Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "Bubble wrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bubble wrap is a pliable transparent plastic material used for packing fragile items. Regularly spaced, protruding air-filled hemispheres (bubbles) provide cushioning for fragile items. "Bubble wrap" is a generic trademark owned by Sealed Air Corporation. In 1957 two inventors named Alfred Fielding and Marc Chavannes were attempting to create a three-dimensional plastic wallpaper. Although the idea was a failure, they found that what they did make could be used as packing material. Sealed Air Corp. was co-founded by Alfred Fielding in 1960.

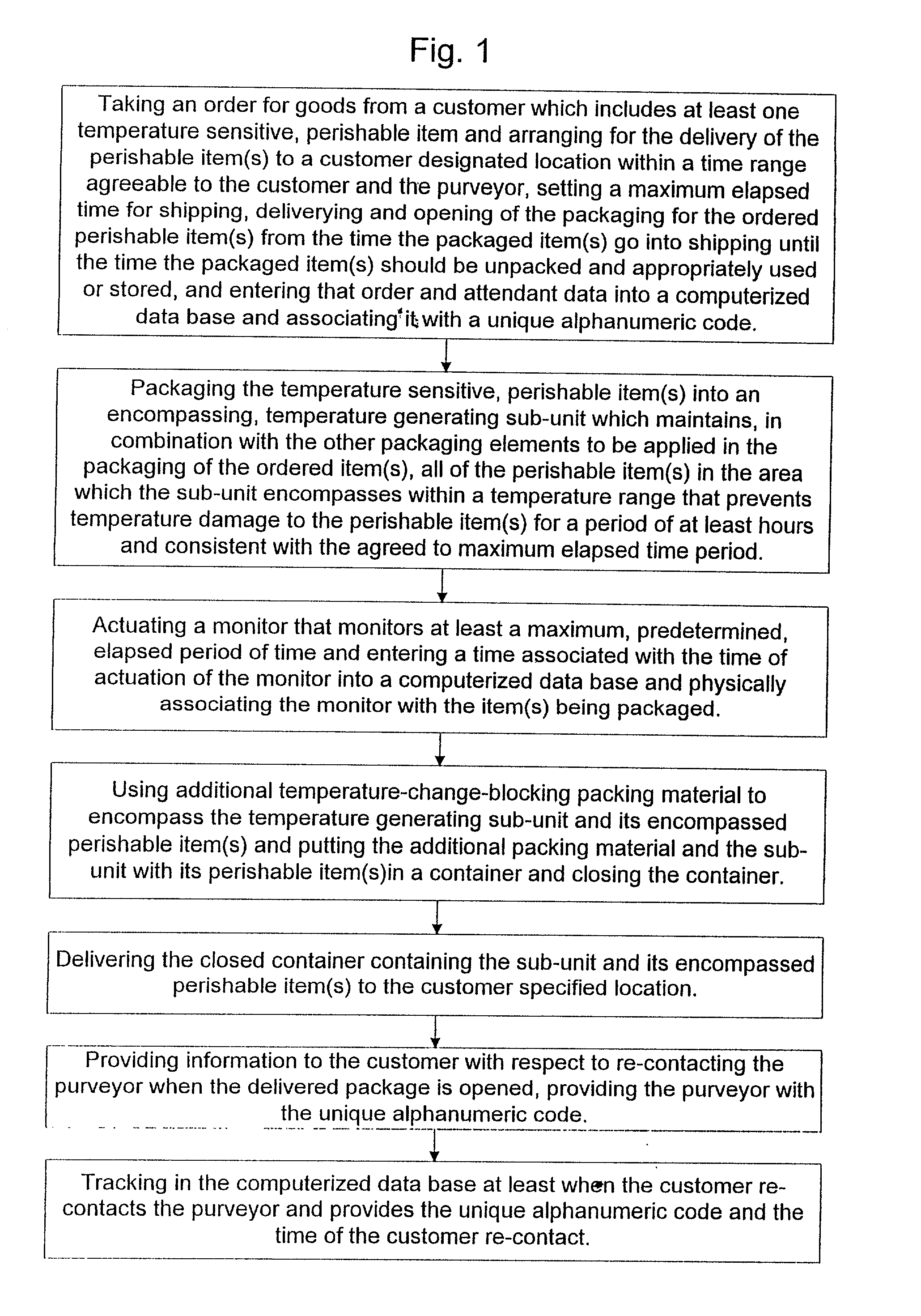

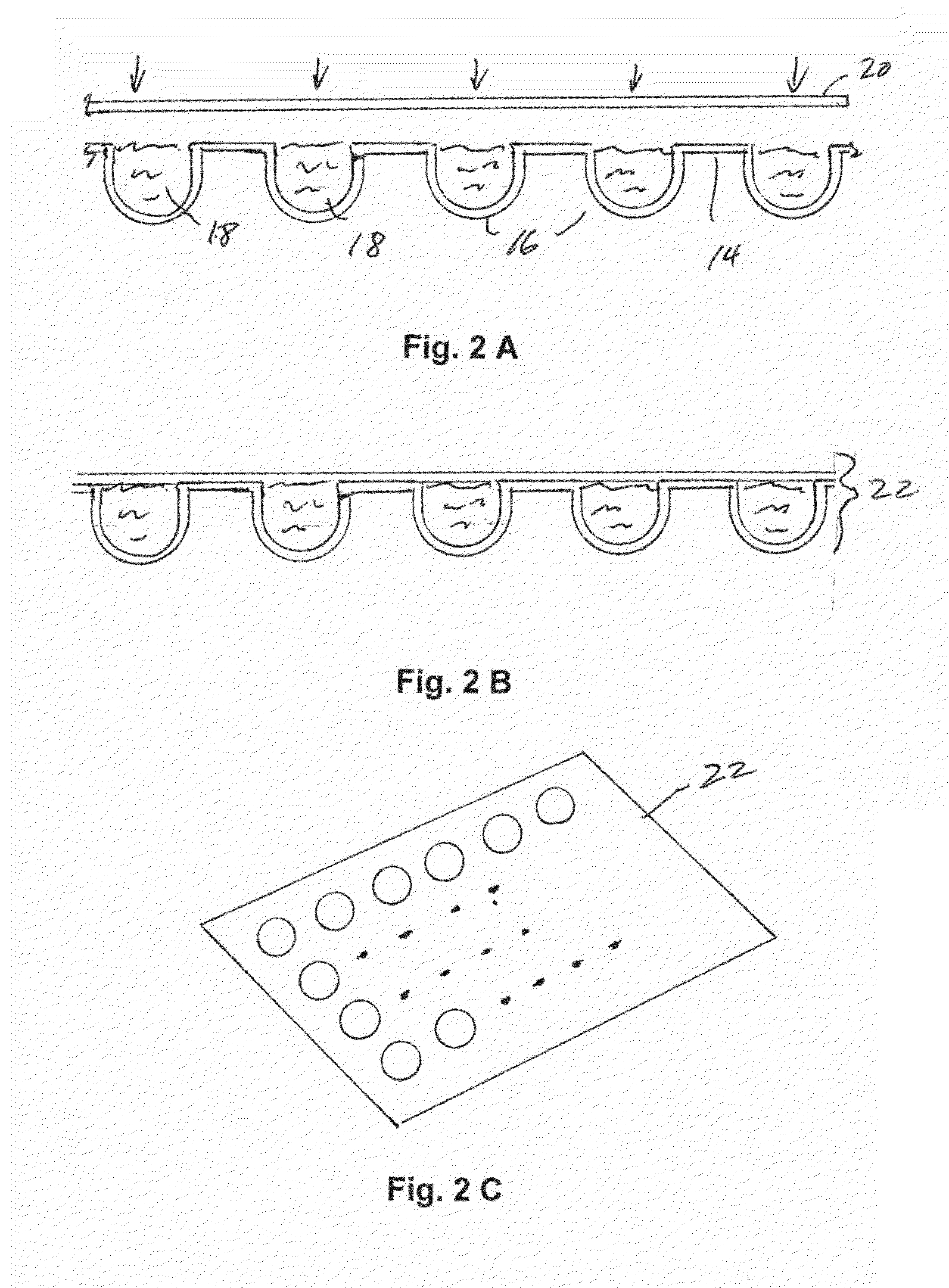

Computerized, monitored, temperature affected, delivery system for perishable goods

InactiveUS6536189B1Keep the heatSlow heatingPackage sterilisationMultiple wrapper applicationSuper absorbentBubble wrap

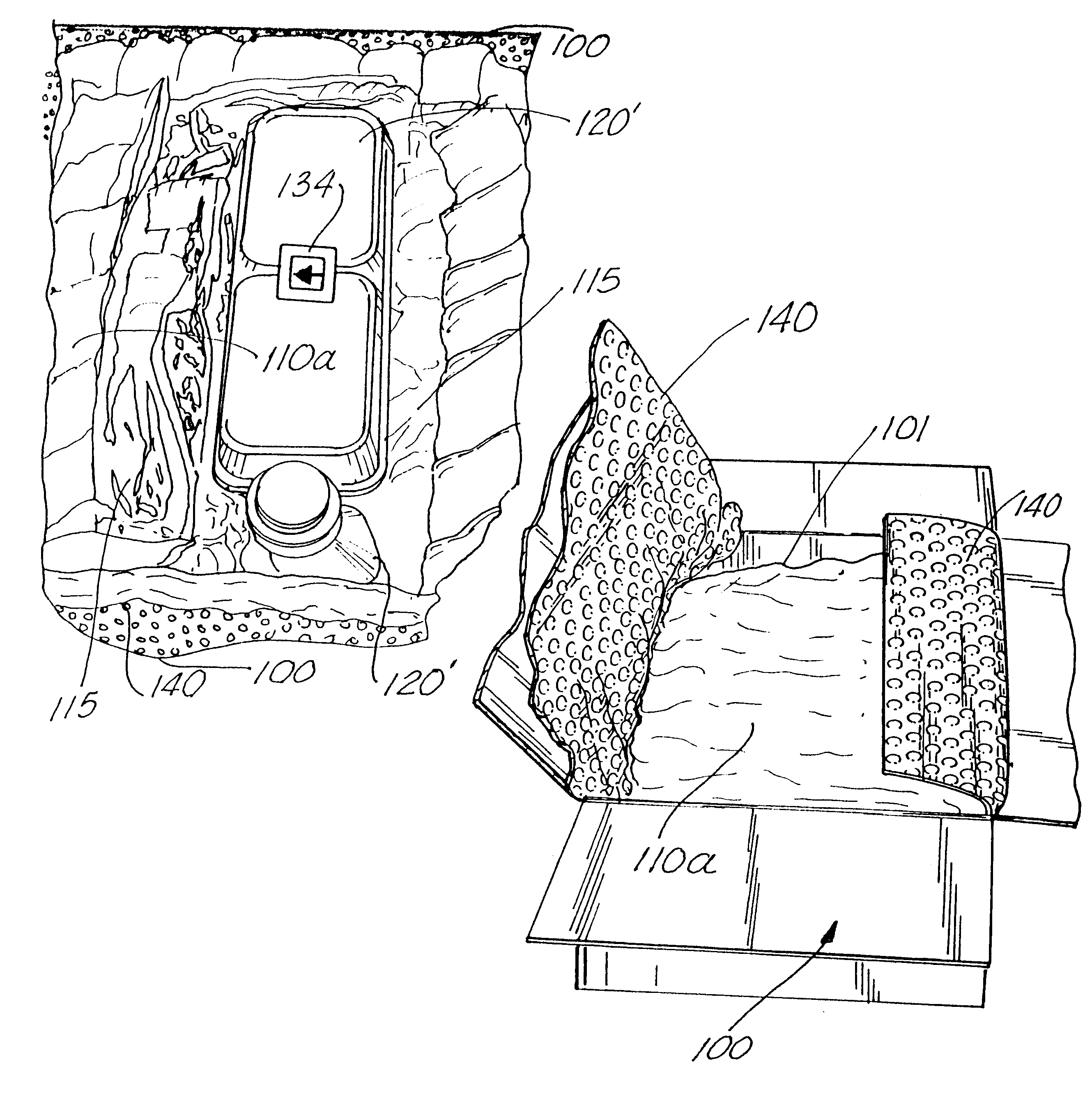

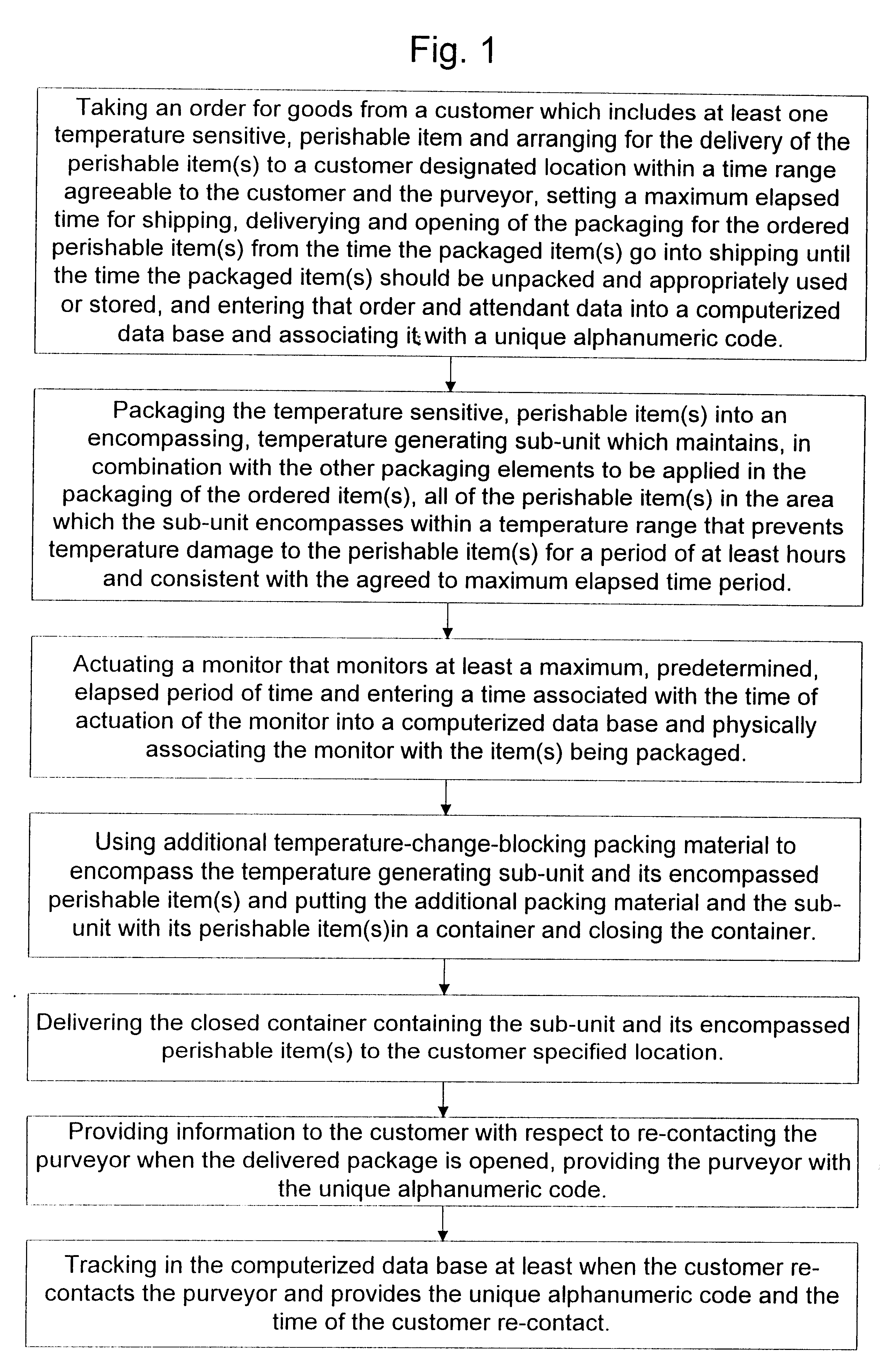

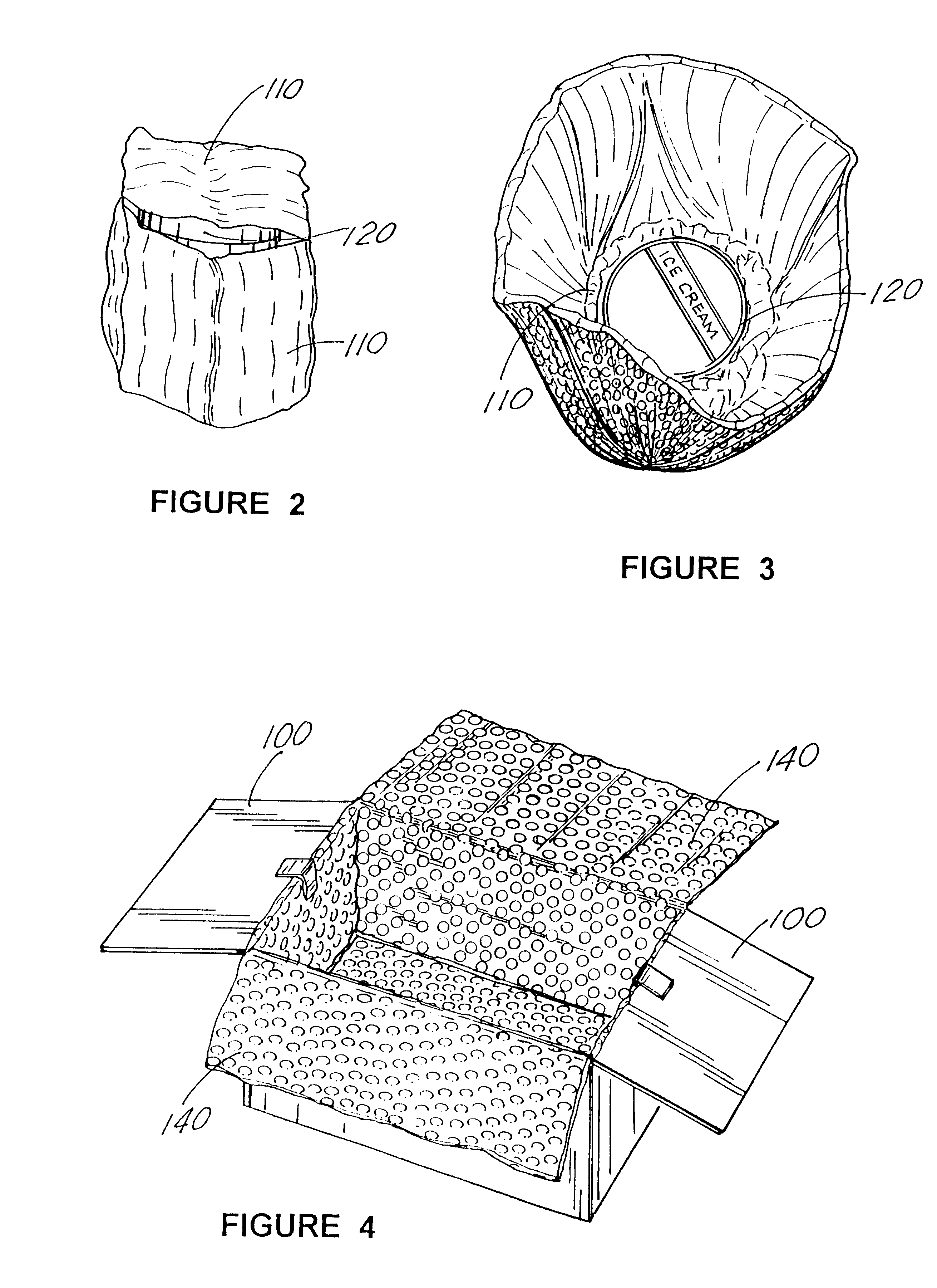

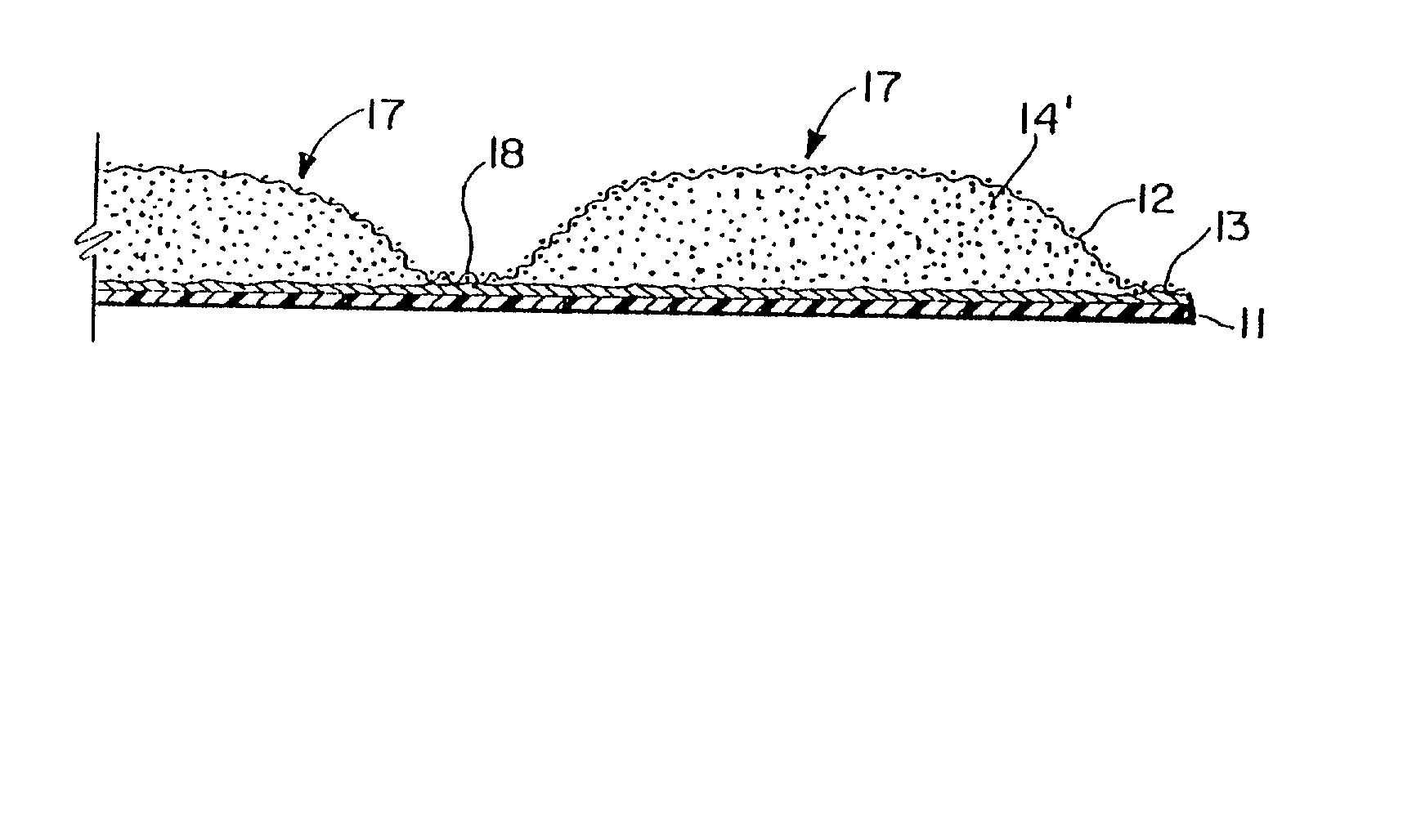

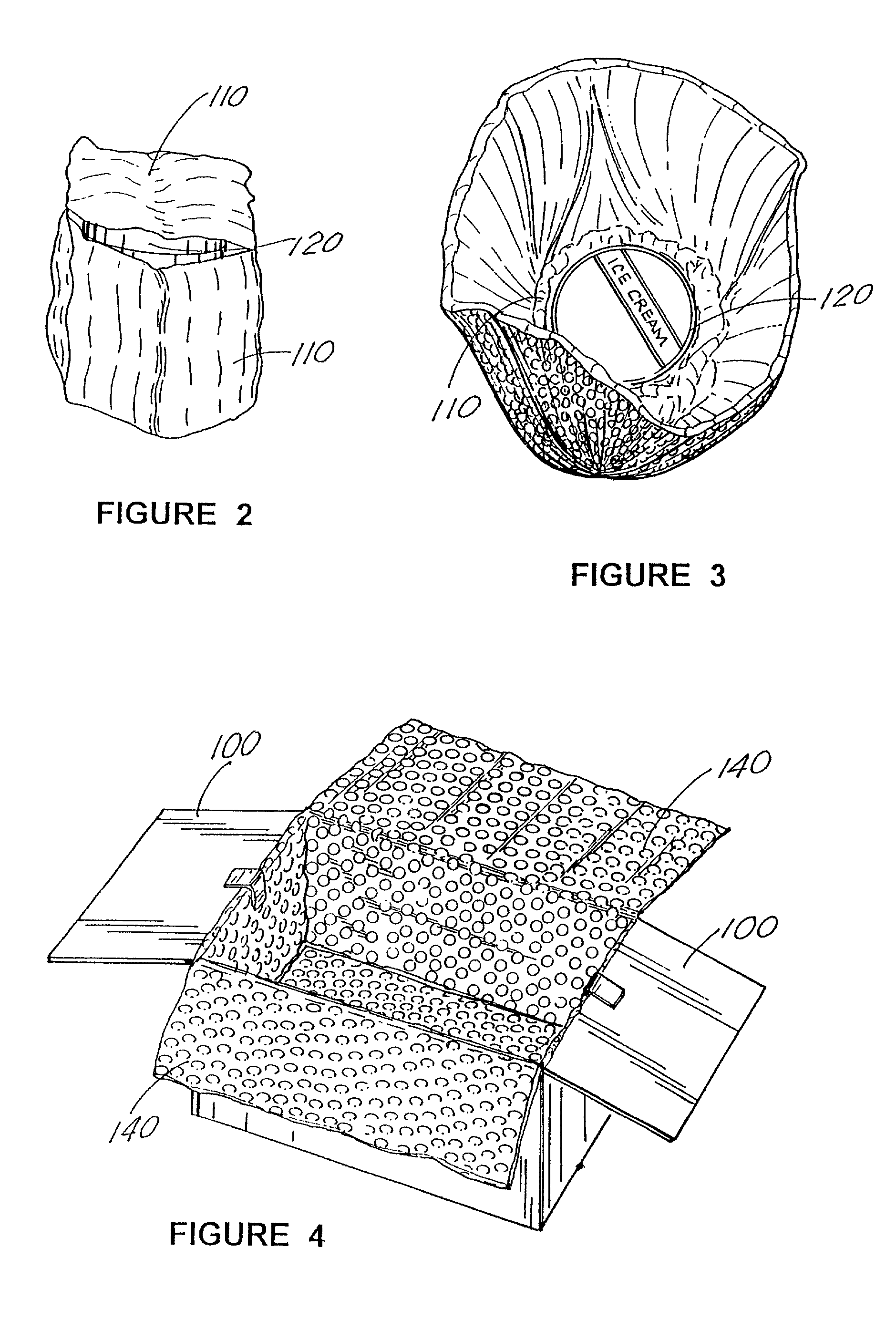

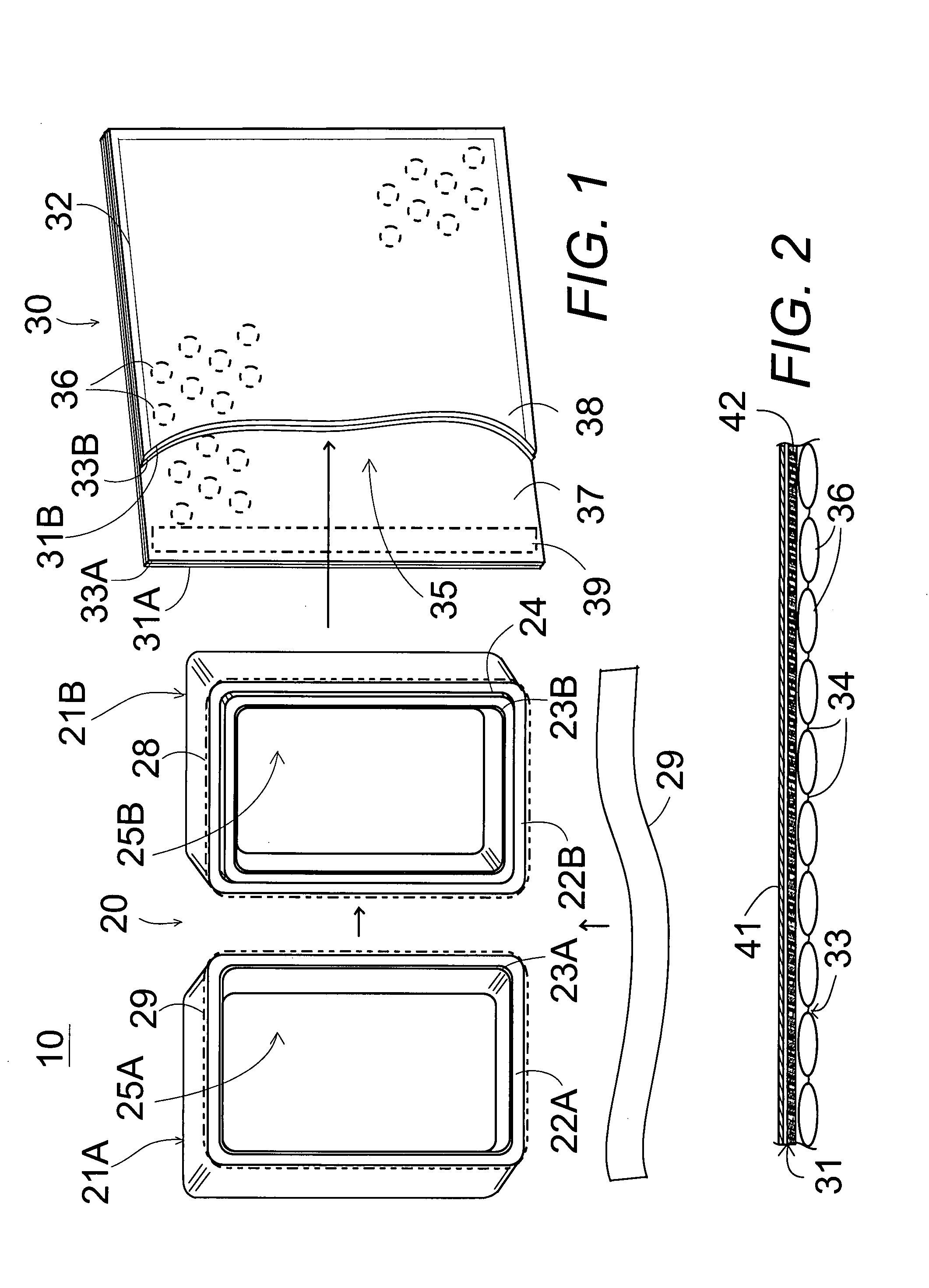

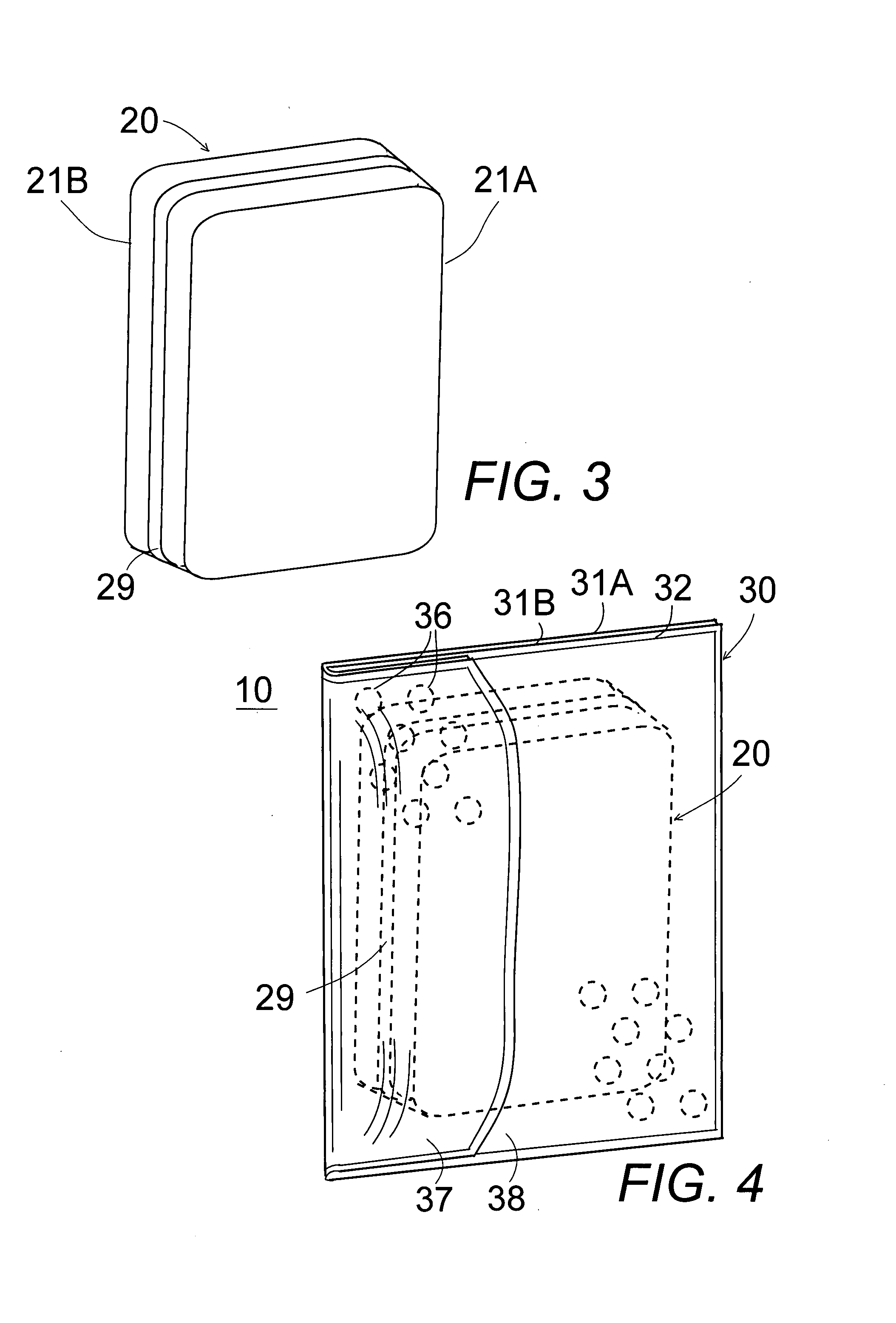

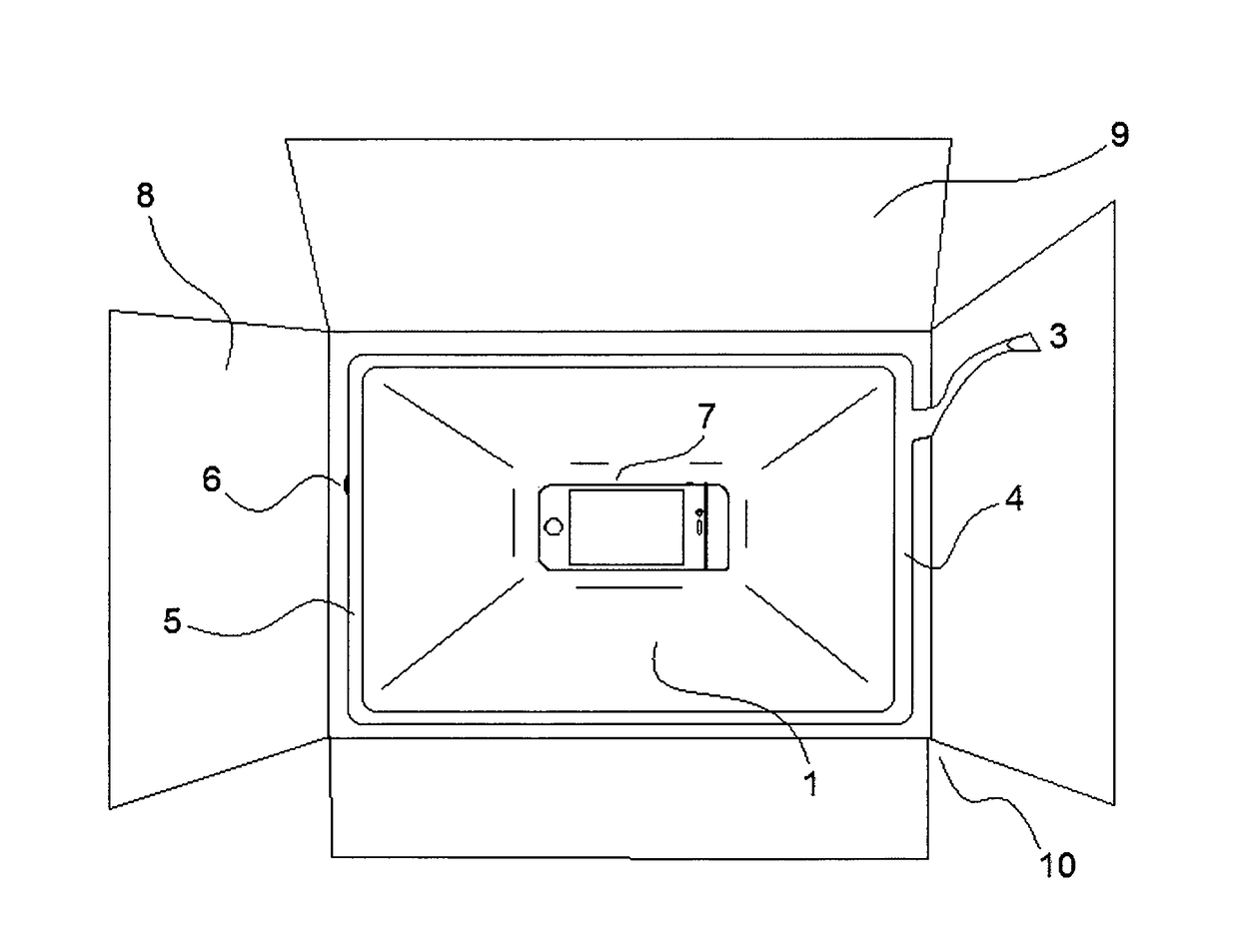

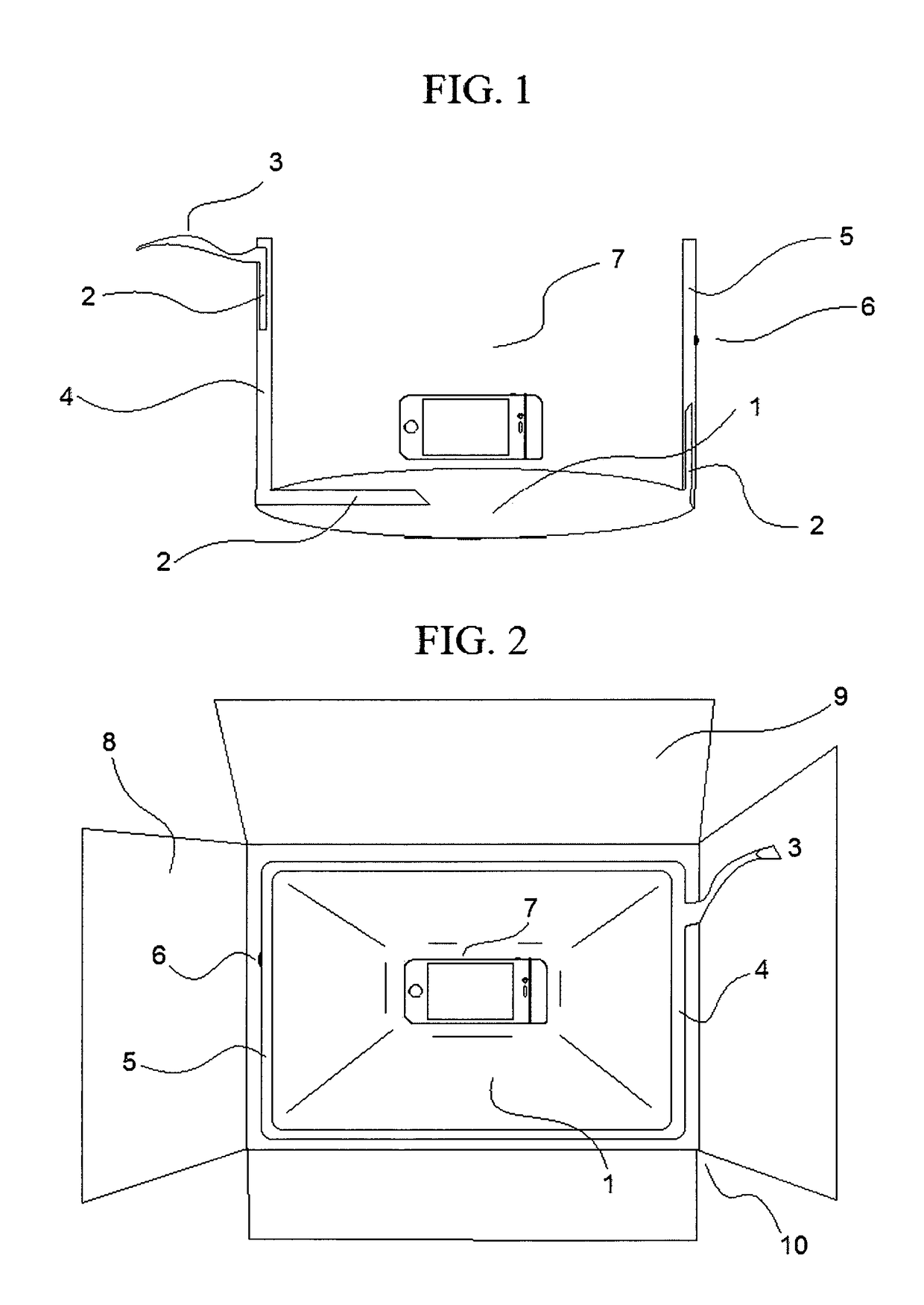

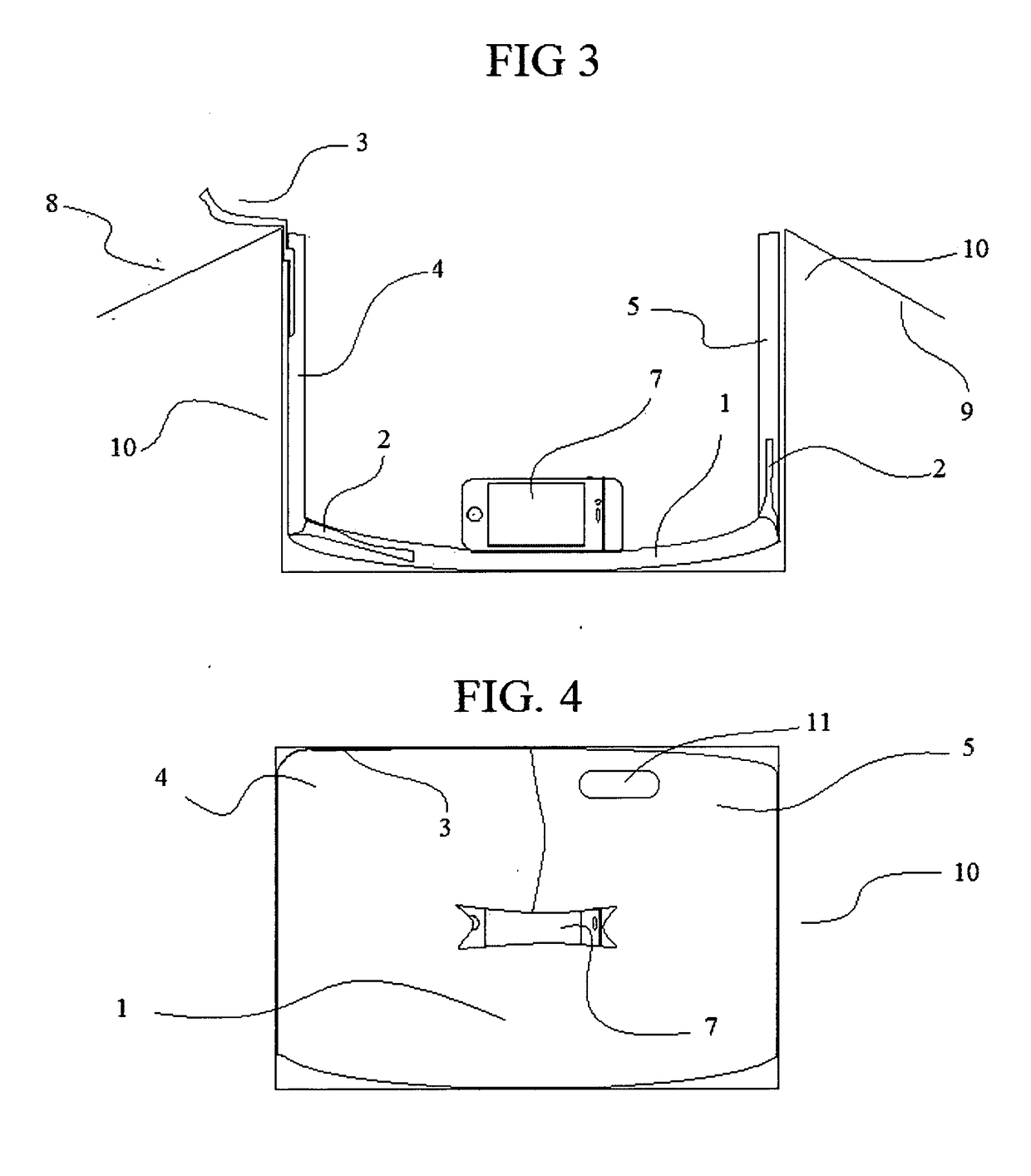

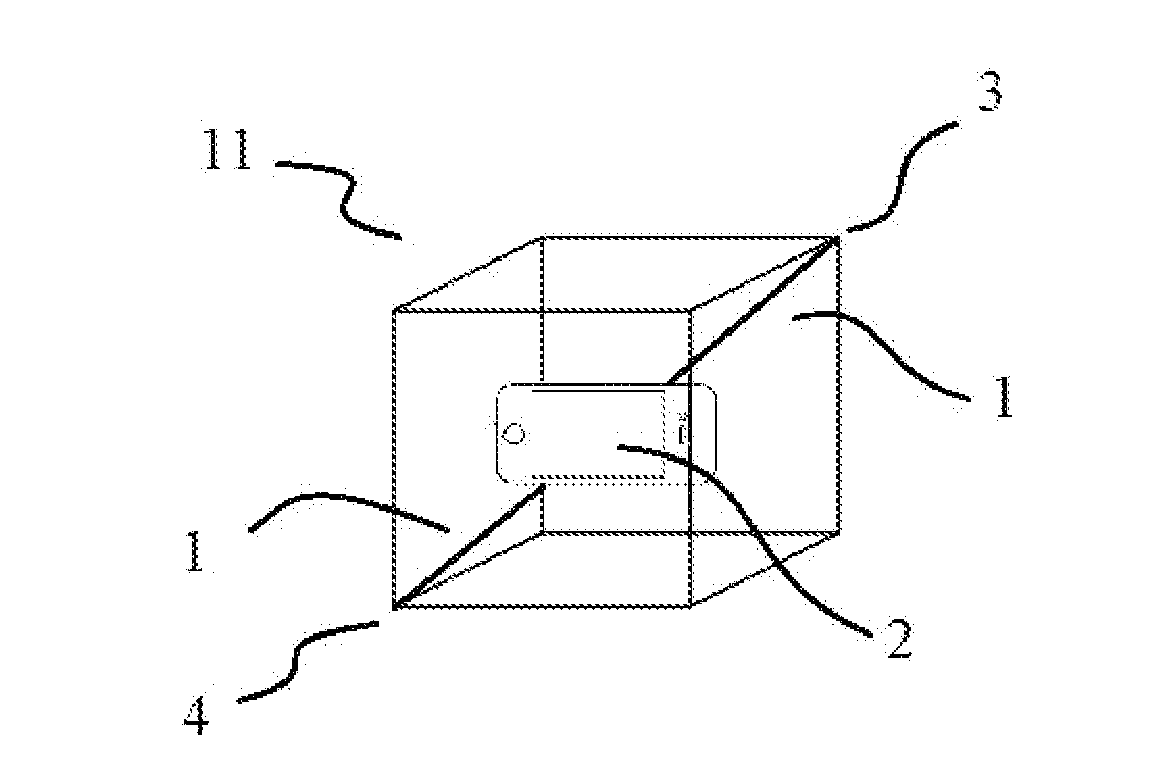

A "safe delivery"SM system for delivering perishable groceries (120 / 120'), including an inexpensive, corrugated cardboard box (100); a source of cold (or heat as needed) maintaining the temperature inside the box within a desired temperature range for hours, using an all encompassing pouch of packet material (110 / 10), used individually (FIGS. 2 & 3) or collectively (FIGS. 5 & 6), with each packet (17) containing a super-absorbent polymer (14, FIG. 12) which is hydrated (14', FIG. 12A) and then either frozen (e.g., in a freezer) or heated (e.g., in a microwave), without producing moisture as the polymer returns to its natural state; a protective cover (130) protecting the box and its contents from heat radiation (e.g., sunlight). Other components (e.g., bubble wrap 140, sealing tape 133) prevent heat attacking convection and / or conduction, with the cover having multiple plies with an outer metallized surface (131); a time / temperature monitoring alert (134) indicating when either a maximum predetermine temperature or a maximum allowed, elapsed time from packing to opening has been exceeded. If so, the customer knows that the perishable items are not warranted to be safe, and the customer is responsible for contacting the purveyor for a return of the goods. A computerized methodology (FIG. 1) insures that the purveyor knows at least approximately when the customer has opened the packed groceries, etc., using a predictive calculator and an automated tracking system, in which the customer is obligated to transmit a unique code, preferably through an automated telephonic or Internet system, when the package is opened.

Owner:THERMAFREEZE PRODS CORP

Multi-layer conductive/insulation pad

InactiveUS20050031832A1Reduce reflectivityReduces or eliminates ground water intrusion into the concrete slabSynthetic resin layered productsHeat proofingEngineeringHeavy duty

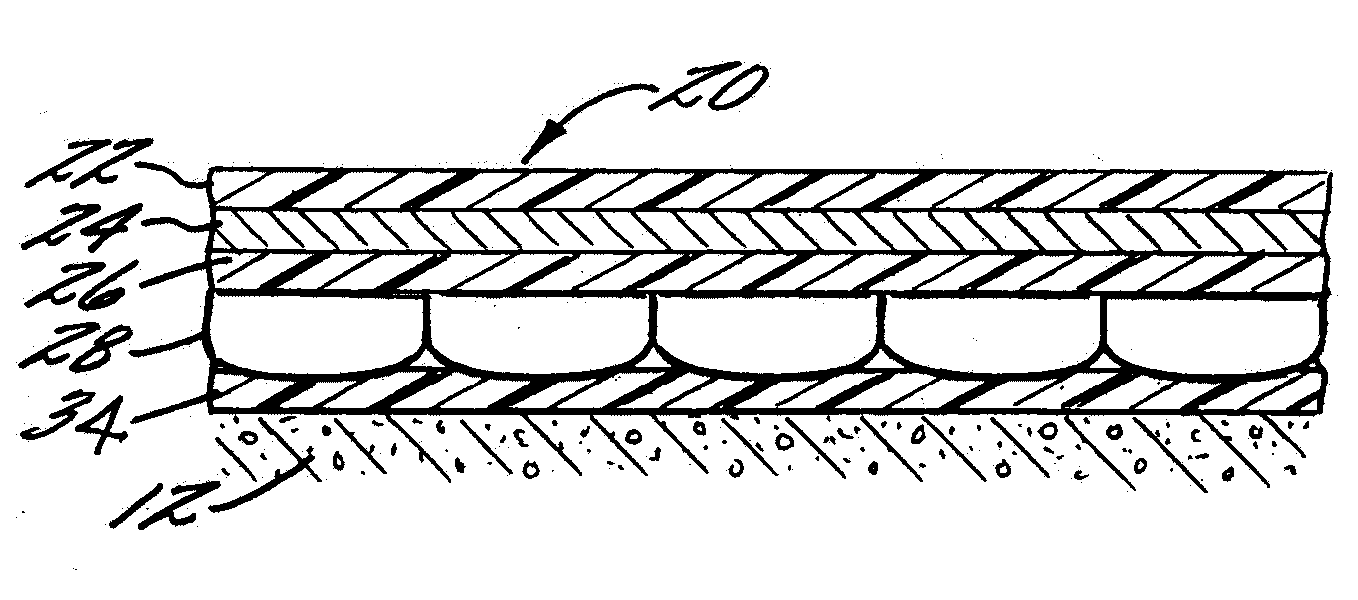

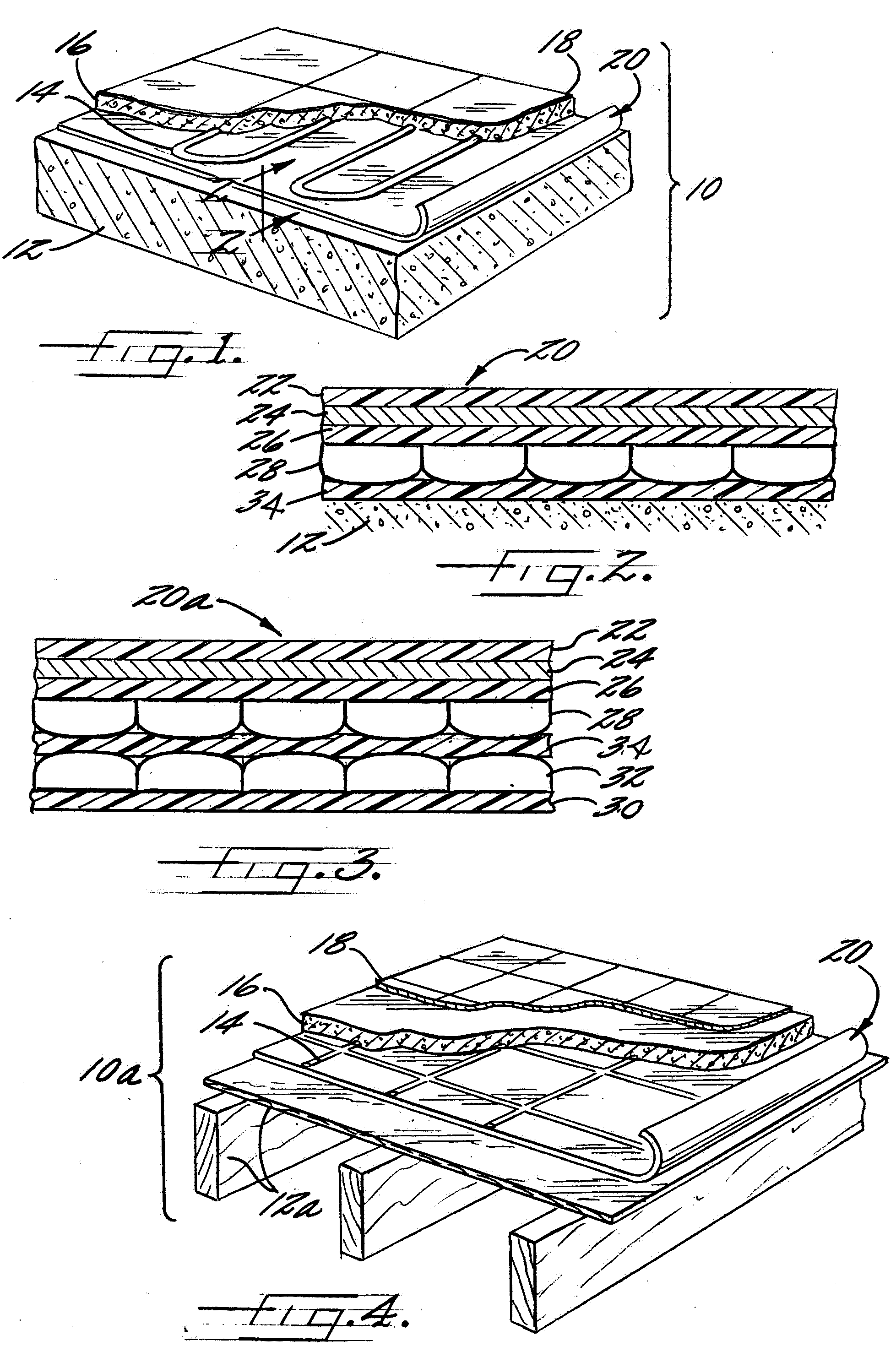

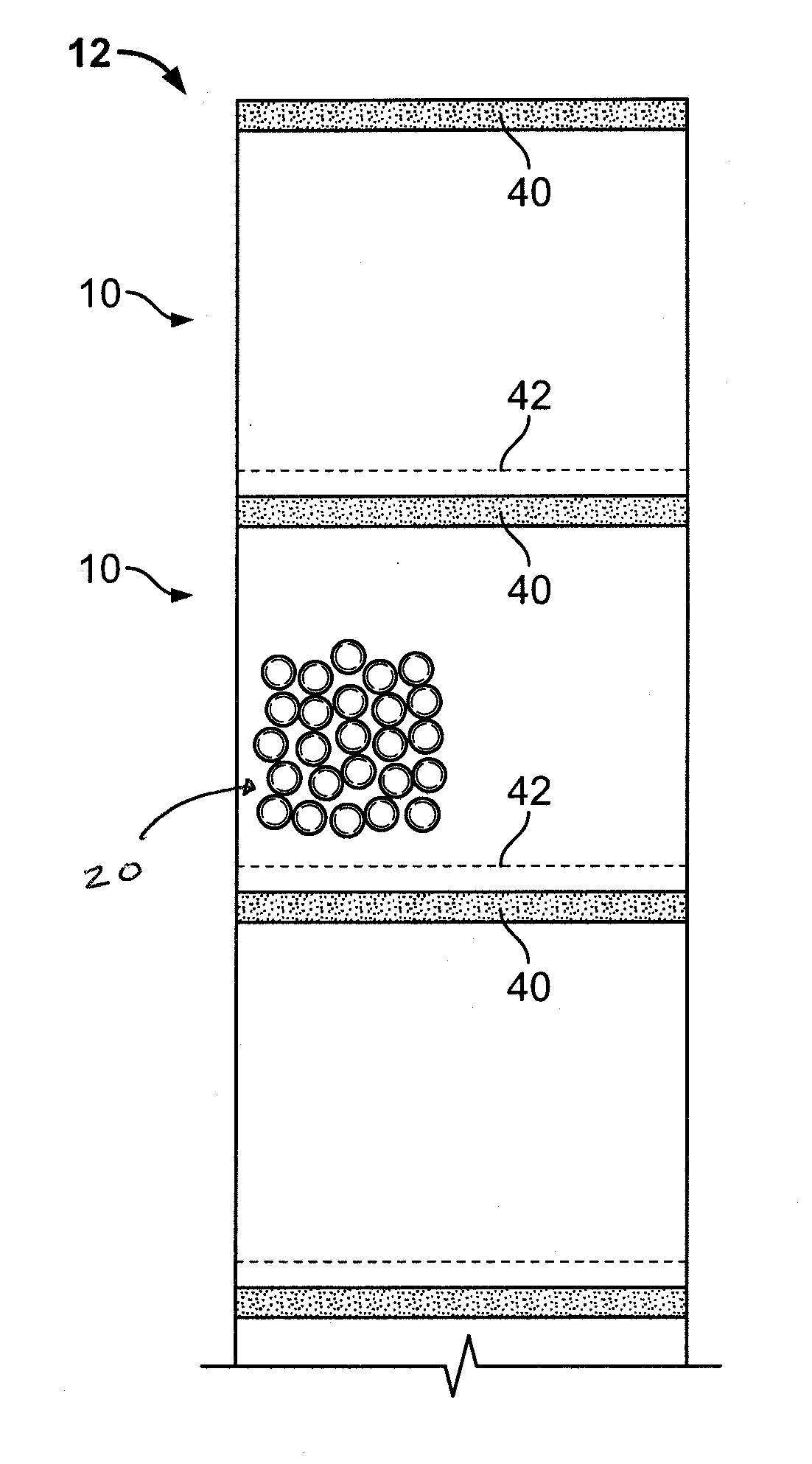

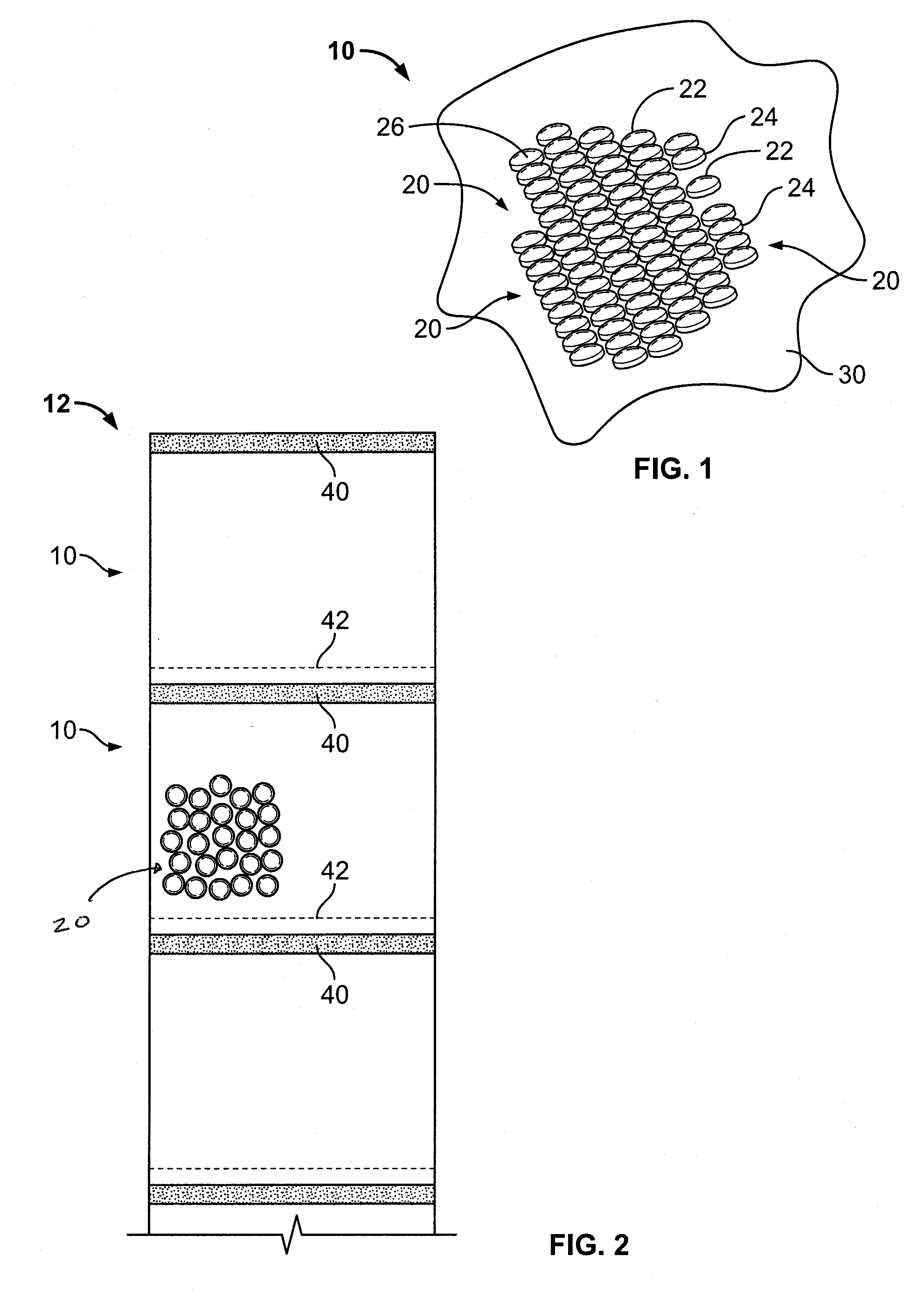

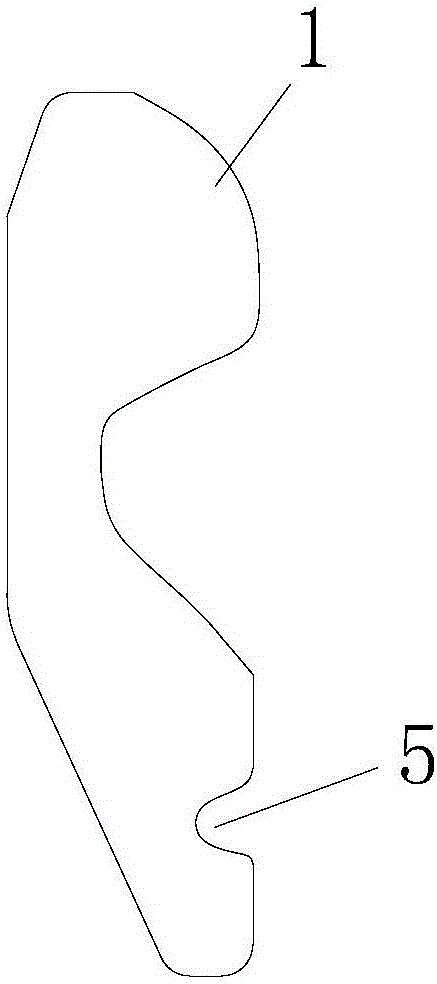

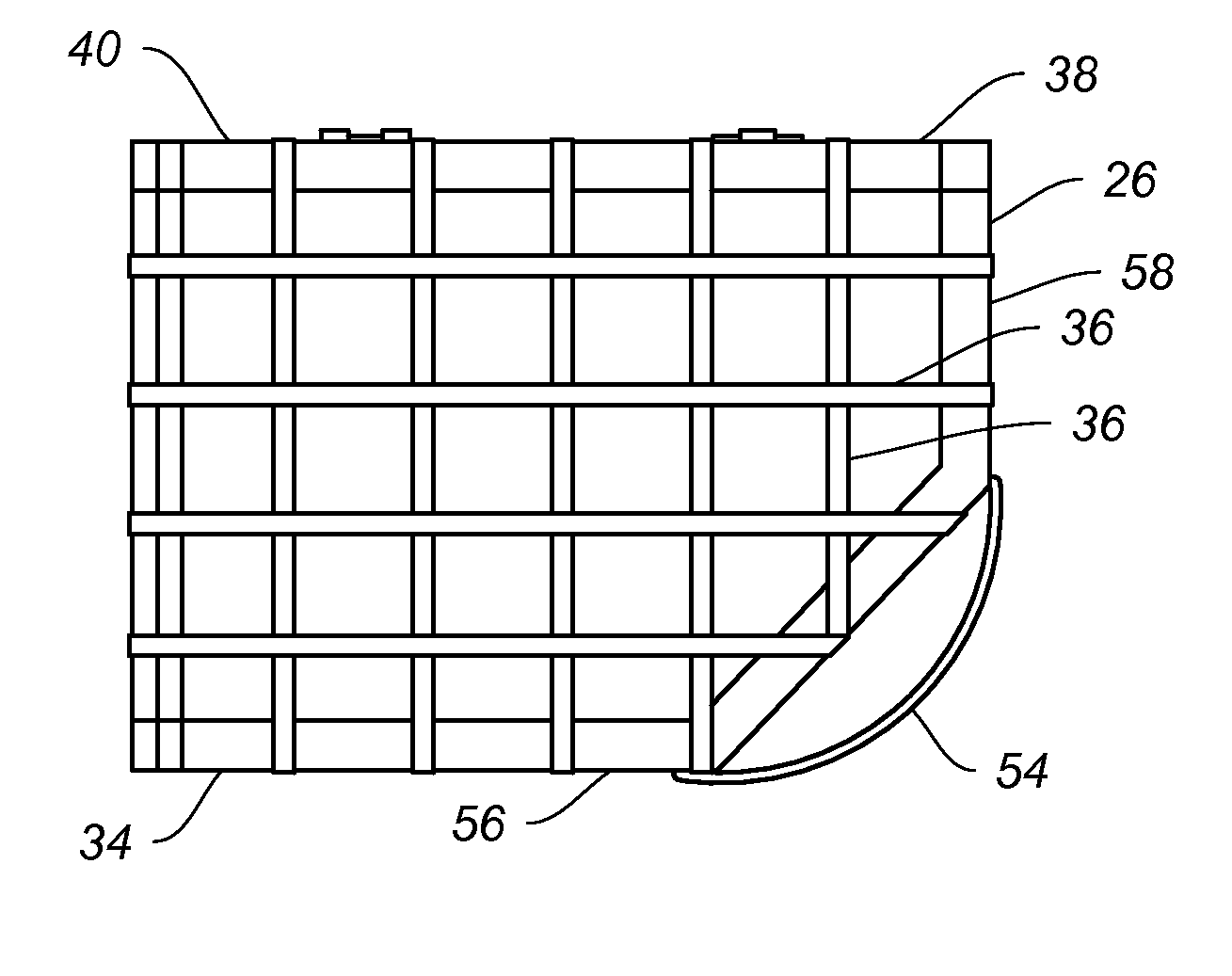

Abstract of the Disclosure There is provides a multi-layer conductive / insulation pad is provided having a first polymer layer, a conductive layer such as a thin foil of metal or a metallized thermoplastic film laminated to the first polymer layer, a second polymer layer laminated to the side of the conductive layer opposite the side of the first polymer layer, and a first bubble wrap layer. The first bubble wrap layer is laminated to the side of the second polymer film opposite the conductive layer. Optionally, a protective heavy-duty polymer layer is laminated to the first bubble wrap layer on the opposite side of the second polymer layer. In another embodiment the multi-layer construction of pad of the first embodiment has added thereto a third polymer layer laminated to the side opposite the first layer of bubble wrap and a second layer of bubble wrap laminated to the third polymer layer on the side opposite the first bubble wrap. Optionally, a protective heavy-duty polymer layer is laminated to the first bubble wrap layer on the opposite side of the second polymer layer.

Owner:SEALED AIR U S

Insulating packaging material and related packaging system

InactiveUS20030087051A1Easy entryTransfer delaySynthetic resin layered productsPackaging foodstuffsCardboardNatural state

Insulating packaging material is wrapped or otherwise positioned around the typically temperature sensitive product, with the packing material including, alternatively, 1 ply (FIG. 22; metallized plastic film), 2 ply (FIGS. 23 & 24) and 3 ply (FIG. 25) material, in which some of the 2 ply & 3 ply embodiments include a layer of bubble wrap material having its bubble side placed or laminated against the flat side of the adjacent ply, which adjacent ply can be, for example, a mettalized plastic film or a foam layer or both layers can be included. With such a bubble side arrangement, multitudinous air pockets are formed between the bubbles of the bubble wrap and the other ply's typically flat interfacing surface. A separate layer of bubble wrap also preferably is placed about the interior of the box with its bubble side placed against the interior flat surfaces of the box, with the bubbles forming air pockets with the flat sides, further enhancing the insulating properties of the packaging for the goods. An exemplary system for delivering perishable groceries (120 / 120'), including a corrugated cardboard or other type box (100); a source of cold (or heat as needed) maintaining the temperature inside the box within a desired temperature range for hours or days, using an all encompassing pouch of packet material (110 / 10), used individually (FIGS. 2 & 3) or collectively (FIGS. 5 & 6), with each packet (17) containing a super-absorbent polymer (14, FIG. 12) which is hydrated (14', FIG. 12A) and then either frozen (e.g., in a freezer) or heated (e.g., in a microwave), without producing moisture as the polymer returns to its natural state; a protective cover (130) protecting the box and its contents from heat radiation (e.g., sunlight).

Owner:THERMAFREEZE PRODS CORP

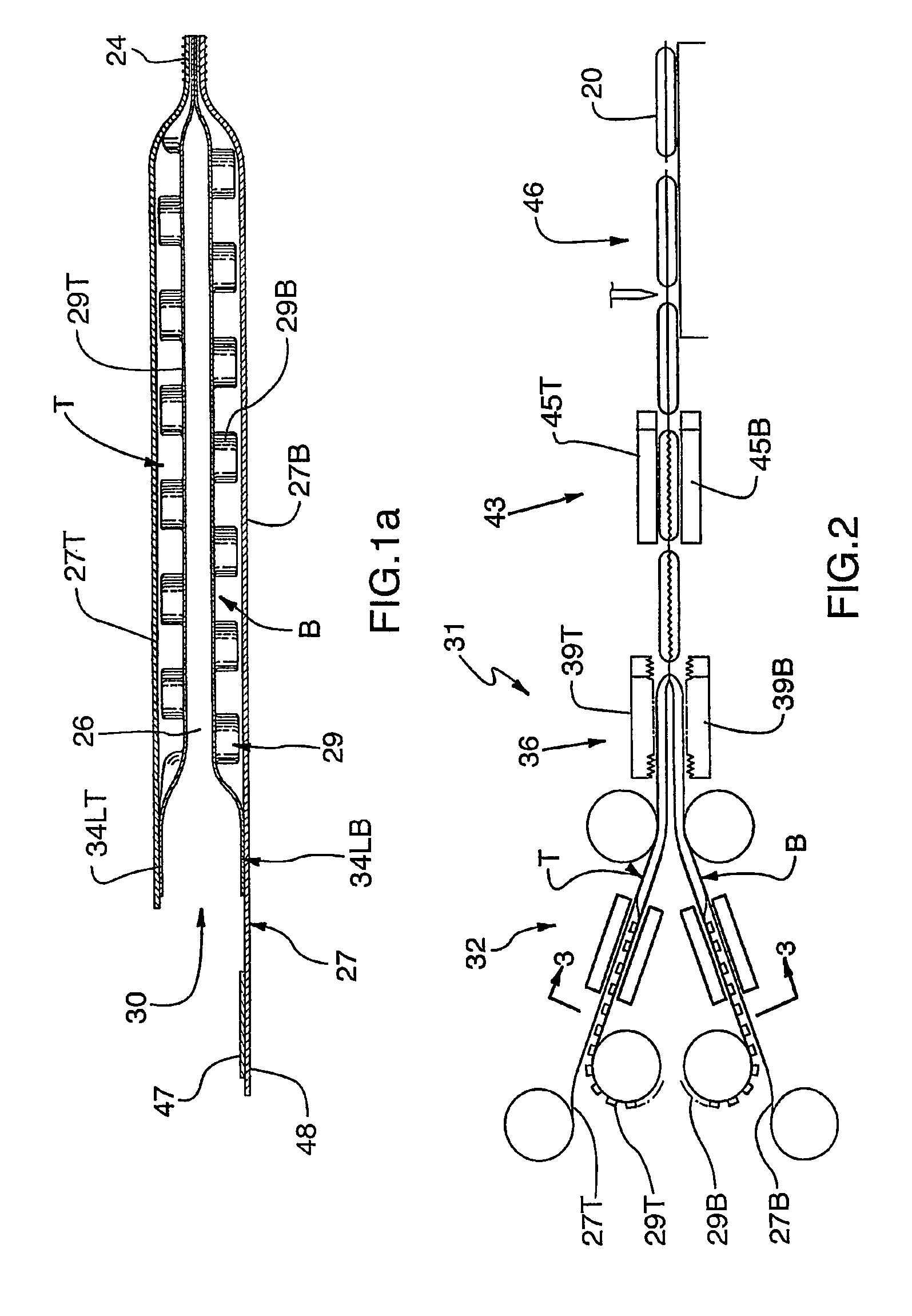

Procedure of attaching sheets and padded envelope

The envelope comprises layers of plain un-coated kraft paper and of bubble-wrap polyethylene. A stack of the layers is joined at the marginal edges of the envelope by squeezing the stack between a pair of points-dies, which are formed with points that puncture the kraft paper but do not puncture the polyethylene. The points push crowns of un-punctured polyethylene through the punctured boles in the paper. Then, the marginal edges are squeezed flat between flat-dies, the flat-dies being heated enough to cause fuse-bonding. The margins of the finished envelope are held together not only by fuse-bonding, but by the presence of the crowns, which, penetrating right through the holes in the paper, serve as mechanical rivets.

Owner:MARZANO DOMENICO

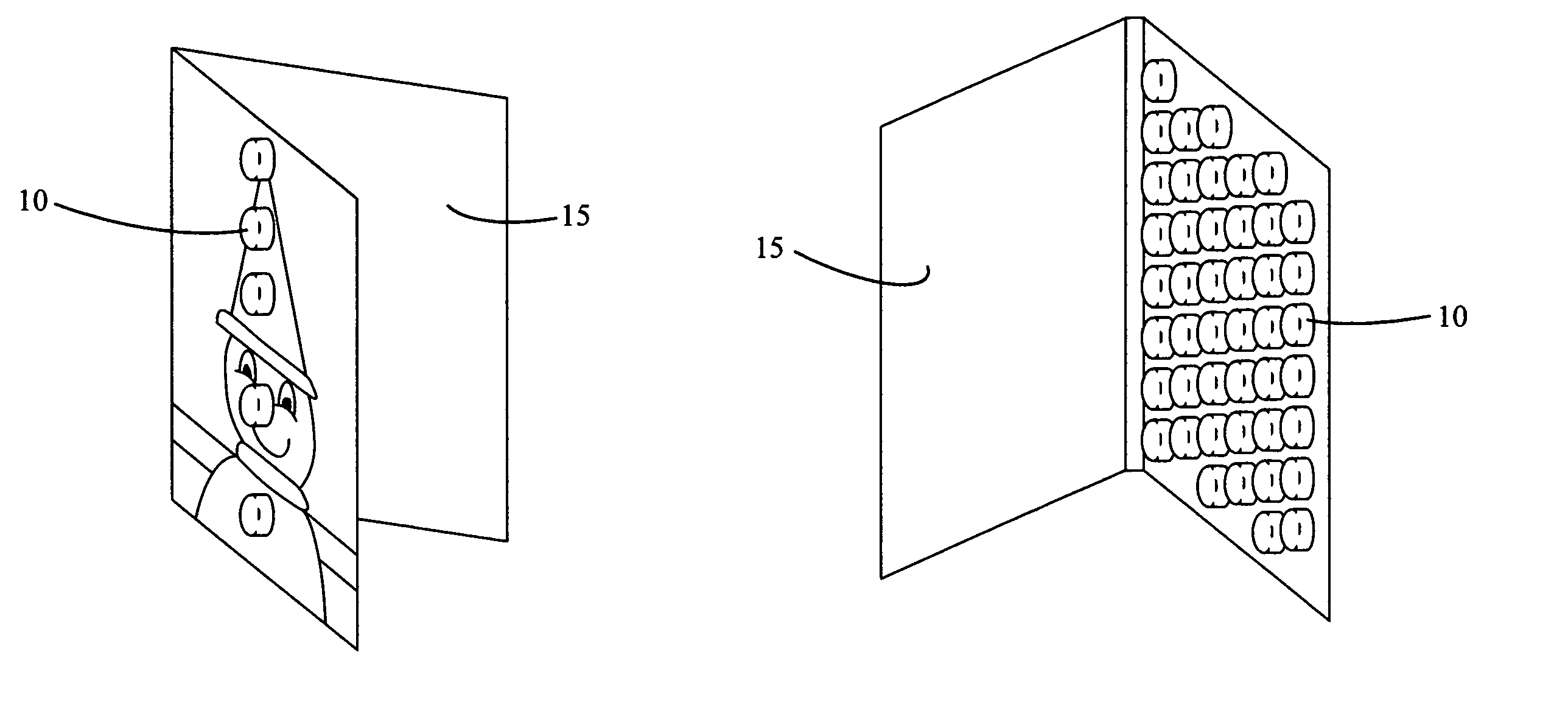

Bubble greeting card

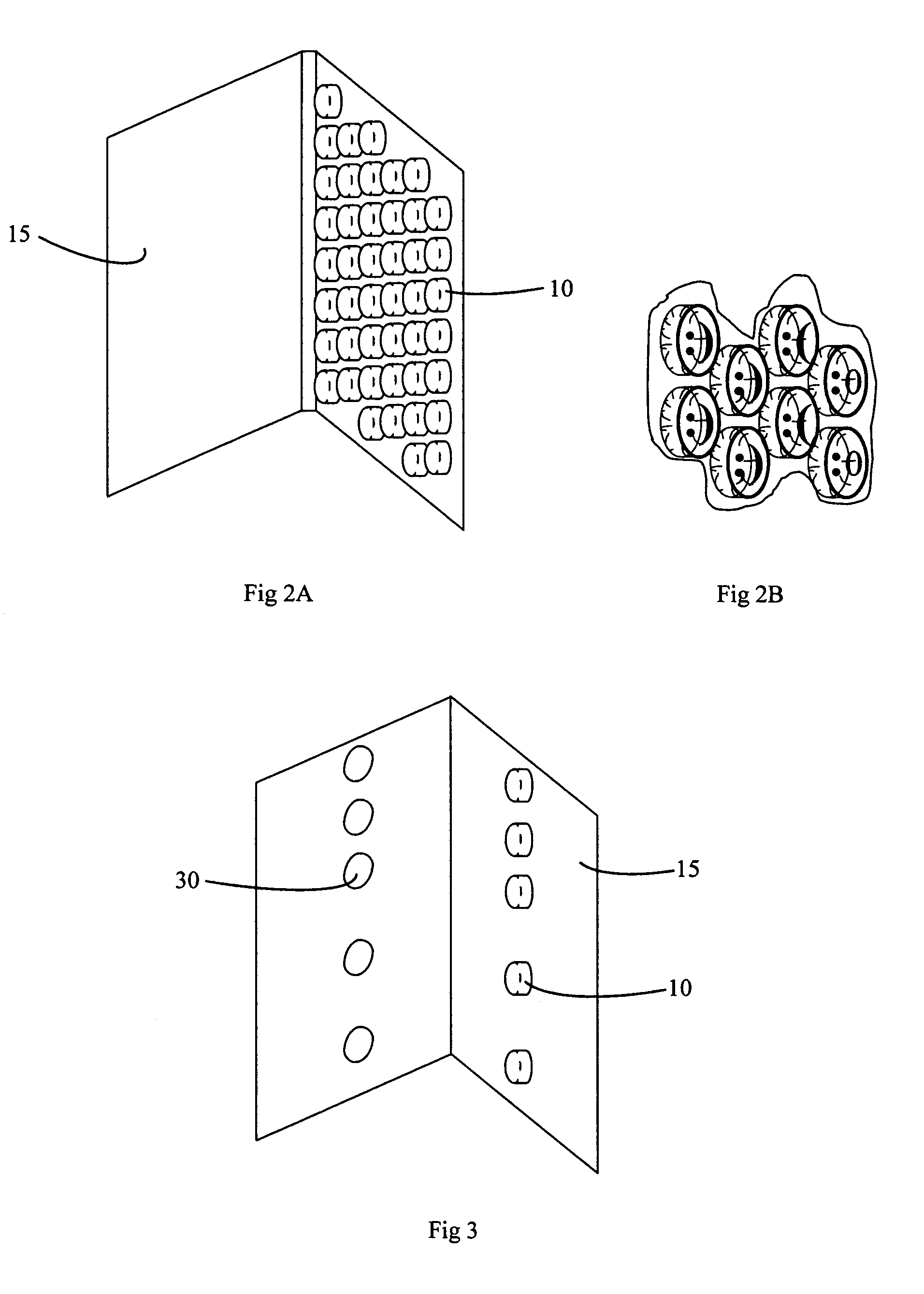

An improved greeting card is presented that incorporates cellular bubble material, such as bubble wrap, into the images and or text thereon. The bubbles of the cellular bubble material may be popped, thereby providing an amusing and pleasurable activity for the recipient of the card. By making reference to the popping activity, the message on the card may be reinforced. The cellular bubble material provides pleasing visual and tactile features, and if used in quantity provides integral protection of the card and its contents.

Owner:HUNTER DAVID GAVIN

Bubble mailer chill pack envelope

An inner thermal container, molded from an expanded polystyrene, seals in temperature sensitive materials with a cooling means for maintaining a low temperature. Inner and outer coatings provide additional thermal, vapor, and moisture insulation. The inner thermal container is inserted and sealed in a bubble wrap mailer envelope with layers of vapor and moisture proof thermal insulation.

Owner:KIRCHER STEPHEN J JR

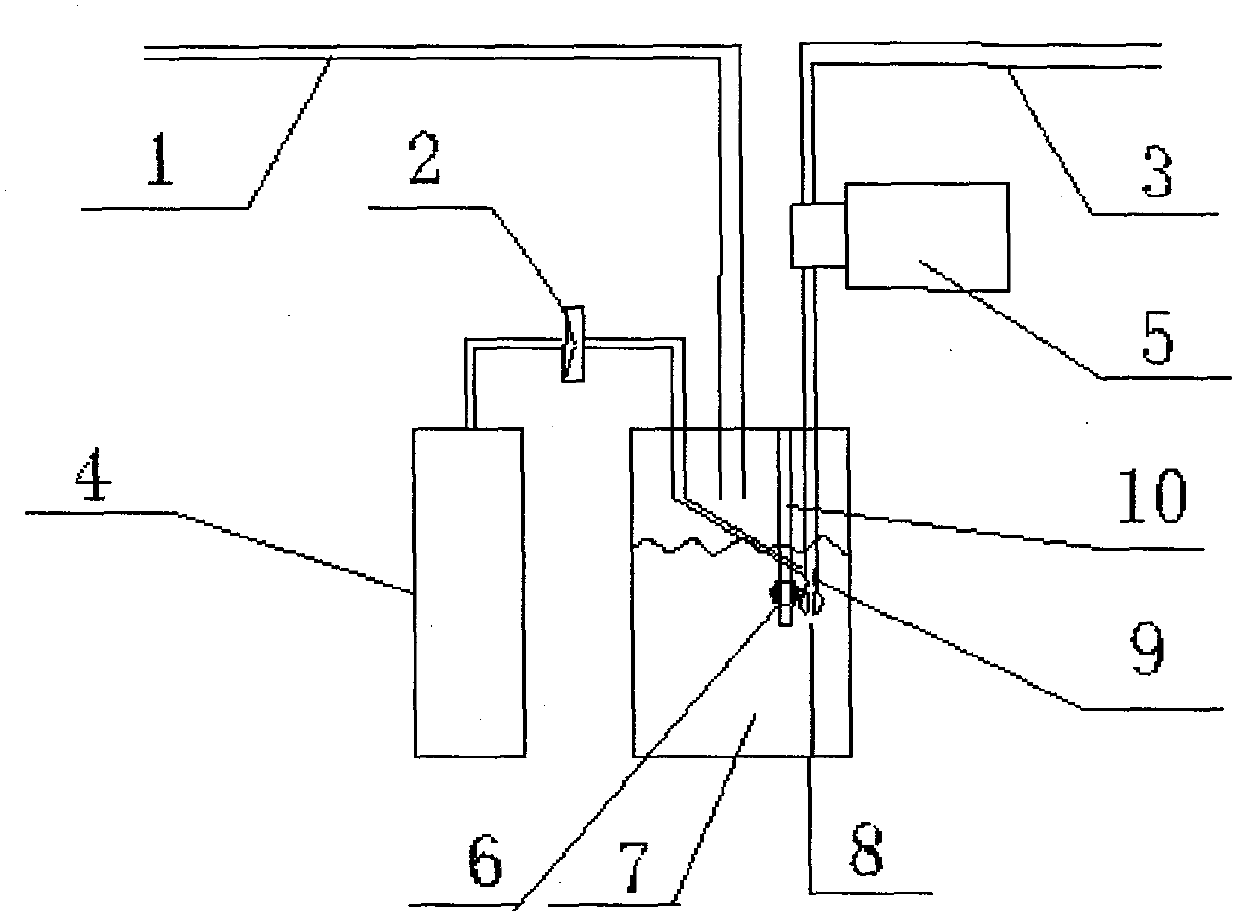

Preparation apparatus for medical debridement ozonated water

InactiveCN102847454AStable Ozone ContentProlong the action timeFlow mixersMixing methodsOzone generatorWater storage tank

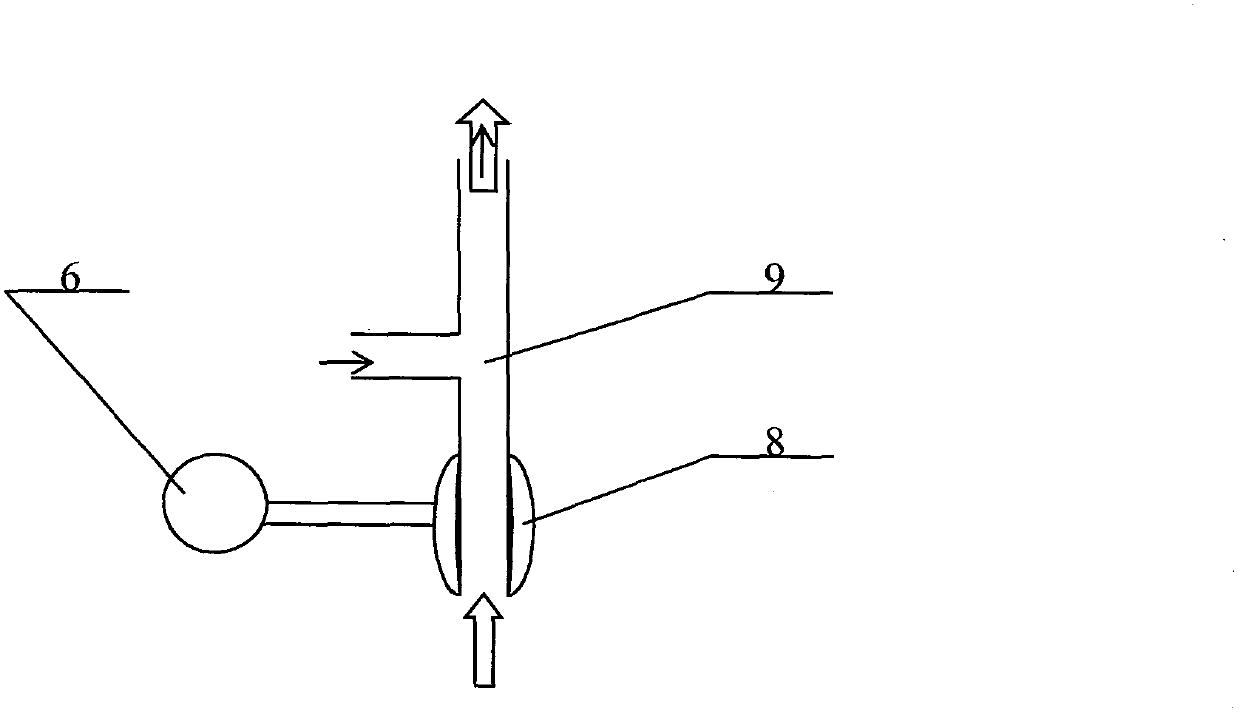

The invention provides a preparation apparatus for medical debridement ozonated water. The front end of a gas outlet pipe of an ozone generator (4) is arranged below the liquid level of a water storage tank (7) and is connected with a water adsorbing mouth (8) of a water outlet pipe (3), ozonated outlet gas is maintained to be introduced into the water adsorbing mouth (8), the water outlet pipe (3) is connected with a floating ball (6) and rises with the height of the floating ball (6), and the water adsorbing mouth (8) is maintained to be no more than 40 cm below the liquid level. According to the invention, through utilization of a floating ball unit, the initial fuse point of ozone gas and water is stably maintained at a fixed relative height below the liquid level in the water storage tank, the prepared ozonated water has high and stable ozone content, effluent contains considerable ozone bubbles wrapped by water, sprayed ozonated water is more suitable for sterilization of a wound and enables action time of ozone on the wound to be prolonged, and the advantages of energy saving, safety, high efficiency and low cost are obtained; the prepared ozonated water is more suitable for medical usage and has a concentration of 3 to 20 mg / L, the solvation rate of ozone is up to 80 to 90%, and volatilization of ozone is reduced, so not only waste is avoided but also pollution is reduced.

Owner:荣建忠

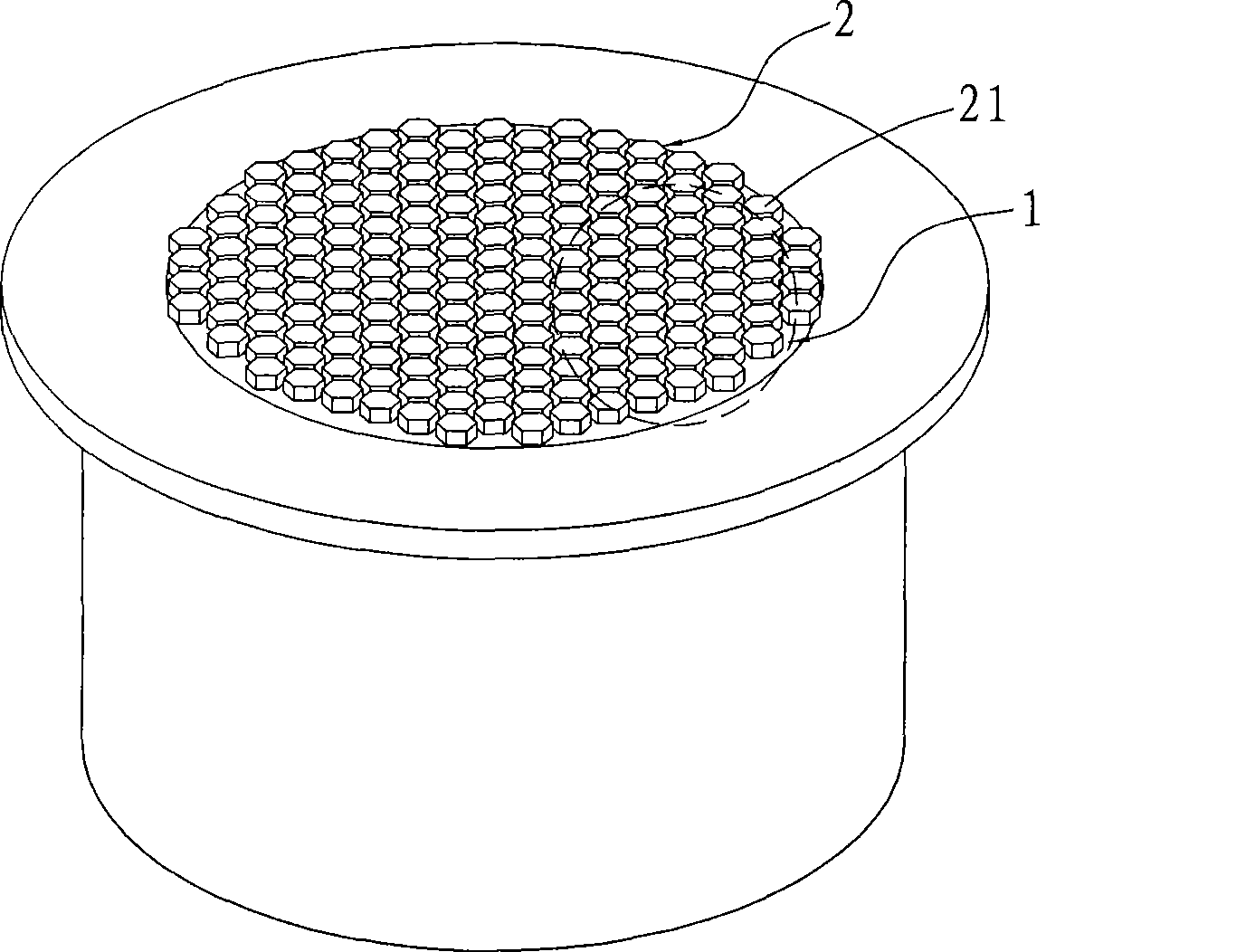

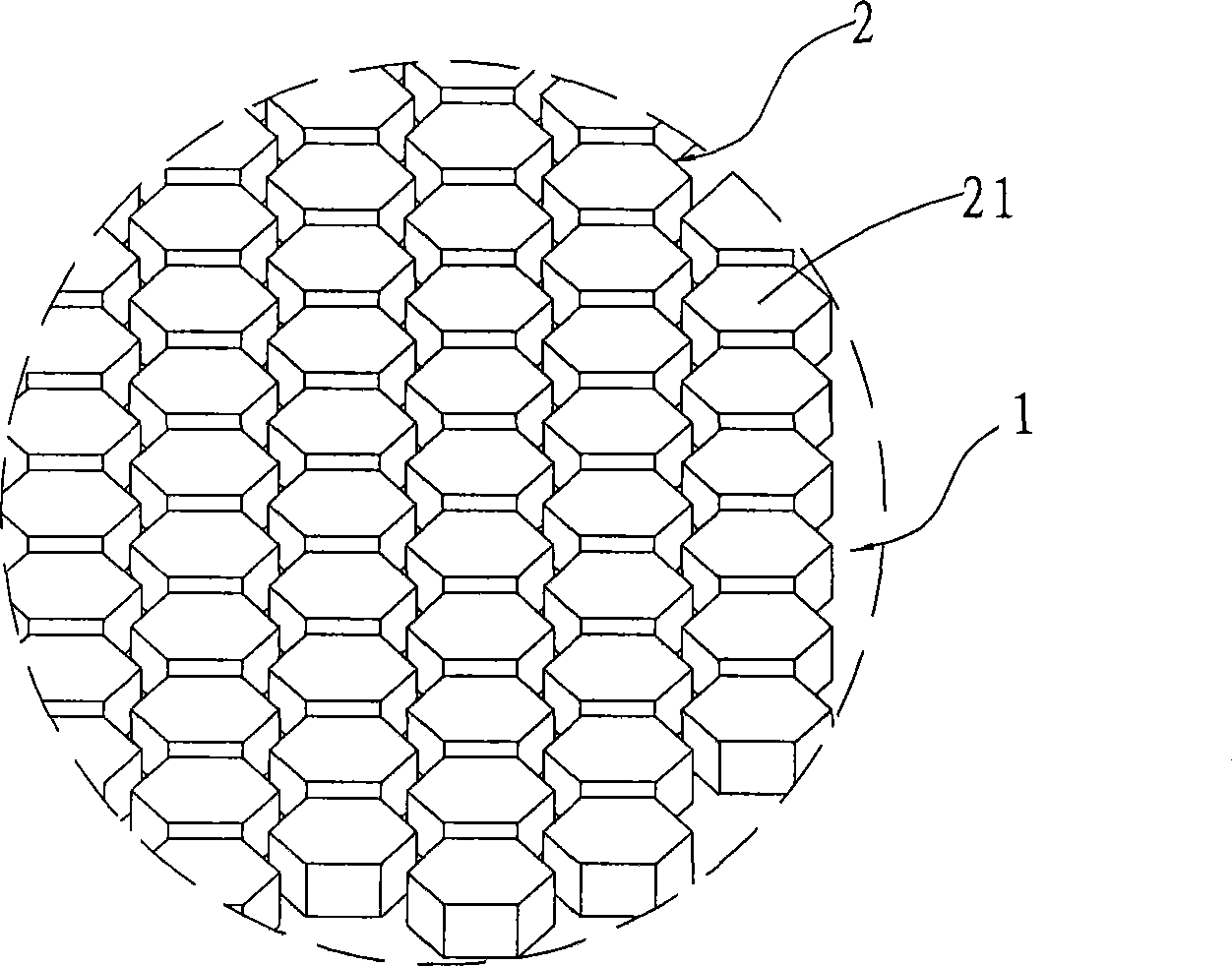

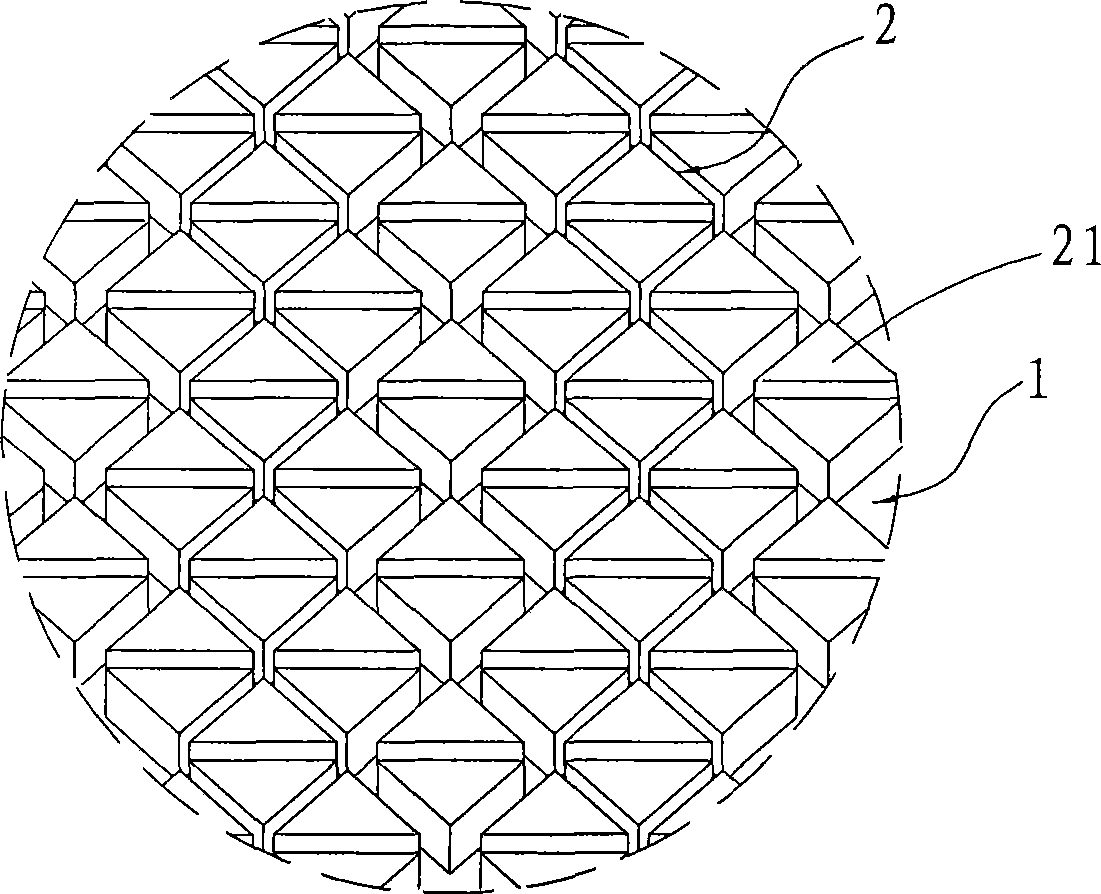

Air bubble pad pond cover and method for producing the same

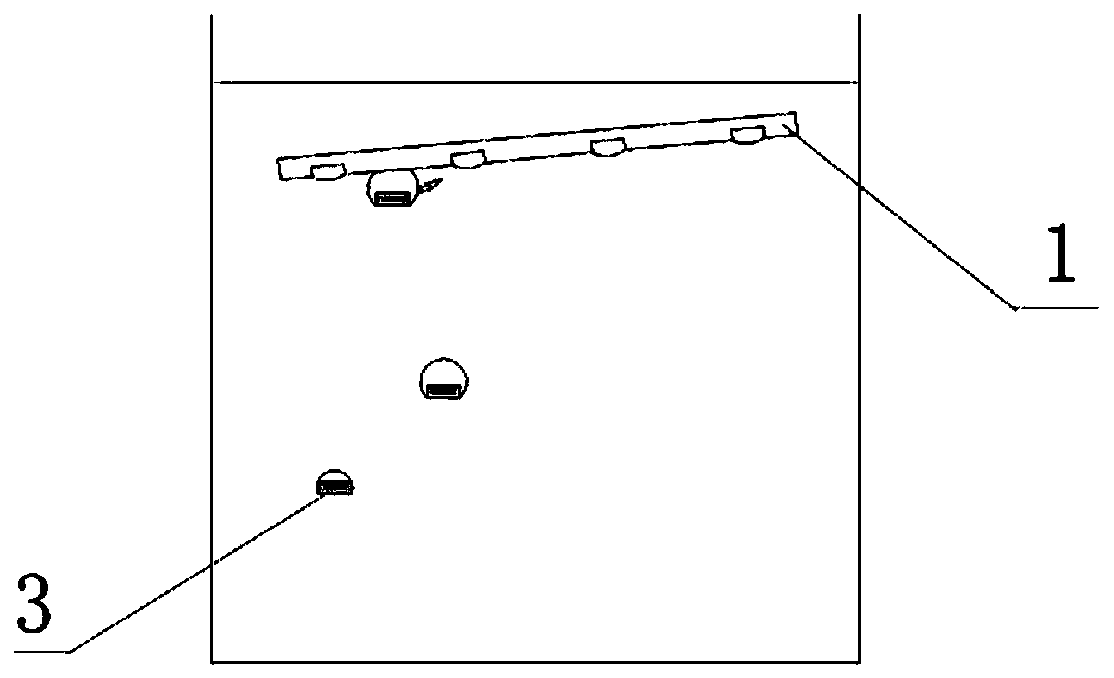

InactiveCN101487348AChange temperatureChange the vacuum degree of the blisterGymnasiumSwimming poolsAntioxidantEngineering

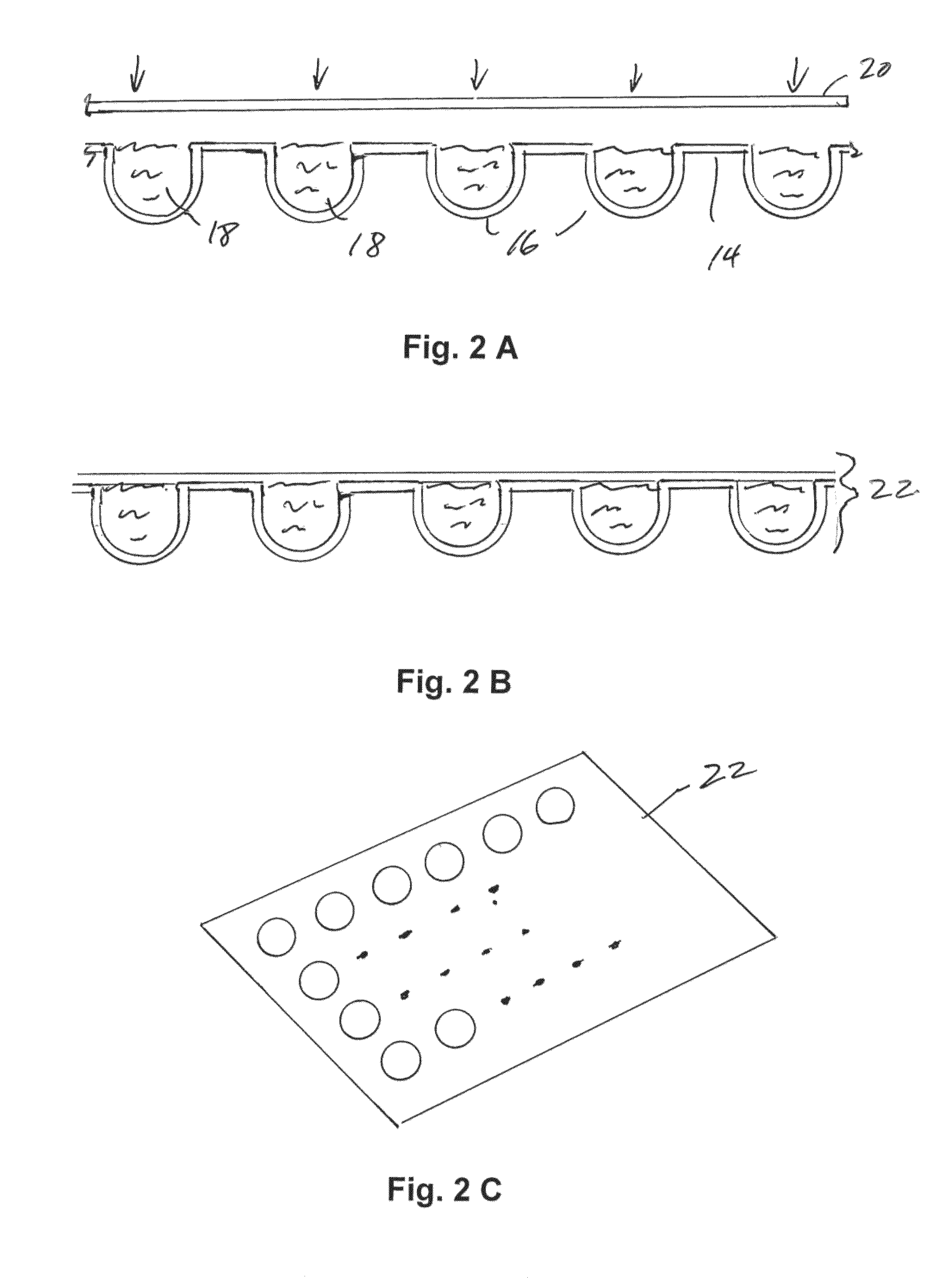

The invention discloses a bubble wrap pool cover, comprising a base layer which is suitable for covering a pool and a bubble layer which is connected on the base layer, wherein, the bubble layer is provided with a plurality of bubbles. The invention also discloses a production method of the bubble wrap pool cover, which comprises the following steps: firstly, the following raw materials are mixed by weight percentage: 99.7 percent of polyethylene resin, 0.2 percent of anti-UV agent and 0.1 percent of antioxidant; secondly, the mixture is extruded from a double-slit casting mould, and then vacuum blistered by a bubble roll into a bubble cap, and closed by hot bonding into a neat and independent bubble wrap; and finally, the bubble wrap is cut, spliced or sewn into a bubble wrap pool cover product. The bubble wrap pool cover can avoid impurities from falling into the pool water to cause pollution, and avoid inconvenience caused by the increase or decrease of the temperature.

Owner:厦门永信隆塑胶包装有限公司

Insulating bubble wrap

InactiveUS20190375193A1Domestic cooling apparatusLighting and heating apparatusEngineeringBubble wrap

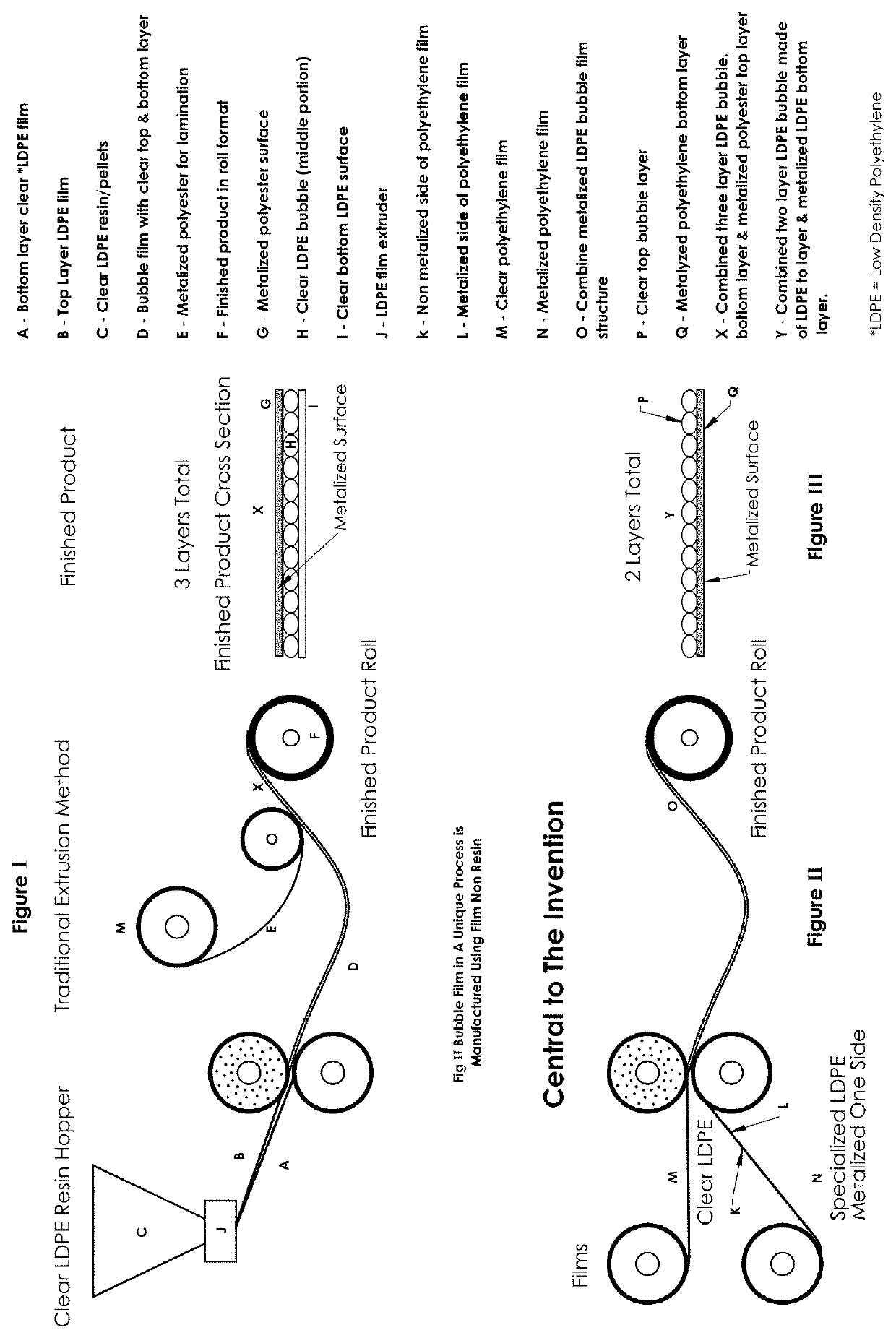

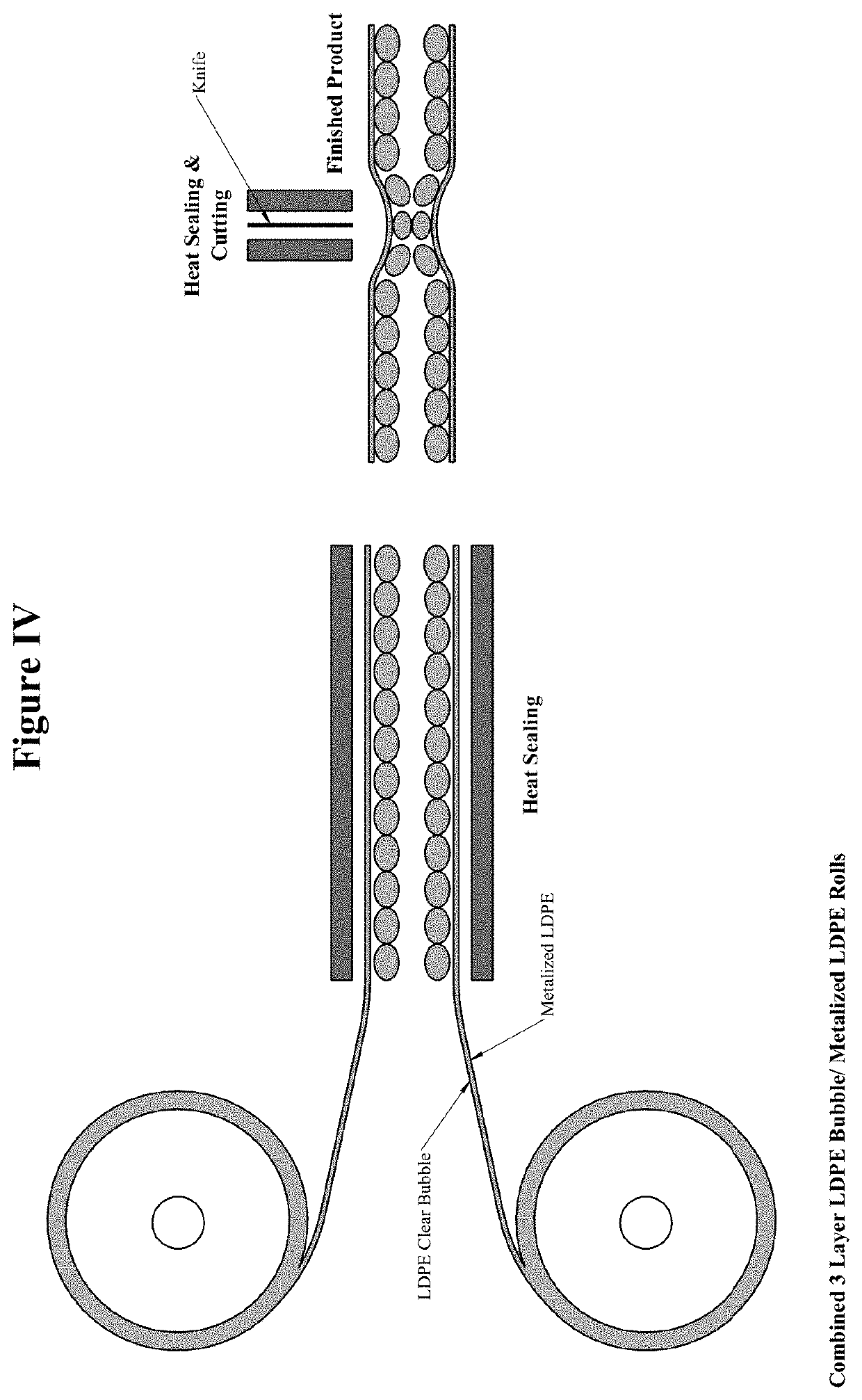

An insulating bubble wrap comprising a metallized polyethylene layer having a first metallized side, a second non-metallized side, and a metal thickness; and a polyethylene bubble film cap layer attached to the metallized polyethylene along the second non-metallized side.

Owner:SIMPLE CONTAINER SOLUTIONS

Insertable inflatable bladder and method of use thereof

A inflatable insertable bladder and method of use thereof. The bladder may be designed in any shape or size made up of an integrated bladder system that be made of any material such as mylar, plastic, nanoparticle, graphine like material, atoms or any material within the realm of science and knowledge that would provide enough strength to act as a bladder and have enough elasticity to provide protection to the item being shipped or stored and of suitable design able to protect the item being shipped with enough strength to hold and protect the item being shipped, stored or otherwise suspended in a box or container that is being shipped, stored or otherwise used in. The inflatable insertable bladder is uniquely designed to allow for a simple one-step process using a bladder with an integrated valve system that is used to suspend an article to be to be packaged. This completely protects the article and removes the need for peanuts, foam, bubble wrap, paper or other fillers in boxes used for shipping goods once the box is closed.

Owner:SMITH JACK

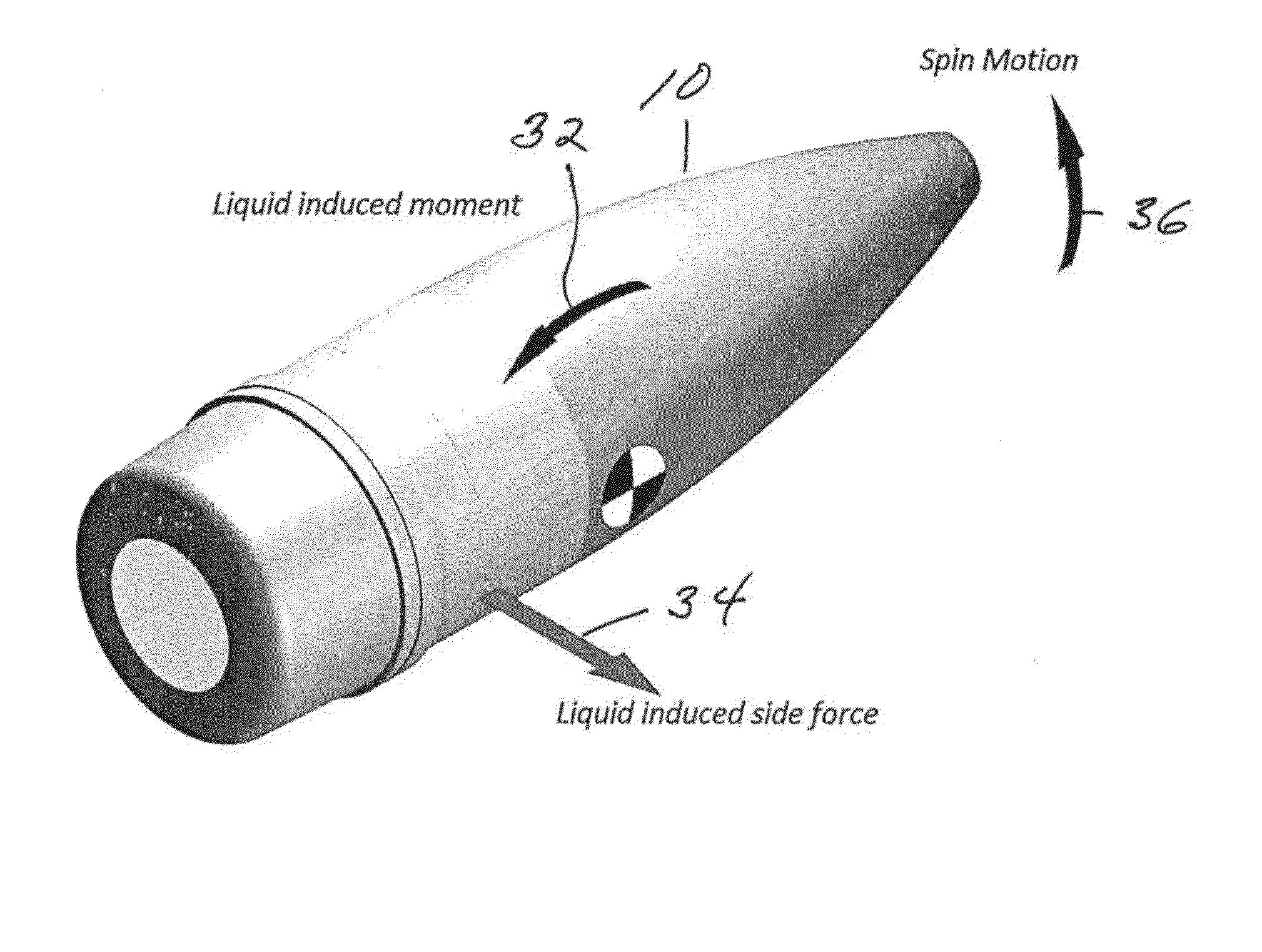

Training ammunition cartridge with reactive liquid materials for marking a point of impact

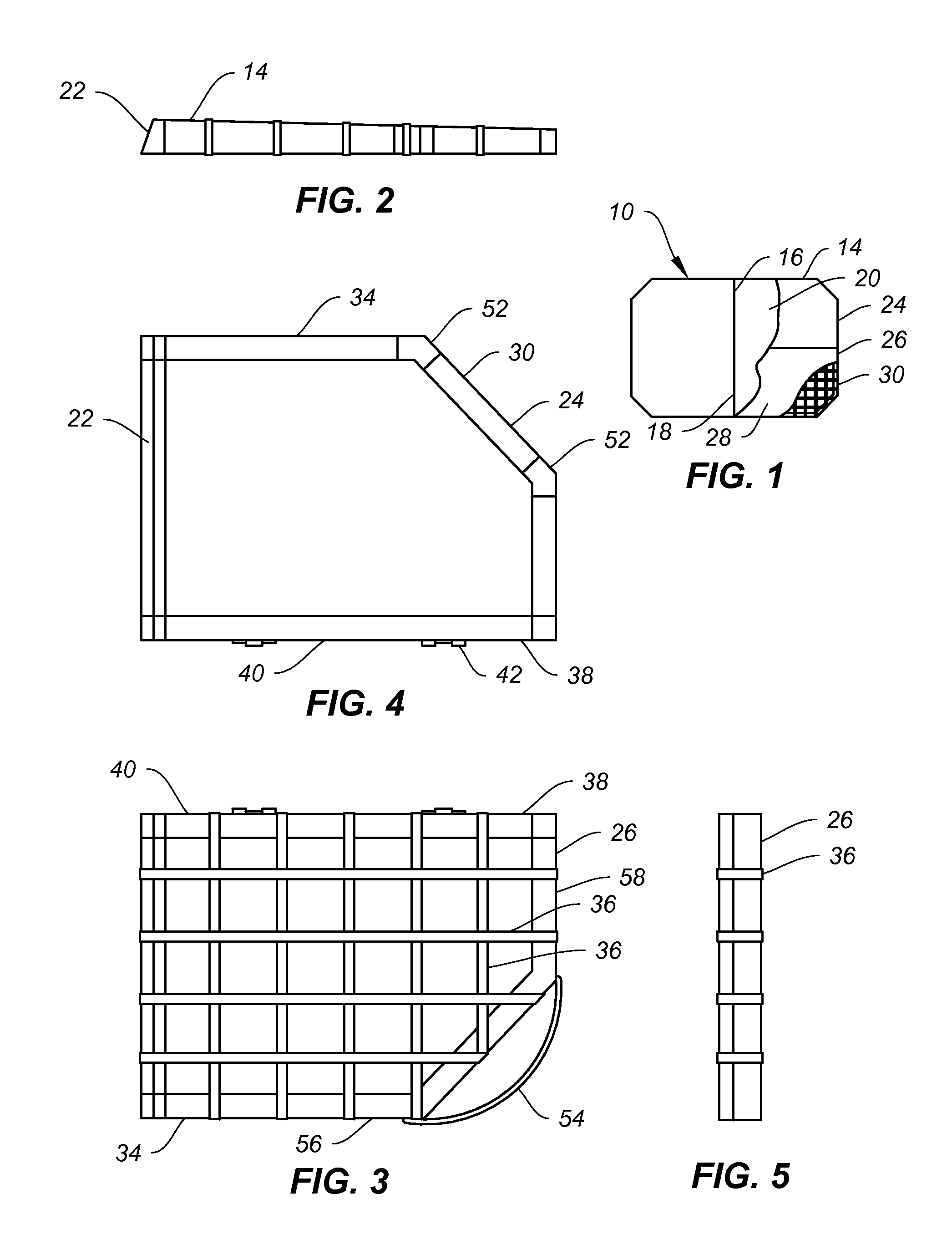

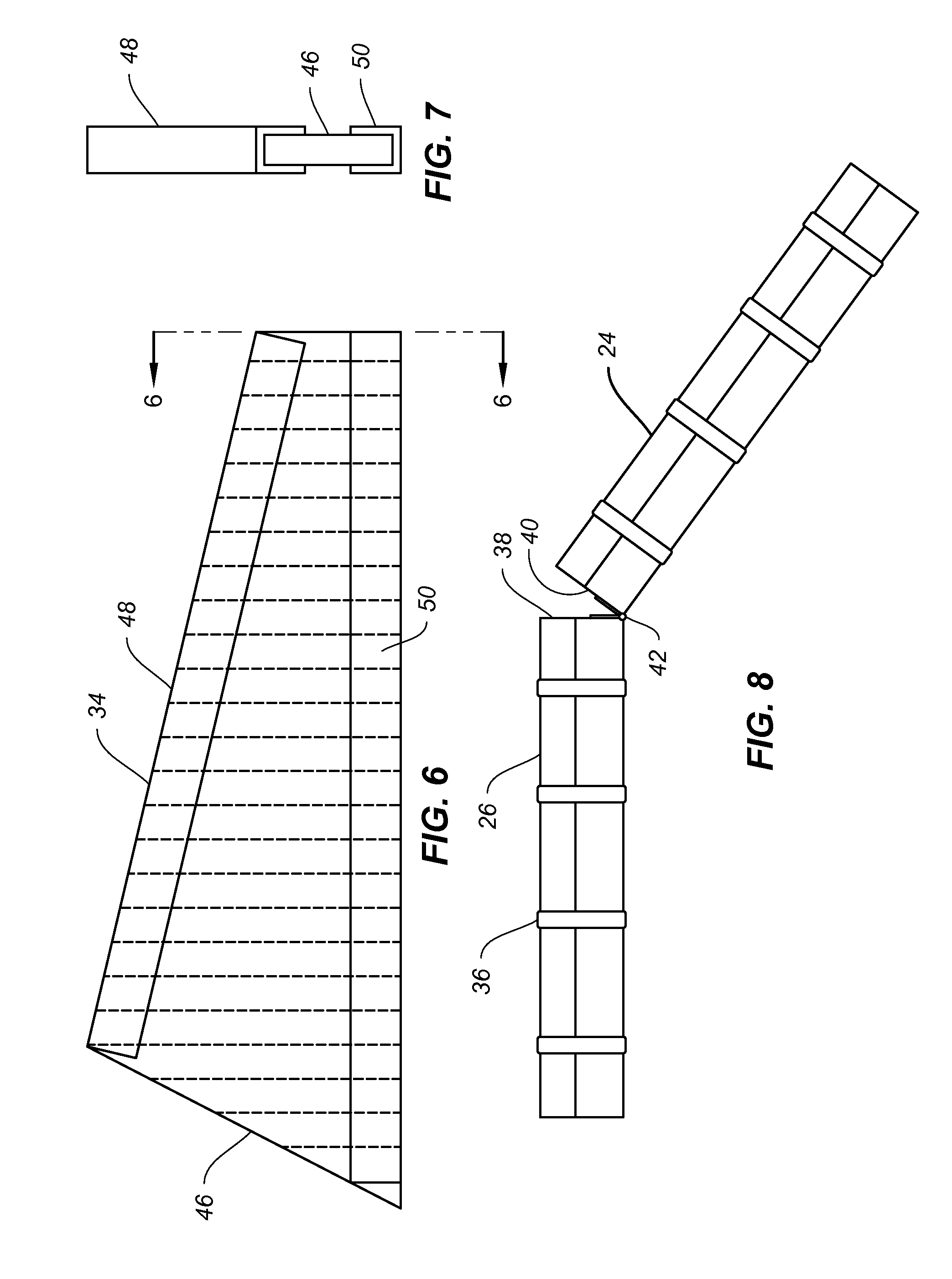

ActiveUS9217627B2Low costAmmunition projectilesTraining ammunitionChemical compositionPlastic materials

Owner:NOSTROMO HLDG LLC

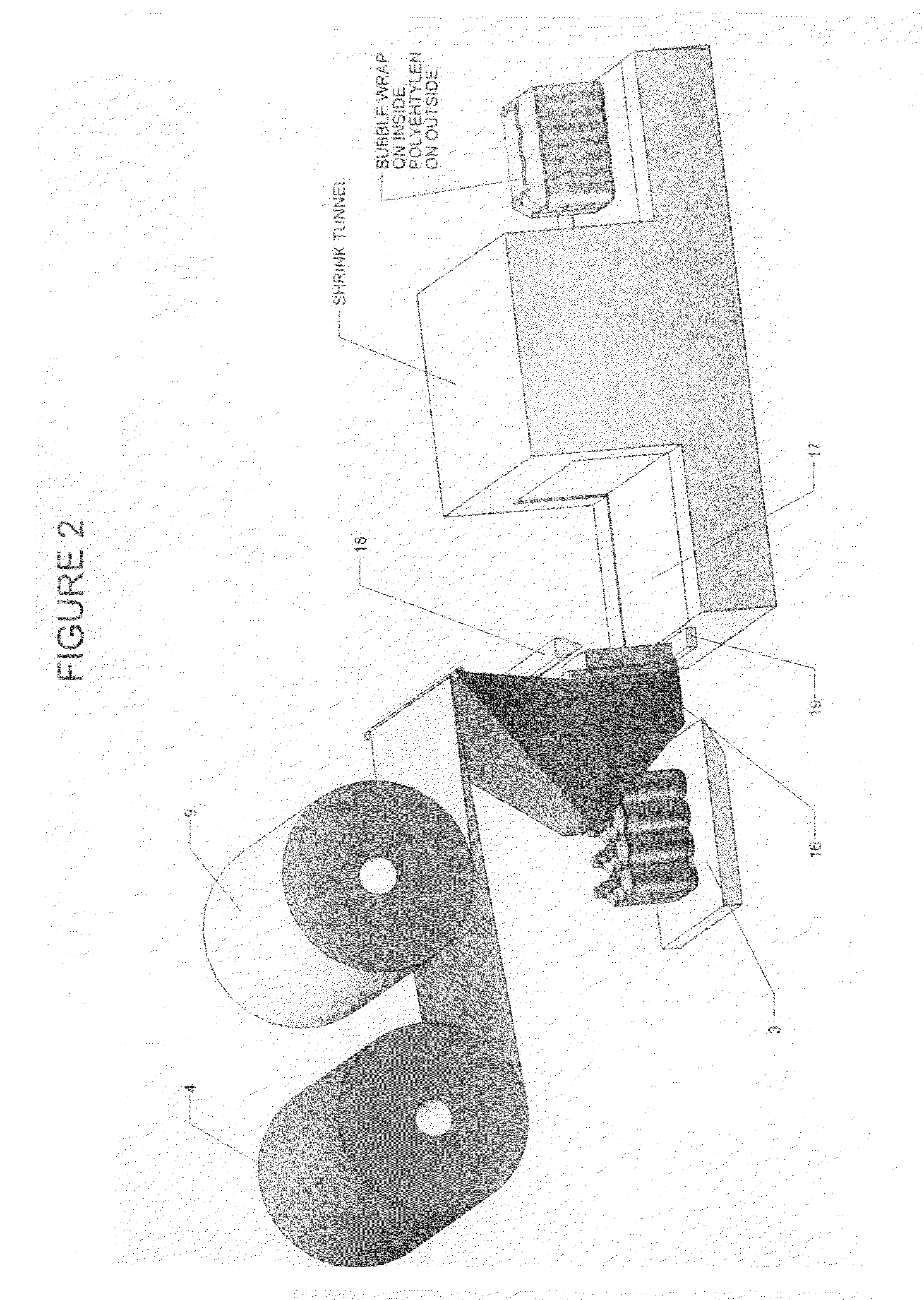

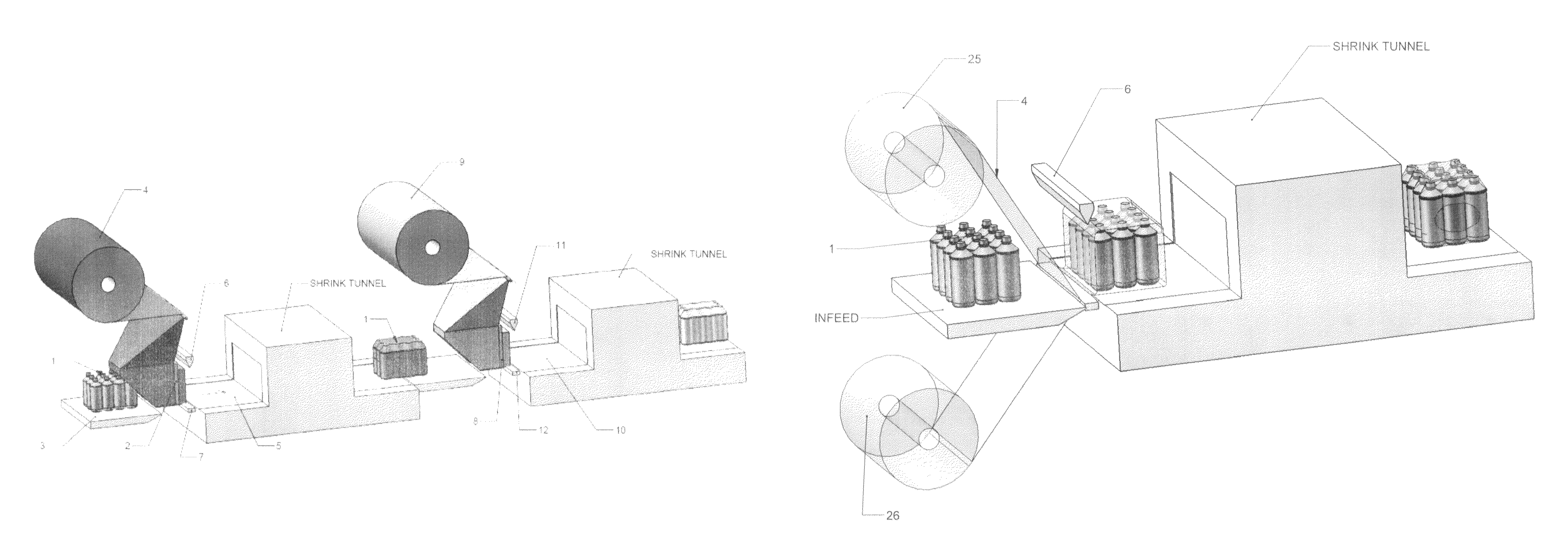

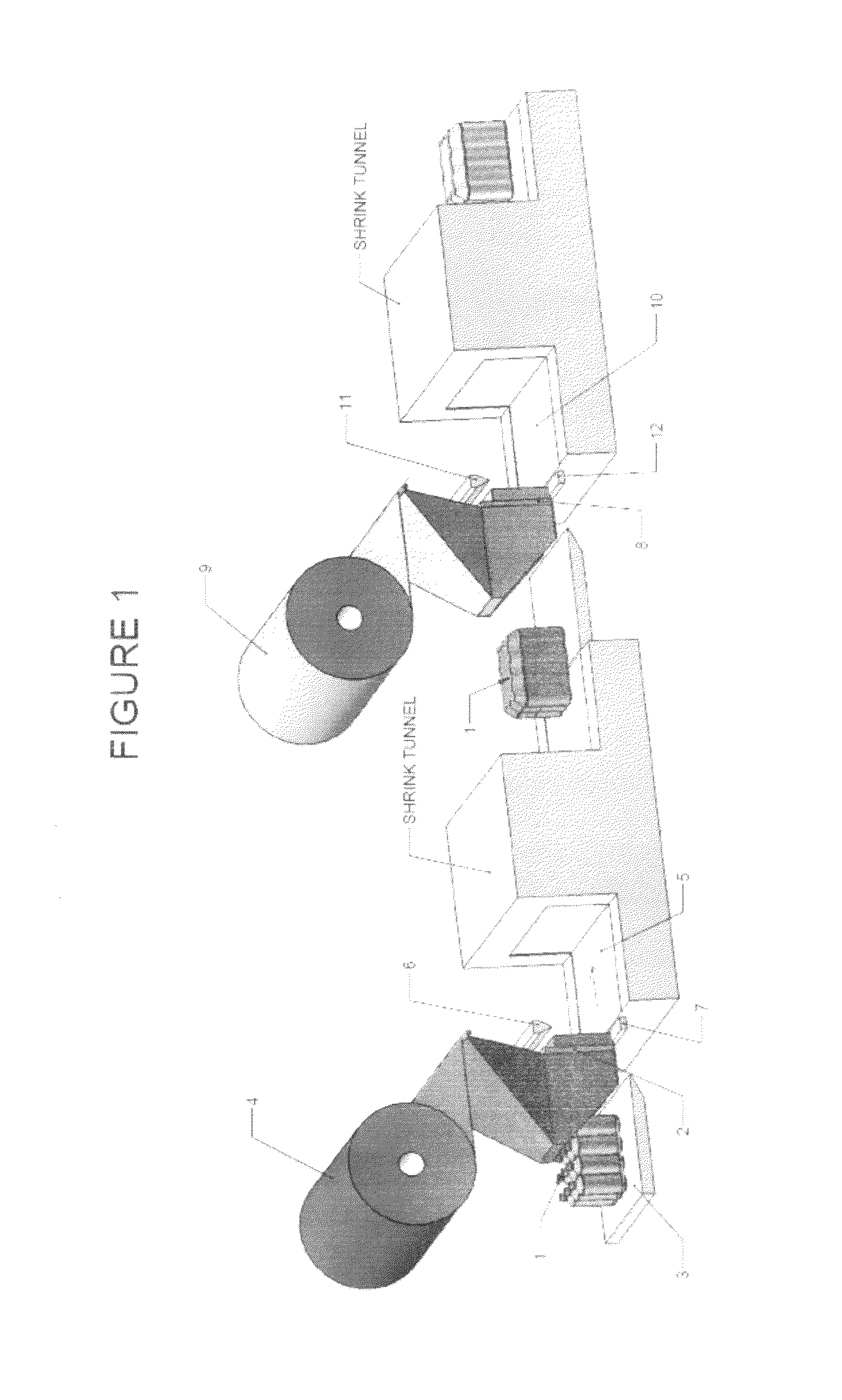

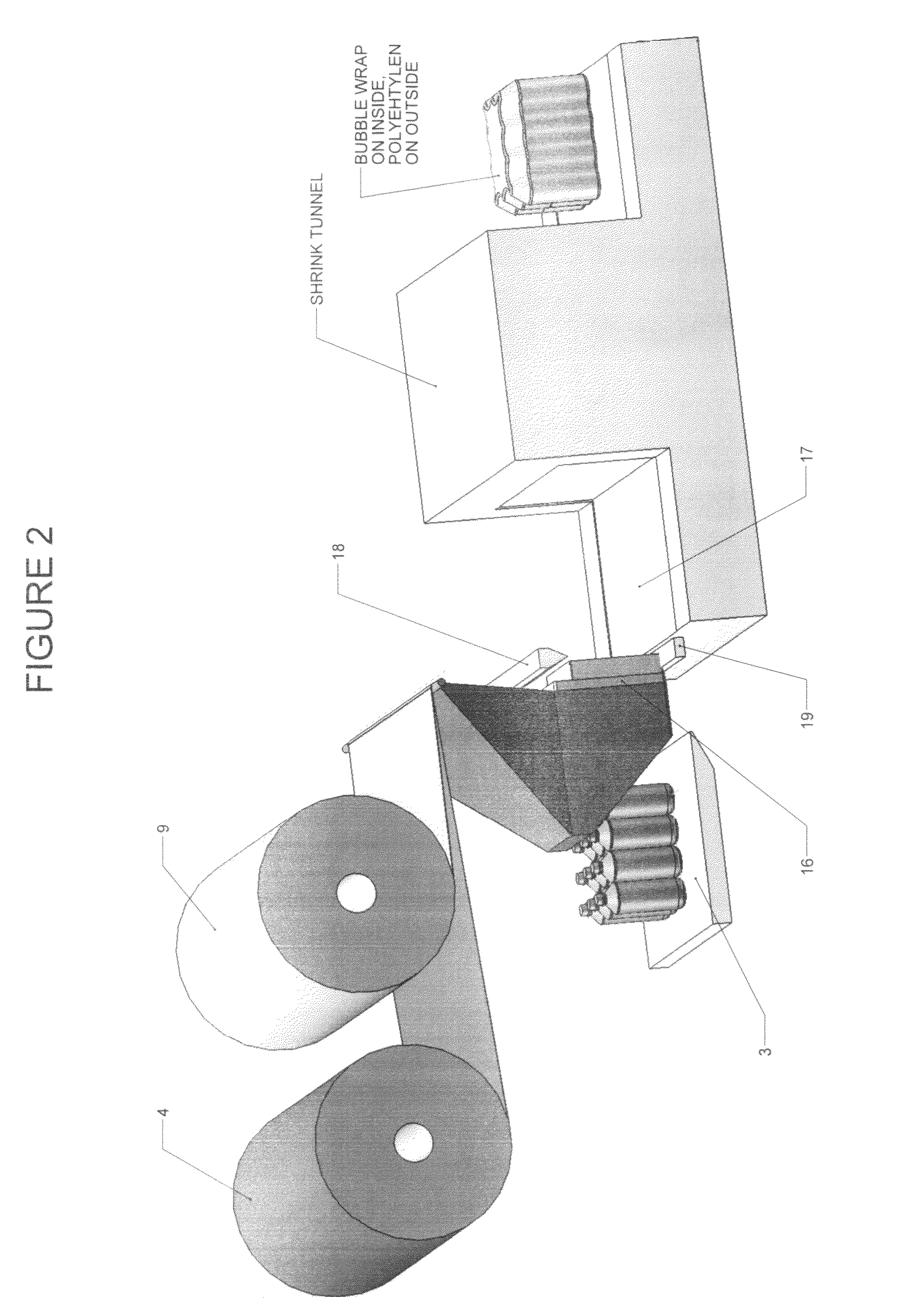

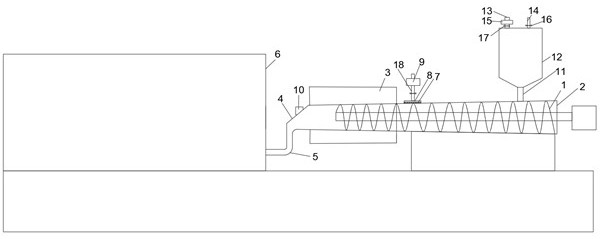

Heat shrinkable bubble wrapping machine

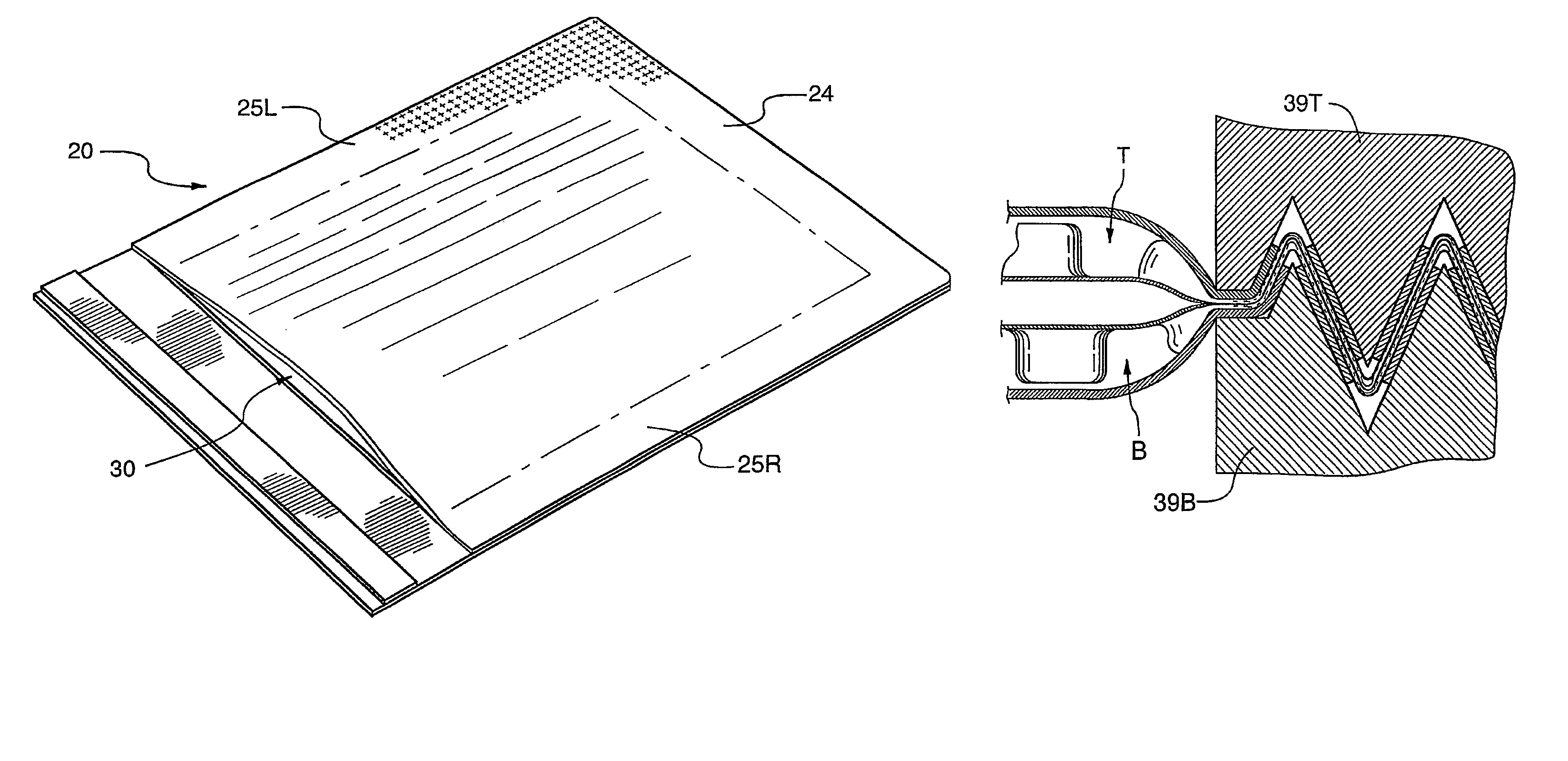

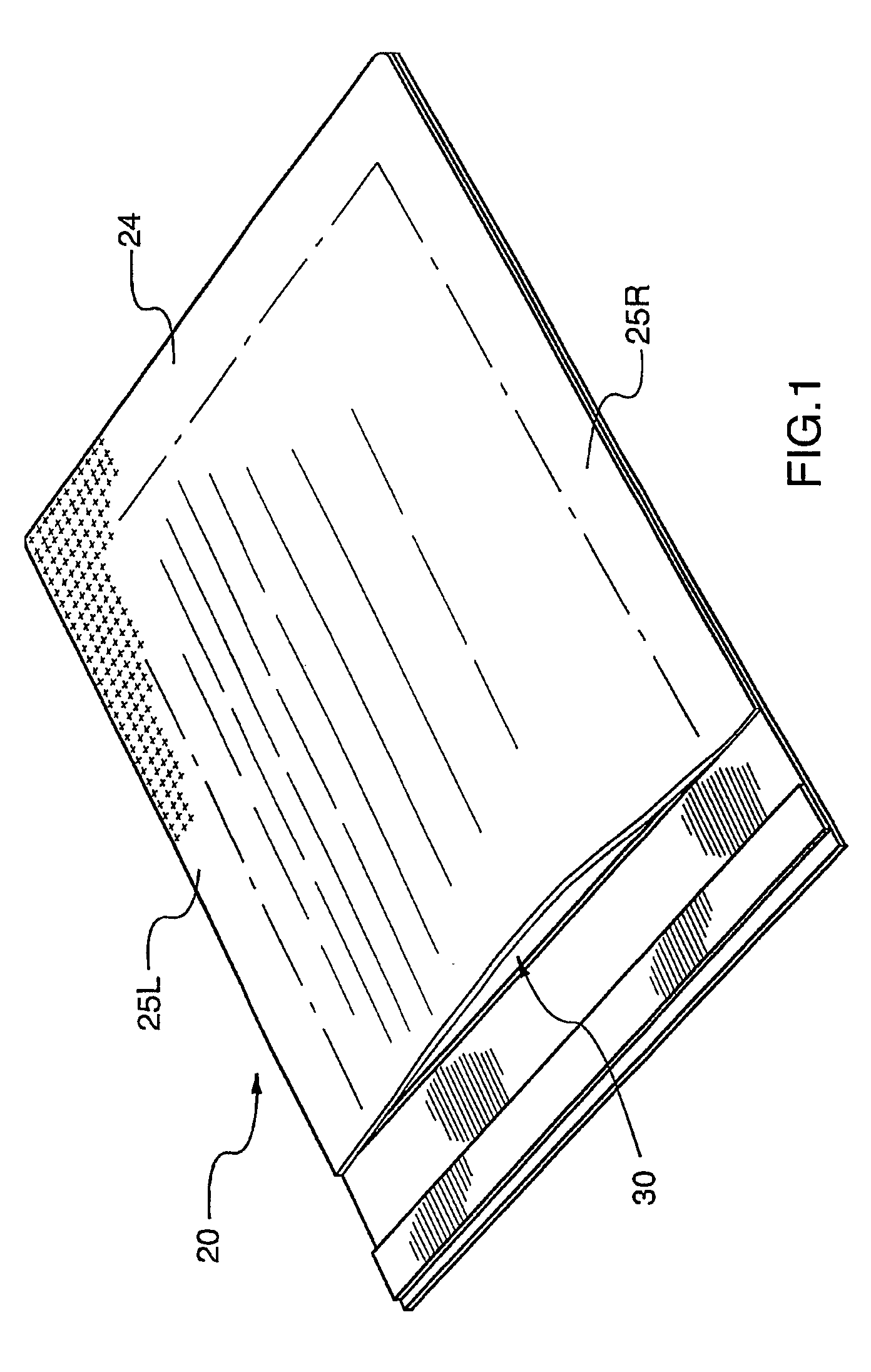

ActiveUS20110284558A1Replacement is neededEnsure integrityWrappers shrinkageSynthetic resin layered productsCartonEngineering

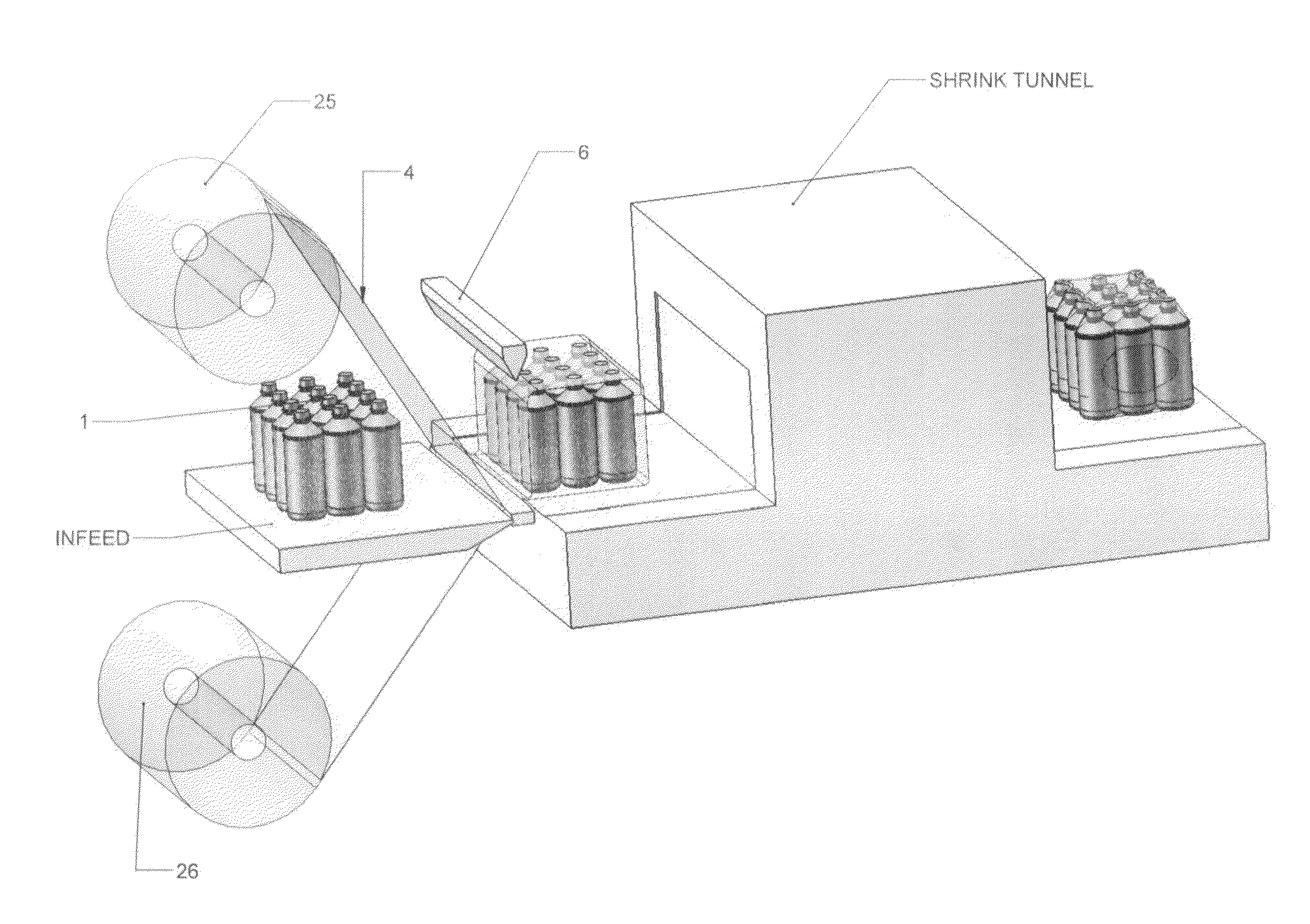

This invention is to replace the need for a corrugated carton by wrapping an article with a heat shrinkable bubble wrap film. Heat shrinking the bubble wrap will allow the bubble wrap to shrink sufficiently to conform to an article such as a group of containers, e.g. bottles. Because of the inability of the bubble wrap film to tightly shrink around the containers, the containers can move and bump each other. To ensure stability, the bubble wrapped article is film wrapped with a heat shrink film and heat shrunk to provide an article that does not require a corrugated box for to ensure the integrity of the containers

Owner:CERF ALAIN

Heat shrinkable bubble wrapping machine

ActiveUS9216832B2Replacement is neededEnsure integrityWrappers shrinkageSynthetic resin layered productsCartonEngineering

This invention is to replace the need for a corrugated carton by wrapping an article with a heat shrinkable bubble wrap film. Heat shrinking the bubble wrap will allow the bubble wrap to shrink sufficiently to conform to an article such as a group of containers, e.g. bottles. Because of the inability of the bubble wrap film to tightly shrink around the containers, the containers can move and bump each other. To ensure stability, the bubble wrapped article is film wrapped with a heat shrink film and heat shrunk to provide an article that does not require a corrugated box for to ensure the integrity of the containers.

Owner:CERF ALAIN

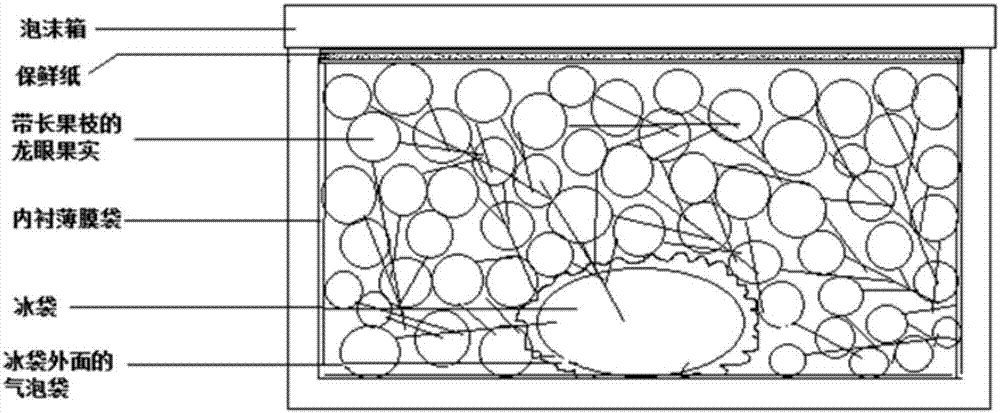

Longan-preserving method applicable for e-commerce logistics

PendingCN107347978AImprove product appearanceResidue reductionFruit and vegetables preservationIsolation effectLogistics management

The invention discloses a longan-preserving method applicable for e-commerce logistics. The method is described as follows: adopting a common foam box with an internally lined polyethylene film preservation bag to form outer packing; placing ice packs sleeved by bubble wrap which has an isolation effect in the central position of the bottom of the foam box; evenly placing longan fruits with fruit spurs around the ice packs and on the ice packs; after the ice packs are fully surrounded by the longan fruits, laying a piece of longan-preserving paper having the same area with the opening of the internal foam box on the longan fruits; laying a piece of isolation paper having the effects of insulating air and resisting humidity on the longan-preserving paper; and finally, folding the upper extra part of the preservation bag flatly, performing sealing, covering the foam box with a lid and sealing tightly around the lid with box-sealing tapes to prevent air leakage and cool leakage. The preservation method provided by the invention can not only increase a good-quality fruit rate and extend the shelf life and the subsequent refrigeration life of the longan fruits but also reduce the residual amount of SO2 in the fruits and improve the uniformity of the SO2 content of the piled fruits.

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI

Training ammunition cartridge with reactive liquid materials for marking a point of impact

ActiveUS20150268018A1Low costAmmunition projectilesTraining ammunitionChemical compositionPlastic materials

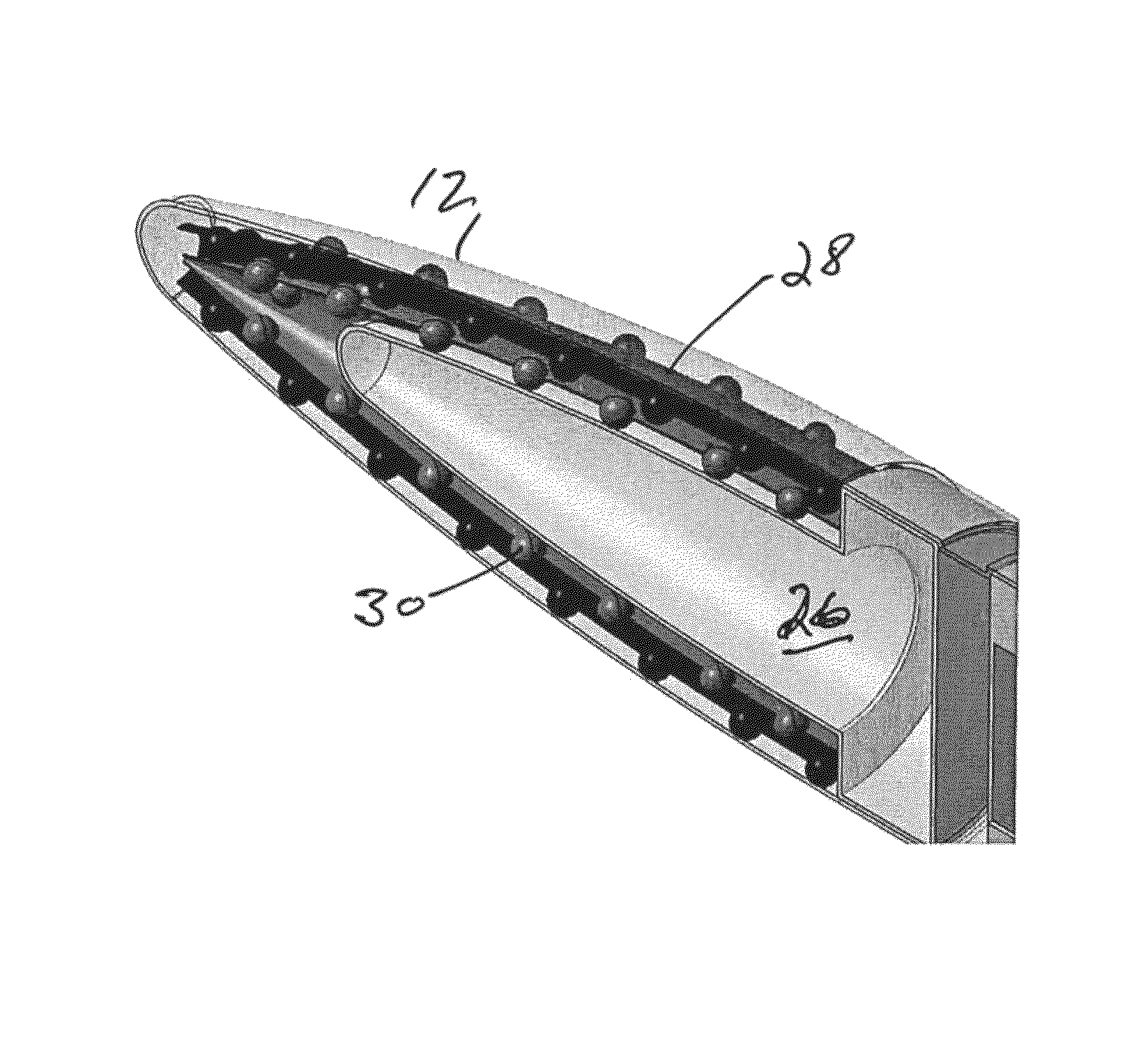

A practice ammunition projectile has a projectile head with one or more sheets of plastic material, each having a plurality of frangible “bubble shaped” compartments containing liquid chemical components for optical and / or Infrared marking of a target upon impact. The sheets are preferably flexible sheets in the nature of a “bubble wrap” of the type used as padding for packaging. These so-called “matrix packages” are installed adjacent the inner surface of the shell forming the projectile head and provide stability when the compartments break up upon setback when the projectile is fired from a weapon.

Owner:NOSTROMO HLDG LLC

Mattress Cover

A mattress cover is provided having a surface that includes a plurality of peaks and valleys to distribute pressure and to allow for air circulation. A bubble wrap material can be utilized. The cover can have an adhesive to prevent slippage. It can be provided in a roll and sections can be separated along pre-defined cut lines or perforations. A section can be separated from the roll and adhered to the mattress. A sheet can be placed over the mattress and cover.

Owner:KHOWAYLO ALEX I

Face protection device for prone position operations

PendingCN106726321AImprove the degree of sealingAvoid stressOperating tablesAmbulance serviceNoseMassage

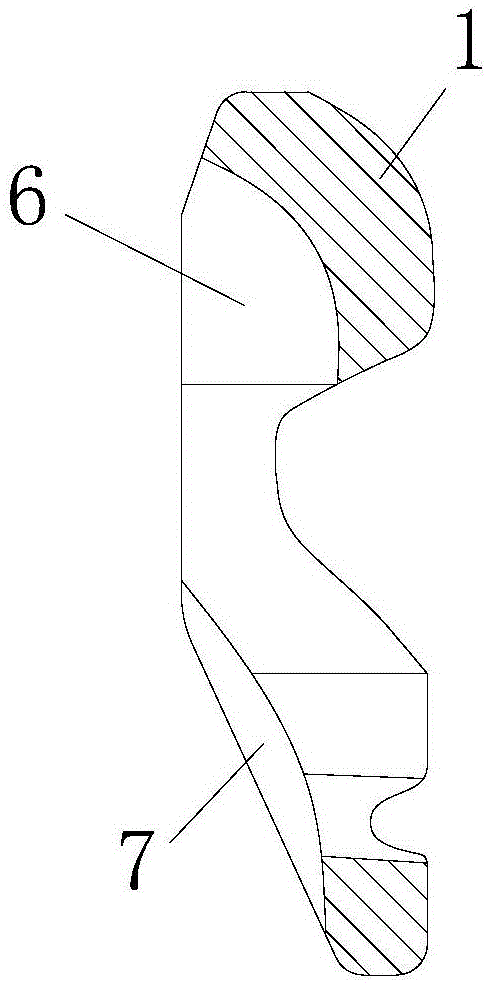

The invention relates to a face protection device for prone position operations. The face protection device comprises a mask body (1), eye openings (2), a nose opening (3) and a mouth opening (4) matched with eyes, the nose and the mouth of a human body are formed in the mask body (1), a duct groove (5) is formed in the front of the mask body (1) and positioned at the mouth opening (4), a forehead groove (6) and a face groove (7) are formed in the back of the mask body (1) and contact with the forehead and the face of the human body, an inflatable bubble wrap is arranged on the face groove (7), massage projections are arranged on the bubble wrap, a plurality of air bags are arranged in the bubble wrap and connected with an air pump through air pipes, and the air pump is connected with a controller. Compared with the prior art, the face protection device is novel and simple in structure, high in comfort, comfortable to use and low in cost and completely fit with the face of a patient, sealing degree of fitting between the mask body and the face of a human body is improved, and potential safety hazard accidents are avoided.

Owner:周许辉

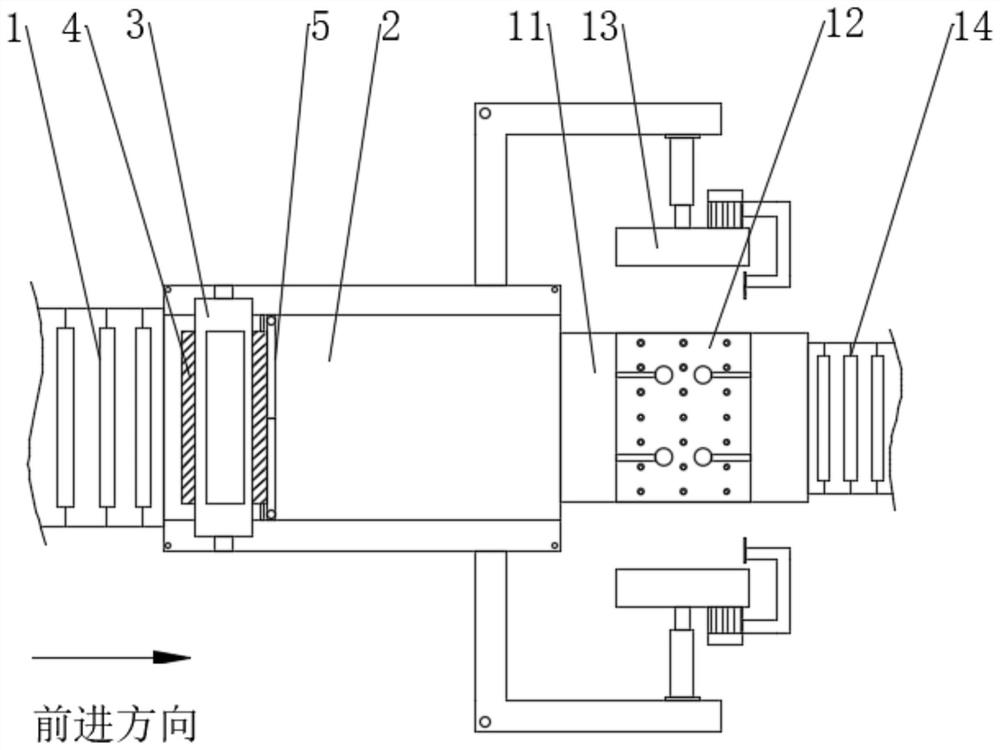

Resistance-type high-temperature superconducting fault current limiter

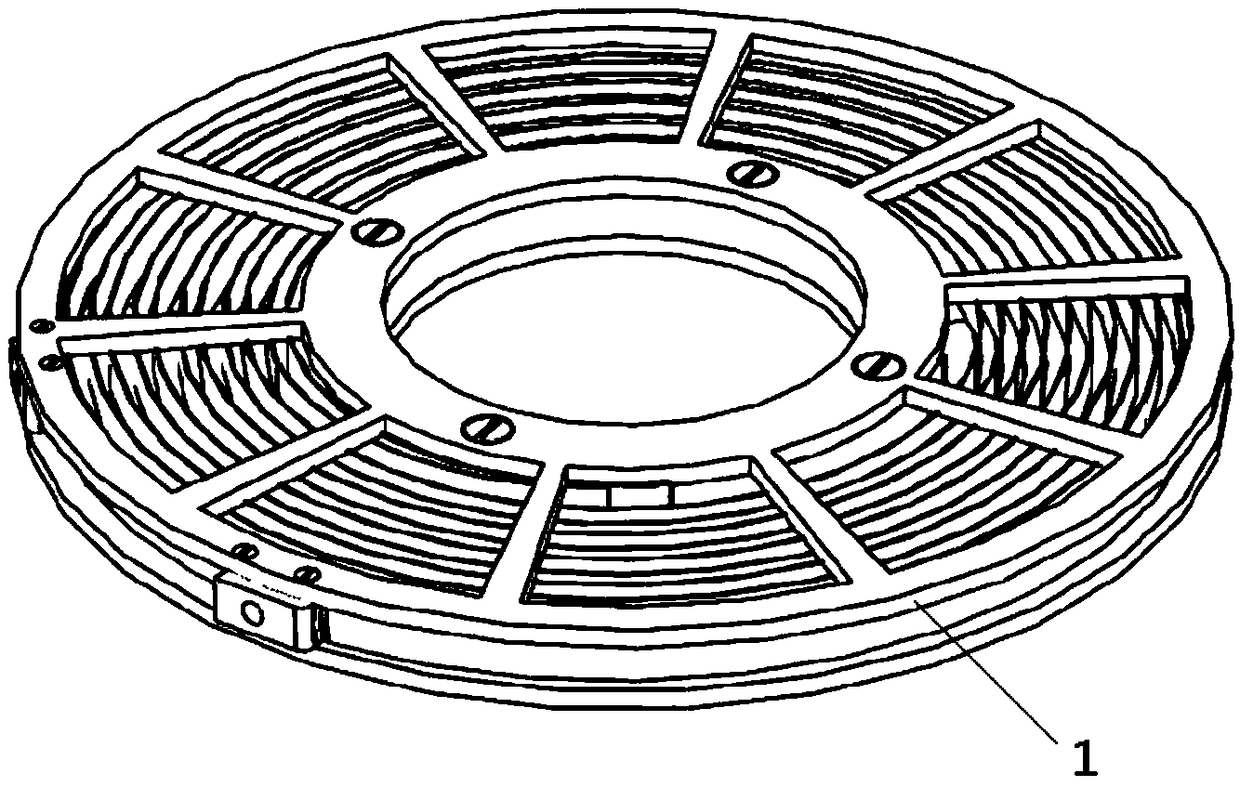

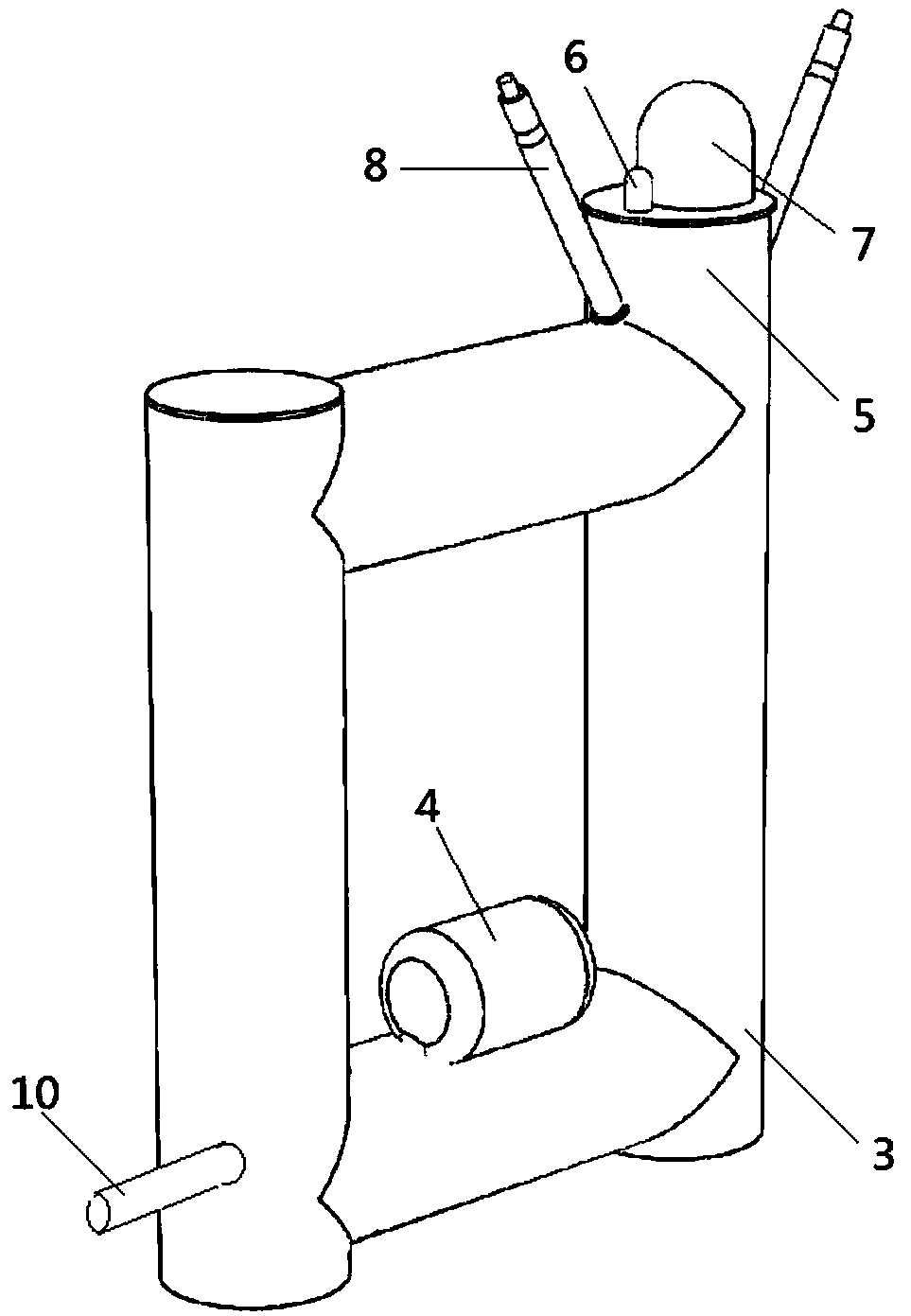

ActiveCN108649547AImprove fault current limiting capabilityEnsure safetyEmergency protective arrangements for limiting excess voltage/currentSuperconductor elements usageHigh temperature superconductingPower grid

A resistance-type high-temperature superconducting fault current limiter comprises a superconducting non-inductive winding (2), a liquid nitrogen cycle container (3), a liquid nitrogen pump (4), a gaschamber (5), a small emptying valve (6), a large emptying valve (7) and a current lead (8); wherein the liquid nitrogen pump (4) is arranged at the bottom of the liquid nitrogen cycle container (3);the small emptying valve (6) and the large emptying valve (7) are arranged parallelly on an end plate at the top of the liquid nitrogen cycle container (3), both the small emptying valve (6) and the large emptying valve (7) are pressure adjustment and control fittings in liquid nitrogen operation; the superconducting non-inductive winding (2) is connected with one end of the current lead (8), theend of the current lead (8) and the superconducting non-inductive winding (2) are arranged in the liquid nitrogen cycle container (3); and the other end of the current lead (8) is leaded outside of the liquid nitrogen cycle container (3) to be connected with a power grid. Through adoption of the resistance-type high-temperature superconducting fault current limiter of the invention, liquid nitrogen is forced to flow by the liquid nitrogen cycle container and the liquid nitrogen pump, so as to quickly take away bubbles wrapping the superconducting non-inductive winding.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

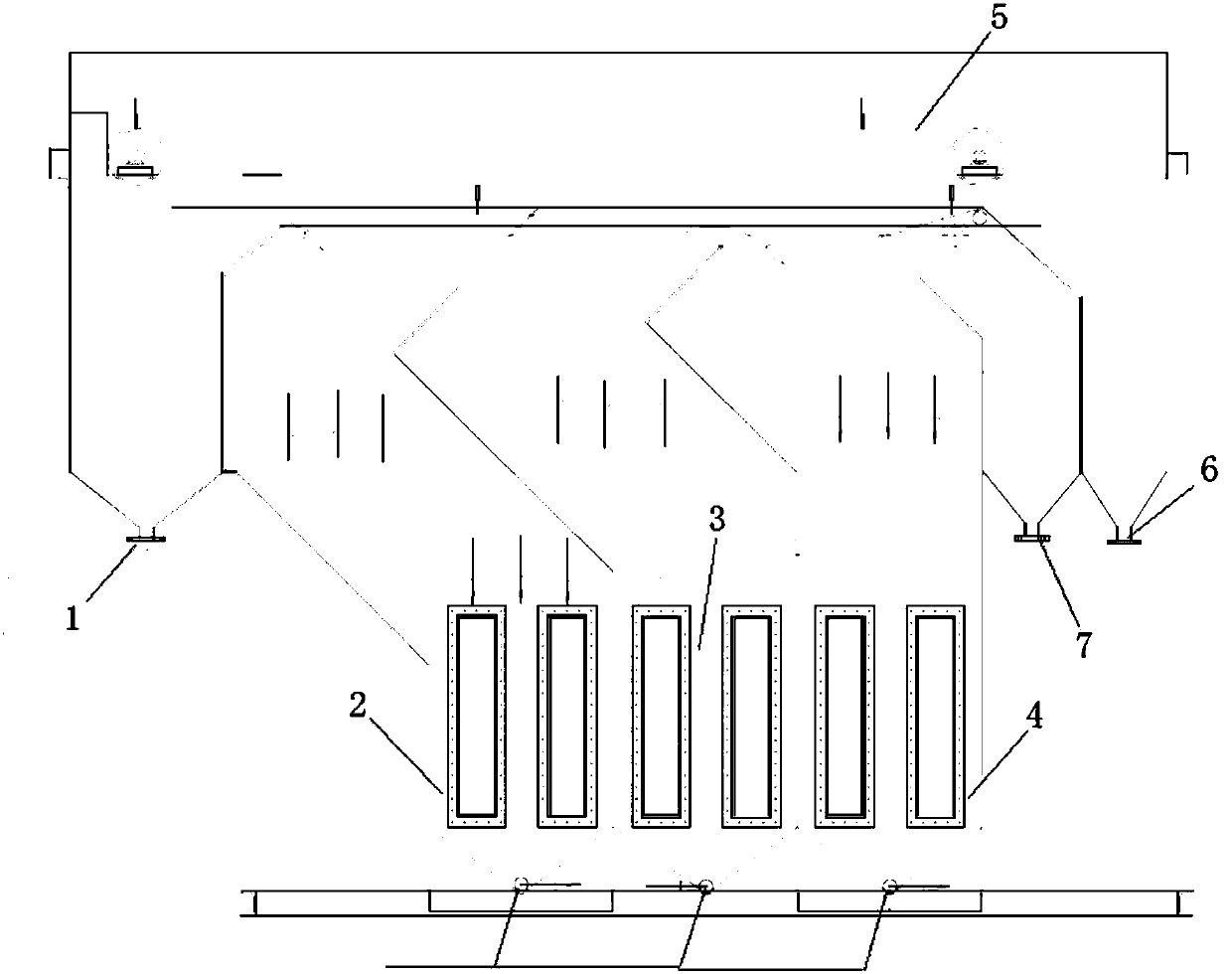

Oil-containing wastewater electro-flocculation depth air-floatation system

PendingCN107867740AIncrease or decrease quantityGood demulsification effectFatty/oily/floating substances removal devicesNature of treatment waterWater dischargeElectrolysis

The invention relates to an oil-containing wastewater electro-flocculation depth air-floatation system. According to the oil-containing wastewater electro-flocculation depth air-floatation system, a scum scraper in the electro-flocculation system is located at the upper part of an electrolysis tank, and is used for treating solid waste produced by flocculation and air flotation of equipment, so that the scraped scum is discharged from a scum outlet, and up-to-standard clear water is discharged from a clear water outlet. In a dissolved air flotation system, a flocculant is added in a water inlet pipe section of a dissolved air floatation tank, so that a large amount of suspended matter in discharged water is flocculated, and the generated flocculates are wrapped by a large amount of micro bubbles which are generated by mixing water and vapor under a high pressure via an air dissolving pump and sending the mixed water vapor to a release device for releasing, thus the wrapped flocculatesfloat upwards to a water surface, and are removed by the scum scraper, and finally the discharged water overflows to a clear water tank. The electro-flocculation depth air-floatation system employs three-stage serial demulsification, is good in demulsification effect, and has a wide equipment application range. The equipment can be improved based on water to be processed, for example, the electrolysis current and the electrode plate number are increased or reduced, the spacing, size and thickness can be adjusted. After second-stage depth air flocculation, the removal rate of COD is up to about90%, and the removal rate of oil substances is up to 95% or more.

Owner:浙江和惠生态环境科技有限公司

String Box and Method of Use Thereof

InactiveUS20160122062A1Easy to useImprove automationContainers to prevent mechanical damageNanoparticleEngineering

A string box and method of use thereof. The string box may be designed in any shape or size and be made up of any rigid material and the string may be designed in any shape or size and be made of any material such as cotton, cat gut, nylon, plastic, nanoparticle, graphine like material, atoms or any material within the realm of science and knowledge that would provide enough strength to act as a string type of material that can be used to suspend the object with enough strength to hold the item being shipped, stored or otherwise used so that the object being placed in the box is in suspension essentially keeping the object being damaged or hitting the sides of the container it is being shipped, stored or otherwise used in. The box is uniquely designed to allow for a simple one-step process using a box with an integrated string system that is used to suspend an article to be to be packaged. This completely protects the article and removes the need for air other gas, peanuts, foam, bubble wrap, paper or other fillers in boxes used for shipping goods once the box is closed.

Owner:SMITH JACK VINCENT

Lightweight Insulating Spa Cover

ActiveUS20120210508A1Eliminate water absorptionEasy to transportGymnasiumSwimming poolsBubble wrapTension band

A lightweight insulating spa cover for a heated spa with an open top, the spa cover constructed with a substantially rigid perimeter frame with a plurality of cross supports in the form of tension bands that encompass the frame in a crisscross pattern to form a support for an outer casing that encases the frame with the outer casing being fabricated of a breathable weatherproof fabric that is stretched over a layer of reflective bubble wrap material that provides a cushion and added insulation for the hollow lightweight cover.

Owner:TUDOR JESS E

Single-class and multi-class tiny object suspension directional movement and self-loading huge transfer method

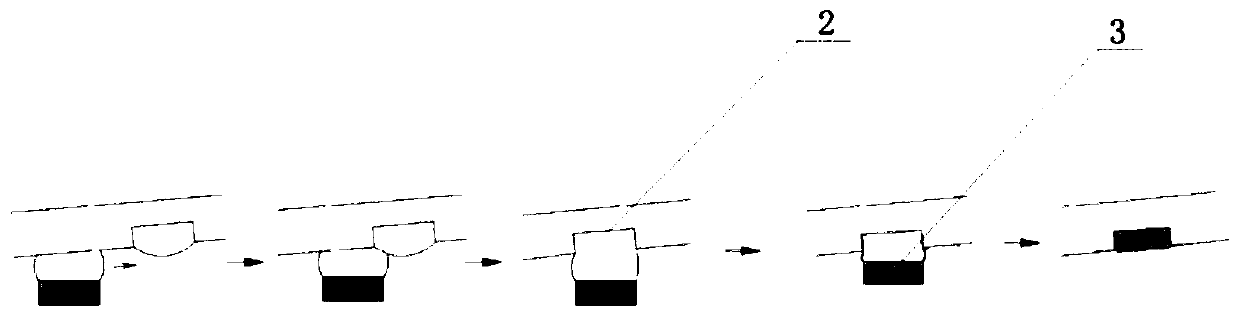

ActiveCN111430272AFind the exact location of the targetEasy to operatePrecision positioning equipmentSoldering apparatusEngineeringComputational physics

The invention provides a single-class or multi-class tiny object suspension directional movement and self-loading huge transfer method. By performing surface treatment on a tiny object and a target carrier plate, the target position of the target carrier plate has different surface energy. By putting the tiny object and the target carrier plate into the solution, dissolving or introducing gas intothe solution, and separating out the bubble wrapped tiny object, the bubble wrapped tiny object suspends and rises to get close to the target carrier plate. By utilizing the difference of the surfaceenergy at the target position of the target carrier plate, the bubble and the chip are captured and stand at the target position, and then by the degassing processing, the bubble is dissolved, and the tiny object is combined with the target position of the target carrier plate. By carrying out differentiated surface treatment on different target positions of the target carrier plate, the suspension directional movement and self-loading huge transfer of multiple types of tiny objects can be further realized in different solutions in sequence. The single-class or multi-class tiny object suspension directional movement and self-loading huge transfer method provided by the present invention has the advantages of high efficiency, high positioning precision and easiness in operation.

Owner:GUANGDONG UNIV OF TECH

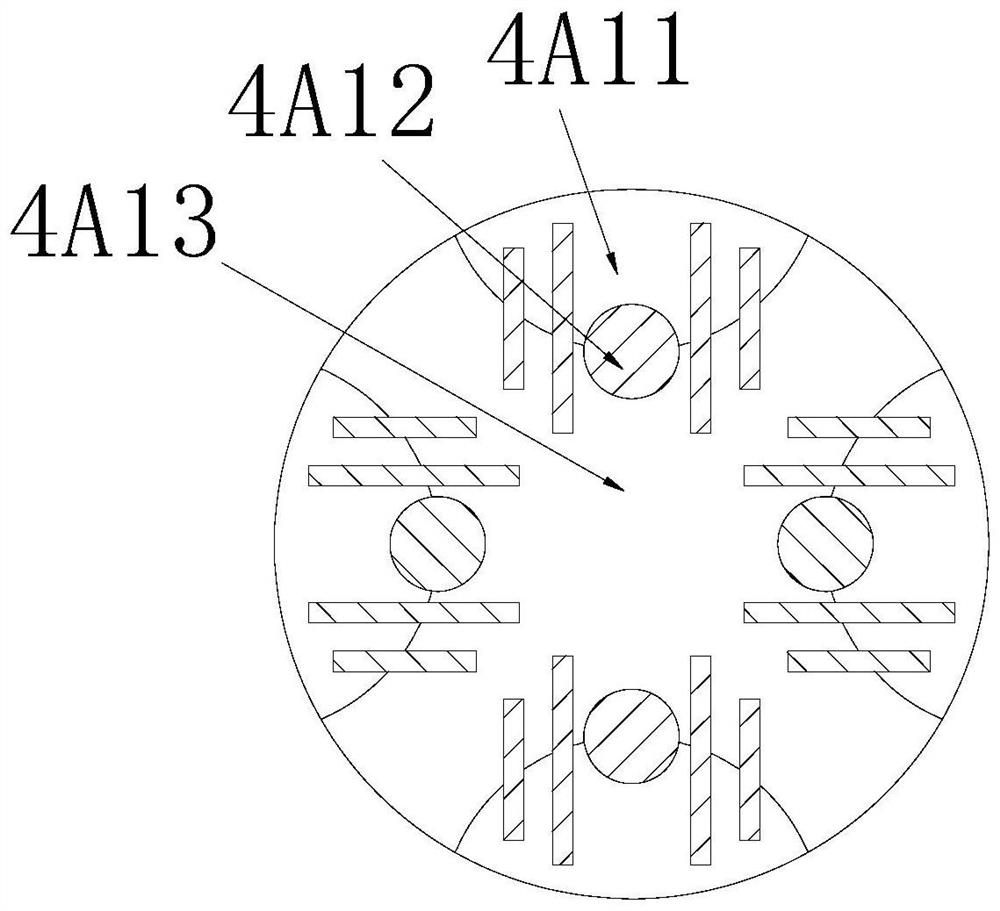

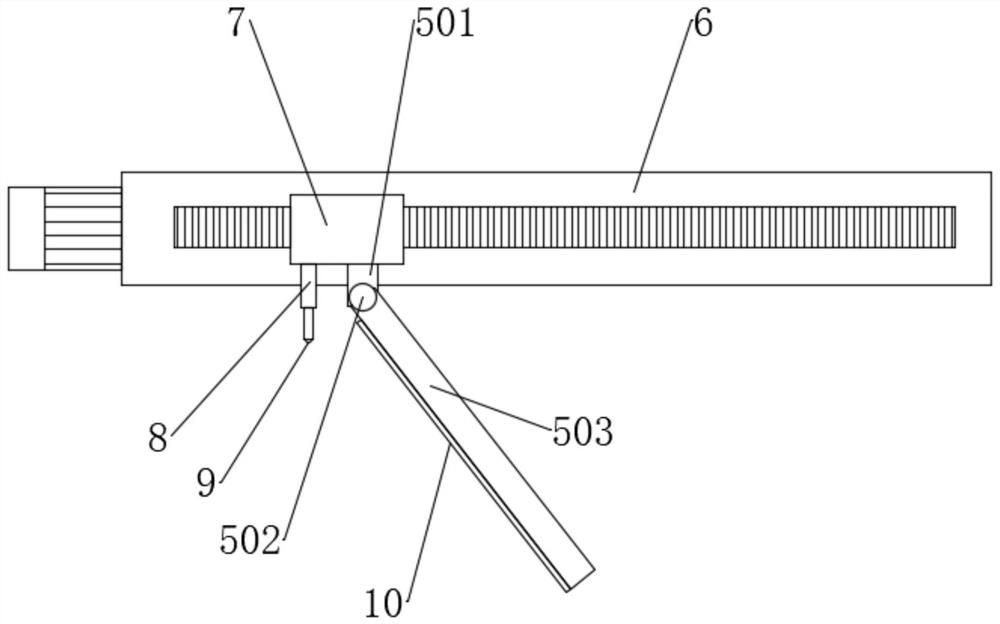

Micro-bubble preparation method, air supply system and preparation equipment

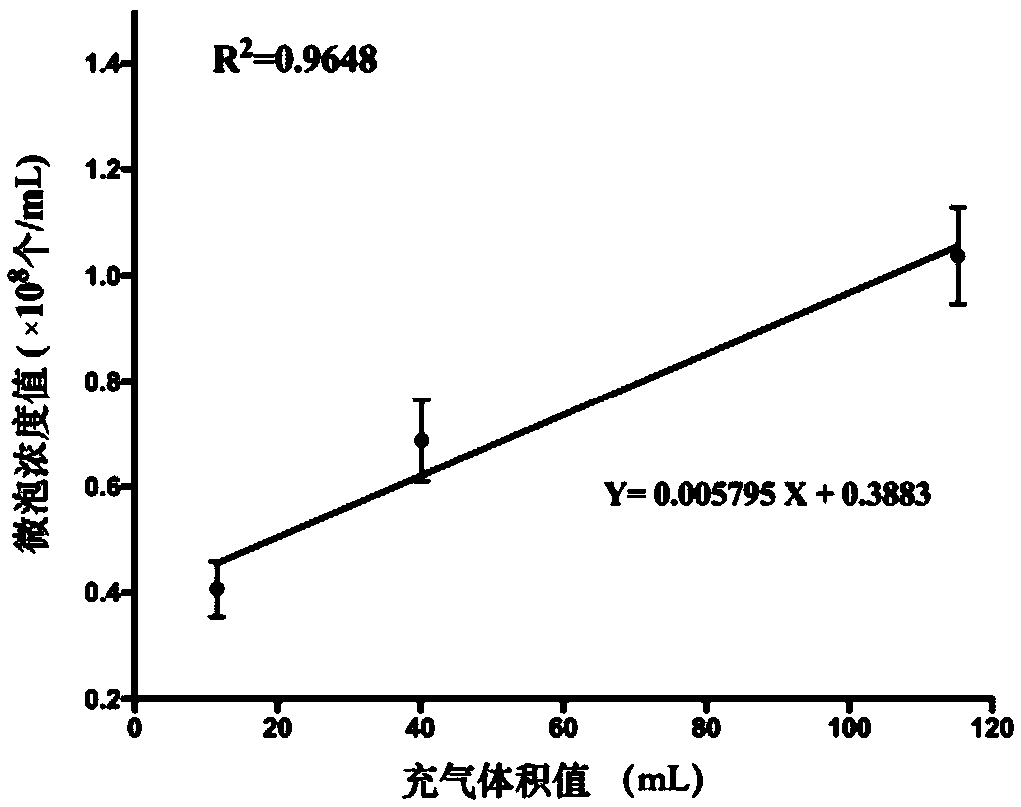

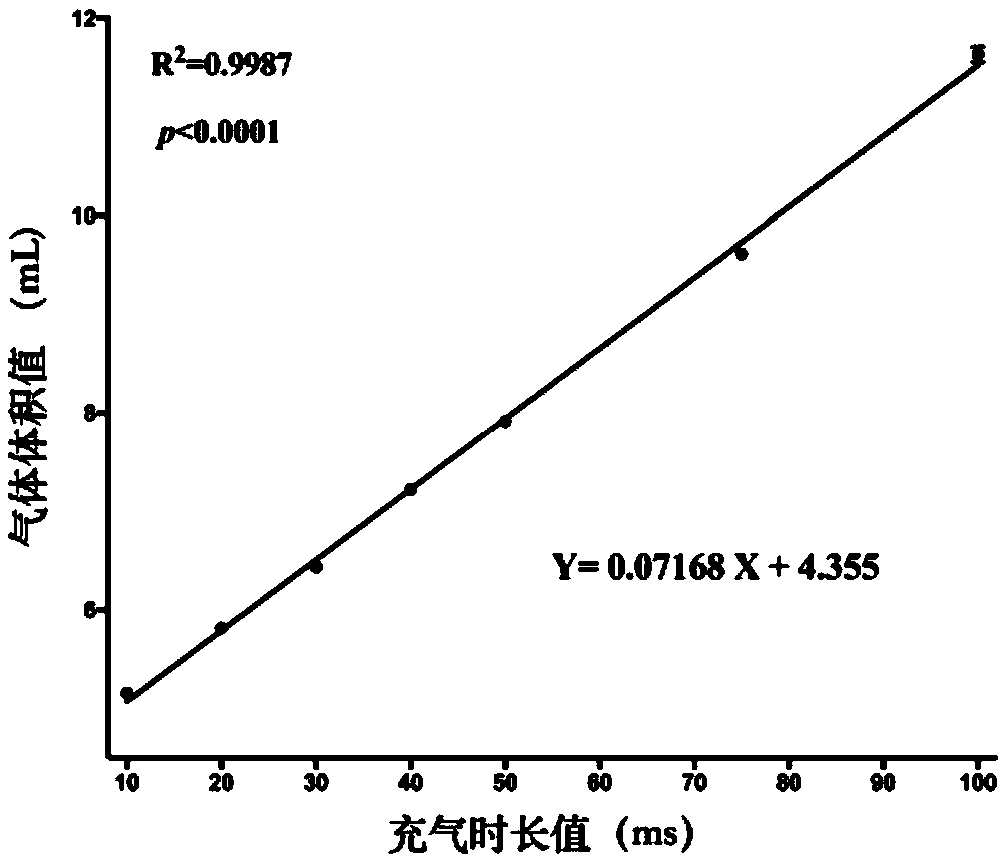

InactiveCN109513016AImprove consistencyEchographic/ultrasound-imaging preparationsMacromolecular non-active ingredientsMicro bubbleAir volume

The invention relates to a micro-bubble preparation method, which comprises the following steps that a membrane forming material is provided for a reaction container; air required for micro-bubble formation is filled into the reaction container; the filled air volume is controlled; air micro-bubbles wrapped by the membrane forming material are generated by a preset method. The problem of poor micro-bubble concentration value consistency of the existing preparation method is solved, so that the beneficial effect that the micro-bubble concentration value consistency is better is achieved.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

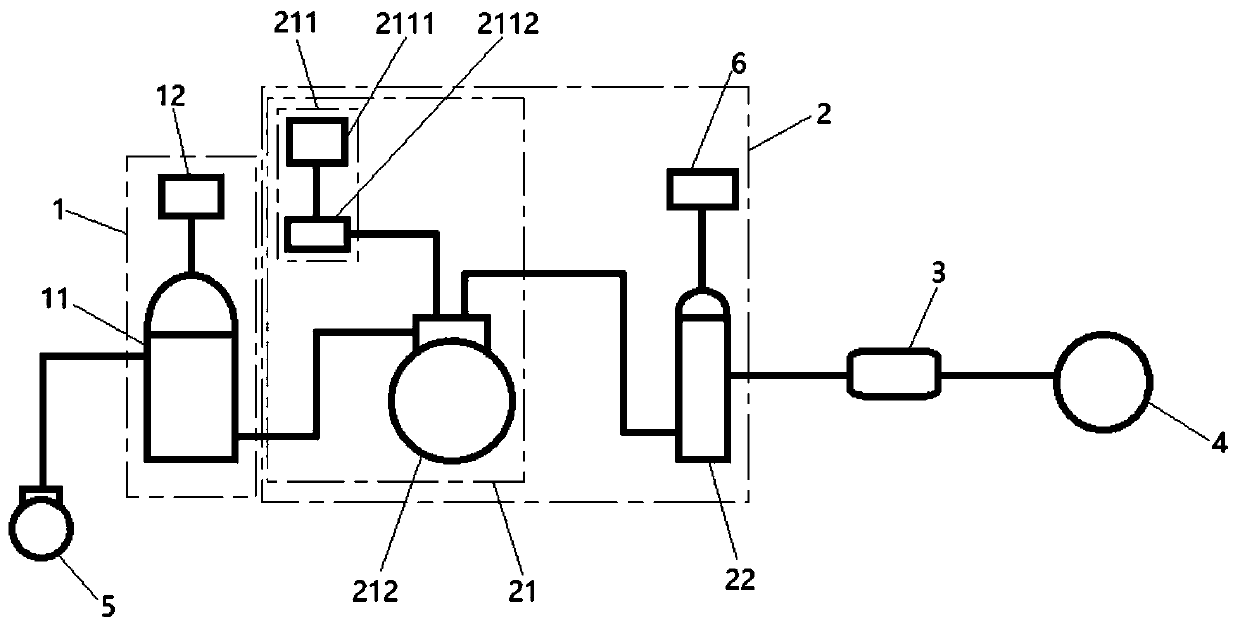

Tubular washing type air purifier

PendingCN108636004AReduce energy consumptionNo consumables requiredUsing liquid separation agentAir filterWater filter

The invention relates to an air purifier, belonging to the field of household electrical appliances. The air purifier overcomes the technical problems of low steam mass transfer efficiency and non-ideal purifying effect of conventional washing type air purifiers. The air purifier provided by the invention simulates air-liquid mixing and pressurized purification in an intestinal tract-like long tube and comprises a water circulation unit, an air circulation unit, a water filtering unit and an air filtering unit. According to the invention, a water pump is connected with an ejector and a staticmixer; air filtered by a filter screen is sucked in and allowed to form uniform and fine bubbles which fully contact with water, so the contact area and action time of the air and the water are improved; and in the long tube with a length of 9 meters, the bubbles wrapped in water do not combine with each other nor rupture under the action of the thrust of the water pump and the resistance of the water tube and undergo collision flowing, so steam mass transfer effect is improved, and the purification process of air by rain is basically simulated. The purifier has good purifying effect, low cost, small noise and no secondary pollution, and is capable of humidifying air, easy for scaling up and extensively applicable to indoor use.

Owner:王宝伊 +1

Seamless garment making method

ActiveCN108741356APromote environmental protectionElasticProtective garmentSpecial outerwear garmentsYarnEngineering

The invention discloses a seamless garment making method. The method comprises the steps of using a garment sample as a motherboard, placing a plastic cloth on the motherboard and cutting to obtain aplastic cloth board, placing a sponge pad, coating the sponge pad with a bubble wrap, placing a bamboo curtain on the bubble wrap, placing the plastic cloth board on the bamboo curtain, placing silk fabric on the plastic cloth board and wetting, coating greasy wool on the silk fabric to obtain the garment base, coating yarn mesh on the greasy wool and spraying water to obtain wet yarn mesh, movinga soap on the wet yarn mesh to form foams and to obtain a laminated body of greasy wool and silk fabric, disclosing the wet yarn mesh, turning the plastic cloth board, the silk fabric and the greasywool totally and operating repeatedly to obtain a parison ready to be rolled, winding up the bamboo curtain towards the internal side, rolling the parison ready to be rolled, and rolling the parison ready to be rolled again from different direction, and then unfolding the bamboo curtain, taking out the plastic cloth to obtain the garment primary parison, pressing out the water, removing soap water, and drying to obtain the product. The seamless garment making method has the advantages that the producing cost is reduced, the method is environment friendly, the connection intensity is long, andwater wash is not afraid.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

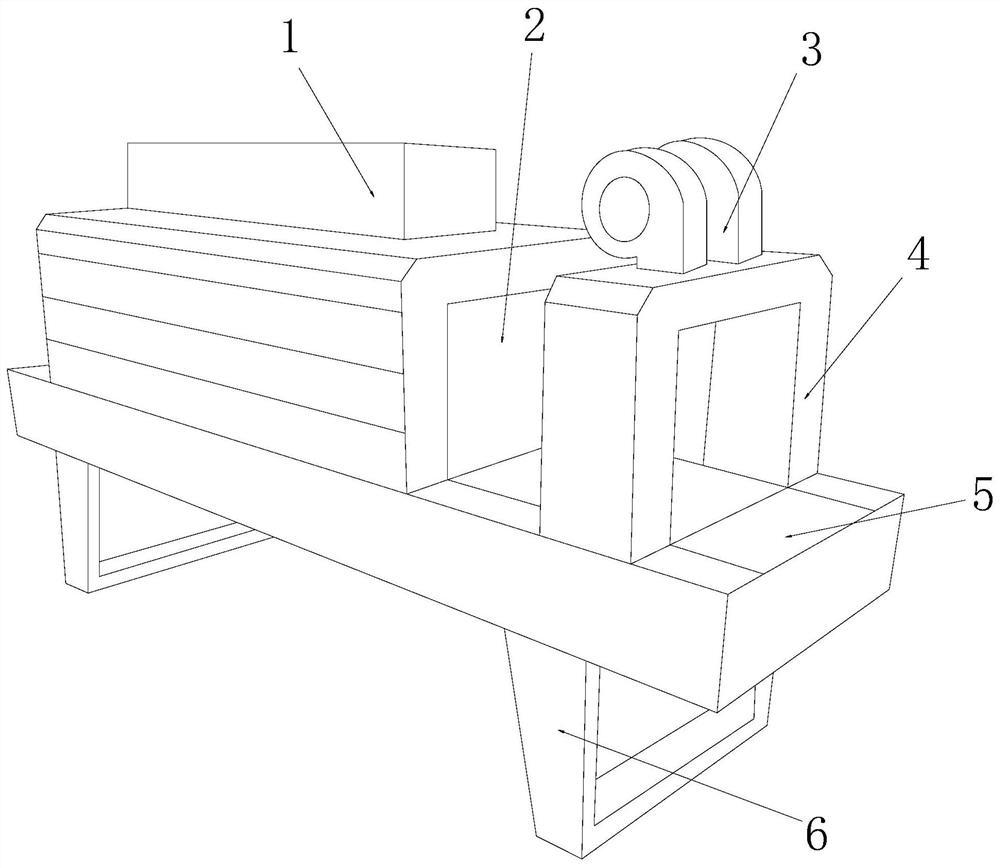

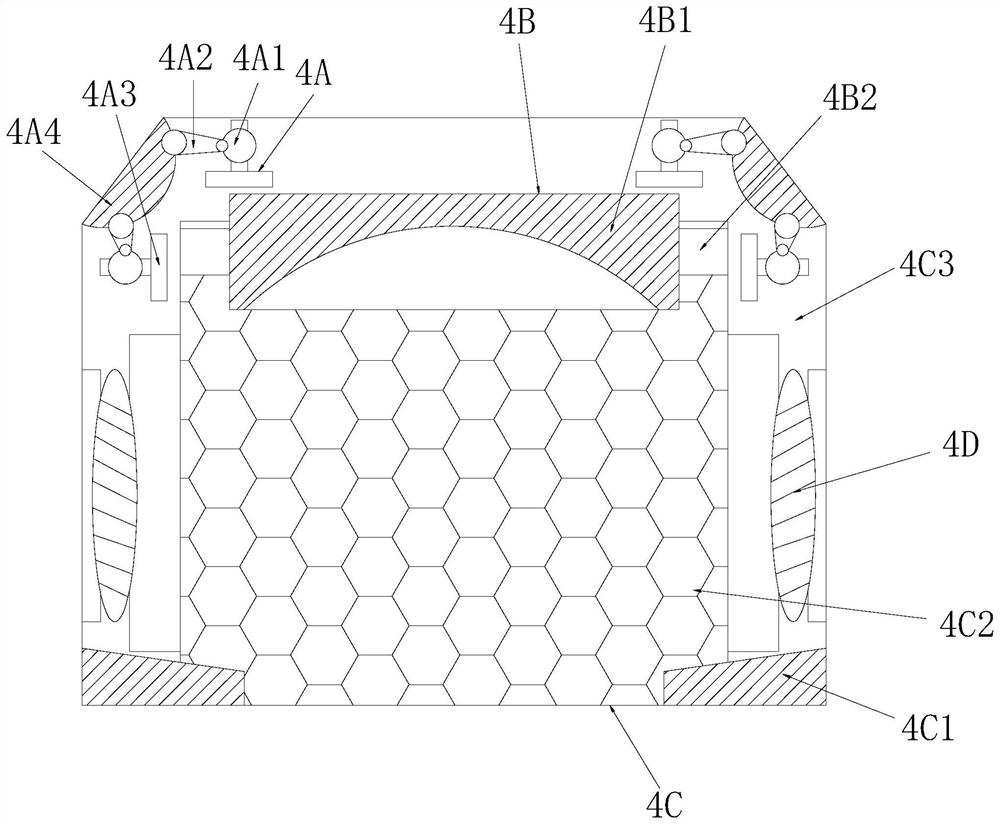

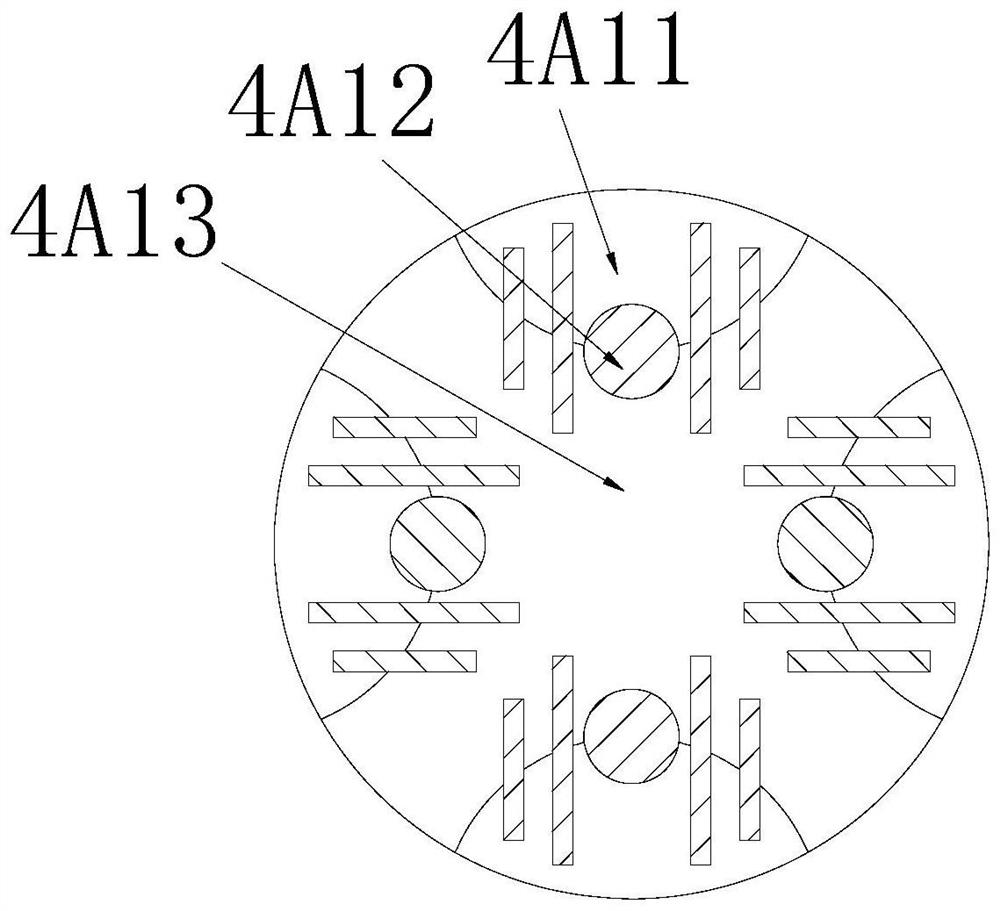

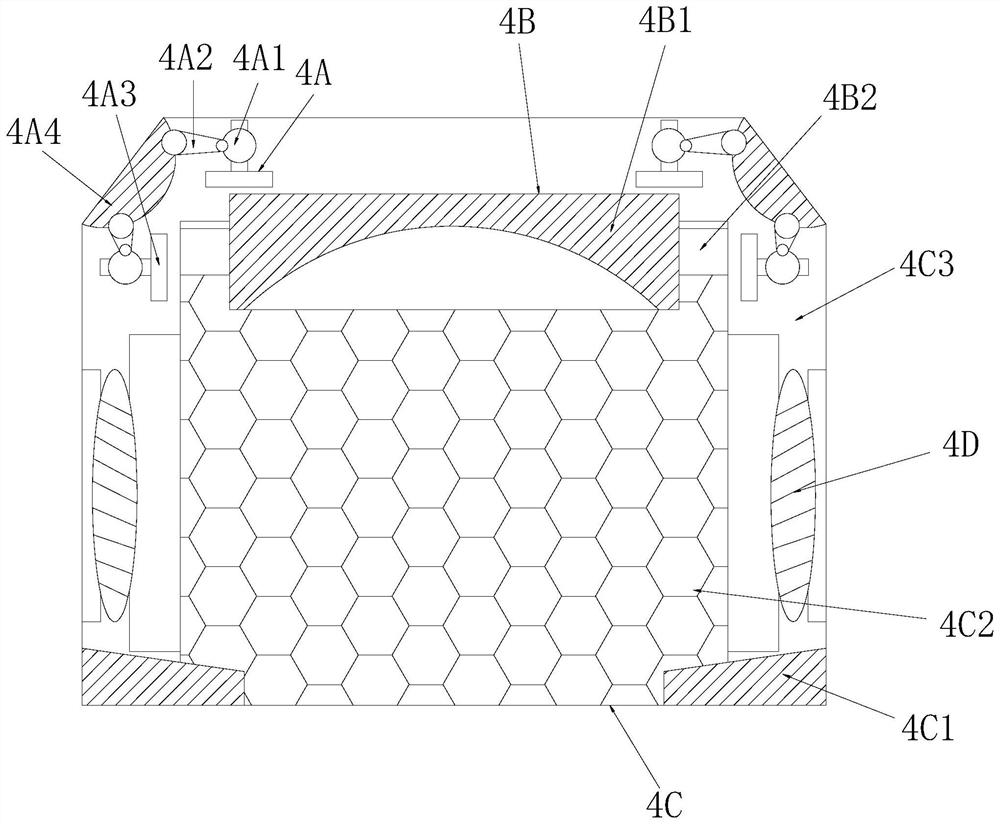

Edge cutting equipment for blown film

ActiveCN112238989AImprove packaging yieldImprove the protective effectFinal product manufacturePackagingBlow moldingThin membrane

The invention discloses blow molding film edge cutting equipment. The blow molding film edge cutting equipment structurally comprises an electric control box, a horizontal packaging groove, an air blower, a blow molding film edge cutting door frame, a conveying belt table and supporting frame foot stands. According to the blow molding film edge cutting equipment, the packaging horizontal groove ismatched with the blow molding film cutting door frame; the operation effect of short-distance smooth adjustment through trimming pressing frames is achieved through blow molding packaging of the packaging horizontal groove at the right side of a grid door frame and the right side of an alignment clamping strip base, and the density of edge strips obtained after end corner trimming is effectivelyadjusted to be flatness sliding pressing and toughness adjustment wrapping pressing operation of attaching, tightening and pulling through sliding pressing column plates. The integrity of the packaging degree of a gas collecting machine after blow molding middle film bulges are improved, the smooth anti-wrinkle adjustment of the end face of the film forms sliding pressing operation through slidingpressing chopping plates, bubbles wrapped by the film are pressed out, and the smoothness and the uniform texture of a product after film pasting are guaranteed.

Owner:临沂天勤塑业有限公司

A kind of edge trimming equipment for blown film

ActiveCN112238989BImprove packaging yieldImprove the protective effectFinal product manufacturePackagingBlow moldingElectrical control

The invention discloses a blown film edge trimming device, the structure of which comprises: an electric control box, a packaging horizontal tank, a blower, a blown film cutting door frame, a conveyor belt table, a bracket frame tripod, and the invention realizes the use of the packaging horizontal tank and The blown film is matched with the door frame, and the right side of the grid door frame and the alignment clip seat is blown and packaged by encapsulating the horizontal groove to form a smooth adjustment of the operation effect through a short distance of the trimming pressing frame, so that the edge strip density after edge trimming is effective Adjust the flatness by sliding and pressing the column plate and adjust the toughness of sliding and pressing and attaching tight pull to improve the integrity of the air-absorbing mechanical package after the blown centered film bulges, and the smooth anti-wrinkle adjustment of the film end surface The sliding pressure operation is formed by the sliding pressure guillotine, so that the air bubbles wrapped in the film are pressed out to ensure the smoothness and uniformity of the product after filming.

Owner:临沂天勤塑业有限公司

A fully automatic film and coil packaging integrated production process

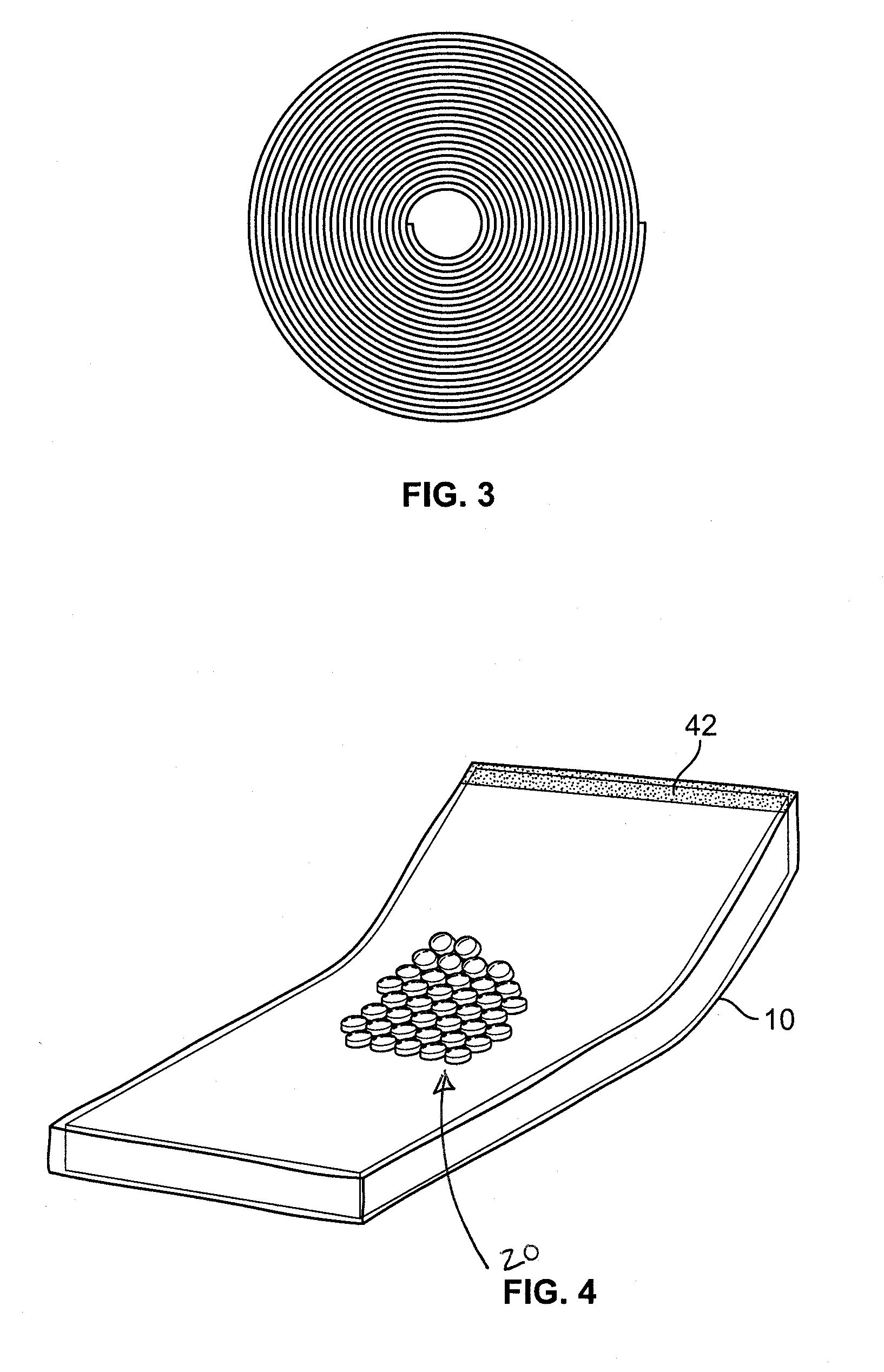

ActiveCN110803318BSmall footprintLow costWrapper twisting/gatheringWrapping with article rotationThin membraneBubble wrap

The invention discloses a fully automatic film and coil packaging integrated production process, which belongs to the field of film and coil packaging production. The multi-step process of wrapping, hot-melting, capping and fixing, turning and erecting, and palletizing is reduced and synchronized, and it can automatically adapt to film coils with different specifications and diameters or film coils with certain production deviations without stopping Calibration and adjustment, occupy less space, reduce equipment costs, greatly improve production efficiency, when faced with large quantities of film coils of different specifications and diameters, it has incomparable advantages of high efficiency and high production, especially for large-diameter films When coiled, it can be turned over and erected directly after being wrapped with a cover. The stability is extremely high, and it can be automatically adjusted according to different diameters. Compared with the existing mechanical arm or turning table, the safety has been improved.

Owner:浙江嘉毅新材料有限公司

Water treatment system

PendingCN109851092ALarge specific surface areaSlow ascentMultistage water/sewage treatmentMicro nanoBubble wrap

The invention relates to the technical field of water treatment, in particular to a water treatment system. The system comprises a mixing device, an activation buffer device, a micro-nano bubble generation device and a release device which are sequentially connected. The mixing device is used for mixing water with a medicament or a microorganism; the activation buffer device is used for mixing thewater mixed with the medicament or the microorganism with the activated air; the micro-nano bubble generation device is used for scattering large bubbles in water into micro-nano bubbles; and the release device is used for discharging water with micro-nano bubbles. Through the micro-nano bubble generation device installed between the rear activation buffer device and the release device, the micro-nano bubble generation device can scatter large bubbles in water to generate micro-nano bubbles, and the micro-nano bubbles wrap microorganisms. The micro-nano bubbles have the characteristics of large specific surface area, low rising speed, long retention time in water, generation of a large number of free radicals, high mass transfer efficiency and the like; therefore, the system enables the to-be-treated water to be fully aerated, and is greatly beneficial to water quality purification and microbial growth.

Owner:北京爱尔斯生态环境工程有限公司

Feeding system of food packaging barrel injection molding machine

The invention discloses a feeding system of a food packaging barrel injection molding machine. The feeding system comprises a spiral feeder, and a shell of the spiral feeder is conical; a heater is fixedly wrapped at the tail end of the shell; an inclined baffle which gradually inclines downwards in the feeding direction is formed at the tail end of the shell, and the bottom of the tail end of the shell communicates with an injection molding machine body through an L-shaped feeding pipeline; the inner diameter of the tail end of the shell is larger than that of the L-shaped feeding pipeline; and the middle of the spiral feeder communicates with a negative pressure cavity through a plurality of micropores, and the negative pressure cavity is provided with a first negative pressure pump through a communicating pipe. The feeding system is simple in structure and convenient to use, bubbles wrapped after melting move upwards and overflow through the inclined baffle, a vibrator and the L-shaped feeding pipeline, new gas is prevented from being wrapped when materials move, in addition, the inner diameter of the L-shaped feeding pipeline is small, extrusion is formed, and therefore gas in the L-shaped feeding pipeline is effectively extruded out.

Owner:苏州得高塑胶容器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com