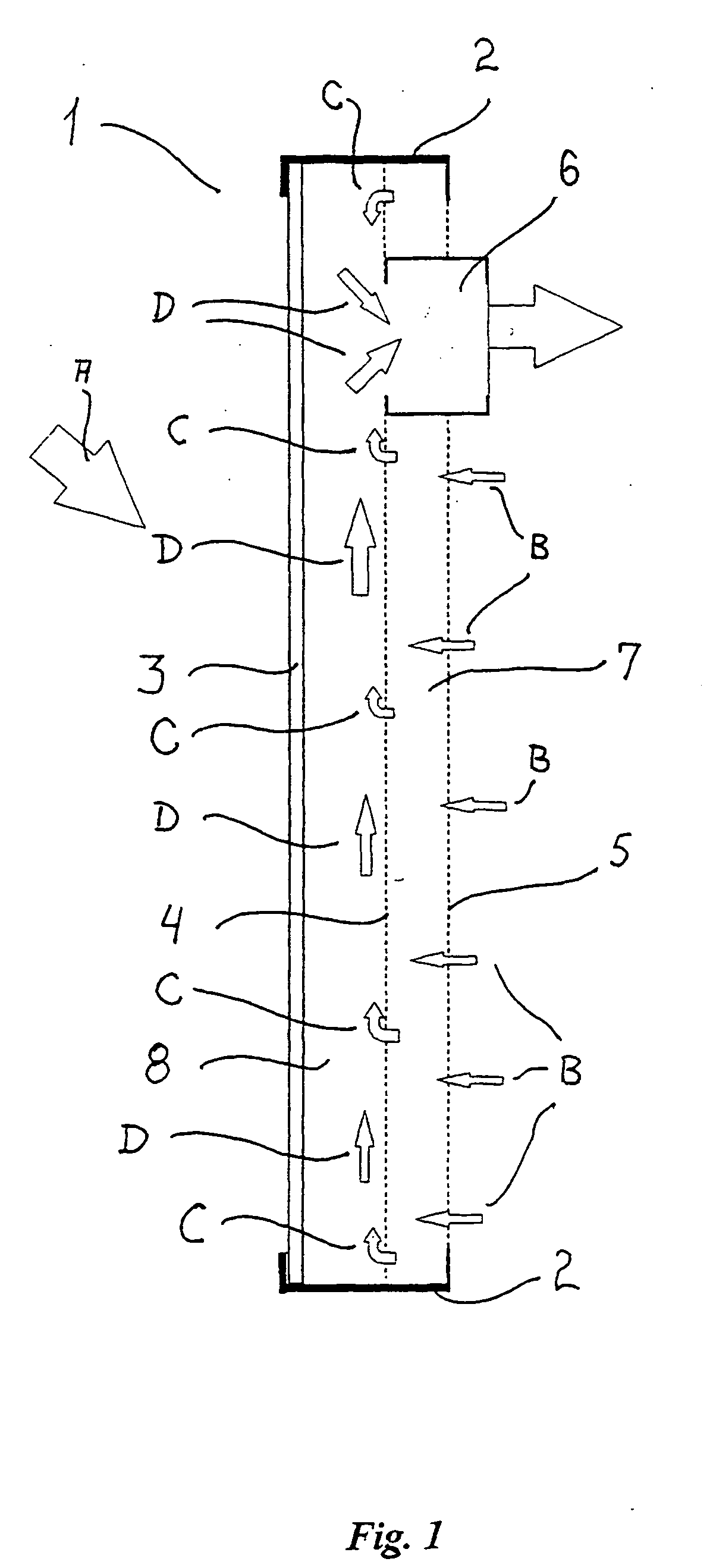

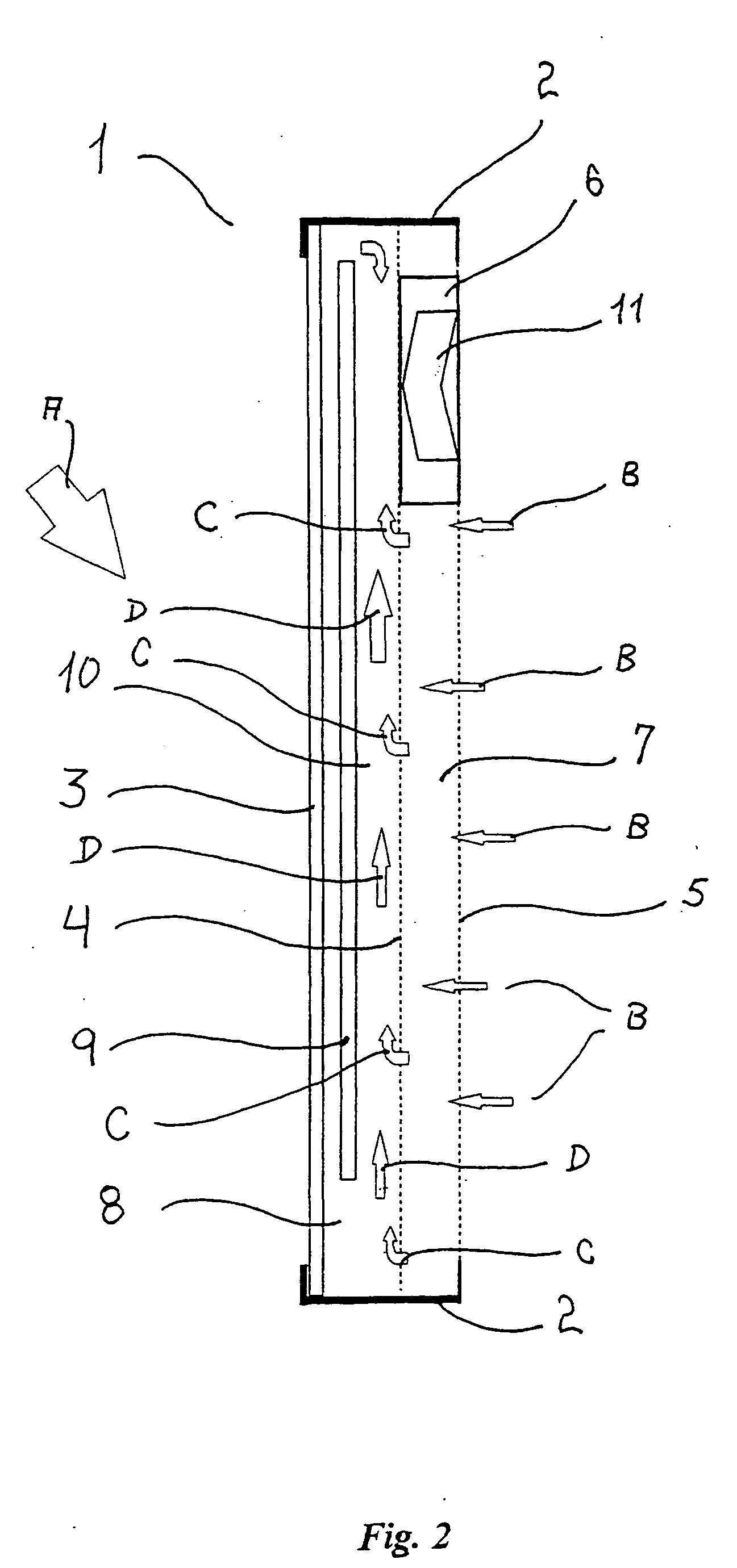

ActiveUS20050061311A1Reduce quality problemsGood effectRoof covering using slabs/sheetsSolar heating energyRadiative heat lossElectricity

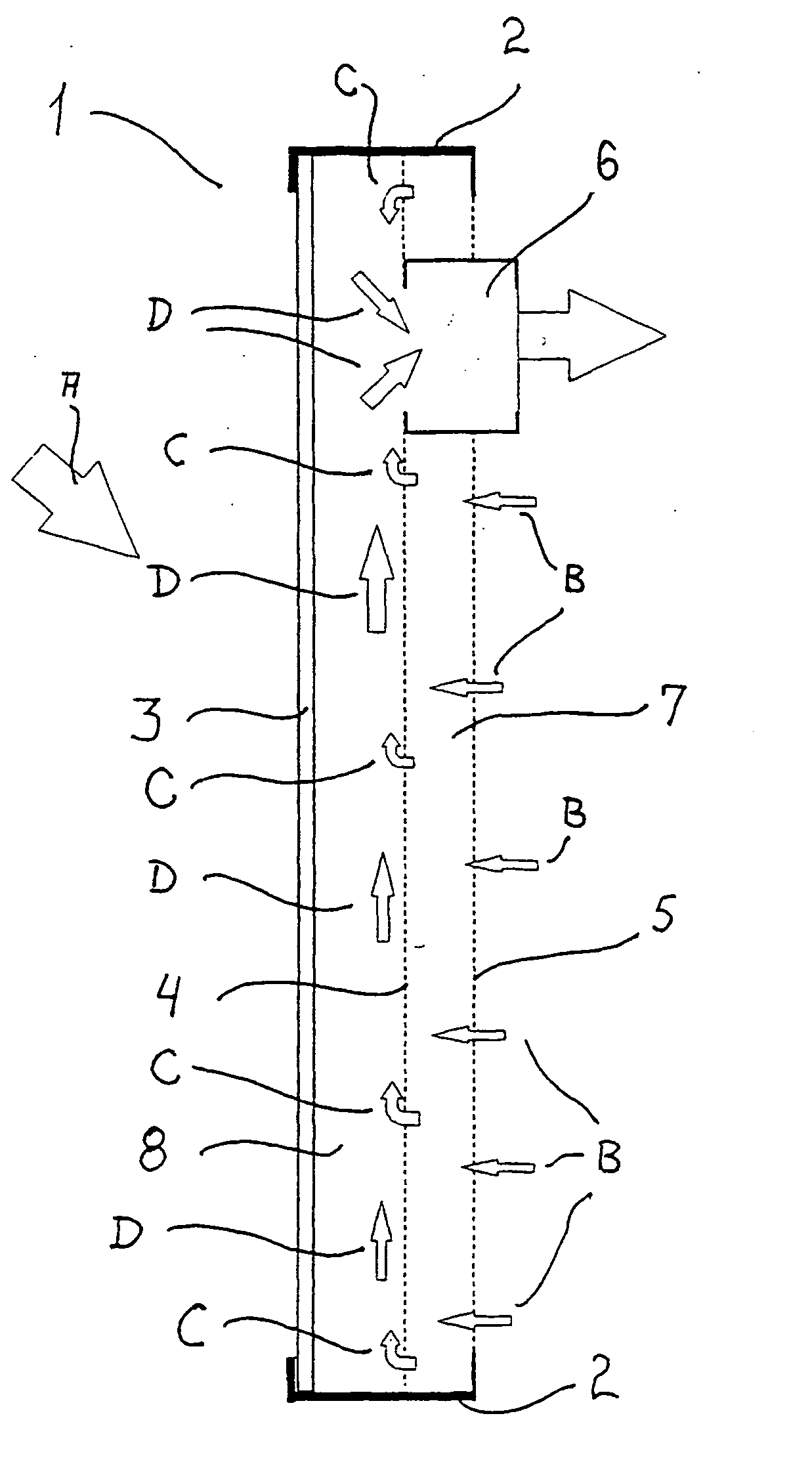

A solar collector panel is disclosed for heating of air, in which the conventional insulation material on the back panel facing away from the sun is replaced by a spacing between a permeable back panel and a permeable heat absorber means, so that a heat convection airflow through the back panel and into the interior of the solar energy panel against the temperature gradient prevents the convection heat loss in the opposite direction. The back panel also reduces the radiation heat loss from the heat absorber means. Furthermore, in case the flow of air through the solar energy panel is stopped, the convection-insulation will no longer be effective, and a photovoltaic cell panel placed within the solar energy panel and generating electricity from the solar radiation will not be subjected to the damaging high stagnation temperature of a traditionally insulated solar collector panel.

Owner:NORTON CHRISTENSEN INC

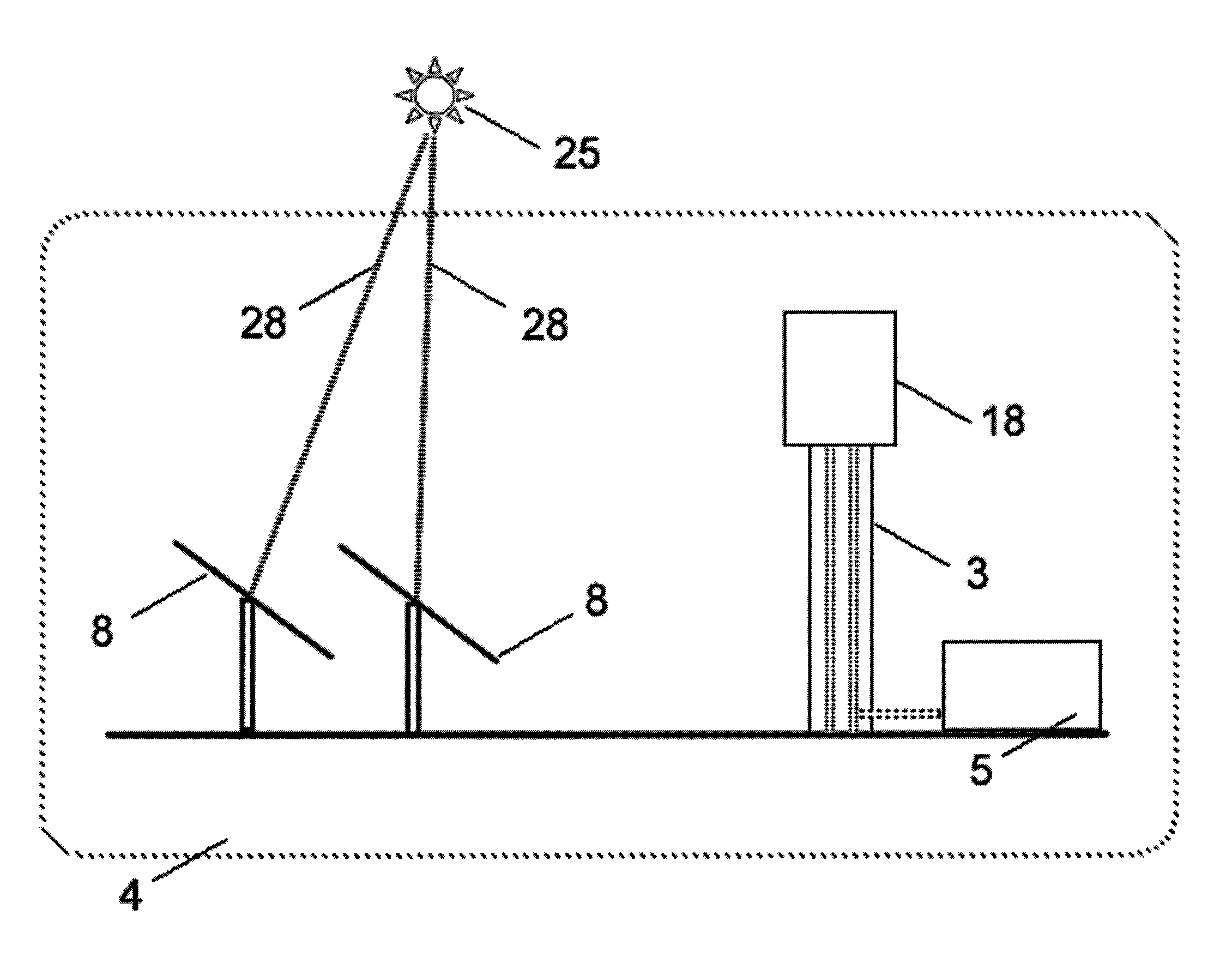

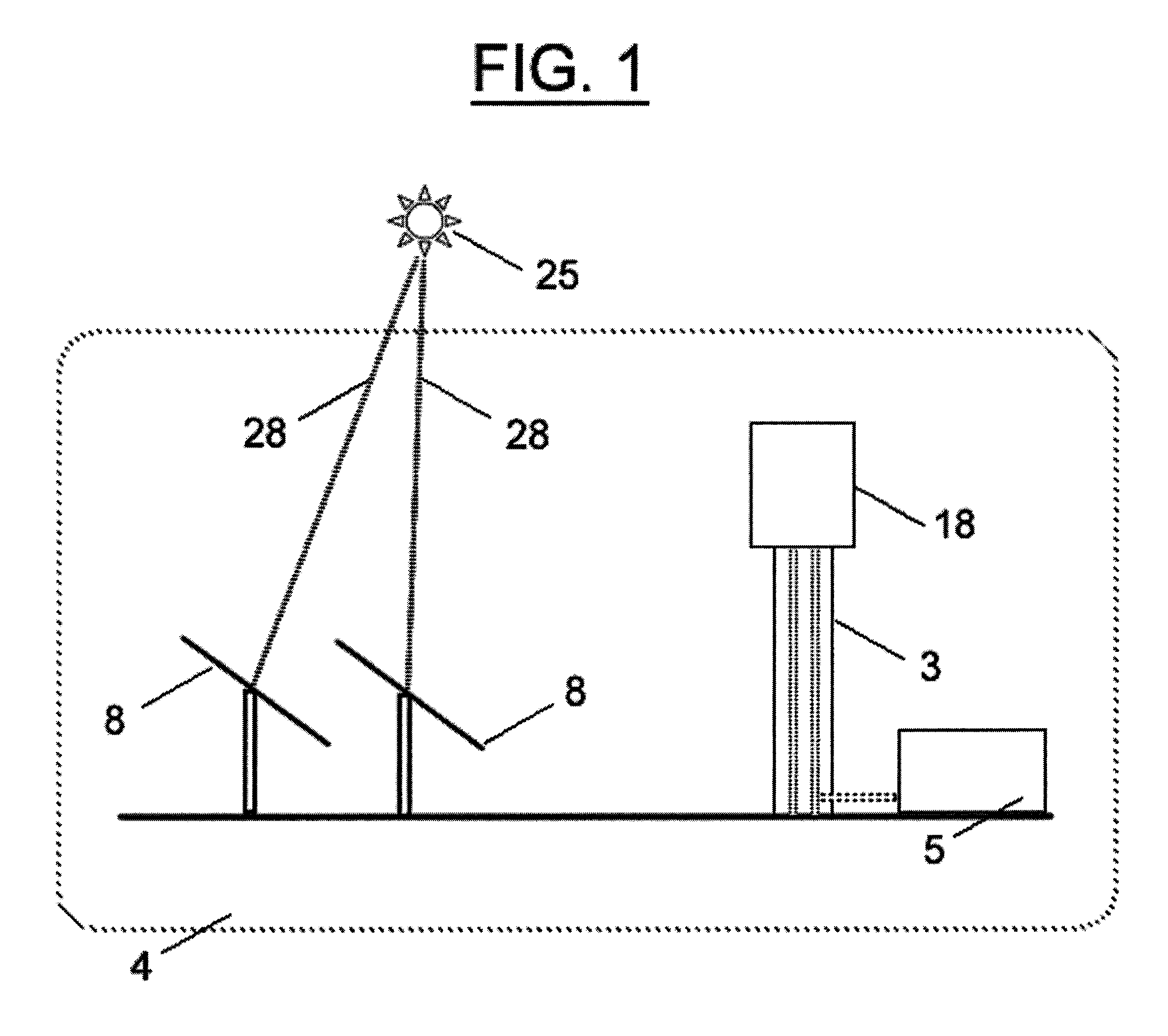

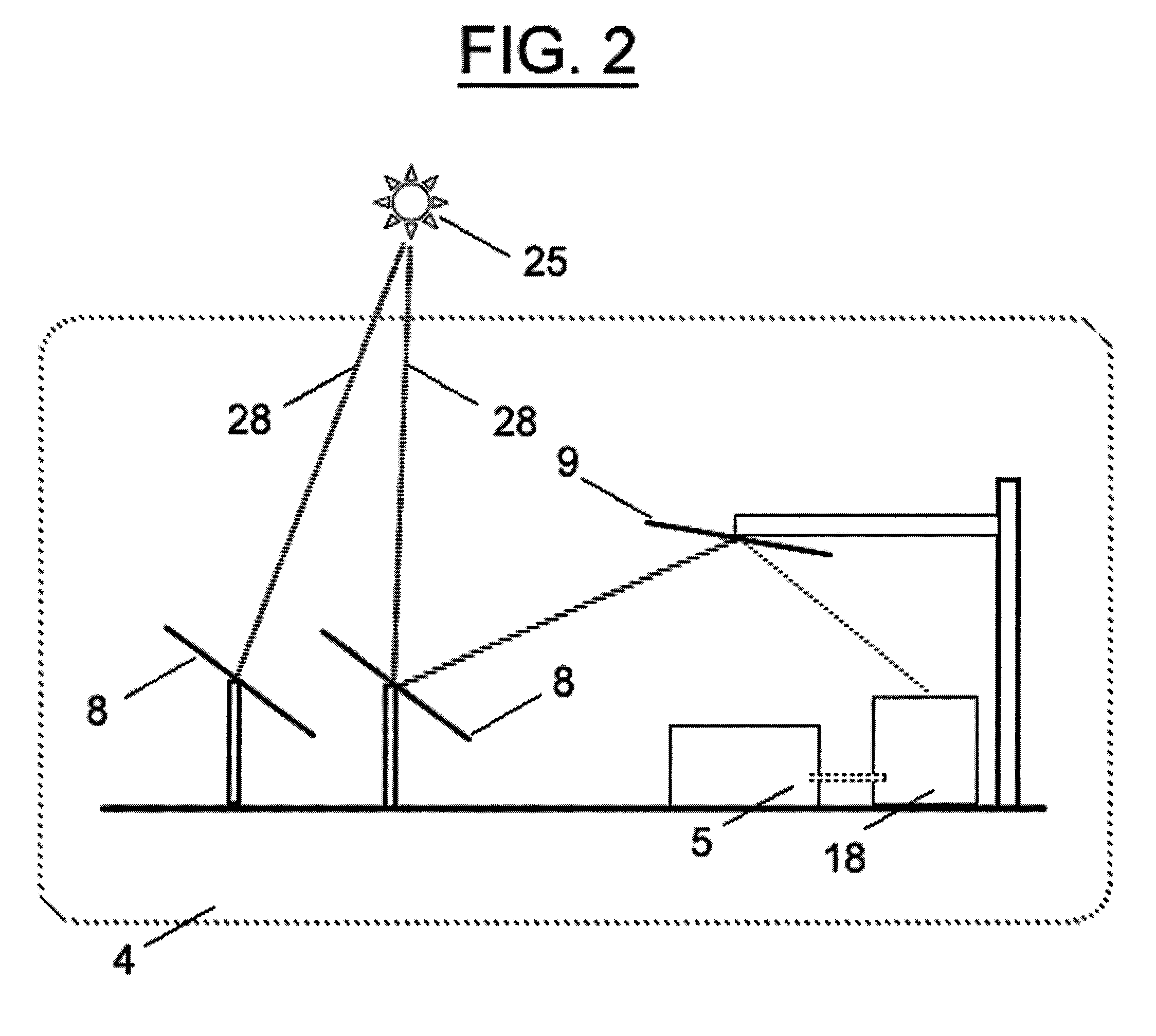

High temperature solar receiver

InactiveUS7690377B2Reduce radiative heat lossSolar heating energySolar heat devicesRadiative heat lossWorking fluid

The invention provides receivers which can be used to heat a working fluid to high temperature. In preferred embodiments, concentrated solar radiation is received and converted to heat at varying depths in the receiver such that multiple layers of surface are used to heat the working fluid. In addition, the depth-loading configuration helps to trap received heat to reduce radiant thermal loss.

Owner:BRIGHTSOURCE ENERGY

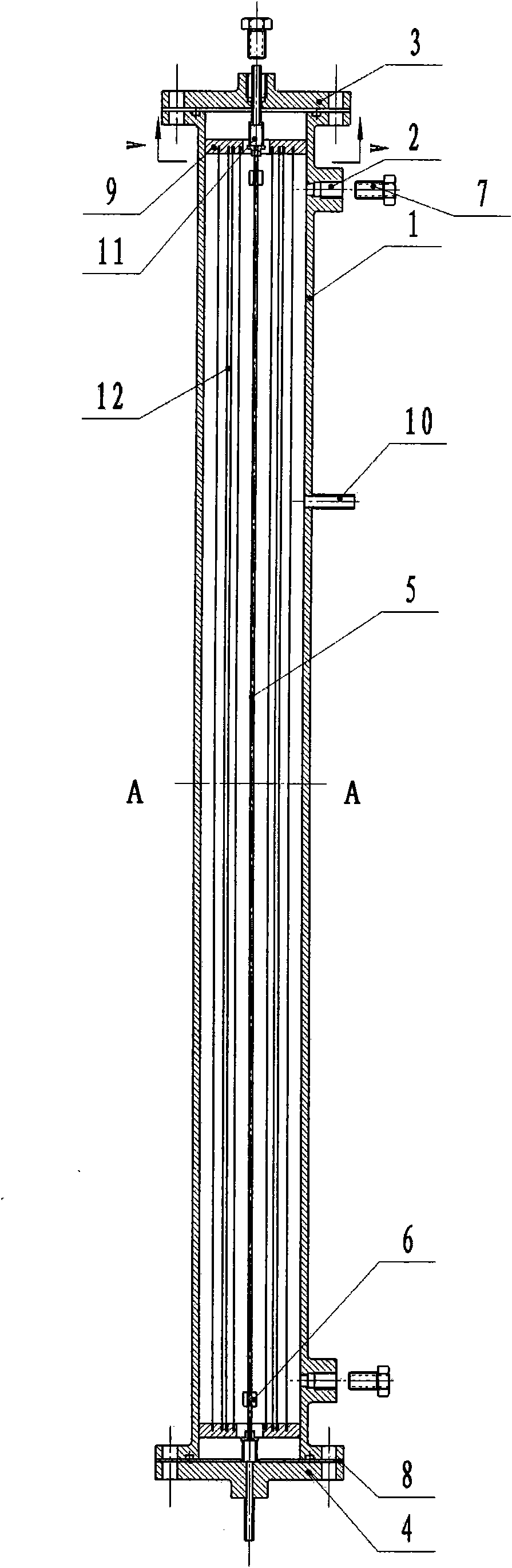

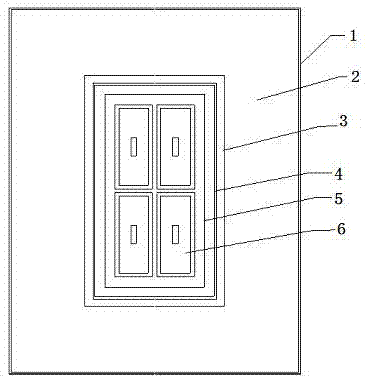

Testing device suitable for measuring constant-pressure specific heat capacity of flow fluid

InactiveCN101793850AOvercoming the Inherent Flaws of Static ExperimentsReduce lossesMaterial heat developmentRadiative heat lossEngineering

The invention discloses a testing device suitable for measuring constant-pressure specific heat capacity of a flow fluid, which is used for measuring the constant-pressure specific heat capacity (within the pressure range of 0-7 MPa) of a fluid in the flow state. The testing section of the device is positioned in a vacuum cavity, and a multilayer thermal shield is utilized to reduce the radiation heat loss. A stabilized voltage supply is utilized to heat the stainless steel tube at the testing section, and the electric power of heating is obtained through measurement. A K-type armored thermocouple positioned at the port of the testing section is used for measuring the absolute temperature and the relative temperature of the fluid port. The vacuum cavity and the thermal shield reduce the heat loss of convection heat exchanging and the radiation heat loss, so that the proportion of the heat loss accounting for the total thermal power is reduced to about 10%.

Owner:BEIHANG UNIV

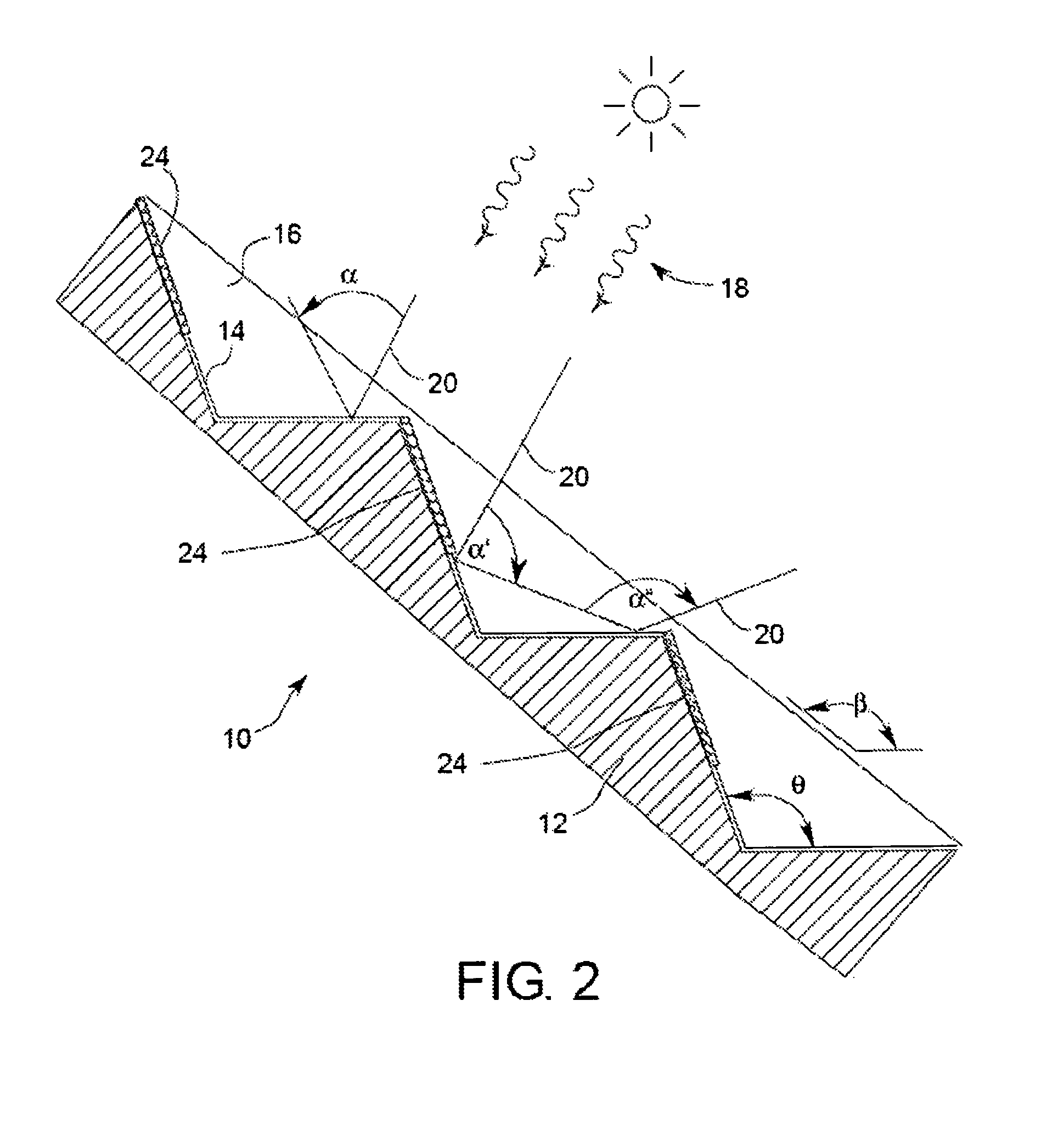

Reflective energy management system

ActiveUS8689490B2Limit radiantImprove the heating effectPhotovoltaic supportsRoof covering using slabs/sheetsRadiative heat lossEngineering

Owner:SUMNER WALTON

Bulk Growth Grain Controlled Directional Solidification Device and Method

InactiveUS20130152851A1Reduce heat lossAvoid insufficient heatingPolycrystalline material growthFrom melt solutionsRadiative heat lossCrucible

A solidification system is provided and includes a crucible, heater, insulation, movable insulation, and radiation regulator. The crucible is configured to retain a volume of silicon. The heater is to heat the crucible. The heater being configured to provide sufficient heat to melt the volume of silicon. The insulation is to reduce heat loss from a first portion of the crucible. The movable insulation to regulate heat loss from a second portion of the crucible. The radiation regulator is to regulate radiant heat loss over the second portion of the crucible. The radiation regulator is configured to modulate a size of an opening in the radiation regular through which radiant heat dissipates from.

Owner:SPX CORP

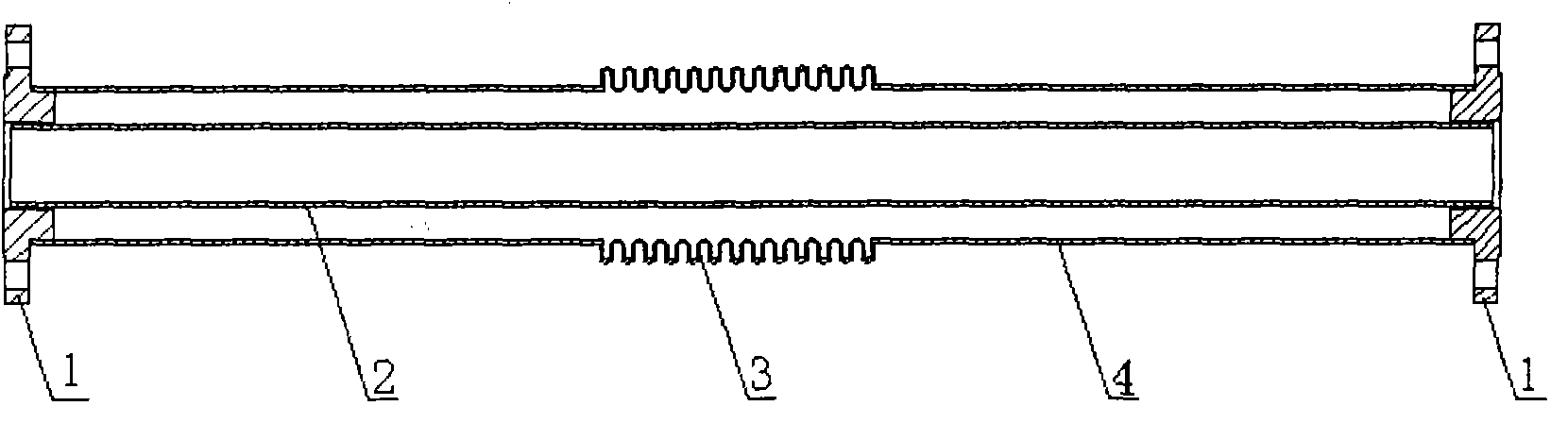

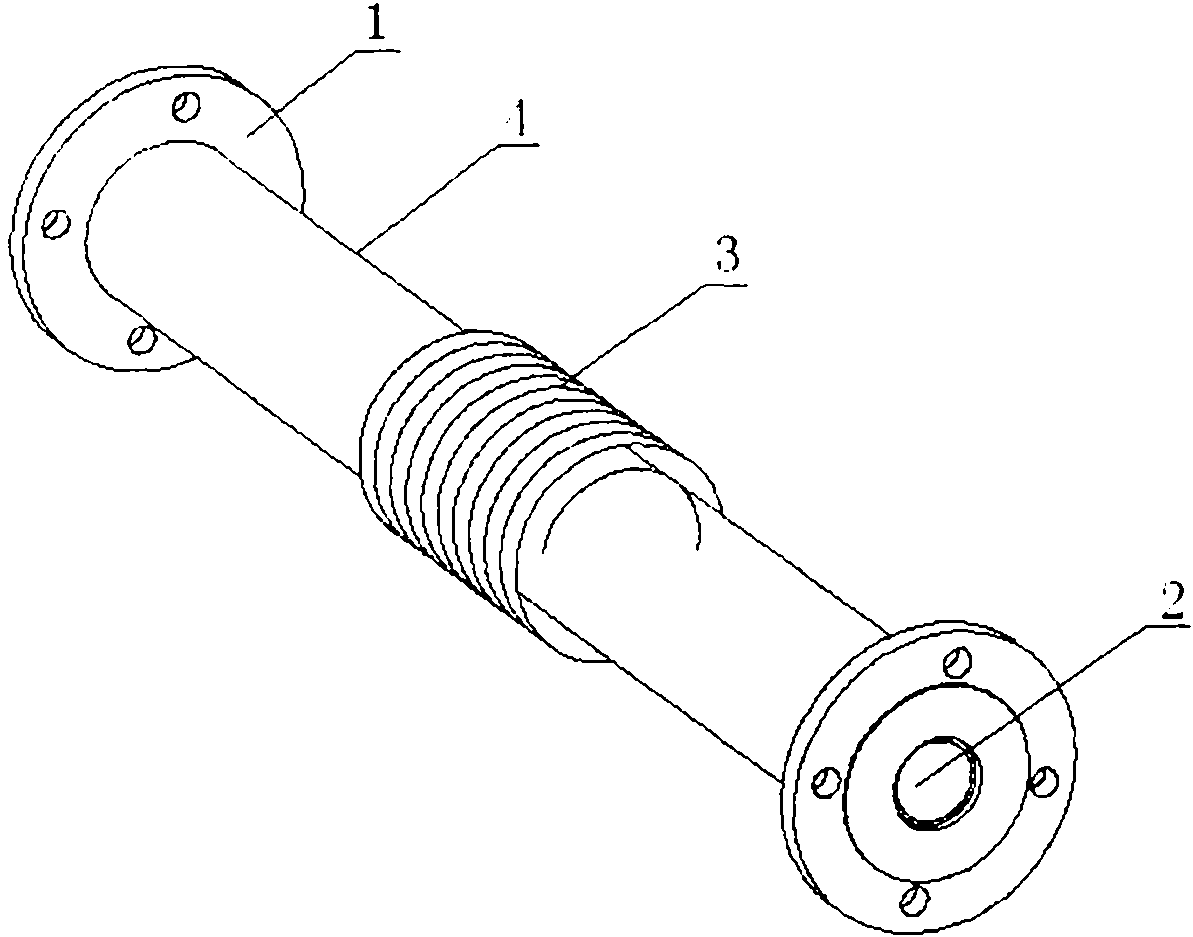

High-temperature vacuum tube

InactiveCN102147043AReduce lossesLow reflexThermal insulationPipe protection by thermal insulationRadiative heat lossEngineering

The invention discloses a high-temperature vacuum tube. The vacuum tube mainly comprises flanges, an inner tube, a corrugated tube and an outer tube, wherein two ends of the inner tube and the outer tube are connected with the flanges respectively; the corrugated tube is connected with the outer tube and used for compensating swelling amount; and the inner wall of the outer tube is polished. The heat radiation of infrared band is reflected by adopting a metal surface with high finishment, so radiation heat loss is effectively reduced; and heat loss caused by air heat conduction and heat convection is inhibited by the interlayer vacuumizing design between the inner and outer tubes. The high-temperature vacuum tube inhibits radiation heat transfer at a high temperature more effectively, has good inhibiting effect on heat transfer, and effectively prevents the loss of heat during transferring.

Owner:SOLAR & ENVIRONMENTAL TECH TIANJIN CORP

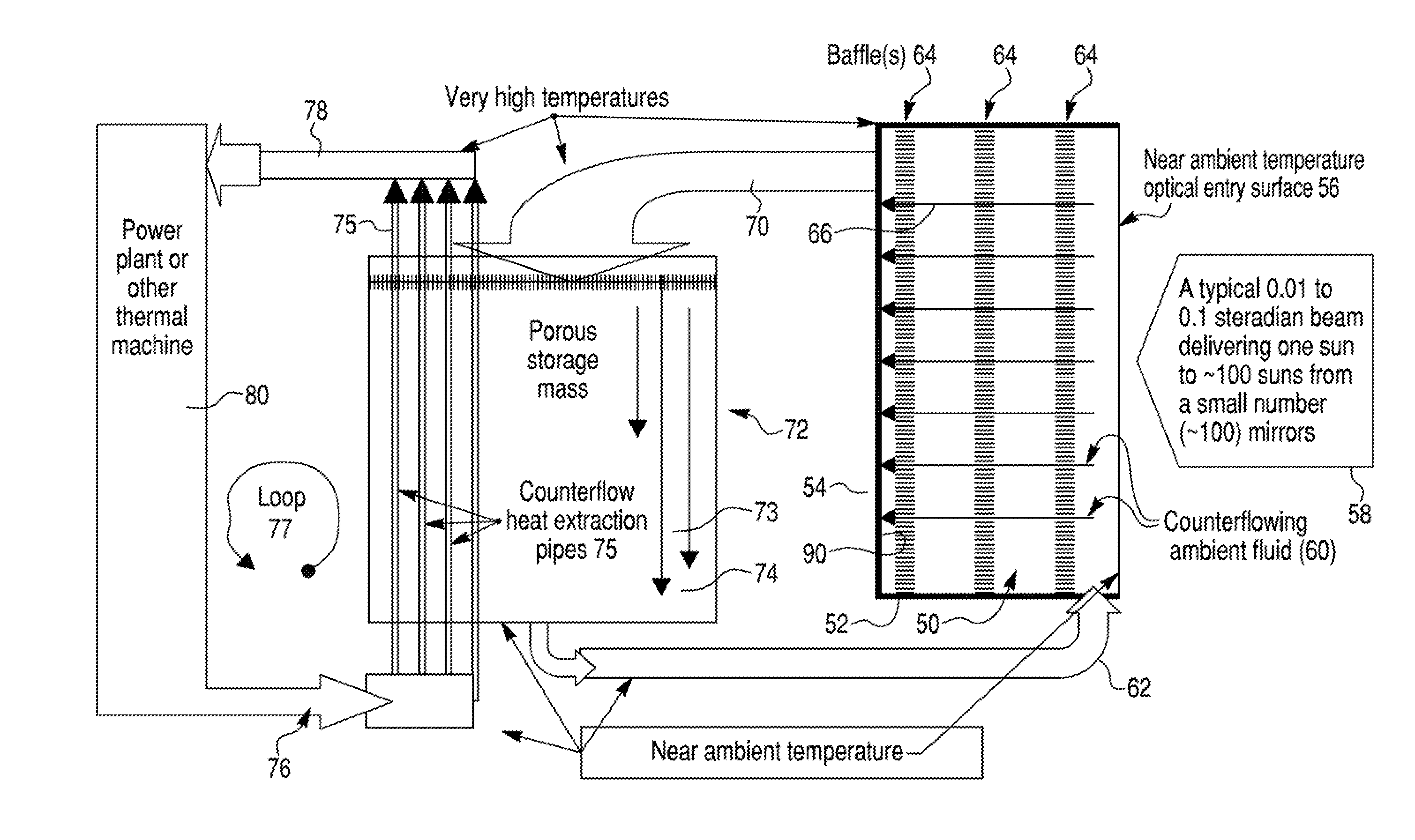

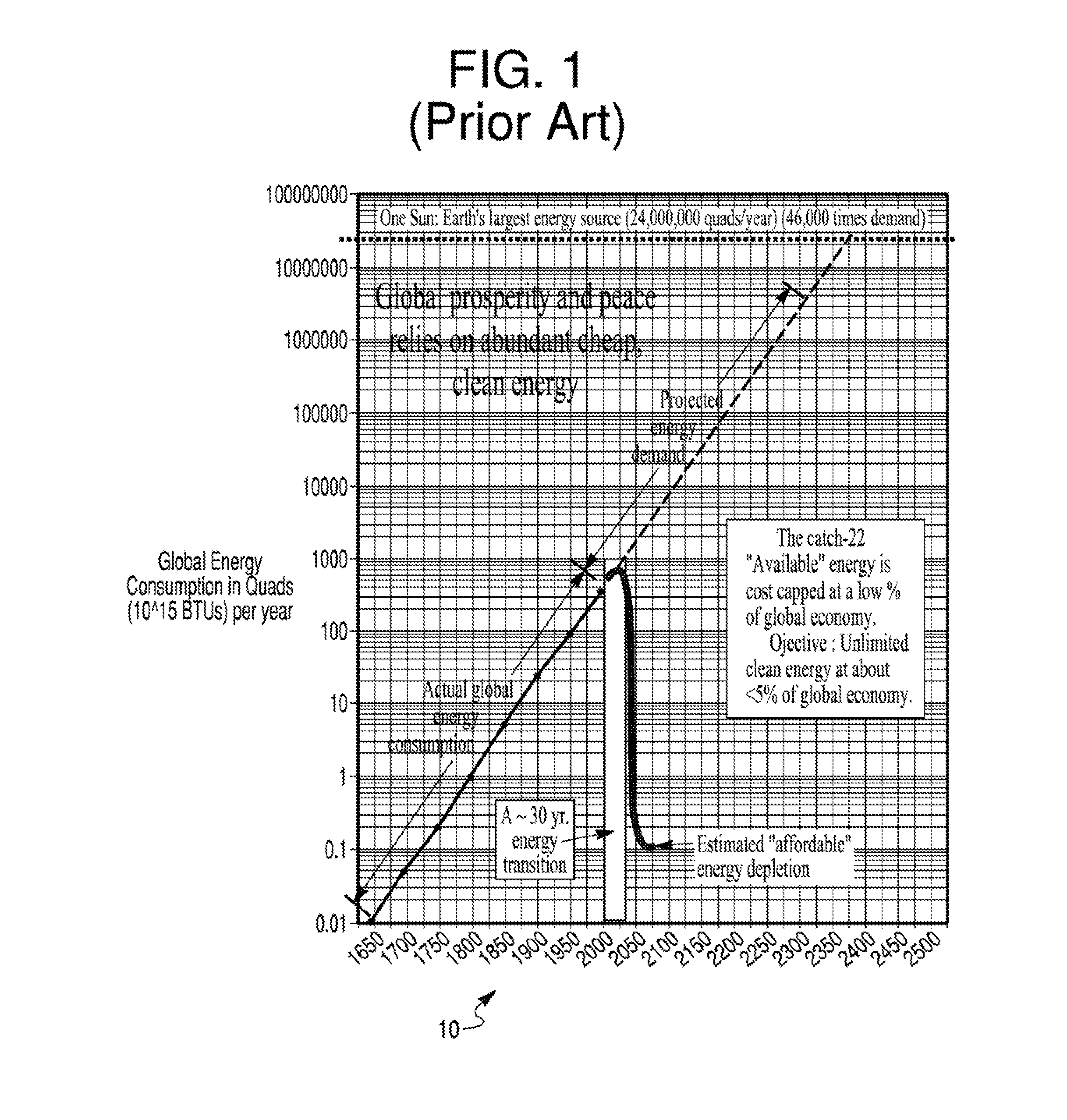

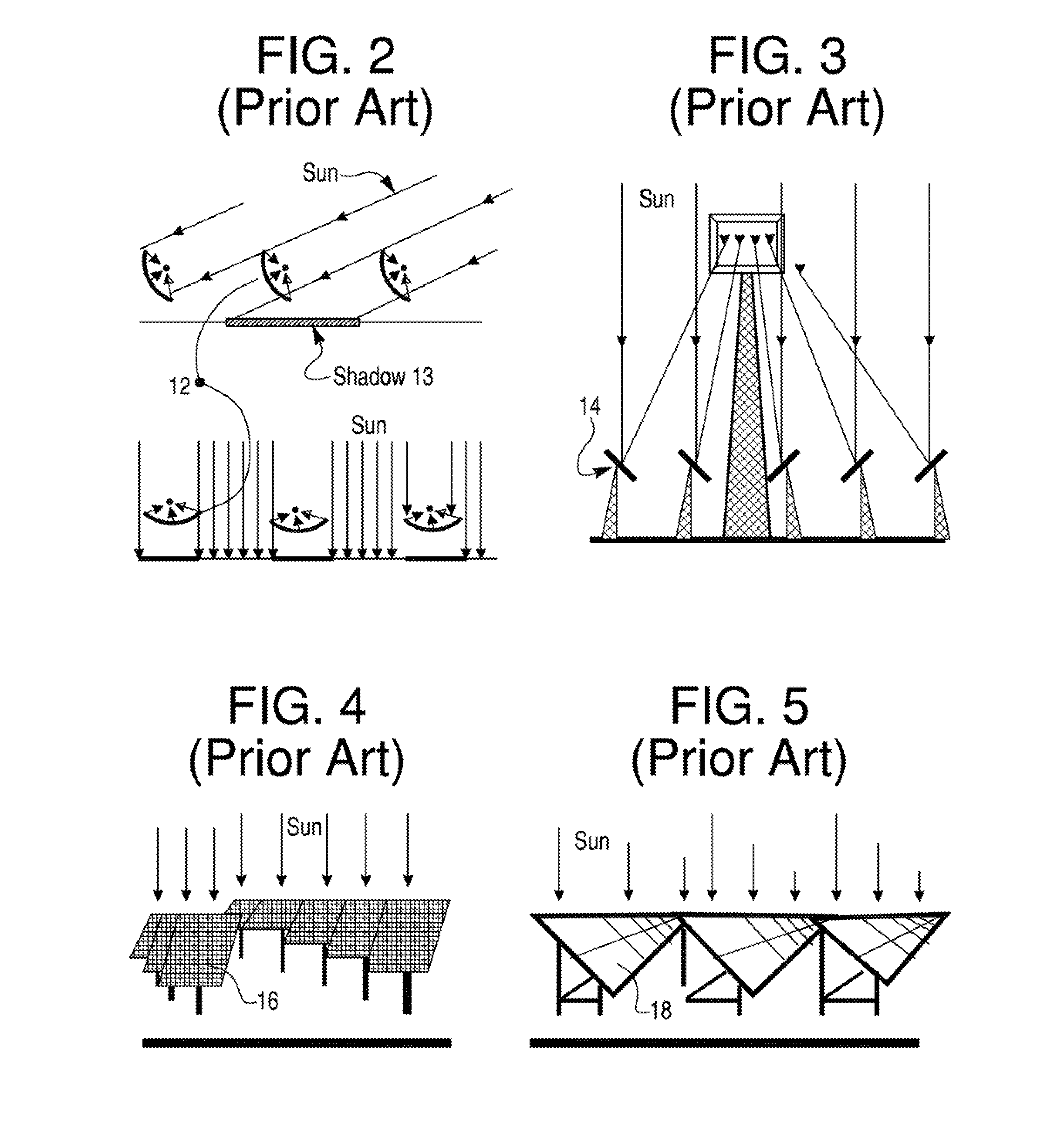

Ultra high efficiency, high temperature solar collection and storage

InactiveUS20170016649A1Little to no emissive lossKeep energy smallSolar heating energySolar heat devicesRadiative heat lossCounter flow

High-temperature solar trap collectors provide near ambient temperature solar entry surfaces and negligible thermal radiation losses by counterflowing low velocity transparent gases or liquids (fluids) to nullify internal thermal diffusion and radiative heat losses at the solar entry surface. Small steradian (sr) baffling plus wavelength-selective materials trap the entire 0.35 u to 2.7 u incoming solar spectrum and heat highly absorbing internal surfaces to high temperatures; only a small solid angle of the 2π steradians—on the order of 0.01 sr—of internal thermal radiation escapes. A nearly 100% efficient flat panel solar trapping embodiment exhibits alpha (α) absorption nearing 1.0 and radiant emission losses nearing 0.0 even at solar collection temperatures in excess of 1,000° K. Ultra high collection efficiency counterflow configurations are ideal for solar hot water, space heating, cooling, energy storage, and electric power generation applications.

Owner:ACE RONALD S

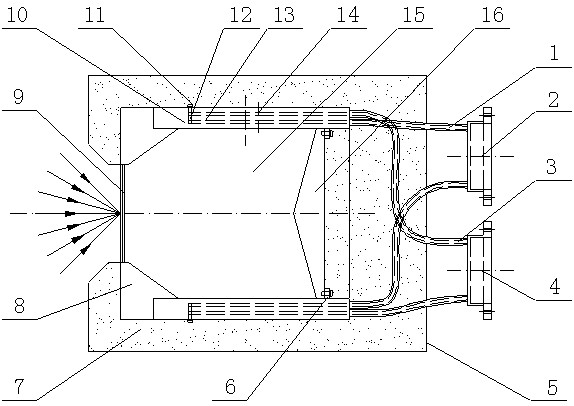

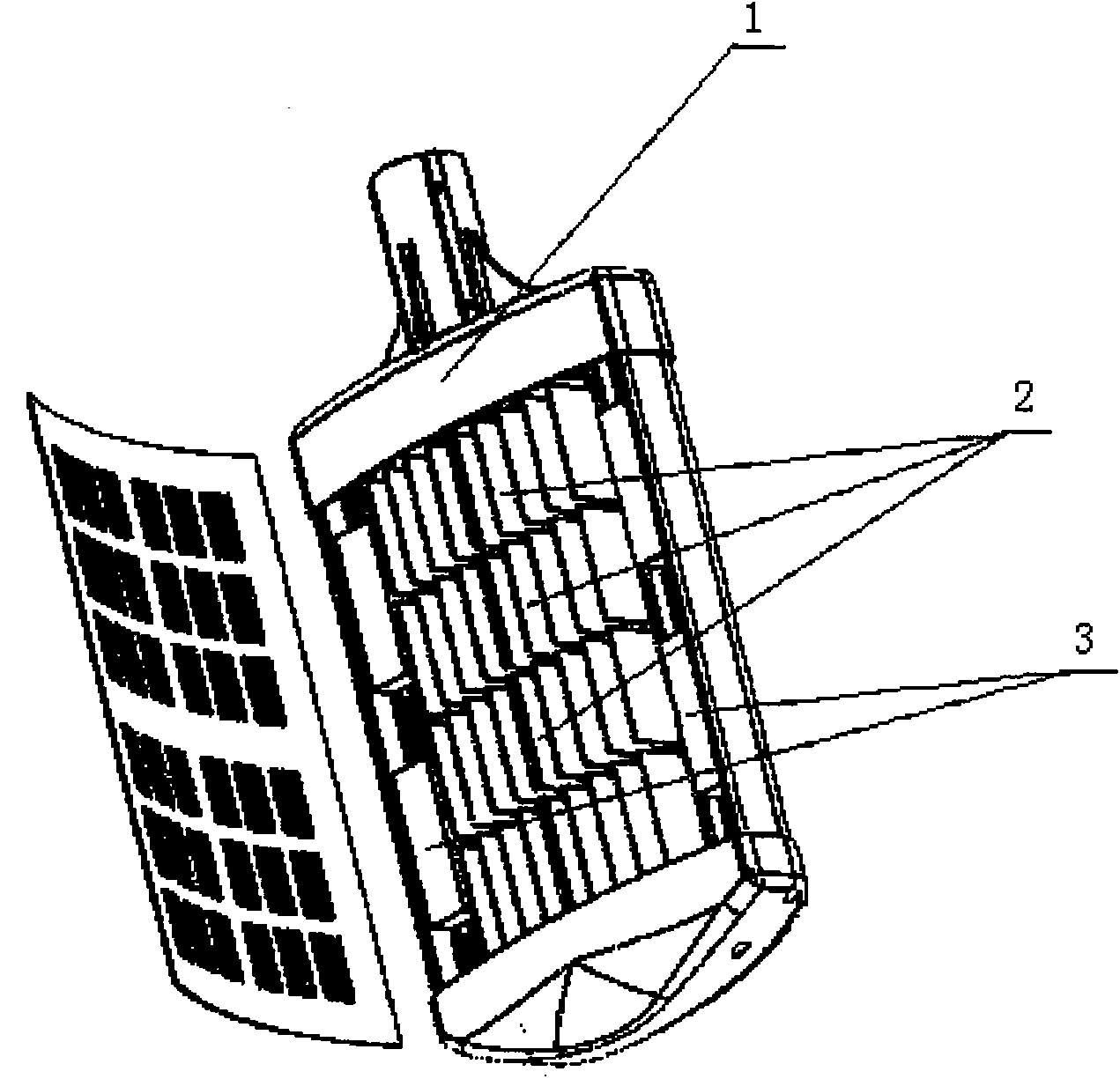

Volumetric air heat absorber of multi-cavity surface for solar thermal power generation

ActiveCN106196655AImprove follow-up performanceIncrease contact areaSolar heating energySolar heat devicesThermal energyRadiative heat loss

The invention discloses a volumetric air heat absorber of a multi-cavity surface for solar thermal power generation. The volumetric air heat absorber comprises a heat absorbing carrier, a heat insulation body and a metal container and is characterized in that the heat insulation body is arranged on the outer side of the metal container, an opening is formed in the front end of the metal container, a solar gathering portion is arranged at the front end of the metal container, an air inlet pipe, an air outlet pipe and a light absorbing cavity are formed in the metal container, and the air inlet pipe is communicated with an inner cavity of the metal container; the light absorbing cavity is formed in the inner cavity of the metal container and is communicated with the solar gathering portion, and the light absorbing cavity faces the opening direction of solar energy projection; the heat absorbing carrier is arranged in the metal container, and a sealed heat absorber cavity is formed by the inner cavity of the metal container and the heat absorbing carrier, and the air outlet pipe is communicated with the heat absorber cavity. A plurality of light absorbing cavities with cavity surfaces are formed in the solar thermal power receiving surface, the contact area of a foam ceramic heat absorbing carrier of a porous medium and the light absorbing cavities can be increased, the heat conduction performance is improved, and meanwhile radiant heat losses of the heat absorber can be reduced.

Owner:HUNAN UNIV OF SCI & TECH

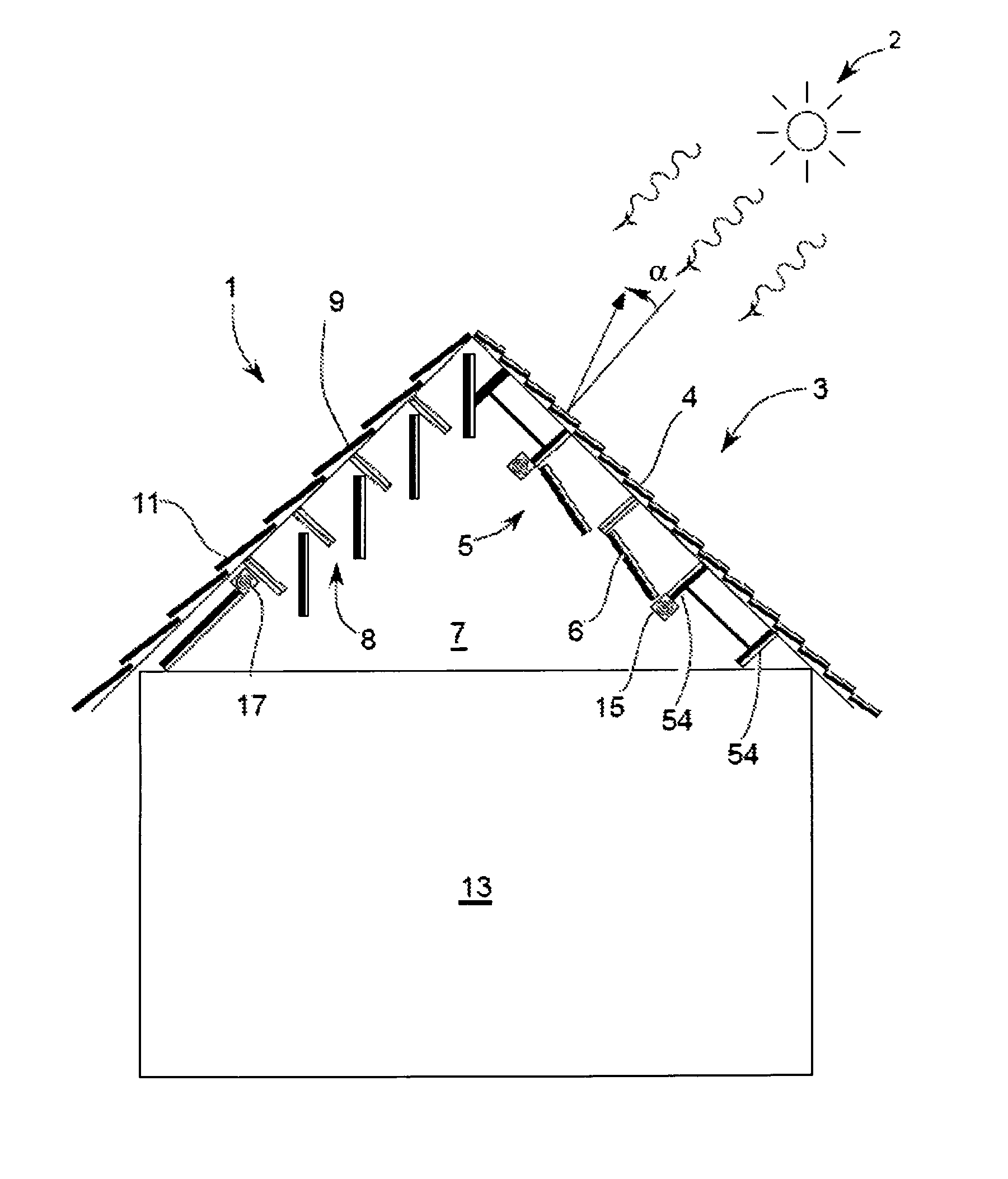

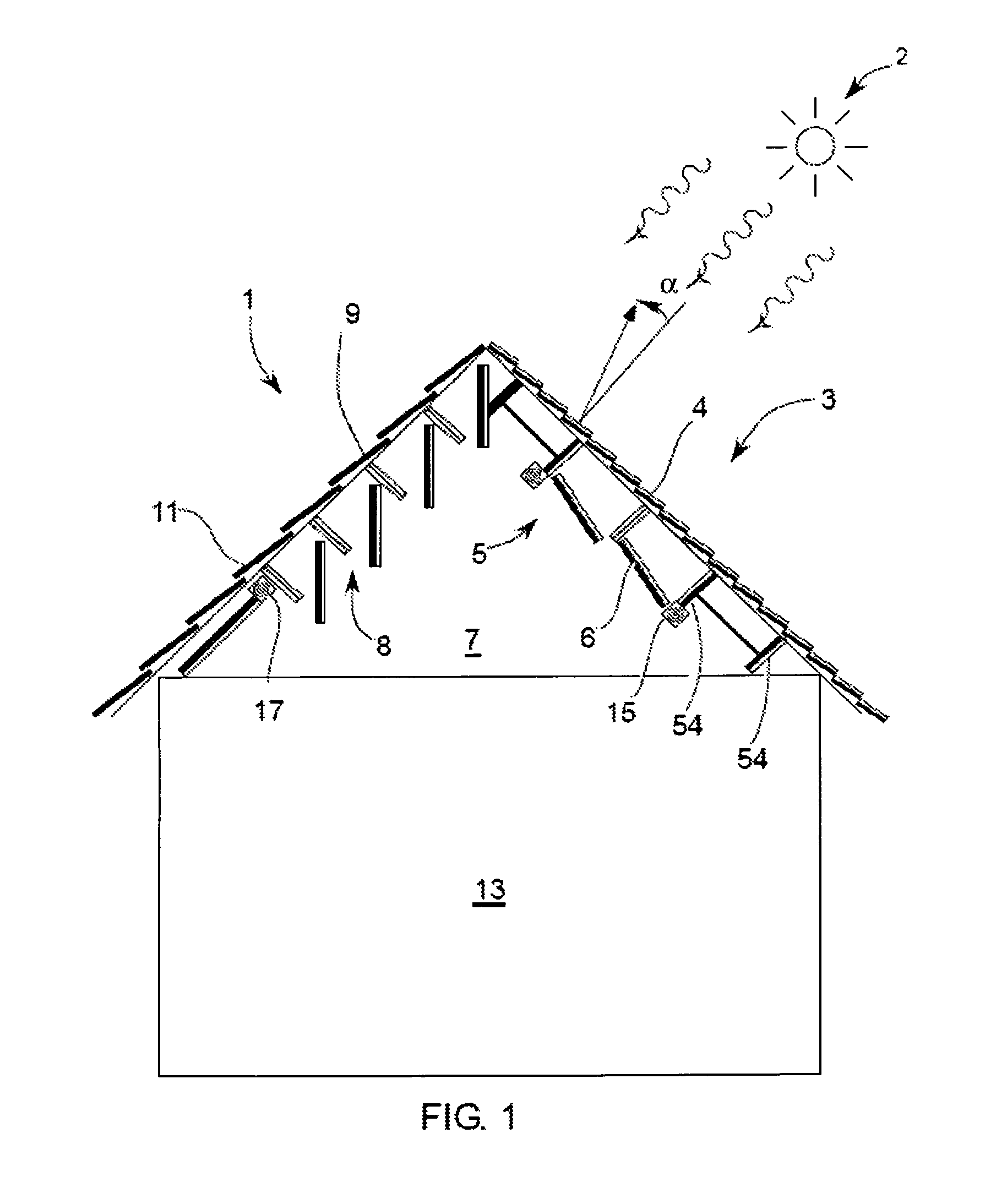

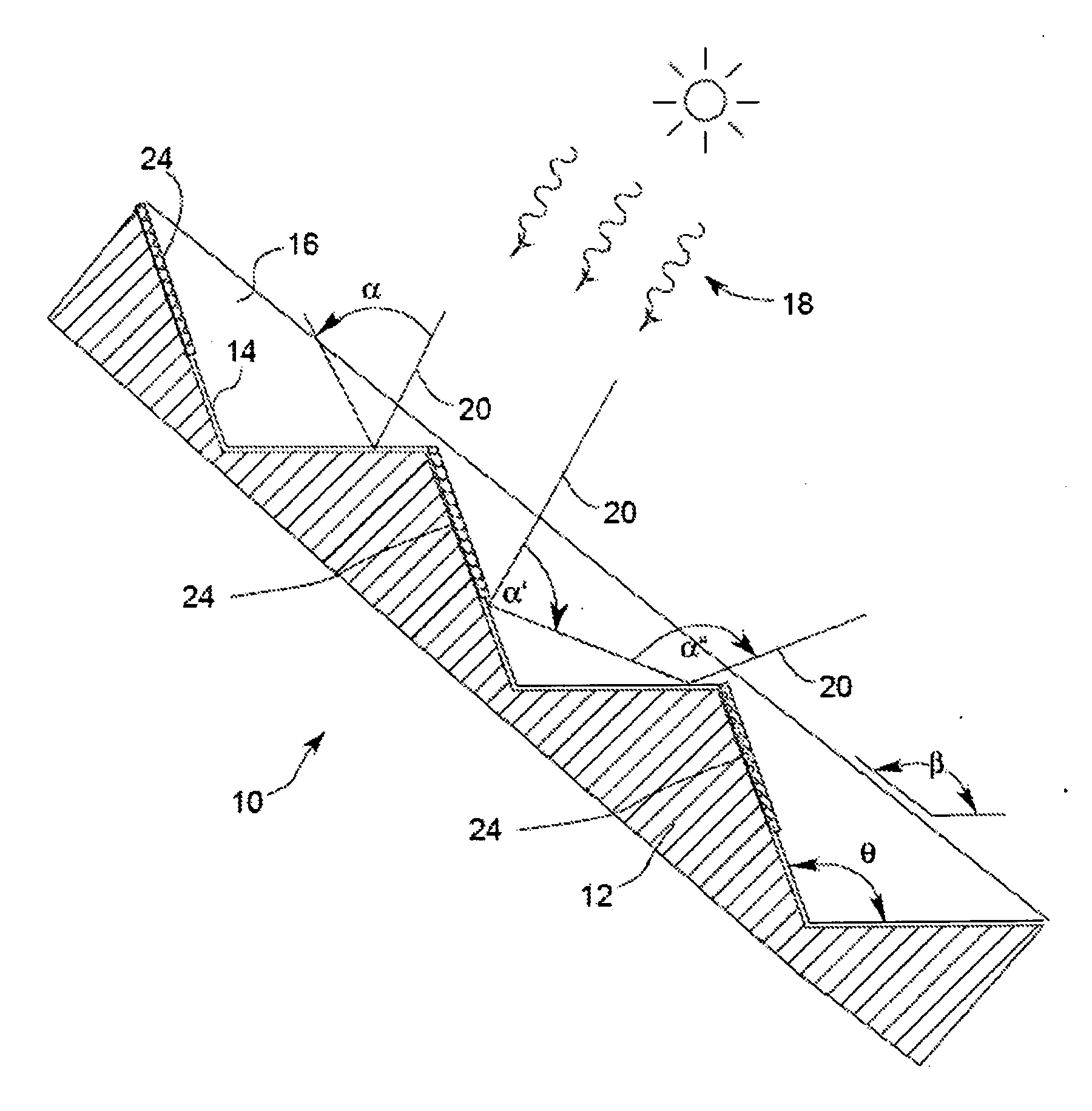

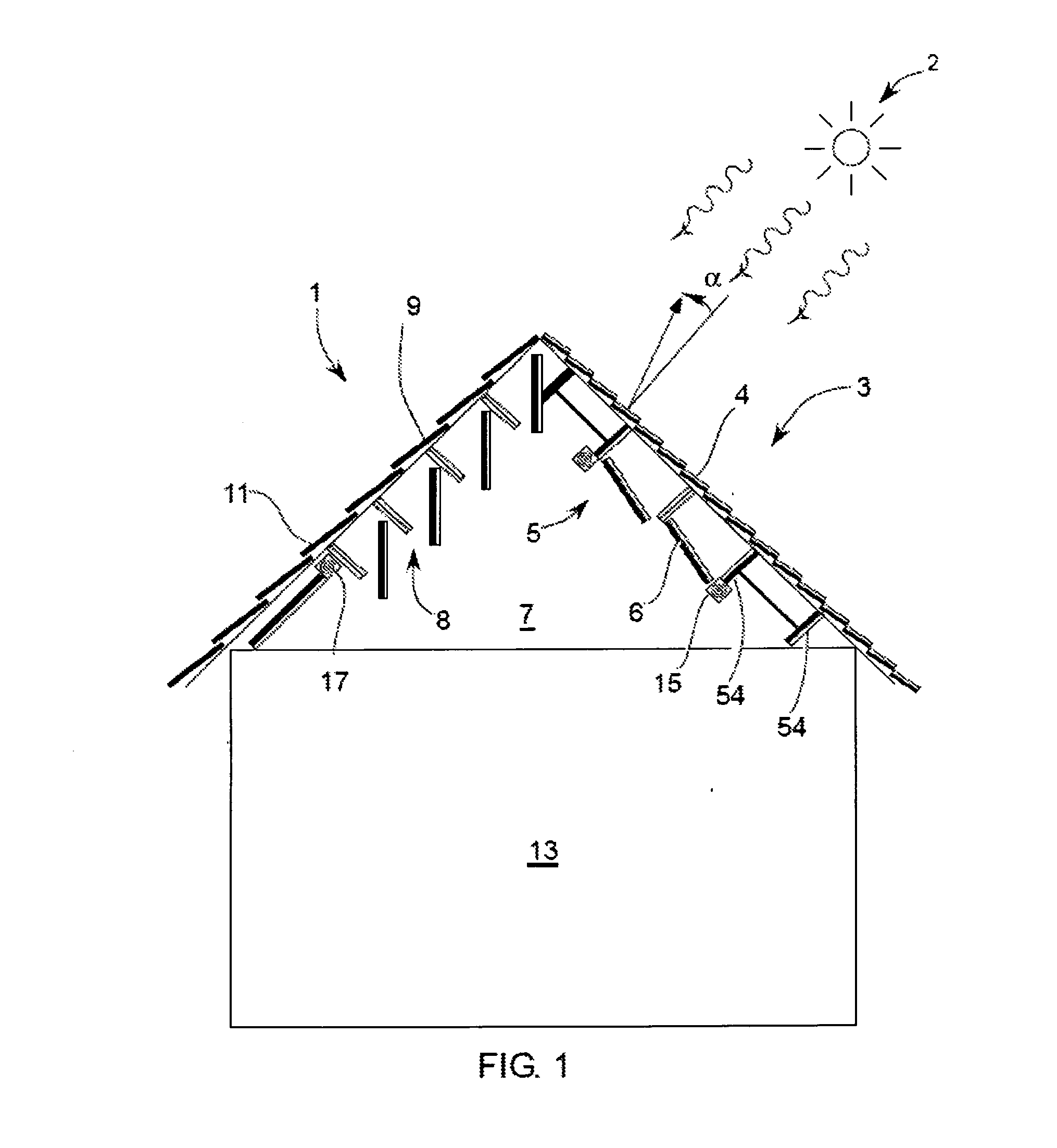

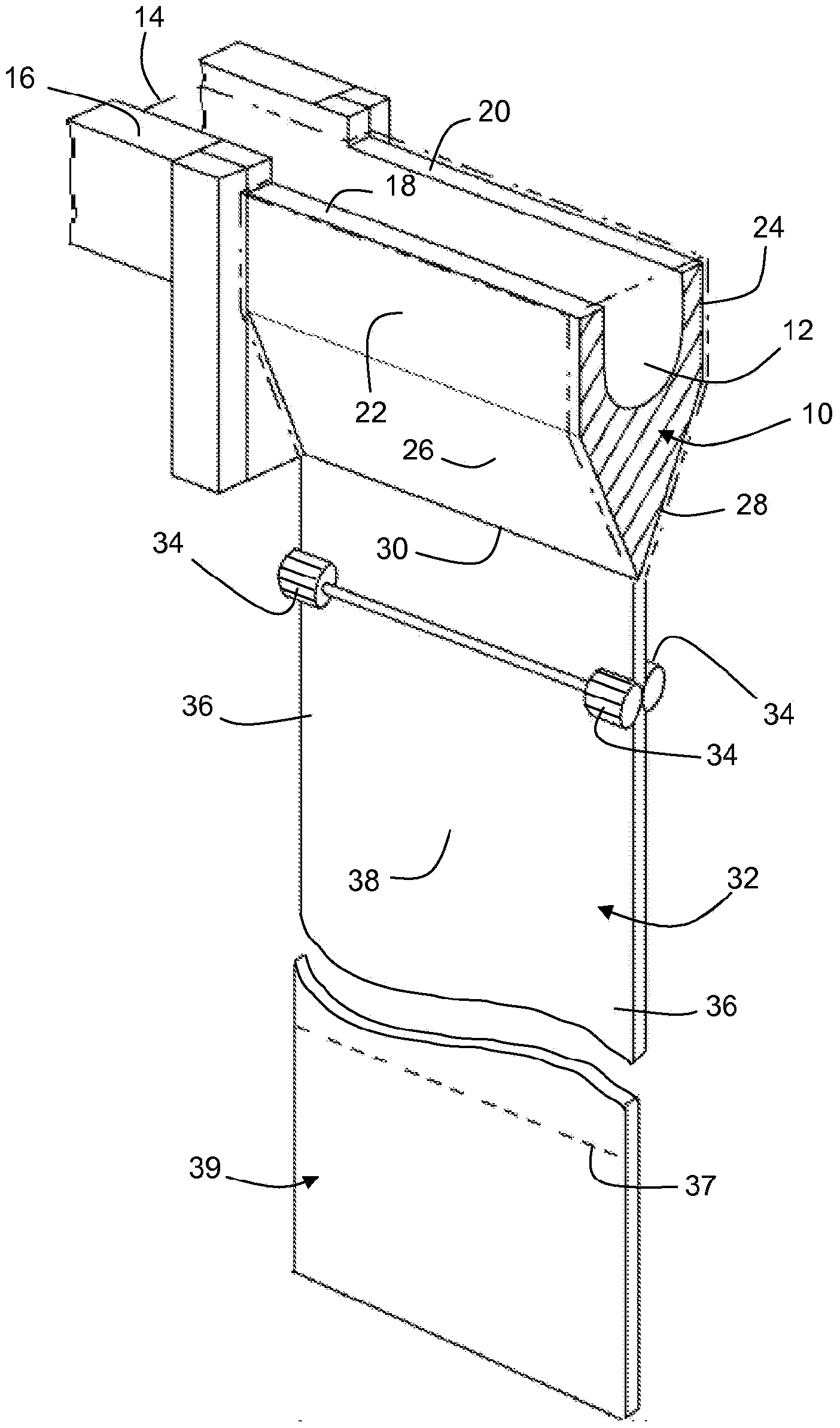

Reflective energy management system

ActiveUS20110167735A1Save heatFacilitate radiant heat lossPhotovoltaic supportsRoof covering using slabs/sheetsRadiative heat lossEngineering

A four component roofing system uses three reflective subsystems and one radiant subsystem to provide passive temperature control of a building comprising: (1) Shingles that reflect high angle summer sun light back to the sky, but absorb low angle winter sunlight; (2) A temperature sensitive attic insulator placed under a sunlit roof that reflects radiation and blocks convection from the roof to the attic at hot temperatures, permits radiation and convection at warm temperatures, and blocks radiation and convection from the attic at cold temperatures; (3) A temperature sensitive attic insulator placed under a shaded roof that permits radiation and convection at warm or hot temperatures, and blocks radiation and convection from the attic at cold temperatures; (4) Non-reflective shingles on a shaded roof that emit radiation continuously, but that are heated by air and radiation from the attic only when the second temperature sensitive attic insulator permits convection, so that radiant heat loss is reduced at cold temperatures.

Owner:SUMNER WALTON

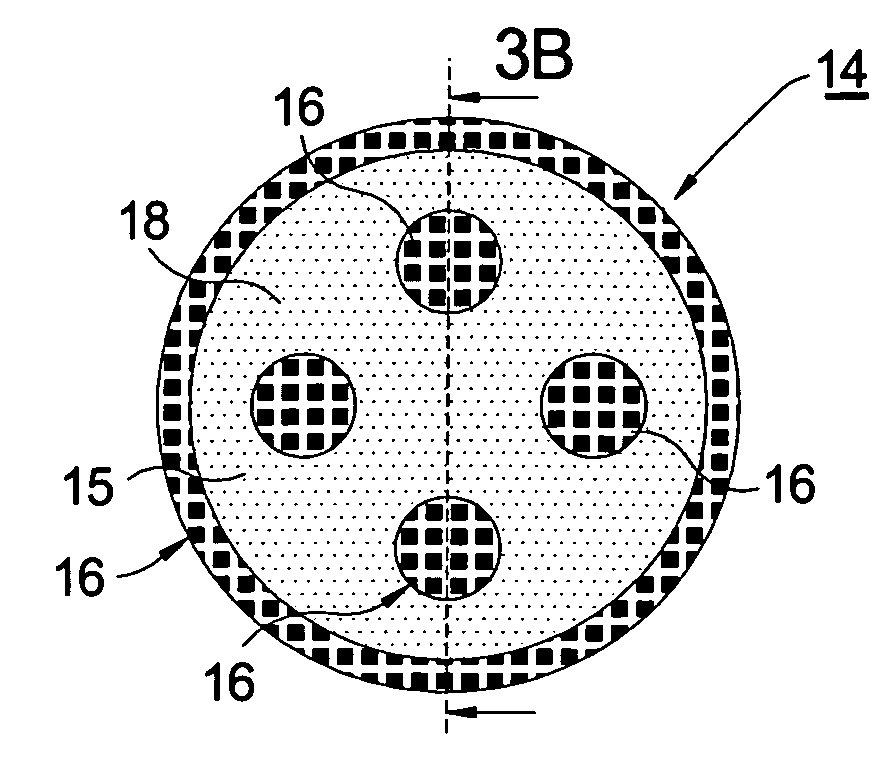

Hydrocarbon reformer substrate having a graded structure for thermal control

InactiveUS20100062212A1Reduce heat lossQuality improvementHydrogenPhysical/chemical process catalystsRadiative heat lossMullite

A reformer substrate for supporting a catalyst in a hydrocarbon reformer, comprising a graded structure that is inhomogeneous either radially, longitudinally, or both. The inhomogeous graded structure components are selected and arranged to maintain the catalyst operating temperature during extended periods of catalytic inactivity. Selection is based primarily on heat capacity and / or thermal loss properties. Generally, the perimeter of the substrate, radially and / or longitudinally comprises a thick wall of high thermal mass materials to reduce conductive and radiated heat loss, and a high thermal capacity material within the substrate to reduce radiated heat loss. Preferred materials are open-cell rigid foams such as zirconia-toughened alumina reticulated foam, for negative thermal loads in endothermic reaction regimes, and zirconia-mullite honeycomb monolith, for positive or neutral thermal loads in exothermic or autothermic reaction regimes.

Owner:DELPHI TECH INC

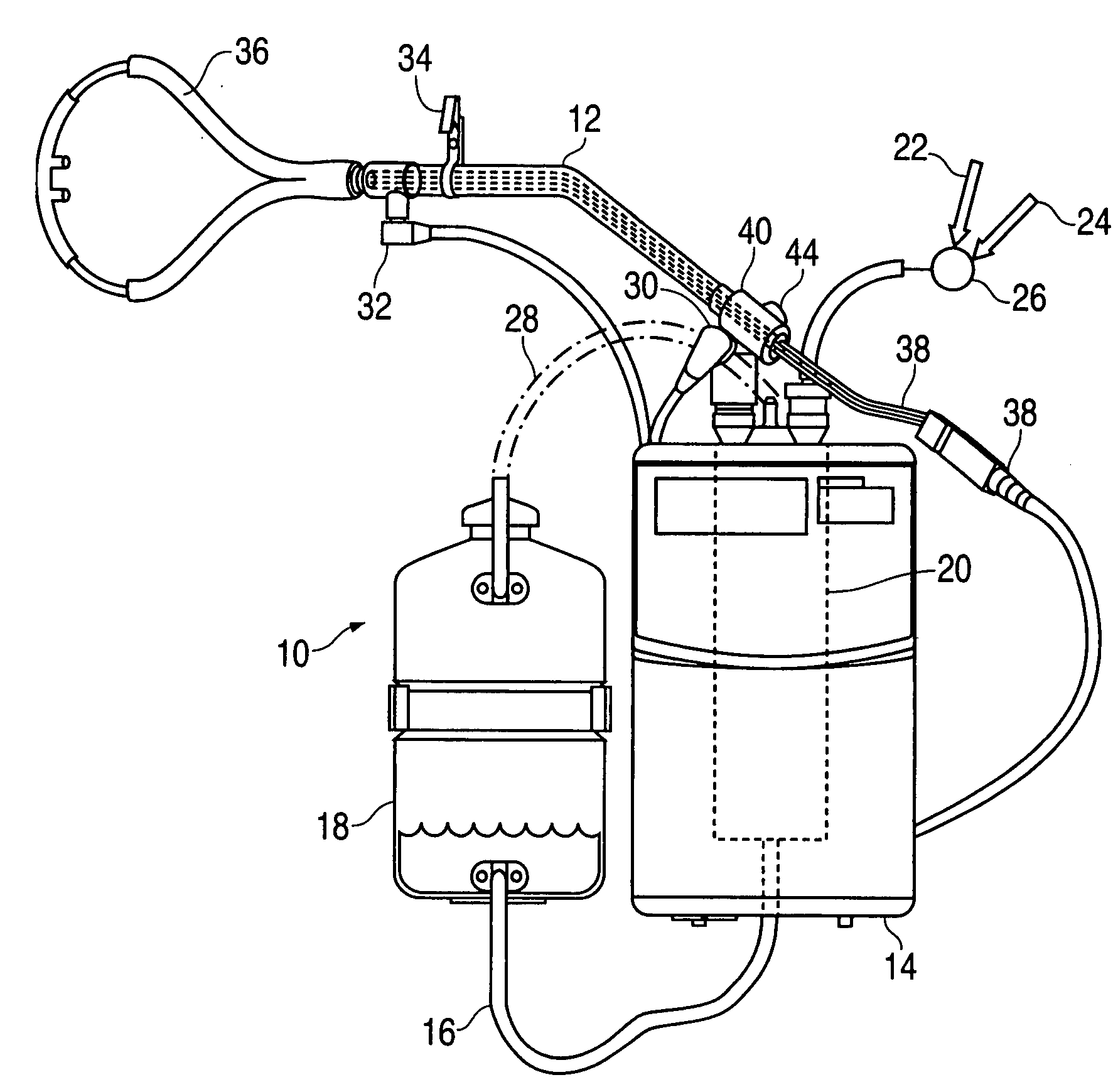

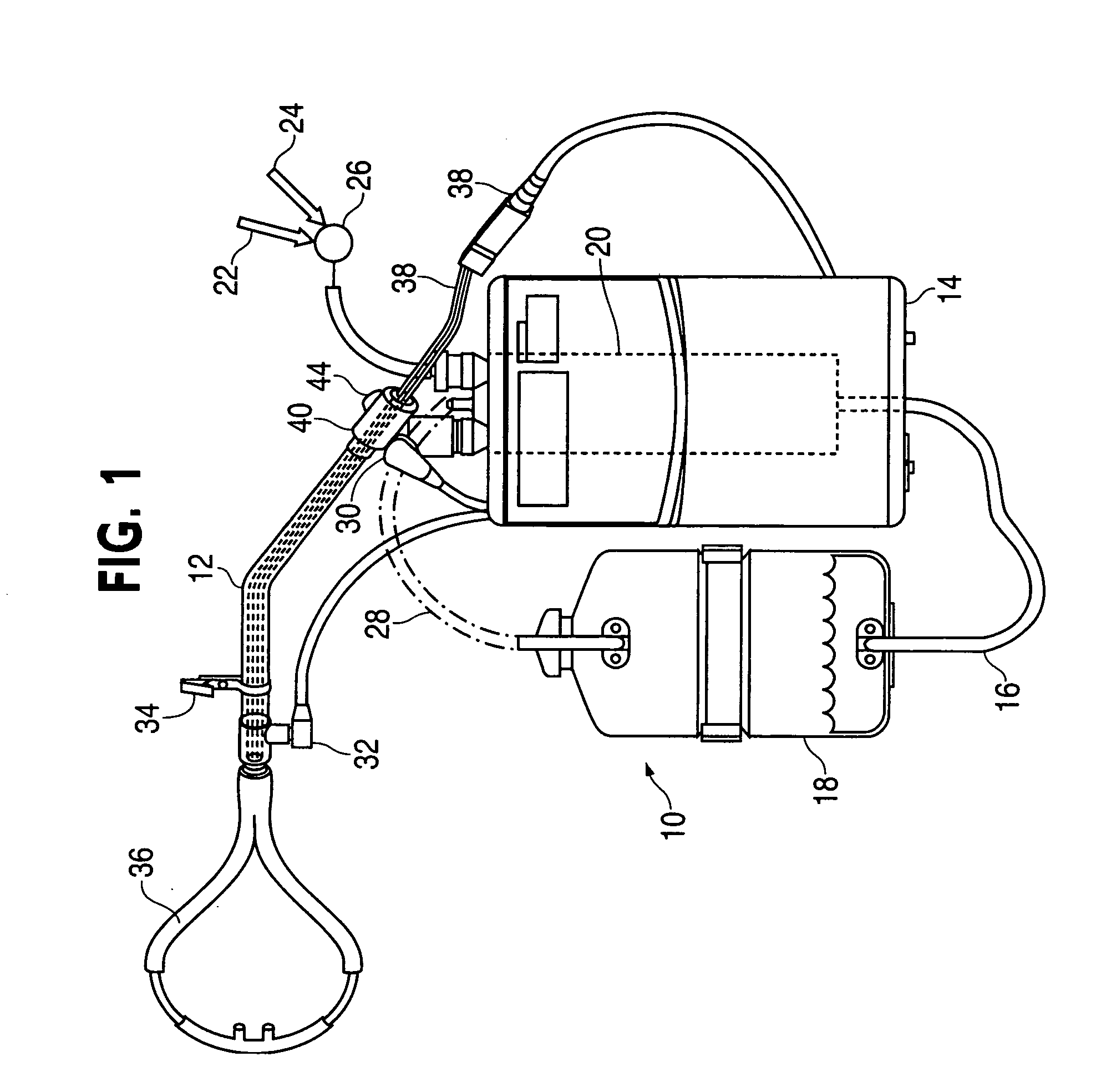

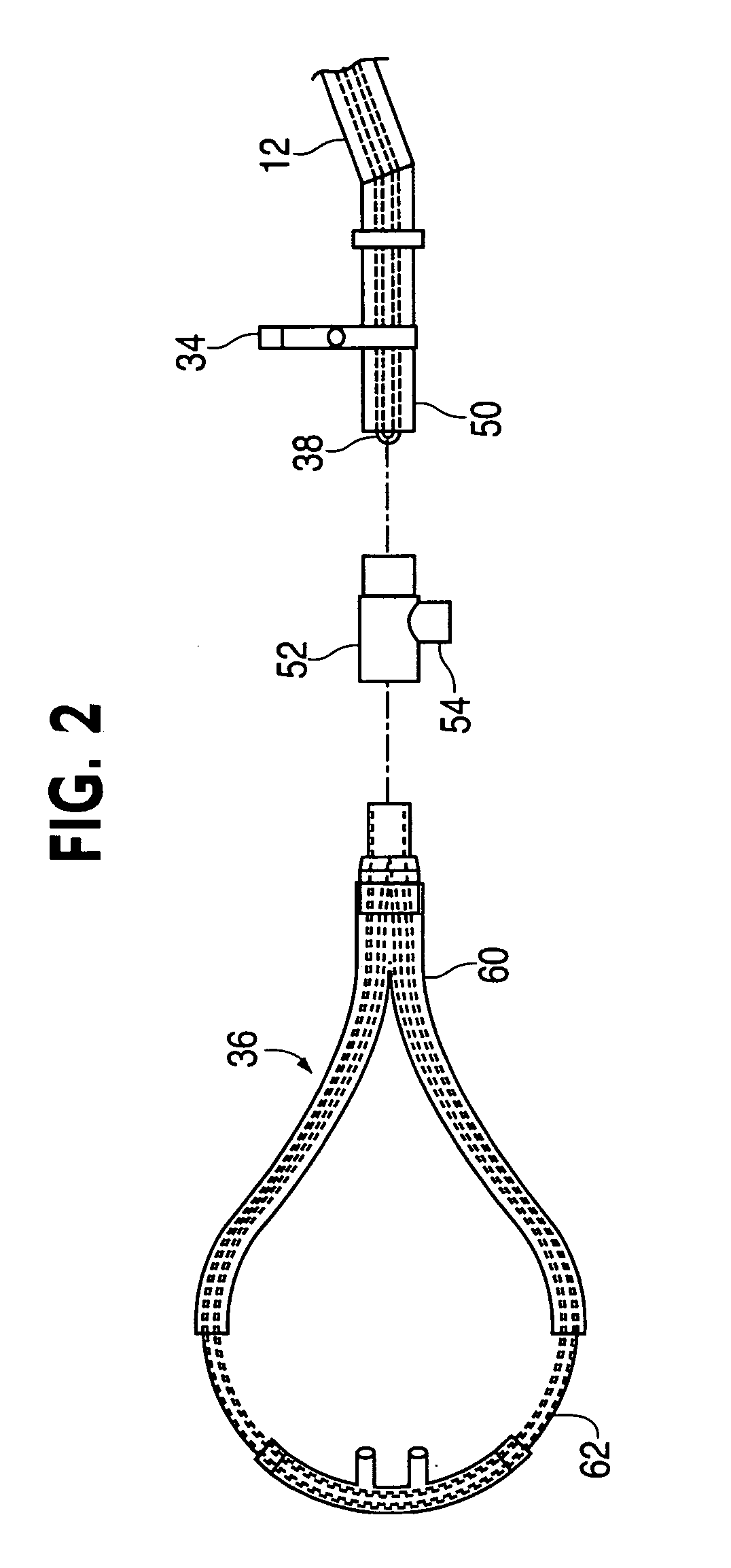

High flow respirator circuit

InactiveUS20080072903A1Avoid condensationPrevent heat lossRespiratorsOperating means/releasing devices for valvesThermal energyRadiative heat loss

A respiratory breathing circuit prevents heat loss and condensation in a flow of humidified air through a conduit from a humidification system to a patient interface, such as a nasal cannula. The circuit directly impedes heat loss or insulates the flow of a humidified gas therein, and provides a heating source inside the circuit along the length of the circuit to prevent net heat loss from the circuit tubing by providing thermal energy and / or insulation to impede convective, conductive, or radiative heat loss by the gas as it flows through the system. A temperature, humidity, or other flow quality measuring probe is disposed at the distal end of the circuit near the patient interface to actively measure a corresponding quality of the humidified gas flow to provide feedback to the system. A pressure relief valve is provided on the circuit to prevent a pressure build-up and / or structural failure.

Owner:TELEFLEX MEDICAL INC

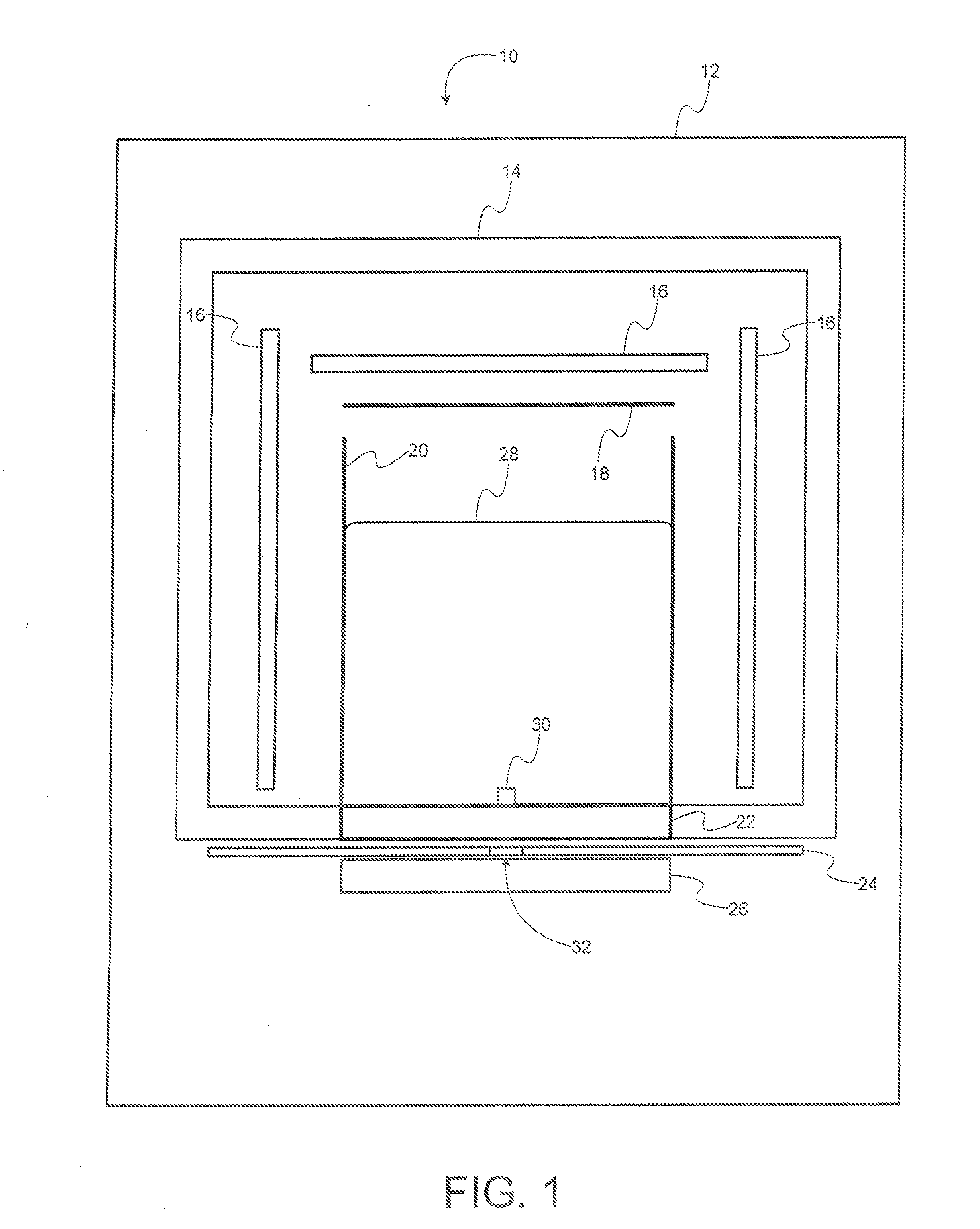

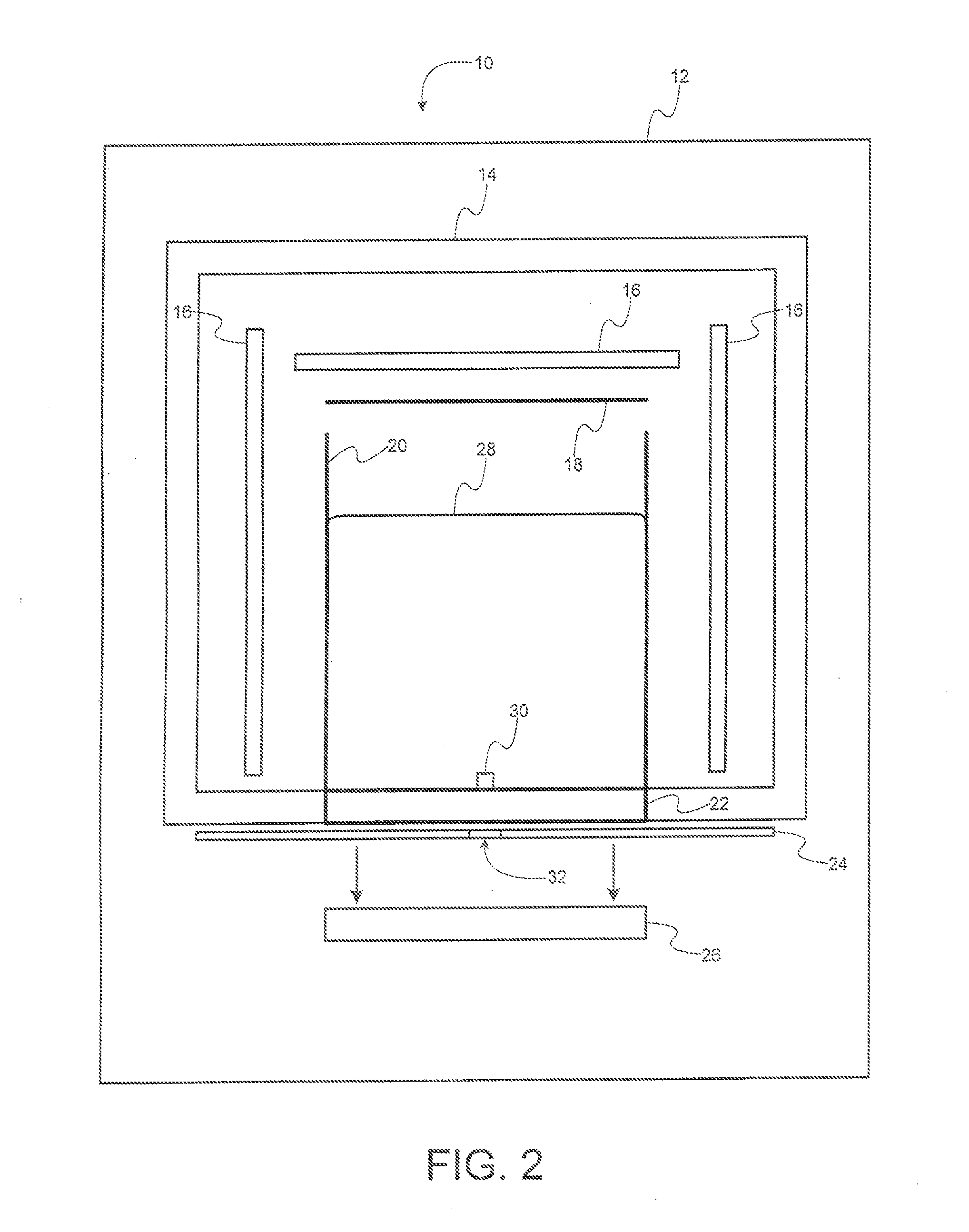

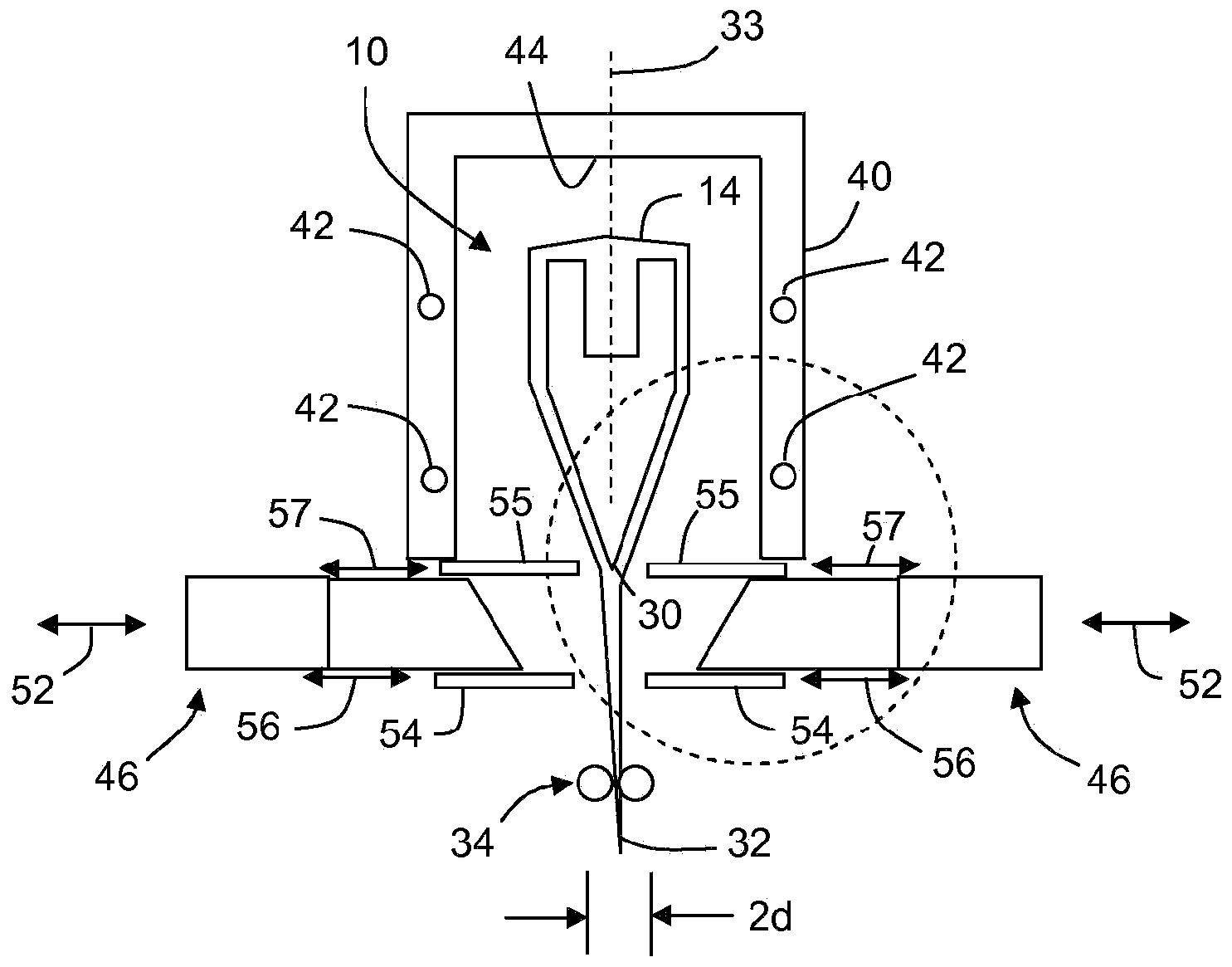

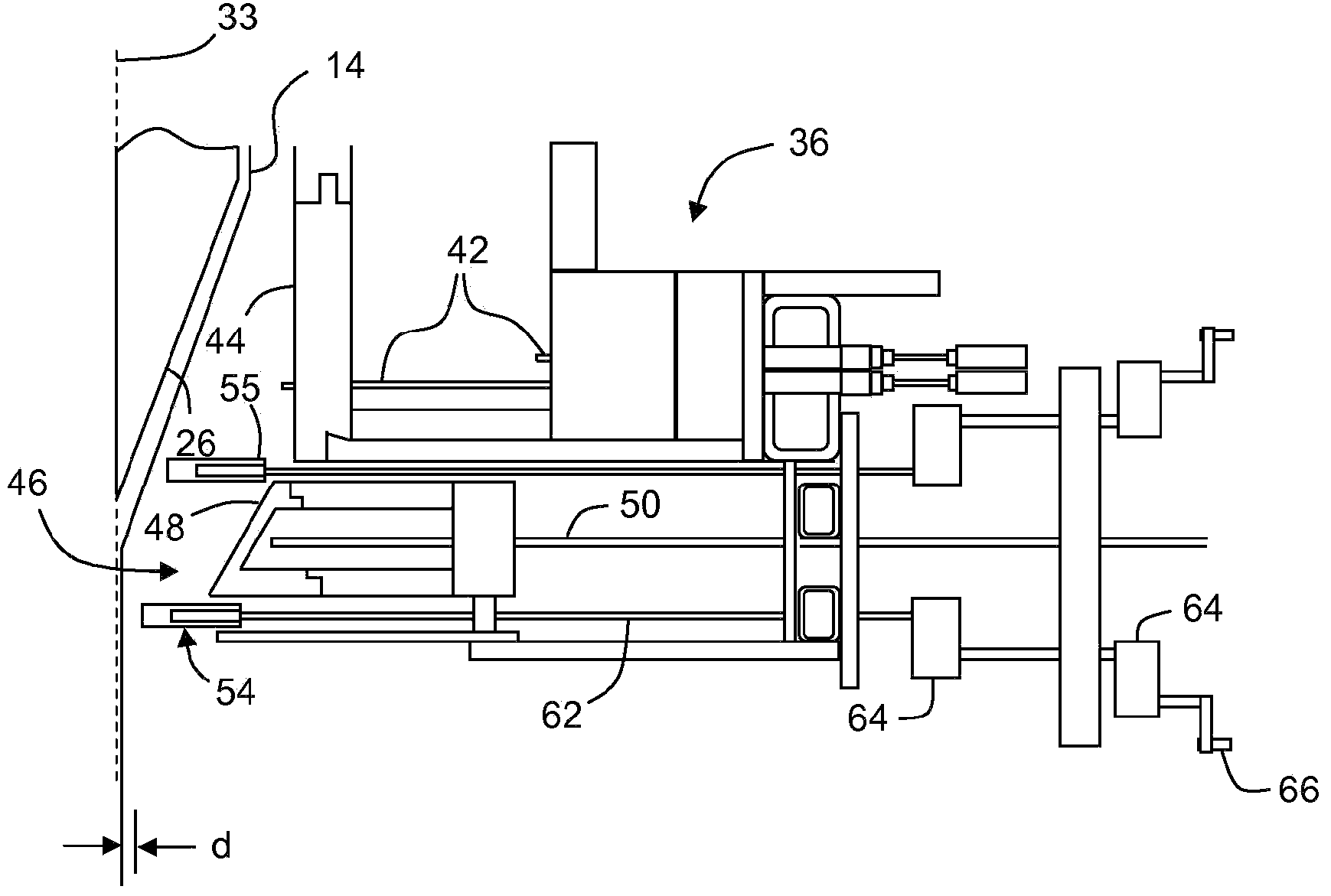

Apparatus for reducing radiative heat loss from a forming body in a glass forming process

Disclosed is an apparatus for producing a glass sheet comprising lower thermal shields positioned below cooling doors for minimizing radiative heat loss from a forming body used to form a ribbon of molten glass from which a glass sheet is cut, and upper thermal shields positioned between the cooling doors and a root of the forming body for minimizing radiative heat loss from the forming body. The thermal shields are typically arranged as pairs and positioned on horizontally opposite sides of a flow of molten glass descending as a continuous ribbon from the forming body. Each thermal shield of the lower and upper thermal shield pairs may comprise a plurality of segments, including end segments and a central segment, wherein the end segments may be separately movable relative to the central segment, allowing an edge of the thermal shield adjacent the ribbon to be varied.

Owner:CORNING INC

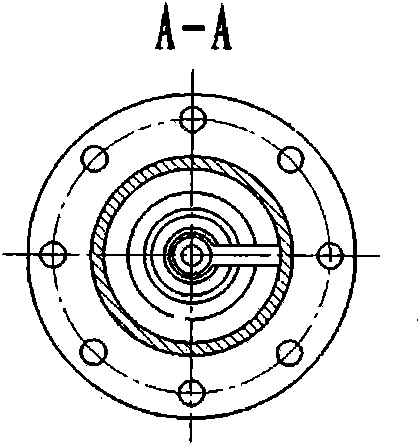

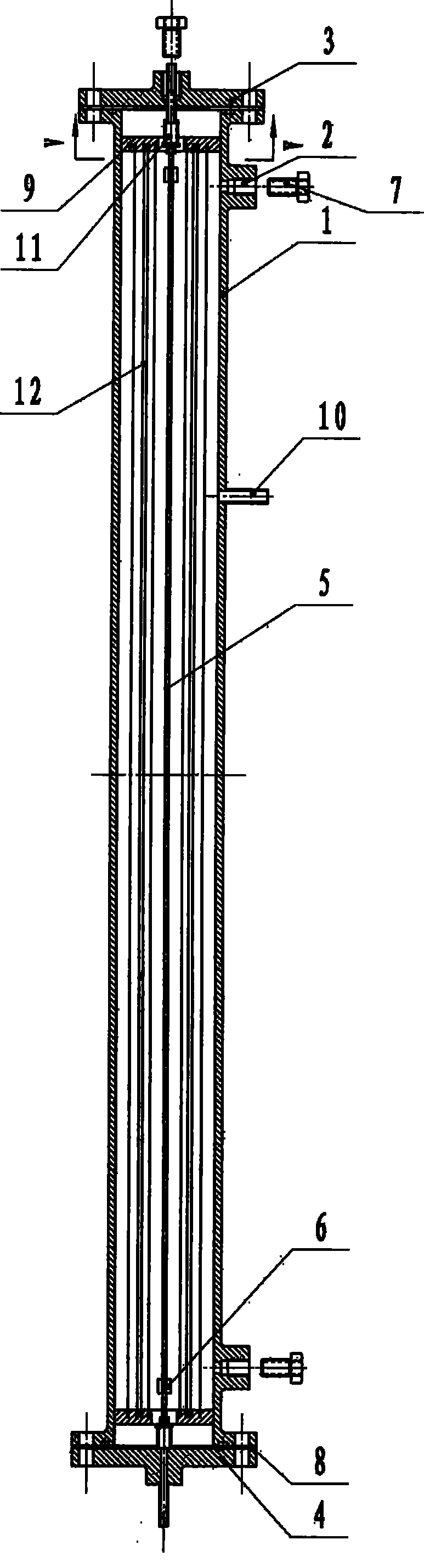

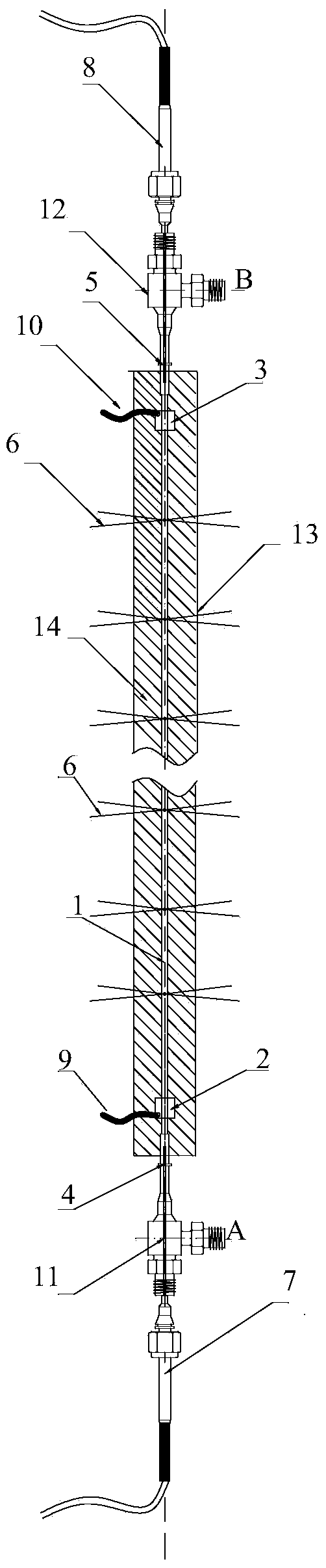

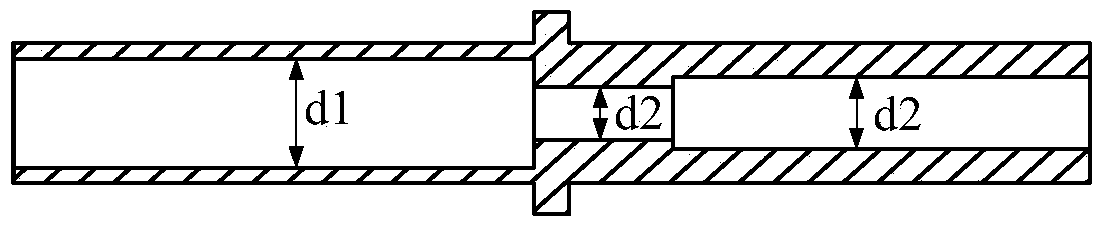

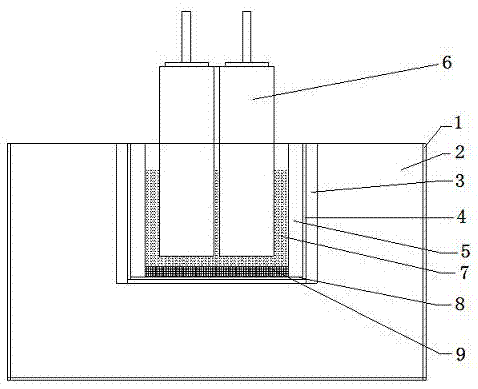

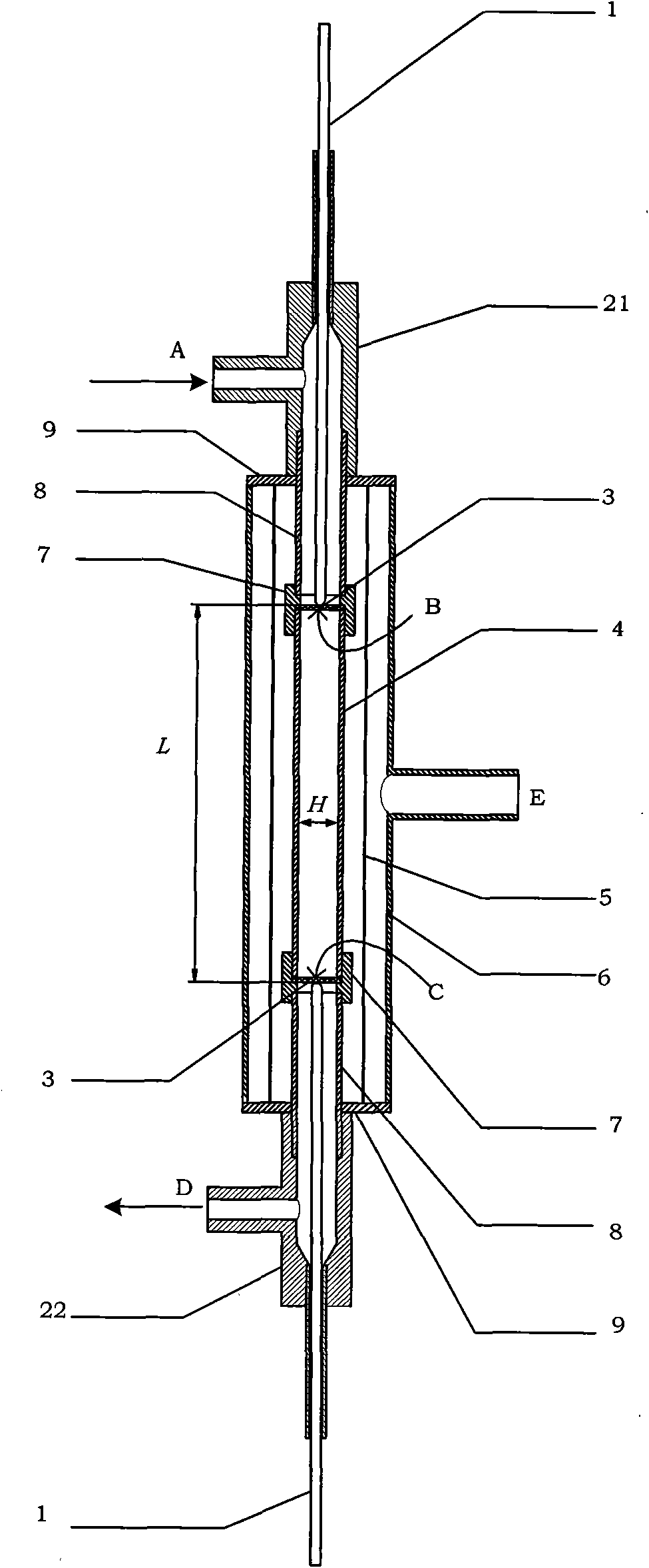

Method and experimental device suitable for measuring heat conductivity coefficient of flowing high-temperature high-pressure fluid

InactiveCN103728340AExpand the measurement rangeSimple structureMaterial heat developmentRadiative heat lossThermal insulation

The invention discloses a method and an experimental device suitable for measuring the heat conductivity coefficient of flowing high-temperature high-pressure fluid. The experimental device comprises a test tube, a heating copper electrode A, a heating copper electrode B, a temperature measuring mixed cavity A, a temperature measuring mixed cavity B, a wall temperature thermocouple, a fluid temperature thermocouple A, a fluid temperature thermocouple B, a copper electrode lead A, a copper electrode lead B, a switchover tee joint A and a switchover tee joint B, and also comprises a heat shielding screen and a thermal insulation material wrapping the outer wall of the test tube. According to the experimental device, the test tube can be well subjected to heat insulation, so that loss of natural convection heat exchange and radiant heat can be effectively reduced in experiment, the experiment date error is small, and effective basis is provided for accurate experiment data of the heat conductivity coefficient and design and application of the heat conductivity coefficient. The experimental device provides effective help for research of a novel cooling manner, and also provides experimental feasibility for accurate experimental measurement of the heat conductivity coefficient of the high-temperature high-pressure fluid under pressure of 0-7MPa.

Owner:BEIHANG UNIV

Rare earth fused-salt electrolysis cell for producing rare earth metals and alloys by using liquid cathode

InactiveCN105441987AImprove current efficiencyExtended service lifeCellsElectrodesRadiative heat lossRare-earth element

The invention discloses a rare earth fused-salt electrolysis cell for producing rare earth metals and alloys by using a liquid cathode. The rare earth fused-salt electrolysis cell mainly comprises an electrolysis cell body, an anode and the liquid cathode; the anode and the cathode are provided with horizontal planes parallel to and facing each other; the anode is vertically inserted in the electrolysis cell body; the liquid cathode is a liquid metal electrolyzed at the bottom; a tungsten plate is inlaid in the internal bottom of the electrolysis cell body; a molybdenum plate or a niobium plate can be taken as a cathode bottom plate or a rare earth metal catcher for an electrolytic product separated out on the cathode. The rare earth fused-salt electrolysis cell for producing rare earth metals and alloys by using the liquid cathode has the advantages of high current efficiency, low radiant heat losses, high anode utilization rate, long electrolysis cell service life and low investment of the electrolysis cell body; the single plant capacity can reach above 100 KA, the energy consumption per unit product is greatly reduced, and produced products are stable in quality, low in production cost and relatively closed.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP HLDG CO LTD

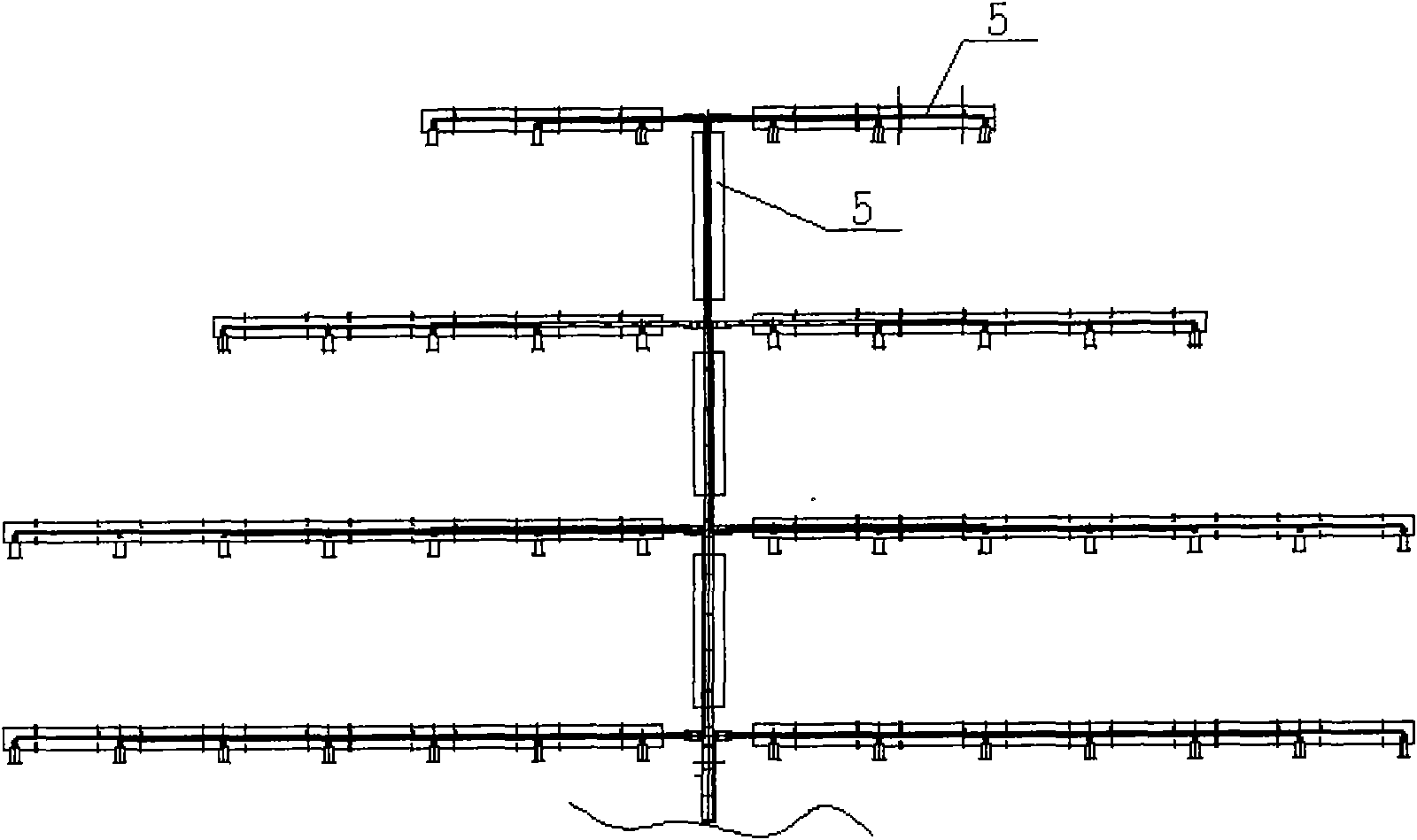

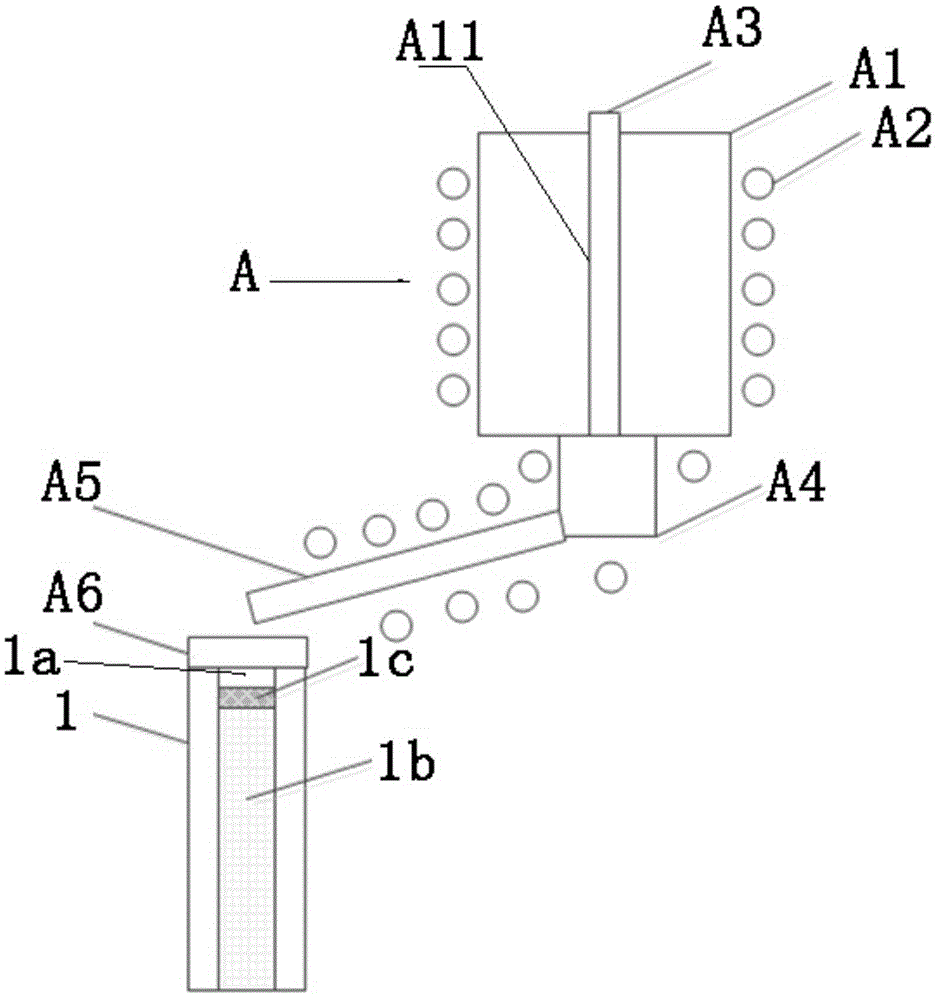

Pipe-cavity integrated disc solar heat receiver

InactiveCN102141301ARealize integrationCircumferential temperature uniformitySolar heating energySolar heat devicesRadiative heat lossThermal fatigue

The invention relates to a pipe-cavity integrated disc solar heat receiver. An integrated structure of a heat absorption cavity and a heat exchanging pipeline is adopted, the cylindrical cavity is provided with two rows of pores to form a circulating pipeline of the gas; the heat exchanging gas flows in an air passage at a high speed and takes away the heat; two groups of the air passages are connected with two gas distribution / gas collection covers via a vent pipe respectively, and the gas distribution / gas collection covers play a role in distributing the gas and collecting the gas alternately during the continuous operation of a system. The inlet of the heat absorption cavity is provided with an annular diffuse reflector, and the bottom of the heat absorption cavity is provided with a diffuse reflecting cone to reduce the radiation heat loss of the heat absorption cavity. The invention solves the thermal fatigue problem generally existent in the conventional direct receiver compared with the past direct solar heat receiver. The receiver has a more compact structure and a longer service life; meanwhile the system has the advantages of small air resistance, good air-tightness, high heat exchanging efficiency and the like, so the overall operation efficiency and the stability of the disc system are facilitated.

Owner:ZHEJIANG UNIV

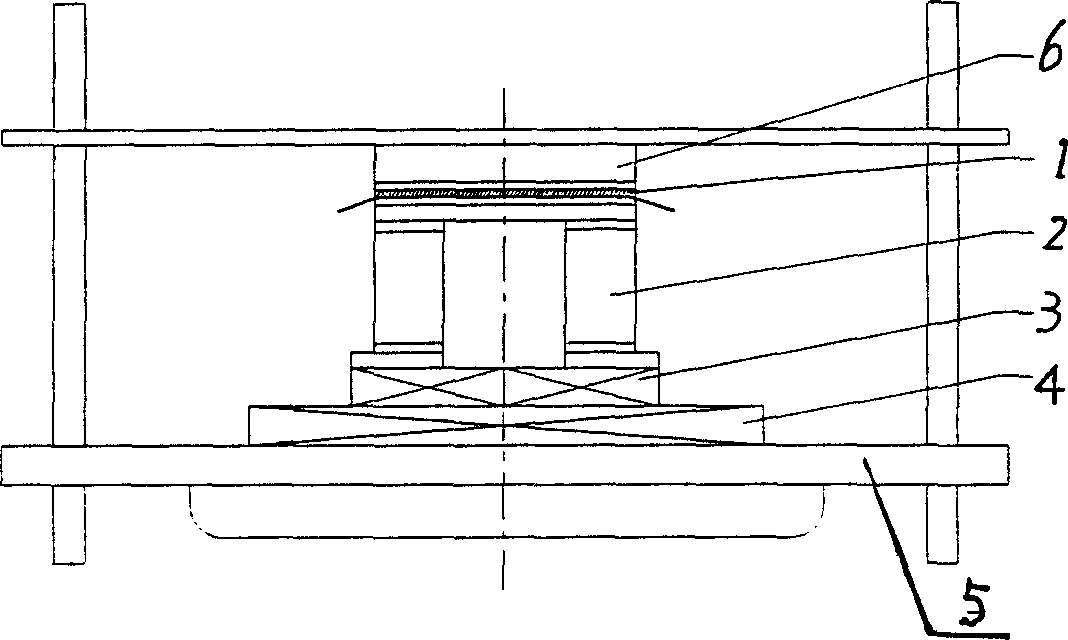

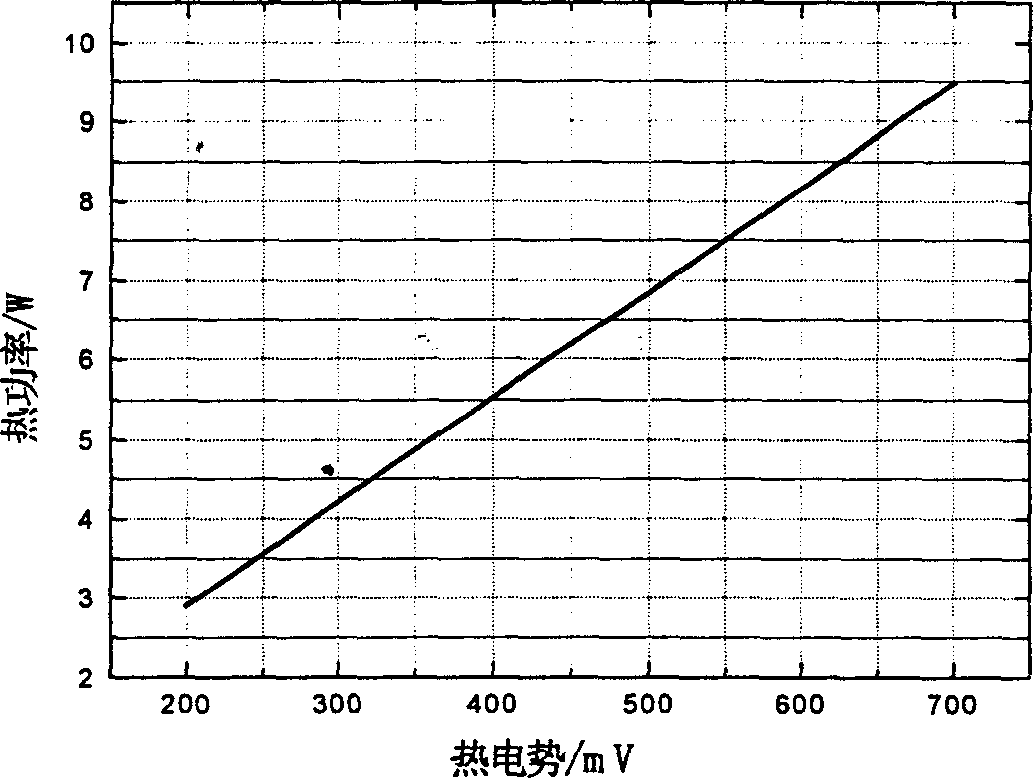

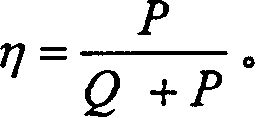

Detecting method for thermoelectric conversion efficiency of thermoelectric element device

InactiveCN1782680AAvoid side convectionAvoid protectionThermometers using electric/magnetic elementsUsing electrical meansRadiative heat lossElectricity

The detecting method of thermoelectric conversion efficiency of thermoelectric element or device includes the following steps: 1. measuring the electric power P of thermoelectric element or device with a common power meter; 2. measuring thermal potential E with a thermoelectric power meter set in the cold side of the thermoelectric element or device and calculating the thermal power Q by means of the formula Q=AE+B, where A and B are determined through calibrating the thermoelectric power meter; and 3. calculating the thermoelectric conversion efficiency Eta of thermoelectric element or device by means of the formula Eta=P / Q+P. Owing to measuring the thermal power the cold side of the thermoelectric element or device outputs, rather than the input thermal power, the present invention avoids the heat loss of side convection of the thermoelectric element or device and has raised measurement precision of thermoelectric conversion efficiency.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

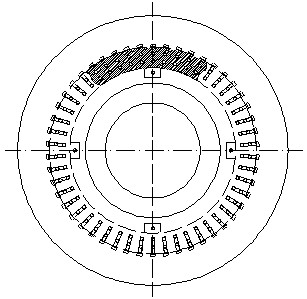

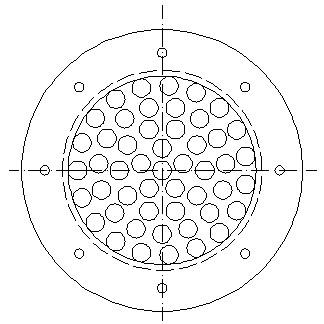

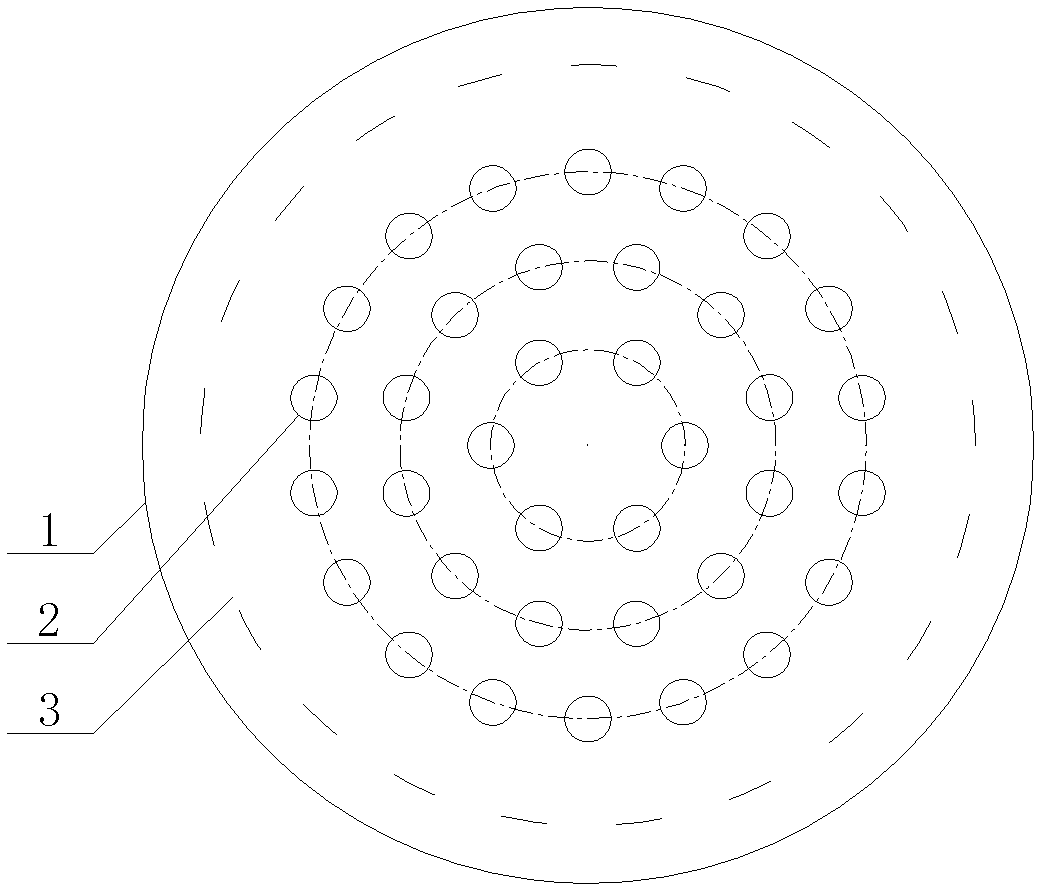

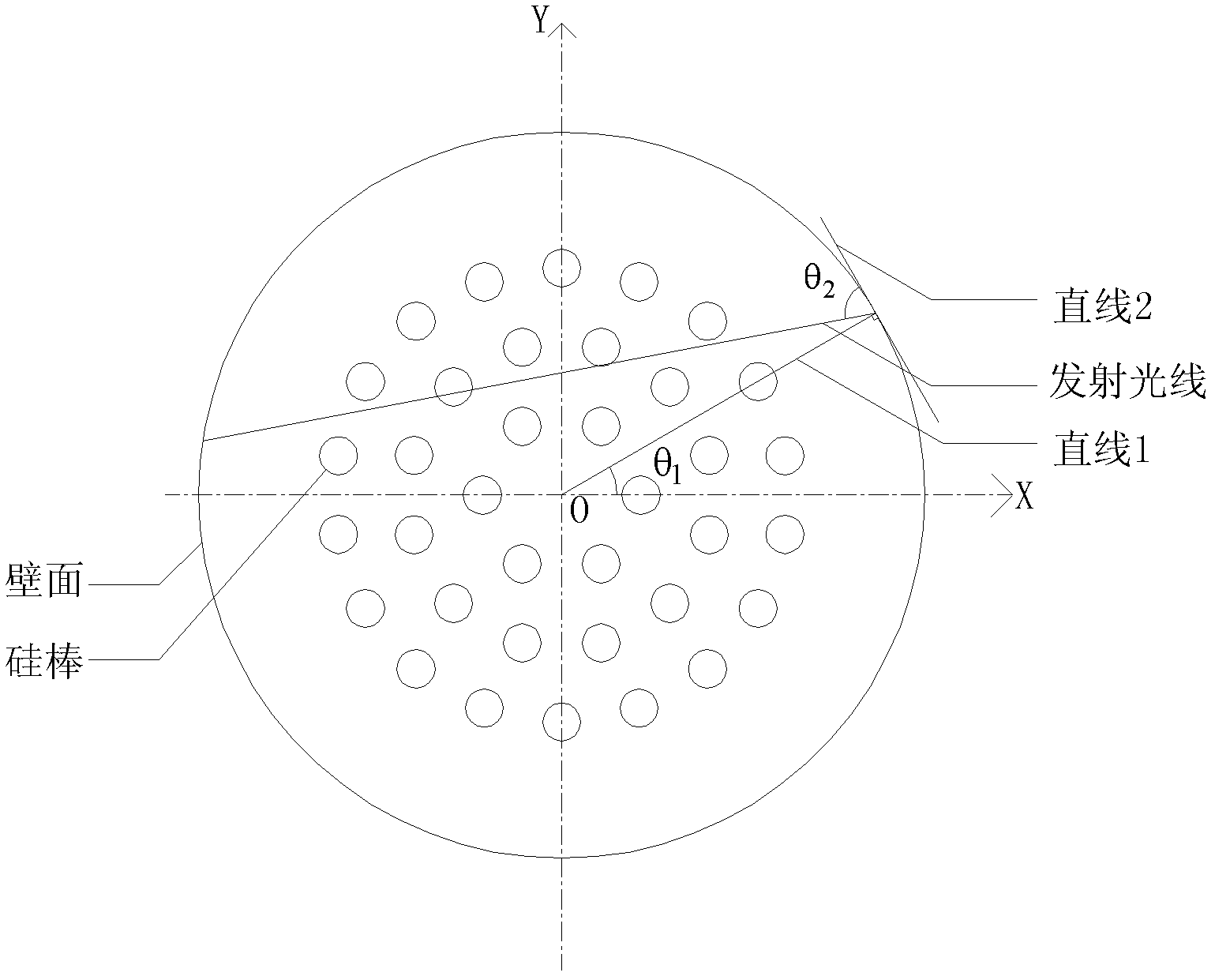

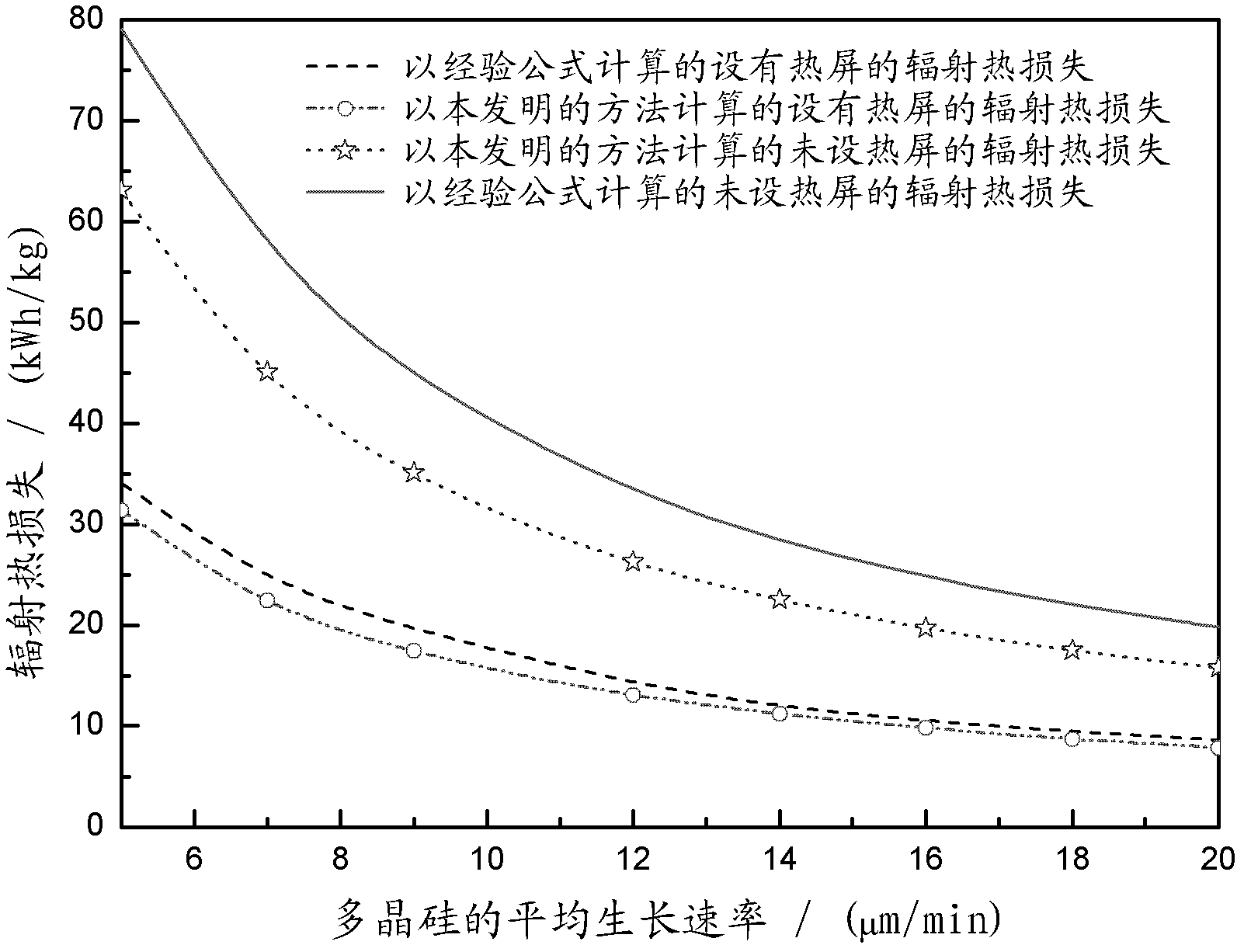

Method for estimation of radiation heat loss of polysilicon CVD (chemical vapor deposition) reactor

ActiveCN102354336AImprove accuracyFully consider and solve the occlusion problemSiliconChemical industryRadiative heat lossTemperature control

The invention relates to a method for estimation of radiation heat loss of a polysilicon CVD (chemical vapor deposition) reactor. The key technical parameter of radiation heat exchange, i.e. angle factor, is obtained accurately in a Monte Carlo method, and then the radiation heat loss in the CVD reactor can be calculated accurately. The radiation heat loss of the polysilicon CVD reactor can be estimated rapidly and accurately, and the method has a wide scope of application and is particularly suitable for reactors with any number of silicon cores and complex structures. When the method for estimation of the radiation heat loss is adopted, more accurate radiation heat leakage data can be provided for operators of the polysilicon CVD reactor, necessary feedback information can be provided for accurate control and even automated control of the working current, the temperature of the silicon cores in reduction furnaces can be controlled in a more accurate and effective range, the power consumption for reaction can be saved greatly, the quality of polysilicon products and the yield of production can be improved, and great economic benefits and social value can be produced for enterprises. The method is also applicable to estimation of radiation heat leakage of other reactors with complex structures.

Owner:南京中盛宏信环保工程有限公司

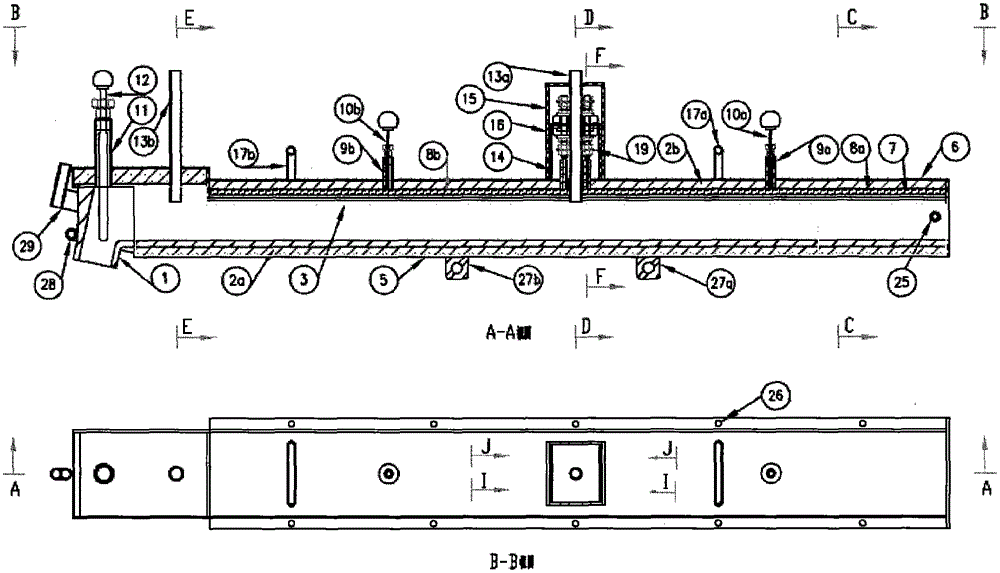

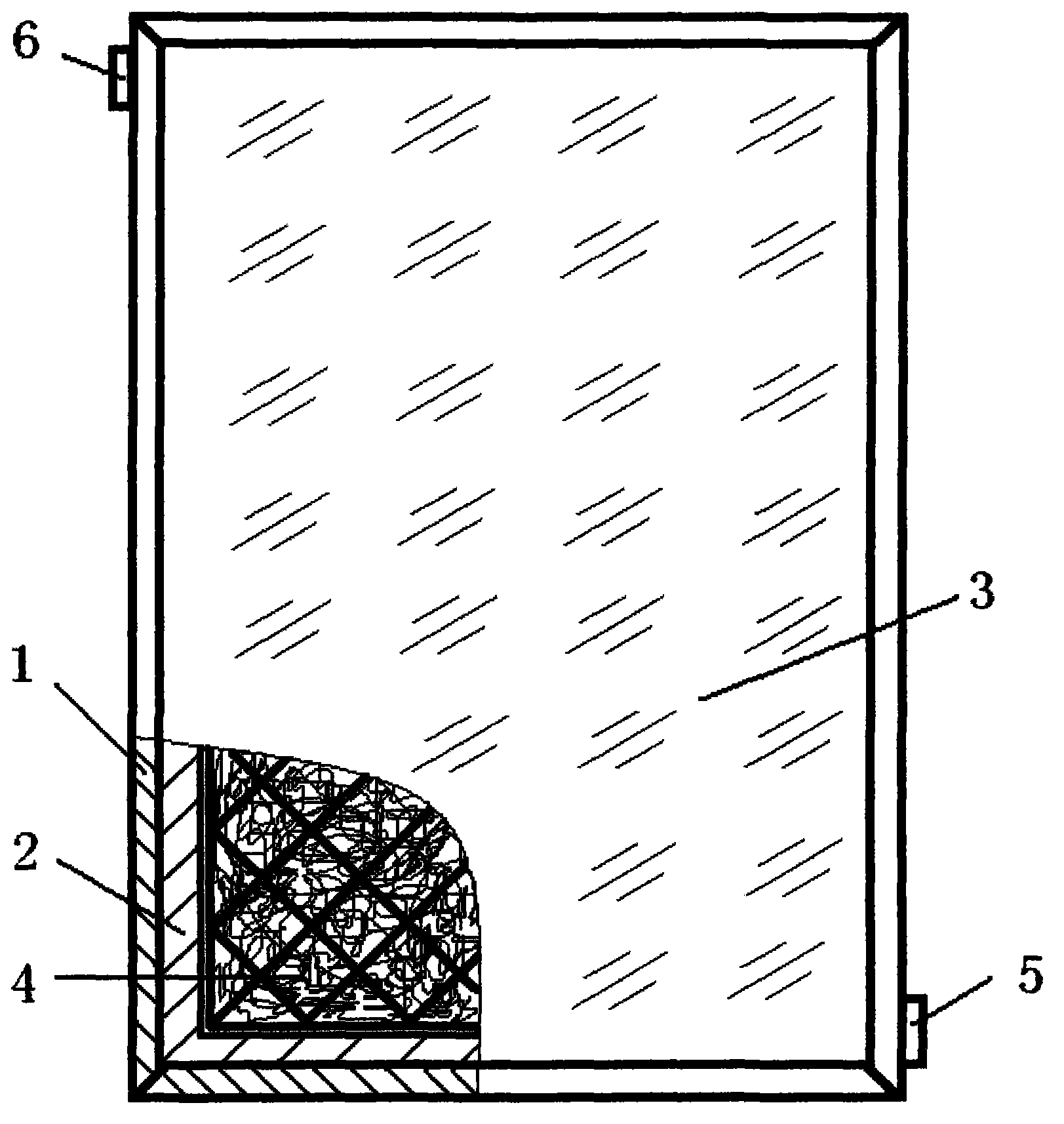

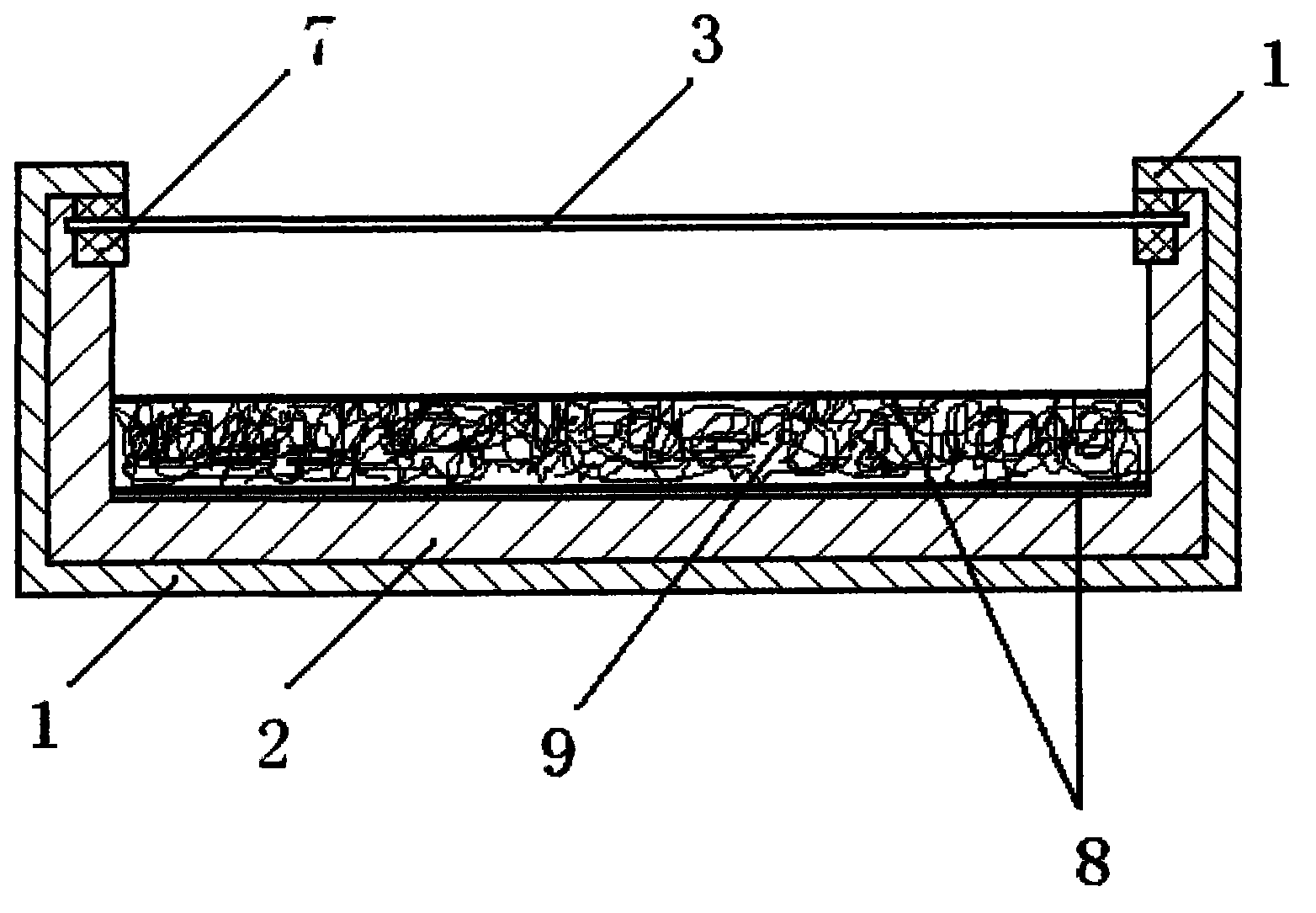

Efficient thermal-insulation anti-oxidization aluminum water runner not adhering with aluminum

InactiveCN104972078AEasy to assemble and disassembleEasy maintenanceMolten metal conveying equipmentsCasting parameters measurement/indication devicesRadiative heat lossFiber

The invention discloses an efficient thermal-insulation anti-oxidization aluminum water runner not adhering with aluminum, which is suitable for aluminum water high-quality conveying of the aluminum alloy casting field. The problems to be solved are temperature drop, oxidization and corrosion on the runner due to aluminum water adhering in an aluminum water conveying process. According to the technical scheme adopted by the invention, the key point is that a reinforced fiber glass ceramic runner (1) is used to prevent the aluminum water from adhering on and corroding the runner, so that heat conduction loss of the runner is reduced; a nano microporous heat-insulating material (2) and ceramic fiber heat-insulating materials (3, 4) are used to reduce heat conduction loss of the runner to a minimum; by virtue of a ceramic heating unit (8) on a stainless steel supporting plate (7) in a runner cover (6) is used to heat the runner cover to the aluminum water temperature, so that aluminum water radiation heat loss is reduced to a minimum, and convective heat exchange loss is compensated; a temperature measuring device (12) is used to monitor the practical temperature of the aluminum water in a runner outlet; and an atmosphere control tube (13) is used to lead in an inert gas, so that the aluminum water is oxidized to a minimum. The efficient thermal-insulation anti-oxidization aluminum water runner not adhering with aluminum is especially suitable for conveying high-quality aluminum water of an aluminum alloy quantitative furnace.

Owner:高鸿

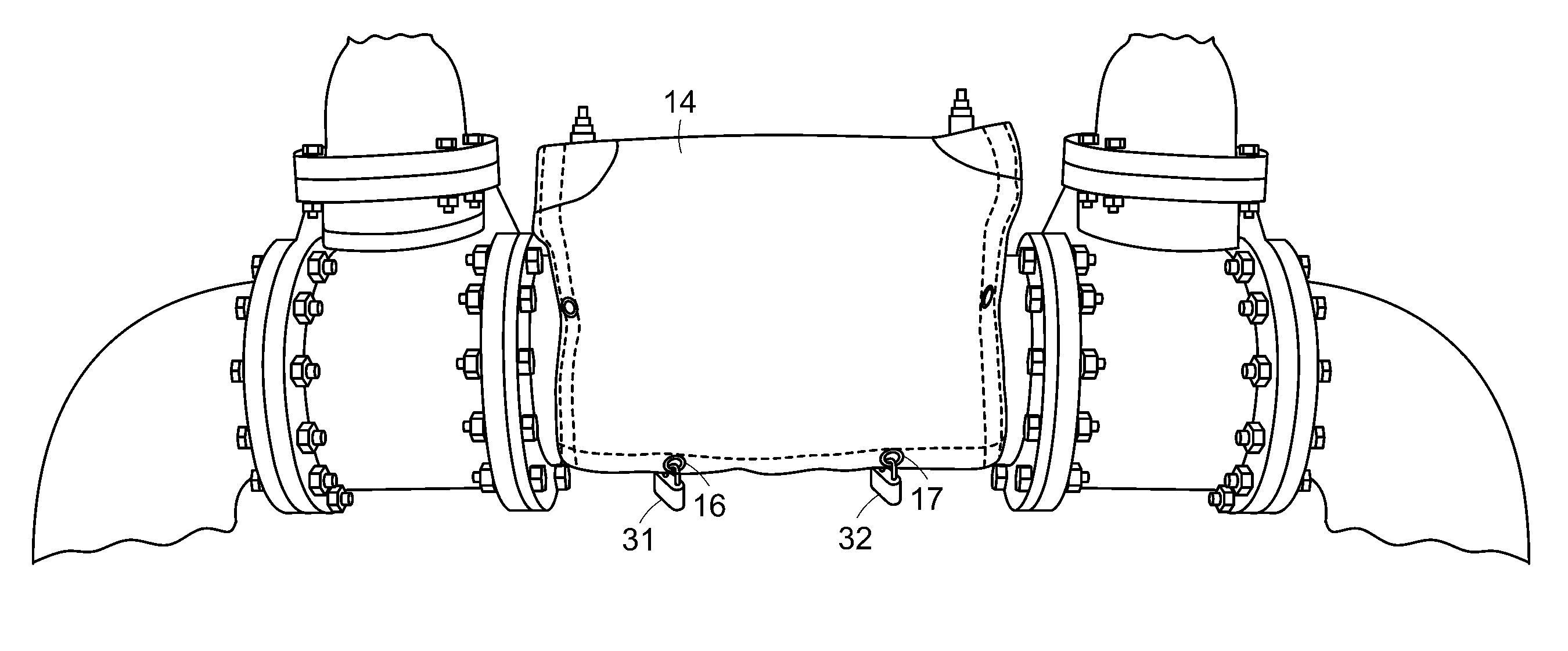

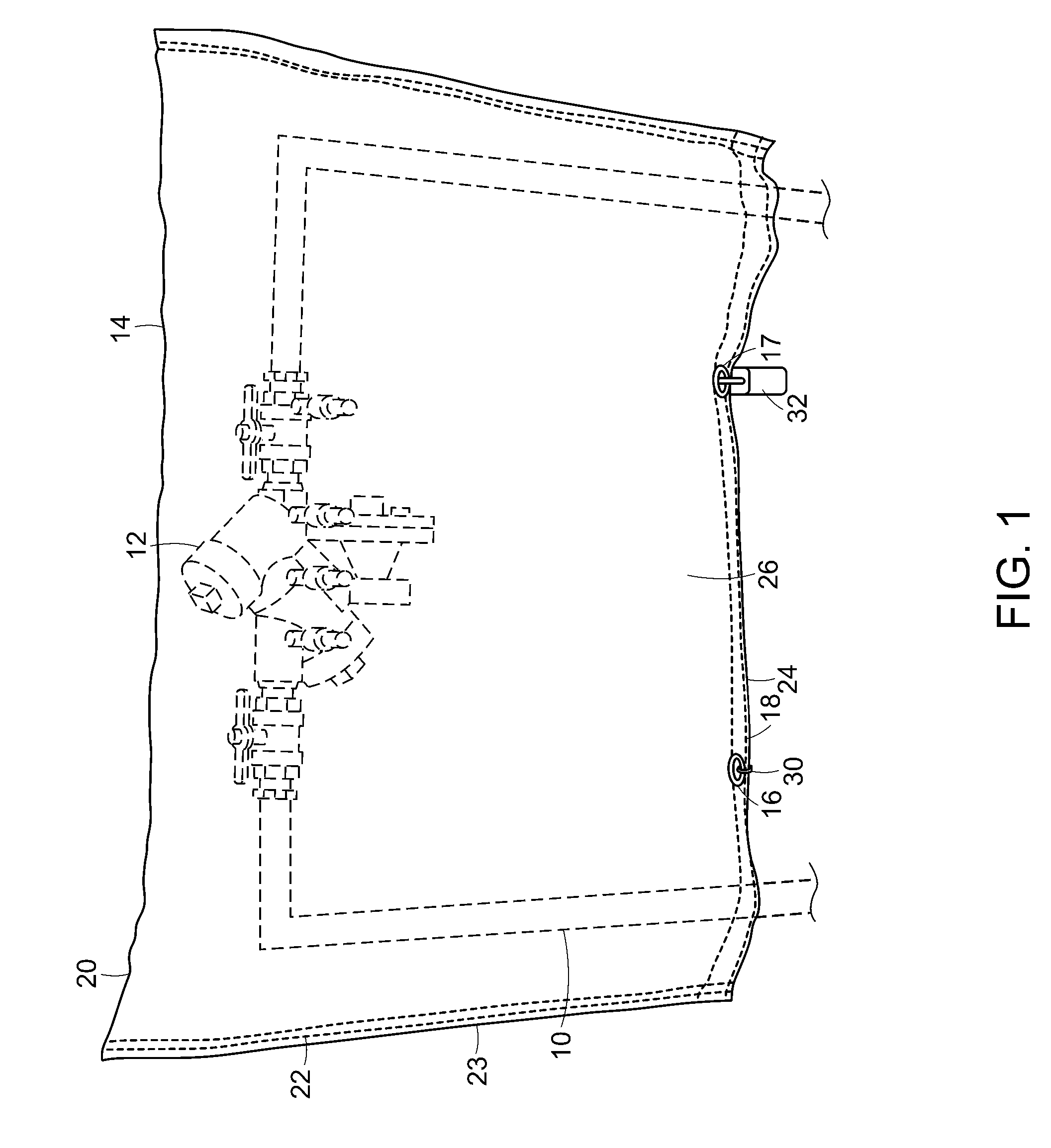

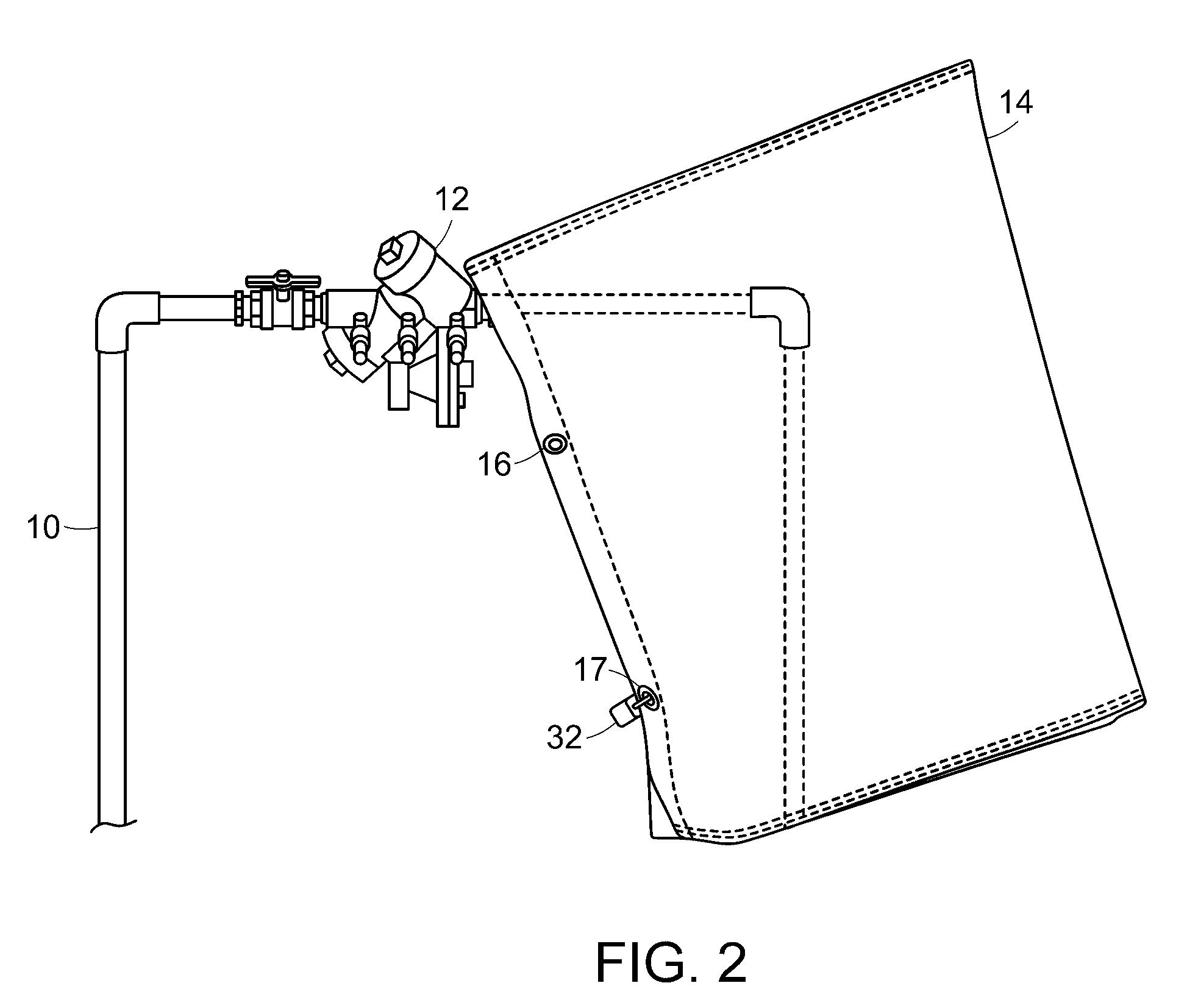

Thermal Cover

InactiveUS20090223585A1Superior passive freeze resistanceReduce transferPipe heating/coolingFlexible pipesRadiative heat lossEngineering

The invention is directed to improvement in thermal covers used to protect piping, liquid transmission, backflow prevention systems, etc. The improved thermal cover includes an insulated pad, a heat barrier and wrapper to hold the insulated pad configured in a specific fashion so as to improve freezing resistance and / or reduction of damage due to excessive heat. Padlocks, ties, etc. secure a thermal cover by means of grommets to an underlying piping, liquid transmission, backflow prevention system, etc. component. Removal of a tie permits access to the underlying components. Padlocks provide security for the thermal cover simultaneously with the access afforded due to removal of a tie. One or more foil layers further enhance protection against radiant heat loss. The combination of the one or more components of foil backing attached to structurally strong foam contributes to the thermal cover's ability to maintain its shape and it's effectiveness over time.

Owner:BULLER DENNIS WILSON

Solar collector panel for heating ventilation air

ActiveUS7694672B2Easy to manufactureImprove reliabilityRoof covering using slabs/sheetsSolar heating energyRadiative heat lossEngineering

A solar collector panel is disclosed for heating of air, in which the conventional insulation material on the back panel facing away from the sun is replaced by a spacing between a permeable back panel and a permeable heat absorber means, so that a heat convection airflow through the back panel and into the interior of the solar energy panel against the temperature gradient prevents the convection heat loss in the opposite direction. The back panel also reduces the radiation heat loss from the heat absorber means. Furthermore, in case the flow of air through the solar energy panel is stopped, the convection-insulation will no longer be effective, and a photovoltaic cell panel placed within the solar energy panel and generating electricity from the solar radiation will not be subjected to the damaging high stagnation temperature of a traditionally insulated solar collector panel.

Owner:NORTON CHRISTENSEN INC

Radiative heat loss cooling coating, preparation method and application thereof

InactiveCN103756389AImprove reflectivityImprove emissivityReflecting/signal paintsRadiative heat lossJunction temperature

The invention discloses a radiative heat loss cooling coating which comprises a component A, a component B and a filler, wherein the component A is a main coating, and is a solution prepared by condensing modified colloidal particles treated at a high temperature, the component B is an ethidene diamine curing agent, the weight ratio of the component A to the component B is 9:1, and the filler is a material which is high in heat conductivity and has an infrared emitting property. The radiative heat loss cooling coating disclosed by the invention can be applied to an LED (Light Emitting Diode) lamp, automatically radiates heat into an atmosphere space or a lamp body at an emitting rate of about 0.9 epsilon and an infrared wavelength band of 0.5-13.5 mu m so as to accelerate heat exchange and reducing temperatures of the surface and the interior of an LED lamp body, thereby driving the reduction of a work junction temperature of an LED chip.

Owner:SHANDONG YAMING LIGHTING TECH

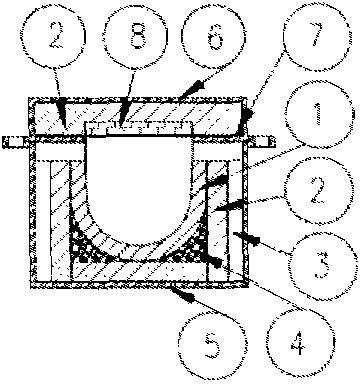

Method and device for improving surface quality of cast blank of continuous casting machine by adding covering slag

The invention relates to a method and a device for improving the surface quality of a cast blank of a continuous casting machine by adding covering slag. The device comprises a crystallizer, wherein a crystallizer liquid covering slag adding system is connected to a crystallizer opening in the upper part of the crystallizer; by means of the system, solid covering slag is molten by using a medium frequency induction heating technology and is then heated to a certain temperature, the outflow volume of liquid covering slag is controlled by adopting a stopper bar, and the liquid covering slag is added into the crystallizer after passing through a liquid covering slag distributor and a guide pipe, so as to form a full-liquid covering slag layer at the upper part of molten steel in the crystallizer. Meanwhile, a crystallizer heat-insulation cover is additionally arranged at the upper part of the crystallizer to reduce radiant heat loss at the upper part of the crystallizer. According to the method and the device disclosed by the invention, the liquid covering slag is added to the continuous casting machine, and the addition amount of the liquid covering slag is controlled according to the thickness of the liquid covering slag layer, such that the surface quality of a continuously cast blank is improved; in addition, The method disclosed by the invention is a substitute method of a conventional solid covering slag adding method for a continuous casting machine, has universality and can be applied to various continuous casting machines for, such as, square billets, round billets and plate billets.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Preparation method of infrared electrothermal film

InactiveCN105813241AIncrease profitReduce radiative heat lossHeating element materialsRadiative heat lossFar infrared

The invention discloses a preparation method of an infrared electrothermal film. The infrared electrothermal film comprises a substrate, a first electrothermal film and a second electrothermal film. The infrared electrothermal film prepared according to the method is combined with the advantages of a graphene heating film and a semiconductor heating film, a graphene far infrared heating part can be simulated by tiny current, energy is saved by 60% compared with a traditional heating mode, and the utilization ratio of electric energy is improved; the semiconductor heating film employing the above material and proportion is small in heat conduction resistance, and heat can be rapidly transferred to a heated body during energization; and moreover, the heating mode is high in heat conductivity, thus, the far infrared heating film is not high in temperature, no phenomena such as red getting and hot is generated, and the radiation heat loss is low.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

Novel solar heat collector with net wires

InactiveCN103075814AIncrease heat absorptionIncrease the areaSolar heating energySolar heat devicesRadiative heat lossEngineering

The invention relates to a novel solar heat collector with net wires, which comprises a casing body, a heat-preservation heat insulating layer, a transparent cover plate and a sealing component, wherein the heat-preservation heat insulating layer is stuck at the inner wall of the casing body, and the transparent cover plate is connected with the casing body by using the sealing component so as to form a hollow cavity. The novel solar heat collector with the net wires is characterized by also comprising a heat absorbing body with net wires, wherein the heat absorbing body with the net wires is arranged on the bottom heat-preservation heat insulating layer in the hollow cavity, which is opposite to the transparent cover plate. The heat absorbing body with the net wires comprises a metal net and a metal wire layer. The heat absorbing body with the net wires can comprise a layer of metal net and a layer of metal wire layer and can also comprise two layers of metal nets at the upper part and the lower part and a layer of metal wire layer clamped in the middle, and the metal wire layer is formed by evenly laying bulk metal wires. The novel solar heat collector with the net wires has higher sunlight absorption efficiency and higher photo-thermal conversion efficiency. The convective heat loss and the radiative heat loss can be reduced, the processing difficulty is small, and the cost is low.

Owner:SHANXI MINGHAO JINDA NEW ENERGY

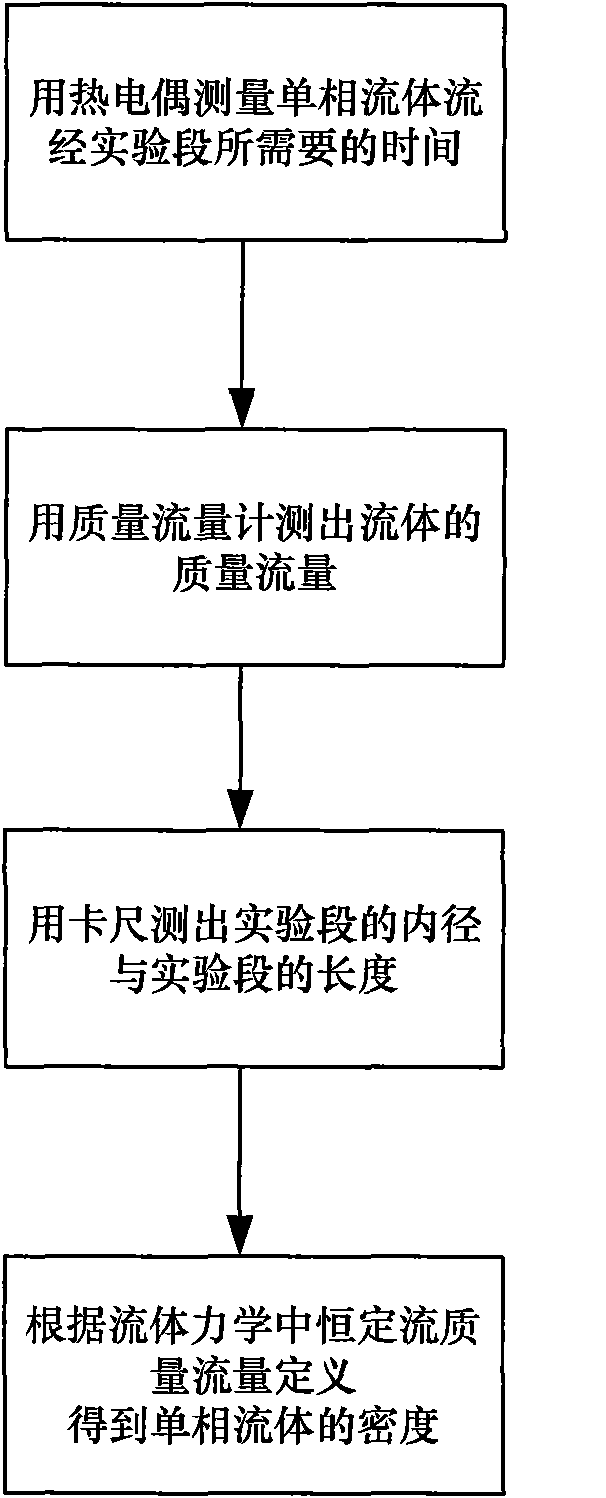

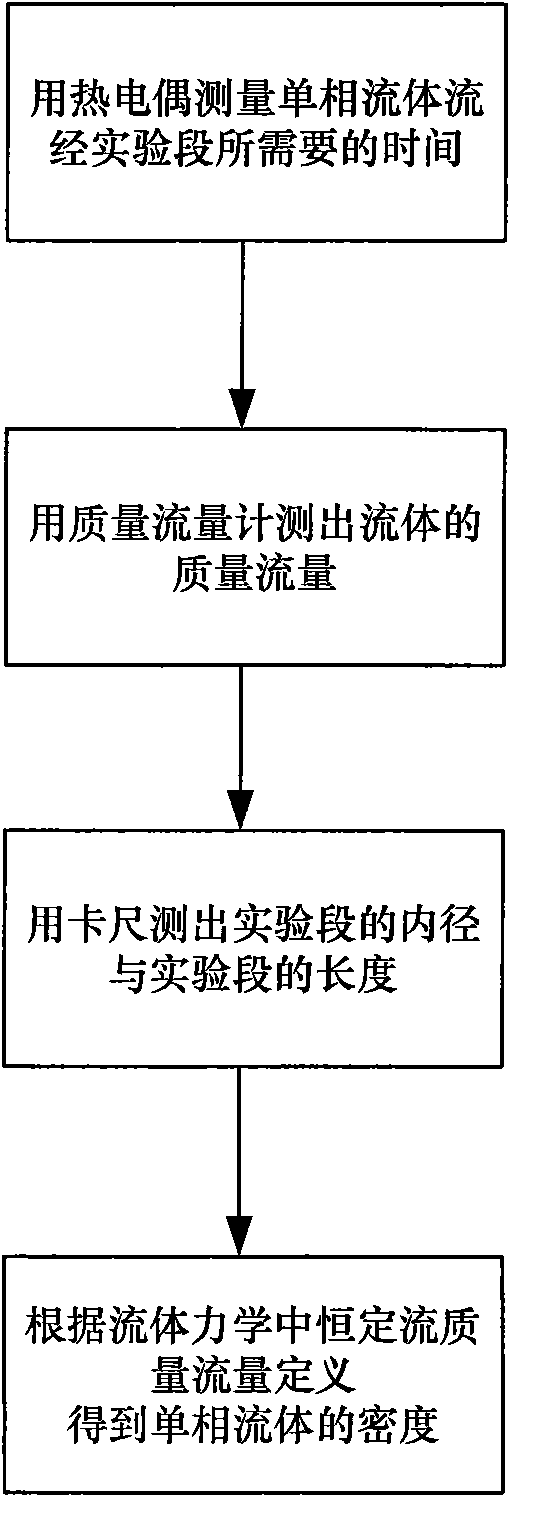

Density measuring method suitable for single-phase flow fluid and measuring device thereof

InactiveCN101936865AEasy to operateOvercoming the pitfalls of density measurementSpecific gravity using flow propertiesRadiative heat lossStreamflow

The invention discloses a density measuring method suitable for single-phase flow fluid and a measuring device thereof. In the density measuring method, the flow speed of single-phase fluid in an experimental section is mainly calculated according to the response time difference of thermoelectric couples at the inlet and outlet of the experimental section based on the principle of mass conservation of steady flow in fluid mechanics and mass flow and other relevant data are measured, so that the density of the single-phase fluid is calculated. The inside of the measuring device for applying the method is vacuumized, a heat-shielding screen is arranged in a vacuum cavity and the experimental section is arranged in the heat-shielding screen, so that convective heat exchange loss and radiation heat loss are reduced effectively and correct density experimental data can be obtained. The method has simple and convenient operation and is suitable for measuring the density of the single-phase fluid under various pressures and at various temperatures.

Owner:BEIHANG UNIV

Submerged arc foaming agent

InactiveCN101696465ARealize full submerged arc operationExtend your lifeRadiative heat lossFoaming agent

The invention discloses a submerged arc foaming agent that is used for the foaming submerged arc in the whole smelting process of a refining furnace. The submerged arc foaming agent is prepared by mixing the following materials by weight percent: 6-8 percent of SiO2, 40-50 percent of CaO, 10-15 percent of CaC2, 2-6 percent of Al2O3, 10-15 percent of Fe2O3, 1-6 percent of MgO, 8-10 percent of BaO and 8-15 percent of powder C. Compared with the prior art, the product is used on the LF steel ladle refining furnace so as to ensure the foaming submerged arc in the overall smelting process, thereby reducing the radiation heat loss of the electric arc, improving the heat efficiency, avoiding radiation erosion of high-temperature arc light to a burner liner, prolonging the service life of the burner liner, ensuring high dephosphorizing efficiency and rapid speed and shortening the smelting time.

Owner:西峡县鑫宇冶金耐材有限责任公司

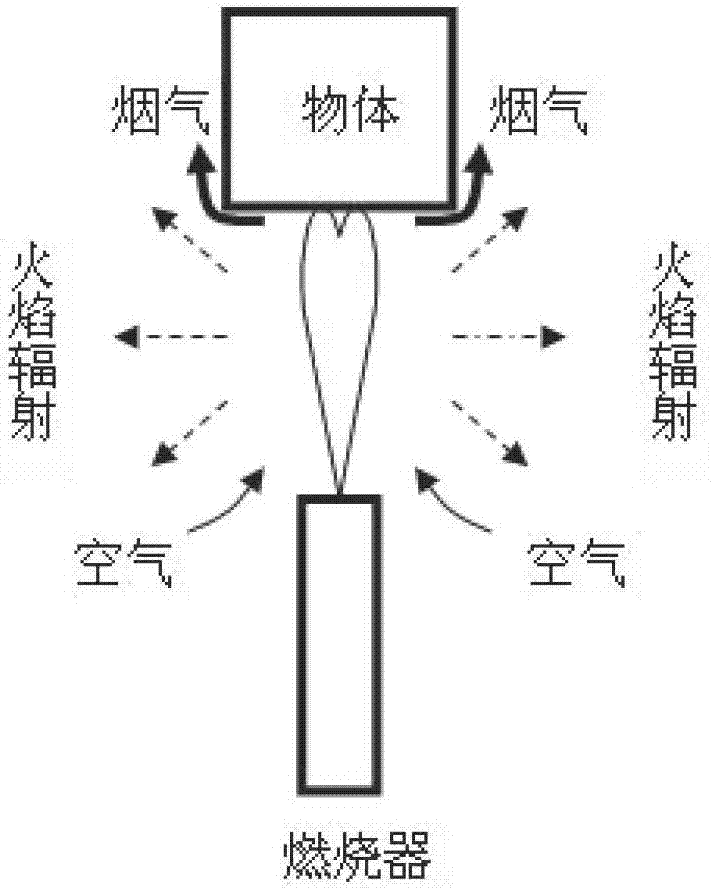

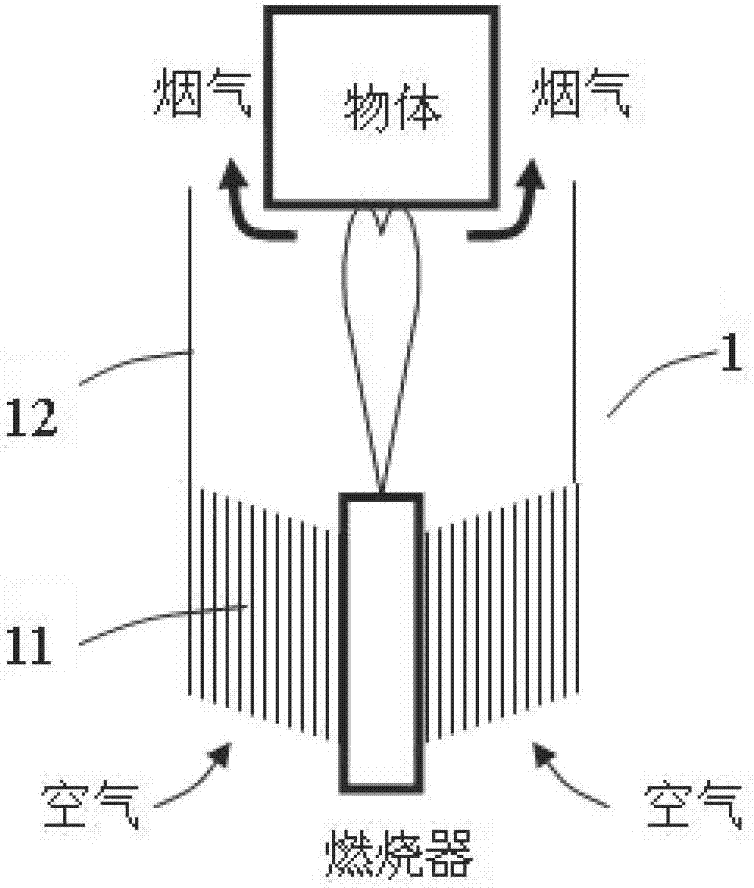

Preheating body for preheating combustion-supporting air by using flame radiation and heat energy equipment with preheating body

PendingCN107314394AReduce heat lossHigh thermal efficiencyDomestic stoves or rangesCombustion processThermal energyRadiative heat loss

The invention discloses a preheating body for preheating combustion-supporting air by using flame radiation. The preheating body is characterized by being provided with a series of heat absorption and transfer surfaces for absorbing the flame radiation, wherein a combustion-supporting air channel is formed between every two adjacent heat absorption and transfer surfaces; the preheating body transmits heat energy, which is obtained by conversion of flame radiation energy, to the combustion-supporting air which flows through and is in direct with the heat absorption and transfer surfaces; and the structural form of the preheating body is that the preheating body has a blackbody effect on the flame radiation towards the preheating body. The preheating body is in the following specific forms: a spiral winding sheet form, a radiation fin form, a multihole breathable form, a vortex fin form and the like. The invention further discloses heat energy equipment with the preheating body for preheating the combustion-supporting air by using the flame radiation. The preheating body absorbs and converts the outwards emitted flame radiation energy in basic modes for heating an object with flame into heat energy, and then preheats the combustion-supporting air by using the heat energy, so that flame radiation heat loss is avoided, and the heat efficiency is improved.

Owner:GUANGDONG UNIV OF TECH

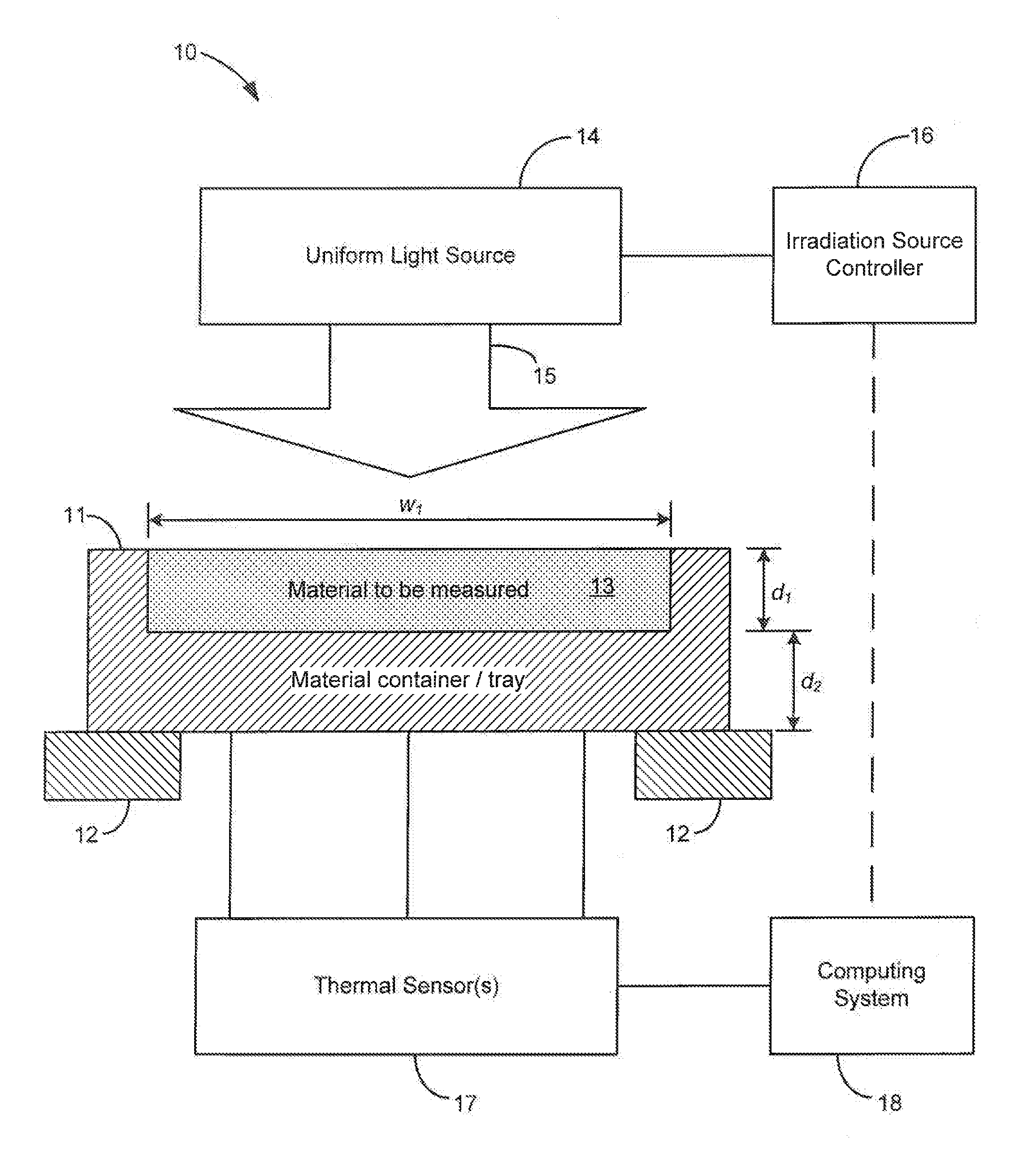

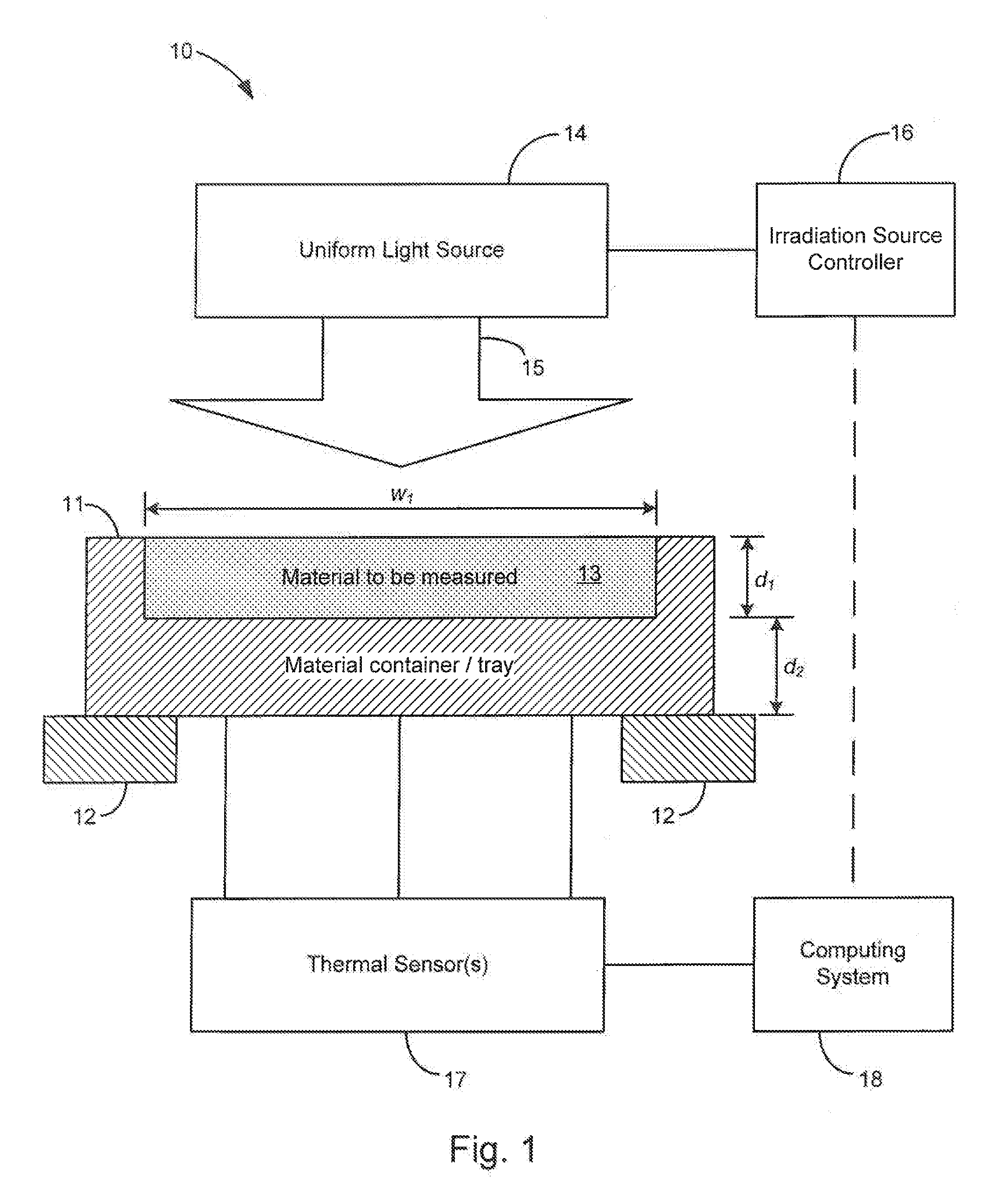

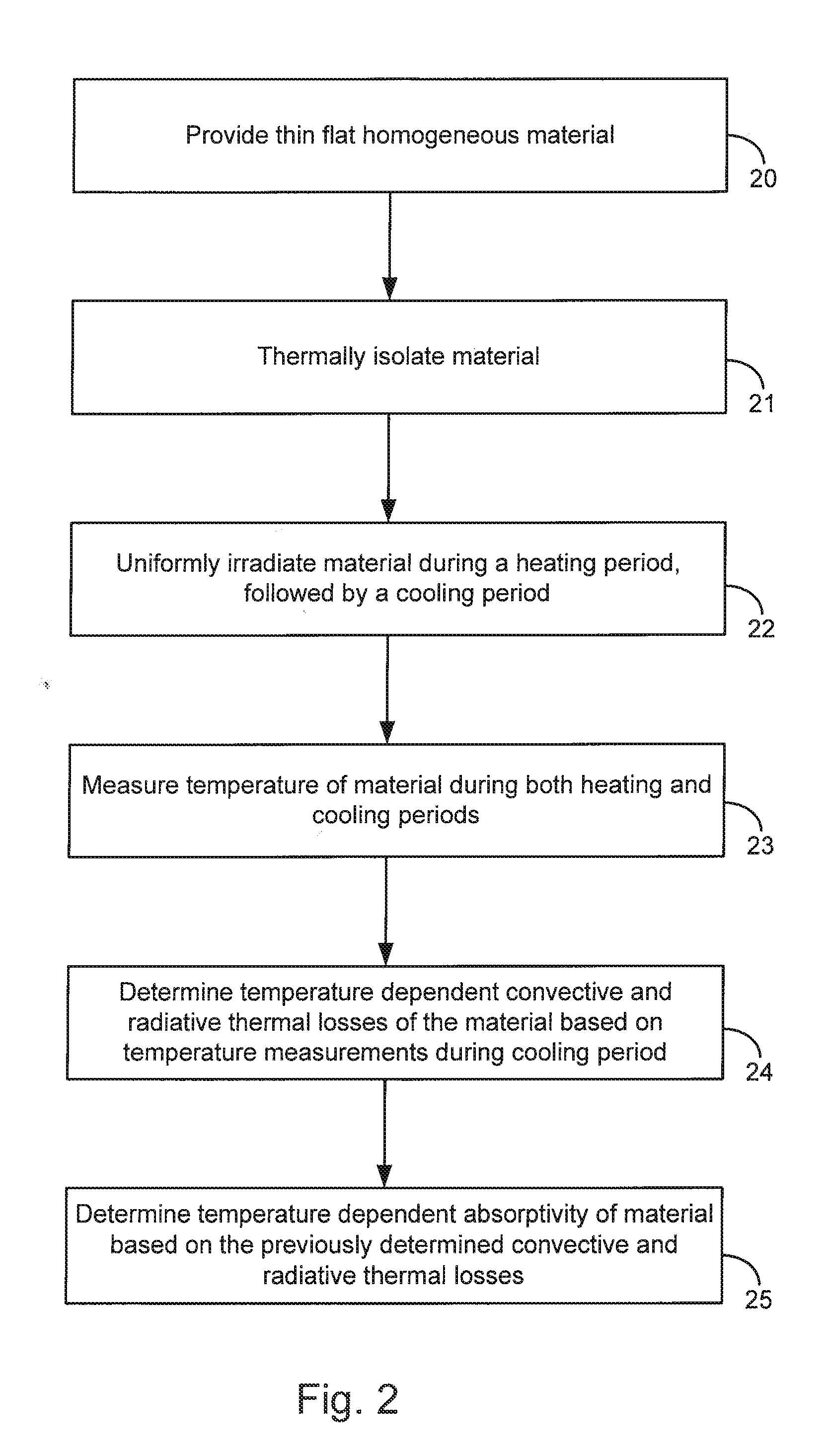

System and method for the direct calorimetric measurement of laser absorptivity of materials

ActiveUS20170016839A1Eliminate the effects ofMaterial heat developmentCalorimeterPorosityRadiative heat loss

A method and system for calorimetrically measuring the temperature-dependent absorptivity of a homogeneous material dimensioned to be thin and flat with a predetermined uniform thickness and a predetermined porosity. The system includes a material holder adapted to support and thermally isolate the material to be measured, an irradiation source adapted to uniformly irradiate the material with a beam of electromagnetic radiation, and an irradiation source controller adapted to control the irradiation source to uniformly heat the material during a heating period, followed by a cooling period when the material is not irradiated. A thermal sensor measures temperature of the material during the heating and cooling periods, and a computing system first calculates temperature-dependent convective and radiative thermal losses of the material based on the measured temperature of the material during the cooling period when beam intensity is zero, followed by calculation of the temperature-dependent absorptivity of the material based on the temperature-dependent convective and radiative thermal losses determined from the cooling period.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

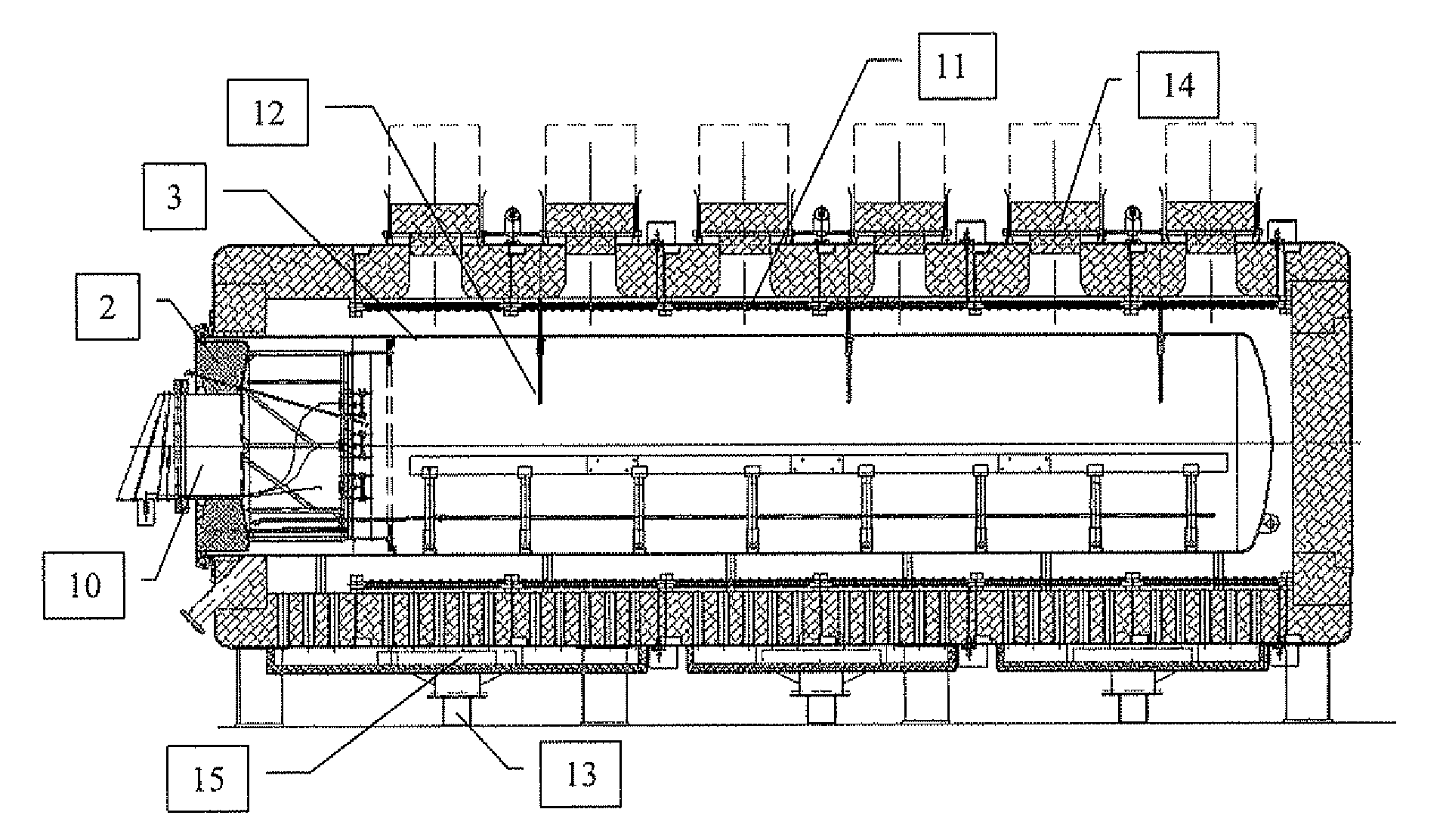

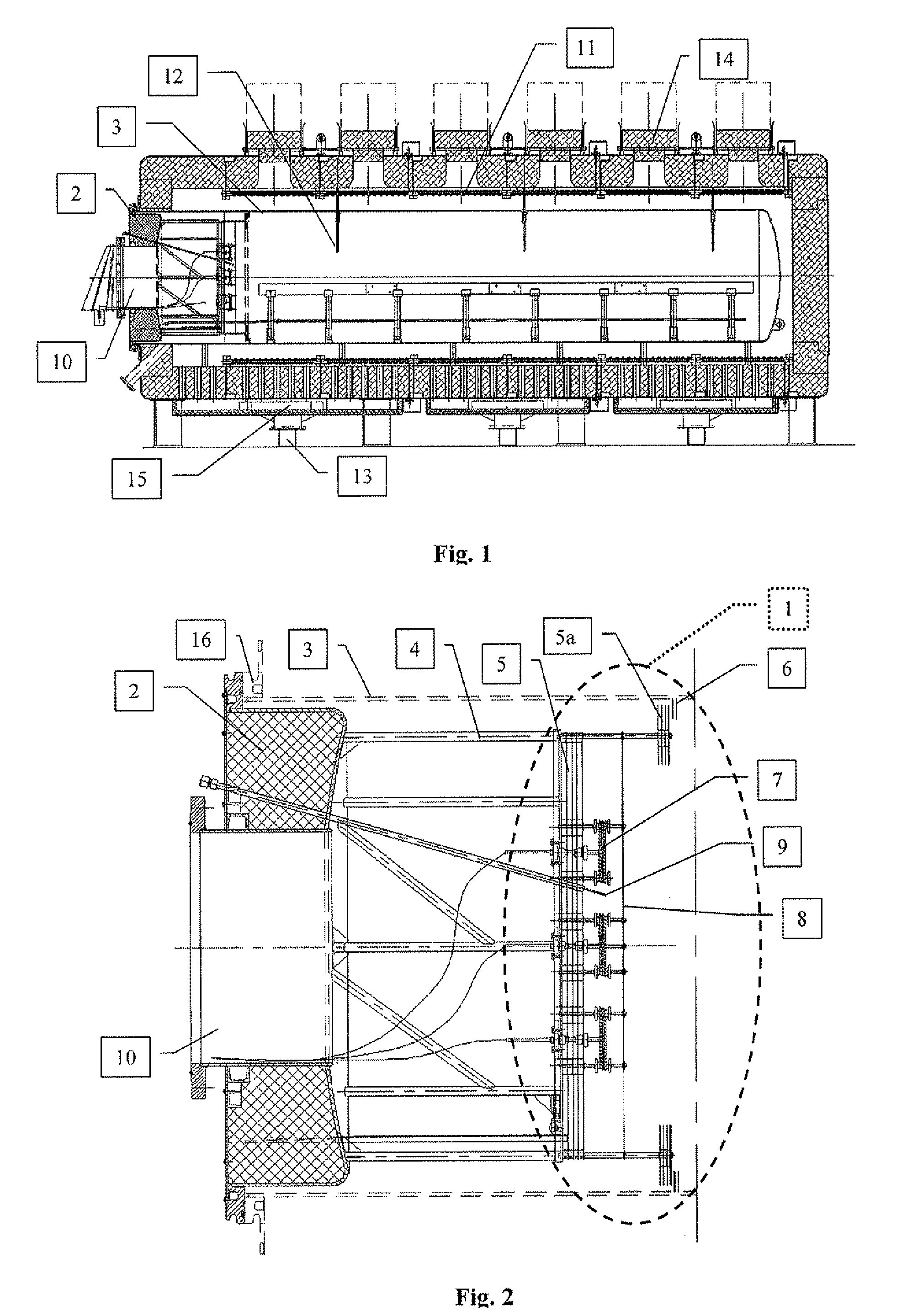

Retort furnace for heat and/or thermochemical treatment

ActiveUS20100272422A1Prevent heat lossLower working temperatureMuffle furnacesHigh-frequency/infra-red heating bakingChemical treatmentThermal insulation

A retort furnace designed for heat and heat and chemical treatment in protective gas atmosphere, process gas atmosphere or in vacuum, equipped with a retort with a lid, made of steel or heat-resisting or creep-resisting alloys, separating the process atmosphere from the ambient atmosphere, with heating elements and thermal insulation outside the retort and with a cooling system. The radiation screens, in the form of at least two metal boards, are installed at supports located at the lid inside the retort; the heating elements are located behind the radiation screens, on the retort side and are separated with the metal screen. A few radiation sealing rings are placed in the extreme area of the brackets. The radiation screens and sealing rings, as well as the circumferential sealing rings permanently fixed in the casing of retort make up the system of reducing heat losses through radiation at the wall of the retort.

Owner:SECOWARWICK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com