Continuous transonic wind tunnel semi-flexible wall nozzle throat block vertical space electric drive device

An electric drive, vertical space technology, applied in the field of continuous transonic wind tunnel test, can solve the problems of large swing mass, low reliability, slow response, etc., to achieve increased effective component force, low maintenance cost, and reduced difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

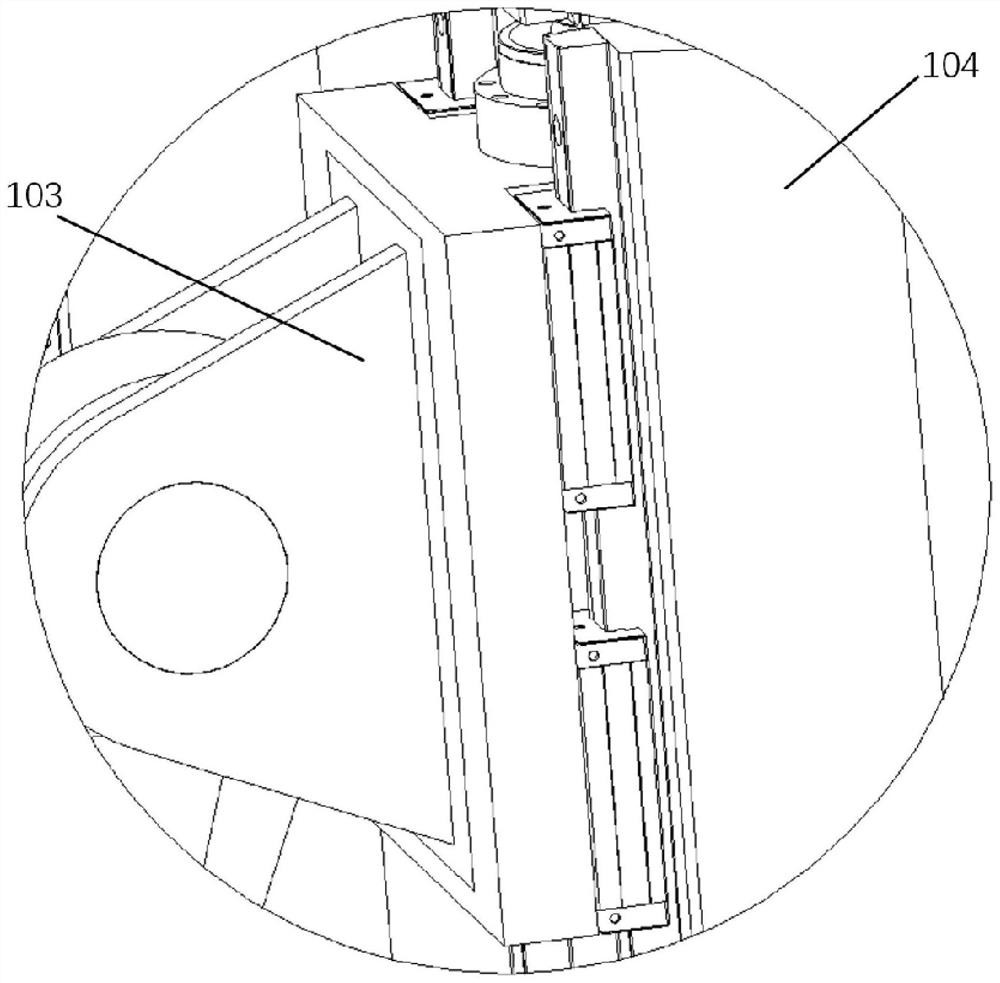

[0043] The vertical space type electric drive device of the semi-flexible throat block of the nozzle section of the continuous transonic wind tunnel is characterized in that:

[0044] The device includes several execution units C, and the execution unit C includes: a drive rod unit, a slide table, a guide unit, and a drive unit. The device includes a mount (10), which is a flat plate placed vertically. The device includes a throat block (9), which is located directly below the mounting base (10);

[0045] The guide unit in each executive unit C comprises a guide rail arranged in parallel in the vertical direction and a base for installing the guide rail, the guide rail base is fixedly installed on the corresponding mounting seat (10), and a displacement sensor is fixedly installed next to the guide unit; The drive unit in each execution unit C drives the corresponding sliding table to move in the vertical direction, and the motor in the drive unit is fixedly installed on the ...

Embodiment 2

[0048] A continuous transonic wind tunnel semi-flexible wall surface nozzle throat block vertical space type electric drive device as described in Embodiment 1 is characterized in that the continuous transonic wind tunnel semi-flexible wall surface nozzle throat block vertical space Type electric drives include:

[0049] According to the requirements of the wind tunnel test, there are 3 mounting seats (10) for vertically arranging the driving unit;

[0050] The number of execution units C arranged in the vertical direction determined according to the requirements of the wind tunnel test is 8 groups;

[0051] According to the requirements of the wind tunnel test, it is determined that the driving unit of each group of execution units C is driven by a motor, driven by a screw, and can also be directly driven by a motor electric cylinder;

[0052] According to the requirements of the wind tunnel test, each group of executive units C includes 1 set of guide units, and 1 set of gu...

Embodiment 3

[0057] As described in the first and second embodiments, a continuous transonic wind tunnel semi-flexible wall surface nozzle throat block vertical space type electric drive device is characterized in that the continuous transonic wind tunnel semi-flexible wall surface nozzle throat block vertical Direct space electric drives include:

[0058] The throat block drive rod unit under each execution unit C is connected to the throat block by a ball pair connection, and the drive rod unit is respectively connected to the corresponding throat block section slide table and throat block section (9). The spherical pair is based on the actual working conditions. The required adjustment angle can be determined as a ball joint or a rod end bearing;

[0059]According to the requirements of the wind tunnel test, the position distribution of the connection points between the drive rod unit and the throat block section in each actuator unit C is determined. The number of drives is greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com