Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Play the role of filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

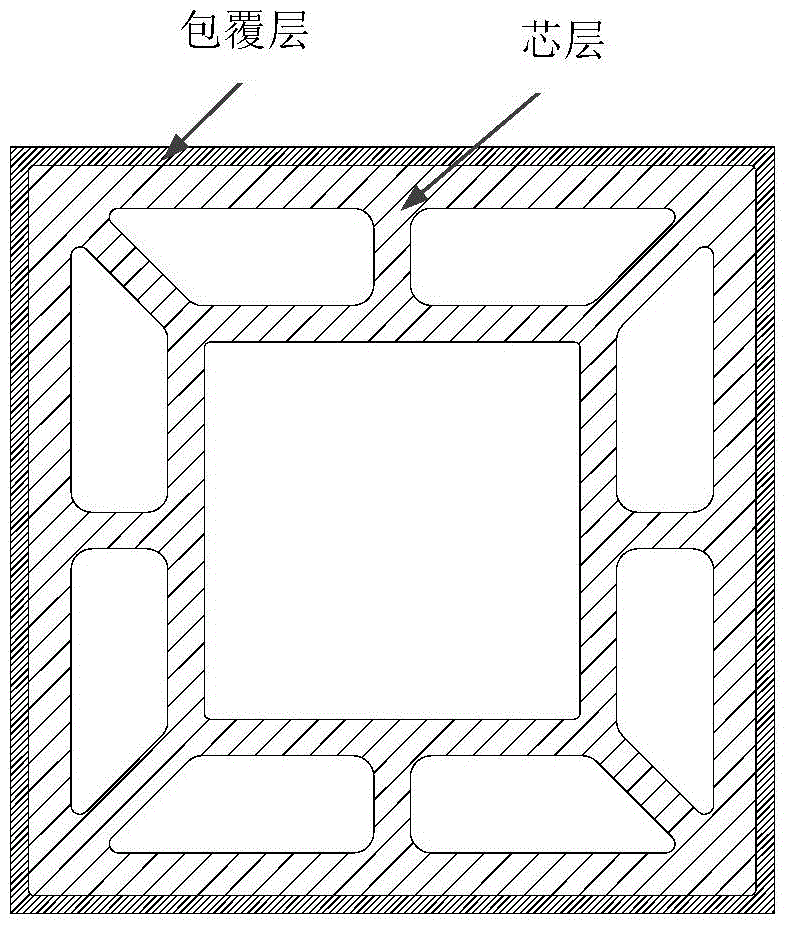

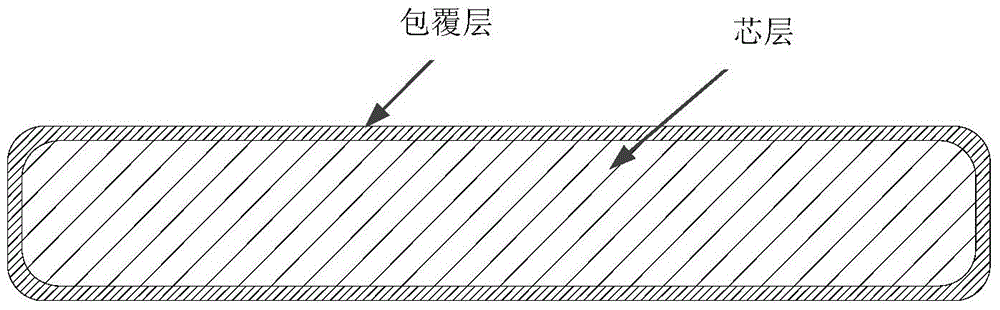

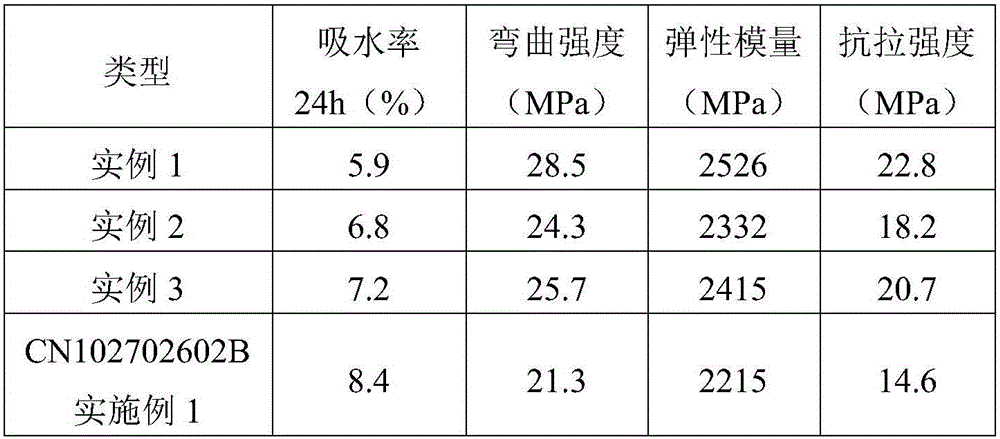

High strength wood-plastic coated coextruded composite material and preparation method thereof

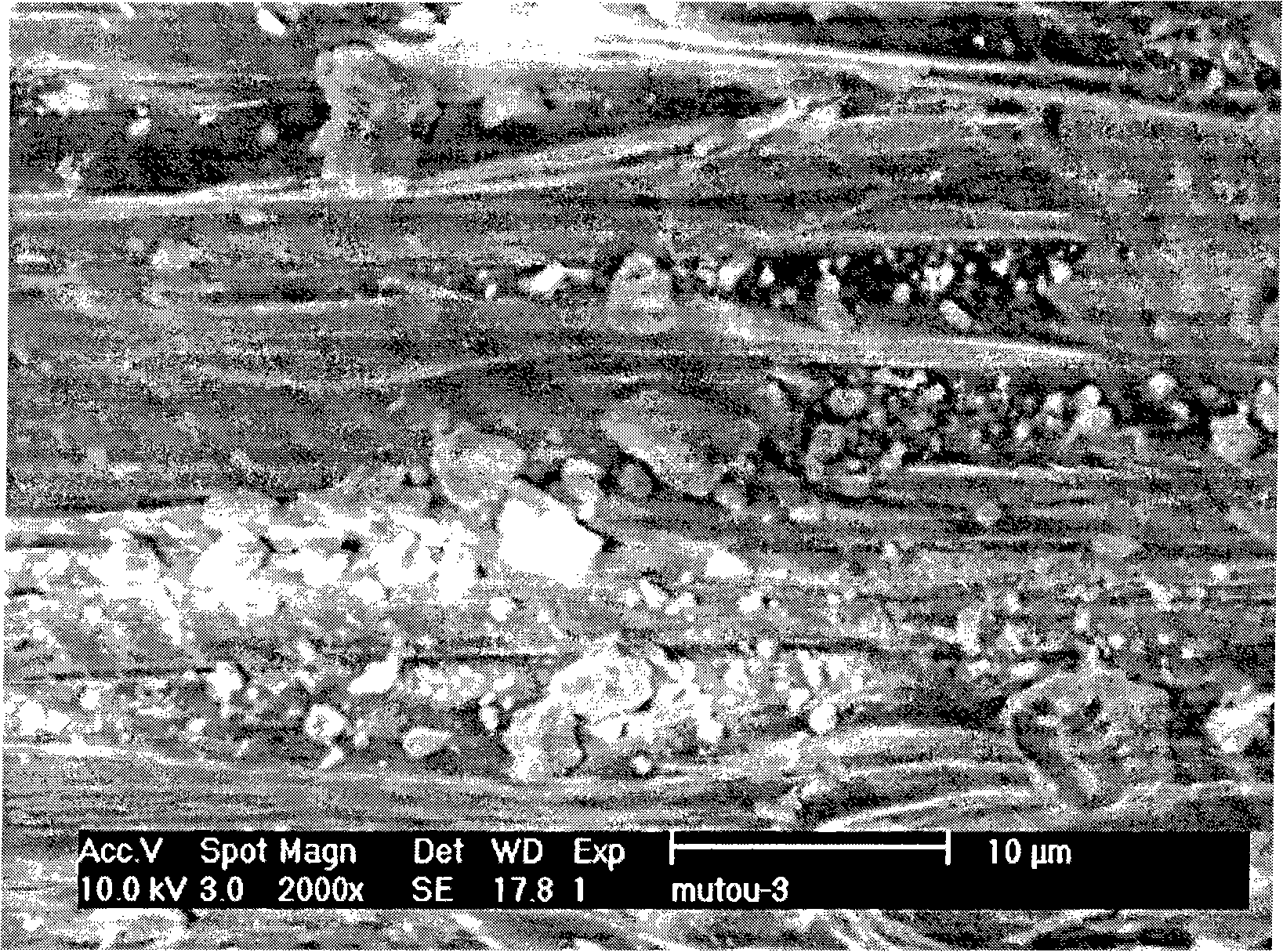

InactiveCN105644074APlay the role of "filling"Improve mechanical propertiesSynthetic resin layered productsLaminationFiberDiameter ratio

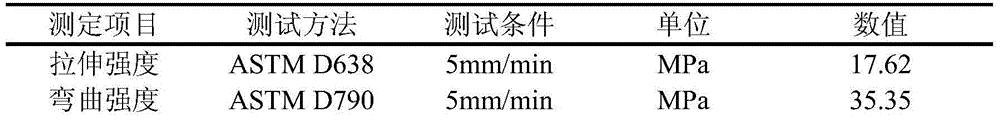

The invention provides a high strength wood-plastic coated coextruded composite material. The material is composed of a core layer and a coating layer. The coating layer coats the surface of the core layer through a co-extrusion technology, biomass powder in the core layer is improved to a biomass fiber material, because of a large length-diameter ratio, the biomass fiber material not only plays a "filling" role in a wood-plastic composite material, but also plays a "reinforcing" role, greatly improves the mechanical properties of the composite material, especially improves the impact resistance, creep resistance and other properties, thereby broadening the application scope of the wood-plastic composite material. In addition, the coating layer involved in the invention preferably contains ethylene-methyl acrylate copolymer resin, ethylene-vinyl alcohol copolymer resin and high strength fiber, thus being conducive to further enhancing the mechanical properties of the composite material and the binding force with the core layer.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

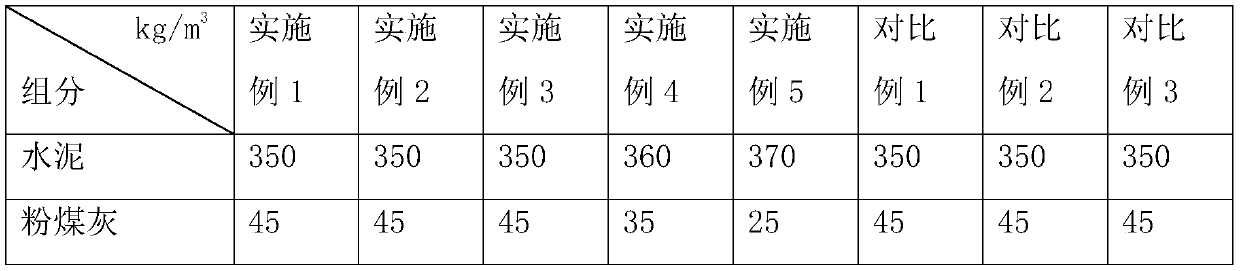

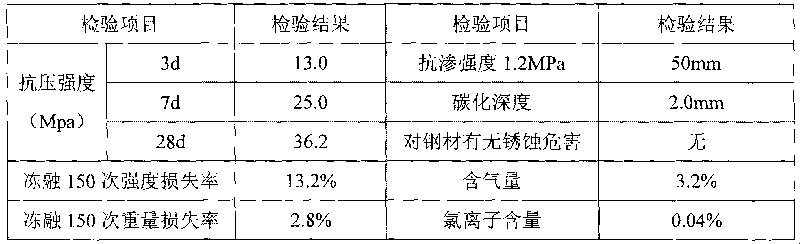

Anti-seepage, anti-freeze-thaw self-compacting concrete and preparation method thereof

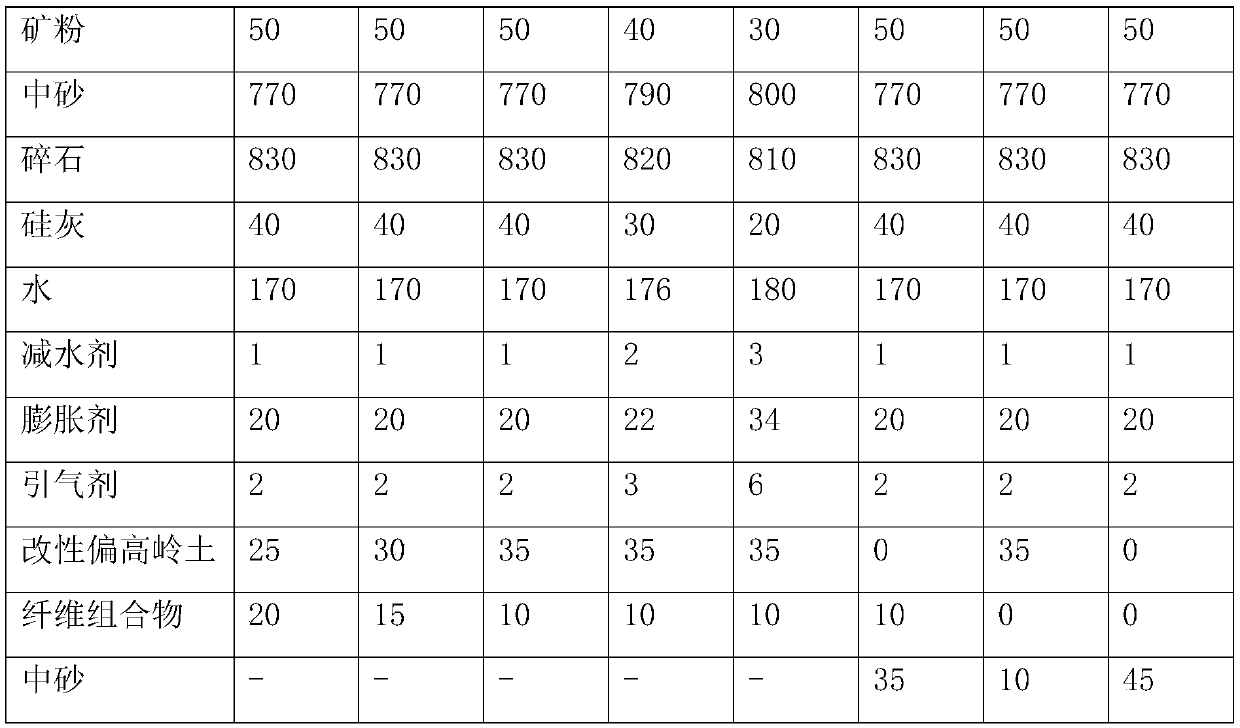

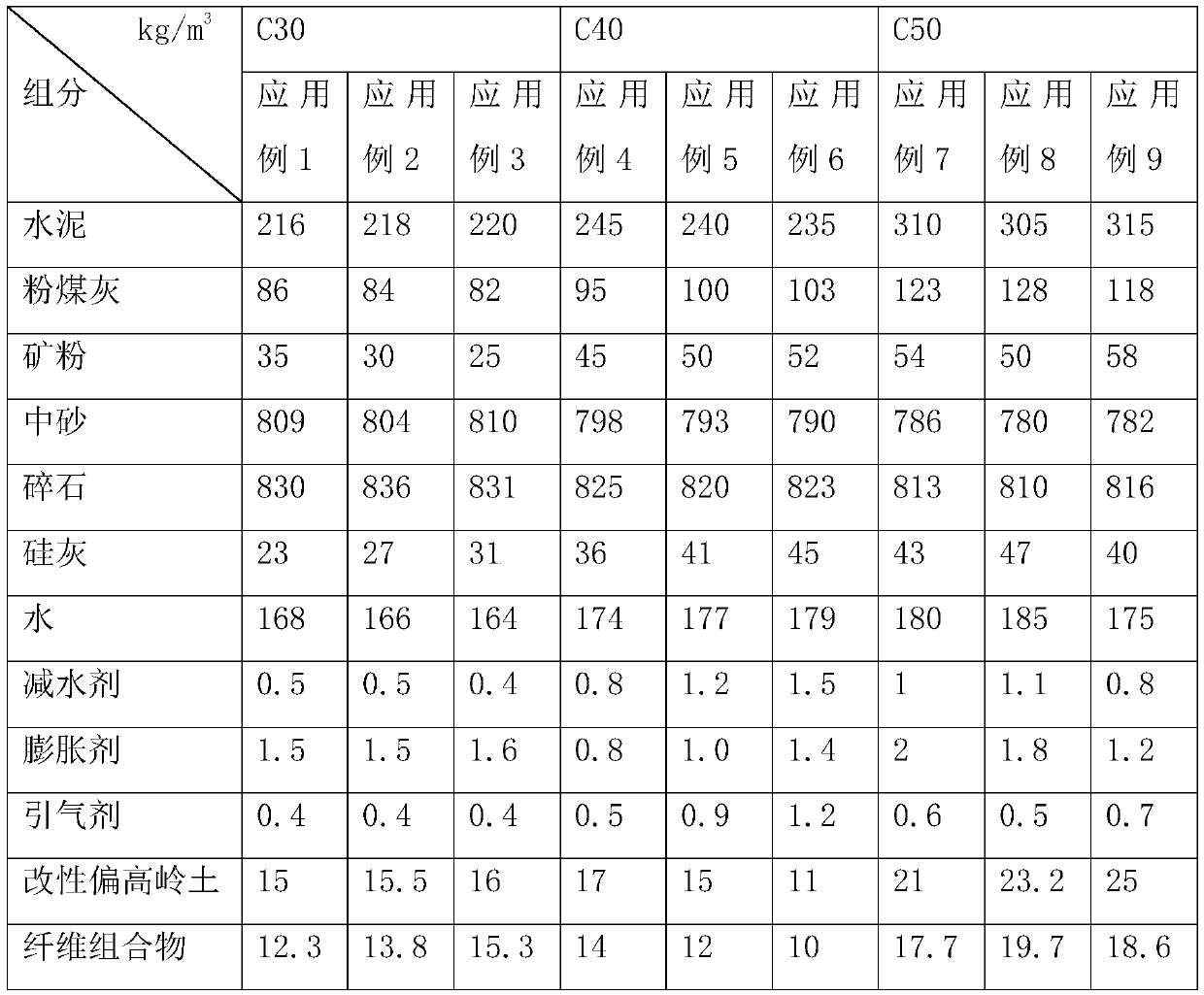

The invention discloses anti-seepage, anti-freeze-thaw self-compacting concrete and a preparation method thereof. The anti-seepage, anti-freeze-thaw self-compacting concrete comprises the following components in parts by weight: 350-370 parts of cement, 25-45 parts of fly ash, 25-35 parts of modified metakaolin, 30-50 parts of mineral powder, 770-800 parts of medium sand, 810-830 parts of crushedstone, 20-40 parts of silica fume, 170-180 parts of water, 1-3 parts of a water reducing agent, 20-34 parts of an expansion agent, 2-6 parts of an air entraining agent, and 10-20 parts of a fiber composition, wherein the fiber composition is prepared by mixing a modified polyester fiber, a basalt fiber and a polyacrylonitrile fiber in a mass ratio of 1:0.6-0.9:0.3-0.6. The anti-seepage, anti-freeze-thaw self-compacting concrete has the advantages of good workability and fluidity, and excellent anti-seepage performance and anti-freezing performance.

Owner:西安新意达建筑制品有限公司

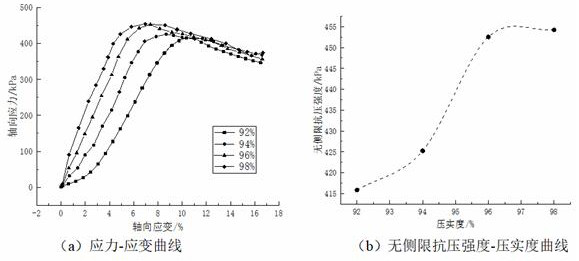

Vitamin E microcapsule preparation method

InactiveCN101444495AReduce lossesPlay the packageOrganic active ingredientsAntinoxious agentsFood additiveWater content

A vitamin E microcapsule preparation method belongs to the technical field of preparation of controlled-release microcapsule for food additives and bioactive substances. The vitamin E microcapsule preparation method can improve the stability of vitamin E and amplify the application range. The method comprises the following steps: selecting chitosan and maltodextrin as wall material, selecting soybean lecithin (P powder) and Tween-80 as the composite emulsifying agent; and synthesizing vitamin E microcapsule by spray drying. The vitamin E microcapsule has embedding rate up to 92.45%, retention rate up to 91.73%, and water content lower than 3%, and has wide application prospect in the fields of bread or snack products, beverages, biscuits, health products and nutrient fortified food, etc. The method has the advantage of low cost and simple process, can meet the environmental protection and practical requirement.

Owner:JIANGNAN UNIV

Method for preparing micro-encapsulation glucose oxidase

InactiveCN101250515APorousStrong adsorption capacityPre-baking dough treatmentOn/in organic carrierReticular formationGlucose polymers

The invention relates to a method for preparing microencapsulation glucose oxidase, which belongs to the technical field of food processing. The invention aims at improving the quality of flour to researche a method for preparing new flour modifying agent, namely, the microencapsulation glucose oxidase, chitose-calcium alginate-glucose oxidase microcapsule which is obtained through the method is copolymer hydrogel which is obtained through double cross-linking, both amidogen and carboxyl group are fixed, and the whole system is a reticular formation. The method controls the catalytic speed of the microencapsulation glucose oxidase through adjusting the molecular weight and the degree of deacetylation of microcapsule exine chitose, thereby the method is beneficial for oxidation-linking of gluten protein and for increasing the quality of the flour and flour products, simultaneously, the glucose oxidase after microencapsulation avoids the contact between enzyme and the flour and improves storage and the stability, and the microencapsulation glucose oxidase is excellent flour modifying agent and accords with practical production and application. The process of the method is simple, safe and convenient, and accords with the requirements of environmental protection and utility.

Owner:JIANGNAN UNIV +1

Preparation method of high thermal conductivity nano cellulose based electrical insulating composite film

InactiveCN107099045APlay the role of fillingImprove insulation performanceHeat-exchange elementsComposite filmHigh pressure

The invention discloses a preparation method of a high thermal conductivity of nano cellulose based electrical insulating composite film, nano cellulose is prepared by a technique of combination of TEMPO oxidation and high pressure homogenization, and the thermal conductivity nano cellulose based insulating composite film is prepared by adding a thermal-conducting insulating filler into nano cellulose suspension by a casting forming method. The insulation performance and the dielectric strength of the thermal conductivity nano cellulose based insulating composite film are improved by addition of the thermal-conducting insulating filler, and the thermal-conducting insulating filler is filled in the thermal conductivity nano cellulose based insulating composite film to form heat transfer network chains to provide channels for heat transfer, so that the thermal conductivity nano cellulose based insulating composite film exhibits good thermal conductivity. Compared with conventional insulating films, the thermal conductivity nano cellulose based insulating composite film has the advantage of high thermal conductivity coefficient, and can be used as internal insulation and packaging materials in electronic devices and components to improve heat dispersion performance.

Owner:NANJING FORESTRY UNIV

Inorganic composite plate and preparation and use thereof

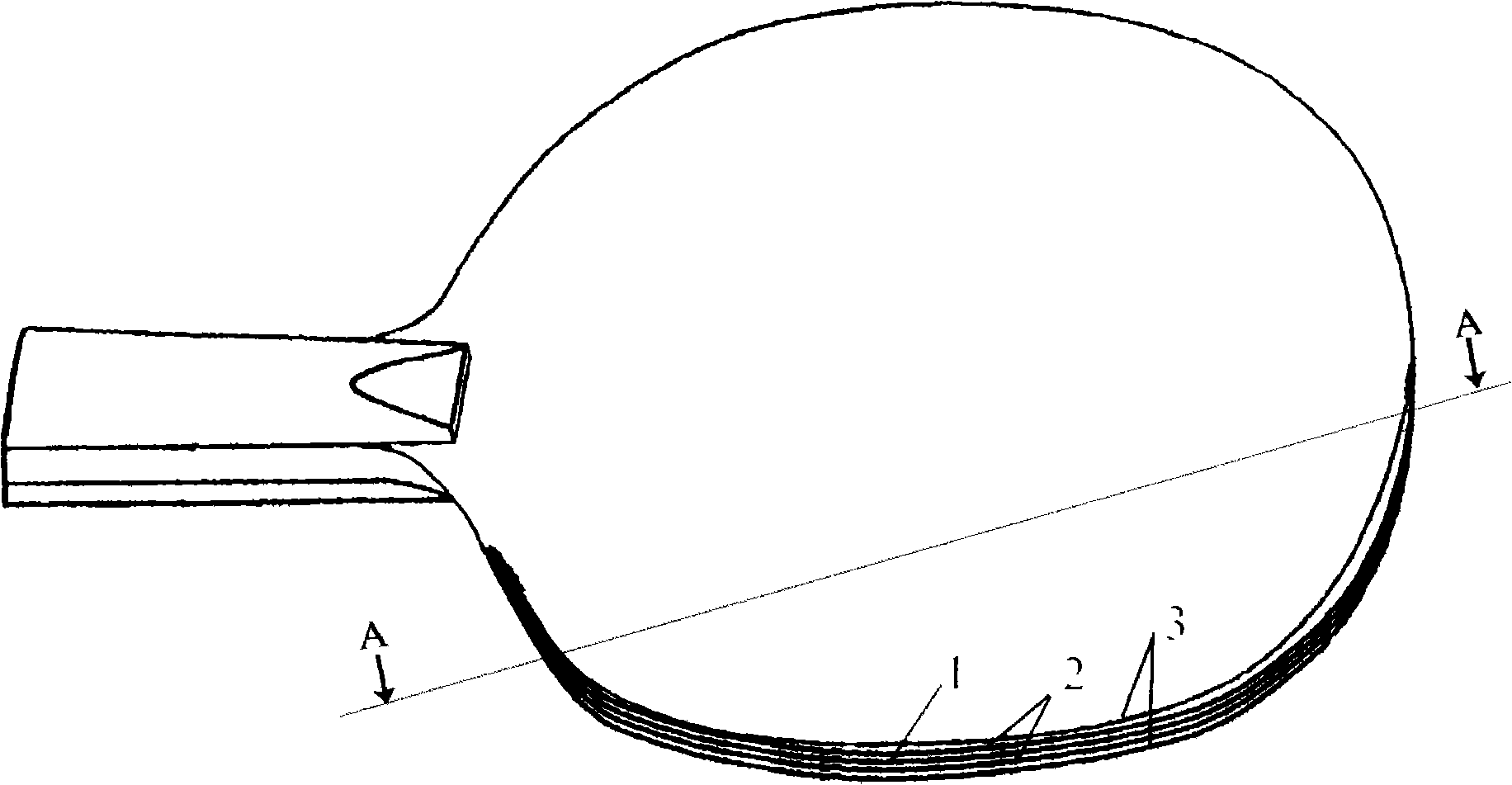

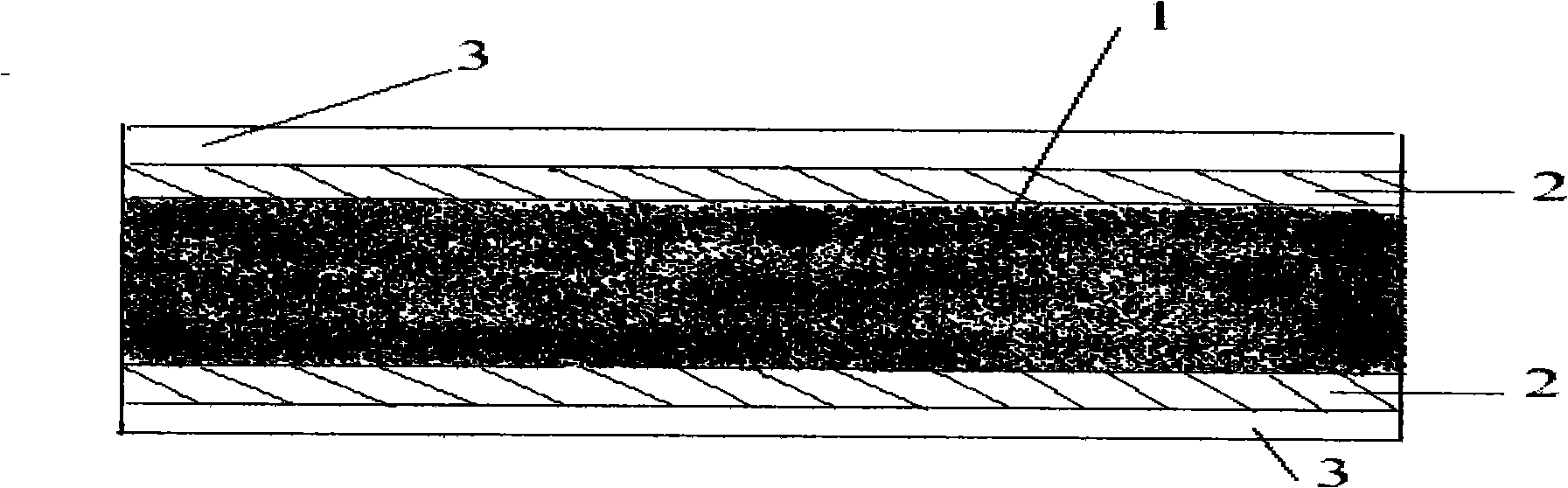

InactiveCN101279458AIncrease elasticityImprove mechanical propertiesWood treatment detailsRacket sportsRoom temperatureComposite plate

The invention provides a method for preparing inorganic composite plates. The invention includes the steps that: the plates are put into alkaline cooking liquor with the temperature ranging from 100 to 130 DEG C and taken out after being steamed and cooked for 1.5 to 3 hours; the processed plates are put into clear water for an immersion lasting for 24 to 48 hours at room temperature and dried in vacuum to reach the water content ranging from 10 percent to 15 percent so as to obtain the delignification plates; the delignification plates are then put into silicasol solution with a quality percentage concentration ranging from 10 percent to 20 percent for an immersion lasting for 20 to 26 hours and takes out to rest for 20 to 26 hours; the process is repeated for 3 to 5 times and finally the delignification plates are dried in vacuum at the temperature ranging from 60 to 110 DEG C till the water content of plates reaches 10 to 15 percent. The inorganic composite plates prepared according to the preparation method can be used for making bottom plates of table tennis bats which have the advantages of adjustable service performance, stable ball control, good rebound force, etc.

Owner:SOUTH CHINA UNIV OF TECH

Biomass granular fuel and processing method thereof

The invention discloses a biomass granular fuel. Raw materials comprises the following components in proportions by weight: 4 to 6 parts of shaving, 12 to 18 parts of wood chip, 0.1 to 0.4 part of swelling agent and 0.1 to 0.4 part of flame accelerator, wherein the water content of the shaving is 4 to 6 percent; the wood chip is a mixture of a wood chip of which the water content is 25 to 35 percent and a wood chip of which the water content is 8 to 10 percent according to a weight ratio of 1 to 2. The invention also provides a processing method of the biomass granular fuel. The processing method comprises pulverization, primary mixing, secondary mixing, tertiary mixing and granulation. The biomass granular fuel which is provided by the invention and is processed by utilizing the production waste of a timber is more convenient to use and transport; the resource utilization rate is improved; the heat value of the biomass granular fuel can reach 4500 to 4700 kilocalories per kilogram; a liquid fuel is added into the raw materials in a spraying manner as the flame accelerator; sodium hydrogen carbonate and ammonium hydrogen carbonate are used as the swelling agent; the combustion performance of the biomass granular fuel is further improved; according to the biomass granular fuel and the processing method thereof, the raw materials are subjected to the primary mixing and the secondary mixing; the uniform distribution of moisture is facilitated; the flame accelerator is atomized and sprayed into a secondary mixture; the uniform distribution of the flame accelerator is promoted.

Owner:玉溪加宝生物能源有限公司

Polypropylene micro-foamed material with high surface quality and preparation method thereof

The invention relates to a polypropylene material and a preparation method thereof, especially to a polypropylene micro-foamed material with high surface quality and a preparation method thereof, belonging to the technical field of high-molecular materials. The polypropylene micro-foamed material comprises the following raw materials by weight: 50 to 80 parts of polypropylene, 10 to 40 parts of inorganic powder, 3 to 10 parts of a micro-foaming adjusting auxiliary agent, 0.5 to 5 parts of a foaming agent and 0.2 to 2 parts of an anti-oxidant. Through the micro-foaming adjusting auxiliary agent, surface quality of the polypropylene micro-foamed material is substantially improved, the severe surface quality problems like surface scratches and gas marks on a polypropylene micro-foamed product in the process of injection molding are overcome, and the polypropylene micro-foamed material with excellent performance and high surface quality is obtained. The prepared polypropylene micro-foamed material is applicable to skinned and fabric-covered automobile components and to interior and exterior trimming parts for an automobile in a visual environment, e.g., door trim panels, guard boards of columns, hallstands, instrument desks, air-conditioner shells, guard boards for side skirts, scuff plates, thereby realizing lightweighting of materials for automobile parts; and the material is also applicable to other fields like architecture, electronics and shipbuilding.

Owner:NANJING JULONG SCI&TECH CO LTD

Inorganic foaming filling and reinforcing composition for coal mine as well as using method and application thereof

ActiveCN104446624AResolution timeSolve the non-plasticUnderground chambersMaterial fill-upCoalMaterials science

The invention provides an inorganic foaming filling and reinforcing composition for a coal mine as well as a using method and application thereof. The inorganic foaming filling and reinforcing composition for the coal mine can be used as a novel safe plugging and reinforcing material, is especially suitable for plugging and reinforcing of the coal mine, and is the best water-proof, fire-proof, gas-proof, collapse-proof and accident-proof material.

Owner:廊坊坐城矿用材料有限公司

Green alkali-activated material for repair and protection and preparation method thereof

The invention relates to a green alkali-activated material for repair and protection. The green alkali-activated material is composed of 55%-70% of an alkali-activated active matter, 0-20% of concretewaste slurry powder, 1%-2% of a reinforcing component, 6%-10% of an alkali activator, 1.5%-2% of a water reducing component and the balance water, and the total mass of the green alkali-activated material is 100%. The material is high in early strength, high in fluidity and suitable for construction. Specifically, the concrete waste slurry powder can provide part of excitation alkalinity requiredby an early reaction, aluminosilicate in the waste residue powder has potential alkali-activated active matters, and has a good way of absorbing mixing plant waste residues. The fluidity of a geopolymer can be improved by doping the fly ash and silica fume, the yield stress of the slurry is reduced, and the fluidity required by repair and protection is met. The ultra-dispersed nano reinforcing material is doped, so that the filling effect can be achieved in the alkali-activated reaction process, the dissolution of aluminosilicate minerals is promoted, and the mechanical properties of the alkali-activated material are improved. The green alkali-activated material for repair and protection is low in cost and environmentally friendly, and has high promotable value.

Owner:HUNAN CSCEC5B CONCRETE +1

Premixed concrete and production method thereof

InactiveCN101747010AReduce heat of hydrationCrack suppressionSolid waste managementCrushed stoneFly ash

The invention relates to premixed concrete and a production method thereof. The premixed concrete is prepared by the following raw materials in percentage by weight: 200-350 p.s32.5 cement, 90-120 fly ash, 530-740 river sand, 950-1110 rubble, 170-300 mine tailings powder, 170-190 water and 3.4-9.8 mine tailings modifier. The production method comprises the following steps: firstly, naturally air-drying waste tailings to lose water; preparing various raw materials according to the mixture ratio; the feeding sequence in mixing is: the river sand, the mine tailings powder, the cement and the fly ash; mixing for 20 seconds, then adding the rubble to be mixed for 20 seconds, finally adding the water and the mine tailings modifier to be mixed for 60 seconds; and slapping out from a mixer. The method makes full use of the abandoned mine tailings, saves the production cost, and can be widely used in concrete production.

Owner:ANGANG MINE CONSTR

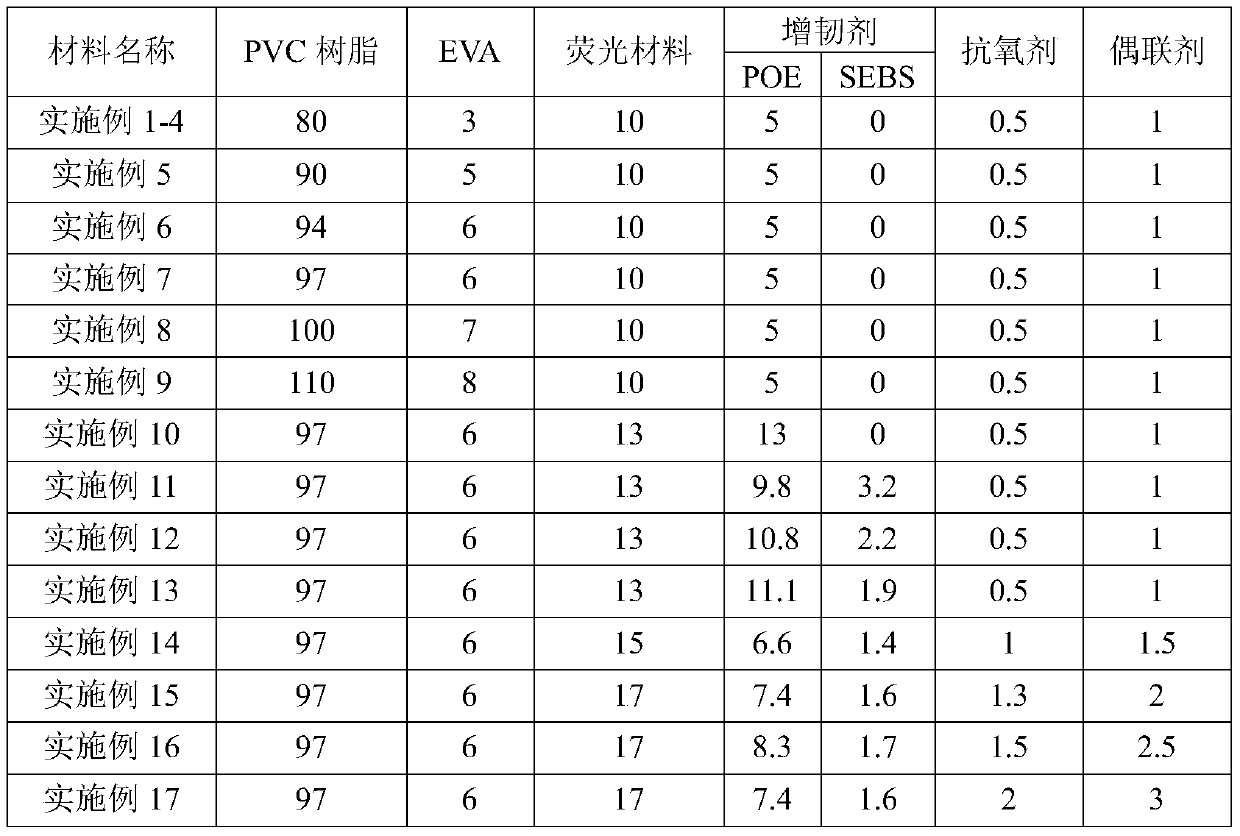

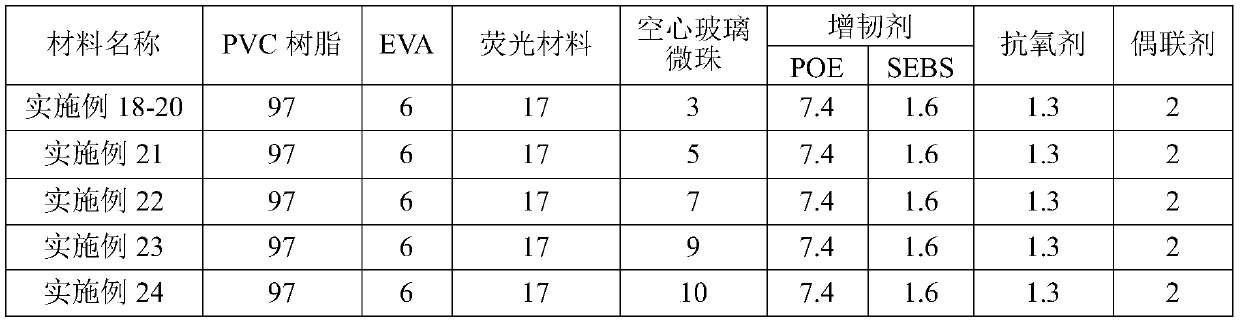

Noctilucent ground wire and processing technology thereof

ActiveCN110903570AAvoid instabilityImprove luminous performancePlastic/resin/waxes insulatorsInsulated cablesPolyvinyl chlorideEngineering

The invention relates to the technical field of grounding wires, in particular to a noctilucent grounding wire and a processing technice. The noctilucent grounding wire comprises a grounding wire body, the grounding wire body comprises a copper core and an insulating sheath wrapping the copper core, and the insulating sheath is wrapped with a fluorescent sheath; the fluorescent sheath is preparedfrom the following raw material in parts by weight: 80-110 parts of polyvinyl chloride resin, 3-8 parts of an ethylene-vinyl acetate copolymer, 10-20 parts of a fluorescent material, 5-13 parts of a flexibilizer, 0.5-2 parts of an antioxidant and 1-3 parts of a coupling agent, the weight percentage of vinyl acetate in the ethylene-vinyl acetate copolymer is 30-35%; a fluorescent substance is addedinto the insulating sheath as a raw material, and the fluorescent substance can be uniformly dispersed in the insulating sheath, so that the grounding wire can emit light stably, and the problem thatthe grounding wire is omitted to be dismounted due to insufficient light is avoided; the tensile strength of the processed fluorescent sheath is up to 38 MPa, the elongation at break of the processedfluorescent sheath is up to 187%, the tensile strength and elongation at break of the processed fluorescent sheath are basically kept unchanged after aging, and the aging resistance of the processedfluorescent sheath is excellent.

Owner:HEBEI JINHE ELECTRIC

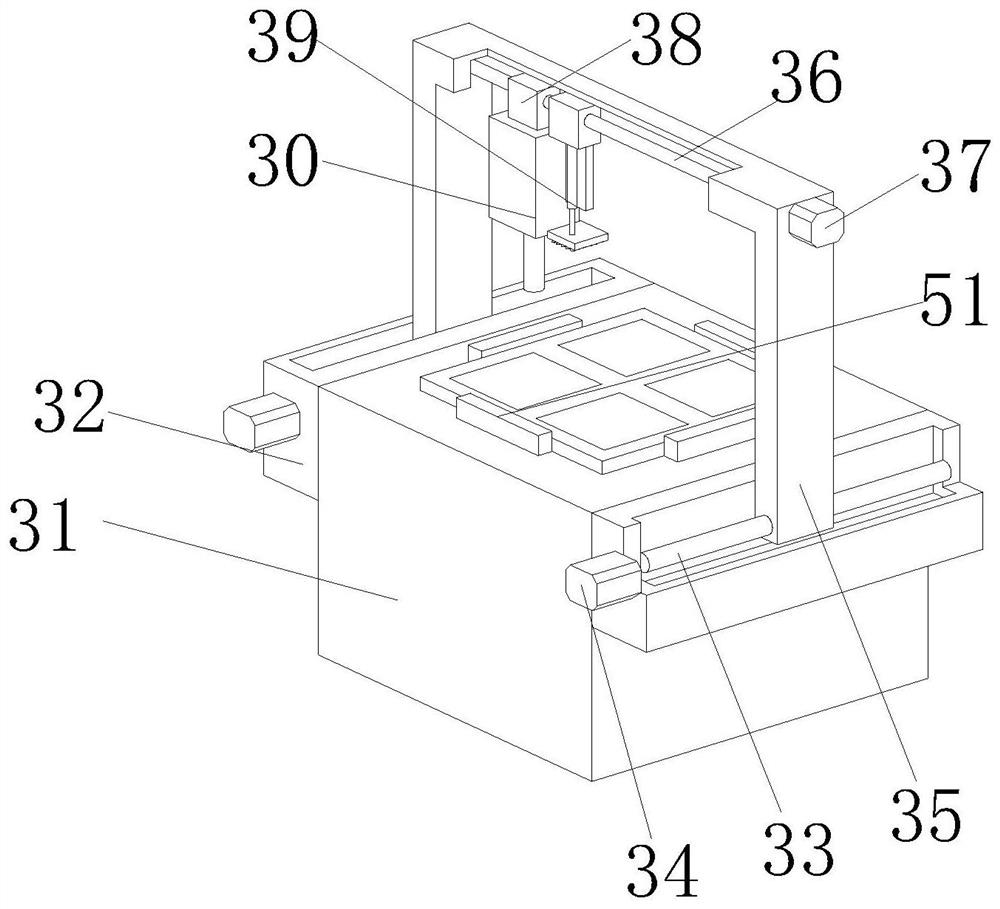

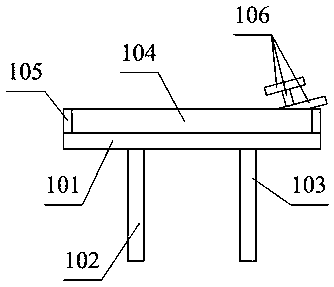

Stainless steel sheet metal material laser cutting machine and laser cutting method

InactiveCN113001040APlay the role of fillingReduce secondary processingOther manufacturing equipments/toolsLaser beam welding apparatusPolishingLaser cutting

The invention provides a stainless steel sheet metal material laser cutting machine and a laser cutting method, and relates to the field of laser cutting machines. The stainless steel sheet metal material laser cutting machine comprises a bottom plate, a conveying mechanism, a cutting mechanism and a polishing mechanism, the cutting mechanism is fixedly installed on the bottom plate, the polishing mechanism is arranged on the cutting mechanism, and the conveying mechanism is arranged on the polishing mechanism. According to the stainless steel sheet metal material laser cutting machine, automatic stainless steel metal plate laser cutting can be effectively achieved, meanwhile, the laser cutting stability is improved through the cutting mechanism, polishing after cutting can be achieved through the polishing mechanism, secondary treatment operation is effectively avoided, cost consumption is reduced, and meanwhile the machining efficiency can be improved.

Owner:吴炼

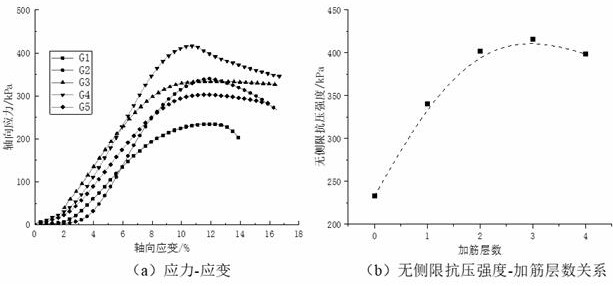

Road structure processing method based on reinforced alkaline residue improved soil

The invention relates to the technical field of road traffic construction, and discloses a road structure processing method based on reinforced alkaline residue improved soil, which comprises the following steps: taking a proper amount of alkaline residue, fly ash and cohesive soil, adding water for mixing by adopting the optimal water content of 23%, and then conducting sealing for 14 days to promote volcanic ash reaction; smearing engine oil in a road structure mold cylinder for lubrication, and packing the mixture into the alkaline residue improved soil in a multi-layer volume-controlled manner; after each layered volume is filled, laying a layer of reinforced material, laying 8-12 cm of alkaline residue improved soil for rolling compaction, and after compaction, sequentially packing the upper-layer mixture until a next-layer reinforcing layer is reached; and circulating and repeating the steps to form the reinforced road structure. Compared with the prior art, the reinforced alkaline residue improved soil is reasonably designed, geogrids and the alkaline residue improved soil are used as raw materials according to the optimal grid spacing, the base layer structure for the solid waste regeneration road is constructed, the design requirements of roads at or below a second level can be met, and resource utilization of alkaline residue solid waste is greatly promoted.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY +1

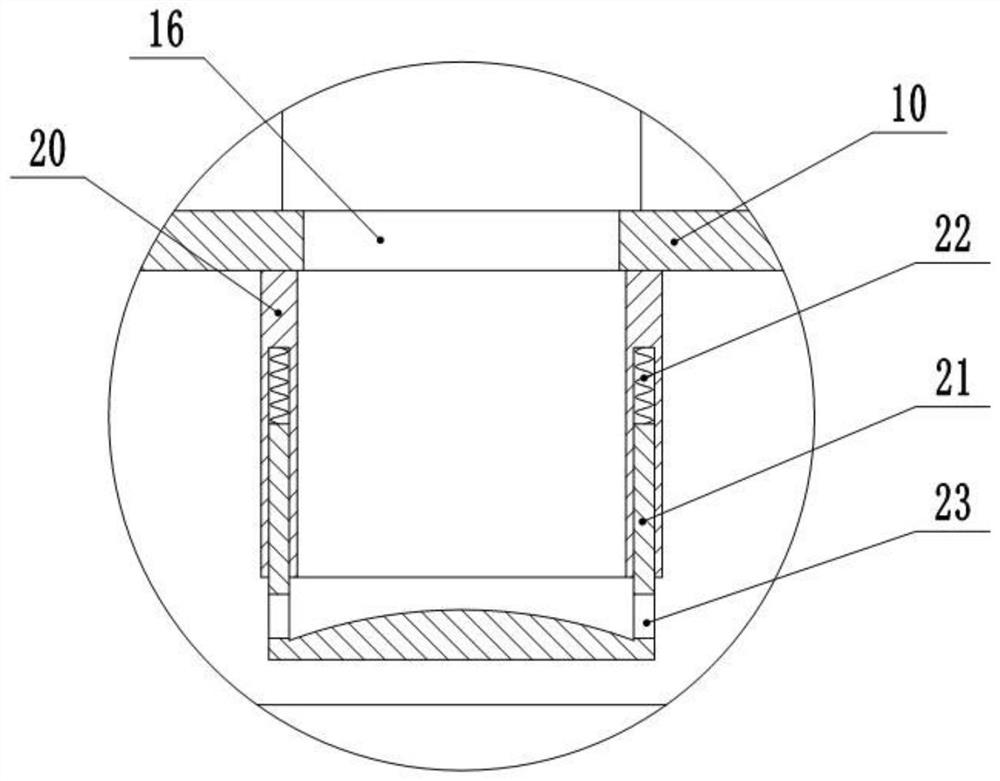

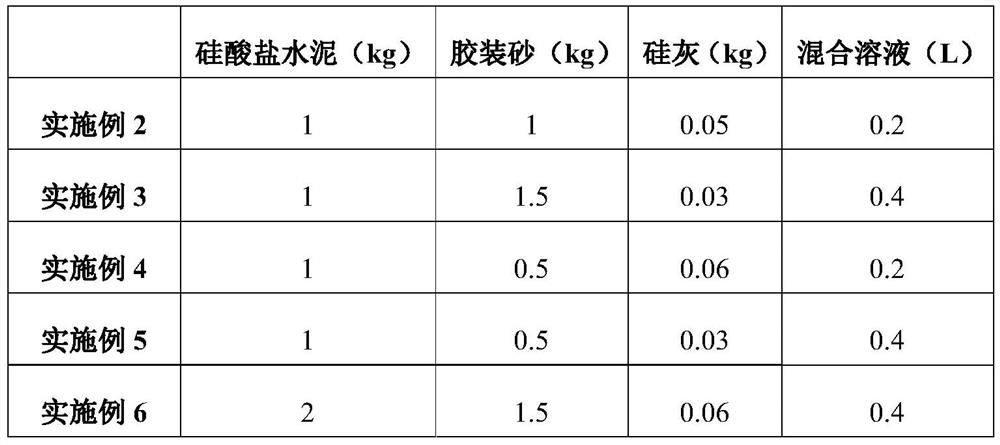

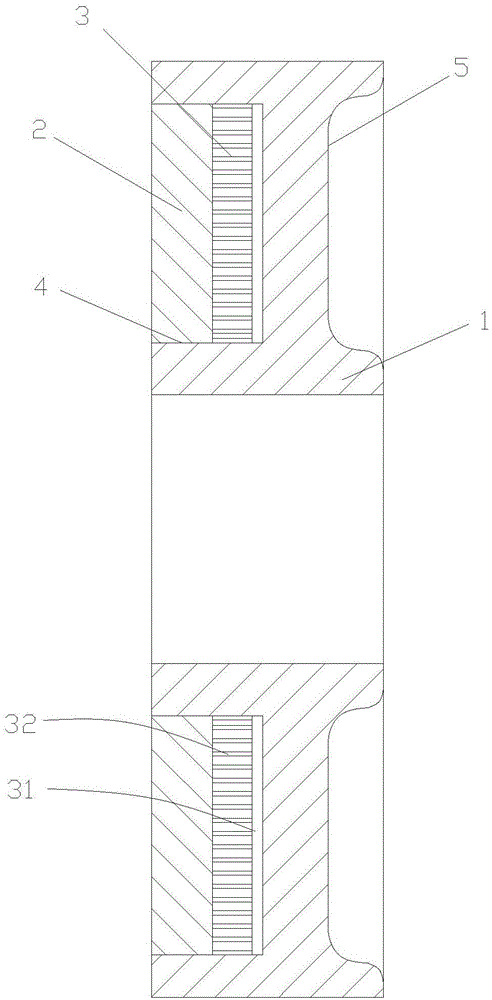

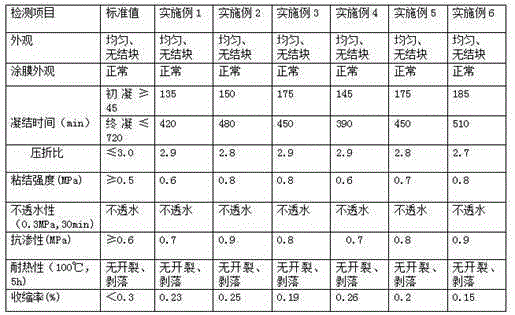

Adhesive for insulator

The invention relates to the technical field of insulator production materials, and particularly discloses an adhesive for insulators. The adhesive comprises the following raw materials in parts by weight: 1-2 parts of Portland cement, 0.5-1.5 parts of cementing sand, 0.03-0.06 part of silica fume and 0.2-0.4 part of a mixed solution, and the mixed solution comprises a defoaming agent, a water reducing agent and water. By adopting the adhesive obtained according to the proportion in the patent, the problems that in the prior art, the breaking strength of an insulator is reduced and the breakdown rate is increased due to the fact that the shrinkage rate is increased while high breaking strength is generated by increasing the lime-sand ratio are solved.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

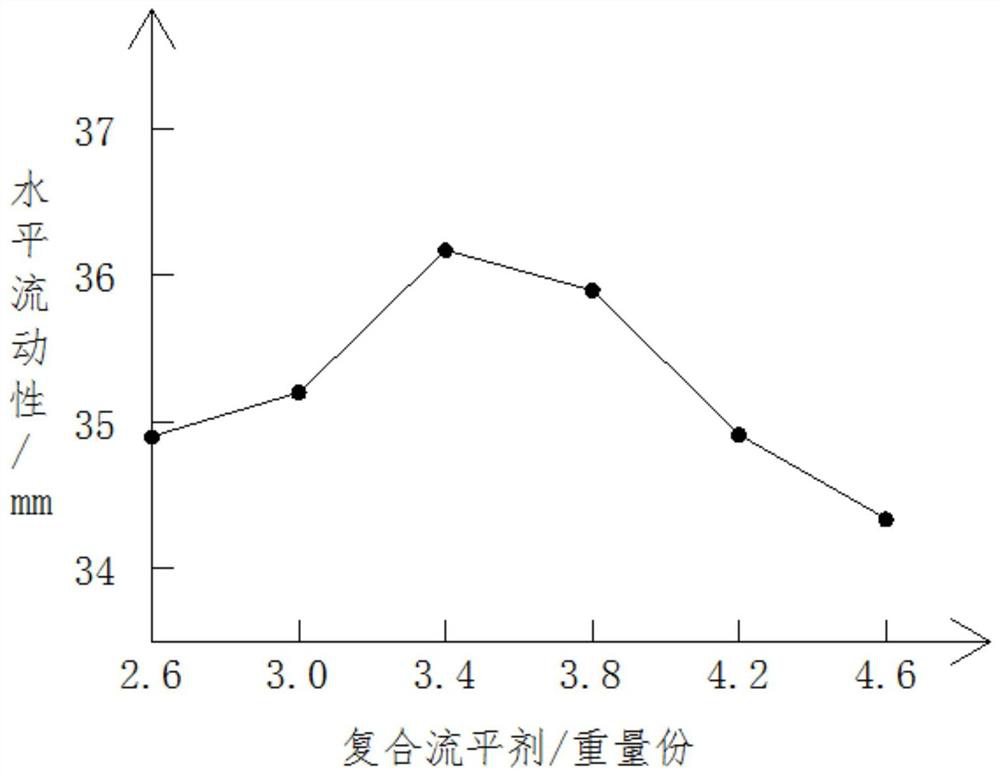

Super-leveling powder coating and preparation method thereof

PendingCN113698852AImprove adhesionImprove mechanical propertiesPowdery paintsEpoxy resin coatingsTitanium dioxidePolytetrafluoroethylene

The invention discloses a super-leveling powder coating and a preparation method thereof. The powder coating relates to the technical field of powder coating production, and is prepared from the following components: modified polyester resin, titanium dioxide, acrylic resin, nano silicon dioxide, epoxy resin, a composite leveling agent, a curing agent, ceramic micro powder, polytetrafluoroethylene micro powder wax and an auxiliary agent. The invention provides a super-leveling powder coating and a preparation method thereof. The powder coating prepared by the invention has excellent comprehensive performance, high coating surface hardness, good leveling property and wide application.

Owner:浙江绿环新材料科技有限公司

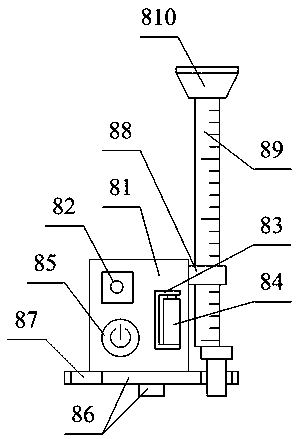

Ground seam beautifying device

ActiveCN112681683AAvoid material wasteAvoid less slipBuilding constructionsStructural engineeringManual handling

The invention relates to a decoration related device, in particular to a ground seam beautifying device. The ground seam beautifying device comprises a moving mechanism, a sweeping and limiting mechanism, an angle adjusting mechanism, a seam pressing mechanism, an angle fixing mechanism and a discharging mechanism, wherein the sweeping and limiting mechanism is hinged to the moving mechanism, the angle adjusting mechanism is fixedly installed on the moving mechanism, the seam pressing mechanism is fixedly installed on the angle adjusting mechanism, the discharging mechanism is fixedly installed on the angle adjusting mechanism, the angle fixing mechanism is fixedly installed on the discharging mechanism, and the angle fixing mechanism is engaged with the angle adjusting mechanism. According to the device, seam cleaning, seam beautifying agent filling and seam beautifying agent compaction are realized, manual operation is completely replaced, a large amount of working hours and manpower are saved, the device has a filling angle adjusting function and can be correspondingly adjusted according to the depth of seams, the filling effect is achieved, the waste of materials is avoided, and the problem of uneven filling of manual operation is solved.

Owner:金华市易途新材料有限公司

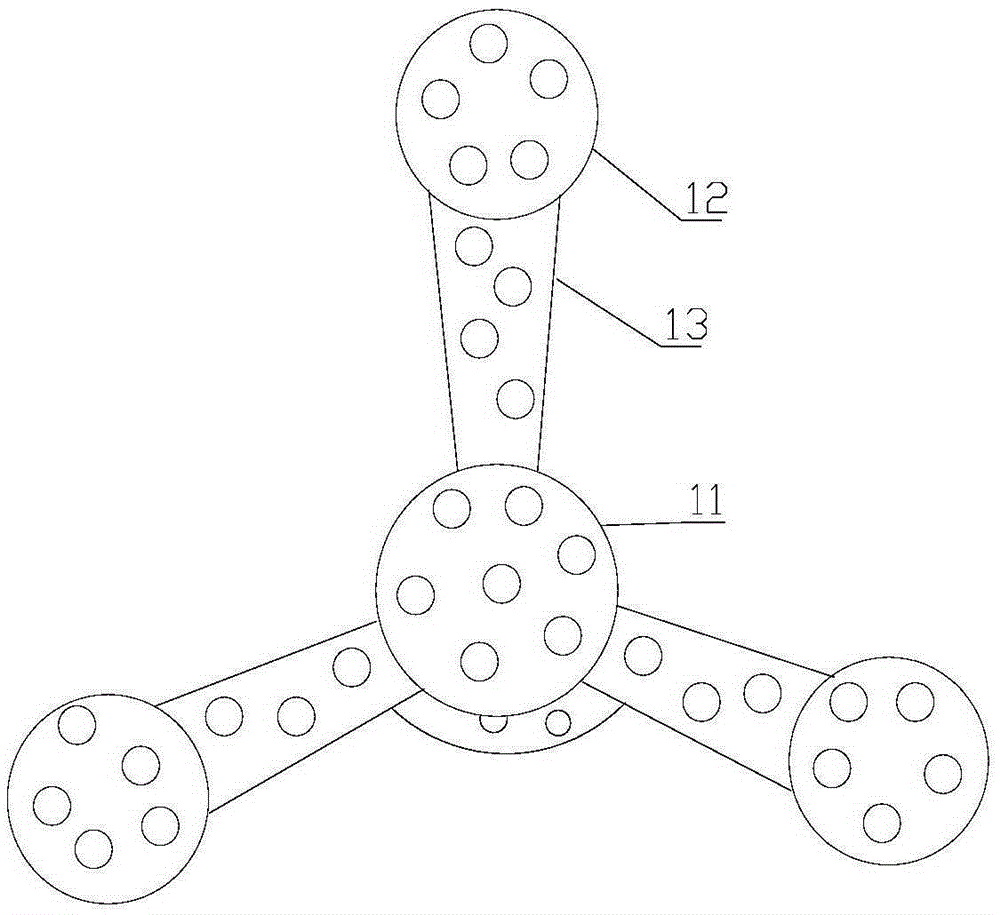

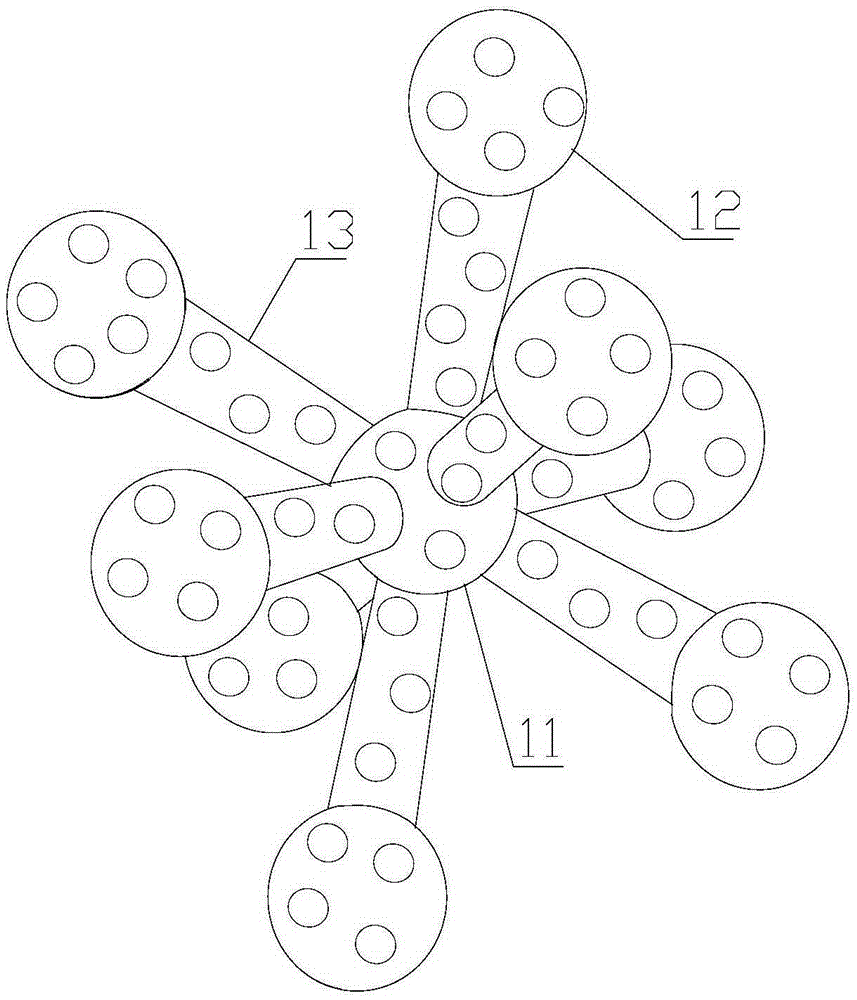

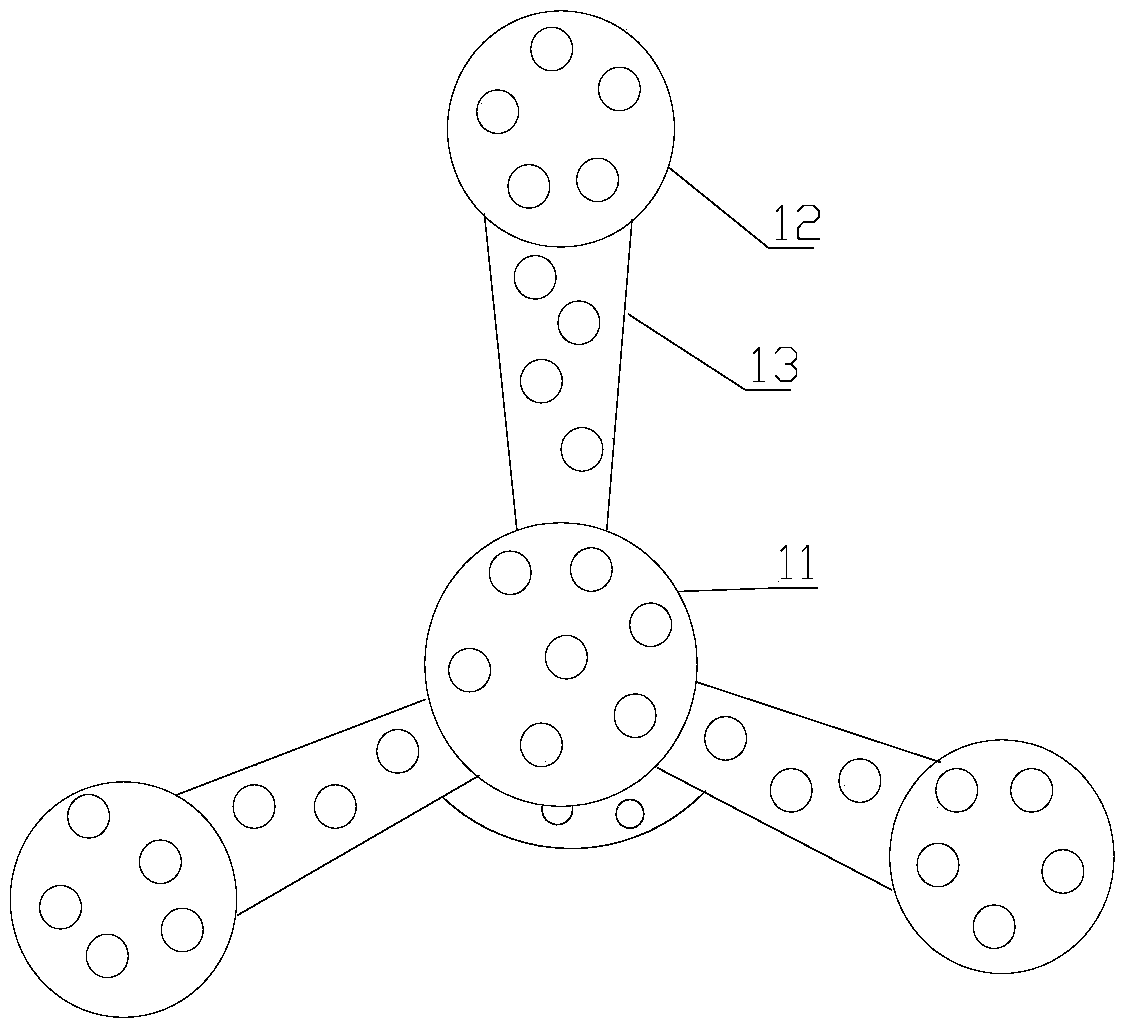

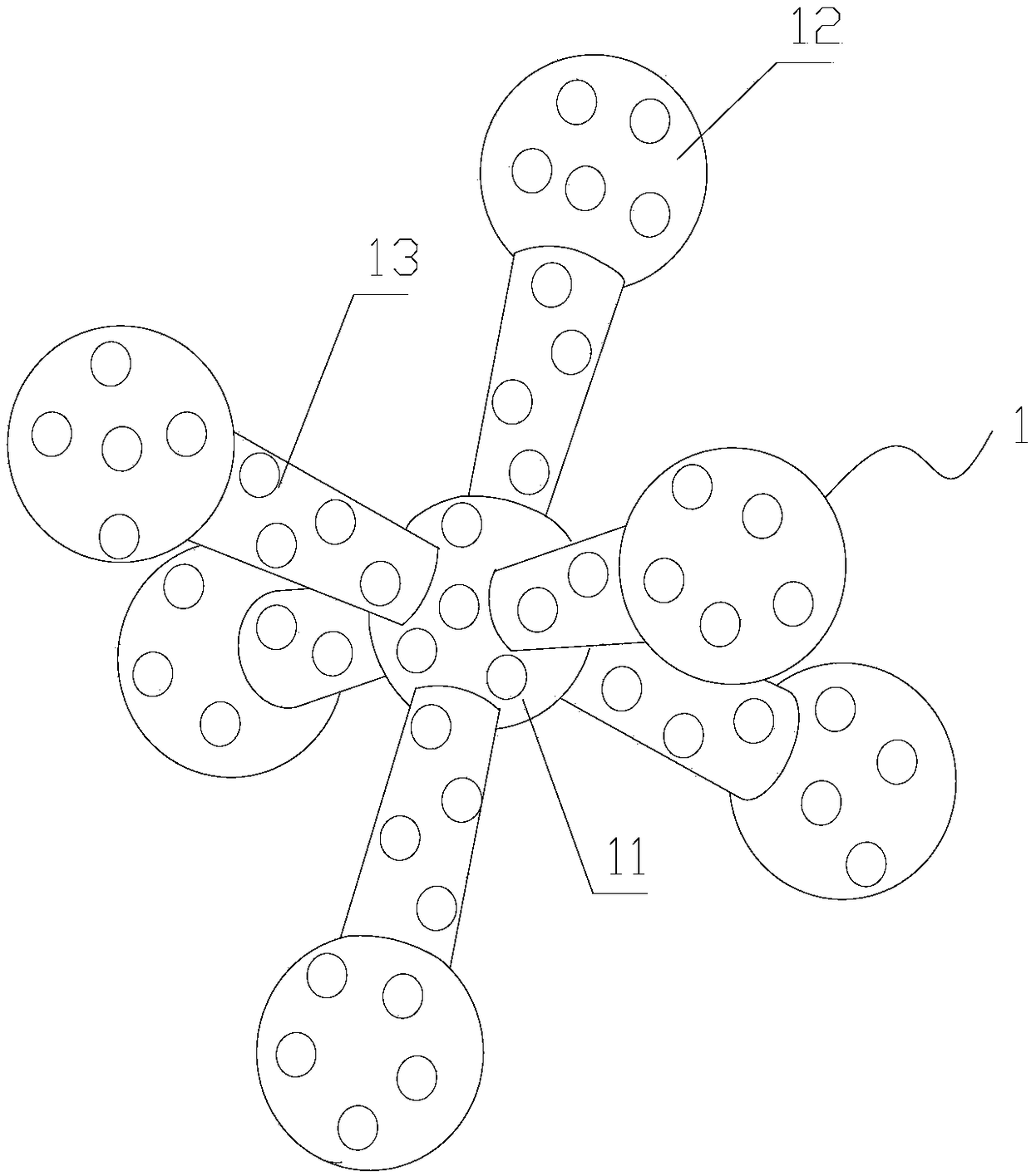

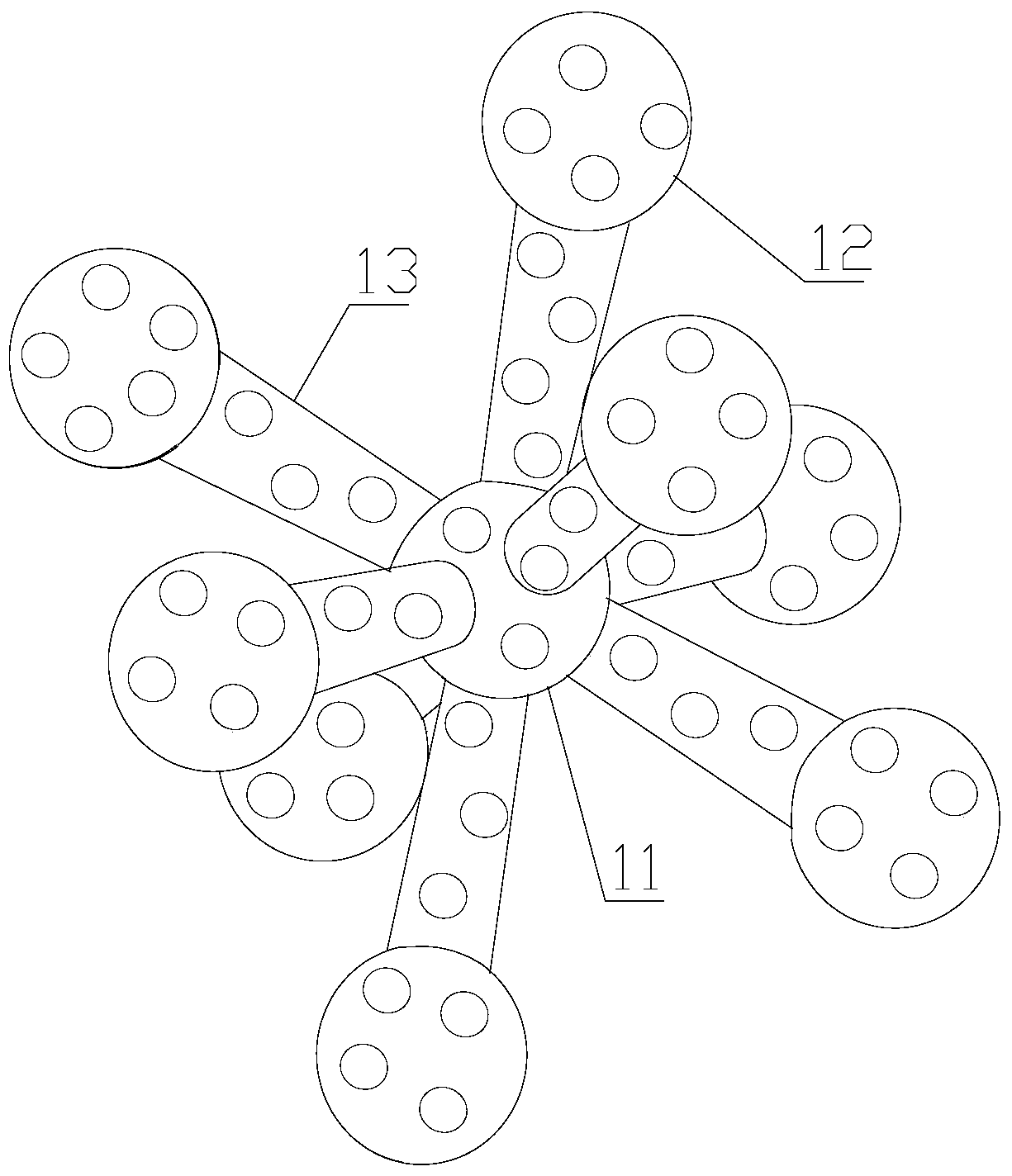

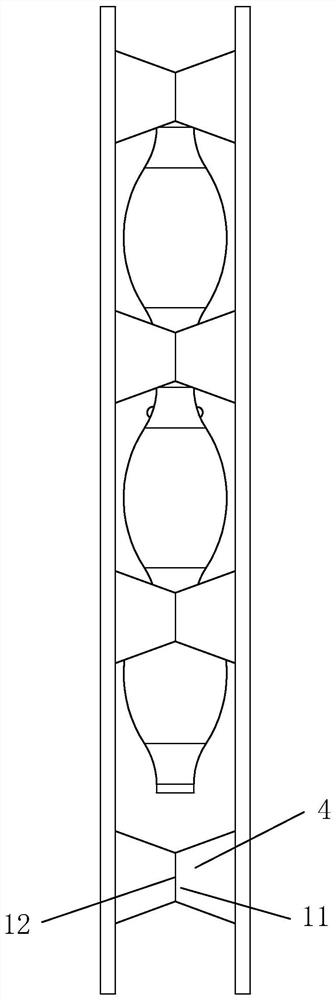

3D printing bone defect filling material

The invention belongs to the technical field of medical materials and particularly relates to a 3D printing bone defect filling material. The filling material comprises particles and a flexible screen for wrapping the particles, wherein mesh openings are formed in the surface of the flexible screen, the aperture of each mesh opening is smaller than that of each particle, each particle is formed through supporting of 4, 6 or 8 support vertices, and micropores are uniformly formed in the surface of each particle. The 3D printing bone defect filling material is applicable to the bone defect conditions of different parts.

Owner:TRAUSON CHINA MEDICAL INSTR COMPANY

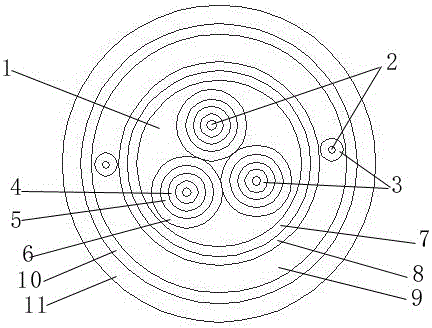

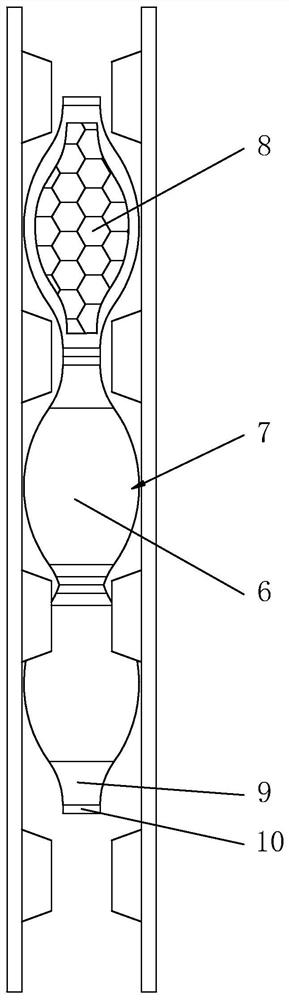

High-strength optical fiber composite cable

InactiveCN105976921ASolve the problem of being easily damaged by external forcesAvoid uneven forceInsulated cablesFibre mechanical structuresElectric power systemHigh intensity

The invention discloses a high-strength optical fiber composite cable, and the center of the cable is provided with a reinforcing filling body composed of glass silks. The reinforcing filling body is provided with three first circular holes, and the interior of each first circular hole is provided with an insulating optical fiber composite wire core. The exterior of the reinforcing filling body is provided with a fireproof layer with the thickness from 2mm to 3mm, and the exterior of the fireproof layer is provided with a metal armored layer with the thickness from 2mm to 3mm. The exterior of the metal armored layer is provided with a stress control tube with the thickness from 4mm to 6mm, and the stress control tube is wrapped by an aluminum sheath with the thickness from 2mm to 3mm. The stress control tube is provided with one second circular hole, and the interior of the second circular hole is provided with a standby optical fiber unit. The cable improves the capability of optical fibers in bearing tension and pressure, improves the safety in a normal use process, prolongs the service life, and greatly reduces the operation cost of a power system.

Owner:JIANGSU HONGFENG CABLE GROUP

Method for manufacturing calcium silicon light-weight wallboard

InactiveCN103979922AHigh strength wall materialGood adhesionSolid waste managementCeramicwareFoaming agentPalm fiber

The invention relates to the technical field of building materials and particularly relates to a method for manufacturing a calcium silicon light-weight wallboard. The method comprises the following steps: A, preparing brine; B, preparing a magnesite foaming agent; and C, manufacturing a light-weight wallboard material: firstly adding 45-50 parts by weight of evenly-mixed brine into an agitator, starting the agitator to homogenize the brine, secondly adding 50-56 parts by weight of magnesium oxide and 10-15 parts by weight of gypsum powder, clockwise-anticlockwise stirring for 10-15 minutes, adding coal ash and palm fibers to obtain a first fixture, throwing the magnesite foaming agent into the first mixture by a foaming machine, stirring to obtain a second mixture, pouring the second mixture into a mold, and performing demolding and curing, thereby obtaining the light-weight wallboard material. The manufactured product has the advantages of no scumming, light weight, good heat preserving performance, high strength and enhanced toughness, and the product strength is scarcely affected.

Owner:张振民

Multi-core self-cooling high-strength optical fiber composite cable

InactiveCN105976920AEnsure the uniformity of forceReduce construction workloadPower cables with screens/conductive layersInsulated cablesAluminiumEngineering

The invention discloses a multi-core self-cooling high-strength optical fiber composite cable. The center of the cable is provided with a reinforcement filler made of glass filaments. The reinforcement filler is provided with three first circular holes, and each first circular hole There is an insulated fiber optic composite core, a refractory layer with a thickness of 2-3mm is provided outside the reinforced filler body, a metal armor layer with a thickness of 2-3mm is provided outside the refractory layer, and a metal armor layer with a thickness of 4-3mm is provided outside the metal armor layer. 6mm stress control tube, the stress control tube is equipped with a cooling tube equipped with cooling liquid, and the cooling tube is extruded with an aluminum sheath with a thickness of 2-3mm; the stress control tube is provided with two symmetrical second circles hole, and a group of optical fiber units as a spare is arranged in the second round hole. The invention increases the ability of the optical fiber to bear tension and pressure, improves the safety of the cable during normal use and prolongs the service life of the cable, greatly reduces the operating cost of the power system, and has a self-cooling function to ensure the performance of the cable.

Owner:JIANGSU HONGFENG CABLE GROUP

Bowl-type washer and manufacturing method thereof

The invention provides a bowl-type washer and a manufacturing method thereof and relates to the technical field of washers. The bowl-type washer comprises a rubber pad, a metal pad and a grid pad. One side of the rubber pad is provided with a rectangular groove, and the other side of the rubber pad is provided with a bowl-shaped groove. The grid pad is disposed on the internal bottom part of the rectangular groove. The grid pad is made of soft rubber material. The metal pad is fixedly arranged in the rectangular groove and is located on the upper side of the grid pad. The outer end side of the metal pad is flush with the outer end side of the rubber pad. The manufacturing method comprises the steps of respectively producing the above parts; padding the grid pad into the rectangular groove of the rubber pad, and filling a filler and a binder in the rectangular ground, wherein the binder is already ground into powders; pre-heating the metal pad, padding the pre-heated metal pad into the rectangular groove of the rubber pad to subject the pre-heated metal pad to thermo-compression formation, and quickly cooling in a mold after the formation process; warming up an obtained product after standing the product, wherein the temperature of the warming-up treatment is one third to one second of that of the thermo-compression formation treatment. The bowl-type washer is convenient to use, high in hardness, easily deformable, good in sealing performance, and high in flattening accuracy of end-to-side cooperation.

Owner:宁国市格斯特密封件有限公司

Preparation method of wood-plastic composite material aid

The invention discloses a preparation method of a wood-plastic composite material aid. The aid is aluminum oxide-aluminum nitride composite heat-conducting ceramic composed of aluminum oxide heat-conducting ceramic and aluminum nitride heat-conducting ceramic. The preparation method mainly comprises the following steps: ball milling, calcination, ball milling, granulation, sintering, pulverization and the like. By adding the aluminum oxide-aluminum nitride composite heat-conducting ceramic, the wood-plastic composite material can have favorable mechanical properties and low water absorptivity, and thus, has wider application range and longer service life. Besides, the aluminum oxide-aluminum nitride composite heat-conducting ceramic has a certain porous structure, and thus, can adsorb harmful gas and purify air, thereby being beneficial to environmental protection. Therefore, the preparation method of the wood-plastic composite material aid has great development potential.

Owner:东莞市振中塑胶有限公司

Mirabilis jalapa seedling substrate and preparing method thereof

InactiveCN105981606APlay the role of fillingSuitable for growthCultivating equipmentsFertilizer mixturesMirabilis jalapaAdditive ingredient

The invention relates to a Mirabilis jalapa seedling substrate and a preparing method thereof. The preparing method includes: smashing two kinds of excrement and mushroom sticks, and drying the smashed excrement and the smashed mushroom sticks; adding urea and water in the smashed excrement and the smashed mushroom sticks, and evenly stirring the mixture; performing composting fermentation; adding vermiculite, garden soil and furnace slag in the mixture to obtain a finished product. According to the method, the two kinds of excrement and the mushroom sticks are thoroughly decomposed, the mixture of the excrement and the mushroom sticks are rich in nutrient substances such as organic matters and can provide sufficient nutritional ingredients for the growth of seed; the vermiculite, the garden soil and the furnace slag play a role in filling, and appropriate holes are formed in the substrate and can facilitate the growth of the root systems and nutrient uptake; and the prices of the chicken excrement, the mushroom sticks, and the furnace slag are low, the whole cost is reduced, the total use cost is reduced, and the income is increased.

Owner:天津市蓟县硕果苗木种植专业合作社

3d printed bone defect filling material

The invention belongs to the technical field of medical materials and particularly relates to a 3D printing bone defect filling material. The filling material comprises particles and a flexible screen for wrapping the particles, wherein mesh openings are formed in the surface of the flexible screen, the aperture of each mesh opening is smaller than that of each particle, each particle is formed through supporting of 4, 6 or 8 support vertices, and micropores are uniformly formed in the surface of each particle. The 3D printing bone defect filling material is applicable to the bone defect conditions of different parts.

Owner:TRAUSON CHINA MEDICAL INSTR COMPANY

Eco-friendly waterproof paint

InactiveCN105384412AEnvironmental protection is goodGood waterproof and anti-seepageSolid waste managementEtherCellulose

The invention discloses eco-friendly waterproof paint and belongs to the technical field of paint. The eco-friendly waterproof paint comprises, by weight, 70-96 parts of low-heat portland cement, 0-10 parts of fly ash, 0-10 parts of limestone powder, 4-15 parts of dispersible latex powder, 0.3-0.5 parts of cellulose ether and 0.5-0.8 parts of a water reducer. The eco-friendly waterproof paint has the advantages of environmental friendliness, good water resistance, high later strength, good use performance and low cost.

Owner:JIAHUA SPECIAL CEMENT

Additives for wood-plastic composites (WPC) and preparation method thereof

The invention discloses additives for wood-plastic composites (WPC) and a preparation method of the additives for the WPC, wherein the additives are alumina-aluminum nitride-boron nitride composite conductive ceramic which comprises alumina conductive ceramic, and aluminum nitride and boron nitride conductive ceramic. The preparation method mainly comprises the steps of ball milling, calcining, secondary ball milling, granulation, sintering, grinding and the like. According to the invention, the prepared alumina-aluminum nitride-boron nitride composite conductive ceramic is added, thereby being capable of making the WPC have good mechanical properties, and further have lower water absorption rates to facilitate wider application fields and longer service life of the WPC. In addition, the alumina-aluminum nitride-boron nitride composite conductive ceramic has a certain pore structure, so that harmful gases can be absorbed and the air can be purified, thereby being conducive to environmental protection.

Owner:浙江祥景科技有限公司

Intelligent building detecting leveling equipment and detecting leveling method

InactiveCN108868140ASmooth rotationEasy to useRoad cleaningBuilding material handlingIntelligent lightingLaser transmitter

The invention provides intelligent building detecting leveling equipment and a detecting leveling method. The intelligent building detecting leveling equipment comprises a parallel ruler, a detectingscraping seat, a connection handle rod, an antiskid sleeve, a first level gauge, a groove, a bearing, a measurement box structure, a water spray box structure, a work plate structure, a protection padstructure, a storage barrel structure, a cross belt, a protecting cover and a connection pad, wherein the detecting scraping seat and the connection handle rod are respectively welded to the middle parts of the upper surface and the lower surface of the parallel ruler, the antiskid sleeve is in sleeve connection to an outer wall of the connection handle rod, the first level gauge is embedded to the left middle side of the upper surface of the parallel ruler, and the groove is arranged on the right middle side of the upper surface of the first level gauge. The intelligent building detecting leveling equipment disclosed by the invention has the beneficial effects that as the measurement box structure is arranged, favorability for light emitted by a laser transmitter to shine on a detectionruler in work is achieved; furthermore, whether convex or concave appears on a part of the ground can be determined more accurately; meanwhile, convenience is brought to use of the measurement box structure.

Owner:杨晓虹

Composite corrugated cardboard

ActiveCN110978713BIncrease the supportable rangeIncrease contact areaPaper/cardboard layered productsCardboardEngineering

The invention relates to cardboard, and discloses a composite corrugated cardboard, comprising a face paper layer, a corrugated core layer and an inner paper layer, and the corrugated core layer includes a plurality of supporting paper blocks between the inner paper layer and the face paper layer and supplementary paper blocks There is a supplementary channel between the supporting paper blocks, and the supplementary paper block slides in the supplementary channel, and the middle part of the supplementary paper block protrudes to form an abutment end, and the abutment end abuts between the inner paper layer and the surface paper layer, supporting One end of the paper block extends toward the supplementary channel to form a leading end, the side of the leading end is bent inward and abuts inside it, the side of the leading end is in contact with the side of the abutting end, and the distance between adjacent leading ends is less than the maximum of the supplementary paper block The minimum width of the section; if a part of the composite corrugated cardboard is crushed by external force, squeeze the supplementary paper blocks next to this part, let the supplementary paper blocks fill into the crushed part, let the part bulge, and the supplementary paper blocks in other parts will be in order Fill the gap and realize self-healing after partial damage.

Owner:上海绚丽包装彩印有限公司

A kind of high surface quality polypropylene micro-foaming material and preparation method thereof

Owner:NANJING JULONG SCI&TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com