Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4681results about "Assembling battery machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

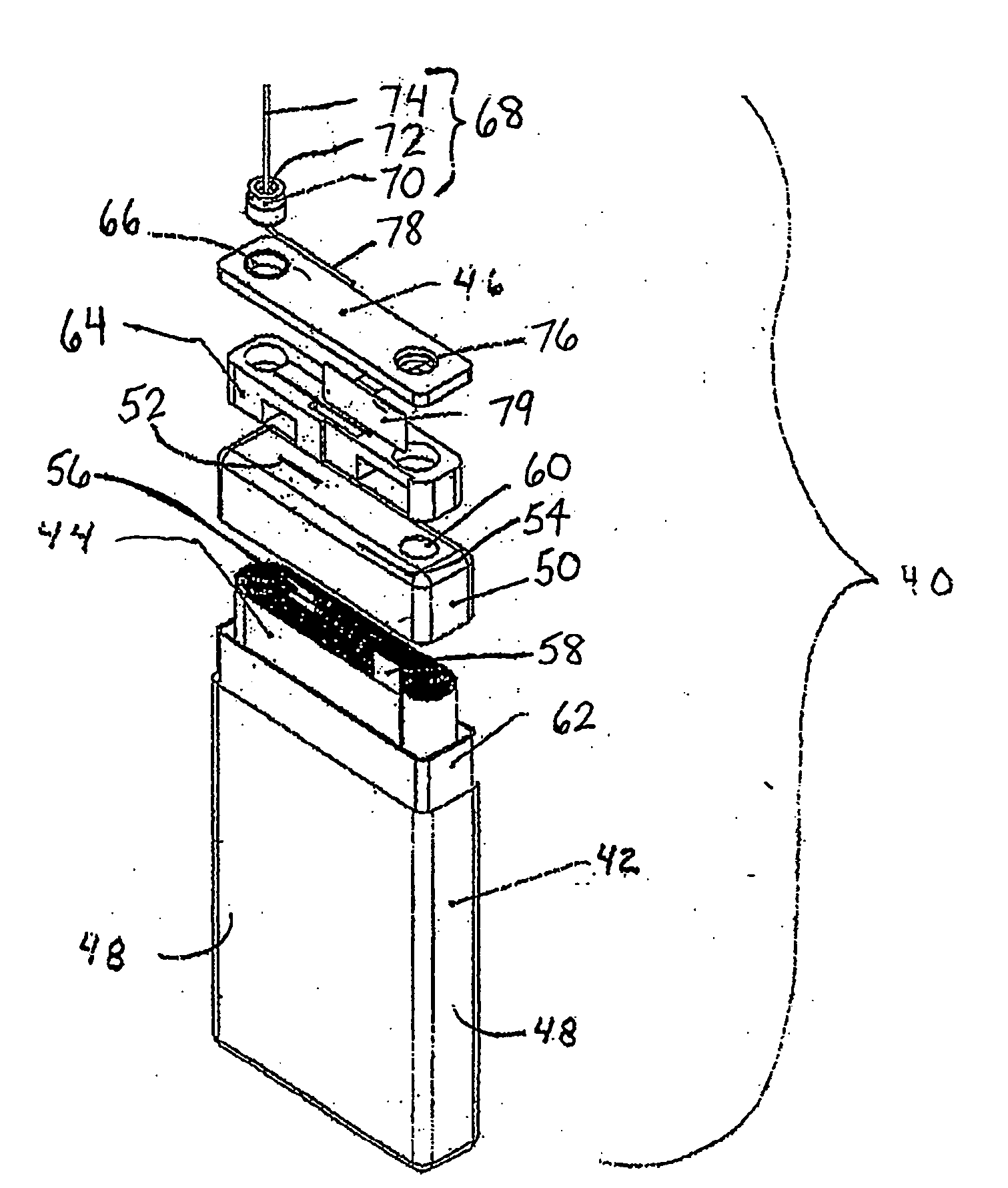

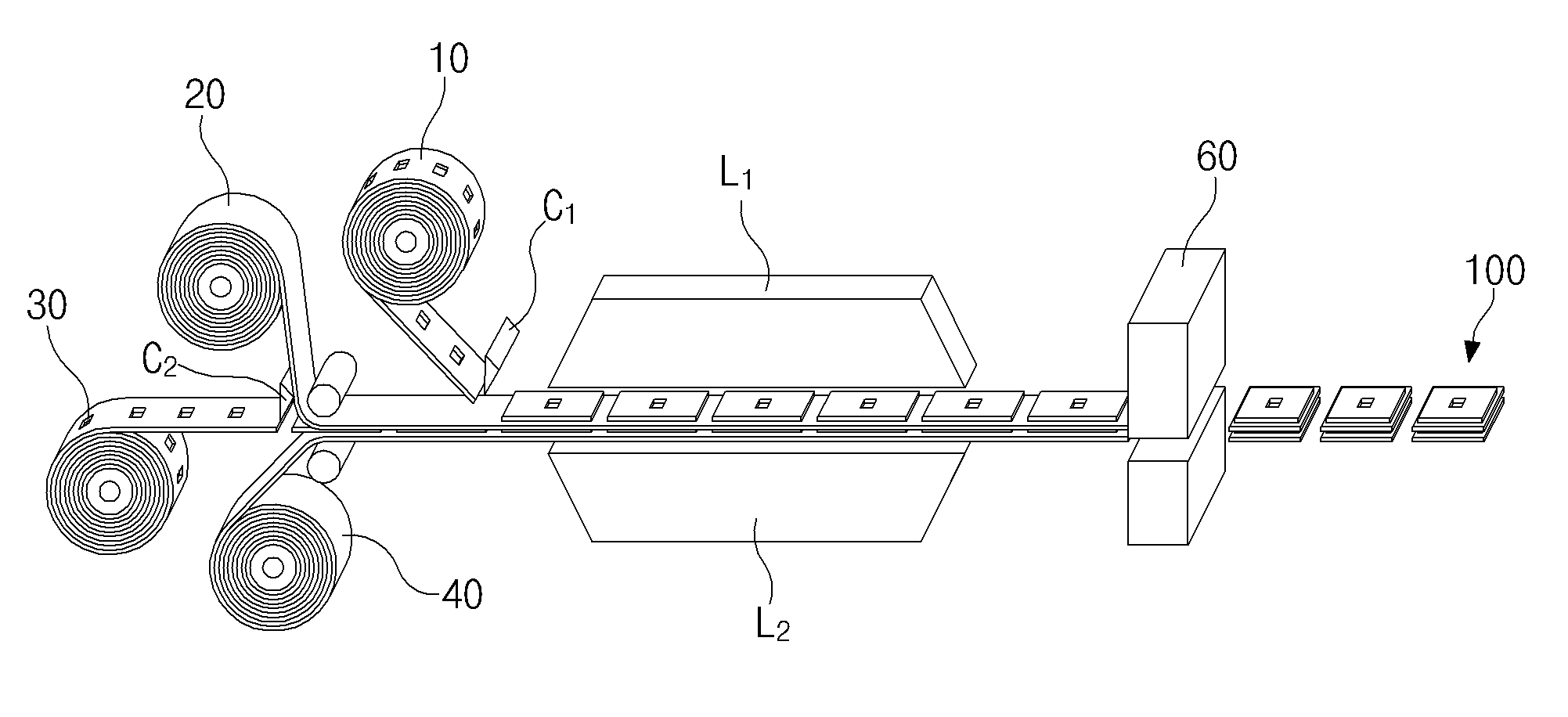

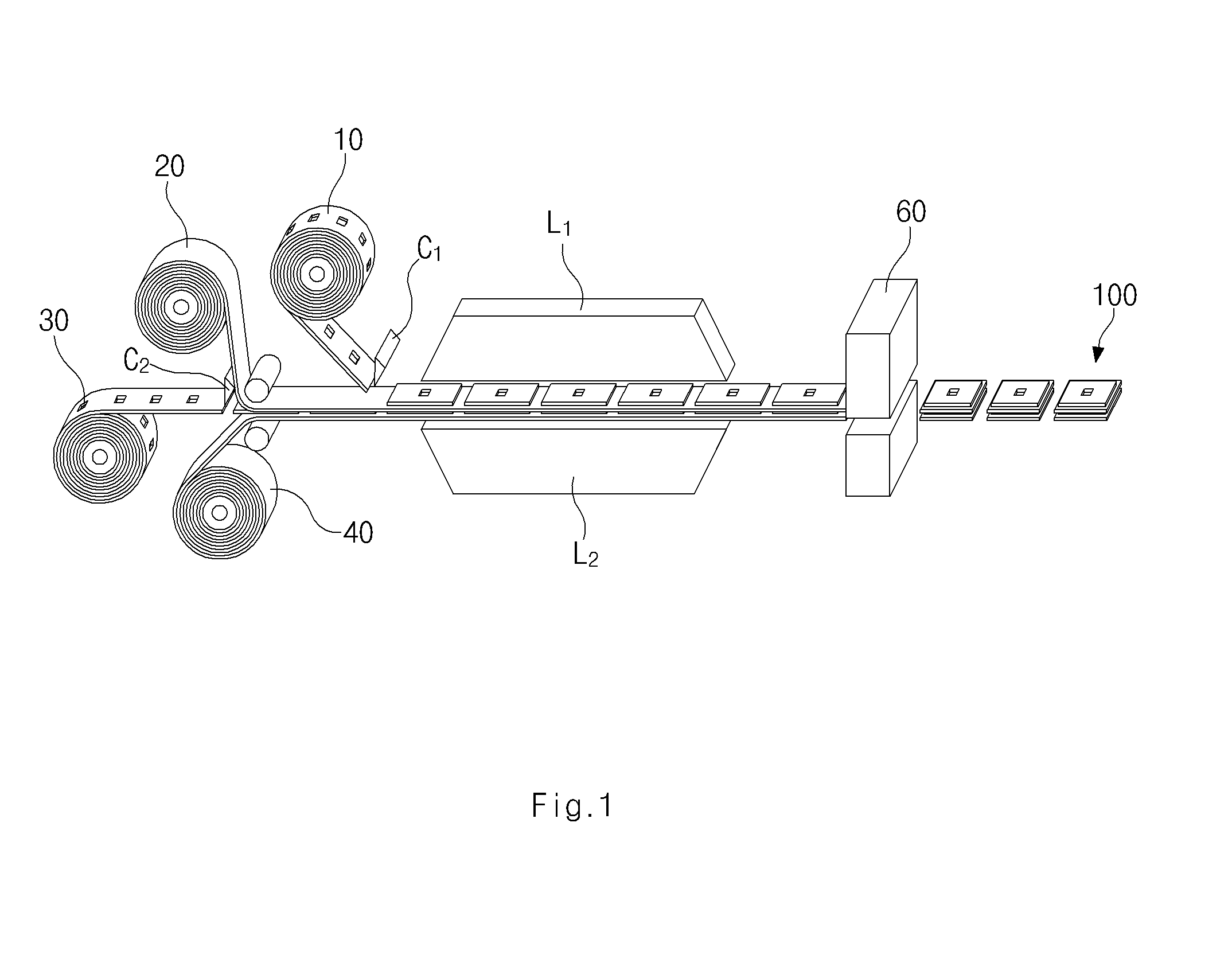

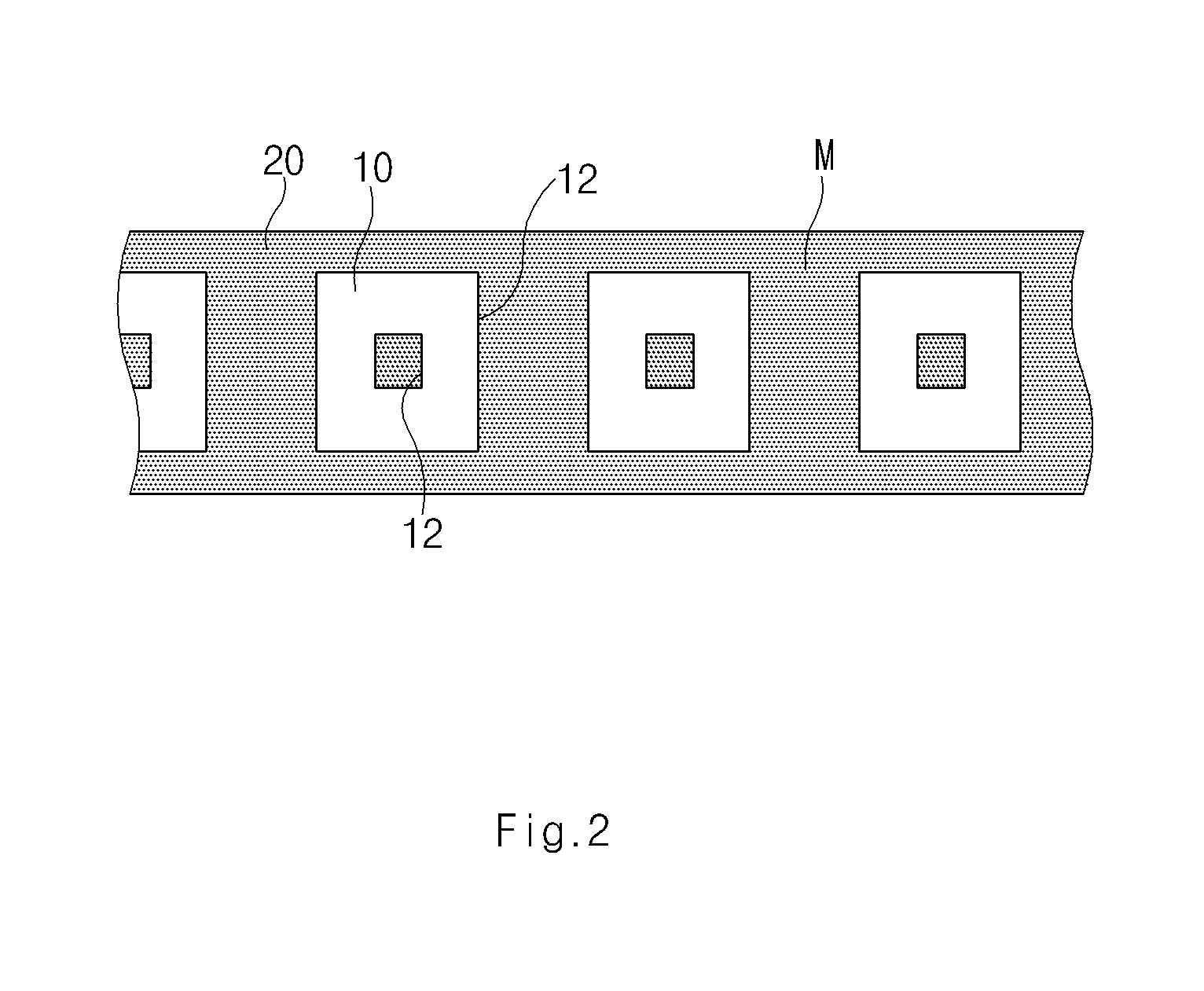

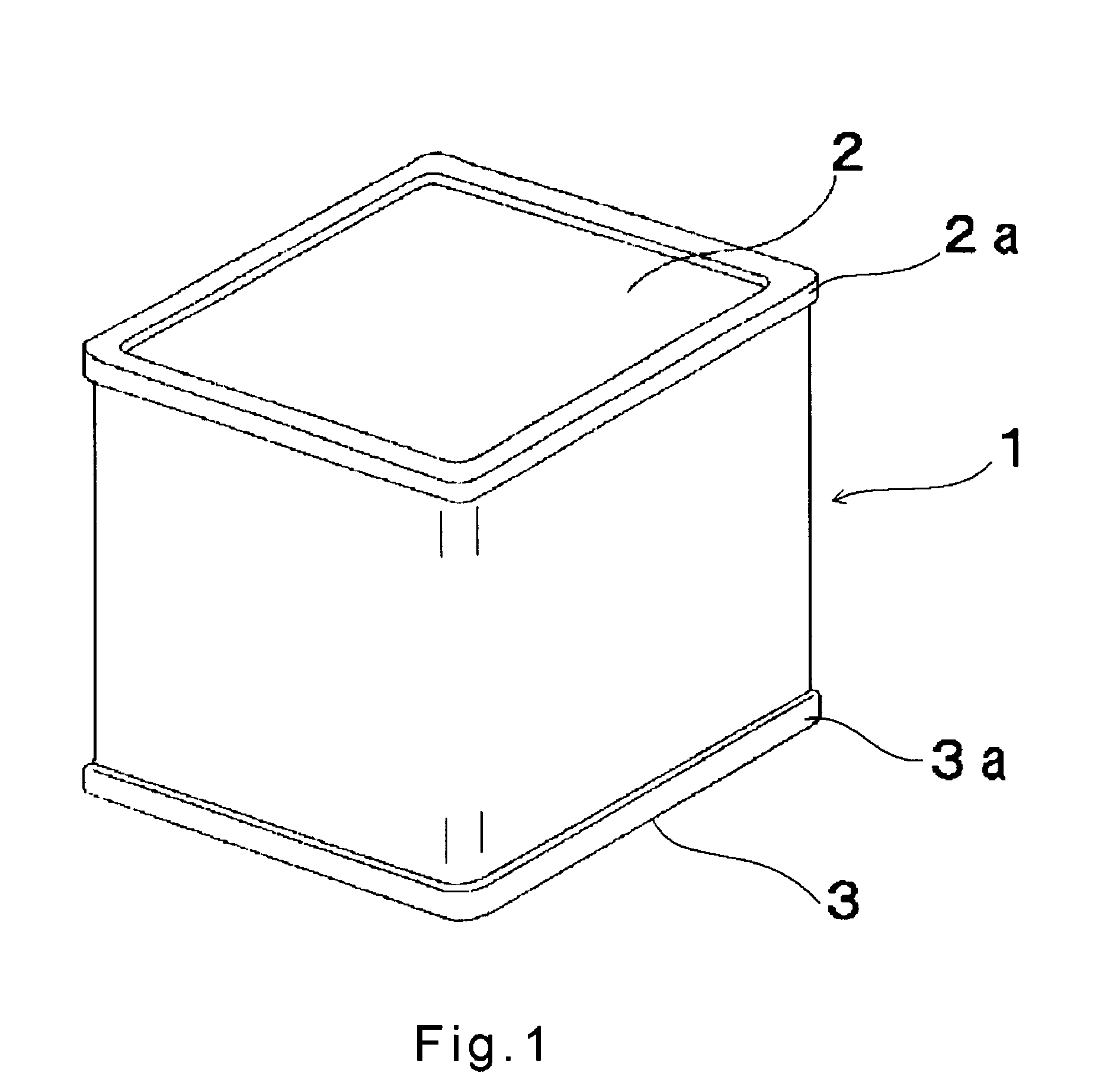

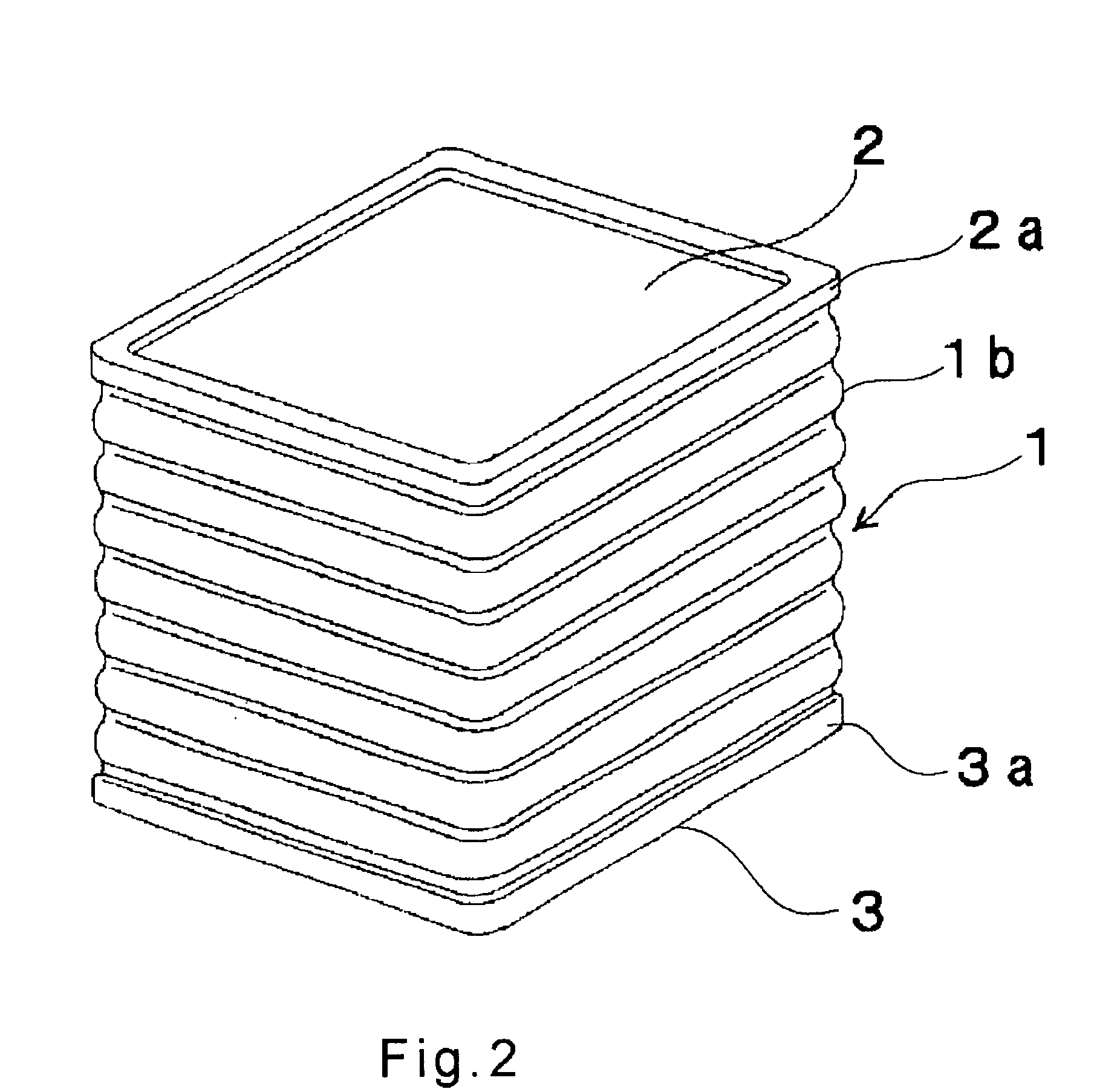

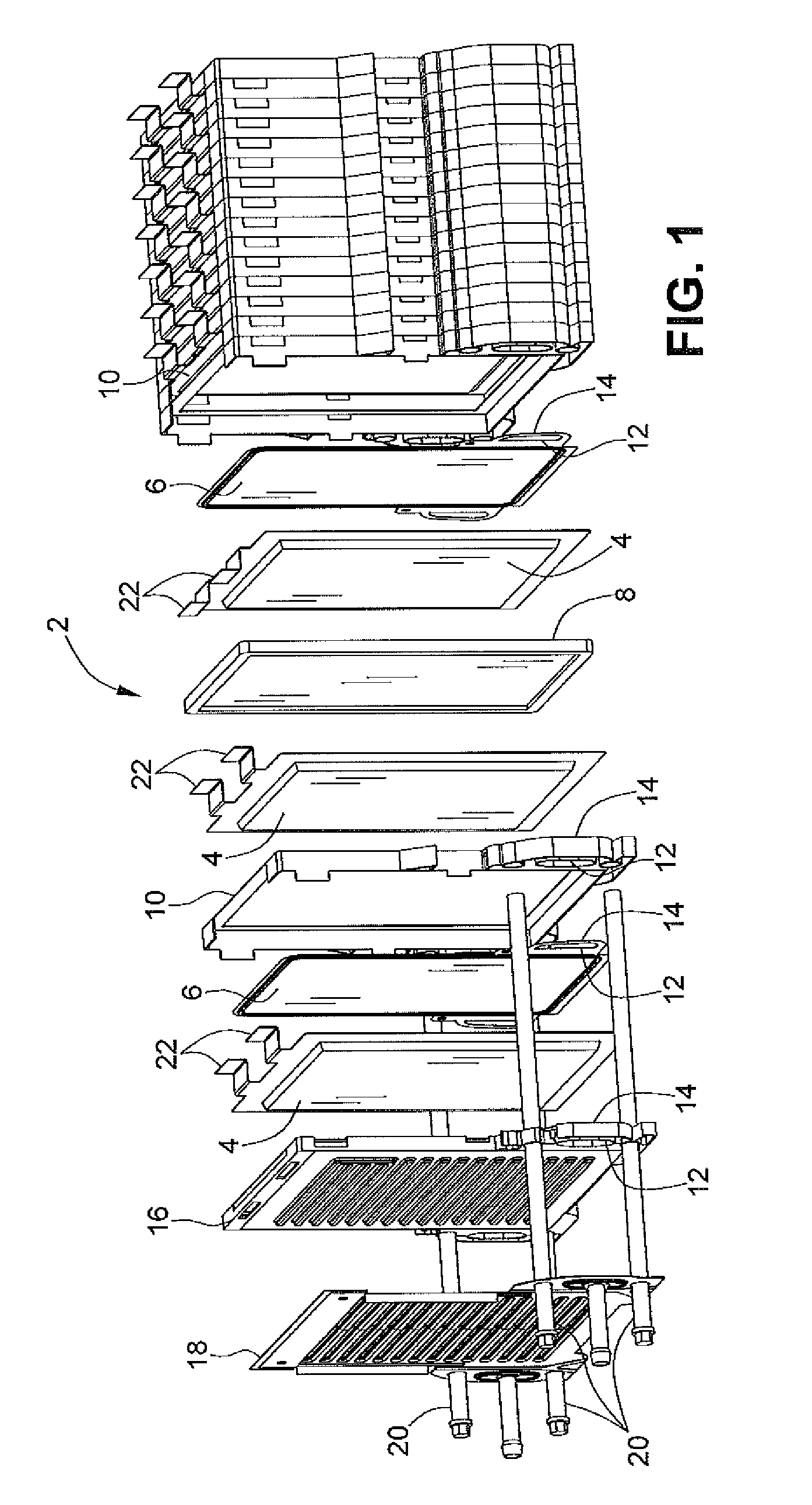

Battery assembly manufacturing method

InactiveUS20100190049A1Efficient preparationPrimary cell to battery groupingAssembling battery machinesElectrical and Electronics engineering

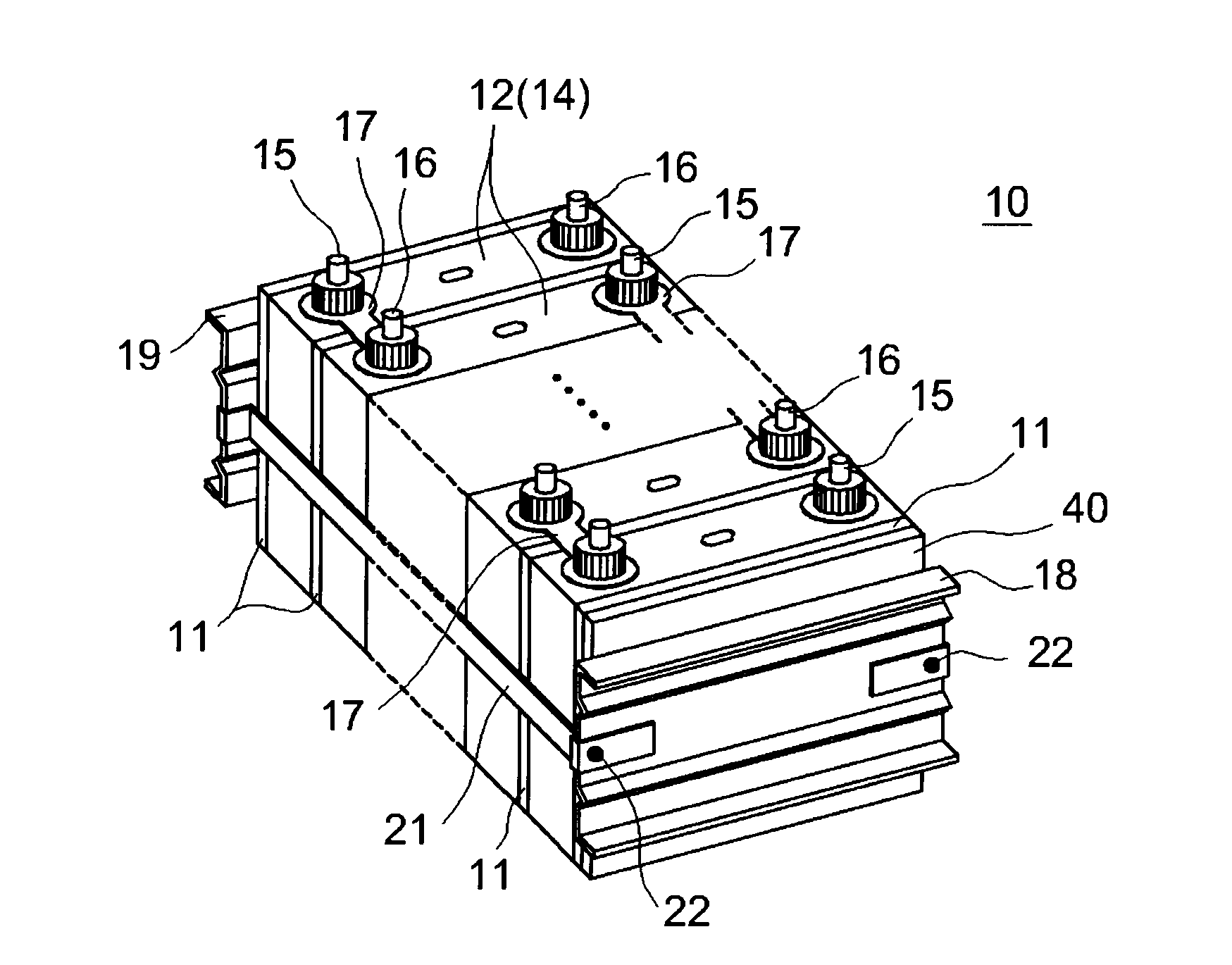

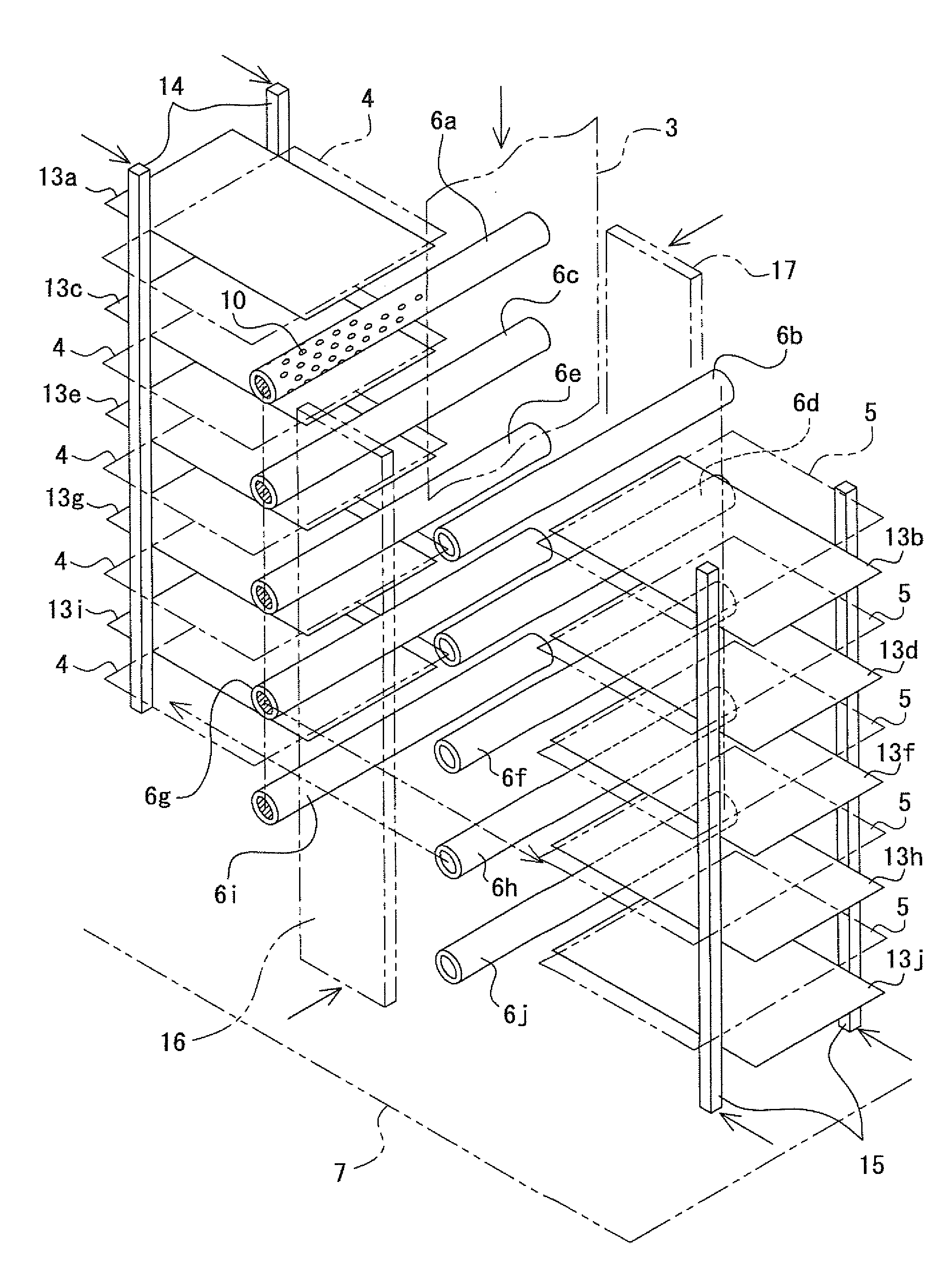

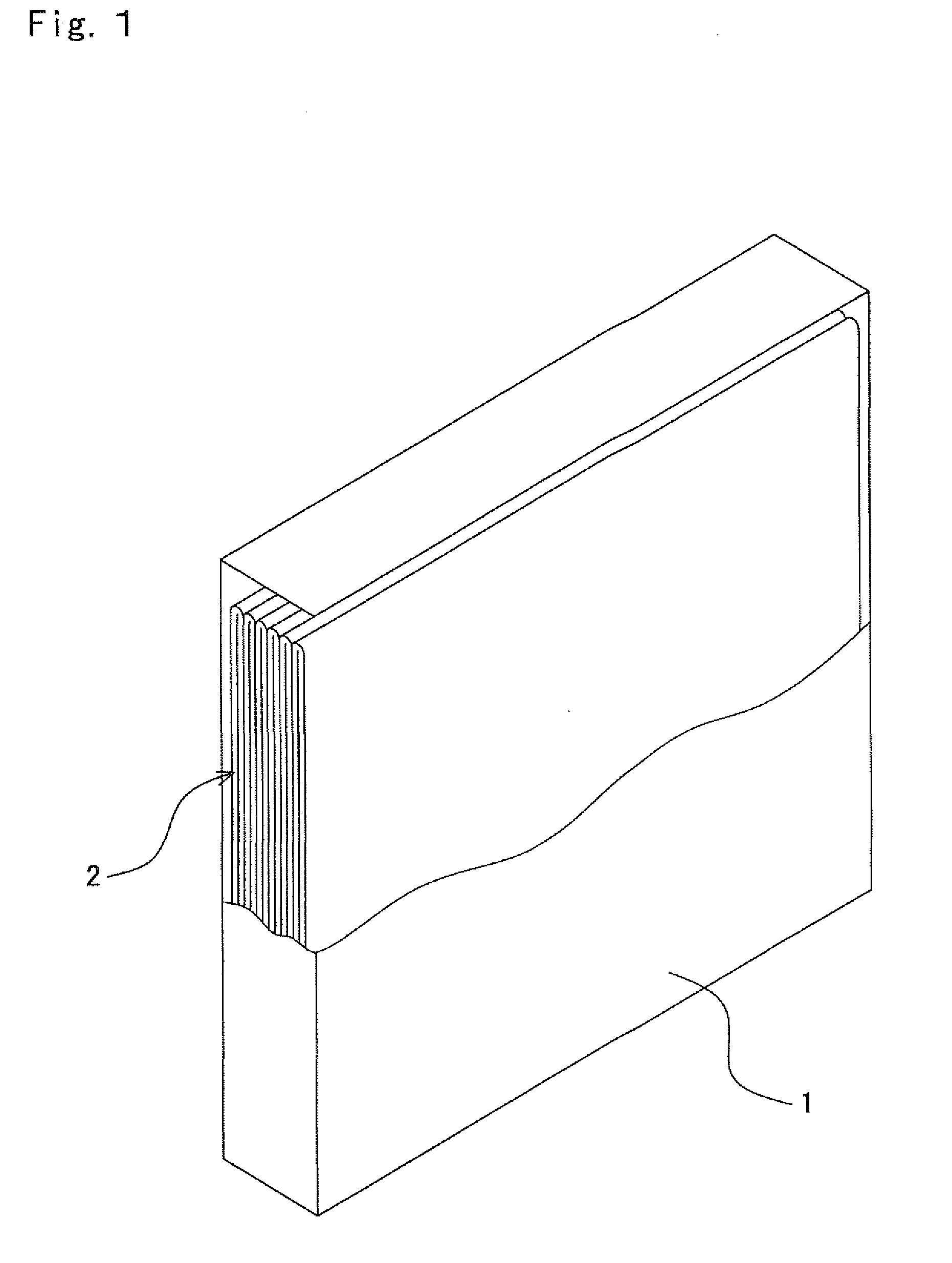

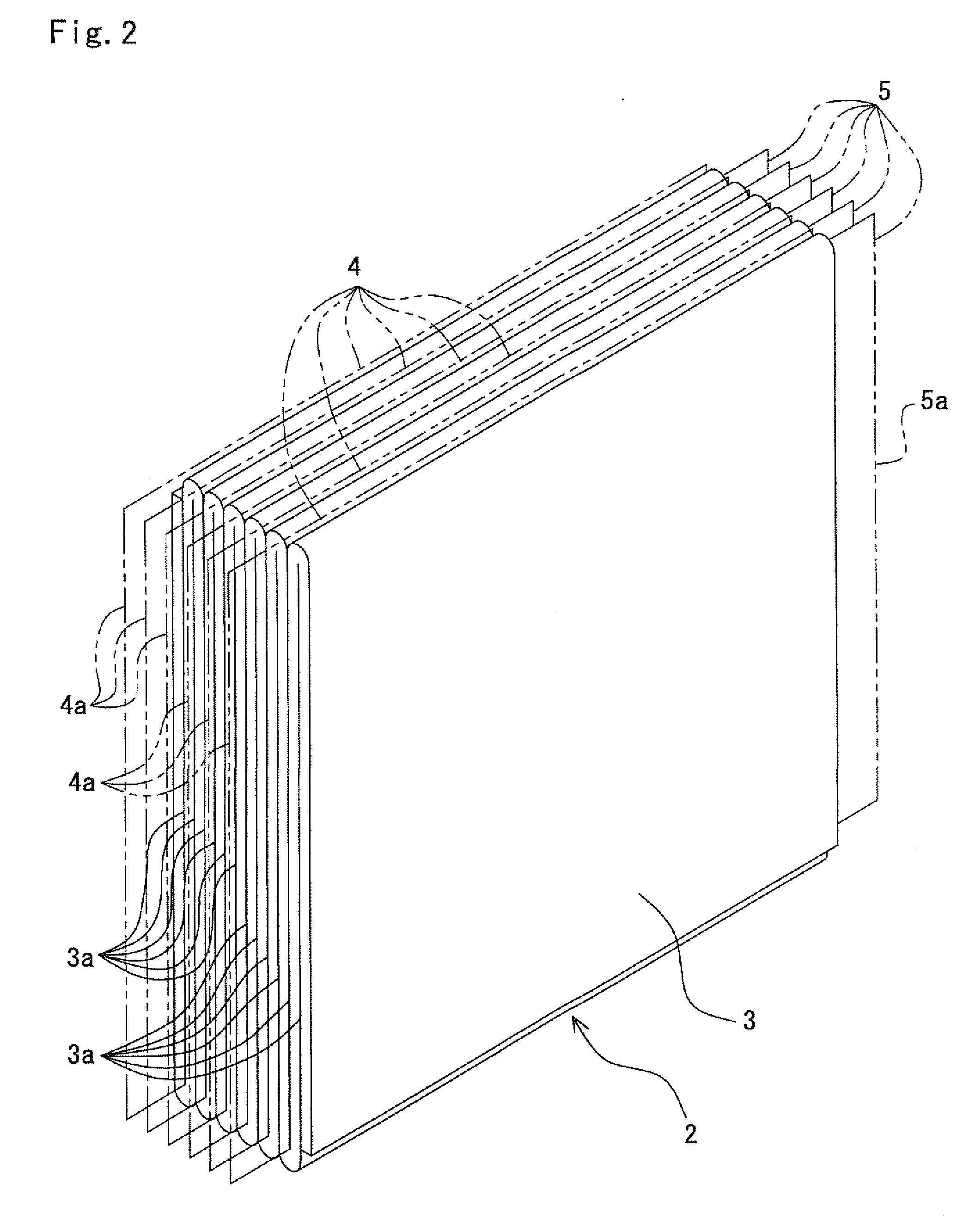

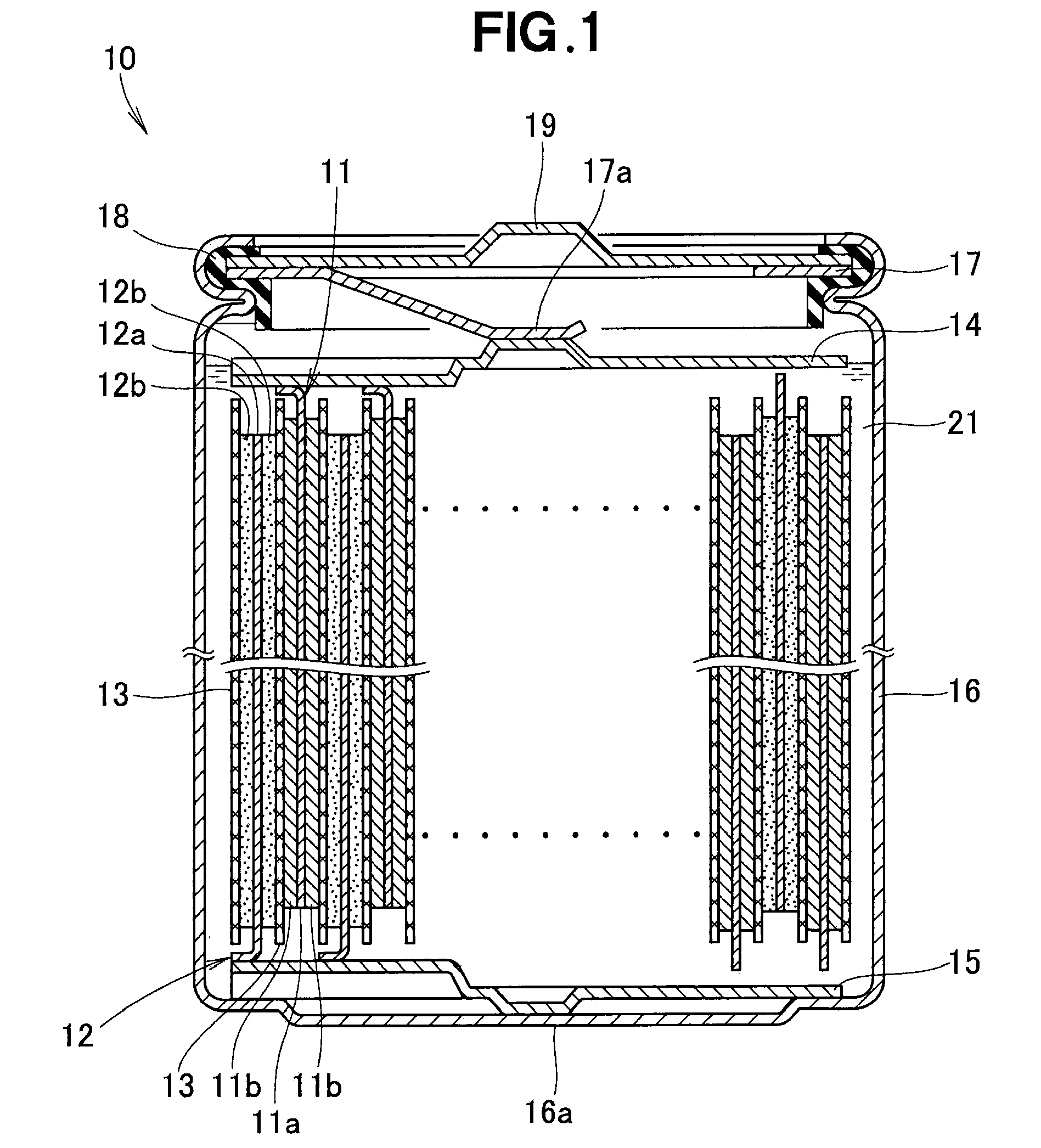

A method for manufacturing a battery assembly provided by the present invention includes a step of measuring a stacking direction length of a stacked body including a predetermined number of unit cells (12) constituting a battery assembly (10) and arranged in the stacking direction; and a step of bundling a body (20) to be bundled that includes the stacked body. Here, the body to be bundled is provided with length adjusting means (40) for converging a spread in stacking direction length. The bundling step is implemented by setting the length adjusting means according to the stacking direction length of the stacked body, so that a length of the battery assembly in the stacking direction is a stipulated length (LT) and a bundling pressure of the body to be bundled is a stipulated pressure.

Owner:TOYOTA JIDOSHA KK

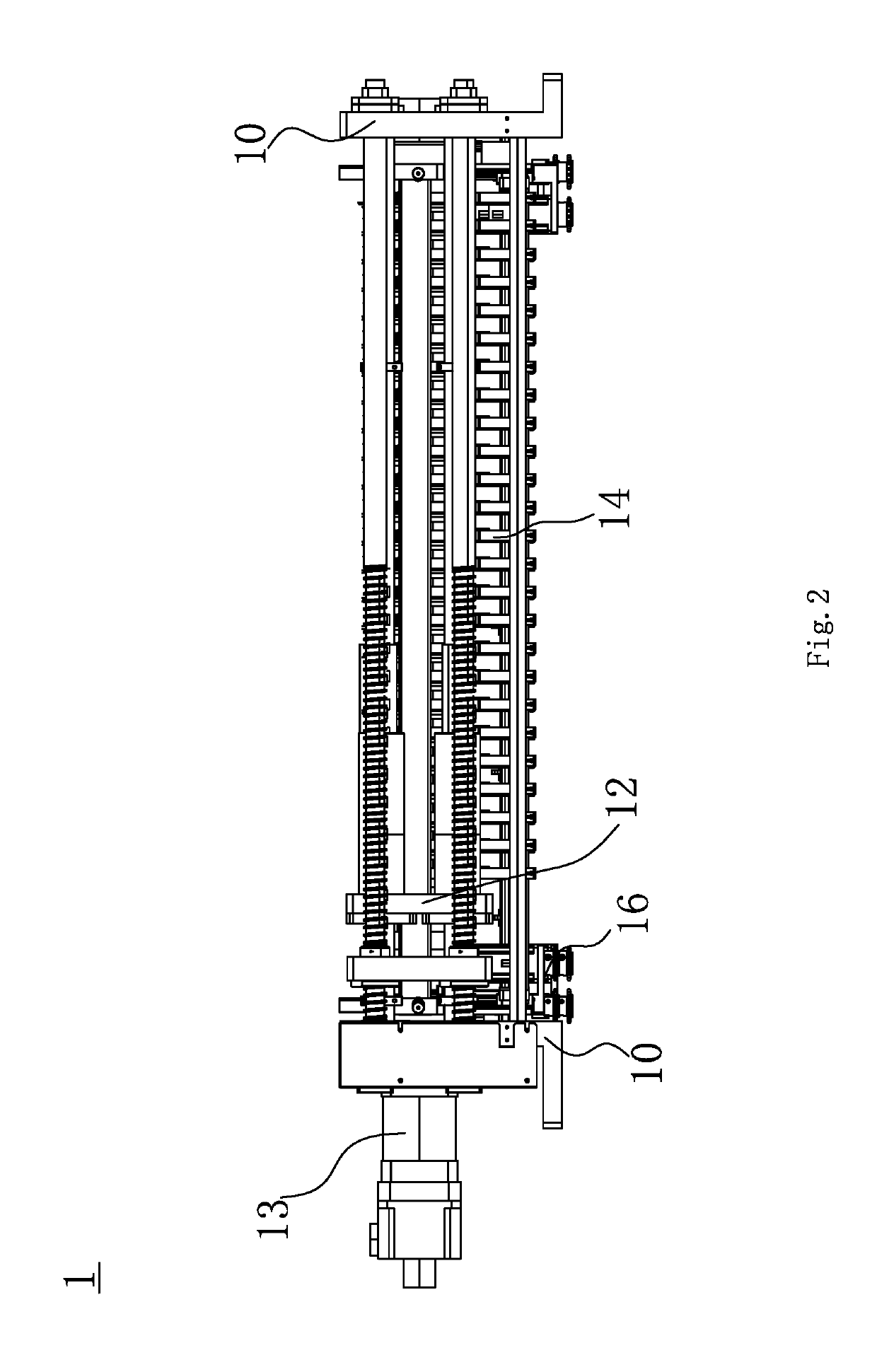

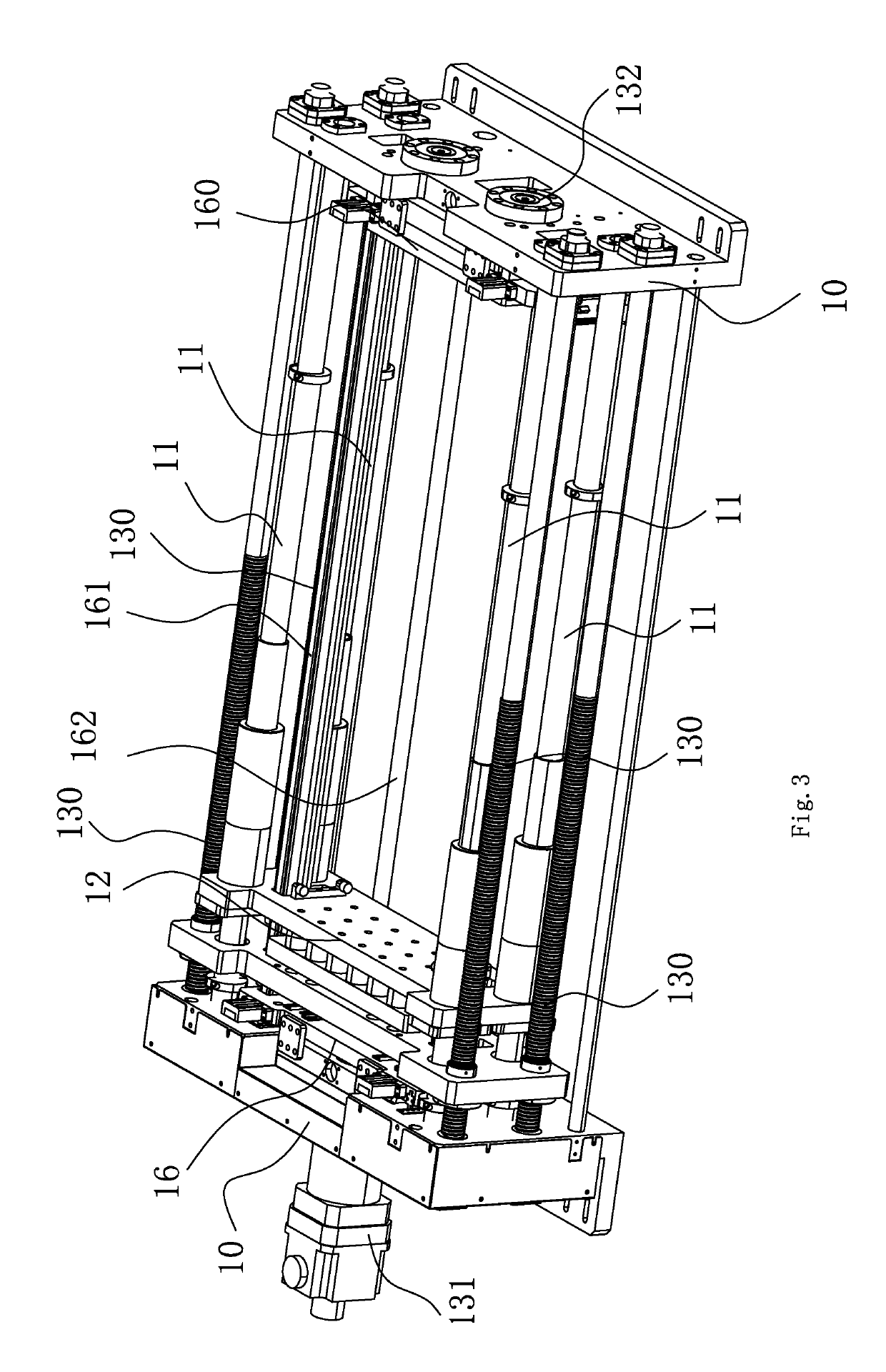

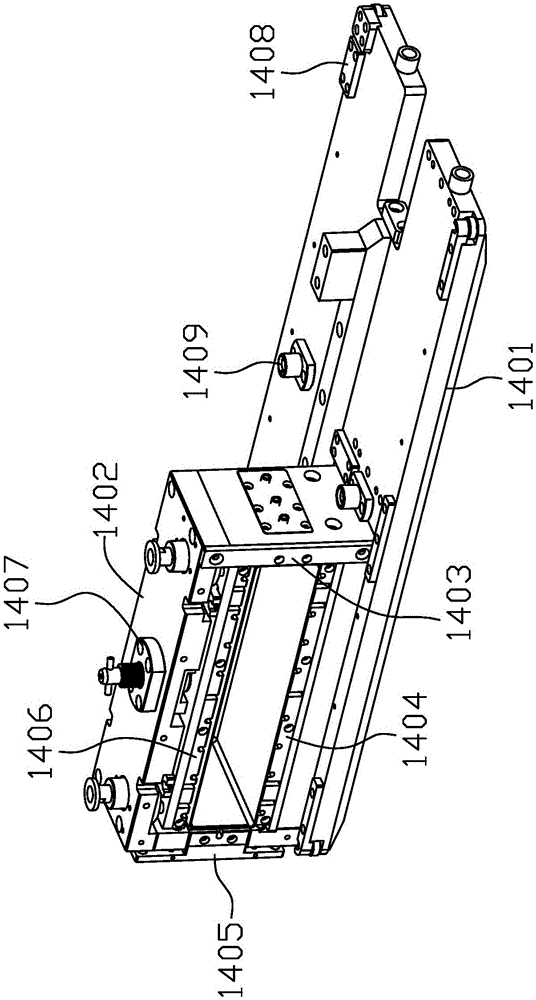

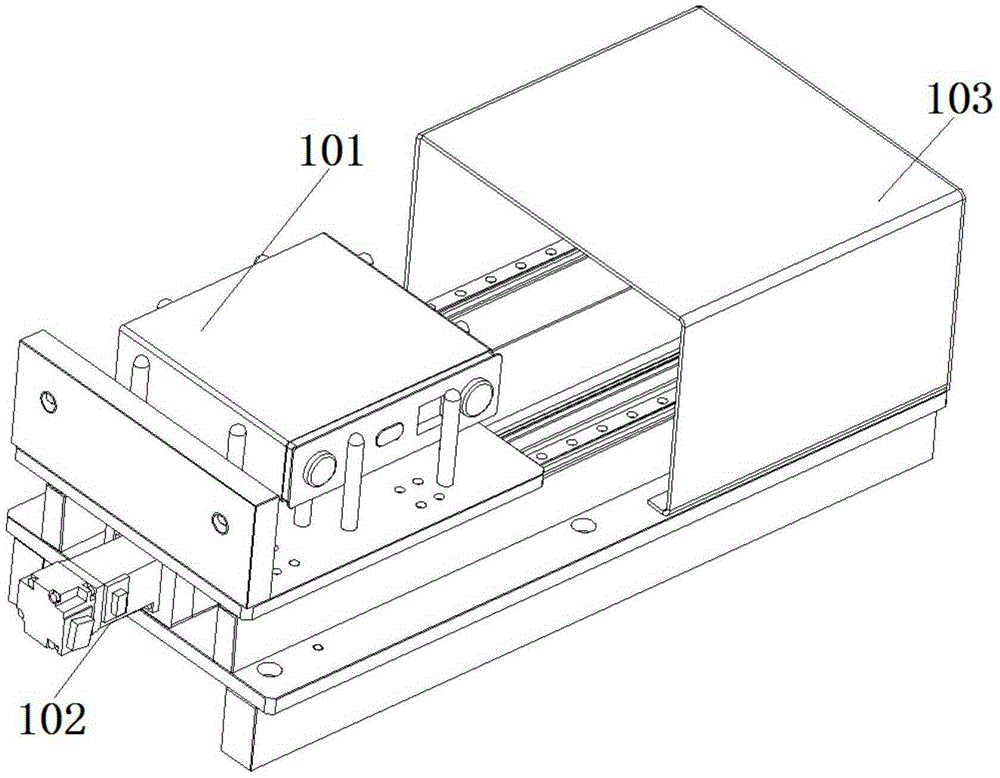

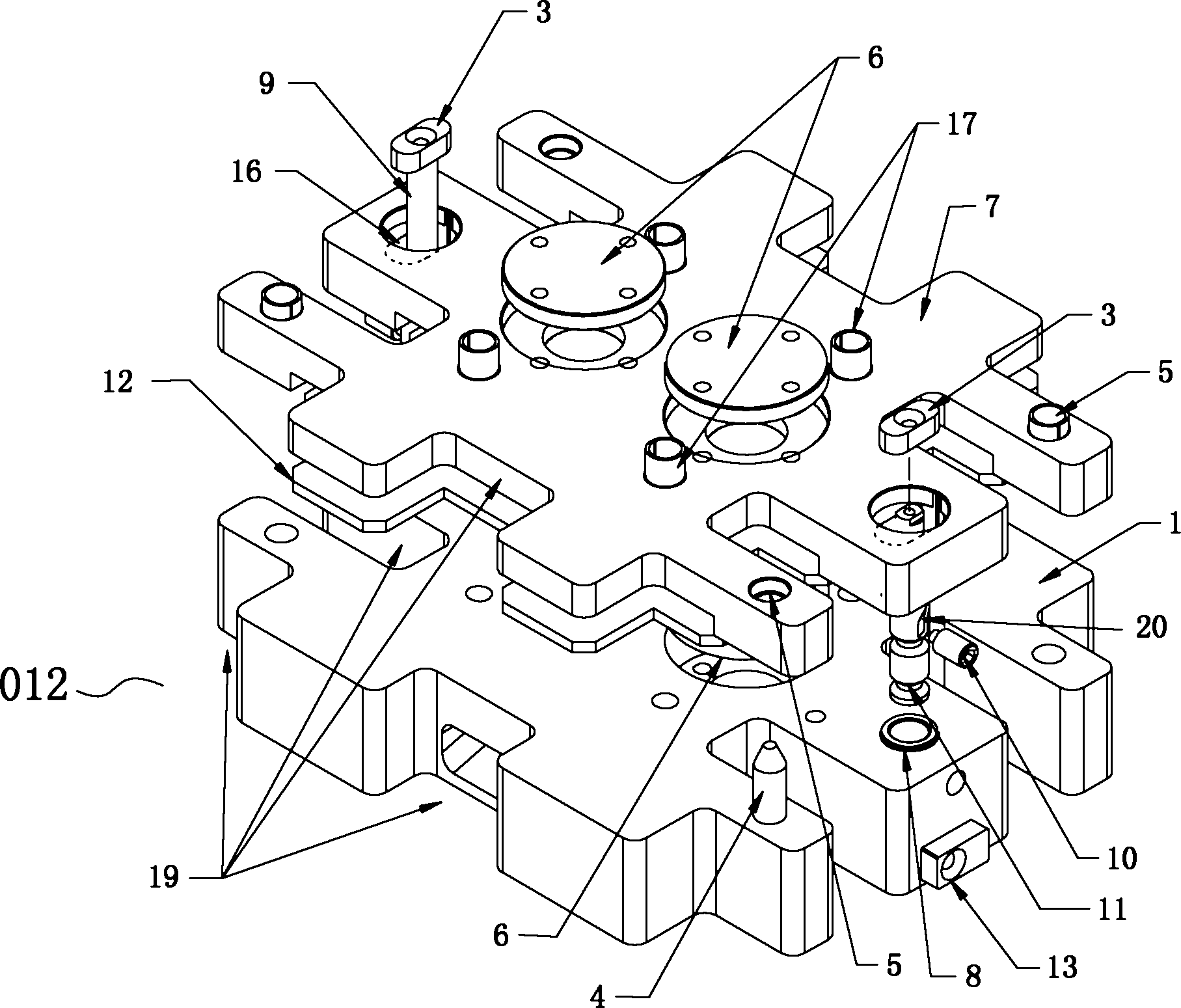

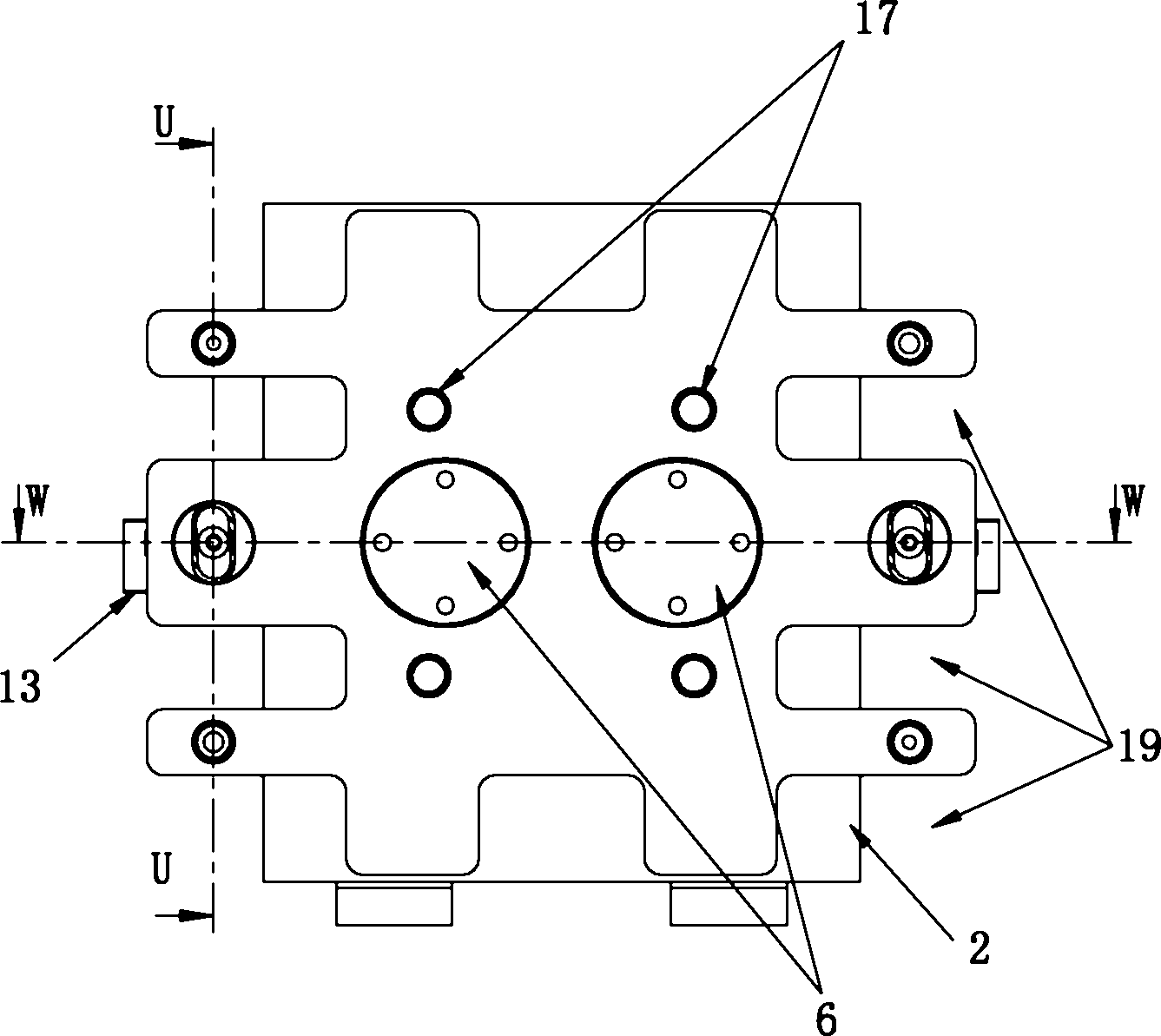

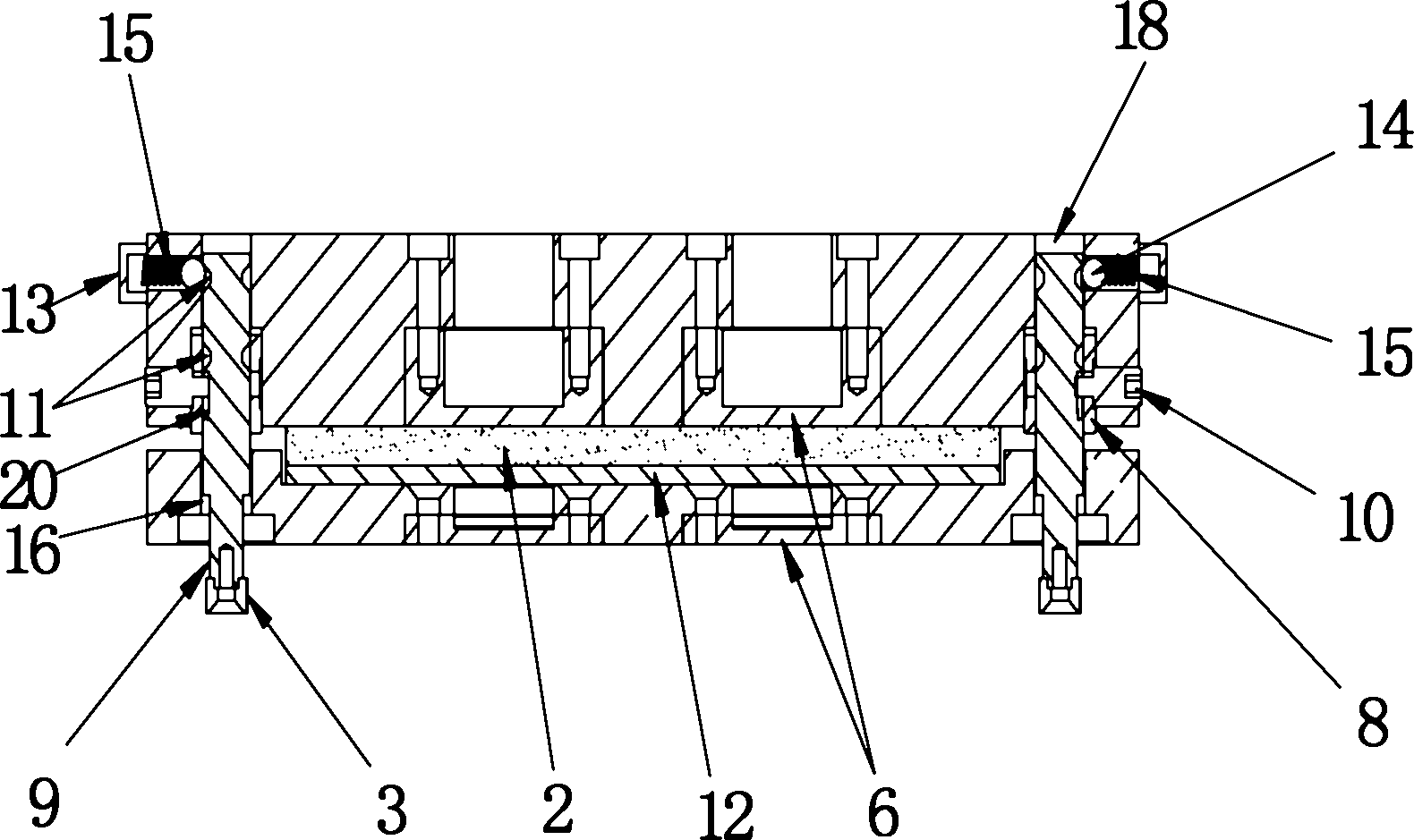

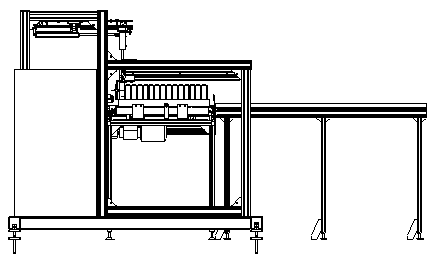

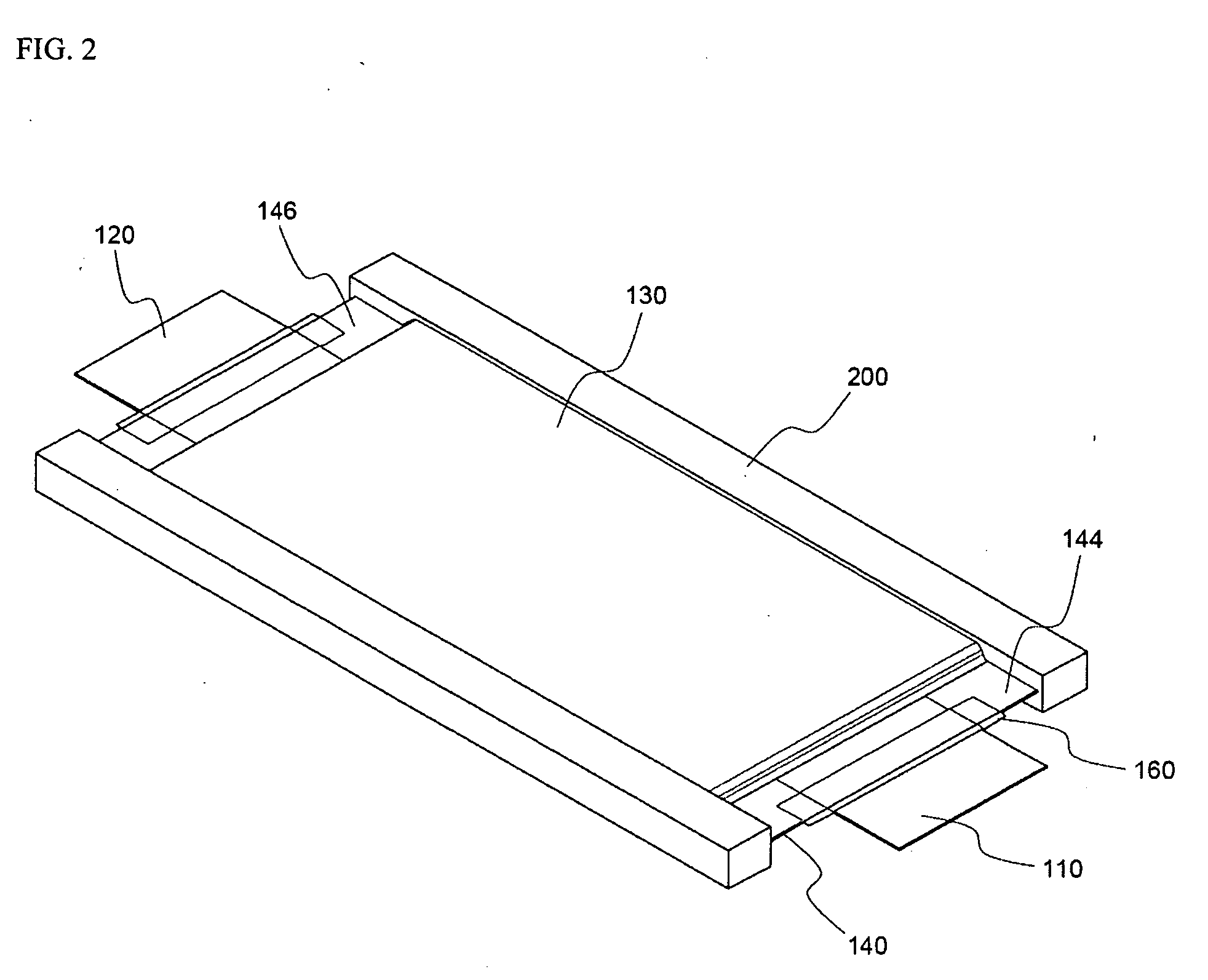

Lithium Battery Formation Fixture and Automation Battery Formation Equipment

InactiveUS20190157708A1Improve formation efficiencyLow costAssembling battery machinesFinal product manufactureElectrical batteryEngineering

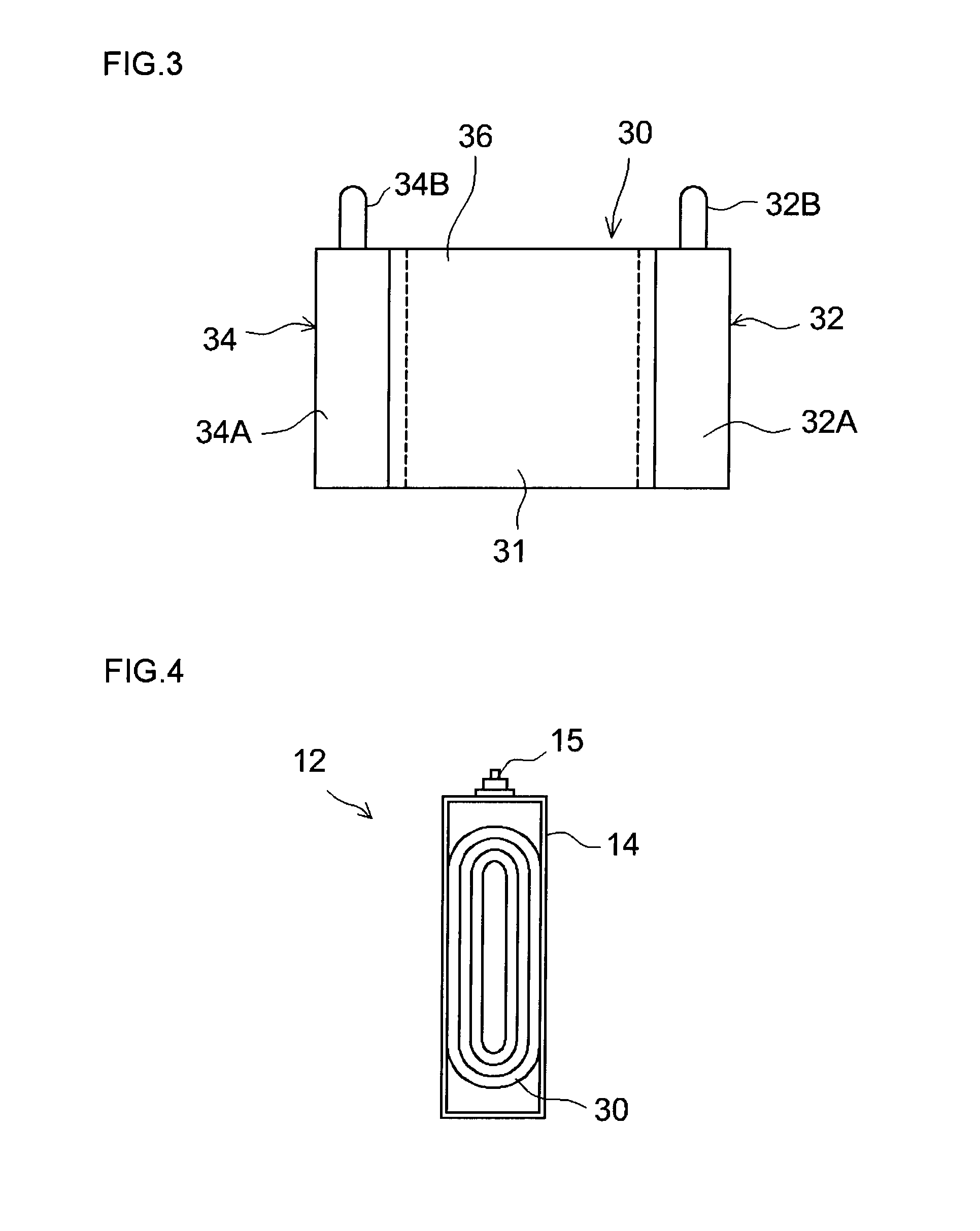

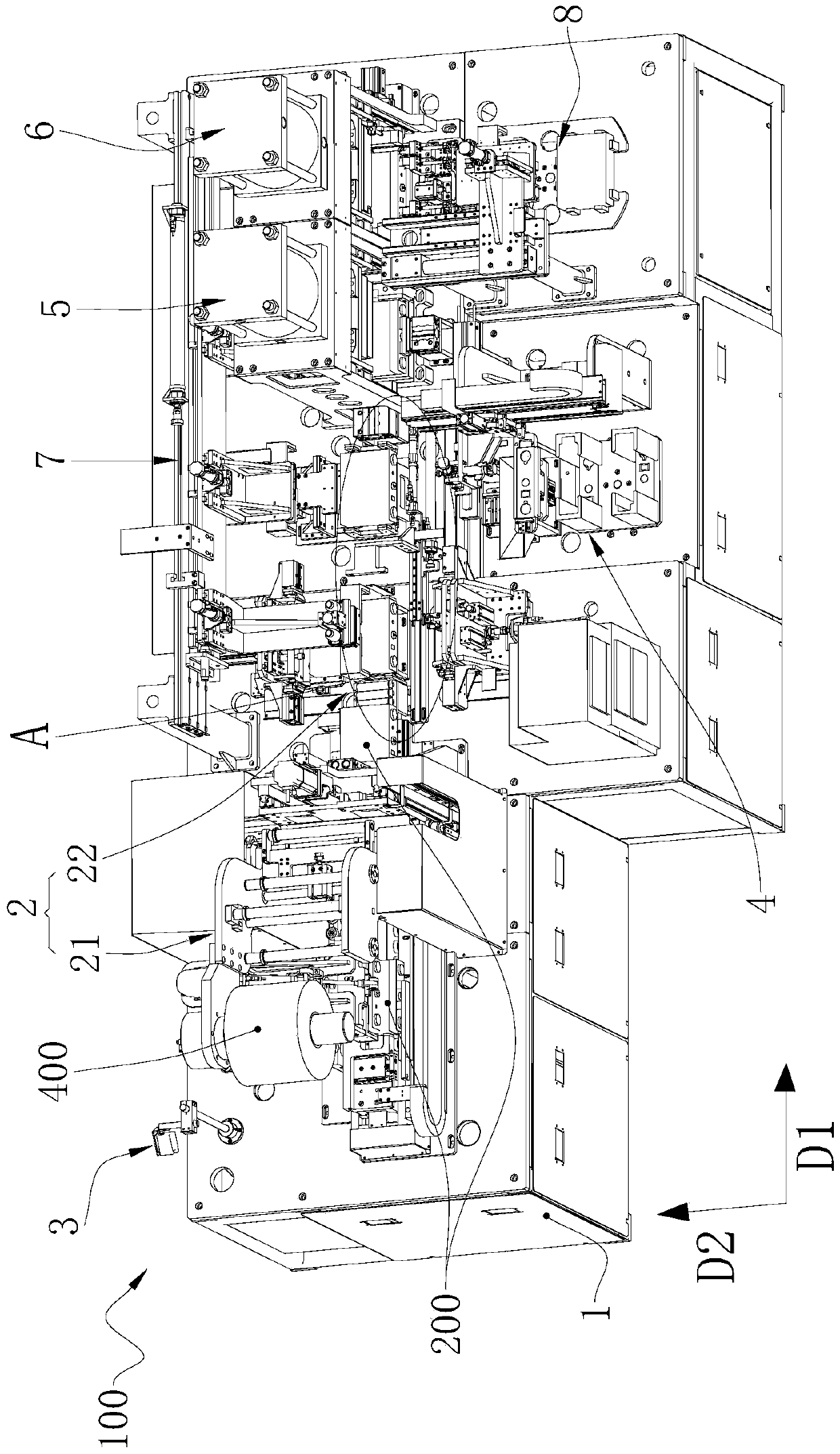

The invention discloses a lithium battery information fixture, which includes two relatively arranged supporting seats, a plurality of guide pillars arranged between the supporting seats, a compressing assembly arranged on the guide pillars, and a pushing mechanism arranged on the supporting seats driving the compression assemblies to slide along the guide pillars. A plurality of forming laminate assemblies are arranged between the two supporting seats, PCB board assemblies bonding to the electrode ears of the lithium batteries are arranged on the forming laminate assemblies, and adjusting laminates are arranged between the two supporting seats to adjust upper and lower position of the forming laminate assemblies and the PCB board assemblies. When the lithium batteries are placed between the adjacent laminates, the center position of the lithium batteries and the PCB board assemblies can be adjusted, thus realizing the formation of lithium batteries with different polar ear positions.

Owner:SHENZHEN NEWPOWER AUTOMATION EQUIP CO LTD

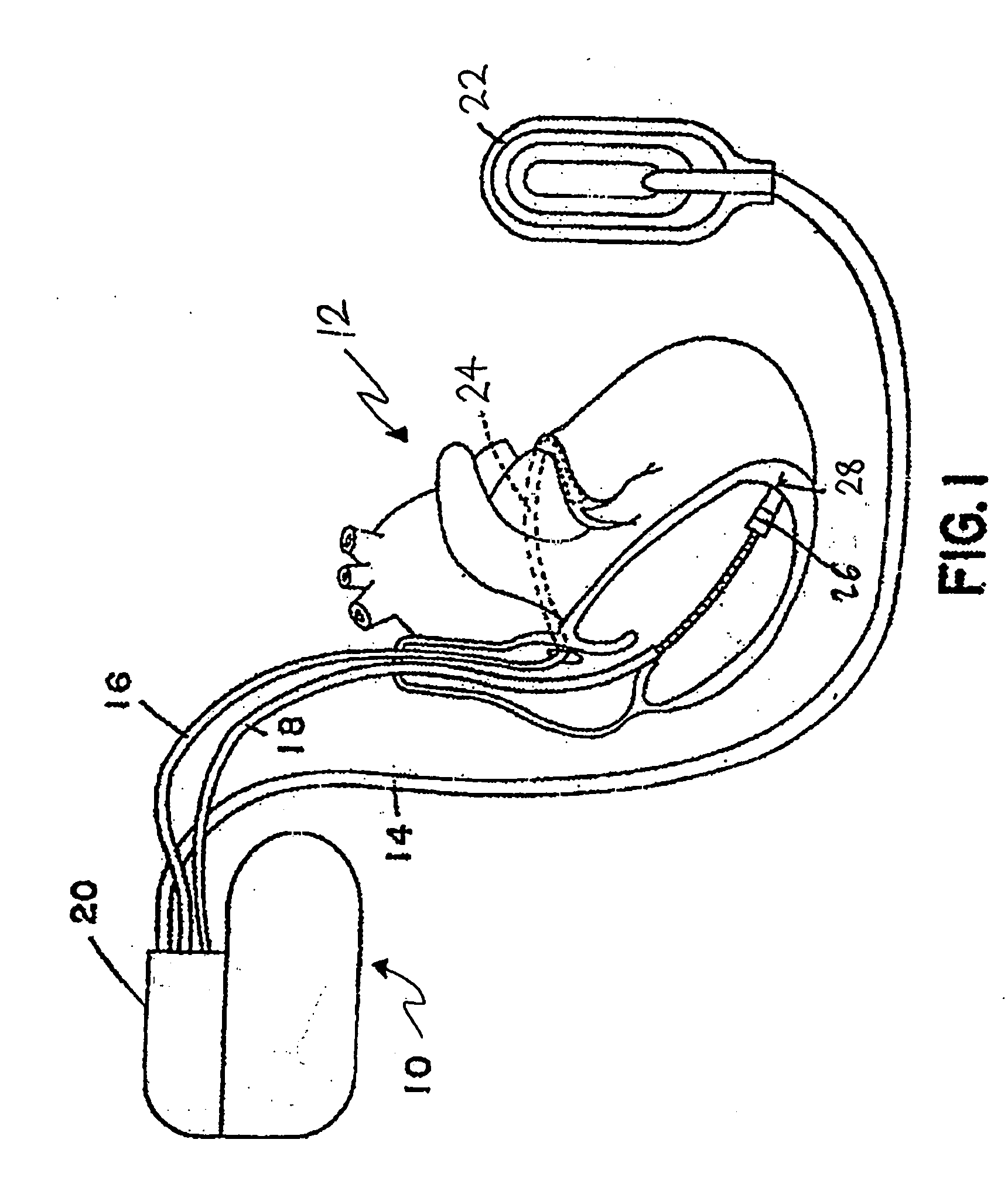

Welding methods and apparatus for batteries

InactiveUS20060222942A1Low variabilityHigh yieldAssembling battery machinesLarge-sized flat cells/batteriesEngineeringElectrochemical cell

Embodiments of the invention provide an electrochemical cell including an electrode assembly having one or more of the electrodes being coupled to a feedthrough assembly. The one or more electrodes each include a connection tab. The connection tab extends a distance from separation material between the one or more electrodes (e.g., anode and cathode). The connection tab is provided to contact (e.g., electrically connected) a feedthrough pin of the feedthrough assembly by laser welding. The feedthrough pin with respect to the connection tab is oriented in at least one position lying within a 90 degree orientation on the connection tab. The feedthrough pin is coupled to the connection tab by laser welding.

Owner:MEDTRONIC INC

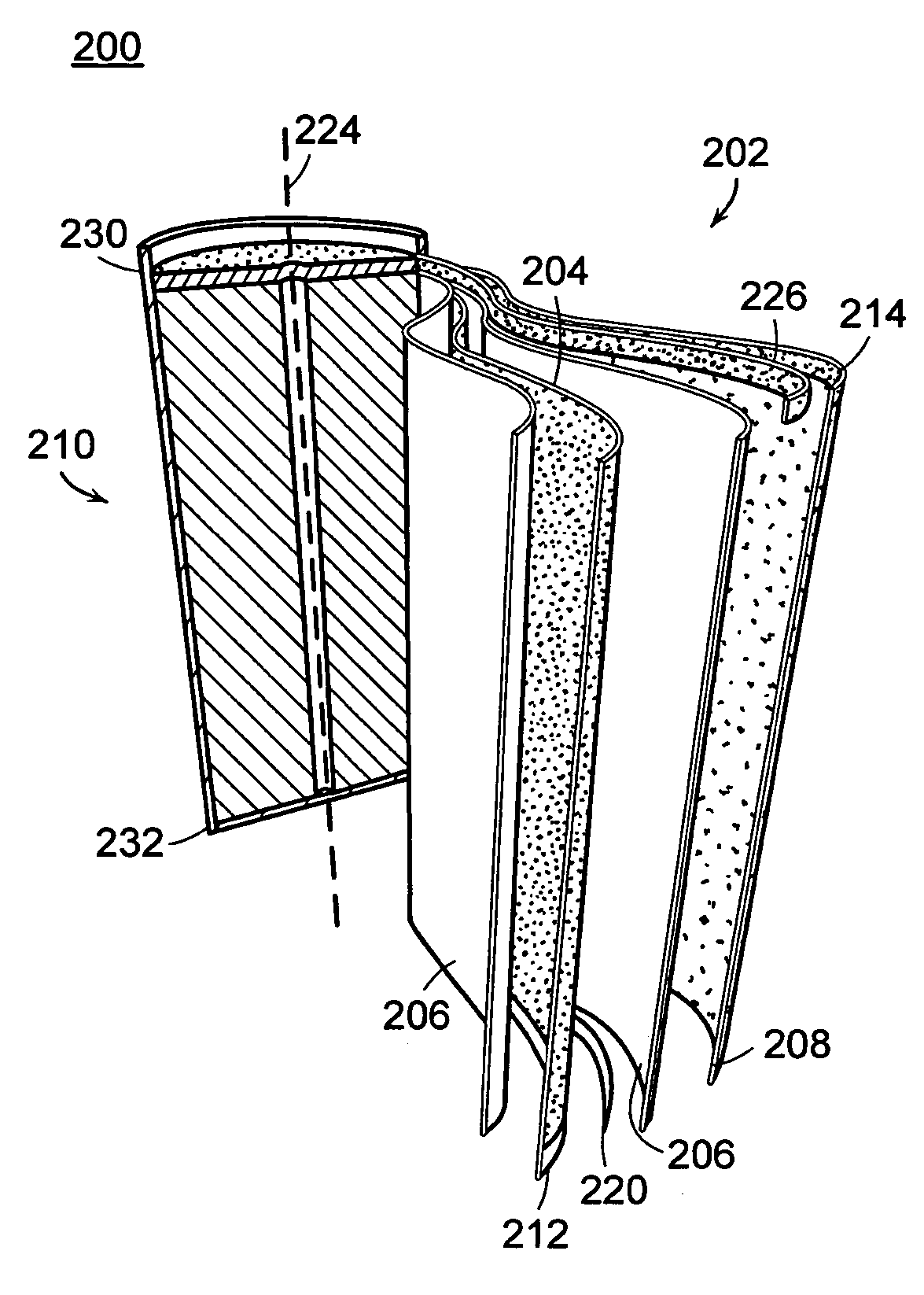

Low impedance layered battery apparatus and method for making the same

ActiveUS20050277019A1Primary cell to battery groupingAssembling battery machinesEngineeringExternal circuit

An electrochemical storage device is described, and a method for making the same. In some aspects, a guidewire is co-wound with sheet or ribbon-like electrode materials so that contact is made between the guidewire and collector extensions of the electrode materials thereby forming an endcap with low impedance and high thermal sinking capabilities. In one embodiment, the storage device includes a negative electrode sheet have an edge which is substantially free of electrode active material, a positive electrode sheet have an edge which is substantially free of electrode active material, a first conductive guidewire disposed adjacent to the edge of the negative electrode sheet which is substantially free of electrode active material, and a second conductive guidewire disposed adjacent to the edge of the positive electrode sheet which is substantially free of electrode active material. The first conductive guidewire and the edge of the negative electrode sheet which is substantially free of electrode active material define a first electrode endcap and the second conductive guidewire and the edge of the positive electrode sheet which is substantially free of electrode active material define a second electrode endcap. The electrode endcaps are coupled to terminals of the storage device, which are capable of being connected to the terminals of an external circuit.

Owner:LITHIUM WERKS TECH BV +1

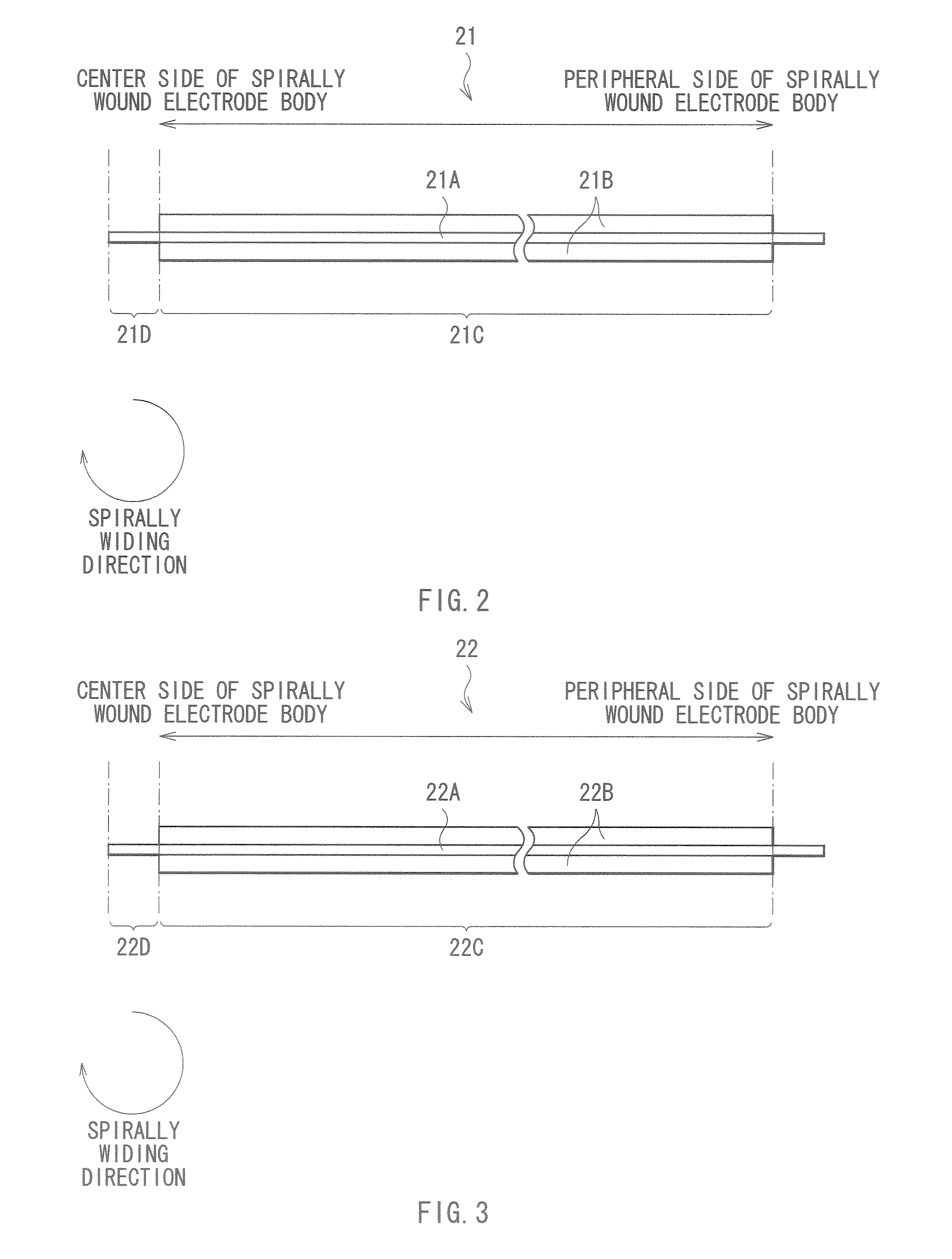

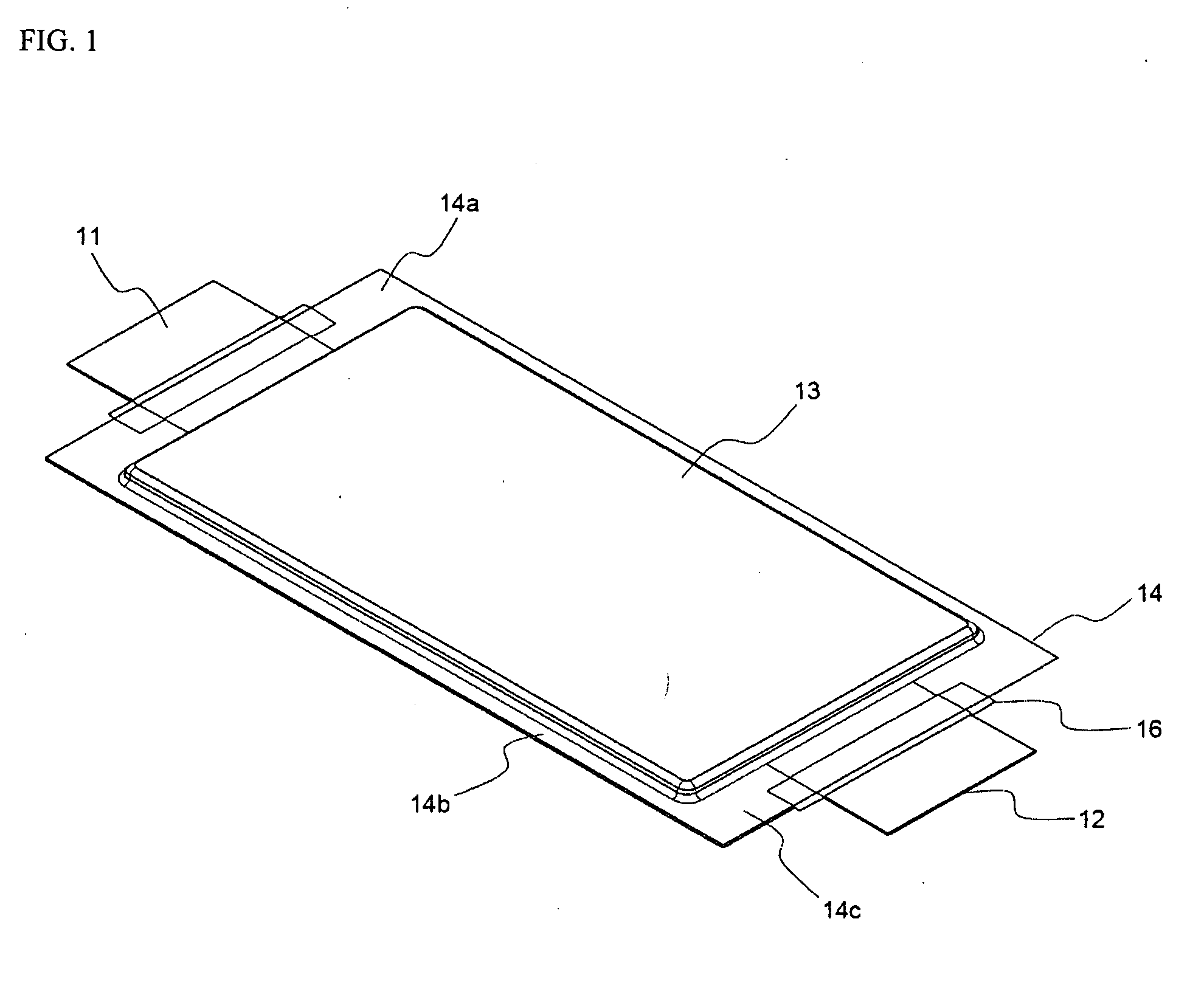

Electrode assembly manufacturing method including separator cutting process

ActiveUS20150033547A1Efficient cuttingAvoid damageElectrode manufacturing processesAssembling battery machinesEngineeringElectrode material

Provided is an electrode assembly manufacturing method including a process of cutting a separator included in an electrode assembly to have a margin protruding from an electrode plate. The method includes a first process of manufacturing one type of basic unit sheets having a structure in which electrode materials and separator materials, which are the same in number, are alternately stacked, or two or more types of basic unit sheets having a structure in which electrode materials and separator materials, which are the same in number, are alternately stacked, and a second-A process of cutting a portion of a margin area of the separator materials, which are not covered with the electrode materials, such that the separator materials of the basic unit sheets protrude over a specific distance from edges of the electrode materials.

Owner:LG ENERGY SOLUTION LTD

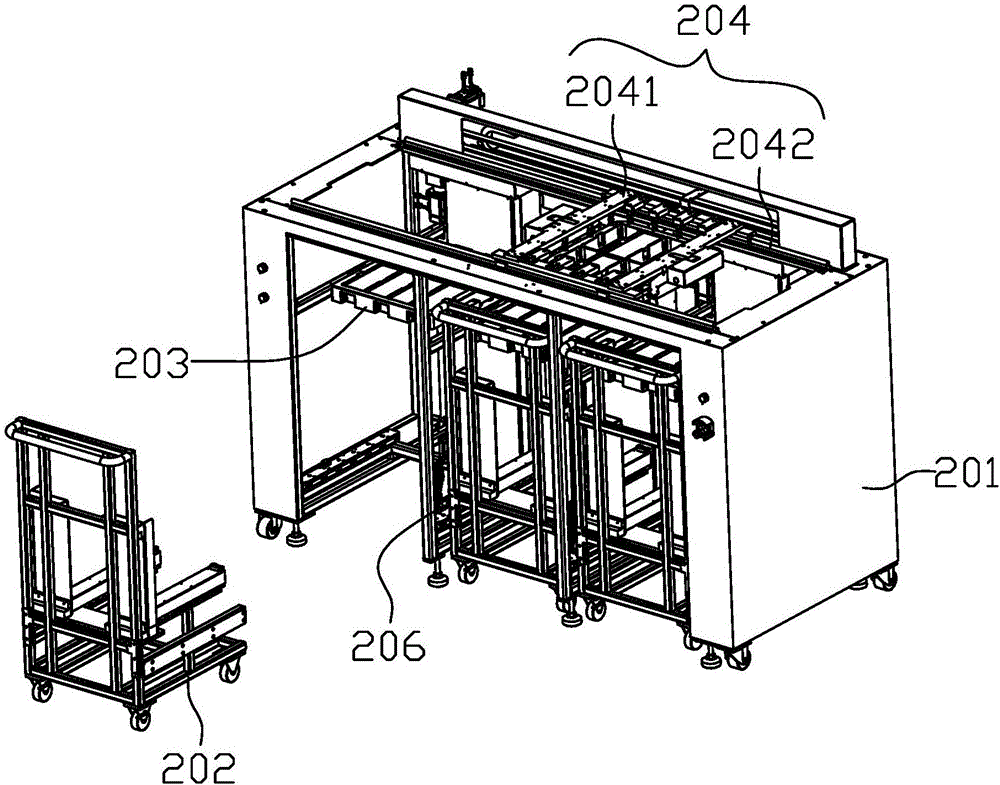

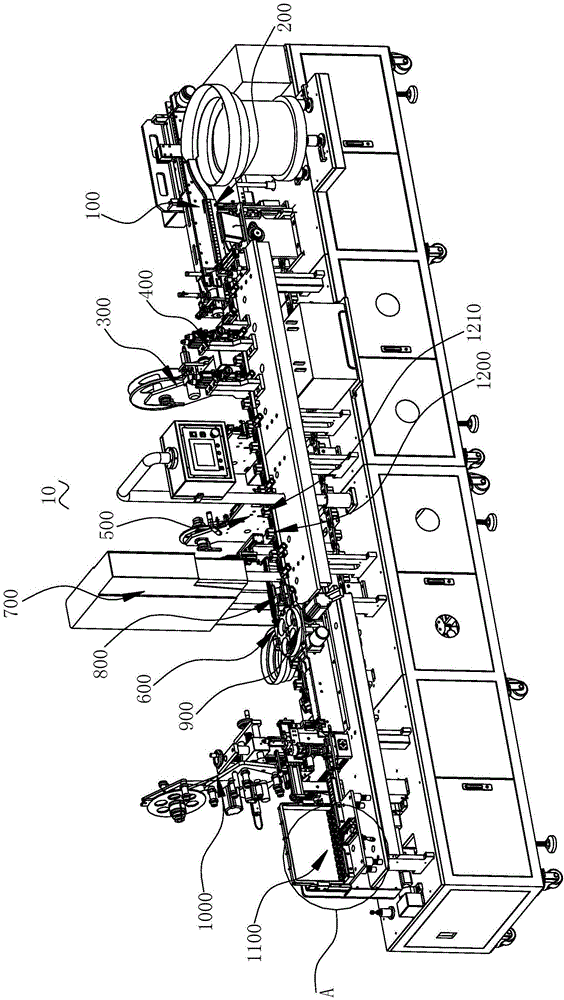

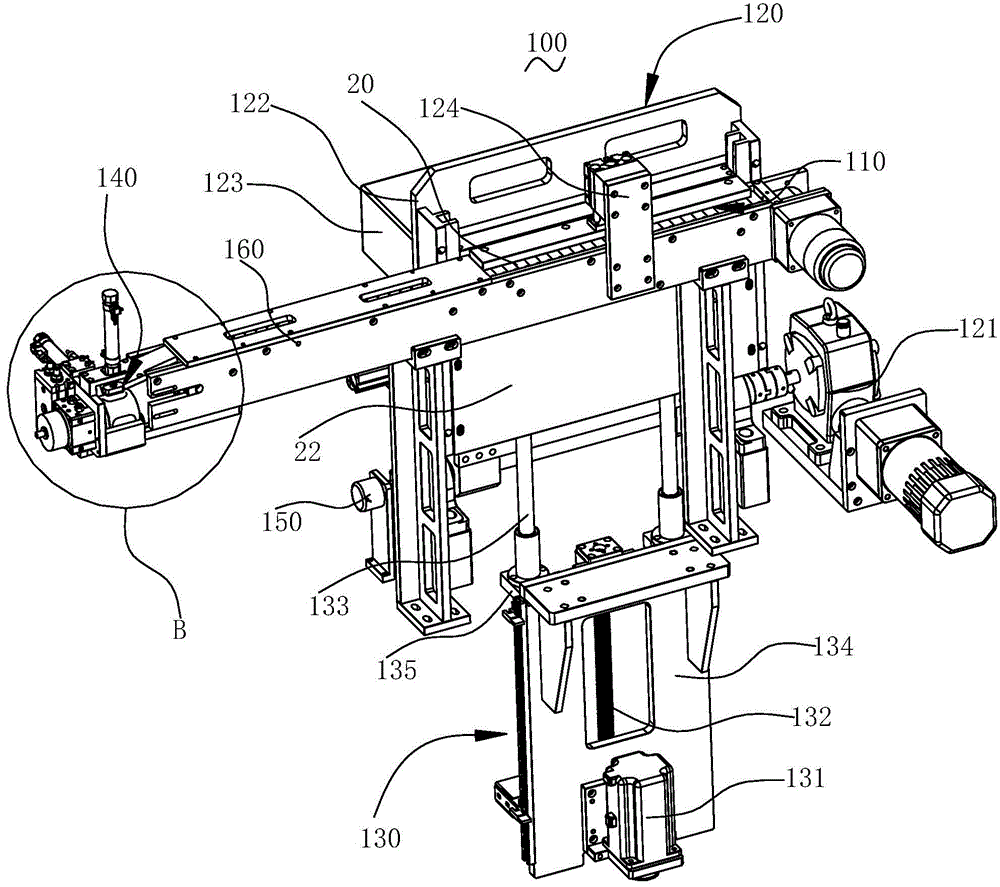

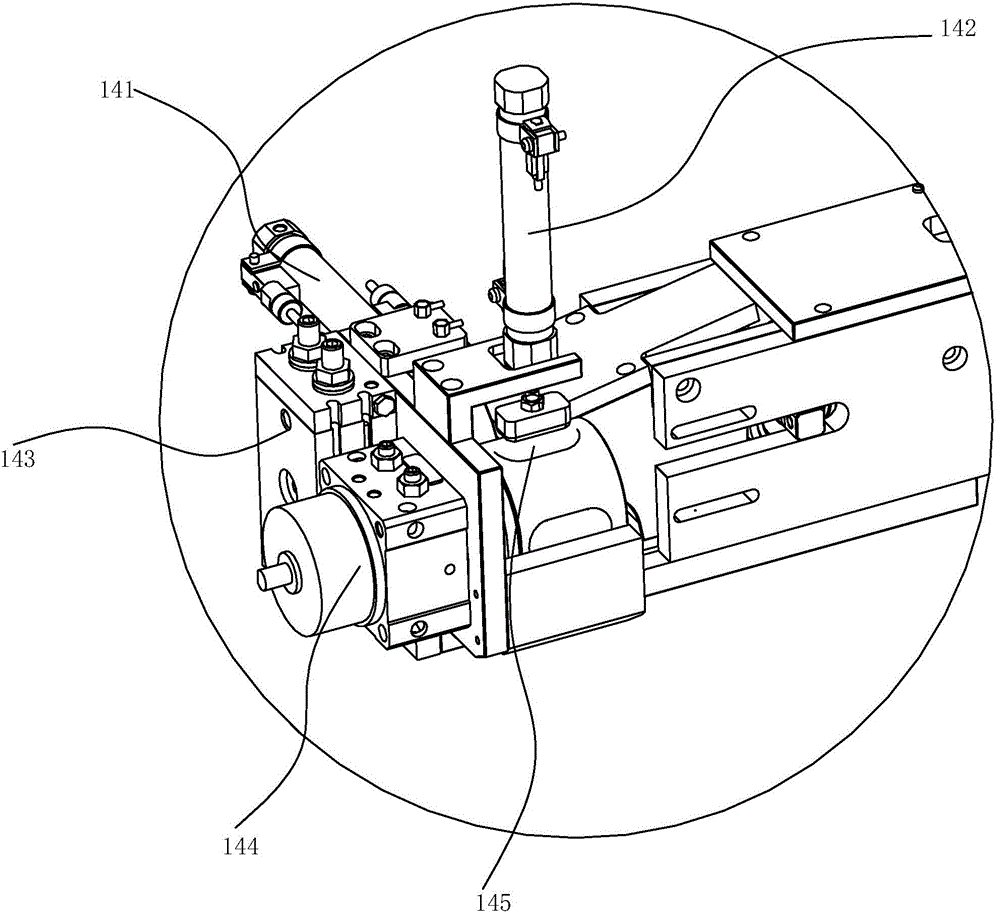

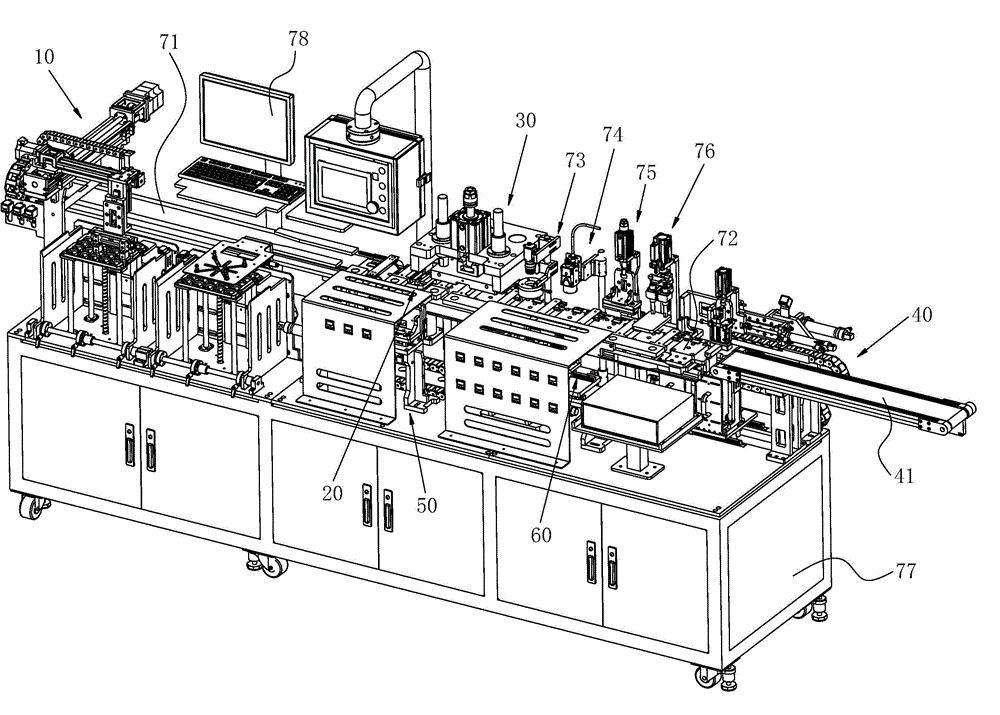

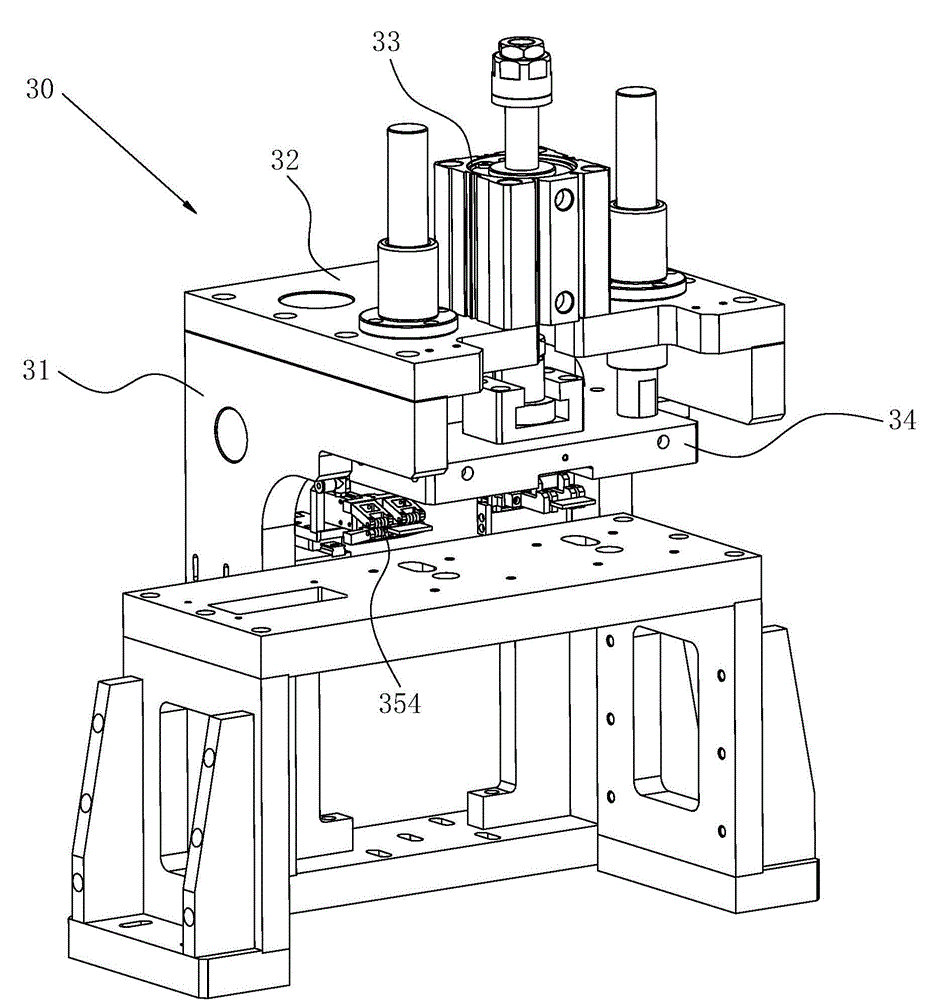

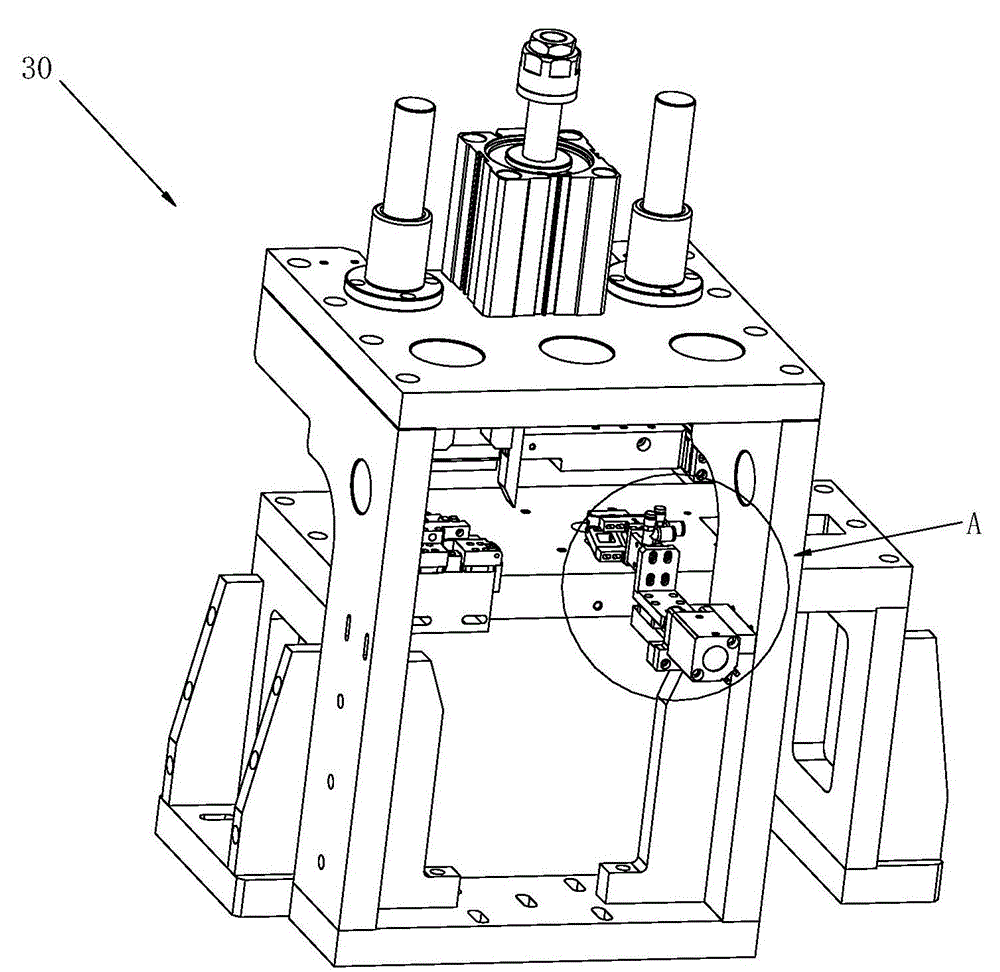

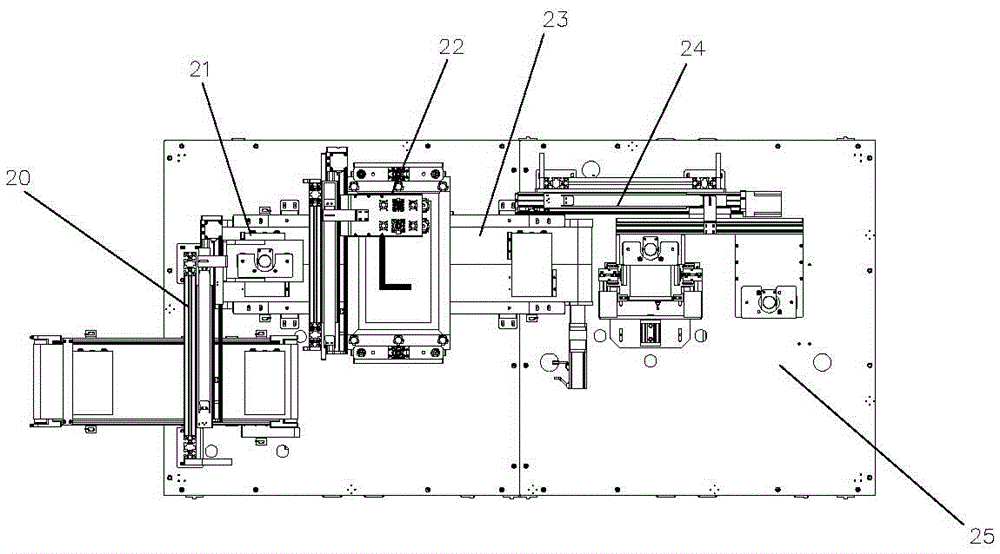

Automatic assembly line for assembling battery cell and shell

ActiveCN106129447AIncrease production capacityLow costAssembling battery machinesFinal product manufactureAssembly lineEngineering

The present invention relates to the field of automation equipment, and discloses an automatic assembly line for assembling a battery cell and a shell. The automatic assembly line comprises a shell feeding module, a shell transferring module, a cell feeding module, a cell transferring module, a entering-shell module, a welding module and a discharging module. The shell transferring module is used for movement of a shell between the shell feeding module and the entering-shell module. The cell transferring module is used for movement of a cell between the cell feeding module and the entering-shell module. The entering-shell module is used for assembling of the cell and the shell. The assembled cell and shell move to the welding module to be welded. The discharging module performs discharging operation. According to the automatic assembly line, feeding of the shell and the cell, assembling of the shell and the cell, welding of the shell and the cell, and discharging of finished products can all be performed, and the whole process is completed automatically without manual intervention, so that manpower is saved effectively, the production efficiency and the percent of pass of the products are improved, and the automatic assembly line is of positive significance to reduction of enterprise cost and improvement of enterprise production capacity.

Owner:SHENZHEN HYMSON LASER INTELLIGENT EQUIP CO LTD

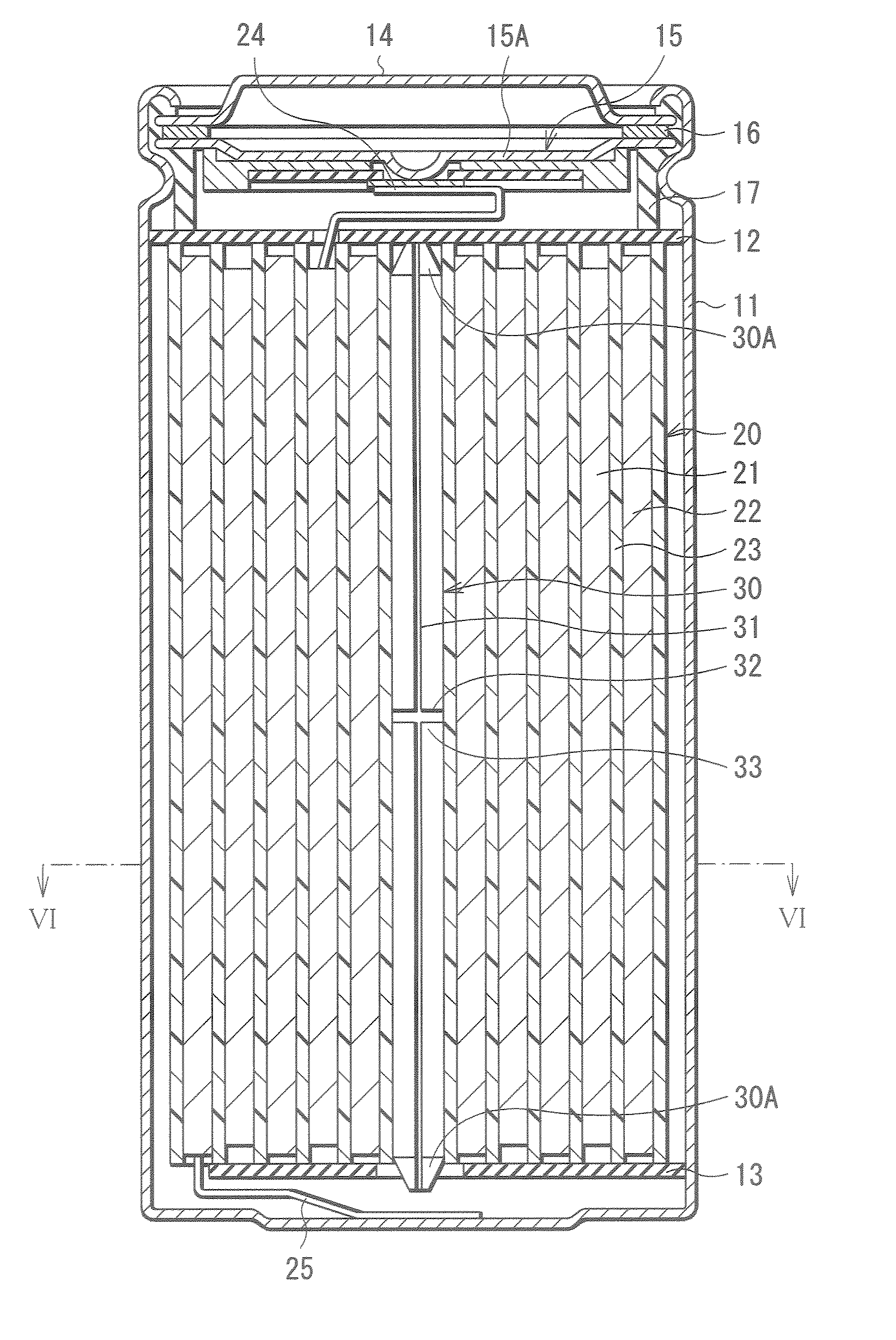

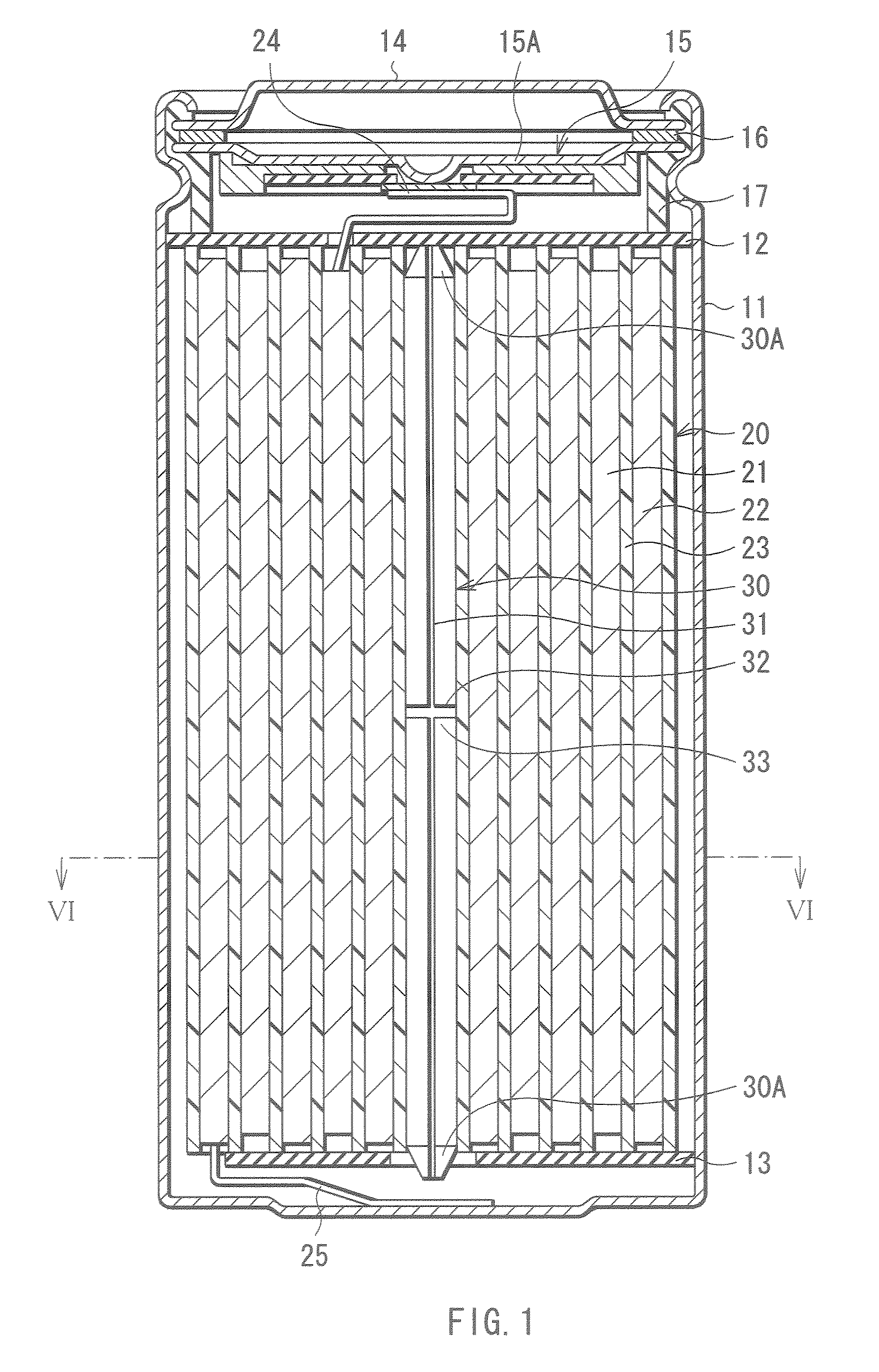

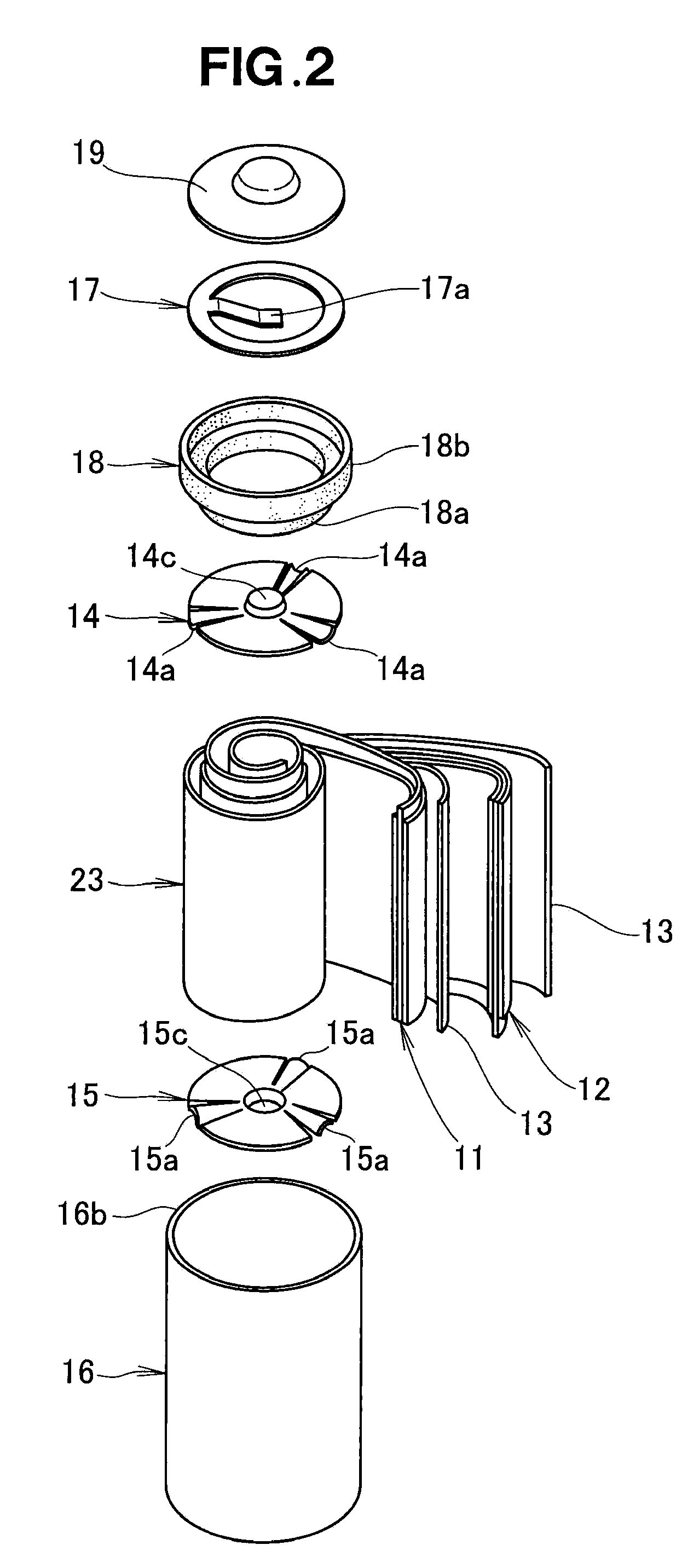

Battery and Center Pin

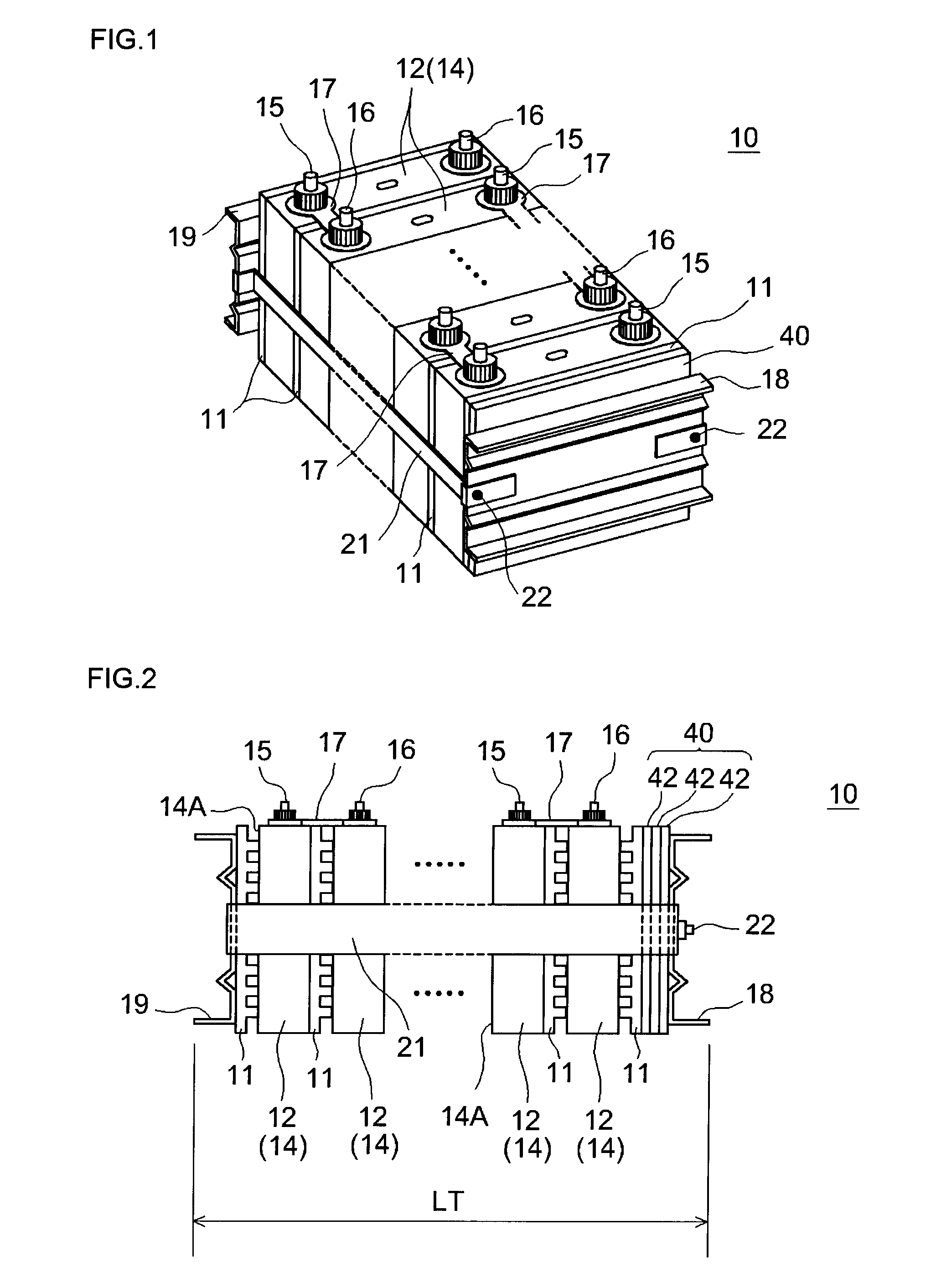

ActiveUS20070269711A1Improve securityLarge energy densityAssembling battery machinesCell electrodesEllipseEngineering

A battery with improved safety that can more surely short-circuit electrodes when flattened out by the external force is provided. A center pin (30) is inserted in the center of a spirally wound electrode body formed by layering and spirally winding a cathode and an anode with a separator in between. The center pin (30) has a cut line (31) provided in the longitudinal direction and a first cutout (32) vertically crossing the cut line (31). When flattened out by the external force, a corner (33) at an intersection of the cut line (31) and the first cutout (32) is projected, and short-circuit is surely generated. Further, it is preferable that the center pin (30) has a second cutout (34) in the direction perpendicular to the cut line (31) in a position facing the cut line (31) in the circumferential direction. It is also preferable that the center pin (30) has a cross sectional shape of an oval or an ellipse, and the cut line (31) is provided in a position where the diameter of the oval or the ellipse is the largest.

Owner:MURATA MFG CO LTD

Battery production equipment

ActiveCN104485472APrimary cell manufactureAssembling battery machinesUltrasonic weldingAssembly line

The invention discloses battery production equipment. The battery production equipment is used for assembling a cell on a tray into a glue shell, welding a resistor on a resistance material strap to the cell, pasting a buffer glue on the cell, covering the glue shell with a cover plate, welding the cover plate and the glue shell, screening good and bad products, pasting a brand on the surface of the glue shell, and panning finished products. The battery production equipment comprises a cell loading mechanism, a glue shell loading mechanism, a resistor conveying mechanism, a resistor welding mechanism, a buffer glue pasting mechanism, a cover plate assembling mechanism, an ultrasonic welding mechanism, a detection mechanism, a detaching mechanism, a brand pasting mechanism, a panning mechanism and an assembly line, the battery production equipment finishes the operations of loading the cell into the glue shell, welding the resistor, pasting the buffer glue, loading the cover plate and performing sealing weld, screening the good and bad products, pasting the brand and panning by virtue of the cell loading mechanism, the glue shell loading mechanism, the resistor conveying mechanism, the resistor welding mechanism, the buffer glue pasting mechanism, the cover plate assembling mechanism, the ultrasonic welding mechanism, the detection mechanism, the detaching mechanism, the brand pasting mechanism and the panning mechanism, so that the standardized, mechanized, and automated production is finished.

Owner:EVE ENERGY CO LTD

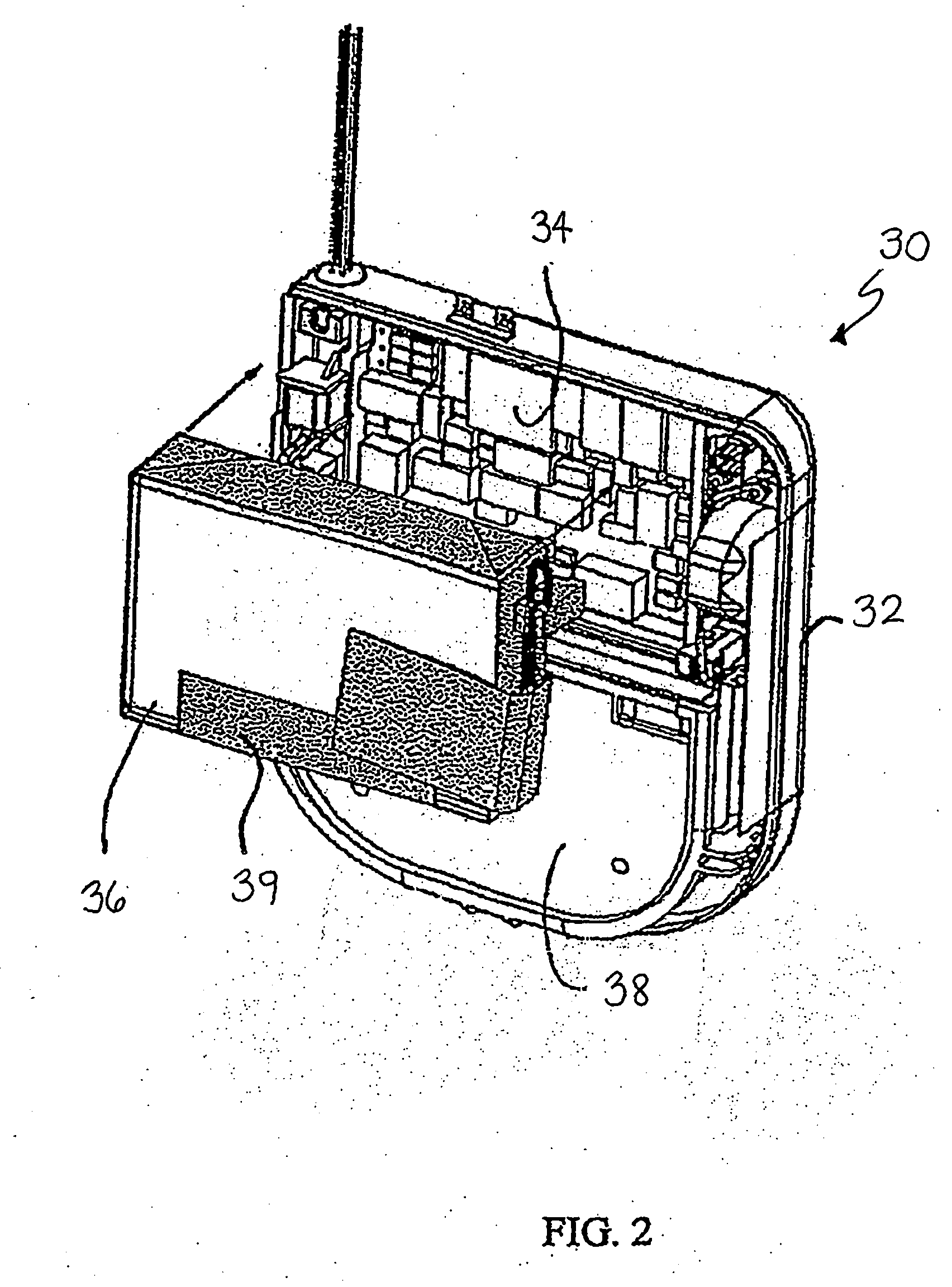

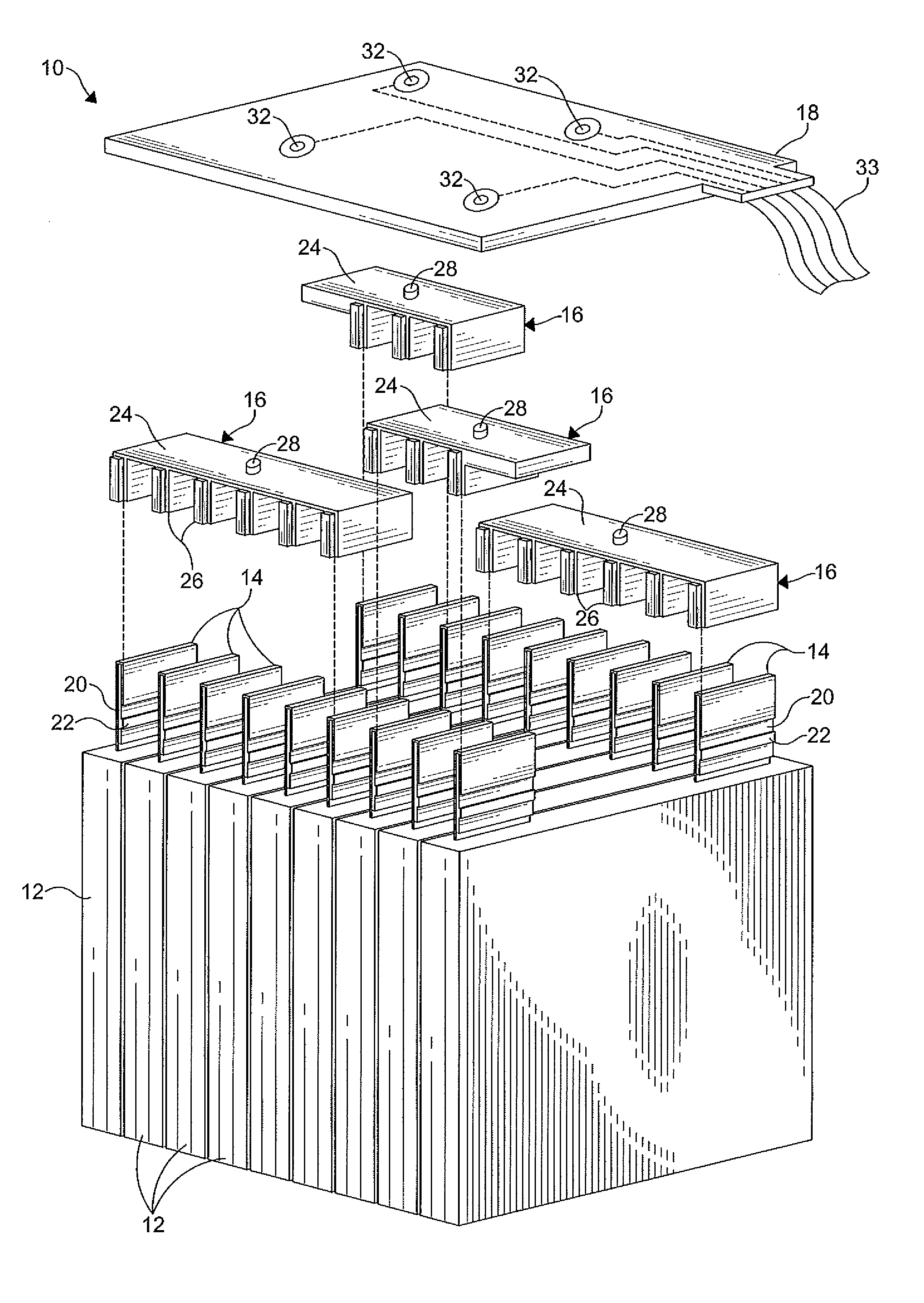

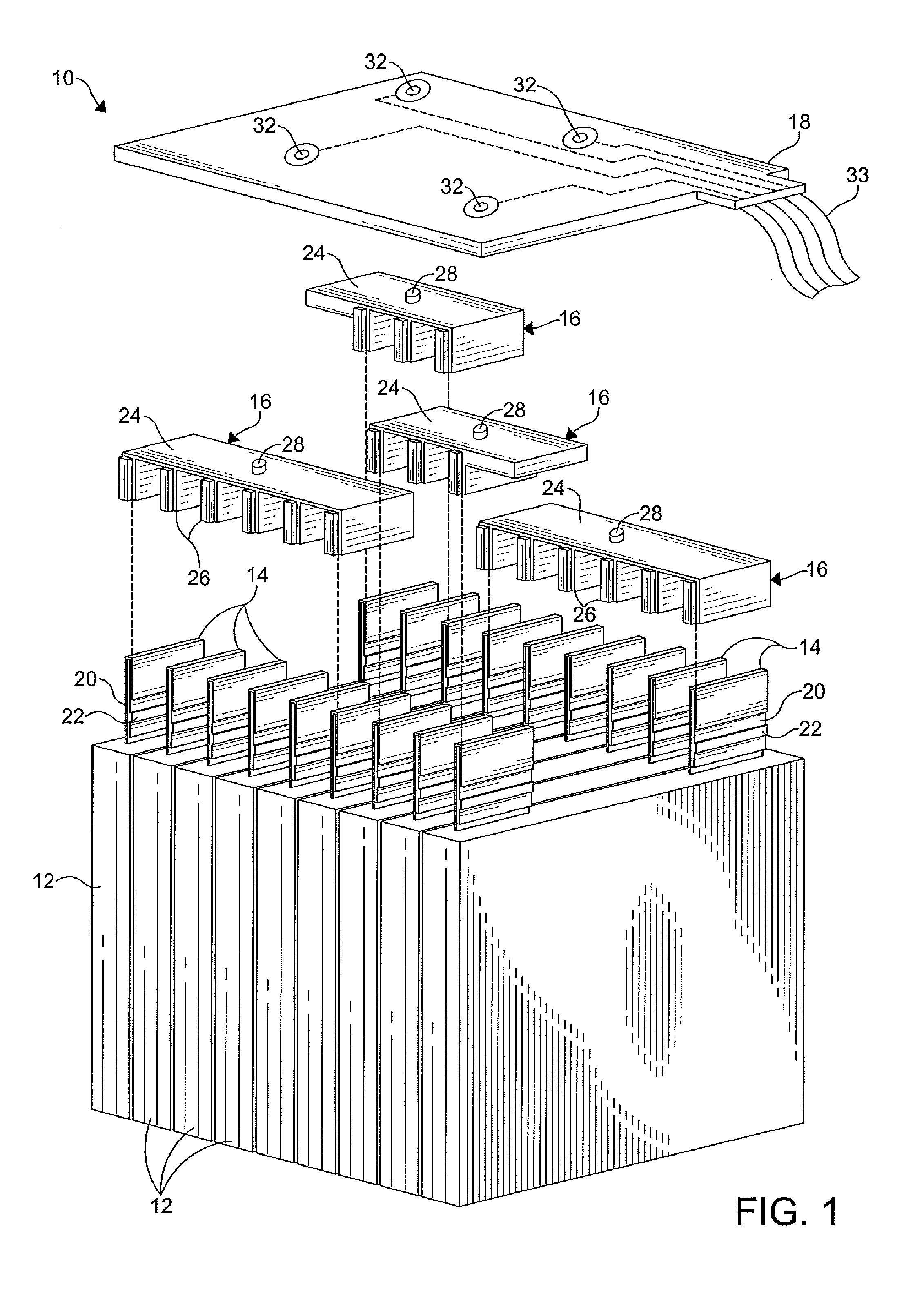

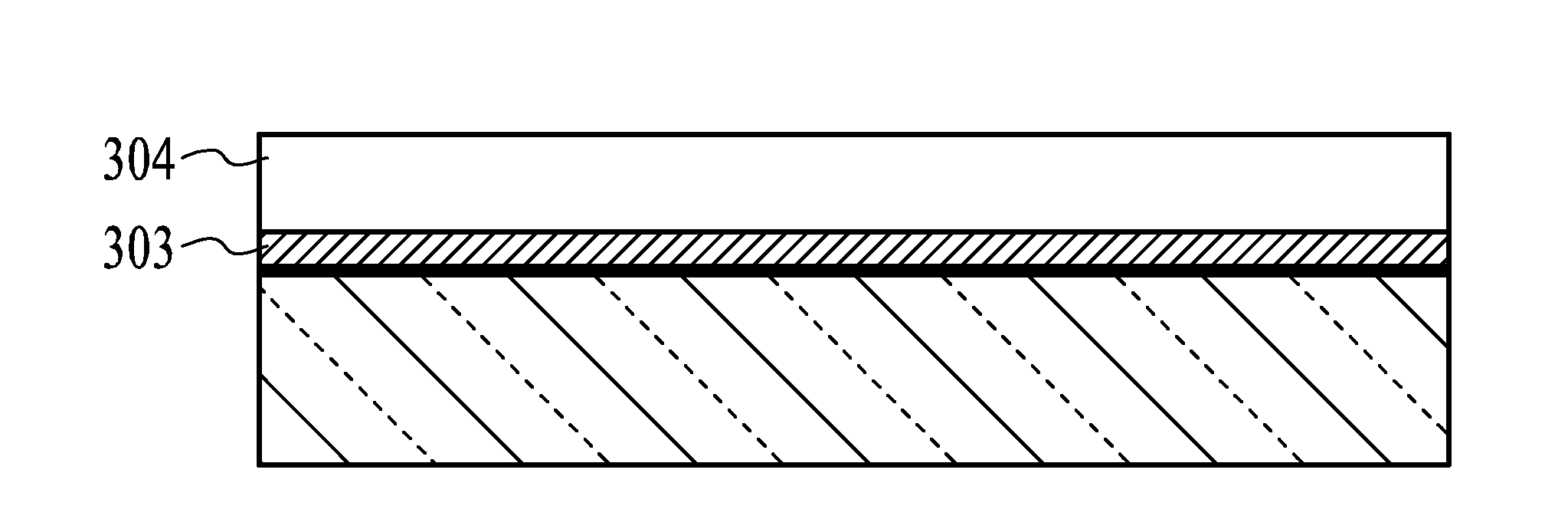

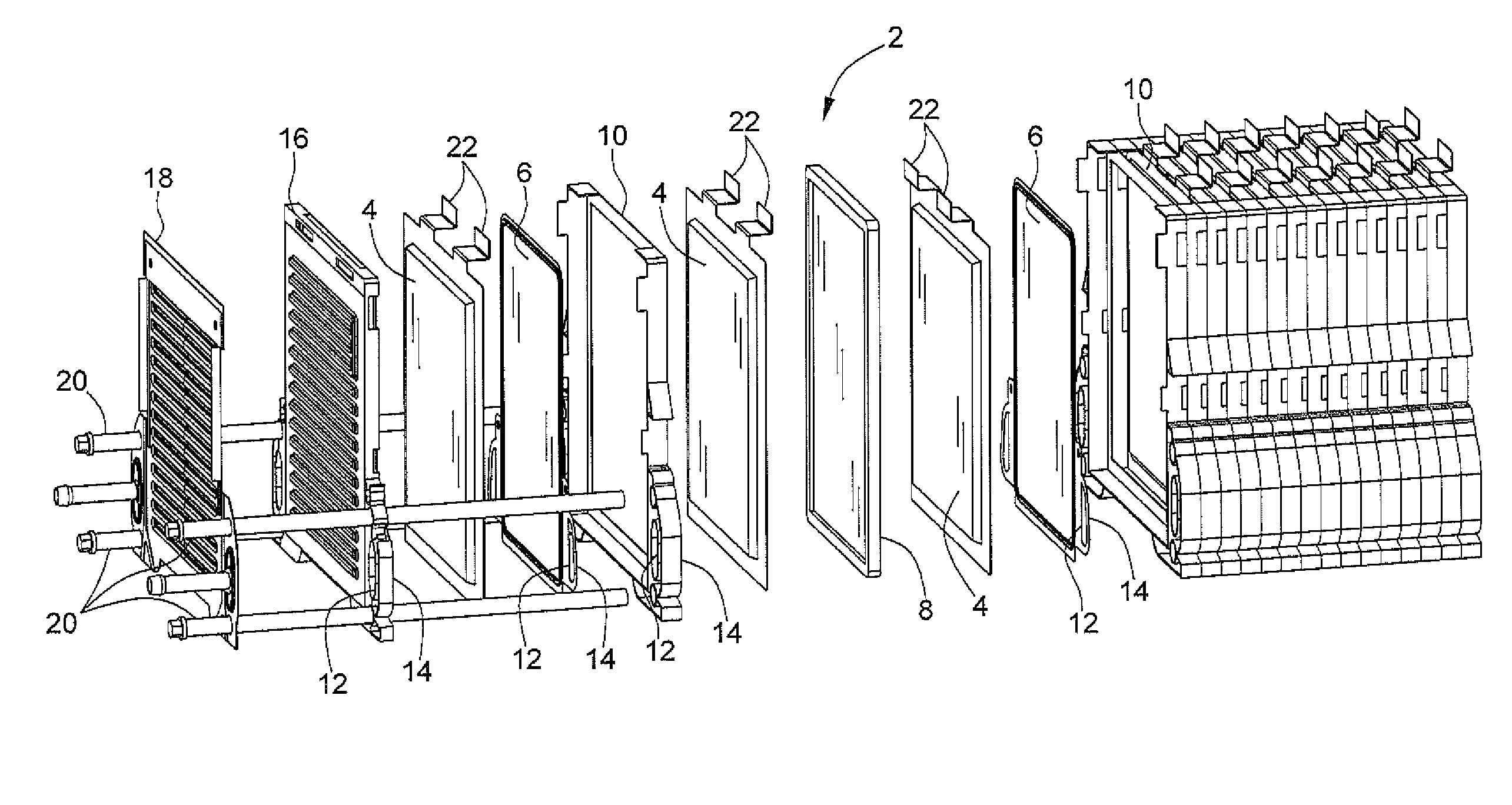

Reversible battery assembly and tooling for automated high volume production

ActiveUS20110229754A1Minimal effortMinimal costPrimary cell to battery groupingAssembling battery machinesBusbarEngineering

A battery module includes a plurality of battery cells arranged in a stack, each of the battery cells including a pair of spaced apart tabs extending therefrom, a rigid support plate coupled to at least one of the tabs, and a busbar coupled to at least one of the tabs of each of a pair of adjacent battery cells.

Owner:GM GLOBAL TECH OPERATIONS LLC

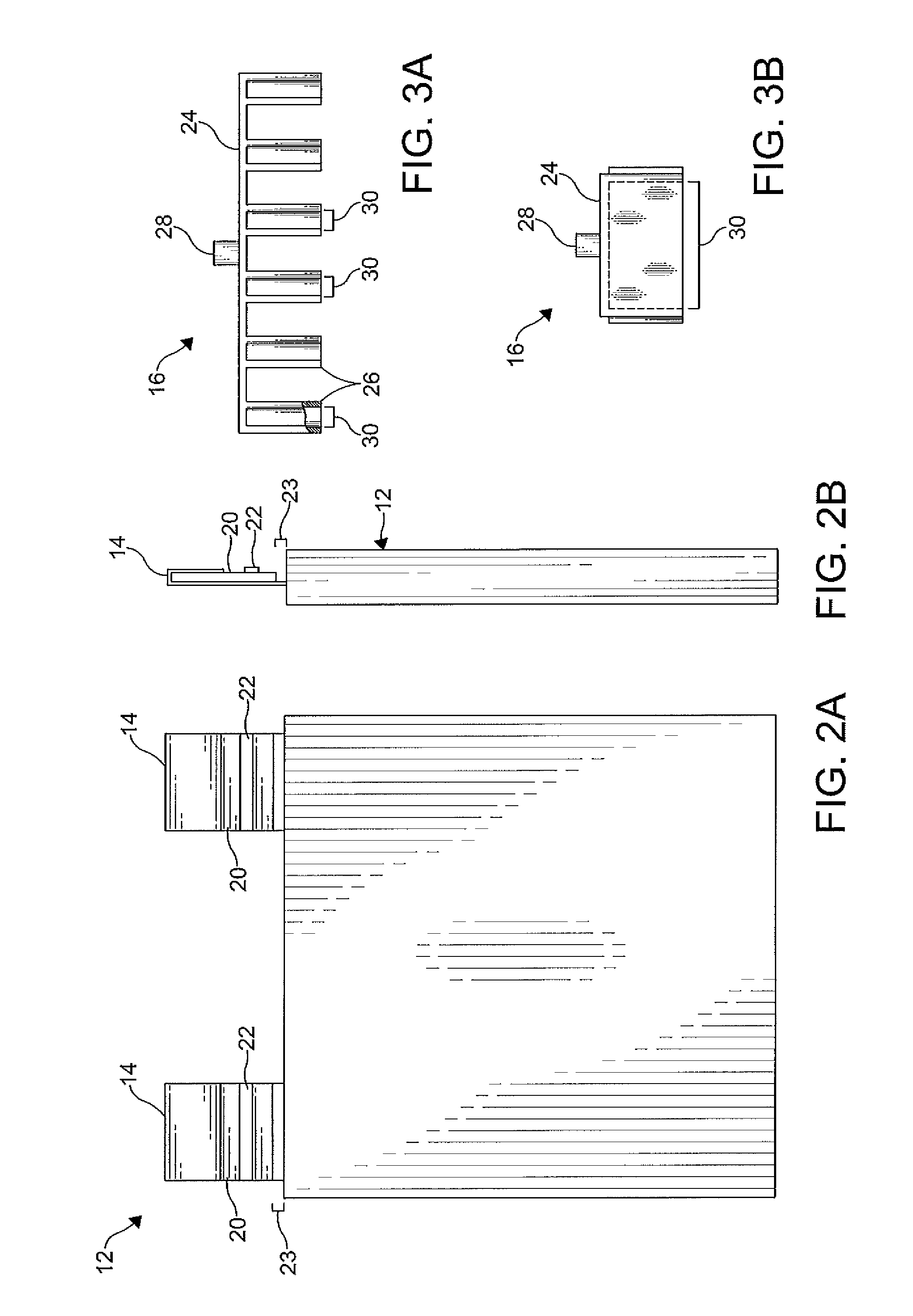

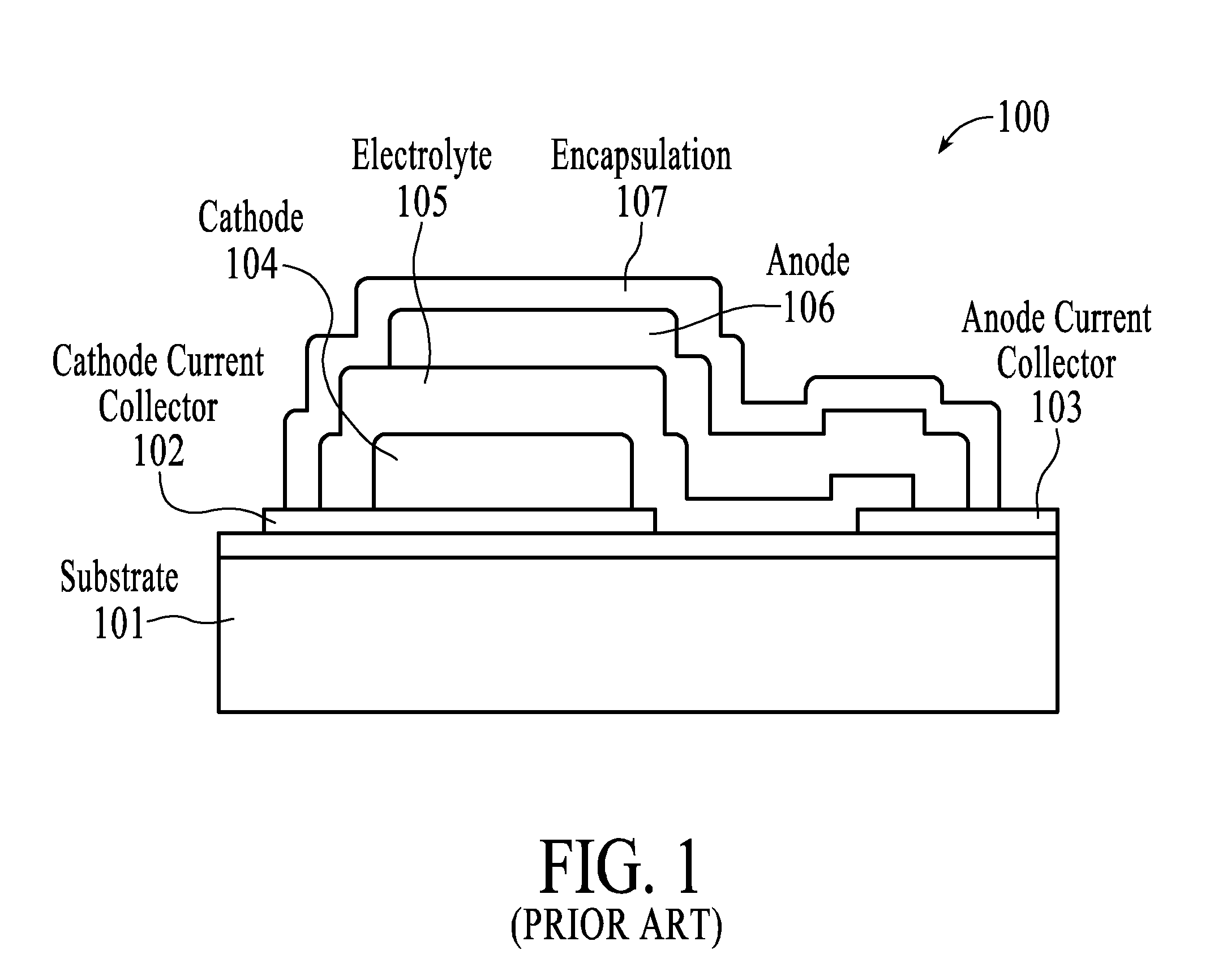

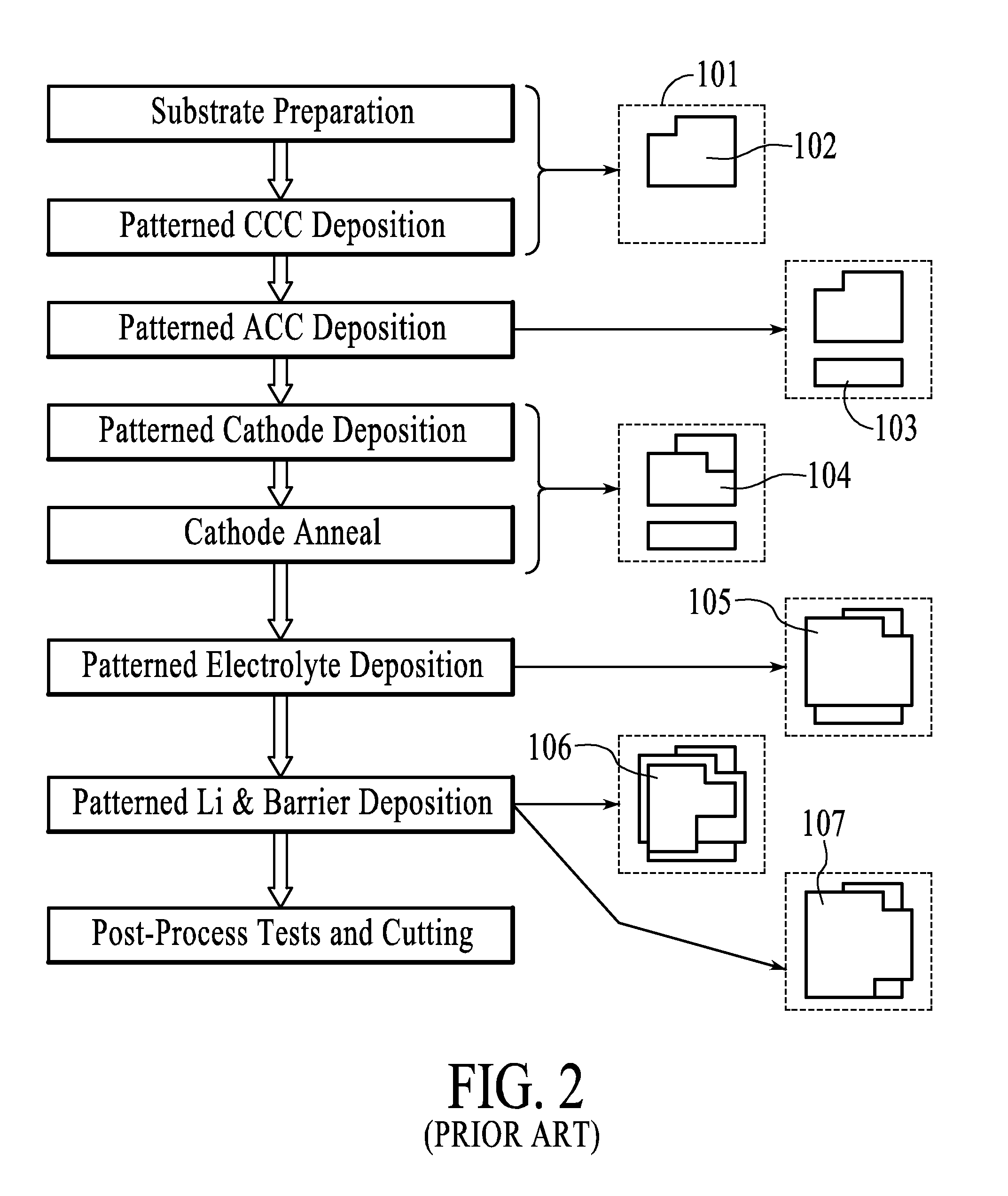

Mask-Less Fabrication of Thin Film Batteries

InactiveUS20140007418A1Reduce complexityLow costNitrogen compoundsFinal product manufactureLaser patterningOptoelectronics

Thin film batteries (TFB) are fabricated by a process which eliminates and / or minimizes the use of shadow masks. A selective laser ablation process, where the laser patterning process removes a layer or stack of layers while leaving layer(s) below intact, is used to meet certain or all of the patterning requirements. For die patterning from the substrate side, where the laser beam passes through the substrate before reaching the deposited layers, a die patterning assistance layer, such as an amorphous silicon layer or a microcrystalline silicon layer, may be used to achieve thermal stress mismatch induced laser ablation, which greatly reduces the laser energy required to remove material.

Owner:APPLIED MATERIALS INC

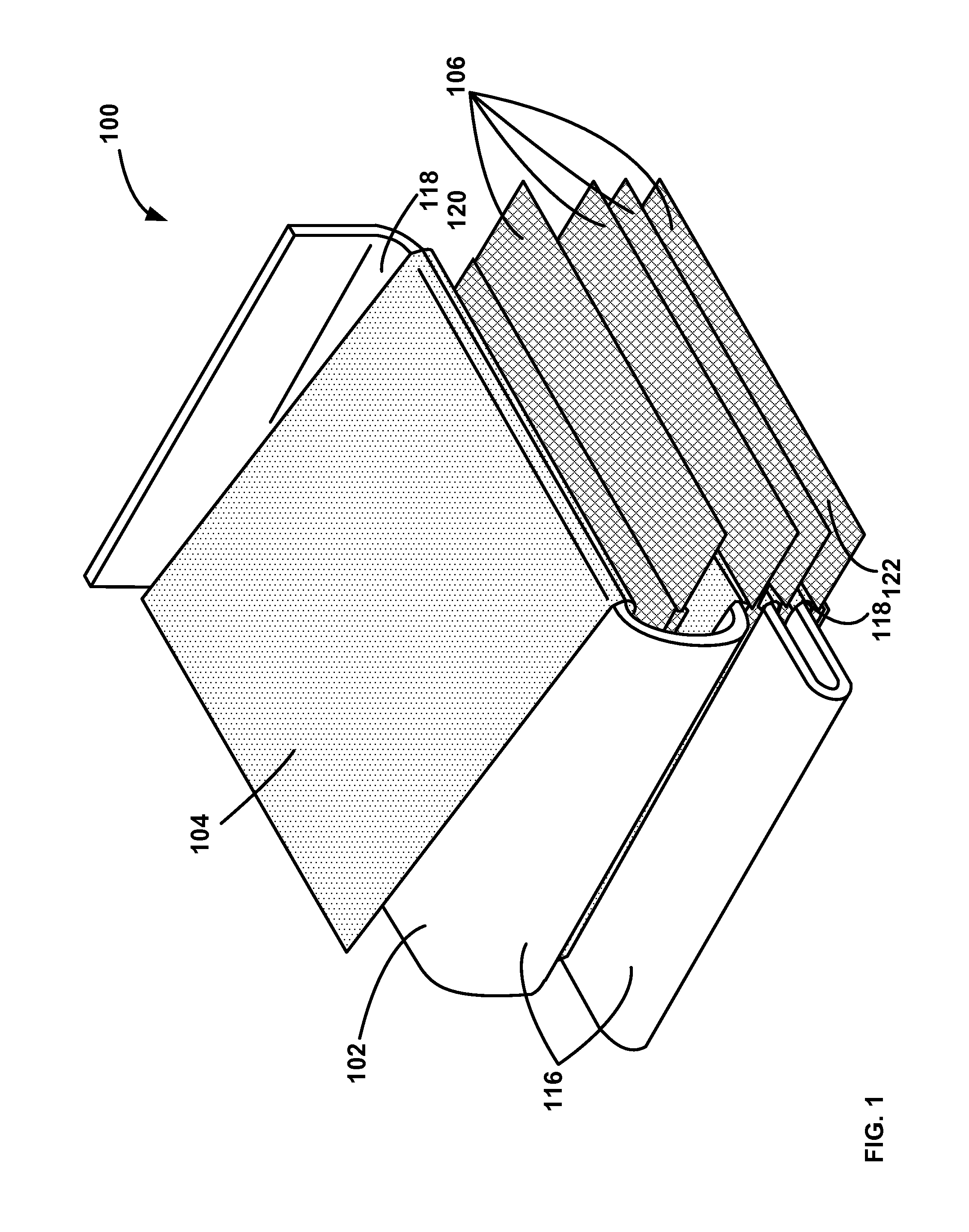

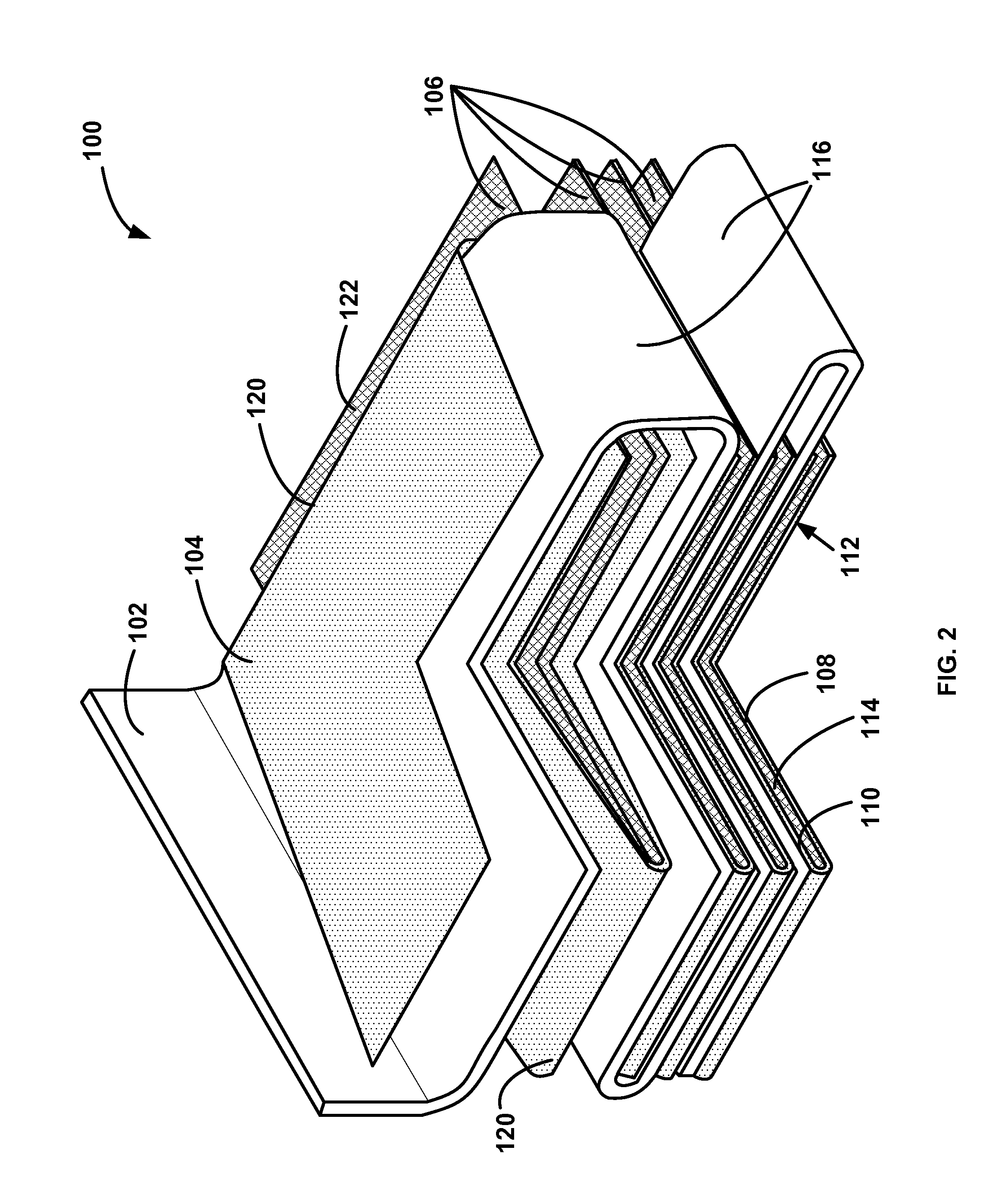

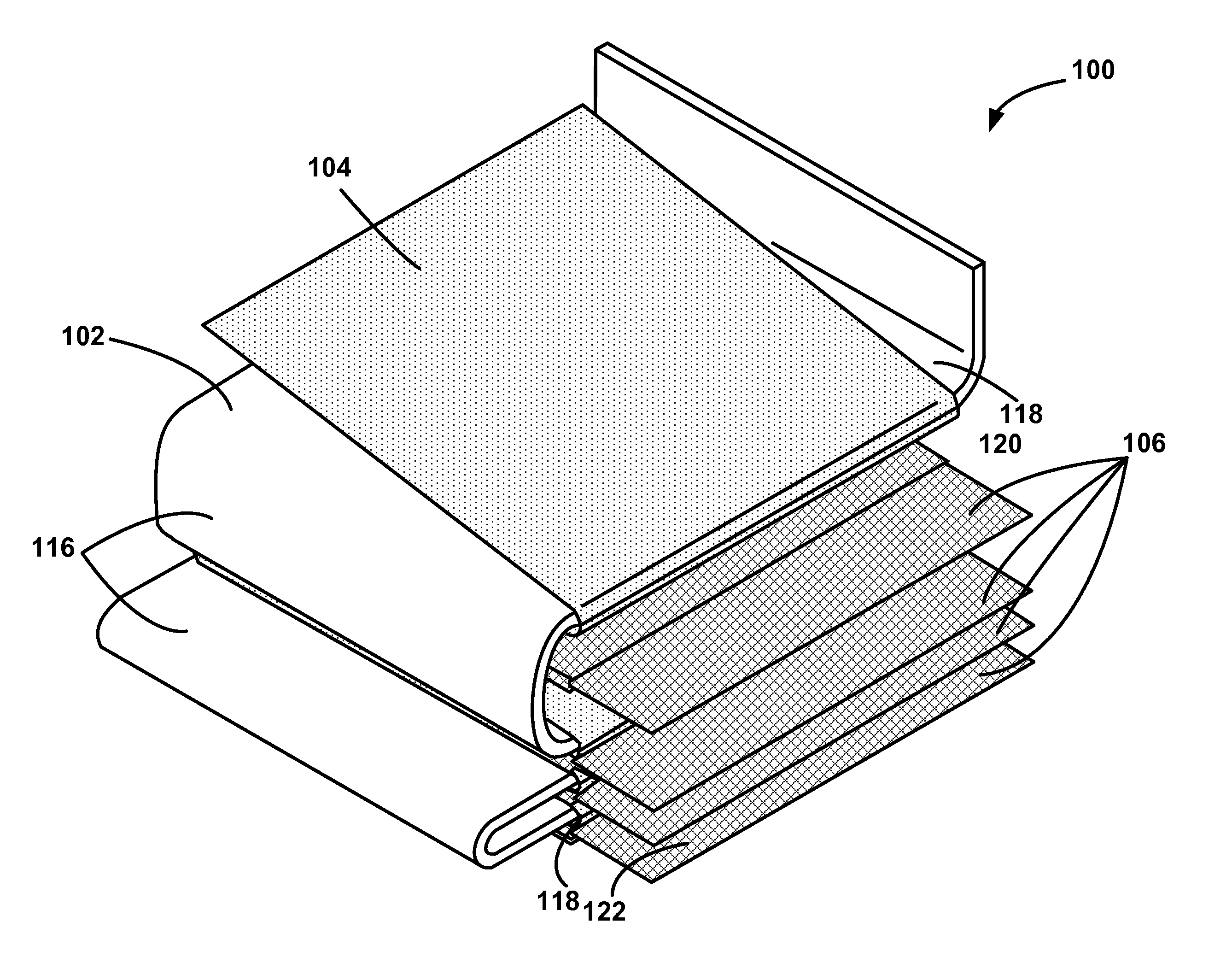

Electrochemical cell having a folded electrode and separator, battery including the same, and method of forming same

ActiveUS20140272537A1Reduce manufacturing costIncrease energy densityPrimary cell to battery groupingElectrode manufacturing processesEngineeringElectrochemical cell

An electrochemical cell including a folded electrode layer and a folded separator, a battery including the electrochemical cell, and methods of forming the electrochemical cell and battery are disclosed. The electrode layer is folded in a first direction and the separator is folded in a second direction, such that the first direction and second direction are orthogonal each other.

Owner:ROBERT BOSCH GMBH +1

Solder-wire-free high-frequency automatic welding method for storage battery connecting piece

InactiveCN104070283AThe size is easy to controlReduce economic spendingAssembling battery machinesHigh frequency current welding apparatusHigh frequency powerElectrical battery

The invention discloses a solder-wire-free high-frequency automatic welding method for a storage battery connecting piece. The connecting piece is sleeved by a battery binding post exposed out of the head end of a storage battery, the storage battery is fed to a soldering flux adding station through a conveying mechanism of a high-frequency automatic welding machine, a soldering flux adding mechanism applies a soldering flux on the head end of the battery binding post and the connecting piece, a workpiece moving mechanism enables the storage battery to be moved to a station to be welded, and a welding mechanism descends to enable a welding coil to be located above the head end of the battery binding post. A high-frequency power supply generator of the welding mechanism takes the effect, the welding coil connected with the high-frequency power supply generator produces an induced magnetic field, an energy-gathered core placed in the welding coil gathers the high-frequency magnetic field at the head end to enable the head end of the battery binding post body to produce high temperature and be rapidly molten into molten lead, the molten lead flows down, cools down to be welded with the connecting piece, and then the storage battery is sent out through the conveying mechanism. The welding method enables the welding quality and machining efficiency to be high, does not need solder wire materials, saves the cost, saves manpower and material resources and creates great economic benefit.

Owner:贵阳市江山自动化设备有限公司

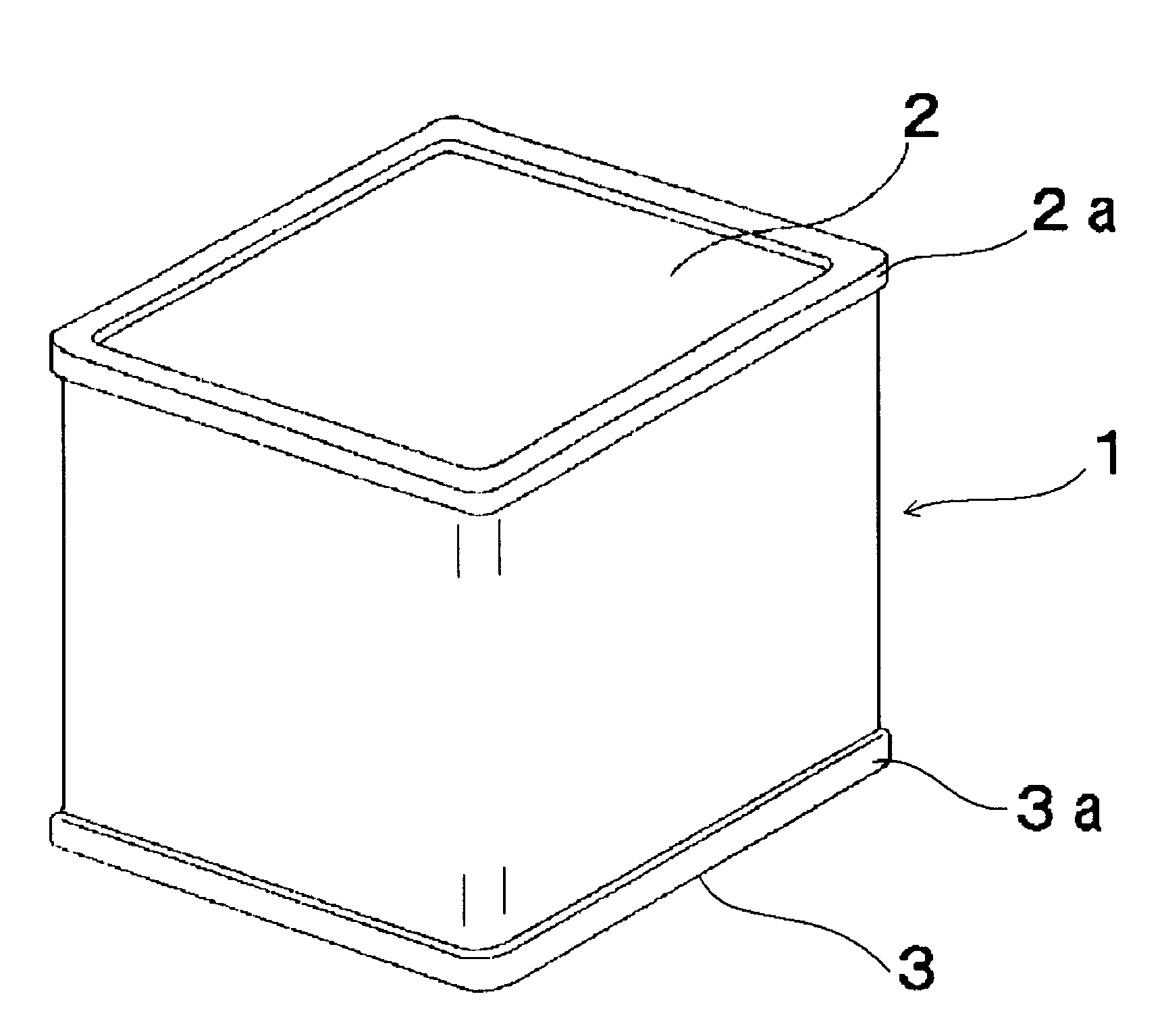

Three-piece square can and method of manufacturing the same

InactiveUS20090206096A1Improve the anti-leakage effectAvoid it happening againAssembling battery machinesSmall-sized cells cases/jacketsOrganic filmBody joints

The present invention provides a three-piece rectangular can which can overcome drawbacks (joint defect) of a can body joint portion of a three-piece can, and is of a new type which overcomes shortage of a can body strength which a two-piece can possesses, and exhibits excellent liquid leakage resistance, excellent can body strength and excellent heat radiation property or the like even when the can is used as a casing of a battery or electric equipment. For this end, the three-piece rectangular can of the present invention is formed such that a circular blank formed of an aluminum plate which forms an organic film on at least one surface thereof is formed into a bottomed circular can by deep drawing such that the organic film forms an inner side of the can, a cylindrical sleeve having no seam on a side surface thereof is formed by cutting a can bottom of the bottomed circular can, a rectangular can body portion having no seam on a side surface thereof is formed by deforming the cylindrical sleeve into a rectangular shape, a necking formed portion is formed by applying necking forming to opening portions at both ends of the rectangular can body, and a top lid and a bottom lid are mounted on the opening portions at both ends of the rectangular can body by double seaming by way of an organic compound.

Owner:TOYO SEIKAN KAISHA LTD +1

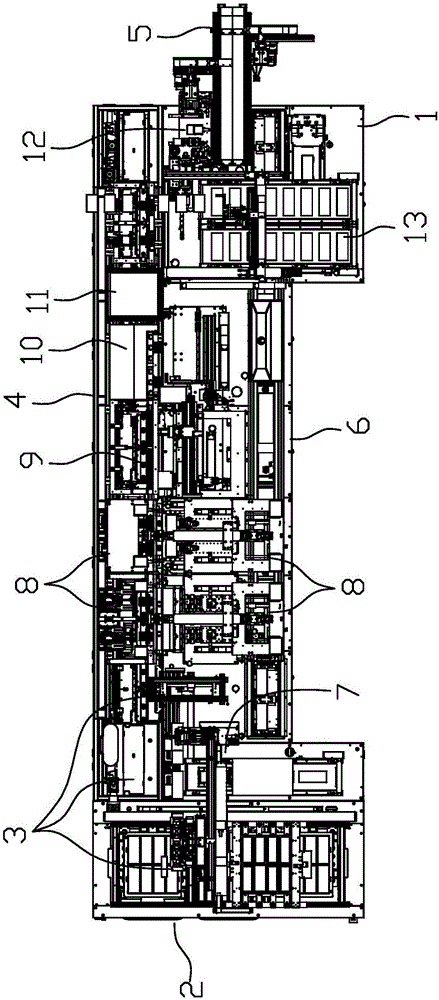

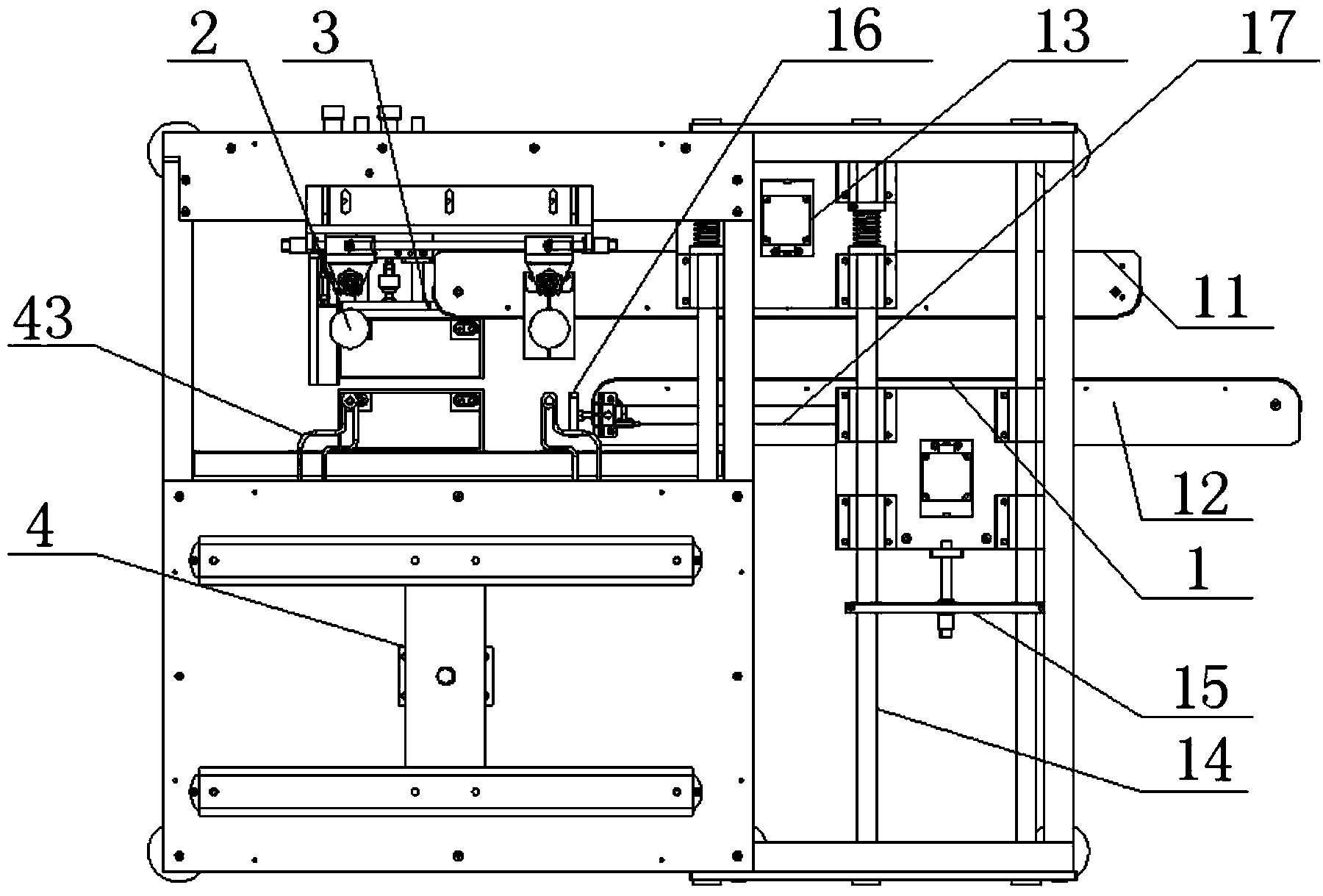

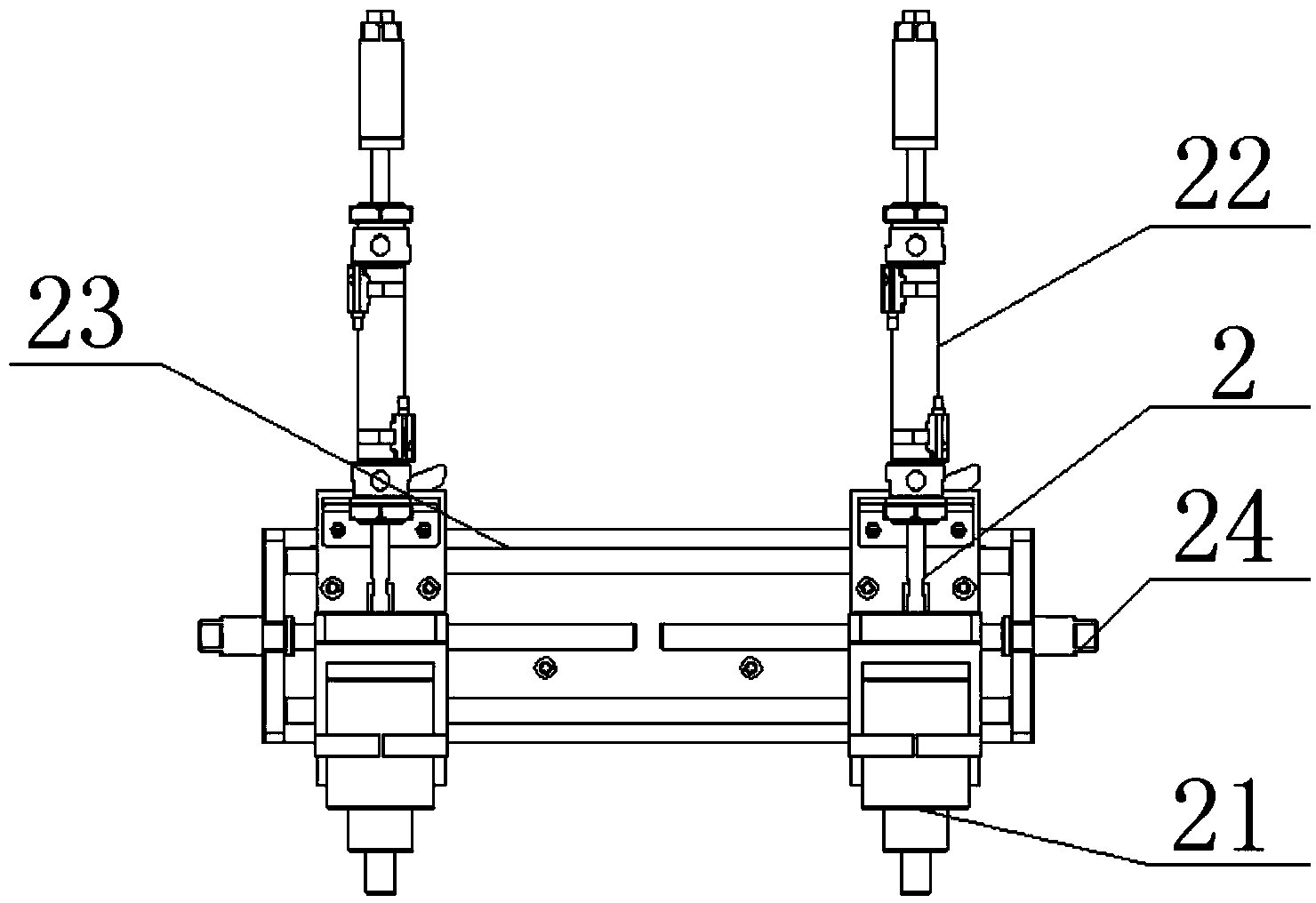

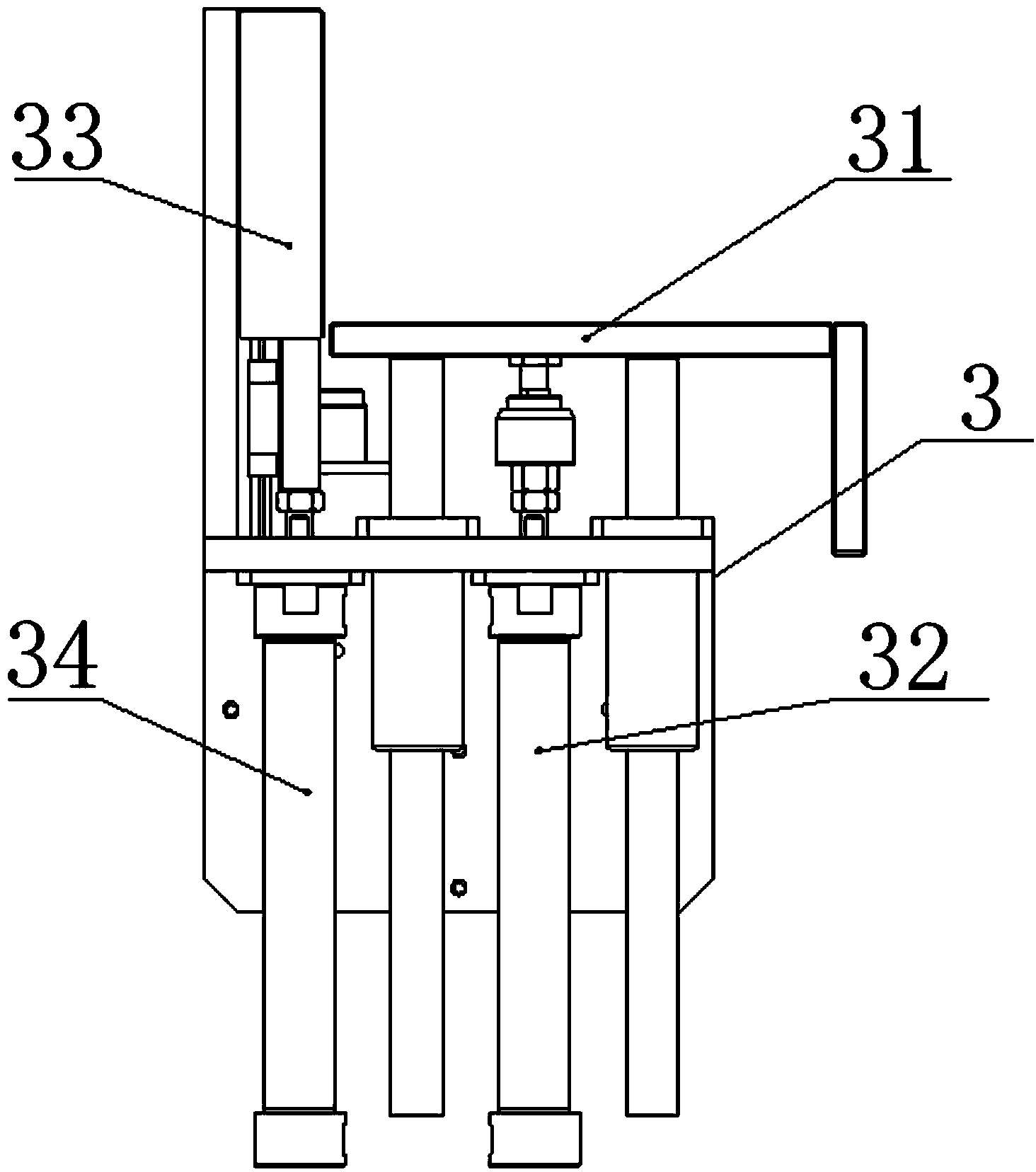

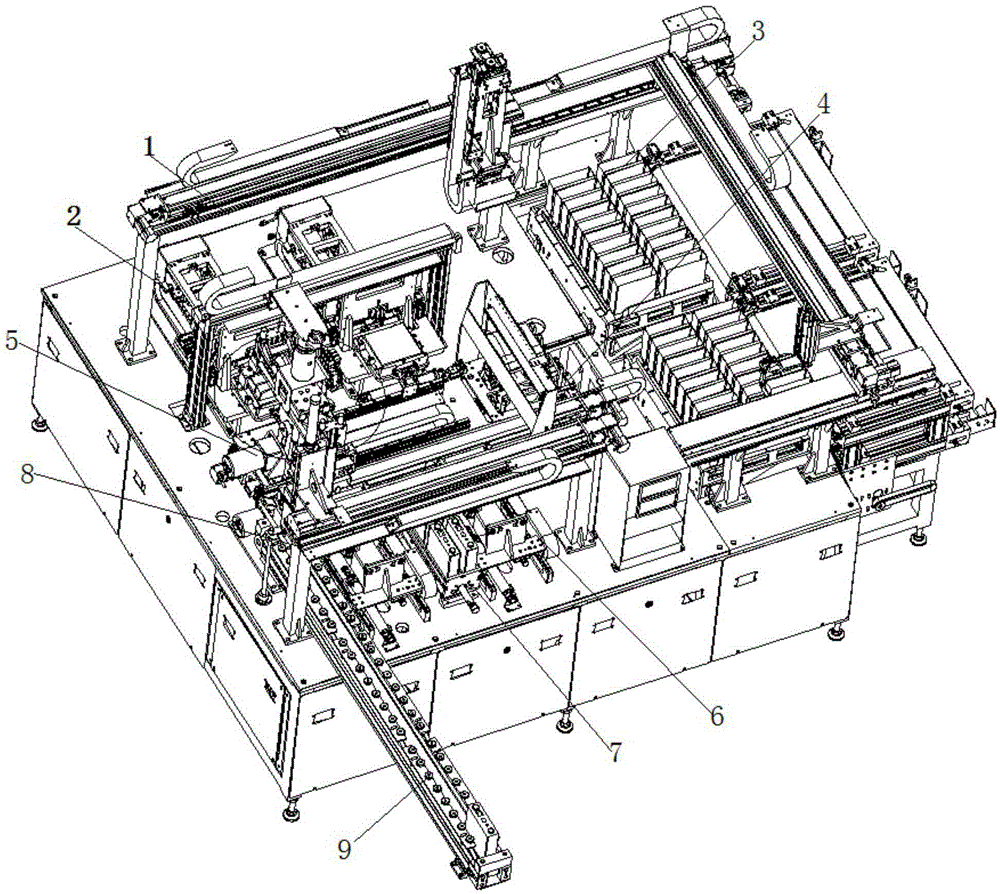

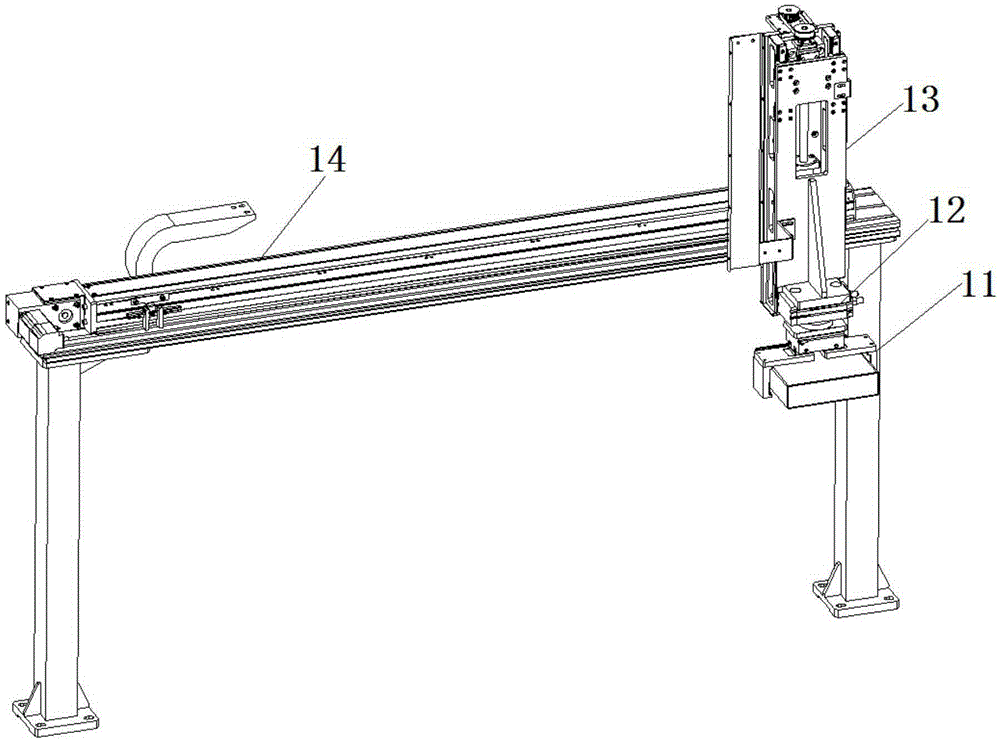

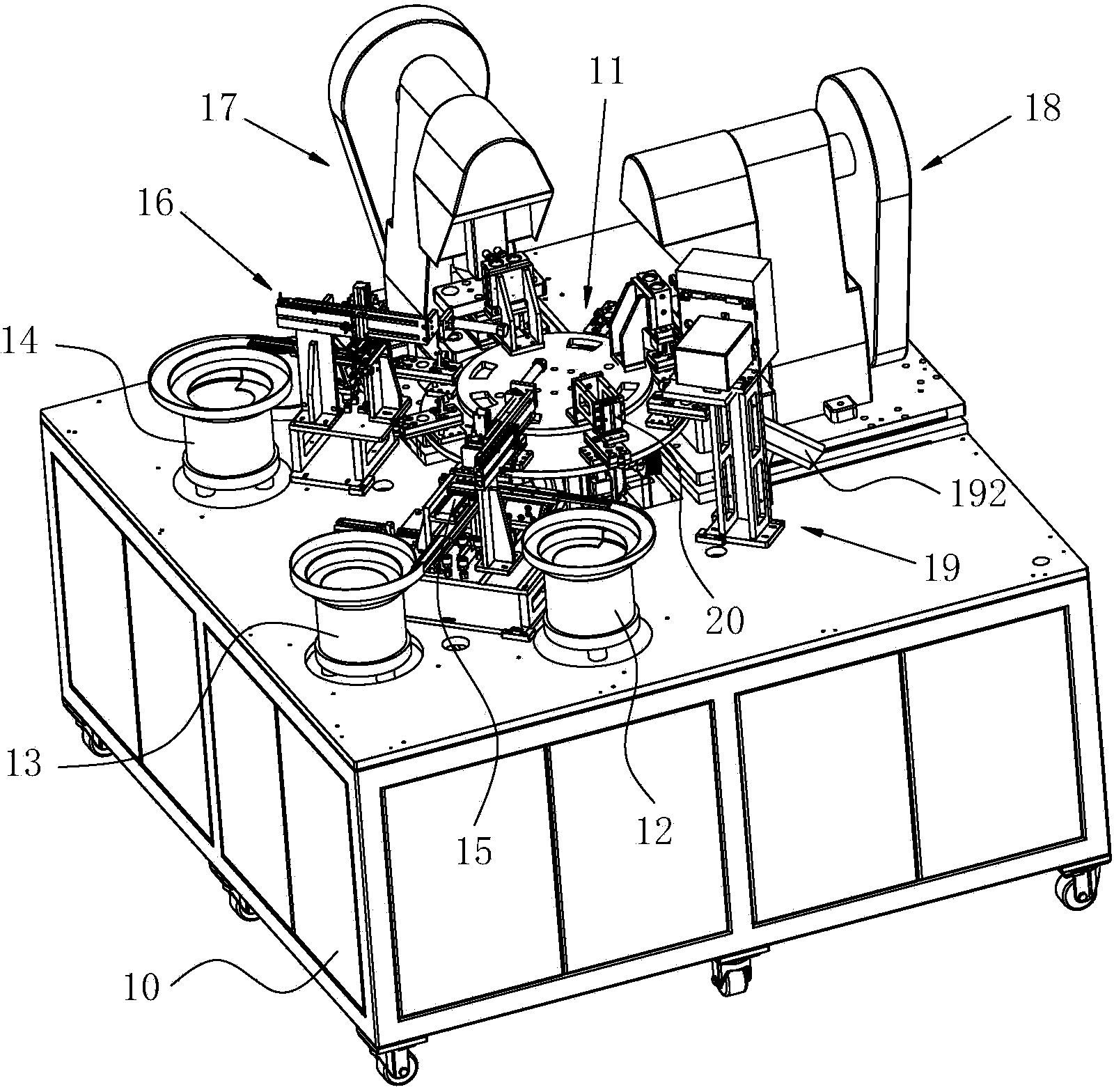

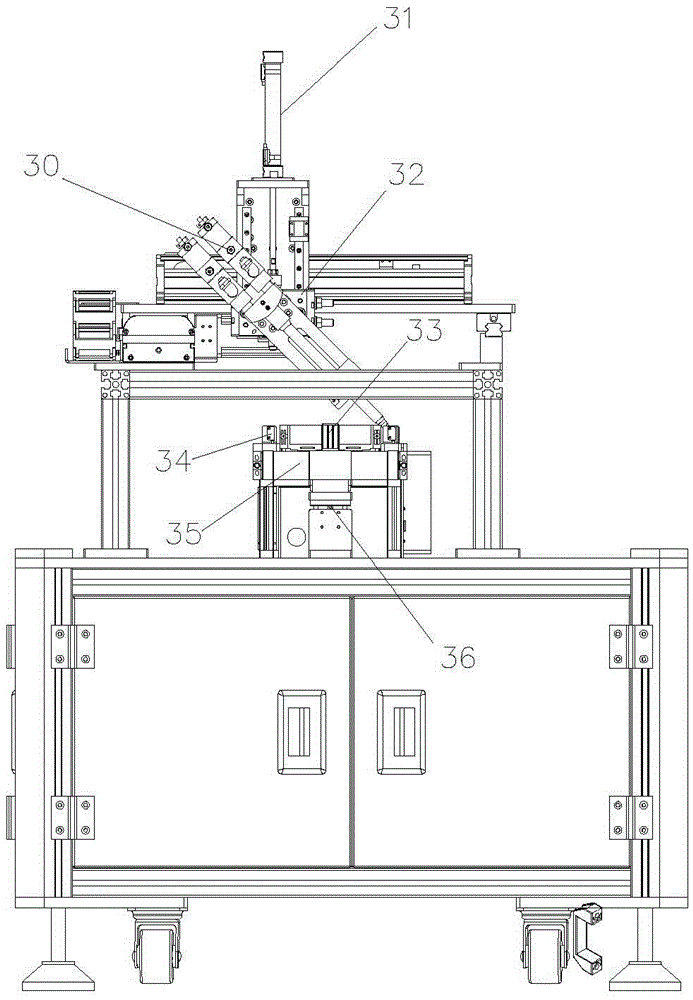

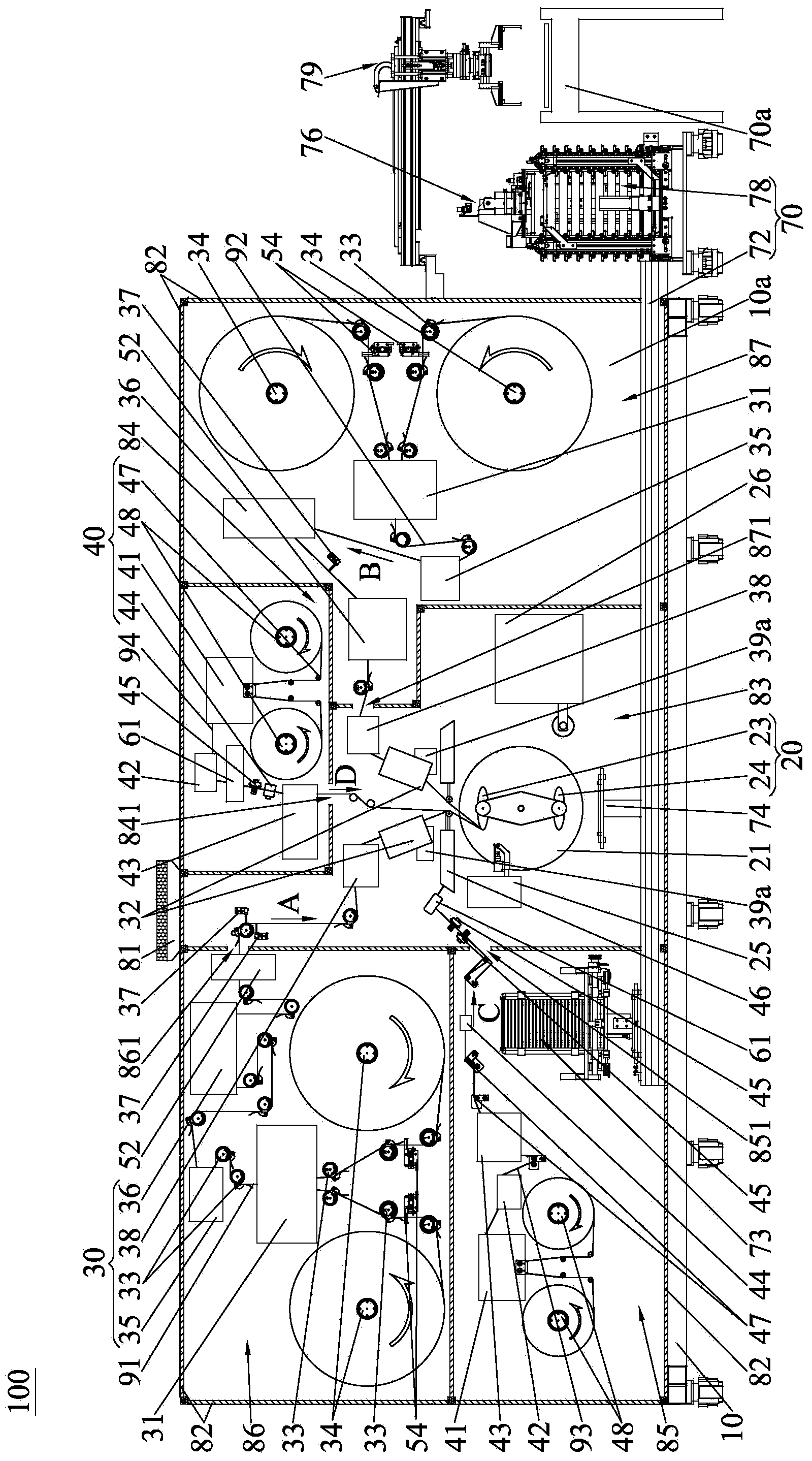

Machine for automatically mounting battery cell of square power battery into shell

PendingCN105390732AQuality assuranceGuaranteed efficiencyAssembling battery machinesFinal product manufacturePower batteryEngineering

The invention discloses a machine for automatically mounting a battery cell of a square power battery into a shell. The machine comprises a machine frame, wherein a bare battery cell dust removal component used for performing dust removal on a bare battery cell is arranged on the machine frame; an aluminum shell charging component used for conveying an aluminum shell is further arranged on the machine frame; an aluminum shell dust removal component used for performing dust removal on the aluminum shell on the aluminum shell conveying component is further arranged on the machine frame; a tool component used for mounting the bare battery cell into the aluminum shell is further arranged on the machine frame; a bare battery cell charging mechanical hand used for picking the bare battery cell subjected to dust removal on the bare battery cell dust removal component and conveying the bare battery cell subjected to dust removal into a bare battery cell discharging position of the tool component is further arranged on the machine frame; a rotary mechanical hand component used for picking the aluminum shell on the aluminum shell dust removal component and conveying the aluminum shell into an aluminum shell charging position of the tool component is further arranged on the machine frame; an HI-POT test component used for performing an HI-POST test on the battery comprising the bare battery cell and the aluminum shell is further arranged on the machine frame; and a discharging pull line component is further arranged on the machine frame.

Owner:SHENZHEN YUCHEN AUTOMATION EQUIP CO LTD

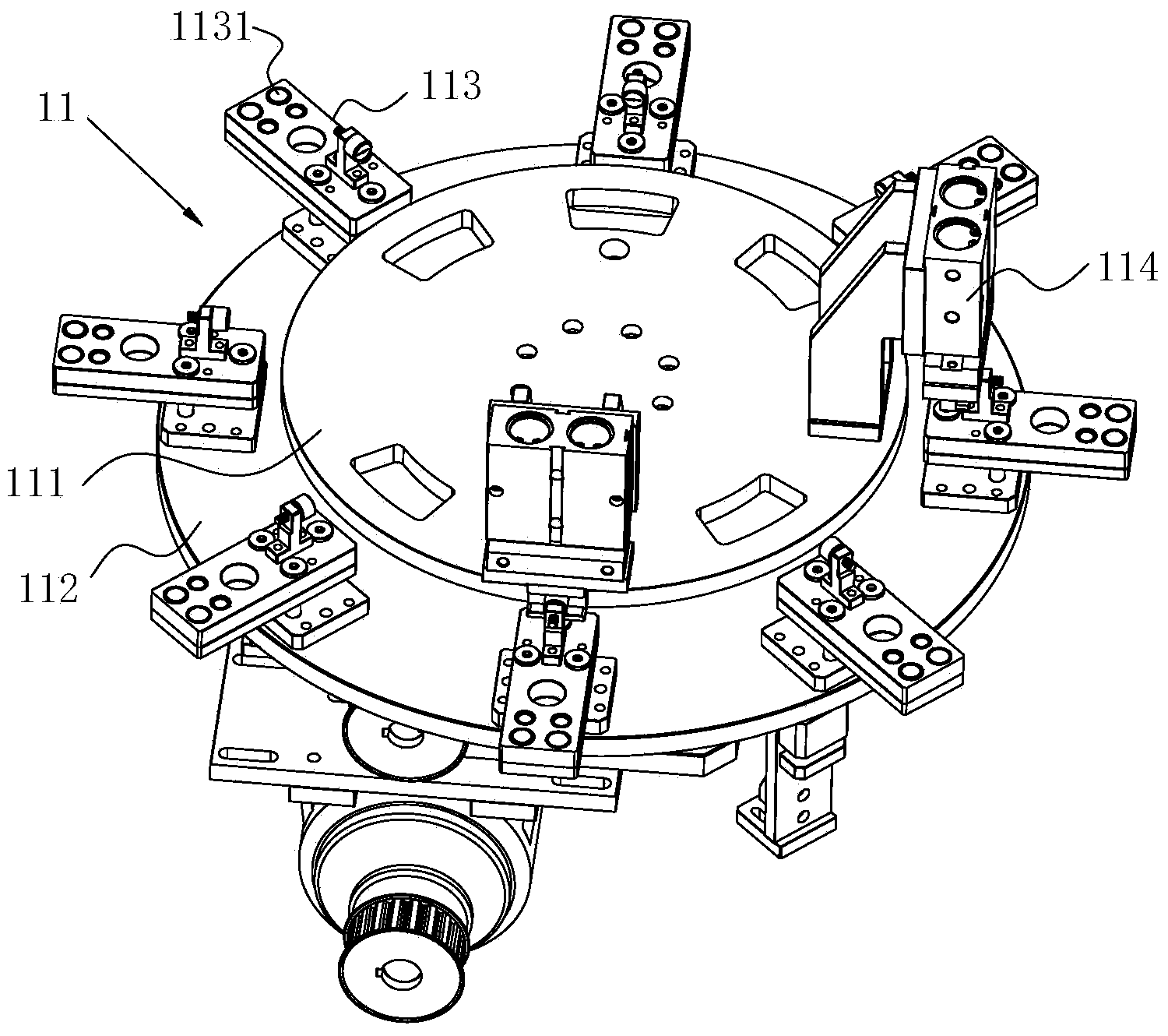

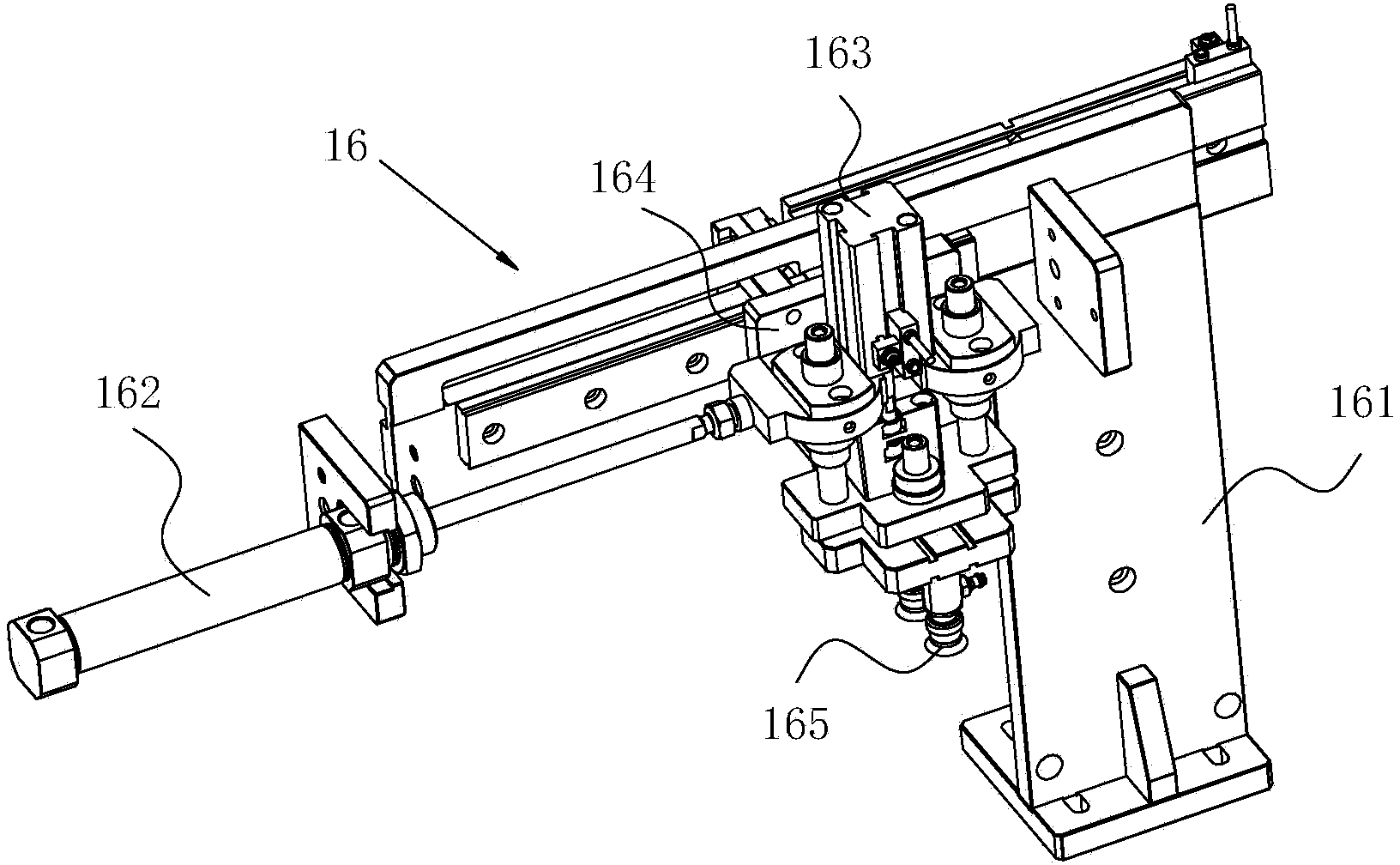

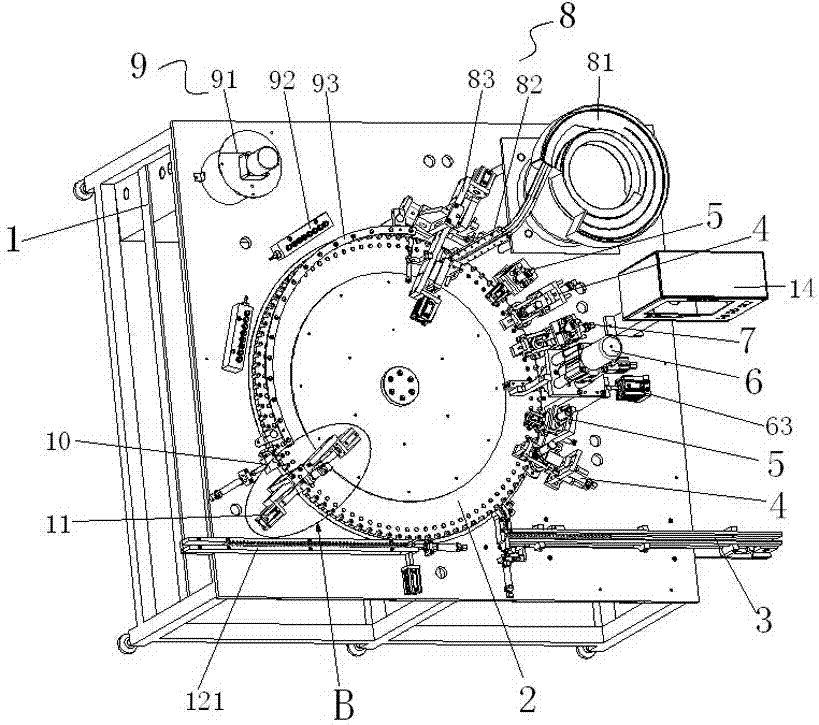

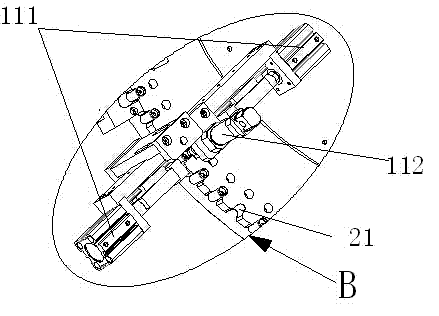

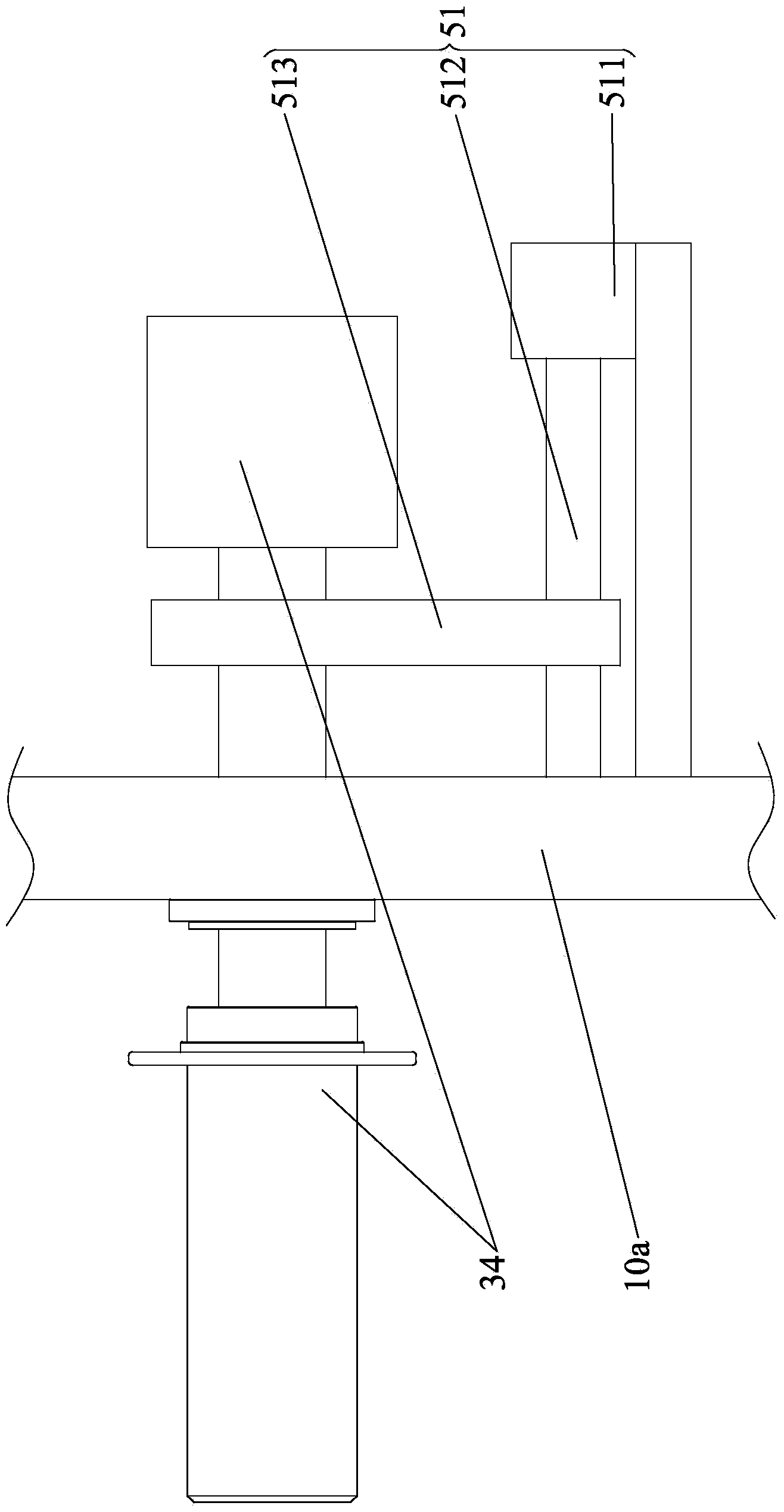

Automatic battery end cover assembling machine

ActiveCN104241694ARealize automatic feedingRealize the assemblyAssembling battery machinesFinal product manufacturePunch pressEngineering

The invention discloses an automatic battery end cover assembling machine which comprises a rack and a central rotary table, wherein a plurality of positioning molds are uniformly arranged at the periphery of the central rotary table; a pre-assembling device, an iron ring feeding component, a punch press component and a finished product blanking component, corresponding to the positioning molds, are sequentially arranged on the rack; the pre-assembling device comprises a cover plate feeding component, a pole feeding component and an assembly component which is arranged between the cover plate feeding component and the pole feeding component and is used for assembling cover plates and poles; feeding mechanical arms which are used for transferring materials to the positioning molds are respectively arranged on one side of the assembly component, as well as between the iron ring feeding component and the central rotary table. According to the automatic battery end cover assembling machine, due to arrangement of the central rotary table with the plurality of positioning molds, as well as the feeding component, the assembly component, the punch press component and the finished product blanking component for various parts, which cooperate with the central rotary table, battery end covers can be automatically fed, assembled and discharged, and the production efficiency and reliability are effectively improved.

Owner:荆门亿纬创能锂电池有限公司

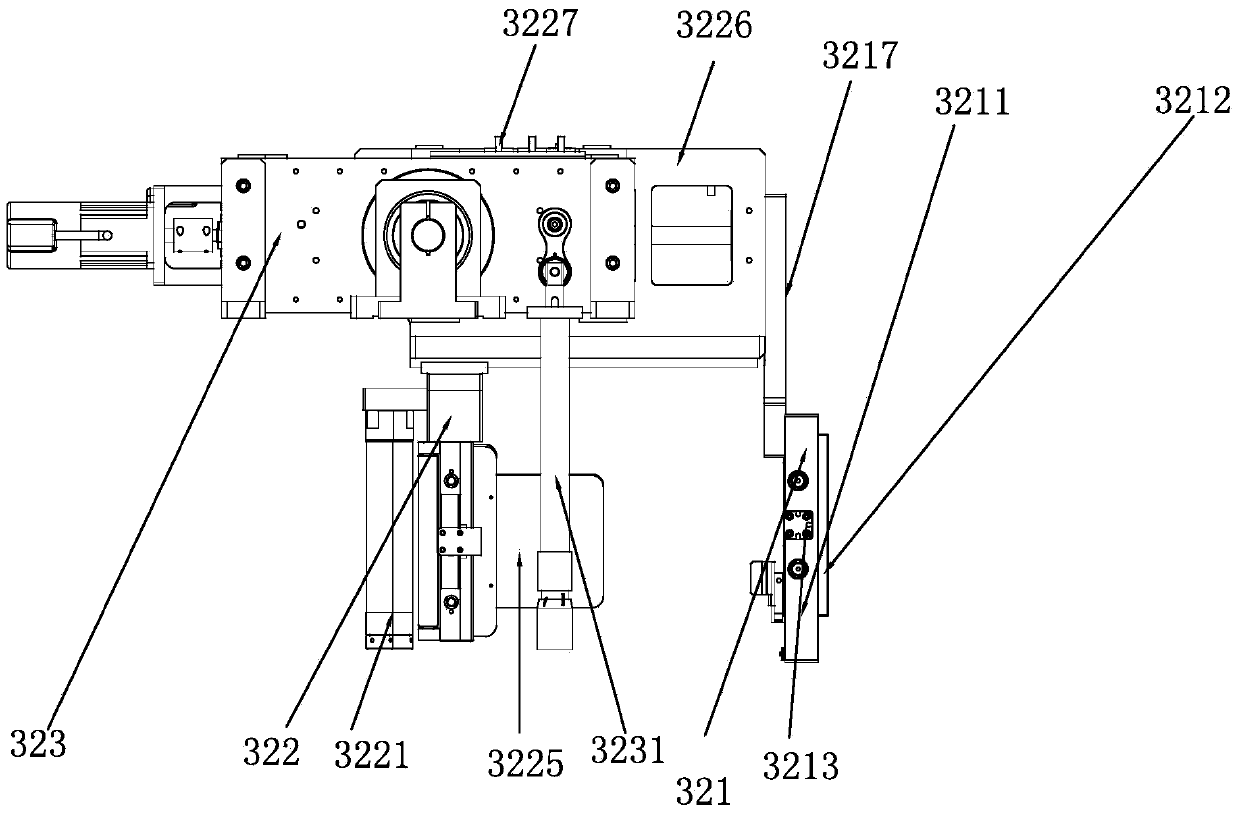

Turnover fixture, power battery assembling method and equipment

ActiveCN102376982AReduce positioning deviationRealize automatic transferAssembling battery machinesFinal product manufacturePower batteryProduction line

The invention discloses a turnover fixture, a power battery assembling method and equipment which can be applied in the field of power battery soft packaging. The turnover fixture is composed of a base plate, an upper cap and a buffering mechanism. The fixture is coupled with a battery core, and is used for positioning the battery core. During a transportation process, the turnover fixture can beused for protecting the battery core, and for improving the battery core positioning precision. With the turnover fixture provided by the invention, positioning deviation during battery core transportation is reduced, and the battery core is prevented from being directly contacted. The invention also provides the equipment comprising a conveyor, a cap fixing machine, a cap opening machine, and a conveyer manipulator. The invention establishes a production line with the turnover fixtures as battery core carriers. With the production line, automatic transportation can be carried out by using the fixtures, such that the battery cores are prevented from being repeatedly transported by using human hands or manipulators, such that the consistency of the battery cores can be endured.

Owner:GEESUN AUTOMATION TECH

New energy power module assembling line

ActiveCN107819134ARealize the assemblyRealize automatic assemblyPrimary cell manufactureAssembling battery machinesNew energyBattery cell

The invention discloses a new energy power module assembling line relating to the technical field of tools for battery modules. A battery cell detection station is arranged on one side of a battery cell loading assembly, a automatic battery cell frame mounting station is arranged on one side of the battery cell detection station, a battery cell splicing station is arranged on one side of the automatic battery cell frame mounting station, a side loading line of the battery cell splicing station is arranged on one side of the battery cell splicing station, a battery cell module transplanter is arranged on one side of the side loading line of the battery cell splicing station, and a riveting machine is mounted on the battery cell module transplanter. The new energy power module assembling line can achieve assembly of a new energy battery module and can achieve automatic assembling, so that the labor and the time are saved and the efficiency is high.

Owner:丁琛琦

Apparatus for manufacturing secondary battery

ActiveUS20070154799A1Improve structural stabilityAvoid damageFinal product manufactureConfectioneryManufactured apparatusEngineering

Disclosed herein is an apparatus for manufacturing a secondary battery by performing insert injection molding with respect to a portion of a battery cell while the battery cell is located in a mold, wherein the apparatus comprises a pair of upper and lower molds, at which are formed shapes corresponding to the battery cell, the upper and lower molds are provided at the inside surfaces thereof with elastic members, and the elastic members are constructed in a structure in which the elastic members support a cell body of the battery cell and isolate a non-molding region from a molding region while the battery cell is mounted in the upper and lower molds. The secondary battery manufacturing apparatus according to the present invention has the effect of preventing a battery case from being damaged due to the contact between the battery case and the mold when the mold is brought into tight contact with the cell body of the battery cell during insert injection molding to form a molding member at a specific region of the secondary battery, and effectively preventing a material for insert injection molding, which is injected into the molding region, from being injected into the non-molding region.

Owner:LG ENERGY SOLUTION LTD

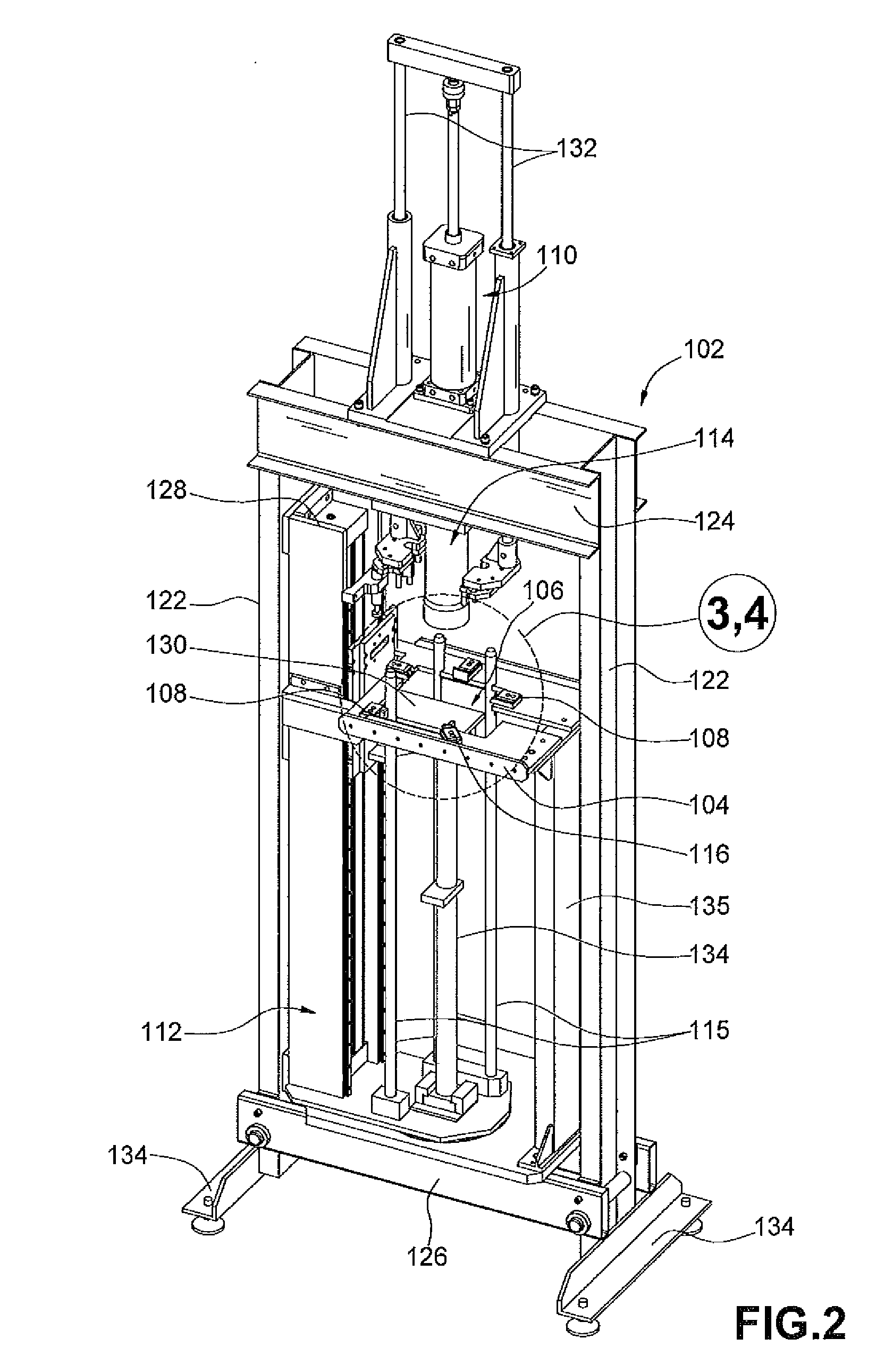

Press apparatus

InactiveUS20100306995A1Maintaining dimensional qualityAssembling battery machinesPrimary cellsEngineeringBattery pack

Owner:GM GLOBAL TECH OPERATIONS LLC

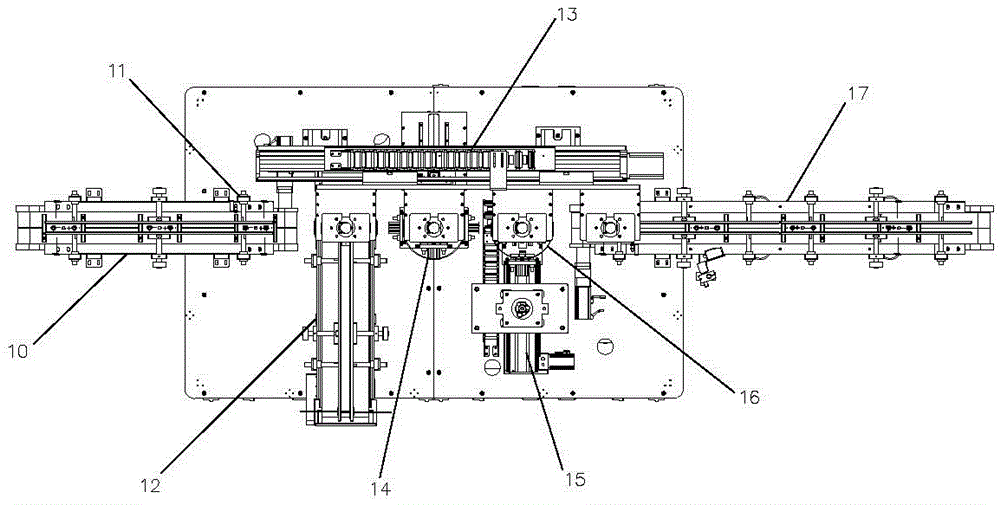

Square battery shaping and testing machine

ActiveCN104934625AImprove processing efficiencyHigh positioning accuracyPrimary cell manufactureAssembling battery machinesManipulatorTraining set

The invention discloses a square battery shaping and testing machine. The machine comprises an operation conveying line, a battery universal feeding system and a battery classification blanking system which are arranged at two ends of the operation conveying line. A feeding connecting line for conveying batteries is arranged between the battery universal feeding system and the operation conveying line. One end of the operation conveying line, close to the feeding connecting line, is provided with a first conveying mechanical arm for transferring the batteries from the feeding connecting line to the operation conveying line. One side of the operation conveying line is provided with a second conveying mechanical arm for transferring the batteries from the start end of the operation conveying line to the tail end of the operation conveying line. The other side of the operation conveying line is sequentially provided with a battery shaping device, an appearance testing device, a code scanning device, a performance testing device and a thickness testing device. Due to arrangement of the battery universal feeding system and the battery classification blanking system, full automated processing of battery feeding, shaping, testing and classified recovery is realized, and the battery processing efficiency is improved.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

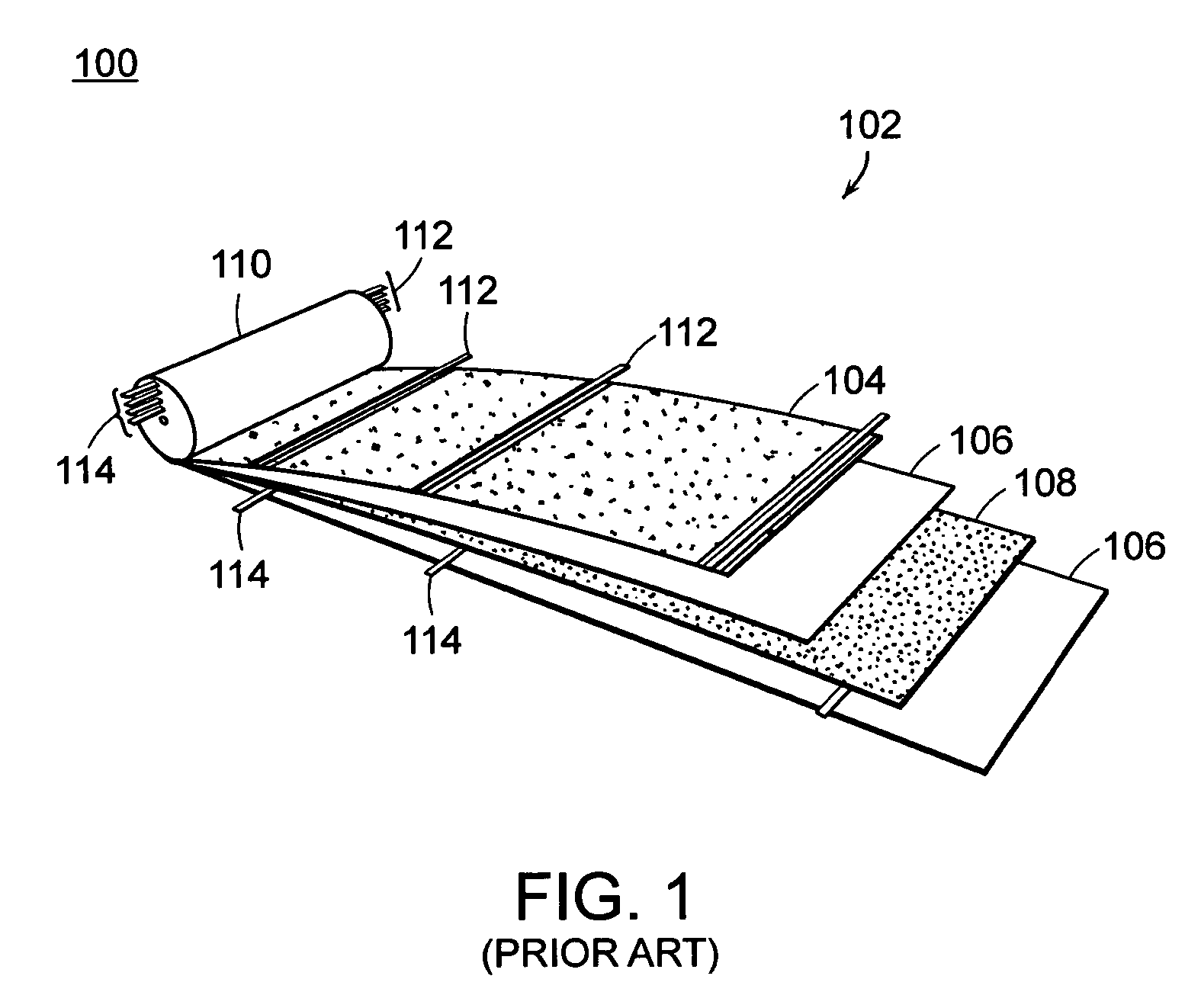

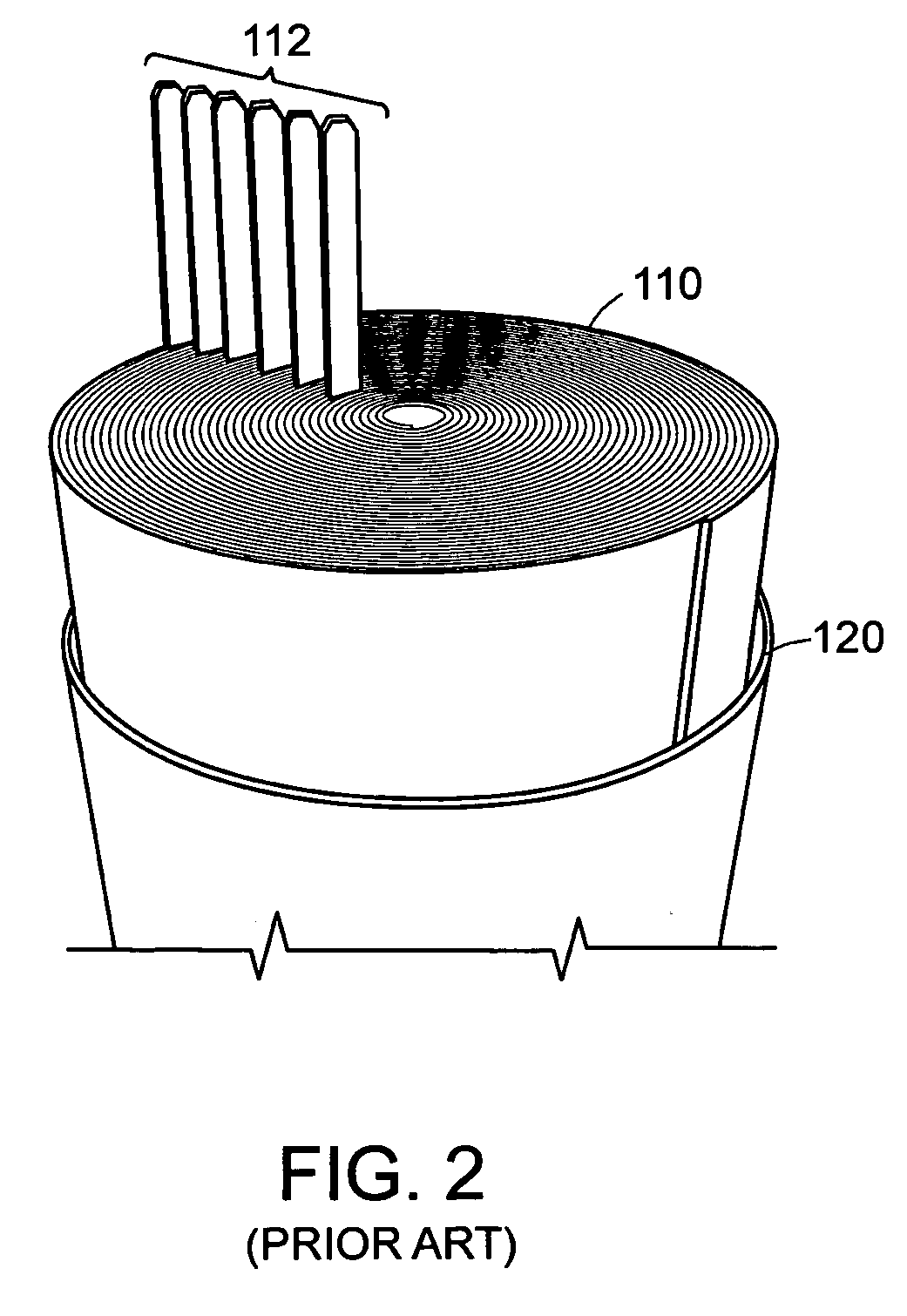

Method and apparatus for manufacturing electrode assembly for rectangular battery

ActiveUS20090165936A1Improve performanceAssembly precisionLamination ancillary operationsAssembling battery machinesElectrical batteryPerpendicular direction

In a method of manufacturing an electrode assembly for a rectangular battery, in which positive electrodes and negative electrodes are alternately laminated so that a separator exists between the respective positive and negative electrodes, the manufacturing method includes the steps of: arranging a plurality of guide members in zigzag form in a perpendicular direction; inserting a continuous member of the separator between one and another one rows of the guide members; folding, into zigzag form, the continuous member by intersecting the rows of the guide members in a horizontal direction; inserting alternately the positive electrodes and the negative electrodes in respective valley grooves of the zigzag-folded continuous member; withdrawing the guide members from the respective valley grooves of the continuous member; and pressing, thereafter, the continuous member in the zigzag direction so as to make flat the continuous member.

Owner:ELIIY POWER

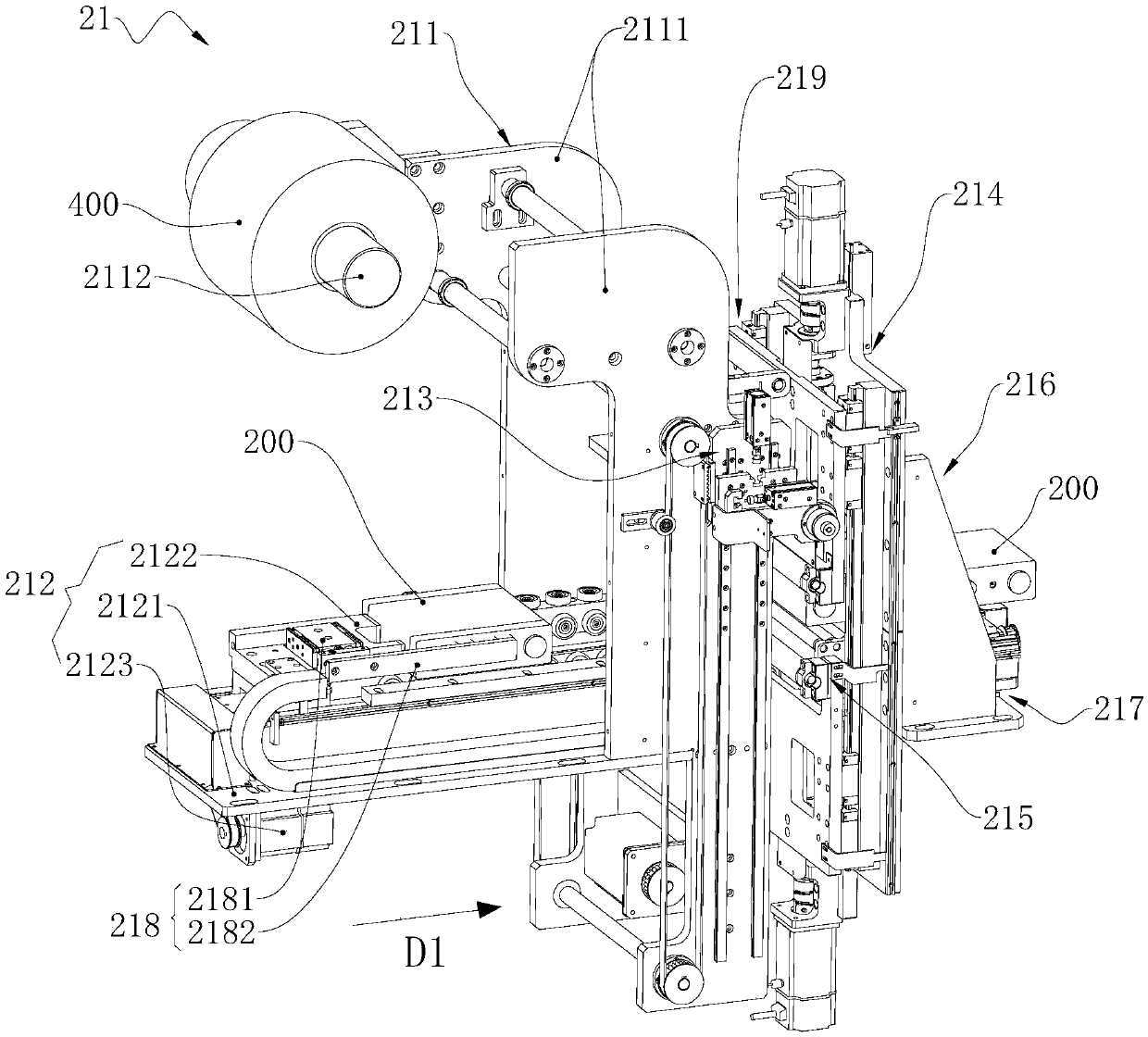

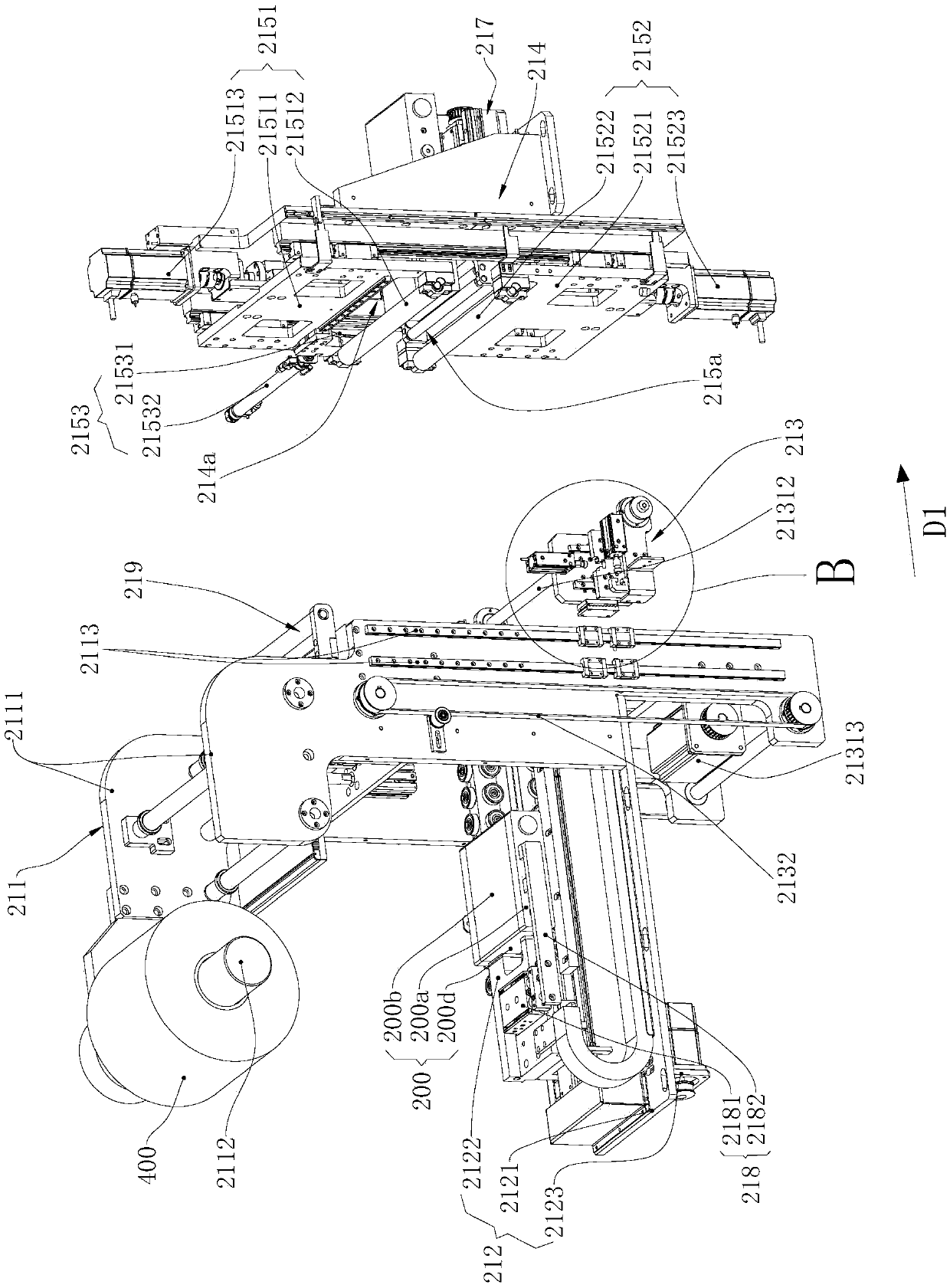

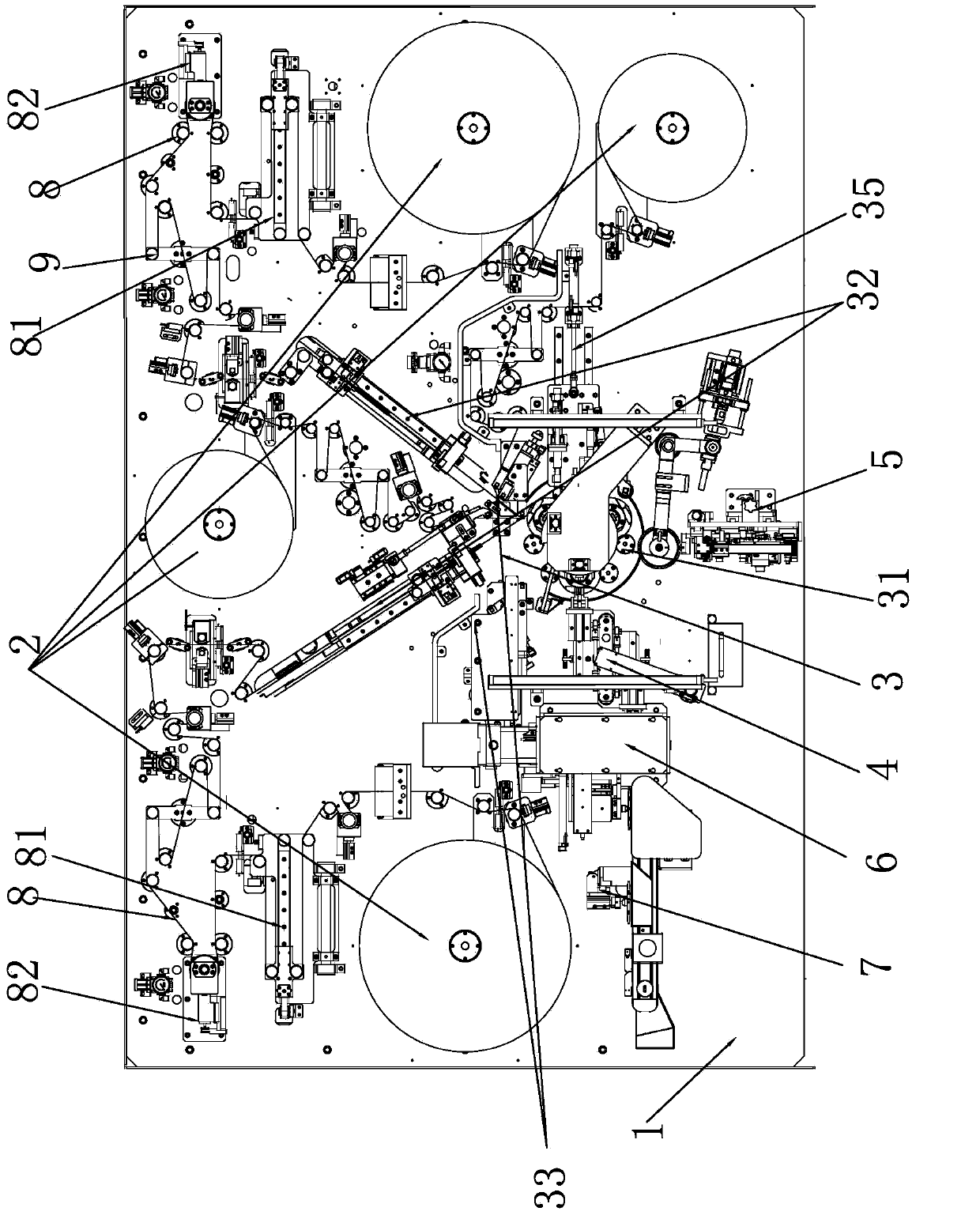

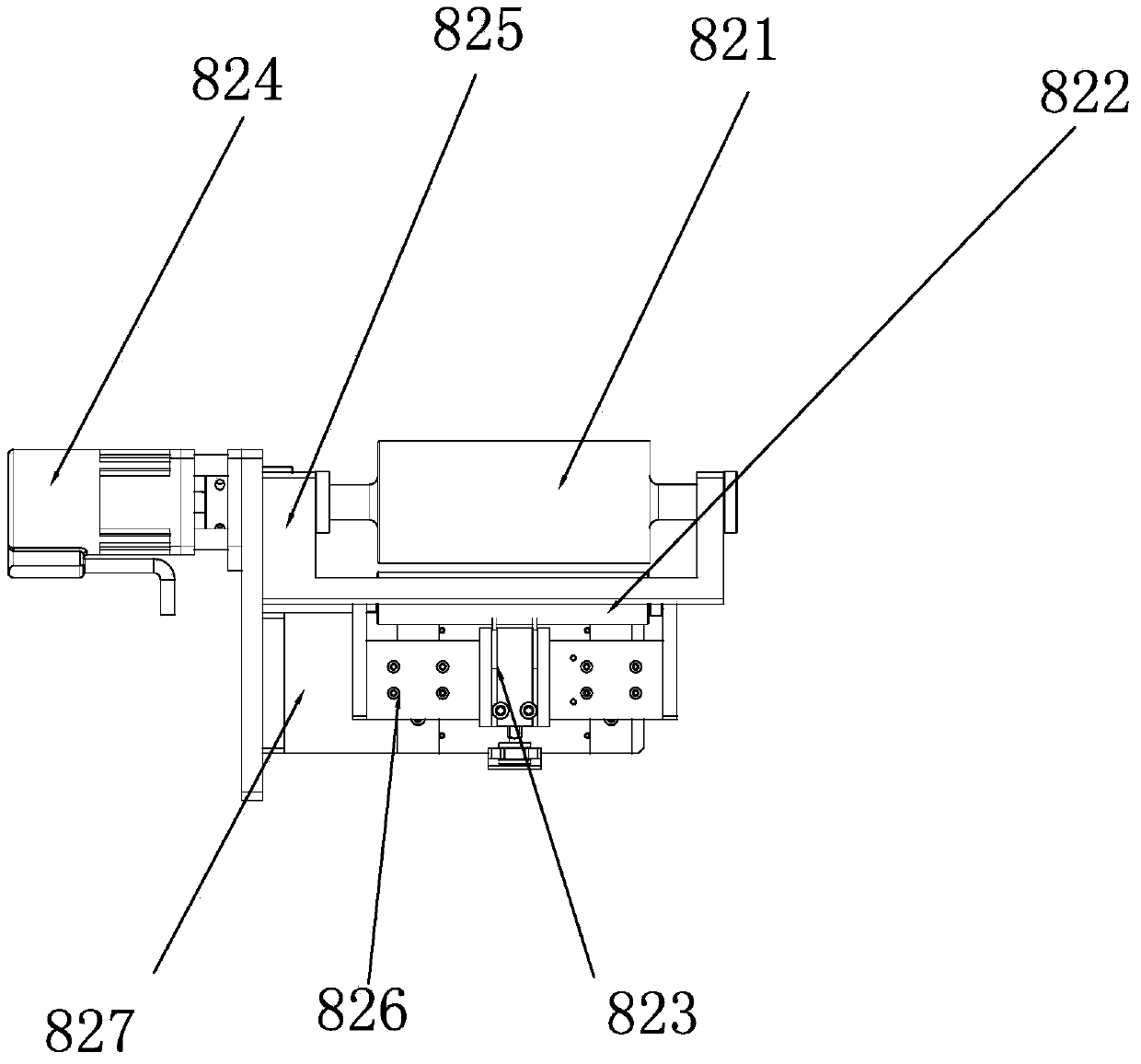

Battery enveloping device and enveloping equipment

ActiveCN105514477ARealize automatic coatingAvoid contactPrimary cell manufactureAssembling battery machinesSize measurementElectrical battery

The invention relates to the technical field of battery enveloping and provides a battery enveloping device and enveloping equipment. The battery enveloping device comprises a side enveloping device for coating the side surface of a battery with a film, wherein the side enveloping device comprises a first mounting rack, a second mounting rack, a film drawing mechanism, a battery pushing mechanism, a first enveloping mechanism, a battery discharging mechanism and a second enveloping mechanism. Compared with the prior art, the battery enveloping device provided by the invention can be used for enveloping batteries automatically so as to lower labor intensity, is high in productivity and production efficiency, and can avoid contact between workers and batteries and eliminate hidden danger to quality. The enveloping equipment can be used for attaching insulation films to batteries and for performing insulation test and size measurement on the batteries, and is capable of effectively improving the yield of batteries and guaranteeing production quality.

Owner:SHENZHEN YUCHEN AUTOMATION EQUIP CO LTD

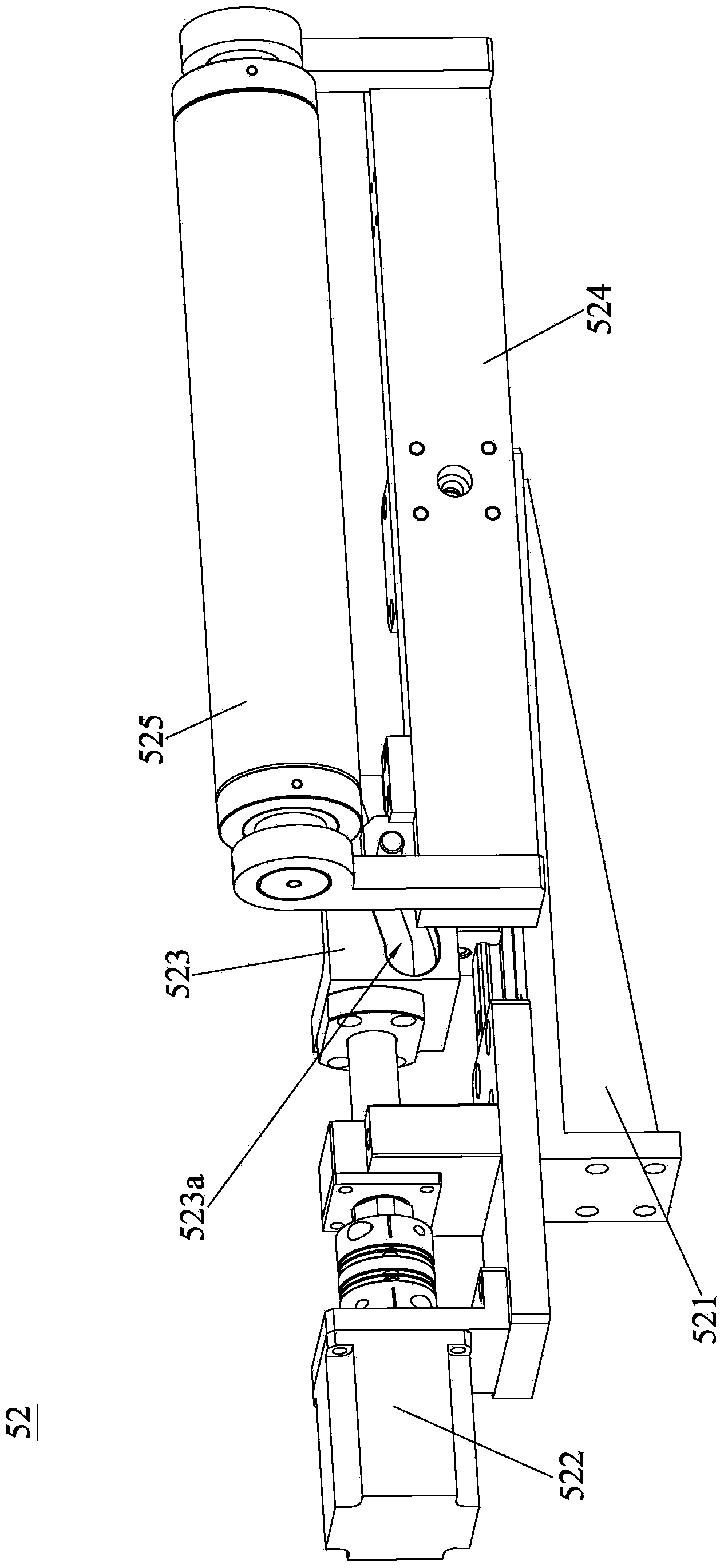

Reeling machine

ActiveCN104009249ATension balanceStable tensionPrimary cell manufactureAssembling battery machinesControl engineeringMachine

The invention discloses a reeling machine which comprises a rack assembly, an unreeling mechanism, a reeling mechanism, a feeding mechanism, a rubberizing device and a tension control mechanism, wherein the tension control mechanism comprises a pole piece deviation correcting device and a driving device which are arranged between the unreeling mechanism and the reeling mechanism; a reeling needle of the reeling mechanism performs a cam motion; the driving device is used for driving a pole piece to be synchronous with the traction of the reeling needle performing the cam motion to the pole piece and simultaneously preventing the unreeling of the pole piece and an deviation correcting operation from influencing the tension of the pole piece. According to the reeling machine, the stable tension control is effectively realized.

Owner:SHENZHEN YINGHE TECH

Automatic cylindrical battery assembling machine

ActiveCN104505531ARealize fully automatic assemblyShorten the timePrimary cell manufactureAssembling battery machinesEngineeringAutomatic testing

The invention provides an automatic cylindrical battery assembling machine. The automatic cylindrical battery assembling machine comprises a rack and an indexing plate arranged on the rack and driven to rotate by a divider controlled by a stepping motor, wherein a clamping groove for adsorbing a cylindrical battery to be assembled is arranged on the circumference of the indexing plate according to the dividing angle of the divider; and the automatic cylindrical battery assembling machine also comprises a feeding chute, a tab locating device, a tab shaping device, a groove rolling device, a gluing device, a cap welding device, a liquid injection device, an unqualified product discharging device, a cap pressing device, an automatic sealing machine and a finished product discharging device which are arranged around the indexing plate and sequentially work cooperatively. According to the automatic cylindrical battery assembling machine, the working procedures such as feeding, tab locating, tab shaping, groove rolling, gluing, cap welding, liquid injection, discharging of unqualified products, cap pressing, and automatic sealing and discharging of finished products in the assembling procedures of the cylindrical battery are integrated, the cylindrical battery can be assembled in a full-automatic manner, the whole machine only is required to be monitored by one person, the cost and the time are saved, and the production efficiency is greatly improved.

Owner:惠州亿恒特自动化科技有限公司

Aluminum-casing battery module assembly line and assembling process

InactiveCN106450414AIncrease productivityAssembling battery machinesFinal product manufactureElectrical batteryInternal resistance

The invention relates to the technical field of battery production equipment, in particular to an aluminum-casing battery module assembly line and an assembling process. The aluminum-casing battery module assembly line comprises a voltage internal resistance measuring and automatic cleaning and sorting machine, an aluminum-casing battery screen printer, a thermal conductive casing inside dispensing machine, a thermal conductive casing laser marking machine, a thermal conductive casing outside dispensing machine, an aluminum-casing battery module speed multiplication line and a battery pack assembly line which are arranged in sequence according to production processes; and production efficiency can be increased greatly.

Owner:东莞市大族骏卓自动化科技有限公司

Electrochemical cell having a folded electrode and separator, battery including the same, and method of forming same

ActiveUS9246185B2Relative easeReduce manufacturing costPrimary cell to battery groupingElectrode manufacturing processesEngineeringElectrochemical cell

An electrochemical cell including a folded electrode layer and a folded separator, a battery including the electrochemical cell, and methods of forming the electrochemical cell and battery are disclosed. The electrode layer is folded in a first direction and the separator is folded in a second direction, such that the first direction and second direction are orthogonal each other.

Owner:ROBERT BOSCH GMBH +1

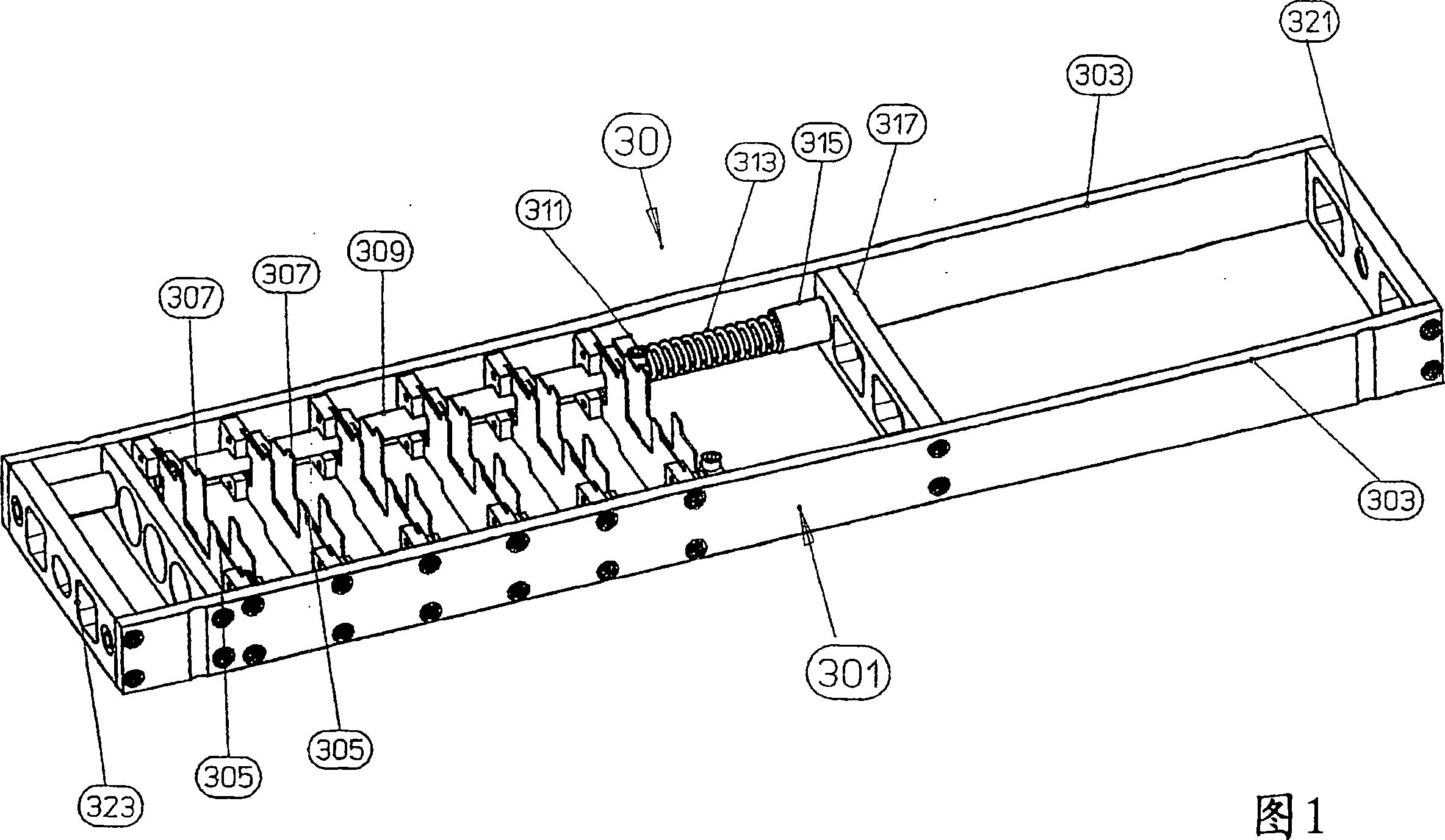

Method and device for connecting each storage battery plate into plate stack and inserting the said plate stack into storage battery case

InactiveCN101061598ASimplify work stepsAdapt to requirementsAssembling battery machinesFinal product manufactureFlangeElectrical and Electronics engineering

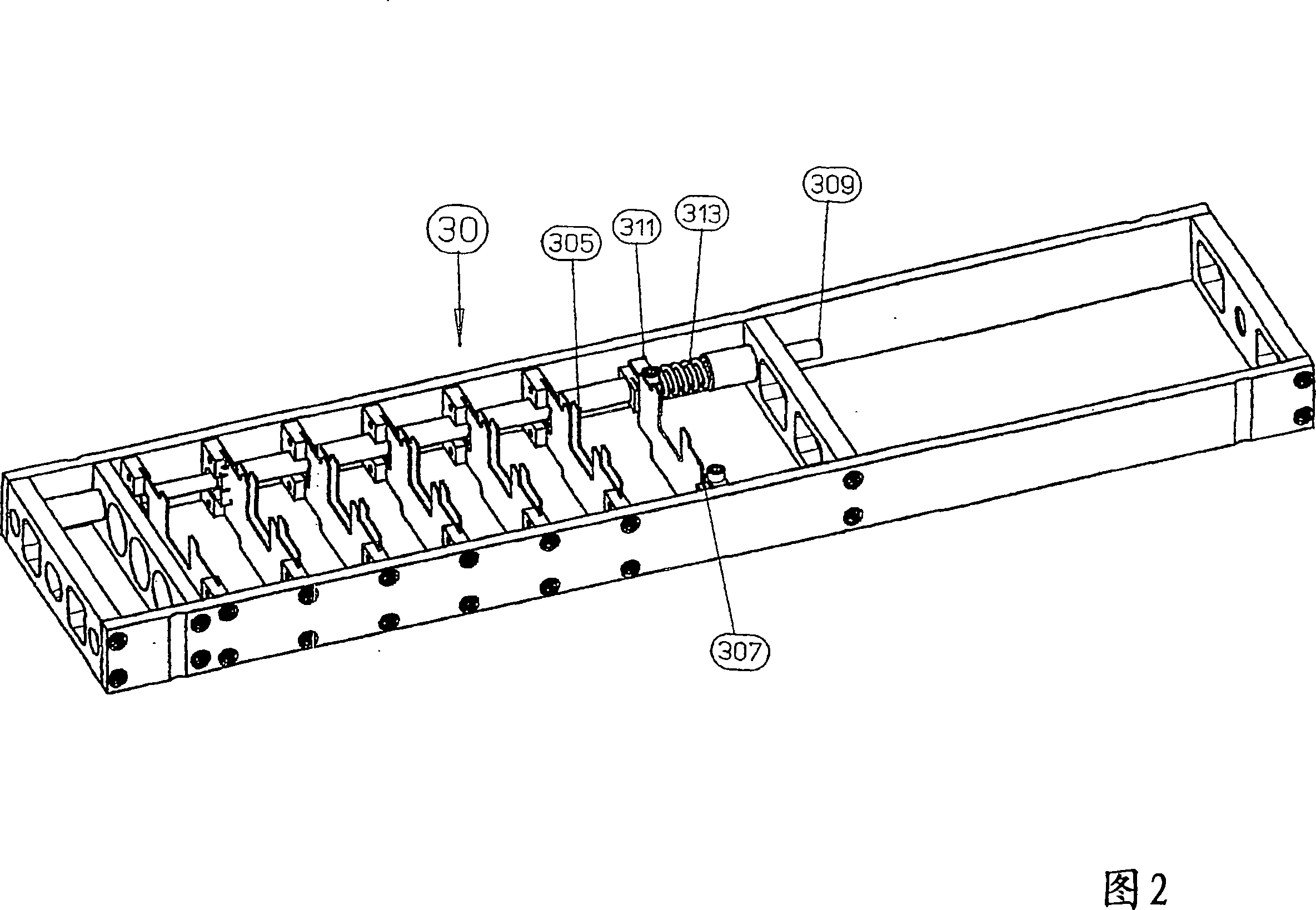

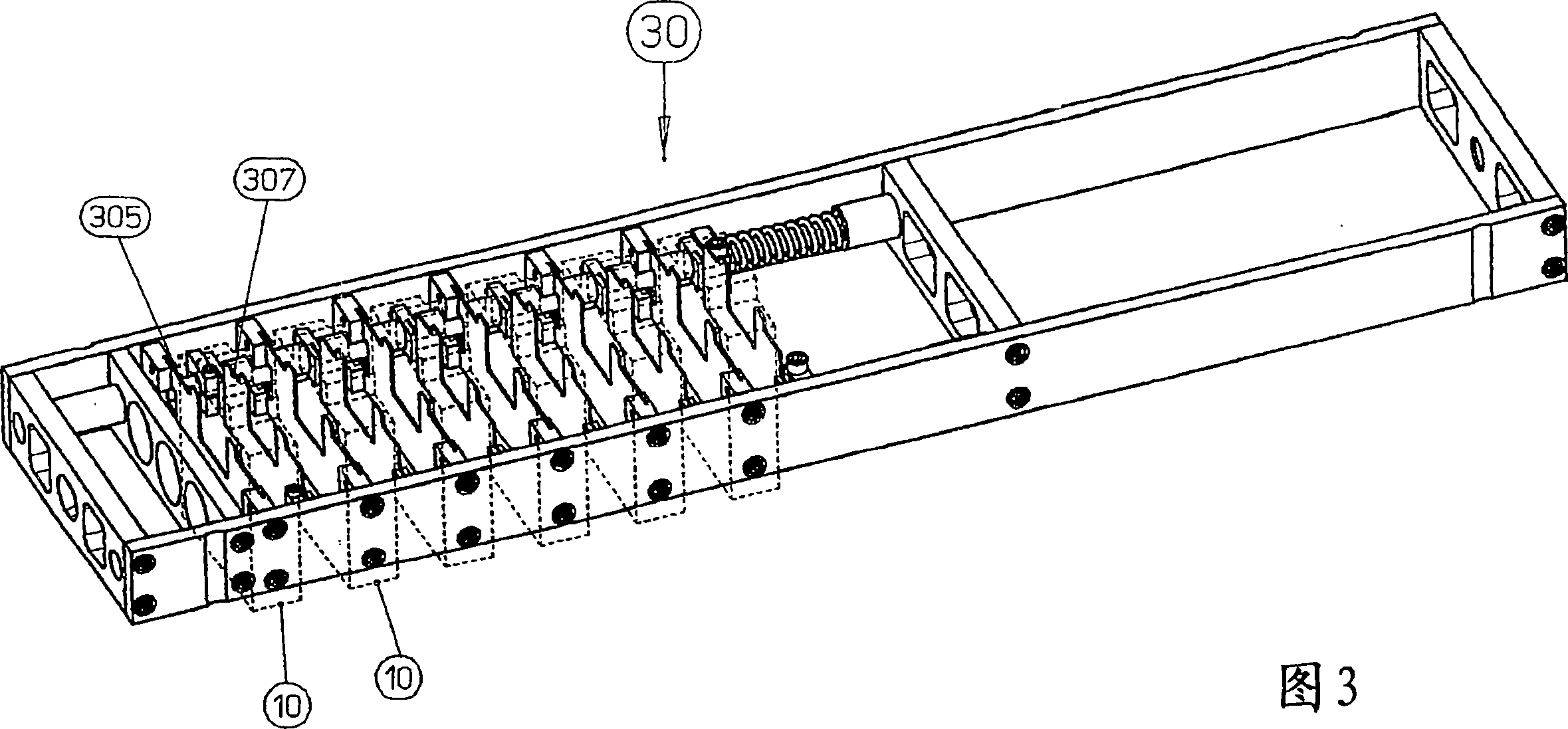

The invention relates to a system in which bridges (16, 18) with flanges (17, 19) for intercell connectors (24), said bridges connecting positive lugs (12), on the one hand, and negative lugs (14), on the other, are, in a casting station (270), cast onto the lugs (12, 14) of positive and negative battery plates, which are assembled to form packs (10), after subjecting the lugs (12, 14) to a pretreatment by brushing and with flux. The packs (10), which are comprised of battery plates and which are provided with bridges (16, 18) in the aforementioned manner, are placed inside compartments (22) for cells in battery cases (20) while being arranged in groups each consisting of three packs. Cassettes (30) are used for moving the packs (10) of battery plates, and the packs (10) are held in these cassettes while being squeezed between fixed and moving partitions (305, 307). The packs (10) are placed inside these cassettes (30) in such a manner that solely lugs (12) of positive plates are placed on one longitudinal side, and solely lugs (14) of negative plates are placed on the other longitudinal side.

Owner:BM BATTERY MASCH GMBH

Battery manufacturing method and apparatus

InactiveUS20090100669A1Minimize thickness changeMinimize lowering of processing accuracyElectrode rolling/calenderingAssembling battery machinesElectrical and Electronics engineeringCurrent collector

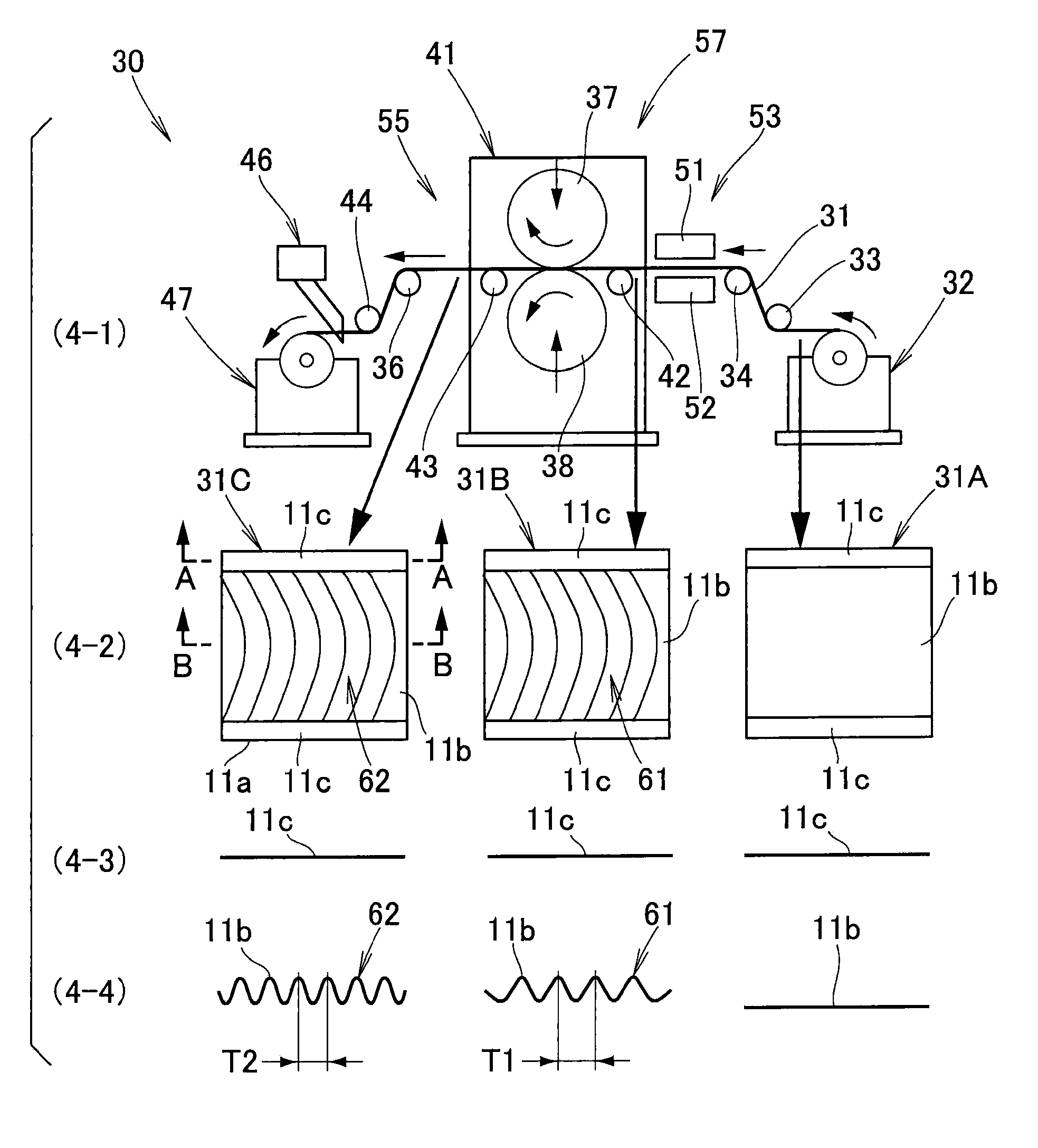

For manufacturing a battery including positive and negative sheet electrodes formed from positive and negative electrode sheets each having active-material-coated portions on opposite surfaces, except for opposite surfaces of one side edge portion, of the sheet and non-active-material-coated portions on the opposite surfaces of the one side edge portion, a method includes: forming a succession of corrugations on each of the sheets, having the coated portions provided thereon, in a longitudinal direction of the sheet; roll-pressing each of the sheets having the corrugations formed thereon; constructing an electrode assembly of the positive and negative sheet electrodes with a separator interposed therebetween; and connecting current collectors to the non-coated portions of the sheet electrodes.

Owner:HONDA MOTOR CO LTD

Battery winder

ActiveCN103915654ASimple structureImprove job stabilityMeasurement devicesAssembling battery machinesEngineeringPole piece

The invention discloses a battery winder which comprises a rack, an installation base board, a winding device, a delivery mechanism of two pole pieces and a delivery mechanism of two membranes, wherein the installation base board is arranged on the rack along the vertical direction, the winding device is arranged on the installation base board, a positive pole piece and a negative pole piece are respectively delivered to the winding device by virtue of the delivery mechanism of the two pole piece, a left membrane and a right membrane are respectively delivered to the winding device by the delivery mechanism of the two membranes, the left membrane, the positive pole piece, the right membrane and the negative pole piece which are successively superposed are wound and formed, so as to obtain a cell, a pole piece edge detection device and a pole piece centring device are arranged on the pole piece delivery mechanism, the pole piece edge detection device is used for detecting the edge of the positive pole piece or the negative pole piece in real time, the pole piece centring device is used for rectifying a deviation for the positive pole piece or the negative pole piece in real time according to the detection data of the pole piece edge detection device, a membrane edge detection device and a membrane centring device are arranged on the membrane delivery mechanism, the membrane edge detection device is used for detecting the edge of the left membrane or the right membrane in real time, and the membrane centring device is used for rectifying a deviation for the left membrane or the right membrane in real time according to the detection data of the membrane edge detection device.

Owner:东莞市博拓锂电科技有限公司

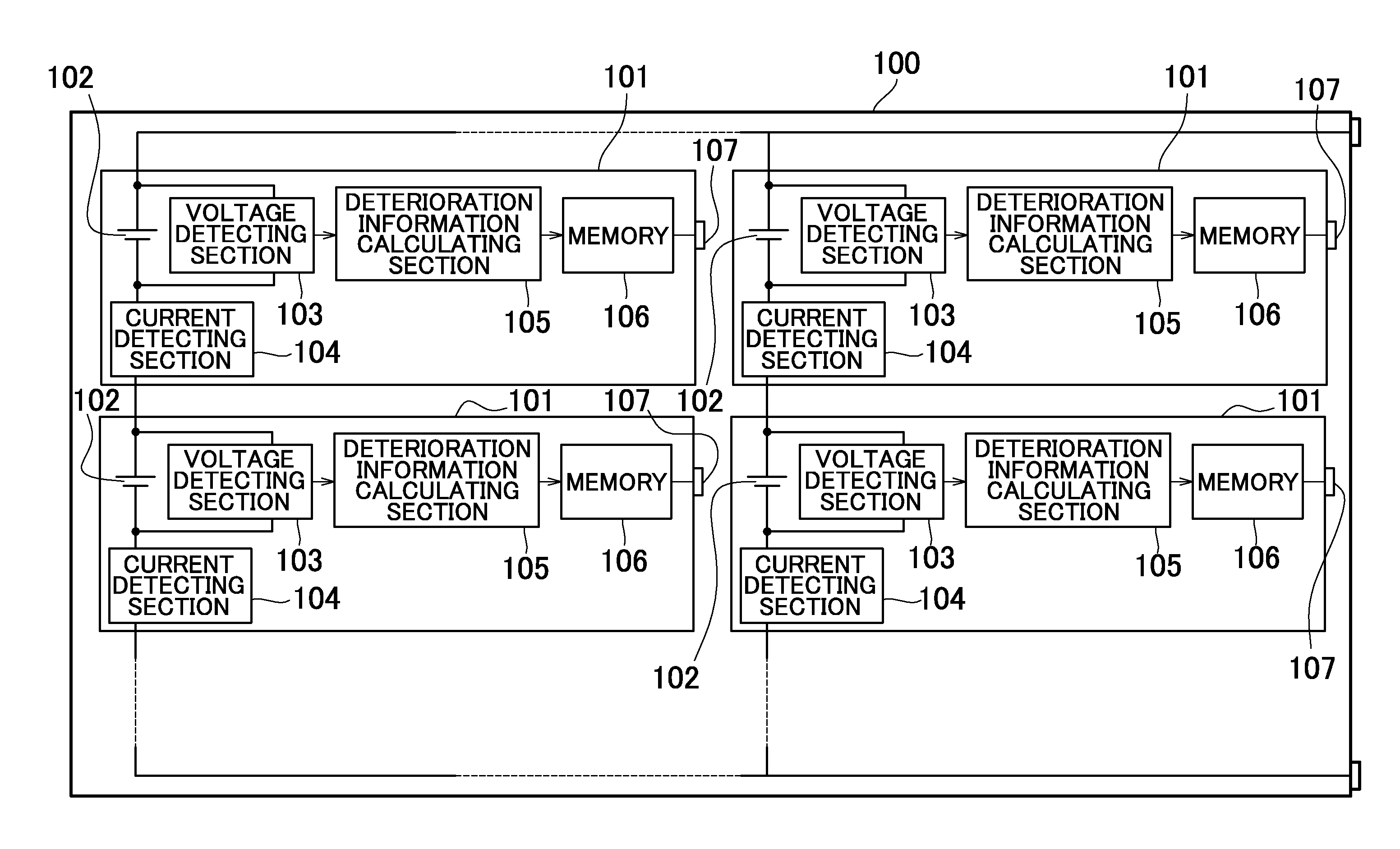

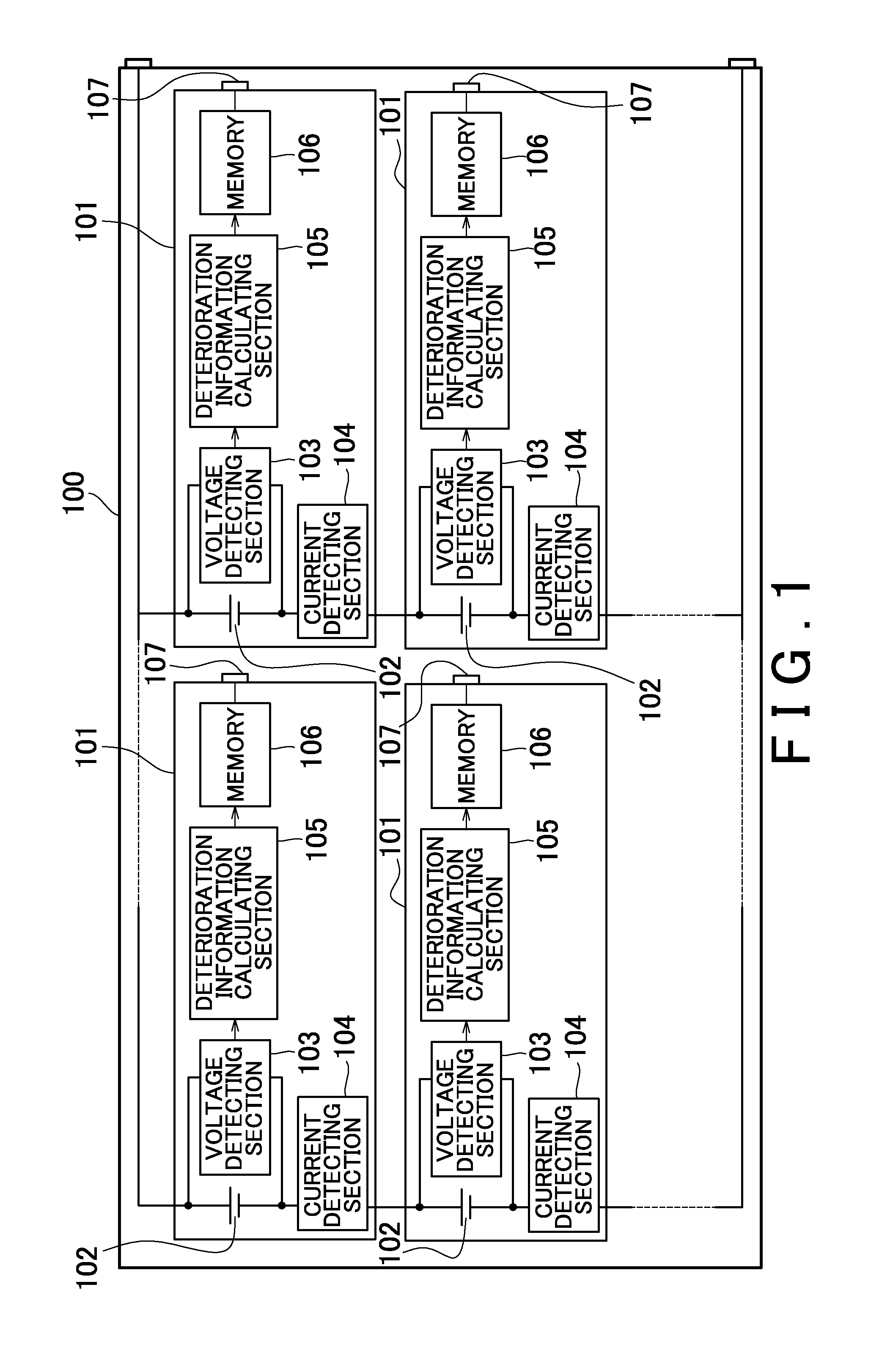

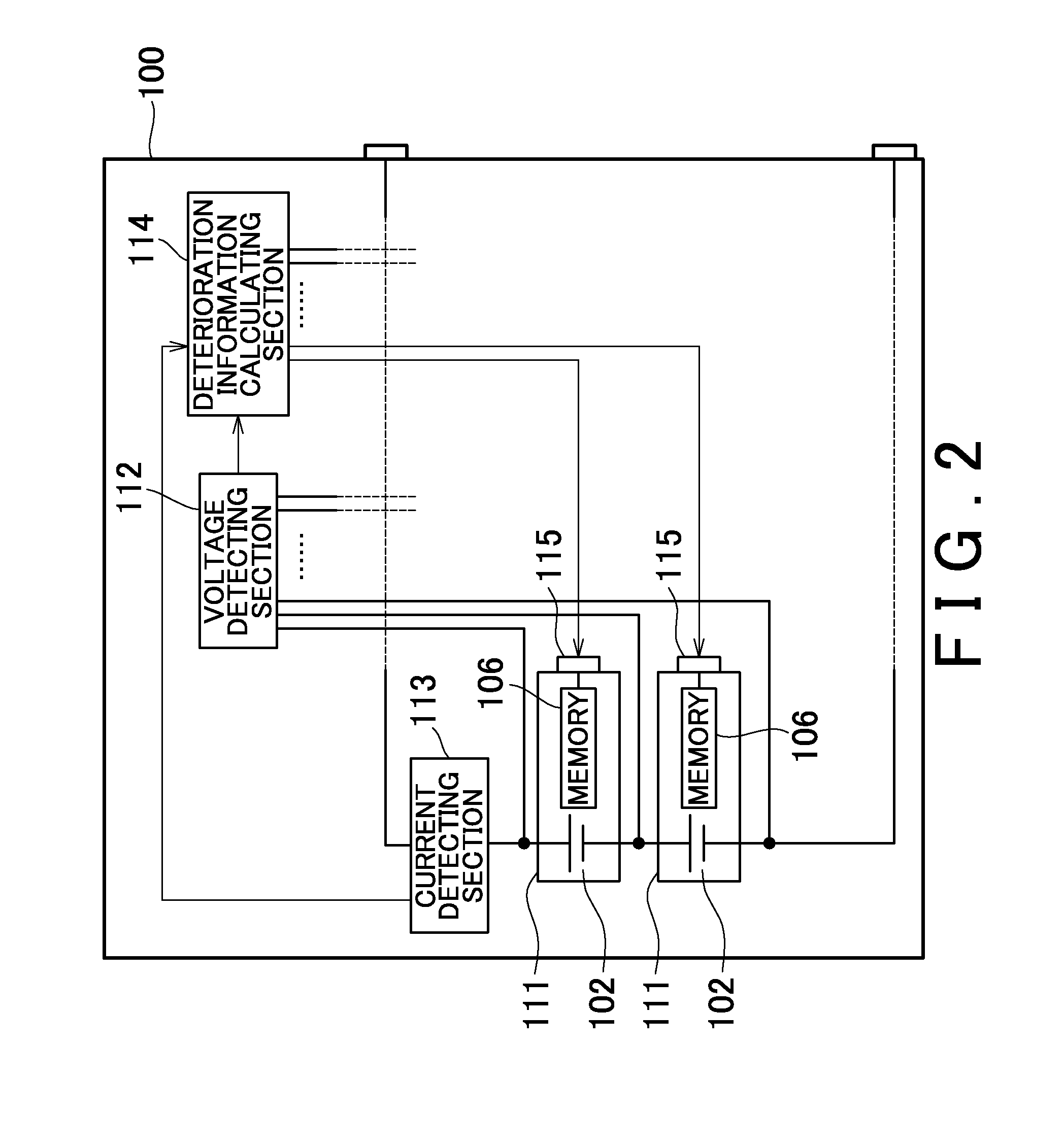

Battery pack

ActiveUS20120015221A1Batteries circuit arrangementsAssembling battery machinesEngineeringBattery cell

Provided is a battery pack comprising a plurality of batteries; and a plurality of memories that correspond respectively to the batteries and that each record deterioration information of the corresponding battery. Each set of a battery and a corresponding memory may be formed integrally as a battery cell. As a result, the deterioration information of each battery cell can be known even after the battery pack is disassembled.

Owner:ITOCHU CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com