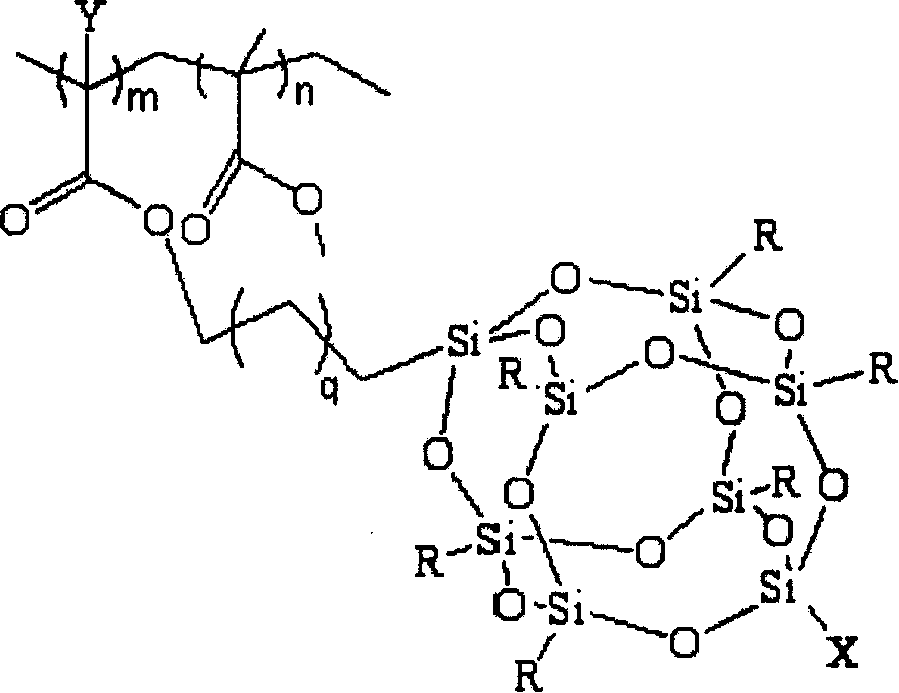

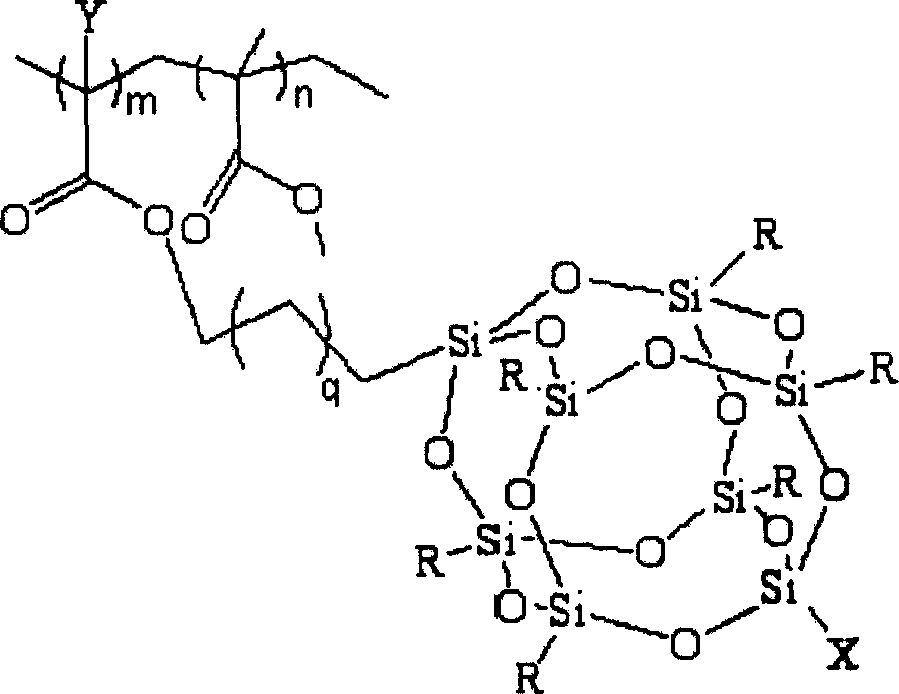

Fluoride POSS acrylic ester block multipolymer resin and its synthesis

A technology of block copolymer and acrylate, applied in the field of acrylate copolymer resin and its synthesis, can solve the problems of increased water absorption on the surface of the coating, environmental pollution, and high cost, and achieves improved production efficiency, improved hydrophobicity, and improved The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

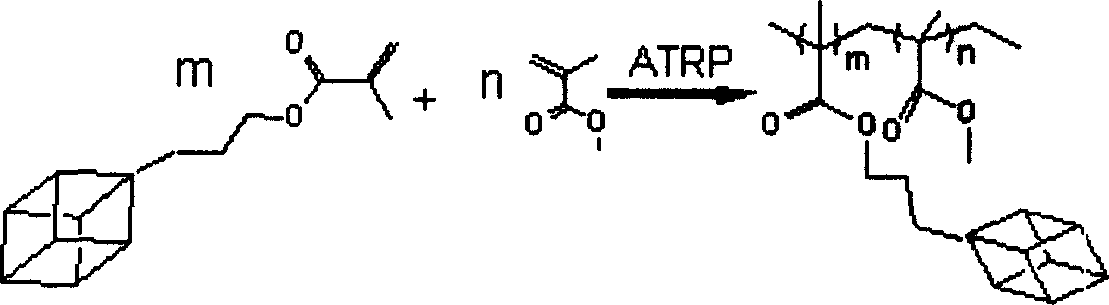

Method used

Image

Examples

Embodiment 1

[0032] Step 1. Put the weighed 0.144g of CuBr and 0.346g of PMDETA into a two-neck bottle, seal it, vacuumize it, and blow nitrogen gas. This replacement process is carried out 3 times.

[0033]Step 2. Dissolve 0.195g of initiator EBriB in 100g of monomer MMA, introduce nitrogen gas under the liquid surface of the monomer to bubble and deoxygenate, add it to the two-necked bottle together after 1 minute, vacuumize and ventilate nitrogen, and the replacement process is carried out 3 times. The ratio of the amount of substances in the system is EbriB:CuBr:PMDETA:MMA=1:1:2:1000. Then put the two-necked bottle in a silicone oil bath at 85°C and react for 24 hours.

[0034] Step 3, dilute the reacted solution with 100g of tetrahydrofuran, remove excess catalyst and initiator by alumina adsorption, then precipitate with methanol, filter, and vacuum dry at room temperature to constant weight to obtain pre Polymer;

[0035] Step 4, take another two-necked bottle, add 10g tetrahydro...

Embodiment 2

[0040] Step 1. Put the weighed 0.288g of CuBr and 0.692g of PMDETA into a two-neck bottle, seal it, vacuumize it, and ventilate it with nitrogen. The replacement process is carried out 3 times.

[0041] Step 2. Dissolve 0.195g of initiator EbriB in 100g of monomer MMA, introduce nitrogen gas under the liquid surface of the monomer to bubble and deoxygenate, add it to the two-necked bottle together after 1 minute, vacuumize and ventilate nitrogen, and the replacement process is carried out 3 times. The ratio of the amount of substances in the system is EbriB:CuBr:PMDETA:MMA=1:2:6:1500. Then put the two-necked bottle in a silicone oil bath at 80°C and react for 20 hours.

[0042] Step 3, dilute the reacted solution with 100g of tetrahydrofuran, remove excess catalyst and initiator by alumina adsorption, then precipitate with methanol, filter, vacuum dry at room temperature to constant weight, and obtain methyl methacrylate with Br-terminated Ester prepolymer;

[0043] Step 4,...

Embodiment 3

[0048] Step 1. Weigh 0.288g of CuBr and 0.692g of PMDETA, put them into a two-necked bottle, put them into a two-necked bottle, seal it, vacuumize it, and ventilate nitrogen. The replacement process is carried out 3 times.

[0049] Step 2. Dissolve 0.195g of initiator EbriB in 100g of monomer MMA, introduce nitrogen gas under the liquid surface of the monomer to bubble and deoxygenate, add it to the two-necked bottle together after 1 minute, vacuumize and ventilate nitrogen, and the replacement process is carried out 3 times. The ratio of the amount of substances in the system is EbriB:CuBr:PMDETA:MMA=1:3:8:1000. Put the two-neck bottle in a microwave oven, set the power to 300W, and react for 4h.

[0050] Step 3, dilute the reacted solution with 100g of tetrahydrofuran, remove excess catalyst and initiator by alumina adsorption, then precipitate with methanol, filter, vacuum dry at room temperature to constant weight, and obtain methyl methacrylate with Br-terminated Ester ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com