Battery diaphragm and application thereof

A battery diaphragm and base film technology, applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems of increased tortuosity of diaphragm aperture, increased ionic conductivity, inconsistent porosity, etc., to improve wettability and absorption liquid performance, reduce ionic conductivity, and enhance the effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

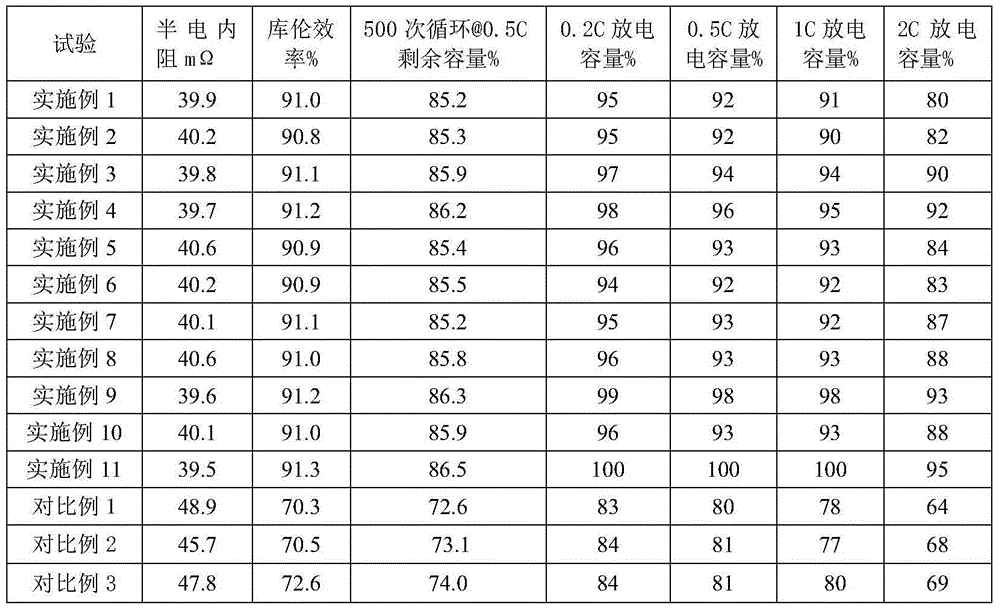

Examples

Embodiment 1

[0028] In this example, 0.99 kg of polyvinylidene fluoride purchased from Arkema, D50 = 0.05um, and 8.91 kg of alumina purchased from Sumitomo Chemical, D50 = 0.4um, the weight ratio of these two nanoparticles is that of ceramic particles : Organic polymer particles = 9:1, add 15 kg of deionized water, and pre-mix for 180 min with a mixer at a linear speed of 10 m / min. Then disperse through sand milling equipment, the dispersion line speed is 25m / min, and the sand milling time is 20min. Then add 100 gram polyoxyethylenes, make the weight ratio of binder and nano particle be binder: nano particle=1:99, stir 300min with the linear velocity of 5m / min, vacuumize 180min, obtain total solid content be 40 % of coating slurry. A PE diaphragm with a thickness of 9 um purchased from Asahi Kasei, Japan was used as a base material, and coated by a micro-gravure coater to obtain a composite diaphragm with a thickness of 12 um.

Embodiment 2

[0030] In this example, 4.75 kg of polyvinylidene fluoride purchased from Arkema, D50 = 0.6um, and 4.75 kg of alumina purchased from Sumitomo Chemical, D50 = 2.0um, the weight ratio of these two nanoparticles is that of ceramic particles : Organic polymer particles = 1:1, add 15 kg of deionized water, and pre-mix for 180 min with a mixer at a linear speed of 10 m / min. Then disperse through conical mill equipment, the dispersion line speed is 40m / min, and the residence time is 600s. Add 600 gram polyoxyethylenes then, make the weight ratio of binder and nano particle be binder: nano particle=5:95, stir 300min with the linear velocity of 5m / min, vacuumize 180min, obtain total solid content and be 40 % of coating slurry. A 9um PE separator purchased from Asahi Kasei, Japan was used as a base material, and coated by an extrusion coater to obtain a composite separator.

Embodiment 3

[0032]In this example, 1.92 kg of polyvinylidene fluoride purchased from Arkema, D50 = 0.2um, and 7.68 kg of alumina purchased from Sumitomo Chemical, D50 = 0.6um, the weight ratio of these two nanoparticles is that of ceramic particles : Organic polymer particles=8:2, add 15 kg of deionized water, and pre-mix for 180 min with a mixer at a linear speed of 10 m / min. Then disperse through high-speed dispersing equipment, the dispersion line speed is 50m / min, and the residence time is 60s. Add 400 gram polyoxyethylenes then, make the weight ratio of binder and nano particle be binder: nano particle=4:96, stir 300min with the linear velocity of 5m / min, vacuumize 180min, obtain total solid content to be 40 % of coating slurry. A 9um PE separator purchased from Asahi Kasei, Japan was used as a base material, and coated by a three-roll coater to obtain a composite separator with a thickness of 12um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com