Molding method of integral type bibcock waterway inner core

A molding method and an integrated technology, applied in the field of faucet manufacturing, can solve the problems affecting the service life of the faucet, leakage of the joint surface, difficulty in processing, etc., and achieve the effects of easy installation and use, prolonging the service life and improving the leakage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with accompanying drawing:

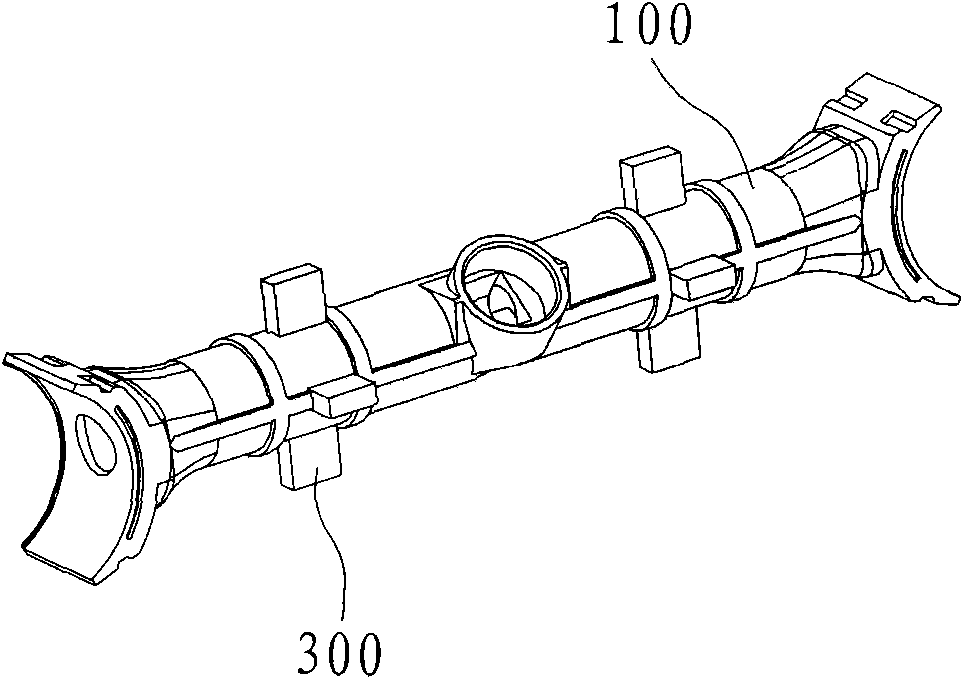

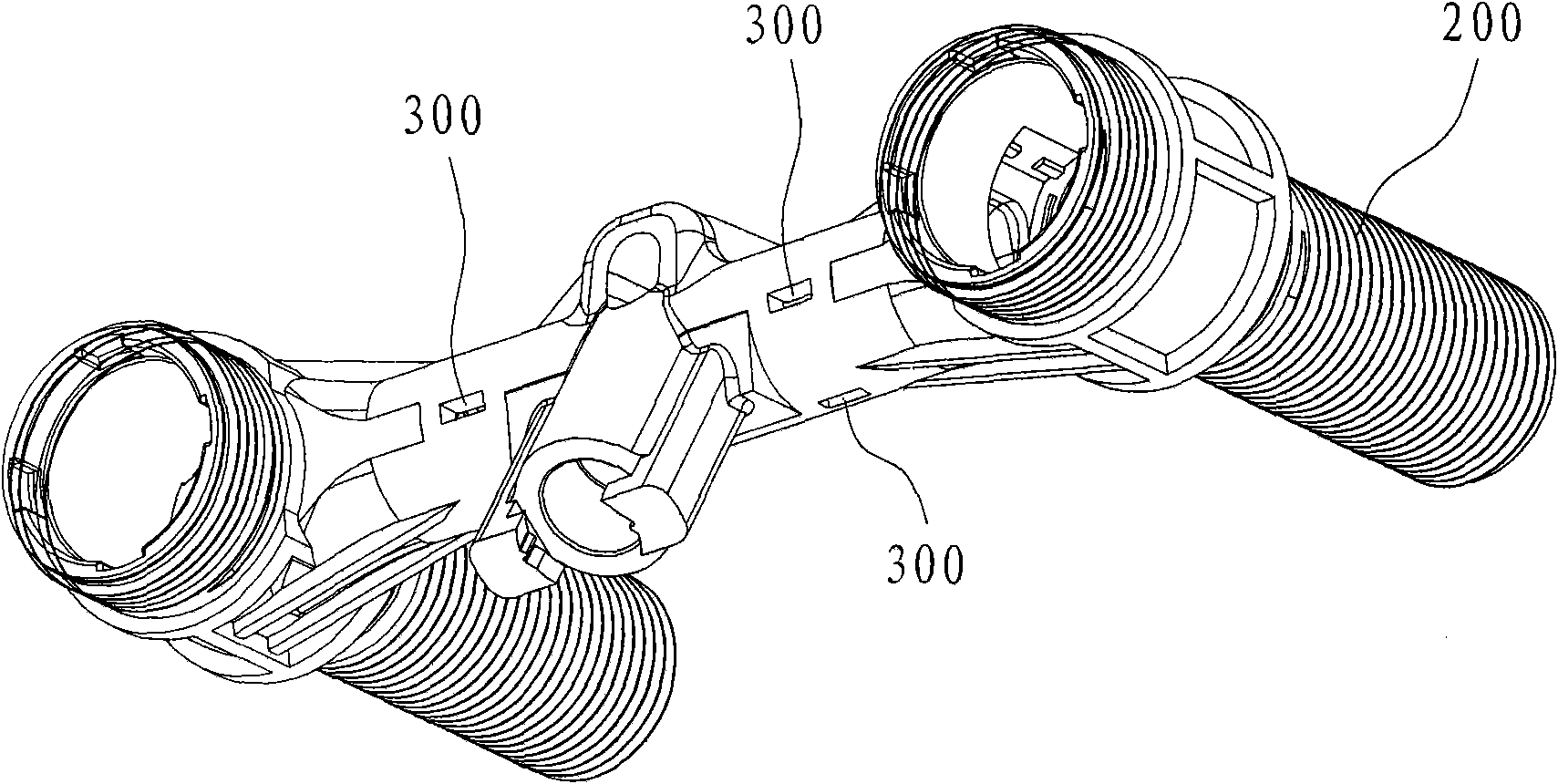

[0074] like Figure 3 to Figure 14 As shown, the present invention is applied to the processing of the integrated faucet inner core of the double handle, which includes the following steps:

[0075] The first step, with the help of a one-time injection mold (see Figure 6 , Figure 8 to Figure 10 , including upper mold 11 and lower mold 21), this mold also includes two water inlet channel mandrels 30 (see Figure 5 , Figure 8 , Figure 10 and Figure 11 ), a water outlet channel mandrel 40 (see Figure 5 , Figure 8 , Figure 10 , Figure 11 and Figure 12 , in this embodiment, in order to meet the design requirements, the axial direction of the water outlet channel mandrel 40 forms an angle with the plane formed by the axes of the two water inlet channel mandrels 30), two intermediate fluid channel mandrels 50 (see Figure 5 , Figure 8 , Figure 10 , Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com