Planet speed reducer for bridge crane

A planetary reducer, bridge crane technology, applied in the direction of walking bridge cranes, cranes, clockwork mechanisms, etc., can solve the problem that the processing and assembly positioning accuracy is not easy to guarantee, the trolley cannot run normally, and the final stage planetary transmission volume. Large and other problems, to achieve the effect of novel transmission mode, low cost, easy manufacturing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

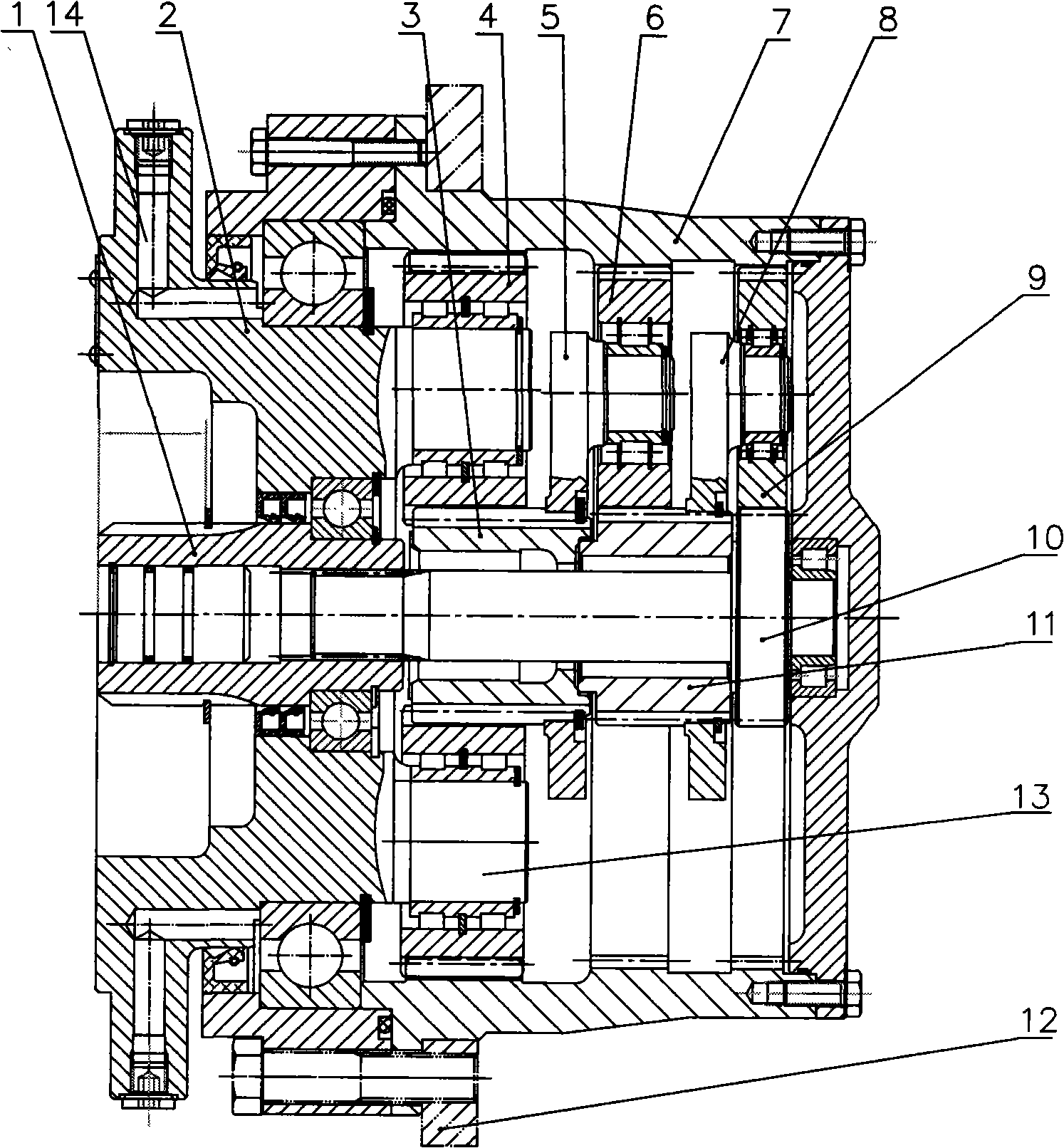

[0009] The accompanying drawing is an embodiment of the present invention, including a bracket 2, an input spline sleeve 1, a three-stage planetary transmission, a ring gear 7, and the like. Bracket 2 is fixed on the support of trolley (in a single-arm suspension shape), input spline sleeve 1 is set in the center hole of bracket 2 through bearing and oil seal, and one end of input spline sleeve 1 is connected with trolley through coupling In the three-stage planetary transmission, the shaft of the first-stage sun gear 10 of the first-stage planetary module is inserted into the other end of the input spline sleeve 1 and splined with the input spline sleeve 1. In the three-stage planetary transmission, the third-stage The three-stage planetary carrier 13 of the planetary module is fixedly connected with the bracket 2, the ring gear 7 is arranged on the outside of the three-stage planetary transmission, and meshes with the three planetary carriers at the same time, and the ring ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com