Polyether crude oil demulsifier using straight chain alkyl phenolic resin as initiator and preparation method and application thereof

A technology of crude oil demulsifier and straight-chain alkyl, which is applied in the direction of dehydration/demulsification by chemical methods, can solve the problems of poor universality of demulsification ability and decline of demulsification ability, and achieve strong demulsification ability and diffusion ability, Strong universality and clear water phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

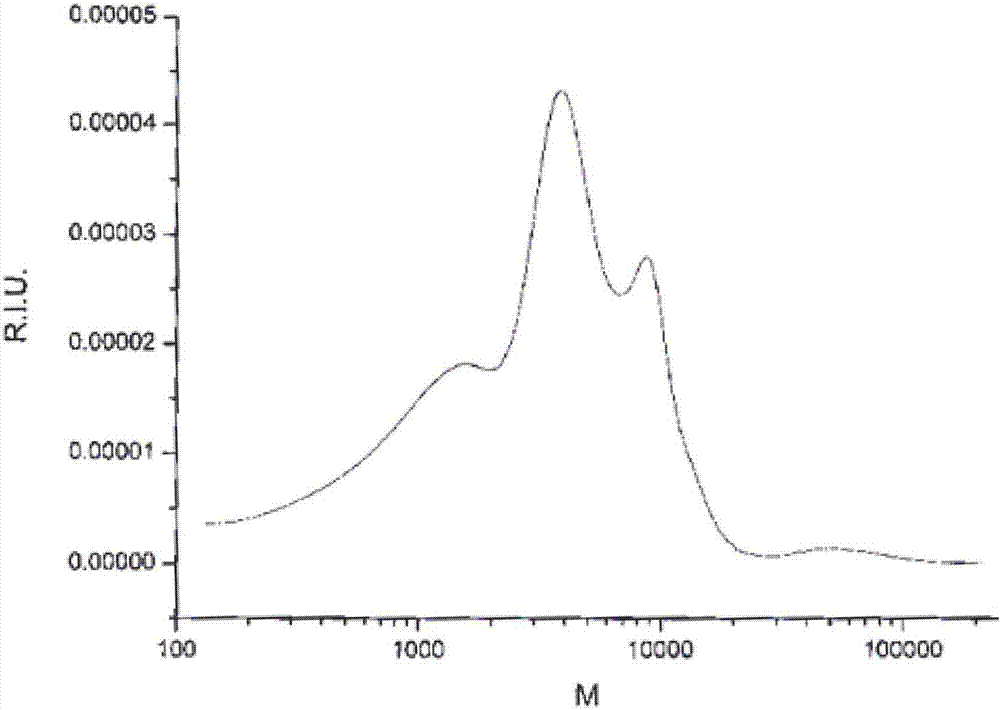

Image

Examples

Embodiment 1

[0026] 15% of the sum of PO and EO mass in the product:

[0027] (1) Synthesis of starter nonylphenolic resin

[0028] Add 190g of melted nonylphenol into a three-necked glass flask, stir, add 1g of potassium hydroxide, and slowly add 150g of 37% formaldehyde solution dropwise at a temperature of 50°C to 80°C; after adding the formaldehyde solution, raise the temperature to 100°C ~120°C, react for 1.5~2.0 hours, then dehydrate for 2~3 hours under the conditions of vacuum degree -0.08Mpa~-0.1Mpa and 145°C~155°C, then cool down and discharge.

[0029] (2) Synthesis of intermediates

[0030] Put 200g of the initiator obtained in step (1) and 33g of the catalyst KOH into a high-pressure reactor, and polymerize 200g of PO10 at a temperature of 115-155°C and a reaction pressure of 0.1-0.8MPa.

[0031] (3) Synthesis of polyether

[0032] Put 40g of the intermediate obtained in step (2) and 3.2g of catalyst KOH into a 1L autoclave, under the conditions of temperature 115-155°C and ...

Embodiment 2

[0034] The mass of EO in the product is 20% of the mass sum of PO and EO:

[0035] Put 40g of the intermediate synthesized in step (2) in Example 1 and 3.2g of catalyst KOH into a 1L high-pressure reactor, and polymerize 200g of PO at a temperature of 115-155°C and a reaction pressure of 0.1-0.8MPa, and then polymerize Connect EO120g, then polymerize PO240g, dehydrate and discharge to obtain polyether.

Embodiment 3

[0037] The mass of EO in the product is 25% of the mass sum of PO and EO:

[0038] Put 40g of the synthetic intermediate in step (2) of Example 1 and 3.2g of catalyst KOH into a 1L high-pressure reactor, and polymerize 185g of PO at a temperature of 115-155°C and a reaction pressure of 0.1-0.8MPa, and then polymerize EO150g, then polymerized PO225g, dehydrated and discharged to obtain polyether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com