Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

399results about How to "Improve the anti-leakage effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

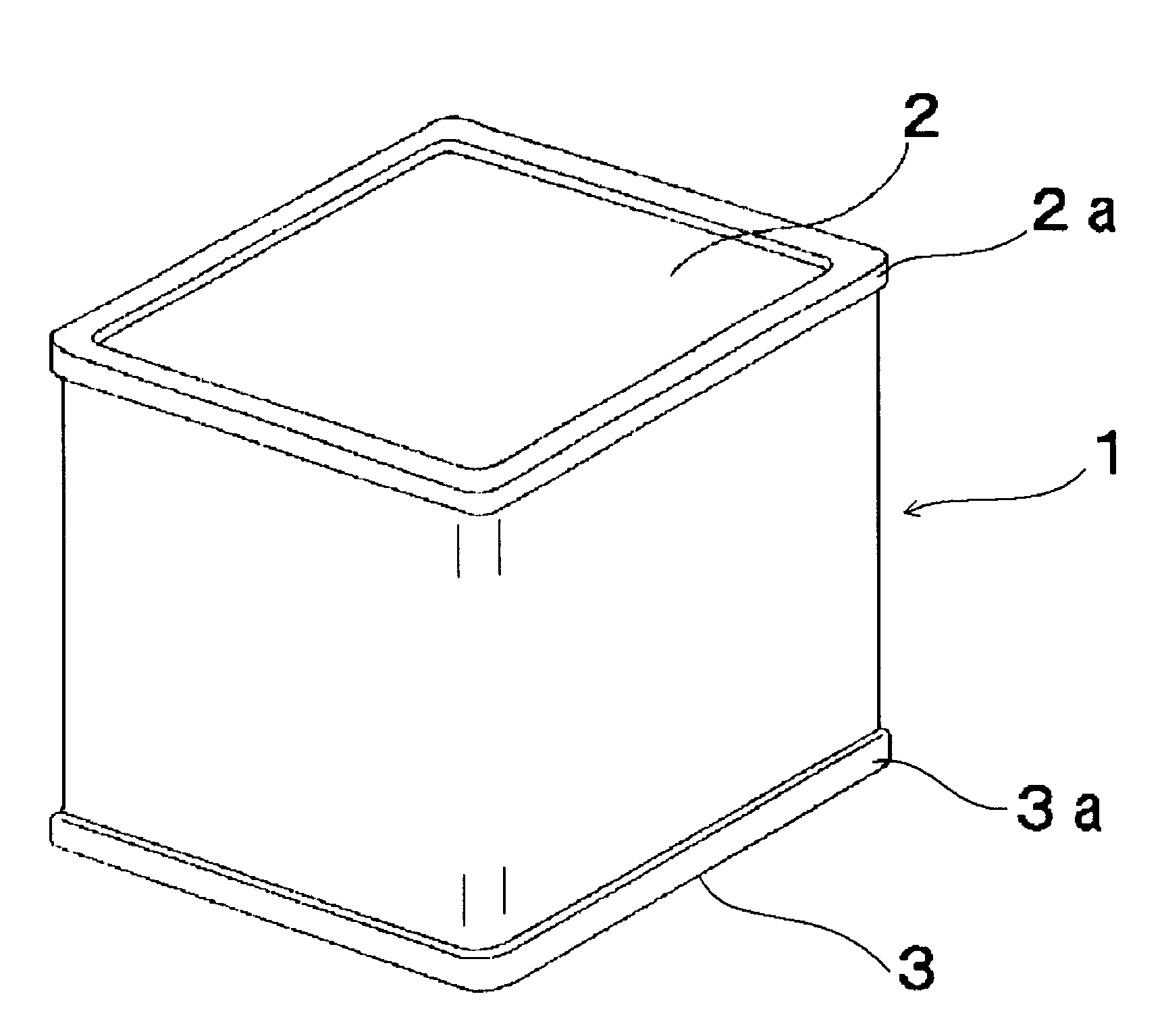

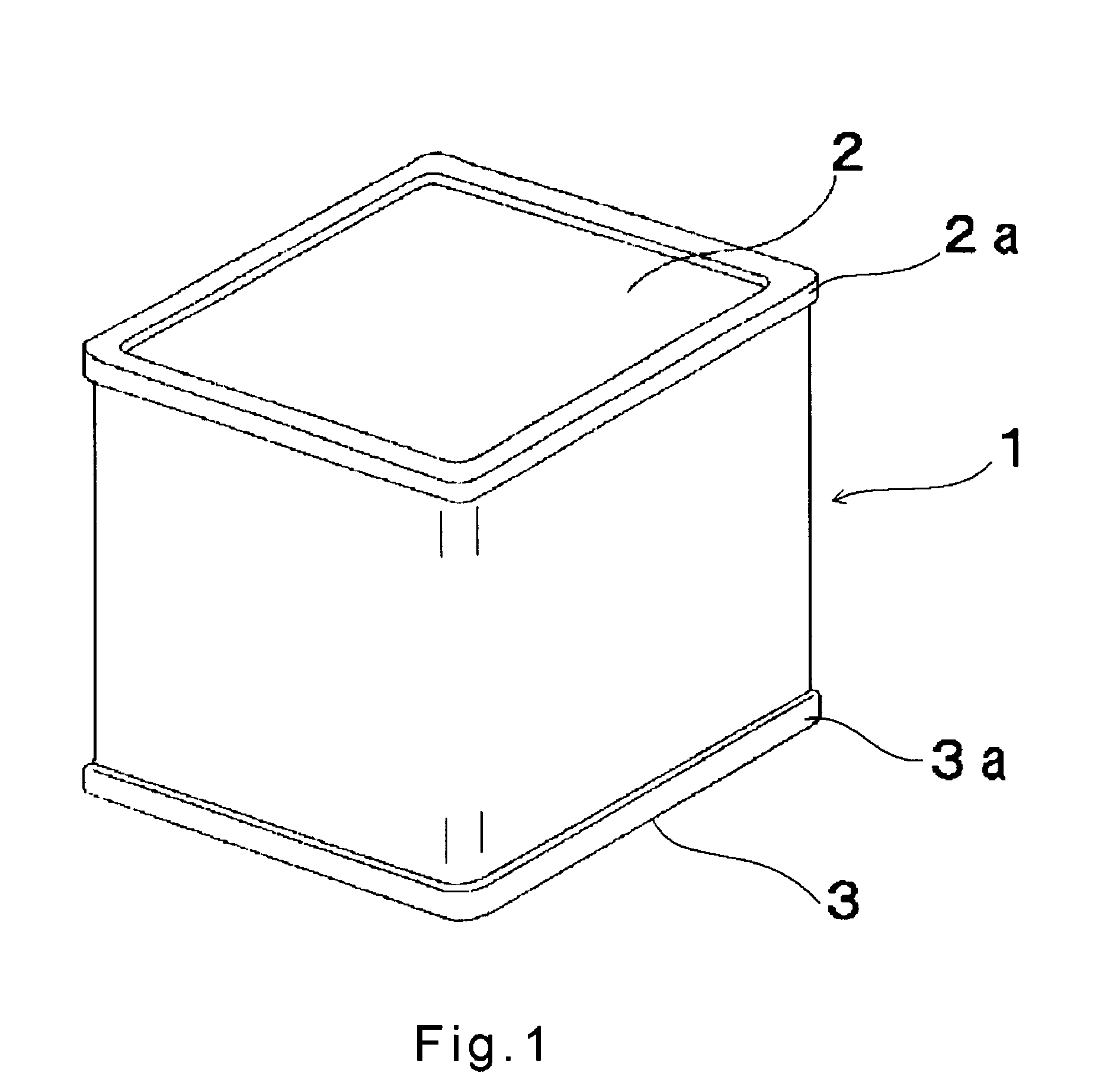

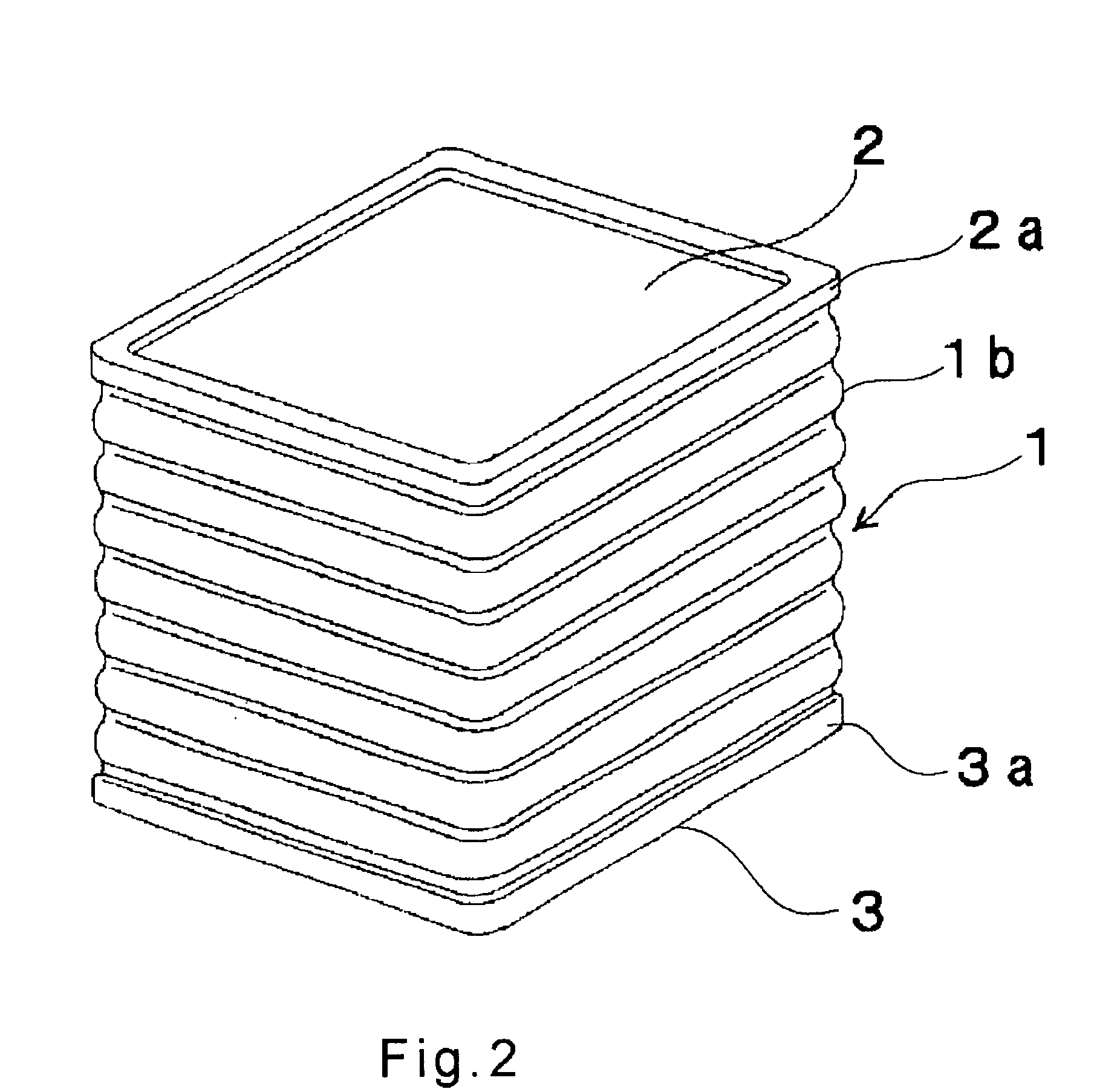

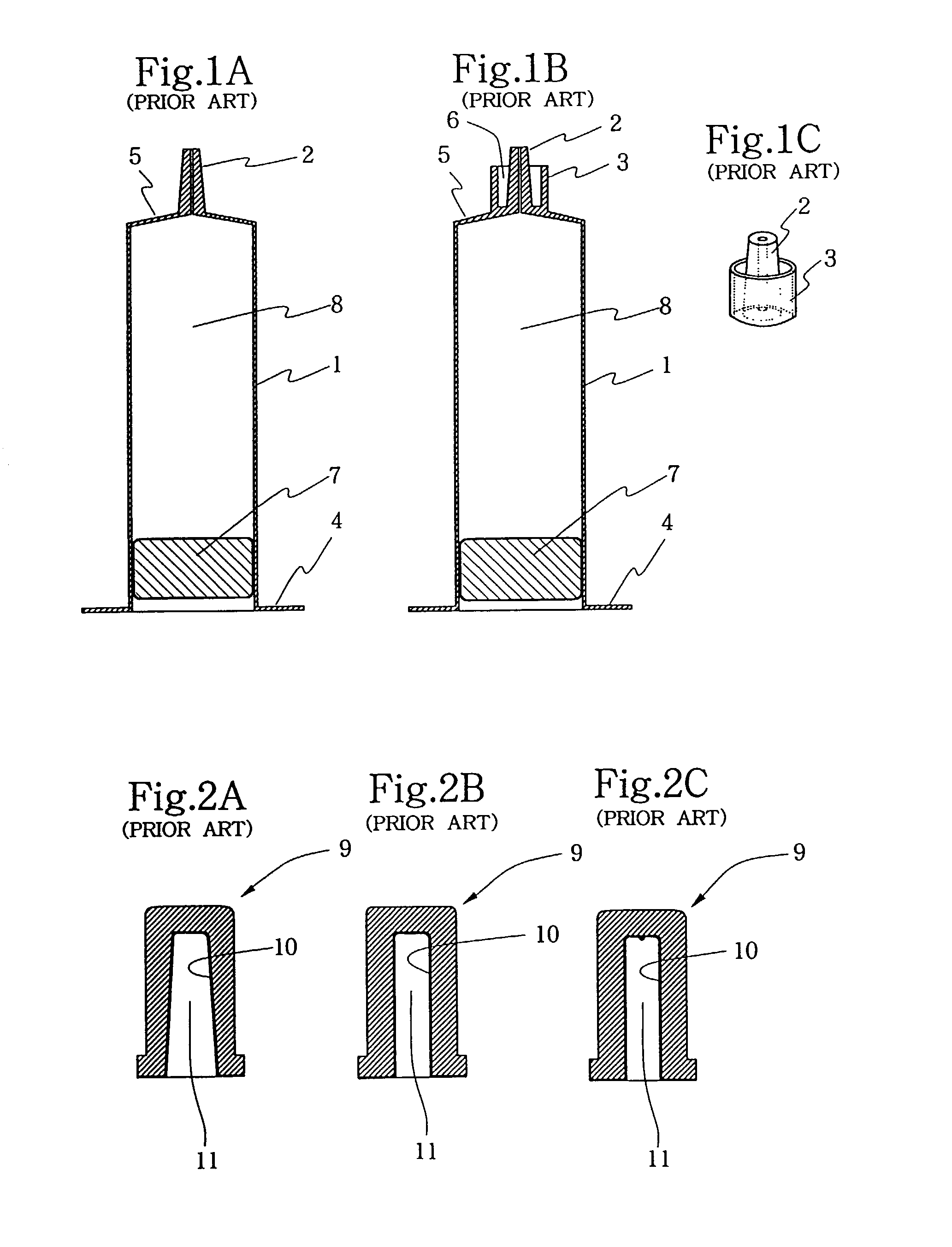

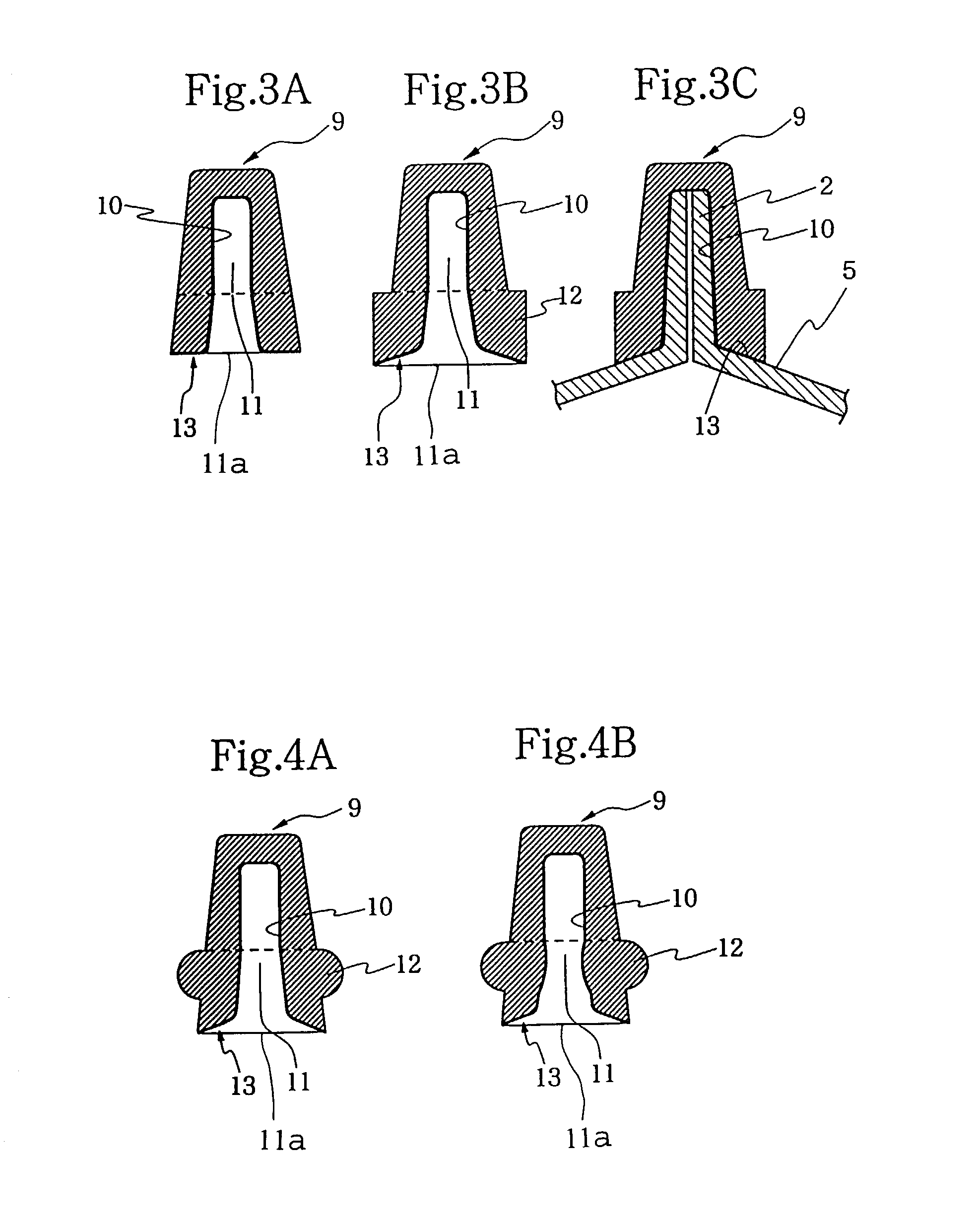

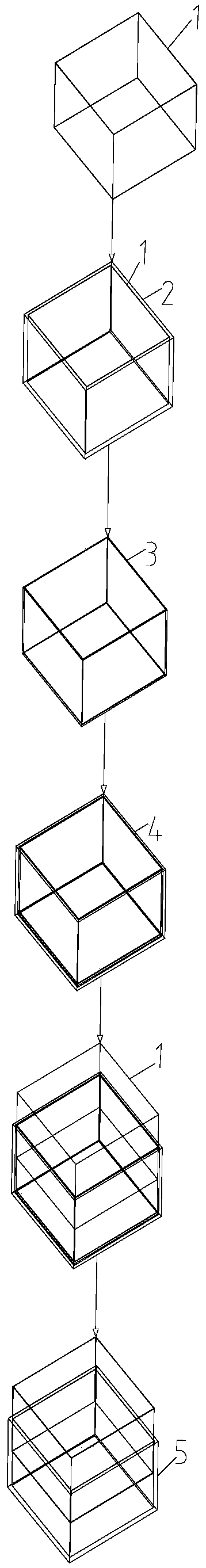

Three-piece square can and method of manufacturing the same

InactiveUS20090206096A1Improve the anti-leakage effectAvoid it happening againAssembling battery machinesSmall-sized cells cases/jacketsOrganic filmBody joints

The present invention provides a three-piece rectangular can which can overcome drawbacks (joint defect) of a can body joint portion of a three-piece can, and is of a new type which overcomes shortage of a can body strength which a two-piece can possesses, and exhibits excellent liquid leakage resistance, excellent can body strength and excellent heat radiation property or the like even when the can is used as a casing of a battery or electric equipment. For this end, the three-piece rectangular can of the present invention is formed such that a circular blank formed of an aluminum plate which forms an organic film on at least one surface thereof is formed into a bottomed circular can by deep drawing such that the organic film forms an inner side of the can, a cylindrical sleeve having no seam on a side surface thereof is formed by cutting a can bottom of the bottomed circular can, a rectangular can body portion having no seam on a side surface thereof is formed by deforming the cylindrical sleeve into a rectangular shape, a necking formed portion is formed by applying necking forming to opening portions at both ends of the rectangular can body, and a top lid and a bottom lid are mounted on the opening portions at both ends of the rectangular can body by double seaming by way of an organic compound.

Owner:TOYO SEIKAN KAISHA LTD +1

Sealing rubber closure for syringe/container

InactiveUS7214214B2Improve air tightnessAvoid contactCapsAmpoule syringesPlastic filmInternational standardization

Owner:DAIKYO SEIKO LTD

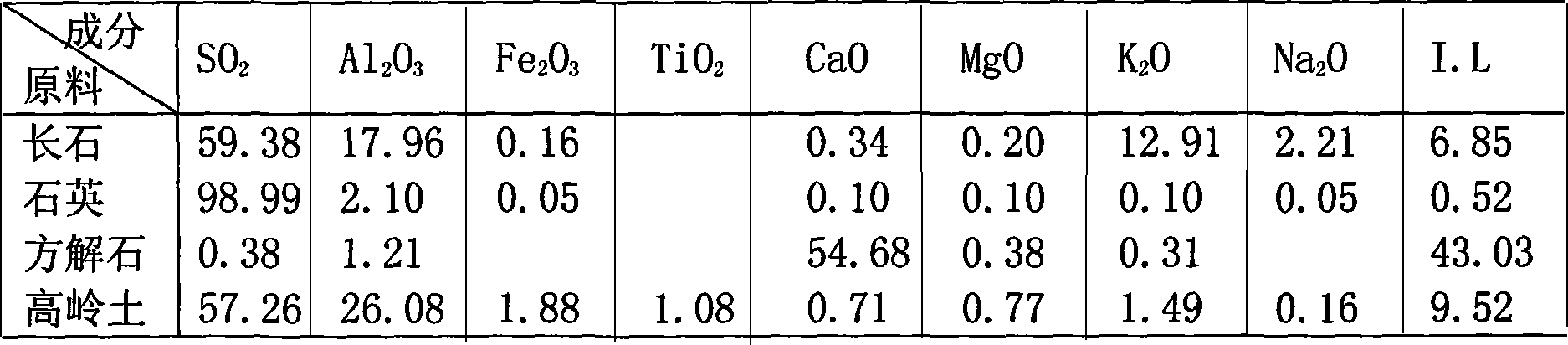

Antiseep glaze material and glair for Ruyao kiln package container and preparing method thereof

InactiveCN101058476AImprove the anti-leakage effectGet rid of the status quo of pure handicraftsGlazeKaolin clay

The invention discloses an antiseptic glaze, slip and making method for herporcelain ash embryo, which comprises the following parts: 16-30% feldspar, 6-17% quartz, 12-26% calcite and 38-55% caoline, wherein the herporcelain packing container of antiseptic glaze slurry is composed of 5. 3% feldspar, 2-8. 5% quartz, 4-13% calcite, 12. 6-27. 5% caoline and 50-67% water. The invention can contain liquid material, which can also be ornamental craft.

Owner:王振芳

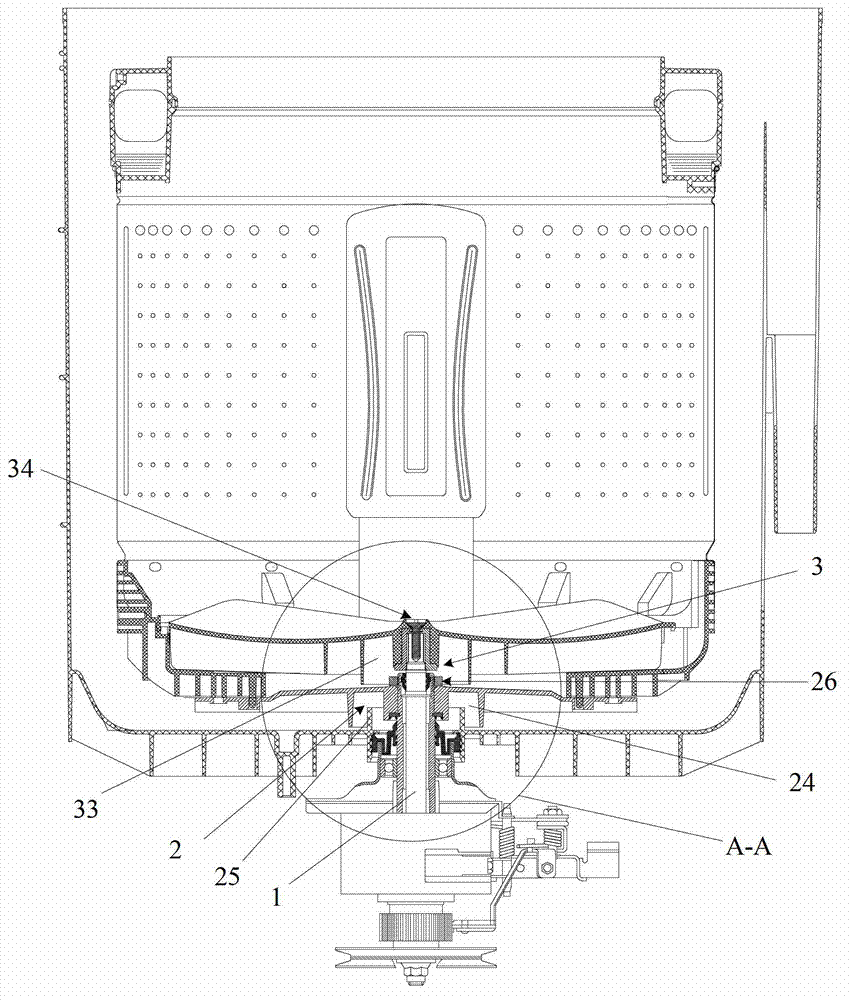

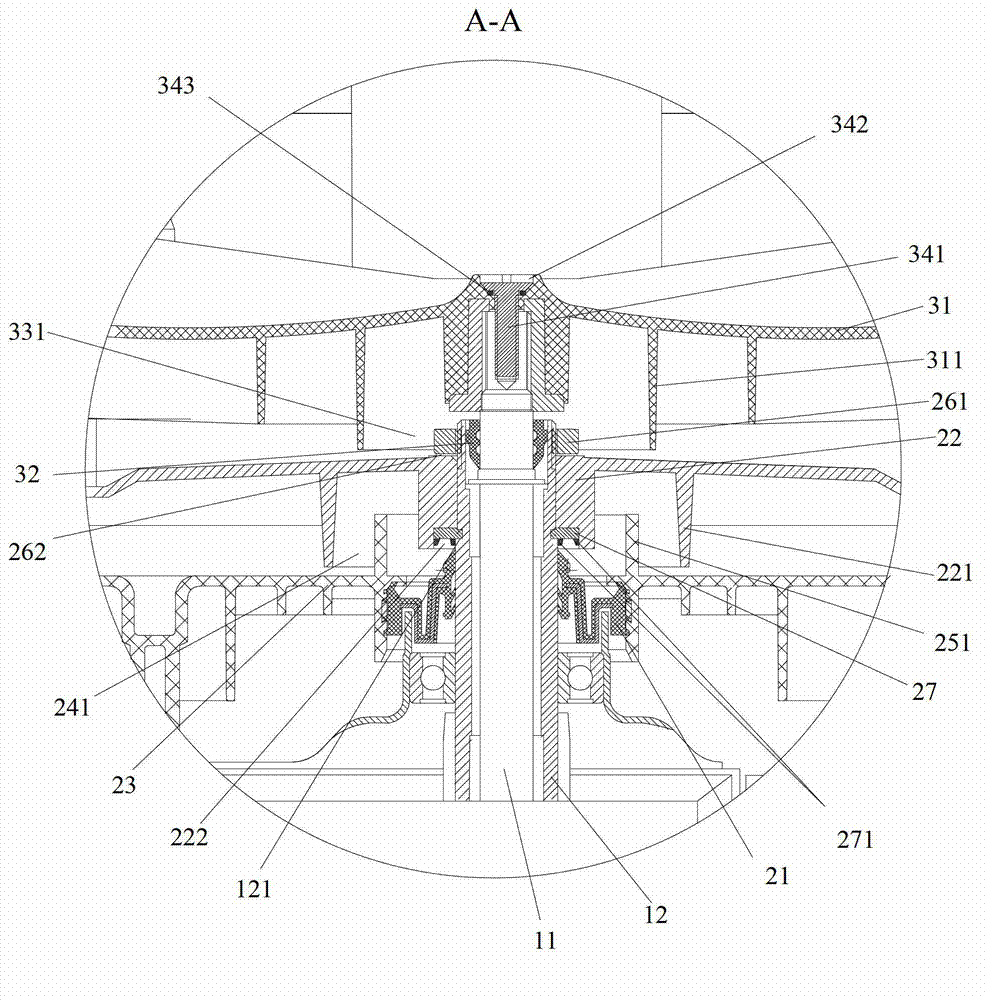

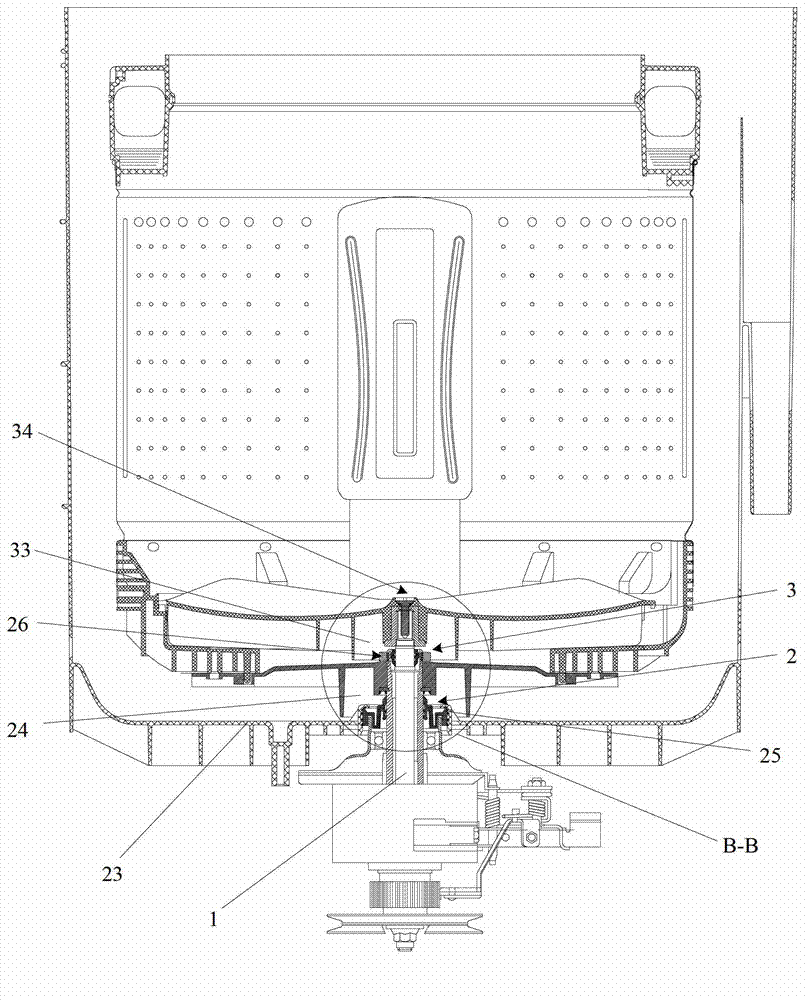

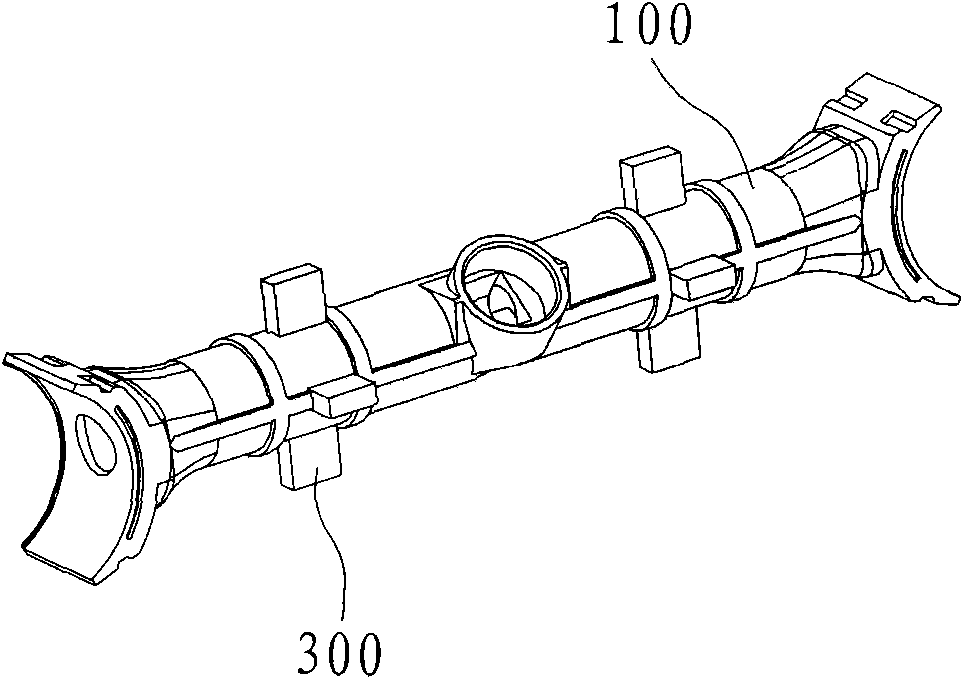

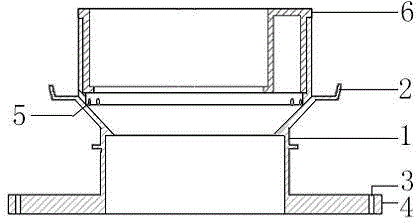

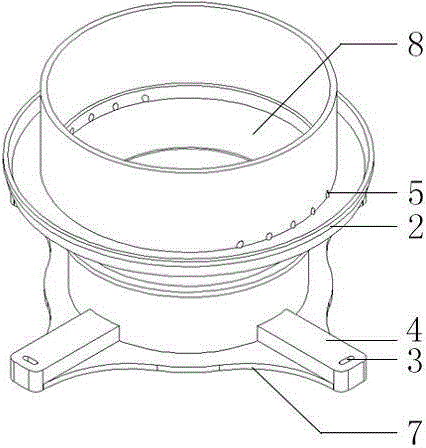

Anti-leakage pulsator washing machine

InactiveCN103088598APrevent rustLow costEngine sealsWashing machine with receptaclesLeaking waterImpeller

The invention discloses an anti-leakage pulsator washing machine. The anti-leakage pulsator washing machine comprises a clutch, a first waterproof device and a second waterproof device. The clutch comprises a washing shaft and a dehydrating shaft, wherein the dehydrating shaft coaxially rotates around the washing shaft. The first waterproof device comprises a first water seal, an inner barrel flange and an outer barrel, wherein a first waterproof space is formed among the first water seal, the inner barrel flange, the dehydrating shaft and the outer barrel. The second waterproof device comprises an impeller and a second water seal, wherein a second waterproof space is formed among the impeller, the second water seal, the washing shaft and the dehydrating shaft. According to the anti-leakage pulsator washing machine, water which is poured in the process of washing is used for compressing air sealed in the first waterproof space and the second waterproof space, the compressed air effectively blocks the water and prevents a portion prone to leakage from contacting with the water in the washing machine, and therefore a condition that the clutch portion leaks water so as to enable the clutch to get rusty and corroded and influence the performance of the whole machine is effectively avoided. The anti-leakage pulsator washing machine is low in cost and good in anti-leakage effect.

Owner:NANJING CHUANGWEI HOUSEHOLD ELECTRONICS APPLIANCES LTD

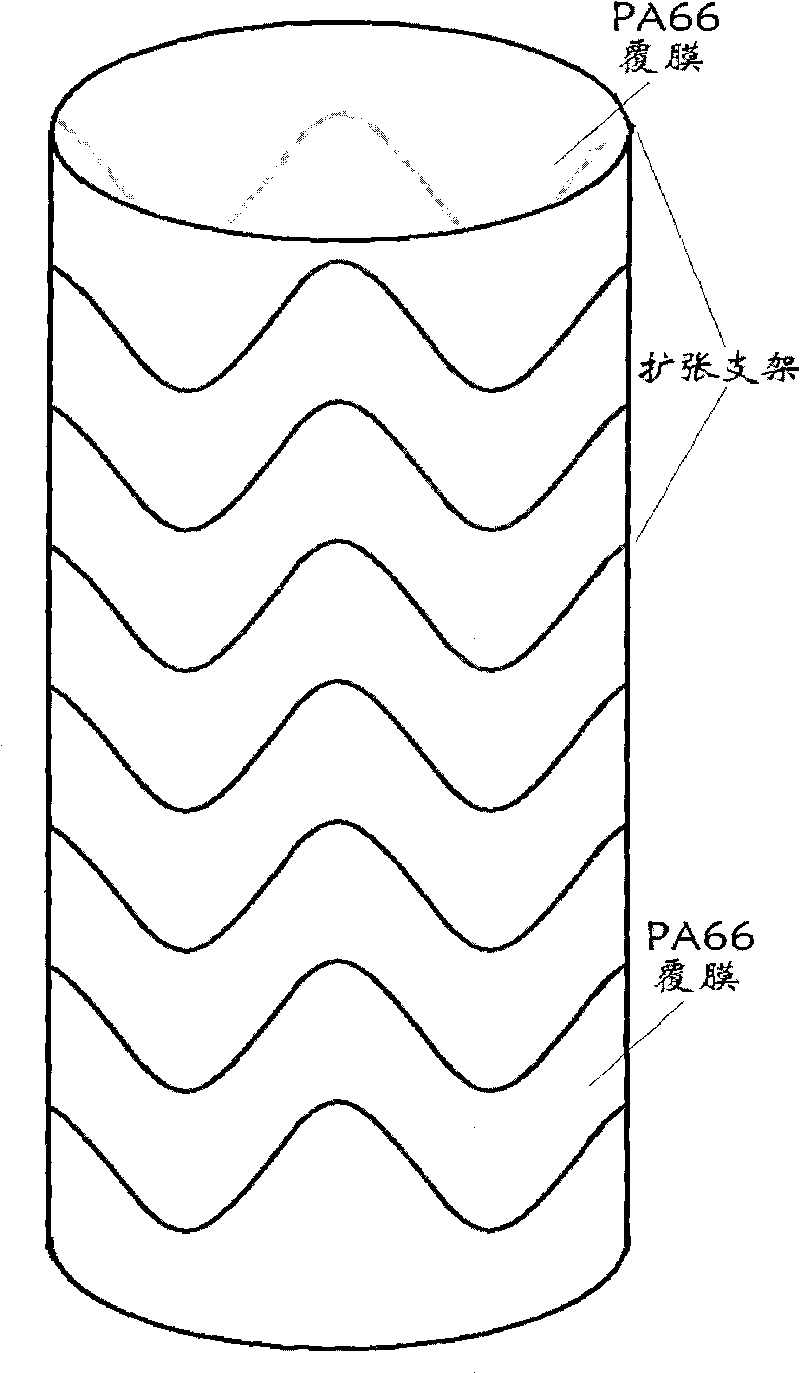

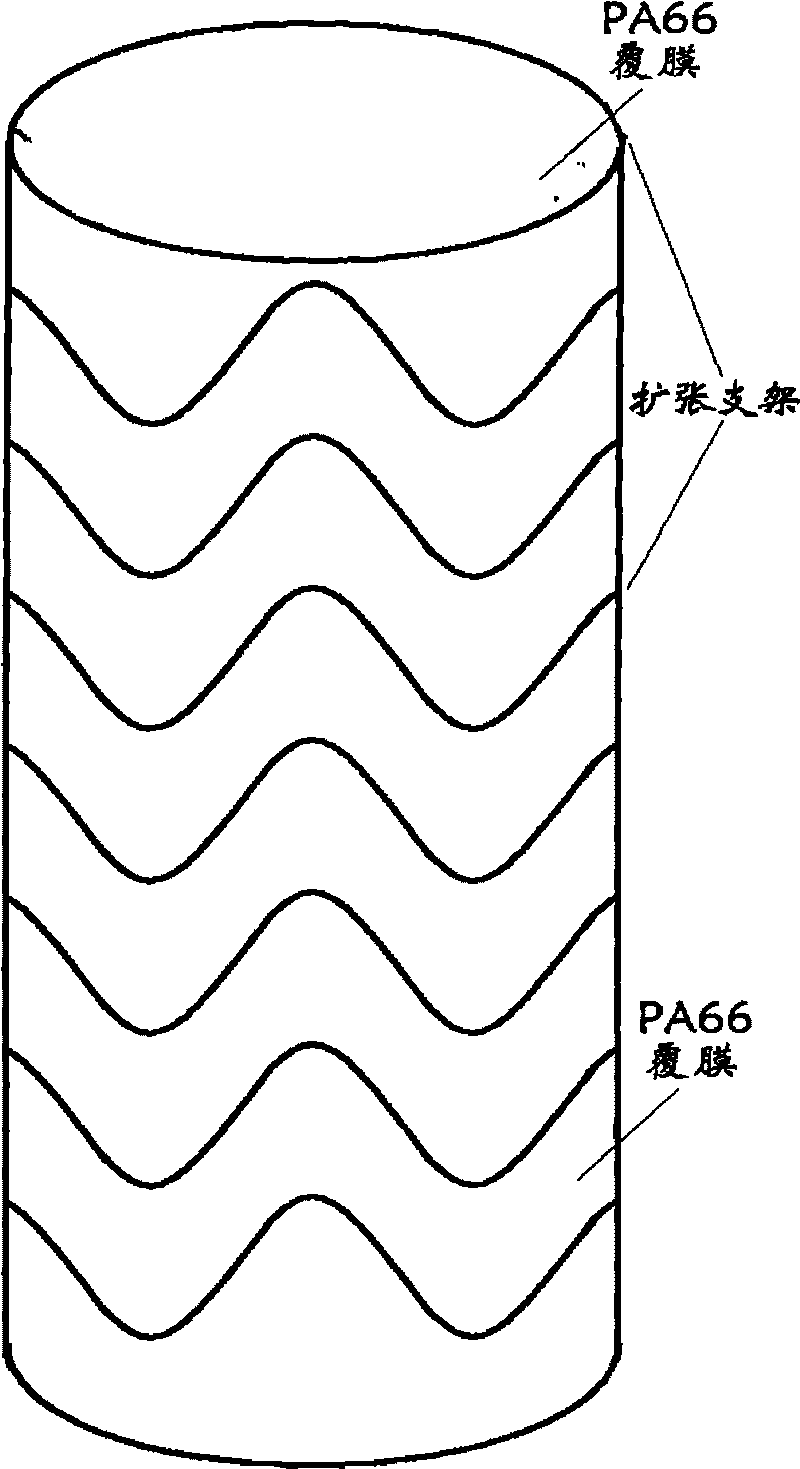

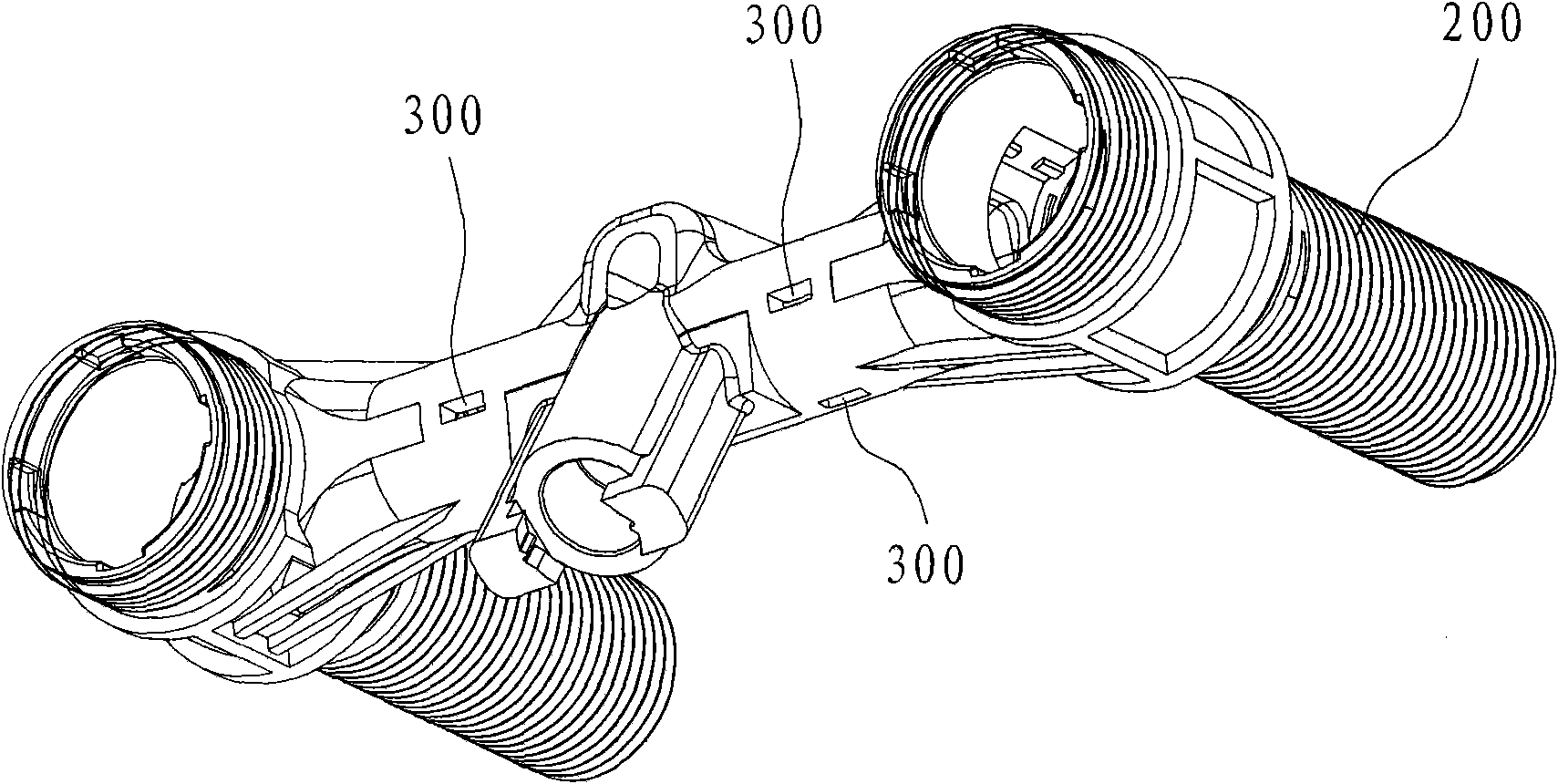

Polyamide 66 membrane covered nickel-titanium alloy intravascular scaffold and preparation method thereof

InactiveCN101703812AImprove impact toughnessExcellent formabilityLiquid surface applicatorsSurgeryNitinol stentPolyamide

The invention relates to a polyamide 66 membrane covered nickel-titanium alloy intravascular scaffold and a preparation method thereof. The intravascular scaffold comprises a nickel-titanium alloy scaffold and a polyamide 66 membrane, and is provided with a tubular blood vessel shaped structure or a cylindrical blood vessel shaped structure, wherein the surfaces of an inner wall and an outer wallof the scaffold are covered by thin membranes with the thickness between 0.2 and 5 millimeters. The preparation method comprises the following steps of: preparing 1 to 20 percent of polyamide 66 solution by using formic acid as a solvent; coating a layer of the polyamide 66 solution on a glass rod and volatizing the solvent; sleeving a nickel-titanium shape memory alloy expanding scaffold on the glass rod; coating another layer of the polyamide 66 solution on the glass rod and volatizing the solvent; and peeling off the polyamide 66 membrane and the nickel-titanium alloy intravascular scaffold from the glass rod, and performing vacuum drying to obtain the polyamide 66 membrane covered intravascular scaffold. The intravascular scaffold prepared by the method has a stable structure, good mechanical property, transportability and anti-seepage property, overcomes the performance defects of a single material, and has a simple preparation process.

Owner:DONGHUA UNIV

Glass flake plasticine coating

InactiveCN1789351AImprove heat resistanceImprove mechanical propertiesAnti-corrosive paintsEpoxy resin coatingsVinyl esterCoating

The invention provides a glass flake clay paint, whose constituents include (by weight ratio) vinyl ester 55-65%, glass flake 25-35%, and addition agent 0.001-10%. The paint has good tenacity, fatigue resistance, antiseep property and hermeticity.

Owner:吴凡 +1

Environmental protection flower-pot capable of natural degrading and preparation method thereof

The invention relates to a flowerpot and a manufacturing method thereof, in particular to a degradable environmental-friendly flowerpot and a manufacturing method thereof. Components of the flowerpot comprise: plant fiber powder and a cementing compound, weight percentage of the plant fiber powder is 50 percent to 70 percent and that of the cementing compound is 30 percent to 50 percent; the plant fiber powder comprises rice hull powder, bamboo powder and soybean powder, and the weight percentage of the plant fiber powder is: 40 percent to 70 percent the rice hull powder, 10 percent to 40 percent the bamboo powder and 20 percent to 30 percent the soybean powder. Main processing technique is: mixing, dehydration, pressing, grinding and packaging. The environment-friendly flowerpot manufactured by the invention has the advantages of natural degradation, good stiffness, high strength and being uneasy to deform.

Owner:姚维生 +1

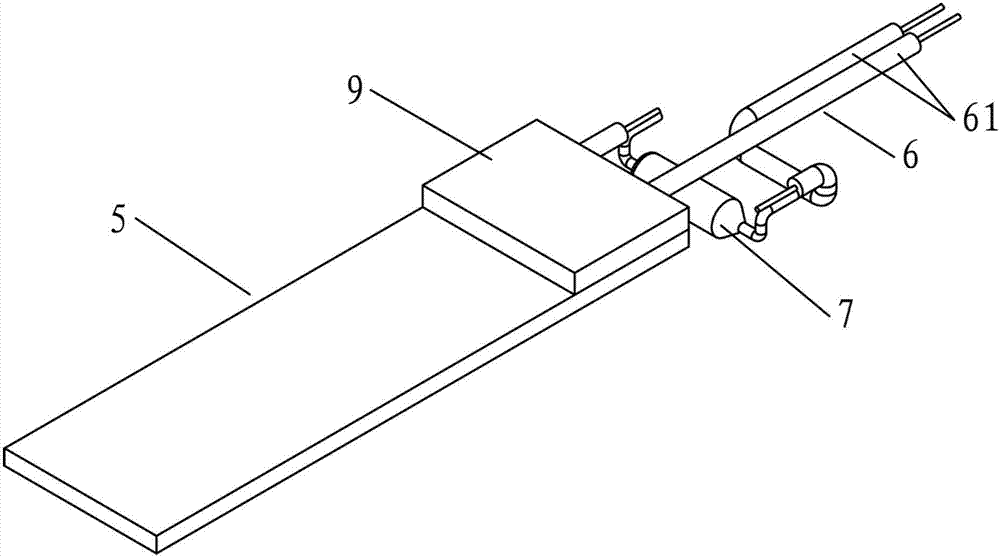

Heat barrier material high temperature heat conductivity plane heat source test system and method

InactiveCN104502400AImprove antioxidant capacityImprove anti-interference abilityMaterial heat developmentConstant powerEngineering

The invention provides a heat barrier material high temperature heat conductivity plane heat source test system and method, and heat barrier material heat conductivity at the temperature of room temperature to 1200 DEG C can be tested. Three stacked to-be-tested samples are placed in a high temperature furnace, a plane heat source providing a constant power output is placed between a middle sample and a lower sample, the plane heat source is connected with a constant flow source meter by a high temperature resistant wire, a temperature testing thermocouple responding test temperature is arranged between an upper sample and the middle sample, and the temperature testing thermocouple is connected with a temperature display instrument. After the high temperature furnace is heated, the plane heat source is charged with a step type heating current, and temperature change of the temperature testing thermocouple is tested and recorded under constant pressure so as to calculate the heat conductivity of the to-be-tested sample. The plane heat source and the temperature testing thermocouple can solve the problem of temperature signal interference during test of heat conductivity of a low resistivity material by use of transient plane source method, and can achieve test of high temperature heat conductivity of the low resistivity material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

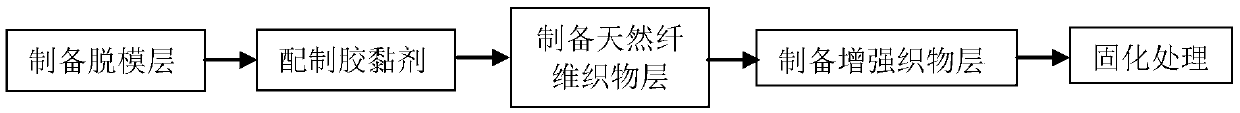

Lining layer of bamboo-wound composite pipe and preparation method thereof

ActiveCN105508809AMeet hygiene requirementsHigh tensile strengthCorrosion preventionPipe protection against corrosion/incrustationNatural fiberCorrosion

The invention discloses a lining layer of a bamboo-wound composite pipe and a preparation method thereof. The lining layer comprises a natural fiber fabric layer and a reinforced fabric layer in sequence from inside to outside in the radial direction of the pipe; a natural fiber fabric of the natural fiber fabric layer and a reinforced fabric of the reinforced fabric layer are both dipped with adhesive; the adhesive dipping rate of the natural fiber fabric is higher than 92%; the adhesive dipping rate of the reinforced fabric is higher than 71%; and the adhesive includes a resin and a curing agent. The method comprises the following steps: firstly, a demolding layer is prepared; one layer of adhesive is poured on the surface of the demolding layer, then, the natural fiber fabric is wound, and the adhesive infiltrates the natural fiber fabric to obtain the natural fiber fabric layer; one layer of adhesive is poured on the surface of the natural fiber fabric layer, the reinforced fabric is wound, the adhesive infiltrates the reinforced fabric to obtain the reinforced fabric layer; and then, the needed lining layer is obtained through curing treatment. The lining layer is excellent in leakage resistance and corrosion resistance, and satisfies the sanitation requirement; and the preparation method is simple in operation and high in efficiency.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

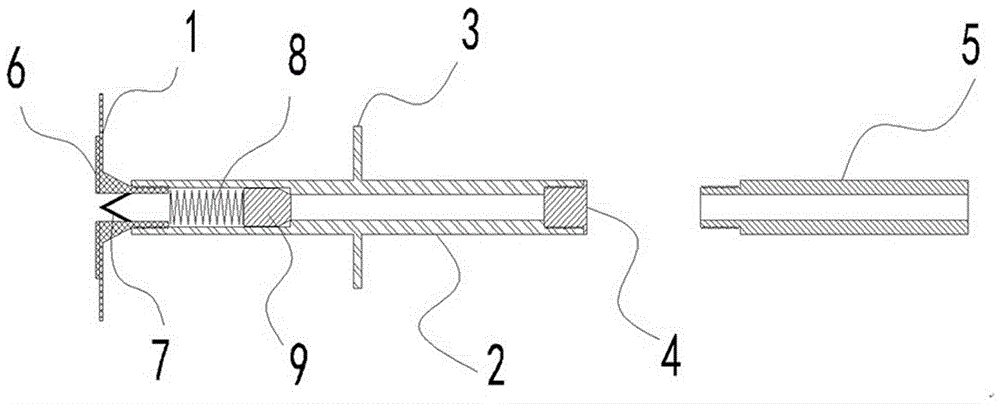

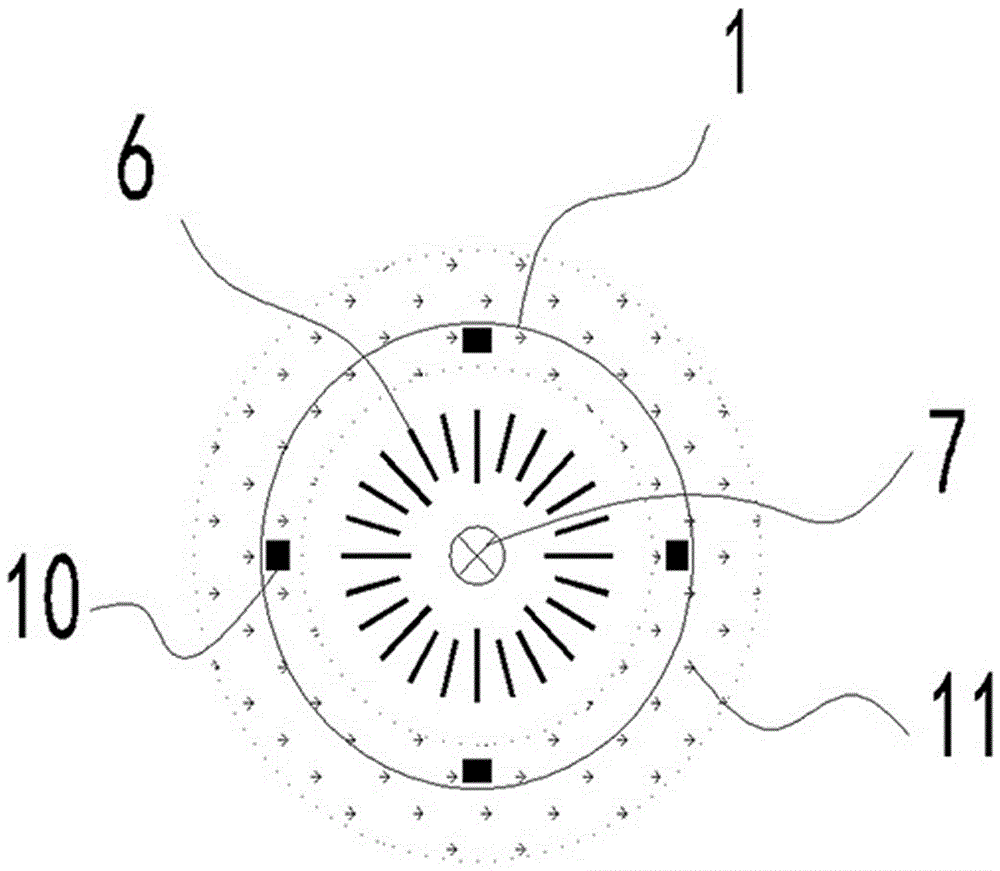

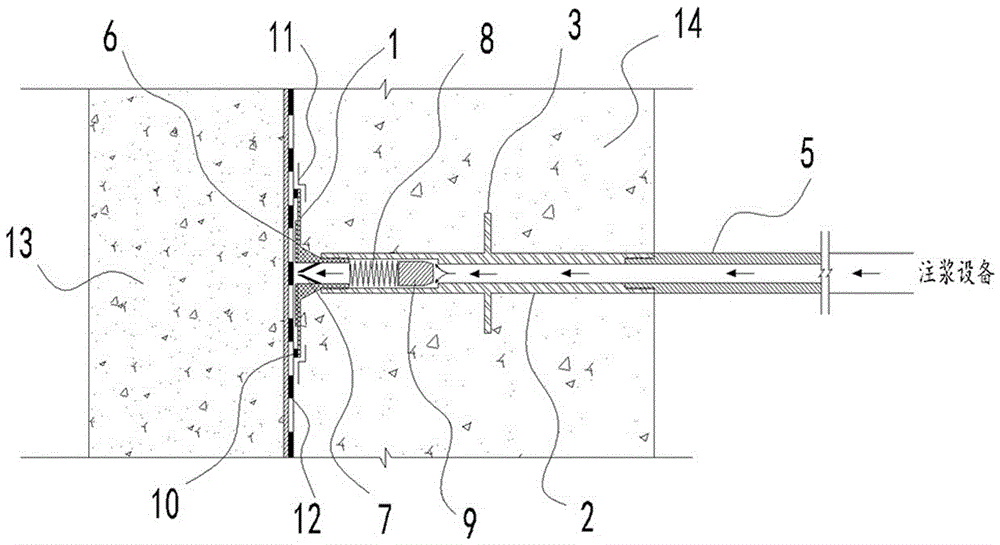

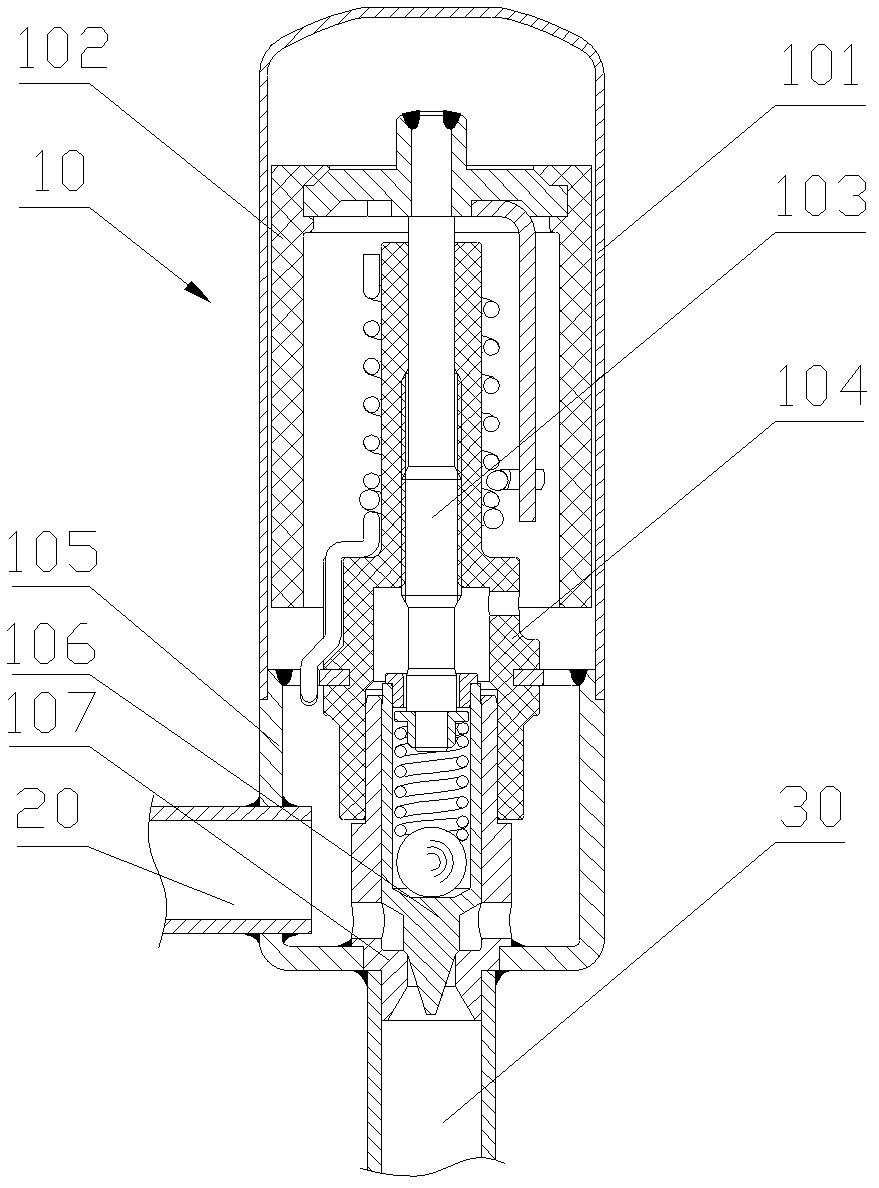

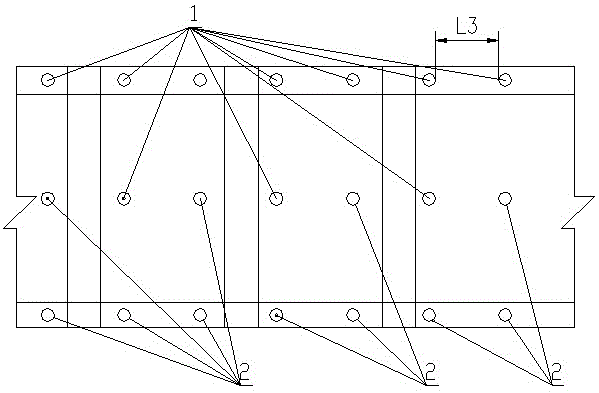

Grouting system and grouting method used for composite lining structure backfill and grouting

ActiveCN105697034ASolve the problem that grouting cannot be repeatedRealize repeated groutingUnderground chambersTunnel liningScrew threadGrout

The invention discloses a grouting system and a grouting method used for composite lining structure backfill and grouting.The grouting system comprises a one-way non-return suction cup, a one-way non-return grouting pipe, a water-stopping ring, a sealing plug and a connection pipe, wherein the one-way non-return suction cup is composed of a grouting disc and a non-return hole; the one-way non-return grouting pipe comprises a grouting pipe first end and a grouting pipe second end, a one-way valve is arranged at the grouting pipe first end, and the grouting pipe first end is communicated with a grout inlet of the grouting disc through a screw thread; the water-stopping ring is located on the outer wall of the middle of the one-way non-return grouting pipe; the sealing plug is connected with the grouting pipe second end through a screw thread; the connection pipe comprises a first end and a second end; the first end of the connection pipe is connected with the grouting pipe second end are connected through a screw thread, and the second end of the connection pipe is used for being connected with grouting equipment.The water-stopping ring is additionally arranged on the middle of the grouting pipe, and the water-stopping effect of a contact face between the outer wall of the pipe and a secondary lining structure can be effectively improved.The one-way non-return suction cup is arranged at the tail end of the one-way non-return grouting pipe, repeated grouting can be achieved, and the defect that a traditional grouting system cannot achieve repeated grouting is overcome.

Owner:BCEG CIVIL ENG

Electrically operated valve device

The invention discloses an electrically operated valve device which comprises an electrically operated valve and a first connecting pipe connected with the electrically operated valve. The electrically operated valve is provided with a valve seat and a valve seat core. The valve seat core is plugged into an axial through hole of the valve seat to form a valve opening, the first connecting pipe is communicated with the valve opening, an outer peripheral wall of the valve seat core is welded and fixed with a peripheral wall of the axial through hole, and the upper end of the first connecting pipe and the bottom of the valve seat are welded and fixed. The upper end of the first connecting pipe of the electrically operated valve device is welded and fixed with the bottom of the valve seat, so that a formed weld joint can prevent a coolant permeated from a weld joint between the valve seat and the valve seat core from leaking, and the sealing performance of the electrically operated valve is improved.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

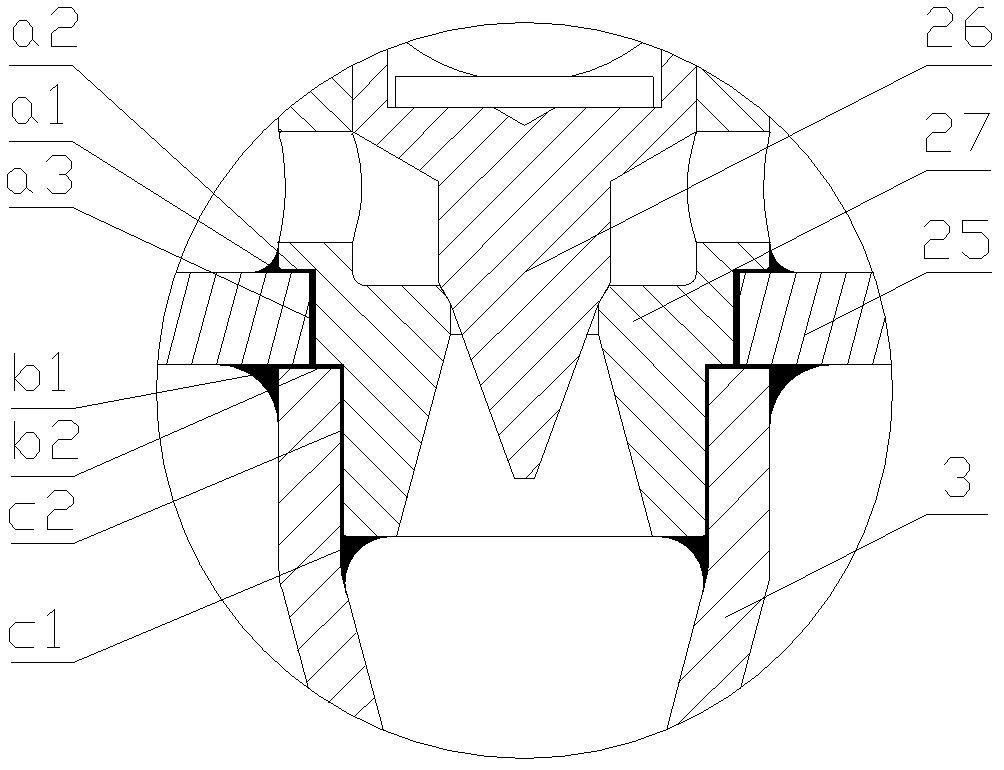

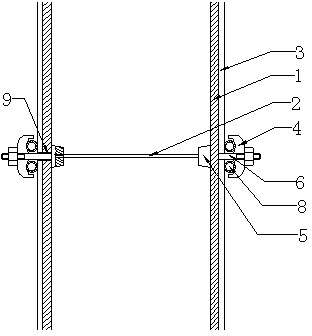

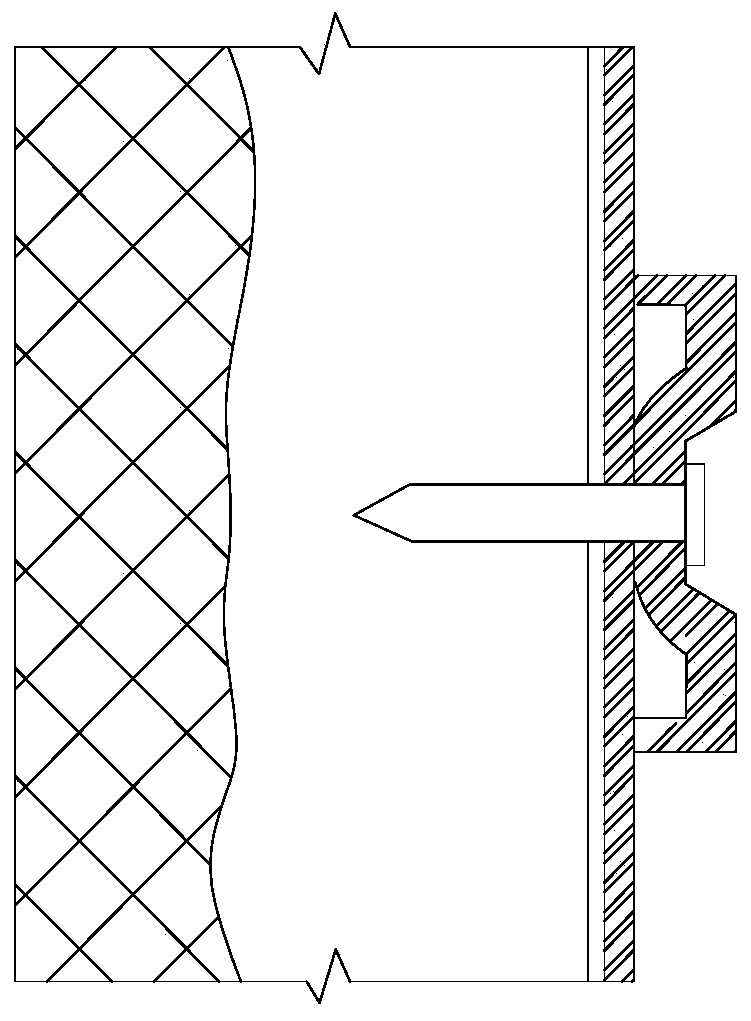

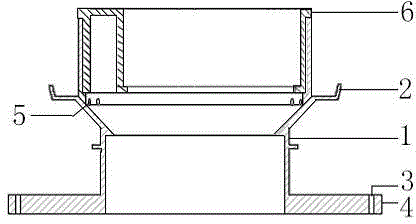

Building formwork forming structure, fasteners and construction method of building formwork

InactiveCN102296812AReduce wasteDensely packedAuxillary members of forms/shuttering/falseworksBuilding material handlingArchitectural engineeringScrew thread

The invention relates to a building formwork forming structure, a fastener used for the structure and a construction method, belonging to the formwork technology for concrete pouring in the construction industry. Its building formwork forming structure includes templates, tensioning screws, reinforcing ribs and clamps. The templates are arranged on both sides of the concrete filling cavity in parallel. There are one pair of tensioning bolt holes set opposite to each other on the formwork. The two ends of the pull bolts are matched, and the two ends of the pull bolts are threaded to connect a pair of frustum-shaped fasteners; the frustum-shaped fasteners are arranged on the inside of the two templates, and the large end faces of the frustum-shaped fasteners facing the outside are arranged There is an extended screw that can pass through the hole of the pull bolt on the template; the protruding part of the extended screw passes through the column on the outside of the template and is tightened and fixed by a conventional clamp. The structure and method of the invention reduce the waste caused by cutting the ends of the pull bolts in the traditional structure, and simultaneously simplify the construction and improve the efficiency.

Owner:黄学贵

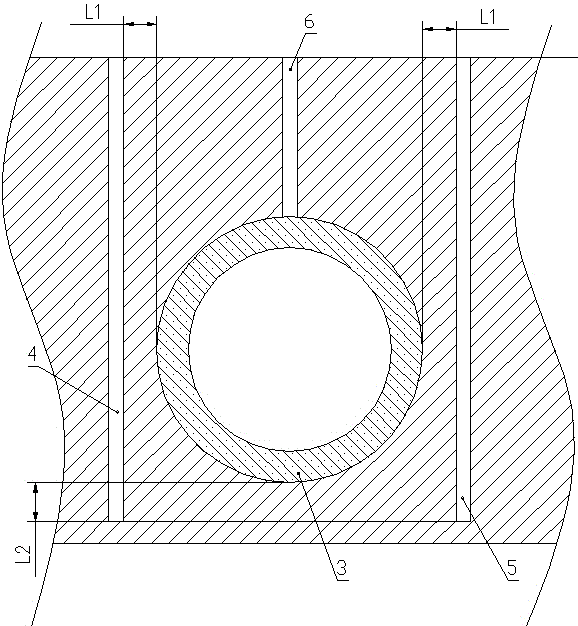

Anti-seepage structure of kitchen and bathroom reserved hole and construction method

InactiveCN105464224AIncrease binding areaGood anti-leakage performancePipesBuilding insulationsWater leakageDraining tube

The invention relates to anti-seepage structures of building engineering, in particular to an anti-seepage structure of a kitchen and bathroom reserved hole and a construction method. The anti-seepage structure of the kitchen and bathroom reserved hole comprises the pipeline reserved hole formed by cast-in-place concrete, a drain pipe and filling concrete poured between the pipeline reserved hole and the drain pipe are arranged in the pipeline reserved hole, the filling concrete is composed of a first concrete layer and a second concrete layer, the first concrete layer is located below the second concrete layer, the first concrete layer is in a straight cylinder shape, and the second concrete layer is in an inverted-circular-cone shape. The two concrete layers in different shapes are combined, so that the combination area with the pipeline reserved hole (1) is enlarged, and the anti-seepage performance of the plugged hole is improved. Thus, maintenance cost increased by water leakage can be reduced, and resources can be easily saved. An anti-seepage agent is arranged in the filling concrete, and thus the anti-seepage effect is better.

Owner:SICHUAN AEROSPACE CONSTR ENG

Tunnel waterproof and drainage construction technology

InactiveCN110748359AAffect the waterproof effectImprove the anti-leakage effectUnderground chambersDrainageArchitectural engineeringStructural engineering

The invention discloses a tunnel waterproof and drainage construction technology. The tunnel waterproof and drainage construction technology comprises the following steps of arranging an expansion water-stop strip on the whole section of a secondary lining construction seam of a tunnel, arranging a rubber water-stop band on the whole section of a settlement seam, arranging back-mounted water-stopbands at both the construction seam and the settlement seam, arranging longitudinal drainage blind pipes on the two sides of an arch foot, arranging a circumferential drainage blind pipe at the back of a secondary lining, and fully paving geotextile and waterproof boards, wherein the secondary lining adopts waterproof concrete with an impermeability grade of greater than or equal to S8 for the secondary lining. With the adoption of the tunnel waterproof and drainage construction technology, the waterproof effect of the construction seam can be ensured, and the anti-leakage performance can be improved.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

Molding method of integral type bibcock waterway inner core

InactiveCN101973104AOvercome the disadvantage of easy leakageExtended service lifeValve arrangementsDomestic articlesInjection molding machineInjection moulding

The invention discloses a molding method of an integral type bibcock waterway inner core, which comprises the following steps: (1) a main body with two water entry channels, at least one water effluent channel and at least one intermediate fluid channel is integrally formed through once injection by means of a once-injection mold and a mandril in a position corresponding to the position of the mold, wherein the intermediate fluid channel is perpendicular to the two water entry channels, and the external ends of the channels are respectively provided with a water inlet, a water outlet and a core loosing hole; and a plug for sealing the core loosing hole is formed in an injection molding mode by means of a plug mold; (2) the plug and a seal ring are arranged in the core loosing hole of the main body to form an insert for secondary injection molding; and (3) the insert is placed into the mold for secondary injection molding; a cladding layer for maintaining the relative position of the plug and the main body is coated on the insert through secondary injection molding; and the integral type bibcock waterway inner core is obtained after demoulding. The bibcock inner core body processed and molded according to the method of the invention has firm structure, is convenient to install and use, prolongs the service life of a bibcock, and has less possibility of leakage.

Owner:XIAMEN RUNNER IND CORP

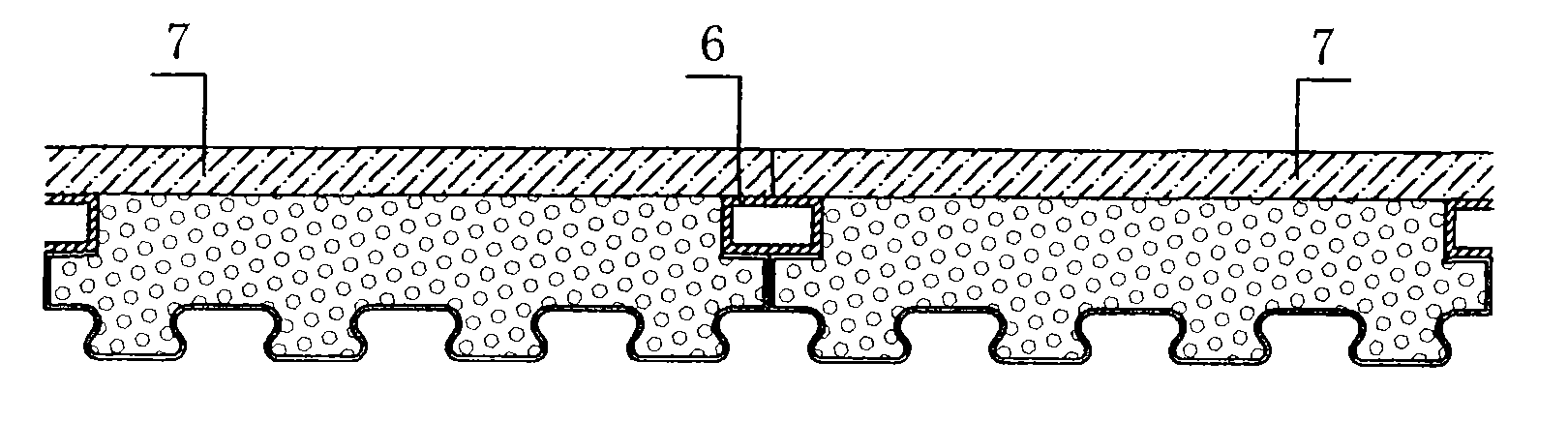

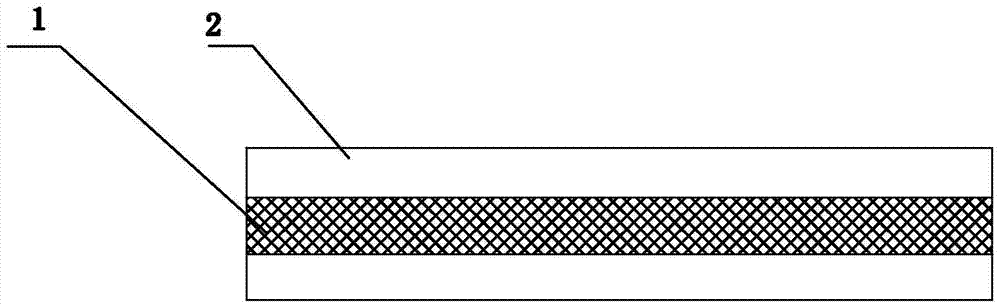

Dovetailing cold-rolled steel composite plate

InactiveCN101929217AReduce rustImprove the anti-leakage effectRoof covering using slabs/sheetsWallsSheet steelComposite plate

The invention discloses a dovetailing cold-rolled steel composite plate. The plate comprises a surface plate with dovetail joint, a cold-rolled steel plate with dovetail groove and a heat insulating material, wherein the heat insulating material is arranged between an upper cold-rolled dovetail steel plate and a lower cold-rolled dovetail steel plate and embedded into the dovetail grooves of the upper cold-rolled dovetail steel plate and the lower cold-rolled dovetail steel plate; the upper panel is embedded into the dovetail groove on the upper part of the upper cold-rolled dovetail steel plate; and a lower panel is embedded into the dovetail groove on the lower part of the lower cold-rolled dovetail steel plate.

Owner:王广武

Manufacturing process of mold for manufacturing carbon fiber box

InactiveCN105500731AHigh thermal deformation coefficientImprove the finishSteel platesHigh intensity

The invention relates to a manufacturing process of a mold for manufacturing a carbon fiber box. In the process, a male mold is used. The manufacturing process comprises the following steps: step 1, spraying a gel coat on the outer surface of the male mold and curing to form a gel coat layer; step 2, coating the gel coat layer with surface felt to form a surface felt layer; step 3, gluing at least three layers of shortly-chopped felt on the surface felt layer to form a shortly-chopped felt layer, and curing the surface felt layer, resin and the shortly-chopped felt layer to form a glass fiber reinforced plastic layer; step 4, sequentially laying the shortly-chopped felt layer, a multi-axial cloth layer and a bordering cloth layer on the glass fiber reinforced plastic layer; step 5, filling in vacuum, namely sequentially laying de-molding cloth, a double-layered flow guide net, a flow guide belt, a flow guide pipe and a double-layered vacuum bag on the layer in the step 4, and after keeping pressure, filling to primarily form a female mold shell plate; step 6, gluing a steel frame and a steel plate; and step 7, after sticking the steel frame and the female mold shell plate for at least 48 hours, taking out the male mold from the female mold shell plate so as to manufacture the mold. The manufacturing process provided by the invention has the characteristics that the high-strength performance of the mold is guaranteed, the durability of the mold is improved, the service life of the mold is prolonged and the like.

Owner:NEWTRY COMPOSITE

Inorganic foaming filling and reinforcing composition for coal mine as well as using method and application thereof

ActiveCN104446624AResolution timeSolve the non-plasticUnderground chambersMaterial fill-upCoalMaterials science

The invention provides an inorganic foaming filling and reinforcing composition for a coal mine as well as a using method and application thereof. The inorganic foaming filling and reinforcing composition for the coal mine can be used as a novel safe plugging and reinforcing material, is especially suitable for plugging and reinforcing of the coal mine, and is the best water-proof, fire-proof, gas-proof, collapse-proof and accident-proof material.

Owner:廊坊坐城矿用材料有限公司

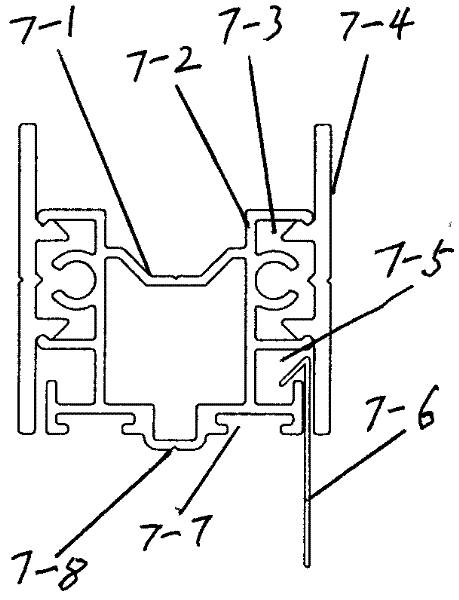

Multifunctional burglary-resisting window and section thereof

ActiveCN102373870AImprove anti-theftImprove permeabilityBurglary protectionRain/draught deflectorsSash windowEngineering

The invention discloses a multifunctional burglary-resisting window and a section thereof. The multifunctional burglary-resisting window is composed of a window frame, window sashes, a jacket, a connecting rod pull ring, a wool strip and a flexible water baffle, wherein the rotary window sashes are uniformly distributed and arranged in one connecting frame, and the connecting frame is fixed in the window frame; upper and lower end surfaces of each window sash are respectively provided with a shaft hole; lower pin shafts are alternately installed in the lower shaft holes of every two window sashes; upper pin shafts are respectively installed in the upper shaft holes of the window sashes adjacent to the window sashes on which the lower pin shaft are installed; at least two upper pin shafts and lower pin shafts are respectively connected with a connecting rod; and each connecting rod is provided with a pull ring and a locker. The multifunctional burglary-resisting window not only has good burglary resisting property and permeability, but also has high leakage prevention performance, thus reaching state-specified inspection standard.

Owner:李一达

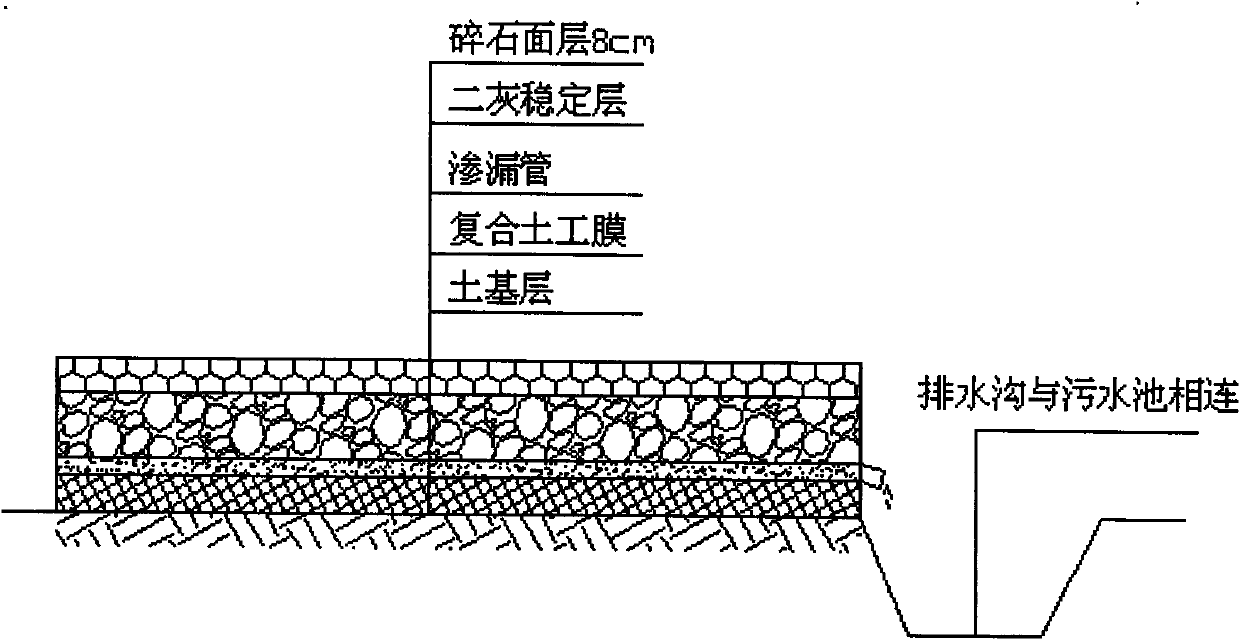

Method of anti-leak treatment on petroleum drilling place by adopting composite geo-membrane

ActiveCN101906785AAvoid pollutionConvenient and harmless disposalProtective foundationSoil preservationLand resourcesSurface layer

The invention discloses a method of anti-leak treatment on a petroleum drilling place by adopting a composite geo-membrane, relating to the technical field of adopting composite geotechnical materials to treat leakage of the petroleum drilling place. The method comprises the following steps of firstly, leveling the place; secondly, paving the composite geo-membrane; thirdly, paving a leakage pipeline: arranging the leakage pipeline at a position of easily having leakage; fourthly, paving a lime-ash stabilizing layer: with crushed stones, lime and fly ash as raw materials, paving the lime-ash stabilizing layer on the composite geo-membrane, wherein the lime-ash stabilizing layer comprise the following raw materials in percentage by weight, calculated by occupying the total volume of the raw materials: 8-10 percent of the lime, 10-12 percent of the fly ash and the balance of the crushed stones; and fifthly, paving a crushed stone surface layer: paving a 8-10cm crushed stone surface layer on the lime-ash stabilizing layer. By adopting the invention, waste mud and waste liquid of petroleum can be prevented from polluting the drilling place to enable idle land after drilling to be in second plowing, thereby having the effects of protecting land resources and lowering the land using cost.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Water proofing and leak repairing construction method for sewage pipe network below underground water level

The invention discloses a water proofing and leak repairing construction method for a sewage pipe network below the underground water level. The method is performed through the following steps that 1, sewage removal is performed on a pipeline; 2, leak points are found and marked; 3, a precipitation well is drilled, and precipitation processing is performed on a construction well point; 4, leaking stoppage is performed on the interior of the pipeline; 5, a grouting hole is drilled, and cement paste is backfilled and grouted. According to the method, a lining pipe does not need to be used, the construction cost is saved by 50% compared with the method that water proofing and leak repairing are performed on the sewage pipe network in a lining pipe mode, and the high application and popularization value is achieved; the actual available pipe diameter of the sewage pipeline cannot be reduced, and the phenomenon that the drainage capacity of the sewage pipeline is reduced due to water proofing and leak repairing cannot occur; by grouting on the exterior of the pipeline to form a grouting layer at the periphery of the sewage pipeline, the strata at the periphery of the sewage pipeline is reinforced, and effective protection on the sewage pipeline is formed to prevent formation stress from destroying the sewage pipeline.

Owner:XUCHANG WATER CONSERVANCY CONSTR ENG CO LTD

Embedded leak-proof joint

InactiveCN104452949AEasy to rotate and alignRealize the inconvenience of installationSewerage structuresDomestic plumbingArchitectural engineeringBuilding construction

Owner:湖南中财化学建材有限公司

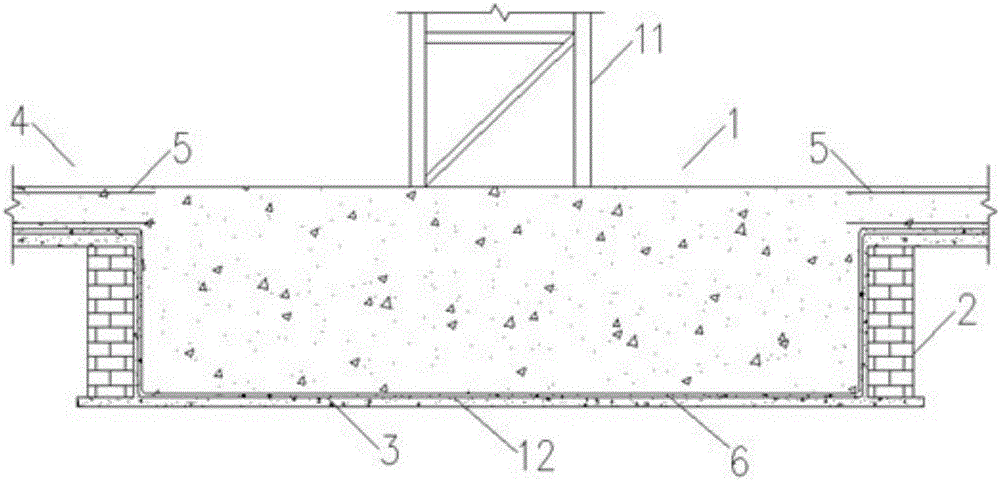

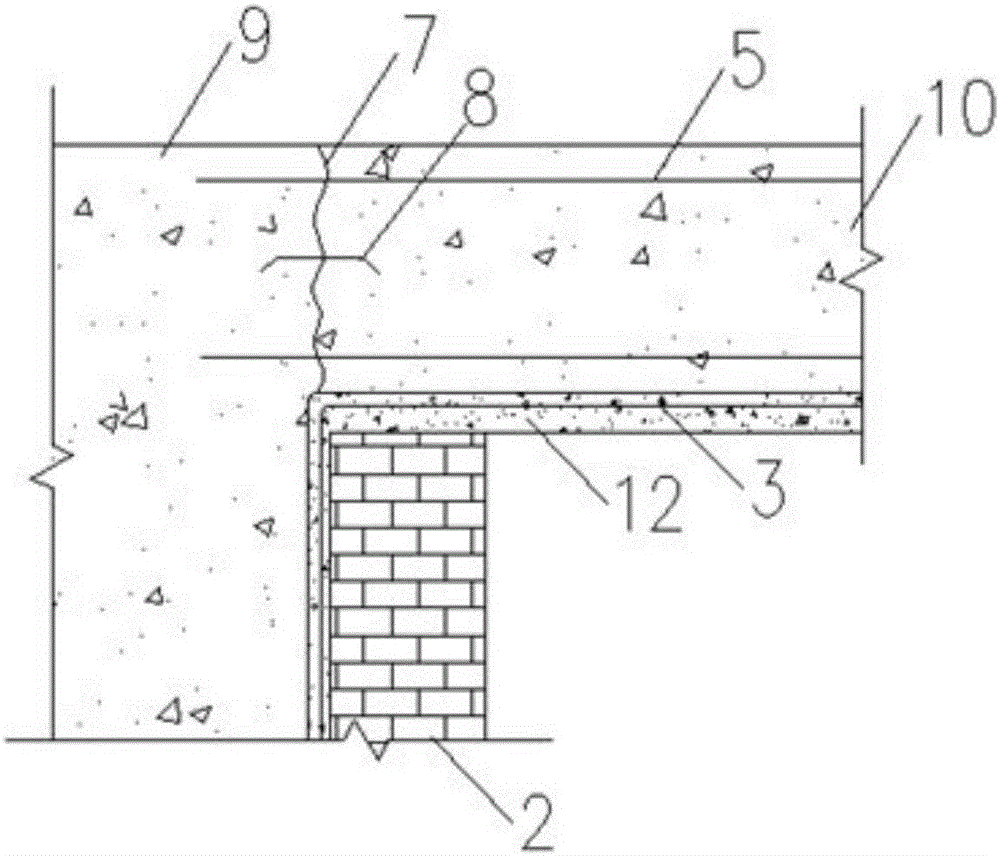

Leakage-proof construction method combining tower crane foundation and basement floor

InactiveCN106120872AEliminate potential safety hazards such as rustAvoid prolonged water accumulationProtective foundationProof constructionBrick

The invention discloses a leakage-proof construction method combining a tower crane foundation and a basement floor. The method comprises the following steps: excavating an earthwork groove and building a brick membrane along an inner wall of the earthwork groove, laying a waterproof material, distributing a foundation reinforcement cage, mounting supporting feet of a tower crane, mounting a grounding device, pouring concrete, mounting standard sections of the tower crane and the like. The leakage-proof construction method has the advantages that problems in a utilization process of the tower crane that the standard sections of a tower body are immersed in water for a long period to cause potential safety hazards including rusting and the like and the water is deposited in an installation position of the tower crane for a long period are effectively avoided, a dismounting procedure of the tower crane is simplified and the stability of connection between the earthwork groove and the basement floor is increased after the concrete is poured into the earthwork groove; and the leakage-proof construction method has very good leakage-proof effect and is suitable for being applied to a tower crane construction process of various types of mid-rise buildings and high-rise buildings.

Owner:TIANJIN 20 CONSTR

Tin pot base production method of float glass production line

The invention relates to a method for manufacturing a tin bath bottom shell of a float glass production line. The method comprises the following: a step 1 of prophase preparation, which is to work out a manufacturing process and proposal according to a drawing as well as manufacturing standards and requirements, draw a typesetting drawing of folding the edge of a bottom plate, obtain the reasonable order size of a wide plate and customize materials; a step 2 of folding the edge of the wide plate, which is to determine accurate blanking size, form a welding groove via cutting blanking, plate leveling and edge planing, fold the edges of two ends of the wide plate and use an assembled die to fold the edges and control the radius of a fillet; a step 3 of assembling a bottom frame, which is to assemble a platform first, assemble and weld the bottom frame then, calibrate and polish after welding is over; and a step 4 of assembling the wide plate and the bottom frame, which is to assemble the bottom frame calibrated on the platform in the step 3 together with the wide plate, weld, calibrate, spray sand, paint, number and package. The method ensures that users can directly obtain every part of the production line and only need to splice the parts, thereby guaranteeing the manufacturing quality of the production line.

Owner:SHANGHAI BAOYE GRP CORP +1

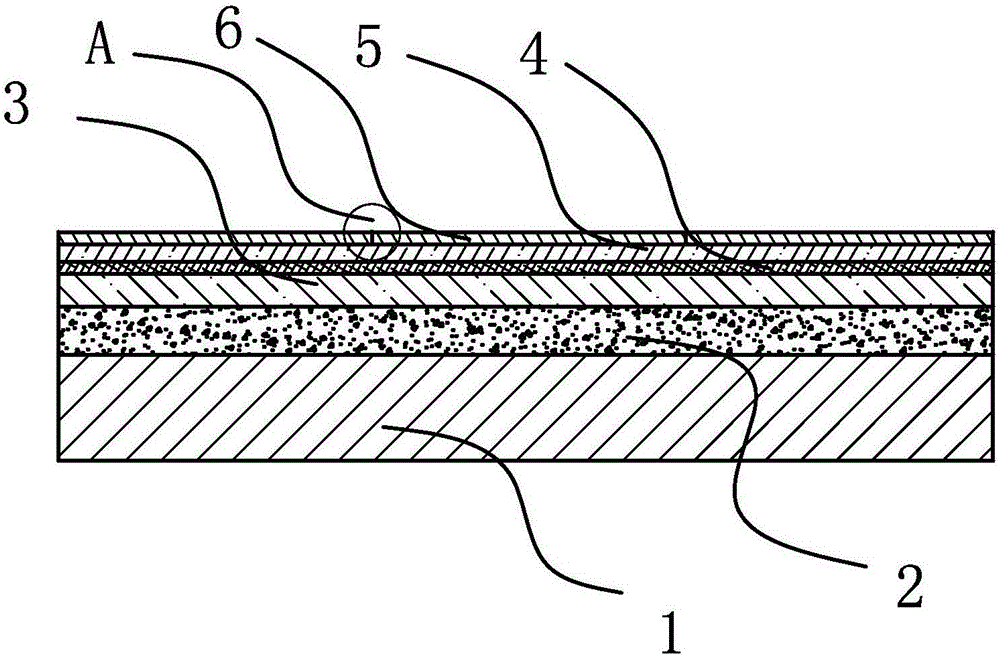

Leakage-proof structure and method for leakage maintenance of toilet floor

InactiveCN106049801AImprove adhesion fastnessImprove anti-leakage abilityFlooring insulationsCeramic tilesEngineering

The invention relates to a leakage-proof structure and method for leakage maintenance of a toilet floor, and belongs to the field of building decoration. In order to solve the problems that existing maintenance is complex and poor in leakage-proof effect, the invention provides the leakage-proof structure and method for leakage maintenance of the toilet floor. The leakage-proof structure for leakage maintenance of the toilet floor comprises a ground base layer, the surface of the ground base layer is paved with a cement mortar combined layer, the surface of the cement mortar combined layer is paved with a ceramic tile layer, the surface of the ceramic tile layer is coated with a waterproof paint layer, the surface of the waterproof paint layer is paved with a self-leveling layer, the surface of the self-leveling layer is coated with multiple plastic floorings in a bound mode, all the plastic floorings are tightly arranged and paved, and the edges of every two adjacent plastic floorings abut against each other. The method comprises the steps that the toilet floor is cleaned, and the surface of the cleaned toilet floor is coated with the waterproof paint layer; self-leveling treatment is conducted; the toilet floor subjected to self-leveling treatment is covered with the plastic floorings in the bound mode; sealing treatment is conducted, and maintenance is completed. The leakage-proof structure and method for leakage maintenance of the toilet floor have the advantages that the leakage-proof effect is good, the service life is long, and the maintenance construction period is short.

Owner:浙江一方建筑装饰实业有限公司

Multifunctional phase change composite material and preparation method thereof

ActiveCN109486473AModerate elasticity and toughnessGood hold and leak-proofHeat-exchange elementsParaffin oilsRail traffic

The invention discloses a multifunctional phase change composite material and a preparation method thereof. The multifunctional phase change composite material contains the following components by mass percentage: 15-35% of EPDM, 40-75% of paraffin, 5-25% of expanded graphite, 5-25% of fire retardant, 0.5-5% of cross-linking agent, 0.01-5% of cross-linking aid, and 0-10% of processing aid; the mass percentage sum of the components is 100%. The phase change energy storage composite material disclosed by the invention has partial features of thermal vulcanized rubber, is moderate in elasticity and toughness, and good in sizing and antiseep effect, and meanwhile has the advantages of high latent heat of phase change, high conductivity coefficient, flame resistance and insulation, is simple inproduction process, and has good application prospect in multiple thermal design and heat management fields including new-energy vehicles, rail traffics, communication base stations, laser equipment,unmanned aerial vehicles and intelligent terminal equipment.

Owner:深圳航美新材料科技有限公司

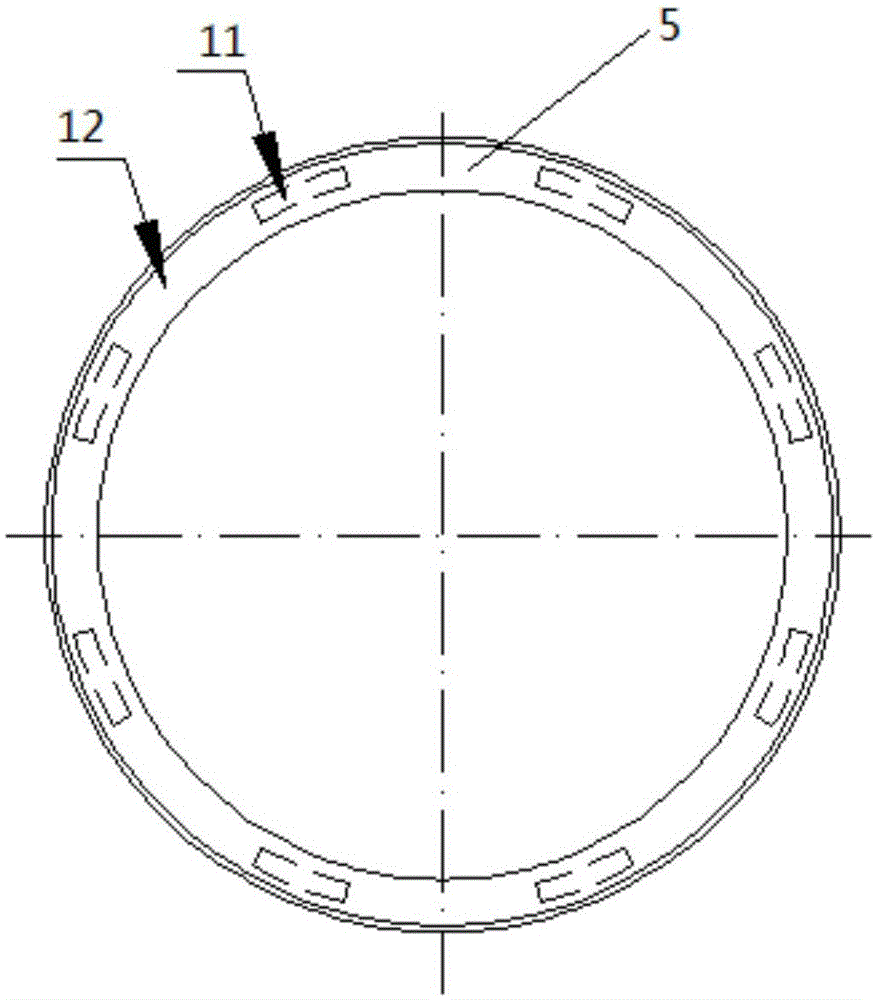

Round zinc air battery with seal rings and without zinc lugs

ActiveCN105024112AImprove sealingProfessional and reasonable sealing structureFuel and primary cellsCell sealing materialsZinc–air batteryZinc

The invention discloses a round zinc air battery with seal rings and without zinc lugs. The battery comprises a round multifunctional connecting ring and a battery outer frame; the bottom surface of the battery outer frame is provided with a diaphragm paper, a fuel zinc cake is placed on the diaphragm paper, and a zinc current collector is placed on the battery outer frame and is in conductive contact with the fuel zinc cake; a structure of upper and lower seal rings is added in the battery, the seal rings can realize good sealing property, and can avoid leakage of electrolyte for long time; when battery packs are superposed, a bottom ring of the multifunctional connecting ring is in surface contact with the zinc current collector 1 of the lower battery, thus, electric conduction is enhanced, and a lug structure is omitted skilfully, battery failure occurring possibly caused by fracture of the lugs is prevented, battery reliability is increased, technology is more simple, moreover, utilization rate of battery space is higher than before, and structure is more rational.

Owner:合肥伏雷科技有限公司

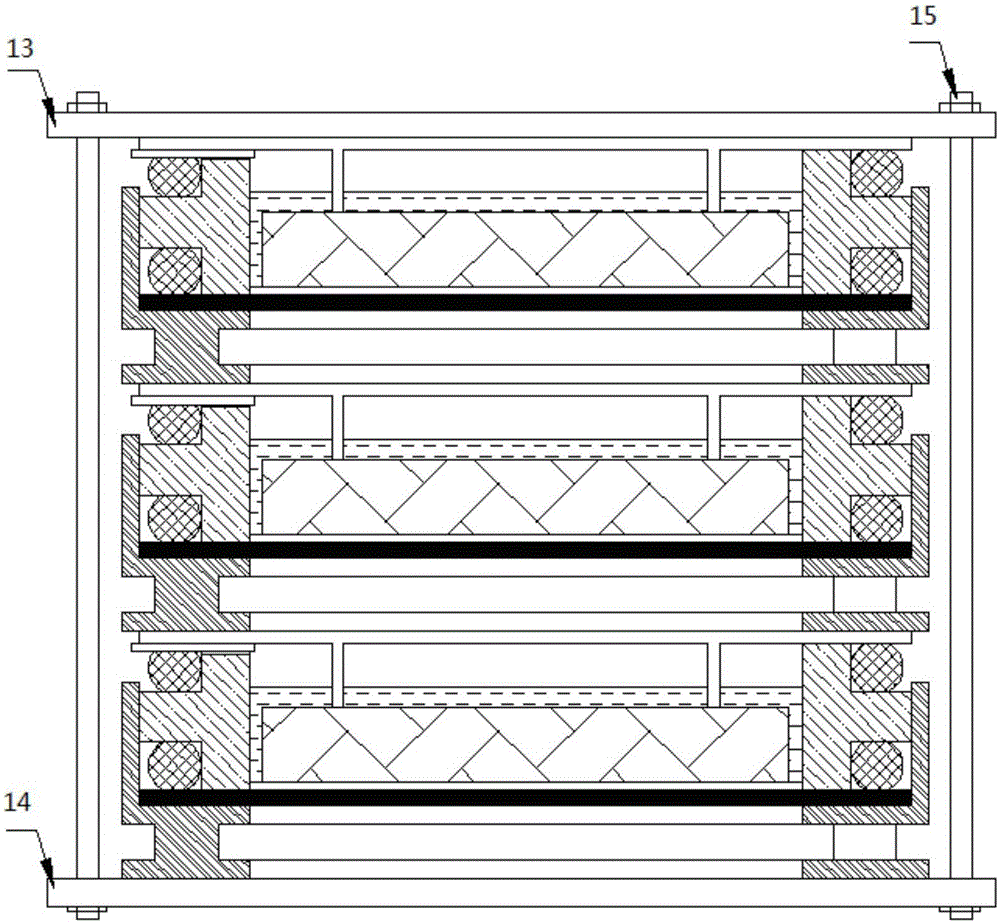

Waterproof construction method for preventing leakage of deformation joint

InactiveCN108442412AImprove the anti-leakage effectAvoid the defect of uneven materialArtificial islandsProtective foundationStructural engineeringWaterstop

The invention discloses a waterproof construction method for preventing leakage of a deformation joint. The waterproof construction method comprises the steps that an arc-shaped supporting strip is arranged in the deformation joint along a central buried waterstop belt, and a cavity is formed between the inner wall of the arc-shaped supporting strip and the central buried waterstop belt; a first layer of leaking-stoppage materials are arranged on the outer wall of the arc-shaped supporting strip along the deformation joint; grouting water-stopping materials are injected into the cavity; jointfilling materials and a second layer of leaking-stoppage materials are sequentially arranged on the outer wall of the first layer of leaking-stoppage materials along the deformation joint; and an external waterstop belt is arranged on the second layer of leaking-stoppage materials along the deformation joint. The arc-shaped supporting strip is arranged in the deformation joint along the central buried waterstop belt and fixed in the deformation joint by the first layer of leaking-stoppage materials, then the grouting water-stopping materials are injected into the cavity, the grouting water-stopping materials injected into the deformation joint are made compact and uniform by the arc-shaped supporting strip, and thus, the anti-leakage effect of the grouting water-stopping materials is improved; and a waterproof structural layer is additionally arranged, so that the anti-leakage effect of the deformation joint is further improved, and the waterproof effect after repair is improved through rigid-flexile combination.

Owner:SHANGHAI ORIENTAL YUHONG WATERPROOF TECH +1

Electric heating hand warmer with ceramic electric heating substrate

InactiveCN102860899AExtended service lifeSimple structureImmersion heating arrangementsTherapeutic coolingElectricityDry heating

The invention relates to an electric heating hand warmer with a ceramic electric heating substrate. The electric heating hand warmer comprises a bag body and an electric heating body disposed in the bag body. The electric heating hand warmer is characterized in that the electric heating body is the ceramic electric heating substrate serially connected with an overheat protector. By using the ceramic electric heating substrate as the electric heating body with the serially connected overheat protector, the electric heating hand warmer is simple and reasonable in structure and fast in heating, heating conditions of the ceramic electric heating substrate can be monitored by the overheat protector in real time, when dry heating due to the ceramic electric heating substrate exposes out of liquids occurs, power-off protection is performed by the overheat protector, dry heating is avoided, and accordingly the electric heating hand warmer is safe, reliable and long in service life. In addition, the novel heating body is high in heating efficiency, electricity-saving and environment-friendly, and sustainable development of industrialization is benefited.

Owner:广东美美创新电器有限公司

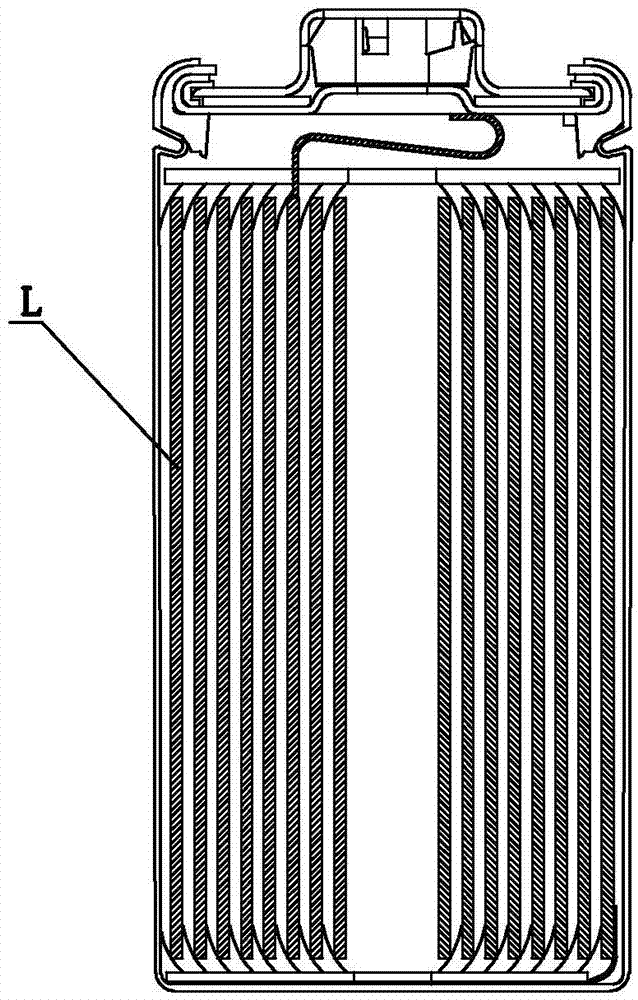

Positive pole piece of winding lithium-manganese battery

InactiveCN104124428AIncrease storage spaceImprove retentionNon-aqueous electrolyte accumulator electrodesLithiumDischarge efficiency

The invention discloses a positive pole piece of a winding lithium-manganese battery. The positive pole piece comprises a positive pole current collector and active matter layers coating surfaces of two sides of the positive pole current collector, wherein mutually-communicated net-shaped grooves are arranged on the upper surfaces of the active matter layers. The positive pole piece has the advantages that the mutually-communicated net-shaped grooves are arranged on the upper surfaces of the active matter layers, and a groove structure is arranged on the positive pole piece and is smoother than a conventional positive pole piece, thus the storage space of an electrolyte is increased; and the inventory of the electrolyte is increased. The grooves on the surface of the positive pole piece are mutually communicated, thus the electrolyte on the whole positive pole piece can be effectively mutually complemented, and the state of no electrolyte in a local place is prevented. A vacuumizing electrolyte injecting manner is adopted as a main manner in the current industry of winding lithium-manganese batteries, but the electrolyte has difficulty in permeating to a middle section of the positive pole piece at present to cause the result that a part of a positive plate at the middle section does not participate in reaction, the phenomenon is effectively improved through a manner of additionally arranging the grooves on the surface of the positive pole, the whole positive pole piece participates in the reaction, and thus the discharge efficiency of the battery is increased.

Owner:NINGBO XINGRUI ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com