Convolution cavitation device

A cavitator and eddy current technology, which is applied in the device field of equipment, can solve problems such as complex operation process, and achieve the effect of simple equipment structure, large processing capacity and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

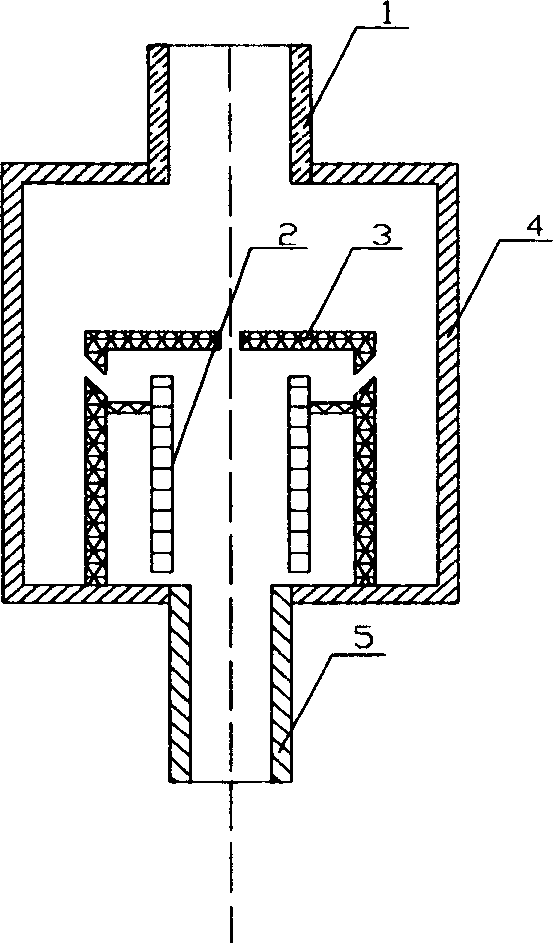

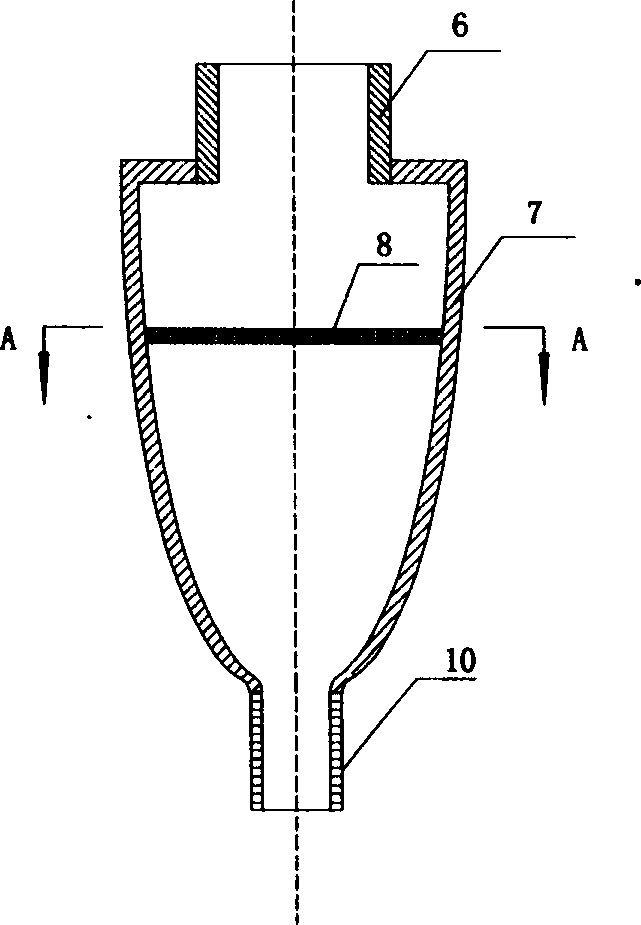

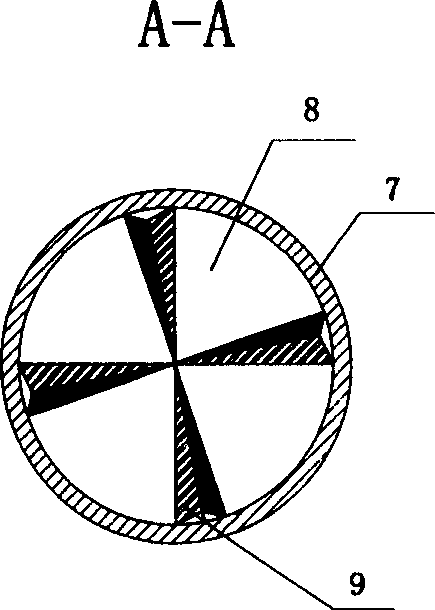

[0015] Such as figure 1 As shown, the present invention comprises: liquid inlet pipe 1, three coaxial inner cylinders 2, middle cylinder 3, outer cylinder 4 and outlet section 5, wherein outer cylinder 4 and middle cylinder 3 have their respective The top and the common bottom, while the inner cylinder 2 is a hollow cylinder, each has its own entrance at the center of the top of the middle cylinder 3 and the outer cylinder 4, and the middle cylinder 3 and the outer cylinder 4 have a common bottom, Their bottoms are connected with the inlet end of the nozzle 5, and the inner cylinder 2 is connected with the middle cylinder 3 with four beams evenly distributed in the radial direction. A plurality of tangential slits are arranged on the wall of the upper half of the middle cylinder 3 . When water-containing emulsified oil or emulsified oily waste water enters the outer cylinder 4 of the vortex cavitator at a certain pressure and flow rate through the pump, part of the fluid flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com