Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

566 results about "Cell fabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

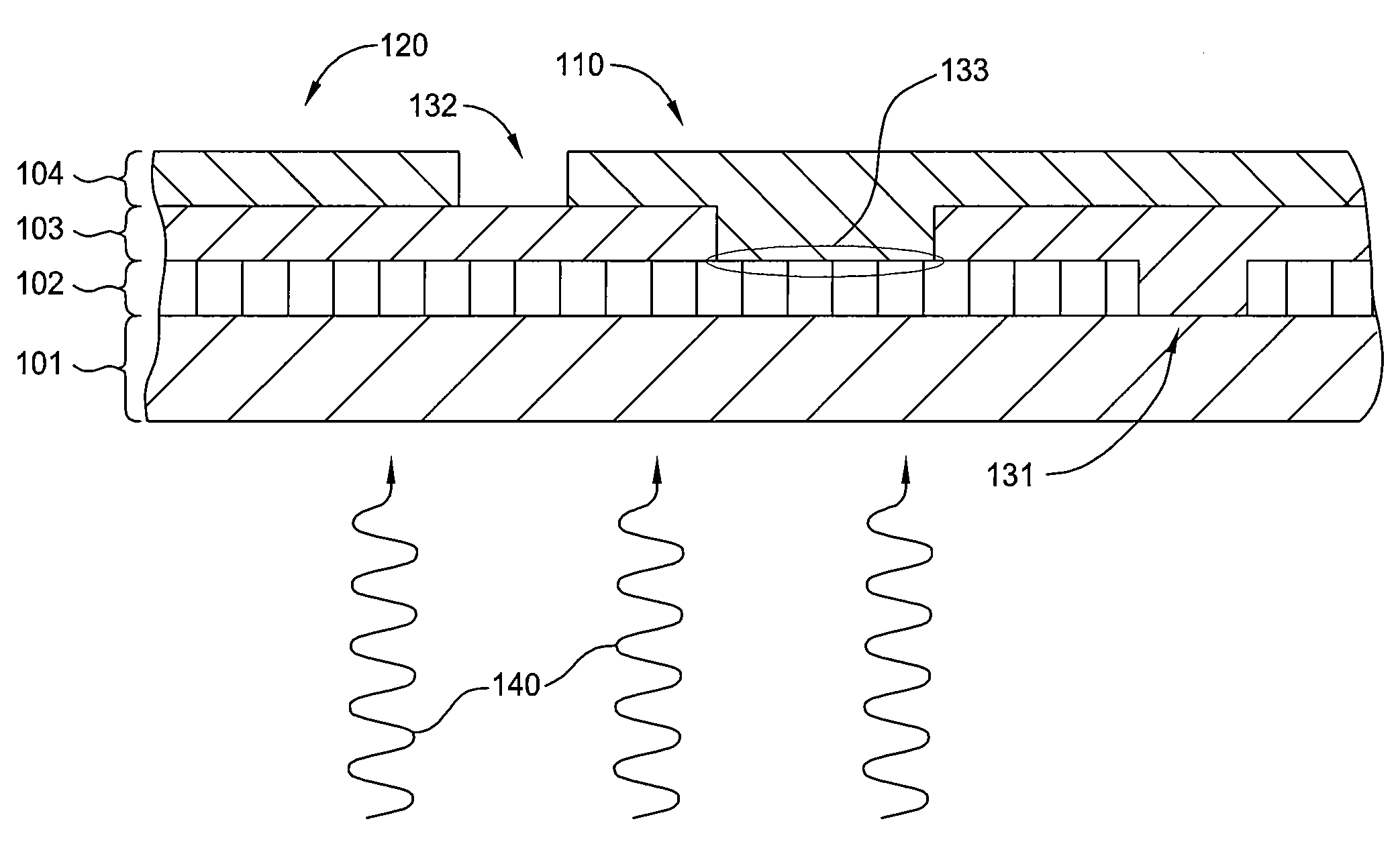

Photovoltaic fibers

InactiveUS20050040374A1Easy to manufactureLight-sensitive devicesFinal product manufactureFiberCell fabrication

Owner:MERCK PATENT GMBH

Photovoltaic fibers

InactiveUS20070079867A1Easy to manufactureElectrolytic capacitorsFinal product manufactureFiberCell fabrication

Owner:MERCK PATENT GMBH

Photovoltaic fibers

Owner:MERCK PATENT GMBH

Novel detection method for self-discharge characteristics of lithium iron phosphate system power lithium ion batteries

ActiveCN104360284AStable self-discharge characteristicsExacerbated self-discharge trendElectrical testingCell fabricationEngineering

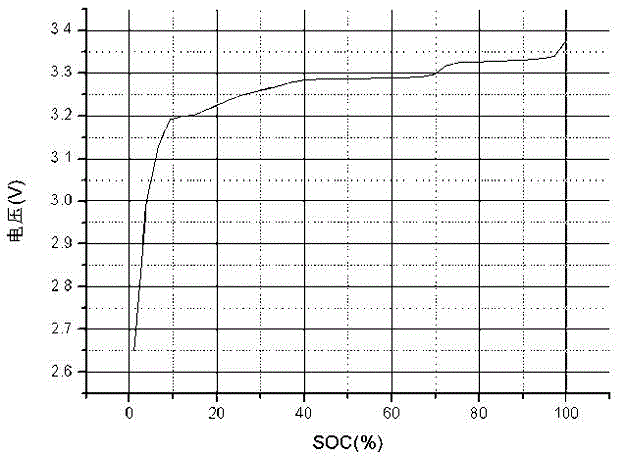

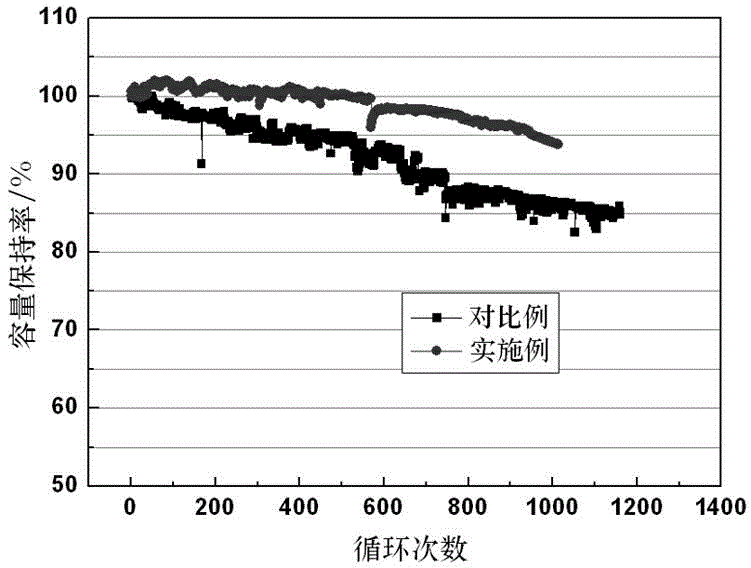

The invention discloses a novel detection method for self-discharge characteristics of lithium iron phosphate system power lithium ion batteries. The method comprises the following steps: step 1, charging and discharging batteries, and adjusting SOC (System On Chip) states of the batteries to be 20-40%; step 2, standing for a certain period of time at normal temperature, and measuring open-circuit voltage (OCV)1 of the batteries; step 3, performing high-temperature aging on the batteries; step 4, standing for a certain period of time at normal temperature, and then detecting OCV2 of the batteries; step 5, calculating a voltage drop deltaU of the batteries, wherein deltaU is equal to OCV1-OCV2; and step 6, calculating an average value and standard deviations of the voltage drops of the same group of batteries, determining a self-discharge detection standard of the batteries, and screening. The method for detecting the self-discharge characteristics of the batteries by virtue of voltage differences of the batteries disclosed by the invention can be used for well shielding interference of factors such as equipment, operations and environment temperature existing in a manufacturing process of the batteries in the self-discharge data acquisition accuracy of the batteries, so that the self-discharge characteristic data distortion of a single battery can be avoided, the matching reliability of the batteries can be effectively improved, and the cycle life of a battery pack can be prolonged.

Owner:SHANGHAI AEROSPACE POWER TECH +1

Alkali metal-wax micropackets for alkali metal handling

ActiveUS7666485B2Inexpensive and flexible manufacturingEasy to operateEnvelopes/bags making machineryApparatus using atomic clocksWaxPhysical chemistry

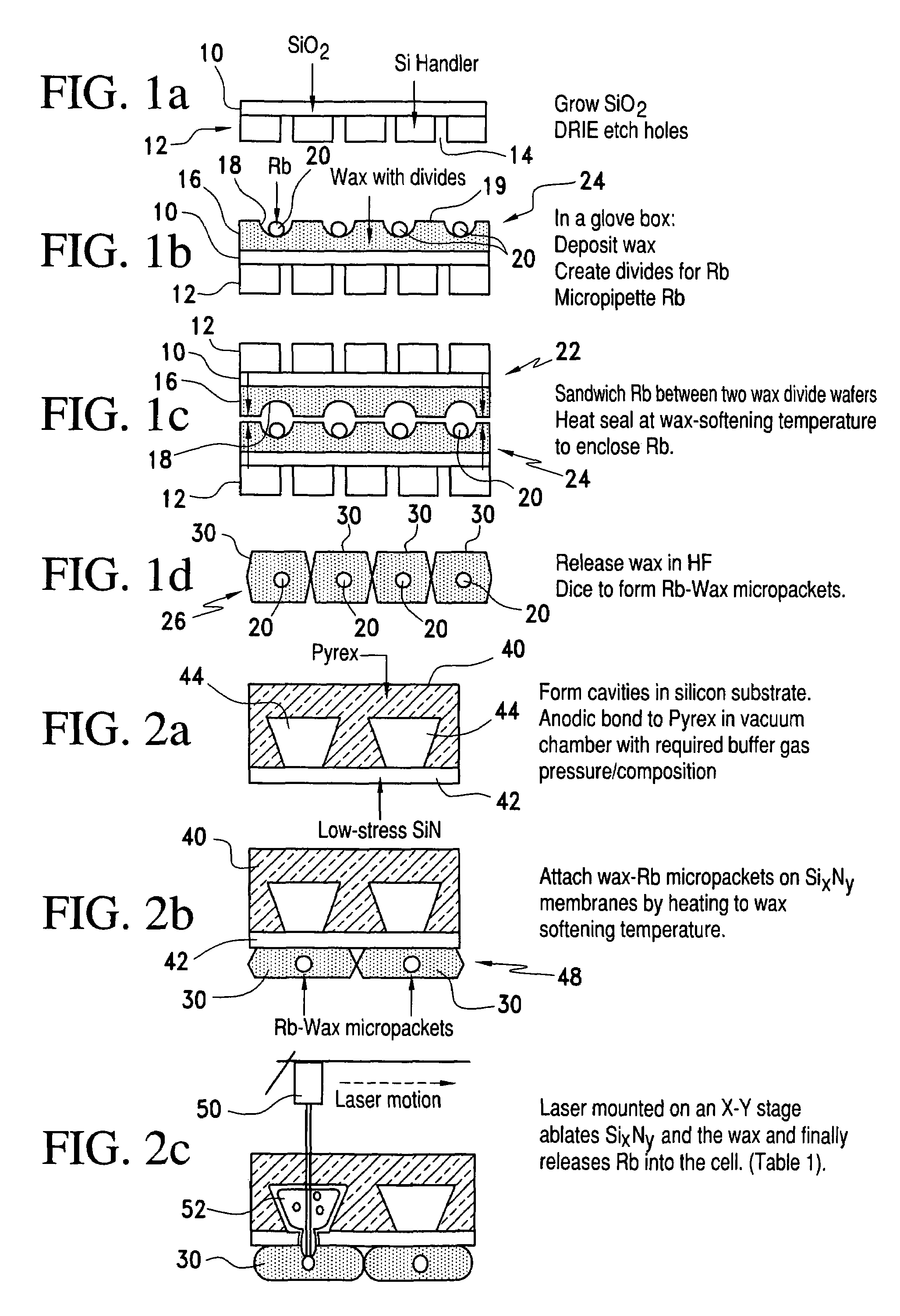

A method of making alkali-metal vapor cells by first forming microscale-wax micropackets with alkali metals inside allows fabrication of vapor cells at low cost and in a batch fabricated manner. Alkali metals are enclosed in a chemically inert wax to preform alkali metal-wax micropackets, keeping the alkali metals from reacting with the ambient surroundings during the vapor cell fabrication. This enables the deposition of precise amounts of pure alkali metal inside the vapor cells. Laser ablation of the alkali metal-wax micropackets provides a simple and effective way of releasing the enclosed metal. The method reduces the cost of making chip-scale atomic clocks and allows shipping of alkali vapor packets without contamination issues, thereby creating a technology for alkali-metal vendors to provide small packets of alkali metals.

Owner:CORNELL UNIVERSITY

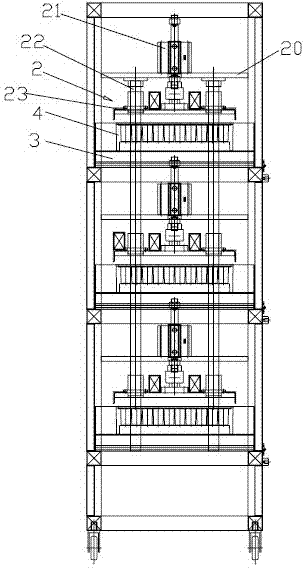

Vacuum air-suction sealing, trimming and folding all-in-one machine and battery production technology

ActiveCN102354768AFull production monitoringHigh precision of process operationFinal product manufactureElectrolyte accumulators manufactureVacuum pumpingCell fabrication

The invention relates to the technical field of battery manufacture equipment, in particular to a vacuum air-suction sealing, trimming and folding all-in-one machine and a battery production technology. The vacuum air-suction sealing, trimming and folding all-in-one machine comprises a rack, wherein the rack is successively provided with a material loading mechanism, a loaded material positioning and arranging mechanism, a vacuum air-suction sealing mechanism, a trimming mechanism, a folding mechanism and a material discharging mechanism; the rack is also provided with a material conveying mechanism, wherein the material conveying mechanism comprises a first material conveying mechanism and a second material conveying mechanism; the loaded material positioning and arranging mechanism and the vacuum air-suction sealing mechanism are respectively arranged on two sides of the first material conveying mechanism; and the second material conveying mechanism is laterally arranged below the trimming mechanism and the folding mechanism. The battery production technology applying the vacuum air-suction sealing, trimming and folding all-in-one machine comprises the following steps: loading materials, positioning, vacuum air-suction sealing, trimming, folding, discharging materials and the like. In the vacuum air-suction sealing, trimming and folding all-in-one machine, the vacuum air-suction sealing function and the functions of trimming and folding are integrally designed, and the vacuum air-suction sealing, trimming and folding all-in-one machine has the characteristics of high production efficiency and high product percent of pass.

Owner:DONGGUAN CHAOYE PRECISION EQUIPMENT CO LTD

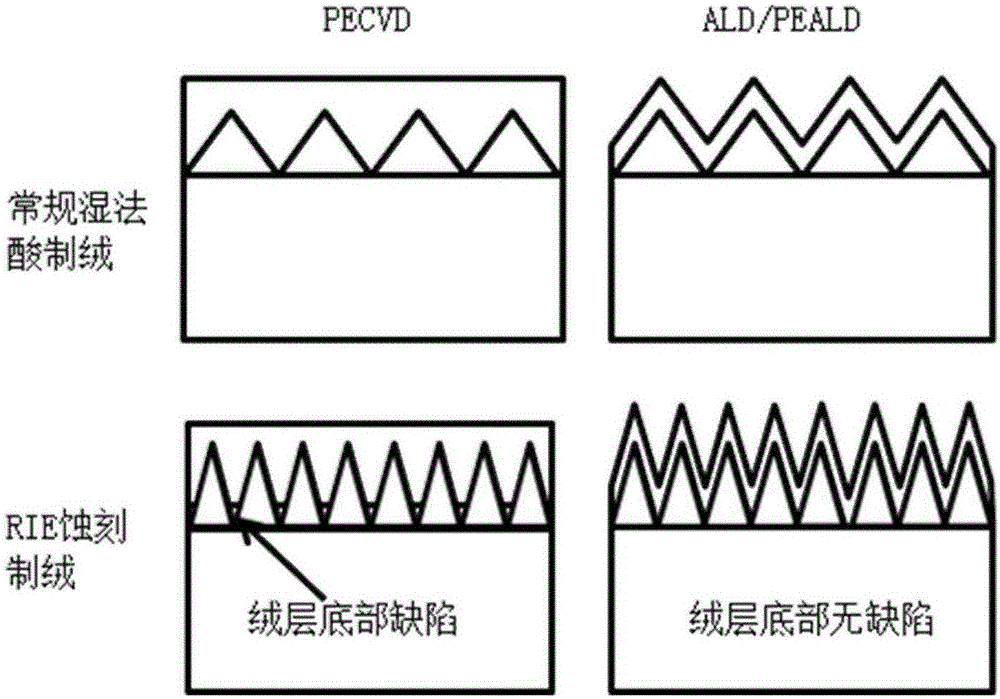

Fabrication process of crystalline silicon solar cell

ActiveCN105870249AImprove photoelectric conversion efficiencyExtend your lifeFinal product manufactureSemiconductor/solid-state device manufacturingCell fabricationMetallurgy

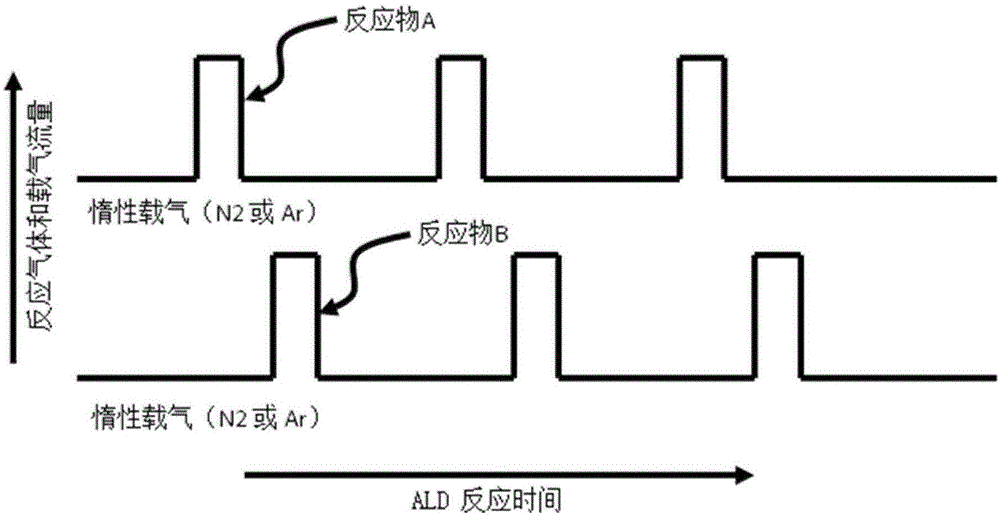

The invention relates to the field of fabrication of a solar cell, in particular to a surface passivation and anti-reflection technology of crystalline silicon cell for improving photoelectric conversion efficiency. Aiming at the existing cell technology process flow, nanometer lamination of a material such as SiO2, Al2O3 and SiNx and a composite material are fabricated by atomic layer deposition and plasma atomic layer deposition, passivation layer plating is carried out on the front surface and the back surface of the crystalline silicon cell, so that the minority carrier lifetime is prolonged, and the photoelectric conversion efficiency of the cell is improved; and SiNx anti-reflection layer plating can be continuously carried out after passivation layer plating, so that passivation and anti-reflection processes can be integrated in the same flow, the cost is reduced, and the yield is improved. The fabrication method is particularly and suitably used for combining with a black silicon technology, and multiple processes are avoided; and moreover, for a double-sided battery, the fact that double-sided passivation is carried out by using the fabrication method is a necessary choice.

Owner:JIANGSU MICROVIA NANO EQUIP TECH CO LTD

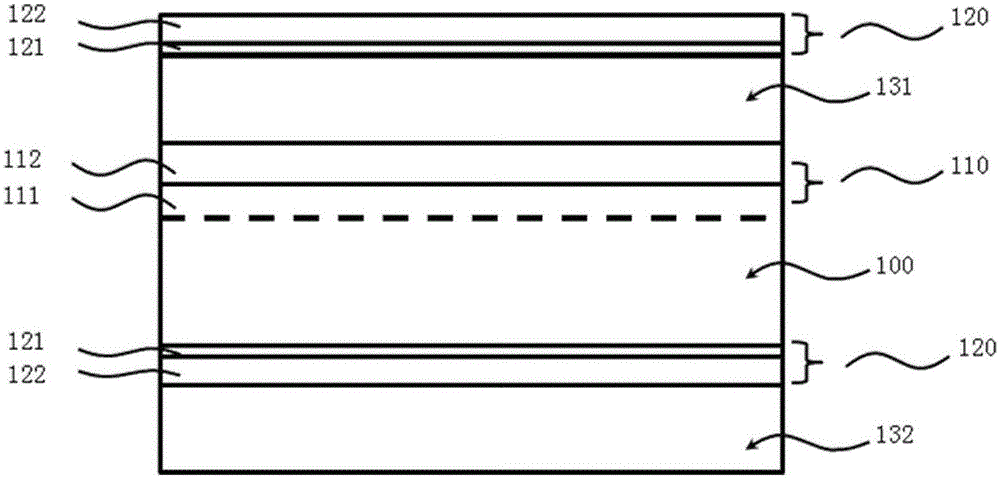

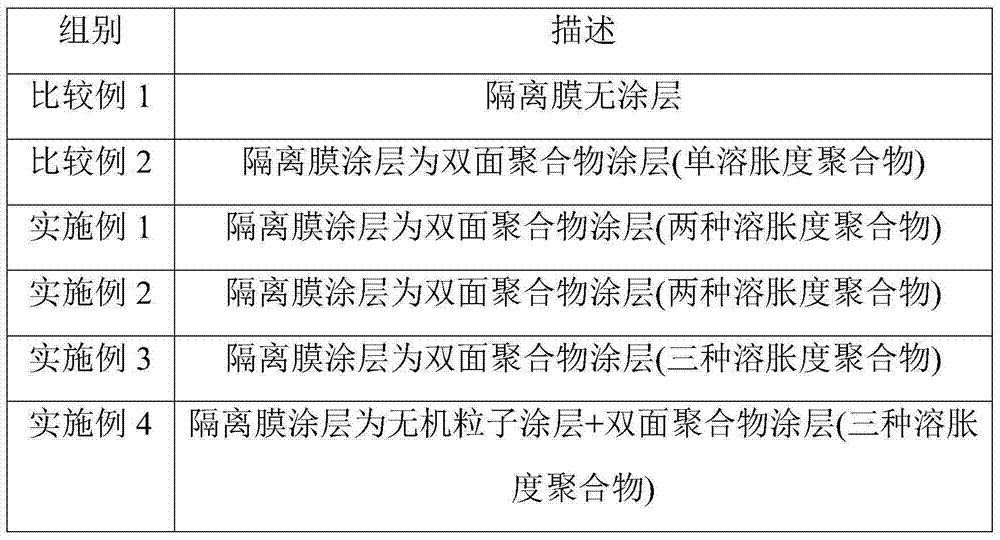

Isolating membrane for lithium ion secondary battery

InactiveCN104852008AGuaranteed not to deformPerformance is not affectedSecondary cellsCell component detailsCell fabricationPhysical chemistry

The invention belongs to the technical field of battery manufacture, and specifically relates to an isolating membrane for a lithium ion secondary battery, comprising an isolating membrane main body, wherein at least one surface of the isolating membrane main body is coated with a binder-polymer coating, and the binder-polymer coating comprises a binder polymer and a binder, and the binder-polymer coating at least comprises two polymers with different swelling degrees, wherein at least one polymer with lower swelling degree is used as cage construction for holding a certain expansion space for a pole piece of the lithium ion battery, and at least one polymer with higher swelling degree can be well bonded with the pole piece. Because the binder-polymer coating comprises the binder polymer and the binder, and the system is an environmental water system, and the coating coverage rate is 10 percent to 90 percent, the isolating membrane for the lithium ion secondary battery not only can be used for providing the expansion space of the pole piece, but also has small blockage for the hole of the isolating membrane, which cannot have influence on the battery performance. The polymer with high swelling degree can be well bonded with the pole piece so as to effectively restrain the deformation of the battery.

Owner:东莞市魔方新能源科技有限公司 +1

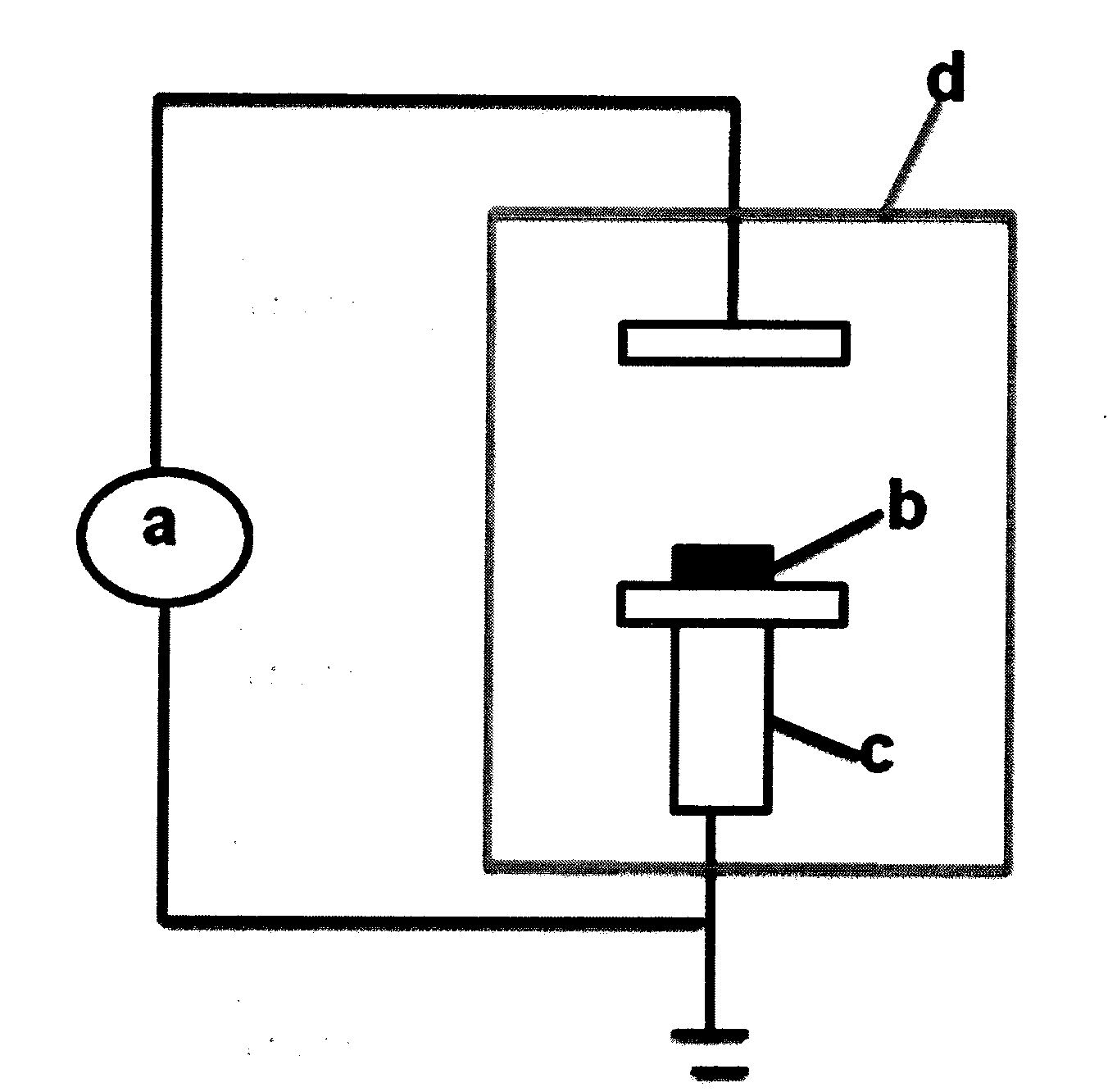

Method for testing corrosion resistance of lead acid battery plate grid

InactiveCN104215545AAvoid production risksImprove accuracyWeighing by removing componentWeather/light/corrosion resistanceThermodynamicsMetallurgy

The invention belongs to the field of battery manufacture and relates to a method for testing corrosion resistance of a lead acid battery plate grid. The method comprises the following steps of putting a dilute sulphuric acid solution into a container, respectively putting a battery plate grid to be tested as a positive pole and a battery plate grid as a negative pole into the container, carrying out constant current charging, immersing the charged battery plate grid to be tested in a treatment solution so that surface oxides of the corroded battery plate grid to be tested are dissolved, taking out the battery plate grid to be tested, carrying out drying, calculating weight reduction amount of the battery plate grid to be tested, and carrying out determination on the corrosion degree of the battery plate grid according to the weight reduction amount of the battery plate grid.

Owner:CHAOWEI POWER CO LTD

Silicon Heterojunction Solar Cells

InactiveUS20130180578A1Improve device performanceCostSemiconductor/solid-state device manufacturingPhotovoltaic energy generationCell fabricationSolar cell

Methods are described for fabricating HIT solar cells, including double heterojunction and hybrid heterojunction-homojunction solar cells, with very thin single crystal silicon wafers, where the silicon wafer may be less than 80 microns thick, and even less than 50 microns thick. The methods overcome potential issues with handling these very thin wafers by using a process including epitaxial silicon deposition on a growth substrate, partial cell fabrication, attachment to a support substrate and then separation from the growth substrate. Some embodiments of the present invention may include a solar cell device architecture comprising the combination of a heterostructure on the front side of the device with a homojunction at the rear of the device. Furthermore, device performance may be enhanced by including a dielectric stack on the backside of the device for reflecting long wavelength infrared radiation.

Owner:SVAGOS TECHNICK INC

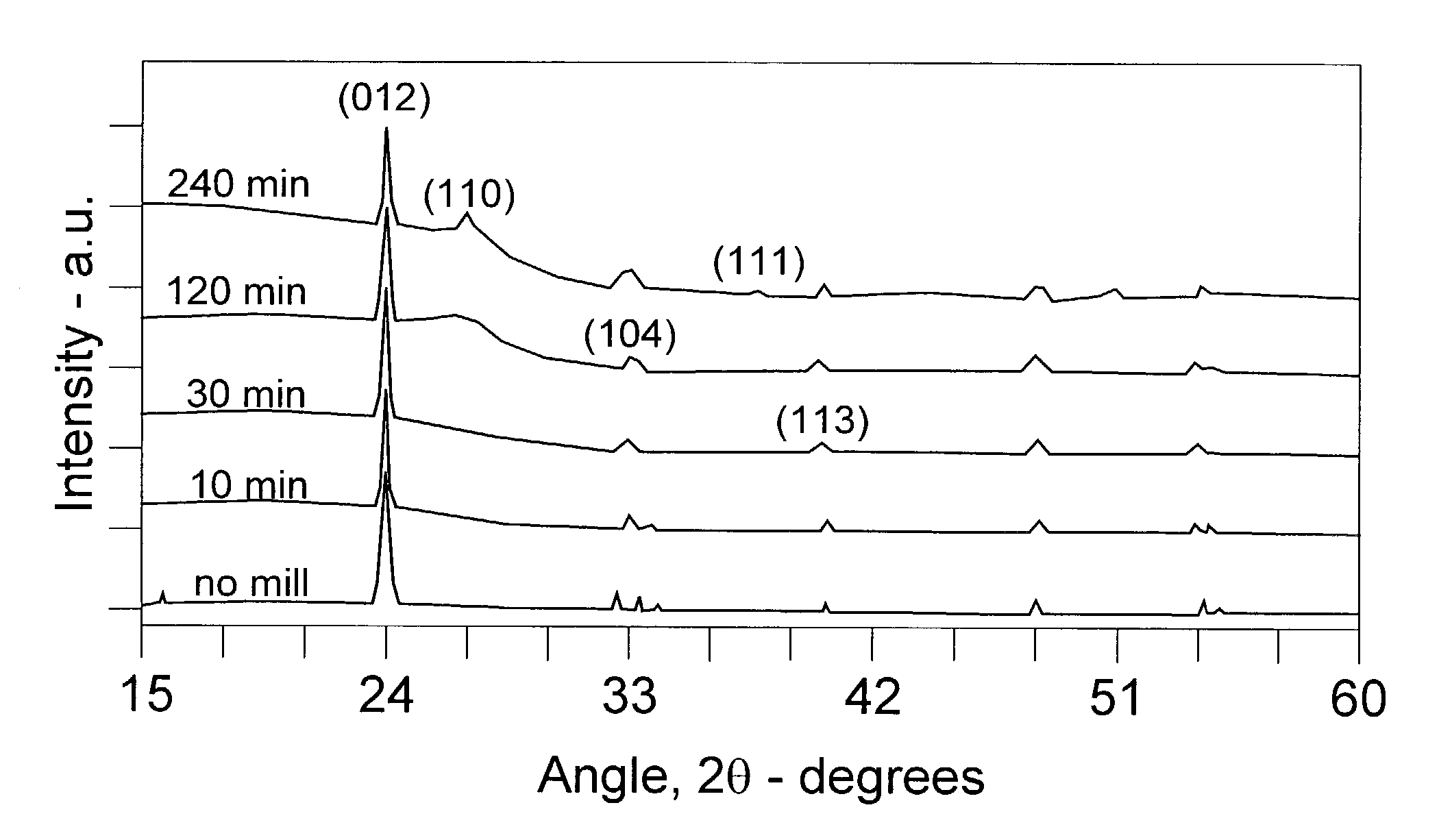

Transition metal fluoride: carbon nanoamalgam rechargeable battery cell electrode material

ActiveUS7625671B2Improve conductivityHigh ionicityOrganic electrolyte cellsPositive electrodesCell fabricationHigh energy

A safe and economical electrochemically active material useful in rechargeable battery cell electrode compositions comprises a nanostructure amalgam of a transition metal fluoride and carbon. The nanoamalgam may be prepared by subjecting a precursor mixture of a transition metal fluoride, such as FeF3, and carbon to extreme, high energy impact comminution milling which results in the conversion of the mixture to a unique and distinct nanostructure material. When incorporated as active electrode material in lithium battery cell fabrications, the nanoamalgam enables the attainment of stable specific discharge capacities in the range of 250 to 500 mAh / g.

Owner:RUTGERS THE STATE UNIV

Lithium supplementing material and preparation method and application thereof

PendingCN112002894AReasonable formulaLower potentialCell electrodesSecondary cellsElectrolytic agentPtru catalyst

The invention discloses a lithium supplementing material for a lithium secondary battery as well as a preparation method and application thereof. The lithium supplementing material comprises a lithium-containing compound and an inorganic nonmetal reducing agent. According to the lithium supplementing material provided by the invention, inorganic sulfide is used as a reducing agent; meanwhile, metal and nonmetal catalysts are added; the potential of the lithium supplementing agent for exerting the capacity can be effectively reduced, and no gas is generated in the process of releasing lithium ions; the lithium supplementing material has good compatibility with the current commercial positive electrode and negative electrode, can be suitable for various battery systems, does not need to adjust and redesign an electrolyte and a battery manufacturing process, and is very suitable for the current secondary lithium ion battery. The preparation method of the lithium supplementing material provided by the invention is simple in process step, compatible with the existing lithium ion energy storage device preparation process, low in cost and suitable for mass production.

Owner:SONGSHAN LAKE MATERIALS LAB +1

Solar panel edge deletion module

The present invention generally relates to an edge deletion module positioned within an automated solar cell fabrication line. The edge deletion module may include a grinding wheel device for removing material from edge regions of a solar cell device and cleaning the edge regions of the solar cell device after removing the material. The edge deletion module may also include an abrasive element, a portion of which is ground as it is periodically, laterally advanced toward the grinding wheel device. A controller is provided for controlling the operation and function of various facets of the module.

Owner:APPLIED MATERIALS INC

Environment-friendly halogen-free inflaming retarding adhesive tape and production process thereof

The invention relates to an adhesive tape for electronic products and a production process thereof, in particular to an environment-friendly halogen-free inflaming retarding adhesive tape and a production process thereof. The environment-friendly halogen-free inflaming retarding adhesive tape successively consists of a halogen-free inflaming retarding adhesive layer, a tissue paper layer, a halogen-free inflaming retarding adhesive layer and a double-silicon release paper layer from top to bottom. The halogen-free inflaming retarding glue comprises the following components by weight percent: 50-60% of a mixture of acrylate polymer, adhesive, tackifying resin and fire retardant, 20-30% of acetic ether and 15-20% of toluene. The adhesive tape is an environment-friendly halogen-free inflaming retarding adhesive tape and is mainly applied to winding and fixing in electronic products and adhesion of battery production materials and other inflaming retarding materials (i.e. Normex). The halogen-free inflaming retarding adhesive tape obtained by the production process not only can reach the highest inflaming retarding grade, but also is halogen-free and more environment-friendly under the condition of unchanging the original inflaming retarding function of the adhesive tape.

Owner:TAICANG JIN YU ELECTRONICS MATERIALS +1

All-solid-state polymer electrolyte used for lithium-sulfur secondary battery and its preparation method

InactiveCN102496736ALow costShort production processSecondary cellsCell component detailsPolymer electrolytesAll solid state

Belonging to the technical field of lithium-sulfur secondary battery preparation, the invention relates to an all-solid-state polymer electrolyte used for a lithium-sulfur secondary battery and its preparation method. Directed at the current situation that a metal lithium negative electrode is likely to generate a dendrite which can break a diaphragm so as to cause a short circuit when the liquid electrolyte or gel polymer electrolyte of a lithium-sulfur secondary battery matches with metal lithium, the invention provides an all-solid-state polymer electrolyte used for a lithium-sulfur secondary battery. The electrolyte comprises PEO (polyethylene oxide), a Li4Ti5O12 particle and a lithium salt, which can be LiClO4, LiPF6, LiBF4, LiCF3SO3 or LiTFSI. At a temperature of 30DEG C, the electrolyte has electric conductivity greater than 10<-4>S / cm, which is far higher than the electric conductivity of 10<-6>-10<-7>S / cm of PEO / a lithium salt at a temperature of 30DEG C. In a lithium-sulfur secondary battery, the electrolyte can serve both as an electrolyte and a diaphragm, and the double functions can substantially enhance the utilization rate and circulation stability of a positive active material.

Owner:RUISHENG NEW ENERGY DEV CHANGZHOU

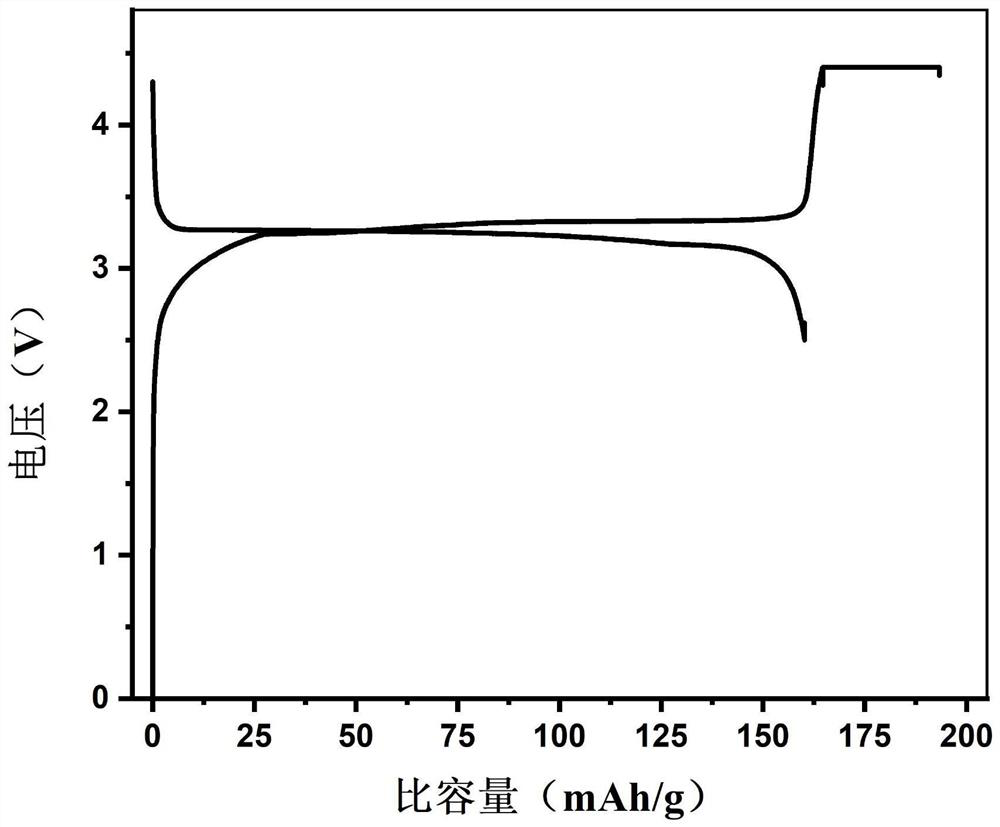

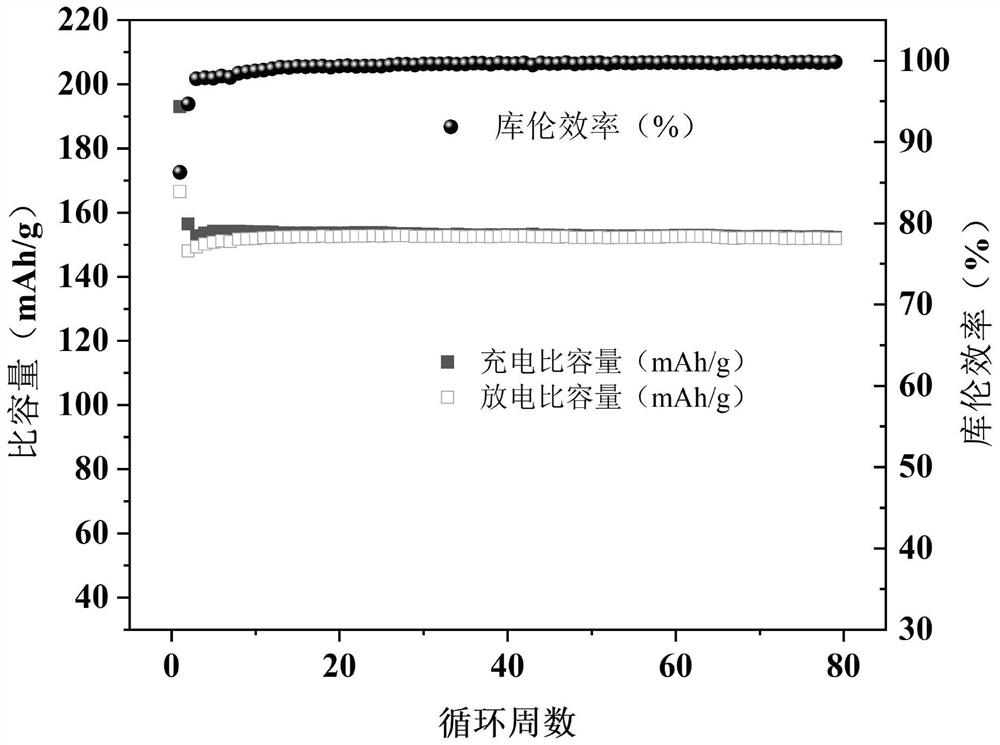

High-capacity high-power ferrous phosphate lithium power battery and manufacturing method thereof

ActiveCN102195079ALarge capacityImprove securityFinal product manufactureCell electrodesElectrical batteryPhosphate

The invention discloses a high-capacity high-power ferrous phosphate lithium power battery and a manufacturing method thereof, relating to the technical field of lithium ion secondary batteries. The battery comprises a positive plate, a negative plate, a diaphragm, electrolyte and a battery shell, wherein the positive plate is formed by coating positive slurry on a aluminum foil; the negative plate is formed by coating negative slurry on a copper foil; the positive slurry comprises a positive active material, a bonder and the like; the negative slurry comprises MCMBs (mesocarbon microbeads), a conductive agent, a bonder and the like; and the battery shell comprises a shell and a nut cap. According to the invention, lithium iron phosphate positive material is pretreated, thus improving the electroconductibility of the material and the processing performance of the slurries. By means of an optimal structure design, the battery has the advantages of high capacity and lower internal resistance; and the battery can perform large current charge and discharge, has low temperature rise, and is mainly used as a power supply of an electric vehicle.

Owner:江苏海四达电源有限公司 +1

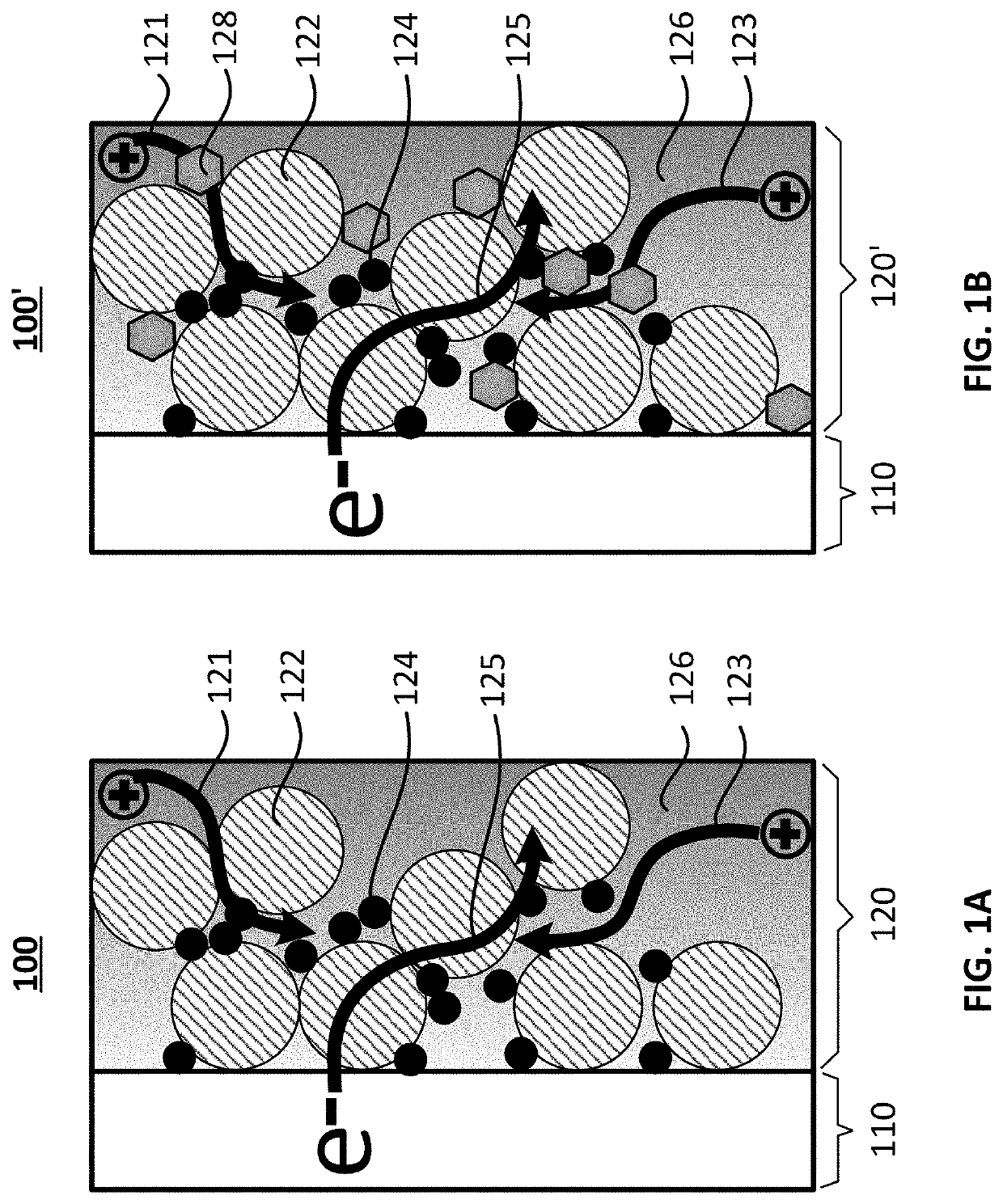

Electrodes having electrode additive for high performance batteries and applications of same

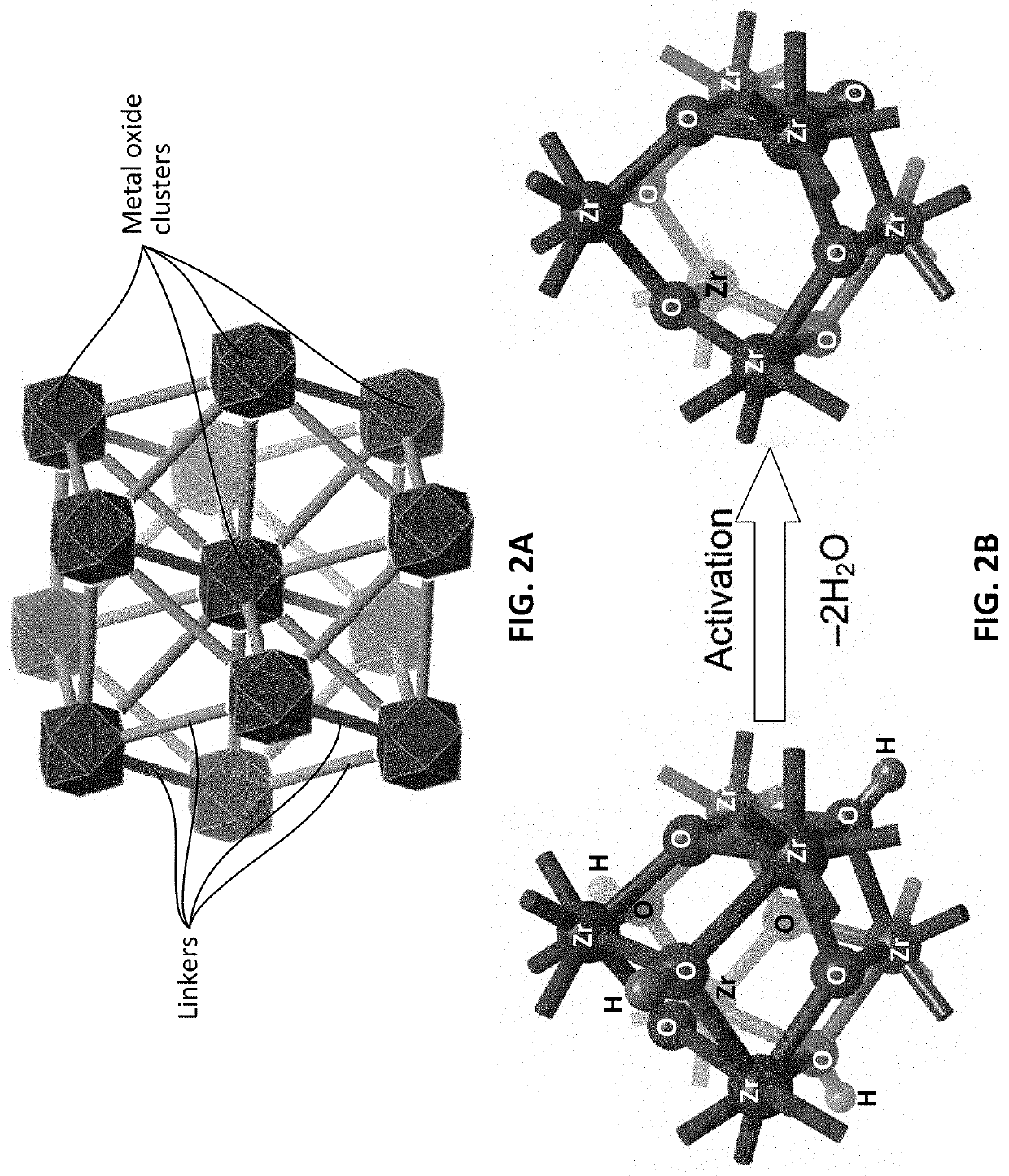

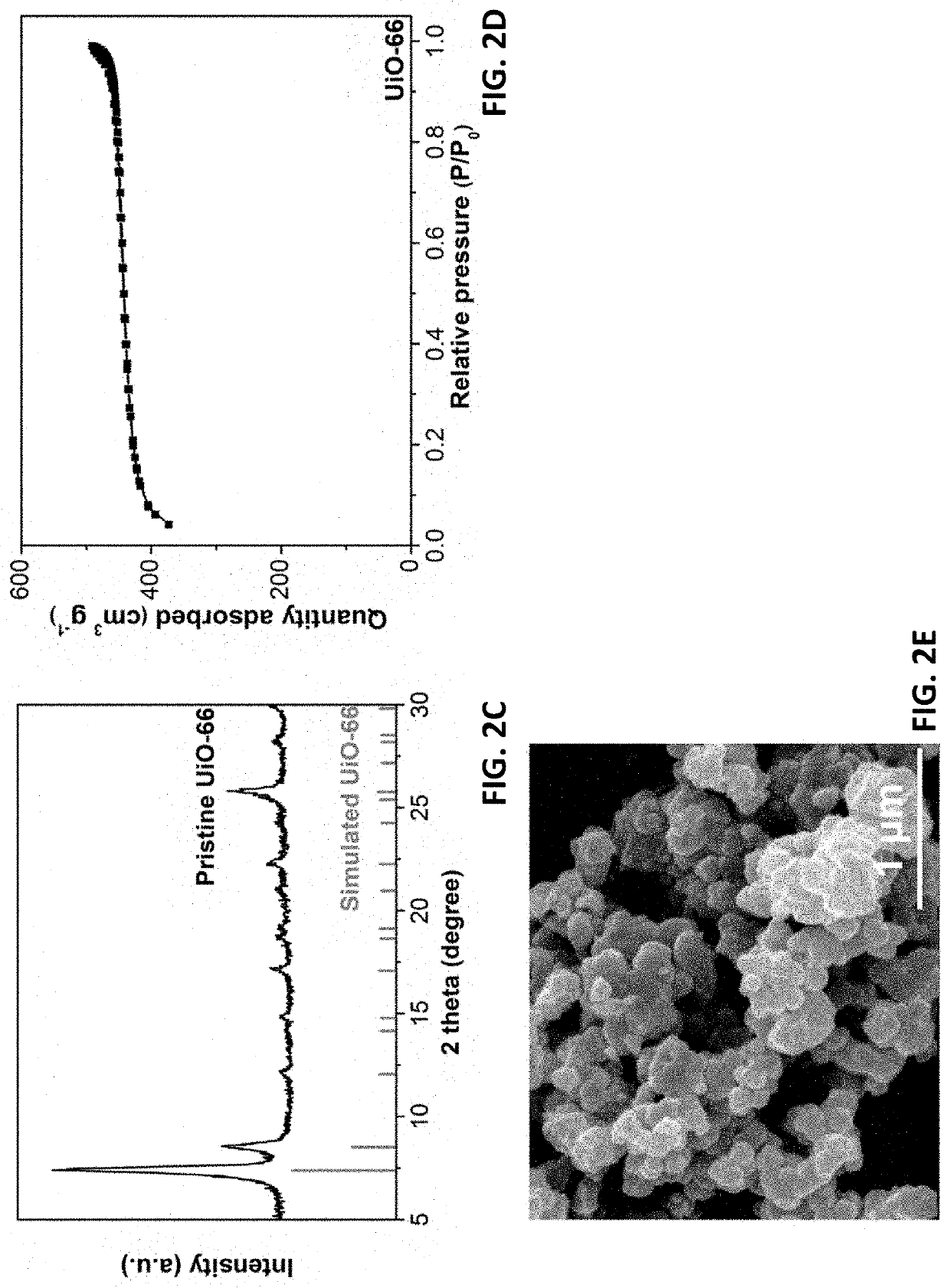

PendingUS20200185788A1Improve thermal stabilityIncrease ratingsCell electrodesWaste accumulators reclaimingInterfacial resistanceElectrical battery

The invention provides a general type of porous coordination solids, metal-organic frameworks (MOFs), as an electrode additive to improve thermal stability, rate and cycle performances of batteries, and an electrode having the electrode additive. The incorporation of the MOF additive into the electrode is fully compatible with current battery manufacturing process. Activated MOF additive serves as an electrolyte modulator to enhance cationic transport and alleviates interfacial resistance by interacting liquid electrolyte with unsaturated open metal sites. Moreover, the flow-free liquid in solid configuration is realized by encapsulating liquid electrolyte into porous scaffold of MOF, which offers superior thermal stability.

Owner:RGT UNIV OF CALIFORNIA +1

Flash memory cells with reduced distances between cell elements

InactiveUS20060003588A1Reduce spacingSolid-state devicesSemiconductor/solid-state device manufacturingAnti-reflective coatingCell fabrication

An anti-reflective coating (ARC) is formed over the various layers involved in a cell fabrication process. The ARC is selectively etched such that the edges of the etched areas of the ARC slope downward at an angle determined by the thickness of the ARC. The etching process could include CF4 chemistry. The inner edges of the sloped ARC areas reduce the original photo-defined space since the underlying layers are now defined by the sloped edges.

Owner:MICRON TECH INC

Binder composition for electrode

ActiveUS20140307364A1Superior in property and storage stabilityGood storage stabilityElectrolytic capacitorsHybrid capacitor electrodesCell fabricationPhysical chemistry

An object of the invention is to provide an electrode material slurry for preparation of lithium-ion secondary batteries favorable in properties and superior in storage stability and an aqueous binder composition for lithium-ion secondary batteries that can be used for production of lithium-ion secondary batteries superior in discharge rate characteristics and cycle characteristics.Provided is a binder composition for lithium-ion secondary battery electrode, comprising polymer particles containing (a) an ethylenic unsaturated carboxylic ester compound and (b) an ethylenic unsaturated sulfonic acid compound at a (a) / (b) mass ratio of (98 to 91) / (2 to 9) in a total (a) and (b) amount of 70 mass % or more, based on the monomeric raw materials.

Owner:DENKA CO LTD

A kind of transparent conductive film with high cashmere value and preparation method thereof

InactiveCN102280529AImprove transmittanceHigh pileConductive layers on insulating-supportsFinal product manufactureEtchingCell fabrication

The invention relates to a transparent conductive film with high velvet value and a preparation method thereof, belonging to the technical field of thin film solar cell manufacturing. The technical solution is: ① On the cleaned glass substrate, use the magnetron sputtering process to prepare a layer of 1000nm-1500nm ZnO transparent conductive layer; ② Keep the gas pressure, substrate temperature, and RF power unchanged, and change the input Argon flow in the reaction chamber to prepare ZnO transparent conductive film; ③The obtained ZnO transparent conductive film is wet-etched; ④After etching, the ZnO transparent conductive film is cleaned with deionized water and dried with nitrogen gas to obtain Textured ZnO transparent conductive film. Advantages and positive effects of the present invention: high velvet, high light scattering ability, high near-infrared light scattering ability, high transmittance, low conductance, and the prepared ZnO transparent conductive film has high scattering transmittance, high transmittance and low resistivity.

Owner:BAODING TIANWEI GRP CO LTD

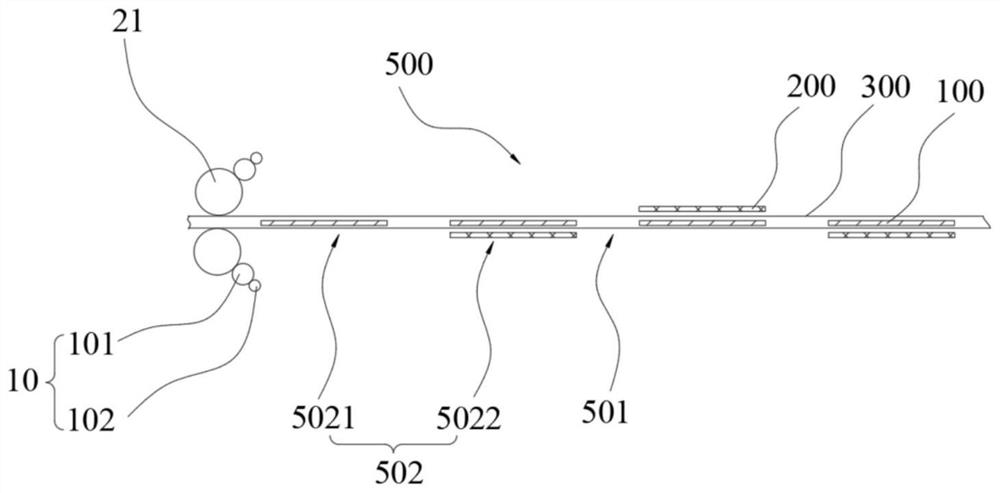

Thermal composite lamination equipment and thermal composite lamination method

ActiveCN113555595ACompact structureIncrease productivityAssembling battery machinesFinal product manufactureElectrical batteryCell fabrication

The invention relates to the technical field of battery manufacturing, and discloses thermal composite lamination equipment and a thermal composite lamination method. The thermal composite lamination equipment comprises a first rolling mechanism, a second rolling mechanism, a main conveying mechanism, a first conveying mechanism, a heating conveying mechanism and a second conveying mechanism, and the main conveying mechanism can convey paired diaphragms to sequentially pass through the first rolling mechanism and the second rolling mechanism; the first conveying mechanism can feed a preheated first polar sheet with a preset size into the first rolling mechanism, the first polar sheet is clamped between the diaphragms, and the heating conveying mechanism can compound the diaphragms and the first polar sheet into an intermediate complex; and the second conveying mechanism can convey a preheated second polar piece with a preset size into the second rolling mechanism and enables the second polar piece to be located on the outer side of the diaphragm, and the second rolling mechanism presses the second polar piece and the middle composite body into a material belt. Energy loss is low, the structure is compact, and production efficiency is high.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Battery equalization device

ActiveCN103094969ASolve the problem of inconsistent powerBatteries circuit arrangementsElectric powerCell fabricationComputer science

The invention is suitable for the field of battery manufacture devices, and provides a battery equalization device. The device comprises a device body and an equalization unit, wherein the equalization unit comprises an upper platform and a lower platform used for placement of batteries, space used for vertical placement of two or more batteries is arranged between the upper platform and the lower platform, and the upper platform and the lower platform can be used for clamping positive poles and negative poles of the batteries to enable the batteries placed between the upper platform and the lower platform to be in parallel connection. After the technical scheme is adopted, the two or more batteries are placed between the upper platform and the lower platform, when the upper platform and the lower platform clamp the positive poles and the negative poles of the batteries, the batteries are in parallel connection, and voltage and charged amount of the batteries are the same after current exchange for a certain period of time.

Owner:OPTIMUM BATTERY CO LTD

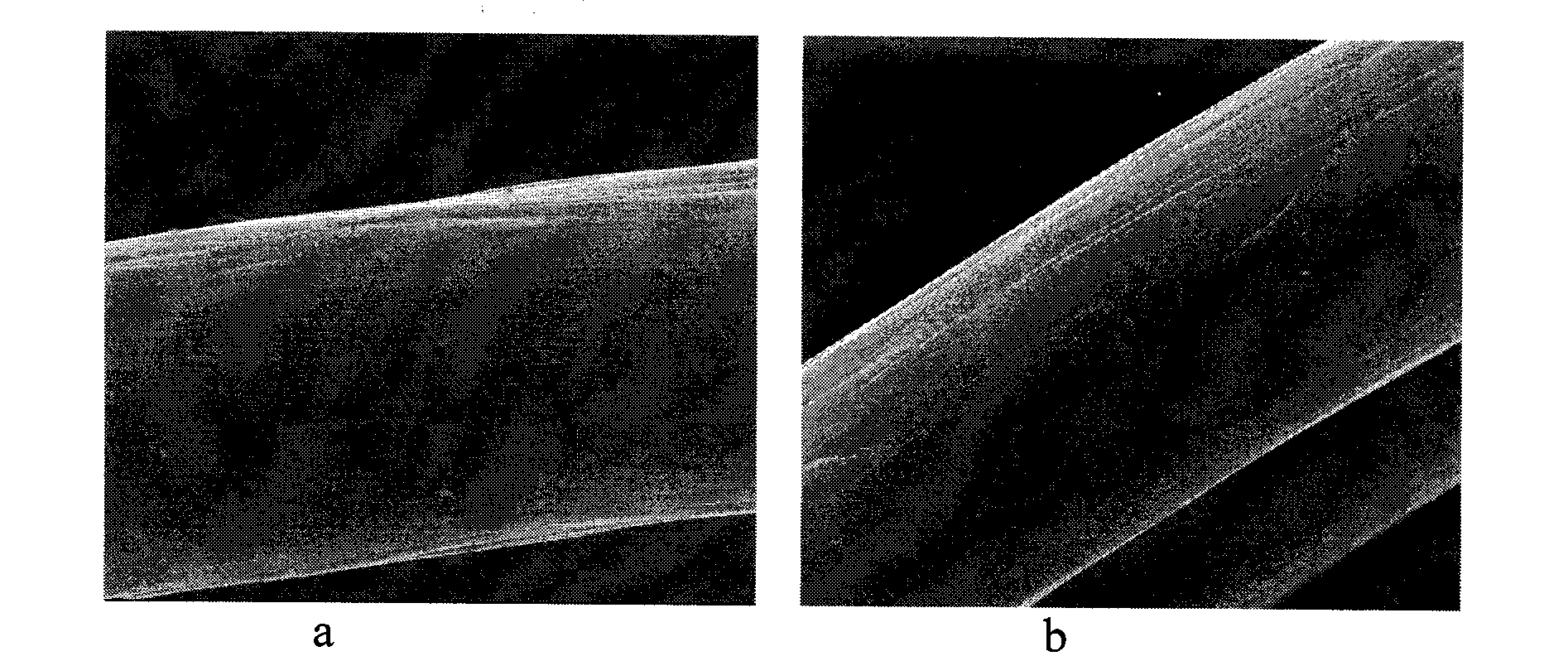

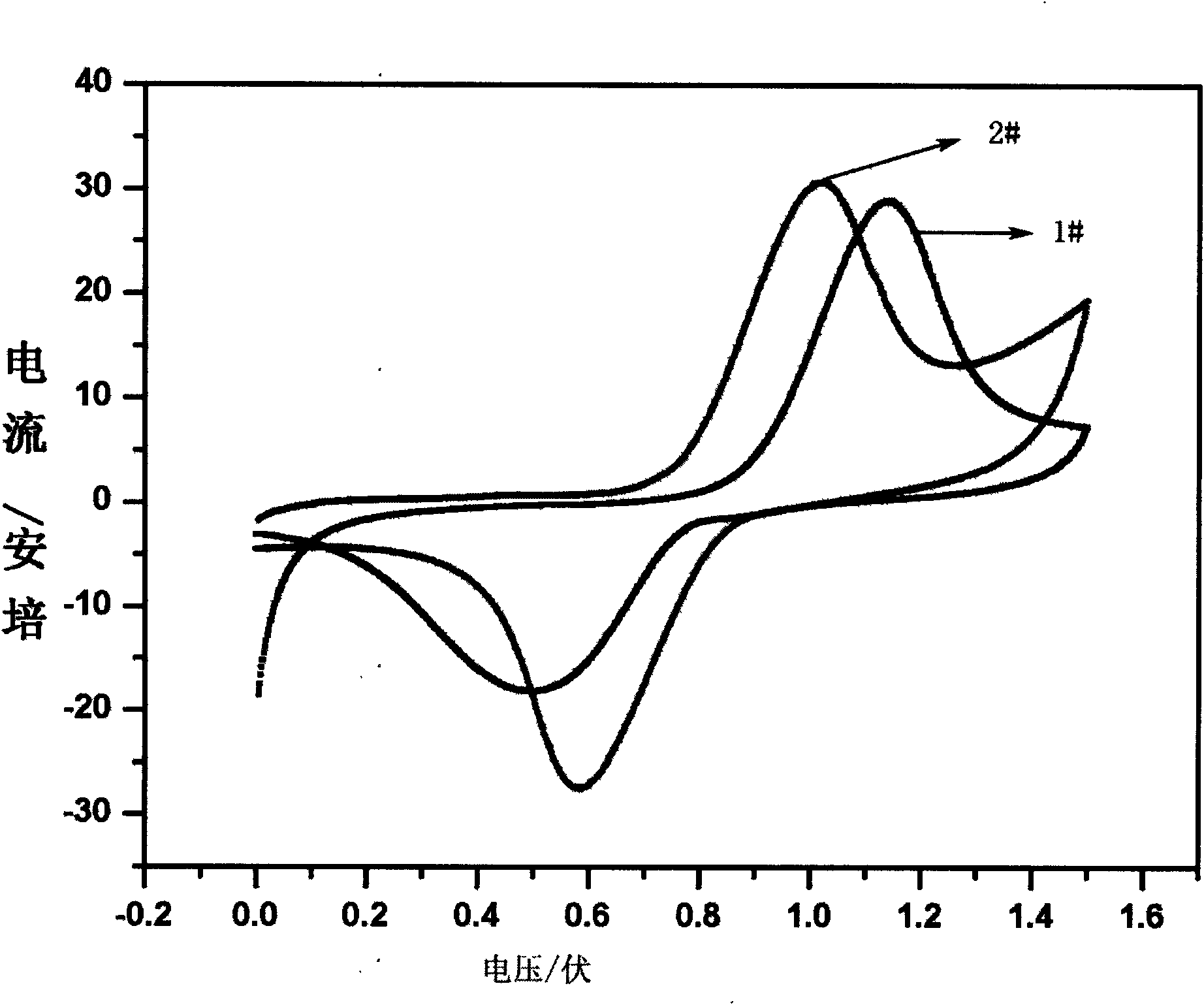

Surface modification method for raising activity of electrode material of vanadium cell

ActiveCN102723502AImprove energy storage efficiencyImprove hydrophilic propertiesCell electrodesCell fabricationElectrical polarity

The invention, relating to the field of cell manufacturing and energy storage, discloses a surface modification method for raising the activity of an electrode material of a vanadium cell, comprising the following steps: firstly cleaning the electrode material of the vanadium cell to remove surface impurities, then carrying out modification treatment of the electrode material by using plasma, reacting the gas which generates plasma with the electrode surface under ionization state to generate polar functional groups; and finally carrying out ultrasonic cleaning on the modified electrode material for 5-30 min and drying at 60-120 DEG C. According to the invention, by using the method of the invention to carry out surface modification on the electrode material of the vanadium cell, the hydrophilcity of the electrode surface is enhanced, partial polar functional groups has good catalytic influence on electrode reaction, and the energy storage efficiency of the cell is expected to increase. The method can be used for processing material surfaces with various morphologies and can keep mechanical properties and the like of material matrixes, the experiment condition are easy to control and the method has no pollution to environment. The method is efficient and environmentally friendly.

Owner:辽宁科京新材料有限公司

Method for preparing lithium iron cell protective film and solvent for cleaning said protective film

InactiveCN1588671ASolve corrosiveEasy to operateAnti-corrosive paintsCell component detailsEpoxy polyamideDiethyl ether

A prepn. method for protective film of lithium ion cell. At least one organic polymer among phenolic resin, epoxy resin, polyvinyl acetate, polyurethane, polytetrafluoroethylene, chloronorgutta, phenolic chloronorgutta, epoxy polyamide and phenolic polyvinyl acetal is added into particular solvent selected at least one from diionized water, carbinol, benzene, toluene, chloroform dichloroethylene, diethyl ether, acetone, ethyl acetate and normal ethane, they are mixed and stirred to organic solution which is coated on case of lithium ion cell, then the case is static placed to volatilize particular solvent in the organic solution in room temp. to form a layer of uniform and densify protective film on cell case. Said film can prevent corrding of electrolyte and perspiration in prodn process. The invent is also relates to a solvent used for cleaning said proctive film selected from deionized water, alcohol, acetone, oxolane and formyldimethylamine.

Owner:HENAN HUANYU GROUP

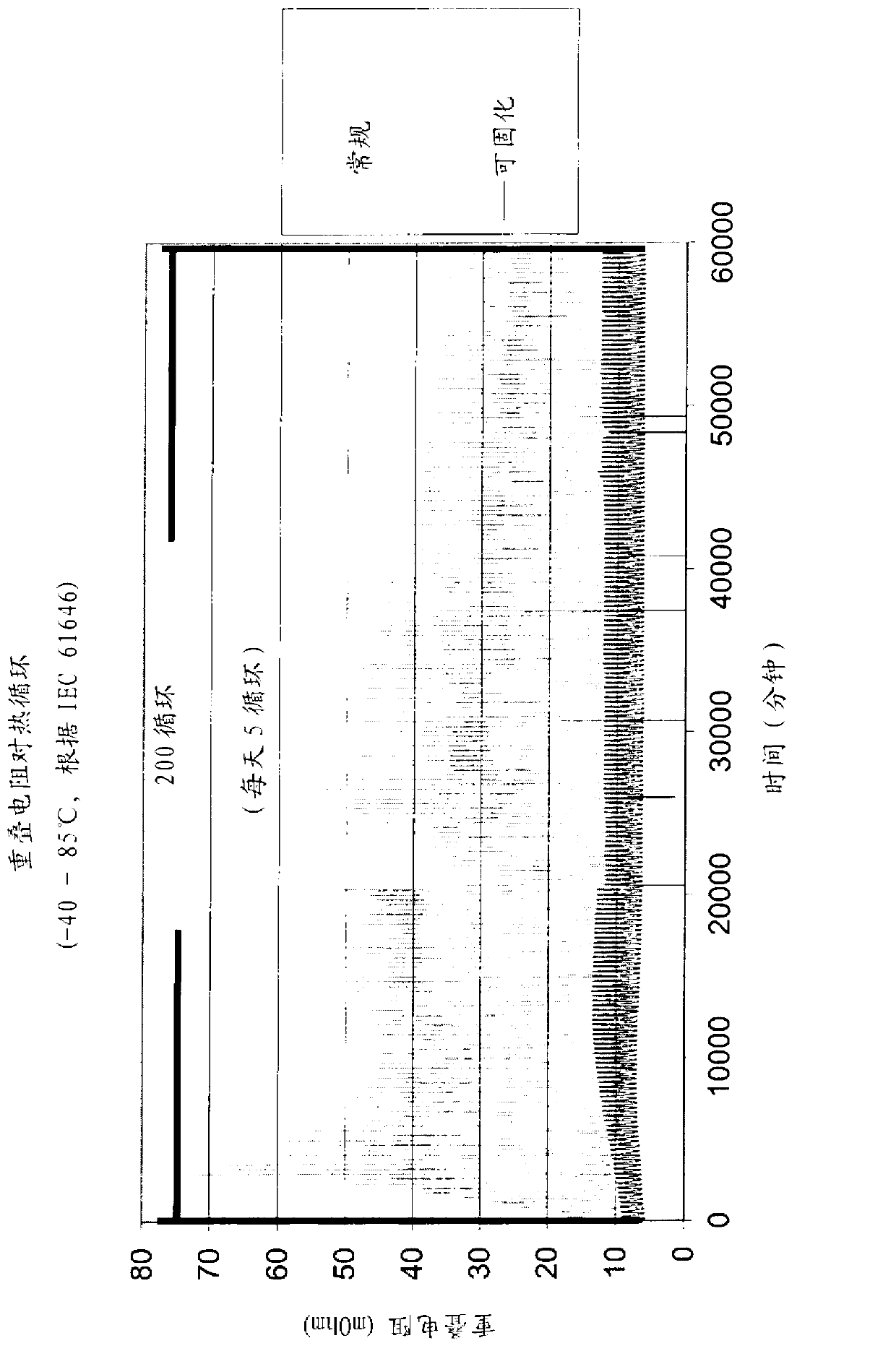

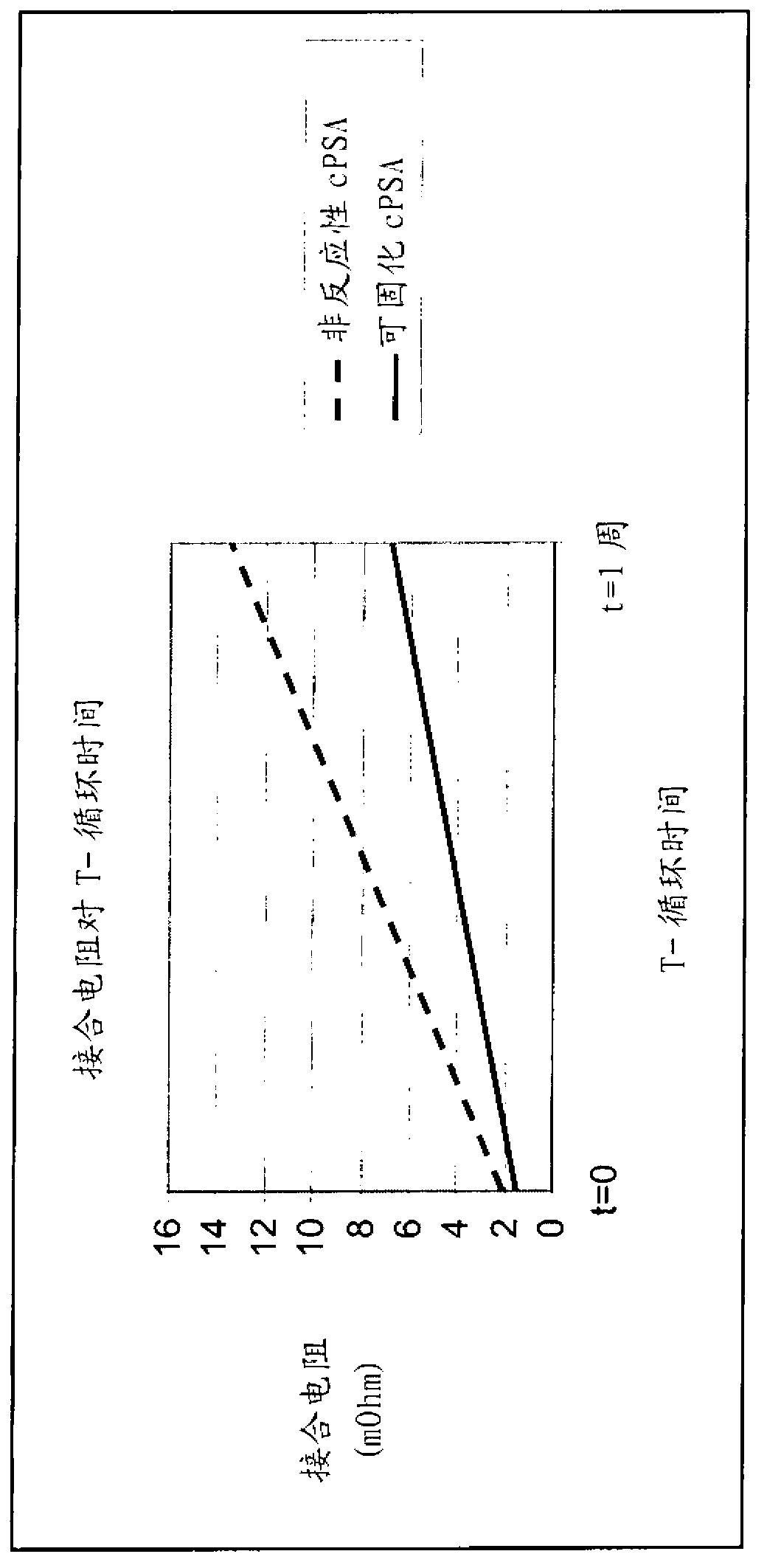

Reactive conductive pressure-sensitive adhesive tape

InactiveCN103314066AImprove electrical reliabilityShorten the timeFilm/foil adhesivesWoven fabricsCell fabricationPressure sensitive

A reactive pressure sensitive adhesive composition is disclosed. A tape formed using the reactive pressure sensitive adhesive is also disclosed. In its cured state, the pressure sensitive adhesive shows superior mechanical and electrical properties compared to conventional, non-curable charge collection tapes. The tape has a cure profile pre-selected to correspond to that of a photovoltaic cell fabrication process, such that curing can take place during cell fabrication and may occur simultaneously with one or more other curing steps employed in cell fabrication.

Owner:ADHESIVES RES

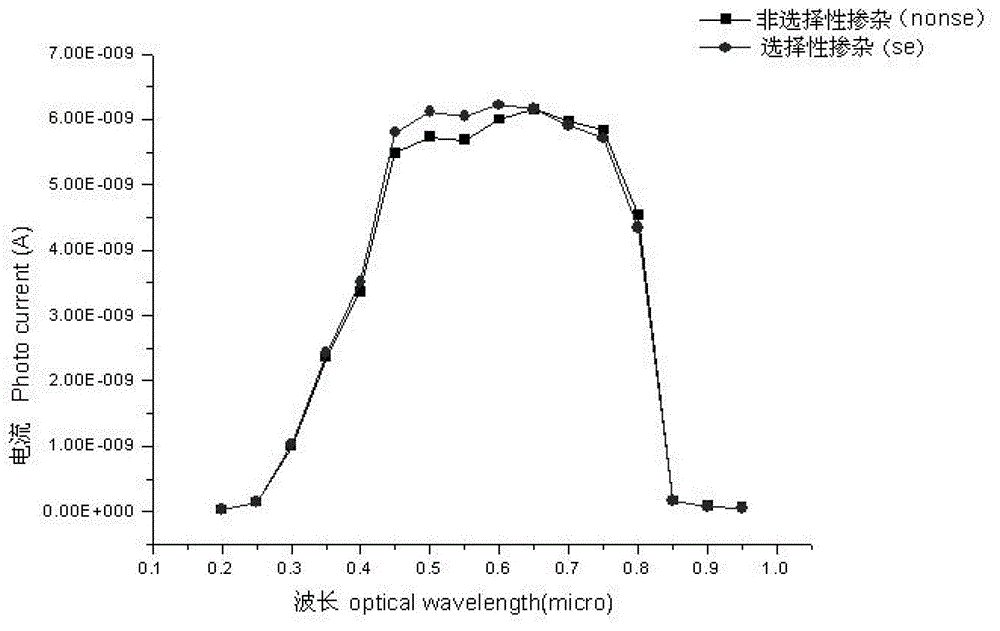

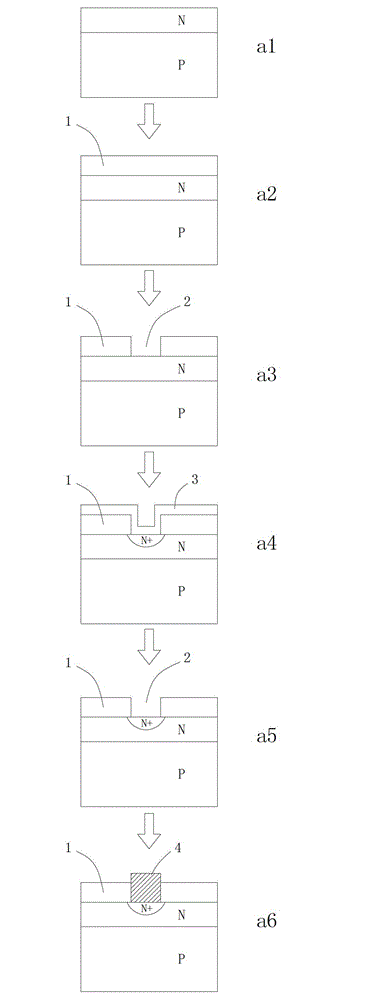

Method for manufacturing solar cell

InactiveCN102945892AAvoid technical problems of preparationSolve the contradiction between the compound rateFinal product manufactureSemiconductor devicesCell fabricationEngineering

The invention relates to a method for manufacturing a solar cell. The etching ratio of hydrofluoric acid buffer solution to silica and silicon nitride is skillfully utilized to keep a silicon nitride masking layer as an anti-reflection layer of the cell, therefore, the anti-reflection layer is not needed to be independently manufactured before sintering an electrode, the process is simplified, and the production efficiency is improved. The method utilizes good blocking performance of the silicon nitride to impurities to well solve a problem that the solar cell is selectively doped, thus improving doping density of an area lower than the metal electrode, reducing series resistance, reducing the deposing density of the area outside the electrode, reducing composition of photon-generated carriers and improving short-circuit current. The non-sacrificial silicon nitride masking layer is used for preventing other impurity elements from diffusing to a silicon wafer and using a silicon nitride etching slot in the process as an alignment mark of a main grid line, so that the alignment during the production is simpler.

Owner:NANTONG UNIVERSITY

Front composite film for improving edge winding and plating color difference of tubular PERC solar cell

PendingCN111029415AImprove uniformityReduce edge chromatic aberrationPhotovoltaic energy generationSemiconductor devicesCell fabricationRefractive index

The invention discloses a front composite film for improving the edge winding and plating color difference of a tubular PERC solar cell, and the front composite film sequentially comprises a SiNx:Hy layer, a SiOxNy layer and a SiOx layer. The SiNx:Hy layer at least comprises five layers of SiNx:Hy with different refractive indexes and thicknesses which are respectively a first SiNx:Hy layer, a second SiNx:Hy layer, a third SiNx:Hy layer, a fourth SiNx:Hy layer and a fifth SiNx:Hy layer, and the SiOxNy layers at least comprise 2-3 SiOxNy layers with different refractive indexes and thicknesse,wherein the SiOx layer at least comprises one SiOx layer with different refractive indexes and thicknesses. By adopting the method, the front edge winding and plating color difference caused by adopting tubular plasma equipment to prepare the back passivation film in the PERC battery manufacturing process can be effectively improved, and the appearance uniformity of the photovoltaic module is improved.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH

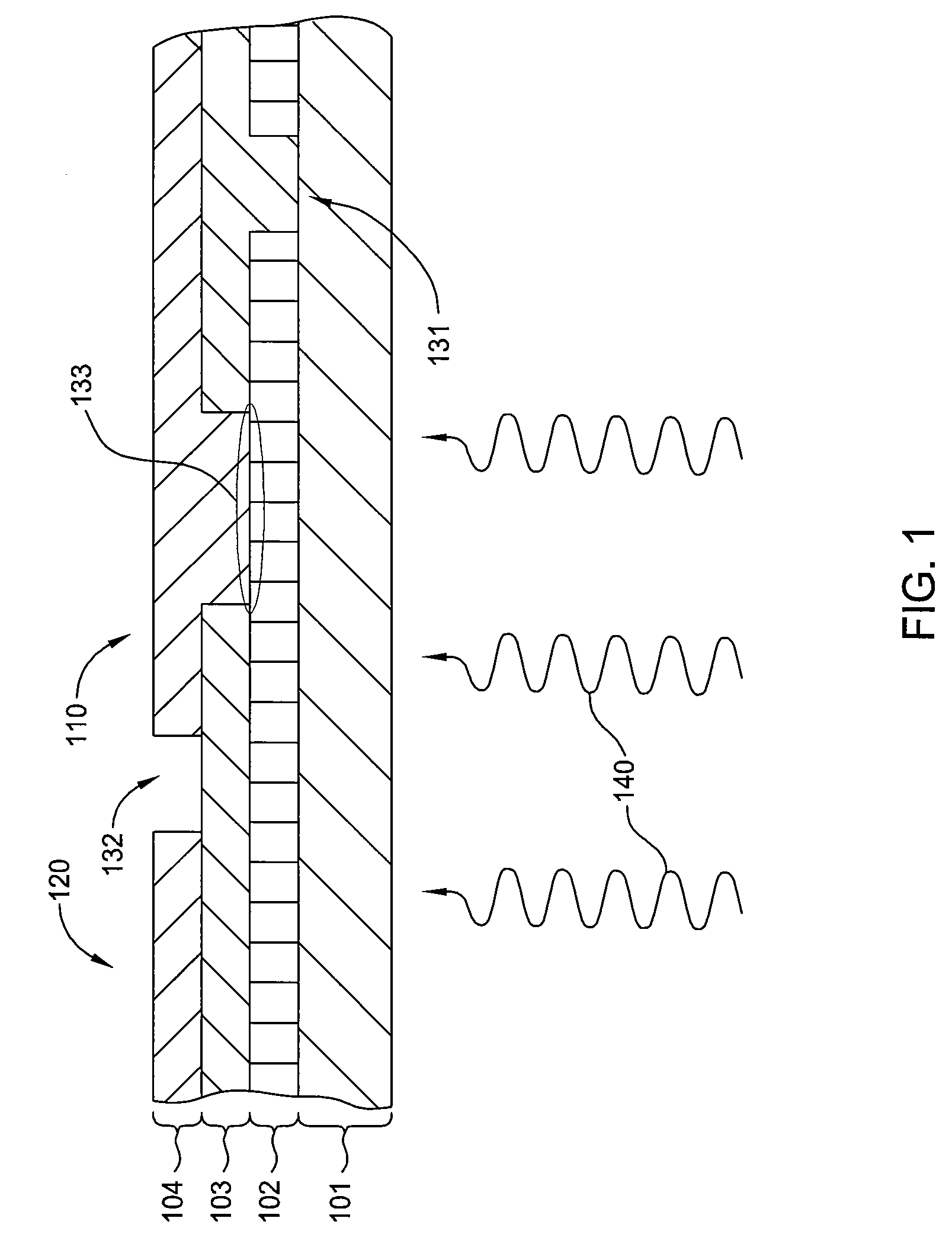

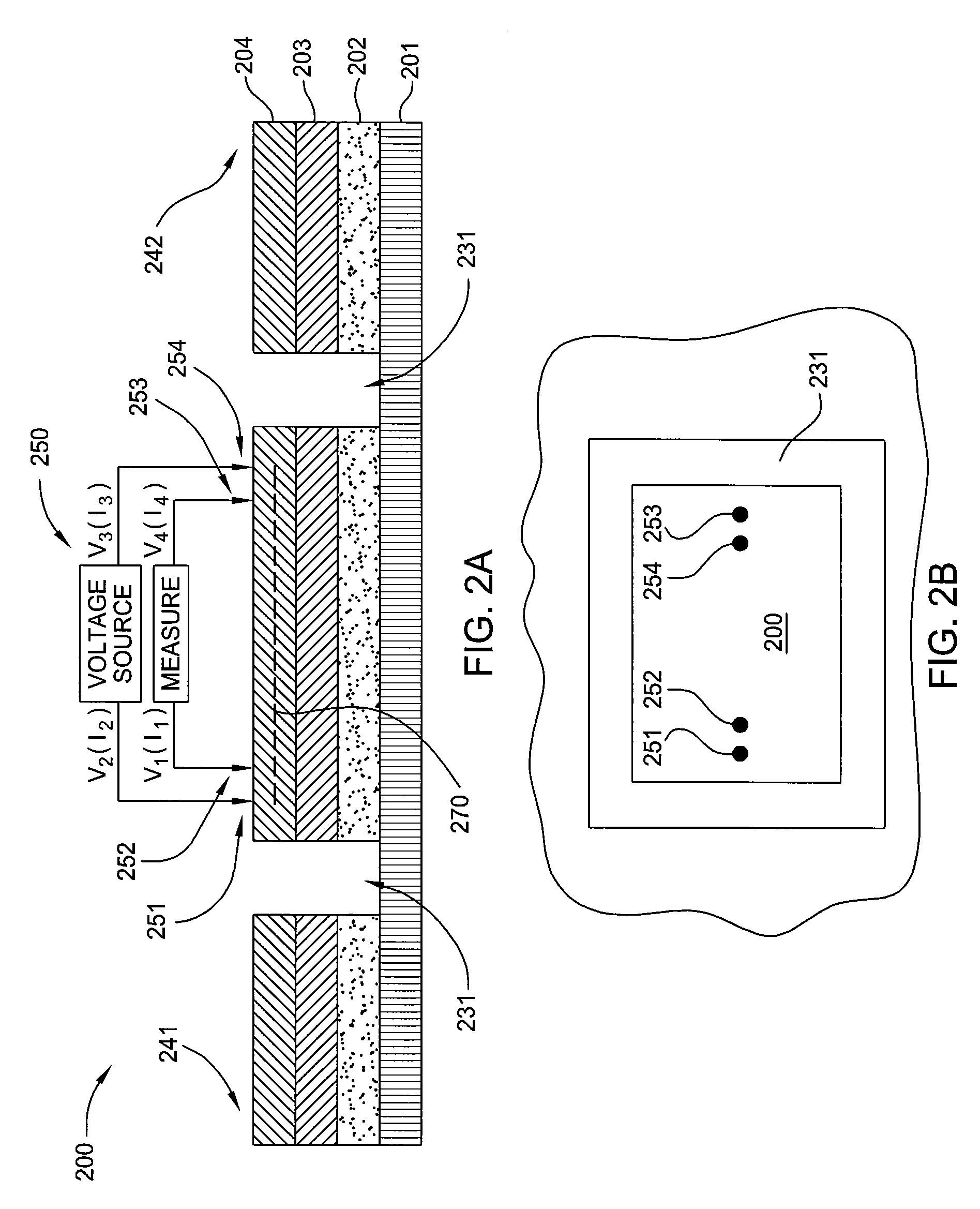

Photovoltaic fabrication process monitoring and control using diagnostic devices

InactiveUS20090104342A1Improve the immunitySemiconductor/solid-state device testing/measurementFinal product manufactureElectrical batteryCell fabrication

The formation of diagnostic devices on the same substrate used to fabricate a photovoltaic (PV) cell is described. Such devices, also referred to as process diagnostic vehicles (PDVs), are configured for in-line monitoring of electrical characteristics of PV cell features and are formed on the substrate using the same process steps for PV cell fabrication. The data collected via the PDVs can be used to tune or optimize subsequent PV cell fabrication, i.e., used as feedback for the fabrication process. Alternatively, the data collected via PDVs can be fed forward in the fabrication process, so that later process steps performed on a PV cell substrate can be modified to compensate for issues detected on the PV cell substrate via the PDVs.

Owner:APPLIED MATERIALS INC

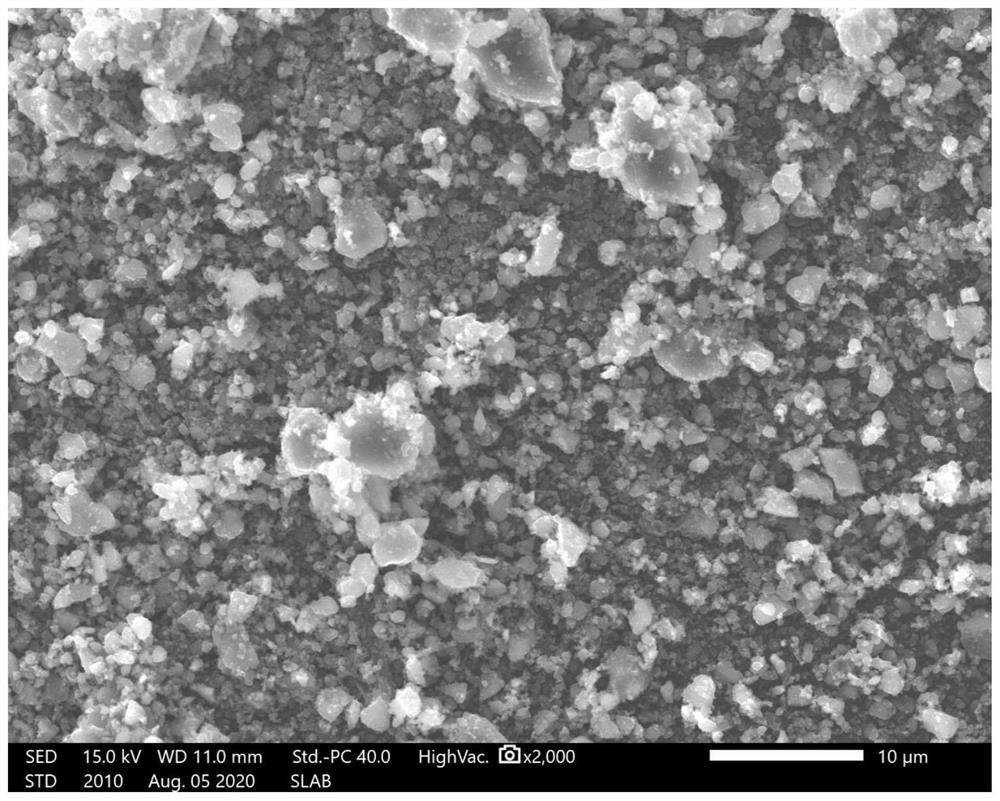

Method for manufacturing lithium iron phosphate all-solid-state film cell by in-situ spray pyrolysis

InactiveCN102456929AImprove conductivityImprove electronic conductivityFinal product manufactureElectrolyte accumulators manufacturePhase compositionElectronic conductivity

The invention discloses a method for manufacturing a lithium iron phosphate all-solid-state film cell by in-situ spray pyrolysis. The method is characterized in that an in-situ spray pyrolysis technology is adopted; a slightly excess amount of a nonvolatile high-boiling point organic polymer is added into an anode precursor solution so that in a spray process, the anode precursor solution and anode active substances are mixed well; in follow-up heat treatment, a cracking process is carried out in the air-free environment and ferric iron is reduced in situ by carbon obtained by the cracking process so that the lithium iron phosphate all-solid-state film cell is obtained; after in-situ reduction, a trace amount of carbon is utilized as an electronic link of an anode material so that electronic conductivity of the anode material is improved; and in the spray process, through a spray gun, two buffer layers are formed at junction parts of an anode layer, a solid electrolyte layer and a cathode layer and phase composition of each adjacent two of the anode layer, the solid electrolyte layer and the cathode layer continuously changes in the buffer layers. Through the method provided by the invention, adjacent layers are bonded closely; a layer-to-layer matching degree is greatly improved; stress and a crystal boundary are reduced; interfacial conductance is improved; the influences of interfacial conductance on cell integral performances are greatly reduced; and cell stability is improved.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com