Method for treating heavy metal sludge by using stainless steel molten slag

A technology for heavy metal sludge and stainless steel, which is applied in sludge treatment, special treatment targets, chemical instruments and methods, etc., can solve the problems of high equipment investment or operating costs, low recovery rate of heavy metals, and high energy consumption in the utilization process. The effect of industrialization promotion, large processing capacity, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The heavy metal sludge comes from the stainless steel cold-rolling wastewater treatment station, which is a by-product of the lime milk-chemical precipitation process for cold-rolling wastewater (referred to as cold-rolling sludge). In a warehouse with good infiltration and ventilation, the typical chemical components of the sludge are: Cr (0.5-5%), Ni (0.1-1.0%), Zn (0.05-0.5%), Pb (0.05-0.5%), Fe (10-25%), CaSO4 (5-25%), CaF2 (5-15%), CaCl2 (1-5%), others (5-10%), heavy metal sludge particles are fine, complex components, leaching Highly toxic and classified as hazardous waste (National Hazardous Waste List HW17 and HW21), it needs to be properly disposed of by outsourced qualified enterprises.

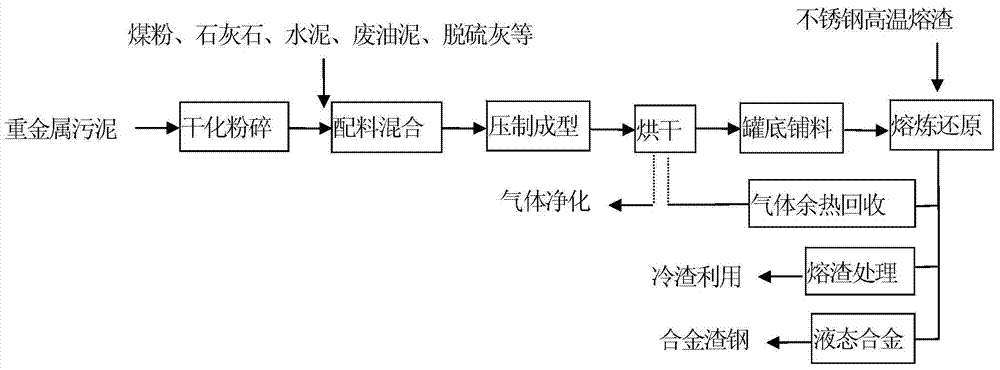

[0057] like figure 1 As shown, when the cold-rolled sludge is naturally dried to a moisture content of 55%, it is crushed and sieved, and mixed with coal powder, quicklime, cement, waste oil sludge, and desulfurization ash in proportion (cold-rolled sludge 50%, coal powder 1...

Embodiment 2

[0066] Heavy metal sludge comes from the electroplating wastewater treatment process. The sludge is naturally dried to a water content of 60%, crushed and sieved, and mixed with coke powder, dolomite, attapulgite, waste oil sludge, and desulfurization ash in proportions by weight (sludge 40%, coke powder 15%, dolomite 15%) , Attapulgite 15%, waste oil sludge 10%, desulfurization ash 5%), using a twin-shaft screw mixer to mix evenly.

[0067] Dry the sludge agglomerate to a moisture content of 33%. In the compression molding process, the size of the sludge agglomerate is a pellet with a particle size of 15 mm.

[0068] Put the dried sludge pellets at a ratio of 15% (the proportion of sludge pellets to the total weight of stainless steel slag and sludge pellets in the slag tank), and put about 4.5t into the bottom of the stainless steel slag tank.

[0069] Others are with embodiment 1.

Embodiment 3

[0071] Heavy metal sludge comes from the chemical wastewater treatment process. The sludge is naturally dried to a water content of 50%, crushed and sieved, and mixed with coal powder, limestone, bentonite, waste oil sludge, and desulfurized ash in proportions by weight (30% of sludge, 10% of coal powder, 25% of limestone, and 15% of bentonite) , waste oil sludge 5%, desulfurization ash 15%), mixed evenly with a twin-shaft screw mixer.

[0072] The sludge lumps were dried to a moisture content of 8%. In the compression molding process, the size of the sludge agglomerate is a pellet with a particle size of 20 mm.

[0073] Put the dried sludge pellets at a ratio of 10% (the proportion of sludge pellets to the total weight of stainless steel slag and sludge pellets in the slag tank), and put about 3t into the bottom of the stainless steel slag tank.

[0074] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com