Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1247results about How to "Adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

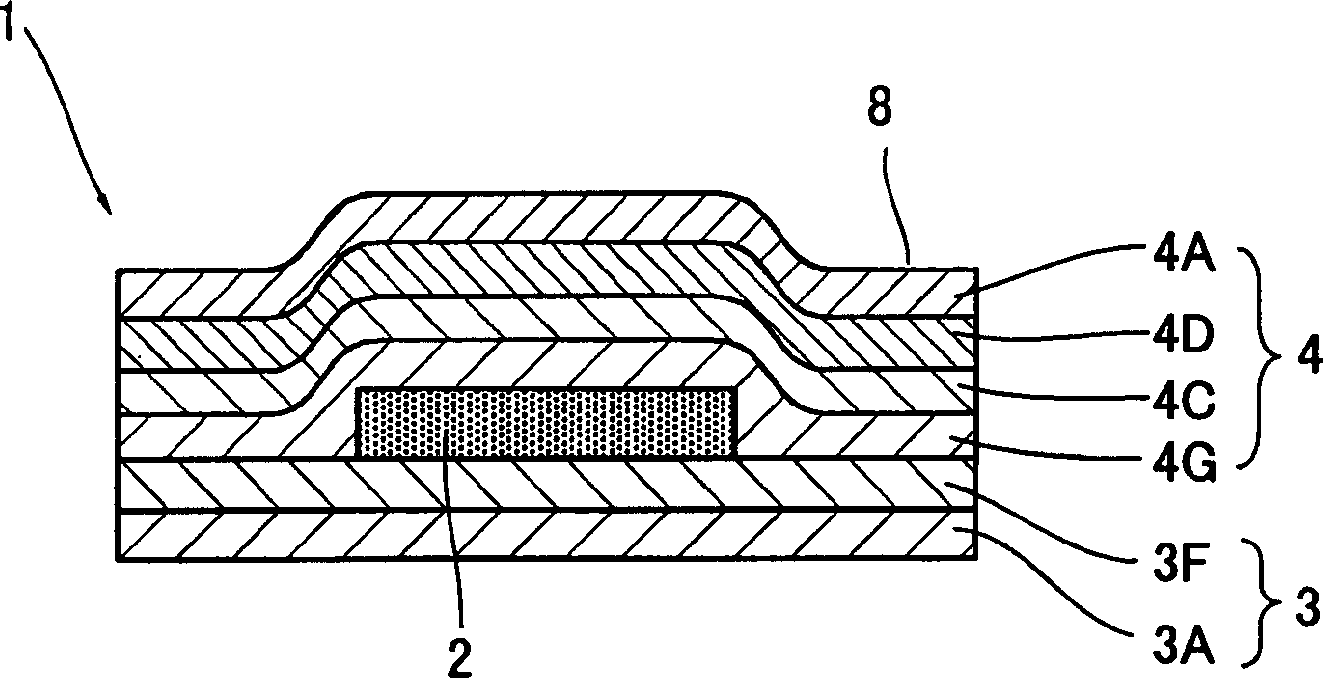

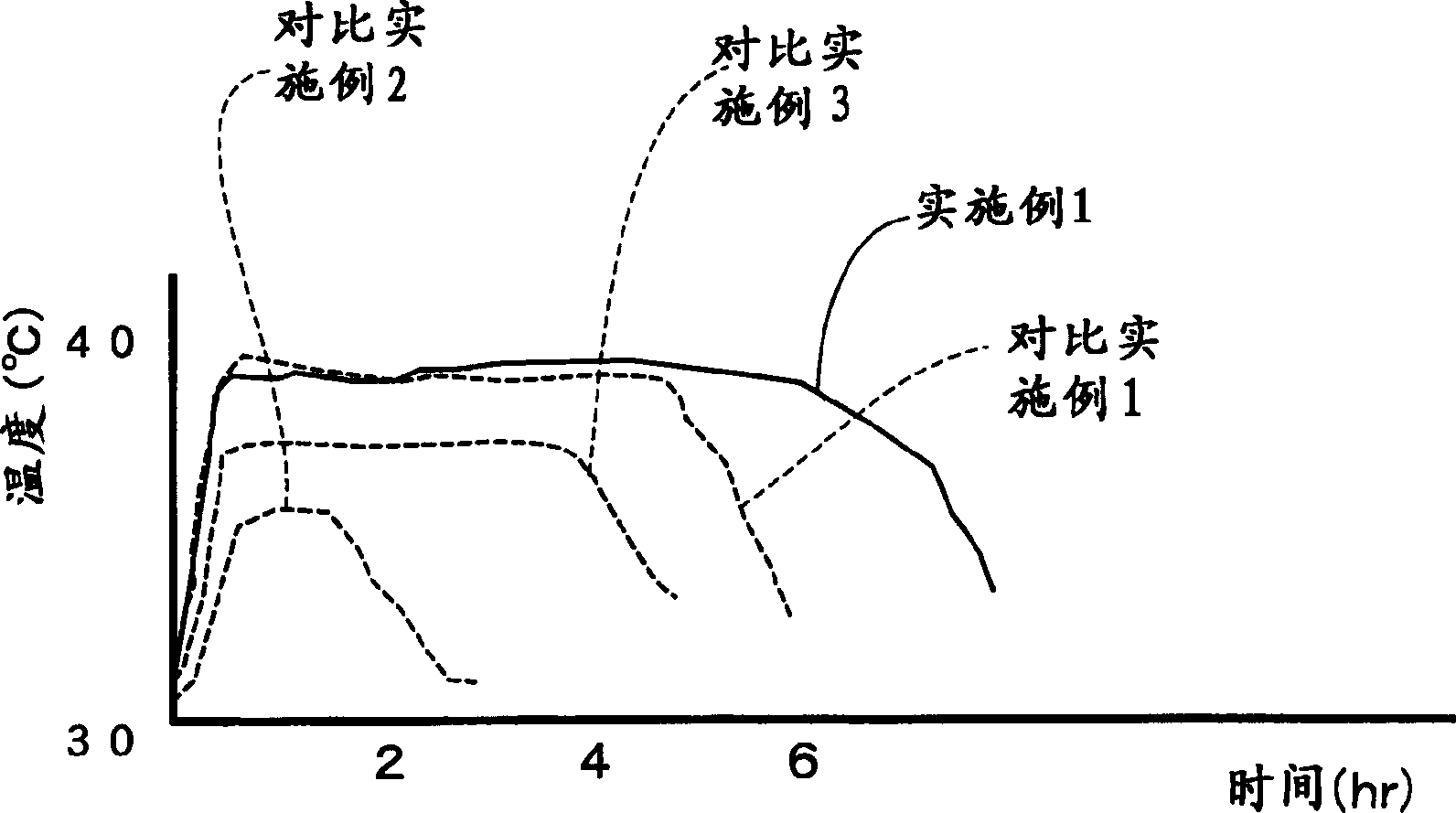

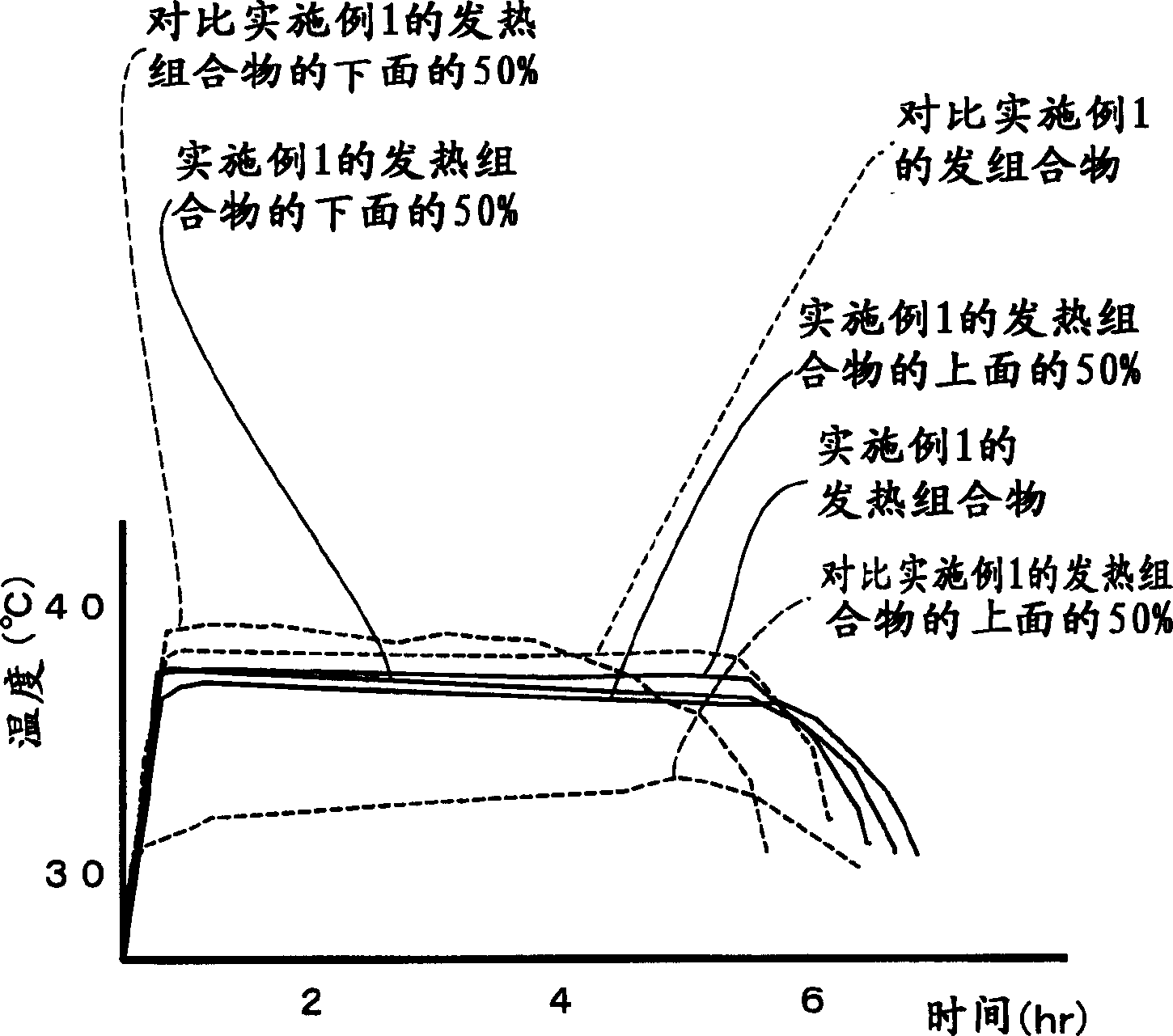

Exothermic composition and exothermic article using composition, and method for producing exothermic article

InactiveCN1491271AAccurate Guaranteed QuantityHas dispersion stabilityExothermal chemical reaction heat productionHeat-exchange elementsDispersion stabilityChemical composition

It relates to a heat-generating composition having such dispersion stability that withstands continuous molding, and has excellent drainage property, excellent heat-generating characteristics, excellent molding property and excellent shape retaining property, without becoming viscous, and relates to a heat-generating body using the same and a process for producing the heat-generating body. It contains, as essential components, a heat-generating substance generating heat upon reaction with oxygen, a carbon component, an oxidation promoter and water, characterized in that the composition further contains a water separation-preventing stabilizer in a proportion of from 0.001 to 0.25 part by mass per 100 parts by mass of the heat-generating composition, and has a water mobility value of from 7 to 40 and a separation degree of from 0 to 30.

Owner:MYCOAL

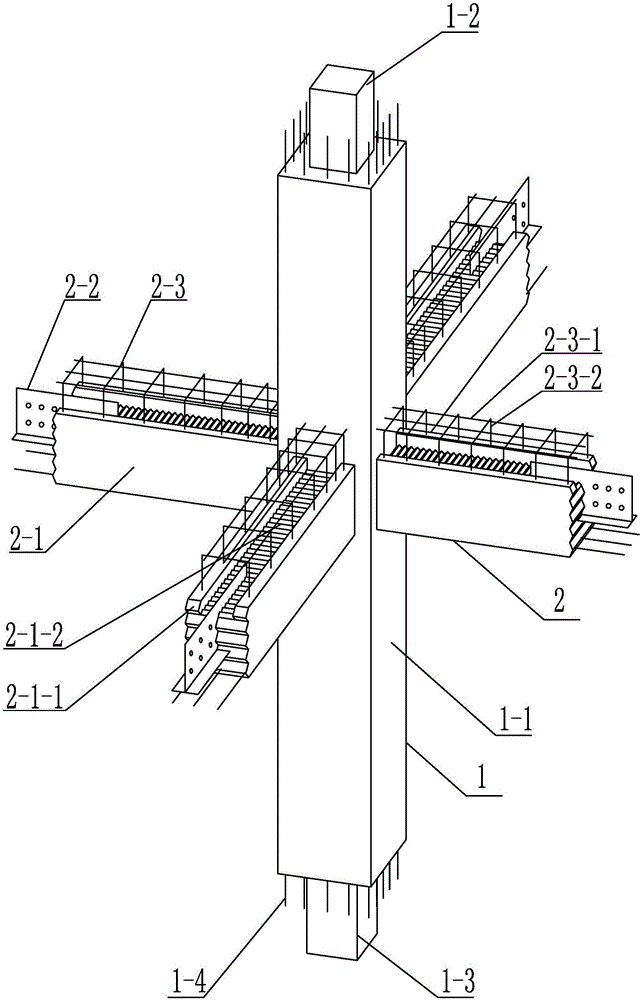

Single-layer prefabricated assembly type reinforced concrete beam-column joint

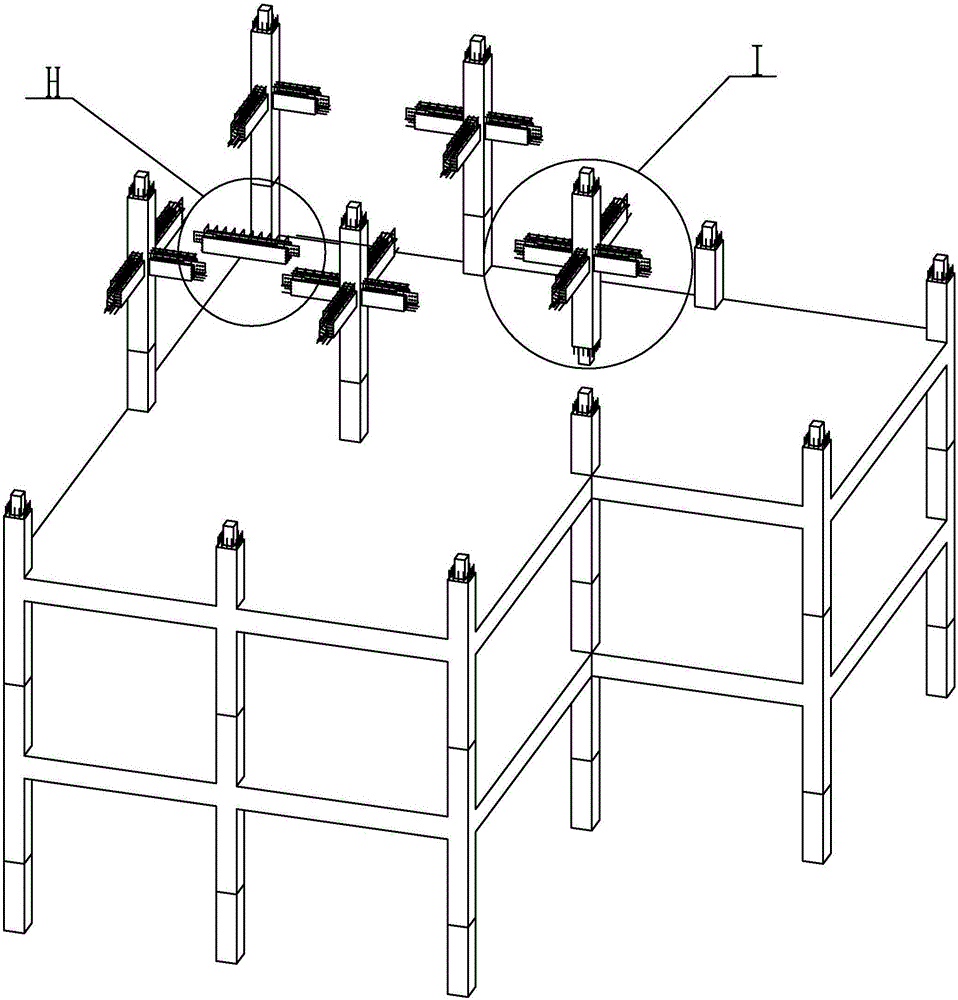

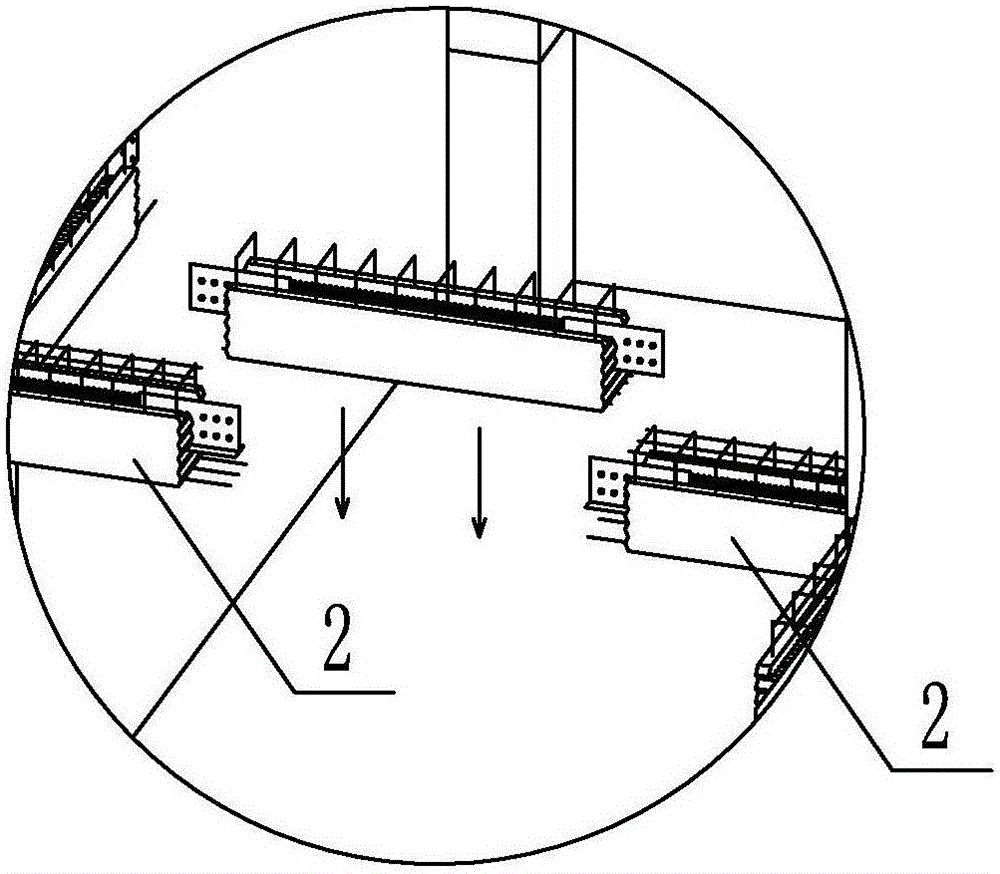

The invention relates to a prefabricated reinforced concrete beam-column joint, in particular to a single-layer prefabricated assembly type reinforced concrete beam-column joint. In order to solve the problem that the connection integrity of existing prefabricated beams and prefabricated columns is hard to guarantee, the prefabricated joint for one-piece casting manufacturing of a column section and part of beam sections is provided according to the concept of the point of inflection. The single-layer prefabricated assembly type reinforced concrete beam-column joint is formed by overall manufacturing of a vertical column section (1) and joint superposed beam sections (2) in a factory for prefabrication. A manufacturing method comprises the steps of beam-column longitudinal bar and stirrup binding, connector pre-burying, formwork erecting and concrete pouring and curing. The height of the vertical column section (1) of the joint is 1 / 2 of the storey height, and the length of each joint superposed beam section (2) is 1 / 3 of the span of adjacent columns. The vertical column section (1) comprises a pouring section (1-1), a concrete filled steel tube connector (1-2), a steel tube connector (1-3) and column section longitudinal bars (1-4). Each joint superposed beam section (2) comprises a groove-shaped pouring section (2-1), inverted-T-shaped structural steel connectors (2-2) and a reinforcement cage framework (2-3). The single-layer prefabricated assembly type reinforced concrete beam-column joint is applied to the construction industry.

Owner:HARBIN INST OF TECH

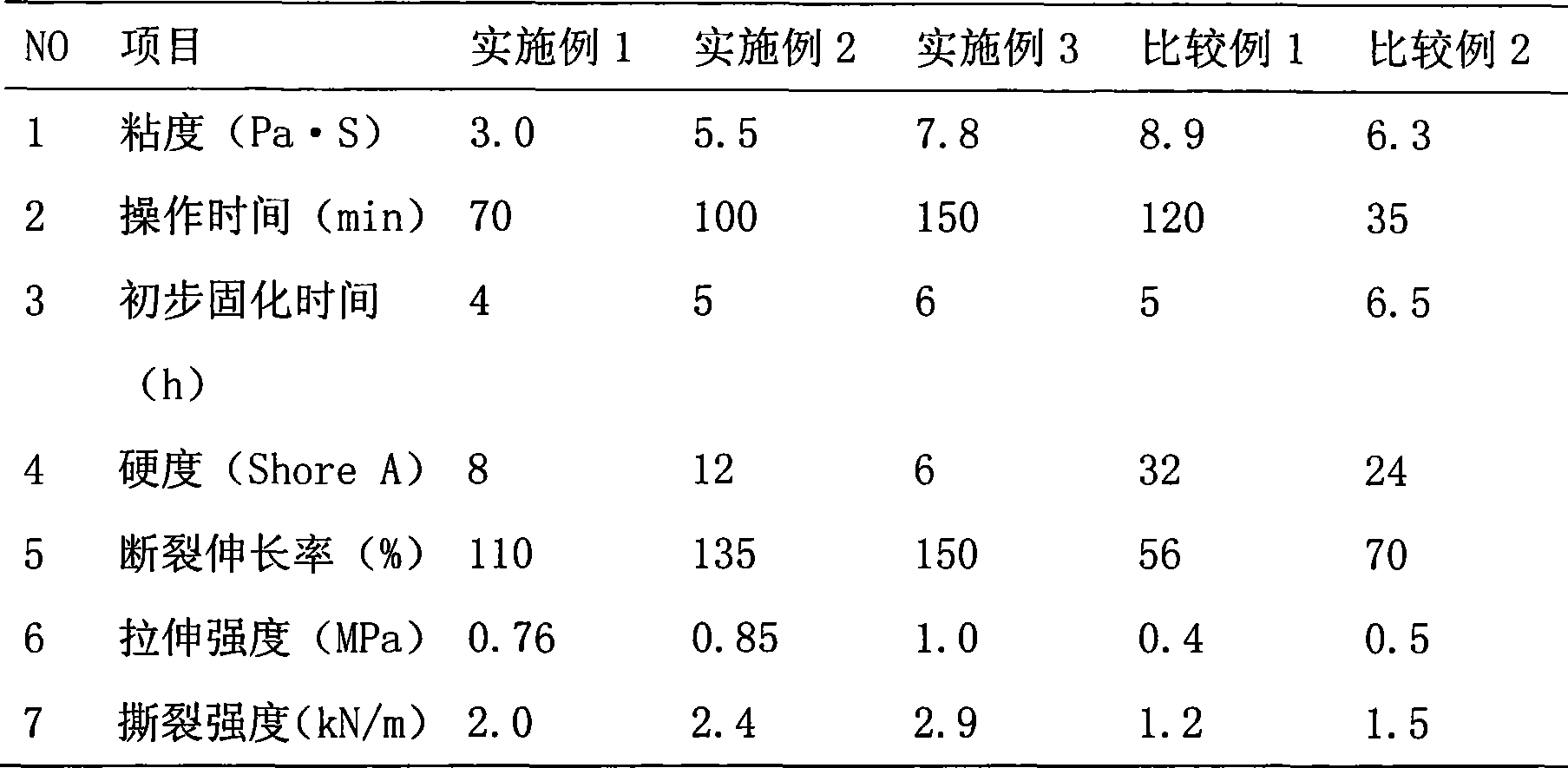

Method for producing synthetic leather by using solvent-free double-component polyurethane scraping and coating method

The invention discloses a method for producing synthetic leather by using a solvent-free double-component polyurethane scraping and coating method and the synthetic leather produced by using the same. The method comprises the following steps: (1) controlling the flow of a material loading machine so that an M material and an N material are mixed in the mixing chamber of the material loading machine and then poured, scraped and coated to release paper coated with an isolation layer, drying so as to obtain a foamed material layer, wherein the coating amount of scraping and coating is 50-2000g / m<2>; (2) pressing and compounding the foamed material layer, heating and solidifying; and (3) coiling, curing, and separating out the release paper at last, so as to obtain the synthetic leather finished product. According to the invention, an organic solvent and water are not used in the synthesis and mixing of polyurethane resin on a foaming layer and a bonding layer and in the various links of embarkation. Compared with the method for producing the foaming layer with a water-based polyurethane composite material, the method disclosed by the invention can greatly reduce energy consumption; and the synthetic leather has good property and excellent hand feeling.

Owner:佛山市飞凌皮革化工有限公司

High-permeability liquid rubber spray coating

InactiveCN102329566AHigh bonding strengthImprove waterproof and anti-seepage performanceUnspecified rubber coatingsConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

The invention discloses a high-permeability liquid rubber spray coating, and relates to the technical field of spray coatings. The high-permeability liquid rubber spray coating comprises a component A and a component B, wherein the component A is anionic liquid rubber asphalt emulsion; the component B is a coagulant solution; the component A has the solid content of liquid rubber asphalt emulsion of 50-75 weight percent, and comprises the following components in percentage by mass: 1 to 35 percent of rubber emulsion, 10 to 50 percent of asphalt emulsion, 0.01 to 2 percent of anionic dispersing agent, 0.01 to 2 percent of anionic surfactant, 0.1 to 10 percent of fatty alcohol-polyoxyethylene ether, 0.1 to 10 percent of alkali resistant wetting agent OEP-70 and 0.1 to 10 percent of alkali resistant wetting agent AEP; and the component B is an aqueous solution at the concentration of 3-18 percent, which is prepared by mixing calcium chloride and composite aluminum-iron polymer in percentage by mass. The wetting agents are added into the spray coating, and the coating has high permeability and wider application range.

Owner:DALIAN MEICHENTE TECH

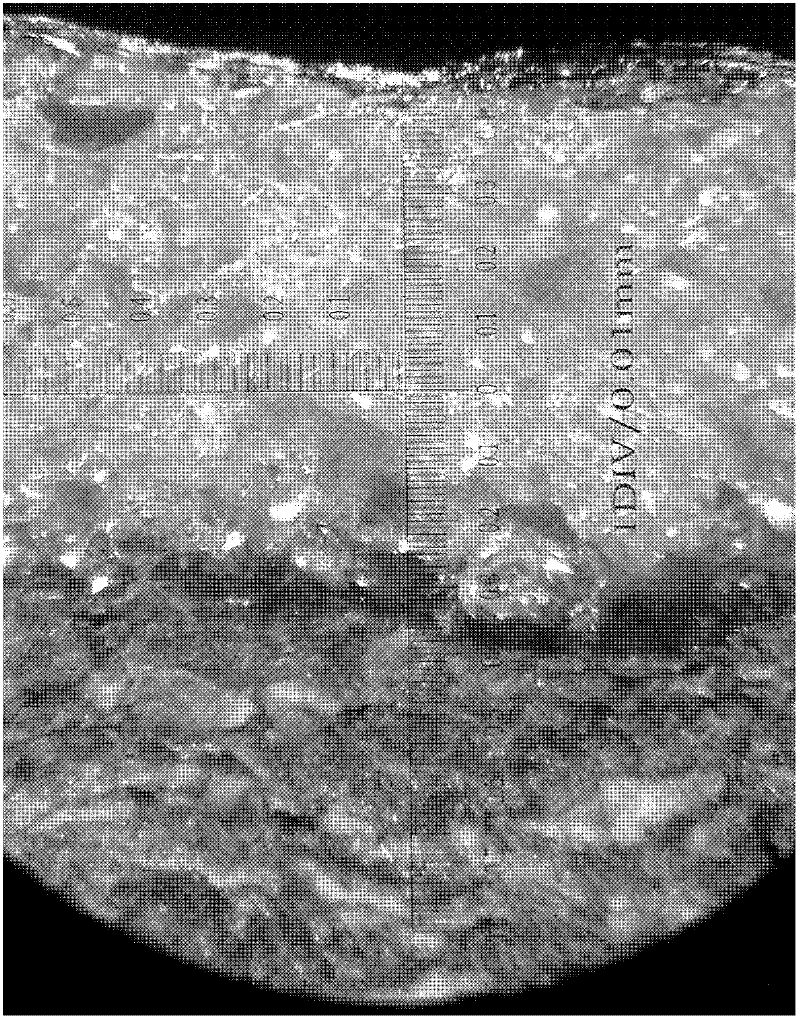

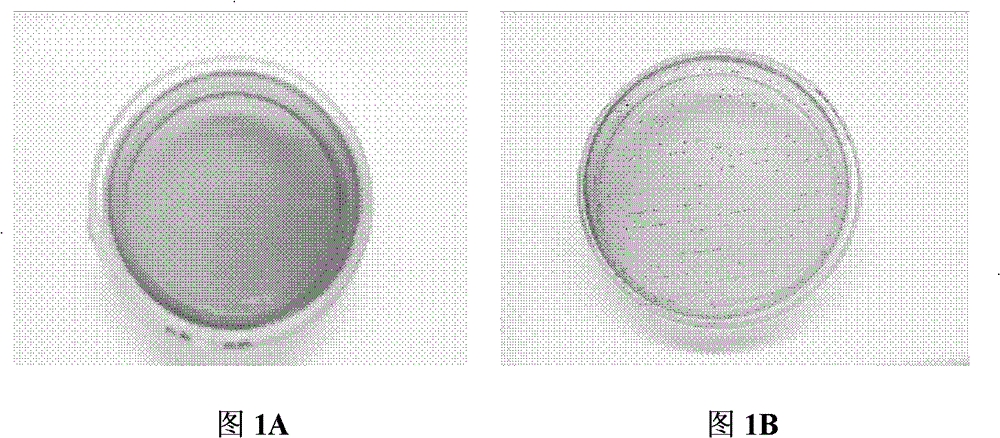

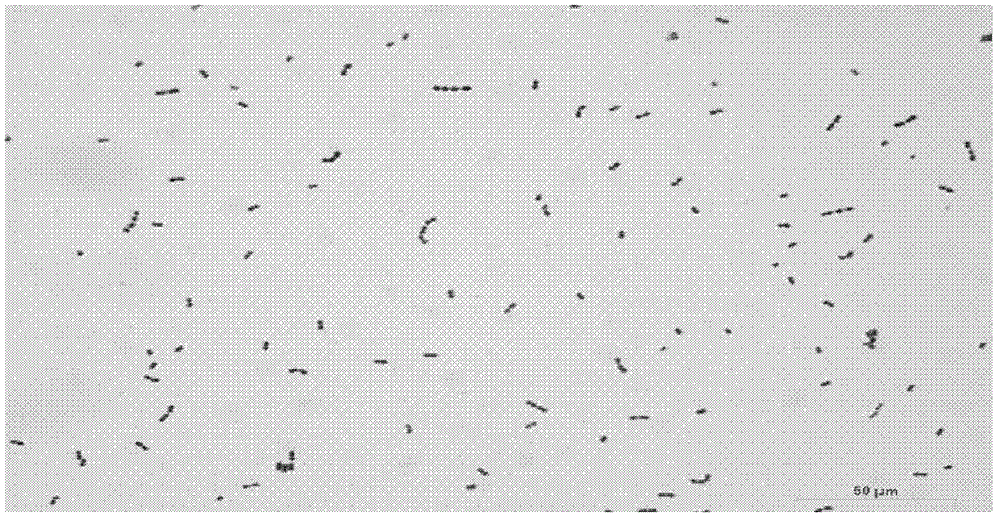

Screening and application of probiotic Enterococcus faecium

ActiveCN102747003AGood antibacterial effectImprove securityAntibacterial agentsBacteriaDiseaseSynechococcus

The invention belongs to the technical field of veterinary microbial additive preparation, and specifically relates to a strain of separated and screened Enterococcus faecium providing significant bacterial inhibition effects for common enteropathogenic bacteria such as staphylococcus aureus, escherichia coli and salmonella in breeding animals, and an application thereof. The probiotic Enterococcus faecium of the present invention is characterized in that: the strain is Enterococcus faecium HDRsEf1, and is preserved in the China General Microbiological Culture Collection Center (CGMCC), and the preservation number is CCTCC NO:M2011031. The probiotic Enterococcus faecium of the present invention has characteristics of fast growth, high acid production capacity, strong stress resistance, safety, disease resistance and growth promotion, and can be used as the microbial feed additive for livestock and poultry feeds.

Owner:武汉华大瑞尔科技有限公司 +1

Medical adhesives and preparation method thereof

The invention relates to medical adhesives and a preparation method thereof. The adhesives are prepared from aldehyde sodium alginate and amination carboxymethyl chitosan. The preparation method includes the steps of mixing equal volumes of aldehyde sodium alginate solution with concentration of 10-50 wt% and amination carboxymethyl chitosan solution with concentration of 1-6 wt%, conducting a Schiff base reaction to form hydrogel, and obtaining the medical adhesives. Selected aldehyde sodium alginate and amination carboxymethyl chitosan are both natural biological materials, are free of toxin and odor, quite high in biological compatibility, low in price, safe, reliable, capable of being locally sprayed or injected to any part of a body in situ and low in cost, and is ideal substitute goods for fibrin glue sold on the market. The preparation method is simple.

Owner:莫秀梅 +1

Super-soft SS (spunbond and spunbond) nonwoven fabric and production process thereof

ActiveCN103132241AAppropriately meet the requirements of tender skinSoft and smoothNon-woven fabricsElastomerMasterbatch

The invention discloses super-soft SS (spunbond and spunbond) nonwoven fabric. The super-soft SS nonwoven fabric is mainly made from, by weight, 55-90 parts of polypropylene, 5-40 parts of elastomer, 1-4 parts of softener and 0.5-1 part of cooling masterbatch. The invention further discloses a production process of the super-soft SS nonwoven fabric. The production process includes the steps of preparing raw materials and auxiliary materials according to the proportion, mixing well, melt-compressing by a screw extruder to obtain viscous flow melt, sending the melt into a melt filter for filtration, allowing the melt to enter a spinning die head, allowing trickle of the melt to be extruded out of spinneret orifices, allowing a drafting air channel to draft and shape the trickle of the melt under the action of process cooling air so as to obtain fiber of certain strength, allowing the fiber to be evenly adsorbed to a forming conveyor belt by a diffusion air channel to form a continuous mesh fiber layer, and rolling the fiber mesh into the nonwoven fabric of certain longitudinal and transverse tension by a hot rolling mill. The SS nonwoven fabric produced according to the formula by the process is smaller than 1.5g in softness, and is as soft and smooth as silk to touch and highly suitable for shell fabrics of baby diapers.

Owner:JINJIANG XINGTAI NON WOVEN PRODS

Additive pouring sealant used for wind driven generator and preparation method thereof

ActiveCN102093839AHigh thermal conductivityDissipate quicklyNon-macromolecular adhesive additivesOther chemical processesWind drivenMass ratio

The invention discloses an additive pouring sealant used for a wind driven generator and a preparation method thereof. The preparation method is characterized by comprising the following steps of: dewatering and blending 100 parts by weight of vinyl silicone oil, 50-200 parts by weight of aluminium oxide filler, 50-150 parts by weight of fire retardant, 0-15 parts by weight of white carbon black, 0-150 parts by weight of processed calcium carbonate, 10-30 parts by weight of alpha and omega-dimethyl polydimethylsiloxane for 30-200 minutes at the temperature of 120-170DEG C and the vacuum degree of 0.06-0.99mpa to obtain base stock; at the constant temperature, taking 100 parts by weight of base stock, adding 1-4 parts by weight of hydrogen-containing silicone oil and 0-0.06 part by weight of inhibitor, stirring in a stirrer for 20-30 minutes to obtain sealant A; taking 100 parts by weight of base stock, 1-6 parts by weight of platinum catalyst and 0.6-2 parts by weight of tackifier, and stirring in the stirrer to obtain sealant B; evenly mixing the sealant A and the sealant B at the mass ratio of 5:1; and solidifying the mixture is solidified at the room temperature to obtain the additive pouring sealant used for a wind driven generator, wherein the additive pouring sealant used for a wind driven generator has the advantages of high thermal conductivity coefficient, excellent electrical property, high and low temperature impact resistance, salt mist resistance, good adhesive property at high temperature and high moisture, and the fire resistance of V-1 level.

Owner:CHENGDU GUIBAO SCI & TECH

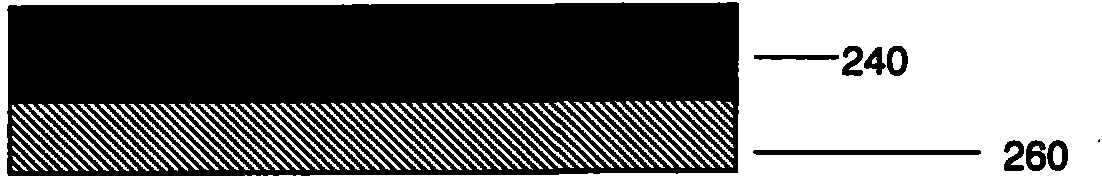

Battery diaphragm and application thereof

InactiveCN104600230AHigh porosityReduced ionic conductivitySecondary cellsCell component detailsCeramic particleLithium electrode

The invention discloses a battery diaphragm and application thereof. The battery diaphragm provided by the invention is composed of a base membrane and a nanoparticle coating coated on at least one surface of the base membrane. The nanoparticle coating contains at least two nanoparticles, which include ceramic particles and organic polymer particles. According to the battery diaphragm provided by the invention, the organic polymer particles are firstly added into the nanoparticle coating, thus not only enhancing the porosity of the nanoparticle coating, reducing the ionic conductivity of the battery diaphragm, but also enhancing the heat resistance of the battery diaphragm, decreasing the dosage of ceramic particles, and reducing the thickness of the nanoparticle coating. In addition, by adding the organic polymer particles, certain caking property exists between the battery diaphragm and the battery anode and cathode, so that the prepared battery has better oneness, and the diaphragm electrolyte solution wettability and absorption performance can also be improved, thus laying the foundation for providing lithium ion batteries with high security performance.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

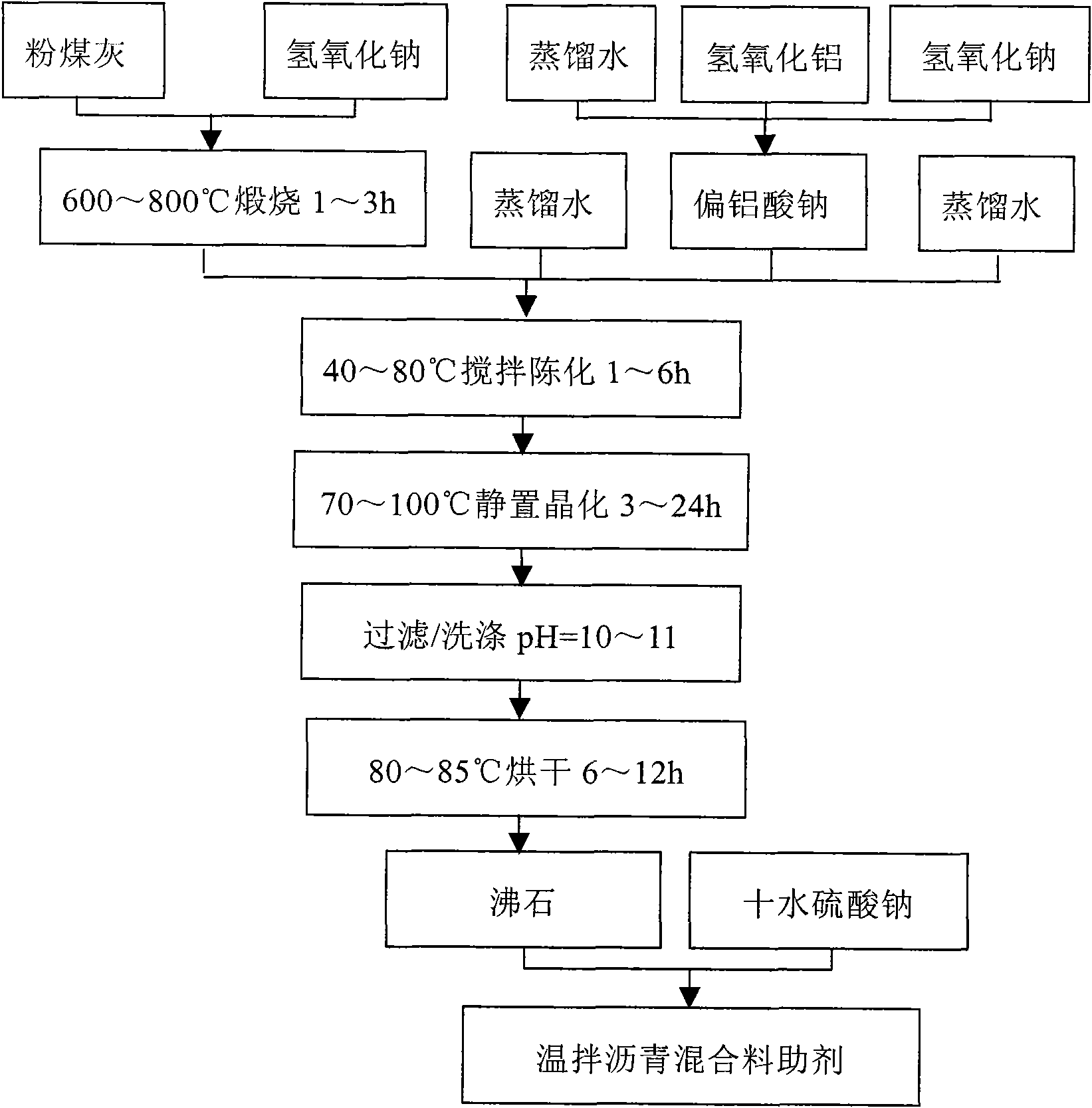

Warm-mixed auxiliary agent for asphalt mixture and preparation method thereof

ActiveCN101602583AEnergy savingReduce exhaust emissionsClimate change adaptationFilling materialsPitch blende

The invention relates to a warm-mixed auxiliary agent for asphalt mixture. The auxiliary agent is formed by uniformly mixing 93 to 97 percent of synthetic zeolite with 3 to 7 percent of granular sodium sulfate decahydrate by weight, wherein the synthetic zeolite includes 15 to 22 percent of crystal water, and the sodium sulfate decahydrate includes 55.9 percent of crystal water. Under normal temperature, the auxiliary agent is mixed with other raw materials according to the content of 0.3 to 0.5 percent of the total mass of the mixture, thereby preparing the product of the warm-mixed asphalt mixture; and other raw materials are 150 to 165 DEG C asphalt, 140 to 180 DEG C aggregate and mineral powder filling materials. During the blending of the mixture, the warm-mixed addition agent and the heated asphalt are added simultaneously, great amount of vapor generated by the moisture-containing auxiliary agent are released, which results in volumetric expansion of the asphalt, thereby forming foamed asphalt; meanwhile, the workability of the asphalt can be enhanced, the blending and mold temperature of the mixture can be reduced by 15 to 25 DEG C, exhaust emission can be effectively reduced, energy consumption is lowered, the aging of asphalt during blending is reduced, and the auxiliary agent has the advantages of simple preparation and low cost.

Owner:WUHAN UNIV OF TECH

Anti-slide fog seal material and its construction method

ActiveCN102815892AImprove skid resistanceAvoid the problem of insufficient skid resistanceIn situ pavingsKaolin clayRoad surface

The invention relates to an anti-slide fog seal material and its construction method. The anti-slide fog seal material is obtained by the following steps of: mixing 15-30 parts by weight of composite kaolin, 35-70 parts by weight of water and 1.2-2.0 parts by weight of an asphalt emulsifier, adjusting the pH value into a range required by the corresponding asphalt emulsifier with a pH value conditioning agent, then emulsifying 25-40 parts by weight of hot melt asphalt so as to obtain a stable mixed emulsion, and finally mixing the emulsion with 50-80 parts by weight of sand and conducting stirring. When the anti-slide fog seal material is sprayed on a road surface uniformly by a spraying vehicle, it can bond well with the road surface. Thus, the material not only seals original road surface micro-cracks and voids, plays a strong waterproof role, but also prolongs the road service life. And the sand in the anti-slide fog seal material can substantially improve the anti-slide performance of the road surface.

Owner:GAOYUAN HIGHWAY MAINTENANCE TECH HENAN PROV

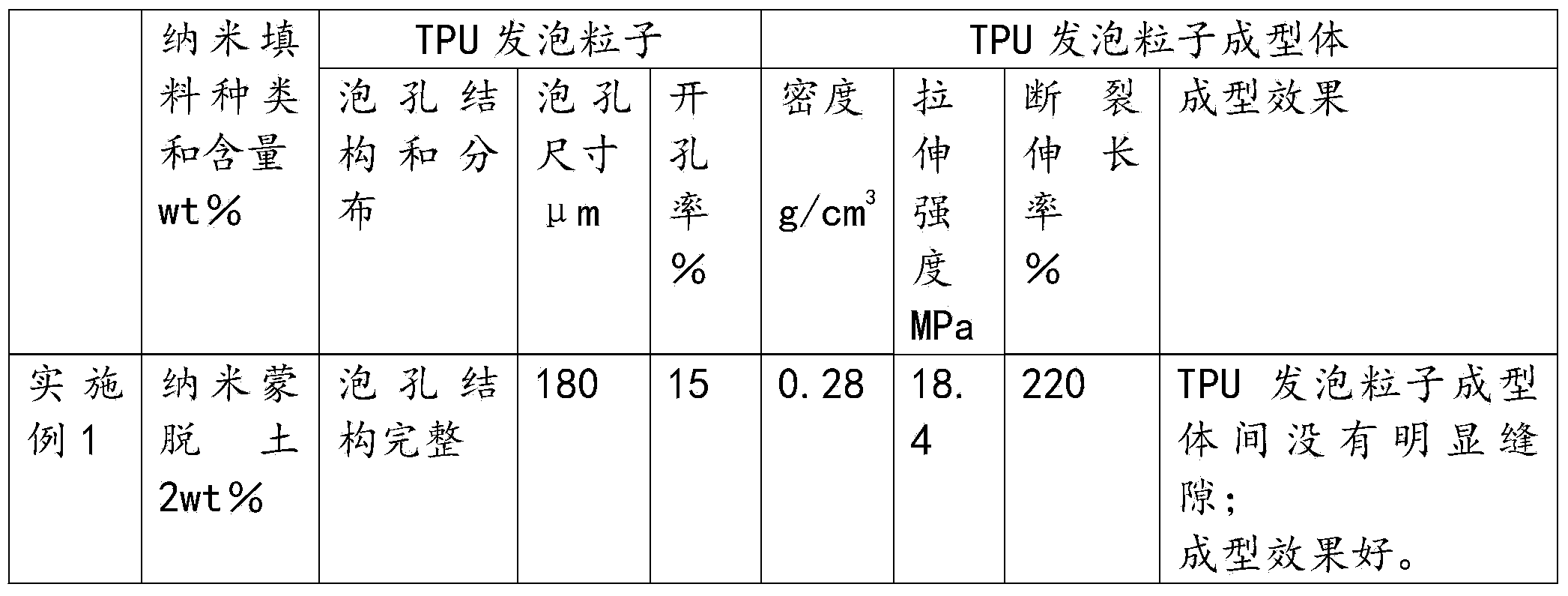

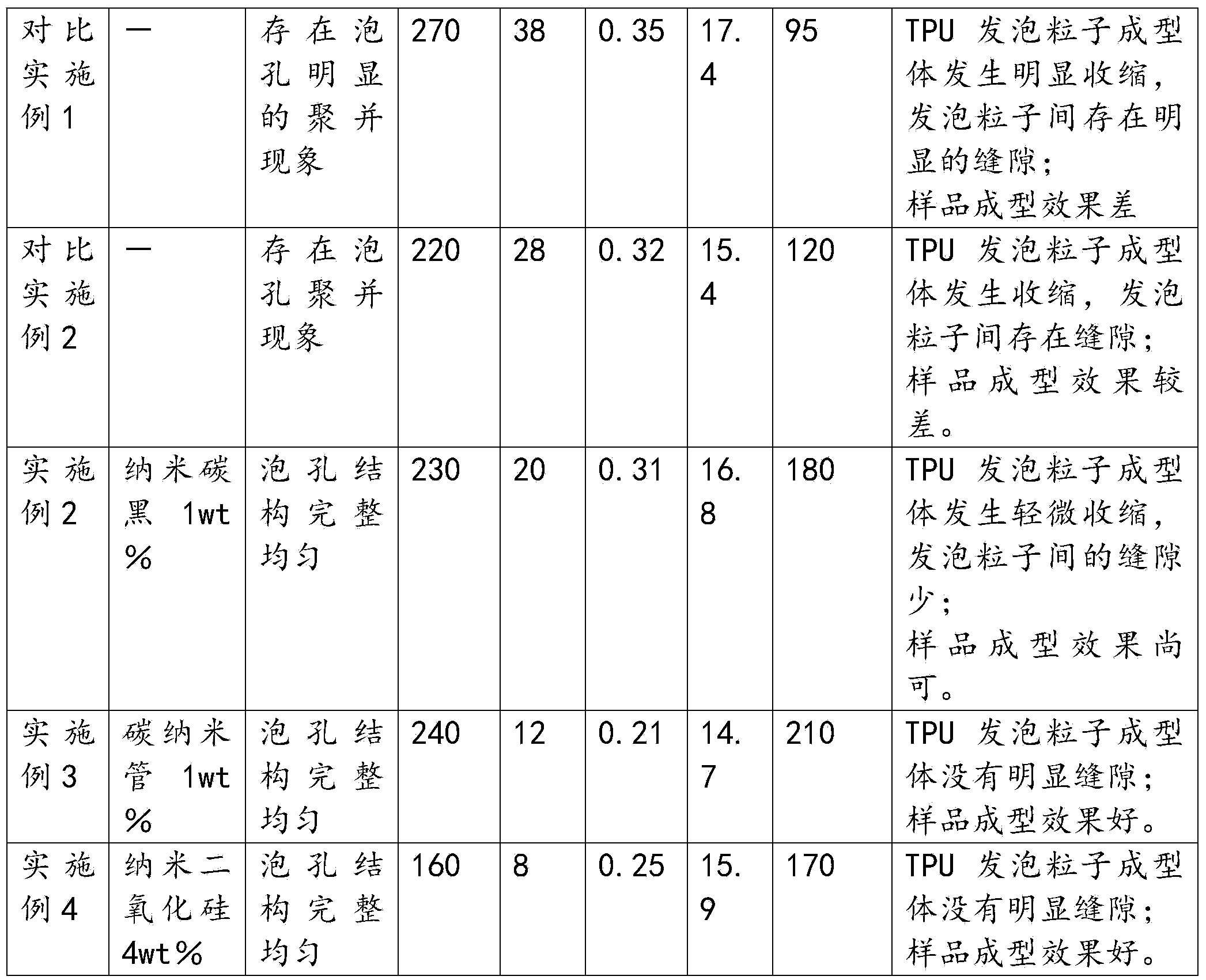

Method for preparing TPU foamed beads by continuous extrusion foaming

The invention discloses a method for preparing TPU (Thermoplastic Polyurethane) foamed beads by continuous extrusion foaming. The method comprises the steps of (1) mixing TPU particles with inorganic nano-particles which are organically modified, adding the mixed TPU particles into a material barrel of a first extruder, melting the TPU particles into a polymer melt by screw heating, and injecting a supercritical fluid into the tail end of the first extruder to mix the supercritical fluid with the polymer melt; (2) injecting a mixed polymer / high-pressure fluid melt into a second extruder through a melt pump, and gradually reducing the temperature of a heating area of the second extruder to obtain a polymer / supercritical fluid melt which is cooled and uniformly mixed; (3) extruding the polymer / supercritical fluid melt from an opening mold of the second extruder, and performing underwater ring cutting to obtain TPU foamed particles. According to the method, a TPU foamed particle molding body material which enables the foamed particles to be well bonded after steam molding can be quickly prepared.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

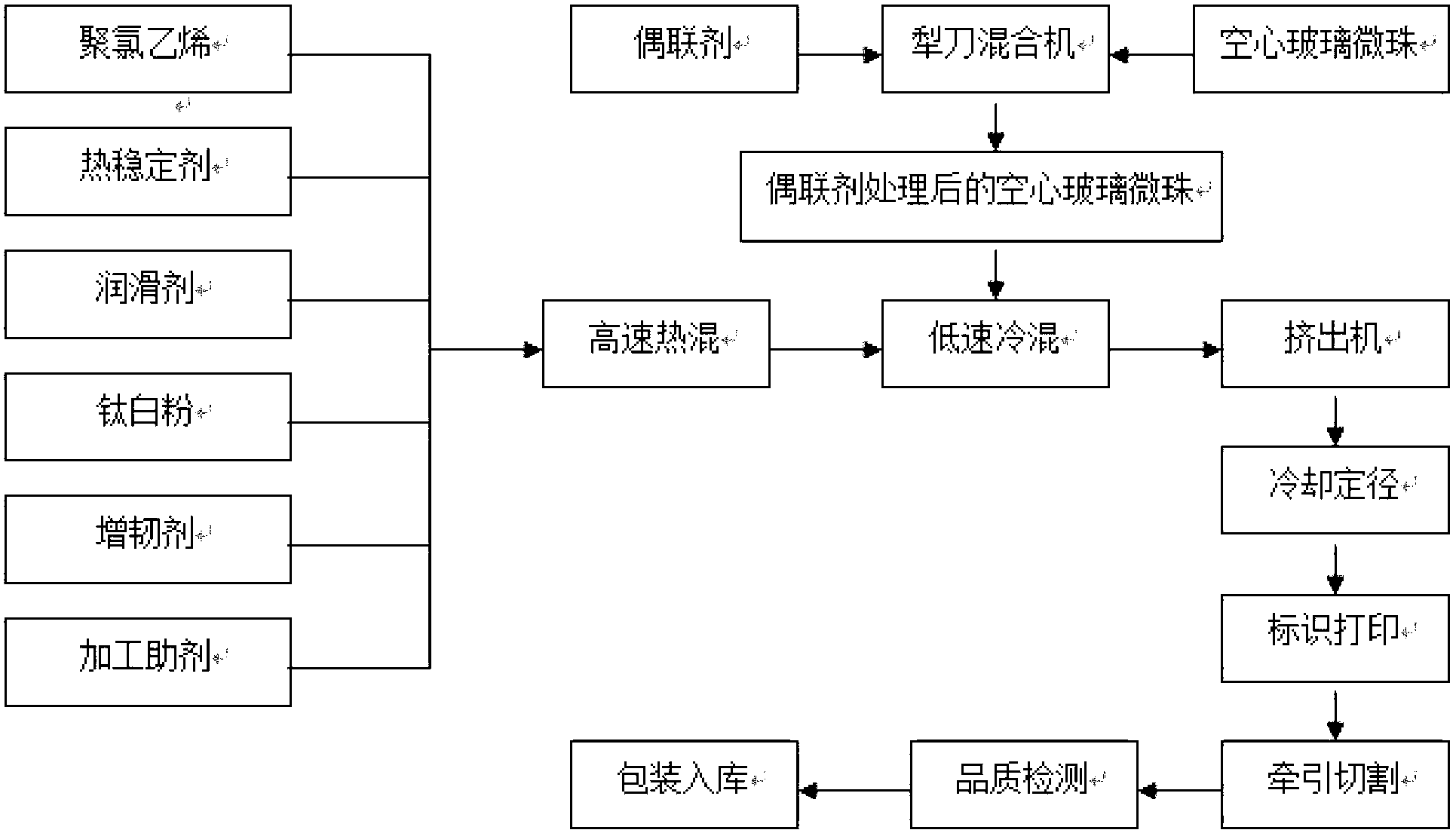

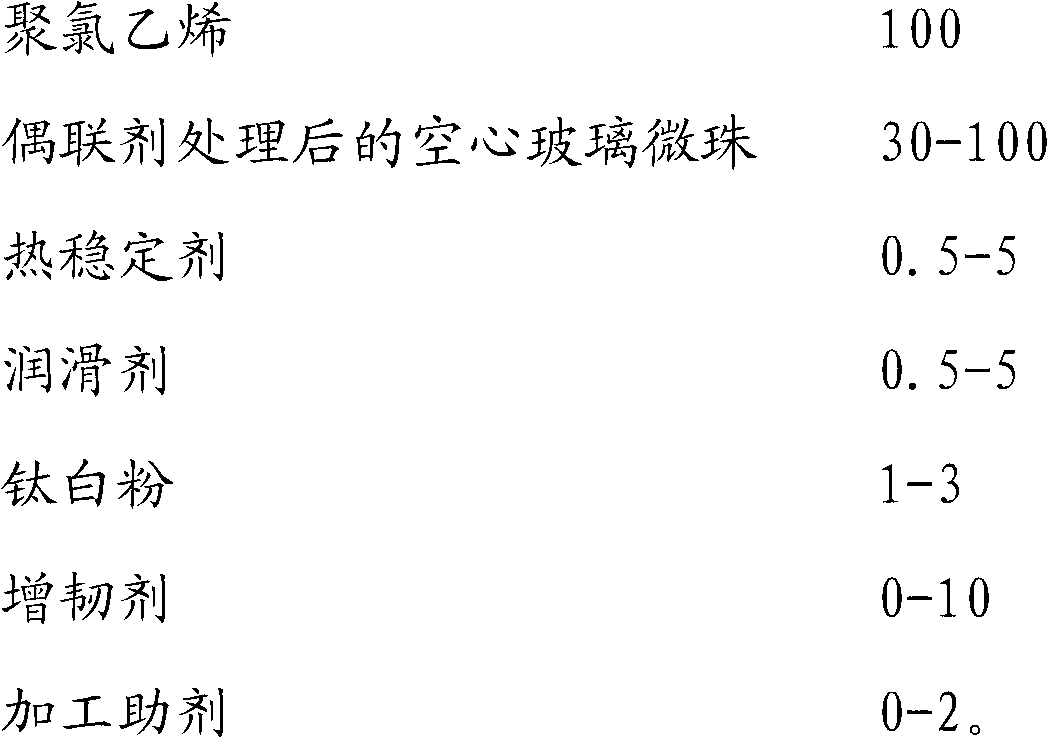

Polyvinyl chloride drain pipe and preparation method thereof

The invention discloses a polyvinyl chloride drain pipe and a preparation method thereof. The polyvinyl chloride drain pipe comprises the following raw materials in part by weight: 100 parts of polyvinyl chloride, 30 to 100 parts of hollow glass microsphere processed by coupling agent, 0.5 to 5 parts of thermal stabilizer, 0.5 to 5 parts of lubricating agent, 1 to 3 parts of titanium dioxide, 0 to 10 parts of flexibilizer and 0 to 2 parts of processing agent. The method adopts the mode of plastic modifying, creatively introduces the hollow glass microsphere for filling, effectively improves the product toughness on the basis that the product rigidity is guaranteed, simultaneously effectively reducing noises through a hollow structure, greatly reduces the product density, reduces the product weight, and can also reduce the product cost.

Owner:RIFENG ENTERPRISE FOSHAN CO LTD +1

Laminated material without metal foil for blocking package

The invention discloses a laminated material without metal foil for a blocking package. The material at least comprises a substrate layer assembly and a composite blocking layer assembly, wherein the substrate layer assembly and the composite blocking layer assembly are laminated together; the substrate layer assembly has the effect of supporting; and the composite blocking layer assembly comprises at least one composite blocking layer which is prepared through a partition-laminated confluence layer multiplication and coextrusion method and comprises a plurality of repeated units. The material is characterized in that each repeated unit at least comprises three polymer constitutes, and each polymer constitute can form an individual layer or more than one individual layer; and only one of the polymer constitutes is a blocking polymer constitute which can block gas.

Owner:厦门天策材料科技有限公司

Non-whitening emulsion pressure sensitive adhesives

InactiveCN1284106ALow hazeAdhesiveNon-macromolecular adhesive additivesEster polymer adhesivesMethacrylateEmulsion

Water resistant, low haze acrylic emulsion pressure sensitive adhesive compositions for use in decorative, light management or optical articles are disclosed. These emulsion pressure sensitive adhesives comprise (a) 50-90% by weight n-butyl acrylate, and (b) 10-50% by weight 2-hydroxy ethyl acrylate, or 2-hydroxy ethyl methacrylate, hydroxy propyl acrylate monomer, or mixtures thereof. These emulsion pressure sensitive adhesives can be used in wet lamination processes, and exhibit less than 2% increase in haze, less than 2% increase in opacity and greater than 95% transmittance after the wet lamination process.

Owner:3M CO

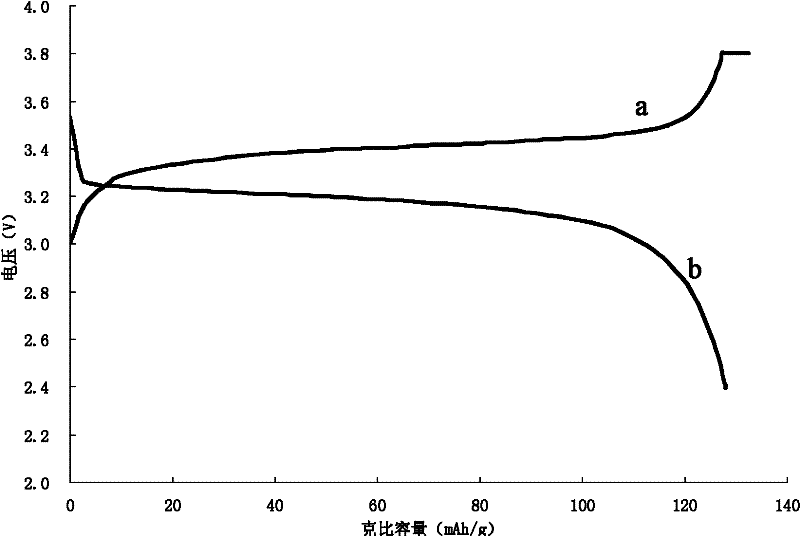

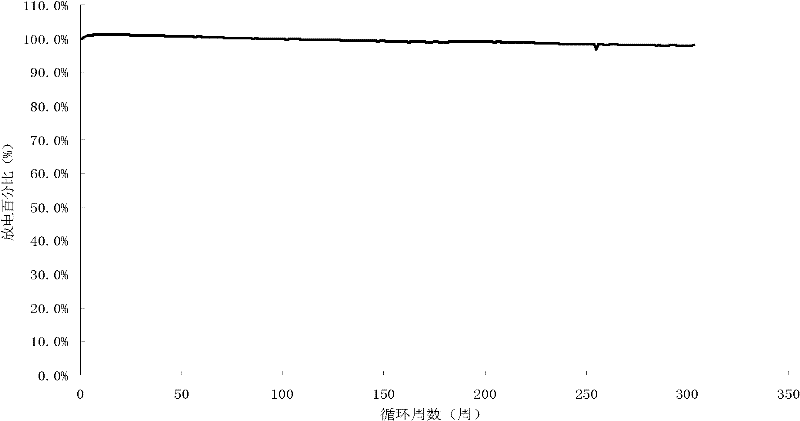

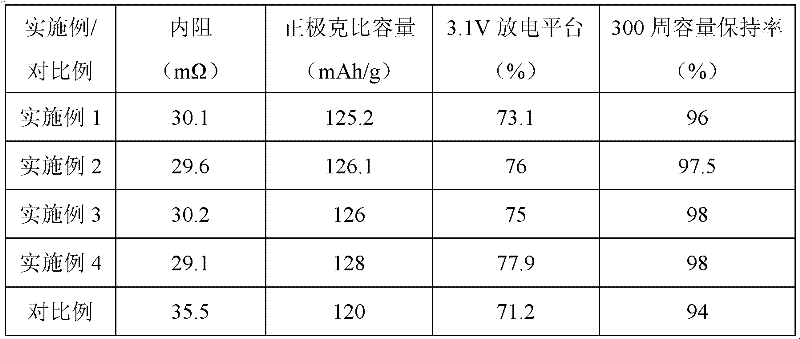

Lithium iron phosphate lithium ion battery and machining method thereof

ActiveCN102185129AAdhesiveImprove slurry uniformityElectrode carriers/collectorsCurrent collectorLithium electrode

The invention provides a lithium iron phosphate lithium ion battery and a machining method thereof, which relate to lithium ion batteries and aim to effectively improve adhesiveness between a current collector and active substances. The lithium iron phosphate lithium ion battery is provided with the current collector, wherein the front and back of the current collector are coated with a conductive layer respectively; and the conductive layer comprises the following components in percentage by mass: 1 to 6 percent of conductive agent, 3 to 5 percent of adhesive and the balance of positive active substance. The machining method comprises the following steps of: mixing the adhesive and water to obtain assembly glue; adding the conductive agent into the assembly glue to obtain a conductive adhesive; adding lithium iron phosphate into the conductive adhesive to obtain positive paste; stirring the positive paste, regulating the viscosity to be 4,000 to 8,000 mpa.s, and performing screening to obtain paste; and coating the screened paste onto the front and back of the current collector, and drying the current collector to finish the coating to obtain the lithium iron phosphate lithium ion battery.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

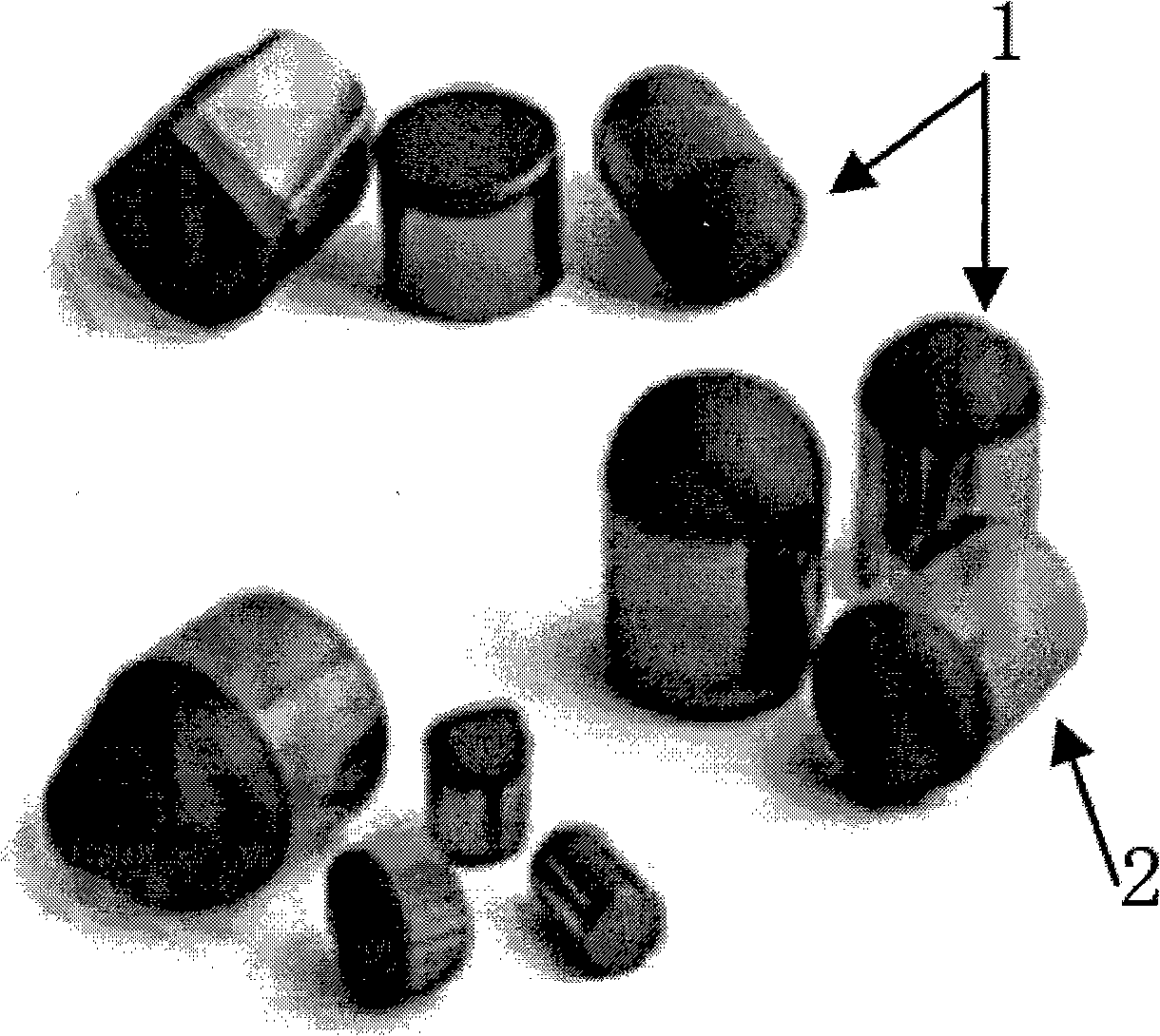

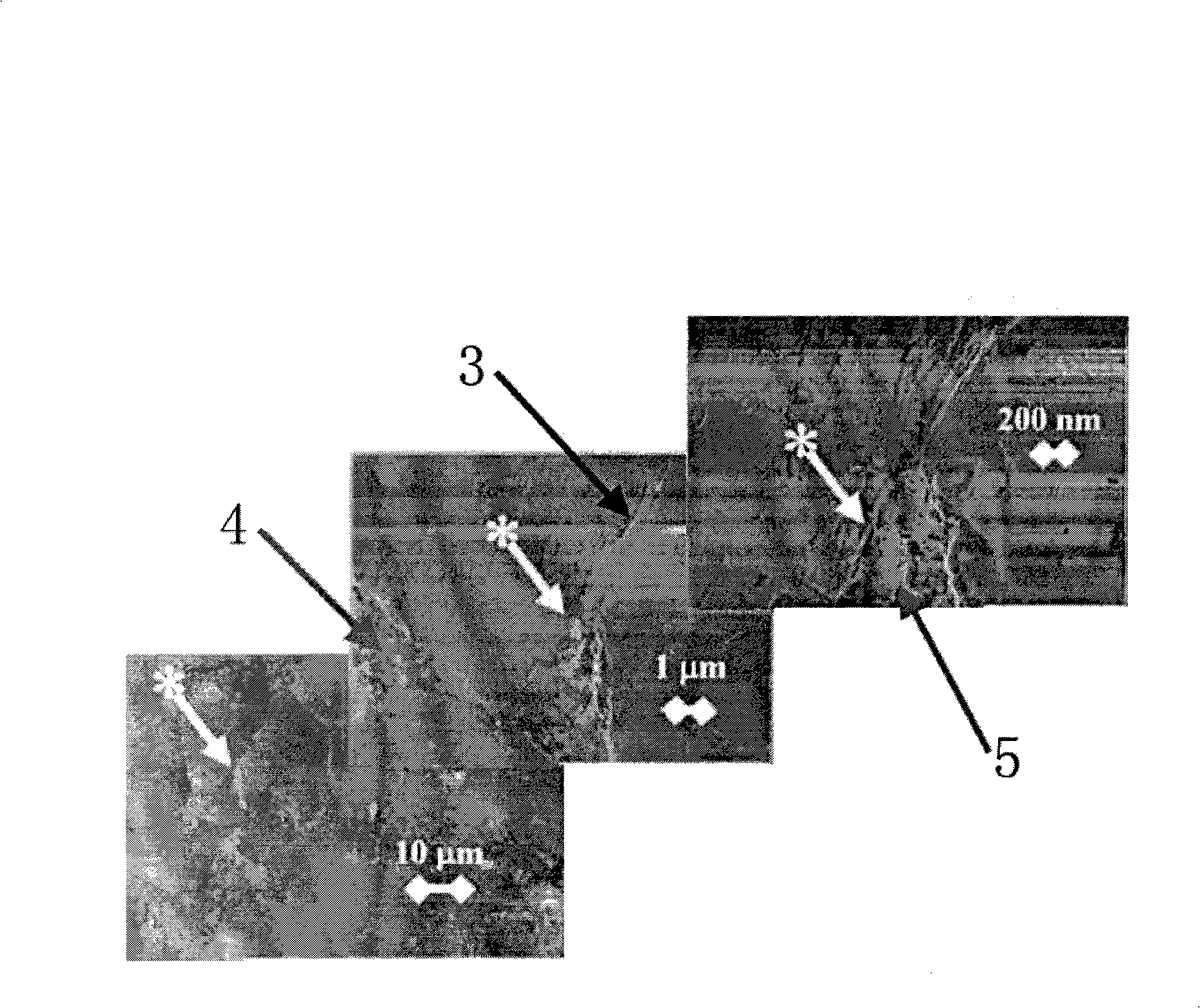

Diamond-silicon carbide combination drill teeth for petroleum probe boring and manufacture method thereof

The invention relates to a diamond-silicon carbide composite drilling tooth used for oil drilling, the material of a substrate is hard alloy, and the material of a tooth crown is a diamond-silicon carbide compound in nano-structure. The microstructure of the diamond-silicon carbide compound in the nano-structure is formed by the direct combination of micron-sized diamond grains, and nano-silicon carbide binder and nano-diamond grains are filled in the slits of the micron-sized diamond grains. The preparation method of the composite drilling tooth comprises the steps that: diamond powder and silica powder are ground by a ball grinder after being mixed, then ground mixed powder material is mixed with carbon nanotube fiber to form diamond-amorphous silicon-carbon nanotube fiber mixed powder material which is put into a die, and the substrate is covered and treated with pressure forming to form a blank; high pressure sintering is carried out to the blank. The product greatly improves the fracture toughness and the anti-impact strength of the material on the premise of keeping the high hardness, high wearing resistance and high heat stability of the diamond-silicon carbide composite.

Owner:贺端威 +1

Asphalt-based non-curable heat-resistant waterproof sealant and preparation method thereof

ActiveCN102775956AImprove adhesionAdhesiveNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePolyolefin

The invention relates to an asphalt-based non-curable heat-resistant waterproof sealant and a preparation method of the sealant. The sealant comprises the following components in percentage by weight: 10-35% of asphalt, 5-15% of rubber oil, 1-3% of polyolefin processing modifier, 20-30% of 30Mu-100Mu glue powder, 5-10% of tackifier, 10-30 of sodium bentonite, and 3-5% of wetting dispersant reagent. The sealant has the following characteristics of good bonding property, high percentage elongation, good self-healing property, good creep property, possible construction of knife coating, spray coating or grouting, no need to maintain, capability of being constructed on wet foundation surface even under condition of (-40) DEG C and thus effectively shortening the construction period, no organic solvent, low energy consumption in construction, safety, environmental friendliness, no pollution, high-temperature resistance (not flowing at 110 DEC C), low-temperature resistance (not cracking at (-40) DEG C), stable property, good stickiness, and capability of sealing base layer cracks and pores so as to avoid water channeling phenomenon.

Owner:中建材苏州防水研究院有限公司 +1

Compound chemical coal dust suppressant and preparation method thereof

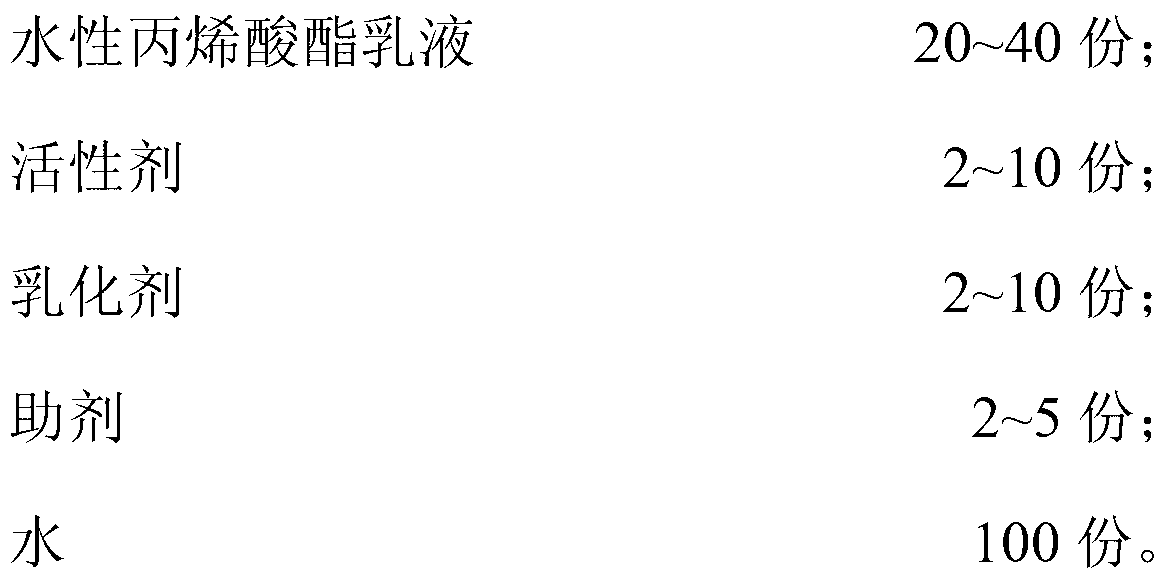

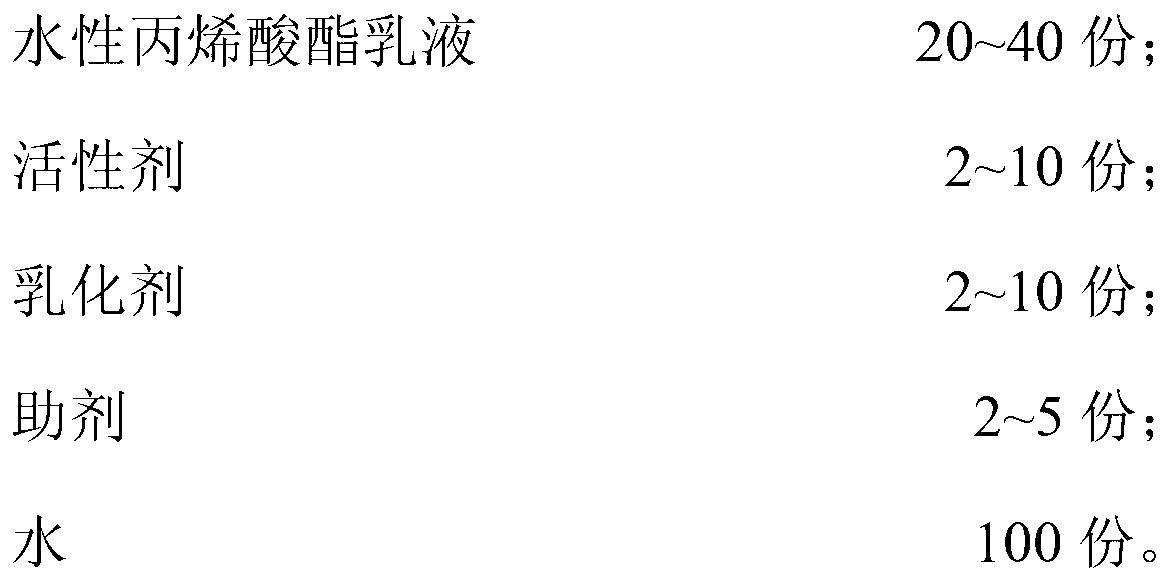

ActiveCN103305187AFly effectivelyEffectively suppress flyingOther chemical processesWater basedEmulsion

The invention discloses a compound chemical coal dust suppressant and a preparation method thereof. The preparation method comprises the steps of uniformly stirring 20-40 parts of water-based acrylate emulsion, 2-10 parts of activating agents, 2-10 parts of emulsifying agents, 2-5 parts of aids and 100 parts of water uniformly for 0.5 hour at 40-60 DEG C and then cooling the mixture to the room temperature. The compound chemical coal dust suppressant has the functions of wetting, bonding and coagulating. When used, the dust suppressant is diluted with water according to a ratio of 1:(10-1000), then the dust suppressant water solution is injected into a sprayer, and coal pile dust flying can be effectively suppressed for a long time by uniformly spraying the dust suppressant water solution onto the coal pile surface according to the amount of 1.0-2L / m<2>.

Owner:SHAANXI COAL & CHEM TECH INST

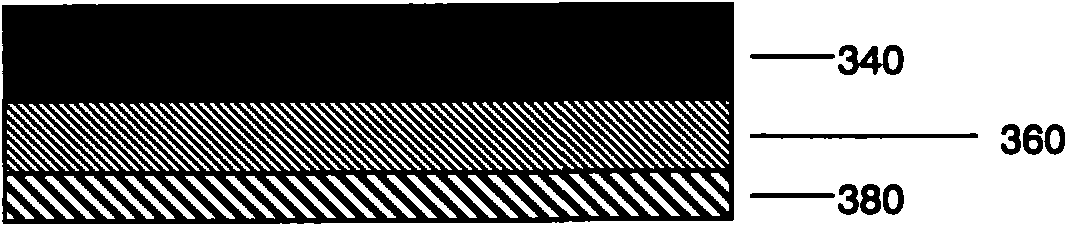

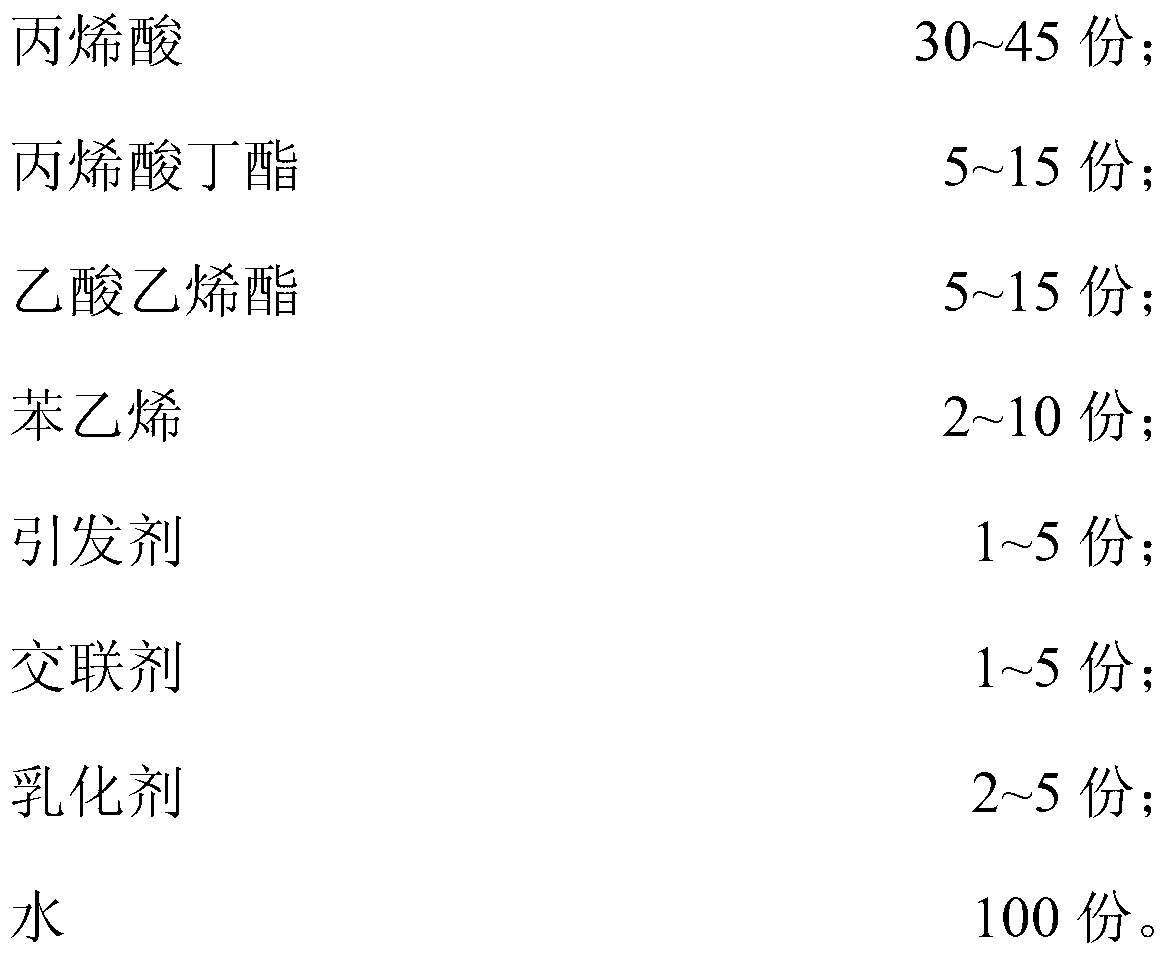

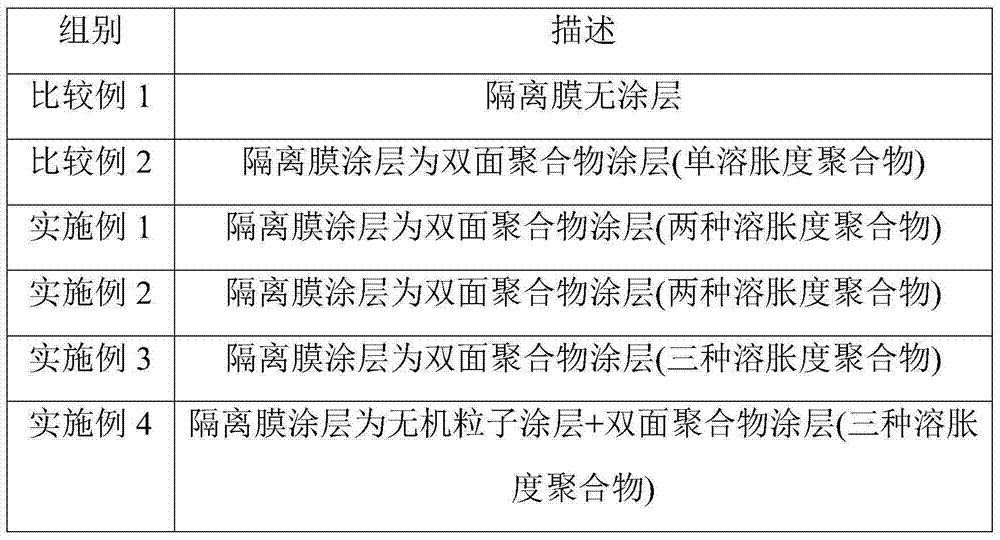

Isolating membrane for lithium ion secondary battery

InactiveCN104852008AGuaranteed not to deformPerformance is not affectedSecondary cellsCell component detailsCell fabricationPhysical chemistry

The invention belongs to the technical field of battery manufacture, and specifically relates to an isolating membrane for a lithium ion secondary battery, comprising an isolating membrane main body, wherein at least one surface of the isolating membrane main body is coated with a binder-polymer coating, and the binder-polymer coating comprises a binder polymer and a binder, and the binder-polymer coating at least comprises two polymers with different swelling degrees, wherein at least one polymer with lower swelling degree is used as cage construction for holding a certain expansion space for a pole piece of the lithium ion battery, and at least one polymer with higher swelling degree can be well bonded with the pole piece. Because the binder-polymer coating comprises the binder polymer and the binder, and the system is an environmental water system, and the coating coverage rate is 10 percent to 90 percent, the isolating membrane for the lithium ion secondary battery not only can be used for providing the expansion space of the pole piece, but also has small blockage for the hole of the isolating membrane, which cannot have influence on the battery performance. The polymer with high swelling degree can be well bonded with the pole piece so as to effectively restrain the deformation of the battery.

Owner:东莞市魔方新能源科技有限公司 +1

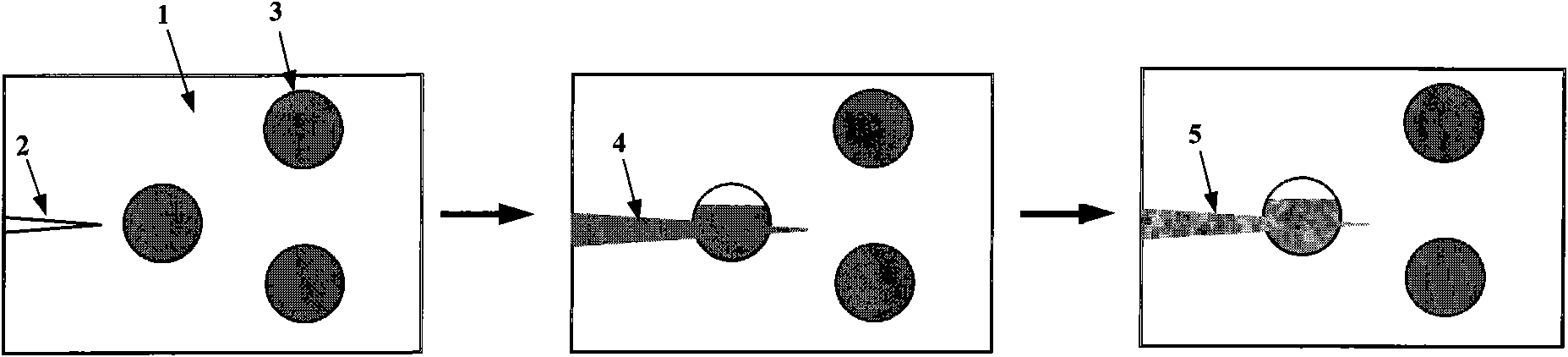

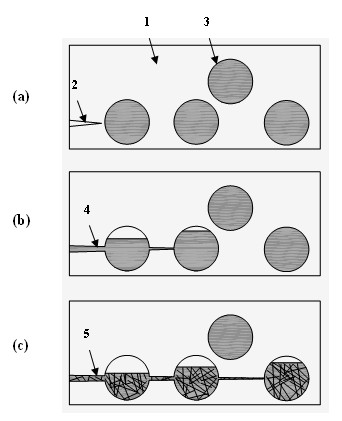

Room-temperature self-repairing type thermoplastic polymer material and preparation method thereof

The invention relates to the technical field of self-repairing materials and discloses a room-temperature self-repairing type thermoplastic polymer material and a preparation method thereof. The room-temperature self-repairing type thermoplastic polymer material comprises the following components, by weight percent: 72-92% of monomer used for preparing a thermoplastic resin substrate, 0.1-0.4% ofinitiator used for preparing the thermoplastic resin substrate, 2.5-8% of catalyst used for preparing the thermoplastic resin substrate and 4-20% of micro-capsule containing a vinyl monomer. When theroom-temperature self-repairing type thermoplastic polymer material generates a micro-crack due to the action of external force in the use process, the micro-capsule embedded in the substrate is broken, and a repairing agent is released and generates atom transferring free radical active polymerization with the substrate, thus rupture faces are stuck and connected together, the crack is prohibitedfrom being further expanded, and the self repairing of the material is realized. The self-repairing type thermoplastic polymer material prepared by the invention has the characteristics of simple preparation (single-component micro-capsule), automatic completion of crack repairing at room temperature (no need of heating) and the like.

Owner:SUN YAT SEN UNIV

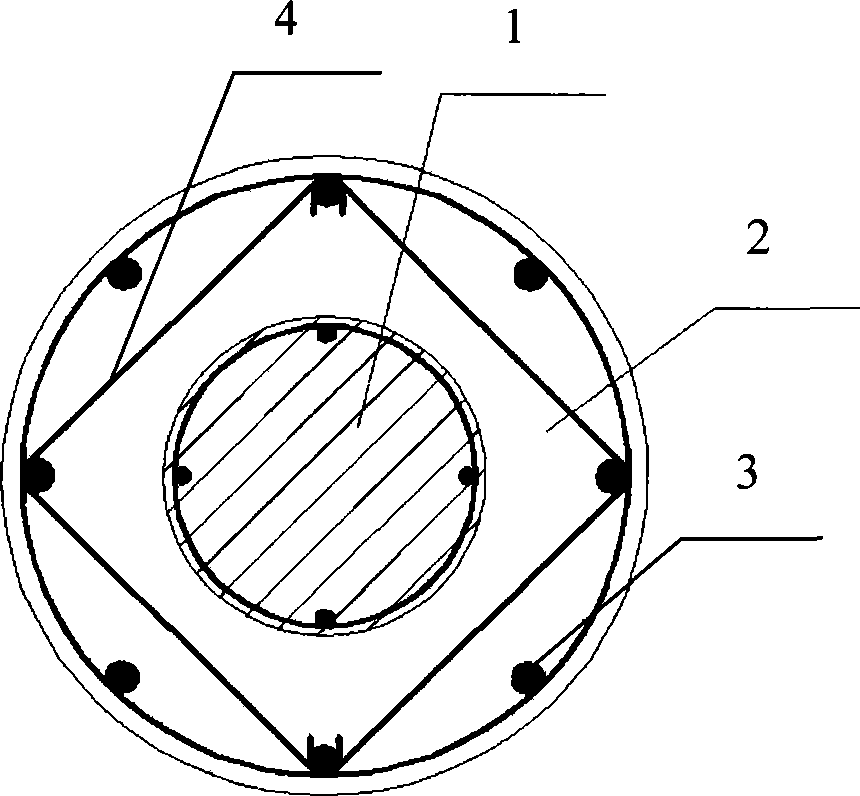

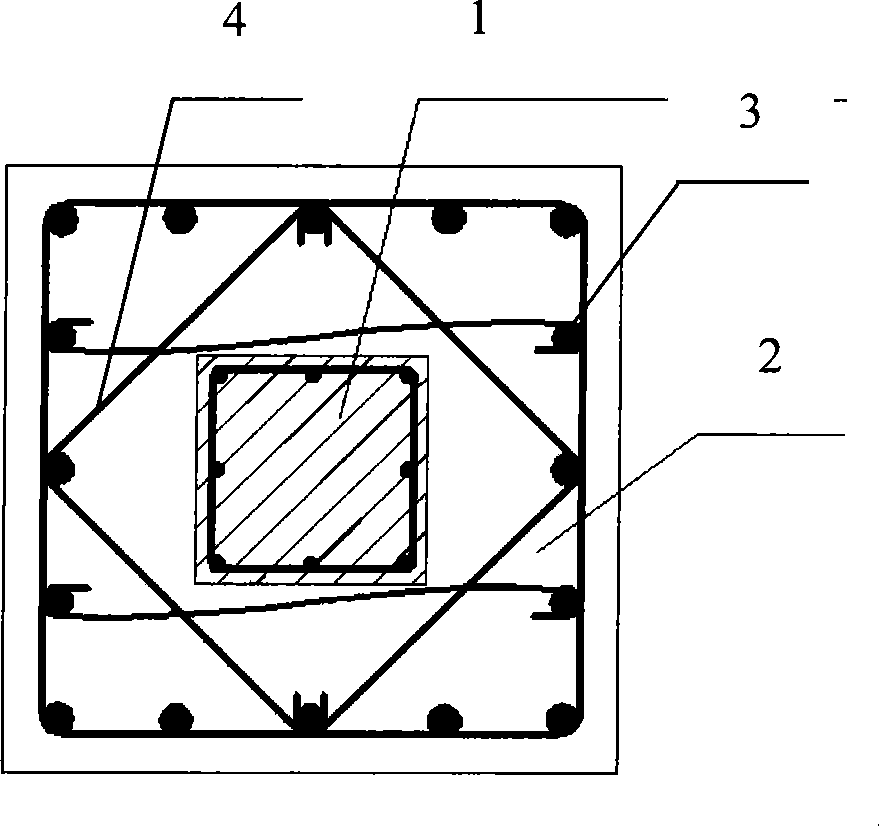

Recycled concrete superposed column and its implementing method

InactiveCN101487333AIncreased durabilityImprove seismic performanceStrutsPillarsRebarSurface processing

The invention relates to a recycled concrete laminated column and an implementation method thereof. The laminated column adopts a new section shape and the structure of the laminated column comprises an inner prefabricated recycled concrete core column or an abandoned concrete column dismantled from the building (including a round column and a square column), wherein, the surface of the recycled concrete core column is kept naturally crude instead of polishing. The interior of the recycled concrete core column is internally provided with quantitative reinforcing bars for the purpose of guaranteeing the recycled concrete core column from being damaged during the processes of transportation and hoisting. The surface of the abandoned concrete column is subjected to surface treatment, the plastering is removed from the surface and the surface of the abandoned concrete column is polished to be crude. The recycled concrete laminated column further includes an external cast-in-place common concrete peripheral column, wherein, the common concrete is internally provided with reinforcing bars. The invention improves the endurance of the recycled concrete and also the stressing of the entire recycled concrete column, and the like, has good market prospect, and can accelerate the popularization of the recycled concrete, and the popularization and the application of the abandoned concrete.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP +1

Room temperature self-repair thermoplastic polymer material

The invention relates to the technical field of self-repair materials, and discloses a room temperature self-repair thermoplastic polymer material. The material consists of the following components in percentage by weight: 77 to 94 percent of monomers for preparing thermoplastic resin matrix, 0.6 to 1.5 percent of initiator for preparing the thermoplastic resin matrix, 0.2 to 2.6 percent of chain transfer agent for preparing the thermoplastic resin matrix, and 2.5 to 20 percent of microcapsules containing vinyl monomers. According to the room temperature self-repair thermoplastic polymer material, when micro cracks are generated due to the action of an external force in use, the microcapsules embedded into the matrix crack to release a repair agent, and the repair agent and the matrix can undergo reversible addition-fragmentation transfer free radical polymerization, so that the fractured surfaces are stuck together, the cracks are prevented from being further expanded, and self-repair of the material is realized. The prepared self-repair thermoplastic polymer material is simple to prepare, and can automatically complete repair of the cracks at room temperature.

Owner:SUN YAT SEN UNIV

Road dust inhibitor and preparation method thereof

InactiveCN104449579AWith moisturizing functionWith bonding functionOther chemical processesCarrying capacityAnti freezing

The invention discloses a road dust inhibitor and a preparation method thereof. The road dust inhibitor is characterized in that the raw materials of the road dust inhibitor comprises surface active agents, stabilizers, hydrophilic agents, thickeners, anti-freezing auxiliaries, antibacterial agents and water. The preparation method comprises, firstly, adding an appropriate amount of water into a reactor; secondly, adding the surface active agents and the stabilizers in; thirdly, after the surface active agents and the stabilizers are fully dissolved, slowly adding the hydrophilic agents and the thickeners in and stirring to achieve dissolution; fourthly, adding the anti-freezing auxiliaries and the antibacterial agents in; lastly, adding the residue water in until reaching a designated concentration. By means of the surface active agent, the road dust inhibitor can form a layer of isolating film on the contact surface between dust and air, and the isolating film has high water carry capacities and adhesive performance; by adding a small amount of salt, the road dust inhibitor obtain certain anti-freezing and antibacterial effects.

Owner:HEFEI UNIV OF TECH

Production process for corona resistant polyimide film to produce winding wire

InactiveCN101252033AStrong bondHigh mechanical strengthWindingsFlat/ribbon cablesPlasma treatmentMoisture

The present invention discloses a method for manufacturing winding wires by corona resistant polyimide films, comprising the following steps: 1) alkaline solution processing; 2) cleaning and drying; 3) plasma processing at normal temperature; 4) coating resin latex; 5) baking and flowing and leveling; 6) withdrawing trays; 7) releasing copper flat wires; 8) folding packages; 9) high-frequency heating; 10) roll-up. With the present invention, after a surface chemical treatment and a normal temperature plasma treatment, the adhesion between the film and the copper conducting wires and between the films is firm, the mechanical strength is high. After being bent or stretched, the winding wire still has good adhesion performance and electric insulation performance, sealing and moisture resistant performance, heat resistant performance, and heat conduction performance. The thickness of the film is controlled between 0.03 and 0.038 mm. In the condition that the volume of a motor is not changed, the cross section of the conductor of the motor can be enlarged. The thermal resistance encountered during the period, when the heat generated during the running process of the motor is dissipated outward, is reduced. The insulation thermal aging speed is slowed and the service life of the motor is greatly prolonged.

Owner:JIANGSU ICE CITY INSULATION MATERIALS STOCK

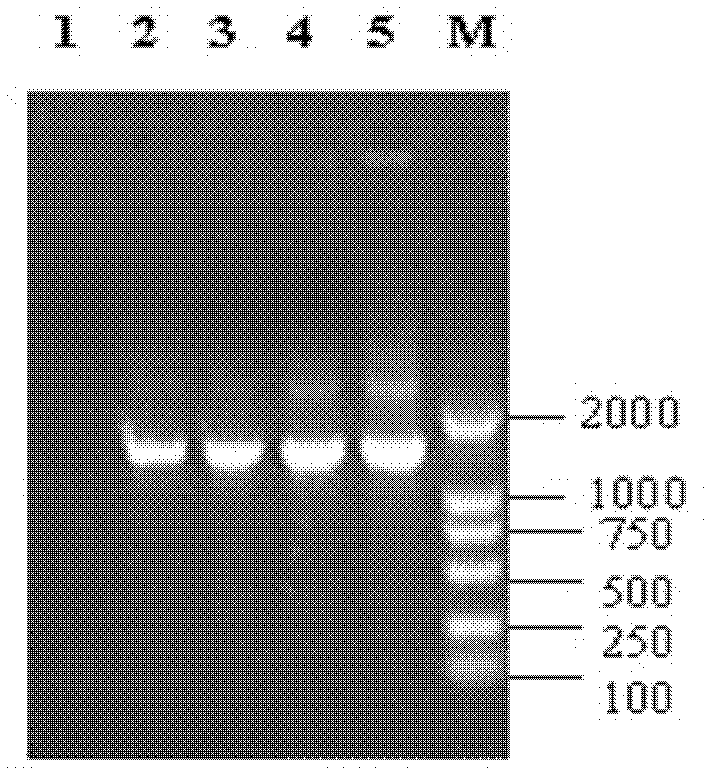

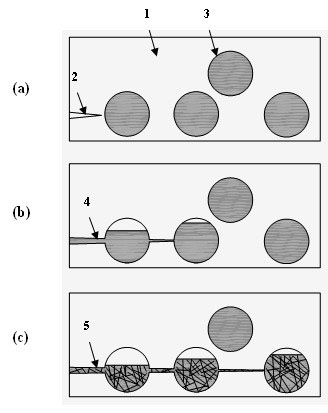

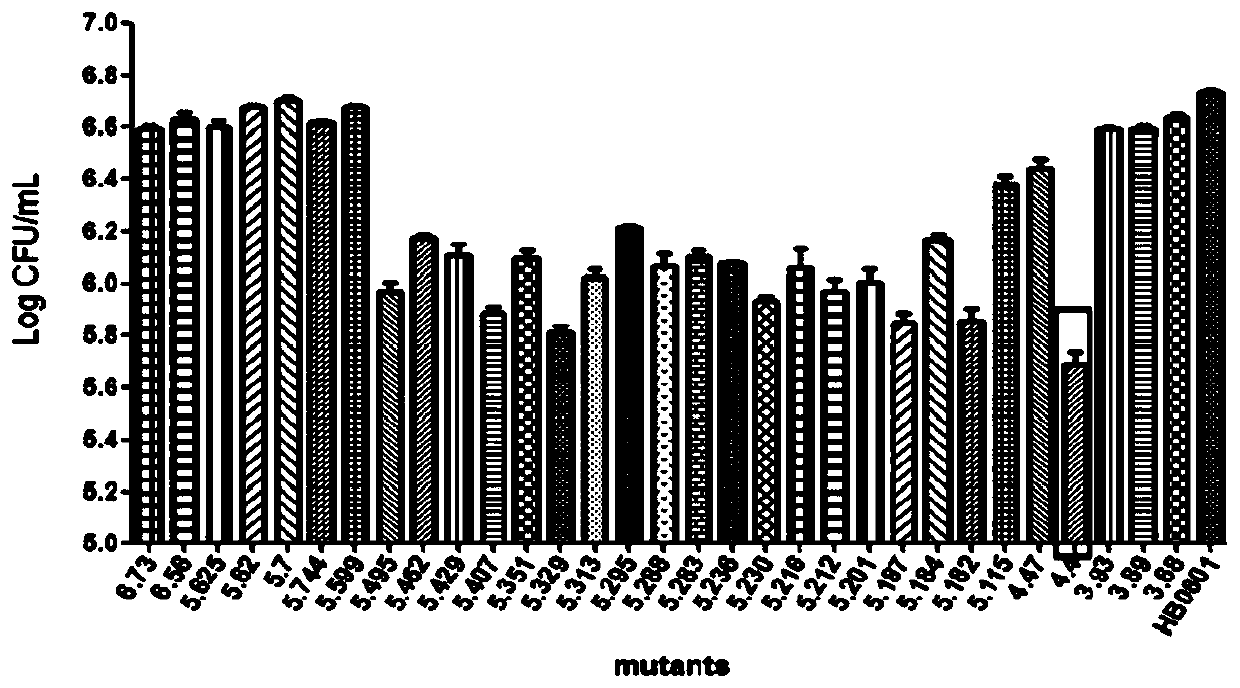

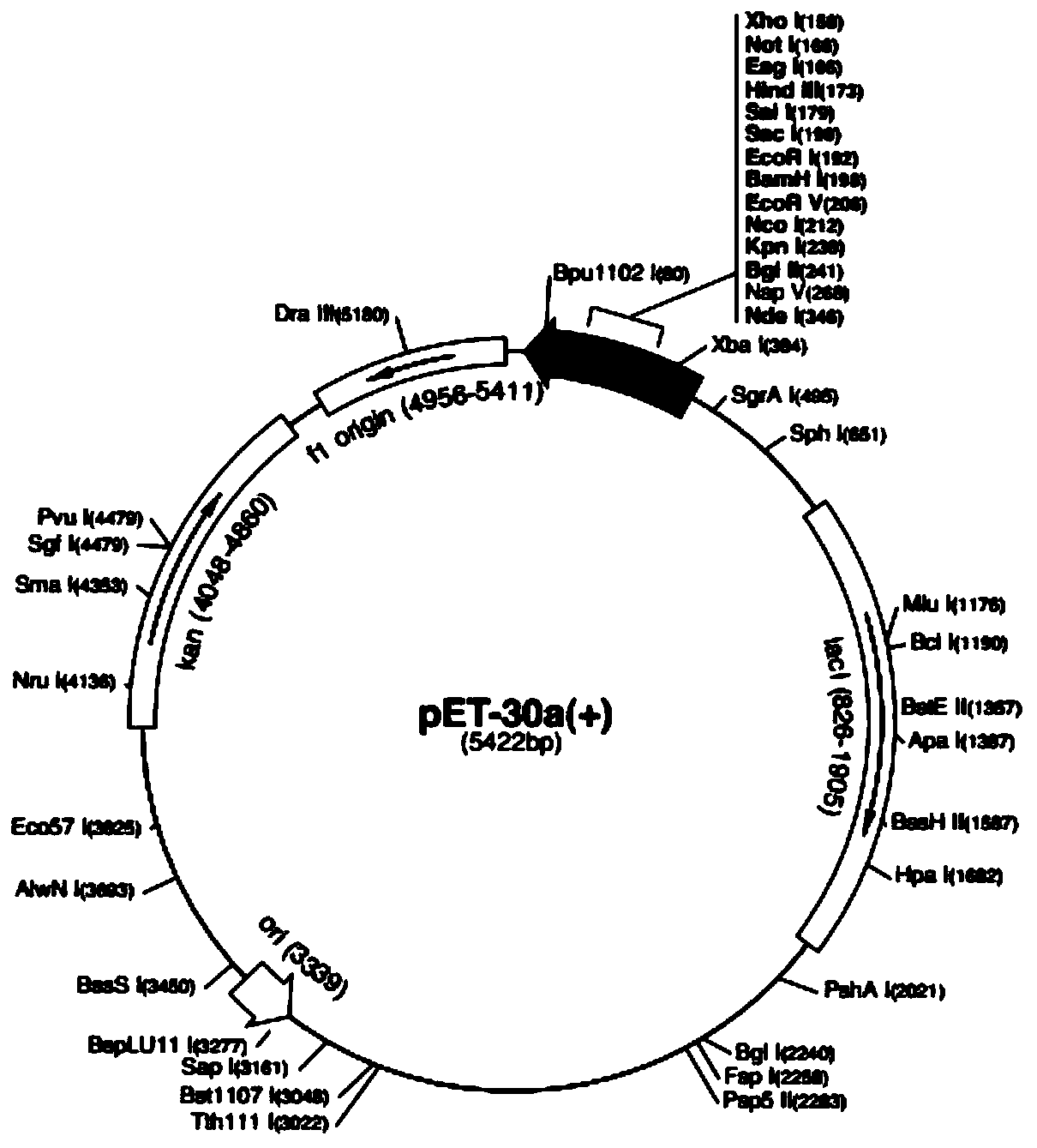

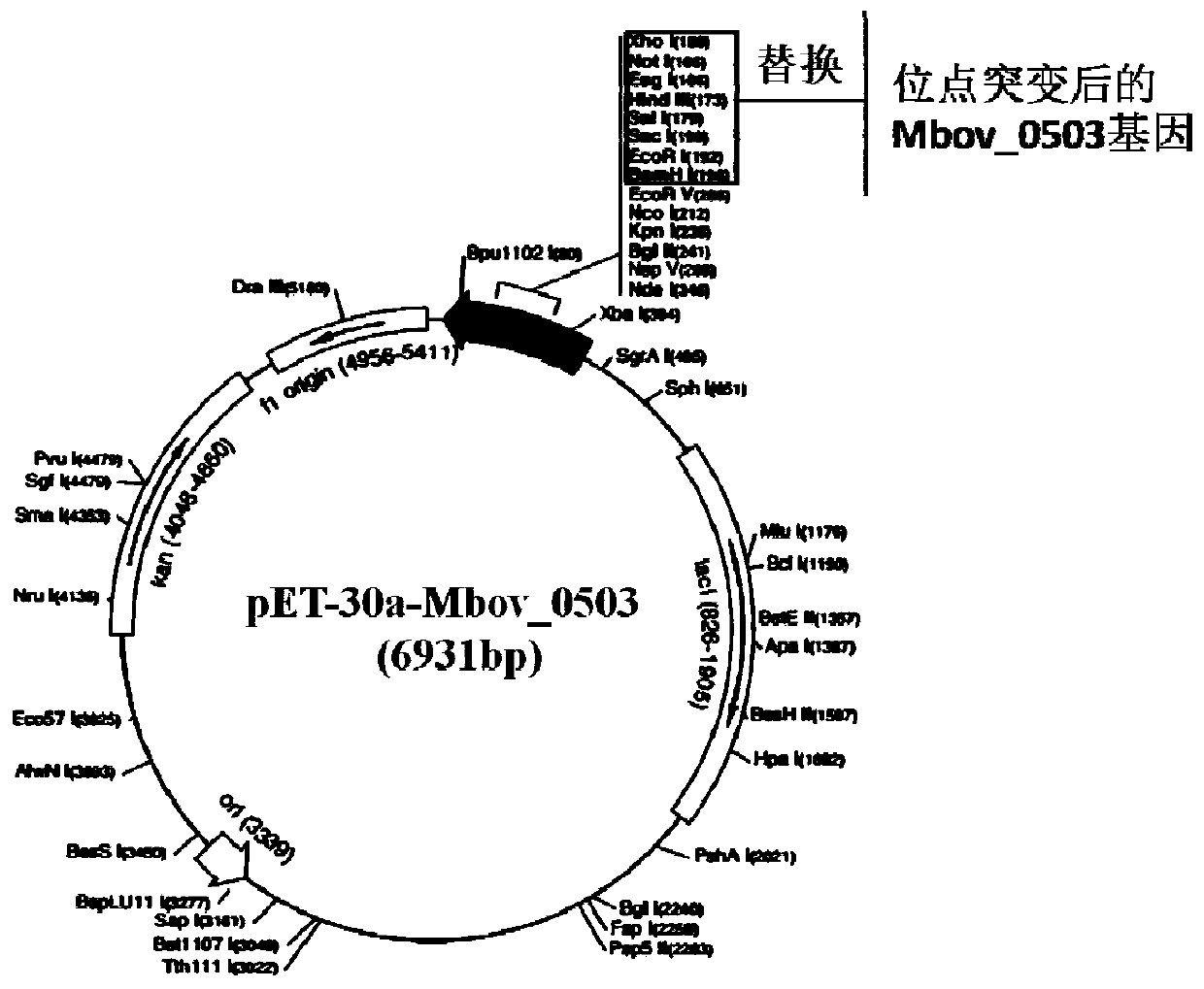

Mycoplasma bovis gene mutation strain having reduced adhesion capacity and adhesion protein

ActiveCN109837226AReduce adhesionDemonstrated adhesionBacteriaMicrobiological testing/measurementDiseaseEscherichia coli

The invention belongs to the technical field of prevention and treatment of animal borne diseases, and relates to a mycoplasma bovis gene mutation strain having reduced adhesion capacity and adhesionprotein. The protein gene Mbov_0503 is cloned from a mycoplasma bovis HB0801 genome. According to the partiality properties of escherichia coli to codons, the Mbov_0503 gene is modified, and mycoplasma bovis tryptophan codons UGA are mutated into codons UGG for coding tryptophan in the escherichia coli, so that recombination protein Mbov0503 is obtained. The nucleotide sequence of the protein geneis shown as SEQID NO:13, and the coded protein sequence is shown as SEQID NO:14. The mutation strain is the adhesion defect strain screened from a mutant library. Compared with wild strains, the mutation stain has the advantages that the adhesion capacity to host EBL cells, the cross-membrane transmission capacity to MDBK cells and destructivity to tight connection between cells of the mutation strain are notably reduced. The mycoplasma bovis gene mutation strain can be used for prevention and treatment of mycoplasma bovis diseases.

Owner:HUAZHONG AGRI UNIV

Bi-component silicone pouring sealant for LED photoelectric display device and method for manufacturing same

ActiveCN101544881AAvoid thickeningSimple processOther chemical processesSemiconductor/solid-state device manufacturingHydroxylamineDisplay device

The invention relates to a bi-component silicone pouring sealant for an LED optoelectronic display device and a method for manufacturing the same. The bi-component silicone pouring sealant is characterized in that the sealant is obtained through the reaction of components A and B by using alpha,omega-dihydroxy polydimethylsiloxane of which the structural formula shown on the right as a main material. The component A is prepared from the following components by weight portion through mixing: 100 portions of the alpha,omega-dihydroxy polydimethylsiloxane, 10 to 35 portions of organosilicon based gel, 0 to 50 portions of stuffing, and 10 to 30 portions of plasticizer; and the component B is prepared from the following components in portion by weight through mixing: 5 to 10 portions of cross-linking agent, 0.3 to 3 portions of coupling agent, 0.1 to 0.5 portion of titanate complex, 0.1 to 0.5 portion of diethyl hydroxylamine, 0.01 to 0.1 portion of dibutyltin dilaurate catalyst, and 2 to 10 portions of plasticizer. The silicone pouring sealant prepared by the method has the advantages of simple process flow, good adhesive property, excellent temperature and weather resistant properties, and good flow property, and can be widely applicable for embedding electronic devices such as the LED optoelectronic display device and the like.

Owner:CHENGDU GUIBAO SCI & TECH

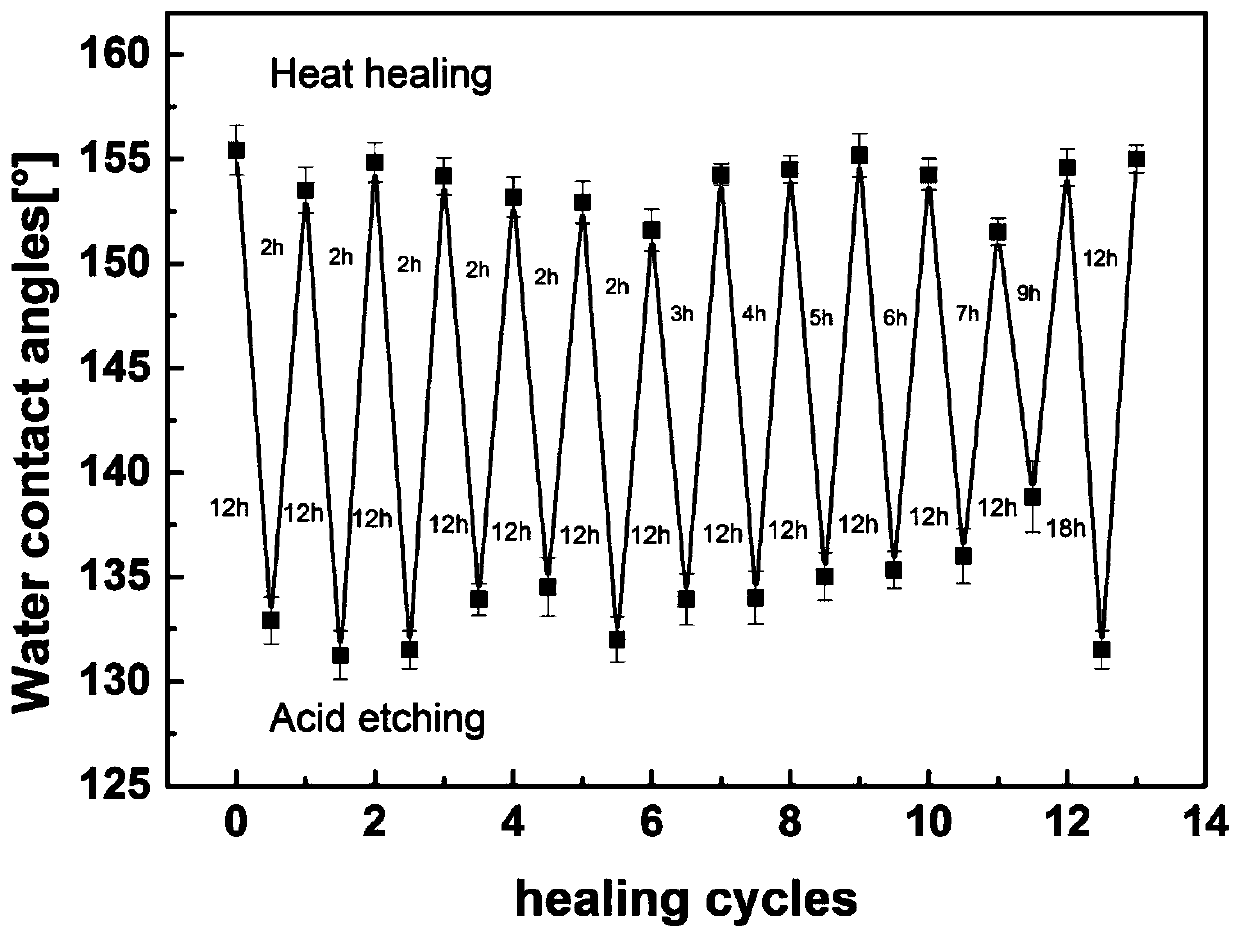

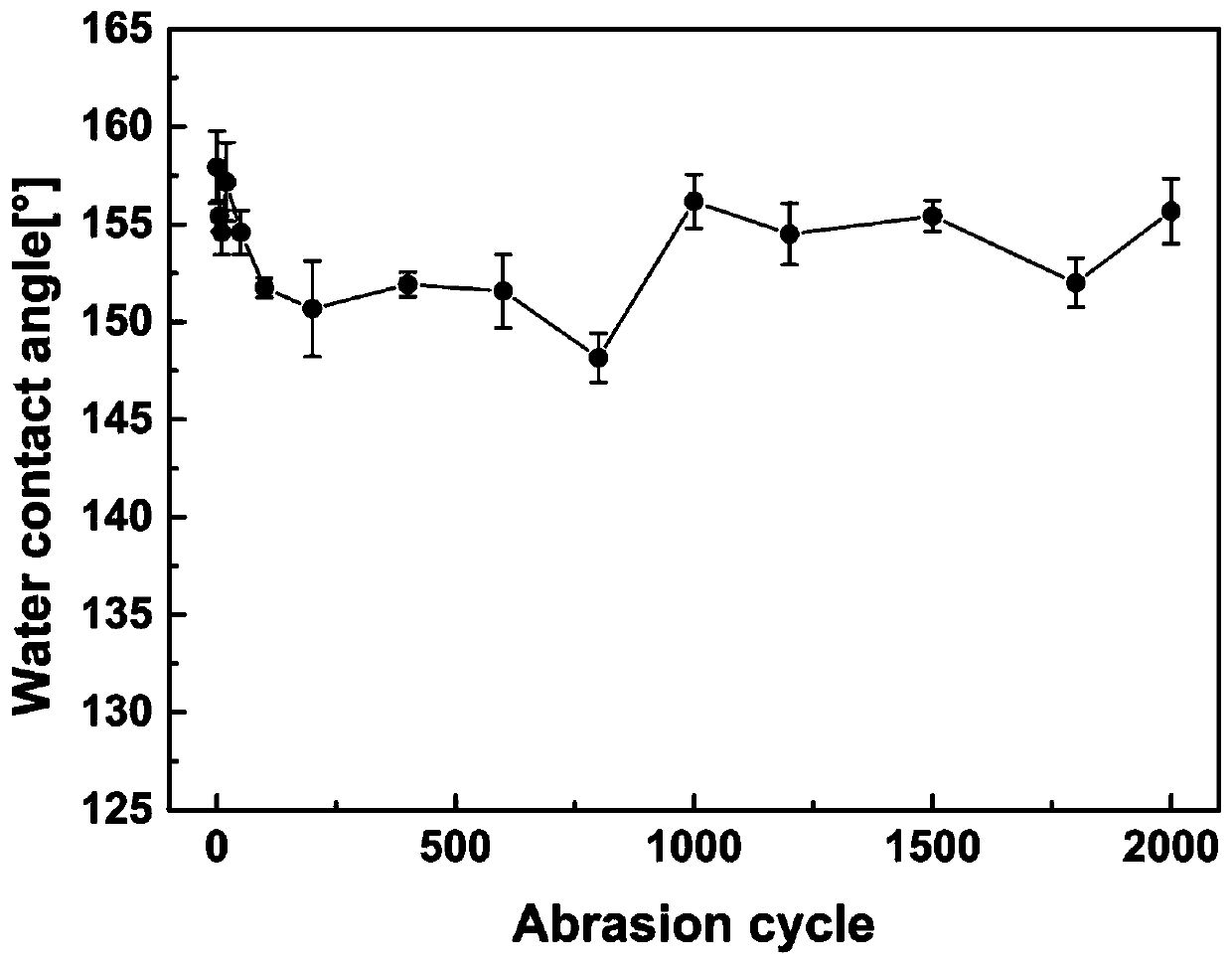

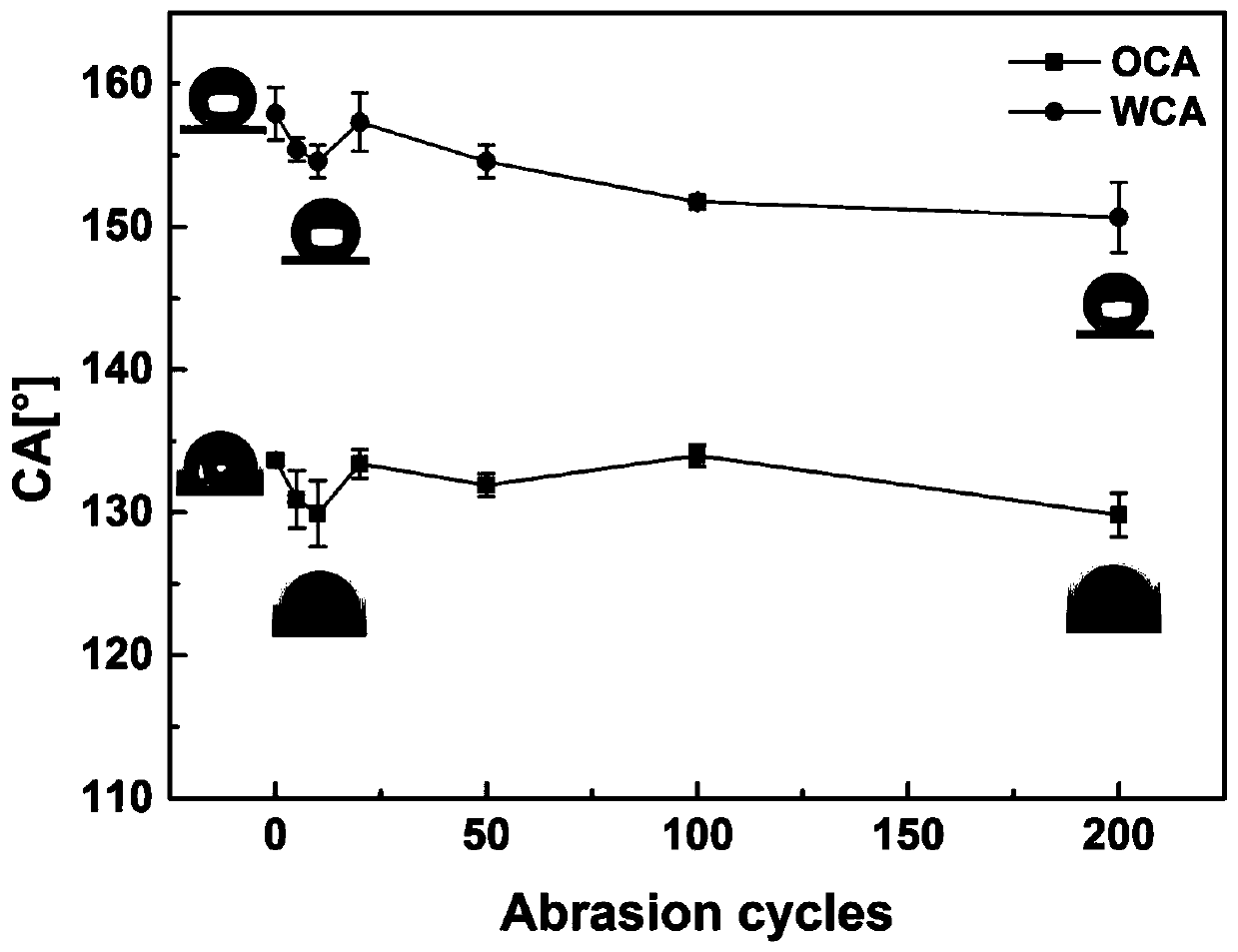

Microencapsulated self-repairing superhydrophobic coating layer and preparation method thereof

ActiveCN109971331AMeet the micro-nano multilevel structureIncrease roughnessPaper coatingPolyurea/polyurethane coatingsFree energiesSurface layer

The present invention discloses a microencapsulated self-repairing superhydrophobic coating layer. The superhydrophobic coating layer comprises 35-51 wt% of a polymer matrix and 49-65 wt% of a microcapsule coated with fluorosilane. The superhydrophobic coating layer has a good hydrophobic property, and the fluorosilane stored in the microcapsule migrates to the surface of the capsule under the driving of surface free energy to provide a low surface energy substance, and is released from the capsule after the capsule is worn and damaged in order to repair the damaged superhydrophobic surface; the microcapsules and the polymer matrix blended to form an "integrated" self-similar structure, and the fresh surface exposed after the rough structure of the surface layer is damaged still has a highroughness, so the loss of low surface energy components and the reduction of surface roughness due to chemical corrosion or external force wearing are greatly reduced; and the damaged superhydrophobic surface of the coating layer is repaired by the synergistic action of the microcapsule and the polymer matrix. The invention also provides a preparation method of the microencapsulated self-repairing superhydrophobic coating layer.

Owner:珠海智仁科技有限公司

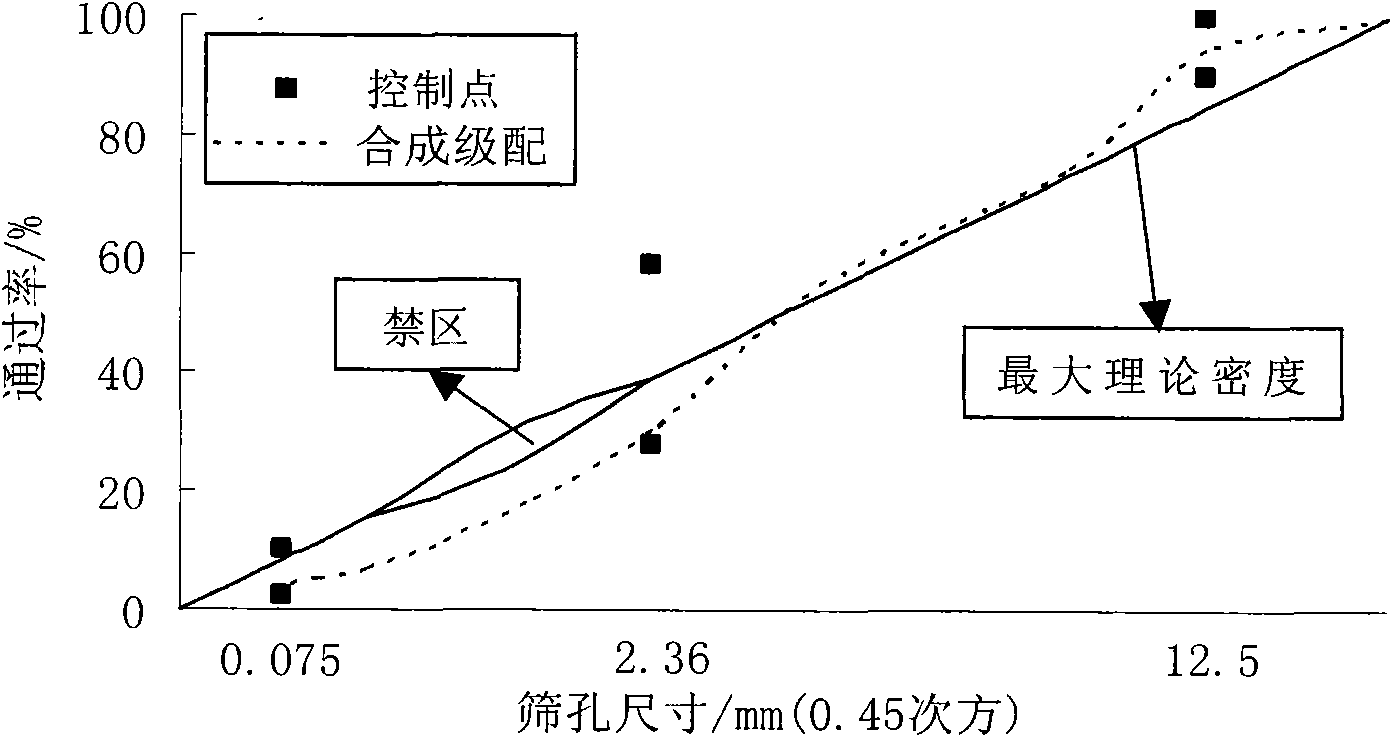

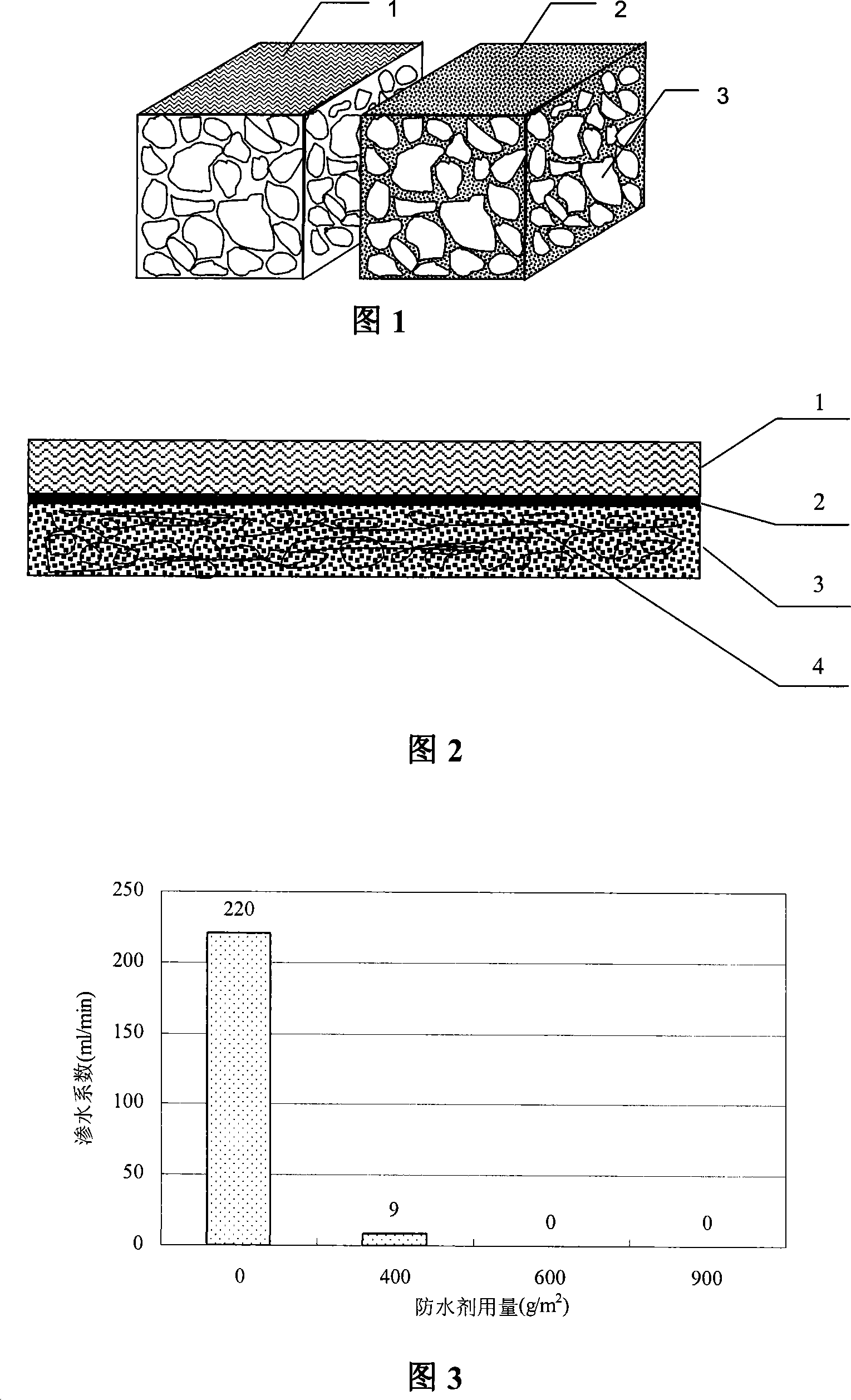

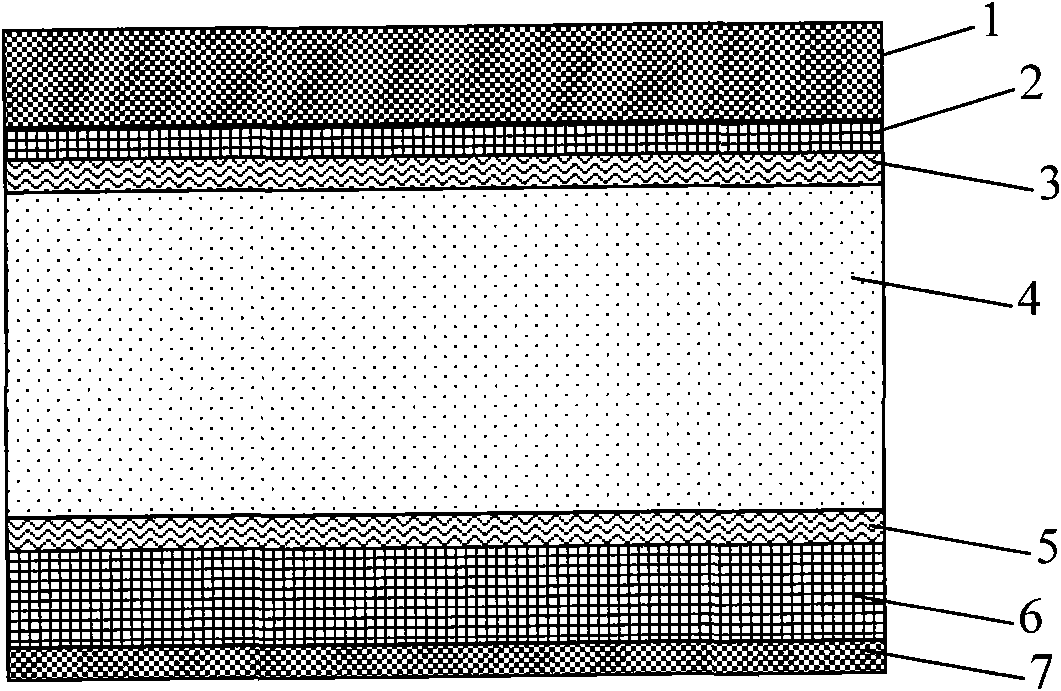

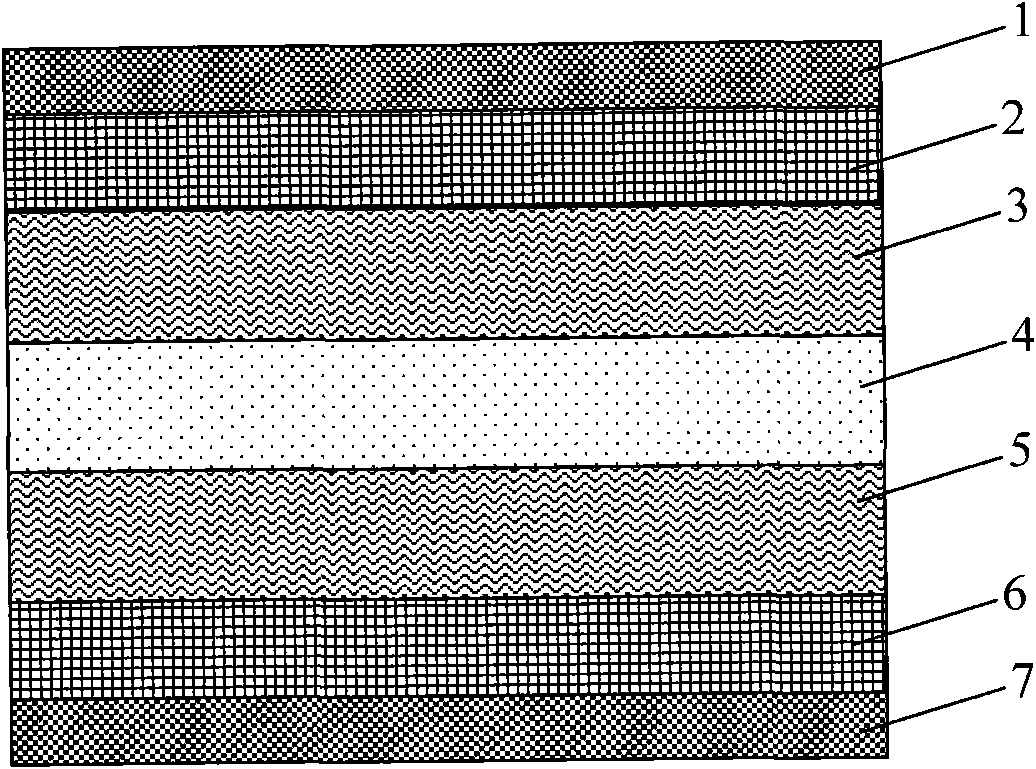

Special-purpose waterproof bonding layer for drainage asphalt pavement and design method thereof

InactiveCN101215818AIncreased durabilityExtended service lifeIn situ pavingsPorous asphalt concretePitch blende

The invention provides a waterproof and cohesive layer exclusive for porous asphalt pavement, which comprises a structure as: a porous asphalt concrete surface layer (1), an emulsification asphalt cohesive layer (2) and a dense grad asphalt concrete surface layer (3) are orderly arranged from the upper side to the lower side, also a silicon rubber waterproof agent filtration layer (4) is arranged on or infiltrated the dense grad asphalt concrete surface layer (3). The invention can improve the waterproof property of the dense grad asphalt concrete surface layer under the porous asphalt concrete road surface, strengthens the cohesive property between the dense grad asphalt concrete surface layer and the porous asphalt concrete surface layer, prevents any moving between the porous asphalt surface layer and the dense grad asphalt concrete surface layer, effectively avoids water damages on the asphalt mixture which is resulted by rain infiltrating through the dense grad asphalt concrete surface layer, improves the waterproof property of the dense grad asphalt concrete, and improves the endurance of the dense grad asphalt surface layer of high-speed road and lengthens whole road surface service life.

Owner:WUHAN UNIV OF TECH

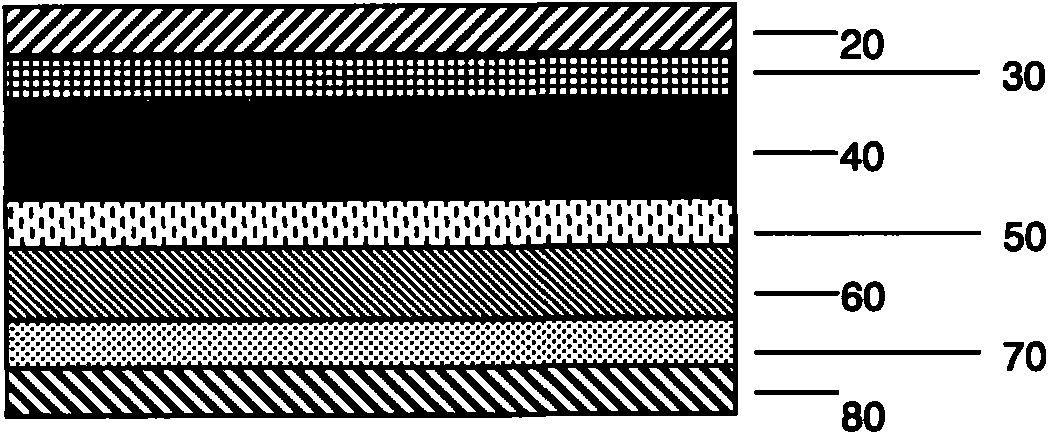

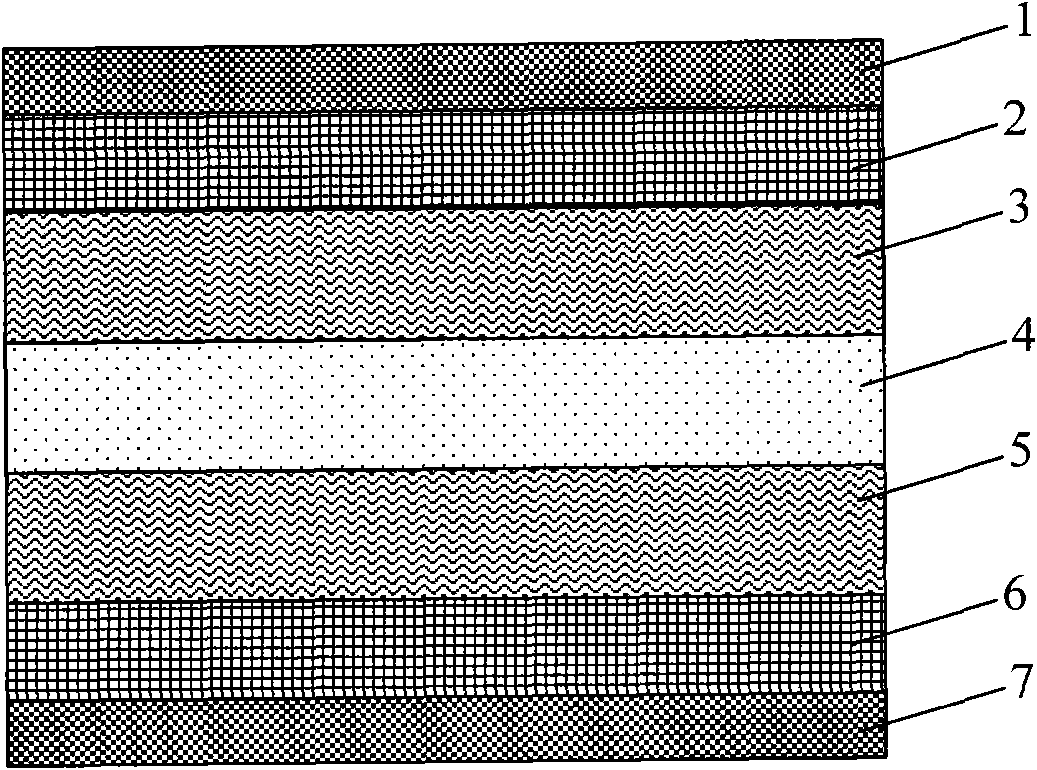

Backboard of solar battery with seven-layer structure

ActiveCN101916789AGood compatibilityAdhesiveSynthetic resin layered productsPhotovoltaic energy generationEngineeringSolar battery

The invention relates to a backboard of a solar battery with a seven-layer structure, which comprises a first fluoroplastic weather-resistant layer, a first transition layer, a first bonding layer, a structure enhancing layer, a second bonding layer, a second transition layer and a second fluoroplastic weather-resistant layer. The first fluoroplastic weather-resistant layer is attached to the first transition layer; the first transition layer is bonded with the structure enhancing layer through the first bonding layer; the structure enhancing layer is bonded with the second transition layer through the second bonding layer; the second transition layer is attached to the second fluoroplastic weather-resistant layer; and more preferably, the first transition layer and the second transition layer are polymer layers containing crylic acid or esters thereof or alloy layers made from polymer containing crylic acid or esters thereof and fluoroplastic containing vinylidene fluoride groups. The invention has two transition layers perfectly compatible with the fluoroplastic, which greatly enhances the bonding strength of the fluoroplastic and the structure enhancing layer and improves the reliability of the backboard of the solar battery, being remarkably significant to the solar energy industry.

Owner:SHANGHAI HIUV NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com