A remote operation and maintenance management system and method for industrial manufacturing equipment

An operation and maintenance management, operation and maintenance management platform technology, applied in manufacturing computing systems, transmission systems, digital transmission systems, etc., can solve problems such as uneven utilization of equipment, low equipment utilization, affecting production progress, etc., to improve the operating state The effect of monitoring ability, reducing operation and maintenance costs, and reducing equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] In the technical solutions disclosed in one or more embodiments, such as figure 1 As shown, the remote operation and maintenance management system described in this disclosure is composed of six types of nodes: cloud platform, operation and maintenance center, management center, manufacturing node, maintenance support node, and technical expert node. Among them, the cloud platform deploys a relational database system, FTP Server software and remote measurement and control service middleware (referred to as RTC), provide efficient, stable, safe and reliable database management services, FTP services and publish / subscribe services; all nodes except the cloud platform are equipped with production and manufacturing operation and maintenance management based on state monitoring On the network terminal computer of the platform (referred to as CMMAPP), users of different nodes log in to CMMAPP with different user rights to perform their own work; in addition, the production and...

Embodiment 2

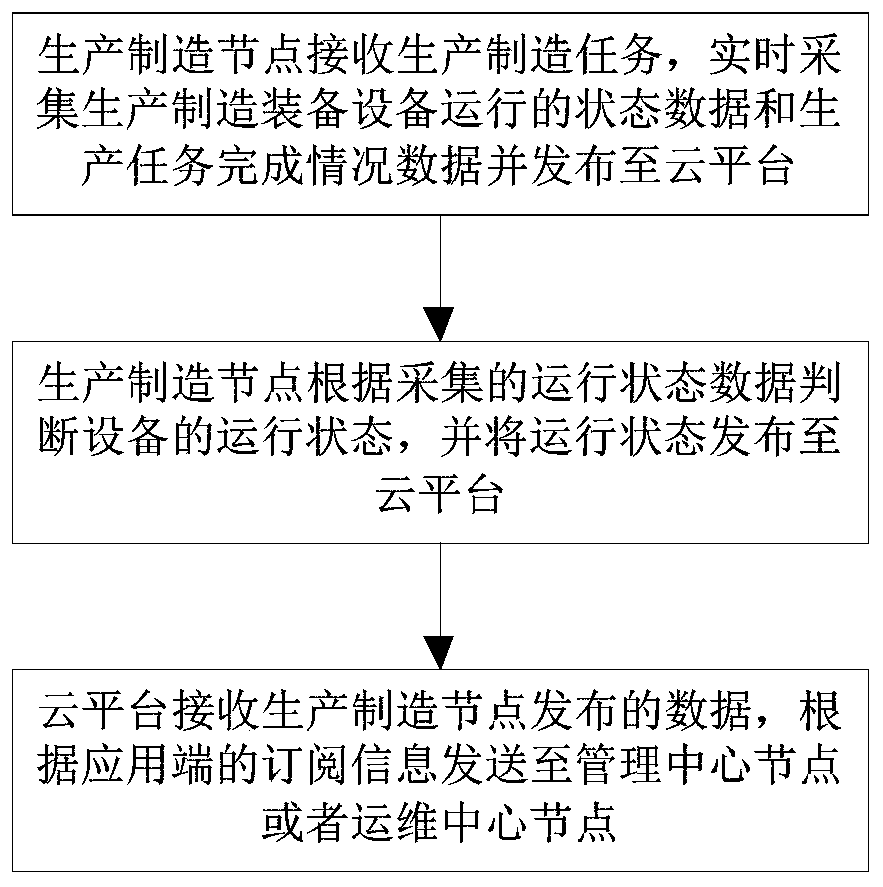

[0090] This embodiment provides an operation and maintenance management method based on the above-mentioned remote operation and maintenance management system, such as figure 2 The first flow chart shown includes the following steps:

[0091] The manufacturing node receives the manufacturing task, collects the completion status data of the production task and the operation status data of the manufacturing equipment in real time, and records the status data of the equipment operation and the completion status data of the production task by category and publishes it to the cloud platform layer in real time;

[0092] The manufacturing node judges the operating status of the equipment based on the collected operating status data, and publishes the operating status to the cloud platform;

[0093] The cloud platform transmits the status data based on publish / subscribe service, receives the data released by the manufacturing node, and sends the running status data or production task...

Embodiment 3

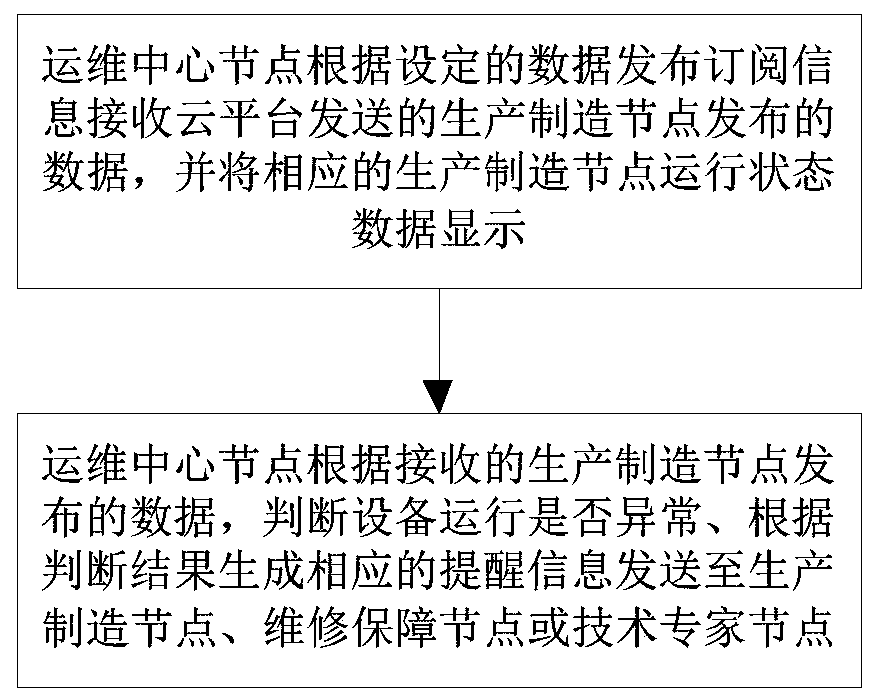

[0096] This embodiment provides an operation and maintenance management method based on the above-mentioned remote operation and maintenance management system, such as image 3 The second flow chart shown includes the following steps:

[0097] The operation and maintenance center node receives the data released by the production and manufacturing nodes sent by the cloud platform according to the set data publishing and subscription information, and displays the corresponding production and manufacturing node operation status data;

[0098] The operation and maintenance center node judges whether the equipment is running abnormally according to the received data released by the manufacturing node, and generates corresponding reminder information according to the judgment result and sends it to the manufacturing node, maintenance support node or technical expert node.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com