Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4438 results about "Methyl acrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl acrylate is an organic compound, more accurately the methyl ester of acrylic acid. It is a colourless liquid with a characteristic acrid odor. It is mainly produced to make acrylate fiber, which is used to weave synthetic carpets. It is also a reagent in the synthesis of various pharmaceutical intermediates.

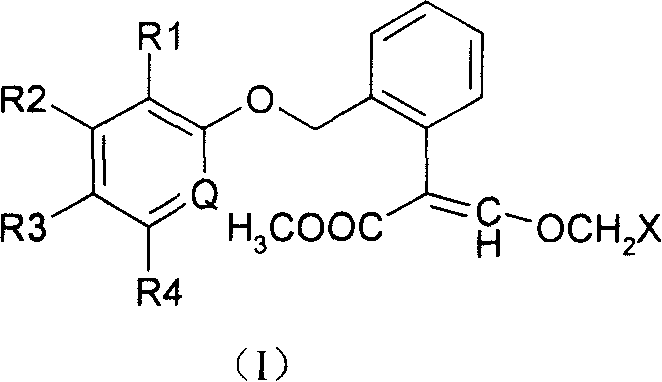

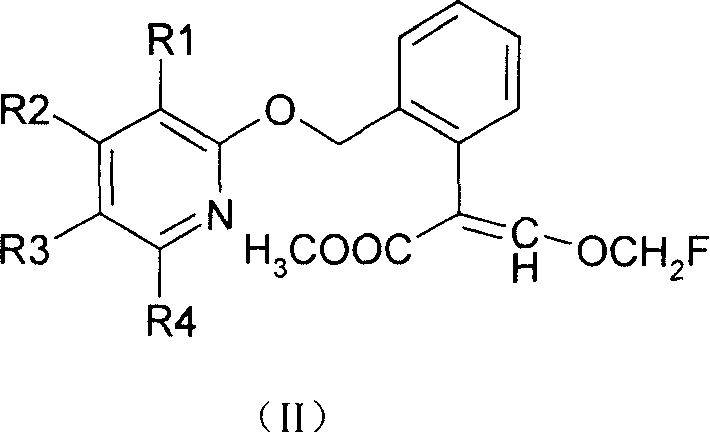

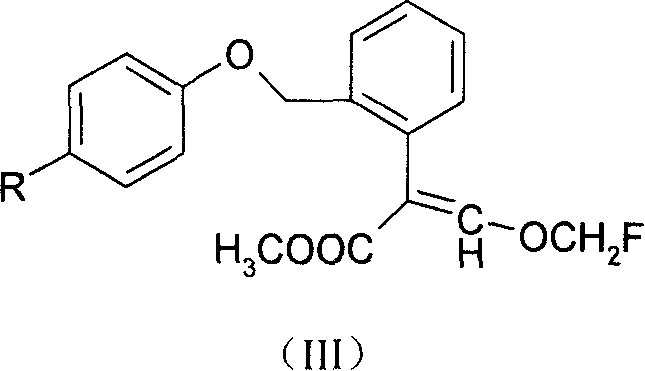

Methoxyl group displacement methyl acrylate compound bactericidal agent

InactiveCN1907024AEasy to solveGood prevention effectBiocideAnimal repellantsUnsaturated hydrocarbonMethyl acrylate

The invention relates to a group of methoxyl methyl acrylate compounds having a formula (I), wherein X=F or H, Q=N or CH; R1, R2, R3, R4=H, NO2, CN, Cl, C1-C9 alkyl or unsaturated hydrocarbons, C1-C6 alkoxy imine methyl, or C1-C6 alkoxy carbonyl. The invention also discloses the process for preparing the compounds and the use of the compounds in making agricultural bactericides.

Owner:ZHEJIANG CHEM TECH GRP CO LTD

Thermoset materials with improved impact resistance

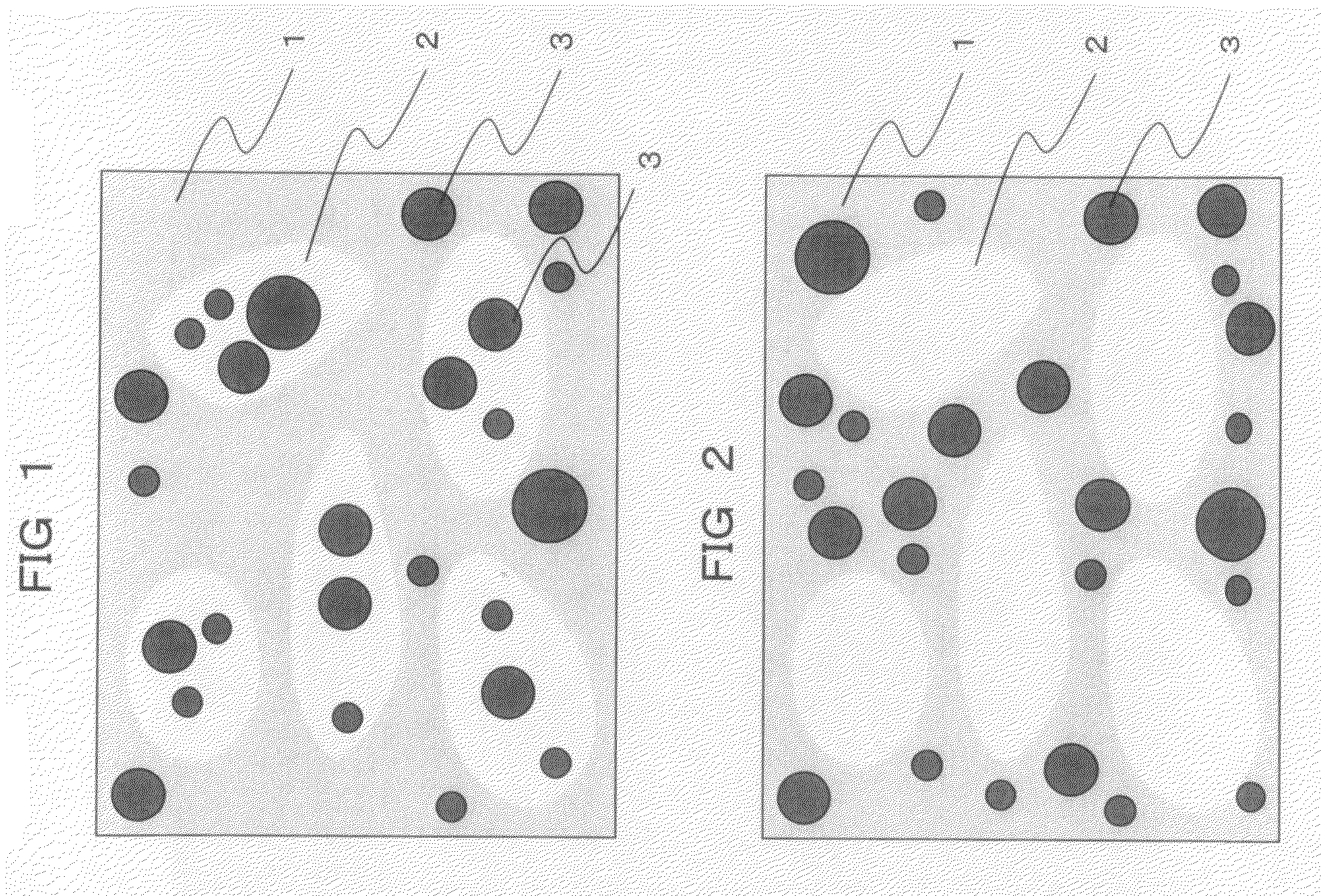

The present invention relates to a thermoset material with improved impact resistance comprising:99 to 20% of a thermoset resin, and1 to 80% of an impact modifier comprising at least one copolymer comprising S-B-M, B-M and M-B-M blocks,wherein:each block is connected to the other by means of a covalent bond or of an intermediate molecule connected to one of the blocks via a covalent bond and to the other block via another covalent bond,M is a PMMA homopolymer or a copolymer comprising at least 50% by weight of methyl methacrylate,B is incompatible with the thermoset resin and with the M block and its glass transition temperature Tg is less than the operating temperature of the thermoset material, andS is incompatible with the thermoset resin, the B block and the M block and its Tg or its melting temperature is greater than the Tg of B.S is advantageously polystyrene and B polybutadiene. The thermoset resin advantageously originates from the reaction of a thermosetting epoxy resin and of a hardener.

Owner:ATOFINA

Thermoset materials with improved impact resistance

The present invention relates to a thermoset material with improved impact resistance comprising: 99 to 20% of a thermoset resin, 1 to 80% of an impact modifier comprising at least one copolymer chosen from copolymers comprising S-B-M, B-M and M-B-M blocks, in which: each block is connected to the other by means of a covalent bond or of an intermediate molecule connected to one of the blocks via a covalent bond and to the other block via another covalent bond, M is a PMMA homopolymer or a copolymer comprising at least 50% by weight of m thyl methacrylate, B is incompatible with the thermoset resin and with the M block and its glass transition temperature Tg is less than the operating temperature of the thermoset material, S is incompatible with the thermoset resin, the B block and the M block and its Tg or its melting temperature M.t. is greater than the Tg of B. S is advantageously polystyrene and B polybutadiene. The thermoset resin advantageously originates from the reaction of a thermosetting epoxy resin and of a hardener.

Owner:ATOFINA

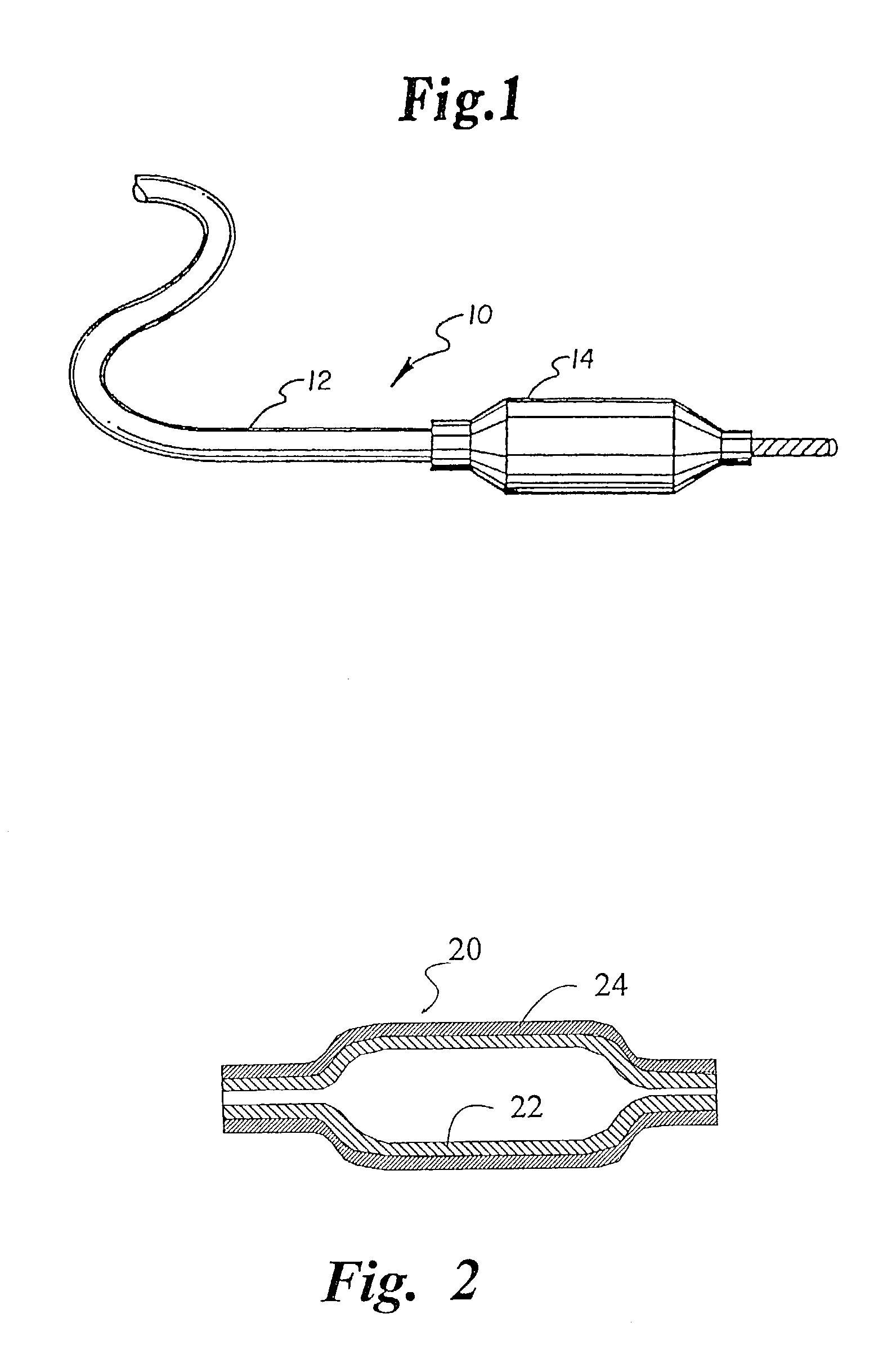

Balloons made from liquid crystal polymer blends

Balloons for use on medical devices such as catheter balloons are formed from polymer blend products which include a liquid crystal polymer (LCP), a crystallizable thermoplastic polymer, especially thermoplastic polyesters such as PET, and a compatabilizer. The compatabilizer may be an ethylene-maleic anhydride copolymer, an ethylene-methyl acrylate copolymer, an ethylene-methyl acrylate copolymer, an ethylene-methyl acrylate-maleic anhydride terpolymer, an ethylene-methyl-methacrylic acid terpolymer, an acrylic rubber, an ethylene-ethyl acrylate-glycidyl methacrylate terpolymer or a mixture of two or more such polymers.

Owner:BOSTON SCI SCIMED INC

Touch panel

ActiveUS20140134433A1Enhancing performance of inhibiting changeImprove cohesive strengthFilm/foil adhesivesMacromolecular adhesive additivesElectrical conductorMeth-

Provided is a touch panel. The touch panel includes a base and a pressure-sensitive adhesive layer attached to the base and including an acryl-based polymer containing an acryl polymer containing 5 to 30 parts by weight of isobornyl (meth)acrylate, and 5 to 40 parts by weight of methyl (meth)acrylate in a polymerized form. Accordingly, it can effectively inhibit penetration of oxygen, moisture or other impurities at an interface between the base and the pressure-sensitive adhesive layer, or at an interface between a conductor thin film and the pressure-sensitive adhesive layer, and prevent degradation in optical properties such as visibility, etc. due to bubbles generated at the pressure-sensitive adhesive interface. In addition, when the pressure-sensitive adhesive layer is directly attached to the conductor thin film and even exposed to severe conditions such as high temperature or high temperature and high humidity, a change in the resistance of the conductor thin film may be effectively inhibited, and thus the touch panel can be stably driven for a long time.

Owner:LG CHEM LTD

Non-crosslinking halogen-free flame-retardant cable insulating material or sheath material and preparation method thereof

ActiveCN103012941ACause damageReduce manufacturing costPlastic/resin/waxes insulatorsInsulated cablesElastomerHalogen

The invention discloses a non-crosslinking halogen-free flame-retardant cable insulating material or sheath material, comprising the following components in part by weight: 100 parts of ethylene and ethylene copolymer and / or ethylene propylene diene monomer, 0-20parts of compatilizer, 20-250 parts of halogen-free flame retardant, 0-5 parts of antioxidant, 0-5 parts of lubricating agent, 0-40 parts of polymeric elastomer, 0-3 parts of coupling agent, and 0-20parts of color master batch, wherein the ethylene and ethylene copolymer are selected from one or more of the following materials: ethylene-vinyl acetate copolymer, ethylene-methyl acrylate copolymer, ethylene-ethyl acrylate copolymer and the like. According to the halogen-free flame-retardant cable insulating material or sheath material, the insulating layer or the sheath layer prepared by the uncrosslinked halogen-free flame-retardant cable insulating material or sheath material can be adaptive to the environment at -40 to 80 DEG C, and the material can not generate poisonous gases such as halogen hydride in case of fire, so that harm to lives and property loss can not be caused by the poisonous gases such as halogen hydride; and besides, the production cost of the material is low.

Owner:SHENZHEN WOER NEW ENERGY ELECTRICAL TECH CO LTD

High temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material and method for preparing high temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material

ActiveCN103012940AReduce manufacturing costPlastic/resin/waxes insulatorsInsulated cablesElastomerPolymer science

The invention discloses a high temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material. The cable insulation material or sheath material comprises the following components in parts by weight: 100 parts of ethylene and copolymer thereof and / or ethylene propylene diene monomer, 0-20 parts of compatilizer, 20-250 parts of halogen-free flame retardant, 0-5 parts of antioxidant, 0-5 parts of lubricating agent, 0.01-5 parts of peroxide crosslinking agent, 0-40 parts of polymer elastomer, 0-3 parts of coupling agent and 0-20 parts of color masterbatch; and the ethylene and the copolymer thereof are selected from one or a plurality of the following materials of ethylene-vinyl acetate copolymer, ethylene-methyl acrylate copolymer, ethylene-ethyl acrylate and the like. The high temperature peroxide crosslinking agent crosslinks under the temperature condition of above 150 DEG C only, during a cable material mixing extrusion and insulating layer or sheath layer formation process, chemical crosslinking or micro-crosslinking cannot be caused, but the high temperature peroxide crosslinking agent generates a crosslinking function when the temperature is higher than 150 DEG C in the case of fire, so that the production cost is lowered.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Cement additive and cement composition using same

A novel cement admixture is provided which fulfills the function as a thickener basically, possesses an ability to inhibit segregation of materials, excels in workability as well, and permits a decrease in the amount of addition while keeping these functions intact. The cement admixture is characterized by comprising a cement additive formed of a polymer resulting from polymerizing a monomer mixture having methyl acrylate as a main component thereof and a cement water reducing agent.

Owner:NIPPON SHOKUBAI CO LTD

Dosage form and method for producing the same

ActiveUS20050152977A1Quick releaseDelay releasePowder deliveryNervous disorderAdditive ingredientCoated drugs

The invention relates to a process for producing a coated drug form or a drug form in the form of an active ingredient matrix, by processing a copolymer, an active pharmaceutical ingredient, a core if present and / or pharmaceutically customary excipients in a conventional manner by melting, injection molding, extrusion, wet granulation, casting, dipping, spreading, spraying or compression to form a coated drug form and / or to form an active ingredient matrix, characterized in that a copolymer is used which is composed of 20 to 33% by weight methacrylic acid, 5 to 30% by weight methyl acrylate, 20 to 40% by weight ethyl acrylate and more than 10 to 30% by weight butyl methacrylate and, if desired, 0 to 10% by weight further vinylically copolymerizable monomers, with the proviso that the glass transition temperature of the copolymer in accordance with ISO 11357-2, section 3.3.3, is 55 to 70° C. The invention further relates to the drug form produced in accordance with the invention, to the copolymer, and to the use thereof.

Owner:EVONIK OPERATIONS GMBH

Fabric coating compositions providing excellent resistance to seam combing, particularly for use on automotive airbag fabrics

InactiveUS6348543B1Highly cost-effectiveEasy to handlePedestrian/occupant safety arrangementWoven fabricsYarnAirbag deployment

This invention relates to a new adhesive coating composition, particularly for use on airbag fabrics, which is composed of a crosslinked blend of a polyalkyl- or polyphenylsiloxane with vinyl functionality and a copolymer of ethylene and methyl acrylate. This coating provides excellent adhesive properties to the coated fabric, in that it restricts the movement, when put under stress, of the yarns constricting that fabric, which are situated adjacent to seams in the fabric. This reduces the effect known in the trade as combing. Fabric treated with this material in the mainer described herein, requires a marked increase in the amount of force required for this yarn movement. This distortion of the fabric can be detrimental in an automotive airbag, in that, it may result in the loss of inflating air, and under extreme conditions may result in a seam failure.

Owner:MILLIKEN & CO

Production of methyl a-methacrylate with methanal as raw material

InactiveCN101074192AImprove conversion rateReduce manufacturing costPreparation by aldehyde oxidation-reductionMethacrylateDivinylbenzene

Production of methyl-methyl acrylate from methanal is carried out by reacting methanal with propanal in diethylamine muriate solution at 40-45 degree to obtain methyl-acryl, mixing methyl-acryl with methanol in proportion of 30-50:1, adding them into reactor, adding into 2.0-4.0% catalyst, inducing into oxygen at 40-60 degree and flow 10 ml / min, reacting for 4-6 hrs and synthesizing to obtain final product. The catalyst carrier is styrene-divinylbenzene polymer organic resin, which consists of palladium 2-5 wt%, bismuth 0-3 wt%, lead 0.3-1 wt% and iron 0.3-1 wt%. It's cheap, has friendly reactive environment, better selectivity and conversion rate.

Owner:TIANJIN UNIV

Resin composition and molded article made thereof

The present invention provides a resin composition excellent in strength, impact resistance, heat resistance and moldability and further, of low environmental load capable of decreasing CO2 exhaustion in its production.The present invention is a resin composition comprising a styrene-based resin (A), an aliphatic polyester (B) and at least one species selected from a compatibilizer (C) and a dicarboxylic anhydride (D), and the compatibilizer is preferably at least one species described below.(C-1) methyl methacrylate polymer(C-2) a vinyl-based polymer to which epoxy unit or acid anhydride unit is copolymerized(C-3) a graft polymer in which methyl methacrylate unit is grafted to a rubbery polymer(C-4) a block copolymer in which polylactide segment and a vinyl-based polymer segment

Owner:TORAY IND INC

Coated Particles Containing Pharmaceutically Active Agents

ActiveUS20090324716A1Pretreated surfacesPharmaceutical non-active ingredientsPolymer scienceActive agent

The present invention features a tablet including particles containing a pharmaceutically active agent, wherein the particles are coated with (a) a first film layer containing a modified release polymer; and (b) a second film layer containing (i) a first polymer, wherein the first polymer is a polymer of ethyl acrylate and methyl methacrylate and (ii) a second polymer, wherein the second polymer is a polymer of methyl acrylate, methyl methacrylate and methacrylic acid.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

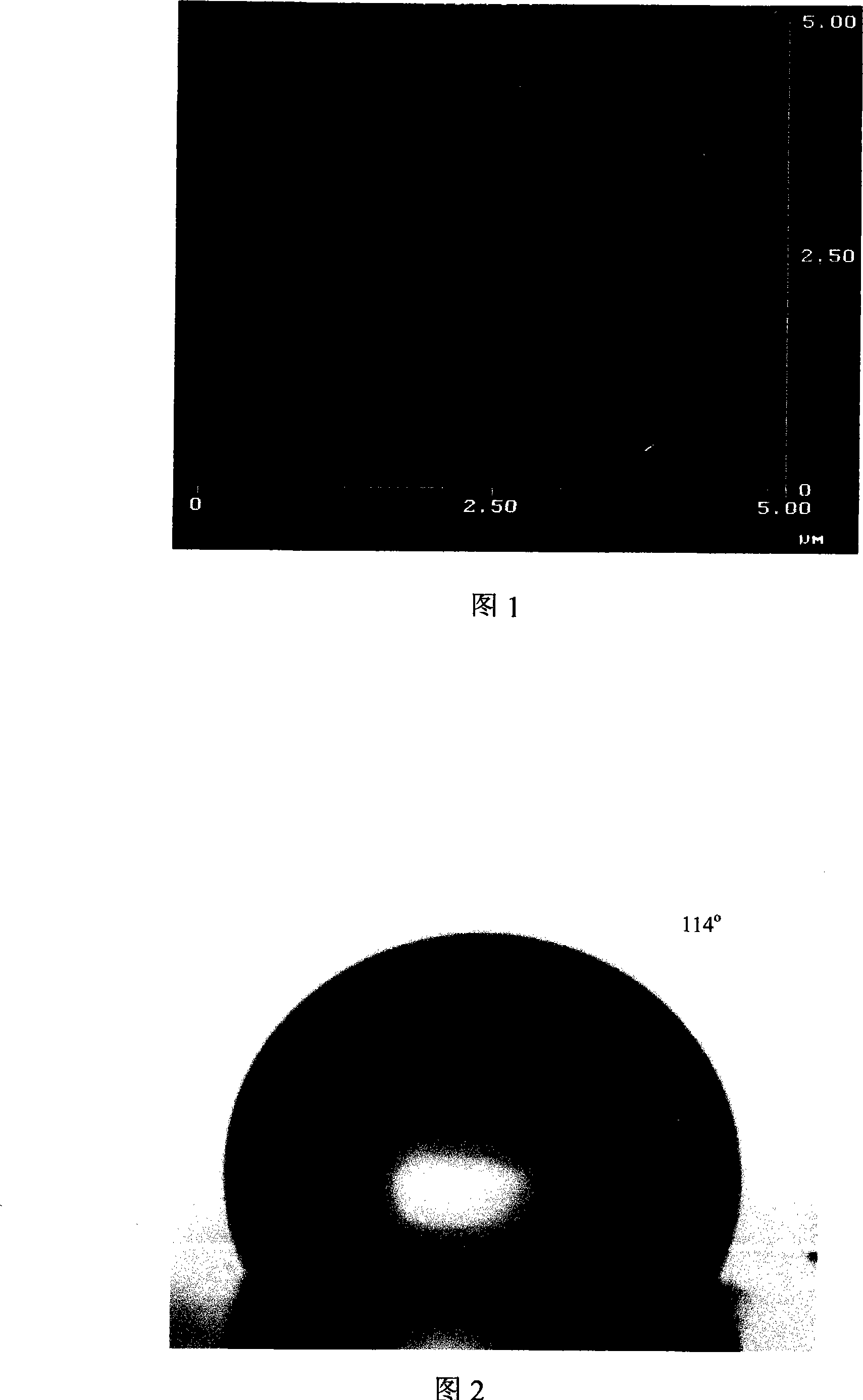

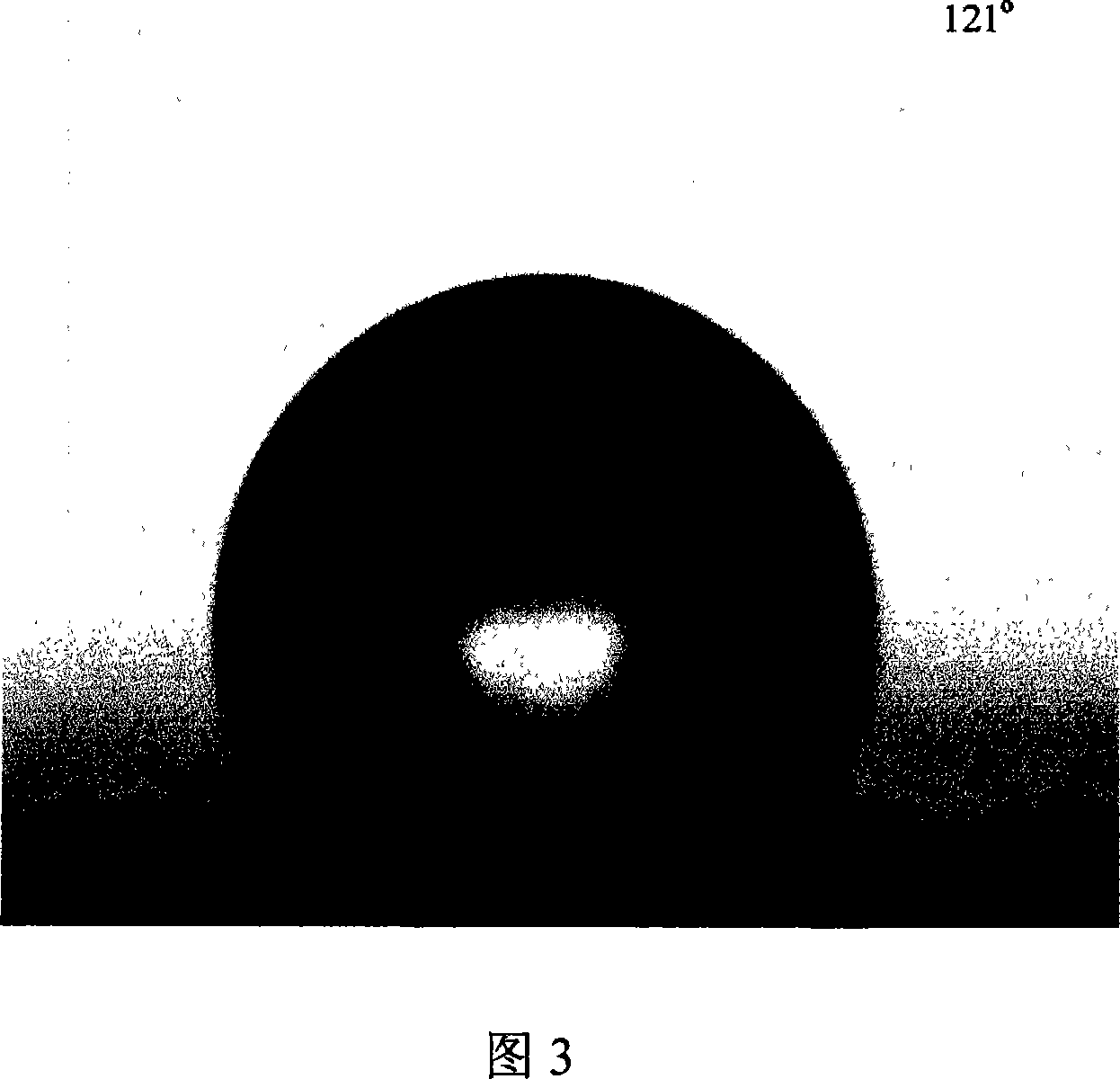

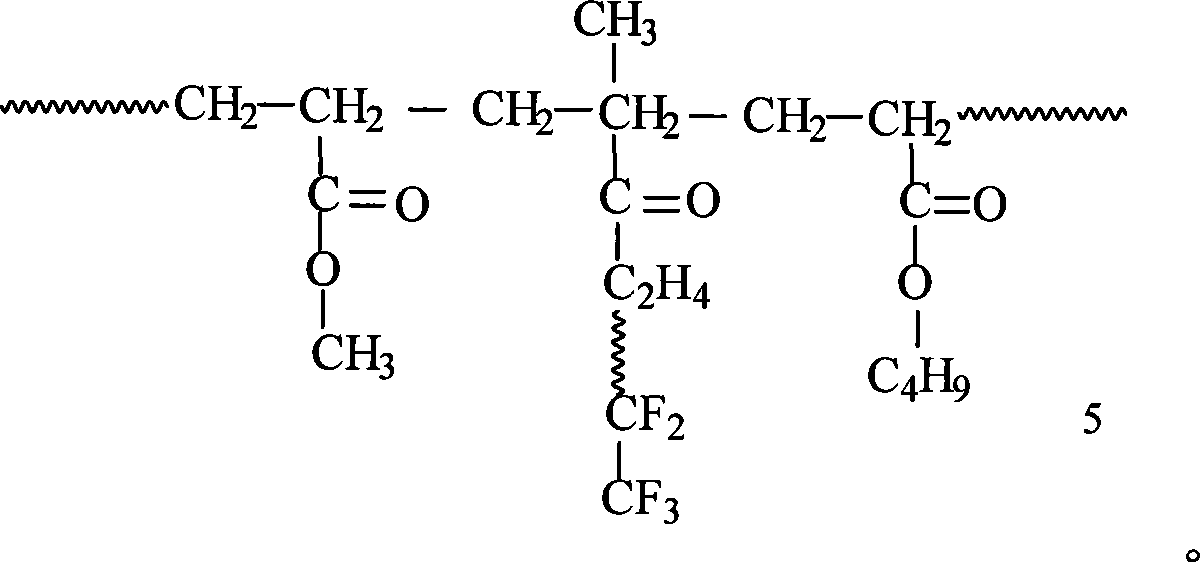

Fluorin-containing acrylic resin having ultra-low surface energy and preparation method and application in paint thereof

A fluorine-containing acrylic resin with the ultra low surface energy is prepared by the raw materials with the following weight percentages: 20 to 30 percent of acrylate or methyl acrylate hard monomer; 10 to 20 percent of acrylate or methyl acrylate soft monomer; 5 to 10 percent of acrylic hydroxy ester or methyl acrylic hydroxy ester; 5 to 12 percent of fluorine-containing acrylate monomer; 0.5 to 1 percent of acrylic acid or methyl acrylic acid; 0.5 to 1 percent of modifier; 40 to 50 percent of solvent; and 0.5 to 1.5 percent of initiator. The present invention makes use of a Perfluoro alkyl compound containing an active terminal group as the modifier and carries out the reaction with a polymer main chain by graft polymerization, thus greatly improving the storage stability of the fluorocarbon surfactant, prolonging the time effect of the nature of the resin low surface energy and enhancing the compatibility of the fluorocarbon surfactant and the acrylic resin, the resin varnish can have the ultra low surface energy, and the water contact angle can achieve more than 120 degrees.

Owner:MARINE CHEM RES INST CO LTD

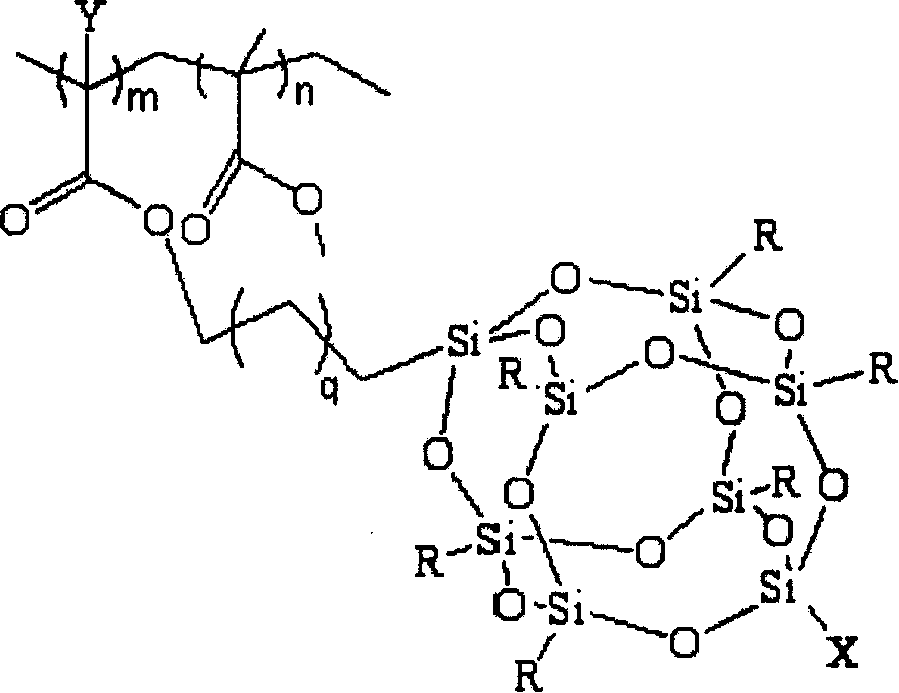

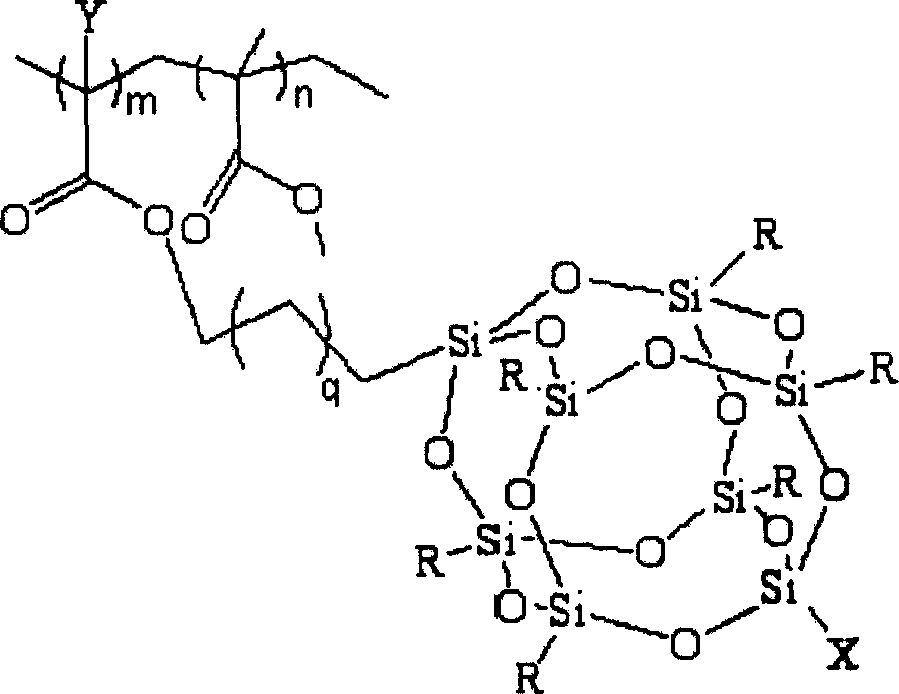

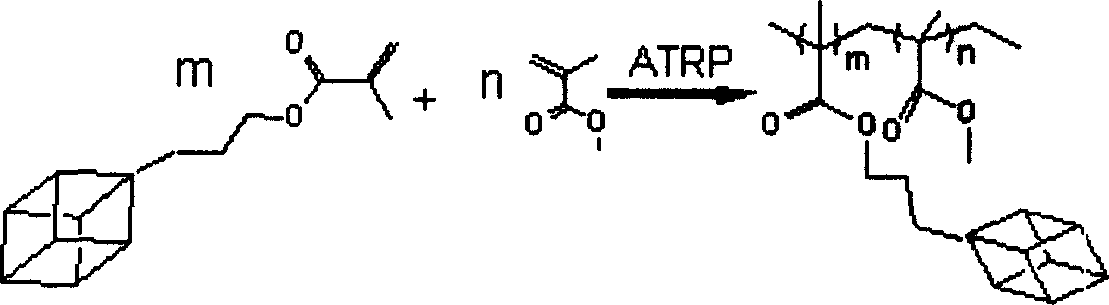

Fluoride POSS acrylic ester block multipolymer resin and its synthesis

InactiveCN101029137AImprove utilization efficiencyImprove hydrophobicityCyclohexanonePolymer science

A fluoride POSS acrylic resin block copolymer resin and its synthesis are disclosed. The molecular-weight of copolymer Mn is 20000-60000, Mn / Mw is 1.1-1.5, contact angle between coating and water is 85-120degree. The process is carried out by adding components into reactor to obtain methyl acrylate performed polymer with Br end capping, reacting with CuBr, PMDETA and F-POSS, removing catalyst from reactant, depositing while filtering by methanol, vacuum drying to constant weight to obtain the final product. The polymer powders can be dissolved into acetic ether, acetone, 1,2-dichloroethane, dioxane and cyclohexanone or their mixtures, then it can be used for coating or filming.

Owner:XIAMEN UNIV

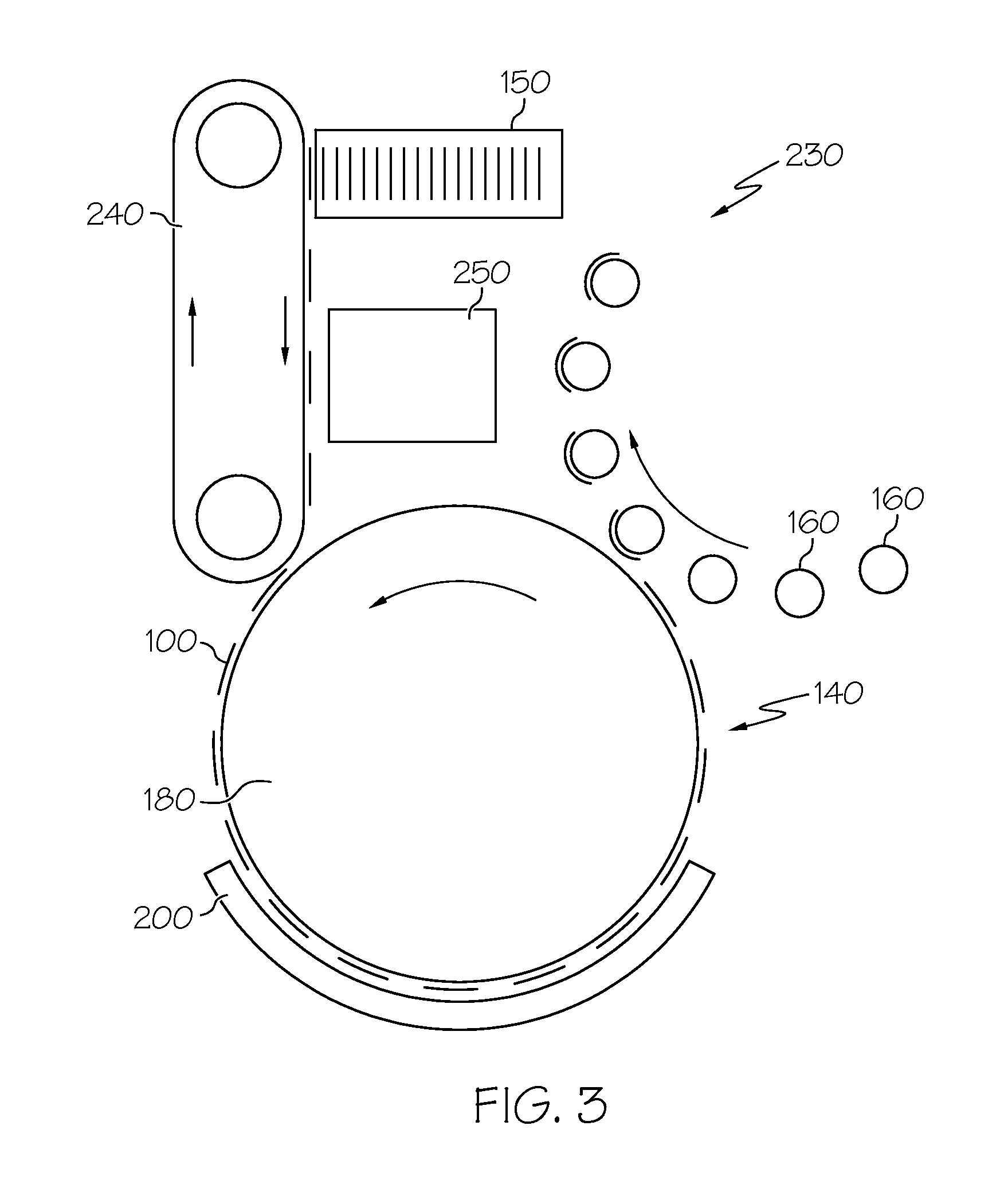

Linerless labels and activatable adhesives, systems, machines and methods therefor

InactiveUS20130133532A1Improve securityEasy to operateStampsRecord information storagePlasticizerAdhesive

A system is disclosed for printing, activating and applying a flow of linerless activatable labels to a flow of items to be labeled. An activatable adhesive is formulated to readily absorb energy from a given radiation source, an activatable adhesive linerless label incorporates such the activatable adhesive. Related methods and uses are described. The activatable adhesive includes a plasticizer, a tackifier, and an adhesive base polymer that includes butyl acrylate, styrene, methyl methacrylate, methacrylic acid, and acrylic acid.

Owner:AVERY DENNISON CORP

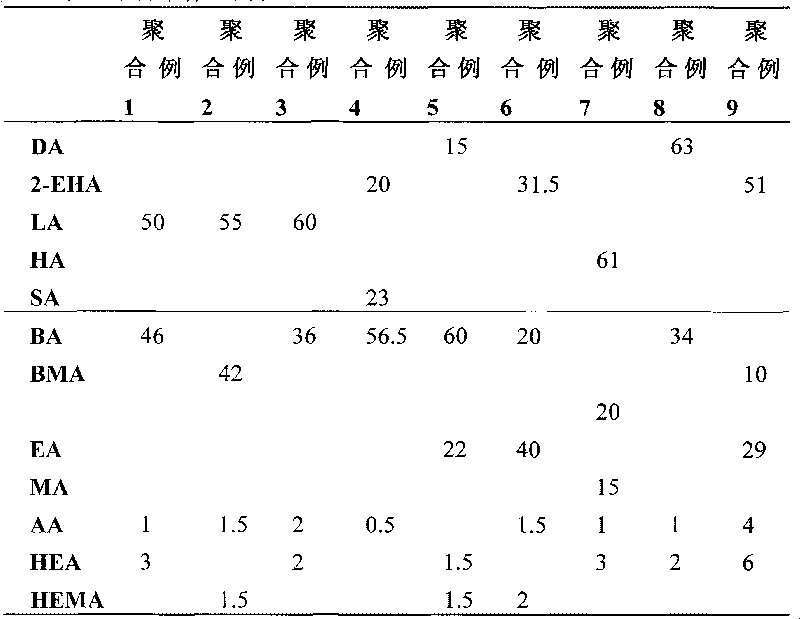

Methyl acrylate pressure-sensitive adhesive for LCD polarizer and preparation method thereof

InactiveCN101693820AStrong initial adhesionHigh peel strengthFilm/foil adhesivesEster polymer adhesivesFunctional monomerCross linker

The invention relates to a methyl acrylate pressure-sensitive adhesive for an LCD polarizer and a preparation method thereof, which belong to the technical field of tackiness agent. The pressure-sensitive adhesive comprises the following three materials with the quality shares: a. weight average molecular weight Mw is 100000-2000000, dispersion degree Mw / Mn is 4-20 acrylate copolymer 100 shares, b. coupling agent, c. cross linker 0-15 shares, the comonomer of prepared acrylate copolymer comprises two parts: 1. (methyl) acrylate monomer : 90%-99.5%, 2. functional monomer: 0.5%-10%, wherein the functional monomer is one or several of (methyl) acroleic acid and (methyl) acroleic acid hydroxy ethyl, (methyl) acroleic acid hydroxypropyl acrylate, itaconic acid, acrylamide, N-hydroxymethyl acrylamide and maleic anhydride. The methyl acrylate pressure-sensitive adhesive does not contain elasticizer or low-molecular-weight acrylate copolymer and the like, can reach the use requirement without cross linker under the condition that the requirement to sticking property is low, and the glue layer has better stress relaxation property, and pressure-sensitive adhesive initial adhesion and stripping strength are both extremely ideal.

Owner:BEIJING UNIV OF CHEM TECH

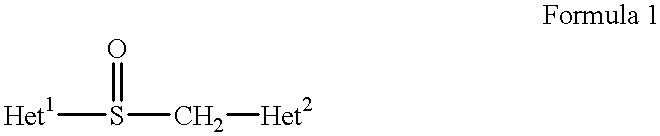

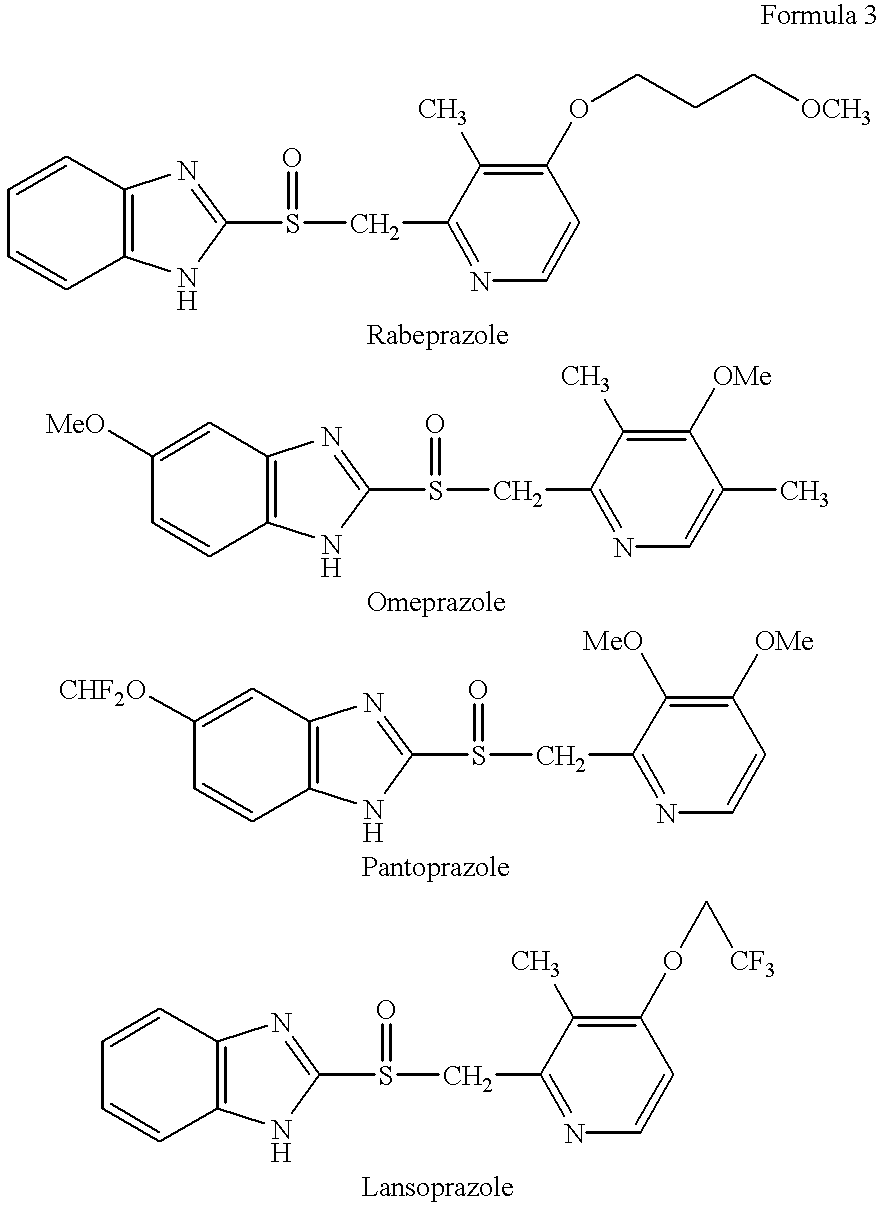

Stabilized compositions containing benzimidazole-type compounds

InactiveUS20020039597A1Improve stabilityLess color changeDigestive systemPill deliveryCrospovidonesMetallole

The present invention provides a chemically stable pharmaceutical preparation of a benzimidazole type compound. That is, the present invention relates to a composition comprising at least one substance selected from sodium carbonate, potassium carbonate, sodium hydroxide, potassium hydroxide, aminoalkyl methaacrylate copolymer E, arginine aspartate, hydroxypropyl cellulose and crospovidone incorporated into a benzimidazole type compound or an alkali metal salt thereof.

Owner:EISIA R&D MANAGEMENT CO LTD

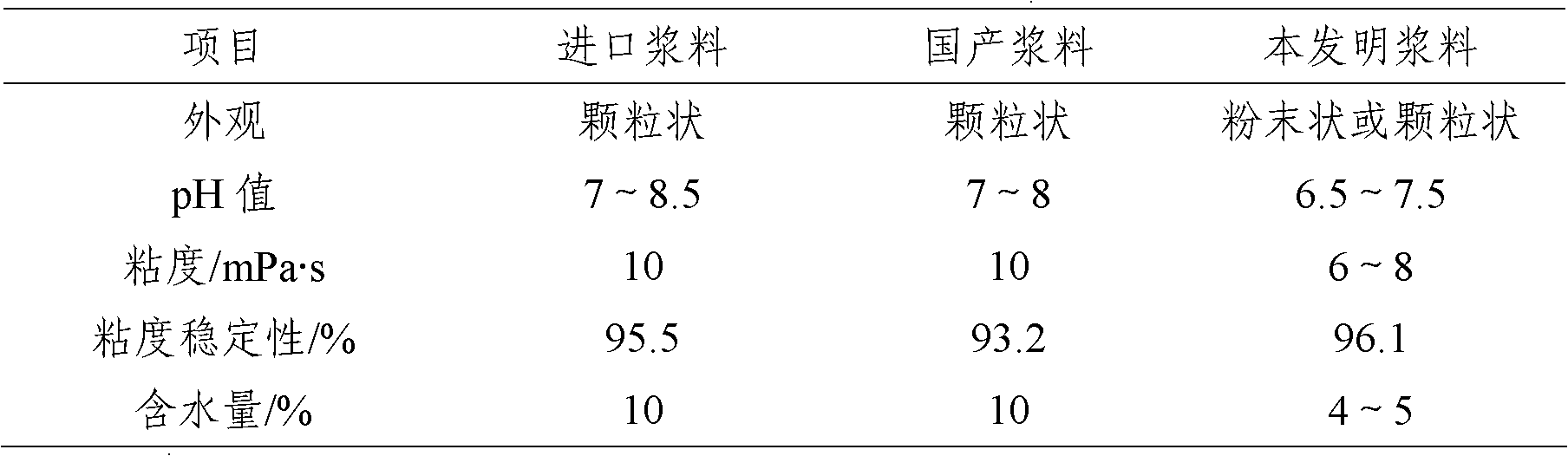

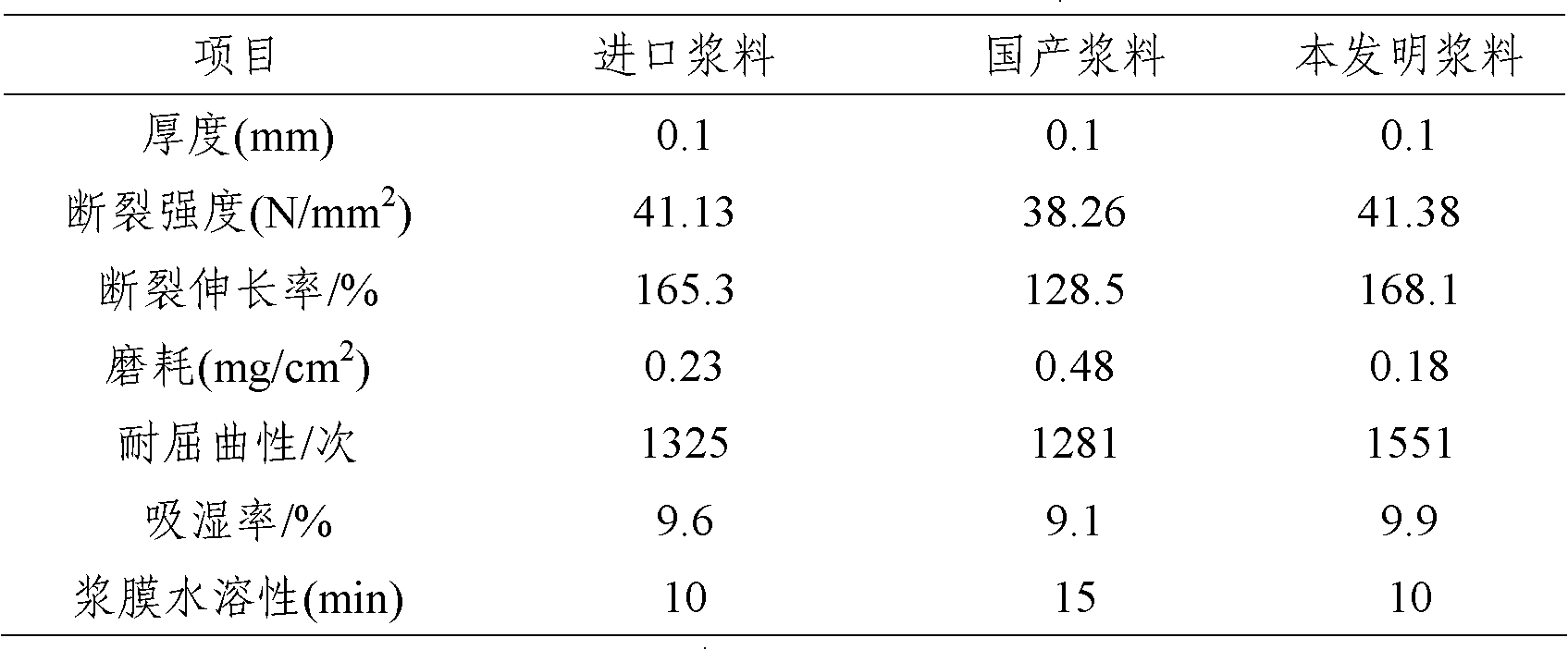

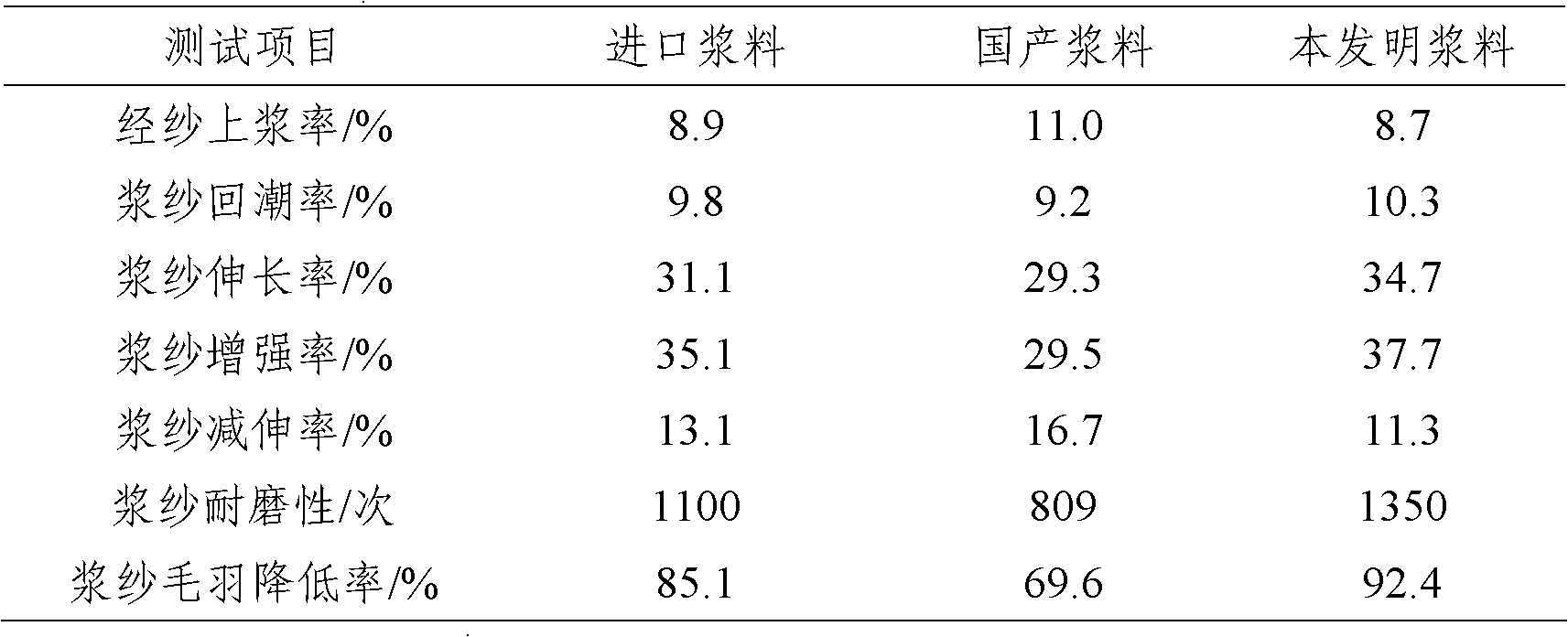

Textile size combination

The invention provides a textile size combination which is prepared by mixing solid acrylate with nano SiO2 compound modified starch in proportion, wherein the solid acrylate is prepared by the following steps: mixing acrylonitrile, methyl acrylate, butyl acrylate, methyl methacrylate, acroleic acid, methacrylic acid with acrylamide in proportion, and enabling the mixed solvent to be subject to internal polymerization under the action of compound initiator and chain transfer agent, neutralizing with sodium hydroxide and drying; and the nano SiO2 compound modified starch is prepared by the following steps: sequentially acidifying, crosslinking and oxidizing starch, introducing surface-modified nano-level SiO2 and carrying out ultrasonic dispersion. The size can obviously improve the warp sizing performance and improve the weaving efficiency, can be completely replace PVA and imported sizes in the same amount or partial amount, and is widely used for the warp sizing of purified cotton, terylens, novel fibers and mixed yarns of various counts.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

Aqueous acrylic acid-modified alkyd resin and preparation method thereof

ActiveCN103554379AImprove water resistanceImprove aging resistanceCoatingsBenzoic acidPolymer science

The invention discloses aqueous acrylic acid-modified alkyd resin and a preparation method thereof. Basic alkyd resin of the aqueous acrylic acid-modified alkyd resin is prepared from an unsaturated fatty acid, benzoic acid, trimethylolpropane, pentaerythritol, maleic anhydride, isophthalic acid, ethylene glycol monobutyl ether and butanol. The aqueous acrylic acid-modified alkyd resin is prepared by adding styrene, methyl methacrylate, butyl acrylate, acrylic acid, a silane coupling agent, benzoyl peroxide, tert-butyl hydroperoxide, ethylene glycol monobutyl ether and a mixing neutralizer into the basic alkyd resin. According to the aqueous acrylic acid-modified alkyd resin and the preparation method thereof, the advantages of alkyd resin and acrylic resin are integrated, and a product has high gloss retention, color retention and weather resistance; a production process is simple, the raw materials are readily available, and the production cost is low; a paint production process is simple, water is used as a diluting agent, and safety and convenience in construction are ensured.

Owner:西北永新涂料有限公司

Method for synthesizing carboxyl butadiene-styrene latex used for cement group water-proofing material

ActiveCN101139413AAvoid pollutionReduce energy consumptionAntifouling/underwater paintsPaints with biocidesSodium bicarbonateEthylenediamine

This invention relates to a synthesis method for carboxylated styrene-butadiene latex used in the cement-based waterproof coating. The preparation method involves 30 to 50 shares of butadiene or isoprene isoprene, 30 to 55 shares of styrene, 0.1 to 5 shares of methyl acrylate , 1 to 5 shares of itaconic acid, 1 to 8 shares of n-butyl acrylate butyl acrylate, 1.2 to 2.8 hares of emulsifier, 0.3 to 1.2 hares of initiator potassium supersulphate, 0.2 to 0.8 shares of molecular weight regulator, 0.01 to 0.5 shares of pH buffer sodium bicarbonate, 0.01 to 5 shares of electrolyte, 0.01 or 5 shares of chelating agent ethylenediamine tetraacetic acid or endrate disodium and 100 to 150 shares of soft water for polymerization. The electrolyte is the combination of potassium phosphate and disodium hydrogen phosphate, with the ratio of 3 to 2: 1; in the polymerization reaction, monomer and a variety of agents are added with intermission. And reaction temperature control adopts the two-step laddered control. When the conversion rate reaches 99.0 percent, the mixture experiences the vacuum degassing treatment. The latex produced by the present invention is of good compatibility with the additives as the paint during the paint preparation. The prepared paint is of excellent fluidity, water retention and machinery stability under the high-cut condition. The improved mortar has the advantages of good permeability, high bond strength and so on.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

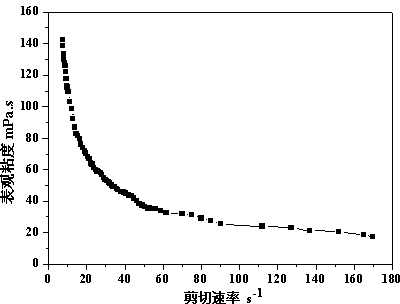

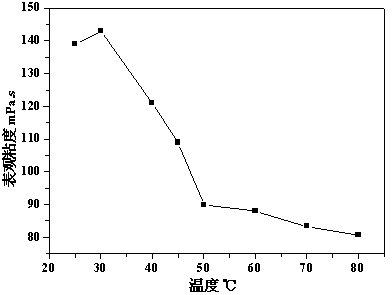

Polyamide and amine hybridized nanosilicon dioxide hyperbranched polymer and preparation method thereof

ActiveCN103865008AImprove temperature resistanceStrong salt resistanceDrilling compositionEthylenediaminePolymer science

The invention discloses a polyamide and amine hybridized nanosilicon dioxide hyperbranched polymer and a preparation method thereof. The preparation method of the polymer comprises the following steps of firstly, modifying the surface of nanosilicon dioxide by using a coupling agent; then, carrying out Michael addition reaction and amidation reaction on the modified nanosilicon dioxide by using ethylenediamine and methyl acrylate; finally, carrying out functional modification by using allyl glycidyl ether to obtain a functional polyamide and amine hybridized nanosilicon dioxide monomer, and initiating polymerization reaction on the functional polyamide and amine hybridized nanosilicon dioxide monomer, acrylamide, acrylic acid and a heat-resistant and salt-tolerant monomer by using a redox initiator or azobis(isobutylamidine) initiator. The hyperbranched polymer has a network structure with a polyamide and amine hybridized nanosilicon dioxide unit as a center, has excellent shear resistance, strong thickening property, heat resistance and salt tolerance, and is wide in adaptability and capable of being used as an oil displacement agent for increasing the recovery rate of raw oil in an oil field environment with a high mineralization degree and a wide temperature range; the preparation method of the polyamide and amine hybridized nanosilicon dioxide hyperbranched polymer is reliable in principle, simple and convenient to operate and wide in application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of polymer for polyacrylonitrile base carbon fiber precursors

ActiveCN101161694ANarrow molecular weightMolecular orderFibre chemical featuresCarbon fibersPolymer science

A method for preparing polymer for PAN precursor, by copolymerizing the water phase suspend using ammonium persulphate-ammonium sulfite or ammonium bisulfite as a primosome, is disclosed. The polyacrylonitrile powder material is obtained by adding the first monomer acrylonitrile, the second monomer crylic acid, methyl acrylate or acrylamide, and the third itaconic acid, or the first monomer crylic acid, the second monomer methyl acrylate or itaconic acid, and inorganic oxidation-reduction primosome without any metallic ion which comprises ammonium persulphate, ammonium sulfite or ammonium bisulfite and acidified deionized water into the polymerization kettle in defined proportions, controlling the temperature and stirring to react for a time, and discharging by removing the residual monomer, washing and drying. The average molecular weight is from 17.5 myriads to 26.1 myriads, and the distribution index of molecular weight is from 2.70 to 2.91; the intension of polyacrylonitrile precursor tested by spinning sample is from 4.58 to 6.61 CN / dtex; and the carbon fiber strength is 3.61-5.06MPa.

Owner:吉林碳谷碳纤维股份有限公司

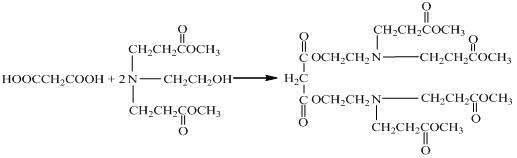

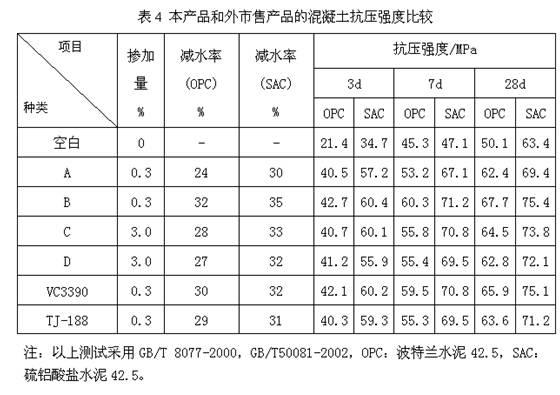

Hyperbranched polymer, hyperbranched type water reducing agent of polycarboxylic acid series and preparation method and application thereof

ActiveCN102002134AGood dispersionAvoid reunionAtom-transfer radical-polymerizationPolyethylene glycol

The invention provides a hyperbranched polymer and a preparation method thereof, wherein the preparation method comprises the steps of taking methyl acrylate, ethanolamine, 2-bromoethanol and propandioic acid as raw materials to synthesize a hyperbranched poly (amine-ester) nuclear molecule comprising a bromine terminal group; taking cuprous bromide and 2,2-bipyridyl as a catalyst and a coordinating agent; respectively grafting acrylic acid and single methyl oxygen radical sealed allyl polyethylene glycol into the hyperbranched poly (amine-ester) comprising bromine terminal group by means of an atom transfer radical polymerization method so as to obtain a hyperbranched polymer. The invention further provides a hyperbranched type water reducing agent of polycarboxylic acid series mainly comprising the hyperbranched polymer and the application thereof, wherein the water reducing agent improves the faults of existing water reducing agent of which the adding quantity is large and the cement adaptability is bad and the like,. and has the advantages that the adding quantity is low, the water reducing efficiency is high, the loss of slump is less, the compatibility to the cement is good, the frozen resistance is strong and the like, the properties of the product are stable, and the water reducing agent has no tendency of layering and precipitating and has no toxicity and pollution after storing for a long time.

Owner:江苏超力建材科技有限公司

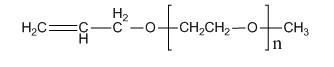

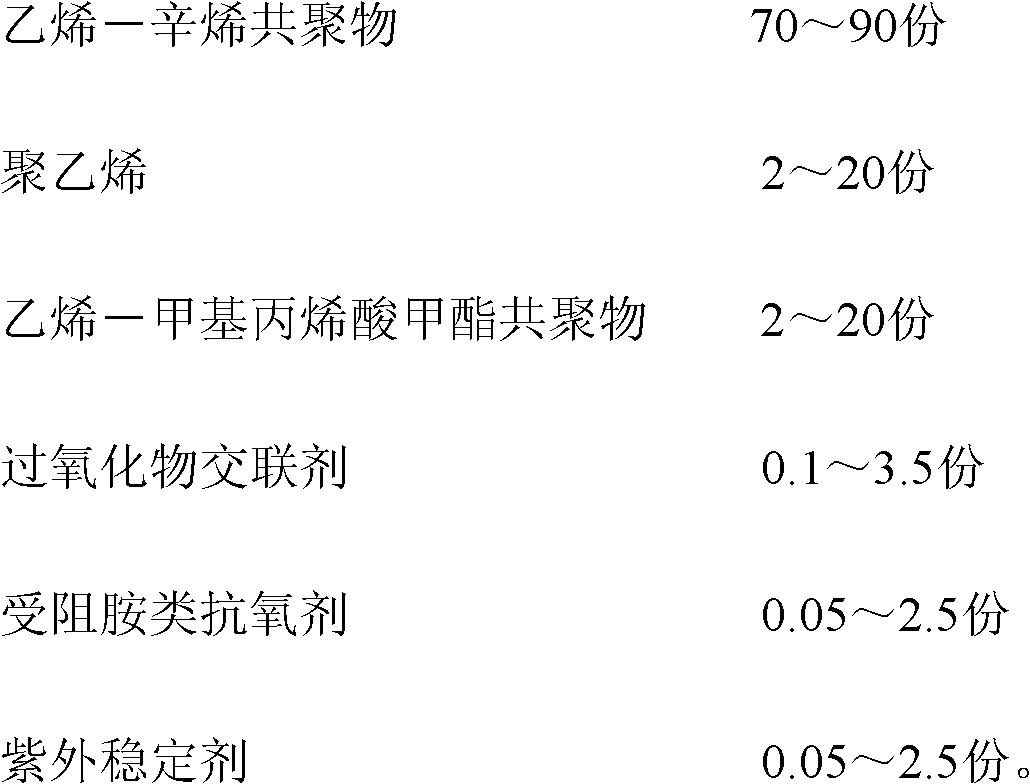

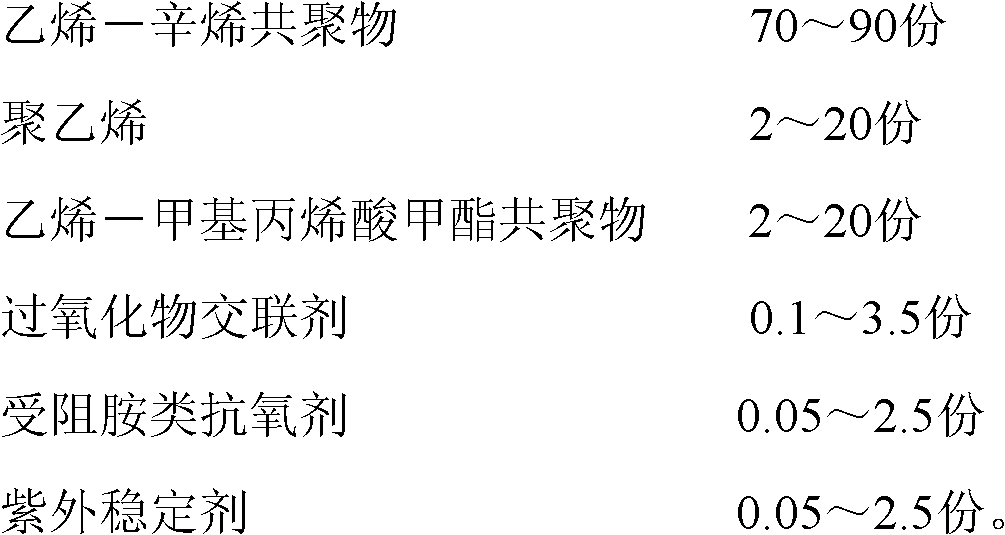

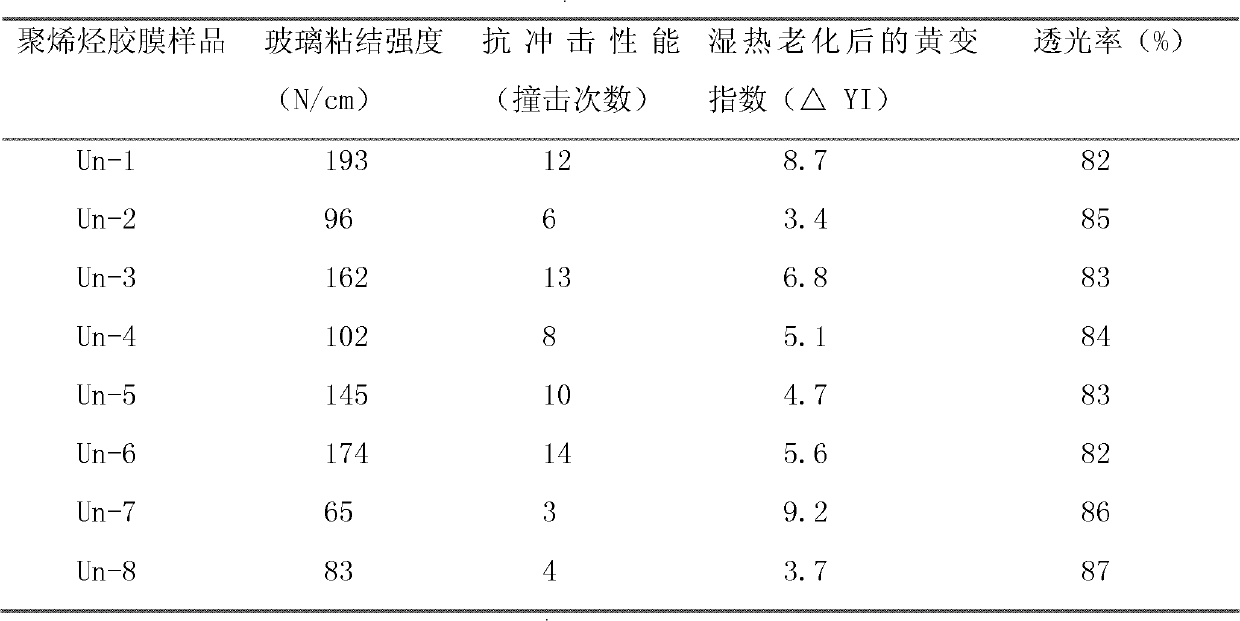

Novel polyolefin packaging glue film composite and application thereof

ActiveCN102585731AExcellent mechanical impact modulusImprove aging resistanceNon-macromolecular adhesive additivesPhotovoltaic energy generationPolyolefinPolymer science

The invention discloses a novel polyolefin packaging glue film composite, which comprises the following components, by weight percentage, 70-90 parts of ethylene-octylene copolymer, 2-20 parts of polyethylene, 2-20 parts of ethylene-methyl acrylate, 0.1-3.5 parts of peroxide cross-linking agents, 0.05-2 parts of hindered amine antioxidants, and 0.05-2 parts of ultraviolet stabilizers. The polyolefin packaging glue film composite has excellent mechanical impact modulus and ageing-resistant performance and strong glass adhesion, simultaneously is convenient in machine-shaping, and can achieve on-line repairing and recycling of solar assemblies.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

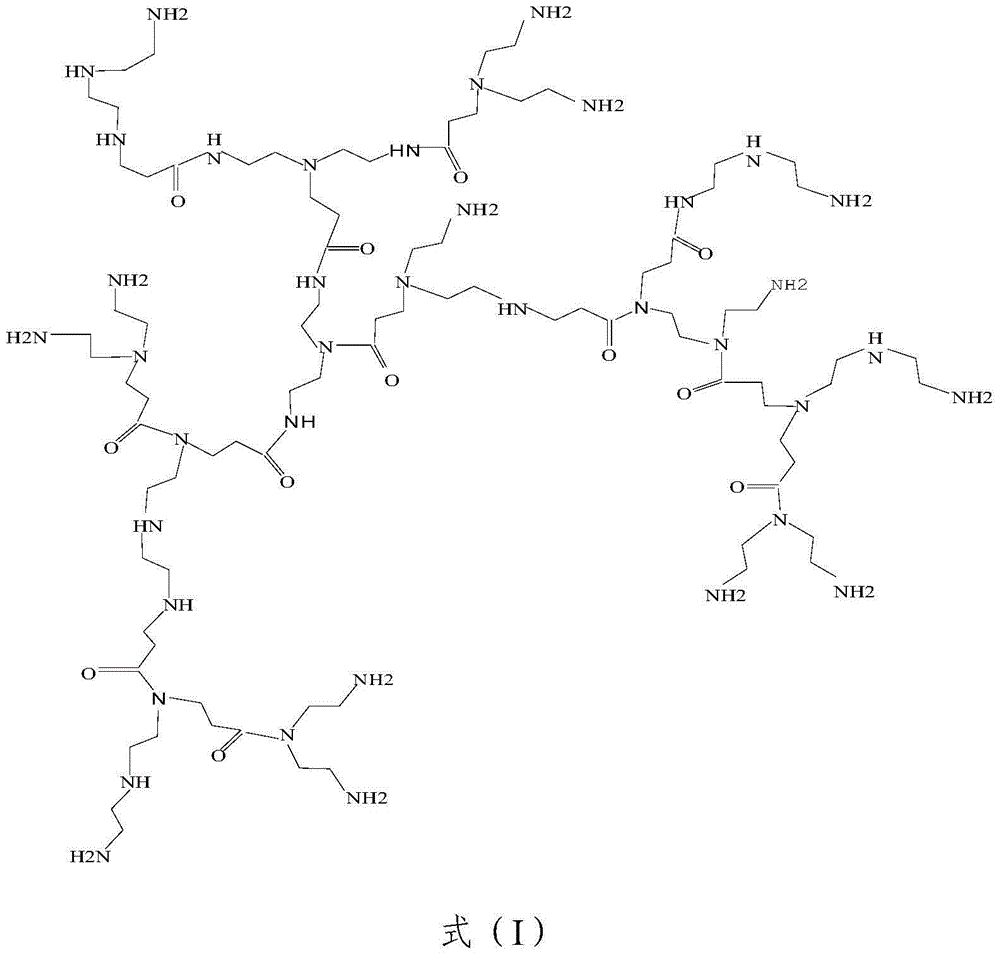

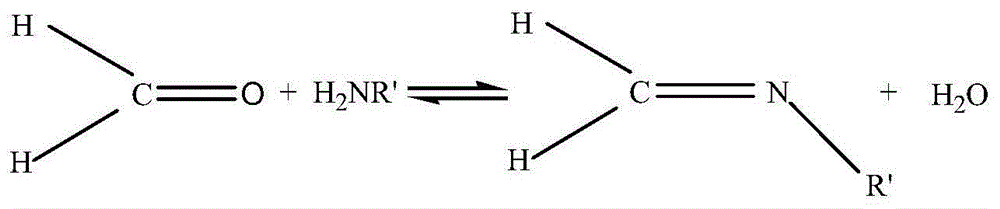

Formaldehyde catching agent and preparation method thereof

ActiveCN104645800ANon-volatileNo irritating smellDispersed particle separationPolyamine CompoundMethyl acrylate

The invention provides a formaldehyde catching agent. An efficient macromolecular type formaldehyde catching agent is synthesized by performing addition polycondensation reaction on a methyl acrylate monomer and a polyamine compound to generate an amino-group-enriched hyperbranched polymer and adding corresponding auxiliaries. According to the catching agent, formaldehyde is caught by using an amino group of the hyperbranched polymer and film forming fixing is implemented by using a carbon framework of an acrylate type substance; modification is realized by the corresponding various auxiliaries, so that the physical performance and the formaldehyde elimination effect are improved. The formaldehyde catching agent has the characteristics of no toxicity, no volatility and no irritating odor, and secondary harm to a human body is avoided; the formaldehyde catching agent can be limitlessly dissolved in water, is mild in property, free from corrosion, easy to add and spray, high in film forming property and durable.

Owner:BEIJING CENT FOR PHYSICAL & CHEM ANALYSIS

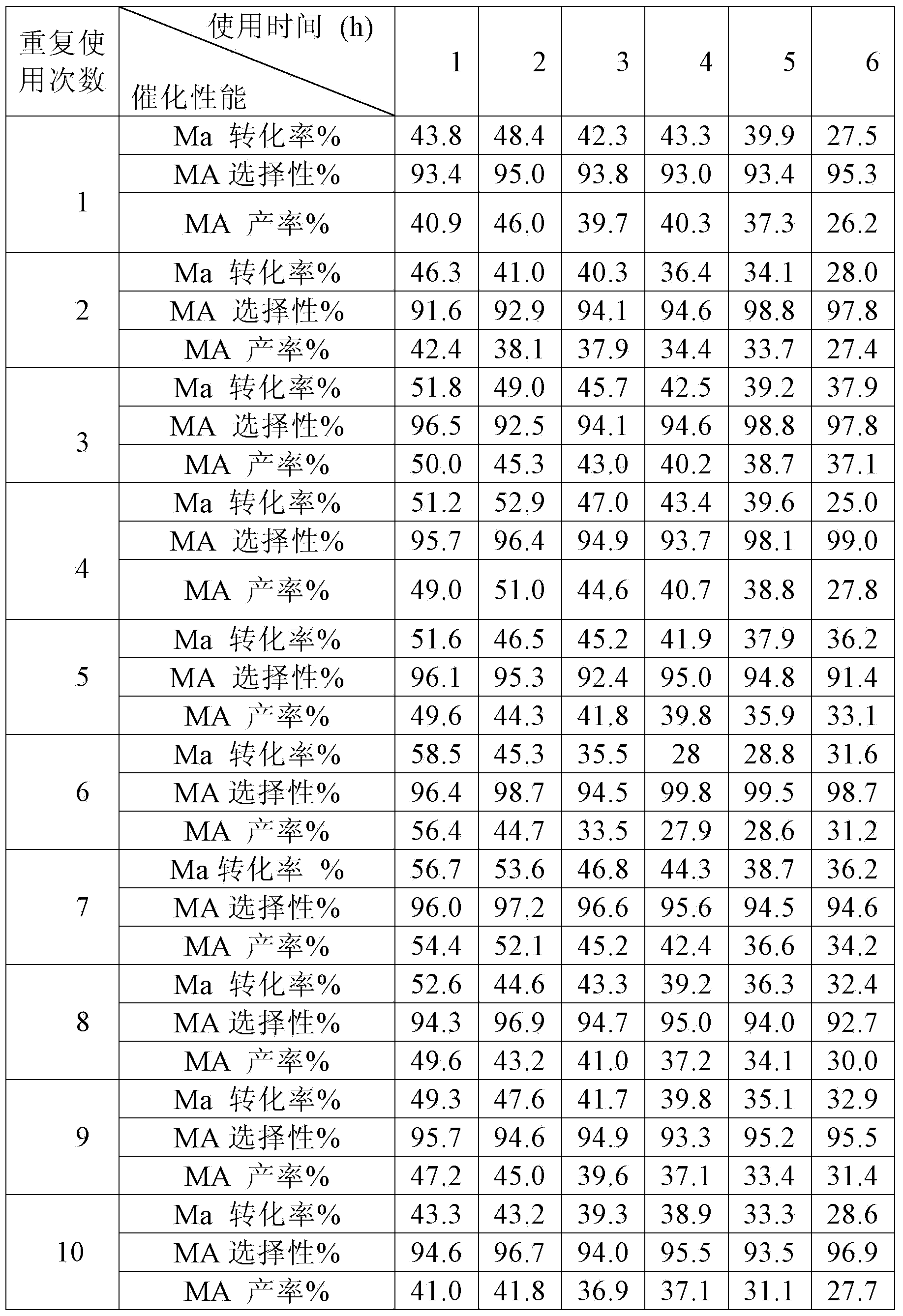

Cs-supported silica-based catalyst and preparation method and application thereof

InactiveCN103801280AImprove stabilityContinuous productionMolecular sieve catalystsOrganic compound preparationGas phaseMethyl acetate

The invention provides a Cs-supported silica-based catalyst. One of SBA-15, SiO2 or silicon dioxide prepared by a silica sol method is used as a carrier, the support is selected from one of Cs salt and a mixture of Cs and modified elements, the catalyst is prepared by a dipping method, the Cs content is 0.1wt%-10wt%, and the content of the modified elements is 0-2wt%. Meanwhile, the invention further provides a preparation method of the Cs-supported silica-based catalyst and application of the Cs-supported silica-based catalyst to the process of preparing methyl acrylate by catalyzing condensation reaction of methyl acetate and a methanal gas phase. The prepared catalyst is capable of realizing the aldol condensation of the methyl acetate and the methanal gas phase under proper conditions so as to prepare the methyl acrylate, wherein the activity of the Cs / SBA-15 catalyst is higher than that of other Cs-supported silica-based catalysts, and the selectivity on the methyl acrylate is good.

Owner:SHANGHAI HUAYI GRP CO

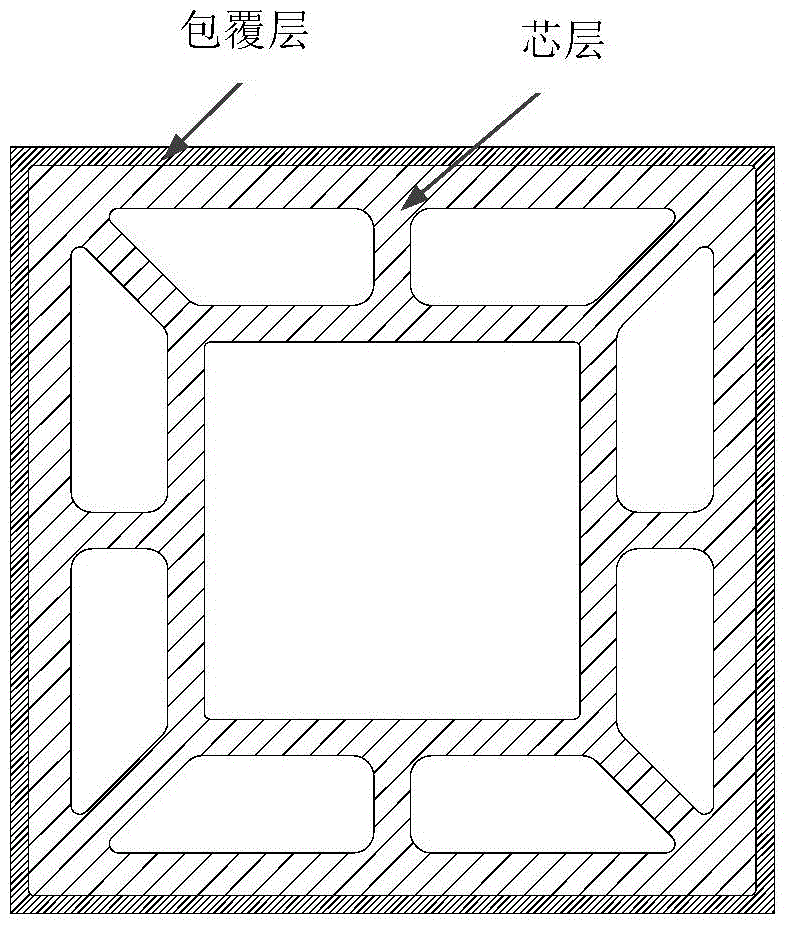

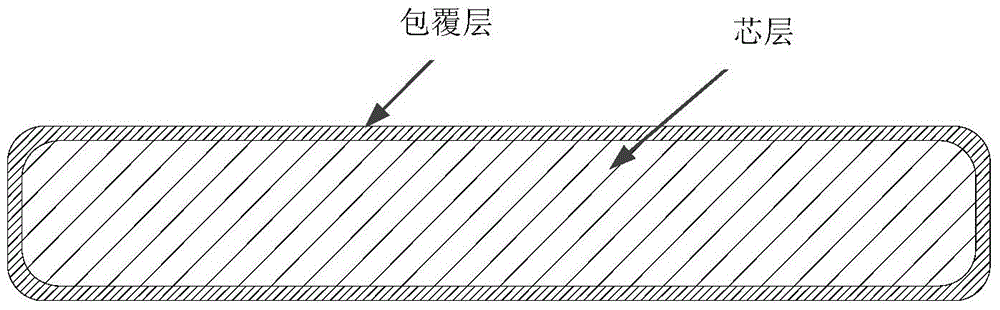

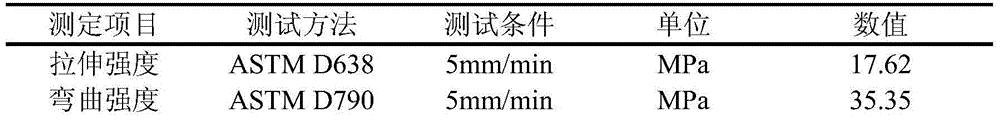

High strength wood-plastic coated coextruded composite material and preparation method thereof

InactiveCN105644074APlay the role of "filling"Improve mechanical propertiesSynthetic resin layered productsLaminationFiberDiameter ratio

The invention provides a high strength wood-plastic coated coextruded composite material. The material is composed of a core layer and a coating layer. The coating layer coats the surface of the core layer through a co-extrusion technology, biomass powder in the core layer is improved to a biomass fiber material, because of a large length-diameter ratio, the biomass fiber material not only plays a "filling" role in a wood-plastic composite material, but also plays a "reinforcing" role, greatly improves the mechanical properties of the composite material, especially improves the impact resistance, creep resistance and other properties, thereby broadening the application scope of the wood-plastic composite material. In addition, the coating layer involved in the invention preferably contains ethylene-methyl acrylate copolymer resin, ethylene-vinyl alcohol copolymer resin and high strength fiber, thus being conducive to further enhancing the mechanical properties of the composite material and the binding force with the core layer.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

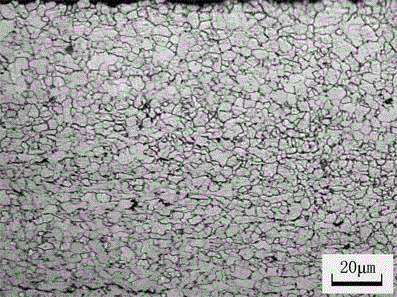

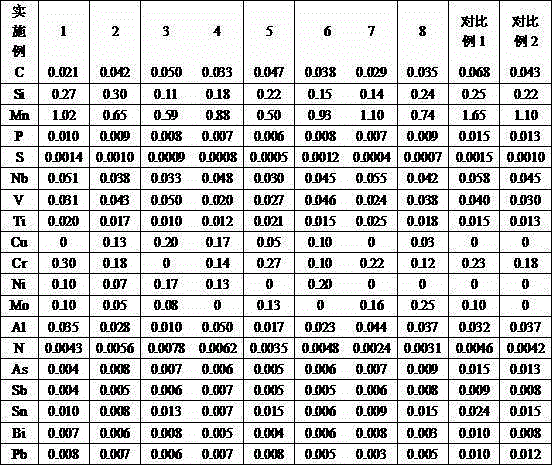

Pipeline steel excellent in acid corrosion resistance on seabed and production method

The invention discloses pipeline steel excellent in acid corrosion resistance on the seabed. The pipeline steel comprises, by weight, 0.020-0.050% of C, 0.10-0.30% of Si, 0.50-1.10% of Mn, 0.012% of P or less, 0.0015% of S or less, 0-0.20% of Cu, 0-0.30% of Cr, 0-0.20% of Ni, 0-0.25% of Mo, 0.030-0.055% of Nb, 0.020-0.050% of V, 0.010-0.025% of Ti, 0.010-0.050% of Al and 0.008% of N or less. A production method comprises the steps of heating after continuous casting and blank forming, rough rolling, precise rolling, cooling, reeling and cooling to indoor temperature. By means of the pipeline steel and the production method, an ideal complex-phase structure containing ultra-fine grain polygonal ferrite and a small number of methyl acrylate (MA) components which are distributed dispersively can be obtained, the Rt0.5 is equal to or higher than 485 MPa, the Rm is equal to or higher than 570 MPa, -20 DEG C KV2 is equal to or higher than 250 J, and -15 DEG C DWTT SA is equal to or higher than 85%. A hydrogen induced crack j (HICj) test and a sulfide stress corrosion cracking (SSCC) test indicate that no fracture or crack occurs.

Owner:武汉钢铁有限公司

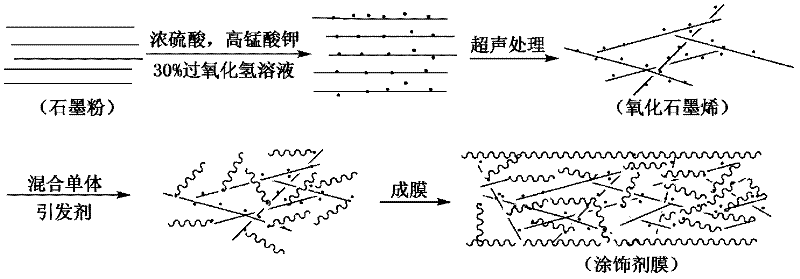

Preparation method of acrylic resin/graphene oxide nanometer composite leather finishing agent

The invention relates to a preparation method for an acrylic resin / graphene oxide nanometer composite leather finishing agent. In the preparation method, a nanometer graphene oxide suspension liquid is formed through peeling and dispersing; and then the acrylic resin / graphene oxide nanometer composite acrylic resin finishing agent is prepared through in-situ polymerization. The preparation methodcomprises the following specific steps: carrying out oxidization and ultrasonic stripping on natural graphite powder to prepare graphene oxide; adding graphene oxide to a mixed monomer of methyl acrylate, ethyl acrylate, butyl acrylate, acrylic acid and hydroxyethyl acrylate under the action of ultrasonic waves; and carrying out in-situ free radical copolymerization reaction under the action of an initiator ammonium persulfate to obtain the acrylic resin / graphene oxide nanometer composite leather finishing agent. The preparation method has the characteristics that the acrylic resin / graphene oxide nanometer composite leather finishing agent with excellent film-forming hand feel, strength and anti-static performances and no heat bonding and cold brittleness defects is prepared by using the specific laminated structure and performance of graphene oxide.

Owner:JIANGSU BESCON PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com