Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Breakdown rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

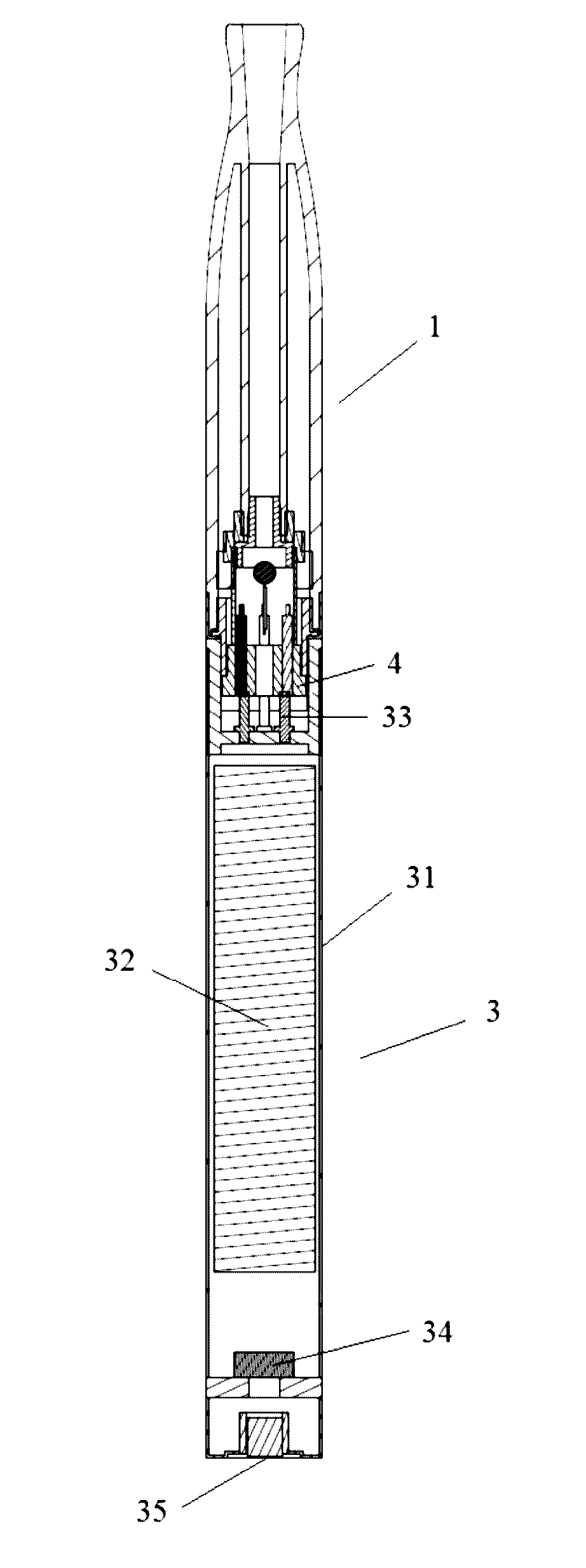

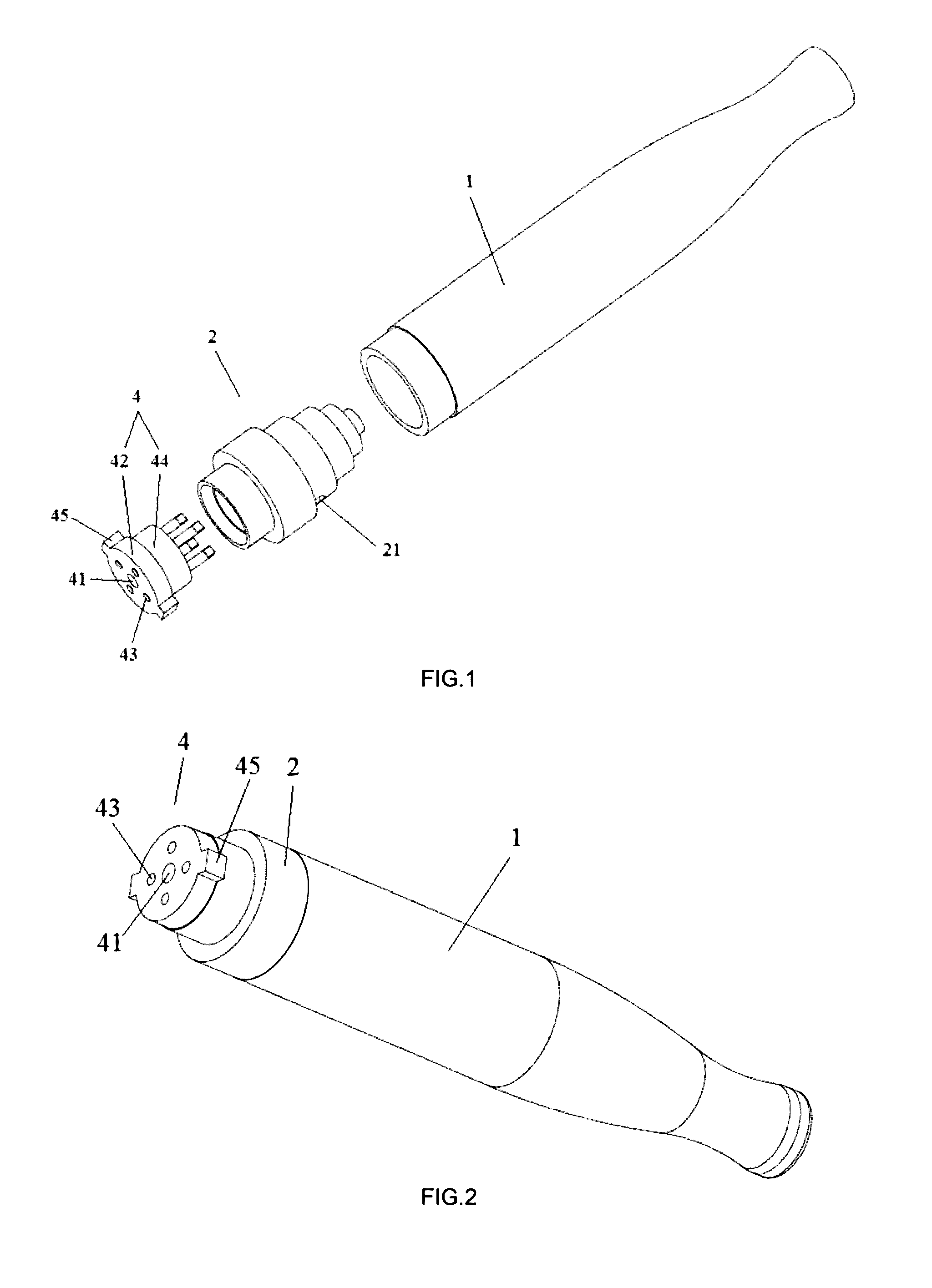

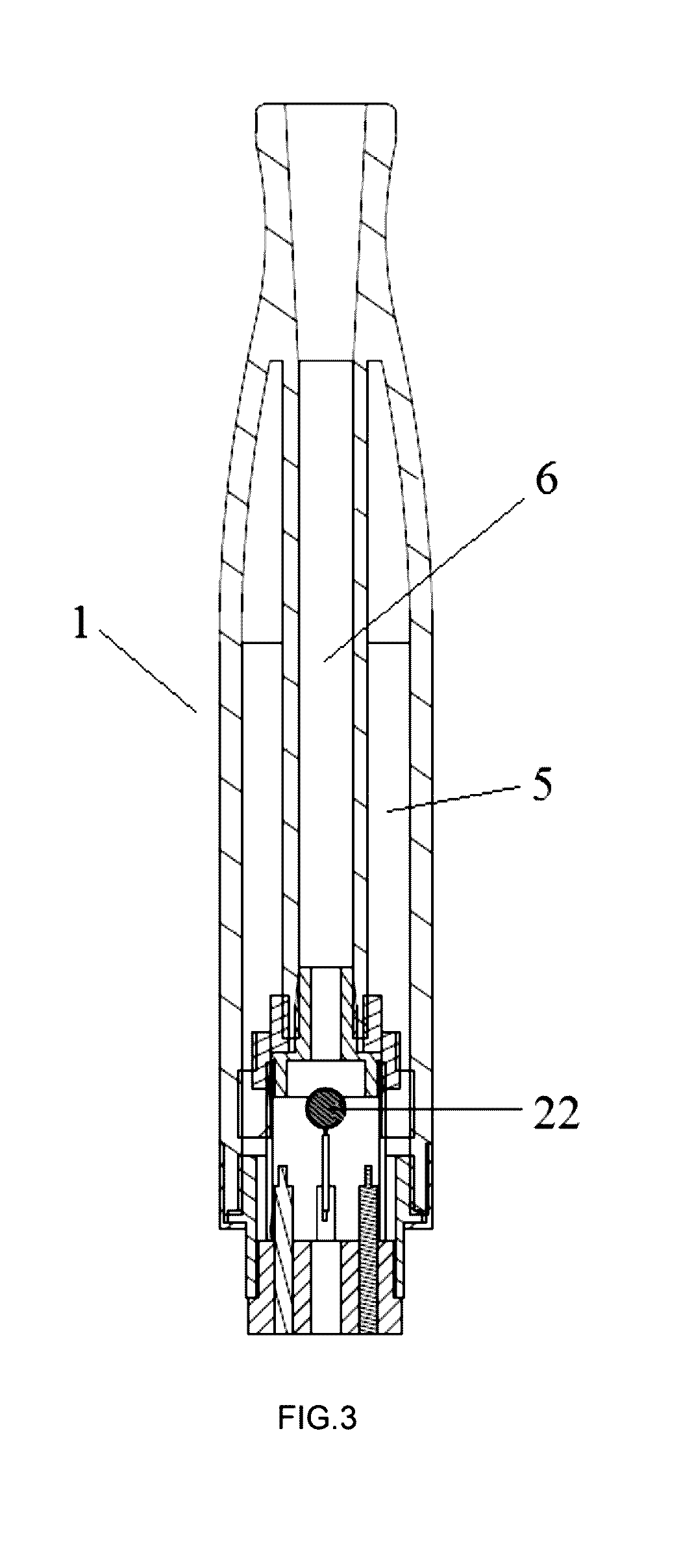

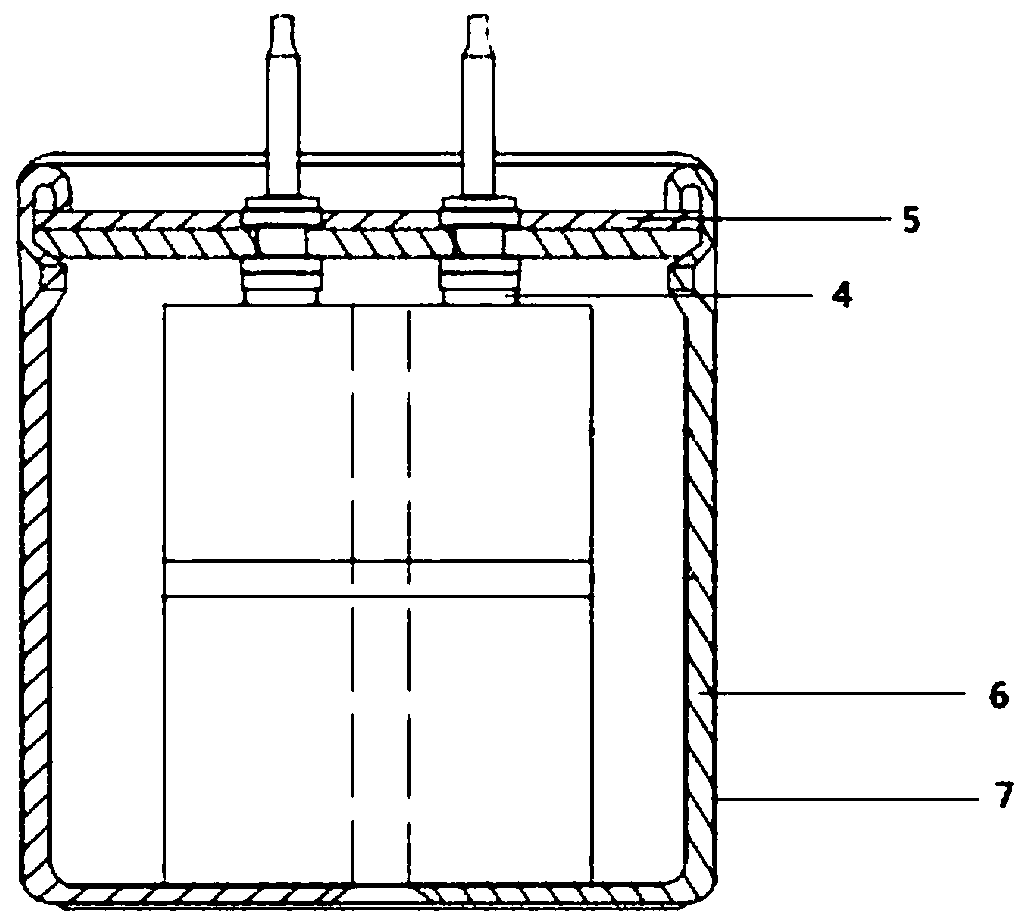

Electronic cigarette and an atomizing device thereof

InactiveUS20160366938A1Prevent replenishmentImprove the safety of useTobacco pipesTobacco devicesMortise and tenonEngineering

An atomizing device of an electronic cigarette comprises an atomizing tube, an atomizing component disposed internal to the atomizing tube, and a connector for connecting a battery component; an e-liquid storage space is provided in an inner portion of the atomizing tube; a bottom part of the e-liquid storage space is sealed by inner walls of the atomizing tube and side walls of the atomizing component; an e-liquid inlet is provided on the atomizing component for inlet of the e-liquid; one end of the connector is fixed at a bottom part of the atomizing component; another end of the connector is fixedly connected to the battery component via mortise and tenon joints. The present invention can prevent unrestricted replenishment of e-liquid and enhance safety of use. Mortise and tenon joints are used to connect the atomizing device and the battery component, thereby facilitating connection and reducing breakdown rate.

Owner:SHENZHEN SMACO TECHNOLOGY LIMITED

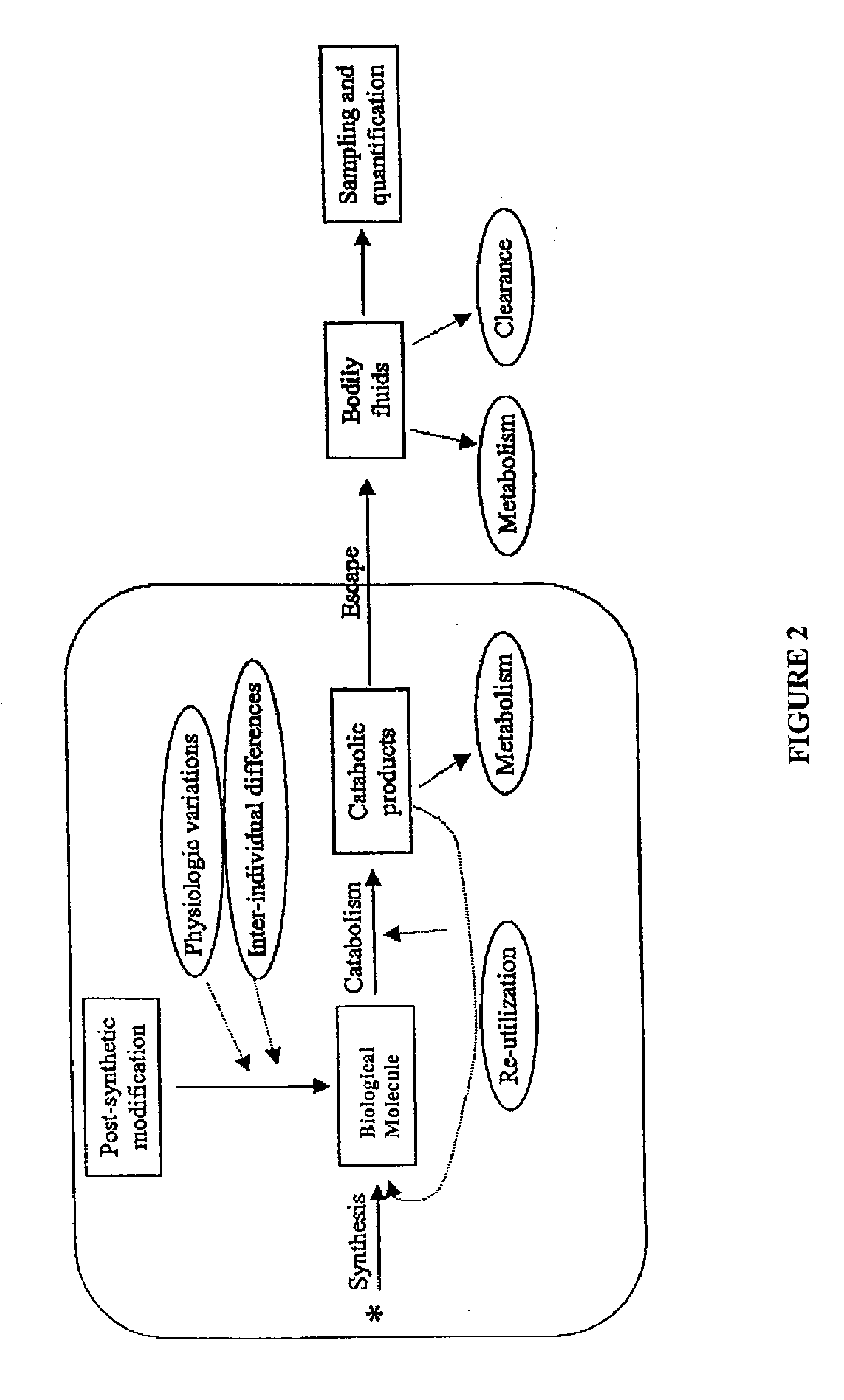

Measurement of biosynthesis and breakdown rates of biological molecules that are inaccessible or not easily accessible to direct sampling, non-invasively, by label incorporation into metabolic derivatives and catabolic products

Methods of determining rate of biosynthesis or breakdown of biological molecules from metabolic derivatives and catabolic products are disclosed herein. In particular, methods of measuring the rates of biosynthesis and breakdown of biological molecules inaccessible or not easily accessible to direct sampling by sampling metabolic derivatives and catabolic products in accessible biological samples are disclosed herein.

Owner:RGT UNIV OF CALIFORNIA

Measurement of biosynthesis and breakdown rates of biological molecules that are inaccessible or not easily accessible to direct sampling, non-invasively, by label incorporation into metabolic derivatives and catabolitic products

Methods of determining rate of biosynthesis or breakdown of biological molecules from metabolic derivatives and catabolic products are disclosed herein. In particular, methods of measuring the rates of biosynthesis and breakdown of biological molecules inaccessible or not easily accessible to direct sampling by sampling metabolic derivatives and catabolic products in accessible biological samples are disclosed herein.

Owner:RGT UNIV OF CALIFORNIA

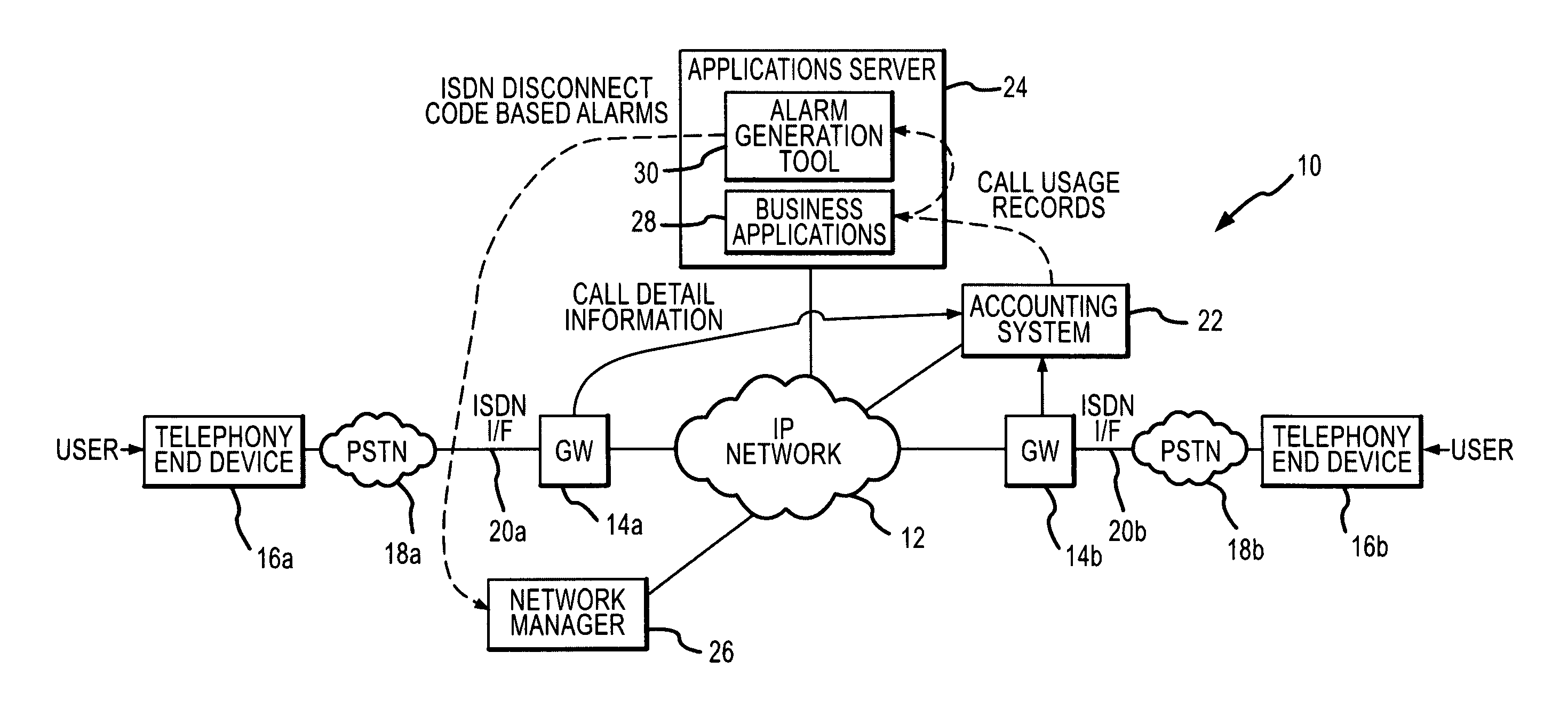

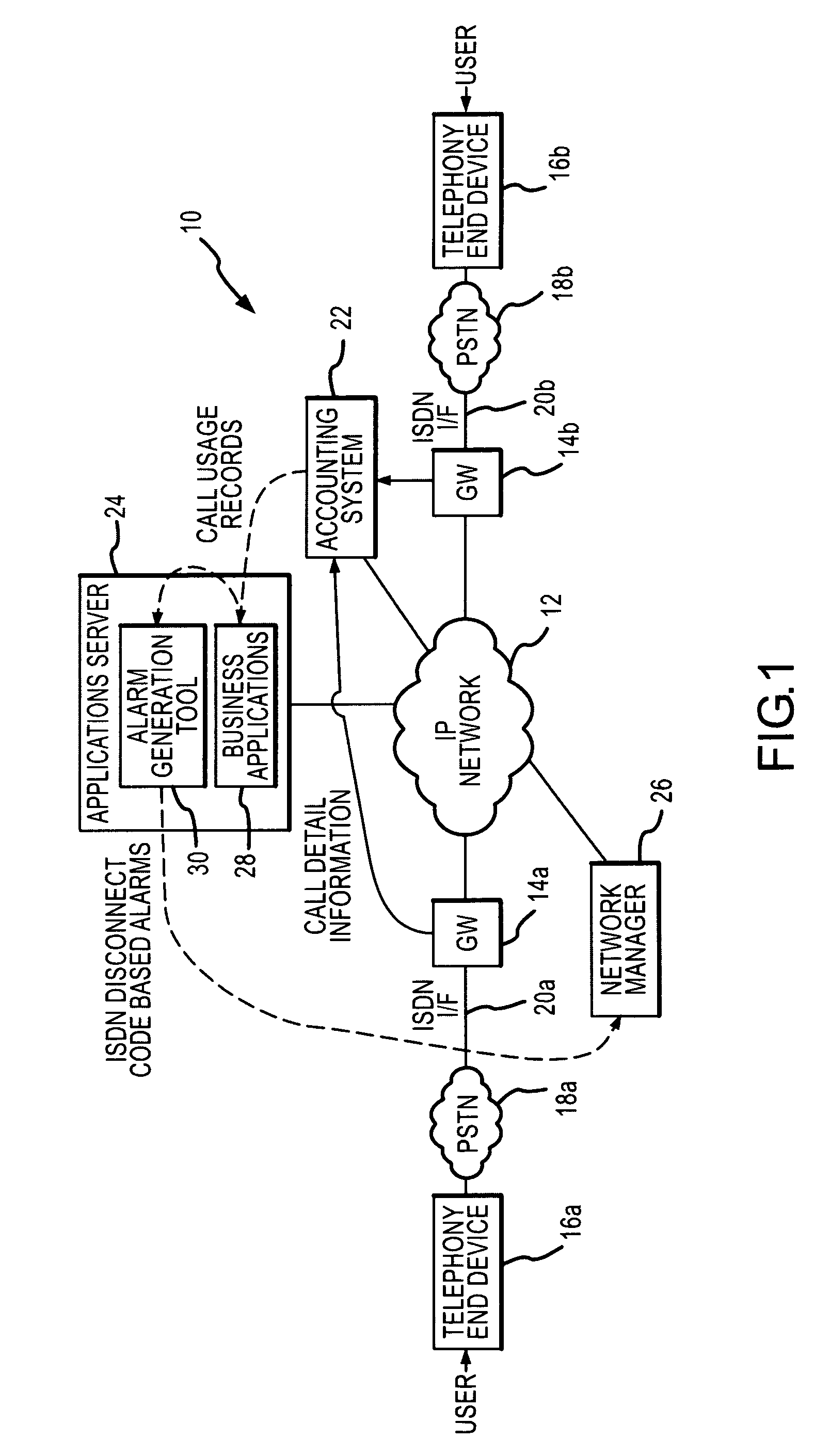

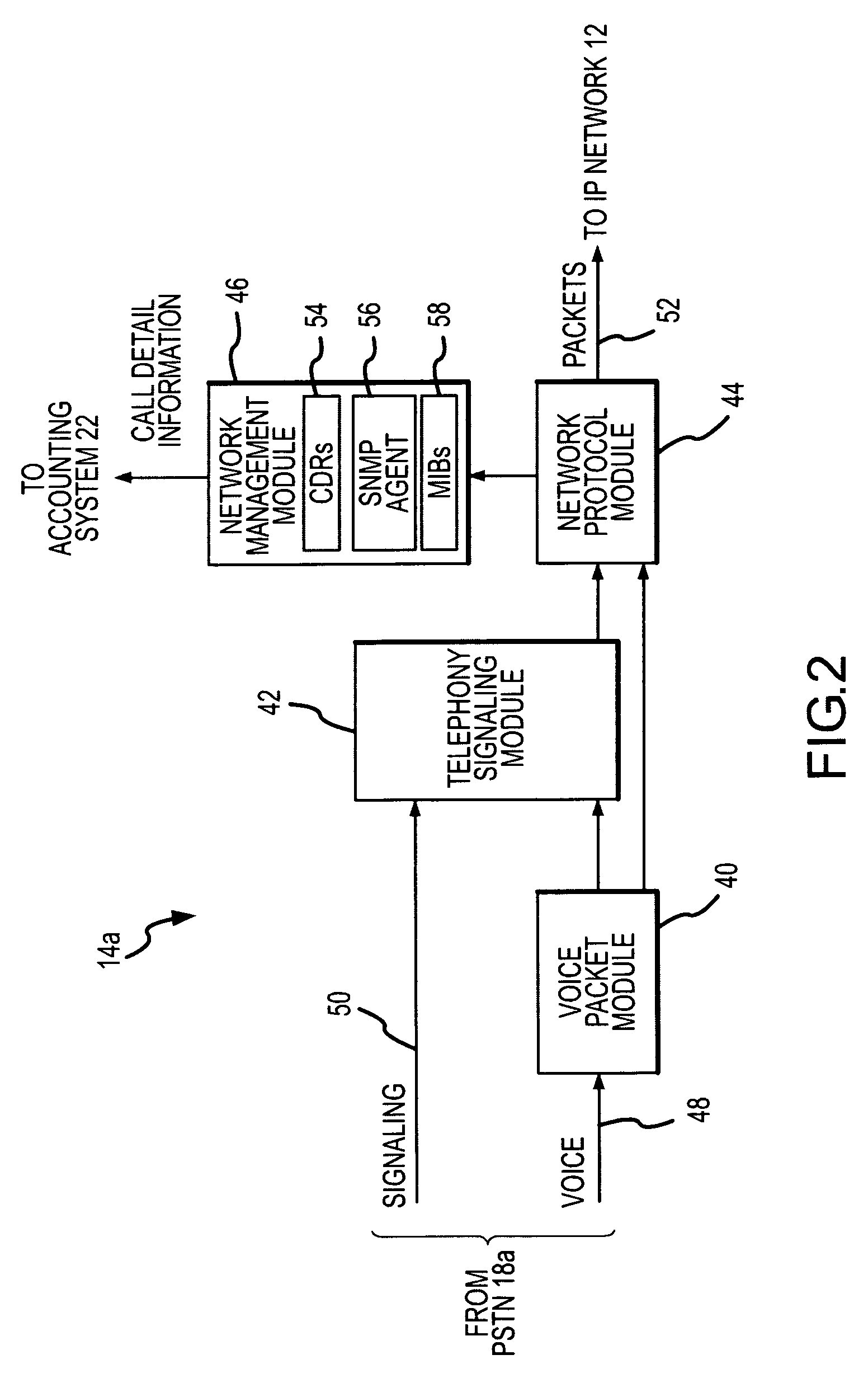

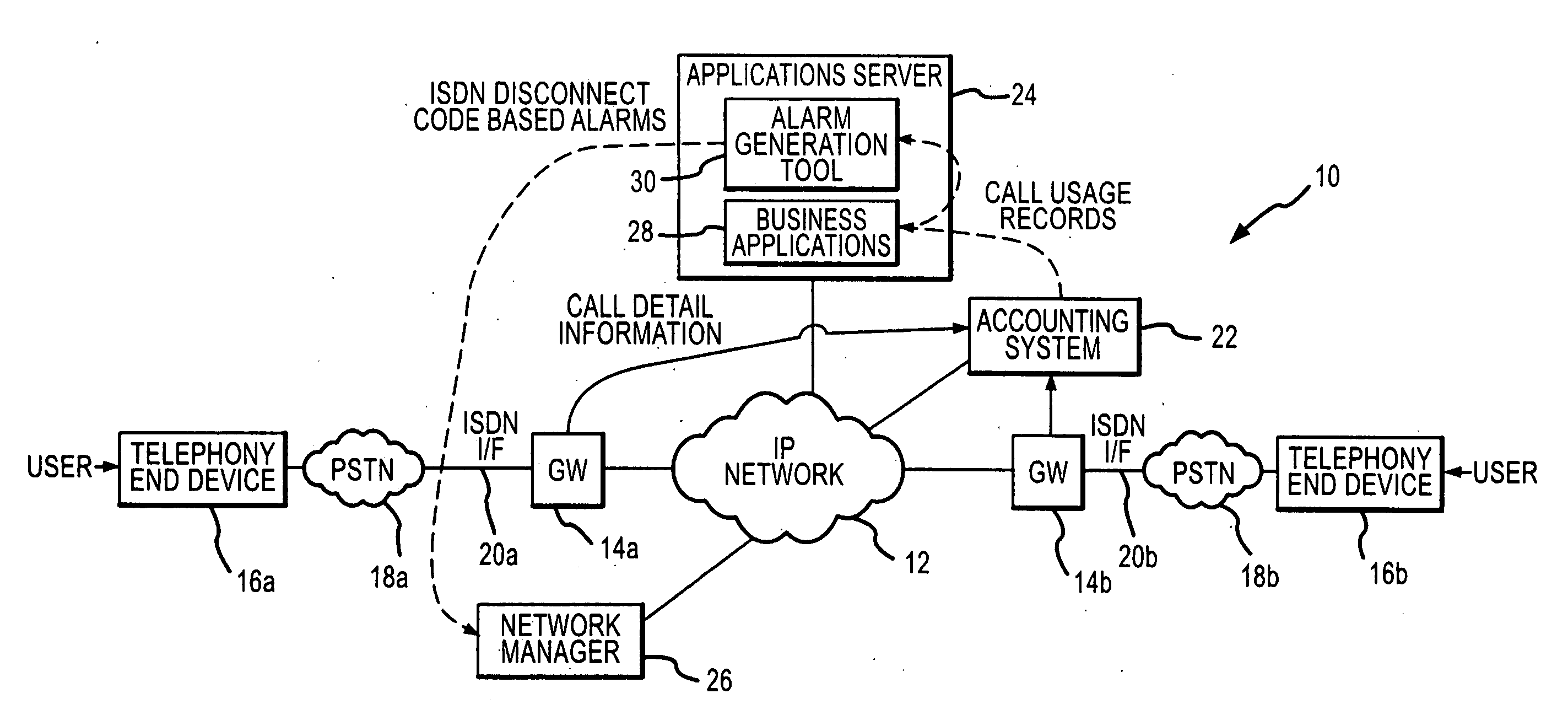

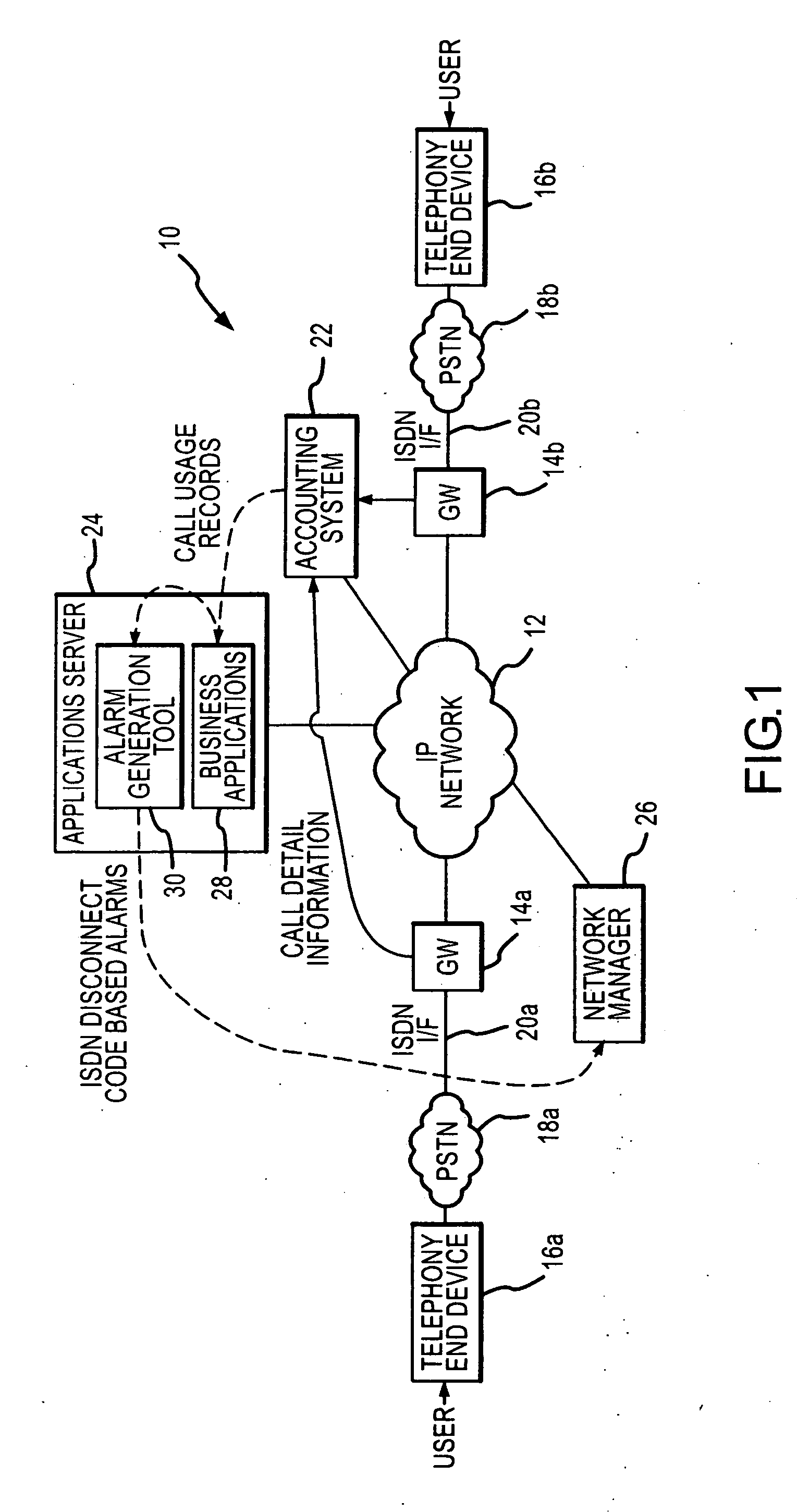

ISDN disconnect alarm generation tool for use in voice over IP (VoIP) networks

ActiveUS7051099B2Improve real-time informationAvoid serious problemsMultiplex system selection arrangementsISDN systemsTraffic capacityFailure rate

An alarm generation tool that operates within a Voice over IP (VoIP) network environment to generate alarms based on ISDN disconnect cause codes. The tool examines call-specific usage records associated with VoIP traffic to detect ISDN disconnect cause codes and determines failure rate information from failure-type disconnect cause codes among the ISDN disconnect cause codes on a per-gateway basis. The tool generates alarms when the failure rate information, such as failure rates and / or counts, exceeds defined thresholds.

Owner:LEVEL 3 COMM LLC

ISDN disconnect alarm generation tool for use in Voice over IP (VoIP) networks

InactiveUS20060230143A1Improve real-time informationMultiplex system selection arrangementsISDN systemsTraffic capacityFailure rate

An alarm generation tool that operates within a Voice over IP (VoIP) network environment to generate alarms based on ISDN disconnect cause codes. The tool examines call-specific usage records associated with VoIP traffic to detect ISDN disconnect cause codes and determines failure rate information from failure-type disconnect cause codes among the ISDN disconnect cause codes on a per-gateway basis. The tool generates alarms when the failure rate information, such as failure rates and / or counts, exceeds defined thresholds.

Owner:LEVEL 3 COMM LLC +1

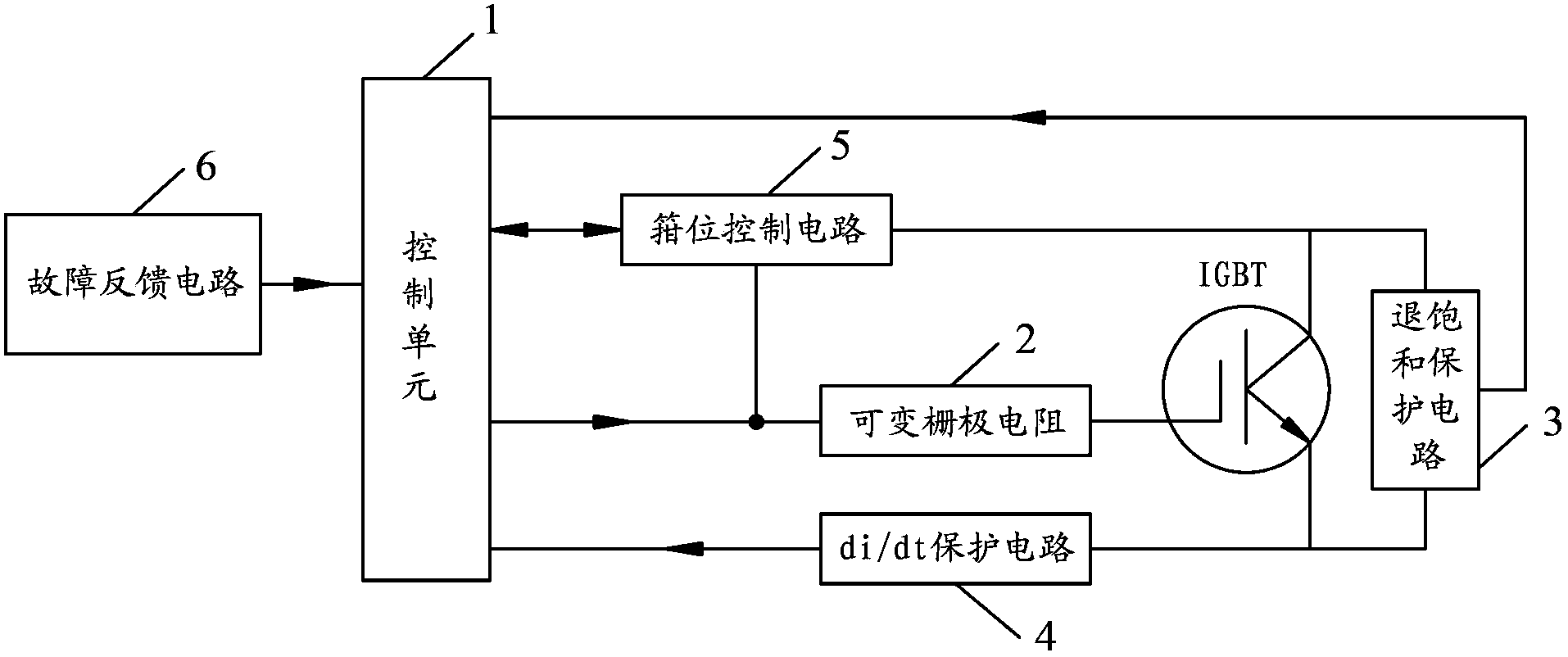

Protective circuit of insulated gate bipolar transistor

ActiveCN103427809AImprove protectionPerfect protectionElectronic switchingFailure rateFeedback circuits

The invention provides a protective circuit of an insulated gate bipolar transistor. The protective circuit of the insulated gate bipolar transistor comprises a control unit, a variable grid resistor, a withdraw saturation protective circuit, a di / dt protective circuit, a clamping control circuit and a fault feedback circuit. Intelligent protection of the insulated gate bipolar transistor is achieved through the arrangement of the control unit, main embodiments are that under the control of the control unit, a resistance value of the variable grid resistor can be changed and on-off losses of insulated gate bipolar transistor devices are effectively reduced; under the control of the control unit, the withdraw saturation protective circuit, the di / dt protective circuit, the clamping control circuit and the fault feedback circuit can achieve the relatively complete protection function. Therefore, the protective circuit of the insulated gate bipolar transistor is more complete in protection function, and the failure rate of the insulated gate bipolar transistor is low.

Owner:CRRC YONGJI ELECTRIC CO LTD

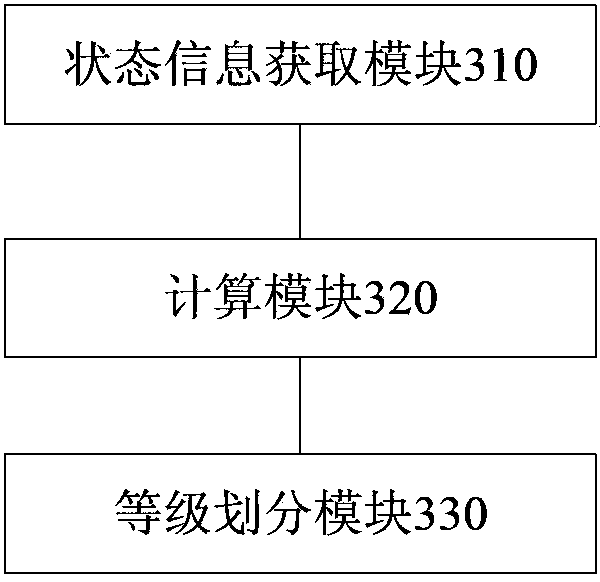

Method and device for grading and dispatching management of server hardware equipment and server

ActiveCN104346221AIncrease profitLow failure rateProgram initiation/switchingResource allocationFailure rateComputer science

The invention provides a method for grading server hardware equipment. The method comprises the following steps: obtaining status information of a plurality of server hardware equipment; calculating a health weight of the hardware equipment according to the status information of the hardware equipment and a preset model; determining health grade information corresponding to the plurality of server hardware equipment according to the health weight of the hardware equipment and a plurality of preset weight sections. The method is used for classifying the server hardware equipment according to the health level and marking the availability level under a large-scale application environment, so that the utilization rate of highly-available resources is increased, the failure rate and the fault cost of low-available resources are lowered, and the reliability of the server and a clustering system is improved; meanwhile, the method can support service grading and put the important service to the highly-available server, so as to improve the effectiveness on power consumption management of the server hardware equipment according to the health level. The invention further discloses a grading device for the server hardware equipment, a dispatching management method and a device for the server hardware equipment, and a server.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

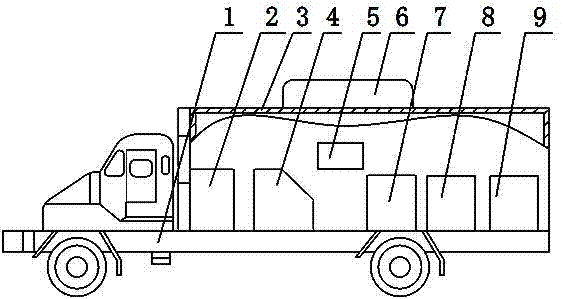

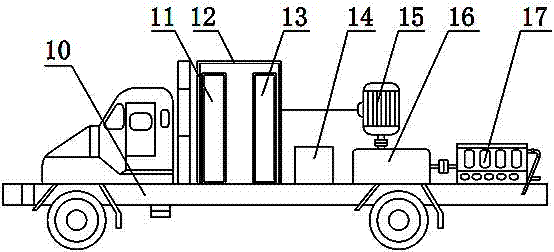

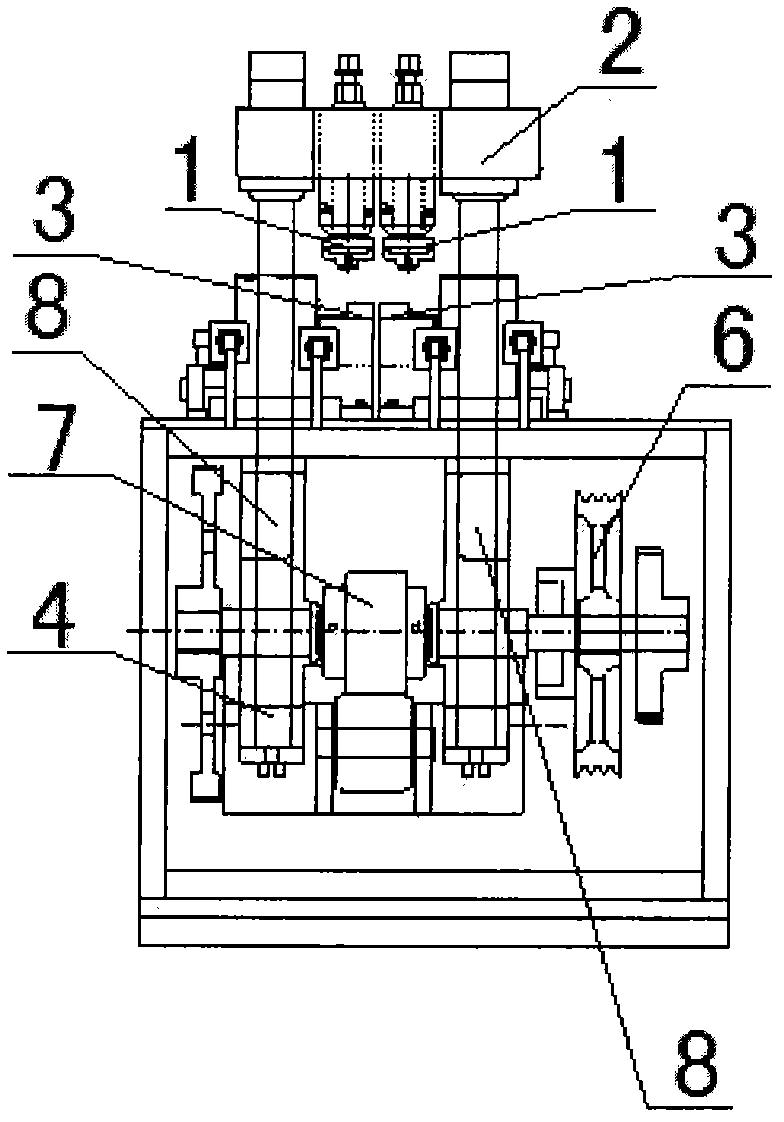

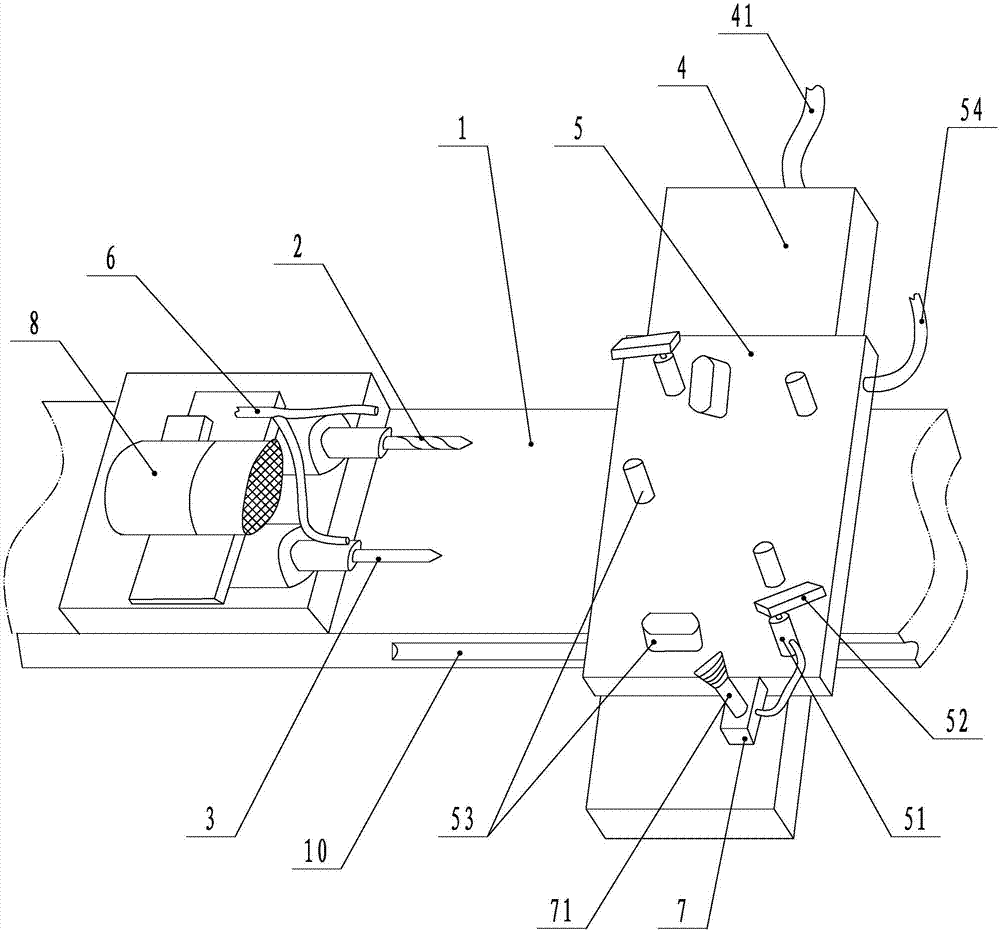

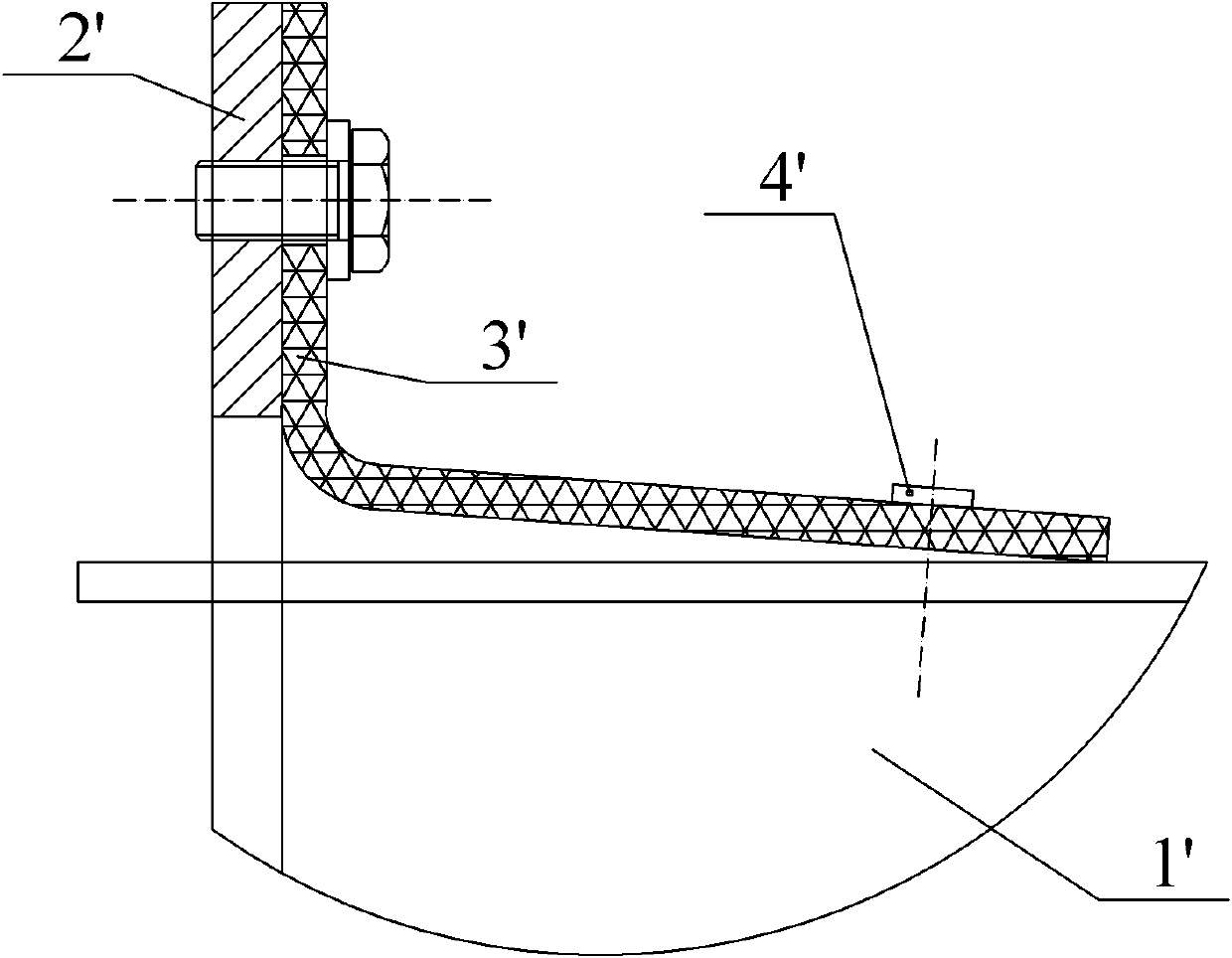

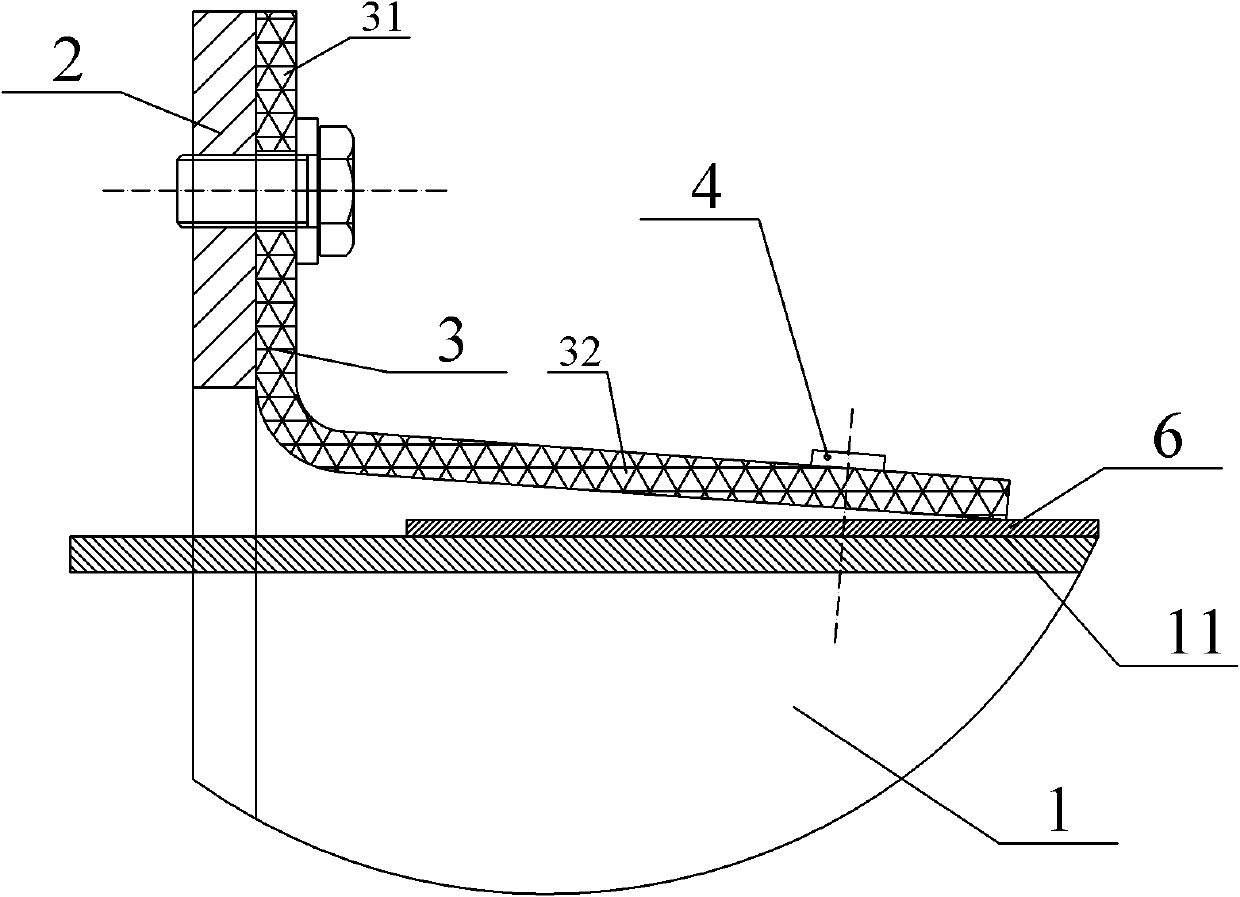

Fracturing unit for oil field exploitation

ActiveCN103089226AEasy to operateReduce connectionsFluid removalItem transportation vehiclesCollection systemData acquisition

The invention relates to a fracturing unit for oil field exploitation. The unit comprises a signal collection system, a measuring truck, a fracturing pump truck, a manifold truck and a fracturing blender truck. The measuring truck comprises a data collection and analysis system (4), a communication system (6), a controlling system (7) of the pump truck, a controlling system (8) of the fracturing blender truck and a controlling system (9) of the manifold truck. The fracturing pump truck comprises a controlling system, a motor driven device, a data sending and receiving device and a plurality of sets of fracturing pumps. The manifold truck comprises a hydraulic controlling system, a roller assembly and an automatic coiler device. The unit has the advantages that the centralized control of the fracturing pump truck, the manifold truck and the fracturing blender truck on the measuring truck is achieved through the data sharing of a local area network, and the unit improves the controlling precision and the construction safety of the equipment and the operation is convenient and simple. The unit reduces the cable connection between the trucks, and updates the controlling technique, thereby lowering the breakdown rate of the equipment and reducing the maintaining cost drastically.

Owner:SICHUAN HONGHUA ELECTRIC

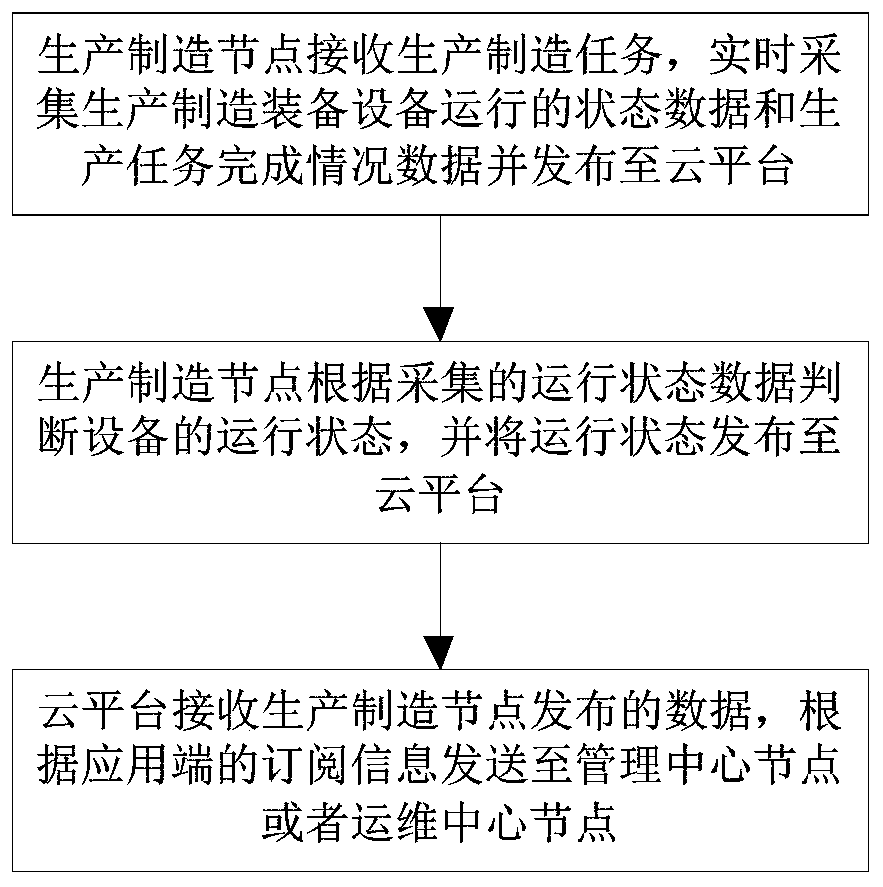

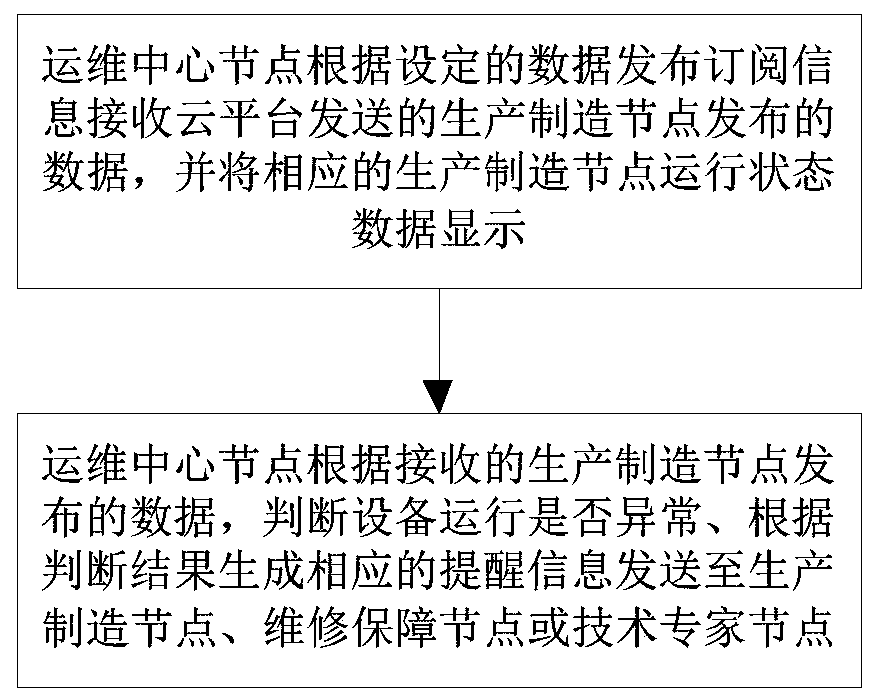

A remote operation and maintenance management system and method for industrial manufacturing equipment

InactiveCN109840602AReal-timeRealize uploadResourcesData switching networksMaintenance managementEngineering

The invention provides a remote operation and maintenance management system and method for industrial manufacturing equipment. By deploying a a remote measurement and control service middleware on a cloud platform, deploying a production and manufacturing operation and maintenance management platform on each node and deploying a measurement and control task action processing assembly on the production and manufacturing equipment, a remote transmission and interaction link of equipment state data and production data is broken through, and remote real-time state monitoring of the equipment and efficient operation and maintenance in the production and manufacturing process are achieved. The operation state monitoring capability and the equipment utilization rate of the industrial manufacturing equipment are effectively improved, the equipment failure rate is reduced, and the operation and maintenance cost is reduced while the equipment efficiency is improved.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

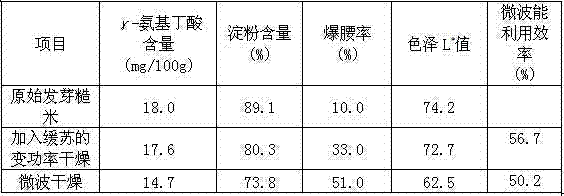

Microwave drying germinated brown rice quality protecting method based on tempering and variable power

InactiveCN104489082ARich in nutrientsReduce waist burst rateSeed preservation by dryingMicrowaveGamma-Aminobutyric acid

The invention discloses a microwave drying germinated brown rice quality protecting method based on tempering and variable power, and relates to a drying method of germinated brown rice. The microwave drying germinated brown rice quality protecting method based on the tempering and the variable power solves the problems that an existing microwave drying method of the germinated brown rice destroys nutritional ingredients in the germinated brown rice, and microwave energy is low in utilization efficiency. The microwave drying germinated brown rice quality protecting method based on the tempering and the variable power includes: evenly and flatly spreading the germinated brown rice on a continuous microwave drying device conveying belt, introducing a tempering and variable power technology under certain microwave drying power and certain air speed, and drying the germinated brown rice until moisture content of the germinated brown rice ranges from 14% to 15%. The microwave drying germinated brown rice quality protecting method based on the tempering and the variable power retains the nutritional ingredients in the germinated brown rice to the utmost. The germinated brown rice after being dried through the microwave drying germinated brown rice quality protecting method based on the tempering and the variable power contains 13.1-18.5mg / 100g of gamma-aminobutyric acid, and starch content in the germinated brown rice after being dried through the microwave drying germinated brown rice quality protecting method based on the tempering and the variable power is 69.0%-89.3%. Breakdown rate of the germinated brown rice after being dried through the microwave drying germinated brown rice quality protecting method based on the tempering and the variable power is 30.0%-40.0%. Color L* value of the germinated brown rice after being dried through the microwave drying germinated brown rice quality protecting method based on the tempering and the variable power is 60.6-70.4. Microwave energy utilization efficiency of the microwave drying germinated brown rice quality protecting method based on the tempering and the variable power is 50.7%-60.5%. The microwave drying germinated brown rice quality protecting method based on the tempering and the variable power obtains good quality products, retains the intrinsic nutritional ingredients and intrinsic colors of the germinated brown rice to the utmost, and achieves good quality.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Fault diagnosis device for coal mine digging machine

InactiveCN101975672AExtended service lifeObserve the running status in real timeBus networksWireless transceiverTransceiver

Owner:CHINA UNIV OF MINING & TECH

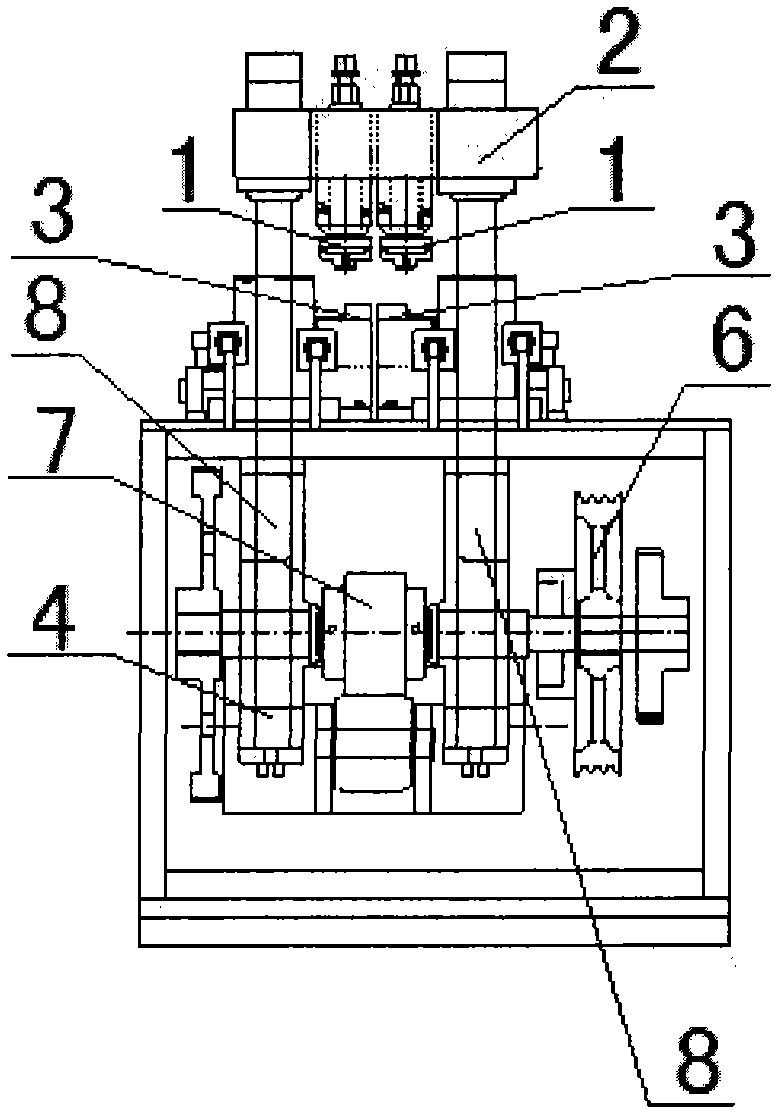

Pouring technology for dry-type transformer coils

ActiveCN105321705AImprove technical indicatorsLow equipment requirementsCoils manufactureTransformerNational standard

A pouring technology for dry-type transformer coils is disclosed. The pouring technology comprises the working procedures of drying, degassing, mixing materials, pouring, curing and de-molding. The pouring method can be widely applied to resin pouring type coils of various capacities and structural forms, and has a low equipment demand. The coils processed by the technology have the advantages of less coil air gaps, high epoxy toughness and high de-molding efficiency; the magnitude of partial discharge of the coils is far below the magnitude of partial discharge of the national standard; and breakdown rate in a power-frequency voltage-withstand test is low than 0.1%

Owner:STATE GRID CORP OF CHINA +2

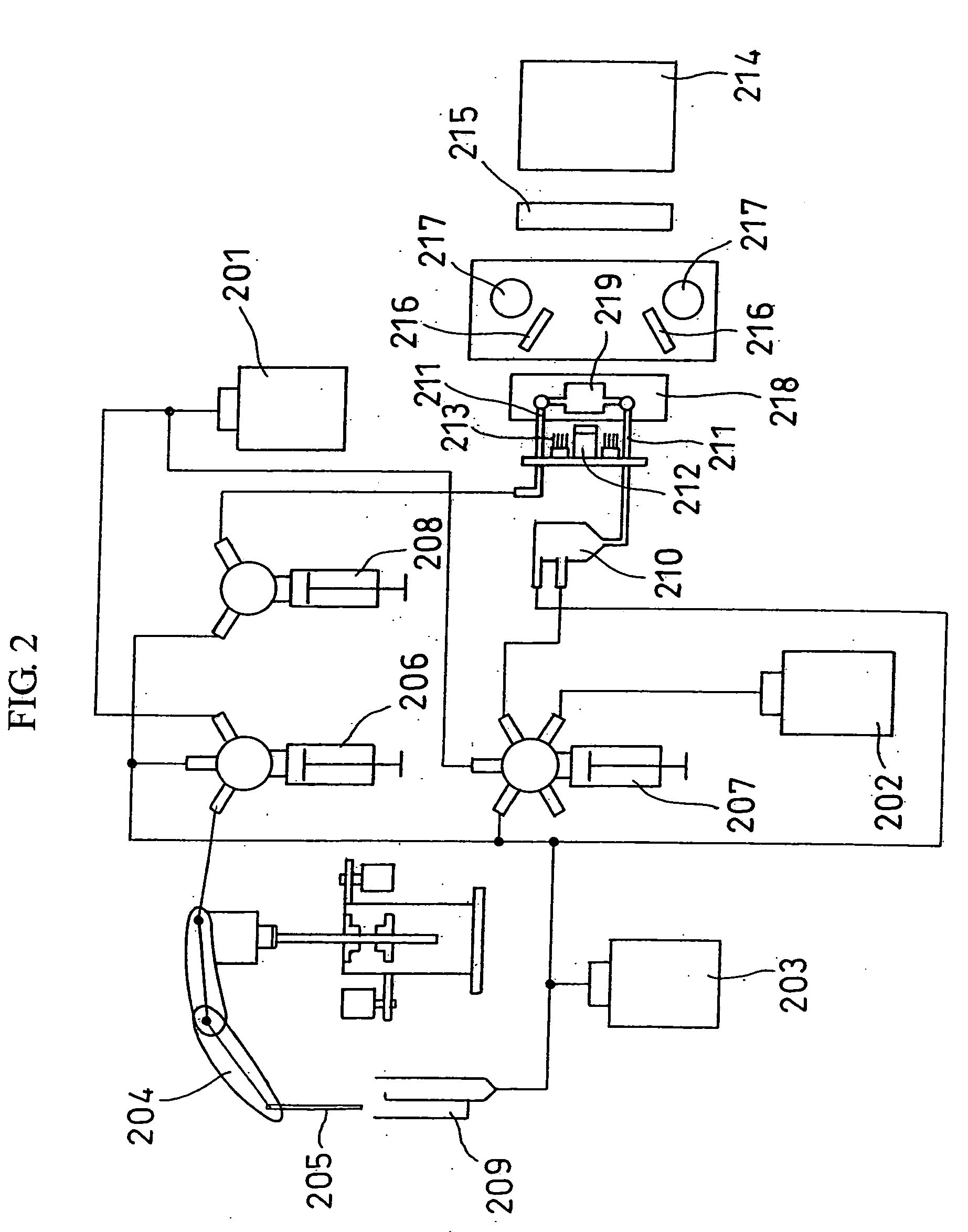

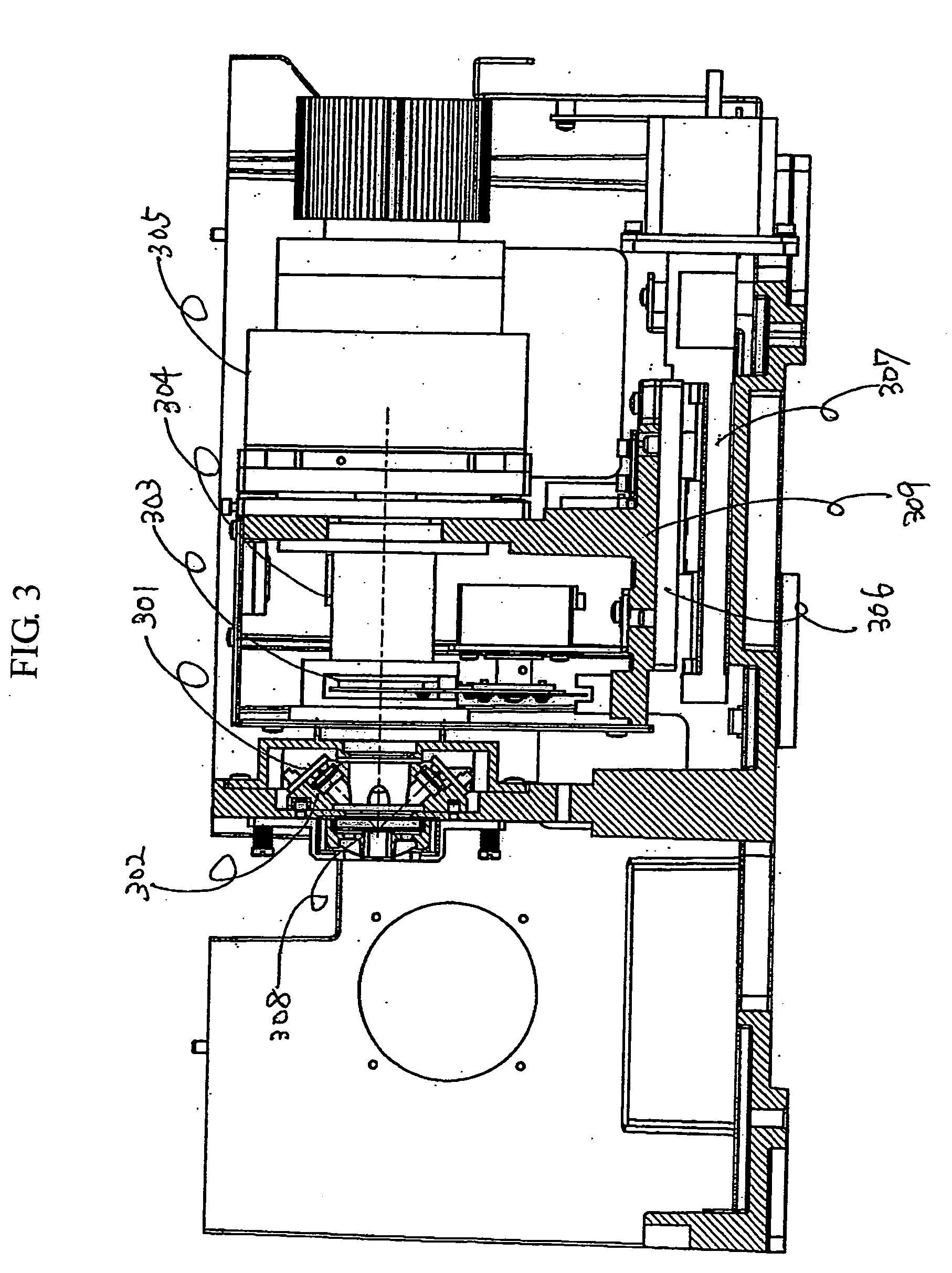

Nucleic acid analysis apparatus

InactiveUS20050196778A1High measurement accuracyLow costBioreactor/fermenter combinationsBiological substance pretreatmentsFailure rateFluorescence

An apparatus measures individual measurement sites on a DNA chip in a short period of time. The DNA chip is irradiated by light-emitting diodes (LEDs) so as to excite fluorescent dye at each measurement site, and fluorescence emitted from the individual measurement sites is detected all at once. Since substantially uniform measurement conditions can be obtained for each measurement site, measurement accuracy increases. The read mechanism requires less space and is less costly, thereby decreasing the failure rate and virtually eliminating the need for maintenance of the apparatus.

Owner:HITACHI HIGH-TECH CORP

Aluminum electrolytic capacitor and manufacturing method thereof

ActiveCN109616327ALow costShorten the lengthLiquid electrolytic capacitorsWinding capacitor machinesElectrolysisBreakdown rate

The invention provides an aluminum electrolytic capacitor. A basic structure of the aluminum electrolytic capacitor is of a foil-type winding structure and is fabricated by winding a positive electrode foil corroded to form an oxide film, a corroded negative electrode foil and electrolyte paper partitioned between the positive electrode foil and the negative electrode foil to form a core pack, immersing the core pack in an electrolyte, riveting a cover plate and sealing in an aluminum shell. The length of the positive electrode foil is reduced, the winding number of the aluminum electrolytic capacitor can be reduced after winding is completed, so that the volume of the aluminum electrolytic capacitor can be reduced; compared with electrolyte paper selecting general thickness and general density in the prior art, the volume of the aluminum electrolytic capacitor formed by winding can be reduced after winding is completed, the breakdown rate of the aluminum electrolytic capacitor is reduced, meanwhile, the oxidization time of the positive electrode foil during oxidization can be reduced, the efficiency is improved, and the cost is reduced.

Owner:横店集团东磁有限公司

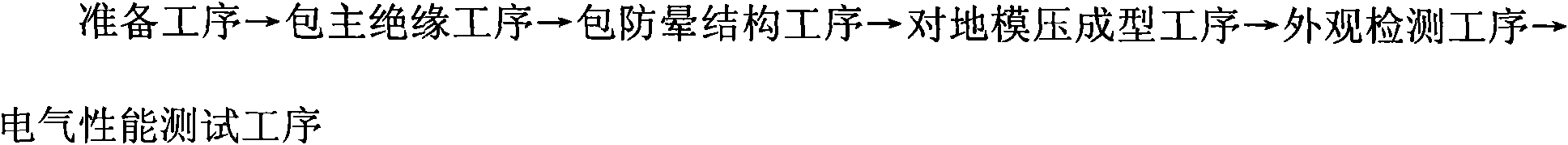

Die-pressing processing method for bar coils of motor

InactiveCN101604889ANice appearanceConsistent section sizeApplying solid insulationHydraulic cylinderEngineering

The invention relates to a die-pressing processing method for bar coils of a motor, and belongs to the technical field of motor coils. The die-pressing processing method for the bar coils of the motor is characterized in that transposition is carried out from the straight line of the bar coils to two thirds of the end, and a lead wire welds the finished coils. The method comprises the following processes: 1) binding a main insulator: a, placing upper and lower bar coils on a coil bracket of a binding machine respectively; b, adjusting the geometrical size of the end of the binding machine, and arranging a required end elevating cushion block at the end of the binding machine; and c, binding the main insulator according to the compression amount given by the process; 2) treating an anti-halation structure; and 3) die-pressing processing and molding, namely flatly wrapping a layer of polytetrafluoroethylene film strip on the upper and lower bar coils, putting the bar coils into a bar coil die-pressing die respectively, providing current from the lead wire of the coils by adopting a pressurizing mode of a hydraulic cylinder, and performing die-pressing processing and molding on the coils from the interior to the surface by adopting a curing mode and a heating method. The method has the advantages of simple process, high insulating strength, reduced breakdown rate, long service life, high production efficiency, attractive appearance, and the like.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

Security function starting method and terminal

ActiveCN103686332AIncrease productivityReduce bad chanceSelective content distributionBreakdown rateEncryption

The embodiment of the invention discloses a security function starting method. The method includes the first step of running startup resetting software stored in a flash memory when detecting that the security function of a chip security module is not at the time of booting, the second step of opening the security function of the chip security module by running the startup security function of the startup resetting software stored in the flash memory, the third step of obtaining encryption signature software stored in the flash memory when detecting that security function of the chip security module is opened at the time of rebooting, and the fourth step of verifying the obtained encryption signature software stored in the flash memory through the opened security function of the chip security module so that programs can be played through the verified encryption signature software. The embodiment of the invention further discloses a security function starting terminal. Through the adoption of the security function starting method and the terminal, the purpose of starting the security function in the production process is achieved, production efficiency is improved and the breakdown rate is reduced.

Owner:SHENZHEN SKYWORTH DIGITAL TECH CO LTD +1

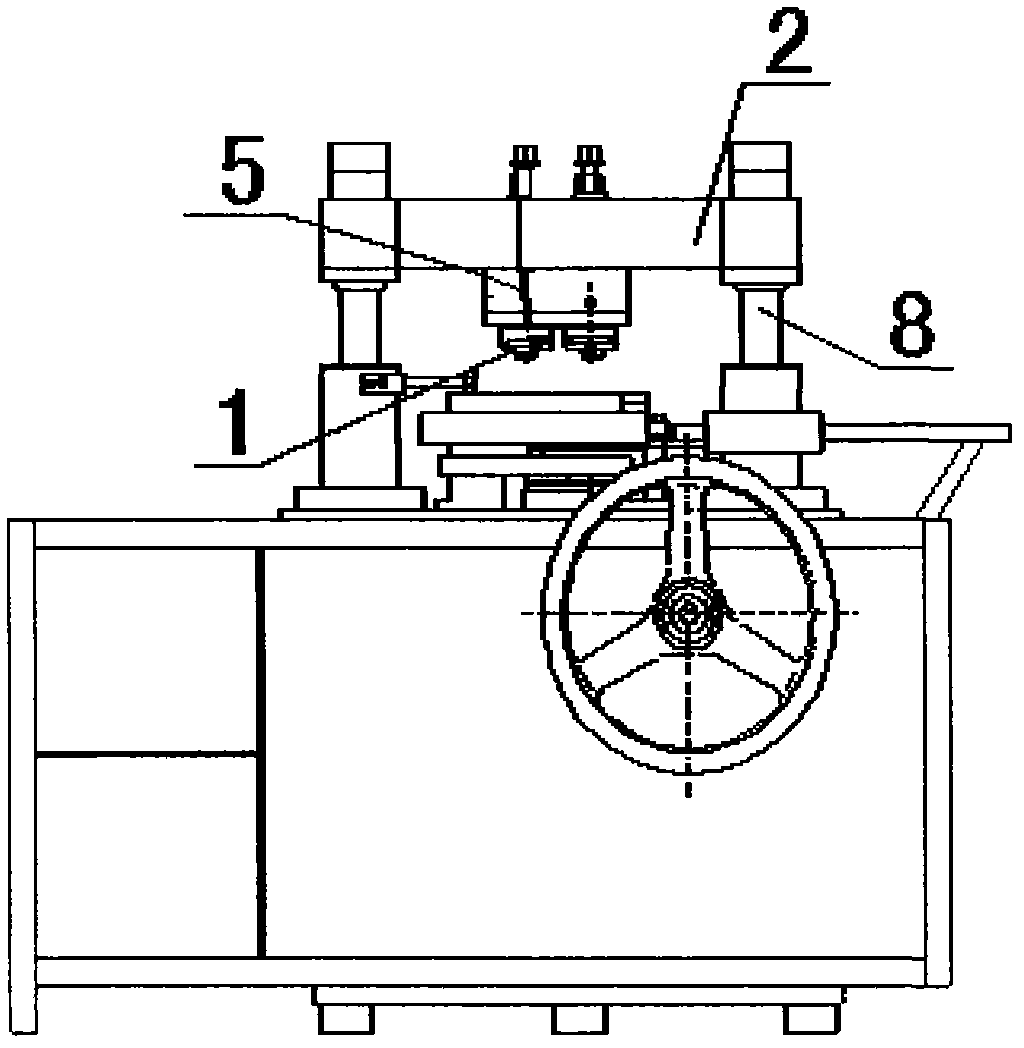

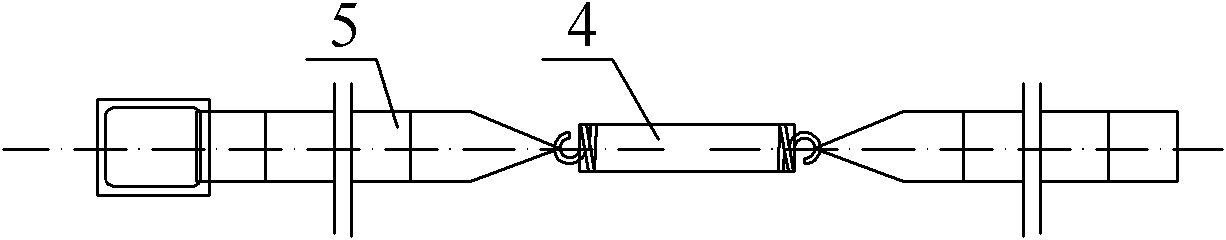

Biserial chain quadrangular riveting machine

InactiveCN102615242ASmooth runningImprove operating conditionsMetal chainsEngineeringMechanical engineering

The invention discloses a biserial chain quadrangular riveting machine which comprises a power device, a support device, a stamping die and a safety protection device; a chain to be riveted is arranged in the stamping die; the power device is arranged below a working platform of the riveting machine and is matched with the stamping die through being connected with the support device; and the safety protection device is arranged on the support device for protection. According to the riveting machine, riveting heads are arranged side by side and in pairs so as to enable the number of the riveting heads to be increased by two times, so that the original yield can be achieved at half of the original rotation speed, the machine can rotate more stably, the breakdown rate is greatly reduced, and the quantity and quality of products can be improved favorably; and the additionally arranged safety protection device can prevent fracture of an upper cross beam to safeguard the interests and safety of a user in the case of misoperation by the user.

Owner:QINGDAO JIAFU MACHINERY

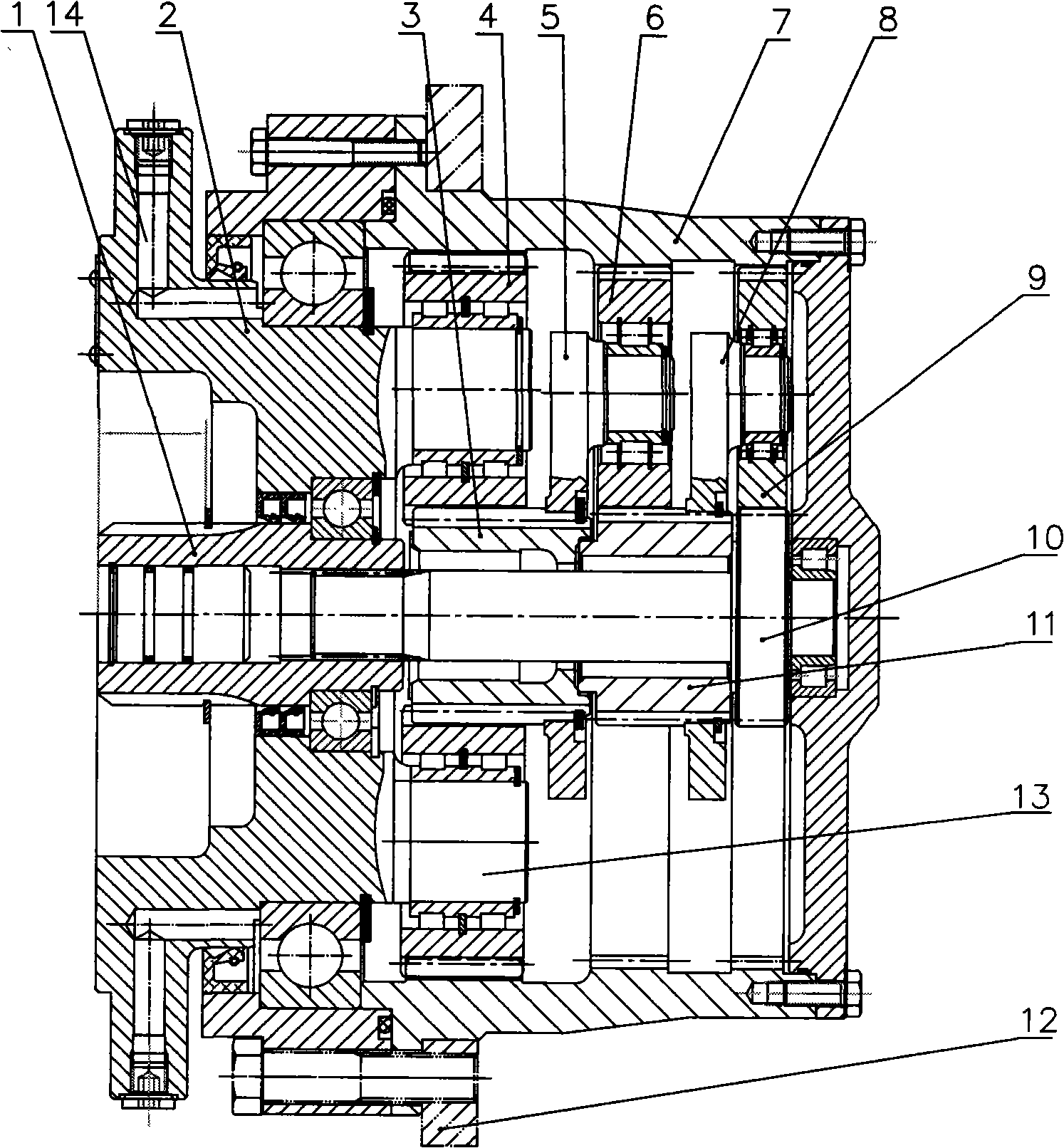

Planet speed reducer for bridge crane

InactiveCN101279696AEliminate damaged failure modesUniform loadTravelling cranesWinding mechanismsThree levelGear wheel

The invention relates to a planetary reducer essentially used for a small traveling crane on a bridge crane at port bank and also used for a hoisting mechanism of other similar machines; the planetary reducer comprises a bracket (2), an input spline housing (1), a three-level planetary transmission device, a ring gear (7) and so on. The bracket (2) is fixed on the small traveling crane. The input spline housing (1) is arranged on a central hole of the bracket (2). The axle of a primary solar wheel (10) in the three-level planetary transmission device is inserted in the other end of the input spline housing (1). A three-level planetary bracket (13) is fixedly connected with the bracket (2). The ring gear (7) fixed on a hoisting mechanism drum (12) is arranged on the external side of the three-level planetary transmission device and is meshed with the three-planetary bracket at the same time. The three planetary gears transport the torque to the ring gear (7) at the same time. The ring gear (7) is directly output to the hoisting mechanism. The planetary reducer has the advantages of simple and compact structure, novel transmission way, high transmission efficiency, simple manufacturing and maintenance, high reliability, low breakdown rate and low cost, etc.

Owner:泰安泰山福神齿轮箱有限责任公司

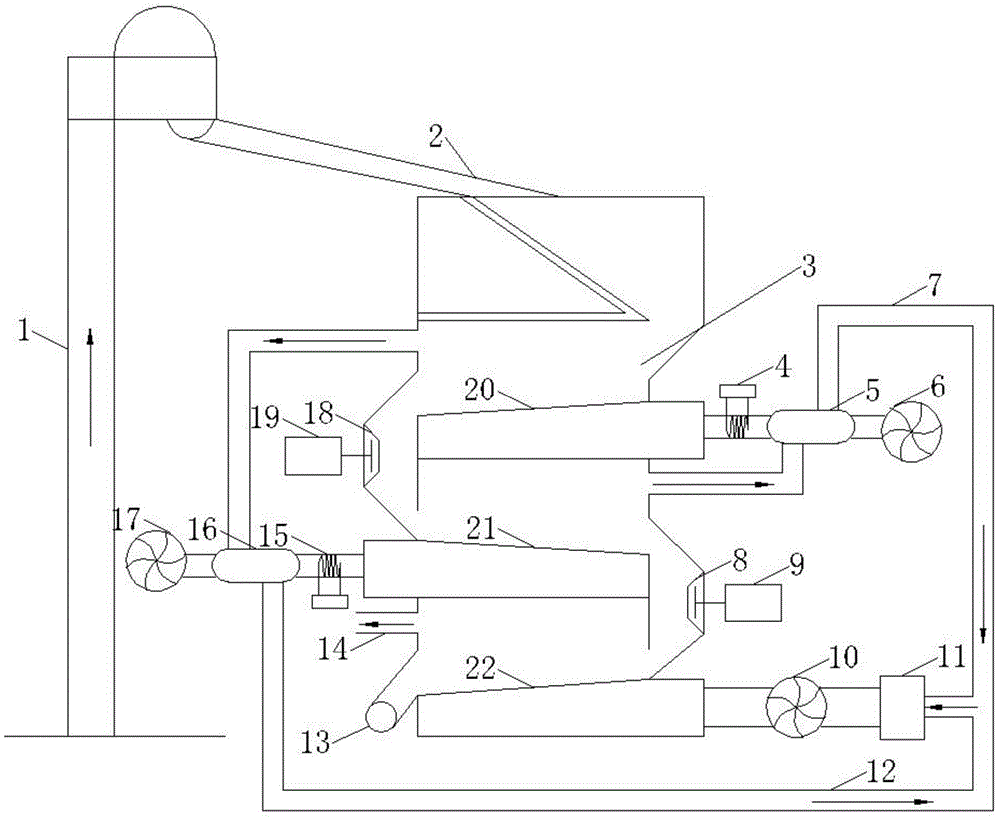

Unhusked rice drying device under effect of combination of ultrasonic waves and hot air

InactiveCN104663876AReasonable useGuaranteed qualitySeed preservation by dryingUltrasound - actionHigh energy

The invention mainly discloses an unhusked rice drying device. The drying process comprises the steps of drying, carrying out ultrasonic tempering, drying, carrying out ultrasonic tempering and cooling. The process comprises the following steps: drying unhusked rice layeredly and sectionally under the condition that low-temperature hot air with certain air speed is used so that a material has a fluidic state; then tempering for a period of time under ultrasonic effect; then drying at high temperature with hot air, and tempering again under the ultrasonic effect after drying completely; meanwhile, recovering dry hot air which performs damp and hot exchange on a first layer and a second layer, and preheating dry media of the second layer and the first layer by an efficient gas heat exchanger via dry hot air; and finally drying the hot air with a certain drying capacity, and cooling the unhusked rice. The unhusked rice drying device can solve the problems of low economic benefit and the like caused by high energy consumption, low heat transfer and mass transfer efficiency, low dried unhusked rice quality of the traditional unhusked rice drying device; the dried unhusked rice has the characteristics of good condition, low breakdown rate and convenience in subsequent processing.

Owner:CHANGZHOU UNIV

Broussonetia papyrifera leaves health obesity attenuation capsule and its preparation method

ActiveCN101306086AWide variety of sourcesReduce processing costsMetabolism disorderCapsule deliveryAspergillusObesity

The invention relates to a broussonetia papyrifera leaf health protection and slimming gelatine capsule and a method for preparing the lotus leaf health protection and slimming gelatine capsule. The broussonetia papyrifera leaf health protection and slimming gelatine capsule comprises 50 to 70 parts of broussonetia papyrifera leaf extract and 30 to 50 parts of lotus leaf extract. The broussonetia papyrifera leaf extract is generated by fermenting powdered broussonetia papyrifera leaves with aspergillus and microzyme; the lotus leaf extract is generated by fermenting powdered lotus leaves with aspergillus and microzyme. After the powdered broussonetia papyrifera leaves are fermented, protein is resolved into polypeptide and amino acid, and can activate lipolytic enzymes. After the lipolytic enzymes are activated, the breakdown rate of excess fat in human bodies is significantly improved, and the excess fat is converted into adenosine triphosphate which is the bioenergy necessary for movement of human beings. The broussonetia papyrifera leaf health protection and slimming gelatine capsule can resist cellular oxidation, senility, reduce blood fat, slim and improve the immunity of human bodies.

Owner:刘尚文 +2

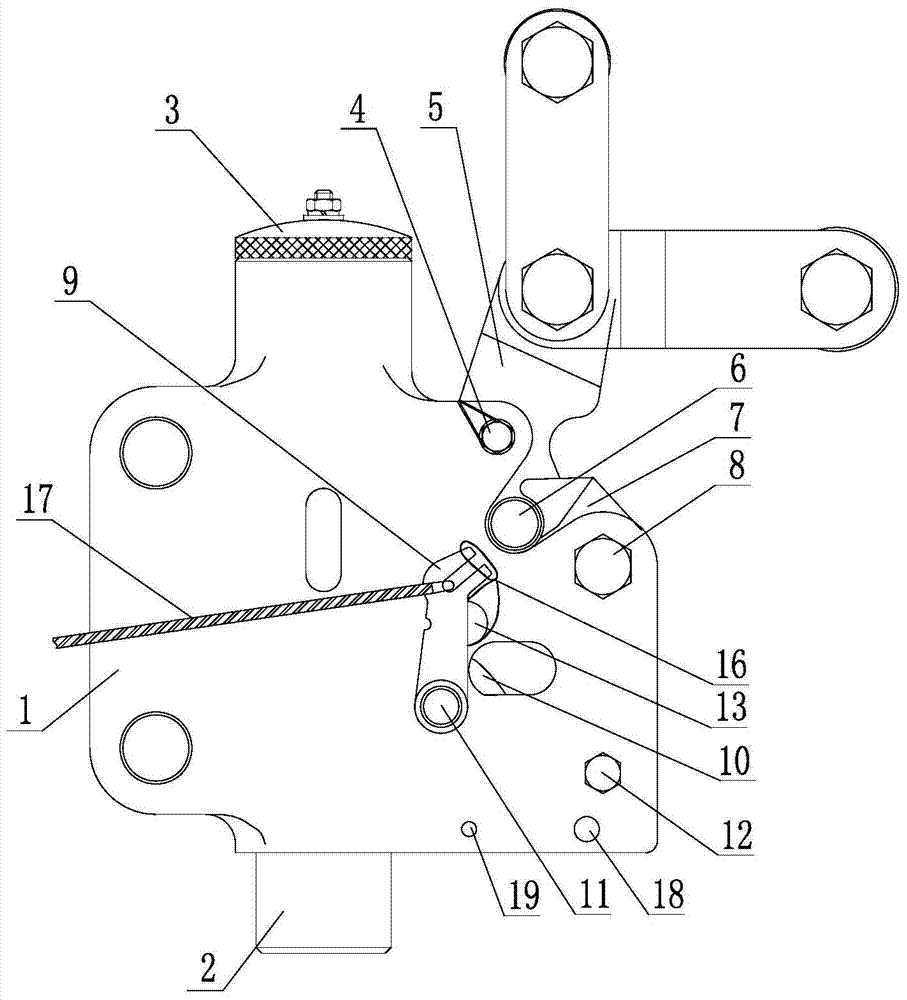

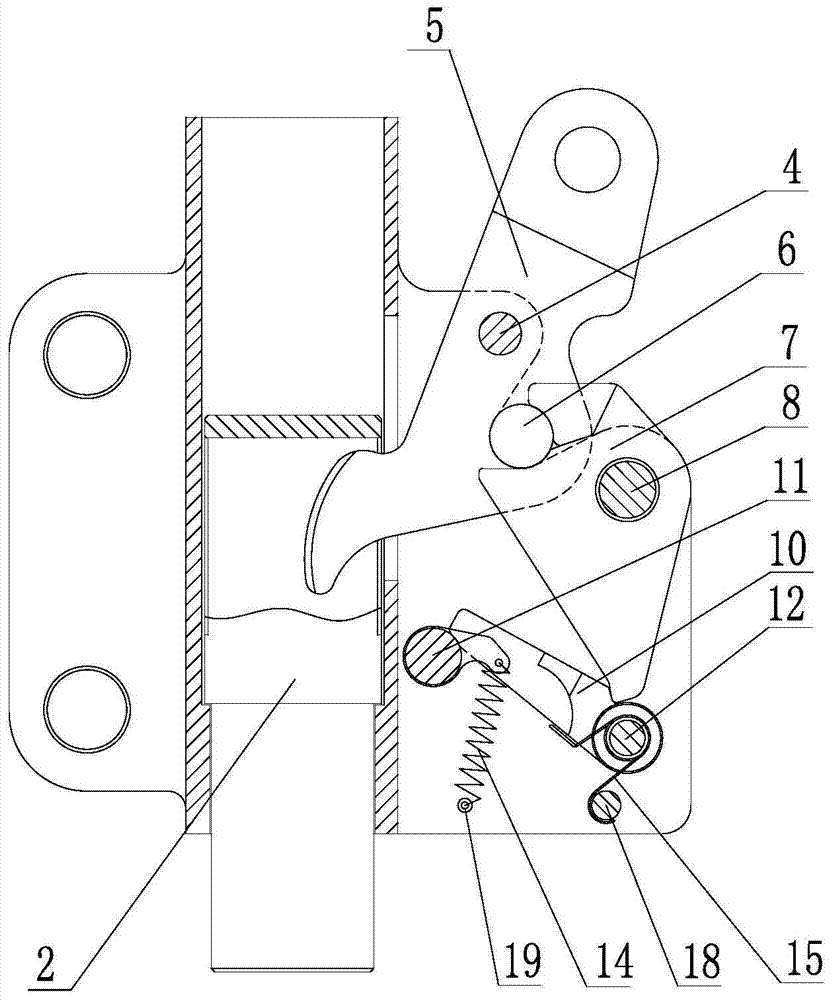

Traction disconnecting device

ActiveCN103612758ALock releaseWon't shakeAircraft componentsLaunching weaponsEngineeringBreakdown rate

The invention relates to a traction disconnecting device which comprises a shell (1), a locking lever (5), a piston rod (2), a rocker arm (7), an unlocking lever (9) and a disconnecting cable (17). A movable tube is arranged in the shell (1), the piston rod (2) moves in the movable tube, a clamping groove is formed in the side wall of the piston rod (2), one end of the locking lever (5) is clamped in the clamping groove, and the other end of the locking lever (5) is used for being connected with a traction umbrella. A rotating shaft (6) of the locking lever (5) is clamped between a clamping opening of the shell (1) and a clamping opening in the upper end of the rocker arm (7), the rotating shaft (6) of the locking lever (5) drives the rocker arm (7) to rotate when moving, and the locking lever (5) is fixed on the shell (1) through a shear pin (4). According to the traction disconnecting device, a multi-level lever mechanism is used, the transmission force ratio is large, the structure is compact, the size is small, constrains can be released automatically and easily, airdrop equipment can be locked through anchoring force, and the breakdown rate is greatly lowered.

Owner:AEROSPACE LIFE SUPPORT IND LTD

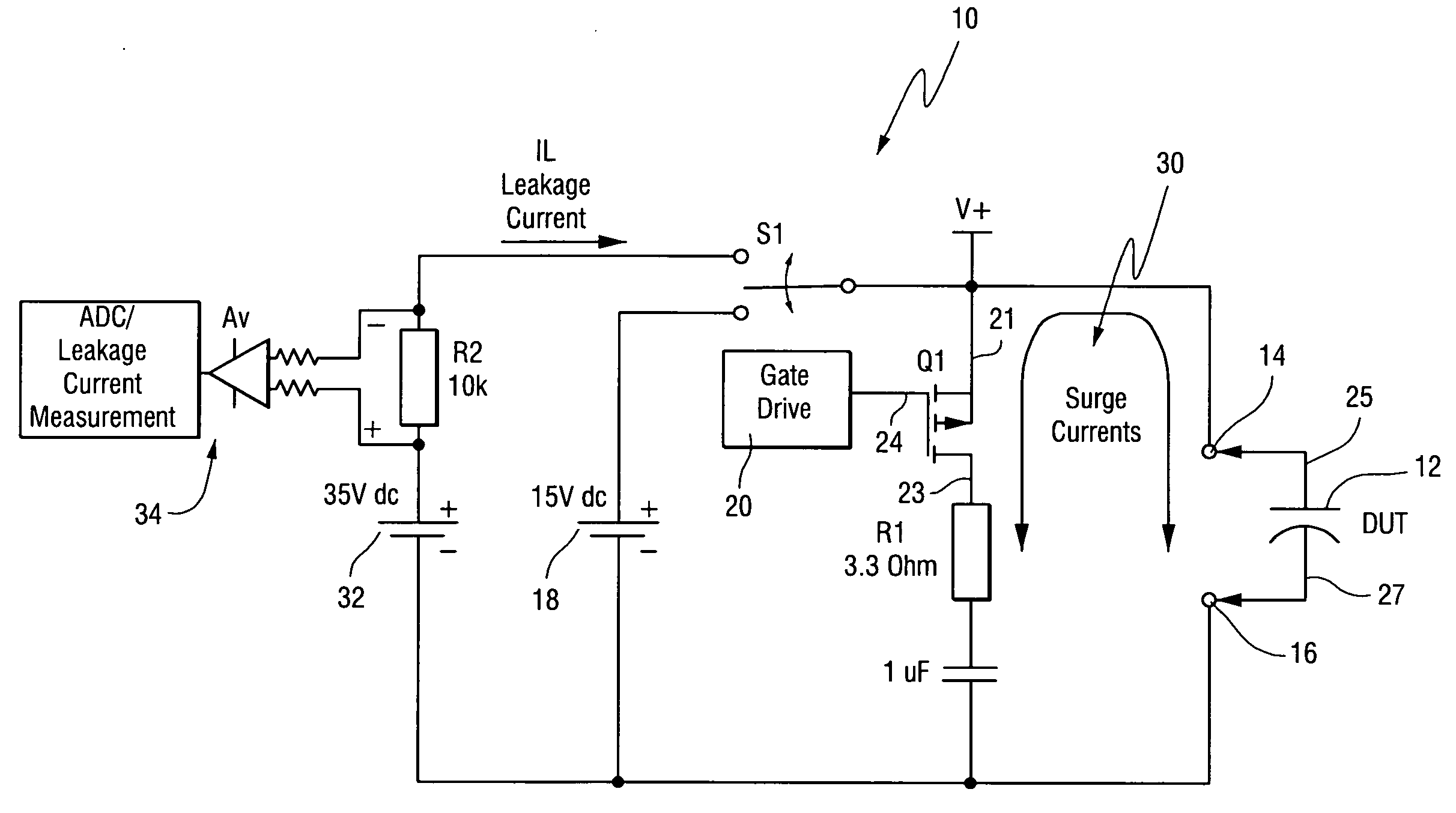

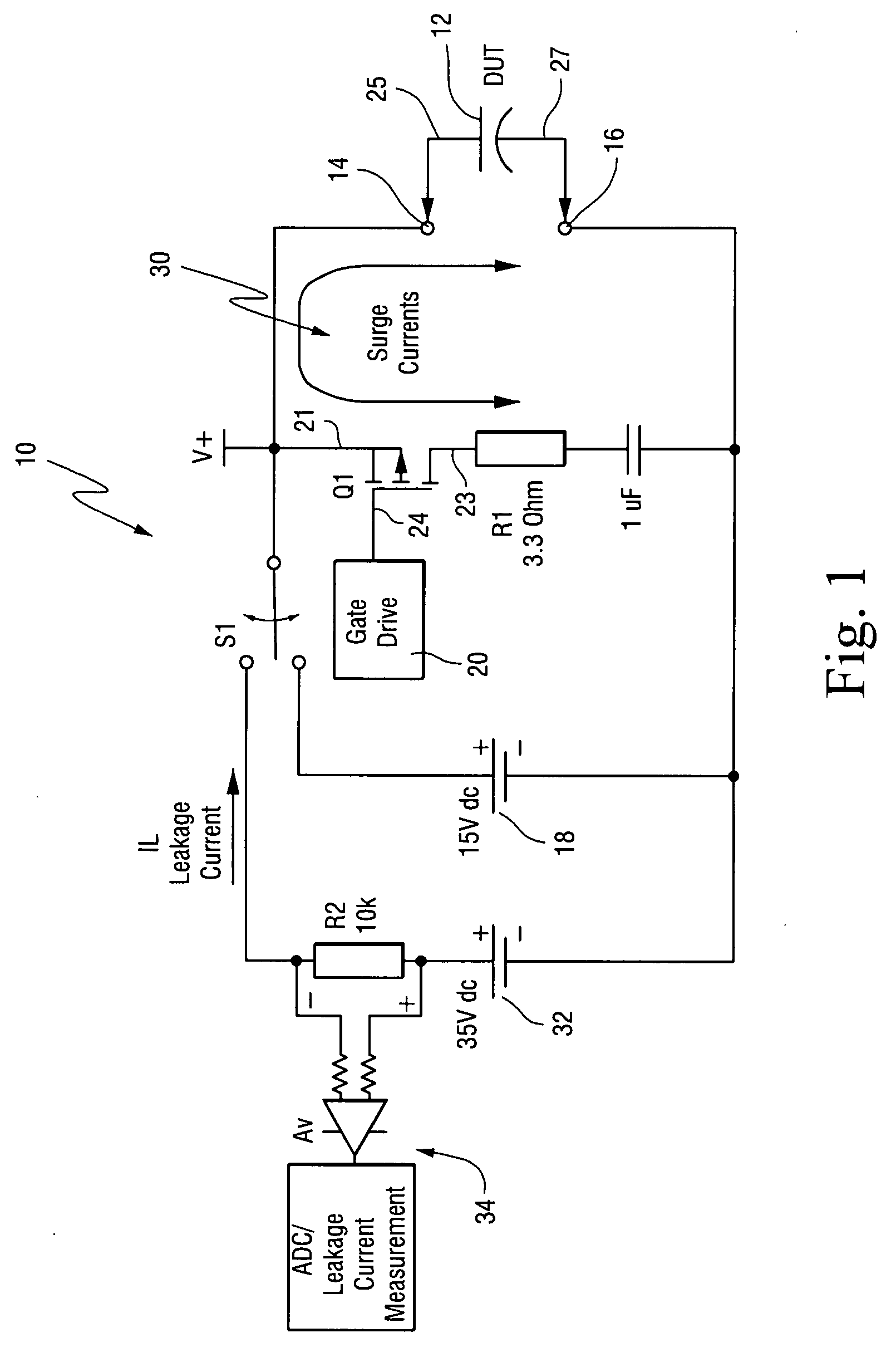

Processing tantalum capacitors on assembled PWAs to yield low failure rate

InactiveUS20080246492A1Low failure rateTesting dielectric strengthResistance/reactance/impedenceFailure rateTantalum capacitor

A method of conditioning tantalum capacitors on printed wire assemblies is disclosed. According to the method, each of the capacitors on an assembly is subjected to the same conditioning level during testing. To condition the tantalum capacitors, surge currents are induced in the capacitors in a controlled manner as a means of aging the capacitors so that they can be used without de-rating rating with low failure rates. The level of voltage, timing and current levels are set by circuitry used to perform the testing. The same circuits that are used with the capacitors in a system application are also used for the tantalum capacitor test circuit during the conditioning process.

Owner:GENERAL ELECTRIC CO

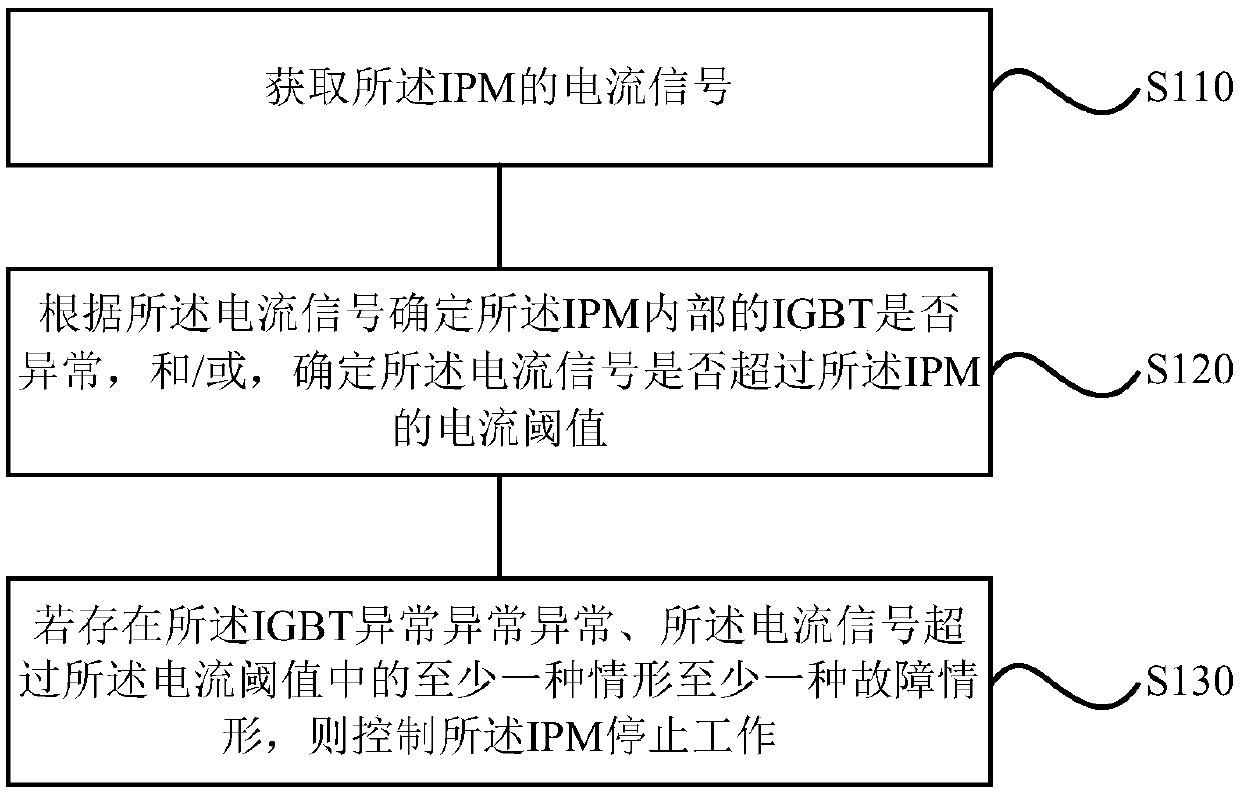

Method and device for protecting IPM, storage medium and IPM

InactiveCN109687697ALow operating failure rateEfficient detectionCurrent/voltage measurementPower conversion systemsFailure rateStopped work

The invention discloses a method and device for protecting an IPM, a storage medium and the IPM. The method comprises the steps that a current signal of the IPM is acquired; whether an IGBT in the IPMis abnormal or not is determined according to the current signal, and / or whether the current signal exceeds the current threshold value of the IPM or not is determined; if the at least one of the situations that the IGBT is abnormal and the current signal exceeds the current threshold value happens, the IPM is controlled to stop working. According to the scheme, the problem that due to the situation that the defect of the IPM cannot be recognized, the IPM is high in operation failure rate under the defect situation can be solved, and the effect of reducing the operation failure rate is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

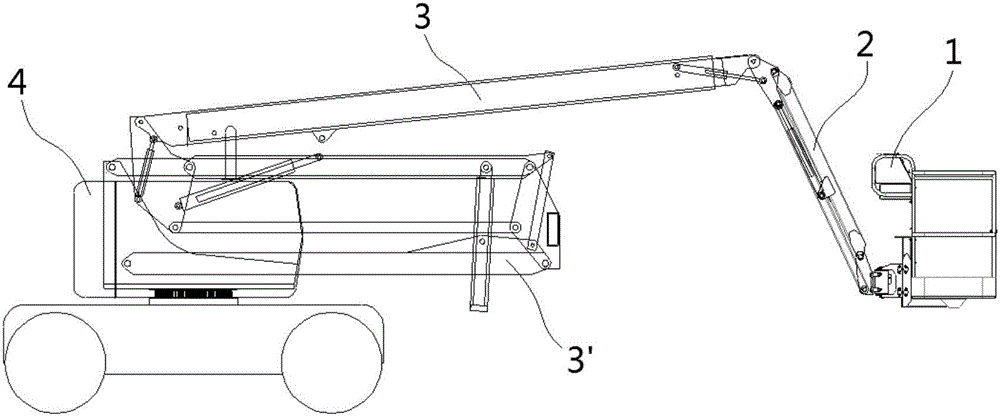

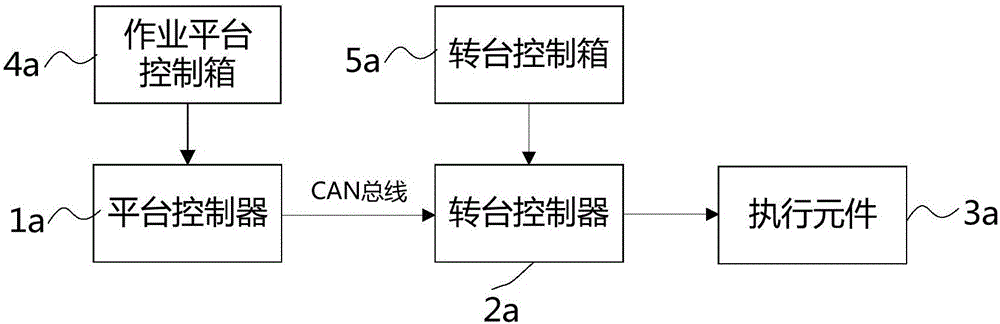

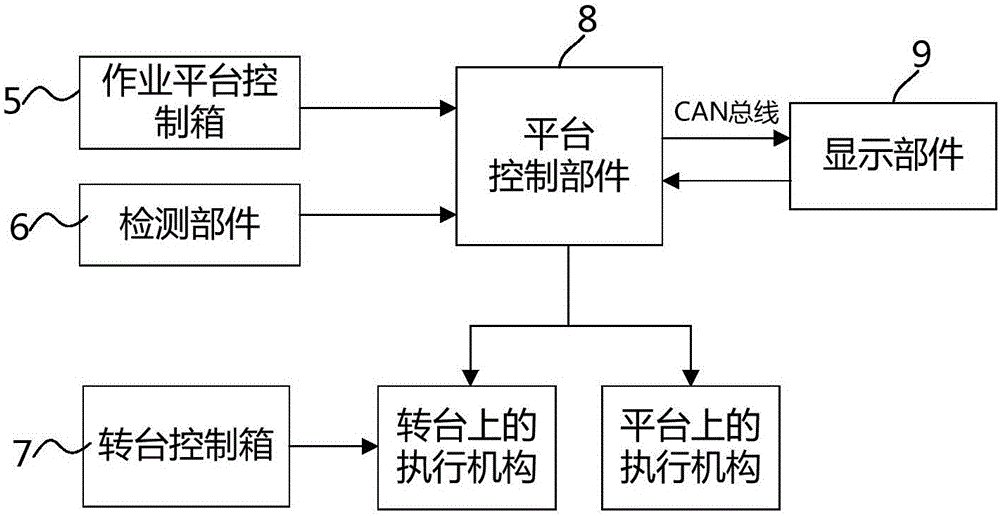

Aerial work platform electronic control system, electronic control method and aerial work platform

ActiveCN106829812AImprove securityReduce signaling linksSafety devices for lifting equipmentsTotal factory controlElectronic control systemElectric control

The invention relates to an aerial work platform electronic control system, an electronic control method and an aerial work platform. The electronic control system comprises a work platform control box (5) arranged on a platform body (1), a rotary table control box (7) arranged on a rotary table (4) and a master control part. One of the work platform control box (5) and the rotary table control box (7) can control all executing elements on the platform body (1) and the rotary table (4) through the master control part, and the other one can directly control part of the executing elements on the platform body (1) and the rotary table (4). According to the electronic control system, the master control part is adopted to intensively control all the executing elements so that signal transmitting links can be reduced, the breakdown rate is decreased to improve control reliability accordingly, and control cost is reduced; and redundancy control is adopted for part of the executing elements, when breakdown occurs in one control route, another control route can be switched, a vehicle can make reliable actions through two advantages, and work safety is improved.

Owner:XCMG FIRE FIGHTING SAFETY EQUIP CO LTD

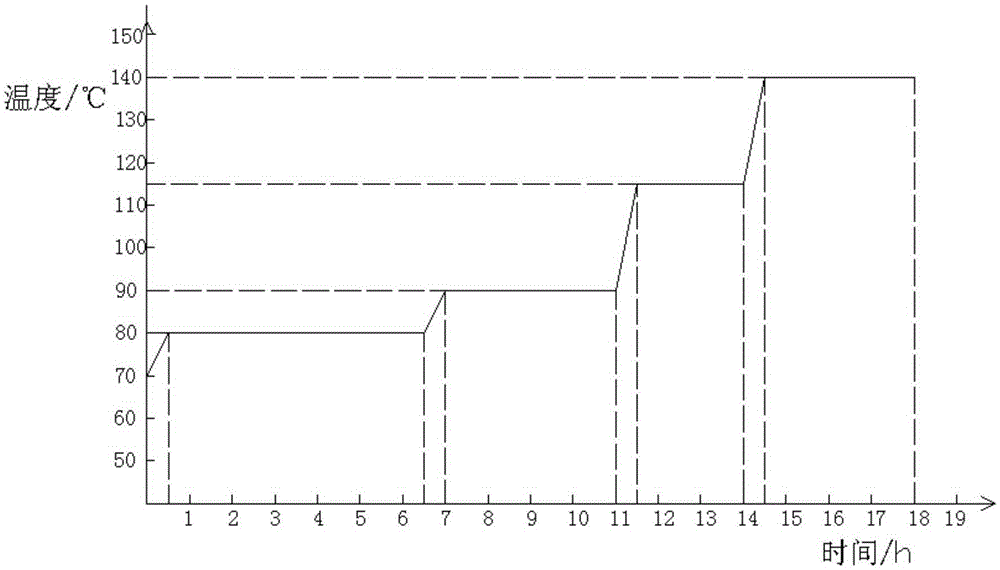

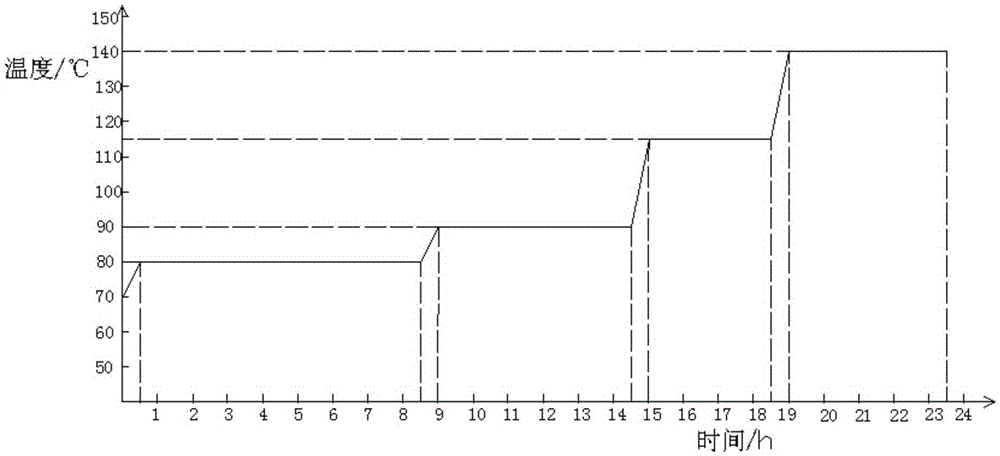

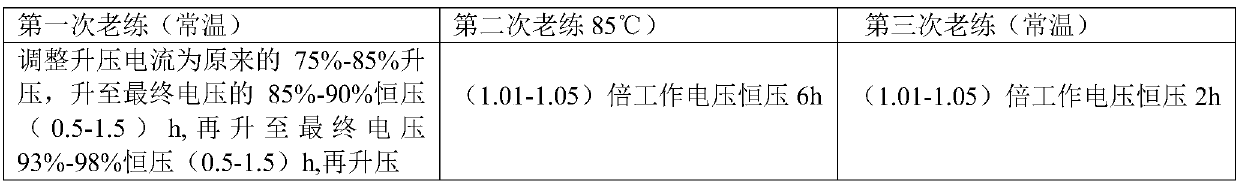

Aging method and manufacturing method of aluminum electrolytic capacitor

InactiveCN109741942AReduce leakage currentImprove performanceLiquid electrolytic capacitorsWinding capacitor machinesAge methodBreakdown rate

The invention discloses an aging method and a manufacturing method of an aluminum electrolytic capacitor. According to the scheme, an aging process is divided into at least two aging steps, and in thefirst aging step, the aging voltage is gradually increased instead of being increased to the final voltage, so that a foil has a buffering time, an oxide film on the surface of the foil is graduallyrepaired, the repairing effect of the oxide film on the surface of the foil is further improved, the breakdown rate of the aluminum electrolytic capacitor is reduced, the repairing effect of the oxidefilm on the surface of the foil is improved, the breakdown rate and leakage current of the aluminum electrolytic capacitor are reduced, and the yield and service life of the aluminum electrolytic capacitor are improved.

Owner:横店集团东磁有限公司

Method for making printed circuit board and etched half-finished circuit board

The invention discloses a method for manufacturing a printed wiring board and an etched semi-finished wiring board. The method at least comprises the steps as follows: a. exposing; b. developing: a protective film is caused to form on each unit plate of the wiring board, and the protective film forms a circuit pattern, protective films are also caused to form on at least some parts of connection areas between the unit plates and frame areas of the wiring board; c. etching: an erosion nozzle sprays erosive liquid to the wiring board to erode an exposed base copper on the wiring board, and circuit patterns are etched on the unit plates of the wiring board while at least some part of the base copper in the frame areas of the wiring board and the connection areas between the unit plates is reserved; by adopting the method, the base copper is still reserved on the surfaces of two sides of either the connection areas or the frame areas of the etched semi-finished wiring board so as to form an reinforced copper block. In the etching and follow-up procedures of the wiring board, the strength and rigidity of the wiring board are improved, with low breakdown rate and high product qualification rate.

Owner:SHENZHEN FASTPRINT CIRCUIT TECH

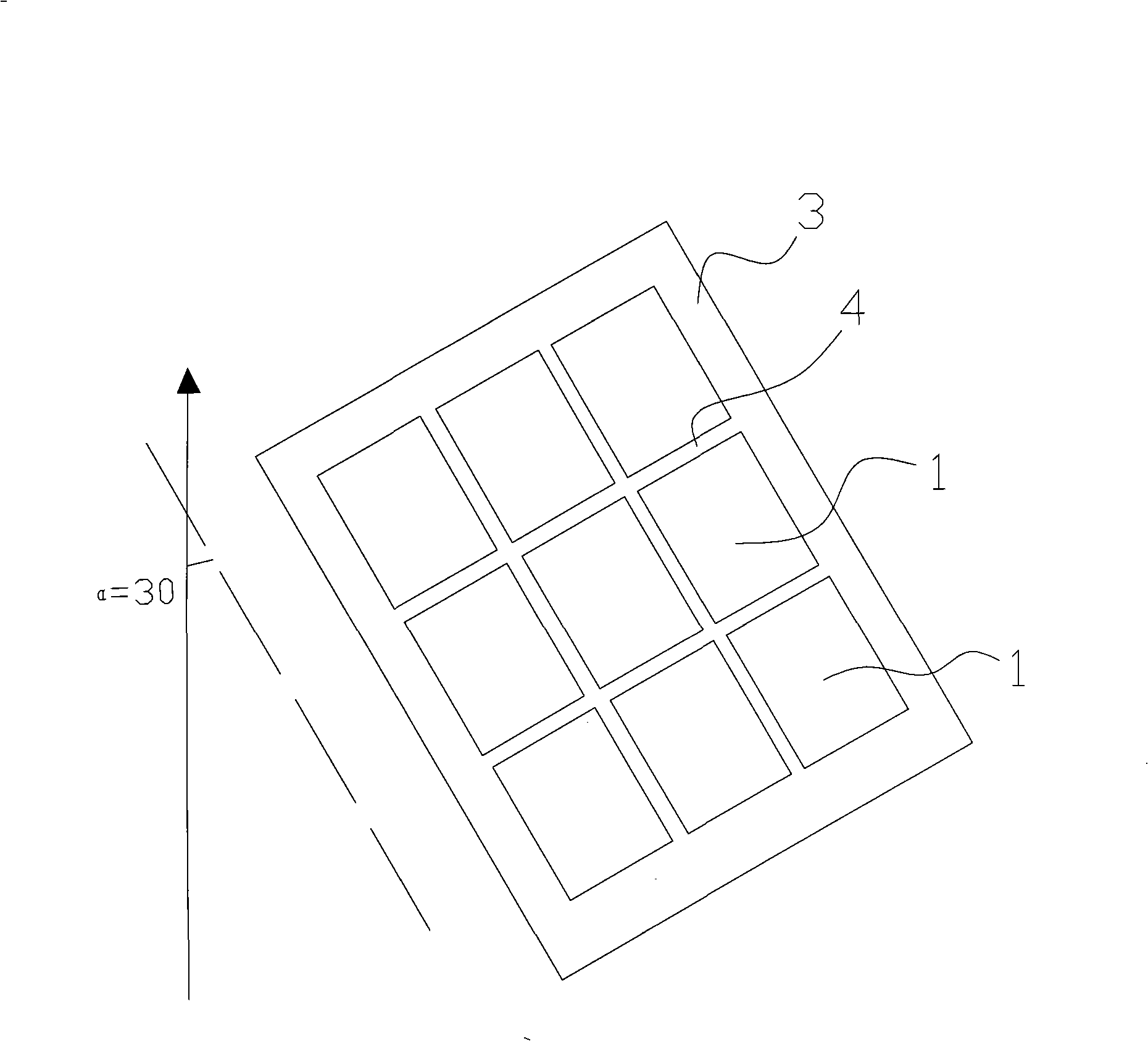

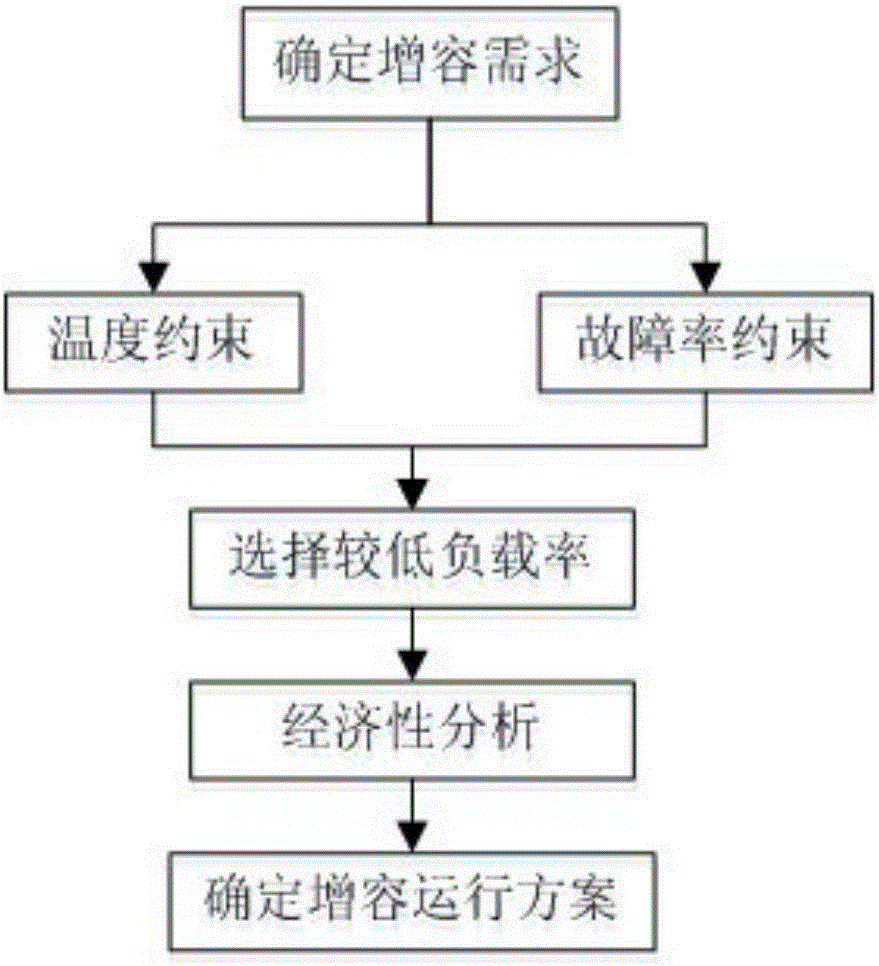

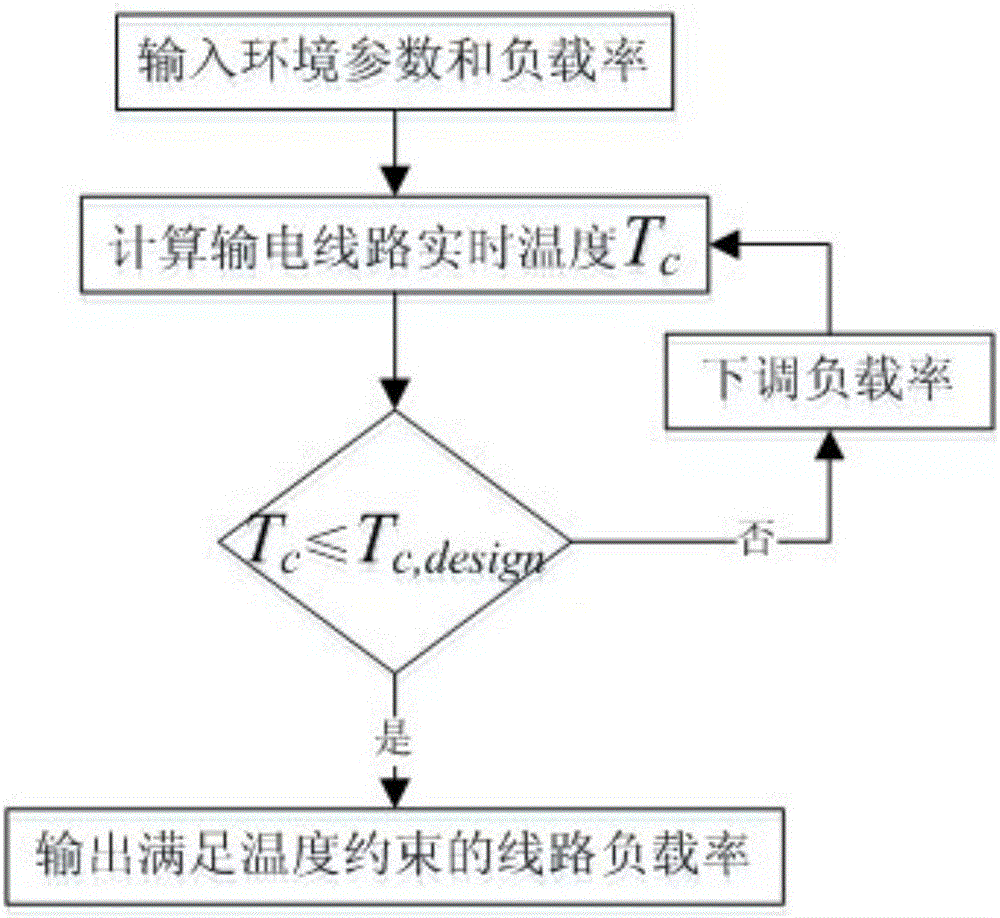

Method of increasing capacity of transmission line considering safety check and economic analysis

The invention provides a method of increasing capacity of a transmission line considering safety check and economic analysis, which includes ensuring a capacity increasing demand of the transmission line and a temperature constraint check, obtaining a maximum load rate which satisfies temperature constraint and a failure rate constraint checking, obtaining a maximum load rate which satisfies the failure rate, choosing a transmission line load rate which satisfies both the temperature constraint and the failure rate constraint, carrying out an economic verification, and obtaining a final increasing program of the transmission line. A real-time temperature of line is calculated according to the heat balance equation, a short term failure rate of line is calculated by establishing a short term failure rate model of transmission line which is based on PHM, profits of increasing capacity of the transmission line is evaluated by three indexes of transmission revenue, line loss cost and life loss cost. The method of increasing capacity of the transmission line considering safety check and economic analysis belongs to the evaluated field of loading capacity of power transmission and transformation equipment.

Owner:GUIYANG POWER SUPPLY BUREAU OF GUIZHOU POWER GRID CO LTD

Processing device for clutch hole of engine cover

InactiveCN107470670ASimple structureReduce volumeWork clamping meansLarge fixed membersEngineeringBreakdown rate

The invention discloses a processing device for a clutch hole of an engine cover. The processing device for the clutch hole of the engine cover comprises a the drilling mechanism and a working table, the working table is arranged obliquely upwards, the drilling mechanism is fixedly mounted on the working table, and a longitudinal mounting plate capable of sliding transversely on the working table are arranged on the other side of the working table; and the longitudinal mounting plate is provided with a fixture capable of sliding longitudinally on the longitudinal mounting plate, transverse movement of the longitudinal mounting plate and longitudinal movement of the fixture are controlled by a pedal switch, so that a first processing tool and a second processing tool can correspondingly conduct drilling on the engine cover placed on the fixture of the longitudinal mounting plate. The structure is very simple, the size is small, the cost is low, operation is convenient, the breakdown rate is low, and maintenance is not required by professional personnel operating; and use is very convenient, the working table is arranged obliquely upwards, so that chip removing during processing is smoother, and practicability is high.

Owner:江门市鑫宝实业有限公司

Inlet and outlet sealing structure of tobacco dryer

The invention discloses an inlet and outlet sealing structure of a tobacco dryer, which comprises a barrel and a sealing piece. The surface of the barrel is the sealing face of the barrel. The sealing piece is bended and comprises a first part and a second part; the first part is attached on the sealing face of the barrel and the second part is fixedly connected with a front chamber and a back chamber of the tobacco dryer; a bandage is wound around the sealing piece and the barrel; two ends of the bandage are both arranged on the sealing piece and are tensioned through tension springs; and the sealing piece is a silica gel plate. The sealing performance of the silica gel plate is superior to the sealing performance of felted wool, so loss of cut tobacco is reduced to a certain degree, breakdown rate of equipment is reduced and stability of the quality of the cut tobacco is improved.

Owner:CHINA TOBACCO GUIZHOU IND

Processing technology and applications of anti-drop magnetic steel for permanent magnet motor

InactiveCN103866310ANot easy to fall offGood light fastnessPretreated surfacesInductances/transformers/magnets manufactureCooking & bakingMetallurgy

The invention relates to a processing technology and applications of an anti-drop magnetic steel for permanent magnet motor. The processing technology comprises steps of surface processing, phosphating, polishing, paint spraying, and baking. During the paint spraying process, the faying surface between the magnetic steel and the stator or rotor of a permanent magnet motor is a recessed surface and is not covered by baking varnish, the recessed surface of the magnetic steel is painted with glue, and then the magnetic steel is stuck to the rotor or stator of the permanent magnet motor. The magnetic steel manufactured by the processing technology can tightly adhere to the rotor or stator of permanent magnet motor and thus is not easy to fall off. During the motor operation process, the parts do not rub with each other, thus the problem of part wearing is avoided, and moreover the motor rotor magnetic field is stable. The accidental breakdown rate of motor is greatly reduced by the processing technology.

Owner:宁波市鄞州大宇星极磁钢厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com