Reverse demulsifier and its preparation method

An inverse demulsifier and reaction technology, which is applied in the field of petroleum industry, can solve the problems of sludge clogged filter, high oil content in water phase, etc., and achieve the effect of low equipment requirements, no high temperature and high pressure reaction, and good demulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

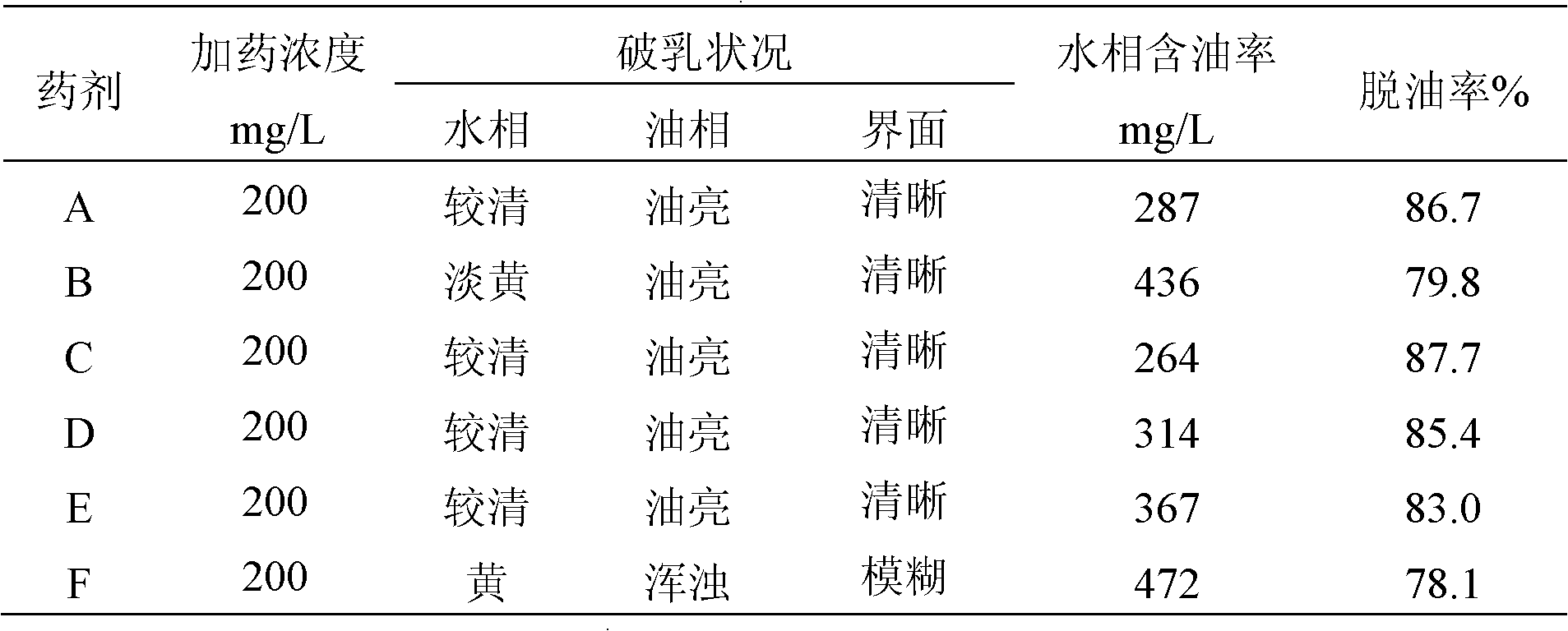

Examples

Embodiment 1

[0020] Embodiment 1, the synthesis of inverse demulsifier A

[0021] (1) Synthesis of linear polyamide-amine quaternary ammonium salt

[0022] At room temperature, slowly add methyl acrylate dropwise to ethylenediamine, react at 70°C for 4h, then raise the temperature to 90°C~95°C for 24h to obtain linear polyamide-amine; drip epichlorohydrin at 5°C Add it to a polyamide-amine aqueous solution with a concentration of 50% by mass, react at room temperature for 5 hours, raise the temperature to 65°C and react for 1 hour, and distill off water under reduced pressure to obtain the linear polyamide-amine quaternary ammonium salt JXY01; The molar ratio of the ester to ethylenediamine is 1:1, and the mass-number ratio of the polyamidoamine to epichlorohydrin is 12:10.

[0023] (2) Synthesis of amphiphilic cationic polymers

[0024] Using nonylphenol as the starting agent, carry out alkoxylation reaction with ethylene oxide under the catalysis of potassium hydroxide at 120-130°C and...

Embodiment 2

[0028] Embodiment 2, the synthesis of inverse demulsifier B

[0029] (1) Synthesis of linear polyamide-amine quaternary ammonium salt

[0030] At room temperature, slowly add methyl acrylate dropwise to ethylenediamine, react at 70°C for 4h, then raise the temperature to 90°C~95°C for 24h to obtain linear polyamide-amine; drip epichlorohydrin at 5°C Add it to a polyamide-amine aqueous solution with a concentration of 50% by mass, react at room temperature for 5 hours, raise the temperature to 65°C for 1 hour, and distill off water under reduced pressure to obtain the linear polyamide-amine quaternary ammonium salt JXY02; The molar ratio of ester to ethylenediamine is 1:1, and the ratio by mass and number of polyamidoamine to epichlorohydrin is 50:3.

[0031] (2) Synthesis of amphiphilic cationic polymers

[0032] Using nonylphenol as the starting agent, at 120-130°C and 0.2-0.4MPa, potassium hydroxide is used to catalyze the alkoxylation reaction with ethylene oxide to obtai...

Embodiment 3

[0036] Embodiment 3, the synthesis of inverse demulsifier C

[0037] Dissolve linear polyamide-amine quaternary ammonium salt JXY01, amphiphilic cationic polymer LYJ01, and cationic surfactant dodecyltrimethylammonium bromide in water to obtain reverse phase demulsifier C; among them, linear polyamide- The ratio of amine quaternary ammonium salt, amphiphilic cationic polymer, cationic surfactant to water is 30:17:3:250.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com