Polyamide 66 membrane covered nickel-titanium alloy intravascular scaffold and preparation method thereof

A technology of vascular stent and nickel-titanium alloy, which is applied in the field of vascular stent material and its preparation, to achieve the effects of good impact toughness, stable structure, and good forming and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

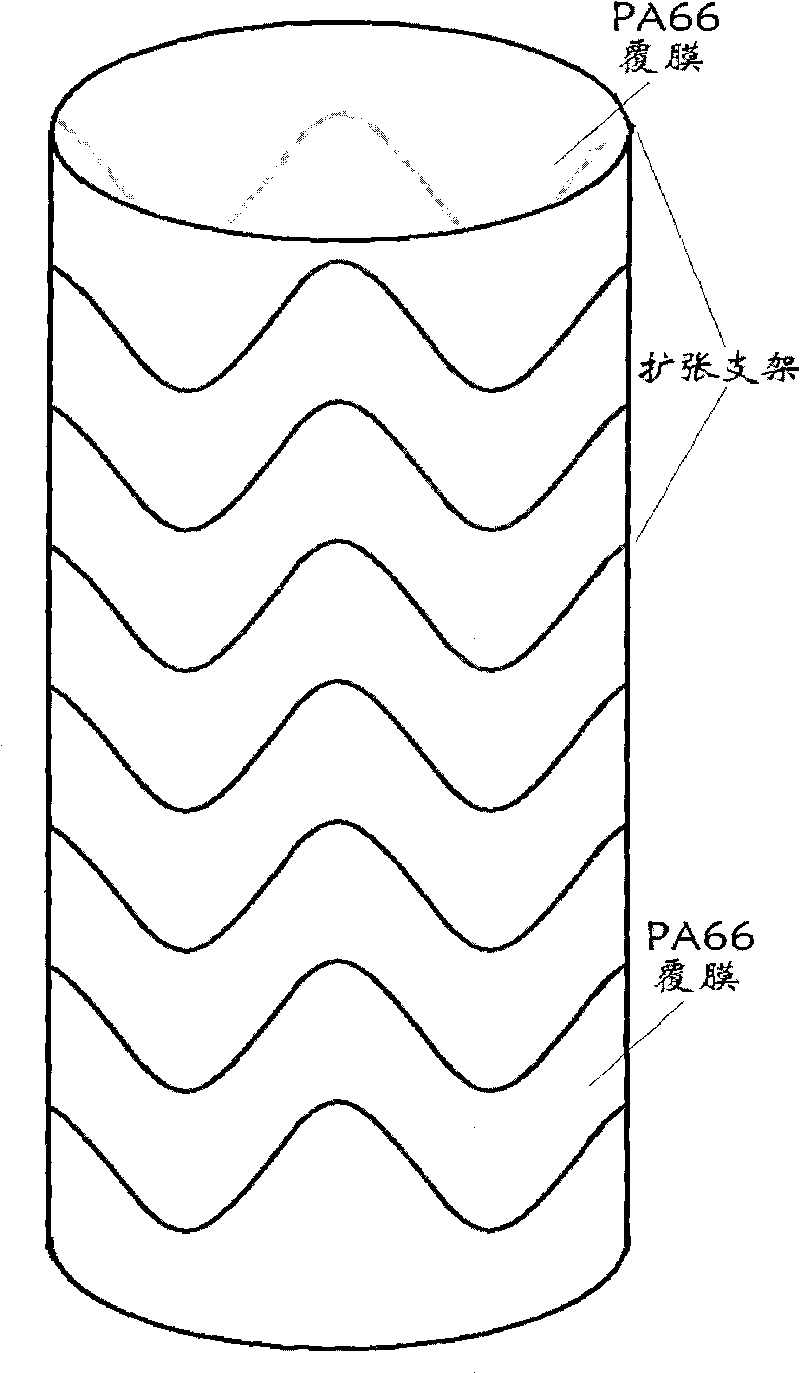

[0025] Dissolve PA66 in formic acid with a concentration of 90% to make a PA66 solution with a concentration of 6wt%; coat the resulting PA66 solution on a glass rod with a diameter of 15mm several times, and place it at a temperature of 65°C to evaporate the solvent Form the inner PA66 film of the vascular stent; put the nickel-titanium shape memory alloy expansion stent evenly on the glass rod coated with the PA66 film; again coat the glass rod with PA66 solution multiple times, and place it at a temperature of 65°C The solvent was volatilized to form the outer PA66 film of the stent; the covered stent was peeled off from the glass rod, and the PA66 covered stent was obtained after vacuuming at 60°C for 5 hours to remove the residual solvent.

Embodiment 2

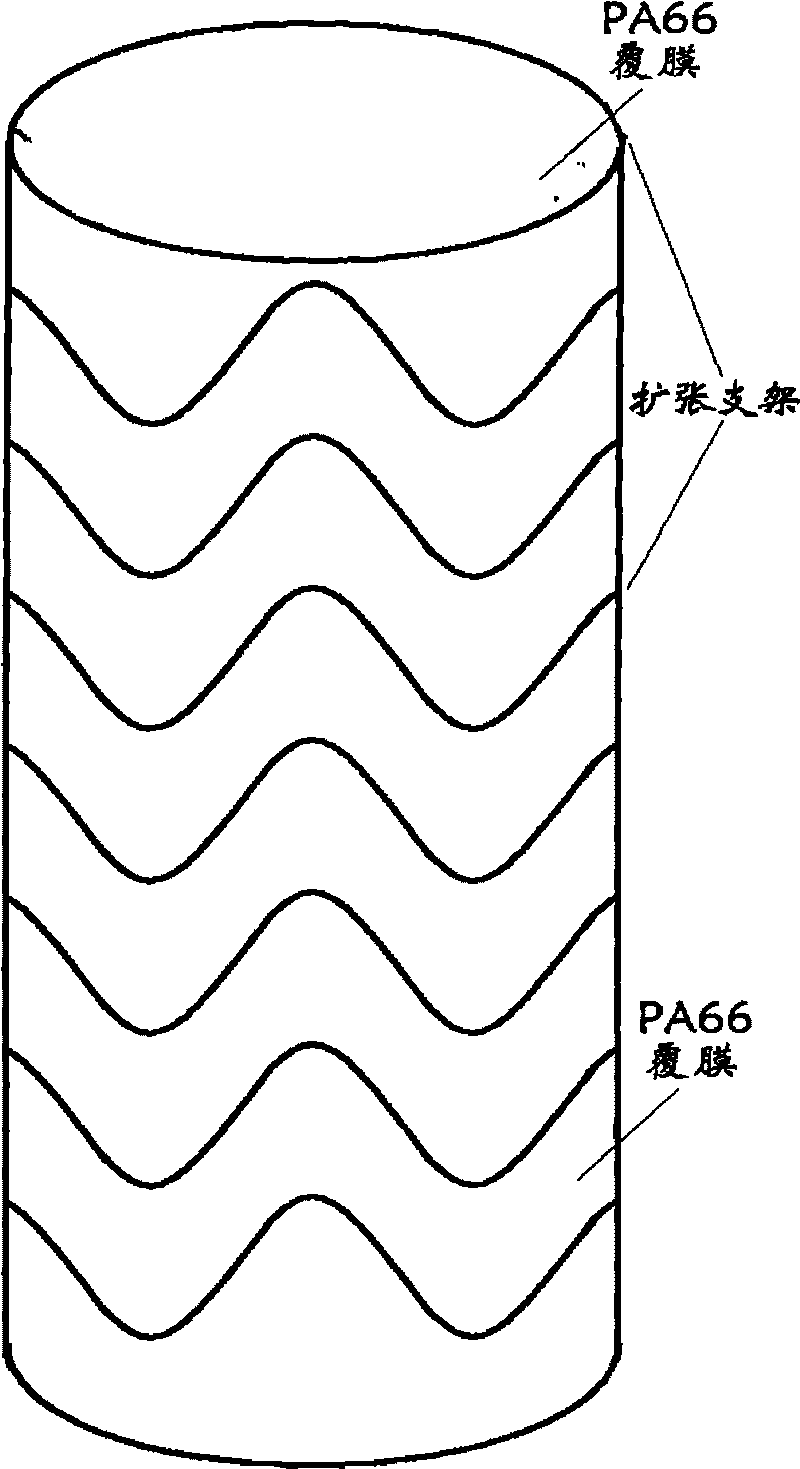

[0027] Dissolve PA66 in formic acid with a concentration of 92% to make a PA66 solution with a concentration of 9wt%; coat the resulting PA66 solution on a glass rod with a diameter of 25mm in several times, and place it at a temperature of 70°C to evaporate the solvent Form the inner PA66 film of the vascular stent; put the nickel-titanium shape memory alloy expansion stent evenly on the glass rod coated with the PA66 film; again coat the glass rod with PA66 solution multiple times, and place it at a temperature of 70°C The solvent was volatilized to form the outer PA66 film of the stent; the covered stent was peeled off from the glass rod, and the PA66 covered stent was obtained after vacuuming at 60°C for 5 hours to remove the residual solvent.

Embodiment 3

[0029] Dissolve PA66 in formic acid with a concentration of 95% to make a PA66 solution with a concentration of 12wt%; coat the resulting PA66 solution on a glass rod with a diameter of 35mm several times, and place it at a temperature of 75°C to evaporate the solvent Form the inner PA66 film of the vascular stent; put the nickel-titanium shape memory alloy expansion stent evenly on the glass rod coated with the PA66 film; again coat the glass rod with PA66 solution multiple times, and place it at a temperature of 75°C The solvent was volatilized to form the outer PA66 film of the stent; the covered stent was peeled off from the glass rod, and the PA66 covered stent was obtained after vacuuming at 70° C. for 5 hours to remove the residual solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com