Novel solar heat collector with net wires

A technology of solar heat collectors and mesh wires, applied in the field of solar heat collectors, can solve the problems of increased radiation heat loss, the inability to increase the volume of solar heat collectors, and high processing costs, and achieve the suppression of convective heat loss and radiant heat Loss, improve the effect of heat transfer and heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

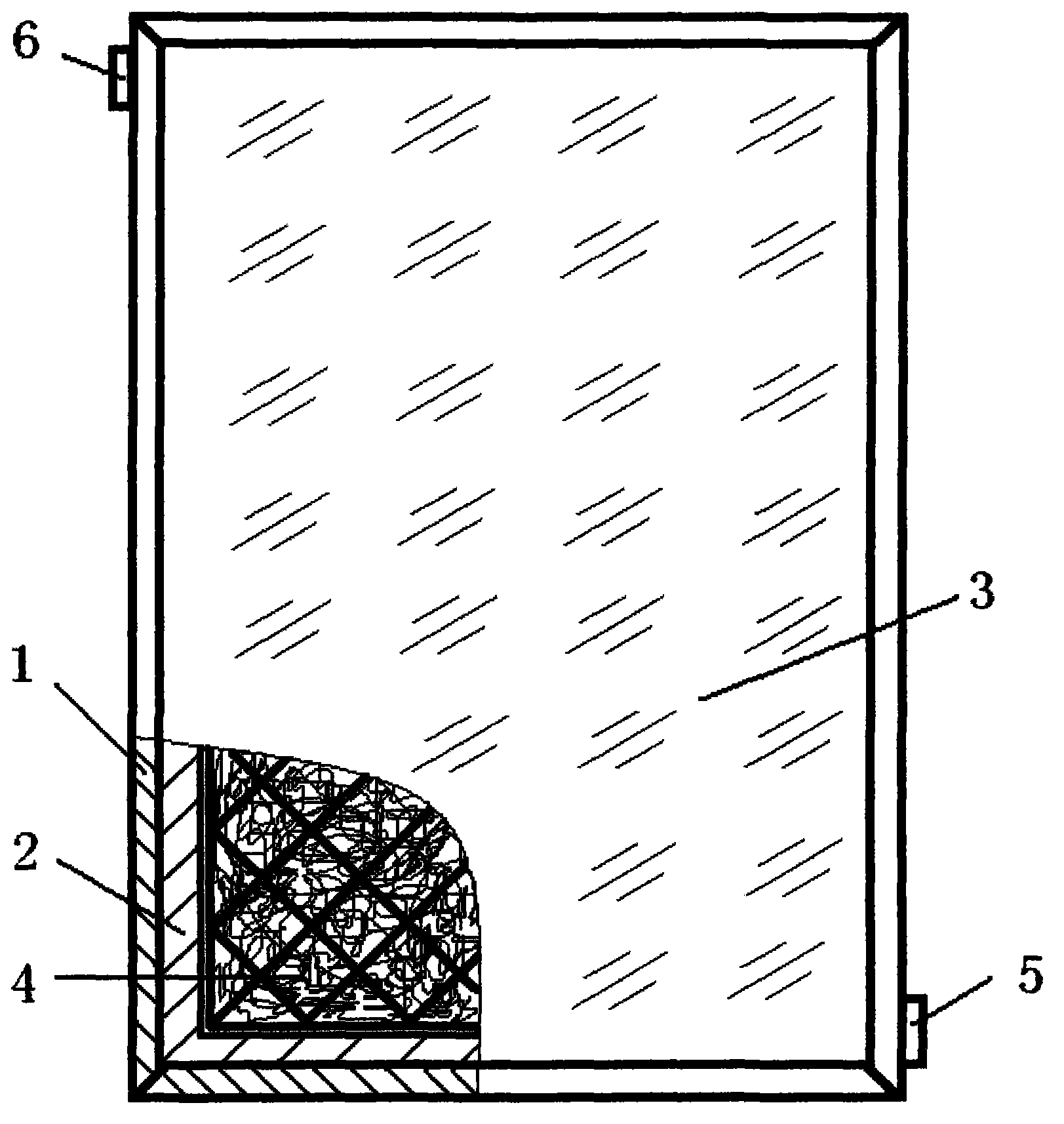

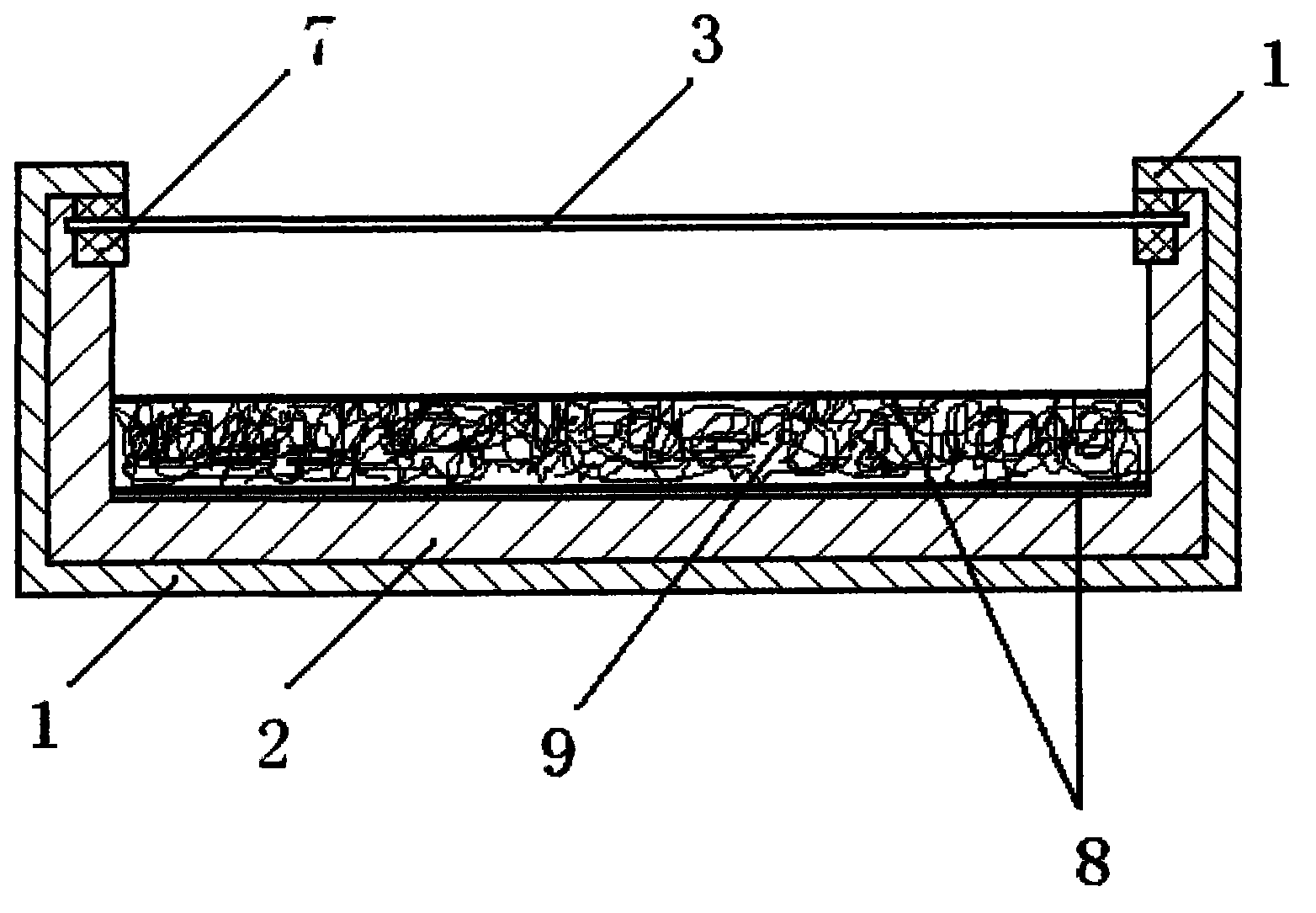

[0013] figure 1 , figure 2 Shown is a best embodiment of the present invention, the present invention is a new type of mesh solar thermal collector, which is the same as the existing flat solar thermal collector and includes an outer casing 1, a thermal insulation layer 2, and a transparent cover Plate 3, seal 7, heat transfer medium inlet 5 and outlet 6, thermal insulation layer 2 are pasted on the inner wall of outer shell 1, and transparent cover plate 3 is connected with outer shell 1 by seal 7 to form a cavity. The technical solution of the present invention is different from the flat-plate solar heat collector in that the mesh heat absorber 4 is used as the core component of the solar heat collector, and the mesh heat absorber 4 is placed in the cavity and is opposite to the transparent cover plate 3 On the bottom thermal insulation layer 2. The mesh heat absorber 4 is composed of upper and lower layers of metal mesh 8 and a metal wire layer sandwiched in the middle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com