Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

351results about How to "Good demulsification effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thick oil demulsifier and its prepn

ActiveCN1810933ALow densityIncrease viscosityHydrocarbon oil dewatering/demulsificationEpoxyDemulsifier

The present invention is one kind of thick oil demulsifier and its preparation process, and belongs to the field of petrochemical technology. The present invention features that phenol-amine resin as the initial material is block polymerized with epoxy propane ad epoxy ethane under the action of catalyst to obtain stereo netted macromolecular polyether as the thick oil demulsifier. The polyether as the thick oil demulsifier may be further chain expanded for even high demulsifying effect. The thick oil demulsifier can reach the oil-water interface fast to lower the elasticity and viscosity of the interface film, speed the aggregation of liquid drops and demulsify effectively. The thick oil demulsifier has simple preparation process, is suitable for industrial production, and may be used in the efficient dewatering of oil field produced liquid with different water contents.

Owner:LIAONING OXIRANCHEM INC

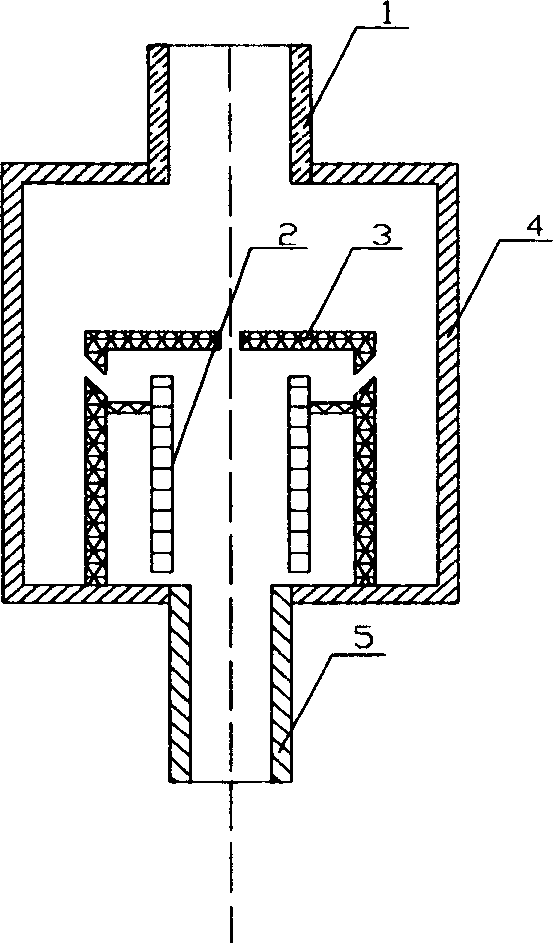

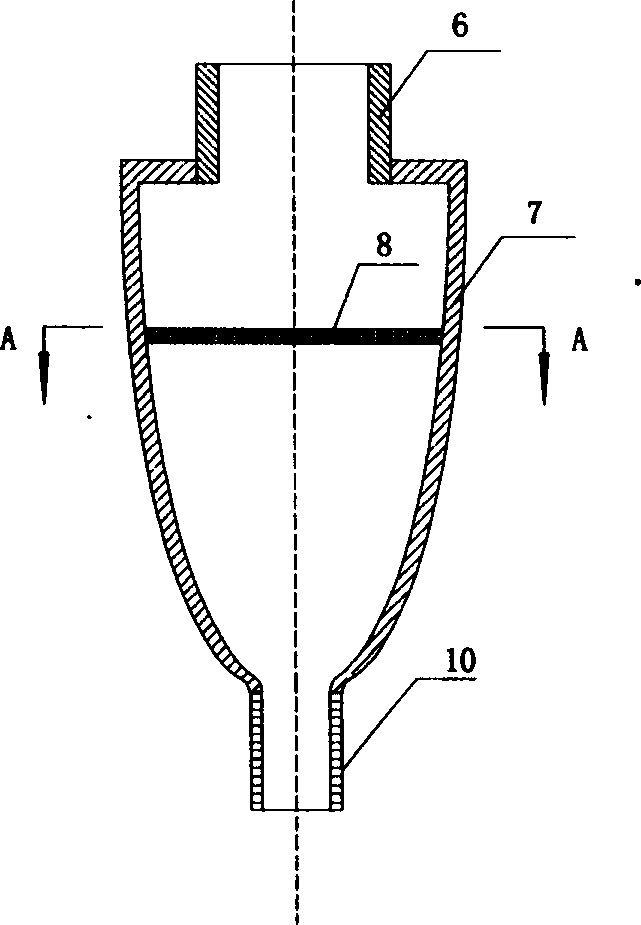

Convolution cavitation device

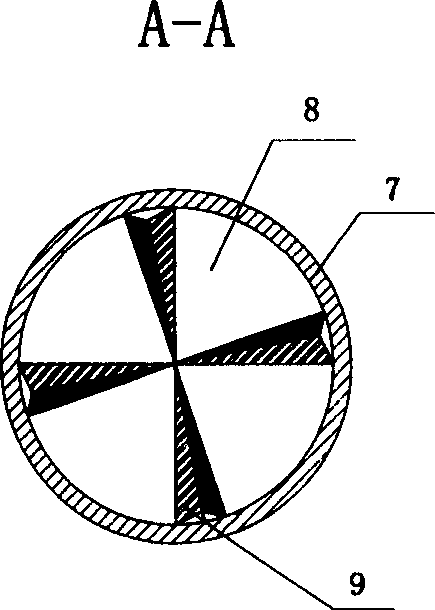

InactiveCN1605376ALarge amount of processingGood demulsification effectNon-miscible liquid separationHollow cylinderEngineering

The eddy cavitating unit used in the technological field of chemical separation consists of liquid inlet pipe and three coaxial cylinders including inner cylinder, middle cylinder and outer cylinder, the outer cylinder and the middle cylinder have individual tops with central inlet and common bottom, and the inner cylinder is a hollow cylinder and is connected to the middle cylinder via four radial cross beams. Or, the eddy cavitating unit consists of liquid inlet pipe, paraboloidal cone, disc with slit, flow guide plate and nozzle. Or, the eddy cavitating unit consists of liquid inlet pipe, outer paraboloidal cone, inner funnel cone and nozzle.

Owner:SHANGHAI JIAO TONG UNIV

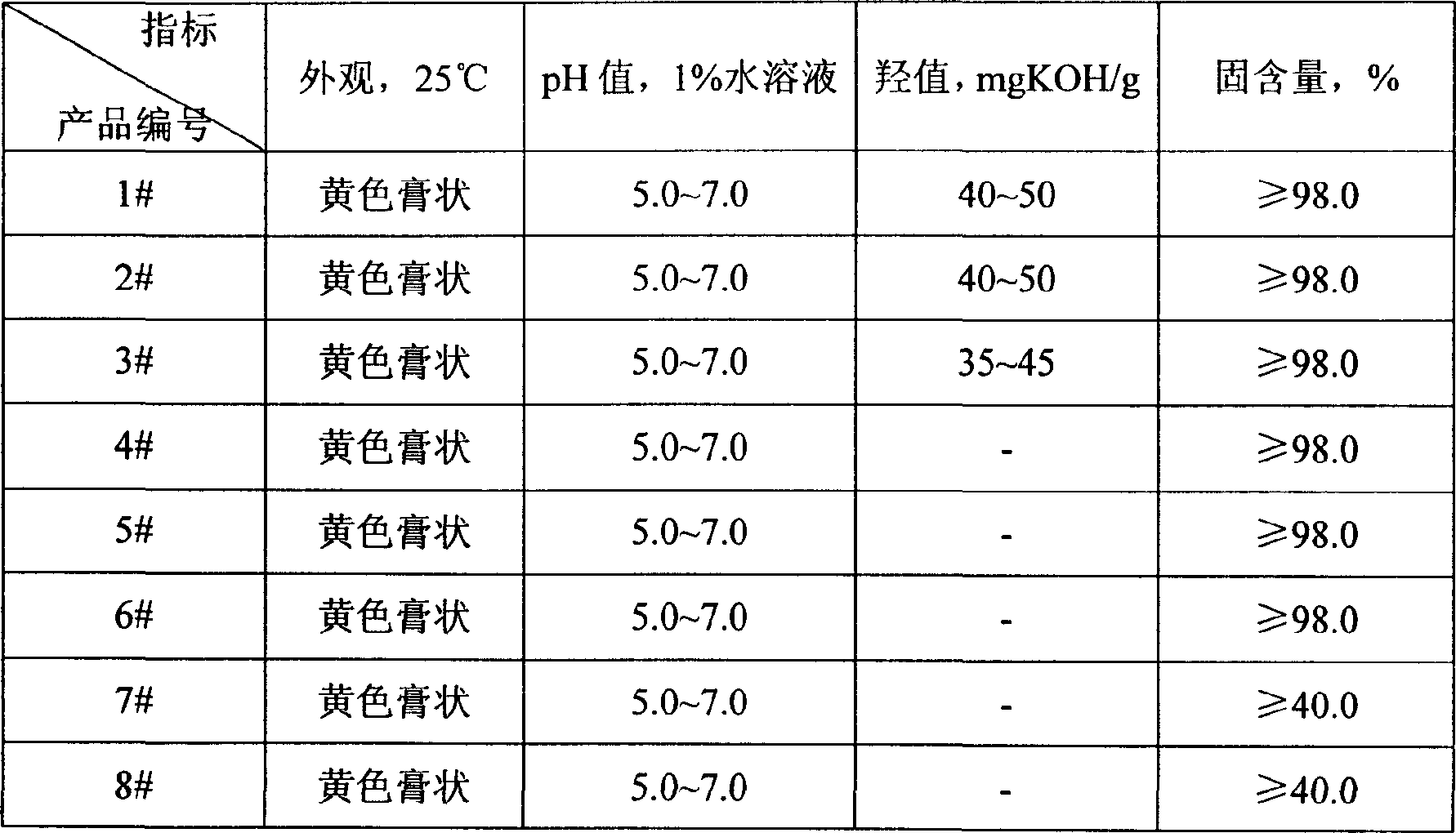

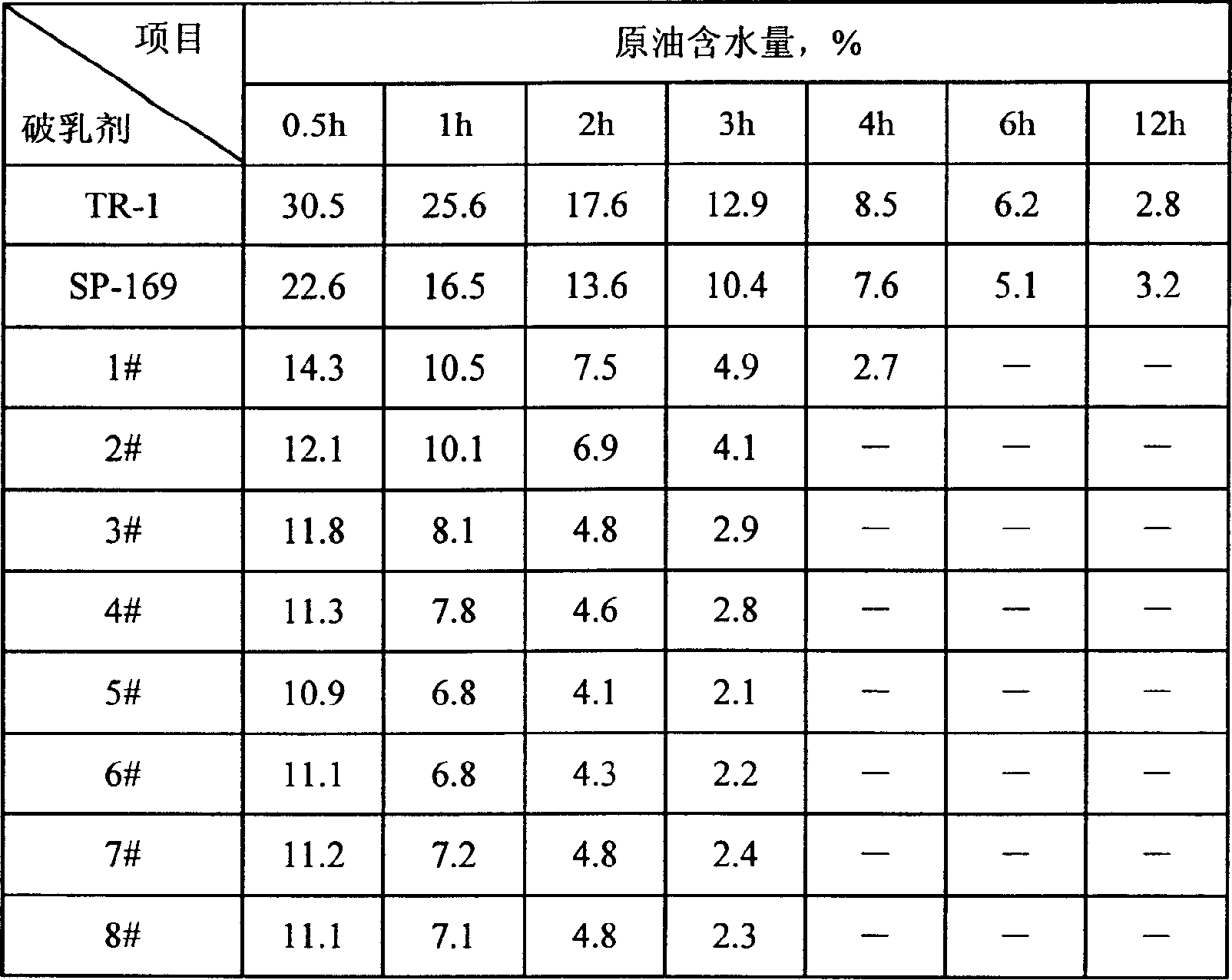

Novel crude oil demulsifier and preparation method thereof

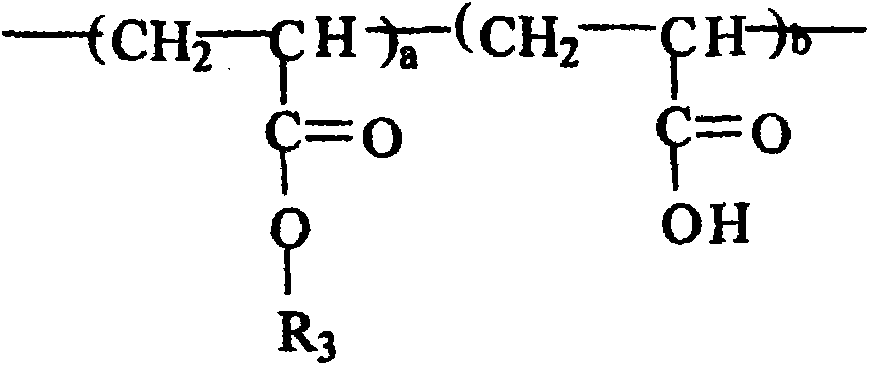

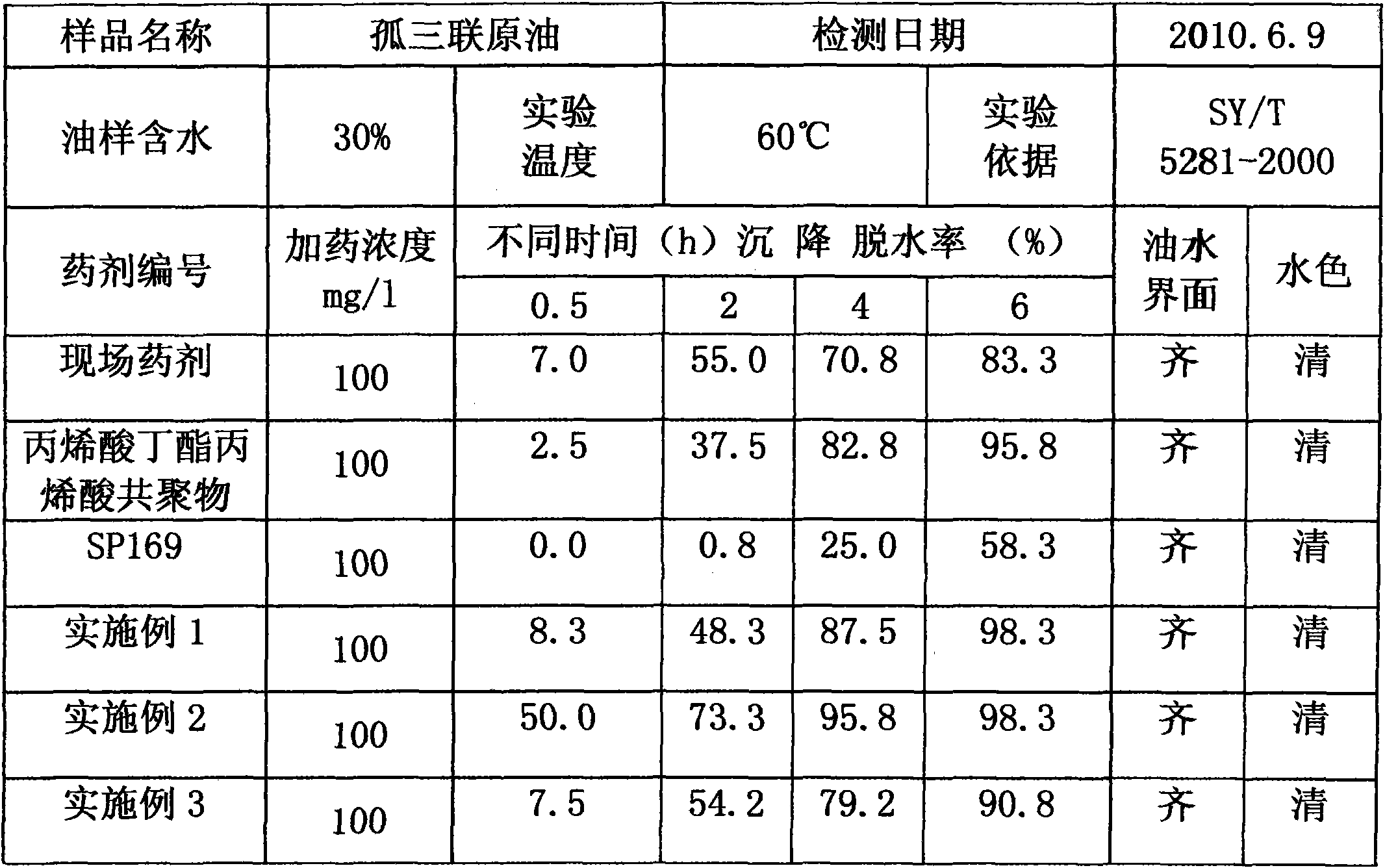

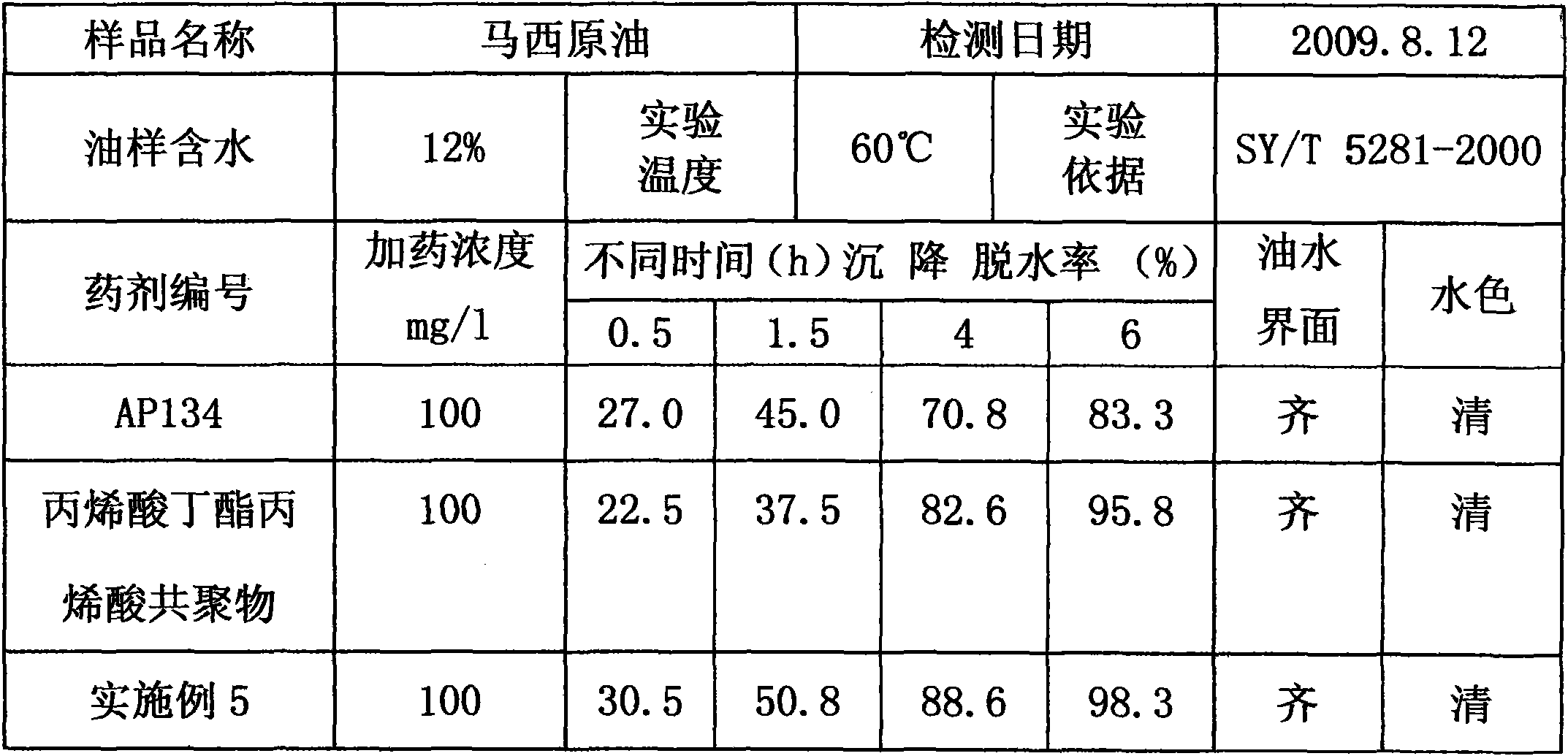

InactiveCN102399576AGood demulsification effectDewatering/demulsification with chemical meansDemulsifierHydroquinone Compound

The invention relates to a novel crude oil demulsifier and a preparation method thereof. The novel crude oil demulsifier is prepared from esterified butyl acrylate acrylic acid copolymer and polyether demulsifier. Calculated according to a total weight of the butyl acrylate acrylic acid copolymer and the polyether demulsifier as 100%, the novel crude oil demulsifier comprises components of, by weight: 10-95% of the butyl acrylate acrylic acid copolymer, 5-90% of the polyether demulsifier, 0.1-3% of an acidic catalyst, 0.1-0.2% of a polymerization inhibitor of hydroquinone, and a solvent which is a good solvent for the butyl acrylate acrylic acid copolymer and the polyether demulsifier. According to the novel crude oil demulsifier and the preparation method thereof, the butyl acrylate acrylic acid copolymer and the polyether demulsifier with demulsification functions are subject to an esterification reaction. The prepared demulsifier provides a good demulsification effect upon crude oil emulsion.

Owner:CHINA PETROLEUM & CHEM CORP +1

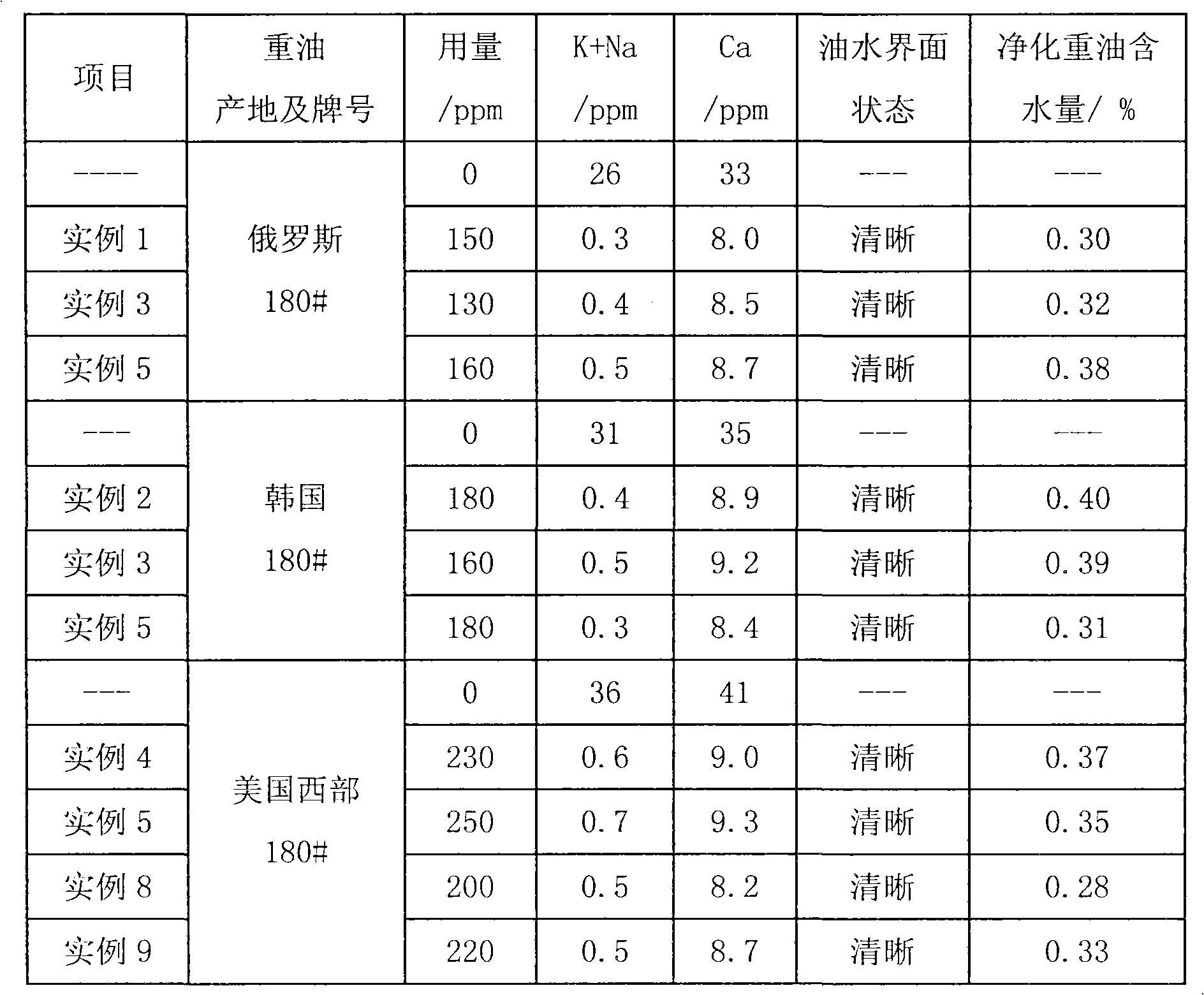

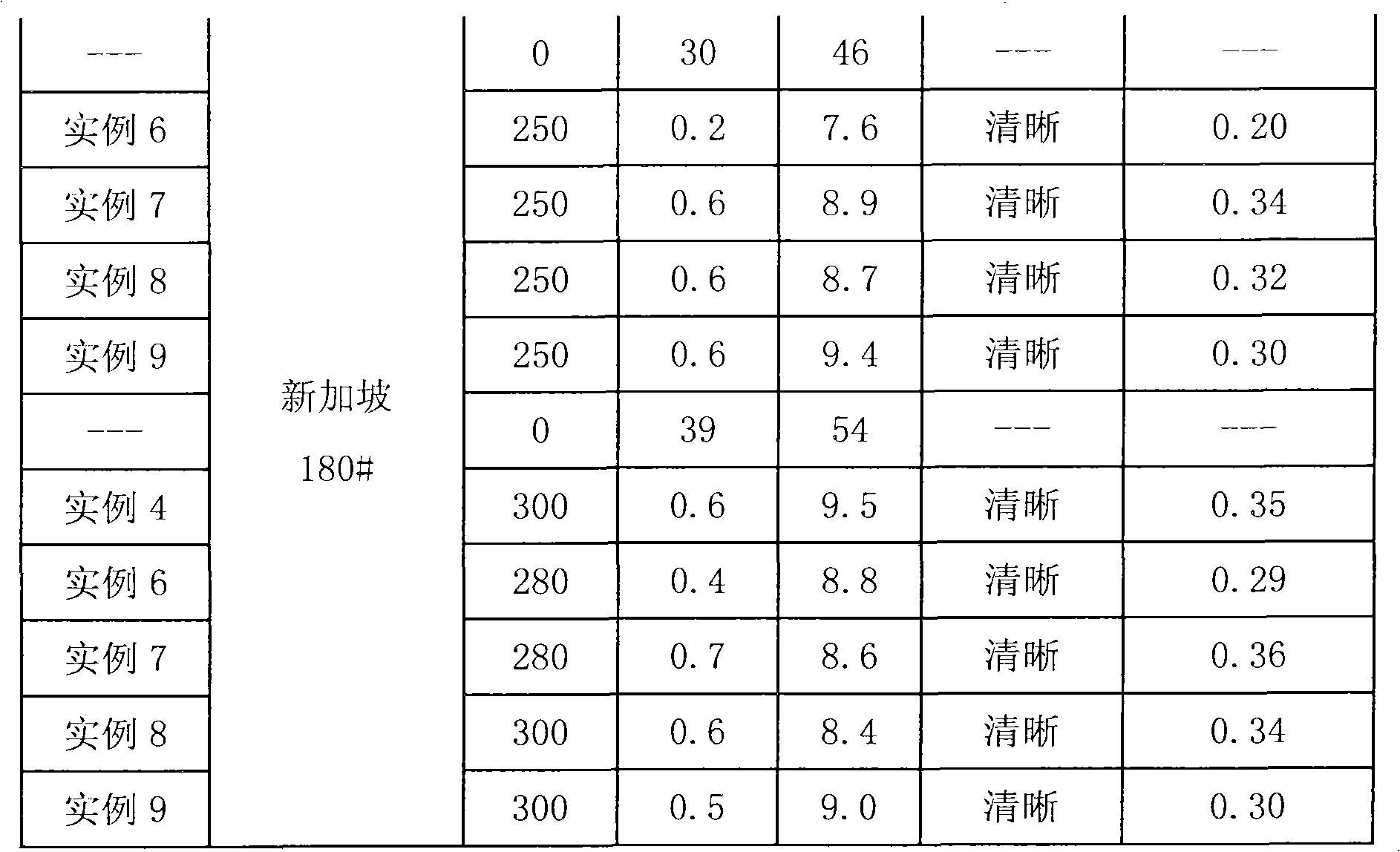

Polyelement composite heavy oil emulsion splitter and preparation method thereof

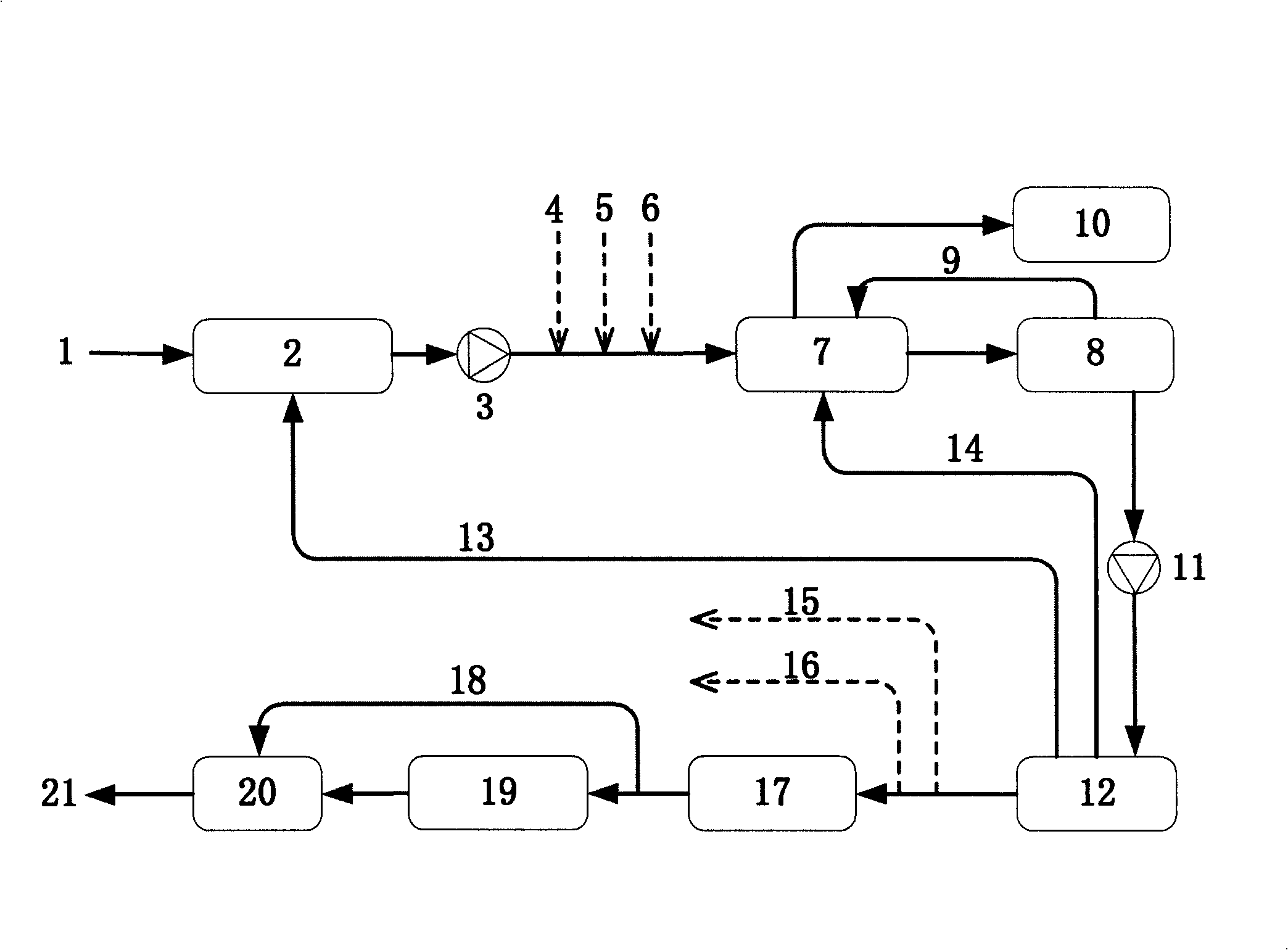

InactiveCN101831316AReduce dosageGood demulsification effectDewatering/demulsification with chemical meansRefining by water treatmentWater contentSolvent

The invention discloses a polyelement composite heavy oil emulsion splitter and a preparation method thereof. The heavy oil emulsion splitter comprises the following components in percentage by weight: 30-55 percent of polyether, 5-15 percent of surface active agent and 40-60 percent of solvent, wherein the polyether is formed by mixing polyethylene polyamine polyoxyethylene polyoxypropylene ether and fatty alcohol polyoxyethylene polyoxypropylene ether, the surface active agent is polyacrylic acid, and the solvent comprises ethanol and deionized water. The heavy oil emulsion splitter is mainly used for the water scrubbing purification of heavy oil of a gas-turbine power plant and has emulsion splitter dosage of 100-300ppm and good emulsion splitting effect; the K and Na total content of purified heavy oil is less than 1ppm, an oil-water interface is clear, and the water content of the purified heavy oil is less than 0.4 percent and has good broad spectrum activity and lower cost. The polyelement composite heavy oil emulsion splitter can also be used for processing inferior crude oil or crude oil mixed with heavy oil with a larger proportion before catalysis and cracking.

Owner:广州市金汇杰环保科技实业有限公司 +1

Base oildeemulsifier in high performance

ActiveCN101050380ASimple processMild operating conditionsHydrocarbon oil dewatering/demulsificationDemulsifierProton

This invention discloses a method for synthesizing a high-efficiency crude oil demulsifier from cornstarch and conventional polyether demulsifier by graft copolymerization. The method comprises: (1) adding solvent and cornstarch into a reaction kettle with a stirrer, slowly adding proton acid (20-80 wt.% of cornstarch), and stirring for 1-4 h; (2) adding polyether demulsifier and solvent, and refluxing under heating for 2-8 h; (3) adding NaOH solution for neutralization, ending NaOH addition when the pH value is 6.5-8.0, and reacting for 1-3 h until the solution is transparent. The demulsifier has such advantages as simple process, mild operation conditions, wide applications, and good demulsification effect.

Owner:DAQING HUAYING CHEM IND

Method and device for treating a great variety of waste emulsion of high concentration using hyperfiltration membrane method

ActiveCN101311127AGood demulsification effectEasy to handleUltrafiltrationWater/sewage treatment bu osmosis/dialysisHigh concentrationLiquid waste

The invention discloses a method for treating the waste emulsion with high concentration and a plurality of varieties by an ultrafiltration membrane method and a device thereof, which belongs to the technical field of waste water and waste liquid treatment. The main technique of the invention is 'dissolved air flotation-ultrafiltration membrane-electrolysis floatation', which can effectively reduce the dosage of medicament and improve emulsion breaking effect by adopting an efficient dissolved air flotation system, moreover, the water for dissolved air flotation, which is taken from a subsequent intermediate water tank, can flexibly adjust and dilute the concentration of the waste water, thus improving the running stability and the shock resistant loading capability of the system. An ultrafiltration membrane with large flux, high separative efficiency and long service life is adopted in an ultrafiltration system to realize oil-water separation and to concentrate the emulsion for a plurality of times and then floating oil is recovered, the waste water generated in ultrafiltration washing is treated again after reflow, thus reducing waste liquid discharging. Electrolysis floatation can remove residual emulsified oil and dissolved oil in the waste water, thus further lowering the COD value of yielding water. When the quality of raw water is changed, an activated carbon adsorption unit can guarantee the quality of the yielding water to be standard. The method and the device of the invention can process waste emulsion with high concentration and a plurality of varieties and have simple and reasonable technique, good quality of yielding water, compact layout of the device, thus facilitating automatic control and realizing recovery of emulsion and recycle economy as well as changing waste to be profitable simultaneously.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

Non-polyether type demulsifying agent and preparation method thereof

ActiveCN1883740AImprove adsorption capacityAchieve demulsification effectDewatering/demulsification with chemical meansNon-miscible liquid separationMethacrylateHydrophilic monomer

Disclosed are a novel non-polyether demulsifier for oil field crude oil demulsification and preparation thereof. The demulsifier disclosed is prepared by adding hydrophilic monomers and hydrophobic monomers alternately and continuously for multiple steps as following: mixing alkyl-acrylate and methyl acrylate as raw material at a certain ratio to prepare a hydrophobic monomer mixture, mixing methyl acrylate and acrylic acid as raw material at a certain ratio to prepare hydrophilic monomer mixture, dripping said hydrophobic monomer mixture and said hydrophilic monomer mixture into stable micelle solution continuously and alternately at certain temperature to prepare the product of non-polyether demulsifier, In which the ratio of monomer methacrylate ester is 30-60% of the total weight, the ratio of monomer acrylic ester is 15-40% of the total weight, the ratio of methacrylic acid is 5-30% of the total weight, the ratio of monomer acroleic acid is 5-30% of the total weight. The non-polyether demulsifier disclosed has excellent hydrophilicity and lipophilicity, and a good demulsification effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fast emulsion breaking method

InactiveCN101121898AImprove dehydration rateImprove demulsification efficiencyHydrocarbon oil dewatering/demulsificationNon-miscible liquid separationMass ratioRadiation frequency

The invention relates to a rapid emulsion breaking method, including microwave radiation. Emulsion breaker is added according to the water content of the rolly oil (calculated by weight percent), the mass ratio of the water and emulsion breaker is 1:0.5*10-4 to 5*10-4, and microwave is adopted for emulsion breaking. The emulsion breaker is one or more than two types of mixtures of polyamine polyoxy-propylene polyoxyethylene ether, resin polyoxy-propylene polyoxyethylene ether, higher-alcohol initiator emulsion breaker or propylene glvcol emulsion breaker. The microwave radiation and microwave radiation frequency are 2450MHz or 915MHz. Under the synergistic reaction, water-in-oil emulsion liquid is broken within a relatively short period, a bigger anhydration rate is achieved, and the emulsion-breaking efficiency is improved. In the circumstance of a little emulsion breaker, microwave radiation breaking method can be adopted, and the emulsion breaking speed is increased by 1-2 orders of magnitude compared with the traditional emulsion breaking by heating. The method is easy to implement, energy efficient, rapid in emulsion breaking, and the emulsion breaking effect is good.

Owner:LIAONING UNIVERSITY

Reverse demulsifier and its preparation method

ActiveCN102559246AGood demulsification effectLow equipment requirementsDewatering/demulsification with chemical meansEthylenediamineHigh pressure

The invention discloses a reverse demulsifier and its preparation method. The method comprises allowing reaction between methyl acrylate and ethylenediamine to obtain linear polyamidoamine, and allowing reaction between the linear polyamidoamine and epoxy chloropropane to obtain quaternary ammonium salt of linear polyamidoamine; allowing free-radical polymerization between polyoxyethylene nonylphenyl ether acrylate, acryloyloxyethyltrimethylammonium chloride and acrylamide in the present of an initiator and a terminator to obtain amphipathic cationic polymer; and mixing the quaternary ammonium salt of linear polyamidoamine, the amphipathic cationic polymer, a cationic surfactant and water to obtain the reverse demulsifier. The inventive reverse demulsifier has good demulsification effect on oil-in-water emulsion produced from oil field, and is suitable for chemical flooding produced fluid; and the inventive preparation method has low requirement for equipment, and is free of high-temperature high-pressure reaction.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Multiple combination oil soluble demulsifier

ActiveCN101693846AImprove dehydration effectStrong broad spectrumDewatering/demulsification with chemical meansSodium phosphatesSolvent

The invention relates to a multiple combination oil soluble demulsifier which comprises 36-50 percent of demulsifier, 5-10 percent of surfactant containing fluorin and 40-59 percent of solvent, wherein the demulsifier comprises modified polyether taking phenolic resin as an initiator and modified polyether taking higher aliphatic alcohol as an initiator, and the weight ratio of the modified polyether taking the phenolic resin as the initiator to the modified polyether taking the higher aliphatic alcohol as the initiator is 0.8-3. The surfactant containing fluorin is preferably sodium perfluorous nonenyloxybenzenesulfonyl, perfluorous ethyldiethanolamine sodium phosphate or N-ethyl Perfluorooctanesulfonamide. The invention is mainly applied to atmospheric and vacuum process of a refinery with the operation temperature of 70-150 DEG C. When the use level is 3-30 ppm, the demulsifier has the advantages of good demulsifying effect, clear water and emulsion layers of demulsifying, high dehydration speed, low water content in purified oil, low oil content of water of dehydration, good broad spectrum activity and low cost.

Owner:金浦新材料股份有限公司

Superheavy oil crude oil reverse-phase demulsifier preparation method

InactiveCN104479731AGood demulsification effectLow costDewatering/demulsification with chemical meansEthylenediamineEpoxy

The invention provides a superheavy oil crude oil reverse-phase demulsifier preparation method characterized in that: epoxy chloropropane, glycerol and trimethylamine and the like are used as raw materials for preparation of multi segment poly quaternary ammonium salt, methyl acrylate and ethylenediamine are used as raw materials for preparation of 3.0 generation polyamidoamine-amine, and a water-soluble solution, namely a composite type reverse-phase demulsifier is prepared from the poly quaternary ammonium salt, the 3.0 generation polyamidoamine-amine, polymeric aluminium and a solvent according to the mass fraction ratio of (10-30): (10-40): (1-20): (100-500). The reverse-phase demulsifier prepared by the method has good demulsification effect on crude oil exploited from an oil field, and is a reverse-phase demulsifier suitable for chemical flooding produced liquid, and the preparation method provided by the invention has the advantages of simple operation, low requirement on equipment, wide application range and reduces the cost of crude oil exploitation.

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

Method for treating oil-containing waste water

InactiveCN1955122AImprove water qualityHigh oil contentWater/sewage treatment by flocculation/precipitationChemistryPolyacrylamide

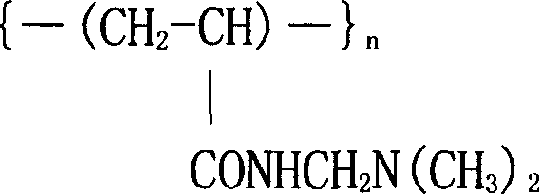

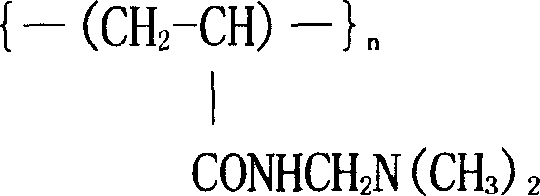

A process for treating the oil contained sewage in oil field includes such steps as adding demulsifier (linear low-molecular cationic ammine polymer with multiple hydroxy groups), demulsifying, and adding flocculant (cationic polymer whose principal component is aminomethyl polyacrylamide).

Owner:CHINA PETROLEUM & CHEM CORP +1

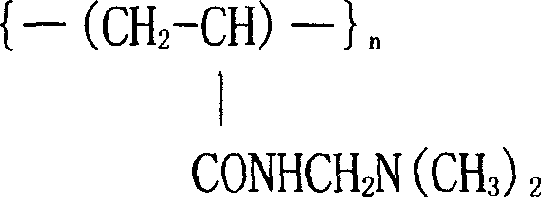

Method for producing pentaerythritol oleate under catalysis of granular solid superacid

InactiveCN102875374ANo pollutionHigh yieldOrganic compound preparationCarboxylic acid esters separation/purificationPentaerythritolAcid catalyzed

The invention discloses a method for producing pentaerythritol oleate under catalysis of granular solid superacid, and relates to a method for synthesizing ester base oil in biodegradable lubricating oil. The method comprises the following steps of: mixing pentaerythritol and oleic acid in a mass ratio of 1:(7.2-9.5), adding the granular solid superacid, and reacting at the temperature of between 140 and 240DEG C for 4 to 10 hours in the vacuum degree of 100-1,000Pa; filtering by using a 200-12,500 mesh filter screen or filter plate; and heating crude grease to the temperature of between 160 and 280DEG C, removing unreacted acid or alcohol, keeping the vacuum degree of the system ranging from 1 to 500Pa, and distilling under reduced pressure for 40 to 120 minutes to obtain the pentaerythritol oleate. The pentaerythritol oleate produced by the method has excellent low temperature fluidity, lubricity, viscosity-temperature characteristics, oxidation safety, cleanness and good biodegradability, and the method is an environment-friendly and high-efficiency production method having advantages of simple treatment, short production period, high esterification rate and high product yield.

Owner:SICHUAN SIPO CHEMICAL CO LTD

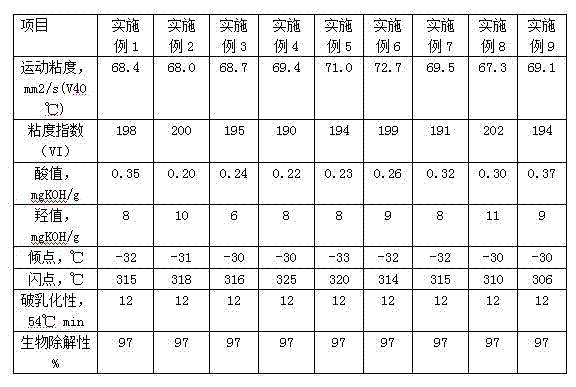

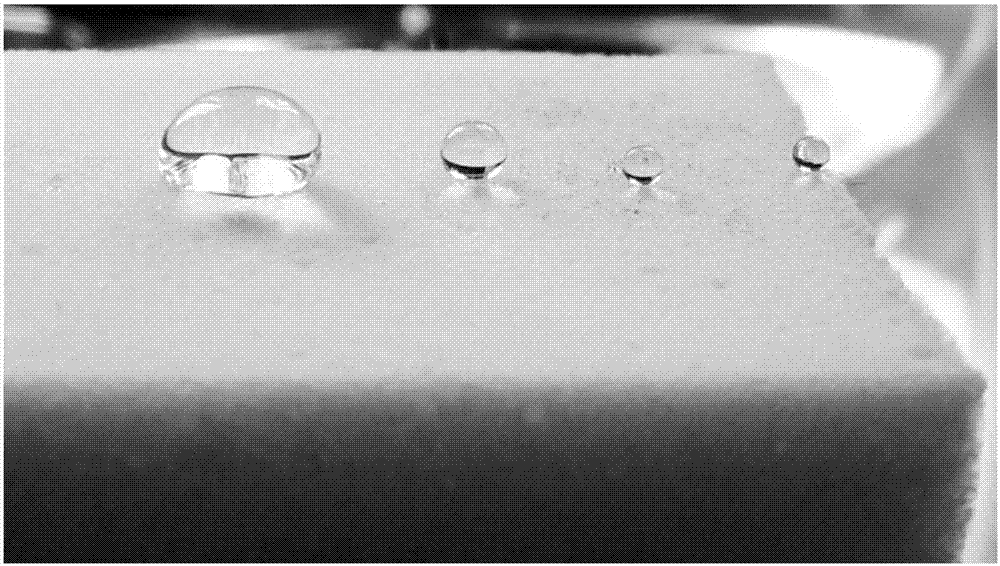

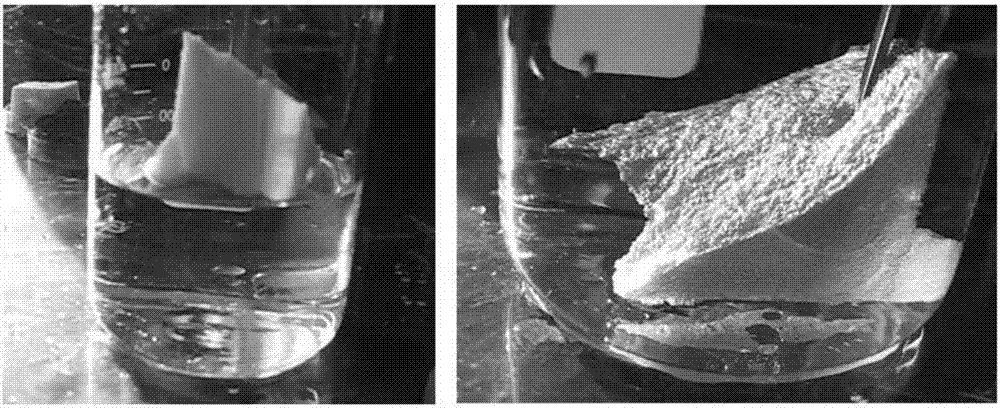

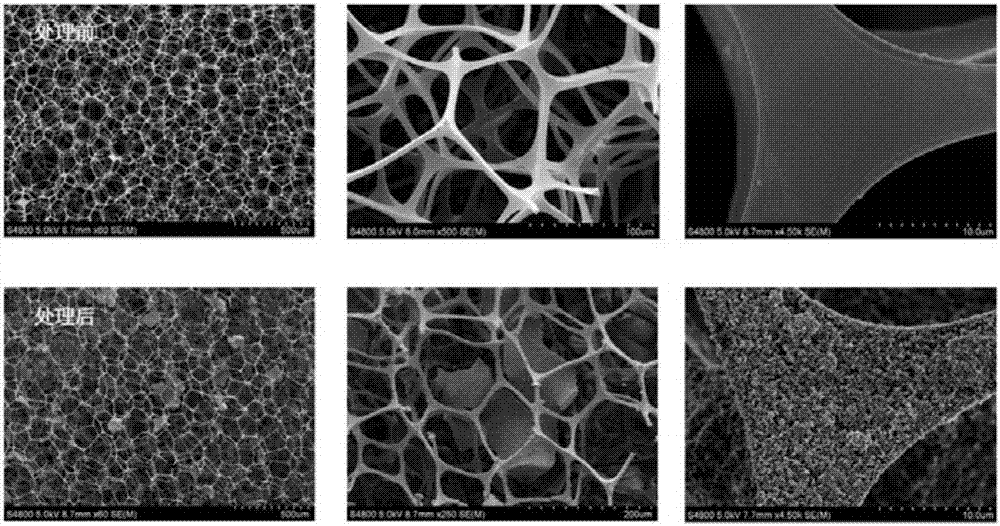

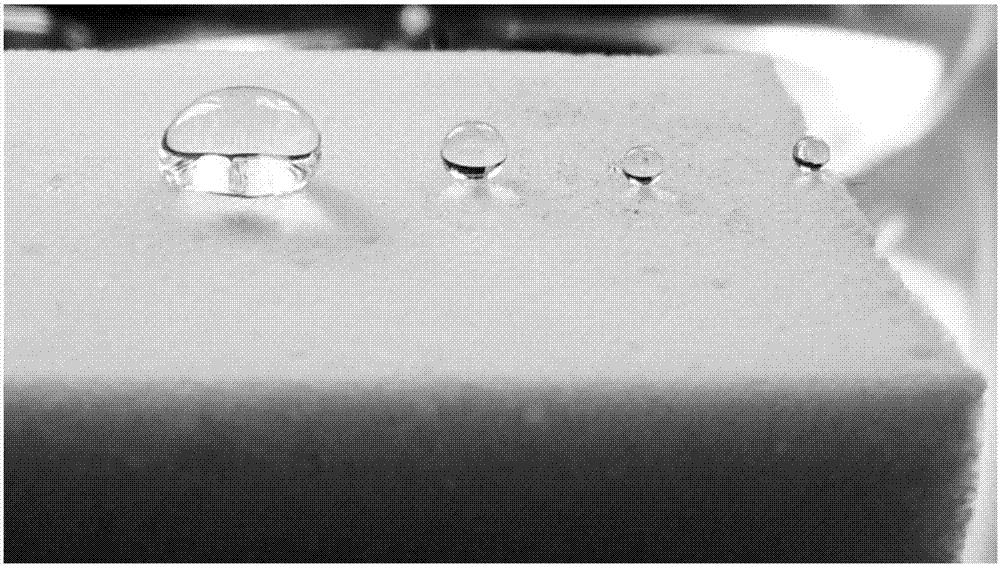

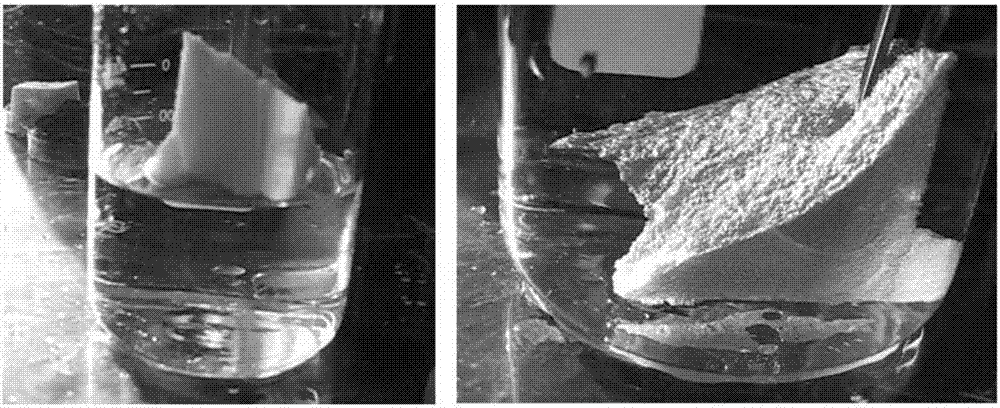

Superhydrophobic sponge body and preparation method thereof

The present invention relates to a superhydrophobic sponge body and a preparation method thereof. A purpose of the present invention is to mainly solve the problem of poor hydrophobic effect of the existing adsorption recovery material. The technical scheme of the present invention comprises a superhydrophobic sponge body and a preparation method thereof, wherein the superhydrophobic sponge body comprises a sponge body and a nanometer modifier, the sponge body is a melamine sponge or a polyurethane sponge, and the nanometer modifier preparation method comprises: dissolving a nanometer material in a hydrophobic organosilicon compound agent, and stirring until completely dissolving so as to obtain the nanometer modifier. With the technical scheme of the present invention, the problem in the prior art is well solved. The preparation method of the present invention can be used in the preparation of superhydrophobic sponge bodies.

Owner:CHINA PETROLEUM & CHEM CORP +1

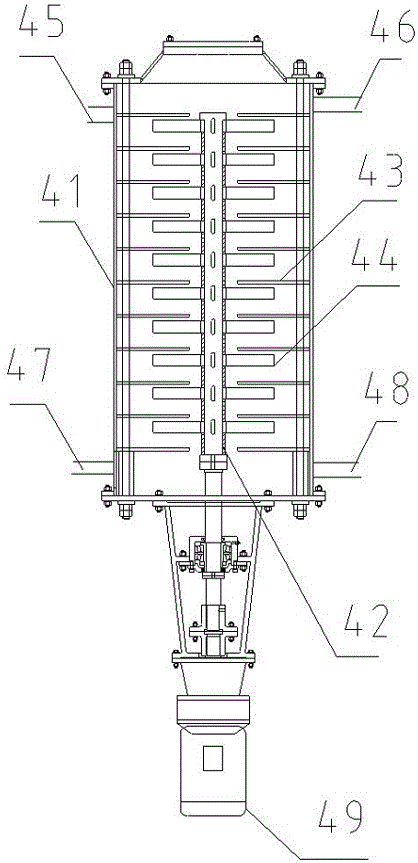

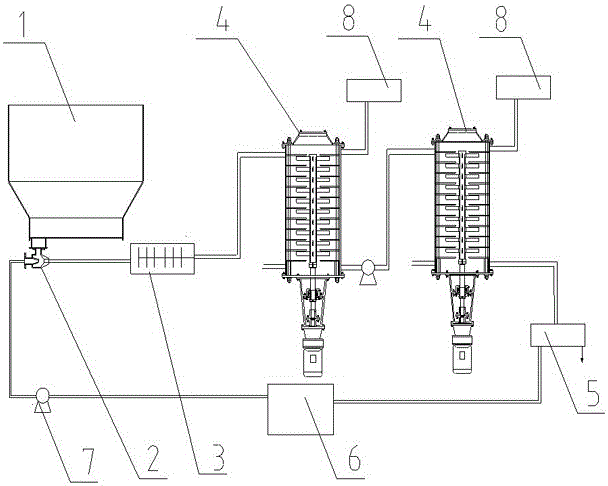

Treating system, separating apparatus and treating method for oily sludge

PendingCN106630514AExpand the scope of applicationLow oil contentWaste water treatment from quariesSievingOil contentHandling system

The invention discloses a treating system, separating apparatus and treating method for oily sludge. The separating apparatus comprises a stirring drum, a first drive unit, a stirring shaft, multiple layers of separator plates and stirring members, wherein the stirring shaft is arranged in the stirring drum; the multiple layers of separator plates divide the stirring drum into multiple layers of space; each of the multiple layers of space is provided with one stirring member which is connected with the stirring shaft; the upper part of the stirring drum is provided with a sludge inlet and first floating oil discharge outlet; the lower part of the stirring drum is provided with a sludge outlet; and the bottom or lower part of the stirring drum is provided with a feed inlet for one or more selected from a group consisting of an extractant, air-dissolved water and solid foam particles. The treating system is applicable to dehydration of a variety of oily sludge, enables the oil content of oily sludge to be decreased to 3% or below, can maximally recover oil and does not produce secondary pollution like waste water.

Owner:仇霞霞

Magnetic covalent bond type chitosan-based modified flocculant and preparation method and application thereof

ActiveCN113121840AGood chemical stabilityGood mechanical strengthWater/sewage treatment by flocculation/precipitationLipophilicitySuperparamagnetism

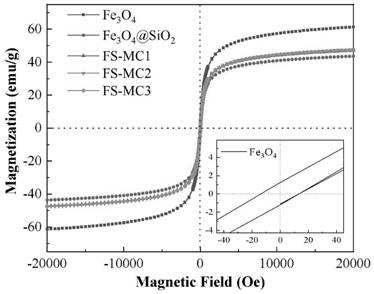

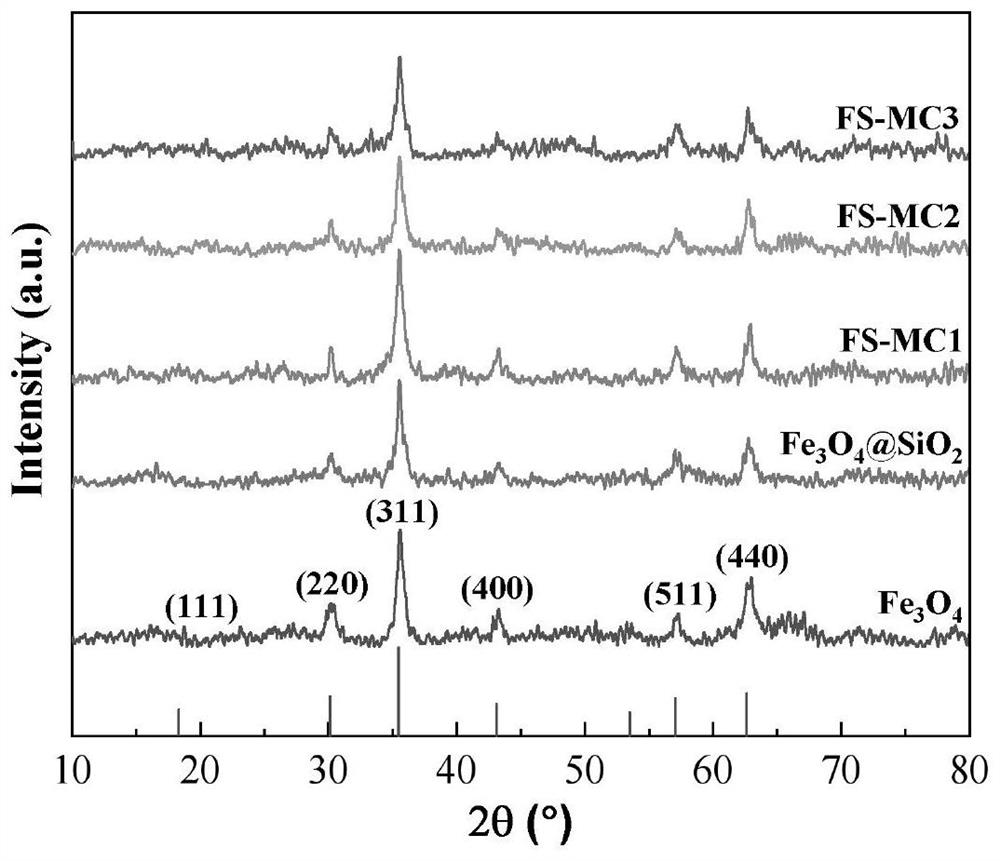

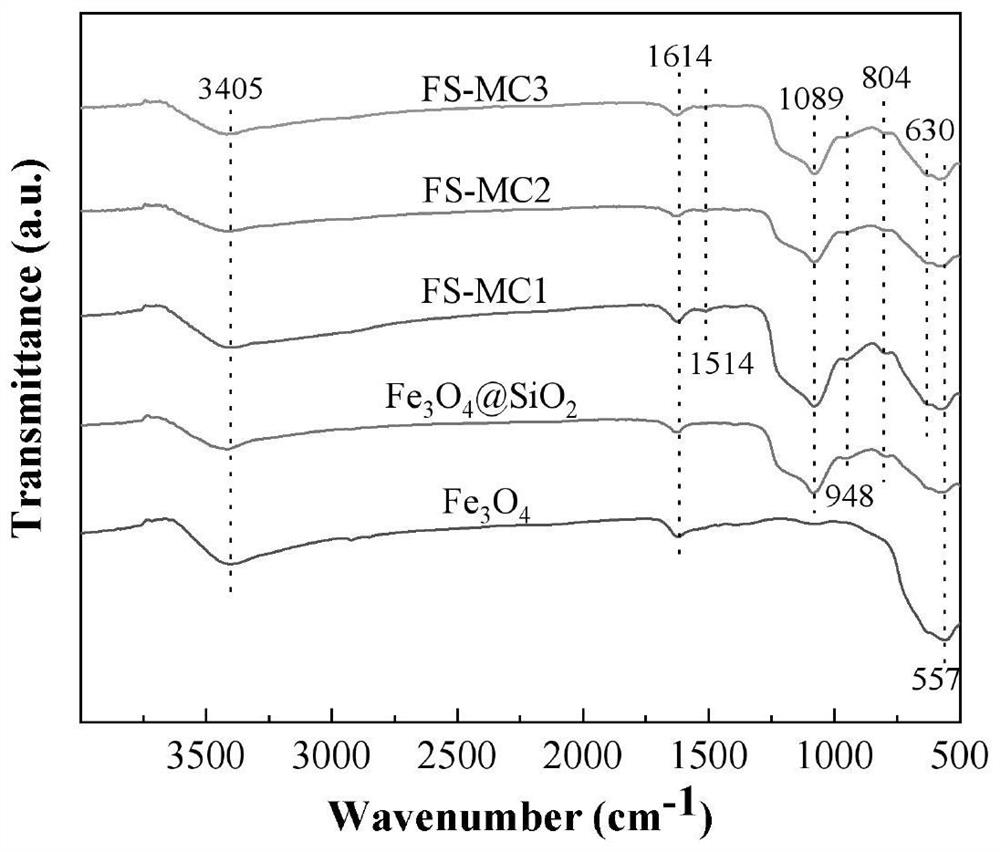

The invention belongs to the field of water treatment, and particularly relates to a magnetic covalent bond type chitosan-based modified flocculant and a preparation method and application thereof. According to the invention, a cationic monomer and a hydrophobic monomer are introduced into chitosan molecules through a graft copolymerization reaction, so that the flocculant is ensured to have good stability, the electricity neutralization capability and the demulsification capability on oil droplets of the flocculant in a flocculation process are improved, the solubility of the flocculant is increased, the pH application range of the flocculant is widened, the dosage is reduced, meanwhile, the nano Fe3O4 has superparamagnetism, the settling performance of floc can be remarkably improved under the action of an external magnetic field when the nano Fe3O4 is introduced into the flocculating agent, and the settling time is shortened. Results of the embodiment show that the flocculant provided by the invention is good in lipophilicity and excellent in flocculation performance, and has efficient oil-water separation capacity, wider pH application range and excellent recoverability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method and device for performing emulsion breaking on oil-water emulsion by ultrasonic wave

InactiveCN102051201ASimple structureSettling fastDewatering/demulsification with electric/magnetic meansUltrasonic radiationOil water

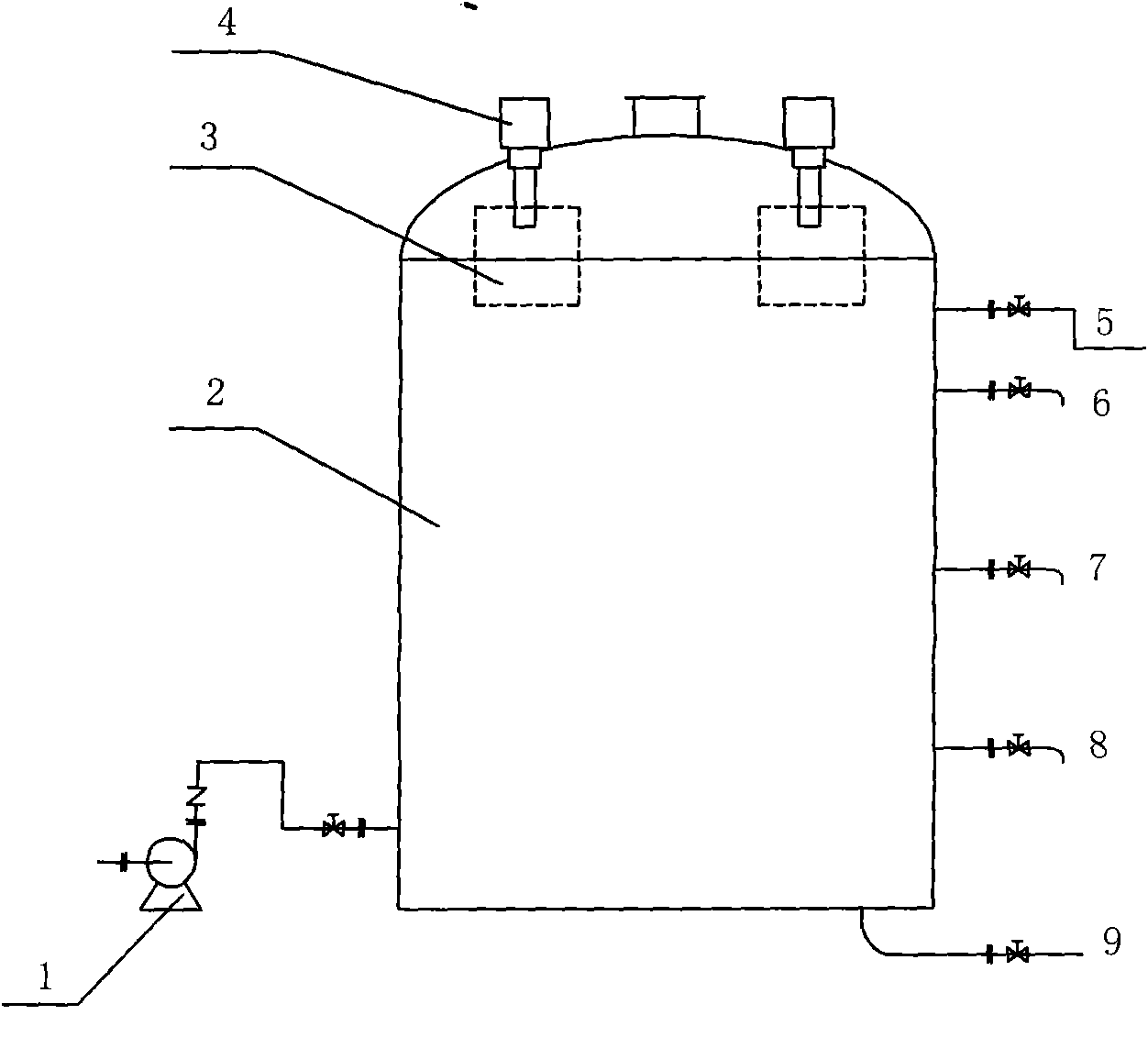

The invention relates to a method for performing emulsion breaking on an oil-water emulsion by an ultrasonic wave. In the method, one or more ultrasonic generators are arranged in a raw material storage tank or a settlement tank in the gravity settling direction, only one ultrasonic generator acts in the direction of the same vertical line. An emulsion breaking device for implementing the method comprises the raw material storage tank or the settlement tank, and one or more ultrasonic generators are arranged at the bottom or / and top of the raw material storage tank or the settlement tank. The ultrasonic generators are distributed reasonably according to structural size and ultrasonic radiation areas, so that the ultrasonic generators cover comprehensively, and are prevented from being overlapped. The ultrasonic generators are connected with ultrasonic distributors, and one ultrasonic generator is arranged in one ultrasonic distributor. The action direction of the ultrasonic wave is the vertical direction and is consistent with the gravity settling direction, so the driving force is added in the oil-water settling direction, and the oil-water settling speed is accelerated. The device is uniform in ultrasonic wave energy distribution, excellent in emulsion breaking effect, simple in operation, convenient to run and maintain and low in running cost.

Owner:CHINA PETROLEUM & CHEM CORP

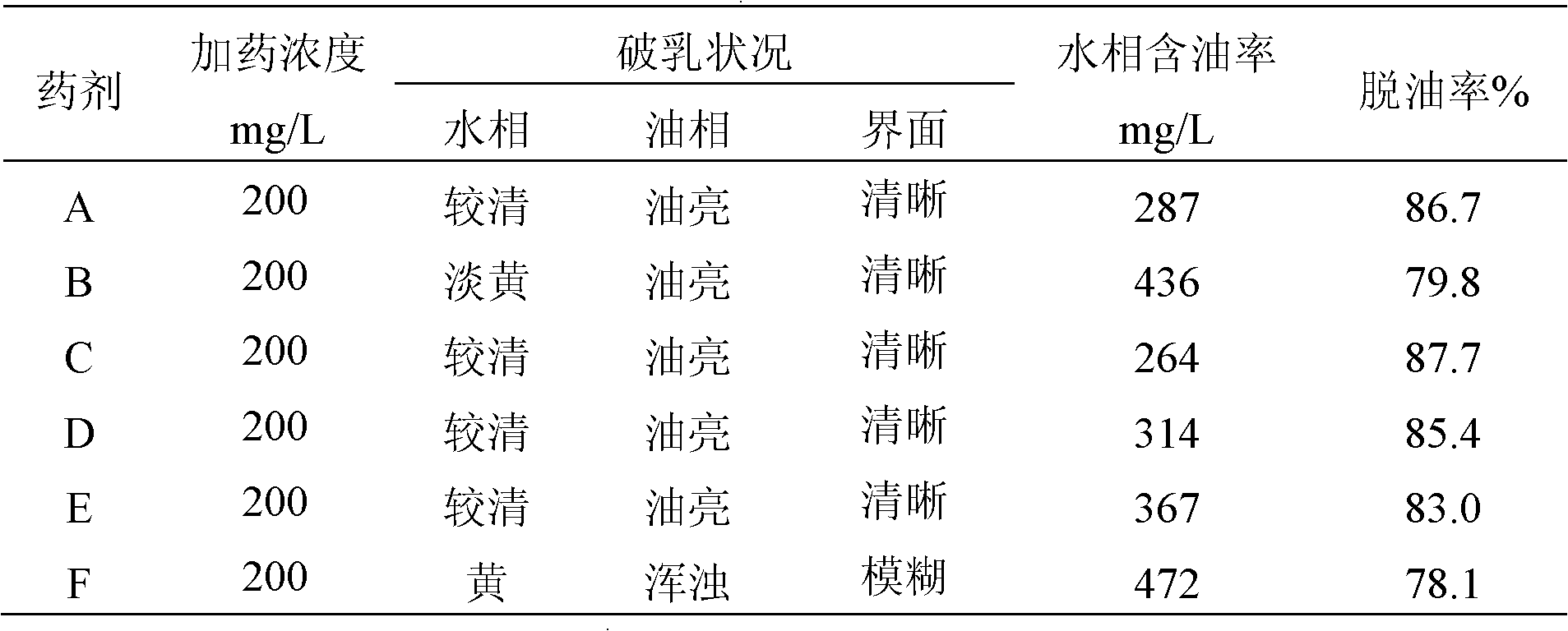

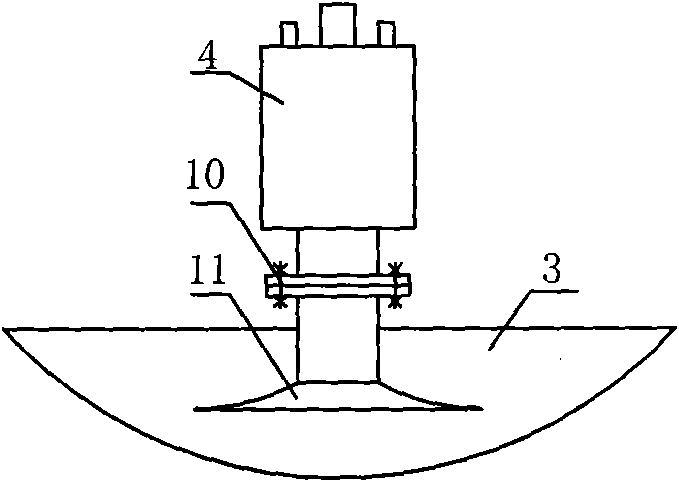

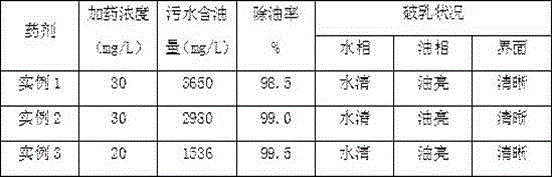

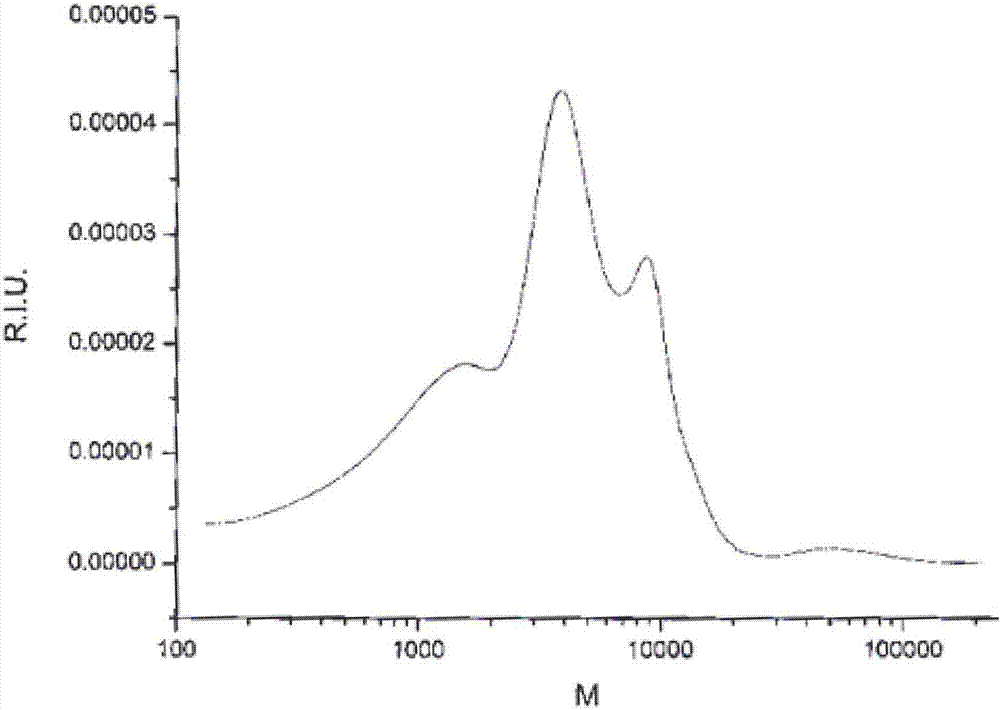

Oil-in-water type emulsion demulsifying agent and preparation method thereof

ActiveCN105384927ANo lumpsFast separationWaste water treatment from quariesFatty/oily/floating substances removal devicesDemulsifierWastewater

The present invention discloses an oil-in-water type emulsion demulsifying agent and a preparation method thereof. Firstly, bisamide is prepared, then chlorinated polyether is prepared, and finally cationic polyether is obtained, namely the oil-in-water emulsion demulsifying agent. The preparation method has readily available raw materials, is simple in operation, and has low equipment requirements. The prepared demulsifying agent is a cationic polymer with a network structure formed by the reaction of bisamide and epichlorohydrin, has a special network structure and a very strong surface activity, has a good demulsification function, is a reverse demulsifying agent suitable for chemical flooding produced liquid, can be used in oilfield produced wastewater treatment, can break the emulsion interfacial energy, and has an oil removal rate of more than 98% in a use amount of 20-30 mg / L. The prepared demulsifying agent is not layered, has no caking and no mechanical impurities, and has characteristics of being fast in oil and water separating speed and being low in oil content of water, and a good demulsifying effect for a three compound combination flooding O / W emulsion and high oil removal efficiency.

Owner:克拉玛依新科澳石油天然气技术股份有限公司

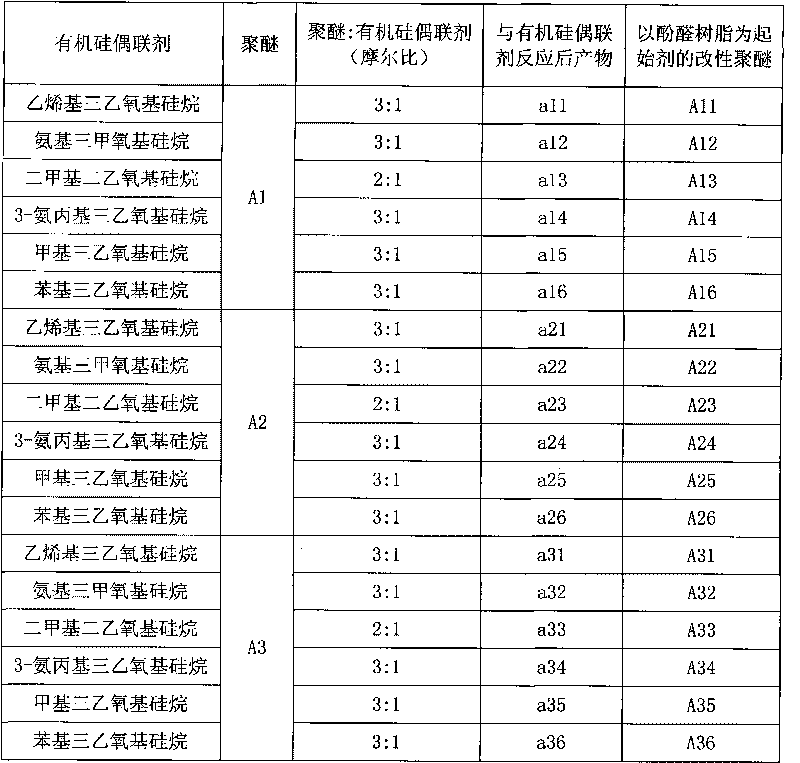

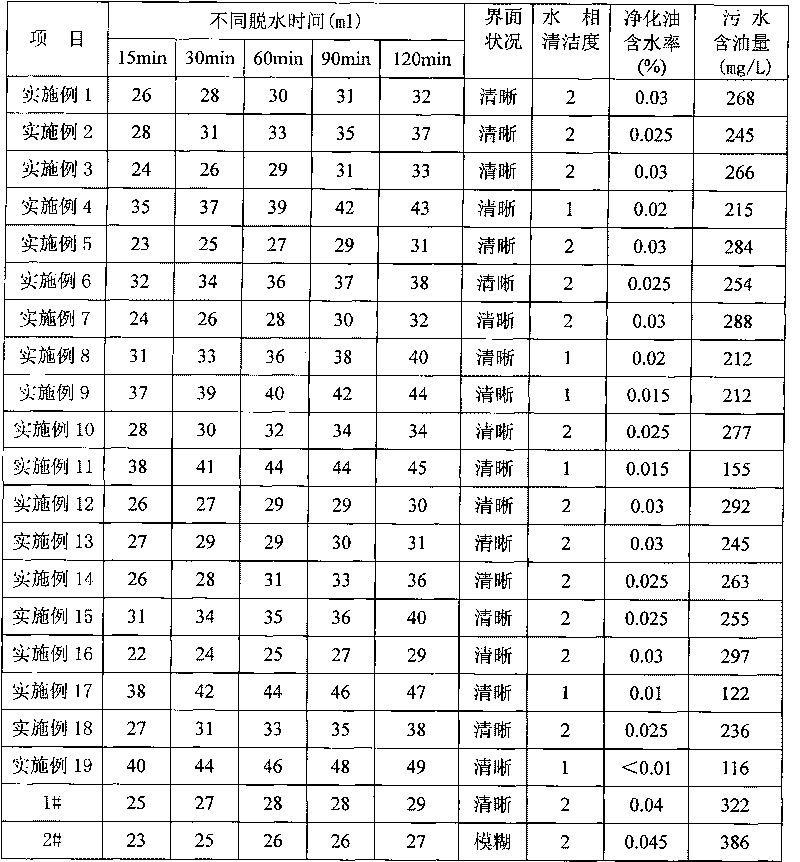

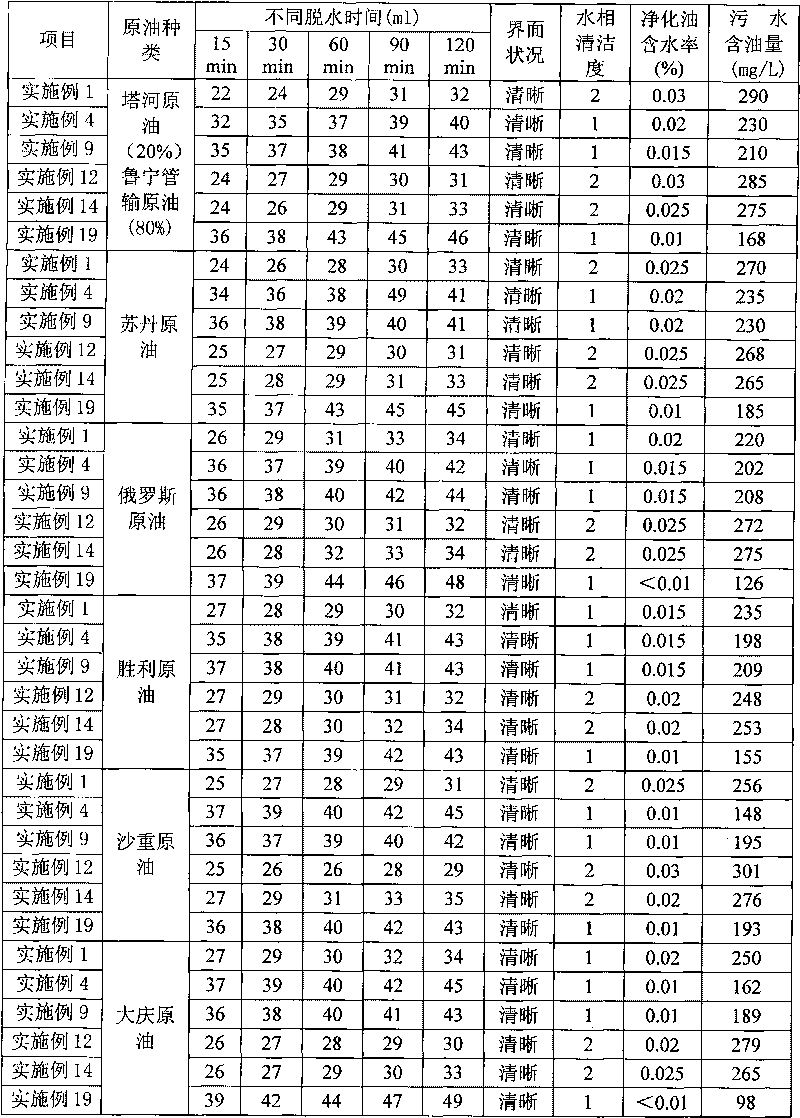

Polyether crude oil demulsifier using straight chain alkyl phenolic resin as initiator and preparation method and application thereof

ActiveCN103396828ASimple preparation processImprove surface activityDewatering/demulsification with chemical meansCarbon numberDemulsifier

The invention discloses a polyether crude oil demulsifier using straight chain alkyl phenolic resin as an initiator and a preparation method and an application thereof. The general formula of the polyether crude oil demulsifier using straight chain alkyl phenolic resin as an initiator is A-(PO)a-(PO)b-(EO)c-(PO) m, wherein PO is -(CH2-O-CH2CH2)-, EO is -(O-CH2CH2)-, A and R are straight chain alkyls with carbon number of 6, n is an integer of 5-13, a+b is equal to m, and in the general formula, the mass of EO accounts for 15-25% of the mass sum of EO and PO. The polyether crude oil demulsifier prepared by the invention is simple in preparation process, good in surface activity, strong in demulsification capability and diffusion capability, good in dehydration effect, excellent in capability of perfecting oil-water interface emulsification performance and strong in universality, and the demulsification and dehydration rate of the crude oil reaches to 80-92%.

Owner:金浦新材料股份有限公司

Broad-spectrum demulsifier for crude oil

InactiveCN1396238AGood broad spectrumHigh broad spectrumDewatering/demulsification with chemical meansTransportation and packagingDemulsifierPolyol

A broad-spectrum deemulsifier for crude oil contains the polymer of polyol, ethylene oxide and propylene oxide (20-50 wt.%), the polymen of polyamine, ethylene oxide and propylene oxide (20-50), pour depressor (10-20) and solvent (15-25). Its advantages are broad spectrum for more than 10 kinds of crude oils, and low dosage (5-10 ppm).

Owner:CHINA PETROCHEMICAL CORP +1

Oily sludge advanced treatment technology

ActiveCN104649563AGood demulsification effectGood biodegradabilitySludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesPetroleumSludge dewatering

The invention discloses an oily sludge advanced treatment technology which comprises the following contents: oily sludge in a raw material storage sludge-tank enters a sludge mixing tank; a demulsifier is added to carry out demulsification treatment; demulsified oily sludge enters screw-type sludge dewatering equipment to undergo solid-liquid separation so as to obtain a filtrate and sludge cake; the filtrate enters a two-phase cyclone to be separated; after two-phase separation, excess sludge at the lower layer flows back to the raw material storage sludge-tank, a mixed liquor at the upper layer is sent into a gas-liquid mixing tank to be mixed with the air and then enters a separation pond to carry out primary separation of sump oil and sewage; sump oil is recovered to a sump oil tank by the use of a sludge scraper; sewage enters a filter to separate suspended particles and residual sump oil in the sewage from water; sump oil separated from the top of the filter is recovered to a sump oil recovery tank; and sewage discharged from the filter is sent to a sewage treatment plant to undergo subsequent processing. By the technology, water content of the oily sludge can be reduced from 80-98% to about 50%, and most crude oil in the oily sludge can be recovered. Thus, sludge subsequent processing difficulty is greatly reduced. The technology provided by the invention has a wide range of application, is especially suitable for processing of oily sludge at the bottom of an oil-tank, dross and activated sludge as well as processing of various oily sludge generated from oil exploitation and storage transportation enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method of oil-containing sludge

InactiveCN108314290AHigh surface tension reduction abilityStrong flocculationDewatering/demulsification with chemical meansSludge treatment by de-watering/drying/thickeningAlkylphenolOil sludge

The invention discloses a treatment method of oil-containing sludge and belongs to the field of environmental engineering. The treatment method comprises the following steps of: introducing the oil-containing sludge into a separating groove, discharging into a deemulsifying groove for deemulsification after initially separating, and carrying out oil-water-sludge separation on deemulsified productsin an oil-sludge separating device; recovering dirt oil at the upper part, settling sludge-water mixture at the lower part, recovering clear liquor, and carrying out coagulation treatment, settling separation, mechanical dewatering, sludge drying and sludge incineration treatment in sequence on the sludge-water mixture at the bottom part and residual active sludge. Composite deemulsifying agentspreferred by the invention include a polyethylene polyamine blocked polyether deemulsifying agent, a silicon-containing deemulsifying agent, a phenolic-resin deemulsifying agent, an alkylphenol polyoxyethylene ether deemulsifying agent, a polyphosphoester deemulsifying agent or a polyaluminium-chloride deemulsifying agent. The deemulsifying method disclosed by the invention has the beneficial effects that the safe and environment-friendly effects are achieved, the water content of oil sludge can be reduced, most crude oil in the oil sludge can be recovered, and the difficulty of the followingtreatment of the sludge can be reduced.

Owner:YANGZHOU DAYANG WATER SUPPLY EQUIP

Extra-heavy oil functional demulsifier as well as preparation and application thereof

ActiveCN102373077AImprove dehydration effectReduce oil contentDewatering/demulsification with chemical meansPolyethylene polyamineSolvent

The invention relates to an extra-heavy oil functional demulsifier as well as preparation and application thereof. The extra-heavy oil functional demulsifier comprises the following components in percentages by weight: 10-15% of polyethylene polyamine polyoxyethylene polyoxypropylene, 30-40% of phenolic resin polyoxyethylene polyoxypropylene ether, 10-15% of water demulsifier, 5-10% of organic small molecular auxiliary agent, 5-10% of solid particle surface modifier and the balance of solvent. In the invention, the synergistic action between demulsifiers is utilized, a plurality of demulsifiers are cross-linked and compounded, and the functional auxiliary agent is added, therefore, the dehydration effect of an extra-heavy oil is effectively improved, the oil content of dehydrated sewage is reduced, and the external discharging standard is achieved.

Owner:PETROCHINA CO LTD

Condensing washing method of polyvinylidene fluoride emulsion

The invention relates to a condensing washing method of polyvinylidene fluoride emulsion. The condensing washing method comprises the steps as follows: (1) adding water at 1 to 15 DEG C to polyvinylidene fluoride emulsion; adjusting specific gravity of emulsion to value between 1.04 and 1.18; (2) condensing the polyvinylidene fluoride emulsion obtained in an agitating mode; controlling the agitating speed to 500 to 2000 rotation per minute; completely demulsifying for 1 to 15 minutes; and (3) washing the separated polyvinylidene fluoride emulsion resin after condensing with water. According to the condensing washing method provided by the invention, the production capacity of equipment is greatly improved, water consumption is reduced, the processing period is shortened, and the benefit is brought to the scale industrial production.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

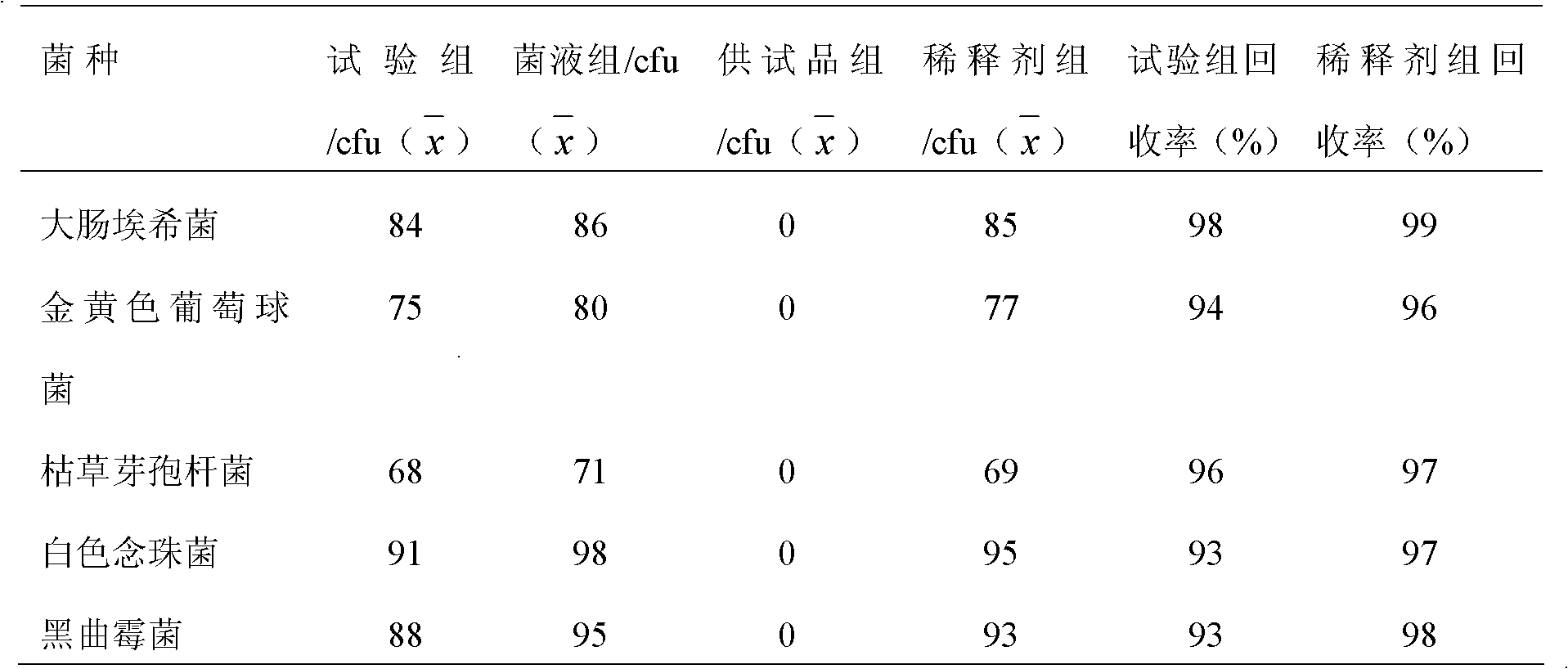

Microbial limit detection method of miconazole nitrate suppository

InactiveCN102586393AGood antibacterial effectPromote stratificationMicrobiological testing/measurementMicroorganism based processesFiltrationStaphyloccocus aureus

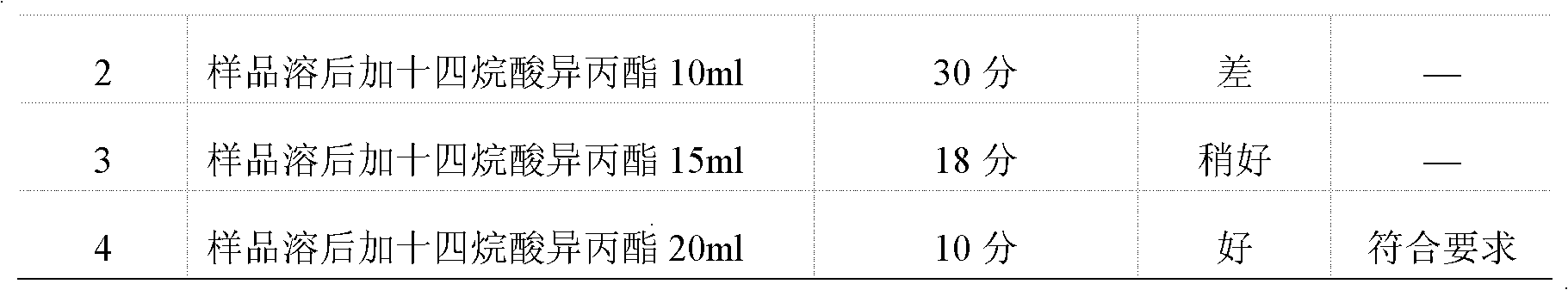

The invention discloses a microbial limit detection method of miconazole nitrate suppository. The method comprises dissolving sample with sodium chloride-peptone buffer solution (pH 7.0) containing 10 vol% polysorbate 80 (Tween 80), adding 20ml of isopropyl myristate, and washing with aqueous solution containing 0.1 vol% polysorbate 80 and 0.1 wt% peptone. Membrane filtration method is adopted for bacteria, mildew, yeast, Staphyloccocus aureus and Monilia albican, with recovery rate all above 70%. Culture medium dilution method is adopted to detect Pseudomonas Aeruginosa. The addition of isopropyl myristate can accelerate fat / water layer separation, shorten experiment time, stabilize flow rate, reduce test cost, and achieve strong operability.

Owner:SHAANXI INST FOR FOOD & DRUG CONTROL

Polyether modified phenyl hydrogen-containing silicone oil and preparation method thereof

InactiveCN105367802AImprove high temperature resistanceImprove the lubrication effectDewatering/demulsification with chemical meansTransportation and packagingHydrogenNitrogen

The invention relates to polyether modified phenyl hydrogen-containing silicone oil and a preparation method thereof. According to the invention, under nitrogen protection, an isopropyl alcohol solution of chloroplatinic acid, the phenyl hydrogen-containing silicone oil and polyether are added in a reaction vessel, the above components are subjected to a reaction for 7-10 hours at temperature of 100-130 DEG C to obtain the polyether modified phenyl hydrogen-containing silicone oil; wherein, a mol ratio of phenyl hydrogen-containing silicone oil to polyether is 1:(1-1.3). According to the invention, platinum is employed as a catalyst, the provided preparation method realizes good performance of the modified silicone oil, and the method for the hydrogen-containing silicone oil has the advantages of simple operation, low cost and high efficiency, a purpose of large-scale production requirement can be satisfied, the employed hydrogen-containing silicone oil can save preparation steps and can reach the purpose of enhancing thermostability of polysiloxane.

Owner:SHAANXI UNIV OF SCI & TECH

Industrial sewage treatment agent

InactiveCN105948213AImprove securityFast flocculationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionPhosphateThiourea

The invention discloses an industrial sewage treatment agent, which comprises the following raw materials by weight: 20-40 parts of chrysotile, 10-30 parts of diatomite, 10-30 parts of modified activated carbon, 10-20 parts of polymeric aluminum phosphate, 5-15 parts of polymeric phosphate-ferric chloried, 1-5 parts of aluminum potassium sulfate, 5-10 parts of bentonite, 1.5-2.5 parts of polyacrylamide, 1.4-2.5 parts of sodium hexametaphosphate, 1-3 parts of modified attapulgite, 10-30 parts of isopropanol, 5-15 parts of sodium nitrite, 2-10 parts of thiourea, and 2-4 parts of acrolein. The industrial sewage treatment agent provided by the invention can be used for industrial sewage treatment, and has the advantages of fast flocculation and purification speed, thorough sewage treatment, excellent stability and high safety.

Owner:林元文

Demulsification method in production processes for extracting tea-seed oil extraction with participation of water phase

InactiveCN103396879AAvoid emulsificationSimple methodFatty-oils/fats refiningFatty-oils/fats productionOil and greaseOil water

The invention discloses a demulsification method in production processes for extracting tea-seed oil extraction with the participation of a water phase, relates to a technology for breaking an oil-water emulsification state during tea-seed oil production, and in particular to a technology for breaking emulsification in production processes for extracting tea-seed oil extraction with the participation of a water phase, such as an aqueous enzymatic method, an aqueous solution method or an aqueous extraction method. The technical scheme is as follows: after tea seeds are moderately crushed, an appropriate amount of water phase is added, and the purpose of breaking an oil-water emulsification phenomenon is achieved by virtue of the comprehensive methods of increasing temperature, regulating pH value and centrifugally separating. The method provided by the invention is simple, feasible and strong in practicability, solves the problem of a low oil yield caused by the fact that oil and water are seriously emulsified and difficult to separate in a water-phase oil extraction process, and is beneficial to actual industrial application and popularization for the water-phase tea-seed oil extraction process technology.

Owner:CHANGSHA HAORUI BIOLOGICAL SCI & TECH

Superhydrophobic sponge body material and preparation method thereof

InactiveCN107312197AEasy to prepareImprove hydrophobicityOther chemical processesMelamineHydrophobic effect

The present invention relates to a superhydrophobic sponge body material and a preparation method thereof. A purpose of the present invention is to mainly solve the problem of poor hydrophobic effect of the existing adsorption recovery material. The technical scheme of the present invention comprises a superhydrophobic sponge body material and a preparation method thereof, wherein the superhydrophobic sponge body material comprises a sponge body and a nanometer modifier, the sponge body is a melamine sponge or a polyurethane sponge, and the nanometer modifier preparation method comprises: dissolving a nanometer material in a hydrophobic organosilicon compound agent, and stirring until completely dissolving so as to obtain the nanometer modifier. With the technical scheme of the present invention, the problem in the prior art is well solved. The preparation method of the present invention can be used in the preparation of superhydrophobic sponge bodies.

Owner:CHINA PETROLEUM & CHEM CORP +1

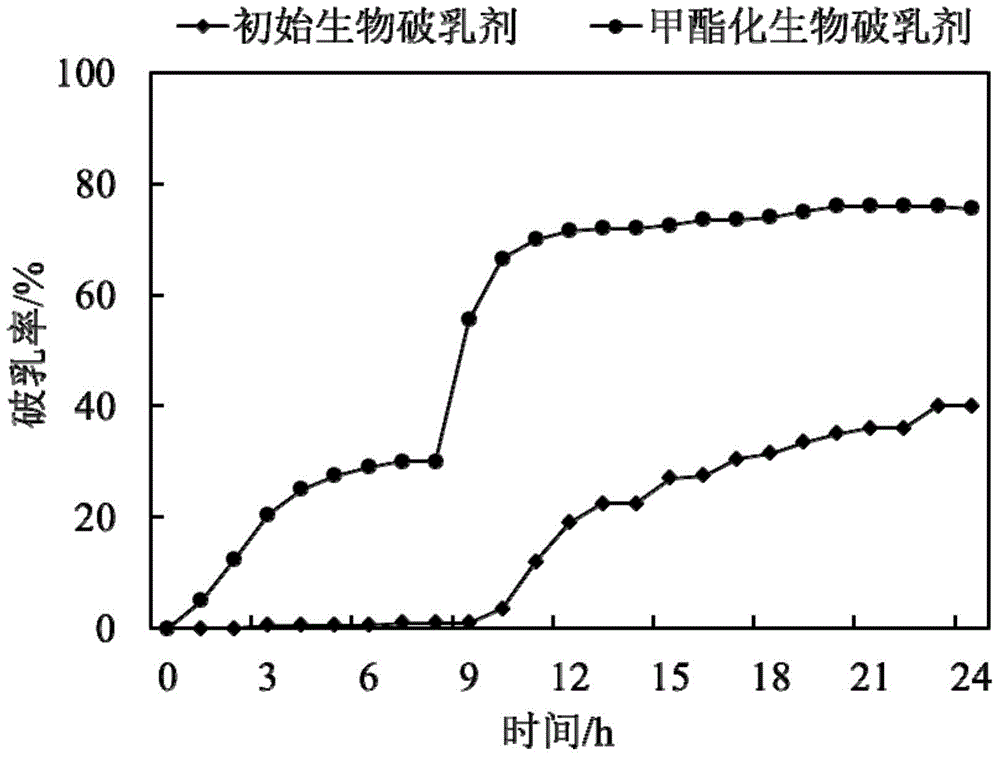

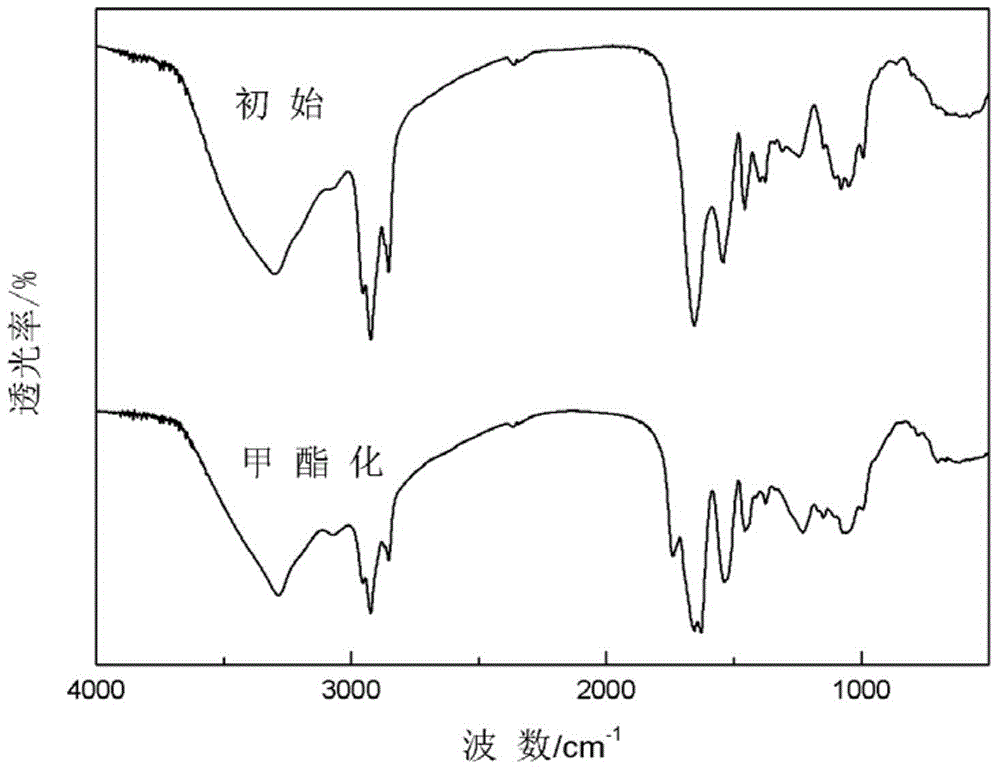

Method for improving demulsification performance of cell wall combined biological de-emulsifier

The invention relates to a method for improving a demulsification performance of a cell wall combined biological de-emulsifier. The method comprises the following steps: performing freeze drying on the cell wall combined biological de-emulsifier, so as to obtain dried biological de-emulsifier powder; mixing and stirring the dried biological de-emulsifier powder and a mixed solution of methanol and hydrochloric acid according to a certain ratio, carrying out methyl esterification reaction, and finally performing rotary evaporation and drying to obtain the cell wall combined biological de-emulsifier of which the demulsification performance is improved. Compared with the prior art, the method disclosed by the invention is simple and relatively low in cost, the demulsification performance of the cell wall combined biological de-emulsifier is obviously improved, and the large-scale application is easily realized.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com