Thermal Cover

a technology of thermal cover and liquid transmission mechanism, which is applied in the direction of service pipe system, pipe heating/cooling, mechanical equipment, etc., can solve the problems of premature deterioration of system components, liquid transmission mechanism and system, piping system and associated devices, etc., and achieves the effect of reducing heat transfer and superior passive freeze resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

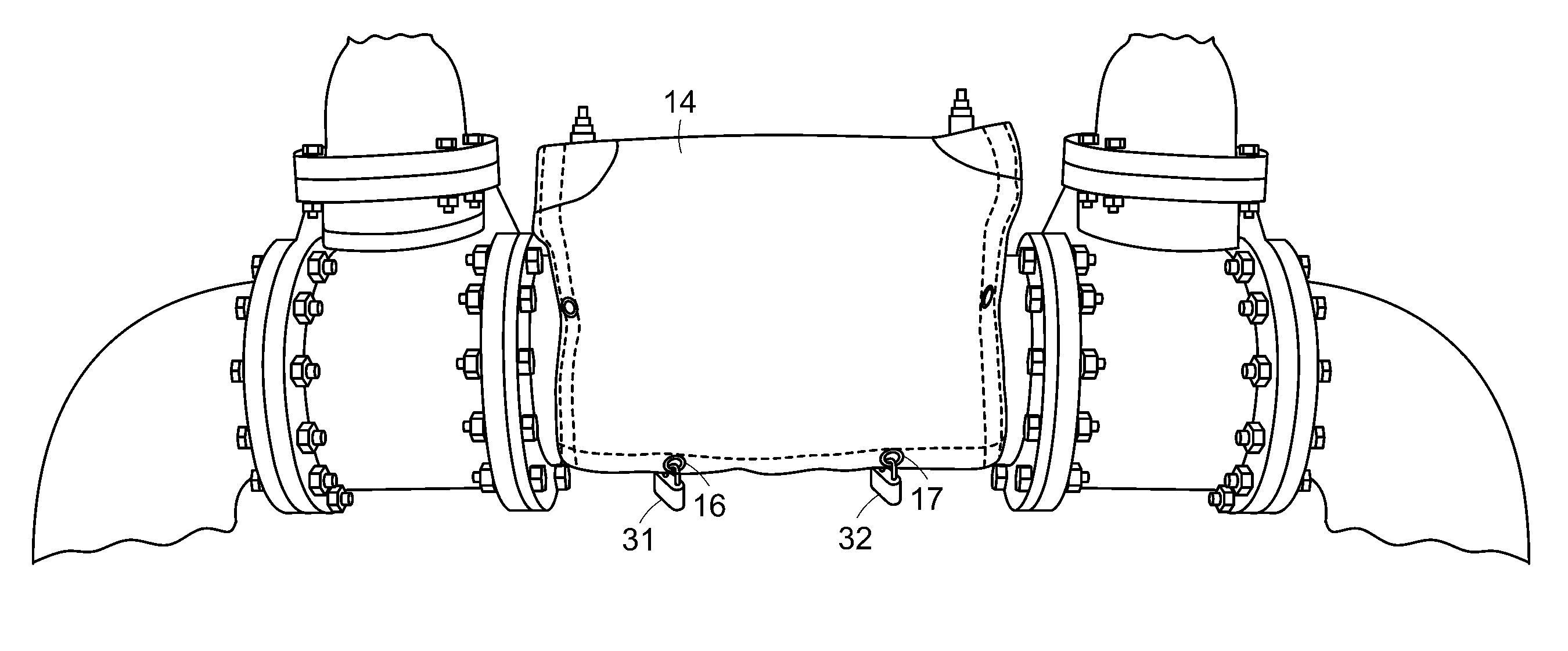

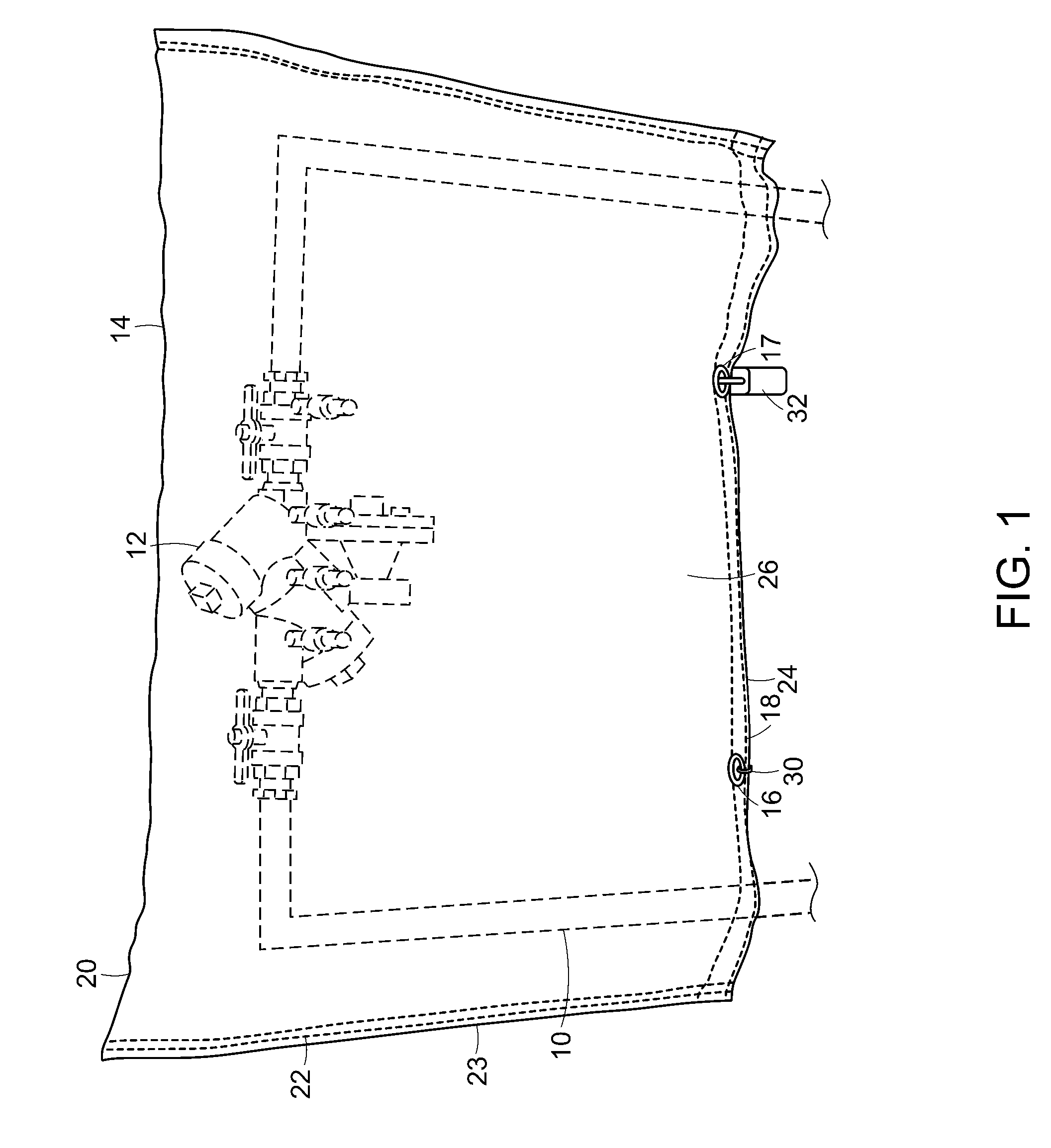

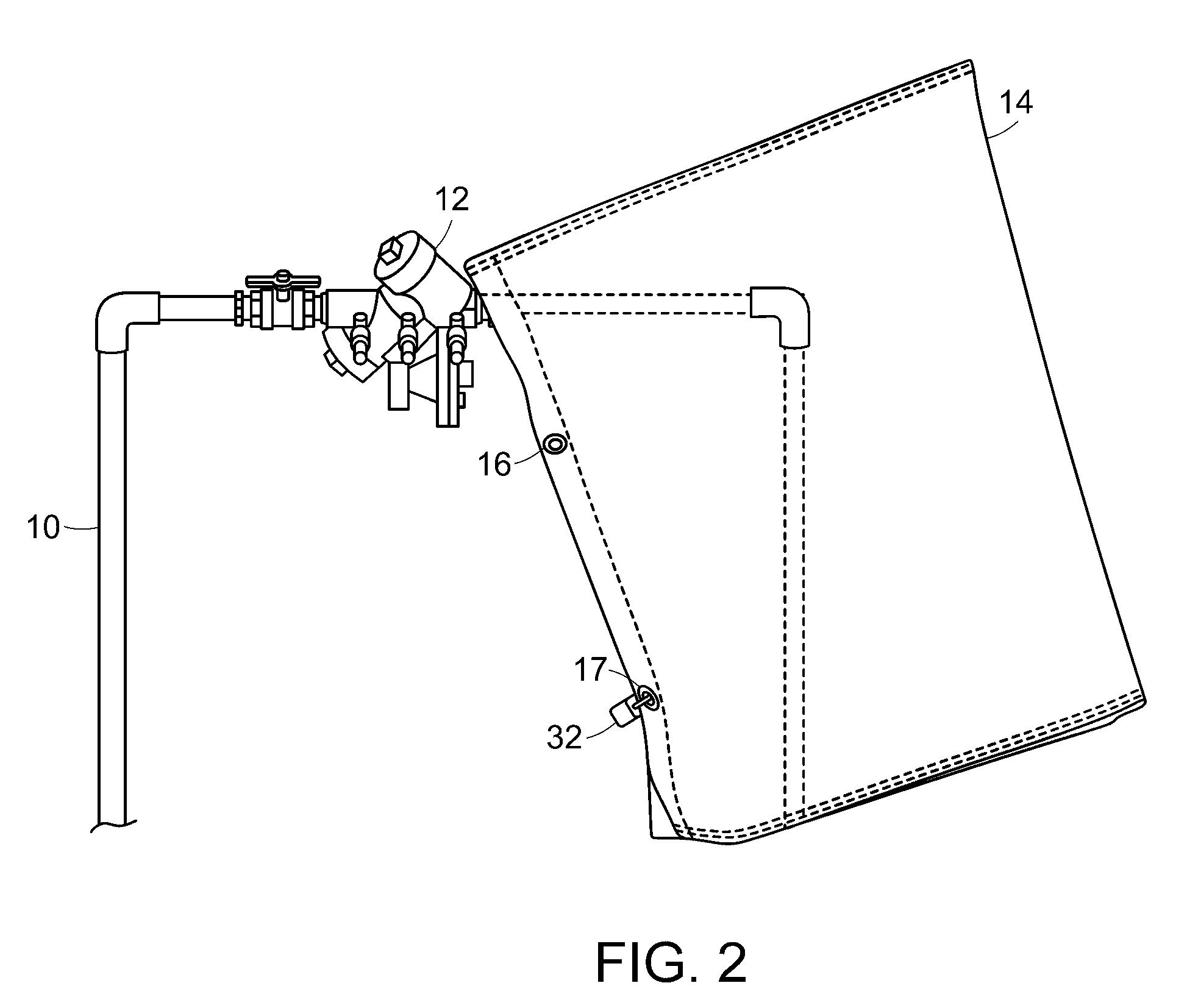

[0023]Embodiments of the invention provide more effective thermal protective covering for backflow prevention assemblies, other pipe, plumbing systems and devices, test assemblies such as test cocks, irrigation, water and other systems, etc. such as for transmission of liquids. A central feature of the present invention is the employment of a heat barrier that limits heat loss that would otherwise radiate from the protected device / system into the open air. The heat barrier includes a layer of foam or other material such as bubble wrap. In addition, the layer of foam may be backed with foil on one or both sides. The foil may or may not be bonded to the foam. The foil-backed foam combination provides a barrier to radiant heat transfer exceeding the level of heat transfer protection that would otherwise be possible. The heat barrier also reflects heat back into an insulated pad component of the thermal cover as such, acting like a “heat dam” and ultimately reducing the transfer of heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com