Pouring technology for dry-type transformer coils

A dry-type transformer and coil technology, which is applied in the field of transformer manufacturing, can solve the problems of resin machinery, coil partial discharge, unqualified power frequency withstand voltage test index, and many air gaps, so as to achieve the effect of improving technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

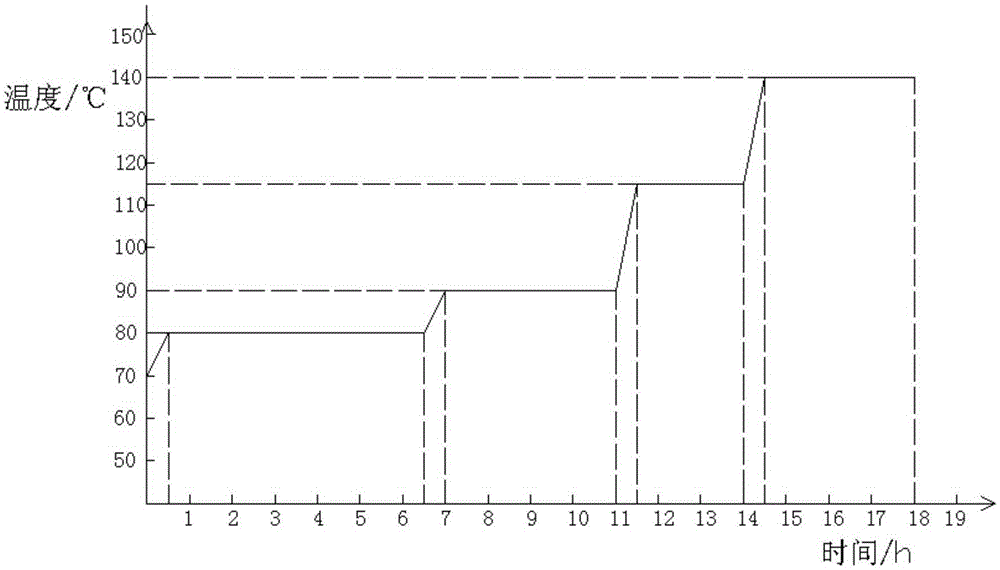

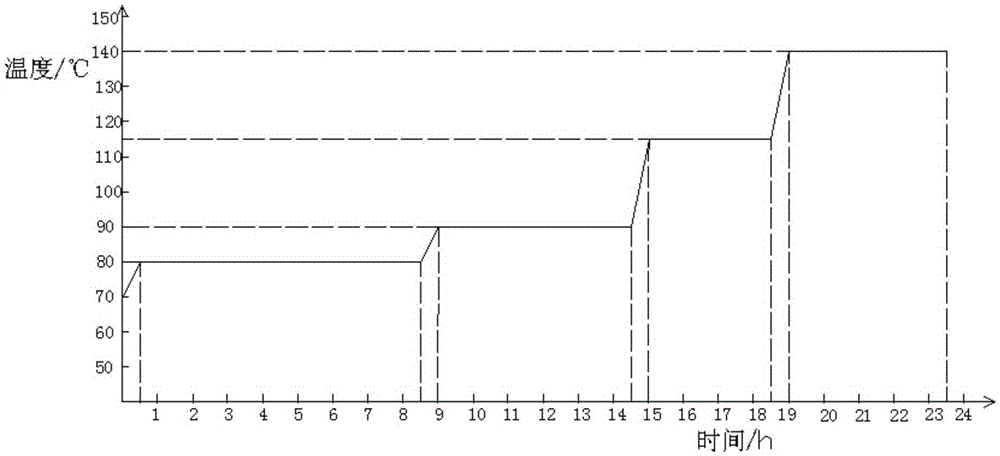

[0061] The process conditions of Examples 1-4 are shown in Table 1.

[0062] Table 1

[0063]

[0064]

[0065] In the table: the results of partial discharge level and power frequency withstand voltage breakdown rate are obtained in accordance with "National Standard of the People's Republic of China: Partial Discharge Measurement (GB / T7354-2003 / IEC60270·2000)".

[0066] It can be seen that the drying process 110, the degassing process 210 / 220, the mixing process 320, and the demolding process 620 can achieve better results than the corresponding other processes.

[0067] In addition, as the control accuracy level increases from F1 to F3, the average partial discharge level and average power frequency withstand voltage breakdown rate have decreased. However, as the requirements for equipment and control will also increase, the cost and operation difficulty will increase. Therefore, under the premise of meeting the requirements, the control level F1 or F2 can usually be adopted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com